Page 1

MVI56E-61850S

ControlLogix Platform

IEC 61850 Server Communication

Module

September 3, 2014

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

© 2014 ProSoft Technology, Inc. All rights reserved.

MVI56E-61850S User Manual

September 3, 2014

ProSoft Technology®, is a registered copyright of ProSoft Technology, Inc. All other brand or product names are or

may be trademarks of, and are used to identify products and services of, their respective owners.

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed DVD and are

available at no charge from our web site: http://www.prosoft-technology.com

Content Disclaimer

This documentation is not intended as a substitute for and is not to be used for determining suitability or reliability of

these products for specific user applications. It is the duty of any such user or integrator to perform the appropriate

and complete risk analysis, evaluation and testing of the products with respect to the relevant specific application or

use thereof. Neither ProSoft Technology nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. Information in this document including illustrations, specifications and

dimensions may contain technical inaccuracies or typographical errors. ProSoft Technology makes no warranty or

representation as to its accuracy and assumes no liability for and reserves the right to correct such inaccuracies or

errors at any time without notice. If you have any suggestions for improvements or amendments or have found errors

in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without express written permission of ProSoft Technology. All pertinent state, regional, and local safety

regulations must be observed when installing and using this product. For reasons of safety and to help ensure

compliance with documented system data, only the manufacturer should perform repairs to components. When

devices are used for applications with technical safety requirements, the relevant instructions must be followed.

Failure to use ProSoft Technology software or approved software with our hardware products may result in injury,

harm, or improper operating results. Failure to observe this information can result in injury or equipment damage.

© 2014 ProSoft Technology. All Rights Reserved.

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1 (661) 716-5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Page 3

Agency

RoHS

ATEX

CSA

CE

CSA CB Safety

cULus

GOST-R

Important Safety Information

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in Hazardous Locations, turn off power before replacing or rewiring

modules.

C Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be nonhazardous.

D Suitable for use in Class I, Division 2 Groups A, B, C, and D, Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage:

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Agency Approvals and Certifications

<Ex>

II 3 G

Ex nA T5

0°C <= Ta <= 60°C

II – Equipment intended for above ground use (not for use in mines).

3 – Category 3 equipment, investigated for normal operation only.

G – Equipment protected against explosive gasses.

<cULus>

E183151

Class I, DIV 2, groups A,B,C,D

T5 for all models

0°C to +60°C

Page 4

Page 5

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

Content Disclaimer .............................................................................................................................. 2

Important Safety Information ............................................................................................................... 3

1 Start Here 7

1.1 System Requirements ............................................................................................... 8

1.2 Package Contents ..................................................................................................... 9

1.3 Setting Jumpers ........................................................................................................ 9

1.4 Installing the Module in the Rack ............................................................................ 10

1.5 Connecting Your PC to the ControlLogix Processor ............................................... 12

1.6 Downloading the Sample Program to the Processor .............................................. 13

1.6.1 Configuring the RSLinx Driver for the PC COM Port .............................................. 14

2 Setting Up ProSoft Configuration Builder 17

2.1 Installing ProSoft Configuration Builder .................................................................. 17

2.2 Setting Up the Project ............................................................................................. 18

3 MVI56E-61850S Configuration 21

3.1 Backplane Configuration ......................................................................................... 22

3.2 Ethernet1 ................................................................................................................. 23

3.3 61850S Identification ............................................................................................... 24

3.4 61850S Network ...................................................................................................... 25

3.5 61850S IP Filter ....................................................................................................... 26

3.6 61850S Data DB Configuration ............................................................................... 28

3.7 61850S Data SoE .................................................................................................... 30

3.8 61850S Data Control ............................................................................................... 32

3.9 61850S Buffered Reports ........................................................................................ 34

3.9.1 61850S BR0x Dataset ............................................................................................. 36

3.10 61850S Unbuffered Reports ................................................................................... 38

3.10.1 61850S UR0x Dataset ............................................................................................. 40

3.11 Downloading the Project to the Module .................................................................. 42

3.11.1 Connecting Your PC to the Module's Ethernet Port ................................................ 44

4 RSLogix 5000 Configuration 49

4.1 MVI56E-61850S User-Defined Data Types ............................................................ 49

4.2 MVI56E-61850S Controller Tags ............................................................................ 49

4.2.1 61850S Controller Tag Overview ............................................................................ 49

4.2.2 MVI56E61850S.DATA ............................................................................................. 50

4.2.3 MVI56E61850S.COMMAND ................................................................................... 51

4.2.4 MVI56E61850S.STATUS Tag ................................................................................. 52

4.2.5 MVI56E61850S.UTIL Tag ....................................................................................... 52

ProSoft Technology, Inc. Page 5 of 81

September 4, 2014

Page 6

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

5 Examples 53

5.1 Data DB Example ................................................................................................... 53

5.2 SoE Example .......................................................................................................... 58

5.3 Control Example ..................................................................................................... 62

6 Diagnostics and Troubleshooting 65

6.1 Ethernet LED Indicators .......................................................................................... 65

6.1.1 Scrolling LED Status Indicators .............................................................................. 66

6.1.2 Non-Scrolling LED Status Indicators ...................................................................... 67

6.2 Clearing a Fault Condition ...................................................................................... 67

6.3 Troubleshooting ...................................................................................................... 68

6.4 Using the Diagnostics Menu in ProSoft Configuration Builder ............................... 69

6.4.1 Monitoring Module Information ............................................................................... 72

6.4.2 Monitoring Backplane Information .......................................................................... 73

6.4.3 Monitoring Base Configuration Information ............................................................ 74

6.4.4 Monitoring Data Mappings Information ................................................................... 75

6.4.5 Monitoring Backplane Information .......................................................................... 76

6.4.6 Monitoring Flat Database Information .................................................................... 77

6.5 Connect to the Module’s Web Page ....................................................................... 78

7 Support, Service & Warranty 79

7.1 Contacting Technical Support ................................................................................. 79

7.2 Warranty Information .............................................................................................. 80

Index 81

Page 6 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 7

MVI56E-61850S ♦ ControlLogix Platform Contents

In This Chapter

System Requirements............................................................................. 8

Package Contents .................................................................................. 9

Setting Jumpers ...................................................................................... 9

Installing the Module in the Rack ...........................................................10

Connecting Your PC to the ControlLogix Processor ..............................12

Downloading the Sample Program to the Processor .............................13

IEC 61850 Server Communication Module User Manual

1 Start Here

To get the most benefit from this User Manual, you should have the following skills:

Rockwell Automation® RSLogix™ software: launch the program, configure ladder

logic, and transfer the ladder logic to the processor

Microsoft Windows®: install and launch programs, execute menu commands, navigate

dialog boxes, and enter data

Hardware installation and wiring: install the module, and safely connect IEC 61850

and ControlLogix devices to a power source and to the MVI56E-61850S module’s

application port(s)

ProSoft Technology, Inc. Page 7 of 81

September 4, 2014

Page 8

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

1.1 System Requirements

The MVI56E-61850S module requires the following minimum hardware and software

components:

Rockwell Automation® ControlLogix® processor (firmware version 10 or higher) with

compatible limited voltage power supply and one free slot in the rack for the MVI56E61850S module. The module requires 800 mA of available 5 VDC and 3 mA of available

24 VDC power.

Rockwell Automation RSLogix™ 5000 programming software

o Version 16 or higher required for Add-On Instruction

Rockwell Automation RSLinx® communication software version 2.51 or higher

ProSoft Configuration Builder (PCB) (included)

ProSoft Discovery Service (PDS) (included in PCB)

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better) recommended

Supported operating systems:

o Microsoft Windows

o Microsoft Windows XP Professional with Service Pack 1 or 2

o Microsoft Windows 7 Professional (32 or 64-bit)

o Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o Microsoft Windows Server 2003

128 MB of RAM minimum, 256 MB of RAM recommended

100 MB of free hard disk space (or more based on application requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color 1024 768

recommended)

DVD drive

®

Vista

Note: The Hardware and Operating System requirements in this list are the minimum recommended to install

and run software provided by ProSoft Technology®. Other third party applications may have different minimum

requirements. Refer to the documentation for any third party applications for system requirements.

Note: You can install the module in a local or remote rack. For remote rack installation, the module requires

EtherNet/IP or ControlNet communication with the processor.

Page 8 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 9

MVI56E-61850S ♦ ControlLogix Platform Contents

Qty.

Part Name

Part Number

Part Description

1

MVI56E-61850S Module

MVI56E-61850S

IEC 61850 Server Communication Module

1

Ethernet Cable

RL-CBL025

Straight-through Ethernet cable

1

ProSoft Solutions DVD

DVD-001

Contains sample programs, utilities, and documentation.

Files can also be found at

http://www.prosoft-technology.com

IEC 61850 Server Communication Module User Manual

1.2 Package Contents

The following components are included with your MVI56E-61850S module, and are all

required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are present.

If any of these components are missing, please contact ProSoft Technology Technical

Support for replacement parts. If the DVD is not present, please visit

http://www.prosoft-technology.com for the latest files.

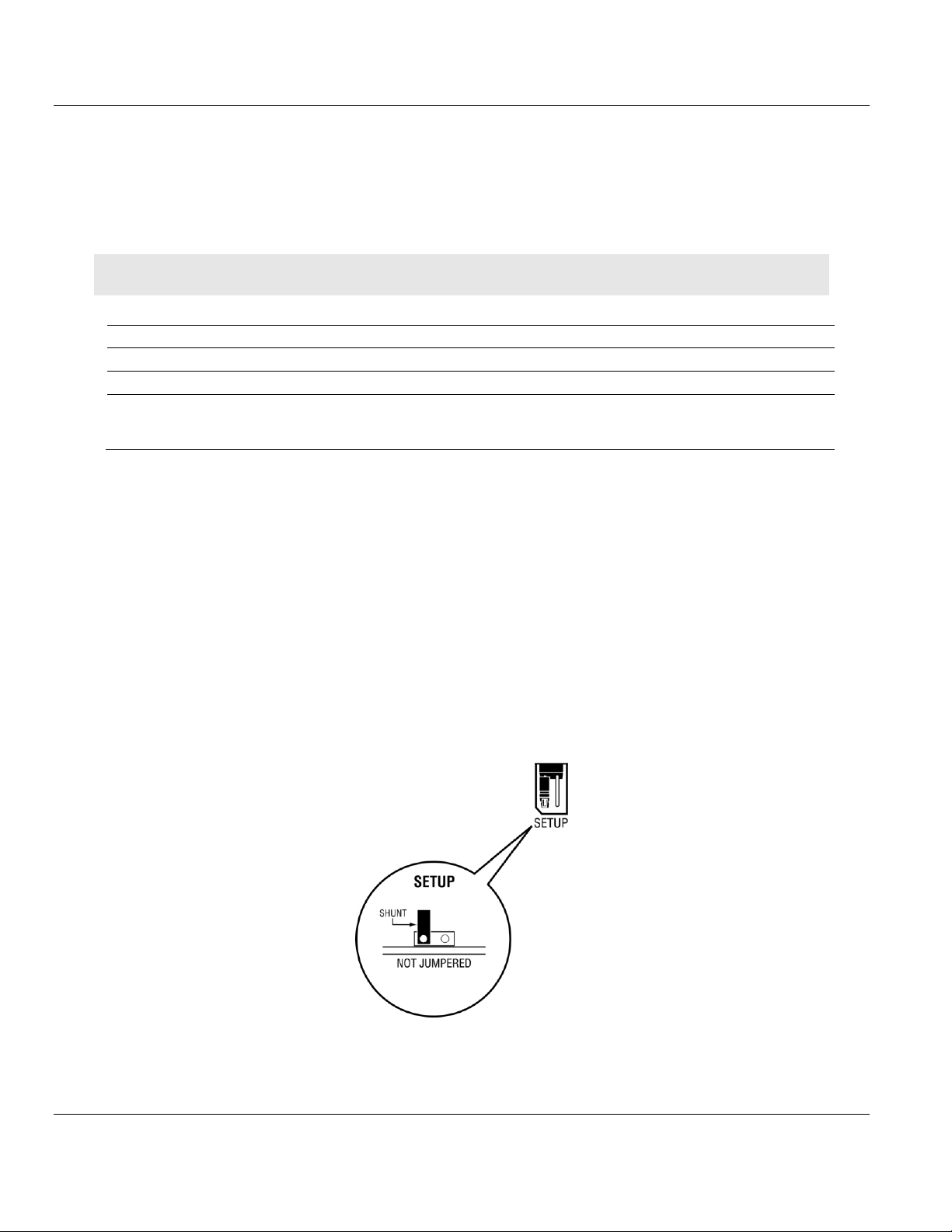

1.3 Setting Jumpers

The Setup Jumper acts as "write protection" for the module’s flash memory. In "write

protected" mode, the Setup pins are not connected, and the module’s firmware cannot be

overwritten. The module is shipped with the Setup jumper OFF. Do not jumper the Setup

pins together unless you are directed to do so by ProSoft Technical Support (or to update

the module firmware).

The following illustration shows the MVI56E-61850S jumper configuration with the Setup

Jumper OFF.

ProSoft Technology, Inc. Page 9 of 81

September 4, 2014

Page 10

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

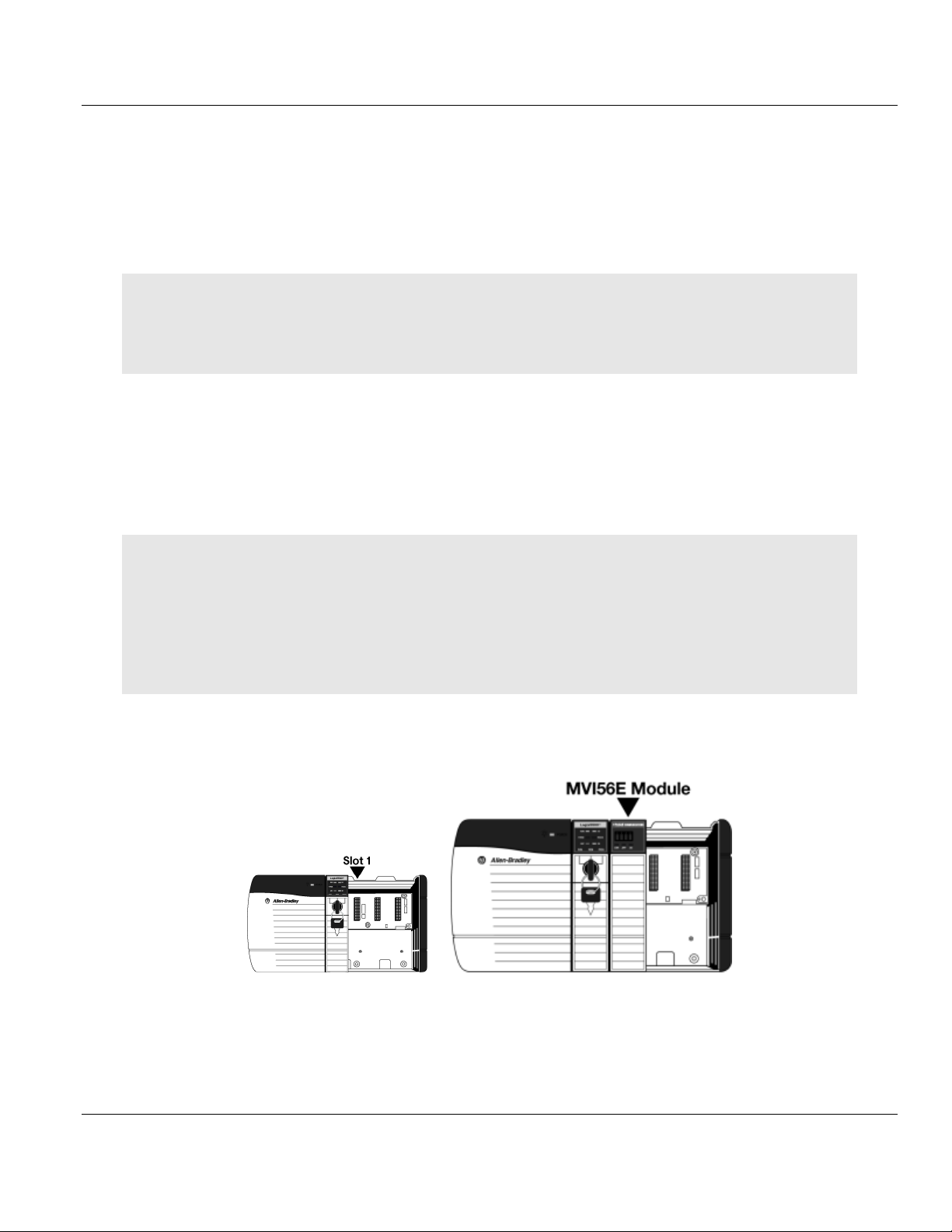

1.4 Installing the Module in the Rack

Make sure your ControlLogix processor and power supply are installed and configured,

before installing the MVI56E-61850S module. Refer to your Rockwell Automation product

documentation for installation instructions.

Warning: You must follow all safety instructions when installing this or any other electronic devices. Failure to

follow safety procedures could result in damage to hardware or data, or even serious injury or death to

personnel. Refer to the documentation for each device you plan to connect to verify that suitable safety

procedures are in place before installing or servicing the device.

After you have checked the placement of the jumpers, insert the MVI56E-61850S into the

ControlLogix chassis. Use the same technique recommended by Rockwell Automation to

remove and install ControlLogix modules.

You can install or remove ControlLogix system components while chassis power is applied

and the system is operating. However, please note the following warning.

Warning: When you insert or remove the module while backplane power is on, an electrical arc can occur. An

electrical arc can cause personal injury or property damage by sending an erroneous signal to the system’s

actuators. This can cause unintended machine motion or loss of process control. Electrical arcs may also cause

an explosion when they happen in a hazardous environment. Verify that power is removed or the area is nonhazardous before proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the module and its mating connector.

Worn contacts may create electrical resistance that can affect module operation.

1 Align the module with the top and bottom guides, and then slide it into the rack until the

module is firmly against the backplane connector.

2 With a firm, steady push, snap the module into place.

3 Check that the holding clips on the top and bottom of the module are securely in the

locking holes of the rack.

Page 10 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 11

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

4 Make a note of the slot location. You must identify the slot in which the module is

installed in order for the sample program to work correctly. Slot numbers are identified

on the green circuit board (backplane) of the ControlLogix rack.

5 Turn power ON.

Note: If you insert the module improperly, the system may stop working or may behave unpredictably.

ProSoft Technology, Inc. Page 11 of 81

September 4, 2014

Page 12

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

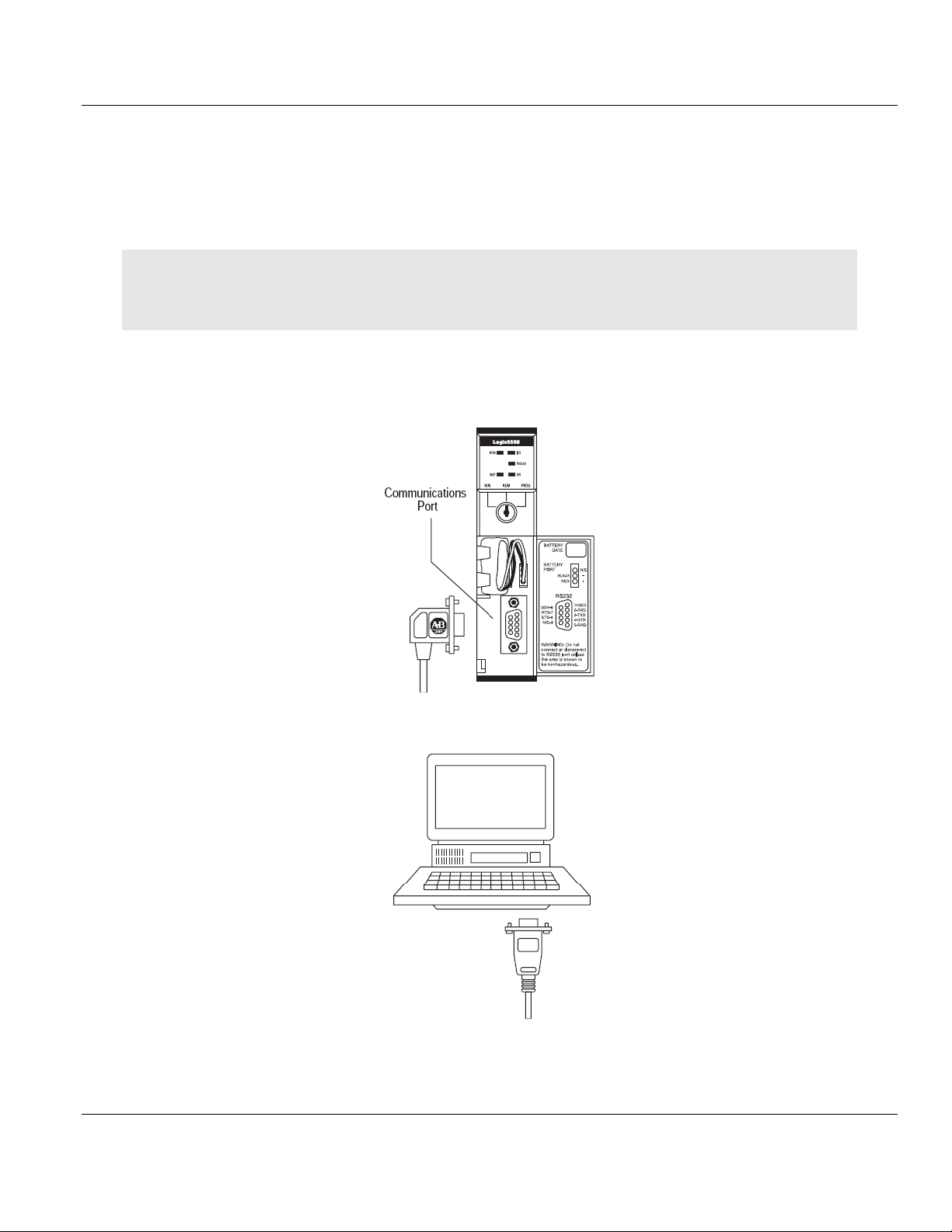

1.5 Connecting Your PC to the ControlLogix Processor

There are several ways to establish communication between your PC and the ControlLogix

processor. The following steps show how to establish communication through the serial

interface.

