Page 1

MVI56-AFC

ControlLogix Platform

Liquid and Gas Flow Computer

February 25, 2011

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2011 ProSoft Technology, Inc., all rights reserved.

MVI56-AFC User Manual

February 25, 2011

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM,

and are available at no charge from our web site: www.prosoft-technology.com

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIV. 2;

B WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

C WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

D THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Warnings

North America Warnings

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or rewiring modules.

C Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

Avertissement - Risque d'explosion - Avant de déconnecter l'équipement, couper le courant

ou s'assurer que l'emplacement est désigné non dangereux.

D Suitable for use in Class I, Division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction.

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Battery Life Advisory

The MVI46, MVI56, MVI56E, MVI69, and MVI71 modules use a rechargeable Lithium Vanadium Pentoxide battery to

backup the real-time clock and CMOS. The battery should last for the life of the module. The module must be

powered for approximately twenty hours before the battery becomes fully charged. After it is fully charged, the battery

provides backup power for the CMOS setup and the real-time clock for approximately 21 days. When the battery is

fully discharged, the module will revert to the default BIOS and clock settings.

Note: The battery is not user replaceable.

Page 4

Markings

Electrical Ratings

Backplane Current Load: 800 mA @ 5.1 Vdc; 3 mA @ 24 Vdc

Operating Temperature: 0°C to 60°C (32°F to 140°F)

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

Shock: 30 g, operational; 50 g, non-operational; Vibration: 5 g from 10 Hz to 150 Hz

Relative Humidity: 5% to 95% with no condensation

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground conductors must be at least

4mm(squared).

Label Markings

ATEX

II 3 G

EEx nA IIC T6

0°C <= Ta <= 60°C

cULus

E183151

Class I Div 2 Groups A,B,C,D

T6

-30°C <= Ta <= 60°C

Agency Approvals and Certifications

Agency Applicable Standard

RoHS

CE EMC-EN61326-1:2006; EN61000-6-4:2007

ATEX EN60079-15:2003

cULus UL508; UL1604; CSA 22.2 No. 142 & 213

CB Safety CA/10533/CSA

IEC 61010-1 Ed.2; CB 243333-2056722 (2090408)

GOST-R EN 61010

CSA EN 61010

243333

ME06

E183151

Page 5

MVI56-AFC ♦ ControlLogix Platform Contents

Liquid and Gas Flow Computer User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

MVI (Multi Vendor Interface) Modules ................................................................................................ 3

Warnings ............................................................................................................................................. 3

Battery Life Advisory ........................................................................................................................... 3

Markings .............................................................................................................................................. 4

1 Introduction 11

1.1

1.2

1.3

Update Notice .......................................................................................................... 12

MVI56-AFC Module ................................................................................................. 14

Configuration Modification Lockout and Seal .......................................................... 15

2 Quick Start 17

2.1

2.2

2.3

2.4

2.5

2.6

2.1.1

2.3.1

2.3.2

2.3.3

2.3.4

2.3.5

2.3.6

2.3.7

Install AFC Manager ................................................................................................ 18

System Requirements ............................................................................................. 18

Starting AFC Manager ............................................................................................. 19

Using AFC Manager ................................................................................................ 20

Starting a New Project ............................................................................................. 20

Loading an Existing project ..................................................................................... 21

Printing the Configuration Report ............................................................................ 21

Converting a Project ................................................................................................ 22

Resetting Configuration Parameters ....................................................................... 23

Downloading the Project to the Module .................................................................. 24

Verifying Correct Operation ..................................................................................... 25

Ladder Logic Implementation .................................................................................. 26

Setting the Wallclock ............................................................................................... 28

Module Initialization ................................................................................................. 29

3 Meter Channel Functionality 31

3.1

3.2

3.2.1

3.2.2

3.3

3.3.1

3.3.2

3.4

3.5

3.5.1

3.5.2

3.5.3

3.5.4

3.6

3.6.1

Meter Channels ....................................................................................................... 32

Linear (Pulse) Meter Overview ................................................................................ 33

Primary Input = Pulse Count ................................................................................... 33

Primary Input = Pulse Frequency ............................................................................ 33

Differential (Orifice) Meter Overview ....................................................................... 34

Primary Input = Differential Pressure ...................................................................... 34

Primary Input = Flow Rate ....................................................................................... 34

Gas Product Overview ............................................................................................ 35

Liquid Product Overview ......................................................................................... 36

To use a densitometer ............................................................................................. 36

Module Configuration .............................................................................................. 36

Density Units ........................................................................................................... 36

Measuring Water Diluent ......................................................................................... 36

General Features .................................................................................................... 37

Process Variable Interface ...................................................................................... 37

ProSoft Technology, Inc. Page 5 of 316

February 25, 2011

Page 6

Contents MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

3.6.2

3.6.3

3.6.4

3.6.5

3.6.6

3.6.7

3.6.8

Meter Scan Time..................................................................................................... 37

Multiple Meter Accumulators .................................................................................. 37

Product Batching .................................................................................................... 37

Data Archiving......................................................................................................... 38

Event Log Function ................................................................................................. 38

Measurement Units ................................................................................................. 38

Process Input Scaling ............................................................................................. 39

4 Meter Proving 41

4.1

4.2

4.3

4.4

4.1.1

4.1.2

4.1.3

4.1.4

4.1.5

4.2.1

4.2.2

4.2.3

4.4.1

4.4.2

Prover Configuration ............................................................................................... 42

Prover Type ............................................................................................................ 42

Prover Options ........................................................................................................ 46

Run Counts ............................................................................................................. 47

Run Input Setup ...................................................................................................... 47

Prover Characteristics ............................................................................................ 49

Setting up the AFC module for Meter Proving ........................................................ 51

Initial Requirements ................................................................................................ 53

Meter Proving Alarms ............................................................................................. 54

Prover Operation (How to do a Prove) ................................................................... 57

Meter Proving Reports ............................................................................................ 63

Protected Meter Proving Data in the AFC's Input Register Bank ........................... 64

Latest Prove Results ............................................................................................... 64

Meter Previous Prove Summary ............................................................................. 67

5 Modbus Database 69

5.1

5.2

5.3

5.1.1

5.2.1

5.2.2

5.2.3

5.2.4

5.3.1

AFC Modbus Address Space ................................................................................. 70

Accessing the Data ................................................................................................. 70

Primary Slave.......................................................................................................... 71

Modbus Address References ................................................................................. 71

Modbus Address Examples .................................................................................... 71

Meter-relative Data ................................................................................................. 72

Scratchpad .............................................................................................................. 73

Virtual Slave ............................................................................................................ 74

Virtual Slave Example Application .......................................................................... 75

6 Modbus Communication 77

6.1

6.2

6.3

6.4

6.3.1

Communication Parameters ................................................................................... 78

Port Options ............................................................................................................ 79

Modbus Master ....................................................................................................... 80

Example .................................................................................................................. 81

Modbus Pass-Through ........................................................................................... 82

7 Accumulators 83

7.1

7.2

7.2.1

7.2.2

7.2.3

Accumulator Totalizer and Residue ........................................................................ 84

Accumulator Types ................................................................................................. 85

Non-Resettable Accumulators ................................................................................ 85

Resettable Accumulators ........................................................................................ 85

Archive Accumulators ............................................................................................. 88

Page 6 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 7

MVI56-AFC ♦ ControlLogix Platform Contents

Liquid and Gas Flow Computer User Manual

7.3

7.4

Net Accumulator Calculation ................................................................................... 89

Frequently Asked Questions ................................................................................... 90

8 Archives 91

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

8.8.1

Archive Overview .................................................................................................... 92

Archive Generation .................................................................................................. 93

Archive Types .......................................................................................................... 94

Archive Order .......................................................................................................... 95

Archive Options ....................................................................................................... 97

Archive Locations .................................................................................................... 98

Editing the Archive Structure ................................................................................. 100

Extended Archives ................................................................................................ 102

Retrieving Extended Archives ............................................................................... 102

Archive Reports ..................................................................................................... 105

Archive Monitor ..................................................................................................... 107

9 Events 113

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

9.10

9.11

9.12

9.13

9.14

9.5.1

9.5.2

9.5.3

9.5.4

9.5.5

9.5.6

9.5.7

9.5.8

The Event Log ....................................................................................................... 114

Event Log Structures ............................................................................................. 115

Event Id Tag .......................................................................................................... 116

Event-triggered Archives and Accumulator Resets .............................................. 117

Downloading the Event Log in Firmware Version 2.07 and Later ......................... 118

Basic Principles of Implementation ....................................................................... 125

Data Elements ....................................................................................................... 127

Virtual Slave Precedence Relations ...................................................................... 129

Security and Optimization ..................................................................................... 130

The Log-Download Window (LDW) ....................................................................... 131

Modbus Transaction Sequencing and Constraints ............................................... 132

Access by Multiple Hosts ...................................................................................... 137

Other Considerations ............................................................................................ 138

Period-end Events ................................................................................................. 139

Loggable Events .................................................................................................... 140

Special Events ....................................................................................................... 141

Site Data Point Events .......................................................................................... 142

Meter Data Point Events ....................................................................................... 143

Stream Data Point Events ..................................................................................... 146

Prover Data Point Events ...................................................................................... 148

"Rkv" Notes ........................................................................................................... 151

Downloading the Event Log in Firmware Version 2.05 and Earlier ...................... 152

10 Security (Passwords) 155

10.1

Hard Password ...................................................................................................... 157

11 MVI56-AFC Backplane Communication 159

11.1

11.1.1

11.1.2

11.2

MVI56-AFC Module Data Transfer ........................................................................ 160

Input/Output Blocks for Data Transfer ................................................................... 160

Input/Output Transactions ..................................................................................... 162

MVI56-AFC Function Block Interface .................................................................... 167

ProSoft Technology, Inc. Page 7 of 316

February 25, 2011

Page 8

Contents MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

11.2.1 Function Block Structure .......................................................................................

11.2.2 Function Block Definition - 0: Null ......................................................................... 171

11.2.3 Function Block Definition - 1: Wall Clock .............................................................. 172

11.2.4 Function Block Definition - 4, 5, 6 & 7: Modbus Pass Through ............................ 173

11.2.5 Function Block Definition - 8: Meter Process Variables........................................ 175

11.2.6 Function Block Definition - 9: Meter Analysis, 16-bit ............................................ 184

11.2.7 Function Block Definition - 10: Meter Type Fetch ................................................. 186

11.2.8 Function Block Definition - 11: Meter Analysis, 32-bi

11.2.9 Function Block Definition - 12: Site/Meter Signals ................................................ 190

11.2.10 Function Block Definition - 14: Meter Archive Fetch............................................. 192

11.2.11 Function Block Definition - 16/17/18/19: Modbus Gateway Read ........................ 193

11.2.12 Function Block Definition - 20, 21: Modbus Gateway Write ................................. 196

11.2.13 Function Block Definition - 24, 25, 26: Modbus Master ........................................ 199

11.2.14 Function Block Definition - 28, 29: Disable/Enable Meters .................................. 203

t .......................................... 187

168

12 MVI56-AFC Sample Logic 205

12.1 Sample Logic Overview ........................................................................................ 206

12.1.1 Process Block (uses Transaction Numbers from 1 to 16) .................................... 208

12.1.2 Modbus Gateway Block (uses Transaction Numbers from 17 to 25) ................... 209

12.1.3 Wallclock Block (uses Transaction Number =99) ................................................. 209

12.1.4 Sample MVI56-AFC Logic Tasks.......................................................................... 210

12.2 Using the Sample Add-On Instruction .................................................................. 211

12.2.1 Import Procedure .................................................................................................. 211

