Page 1

Configuration guide

Technical Catalogue 3.4 – August 2008 edition

PNOZmulti Modular Safety System

KURAL TEKNOLOJİ ELEKTRO MARKET

KURAL TECHNOLOGY ELECTRO MARKET

www.kuralteknoloji.com

bilgi@kuralteknoloji.com - info@kuralteknoloji.com

Page 2

Exclusion of liability

We have taken great care in

compiling our application manual. It

contains information about our

company and our products. All

statements are made in accordance

with the current status of technology

and to the best of our know-ledge

and belief. However, we cannot

except liability for the accuracy and

entirety of the information provided,

except in the case of gross

negligence. In particular it should be

noted that statements do not have

the legal quality of assurances or

assured properties. We are grateful

for any feedback on the contents.

August 2008

All rights to this publication are reserved by Pilz GmbH & Co. KG. We

reserve the right to amend

specifications without prior notice.

Copies may be made for the user’s

internal purposes. The names of

products, goods and technologies

used in this manual are trademarks

of the respective companies.

Why does Pilz offer more?

Because the integrality

of our business activities

is what sets us apart.

Pilz is a solution supplier for all automation functions. Including standard

control functions. Developments from

Pilz protect man, machine and the

environment. That’s why all our experience and knowledge goes into

individual products as well as

consistently sophisticated system

solutions.

Sensor technology

Control and communication

Motion Control

Operating and monitoring

Software

Consulting

Engineering

Training

Appropriate services relating to individual components and independent

generic services guarantee that our

customers obtain customised

automation solutions, all from one

source.

You can find more details about

Pilz and your products and

services on the Internet:

www.pilz.com

Pilz is a family business

that’s closer to its customers

Pilz has a tradition as a family-run

company stretching back over 50

years. Real proximity to customers is

visible in all areas, instilling

confidence through individual

consultation, flexibility and reliable

service.

We are your contact, guide and

competency leader en route to an

optimum automation solution.

Support –

Technical help round the clock!

Technical support is available from

Pilz round the clock. This service is

provided free of charge beyond

standard business hours.

You can reach our

international hotline on:

+49 711 3409-444

Page 3

Contents

3

Contents1.02007-11

Basics

1.0

System description

1.1

Installation

1.2

Electrical installation

1.3

Configuration and Wiring

1.4

Products

2.0

Selection guide

2.1

Base units

2.2

Expansion modules

2.3

Adapter for PNOZ ms1p and PNOZ ms2p

2.4

Software

2.5

Applications

3.0

Accessories

4.0

Order reference

5.0

Order reference

5.1

Standards and directives

6.0

Standards and directives

6.1

Service

7.0

Service

7.1

Page 4

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.0-0

1.0

Basics1.0

Page 5

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2007-11

1.0-1

1.0

Contents Page

System description from 1.1-1

Installation from 1.2-1

Electrical installation from 1.3-1

Configuration and Wiring from 1.4-1

Page 6

Basics

System description

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.1-0

1.1

BasicsSystem description1.1

Page 7

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

System description

2007-11

1.1-1

1.1

Contents Page

System description

Overview 1.1-2

Hardware 1.1-3

Software 1.1-4

Maximum system expansion 1.1-5

Diagnostics 1.1-7

Safety 1.1-8

Page 8

Basics

System description

Overview

2007-11Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.1-2

1.1

Overview1.12007-11BasicsSystem descriptionOverview

Modular design

` The modular safety system consists

of a base unit and several expansion modules.

` The base unit has several inputs

and outputs and is fully functional

even without an expansion module.

` The expansion modules supple-

ment the base unit with additional

inputs or outputs.

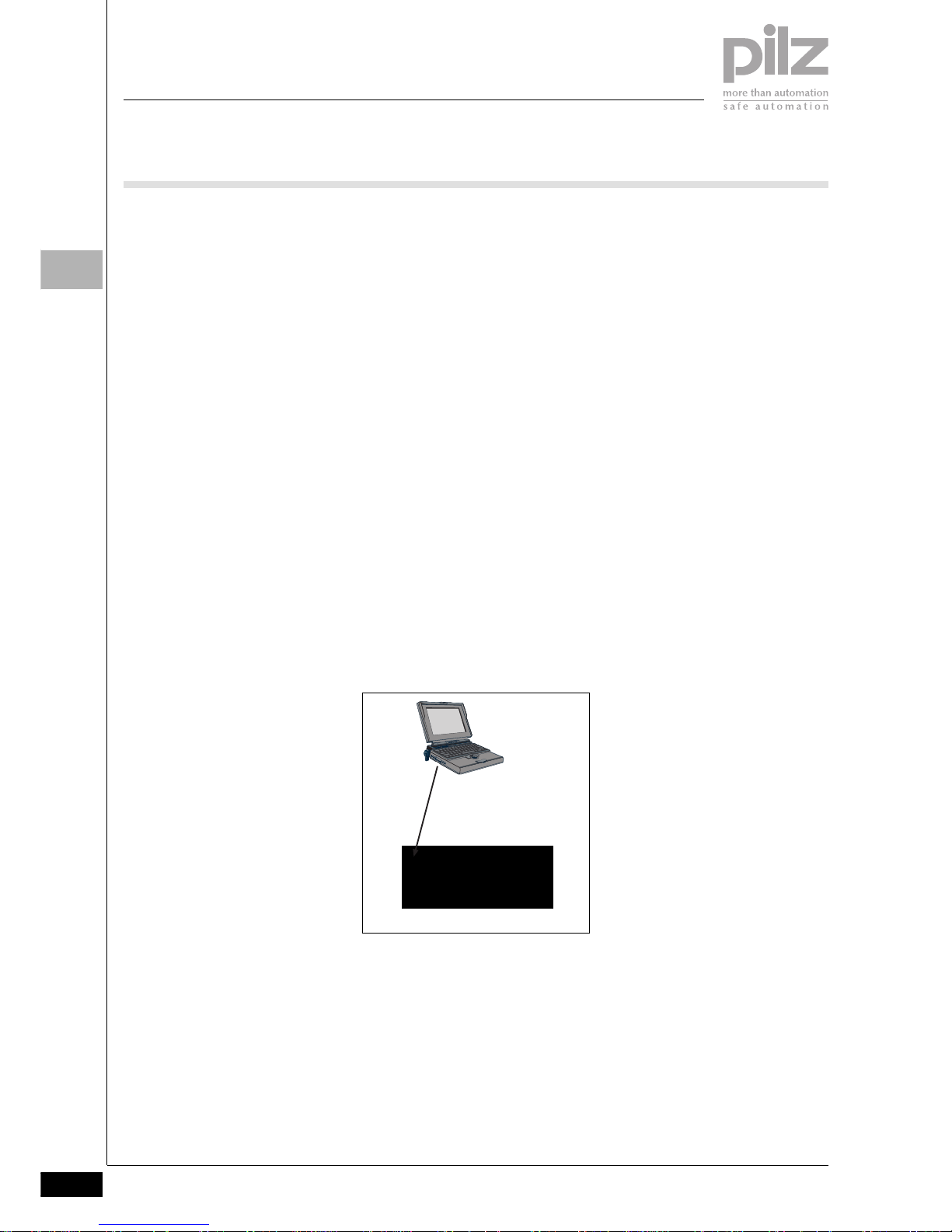

Configuration in the PNOZmulti

Configurator

` The function of the safety system is

established through the PNOZmulti

Configurator.

` The PNOZmulti Configurator is a

graphic tool which is used to define

the functions of the units. Using

predefined symbols, a simple circuit diagram shows how the units'

inputs and outputs should be connected. This circuit diagram is then

downloaded to the base unit.

` From this data, the base unit recog-

nises the safety functions it is to

perform. For example, safety functions such as E-STOP, two-hand

monitoring and safety gate monitoring are available. With the correct

circuitry it is possible to achieve

categories 2, 3 and 4 in accordance

with EN 954-1.

` The fact that the system is modular

and configurable guarantees the

highest level of flexibility. The safety

system can be expanded or the

safety functions modified at any

time.

Inputs

` Units in the PNOZmulti modular

safety system have semiconductor

inputs for safety-related and standard applications.

` The inputs for standard applica-

tions can also be set via the serial

interface or via fieldbus modules

(e.g. PROFIBUS-DP, CANopen, ...).

` One expansion module in the

PNOZmulti modular safety system

has safe, analogue inputs. The input signals are converted into digital signals.

` For standard applications, the ex-

act analogue values are made available to the base unit to forward to a

fieldbus.

Outputs

` Units in the PNOZmulti modular

safety system have both semiconductor and relay safety outputs.

` The outputs for standard functions

use semiconductor technology.

` The safety outputs use semicon-

ductor technology, require no maintenance and are non-wearing; they

are therefore suitable for applications with frequent operations or

cyclical functions. They can be

used for 24 VDC applications.

` The relay safety outputs are suita-

ble for less frequent operations, but

they have a higher breaking capacity and can be used for AC applications.

` The outputs for standard applica-

tions can also be evaluated via the

serial interface or via fieldbus modules (e.g. PROFIBUS-DP, CANopen, ...).

Base unit + expansion modules

Download

PNOZm Config

Page 9

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

System description

Hardware

2007-11

1.1-3

1.1

Hardware1.12007-11BasicsSystem descriptionHardwarePNOZmulti zusammengestell te Texte

Design of the modular safety system

The modular safety system consists of

the base unit and expansion modules.

The base unit itself has

` 20 inputs

` 2 relay outputs

` 4 semiconductor outputs

` 1 auxiliary output, which is required

for deleting the configuration data

in the base unit

` 1 cascading input

` 1 cascading output

The number of inputs and outputs can

be increased at any time using the expansion modules. The modules are

linked via a jumper. The system is configured using the PNOZmulti Configurator. Special expansion modules

enable data to be exchanged via a

fieldbus (non-safety-related) or safe

speed monitoring, for example.

Operation of the units

The PNOZmulti Configurator generates a project file which is downloaded

to the base unit; there it defines:

` Which safety functions the inputs

are to carry out, e.g. E-STOP monitoring, safety gate monitoring

` How the inputs are connected to

the outputs via logic functions

` Which output is configured (semi-

conductor, relay)

The units react the same, irrespective

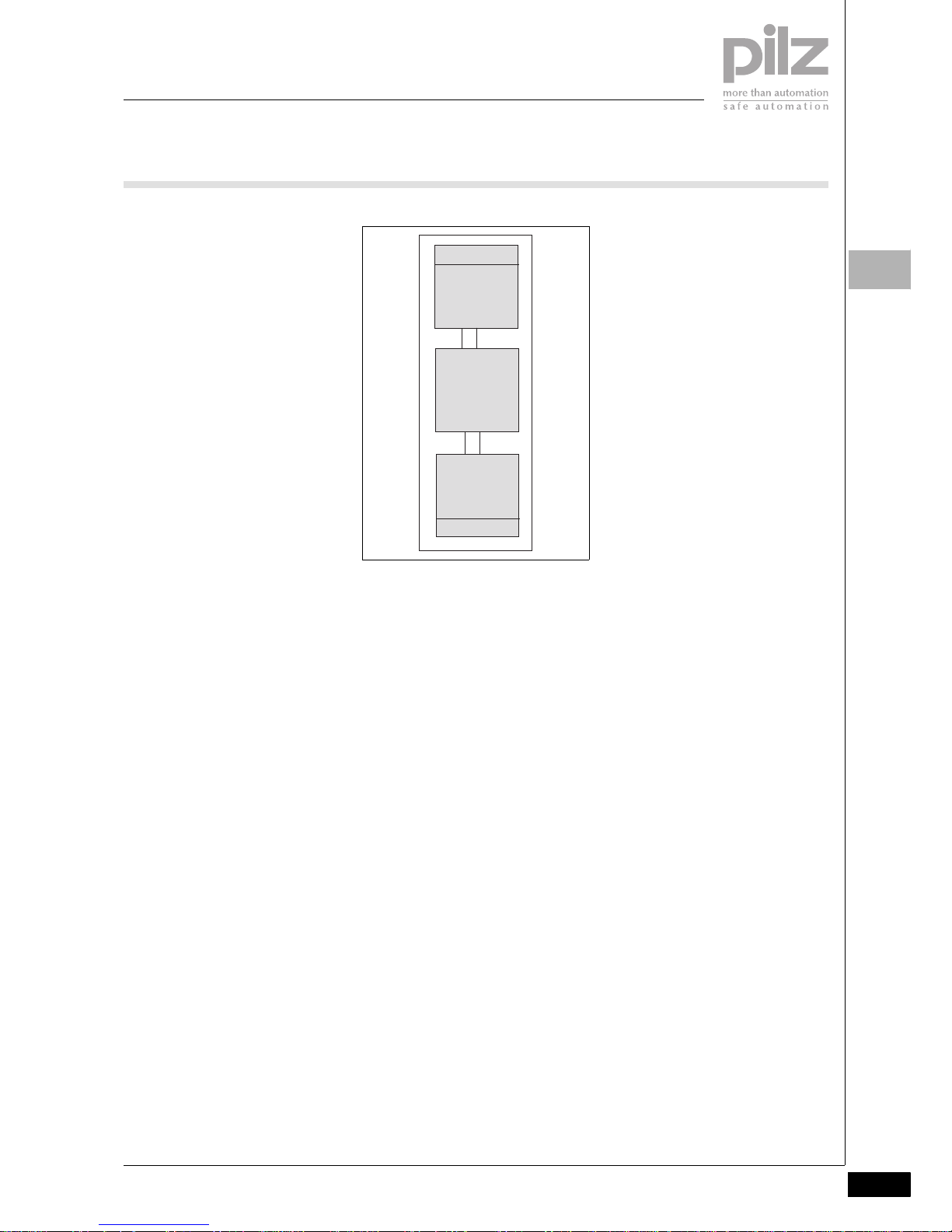

of these functions:

If the start-up condition of the specific

safety function is met, there will be a

high signal at the output “Out1”. The

output signal can be linked via a logic

function and is then present as the

“Out2” signal at the output on the

PNOZmulti unit.

