Page 1

MVI56-PDPMV1

ControlLogix Platform

PROFIBUS DPV1 Master

USER MANUAL

March 22, 2011

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2011 ProSoft Technology, Inc., all rights reserved.

MVI56-PDPMV1 User Manual

March 22, 2011

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM in

Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be freely downloaded from

our web site: www.prosoft-technology.com

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS

I, DIV. 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Warnings

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in Hazardous Locations, turn off power before replacing or rewiring

modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be nonhazardous.

C Suitable for use in Class I, Division 2, Groups A, B, C, and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Battery Life Advisory

The MVI46, MVI56, MVI56E, MVI69, and MVI71 modules use a rechargeable Lithium Vanadium Pentoxide battery to

backup the real-time clock and CMOS. The battery should last for the life of the module. The module must be

powered for approximately twenty hours before the battery becomes fully charged. After it is fully charged, the battery

provides backup power for the CMOS setup and the real-time clock for approximately 21 days. When the battery is

fully discharged, the module will revert to the default BIOS and clock settings.

Note: The battery is not user replaceable.

Page 4

Markings

Electrical Ratings

Backplane Current Load: 800 mA @ 5 Vdc; 3 mA @ 24 Vdc

Operating Temperature: 32°F to 140°F (0°C to 60°C)

Storage Temperature: -40°F to 185°F (-40°C to 85°C)

Shock: 30 g operational; 50 g non-operational; Vibration: 5 g from 10 Hz to 150 Hz

Relative Humidity 5% to 95% (with no condensation)

All phase conductor sizes must be at least 1.3 mm (squared) and all earth ground conductors must be at least

4mm (squared).

Label Markings

<Ex>

II 3 G

Ex nA IIc T6 X

0°C <= Tamb <= 60°C

Agency Approvals and Certifications

CE EMC-EN61326-1:2006; EN61000-6-4:2007

CB Safety CA/10533/CSA IEC 61010-1 Ed. 2,

CB 243333-2056722 (2090408)

GOST-R EN61010

CSA 61010

DNV DET NORSKE VERITAS Test 2.4

Lloyds Lloyds Register Test Specification Number 1,2002

ATEX EN 60079-0:July 2006; EN60079-15:Oct 2005

243333 ME06

Page 5

MVI56-PDPMV1 ♦ ControlLogix Platform Contents

PROFIBUS DPV1 Master User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

MVI (Multi Vendor Interface) Modules ................................................................................................ 3

Warnings ............................................................................................................................................. 3

Battery Life Advisory ........................................................................................................................... 3

Markings .............................................................................................................................................. 4

Guide to the MVI56-PDPMV1 User Manual 9

1 Start Here 11

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.5.1

1.5.2

1.5.3

1.5.4

1.7.1

1.7.2

1.8.1

1.8.2

1.8.3

1.8.4

1.8.5

System Requirements ............................................................................................. 12

Package Contents ................................................................................................... 13

Installing ProSoft Configuration Builder Software ................................................... 14

Installing the Module in the Rack ............................................................................ 15

Choosing Sample Ladder Logic For Your Application ............................................ 16

Determining the Firmware Version of Your Processor ............................................ 17

Determining the Firmware Version of the MVI56-PDPMV1 Module ....................... 18

Determining the Module Mode (LEGACY or FLEX) ................................................ 20

Sample Program Summary ..................................................................................... 22

Using the MVI56-PDPMV1 Sample Ladder Logic .................................................. 23

Using the MVI56-PDPMV1 Add-On Instruction ...................................................... 24

LEGACY Sample Add-On Instruction Import Procedure ........................................ 24

FLEX Sample Add-On Instruction Import Procedure .............................................. 38

Common Settings for All Sample Programs ............................................................ 65

Choosing the Controller Type ................................................................................. 65

Selecting the Slot Number for the Module .............................................................. 68

Selecting the Connection Parameters for the Module ............................................ 69

Selecting the RPI Time for the Module ................................................................... 71

Changing and Importing Configuration Changes (for PCB v 2.2.0 and up only) .... 72

Downloading the Sample Program to the Processor .............................................. 76

Connecting Your PC to the Module ......................................................................... 77

2 Configuring the MVI56-PDPMV1 Module 79

2.1

2.2

2.3

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

2.4

2.4.1

Setting Up the Project ............................................................................................. 80

Setting Module Parameters ..................................................................................... 82

Configuring the PROFIBUS Master ........................................................................ 84

Installing the GSD Files ........................................................................................... 85

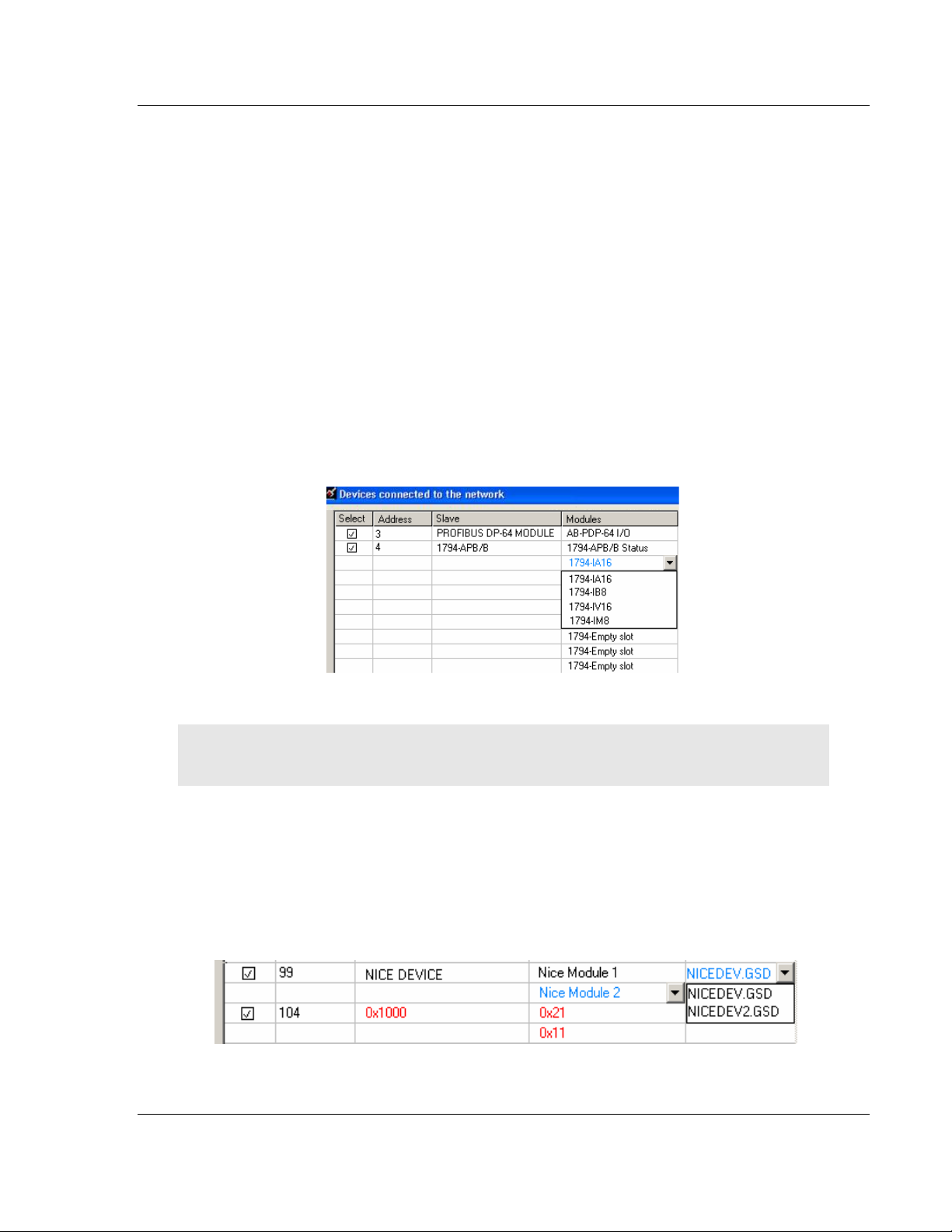

Configuring the PROFIBUS Slaves ......................................................................... 86

Printing the Processor Network Memory Map....................................................... 104

Exporting the Processor Files Prior to PCB v2.2.0 ............................................... 105

Exporting the Processor Files for PCB v2.2.0 or later .......................................... 107

Backing Up the Project .......................................................................................... 109

Downloading the Project to the Module ................................................................ 111

Example 1: Local Rack Application ....................................................................... 113

ProSoft Technology, Inc. Page 5 of 255

March 22, 2011

Page 6

Contents MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

2.4.2

2.5

2.5.1

2.5.2

2.5.3

2.5.4

2.5.5

Example 2: Remote Rack Application .................................................................. 117

Verifying Correct Operation .................................................................................. 123

Checking the PROFIBUS LEDs on the MVI56-PDPMV1 ..................................... 123

Viewing the Online Status of the PROFIBUS Network ......................................... 124

Viewing the Fieldbus Data from the MVI56-PDPMV1’s Configuration/Debug Menu126

Viewing the Controller Tags in RSLogix 5000 ...................................................... 129

Sending a Mailbox Message in RSLogix 5000 ..................................................... 130

3 Mailbox Messaging 133

3.1

3.2

3.3

3.4

3.5

3.6

3.1.1

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.3.1

3.3.2

3.3.3

3.5.1

3.5.2

3.5.3

3.5.4

3.5.5

3.5.6

3.5.7

3.5.8

3.5.9

3.5.10

3.5.11

3.6.1

3.6.2

3.6.3

3.6.4

Mailbox Message Queuing ................................................................................... 134

Queue Timeouts ................................................................................................... 134

Flex Mode Mailbox Communication...................................................................... 135

Using FLEX Mode MSG Instructions .................................................................... 136

Retrieving Status Information ............................................................................... 137

Sending Mailbox Commands ................................................................................ 139

Reading Alarms .................................................................................................... 143

Rebooting the Module ........................................................................................... 144

Legacy Mode Mailbox Communication ................................................................. 145

Input Mailbox: Legacy Mode ................................................................................. 145

Output Mailbox: Legacy Mode .............................................................................. 146

Receiving Mailbox Message Responses from the Module: Legacy Mode ........... 146

Special Function Mailbox Messaging Commands ................................................ 148

Mailbox Message Commands .............................................................................. 150

Mailbox Message: Set Slave Mode ...................................................................... 150

Mailbox Message: Get Slave Diagnostics ............................................................ 153

Mailbox Message: Get Slave Configuration ......................................................... 155

Mailbox Message: Set Slave Address .................................................................. 157

Mailbox Message: Get Live List ............................................................................ 160

Mailbox Message: Acyclic Data Read: Class 1 .................................................... 161

Mailbox Message: Acyclic Data Write: Class 1 .................................................... 164

Mailbox Message: Alarm Indication ...................................................................... 165

Mailbox Message: Set Operating Mode ............................................................... 167

Mailbox Message: Start Slave .............................................................................. 169

Mailbox Message: Stop Slave .............................................................................. 170

Mailbox Messaging Error Codes........................................................................... 173

Acyclic Message Status Word .............................................................................. 173

Return Codes ........................................................................................................ 174

Error Codes ........................................................................................................... 175

DP-V1 Error Codes ............................................................................................... 176

4 Diagnostics and Troubleshooting 177

4.1

4.2

4.2.1

4.2.2

4.2.3

4.2.4

4.2.5

4.3

4.3.1

4.3.2

Basic Troubleshooting Steps ................................................................................ 178

LED Status Indicators: Front of MVI56 Module .................................................... 179

Module Faceplate Status Indicators ..................................................................... 179

PROFIBUS Master Indicators ............................................................................... 180

Examples .............................................................................................................. 180

Legacy Mode (Use Legacy Mode = Yes) ............................................................. 182

Flex Mode (Use Legacy Mode=No) ...................................................................... 183

Using ProSoft Configuration Builder (PCB) for Diagnostics ................................. 184

Disabling the RSLinx Driver for the Com Port on the PC ..................................... 184

RS-232 Configuration/Debug Port ........................................................................ 186

Page 6 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 7

MVI56-PDPMV1 ♦ ControlLogix Platform Contents

PROFIBUS DPV1 Master User Manual

4.3.3

4.3.4

DB9 to RJ45 Adaptor (Cable 14) .......................................................................... 186

Using the Diagnostic Window in ProSoft Configuration Builder ............................ 187

5 Reference 197

5.1

5.2

5.3

5.4

5.1.1

5.1.2

5.1.3

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.2.7

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.4.1

5.4.2

Product Specifications ........................................................................................... 198

General Specifications .......................................................................................... 198

Hardware Specifications........................................................................................ 199

Functional Specifications....................................................................................... 199

About the PROFIBUS Protocol ............................................................................. 201

PROFIBUS DP Architecture .................................................................................. 201

Bus Access ............................................................................................................ 201

Master/Slave Communication Phases .................................................................. 202

How Cable Length Affects Communication Rate .................................................. 202

PROFIBUS Master Port ........................................................................................ 203

Constructing a Bus Cable for PROFIBUS DP ....................................................... 204

Supported PROFIBUS Services ........................................................................... 208

PROFIBUS comDTM ............................................................................................ 209

ProSoft Technology Product Availability ............................................................... 209

Introduction to PROFIBUS comDTM .................................................................... 210

System Requirements ........................................................................................... 212

Installation ............................................................................................................. 213

Quick Start ............................................................................................................. 215

Verifying the comDTM Version and comDTM Install Version ............................... 223

Module Functional Overview ................................................................................. 229

Legacy Mode Input and Output Data Blocks......................................................... 230

Flex Mode Input and Output Data Blocks ............................................................. 236

6 Support, Service & Warranty 245

Contacting Technical Support ......................................................................................................... 245

6.1

6.2

6.1.1

6.1.2

6.1.3

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.2.6

6.2.7

6.2.8

6.2.9

6.2.10

Return Material Authorization (RMA) Policies and Conditions.............................. 247

Returning Any Product .......................................................................................... 247

Returning Units Under Warranty ........................................................................... 247

Returning Units Out of Warranty ........................................................................... 248

LIMITED WARRANTY ........................................................................................... 248

What Is Covered By This Warranty ....................................................................... 249

What Is Not Covered By This Warranty ................................................................ 249

Disclaimer Regarding High Risk Activities ............................................................ 250

Intellectual Property Indemnity .............................................................................. 250

Disclaimer of all Other Warranties ........................................................................ 251

Limitation of Remedies ** ...................................................................................... 251

Time Limit for Bringing Suit ................................................................................... 252

No Other Warranties ............................................................................................. 252

Allocation of Risks ................................................................................................. 252

Controlling Law and Severability ........................................................................... 252

Index 253

ProSoft Technology, Inc. Page 7 of 255

March 22, 2011

Page 8

Contents MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

Page 8 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 9

MVI56-PDPMV1 ♦ ControlLogix Platform Guide to the MVI56-PDPMV1 User Manual

PROFIBUS DPV1 Master User Manual

Guide to the MVI56-PDPMV1 User Manual

Function

Introduction

(Must Do)

Diagnostic and

Troubleshooting

Reference

Product Specifications

Support, Service, and

Warranty

Index

Section to Read Details

Start Here (page 11) This section introduces the customer to the

→

Diagnostics and

→

Troubleshooting

(page 177)

Reference (page

→

197)

Product

Specifications (page

198)

Support, Service

→

and Warranty (page

245)

Index

module. Included are: package contents,

system requirements, hardware installation, and

basic configuration.

