Page 1

MVI56E-GSC/GSCXT

CompactLogix or MicroLogix Platform

Enhanced Generic ASCII Serial

Communication Module

April 24, 2017

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology, Inc.

9201 Camino Media, Suite 200

Bakersfield, CA 93311

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

© 2017 ProSoft Technology, Inc. All rights reserved.

MVI56E-GSC/GSCXT User Manual

April 24, 2017

ProSoft Technology®, is a registered copyright of ProSoft Technology, Inc. All other brand or product names are or

may be trademarks of, and are used to identify products and services of, their respective owners.

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided at:

www.prosoft-technology.com

Important Safety Information

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or rewiring modules.

C Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be nonhazardous.

D Suitable for use in Class I, Division 2 Groups A, B, C, and D, Hazardous Locations or Non-Hazardous Locations.

ATEX/IECEx Warnings and Conditions of Safe Usage:

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an ATEX/IECEx Certified, tool-secured, IP54 enclosure. The

devices shall provide external means to prevent the rated voltage being exceeded by transient disturbances of

more than 40%. This device must be used only with ATEX certified backplanes.

D Before operating the reset switch, be sure the area is known to be non-hazardous.

Page 3

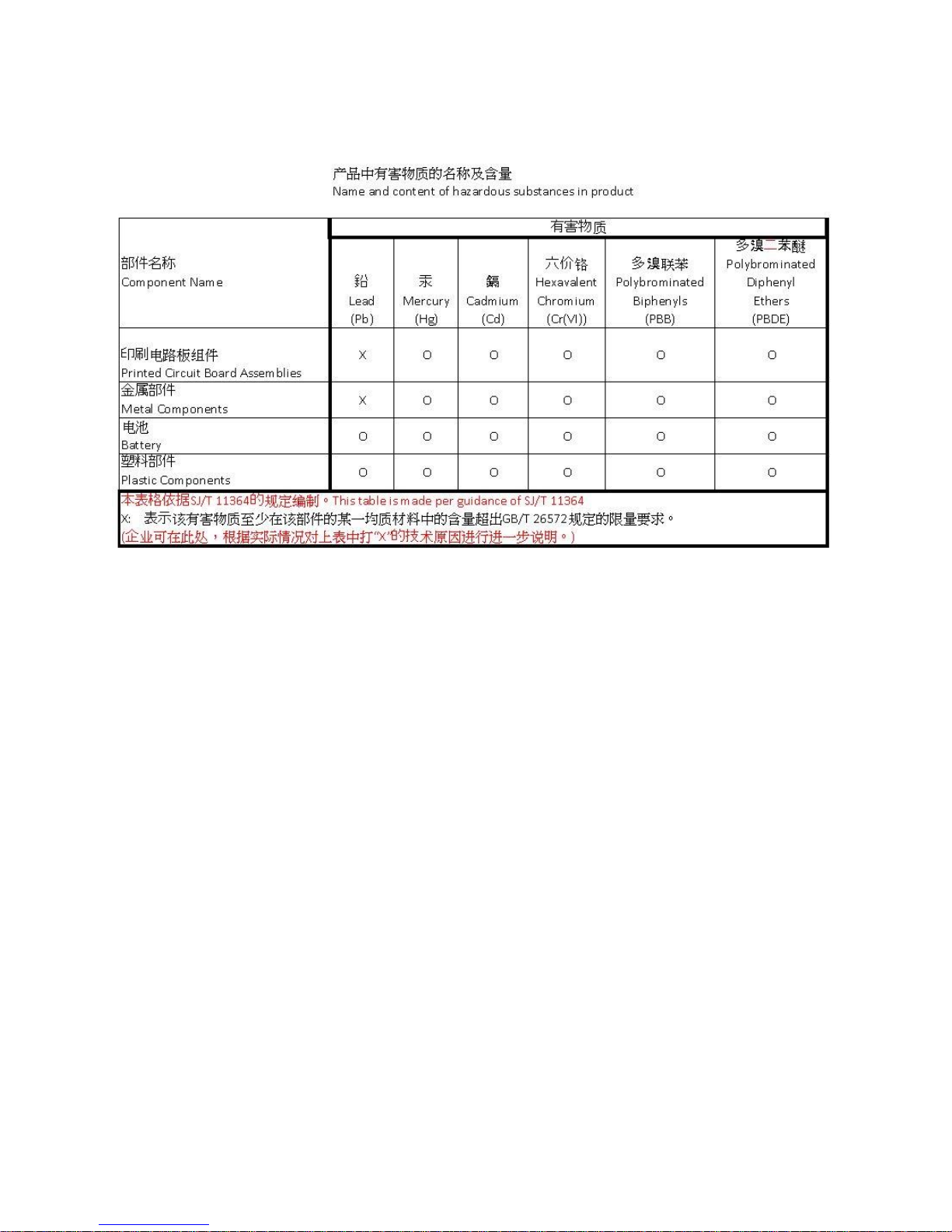

China RoHS Hazardous Material Declaration Table

Electrical Ratings

Backplane Current Load: 800 mA @ 5 VDC; 3 mA @ 24 VDC

Operating Temperature:

0°C to 60°C (32°F to 140°F) - MVI56E-GSC

-25°C to 70°C (-13°F to 158°F) - MVI56E-GSCXT

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

Shock: 30 g operational; 50 g non-operational; Vibration: 5 g from 10 to 150 Hz

Relative Humidity 5% to 95% (without condensation)

All phase conductor sizes must be at least 1.3 mm (squared) and all earth ground conductors must be at least

4mm (squared).

Label Markings

<Ex>

II 3 G

Ex nA IIC T4 Gc

0°C <= Ta <= 60°C

-25°C <= Ta <= 70°C (XT models only)

II – Equipment intended for above ground use (not for use in mines).

3 – Category 3 equipment, investigated for normal operation only.

G – Equipment protected against explosive gasses. <cULus>

E183151

Class I, DIV 2, groups A,B,C,D

T5 for all models

0°C to +60°C

-25°C to +70°C (XT models only)

Page 4

Agency

RoHS

ATEX

CSA

CE

CSA CB Safety

cULus

GOST-R

Lloyds

Agency Approvals and Certifications

Page 5

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Contents

Enhanced Generic ASCII Serial Communication Module User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

Important Safety Information ............................................................................................................... 2

1 Start Here 9

1.1 What's New? ........................................................................................................... 10

1.2 What's Different? ..................................................................................................... 10

1.3 System Requirements ............................................................................................. 11

1.4 Deployment Checklist .............................................................................................. 12

1.5 Package Contents ................................................................................................... 13

1.6 Setting Jumpers ...................................................................................................... 13

1.7 Installing the Module in the Rack ............................................................................ 14

1.8 Using ProSoft Configuration Builder Software ........................................................ 15

1.8.1 Setting Up the Project ............................................................................................. 16

1.8.2 Connecting Your PC to the Module's Ethernet Port ................................................ 18

1.8.3 Setting Up a Permanent IP Address ....................................................................... 22

1.9 Before You Begin .................................................................................................... 34

1.9.1 About the Optional Add-On Instruction ................................................................... 34

1.10 Creating a New RSLogix 5000 Project .................................................................... 35

1.10.1 Creating the Module ................................................................................................ 36

1.10.2 Importing the Ladder Rung...................................................................................... 38

1.11 Connecting Your PC to the ControlLogix Processor ............................................... 46

1.12 Downloading the Sample Program to the Processor .............................................. 47

2 MVI56E-GSC Configuration 49

2.1 GSC.UTIL.BackplaneFail ........................................................................................ 50

2.2 GSC.CONFIG.PortX ................................................................................................ 51

2.2.1 Port[x].Enabled ........................................................................................................ 51

2.2.2 Port[x].Type ............................................................................................................. 52

2.2.3 Port[x].Baudrate ...................................................................................................... 53

2.2.4 Port[x].Parity ............................................................................................................ 53

2.2.5 Port[x].DataBits ....................................................................................................... 54

2.2.6 Port[x].StopBits ........................................................................................................ 54

2.2.7 Port[x].RTSOn ......................................................................................................... 54

2.2.8 Port[x].RTSOff ......................................................................................................... 54

2.2.9 Port[x].Handshaking ................................................................................................ 54

2.2.10 Port[x].RTermCnt .................................................................................................... 54

2.2.11 Port[x].RTermChar .................................................................................................. 55

2.2.12 Port[x].RPacketLen ................................................................................................. 55

2.2.13 Port[x].RTimeout ..................................................................................................... 55

2.2.14 Port[x].RDelay ......................................................................................................... 55

2.2.15 Port[x].WTermCnt .................................................................................................... 55

2.2.16 Port[x].WTermChar ................................................................................................. 55

2.2.17 Port[x].WPacketLen ................................................................................................. 55

2.2.18 Port[x].WTimeout ..................................................................................................... 56

2.2.19 Port[x].Spare ........................................................................................................... 56

2.2.20 Port[x].WMinDelay ................................................................................................... 56

2.3 Changing parameters during operation ................................................................... 56

ProSoft Technology, Inc. Page 5 of 140

April 24, 2017

Page 6

Contents MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

3 Diagnostics and Troubleshooting 57

3.1 Reading Status Data from the Module ................................................................... 57

3.2 The Diagnostics Menu ............................................................................................ 58

3.2.1 Using the Diagnostics Menu in ProSoft Configuration Builder ............................... 58

3.3 Monitoring Module Information ............................................................................... 61

3.3.1 Version Menu .......................................................................................................... 61

3.3.2 Config ...................................................................................................................... 62

3.3.3 NIC Status ............................................................................................................... 62

3.4 Monitoring Backplane Information .......................................................................... 62

3.4.1 Backplane Status Menu .......................................................................................... 62

3.5 Data Analyzer ......................................................................................................... 63

3.5.1 Starting the Data Analyzer ...................................................................................... 63

3.5.2 Stopping the Data Analyzer .................................................................................... 65

3.5.3 Data Analyzer Tips ................................................................................................. 66

3.6 Scrolling LED Status Indicators .............................................................................. 68

3.7 Ethernet LED Indicators .......................................................................................... 69

3.8 Non-Scrolling LED Status Indicators ...................................................................... 70

3.9 ControlLogix Processor Not in RUN or REM RUN ................................................. 70

3.10 Clearing a Fault Condition ...................................................................................... 70

3.11 Troubleshooting ...................................................................................................... 71

4 Reference 73

4.1 Product Specifications ............................................................................................ 73

4.1.1 General Specifications ............................................................................................ 73

4.1.2 Functional Specifications ........................................................................................ 74

4.1.3 Hardware Specifications ......................................................................................... 75

4.2 General Concepts ................................................................................................... 76

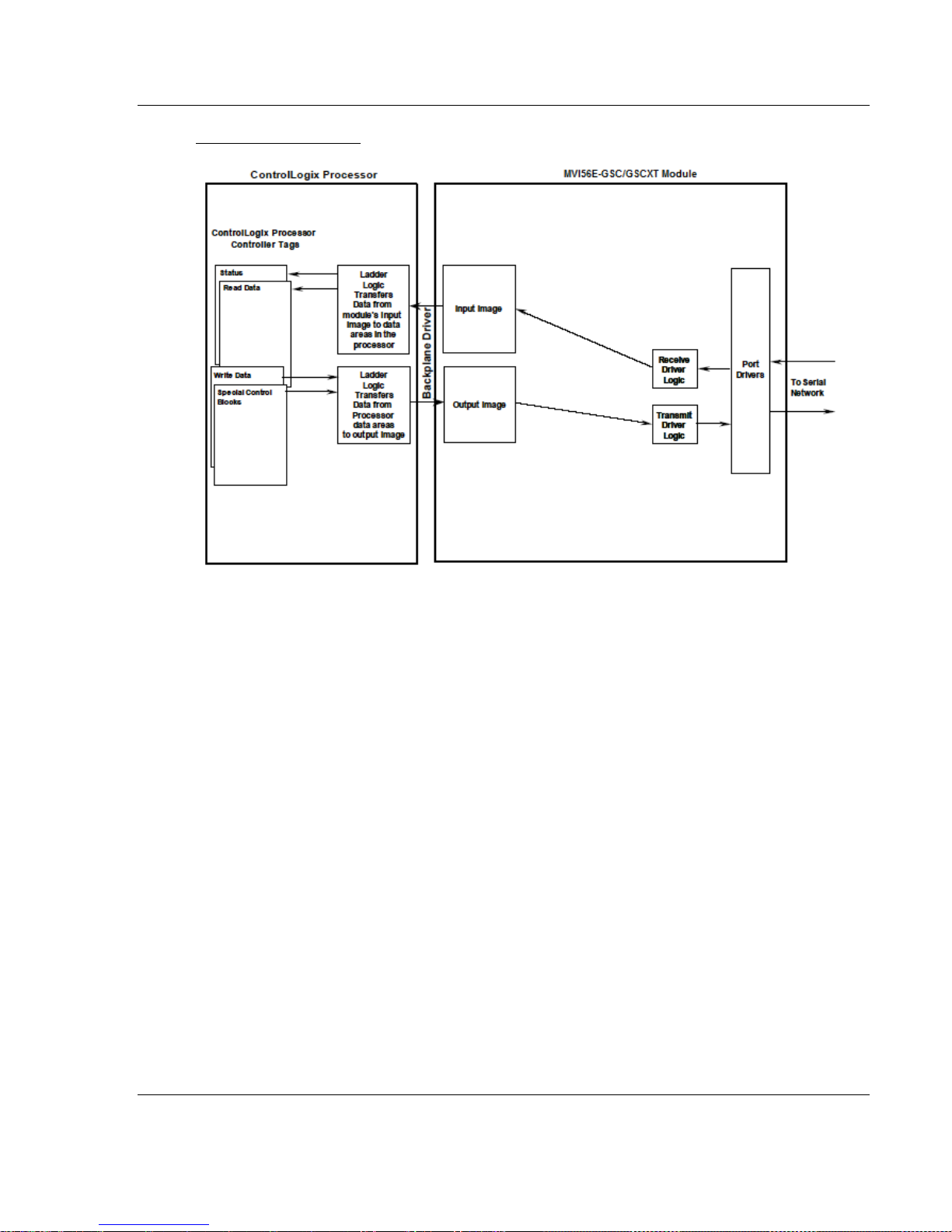

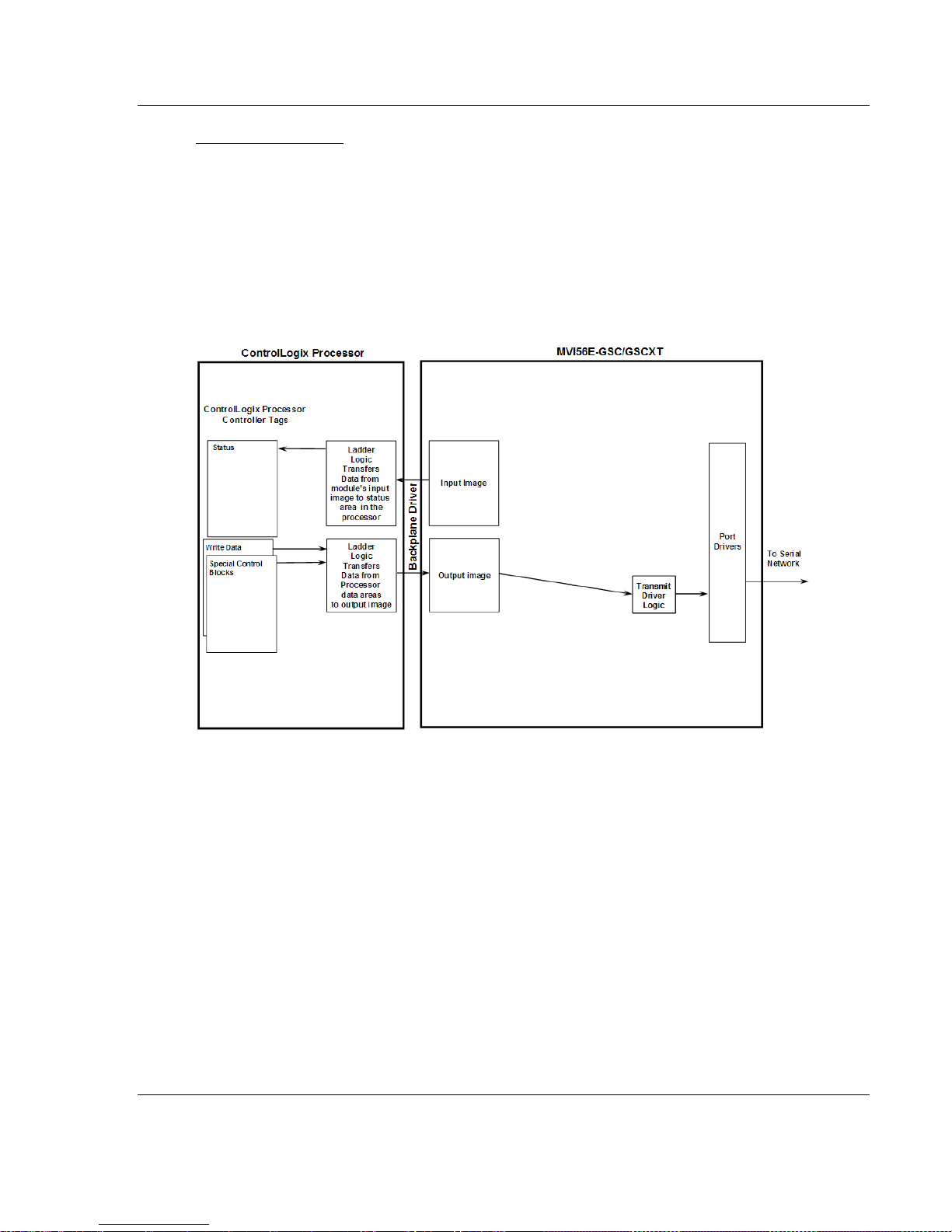

4.2.1 Backplane Data Transfer ........................................................................................ 76

