Page 1

3

Drill Pump

KOMPERNASS GMBH

BURGSTRASSE 21 · D-44867 BOCHUM

www.kompernass.com

ID-Nr.: 54359-06/10-V3

Drill Pump

Operating instructions

Borrmaskinspump

Bruksanvisning

Bohrmaschinenpumpe

Bedienungsanleitung

Porakonepumppu

Käyttöohje

Boremaskinepumpe

Betjeningsvejledning

Page 2

q

y

o

t

u

i

a

e

r

w

Page 3

CONTENT PAGE

Safety instructions 2

Intended Usage 3

Technical Data 3

Items supplied 4

Overview of the appliance 4

Assembly material required 4

Assembly and connection 5

Disassembly of the drive shaft 7

Utilisation 8

Cleaning and care 8

Disposal 9

Declaration of conformity 9

Importer 9

Warranty and Service 10

Read these operating instructions carefully before using the appliance for the

first time and preserve these instructions for later reference. Pass these instructions on to whoever may acquire the appliance at a future date.

- 1 -

Page 4

Safety instructions

To avoid the risk of accidents and damage to the

appliance:

• Operate the pump ONLY when it is secured by the supplied mounting

against jolting, twisting and canting.

• Check the pump for a faultfree condition before ever taking it into use.

The pump may not be used if it shows signs of damage.

The drive shaft of the pump does not allow itself to be turned by hand.

This does not indicate that the pump is defective.

• Use only hoses certified as being able to withstand a pressure of at least

3 bars (44 psi).

• Check the plug-in connectors on the hoses for firm seating.

• Take steps to ensure that the fluid being pumped cannot come into contact

with the electric drill during pumping. Should it nonetheless occur, immediately remove the power plug.

• Avoid the intake of coarse dirt, otherwise the pump could be damaged.

If needs be, use a filter on the suction hose.

• This appliance is not intended for use by children or other individuals whose

physical, sensorial or intellectual abilities prevent safe usage of the appliance should they not receive support or supervision in the correct operation of the appliance. Children should be supervised to ensure that they do

not play with the appliance.

- 2 -

Page 5

Intended Usage

This pump is intended for ...

– standard commercial right/left rotating electric drills with a 43 mm Euro-

spindle and a gear-wheel rim chuck/quick-release chuck or drill chuck

with SDS fitting, up to rotation speed of 3400 rpm,

– the pumping of cold or up to 40°C warm fluids, such as non-potable or

dirty water from fish tanks or ponds.

This pump is

– the pumping of flammable, explosive, poisonous or caustic liquids or

foodstuffs.

– for industrial or commercial applications.

NNOOTT

intended for ...

Technical Data

Capacity: max. 2,4 m3/h

Hose connection: 3/4” (19 mm)

Pressure: max. 3 bar

Delivery height: max. 30 m

Suction height: max. 3 m

Temperature of the fluid being pumped: max. 40°C

Dry run time: max. 12 seconds

Rotation speed: max. 3400 rpm

- 3 -

Page 6

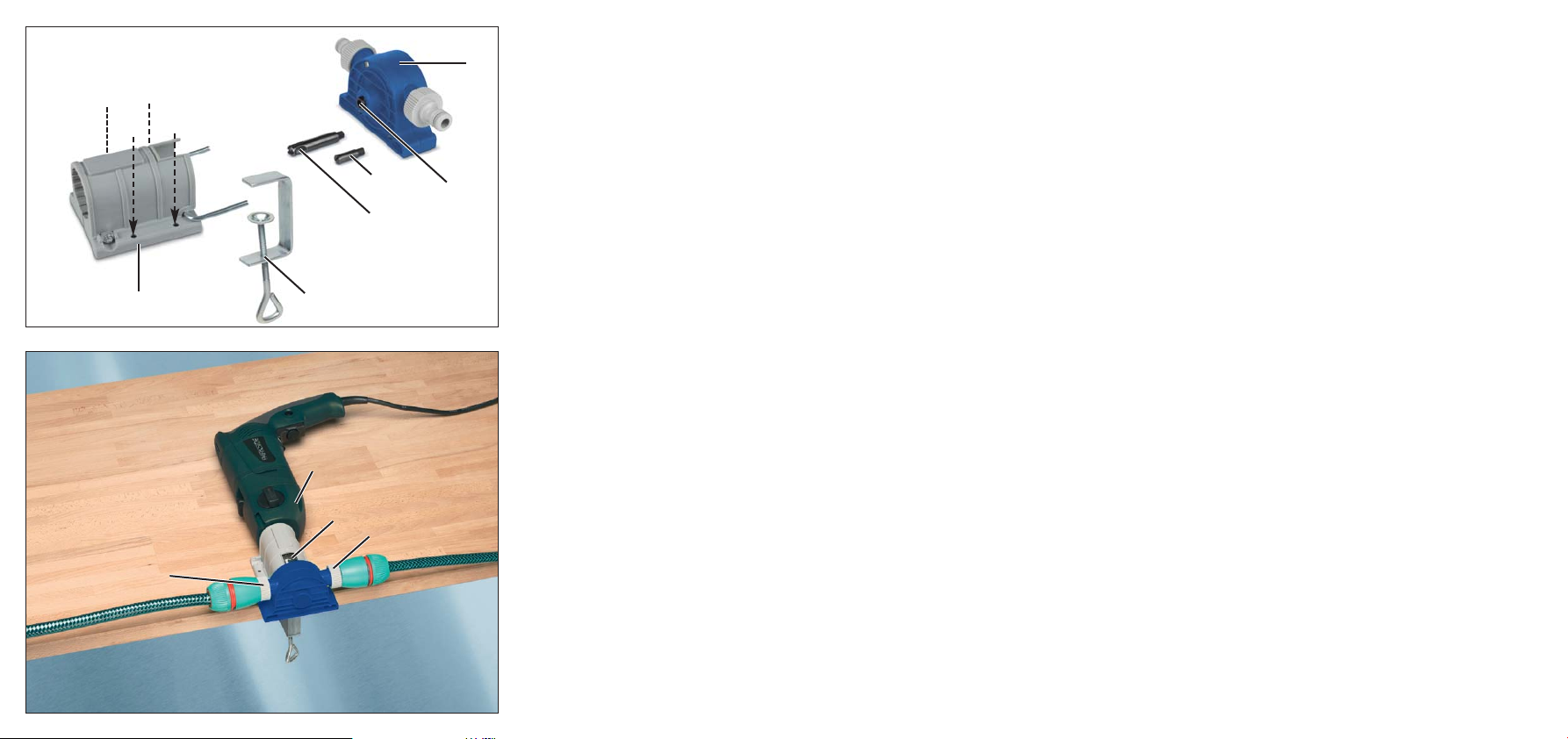

Items supplied

- Pump

- Short drive shaft

- Long drive shaft

- Clamp fixing

- Mounting

- Open-ended spanner

- Storage box for the drive shafts and open-ended spanner

- This operating manual

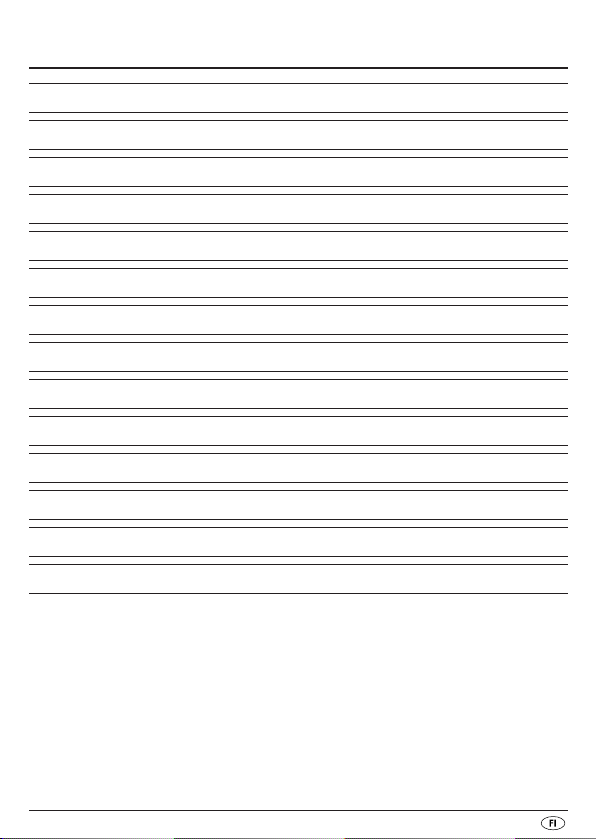

Overview of the appliance

Pump

q

Drive shaft of the pump

w

Short drive shaft (suitable for gear-wheel/quick-release chuck)

e

Long drive shaft (suitable for a drill chuck with SDS fitting)

r

Clamp fastening

t

Mounting

y

Electric drill (not supplied)

u

Recess for chuck key

i

Connection for suction hose

o

Connection for pressure hose

a

Assembly material required

- Philips-type screwdriver

- Flat-headed screwdriver

- Open-ended spanner (supplied)

- 4 -

Page 7

Assembly and connection

µ Assemble the mounting

as shown in the illustration.

