Page 1

hobby

4240,

4250,

F

4260

-4

Instructions

for

use

Page 2

For

please

easier

fold

understanding

or

this

the

Safety

For

The

to

with

The

according

As

of

colour

proceed

The

nected

the

The

connected

with

Cut-off

used,

mains

Only

approved

the

the

The plug

cover.

electrical

Please

on

this

of

last

page

rules

the

United

must

leads

safety

the

the

this appliance

pins.

three

in

the

wires

Blue:

Brown:

wire

letter

wire which

fuse

corresponding

page

to

colours

coding

follows:

as

which

the

to

N

to

letter

the

mains

disposed

but

leads

3Aspare

by

cover

must

Spare

suppliers

also

2.

the

or

must

observe

instruction

out

Kingdom

definitely

terminal

load

mains

following

Neutral

Live

the

of

may

of

the

is

coloured

terminal

coloured

coloured

is

the

terminal

or

coloured

L

plugs

of

be

fuses

according

ASTA

must

colour

never

covers

fuse

or

when

only

not

lead

code:

wires

in

correspond

not

terminals

blue

which

black.

brown

which

definitely

are

immediately.

replaced

must

be

marked

be

code.

be

used

are

PFAFF

the

general

the

manual

reading.

be

I

nor

are

coloured

the

your

in

must

marked

is

is

red.

completely.

used

BS

to

3

without

available

agencies.

safety

connected

plug

a

to

mains

with

plug,

be

with

must

marked

not

to

Defective

as

1362

with

or

A

fuse

from

notes

lead

the

con

be

be

and

find

the

will

You

contents

on

page

and

5

4

Page 3

from

unplug

reach

place

in

To

machine

the

before

for

or

store

drop

or

DANGER

sewing

The

1.

appliance

Always

2.

not

Do

3.

not

Do

4.

place

not

reduce

electric

sewing

a

the

should

relamping.

sewing

a

water

into

Important

United

the

For

use

you

When

ons

tions

risk

never

outlet

machine

machine

or

of

immediately

other

should

before

electric

left

be

Replace

that

always

unattended

bulb

has

where

liquid.

States

an

using

shock:

after

fallen

it

safety

and

electrical

adhered

be

this

sewing

when

using

same

with

water.

into

fall

can

instructions

only

Canada

as

to

machine.

before

rated

Unplug

pulled

basic

follows:

Always

in.

cleaning

5

Watts.

1

immediately.

into

a

appliance,

plugged

and

type

be

or

safety

Read

it.

tub

precauti

all

unplug

sink.

or

instruc

this

Do

reduce

VVARNING

allow

not

Do

1.

2.

3.

4,

5.

6.

7.

9.

10.

11.

12.

1

14.

1

16.

Please

used

Use

attachments

Never

perly,

nearest

adjustment.

Never

the

of

cloth.

Never

not

Do

not

Do

administered.

disconnect,

To

8.

Never

blocked.

Do

Keep

machine

Always

Do

3.

Do

Switch

5.

threading

as

Always

when

also

by

this

operate

it

if

authorized

operate

sewing

drop

use

operate

operate

unplug

not

fingers

use

not

pullorpush

not

the

making

observe

to

near

or

sewing

recommended

has

or

outdoors.

away

needle.

the

use

bent

sewing

unplug

To

be

children.

machine

this

been

sewing

the

machine

insert

where

turn

on

a

pulling

by

proper

or

needle,

sewing

any

the

used

sewing

dropped

dealer

any

aerosol

all

soft

from

blunt

fabric

machine

changing

other

general

the

a

as

only

by

machine

or

machine

foot control

and

object

controls

surface

on

moving

all

needle

needles.

while

machine

user

riskofburns,

Close

toy.

its

for

manufacturer

the

if

damaged,

or

service

with

into

(spray)

off

to

such

To

cord.

parts.

plate.

Use

stitching.

(“0”)

off

needle,

from

servicing

notes

safety

attention

intended

it

has

center

any

free

opening.

any

products

(“0”)

a

as

unplug,

The

needles

when

threading

the

adjustments

fire,

a

dropped

or

for

air

from

position,

bed

Special

wrong

It

may

making

electric

on

page

use

damaged

electric

necessary

Is

described

as

contained

as

cord

into

examination,

openings

accumulation

the

being

are

then

couch

or

grasp

the

is

care

can

plate

recommended

deflect

any

bobbin,

outlet

mentioned

2.

shock,

when

in

in

plug,

or

water.

repair,

blocked.

or

used

remove

the

where

plug,

not

required

cause

by

needle,

the

adjustments

changing

or

removing

when

in

injury

or

this

this

Return

electrical

Keep

of

where

plug

air

the

around

the

the

the

to

sewing

this

manual.

manual.

not

is

if

it

the

ventilation

lint,

dust,

oxygen

outlet.

from

openings

cord.

the

needle

to

manufacturer

causing

needle

in

the

presser

covers,

instruction

persons:

machine

Use

working

appliance

mechanical

or

and

is

may

sewing

break.

it

to

foot,

lubricating,

manual.

only

openings

loose

being

be

only.

break.

area,

etc.

to

is

pro

the

such

or

instructions

designed

is

and

sewing

these

machine

Keep

This

in

manufactured

safe

a

for

place

HOUSEHOLD

use

only.

Page 4

20

19

18

17

16

15

____________

PFAFF

H

10

11

—d

12

13

14

—

29

26------------

232425

Page 5

Parts

of

the

sewing

machine

hobby

Bobbin

1

Thread

2

Needle

3

Carrying

4

Bobbin

5

Bobbin

6

7

Stitch-width

Hand

8

Hand

9

Stitch-length

10

Reverse

11

Connection

1

2

On/off

3

1

Baseplate

14

5

Detachable

1

Needle

6

1

Presser

7

1

Thread

8

1

Thread

9

1

Threading

20

Take-up

21

Needle

22

Presser

23

Stitch

24

Stitch

25

Free-arm

26

Feed

27

Needle

28

Sewing

29

Thread

30

4260

winder

guide

thread

handle

pins

winder

wheel

wheel

key

switch

plate

foot

guide

guide

lever

holder

foot

pattern

pattern

dog

bar

lamp

trimmer

tension

tension

adjustment

release

adjustment

bushing

work

holder

slots

with

lifter

adjustment

chart

cover

(enclosing

disc

support

with

retaining

dial

dial

with

presser

knob

sewing

accessory

foot

screw

hook)

box

Page 6

Notes

safety

on

Notes

machines

or

28

The

1.

with

of

sewing

When

2.

maintenance

mechanical

always

the

plug.

