Page 1

Page 2

Page 3

Quick Table of Contents

PART 1: INTRODUCTION.. ..................................................................... ..........1

PART 2: CAB AND FRAME ACCESS.................................... ............................ 6

PART 3: GETTING TO YOUR ENGINE...... ... ..................................................10

PART 4: CONTROLS AND DISPLAYS............. ....................................... ........15

PART 5: SEAT AND RESTR AINT SYSTEMS.................. ............ ............ ........57

PART 6 : DRIVER’S CHECKLIST.. ...................................... ............................. 69

PART 7: STARTING & OPERATING THE VEHICLE.. .....................................73

PART 8 : MAINTENANCE AND SERVICE.. ................................................... 110

PART 9: VEHICLE IDENTIFICATION NUMBERS.. .......................................196

PART 1 0: CO NSUMER INFORMATION........................................................199

PART 11: SUBJECT INDEX....................................... ....................................202

Other Publications.. ........................................................................................206

California Proposition 65 Warning

• Diesel engine exhaust and some of its constituents are known to the State

of California to cause cancer, birth defects, and other reproductive harm.

• Other chemicals in this vehicle are also known to the State of California to

cause cancer, birth defects or other reproductive harm.

• Battery posts, terminals, and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after handling.

Page 4

Page 5

PART1: INTRODUCTION HowToFindWhatYouWant

PART 1: INTRODUCTION

This manual contains useful information for the safe and

efficient operation of your Model 320. It also provides information on maintaining your vehicle in the best condition,

with an outline for performing safety checks and basic preventive maintenance inspections.

We have tried to present the information you’ll need to learn

about your vehicle’s functions, controls, and operation and to present it as clearly as possible. We hope you’ll

find this manual easy to use.

There will be times when you need to take this manual out

of your Peterbilt. When you do, please be sure to return it

to the cab when you are finished using it. That way it will

be there when you need it the next time or when you pass

the vehicle on to the next user.

Your Model 320 may not have all the features or options

mentioned in this manual. Therefore, you should pay c areful attention to the instructions that pertain to just your vehicle. In addition, if your vehicle is equipped with special

equipment or options not discussed in this manual, consult

your dealer or the manufacturer of the equipment.

All information contained in this manual is based on the latest production information available at the time of publication. Peterbilt Motors Company reserves the right to make

changes at any time without notice.

HowToFindWhatYouWant

There are several tools built into this manual to help you

find what you need quickly and easily.

First is the Quick Table of Contents. Located at the front of

the manual, this lists the main subjects covered and gives

page numbers where you can find these subjects. Use

the Quick Table of Contents to find information on a large

subject like "Maintenance."

Cross-referenced Citations also help you get the information you need. If some other part of the manual contains

further information on the subject you are reading about,

we’ll indica te that in a cross-reference like this: (See "

6: DRIVER’S CHECKLIST". You won’t have to go searching for more information.

Finally you’ll find a helpful Subject Index. It’s in the back

of the manual and alphabetically lists the subjects covered.

PART

R(08/07) Y53-6015 – 1 –

Page 6

Additional Sources of Information PART 1: INTRODUCTION

So if you want information on brakes, for example, just look

under Brake in the Subject Index. You’ll find all the pages

listed where brakes or braking are discussed.

A Special Word About Repairs

Your Peterbilt dealer’s service center is the best place to

have your vehicle repaired. You can find Peterbilt dealers

all over the country with the equipment and trained personnel to get you back on the road quickly - and keep you there.

Your vehicle is a complex machine. Anyone attempting repairs on it needs good mechanical training and the proper

tools. If you are sure you have these requirements, then

you can probably perform some repairs yourself. However,

all warranty repairs must be performed by an authorized

Peterbilt service fa cility. If you aren’t an experienced mechanic, or don’t have the right equipment, please leave all

repairs to an authorized service facility. They are the ones

equipped to do the job safely and correctly.

WARNING! Attempting repair work without sufficient training, service manuals, and the proper

tools can be dangerous. You could be injured

or you could make your truck unsafe. Do only

those tasks you are fully qualified to do.

Maintenance Manuals. Ifyoudodecidetodoanycomplex repair work, you’ll need the Peterbilt Maintenance

manuals. Order them from your authorized dealer. Please

provide your Chassis Serial Number when you order, to be

sure you get the correct manuals for your vehicle. Allow

about four weeks for delivery. There will be a charge for

these manuals.

Final Chassis Bill of Material. A complete, nonillustrated

computer printout listing of the parts used to custom- b uild

your Peterbilt vehicle is available through the Peterbilt

dealer from whom your purchased your veh icle.

WARNING! Modifying your vehicle can make

it unsafe. Some modifications can affect your

truck’s electrical system, stability, or other

important functions. Before modifying your

vehicle, check with your dealer to ma ke s u re it

can be done safely.

Additional Sources of Information

Operator’s manuals are also supplied by the m a nufacturers

of components such as the engine, seats, transmission,

and radio in your Peterbilt. If you are missing any of these

manuals, ask your Peterbilt dealer to supply them.

– 2 – Y53-6015 R(08/07)

Page 7

PART 1: INTRODUCTION Warnings

Your new Peterbilt also contains a copy of the Truck

Driver’s Handbook, published by the American Trucking

Association. Refer to it for important information on driving

your vehicle. Another place to learn more about trucking is

a local truck driving school. Contact one near you to find

out what kinds of instruction it offers.

Federal and state agencies also have information you can

ask for. The Interstate Commerce Commission can give

you information about regulations governing transportation

across state lines. And various agencies in state governments are sources for regulations which differ from state to

state.

Warnings

We’ve put a number of warning messages in this manual.

They are there for your protection and information. Please

read them and follow them. They can help you to avoid injury to yourself and your passengers as well as to prevent

costly damage to your vehicle. We’ve used certain symbols and "signal words" to indicate what kind of message is

going to follow. When you see these symbols & words, you

know that you need to pay special attention. Please don’t

ignore any of these signals.

WARNING:

When you see this symbol & word, the message that follows is especially vital. This signals something that can

cause serious injury or death. This message will tell you

what the hazard is, what can happen if you don’t heed the

warning, and how to avoid it. For example:

WARNING! Attempting repair work without sufficient training, service manuals, and the proper

tools can be dangerous. You could be injured

or you could make your vehicle unsafe. Do only

those tasks you are fully qualified to do.

CAUTION:

This symbol & word signals something that could damage

your vehicle. You might receive an injury, too. For example:

CAUTION: Continuing to operate a vehicle with

insufficient oil pressure will cause serious engine damage.

R(08/07) Y53-6015 – 3 –

Page 8

Vehicle Safety PART 1: INTRODUCTION

NOTE:

Gives you information we feel you’d like to have. It could

have to do with care of your vehicle or with driving more

efficiently:

NOTE: A cold compressor can cause refrigerant to

liquefyandwarpthevalveplatesorcauseahydraulic lock. Warm the engine before starting the

air conditioner.

Please take the time to read these messages when you see

them. And remember:

WARNING! Something that could injure you seriously.

CAUTION: Something that could cause injury to you or your

vehicle.

NOTE: Useful information.

Vehicle Safety

Make sure your Peterbilt is in top working condition before heading out on the road—it is the responsible driver’s

duty to do so. Inspect the vehicle according to"

DRIVER’S CHECKLIST".

WARNING! Do not drink and drive. Your reflexes, perceptions, and judgment can be affected by even a small amount of alcohol. You

could have a serious—or even fatal accident—if

you drive after drinking. Please do not drink

and drive or ride with a driver who has been

drinking.

WARNING! The use of alcohol, drugs, and certain medications will seriously impair perception, reactions, and driving ability. These circumstances can substantially increase the risk

of an accident and personal injury.

Please remember, this manual is not a training manual. It

cannot tell you everything you need to know about driving your Peterbilt vehicle. For that you need a good training program or truck driving school. If you have not been

trained, get the proper training before you drive. Only qualified drivers should drive this vehicle.

Every new Peterbilt vehicle is designed to conform to all

Federal Motor Vehicle Safety Standards applicable at the

PART 6:

– 4 – Y53-6015 R(08/07)

Page 9

PART 1: INTRODUCTION Vehicle Safety

time of manufacture. However, even with these safety

features, continued safe and reliable operation depends

greatly upon regular vehicle maintenance. The vehicle

must be operated within the range of its mechanical capabilities and the limits of its load ratings. Se e the axle and tire

load rating information located on the driver’s door jamb.