This section describes Diagnostic and

Troubleshooting procedures.

These sections contain general references

associated with this product and its

Specifications..

This section contains Support, Service and

Warranty information.

Index of chapters.

ProSoft Technology, Inc. Page 9 of 255

March 22, 2011

Page 10

Guide to the MVI56-PDPMV1 User Manual MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

Page 10 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 11

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

1 Start Here

In This Chapter

System Requirements ........................................................................... 12

Package Contents ................................................................................. 13

Installing ProSoft Configuration Builder Software .................................. 14

Installing the Module in the Rack ........................................................... 15

Choosing Sample Ladder Logic For Your Application ........................... 16

Using the MVI56-PDPMV1 Sample Ladder Logic ................................. 23

Using the MVI56-PDPMV1 Add-On Instruction ..................................... 24

Common Settings for All Sample Programs .......................................... 65

Downloading the Sample Program to the Processor ............................. 76

Connecting Your PC to the Module ....................................................... 77

For most applications, the installation and configuration steps described in this

section will work without additional programming. ProSoft Technology strongly

recommends that you complete the steps in this chapter before developing a

custom application.

After you have verified that the module is installed and communicating

successfully with the processor and the PROFIBUS network.

ProSoft Technology, Inc. Page 11 of 255

March 22, 2011

Page 12

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

1.1 System Requirements

The MVI56-PDPMV1 module requires the following minimum hardware and

software components:

Rockwell Automation ControlLogix processor, with compatible power supply

and one free slot in the rack, for the MVI56-PDPMV1 module. The module

requires 800 mA of available power.

Rockwell Automation RSLogix 5000 programming software version 2.51 or

higher.

Rockwell Automation RSLinx communication software

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o

Microsoft Windows XP Professional with Service Pack 1 or 2

o

Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o

Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 x 768 recommended)

CD-ROM drive

Dial-up Internet connection (Broadband connection recommended)

Approved PROFIBUS cabling and connectors.

Small flat blade screwdriver to secure the PROFIBUS connector to the

module

Note: You can install the module in a local or remote rack. For remote rack installation, the module

requires Ethernet I/P or ControlNet access to the processor.

Page 12 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 13

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

1.2 Package Contents

The following components are included with your MVI56-PDPMV1 module, and

are all required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

Qty. Part Name Part Number Part Description

1 MVI56-PDPMV1

Module

1 Cable Cable #15 - RS232

1 Cable Cable #14 - RJ45

1 inRAx Solutions CD Contains sample programs, utilities and

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

MVI56-PDPMV1 PROFIBUS DPV1 Master

For RS232 between a Personal Computer

Null Modem

to DB9 Male

Adapter

(PC) and the CFG port of the module

For connecting the module’s port to Cable

#15 for RS-232 connections

documentation for the MVI56-PDPMV1

module.

ProSoft Technology, Inc. Page 13 of 255

March 22, 2011

Page 14

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

1.3 Installing ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software to configure

the module. You can always get the newest version of ProSoft Configuration

Builder from the ProSoft Technology website.

To install ProSoft Configuration Builder from the ProSoft Technology website

1 Open your web browser and navigate to http://www.prosoft-

technology.com/pcb

2 Click the D

Configuration Builder.

3 Choose S

4 Save the file to your Windows Desktop, so that you can find it easily when

you have finished downloading.

5 When the download is complete, locate and open the file, and then follow the

instructions on your screen to install the program.

If you do not have access to the Internet, you can install ProSoft Configuration

Builder from the ProSoft Solutions Product CD-ROM, included in the package

with your module.

To install ProSoft Configuration Builder from the Product CD-ROM

1 Insert the ProSoft Solutions Product CD-ROM into the CD-ROM drive of your

PC. Wait for the startup screen to appear.

2 On the startup screen, click P

Windows Explorer file tree window.

3 Click to open the U

and files you will need to set up and configure your module.

4 Double-click the S

PCB_*.

software on your PC. The information represented by the "*" character in the

file name is the PCB version number and, therefore, subject to change as

new versions of PCB are released.

OWNLOAD HERE

AVE

or S

AVE FILE

TILITIES

ETUP CONFIGURATION TOOL

EXE

file and follow the instructions on your screen to install the

link to download the latest version of ProSoft

when prompted.

RODUCT DOCUMENTATION

folder. This folder contains all of the applications

folder, double-click the

. This action opens a

Note: Many of the configuration and maintenance procedures use files and other utilities on the

CD-ROM. You may wish to copy the files from the Utilities folder on the CD-ROM to a convenient

location on your hard drive.

Page 14 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 15

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

1.4 Installing the Module in the Rack

If you have not already installed and configured your ControlLogix processor and

power supply, please do so before installing the MVI56-PDPMV1 module. Refer

to your Rockwell Automation product documentation for installation instructions.

Warning: You must follow all safety instructions when installing this or any other electronic

devices. Failure to follow safety procedures could result in damage to hardware or data, or even

serious injury or death to personnel. Refer to the documentation for each device you plan to

connect to verify that suitable safety procedures are in place before installing or servicing the

device.

Warning: When you insert or remove the module while backplane power is on, an electrical arc

can occur. This could cause an explosion in hazardous location installations. Verify that power is

removed or the area is non-hazardous before proceeding. Repeated electrical arcing causes

excessive wear to contacts on both the module and its mating connector. Worn contacts may

create electrical resistance that can affect module operation.

1 Turn power OFF.

2 Align the module with the top and bottom guides, and slide it into the rack

until the module is firmly against the backplane connector.

3 With a firm but steady push, snap the module into place.

4 Check that the holding clips on the top and bottom of the module are securely

in the locking holes of the rack.

5 Make a note of the slot location. You must identify the slot in which the

module is installed in order for the sample program to work correctly. Slot

numbers are identified on the green circuit board (backplane) of the

ControlLogix rack.

6 Turn power ON.

Note: If you insert the module improperly, the system may stop working, or may behave

unpredictably.

ProSoft Technology, Inc. Page 15 of 255

March 22, 2011

Page 16

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

1.5 Choosing Sample Ladder Logic For Your Application

The sample program for your MVI56-PDPMV1 module includes custom tags,

data types and ladder logic for data I/O, status and alarm monitoring, and

mailbox messaging. For most applications, you can run the sample ladder

program without modification, or, for advanced applications, you can incorporate

the sample program into your existing application.

NOTE: ControlLogix firmware versions 15 or earlier do not support Add-On Instructions (AOIs).

For these applications, you will need to use the plain ladder logic sample programs.

For applications with ControlLogix firmware version 16 or newer, you can use the supplied AOI

samples, which encapsulate the ladder logic, controller tags, and user-defined data types into one

convenient import file.

SPECIAL NOTE: For AOI applications created using ProSoft Configuration Builder (PCB) version

2.2.0 or later, the following process of sample ladder selection is not necessary. PCB versions

2.2.0 and up allow you to export custom-made RSLogix 5000 .L5X Rung Import files that precisely

match the module's configuration. Selecting and modifying sample logic will not be required if you

use PCB 2.2.0. or later and follow the procedure found in the topic, Export the Processor Files for

PCB v2.2.0 or later (page 107). For more details, see the section, Using the MVI56-PDPMV1 AddOn Instructions (page 24).

The inRAx Solutions CD provides several versions of the sample ladder logic.

The version number appended to the sample file name (for example, "_v13" or

"_v15") indicates which ControlLogix firmware version the sample program was

created to match. It is best if the ControlLogix processor firmware version and

sample program version match. However, RSLogix 5000 can convert an older

version sample to a later ControlLogix firmware version, if necessary.

The following criteria determine which sample program to select:

o

Processor Firmware Version

o

MVI56-PDPMV1 module firmware version

o

MVI56-PDPMV1 mode used (FLEX or LEGACY)

Note: FLEX mode is available only for module firmware versions 1.21 or later.

The next few topics will help you determine which sample programs will work

best for your application.

Page 16 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 17

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

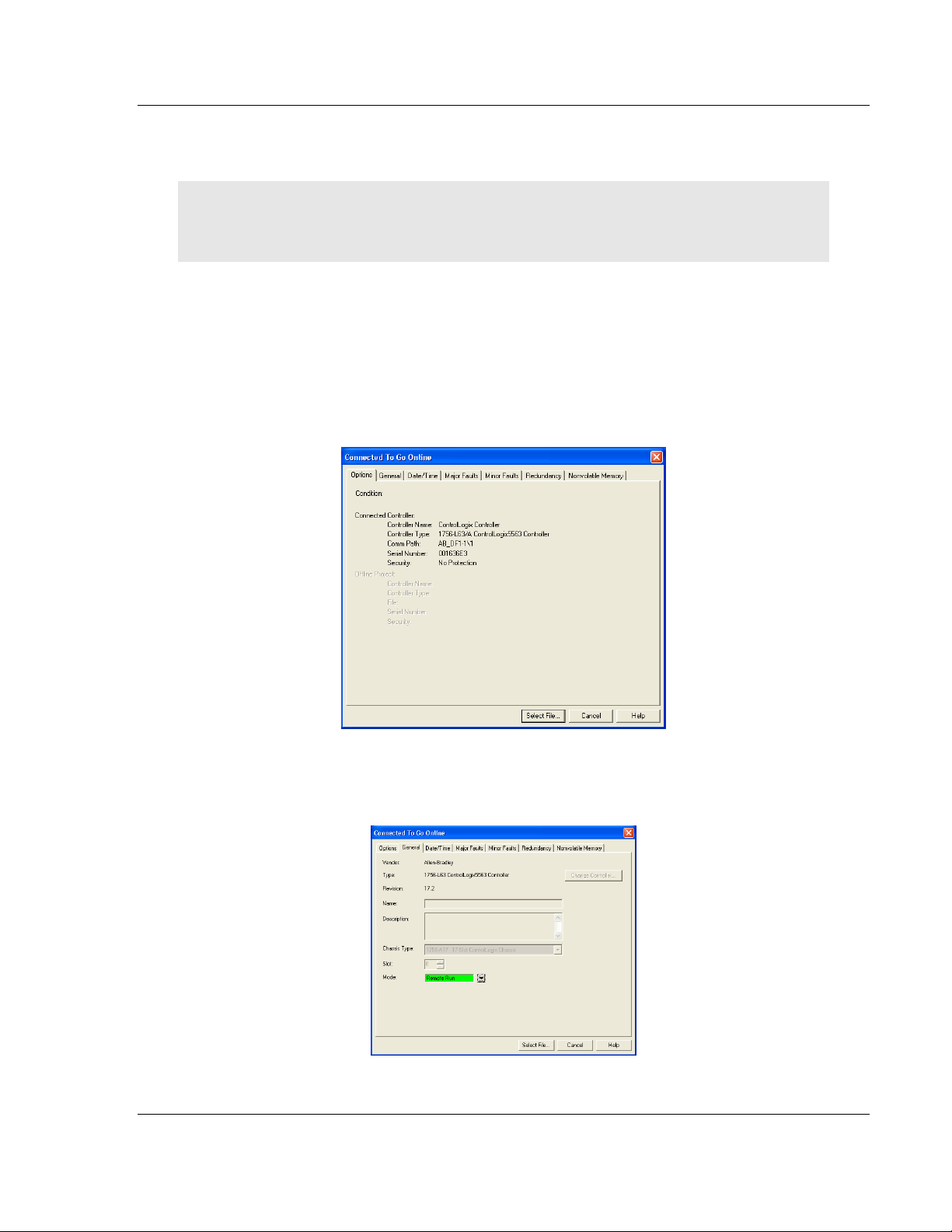

1.5.1 Determining the Firmware Version of Your Processor

Important: The RSLinx service must be installed and running on your computer in order for

RSLogix to communicate with the processor. Refer to your RSLinx and RSLogix documentation for

help configuring and troubleshooting these applications.

1 Connect an RS-232 serial cable from the COM (serial) port on your PC to the

communication port on the front of the processor.

2 Start RSLogix 5000 and close any existing project that may be loaded.

3 Open the C

establish communication with the processor. This may take a few moments.

4 When RSLogix has established communication with the processor, the

Connected To Go Online dialog box will open.

OMMUNICATIONS

menu and choose GO O

NLINE

. RSLogix will

5 In the Connected To Go Online dialog box, click the G

ENERAL

tab. This tab

shows information about the processor, including the Revision (firmware)

version. In the following illustration, the firmware version is 17.2.