Alternatively, the mounting

with screws (assembly material not supplied).

with the clamp fastening tonto a work surface,

y

can also be secured to a work surface

y

When using a gear-wheel chuck and the short drive

shaft e...

µ Screw the short drive shaft

µ Insert the electric drill

µ Now push the pump

projects into the chuck and the pins of the mounting yare located in the

reception holes on the pump

q

µ Now tighten the chuck with the chuck key through the recess

that the pump

can no longer release itself from the mounting y.

q

µ Tighten the cross-headed screw on the mounting

cannot jolt around.

u

µ Attach the suction hose to the connection

connection

pump

. Pay heed to the direction of flow detailed on the

a

.

q

onto the drive shaft wof the pump q.

e

with the chuck into the mounting y.

u

onto the mounting yso that the drive shaft

.

q

i

firmly, so that the drill

y

and the pressure hose to the

o

so firmly

When using a quick-release chuck and the short drive

shaft e...

µ Secure the short drive shaft

µ Insert the electric drill

chuck, into the mounting

u

µ Securely tighten the cross-head screw on the mounting

is being firmly held.

into the chuck.

e

, with the pre-assembled drive shaft ein the

.

y

so that the drill

y

e

u

- 5 -

Page 8

µ Now push the pump

projects into the thread of the drive shaft w, and the pins of the mounting

are located in the reception holes on the pump q.

y

µ Let the drill

and then guide the pump

shaft

e

start to run in a clockwise rotation and at low revolutions

u

is thereby secured to the pump q.

µ Attach the suction hose to the connection

connection

pump

. Pay heed to the direction of flow detailed on the

a

.

q

onto the mounting yso that the drive shaft

q

straight onto the drive shaft e. The drive

q

and the pressure hose to the

o

e

When using a chuck with SDS fitting and the long drive

shaft r...

µ Attach the long drive shaft

µ Insert the electric drill

chuck, into the mounting

µ Tighten the cross-headed screw on the mounting

cannot jolt around.

µ Now push the pump

projects into the thread of the drive shaft wand the pins of the mounting

are located in the reception holes on the pump q.

y

q

µ Allow the electric drill

ons and guide the pump

drive shaft

will be fixated onto the pump q.

r

µ Attach the suction hose to the connection

connection

pump

. Pay heed to the direction of flow detailed on the

a

.

q

into the chuck.

r

, with the pre-assembled drive shaft rin the

u

.

y

firmly, so that the drill

y

onto the mounting yso that the drive shaft

to run with a clockwise rotation and low revoluti-

u

straight on to the drive shaft r. With this the

q

and the pressure hose to the

o

r

u

- 6 -

Page 9

Disassembly of the drive shaft

Disassembly of the short drive shaft

Wheel rim chuck

e

µ Open the chuck with the chuck key through the recess

the pump

µ Unscrew the short drive shaft

the open-ended spanner from the pump

Quick-release chuck

µ Using the open-ended spanner through the recess

drive shaft

µ Allow the electric drill

volutions. The drive shaft

µ Remove the pump

µ Remove the drive shaft

Disassembly of the long drive shaft

Chuck with SDS fitting

from the mounting y.

q

of the pump q.

w

to run with an anti-clockwise rotation and low re-

u

e

from the mounting y.

q

e

by using a cross-headed screwdriver and

e

.

q

i

is thereby released from the pump q.

from the chuck.

r

µ Using the open-ended spanner through the recess,

drive shaft

µ Allow the electric drill

revolutions. With this the drive shaft

µ Remove the pump

µ Remove the drive shaft

of the pump q.

w

q

to run with an anti-clockwise rotation and low

u

will be released from the pump q.

r

from the mounting y.

from the chuck.

r

and then remove

i

, counter screw the

counter screw the

i

- 7 -

Page 10

Utilisation

Attention!

The pump is self priming. If the pump qdoes not start to suck up within 12

seconds, turn the drill

son, do not allow the pump

the discharge side is closed.

µ Place the open end of the suction hose into the liquid that is to be pumped.

The suction hose may not be longer than 3 m. Ensure that the suction hose

does not pull in air.

off immediately to avoid seizure. For this same rea-

u

to commence suction if the pressure hose on

q

If the pump

and then lift it so that the liquid runs before the pump.

µ Allow the drill

so that you can react quickly in the event of danger. Absolutely ensure

that the electric drill

Should the rotation speed of the electric drill

use this to regulate the discharge flow.

does not commence suction, fill the hose with some water

q

, now the pump q, to start-up – but not without supervision,

u

is rotating to the right, as with normal drilling.

u

be adjustable, you can

u

µ Turn the drill off immediately after the container is empty.

Cleaning and care

Clean the pump qwith a dry or lightly moistened cloth only. To avoid damage

to the plastic surfaces, do not use solvents or abrasive cleaning agents.

The pump is maintenance free.

- 8 -

Page 11

Disposal

Do not dispose of the appliance in your normal domestic waste.

Dispose of the appliance through an approved disposal centre or at your

community waste facility.

Observe the currently applicable regulations. In case of doubt, please

contact your waste disposal centre.

Dispose of all packaging materials in an environmentally friendly

manner.

Declaration of conformity

We, Kompernaß GmbH, Burgstraße 21, D-44867 Bochum, declare with sole

responsibility that the product described here, “Drill Pump 54359”,

to which this declaration refers, complies fully with the valid requirements of

the EU Directive 2006/42/EC (Machines) in the construction that is being

marketed by us.

Should the product be modified in any way without our agreement,

this declaration loses its validity.

Bochum, 06.15.2010

Hans Kompernaß

- Managing Director -

Importer

KOMPERNASS GMBH

BURGSTRASSE 21

D-44867 BOCHUM

www.kompernass.com

- 9 -

Page 12

Warranty and Service

The warranty for this appliance is for 3 years from the date of purchase. The

appliance has been manufactured with care and meticulously examined before delivery. Please retain your receipt as proof of purchase. In the event of

a warranty claim, please make contact by telephone with our Service Department. Only in this way can a post-free despatch for your goods be assured.

The warranty covers only claims for material and maufacturing defects, but

not for transport damage, for wearing parts or for damage to fragile components, e.g. buttons or batteries. This product is for private use only and is not

intended for commercial use. The warranty is void in the case of abusive and

improper handling, use of force and internal tampering not carried out by our

authorized service branch. Your statutory rights are not restricted in any way

by this warranty.

The warranty period will not be extended by repairs made under warranty.

This applies also to replaced and repaired parts. Any damage and defects

extant on purchase must be reported immediately after unpacking the appliance, at the latest, two days after the purchase date. Repairs made after the

expiration of the warranty period are subject to payment.

DES UK LTD

Tel.: 0871 5000 700

e-mail: support.uk@kompernass.com

Kompernass Service Ireland

Tel.: 1850 930 412 (0,082 EUR/Min.)

Standard call rates apply. Mobile operators may vary.

e-mail: support.ie@kompernass.com

(£ 0.10 / minute)

- 10 -

Page 13

SISÄLLYSLUETTELO SIVU

Turvaohjeet 12

Määräystenmukainen käyttö 13

Tekniset tiedot 13

Toimituslaajuus 14

Laite 14

Tarvittava asennusmateriaali 14

Asennus ja liitäntä 15

Käyttövarren irrottaminen 17

Käyttö 18

Puhdistus ja huolto 18

Hävittäminen 19

Vaatimustenmukaisuusvakuutus 19

Maahantuoja 19

Takuu ja huolto 20

Lue käyttöohje ennen ensimmäistä käyttökertaa huolellisesti läpi ja pidä sitä

lähettyvillä myös myöhemmissä käytöissä. Jos myyt laitteen, anna ohje myös

seuraavalle omistajalle.

- 11 -

Page 14

Turvaohjeet

Tapaturmavaaran ja laitevaurioiden välttämiseksi:

• Käytä pumppua vain, kun se on varmistettu mukana tulevalla pidikkeellä

iskeytymistä, kiertymistä tai taittumista vastaan.

• Tarkasta pumpun moitteeton kunto ennen jokaista käyttökertaa. Pumppua

ei saa käyttää, jos siinä havaitaan vaurioita.