12.3 ControlLogix Sample Logic Details ....................................................................... 220

12.3.1 Enable/Disable Status .......................................................................................... 220

12.3.2 Disable Meter ........................................................................................................ 220

12.3.3 Enable Meter......................................................................................................... 221

12.3.4 Wallclock ............................................................................................................... 222

12.3.5 Meter Profile .......................................................................................................... 223

12.3.6 Meter Process Variables ....................................................................................... 224

12.3.7 Meter Calculation Results ..................................................................................... 227

12.3.8 Meter Signals ........................................................................................................ 229

12.3.9 Molar Analysis (For Gas Product Only) ................................................................ 231

12.3.10 Set the Processor Time ........................................................................................ 236

12.3.11 Checking Meter Alarms ........................................................................................ 237

12.3.12 Site Status ............................................................................................................. 239

12.3.13 Modbus Master ..................................................................................................... 239

12.3.14 Modbus pass-through ........................................................................................... 244

12.3.15 Modbus Gateway .................................................................................................. 245

13 Diagnostics and Troubleshooting 255

13.1 User LEDs ............................................................................................................. 256

13.1.1 App Status LED .................................................................................................... 256

13.1.2 BP Act and P1, P2, or P3 ..................................................................................... 256

13.2 BBRAM LEDs ....................................................................................................... 257

13.3 Meter Alarms ......................................................................................................... 258

13.4 Checksum Alarms ................................................................................................. 262

13.5 Events ...................................................................................................................

13.6 Audit Scan ............................................................................................................. 264

263

Page 8 of 316 Pr

oSoft Technology, Inc.

February 25, 2011

Page 9

MVI56-AFC ♦ ControlLogix Platform Contents

Liquid and Gas Flow Computer User Manual

14 Reference 269

14.1 General Specifications .......................................................................................... 270

14.1.1 On-line Communication & Configuration ............................................................... 271

14.1.2 Reports .................................................................................................................. 271

14.1.3 Modbus Interface ................................................................................................... 271

14.1.4 Configurable Options ............................................................................................. 272

14.1.5 Supported Meters ...................................

14.1.6 Hardware Specifications........................................................................................ 273

14.2 Measurement Standards ....................................................................................... 274

14.2.1 Basic Metering According to Meter type ............................................................... 275

14.2.2 Liquid Correction Factor Details ............................................................................ 277

14.3 Wedge Meter Applications .................................................................................... 279

14.4 Configurable Archive Registers ............................................................................. 280

14.4.1 Information for Users of AFC Manager Versions Older Than 2.01.000 ................ 284

14.5 Archive Data Format ............................................................................................. 286

14.5.1 Timestamp Date and Time Format ....................................................................... 286

14.5.2 Pre-defined Header ............................................................................................... 287

14.5.3 Orifice (Differential) Meter with Gas Product......................................................... 288

14.5.4 Pulse (Linear) Meter with Gas Product ................................................................. 289

14.5.5 Orifice (Differential) Meter with Liquid Product...................................................... 289

14.5.6 Pulse (Linear) Meter with Liquid Product .............................................................. 290

14.5.7 Flow Rate Integration with Gas Product ................................................................ 290

14.5.8 Pulse Frequency Integration with Gas Product ..................................................... 291

14.5.9 Flow Rate Integration with Liquid Product............................................................. 291

14.5.10 Pulse Frequency Integration with Liquid Product .................................................. 292

14.6 Modbus Addressing Common to Both Primary and Virtual Slaves ....................... 293

14.7 Modbus Port configuration .................................................................................... 296

14.8 Startup Basics and Frequently Asked Questions .................................................. 298

14.9 Cable Connections ..................................

14.9.1 RS-232 Configuration/Debug Port ........................................................................ 299

14.9.2 RS-232 Application Port(s) ................................................................................... 299

14.9.3 RS-422 .................................................................................................................. 302

14.9.4 RS-485 Application Port(s) .................................................................................... 302

14.9.5 DB9 to RJ45 Adaptor (Cable 14) .......................................................................... 303

............................................................... 272

.............................................................. 299

15 Support, Service & Warranty 305

Contacting Technical Support ......................................................................................................... 305

15.1 Return Material Authorization (RMA) Policies and Conditions.............................. 307

15.1.1 Returning Any Product .......................................................................................... 307

15.1.2 Returning Units Under Warranty ........................................................................... 308

15.1.3 Returning Units Out of Warranty ........................................................................... 308

15.2 LIMITED WARRANTY ........................................................................................... 309

15.2.1 What Is Covered By This Warranty ....................................................................... 309

15.2.2 What Is Not Covered By This Warranty ................................................................ 310

15.2.3 Disclaimer Regarding High Risk Activities ............................................................ 310

15.2.4 Intellectual Property Indemnity .............................................................................. 311

15.2.5 Disclaimer of all Other Warranties ........................................................................ 311

15.2.6 Limitation of Remedies ** ...................................................................................... 312

15.2.7 Time Limit for Bringing Suit ................................................................................... 312

15.2.8 No Other Warranties ................................

15.2.9 Allocation of Risks ................................................................................................. 312

............................................................. 312

ProSoft Technology, Inc. P

February 25, 2011

age 9 of 316

Page 10

Contents MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

15.2.10

Controlling Law and Severability .......................................................................... 312

Index 313

Page 10 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 11

MVI56-AFC ♦ ControlLogix Platform Introduction

Liquid and Gas Flow Computer User Manual

1 Introduction

In This Chapter

Update Notice ........................................................................................ 12

MVI56-AFC Module ............................................................................... 14

Configuration Modification Lockout and Seal ........................................ 15

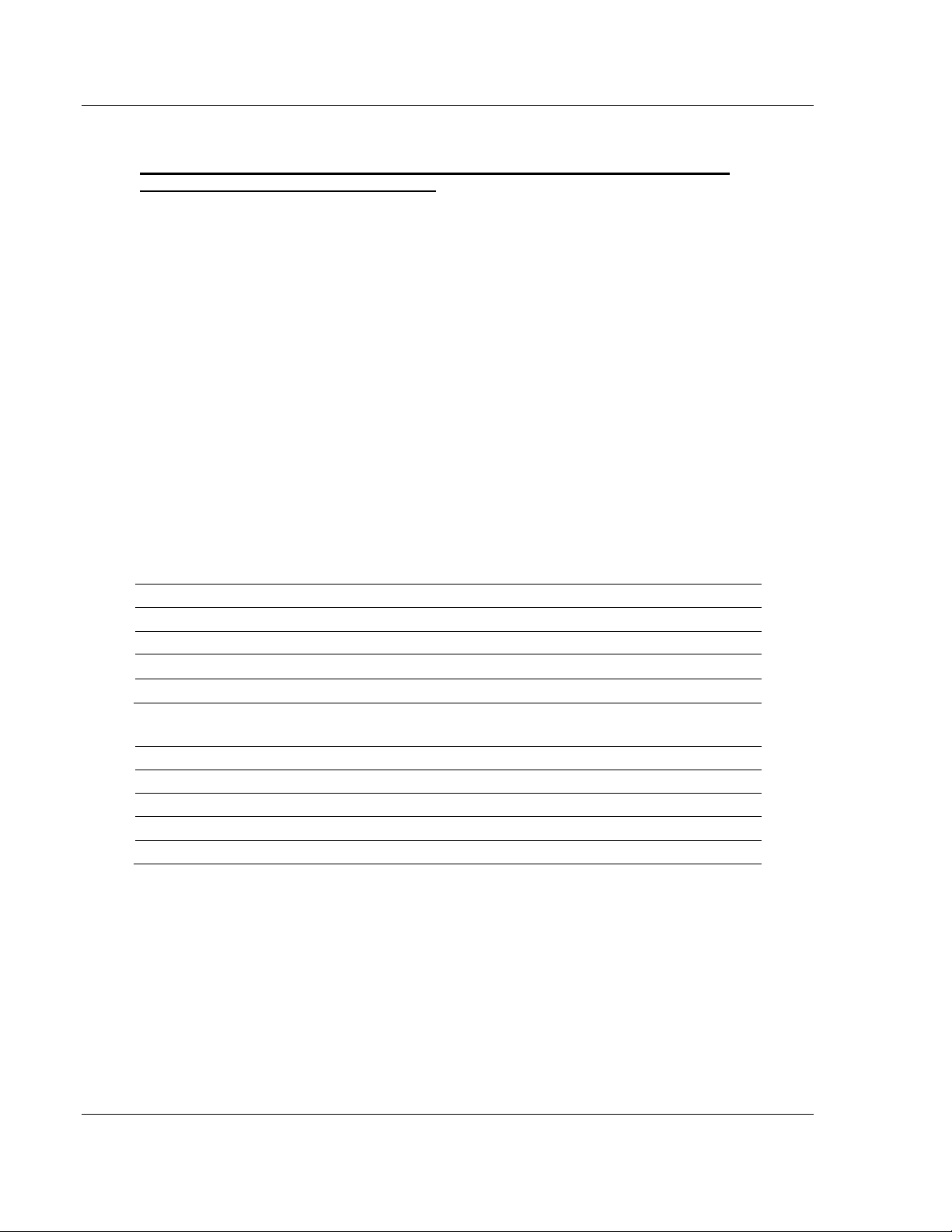

The MVI56-AFC Flow Computer module performs measurement of hydrocarbon

gases and liquids using currently accepted industry measurement standards. The

module consists of a single-slot solution for Rockwell Automation chassis. To

obtain its process inputs for calculations, the module uses the process data

collected by analog and pulse I/O modules. The processor transfers this data to

the AFC module, which then calculates flow rates, accumulated volumes, and

accumulated mass. The results of the calculations are transferred back to the

processor for use in the application logic, or for transfer to a SCADA host.

The module has two communication ports for Modbus communication allowing

easy access to a remote Modbus device. The module works as a Modbus slave

or master device.

As discussed later in this manual, the internal Modbus database can be

accessed by a Modbus Master device and by the processor (using the Modbus

Gateway Function).

The AFC Manager software can be used for easy meter configuration and

application monitoring. Refer to the AFC Manager User Manual for complete

information about this tool.

The following section provides a sample application where input data is

transferred from the transmitters to analog input cards on the Rockwell

Automation rack and the values are transferred from the processor to the module

(the module supports floating-point, scaled integer, or 4 to 20 mA format).

For Pulse meter applications, the pulse count and pulse frequency values are

typically transmitted through high-speed counter modules in the rack.

The module performs the flow calculation based on the values transferred

through the backplane. The calculation results can be read to the processor or

polled from a remote Modbus master unit connected to one of the communication

ports.

ProSoft Technology, Inc. Page 11 of 316

February 25, 2011

Page 12

Introduction MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

1.1 Update Notice

If your module measures liquids, please read this notice before upgrading from

version 2.04 (or earlier) to 2.05 (or later).