Note: It is not mandatory that you use the processor's serial interface. You may access the processor through

whatever network interface is available on your system. Refer to your Rockwell Automation documentation for

information on other connection methods.

1 Connect the right-angle connector end of the cable to your controller at the

communications port.

2 Connect the straight connector end of the cable to the serial port on your computer.

Page 12 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 13

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

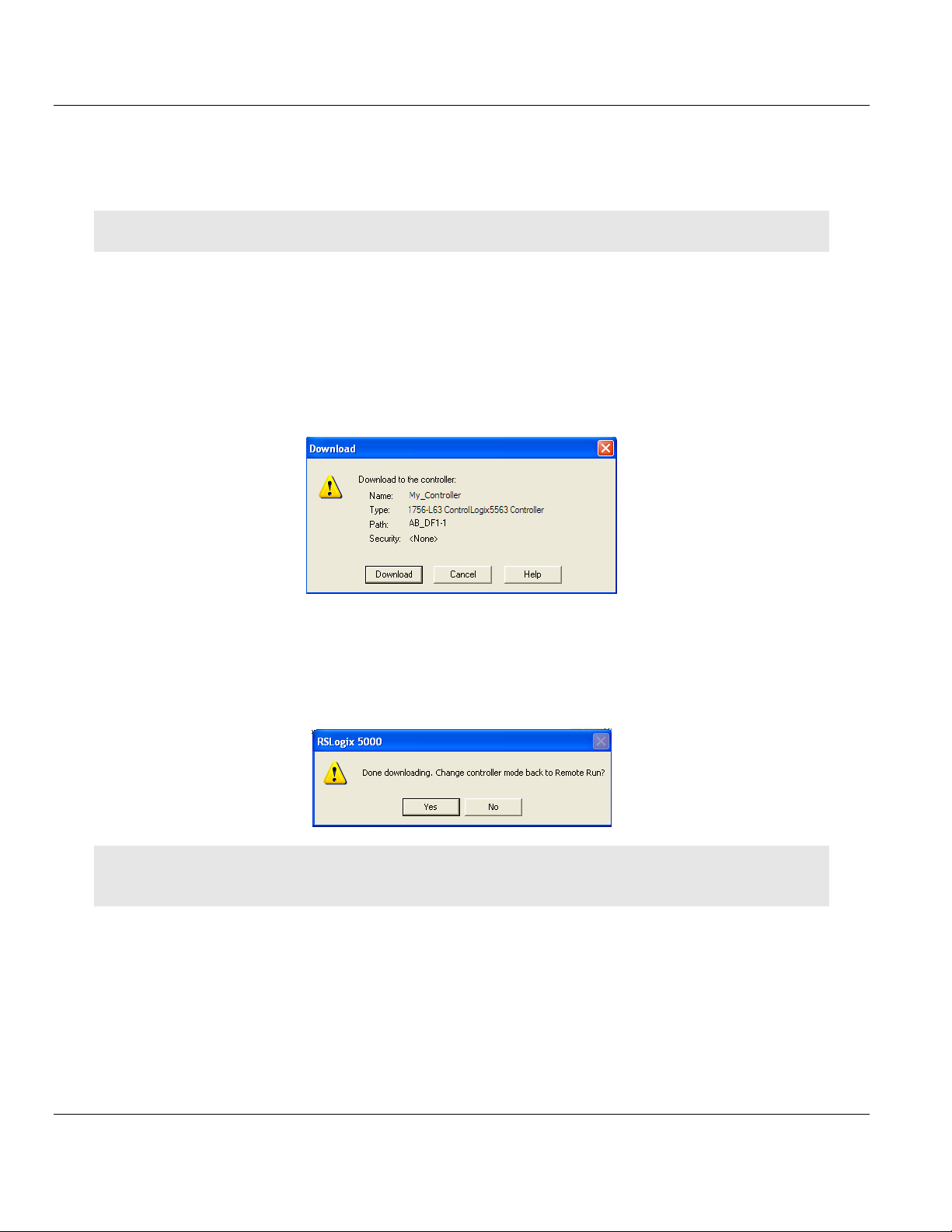

1.6 Downloading the Sample Program to the Processor

Note: The key switch on the front of the ControlLogix processor must be in the REM or PROG position.

1 If you are not already online with the processor, in RSLogix 5000 open the

Communications menu, and then choose DOWNLOAD. RSLogix 5000 will establish

communication with the processor. You do not have to download through the

processor's serial port, as shown here. You may download through any available

network connection.

2 When communication is established, RSLogix 5000 will open a confirmation dialog box.

Click the DOWNLOAD button to transfer the sample program to the processor.

3 RSLogix 5000 will compile the program and transfer it to the processor. This process

may take a few minutes.

4 When the download is complete, RSLogix 5000 will open another confirmation dialog

box. If the key switch is in the REM position, click OK to switch the processor from

PROGRAM mode to RUN mode.

Note: If you receive an error message during these steps, refer to your RSLogix documentation to interpret and

correct the error.

ProSoft Technology, Inc. Page 13 of 81

September 4, 2014

Page 14

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

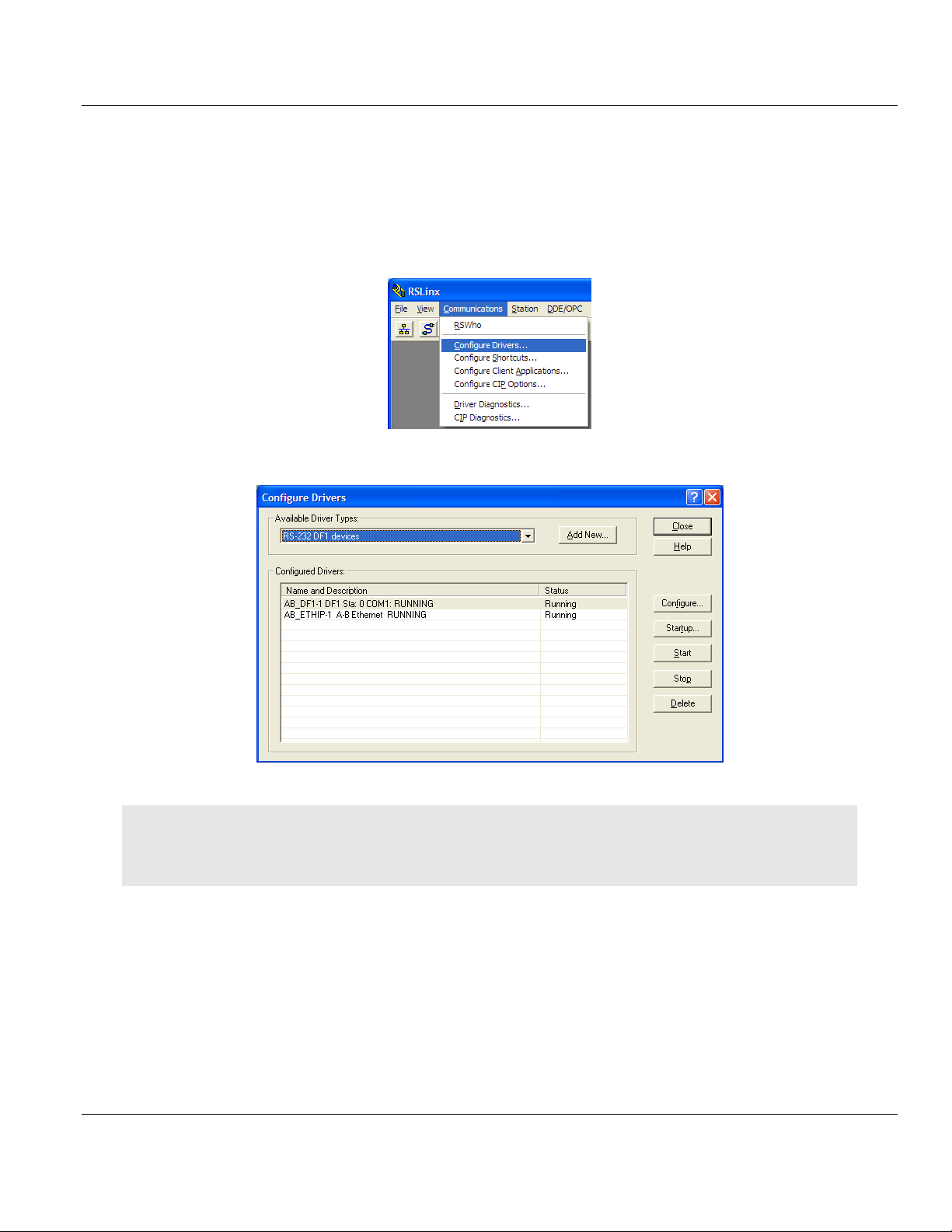

1.6.1 Configuring the RSLinx Driver for the PC COM Port

When trying to connect serially, if RSLogix is unable to establish communication with the

processor, follow these steps.

1 Open RSLinx.

2 Open the COMMUNICATIONS menu, and click CONFIGURE DRIVERS.

This action opens the Configure Drivers dialog box.

Note: If the list of configured drivers is blank, you must first choose and configure a driver from the Available

Driver Types list. The recommended driver type to choose for serial communication with the processor is RS-232

DF1 Devices.

Page 14 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 15

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

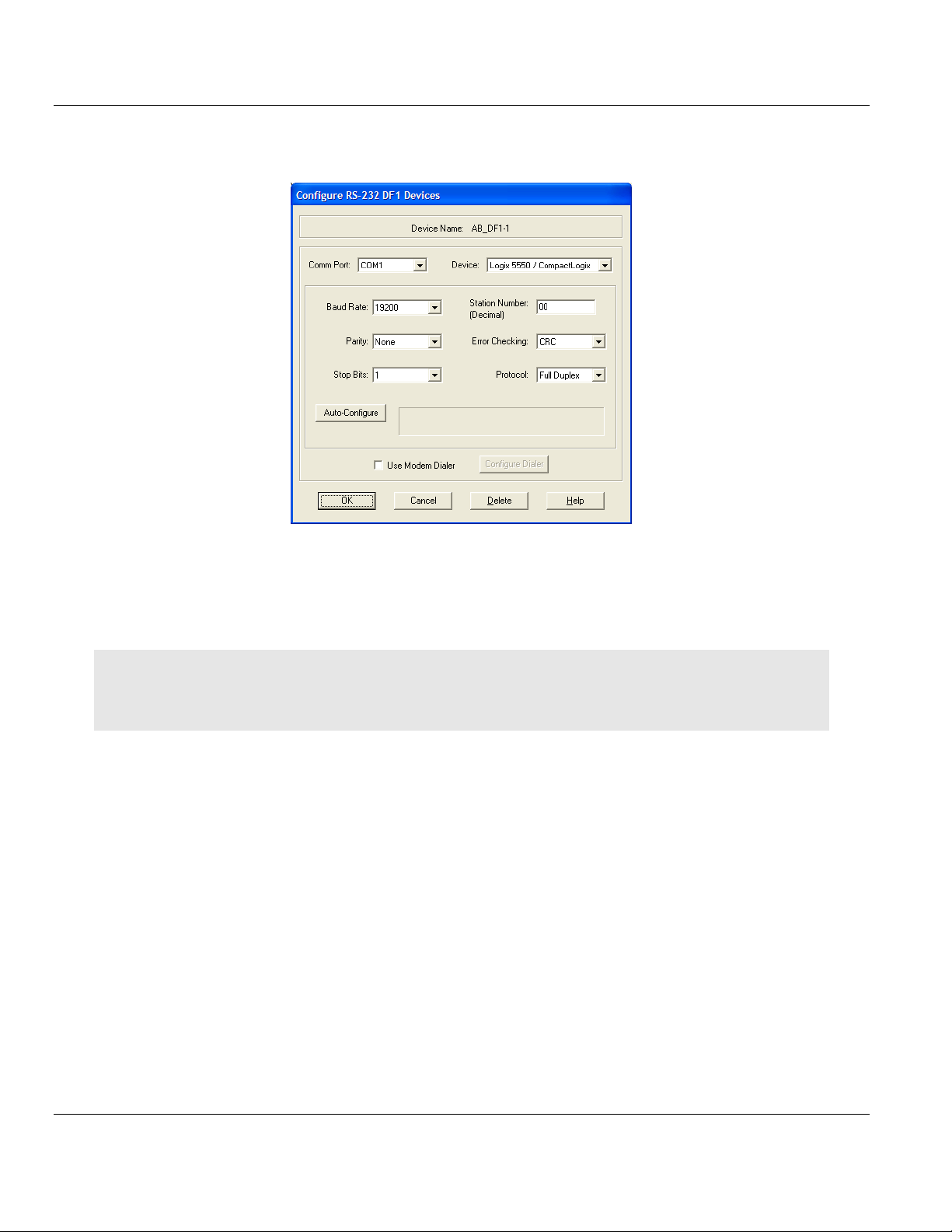

3 Click to select the driver, and then click CONFIGURE. This action opens the Configure

RS-232 DF1 Devices dialog box.

4 Click the AUTO-CONFIGURE button. RSLinx will attempt to configure your serial port to

work with the selected driver.

5 When you see the message Auto Configuration Successful, click the OK button to

dismiss the dialog box.

Note: If the auto-configuration procedure fails, verify that the cables are connected correctly between the

processor and the serial port on your computer, and then try again. If you are still unable to auto-configure the

port, refer to your RSLinx documentation for further troubleshooting steps.

ProSoft Technology, Inc. Page 15 of 81

September 4, 2014

Page 16

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

Page 16 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 17

MVI56E-61850S ♦ ControlLogix Platform Contents

In This Chapter

Installing ProSoft Configuration Builder .................................................17

Setting Up the Project ............................................................................18

IEC 61850 Server Communication Module User Manual

2 Setting Up ProSoft Configuration Builder

ProSoft Configuration Builder (PCB) software provides a convenient way to configure,

monitor, and troubleshoot your MVI56E-61850S module.

2.1 Installing ProSoft Configuration Builder

The ProSoft Configuration Builder (PCB) software is used to configure the module. You can

find the latest version of the ProSoft Configuration Builder (PCB) on our web site:

http://www.prosoft-technology.com, or you can install it from the ProSoft Solutions DVD. The

installation filename contains the PCB version number. For example,

PCB_4.1.0.4.0206.EXE.

If you are installing PCB from the ProSoft website:

1 Open a browser window and navigate to http://www.prosoft-technology.com/pcb.

2 Click the download link for ProSoft Configuration Builder, and save the file to your

Windows desktop.

3 After the download completes, double-click the file to install. If you are using Windows 7,

right-click on the PCB installation file and click RUN AS ADMINISTRATOR. Follow the

instructions that appear on the screen.

4 If you want to find additional software specific to your MVI56E-61850S, enter the model

number into the website search box and press the Enter key.

If you are installing PCB from the ProSoft Solutions DVD:

1 Insert the ProSoft Solutions DVD into your computer's DVD drive and wait for the

ProSoft Installation program to start.

2 If the ProSoft Installation program does not start, open the Windows file Explorer,

navigate to the DVD, and double-click on the ProSoft_DVD.exe file.

3 Navigate to the MVI56E-61850S selection using the PLATFORM and PRODUCT selections.

4 Click PROSOFT CONFIGURATION BUILDER.

5 Follow the instructions that appear on the screen.

ProSoft Technology, Inc. Page 17 of 81

September 4, 2014

Page 18

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

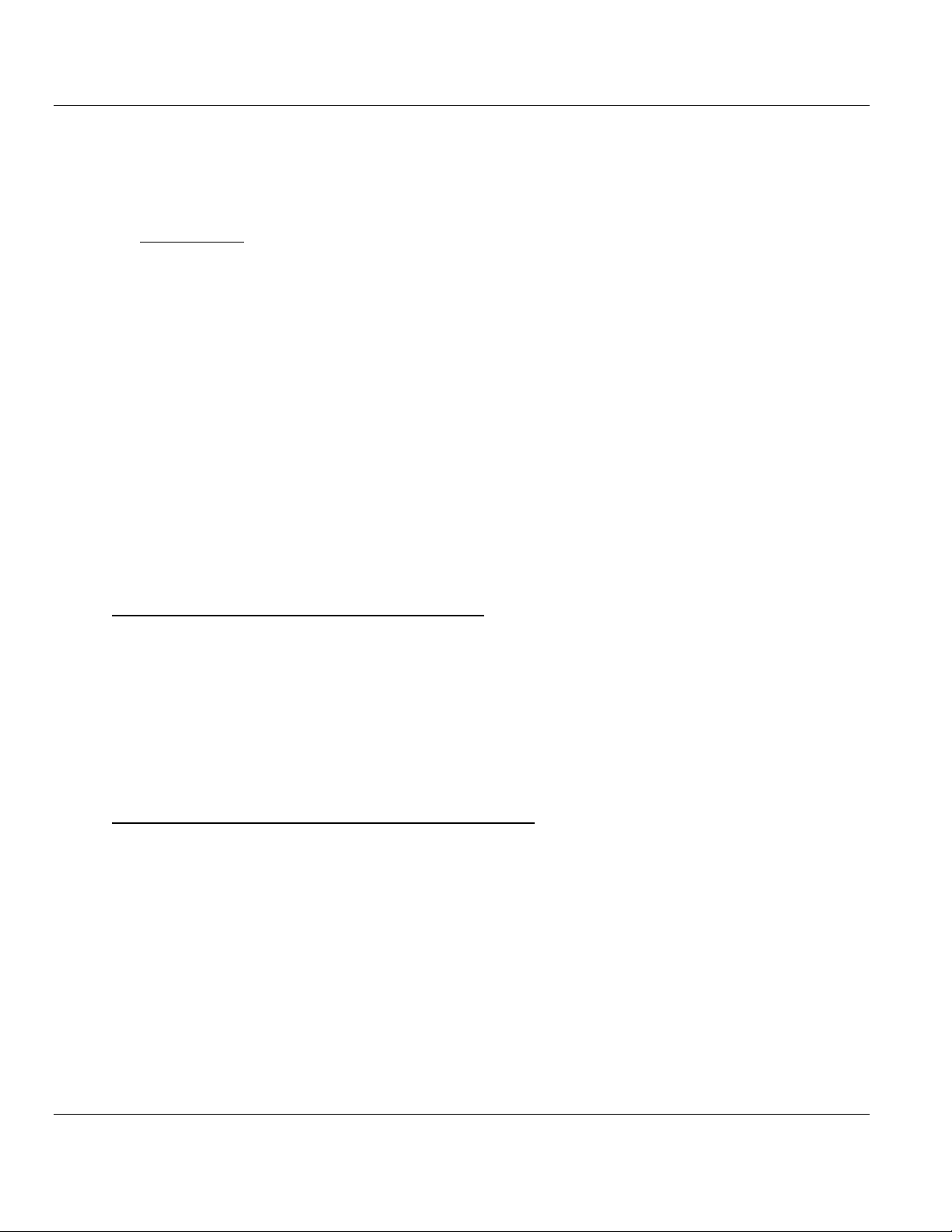

2.2 Setting Up the Project

To begin, start PROSOFT CONFIGURATION BUILDER (PCB).

If you have used other Windows configuration tools before, you will find the screen layout

familiar. PCB’s window consists of a tree view on the left, and an information pane and a

configuration pane on the right side of the window. When you first start PCB, the tree view

consists of folders for Default Project and Default Location, with a Default Module in the

Default Location folder. The following illustration shows the PCB window with a new project.

