Page 1

MVI56-104S

ControlLogix Platform

IEC 60870-5-104 Server

Communication Module

USER MANUAL

November 18, 2009

Page 2

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIV. 2;

B WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

C WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

D THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

MVI (Multi Vendor Interface) Modules

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'EQUIPMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

CL I Div 2 GPs A, B, C, D

Temp Code T5

II 3 G

Ex nA IIC T5 X

0° C <= Ta <= 60° C

II - Equipment i ntended for above ground use (not for use in mines) .

3 - Category 3 equipm ent, investigated for normal operation only.

G - Equipment prot ected against explosive gasses.

Warnings

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in Hazardous Locations, turn off power before replacing or rewiring

modules.

Warning - Explosion H azar d - Do not disconnect eq uipment unless power has been switch ed off or t he area i s

known to be nonhazardous.

C Suitable for use i n Class I, division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage:

Power, Input, and Out put (I/O) wiring must be in accordance with the authority having j urisdiction

A Warning - Explosion Hazard - W hen in hazardous locations, tur n off power before replacing or wiring modules.

B Warning - Explosion H azar d - Do not disconnect eq uipment unless power has been switch ed off or t he area i s

known to be non-hazardous.

C These products are intended to be mounted in an IP54 encl osure. The devices shall provide ext ernal m eans to

prevent the rated voltage being exceeded by transient disturbances of more t han 40%. This device m ust be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Page 3

Elect

rical Ratings

Backplane Current Load: 800 m A @ 5 V DC; 3mA @ 24V DC

Operating Temperature: 0 to 60°C (32 to 140°F)

Storage Temperature: -40 to 85°C (-40 to 185°F)

Shock: 30g Oper ati onal; 50g non-operational; Vi br ation: 5 g from 10 to 150 Hz

Relative Humidity 5% to 95% (non-condensing)

All phase conductor sizes must be at least 1.3 mm(squar ed) and all earth ground conductors must be at least

4mm(squared).

Markings:

CSA/cUL C22.2 No. 213-1987

CSA CB Certified IEC61010

ATEX EN60079-0 Category 3, Zone 2

EN60079-15

243333

Battery Life Advisory

The MVI46, MVI56, MVI69, and MVI71 modules use a rechargeable Lithium Vanadium Pentoxide battery to backup

the real-time clock and CMOS. The battery should last for the life of the module. The m odule must be powered for

approximately twenty hours before the battery becomes fully charged. After it is fully charged, the battery provides

backup power for the CMOS setup and the real-time clock for approxim at ely 21 days. When the battery is f ully

dischar g ed, t h e modul e will revert to the default BIO S and clock s ett ings.

Note: The battery is not user replaceable.

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comment s,

compliments or complaints about t he product, documentation, or support, pl ease write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 ( Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © ProSoft Technology, I nc. 2009. All Rights Reserved.

MV

I56-104S User Manual

November 18, 2009

®

ProSoft Technology

Technology, Inc. All other brand or product names are or m ay be trademarks of, and are used to identify products

and services of, their respec t ive owners.

, ProLinx ®, inRAx ®, ProTalk®, and RadioLinx ® are R egistered Tra demarks of ProSoft

Page 4

ProSof t Techn ol ogy® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Dat asheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-RO M,

and are available at no charge from our web site: www.prosoft-technology.com

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1.661.716.5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Page 5

Contents MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

Contents

Importan t In stallation Ins tru c t io n s...................................................................................................2

MVI (Multi Vendor Interface) Modules............................................................................................2

Warnings.......................................................................................................................................2

Battery Life Advisory......................................................................................................................3

Your Feedback Please................................................................................................................... 3

ProSoft Technology® Product Documentation ................................................................................ 4

Guide to the MVI56-104S User Manual 7

1 Start Here 9

1.1 System Requirem ents...........................................................................................9

1.2 Package Contents...............................................................................................10

1.3 Install ProSoft Configuration Builder Software .....................................................11

1.4 Setting Jumpers..................................................................................................12

1.5 Install the Module i n the Rack.............................................................................13

1.6 Connect your PC to the ControlLogix Processor..................................................14

1.7 Open the Sample Ladder Logic........................................................................... 15

1.8 Download the Sample Pr ogram to the Processor................................................. 20

1.9 Connect your PC to the Modul e........................................................................... 21

2 Configuring the MVI56-104S Module 23

2.1 Using ProSoft Configuration Builder ....................................................................23

2.2 [Backplane Configuration] ................................................................................... 28

2.3 [SNTP CLIENT]...................................................................................................30

2.4 [IEC-870-5-104] .................................................................................................. 32

2.5 [IEC-870-5- 104 IP Addresses] ............................................................................. 38

2.6 [IEC-870-5- 104 Database]...................................................................................39

2.7 [M_SP_NA_1 104] .............................................................................................. 43

2.8 [M_DP_NA_1 104]..............................................................................................43

2.9 [M_ST_NA_1 104] .............................................................................................. 43

2.10 [M_ME_NA_1 104]..............................................................................................44

2.11 [M_ME_NB_1 104]..............................................................................................44

2.12 [M_ME_NC_1 104].............................................................................................. 45

2.13 [M_IT_NA_1 104]................................................................................................ 45

2.14 [C_SC_NA_1 104] .............................................................................................. 46

2.15 [C_DC_NA_1 104] .............................................................................................. 46

2.16 [C_RC_NA_1 104] .............................................................................................. 47

2.17 [C_SE_NA_1 104]...............................................................................................47

2.18 [C_SE_NB_1 104]...............................................................................................48

2.19 [C_SE_NC_1 104] .............................................................................................. 48

2.20 Group Codes ......................................................................................................49

2.21 Ethernet Configuration........................................................................................50

2.22 Download the Project to the Module....................................................................51

2.23 Adding the Module t o an Existing Project.............................................................52

ProSoft Technology, Inc. Page 5 of 188

November 18, 2009

Page 6

MVI56-104S ♦ ControlLogix Platform Contents

IEC 60870-5-104 Server Communication Module User Manual

3

Ladder Logic 55

3.1 User-defi ned Data Types.................................................................................... 56

3.2 Normal Data Transfer ......................................................................................... 65

3.3 Special Function Blocks...................................................................................... 67

4 Diagnostics and Troubleshooting 77

4.1 Reading Status Data from the M odule................................................................. 77

4.2 Ethernet LED Indicators...................................................................................... 91

4.3 LED Status Indicators......................................................................................... 92

4.4 Clearing a Fault Condition................................................................................... 93

4.5 Troubleshooting.................................................................................................. 93

5 Reference 95

5.1 Product Specifi cations ........................................................................................ 95

5.2 IEC-60870-5-104 (104S ) P r otocol Implementation .............................................. 99

5.3 General Concept s..............................................................................................145

5.4 Data Flow Between the MVI56- 104S M odule and the ControlLogix Proc essor....152

5.5 Cable Connecti ons ............................................................................................153

5.6 IEC 60870-5-104 Server Interoperability Document............................................158

6 MVI56-104S Database Design Forms 171

6.1 M_SP_NA_1, M_DP_NA _1, M _ST_NA _1 and M _IT _NA _1 Form ......................172

6.2 M_ME_NA_1 and M_ME_NB _1 Form................................................................173

6.3 C_RC_NA_1 Form.............................................................................................174

6.4 Form for all C_ (Command) data t y pes, ex c ept C_RC_NA_1 .............................175

7 Support, Service & Warranty 177

7.1 How to Contact Us: Technical S upport...............................................................177

7.2 Return Material A uthorization (RMA) Policies and Conditions.............................178

7.3 LIMITED WARRAN TY.......................................................................................179

Index 185

Page 6 of 188 ProSoft Technology, Inc.

November 18, 2009

Page 7

Start Here MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

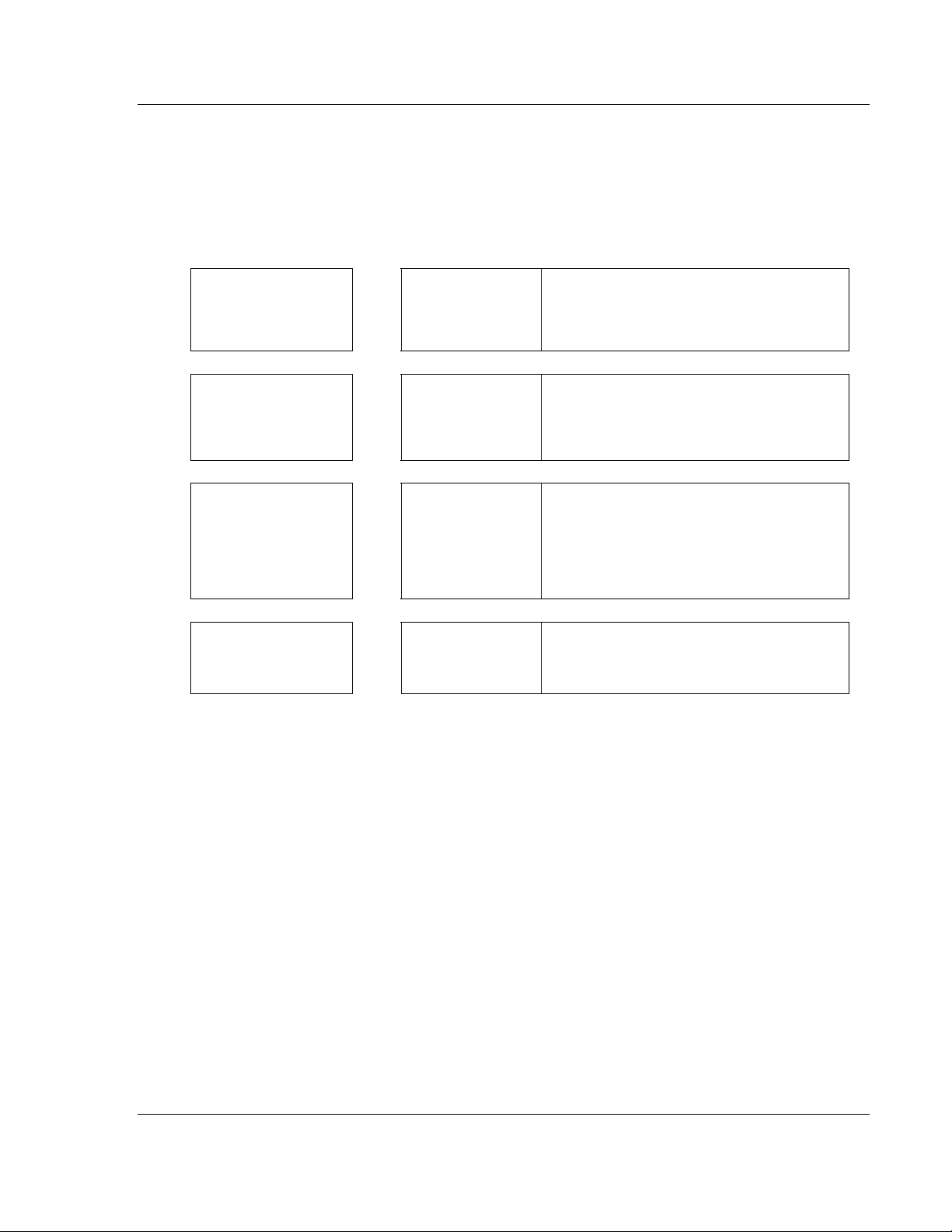

Guide to the MVI56-104S User Manual

Function Section to Read Details

Introduction

(Must Do)

Diagnostic and

Troubleshooting

Reference

Product Specifications

Functional Overview

Support, Service, and

Warranty

Index

→

→

→

→

Start Here (page 9) This Section introduces the customer to the

module. Included ar e: package contents,

system requirements, hardware installation, and

basic configuration.

Diagnostics and

Troubleshooting

(page 77)

Reference (page 95)

Functional Overview

(page 145)

Product

Specifications (page

145)

Support, Service

and Warranty (page

177)

This section describes Diagnostic and

Troubleshooting procedur es.

These sections contain general ref erences

associated with this product, Specifications , and

the Functional Overview.

This section cont ains Support, Service and

Warranty information.

Index of chapters.

ProSoft Technology, Inc. Page 7 of 188

November 18, 2009

Page 8

MVI56-104S ♦ ControlLogix Platform Start Here

IEC 60870-5-104 Server Communication Module User Manual

Page 8 of 188 ProSoft Technology, Inc.

November 18, 2009

Page 9

Start Here MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

1 Start Here

In This Chapter

System Requirements..........................................................................9

Package Contents .............................................................................10

Install ProSoft Configuration Builder Software.....................................11

Setting Jumpers.................................................................................12

Install the Module in the Rack............................................................13

Connect your PC to the ControlLogix Processor .................................14

Open the Sample Ladder Logic..........................................................15

Download the Sample Program to the Processor................................20

Connect your PC to the Module..........................................................21

To get the most benefit from this User Manual, you should have the following

skills:

Rockwell Automation

®

RSLogix™ software: launch the program, configure

ladder logic, and transfer the ladder logic to the processor

Microsoft Windows: install and launch programs, execute menu commands,

navigat e di alog boxes, an d enter data.

Hardware installation and wiring : install the module, and safely connect

104 and ControlLogix devices to a power source and to the MVI56-104S

module’s application port(s).

Caution: You must be able to complete the application without exposing personnel or

equipment to unsafe or inappropriate working conditions.

1.1 System Requirements

The MVI56-104S module requires the following minimum hardware and software

components:

Rockwell Automation ControlLogix™ processor, with compatible power

supply and one free slot in the rack, for the MVI56-104S module. The module

requires 800mA of available power.

Rockwell Automation RSLogix 5000 programming software version 2.51 or

higher.

Rockwell Automation RSLinx communication software

ProSoft Technology, Inc. Page 9 of 188

November 18, 2009

Page 10

MVI56-104S ♦ ControlLogix Platform Start Here

IEC 60870-5-104 Server Communication Module User Manual

Pentium

®

II 450 MHz minimum. Pentium III 733 MHz (or better)

recommended

Supported operating systems:

o Microsoft Windows XP Professional with Service Pack 1 or 2

o Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3

o Microsoft Windows Server 2003

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application

requirements)

256-color VGA g raphic s adapter, 800 x 600 minimum res olution (True Color

1024 × 768 recommended)

CD-ROM drive

ProSoft Configuration Builder, HyperTerminal or other terminal emulator

program.

Note: You can install the module in a local or remote rack. For remote rack installation, the module

requires EtherNet/IP or ControlNet communication with the processor.