R(08/07) Y53-6015 – 5 –

Page 10

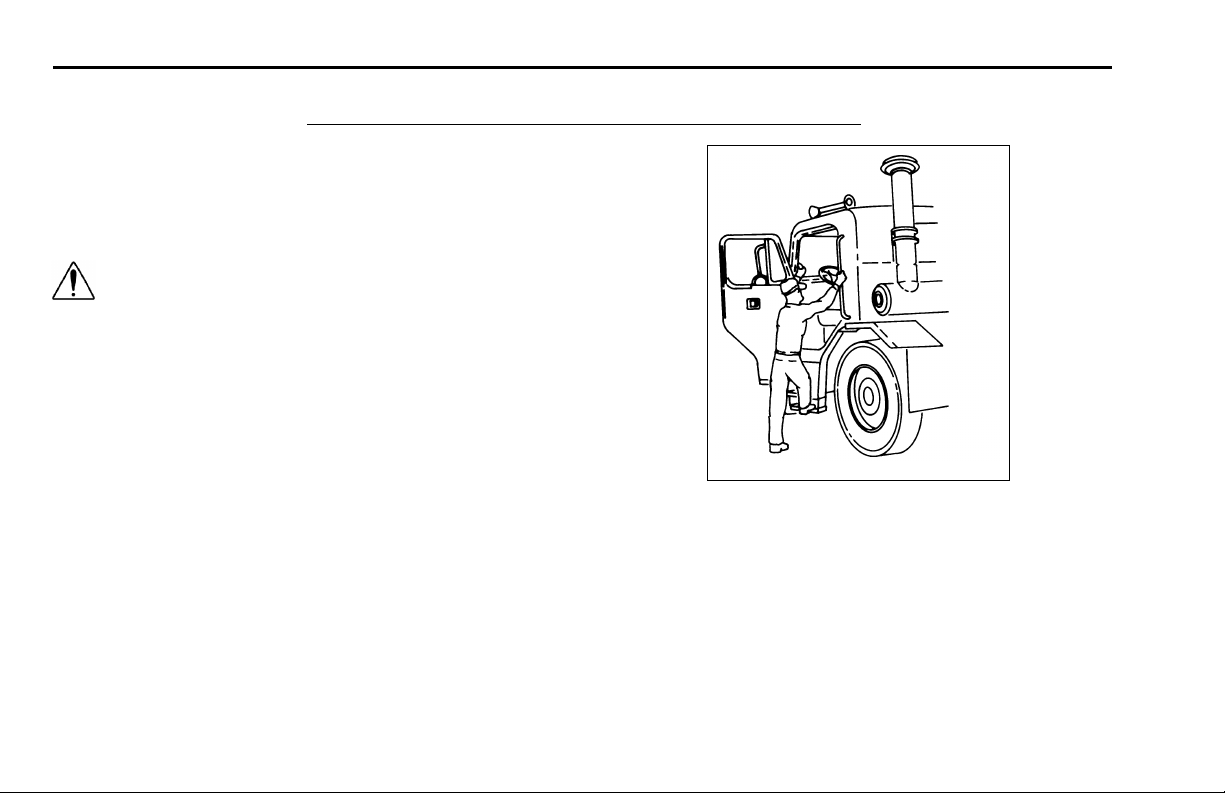

PART 2: CAB AND FRAME ACCESS

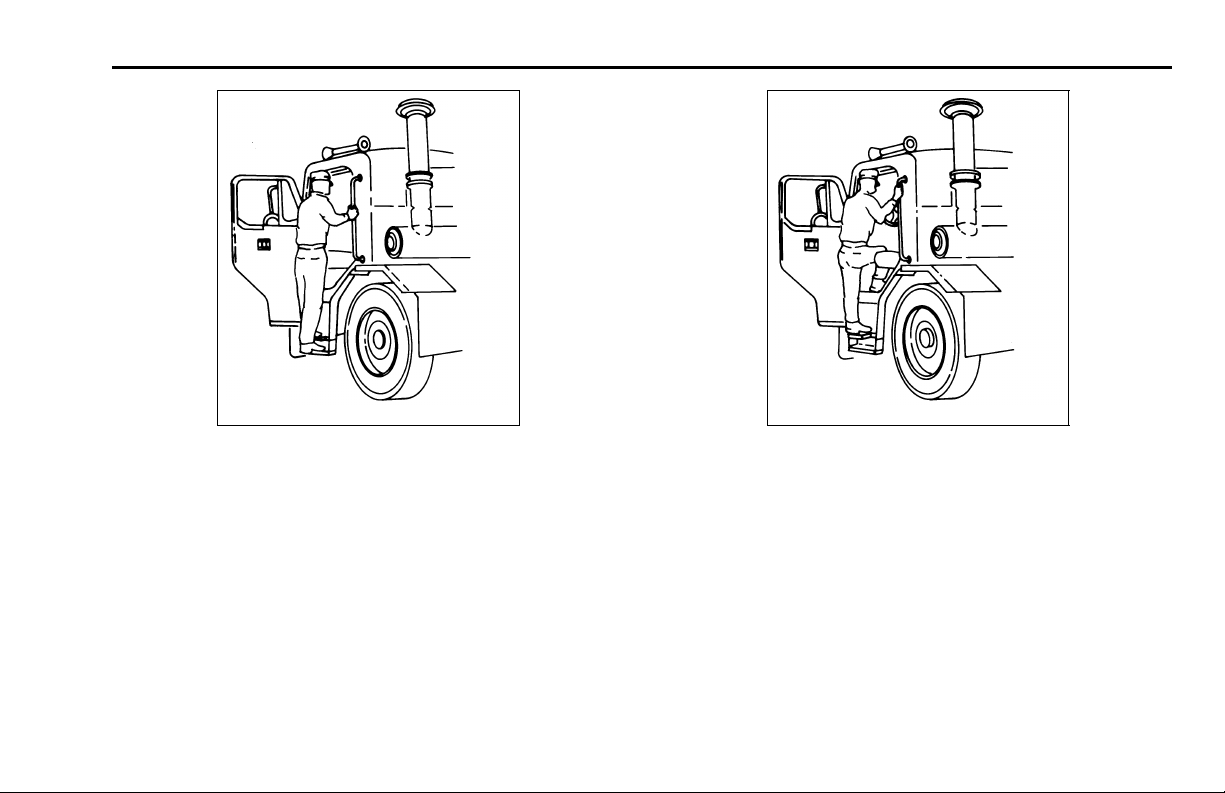

Be careful whenever you get into or out of your vehicle’s

cab. Always maintain at least three points of contact with

your hands on the grab handles and your feet on the steps.

WARNING! Jumping out of the cab or getting

into the cab without proper caution is dangerous. You could slip and fall, possibly suffering

a serious injury. Keep steps clean. Clean any

fuel, oil, or grease off of the steps before entering the cab. Use the steps and grab handles

provided, and always keep at least three points

of contact between your hands and feet and the

truck. Look where you are going.

The following pictures show the best way to enter and exit

a Model 320.

PART 2: CAB AND FRAME ACC ESS

02871

Three points of contact as you begin or finish

– 6 – Y53-6015 R(08/07)

Page 11

PART 2: CAB AND FRAME ACCESS Door Lock and Keys

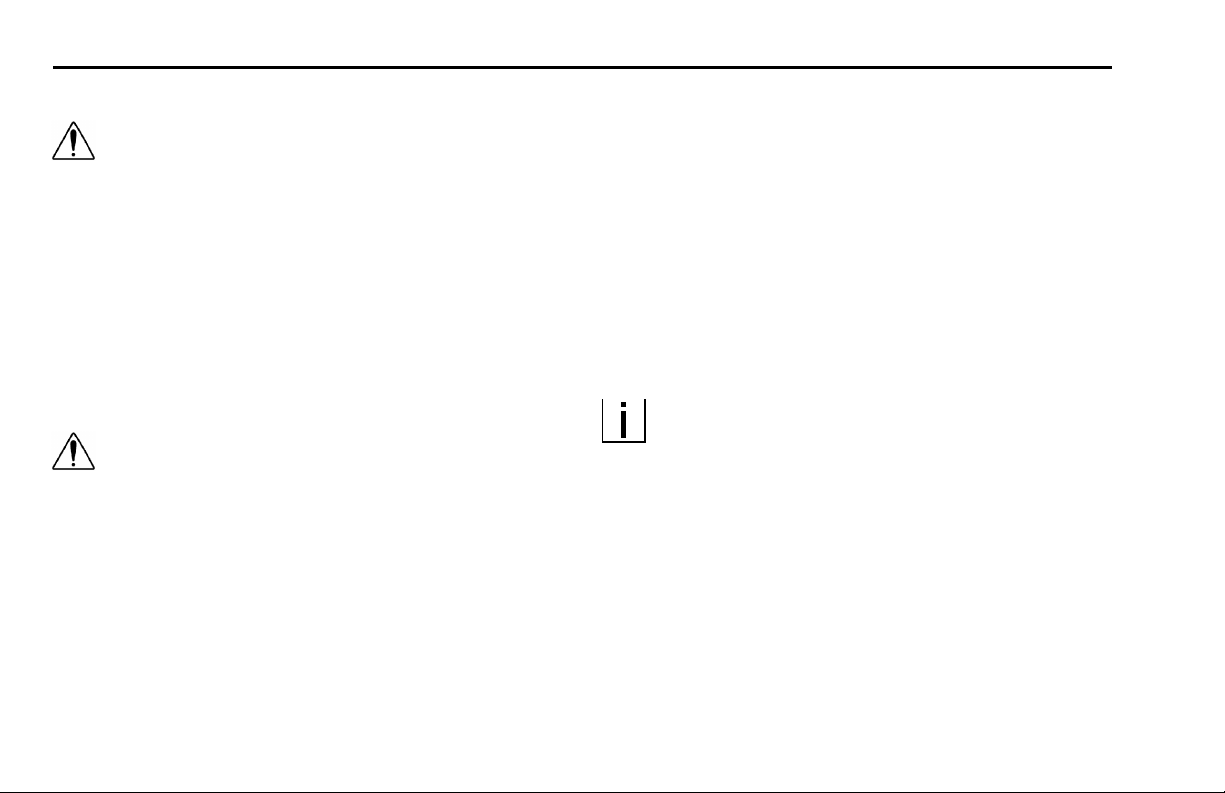

02872

Three points of contact as you climb up or down

Three points of contact as you step in or out

02873

Door Lock and Keys

Doors can be locked from the inside by using the lock button. Close the door then push the button down to lo c k.

Doors automatically unlock when you open them from the

inside,andcanbelockedfromtheoutsidewithakeyonly.

R(08/07) Y53-6015 – 7 –

Page 12

Climbing Onto the Deck Plate PART 2: CAB AND FRAME ACCESS

WARNING! To lessen the chance and/or severity of personal injury in case of an accident, always lock the doors while driving. Along with

using the lap/shoulder belts properly, locking

the doors helps prevent occupants from being

thrown from the vehicle.

To lock or unlock the doors from outside the cab, insert the

key in the lock. Turn the key toward the rear to lock; forward

to unlock.

Climbing Onto the Deck Plate

WARNING!

• You can be hurt if you aren’t careful climbing onto and off the deck plate. You can slip

and fall, especially if the surfaces are wet or

icy, or if you step in oil, fuel, or grease. Keep

steps clean. Always maintain at least three

points of contact between your hands and

feet and the steps and deck plate.

• Do not climb onto and off the deck plate– use

steps and grab handle provided. If there is

no deck plate, or if proper steps and grab

handles aren’t provided, don’t climb onto the

area behind the cab. Peterbilt did not intend

for the area to be a step if handrails or proper

steps are not provided.

NOTE: Any alteration (adding bulkheads, headache racks, tool boxes, etc.) that affects the utilization of grab handles, deck plates, or frame

access steps installed by Peterbilt must comply

with FMCSR 399.

– 8 – Y53-6015 R(08/07)

Page 13

PART 2: CAB AND FRAME ACCESS Front Cab Guard/Ladder

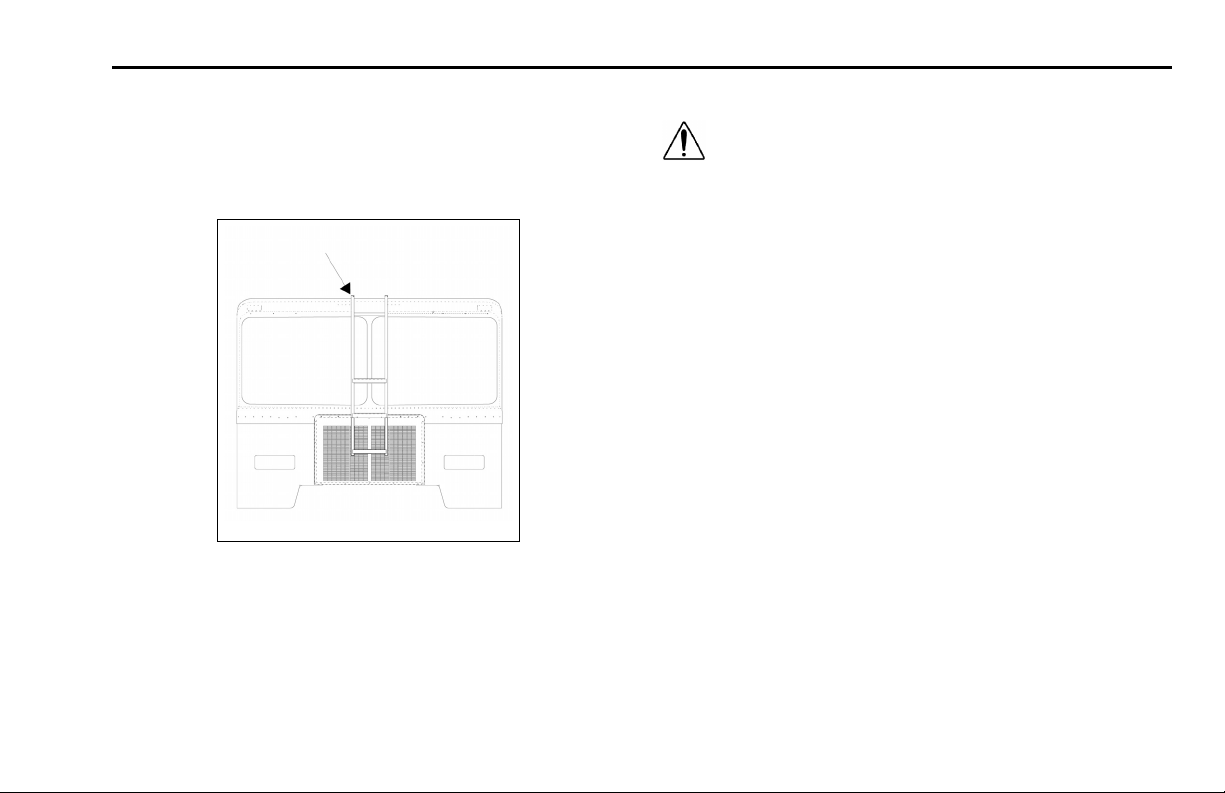

Front Cab Guard/Ladder

The optional front cab guard/ladder is used on front-loading refuse vehicles to protect the cab from damage and to

stand on in order to remove debris from above the cab.

