Page 1

MVI56E-MNETC

ControlLogix Platform

Modbus TCP/IP Client Enhanced

Communication Module

February 3, 2013

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2013 ProSoft Technology, Inc., all rights reserved.

MVI56E-MNETC User Manual

February 3, 2013

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed DVD, and are

available at no charge from our web site: http://www.prosoft-technology.com/

Content Disclaimer

This documentation is not intended as a substitute for and is not to be used for determining suitability or reliability of

these products for specific user applications. It is the duty of any such user or integrator to perform the appropriate

and complete risk analysis, evaluation and testing of the products with respect to the relevant specific application or

use thereof. Neither ProSoft Technology nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. Information in this document including illustrations, specifications and

dimensions may contain technical inaccuracies or typographical errors. ProSoft Technology makes no warranty or

representation as to its accuracy and assumes no liability for and reserves the right to correct such inaccuracies or

errors at any time without notice. If you have any suggestions for improvements or amendments or have found errors

in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without express written permission of ProSoft Technology. All pertinent state, regional, and local safety

regulations must be observed when installing and using this product. For reasons of safety and to help ensure

compliance with documented system data, only the manufacturer should perform repairs to components. When

devices are used for applications with technical safety requirements, the relevant instructions must be followed.

Failure to use ProSoft Technology software or approved software with our hardware products may result in injury,

harm, or improper operating results. Failure to observe this information can result in injury or equipment damage.

© 2013 ProSoft Technology. All rights reserved.

Page 3

Important Safety Information

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or rewiring modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be nonhazardous.

C Suitable for use in Class I, Division 2 Groups A, B, C, and D, T5 Hazardous Locations or Non-Hazardous

Locations.

ATEX Warnings and Conditions of Safe Usage

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Electrical Ratings

Backplane Current Load: 800 mA @ 5 Vdc; 3 mA @ 24 Vdc

Operating Temperature: 0°C to 60°C (32°F to 140°F)

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

Shock: 30 g operational; 50 g non-operational; Vibration: 5 g from 10 Hz to 150 Hz

Relative Humidity 5% to 95% (without condensation)

All phase conductor sizes must be at least 1.3 mm (squared) and all earth ground conductors must be at least

4mm (squared).

Page 4

Agency

RoHS

CSA

CE

CSA CB Safety

cULus

GOST-R

ATEX

Agency Approvals and Certifications

<cULus>

E183151

Class I Division 2 Groups A, B, C, and D

Temp Code T5

0°C to +60°C

Atex

Class I Division 2 Groups A, B, C, and D

Temp Code T5

0°C <= Ta <= 60°C

Battery Life Advisory

The module uses a rechargeable Lithium Vanadium Pentoxide battery to back up the real-time clock and CMOS

settings. The battery itself should last for the life of the module. However, if left in an unpowered state for 14 to 21

days, the battery may become fully discharged and require recharging by being placed in a powered-up ControlLogix

chassis. The time required to fully recharge the battery may be as long as 24 hours.

Once it is fully charged, the battery provides backup power for the CMOS setup and the real-time clock for

approximately 21 days. Before you remove a module from its power source, ensure that the battery within the module

is fully charged (the BATT LED on the front of the module goes OFF when the battery is fully charged). If the battery

is allowed to become fully discharged, the module will revert to the default BIOS and clock settings.

Note: The battery is not user-replaceable or serviceable.

Page 5

MVI56E-MNETC ♦ ControlLogix Platform Contents

Modbus TCP/IP Client Enhanced Communication Module User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

Important Safety Information ............................................................................................................... 3

Battery Life Advisory ........................................................................................................................... 4

Guide to the MVI56E-MNETC User Manual 9

1 Start Here 11

1.1 What's New? ........................................................................................................... 12

1.2 System Requirements ............................................................................................. 13

1.3 Package Contents ................................................................................................... 14

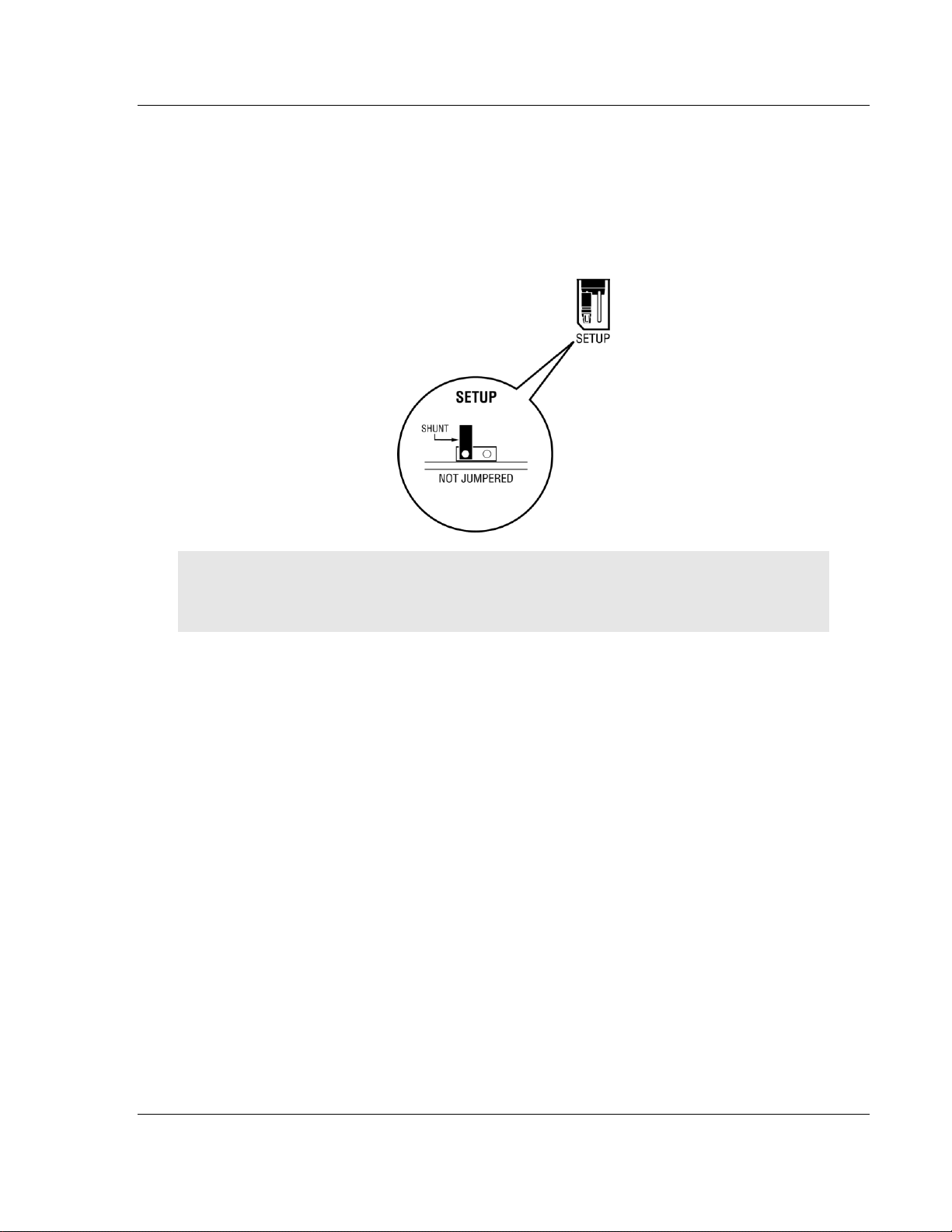

1.4 Setting Jumpers ...................................................................................................... 15

1.5 Installing the Module in the Rack ............................................................................ 16

1.6 Importing the Sample Add-On Instruction ............................................................... 18

1.7 Creating a New RSLogix 5000 Project .................................................................... 19

1.7.1 Creating the Module ................................................................................................ 20

1.7.2 Importing the Add-On Instruction ............................................................................ 23

1.8 Connecting Your PC to the ControlLogix Processor ............................................... 34

1.9 Downloading the Sample Program to the Processor .............................................. 35

2 Configuring the MVI56E-MNETC Module 37

2.1 Installing ProSoft Configuration Builder .................................................................. 38

2.2 Using ProSoft Configuration Builder Software ........................................................ 39

2.2.1 Upgrading from MVI56-MNETC in ProSoft Configuration Builder .......................... 39

2.2.2 Setting Up the Project ............................................................................................. 40

2.2.3 Setting Module Parameters ..................................................................................... 42

2.2.4 Module ..................................................................................................................... 43

2.2.5 MNET Servers ......................................................................................................... 46

2.2.6 MNET Client x ......................................................................................................... 48

2.2.7 MNET Client x Commands ...................................................................................... 51

2.2.8 Static ARP Table ..................................................................................................... 59

2.2.9 Ethernet Configuration ............................................................................................ 60

2.3 Connecting Your PC to the Module ......................................................................... 61

2.3.1 Setting Up a Temporary IP Address ....................................................................... 61

2.4 Downloading the Project to the Module .................................................................. 65

2.4.1 Using CIPconnect to Connect to the Module .......................................................... 66

2.4.2 Using RSWho to Connect to the Module ................................................................ 75

3 Ladder Logic 77

3.1 Controller Tags ........................................................................................................ 78

3.1.1 MVI56E-MNETC Controller Tags ............................................................................ 78

3.2 User-Defined Data Types (UDTs) ........................................................................... 80

3.2.1 MVI56E-MNETC User-Defined Data Types ............................................................ 80

3.3 Using Controller Tags .............................................................................................. 82

3.4 Controller Tag Overview.......................................................................................... 82

ProSoft Technology, Inc. Page 5 of 183

February 3, 2013

Page 6

Contents MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

3.4.1 MNETC.DATA......................................................................................................... 82

3.4.2 MNETC.CONTROL ................................................................................................ 85

3.4.3 MNETC.STATUS .................................................................................................... 85

3.4.4 MNETC.UTIL .......................................................................................................... 86

4 Diagnostics and Troubleshooting 87

4.1 LED Status Indicators ............................................................................................. 88

4.1.1 Scrolling LED Status Indicators .............................................................................. 88

4.1.2 Ethernet LED Indicators .......................................................................................... 89

4.1.3 Non-Scrolling LED Status Indicators ...................................................................... 89

4.1.4 Troubleshooting ...................................................................................................... 90

4.1.5 Clearing a Fault Condition ...................................................................................... 91

4.2 Using the Diagnostics Menu in ProSoft Configuration Builder ............................... 92

4.2.1 Connecting to the Module's Web Page .................................................................. 94

4.2.2 The Diagnostics Menu ............................................................................................ 95

4.2.3 Monitoring Module Information ............................................................................... 96

4.2.4 Monitoring Backplane Information .......................................................................... 96

4.2.5 Monitoring Database Information............................................................................ 98

4.2.6 Monitoring MNETC Server Information .................................................................. 99

4.2.7 Monitoring MNET Client Information....................................................................... 99

4.3 Reading Status Data from the Module ................................................................. 101

4.3.1 Status Data Definition ........................................................................................... 102

4.3.2 Configuration Error Word ...................................................................................... 105

4.3.3 Client Command Errors ........................................................................................ 106

5 Reference 109

5.1 Product Specifications .......................................................................................... 110

5.1.1 General Specifications .......................................................................................... 110

5.1.2 Modbus TCP/IP Specifications ............................................................................. 110

5.1.3 Functional Specifications ...................................................................................... 111

5.1.4 Hardware Specifications ....................................................................................... 111

5.2 Backplane Data Transfer ...................................................................................... 112

5.2.1 Normal Data Transfer Blocks ................................................................................ 114

5.2.2 Special Function Blocks ........................................................................................ 118

5.3 Data Flow between MVI56E-MNETC Module and Processor .............................. 138

5.3.1 Server Driver ......................................................................................................... 138

5.3.2 Client Driver .......................................................................................................... 141

5.3.3 Client Command List ............................................................................................ 142

5.4 Ethernet Cable Specifications ............................................................................... 143

5.4.1 Ethernet Cable Configuration ............................................................................... 143

5.4.2 Ethernet Performance ........................................................................................... 144

5.5 Modbus Protocol Specification ............................................................................. 145

5.5.1 About the Modbus TCP/IP Protocol ...................................................................... 145

5.5.2 Read Coil Status (Function Code 01) ................................................................... 146

5.5.3 Read Input Status (Function Code 02) ................................................................. 147

5.5.4 Read Holding Registers (Function Code 03) ........................................................ 148

5.5.5 Read Input Registers (Function Code 04) ............................................................ 149

5.5.6 Force Single Coil (Function Code 05) .................................................................. 150

5.5.7 Preset Single Register (Function Code 06) .......................................................... 151

5.5.8 Read Exception Status (Function Code 07) ......................................................... 152

5.5.9 Diagnostics (Function Code 08) ........................................................................... 152

Page 6 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 7

MVI56E-MNETC ♦ ControlLogix Platform Contents

Modbus TCP/IP Client Enhanced Communication Module User Manual

5.5.10 Force Multiple Coils (Function Code 15) ............................................................... 154

5.5.11 Preset Multiple Registers (Function Code 16) ...................................................... 155

5.5.12 Modbus Exception Responses .............................................................................. 155

5.6 Using the Optional Add-On Instruction Rung Import ............................................. 158

5.6.1 Before You Begin .................................................................................................. 158

5.6.2 Overview................................................................................................................ 158