Fieldbus modules

The fieldbus modules are used to

` Read the diagnostic data

` Set virtual inputs for standard func-

tions

` Read virtual outputs for standard

functions

RS 232 interface

The base unit has an RS 232 interface

to

` Download the project

` Read the diagnostic data

` Set virtual inputs for standard func-

tions

` Read virtual outputs for standard

functions

Safety functions

The safety system has inputs and outputs, which can be used for safety

functions. The PNOZmulti safety system can be configured to monitor

` E-STOP pushbuttons

` Operating mode selector switches

` Enable switches

` Two-hand buttons

` Safety gates

` Light curtains

` Light beam devices

` Speeds

` Analogue input signals

` Safety mats

` Muting

`

Mechanical presses

` Standstill

Various switch types are available for

the required safety-related applications. With some switch types it is

possible to monitor for simultaneity

(see chapter on “Configuration and

Wiring”).

Standard functions

Expansion modules are available with

inputs and outputs for standard functions.

Press applications

The PNOZ m2p base unit is designed

for applications on mechanical presses.

Inputs

Safety

functions

e.g.

E-STOP

safety gate

Outputs

Out1

Logic

functions

e.g.

AND

OR

Delay

Out2

Semiconductor

Relay

Page 10

Basics

System description

Software

2006-02Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.1-4

1.1

Software1.12006-02BasicsSystem descriptionSoftware

The functions of the PNOZmulti system are defined in the PNOZmulti

Configurator software.

Procedure

` In the PNOZmulti Configurator, the

first step is to enter the units that

are to be used in the safety system.

Each unit must be given a resource

label.

` When all the units are selected, the

interface appears for entering the

circuit diagram. The circuit diagram

describes the application for which

the safety system is to be used. It is

here that you determine which in-

puts are assigned to which safety-

related or standard functions.

` The inputs and/or the results of the

safety-related or standard functions

can be linked through logic func-

tions. The results of the logic func-

tions or the results of the safety-

related or standard functions are

channelled to the outputs on the

PNOZmulti units.

` The circuit diagram is generated on

a graphical interface. Symbols are

provided for the safety-related or

standard functions, logic functions

and the various output types. These

are simply dragged on to a work-

space, configured and intercon-

nected.

` Once the circuit diagram is com-

plete, the data must be saved and

downloaded to the base unit. The

circuit diagram, unit configuration

and all the data that has been en-

tered are stored within a project.

` When the project is saved, various

passwords can be used to protect it

from unauthorised access.

` Once it is saved, the project has to

be downloaded to the base unit. To

do this, the project data is down-

loaded on to a chip card. The data

is either downloaded via the RS 232

interface or via a chip card reader.

` After downloading, a test must be

performed to check that the safety

devices function correctly.

Page 11

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

System description

Maximum system expansion

2007-11

1.1-5

1.1

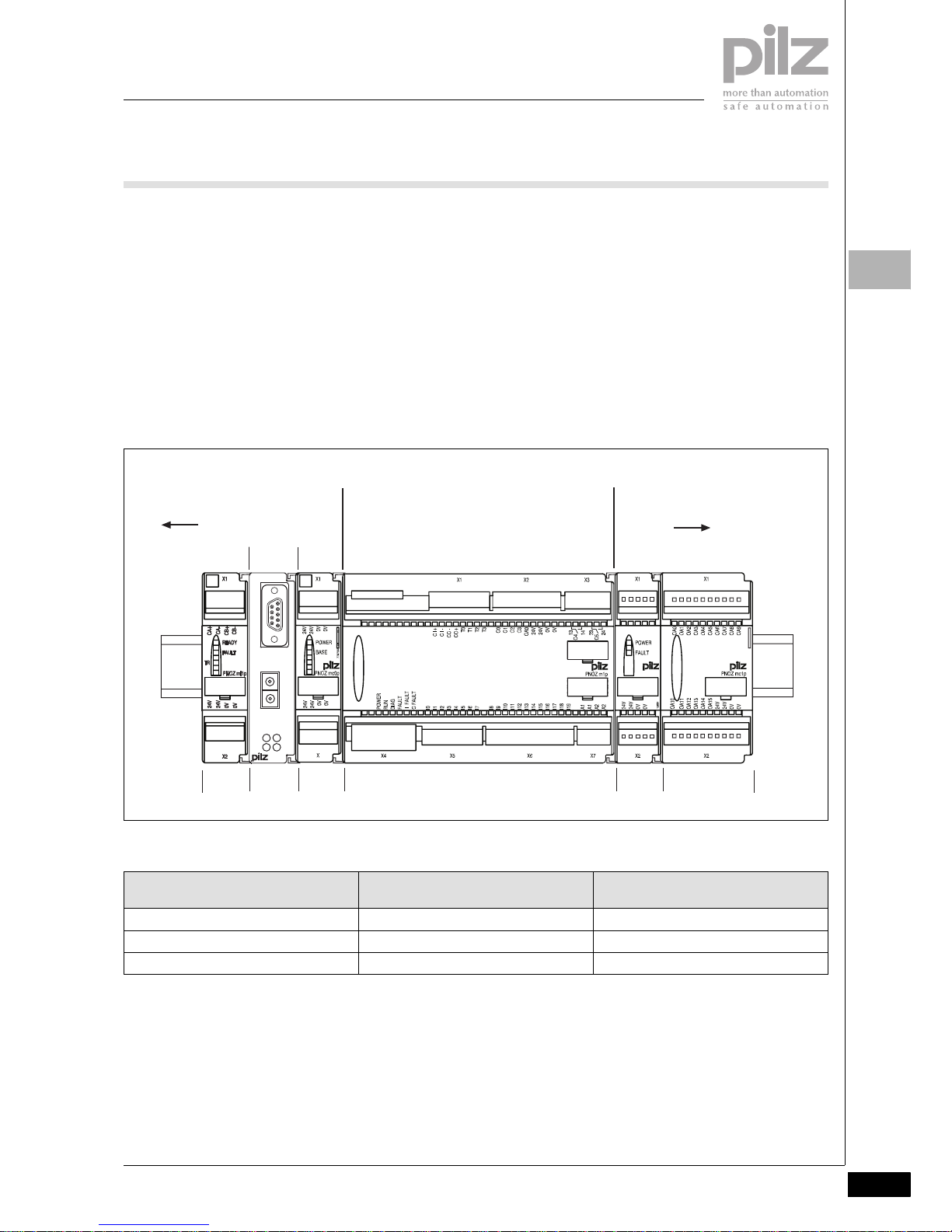

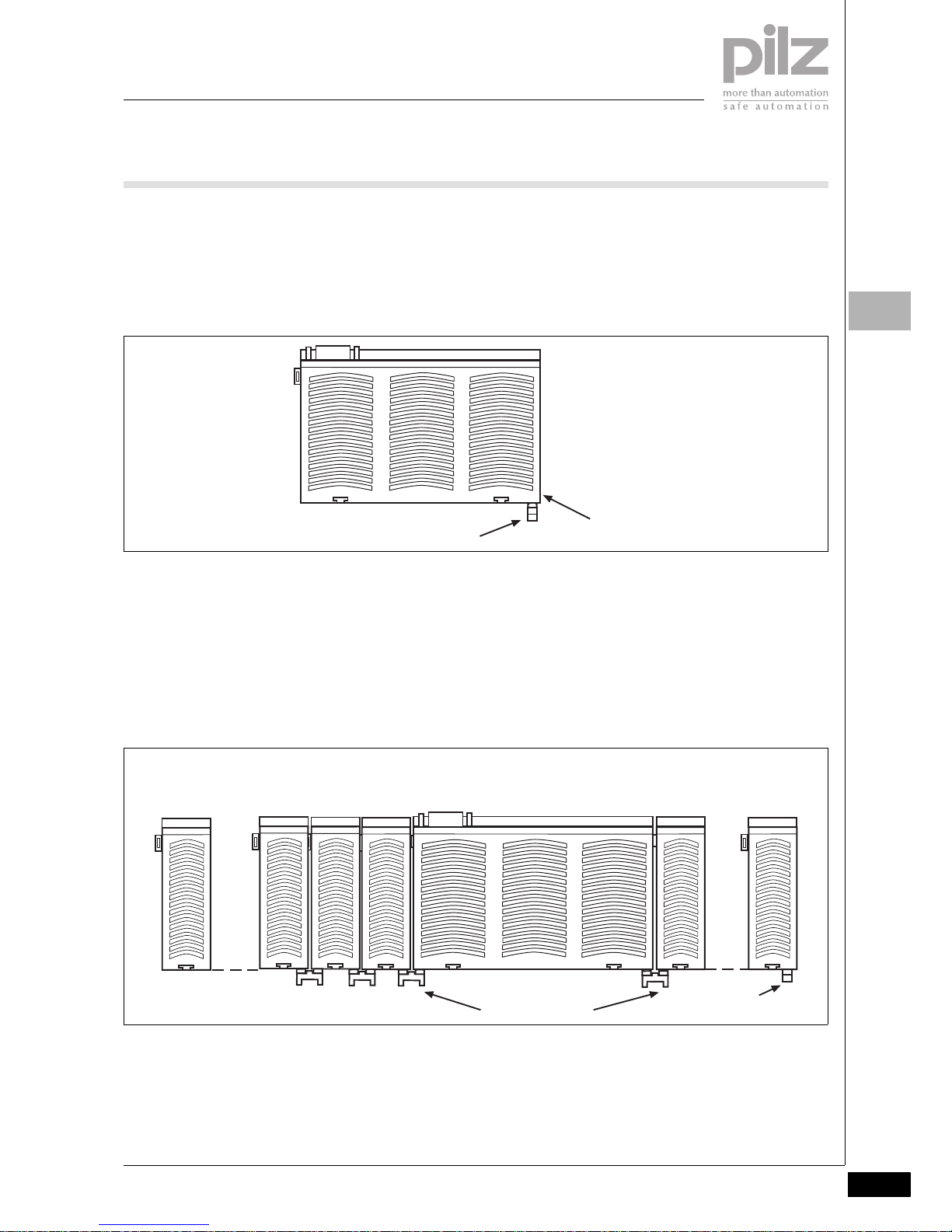

Maximum system expansion1.12007-11BasicsSystem descriptionMaximum system expansion

The PNOZmulti Configurator software

provides support when assembling a

PNOZmulti system. The maximum

system expansion is limited only by

the maximum permitted number of expansion modules that can be connected.

The following modules are available:

` Base units

` Expansion modules

` Fieldbus modules

Positioning of units

` Only one base unit may be used.

` Expansion modules and a fieldbus

module may be connected to the

left or right, depending on the base

unit type. The maximum number

per type is given in the tables below.

` The position of the expansion mod-

ules is defined in the PNOZmulti

Configurator.

` Expansion modules for safety-relat-

ed and standard applications may

be combined as required.

` However, if expansion modules of

the same function are combined

into groups it makes things clearer

and simplifies the wiring.

` The power supply for a fieldbus

module is not given a position

number.

` If there is no fieldbus module, the

position numbers to the left of the

base unit will be -1 ... -4.

Base units:

CHIP-Card

PNOZ mo3p

O1+

O0-

O0+

O1-

PROFIBUS-DP

PNOZ mc3p

FAULT

OFFLINE

x1

x10

X1

ONLINE

ADDRESS

773700

Base unit

Fieldbus module

Max. 8 expansion

modules

8

Position

1

2

...

2

Shield

Power supply

Max. 4 expansion

modules

0-5 -1-2...