For compliance with new measurement standards, the AFC version 2.05 has

introduced several new liquid product groups. In particular, the two non-refined

liquid product groups of version 2.04, which covered the entire density range of

crudes and NGLs, have each been split into two separate product groups, one

for the higher density range of crudes and the other for the lower density range of

NGLs. If your module has meter channels configured for either "Crude, NGL" or

"Oil-water emulsion", you should decide before upgrading the firmware the

new product group (light or heavy) to which each such channel should be

assigned. This assignment will be performed during the upgrade process and will

preserve all other configuration and historical records including accumulator

values and archives, in contrast to changing a product group after the upgrade

which resets the meter configuration and erases all historical records. Meter

channels configured for "Gas" or "Refined products" are not affected.

AFC Manager exhibits the same behavior when converting a project between

versions 2.04 (or earlier) and 2.05 (or later).

The criterion for assigning the new product group depends on the density units

and the Default Reference Density, as described in the following tables:

Density Units = kg/m3

Version 2.04 Product Group Default Reference Density Version 2.05 Product Group

Crude, NGL

Crude, NGL > 0 AND < 610.0 NGLs, LPGs

Oil Water Emulsion

Oil Water Emulsion

= 0 OR ≥ 610.0

= 0 OR ≥ 610.0

> 0 AND < 610.0

Crude oils, JP4

Oil-water emulsion (Crd)

Oil-water emulsion (NGL)

Density Units = Rd/60

Version 2.04 Product Group Default Reference Density Version 2.05 Product Group

Crude, NGL

Crude, NGL > 0 AND < 0.6100 NGLs, LPGs

Oil Water Emulsion

Oil Water Emulsion > 0 AND < 0.6100 Oil-water emulsion (NGL)

= 0 OR ≥ 0.6100

= 0 OR ≥ 0.6100

Crude oils, JP4

Oil-water emulsion (Crd)

Due to roundoff error of numeric conversions, a Relative Density very close to

the cutoff value of 0.6100 may cause the module to assign the new product

group opposite to the one that was intended. Before upgrading, change the

Default Reference Density to a number significantly different from 0.6100, such

as 0.6110 (to target Crude) or 0.6090 (to target NGLs). You may change it back

to the correct value after the upgrade.

Page 12 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 13

MVI56-AFC ♦ ControlLogix Platform Introduction

Liquid and Gas Flow Computer User Manual

Density Units = API Gravity

Version 2.04 Product Group Default Reference Density Version 2.05 Product Group

Crude, NGL

= 0 OR ≤ 100.0

Crude, NGL > 0 AND > 100.0 NGLs, LPGs

Oil Water Emulsion

Oil Water Emulsion > 0 AND > 100.0 Oil-water emulsion (NGL)

= 0 OR ≤ 100.0

Crude oils, JP4

Oil-water emulsion (Crd)

ProSoft Technology, Inc. Page 13 of 316

February 25, 2011

Page 14

Introduction MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

1.2 MVI56-AFC Module

Page 14 of 316 P

roSoft Technology, Inc.

February 25, 2011

Page 15

MVI56-AFC ♦ ControlLogix Platform Introduction

Liquid and Gas Flow Computer User Manual

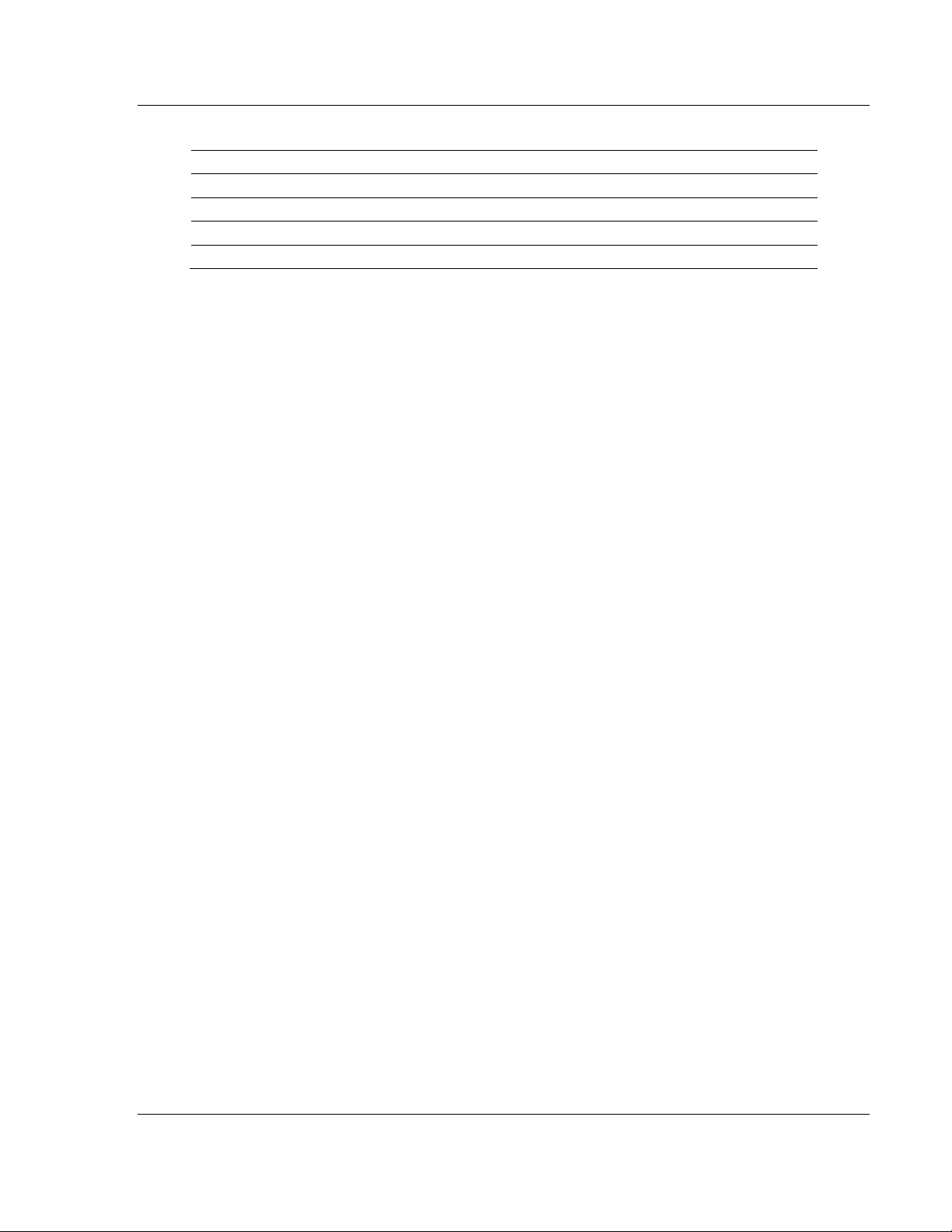

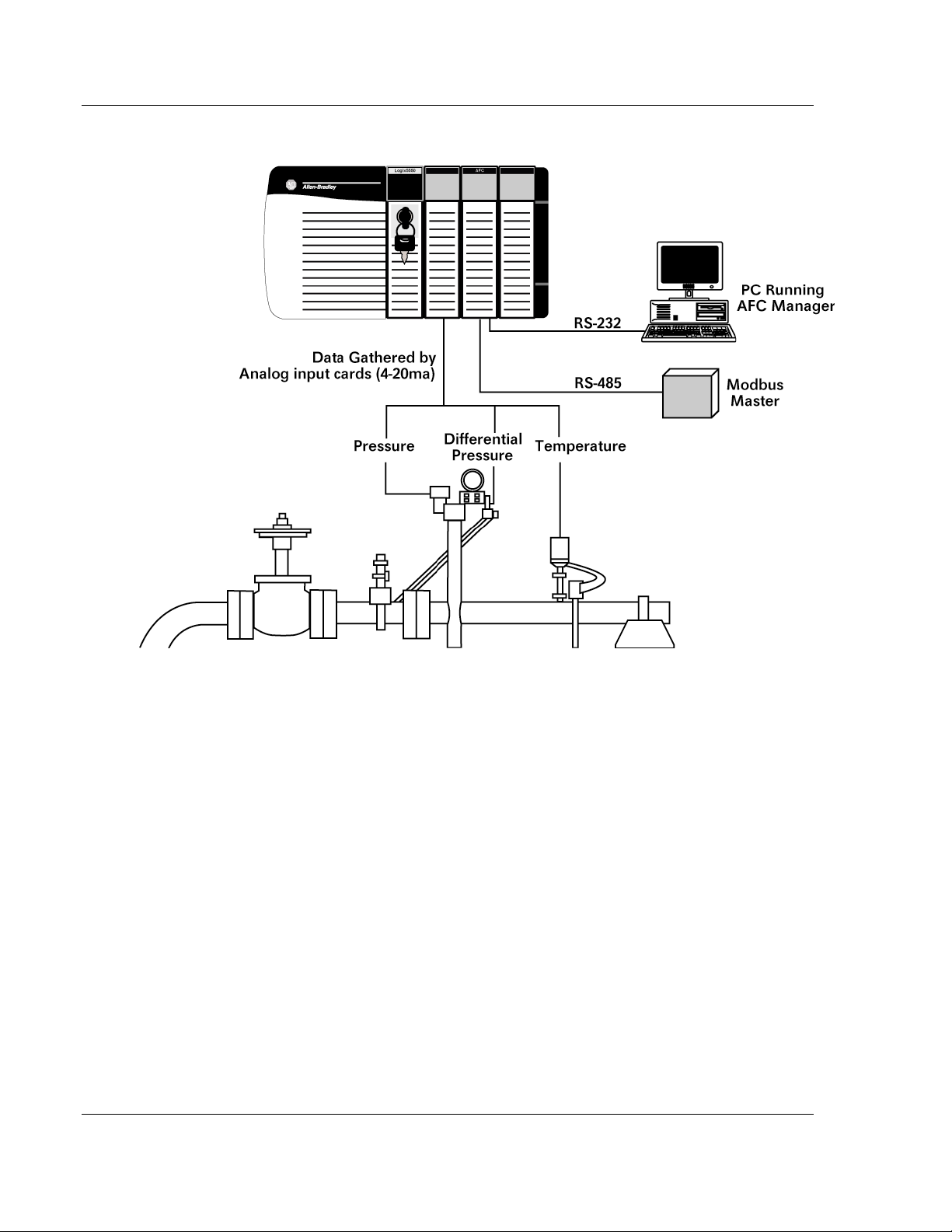

1.3 Configuration Modification Lockout and Seal

The MVI56-AFC application configuration can be certified and sealed with a userinstallable Lockout jumper and a tamper-evident lead seal. The Lockout jumper

and seal are commonly required for Weights & Measures certification, or custody

transfer applications.

Important: When the jumper is installed, the module will not accept configuration changes to

Sealable Parameters, which are parameters that affect the accuracy of flow calculation. Before

breaking the seal to remove the jumper, you should verify the steps required to recertify the module

with the appropriate regulatory agency.

For more information on sealing procedures, refer to "Sealing Provisions", on

page 8 of the MVI56-AFC Custody Transfer Certification document, which is

available from the ProSoft Technology web site at http://www.prosofttechnology.com/content/view/full/4613

ProSoft Technology, Inc. Page 15 of 316

February 25, 2011

Page 16

Introduction MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

To install the Lockout jumper and seal, follow these steps.