5.6.3 Installing the Rung Import with Optional Add-On Instruction ................................ 159

5.6.4 Reading the Ethernet Settings from the Module ................................................... 164

5.6.5 Writing the Ethernet Settings to the Module.......................................................... 166

5.6.6 Reading the Clock Value from the Module ............................................................ 167

5.6.7 Writing the Clock Value to the Module .................................................................. 168

5.7 Adding the Module to an Existing Project ............................................................. 169

5.8 Using the Sample Program ................................................................................... 172

5.8.1 Opening the Sample Program in RSLogix ............................................................ 172

5.8.2 Choosing the Controller Type ............................................................................... 174

5.8.3 Selecting the Slot Number for the Module ............................................................ 175

5.8.4 Downloading the Sample Program to the Processor ............................................ 176

5.8.5 Adding the Sample Ladder to an Existing Application .......................................... 177

6 Support, Service & Warranty 179

Contacting Technical Support ......................................................................................................... 179

6.1 Warranty Information ............................................................................................. 180

Index 181

ProSoft Technology, Inc. Page 7 of 183

February 3, 2013

Page 8

Contents MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

Page 8 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 9

MVI56E-MNETC ♦ ControlLogix Platform Guide to the MVI56E-MNETC User Manual

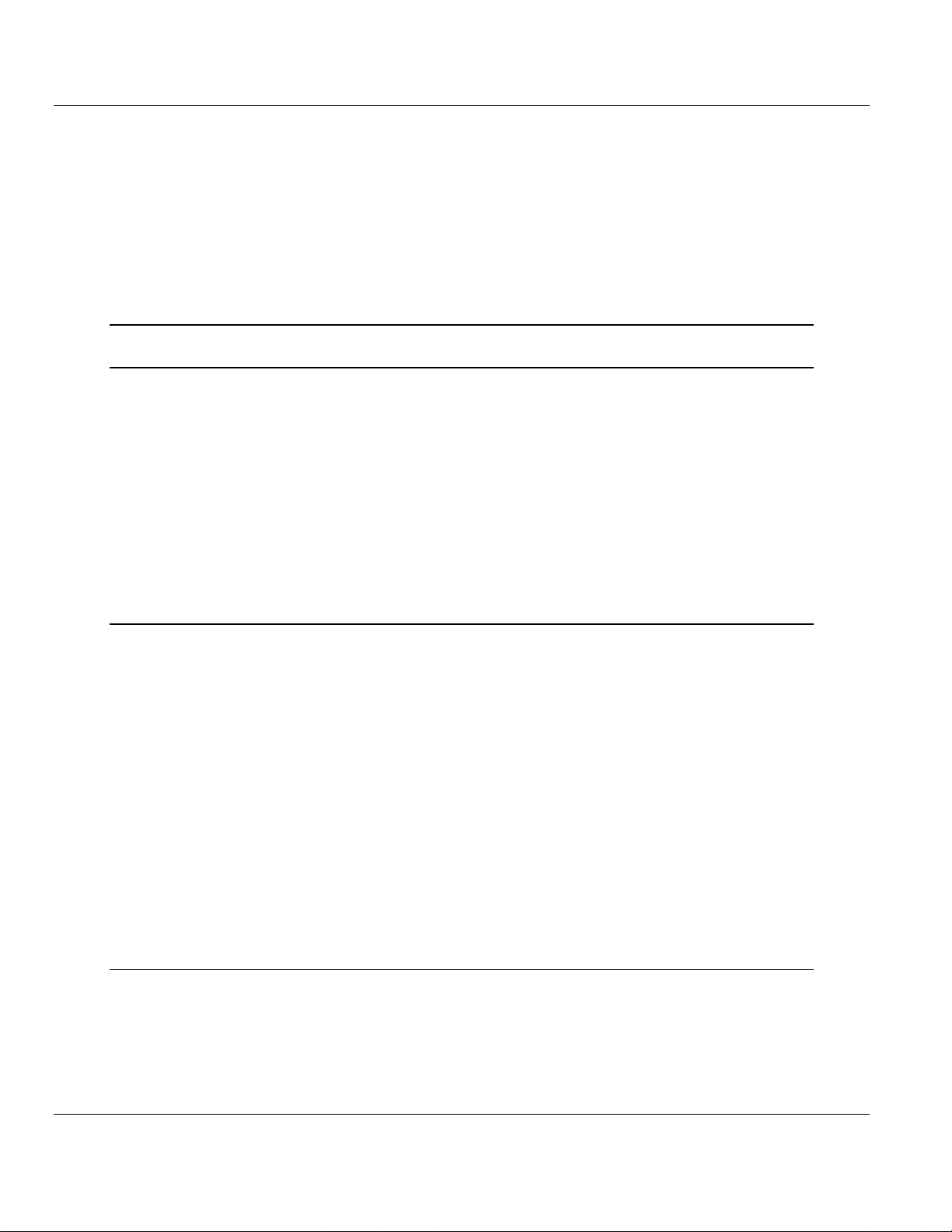

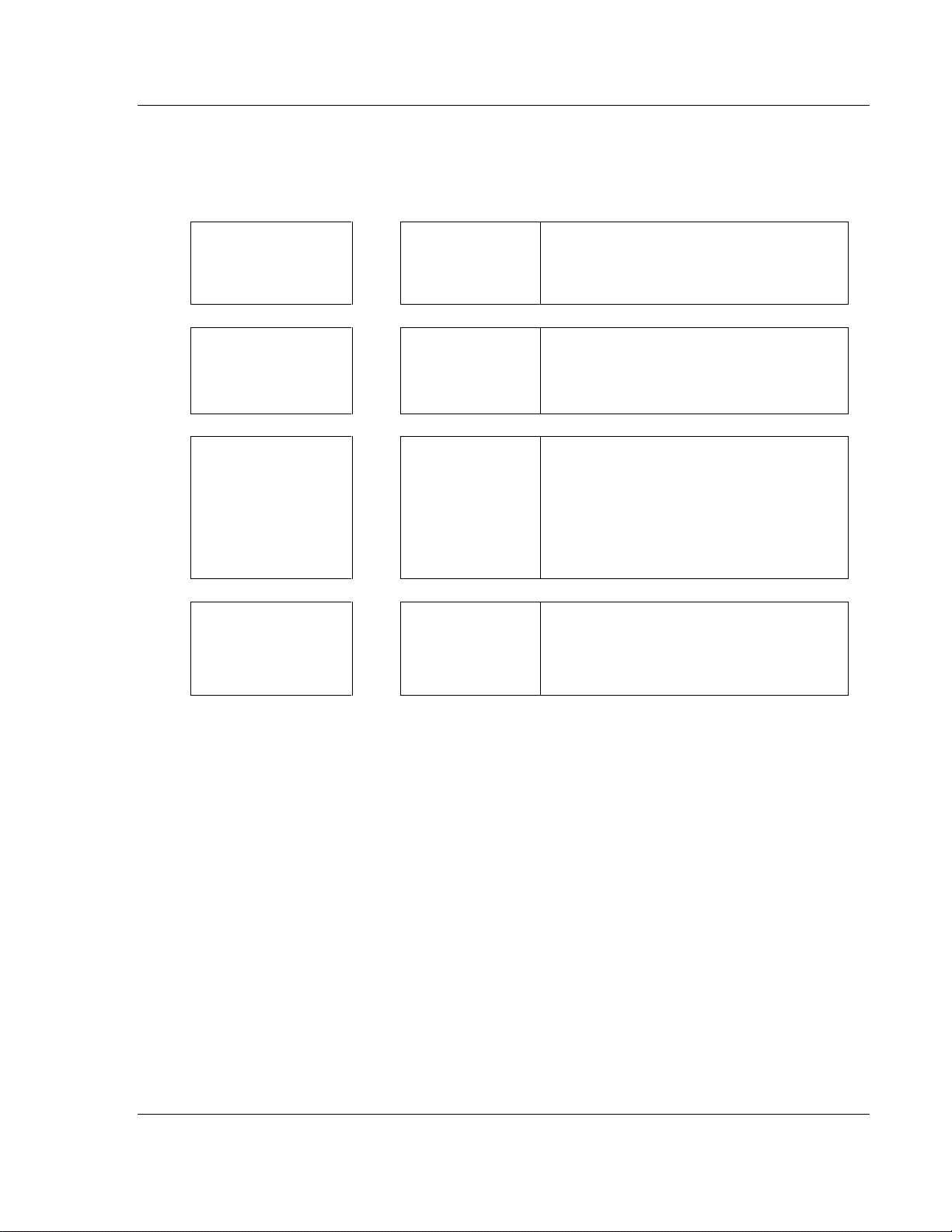

Function

Section to Read

Details

Introduction

(Must Do)

Start Here (page 10)

This section introduces the customer to the

module. Included are: package contents,

system requirements, hardware installation, and

basic configuration.

Diagnostic and

Troubleshooting

Diagnostics and

Troubleshooting

(page 87)

This section describes Diagnostic and

Troubleshooting procedures.

Reference

Product Specifications

Reference (page

109)

Product

Specifications (page

110)

These sections contain general references

associated with this product and its

Specifications.

Support, Service, and

Warranty

Index

Support, Service

and Warranty (page

179)

Index

This section contains Support, Service and

Warranty information.

Index of chapters.

Modbus TCP/IP Client Enhanced Communication Module User Manual

Guide to the MVI56E-MNETC User Manual

ProSoft Technology, Inc. Page 9 of 183

February 3, 2013

Page 10

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

Page 10 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 11

MVI56E-MNETC ♦ ControlLogix Platform Guide to the MVI56E-MNETC User Manual

In This Chapter

What's New? ......................................................................................... 12

System Requirements ........................................................................... 13

Package Contents ................................................................................. 14

Setting Jumpers .................................................................................... 15

Installing the Module in the Rack ........................................................... 16

Importing the Sample Add-On Instruction.............................................. 18

Creating a New RSLogix 5000 Project .................................................. 19

Connecting Your PC to the ControlLogix Processor .............................. 34

Downloading the Sample Program to the Processor ............................. 35

Modbus TCP/IP Client Enhanced Communication Module User Manual

1 Start Here

To get the most benefit from this User Manual, you should have the following

skills:

Rockwell Automation® RSLogix™ software: launch the program, configure

ladder logic, and transfer the ladder logic to the processor

Microsoft Windows: install and launch programs, execute menu commands,

navigate dialog boxes, and enter data

Hardware installation and wiring: install the module, and safely connect

Modbus TCP/IP and ControlLogix devices to a power source and to the

MVI56E-MNETC module’s application port(s)

ProSoft Technology, Inc. Page 11 of 183

February 3, 2013

Page 12

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

1.1 What's New?

MVI56E products are backward compatible with existing MVI56 products,

ladder logic, and module configuration files already in use. Easily swap and

upgrade products while benefiting from an array of new features designed to

improve interoperability and enhance ease-of-use.

Note: To take advantage of the new expanded database and server capabilities, your MVI56EMNETC module needs to have firmware version 3.01 or higher, and your MVI56E-MNETC Add-On

Instruction needs to be version 1.8 or higher. Earlier versions have no server capabilities and

support up to 5000 user database registers.

More data memory: There are now 10,000 16-bit registers available for

user-defined module data memory (an increase from 5000).

Server capability: The module now supports up to 20 server connections

(10 MNET, 10 MBAP).

ProSoft Configuration Builder (PCB): New Windows software for

diagnostics, connecting via the module's Ethernet port or CIPconnect®, to

upload/download module configuration information and access

troubleshooting features and functions.

ProSoft Discovery Service (PDS): Utility software to find and display a list

of MVI56E modules on the network and to temporarily change an IP address

to connect with a module's web page.

CIPconnect-enabled: Allows PC-to-module configuration and diagnostics

from the Ethernet network through a ControlLogix 1756-ENBT EtherNet/IP™

module.

Personality Module: An industrial compact flash memory card storing the

module’s complete configuration and Ethernet settings, allowing quick and

easy replacement.

LED Scrolling Diagnostic Display: 4-character, alphanumeric display,

providing standard English messages for status and alarm data, and for

processor and network communication status.

Page 12 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 13

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

1.2 System Requirements

The MVI56E-MNETC module requires the following minimum hardware and

software components:

Rockwell Automation ControlLogix® processor (firmware version 10 or

higher), with compatible power supply, and one free slot in the rack for the

MVI56E-MNETC module. The module requires 800 mA of available 5 Vdc

power

Rockwell Automation RSLogix 5000 programming software

o Version 16 or higher required for Add-On Instruction

o Version 15 or lower must use Sample Ladder, available from

www.prosoft-technology.com

Rockwell Automation RSLinx® communication software version 2.51 or higher

ProSoft Configuration Builder (PCB) (included)

ProSoft Discovery Service (PDS) (included in PCB)

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o Microsoft Windows

o Microsoft Windows XP Professional with Service Pack 1 or 2

o Microsoft Windows 7 Professional (32-or 64-bit)

o Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 768 recommended)

CD-ROM drive

®

Vista

Note: The Hardware and Operating System requirements in this list are the

minimum recommended to install and run software provided by ProSoft

Technology®. Other third party applications may have different minimum

requirements. Refer to the documentation for any third party applications for

system requirements.

Note: You can install the module in a local or remote rack. For remote rack

installation, the module requires EtherNet/IP or ControlNet communication with

the processor.