Pumpun käyttöakselia ei voida pyörittää käsin.

Se ei tarkoita, että pumpussa on vikaa.

• Käytä vain letkuja, jotka kestävät vähintään 3 baarin painetta.

• Varmista letkujen pistoliittimien tiivis paikoillaanolo.

• Huolehdi siitä, ettei pumpun käyttöön käytettävään porakoneeseen pääse

nesteitä. Mikäli näin käy, irrota verkkopistoke välittömästi.

• Vältä karkean lian imemistä, koska muuten pumppu voi vaurioitua. Käytä

tarvittaessa suodatinta imuletkussa.

• Tätä laitetta ei ole tarkoitettu lasten tai muiden henkilöiden käytettäväksi

ilman apua tai valvontaa, jos heidän fyysiset, aistilliset tai henkiset

kykynsä estävät heitä käyttämästä sitä turvallisesti. Lapsia on valvottava

ja varmistettava, etteivät he leiki laitteella.

- 12 -

Page 15

Määräystenmukainen käyttö

Tämä pumppu on tarkoitettu ...

– tavanomaisille myötä-/vastapäivään pyöriville käsiporakoneille, joissa on

43 mm:n kiinnitys (Eurohals) ja hammasistukka/pikaistukka tai SDS-liitännällä

varustettu poraistukka, korkeintaan 3400 krs/min kierroslukuun asti,

– kylmän tai korkeintaan 40°C lämpimän nesteen, kuten esim. käyttö- tai

likaveden pumppaamiseen akvaarioista tai puutarhalammikoista.

Tätä pumppua

– palavien, räjähtävien, myrkyllisten tai syövyttävien nesteiden tai elintarvik-

keiden pumppaamiseen.

– teollisiin tai ammatillisiin käyttötarkoituksiin.

eeii

ole tarkoitettu...

Tekniset tiedot

Siirtomäärä: kork. 2,4 m3/h

Letkuliitäntä: 3/4” (19 mm)

Paineteho: kork. 3 bar

Siirtokorkeus: kork. 30 m

Imukorkeus: kork. 3 m

Siirrettävän nesteen

lämpötila: kork. 40 °C

Kuivakäyntiaika: kork. 12 sekuntia

Kierrosluku: kork. 3400 krs/min

- 13 -

Page 16

Toimituslaajuus

- Pumppu

- Lyhyt käyttövarsi

- Pitkä käyttövarsi

- Puristuskiinnitin

- Pidike

- Kita-avain

- Säilytyslaatikko käyttövarsille ja kita-avaimelle

- Tämä käyttöohje

Laite

Pumppu

q

Pumpun käyttöakseli

w

Käyttövarsi lyhyt (soveltuu hammas-/pikaistukalle)

e

Käyttövarsi pitkä (sopii SDS-liitännälle)

r

Puristuskiinnitin

t

Pidike

y

Porakone (ei sisälly toimitukseen)

u

Aukko poraistukka-avaimelle

i

Imuletkun liitäntä

o

Paineletkun liitäntä

a

Tarvittava asennusmateriaali

- Ristipääruuvimeisseli

- Rakopääruuvimeisseli

- Kita-avain (sisältyy toimitukseen)

- 14 -

Page 17

Asennus ja liitäntä

µ Asenna pidike

tavalla.

Vaihtoehtoisesti voidaan pidike

(asennusmateriaali ei sisälly toimitukseen).

puristuskiinnittimellä ttyötasoon kuvassa esitetyllä

y

asentaa työtasoon myös ruuveilla

y

Käytettäessä hammasistukkaa ja lyhyttä käyttövartta e...

µ Ruuvaa lyhyt käyttövarsi

µ Liitä porakone

poraistukalla pidikkeeseen y.

u

µ Työnnä nyt pumppu

poraistukkaan ja pidikkeen

µ Kiristä poraistukka poraistukka-avaimella aukon

pumppu

µ Kiristä pidikkeen

heilumaan.

ei enää pääse irtoamaan pidikkeestä y.

q

y

µ Liitä imuletku liitäntään

pumpussa

ilmoitettu virtaussuunta .

q

pumpun qkäyttöakselille w.

e

pidikkeeseen yniin, että käyttövarsi eulottuu

q

tapit työntyvät pumpun qkiinnitysaukkoihin.

y

läpi niin kireälle, että

i

ristipääruuvi tiukalle, jotta porakone uei pääse

ja paineletku liitäntään a. Huomaa tällöin

o

Käytettäessä pikaistukkaa ja lyhyttä käyttövartta e...

µ Kiinnitä lyhyt käyttövarsi

µ Aseta porakone

seen

.

y

µ Kierrä pidikkeen

heilumaan.

u

y

poraistukkaan.

e

ja esiasennettu käyttövarsi eporaistukassa pidikkee-

ristipääruuvi tiukalle, jotta porakone uei pääse

- 15 -

Page 18

µ Työnnä pumppu

töakselin

tysaukkoihin.

w

µ Anna porakoneen

vie pumppu

pumppuun

µ Liitä imuletku liitäntään

pumpussa

q

pidikkeeseen yniin, että käyttövarsi eosuu käyt-

q

kierteeseen ja pidikkeen ytapit työntyvät pumpun qkiinni-

käydä myötäpäivään ja alhaisella kierrosluvulla ja

u

suoraan käyttövarrelle e. Näin käyttövarsi ekiinnittyy

q

.

q

ja paineletku liitäntään a. Huomioi tällöin

o

ilmoitettu virtaussuunta .

Käytettäessä SDS-liitännällä varustettua poraistukkaa ja

pitkää käyttövartta r...

µ Kiinnitä pitkä käyttövarsi

µ Liitä porakone

seen

.

y

µ Kiristä pidikkeen

heilumaan.

ja poraistukkaan esiasennettu käyttövarsi rpidikkee-

u

y

µ Työnnä nyt pumppu

käyttöakselin

kiinnitysaukkoihin.

µ Anna porakoneen

la ja vie pumppu

kiinnittyy pumppuun q.

kierteisiin ja pidikkeen ytapit työntyvät pumpun

w

u

q

µ Liitä imuletku liitäntään

pumpussa

ilmoitettu virtaussuunta .

q

poraistukkaan.

r

ristipääruuvi tiukalle, jotta porakone uei pääse

pidikkeeseen yniin, että käyttövarsi rulottuu

q

q

käydä myötäpäivään ja alhaisella kierrosnopeudel-

suorassa käyttövarrelle r. Näin käyttövarsi

ja paineletku liitäntään a. Huomaa tällöin

o

r

- 16 -

Page 19

Käyttövarren irrottaminen

Lyhyen käyttövarren eirrottaminen

Hammasistukka

µ Avaa poraistukka poraistukka-avaimella aukon

pidikkeestä y.

µ Kierrä lyhyt käyttövarsi

pumpusta

Pikaistukka

q

.

µ Pidä kita-avaimella aukon

µ Anna porakoneen

Käyttövarsi

µ Ota pumppu

µ Ota käyttövarsi

Pitkän käyttövarren rirrottaminen

SDS-liitännällä varustettu poraistukka

irtoaa näin pumpusta q.

e

pidikkeestä y.

q

e

µ Pidä kita-avaimella aukon

µ Anna porakoneen

Näin käyttövarsi

µ Ota pumppu

µ Poista käyttövarsi

r

pidikkeestä y.

q

r

rakoruuvimeisselin ja kita-avaimen avulla

e

läpi kiinni pumpun qkäyttöakselista w.

i

käydä vastapäivään ja alhaisella kierrosnopeudella.

u

poraistukasta.

läpi kiinni pumpun qkäyttöakselista w.

i

käydä vastapäivään ja alhaisella kierrosluvulla.

u

irrotetaan pumpusta q.

poraistukasta.

kautta ja ota pumppu

i

q

- 17 -

Page 20

Käyttö

Huomautus:

Pumppu on itseimevä. Jos pumppu qei ime 12 sekunnin sisällä, sammuta

porakone

anna pumpun

tynä poistopuolelle.

µ Aseta imuletkun avoin pää imettäväksi tarkoitettuun nesteeseen. Imuletku

ei saa olla yli 3 m pitkä. Varmista, ettei imuletku ime ilmaa.

välittömästi kiinnileikkautumisen välttämiseksi. Älä myöskään

u

tästä syystä pumpata niin kauan, kun paineletku on liitet-

q

Jos pumppu

ta neste kulkeutuu pumpun eteen.

