Regency E33-LP, E33-NG User Manual

E33 Gas Insert

MODELS: E33-NG Natural Gas E33-LP Propane

Owners & Installation Manual

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause injury, property damage, or loss of life. Refer to this manual. For assistance or additional information consult an authorized installer, service agency or the gas supplier.

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapours and liquids in the vicinity of this or any other appliance.

Installation and service must be performed by an authorized installer, service agency or the gas supplier.

FOR YOUR SAFETY:

What to do if you smell gas:

Do not try to light any appliance

Do not try to light any appliance

Do not touch any electrical switch: do not use any phone in your building.

Do not touch any electrical switch: do not use any phone in your building.

Immediately call your gas supplier from a neighbour's phone. Follow the gas supplier's instructions.

Immediately call your gas supplier from a neighbour's phone. Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

If you cannot reach your gas supplier, call the fire department.

Tested by:

Installer: Please complete the details on the back cover and leave this manual with the homeowner.

Homeowner: Please keep these instructions for future reference.

918-408 |

FPI FIREPLACE PRODUCTS INTERNATIONAL LTD. 6988 Venture St., Delta, BC, Canada V4G 1H4 |

08/16/05 |

FPI GAS FIREPLACE INSERT

TO THE NEW OWNER

Congratulations! You are the owner of a state-of-the-art Gas Insert by FPI.

The E33 Gas Insert has been designed to provide you with all the warmth and charm of a fi replace, at the fl ick of a switch. The E33-NG and E33-LP have been approved by Warnock Hersey for both safety and efficiency. As it also bears our own mark, it promises to provide you with economy, comfort and security for many trouble free years to follow. Please take a moment now to acquaint yourself with these instructions and the many features of your FPI Fireplace.

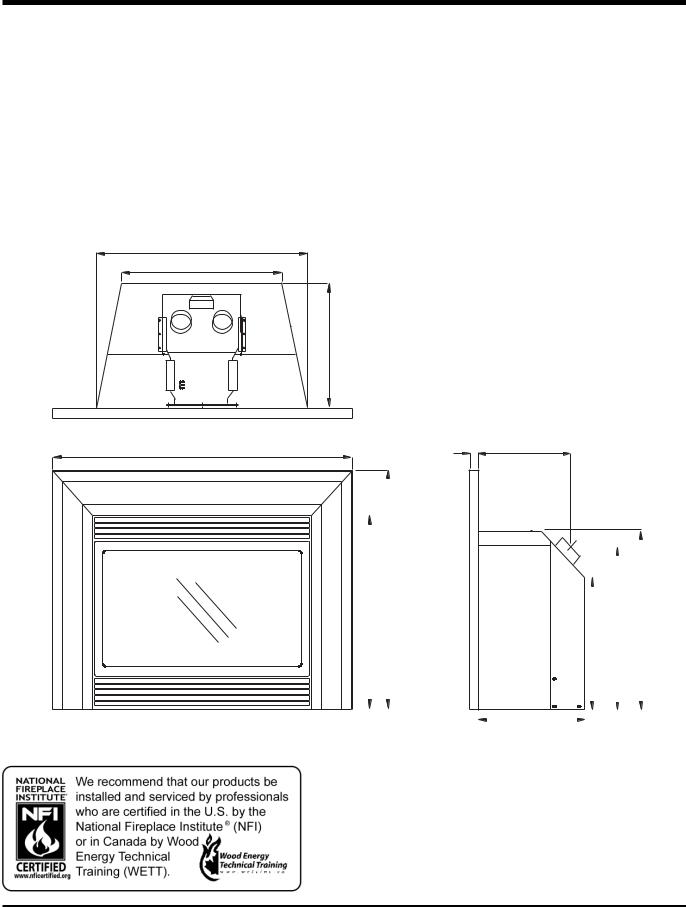

32-1/4"(819mm) |

|

24-1/2"(622mm) |

|

|

16-1/8"(410mm) |

|

11-1/4" |

45-9/16"(1157mm) |

(286mm) |

|

1-3/8" |

|

(35mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25"(635mm) |

31-1/8"(790mm) |

|

|

|

|

|

|

23-13/16"(605mm) |

||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

18"(203mm) |

23"(583mm) |

||||||||

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

16-1/2"(419mm)

2 |

E33 FPI Direct Vent Gas Insert |

TABLE OF CONTENTS

FPI GAS FIREPLACE INSERT

|

Page |

Unit Dimensions ..................................................................... |

2 |

Safety Label .......................................................................... |

4 |

INSTALLATION REQUIREMENTS |

|

For Your Safety....................................................................... |

5 |

Gas Pressure Testing ............................................................. |

5 |

Specifi cations ......................................................................... |

5 |

Installation into a Solid Fuel Burning |

|

Fireplace or Factory Built Fireplace ................................ |

5 |

General Safety Information .................................................... |

5 |

Installation Checklist............................................................... |

6 |

Materials Required ................................................................ |

6 |

Minimum Fireplace Dimensions ............................................. |

6 |

Clearances to Combustibles .................................................. |

7 |

Combustible Mantel Clearances ............................................ |

7 |

INSTALLATION |

|

Gas Connection...................................................................... |