1 Locate the Lockout Jumper pins and Lockout Block,

labeled "W & M Lock" inside the module door, and

below the BBRAM ERR and OK LEDs.

1 Install the provided Lockout Jumper to connect the two

pins.

1 Carefully slide the Lockout Block up through the hole in

the Lockout Jumper. Be careful not to bend or break

the jumper block pins.

1 When the Lockout Block is positioned correctly, it will

expose a hole in the block, through which you may

pass the seal wire.

1 Slide the seal wire through the hole in the Lockout

Block. Pass the wire through the slot in the lead seal,

and then crimp the lead seal around the wire.

Once sealed, the Lockout block and jumper cannot be removed without

damaging the seal, the block, or the jumper.

Page 16 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 17

MVI56-AFC ♦ ControlLogix Platform Quick Start

Liquid and Gas Flow Computer User Manual

2 Quick Start

In This Chapter

Install AFC Manager .............................................................................. 18

Starting AFC Manager ........................................................................... 19

Using AFC Manager .............................................................................. 20

Ladder Logic Implementation ................................................................ 26

Setting the Wallclock ............................................................................. 28

Module Initialization ............................................................................... 29

This section provides a general overview of the steps required to install and

configure the module. You should read the AFC Manager User Manual to obtain

a clear understanding of the steps outlined in this section.

ProSoft Technology, Inc. Page 17 of 316

February 25, 2011

Page 18

Quick Start MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

2.1 Install AFC Manager

The AFC Manager application is included on the CD-ROM shipped with your

module. Before you can use the application, you must install it on your computer.

2.1.1 System Requirements

The following system requirements are the recommended minimum

specifications to successfully install and run AFC Manager:

Microsoft Windows compatible PC

Windows 2000 with Service Pack 2 or higher, or Windows XP Professional

with Service Pack 2 or higher, or Windows 2003 or Windows Vista, or

Windows 7.

300 mHz Pentium processor (or equivalent)

128 megabytes of RAM

20 megabytes of free disk space

Available serial port (COM port) or USB to Serial adapter cable with

necessary drivers, required for communication between AFC Manager

software and the AFC module.

DB9 adapter cable (included with module), required for connection between

PC serial port and AFC module (PTQ-AFC module does not require an

adapter).

To install the AFC Manager application

1 Insert the ProSoft Solutions CD in your CD-ROM drive. On most computers,

a menu screen will open automatically. If you do not see a menu within a few

seconds, follow these steps:

a Click the Start button, and then choose Run.

b In the Run dialog box, click the Browse button.

c In the Browse dialog box, click "My Computer". In the list of drives,

choose the CD-ROM drive where you inserted the ProSoft Solutions CD.

d Select the file prosoft.exe, and then click Open.

e On the Run dialog box, click OK.

2 On the CD-ROM menu, click Documentation and Tools. This action opens a

Windows Explorer dialog box.

3 Open the Utilities folder, and then open the AFCManager folder.

4 Double-click the file Setup.exe. If you are prompted to restart your computer

so that files can be updated, close all open applications, and then click OK.

When your computer has finished restarting, begin again at Step 1.

5 Click OK or Yes to dismiss any confirmation dialog boxes.

6 It may take a few seconds for the installation wizard to start. Click OK on the

AFC Manager Setup dialog box to begin installing AFC Manager.

7 Follow the instructions on the installation wizard to install the program with its

default location and settings.

8 When the installation finishes, you may be prompted to restart your computer

if certain files were in use during installation. The updated files will be

installed during the restart process.

Page 18 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 19

MVI56-AFC ♦ ControlLogix Platform Quick Start

Liquid and Gas Flow Computer User Manual

2.2 Starting AFC Manager

To start AFC Manager

1 Click the S

2 In the Programs menu, choose ProSoft Technology.

3 In the ProSoft Technology menu, choose AFC Manager.

TART

button, and then choose P

ROGRAMS

.

ProSoft Technology, Inc. Page 19 of 316

February 25, 2011

Page 20

Quick Start MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

2.3 Using AFC Manager

The AFC module is configured with configuration files that you create using AFC

Manager. A configuration file is called a Project.

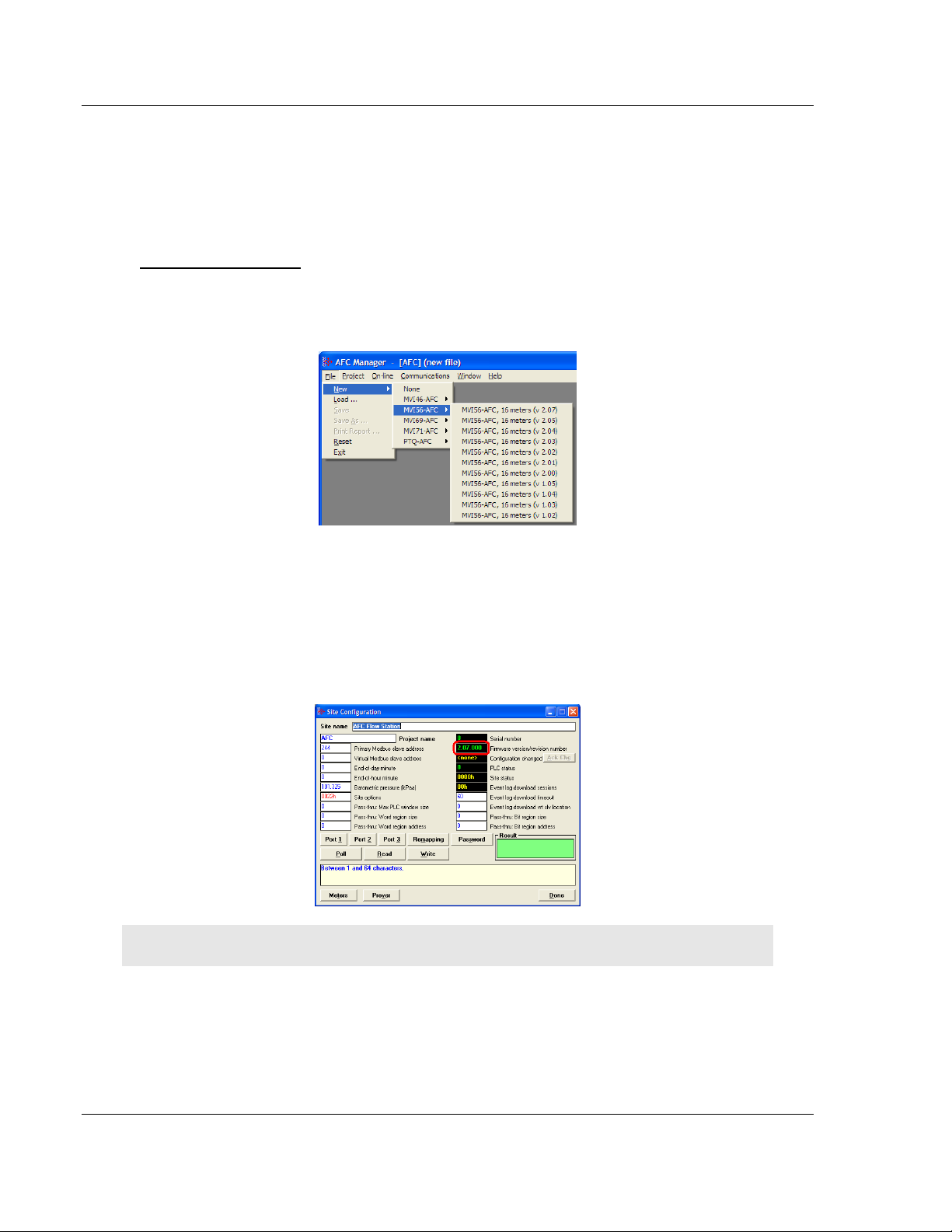

2.3.1 Starting a New Project

To start a new project

1 Start AFC M

2 On the File Menu, choose NEW, and then select your module and firmware

version number.

The version number refers to the firmware version of your module. If you do

not know the firmware version number, follow these steps:

a) Open the Project menu.

b) Choose S

dialog box.

c) Click the R

number, in the upper right part of the dialog box.

ANAGER

ITE CONFIGURATION

EAD

button. The firmware version is listed below the serial

, and then open the File Menu.

. This action opens the Site Configuration

Important: You must be connected to the module and "online" to read data from the module.

3 Follow the steps in the remainder of this User Guide to configure your module

and your AFC device.

4 Before closing the program, open the File menu and choose S

AVE AS

, to

save your project so you can open it again later.

Page 20 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 21

MVI56-AFC ♦ ControlLogix Platform Quick Start

Liquid and Gas Flow Computer User Manual

2.3.2 Loading an Existing project

You can open and edit a project you have previously saved. Do this if you have

started, but not completed, the configuration of your project, or if you need to

modify the settings for a project that has already been downloaded to the

module.

To load an existing project

1 Start AFC M

2 On the File menu, choose L

ANAGER

, and then open the File menu.

OAD

. This action opens a dialog box that shows a

list of AFC Manager project files (AFC files) in the current folder.

3 Choose the project to load, and then click O

PEN

.

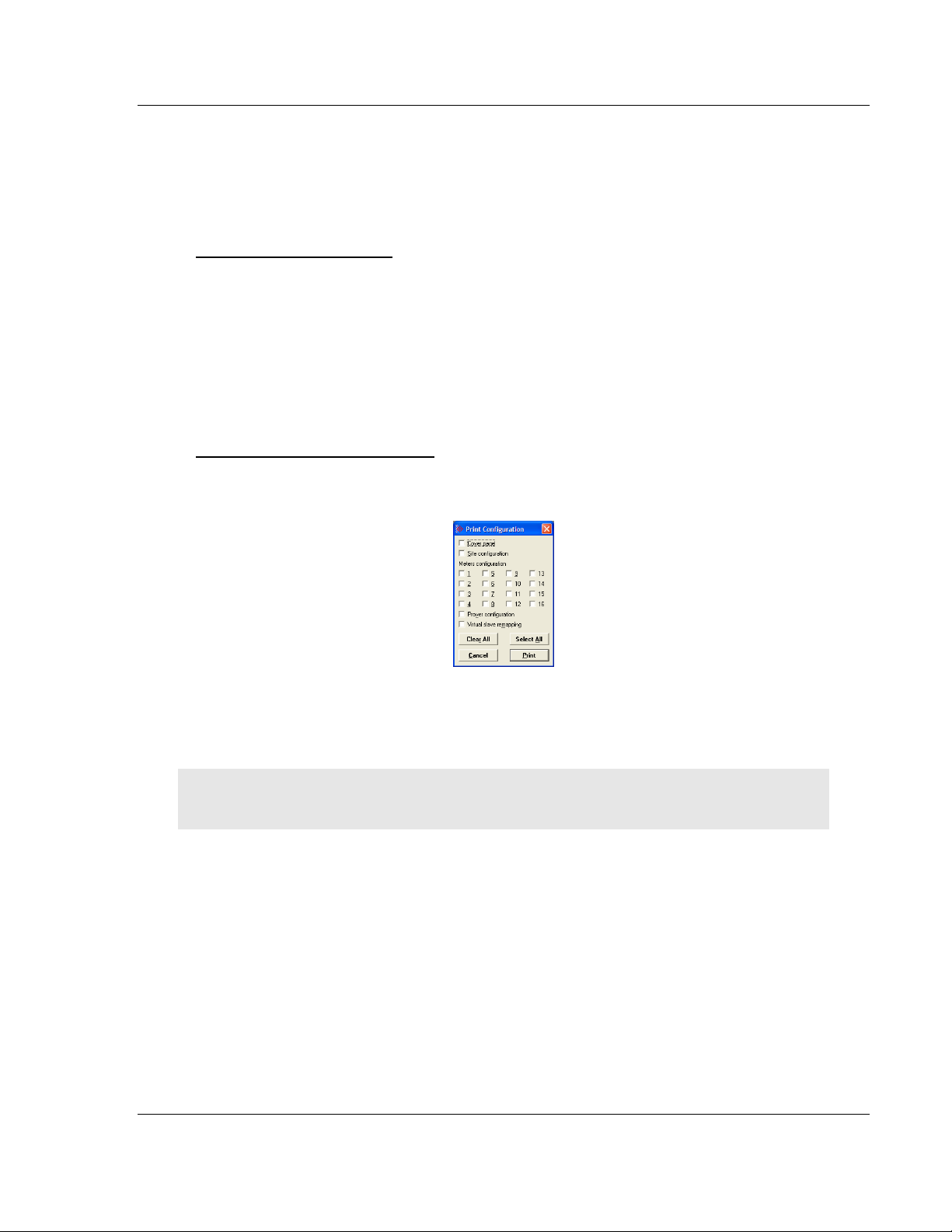

2.3.3 Printing the Configuration Report

You can print a report of your configuration for future reference, or for archival

purposes.

