Page 1

MVI56E-LDM

ControlLogix Platform

"C" Programmable

Linux Application Development

Module

DEVELOPER'S MANUAL

March 12, 2014

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

© 2014 ProSoft Technology, Inc. All rights reserved.

MVI56E-LDM Developer's Manual

March 12, 2014

ProSoft Technology ®, is a registered Copyright of ProSoft Technology, Inc. All other brand or product names are or

may be trademarks of, and are used to identify products and services of, their respective owners.

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed DVD and are

available at no charge from our web site: http://www.prosoft-technology.com

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS

I, DIV. 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Warnings - MVI56E-LDM

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

Page 3

B Warning - Explosion Hazard - When in Hazardous Locations, turn off power before replacing or rewiring

modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be nonhazardous.

C Suitable for use in Class I, Division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage:

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B *Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

CPU, Memory, and OS Specifications

CPU: 400MHz ARM9 G20

Operating System: Linux (kernel 2.6.33.7)

Linux Distribution: Debian GNU/Linux

System Memory: 64MB SDRAM

Flash Memory: 64MB ROM

Compact Flash: 64MB card provided (16GB max supported)

General Specifications

Backplane Current Load: 800 mA @ 5 V DC; 3mA @ 24V DC

Operating Temperature: 0 to 60°C (32 to 140°F)

Storage Temperature: -40 to 85°C (-40 to 185°F)

Shock: 30g Operational; 50g non-operational; Vibration: 5 g from 10 to 150 Hz

Relative Humidity: 5% to 95% (non-condensing)

LED Indicators: ERR - Application driven, APP - Application driven, OK - Application driven

4-Character, Scrolling, Alpha-numeric LED Display: Application driven - possible uses

are: Module Version, IP, Application Port Setting, Status/Error Information

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground

conductors must be at least 4mm(squared).

Ethernet Ports

2 Ethernet Ports

10/100 Mbps

RJ45 Connector,

Link and Activity Indicators

Auto-sensing crossover cable detection

Serial Ports

Full hardware handshaking control provides radio, modem, and multi-drop support.

RJ45 (DB-9M with supplied adapter cable)

Configurable RS-232 hardware handshaking

500V Optical isolation from backplane

RS-232, RS-422, RS-485 jumper-select, each port

Rx (Receive) and Tx (Transmit) LEDs, each port

Page 4

Atex

CE

CSA, CSA CB Safety

cULus

GOST-R

Lloyds

Agency Approvals and Certifications

Page 5

ControlLogix Platform ♦ "C" Programmable Contents

Linux Application Development Module Developer's Manual

Contents

Your Feedback Please ........................................................................................................................ 2

Important Installation Instructions ....................................................................................................... 2

MVI (Multi Vendor Interface) Modules ................................................................................................ 2

Warnings - MVI56E-LDM .................................................................................................................... 2

1 LDM Introduction 4

2 Preparing the MVI56E-LDM Module 6

2.1 System Requirements ............................................................................................... 6

2.2 Package Contents - LDM .......................................................................................... 7

2.3 Recommended Compact Flash (CF) Cards .............................................................. 7

2.4 Jumper Locations and Settings ................................................................................. 7

2.4.1 Setup Jumper - MVI56E ............................................................................................ 8

2.4.2 Port 1 and Port 2 Jumpers MVI56E .......................................................................... 8

2.5 Setting Up a Connection with the Module ................................................................. 8

2.5.1 Installing the Module in the Rack .............................................................................. 9

2.5.2 Making Configuration Port Connections .................................................................. 10

2.6 Enabling and Disabling the Console Port................................................................ 15

2.7 Establishing Module Communication ...................................................................... 18

2.8 Module Rescue ....................................................................................................... 21

3 Development Environment 23

3.1 Setup ....................................................................................................................... 23

3.2 Using Eclipse ........................................................................................................... 27

3.2.1 Building a Project .................................................................................................... 27

4 Understanding the MVI56-LDM API 33

4.1 API Library - MVI56E ............................................................................................... 33

4.1.1 Header File .............................................................................................................. 33

4.1.2 Sample Code ........................................................................................................... 33

4.1.3 Specifying the Communications Path ..................................................................... 34

4.1.4 ControlLogix Tag Naming Conventions .................................................................. 34

4.2 MVI56E-LDM Development Tools ........................................................................... 35

4.3 CIP API Functions ................................................................................................... 36

4.4 Backplane Device Driver ......................................................................................... 36

4.5 Sample Code ........................................................................................................... 38

4.6 Establishing a Console Connection ........................................................................ 39

4.7 Physically Connect to the Module ........................................................................... 40

4.8 Configuring Serial Communication .......................................................................... 41

4.9 Setting Up the ControlLogix 5000 ........................................................................... 43

4.10 Sample Tutorials ..................................................................................................... 45

4.11 Ethernet Sample ...................................................................................................... 46

4.12 Serial Sample .......................................................................................................... 49

4.13 Led_Sample ............................................................................................................ 50

4.14 Backplane_Sample ................................................................................................. 51

ProSoft Technology, Inc. Page 5 of 264

March 12, 2014

Page 6

Contents ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

4.15 Tag_Sample............................................................................................................ 53

4.16 Sample Applications ............................................................................................... 55

4.17 Ethernet Communications Sample ......................................................................... 56

4.18 Serial Application Sample ....................................................................................... 61

5 CIP API Functions 70

5.1 CIP API Initialization Functions ............................................................................... 73

OCXcip_Open ............................................................................................................................. 73

OCXcip_OpenNB ........................................................................................................................ 74

OCXcip_Close ............................................................................................................................. 77

5.2 Object Registration ................................................................................................. 79

OCXcip_RegisterAssemblyObj ................................................................................................... 79

OCXcip_UnregisterAssemblyObj ................................................................................................ 82

5.3 Special Callback Registration ................................................................................. 84

OCXcip_RegisterFatalFaultRtn ................................................................................................... 84

OCXcip_RegisterResetReqRtn ................................................................................................... 86

5.4 CIP Callback Functions .......................................................................................... 88

connect_proc ............................................................................................................................... 88

service_proc ................................................................................................................................ 93

fatalfault_proc .............................................................................................................................. 97

5.5 Connected Data Transfer ....................................................................................... 99

OCXcip_WriteConnected ............................................................................................................ 99

OCXcip_ReadConnected .......................................................................................................... 101

OCXcip_ImmediateOutput ........................................................................................................ 103

OCXcip_WaitForRxData ........................................................................................................... 105

OCXcip_WriteConnectedComplete ........................................................................................... 107

5.6 Tag Access Functions .......................................................................................... 110

OCXcip_AccessTagData ........................................................................................................... 110

OCXcip_AccessTagDataAbortable ........................................................................................... 113

OCXcip_CreateTagDbHandle ................................................................................................... 114

OCXcip_DeleteTagDbHandle ................................................................................................... 115

OCXcip_SetTagDbOptions ....................................................................................................... 116

OCXcip_BuildTagDb ................................................................................................................. 119

OCXcip_TestTagDbVer ............................................................................................................. 121

OCXcip_GetSymbolInfo ............................................................................................................ 123

OCXcip_GetStructInfo ............................................................................................................... 126

OCXcip_GetStructMbrInfo ......................................................................................................... 129

OCXcip_GetTagDbTagInfo ....................................................................................................... 132

OCXcip_AccessTagDataDb ...................................................................................................... 135

5.7 Messaging ............................................................................................................. 138

OCXcip_GetDeviceIdObject ...................................................................................................... 139

OCXcip_GetDeviceICPObject ................................................................................................... 142

OCXcip_GetDeviceIdStatus ...................................................................................................... 145

OCXcip_GetExDeviceObject..................................................................................................... 149

OCXcip_GetWCTime ................................................................................................................ 152

OCXcip_SetWCTime ................................................................................................................. 156

OCXcip_GetWCTimeUTC ......................................................................................................... 159

OCXcip_SetWCTimeUTC ......................................................................................................... 163

5.8 Miscellaneous Functions ...................................................................................... 166

OCXcip_GetIdObject ................................................................................................................. 167

OCXcip_SetIdObject ................................................................................................................. 169

OCXcip_GetActiveNodeTable ................................................................................................... 171

Page 6 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 7

ControlLogix Platform ♦ "C" Programmable Contents

Linux Application Development Module Developer's Manual

OCXcip_MsgResponse.............................................................................................................. 173

OCXcip_GetVersionInfo............................................................................................................. 176

OCXcip_GetUserLED ................................................................................................................ 178

OCXcip_SetUserLED................................................................................................................. 180

OCXcip_GetModuleStatus ......................................................................................................... 182

OCXcip_SetModuleStatus ......................................................................................................... 184

OCXcip_GetLED3 ...................................................................................................................... 186

OCXcip_SetLED3 ...................................................................................................................... 188

OCXcip_ErrorString ................................................................................................................... 190

OCXcip_SetDisplay ................................................................................................................... 192

OCXcip_GetDisplay ................................................................................................................... 194

OCXcip_GetSwitchPosition ....................................................................................................... 196

OCXcip_GetSerialConfig ........................................................................................................... 198

OCXcip_Sleep ........................................................................................................................... 201

OCXcip_CalculateCRC .............................................................................................................. 203

OCXcip_SetModuleStatusWord ................................................................................................ 205

OCXcip_GetModuleStatusWord ................................................................................................ 207

6 Cable Connections 209

6.1 RS-232 Configuration/Debug Port ........................................................................ 209

6.2 RS-232 Application Port(s) ................................................................................... 210

6.2.1 RS-232: Modem Connection (Hardware Handshaking Required) ........................ 210

6.2.2 RS-232: Null Modem Connection (Hardware Handshaking) ................................ 211

6.2.3 RS-232: Null Modem Connection (No Hardware Handshaking) ........................... 211

6.3 RS-422 .................................................................................................................. 212

6.4 RS-485 Application Port(s) .................................................................................... 212

6.4.1 RS-485 and RS-422 Tip ........................................................................................ 213

6.5 DB9 to RJ45 Adaptor (Cable 14) .......................................................................... 213

7 Support, Service & Warranty 214

7.1 Contacting Technical Support ............................................................................... 214

7.2 Return Material Authorization (RMA) Policies and Conditions.............................. 215

7.2.1 Returning Any Product .......................................................................................... 215

7.2.2 Returning Units Under Warranty ........................................................................... 216

7.2.3 Returning Units Out of Warranty ........................................................................... 216

7.3 LIMITED WARRANTY ........................................................................................... 217

7.3.1 What Is Covered By This Warranty ....................................................................... 218

7.3.2 What Is Not Covered By This Warranty ................................................................ 219

7.3.3 Disclaimer Regarding High Risk Activities ............................................................ 220

7.3.4 Intellectual Property Indemnity .............................................................................. 221

7.3.5 Disclaimer of all Other Warranties ........................................................................ 222

7.3.6 Limitation of Remedies ** ...................................................................................... 222

7.3.7 Time Limit for Bringing Suit ................................................................................... 223

7.3.8 No Other Warranties ............................................................................................. 223

7.3.9 Allocation of Risks ................................................................................................. 223

7.3.10 Controlling Law and Severability ........................................................................... 223

7.4 Open Source Licensing ......................................................................................... 224

7.5 GNU Public License .............................................................................................. 225

7.6 Eclipse Public License ........................................................................................... 239

7.7 Python Public License ........................................................................................... 245

7.8 GCC Public License .............................................................................................. 251

ProSoft Technology, Inc. Page 7 of 264

March 12, 2014

Page 8

Contents ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

8 Glossary of Terms 254

Index 257

Page 8 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 9

Page 10

ControlLogix Platform ♦ "C" Programmable LDM Introduction

API

Application Programming Interface

Backplane

Refers to the electrical interface or bus to which modules

connect when inserted into the rack. The MVI56E-LDM

module communicates with the control processor(s)

through the ControlLogix backplane.