4.2.2 Data Flow between MVI56E-GSC Module and ControlLogix Processor................ 77

4.2.3 Termination of Received Data ................................................................................ 81

4.3 Normal Data Transfer ............................................................................................. 85

4.3.1 Block Request from the Processor to the Module .................................................. 85

4.3.2 Read Block .............................................................................................................. 86

4.4 Special Function Blocks .......................................................................................... 90

4.4.1 Block 9998: Warm Boot .......................................................................................... 90

4.4.2 Block 9999: Cold Boot ............................................................................................ 90

4.4.3 Configuration Data Transfer Block ......................................................................... 90

4.5 Using the Sample Add-On Instruction .................................................................... 92

4.5.1 Input/Output (I/O) Configuration and Module Properties ........................................ 92

4.5.2 User-Defined Data Types ....................................................................................... 93

4.5.3 Controller Tags ..................................................................................................... 101

4.5.4 Add-On-Defined Data Types ................................................................................ 107

4.6 Using the Optional Add-On Instruction ................................................................. 112

4.6.1 Before You Begin .................................................................................................. 112

4.6.2 Overview ............................................................................................................... 112

4.6.3 Importing the Optional Add-On Instruction Rung .................................................. 113

4.6.4 Reading Ethernet Settings from the Module ......................................................... 117

4.6.5 Writing the Ethernet Settings to the Module ......................................................... 119

4.6.6 Reading the Clock Value from the Module ........................................................... 120

4.6.7 Writing the Clock Value to the Module ................................................................. 121

4.7 Using the Sample Program - RSLogix 5000 Version 15 and earlier .................... 122

Page 6 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 7

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Contents

Enhanced Generic ASCII Serial Communication Module User Manual

4.7.1 Opening the Sample Program in RSLogix ............................................................ 122

4.7.2 Choosing the Controller Type ............................................................................... 125

4.7.3 Select the Slot Number for the Module ................................................................. 126

4.7.4 Downloading the Sample Program to the Processor ............................................ 127

4.8 Adding the Sample Ladder to an Existing Application .......................................... 128

4.9 Error/Configuration Word ...................................................................................... 130

4.10 Cable Connections ................................................................................................ 130

4.10.1 Ethernet Cable Specifications ............................................................................... 131

4.10.2 Ethernet Performance ........................................................................................... 131

4.10.3 Ethernet Cable Configuration ................................................................................ 132

4.10.4 RS-232 Application Port(s) ................................................................................... 132

4.10.5 RS-422 .................................................................................................................. 135

4.10.6 RS-485 Application Port(s) .................................................................................... 135

4.10.7 DB9 to RJ45 Adaptor (Cable 14) .......................................................................... 136

5 Support, Service & Warranty 137

5.1 Contacting Technical Support ............................................................................... 137

5.2 Warranty Information ............................................................................................. 138

Index 139

ProSoft Technology, Inc. Page 7 of 140

April 24, 2017

Page 8

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

ProSoft Technology, Inc. Page 8 of 140

April 24, 2017

Page 9

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

In This Chapter

What's New? ........................................................................................... 9

What's Different? ................................................................................... 10

System Requirements ........................................................................... 11

Deployment Checklist ............................................................................ 12

Package Contents ................................................................................. 13

Setting Jumpers .................................................................................... 13

Installing the Module in the Rack ........................................................... 14

Using ProSoft Configuration Builder Software ....................................... 15

Before You Begin .................................................................................. 34

Creating a New RSLogix 5000 Project .................................................. 35

Connecting Your PC to the ControlLogix Processor .............................. 46

Downloading the Sample Program to the Processor ............................. 47

Enhanced Generic ASCII Serial Communication Module User Manual

1 Start Here

To get the most benefit from this User Manual, you should be familiar with:

Rockwell Automation® RSLogix™ software: launch the program, configure

ladder logic, and transfer the ladder logic to the processor

Microsoft Windows®: install and launch programs, execute menu

commands, navigate dialog boxes, and enter data

Hardware installation and wiring: install the module, and safely connect

generic ASCII serial and ControlLogix devices to a power source and to the

MVI56E-GSC module’s application port(s)

Important: All references to the module pertain to both the MVI56E-GSC and MVI56E-GSCXT

unless stated otherwise.

ProSoft Technology, Inc. Page 9 of 140

April 24, 2017

Page 10

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

1.1 What's New?

MVI56E products are backward compatible with existing MVI56 products,

ladder logic, and module configuration files already in use. Easily swap and

upgrade to benefit from an array of new features designed to improve

interoperability and enhance ease of use.

ProSoft Configuration Builder (PCB): Microsoft Windows®-based utility

software for diagnostics. Connect through the module's Ethernet port or use

CIPconnect® to access troubleshooting features and functions.

ProSoft Discovery Service (PDS): New Windows-based utility software to

find and display a list of MVI56E modules on the network and to temporarily

change a module's IP address to be able to connect with a module's web

page.

CIPconnect-enabled: Allows PC-to-module diagnostics from the Ethernet

network through a ControlLogix® 1756-ENxT EtherNet/IP™ module.

Personality Card: An industrial-grade compact flash memory card storing

the module’s Ethernet settings, allowing quick and easy replacement.

LED Scrolling Diagnostic Display: 4-character, alphanumeric display,

providing English messages for status and alarm data, and for processor and

network communication status.

1.2 What's Different?

The MVI56E-GSC Generic ASCII Serial Communication module is configured in

RSLogix™ 5000 software using the sample ladder or Add-On Instruction (AOI). It

also uses ProSoft Discovery Service (PDS), ProSoft Configuration Builder (PCB),

as well as all required product documentation.

PDS is the software utility used to allow your PC to connect to the module to

set a temporary Ethernet IP address. Then you can connect to the module's

web page to retrieve or change the module's firmware though an Ethernet

link.

PCB is the software used to provide access to the module's diagnostic

menus and application serial port communication data analyzer features.

Page 10 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 11

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

1.3 System Requirements

The MVI56E-GSC module requires the following minimum hardware and

software components:

Rockwell Automation ControlLogix® processor (firmware version 10 or higher)

with compatible limited voltage power supply and one free slot in the rack for

the MVI56E-GSC module. The module requires 800mA of available 5 VDC

and 3 mA of available 24 VDC power.

Rockwell Automation RSLogix 5000 programming software

o Version 16 or higher required for Add-On Instruction

o Version 15 or lower must use Sample Ladder, available from

www.prosoft-technology.com

Rockwell Automation RSLinx® communication software version 2.51 or higher

ProSoft Configuration Builder (PCB) (included)

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o Microsoft Windows

o Microsoft Windows XP Professional with Service Pack 1 or 2

o Microsoft Windows 7 Professional (32-or 64-bit)

o Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color

1024 768 recommended)

®

Vista

Note: The Hardware and Operating System requirements in this list are the minimum

recommended to install and run software provided by ProSoft Technology®. Other third party

applications may have different minimum requirements. Refer to the documentation for any third

party applications for system requirements.

Note: You can install the module in a local or remote rack. For remote rack installation, the module

requires EtherNet/IP or ControlNet communication with the processor.

ProSoft Technology, Inc. Page 11 of 140

April 24, 2017

Page 12

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

1.4 Deployment Checklist

Before you begin configuring the module, consider the following questions. Your

answers will help you determine the scope of your project, and the configuration

requirements for a successful deployment.

1 ____________ Are you creating a new application or integrating the module

into an existing application?

Most applications can use the Sample Add-On Instruction or Sample Ladder

Logic without any edits to the Sample Program.

2 ____________ Which slot number in the chassis will the MVI56E-GSC

module occupy?

For communication to occur, you must enter the correct slot number in the

sample program.

3 ____________ Are RSLogix 5000 and RSLinx installed?

RSLogix and RSLinx are required to communicate to the ControlLogix

processor (1756-L1, L5x, L6x). Sample Ladder programs are available for

different versions of RSLogix 5000.

4 ____________ How many words of data do you need to transfer in your

application (from ControlLogix to Module / to ControlLogix from Module)?

The MVI56E-GSC module can transfer a maximum of 5000 (16-bit) registers

to and from the ControlLogix processor. The Sample Ladder transfers 600

words to the ControlLogix processor (into the Read Data array), and obtains

600 words from the ControlLogix processor (from the Write Data array)

5 Serial Communication Parameters for the network:

____________ Baud rate?

____________ Data bits?

____________ Parity?

____________ Stop bits?

6 ____________ Wiring type to use (RS232, 422 or 485). Configured by

jumper settings.

Required for proper implementation of the module.

Note: If you are installing your module into a new system, and plan to use our Sample Ladder

Logic, refer to the printed Quick Start Guide in the module package for simple installation

procedures.

For version 16 or newer of RSLogix 5000, refer to Upload the Add-On Instruction from the

Module.

For EXISTING system installations, refer to Using the Sample Program - RSLogix 5000

Version 15 and earlier (page 122).

Note: Most applications can use the Sample Ladder Logic without modifying the sample program.

Page 12 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 13

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Qty.

Part Name

Part Number

Part Description

1

MVI56E-GSC Module

MVI56E-GSC

Enhanced Generic ASCII Serial

Communication Module

1

Cable

RL-CBL025

5 foot Ethernet Straight-Through Cable

2

Cable

Cable #14, RJ45 to

DB9 Male Adapter

cable

For DB9 Connection to Module’s

Application Serial Port

2

Adapter

1454-9F

Two Adapters, DB9 Female to Screw

Terminal. For RS422 or RS485

Connections to Port 1 and 2 of the Module

Enhanced Generic ASCII Serial Communication Module User Manual

1.5 Package Contents

The following components are included with your MVI56E-GSC module, and are

all required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

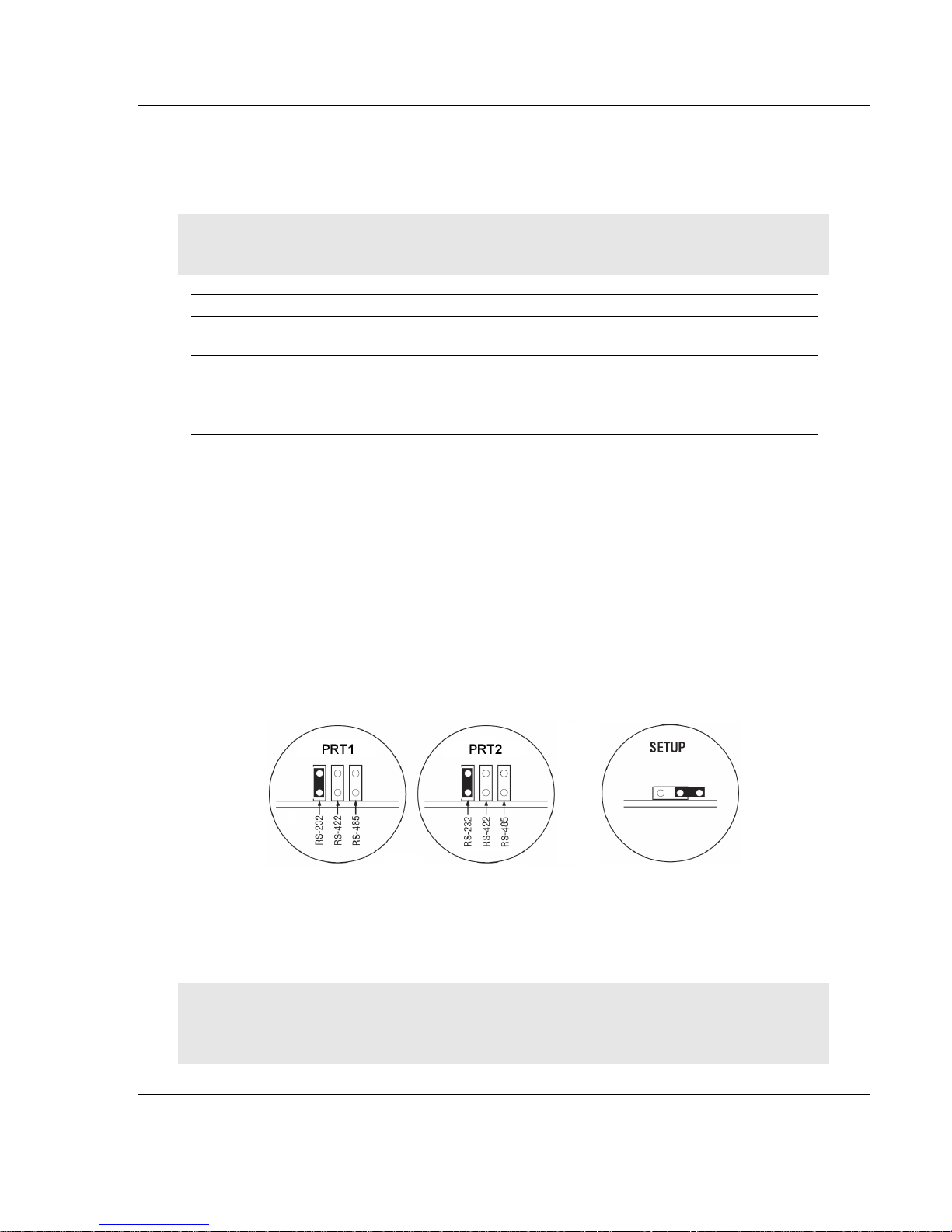

1.6 Setting Jumpers

There are three jumpers located at the bottom of the module. The first two

jumpers (P1 and P2) set the serial communication mode: RS-232, RS-422 or RS-

485.

The following illustration shows the MVI56E-GSC jumper configuration, with the

Setup Jumper OFF.