Page 18 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 19

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

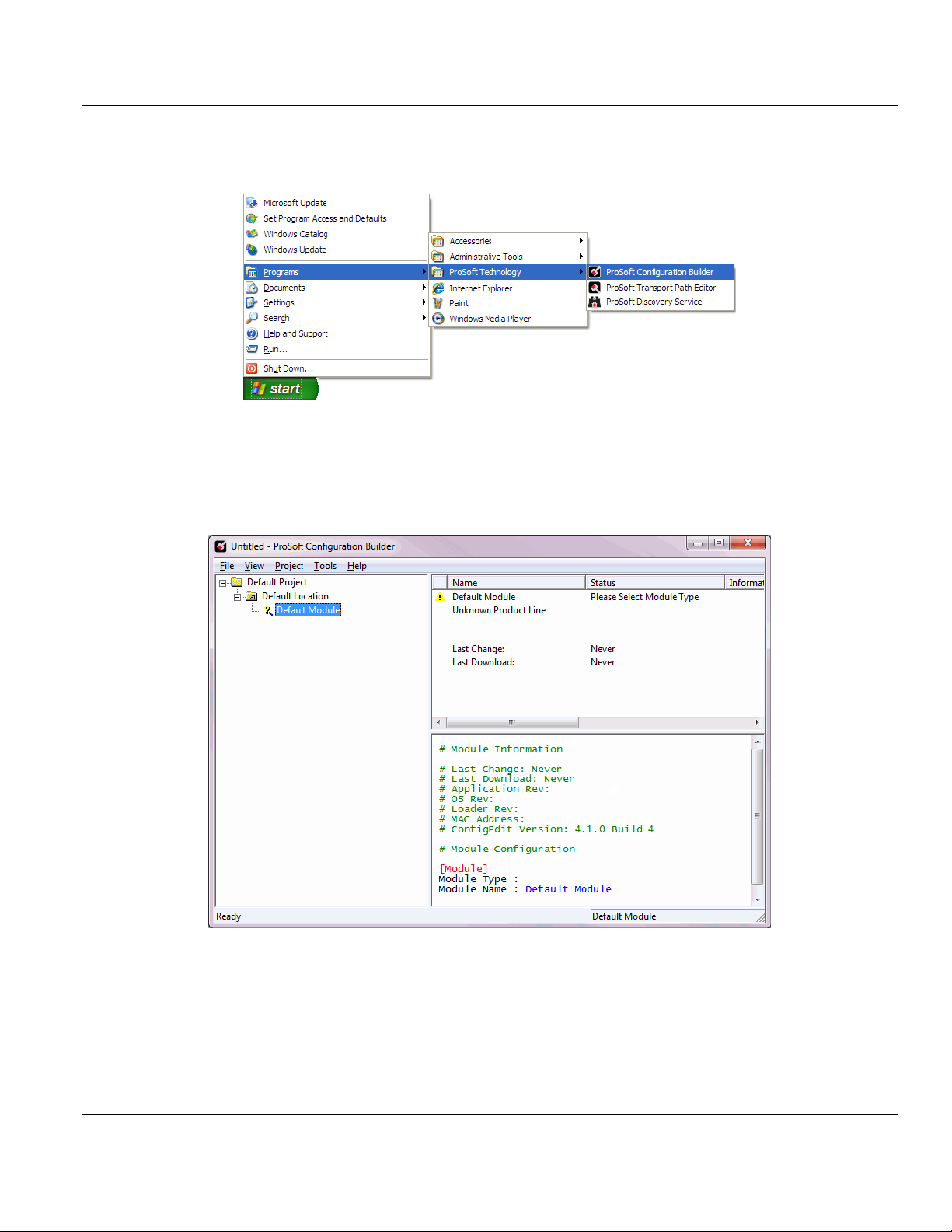

Your first task is to add the MVI56E-61850S module to the project.

1 Use the mouse to select DEFAULT MODULE in the tree view, and then click the right

mouse button to open a shortcut menu.

2 On the shortcut menu, select CHOOSE MODULE TYPE. This action opens the Choose

Module Type dialog box.

3 In the Product Line Filter area of the dialog box, select MVI56E. In the Select Module

Type dropdown list, select MVI56E-61850S, and then click OK to save your settings and

return to the ProSoft Configuration Builder window.

ProSoft Technology, Inc. Page 19 of 81

September 4, 2014

Page 20

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

Page 20 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 21

MVI56E-61850S ♦ ControlLogix Platform Contents

In This Chapter

Backplane Configuration ........................................................................22

Ethernet1 ...............................................................................................23

61850S Identification .............................................................................24

61850S Network ....................................................................................25

61850S IP Filter .....................................................................................26

61850S Data DB Configuration ..............................................................28

61850S Data SoE ..................................................................................30

61850S Data Control .............................................................................32

61850S Buffered Reports ......................................................................34

61850S Unbuffered Reports ..................................................................38

Downloading the Project to the Module .................................................42

IEC 61850 Server Communication Module User Manual

3 MVI56E-61850S Configuration

This chapter covers the MVI56E-61850S configuration within ProSoft Configuration Builder.

ProSoft Technology, Inc. Page 21 of 81

September 4, 2014

Page 22

Contents MVI56E-61850S ♦ ControlLogix Platform

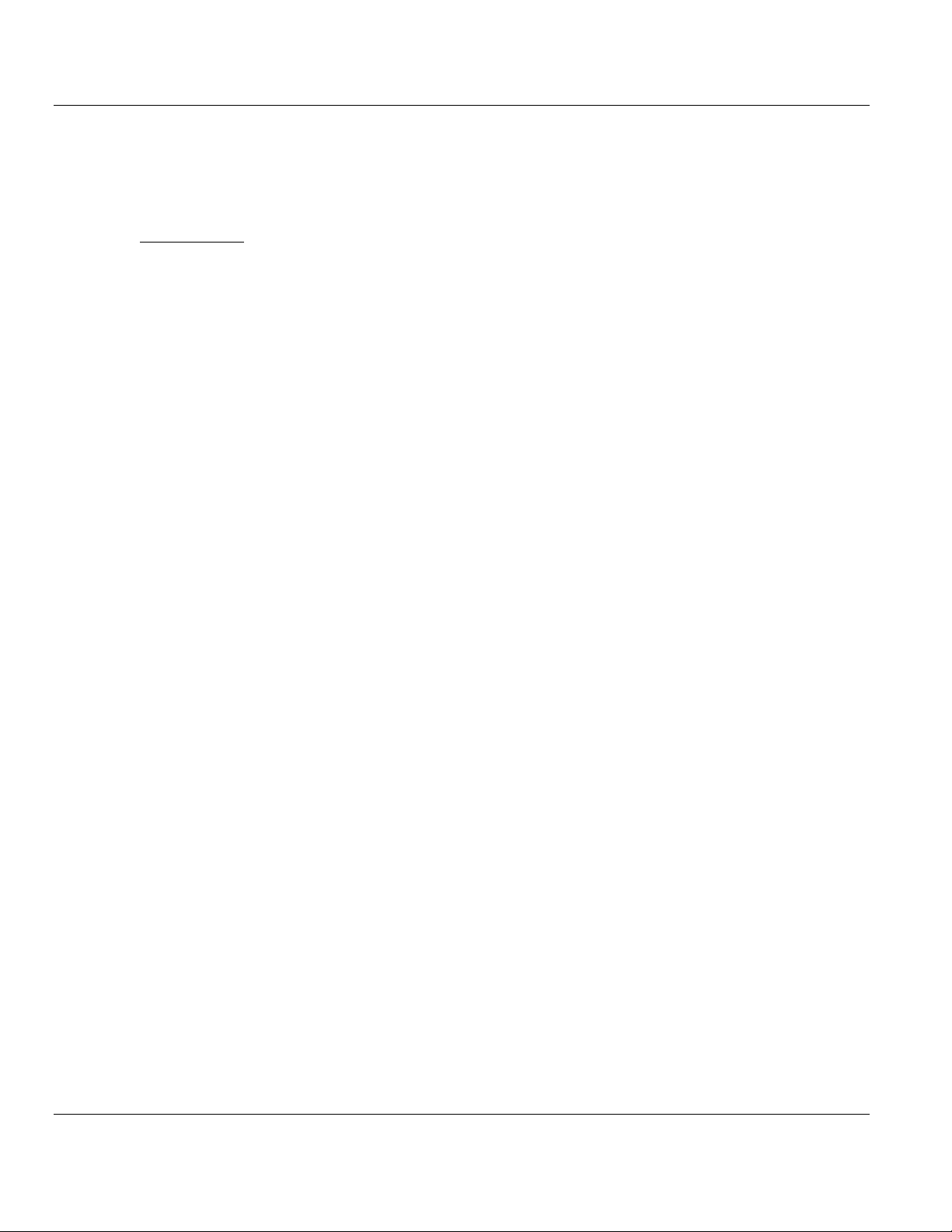

Name

Range

Description

Write Register Count

0 to 4000

For Data DB objects. Number of registers to write

from processor to module. The starting register is

0. This parameter must be set according to the

status and measured data configured through the

[61850S Data DB] section, which is transferred to

the module through the database.

Stale Database Delay

1 to 300000

-1 = Ignore

0 = No delay (issue a

stale-database event

upon detecting failure)

Minimum duration (ms) of backplane I/O failure that

causes the database to be marked stale.

Stale Database Shutdown

Yes/No

Determines whether to shut down the 61850

protocol upon a stale-database event.

User Manual IEC 61850 Server Communication Module

3.1 Backplane Configuration

This section of the configuration describes the database setup and module-level

parameters. Double-click the BACKPLANE CONFIGURATION icon to edit the parameters.

Page 22 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 23

MVI56E-61850S ♦ ControlLogix Platform Contents

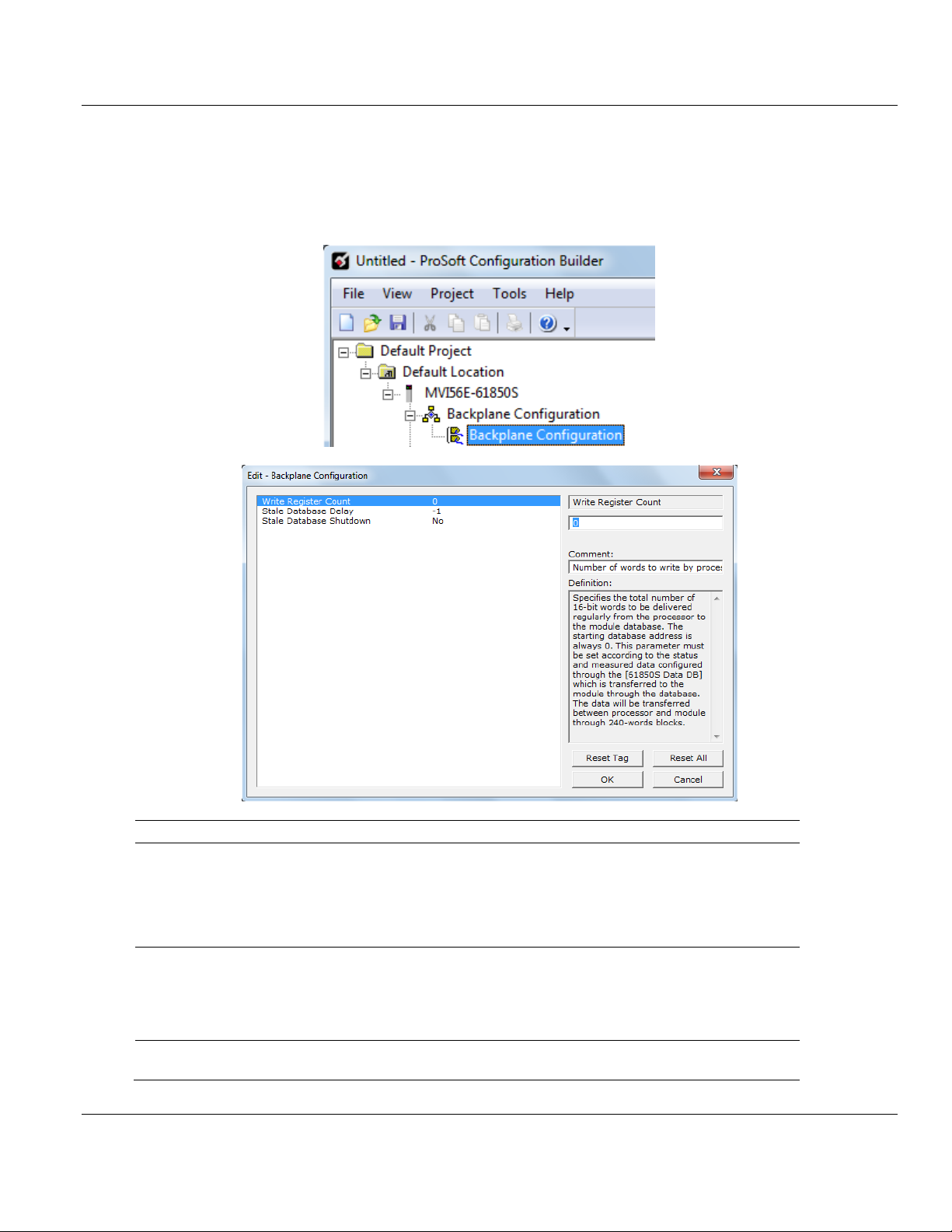

Name

Description

NIC Operation Mode

Mode in which the NIC negotiates a datalink

0 = Auto-negotiate

1 = 10MB/half-duplex

2 = 10MB/full-duplex

3 = 100MB/half-duplex

4 = 100MB/full-duplex

IP Address

Default private class 3 address

Netmask

Default class 3 network mask

Gateway

Default gateway to another network

IEC 61850 Server Communication Module User Manual

3.2 Ethernet1

In this step, you assign an IP address for the MVI56E-61850S module. This becomes the

permanent IP address for the module after you download the configuration to the module.

The module’s default IP address is 192.168.0.250. Determine the network settings for your

module, with the help of your network administrator if necessary.

o IP address (fixed IP required) _____ . _____ . _____ . _____

o Subnet mask _____ . _____ . _____ . _____

o Gateway address _____ . _____ . _____ . _____

Note: The gateway address is optional, and is not required for networks that do not use a default gateway.

Double-click the ETHERNET1 icon to edit the parameters.

ProSoft Technology, Inc. Page 23 of 81

September 4, 2014

Page 24

Contents MVI56E-61850S ♦ ControlLogix Platform

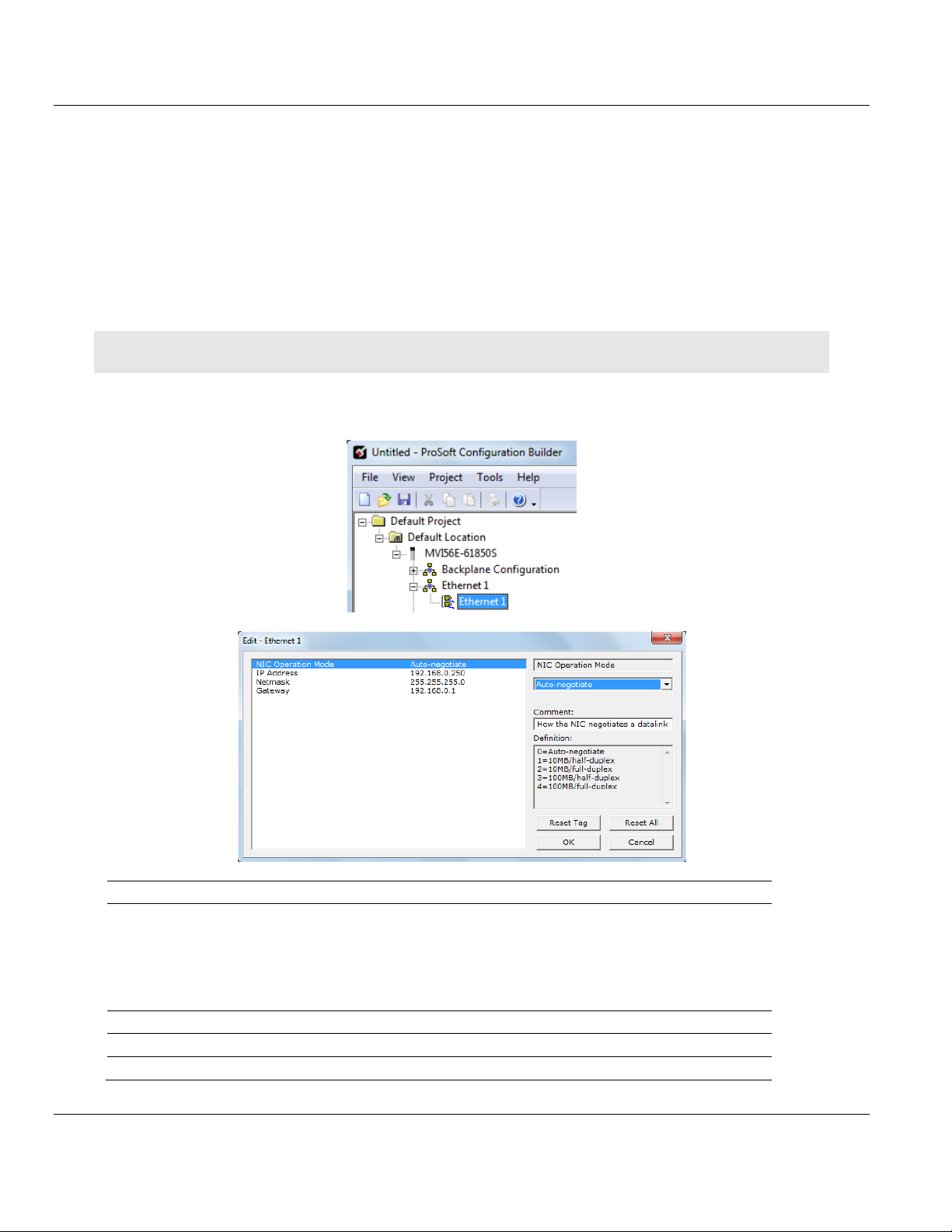

Name

Description

configVersion

Version of the configuration. It should match attribute "configVersion" of CID's "IED"

element

IED Name

Name of this IED, which must be unique over all IEDs

configRev

Uniquely identifies the configuration the IED. Mapped 61850 to data attribute

LLN0$DC$NamPlt$configRev

Subnet Name

Name of the station "subnetwork" on which this IED resides; meaningful only for SCD files

User Manual IEC 61850 Server Communication Module

3.3 61850S Identification

This section allows you to assign unique IED identification parameters to the module.

Double-click the 61850S IDENTIFICATION icon to edit the parameters.

Page 24 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 25

MVI56E-61850S ♦ ControlLogix Platform Contents

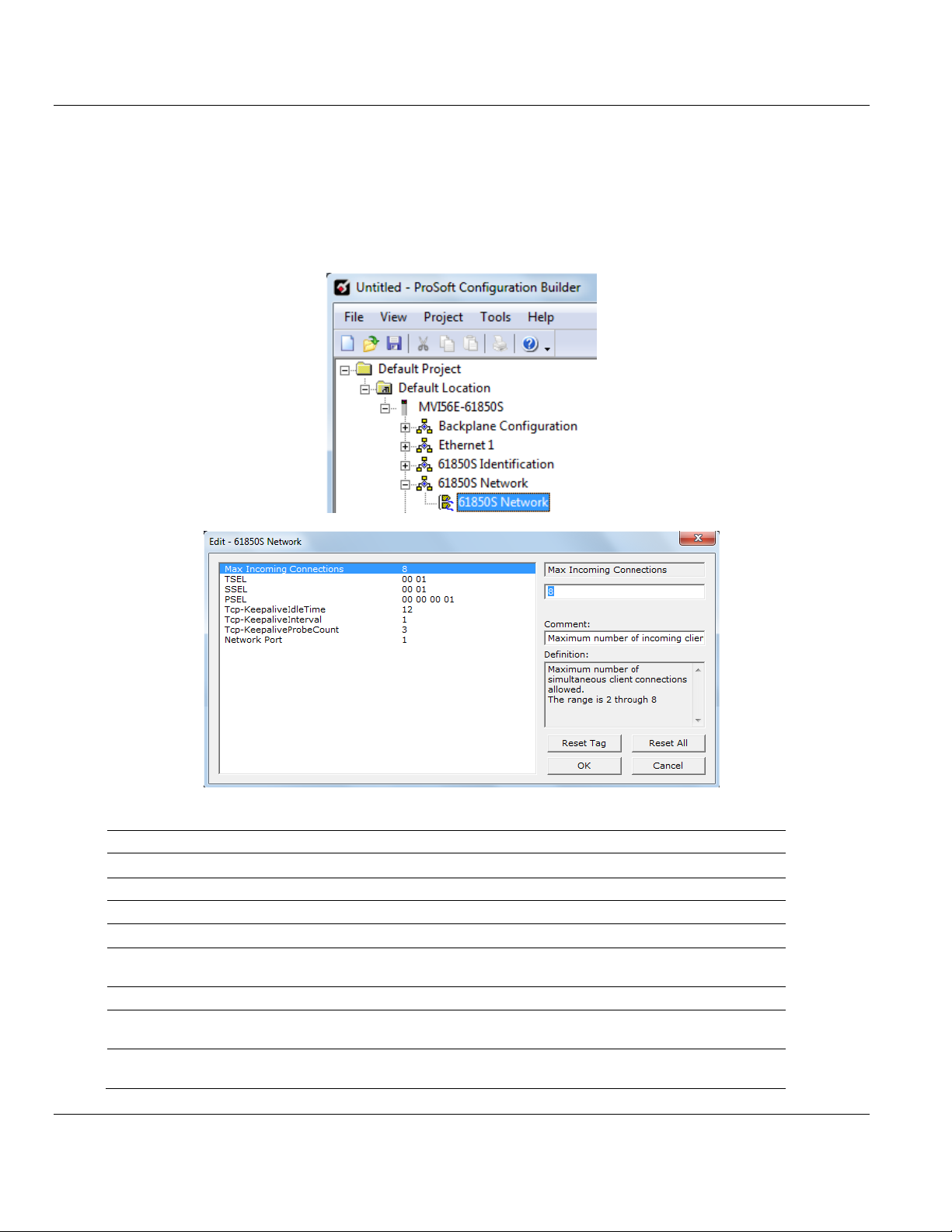

Name

Range

Description

Max Incoming Connections

2 to 8

Maximum number of simultaneous client connections allowed.