To print the configuration report

1 Open the File menu, and then select P

Print Configuration dialog box.

RINT REPORT

. This action opens the

2 On the Print Configuration dialog box, select (check) the items to include in

the printed report.

3 Click P

RINT

to send the report to your default printer.

Note: The size of the report depends on items you choose to include, and may require 75 pages or

more. Consider this before printing.

ProSoft Technology, Inc. Page 21 of 316

February 25, 2011

Page 22

Quick Start MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

2.3.4 Converting a Project

You can convert an existing project (configuration file) to use it with a different

module or firmware version. Do this if:

You want to reuse an application created for a different AFC module, for

example a project that was created for a PTQ-AFC that you want to use for

an MVI69-AFC.

You apply a firmware upgrade to a module.

To convert a project:

1 Open the File menu, and then choose O

2 Open the project (configuration file) to convert.

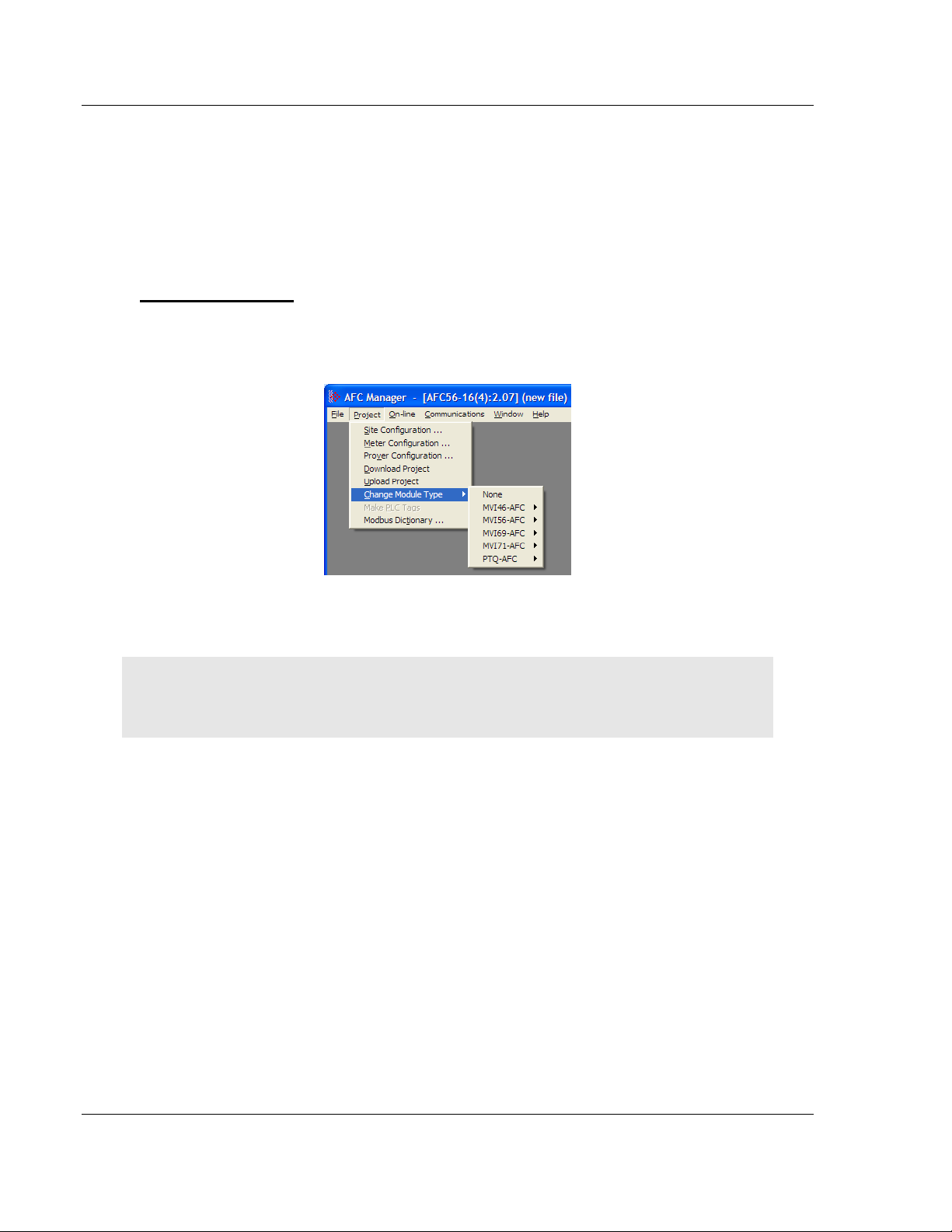

3 Open the Project menu, and then choose C

PEN

.

HANGE MODULE TYPE

.

4 Choose the module type and firmware version from the menu.

5 Save your project.

Note: AFC Manager will save your updated configuration file with the same name as the file you

loaded. If you need to keep your original configuration, change the file name of your updated

configuration before saving.

Page 22 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 23

MVI56-AFC ♦ ControlLogix Platform Quick Start

Liquid and Gas Flow Computer User Manual

2.3.5 Resetting Configuration Parameters

If you have modified your project (configuration file), or if you have loaded a

configuration file from disk, but you want to start a new project, you can reset the

configuration parameters back to their defaults without having to close and

reopen the AFC Manager.

To reset configuration parameters

1 Close any dialog boxes that are open.

2 Save the configuration file you were working on, if you would like to load it

again later.

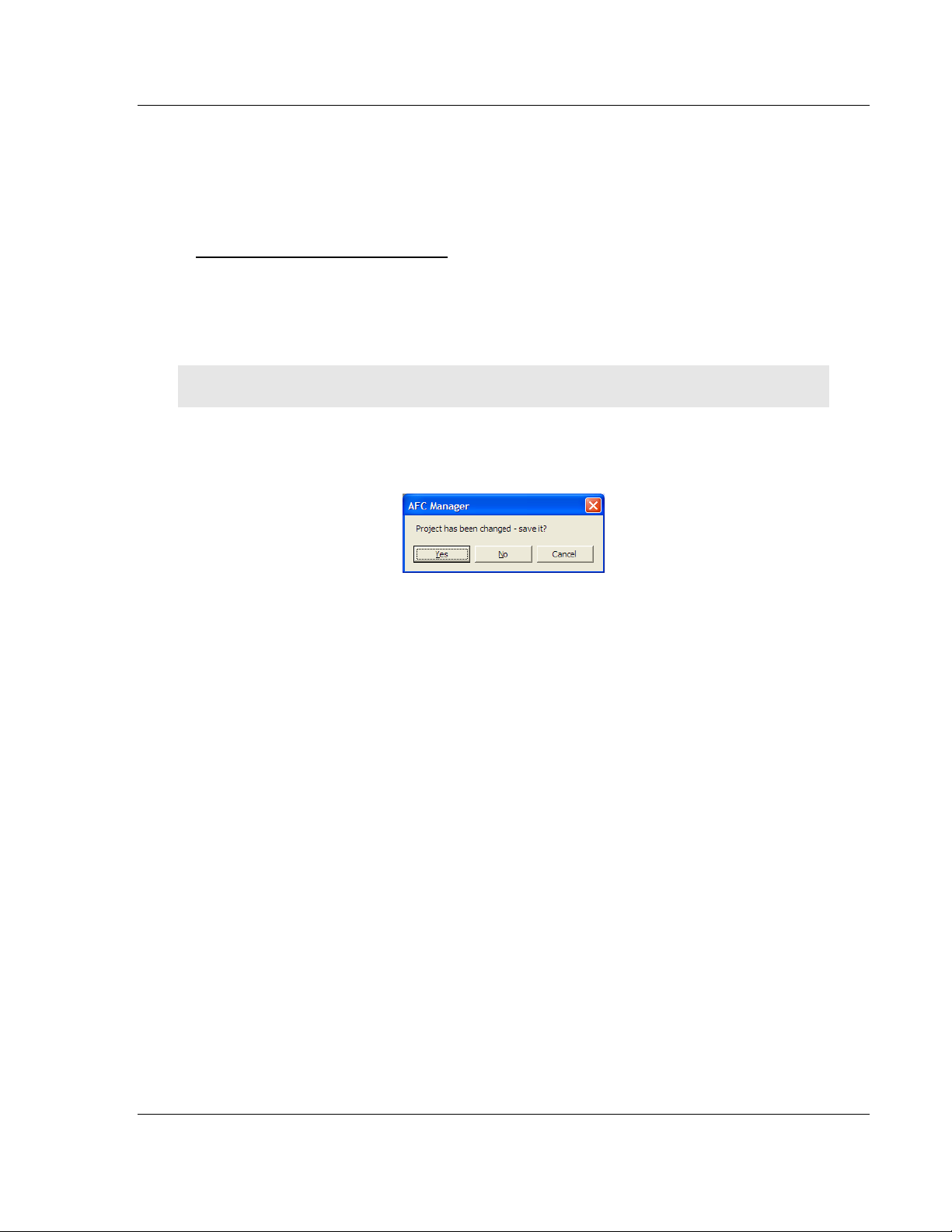

3 On the File menu, choose R

Note: This procedure has the same effect as choosing File / New / None.

If you have made changes to the configuration that have not yet been saved, a

confirmation dialog box will open.

ESET

.

Answer Yes to save your changes, or No to discard your changes and begin

working on a new configuration. Click Cancel to abandon the attempted action

that caused this message.