The Setup Jumper acts as "write protection" for the module’s firmware. In "write

protected" mode, the Setup pins are not connected, and the module’s firmware

cannot be overwritten. The module is shipped with the Setup jumper OFF. If you

need to update the firmware, apply the Setup jumper to both pins.

Note: If you are installing the module in a remote rack, you may prefer to leave the Setup pins

jumpered. That way, you can update the module’s firmware without requiring physical access to

the module.

ProSoft Technology, Inc. Page 13 of 140

April 24, 2017

Page 14

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

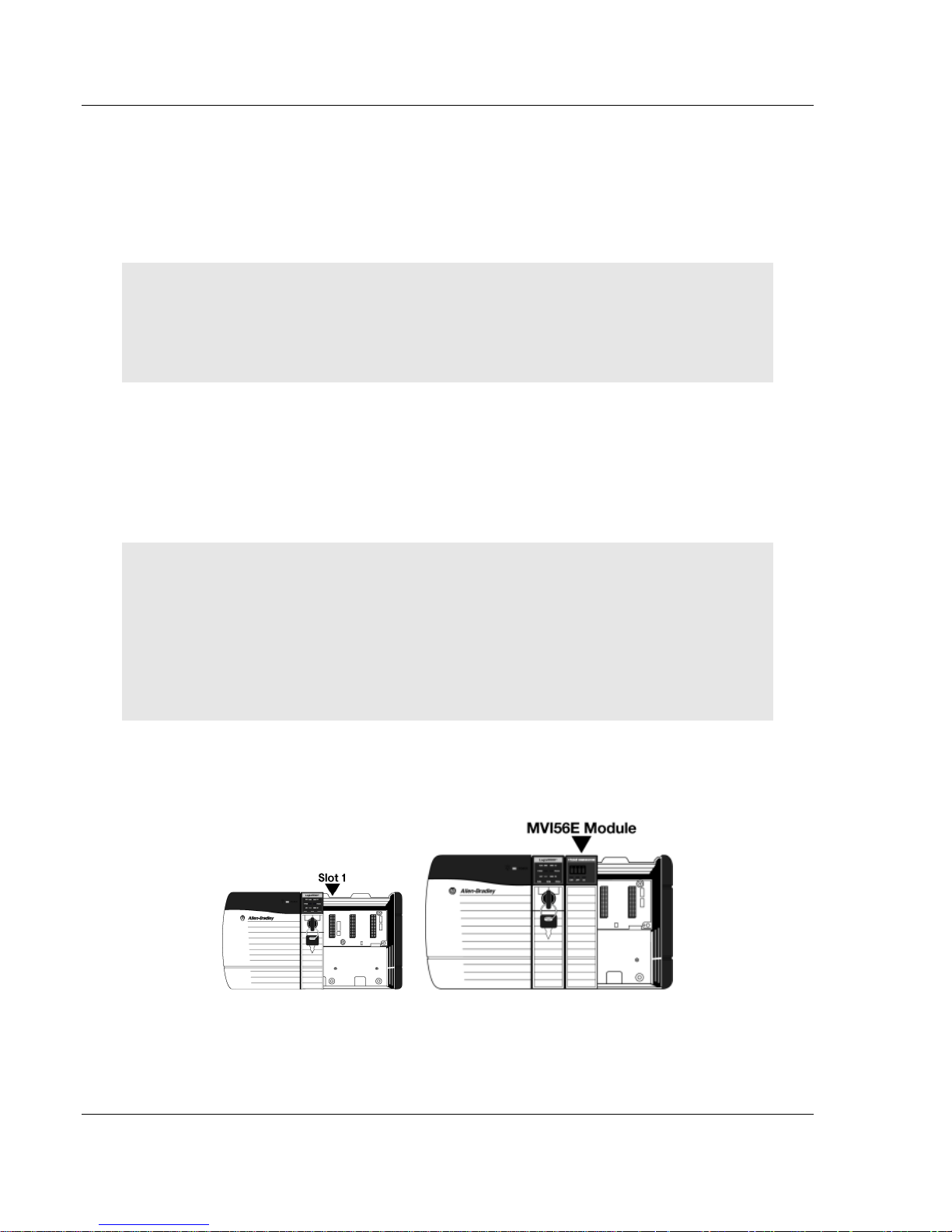

1.7 Installing the Module in the Rack

Make sure your ControlLogix processor and power supply are installed and

configured, before installing the MVI56E-GSC module. Refer to your Rockwell

Automation product documentation for installation instructions.

Warning: You must follow all safety instructions when installing this or any other electronic

devices. Failure to follow safety procedures could result in damage to hardware or data, or even

serious injury or death to personnel. Refer to the documentation for each device you plan to

connect to verify that suitable safety procedures are in place before installing or servicing the

device.

After you have checked the placement of the jumpers, insert the MVI56E-GSC

into the ControlLogix chassis. Use the same technique recommended by

Rockwell Automation to remove and install ControlLogix modules.

You can install or remove ControlLogix system components while chassis power

is applied and the system is operating. However, please note the following

warning.

Warning: When you insert or remove the module while backplane power is on, an electrical arc

can occur. An electrical arc can cause personal injury or property damage by sending an

erroneous signal to the system’s actuators. This can cause unintended machine motion or loss of

process control. Electrical arcs may also cause an explosion when they happen in a hazardous

environment. Verify that power is removed or the area is non-hazardous before proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the module and its mating

connector. Worn contacts may create electrical resistance that can affect module operation.

1 Align the module with the top and bottom guides, and then slide it into the

rack until the module is firmly against the backplane connector.

2 With a firm, steady push, snap the module into place.

3 Check that the holding clips on the top and bottom of the module are securely

in the locking holes of the rack.

Page 14 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 15

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

4 Make a note of the slot location. You must identify the slot in which the

module is installed in order for the sample program to work correctly. Slot

numbers are identified on the green circuit board (backplane) of the

ControlLogix rack.

5 Turn power ON.

Note: If you insert the module improperly, the system may stop working or may behave

unpredictably.

Note: When using the MVI56E-GSCXT, you must use the 1756-A5XT or 1756-A7LXT chassis to

uphold the XT specifications. In these chassis, modules are spaced further apart than in standard

ControlLogix chassis. Blank spacers are inserted between active modules.

1.8 Using ProSoft Configuration Builder Software

ProSoft Configuration Builder (PCB) provides a quick and easy way to manage

module configuration files customized to meet your application needs. PCB is not

only a powerful solution for new configuration files, but also allows you to import

information from previously installed (known working) configurations to new

projects.

The ProSoft Discovery Service (PDS) is available as a stand-alone application,

or as part of ProSoft Configuration Builder. ProSoft Discovery Service shows you

all the MVI56E modules available on your local area network.

Note: The MVI56E-GSC module receives its protocol and backplane configuration information from

the Ladder Logic. Use ProSoft Configuration Builder to configure the module’s Ethernet settings.

ProSoft Technology, Inc. Page 15 of 140

April 24, 2017

Page 16

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

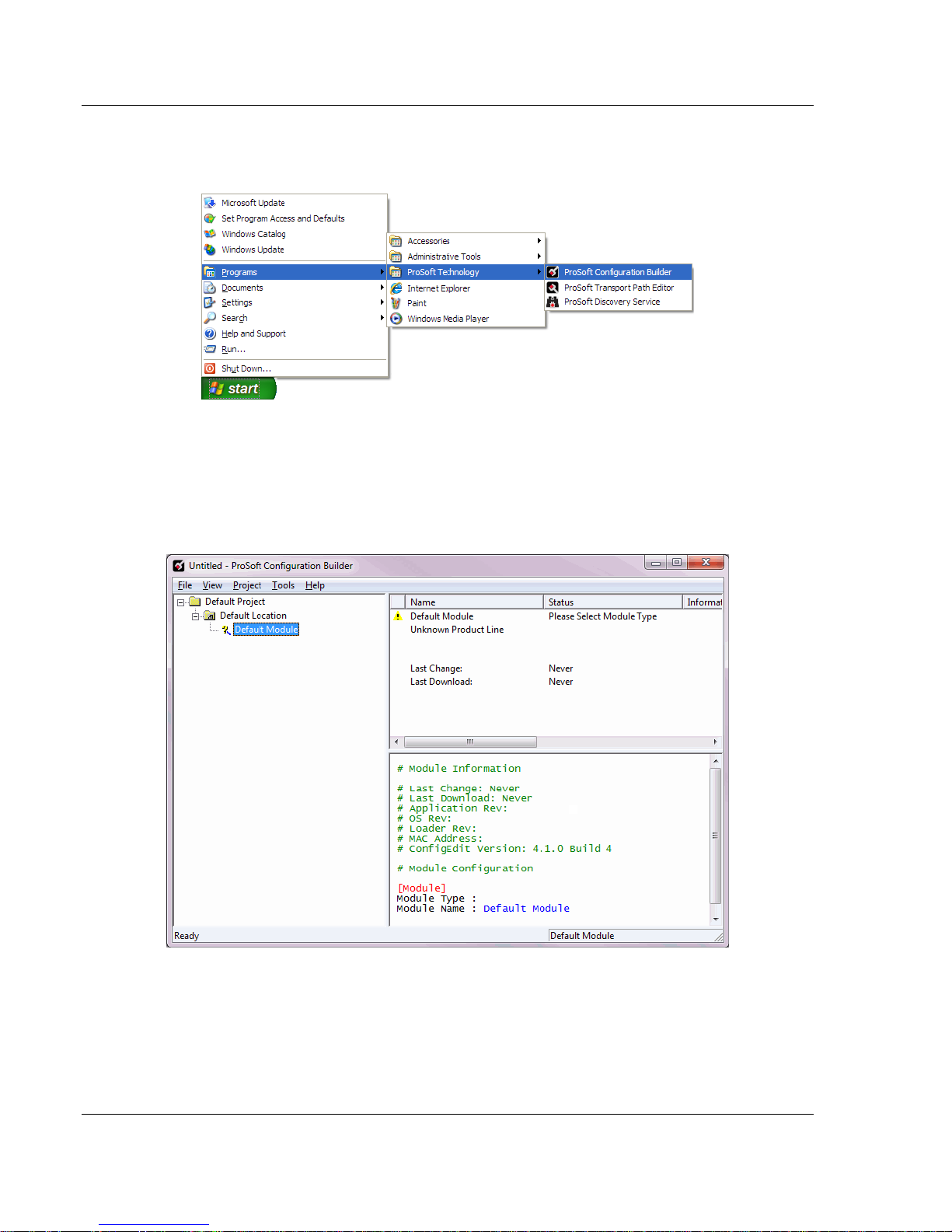

1.8.1 Setting Up the Project

To begin, start PROSOFT CONFIGURATION BUILDER (PCB).

If you have used other Windows configuration tools before, you will find the

screen layout familiar. PCB’s window consists of a tree view on the left, and an

information pane and a configuration pane on the right side of the window. When

you first start PCB, the tree view consists of folders for Default Project and

Default Location, with a Default Module in the Default Location folder. The

following illustration shows the PCB window with a new project.

Page 16 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 17

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

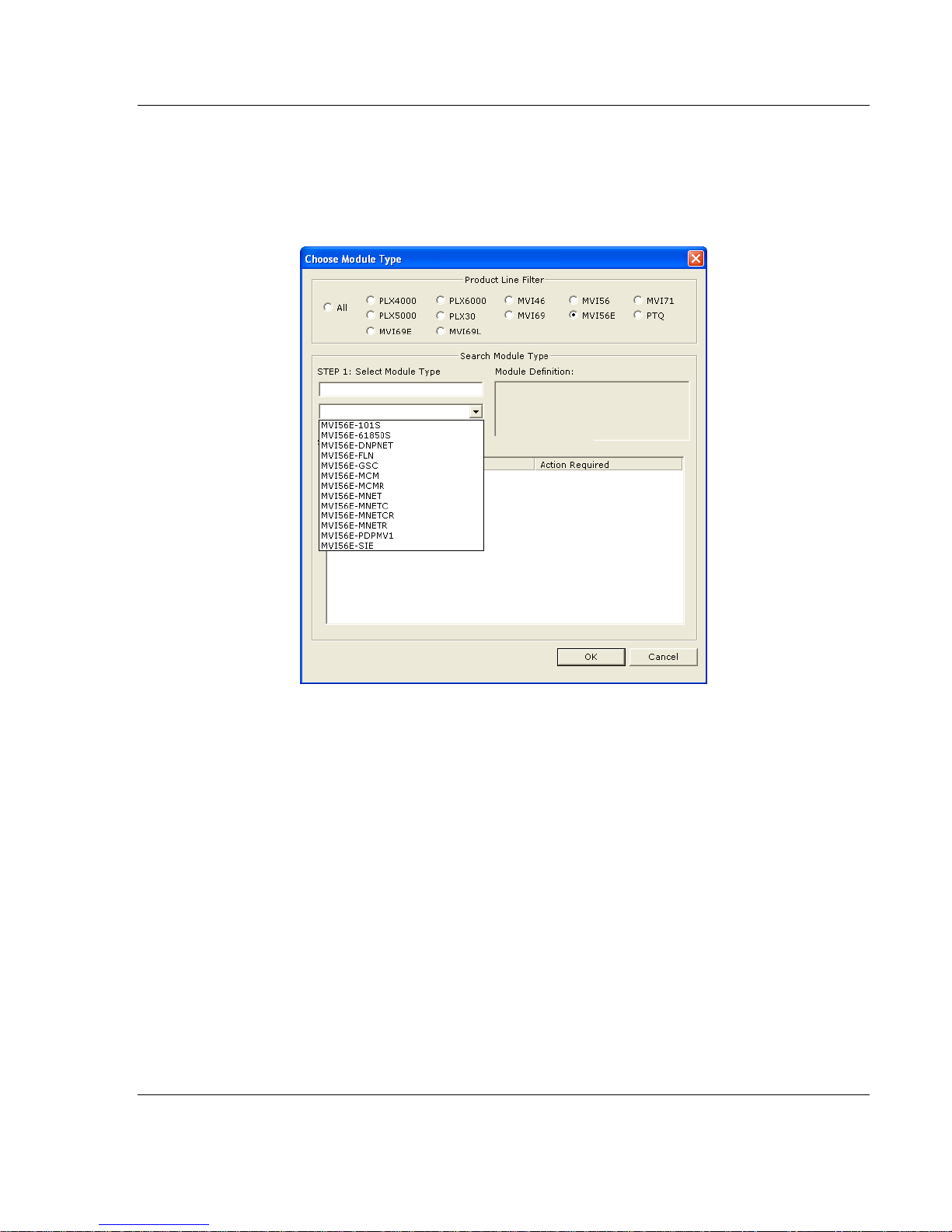

Your first task is to add the MVI56E-GSC module to the project.

1 Use the mouse to select DEFAULT MODULE in the tree view, and then click the

right mouse button to open a shortcut menu.

2 On the shortcut menu, select CHOOSE MODULE TYPE. This action opens the

Choose Module Type dialog box.

3 In the Product Line Filter area of the dialog box, select MVI56E. In the Select

Module Type dropdown list, select MVI56E-GSC, and then click OK to save

your settings and return to the ProSoft Configuration Builder window.