CIP

Control and Information Protocol. This is the messaging

protocol used for communications over the ControlLogix

backplane.

Connection

A logical binding between two objects. A connection

allows more efficient use of bandwidth because the

messaging path is not included after the connection is

established.

Consumer

A destination for data.

Library

Refers to the library file that contains the API functions.

The library must be linked with the developer's application

code to create the final executable program.

Originator

A client that establishes a connection path to a target.

Producer

A source of data.

Target

The end-node to which a connection is established by an

originator.

Linux Application Development Module Developer's Manual

1 LDM Introduction

The MVI56E-LDM module is a ControlLogix backplane compatible module that

allows Rockwell Automation ControlLogix processors to interface with any

Ethernet or Serial device. With the supplied development tools and sample

applications, you are the developer who controls exactly what this module can

and cannot do.

ProSoft Technology's Linux Development modules make it possible for users to

easily develop and deploy C/C++ applications that interface with Bar Code

Scanners, Legacy ASCII protocols, Terminal Port Emulation, Printer Drivers

(Alarm/Status printer), or any other device requiring custom/proprietary Ethernet

and Serial communications.

This document provides information needed for development of application

programs for the MVI56E-LDM Applications Module for ControlLogix.

This document assumes the reader is familiar with software development in the

Linux environment using C/C++ programming languages. This document also

assumes that the reader is familiar with Rockwell Automation programmable

controllers and the ControlLogix platform.

The reader should be familiar with the following terms:

ProSoft Technology, Inc. Page 4 of 264

March 12, 2014

Page 11

ControlLogix Platform ♦ "C" Programmable LDM Introduction

Linux Application Development Module Developer's Manual

ProSoft Technology, Inc. Page 5 of 264

March 12, 2014

Page 12

Preparing the MVI56E-LDM Module ControlLogix Platform ♦ "C" Programmable

In This Chapter

System Requirements ............................................................................. 6

Package Contents - LDM ......................................................................... 7

Recommended Compact Flash (CF) Cards ............................................. 7

Jumper Locations and Settings ............................................................... 7

Setting Up a Connection with the Module ................................................ 8

Establishing Module Communication ..................................................... 18

Module Rescue ...................................................................................... 21

Developer's Manual Linux Application Development Module

2 Preparing the MVI56E-LDM Module

2.1 System Requirements

The MVI56E-LDM module requires the following hardware and software

components:

Rockwell Automation ControlLogix processor (firmware version 10 or greater)

with compatible power supply and one free slot in the rack for the module.

The module requires 5 VDC power

Rockwell Automation RSLogix 5000 programmer software

o Version 15 or lower must use Sample Ladder available from www.prosoft-

technology.com

Rockwell Automation RSLinx communication software version 2.51 or greater

Pentium II 450 MHz minimum. Pentium III 733 MHz or greater recommended

Supported operating systems:

o Microsoft Windows 7 Professional (32 or 64-bit)

o Microsoft Windows Vista

o Microsoft Windows XP Professional with Service Pack 1 or 2

o Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o Microsoft Windows Server 2003

128 MB RAM (minimum), 256 MB of RAM recommended

100 MB of free hard disk space (or more based on application requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 x 768 recommended)

DVD drive

Note: The Hardware and Operating System requirements in this list are the minimum

recommended to install and run software provided by ProSoft Technology. Other third party

applications may have different requirements. Refer to the documentation for any third party

applications.

Page 6 of 264 ProSoft Technology, Inc.

March 12, 2014

Port 1

Page 13

ControlLogix Platform ♦ "C" Programmable Preparing the MVI56E-LDM Module

Linux Application Development Module Developer's Manual

Port 2

2.2 Package Contents - LDM

Your MVI56E-LDM package includes:

MVI56E-LDM Module

ProSoft Technology Solutions DVD (includes all documentation, sample

code, and sample ladder logic).

(1) Null Modem Cable (Cable 15)

(2) Config/Debug Port to DB-9 adapter (Cable 14)

(2) 1454-9F Connectors for RS422/RS485

(1) Ethernet Cable (Cable 25)

Note: The Virtual Machine, toolchain, and other development files are not

shipped with the product. You may purchase the ProSoft Technology LDMdevKit

Part # LDMdevKit from your Rockwell Automation distributor.

If any of these components are missing, please contact ProSoft Technology

Support.

2.3 Recommended Compact Flash (CF) Cards

What Compact Flash card does ProSoft recommend using?

Some ProSoft products contain a "Personality Module", or Compact Flash card.

ProSoft recommends using an industrial grade Compact Flash card for best

performance and durability. The following cards have been tested with ProSoft’s

modules, and are the only cards recommended for use. These cards can be

ordered through ProSoft, or can be purchased by the customer.

Approved ST-Micro cards:

32M = SMC032AFC6E

64M = SMC064AFF6E -

128M = SMC128AFF6E

Approved Silicon Systems cards:

256M = SSD-C25MI-3012

512M = SSD-C51MI-3012

2G = SSD-C02GI-3012

4G = SSD-C04GI-3012

ProSoft provides the 64M = SMC064AFF6E Compact Flash Card. The

endurance spec for this card is 2 million write/erase cycles.

WARNING: Do not shutdown or power cycle the module in any way during a

NAND write to the CF.

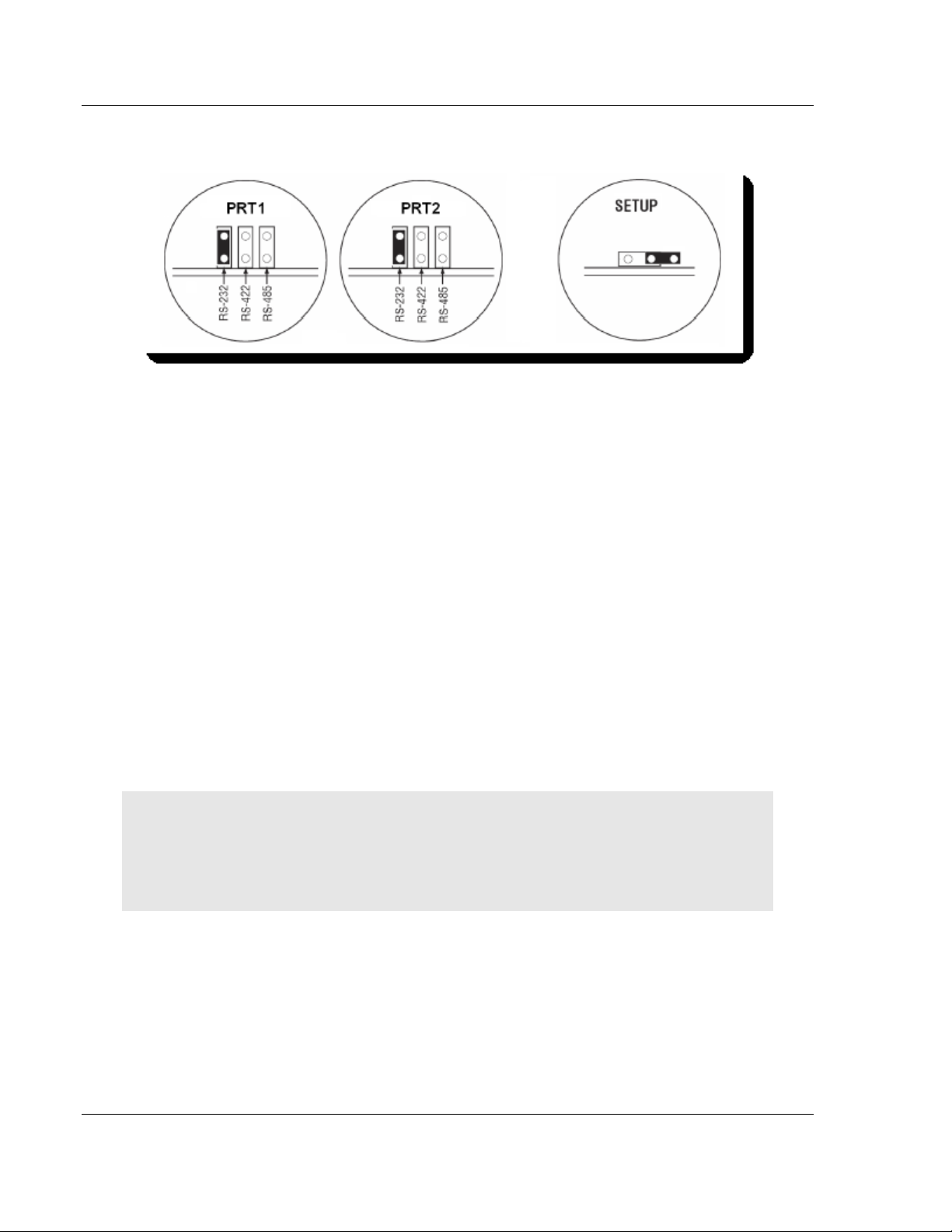

2.4 Jumper Locations and Settings

Each module has three jumpers:

Setup

ProSoft Technology, Inc. Page 7 of 264

March 12, 2014

Page 14

Preparing the MVI56E-LDM Module ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

Port 1

Port 2

2.4.1 Setup Jumper - MVI56E

The Setup Jumper acts a write protection for the module's firmware. In "writeprotected" mode, the setup pins are not connected which prevents the module's

firmware from being overwritten.

The module is shipped with the Setup Jumper OFF. If you need to update the

firmware or run a module rescue (recovery), apply the setup shunt over both

pins.

2.4.2 Port 1 and Port 2 Jumpers MVI56E

These jumpers, located at the bottom of the module, configure the port settings

to RS-232, RS-422, or RS-485. By default, the jumpers for both ports are set to

RS-232.

2.5 Setting Up a Connection with the Module

If you have not already done so, please install and configure your ControlLogix

processor and power supply. Refer to the Rockwell Automation product

documentation for installation instructions.

Warning: You must follow all safety instructions when installing this or any other electronic

devices. Failure to follow safety procedures could result in damage to hardware or data, or even

serious injury or death to personnel. Refer to the documentation for each device you plan to

connect to verify that suitable safety procedures are in place before installing or servicing this

device.

After verifying proper jumper placement, insert the module into the ControlLogix

chassis. Use the same technique recommended by Rockwell Automation to

remove and install ControLogix modules.