Unit type Max. number of expansion modules

installed on the left

Max. number of expansion modules

installed on the right

PNOZ m0p 4 + 1 fieldbus module --PNOZ m1p 4 + 1 fieldbus module 8

PNOZ m2p 4 + 1 fieldbus module 8

Page 12

Basics

System description

Maximum system expansion

2007-11Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.1-6

1.1

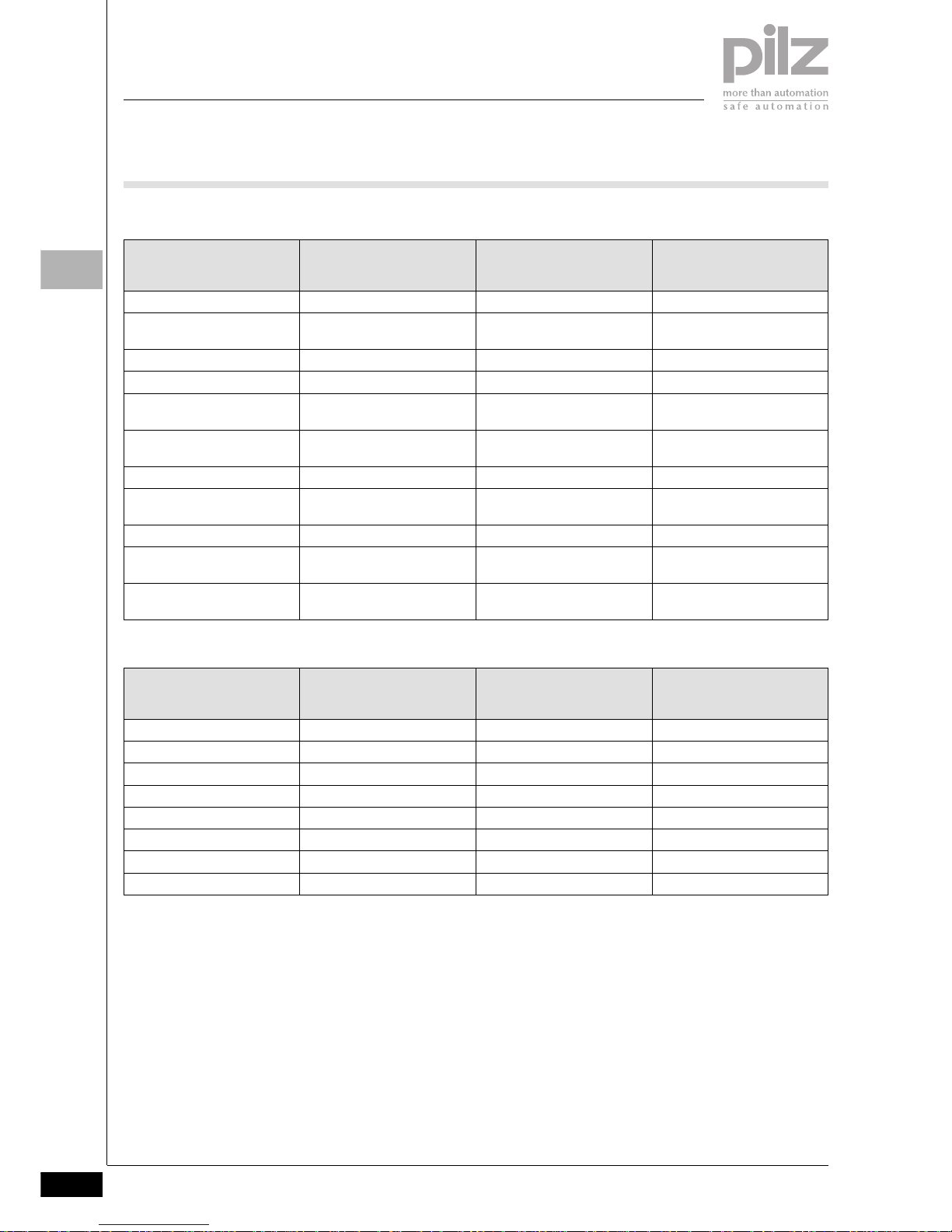

Expansion modules:

Fieldbus modules:

Unit type Function Max. number of expansion

modules

installed on the left

Max. number of expansion

modules

installed on the right

PNOZ ma1p 2 safe analogue inputs 4 --PNOZ mc1p 16 outputs for standard func-

tions

--- 8

PNOZ mi1p 8 safe inputs --- 8

PNOZ mi2p 8 inputs for standard functions --- 8

PNOZ ml1p Connection module for 32 virtu-

al inputs and outputs

4 ---

PNOZ mo1p 4 safe 1-pole semiconductor

outputs

--- 6

PNOZ mo2p 2 safe relay outputs --- 6

PNOZ mo3p 2 safe 2-pole semiconductor

outputs

--- 6

PNOZ mo4p 4 safe relay outputs --- 6

PNOZ ms1p 2 incremental encoders or

proximity switches

--- 4

PNOZ ms1p 2 incremental encoders or

proximity switches

--- 4

Unit type Fieldbus Max. number of expansion

modules

installed on the left

Max. number of expansion

modules

installed on the right

PNOZ mc3p PROFIBUS-DP 1 --PNOZ mc4p DeviceNet 1 --PNOZ mc5p Interbus 1 --PNOZ mc5.1p Interbus fibre-optic cable 1 --PNOZ mc6p CANopen 1 --PNOZ mc7p CC-Link 1 --PNOZ mc8p Ethernet IP/Modbus TCP 1 --PNOZ mc9p PROFINET IO 1 ---

Page 13

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

System description

Diagnostics

2006-02

1.1-7

1.1

Diagnostics1.12006-02BasicsSystem descriptionDiagnostics

The PNOZmulti has many options for

diagnostics and fault detection:

` LEDs on the base unit and expan-

sion modules

` Diagnostic data via serial interface

and fieldbus

` Expanded diagnostic options using

a visualisation system, e.g. PMImi-

cro diag

` Error stack

` Diagnostic word in the PNOZmulti

Configurator

Note

Please refer to the chapters

` “Diagnostic interface” and

` “Diagnostic word”

in the configuration guide “PNOZmulti

– Special applications”.

LEDs on the base unit and expansion modules

The LEDs signal

` Operating statuses (e.g. “RUN”)

` External and internal errors

The key to the LEDs can be found in

the operating instructions supplied

with the units.

Diagnostic Interface

The serial interface on the PNOZmulti

modular safety system is used to

transfer diagnostic data to a user program.

Diagnostic data

The diagnostic data can be called up

via the serial interface or via a connected fieldbus.

The diagnostic data may only be used

for non-safety purposes, e.g. visualisation.

Diagnostic data on the PNOZmulti

modular safety system comprises:

` Version:

Product number, unit version, serial

number

` Status of inputs/outputs:

Indicates whether inputs and out-

puts are active or inactive (open/

closed)

` LED status:

Indicates the status of the LEDs on

the base unit and expansion mod-

ules (on/off/flashes), plus the operating mode (start up, RUN, STOP)

` Simplified status scan:

Shows group messages relating to

the safety system: Signal changes,

LED status, operating statuses

` Virtual inputs and outputs:

Virtual inputs can be set. The status

of the virtual inputs and outputs can

be scanned.

` Diagnostic word:

The diagnostic word contains the

status of elements from the user

program within the PNOZmulti.

` Test data:

To check commmunication.

` Data in table form:

This is structured data (arranged in

tables and segments) from the

PNOZmulti, as it could also be read

via a fieldbus module:

– Configuration

– Status of the inputs and outputs

–LED status

– Diagnostic word

–Element types

Expanded diagnostic options using

a diagnostic terminal, e.g. PMImicro

diag

An expanded diagnsotic configuration

can be created in the PNOZmulti Configurator. The diagnostic configuration

enables appropriate event messages

to be displayed in the case of:

` Errors in or on the PNOZmulti:

Contains the event messages that

are triggered when there are errors

in or on the PNOZmulti (error stack)

` Changes in the operating status of

the PNOZmulti

` which are triggered when safety de-

vices, inputs, outputs and connec-

tion points have a defined status

PNOZmulti event messages can also

be supplemented through additional

information, which is helpful during diagnostics.

With expanded diagnostics, a display

unit (e.g. PMImicro diag) is connected

to a PNOZmulti. If an event occurs in

or on the PNOZmulti, an event telegram is sent to the display unit. The

event telegram is evaluated in the display unit. In most cases, the event

message that corresponds to the

event is displayed and is entered in the

event list. The event message contains

a description of the event. A remedy

can be displayed for each event message. The remedy describes how to

react to the event, in other words,

what “actions” to take.

The diagnostic configuration is

project-related, i.e. a separate diagnostic configuration is created for

each PNOZmulti project (see Create a

diagnostic configuration).

Then the diagnostic configuration is

downloaded to the PNOZmulti and to

the display unit.

The diagnostic configuration is described in detail in the PNOZmulti

Configurator's online help.

Error stack

The error stack on the PNOZmulti contains important information for diagnostics and troubleshooting. The error

stack can be read out by the PNOZmulti Configurator. It contains messages and help texts such as

` Hardware errors

` Wiring errors

` Configuration errors

` Errors in the operation of the inter-

face or fieldbus

` Errors in the project's user program

` Messages relating to differences

between the programs stored on

the PNOZmulti and chip card

Diagnostic word

A diagnostic word can be called up for

those elements of the PNOZmulti Configurator interface that have the ability

to store a status:

` Online in the PNOZmulti Configura-

tor

` Via the base unit's serial interface

` Via a connected fieldbus

The diagnostic word contains information about a certain element, e.g.:

` Operating statuses (e.g. switch op-

erated)

` Error messages (e.g. monitoring

time elapsed)

An individual bit from a diagnostic

word can be evaluated in the user program of the PNOZmulti Configurator.

Page 14

Basics

System description

Safety

2006-02Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.1-8

1.1

Safety1.12006-02BasicsSystem descriptionSafetyPNOZmulti z usammengestellte Te xte

Safety assessments

Before using a unit it is necessary to

perform a safety assessment in accordance with the Machinery Directive. The safety system guarantees

functional safety, but not the safety of

the entire application. You should

therefore define the safety requirements for the plant as a whole, and

also define how these will be implemented from a technical and organisational standpoint.

General safety requirements

Always ensure the following safety requirements are met:

` Only install and commission the

unit if you are familiar with the information in the operating instructions

or this technical catalogue, as well

as the relevant regulations concerning health and safety at work and

accident prevention.

` Only use the unit for the purpose for

which it is intended and comply

with both the general and specific

technical details.

` Transport, storage and operating

conditions should all conform to EN

60068-2-6, 01/00 (see general

technical details).

` Adequate protection must be pro-

vided for all inductive consumers.

` Do not open the housing or make

any unauthorised modifications.

` Failure to comply with the safety re-

quirements will render the guarantee invalid.

Intended use

` The PNOZmulti Configurator soft-

ware is designed to configure units

from the PNOZmulti modular safety

system for use on E-STOP equipment and safety circuits, in accordance with EN 60204-1 (VDE 0113-

1), 11/98 and IEC 60204-1, 12/97.

` The units' intended use depends on

the individual unit and is therefore

explained in the chapter entitled

“Units”.

` The PNOZ m2p base unit is de-

signed for applications on mechanical presses. Please refer to the

safety guidelines in the chapter on

“Safety solutions for presses” in the

configuration guide “PNOZmulti –

Special applications”.

Page 15

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

System description

Safety

2006-02

1.1-9

1.1

Page 16

Basics

Installation

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.2-0

1.2

BasicsInstallation1.2

Page 17

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Installation

2007-11

1.2-1

1.2

Contents Page

Installation

Installing within the control cabinet 1.2-2

Installing the units 1.2-3

Page 18

Basics

Installation

Installing within the control cabinet

2006-02Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.2-2

1.2

Installing within the control cabinet1.22006-02BasicsInstallationInstalling within the control cabinetPNOZmulti zusammengestell te Texte

` The safety system should be in-

stalled in a control cabinet with a

protection type of at least IP54. Fit

the safety system to a horizontal

DIN rail. The venting slots must face

upward and downward. Other

mounting positions could destroy

the safety system.

` Use the notches on the back of the

unit to attach it to a DIN rail. Connect the safety system to the DIN

rail in an upright position, so that

the earthing springs on the safety

system are pressed on to the DIN

rail.

` The ambient temperature of the

PNOZmulti units in the control cabinet must not exceed the figure

stated in the technical details, otherwise air conditioning will be required.

` To comply with EMC requirements,

the DIN rail must have a low impedance connection to the control cabinet housing.

Positioning of units

` Expansion modules and a fieldbus

module may be connected, depending on the base unit type.

` Install the expansion modules in the

position defined in the PNOZmulti

Configurator (see section entitled

“Maximum system expansion” in

Chapter 1.1 “System Description”).

Page 19

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Installation

Installing the units

2006-02

1.2-3

1.2

Installing the units1.22006-02BasicsInstallationInstalling the units

Installing a base unit without expansion modules

` The terminator must be fitted to the

side of the base unit marked “Termination/Link”.

` Do not fit a terminator to the left

side of the base unit.

Connecting the base unit and expansion modules (PNOZ m1p, PNOZ

m1p coated version, PNOZ m2p only)

Jumpers are used to connect the

modules.

There are 2 pin connectors on the rear

of the base unit.