0001

WARNING!

• Do not climb on the cab roof. The cab roof

is not a slip-resistant surface and is not

equipped with handholds. A slip and fall

could cause serious injury.

• Do not step or stand on the top rung of the

ladder. This is not a step; it is meant to used

only as a handhold. You could slip or fall and

injureyourselfifyouuseitasastep.

R(08/07) Y53-6015 – 9 –

Page 14

Cab Tilting PART 3: GETTING TO YOUR ENGINE

PART 3: GETTING TO YOUR ENGINE

Cab Tilting

WARNING! You can be seriously injured by the

cab if you do not follow safety precautions.

Whenever you raise or lower the cab, or when

you work under the cab, please remember the

following safety rules:

• Be sure no one is under the front of the cab.

Whether you are raising or lowering the cab,

KEEP CLEAR.

• Never work under a raised cab unless it is

properly supported. This means use an overheadhoistofsufficient capacity to support

the cab safely. Never prop the cab up instead

of using a hoist. The prop could fail and let

the cab fall on you or anyone else working

under the cab.

• Always be sure the safety latch is engaged

when you or anyone else works under the

cab.

– 10 – Y53-6015 R(08/07)

• Perform work only when the cab is in the mechanically locked position or in the full tilt position.

• When your cab’s hydraulic system needs

service or repair:

• Have maintenance an d repair don e o nly by

someone qualified in hydraulic systems.

• Besurenoonetriestobleedthesystem

with the cab raised. This will defeat the

safety system. The cab can fall and crush

anyone under it.

• Do not tamper with any part of the cab tilt

cylinders, including removing the velocity

fuses. To do so will defeat their purpose.

The cab could fall and crush anyone under

it. If you have any need for repair involving

the velocity fuses, have a qualified truck

mechanic do the work.

NOTE: In case of oil loss in the system or a lockup

in the tilt cylinders, refer to the maintenance manual

for repair instructions.

Page 15

PART 3: GETTING TO YOUR ENGINE Raising the Cab

Raising the Cab

An independent hydraulic system raises and lowers the

cab. A positive, dual-locking device ensures safety and

eliminates danger of mishaps while driving.

WARNING! Do not get any part of your body under an unsecured cab. It could cause a serious

or fatal accident. The cab could fall and crush

you. Always ensure the locking bar is fully engaged before getting under the cab, or before

letting anyone else get under it (see following

instructions on using the locking bar).

WARNING!

• Raising the cab with heavy objects in the cab

can cause serious damage to the cab tilting

mechanism and cab. Before raising the cab,

remove heavy items su ch as tire chai n s and

tools. Remove or stow securely any loose

items. And shut the doors tightly.

• Straighten the front wheels before tilting the

cab or cab/tire damage could occur.

The following cab tilting instructions are labelled and installed on the base of the companion seat:

1. Park the vehicle on a level surface.

2. Apply the parking brake.

3. Make sure the shift lever is in Neutral. This will prevent

the shift lever from getting caught on the cab during

tilting operations.

4. Secure or remove all loose items in the cab. Close all

doors.

5. Check the clearance above and ahead of the cab. Ensure there will be enough room to clear roof antennae

when you tilt the cab. Check for obs tructions overhead

(branches, power lines, lights, etc.) and in front (walls,

work benches, other vehicles, etc.).