1.2 Package Contents

The following components are included with your MVI56-104S module, and are

all required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

Qty. Part Name Part Number Part Description

1 MVI56-104S

Module

1 Cable Cable #15, RS232

1 Cable RJ45 to DB9 Mal e

1 inRAx

Solutions CD

MVI56-104S IEC 60870-5-104 Ser v er Communication Module

For RS23 2 Conn ection to the C FG Port

Null Modem

For DB9 Connection to Module’s Port

Adapter

Contains sample pr ograms, utilities and

documentation for the MVI56-104S module.

If any of these components are missin g, please contact ProSo ft Tech n ol ogy

Support for replacement parts.

Page 10 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 11

Start Here MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

1.3 Install ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software in order to

configure the modul e. You can always get the newest version of ProSoft

Configuration Builder from the ProSoft Technology web site.

To install ProSoft Configuration Builder from the ProSoft Web Site

1 Open your web browser and navigate to http://www.prosoft-

technology.com/pcb

2 Click the D

Configuration Builder .

3 Choose "S

4 Save the file to your Windows Desktop, so that you can find it easily when

you have fini s h ed dow nloading.

5 When t h e download is complete, locate and open the file, and then follow the

instructions on your screen to in stall the program.

If you do not have access to the Internet, you can install ProSoft Configuration

Builder from the ProSoft Solutions CD-ROM, included in the package with your

module.

To install ProSoft Configuration Builder from the Product CD-ROM

1 Insert the ProSoft Solutions Product CD-ROM into the CD-ROM drive of your

PC. Wait for the startup screen to appear.

2 On the startup screen, click P

Windows Explorer file tree window.

3 Click to open th e U

and files you will need to set up and configure your module.

4 Double-click the S

"PCB_*.

software on your PC. The information represented by the "*" character in the

file name is the PCB version number and, therefore, subject to change as

new versions of PCB are released.

OWNLOAD HERE link to download the latest version of ProSoft

AVE" or "SAVE FILE" when prompted.

RODUCT DOCUMENTATION. This action opens a

TILITIES folder. This folder contains all of the applications

ETUPCONFIGURATIONTOOL folder, double-click the

EXE" file and follo w the instructions on your screen to install the

Note: Many of the configuration and maintenance procedures use files and other utilities on the

CD-ROM. You may wish to copy the files from the Utilities folder on the CD-ROM to a convenient

location on your hard drive.

ProSoft Technolo gy, Inc . Page 11 of 188

November 18, 2009

Page 12

MVI56-104S ♦ ControlLogix Platform Start Here

IEC 60870-5-104 Server Communication Module User Manual

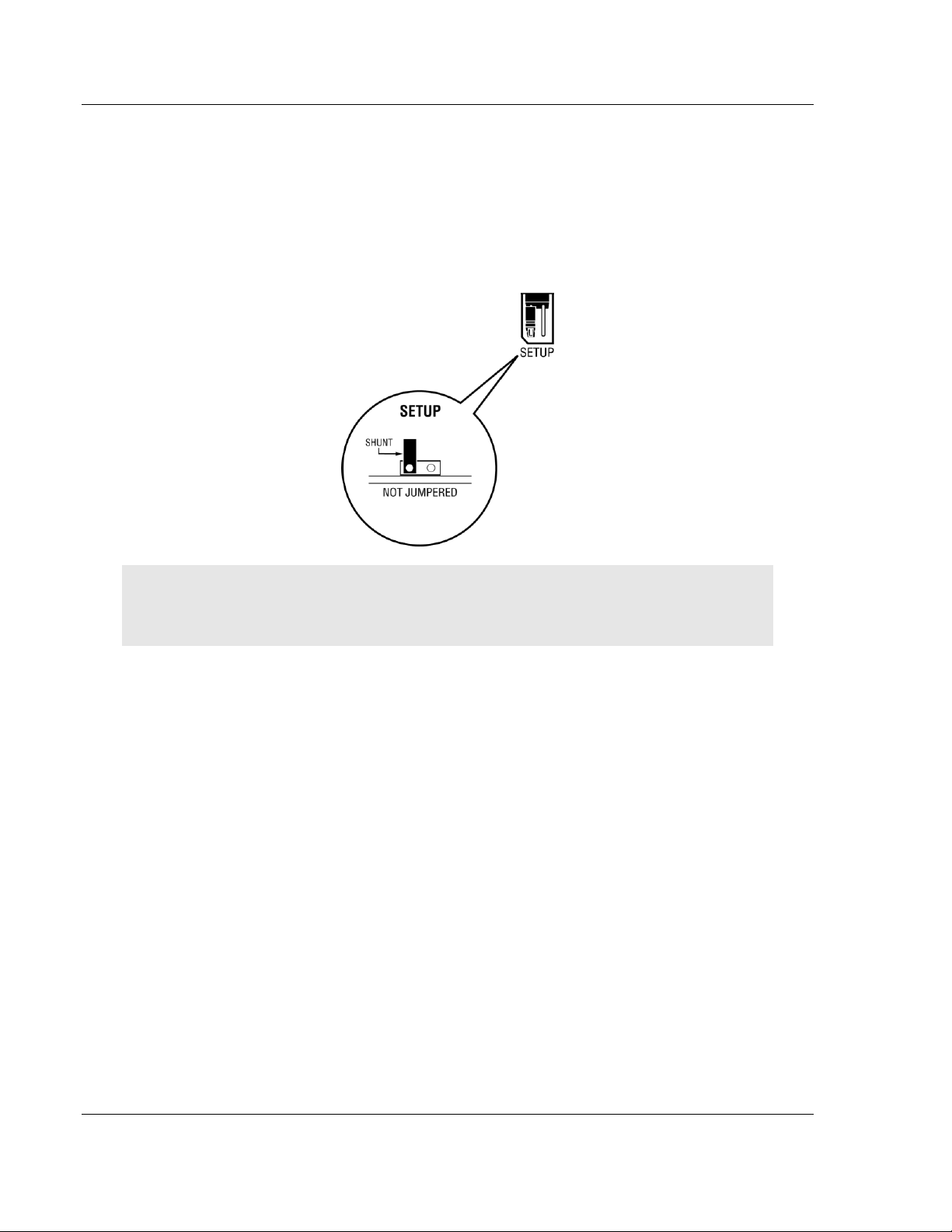

1.4 Setting Jumpers

The Setup Jumper acts as "write protection" for the module’s flash memory. In

"write protected" mode, the Setup pins are not connected, and the module’s

firmware cannot be overwritten. Do not jumper the Setup pins together unless

you are directed to do so by ProSoft Technical Support.

The following illu stration shows the MVI56-104S jumper configu ration.

Note: If you are installing the module in a remote rack, you may prefer to leave the Setup pins

jumpered. That way, you can update the module’s firmware without requiring physical access to

the module.

Page 12 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 13

Start Here MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

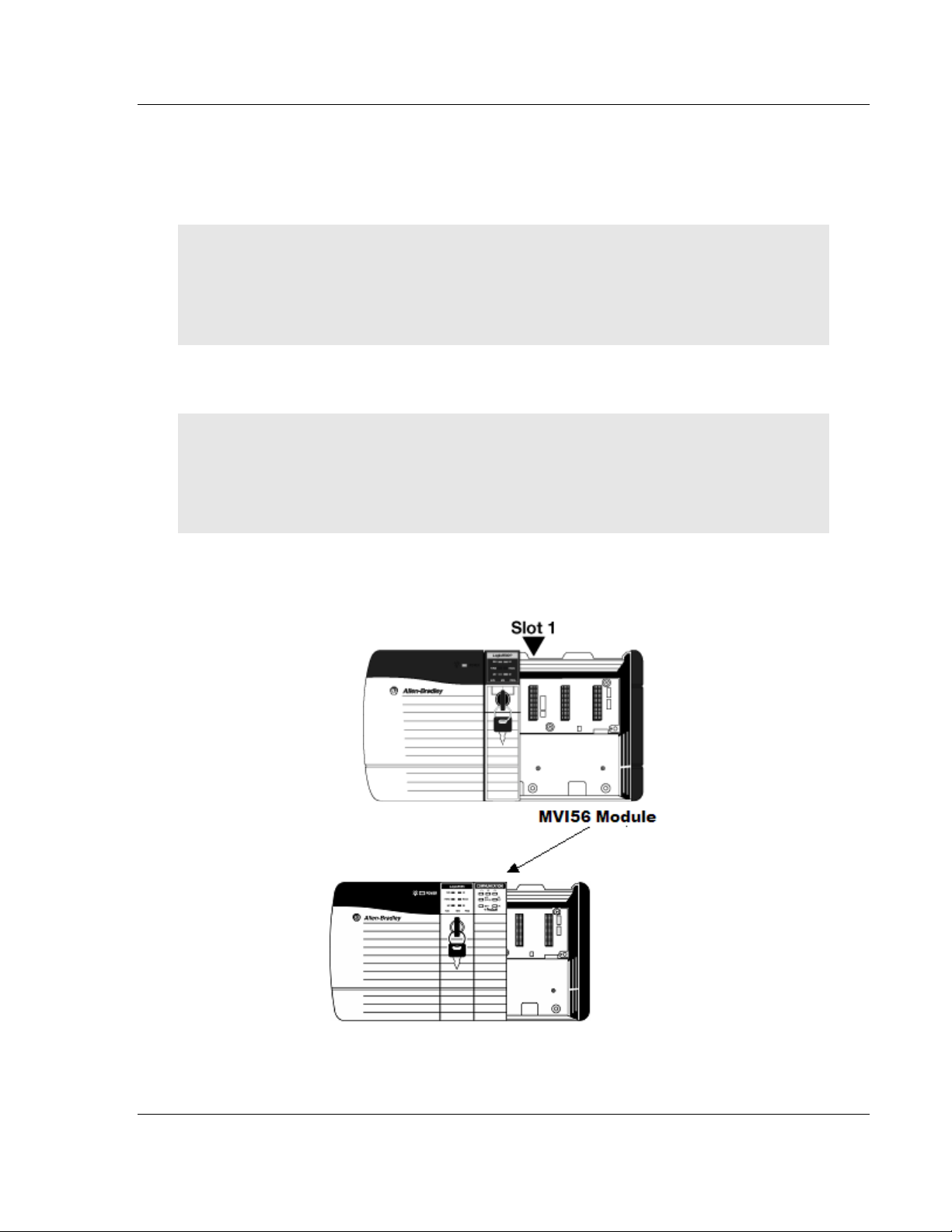

1.5 Install the Module in the Rack

If you have not already installed and configured your ControlLogix processor and

power supply, please do so before installing the MVI56-104S module. Refer to

your Rockwell Automation product documentation for installa tion instructions.

Warning: You must follow all safety instructions when installing this or any other electronic

devices. Failure to follow safety procedures could result in damage to hardware or data, or even

serious injury or death to personnel. Refer to the documentation for each device you plan to

connect to verify that suitable safety procedures are in place before installing or servicing the

device.

After you have checked the placement of the jumpers, insert MVI56-104S into

the ControlLogix chassis. Use the same technique recommended by Rockwell

Automation to remove and install ControlLogix modules.

Warning: When you insert or remove the module while backplane power is on, an electrical arc

can occur. This could cause an explosion in hazardous location installations. Verify that power is

removed or the area is non-hazardous before proceeding. Repeated electrical arcing causes

excessive wear to contacts on both the module and its mating connector. Worn contacts may

create electrical resistance that can affect module operation.

1 Turn power OF F.

2 Align the module with the top and bottom guides, and slide it into the rack

until the module is firmly against the backplane connector.

3 With a firm but steady push, snap the module into place.

ProSoft Technolo gy, Inc . Page 13 of 188

November 18, 2009

Page 14

MVI56-104S ♦ ControlLogix Platform Start Here

IEC 60870-5-104 Server Communication Module User Manual

4 Check that the holding clips on the top and bottom of the module are securely

in the locking holes of the rack.

5 Make a note of the slot location. You must identify the slot in which the

module is installed in order for the sample program to work correctly. Slot

numbers are identified on the green circuit board (backplane) of the

ControlLogix rack.

6 Turn power ON.

Note: If you insert the module improperly, the system may stop working, or may behave

unpredictably.

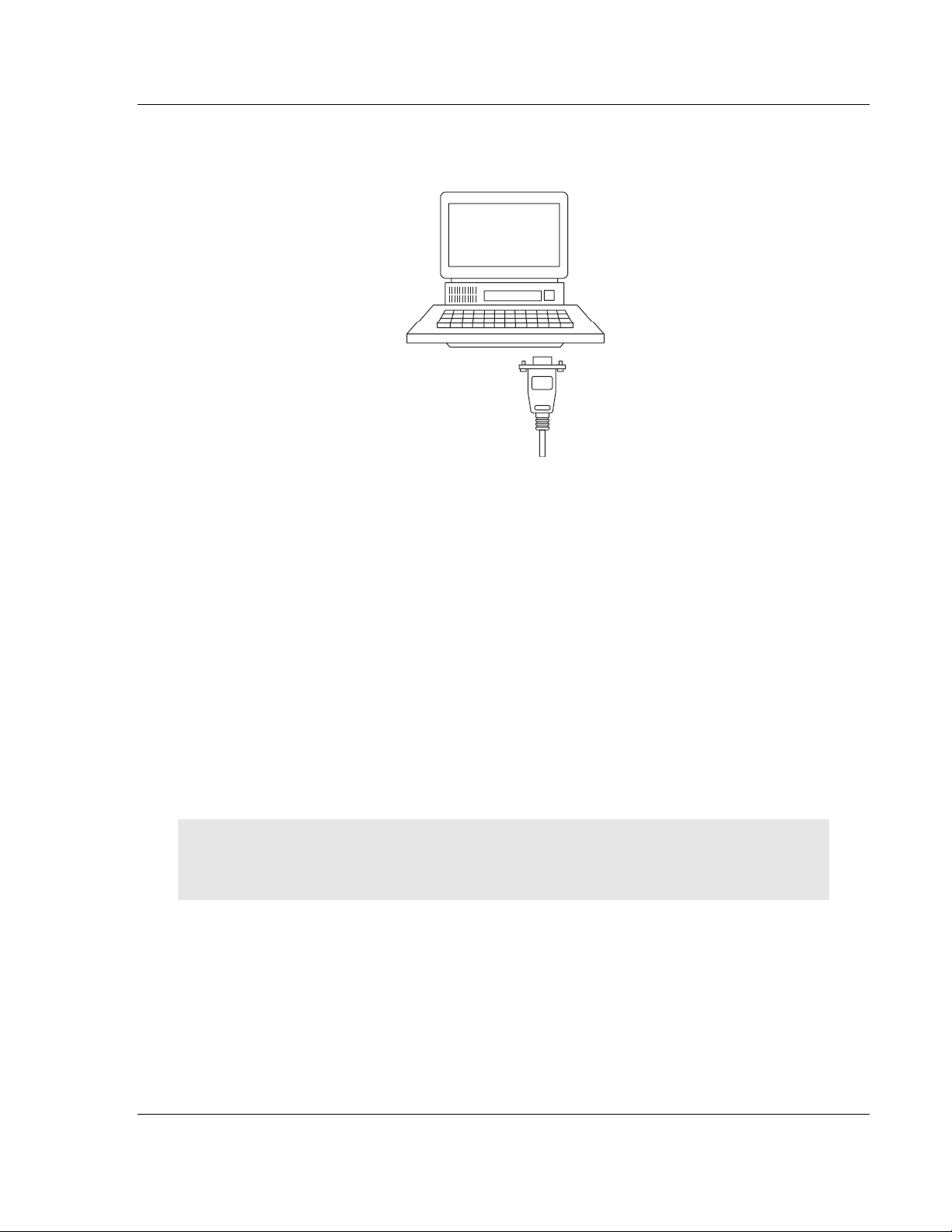

1.6 Connect your PC to the ControlLogix Processo r

There are several ways to establish communication between your PC and the

ControlLogix processor. The following steps show how to establish

communication through the serial interface. It is not mandatory that you use the

processor's serial interface. You may access the processor through whatever

network interface is available on your system. Refer to your Rockwell Automation

documentation for information on other connection methods.