Page 8 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 15

ControlLogix Platform ♦ "C" Programmable Preparing the MVI56E-LDM Module

Linux Application Development Module Developer's Manual

2.5.1 Installing the Module in the Rack

You can install or remove ControlLogix system components while chassis power

is applied and the system is operating. However, please note the following

warning.

Warning: When you insert or remove the module while backplane power is on, an electrical arc

can cause personal injury or property damage by sending an erroneous signal to your system's

actuators. This can cause unintended machine motion or loss of process control. Electrical arcs

may also cause an explosion they occur in a hazardous environment. Verify that power is

removed, or that the area is non-hazardous before proceeding. Repeated electrical arching

causes excessive wear to contacts on both the module and its mating connector. Worn contacts

may create electrical resistance that can affect module operation.

Align the module with the top and bottom guides, and then slide it into the rack

until the module is firmly seated against the backplane connector.

With a firm, steady push, snap the module into place. Ensure that the holding

clips on the top and bottom of the module are securely in the locking holes of the

rack.

Make a note of the slot location. Slot numbers are identified on the green circuit

board (backplane) of the ControlLogix rack.

Turn power On.

ProSoft Technology, Inc. Page 9 of 264

March 12, 2014

Page 16

Preparing the MVI56E-LDM Module ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

2.5.2 Making Configuration Port Connections

You can communicate with the module via RS232 through the Console or

through one of the Ethernet ports using Telnet.

RS-232 Console

You access the Console through Serial Port 1. As a default, the RS-232 Console

port is "enabled". You can "disable" or "enable" this port. Refer to Enabling and

Disabling the Console Port in the next section.

1 Connect the RJ45 end of an RJ45 - DB9m cable (Cable 14) to the Serial Port

1 of the module.

2 Connect one end of the Null Modem Cable (Cable 15) to the DB9m end

Cable 14.

3 Connect the other end of Cable 15 (null modem cable) to your a serial port on

your PC or laptop.

Page 10 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 17

ControlLogix Platform ♦ "C" Programmable Preparing the MVI56E-LDM Module

Linux Application Development Module Developer's Manual

Ethernet Port

The module contains a Telnet client which is accessed through Ethernet Port 1

(E1) as shown.

Connect an Ethernet RJ45 cable to the E1 port of the module and the other end

to the network switch.

ProSoft Technology, Inc. Page 11 of 264

March 12, 2014

Page 18

Preparing the MVI56E-LDM Module ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

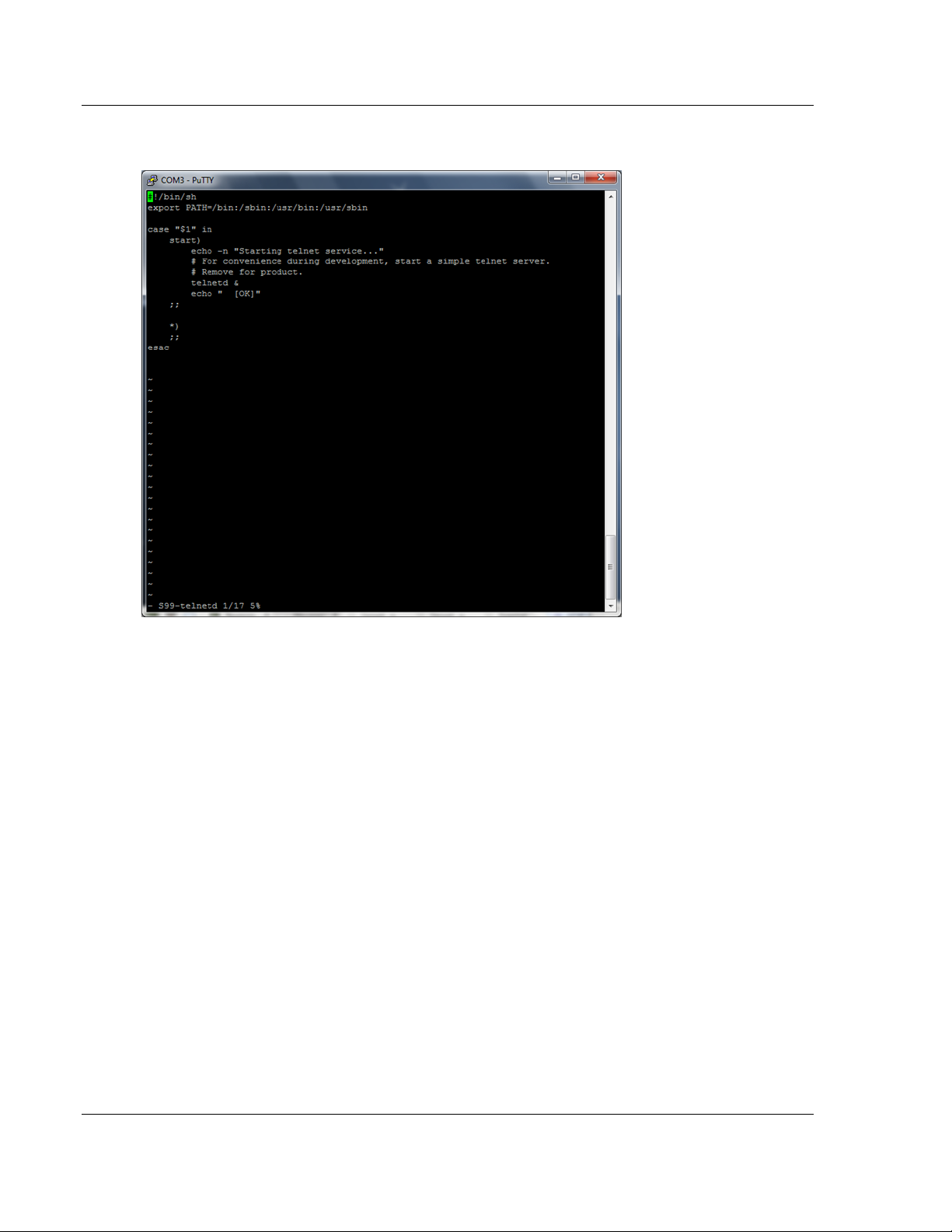

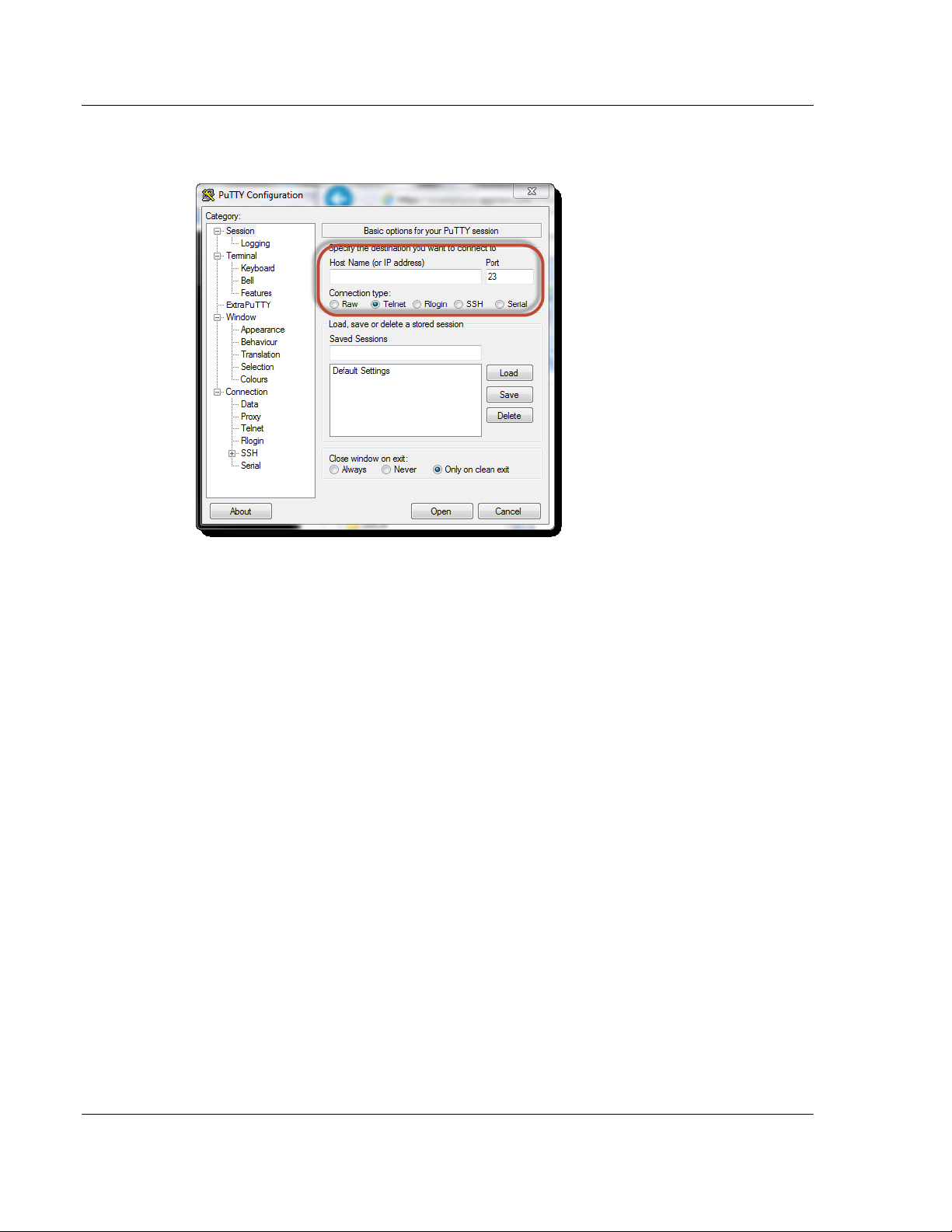

You can also "enable" or "disable" the Telnet port. Open a Putty session as

shown below. The following screenshot shows the Telnet Port "enabled"

To disable the Telnet port...