ProSoft Technology, Inc. Page 17 of 140

April 24, 2017

Page 18

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

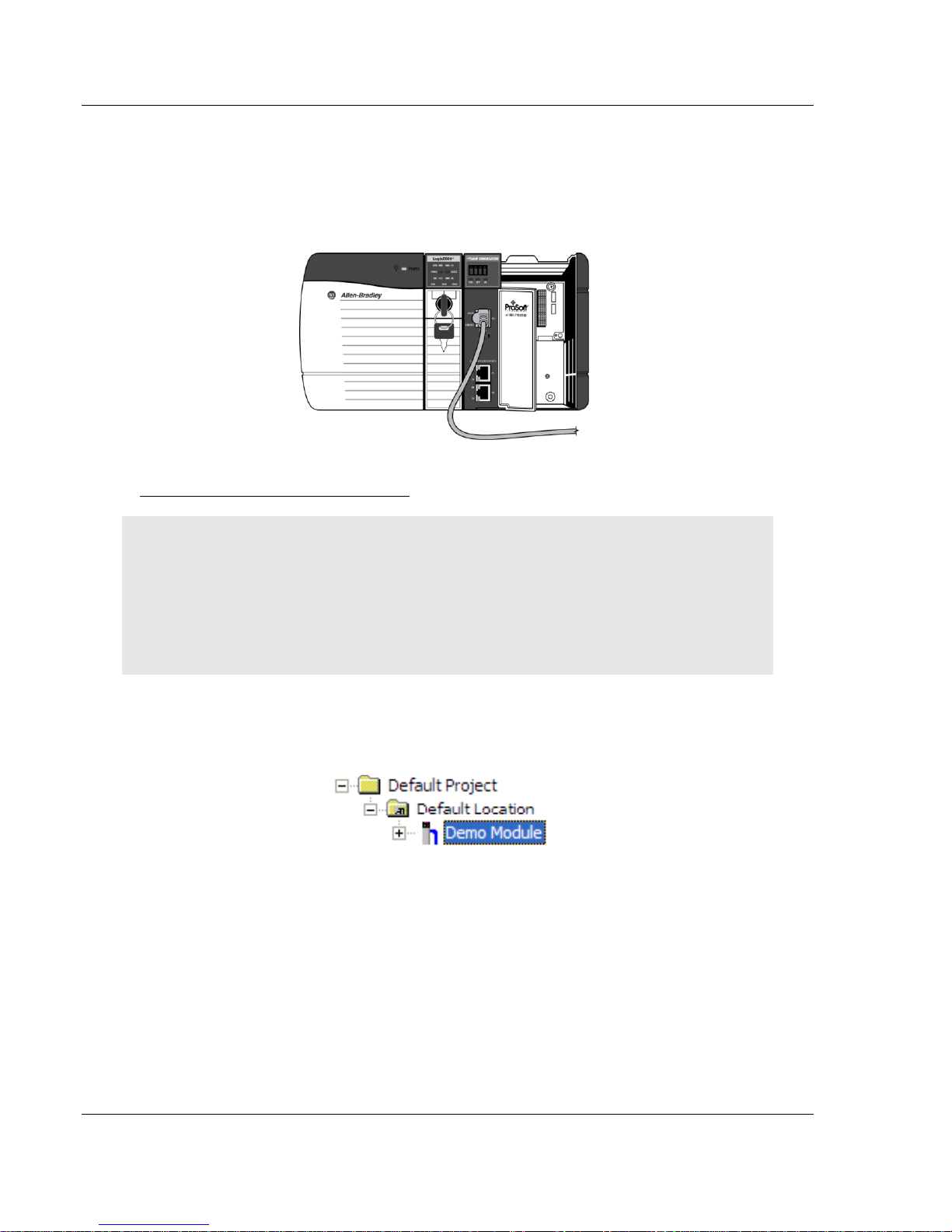

1.8.2 Connecting Your PC to the Module's Ethernet Port

With the module securely mounted, connect one end of the Ethernet cable to the

CONFIG (E1) Port, and the other end to an Ethernet hub or switch accessible from

the same network as your PC. Or, you can connect directly from the Ethernet

Port on your PC to the CONFIG (E1) Port on the module.

Setting Up a Temporary IP Address

Important: ProSoft Configuration Builder locates MVI56E-GSC modules through UDP broadcast

messages. These messages may be blocked by routers or layer 3 switches. In that case, ProSoft

Discovery Service will be unable to locate the modules.

To use ProSoft Configuration Builder, arrange the Ethernet connection so that there is no router/

layer 3 switch between the computer and the module OR reconfigure the router/ layer 3 switch to

allow routing of the UDP broadcast messages.

1 In the tree view in ProSoft Configuration Builder, select the MVI56E-GSC

module.

Page 18 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 19

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

2 Click the right mouse button to open a shortcut menu. On the shortcut menu,

choose DIAGNOSTICS.

3 In the Diagnostics window, click the SET UP CONNECTION button.

ProSoft Technology, Inc. Page 19 of 140

April 24, 2017

Page 20

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

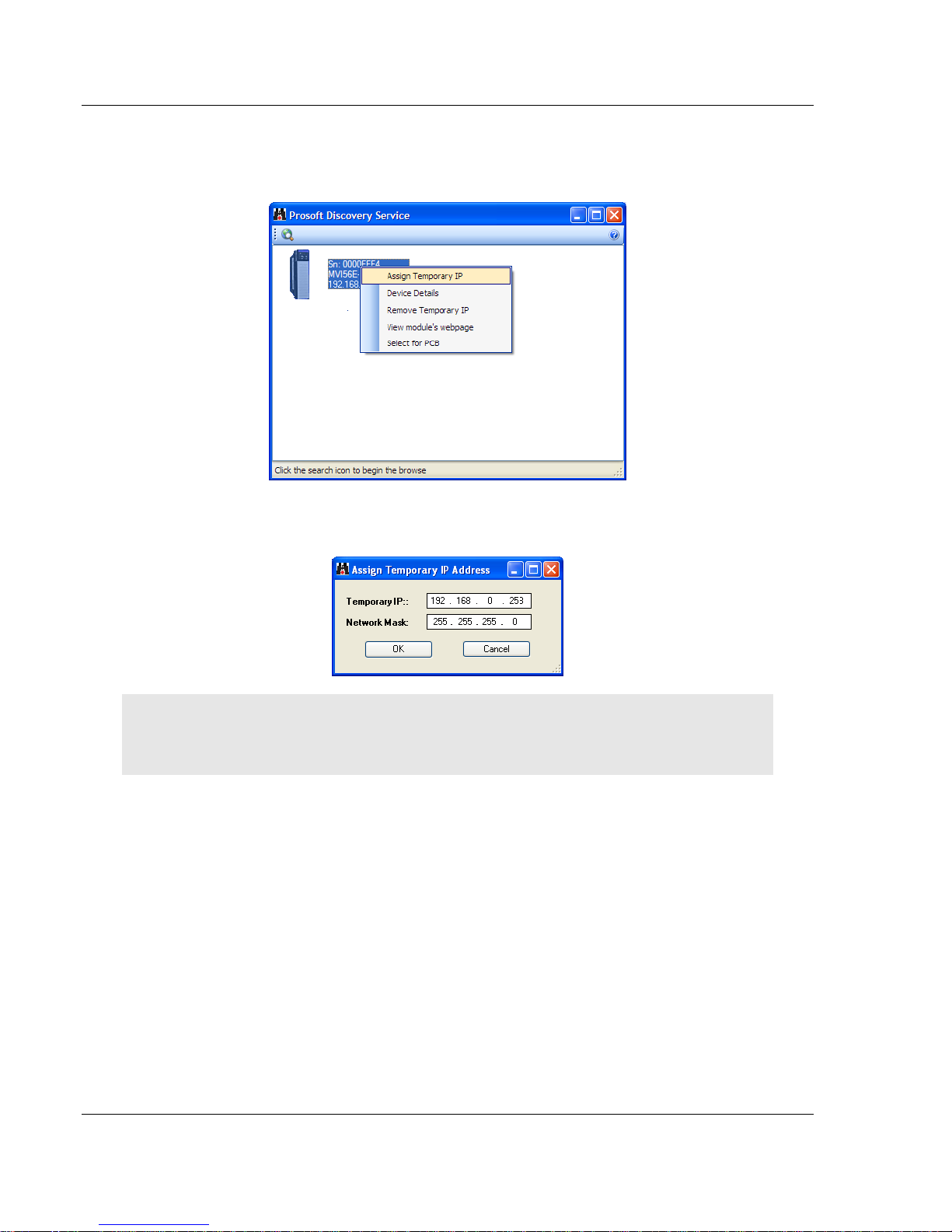

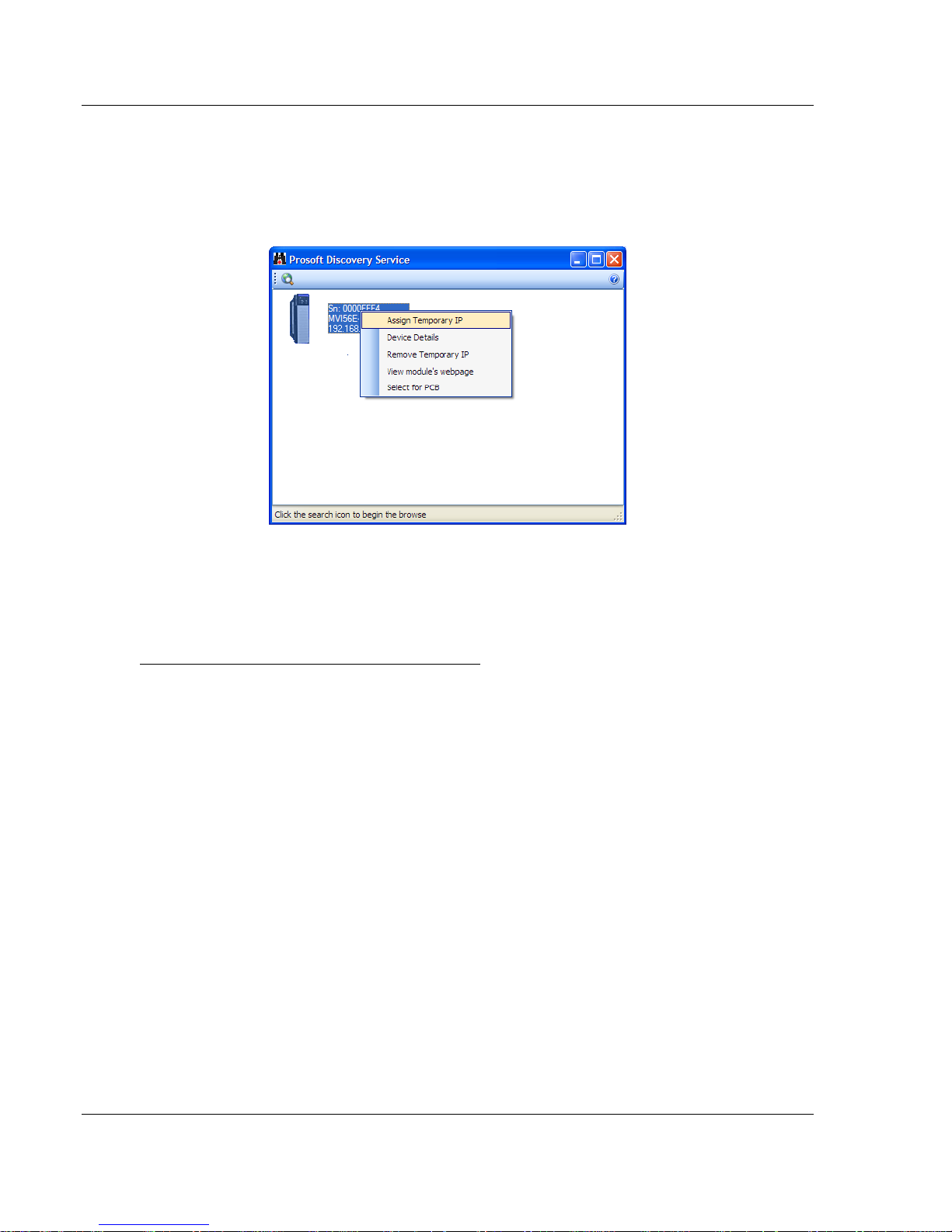

4 In the Connection Setup dialog box, click the BROWSE DEVICE(S) button to

open the ProSoft Discovery Service. Select the module, then right-click and

choose ASSIGN TEMPORARY IP.

5 The module’s default IP address is usually 192.168.0.250. Choose an unused

IP within your subnet, and then click OK.

Important: The temporary IP address is only valid until the next time the module is initialized. For

information on how to set the module’s permanent IP address, see Setting Up a Permanent IP

Address (page 22).

Page 20 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 21

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

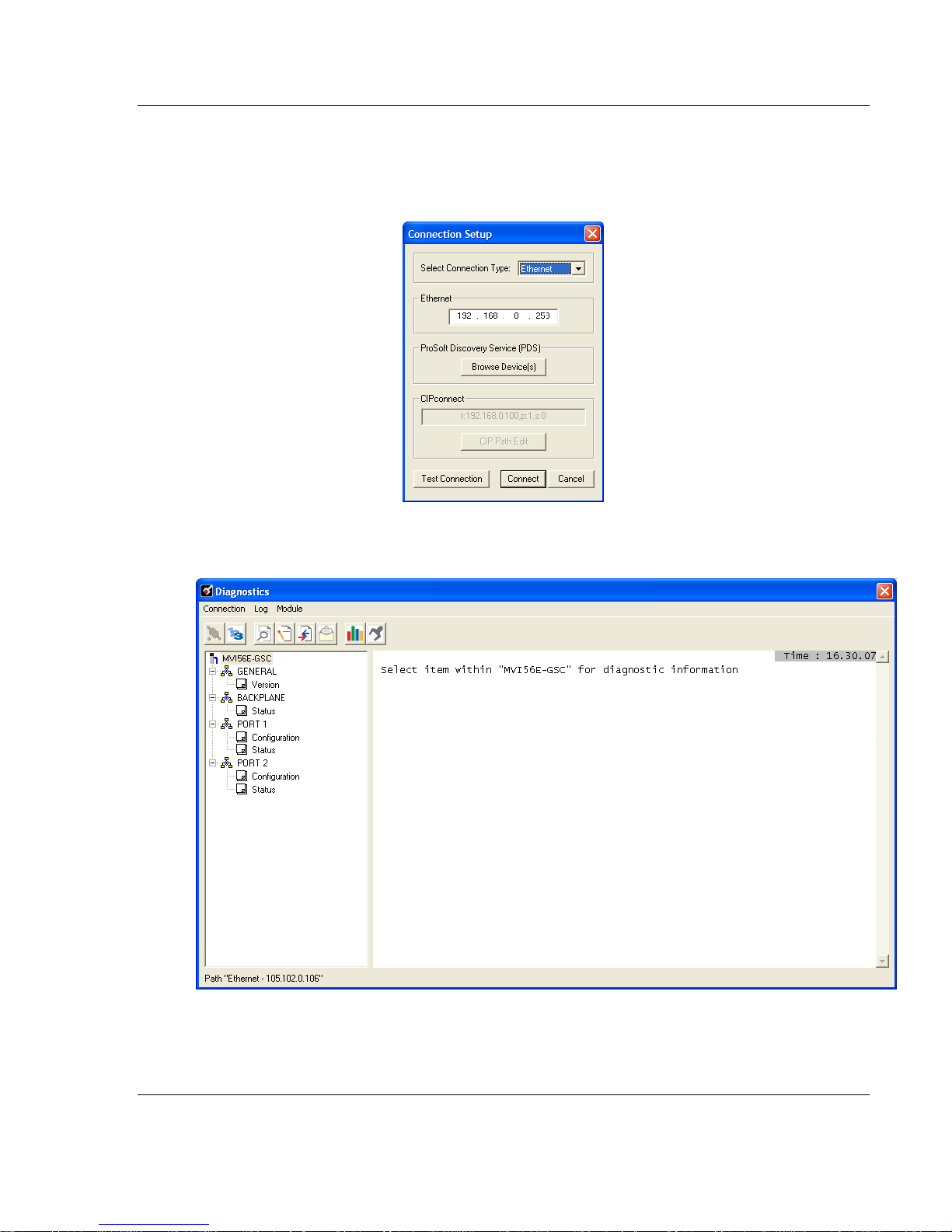

6 Close the ProSoft Discovery Service window. Enter the temporary IP in the

Ethernet address field of the Connection Setup dialog box, then click the

TEST CONNECTION button to verify that the module is accessible with the

current settings.