1 Connect the right-angle connector end of the cable to your controller at the

communic ati o ns por t.

Page 14 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 15

Start Here MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2 Connect the straight connector end of the cable to the serial port on your

computer.

1.7 Open the Sample Ladder Logic

The sample program for your MVI56-104S module includes custom tags, data

types and ladder logic for data I/O and status monitoring. For most applications,

you can run the sample ladder program without modification, or, for advanced

applications, you can incorporate the samp le program into your existing

application.

The inRAx Solutions CD provides on e or more v ersions of the sample lad der

logic. The versi o n num b er appended to the file na m e corresponds with the

firmware vers i o n number of your Control Lo gi x pr o c ess or . Th e firm w ar e ver s i o n

and sample program version must match.

1.7.1 To Determine the Firmware Version of your Processor

Important: The RSLinx service must be installed and running on your computer in order for

RSLogix to communicate with the processor. Refer to your RSLinx and RSLogix documentation for

help configuring and troubleshooting these applications.

1 Connect an RS-232 serial cable from the COM (serial) port on your PC to the

communication port on the front of the pr ocessor.

2 Start RSLogix 5000 and close any existing project that may be loaded.

3 Open the Communications menu and choose Go Online. RSLogix will

establish communication with the processor. This may take a few moments.

ProSoft Technolo gy, Inc . Page 15 of 188

November 18, 2009

Page 16

MVI56-104S ♦ ControlLogix Platform Start Here

IEC 60870-5-104 Server Communication Module User Manual

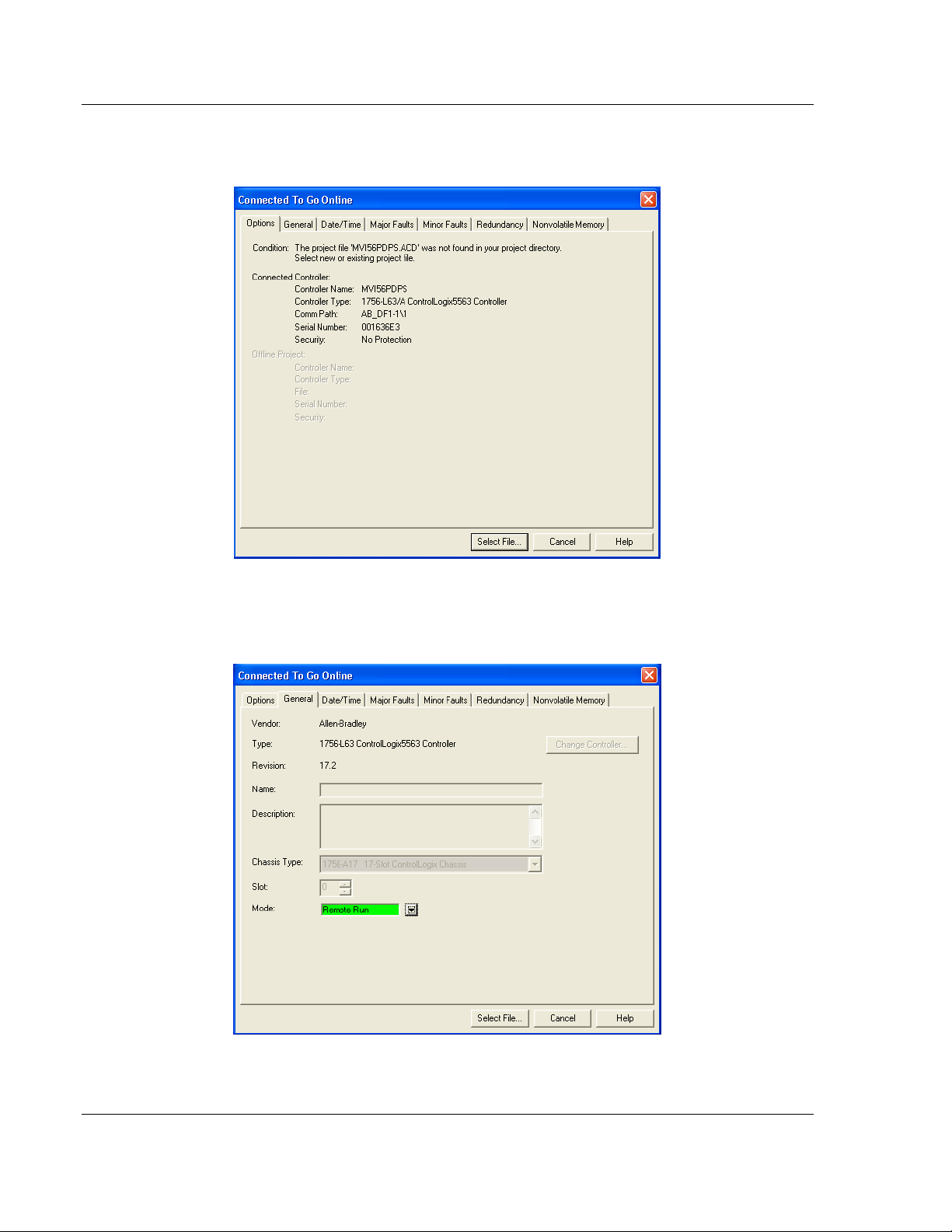

4 When RSLogix has est a blished communica tion wit h the processor, the

Connected To Go Online dialog box will open.

5 On the Connected To Go Online dialog box, click the General tab. This tab

shows information about the processor, including the Revision (firmware)

version. In the following illustration, the firmwa re version is 17.2.

Page 16 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 17

Start Here MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

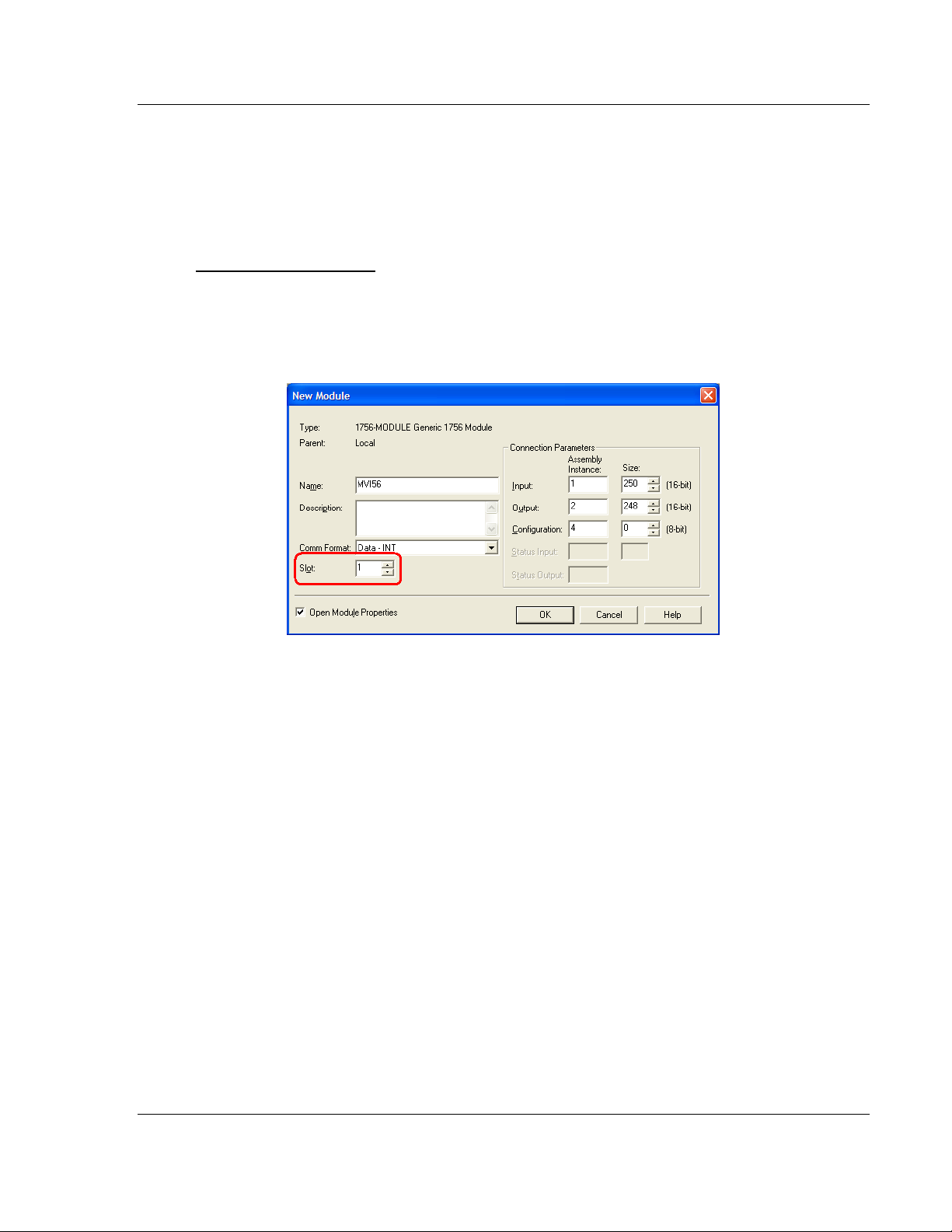

1.7.2 Select the Slot Number for the Modu le

The sample application is for a module installed in Slot 1 in a ControlLogix rack.

The ladder logic uses the slot number to identify the module. If you are installing

the module in a different slot, you must update the ladder logic so that program

tag s and variables ar e corre ct, and do not conflict with othe r m odules in the rack.

To change the slot number

1 In the Controller Organization list, select the module [1] 1756-MODULE

MVI56, and then click the right mouse button to open a shortcut menu.

2 On the shortcut menu, choose Properties. This action opens the Module

Properti es di alog box.

3 In the Slot: field, use the spinners on the right side of the field to select th e

slot number where the module will reside in the rack, an d the n click OK.

RSLogix will automatically app ly the slot number change to all tags, variables

and ladder logic rungs that use the MVI56-104S slot number for computation.

ProSoft Technolo gy, Inc . Page 17 of 188

November 18, 2009

Page 18

MVI56-104S ♦ ControlLogix Platform Start Here

IEC 60870-5-104 Server Communication Module User Manual

1.7.3 Configuring the RSLinx Driver for the PC COM Port

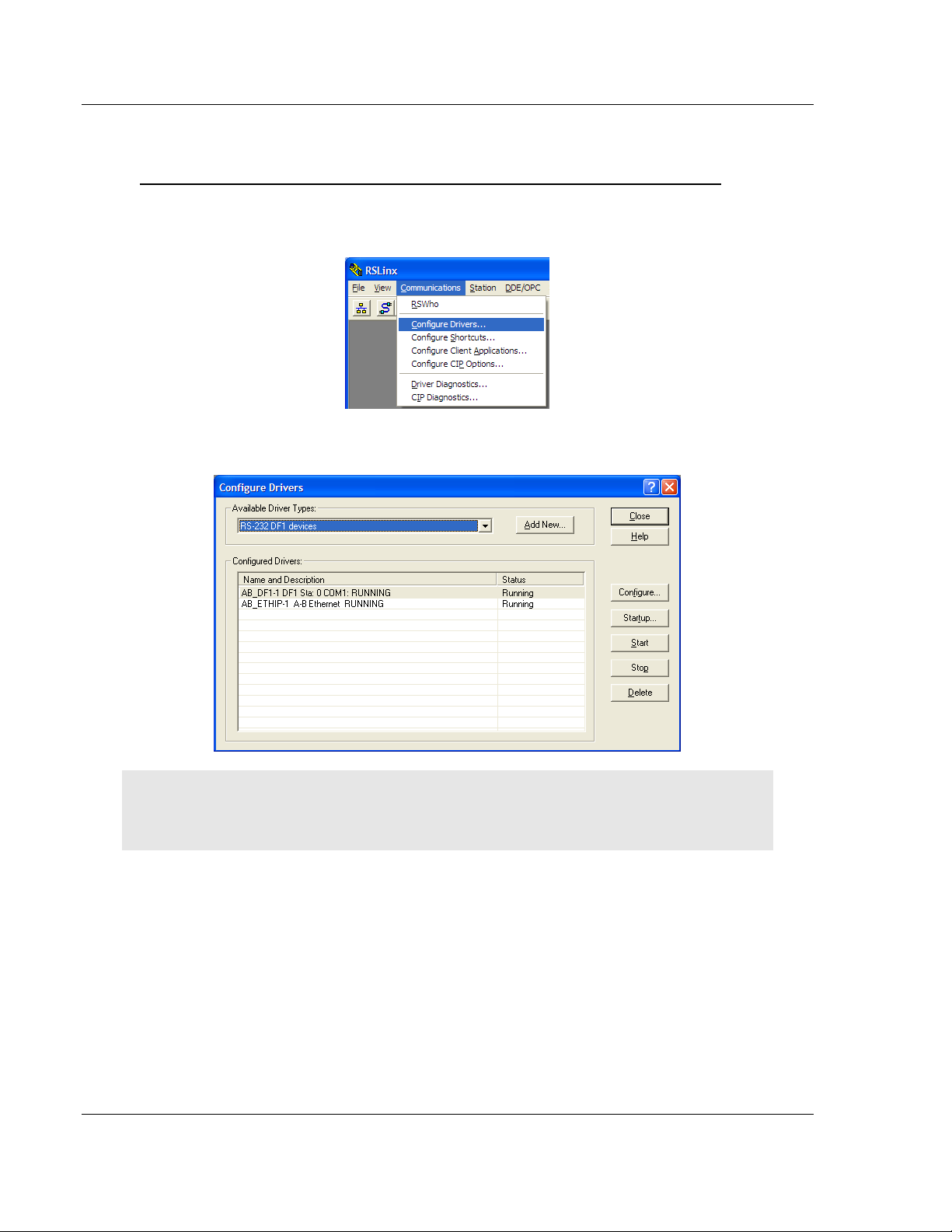

If RSLogix is unable to establish communication with the processor, follow these steps

1 Open RSL

2 Open the C

This action opens the C

INX.