The

3.

sewing

The

4.

be

The

5.

according

specification

6.

the

7.

8.

9.

10.

11.

on

IEC

user

the

adjusted

Do

Do

there

—

its

—

it

—

Do

socket

this

If

pose

rated,

any

To

open

inside

repair.

of

Be

parts.

safety

according

Section

335,

must

regard

needle

area

leaving

disconnect

mains

maximum

lamp

tension

machine

place

not

machine.

use

not

is

function

wet,

is

pull

not

by

appliance

than

we

damage

the

avoid

the

the

This

qualified

our

to

sure

domestic

for

exercise

the

to

and

during

the

work

parts

pulling

by

permissible

15

is

the

of

by

must

the

to

plate.

any

the

visible

is

with

e.g.

the

cord.

its

intended

not

will

caused.

risk

machine.

machine

solely

is

use

DIN

to

28.

and

up

constantly

work.

machine,

or

accessories,

or

the

out

Watts.

drive

Pfafl

a

put

be

indications

objects

sewing

damage,

disturbed,

condensation.

mains

used

is

or

accept

electric

of

There

which

the

service

only

sewing

700,

57

adequate

down

when

machine

the

wattage

belt

mechanic.

into

openings

in

machine

plug

for

is

it

if

any

are

the

responsibility

staff.

original

caution

moving

observe

during

changing

mains

must

operation

on

of

out

another

wrongly

liability

shock,

no

user

PFAFF

Section

from

for

only

the

if:

the

pur

do

parts

can

the

the

on

ope

for

not

Environment

recommended

The

temperature

80%.

sewing

This

nic-mechanical

supervised

in

such

rated

severe

dust,

electricity,

tic

chemicals

rosive

ventilation

For

used

even.

Treatment

on

Always

which

Cleaning

Housing:

clean

To

cloth

stubborn

paraffin.

Please

not

Do

ducts

cleaning

for

a

protect

night

the

which

Note!

use

such

100

C

machine

appliance;

in

use

way

a

dampness,

heat-producing

purposes

surface,

free

the

occur

housing,

free

is

use

dirt,

any

petrol

as

the

environment

40°

to

is

a

home.

the

itisnot

that

liquids.

or

the

which

machine

hitting

by

use

fluff.

of

soft

a

insecticides

(gas)

housing.

is:

Humidity

C,

high-quality

machine

is

a

it

should

It

subjected

sunlight,

direct

objects,

machine

is

both

against

dropping

or

dry,

a

remove

To

with

cloth

chemical

or

thin

or

Ambient

damage

clean

alcohol

chemicals

20%

electro

ope

be

cor

must

firm

and

any

to

for

to:

sta

be

and

it.

soft

or

pro

2

Page 7

Effective

and

modern

sewing

Congratulations!

Your

any

you.

machine

take

carefully,

it!

about

and

should

PFAFF

it!

for

reality.

a

quality

material

and

are

the

how

specialist

highest

the

benefits.

almost

for

thin

design

The

state-of-the-art

are

instructions

sewing

you

If

booklet

worth

It’s

out

find

offer

to

you

If

Your

go

So

ideas

You

which

new

technology

just

itself.

time

nothing

Because

of

all

to

have

have

And

have

sewing

and

and

easy

as

read

to

this

the

make

questions

any

is

fun

purchased

offers

machine

will

used

will

you

to

through

can

is

options

the

always

making

sew

go

the

you

through

on

find

use

only

your

most

happy

a

unique

can

this

that

your

as

the

wrong.

way

machine

of

No

—

your

product

deal

thick

machine

these

PFAFF

instruction

to

them.

problem!

help.

to

fashion

of

with

and

really

has

3

Page 8

Contents

Accessories

Accessory

Adjusting

Attaching

Bias

Blind-stitch

Bobbin

Bobbin

Bobbin

Buttonhole

Changing

Changing

Cleaning

Closed

Control

Control

Cording

Covering

Darning

Darning

Darning

Detachable

Drawing

Edge

Elastic

Elastic

stretch

binder

tape

case

thread

winding

and

overlock

panel

pedal

foot

plate

tears

guide

blind

stitch

stitches

Elastic

Electrical

control

Foot

arm

Free

Gathering

Gathering

General

Handwheel

with

Hem

Hem-stitching

Honeycomb

Knit-edge

Lace

feller

Lap

needle-position

Left

bulb

Light

buttonhole

Linen

buttonhole

Linen

Lubrication

Mounting

Multi-stitch

Needle

needles.

and

compartment

stitches

buttons

foot

tension

needle

the

presser

the

oiling

stitch

dog

feed

the

support

work

bobbin

the

up

stitch

connection

the

with

the

with

aids

sewing

release

twin

the

stitch

foot

bobbin

the

gathering

chart

foot

elastic

straight

disc

needle

with

.

.

.

thread

thread

stitch

.

.

.

gimp

attachment.

thread

4

Page 9

position

Needle

thread

Needle

Non-elastic

on

Notes

switch

On/off

overlock

Open

Overlock

Patches

Patchwork

Practical

Presser

Presser

Presser

and

Quilt

Removing

Reverse

Richelieu

Serging

Serging

Servicing

Setting

Sewing

Sewing

edging

Shell

Smocking

Special

Spring

Stabilizing

Stitch

Stitch

Stitch

Stitch

Straight

Stretch

Stretch

Thread

Threading

Threading

Topstitching

Trouble

Trouble

needle

Twin

Unlocking

Utility

Zigzag

stitches

safety

stitches

quilt

sewing

feet

feet

foot

patchwork

the

sewing

with

with

and

the

lamp

zippers

on

accessory

stitch

chart

density

length

width

stitch

triple

triple

trimmer

the

the

shooting

shooting

stitch

stitch

tension

stitch

(special

(standard

lifter

needle

blind

the

zigzag

the

trouble

utility

adjustment

adjustment

straight

zigzag

machine

needle

hook

the

chart

accessories)

accessories)

foot

plate

stitch

stitch

shooting

stitches

chart

stitch

stitch

thread

button

button

foot

29

20,

39

1

10

34

34

42

51

27

55

54

58

18

63

22

50

29,

29

61

24

63

44,

48

39

46

28

48

—

34

30,

64

—

45

55

35

8

—

6

22

23

23

29

32

32

18

17

16

28

64

64

38

23,

62

8

—

6

29

5

Page 10

hobby

A

C

FE

these

For

stitch-length

the

Program

B/AC/D

E

F

G

H

I

K

L

flfl

JI

till

Ill!

fl

jflj

Iii

E

F

G

H

I

K

L

4260

I

I

I

programs

Name

Buttonhole

Straight

Zigzag

Elasticstitch

Elastic

Decorativ

Greek

Shell-edging

Stretch

straight

Stretch

zigzag

-

,,

..