ProSoft Technology, Inc. Page 17 of 255

March 22, 2011

Page 18

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

1.5.2 Determining the Firmware Version of the MVI56-PDPMV1

Module

There are two ways to verify the module firmware version:

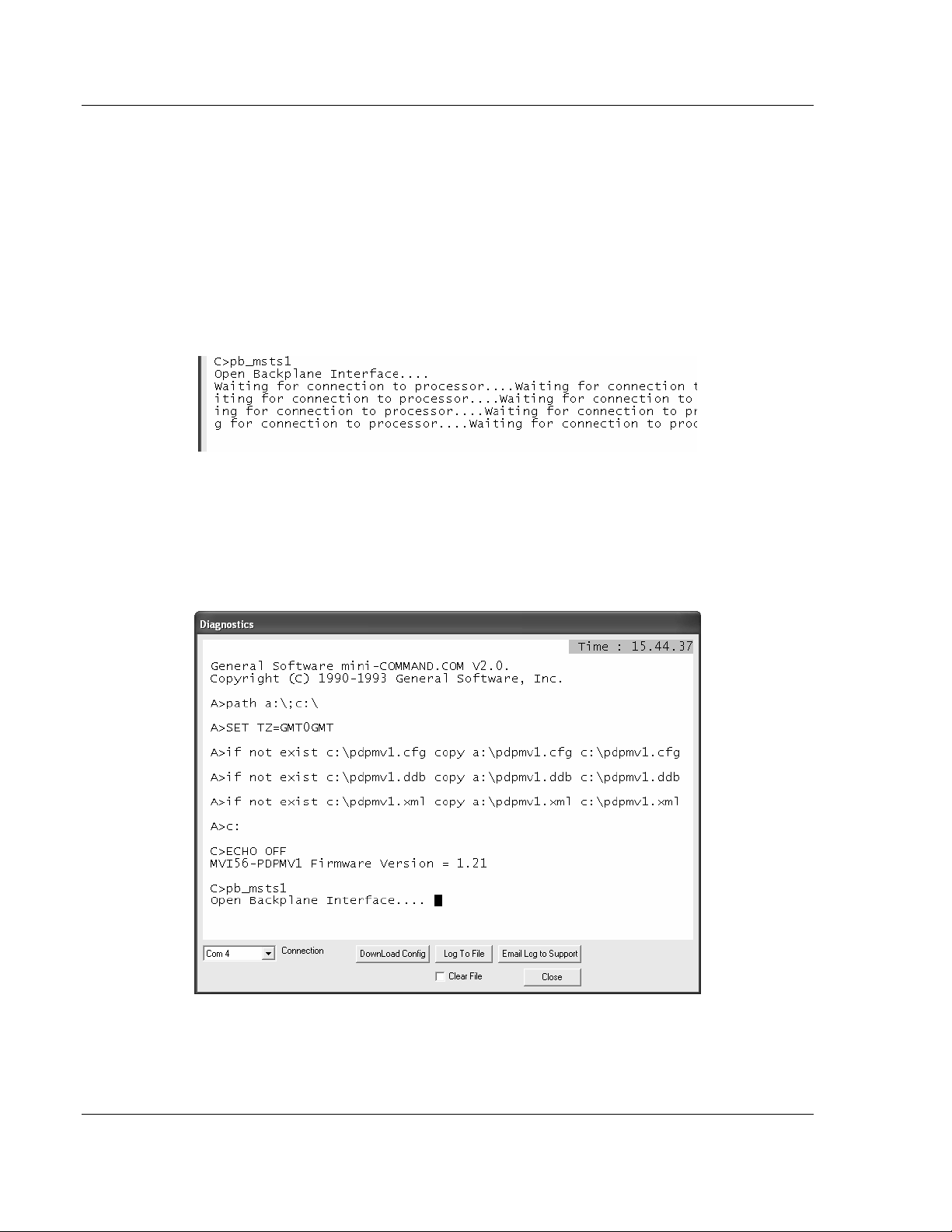

Checking the Version During Power-Up

When the module powers up, it will search for the ControlLogix processor to

establish backplane connectivity. If the correct ladder is not loaded to the

processor, or if the module is not located in the configured slot, or the processor

is missing, the module will not allow access to the debug menu and will print the

message "Waiting for Connection to the processor…"

Because debug menu access is not allowed at this point, view the debug menu

messages that are printed during power-up for the module firmware version.

Refer to the message that appears just before the message "C>pb_msts1":

If the message "MVI56-PDPMV1 Firmware Version = x.xx" appears on the

screen as shown in the following illustration, the module firmware is version 1.21

or later.

Page 18 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 19

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

If the message "MVI56-PDPMV1 Firmware Version = x.xx" does not appear on

the screen, the module firmware version is 0.30.

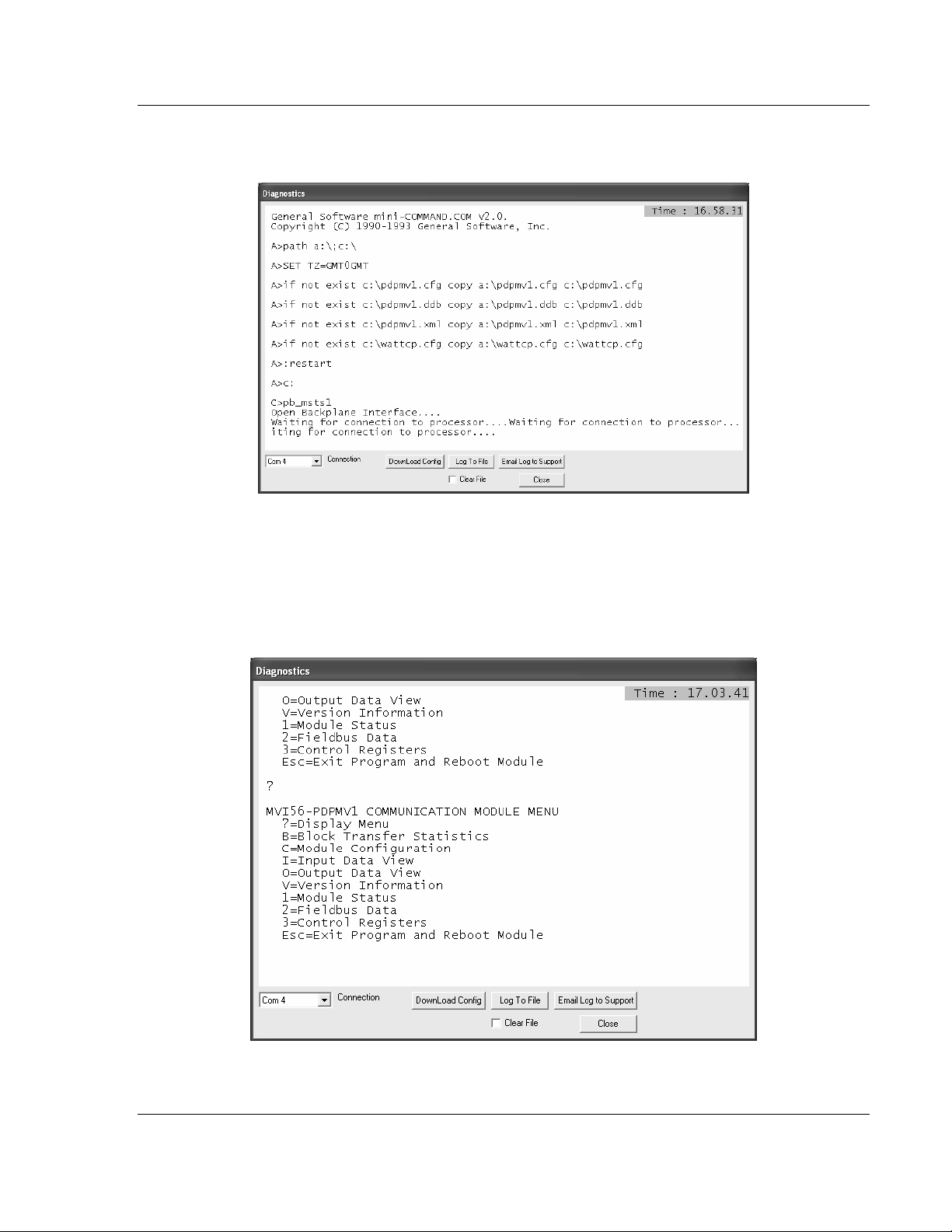

Checking the Version After Power-Up

If the correct sample program (LEGACY or FLEX) is loaded into your processor

and the module is located in same slot that was configured, then after module

power-up it will be possible to access the debug menu through ProSoft

Configuration Builder (PCB).

1 Press [?] to display the main menu:

ProSoft Technology, Inc. Page 19 of 255

March 22, 2011

Page 20

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

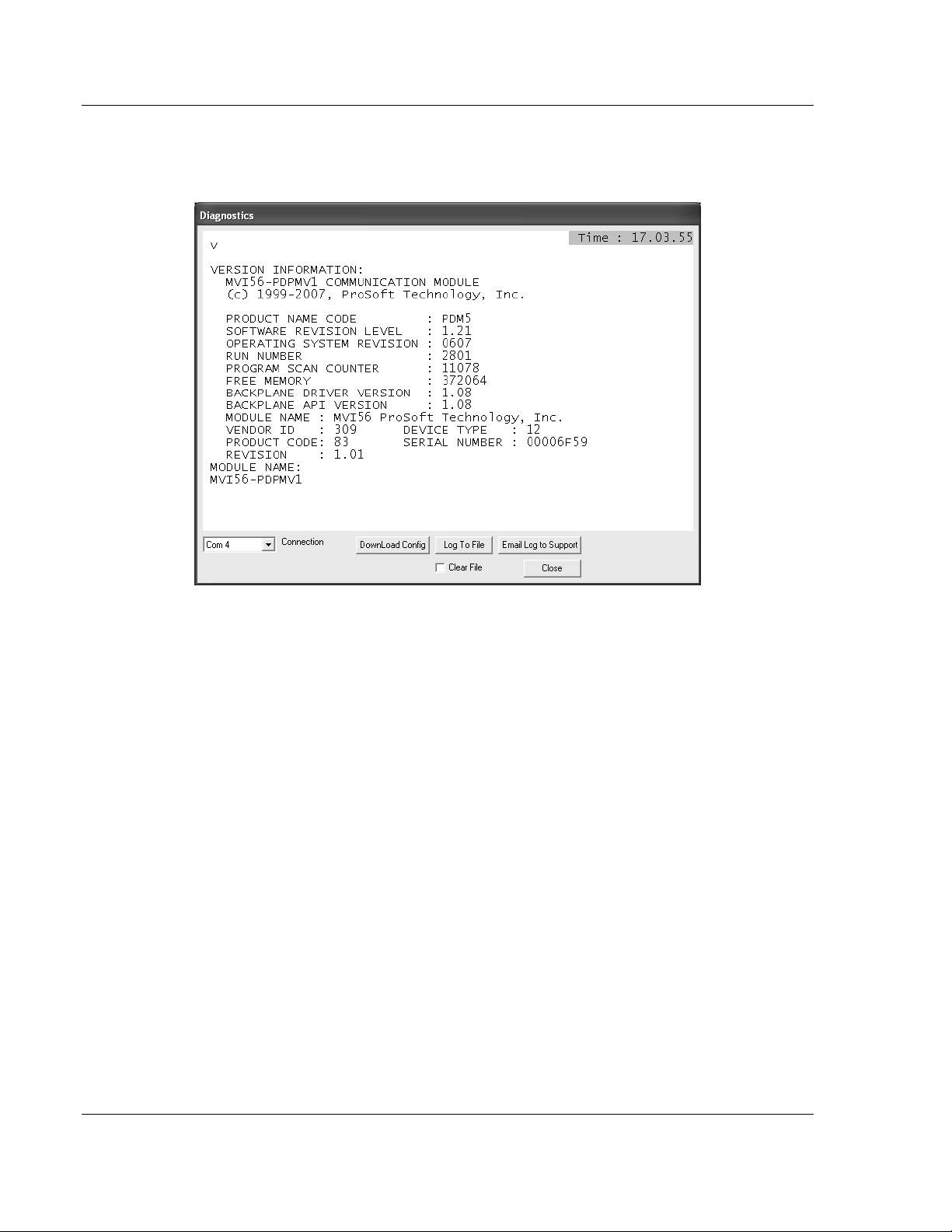

2 Press [V] to display the module version information. Verify "SOFTWARE

REVISION LEVEL" for the module firmware version (1.21 for the example

below):

1.5.3 Determining the Module Mode (LEGACY or FLEX)

There are two versions of the sample program: LEGACY (fixed I/O sizes) and

FLEX (variable I/O sizes) versions.

MVI56-PDPMV1 firmware version 0.30 must use the LEGACY sample

program and fixed I/O sizes.

MVI56-PDPMV1 firmware version 1.21 or later can use either the LEGACY or

FLEX mode sample programs.