OMMUNICATIONS menu, and choose CONFIGURE DRIVERS.

ONFIGURE DRIVERS dialog box.

Note: If the list of configured drivers is blank, you must first choose and configure a driver from the

Available Driver Types list. The recommended driver type to choose for serial communication with

the processor is RS-232 DF1 DEVICES.

Page 18 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 19

Start Here MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

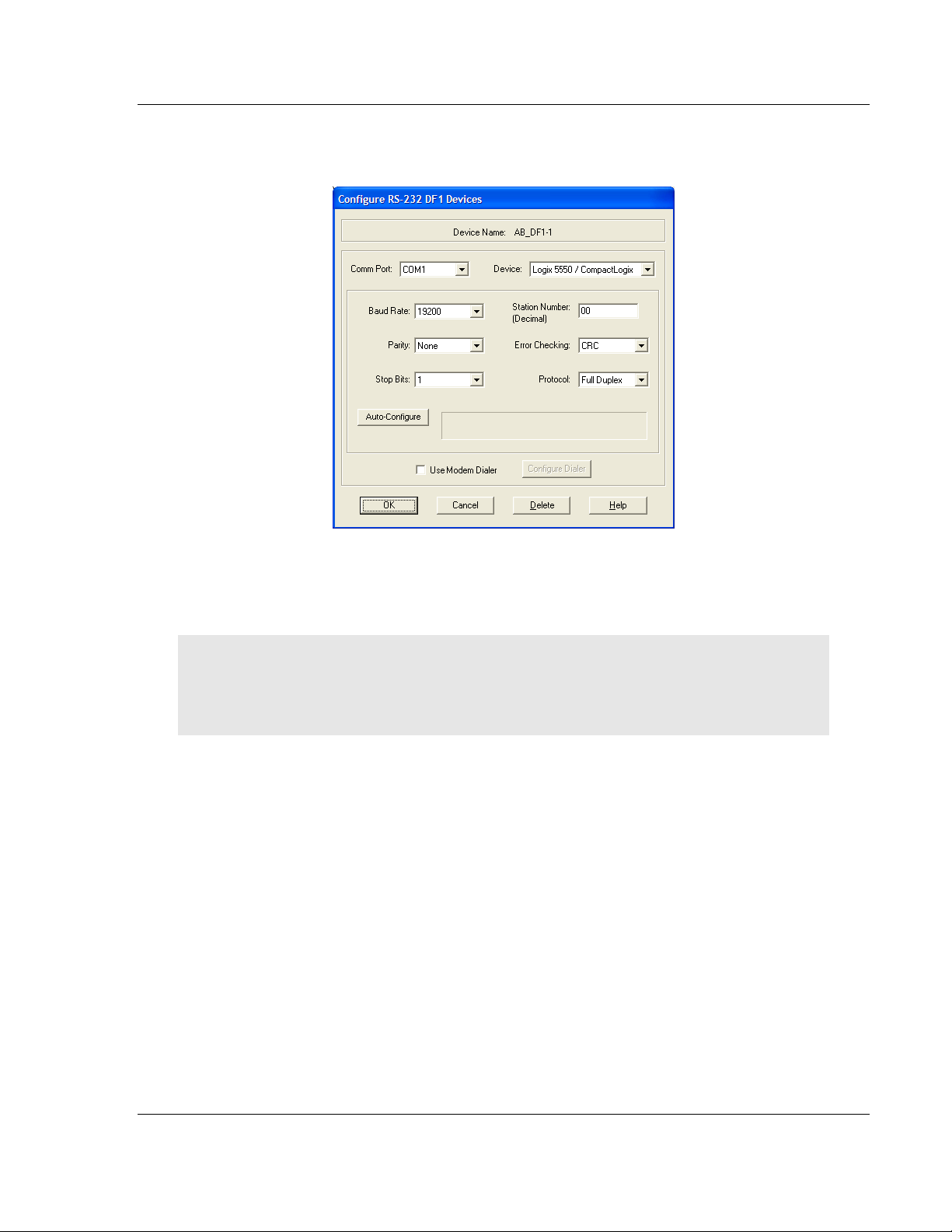

3 Click to select the driver, and then click C

C

ONFIGURE RS-232 DF1 DEVICE dialog box.

ONFIGURE. This action opens the

4 Click the A

UTO-CONFIGURE button. RSL inx will attempt to configure your

serial port to work with the selected driver.

5 When you see the message A

UTO CONFIGURATION SUCCESSFUL, click the OK

button to dismiss the dialog box.

Note: If the auto-configuration procedure fails, verify that the cables are connected correctly

between the processor and the serial port on your computer, and then try again. If you are still

unable to auto-configure the port, refer to your RSLinx documentation for further troubleshooting

steps.

ProSoft Technolo gy, Inc . Page 19 of 188

November 18, 2009

Page 20

MVI56-104S ♦ ControlLogix Platform Start Here

IEC 60870-5-104 Server Communication Module User Manual

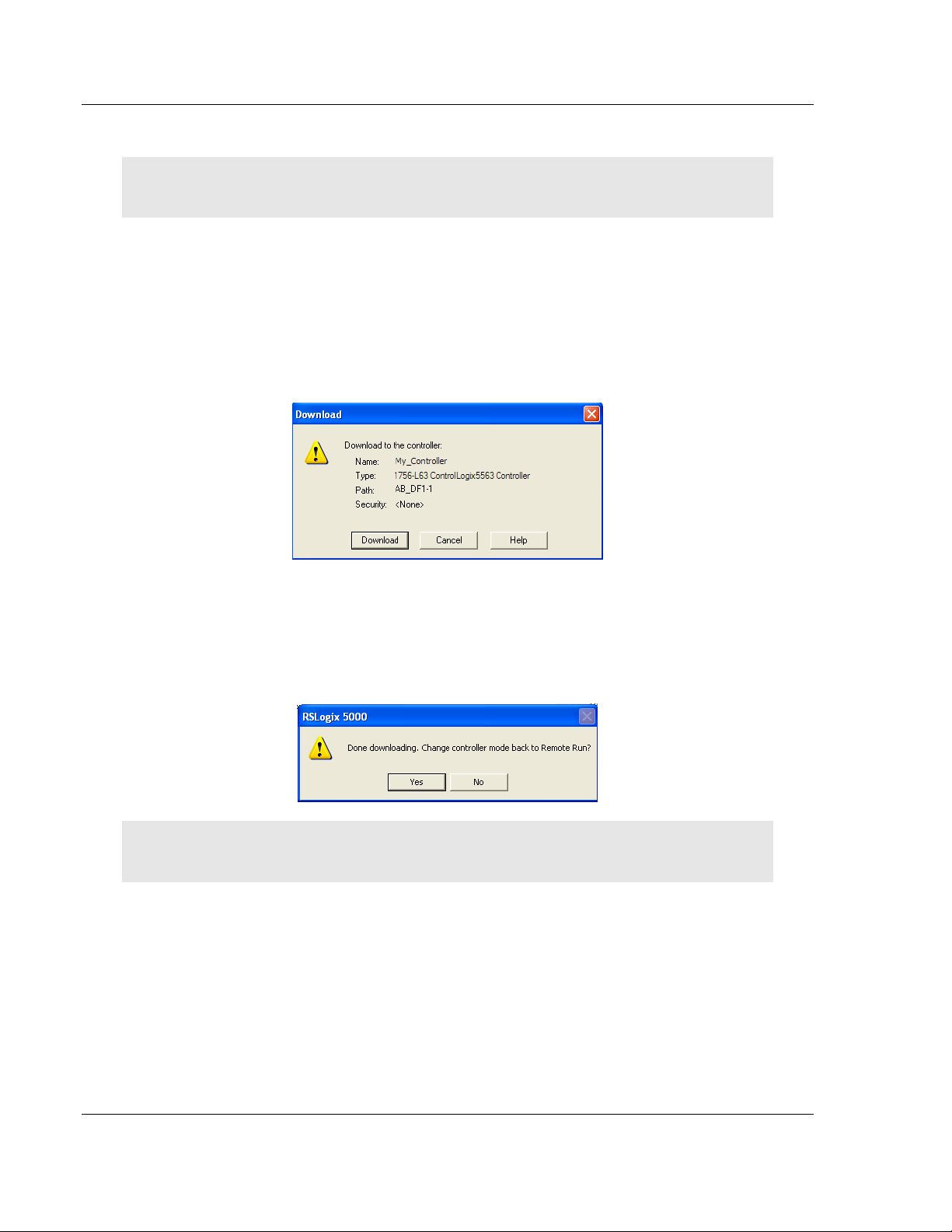

1.8 Download the Sample Program to the Processor

Note: The key switch on the front of the ControlLogix processor must be in the REM or PROG

position.

1 If you are not already online with the pr oc e ss or , o pe n the COMMUNICATIONS

menu, and then choose DOWNLOAD. RSLogix will estab lish communication

with the processor. You do not hav e to download through the pr ocessor's

serial por t, as shown here. You may dow nl o ad through any available network

connection.

2 When co mmunication is established, RS Logix will open a confirmation dialog

box. Click the D

processor.

OWNLOAD button to transfer the sample program to the

3 RSLogix will compile the program and t ransfe r it to the processor. This

process may take a few minutes.

4 When the download is complete, RSLogi x will open another confirmation

dialog box. If the key switch is in the REM position, click OK

process or fr om P

ROGRAM mode to RUN mode.

to switch the

Note: If you receive an error message during these steps, refer to your RSLogix documentation to

interpret and correct the error.

Page 20 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 21

Start Here MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

1.9 Connect your PC to the Module

With the module securely mounted, connect your PC to the

Configuration/Debug port using an RJ45-DB-9 Serial Adapter Cable and a Null

Modem Cable.

1 Attach both ca bl es as s hown.

2 Insert the RJ45 cable connector into the Configuration/Debug port of the

module.

3 Attach the other en d to the serial port on your PC.

ProSoft Technolo gy, Inc . Page 21 of 188

November 18, 2009

Page 22

MVI56-104S ♦ ControlLogix Platform Start Here

IEC 60870-5-104 Server Communication Module User Manual

Page 22 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 23

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2 Configuring the MVI56-104S Modul e

In This Chapter

Using ProSoft Configuration Builder ...................................................23

[Backplane Configuration]..................................................................28

[SNTP CLIENT] .................................................................................30

[IEC-870-5-104] .................................................................................32

[IEC-870-5-104 IP Addresse s]............................................................38

[IEC-870-5-104 Database] .................................................................39

[M_SP_NA_1 104].............................................................................43

[M_DP_NA_1 104] .............................................................................43

[M_ST_NA_1 104].............................................................................43

[M_ME_NA_1 104] ............................................................................44

[M_ME_NB_1 104] ............................................................................44

[M_ME_NC_1 104]............................................................................45

[M_IT_NA_1 104] ..............................................................................45

[C_SC_NA_1 104].............................................................................46

[C_DC_NA_1 104].............................................................................46

[C_RC_NA_1 104].............................................................................47

[C_SE_NA_1 104] .............................................................................47

[C_SE_NB_1 104] .............................................................................48

[C_SE_NC_1 104].............................................................................48

Group Codes.....................................................................................49

Ethernet Configuration.......................................................................50

Download the Project to the Module...................................................51

Adding the Module to an Existing Project............................................52

2.1 Using ProSoft Configuration Builder

ProSoft Configuration Builder (PCB) pr ovi d es a qu i ck and easy way to man ag e

module configuration files customized to meet your application needs. PCB is not

only a powerful solution for new configuration files, but also allows you to import

information from previously installed (known working) configurations to new

projects.