Page 12 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 19

ControlLogix Platform ♦ "C" Programmable Preparing the MVI56E-LDM Module

Linux Application Development Module Developer's Manual

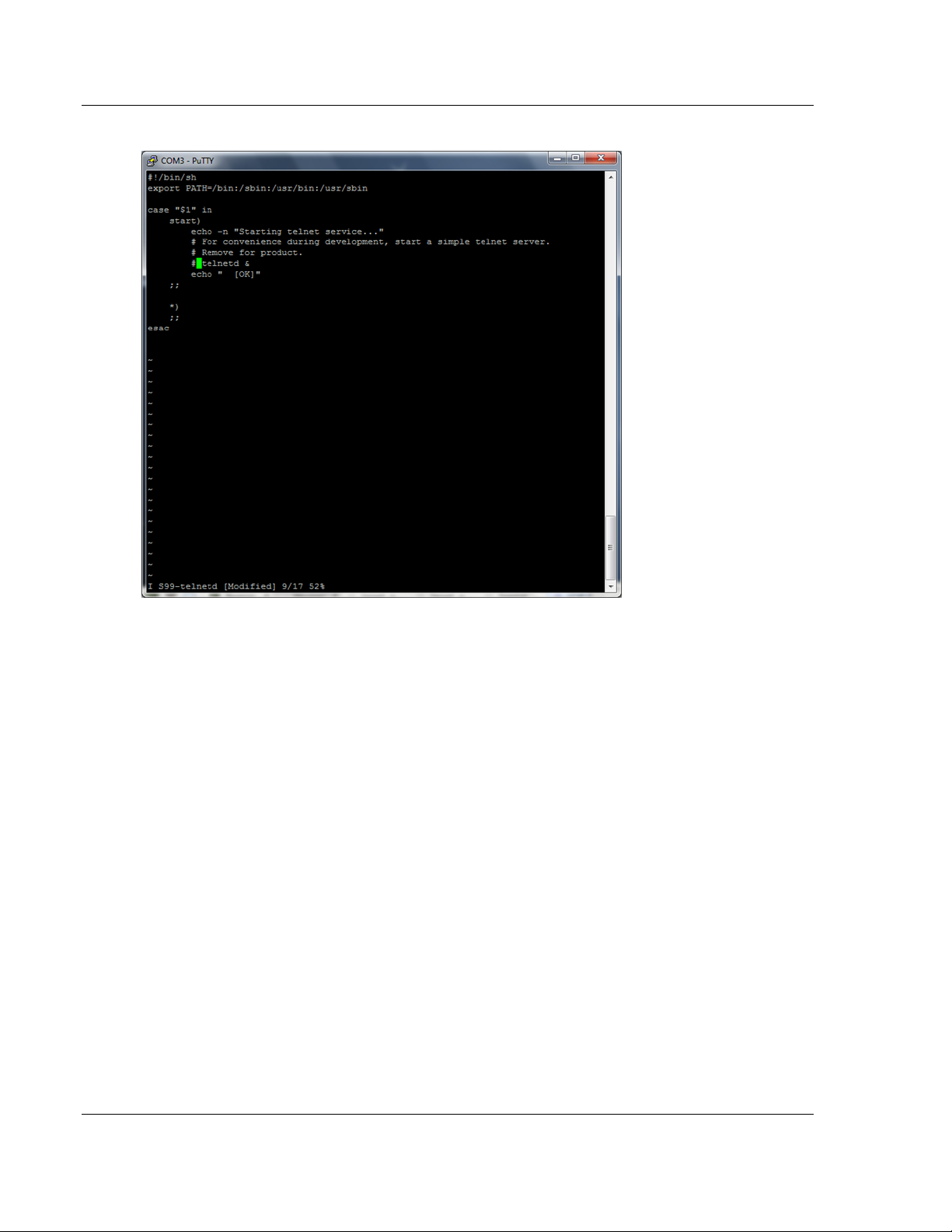

cd\etc\init.d\S99-telnetd.

ProSoft Technology, Inc. Page 13 of 264

March 12, 2014

Page 20

Preparing the MVI56E-LDM Module ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

Comment out the telnetd file.

To enable the port, simply un-comment the same line.

Page 14 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 21

ControlLogix Platform ♦ "C" Programmable Preparing the MVI56E-LDM Module

Linux Application Development Module Developer's Manual

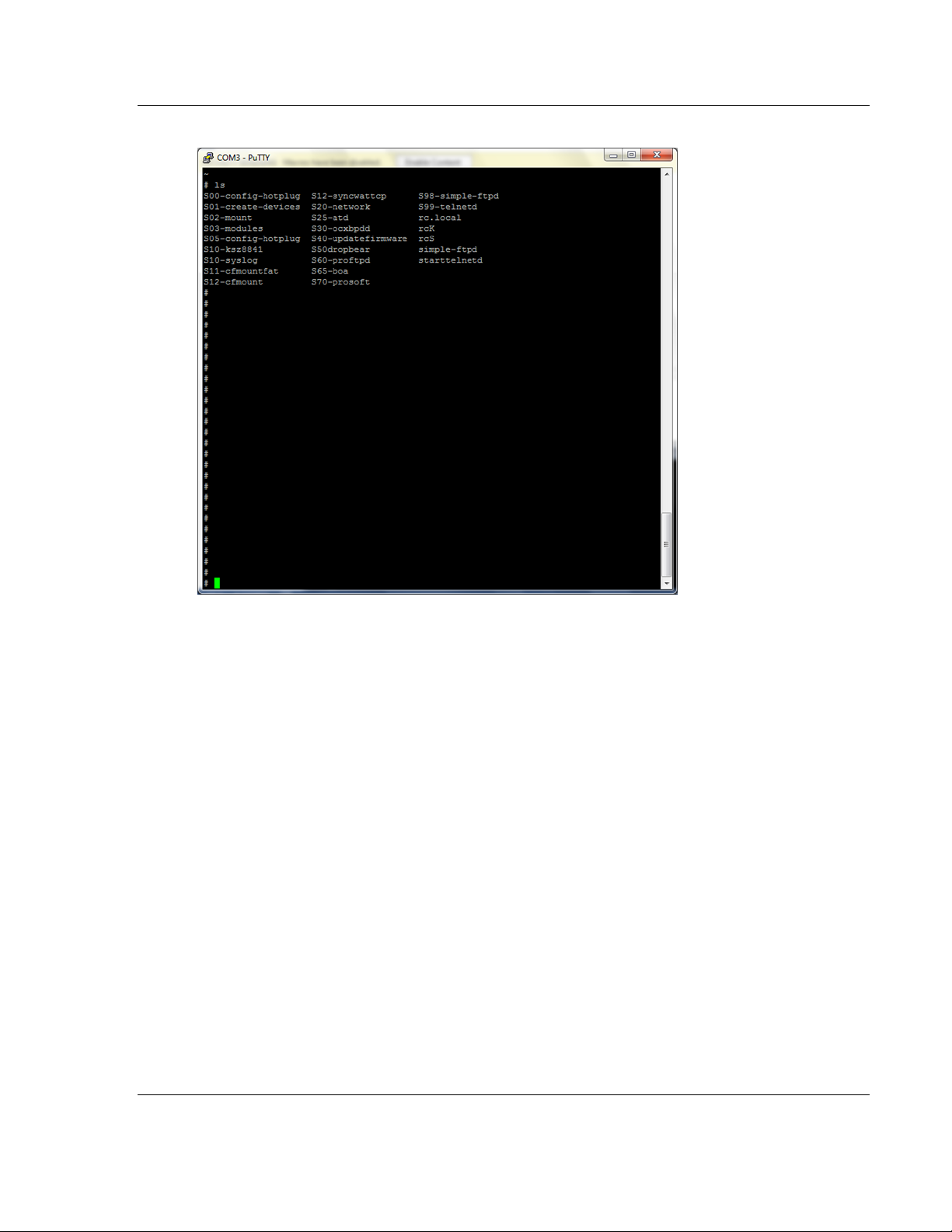

2.6 Enabling and Disabling the Console Port

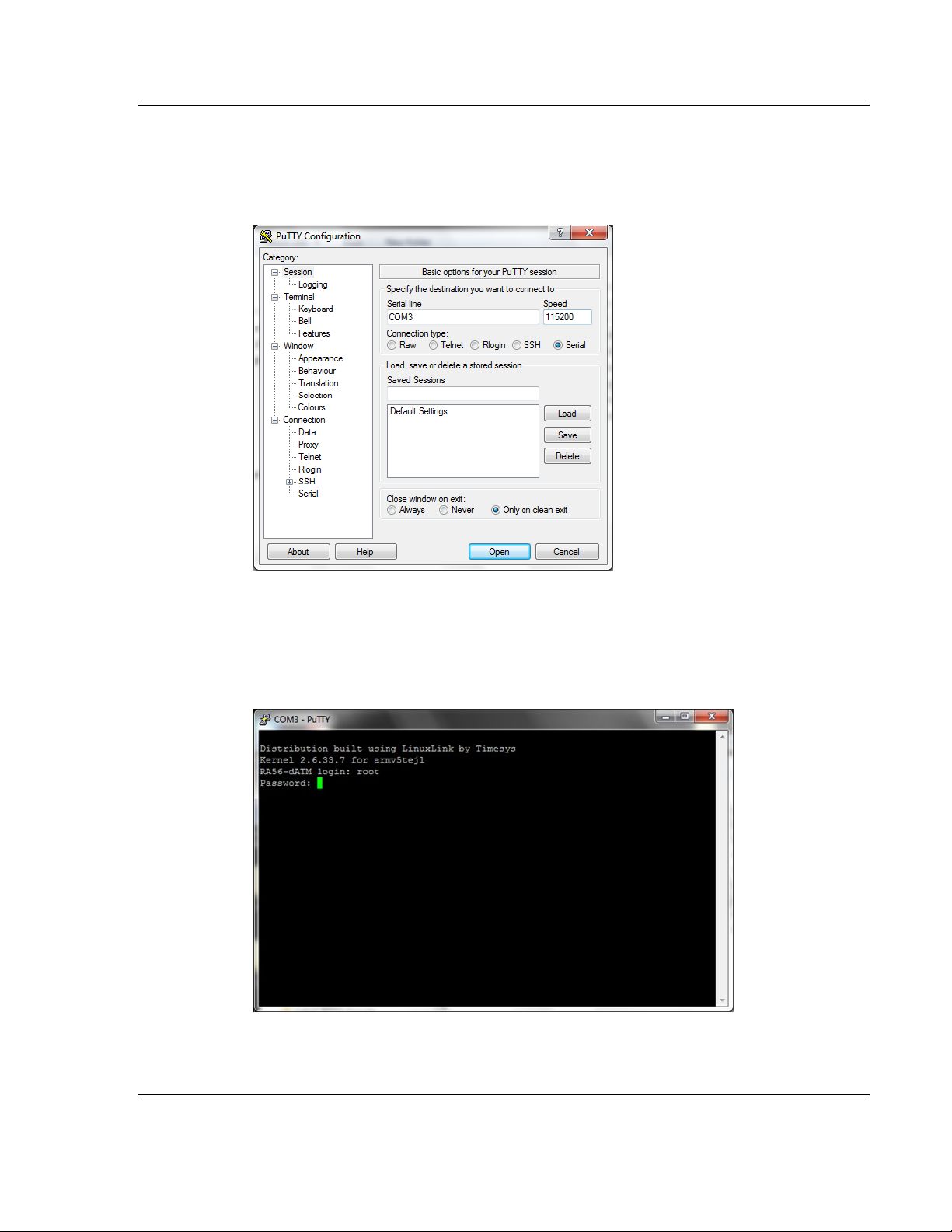

Establish a connection to the module. In the following example, PUTTY is being

used.

1. Open PUTTY.

Set the Speed to 115200

Set the appropriate COM port

Ensure that the Connection Type is set to Serial.

2. Click Open. The Putty session opens.

3. Enter your login and password. RA56-daTM login: root, Password:

password.