7 If the Test Connection is successful, click CONNECT. The Diagnostics menu

displays in the Diagnostics window.

ProSoft Technology, Inc. Page 21 of 140

April 24, 2017

Page 22

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

1.8.3 Setting Up a Permanent IP Address

Note: For alternative methods of connecting to the module with your PC, refer to Using

CIPconnect® to Connect to the Module (page 24) or Using RSWho to Connect to the Module (page

33).

These steps show you how to set a permanent IP address on the module. This

example assumes module’s default IP address is 192.168.0.250.

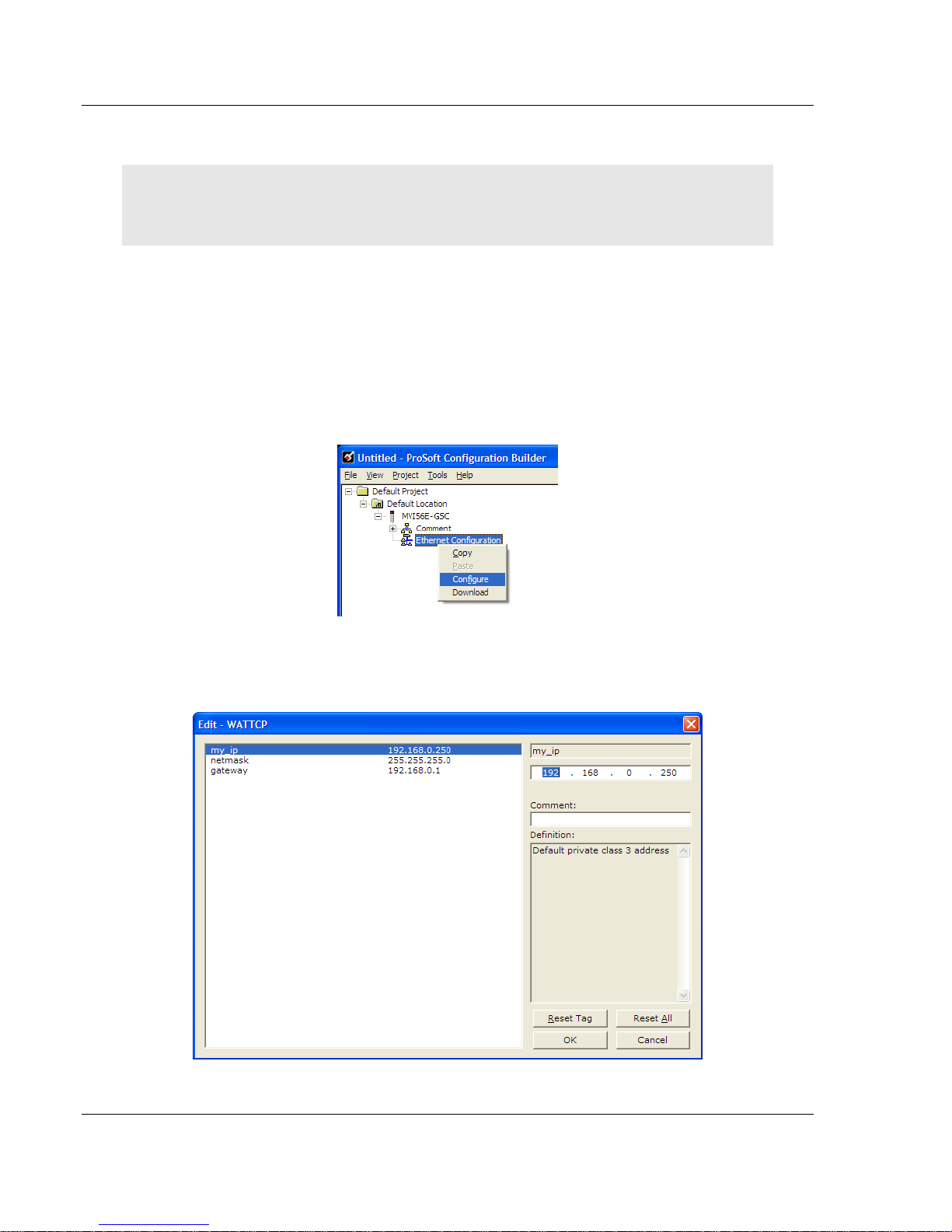

1 Start ProSoft Configuration Builder.

2 Select the MVI56E-GSC icon, and then click the [+] symbol to expand the

MVI56E-GSC tree.

3 Select ETHERNET CONFIGURATION, and then click the right mouse button to

open a shortcut menu.

4 On the shortcut menu, select CONFIGURE.

This action opens the Edit-WATTCP dialog box. Use this dialog box to enter

the MVI56E-GSC module’s permanent IP Address (MY_IP), SUBNET MASK

(NETMASK) and DEFAULT GATEWAY (GATEWAY).

Page 22 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 23

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

5 Click OK to save the updated Ethernet configuration.

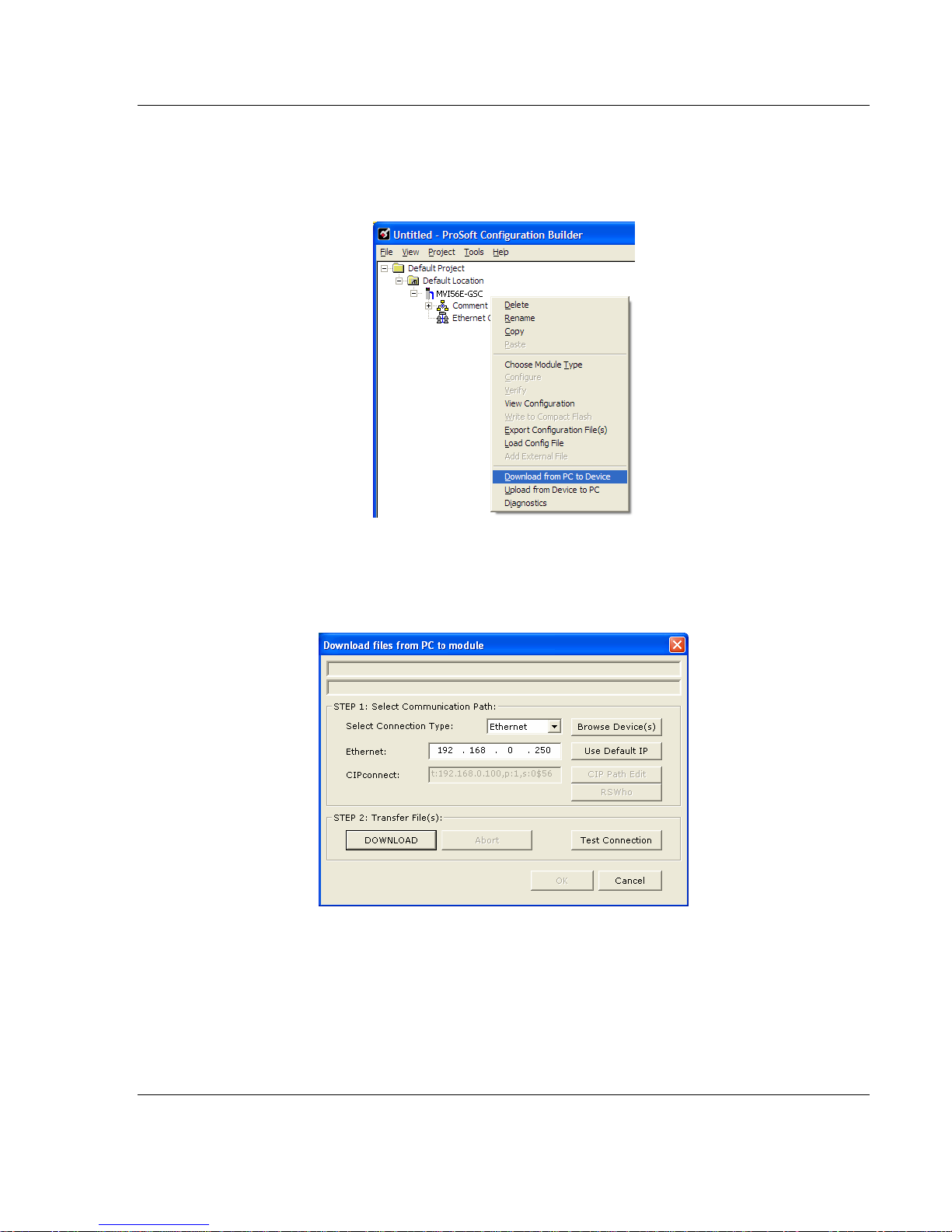

6 Next, select the MVI56E-GSC icon, and then click the right mouse button to

open a shortcut menu. On the shortcut menu, choose DOWNLOAD FROM PC

TO DEVICE.

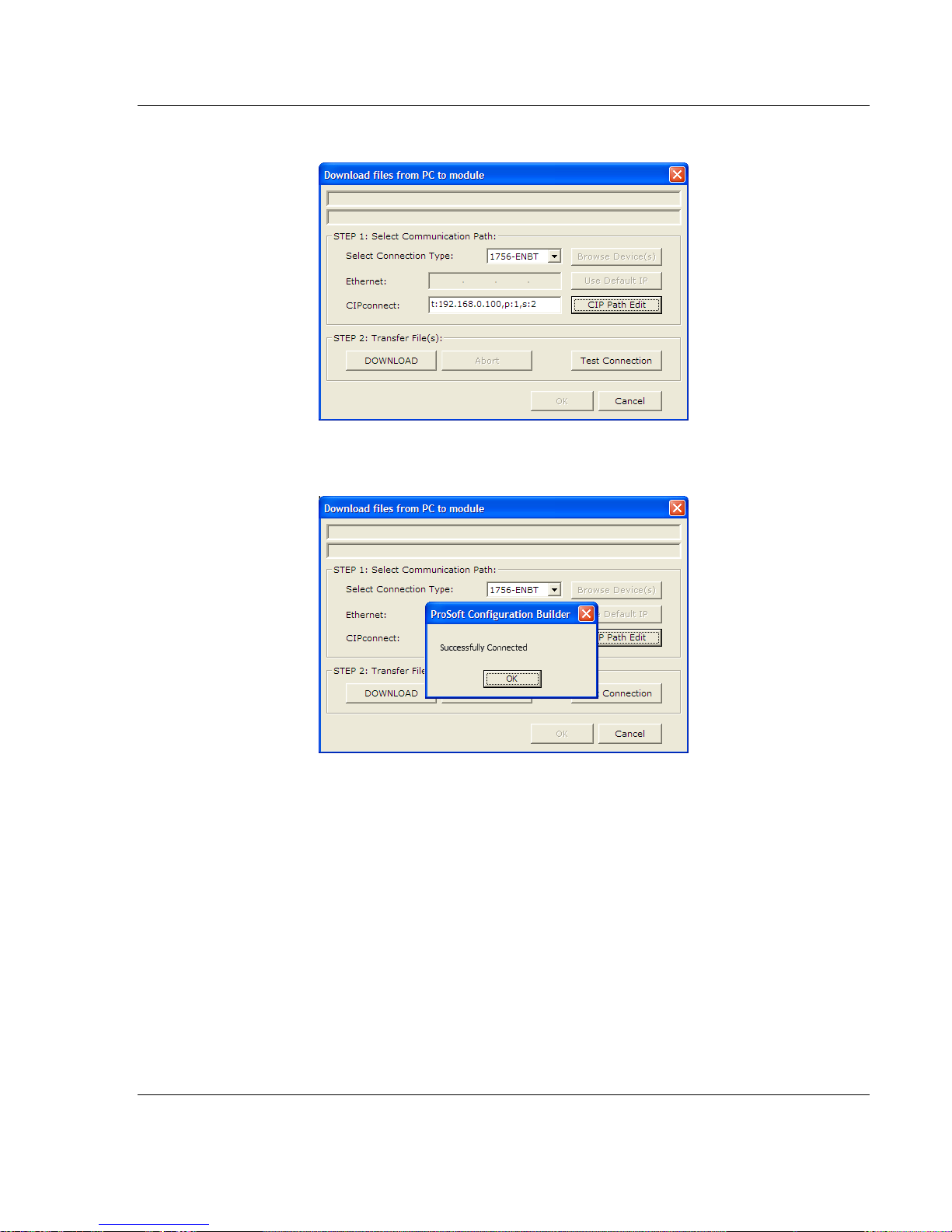

This action opens the DOWNLOAD dialog box. Notice that the Ethernet

address field contains the temporary IP address you assigned previously.

ProSoft Configuration Builder will use this temporary IP address to connect to

the module.

Click TEST CONNECTION to verify that the temporary IP address is correct.

7 If the connection succeeds, click DOWNLOAD to transfer the Ethernet

configuration to the module.

ProSoft Technology, Inc. Page 23 of 140

April 24, 2017

Page 24

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

If the Test Connection procedure fails, you will see an error message. To correct

the error, follow these steps.

1 Click OK to dismiss the error message.

2 On the DOWNLOAD dialog box, click BROWSE DEVICES to open PROSOFT

DISCOVERY SERVICE.

3 Select the module, and then click the right mouse button to open a shortcut

menu. On the shortcut menu, choose SELECT FOR PCB.

4 Close Prosoft Discovery Service.

5 Click DOWNLOAD to transfer the Ethernet configuration to the module.

Using CIPconnect® to Connect to the Module

You can use CIPconnect® to connect a PC to the ProSoft Technology MVI56EGSC module over Ethernet using Rockwell Automation’s 1756-ENBT

EtherNet/IP® module. This allows you to configure the MVI56E-GSC network

settings and view module diagnostics from a PC. RSLinx is not required when

you use CIPconnect. All you need are:

The IP addresses and slot numbers of any 1756-ENBT modules in the path

The slot number of the MVI56E-GSC in the destination ControlLogix chassis

(the last ENBTx and chassis in the path).