ProSoft Technolo gy, Inc . Page 23 of 188

November 18, 2009

Page 24

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

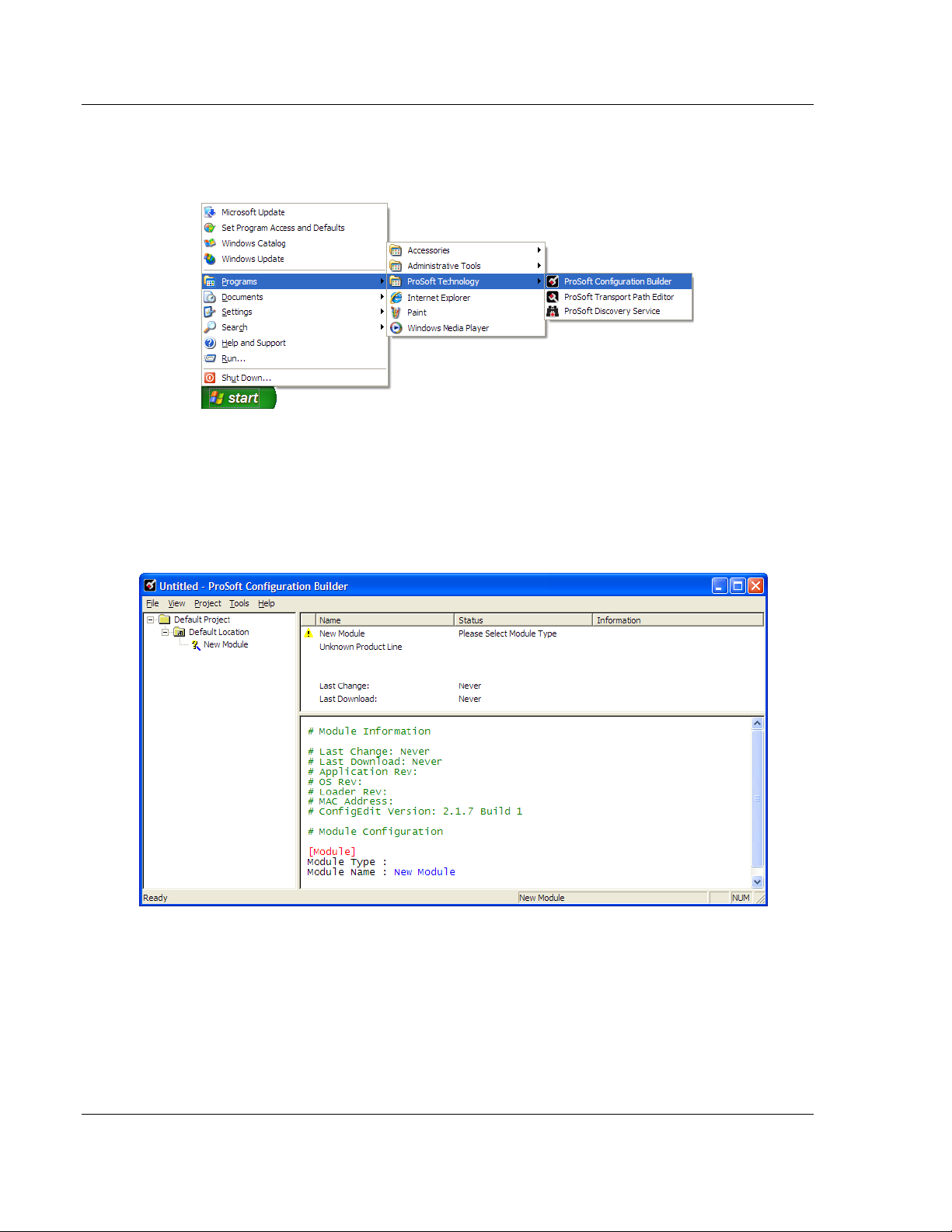

2.1.1 Set Up the Project

To begin, start PROSOFT CONFIGURATION BUILDER (PCB).

If you have used other Windows configuration too ls before, you will find the

screen layout familiar. PCB’s window consists of a tree view on the left, and an

information pane and a configuration pane on the right side of the window. When

you first star t PCB, the tree view consists of fol ders for D

D

EFAULT LOCATION, with a DEFAULT MODULE in the Default Location folder. The

following illustration shows the PCB window with a new project.

EFAULT PROJECT and

Page 24 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 25

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

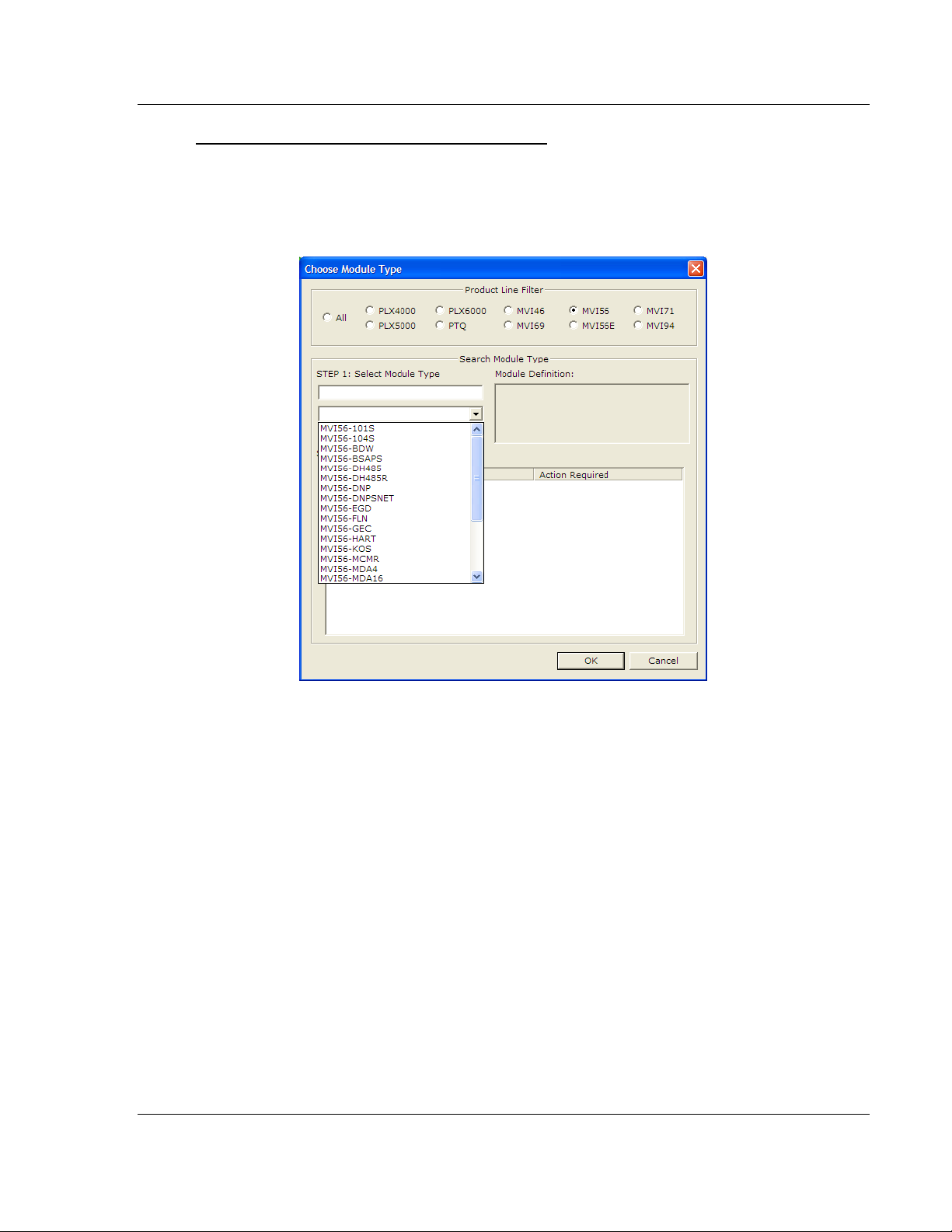

To add the MVI56-104S module to the project:

1 Use the mouse to select D

EFAULT MODULE in the tree view, and then clic k the

right mouse button to open a shortcut menu.

2 On the shortcut menu, choose C

HOOSE MODULE TYPE. This actio n op ens the

CHOOSE MODULE TYPE dialog box.

3 In the P

S

ELECT MODULE TYPE dropdown list, select MVI56-104S, and then click OK

RODUCT LINE FILTER area of the dialog box, select MVI56. In the

to save your settings and return to the ProSoft Configuration Builder window.

ProSoft Technolo gy, Inc . Page 25 of 188

November 18, 2009

Page 26

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

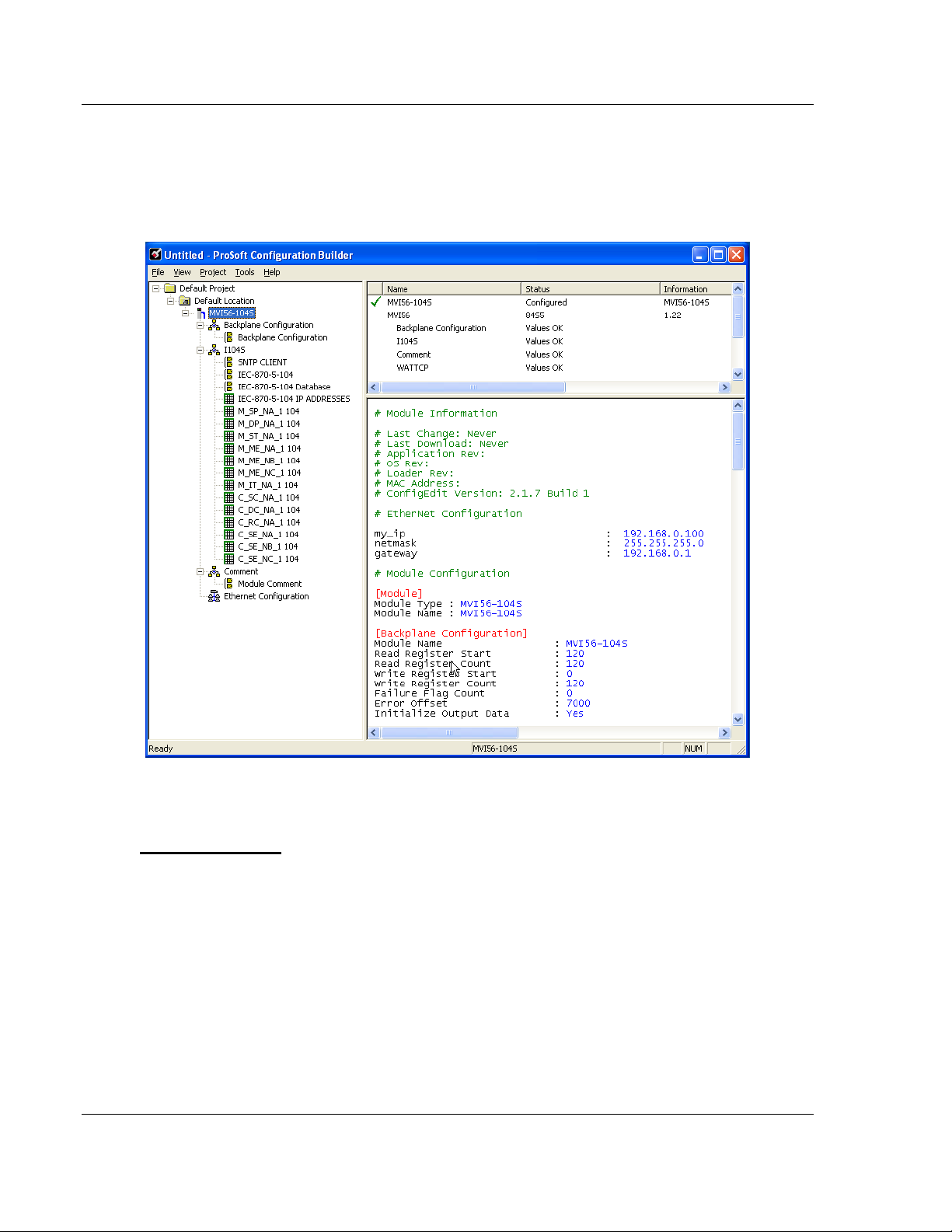

2.1.2 Set Module Parameters

The next task is to configure module parameters. Notice that the contents of the

information pane and the configuration pane changed when you added the

MVI56-104S module to the project.

At this time, you may wish to rename the "Default Project" and "Default Location"

folders in the tree view.

To rename an object:

1 Select the object, and then click the right mouse button to open a shortcut

menu. From the shortcut menu, choose R

ENAME.

2 Type the name to assi gn to the object.

3 Click away from the object to save the new name.

Page 26 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 27

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

To Configure Module Parameters

1 Click on the plus sign next to the

2 Double-click the

icon to open the EDIT dialog box.

icon to expand module information.

3 To edi t a parameter , select the parameter in the left pane and make your

changes in the right pane.

4 Click OK

to save your changes.

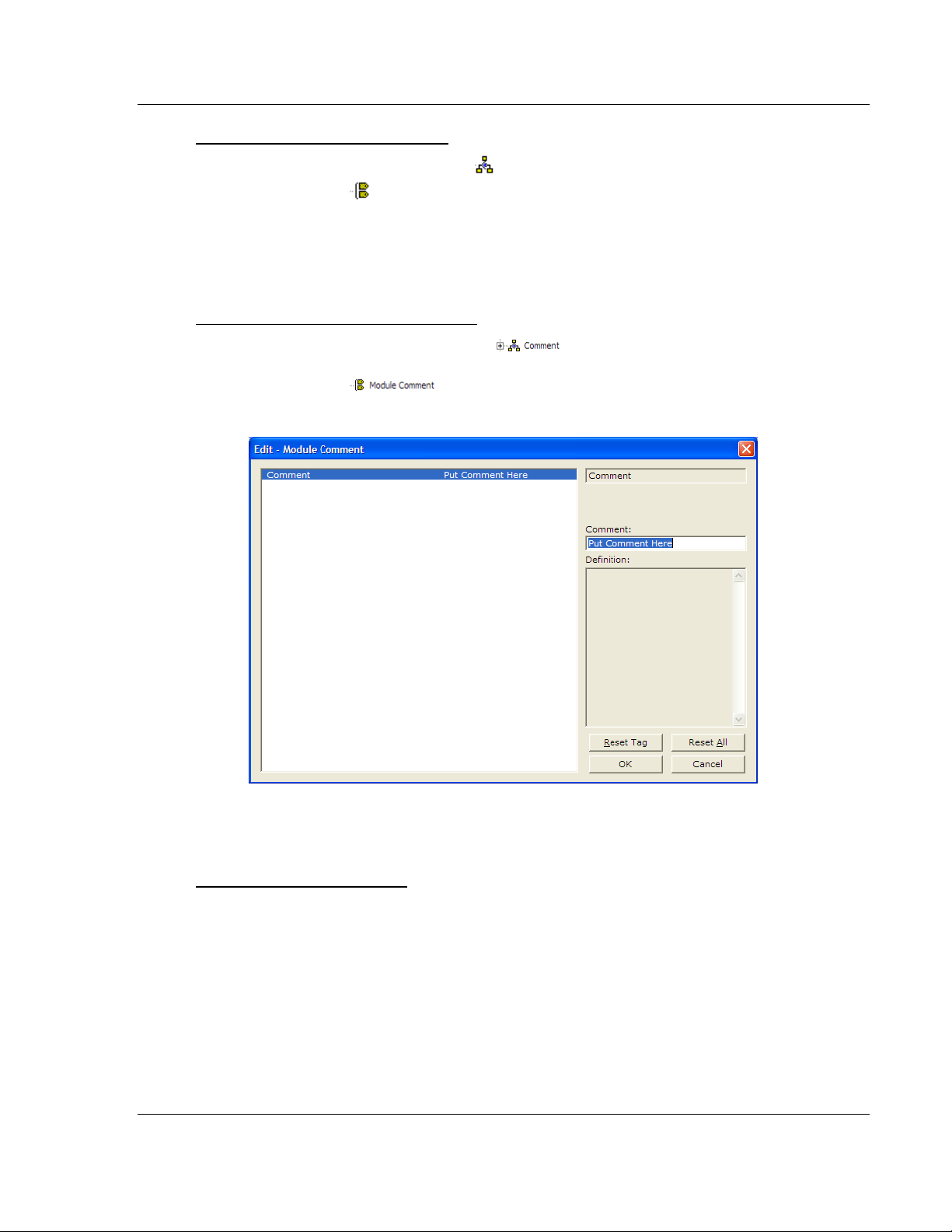

To Create Optional Comment Entrie s

1 Click the plus sign to the left of the

icon to expand the module

Comments.