ProSoft Technology, Inc. Page 23 of 316

February 25, 2011

Page 24

Quick Start MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

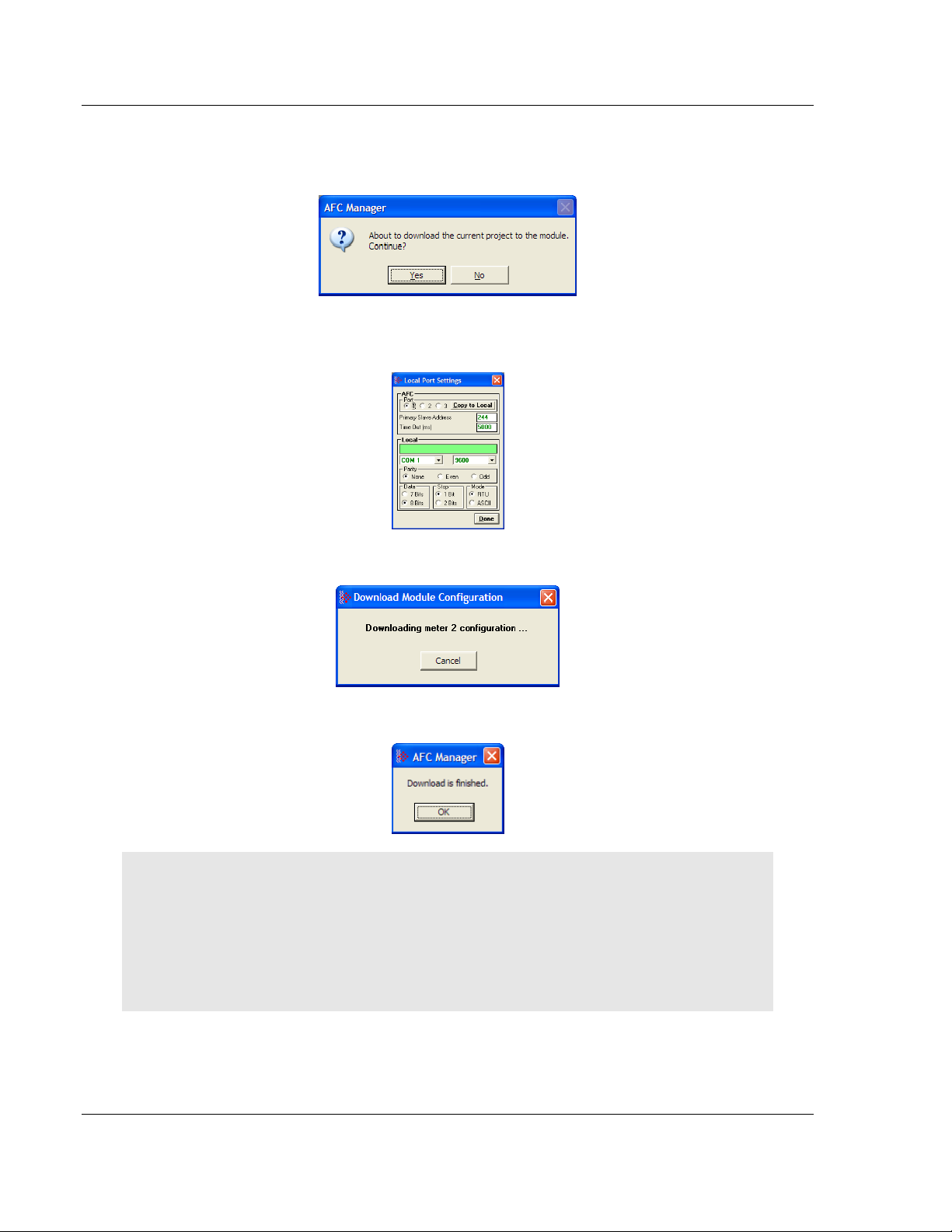

2.3.6 Downloading the Project to the Module

1 Click P

2 This action opens the Local Port Settings window. Enter the port parameters

to use, and then click D

3 During the download operation, the following progress window is displayed:

ROJECT / DOWNLOAD PROJECT

ONE

.

.

4 When the file transfer is complete, the following window is displayed:

Note: The virtual slave remapping data (page 74) is not downloaded during the procedure because

it requires a separate download operation.

Troubleshooting Tip: If the AFC Manager displays an "Illegal Data Value" message, it typically

indicates an invalid meter type or product group configuration. The module does not accept a

configuration file that attempts to change a meter type or product group for a meter that is currently

enabled. Disable all meters, change the meter types and product groups, and then enable the

meters again.

Page 24 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 25

MVI56-AFC ♦ ControlLogix Platform Quick Start

Liquid and Gas Flow Computer User Manual

2.3.7 Verifying Correct Operation

When all of the configuration steps have been completed, the module should be

ready to perform measurement calculations. To verify that the module is

configured correctly, follow these steps:

1 Enable all meters that will be used, as any meter will only perform

calculations if it is enabled. Any meter can be enabled either with ladder logic

(MVI56-AFC modules), function blocks (PTQ modules) or with AFC Manager.

2 Make sure that the wallclock is running, and that it has valid date and time

information. After power-up, the wallclock will be stopped, therefore the

module will not perform any time-scheduled operations, such as writing

period-end archives, and will not timestamp records written to the event log

until it receives a wallclock command from the ladder logic.

The sample ladder logic programs the wallclock update command upon

detecting "power-up" status from the AFC. The date/time information used is

the same as the processor, therefore you should use the configuration tool for

your processor to verify that the processor has valid date/time data. If the

processor wallclock is not valid (for example if the year = 1900), the module

will not accept the command. You may easily determine if the wallclock is

running by performing two consecutive read operations in the Meter Monitor.

3 Make sure that the meter does not have any alarms. A meter alarm may

affect flow calculation. Look at the Meter Monitor dialog box for alarms.

4 Make sure that the input parameters transferred from the processor are

correct. You can look at these values in the Meter Monitor dialog box.

5 When using a pulse meter, make sure that the pulse input rollover parameter

in Meter Configuration matches the actual input rollover value used in the

high speed counter module.

ProSoft Technology, Inc. Page 25 of 316

February 25, 2011

Page 26

Quick Start MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

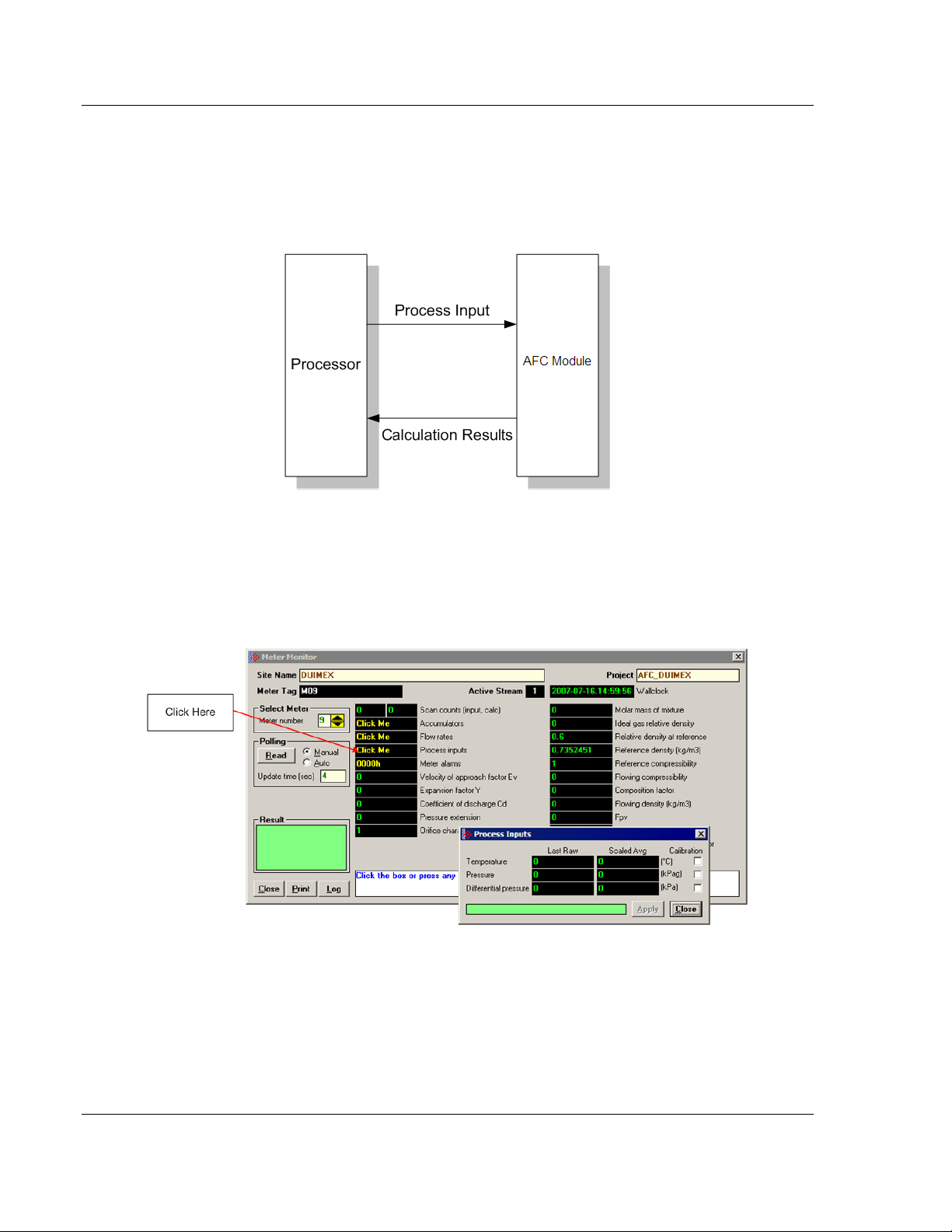

2.4 Ladder Logic Implementation

The sample ladder logic performs tasks that are covered in the Ladder Logic

sections of this manual. The most important task is to continuously write meter

process input variables from the processor to the module, and read calculation

results from the module to the processor.

Refer to the Ladder Logic sections for instructions on how to transfer the meter

process variables from the processor to the module. Ladder logic is required to

move the process variables to the correct data file or controller tag in the

processor.