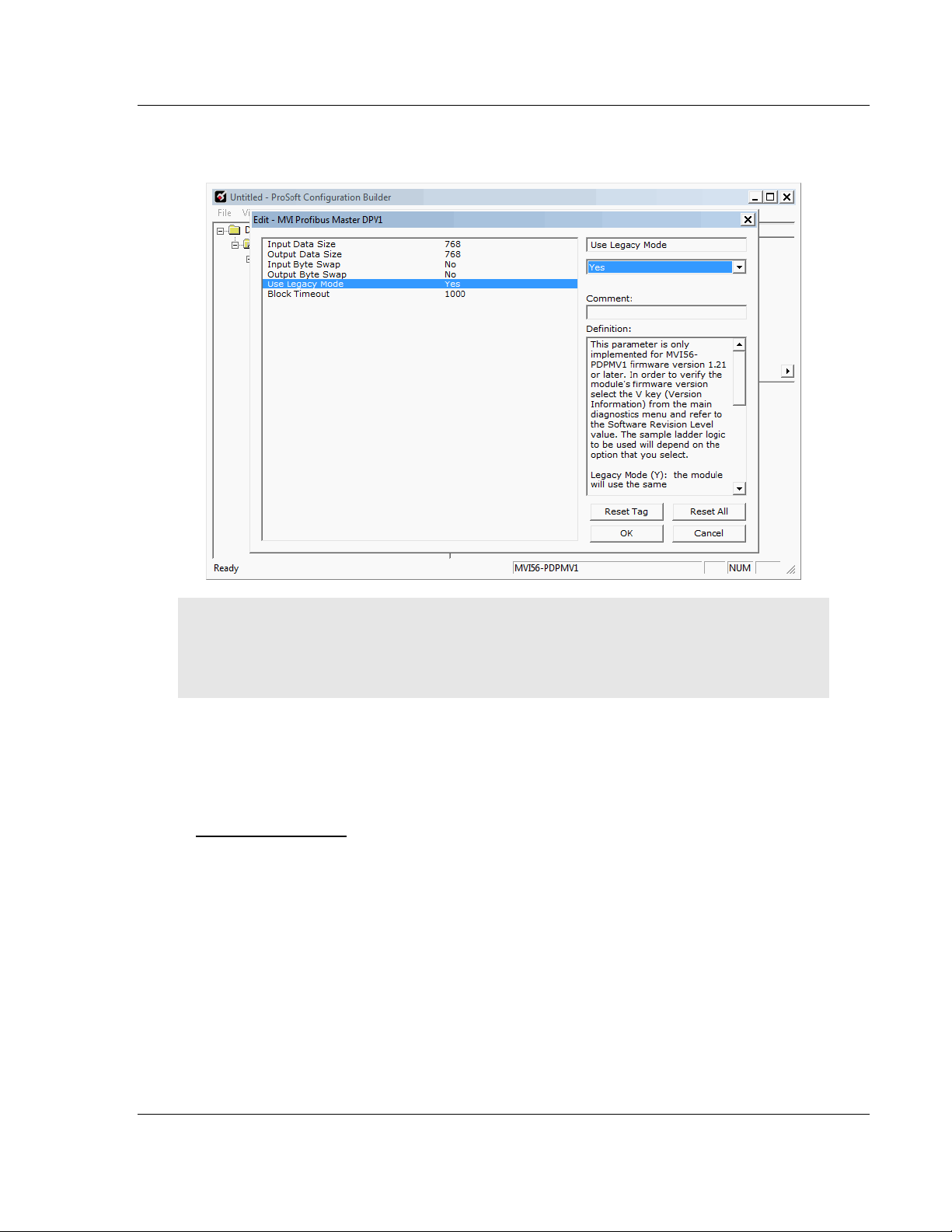

For module firmware version 1.21 or later, the U

parameter in ProSoft Configuration Builder selects which mode you will use.

Setting the parameter to YES says to use fixed I/O sizes in LEGACY mode.

Setting the parameter to NO says to use variable I/O sizes in FLEX mode. This

step is described in Select the Connection Parameters for the Module (page 69).

LEGACY mode allows backward compatibility with firmware version 0.30 and

implements the following features:

Fixed backplane I/O block size (input size = 250 words, output size = 248

words)

Status and Mailbox transferred through regular I/O blocks.

SE LEGACY MODE

configuration

Page 20 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 21

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

LEGACY mode offers these advantages:

Works with all module firmware versions; use LEGACY mode for backward

compatibility in older applications.

Since all parameters are fixed, configuration is simpler than FLEX mode.

Status data is bought across the backplane as I/O data without the need for

additional logic to trigger MSG instructions.

FLEX mode implements the following features:

Supports variable backplane I/O block sizes (input backplane block size can

be set from 12 words to 250 words; output backplane block size can be set

from 5 to 248 words).

Status, Slave Diagnostic, and Mailbox data transferred through MSG

instructions.

Supports IOT instruction for immediate write of backplane output.

When transfer speed for smaller data configurations is a priority or when

backward compatibility is not required, consider using FLEX mode, which

provides these advantages:

Makes it easier to support installing the module in a remote rack. The flexible

backplane I/O block size allows you to adjust the amount of data to transfer

for any specific remote rack application and optimize network bandwidth

utilization.

Improves backplane I/O block transfer performance by implementing MSG

instructions to retrieve module status. This means regular I/O block transfers

are not needed for status data, so process I/O data can be updated more

often. The same applies to Mailbox MSG data transfers.

Improves backplane performance by implementing the IOT instruction for

Immediate Output Transfers, which overrides the module RPI time and sends

data as fast as possible.

ProSoft Technology, Inc. Page 21 of 255

March 22, 2011

Page 22

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

1.5.4 Sample Program Summary

Use the following table to determine which sample program to use for your

application.

MVI56-PDPMV1

Version

0.30 13 - MVI56PDPMV1_LEGACY_v13.ACD -

0.30 15 - MVI56PDPMV1_LEGACY_v15.ACD -

0.30 16 - MVI56PDPMV1_LEGACY_v16.ACD MVI56PDPMV1_LEGACY_v1_3.L5X

1.21 or later 13 Y (LEGACY) MVI56PDPMV1_LEGACY_v13.ACD -

1.21 or later 15 Y (LEGACY) MVI56PDPMV1_LEGACY_v15.ACD -

1.21 or later 16 Y (LEGACY) MVI56PDPMV1_LEGACY_v16.ACD MVI56PDPMV1_LEGACY_v1_3.L5X

1.21 or later 17 Y (LEGACY) MVI56PDPMV1_LEGACY_v17.ACD MVI56PDPMV1_LEGACY_v1_3.L5X

1.21 or later 13 N (FLEX) MVI56PDPMV1_FLEX_v13.ACD -

1.21 or later 15 N (FLEX) MVI56PDPMV1_FLEX_v15.ACD -

1.21 or later 16 N (FLEX) MVI56PDPMV1_FLEX_v16.ACD MVI56PDPMV1_FLEX_v1_2.L5X

1.21 or later 17 N (FLEX) MVI56PDPMV1_FLEX_v17.ACD MVI56PDPMV1_FLEX_v1_2.L5X

Note: For ControlLogix version 16, you will use the Add-On Instruction (AOI) rung import (.L5X)

files, which encapsulate all the required ladder logic, controller tags, and user-defined data types

into a single import file; or you can use the version 16 ladder logic sample files (.ACD), which

already have the AOI files imported. The plain ladder logic sample files (.ACD) for versions 13 and

15 use the same logic as the AOI versions but display them as standard ladder logic. The separate

AOI .L5K file exists to make it easier to import the sample application into an existing project or

new project file. You do not need to import the AOI .L5K files into any of the .ACD ladder logic

sample programs. ControlLogix versions 15 and earlier do not support Add-On Instructions; so do

not try to import the AOI .L5K files into those older versions of RSLogix 5000.

For ControlLogix firmware version 16, refer to Using the MVI56-PDPMV1 Add-On Instructions

(page 24).

For ControlLogix firmware version 15 or older, Using the MVI56-PDPMV1 Sample Ladder

Logic (page 23).

ControlLogix

Version

Use Legacy

Mode

parameter

value

Sample Ladder Add-On Instruction

Page 22 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 23

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

1.6 Using the MVI56-PDPMV1 Sample Ladder Logic

If you will be using ControlLogix firmware versions 16 or higher, you may skip to

the section on Using the MVI56-PDPMV1 Add-On Instructions (page 24).

If you will be using ControlLogix firmware versions 13 or 15, then follow this

procedure:

1 Copy any of the sample programs you may want to use from the distribution

CD in a convenient folder on your local PC hard drive.

2 Start RSLogix 5000 and close any project or programs that may open

automatically when the program starts.

3 On the F

4 Browse to the location where you saved the sample program files on your

local drive and select (left-mouse-click) the one that matches your firmware

version of your ControlLogix processor firmware.

5 Left-click the O

6 RSLogix will load the sample program.

The next step is to configure the correct controller type and slot number for your

application. For details, skip to the section on Common Settings for All Sample

Programs (page 65).

If you want to add the sample file to an existing application, do the following:

1 Open the RSLogix 5000 project .ACD file you wish to use.

2 In a separate instance of RSLogix 5000, open the sample ladder logic you

wish to use.

3 Follow the procedures for adding a Module to the project and setting

Connection Parameters, as found in Creating the MVI56-PDPMV1 Module

Profile - Legacy (page 25), Creating the MVI56-PDPMV1 Module Profile Flex (page 50), and Common Settings for All Sample Programs (page 65).

4 Manually copy the user-defined data types from the sample program and

paste them into your existing application.

5 Manually copy the controller tags from the sample program and paste them

into your existing application.

6 Manually copy the ladder logic tasks and rungs from the sample program and

paste them into your existing application.

ILE

menu, click the O

PEN

button.

PEN

button.

ProSoft Technology, Inc. Page 23 of 255

March 22, 2011

Page 24

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

1.7 Using the MVI56-PDPMV1 Add-On Instruction

Note: This section applies only for applications with ControlLogix firmware version 16 or higher.

For earlier firmware versions, refer to Using the MVI56-PDPMV1 Sample Ladder Logic (page 23).

The Add-On Instruction (AOI) is supplied already installed as part of a complete

.ACD program file and also as an .L5X ladder import file that can be imported

into an existing or new application. Importing the AOI reduces module setup time

and simplifies your application logic. The .L5X file automatically imports the

following components into an application:

User-defined data types

Controller tags and tag arrays

Add-On Instruction logic

Ladder rung required to call the Add-On Instruction

This section will show the procedure on how to import the Add-On Instruction into

your existing ladder for both module modes (LEGACY or FLEX).

1.7.1 LEGACY Sample Add-On Instruction Import Procedure

Note: This section applies only if your application meets one or more of the following conditions:

MVI56-PDPMV1 module firmware version 0.30

MVI56-PDPMV1 module firmware version 1.21 (or later) AND configured in LEGACY mode

(U

SE LEGACY MODE

= YES)

Before You Begin

The following file is required before you start this procedure. Copy the file from

the ProSoft Solutions CD-ROM, or download it from

www.prosoft-technology.com.

File Name Description

MVI56PDPMV1_LEGACY_v*.L5X

(where * is the current sample

program version number)