TSEL

Transport Selector

SSEL

Session Selector

PSEL

Presentation Selector

Tcp-KeepaliveIdleTime

1 to 60

Maximum TCP-connection idle time before beginning keepalive probes, in seconds.

Tcp-KeepaliveInterval

1 to 60

Interval between failed keep-alive probes, in seconds.

Tcp-KeepaliveProbeCount

1 to 9

Number of consecutive failed keep-alive probes causing

connection to be deemed broken

Network Port

1

This number selects the physical Ethernet interface to be used

for the 61850 protocol. This value cannot be changed.

IEC 61850 Server Communication Module User Manual

3.4 61850S Network

This section allows you to set the parameters on incoming IEC 61850 client connections.

Double-click the 61850S NETWORK icon to edit the parameters.

ProSoft Technology, Inc. Page 25 of 81

September 4, 2014

Page 26

Contents MVI56E-61850S ♦ ControlLogix Platform

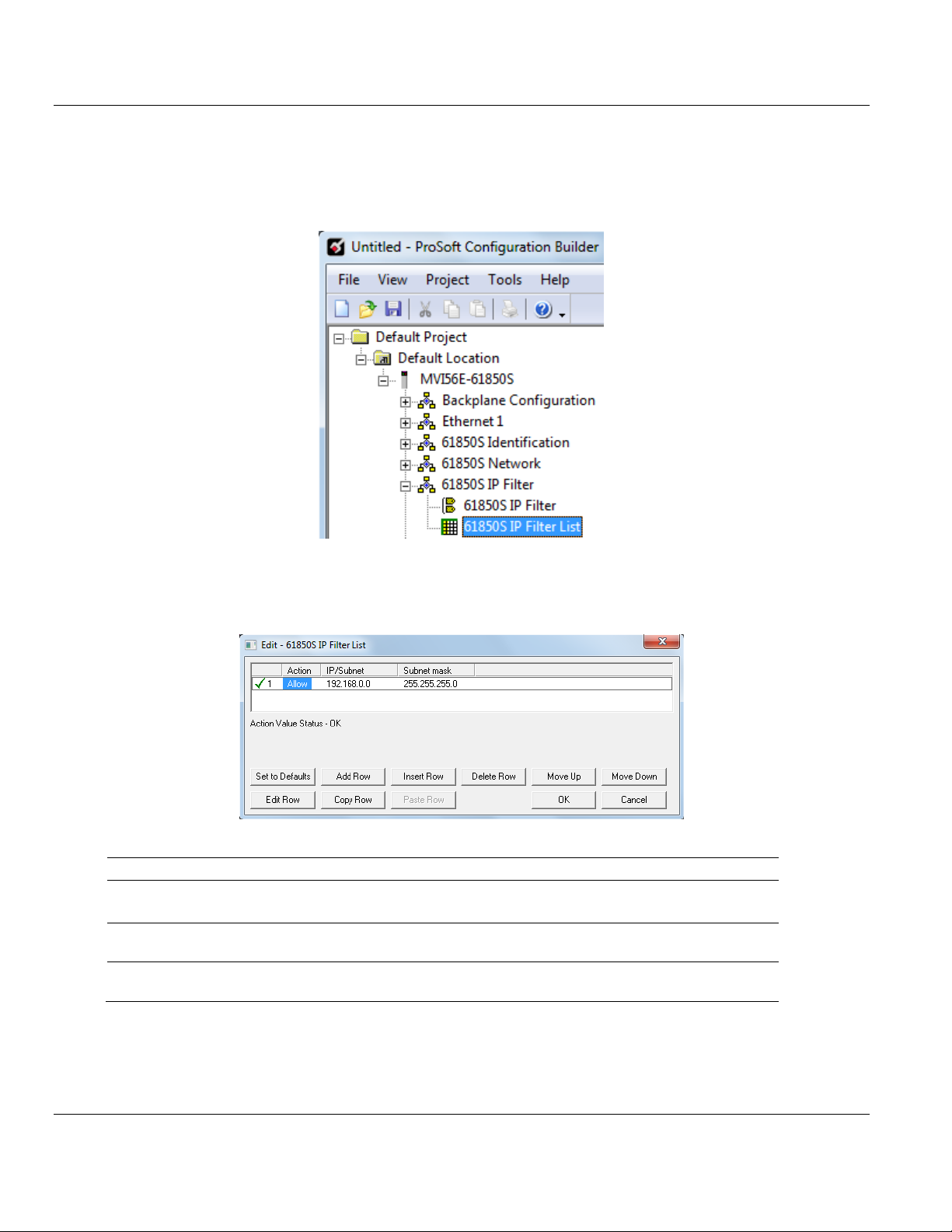

Name

Range

Description

Enable IP Filter

Yes/No

Enables control of the remote client access based on its IP

address.

IP Filter Type

Whitelist/Blacklist

Whitelist denies all IPs except those IPs or subnets listed as

allowed in IP Filter List.

Blacklist allows all IPs except those listed as denied in IP Filter List.

User Manual IEC 61850 Server Communication Module

3.5 61850S IP Filter

This section allows you to create a whitelist or blacklist to allow/deny outside IP address

connections.

Double-click the 61850S IP FILTER icon to edit the parameters.

Page 26 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 27

MVI56E-61850S ♦ ControlLogix Platform Contents

Name

Range

Description

Action

Allow/Deny

Select Allow for allowed IP or subnet for Whitelist filter type.

Select Deny for denied IP or subnet for Blacklist filter type.

IP/Subnet

Enter an IPv4 address or subnet in standard dotted notation. The

candidate IP matches this entry if it matches this IP or subnet.

Subnet mask

Enter an IPv4 subnet mask in standard dotted notation. The candidate

IP and the IP/subnet match if they are the same under this mask.

IEC 61850 Server Communication Module User Manual

If the IP Filter is enabled, you will need to configure the IP addresses to be filtered.

1 Double-click the 61850S IP FILTER LIST icon.

2 Click ADD ROW then EDIT ROW to enter the IP address information.

ProSoft Technology, Inc. Page 27 of 81

September 4, 2014

Page 28

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

3.6 61850S Data DB Configuration

This section allows you to configure DB data objects (DO's) for the MVI56E-61850S. This

data will be updated to the module from the processor.

1 Double-click the 61850S DATA DB icon to open the configuration window.

2 Click ADD ROW then EDIT ROW to edit.

Page 28 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 29

MVI56E-61850S ♦ ControlLogix Platform Contents

Name

Description

Data Object

This value identifies the 61850 data object (DO) instantiated from a 61850 CDC to

which the data point is mapped.

The data object number has to be set within a specific range according to its data type:

BOOL: 100000 to 109999

SINT: 200000 to 209999

INT: 210000 to 219999

DINT: 220000 to 229999

REAL: 300000 to 309999

FLOATDB: 350000 to 359999 (50 points maximum)

Data Type

Type of the data as it resides in the internal database.

BOOL: Boolean / Bit

SINT: (Signed-8 bits) / Byte

INT: (Signed-16 bits) / Word

DINT: (Signed-32 bits) / Double word

REAL: (32-bit floating) / Double word

FLOATDB: (32-bit floating) / Double word deadbanded

DB Value Offset

The offset of the data point value in the internal database. The database addressing

value is interpreted according to the data type as follows:

BOOL: Boolean addressing

SINT: Byte addressing

INT: Word addressing

DINT: Double-word addressing

REAL: Double-word addressing

FLOATDB: Double-word addressing

Specify -1 if the associated status data attribute is not to be mapped.

DB Quality Offset

The offset (in bytes) of the corresponding quality byte in the internal database, which

must reside in the same backplane block (240-word block) as the status value itself.

The database is transferred from the processor to the module in blocks of 240 words.

As the quality information is tightly linked to the actual status value data, the module

must receive them both simultaneously in order for them both to be correctly

processed. If the status point has no associated quality information in the processor,

therefore no quality byte is to be delivered, specify as -1.

Min

*Only applicable for FLOATDB type.

The minimum valid value of the instantaneous analog value, delivered from the

processor to the 61850 data attribute. If the received status value from processor is less

than configured minimum value, the module will set the Out of Range quality flag.

Max

*Only applicable for FLOATDB type.

The maximum valid value of the instantaneous analog value, delivered from the

processor to the 61850 data attribute. If the received status value from processor is

greater than configured maximum value, the module will set the Out of Range quality

flag.

Deadband Width

*Only applicable for FLOATDB type.

The deadband width, as parts per 100,000 of the extent "Max"-"Min" of the valid range.

The actual width, in the engineering units of the analog input is set by: DbWdth *

[(Max-Min)/100000]

Comment

Comments cannot be edited

IEC 61850 Server Communication Module User Manual

ProSoft Technology, Inc. Page 29 of 81

September 4, 2014

Page 30

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

3.7 61850S Data SoE

This section allows you to configure SoE data objects (DO's) for the MVI56E-61850S. This

data will be updated to the module from the processor.

1 Double-click the 61850S DATA SOE icon to open the configuration window.

2 Click ADD ROW then EDIT ROW to edit.

Page 30 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 31

MVI56E-61850S ♦ ControlLogix Platform Contents

Name

Description

Data Object

This value identifies the 61850 data object (DO) instantiated from a 61850 CDC to

which the data point is mapped. The data object number has to be set within a specific

range according to its data type:

BOOL: 400000 to 409999

SINT: 500000 to 509999

INT: 510000 to 519999

DINT: 520000 to 529999

REAL: 600000 to 609999

FLOATDB: 650000 to 659999 (50 points maximum)

Data Type

Type of the data as it resides in the internal database.

BOOL: Boolean / Bit

SINT: (Signed-8 bits) / Byte

INT: (Signed-16 bits) / Word

DINT: (Signed-32 bits) / Double word

REAL: (32-bit floating) / Double word

FLOATDB: (32-bit floating) / Double word deadbanded

Point ID

Unique identifier for the SoE point in the processor. It is a 16-bit value.

Min

*Only applicable for FLOATDB type.

The minimum valid value of the instantaneous analog value, delivered from the

processor to the 61850 data attribute. If the received status value from processor is less

than configured minimum value, the module will set the Out of Range quality flag.

Max

*Only applicable for FLOATDB type.

The maximum valid value of the instantaneous analog value, delivered from the

processor to the 61850 data attribute. If the received status value from processor is

greater than configured maximum value, the module will set the Out of Range quality

flag.

Deadband Width

*Only applicable for FLOATDB type.

The deadband width, as parts per 100,000 of the extent "Max"-"Min" of the valid range.

The actual width, in the engineering units of the analog input is set by: DbWdth *

[(Max-Min)/100000]

Comment

Comments cannot be edited

IEC 61850 Server Communication Module User Manual

ProSoft Technology, Inc. Page 31 of 81

September 4, 2014

Page 32

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

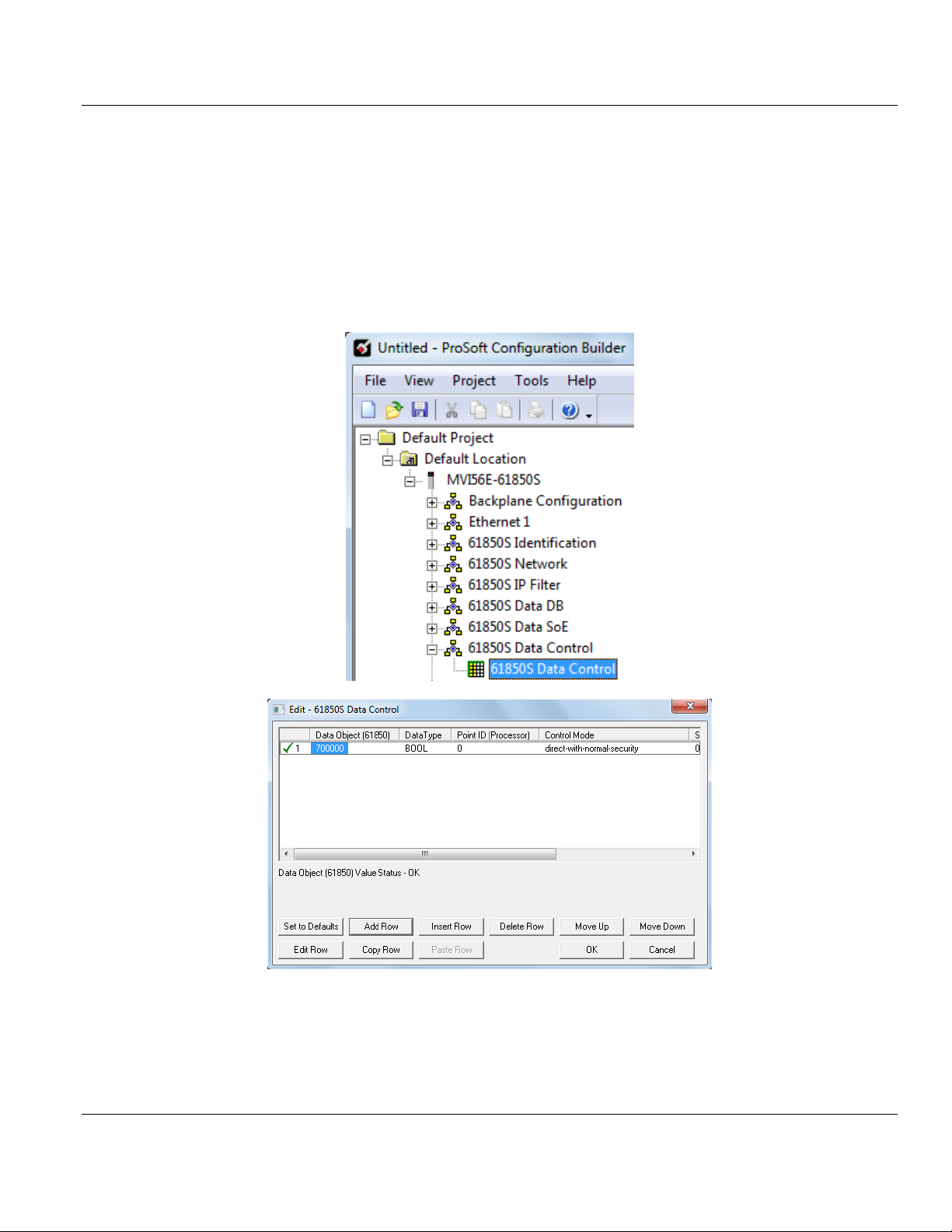

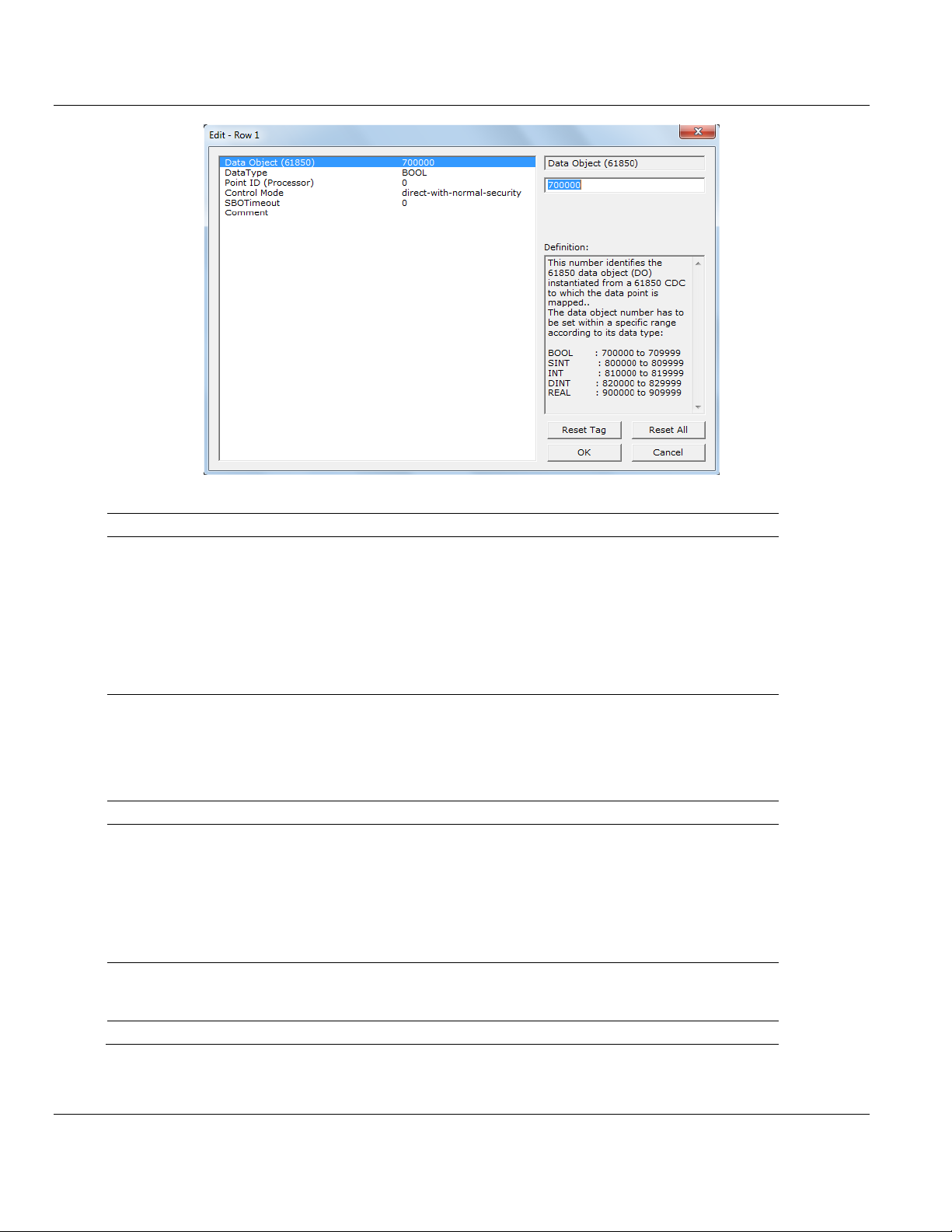

3.8 61850S Data Control

This section allows you to you to configure Control data objects (DO's) for the MVI56E61850S. Control data originates from an IEC 61850 client. The module passes this data to

the processor where it is acknowledged. This processor-acknowledged data is updated back

to the module for a handshake back to the client.

1 Double-click the 61850S DATA CONTROL icon to open the configuration window.

2 Click ADD ROW then EDIT ROW to edit.

Page 32 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 33

MVI56E-61850S ♦ ControlLogix Platform Contents

Name

Description

Data Object

This value identifies the 61850 data object (DO) instantiated from a 61850 CDC to

which the data point is mapped.

The data object number has to be set within a specific range according to its data

type:

BOOL: 700000 to 709999

SINT: 800000 to 809999

INT: 810000 to 819999

DINT: 820000 to 829999

REAL: 900000 to 909999

Data Type

Type of the data as it resides in the internal database.

BOOL: Boolean / Bit

SINT: (Signed-8 bits) / Byte

INT: (Signed-16 bits) / Word

DINT: (Signed-32 bits) / Double word

REAL: (32-bit floating) / Double word

Point ID

Unique identifier for the Control point in the processor. It is a 16-bit value.

Control Mode

A code that selects the 61850 control mode according to IEC61850 specification:

Direct-with-normal-security

Sbo-with-normal-security, operate-once

Sbo-with-normal-security, operate-many

Direct-with-enhanced-security

Sbo-with-enhanced-security, operate-once

Sbo-with-enhanced-security, operate-many

SBO Timeout

*Only applicable for SBO control mode

The timeout in milliseconds for the control object to remain selected without receiving

an Oper or Cancel request

Comment

Comments cannot be edited

IEC 61850 Server Communication Module User Manual

ProSoft Technology, Inc. Page 33 of 81

September 4, 2014

Page 34

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

3.9 61850S Buffered Reports

A buffered report logs the changes in data if the IEC 61850 client/server connection has

been lost. Once the connection has be re-established, the report can be sent upon

condition.

1 Double-click the 61850S BUFFERED REPORTS icon to open the configuration window.

2 Double-click on the row to be edited.

Page 34 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 35

MVI56E-61850S ♦ ControlLogix Platform Contents

Name

Range

Description

Max Instances

0 to 8

Maximum number of instantiations of this RCB. The matching

Report Control element is generated only if this value is nonzero.

This number should reflect the number of clients associated to

this report.

The total sum of all values in this column over all lines must not

exceed 8.

Integrity Period

0 to 2,147,483,647

The integrity period for this report in milliseconds, at which the

module will send the report to the client associated to this report.

This value may be overridden by the 61850 client during the

report-enable sequence.