` Make sure that no terminator is fit-

ted.

` Connect the base unit, the expan-

sion modules and the fieldbus module using the jumpers supplied.

` The terminator must be fitted to the

last expansion module to the right

of the base unit.

` Do not fit a terminator to the last ex-

pansion module to the left of the

base unit.

Terminator

Termination/Link

Expansion module 1 ... 8

Jumpers

Terminator

Fieldbus module

Base unit

Expansion module 1 ... 4

Power supply

Page 20

Basics

Electrical installation

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.3-0

1.3

BasicsElectrical installation1.3

Page 21

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Electrical installation

2007-11

1.3-1

1.3

Contents Page

Electrical installation

General requirements 1.3-2

Page 22

Basics

Electrical installation

General requirements

2006-02Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.3-2

1.3

General requirements1.32006-02BasicsElectrical installationGeneral requirementsPNOZmulti zusammengestellte T exte

EMC

` The PNOZmulti is designed for use

in an industrial environment. It is not

suitable for use in a domestic environment, as this can lead to interference.

` To comply with EMC requirements,

the DIN rail must have a low impedance connection to the control cabinet housing.

Supply voltage

` Power for the safety system and in-

put circuits must always be provided from a single power supply. The

power supply must meet the regulations for extra low voltages with

safe separation (SELV, PELV).

` Two connection terminals are avail-

able for each of the supply connections 24 V and 0 V (semiconductor

outputs), plus A1 and A2 (power

supply). This means that the supply

voltage can be looped through several connections. The current at

each terminal may not exceed 9 A.

Cables

` Do not route the test pulse lines to-

gether with actuator cables within

an unprotected multicore cable.

` Use copper wiring that can with-

stand temperatures of 60/75°C.

Terminals

` The plug-in terminals for the inputs

and outputs are not supplied with

the system. You can select between a cage clamp connection or

a screw connection.

` The plug-in connection terminals

on the relay outputs carry mains

voltage and should only be connected and disconnected when the

voltage is switched off.

ESD

Electrostatic discharge can damage

components. Ensure against discharge before touching the units, e.g.

by touching an earthed, conductive

surface or by wearing an earthed armband.

Page 23

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Electrical installation

General requirements

2006-02

1.3-3

1.3

Page 24

Basics

Configuration and Wiring

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.4-0

1.4

BasicsConfiguration and Wiring1.4

Page 25

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Configuration and Wiring

2007-11

1.4-1

1.4

Contents Page

Configuration and Wiring

Inputs 1.4-2

Logic elements 1.4-7

Outputs 1.4-8

Inputs and outputs for standard functions 1.4-9

Cascading 1.4-10

Page 26

Basics

Configuration and Wiring

Inputs

2007-11Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.4-2

1.4

Inputs1.42007-11BasicsConfiguration and WiringInputsPNOZmulti zusammengestell te Texte

Connection options

Depending on the unit type, the following may be connected to the inputs on

the PNOZmulti:

` E-STOP pushbutton

` Safety gate limit switch

` Two-hand button

` Reset button

` Light beam device, light curtain

` Safety mats

` Enable switch

` Operating mode selector switch

` Proximity switch

` Incremental encoder

` Foot switch

` Key switch

` Limit switch

` Pushbutton

` Encoder or transducer to monitor

safe analogue input signals

The PNOZmulti has inputs for both

safety-related and standard applications.

` Only safety inputs should be used

for safety-related applications.

` Inputs for standard functions may

be used for a reset button, for example.

Application with safety mats

The application with safety mats is described in detail in the configuration

guide under “Special applications”.

Configuration in the PNOZmulti

Configurator

The inputs on the PNOZmulti units are

configured in the PNOZmulti Configurator.

For example, you can define the following:

` Switch types for various safety

functions

` Connection assignment

` Detection of shorts between con-

tacts in the input circuit

` Reset types

` Start-up test

` Detection of shorts between con-

tacts in the reset circuit with test

pulse assignment

` Input for standard function

Some configuration options can only

be selected for particular safety functions (e.g. the start-up test can only be

selected for the safety gate and light

curtain safety functions).

Input signals

Due to the cyclical processing, changes in the input signal will only be detected safely if the off-time >15 ms.

Connection assignment

Inputs on the PNOZmulti units are assigned to particular safety functions

(e.g. E-STOP, safety gate) in the

PNOZmulti Configurator. The safety

contacts must be connected to the inputs on the PNOZmulti units in accordance with their configuration.

Select switch type

The PNOZmulti Configurator provides

the user with various switch types for

safety-related applications. The switch

types that can be selected will depend

on the type of input element (e.g. ESTOP, safety gate). The switches

drawn below are shown in the state

when not activated, such as with the

safety gate closed or E-STOP not

pressed.

On switches that are monitored for simultaneity, the maximum switch-on

time and the maximum switch-off time

are the same. These values can be

found in the “Description” and “Timing

diagram” columns.

Page 27

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Configuration and Wiring

Inputs

2007-11

1.4-3

1.4

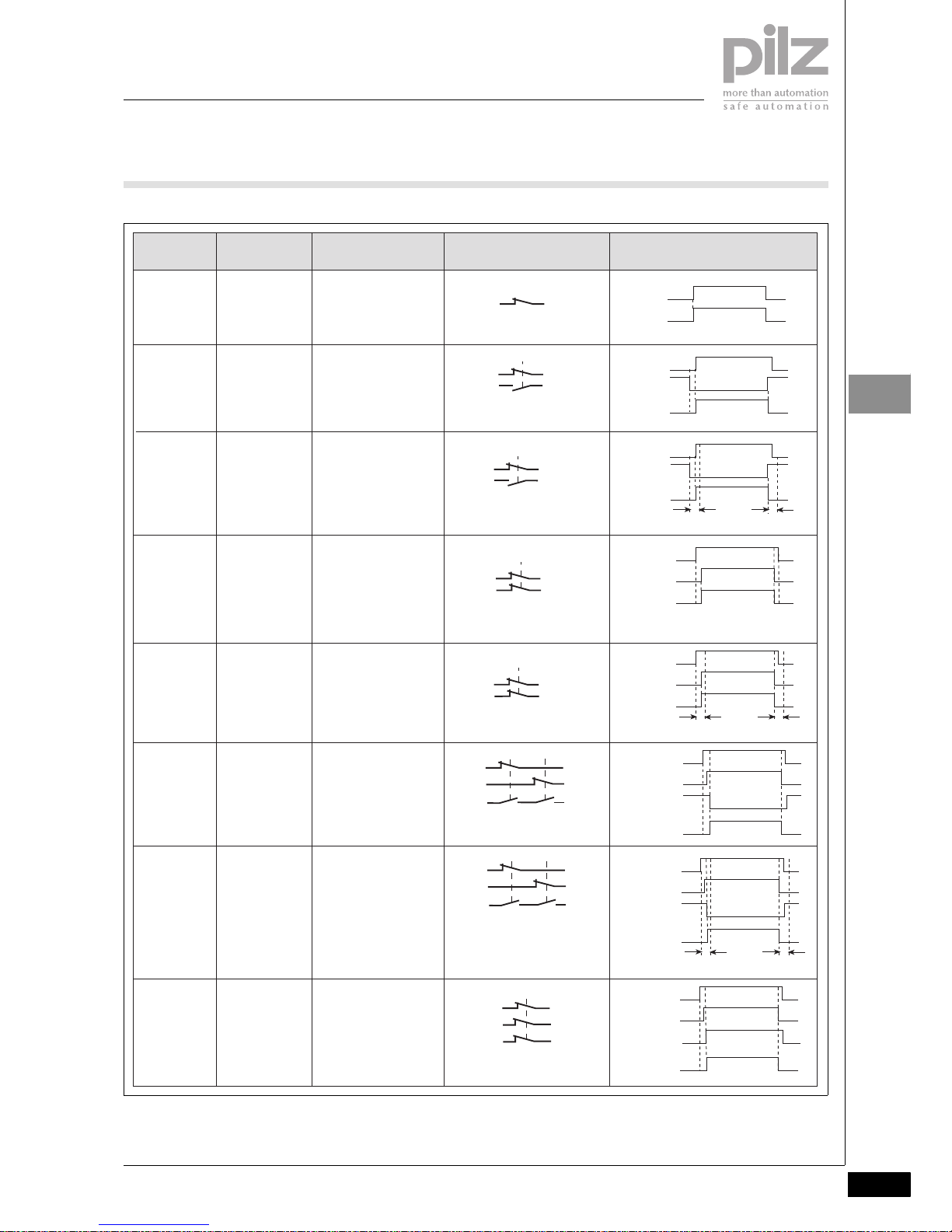

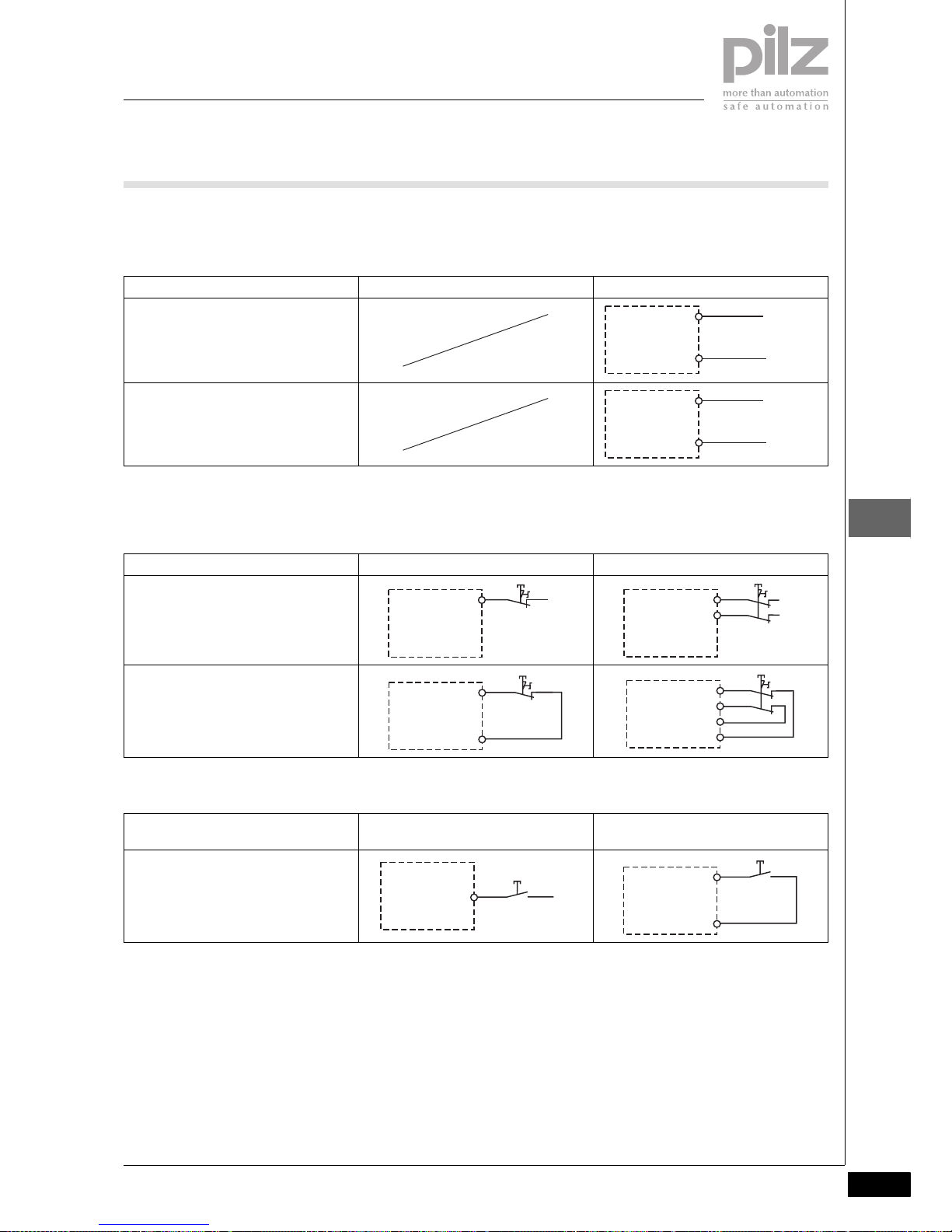

Application Description Switch symbol Timing diagram

E-STOP

Safety gate

Enable switch

Foot switch

Safety contacts:

1 normally closed (N/C)

without on and off-time

1

E-STOP

Safety gate

Foot switch

Safety contacts:

1 normally closed (N/C)

1 normally open (N/O)

without on and off-time

E-STOP

Safety gate

Foot switch

Safety contacts:

1 normally closed

(N/C)

1 normally open

(N/O)

with on and off-time

3 s

2

Safety contacts:

2

normally closed

(N/C)

without on and offtime

2 Simultaneity

E-STOP

Safety gate

Safety gate

with

Interlock

Light curtain

Enable switch

Foot switch

3

3 Simultaneity

E-STOP

Safety gate

Light curtain

Enable switch

Foot switch

Safety contacts:

2 normally closed

(N/C)

with on and off-time

3 s

4 Safety contacts:

2 normally closed (N/C)

1 normally open (N/O)

without on and off-time

Safety

gate

4 Simultaneity

Safety contacts:

2 normally closed (N/C)

1 Schließer (S)

with on and off-time 3 s

Safety

gate

5 Safety contacts:

3 normally closed (N/C)

without on and off-time

Safety

gate

Switch type

t

t

t

t

N/C

Output

N/O

Output

N/C

max. 3 s

max. 3 s

N/O

Output

N/C

N/C

Output

N/C

N/C

Output

N/C

max. 3 s

max. 3 s

N/C

Output

N/C

N/O

N/C

Output

N/C

max. 3 s

max. 3 s

N/O

N/C

Output

N/C

N/C

Page 28

Basics

Configuration and Wiring

Inputs

2007-11Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.4-4

1.4

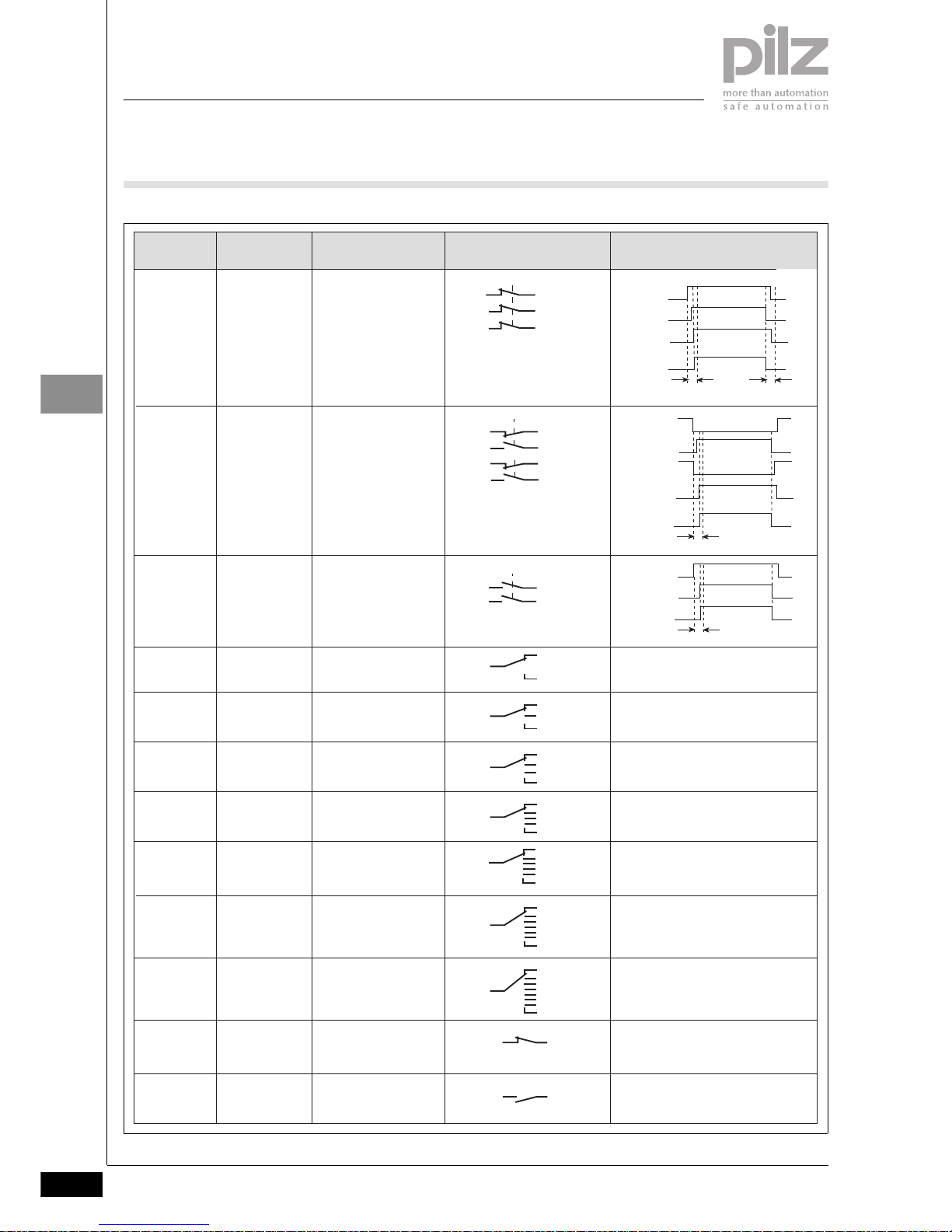

5 Simultaneity

Safety contacts:

3 normally closed (N/C)

with on and off-time 3 s

Safety

gate

Safety contacts:

2 changeover contacts

(C/O) with simultaneity

monitoring 0.5 s, off-time

not monitored

Safety contacts:

2 normally open (N/O)

(C/O) with simultaneity

monitoring 0.5 s, off-time

not monitored

Two-hand button

Ohne Taktung

nur bis Kategorie

1 nach EN 954-1

einsetzbar

7

9

Operating mode Safety contacts:

Switch 1 from 2

10 Operating mode Safety contacts:

Switch 1 from 3

11 Operating mode Safety contacts:

Switch 1 from 4

12 Operating mode Safety contacts:

Switch 1 from 5

13 Operating mode Safety contacts:

Switch 1 from 6

14 Operating mode Safety contacts:

Switch 1 from 7

15 Operating mode Safety contacts:

Switch 1 from 8

Button

Key switch

Limit switch

Safety contacts:

1 normally closed (N/C)

16

Safety contacts:

1 normally open (N/O)

17

Two-hand

button

6

N/C

Output

N/C

max. 3 s

max. 3 s

N/C

N/C 1

Output

N/O 1

max. 0,5 s

N/C 2

N/O 2

Output

N/O 1

max. 0,5 s

N/O 2

t

t

Application Description Switch symbol Timing diagramSwitch type

Button

Key switch

Limit switch

Page 29

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Configuration and Wiring

Inputs

2007-11

1.4-5

1.4

Input devices

When selecting input devices, you

must comply with the technical details

of the input circuits on the PNOZmulti

units. To help you in your selection,

Pilz has performed application tests

with a number of input devices. The

following input devices have passed

the application test:

` Light curtains:

–SICK FGS

– SICK C4000

– Honeywell MEYLAN

– CEDES Safe 4

–OMRON F3SN-A

– Fiessler ULVT

– STI Minisafe MS 4600 (from S/N:

AC283791 / BA022933)

– STI Optofence OF 4600

` Limit switches:

– Schmersal AZ 16-02

– Guardmaster ferrocode

– Euchner NP1-628AS

– Euchner CES-A-C5E-01 (only

when operating without detection of shorts across contacts)

– Euchner CES-A-C5E-01 (only

with test pulse wiring)

– Euchner ENG-071990

– Euchner NM11KB

The following may not be used:

` Limit switches:

– Euchner CES-A-C5E-01 with

pulse signals

The following is generally valid: Input

devices with mechanical contacts (relays) can be used in operating modes

with or without detection of shorts

across contacts, provided you comply

with the technical details. It is not always possible to use input devices

with semiconductor outputs when operating with detection of shorts across

contacts.

Units with OSSD semiconductor

outputs

Units with OSSD semiconductor outputs (e.g. self-testing light barriers)

may only be used if the PNOZmulti is

operated without detection of shorts

across contacts.

ESPE

If the function of an ESPE (e.g. light

barrier) is switched off via an operating

mode selector switch, the supply voltage to the ESPE must be switched off

at the same time.

Operating modes

The following operating modes are

available, depending on the selected

safety function:

` Single-channel operation: Input

wiring in accordance with EN

60204, no redundancy in the input

circuit; earth faults in the input circuit are detected.

` Dual-channel operation: Redun-

dant input circuit; earth faults in the

input circuit are detected, with or

without detection of shorts between the input contacts.

` Triple-channel operation: Redun-

dant input circuit; earth faults in the

input circuit are detected, with or

without detection of shorts between the input contacts.

` Automatic reset: Unit is active as

soon as the input circuit is closed.

` Manual reset: The unit is not active

until the reset button has been operated.

` Monitored reset: Unit is not active

until the reset button has been operated and then released. This eliminates the possibility of the reset

button being overridden, triggering

automatic activation.

` Detection of shorts between con-

tacts in the input circuit: Enabled by

pulsing the input circuits. This operating mode is automatically detected on start-up.

` Detection of shorts between con-

tacts in the reset circuit:

` Only on E-STOP, safety gate and

light curtain

` Start-up test: The unit checks

whether safety gates that are

closed are opened and then closed

again when supply voltage is applied.

` Increase in the number of safety

contacts available by connecting a

contact block (e.g. PZE 9P) or external contactors.

Reset button

A reset button triggers an enable for a

safety device when all the corresponding safety switches (e.g. E-STOP) are

closed. This prevents a machine starting up automatically after the supply

has been interrupted or after a safety

device has closed, for example.

Reset modes

When configuring inputs for E-STOPs,

safety gates or light guards in the

PNOZmulti Configurator, it is possible

to define the reset mode:

` Automatic reset

` Manual reset

` Monitored reset

For a manual and monitored reset, the

reset button can also be configured as

a standard input.

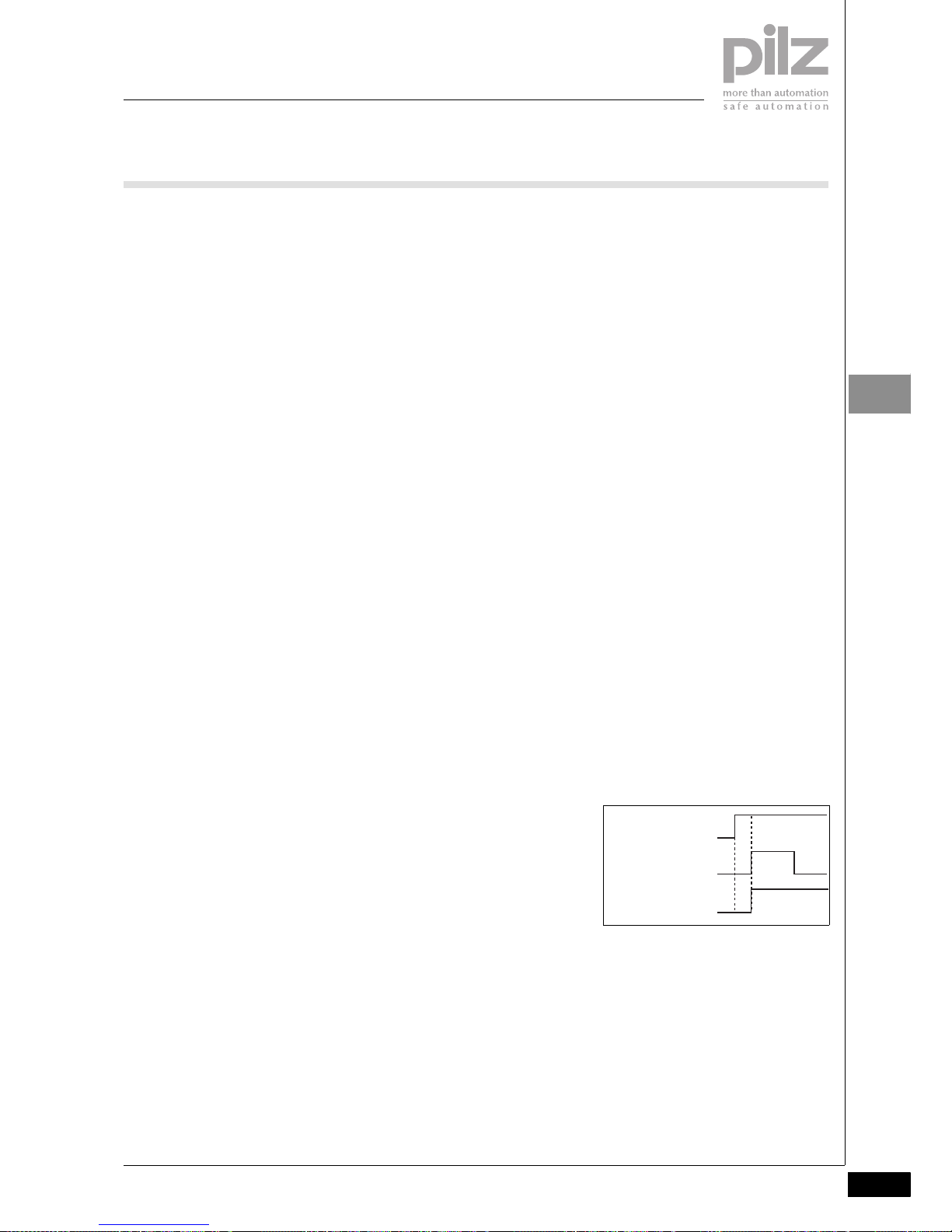

` Automatic reset

With an automatic reset, the output on

the function element goes to “1” when

the safety switches on the input circuit

are closed.