µ Anna porakoneen

valvontaa, jotta vaaratilanteissa voitaisiin toimia nopeasti. Varmista myös

ehdottomasti, että porakone

Jos porakoneen

säätää sen avulla.

ei ime, täytä imuletkuun hieman nestettä ja nosta sitä, jot-

q

nyt käyttää pumppua q– älä kuitenkaan ilman

u

käy myötäpäivään, eli kuten porattaessa.

u

kierroslukua voidaan säätää, voidaan siirtomäärää

u

µ Kytke porakone pois päältä heti tyhjäimun jälkeen.

Puhdistus ja huolto

Puhdista pumppu qvain kuivalla tai kevyesti kostutetulla liinalla. Älä käytä

liuotin- tai hankausaineita, jotta muovipinnat eivät vaurioituisi.

Pumppua ei tarvitse huoltaa.

- 18 -

Page 21

Hävittäminen

Älä hävitä laitetta tavallisen talousjätteen mukana.

Hävitä laite hyväksytyn jätteenhuoltoyrityksen tai kunnallisen jätehuollon

kautta.

Noudata voimassa olevia määräyksiä. Ota epävarmoissa tapauksissa yhteyttä

jätelaitokseesi.

Hävitä kaikki pakkausmateriaalit ympäristöystävällisesti.

Vaatimustenmukaisuusvakuutus

Me, Kompernaß GmbH, Burgstraße 21, D-44867 Bochum, vakuutamme

ainoana vastaavana, että tässä kuvattu tuote "Porakonepumppu 54359",

jota tämä vakuutus koskee, vastaa liikkeelle lasketussa muodossaan EY-direktiivin 2006/42/EC (konedirektiivi) voimassa olevia vaatimuksia.

Jos tuotetta muutetaan siitä meidän kanssamme sopimatta, tämä vakuutus

ei ole enää voimassa.

Bochum, 15.06.2010

Hans Kompernaß

- Toimitusjohtaja -

Maahantuoja

KOMPERNASS GMBH

BURGSTRASSE 21

D-44867 BOCHUM, SAKSA

www.kompernass.com

- 19 -

Page 22

Takuu ja huolto

Laitteen takuu on 3 vuotta ostopäivästä. Laite on valmistettu huolellisesti ja

tarkistettu tarkasti ennen toimitusta. Säilytä ostokuitti todisteeksi takuun voimassaolosta.

Ota takuutapauksessa puhelimitse yhteyttä huoltopisteeseesi. Vain näin voidaan taata tuotteesi maksuton lähettäminen huoltoon.

Takuu koskee ainoastaan materiaali- ja valmistusvirheitä, ei kuitenkaan kuljetusvaurioita, kuluvia osia tai herkästi vaurioituvien osien, esim. kytkinten tai

akkujen vaurioita.

Tuote on tarkoitettu ainoastaan yksityiseen, ei kaupalliseen käyttöön.

Väärä tai asiaton käyttö, väkivallan käyttö ja muiden kuin valtuutetun huoltopisteen suorittamat korjaukset aiheuttavat takuun raukeamisen. Tämä takuu ei

rajoita kuluttajan lakisääteisiä oikeuksia.

Takuukorjaus ei pidennä takuuaikaa. Tämä koskee myös vaihdettuja ja korjattuja osia. Mahdollisista jo ostettaessa olemassa olevista vahingoista ja puutteista on ilmoitettava välittömästi pakkauksesta purkamisen jälkeen, kuitenkin

viimeistään kaksi päivää ostopäiväyksen jälkeen. Takuuajan jälkeen suoritetut

korjaukset ovat maksullisia.

Kompernass Service Suomi

Tel.: 010 30 935 80

(Soittamisen hinta lankaliittymästä: 8,21 snt/puh + 5,9 snt/min /

Matkapuhelimesta: 8,21 snt/puh + 16,90 snt/min)

e-mail: support.fi@kompernass.com

- 20 -

Page 23

INNEHÅLLSFÖRTECKNING SIDAN

Säkerhetsanvisningar 22

Föreskriven användning 23

Tekniska data 23

Leveransens innehåll 24

Produktöversikt 24

Nödvändigt monteringsmaterial 24

Montering och anslutning 25

Demontera drivskaft 27

Användning 28

Rengöring och skötsel 28

Kassering 29

Försäkran om överensstämmelse 29

Importör 29

Garanti och service 30

Läs igenom bruksanvisningen noga innan du börjar använda produkten och

spara den för senare bruk. Lämna över bruksanvisningen tillsammans med

produkten om du överlåter den till någon annan person.

- 21 -

Page 24

Säkerhetsanvisningar

För att minska risken för olyckor och materialskador:

• Använd endast pumpen om den spärrats med medföljande hållare så att

den inte kan slå runt, vridas ur sitt läge eller välta.

• Kontrollera alltid att pumpen är i felfritt skick innan du använder den.

Du får inte använda pumpen om du upptäcker att den är skadad.

Pumpens drivaxel går inte att snurra för hand. Det innebär inte att

pumpen är defekt.

• Använd endast slangar som tål ett tryck på 3 bar.

• Kontrollera att slangkopplingarna sitter ordentligt fast på slangarna.

• Se till att det inte kan komma in vätska i den borrmaskin som används

för att driva pumpen. Om det ändå råkar komma in vätska i den ska du

genast dra ut strömkontakten.

• Undvik att suga upp stora smutspartiklar, eftersom det kan skada pumpen.

Sätt ev. ett filter i insugsslangen.

• Barn eller andra personer som fysiskt, psykiskt eller på annat sätt inte

klarar av att använda apparaten på ett säkert sätt får inte använda den

utan att någon ansvarig person hjälper till eller håller uppsikt. Passa

barnen och se till att de inte leker med apparaten.

- 22 -

Page 25

Föreskriven användning

Pumpen är avsedd för ...

– vanliga höger/vänsterroterande handborrmaskiner med 43 mm eurohals

och kuggkrans/snabbspännchuck eller borrchuck med SDS-fäste och ett

varvtal på 3400 U/min,

– för att pumpa upp kalla vätskor eller vätskor med en temperatur på högst

40°C, som t ex slagg eller smutsvatten ur akvarier och dammar.

eenn hhäärr ppuummppeenn äärr iinnttee aavvsseedddd

D

– för att pumpa upp brännbara, explosiva, giftiga eller frätande vätskor

eller livsmedel.

– för industriellt eller yrkesmässigt bruk.

...

Tekniska data

Matarmängd: max. 2,4 m3/h

Slangkoppling: 3/4” (19 mm)

Tryckeffekt: max. 3 bar

Matarhöjd: max. 30 m

Insugshöjd: max. 3 m

Temperatur för

matarvätska: max. 40° C

Torrkörningstid: max. 12 sekunder

Varvtal: max. 3400 U/min

- 23 -

Page 26

Leveransens innehåll

- Pump

- Kort drivskaft

- Långt drivskaft

- Klämfäste

- Hållare

- Skruvnyckel

- Förvaringsbox för drivskaft och skruvnyckel

- Denna bruksanvisning

Produktöversikt

Pump

q

Drivaxel till pump

w

Kort drivskaft (passar till kuggkrans/snabbspännchuck)

e

Långt drivskaft (lämpligt för SDS-fäste)

r

Klämfäste

t

Hållare

y

Borrmaskin (ingår inte i leveransen)

u

Öppning för borrchucknyckel

i

Anslutning för insugsslang

o

Anslutning för tryckslang

a

Nödvändigt monteringsmaterial

- Stjärnskruvmejsel

- Spårskruvmejsel

- Skruvnyckel (ingår i leveransen)

- 24 -

Page 27

Montering och anslutning

µ Montera hållaren

på bilden.

Alternativt kan hållaren

ringsmaterial ingår inte).

på en arbetsplatta med klämfästet tså som visas

y

också skruvas fast på en arbetsplatta (monte-

y

Använda kuggkranschuck och det korta drivskaftet e...

µ Skruva fast det korta drivskaftet

µ Sätt in borrmaskinen

µ För nu pumpen

borrchucken och stiften på hållaren

q

med borrchucken i hållaren y.

u

över hållaren yså att drivskaftet esticks in i

µ Skruva in borrchucken med borrchucknyckeln genom öppningen

pumpen

inte går att lossa ur hållaren ylängre.

q

µ Dra åt stjärnskruven på hållaren

över.

µ Koppla insugsslangen till motsvarande anslutning

anslutning

. Observera den flödesriktning som anges på pumpen q.

a

på drivaxeln wpå pumpen q.

e

sticks in i hålen på pumpen q.

y

så att borrmaskinen uinte kan slå

y

och tryckslangen till

o

i

tills

Använda snabbspännchuck och det korta drivskaftet e...