ProSoft Technology, Inc. Page 15 of 264

March 12, 2014

Page 22

Preparing the MVI56E-LDM Module ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

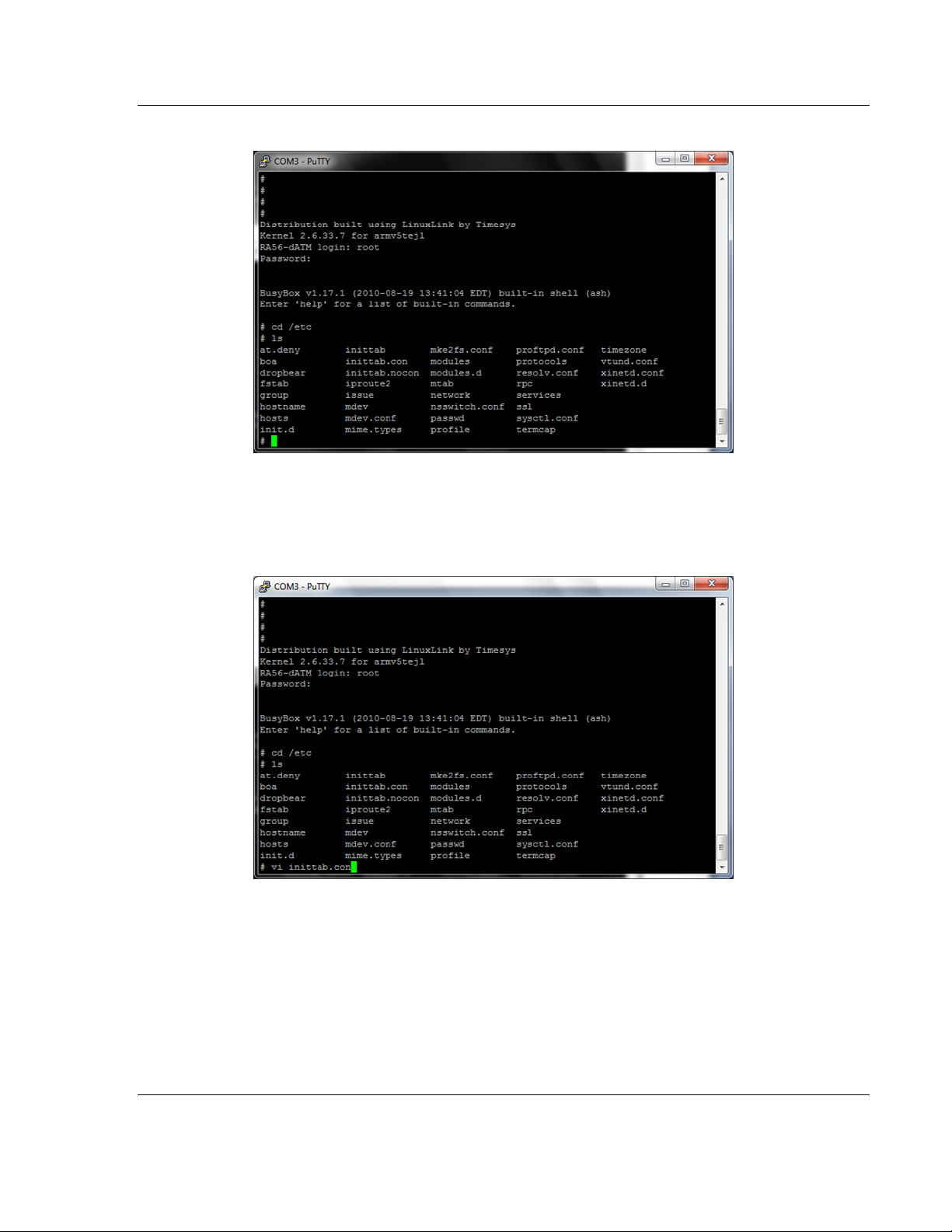

The following appears:

4. cd to /etc.

Page 16 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 23

ControlLogix Platform ♦ "C" Programmable Preparing the MVI56E-LDM Module

Linux Application Development Module Developer's Manual

5. Type ls. The following appears:

There are two files used to enable or disable the console port:

inittab.con - configures the console

inittab.nocon - configures no console

To enable the console.....

1. Open the inittab.con file.

ProSoft Technology, Inc. Page 17 of 264

March 12, 2014

Page 24

Preparing the MVI56E-LDM Module ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

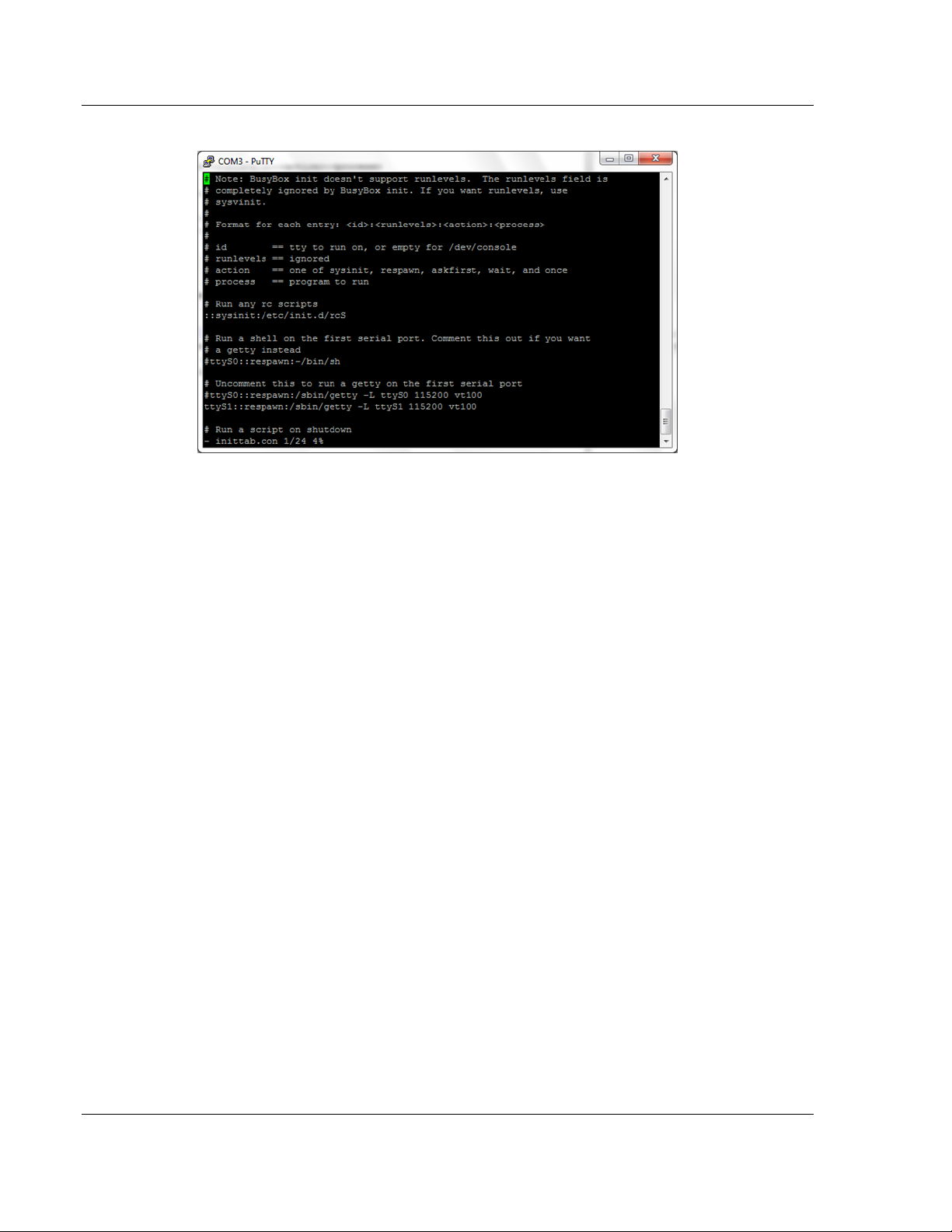

The file content is shown:

2. Copy inittab.con file to the inittab file.

3. Save the file and reboot the module.

To disable the console...

1. Copy inittab.nocon file to the inittab file.

2. Save the file and reboot the module.

2.7 Establishing Module Communication

Ensure that the module is firmly seated in the rack and that the cables described

in the previous section are secure. Ensure that power is applied.

Note: If you require information on cables and port pinouts, please refer to the

section entitled Cable Connections (page 209) at the end of the manual.

RS-232 Console

If you are connected to Serial Port 1 (P1), establish communications with the

module using the following procedure.

Note: The following procedure uses PUTTY to establish communications. You

can use whatever program you desire.

1. Open Putty

Page 18 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 25

ControlLogix Platform ♦ "C" Programmable Preparing the MVI56E-LDM Module

Linux Application Development Module Developer's Manual

Set the Speed to 115200

Set the appropriate COM port

Ensure that the Connection Type is set to Serial.

2. Click Open. The Putty session opens.

3. Enter your login and password:

RA56-daTM login: root

Password: password

Ethernet (Telnet)

You can communicate with the module through Ethernet Port 1 (E1) using

Telnet.

The Ethernet Port (E1) is programmed with eth0 set to IP 192.168.0.250 and a

Subnet Mask of 255.255.255.0. In order for your PC or laptop to talk to the

module, your PC or Laptop must be on the same subnet as the module. This

means that you must temporarily change the IP address and subnet mask on

your PC or laptop to match that of the module. You can then change the

module's IP address to match your needs.

1. Change the IP Address of your PC or Laptop so it matches the subnet of

the module.

ProSoft Technology, Inc. Page 19 of 264

March 12, 2014

Page 26

Preparing the MVI56E-LDM Module ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

2. Ensure that an Ethernet cable is connected to Ethernet Port 1 (E1) of the

module.

3. Use a program such as Putty to Telnet into the module.

Select Telnet as the Connection type.

Enter the IP address (192.168.0.250)

Port 23 should appear as the Port number.

4. Click the Open button to establish a connection.

5. Login into the module.

There are two methods used to change the module's IP address. One is

temporary for use in cases where you want to change the address long enough

to make a quick change. The other is more permanent in that the module is

already programmed and is ready for full deployment.

Temporary IP Address Change

At the Linux prompt, type:

ifconfig eth0 x.x.x.x -- This changes the IP address of the Ethernet E1 port

ifconfig eth1 x.x.x.x -- This changes the IP address of the Ethernet E2 port.

Permanent IP Address Change

At the Linux prompt, type:

cd ../etc/network -- changes the directory to network

vi interfaces -- opens the interfaces file for ethernet assignment in a vi editor

iface eth0 inet static

address 192.168.0.250

network 192.168.0.0

netmask 255.255.255.0

broadcast 192.168.0.255

# gateway 192.168.0.1

Page 20 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 27

ControlLogix Platform ♦ "C" Programmable Preparing the MVI56E-LDM Module

Linux Application Development Module Developer's Manual

auto eth1

iface eth1 inet static

address 192.168.1.250

network 192.168.1.0

netmask 255.255.255.0

broadcast 192.168.1.255

# gateway 192.168.1.1

Using the vi editor, edit the file to change the address.

Save the file.

For help on using the vi editor to write and save the file, refer to

http://www.lagmonster.org/docs/vi.html http://www.lagmonster.org/docs/vi.html.

Change the IP address of your PC back to the original subnet.

Telnet to the new IP Address of the module.