L5X file containing Add-On Instruction, user-defined data

types, controller tags and tag arrays, and ladder logic required

to set up the MVI56-PDPMV1 module in Legacy mode

Page 24 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 25

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

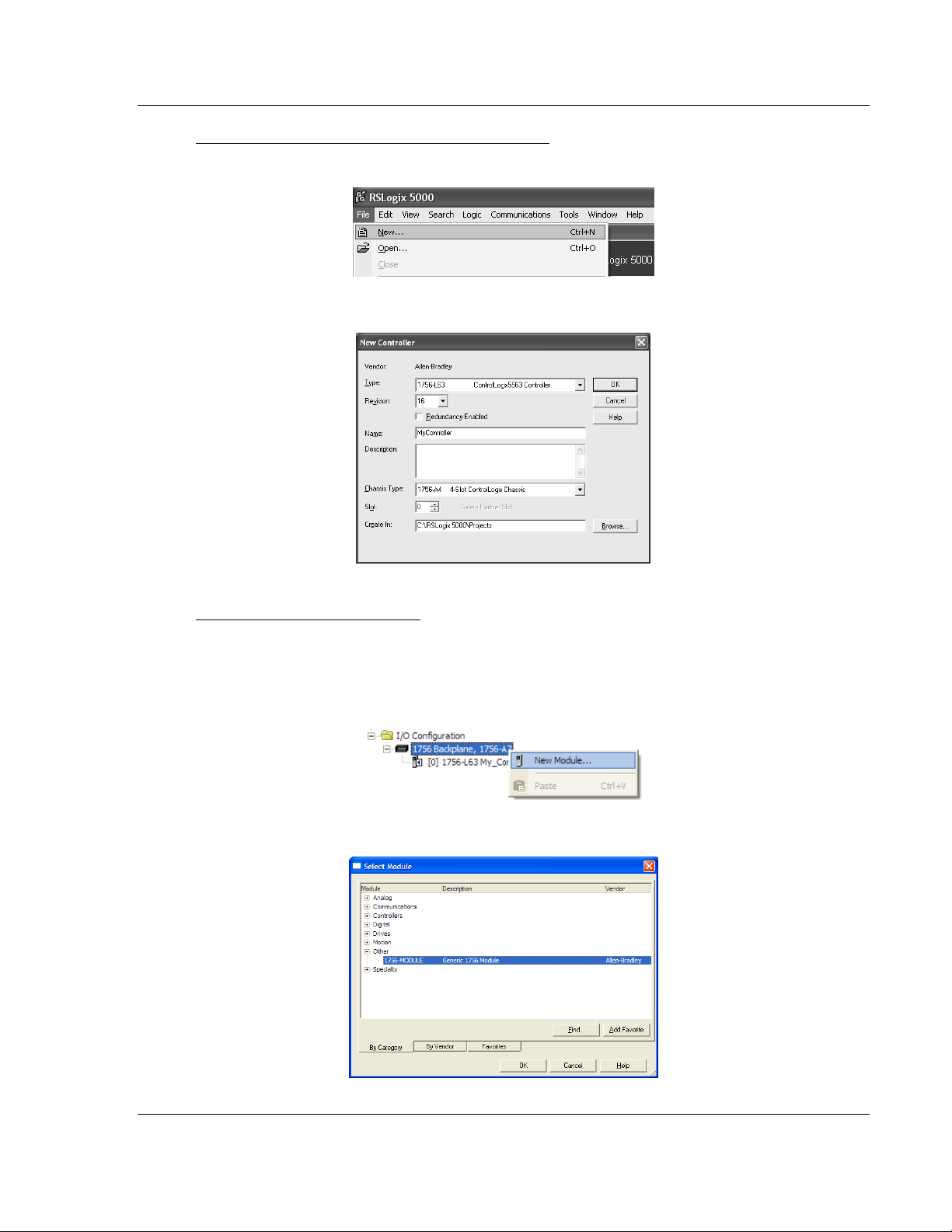

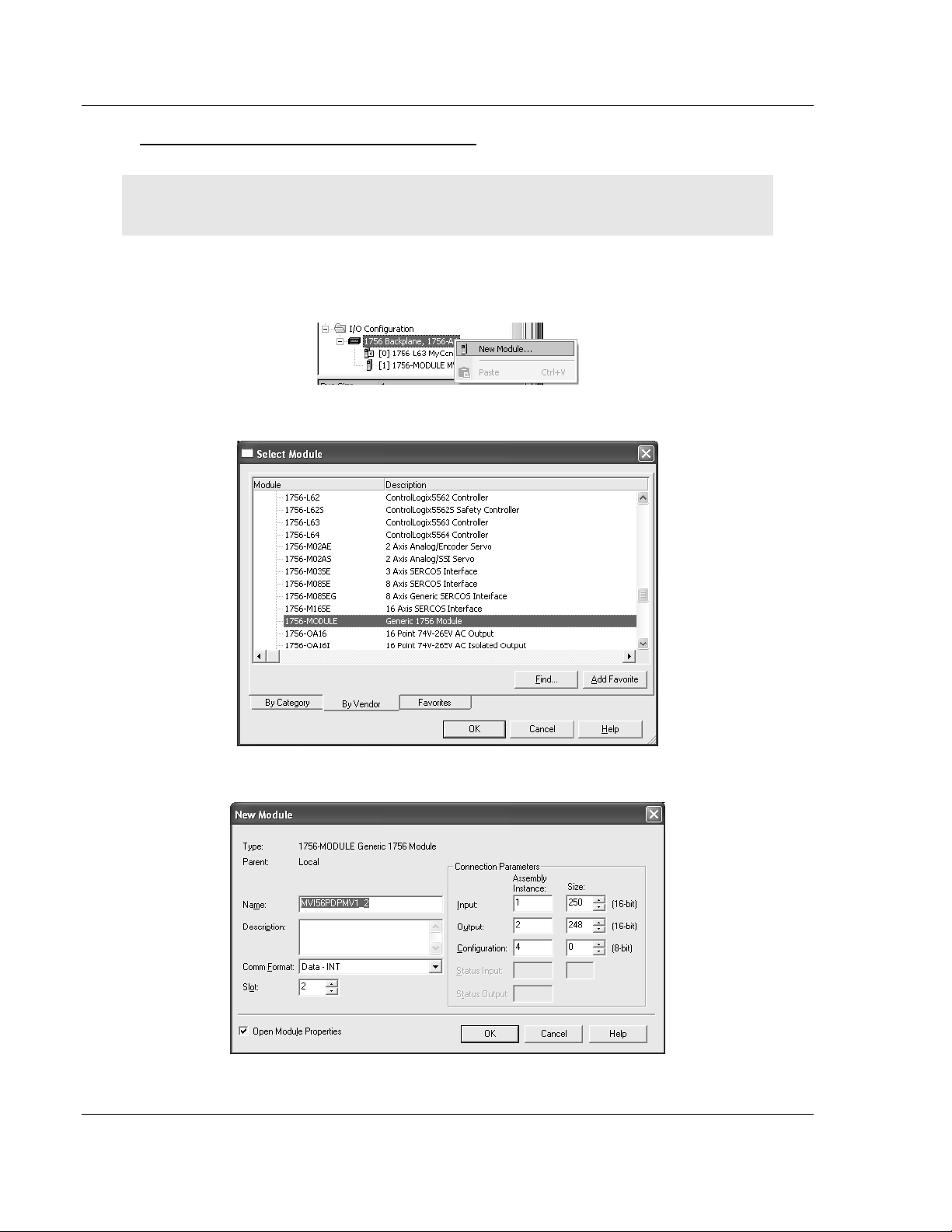

Creating a New RSLogix5000 Project - Legacy

1 Open the File menu, and then choose NEW.

2 Select Revision 16.

Creating the Module - Legacy

1 Add the MVI56-PDPMV1 module to the project.

In the Controller Organization window, select I/O C

ONFIGURATION

the right mouse button to open a shortcut menu. On the shortcut menu,

choose N

EW MODULE

.

This action opens the Select Module dialog box.

and click

ProSoft Technology, Inc. Page 25 of 255

March 22, 2011

Page 26

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

2 Select the 1756-M

ODULE (GENERIC

1756 M

ODULE)

from the list and click OK.

This action opens the New Module dialog box.

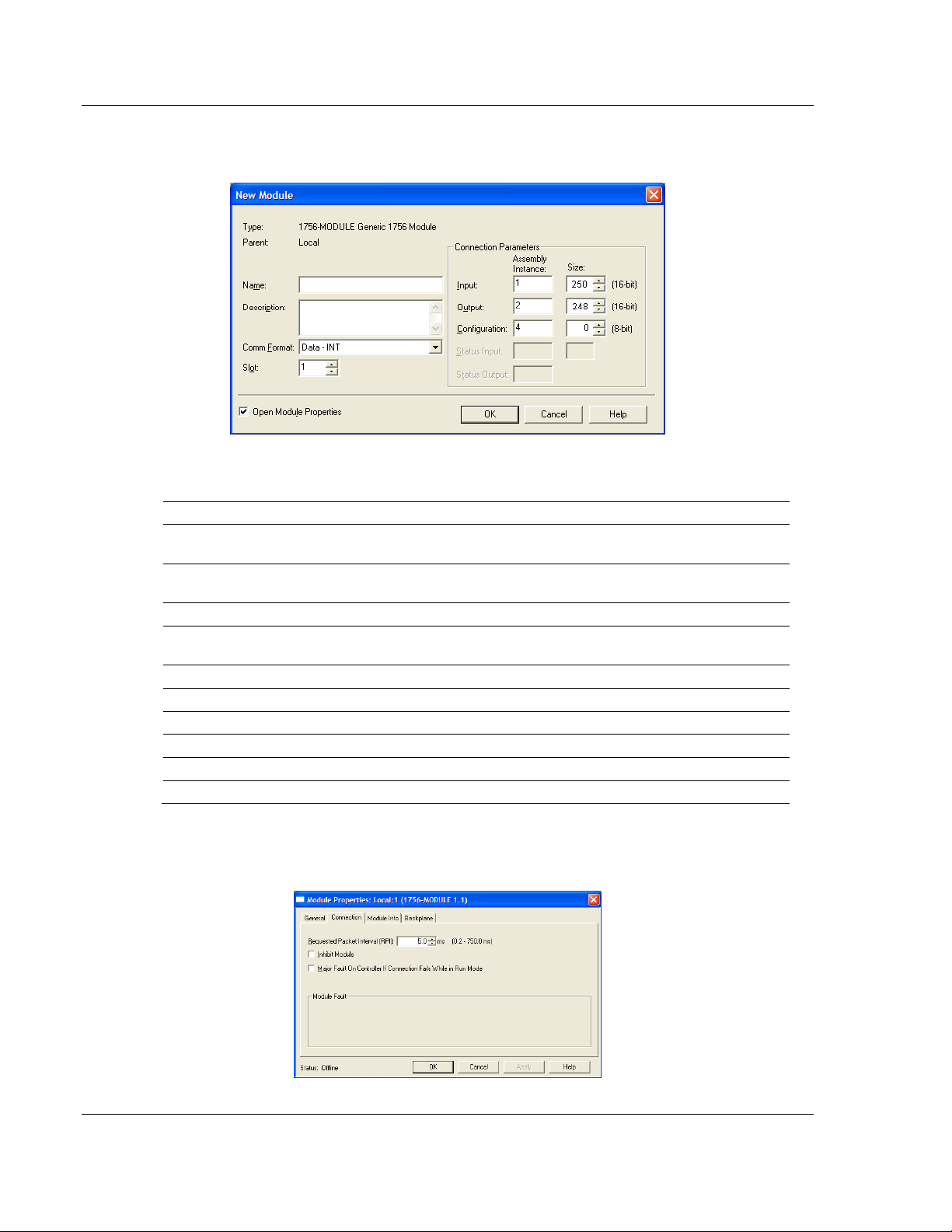

3 Set the Module Properties values as follows:

Parameter Value

Name Enter a module identification string. Example:

MVI56PDPMV1

Description Enter a description for the module. Example: ProSoft

communication module for PROFIBUS communication.

Comm Format

Slot Enter the slot number in the rack where the MVI56-

Input Assembly Instance

Input Size

Output Assembly Instance

Output Size

Configuration Assembly Instance

Configuration Size

Select DATA-INT

PDPMV1 module is located.

1

250

2

248

4

0

4 On the Connection tab, set the RPI value for your project. Click OK to

confirm.

Page 26 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 27

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

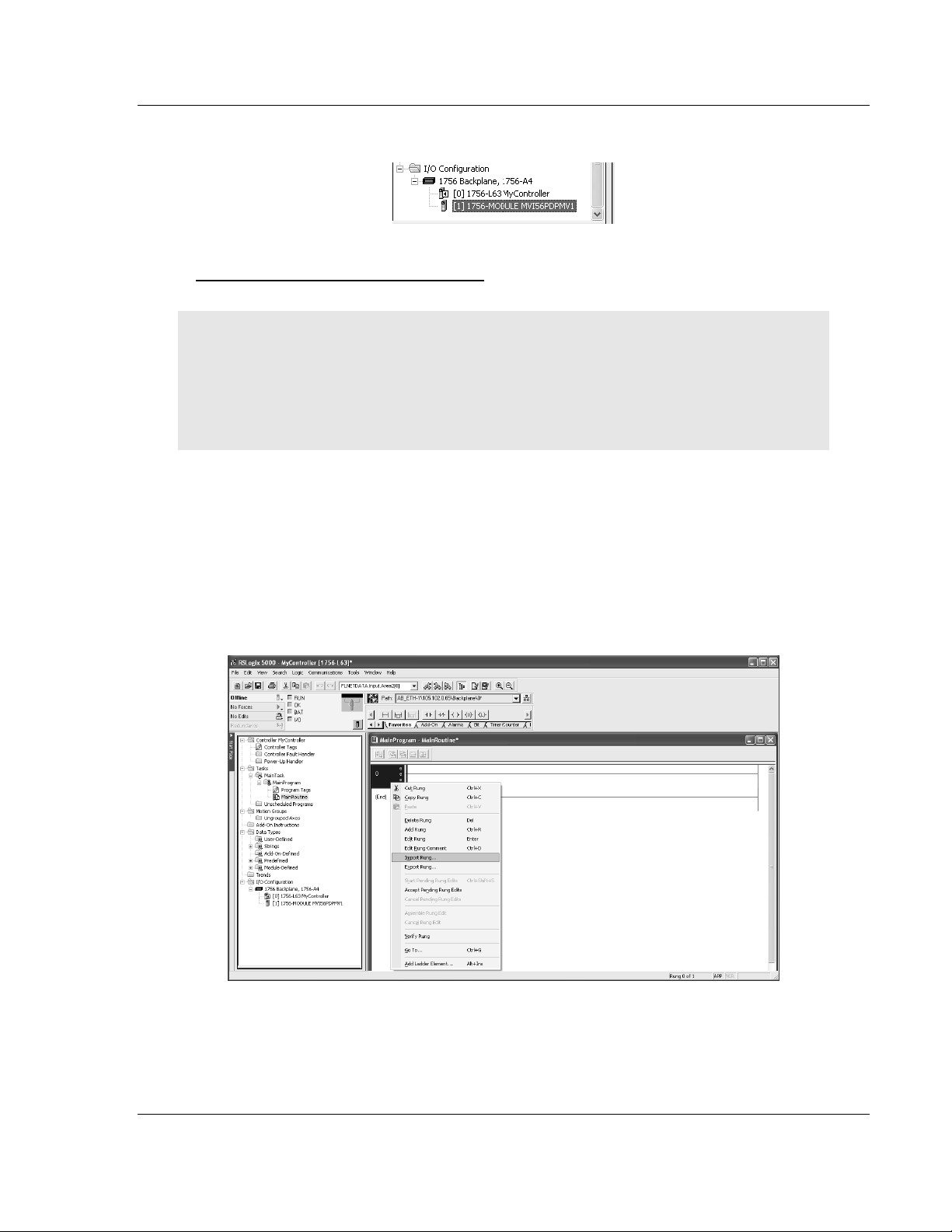

Now the MVI56-PDPMV1 module will be visible in the I/O Configuration section.

Importing the Ladder Rung - LEGACY

Note: ProSoft Configuration Builder (PCB), version 2.2.0, or higher, will allow you to export an .L5X

rung import file based on the configuration information you enter in PCB. When using LEGACY

mode, these custom export files will be very similar to the provided sample LEGACY AOI Rung

Import files.

For additional information on how to export custom-made .L5X files from PCB, please see

Exporting the Processor Files (page 105).

1 Open your application in RSLogix 5000.

2 Expand the Tasks folder, and then expand the MainTask folder.

3 On the MainProgram folder, click the right mouse button to open a shortcut

menu. On the shortcut menu, choose N

EW ROUTINE

.

4 In the New Routine dialog box, enter the name and description of your

routine, and then click OK.

5 Select an empty rung in the new routine, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose I

MPORT RUNG

.