8 |

Venting .......................................................................... |

8 |

Flue Liner Installation ............................................................. |

8 |

Gas Pipe Pressure Test.......................................................... |

9 |

SIT Valve Description ............................................................ |

9 |

Gas Insert Aeration System.................................................... |

9 |

Optional Brick Panel .............................................................. |

9 |

Log Installation .................................................................... |

10 |

E33 Conversion Kit from NG to LPG.................................... |

12 |

Faceplate & Trim .................................................................. |

13 |

Standard Flush Door ............................................................ |

14 |

Flush Louvers....................................................................... |

14 |

Full Screen Front.................................................................. |

14 |

Excalibur Surround Installation............................................. |

15 |

Optional Screen Doors ......................................................... |

16 |

Accent Kit Installation ........................................................... |

16 |

Double Door Option.............................................................. |

16 |

Wiring Diagram..................................................................... |

17 |

Optional Remote Control ..................................................... |

17 |

Optional Wall Thermostat ..................................................... |

17 |

Final Check ........................................................................ |

18 |

|

Page |

OPERATING INSTRUCTIONS |

|

First Fire ........................................................................ |

18 |

Operating Instructions .......................................................... |

18 |

Lighting Procedure ............................................................... |

18 |

Shutdown Procedure............................................................ |

18 |

Copy of Lighting Instruction Plate......................................... |

19 |

Automatic Convection Fan Operation .................................. |

19 |

Normal Operating Sounds of Gas Appliances...................... |

19 |

MAINTENANCE |

|

Maintenance Instructions ..................................................... |

20 |

General Vent Maintenance .................................................. |

20 |

Log Replacement ................................................................. |

20 |

Glass Gasket ....................................................................... |

20 |

Steel or Gold Plated Trim ..................................................... |

20 |

Door Glass ........................................................................ |

21 |

Flush Glass Replacement .................................................... |

21 |

Fan Maintenance.................................................................. |

21 |

Valve Assembly Removal and Installation ........................... |

22 |

REPLACEMENT PARTS LIST |

|

Parts List ........................................................................ |

23 |

WARRANTY |

|

Warranty ........................................................................ |

31 |

E33 FPI Direct Vent Gas Insert |

3 |

|

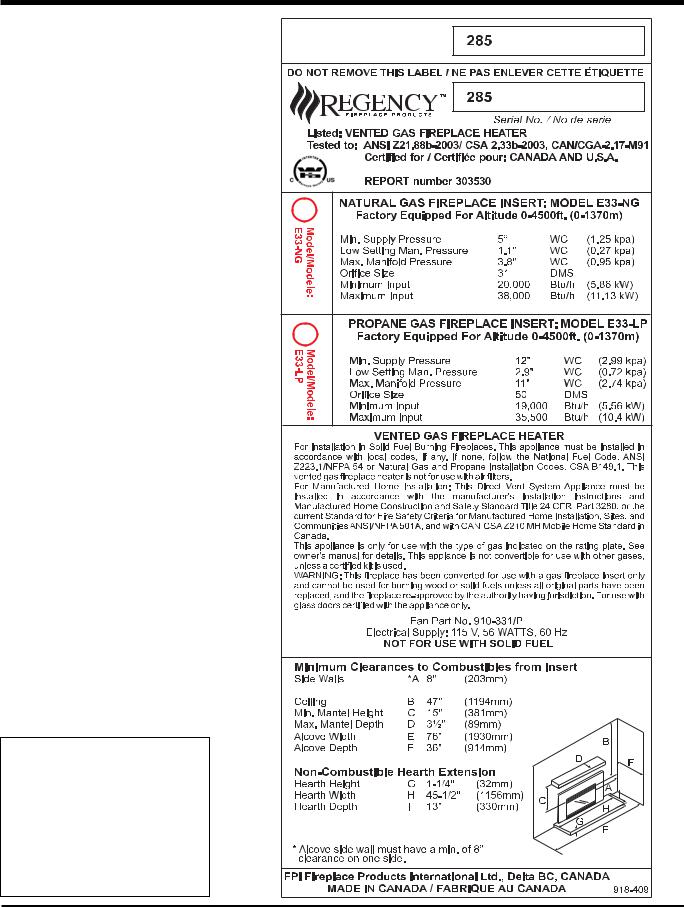

SAFETY LABEL

This is a copy of the labels that accompany each E33 Gas Insert. We have printed a copy of the contents here for your review. The safety label is located on a plate inside the base of the unit visiblewhenthebottomlouverisopened.Ensure that the safety label is attached to the unit.

NOTE: FPI units are constantly being improved. Check the label on the unit and if there is a difference, the label on the unit is the correct one.

For the State of Massachusetts, installation and repair must be done by a plumber or gasfi tter licensed in the Commonwealth of Massachusetts.

For the State of Massachusetts, fl exible connectors shall not exceed 36 inches in length.

For the State of Massachusetts, the appliances individual manual shut-off must be a t-handle type valve.