Page 24 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 25

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

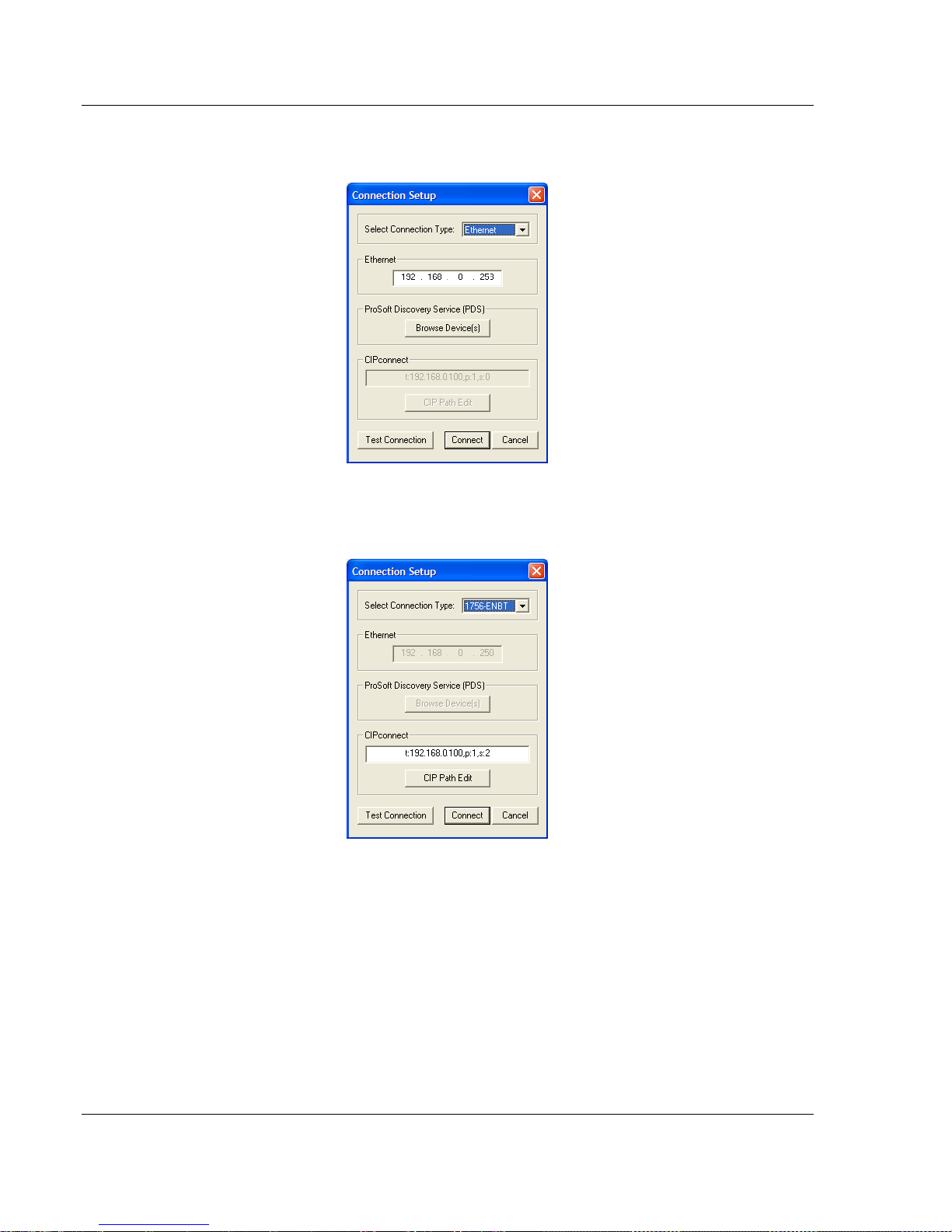

To use CIPconnect, follow these steps.

1 In the tree view in ProSoft Configuration Builder, right-click the MVI56E-GSC

icon to open a shortcut menu.

2 On the shortcut menu, choose DIAGNOSTICS.

3 In the Diagnostics window, click the SET UP CONNECTION button.

ProSoft Technology, Inc. Page 25 of 140

April 24, 2017

Page 26

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

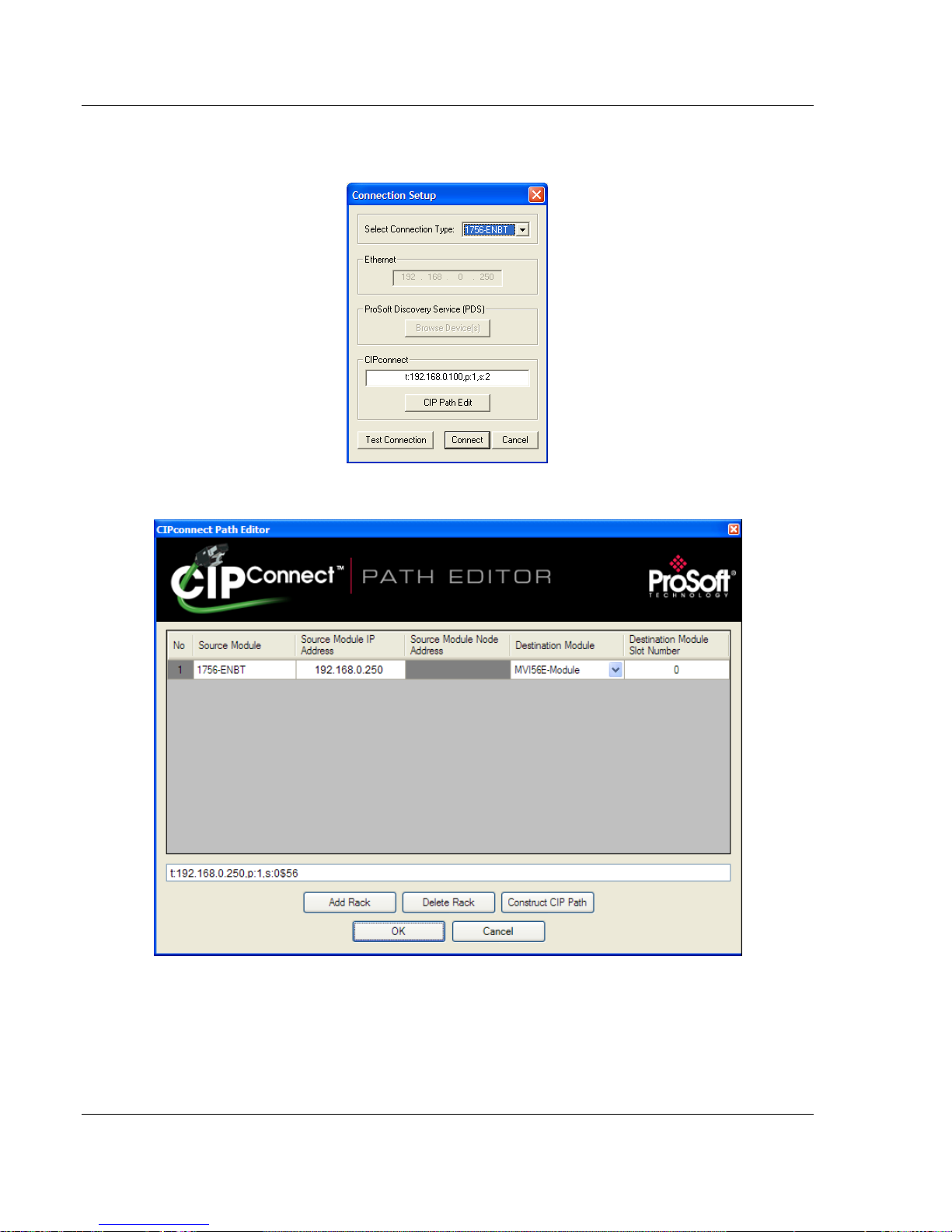

4 In the Select Connection Type dropdown list, choose 1756-ENBT. The

default path appears in the text box, as shown in the following illustration.

5 Click CIP PATH EDIT to open the CIPconnect Path Editor dialog box.

The CIPconnect Path Editor allows you to define the path between the PC and

the MVI56E-GSC module. The first connection from the PC is always a 1756ENBT (Ethernet/IP) module.

Each row corresponds to a physical rack in the CIP path.

Page 26 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 27

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Parameter

Description

Source Module

Source module type. This field is automatically selected

depending on the destination module of the last rack (1756CNB or 1756-ENBT).

Source Module IP Address

IP address of the source module (only applicable for 1756ENBT)

Source Module Node Address

Node address of the source module (only applicable for 1756CNB)

Destination Module

Select the destination module associated to the source module

in the rack. The connection between the source and destination

modules is performed through the backplane.

Destination Module Slot Number

The slot number where the destination MVI56E module is

located.

Ethernet

Rack 1

MVI56E Module 1756-ENBT

0 1 2

3

Enhanced Generic ASCII Serial Communication Module User Manual

If the MVI56E-GSC module is located in the same rack as the first 1756-

ENBT module, select RACK NO. 1 and configure the associated parameters.

If the MVI56E-GSC is available in a remote rack (accessible through

ControlNet or Ethernet/IP), include all racks (by using the ADD RACK button).

To use the CIPconnect Path Editor, follow these steps.

1 Configure the path between the 1756-ENBT connected to your PC and the

MVI56E-GSC module.

o If the module is located in a remote rack, add more racks to configure the

full path.

o The path can only contain ControlNet or Ethernet/IP networks.

o The maximum number of supported racks is six.

2 Click CONSTRUCT CIP PATH to build the path in text format

3 Click OK to confirm the configured path.

The following examples should provide a better understanding on how to set up

the path for your network.

Example 1: Local Rack Application

For this example the MVI56E-GSC module is located in the same rack as the

1756-ENBT that is connected to the PC.

ProSoft Technology, Inc. Page 27 of 140

April 24, 2017

Page 28

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

Slot

Module

Network Address

0

ControlLogix Processor

- 1 Any

-

2

MVI56E-GSC

- 3 1756-ENBT

IP=192.168.0.100

User Manual Enhanced Generic ASCII Serial Communication Module

Rack 1

1 In the Download window, click CIP PATH EDIT.

2 Configure the path as shown in the following illustration, and click

CONSTRUCT CIP PATH to build the path in text format.

Click OK to close the CIP PATH EDITOR and return to the Download dialog

box.

Page 28 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 29

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

3 Check the new path in the download text box.

4 Click TEST CONNECTION to verify that the physical path is available. The

following message should be displayed upon success.

5 Click OK to close the Test Connection pop-up. You are now ready to use

CIPconnect for downloading changes to the module's Ethernet configuration

settings. You may also use this connection to access module diagnostics

screens and menus. For more information, see the chapter on Diagnostics

and Troubleshooting. For more information, see the chapter on Diagnostics

and Troubleshooting (page 57).

ProSoft Technology, Inc. Page 29 of 140

April 24, 2017

Page 30

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

Ethernet

Rack 1

0 1 2 3

ControlNet

0

1 2 3 4 5

6

Rack 2

1756-ENBT

1756-CNB

1756-CNB

MVI56E Module

Slot

Module

Network Address

0

ControlLogix Processor

-

1

1756-CNB

Node = 1

2

1756-ENBT

IP=192.168.0.100

3

Any

-

Slot

Module

Network Address

0

Any

-

1

Any - 2

Any

-

3

Any - 4

Any

-

5

1756-CNB

Node = 2

6

MVI56E-GSC

-

User Manual Enhanced Generic ASCII Serial Communication Module

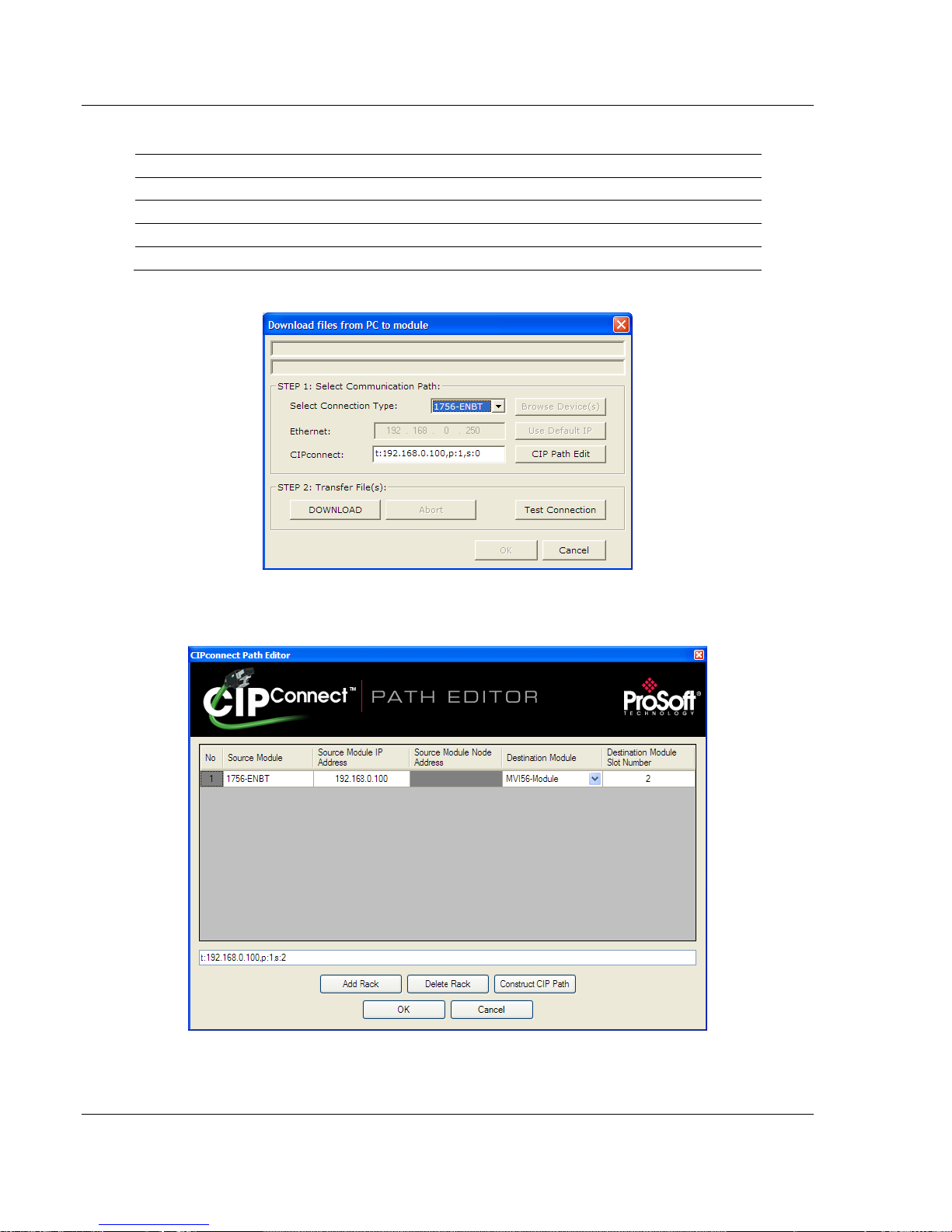

Example 2: Remote Rack Application - CIPconnect No Download

For this example, the MVI56E-GSC module is located in a remote rack

accessible through ControlNet, as shown in the following illustration.

Rack 1

Rack 2

Page 30 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 31

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

1 In the Download window, click CIP PATH EDIT.

2 Configure the path as shown in the following illustration for this example and

click CONSTRUCT CIP PATH to build the path in text format.

Click OK to close the CIP PATH EDITOR and return to the DOWNLOAD dialog

box.

ProSoft Technology, Inc. Page 31 of 140

April 24, 2017

Page 32

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

3 Check the new path in the download text box.

4 Click TEST CONNECTION to verify that the physical path is available. The

following message should be displayed upon success.

5 Click OK to close the Test Connection pop-up. You are now ready to use

CIPconnect for downloading changes to the module's Ethernet configuration

settings. You may also use this connection to access module diagnostics

screens and menus. For more information, see the chapter on Diagnostics

and Troubleshooting. For more information, see the chapter on Diagnostics

and Troubleshooting (page 57).

Page 32 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 33

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

Using RSWho to Connect to the Module

You need to have RSLinx installed on your PC to use this feature. You also need an ENBT module

set up in the rack. For information on setting up the ENBT module, see Using CIPconnect® to

Connect to the Module (page 24).

1 In the tree view in ProSoft Configuration Builder, right-click the MVI56E-GSC

module.

2 From the shortcut menu, choose DOWNLOAD FROM PC TO DEVICE.

3 In the Download dialog box, choose 1756 ENBT from the Select Connection

Type dropdown box.

4 Click RSWHO to display modules on the network. The MVI56E-GSC module

will automatically be identified on the network.

5 Select the module, and then click OK.

ProSoft Technology, Inc. Page 33 of 140

April 24, 2017

Page 34

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

File Name

Description

MVI56EGSC_AddOn_Rung_xxx.L5X

L5X file containing Add-On Instruction, user defined

data types, controller tags and ladder logic required

to configure the MVI56E-GSC module

MVI56EGSC_Optional_Rung_xxx.L5X

Optional L5X file containing additional Add-On

Instruction with logic for changing Ethernet

configuration and clock settings.

User Manual Enhanced Generic ASCII Serial Communication Module

1.9 Before You Begin

Note: This section only applies if your processor is using RSLogix 5000 version 16 or higher. If you

have an earlier version, please see Using the Sample Program - RSLogix 5000 Version 15 and

earlier (page 122).