ProSoft Technology, Inc. Page 27 of 255

March 22, 2011

Page 28

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

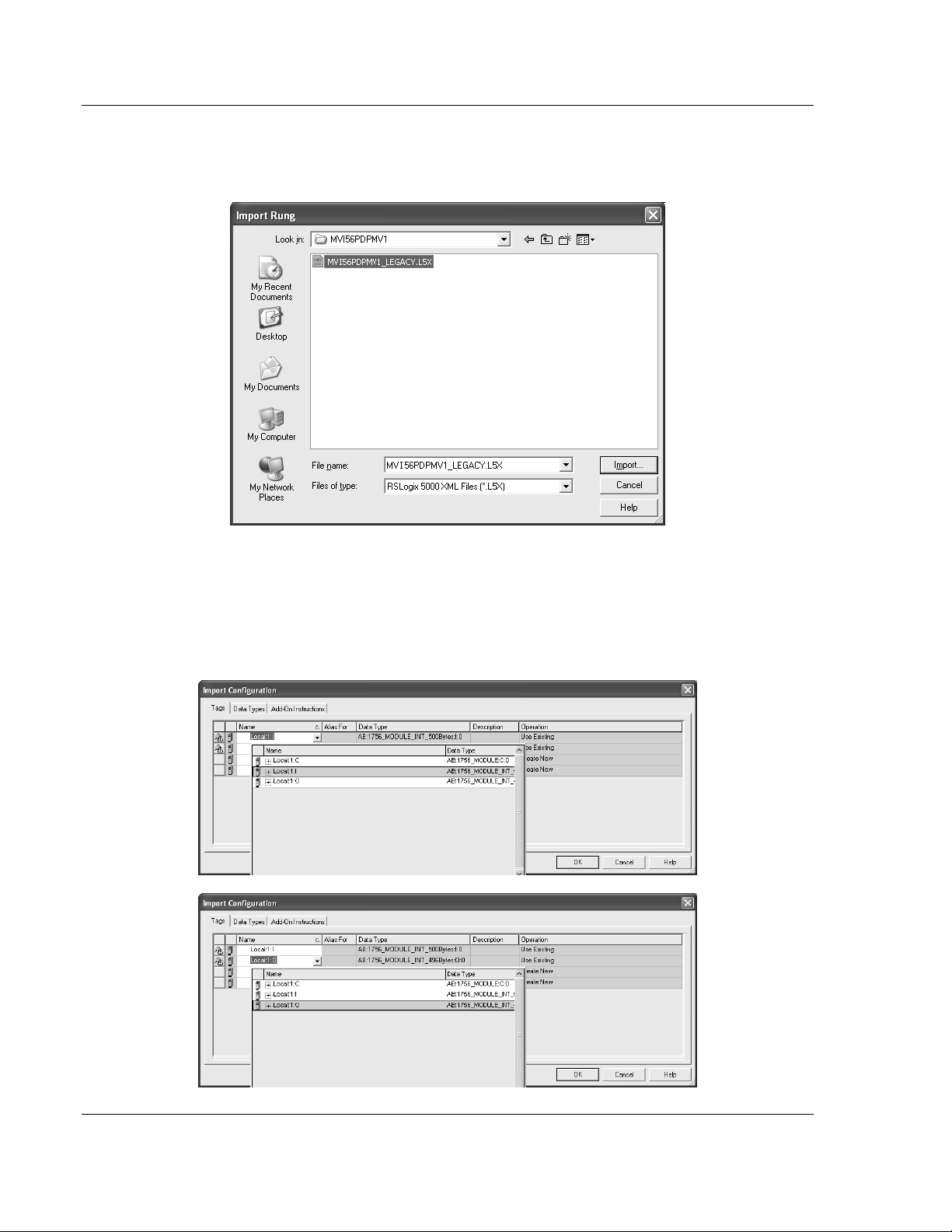

6 Select the MVI56PDPMV1_LEGACY_v*.ACD standard sample file, or the

MVI56PDPMV1_LEGACY_AddOn_Rung_v1_2.L5X custom file you exported

from PCB, and click the I

MPORT

button.

7 A window will be displayed showing the controller tags to be created during

the import procedure.

8 If you are using the module in a different slot (or remote rack) select the

correct connection input and output variables to provide the correct path to

the module. If your module is located in Slot 1 of the local rack, this step is

not required.

Page 28 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 29

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

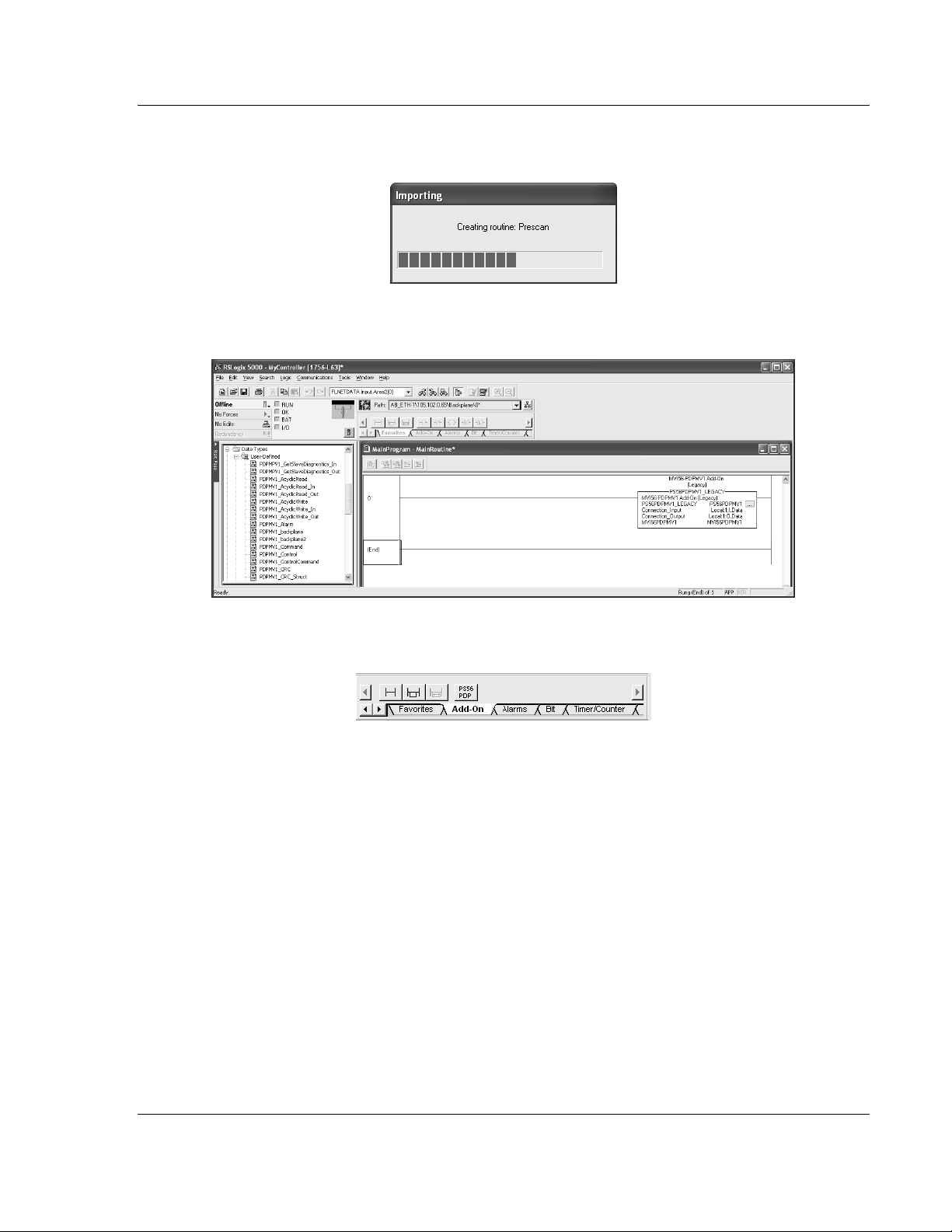

9 Click OK to confirm the import. RSLogix will indicate that the import is in

progress:

10 When the import is completed, the new rung with the Add-On Instruction will

be visible as shown in the following illustration.

The procedure has also imported new user-defined data types, controller tags

and tag arrays, and the Add-On Instruction to be used at your project.

ProSoft Technology, Inc. Page 29 of 255

March 22, 2011

Page 30

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

Adding Multiple Modules (Optional) - Legacy

Important: If your application requires more than one MVI56-PDPMV1 module into the same

project, follow the steps below.

1 In the I/O Configuration folder, click the right mouse button to open a shortcut

menu, and then choose N

EW MODULE

.

2 Select 1756-MODULE.

3 Fill the module properties as follows:

Page 30 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 31

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

Parameter Value

Name Enter a module identification string. Example: MVI56PDPMV1_2

Description Enter a description for the module. Example: ProSoft communication

module for PROFIBUS communication.

Comm Format

Slot Enter the slot number in the rack where the MVI56-PDPMV1 module is

Input Assembly

Instance

Input Size Enter the number of words per backplane input block to copy from the

Output Assembly

Instance

Output Size Enter the number of words per backplane output block to copy from the

Configuration

Assembly Instance

Configuration Size

Select DATA-INT

located.

1

module to the processor. The allowable range is from 12 to 250 words.

Each input block will reserve 8 words for general purposes (CRC, block/CIP

handshaking). The remainder is reserved for PROFIBUS input data.

2

module to the processor. The allowable range is from 5 to 248 words. Each

output block will reserve 5 words for general purposes (CRC and block

handshaking). The remainder is reserved for PROFIBUS output data.

4

0

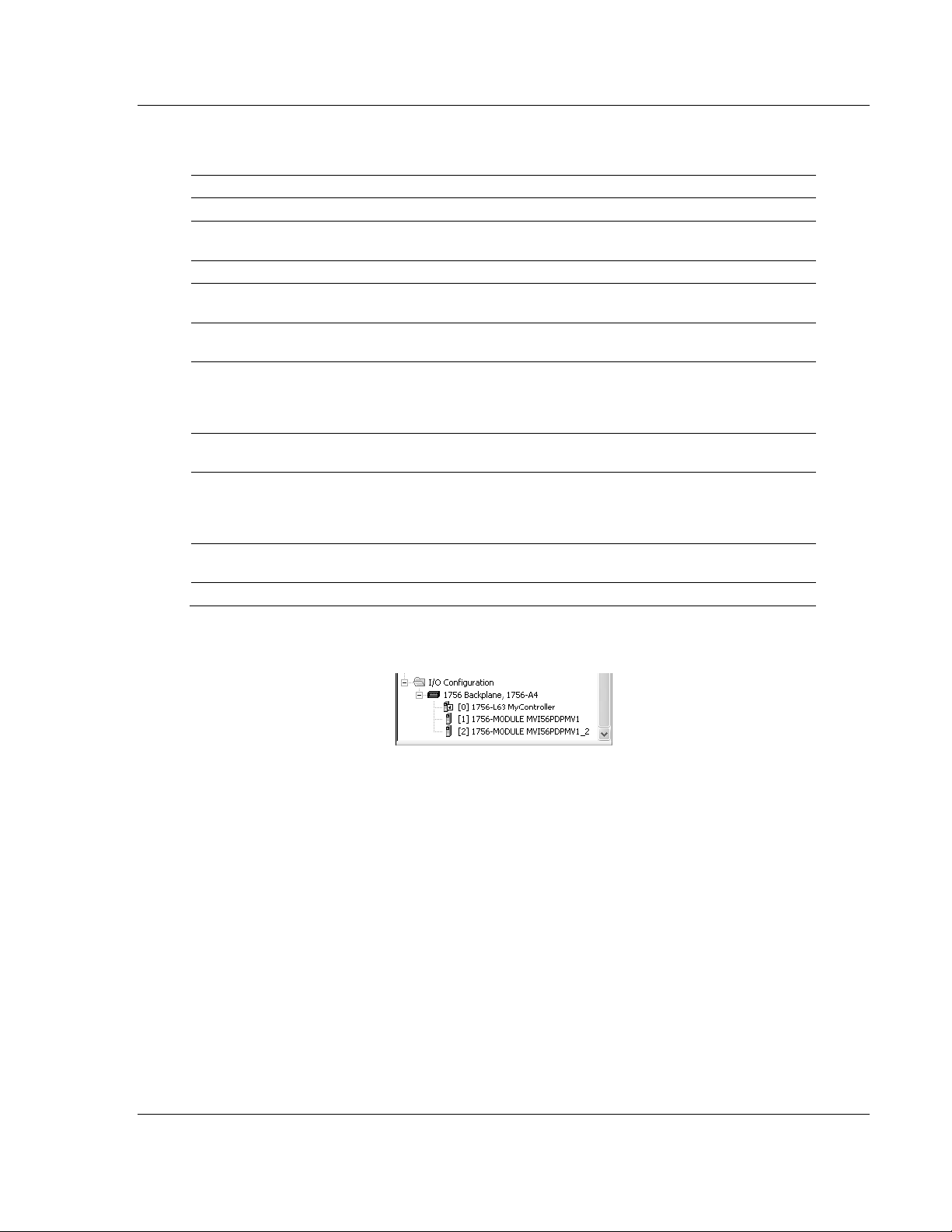

4 Click OK to confirm. The new module is now visible:

5 Expand the Tasks folder, and then expand the MainTask folder.

6 On the MainProgram folder, click the right mouse button to open a shortcut

menu. On the shortcut menu, choose N

EW ROUTINE

.

7 In the New Routine dialog box, enter the name and description of your

routine, and then click OK.

ProSoft Technology, Inc. Page 31 of 255

March 22, 2011

Page 32

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

8 Select an empty rung in the new routine, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose I

MPORT RUNG

.