ProSoft Technology, Inc. Page 13 of 183

February 3, 2013

Page 14

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

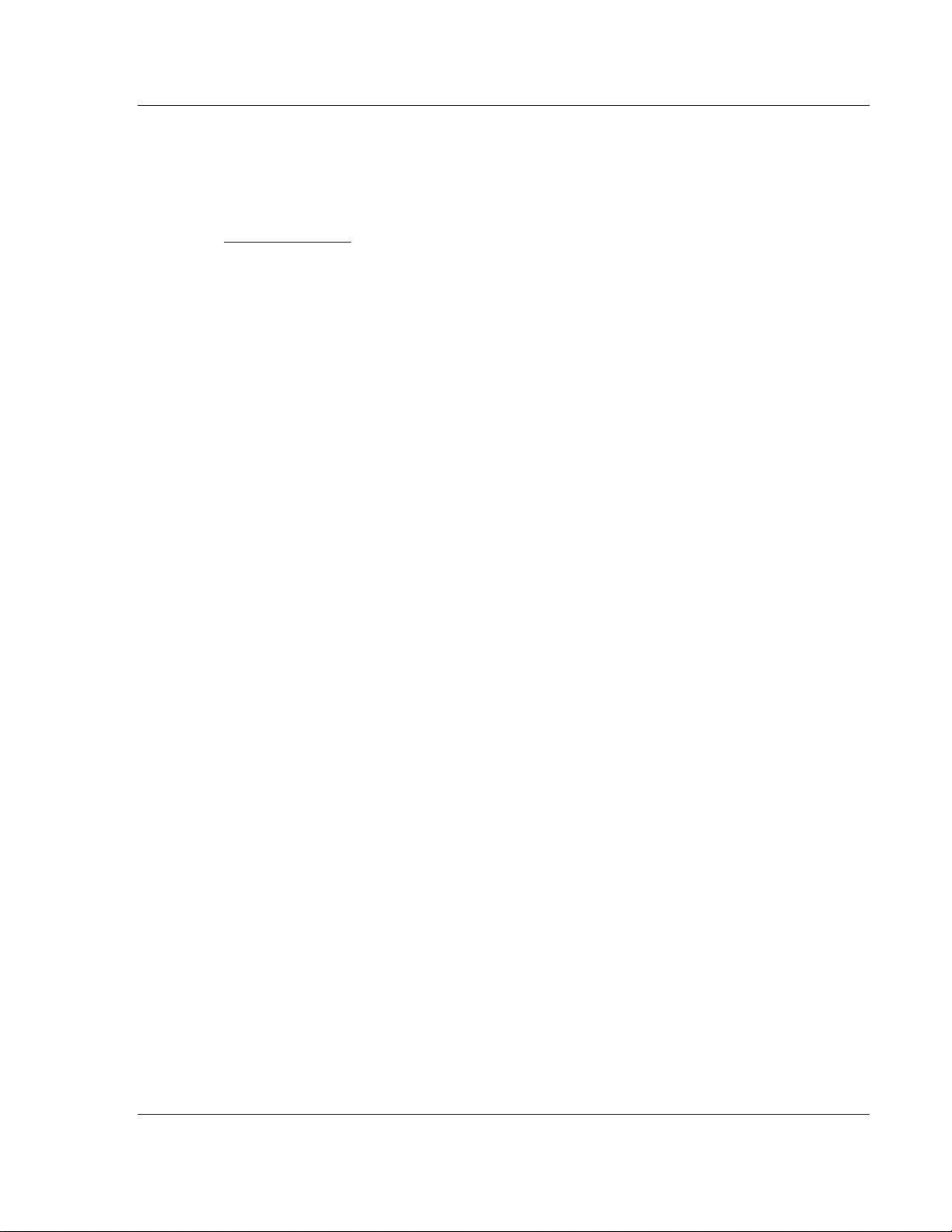

Qty.

Part Name

Part Number

Part Description

1

MVI56E-MNETC

Module

MVI56E-MNETC

Modbus TCP/IP Client Enhanced

Communication Module

1

Cable

RL-CBL025

5-foot Ethernet Straight-Through Cable

(Gray)

1

ProSoft Solutions CD

CD-013

Contains configuration tools for the

MVI56E-MNETC module

User Manual Modbus TCP/IP Client Enhanced Communication Module

1.3 Package Contents

The following components are included with your MVI56E-MNETC module, and

are all required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following

items are present.

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

Page 14 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 15

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

1.4 Setting Jumpers

The Setup Jumper acts as "write protection" for the module’s flash memory. In

"write protected" mode, the Setup pins are not connected, and the module’s

firmware cannot be overwritten. Do not jumper the Setup pins together unless

you are directed to do so by ProSoft Technical Support.

The following illustration shows the MVI56E-MNETC jumper configuration.

Note: If you are installing the module in a remote rack, you may prefer to leave

the Setup pins jumpered. That way, you can update the module’s firmware

without requiring physical access to the module.

ProSoft Technology, Inc. Page 15 of 183

February 3, 2013

Page 16

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

1.5 Installing the Module in the Rack

If you have not already installed and configured your ControlLogix processor and

power supply, please do so before installing the MVI56E-MNETC module. Refer

to your Rockwell Automation product documentation for installation instructions.

Warning: You must follow all safety instructions when installing this or any other

electronic devices. Failure to follow safety procedures could result in damage to

hardware or data, or even serious injury or death to personnel. Refer to the

documentation for each device you plan to connect to verify that suitable safety

procedures are in place before installing or servicing the device.

After you have checked the placement of the jumpers, insert the MVI56EMNETC into the ControlLogix chassis. Use the same technique recommended by

Rockwell Automation to remove and install ControlLogix modules.

You can install or remove ControlLogix system components while chassis power

is applied and the system is operating. However, please note the following

warning.

Warning: When you insert or remove the module while backplane power is on,

an electrical arc can occur. An electrical arc can cause personal injury or

property damage by sending an erroneous signal to your system’s actuators.

This can cause unintended machine motion or loss of process control. Electrical

arcs may also cause an explosion when they happen in a hazardous

environment. Verify that power is removed or the area is non-hazardous before

proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create electrical resistance

that can affect module operation.

1 Align the module with the top and bottom guides, and then slide it into the

rack until the module is firmly against the backplane connector.

2 With a firm, steady push, snap the module into place.

Page 16 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 17

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

3 Check that the holding clips on the top and bottom of the module are securely

in the locking holes of the rack.

4 Make a note of the slot location. You must identify the slot in which the

module is installed in order for the sample program to work correctly. Slot

numbers are identified on the green circuit board (backplane) of the

ControlLogix rack.

5 Turn power ON.

Note: If you insert the module improperly, the system may stop working or may

behave unpredictably.

ProSoft Technology, Inc. Page 17 of 183

February 3, 2013

Page 18

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

File Name

Description

MVI56EMNETC_AddOn_Rung_v1_8.L5X

L5X file containing Add-On Instruction, user defined

data types, controller tags and ladder logic required

to configure the MVI56E-MNETC module

MVI56EMNETC_Optional_AddOn_Rung_v1_

0.L5X

Optional L5X file containing additional Add-On

Instruction with logic for changing Ethernet

configuration and clock settings.

User Manual Modbus TCP/IP Client Enhanced Communication Module

1.6 Importing the Sample Add-On Instruction

Note: This section only applies if your processor is using RSLogix 5000 version

16 or higher. If you have an earlier version, please see Using the Sample

Program (page 172).

Before You Begin

Two Add-On Instructions are provided for the MVI56E-MNETC module. The first

is required for setting up the module; the second is optional.

Copy the files from the ProSoft Solutions CD-ROM, or download them from

www.prosoft-technology.com. Save them to a convenient location in your PC,

such as Desktop or My Documents.

Page 18 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 19

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

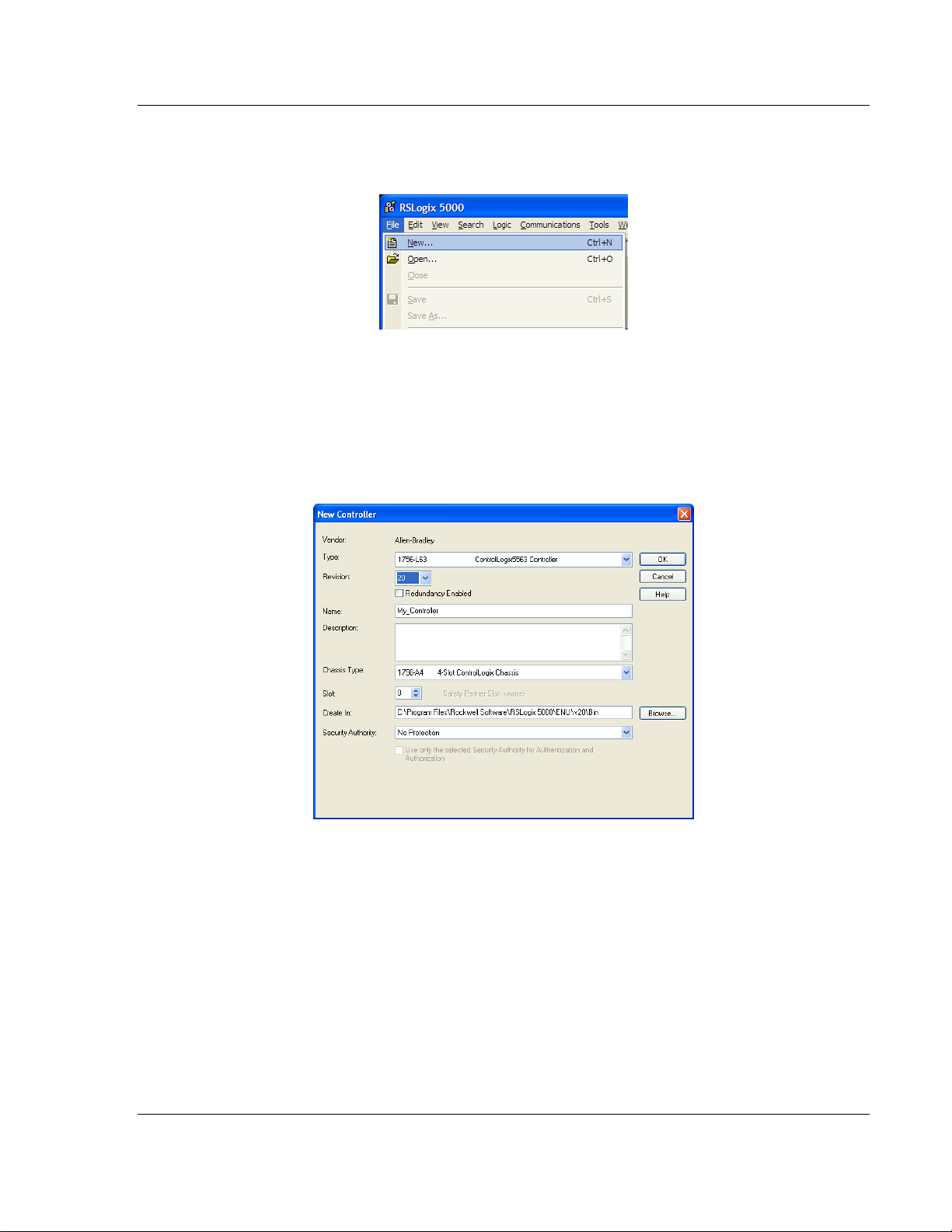

1.7 Creating a New RSLogix 5000 Project

1 Open the FILE menu, and then choose NEW.

2 Select your ControlLogix controller model.

3 Select REVISION 20. You can select an earlier revision number if you have an

earlier version of RSLogix. There may be some small differences in the

appearance of dialog boxes from the ones shown in this Guide.