2 Double-click the

icon. The EDIT - MODULE COMMENT dialog

appears.

3 Enter your comment and click OK

to save your changes.

Printing a Configuration File

1 Select the M

ODULE icon, and then click the right mouse button to open a

shortcut menu.

2 On the shortcut menu, choose V

V

IEW CONFIGURATION window.

3 On the V

P

RINT. This action opens the PRINT dialog box.

4 On the P

IEW CONFIGURATION window, open the FILE menu, and choose

RINT dialog box, choos e th e printer to use from the dropd ow n list,

select printing options, and then click OK.

IEW CONFIGURATION. This action opens the

ProSoft Technolo gy, Inc . Page 27 of 188

November 18, 2009

Page 28

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.2 [Backplane Configuration]

This section provides the module with a unique name, identifies the method of

failure for the communications for the module if the processor is not in run, and

describes how to initialize the module upon startup.

2.2.1 Module Name

0 to 80 characters

This parameter assigns a name to the module that can be viewed using the

configuration/debug port. Use this parameter to identify the module and the

configuration file.

2.2.2 Read Register Start

Range 0 to 39 99

This parameter specifies the starting register in the module where data will be

transferred from the module to the processor. Valid range for this parameter is 0

to 3999.

2.2.3 Read Register Count

0 to 4000

The Read Register Count parameter defines the size of the module’s input

database, up to a maximum value of 4000 words.

2.2.4 Write Register Start

0 to 3999

This parameter specifies the starting register in the module where the data will be

transferred from the processor to the module.

2.2.5 Read Register Count

0 to 4000

The Read Register Count parameter defines the size of the module’s input

database, up to a maximum value of 4000 words.

Page 28 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 29

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.2.6 Failure Flag Count

0 through 65535

This paramete r specifies the number of su ccessive transfer errors that must

occur before halting communication on the application port(s). If the parameter is

set to 0, the application port(s) will cont inu e to operate under all conditions. If the

value is set larger than 0 (1 to 65535), communication s will cease if the specified

number of failures occur.

2.2.7 Error Offset

0 to 3980, or -1 to disable

This parameter specifies the database location where to write status data.

2.2.8 Initialize Output Data

Yes or No

This parameter determines if the output data for the module should be initialized

with values from the processor. If the value is set to No (0), the output data will

be initialized to 0. If the value is set to Yes (1), the data will be initialized with

data from the processor. Use of this option requires associated ladder logic to

pass the dat a fr om the pr oc es sor to th e mo dule.

ProSoft Technolo gy, Inc . Page 29 of 188

November 18, 2009

Page 30

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

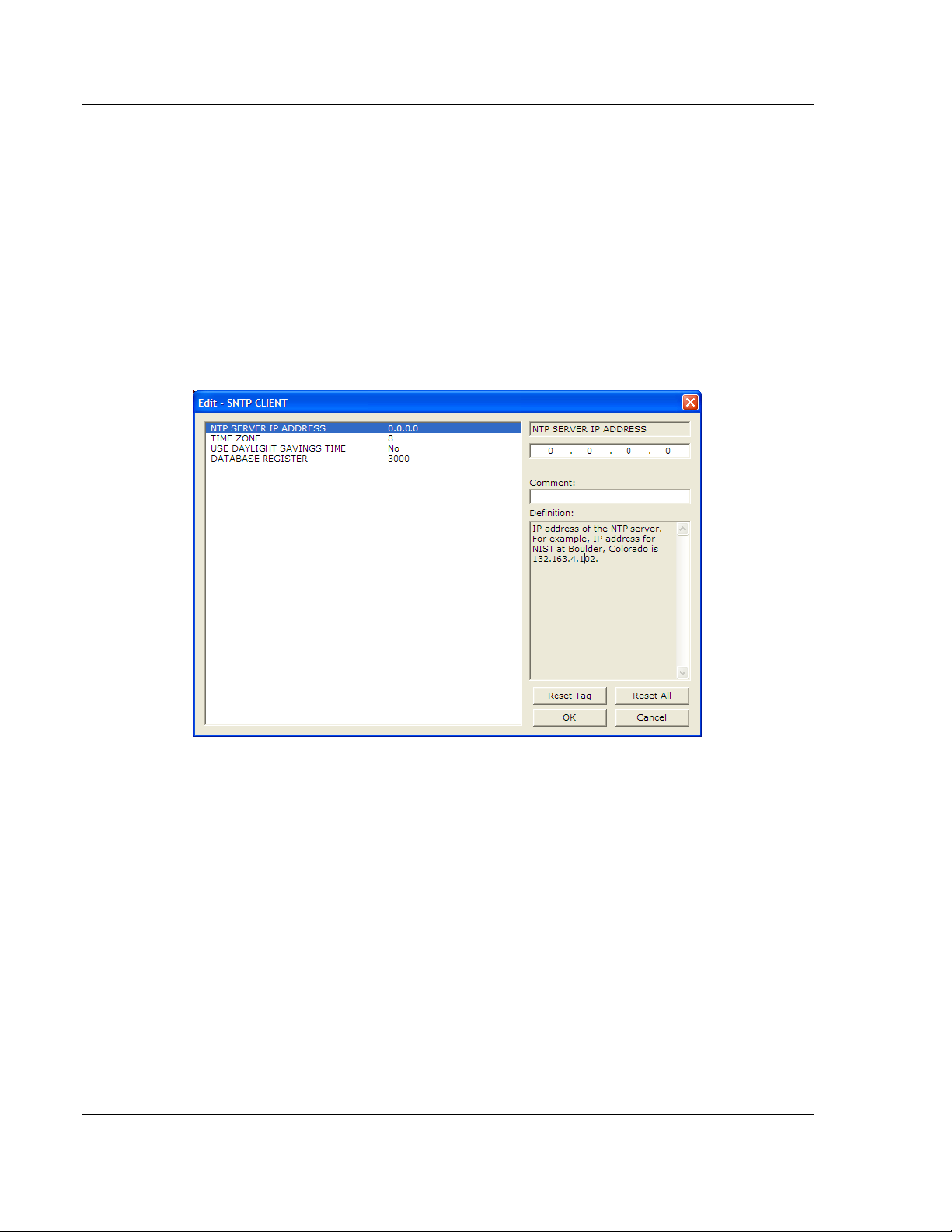

2.3 [SNTP CLIENT]

The [SNTP CLIENT] section of the CFG file is used to speci fy th e par ameters for

the Simple Network Time Protocol (SNTP) client provided with the protocol

driver. This client is required in order to keep the driver's internal clock set

correctly. This version of the driver supports SNTP Revision 3 and stratum

bet ween 1 and 14.

SNTP is used for time synchronization of produced and consumed commands.

When an exchan ge occurs the driver compa res time s tamps from the previo us

exchange. When the new exchange time is less than the previous exchange, the

exchange is ignored. This can occur when the Ethernet packets are routed and

delayed . Tim e sy nc hr oni zation provides for dat a i n tegr i ty .

The SNTP driver will compute a new clock value every 5 minutes using the

average val ue of 10 samples each collec t ed over an ap pr oxi m a t e 6- second

period. This new value will be used to adjust the clock maintained by the SNTP

driver and used by the application. If a valid database register is specified, the

driver will place the time value into the module's database. The first two registers

will contain the number of seconds and the next two registers will contain the

number of microseconds since January 1, 1970.

A list of some of the common NTP servers can be obtained at

http://www.ntp.org/, http://www.eecis.udel.edu/~mills/ ntp/servers.html, along with

the appropriate IP address. Other server lists can be found by searching the

World Wide Web for "NTP Servers".

Page 30 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 31

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.3.1 NTP Server IP Address

Enter in dotte d notation

This parameter sets the IP add ress of the NTP server to utilize for time

acquisition. Select an NTP server with the greatest accuracy that can be

accessed all the time from your network. Setting this IP address to 0.0.0.0

disables SNTP server requests.

2.3.2 Time Zone

-11 to 11

This parameter specifies the time zone offset to be used from the UTC time

zone. A value of zero uses UTC time. If the value entered is positive, the time

zone is west of the UTC time zone (that is, Eastern Standard Time is 5). If the

value entere d is negative, the time zone is east of the UTC time zone (that is,

Continenta l Europe is -1).

2.3.3 Use Daylight Savings Time

Yes or No

This parameter specif ies if dayligh t saving s time will be used in the time

computation.

2.3.4 Database Register

-1 or 0 to 3992 as an eve n val u e

This parameter specifies if the NTP time computed by the driver is to be placed

into the module’s database. If a value of -1 is specified, the time will not be

placed into the database. If the value is between 0 and 3992, the time will be

placed in the database. The first 4 bytes will represent the seconds since

1/1/1970, and the second 4 byte s will represent the number of microseconds. An

even value should be used for the register value in order for the data to be stored

correctly.

ProSoft Technolo gy, Inc . Page 31 of 188

November 18, 2009

Page 32

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.4 [IEC-870-5-104]

This section provides information required to configure a server application with

the module. Most entries contained within this section are self explanatory An

item of concern is the maximum size of the total database, although it is possible

to configure a database of considerable size, this would not work, as the

maximum Class 0 request may not exceed 2048 bytes in size.

2.4.1 Use IP List

0 or 1

This parameter specifies if the IP address of the host connected to the system

will be validated. If the parameter is set to 0, any host may connect to the unit. If

the parameter is set to 1, only hosts in the IP list will be permitt ed to connect to

the unit.

2.4.2 Override StartDT

0 or 1

This parameter is used when testing th e unit with a simulator or with a client unit

that does not meet the IEC 60870-5-104 specification. After the host connects to

the system, it will send a STARTDT.ACT U-format message to the unit to permit

the un it to s tart sending data. If the client does not support t his requirement, set

the parameter to a value of 1. Set the paramete r to 0 if the unit sends the

STARTDT.ACT message.

Page 32 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 33

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.4.3 Clear Queue on Close

0 or 1

Use this command to define whether the module will store the una c knowledged

buffers in the unit after the connection is closed. If the specification is to be

followed, set this parameter to 0 and the packet s will be resent after a connection

is made. If you want to flush the packets after the connection is closed, set this

parameter to 1 (this is not according to the IEC 60870-5-104 specification).

2.4.4 t1 Timeout Set Value

1 to 255

This is the timeout of send or test ASDUs and is in units of seconds. After a

packet is sent from the unit, the client must acknowledge the pa cket within this

time interval or else the unit will close the connection.

2.4.5 t2 Timeout Set Value

1 to 255

This is a timeout of when to send an S-format message to the host to

acknowledge outstanding messages received. This parameter is in units of

seconds and must be less than the value set for t1.

2.4.6 t3 Timeout Set Value

1 to 255

This is the timeout to wait on an idle line before the unit will send a TestFr.Act

message. This value is in units of seconds.

2.4.7 k (maximum queue)

1 to 20

This parameter spec ifies the number of unacknowledged messages th e unit will

buffer. Th is parameter must match that in the host. If the se t number of buffers

are filled in the unit, no other me ssage s will be sent un t il the host unit

acknowledges some or all the messages.

ProSoft Technolo gy, Inc . Page 33 of 188

November 18, 2009

Page 34

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.4.8 w (latest ack threshold)

1 to 20

This parameter must match that of the host unit and specifies the number of

messages the module will receive before sending an S-format sequence

acknowledge message when no I-format data is ready to send. It is

recommended to set this value to 2/3 the value of k.

2.4.9 Time DB Offset

-1 or 0 to 3994

This parameter sets the lo cation in the database where the module’s current date

and time will be copied to.

Note: The following tables lists the 12 byte, data area placed in the database if the Time DB Offset

parameter is set to a value other than -1:

Byte Length Range Description

0 to 1 2 0 to 59,999 Seconds and m il li seconds

2 1 0 to 59 Minutes

3 1 0 to 23 Hour

4 1 Reserved

5 1 1 to 31 Day of the Month

6 1 1 to 12 Month

7 to 8 2 0 to 65,535 Year (four digit format, for example 2005)

9 1 Reserved

10 1 0 or 1 Invalid Flag (0 = Valid, 1 = Invalid

11 1 Reserved

2.4.10 Err or Offset

0 to 3980

-1 to disable

This parameter sets the location in the module’s internal database when the

status and error information for the server will be stored. En ter a va lid database

address of 0 to 3980 to store the information, or enter -1 to disable.

Page 34 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 35

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.4.11 Comm on Address of ASDU

0 to 65535

This parameter specifies the comm o n ad dr ess o f t he ASDU (s ec ti o n ad dr ess ) for

access to data in the module. There is only one value entered for access to all

data in the module.

2.4.12 Cyclic Data Transmission

0 to 2^32

This parameter defines the number of millise c on ds between cyclic updates. The

range of values for this parameter permit upda te times of 1 millisecond to 5

minutes. If the parameter is set to 0, cyclic data reporting will be disabled.

2.4.13 Select/Oper ate Timeout

0 to 2^32

This parameter sets the numbe r of milliseconds after a select command is

received in which to wait for a valid execute command. The range of values for

this parameter permit times of 1 millisec on d to 30 second s. If the parameter is

set to 0, the feature will be disabled.

2.4.14 Use ACTTERM with Setpoint

1 or 0

This parameter determines if an ACTTERM will be sent. If the parameter is set to

1, then setpoint commands will issue an ACTTERM when the command is

complete. If the parameter is set to 0, ACTCON is the last response to a setpoint

command.

2.4.15 Use ACTTERM with Step

1 or 0

This parameter determines if an ACTTERM will be sent. If the parameter is set to

1, then step commands will issue an ACTTERM when the command is complete.

If the parameter is set to 0, ACTCON is the last response to a step command.

ProSoft Technolo gy, Inc . Page 35 of 188

November 18, 2009

Page 36

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.4.16 Freeze Start Type

D=Day, H=Hour, M=Minute, N=Not used

The Freeze Start Type parameter defines when the module starts sending the

M_IT messages.

2.4.17 Interval for Freeze

0 to 65535

Freeze Start Type and Interval for Freeze are used if Mode A operation is to be

used for the counter free ze operation. If they are not used, the modu le will

operate in Mode D.