4 |

E33 FPI Direct Vent Gas Insert |

INSTALLATION

IMPORTANT:

SAVE THESE

INSTRUCTIONS

The FPI Gas Fireplace must be installed in accordance with these instructions. Carefully read all the instructions in this manual fi rst. Consult the building authority having jurisdiction to determine the need for a permit prior to starting the installation.

NOTE: Failure to follow the instructions could cause a malfunction of the heater which could result in death, serious bodily injury, and/or property damage. Failure to follow these instructions may also void your fi re insurance and/or warranty.

FOR YOUR SAFETY

This appliance requires air for proper combustion.Always provide adequate combustion and ventilation air. Follow instructions and information in CSA B149.1 (in Canada) or the National FuelGasCodeANSZ223.1/NFPA(intheUSA), regarding requirements for combustion and ventilation air.

GAS PRESSURE

TESTING

The appliance must be isolated from the gas supply piping system by closing its individual manual shut off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than

1/2 psig. (3.45 kPa).

SPECIFICATIONS

At pressures over 1/2 psig, the pipe to the unit must be disconnected.

Gas Input Capacity:

Natural Gas 38,000 Btu/h

Propane |

35,500 Btu/h |

Min. Input:

Natural Gas 20,000 Btu/h

Propane |

19,000 Btu/h |

Fuels: Approved for use with both natural gas, and propane. Approved as is for use at 0' to 4,500' (0-1370m).

Electrical: 120V A.C. system. Circulation Fan: Variable speed, 127 CFM. Log Set: Ceramic fi bre, 8 per set. Vent System: 3" co-linear aluminum fl ex.

INSTALLATION INTO A SOLID FUEL BURNING FIREPLACE OR FACTORY BUILT FIREPLACE

The E33 Gas Inserts have been tested and approved to be vented into any masonry fi replace or approved solid fuel burning factory built

fireplace that will allow the insert to physically

fit into the fi rebox. Refer to page 6 for minimum

fireplace clearances.

If the factory built fireplace* height is too low for your Insert, you may remove the smoke baffle plate and damper from the factory built fireplace as long as these items are saved and are reinstalled in the event that theInsertisremoved.NOTE:Anyalterations made to the listed solid fuel burning factory built fireplace may void the listing of the fireplace. Cutting any sheet-metal parts of thefireplace,inwhichthegasfireplaceinsert is to be installed, is prohibited.

If the factory-built fireplace has no gas access hole(s) provided, an access hole of 1.5" (37.5mm) or less may be drilled through the lower sides or bottom of the firebox in a proper workmanship like manner. This access hole must be plugged with non-com- bustible insulation after the gas supply line has been installed.

The fireplace and fireplace chimney must be clean and in good working order and constructed of non-combustible materials and chimneycleanoutsmustfitproperly.Refractory, glass doors, screen rails, screen mesh, and log grates can be removed from the fireplace before installing the gas fireplace insert. Smoke shelves, shields and baffles may be removed if attached by mechanical fasteners. A tight connection between the gas fireplace insert flue collar and the fireplace chimney must be made.

*Check with your local inspector before commencing with this installation.

BEFORE YOU START

Safe installation and operation of this appliance requires common sense, however, we are required by the Canadian Safety Standards and ANSI Standards to make you aware of the following:

General Safety Information

1)The appliance installation must conform with local codes or in the absence of local codes, with CAN/CSAB149.1 (in Canada) or the National Fuel Gas CodeANSI Z223.1 NFPA54intheU.S.A.Thisapplianceshould beinstalledbyaqualifiedgasfittertechnician only.

2)Installation and repair should be done by a qualified service person.

3)The appliance should be inspected before use and at least annually by a professional service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding material, animal hair, etc. It is imperative that control compartments, burners and circulating air passageways of the appliance be kept clean.

4)See general construction and assembly instructions. This appliance may only be installed in a vented, noncombustible fi replace.

5)This appliance is Listed for bedroom installations when used with a Listed Millivolt Thermostat. Some areas may have further requirements, check local codes before installation.

6)Always connect this appliance to a vent system vent that is run (or routed) to the outside of the building envelope. Never vent to another room or inside a building. Make sure that the vent is properly sized and is of adequate height to provide the proper draft.

7)Inspect the venting system annually for blockage and any signs of deterioration.

8)Any glass removed for servicing must be replaced prior to operating the appliance.

9)WARNING: Failure to position the parts in accordance with the diagrams in this manualorfailuretouseonlypartsspecifically approved with this appliance may result in property damage or personal injury.

10)To prevent injury, do not allow anyone who is unfamiliar with the operation to use the fi replace.

E33 FPI Direct Vent Gas Insert |

5 |

|

INSTALLATION

11)Due to high temperatures, the appliance should be located out of high traffic areas and away from furniture and draperies. Children and adults should be alerted to the hazards of high surface temperatures, especially the fi replace glass, and should stayawaytoavoidburnsorclothingignition. Young children should be carefully supervised when they are in the same room as the appliance. Clothing or other fl ammable material should not be placed on or near the appliance.