0 = Disabled

ConfRev

0 to 2,147,483,647

Number of reconfigurations of the report's associated dataset

Buffer Time

0 to 65535

Maximum amount of time, in milliseconds, that buffered events

will be held pending before being reported.

Comment

User defined

IEC 61850 Server Communication Module User Manual

ProSoft Technology, Inc. Page 35 of 81

September 4, 2014

Page 36

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

3.9.1 61850S BR0x Dataset

This section allows you to set up datasets for data objects for buffered reports.

1 Double-click the 61850S BR0X DATASET icon to open the configuration window.

2 Click ADD ROW then EDIT ROW to edit.

Page 36 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 37

MVI56E-61850S ♦ ControlLogix Platform Contents

Name

Description

Data Object

Instance

This value identifies the 61850 data object (DO) number already configured at

"DATA DB" or SoE sections that will be included in this dataset.

Comment

User defined

IEC 61850 Server Communication Module User Manual

ProSoft Technology, Inc. Page 37 of 81

September 4, 2014

Page 38

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

3.10 61850S Unbuffered Reports

An unbuffered report logs a change in data if the IEC 61850 client/server connection has

been lost. Once the connection has be re-established, only the last reported data change

will be sent.

1 Double-click the 61850S UNBUFFERED REPORTS icon to open the configuration window.

2 Double-click on the row to be edited.

Page 38 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 39

MVI56E-61850S ♦ ControlLogix Platform Contents

Name

Range

Description

Max Instances

0 to 8

Maximum number of instantiations of this RCB. The matching

Report Control element is generated only if this value is nonzero.

This number should reflect the number of clients associated to

this report.

The total sum of all values in this column over all lines must

not exceed 8.

Integrity Period

0 to 2,147,483,647

The integrity period for this report in milliseconds, at which the

module will send the report to the client associated to this

report.

This value may be overridden by the 61850 client during the

report-enable sequence.

0 = Disabled

ConfRev

0 to 2,147,483,647

Number of reconfigurations of the report's associated dataset

Buffer Time

0 to 65535

Maximum amount of time, in milliseconds, that buffered events

will be held pending before being reported.

Comment

User defined

IEC 61850 Server Communication Module User Manual

ProSoft Technology, Inc. Page 39 of 81

September 4, 2014

Page 40

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

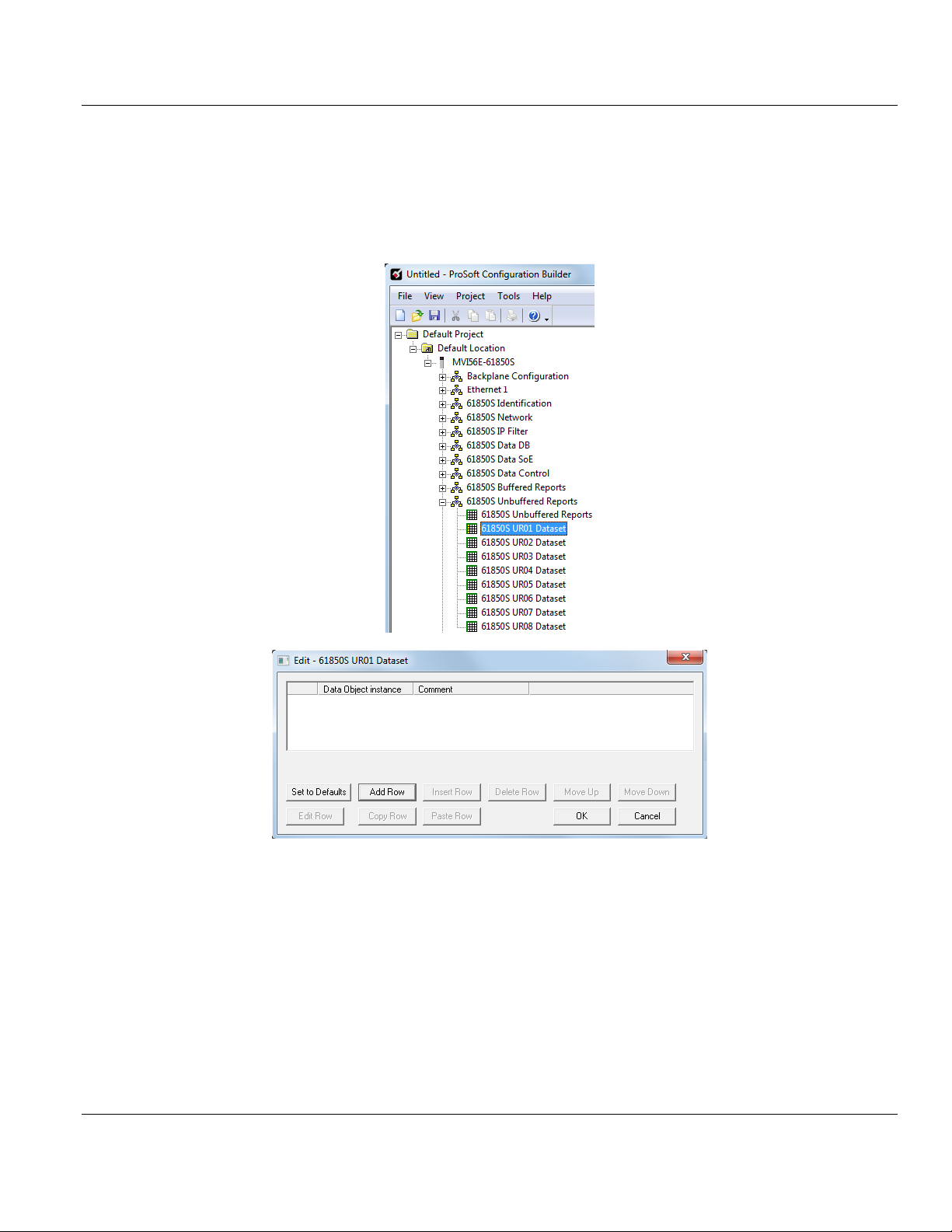

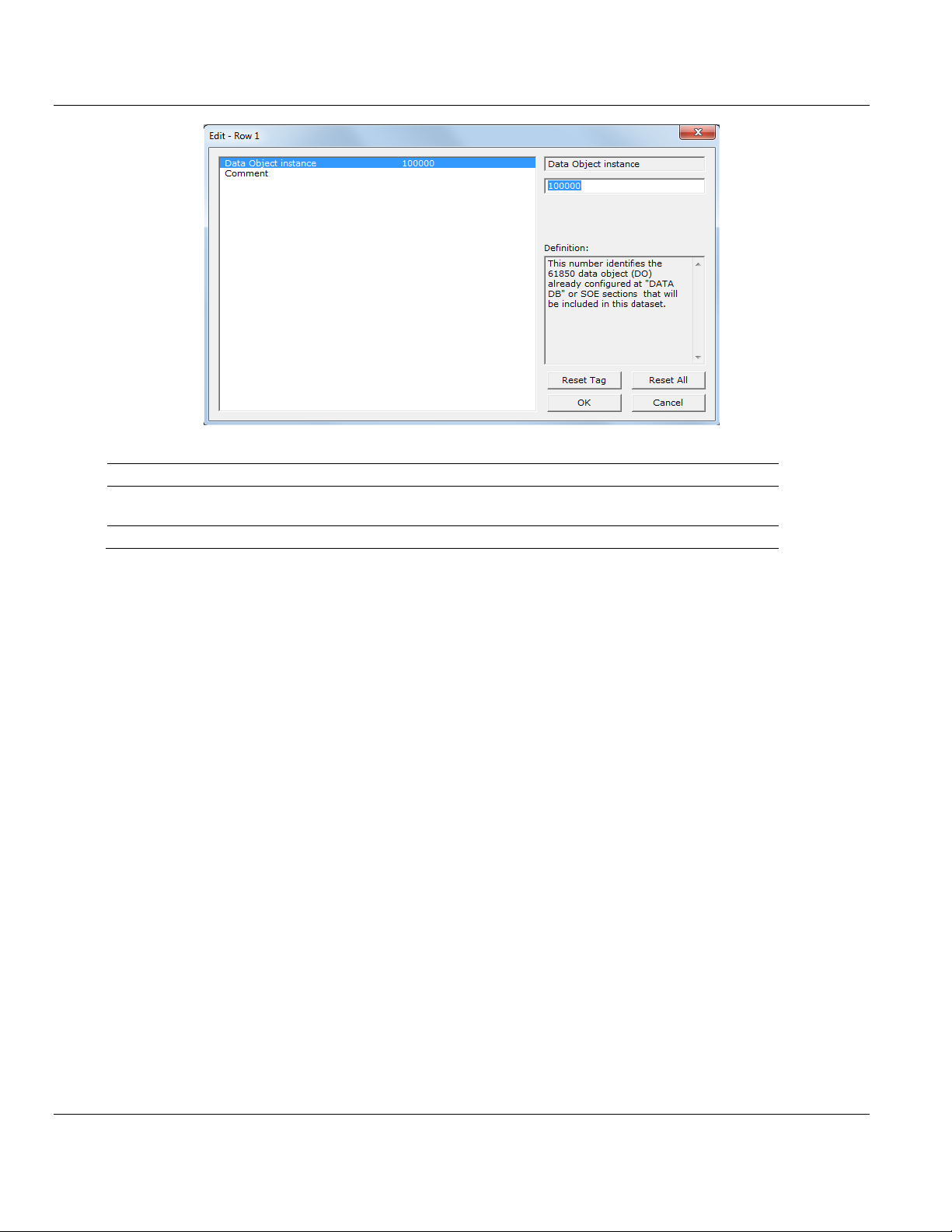

3.10.1 61850S UR0x Dataset

This section allows you to set up datasets for data objects for unbuffered reports.

1 Double-click the 61850S BR0X DATASET icon to open the configuration window.

2 Click ADD ROW then EDIT ROW to edit.

Page 40 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 41

MVI56E-61850S ♦ ControlLogix Platform Contents

Name

Description

Data Object

Instance

This value identifies the 61850 data object (DO) number already configured at

"DATA DB" or SoE sections that will be included in this dataset.

Comment

User defined

IEC 61850 Server Communication Module User Manual

ProSoft Technology, Inc. Page 41 of 81

September 4, 2014

Page 42

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

3.11 Downloading the Project to the Module

In order for the module to use the settings you configured, you must download (copy) the

updated Project file from your PC to the module.

1 In the tree view in ProSoft Configuration Builder, right-click the MVI56E-61850S icon to

open a shortcut menu.

2 Choose DOWNLOAD FROM PC TO DEVICE. This opens the Download dialog box.

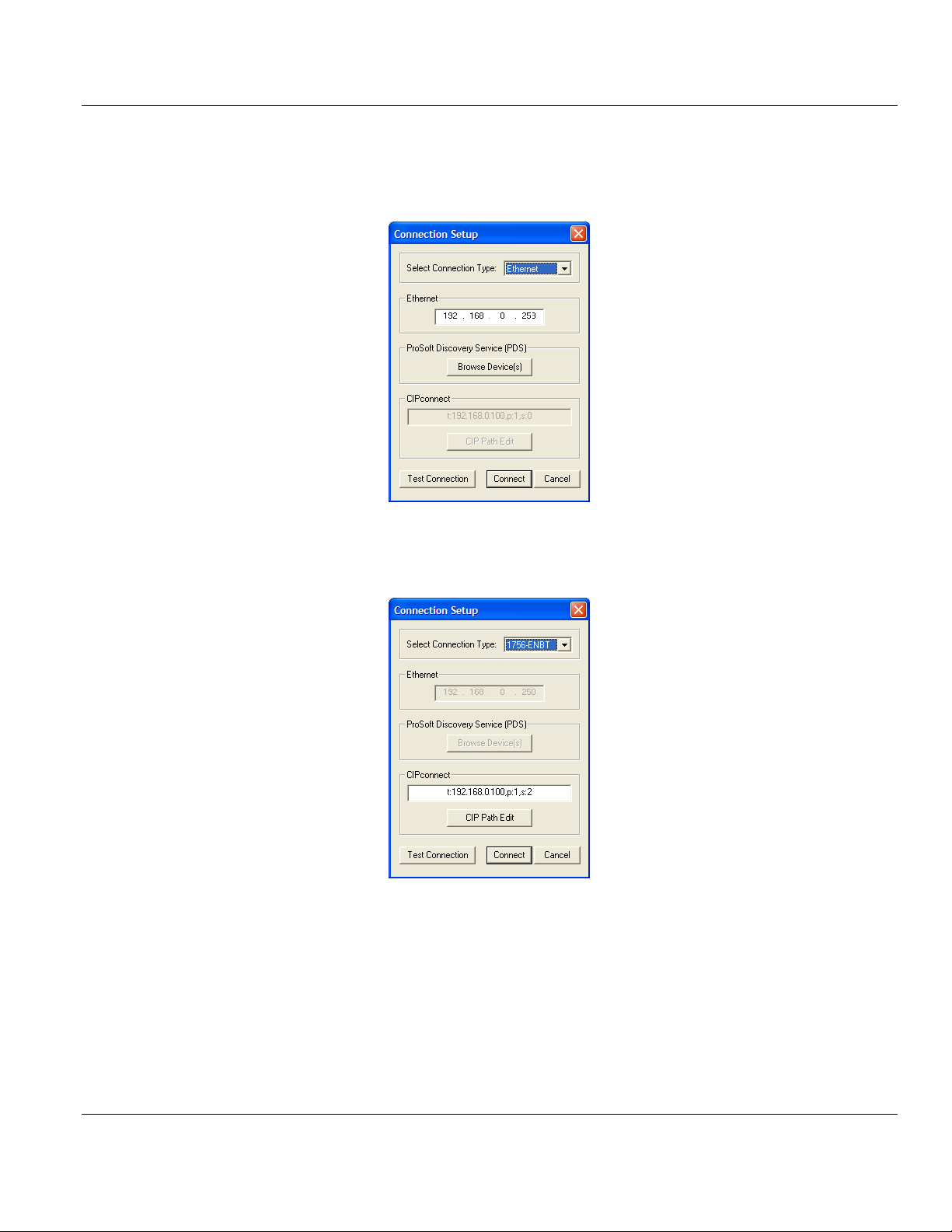

3 In the Download dialog box, choose the connection type in the Select Connection Type

dropdown box:

o Choose ETHERNET if you are connecting to the module through the Ethernet cable.

o Choose 1756 ENBT if you are connecting to the module through CIPconnect or

RSWho.

Refer to Connecting Your PC to the Module's Ethernet Port (Page 44) for more

information.

Note: If you connected to the module using an Ethernet cable and set a temporary IP address, the Ethernet

address field contains that temporary IP address. ProSoft Configuration Builder uses this temporary IP address

to connect to the module.

4 Click TEST CONNECTION to verify that the IP address allows access to the module.

5 If the connection succeeds, click DOWNLOAD to transfer the Ethernet configuration to the

module.

Page 42 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 43

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

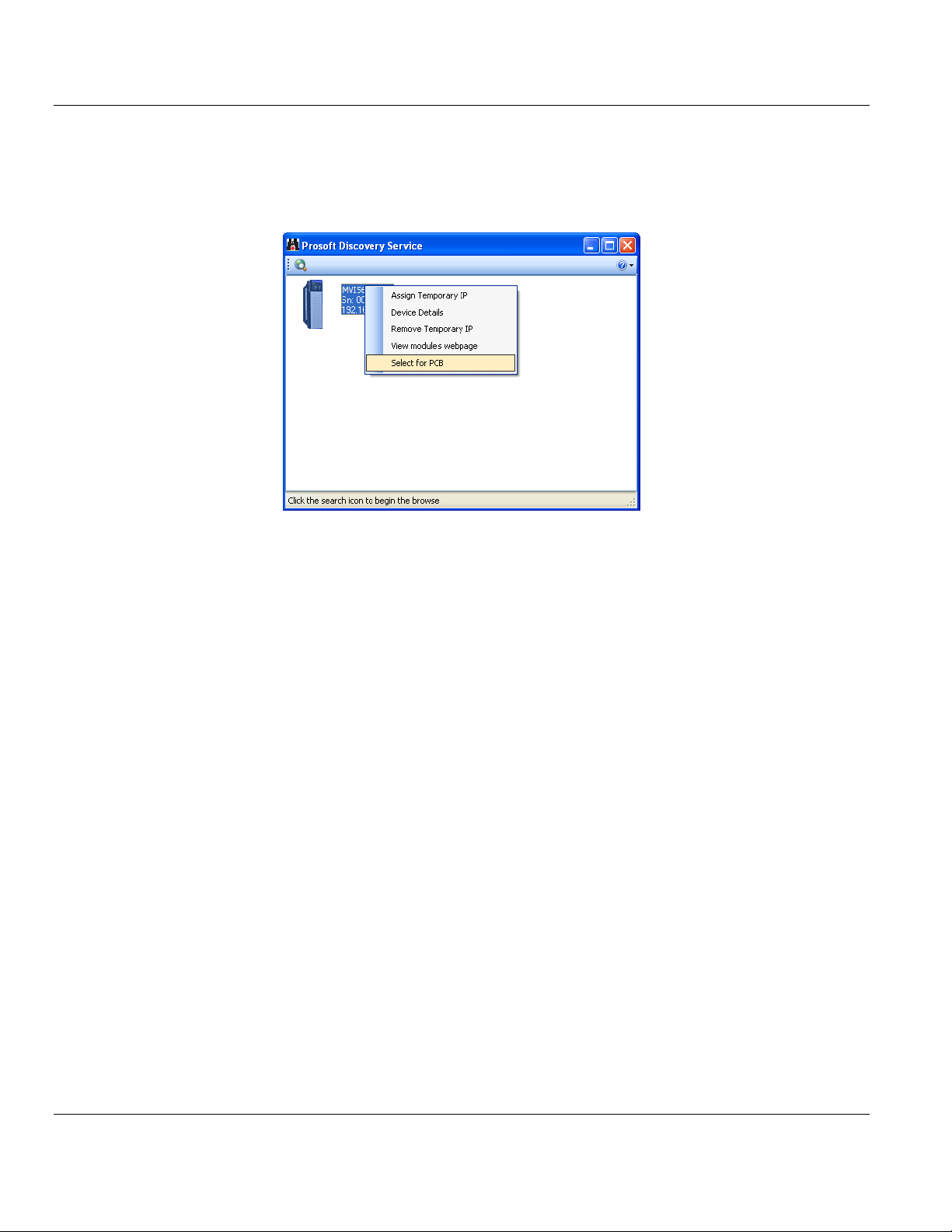

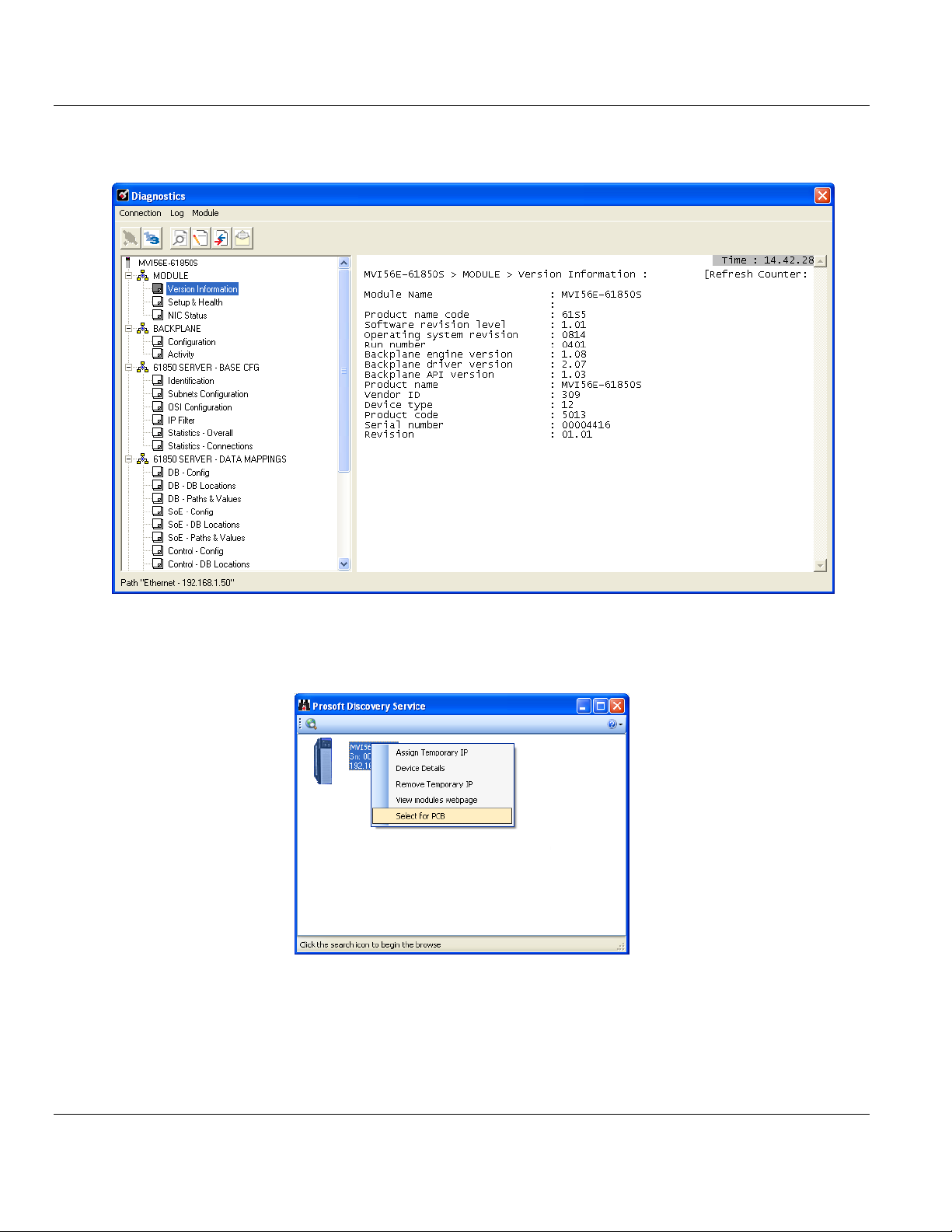

If the Test Connection procedure fails, you will see an error message. To correct the error,

follow these steps.