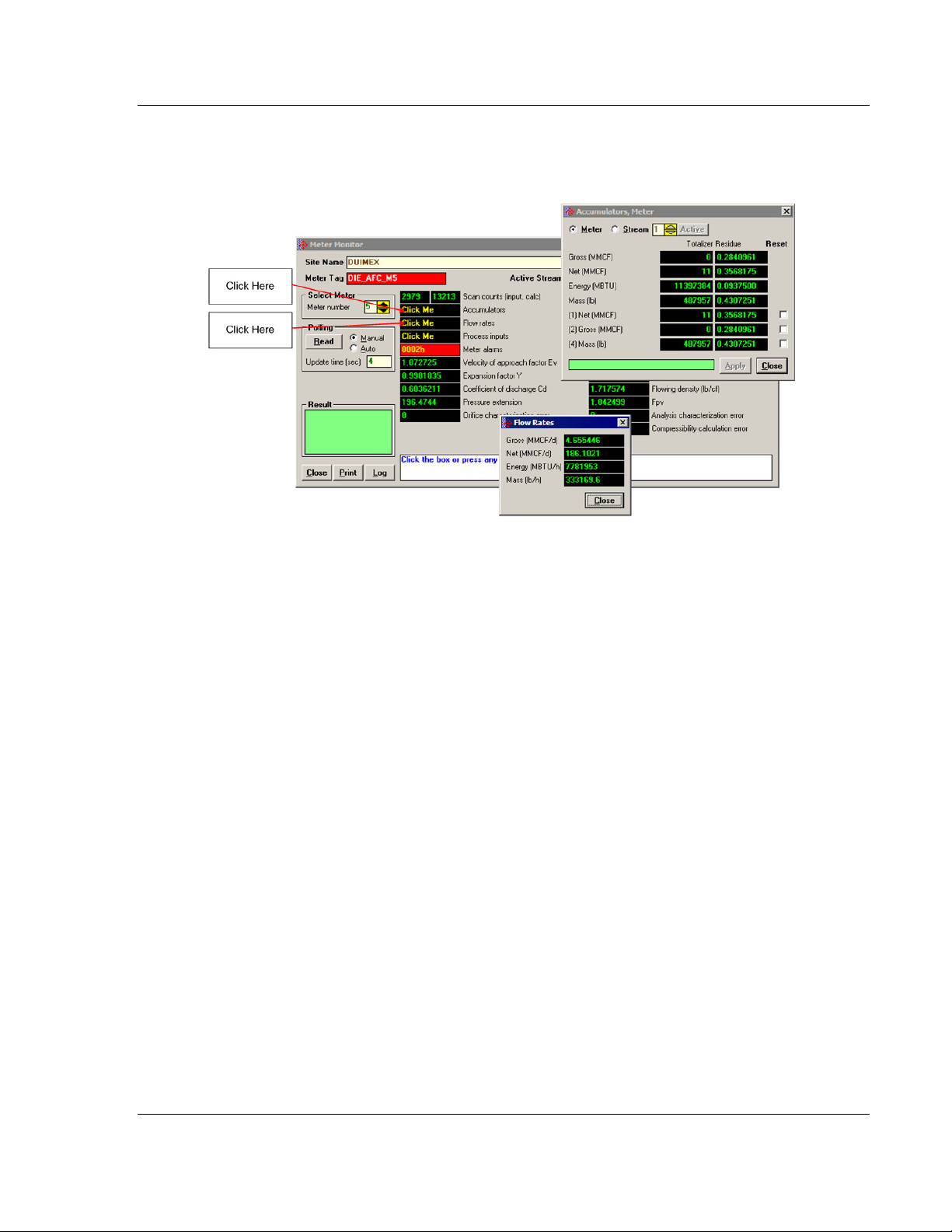

The Meter Monitor window (Process Inputs field) displays the values that are

transferred from the processor.

Page 26 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 27

MVI56-AFC ♦ ControlLogix Platform Quick Start

Liquid and Gas Flow Computer User Manual

The values calculated by the module are continuously transferred to the

processor. You can refer to the Meter Monitor window to verify results

calculated by the module.

Refer to the Ladder Logic section for more information regarding the data files

and controller tags that store the calculation results transferred from the module

(for example, accumulator, flow rate, and so on).

ProSoft Technology, Inc. Page 27 of 316

February 25, 2011

Page 28

Quick Start MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

2.5 Setting the Wallclock

After power-up, the module must receive valid wallclock data from the ladder

logic to perform time-scheduled operations and to properly timestamp historical

records. The sample ladder logic automatically writes the wallclock upon

detecting power-up status from the AFC using the processor’s date and time

information. You should ensure that the processor contains valid date and time

information. If it does not, the module may not accept the wallclock block.

You can verify the wallclock information using the Meter Monitor section as

shown in the following example:

Refer to the Sample Ladder Logic section for more information on this topic.

Page 28 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 29

MVI56-AFC ♦ ControlLogix Platform Quick Start

Liquid and Gas Flow Computer User Manual

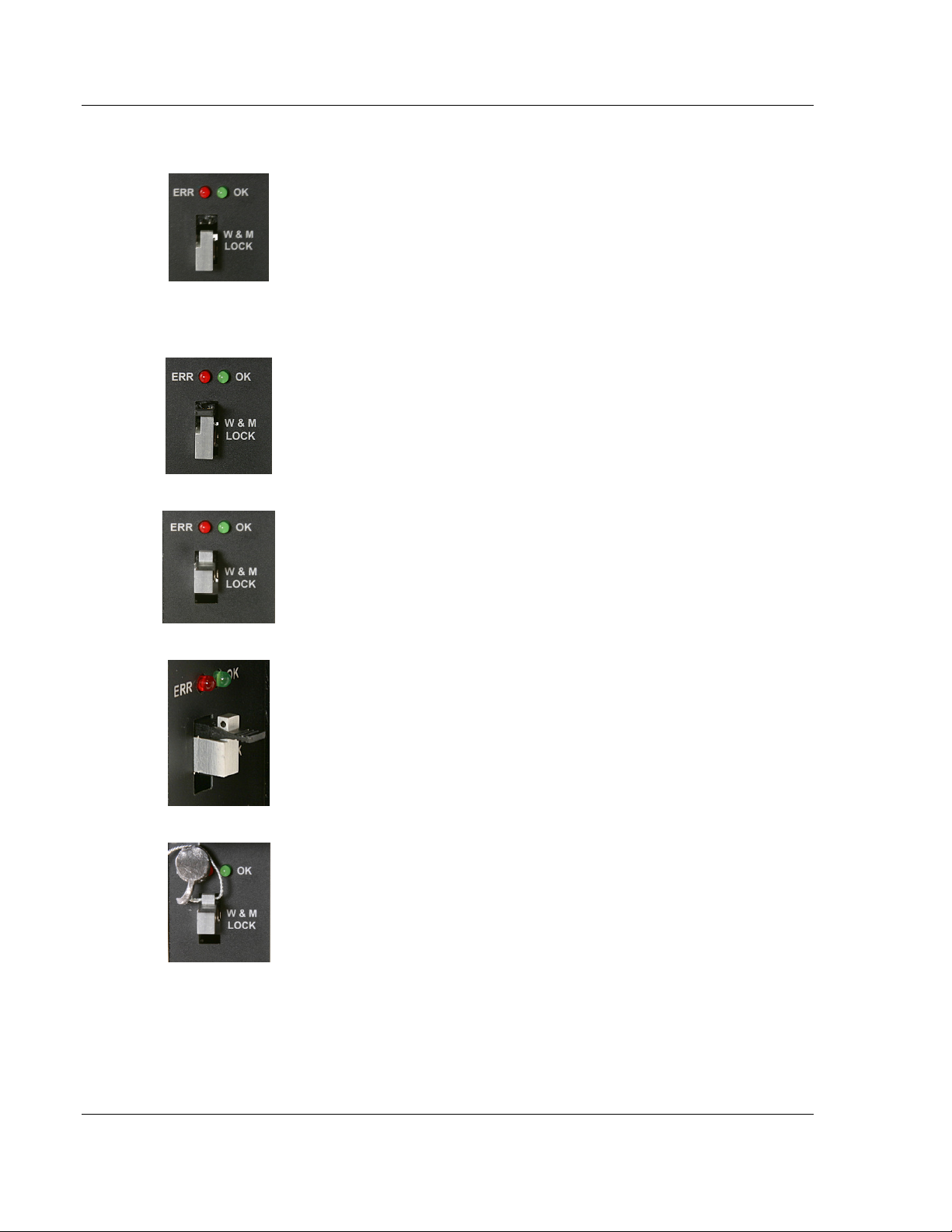

2.6 Module Initialization

When the module is powered up for the first time, both the OK and ERR BBRAM

LEDs are illuminated. This indicates that the module is in the Cold Start state and

is not yet ready to perform calculations. The following steps initialize the module:

Enable at least one meter

Set the processor to RUN mode

After these two steps are accomplished, the state is changed from Cold Start to

Released. This indicates that that module is ready to perform flow calculations.

When in the Released state, the OK LED is ON and the ERR LED is off.

When the module is ready, you will use AFC Manager to monitor meter

operation, archives, and events. The AFC Manager User Manual contains

detailed information on these tasks.

ProSoft Technology, Inc. Page 29 of 316

February 25, 2011

Page 30

Quick Start MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

Page 30 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 31

MVI56-AFC ♦ ControlLogix Platform Meter Channel Functionality

Liquid and Gas Flow Computer User Manual

3 Meter Channel Functionality

In This Chapter

Meter Channels ..................................................................................... 32

Linear (Pulse) Meter Overview .............................................................. 33

Differential (Orifice) Meter Overview ..................................................... 34

Gas Product Overview........................................................................... 35

Liquid Product Overview........................................................................ 36

General Features .................................................................................. 37

ProSoft Technology, Inc. Page 31 of 316

February 25, 2011

Page 32

Meter Channel Functionality MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

3.1 Meter Channels

Each meter channel can be assigned as a linear meter (e.g. a pulse meter) input

or as a differential meter (e.g an orifice meter) input for flow measurement using

either SI (metric) or US units. Selecting the differential meter causes the module

to use the AGA 3 standard for flow calculation (for a gas orifice meter you may

optionally choose ISO 5167-2 instead). Selecting the linear meter causes the

module to use the AGA 7 standard for gas flow calculation.

Each meter channel can be configured for gas or liquid (crude or refined)

product. The Product Group essentially selects the API/AGA Standards to be

used in calculating flow rates/increments.

Selecting "Gas" causes use of AGA8 and either AGA3 or AGA7 Standards.

Selecting any liquid group causes use of API MPMS Chapter 11(tables

23/24/53/54) and related Standards. "Crude oils, JP4" and "Oil-water emulsion

Crd)" use the, "A", tables. “NGLs, LPG’s” and “Oil-water emulsion (NGL) use the

“E” tables. "Refined Products" use the "B" tables. "Lubricating oils" use the "D"

tables, and "Special applications" use the "C" tables. "Crude oils, JP4" and

"NGLs/LPG" are used for propane, butane, NGLs (natural gas liquids), and crude

oils which are relatively water-free (less than 5 percent). The two "Oil-water

emulsion" groups are used for crude and NGL/LPG that might have a high

concentration of water for which API MPMS Chapter 20.1 is applicable. "Refined

products (xJP4)” is used for lighter refined liquids such as gasolines, jet fuels

(except JP4), and fuel oils. "Lubricating oils” is used for heavier refined liquids.

"Special applications" is used for those liquids that cannot reasonably be

assigned to one of the other groups; for this product group an explicit coefficient

of thermal expansion must be supplied.

The following table provides a brief overview of the standards used according to

the Meter Type and Product Group:

Meter Type Product Group Standards

Differential Gas AGA8, AGA3/ISO5167

Differential Liquid MPMS ch 11 AGA3/ISO5167

Linear Gas AGA8, AGA7

Linear Liquid MPMS ch 11, MPMS ch12.2

Note: The meter channel must be disabled in order to change its meter type and product group.

Page 32 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 33

MVI56-AFC ♦ ControlLogix Platform Meter Channel Functionality

Liquid and Gas Flow Computer User Manual

3.2 Linear (Pulse) Meter Overview

The module typically receives the pulse count and pulse frequency values from a

high-speed counter module. The module uses these values to perform

calculations.

You can configure the primary input to be used for volume calculation. You can

configure it as Pulse Count or Pulse Frequency.

3.2.1 Primary Input = Pulse Count

If you select Pulse Count as the primary input, the module uses the pulse count

value transferred through the backplane as the primary input for volume

calculation. In this case, the pulse frequency will be used for flow rate calculation

only.