Emissions from burning wood or gas could contain chemicals known to the State of California to cause cancer, birth defects or other reproductive harm.

14)Install optional Excalibur Surround. See page 15.

15)Install optional remote control or wall thermostat, pages 17.

16)Final check (page 18): Before leaving this unit with the customer, the installer must ensure that the appliance is fi ring correctly. This includes:

a)Clocking the appliance to ensure the correct fi ring rate.

b)Adjusting the primary air, if required, to ensure that the fl ame does not carbon. See page 9.

c)Ensuringthattheapplianceisventing correctly.

INSTALLATION

CHECKLIST

Before installing vent system ensure that the damper plate is open and secure to prevent the damper plate from falling down and crushing the liner.

The FPI Gas Insert is installed as listed below.

1)Check all clearances to combustibles, see page 7.

2)Make the gas connection. See page 8.

3)Installthe3"fluelinertotheslidingconnector plate. See page 8.

4)Slide the unit half way into the fi replace.

5)Pull the vent connector plate through the tapered brackets and fasten to the front plate. See page 8.

6)Slide the unit fully into the fi replace.

7)Test gas pressure, page 9. Check aeration system, page 9.

8)Install the optional brick panels. See page 9.

9)Install the log set. See page 10.

10)Assemble and install the faceplate and trim. See page 13.

11)Install the standard fl ush door. See page 14.

12)Install both louvers. See page 14.

13)Install optional full screen doors. See page 16.

MATERIALS

REQUIRED

Noelectricalpowersupplyisrequiredforthegas control to operate. A 120 Volt AC power cord is hooked up to the fan. Plug the 3 wire cord into a suitable receptacle. Do not cut the ground terminaloffunderanycircumstances. When connected with 120 volts, the appliance must be electrically grounded in accordance with local codes, current version of the Canadian Electrical Code CSA C22.1 (in Canada) or in the absence of local codes, with the National Electrical Code ANSI/NFPA 70.

NOTE: This unit is equipped with a heat sensor thermodisc which will prevent the blower from operating until the unit reaches the correct temperature.

WARNING:

Electrical Grounding Instructions This appliance is equipped with a three pronged (grounding) plug for your protection against shock hazard and should be plugged directly into a properly grounded three-prong receptacle. Do not cut or remove the grounding prong from this plug.

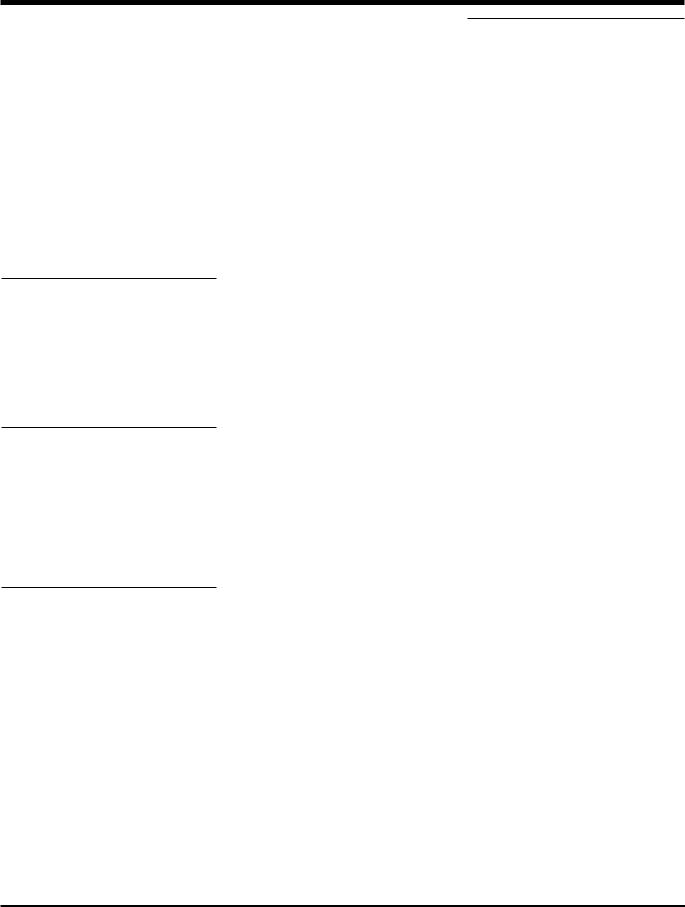

MINIMUM FIREPLACE

OPENING

The minimum fi replace opening for the FPI gas fi replace insert is shown in the following diagrams:

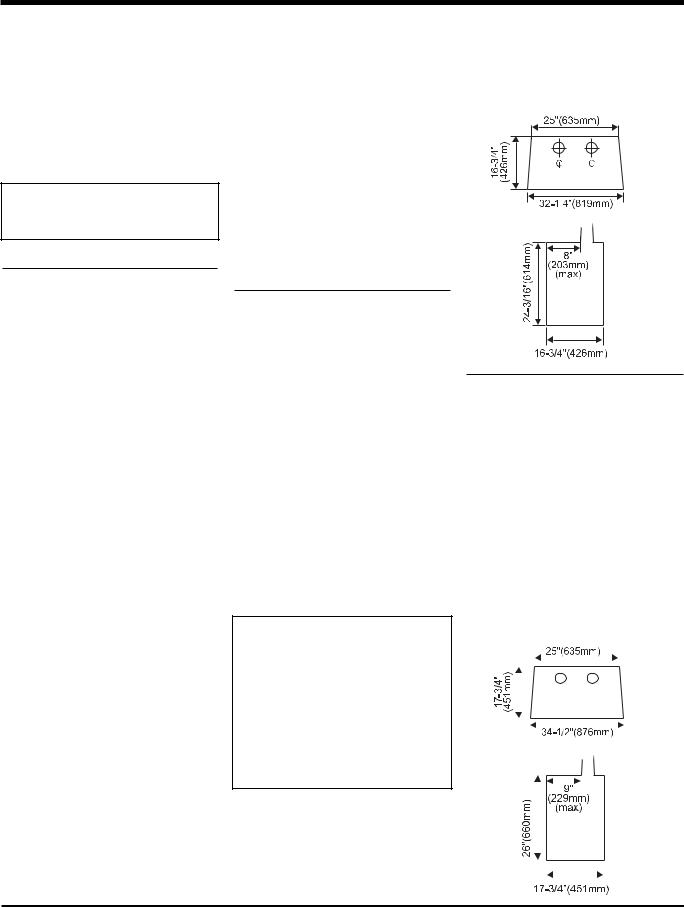

MINIMUM FIREPLACE OPENING EXCALIBUR OPTION

The minimum fi replace opening for the FPI gas fi replace insert is shown in the following diagrams:

NOTE: If you are installing the Excalibur,theminimumfireplacedimensions are as follows:

Width (at front): |

|

34-1/2" (876mm) |

|||||||||||||||||||

Depth: |

|

17-3/4" (451mm) |

|||||||||||||||||||

Height: |

26" |

|

|

|

|

(660mm) |

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

E33 FPI Direct Vent Gas Insert |

INSTALLATION

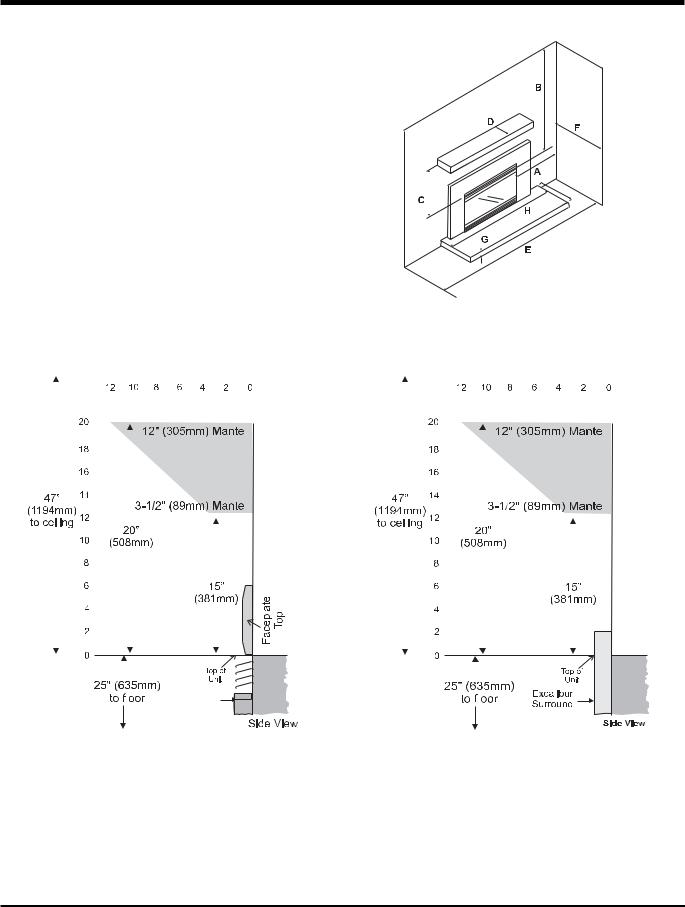

MINIMUM CLEARANCES TO COMBUSTIBLES

From Unit

Side Walls |

* A 8" (203 mm) |

|||||

Ceiling |

B |

47" (1194 mm) |

||||

Min. Mantel Height |

C |

15" (381 mm) |

||||

Max. Mantel Depth |

D |

3-1/2" (89 mm) |

||||

Alcove Width |

E |

76" (1930 mm) |

||||

Alcove Depth |

F |

36" (914 mm) |

|

|

||

|

||||||

Hearth Height |

G |

1-1/4" (32 mm) |

|

|

|

|

|

|

|||||

|

||||||

Hearth Width |

H |

45-1/2" (1156 mm) |

||||

Hearth Depth |

I |

13" (330 mm) |

|

|

||

* Alcove side wall must have a min. of 8" clearance on one side.

|

|

|

|

|

REGENCY FLUSH |

EXCALIBUR SURROUND & FULL SCREEN DOORS |

|||||||||||||||||||||||||||||||||||||||||||||||

COMBUSTIBLE MANTEL CLEARANCES |

COMBUSTIBLE MANTEL CLEARANCES |

||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Because of the extreme heat this fireplace emits, the mantel clearances are critical.