µ Fäst det korta drivskaftet

µ Sätt borrmaskinen

u

µ Dra åt stjärnskruven på hållaren

kan slå runt.

i borrchucken.

e

med drivskaftet emonterat i borrchucken i hållaren y.

ordentligt så att borrmaskinen uinte

y

- 25 -

Page 28

µ För pumpen

gänga och stiften på hållaren ygår in i fästhålen på pumpen q.

w

µ Låt borrmaskinen

rakt över drivskaftet e. Då kommer drivskaftet eatt fastna på pumpen q.

µ Koppla insugsslangen till anslutning

Observera den flödesriktning som anges på pumpen

över hållaren yså att drivskaftet esticker in i drivaxelns

q

rotera åt höger på lågt varvtal och för pumpen

u

och tryckslangen till anslutning a.

o

.

q

Använda borrchuck med SDS-fäste och det långa

drivskaftet r...

µ Fäst det långa drivskaftet

µ Sätt in borrmaskinen

hållaren

y

.

µ Dra åt stjärnskruven på hållaren

över.

µ För pumpen

gänga och stiften på hållaren ysticks in i hålen på pumpen q.

över hållaren yså att drivskaftet ri drivaxelns

q

µ Sätt på borrmaskinen

pumpen

rakt över drivskaftet r. Då fastnar drivskaftet rpå pumpen q.

q

µ Koppla insugsslangen till motsvarande anslutning

anslutning

. Observera den flödesriktning som anges på pumpen q.

a

i borrchucken.

r

med monterat drivskaft ri borrchucken, i

u

så att borrmaskinen uinte kan slå

y

, låt den rotera åt höger på lågt varvtal och för

u

och tryckslangen till

o

q

w

- 26 -

Page 29

Demontera drivskaft

Demontera det korta drivskaftet

Kuggkranschuck

e

µ Öppna borrchucken med borrchucknyckeln i öppningen

pumpen

µ Skruva loss det korta drivskaftet

och skruvnyckeln från pumpen

Snabbspännchuck

µ Kontra pumpens

µ Låt borrmaskinen

tet

e

µ Ta ut pumpen

µ Ta ut drivskaftet

Demontera det långa drivskaftet

Borrchuck med SDS-fäste

µ Kontra drivaxeln

µ Låt borrmaskinen

lossnar från pumpen q.

µ Ta ut pumpen

µ Ta bort drivskaftet

ur hållaren y.

q

drivaxel wmed skruvnyckeln genom öppningen i.

q

u

från pumpen q.

ur hållaren y.

q

ur borrchucken.

e

i öppningen imed skruvnyckeln på pumpen q.

w

u

ur hållaren y.

q

r

med hjälp av en spårskruvmejsel

e

.

q

rotera åt vänster på lågt varvtal. Då lossnar drivskaf-

r

köra vänstervarv på lågt varvtal. Drivskaftet

från borrchucken.

och ta ut

i

r

- 27 -

Page 30

Användning

Akta!

Pumpen är självsugande. Om pumpen qinte börjar suga inom 12 sekunder

ska du genast stänga av borrmaskinen

därför inte heller pumpen

sidan.

mata så länge tryckslangen är stängd på utlopps-

q

µ Lägg den öppna änden av insugsslangen v i den vätska som ska sugas

upp. Insugsslangen får inte vara längre än 3 m. Akta så att insugsslangen

inte suger in luft.

för att den inte ska köra fast. Låt

u

Om pumpen

lyfter slangen så att vätskan rinner ut framför pumpen.

µ Låt nu borrmaskinen

Du måste kunna reagera snabbt om det skulle hända något. Se också

noga till att borrmaskinen

borrar. Om borrmaskinens

också regleras.

inte suger fyller du insugsslangen med lite vätska och

q

driva pumpen q– men lämna den inte utan uppsikt.

u

roterar åt höger, alltså likadant som när man

u

varvtal kan regleras kan matarmängden

u

µ Stäng genast av borrmaskinen när all vätska sugits upp.

Rengöring och skötsel

Rengör endast pumpen qmed en torr eller lite fuktig trasa. Använd inte

lösningsmedel eller slipande medel som skadar plastytorna.

Pumpen är underhållsfri.

- 28 -

Page 31

Kassering

Produkten får absolut inte kastas bland hushållssoporna.

Lämna in den till ett företag som har tillstånd att ta hand om den här typen

av uttjänta apparater eller till din kommunala avfallsanläggning.

Följ gällande föreskrifter. Kontakta din avfallsanläggning om du har några

frågor.

Lämna in allt förpackningsmaterial till miljövänlig återvinning.

Försäkran om överensstämmelse

Företaget Kompernaß GmbH, Burgstraße 21, D-44867 Bochum försäkrar

på eget ansvar att den produkt, “Borrmaskinspump 54359”, som försäkran

avser överensstämmer med gällande krav i EU-direktiv 2006/42/EC

(maskiner) i det utförande den marknadsförs.

Om produkten ändras utan vår tillåtelse förlorar den här försäkran sin giltighet.

Bochum, 15.06.2010

Hans Kompernaß

- VD -

Importör

KOMPERNASS GMBH

BURGSTRASSE 21

D-44867 BOCHUM

www.kompernass.com

- 29 -

Page 32

Garanti och service

För den här apparaten lämnar vi tre års garanti från och med inköpsdatum.

Den här apparaten har tillverkats med omsorg och genomgått en noggrann

kontroll innan leveransen. Var god bevara kassakvittot som köpbevis. Vi ber

dig att kontakta ditt serviceställe per telefon vid garantifall. Endast då kan

produkten skickas in fraktfritt.

Garantin gäller bara för bara för material- eller fabrikationsfel, den täcker

inte transportskador, förslitningsdelar eller skador på ömtåliga delar som t ex

brytare och batterier. Produkten är endast avsedd för privat bruk och får inte

användas yrkesmässigt.

Vid missbruk och felaktig behandling, användande av våld och vid ingrepp

som inte gjorts av vår auktoriserade servicefilial upphör garantin att gälla.

Den lagstadgade garantin begränsas inte av denna garanti.

Garantitiden förlängs inte för att man utnyttjar garantiförmånerna. Det gäller

även för utbytta eller reparerade delar. Eventuella skador och brister som

upptäcks redan vid köpet måste anmälas omedelbart efter uppackningen,

dock senast två dagar efter inköpsdatum. När garantitiden är slut måste man

betala för eventuella reparationer.

Kompernass Service Sverige

Tel.: 0770 93 00 35

e-mail: support.sv@kompernass.com

Kompernass Service Suomi

Tel.: 010 30 935 80

(Soittamisen hinta lankaliittymästä: 8,21 snt/puh + 5,9 snt/min /

Matkapuhelimesta: 8,21 snt/puh + 16,90 snt/min)

e-mail: support.fi@kompernass.com

- 30 -

Page 33

INDHOLDSFORTEGNELSE SIDE

Sikkerhedsanvisninger 32

Bestemmelsesmæssig anvendelse 33

Tekniske data 33

Medfølger ved køb 34

Oversigt over maskinen 34

Nødvendige dele til montering 34

Montering og tilslutning 35

Afmontering af drivskaftet 37

Anvendelse 38

Rengøring og vedligeholdelse 38

Bortskaffelse 39

Overensstemmelseserklæring 39

Importør 39

Garanti og service 40

Læs betjeningsvejledningen omhyggeligt igennem, før du bruger apparatet første

gang, og gem den til senere brug. Hvis du giver apparatet videre til andre, skal

vejledningen også følge med.

- 31 -

Page 34

Sikkerhedsanvisninger

Til undgåelse af ulykker og skader på maskinen:

• Betjen kun pumpen, når den er sikret med den vedlagte holder mod at slå

omkring, blive fordrejet eller sætte sig fast.

• Kontrollér inden enhver brug af pumpen, at pumpen er i en upåklagelig

tilstand. Pumpen må ikke anvendes, hvis der er synlige skader på den.

Pumpens drivaksel kan ikke drejes ved håndkraft.

Dette tyder ikke på en defekt ved pumpen.

• Brug kun slanger, som er trykfaste indtil mindst 3 bar.

• Kontrollér, at stikforbindelserne på slangerne sidder fast.

• Sørg for, at ingen væsker kan komme i kontakt med boremaskinen, som du

betjener pumpen med. Hvis det sker, skal stikket straks trækkes ud.

• Undgå at suge groft snavs op, da pumpen ellers kan beskadiges. Brug

evt. et filter ved indsugningsslangen.

• Denne maskine er ikke egnet til børn eller andre personer, hvis fysiske,

sensoriske eller psykiske tilstand ikke muliggør en sikker anvendelse af

maskinen uden hjælp fra andre eller opsyn. Børn skal være under opsyn,

så det sikres, at de ikke leger med maskinen.