4 Enter a name for your controller, such as My_Controller.

5 Select your ControlLogix chassis type.

6 Select SLOT 0 for the controller.

ProSoft Technology, Inc. Page 19 of 183

February 3, 2013

Page 20

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

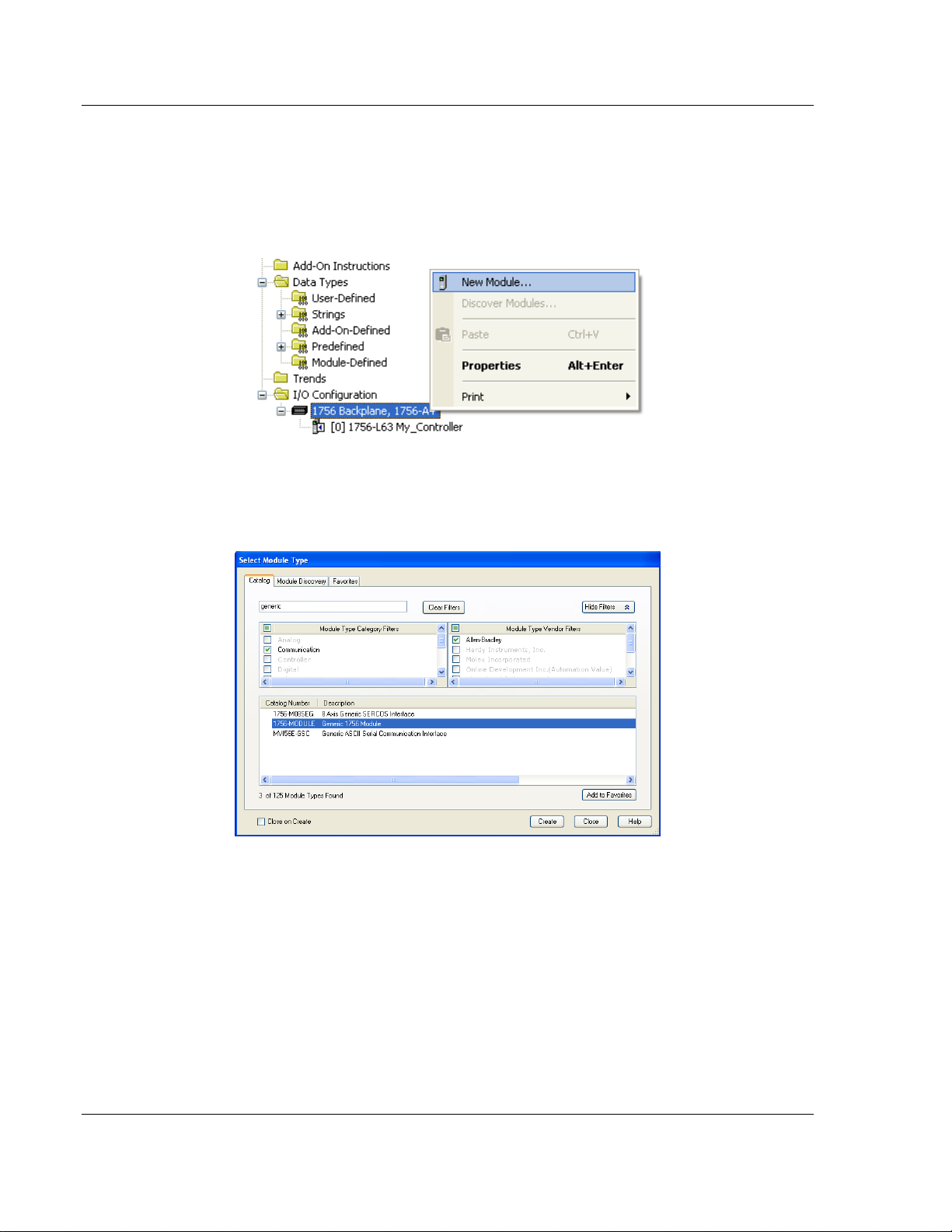

1.7.1 Creating the Module

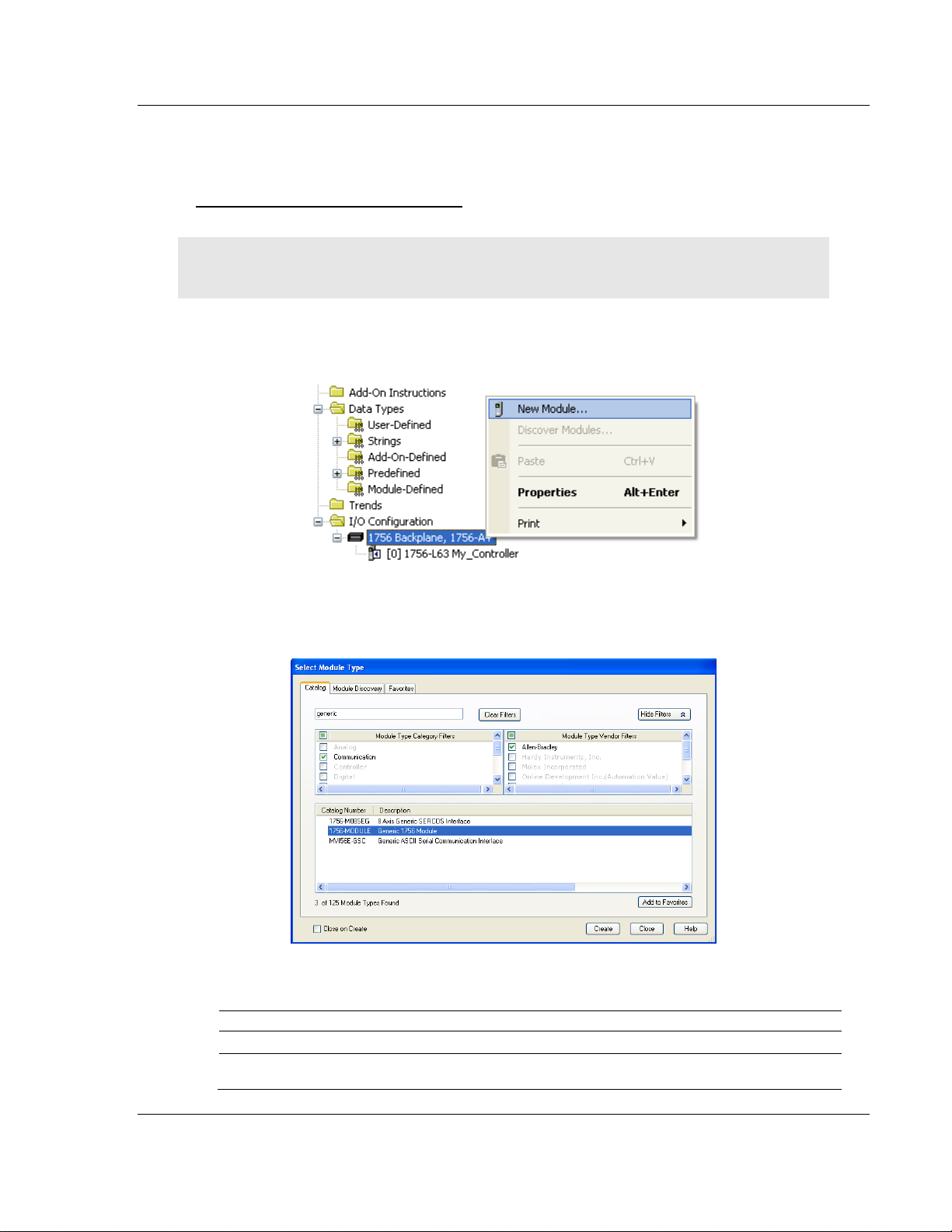

1 Add the MVI56E-MNETC module to the project.

In the Controller Organization window, select I/O CONFIGURATION and click

the right mouse button to open a shortcut menu. On the shortcut menu,

choose NEW MODULE.

This action opens the Select Module dialog box. Enter generic in the text box

and select the GENERIC 1756 MODULE. If you're using an earlier version of

RSLogix, expand OTHER in the Select Module dialog box, and then select the

GENERIC 1756 MODULE.

Page 20 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 21

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

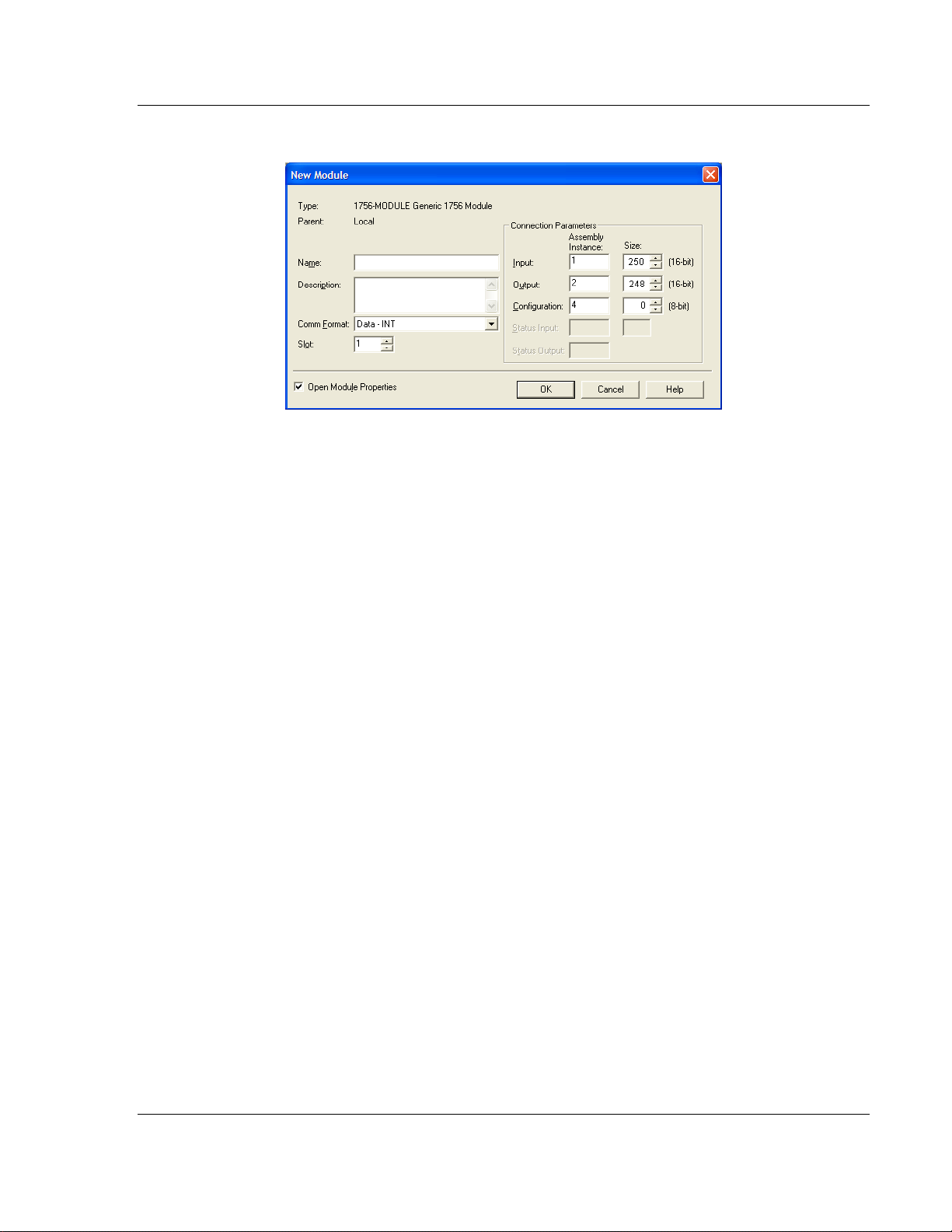

2 Click CREATE.This action opens the New Module dialog box.

ProSoft Technology, Inc. Page 21 of 183

February 3, 2013

Page 22

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

Parameter

Value

Name

Enter a module identification string. Example: MNETC

Description

Enter a description for the module. Example: MODBUS TCP/IP

CLIENT ENHANCED COMMUNICATION MODULE

Comm Format

Select DATA-INT.

Slot

Enter the slot number in the rack where the MVI56E-MNETC

module is located.

Input Assembly Instance

1

Input Size

250

Output Assembly Instance

2

Output Size

248

Configuration Assembly Instance

4

Configuration Size

0

User Manual Modbus TCP/IP Client Enhanced Communication Module

3 In the New Module dialog box, enter the following values.

Important: You must select the Comm Format as DATA - INT in the dialog box;

otherwise the module will not communicate over the backplane of the

ControlLogix rack.

4 Click OK to continue.

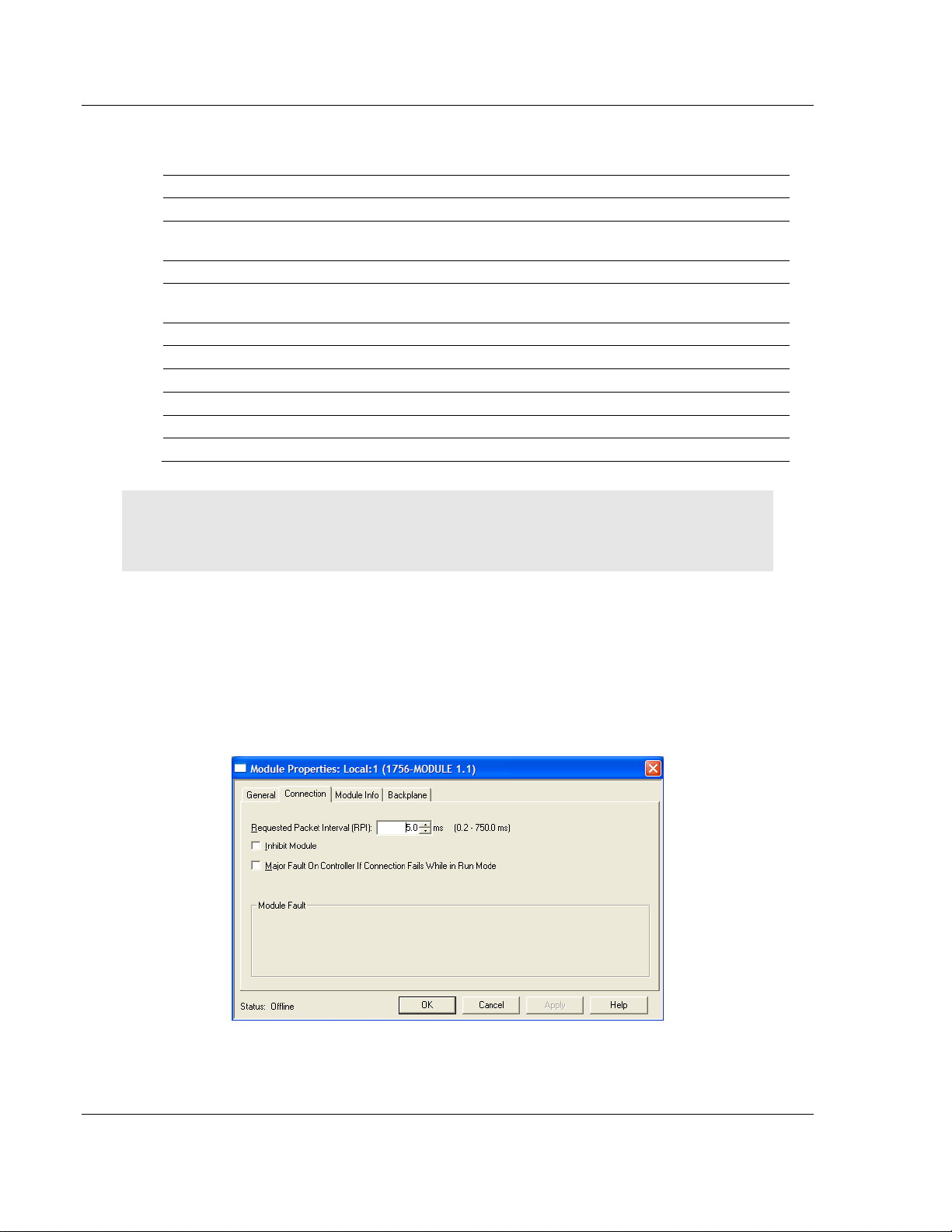

5 Edit the Module Properties. Select the Requested Packet Interval value for

scanning the I/O on the module. This value represents the minimum

frequency at which the module will handle scheduled events. This value

should not be set to less than 1 millisecond. The default value is 5

milliseconds. Values between 1 and 10 milliseconds should work with most

applications.