Combustible mantel clearances from top of unit are shown in the above diagrams.

Note: A non-combustible mantel may be installed at a lower height if the framing is made of metal studs covered with a non-combustible board.

Mantel can be installed anywhere in shaded area or higher using the above scale.

Note: Ensure the paint that is used on the mantel and the facing is "heat resistant" or the paint may discolour.

E33 FPI Direct Vent Gas Insert |

7 |

|

INSTALLATION

GAS CONNECTION

GAS CONNECTION WARNING: Only persons licensed to work with gas piping may make the necessary gas connections to this appliance.

1)If the appliance is to be installed into an existing chimney system, thoroughly clean the masonry or factory built fi replace.

2)The appliance is provided with an opening on the left hand side of the control compartment. A 3/8" NPT gas supply pipe must be brought near this inlet hole.

3)Locate the center point where the vent will pass through the chimney above the appliance. Move the appliance into the exact location where it is to be installed. Ensure that the Insert is level.

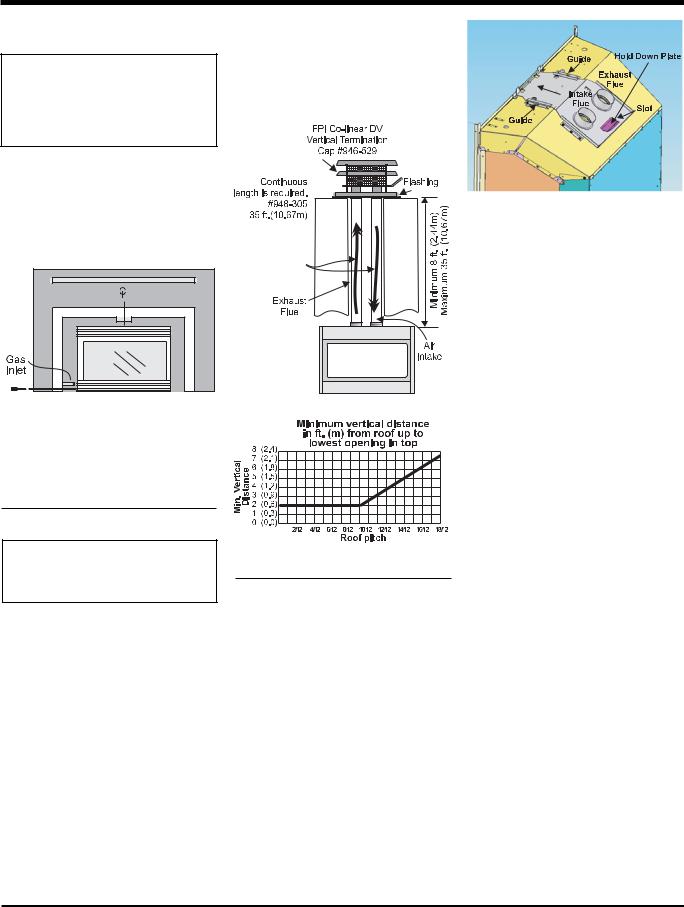

VENTING

THE APPLIANCE MUST NOT BE CONNECTED TO A CHIMNEY FLUE SERVING A SEPARATE SOLID FUEL BURNING APPLIANCE.

This appliance is designed to be attached to two 3" (76mm) co-linear aluminium fl ex running the full length of the chimney. The fl ue length must be a minimum length of 8 ' (2.44m) and a maximum of 35' (10.7m). See chart above for minimum distances from roof. Periodically check that the vent is unrestricted.

Masonry chimneys may take various contours which the fl exible liner will accommodate. However, keep the flexible liner as straight as possible, avoid unnecessary bending.

Part # |

Description |

948-305 |

3" Flex - 35 ft. |

946-529 |

FPI Co-linear DV Vertical |

|

Termination Cap |

Alternate Approved Caps |

|

980 |

Vertical Termination Cap |

991 |

High Wind Cap |

923GK |

3" Co-linear Adaptor with |

|

fl ashing |

In areas of consistently high winds, we recommend using the Simpson Dura-Vent System (923GK adapter and 991 high-wind cap).

TheAir Intake pipe must be attached to the inlet air collar of the termination cap.

FLUE LINER

INSTALLATION

1)Cut the fl ex liner as required.

2)Mark the end of one liner to indicate Exhaust.

3)Connect the other end of the above liner to the exhaust side of the termination adaptor, seal connection with high temperature silicone. Secure with gear clamp.

4)Connect the 2nd liner to the inlet side of the adaptor,sealconnectionwithhightemperature silicone. Secure with gear clamp.

5)Install fl ashing.

6)Insert both liners into chimney, passing through the damper opening.

7)Install termination cap.