6. Place the control valve handle in the "Raise" position.

R(08/07) Y53-6015 – 11 –

Page 16

Raising the Cab PART 3: GETTING TO YOUR ENGINE

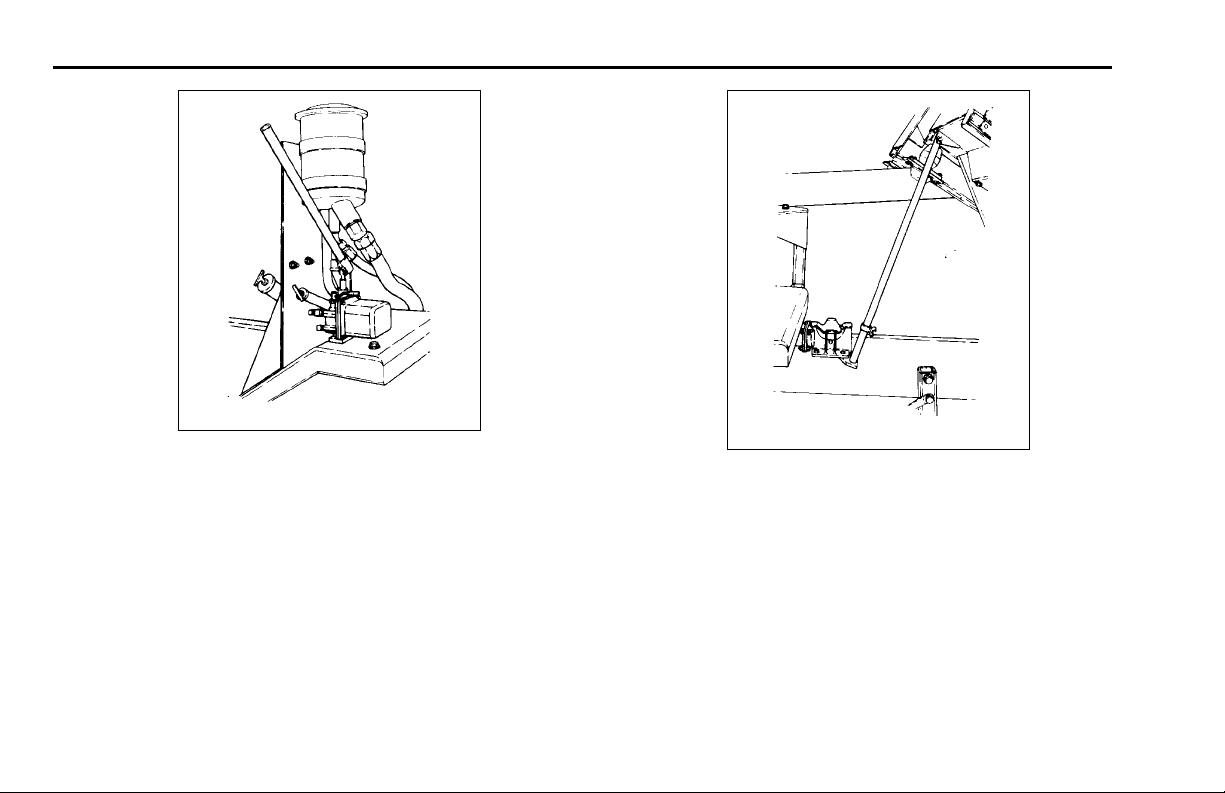

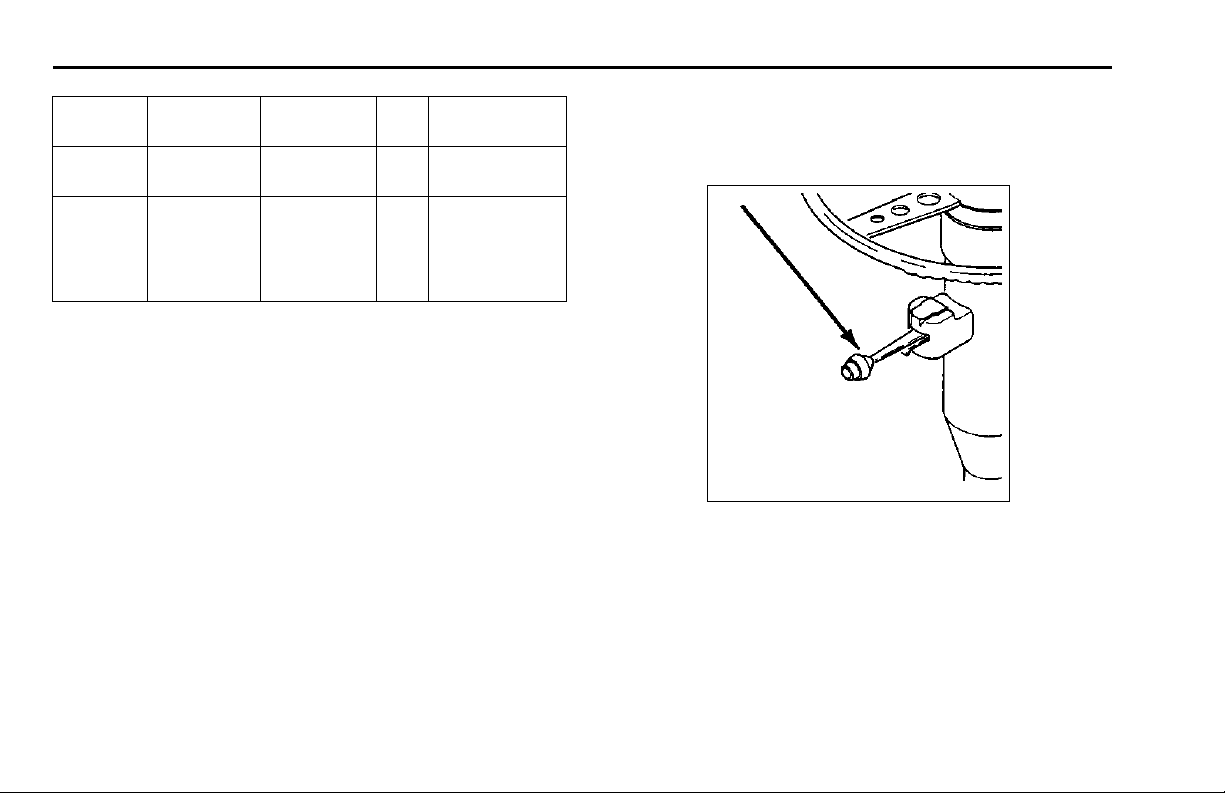

02874

Handle in "Raise" Position

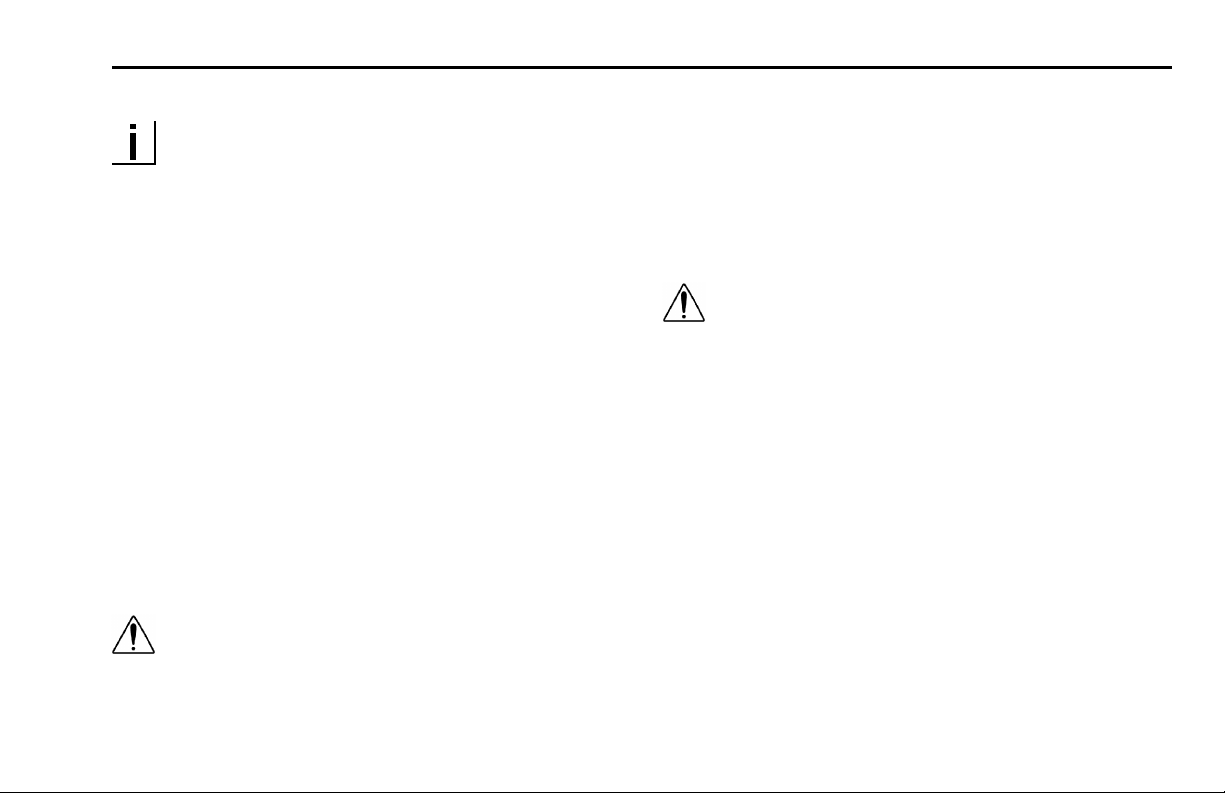

02875

Locking Bar in Anchored Position

7. Attach pump handle to the pump and pump to raise the

cab (the latch hooks will release automatically when

pump is actuated). Pump until the locking bar can

be positioned on the anchor mounted below the right-

8. Place the control valve handle in the “Lower” position

and allow the cab to settle down slightly on the locking

bar.

hand cab suppo rt as shown in the next illustration.

– 12 – Y53-6015 R(08/07)

Page 17

PART 3: GETTING TO YOUR ENGINE Lowering the Cab

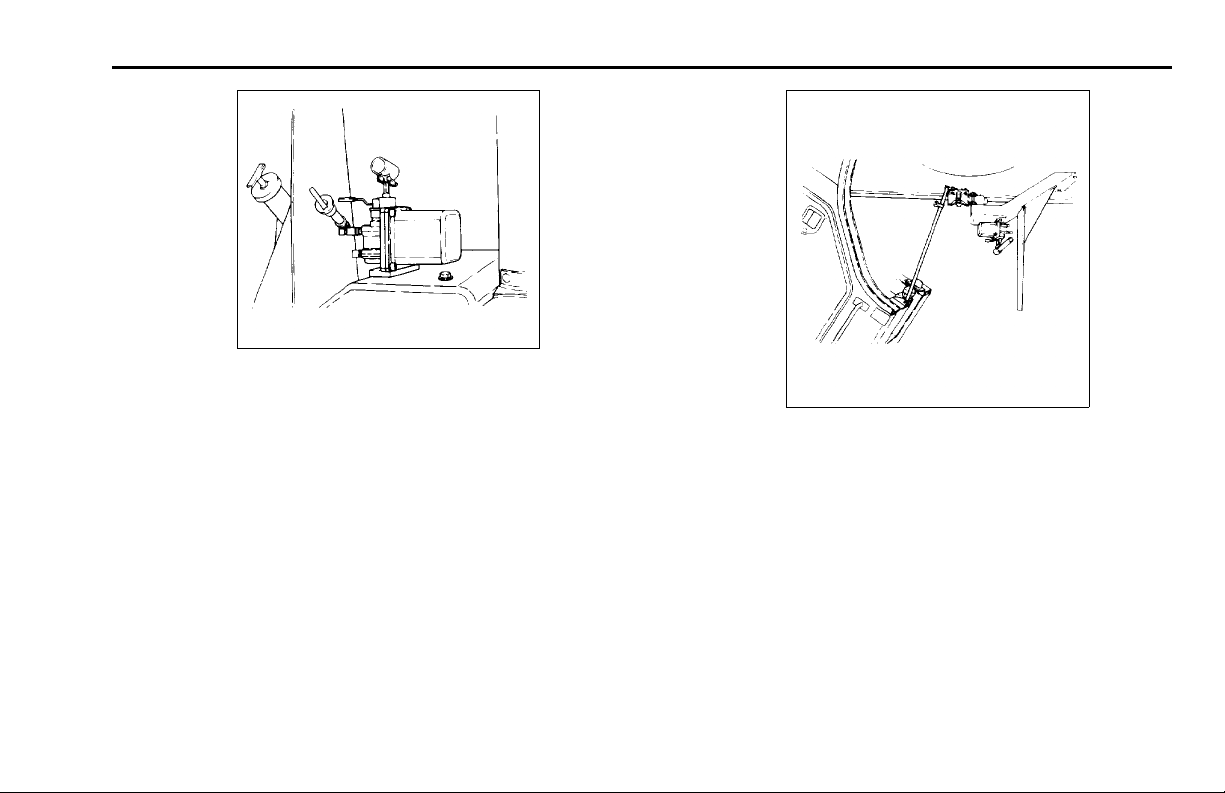

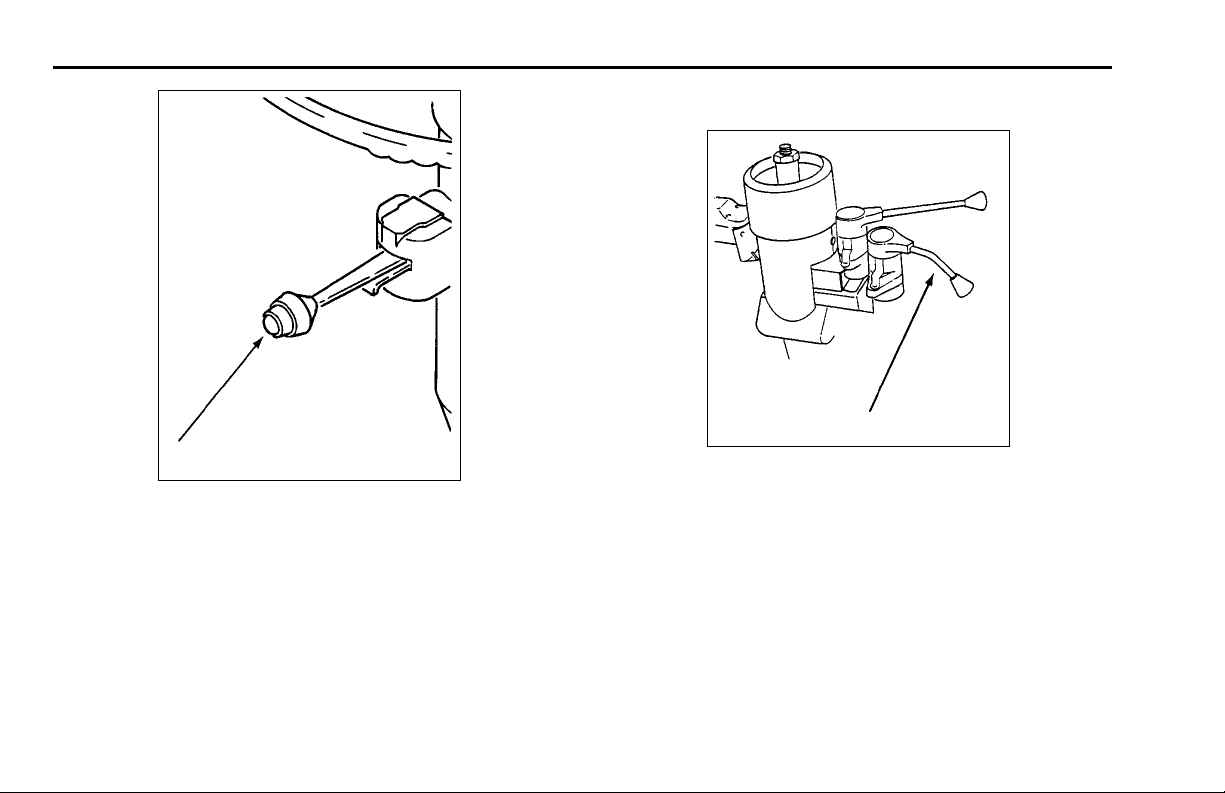

02876

Handle in "Lower" Position

02877

CabinFullTiltPosition

Lowering the Cab

1. Place the control valve handle in the "Raise" position

and pump until the locking bar can be removed from

the anchor and fastened in its stored position.