6 Save the module.

Page 22 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 23

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

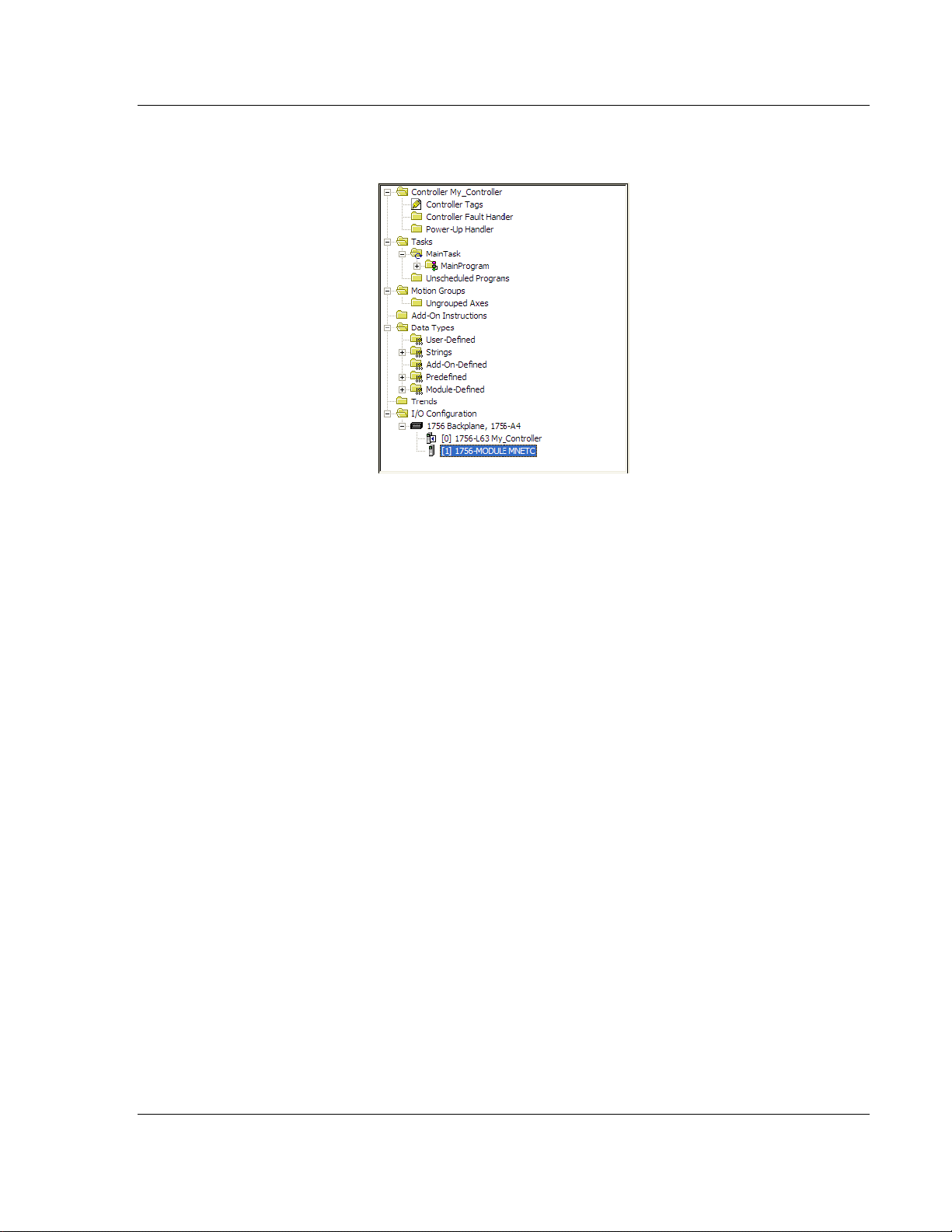

Click OK to close the dialog box. Notice that the module now appears in the

Controller Organization window.

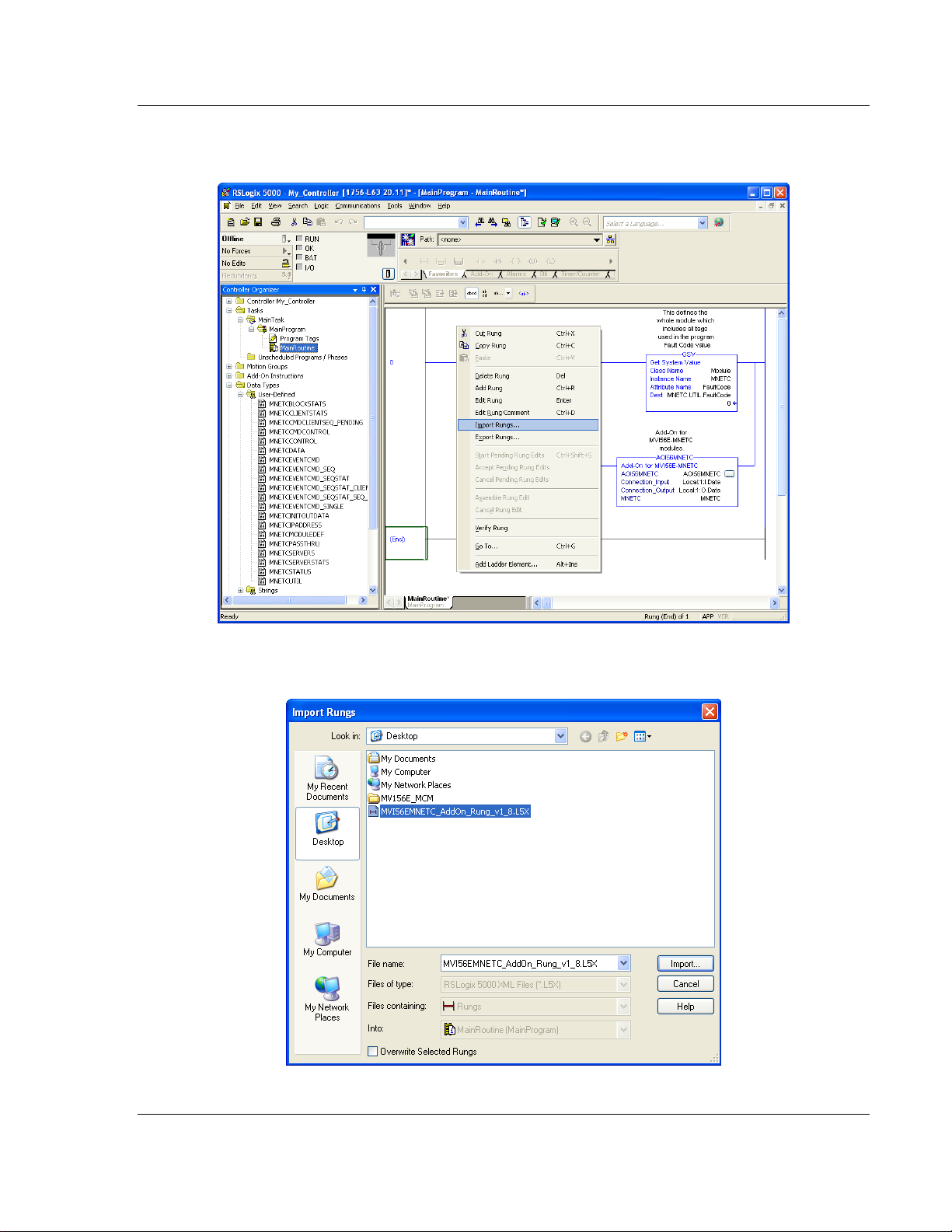

1.7.2 Importing the Add-On Instruction

1 In the Controller Organization window, expand the TASKS folder and

subfolder until you reach the MAINPROGRAM folder.

2 In the MAINPROGRAM folder, double-click to open the MAINROUTINE ladder.

ProSoft Technology, Inc. Page 23 of 183

February 3, 2013

Page 24

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

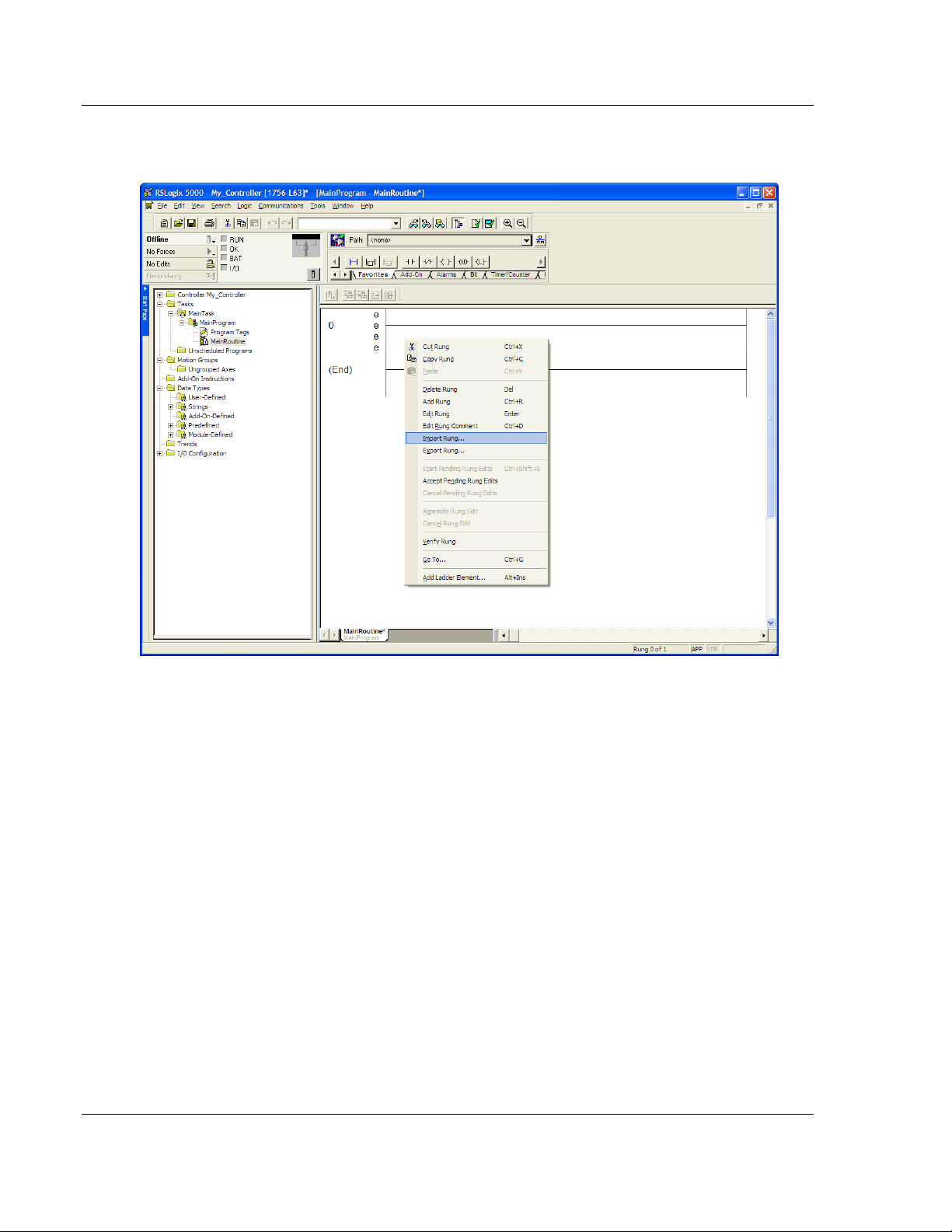

3 Select an empty rung in the new routine, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose IMPORT RUNG.

Page 24 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 25

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

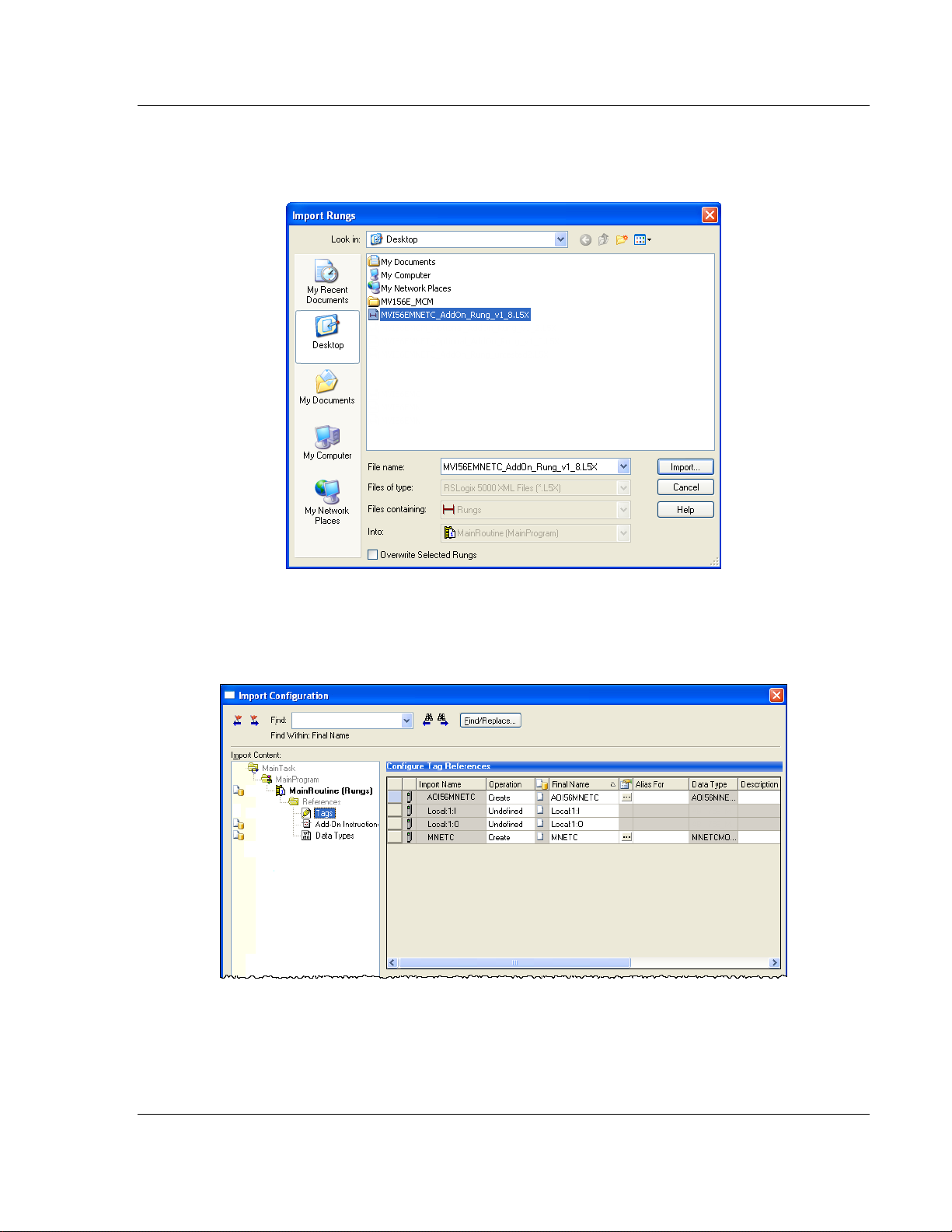

4 Navigate to the location on your PC where you saved (page 18) the Add-On

Instruction (for example, My Documents or Desktop). Select the

MVI56EMNETC_ADDON_RUNG_V1_8.L5X file.