- 32 -

Page 35

Bestemmelsesmæssig anvendelse

Denne pumpe er beregnet til ...

– almindelige højre-/venstredrejede håndboremaskiner med 43 mm euro-

hals og tandkranspatron/hurtig spændepatron eller borepatron med SDSoptagelse indtil et omdrejningstal på 3400 o/min,

– til at pumpe kolde væsker eller varme væsker indtil 40°C som f.eks.

ledningsvand eller snavset vand fra akvarier eller damme.

Denne pumpe er

– at pumpe brændbare, eksplosive, giftige eller ætsende væsker eller

fødevarer.

– til industrielle eller erhvervsmæssige formål.

iikkkkee

beregnet til ...

Tekniske data

Pumpekapacitet: maks. 2,4 m3/h

Slangetilslutning: 3/4” (19 mm)

Trykydelse: maks. 3 bar

Løftehøjde: maks. 30 m

Indsugningshøjde: maks. 3 m

Transportvæskens temperatur: maks. 40°C

Tørløbstid: maks. 12 sekunder

Omdrejningstal: maks. 3400 o/min

- 33 -

Page 36

Medfølger ved køb

- Pumpe

- Drivskaft kort

- Drivskaft langt

- Klemmefastgøring

- Holder

- Gaffelnøgle

- Opbevaringsboks til drivskafterne og gaffelnøglen

- Denne betjeningsvejledning

Oversigt over maskinen

Pumpe

q

Drivaksel til pumpen

w

Kort drivskaft (egnet til tandkrans-/hurtig spændepatron)

e

Langt drivskaft (egnet til SDS-optagelse)

r

Klemmefastgørelse

t

Holder

y

Boremaskine (følger ikke med ved køb)

u

Udskæring til borepatronnøgle

i

Tilslutning indsugningsslange

o

Tilslutning trykslange

a

Nødvendige dele til montering

- Stjerneskruetrækker

- Kærvskruetrækker

- Gaffelnøgle (medfølger ved køb)

- 34 -

Page 37

Montering og tilslutning

µ Montér holderen

således som det er vist på billedet.

Alternativt kan holderen

hjælp af skruer (monteringsdelene medfølger ikke ved leveringen).

med klemmefastgørelsen tpå en arbejdsplade,

y

også monteres på en arbejdsplade ved

y

Ved anvendelse af en tandkranspatron og det korte

drivskaft e...

µ Skru det korte drivskaft

µ Indsæt boremaskinen

µ Skyd nu pumpen

rager ind i borepatronen, og stik stifterne fra holderen yind i optagelseshullerne på pumpen

q

µ Skru borepatronen med borepatronnøglen gennem udsparingen

den sidder så fast, at pumpen

µ Skru stjerneskruen fast på holderen

kan slå om.

µ Tilslut indsugningsslangen ved tilslutningen

ningen

ning på pumpen

. Vær i den forbindelse opmærksom på den angivne strømret-

a

på drivakslen wtil pumpen q.

e

med borepatronen i holderen y.

u

på holderen ypå en sådan måde, at drivskaftet

.

q

, indtil

i

ikke længere kan løsne sig fra holderen y.

q

, således at boremaskinen uikke

y

og trykslangen ved tilslut-

o

.

q

Ved anvendelse af en hurtig spændepatron og det korte

drivskaft e...

µ Fastgør det korte drivskaft

µ Sæt boremaskinen

nen i holderen

y

u

.

µ Skru krydskærvskruen på holderen

slå omkring.

i borepatronen.

e

med det formonterede drivskaft eind i borepatro-

fast, så boremaskinen uikke kan

y

e

- 35 -

Page 38

µ Sæt pumpen

gevind, og holderens stifter ysidder ind i pumpens huller q.

w

µ Lad boremaskinen

pumpen

pumpen

µ Slut indsugningsslangen til tilslutningen

. Vær opmærksom på den angivne strømretning på pumpen q.

a

på holderen y, så drivskaftet erager ind i drivakslens

q

starte op i højreløb med lavt omdrejningstal, og sæt

u

lige på drivskaftet e. Derved fastgøres drivskaftet etil

q

.

q

og trykslangen til tilslutningen

o

Ved anvendelse af en borepatron med SDS-optagelse og

det lange drivskaft r...

µ Fastgør det lange drivskaft

µ Indsæt boremaskinen

i holderen

y

u

.

µ Skru stjerneskruen fast på holderen

kan slå om.

µ Skyd pumpen

rager ind i gevindet på drivakslen w, og stik stifterne fra holderen

ind i optagelseshullerne på pumpen q.

µ Lad boremaskinen

pumpen

q

denne måde på pumpen

på holderen ypå en sådan måde, at drivskaftet

q

u

i lige retning på drivskaftet r. Drivskaftet rfastgøres på

µ Tilslut indsugningsslangen ved tilslutningen

tilslutningen

strømretning på pumpen

. Vær i den forbindelse opmærksom på den angivne

a

i borepatronen.

r

, med det formonterede drivskaft ri borepatronen,

, således at boremaskinen uikke

y

r

y

starte i højreløb og med lavt omdrejningstal, og før

.

q

og trykslangen ved

o

.

q

- 36 -

Page 39

Afmontering af drivskaftet

Afmontering af det korte drivskaft

Tandkranspatron

e

µ Åbn borepatronen med borepatronnøglen gennem udsparingen

tag pumpen

µ Skru det korte drivskaft

og gaffelnøglen.

Hurtig spændepatron

µ Hold pumpens

gen

.

i

µ Lad boremaskinen

løsnes drivskaftet

µ Tag pumpen

µ Tag drivskaftet

Afmontering af det lange drivskaft

Borepatron med SDS-optagelse

µ Hold med gaffelnøglen gennem udsparingen

pumpen

µ Lad boremaskinen

Drivskaftet

µ Tag pumpen

µ Tag drivskaftet

ud af holderen y.

q

af pumpen qved hjælp af en kærvskruetrækker

e

drivaksel wfast med gaffelnøglen gennem udsparin-

q

starte i venstreløb og med lavt omdrejningstal. Derved

u

fra pumpen q.

e

ud af holderen y.

q

ud af borepatronen.

e

fast.

q

starte i venstreløb og med lavt omdrejningstal.

u

frigøres på denne måde fra pumpen q.

r

ud af holderen y.

q

ud af borepatronen.

r

r

drivakslen wpå

i

i

, og

- 37 -

Page 40

Anvendelse

Obs!

Pumpen er selvindsugende. Hvis pumpen qikke suger ind i løbet af 12 sekunder, skal du straks slukke for boremaskinen

fast. Af samme grund må pumpen

på udløbssiden er lukket.

q

µ Læg den åbne ende af indsugningsslangen i væsken, der skal suges op.

Indsugningsslangen må ikke være længere end 3 m. Sørg for, at indsugningsslangen ikke trækker luft ind.

, så det undgås, at den kører

u

heller ikke pumpe, så længe trykslangen

Hvis pumpen

væske og løfte den, så væsken løber før pumpen.

µ Lad nu boremaskinen

at der kan reageres hurtigere i tilfælde af fare. Sørg altid for, at boremaskinen

drejer til højre, det vil sige ligesom ved boring. Hvis boremaskinens

omdrejningstal kan reguleres, kan du regulere pumpekapaciteten hermed.

ikke suger, skal du fylde indsugningsslangen med lidt

q

drive pumpen q– dog ikke uden opsyn, således

u

µ Sluk straks for boremaskinen efter tomsugningen.

Rengøring og vedligeholdelse

Rengør kun pumpen qmed en tør eller en let fugtet klud. Anvend ingen

opløsnings- eller skuremidler, så kunststoffladerne ikke bliver beskadiget.

Pumpen er vedligeholdelsesfri.

- 38 -

u

u

Page 41

Bortskaffelse

Kom under ingen omstændigheder enheden i det normale husholdningsaffald.

Bortskaf uroen via en godkendt bortskaffelsesvirksomhed eller den kommunale

genbrugsstation.

Følg de aktuelt gældende regler. Henvend dig i tvivlstilfælde til det lokale

bortskaffelsessted.

Aflever alle emballagematerialer på et affaldsdepot, så miljøet

skånes.

Overensstemmelseserklæring

Vi, Kompernaß GmbH, Burgstraße 21, D-44867 Bochum, erklærer hermed

som eneansvarlige, at det her beskrevne produkt “Boremaskinepumpe 54359”,

som denne erkæring vedrører, i den udførelse, der er sendt på markedet af

os, opfylder de gældende krav i EF-direktiv 2006/42/EC (maskindirektiv).