1 Click OK to dismiss the error message.

2 In the Download dialog box, click BROWSE DEVICE(S) to open ProSoft Discovery Service.

3 Select the module, and then click the right mouse button to open a shortcut menu. On

the shortcut menu, choose SELECT FOR PCB.

4 Close ProSoft Discovery Service.

5 Click DOWNLOAD to transfer the configuration to the module.

ProSoft Technology, Inc. Page 43 of 81

September 4, 2014

Page 44

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

3.11.1 Connecting Your PC to the Module's Ethernet Port

With the module securely mounted, connect one end of the Ethernet cable to the Config

(E1) Port, and the other end to an Ethernet hub or switch accessible from the same network

as your PC. You can also connect directly from the Ethernet Port on your PC to the Config

(E1) Port on the module by using an Ethernet crossover cable (not included).

Setting Up a Temporary IP Address

Important: ProSoft Configuration Builder locates MVI56E-61850S modules through UDP broadcast messages.

These messages may be blocked by routers or layer 3 switches. In that case, ProSoft Discovery Service will be

unable to locate the modules.

To use ProSoft Configuration Builder, arrange the Ethernet connection so that there is no router/ layer 3 switch

between the computer and the module OR reconfigure the router/ layer 3 switch to allow routing of the UDP

broadcast messages.

1 In the tree view in ProSoft Configuration Builder, select the MVI56E-61850S module.

Page 44 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 45

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

2 Click the right mouse button to open a shortcut menu. On the shortcut menu, choose

DIAGNOSTICS.

3 In the Diagnostics window, click the SET UP CONNECTION button.

4 In the Connection Setup dialog box, click the BROWSE DEVICE(S) button to open the

ProSoft Discovery Service. Select the module, then right-click and choose ASSIGN

TEMPORARY IP.

ProSoft Technology, Inc. Page 45 of 81

September 4, 2014

Page 46

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

5 The module’s default IP address is 192.168.0.250. Choose an unused IP within your

subnet, and then click OK.

Important: The temporary IP address is only valid until the next time the module is initialized. For information on

how to set the module’s permanent IP address, see Ethernet Configuration.

6 Close the ProSoft Discovery Service window. Enter the temporary IP in the Ethernet

address field of the Connection Setup dialog box, then click the TEST CONNECTION button

to verify that the module is accessible with the current settings.

7 If the Test Connection is successful, click CONNECT. The Diagnostics menu will display

in the Diagnostics window.

Page 46 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 47

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

Using RSWho to Connect to the Module

You need to have RSLinx installed on your PC to use this feature. You also need an ENBT module set up in the

rack. For information on setting up the ENBT module, see Using CIPconnect to Connect to the Module.

1 In the tree view in ProSoft Configuration Builder, right-click the MVI56E-61850S module.

2 From the shortcut menu, choose DOWNLOAD FROM PC TO DEVICE.

3 In the Download dialog box, choose 1756 ENBT from the Select Connection Type

dropdown box.

4 Click RSWHO to display modules on the network. The MVI56E-61850S module will

automatically be identified on the network.

5 Select the module, and then click OK.

ProSoft Technology, Inc. Page 47 of 81

September 4, 2014

Page 48

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

Page 48 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 49

MVI56E-61850S ♦ ControlLogix Platform Contents

In This Chapter

MVI56E-61850S User-Defined Data Types ...........................................49

MVI56E-61850S Controller Tags ...........................................................49

Name

Description

MVI56E61850S.DATA

MVI56E-61850S input and output data transferred between the

processor and the module

MVI56E61850S.COMMAND

Governs the data movement between the PLC rack and the module

MVI56E61850S.STATUS

Status data

MVI56E61850S.UTIL

Generic tags used for internal ladder processing (DO NOT MODIFY)

IEC 61850 Server Communication Module User Manual

4 RSLogix 5000 Configuration

Although the MVI56E-61850S configuration is done in PCB, it is maintained in the

MVI56E61850S controller tags of RSLogix 5000. This chapter covers the tag structure and

locations of the MVI56E-61850S parameters in RSLogix 5000.

4.1 MVI56E-61850S User-Defined Data Types

The sample ladder logic relies heavily on the use of User-Defined Data Types (UDTs) to

help group and structure the wide variety and volume of data and control features the

module offers. Lower-order UDT structures are often embedded in higher-order structures to

help further organize data into more easily understood data collections.

All data and control parameters related to the MVI56E-61850S are contained in Userdefined Data Types (UDTs). The MVI56E61850S_MODULEDEF UDT is the primary, top

level data structure in which all other lower-order data types are grouped and organized. All

groups branch down from this UDT.

To utilize all the features and functions of the module, an instance of each data type is

required. This is accomplished by declaring controller tag variables using these data types in

the Controller Tags Edit Tags dialog box.

Some UDTs hold process or status data (Module Data Objects). This data can be monitored

and manipulated by the application-specific ladder logic program. Other UDTs are used to

store and organize the parameters needed for special functions and control features

(Special Data Objects). These data types will be discussed in more detail in succeeding

topics.

4.2 MVI56E-61850S Controller Tags

4.2.1 61850S Controller Tag Overview

ProSoft Technology, Inc. Page 49 of 81

September 4, 2014

Page 50

Contents MVI56E-61850S ♦ ControlLogix Platform

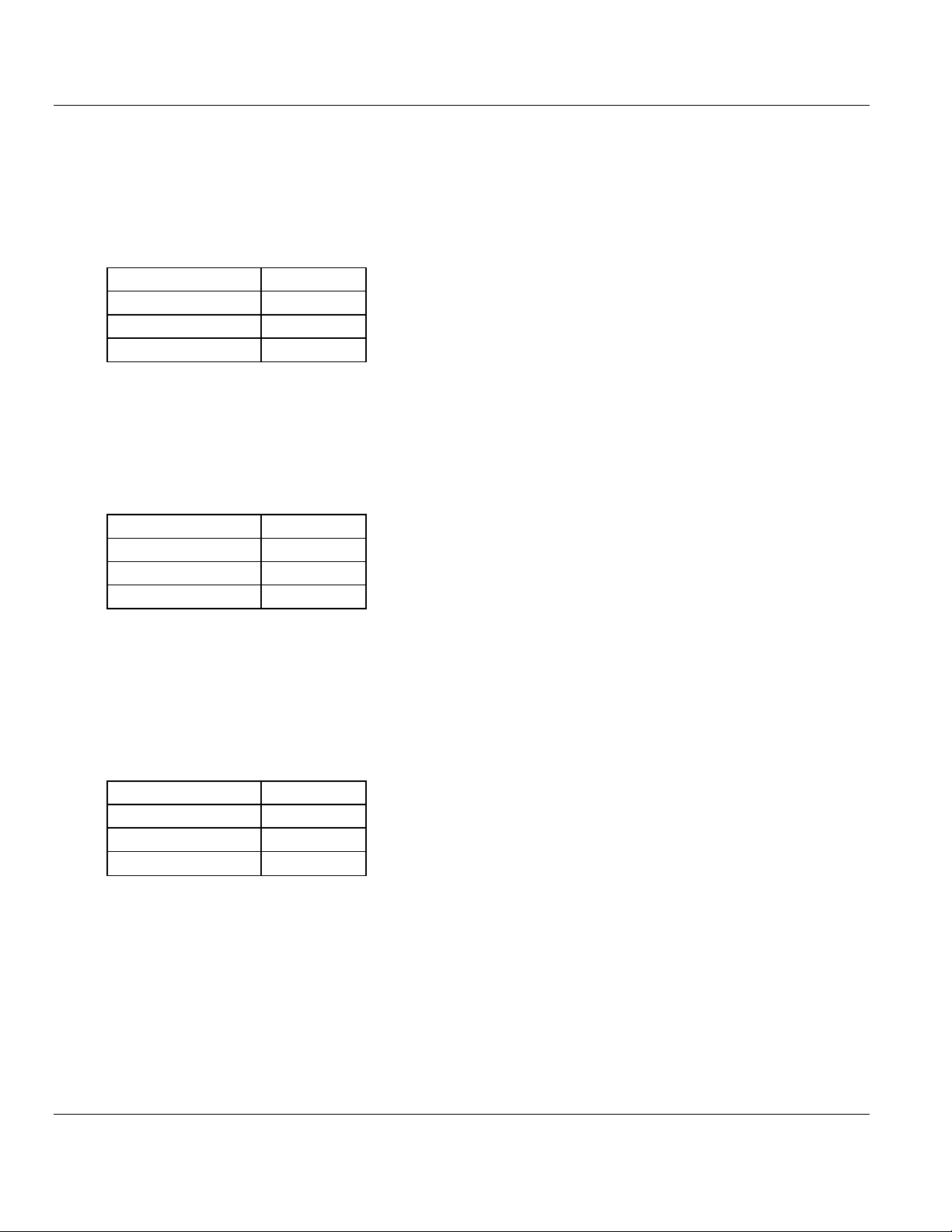

MVI56E61850S.DATA.DATA_DB.

Description

Database.WriteData[x]

MVI56E-61850S database array written from processor to the module.

MVI56E61850S.DATA.SOE.

Description

BOOL

Array contains the tags to populate and trigger SoE Boolean data

SINT

Array contains the tags to populate and trigger SoE SINT data

INT

Array contains the tags to populate and trigger SoE INT data

DINT

Array contains the tags to populate and trigger SoE DINT data

REAL

Array contains the tags to populate and trigger SoE REAL data

FLOATDB

Array contains the tags to populate and trigger SoE FLOATDB data

MVI56E61850S.DATA.CONTROL.

Description

BOOL

Array contains the tags to populate and trigger Control Boolean data

SINT

Array contains the tags to populate and trigger Control SINT data

INT

Array contains the tags to populate and trigger Control INT data

DINT

Array contains the tags to populate and trigger Control DINT data

REAL

Array contains the tags to populate and trigger Control REAL data

User Manual IEC 61850 Server Communication Module

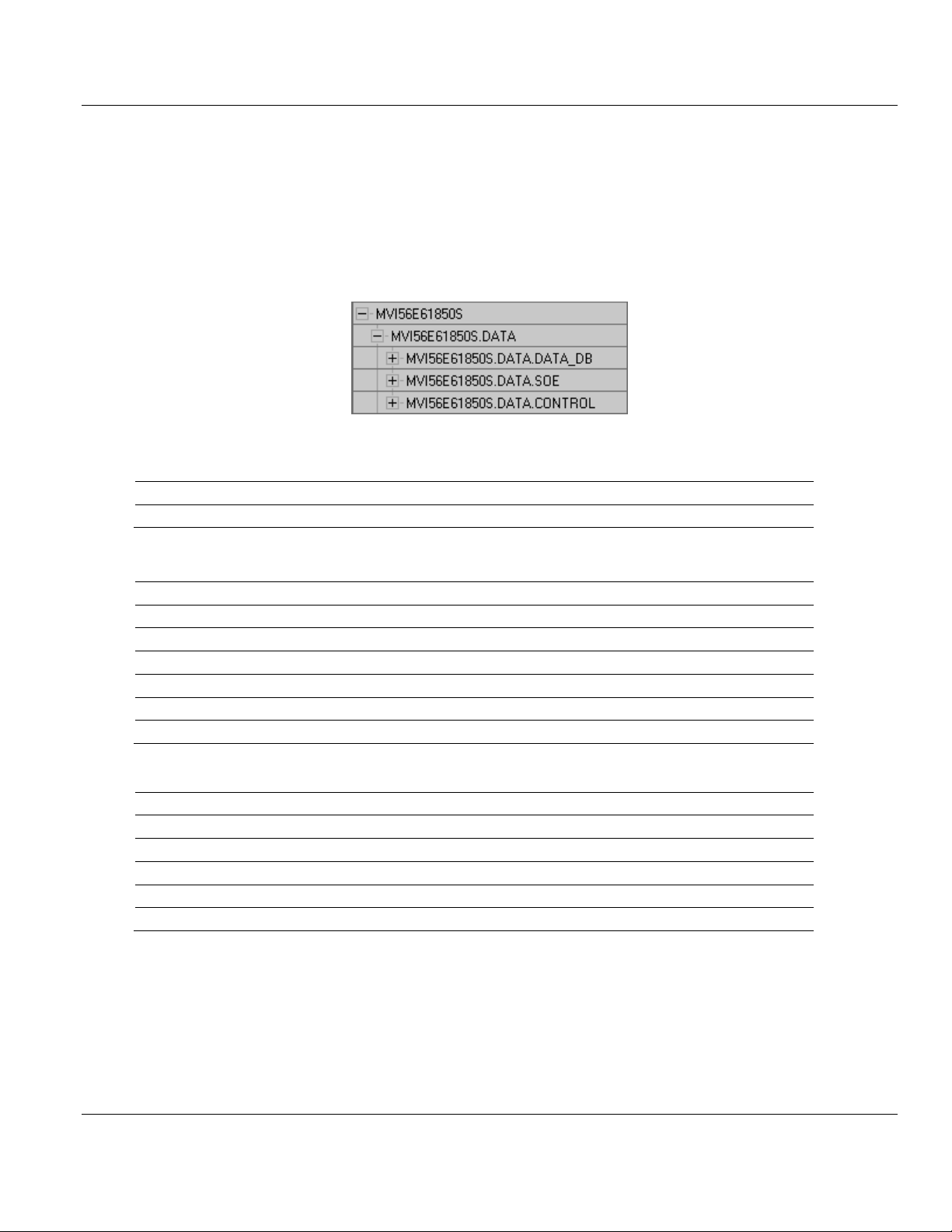

4.2.2 MVI56E61850S.DATA

This array contains the tags used for data transfer (Database, Sequence of Event and

Control). Values written to or received from a remote 61850 client are populated here. Setup

information can be found in Examples (page 53).

Data DB

Sequence of Event (SoE)

Control

Page 50 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 51

MVI56E-61850S ♦ ControlLogix Platform Contents

MVI56E61850S.COMMAND.TIME.

Description

GetProcessorTime

Reads date/time from processor to TIME tag

GetModuleTime

Reads date/time from module to TIME tag

SetModuleTime

Writes date/time from TIME tag to the module

DisableFirstScanGetProcessorTime

0 = Prevents the logic to update TIME from processor time during first

scan

TIME

Date/time to be read/written between the processor and module

MVI56E61850S.COMMAND.CONTROL.

Description

Auto_Ack

ON = Automatically ack every control block.

OFF = User must ack every control block using own logic

User_Ack

When Auto_ACK = OFF, this bit can be used to ack the last control. The

logic will ack with UTIL.ControlAck structure.

Reset_Pending

Resets pending bit without sending ack back to module. This can be used

so the logic can spend multiple scans preparing the ack

Pending

Automatically set to ON once new control block is received. Automatically

reset to OFF once control is acknowledged.

MVI56E61850S.COMMAND.BOOT.

Description

Warmboot

Warmboots the module

Coldboot

Coldboots the module

Coldboot_Reset_SOE_Data

Coldboots the module and resets SoE data stored in the processor

Coldboot_Reset_Control_Data

Coldboots the module and resets Control data stored in processor

IEC 61850 Server Communication Module User Manual

4.2.3 MVI56E61850S.COMMAND

This array includes the control of module time, control block acknowledgement, and reboot

commands.

Time operations for reading/writing time values between the processor and the module:

Control acknowledgement and its status:

Module reboot commands:

ProSoft Technology, Inc. Page 51 of 81

September 4, 2014

Page 52

Contents MVI56E-61850S ♦ ControlLogix Platform

MVI56E61850S.STATUS.

Description

ScanCounter

Scan counter increments at every module scan of the ladder logic

BackplanePhase

0 = Running

2 = Init/Initialize SoE/Control data from Processor

4 = InitTransfer PointIDs

6 = Init/Set clock

7 = InitWaiting Processor

ProductCode

Product Code 61S5

Firmware

Firmware version information

Backplane

Backplane statistics between the module and processor including read/write

data block counts, block error counts, DB, SoE, and Control block counts.

General

General diagnostics including initialization error, time-stamp module and

connection statistics.

Connection

Diagnostics for each of the 8 client connections including time-stamp, IP

address, and data packet status.

User Manual IEC 61850 Server Communication Module

4.2.4 MVI56E61850S.STATUS Tag

This array contains the overall module status.

4.2.5 MVI56E61850S.UTIL Tag

The UTIL array is used for internal ladder implementation. Do not update or delete these

tags.

Page 52 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 53

MVI56E-61850S ♦ ControlLogix Platform Contents

In This Chapter

Data DB Example ..................................................................................53

SoE Example .........................................................................................58

Control Example ....................................................................................62

IEC 61850 Server Communication Module User Manual

5 Examples

This chapter includes examples of setting up the module for Data DB, SoE, and Control data

exchange.