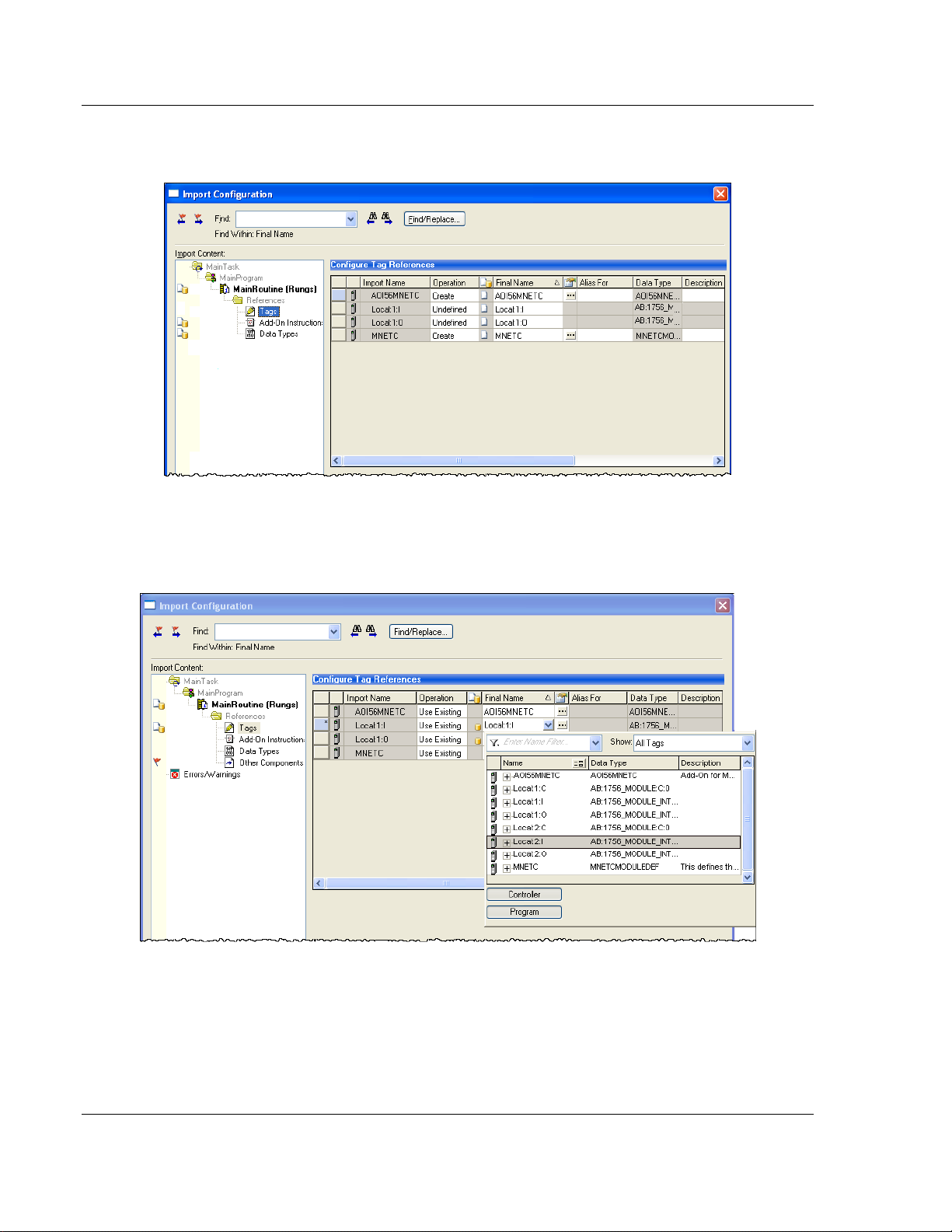

This action opens the Import Configuration dialog box. Click TAGS under

MAINROUTINE to show the controller tags that will be created. Note that if you

are using a controller revision number of 16 or less, the Import Configuration

dialog box does not show the IMPORT CONTENT tree.

ProSoft Technology, Inc. Page 25 of 183

February 3, 2013

Page 26

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

5 If you are using the module in a different slot (or remote rack), edit the

connection input and output variables that define the path to the module in

the FINAL NAME column (NAME column for controller revision 16 or less). For

example, if your module is located in slot 3, change Local:1:I in the above

picture to Local:3:I. Do the same for Local:1:O. If your module is located in

Slot 1 of the local rack, this step is not required.

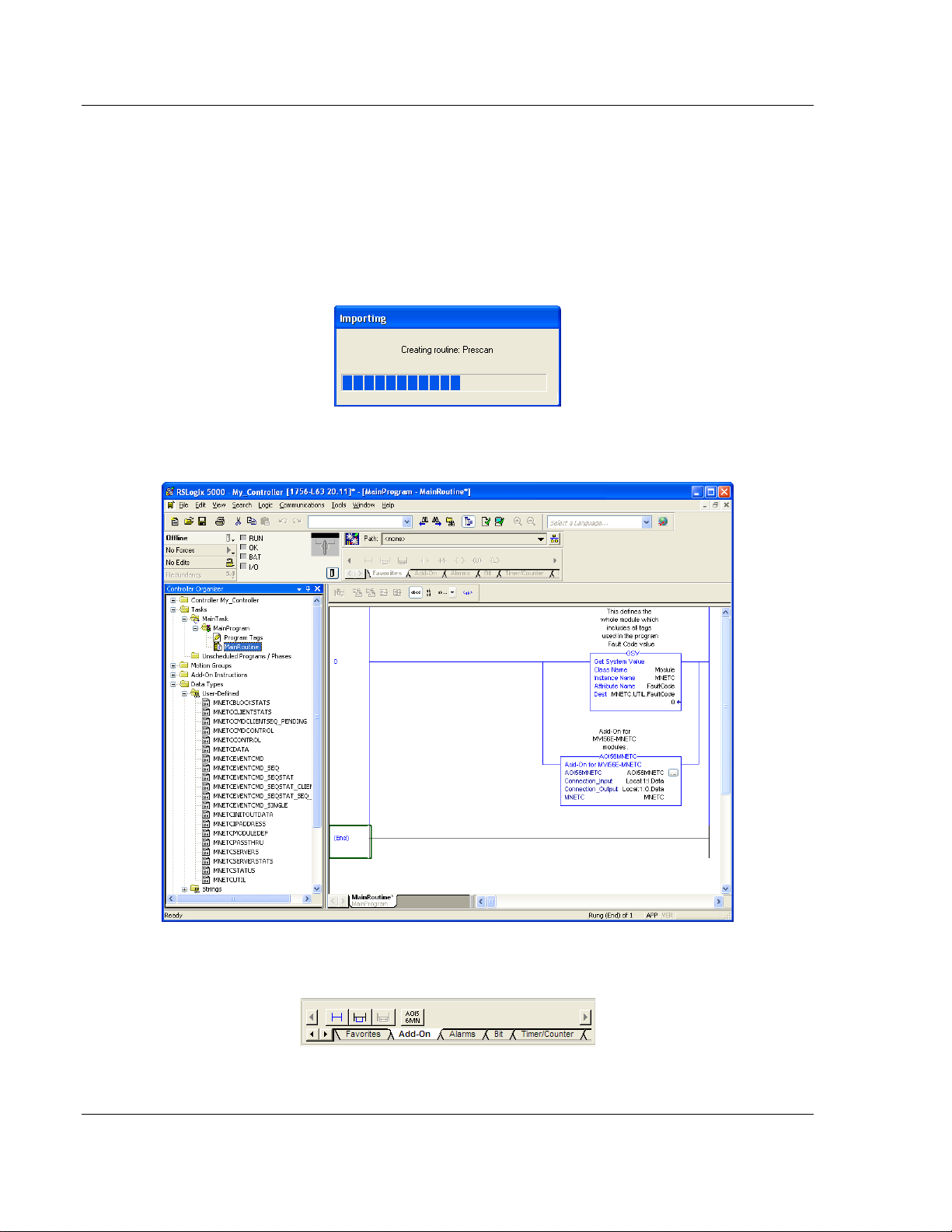

6 Click OK to confirm the import. RSLogix will indicate that the import is in

progress:

When the import is completed, the new rung with the Add-On Instruction will

be visible as shown in the following illustration.

The procedure has also imported new user-defined data types, data objects

and the Add-On Instruction for your project.

Page 26 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 27

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Parameter

Value

Name

Enter a module identification string. Example: MNETC_2.

Description

Enter a description for the module. Example: MODBUS TCP/IP

CLIENT ENHANCED COMMUNICATION MODULE

Modbus TCP/IP Client Enhanced Communication Module User Manual

7 Save the application and then download the sample ladder logic to the

processor.

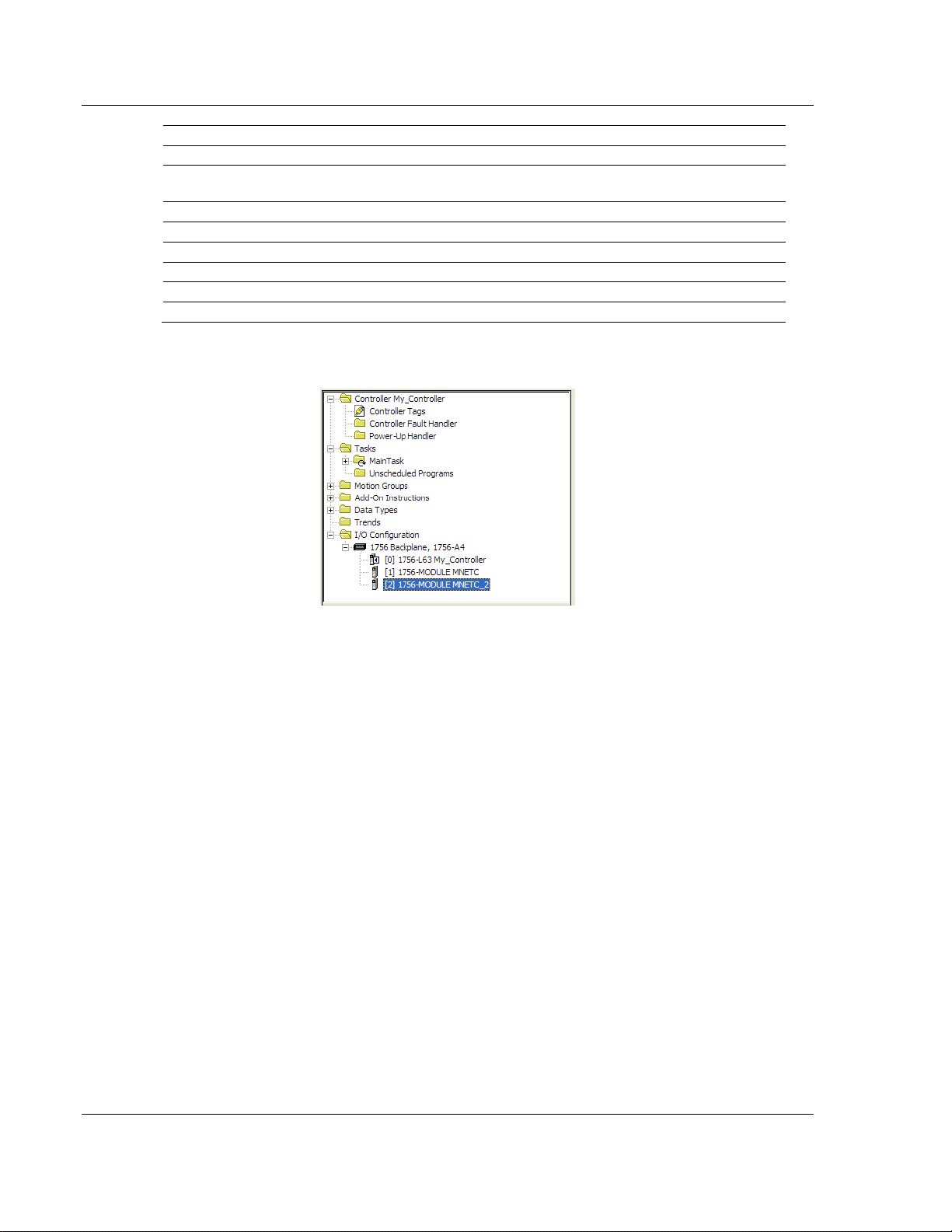

Adding Multiple Modules (Optional)

Important: If your application requires more than one MVI56-MNETC module in

the same project, follow the steps below.