3.2.2 Primary Input = Pulse Frequency

If you select Pulse Frequency as the primary input, the module uses the pulse

frequency value transferred through the backplane as the primary input for both

flow accumulation and flow rate calculation. The pulse count value is ignored by

the module.

ProSoft Technology, Inc. Page 33 of 316

February 25, 2011

Page 34

Meter Channel Functionality MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

3.3 Differential (Orifice) Meter Overview

The static pressure of the gas stream can be measured either upstream of the

meter (before the differential pressure drop), or downstream of the meter (after

the pressure drop). Both AGA3 and AGA8 require the upstream static pressure

for their calculations, where:

upstream pressure = downstream pressure + differential pressure

If the pressure is measured from a downstream tap (typical), the Downstream

Static Pressure option should be set through the AFC Manager.

The module also supports the V-Cone device. You can configure V-Cone meters

and downstream selections in AFC Manager, on the Meter Configuration /

Calculation Options dialog box.

3.3.1 Primary Input = Differential Pressure

The primary input parameter configures the value used as source for the

accumulator calculation. If the parameter is set to Differential Pressure, the

module uses the differential pressure value transferred through the backplane for

accumulator calculation.

3.3.2 Primary Input = Flow Rate

You can configure the primary input parameter as flow rate in order to use this

value for the accumulator calculation.

Note: The flow rate can be converted to a different unit.

The AFC Manager software supports the following parameters:

Orifice Plate and Meter Tube Measured Diameter

Orifice Plate and Meter Tube Measurement Temperature

Orifice Plate and Meter Tube, Coefficient of Thermal Expansion

DP Flow Threshold (kPa)

DP Alarm Threshold (kPa)

Page 34 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 35

MVI56-AFC ♦ ControlLogix Platform Meter Channel Functionality

Liquid and Gas Flow Computer User Manual

3.4 Gas Product Overview

The gas compressibility calculations are based on molar analysis concentrations

of up to 21 components, using the Detail Characterization Method of AGA8

(1992). The module automatically generates alarms if the sum of the molar

concentrations is not 100%

Configure the analysis settings using the AFC Manager (Meter Configuration /

Analysis Config) as follows. This window allows the selection of the

components(Component Selection Map) and analysis precision (Precision and

Stream Assignment – version 2.06.000 or higher). The sample ladder logic

assumes that all components are selected so check all components at the

Component Selection Map window.

Enter the gas analysis concentrations by clicking the Analysis button.You can

also update the concentrations through the backplane as will be later shown in

this User Manual.

The module records events every time a molar concentration value changes. For

applications that involve gas chromatograph devices, this feature might not be

desirable because it is expected that the values should frequently change. You

can disable this feature using AFC Manager (Meter Configuration / Control

Options / Treat Analysis as Process Input).

ProSoft Technology, Inc. Page 35 of 316

February 25, 2011

Page 36

Meter Channel Functionality MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

3.5 Liquid Product Overview

The module supports applications involving crude or refined oil such as crude oil,

oil/water emulsion, propane, butane, NGLs, LPGs, gasoline, jet fuels and

lubricating oils.

When measuring liquids with density correction, density at flowing conditions is

required. This value may be provided directly as a process input, or the module

can calculate a density from the frequency provided by a densitometer device.

3.5.1 To use a densitometer

Follow the steps below to use a densitometer.

1 Configure it, entering all configuration parameters directly from the calibration

data sheet supplied by the densitometer manufacturer.

2 Supply the frequency output from the densitometer in Hz as a floating-point

value in the "Flowing density" process-input location over the backplane

(refer to the Backplane Communication section for your platform in the

MVI56-AFC manual to determine the correct location). The AFC then

calculates a flowing density value, which is then validated by the range check

mandated by the "Density" values of "Process Input Scaling" of the meter

configuration. The "Scaling" sub-selection is not used against the frequency

input, however; the frequency is always input as floating-point.

Note: If using the Densitometer feature, select the Density Process Input Scaling for 4 to 20mA

and enter the densitometer frequency as a floating-point value.

3.5.2 Module Configuration

3.5.3 Density Units

The liquid density units can be expressed as:

Density is in kg/m3

Relative density 60ºF/60ºF

API gravity

3.5.4 Measuring Water Diluent

For liquid measurement applications, the optional automatic calculation of Net Oil

Volume and mass based on the Sediment and Water (S&W) percent input is

supported. Only provide the S&W percent value in the specified controller

register. The module puts the gross standard (or gross clean oil), net oil and

water accumulations in separate accumulators. Refer to Net Accumulator

Calculation (page 89).

Page 36 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 37

MVI56-AFC ♦ ControlLogix Platform Meter Channel Functionality

Liquid and Gas Flow Computer User Manual

3.6 General Features

3.6.1 Process Variable Interface

Process variables for each of the meter runs must be produced by the controller

for consumption by the AFC module. A versatile architecture for backplane

transfer of process variables and other data and signals allow you to easily

implement the data transfer. The sample ladder logic automatically transfers the

process variables to the module and reads the calculation results to the

processor.

3.6.2 Meter Scan Time

For good measurement, the process I/O must be sampled, and the flow

calculations completed quickly in order to avoid losing process information and

measurement accuracy. The process I/O scan time for the module is under one

second for all meter runs.

Note: This is time-dependent on design of the ladder logic implemented to support the two-way

data transfer between the AFC module and the controller. The meter calculation scan independent

of the process I/O scan may take longer.

3.6.3 Multiple Meter Accumulators

Each meter channel supports the following set of full 32-bit accumulators that

may be configured in binary or split decimal format with user-defined rollover

values:

Gross Volume

Gross Standard Volume (liquid only)

Net Volume

Mass

Water (liquid only)

Energy (gas only)

Access to the above accumulators is available directly from the Modbus Slave

communications ports.

3.6.4 Product Batching

Any or all of the available meter runs may be configured for field installation that

requires shipping and/or receiving product batches of predetermined size. The

configuration utility option of selecting resettable accumulators provides a simple

way to use the power of ladder logic to design product batching, monitoring, and

control tailored to suit specific field requirements.

The Meter Signals feature can be used to create an archive or reset an

accumulator after the batch is concluded. Refer to the Ladder Logic section for

your platform for more information on using this feature.

ProSoft Technology, Inc. Page 37 of 316

February 25, 2011

Page 38

Meter Channel Functionality MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

3.6.5 Data Archiving

The module supports the archiving of data for each meter channel. Each time,

one record consisting of all the associated data is date and time stamped and

archived. This option allows for archiving each hour for 2 days (48 records per

meter run) and every day for 35 days (35 daily records per meter run) for each

meter channel. Each record consists of up to 40 process and other variables.

Archives are mapped to the local Modbus Table. Refer to Archives (page 91) for

more information about this topic.

3.6.6 Event Log Function

The module can log up to 1999 critical events in an Event Log File stored as a

set of easily accessible Modbus registers in non-volatile RAM. Changing critical

parameters, such as orifice plate size, Meter Base K factors, and Meter

Correction Factors, are time stamped and logged. Refer to Events for more

information about this topic.

3.6.7 Measurement Units

This option is provided for each meter channel to be configured with SI or US

units of measurement. Units for flow totalization (volumetric and mass) and flow

rate monitoring are configurable for each meter channel separately if the default

configuration is not applicable. Each meter channel may be configured to use

any of the standard units from liters/gallons to thousand cubic meters/barrels.

The flow rate period of each meter channel may be selected from flow rate per

second, per minute, per hour, or per day.

Page 38 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 39

MVI56-AFC ♦ ControlLogix Platform Meter Channel Functionality

Liquid and Gas Flow Computer User Manual

3.6.8 Process Input Scaling

The module allows you to either pre-scale the process inputs via ladder logic for

use in the measurement calculations, or provide unscaled values from the analog

input modules directly. In the second case, the scaling is done internally. You can

directly enter the zero-scale, the full-scale, and the default values for each of the

process variable inputs through the configuration window. Pre-scaled values may

be transferred as floating point or as scaled integer.

When selecting scaled integer, the integer values are scaled as follows:

Scaled Integer

Variable Format Example

Temperature Two decimal places implied A value of 1342 would be

equivalent to 13.42°C

Pressure No decimal places implied for SI

units (kPa) and one decimal

place implied for U.S. units (psi).

Differential Pressure Two decimal places implied for

inches of H2O and 3 places for

kPa

Density (kg/m3) One implied decimal place A value of 5137 would be

Density (Relative Density) Four implied decimal places A value of 10023 would be

Density (API) Two implied decimal places A value of 8045 would be

A value of 200 would be

equivalent to 200kPag

A value of 35142 would be

equivalent to 35.142kPa

equivalent to 513.7 kg/m3

equivalent to 1.0023 60F/60F.

equivalent to 80.45 °API.

When selecting the 4 to 20mA process input scaling, the module uses the

following ranges:

4 to 20mA

Processor Module 0% 100%

SLC MVI46-AFC 3277 16384

ControlLogix MVI56-AFC 13107 65535

CompactLogix MVI69-AFC 6241 31206

PLC MVI71-AFC 819 4095

Quantum PTQ-AFC 4000 20000

The module uses the configured values for zero and full scale to interpret the

process input scaling.

In the Meter Monitor window, the raw values as transferred from the processor

are shown at the "Last Raw" column and the converted values are shown at the

"Scaled Avg" column.

ProSoft Technology, Inc. Page 39 of 316

February 25, 2011

Page 40

Meter Channel Functionality MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

Page 40 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 41

MVI56-AFC ♦ ControlLogix Platform Meter Proving

Liquid and Gas Flow Computer User Manual

4 Meter Proving

In This Chapter

Prover Configuration ............................................................................. 42

Setting up the AFC module for Meter Proving ....................................... 51

Meter Proving Reports........................................................................... 63

Protected Meter Proving Data in the AFC's Input Register Bank .......... 64

As meters continue to be used over time, the meter’s measurement accuracy

deteriorates. Many things can cause the flow sensor bearings to wear down

beyond specified limits so that meters are measuring lower volume levels

causing producers to pump more oil than the consumer is buying. Meter Provers

have a “Known Traceable Volume” which allows using actual flowing and

operating conditions to establish a meter correction factor to restore

measurement accuracy.

There are 4 types of provers. This chapter will give a basic overview for each

type, its options, and configuration.

The Unidirectional Pipe Prover

The Bidirectional Pipe Prover

The Compact Prover

The Master Meter

ProSoft Technology, Inc. Page 41 of 316

February 25, 2011

Page 42

Meter Proving MVI56-AFC ♦ ControlLogix Platform

User Manual Liquid and Gas Flow Computer

4.1 Prover Configuration

Prover type is a parameter that identifies the basic type of the prover. It's values

are:

N

O PROVER CONFIGURED

U

NIDIRECTIONAL PIPE PROVER

(You may also choose this selection for an

atmospheric tank prover.)

B

IDIRECTIONAL PIPE PROVER

C

OMPACT (SHORT, SMALL VOLUME) PROVER

M

ASTER METER

4.1.1 Prover Type

Prover characteristics and configurations will vary based on the type of prover

and options you select. The following topics describe each type of prover.

Page 42 of 316 ProSoft Technology, Inc.

February 25, 2011

Page 43

MVI56-AFC ♦ ControlLogix Platform Meter Proving

Liquid and Gas Flow Computer User Manual