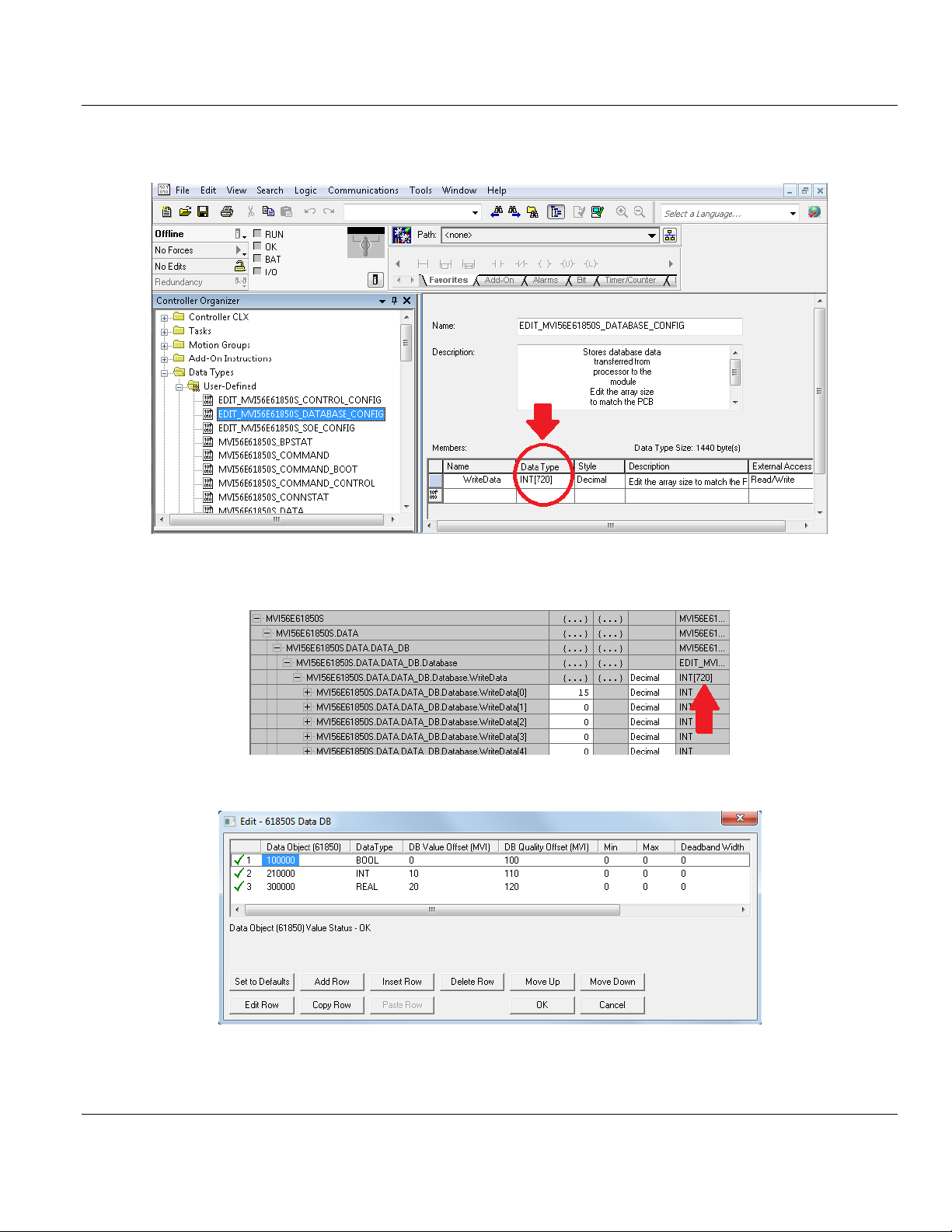

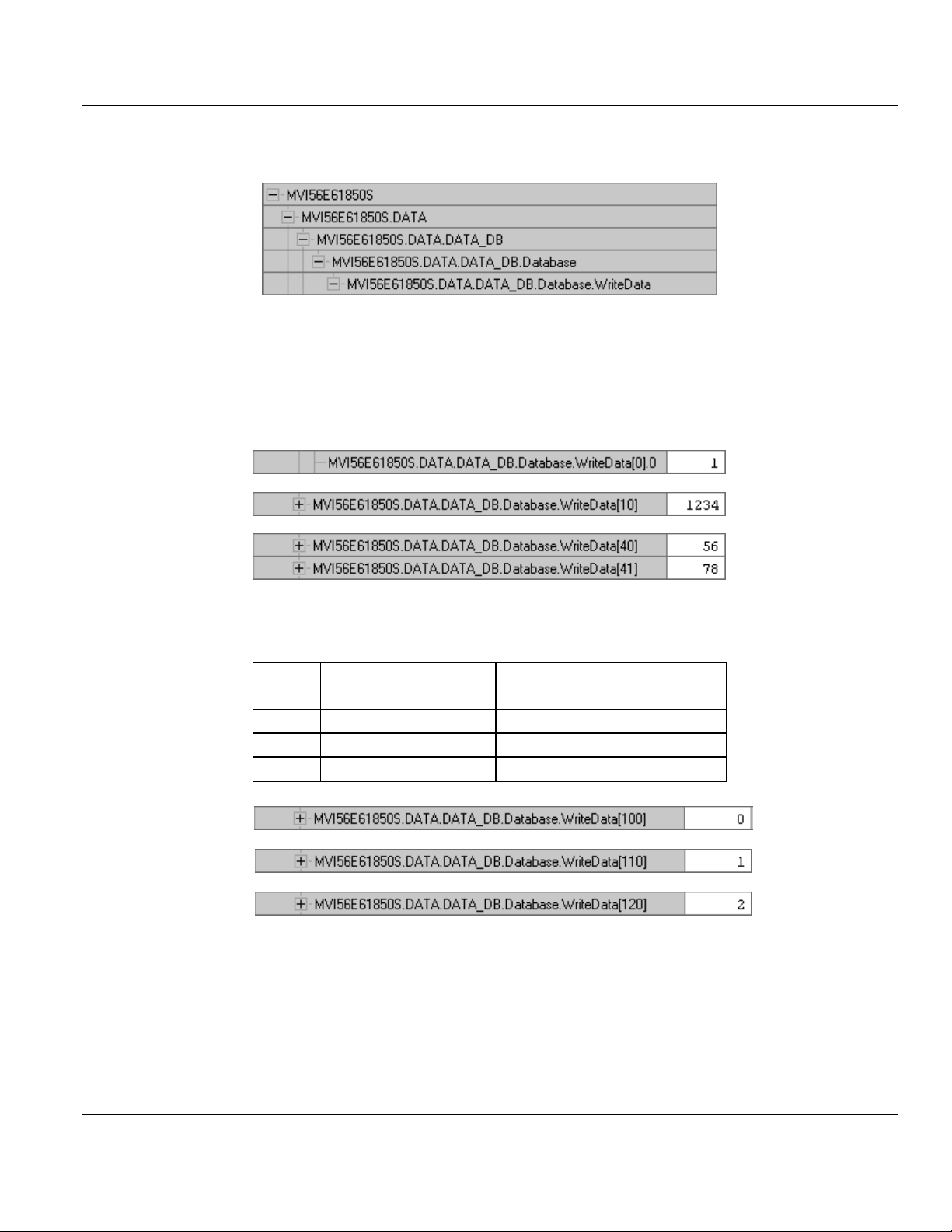

5.1 Data DB Example

This example shows how to set up boolean, integer, and real DB data objects (DO's). In this

section, you will configure the PCB file, edit a data value in RSLogix 5000, and verify the

value has been updated in module memory.

1 In PCB, enter 720 in the Write Register Count parameter value. The module breaks

down this data into blocks of 240 words. Therefore 720 words will cause the module to

generate 3 data blocks to be transferred between the processor and the module.

ProSoft Technology, Inc. Page 53 of 81

September 4, 2014

Page 54

Contents MVI56E-61850S ♦ ControlLogix Platform

User Manual IEC 61850 Server Communication Module

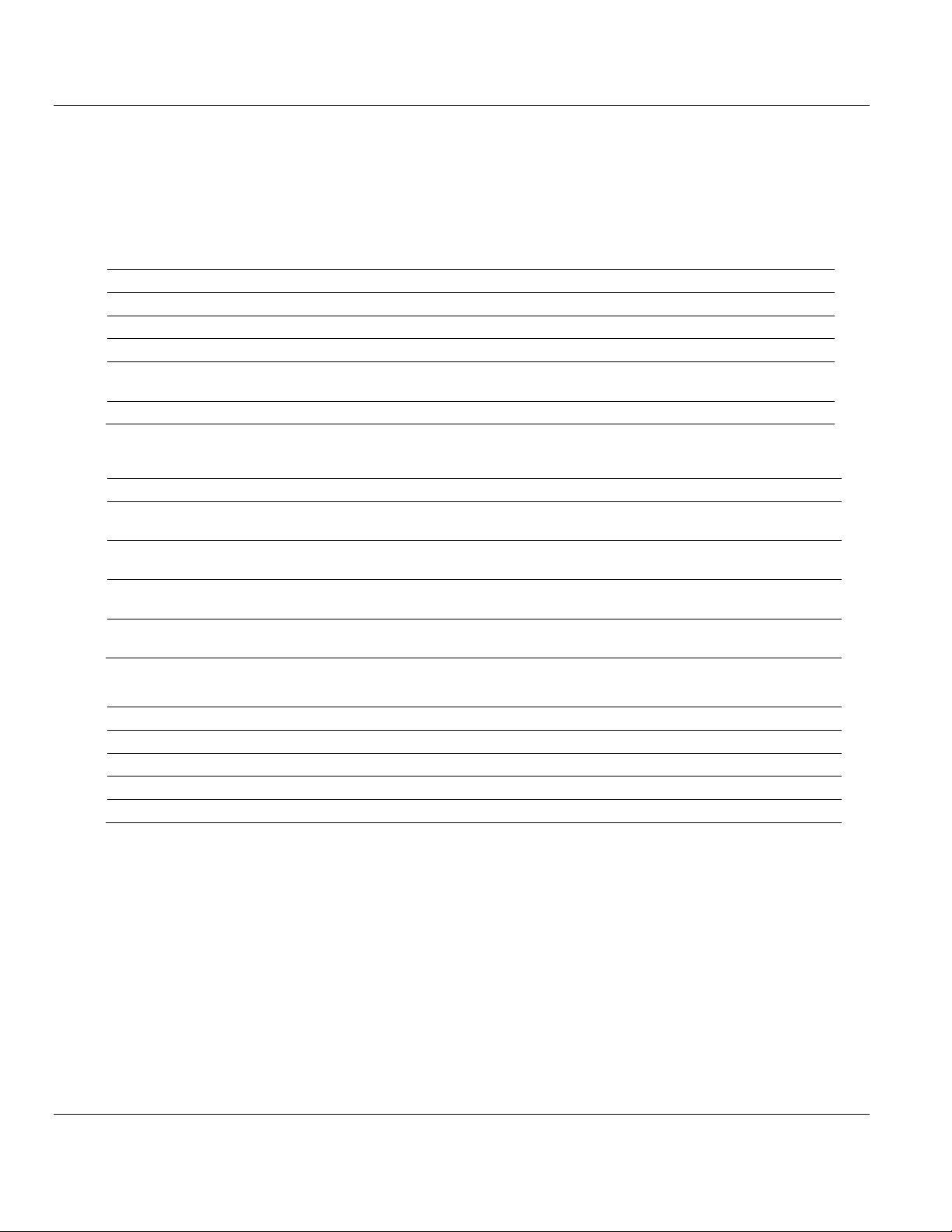

2 In RSLogix 5000, edit the EDIT_MVI56E61850S_DATABASE_CONFIG User-Defined

Data Type to 720:

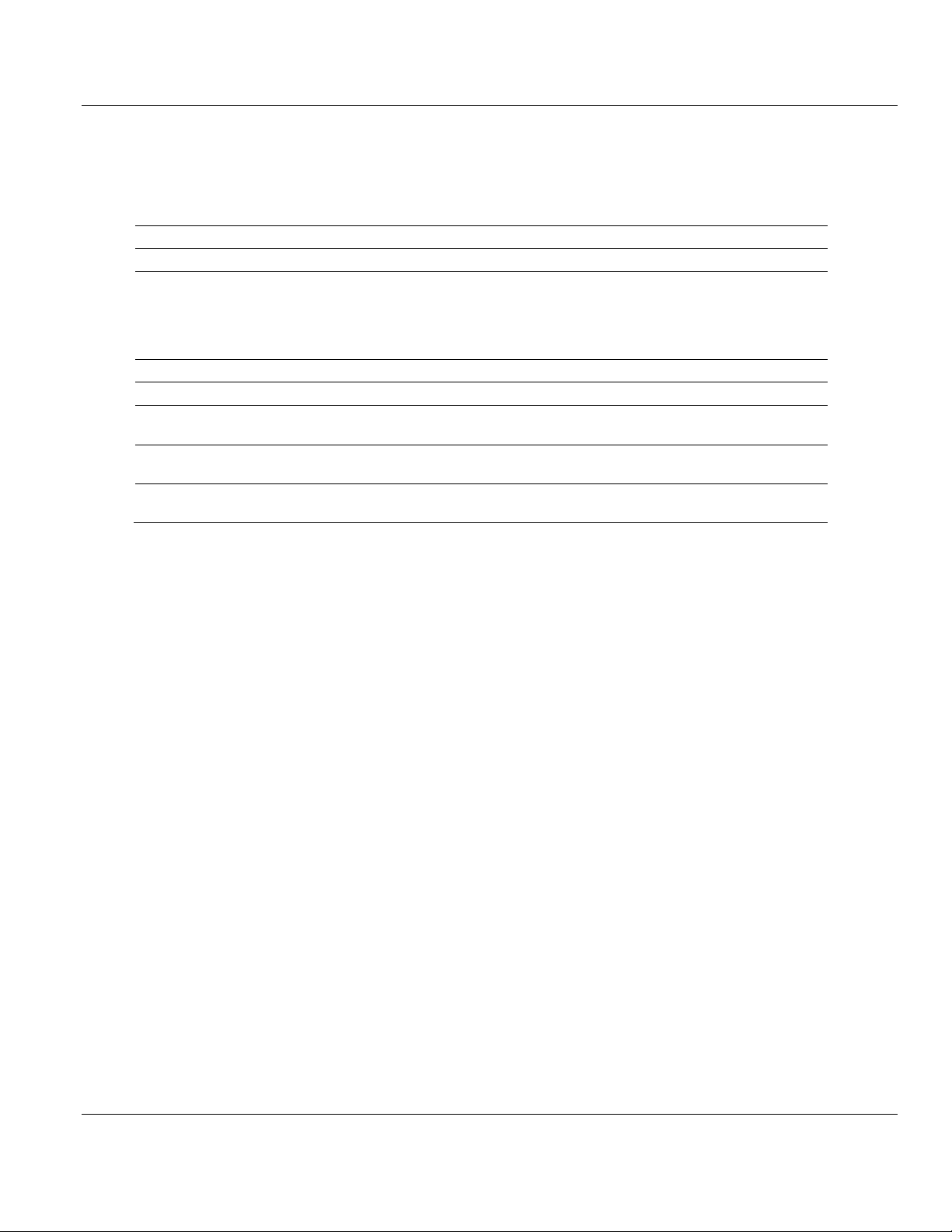

3 The MVI56E61850S.DATA.DATA_DB.Database.WriteData array now contains 720

elements. The sample ladder will adjust to accommodate the 3 data blocks needed.

4 In PCB, configure the DO's in the 61850S Data DB section.

Page 54 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 55

MVI56E-61850S ♦ ControlLogix Platform Contents

Data Object

100000

Data Type

BOOL

DB Value Offset

0

DB Quality Offset

100

Data Object

210000

Data Type

INT

DB Value Offset

10

DB Quality Offset

110

Data Object

300000

Data Type

REAL

DB Value Offset

20

DB Quality Offset

120

IEC 61850 Server Communication Module User Manual

For Boolean data, enter the following values. One bit of data will be allotted for this DO in

the module's internal memory register 0, bit 0. This location corresponds to

MVI56E61850S.DATA.DATA_DB.Database.WriteData[0].0 in RSLogix 5000.

An (optional) quality byte value is assigned to module memory 100. This location

corresponds to the least significant byte in

MVI56E61850S.DATA.DATA_DB.Database.WriteData[50] in RSLogix 5000.

For Integer data, enter the following values. A 16-bit register will be allotted for this DO in

the module's internal memory register 10. This location corresponds to

MVI56E61850S.DATA.DATA_DB.Database.WriteData[10] in RSLogix 5000.

An (optional) quality byte value is assigned to module memory 110. This location

corresponds to the least significant byte in

MVI56E61850S.DATA.DATA_DB.Database.WriteData[55] in RSLogix 5000.

For Real data, enter the following values. A 32-bit value (stored as two 16-bit registers) will

be allotted for this DO in the module's internal memory register 20. This location

corresponds to MVI56E61850S.DATA.DATA_DB.Database.WriteData[40] and [41] in

RSLogix 5000.

An (optional) quality byte value is assigned to module memory 100. This location

corresponds to the least significant byte in

MVI56E61850S.DATA.DATA_DB.Database.WriteData[60] in RSLogix 5000.

5 Save and download the PCB file to the module. For more information, see Downloading

the Sample Program to the Processor (page 13)

ProSoft Technology, Inc. Page 55 of 81

September 4, 2014

Page 56

Contents MVI56E-61850S ♦ ControlLogix Platform

Value

61850 Quality Validity

Descripiton

0

Good

No bit set

1

Questionable

Old data bit set

2

Invalid

Oscillatory bit set

3

Invalid

Old data and oscillatory bits set

User Manual IEC 61850 Server Communication Module

6 With the processor in RUN mode in RSLogix 5000, locate the

MVI56E61850S.DATA.DATA_DB.Database.WriteData array.

7 Enter arbitrary values in each of the corresponding tags for the Boolean, Integer, and

Real points configured in PCB.

Boolean: MVI56E61850S.DATA.DATA_DB.Database.WriteData[0].0

Integer: MVI56E61850S.DATA.DATA_DB.Database.WriteData[10]

Real: MVI56E61850S.DATA.DATA_DB.Database.WriteData[40] and [41]

8 Enter the Quality value describing the data integrity of each DO. This memory address

corresponds to the DB Quality Offset parameter in PCB above.

9 The MVI56E-61850S ladder logic sends these values over the backplane to the MVI56E-

61850S module memory on every scan.

10 Verify the values of the module memory by viewing the MVI56E-61850S database in the

PCB. For more information, see Using the Diagnostics Menu in ProSoft Configuration

Builder

Page 56 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 57

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

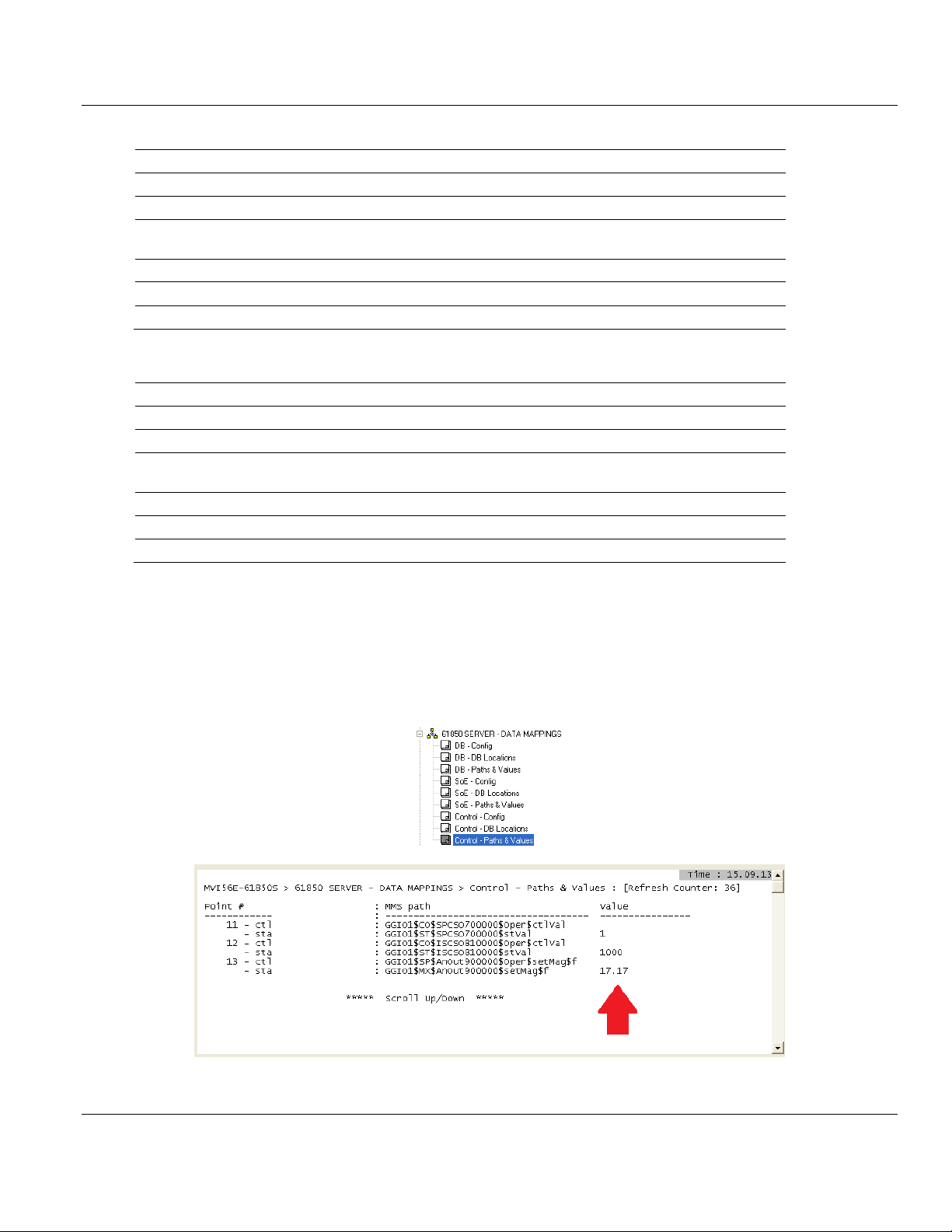

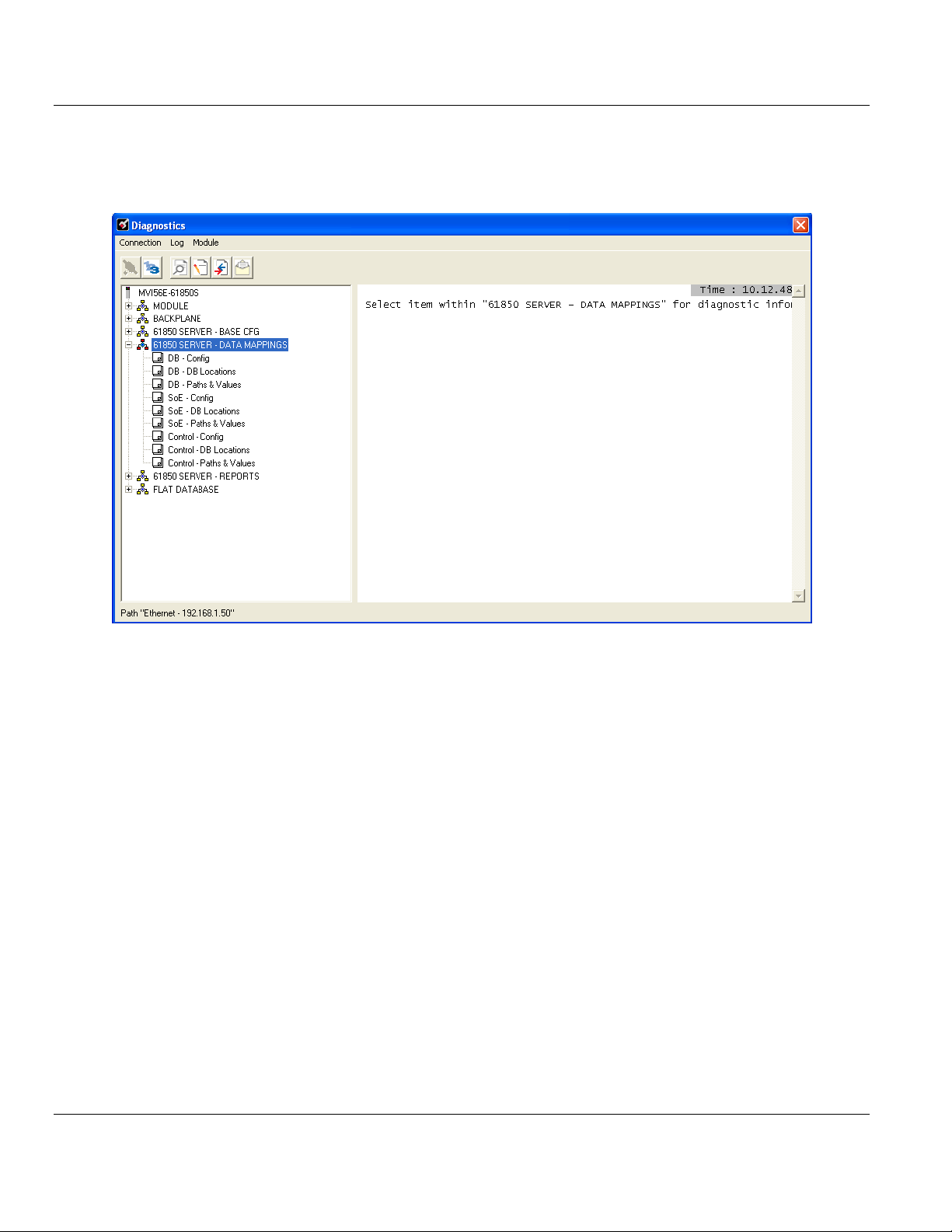

11 In the Diagnostics window, click on 61850 SERVER - DATA MAPPINGS > DB - Paths

& Values. The DO and quality values are displayed here.