“S

“-

V

.-—

‘-..

the

adjustment

stitch

stitch

blind

stitch

triple

stitch

triple

stitch

Honeycomb

Florentine

stitch

Spring

Closed

overlock

Open

overlock

Stitch

—

stitch

stitch

elastic

stitch

stitch

stitch

stitch

stitch

length

button

stitch

chart

(_

N

\

can

(10).

_j

_....

set

be

Application

Standard

For

For

For

and

For

simultaneous

For

layers

A

towels

For

e.

—

anywhere

straight

all

serging

stitching

patches

invisible

overstitching

classical

decorative

linen

g.

stretch

For

and

sport

attaching

For

elastic

sewing

For

towelling

decorative

A

overstitching

For

for

Also

closing

A

materials

closing

A

non-fraying

II)

Ill

III

III

between

buttonhole

stitch

and

on

hem

serging

decorative

seams,

workwear

materials

on

and

stretch

and

and

materials

///

-

.‘,,-

//7

-*..

appliqué

elastic

attachment

two

hems

elastic

elastic

decorative

for

stretch

two

fabrics.

serging

serging

/\/

\/\

i\i

\/\

/\/

\i\

0

for

and

band,

touching

stitch

on

g.

e.

tape

threads,

stitch

touching

-W

‘,,\\

‘

—i,

-‘

“‘\

and

blouses

e.g.

lockstitch

e.g.

fine

crotch

on

seam

seam

‘Si

“,

mm

4

work

darning

and

fabric

for

materials,

seams

overlocking

seams

hem

fabric

fraying

for

stronger,

for

I’

/

l

with

and

tears

borders

on

I—,j

--

i

-

the

bed

up

layers.

to

and

aid

linen

4

.,

of

mm

6

Page 11

hobby

118

U

A

=

C

[

these

For

stitch-length

the

Program

8/AC/D

E

F

G

H

I

K

L

E

liii

fill

fill

fill

4250

EFG

I

G+D<>

programs

Name

Buttonhole

Straight

needle

Straight

needle

Zigzag

Elastic

Elastic

Greekstitch

Shell-edging

Stretch-3fach-Geradstich

Nadelposition

F

G

Stretch

needle

Stretch

zigzag

H

Honeycomb

Stitch

—

,‘

—

stitch

the

adjustment

stitch

position

stitch,

position

stitch

stitch

blind

triple

position

triple

stitch

H

..-

-..

middle

stitch

stitch

straight

stitch

length

button

left

mitte

left

chart

I

can

(10).

stitch

K

—

._.—

set

be

Application

Standard

For

work

For

requiring

For

For

and

For

simultaneous

A

towels

For

e.

For

sport

For

position

For

elastic

For

towelling

E

L

ilflflUflflilflilflO

“

III

I

buttonhole

4

to

sewing

a

workwear

and

materials

between

stitch

mm

and

needle

left

and

on

hem

serging

decorative

seams,

seams

elastic

on

and

anywhere

straight

all

up

all

serging

stitching

patches

invisible

classical

decorative

linen

g.

stretch

stretch

attaching

sewing

F

III

I

for

topstitch

appliqué

elastic

attachment

hems

e.

requiring

elastic

decorative

for

G

,-

‘*

-“/

‘.

0

and

position

band,

stitch

on

g.

tape

threads,

H

,v

/\/

and

blouses

e.

g.

lockstitch

work

e.

fine

crotch

on

..

%

mm

4

darning

and

for

g.

materials,

seams

needle

left

a

overlocking

seams

hem

I

with

and

tears

borders

on

K

_—

‘—

i—.

the

bed

aid

linen

and

L

flu

%.

ii

of

decorative

I

fill

fiji

flil

Florentine

Closed

K

L

overlock

Open

overlock

stitch

stitch

stitch

A

closing

A

materials

closing

A

non-fraying

and

and

materials

stretch

serging

serging

stitch

seam

seam

for

for

fraying

stronger,

7

Page 12

hobby

4240

E

Stitch

-

F,G

chart

H

I

E

F,G

H

It

[I

these

For

stitch-length

the

Program

B/AC/D

E

F,

G

H

I

E

flfl

F,

1W

H

I

Ifil

A

C

I

programs

G

I

adjustment

Name

Buttonhole

Straight

Zigzag

various

in

Elastic

Elastic

Stretch

straight

Stretch

zigzag

various

in

Honeycomb

Florentine

the

stitch

stitch

stitch

blind

triple

stitch

triple

stitch

/

\N

/

\

/

\

stitch

widths

stitch

widths

stitch

stitch

.—

.z

N

—

N

button

length

,

,-“

-,.

(10).

can

set

be

Application

Standard

all

For

to

up

serging

For

stitching

For

darning

invisible

For

simultaneous

For

sport

For

elastic

For

overlocking

decorative

decorative

A

anywhere

buttonhole

straight

mm

4

tears

stretch

and

attaching

materials

sewing

HI

UI

NI

between

stitch

appliqué

and

elastic

on

and

hem

serging

seams,

workwear

elastic

elastic

on

towelling

seams

hem

stretch

\\\‘

///

‘

///

\\\

0

e.

for

and

band,

patches

attachment

crotch

e.

g.

tape

threads,

and

stitch

‘*.

.