` Manual reset

A N/O contact on the reset input generates the reset signal. The reset button must be operated after the safety

switch has closed. The output on the

input element is set to “1” when the reset button is operated.

` Monitored reset

A N/O contact on the reset input generates the reset signal. The reset button must be operated after the safety

switch has closed. The output on the

input element is set to “1” when the reset button is released.

Reset button

Output

Safety contact

Page 30

Basics

Configuration and Wiring

Inputs

2007-11Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.4-6

1.4

Test pulses and detection of shorts

across contacts

` Under certain circumstances, sig-

nal inputs with infrequent operation

(constant signals) supply an unchanging signal over a long period

of time. During this time, the function of the periphery devices can

only be monitored to a limited extent. Faults that arise may remain

undetected. Signal inputs with infrequent operation must therefore

be checked via test pulses from

category 2 onwards, in accordance

with EN 954-1.

` Test pulses are assigned to inputs

in the PNOZm Configurator. If “Detection of shorts between contacts

in the input circuit” has been selected, the base unit provides 4 test

pulses.

` Two-hand button: Switch type 6

contains a N/C / N/O combination

per two-hand button.

` If switch type 7 is used, the two N/

O contacts should use different test

pulses.

` Please refer to clause 4 of EN 574

during configuration.

` Detection of shorts between con-

tacts in the reset circuit: Monitored

reset mode will detect a short

across the contacts. For wiring reasons the reset circuit may also use

test pulses.

` Test pulse outputs may only be

used to test the inputs. They must

not be used to drive loads.

` Test pulse outputs are also used to

supply safety mats that trigger a

short circuit.

Where test pulses are used for the

safety mat, they may not be reused

for other purposes.

Safety mats are supported from the

following base unit versions:

– PNOZ m0p: From Version 1.2

– PNOZ m1p: From Version 4.3

– PNOZ m2p: From Version 1.3

Start-up test

` A start-up test is available for the

safety gate and light curtain safety

functions.

` When supply voltage is removed

and then re-applied, the safety gate

is enabled (output on the safety

gate input element = “1”) only after

the gate has been opened and then

closed. In this way you are forced to

check the correct function of the

safety gate and safety gate switch.

` The PNOZmulti switches to a STOP

condition after an error. The PNOZmulti switches back to a RUN condition when the supply voltage has

been switched on and off. For this

reason the start-up test must be

carried out again after each STOP.

Reset button

Output

Safety contact

Page 31

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Configuration and Wiring

Logic elements

2006-02

1.4-7

1.4

Logic elements1.42006-02BasicsConfiguration and WiringLogic elementsPNOZmulti zusammengestell te Texte

The functions on the PNOZmulti devices are configured using the PNOZmulti Configurator.

Logic elements affect the state of the

function elements. Logic elements include:

` Logic connections e.g. AND, OR

` Time elements

` Event counter

` Speed monitor

` Start element

` Connection point

` Press elements

` Muting

Logic elements can be linked with

` the outputs of the function ele-

ments

` other logic elements

` the inputs of the output elements

Speed monitor

The speed monitor logic element is

used to configure the PNOZ ms1p/

PNOZ ms2p speed monitor. The

speed monitor monitors

` Standstill

` Overspeed

` Direction of rotation

The following input devices can be

evaluated:

` Incremental encoders (TTL and Sin-

Cos)

` Proximity switches

The following can be configured in the

PNOZmulti Configurator:

` Maximum of 4 PNOZ ms1p speed

monitors

` Maximum of 2 independent axes

per speed monitor

Logic elements for press applications

Press-related logic elements are designed for applications on mechanical

presses.

All the functions required for a press

are available.

These include:

` Operating modes

` Set-up mode

` Single stroke

` Automatic

` Monitoring a rotary cam arrange-

ment

` Run monitoring

` Monitoring electrosensitive protec-

tive equipment (pulse mode)

` Driving and monitoring a press

safety valve

For applications on presses (PNOZ

m2p only), please refer to the chapter

on “Safety solutions for presses” in the

configuration guide “PNOZmulti –

Special applications”. It contains safely guidelines and a detailed example.

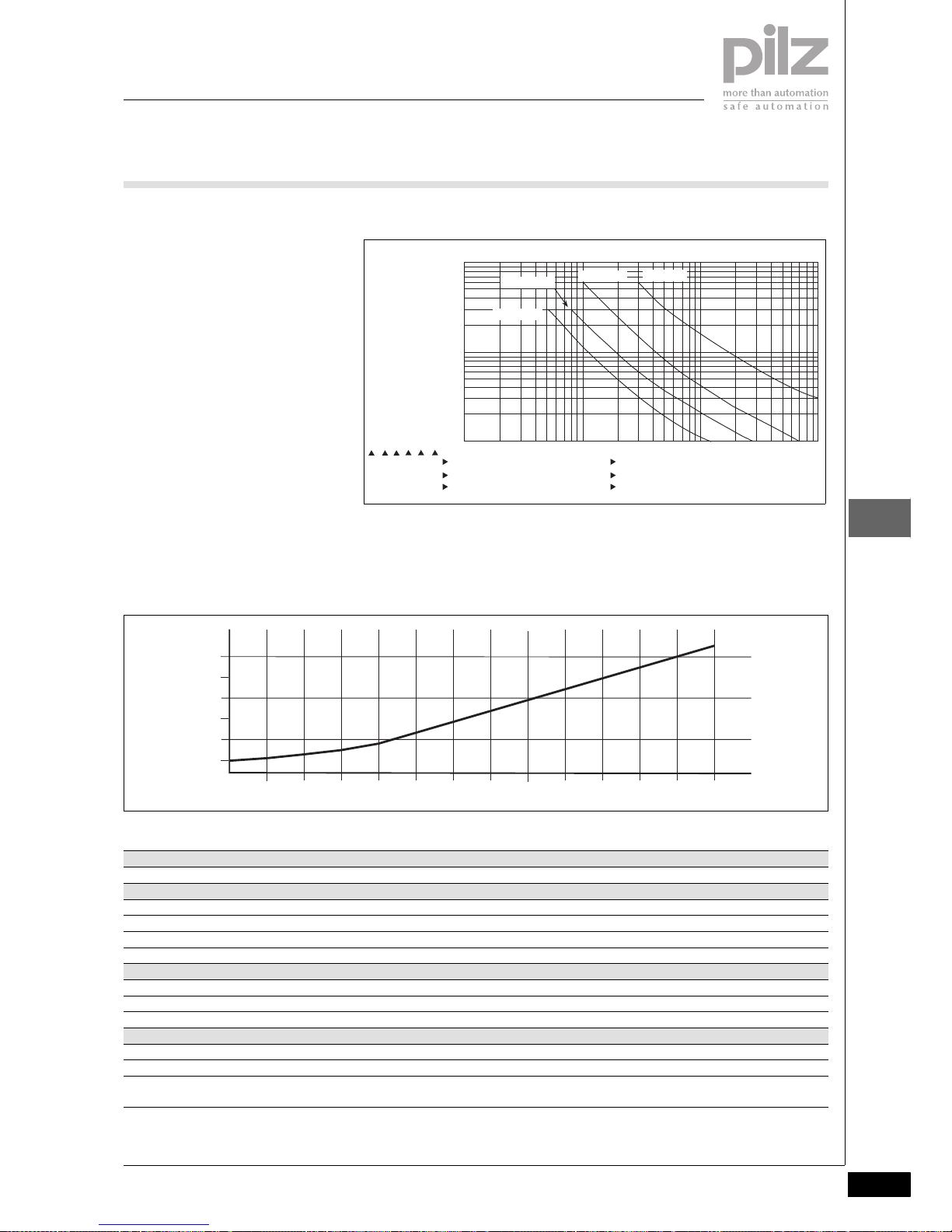

Time elements

Due to the cyclical processing, delay

times on time elements may be up to

15 ms longer than the configured value.

Muting

The muting logic element is used to

temporarily suspend the safety functions (ESPE/AOPD) without interrupting the process (muting).

For a limited period of time, and for a

specific operational phase (e.g. when

feeding materials), it will suspend the

effect of safety devices during the

working process. Once completed, it

will reset the safety function.

Performance features:

` Muting via light beam devices or

limit switches

`

Selectable: sequential, parallel or

cross muting

` Ability to override the muting func-

tion if a fault occurs

` Max. muting time can be set

` Time monitoring of the muting sen-

sors

` Suspension of bounce time

Operating modes:

` Sequential muting

` Parallel muting

` Cross muting

The muting application is described in

detail in the configuration guide under

“Special applications”.

Page 32

Basics

Configuration and Wiring

Outputs

2006-02Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.4-8

1.4

Outputs1.42006-02BasicsConfiguration and WiringOutputsPNOZmulti zusa mmengestellte Texte

Connection options

Depending on the unit type, the following may be connected to the outputs

on the PNOZmulti:

` Relays

` Contactors

` Valves

` Signal lamps

The PNOZmulti has outputs for both

safety-related and standard applications.

` Only safety outputs should be used

for safety-related applications.

` Outputs for standard functions may

be used for a signal lamp, for example.

Configuration in the PNOZmulti

Configurator

The outputs on the PNOZmulti units

are configured in the PNOZmulti Configurator.

For example, you can define the following:

` Relays

` Semiconductors

` Valve control

` Feedback loop

` Output for standard function

Some configuration options can only

be selected for specific safety functions (e.g. single, double or directional

valve)

Switch-off delay

When establishing the reaction time of

the safety device, the switch-off delay

on the outputs must be taken into account (see Technical details). The

switch-off delay indicates the time between the safety function on the input

of the PNOZmulti unit being triggered

and the output contacts switching

over / the semiconductor outputs carrying a low signal.

Relay

The relay contacts meet the requirements for safe separation through increased insulation compared with all

other circuits in the safety system.

Single-channel or redundant relay outputs are available. The redundant outputs are suitable for applications with

a higher level of safety (for wiring options please see the chapter entitled

“Units”).

2-channel operation of loads

` Loads should be driven through 2

separate channels or, in the case of

redundant relay outputs, shorts

across contacts should be prevent-

ed e.g. by installing the safety sys-

tem and its loads (contactors) in a

control cabinet.

` In terms of load on the relays, keep

to the max. permitted operations

stated in the technical details.

Semiconductor

Single-channel or redundant semiconductor outputs are available. The redundant outputs are suitable for

applications with a higher level of safety (for wiring options please see the

chapter entitled “Units”).

Feedback loop

` The feedback loop is used to moni-

tor the actuators that are being driv-

en.

` On a feedback loop, positive-guid-

ed N/C contacts on the driven con-

tactors (actuators) are connected in

series. If 24 VDC are present at the

input on the feedback loop, all the

connected contactors are de-ener-

gised. If the N/O contact on a con-

tactor has welded, the feedback

loop is not closed when switching

off. The safety output will not be

switched if the feedback loop is in-

terrupted.

The PNOZmulti registers an error in

the following cases:

` The output is switched on and 24

VDC is not present at the input on

the feedback loop.

` The feedback loop remains closed

for longer than 3 seconds (24 V on

the feedback loop input) after the

output was switched on.

In both cases, the output will switch off

and the error will be entered in the error stack. The “OFAULT” LED flashes.

The error is reset by switching off the

output.

Contactor with positive-guided contacts

Only contactors with positive-guided

contacts should be used on the

PNOZmulti's safety outputs.

Page 33

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Configuration and Wiring

Inputs and outputs for standard functions

2006-02

1.4-9

1.4

Inputs and outputs for standard functions1.42006-02BasicsConfiguration and WiringInputs and outputs for standard functions

Inputs

Inputs for standard functions may be

` Inputs for standard functions from

units in the PNOZmulti-range

` 24 inputs for standard functions

which are transmitted via the fieldbus

` 24 virtual inputs for standard func-

tions which are transmitted via the

serial interface

` Results of logic operations (RLO =

0, RLO = 1)

Inputs for standard functions may only

be used in the PNOZmulti Configurator

` As a reset button for

– the function elements E-STOP,

safety gate and light curtain

– the reset logic element

` As an input for an AND connection,

which also has an additional safe

input

` As a reset or acknowledgement

button on logic elements

` As an input for a non-safety-related

output element (e.g. non-safety-re-

lated semiconductor outputs)

` As a direct connection to a fieldbus

output

Outputs

Outputs for standard functions may be

` Outputs for standard functions from

units in the PNOZmulti-range

` 24 outputs for standard functions

which are transmitted via the field-

bus

` 24 virtual outputs for standard

functions which are transmitted via

the serial interface

Use

Inputs and outputs for standard functions must not be used for safety-related applications.