ProSoft Technology, Inc. Page 57 of 81

September 4, 2014

Page 58

Contents MVI56E-61850S ♦ ControlLogix Platform

Data Object

400000

Data Type

BOOL

Point ID

1

Data Object

510000

Data Type

INT

Point ID

2

Data Object

600000

Data Type

REAL

Point ID

3

User Manual IEC 61850 Server Communication Module

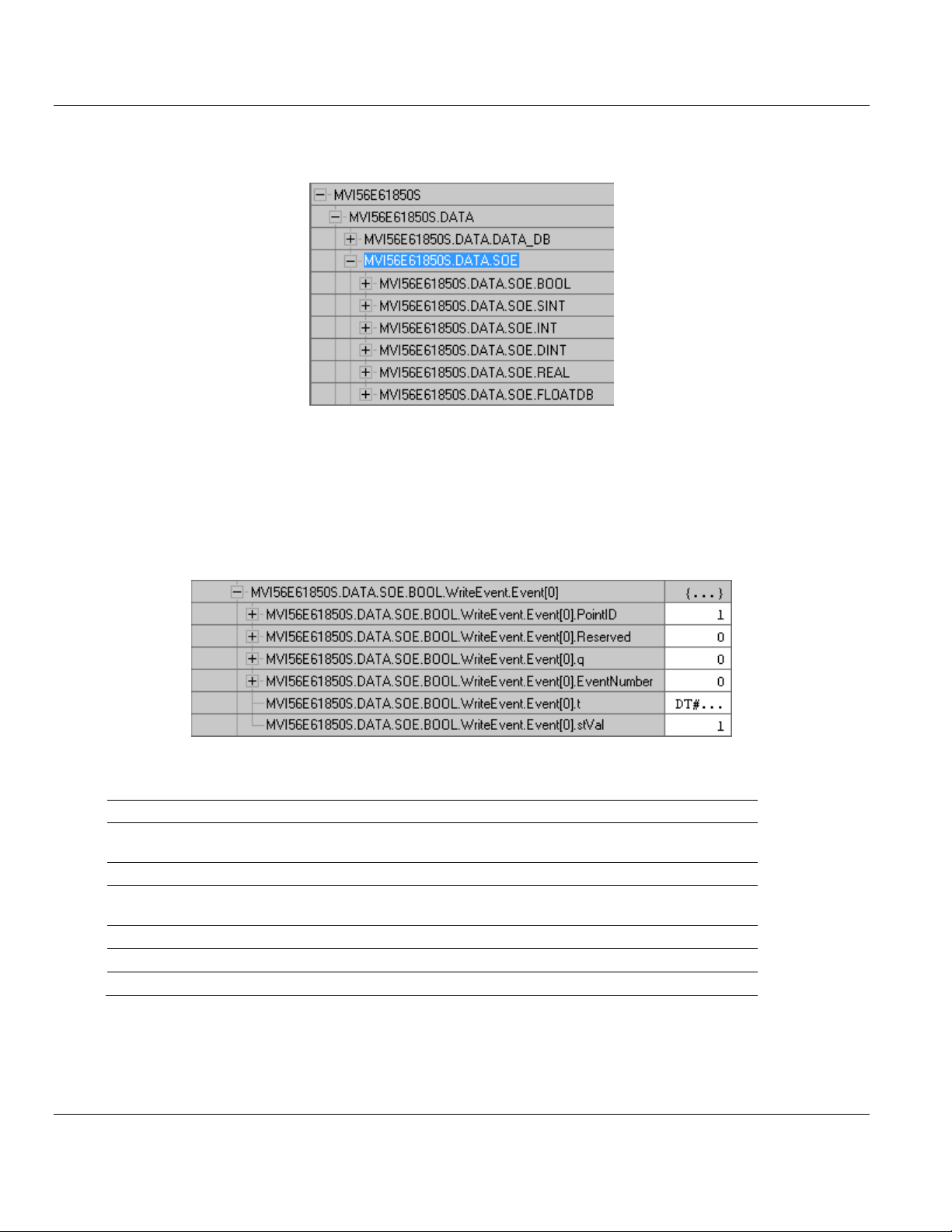

5.2 SoE Example

This example shows how to set up boolean, integer, and real Sequence of Event (SoE) data

objects (DO's). In this section, you will configure the PCB file, edit events in RSLogix 5000,

and verify the value has been updated in module memory.

1 In PCB, configure the DB points in the 61850S Data DB section.

For Boolean data, enter the following values. One bit of data will be allotted for this DO.

For Integer data, enter the following values. A 16-bit register will be allotted for this DO.

For Real data, enter the following values. A 32-bit value (stored as two 16-bit registers) will

be allotted for this DO.

2 Save and download the PCB file to the module. For more information, see Downloading

the Sample Program to the Processor (page 13)

Page 58 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 59

MVI56E-61850S ♦ ControlLogix Platform Contents

Event[0].

Value

Description

PointID

1

This value must match the corresponding BOOL Point ID parameter in

PCB

Reserved

-

Not used at this time

q 0 0 = Good data, No bit set, 1 = Questionable, Old data bit set

2 = Invalid, Oscillatory bit set, 3 = Old data and oscillatory bits set

EventNumber

-

Not used at this time

t

dd/tt

Date and time, Time-stamp of event

stVal

1

Data value: 0 = 'Off', 1 = 'On' (BOOL)

IEC 61850 Server Communication Module User Manual

3 With the processor in RUN mode in RSLogix 5000, locate the

MVI56E61850S.DATA.SOE array.

4 In order for the SoE data to be sent from the processor to the module, you must

populate then trigger an event in this array. You can send the event(s) in a consecutive

group or all at once (up to 24).

5 For Boolean data, locate the MVI56E61850S.DATA.SOE.BOOL.WriteEvent.Event[x]

array. All boolean SoE data will be populated in this array. Enter the values as shown

below. (These steps also apply to SINT, INT, DINT, REAL DO's)

BOOL

ProSoft Technology, Inc. Page 59 of 81

September 4, 2014

Page 60

Contents MVI56E-61850S ♦ ControlLogix Platform

Event[1].

Value

Description

PointID

2

This value must match the corresponding INT Point ID parameter in PCB

Reserved

-

Not used at this time

q 0 0 = Good data, No bit set, 1 = Questionable, Old data bit set

2 = Invalid, Oscillatory bit set, 3 = Old data and oscillatory bits set

EventNumber

-

Not used at this time

t

dd/tt

Date and time, Time-stamp of event

stVal

4321

Data value

Event[2].

Value

Description

PointID

3

This value must match the corresponding REAL Point ID parameter in PCB

Reserved

-

Not used at this time

q 0 0 = Good data, No bit set, 1 = Questionable, Old data bit set

2 = Invalid, Oscillatory bit set, 3 = Old data and oscillatory bits set

EventNumber

-

Not used at this time

t

dd/tt

Date and time, Time-stamp of event

stVal

99.9

Data value

User Manual IEC 61850 Server Communication Module

INT

REAL

6 Once these values are populated, enter the number of boolean events to be sent to the

module.

7 To send the data to the module, enter 1 in the

MVI56E61850S.DATA.SOE.BOOL.WriteEvent.Trigger tag. It will reset back to 0 once

triggered.

Page 60 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 61

MVI56E-61850S ♦ ControlLogix Platform Contents

IEC 61850 Server Communication Module User Manual

8 Verify the values in module memory by viewing the MVI56E-61850S database in the

PCB. For more information, see Using the Diagnostics Menu in ProSoft Configuration

Builder

9 In the Diagnostics window, click on 61850 SERVER - DATA MAPPINGS > SoE - Paths

& Values. The DO values are displayed here.

ProSoft Technology, Inc. Page 61 of 81

September 4, 2014

Page 62

Contents MVI56E-61850S ♦ ControlLogix Platform

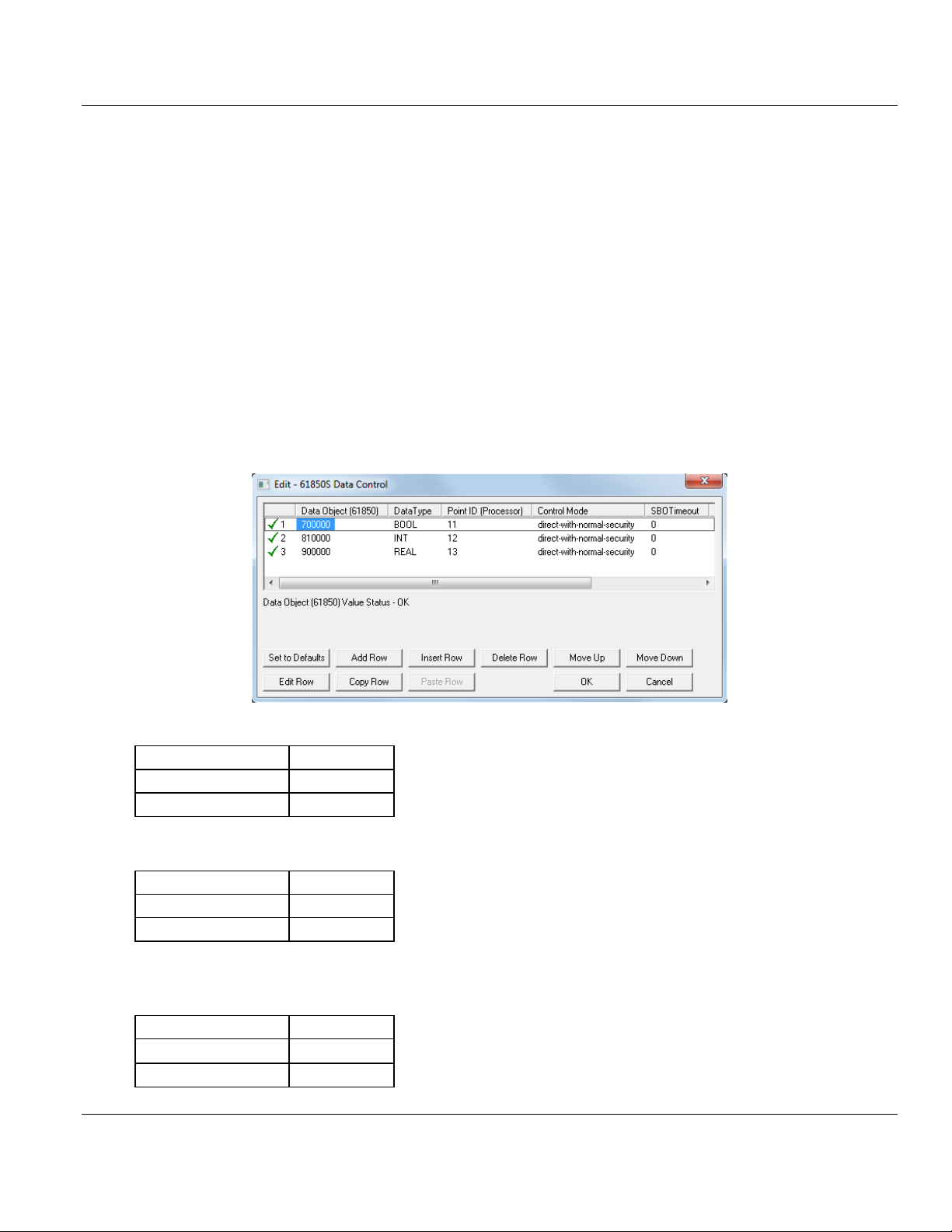

Data Object

700000

Data Type

BOOL

Point ID

11

Data Object

810000

Data Type

INT

Point ID

12

Data Object

900000

Data Type

REAL

Point ID

13

User Manual IEC 61850 Server Communication Module

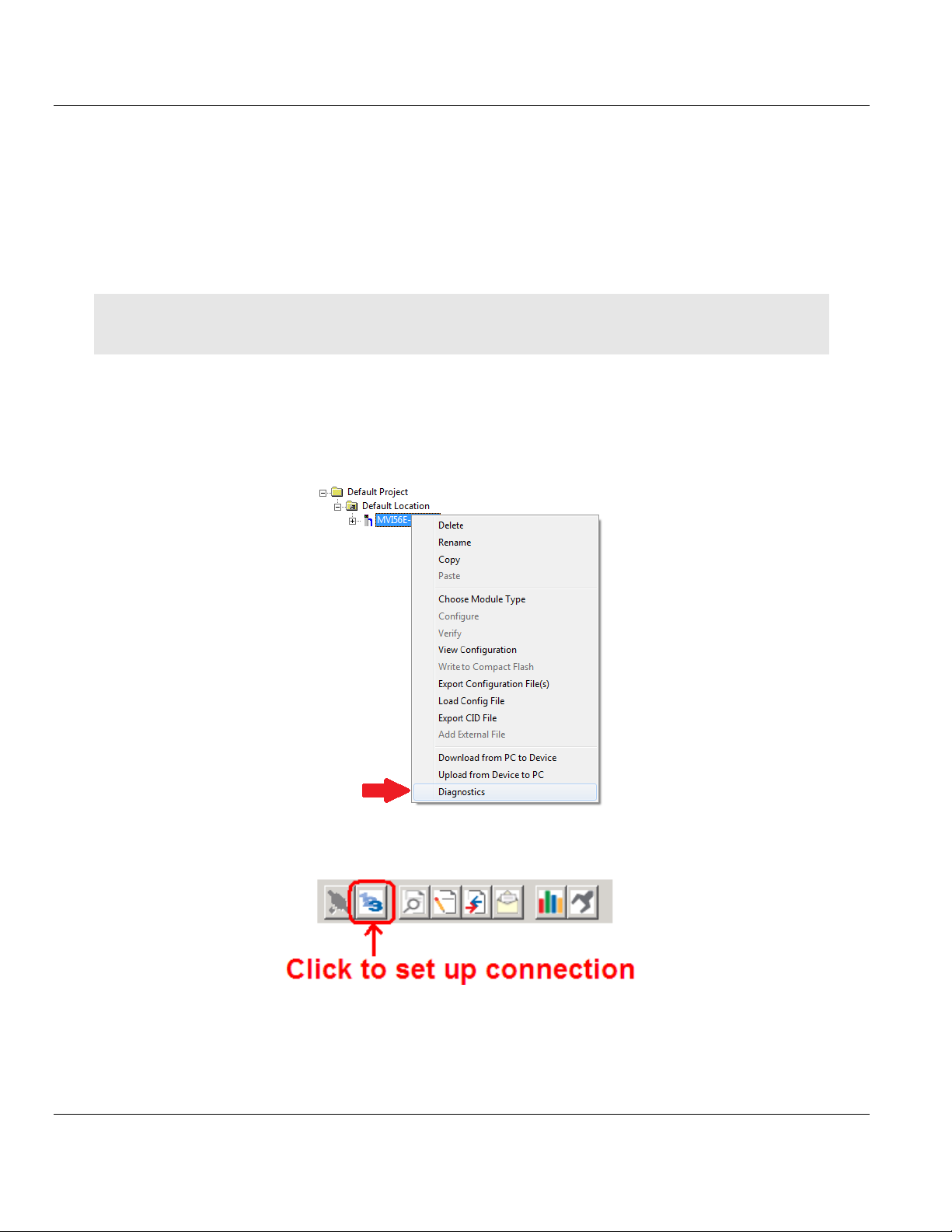

5.3 Control Example

This example shows how to set up boolean, integer, and real Control data objects (DO's). In

this section, you will configure the PCB file, configure the related parameters in RSLogix

5000, and verify the value has been populated in module memory using an automatic

acknowledge feature.

When a IEC 61850 client sends Control DO data to the MVI56E-61850S, the MVI56E-

61850S passes this data to the processor. This data can be analyzed by the user's ladder

logic. Data with time-stamp and quality attributes can then be returned to the module for the

client to read.

The processor can also acknowledge the data with no user-logic needed, this feature is

enabled by default at MVI56E61850S.COMMAND.CONTROL.Auto_Ack.

1 In PCB, configure the DB points in the 61850S Data DB section.

For Boolean data, enter the following values. One bit of data will be allotted for this DO.

For Integer data, enter the following values. A 16-bit register will be allotted for this DO.

For Real data, enter the following values. A 32-bit value (stored as two 16-bit registers) will

be allotted for this DO.

Page 62 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 63

MVI56E-61850S ♦ ControlLogix Platform Contents

BOOL[0].

Value

Description

PointID

11

This value must match the corresponding BOOL Point ID parameter in

PCB

Reserved

-

Not used at this time

q 0 0 = Good data, No bit set, 1 = Questionable, Old data bit set

2 = Invalid, Oscillatory bit set, 3 = Old data and oscillatory bits set

EventNumber

-

Not used at this time

t

dd/tt

Date and time, Time-stamp of event

stVal

1

Data value: 0 = 'Off', 1 = 'On'

IEC 61850 Server Communication Module User Manual

2 Save and download the PCB file to the module. For more information, see Downloading

the Sample Program to the Processor (page 13)

3 With the processor in RUN mode in RSLogix 5000, locate the

MVI56E61850S.DATA.SOE array.

4 For Boolean data, locate the MVI56E61850S.DATA.CONTROL.BOOL[x] array. All

boolean Control data will be populated in this array. Enter the values as shown below.

(These steps also apply to SINT, INT, DINT, REAL DO's)

BOOL

ProSoft Technology, Inc. Page 63 of 81

September 4, 2014

Page 64

Contents MVI56E-61850S ♦ ControlLogix Platform

INT[0].

Value

Description

PointID

12

This value must match the corresponding INT Point ID parameter in PCB

Reserved

-

Not used at this time

q 0 0 = Good data, No bit set, 1 = Questionable, Old data bit set

2 = Invalid, Oscillatory bit set, 3 = Old data and oscillatory bits set

EventNumber

-

Not used at this time

t

dd/tt

Date and time, Time-stamp of event

stVal

1000

Data value

REAL[0].

Value

Description

PointID

13

This value must match the corresponding REAL Point ID parameter in PCB

Reserved

-

Not used at this time

q 0 0 = Good data, No bit set, 1 = Questionable, Old data bit set

2 = Invalid, Oscillatory bit set, 3 = Old data and oscillatory bits set

EventNumber

-

Not used at this time

t

dd/tt

Date and time, Time-stamp of event

stVal

17.17

Data value

User Manual IEC 61850 Server Communication Module

INT

REAL

5 Verify the acknowledged data in module memory by viewing the MVI56E-61850S

database in the PCB. For more information, see Using the Diagnostics Menu in ProSoft

Configuration Builder

6 In the Diagnostics window, click on 61850 SERVER - DATA MAPPINGS >

Control - Paths & Values. The DO values are displayed here.

Page 64 of 81 ProSoft Technology, Inc.

September 4, 2014

Page 65

MVI56E-61850S ♦ ControlLogix Platform Contents

In This Chapter

Ethernet LED Indicators .........................................................................65

Clearing a Fault Condition .....................................................................67

Troubleshooting .....................................................................................68

Using the Diagnostics Menu in ProSoft Configuration Builder ...............69

Connect to the Module’s Web Page ......................................................78

LED

State

Description

Data

OFF

Ethernet connected at 10Mbps duplex speed

AMBER Solid

Ethernet connected at 100Mbps duplex speed

Link

OFF

No physical network connection is detected. No Ethernet

communication is possible. Check wiring and cables.

GREEN Solid

or Blinking

Physical network connection detected. This LED must be ON solid

for Ethernet communication to be possible.

IEC 61850 Server Communication Module User Manual

6 Diagnostics and Troubleshooting

The module provides information on diagnostics and troubleshooting in the following forms:

LED status indicators on the front of the module provide information on the module’s

status.

Status data contained in the module can be viewed in ProSoft Configuration Builder

through the Ethernet port.

Status data values are transferred from the module to the processor.