1 In the I/O CONFIGURATION folder, click the right mouse button to open a

shortcut menu, and then choose NEW MODULE.

2 Select 1756-MODULE. If you’re using a controller revision of 16 or less,

expand OTHER in the Select Module dialog box, and then select the 1756-

MODULE.

3 Fill the module properties as follows:

ProSoft Technology, Inc. Page 27 of 183

February 3, 2013

Page 28

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

Parameter

Value

Comm Format

Select DATA-INT.

Slot

Enter the slot number in the rack where the MVI56E-MNETC

module is located.

Input Assembly Instance

1

Input Size

250

Output Assembly Instance

2

Output Size

248

Configuration Assembly Instance

4

Configuration Size

0

User Manual Modbus TCP/IP Client Enhanced Communication Module

4 Click OK to confirm. The new module is now visible:

5 Expand the TASKS folder, and then expand the MAINTASK folder.

6 In the MAINPROGRAM folder, double-click to open the MAINROUTINE ladder.

Page 28 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 29

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

7 Select an empty rung in the routine, and then click the right mouse button to

open a shortcut menu. On the shortcut menu, choose IMPORT RUNGS.

8 Select the MVI56EMNETC_ADDON_RUNG_V1_8.L5X file, and then click

IMPORT.

ProSoft Technology, Inc. Page 29 of 183

February 3, 2013

Page 30

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

9 This action opens the Import Configuration window Click TAGS under

MAINROUTINE to show the controller tags that will be created.

10 Associate the I/O connection variables to the correct module. The default

values are Local:1:I and Local:1:O so you may have to edit the Final Name

field to change the values. You can also click the drop-down arrow to select

the correct name.

11 Change the default tags MNETC and AOI56MNETC to avoid conflict with

existing tags. In this step, you should append a string to the default tag

names, such as "_2", as shown in the following illustration.

Page 30 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 31

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

12 Click OK to confirm.

The setup procedure is now complete. Save the project and download the

application to your ControlLogix processor.

ProSoft Technology, Inc. Page 31 of 183

February 3, 2013

Page 32

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

Adjusting the Input and Output Array Sizes

Tip: If you have not installed ProSoft Configuration Builder, see page 38 for the

steps to install the software.

The module internal database is divided into two user-configurable areas:

Read Data

Write Data

The Read Data area is moved from the module to the processor, while the Write

Data area is moved from the processor to the module.

The MVI56E-MNETC Add-On Instruction rung is configured for 600 registers of

Read Data and 600 registers of Write Data, which is sufficient for most

applications. However, you can configure the sizes of these data areas to meet

the needs of your application.

1 In ProSoft Configuration Builder, expand the Module icon in the tree view and

double-click MODULE to open an Edit window. Change the READ REGISTER

COUNT to contain the number of words for your Read Data area.

Important: Because the module pages data in blocks of 200 registers at a time,

you should configure your user data areas in multiples of 200 registers.

2 To modify the WriteData array, follow the above steps, substituting WriteData

for ReadData.

Page 32 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 33

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

3 Save and download the configuration to the module (page 65) and reboot.

Make sure that the ReadData and WriteData arrays do not overlap in the module

memory. For example, if your application requires 2000 words of WriteData

starting at register 0, then your Read Register Start parameter must be set to a

value of 2000 or greater.

ProSoft Technology, Inc. Page 33 of 183

February 3, 2013

Page 34

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

1.8 Connecting Your PC to the ControlLogix Processor

There are several ways to establish communication between your PC and the

ControlLogix processor. The following steps show how to establish

communication through the serial interface. It is not mandatory that you use the

processor's serial interface. You may access the processor through whatever

network interface is available on your system. Refer to your Rockwell Automation

documentation for information on other connection methods.

1 Connect the right-angle connector end of the cable to your controller at the

communications port.

2 Connect the straight connector end of the cable to the serial port on your

computer.

Page 34 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 35

MVI56E-MNETC ♦ ControlLogix Platform Start Here

Modbus TCP/IP Client Enhanced Communication Module User Manual

1.9 Downloading the Sample Program to the Processor

Note: The key switch on the front of the ControlLogix processor must be in the

REM or PROG position.

1 If you are not already online with the processor, open the Communications

menu, and then choose DOWNLOAD. RSLogix 5000 will establish

communication with the processor. You do not have to download through the

processor's serial port, as shown here. You may download through any

available network connection.

2 When communication is established, RSLogix 5000 will open a confirmation

dialog box. Click the DOWNLOAD button to transfer the sample program to the

processor.

3 RSLogix 5000 will compile the program and transfer it to the processor. This

process may take a few minutes.

4 When the download is complete, RSLogix 5000 will open another

confirmation dialog box. If the key switch is in the REM position, click OK to

switch the processor from PROGRAM mode to RUN mode.

Note: If you receive an error message during these steps, refer to your RSLogix

documentation to interpret and correct the error.

ProSoft Technology, Inc. Page 35 of 183

February 3, 2013

Page 36

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

Page 36 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 37

MVI56E-MNETC ♦ ControlLogix Platform Configuring the MVI56E-MNETC Module

In This Chapter

Installing ProSoft Configuration Builder ................................................. 38

Using ProSoft Configuration Builder Software ....................................... 39

Connecting Your PC to the Module ....................................................... 61

Downloading the Project to the Module ................................................. 65

Modbus TCP/IP Client Enhanced Communication Module User Manual

2 Configuring the MVI56E-MNETC Module

ProSoft Technology, Inc. Page 37 of 183

February 3, 2013

Page 38

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

2.1 Installing ProSoft Configuration Builder

To install ProSoft Configuration Builder from the CD-ROM

1 Insert the ProSoft Solutions CD-ROM into the CD drive of your PC. Wait for

the startup screen to appear.

2 On the startup screen, click INSTALL PROSOFT CONFIGURATION BUILDER. This

action starts the installation wizard for ProSoft Configuration Builder.

3 Click NEXT on each page of the installation wizard. Click FINISH on the last

page of the wizard.

Page 38 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 39

MVI56E-MNETC ♦ ControlLogix Platform Configuring the MVI56E-MNETC Module

Modbus TCP/IP Client Enhanced Communication Module User Manual

2.2 Using ProSoft Configuration Builder Software

ProSoft Configuration Builder (PCB) provides a convenient way to manage

module configuration files customized to meet your application needs. PCB is not

only a powerful solution for new configuration files, but also allows you to import

information from previously installed (known working) configurations to new

projects.

Note: During startup and initialization, the MVI56E-MNETC module receives its

protocol and backplane configuration information from the installed Personality

Module (Compact Flash). Use ProSoft Configuration Builder to configure module

settings and to download changes to the Personality Module.

2.2.1 Upgrading from MVI56-MNETC in ProSoft Configuration

Builder

MVI56E-MNETC modules are fully backward-compatible with MVI56-MNETC

modules. However, you will need to convert your MVI56-MNETC configuration in

ProSoft Configuration Builder to a form that your new MVI56E-MNETC module

will accept when you download it.

ProSoft Configuration Builder version 2.2.2 or later has an upgrade option that

easily performs this conversion, while preserving all your configuration settings

and any name you may have given your module.

Important: For this procedure, you need to have ProSoft Configuration Builder

version 2.2.2 or later installed on your PC. You can download the latest version

from www.prosoft-technology.com.

1 In ProSoft Configuration Builder's tree view, click the MODULE icon and right-

click to open a shortcut menu.

2 On the shortcut menu, select CHANGE MODULE TYPE TO MVI56E-MNETC.

ProSoft Technology, Inc. Page 39 of 183

February 3, 2013

Page 40

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

2.2.2 Setting Up the Project

To begin, start PROSOFT CONFIGURATION BUILDER (PCB).

If you have used other Windows configuration tools before, you will find the

screen layout familiar. PCB’s window consists of a tree view on the left, and an

information pane and a configuration pane on the right side of the window. When

you first start PCB, the tree view consists of folders for Default Project and

Default Location, with a Default Module in the Default Location folder. The

following illustration shows the PCB window with a new project.

Your first task is to add the MVI56E-MNETC module to the project.

1 Use the mouse to select DEFAULT MODULE in the tree view, and then click the

right mouse button to open a shortcut menu.

Page 40 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 41

MVI56E-MNETC ♦ ControlLogix Platform Configuring the MVI56E-MNETC Module

Modbus TCP/IP Client Enhanced Communication Module User Manual

2 On the shortcut menu, select CHOOSE MODULE TYPE. This action opens the

Choose Module Type dialog box.

3 In the Product Line Filter area of the dialog box, select MVI56E. In the Select

Module Type dropdown list, select MVI56E-MNETC, and then click OK to

save your settings and return to the ProSoft Configuration Builder window.

ProSoft Technology, Inc. Page 41 of 183

February 3, 2013

Page 42

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

2.2.3 Setting Module Parameters

Notice that the contents of the information pane and the configuration pane

changed when you added the MVI56E-MNETC module to the project.

At this time, you may wish to rename the Default Project and Default Location

folders in the tree view.

Renaming an Object

1 Select the object, and then click the right mouse button to open a shortcut

menu. From the shortcut menu, choose RENAME.

2 Type the name to assign to the object.

3 Click away from the object to save the new name.

Configuring Module Parameters

1 Click the [+] sign next to the module icon to expand module information.

2 Click the [+] sign next to any icon to view module information and

configuration options.

3 Double-click any icon to open an Edit dialog box.

4 To edit a parameter, select the parameter in the left pane and make your

changes in the right pane.

5 Click OK to save your changes.

Page 42 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 43

MVI56E-MNETC ♦ ControlLogix Platform Configuring the MVI56E-MNETC Module

Modbus TCP/IP Client Enhanced Communication Module User Manual

Printing a Configuration File

1 Select the module icon, and then click the right mouse button to open a

shortcut menu.

2 On the shortcut menu, choose VIEW CONFIGURATION. This action opens the

View Configuration window.

3 In the View Configuration window, open the FILE menu, and choose PRINT.

This action opens the Print dialog box.

4 In the Print dialog box, choose the printer to use from the drop-down list,

select printing options, and then click OK.

2.2.4 Module

This section of the configuration describes the database setup and module-level

parameters.

Backplane Error/Status Pointer

1 to 9955

This parameter sets the address in the internal database where the backplane

error/status data will be placed. If you want the error/status data to be moved to

the processor and placed into the ReadData array, the value entered should be a

module memory address in the Read Data area. If the value is set to -1, the

error/status data will not be stored in the module's internal database and will not

be transferred to the processor's ReadData array.

Enabling the Error/Status Pointer is optional. The error/status data is routinely

returned as part of the input image, which is continually being transferred from

the module to the processor. For more information, see Normal Data Transfer

Blocks (page 114).

Read Register Start

0 to 9999

The Read Register Start parameter specifies the start of the Read Data area in

module memory. Data in this area will be transferred from the module to the

processor.

Note: Total user database memory space is limited to the first 10,000 registers of

module memory, addresses 0 through 9999. Therefore, the practical limit for this

parameter is 9999 minus the value entered for Read Register Count, so that the

Read Data Area does not try to extend above address 9999. Read Data and

Write Data Areas must be configured to occupy separate address ranges in

module memory and should not be allowed to overlap.

Note: To use the extended database registers, your MVI56E-MNETC module needs to have

firmware version 3.01 or higher, and your MVI56E-MNETC Add-On Instruction needs to be version

1.8 or higher. Earlier versions support up to 5000 database registers.

ProSoft Technology, Inc. Page 43 of 183

February 3, 2013

Page 44

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

Read Register Count

0 to 10,000

The Read Register Count parameter specifies the size of the Read Data area of

module memory and the number of registers to transfer from this area to the

processor, up to a maximum of 10,000 words.

Note: Total Read Register Count and Write Register Count cannot exceed

10,000 total registers. Read Data and Write Data Areas must be configured to

occupy separate address ranges in module memory and should not be allowed

to overlap.

Write Register Start

0 to 9999

The Write Register Start parameter specifies the start of the Write Data area in

module memory. Data in this area will be transferred in from the processor.

Note: Total user database memory space is limited to the first 10,000 registers of

module memory, addresses 0 through 9999. Therefore, the practical limit for this

parameter is 9999 minus the value entered for Write Register Count, so that the

Write Data Area does not try to extend above address 9999. Read Data and

Write Data Areas must be configured to occupy separate address ranges in

module memory and should not be allowed to overlap.

Write Register Count

0 to 10,000

The Write Register Count parameter specifies the size of the Write Data area of

module memory and the number of registers to transfer from the processor to

this memory area, up to a maximum value of 5000 words.

Note: Total Read Register Count and Write Register Count cannot exceed

10,000 total registers. Read Data and Write Data Areas must be configured to

occupy separate address ranges in module memory and should not be allowed

to overlap.

Page 44 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 45

MVI56E-MNETC ♦ ControlLogix Platform Configuring the MVI56E-MNETC Module

Modbus TCP/IP Client Enhanced Communication Module User Manual

Failure Flag Count

If this value is greater than zero the protocol communication will be interrupted

once a backplane failure is detected, or communication with the processor fails.

A value of zero will disable this feature.

Initialize Output Data

0 = No, 1 = Yes

This parameter is used to determine if th e output data for the module should be i nitialized with values from the processor. I f the value is set to 0, the output data will be initialized to 0. If the value is s et to 1, the data will be initialized with d ata from the processor. Use of this opti on requires associated ladder logic to pass t he data from the processor to the mo dule.

Pass-Through Mode

0, 1, 2 or 3

This parameter specifies the pass-through mode for write messages received by

the MNET and MBAP server ports.

If the parameter is set to 0, all write messages will be placed in the module’s

virtual database.

If a value of 1 is entered, write messages received will be sent to the

processor as unformatted messages.

If a value of 2 is entered, write messages received will be sent to the

processor as formatted messages.