2.4.18 Set Priority Queues

Yes or No

This section defines priority queues for the module. You can assign priorities to

data types that can return events so that events of data types will be returned

before other data types. This may cause events to be lost as the event buffers for

low priority queues may overflo w. If th is feature is utilized, each data type must

be assigned a unique index from 0 to 6. The lower the index, the higher the

priority (0=h ighest priority).

Each of the ASDUs affected by this feature must be assigned a unique priority

index from 0 to 6. Events of the ASDU with a priority of 0 will always be reported

before any others when they are present.

For more information, refer to Event Priority.

Page 36 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 37

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.4.19 Cyclic Set IV Time

Minimum 3 times larger than IV Check Delay Time parameter

0 to disable

The Cyclic Set IV Time parameter determines how frequently the IV Checks will

be perform ed . If the IV bit is ON for a number o f tim es given by the IV Fail Count

parameter (page 37 ), the module will consider the point as invalid.

If the IV Fail Count para meter is zero, the feature will be disabled.

For more information on using this featu re, ref er to Invalid Bit Monitoring (page

139).

2.4.20 IV Check Delay Time

Value in Seconds

This feature allows the application to set the invalid (IV) quality bit of the protocol

for all the monitored ASDU types supported. The Cyclic Set IV Time parameter

must be at least 3 times larger than the IV Check Delay Time.

2.4.21 IV Fail Count

0 to disable

This feature allows the application to set the invalid (IV) quality bit of the protocol

for all the monitored ASDU types supported. If you enable this feature, the

processor can determine the individual IV quality bit status of each point you

configured.

To disable this feature, set the IV Fail Count parameter to 0. If used, the Cyclic

Set IV Time parameter must be at least 3 times larger than the IV Check Delay

Time.

2.4.22 Event Scan Delay

1 to 65535

0 to disable

If set to 0, the feature will be disabled and the module will n ot gene rate any

events. If set from 1 to 65535, the parameter represents the number of

milliseconds between event scanning. This parameter defines how often the

program will scan for new events in the databases.

ProSoft Technolo gy, Inc . Page 37 of 188

November 18, 2009

Page 38

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.4.23 Scan Events

Scan for Event s

No Scanning

Defines whether event s of this po int type will be generated by the module. If "No

Scanning", th en events will not be generated. If "Sca n for events", events will be

scanned and generated on change.

2.4.24 Time Type

None, CP24 or CP56

This parame ter de fi nes the time form at use d with data events. 0=None, 1=CP24

and 2=CP56 time formats.

2.5 [IEC-870-5-104 IP Addresses]

This section enters the IP addresses for the hosts to connect to this unit. The unit

will only accept connections from hosts listed here. This list may contain up to 10

entries between the START and END labels. The address must start in column 1,

and must be entered in standa rd dot notation.

The following is an example of the [IEC-870-5-104 IP Addresses] section:

Page 38 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 39

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

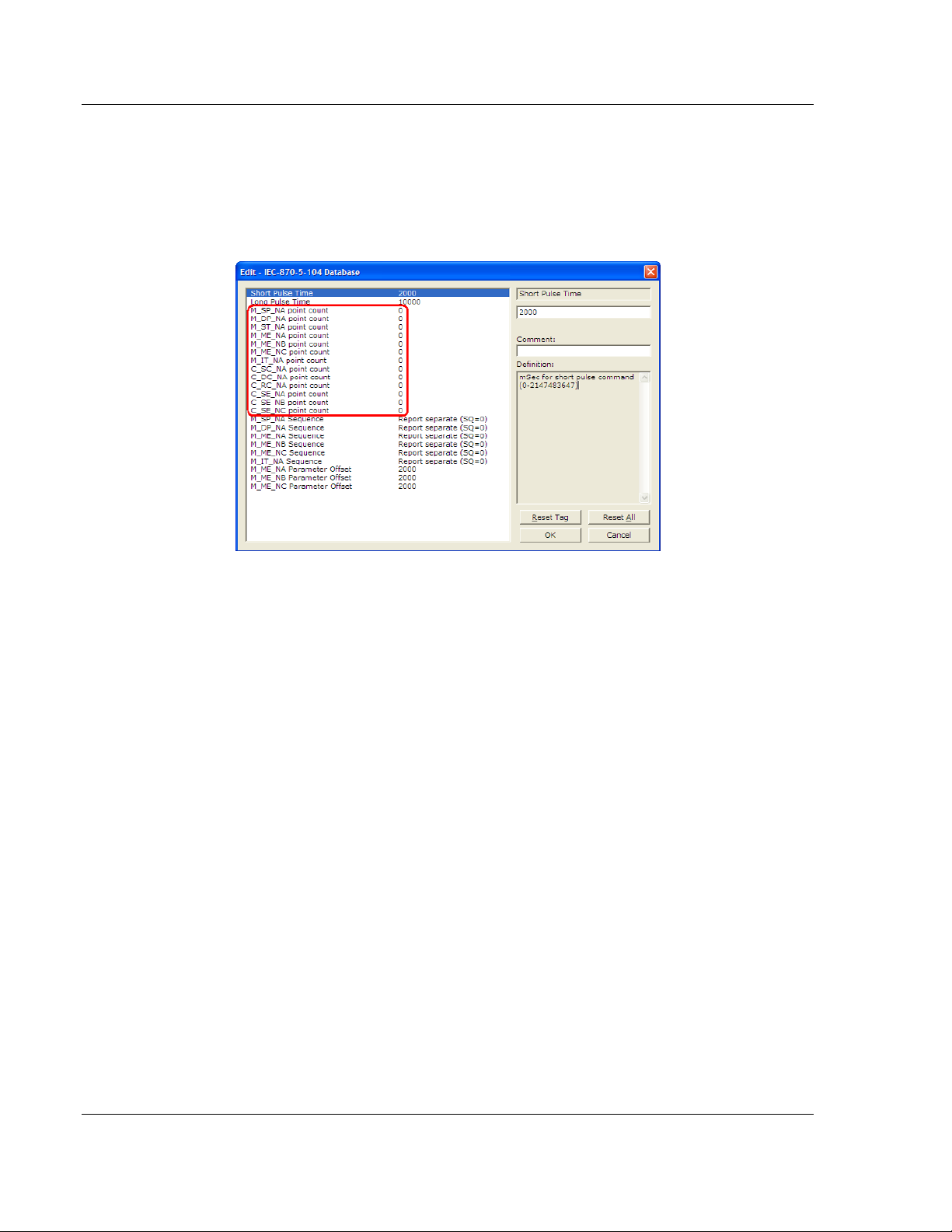

2.6 [IEC-870-5-104 Database]

This section describes the [IEC-870-5-104 Database] section.

2.6.1 Short Pulse Time

0 to 2,147,483,647 millisecon ds

This parameter defines the number of milliseconds to be associated with a short

pulse command.

2.6.2 Long Pulse Time

0 to 2,147,483,647

This parameter def ines the number of milliseconds to be associated with a long

pulse command.

ProSoft Technolo gy, Inc . Page 39 of 188

November 18, 2009

Page 40

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.6.3 Point Count

Point Count configuration ranges in the following configuration items are based

on the assumption that you will be using only one of the available data types for

your application. The number of point counts you configure will have an effect on

module performance, in particular the accuracy of the module’s internal clock.

M_SP_NA point count: This parameter s p ecifies the number of point v alu es

assigned in monitored single-point databa se. Range is 0 to 1000.

M_DP_NA point count: Thi s parameter specifies the number of po int values

assigned in monitored du al-poi nt database. R ange is 0 to 1000 .

M_ST_NA point count: This parameter specifies the number of point value s

assigned in monitored step-point database. Range is 0 to 1000.

M_ME_NA point count: This parameter specifies the number of point values

assigned in monitored normalized-point database. Range is 0 to 1000.

M_ME_NB point count: This parameter specifies the number of point values

assigned in monitored scaled-point database. Range is 0 to 1000.

M_ME_NC point count: This parameter specifies the number of point values

assigned in monitored scaled short-float point database. Range is 0 to 50.

M_IT_NA point count: This parameter specifies the number of point values

assigned in monitored counter-point database. Range is 0 to 99.

C_SC_NA point count: Thi s parameter specifies the number of point value s

assigne d in com m a nd si ngle-point database. Range is 0 to 10 00 .

C_DC_NA point count: This parameter specifies the number of point values

assigned in command dual-point database. Range is 0 to 1000.

C_RC_NA point count: This parameter specifies the number of point values

assigned in command step-point database. Range is 0 to 1000.

C_SE_NA point count: This parameter specifies the number of point values

assigned in command normalized-point database. Range is 0 to 1000.

C_SE_NB point count: This parameter specifies the number of point values

assigne d in com m a nd sc aled-point databa se. Range is 0 to 10 00.

C_SE_NC point count: This parameter specifies the number of point values

assigne d in com mand short-float point datab ase . R ang e is 0 to 50 .

Page 40 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 41

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

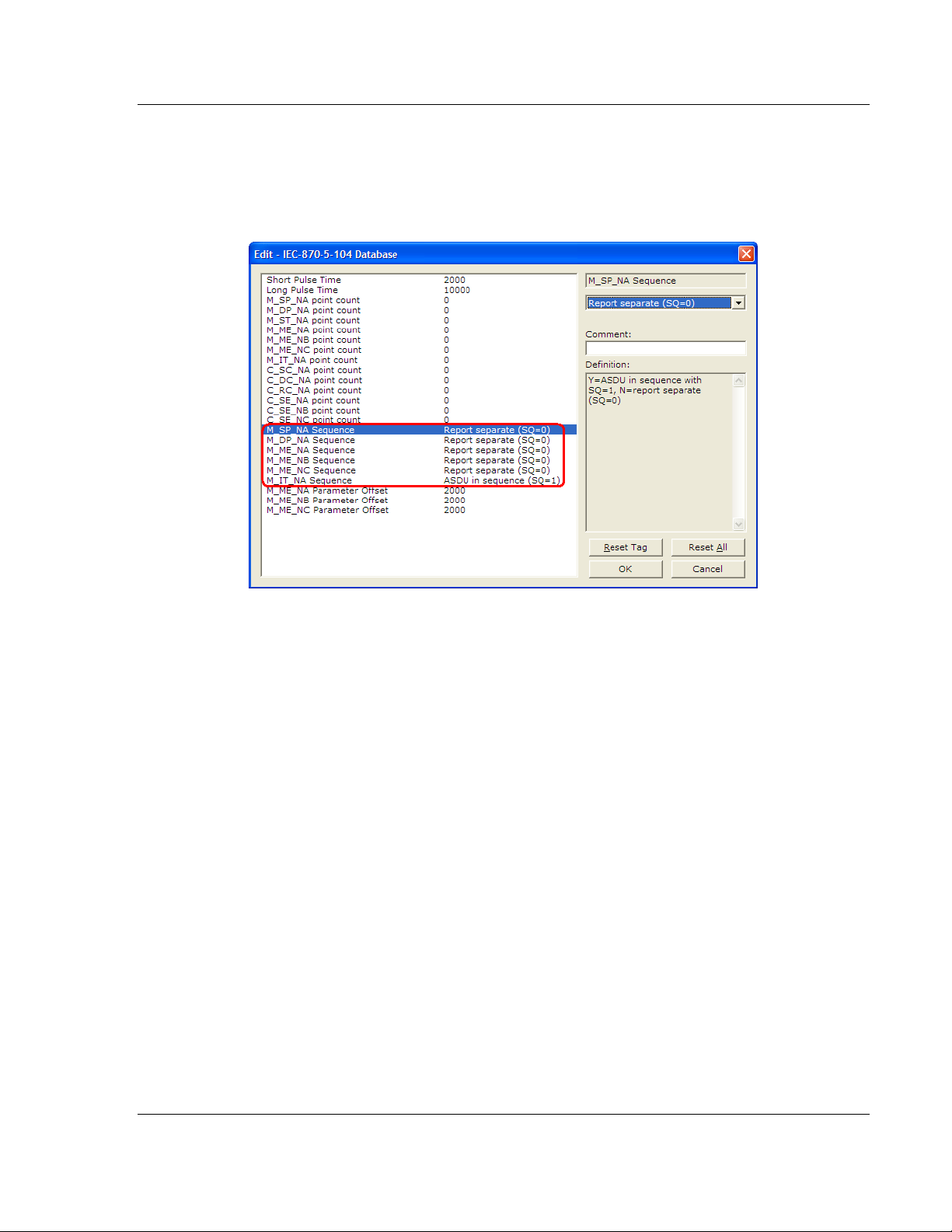

2.6.4 Sequence Flag

In order to save bandwidth, you can configure the module to use the Sequence

Flag feature. If this feature is not selected, the module will send the object

address and its value at every monitored response to the master.

If this parameter is selected, the module will turn the Sequen ce Flag on every

monitored response sending the address for the first point along with all point

values. The master assumes that all other points use information object

addresses in a contiguous order (using the first point as the reference).

ProSoft Technolo gy, Inc . Page 41 of 188

November 18, 2009

Page 42

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.6.5 Parameter Offset

This parameter specifies the IOA (Information Object Address) offset to the

parameter data for the normalized parameter data. The value entered is added to

the Information Object address for th e ass ociated point to compute th e

parameter IOA address.

The Master may send a "Parameter of Measured Normalized" or "Parameter of

Measured Scaled" command using the parameter IOA in order to change the

deadband values for specific points.

Note: The Low Limit and High Limit values are always calculated based on the deadband value as

described in the following table.

Point Value

Threshold Determined by the deadband set in the configuration file or altered by the write

command.

Low Last reported ev ent value - threshold.

High Last reported event value + thr eshold.

For example, if the MVI56-104S configuration sets two M_ME_NA points with

IOA (Point #) o f 600 and 601 and a M_ME_NA Par am eter O f fset v alue of 3000, it

would result in the parameter points shown in the table.

Page 42 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 43

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.7 [M_SP_NA_1 104]

This section defines the monitored single-point database for the server device

emulated. This information is sourced from the database and is transferred to the

remote client unit. Each point in the database occupies 1 bit (1 = On, 0 = Off

state).

This section takes the following parameters:

Point #

DB Address

Group(s)

IV DB Bit

Each point is one bit and the DB address value corresponds to the bit offset in

the database.

2.8 [M_DP_NA_1 104]

This section defines the monitored dual-point database for the server device

emulated. This information is sourced from the database and is transferred to the

remote client unit. Each point in the database occupies two bits (00 =

intermediate, 01 = off, 10 = on and 11 = intermediate).