9 Select the file PS56PDPMV1_LEGACY_v*.L5X

Page 32 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 33

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

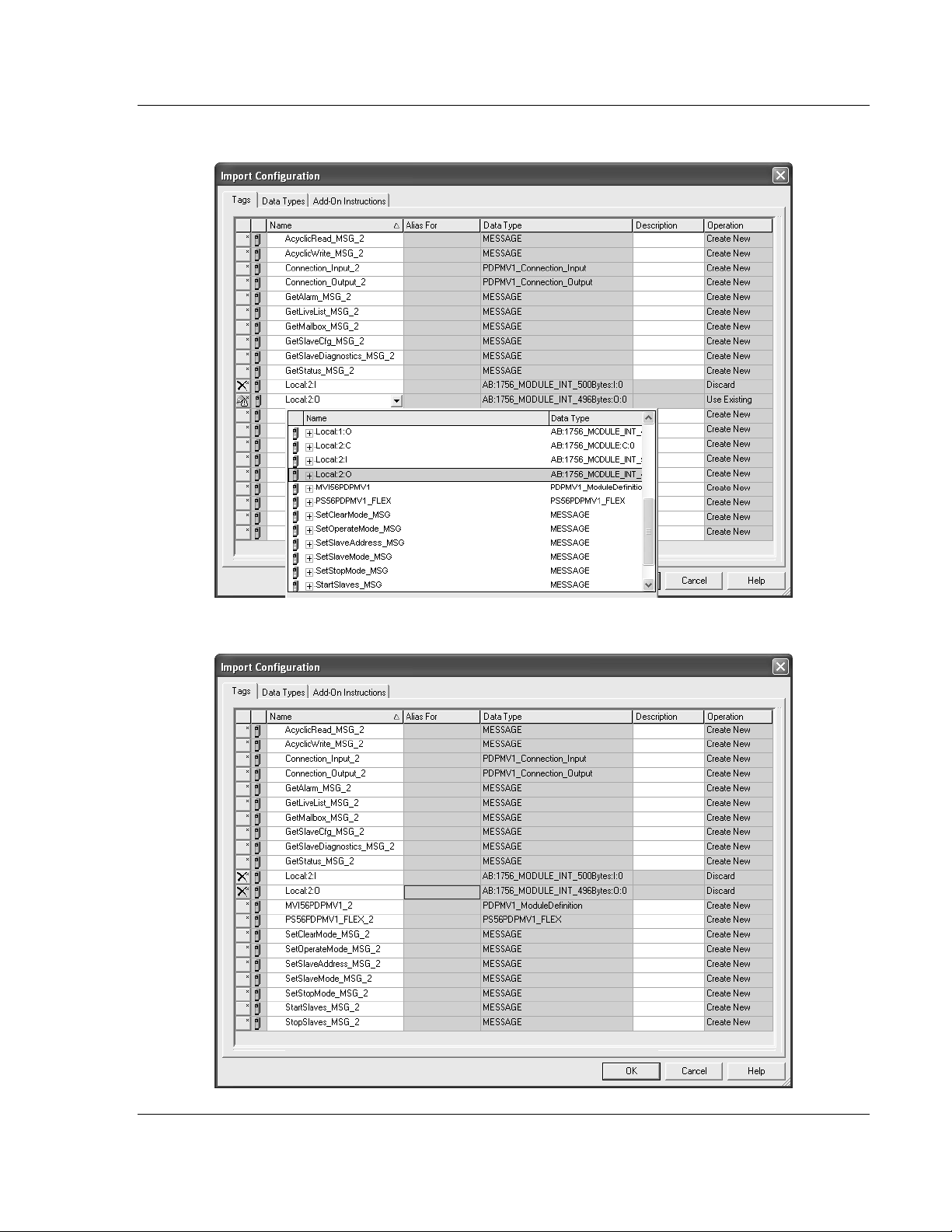

10 The following window will be displayed showing the tags to be imported:

11 Associate the I/O connection variables to the correct module. The default

values are Local:1:I and Local:1:O so these require change.

ProSoft Technology, Inc. Page 33 of 255

March 22, 2011

Page 34

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

12 Change the default tags MVI56PDPMV1 and PS56PDPMV1 to avoid conflict

with existing tags by append the string "_2" (or any other unique identifier

string) as follows:

13 Click OK to confirm.

The setup procedure is now complete. Save the project and download the

application to your ControlLogix processor.

Page 34 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 35

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

Adding MVI56-PDPMV1 Logic To Existing Applications

Perform the following steps to add the sample ladder logic into your existing

application. The controller tags and user-defined data types provided with the

sample ladder logic are critical to incorporating the MVI56-PDPMV1 into your

application.

Legacy Mode

Note: You cannot perform this procedure while you are online to the controller.

1 Open your application in RSLogix 5000.

2 In the Controller Organization list in RSLogix 5000, click the right mouse

button on the I/O Configuration option to open a shortcut menu. On the

shortcut menu, choose N

EW MODULE

. This action opens the Select Module

Type dialog box.

3 In the Select Module Type dialog box, select 1756-M

M

ODULE

) from the list and, and then click OK. This action opens the Module

ODULE (GENERIC

1756

Properties dialog box.

ProSoft Technology, Inc. Page 35 of 255

March 22, 2011

Page 36

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

4 In the Module Properties dialog box, enter the N

AME, DESCRIPTION

and S

LOT

options for your application, using the examples in the following illustration.

You must select the C

OMM FORMAT

as D

ATA -

INT in the dialog box. Failure to

set the correct parameters will result in backplane communication problems

between the module and the processor.

5 Click the C

MS

as shown in the following illustration.

ONNECTION

tab and change the Requested Packet Interval to 5.0

6 Click F

INISH

to save the module into your existing application.

7 Next, open the sample program in RSLogix 5000. Refer to Open the Sample

Program in RSLogix (page 16) to determine the correct version of the sample

program to use.

Page 36 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 37

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

8 Copy the ladder logic routines from the sample ladder logic into your existing

application. Repeat this step for each subroutine.

9 Copy and paste each of the user-defined types from the sample ladder logic

into your existing application.

10 Export the controller tags from the sample program (Tools/Export) into a CSV

file, and then import the CSV file (Tools/Import) into your existing application.

ProSoft Technology, Inc. Page 37 of 255

March 22, 2011

Page 38

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

1.7.2 FLEX Sample Add-On Instruction Import Procedure

Note: This section applies only if the MVI56-PDPMV1 firmware version is 1.21 (or later) AND

configured in FLEX mode (U

Before You Begin

The following file is required before you start this procedure. Copy the file from

the ProSoft Solutions CD-ROM, or download it from

www.prosoft-technology.com.

File Name Description

PS56PDPMV1_FLEX_v*.L5X

(where * is the current sample

program version number)

Flexible Connection I/O Length Overview

This section describes the flexible backplane connection I/O concept.

The connection parameters may assume values within the following ranges:

Minimum Size

(16-bit)

Input 12 250 [input size - 8] 1

Output 5 248 [bp output size - 5] 2

Configuration 0 0 not used 4

SE LEGACY MODE

L5X file containing Add-On Instruction, user-defined data types,

controller tags, and ladder logic required to set up the MVI56PDPMV1 module

Maximum Size (16bit)

= NO)

Maximum PROFIBUS data count per

block (16-bit)

Assembly

Instance

For applications where the module will be used in the local rack (the same rack

as the ControlLogix processor), use the maximum backplane I/O sizes.

For applications where the module will be used in a remote rack, use the

backplane I/O sizes that will provide optimal network performance (PROFIBUS

and ControlNet or EtherNet/IP).

The configured sizes will have an impact on the number of blocks required to

transfer the entire PROFIBUS I/O database between the ControlLogix processor

and the MVI56-PDPMV1 module. Reducing the number of words per backplane

block may improve the ControlNet or EtherNet/IP network performance.

However, doing so will increase the number of backplane block transfers and

have a negative effect on overall backplane data transfer efficiency.

Page 38 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 39

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

IMPORTANT: ControlLogix Version 16 with FLEX Mode

If you change the connection sizes in the module profile, you must also update the following data

types with the new sizes. The connection I/O sizes defined in the module profile must always

match the following user-defined data types:

PDPMV1_C

PDPMV1_C

ONNECTION_INPUT

ONNECTION_OUTPUT

You will also need to adjust limits in some of the ladder logic or AOI logic. For additional details,

see Adjusting the Connection Sizes for Your Application. (page 41)

The array sizes must be modified (in the Data Type column) to match the

connection sizes configured in the module profile. Failure to do so will prevent

the module from establishing backplane communication with the ControlLogix

processor.

Example 1

For the following example, if the module profile is configured as:

ProSoft Technology, Inc. Page 39 of 255

March 22, 2011

Page 40

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

Then, the PDPMV1_C

ONNECTION_INPUT

user-defined data type must have an

array size of 250 words, as shown in the following illustration.

And, the PDPMV1_C

ONNECTION_OUTPUT

user-defined data type must have an

array size of 248 words, as shown in the following illustration.

Note: Each backplane block contains certain registers reserved for general purposes (nonPROFIBUS data transfer). The backplane input block reserves 8 words for general purposes and

the backplane output block reserves 5 words. You must subtract these reserved words from the

total I/O block size to calculate the actual number of PROFIBUS I/O data per backplane I/O block

and where the break points between data blocks will be in the PROFIBUS data arrays.

Page 40 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 41

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

Adjusting the Connection Sizes for Your Application

Note: ProSoft Configuration Builder (PCB), version 2.2.0, or higher, will automatically make the

following adjustments for you based on the configuration information you enter in PCB. The newer

versions of PCB allow you to export custom-made RSLogix 5000 .L5X Add-On Instruction (AOI)

Rung Import files that are already tailored to your application-specific configuration. These custom

files will be similar to the provided sample AOI Rung Import files but will already include the

adjustments shown in the next few topics. If you use the custom import files, you will not need to

do any of the following; it will be done for you already. If this is the case, all you need to do is

import the custom .L5X file according to the procedure found in Importing the Ladder Rung: FLEX

(page 53).

For additional information on how to export custom-made .L5X files from PCB, please see the

topic, Exporting the Processor Files (page 105).

The information provided in this topic shows you what kind of modifications are being done

automatically for you by PCB. This information can also help you manually edit the standard FLEX

sample files to better fit your application or help you determine what kinds of modifications you

might need to make to any existing applications you may already be using.

1 The AOI Connection Input and Output parameters use certain data type sizes

that must be set based on how you configured the MVI56-PDPMV1 module.

2 In the D

PDPMV1_C

ATA TYPES/USER-DEFINED

ONNECTION_INPUT

data type.

folder, double-click

ProSoft Technology, Inc. Page 41 of 255

March 22, 2011

Page 42

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

3 Adjust the array size for your application. The default array size is INT[250]

(maximum size). This example is for 250 input words.

4 In the D

PDPMV1_C

ATA TYPES/USER-DEFINED

ONNECTION_OUTPUT

folder, double-click

data type.

Page 42 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 43

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

5 Adjust the array size for your application. The default array size is INT[248]

(maximum size). This example is for 248 output words.

6 The imported ladder rung has also used the default I/O settings (Input Count

= 250 words, Output Count = 248 words). If different values are used, make

the following changes to the ladder logic:

COP Instruction (input)

Change the Length to match the number of input words configured for the

module. The default uses 250 words.

NEQ Instruction

Change the array element as the last element of the connection input array. The

default refers to element 249, since this is the last element of the array of 250

words. For example, if the module connection input is set as 122 words, set the

last element as 121.

ProSoft Technology, Inc. Page 43 of 255

March 22, 2011

Page 44

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

COP Instruction (output)

Change the Length to match the number of output words configured for the

module. The default uses 248 words.

Example - FLEX application

For this example, if your application requires the PROFIBUS total data sizes

configured as follows (through the ProSoft Configuration Builder):

PROFIBUS I

PROFIBUS O

NPUT DATA SIZE:

UTPUT DATA SIZE:

100

WORDS

100

WORDS

Then, the following four scenarios illustrate the flexible I/O size functionality

(FLEX), using different backplane I/O sizes for the same PROFIBUS I/O size.

Page 44 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 45

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

Scenario 1: The PROFIBUS data fits into one backplane block

This example uses the following backplane configuration:

For this scenario, each backplane block reserves 100 words for PROFIBUS data,

so the data fits into one backplane I/O block. The module will generate two block

IDs, blocks 0 and 1, in order to force a Block ID switch, as required for the ladder

logic to function correctly, but both blocks will contain the same data.

Backplane Block Overview

Block

Number

0 Input 108 100 0 99

1 Input 108 100 0 99

0 Output 105 100 0 99

1 Output 105 100 0 99

Input/

Output

Total word count

in backplane

block

PROFIBUS Data

Word Count in

backplane block

Initial PROFIBUS Data

Word Offset in

backplane block

Last PROFIBUS Data

Word Offset in

backplane block

ProSoft Technology, Inc. Page 45 of 255

March 22, 2011

Page 46

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

Scenario 2: The PROFIBUS data fits into two backplane blocks (different PROFIBUS data

count per block)

For this example, we will subtract one word for each I/O backplane block, using

the following backplane configuration:

For this scenario, each backplane block reserves a maximum of 99 words for

PROFIBUS I/O data. The configured PROFIBUS I/O size (100 words) will not fit

into one block, so two backplane input blocks and two backplane output blocks

will be required to transfer the entire PROFIBUS I/O data.

Note: For this scenario, block 0 is no longer required because there are two backplane blocks with

different data.

Backplane Block Overview

Block

Number

1 Input 107 99 0 98

2 Input 107 1 99 99

1 Output 104 99 0 98

2 Output 104 1 99 99

Input/

Output

Total word count in

backplane block

PROFIBUS Data

Word Count in

backplane block

Initial PROFIBUS Data

Word Offset in

backplane block

Last PROFIBUS Data

Word Offset in

backplane block

Note: This configuration would be inefficient and is therefore not recommended. The previous

example is a more efficient configuration that will accomplish the same thing. This example is here

solely to illustrate how changing the I/O sizes without changing the amount of PROFIBUS data to

be transferred will affect the number of I/O data blocks the module will need to transfer.