8)Connect the marked end of the liner to the exhaust collar of the vent connector plate marked with an "E", seal connection with high temperature silicone. Secure with gear clamp.

9)Connectthe2ndlinertotheintakecollar,seal connection with high temperature silicone. Secure with gear clamp.

10)Align vent connector plate with guides on unit.

11)Slideunitintomasonryopening,whileensuring that the slot at the rear of the connector plate mates up with the hold down plate on the unit.

12)Secure with Screw.

NOTE:

1)Final gas connection should be made after unit is in place to avoid damage to line when pushing the unit into position.

2)Mill-pac may be used instead of high tempture silicone and screws may be used instead of gear clamps at connections of liner to inlet and vent collars.

8 |

E33 FPI Direct Vent Gas Insert |

INSTALLATION

GAS PIPE |

7) |

Pilot Outlet |

|

||

|

8) |

Main Gas Outlet |

PRESSURE TESTING 9) |

Alternative TC Connection Point |

|

The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig. (3.45 kPa). Disconnect piping from valve at pressures over 1/2 psig.

The manifold pressure is controlled by a regulator built into the gas control, and should be checked at the pressure test point.

NOTE:Toproperlycheckgaspressure,both inlet and manifold pressures should becheckedusingthevalvepressure ports on the valve.

1)Make sure the valve is in the "OFF" position.

2)Loosen the "IN" and/or "OUT" pressure tap(s), turning counterclockwise with a 1/8" wide fl at screwdriver.

3)Attach manometer to "IN" and/or "OUT" pressure tap(s) using a 5/16" ID hose.

4)Light the pilot and turn the valve to "ON" position.

5)The pressure check should be carried out with the unit burning and the setting should be within the limits specifi ed on the safety label.

6)When fi nished reading manometer, turn off the gas valve, disconnect the hose and tighten the screw (clockwise) with a 1/8" fl at screwdriver. Note: Screw should be snug, but do not over tighten.

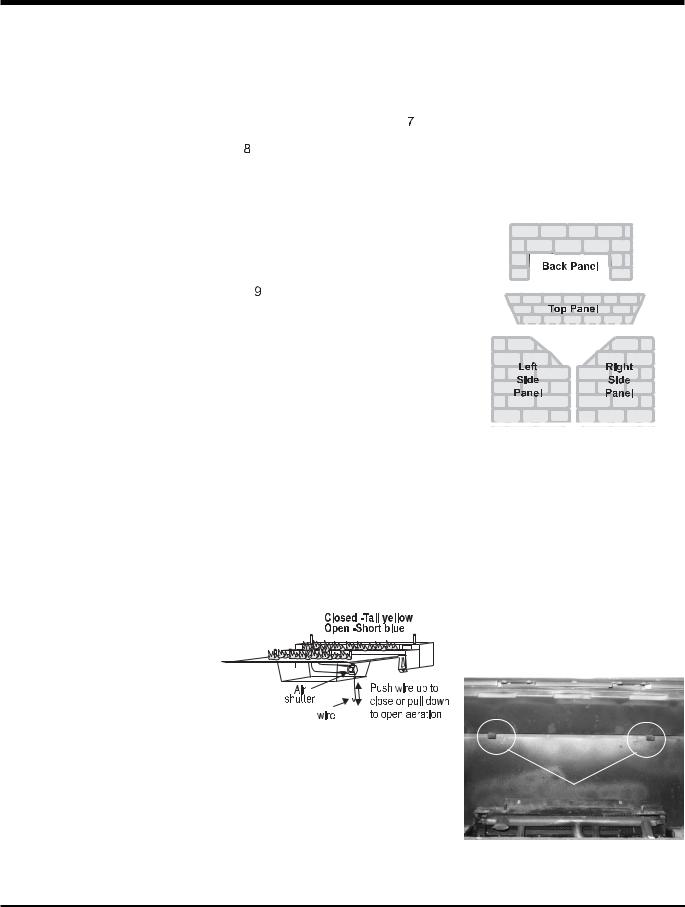

GAS INSERT

AERATION SYSTEM

The air shutter can be adjusted by moving the adjusting wire up or down. The wire is accessed throughthebottomlouveropening.Opentheair shutter for a blue fl ame or close for a yellower fl ame. The burner aeration is factory set but may need adjusting due to either the local gas supply or altitude.

Minimum Air Shutter Opening:

5/16" Natural Gas

7/16" Propane

CAUTION: Carbon will be produced if air shutter is closed too much.

SIT Valve Description

1)Gas cock knob

2)Manual high/low adjustment

3)Pilot Adjustment

4)Thermocouple Connection - option

5)Manifold (Outlet) Pressure Tap

6)Inlet Pressure Tap

OPTIONAL

BRICK PANEL

Optional Brick Panel Set: |

|

|

Part # |

Description |

Qty |

|

Top (brick) panel |

1 |

|

Back (brick) panel |

1 |

|

Left (brick) panel |

1 |

|

Right (brick)panel |

1 |

340-043 |

Top bracket |

1 |

340-094 |

Bottom clips |

2 |

511-031 |

Brick clips |

2 |

Installation of Brick Panels:

1)Remove top louver and glass door if installed.