Before You Begin

Two Add-On Instructions are provided for the MVI56E-GSC module. The first is

required for setting up the module; the second is optional.

Download them from www.prosoft-technology.com. Save them to a convenient

location in your PC, such as Desktop or My Documents.

1.9.1 About the Optional Add-On Instruction

The Optional Add-On Instruction performs the following tasks:

Read/Write Ethernet Configuration

Allows the processor to read or write the module IP address, subnet mask,

and network gateway IP address.

Read/Write Module Clock Value

Allows the processor to read and write the module clock settings. The

module's free-running clock also stores the last time that the Ethernet

configuration was changed or the last time the module was restarted or

rebooted. The date and time of the last change or restart is displayed on the

scrolling LED during module power-up/start-up sequence.

For more information, see Using the Optional Add-On Instruction (page 112).

Note: You can also set the date and time from the module's home page.

Important: The Optional Add-On Instruction supports only the two features listed above. You must

use the regular MVI56E-GSC Add-On Instruction for all other features including backplane transfer

and Modbus data communication.

Page 34 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 35

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

1.10 Creating a New RSLogix 5000 Project

1 Open the FILE menu, and then choose NEW.

2 Select your ControlLogix controller model.

3 Select REVISION 16.

4 Enter a name for your controller, such as My_Controller.

5 Select your ControlLogix chassis type.

6 Select SLOT 0 for the controller.

ProSoft Technology, Inc. Page 35 of 140

April 24, 2017

Page 36

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

1.10.1 Creating the Module

1 Add the MVI56E-GSC module to the project.

In the CONTROLLER ORGANIZATION window, select I/O CONFIGURATION and

click the right mouse button to open a shortcut menu. On the shortcut menu,

choose NEW MODULE...

This action opens the SELECT MODULE dialog box.

2 Select the 1756-MODULE (GENERIC 1756 MODULE) from the list and click OK.

This action opens the NEW MODULE dialog box.

Page 36 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 37

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Parameter

Value

Name

Enter a module identification string. Example: GSC

Description

Enter a description for the module. Example: Enhanced

Generic ASCII Serial Communication Module.

Comm Format

Select DATA-SINT.

Slot

Enter the slot number in the rack where the MVI56E-GSC

module is located.

Input Assembly Instance

1

Input Size

500

Output Assembly Instance

2

Output Size

496

Configuration Assembly Instance

4

Configuration Size

0

Enhanced Generic ASCII Serial Communication Module User Manual

3 Set the Module Properties values as follows:

4 On the Connection tab, set the RPI value for your project. Click OK to

confirm.

The MVI56E-GSC module is now visible in the I/O CONFIGURATION section.

ProSoft Technology, Inc. Page 37 of 140

April 24, 2017

Page 38

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

1.10.2 Importing the Ladder Rung

1 In the CONTROLLER ORGANIZATION window, expand the TASKS folder and

subfolder until you reach the MAINPROGRAM folder.

2 In the MAINPROGRAM folder, double-click to open the MAINROUTINE ladder.

3 Select an empty rung in the new routine, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose IMPORT

RUNG…

Page 38 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 39

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

4 Navigate to the location on your PC where you Before You Begin (page 34)

the Add-On Instruction (for example, "My Documents" or "Desktop"). Select

the MVI56EGSC_ADDON_RUNG_V1_3.L5X file

This action opens the IMPORT CONFIGURATION dialog box, showing the

controller tags that will be created.

5 Click OK to confirm the import. RSLogix will indicate that the import is in

progress:

ProSoft Technology, Inc. Page 39 of 140

April 24, 2017

Page 40

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

When the import is complete, you will see the new Add-On Instruction rung in

the ladder.

The procedure has also imported new User Defined Data Types, data objects

and the Add-On instruction for your project.

Page 40 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 41

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Parameter

Value

Name

Enter a module identification string. Example: GSC_2.

Description

Enter a description for the module. Example: ProSoft

Enhanced Generic ASCII Serial Communication Module.

Comm Format

Select DATA-SINT.

Slot

Enter the slot number in the rack where the MVI56E-GSC

module is located.

Input Assembly Instance

1

Input Size

500

Output Assembly Instance

2

Output Size

496

Configuration Assembly Instance

4

Configuration Size

0

Enhanced Generic ASCII Serial Communication Module User Manual

Adding Multiple Modules (Optional)

1 In the I/O CONFIGURATION folder, click the right mouse button to open a

shortcut menu, and then choose NEW MODULE.

2 Select 1756-MODULE

3 Set the Module Properties values as follows:

ProSoft Technology, Inc. Page 41 of 140

April 24, 2017

Page 42

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

4 Click OK to confirm. The new module is now visible:

5 Expand the TASKS folder, and then expand the MAINTASK folder.

6 On the MAINPROGRAM folder, click the right mouse button to open a shortcut

menu. On the shortcut menu, choose NEW ROUTINE. As an alternative to

creating a separate New Routine, you could skip to Step 8 and import the

AOI for the second module into the same routine you created for the first

module.

7 In the NEW ROUTINE dialog box, enter the name and description of your

routine, and then click OK.

8 Select an empty rung in the new routine or an existing routine, and then click

the right mouse button to open a shortcut menu. On the shortcut menu,

choose IMPORT RUNG…

Page 42 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 43

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

9 Select the file MVI56EGSC_ADDON_RUNG_V1_3.L5X

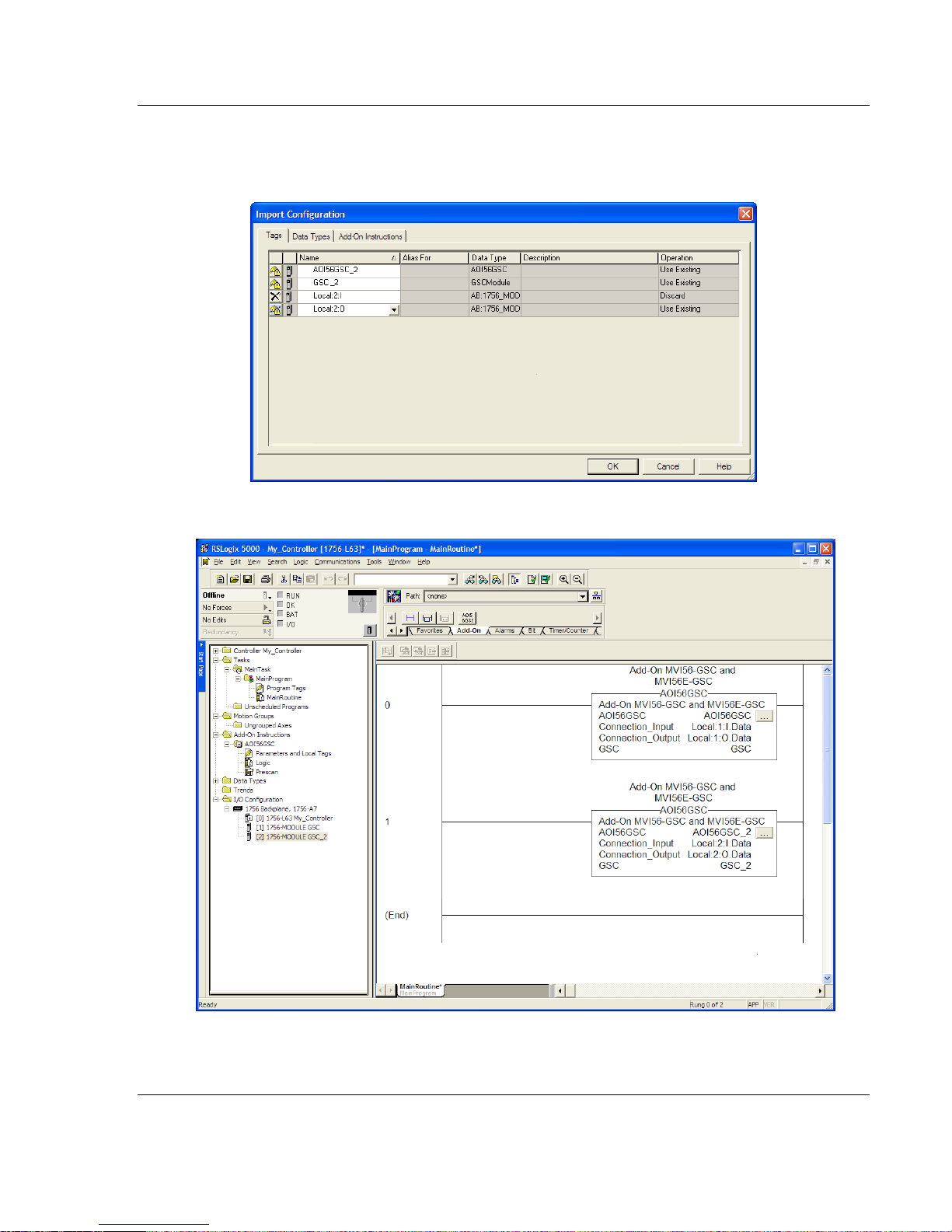

10 The following window will be displayed showing the tags to be imported:

ProSoft Technology, Inc. Page 43 of 140

April 24, 2017

Page 44

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

11 Associate the I/O connection variables to the correct module. The default

values are Local:1:I and Local:1:O so these require change.

Page 44 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 45

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

Change the default tag names AOI56GSC and GSC to avoid conflict with

existing tags. In this step, you should append a string to the default tag

names, such as "_2", as shown in the following illustration.

12 Click OK to confirm.

The setup procedure is now complete. Save the project and download the

application to your ControlLogix processor.

ProSoft Technology, Inc. Page 45 of 140

April 24, 2017

Page 46

Start Here MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

1.11 Connecting Your PC to the ControlLogix Processor

There are several ways to establish communication between your PC and the

ControlLogix processor. The following steps show how to establish

communication through the serial interface.

Note: It is not mandatory that you use the processor's serial interface. You may access the

processor through whatever network interface is available on your system. Refer to your Rockwell

Automation documentation for information on other connection methods

1 Connect the right-angle connector end of the cable to your controller at the

communications port.

2 Connect the straight connector end of the cable to the serial port on your

computer.

Page 46 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 47

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Start Here

Enhanced Generic ASCII Serial Communication Module User Manual

1.12 Downloading the Sample Program to the Processor

Note: The key switch on the front of the ControlLogix processor must be in the REM or PROG

position.

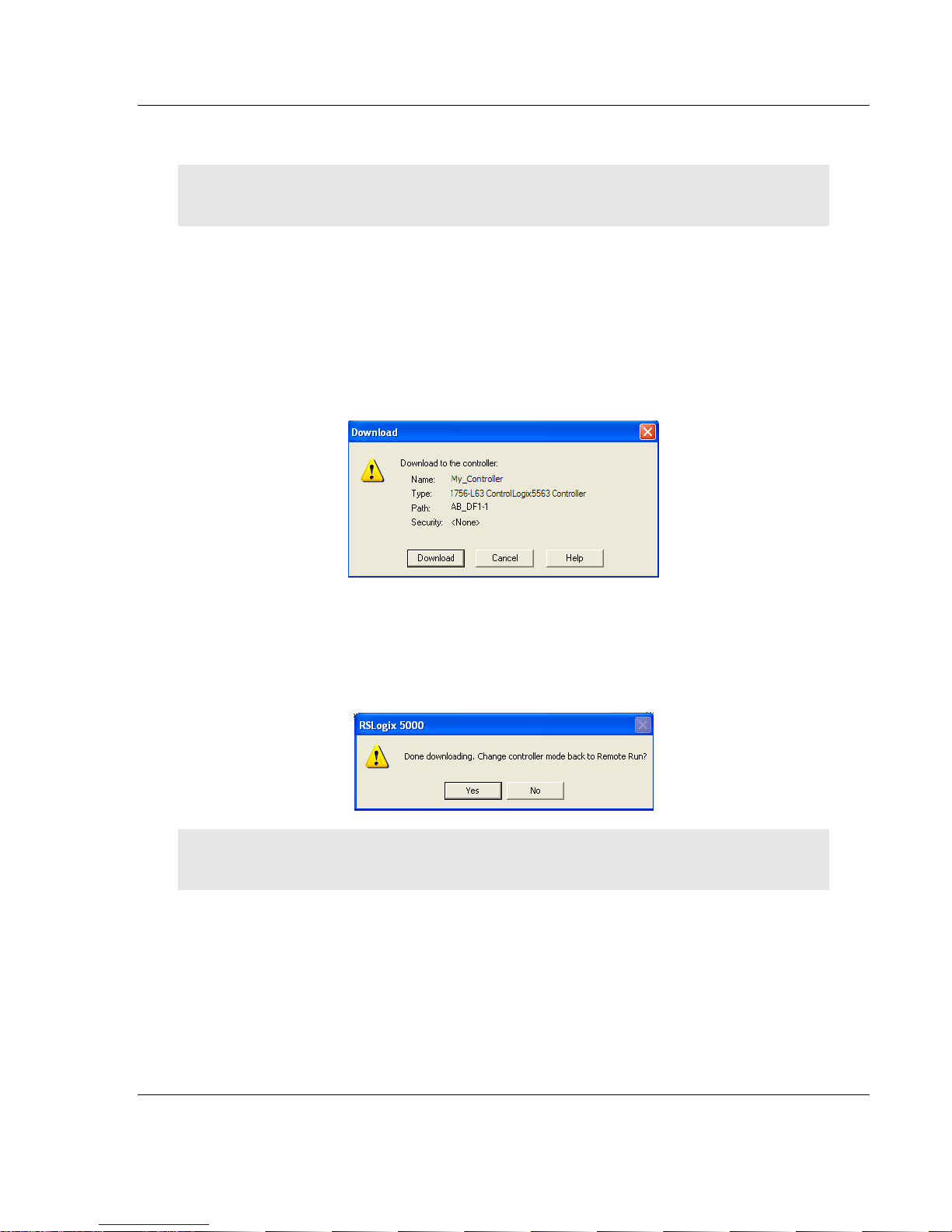

1 If you are not already online with the processor, in RSLogix 5000 open the

Communications menu, and then choose DOWNLOAD. RSLogix 5000 will

establish communication with the processor. You do not have to download

through the processor's serial port, as shown here. You may download

through any available network connection.

2 When communication is established, RSLogix 5000 will open a confirmation

dialog box. Click the DOWNLOAD button to transfer the sample program to the

processor.

3 RSLogix 5000 will compile the program and transfer it to the processor. This

process may take a few minutes.

4 When the download is complete, RSLogix 5000 will open another

confirmation dialog box. If the key switch is in the REM position, click OK to

switch the processor from PROGRAM mode to RUN mode.

Note: If you receive an error message during these steps, refer to your RSLogix documentation to

interpret and correct the error.

ProSoft Technology, Inc. Page 47 of 140

April 24, 2017

Page 48

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

Page 48 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 49

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform MVI56E-GSC Configuration

In This Chapter

GSC.UTIL.BackplaneFail ...................................................................... 50

GSC.CONFIG.PortX (where X = 1 or 2) ................................................ 51

Changing parameters during operation ................................................. 56

Enhanced Generic ASCII Serial Communication Module User Manual

2 MVI56E-GSC Configuration

All module configuration settings, data to be exchanged, status, and error data,

except for Debug Port Ethernet settings, are contained in the RSLogix 5000

controller tag arrays.

Only the following RSLogix controller tags need to be configured for the module

to work as needed for your application.

1 The GSC.UTIL.BACKPLANEFAIL controller tag sets up a backplane

communication failure counter to monitor the health of communication

between the module and the ControlLogix processor across the ControlLogix

backplane.

ProSoft Technology, Inc. Page 49 of 140

April 24, 2017

Page 50

MVI56E-GSC Configuration MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

2 The GSC.CONFIG.PORT1 and GSC.CONFIG.PORT2 controller tag arrays

contain tags to configure the application serial ports. These sets of controller

tags allow you to configure typical serial port parameters, such as baud rate,

data bits, and stop bits.