I tilfælde af en ændring af produktet, der ikke er aftalt med os, mister denne

erklæring sin gyldighed.

Bochum, 15.06.2010

Hans Kompernaß

Direktør

Importør

KOMPERNASS GMBH

BURGSTRASSE 21

D–44867 BOCHUM

www.kompernass.com

- 39 -

Page 42

Garanti og service

På denne donkraft får du 3 års garanti fra købsdatoen. Apparatet er produceret omhyggeligt og inden levering afprøvet samvittighedsfuldt. Opbevar

kassebonen som bevis for købet.

I garantitilfælde bedes du kontakte service-afdelingen telefonisk. På denne

måde kan gratis indsendelse af varen garanteres.

Garantiydelsen gælder kun for materiale- eller fabrikationsfejl, men ikke for

transportskader, sliddele eller skader på skrøbelige dele som f.eks. kontakter eller batterier. Produktet er kun beregnet til privat og ikke til erhvervsmæssigt brug.

Ved misbrug og uhensigtsmæssig behandling, anvendelse af vold og ved indgreb, som ikke er foretaget af vores autoriserede service-afdeling, ophører

garantien. Dine juridiske rettigheder indskrænkes ikke ved denne garanti.

Garantiperioden forlænges ikke på grund af produktansvaret. Det gælder

også for udskiftede og reparerede dele. Eventuelle skader og mangler, som

allerede findes ved køb, skal straks anmeldes efter udpakning og senest to

dage efter købsdatoen. Når garantiperioden er udløbet, skal udgifterne til reparationer betales normalt.

Kompernass Service Danmark

Tel.: 80-889 980

(

Der kan kun ringes til servicenummeret fra fastnet)

e-mail: support.dk@kompernass.com

- 40 -

Page 43

INHALTSVERZEIC HNIS SEITE

Sicherheitshinweise 42

Bestimmungsgemäßer Gebrauch 43

Technische Daten 43

Lieferumfang 44

Geräteübersicht 44

Benötigtes Montagematerial 44

Montage und Anschluss 45

Demontage des Antriebsschafts 47

Verwenden 48

Reinigen und Warten 48

Entsorgen 49

Konformitätserklärung 49

Importeur 49

Garantie und Service 50

Lesen Sie die Bedienungsanleitung vor der ersten Verwendung aufmerksam

durch und heben Sie diese für den späteren Gebrauch auf. Händigen Sie bei

Weitergabe des Gerätes an Dritte auch die Anleitung aus.

- 41 -

Page 44

Sicherheitshinweise

Um Unfallgefahr und Geräteschäden zu vermeiden:

• Betreiben Sie die Pumpe nur, wenn sie mit der beiliegenden Halterung

gegen Herumschlagen, Verdrehen oder Verkanten gesichert ist.

• Kontrollieren Sie die Pumpe auf einwandfreien Zustand vor jedem

Gebrauch. Die Pumpe darf nicht verwendet werden, wenn Schäden

erkennbar sind.

Die Antriebswelle der Pumpe läßt sich nicht mit der Hand drehen.

Dies deutet nicht auf einen Defekt der Pumpe hin.

• Verwenden Sie nur Schläuche, die bis mindestens 3 bar druckfest sind.

• Kontrollieren Sie die Steckverbinder an den Schläuchen auf festen Sitz.

• Sorgen Sie dafür, dass keine Flüssigkeiten an die Bohrmaschine gelangen

können, mit der Sie die Pumpe antreiben. Falls doch, ziehen Sie sofort den

Netzstecker.

• Vermeiden Sie das Ansaugen von groben Schmutz, da sonst die Pumpe

beschädigt werden kann. Verwenden Sie ggf. einen Filter am Ansaugschlauch.

• Dieses Gerät ist nicht für Kinder oder andere Personen geeignet, deren

physische, sensorische oder geistige Fähigkeiten ohne Unterstützung oder

Aufsicht eine sichere Nutzung des Gerätes verhindern. Kinder sollten

beaufsichtigt werden, um sicherzustellen, dass sie nicht mit dem Gerät spielen.

- 42 -

Page 45

Bestimmungsgemäßer Gebrauch

Diese Pumpe ist vorgesehen für ...

– handelsübliche Rechts/Links drehende Handbohrmaschinen mit 43 mm

Eurohals und Zahnkranzfutter/Schnellspannfutter oder Bohrfutter mit SDSAufnahme, bis zu einer Drehzahl von 3400 U/min,

– zum Pumpen von kalten oder bis zu 40°C warmen Flüssigkeiten,

wie z.B. Brauch- oder Schmutzwasser aus Aquarien oder Teichen.

Diese Pumpe ist

– zum Pumpen von brennbaren, explosiven, giftigen oder ätzenden

Flüssigkeiten oder Lebensmitteln.

– für industrielle oder gewerbliche Zwecke.

nniicchhtt

vorgesehen ...

Technische Daten

Fördermenge: max. 2,4 m3/h

Schlauchanschluss: 3/4” (19 mm)

Druckleistung: max. 3 bar

Förderhöhe: max. 30 m

Ansaughöhe: max. 3 m

Temperatur der

Förderflüssigkeit: max. 40°C

Trockenlaufzeit: max. 12 Sekunden

Drehzahl: max. 3400 U/min

- 43 -

Page 46

Lieferumfang

- Pumpe

- Antriebsschaft kurz

- Antriebsschaft lang

- Klemmbefestigung

- Halterung

- Maulschlüssel

- Aufbewahrungsbox für die Antriebsschäfte und Maulschlüssel

- Diese Bedienungsanleitung

Geräteübersicht

Pumpe

q

Antriebswelle der Pumpe

w

Antriebsschaft kurz (geeignet für Zahnkranz-/Schnellspannbohrfutter)

e

Antriebsschaft lang (geeignet für SDS-Aufnahme)

r

Klemmbefestigung

t

Halterung

y

Bohrmaschine (nicht im Lieferumfang enthalten)

u

Aussparung für Bohrfutterschlüssel

i

Anschluss Ansaugschlauch

o

Anschluss Druckschlauch

a

Benötigtes Montagematerial

- Kreuzschlitzschraubendreher

- Schlitzschraubendreher

- Maulschlüssel (im Lieferumfang enthalten)

- 44 -

Page 47

Montage und Anschluss

µ Montieren Sie die Halterung

Arbeitsplatte, wie im Bild gezeigt.

Alternativ kann die Halterung

Arbeitsplatte montiert werden (Montagematerial nicht im Lieferumfang

enthalten).

mit der Klemmbefestigung tauf einer

y

auch mittels Schrauben auf einer

y

Bei Verwendung eines Zahnkranzbohrfutters und des

kurzen Antriebsschafts e...

µ Schrauben Sie den kurzen Antriebsschaft

Pumpe

µ Stecken Sie die Bohrmaschine

µ Schieben Sie nun die Pumpe

Antriebsschaft

in den Aufnahmelöchern an der Pumpe qstecken.

q

.

mit dem Bohrfutter in die Halterung y.

u

so auf die Halterung y, dass der

q

in das Bohrfutter ragt, und die Stifte von der Halterung

e

auf die Antriebswelle wder

e

µ Drehen Sie das Bohrfutter mit dem Bohrfutterschlüssel durch die

Aussparung

Halterung

µ Drehen Sie die Kreuzschlitzschraube an der Halterung

damit die Bohrmaschine

µ Schließen Sie den Ansaugschlauch an den Anschluss

Druckschlauch an den Anschluss

angegebene Flussrichtung auf der Pumpe

Bei Verwendung eines Schnellspannbohrfutters und des

kurzen Antriebsschafts e...

µ Befestigen Sie den kurzen Antriebsschaft

µ Stecken Sie die Bohrmaschine

im Bohrfutter, in die Halterung y.

µ Drehen Sie die Kreuzschlitzschraube an der Halterung

damit die Bohrmaschine

so fest, dass die Pumpe qsich nicht mehr aus der

i

lösen kann.

y

nicht herumschlagen kann.

u

an. Beachten Sie dabei die

a

.

q

im Bohrfutter.

e

, mit dem vormontierten Antriebsschaft

u

nicht herumschlagen kann.

u

- 45 -

y

und den

o

y

fest,

fest,

y

e

Page 48

µ Schieben Sie die Pumpe

schaft

Halterung

in das Gewinde der Antriebswelle wragt, und die Stifte der

e

in den Aufnahmelöchern der Pumpe qstecken.

y

µ Lassen Sie die Bohrmaschine

anlaufen und führen Sie die Pumpe

Der Antriebsschaft

e

µ Schließen Sie den Ansaugschlauch an den Anschluss

Druckschlauch an den Anschluss

angegebene Flussrichtung auf der Pumpe

so auf die Halterung y, dass der Antriebs-

q

im Rechtslauf und mit niedriger Drehzahl

u

gerade auf den Antriebsschaft e.

q

wird dadurch an der Pumpe qbefestigt.

und den

o

an. Beachten Sie dabei die

a

.

q

Bei Verwendung eines Bohrfutters mit SDS-Aufnahme

und des langen Antriebsschafts r...