If a value of 3 is entered, write messages received will be sent to the

processor with the bytes swapped in a formatted message.

Note: To use pass-through mode, your MVI56E-MNETC module needs to have firmware version

3.01 or higher, and your MVI56E-MNETC Add-On Instruction needs to be version 1.8 or higher.

Earlier versions do not support pass-through mode.

Duplex/Speed Code

0, 1, 2, 3 or 4

This parameter allows you to cause the module to use a specific duplex and

speed setting.

Value = 1: Half duplex, 10 MB speed

Value = 2: Full duplex, 10 MB speed

Value = 3: Half duplex, 100 MB speed

Value = 4: Full duplex, 100 MB speed

Value = 0: Auto-negotiate

Auto-negotiate is the default value for backward compatibility. This feature is not

implemented in older software revisions.

ProSoft Technology, Inc. Page 45 of 183

February 3, 2013

Page 46

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

2.2.5 MNET Servers

This section contains database offset information used by the server when

accessed by external Clients. These offsets can be utilized to segment the

database by data type.

Note: To use the server capabilities, your MVI56E-MNETC module needs to have firmware version

3.01 or higher, and your MVI56E-MNETC Add-On Instruction needs to be version 1.8 or higher.

Earlier versions do not support server capabilities.

Float Flag

YES or NO

This flag specifies how the server driver will respond to Function Code 3, 6, and

16 commands (read and write Holding Registers) from a remote Client when it is

moving 32-bit floating-point data.

If the remote Client expects to receive or will send one complete 32-bit floatingpoint value for each count of one (1), then set this parameter to YES. When set to

YES, the server driver will return values from two consecutive 16-bit internal

memory registers (32 total bits) for each count in the read command, or receive

32-bits per count from the Client for write commands. Example: Count = 10,

server driver will send 20 16-bit registers for 10 total 32-bit floating-point values.

Page 46 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 47

MVI56E-MNETC ♦ ControlLogix Platform Configuring the MVI56E-MNETC Module

Modbus TCP/IP Client Enhanced Communication Module User Manual

If, however, the remote Client sends a count of two (2) for each 32-bit floatingpoint value it expects to receive or send, or, if you do not plan to use floatingpoint data in your application, then set this parameter to NO, which is the default

setting.

You will also need to set the Float Start and Float Offset parameters to

appropriate values whenever the Float Flag parameter is set to YES.

Float Start

0 TO 65535

Whenever the Float Flag parameter is set to YES, this parameter determines the

lowest Modbus Address, received in commands from a remote Client, to consider

as requests to read or write floating-point data. All commands with address

values greater than or equal to this value will be considered floating-point data

requests. All commands with address values less than this value will be

considered normal 16-bit register data requests.

This parameter is used only if the Float Flag is set to YES. For example, if a value

of 7000 is entered, all commands received with addresses of 47001 (or 407001)

and above will be considered as requests for floating-point data and 32-bits of

data will be returned for each count of one in the command.

You will also need to set the Float Offset parameter to an appropriate value

whenever the Float Flag parameter is set to YES.

Float Offset

0 to 9999

This parameter defines the start register for floating-point data in the internal

database. This parameter is used only if the Float Flag is enabled. For example,

if the Float Offset value is set to 3000 and the Float Start parameter is set to

7000, data requests for register 7000 will use the internal Modbus register 3000.

Output Offset

0 to 9999

This parameter defines the start register for the Modbus command data in the

internal database. This parameter is enabled when a value greater than 0 is set.

For example, if the Output Offset value is set to 3000, data requests for Modbus

Coil Register address 00001 will use the internal database register 3000, bit 0. If

the Output Offset value is set to 3000, data requests for Modbus Coil register

address 00016 will use the internal database register 3000, bit 15. Function

codes affected are 1, 5, and 15.

ProSoft Technology, Inc. Page 47 of 183

February 3, 2013

Page 48

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

Bit Input Offset

0 to 9999

This parameter defines the start register for Modbus command data in the

internal database. This parameter is enabled when a value greater than 0 is set.

For example, if the Bit Input Offset value is set to 3000, data requests for Modbus

Input Register address 10001 will use the internal database register 3000, bit 0. If

the Bit Input Offset is set to 3000, data requests for Modbus Coil register address

10016 will use the internal database register 3000, bit 15. Function code 2 is

affected.

Holding Register Offset

0 to 9999

This parameter defines the start register for the Modbus Command data in the

internal database. This parameter is enabled when a value greater than 0 is set.

For example, if the Holding Register Offset value is set to 4000, data requests for

Modbus Word register 40001 will use the internal database register 4000.

Function codes affected are 3, 6, 16, & 23.

Word Input Offset

0 to 9999

This parameter defines the start register for Modbus Command data in the

internal database. This parameter is enabled when a value greater than 0 is set.

For example, if the Word Input Offset value is set to 4000, data requests for

Modbus Word register address 30001 will use the internal database register

4000. Function code 4 is affected.

Connection Timeout

0 to 1200 seconds

This is the number of seconds the server will wait to receive new data. If the

server does not receive any new data during this time, it will close the

connection.

2.2.6 MNET Client x

This section defines general configuration for the MNET Client (Master).

Page 48 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 49

MVI56E-MNETC ♦ ControlLogix Platform Configuring the MVI56E-MNETC Module

Modbus TCP/IP Client Enhanced Communication Module User Manual

Client Error/Status Pointer

-1 to 9990

This parameter sets the address in the internal database where the Client

error/status data will be placed. If you want the error/status data to be moved to

the processor and placed into the ReadData array, the value entered should be a

module memory address in the Read Data area. If the value is set to -1, the

error/status data will not be stored in the module's internal database and will not

be transferred to the processor's ReadData array.

Enabling the Error/Status Pointer is optional. Alternatively, the error/status data

for a specific Client can be requested by the processor and returned in a special

Client Status block. For more information, see Client Status Blocks (page 122).

Command Error Pointer

-1 to 9984

This parameter sets the address in the internal database where the Command

Error List data will be placed. If you want the Command Error List data to be

moved to the processor and placed into the ReadData array, the value entered

should be a module memory address in the Read Data area. If the value is set to

-1, the Command Error List data will not be stored in the module's internal

database and will not be transferred to the processor's ReadData array.

Enabling the Command Error Pointer is optional. Alternatively, the Command

Error List data for a specific Client can be requested by the processor and

returned in a special Client Status block. For more information, see Client Status

Blocks (page 122).

Minimum Command Delay

0 to 65535 milliseconds

This parameter specifies the number of milliseconds to wait between the initial

issuances of a command. This parameter can be used to delay all commands

sent to servers to avoid "flooding" commands on the network. This parameter

does not affect retries of a command as they will be issued when failure is

recognized.

Response Timeout

0 to 65535 milliseconds

This is the time in milliseconds that a Client will wait before re-transmitting a

command if no response is received from the addressed server. The value to use

depends on the type of communication network used, and the expected

response time of the slowest device on the network.

Retry Count

0 to 10

This parameter specifies the number of times a command will be retried if it fails.

ProSoft Technology, Inc. Page 49 of 183

February 3, 2013

Page 50

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

User Manual Modbus TCP/IP Client Enhanced Communication Module

Float Flag

YES or NO

This flag specifies how the Client driver will issue Function Code 3, 6, and 16

commands (read and write Holding Registers) to a remote server when it is

moving 32-bit floating-point data.

If the remote server expects to receive or will send one complete 32-bit floatingpoint value for each count of one (1), then set this parameter to YES. When set to

YES, the Client driver will send values from two consecutive 16-bit internal

memory registers (32 total bits) for each count in a write command, or receive 32

bits per count from the server for read commands. Example: Count = 10, Client

driver will send 20 16-bit registers for 10 total 32-bit floating-point values.

If, however, the remote server expects to use a count of two (2) for each 32-bit

floating-point value it sends or receives, or if you do not plan to use floating-point

data in your application, then set this parameter to NO, which is the default

setting.

You will also need to set the Float Start and Float Offset parameters to

appropriate values whenever the Float Flag parameter is set to YES.

Float Start

0 to 65535

Whenever the Float Flag parameter is set to YES, this parameter determines the

lowest Modbus Address, used in commands to a remote server, to consider as

commands to read or write floating-point data. All commands with address values

greater than or equal to this value will be considered floating-point data

commands. All commands with address values less than this value will be

considered normal 16-bit register data commands.

This parameter is used only if the Float Flag is set to YES. For example, if a value

of 7000 is entered, all commands sent with addresses of 47001 (or 407001) and

above will be considered as floating-point data commands and 32 bits of data will

be sent or received for each count of one in the command.

You will also need to set the Float Offset parameter to an appropriate value

whenever the Float Flag parameter is set to YES.

Float Offset

0 to 9999

This parameter defines the start register for floating-point data in the internal

database. This parameter is used only if the Float Flag is enabled. For example,

if the Float Offset value is set to 3000 and the Float Start parameter is set to

7000, data requests for register 7000 will use the internal Modbus register 3000.

ARP Timeout

1 to 60

This parameter specifies the number of seconds to wait for an ARP reply after a

request is issued.

Page 50 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 51

MVI56E-MNETC ♦ ControlLogix Platform Configuring the MVI56E-MNETC Module

Modbus TCP/IP Client Enhanced Communication Module User Manual

Command Error Delay

0 to 300

This parameter specifies the number of 100 millisecond intervals to turn off a

command in the error list after an error is recognized for the command. If this

parameter is set to 0, there will be no delay.

MBAP Port Override

YES or NO

If this parameter is set to YES, all messages generated by the Client driver will be

MBAP format messages to all Service Port values.

If this parameter is set to NO (default value), or is omitted from the configuration

file, all messages sent to Service Port 502 will be MBAP format messages, and

all other Service Ports values will use the encapsulated Modbus message format

(MNET).

Each Client is configured independently in the configuration file.

This parameter applies to firmware version 1.05 and above. For downward

compatibility, you may omit this parameter from the Client's configuration.

2.2.7 MNET Client x Commands

The MNET Client x Commands section of the configuration sets the Modbus

TCP/IP Client command list. This command list polls Modbus TCP/IP server

devices attached to the Modbus TCP/IP Client port. The module supports

numerous commands. This permits the module to interface with a wide variety of

Modbus TCP/IP protocol devices.

The function codes used for each command are those specified in the Modbus

protocol. Each command list record has the same format. The first part of the

record contains the information relating to the MVI56E-MNETC communication

module, and the second part contains information required to interface to the

Modbus TCP/IP server device.

ProSoft Technology, Inc. Page 51 of 183

February 3, 2013

Page 52

Guide to the MVI56E-MNETC User Manual MVI56E-MNETC ♦ ControlLogix Platform

Function Code

Definition

Supported in Client

Supported in Server

1

Read Coil Status

X X 2

Read Input Status

X

X

3

Read Holding Registers

X

X

4

Read Input Registers

X X 5

Force (Write) Single Coil

X X 6

Preset (Write) Single Register

X X 7

Read Exception Status

X X 8

Diagnostics

X 15

Force (Write) Multiple Coils

X

X

16

Preset (Write) Multiple

Registers

X

X

22

Mask Write 4X

X 23

Read/Write

X

User Manual Modbus TCP/IP Client Enhanced Communication Module

Command List Overview

In order to interface the module with Modbus TCP/IP server devices, you must

construct a command list. The commands in the list specify the server device to

be addressed, the function to be performed (read or write), the data area in the

device to interface with, and the registers in the internal database to be

associated with the device data. The Client command list supports up to 16

commands.

The command list is processed from top (command #1) to bottom. A poll interval

parameter is associated with each command to specify a minimum delay time in

tenths of a second between the issuances of a command. If the user specifies a

value of 10 for the parameter, the command will be executed no more frequently

than every 1 second.

NOTE: If you are using only Event Commands or issuing commands from the

Command List using Command Control from ladder logic, it is likely that the

module will not leave any inactive TCP/IP socket connections open for more than

60-seconds. To maintain an open socket connection, your configuration or

application must be designed so that at least one command is issued to each

server connection at less than 60-second intervals. The 60-second connection

timeout is not user-configurable and was put in place to prevent long delays

between commands.

Commands Supported by the Module

The format of each command in the list depends on the Modbus Function Code

being executed.

The following table lists the functions supported by the module.

Each command list record has the same general format. The first part of the

record contains the information relating to the communication module and the

second part contains information required to interface to the Modbus TCP/IP

server device.

Page 52 of 183 ProSoft Technology, Inc.

February 3, 2013

Page 53

MVI56E-MNETC ♦ ControlLogix Platform Configuring the MVI56E-MNETC Module

1 2 3 4 5 6 7 8 9

10

Enable

Code

Internal

Address

Poll Interval

Time

Count

Swap

Code

IP

Address

Serv

Port

Slave

Node

Function Code

Device

Modbus

Address

Code

Register

(bit)

1/10th

Seconds

Bit

Count

0

IP

Address

Port # Address

Read Coil (0x)

Register

Code

Register

(bit)

1/10th

Seconds

Bit

Count

0

IP

Address

Port # Address

Read Input (1x)

Register

Code

Register

1/10th

Seconds

Word

Count

Code

IP

Address

Port # Address

Read Holding

Registers (4x)

Register

Code

Register

1/10th

Seconds

Word

Count

0

IP

Address

Port # Address

Read Input

Registers (3x)

Register

Code

1 bit

1/10th

Seconds

Bit

Count

0

IP

Address

Port # Address

Force (Write)

Single Coil (0x)

Register

Code

1 bit

1/10th

Seconds

Word

Count

0

IP

Address

Port # Address

Preset (Write)

Single Register

(4x)

Register

Code

Register

(bit)

1/10th

Seconds

Bit

Count

0

IP

Address

Port # Address

Force (Write)

Multiple Coil (0x)

Register

Code

Register

1/10th

Seconds