2)Remove the logs if they are already in stalled. Note: the grate must be removed in order to remove the bottom log. Ensure you slide the bottom coal off to the right-hand side to avoid chipping.

3)Unwrap the brick pattern panels from the protectivewrapping.Handlethepanelswith care as they can break easily.

4)Remove the two screws from the bottom of the baffle plate. Install the bottom clips onto the baffle plate (refer to Diagram 1).

1 |

2 |

3 |

4 |

IN OUT

6 5

Note: Any damage due to carboning resulting from improperly setting the aeration controls is NOT covered under warranty.

Note: Aeration Adjustment should only be performed by an authorized FPI Installer at the time of installation or service.

Bottom Clips

Diagram 1

E33 FPI Direct Vent Gas Insert |

9 |

|

INSTALLATION

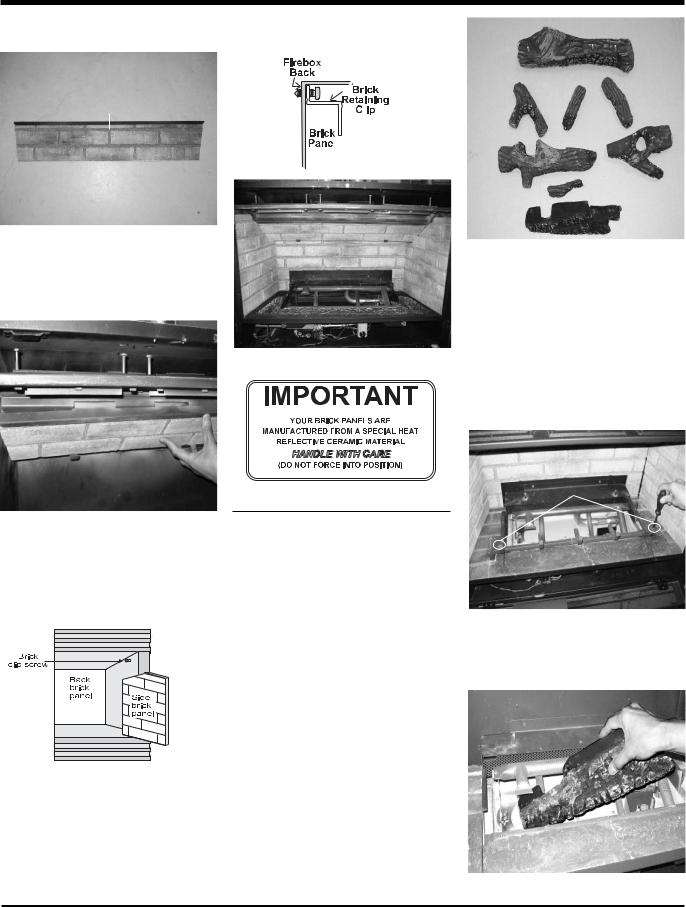

5) Place the top bracket onto the top edge of |

10) Install the 2 brick retaining clips, one on |

|||

the top panel (refer to Diagram 2). |

each side. |

|||

Top Bracket |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diagram 2

6)Slide the top panel and bracket assembly carefully onto the baffle plate ensuring the panel is centered. Make sure the tabs of the topbracketfitintothebaffleopenings(refer to Diagram 3).

Final Installation

|

|

03-23 |

03-22 |

03-18 |

03-24 |

|

03-20

03-19 03-21

03-17

The "03" reference numbers (i.e. 03-23) are molded into the rear of each log.

Instructions:

1)Remove and carefully unwrap the logs from the box. Please handle with care and do not force them into position to avoid chipping.

2)Remove the top louver and fl ush door if installed (refer to page 14).

3)To remove the grate, loosen the two Phillips screws which are securing the grate. Slide the grate outwards to remove it from the unit (refer to Diagram 1).

Screws

Diagram 3

7)Insert the back panel by sliding it between the sidewalls of the fi rebox and the rear log support.

8)Before installing the side brick panels, remove the screws from the side brick clips (refer to Diagram 4).

Diagram 4

9)Insert the side panel by positioning it fl at against the side walls. Tilt the panel towards the middle ofthefirebox, theninsert the bottom front corner. Repeat on the other side.

LOG INSTALLATION

WARNING:Dangerousoperatingconditions may occur if these logs are not positioned in their correct certified locations. Read the following instructions carefully and refer to the attached diagram.

Materials Required:

Complete Log Set (Part # 340-930) Contains the following:

|

Description |

03-17 |

Bottom Log |

03-18 |

Center Top Log |

03-19 |

Front Log |

03-20 |

Left Log |

03-21 |

Right Log |

03-22 |

Left top Log |

03-23 |

Rear Log |

03-24 |

Right Top Log |

Diagram 1

4)Angle log 03-17 and slide it between the top and bottom burner tube under the “T” section until it touches the left grate support bracket (refer to Diagram 2).

03-17

Diagram 2

10 |

E33 FPI Direct Vent Gas Insert |

Loading...

Loading...