R(08/07) Y53-6015 – 13 –

Page 18

Lowering the Cab PART 3: GETTING TO YOUR ENGINE

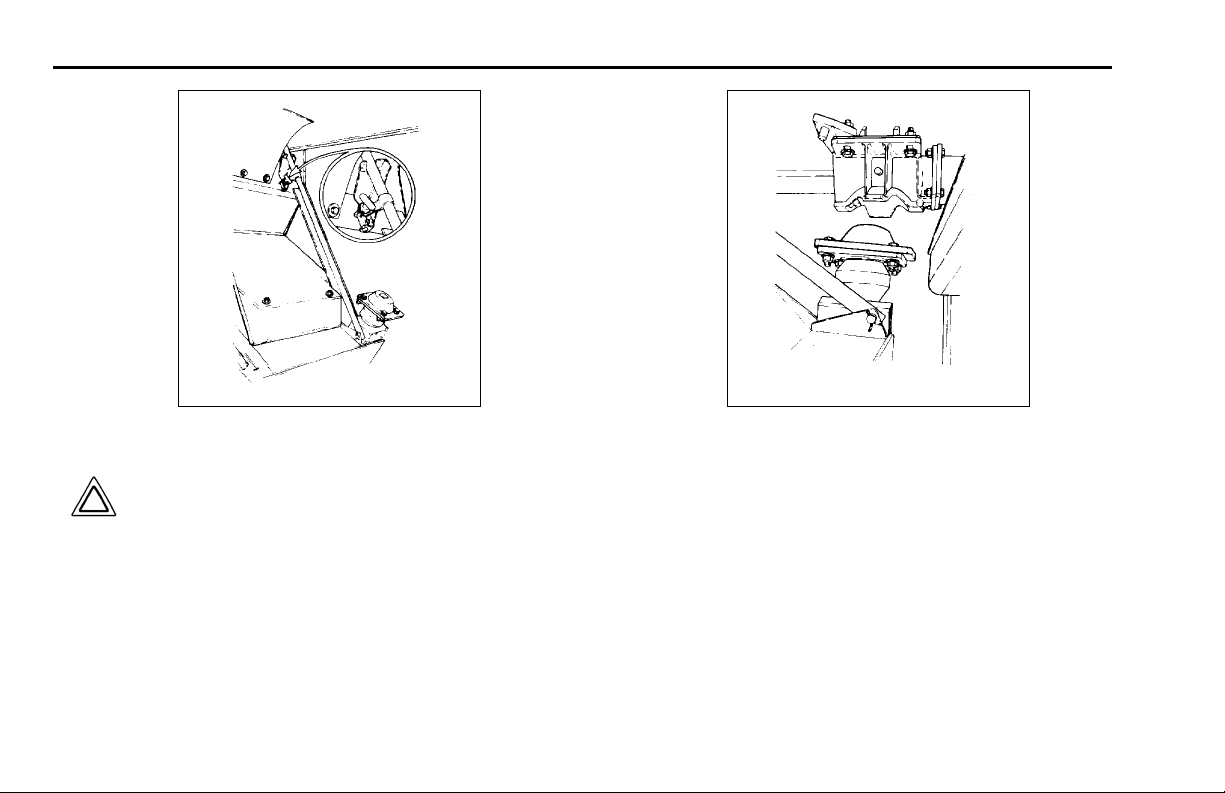

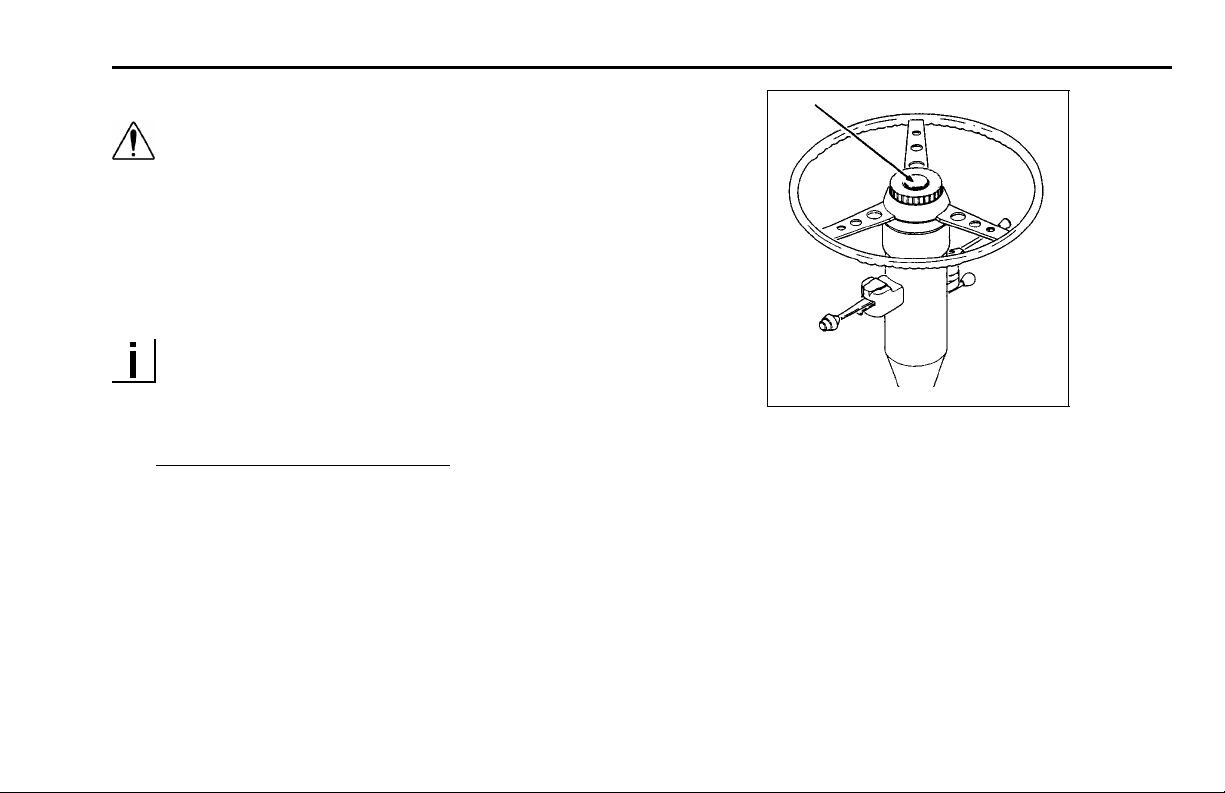

02878

Locking Bar In Stored Position

Upper and Lower Rear Cab Mount

02879

3. Allow at least 20 seconds after the cab touches down

CAUTION: Do not try to pump the cab down

or hold it down with hydraulic force. If you

do, cab damage will occur.

2. Place the control valve handle in the "Lower" position.

The cab should settle down on the rear mounts.

for the full spring force to develop in the latch hooks in

the rear mounts.

4. Remove the pump handle and store in the cab.

5. Visually inspect the cab latch hooks to ensure they are

closed.

6. Ensure that the control valve handle is in the “Lower”

position when operating the vehicle.

– 14 – Y53-6015 R(08/07)

Page 19

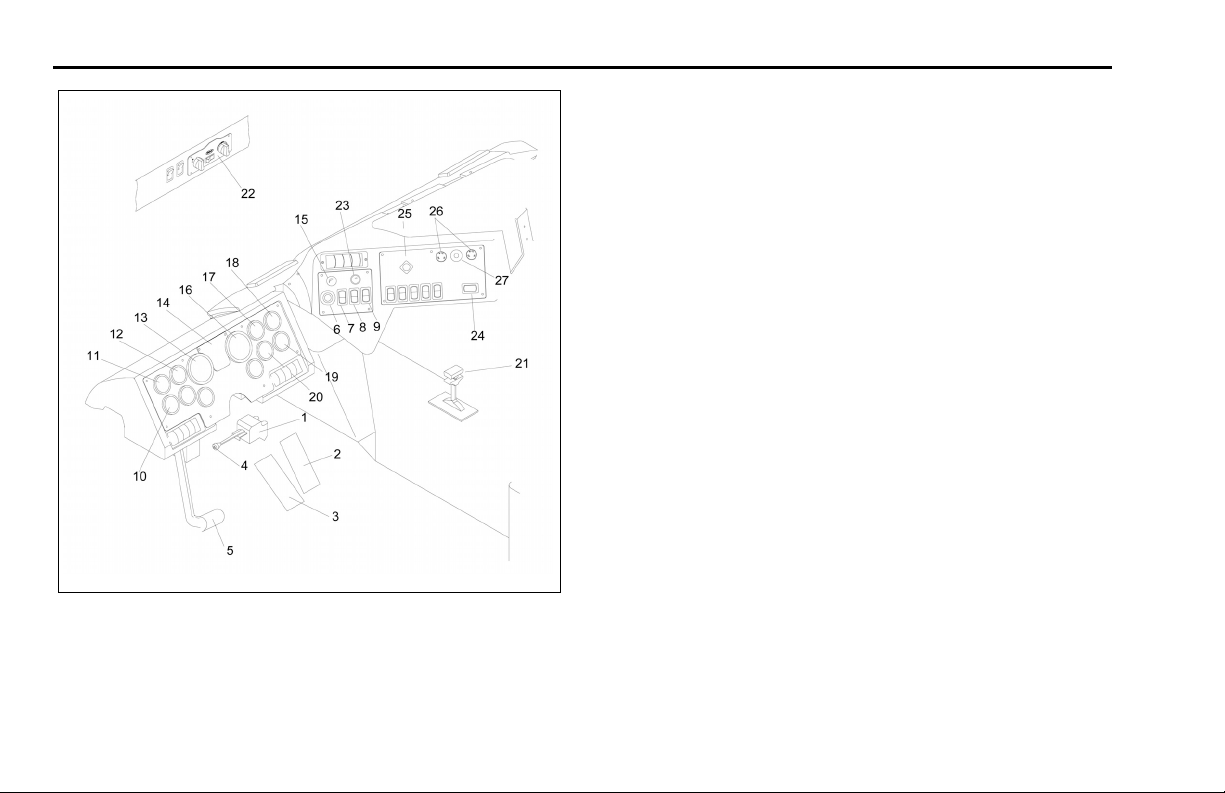

PART 4: CONTROLS AND DISPLAYS Your Instrument Panel

PART 4: CONTROLS AND DISP LAYS

This part explains the location of the various features on

your vehicle and describes their function. For inform at ion

on using these features in driving, see the paragraphs that

follow.

Your Instrument Panel

Please remember that each Peterbilt is custom-made. Your

instrument panel may not look exactly like the one in the

illustrations on the pages that follow.

We have tried to describe all the most common features

and controls available, so your vehicle may not have some

of the ones that appear in this section. You can pick out the

parts that apply to you and read them to be fully informed

on how your particular vehicle operates.

R(08/07) Y53-6015 – 15 –

Page 20

Your Instrument Panel PART 4: CONTROLS AND DISPLAYS

LEFT SIDE

0002

Typical Instruments & C ontrols: Left-Hand Drive Station

1. Turn Signal/Hazard Flasher

2. Accelerator Pedal

3. Brake Pedal

4. High Beam Switch

5. Clutch Pedal

6. Ignition Key Switch

7. Clearance Lamps Switch

8. SMC Select/Reset Switch

9. Headlight Switch

10. Voltmeter

11. Engine Oil Pressure

12. Engine Coolant Temperature

13. Tachometer

14. LED Warning Light Ba r

15. Panel Light Knob

16. Speedometer w/ Message

Center (SMC)

17. Primary Air Pressure

18. Fuel

19. Transmission Oil Temp.

20. Secondary Air Pressure

21. Gearshift or Shift Selector

22. Heater Control Panel

23. Cigar Lighter

24. Interaxle Differential Lock

25. Parking Brake Valve

26. Windshield Wiper Valves

27. Windshield Washer Switch

– 16 – Y53-6015 R(08/07)