4

and

blouses

g.

lockstitch

and

seams

on

for

mm

\/\

\/\

/\/

\,\

work

with

and

on

the

bed

aid

linen

of

8

Page 13

4

Operating

PFAFF

the

ir

machine

Electrical

Detachable

arm

Free

Bobbin

Bobbin

Bobbin

Threading

Drawing

Presser

Thread

Changing

Needle

Covering

Control

Reverse

Stitch

Stitch

Setting

Setting

winding

case

thread

foot

trimmer

thread

length

width

connection

work

tension

needle

the

the

up

lifter

needle

the

tension

feed

the

panel

sewing

adjustment

adjustment

utility

the

stretch

the

support

bobbin

dog

stitches

stitches

thread

thread

button

button

Page

Page

Page

Pages

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

Page

10

11

11

12,

14

15

16,17

18

18

18

19

20

20

21

21

22

23

24

25

13

9

Page 14

case

Carry

carry

The

equipment,

dust

from

case,

protects

and

which

damage

is

your

part

sewing

during

the

of

machine

transport.

basic

Carrying

can

This

round

handle

be

groove

raised

in

the

lightly

by

carrying

pressing

handle

the

(4).

Electrical

Connect

nection

the

and

regulated

appliance

This

intended

fit,

not

this

For

10

connection

the

bushing

electrical

by

fit

to

contact

sewing

plug

pressing

has

polarized

in

a

qulified

a

machine

the

of

(12)

socket.

polarized

a

foot

the

on

The

foot

the

plug

outlet

electrican

model

pedal

sewing

sewing

(one

only

to

4240,

pedal.

one

install

4250,

to

machine

blade

way.

the

speed

wider

If

the

4280

V

con

is

the

than

does

plug

the

outlet.

proper

foot

On/off

sewing

The

switch

ready

other(.

not

Do

controller

switch

(13)

sew.

to

To

fully

fit

not

type

lamp

turned

is

reduce

the

in

modify

YC-482-3

lights

the

outlet,

the

risk

plug

on.

of

reverse

has

up

The

electric

any

in

to

when

the

way.

be

the

machine

shock,

plug.

used.

1

on/off

If

this

it

is

still

now

plug

is

does

Page 15

Accessory

the

Open

Organizing

the

Lay

sory

compartment

detachable

the

enclosed

compartment.

work

L

accessories

accessories

support

into

(15).

the

acces

Detachable

both

Using

support

Removing

arm

free

order

In

must

you

the

to

When

work

flush

machine.

work

hands,

to

(15)

to

swing

and

left

removing

support,

with

the

be

the

the

able

support

swing

left.

detachable

sew

to

detachable

the

out

it

lift

inserting

and

careful

be

arm

free

the

of

to

of

detachable

work

the

with

work

hole.

the

the

ensure

sewing

the

work

support!

arm,

free

support

detachable

that

is

it

11

Page 16

I

7

Preparing

the

Hold

wheel

stops

This

machine

the

handwheel

release

the

is

machine

disc

needle

winding

(9)

the

<8)

for

and

to

from

bobbin.

the

bobbin

press

“bobbin”

moving

-

winding

the

while

4

I

handsymbol.

the

11

far

far

off

the

winding

as

as

It

is

it

the

the

empty

possible.

will

it

only

is

positioned

Mounting

Switch

Place

bobbin

as

as

Note:

when

possible.

12

bobbin

on/off

bobbin

mechanism

Pull

go.

possible

switch

onto

the

to

far

as

(13)

the

and

bobbin

wind

the

to

I

pin

press

to

the

right

the

of

it

the

bobbin

as

down

right

Page 17

—4

I

I

bobbin

and

the

it.

the

the

tight.

the

go

soon

procedure

bobbin

cut

the

spool

thread

tension

thread

Turn

foot

the

of

as

the

holder

pedal.

thread

the

the

to

thread.

(5)

clockwise

and

(1)

is

passed

the

on/off

bobbin

stops

left,

and

up

into

to

it

run

through

switch

few

a

after

the

full

is

automatically.

remove

place

bobbin

the

bobbin.

the

hole

a

(13)

revolutions.

bobbin

Press

from

it

a

the

spool

on

and

and

win

the

pin

Winding

Pull

on

Place

winder

There

held

press

Let

As

ding

full

‘p

Don’t

Press

the

towards

(8)

Bobbin

The

thread

crosses

forget:

handwheel

the

“sewing”

winder

thread

tension

over

symbol

you

passed

is

itself

until

tension

(1)

in

on

release

and

it

a

turn

clicks

through

clockwise

way

the

disc

the

into

the

to

back

(9)

handwheel

place.

bobbin

direction

bobbin.

the

to

and

13

Page 18

_

Hook

Switch

Hold

towards

it

cover

the

off

side

on/off

you.

a

case

bobbin

the

case.

bobbin.

the

bobbin

Release

case

cover

the

cover

and

and

pull

out

remove

the

Removing

open

Raise

bobbin

the

(13)

switch

and

(26)

cover

hook

the

of

ensure

To

adjusted

interlacing

and

holes

14

perfect

each

to

should

darning.

sewing

other

be

and

visible

a

and

the

underneath

durable

threads

seam,

must

the

the

be

bottom

and

top

interlaced

ply

when

bottom

between

sewing

thread-tensions

the

fabric

two

decorative

must

plies.

seams,

be

The

button

well

Page 19

nserting

Insert

doing

then

opening

the

Checking

Hold

case

bobbin

during

Adjusting

Using

turn

thread

Turn

the

the

so,

under

the

and

setting

bobbin

the

bobbin

pull

the

thread

pull

case

this

the

tension

setting

bobbin

into

thread

the

tension

arrow).

(see

bobbin

the

protruding

the

must

movement.

setting:

the

screwdriver

screw

becomes

screw

thread

the

thread

drop

C

C

tension

bobbin

through

plate

thread

down

from

the

to

just

until

B

tension

from

upwards

the

the

left

weaker

little

a

becomes

In

case

slit

the

lies

it

bobbin

the

sharply.

thread

accessories,

bobbin

—

the

the

to

stronger.