2.8 Module Rescue

In the event that it becomes necessary to revert the MVI56E-LDM module back

to its initial out-of-the-box state, there are a number of methods you can use

depending on the condition of the module.

The Rescue process re-installs all of the Operation System commands and

configurations to their original defaults. The files deleted during the rescue

process are the startup scripts in the /etc/init.d path since extra scripts in this

path are automatically executed by the operating system on startup and may

cause problems. All other files may be overwritten to the initial state of the

device. Extra files are not deleted.

If the web pages and services for the module have been altered, it may not be

possible to use the web-based rescue.

Prep and Establish Communications

Place the onboard setup jumper to the installed state.

Ethernet Communication

If the IP address is known, change the network mask and IP of a connected PC

to something compatible.

For example, if the MVI56E-LDM is configured with the default IP address

(192.168.1.250) and network mask (255.255.255.0), the the PC should have the

same IP4 network mask and an IP address in the 192.168.1.xxx subnet.

Note that IP addresses must be unique on the network. If in doubt, create a

physical network consisting of only the MVI56E-LDM and the PC.

Serial Communication

If the IP address if the MVI56E-LDM module is unknown, communication may be

established through the serial configuration port (i.e., Port 1 (upper port)). Use

Telnet or a similar terminal program to communicate with the module. Default

baud is 115,200, 8 data bits,1 stop bit, No Parity, xon/xoff flow control.

Use the following username and password:

Username: root

ProSoft Technology, Inc. Page 21 of 264

March 12, 2014

Page 28

Preparing the MVI56E-LDM Module ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

Password: password

From the shell prompt, run ifconfig to determine the Ethernet IP address and

network mask of device "eth0". Then follow the previous steps to establish

communication via Ethernet.

Web-based Rescue

The web page for the MVI56E-LDM module contains a command to recover the

module on the left-side of the page.

Open the web page for the module by entering the IP address of the module in

the address bar. (your PC/workstation should have an IP address and the same

sub-network).

On the left-side of the page, under Functions, click on Rescue Module. Follow

the instructions to set the module back to its default state.

Note: Most loaded components are left intact by this operation so it may be necessary to make

enough room on the module for the rescue to work. In addition, the Setup Jumper must be in place

for the rescue to function properly.

Manual Rescue

If the default web pages are unavailable, a manual rescue may be required.

Perform the following steps to manually return the module to its default state:

1. Establish a terminal session to the module using either the Serial or

Ethernet port.

2. Ensure that the following file exists:

/backup/systemrestore.tgz

3. Run the following command to remove any startup scripts that may be

interfering with the bootup process:

rm -f /etc/init.d/*

4. Restore the configuration and executables using the following command:

tar -xzf /backup/systemrestore.tgz -C /

5. If successful, reboot the system.

Page 22 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 29

ControlLogix Platform ♦ "C" Programmable Development Environment

In This Chapter

Setup ..................................................................................................... 23

Using Eclipse ......................................................................................... 27

Linux Application Development Module Developer's Manual

3 Development Environment

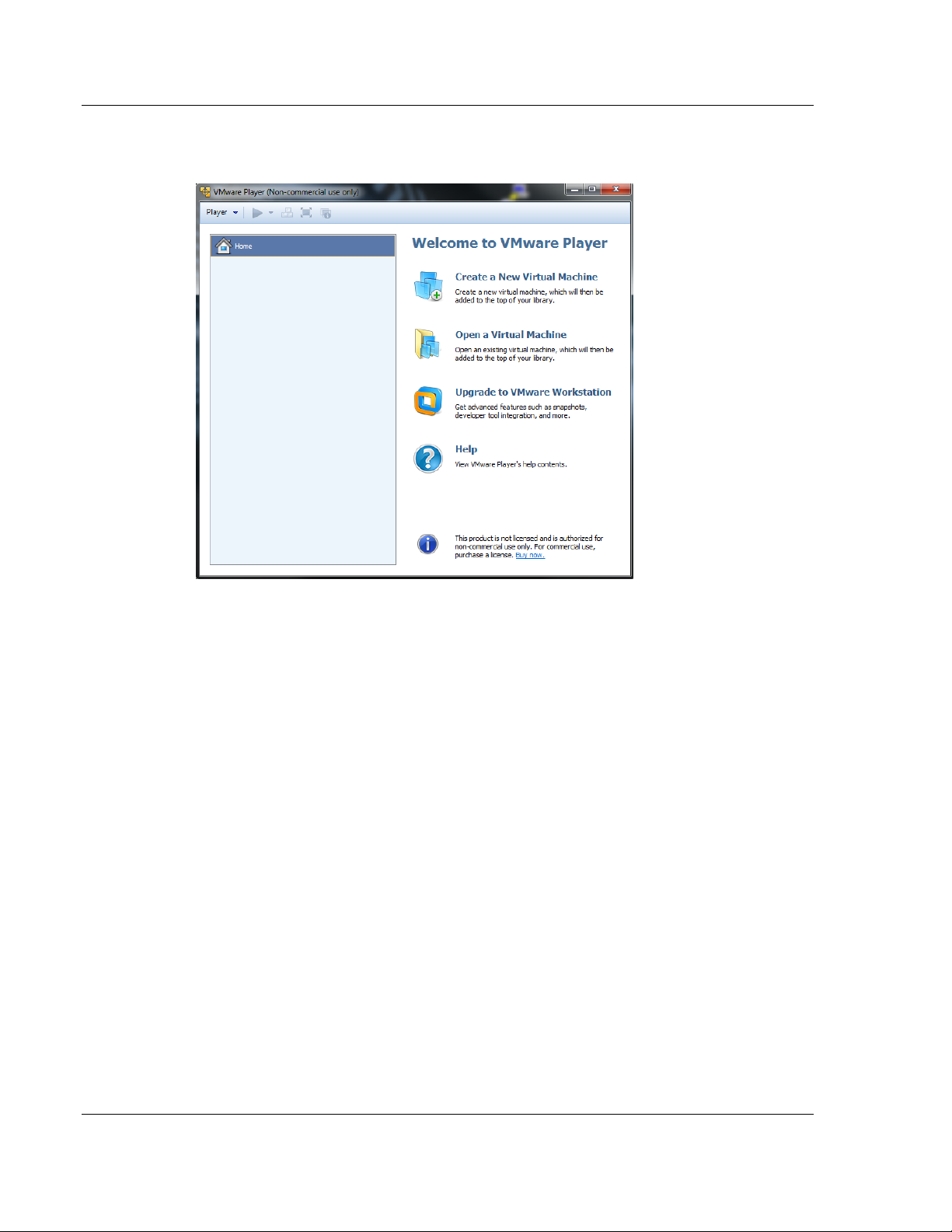

The MVI56E-LDM development tools run under Linux. In order to run these tools

on a Windows-based machine, you must run a Virtual Machine that hosts the

Linux Operating System.

VMware provides a virtual machine player used to host the Linux Operating

System. You can get it at:

https://my.vmware.com/web/vmware/downloads.

3.1 Setup

The file Debian6VM.zip is located on the ProSoft Product DVD shipped with the

module.

1. Copy this file to the VM Player image ico directory (VMware > VMware

2. Uncompress Debian6VM.zip into this directory.

Player > ico).

ProSoft Technology, Inc. Page 23 of 264

March 12, 2014

Page 30

Development Environment ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

3. Start the VM Player by double-clicking on its icon.

4. Select "Open a Virtual Machine".

Page 24 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 31

ControlLogix Platform ♦ "C" Programmable Development Environment

Linux Application Development Module Developer's Manual

5. Navigate to the Debian6VM file and click on Debian6VM.vmx. The image

icon appears in the left window.

6. Double-click on the image icon. The following screen appears:

ProSoft Technology, Inc. Page 25 of 264

March 12, 2014

Page 32

Development Environment ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

7. Click "Play virtual machine". A dialog appears asking if the virtual

machine has been moved or copied. Select "I copied it".

8. After the image loads, the VMware Player prompts you for a username

and password.

Username: user

Password: password

The home screen appears.

Page 26 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 33

ControlLogix Platform ♦ "C" Programmable Development Environment

Linux Application Development Module Developer's Manual

3.2 Using Eclipse

Eclipse is an Integrated Development Environment (IDE) used in the Linux

environment primarily to edit source code. Full documentation and downloads

are available at www.eclipse.org http://www.eclipse.org.

When you initially start Eclipse, you must select a workspace. Select the default:

/home/user/workspace.

To start Eclipse...

1. Double-click on the Eclipse icon.

2. When the Workspace Launcher appears, choose the default.

3. Click OK.

The default workspace is pre-populated with sample programs, makefiles, and

scripts. Building one of the samples is the recommended way to become familiar

with the environment and build process.

3.2.1 Building a Project

Building and using a sample application consists of:

Compiling and Linking

Creating a downloadable image

Downloading an image to the target device

Compiling and Linking

1. Start the Linux (Debian) virtual machine in the VM Player.

ProSoft Technology, Inc. Page 27 of 264

March 12, 2014

Page 34

Development Environment ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

2. Open a Bash Shell window by clicking on the Bash Shell icon on the main

page.

3. Once in the shell, change the directory to one of the samples. In this

case, change the directory to get to the LED_sample program.

cd /workspace/mvi56e-ldm/src/LDM/led_sample$ as shown below:

4. To recompile and link, simply type "make". In this case, the executable is

up to date and nothing needs to be done.

5. If the source is changed, "make" detects the newer time on the source file

and rebuilds the application. In the following example, the Touch Utility is

used to cause the date of the file led_sample.c to be updated as if the file

had been changed and "make" is re-invoked. Make detects this change,

recompiles and re-links the application.

Downloading the Application

There are two ways to place the application on the target:

FTP

Firmware Update Feature

Page 28 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 35

ControlLogix Platform ♦ "C" Programmable Development Environment

Linux Application Development Module Developer's Manual

FTP Transfer

For FTP Transfer, use any ftp transfer program such as FileZilla (https://filezillaproject.org/ https://filezilla-project.org/) from the Windows environment.

Use FileZilla to connect to the target by specifying the MVI56E-LDM's IP

address.

Download the application image to the desired directory on the LDM using the ftp

transfer program.

Since Windows does not have the same detailed permissions as Linux, you will

have to change the file permissions on the application once on the target. Use

the command chmod a+x filename which adds the execute attribute to the

application.

Creating a Download Image

An image contains all of the application-specific components required for the

user application. This includes the executable(s), application-specific shared

libraries, scripts, web pages, and data files. It does not contain the operating

system or common components that are already on the target device.

The image is a compressed tar file of the application components. Once created,

use the device's web page to download the firmware upgrade. The tar file name

is specified in "Image Contents". In the sample image, the firmware files is

'firmware/mvi56e-ldm.firmware revision date'. This firmware file is downloaded to

the directory /psfttmp on the target device. Upon system restart, the system

startup scripts unpack the tar file into the psfttmp directory. The script

/psfttmp/install is executed to move the component files into their final

destination.

A sample install file is included with the sample applications.

The first step is to create all of the components that will be part of the system.

This mainly involves compiling and linking executables and shared libraries.