Page 21

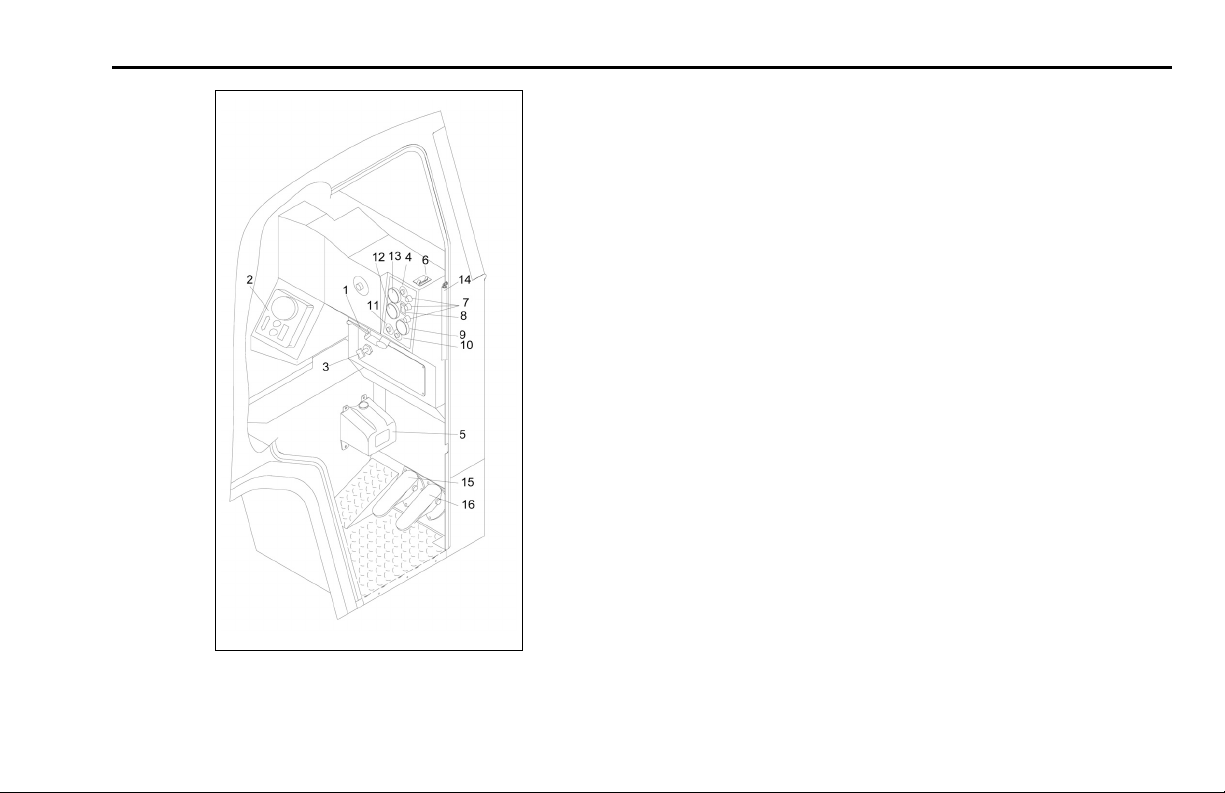

PART 4: CONTROLS AND DISPLAYS Warning Alarms

RIGHT SIDE

0003

Typical Instruments & Controls: Right-Hand Drive Station

1. Turn Signal/Hazard Flasher

2. Transmission Controls

3. Parking Brake Valve

4. Horn Button

5. Windshield Washer

Reservoir

6. Working Brake Switch

7. Warning Lights

8. Headlight Switch

9. Secondary Air Pressure

10. Starter Switch

11. Stop Switch

12. Prim a ry Air Pressure

13. Engine Oil Pressure

14. Safety Chain

15. Bra ke Pedal

16. Accelerator Pedal

Warning Alarms

A warning alarm occurs when some condition in the vehicle

requires attention. A warning alarm cannot be turned off or

manually reset. Once triggered, an alarm w ill continue to

exist until the unacceptable condition or fault in a function

is corrected.

R(08/07) Y53-6015 – 17 –

Page 22

Warning Alarms PART 4: CONTROLS AND DISPLAYS

NOTE:Inadditiontothewarningmessagesmentioned in this part - if any of the following conditions

occur after startup and self-test, the multiplex instrumentation system should be serviced

• The speedometer-message center (SMC)

pointer exhibits windshield wipe r-like motion

and the display reads NO DATA

• One or more gauge pointers exhibit wiper-like

motion.

• A gauge pointer stays at zero with its red light

flashing.

• A gauge pointer goes to and remains at a 2:00

position with its red light on steady.

A multiple x instrumentation system alarm can be sign a lled

by up to four indicators:

• A warning message will appear on the SMC display

(all alarms).

• The light-emitting diode (LED) warning light in the

function’s gauge will go on (all alarms except ABS

and multiplex instrumentation system faults).

• An audible alarm will sound.

• A light bar icon will light.

NOTE:

• Warning messages from system alarms with an

audible alarm can be temporarily overridden by

pressing the Reset switch. You can then press

the Select switch to scroll through other functions

- but the message will reappear in 60 seconds.

The audible alarm will always be on.

• Warning messages from system alarms without

an audible alarm can be dismissed by pressing

the Reset switch. To view dismissed active messages, turn the ignition off and back on.

An alarm’s warning message on the SMC will preemp t all

other SMC displays until the condition that is causing the

alarm is corrected. T his preemption includes other warning

messages from earlier alarms - and some of these alarms

may not have other indicators. Therefore, it is very important that you check the SMC to be aware of all alarm conditions that may exist in your vehicle’s systems - especially

during the start-up procedure. A summary of alarms and

indicators is at the end of this part. Follow this procedure

to check all SMC warning messages.

1. Obse rve the first message displayed after the SMC

comes on.

– 18 – Y53-6015 R(08/07)

Page 23

PART 4: CONTROLS AND DISPLAYS Warning Alarms

• If the odometer is displayed, continue with the

start-up procedure.

• If a warning m essage is displayed instead of the

odometer, it is being generated by the multiplex instrumentation syste m:

– Look in the alarm summary to identify the gauge.

– Go to the description of that gauge in"

PART 4:

CONTROLS AND DISPLAYS" and take the actions indicated to correct the condition.

2. Continue to check and act on all warning messages

until the odometer is displayed.

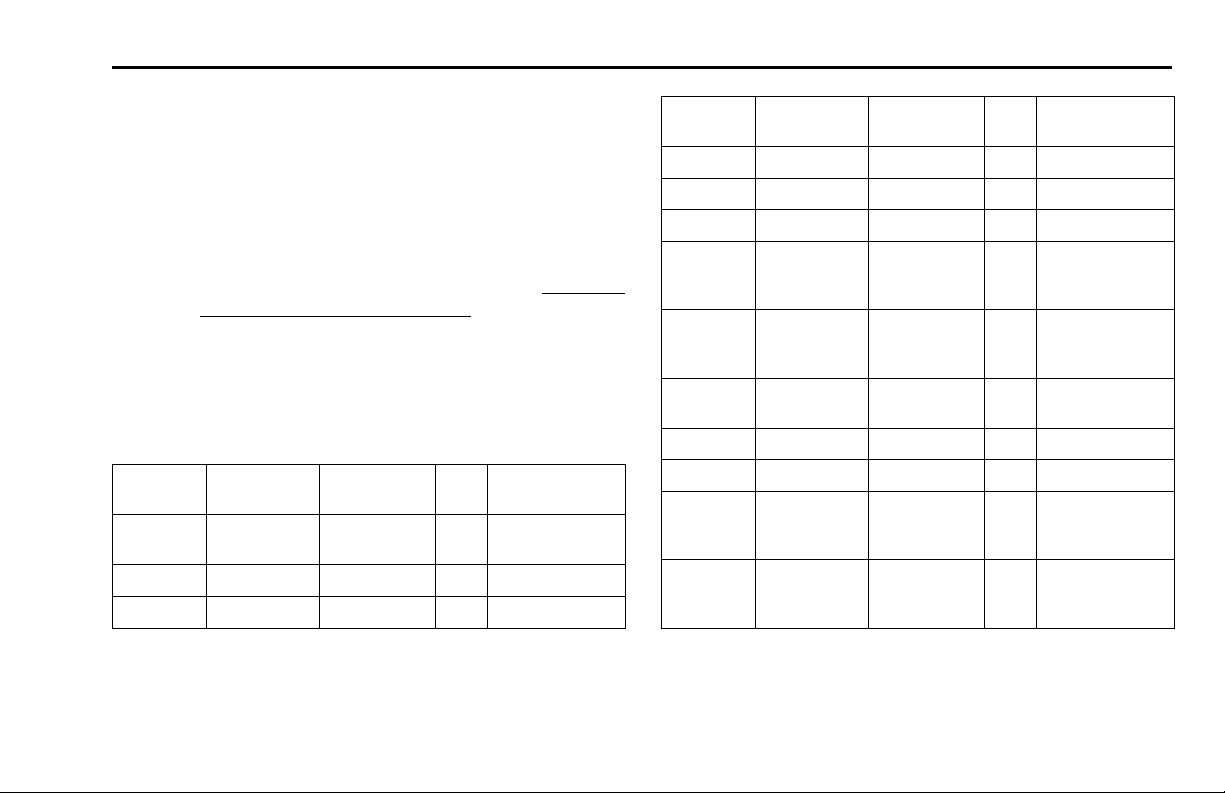

Multiplex Instrumentation System Alarm Summary

Display Activation

Condition

H2O TMP Coolant

temp. is high

IM CAL System Fault

IM CFG System Fault

Gauge LED

Engine Water

Temperature

None

None

Buzz Deactivation

yes

no

no

Display

H2OT OK

None

None

Display Activation

IM DIAG System Fault

IM LIN

IM SLFT System Fault

LOW

AIR1

LOW

AIR2

LO

WATER

NO DATA System Fault

ODO ERR System Fault

OIL TMP

OIL PRES

Condition

System Fault

Low air

pressure in

air tank #1

Low air

pressure in

air tank #2

Coolant level

is low

Engine oil

temperature

is high

Engine oil

pressure is

low

Gauge LED

None

None

None

Primary air

pressure

Secondary

air pressure

Engine Water

Level

None

None

Engine Oil

Temperature

Engine Oil

Pressure

Buzz Deactivation

no

no

no

yes

yes

yes

no

no

yes

yes

Display

None

None

None

AIR1 OK

AIR2 OK

WATER O K

None

None

OILT OK

OIL OK

R(08/07) Y53-6015 – 19 –

Page 24

Turn Signal and Indicator Lights PART 4: CONTROLS AND DISPLAYS

Display Activation

SMC

MEM

TRANTMP Main

Condition

System Fault

transmission

oil

temperature

is high

Gauge LED

None

Main

Transmission

Oil

Temperature

Buzz Deactivation

no

yes

Display

None

TRAN OK

Steering Column-Mounted Controls

Turn Signal and Indicator L igh ts

02882

Turn Signal

The turn signal body is mounted on the left side of the steering column, below the steering wheel.

• At a right-hand drive station, the turn signal body is

mounted on a stub shaft under the dash behind the

steering wheel.

– 20 – Y53-6015 R(08/07)

Page 25

PART 4: CONTROLS AND DISPLAYS High Beam Headlights

other vehicle could run into you if you do not set

NOTE: The ignition key must be turned to ON for

the signal/switch to operate.

To operate either signal, move the lever in the direction of

the turn.

Of course, in normal stopping in traffic, such as at a stop

light, you do not use your flashers.

your flashers. Always move the vehicle a safe

distance off the road when stalled or stopped

for repairs

Hazard Flasher

The four-way Hazard Flasher switch is on the turn signal

body, just below the turn signal lever.

• At a right-hand drive station, the switch is above the

lever.

The flasher will operate with the key switch in the on or off

position. Pull it out to activate the system. All turn signals

will flash at once. To turn it off, move the turn signal lever

up or down.

Use your hazard flasher whenever you are off the road or

on the side of the road, or in a potentially hazardous situation.