A,

in

right

The

—

Inserting

Open

hook

the

finger

case

Check:

the

Pull

case

cover

must

the

D

pin

F

bobbin

not

bobbin

and

as

E

must

thread

fall

slide

far

point

out

case

the

as

sharply.

of

it

into

will

the

bobbin

go.

cutout

The

hook.

case

The

onto

bobbin

G.

bobbin

15

Page 20

2

I

I

I

I

Threading

Switch

the

Pull

thread.

handwheel

the

needle

the

black

The

you

show

Using

to

back

it

pass

slot

ding

upwards

back

to

up

threaded

left.

to

it

lay

guide

the

the

off

spool

the

Raise

are

arrows

the

hands,

both

front

the

downwards

(20).

take

the

through

pass

Now

the

from

and

(19)

needle

on/off

holder

presser

until

their

at

correct

Pass

through

up

right

thread

on

pull

into

through

lever

the

the

(5)

the

the

the

hand

thread

switch

up

take

highest

sewing

path

the

the

thread

the

(21).

take

thread

guide

and

foot

up

for

thread

thread

the

left

up

side

(13).

mount

(23).

lifter

lever

point.

machine

thread.

the

from

guide

right

around

threading

thread

The

from

lever

downwards

behind

(18).

the

(21)

(2)

threa

lug

thread

Turn

and

the

and

(B)

slot

is

right

and

16

Page 21

Threading

Thread

needle

the

the

the

needle

from

needle

thread

the

front

through

the

to

the

back.

eye

of

17

Page 22

I

Presser

The

the

presser

presser

toot

foot

foot

lifter

is

lifter

raised

(23).

and

lowered

I’

I

with

Drawing

Raise

and

needle

bobbin

needle

4

turn

the

returns

thread

thread

up

presser

the

bobbin

the

foot.

handwheel

its

to

formed

has

draw

to

/30

thread

Hold

towards

highest

up

the

position

loop.

a

the

needle

you

Pull

bobbin

-

thread

until

and

the

thread.

the

the

Bobbin

Close

under

18

the

the

thread

hook

presser

cover

foot

(26)

to

the

and

left.

pass

the

thread

Thread

Pull

mer

the

(30).

trimmer

thread

forwards

over

the

thread

trim

Page 23

Disengaging

off

Switch

the

Raise

front

the

presser

the

foot

presser

the

needle

of

the

foot

the

on/off

presser

holder

presser

to

down

its

(17).

foot

switch

highest

foot

until

up

it

clicks

(13).

position.

and

the

out

Press

rear

of

the

of

Engaging

the

Lay

holder

foot

into

click

presser

the

presser

(17)

the

foot

presser

foot

presser

lifter

so

that

(23)

foot

underneath

pins

the

holder

foot

lowered.

is

the

of

when

presser

the

foot

the

Check:

Please

place

in

ensure

by

that

raising

the

the

presser

presser

foot

foot

correctly

is

lifter.

19

Page 24

Changing

Switch

Removal:

retaining

Insertion:

the

insert

retaining

off

screw

screw

the

the

Lower

The

needle

needle

on/off

the

(22)

flat

by

(22).

presser

and

side

pushing

switch

remove

of

the

(13).

foot

needle

upwards

it

the

and

raise

needle

must

A

as

far

the

by

be

needle

pulling

facing

possible.

as

highest

its

to

downwards.

it

rear.

the

Hold

Lower

the

_A

position.

the

needle

Loosen

presser

and

foot

tighten

the

needle

and

the

Adjusting

the

Turn

setting.

red

normal

The

5

and

3

and

20

and

(see

the

needle

setting

for

page

needle

thread

sewing

28).

V

thread

tension

sewing

for

buttonholes

tension

(3)

between

is

the

to

between

desi

4

certain

buttons,

with

fed. Place

dog

must

plate

the

(27).

sewing

the

darning

The

facing

be

procedures

feed

the

narrow

dog

plate

darning

the

(27)

to

half

front.

such

must

stop

plate

sewing

as

cove

be

fabric

the

the

over

darning

the

of

Darning

For

on

red

being

2

feed

plate

Page 25

Control

left

The

With

spacing

Only

With

the

on

provided

panel

adjustment

lower

the

and

model

on

upper

the

straight

for

right

the

sewing

stretch

4260:

right

stitch

button

adjustment

stitches.

adjustment

you

E

with

the

(24)

can

with

twin

button

button

alter

needle.

the

the

letters

(10)

(7)

needle

you

you

for

is

can

can

position.

selecting

adjust

the

vary

various

the

stitch

the

zigzag

Furthermore,

length,

width

limited

a

stitches.

the

from

buttonhole

5

to

0

area

is

mm

and

also

Page 26

I

Reverse

machine

The

reverse

the

‘

sewing

sewing

sews

in

key

I

reverse

(11)

only

pressed.

is

adjustment

stitch

turning

by

the

to

button

length

required

infinitely

the

button

point

length.

(10)

bet

mar

adjustment

length

Stitch

length

stitch

the

With

as

long

as

you

ween

king

can

0

on

adjust

and

the

the

mm

4

button

“Buttonhole”

“buttonhole”

The

the

9,

the

further

stitch

Between

the

optimum

les.

ser

stitch

symbol

numbers

symbol.

density

you

becomes.

turn

4

sew

the

you

button

symbol

stretch

must

(10)

stitches

the

turn

clockwise

on

stitch

to

the

the

black

length

symbol

back

adjust

“Stretch”

den

To

ground

ment

“stretch”.

0

This

sewing

for

dial

the

area

to

the

is

buttonho

the

0,

find

can

you

1

and

Page 27

6ACO

ji

EFG*,(L

button

the

button.

needle

you

1

wish

needle,

mm.

2

point

E

you

for

will

Turn

4d

(7)

to

the

you

marking

vary

can

find

sew

the

can

infinitely

the

on

needle

the

point

width

a

symbol.

Note:

be

not

straight

adjust

button

marking

which

For

wider

stitch

to

position

on

zigzag

than

the

the

from

the

underneath

is

sewing,

2

more

not

of

width

required

“middle”

adjustment

the

and

mm

than

the

width.

the

twin

when

3.5

zigzag

to

button

“twin

needle

mm.

needle”

sewing

cc’

1

adjustment

mm

the

adjustment

the

symbol

4260)

use

widths

needle”.

with

not

button

turning

by

straight

the

stitches!

0

the

exceed

twin

and

twin

If

stitch

you

Stitch

(only

With

stitch

When

,,right”

“Twin

(only

Important:

straight

Above

the

the

stitch

width

on

the

from

sewing

by

symbol

zigzag

model

stitch

0

turning

needle”

model

on

and

the

width

adjustment

4260)

length

5

to

with

Only

zigzag

stitch

“twin

stitch

must

(7)

to

must

the

23

Page 28

Setting

stitch

All

(25).

dial

Using

so

utility

patterns

that

the

the

stitches

that

stitch

required

you

pattern

letter

sew

can

adjustment

is

with

directly

machine

your

button

underneath

(24)

the

you

are

set

point

3

c,

illustrated

the

marking.