Modify any web pages and data files that will be needed. Lastly, update the

install script.

Image Contents

Each component file to be included in the image is listed in the file

'imagecontents' found in the build directory structure for the specific application.

This file contains header information about the image and a list of entries

describing the files to be added to the image. The format of the entry is as

shown:

Add source destination file permissions

where the source file is the path to the file to be included. The destination file is

the full path name of the file on the destination on the target device. Permissions

are the Linux style permissions of the file on the destination.

For example, a line to add the LED_Sample application looks like:

Add ../../src/ldm/led_sample/Release/Led_Sample /psft/sample/Led_Sample

rwxrwxr-x

ProSoft Technology, Inc. Page 29 of 264

March 12, 2014

Page 36

Development Environment ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

Since builds occur in /home/usr/workspace/mvi56e-ldm/build/LDM, source paths

are relative to this directory to simplify moving to a new directory.

Follow the sample provided to create a complete imagecontents file.

Install Script

Before creating the image, an 'install' script must be created and added to the

firmware package. As noted above, the firmware package will be downloaded

into the /psfttmp directory on the device. The 'install' script will copy the files in

psfttmp to their final destination on the target device. The 'install' script can be

used to make backups of the current directory contents before they are

overwritten. The LDM sample install script in build/LDM/scripts illustrates how to

do this.

Creating the Image

In a Linux shell, change the directory to the ...build/LDM directory.

Run python with the following command:

python createimage.py

The python script createimage.py reads and acts on the imagecontents file and

creates a new firmware image in the directory .../build/LDM/firmware.

Note: The script 'build.sh' will compile/link all libs and executables and then

invoke python to create the firmware image.

Page 30 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 37

ControlLogix Platform ♦ "C" Programmable Development Environment

Linux Application Development Module Developer's Manual

Downloading the Image via Web Page

1. Ensure that the Setup Jumper is on. See Setup Jumper in this manual.

2. Navigate to the module homepage using a Web browser.

3. Select Firmware Upgrade. The Update page opens.

ProSoft Technology, Inc. Page 31 of 264

March 12, 2014

Page 38

Development Environment ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

4. Click on the Continue with Update button, and then select the firmware

file to be downloaded.

5. Click on the Update Firmware button and wait for the module to reboot.

During reboot, the compressed file is un-"tar" ed and the install script is

run to move the component files to their final destination.

Note: The IP address will revert to the default after reboot. This is a very

common problem.

Page 32 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 39

ControlLogix Platform ♦ "C" Programmable Understanding the MVI56-LDM API

In This Chapter

API Library - MVI56E ............................................................................. 33

MVI56E-LDM Development Tools ......................................................... 35

CIP API Functions ................................................................................. 36

Backplane Device Driver ....................................................................... 36

Linux Application Development Module Developer's Manual

4 Understanding the MVI56-LDM API

The MVI56E LDM CPI API Suite allows software developers to access the

ControlLogix backplane without requiring detailed knowledge of the module’s

hardware design. The MVI56E-LDM API Suite consists of three distinct

components; the backplane device driver, the backplane interface engine, and

the API library.

Applications for the MVI56E-LDM module may be developed using industrystandard Linux programming tools and the CPI API library.

This section provides general information pertaining to application development

for the MVI56E-LDM module.

4.1 API Library - MVI56E

The API provides a library of function calls. The library supports any

programming language that is compatible with the 'C' calling convention. The

API library is a dynamic library that must be linked with the application to create

the executable program>

Note: The following compiler versions are tested and known to be compatible with the MVI56E

module API:

CNU C/C++ V4.4.4 for ARM9

4.1.1 Header File

A header file is provided along with the API library. This header file contains API

function declarations, data structure definitions, and constant definitions. The

header file is in standard 'C' format. Header files for the CIP API are ocxbpapi.h

and ocxtagdb.h.

4.1.2 Sample Code

Sample applications are provided to illustrate the usage of the API functions. Full

source for the sample application is included, along with make files to build the

sample programs.

ProSoft Technology, Inc. Page 33 of 264

March 12, 2014

Page 40

Understanding the MVI56-LDM API ControlLogix Platform ♦ "C" Programmable

TagName

Single tag

Array[11]

Single dimensioned array element

Array[1,3]

Two dimensional array element

Developer's Manual Linux Application Development Module

4.1.3 Specifying the Communications Path

To construct a communications path, enter one or more path segments that lead

to the target device. Each path segment takes you from one module to another

module over the ControlBus backplane or over a ControlNet or Ethernet network.

Each path contains:

p:x, {s, c, t} :y

where

p:x specifies the device's port number to communicate through.

where x is:

1 - backplane from any 1756 module

2 - ControlNet port from a 1756-CNB module

3 - Ethernet port from a 1756-ENET module

, - separates the starting point and ending point of the path segment.

{s, c, t} :y specifies the address of the module you are going to.

where

s:y - ControlBus backplane slot number

c:y - ControlNet network node number (1 to 99 decimal)

t:y - Ethernet network IP address (for example, 10.0.104.140)

If there are multiple path segments, separate each segment with a comma (,).

Examples

To communicate from a module in slot 4 of the ControlBus backplane to a

module in slot 0 of the same backplane:

p:1, s:0

To communicate from a module in slot 4 of the ControlBus backplane, through a

1756-CNB in slot 2 at node 15, over ControNet to a 1756-CNB in slot 4 at node

21 to a module in slot 0 of a remote backplane"

p:1, s:2, P:2, c:21, p:1, s:0

To communicate from a module in slot 4 of the ControlBus backplane, through a

1755-ENET in slot 2 over Ethernet, to a 1756-ENET (IP address of 10.0.104.42)

in slot 4, to a module in slot 0 of a remote backplane:

p:1, s:2, p:2, t:10.0.104.42, p:1, s:0

4.1.4 ControlLogix Tag Naming Conventions

ControlLogix tags fall into two categories; controller tags and program tags.

Controller Tags have global scope. To access a controller scope tag, you only

need to specify the tag controller name. For example:

Page 34 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 41

ControlLogix Platform ♦ "C" Programmable Understanding the MVI56-LDM API

Array[1, 2, 3]

Three dimensional array element

Structure.Element

Structure element

StructureArray[1].Element

Single element of an array of structures

PROGRAM:MainProgram.TagName

Tag "TagName in program called "MainProgram"

PROGRAM:MainProgram.Array[11]

An array element in program "MainProgram"

PROGRAM:MainProgram.Structure.Element

A Structure Element in program "MainProgram"

Linux Application Development Module Developer's Manual

Program Tags are tags declared in a program and scoped only within the

program in which they are declared. To correctly address a Program Tag, you

must specify the identifier "PROGRAM:" followed by the program name. A dot (.)

is used to separate the program name and the tag name.

PROGRAM:ProgramName.TagName

Rules

A tag name can contain up to 40 characters

A tag name must start with a letter or underscore ("_"). All other characters

can be letters, numbers or underscores.

Names cannot contain two contiguous underscore characters and cannot end

in with an underscore

Letter case is not considered significant

The naming conventions are based on the IEC-1131 Rules for Identifiers.

For additional information on ControlLogix CPU tag addressing, please refer to

the ControlLogix User Manual.

4.2 MVI56E-LDM Development Tools

An application that is developed for the MVI56E-LDM module must be executed

from the module’s Flash ROM disk. Tools are provided with the API to build the

disk image and download it to the module’s Config/Debug port.

ProSoft Technology, Inc. Page 35 of 264

March 12, 2014

Page 42

Understanding the MVI56-LDM API ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

4.3 CIP API Functions

The CIP API communicates with the ControlLogix modules through the

backplane device driver. The following illustration shows the relationship

between the module application, CIP API, and the backplane driver:

4.4 Backplane Device Driver

The backplane device driver contains the functionality to perform CIP messaging

over the ControLogix backplane using the Midrange ASIC. The user application

interfaces with the backplane device driver through the CIP API library.

The backplane device driver for the MVI56E-LDM module is libocxbpeng.so.

The driver implements the following components and objects:

Page 36 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 43

ControlLogix Platform ♦ "C" Programmable Understanding the MVI56-LDM API

Linux Application Development Module Developer's Manual

All data exchange between the application and the backplane occurs through the

Assembly Object, using functions provided by the CIP API. The API includes

functions to register or unregister the object, accept or deny Class 1 schedule

connections requests, access scheduled connection data, and service

unscheduled messages.

ProSoft Technology, Inc. Page 37 of 264

March 12, 2014

Page 44

Understanding the MVI56-LDM API ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

4.5 Sample Code

To help understand the use of the MVI56E-LDM module, a number of example

programs are provided with the module. These programs exist both as source

code in the development environment as well as executable programs in the

MVI56E-LDM module in the /psft/sample directory.

The sample programs can be built and downloaded to the MVI56E-LDM module.

Page 38 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 45

ControlLogix Platform ♦ "C" Programmable Understanding the MVI56-LDM API

Linux Application Development Module Developer's Manual

4.6 Establishing a Console Connection

In order to run the Ethernet and Serial samples and tutorials, you must set up a

connection in order to efficiently communicate with the MVI56E-LDM.

ProSoft Technology, Inc. Page 39 of 264

March 12, 2014

Page 46

Understanding the MVI56-LDM API ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

4.7 Physically Connect to the Module

In order to establish a console session between a PC and the MVI56E-LDM

module, you must physically connect your PC to the console serial port on the

module.

1. Plug in an RJ45 to DB9 cable on Port 1.

2. Connect the null modem cable to the DB9 end of the RJ45 to DB9 cable.

3. Connect the other end of the null modem cable to the appropriate serial

port (USB to Serial Converter) on the computer.