WARNING! Use your Hazard Flasher Warning

System any time you have to stop off the road or

on the side of the road, day or night. A hard to

see vehicle can result in an injury accident. An-

High Beam Headlights

All Model 320 vehicles c o me equipped with a co mbination turn signal and high beam / low beam switch that is

mounted to the steering column. To switch your headlights,

push and release the button on the end of the turn signal lever. The high beam indicator light is displayed in the

tachometer face

WARNING! Your disabled vehicle can be dangerous for you and others. The hot exhaust system could ignite dry grass, spilled fuel, or other

substances. Do not park or operate your vehicle w here the exhaust system could contact dry

grass, brush, spilled fuel, or any other material

that could cause a fire.

R(08/07) Y53-6015 – 21 –

Page 26

Trailer Brake Hand Valve PART 4: CONTROLS AND DISPLAYS

Trailer Brake Hand Valve

02885

02884

High Beam Headlight Switch Button

If your vehicle is a tractor, it will be equipped with a trailer

brake hand valve. This hand valve provides air pressure to

apply the trailer brakes only. It operates independently of

the foot treadle valve.

To operate the trailer brake hand valve: Pull down on

the lever on the right side of the steering column, below

the steering wheel.

Trailer B rak e Hand Valve

– 22 – Y53-6015 R(08/07)

Page 27

PART 4: CONTROLS AND DISPLAYS Electric Horn

WARNING! It is dangerous to use air-applied

trailer brakes for parking or holding a vehicle.

Air system pressure can bleed down and release the brakes. You could have a vehicle rollaway resulting in an accident. You or others

could be badly injured. Always apply the parking brakes for parking or holding your vehicle

on grade.

NOTE: The traile r brake is not to be use d as the

main means of braking. To use this brake frequently

instead of using the foot brake will wear out the

trailer brake sooner.

See "

Parking Brakes and Their Use" for more complete

information on when and how to use your trailer brake. Or

see the Index, under Brake.

Electric Horn Button

Air Horn

Your Pe te rbilt has an a ir horn in addition to an electric horn.

02886

Control the air horn by pulling on the lanyard exten ding from

Electric Horn

the overhead header panel.

Your vehicle has an electric horn. To sound the horn, press

on the button in the center of the steering wheel. At a righthand stand-up drive station, the horn button is located on

the dash panel to the right of the steering wheel.

R(08/07) Y53-6015 – 23 –

Page 28

Ignition Switch PART 4: CONTROLS AND DISPLAYS

Dash-Mounted Features

Keys and Locks

The same key operates the ignition and opens the doors.

Frame-mounted tool box locks and locking fuel tank caps

each have individual keys.

Ignition Switch

Your ignition switch has four positions:

• OFF: In this (center) position, all accessories are off

(except those listed below), and you can remove the

key:

– Brake lights

– Panel lights

– Tail lights

– Cigarette lighter

– Clearance lamps

–Horn

– Headlights

– R adio station memory

– Emergency hazard flasher

– A uxiliary power

– Dome light

This is the key position that w ill stop the engine from the

left-hand drive stat ion.

• ACC (Accessory): In this position (to the left of center),

you can play the radio or use other accessories, but

your engine won’t start.

• ON: In this position (to the right of center), all circuits

except the cranking circuit are energiz ed. The warning light bar and the multiplex instrument system will

begin its start-up (self-test) p rocedure. In this switch

position, the key cannot be removed.

• START: When the key is turned and held in this position (full right of center), the starter motor will engage

and crank the engine. Also, it is not uncommon for

some or all of the multiplex instrument system gauges

to begin their start-up procedure again. This is due to

the drop in the system voltage during engine cranking.

NOTE: The multiplex instrument system start-up

(self-test) procedure is described in "

STARTING & OPERATING THE VEHICLE" of this

manual.

PART 7:

– 24 – Y53-6015 R(08/07)

Page 29

PART 4: CONTROLS AND DISPLAYS Manual Override for Engine Shutdown

Starter Button

02887

With the ignition switch ON, pushing this button at the righthand drive station will perform the same function as turning

the key to the START position at the left-hand drive station.

Stop Button

02888

Pushing this button at the right-hand drive station stops the

engine.

Manual Override for Engine Shutdown

03020

On vehicles with an engine shutdown, you will have to hold

the manual throw switch in the UP position until normal

engine pressures are reached. If you have one of these

systems, a label on the control panel will say so.

For detailed s tarting procedures, see the Index, under

Starting And Operating.

R(08/07) Y53-6015 – 25 –

Page 30

Panel Light Knob PART 4: CONTROLS AND DISPLAYS

Headlights

02890

The headlights are controlled by the control panel

switch(es) showing the above symbol. When the headlights are ON, the dash lights, side, and tail lamps are also

on.

WARNING! Do not use daytime running lights

(DRL) during periods of darkness or reduced

visibility. Do not use DRL as a substitute for

headlights or other lights during operations that

require lighting of your vehicle. Doing so could

lead to an injury accident.

NOTE: On vehicles equipped with daytime running

lights (DRL), the high-beam headlamps go on automatically at reduced brightness if the engine is running and the headlamp s witch is turned off. The

daytime running lights are turned off automatically

while the parking brake is engaged. If the headlamp

switch is turned on, the DRL system is overridden

& headlamps operate normally.

Panel Light Knob

02891

The Panel Light Knob lets you vary the brightness of your

instrument panel lights.

To Operate Your Panel Light Knob:

1. Turn on either the headlights, c learance lights, or fog /

driving lights.

2. To brighten the instrument panel lights, turn the knob

clockwise.

3. To dim the instrument lights or to turn them off, turn the

knob counterclockwise.

– 26 – Y53-6015 R(08/07)

Page 31

PART 4: CONTROLS AND DISPLAYS Fog/Driving Lights Switch

ID and Clearance Lights Switch

02892

These are the amber lights on top of your cab, the lights on

the front and sides of the trailer and the red lights on the

rear of a truck or trailer. They are controlled by the control

panel switch shown above.

Fog/Driving Lights Switch

03021

If your vehicle has fog lights, turn them ON or OFF with the

control panel switch shown above.

NOTE: State requirements vary as to when high

beams and fog lights can and cannot be used together. Further, some states allow only four lights to

be used together; some allow more. Whether you

have dual or composite lights will affect how many

lights you can have on at one time. Always comply

with the state requirements where you are driving.

R(08/07) Y53-6015 – 27 –

Page 32

Windshield Wipers and Washers PART 4: CONTROLS AND DISPLAYS

Dome Light Switch

ENGINEER - 16-04 492

A two-position switch controls each dome light.

Windshield Wipers and Washers

02895

Wiper

To turn on the wiper(s), rotate the knob(s) clockwise. As

the knob is rotated, the speed of the wiper increases. To

turn off the wiper, rotate the knob counterclockwise.

Washer

To use the washer, push the button on the control panel

showing this symbol.

02896

WARNING! Do not drive with worn or dirty wiper

blades. They can reduce visibility, making driving hazardous. Clean blades regularly to remove road film and wax build-up. Use an alcohol based cleaning solution and a lint-free cloth,

and wipe along the blades.

– 28 – Y53-6015 R(08/07)

Page 33

PART 4: CONTROLS AND DISPLAYS Air Suspension DeflateSwitch(DumpValve)

CAUTION: Do not use antifreeze or engine

coolant in the windshield washer reservoir—

damage to seals and other components will

result.

Air Suspension Deflate Switch (Dump

Valve)

03035

If your vehicle is a tractor with a rear air suspension, it may

have an air suspension deflationswitchonthedashthat

allows the air in the suspension to be exhausted. The purpose of this feature is to allow you to lower your tractor to

get under a trailer.

You will notice a guard over the switch. This prevents you

from accidentally deflating the suspension.

WARNING! Operating the Air Suspension Deflate Switch (Dump Valve) while driving can lead

to an accident. Sudden deflation while your vehicle is moving can affect handling and control.

Use this switch only when your vehicle is not

moving.

CAUTION: Operating a vehicle with air suspension bags either overinflated or underinflated

may cause damage to driveline components. If

a vehicle must be operated under such conditions, do not exceed 5 mph.

R(08/07) Y53-6015 – 29 –

Page 34

Air Suspension Deflate Switch (Dump Valve) PART 4: CONTROLS AND DISPLAYS

Engine Fan Switch

03023

The engine fan switch allows you to control the engine fan

manually or autom atically. W ith the ignition key switch ON

and the fan switch in the ON position, the engine fan will

be on regardless of engine temperature. With the engine

fanswitchintheAUTOMATICposition,theenginefanwill

automatically turn on when the engine coolant reaches a

temperature of about 200° F (93° C).

WARNING! Do not work on the fan with the engine running. Anyone near the engine fan when

it turns on could be badly injured. If it is set

at ON, it will turn on any time the ignition key

switch is turned to the ON position. In AUTOMATIC, it could engage suddenly without warning. Before turning on the ignition or switching

from AUTOMATIC to O N, be sure no one is near

the fan.

CAUTION: The fan or equipment near it could be

damaged if the fan turns on suddenly when you

don’t expect it. Keep all tools and equipment

away from the fan.

NOTE: Do not operate the engine fan in the manual

(ON) position for extended periods of time. The fan

hub was designed for intermittent operation. Sustained operation will shorten the fan hub’s service

life as well as reduce fuel economy.

– 30 – Y53-6015 R(08/07)

Page 35

PART 4: CONTROLS AND DISPLAYS Mirror Heat S w it c h

Power Mirror Switch

03024

The power mirror control controls the adjustment o f the

right or left outside mirrors, depending on the option selected.

WARNING! Convex mirrors can distort images

and make objects appe ar smaller and farther

away than they really are. You could have an

accident if you are too close to another vehicle or other object. Keep plenty of space between your vehicle and others when you turn or

change lanes. Remember that other objects are

closer than they may appear.

NOTE: The Power Mirror Switch does not control

the adjustment of the convex mirrors

Mirror Heat Switch

03022

Mirror heat is controlled by the control panel switch shown

above. If the vehicle is equipped with this switch, mirror

heatcanbeswitchedontohelpremovefrostandicefrom

the mirror glass.

R(08/07) Y53-6015 – 31 –

Page 36

Engine Brake PART 4: CONTROLS AND DISPLAYS

Cruise Control Switch

The master switch turns the cruise control ON or OFF. The

second switch allows you to SET the desired speed or RESUME the desired speed after the cruise control function

has been interrupted.

03025_26

WARNING! Do not operate the cruise control

when operating on road surfaces with poor

traction (wet, icy, or snow covered roads) or in

heavy traffic. Accelerations caused by the normal operation of the cruise control could cause

you to lose control of the vehicle resulting in

an injury accident.

NOTE: Cruise control functions and features may

vary depending upon which engine you have. For

specific explanation of your cruise control, see th e

cruise control or engine manual included with your

vehicle.

Engine Brake

03028

– 32 – Y53-6015 R(08/07)

Page 37

PART 4: CONTROLS AND DISPLAYS Interaxle Differential Lock Switch

When an engine brake is energized, the power-producing

diesel engine is converted into a powe r-absorbing air compressor to retard the vehicle.

• The brake is energized whenever the driver’s foot is

completely removed from the accelerator pedal.

• The brake is deenergized during driving by pressure

on the accelerator pedal, and during shifting by depressing the clutch pedal.

The ON/OFF toggle switch turns the system ON or OFF.