2

in

desired

0

I

chart

pattern

stitch

the

stitch

by

turning

the

24

Page 29

I-—-

cc

Adjusting

the

of

All

fabrics.

desired

the

stitches

Turn

stitch

stretch

the

with

on

stitch

the

stitches

the

length

stitch

black

background

adjustment

pattern

are

button

adjustment

stretch

(10)

button

stitches,

the

to

(24).

i.e.

“stretch”

they

are

symbol

suitable

and

for

select

stretch

the

25

Page 30

Page 31

Utility

General

Non-elastic

Elastic

Sewing

Overlock

Buttonhole

Hem

Smocking

stitches

with

Gathering

Darning

Sewing

Stabilizing

Sewing

edging

Shell

stitches

sewing

stitches

buttons

on

stitches

the

zippers

on

edges

lace

aids

twin

and

needle

practical

sewing

Page

Page

Pages

Page

Page

Pages

Page

Page

Pages

Pages

Pages

Page

Page

Page

28

29

31

34

38

39

46

30,

36,

40,

42,

44,

47

48

32,

37

41

43

45

33,

35

27

Page 32

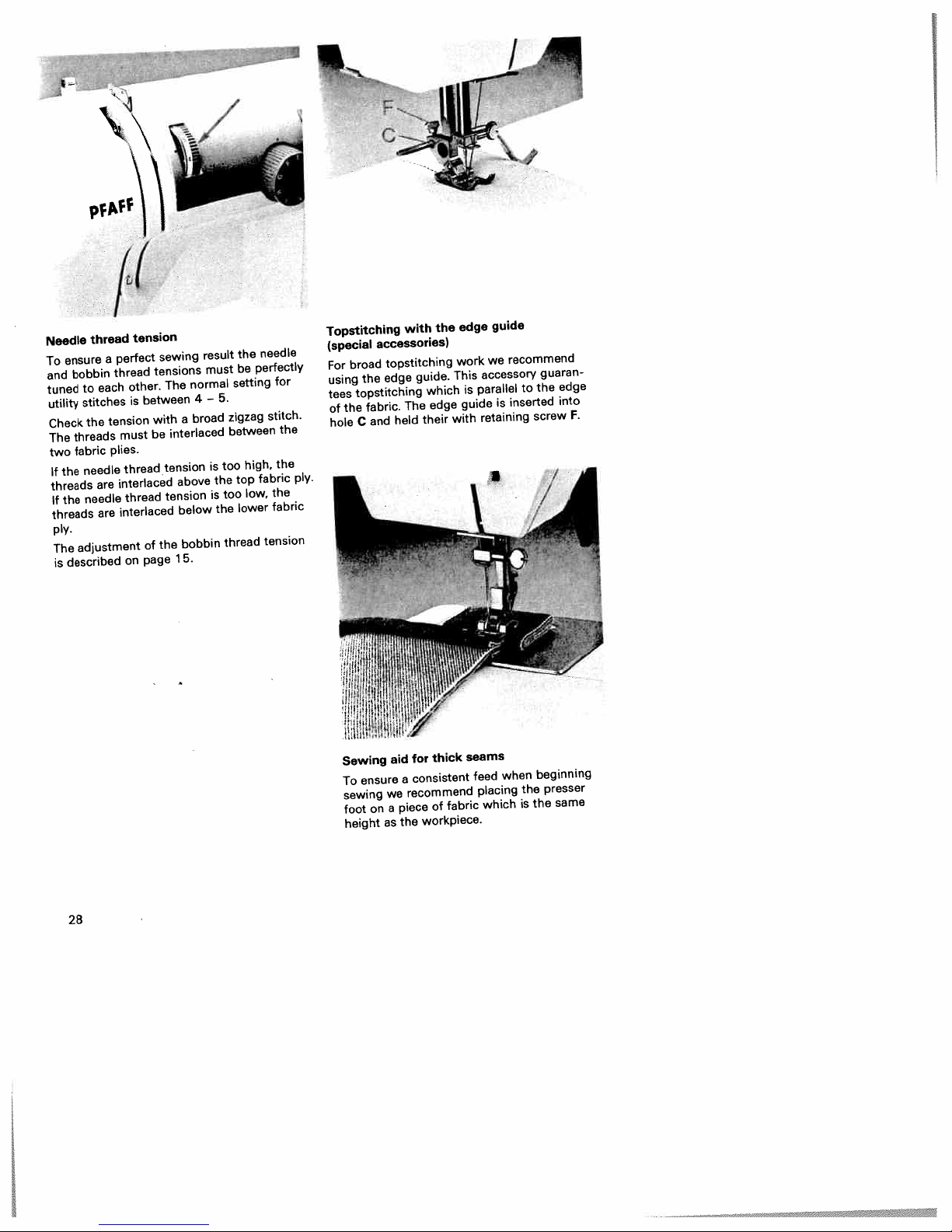

Needle

ensure

To

and

tuned

utility

Check

The

two

the

If

threads

If

the

threads

ply.

The

described

is

\\\

thread

bobbin

each

to

stitches

the

threads

fabric

needle

are

needle

are

adjustment

/1

tension

perfect

a

thread

other.

is

tension

must

plies.

thread

interlaced

thread

interlaced

on

V

sewing

tensions

The

between

with

interlaced

be

tension

tension

the

of

page

normal

a

above

below

bobbin

5.

1

result

must

—

4

broad

5.

is

the

is

the

the

be

setting

zigzag

between

too

top

too

lower

thread

needle

perfectly

high,

fabric

low,

tension

for

stitch.

the

the

the

fabric

I

ply.

Topstitching

(special

broad

For

the

using

topstitching

tees

fabric.

the

of

and

C

hole

r

with

accessories)

topstitching

guide.

edge

The

held

the

which

edge

their

edge

work

This

guide

with

accessory

parallel

is

retaining

guide

recommend

we

inserted

is

to

guaran

the

screw

edge

into

F.

seams

thick

for

ensure

sewing

foot

height

on

aid

a

we

piece

a

the

as

consistent

recommend

fabric

of

workpiece.

feed

placing

which

when

beginning

the

the

is

presser

same

Sewing

To

28

Page 33

Straight

Program

needle

lengthened

be

Basic

“left’s

Some

more

Eg.

per.