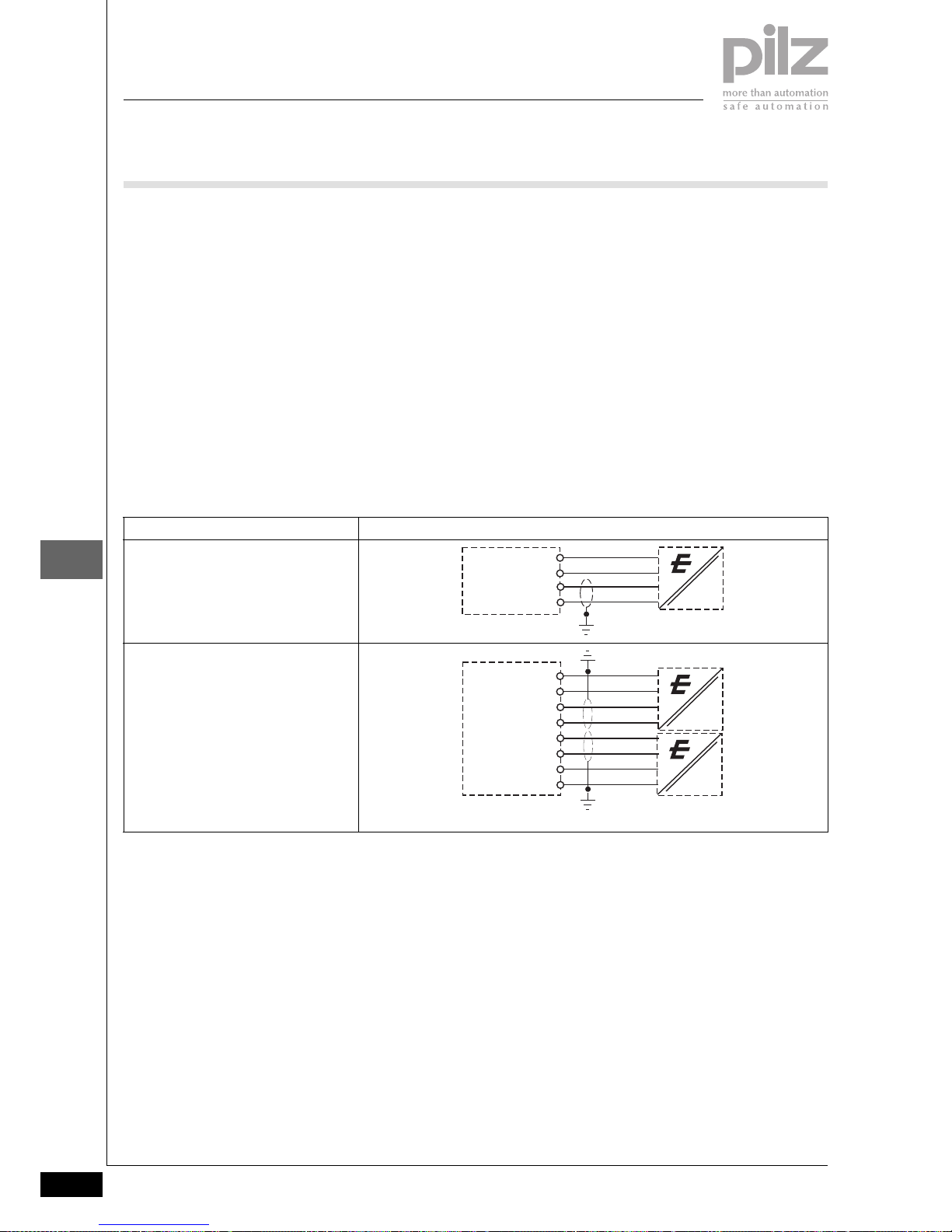

Examples in the PNOZmulti Configurator

ST: Input or output for standard functions

FS: Input or output for safety functions

` Reset button on function elements

` AND connection

` Acknowledgement on reset ele-

ment

` Direct connection of inputs and

outputs for standard functions

` Input for driving an output for

standard functions

ST

FS

FS

ST

ST

FS

FS

ST

FS

FS

ST ST

ST

ST

Page 34

Basics

Configuration and Wiring

Cascading

2008-08Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.4-10

1.4

Cascading1.42008- 08BasicsConfiguration and WiringCascadingPNO Zmulti zusammengest ellte Texte

` Base units on the modular safety

system can be networked. The cas-

cading output on one base unit is

connected to the cascading input

on another base unit. In this way,

one base unit can have direct ac-

cess to a logic output and/or an in-

put on the connected base unit.

` The base units can be connected in

series or a tree structure can be

built.

` PNOZelog units may also be includ-

ed in the network.

` The cascading outputs may not be

used to drive loads. The same also

applies to outputs on PNOZelog

units that are connected to cascading inputs on PNOZmulti units.

` If necessary, a reset lock must be

provided on each cascaded unit.

System requirements

PNOZmulti Configurator: from Version

3.0.0

Please contact Pilz if you have an older

version.

Series connection

As many PNOZ m1p base units as

necessary may be connected in series.

The number of units connected in succession will depend only on the reaction time required by the application.

As the delay times on the individual

units are added together, the reaction

time increases with each unit.

CI+

CI-

CO+

CO-

PNOZ m1p

Unit 1

CI+

CI-

CO+

CO-

PNOZ m1p

Unit 2

CI+

CI-

CO+

CO-

PNOZ m1p

Unit x

Delay time on the PNOZmulti Switch-off delay Switch-on delay

Between input and cascading output Max. 40 ms Typ. 100 ms

Between cascading input and a semicon-

ductor output

Max. 40 ms Typ. 100 ms

Between cascading input and a relay output

Max. 60 ms Typ. 120 ms

Between cascading input and a cascading

output

Max. 40 ms Typ. 120 ms

Page 35

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Configuration and Wiring

Cascading

2008-08

1.4-11

1.4

Example:

` Delay between input I0 - cascading

output Unit 1: 40 ms

` Delay between input I0 - cascading

output Unit 2: 40 ms + 40 ms

` Delay between input I0 - semicon-

ductor output Unit 3: 40 ms + 40 ms

+ 40 ms

` Delay between input I0 - relay out-

put Unit 4: 40 ms + 40 ms + 40 ms

+ 60 ms

Incorporating PNOZelog units:

` PNOZelog units may also be includ-

ed in the series connection. The de-

lay times on the individual units are

also added together with this type

of cascading.

` Remember to consider the switch-

on delay and any potential delay

time for the outputs on the

PNOZelog units (see operating

manual or PNOZelog technical catalogue).

` When connecting PNOZmulti -

PNOZelog, the cascading output

“CO-” is not connected.

I0 CO+

CO-

PNOZ m1p

Unit 1

CI+

CI-

CO+

CO-

PNOZ m1p

Unit 2

CI+

CI-

CO+

CO-

PNOZ m1p

Unit 3

CI+

CI-

O4

PNOZ m1p

Unit 4

N

O0

L-

L+

S1

14

13

L

CI+

CI-

CO+

A2

S36 (S35)

A2

14

(24)

A2

PNOZ m1p PNOZelog

Unit 1 Unit 2

CI+

CI-

CO+

A2

PNOZ m1p

Unit 3

S36 (S35)

A2

14

(24)

A2

PNOZelog

Unit 4

Page 36

Basics

Configuration and Wiring

Cascading

2008-08Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1.4-12

1.4

Tree structure

` Tree structures may be designed

with as many levels as necessary.

Conditions:

` A max. of 4 PNOZmulti units may

be incorporated in parallel on each

level.

` PNOZelog units may only be con-

nected to the PNOZmulti units in

series. Max. of one PNOZelog unit

is permitted on each level.

CI+

CI-

CO+ CO-

PNOZ m1p

S36 (S35)

A2

14 (24) A2

PNOZelog

CI+

CI-

CO+ A2

PNOZ m1p

CI+

CI-

CO+ CO-

PNOZ m1p

CI+

CI-

CO+ CO-

PNOZ m1p

CI+

CI-

CO+ CO-

PNOZ m1p

CI+

CI-

CO+ CO-

PNOZ m1p

CI+

CI-

CO+ CO-

PNOZ m1p

CI+

CI-

CO+ CO-

PNOZ m1p

CI+

CI-

CO+ CO-

PNOZ m1p

CI+

CI-

CO+ CO-

PNOZ m1p

S36 (S35)

A2

14 (24) A2

PNOZelog

Page 37

Basics

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Configuration and Wiring

Cascading

2008-08

1.4-13

1.4

Supply voltage for the cascaded

units

` The cascaded PNOZmulti units

may be supplied via a power sup-

ply. The power consumption of the

individual units should be consid-

ered when deciding on the size of

the power supply.

` Cascaded PNOZelog units and all

PNOZmulti units connected directly

to PNOZelog units must be sup-

plied via a common power supply.

The voltage tolerance on the power

supply may be a maximum of +20%

or -10%.

Installing the cascaded units

` If PNOZmulti units alone are being

networked, the networked units

may be housed in separate control

cabinets.

` If PNOZelog units are integrated

into the network, these PNOZelog

units and their cascade cables must

always be housed in the same control cabinet as the PNOZmulti units

that are connected directly to the

PNOZelog units.

Wiring

Please observe the following when

wiring:

` Cable runs between the connected

units:

` PNOZmulti - PNOZmulti: max. 100

m

` PNOZelog - PNOZmulti cascaded

directly: max. 10 m

` Cable material: see technical de-

tails

` Outside the control cabinet, both

the wires from the cascading input

(CI+, CI-) and the wires from the

cascading output (CO+, CO-) must

be laid in separate multicore cables.

S36 (S35)