2.1 GSC.UTIL.BackplaneFail

A "backplane communication failure" is any failed attempt by the module to

communicate with the ControlLogix processor. For local rack applications, where

the module is installed in the same chassis as the processor, backplane failures

can occur due to a hardware problem or Input/Output (I/O) configuration problem.

For remote rack applications, where the module is installed in a different chassis

from the processor and linked by communication adapters, such as ControlNet or

EtherNet/IP, in addition to hardware and I/O configuration problems, any failure

to communicate with the ControlLogix processor across a process network will

be considered a backplane communication failure.

The GSC.UTIL.BACKPLANEFAIL parameter specifies the number of successive

ControlLogix backplane transfer failures that must occur before the ASCII serial

communication ports are shut down. If the parameter is set to zero, the

communication ports will continue to operate under even if the module has no

communication with the processor. If the value is set greater than 0 (1 to 65535),

serial port communication will cease if the specified number of successive

communication failures occur.

The only ways to restart serial port communication after a Backplane Fail

shutdown are by Cold Boot from ladder logic, by removing and then reinserting

the module in the chassis, or by turning power to the module or chassis off and

then back on (Cold Start).

Page 50 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 51

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform MVI56E-GSC Configuration

Enhanced Generic ASCII Serial Communication Module User Manual

2.2 GSC.CONFIG.PortX

All configuration of the two ASCII application serial ports is done using the tags in

the two GSC.CONFIG.PORTX arrays.

2.2.1 Port[x].Enabled

0 = Disable port, 1 = Enable the port.

This parameter enables or disables the protocol port.

ProSoft Technology, Inc. Page 51 of 140

April 24, 2017

Page 52

MVI56E-GSC Configuration MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

0 = No Bits

Set

1 = Bit 0 Set

2 = Bit 1 Set

4 = Bit 2 Set

8 = Bit 3 Set

Decimal

Value of

Bits

Selected

(S)

Streaming

Mode

Selected

(T)

Terminating

Characters

Selected

(M)

Message

Timeout

Selected

(D)

Intercharacter

Delay

Selected

(P)

Packet Length

Selected

Port Types

Selected by

Bitmap

0

0

S 1 1 T

2 2 M

3 1

2

M, T

4

4

D

5 1 4 D, T

6 2 4 D, M 7

1 2 4 D, M, T

8

8 P 9 1

8

P, T

10 2 8 P, M

11 1

2 8

P, M, T

12

4 8 P, D

13 1 4 8 P, D, T

14 2 4 8 P ,D, M

15 1 2 4

8

P, D, M, T

User Manual Enhanced Generic ASCII Serial Communication Module

2.2.2 Port[x].Type

0 through 15

You can use any combination of one or more termination types. When multiple

termination types are selected, the module will determine the end of the string to

be as soon as any of the selected terminating conditions becomes true. After

that, any new characters received will be considered part of a new string until the

next time a terminating condition is true.

Page 52 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 53

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform MVI56E-GSC Configuration

For Termination Type

Receive Parameters to Set

Terminating Characters

GSC.PortX.RTermCnt

GSC.PortX.RTermChar

Message Timeout

GSC.PortX.RTimeout

Intercharacter Delay

GSC.PortX.RDelay

Packet (String) Length

GSC.PortX.RPacketLen

Value

Baud Rate (bits per second)

110

110 Baud

150

150 Baud

300

300 Baud

600

600 Baud

1200

1200 Baud

2400

2400 Baud

4800

4800 Baud

9600

9600 Baud

19200

19200 Baud

384

38400 Baud

576

57600 Baud

115

115200 Baud

Value

Description

0

None

1

Odd

2

Even

3

Mark

4

Space.

Enhanced Generic ASCII Serial Communication Module User Manual

For each termination type, you must also enter values in the following parameter

configuration tags. Streaming mode is not recommended for general use, as it

creates heavy demands on the ControlLogix processor and requires time-critical

programming logic to properly process.

2.2.3 Port[x].Baudrate

This is the baud rate to use on the port. Enter the baud rate (bits per second) as

a value. All devices on this port must communicate at the same baud rate. For

example, to select 19K baud, enter 19200.

The following table describes the valid parameters for this configuration entry.

2.2.4 Port[x].Parity

Parity is a simple error checking algorithm used in serial communication. This

parameter specifies the type of parity checking to use. All devices connected to

the port must use the same parity.

ProSoft Technology, Inc. Page 53 of 140

April 24, 2017

Page 54

MVI56E-GSC Configuration MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

Value

Description

0

No hardware or software handshaking

1

RTS/CTS hardware handshaking

2

DTR/DSR hardware handshaking

3

XON/XOFF software handshaking

User Manual Enhanced Generic ASCII Serial Communication Module

2.2.5 Port[x].DataBits

5, 6, 7 or 8

This parameter sets the number of data bits for each word used by the protocol.

All devices communicating through this port must use the same number of data

bits.

2.2.6 Port[x].StopBits

1 or 2

Stop bits signal the end of a character in the data stream. For most applications,

use one stop bit. For slower devices that require more time to re-synchronize,

use two stop bits.

All devices communicating through this port must use the same number of stop

bits.

2.2.7 Port[x].RTSOn

0 to 65535 milliseconds

This parameter sets the number of milliseconds to delay after Ready To Send

(RTS) is asserted before data will be transmitted.

2.2.8 Port[x].RTSOff

0 to 65535 milliseconds

This parameter sets the number of milliseconds to delay after the last byte of

data is sent before the RTS modem signal will be set low.

2.2.9 Port[x].Handshaking

Handshaking is a negotiation process between devices that establishes a data

connection. Select the handshaking type that best matches the needs of the

devices connected to the port.

2.2.10 Port[x].RTermCnt

0 to 12 characters

This parameter specifies the number of termination characters that define the

end of a received message. Use this parameter if you set the PORT[X].TYPE

Port[x].Type (page 52) value to 1, 3, 5, 7, 9, 11, 13 or 15.

Page 54 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 55

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform MVI56E-GSC Configuration

Enhanced Generic ASCII Serial Communication Module User Manual

2.2.11 Port[x].RTermChar

This array of up to 12 characters specifies the termination characters that define

the end of a received message. Each character occupies one position in the

array. The number of termination characters you enter here must match the

value in the PORT[X].RTERMCNT tag.

2.2.12 Port[x].RPacketLen

This parameter specifies the number of bytes of data to receive on the port

before considering an incoming message complete and transferring the data to

the processor. Use this parameter if you set the PORT[X].TYPEPort[x].Type (page

52) value to 8, 9, 10, 11, 12, 13, 14, or 15.

2.2.13 Port[x].RTimeout

This parameter specifies the number milliseconds to wait after receiving the first

character on the port before considering an incoming message complete and

automatically sending the data to the processor. Use this parameter if you set the

PORT[X].TYPE Port[x].Type (page 52) value to 2, 3, 6, 7, 10, 11, 14, or 15.

2.2.14 Port[x].RDelay

This parameter specifies the maximum number milliseconds to wait between

each character received on the port to see if more characters are coming before

considering an incoming message complete and automatically sending the data

to the processor. In practice, this can be thought of as a period of time in which

no characters are received after receiving a string of characters. Use this

parameter if you set the PORT[X].TYPE Port[x].Type (page 52) value to 4, 5, 6, 7,

10, 11, 14, or 15.

2.2.15 Port[x].WTermCnt

Not used in current release of product.

2.2.16 Port[x].WTermChar

Not used in current release of product.

2.2.17 Port[x].WPacketLen

Not used in current release of product.

ProSoft Technology, Inc. Page 55 of 140

April 24, 2017

Page 56

MVI56E-GSC Configuration MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

2.2.18 Port[x].WTimeout

This parameter specifies the timeout period to transmit a message out the port. A

message must be transmitted out the port within the specified timeout period.

Message transmission will be aborted if the timeout is exceeded. Use this

parameter if you set the PORT[X].TYPE Port[x].Type (page 52) to 2, 3, 6, 7, 10,

11, 14, or 15.

Note: If this parameter is left at zero, then the Port Configuration Error Word will show a value of

0400. In order to clear this error, this parameter has to be set to any non-zero value.

2.2.19 Port[x].Spare

Not used in current release of product.

2.2.20 Port[x].WMinDelay

This parameter specifies the minimum number of milliseconds to delay before

transmitting a message out the port. This pre-send delay is applied before the

RTS On time. This may be required when communicating with slow devices. Use

this parameter if you set the PORT[X].TYPE Port[x].Type (page 52) to 8, 9, 10, 11,

12, 13, 14, or 15.

2.3 Changing parameters during operation

When you change the configuration parameters in RSLogix, you must reboot or

cycle power to the module off and on before the new configuration takes effect.

You may also change the value of the GSC.ColdBoot or GSC.WarmBoot

controller tags from 0 to 1 to reboot the module from logic.

Page 56 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 57

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Diagnostics and Troubleshooting

In This Chapter

Reading Status Data from the Module .................................................. 57

The Diagnostics Menu ........................................................................... 58

Monitoring Module Information .............................................................. 61

Monitoring Backplane Information ......................................................... 62

Data Analyzer ........................................................................................ 63

Scrolling LED Status Indicators ............................................................. 68

Ethernet LED Indicators ........................................................................ 69

Non-Scrolling LED Status Indicators ..................................................... 70

ControlLogix Processor Not in RUN or REM RUN ................................ 70

Clearing a Fault Condition ..................................................................... 70

Troubleshooting ..................................................................................... 71

Enhanced Generic ASCII Serial Communication Module User Manual

3 Diagnostics and Troubleshooting

The module provides information on diagnostics and troubleshooting in the

following forms:

LED status indicators on the front of the module provide information on the

module’s status.

Status data contained in the module can be viewed in ProSoft Configuration

Builder through the Ethernet port.

Status data values are transferred from the module to the processor.

3.1 Reading Status Data from the Module

The MVI56E-GSC module returns three separate status data areas to the

ControlLogix processor in each read block. This data is transferred to the

ControlLogix processor continuously with each read block. For a complete listing

of the status data object, refer to the Module Configuration section of this

manual.

ProSoft Technology, Inc. Page 57 of 140

April 24, 2017

This guide also includes example ladder logic showing how to extract this data

from the input image and place it in the module’s Controller Logic Tag. Refer to

Diagnostics and Troubleshooting for a discussion of the features available

through the use of this utility.

Page 58

Diagnostics and Troubleshooting MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

3.2 The Diagnostics Menu

The Diagnostics menu, available through the Ethernet configuration port for this

module, is arranged as a tree structure, with the Main menu at the top of the tree,

and one or more submenus for each menu command. The first menu you see

when you connect to the module is the Main menu.

3.2.1 Using the Diagnostics Menu in ProSoft Configuration Builder

Tip: You can have a ProSoft Configuration Builder Diagnostics window open for more than one

module at a time.

To connect to the module’s Configuration/Debug Ethernet port:

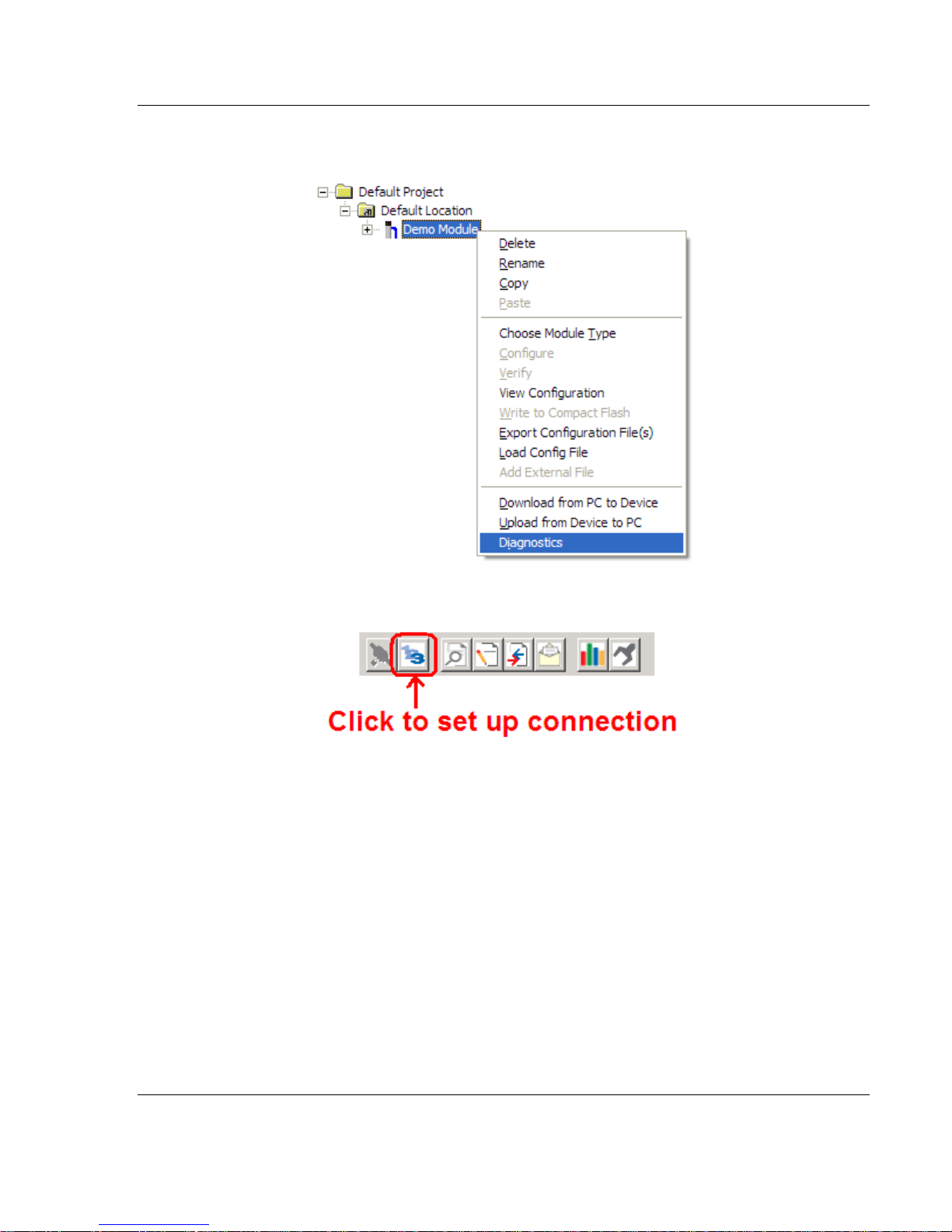

1 In ProSoft Configuration Builder, select the module, and then click the right

mouse button to open a shortcut menu.

Page 58 of 140 ProSoft Technology, Inc.

April 24, 2017

Page 59

MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform Diagnostics and Troubleshooting

Enhanced Generic ASCII Serial Communication Module User Manual

2 On the shortcut menu, choose DIAGNOSTICS.

3 In the Diagnostics window, click the SET UP CONNECTION button to browse for

the module’s IP address.

ProSoft Technology, Inc. Page 59 of 140

April 24, 2017

Page 60

Diagnostics and Troubleshooting MVI56E-GSC/GSCXT ♦ CompactLogix or MicroLogix Platform

User Manual Enhanced Generic ASCII Serial Communication Module

4 In the Connection Setup dialog box, click the TEST CONNECTION button to

verify that the module is accessible with the current settings.

You can also use CIPconnect® to connect to the module through a 1756-

ENBT card. Refer to Using CIPconnect® to Connect to the Module (page 24)

for information on how to construct a CIP path.

5 If the Test Connection is successful, click CONNECT.

If PCB is unable to connect to the module:

Page 60 of 140 ProSoft Technology, Inc.