Model

Select

—

width

Model

Select

—

Please

position

Blind

for

the

the

good,

The

B.

screw

stitch

the

is

E

position

straight

models

(only

sewing

by

easily

topstitching

4260:

straight

adjustment

4250:

stitch

ensure

when

stitch

serging

thread

fabric

smooth

trimmed

can

You

A.

basic

middle.

to

up

stitch

processes

altering

a

stitch

F.

that

adjusting

foot

difficult

passes

edge

seam.

edge

adjust

4

4260

collar

button

the

no.

from

straight

The

mm.

with

cah

the

or

and

E

needle

its

is

3

materials.

bar

over

rolling

must

stop

the

stitch

stitch

needle

4250)

and

carried

be

needle

sewing

set

to

(7)

at

is

setting.

particularly

While

thus

C

up.

guided

be

with

with

length

position

position.

a

on

stitch

the

“0”.

its

preventing

This

retaining

the

can

out

zip

highest

suitable

sewing,

ensures

along

stop

Zigzag

Model

Select

—

ment

ween

Model

—

Model

—

a

stitch

4260:

button

0

Select

Select

careful

Be

fabric

between

fabric

stitch

and

4250:

stitch

4240:

stitch

edges

when

With

F.

you

(7)

mm.

5

G.

F

(2

ensure

to

the

entering

overstitching.

the

can

mm)

that

needle

the

stitch

the

vary

G

or

when

perforations

fabric

(4

and

width

width

mm).

serging

next

adjust

bet

the

alternate

the

to

29

Page 34

Elastic

elastic

The

invisible

for

necessary.

ger

stretch

hem

The

an

i.e.

necessary.

On

—

hem

Fold

—

Now

—

hem

Now

—

foot

red

The

—

when

blind

blind

hems;

non-stretch

and

sewn

is

extra

materials

edge

hem

the

the

lay

edge

the

lay

that

so

guide.

needle

entering

stitch

stitch

is

It

and

serging

which

separately.

width

hem

protrudes

fabric

the

must

sewing

equally

serged

of

back

underneath

crease

catch

the

especially

is

by

suitable

fabrics.

fabric

the

strongly,

fray

inwards.

outwards

about

by

line

only

fabric

suitable

hand

simultaneously,

edge

for

both

is

lon

no

is

serge

that

so

cm.

1

presser

the

along

runs

texture

one

crease

the

in

not

the

the

line.

the

yarn

4260:

4250/40:

stitch

stitch

H

I

30

Page 35

Sewing

sewing

For

removed

be

with

red

Select

—

stitch

4;

Turn

—

the

enters

Now

—

the

Now

—

that

hole

Knot

—

on

model

the

button

button

the

buttons

on

and

darning

the

the

stitch

F.

4250

handwheel

the

lower

sew

needle

the

in

the

buttons,

mm

4

in

right

the

off

on

button.

thread

the

width

and

such

presser

the

the

feed

plate.

zigzag

a

hole

blade.

button.

also

ends

presser

the

dog

stitch

adjustment

4240:

towards

that

way

the

in

foot

Take

enters

the

on

must

(model

stitch

you

the

button.

lifter;

the

reverse

care

right

foot

be

button

G)

and

needle

this

to

must

cove

4260:

move

hand

side.

at

holds

ensure

Sewing

Insert

—

Place

—

ton

column

—

—

on

the

match

a

and

Remove

button

the

Wrap

knot

buttons

presser

sew

this

on

the

the

it.

between

described

as

page.

match

apart.

shank

with

foot.

with

and

a

the

the

button

holes

the

in

111)

pull

sewing

the

shank

in

left

fabric

the

hand

thread

but

and

and

31

Page 36

Stitch

Stretch

With

high

seams.

E

this

level

stretch

triple

program,

of

straight

durability

all

stitch

seams

are

which

sewn:

e.g.

require

crotch

a

4260/4240:

Stitch

4250:

Stretch

stretch

The

decorative

T-shirts

for

Serge

—

Fold

—

Topstitch

—

triple

the

over

Stitch

triple

seam

and

fabric

the

the

stretch

G

zigzag

zigzag

which

underwear.

desired

hem

F

edge.

stretch

is

is

hem

from

elastic

very

a

particularly

width.

face

the

and

suitable

side.

32

Page 37

Stitch

4260:

4250/4240:

Elastic

Because

for

used

underwear.

off

Cut

—

fabric

Gather

—

straight

Slide

—

band

Sew

—

ends

and

On

—

sewn

red

Stitch

stitch

its

of

sewing

the

edge.

the

stitch

workpiece

the

lay

or

on

it

the

of

overstitch

skirts

onto

above,

as

G

high

on

old

fabric

it

using

elastic

and

the

4(1

H

elasticity,

elastic

elastic

with

page

(c.f.

between

underneath

elastic

the

band

the

with

trousers,

which

edge

the

using

/\JfSJV

band.

band

the

40).

to

elastic

the

elastic

I

this

close

mm

4

and

it

stitch.

overlap

elastic

has

stitch

e.g.

the

on

to

long

elastic

pin

Allow

stitch.

been

stitch.

the

a

tape

/

is

it

little

prepa

.f

down.

the

is

Stitch

4260:

4250/4240:

Honeycomb

honeycomb

The

hem

rative

on

hems

Fold

—

which

underwear

hem

the

E

Stitch

stitch

H

stitch

particularly

is

over

is

and

double

elastic

an

T-shirts.

and

and

suitable

overstitch

deco

for

it.

33

Page 38

is

What

elastic

For

models

which

ches

simultaneously.

serge

normal

than

to

fast

We

Tip:

when

3

no.

particularly

even

ring

overlock

an

and

4250

sew

sew.

recommend

sewing

well

on

knitted

and

two

seams,

broad

4260

and

stitch?

materials,

offer

fabric

They

durable

very

using

overlock

prevents

seams.

overlock

layers

are

blind

seams.

more

the

N

N

N

N

N

N

N

N

N

N

N

N

N

hobby

the

together

and

stitch

It

seam

stit

elastic

easy

foot

guides

pucke-

and

and

Stitch

(only

Closed

With

perfectly.

and

Tip:

while

K

models

overlock

this

knit

Ensure

it

stretch

stitch

You

collars.

being

is

that

4250

can

stitch

you

the

sewn.

also

and

can

sleeve

4260)

sew

sew

jersey

on

cuff

sleeve

is

quality

cuffs

stretched

Stitch

(only

Open

With

which

ther

Tip:

hand

it.

I.

on

overlock

this

perfectly.