µ Befestigen Sie den langen Antriebsschaft

µ Stecken Sie die Bohrmaschine

im Bohrfutter, in die Halterung y.

, mit dem vormontierten Antriebsschaft

u

µ Drehen Sie die Kreuzschlitzschraube an der Halterung

damit die Bohrmaschine

µ Schieben Sie die Pumpe

schaft

Halterung

in das Gewinde der Antriebswelle wragt, und die Stifte der

r

in den Aufnahmelöchern der Pumpe qstecken.

y

µ Lassen Sie die Bohrmaschine

anlaufen und führen Sie die Pumpe

Der Antriebsschaft

r

nicht herumschlagen kann.

u

so auf die Halterung y, dass der Antriebs-

q

im Rechtslauf und mit niedriger Drehzahl

u

q

wird dadurch an der Pumpe qbefestigt.

µ Schließen Sie den Ansaugschlauch an den Anschluss

Druckschlauch an den Anschluss

angegebene Flussrichtung auf der Pumpe

a

im Bohrfutter.

r

fest,

y

gerade auf den Antriebsschaft r.

und den

o

an. Beachten Sie dabei die

.

q

r

- 46 -

Page 49

Demontage des Antriebsschafts

Kurzen Antriebsschaft edemontieren

Zahnkranzbohrfutter

µ Öffnen Sie das Bohrfutter mit dem Bohrfutterschlüssel durch die

Aussparung

µ Schrauben Sie den kurzen Antriebsschaft

bendrehers und dem Maulschlüssel von der Pumpe

Schnellspannbohrfutter

µ Kontern Sie mit dem Maulsschlüssel durch die Aussparung

Antriebswelle

µ Lassen Sie die Bohrmaschine

anlaufen. Der Antriebsschaft

µ Entnehmen Sie die Pumpe

µ Entnehmen Sie den Antriebsschaft

Langen Antriebsschaft rdemontieren

Bohrfutter mit SDS-Aufnahme

µ Kontern Sie mit dem Maulsschlüssel durch die Aussparung

Antriebswelle

µ Lassen Sie die Bohrmaschine

anlaufen. Der Antriebsschaft

µ Entnehmen Sie die Pumpe

µ Entnehmen Sie den Antriebsschaft

und entnehmen Sie die Pumpe qaus der Halterung y.

i

mithilfe eines Schlitzschrau-

e

.

q

i

der Pumpe q.

w

im Linkslauf und mit niedriger Drehzahl

u

wird dadurch von der Pumpe qgelöst.

e

aus der Halterung y.

q

aus dem Bohrfutter.

e

i

der Pumpe q.

w

im Linkslauf und mit niedriger Drehzahl

u

wird dadurch von der Pumpe qgelöst.

r

aus der Halterung y.

q

aus dem Bohrfutter.

r

die

die

- 47 -

Page 50

Verwenden

Achtung!

Die Pumpe ist selbstansaugend. Wenn die Pumpe qnicht innerhalb von

12 Sekunden ansaugt, schalten Sie die Bohrmaschine

Festlaufen zu vermeiden. Lassen Sie aus diesem Grund auch die Pumpe

nicht fördern, solange der Druckschlauch auf der Auslaufseite verschlossen ist.

µ Legen Sie das offene Ende vom Ansaugschlauch in die Flüssigkeit, die

angesaugt werden soll. Der Ansaugschlauch darf nicht länger als 3 m

sein. Achten Sie darauf, dass der Ansaugschlauch keine Luft zieht.

sofort ab, um ein

u

q

Sollte die Pumpe

mit etwas Flüssigkeit und heben Sie ihn an, damit die Flüssigkeit vor die

Pumpe läuft.

µ Lassen Sie die Bohrmaschine

nicht unbeaufsichtigt, um bei Gefahr schnell reagieren zu können. Achten

Sie unbedingt auch darauf, dass die Bohrmaschine

also wie beim Bohren. Falls die Drehzahl der Bohrmaschine

können Sie darüber die Fördermenge regulieren.

nicht ansaugen, befüllen Sie den Ansaugschlauch

q

nun die Pumpe qantreiben – jedoch

u

nach rechts dreht,

u

regelbar ist,

u

µ Schalten Sie nach dem Leersaugen sofort die Bohrmaschine aus.

Reinigen und Warten

Reinigen Sie die Pumpe qnur mit einem trockenen oder leicht

angefeuchteten Tuch. Verwenden Sie keine Lösungs- oder Scheuermittel,

um die Kunststoffflächen nicht zu beschädigen.

Die Pumpe ist wartungsfrei.

- 48 -

Page 51

Entsorgen

Werfen Sie das Gerät keinesfalls in den normalen Hausmüll.

Entsorgen Sie das Gerät über einen zugelassenen Entsorgungsbetrieb oder

über Ihre kommunale Entsorgungseinrichtung.

Beachten Sie die aktuell geltenden Vorschriften. Setzen Sie sich im

Zweifelsfall mit Ihrer Entsorgungseinrichtung in Verbindung.

Führen Sie alle Verpackungsmaterialien einer umweltgerechten

Entsorgung zu.

Konformitätserklärung

Wir, Kompernaß GmbH, Burgstraße 21, D-44867 Bochum, erklären in

alleiniger Verantwortung, dass das hier beschriebene Produkt

“Bohrmaschinenpumpe 54359”, auf das sich diese Erklärung bezieht,

in der von uns in Verkehr gebrachten Ausführung übereinstimmt mit den

geltenden Anforderungen der EG-Richtlinie 2006/42/EC (Maschinen).

Bei einer mit uns nicht abgestimmten Änderung des Produkts verliert diese

Erklärung ihre Gültigkeit.

Bochum, den 15.06.2010

Hans Kompernaß

Geschäftsführer

Importeur

KOMPERNASS GMBH

BURGSTRASSE 21

D-44867 BOCHUM

www.kompernass.com

- 49 -

Page 52

Garantie und Service

Sie erhalten auf dieses Gerät 3 Jahre Garantie ab Kaufdatum. Das Gerät

wurde sorgfältig produziert und vor Anlieferung gewissenhaft geprüft.

Bitte bewahren Sie den Kassenbon als Nachweis für den Kauf auf. Bitte setzen

Sie sich im Garantiefall mit Ihrer Servicestelle telefonisch in Verbindung. Nur

so kann eine kostenlose Einsendung Ihrer Ware gewährleistet werden.

Die Garantieleistung gilt nur für Material- oder Fabrikationsfehler, nicht aber

für Transportschäden, Verschleißteile oder für Beschädigungen an zerbrechlichen Teilen, z. B. Schalter oder Akkus. Das Produkt ist lediglich für den privaten

und nicht für den gewerblichen Gebrauch bestimmt.

Bei missbräuchlicher und unsachgemäßer Behandlung, Gewaltanwendung

und bei Eingriffen, die nicht von unserer autorisierten Service-Niederlassung

vorgenommen wurden, erlischt die Garantie. Ihre gesetzlichen Rechte werden

durch diese Garantie nicht eingeschränkt.

Die Garantiezeit wird durch die Gewährleistung nicht verlängert. Dies gilt

auch für ersetzte und reparierte Teile. Eventuell schon beim Kauf vorhandene

Schäden und Mängel müssen sofort nach dem Auspacken gemeldet werden,

spätestens aber zwei Tage nach Kaufdatum. Nach Ablauf der Garantiezeit

anfallende Reparaturen sind kostenpflichtig.

Schraven Service- und Dienstleistungs GmbH

Tel.: +49 (0) 180 5 008107

(0,14 EUR/Min. aus dem dt. Festnetz, Mobilfunk max. 0,42 EUR/Min.)

Fax: +49 (0) 2832 3532

e-mail: support.de@kompernass.com

Kompernaß Service Österreich

Tel.: 0820 899 913 (

0,20 EUR/Min.)

e-mail: support.at@kompernass.com

Kompernaß Service Switzerland

Tel.: 0848 000 525 (

max. 0,0807 CHF/Min.)

e-mail: support.ch@kompernass.com

- 50 -

Loading...

Loading...