This section takes the following parameters:

Point #:

DB Address:

Group(s):

IV DB Bit

Each point is two bits and the DB address value corresponds to the bit offset in

the database.

2.9 [M_ST_NA_1 104]

This section defines the monitored step database for the server device emulated.

This information is sourced from the database and is transferred to th e remote

client unit. Each point in the database occupies one byte.

This section takes the following parameters:

Point #:

DB Address:

Group(s):

IV DB Bit

Each point is one byte and the DB Address value corresponds to the byte offset

in the database.

ProSoft Technolo gy, Inc . Page 43 of 188

November 18, 2009

Page 44

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.10 [M_ME_NA_1 104]

This section defines the monitored measured value, normalized database for the

server device emulated. This information is sourced from the database and is

transferred to the remote client unit. Each point occupies a word position in the

database. To determine the IOA (Information Object Address) for each object,

add the Point # in the following section to the value of the M_ME_NA parameter

offset parameter set in the previous section.

This section takes the following parameters:

Point #:

DB Address:

Group(s):

Default Deadband:

IV DB Bit

Each point is one word and the DB Address value corresponds to the word offset

in the database.

2.11 [M_ME_NB_1 104]

This section defines the monitored measured value, scaled database for the

server device emulated. This information is sourced from the database and is

transferred to the remote client unit. Each point occupies a word position in the

database. To determine the IOA (Information Object Address) for each object,

add the Point # in the following section to the value of the M_ME_NB parameter

offset parameter set in the previous section.

This section takes the following parameters:

Point #:

DB Address:

Group(s):

Default Deadband:

IV DB Bit

Each point is one word and the DB Address value corresponds to the word offset

in the database.

Page 44 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 45

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.12 [M_ME_NC_1 104]

This section defines the monitored short-float point database for the slave device

emulated. This information is sourced from the database and is transferred to the

remote client unit. Each point occupies 4-byte positions in the database. To

determine the IOA (Information Object Address) for each object, add the Point #

in the following section to the value of the M_ME_NC Parameter Offset

parameter set in the previous section.

This section takes the following parameters:

Point #

DB Address

Groups

Default Deadband

IV DB Bit

Each point is one word and the DB Address value corresponds to the word offset

in the database.

Refer to the Group Codes (page 49) section for a listing of Group Codes.

2.13 [M_IT_NA_1 104]

This section defines the monitored integrated totals (counter) database for the

server emulated. This information is sourced from the database and is

transferred to the remote client unit. Each point occupies two words in the

database (4 bytes).

This section takes the following parameters:

Point #:

DB Address:

Group(s):

IV DB Bit

Each point is two words and the DB Address value corresponds to the double word offset in the database.

ProSoft Technolo gy, Inc . Page 45 of 188

November 18, 2009

Page 46

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.14 [C_SC_NA_1 104]

This section defines the single point command database for the server emulated.

This information is sourced from the remote client and is transferre d to the

database. Each point occupies a single bit position in the database. You can

associate a command with a monitored single-poin t database value to coordinate

the command/monitor operation. You must enter the correct Monitor Point # and

Monitor DB Address values in the table. If the Requ ire Select parameter is not

set to zero, a select command must be received before an execute command will

be process e d.

This section takes the following parameters:

Point #:

DB Address:

Monitor Point #:

Monitor DB Addr:

Require Select:

Each point is one bit and the DB Address value corresponds to the bit offset in

the database.

2.15 [C_DC_NA_1 104]

This section defines the double point command database for the server

emulated. This information is sourced from the remote client and is tran sferred to

the database. Each point occupies two bits in the database. You can associate a

command with a monitored double point database value to coordinate the

command/monitor operation. You must enter the correct Monitor Point # and

Monitor DB Addr values in the table. If the Require Select parameter is not set to

zero, a select command must be received before an execute command will be

processed.

This section takes the following parameters:

Point #:

DB Address:

Monitor Point #:

Monitor DB Addr:

Require Select:

Each point is two bits and the DB Address value corresponds to the bit offset in

the database.

Page 46 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 47

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.16 [C_RC_NA_1 104]

This section defines the step command database for the server emulated. This

information is sourced from the remote client and is transferred to the database.

Each point occupies a byte in the database. The control value can be associated

with a monitored point as described in the previous example.

This section takes the following parameters:

Point #:

DB Address:

Monitor Point #:

Monitor DB Addr:

Each point is one byte and the DB Address value corresponds to the byte offset

in the database.

2.17 [C_SE_NA_1 104]

This section defines the normalized setpoint database for the server emulated.

This information is sourced from the remote client and is transferre d to the

database. Each point occupies a word position in the database. You can

associate a command with a monitored normalized database value to coordinate

the command/monitor operation. You must enter the correct Monitor Point # and

Monitor DB Addr values in the table. If the Require Select parameter is not set to

zero, a select command must be received before an execute command will be

processed.

This section takes the following parameters:

Point #

DB Address

Monitor Point #

Monitor DB Addr

Require Select

Each point is one word and the DB Address value corresponds to the word offset

in the database.

ProSoft Technolo gy, Inc . Page 47 of 188

November 18, 2009

Page 48

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.18 [C_SE_NB_1 104]

This section defines the scaled setpoint database for the server emulated. Th is

information is sourced from the remote client and is transferred to the database.

You can associate a command with a monitored scaled database value to

coordinate the command/monitor operation. You must enter the correct Monitor

Point # and Monitor DB Addr values in the table. If the Require Select parameter

is not set to zero, a select command must be received before an execute

command will be processed.

This section takes the following parameters:

Point #:

DB Address:

Monitor Point #:

Monitor DB Addr:

Require Select:

Each point is one word and the DB Address value corresponds to the word offset

in the database.

2.19 [C_SE_NC_1 104]

This section defines the short-float setpoint database for the server emulated.

This information is sourced from the remote client and is transferre d to the

database. Each point occupies a double-word position in the database. If the

Require Select parameter is not set to zero, a select command must be received

before an execute command will be processed.

This section takes the following parameters:

Point #:

DB Address:

Monitor Point #:

Monitor DB Addr:

Require Select:

Each point is two words and the DB Address value corresponds to the double word offset in the database.

Page 48 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 49

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.20 Group Codes

One aspect of the point configuration database that leads to confusion is the

group definition field. This assignment for each point assigns a point to one or

more interroga tion groups. Use of interrogat ion gro ups permits the controlling

unit to interface with a specific set of data. Refer to the IEC 60870-5-104

standar d for a full di sc uss ion of interrogation groups. A specific gr o up, Per i odi c

data grou p, reports data points on a set fr equency. The frequ en cy is set in the

Cyclic Da ta Transmission parameter in the configuration file. Remember that a

point can be assi gned to more th an on e gr ou p.

Group Code Description

0x00000001 Interrogated by general interrogation (station or global)

0x00000002 Interrogated by gr oup 1 interrogation

0x00000004 Interrogated by gr oup 2 interrogation

0x00000008 Interrogated by gr oup 3 interrogation

0x00000010 Interrogated by gr oup 4 interrogation

0x00000020 Interrogated by gr oup 5 interrogation

0x00000040 Interrogated by gr oup 6 interrogation

0x00000080 Interrogated by gr oup 7 interrogation

0x00000100 Interrogated by gr oup 8 interrogation

0x00000200 Interrogated by gr oup 9 interrogation

0x00000400 Interrogated by gr oup 10 interrogation

0x00000800 Interrogated by gr oup 11 interrogation

0x00001000 Interrogated by gr oup 12 interrogation

0x00002000 Interrogated by gr oup 13 interrogation

0x00004000 Interrogated by gr oup 14 interrogation

0x00008000 Interrogated by gr oup 15 interrogation

0x00010000 Interrogated by gr oup 16 interrogation

0x00020000 Interrogated by general counter request

0x00040000 Interrogated by gr oup 1 counter request

0x00080000 Interrogated by gr oup 2 counter request

0x00100000 Interrogated by gr oup 3 counter request

0x00200000 Interrogated by gr oup 4 counter request

0x40000000 Disable event scanning of this point

0x80000000 Periodic/cyclic data returned from unit

If the highest bit (bit 31) is set, data will be produced by the driver for the

specifi ed point at the rate set for periodi c dat a ge n er ati o n. Bi t 30 (0x4 00 00 00 0)

enables scanning of this poin t for event generation. If the bit is clear and the data

type is set for scanning, events will be generated for the point. If the bit is set,

events will not be generated for the point. This feature can be used to select

which points will generate events for the cont rolling station and can get rid of

event data that is not important to the application.

ProSoft Technolo gy, Inc . Page 49 of 188

November 18, 2009

Page 50

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.21 Ethernet Configuration

Use this procedure to configure the Ethernet settings for your module. You must

assign an IP address, subnet mask and gateway address. After you complete

this step, you can connect to the module with an Ethernet cable.

1 Determine the network settings for your module, with the help of your network

administrator if necessary. You will need the following information:

o IP address (fixed IP required) _____ . _____ . _____ . _____

o Subnet mask _____ . _____ . _____ . _____

o Gateway address _____ . _____ . _____ . _____

Note: The Gateway Address is optional, and is not required for networks that do not use a default

gateway.

2 Double-click the ETHERNET CONFIGURATION icon. This act ion opens the EDIT

dialog box.

3 Edit the values for my_ip, netmask (subnet mask) and gateway (default

gateway).

4 When you are finished editing, click OK

to save your changes and return to

the ProSoft Configuration Builder window .

Page 50 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 51

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

2.22 Download the Project to the Module

In order for the module to use the settings you configured, you must download

(copy) the updated Project file from your PC to the module.

To Download the Project File

1 In the tree view in ProSoft Configuration Builder, click once to select the

MVI56-104S module.

2 Open the P

ROJECT menu, and then choose MODULE / DOWNLOAD. The

program will scan your PC for a valid com port (this may take a few seconds).

When PCB has fo und a valid com port, the D

OWNLOAD dialog box will open.

3 Choose the com port to use from the dropdown list, and then click the

D

OWNLOAD button.

The module will perform a platform check to read and load its new sett ing s.

When the pla tform ch eck is complete, the status bar in the D

OWNLOAD dialog

box with the message "Module Running".

ProSoft Technolo gy, Inc . Page 51 of 188

November 18, 2009

Page 52

MVI56-104S ♦ ControlLogix Platform Configuring the MVI56-104S Module

IEC 60870-5-104 Server Communication Module User Manual

2.23 Adding the Module to an Existing Project

1 Add the MVI56-104S module to the project. Select the I/O CONFIGURATION

folder in the C

mouse button to open a shortcut menu. On the shortcut menu, choose N

MODULE.

ONTROLLER ORGANIZATION window, and then click the right

EW

This action opens the

SELECT MODULE dialog box:

Page 52 of 188 ProSoft Technolo gy, Inc .

November 18, 2009

Page 53

Configuring the MVI56-104S Module MVI56-104S ♦ ControlLogix Platform

User Manual IEC 60870-5-104 Server Communication Module

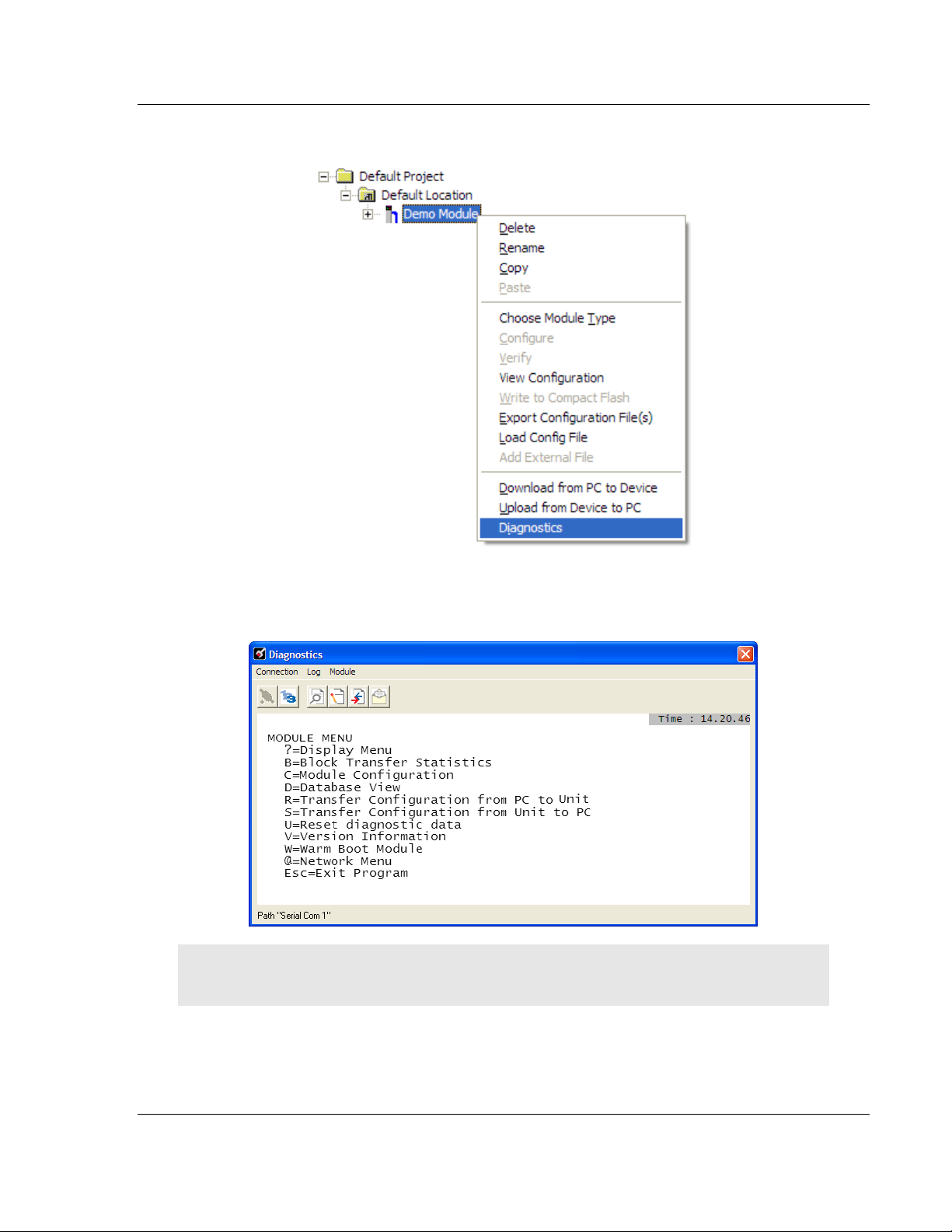

Select the