Page 46 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 47

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

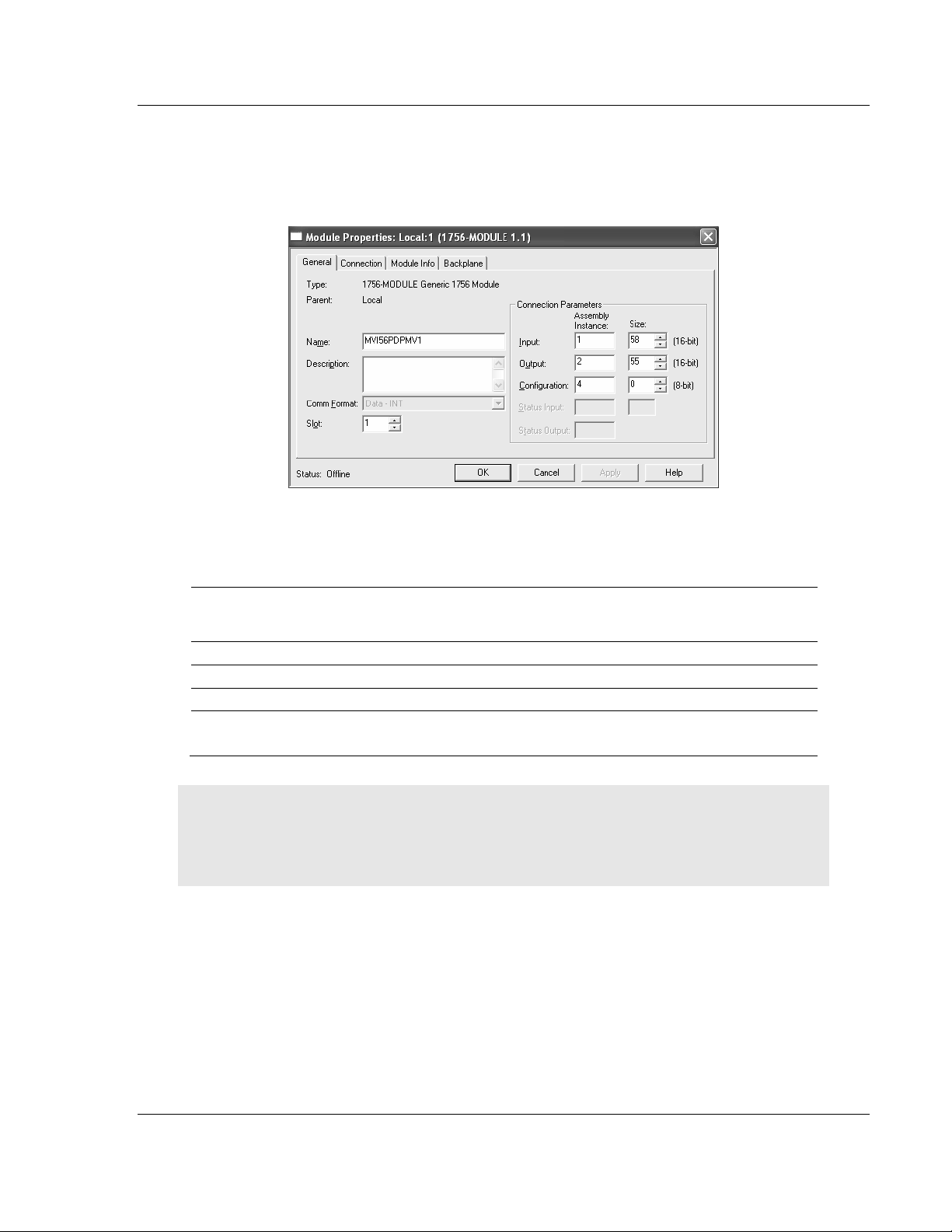

Scenario 3: The PROFIBUS data fits into two backplane blocks (same PROFIBUS data count

per block)

For this example, we will split the PROFIBUS data evenly within two backplane

blocks, using the following backplane configuration:

For this scenario, each backplane block reserves 50 words for PROFIBUS I/O

data. The configured PROFIBUS I/O size (100 words) will not fit into one block,

so two backplane input blocks and two backplane output blocks will be required.

Backplane Block Overview

Block

Number

1 Input 58 50 0 49

2 Input 58 50 50 99

1 Output 55 50 0 49

2 Output 55 50 50 99

Input/

Output

Total word count

in backplane

block

PROFIBUS Data

Word Count in

backplane block

Initial PROFIBUS Data

Word Offset in

backplane block

Last PROFIBUS Data

Word Offset in

backplane block

Note: This configuration would be inefficient and is therefore not recommended. The first example

(Scenario 1) is a more efficient configuration that will accomplish the same thing. This example is

here solely to illustrate how changing the I/O sizes without changing the amount of PROFIBUS

data to be transferred will affect the number of I/O data blocks the module will need to transfer.

ProSoft Technology, Inc. Page 47 of 255

March 22, 2011

Page 48

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

Scenario 4: The PROFIBUS data fits into ten backplane blocks (same PROFIBUS data count

per block)

For this scenario, each backplane block reserves 10 words for PROFIBUS I/O

data. The configured PROFIBUS I/O size (100 words) will not fit into one block,

so ten backplane input blocks and ten backplane output blocks will be required.

Backplane Block Overview

Block

Number

1 Input 18 10 0 9

2 Input 18 10 10 19

3 Input 18 10 20 29

4 Input 18 10 30 39

5 Input 18 10 40 49

6 Input 18 10 50 59

7 Input 18 10 60 69

8 Input 18 10 70 79

9 Input 18 10 80 89

10 Input 18 10 90 99

1 Output 15 10 0 9

2 Output 15 10 10 19

3 Output 15 10 20 29

4 Output 15 10 30 39

5 Output 15 10 40 49

6 Output 15 10 50 59

7 Output 15 10 60 69

8 Output 15 10 70 79

9 Output 15 10 80 89

10 Output 15 10 90 99

Input/

Output

Total word count in

Backplane block

PROFIBUS Data

Word Count in

backplane block

Initial PROFIBUS

Data Word Offset in

backplane block

Last PROFIBUS Data

Word Offset in

backplane block

Note: This configuration would be extremely inefficient and is therefore not recommended. The first

example (Scenario 1) is a more efficient configuration that will accomplish the same thing much

faster with one backplane transfer. This example is here solely to illustrate how changing the I/O

sizes without changing the amount of PROFIBUS data to be transferred will affect the number of

I/O data blocks the module will need to transfer.

Page 48 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 49

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

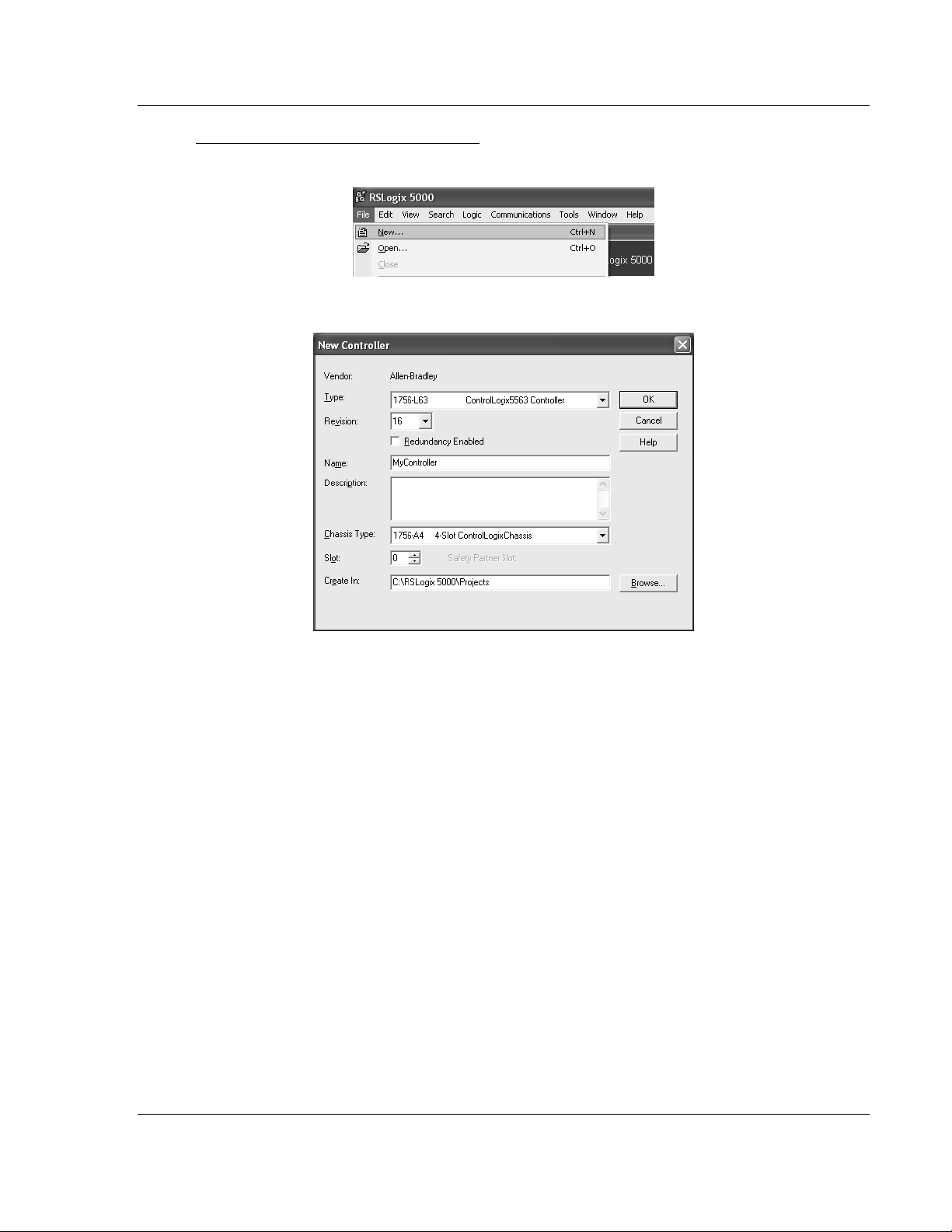

Creating a New RSLogix5000 Project

1 Open the File menu and then choose NEW.

2 Select Revision 16.

ProSoft Technology, Inc. Page 49 of 255

March 22, 2011

Page 50

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

Creating the MVI56-PDPMV1 Module Profile - Flex

1 Right-click I/O C

ONFIGURATION

and then choose N

EW MODULE

.

2 Select 1756-MODULE.

Page 50 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 51

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

Parameter

PROFIBUS DPV1 Master User Manual

3 Fill the module properties as follows:

Value

Name Enter a module identification string. Example: MVI56PDPMV1

Description Enter a description for the module. Example: ProSoft communication

module for PROFIBUS communication.

Comm Format

Slot Enter the slot number in the rack where the MVI56-PDPMV1 module is

Input Assembly

Instance

Input Size Enter the number of words per backplane input block to copy from the

Output Assembly

Instance

Output Size Enter the number of words per backplane output block to copy from the

Configuration

Assembly Instance

Configuration Size

Select DATA-INT

located.

1

module to the processor. The allowable range is from 12 to 250 words.

Each input block will reserve 8 words for general purposes (CRC, block/CIP

handshaking). The remainder is reserved for PROFIBUS input data.

2

module to the processor. The allowable range is from 5 to 248 words. Each

output block will reserve 5 words for general purposes (CRC and block

handshaking). The remainder is reserved for PROFIBUS output data.

4

0

4 The following illustration shows an example for a local rack application where

the module was set with the maximum backplane I/O sizes (250/248 words).

5 Click the C

ONNECTION

tab, and then enter the Requested Package Interval

(RPI) value.

o

If the module is located in the local rack (same rack where the processor

is located) or in a remote rack connected through EtherNet/IP adapters,

select the maximum value of 750

o

If the module is located in a remote rack connected through ControlNet

adapters, adjust the RPI time to be not less than 5

MS

.

MS

and not less than

(and, preferably, some even multiple of) the RSNetWorx for ControlNet

Network Update Time (NUT).

ProSoft Technology, Inc. Page 51 of 255

March 22, 2011

Page 52

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

6 Click OK to confirm.

Now the MVI56-PDPMV1 module will be visible in the I/O Configuration section.

Page 52 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 53

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

Importing the Ladder Rung - Flex

1 Open your application in RSLogix 5000.

2 Expand the Tasks folder, and then expand the MainTask folder.

3 In the MainProgram folder, select an empty rung, and then click the right

mouse button to open a shortcut menu. On the shortcut menu, choose

I

MPORT RUNG

.

4 Select the PS56PDPMV1_FLEX_v*.L5X standard sample file, or the

MVI56PDPMV1_FLEX_AddOn_Rung_v1_2.L5X custom file you exported

from PCB, and click the I

MPORT

button.

ProSoft Technology, Inc. Page 53 of 255

March 22, 2011

Page 54

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

5 The following window will be displayed showing the controller tags associated

with the project. The I/O connection parameters will be set (as default) as

L

OCAL

:1:I and L

OCAL

:1:O, which assumes that the module is located at the

local rack and Slot 1.

6 If your module is located in a different slot or in a remote rack, modify the

parameters to set the correct path to the module, as follows:

Page 54 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 55

MVI56-PDPMV1 ♦ ControlLogix Platform Start Here

PROFIBUS DPV1 Master User Manual

7 Click OK to confirm the import.

8 The new rung will be now visible in the ladder logic showing also the

PS56PDPMV1_FLEX Add-On Instruction.

9 The procedure has also imported new user-defined data types, controller

tags, and controller tag arrays. The new Add-On Instruction can also be used

through the new toolbar button (at Add-On tab).

ProSoft Technology, Inc. Page 55 of 255

March 22, 2011

Page 56

Start Here MVI56-PDPMV1 ♦ ControlLogix Platform

User Manual PROFIBUS DPV1 Master

Adding Multiple Modules (Optional) - Flex

Important: If your application requires more than one MVI56-PDPMV1 module into the same

project, follow the steps below.

1 In the I/O Configuration folder, click the right mouse button to open a shortcut

menu, and then choose N

EW MODULE

.

2 Select 1756-MODULE.

Page 56 of 255 ProSoft Technology, Inc.

March 22, 2011

Page 57