Page 40 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 47

ControlLogix Platform ♦ "C" Programmable Understanding the MVI56-LDM API

Linux Application Development Module Developer's Manual

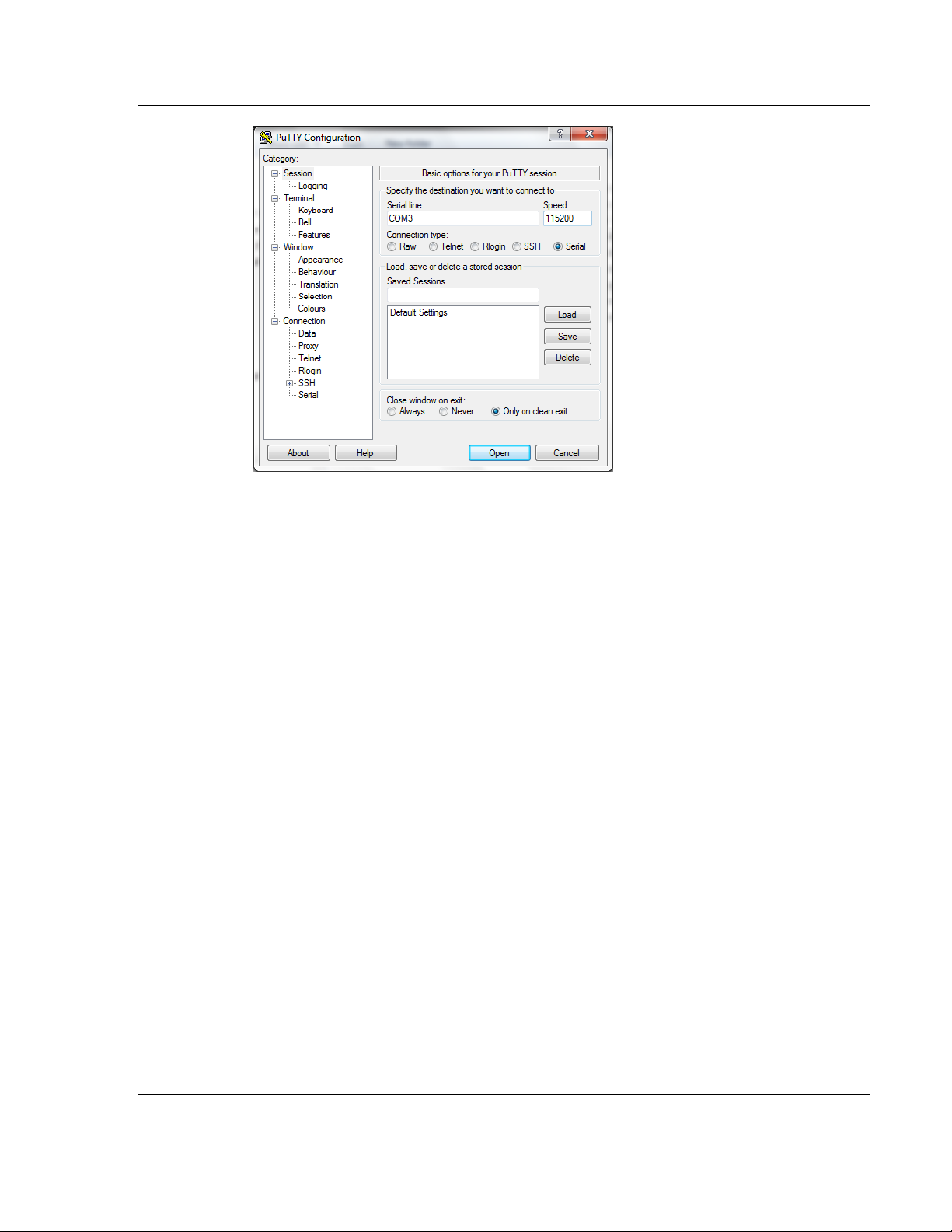

4.8 Configuring Serial Communication

Establish a connection to the module. In the following example, PUTTY is being

used.

Note: You can download PUTTY for free at

http://www.chiark.greenend.org.uk/~sgtatham/putty/download.html.

1. Open PUTTY.

Set the Speed to 115200

Set the appropriate COM port

Ensure that the Connection Type is set to Serial.

2. Click Open. The Putty session opens.

3. Enter your login and password. RA56-daTM login: root, Password:

password.

ProSoft Technology, Inc. Page 41 of 264

March 12, 2014

Page 48

Understanding the MVI56-LDM API ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

Keep PUTTY open while you set up the ControlLogix5000 as described in the

next section.

Page 42 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 49

ControlLogix Platform ♦ "C" Programmable Understanding the MVI56-LDM API

Linux Application Development Module Developer's Manual

4.9 Setting Up the ControlLogix 5000

Open the MVI56E-LDM.ACD program and change the appropriate chassis type

to match your hardware and firmware.

ProSoft Technology, Inc. Page 43 of 264

March 12, 2014

Page 50

Understanding the MVI56-LDM API ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

Download MVI56_LDM.ACD file in the ControlLogix processor by choosing

Communications > Who Active > Download.

Page 44 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 51

ControlLogix Platform ♦ "C" Programmable Understanding the MVI56-LDM API

Linux Application Development Module Developer's Manual

4.10 Sample Tutorials

The following sections describe how to run and understand the sample tutorials

provided with the module.

ProSoft Technology, Inc. Page 45 of 264

March 12, 2014

Page 52

Understanding the MVI56-LDM API ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

4.11 Ethernet Sample

The Ethernet sample comes as two programs; a client, and a server. The server

waits for a client to request a connection, replies with the local time, and closes

the connection. The client is run with the IP4 address of the server. The client

opens a connection to the server, receives the response message, and prints the

message (the time on the server) to the console.

It is recommended that the server be run on one MVI56E-LDM module and the

client on another. Alternately, either of the programs could be ported to another

Linux environment. Attempting to run both programs on the same MVI56E-LDM

is not advised due to the complexity of IP routing.

Server Enet Sample

To run the Server Enet sample:

Open a command window using telnet or a similar terminal software on the PC

through a serial (P1) or Ethernet port.

Login as user: root, password: password.

The Ethernet port E1 is used to communicate with the client device. The server

and client devices must both be connected on the same IPv4 subnet.

Set the IPv4 address and mask of the first Ethernet port using the ifconfig

command.

To execute the sample:

From the default home directory /psft, type the command ./Server_Sample&.

The program runs as a background task. The server will wait forever processing

requests from clients.

While looking at the sample source, you'll see that the following occurs:

register sigquit_handler for four signals

check command line and print usage message if required

open the backplane using open_backplane()

initialize the LEDs on the front panel

call the function socket() to create a unnamed socket inside the kernel.

socket() returns an integer know as socket descriptor.

o The function takes domain/family as its first argument. For Internet family

of IPv4 addresses, use AF_INET.

o The second argument SOCK_STREAM specifies the type of connection to

use. In this case, a sequential, reliable two-way connection is desired

o The third argument selects the protocol to use. Generally, this is zero as

the system normally only has one protocol for each type of connection,

although it is possible to have multiple protocols for a connection type.

Zero tells the system to use the default protocol for the specified

connection. In this case, the default is TCP.

The send_buff and serv_addr variables are zeroed.

In preparation for the call to bind(), serv_addr is then set to the well known

port address SERVER_PORT_NUMBER, and any IP address. This allows a

connection to be accepted from any IP address as long as the well known

port is specified.

Page 46 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 53

ControlLogix Platform ♦ "C" Programmable Understanding the MVI56-LDM API

Linux Application Development Module Developer's Manual

The call to the function bind() assigns the address specified in the structure

serv_addr to the socket created by the call to socket().

The call to the function listen() with second arguments as '10' specifies the

maximum number of client connections that the server will queue for this

listening socket.

The call to listen() makes this socket a functional listening socket.

Code enters an infinite while loop in which:

o the call to accept() puts the server to sleep waiting for an incoming client

request. When a request is received, and the three-way TCP handshake

is complete, accept() wakes up and returns the socket description

representing the client socket.

o time() is called to read the current system time

o Snprintf is used to pu the time into the send buffer in a human-readable

format

o write() is then called to send formatted time to the client

o close() is then used to close the connection to the client

o sleep() is invoked to yield the processor for 1 second

Client ENetSample

To run the Client Enet sample:

1 Open a command window using telnet or a similar terminal software on the

PC through a serial (P1) or Ethernet port.

2 Login as user: root, password: password.

The Ethernet port E1 is used to communicate with the server device. The server

and client devices must both be connected on the same IPv4 subnet.

Set the IPv4 address and mask of the first Ethernet port using the ifconfig

command.

To execute the sample:

From the default home directory /psft, type the command ./Client_Sample

ip.address.of.server to run the program. The IP address of the server node

must be provide so the server will know which node is executing the server

program. The client will send a connection request to the server, print the

response from the server to the console, and then exit.

While looking at the the sample source, you'll see that the following occurs:

register sigquit_handler for four signals

check command line and print usage message if required

open the backplane using open_backplane()

initialize the LEDs on the front panel

create a socket with a call to the socket() function

initialize the server address (serv_addr) structure:

indicate that an IPv4 address is going to be used with AF_INET

set the destination port as the well known port SERVER_PORT_NUMBER

Convert the string version of the server IP address to binary with inet_pton()

After changing the front panel display to run, connect() is called to create the

TCP connection to the server

ProSoft Technology, Inc. Page 47 of 264

March 12, 2014

Page 54

Understanding the MVI56-LDM API ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

When the sockets are connected, the server sends the date and time from

the server as a message back to the clients. The client then uses the read()

function to receive the buffer of data and prints the contents to the console.

Page 48 of 264 ProSoft Technology, Inc.

March 12, 2014

Page 55

ControlLogix Platform ♦ "C" Programmable Understanding the MVI56-LDM API

Linux Application Development Module Developer's Manual

4.12 Serial Sample

To run the Serial sample:

1 Open a command window using telnet or a similar terminal software on the

PC through a serial (P1) or Ethernet port.

2 Login as user: root, password: password.

The second serial port (P2) will be used for the communication sample.

To execute the sample:

1 From the default home directory /psft, type the command ./Serial_Sample&.

The program runs as a background task.

While looking at the sample source, you'll see that the following occurs:

register sigquit_handler for four signals

check command line and print usage message if required

open the backplane using open_backplane()

Read the serial configuration jumpers and make sure that the second serial

port is configured for RS232.

Open the serial port using the open_serial_port() function.

Opens the serial device by calling open()

Reads current serial port attributes using tcgetaddr()

Configures serial port attributes. cfsetispeed() and cfsetispeed() set the

baud rate. tcsetattr() is then used to set the remaining attributes.

Initialize LEDs on the front panel

Changes the front panel display to "Run"

Enters a for loop which transmits a test string one character at a time by

calling write() and then sleeping for 500 msec using OCXcip_Sleep()

Closes the serial driver connection using close().

ProSoft Technology, Inc. Page 49 of 264

March 12, 2014

Page 56

Understanding the MVI56-LDM API ControlLogix Platform ♦ "C" Programmable

Developer's Manual Linux Application Development Module

4.13 Led_Sample

The LED Sample program is designed to show one or more groups of

functionality provided in the module. This sample covers the following functions:

Open backplane driver

Interpreting errors returned by the backplane driver

Reading module configuration jumpers

Display message on the 4-character front panel

Changing the state of the front panel LEDs

This sample program illustrates how to interact with the MVI56E-LDM hardware

at the most basic level.

To use this program, establish a command window using telnet or similar

terminal software on the PC using either the Ethernet or Serial P1 port.

Login as user: root, using password password.

To execute the sample...

From the default home directory (/psft), type the command ./Led_Sample&. This

will run the LED Sample program in the background.

While looking at the sample source, you'll see that the main program will....

open a connection to the hardware via the OCX library API OCXcip_Open.

Although the OCXcip_OpenNB routine could be used, (since this sample does

not communicate across the backplane), the module status will not flash

red/green if opened with the NB variant.

display "open success" on the 4-character display using the function Display.

read the state of the Setup Jumper using the function ReadSwitches and prints

this information to the console.

read the state of the serial configuration jumpers using Get_Serial_Config

and prints this information to the console.

initialize timer functionality

Change LEDs on the front panel to a default state using the SetLed function:

o Module status if the OK LED.

o User LED is the APP LED.

o LED3 is the ERR LED.

The program then goes into an infinite loop, looking for the expiration of two

timers:

a fast timer which cycles the LEDs through their states and scrolls the last

string across the 4-character front panel display.

a slow timer which updates the string for the front panel display.