A2

14 (24) A2

PNOZelog

CI+

CI-

CO+ CO-

PNOZ m1p

CI+

CI-

CO+ CO-

PNOZ m1p

Power

A2

A1

A1

A1

A2

Page 38

Products

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2.0-0

2.0

Products2.0

Page 39

Products

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2008-03

2.0-1

2.0

Contents Page

Selection guide from 2.1-1

Base units from 2.2-1

Expansion modules from 2.3-1

Adapter for PNOZ ms1p and PNOZ ms2p from 2.4-1

Software from 2.5-1

Page 40

Products

Selection guide

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2.1-0

2.1

ProductsSelection guide2.1

Page 41

Products

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Selection guide

2008-03

2.1-1

2.1

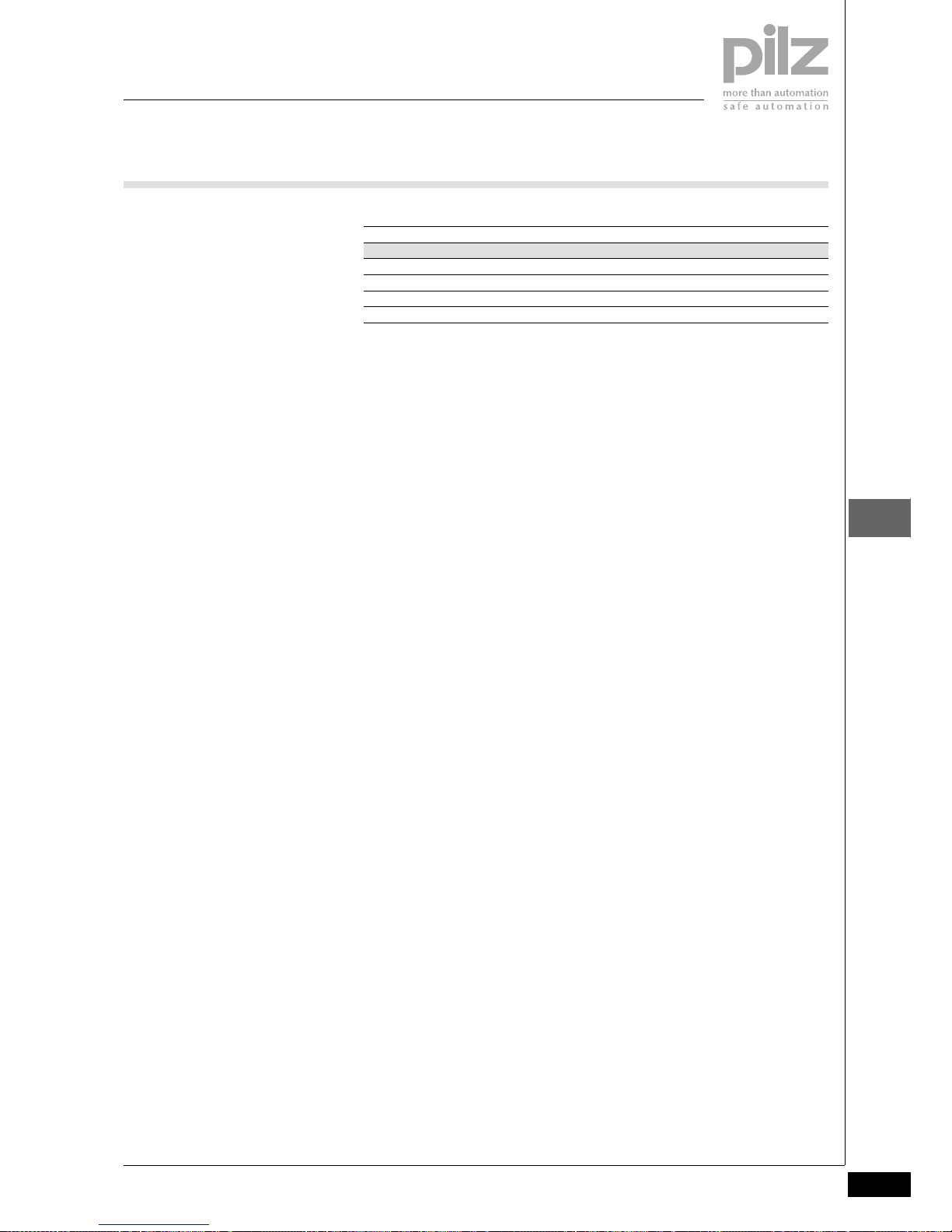

Contents Page

Selection guide

Base units and expansion modules 2.1-2

Fieldbus modules 2.1-3

Page 42

Products

Selection guide

Base units and expansion modules

2008-03Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2.1-2

2.1

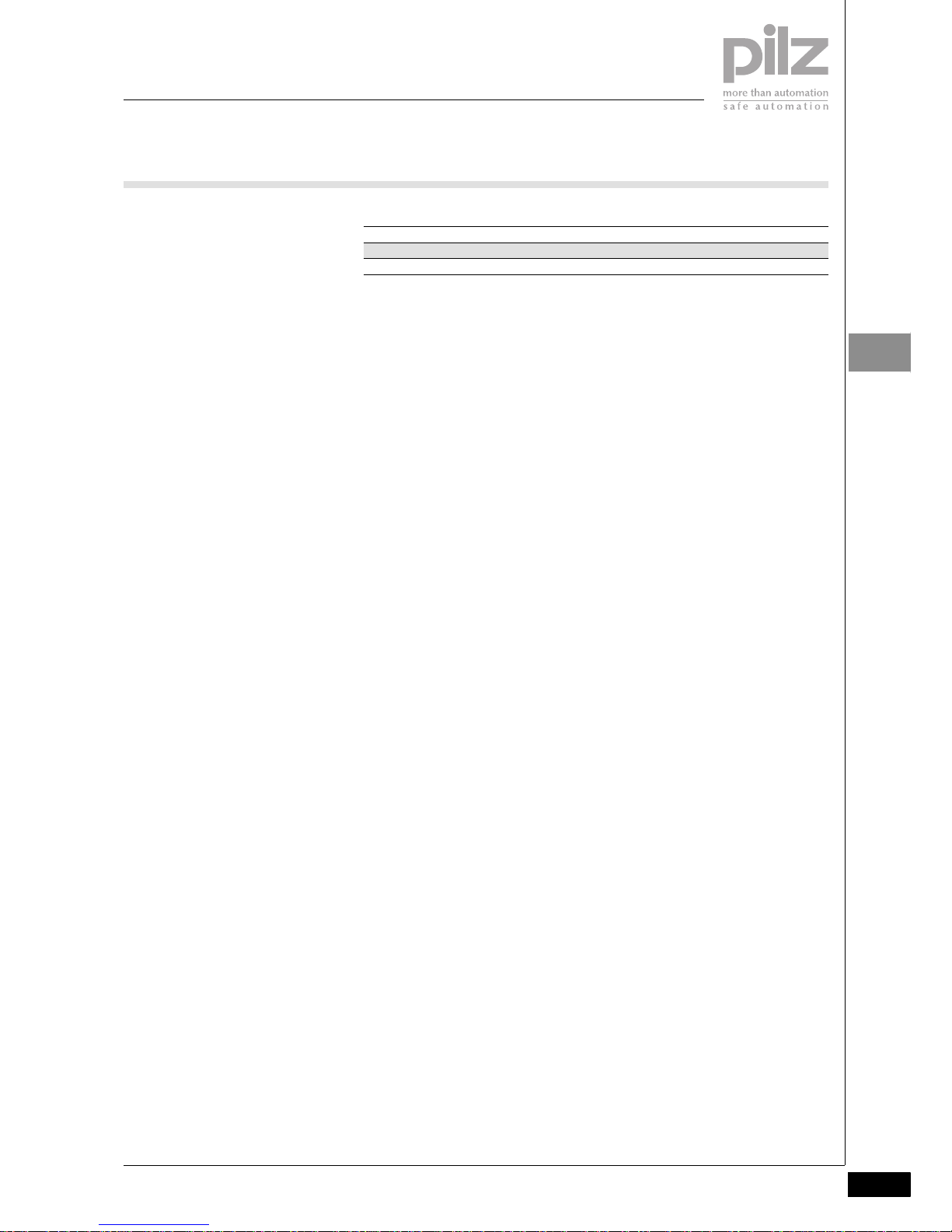

Base units and expansion modules2.12007-11ProductsSelect ion guideBase units and expansion modules

Type

Inputs

Safe

Inputs

Standard

Inputs

Virtual

Inputs

Speed

Safe

Outputs

Semiconductor

Safe

1-pole

Outputs

Semiconductor

Safe

2-pole

Outputs

Semiconductor

Standard

Outputs

Relay

Safe

Outputs

Virtual

Expansion modules

Max.

number

PNOZ m0p 20 4 1 2 1 field-

bus module

PNOZ m1p 20 4 1 2 12 + 1

fieldbus

module

PNOZ m2p 20 4 1 2 12 + 1

fieldbus

module

PNOZ ma1p 2 ana-

logue

4

PNOZ mc1p 16 8

PNOZ mi1p 8 8

PNOZ mi2p 8 8

PNOZ ml1p 32 32 4

PNOZ mo1p 4 6

PNOZ mo2p 2 6

PNOZ mo3p 2 6

PNOZ mo4p 4 6

PNOZ ms1p 2 4

PNOZ ms2p 2 4

Page 43

Products

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Selection guide

Fieldbus modules

2008-03

2.1-3

2.1

Fieldbus modules2.12007-11ProductsSelec tion guideFieldbus modules

Type

Fieldbus

Fieldbus modules

Max.

number

PNOZ mc3p PROFIBUS-DP 1

PNOZ mc4p DeviceNet 1

PNOZ mc5p Interbus 1

PNOZ mc5.1p Interbus fibre-optic cable 1

PNOZ mc6p CANopen 1

PNOZ mc7p CC-Link 1

PNOZ mc8p Ethernet IP/Modbus TCP 1

PNOZ mc9p PROFINET 1

Page 44

Products

Base units

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2.2-0

2.2

ProductsBase units2.2

Page 45

Products

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Base units

2008-03

2.2-1

2.2

Contents Page

Base units

PNOZ m0p 2.2-2

PNOZ m1p 2.2-11

PNOZ m1p coated version 2.2-20

PNOZ m2p 2.2-29

Page 46

Products

Base units

PNOZ m0p

NSG-D-2-358-2007-09Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2.2-2

2.2

PNOZ m0p2.2NSG-D-2-35 8-2007-09ProductsBase unitsPNOZ m 0pPNOZ m0p

Base units from the PNOZmulti modular safety system

Approvals

Unit features

` Can be configured in the PNOZmul-

ti Configurator

` Positive-guided relay outputs:

– 1 safety output in accordance

with EN 954-1, Cat. 4

or 2 safety outputs in accordance with EN 954-1, Cat. 2

` Semiconductor outputs:

– 2 safety outputs in accordance

with EN 954-1, Cat. 4

or 4 safety outputs in accordance with EN 954-1, Cat. 3

– 1 auxiliary output

` 4 test pulse outputs

` 1 cascading input and output; can

also be used as a standard output

` 20 inputs for connecting:

– E-STOP pushbutton

– Two-hand button

– Safety gate limit switch

– Reset button

– Light beam devices

– Scanner

– Enable switch

– PSEN

– Operating mode selector switch

– Safety mats

` Muting function

` Connectable:

– 1 fieldbus module on the left

– 4 expansion modules on the left

` LED for:

– Diagnostics

– Supply voltage

– Output circuits

– Input circuits

` Test pulse outputs used to detect

shorts across the inputs

` Monitoring of shorts between the

safety outputs

` Plug-in connection terminals (either

cage clamp terminal or screw terminal)

Unit description

The PNOZmulti modular safety system

is used for the safety-related interruption of safety circuits and is designed

for use on:

` Emergency stop equipment

` Safety circuits in accordance with

VDE 0113 Part 1 and EN 60204-1

Chip card

Chip cards are available with memories of 8 kByte and 32 kByte. For largescale projects we recommend the 32

kByte chip card (see chapter containing the order references).

Safety features

The relay conforms to the following

safety criteria:

` The circuit is redundant with built-in

self-monitoring.

` The safety function remains effec-

tive in the case of a component failure.

` The relay contacts meet the re-

quirements for safe separation

through increased insulation compared with all other circuits in the

safety system.

` The safety outputs are tested peri-

odically using a disconnection test.

PNOZ m0p

Page 47

Products

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Base units

PNOZ m0p

NSG-D-2-358-2007-09

2.2-3

2.2

Block diagram

=

Power

Input

A1 A2

Test pulse

output

I0 I19I1 I2 I3 I8I5

I11

I4 I9 I12 I13 I14 I15 I16 I17I7 I18I6

I10

O4

=

CI+ CI- CO-

CO+

T3T0

O2

O0

24 V0 V

T2T1

O1

Cascading

OA0

O3

24 V 0 V

Interface

chip card

Interface

diagnostic

module

RS 232

13 23

14 24

O5

Page 48

Products

Base units

PNOZ m0p

NSG-D-2-358-2007-09Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2.2-4

2.2

Function description

The function of the inputs and outputs

on the safety system depends on the

safety circuit created using the PNOZmulti Configurator. A chip card is used

to download the safety circuit to the

base unit. The base unit has 2 microcontrollers that monitor each other.

They evaluate the input circuits on the

base unit and expansion modules and

switch the outputs on the base unit

and expansion modules accordingly.

The online help on the PNOZmulti

Configurator contains descriptions of

the operating modes and all the functions of the PNOZmulti safety system,

plus connection examples.

Wiring

The wiring is defined in the circuit diagram in the Configurator. There you

can select the inputs that are to perform a particular safety function and

the outputs that will switch this safety

function.

Please note:

` Information given in the "Technical

details" must be followed.

` Outputs:

– O0 to O5 are safety outputs.

– O4 and O5 are relay outputs

– O0 to O3 are semiconductor out-

puts

– OA0 is an auxiliary output.

` To prevent contact welding, a fuse

should be connected before the

output contacts (see technical de-

tails).

` Use copper wire that can withstand

75 °C.

` Sufficient fuse protection must be

provided on all output contacts with

inductive loads.

` Power for the safety system and in-

put circuits must always be provid-

ed from a single power supply. The

power supply must meet the regu-

lations for extra low voltages with

safe separation.

` Two connection terminals are avail-

able for each of the supply connec-

tions 24 V and 0 V (semiconductor

outputs), plus A1 and A2 (power

supply). This means that the supply

voltage can be looped through sev-

eral connections. The current at

each terminal may not exceed 9 A.

` Test pulse outputs must exclusively

be used to test the inputs. They

must not be used to drive loads.

Do not route the test pulse lines together with actuator cables within

an unprotected multicore cable.

` Test pulse outputs are also used to

supply safety mats that trigger a

short circuit.

Where test pulses are used for the

safety mat, they may not be reused

for other purposes.

Safety mats are supported from

Version 1.2 of the base unit.

Page 49

Products

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Base units

PNOZ m0p

NSG-D-2-358-2007-09

2.2-5

2.2

Preparing for operation

` Supply voltage

Connection examples:

` Input circuit

` Reset circuit

Supply voltage AC DC

For the safety system

(connector X7)

For the semiconductor outputs

(connector X2)

Must always be present, even if the semiconductor outputs are not used

A1

+ 24 V DC

A2

0 V

24 V

+ 24 V DC

0 V

0 V

Input circuit Single-channel Dual-channel

Example:

E-STOP

without detection of shorts across contacts

Example:

E-STOP

with detection of shorts across contacts

S1

I0

L+

S1

I1

I0

L+

L+

I0

T0

S1

S1

T1

I1

T0

I0

Reset circuit Input circuit without detection of shorts

across contacts

Input circuit with detection of shorts across

contacts

Monitored reset

I5

S3

L+

I5

T0

S3

Page 50

Products

Base units

PNOZ m0p

NSG-D-2-358-2007-09Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2.2-6

2.2

` Semiconductor outputs

` Relay outputs

` Feedback loop

` Key

Redundant output

Single output

K2

L-

O0 (O2)

O1 (O3)

K1

L-

K3

L-

K4

O0 (O2)

O1 ( O3)

K1

L-

K2

Redundant

Single

O5

K1

L1

N

K2

14

13

23

24

O4

O5

K1

L1

N

K2

14

13

23

24

O4

Feedback loop Redundant output

Contacts from external contactors

K1

L+

L-

K2

O0 (O2, O4)