Ensure

stitch

34

stretch

models

do

stitch,

not

that

just

fray

4250

stitch

thicker

strongly

the

next

and

materials

needle

the

to

4260)

can

sews

material

fabrics

and

toge

sewn

be

right

the

and

not

in

Page 39

0(1)

<C)

0

<GD

C

0)

o.

GD

-.

:7

<

ZGD

.

GD

0

p4

3

GD

:3.

GD

0

DI

:3

a.

GIG

GD

0

0

GD

C)

0•

GD

GD

:3-

ci

(0

-.,

o

GD

GO

—

GO

0cD

0

0(

—

EcD

o

cDc

U,

GD

—

00

C)

-0

0

3

ct,

U’

Page 40

Buttonholes

buttonholes

Sewing

models

hobby

be

to

have

even

es

(special

foot

Generally,

doubled

additionally

organza

the

that

sewn.

Avalon

purpose.

this

dissolves

which

and

velvet

it

poorly

fabric.

the

ciently

easier

much

Embroidery

good

larly

Using

points

ting

test

a

because

rotated.

we

easier

accessories).

buttonholes

fabric.

line

viscose

and

does

fabric

Madeira)

(from

This

thick

be

can

The

the

by

to

and

for

magic

a

of

buttonhole

is

To

recommend

However,

some

with

not

a

is

water.

in

wool

used

material

machine

sew.

darning

sewing

marker

buttonholes

the

first.

easy

very

fabric

the

make

sewn

are

is

it

materials

backing

gather

also

is

special

On

fabrics

either

thus

is

and

threads

attractive

pin,

or

with

does

buttonho

sewing

buttonhole

the

into

necessary

such

paper

when

good

very

of

type

materials

which

underneath

or

on

fed

buttonholes

are

seams.

mark

and

all

not

lined,

as

being

fleece

feed

more

particu

the

always

of

to

silk,

so

for

such

are

star

the

as

effi

sew

Note:

every

Before

of

runner

forwards

sories)

is

arrow

0.5

are

determining

36

the

at

cm

buttonhole

buttonhole

first

the

apart.

the

far

as

They

length

red

as

give

of

you

foot

line.

it

must

will

The

you

the

slide

(special

i.e.

go.

red

yardstick

a

buttonhole.

the

acces

the

markings

red

for

Page 41

Program

Stitch

Sewing

foot

Linen

Insert

—

forwards

Position

—

and

desired

Then,

—

ches

fabric

Then

—

buttonhole

the

in

Then

—

stitches

Model

Knot

—

Model

Adjust

—

Model

—

—

—

B/AC/D

length

buttonholes

buttonhole

the

sew

length.

with

for

while

select

same

set

4240:

the

4250:

needle

stitches.

4260:

Adjust

select

stitch

a

Sew

open

Cut

of

pair

wIiIEiT

symbol

buttonhole

far

as

pattern

the

first

the

setting

the

bartack.

the

doing

the

seam

length.

again

AC

while

thread

the

to

position)

setting

the

left

the

adjustment

width

tying

few

the

scissors

“buttonhole’s

with

foot

will

it

as

adjustment

buttonhole

You

this.

letter

the

in

and

holding

ends

straight

and

to

needle

off

buttonhole

a

or

zhe

and

go.

AC.

have

and

0

reverse

sew

the

on

stitch

sew

straight

position

stitches.

slitting

buttonhole

slide

seam

sew

to

sew

direction

few

a

fabric.

reverse

the

setting

few

a

(7)

dial

with

knife.

dial

few

a

the

tying

stitch

by

the

the

at

in

hold

bartack

turning

to

aid

foot

B

the

stit

the

second

and

side.

(left

F

off

and

E

0.

of

Linen

To

sportswear,

thread.

On

cularly

from

—

—

the

a

A

I

sew

elastic

Lay

sion

neath

Clamp

protrusion

Slide

—

as

described

Pull

—

buttonhole

Sewing

presser

Linen

Mark

—

buttonholes

Proceed

—

“Sewing

foot”.

When

—

do

buttonhole

especially

we

materials

important

stretching.

gimp

the

and

A

presser

the

the

buttonhole

the

possible

loop

the

buttonholes

foot

buttonholes

the

sewing

sew

not

point.

with

durable

recommend

the

prevent

to

thread

the

pass

foot

threads

B.

sew

and

left

the

in

the

of

cut

and

0

beginning

the

on

described

as

buttonholes

the

further

gimp

buttonholes,

gimp

over

thread

towards

the

to

runner

the

hand

gimp

the

with

and

fabric.

with

second

than

thread

using

thread

buttonhole

the

rear

the

ends

and

left

as

buttonhole

column.

thread

threads.

the

end

the

in

the

buttonhole

the

e.g.

gimp

a

parti

is

protru

under

front.

the

right

forwards

far

as

into

standard

points

section

buttonhole

beginning

B

the

of

on

of

the

seam.

37

Page 42

with

Hem

Topstitching

and

normal

needle.

Professional

shorts

cycling

the

with

various

in

lable

jersey

the

use

twin

The

when

cm

zigzag

the

needle

avoid

First

—

the

for

Then

—

Finally

—

seam.

the

On

Tip:

it

wear

topstitching

the

stretch

hems

twin

needle

sewing

stitch

over

iron

hem.

topstitch

cut

difficult

advisable

is

twin

work

on

be

can

needle.

widths.

needle

must

with

not

breakages.

the

the

protruding

the

materials

it.

needle

be

can

Materials

T-shirts,

sewn

The

Please

for

not

the

more

width

hem

to

twin

stretch

be

baste

carried

with

knitwear

quickly

needle

ensure

broader

straight

than

fabric

of

from

hem

such

the

out

the

and

fabricsl

stitch

2.0

the

edge

ribbed

as

hem

on

and

easily

is

that

than

mm)

desired

face

back

before

twin

avai

(with

to

side.

you

3.5

knit-

Threading

—

—

to

the

spool

a

Place

Simultaneously

other

—

Lay

(18)

into

the

the

In

must

the

to

the

and

each

through

arrows.

threads

twin

on

thread

right

pass

left

threads

(19)

of

both

pass

of

and

the

needle

both

guide

thread

to

the

behind

thread

right

the

of

the

tension

spool

the

of

marked

slot,

right

the

one

and

and

disc

thread

left

stands.

threads

with

one

the

of

needles.

of

the

C.

the

the

guides

threads

38

Page 43

Smocking

light

Fine,

are