• In Caterpillar and C ummins L10-powered vehicles

equipped with a Jacobs Engine Brake, a second,

two-mode switch is incorporated in the instrument

panel. With this system, you can select either LOW

or HIGH retarding.

For more information on when and how to use the engine

brake in your vehicle, see the owner ’s manual for the engine brake that is included with your vehicle.

WARNING! Using the engine brake when operating on surfaces with poor traction (such as

wet or icy, slippery roads or gravel) could cause

loss of control.

Interaxle Differential Lock S witch

03029

The interaxle differential allows differential action between

the forward rear and the rear driving axles. The interaxle

differential lock switch allows the operator to LOCK or UNLOCK the differential. There is a guard over this switch to

prevent you from accidentally activating the lock.

R(08/07) Y53-6015 – 33 –

Page 38

Fifth Wheel Lock (Slider Adjustment) Switch PART 4: CONTROLS AND DISPLAYS

WARNING! Placing the differential lock in the

“LOCK” position while your wheels are spinning could cause loss of control or axle damage. You could be hurt. Switch to “LOCK” only

when your wheels are not spinning.

See "

Interaxle Differential" for more information on using

your interaxle differential.

Two-Speed Rear Axle (Range) Switch

03030

If your vehicle is equipped with a two-speed rear axle, you

can select the axle range by the dash-mounted switch

shown above. The low range provides maximum torque

for operating off-highway. The high range is a faster ratio

for highway speeds. There is a guard over this switch to

prevent you from accidentally changing speeds.

For information on how to operate your two-speed rear axle

properly and safely, see "

ING TH E VEHICLE" or check the Index, under Two-Speed

Rear Axle (Range) Switch 29.

PART 7: STARTING & OPERAT-

Fifth Wheel Lock (Slider Adjustment)

Switch

03031

Vehicles having an air-slide fifth wheel have a fifth wheel

slider lock controlled by a switch on the instrument panel.

– 34 – Y53-6015 R(08/07)

Page 39

PART 4: CONTROLS AND DISPLAYS Parking Brake Valve and Trailer Air Supply Valve

By placing the switch in the unlock position, you can slide

the fifth wheel to various positions to adjust weight distribution.

There is a guard over this switch to protect you against

accidentally activating or releasing the lock.

WARNING! Do not move the fifth wheel w hile

the tractor-trailer is in motion. Movement of the

fifth wheel while a tractor-trailer is moving can

cause a serious accident. Your load could shift

suddenly, causing you to lose control of the vehicle. Never operate the vehicle with the switch

in the unlock position. Always inspect the fifth

wheel after you lock the switch to be sure the

fifth wheel is engaged.

Parking Brake Valve and Trailer Air

Supply Valve

02908

Single Valve

Your parking brake va lve is a yellow diamond-shaped knob

located on the right-hand control panel. It controls the parking brakes for either straight truck or tractor-trailer combinations.

• At a right-hand drive station, a second single valve is

located on the dash to the left of the steering wheel.

R(08/07) Y53-6015 – 35 –

Page 40

Heating And Air Conditioning Controls PART 4: CONTROLS AND DISPLAYS

If your vehicle is a tractor, a red, octagonal-shaped knob

will be next to the parking brake valve on the right-hand

control panel. This is the trailer air supply valve for selecting operation with or without a trailer

02909

Two-Valve System

• To apply all parking brakes, pull the yellow, or parking

brake, knob out. The truck or tractor parking brakes

will set. If equipped, the Trailer Air Supply Valve (red

octagonal knob) will automatically trip (“pop out”) and

set the trailer parking brakes.

• To release truck parking brakes, push in the yellow

knob. If a tractor with trailer, push in both the yellow

and the red knobs.

For full information on parking bra kes, see the Index, und e r

Brake.

WARNING! Stopping with the parking brake

controls can cause a sudden wheel lock-up,

loss of control, or can cause you to be overtaken by following vehicles. You could be

severely injured. Never pull out the parking

brake valve while the vehicle is moving.

Heating And Air Conditioning Controls

WARNING! Exhaust fumes from the engine contain carbon monoxide, a colorless and odorless

gas. Do not breathe the engine exhaust gas.

A poorly maintained, damaged or corroded exhaust system can allow carbon monoxide to enter the cab. Entry of carbon monoxide into the

cab is also possible from other vehicles nearby.

Failure to properly maintain your vehicle could

cause carbon monoxide to enter the cab and

cause serious illness.

– 36 – Y53-6015 R(08/07)

Page 41

PART 4: CONTROLS AND DISPLAYS Heating And Air Conditioning Controls

CAUTION: Never idle your vehicle for prolonged

periods of time if you sense that exhaust fumes

are entering the cab. Investigate the cause of

the fumes and correct it as soon as possible.

If the vehicle must be driven under these conditions, drive only with the windows slightly

open. Failure to repair the source of the exhaust fumes may lead to personal harm.

NOTE: Keep the engine exhaust system and the

vehicle’s ventilation system properly maintained. It

is recommended that the vehicle’s exhaust system

and cab be inspected

• by a competen t technician every 15,000 miles

• when a change is noticed in the sound of the

exhaust system

• if the exhaust system, underbody, or cab is damaged

NOTE: To allow for proper operation of the vehicle ventilation system, keep the inlet grille at the

base of the windshield clear of snow, ice, leaves

and other obstructions at all times.

NOTE: Do not stay in the vehicle with the engine

running or idling for more than 10 minutes with

the vehicle’s Heater / AC v entilation system in

RECIRC or at LOW FAN SPEED. Even with the

ventilation system On, running the engine while

parked or stopped for prolonged periods of time is

not recommended.

NOTE: If you are required to idle your vehicle for

long periods of time, install an auxiliary heater or

automatic idle control. These auxiliary devices can

reduce fuel consumption and save you money.

NOTE: When idling for short periods of time

• Set the heating or cooling system to Heat or A/C

• Set the fan to Medium or High speed

• Set the controls to FRESH AIR

NOTE: If other vehicles are parked next to you

idling, move your vehicle or do not stay in your

vehicle for prolonged periods of time.

R(08/07) Y53-6015 – 37 –

Page 42

Heating And Air Conditioning Controls PART 4: CONTROLS AND DISPLAYS

Heating System

The heating system is a variable-coolant - flow type of system.

• Hot engine coolant is circulated by the engine water

pump through a heater core within the heater unit.

• Two blowers force air through the core and into the

cab.

The amount of heat is controlled by:

02981A

• the position of the modulating water valve that regulates hot engine coolant flow

• the choice of fresh air or recirculated cab interior air as

feed air to the blowers

• the speed of the blowers

The system’s controls are mounted in the header in front

of the driver. They include the following (see illustration

below):

• A rotary knob to operate the modulating water valve

(for air temperature control), located in the heater con-

Next to the rotary k nobs, two switches are available for the

following functions:

• A switch to select either fresh air or recirculated cab

air as blower feed air.

• A switch to select cab interior or defrost vents for

heated air output.

To heat the cab, select the "Cab” mode and the desired

air source, then adjust the air temperature lever and blower

speed until comfortable.

trol head.

• A rotary switch to select blower speed, located in the

heater control head.

– 38 – Y53-6015 R(08/07)

Page 43

PART 4: CONTROLS AND DISPLAYS Heating And Air Conditioning Controls

WARNING! Do not drive with visibility reduced

by fog, condensation, or frost on the windshield. Your view may be obscured, which

could result in an injury accident. For clear visibility and safe driving it is extremely important

for you to follow the instructions pertaining to

the function and use of the ventilation/heating

and defogging/ defrosting system. If in doubt,

consult your dealer. Maximum heating output

and fast defrosting can be obtained only after

the engine has reached operating temperature.

CAUTION: During extreme cold weather, do not

blow hot defroster air onto cold windshields.

This could crack the glass. Turn the air flow

control lever to Defrost and adjust the fan speed

accordingly while the engine warms. If the engine is already warm, move the temperature selector to Cool, then gradually increase the temperature when you see that the windshield is

starting to warm up.

CAUTION:

• A cold compressor can cause refrigerant to

liquefy and warp the valve plates or cause a

hydraulic lock. Warm the engine before starting the air conditioner.

• To avoid damage to the compressor & blower

motors, turn off all controls when a system is

not in use.

NOTE: Air registers are located on both sides of the

cab. They may be positioned to clear (defrost) the

side windows. Closing these nonwindshield registers may help to defrost the windshield quicker.

• To defrost the windshield, select the "Defrost” mode

and the desired air source, then set the air temperature

lever to “Hot” and the blower speed to “High.” [Note: If

yourvehicleisequippedwitharoofmountedairconditioner, turn the air conditioner switch on.] When the

windshield is clear, adjust the temperature and blower

speed until comfortable.

R(08/07) Y53-6015 – 39 –

Page 44

Heating And Air Conditioning Controls PART 4: CONTROLS AND DISPLAYS

Air Conditioning System

Your vehicle may be equipped with either of two air conditioning systems. Cab interior air is continuously recirculated and cooled by these systems. In both systems, the

compressor, receiver-dryer, and condenser are located in

the engine compartment. (Note: In some applications, the

condenser may be mounted on the cab roof.)

Dash-mounted System

02981A

In one system, the evaporator and blower are located inside the heater unit, under the passenger dashboard. Controls for this system are located in a modified heater control

head.

To cool the cab, turn on the air conditioning system, then

adjust the air temperature and blower speed until comfortable. The amount of cooling is controlled by

• the temperature of the evaporator core

• the speed of the blower that forces air through the core

andintothecab

• the amount of heat added to the recirculated cab air

by the air temperature control

Ceiling-mounted System

In another system, the evaporator and blower are located

in a ceiling-moun te d unit. This system’s control panel is

– 40 – Y53-6015 R(08/07)

Page 45

PART 4: CONTROLS AND DISPLAYS Heating And Air Conditioning Controls

mounted in the cover piece of the unit located in the cab

ceiling. It contains a rotary switch to select blower speed

(see next illustration).

JPR033

To cool the cab, turn on the air conditioning system and

adjust the blower speed until comfortable. The amount of

cooling is controlled by

• the temperature of the evaporator core

• the speed of the blower that forces air through the core

and into the cab

NOTE: When the air conditioner isn’t in regular use,

operate it for at least 15 minutes once a month. This

will lubricate the seals in the system

For More Efficient Heating and Cooling...

• For immediate heating of a cold cab, operate the heating system with the “Fresh/Recirc” switch in the “Recirc” position. Switch to the “Fresh” position when the

cab has reached a comfortable temperature.

• For immediate cooling of a hot cab, initially open a

cab window. For maximum summertime cooling, both

heater control valves on the engine should be shut (if

so equipped).

• For both heating & cooling, use lower blower speeds

and intermediate temperature selector positions to

modulate cab temperature.

R(08/07) Y53-6015 – 41 –

Page 46

Gauges And Displays PART 4: CONTROLS AND DISPLAYS

Cigarette Lighter

02912

To operate your lighter, push the knob in. After a few moments the lighter will automatically pop out, ready to use.

After use, insert the knob, but don’t push it in. The lighter

circuit is p rotected by a 20-ampere fuse to prevent damage

should the lighter get stuck in the IN position. If this fuse

needs replacement, check to ensure that the lighter is not

stuck before replacing the fuse.

WARNING! Do not exceed the voltage/amperage capacity of the cigarette lighter. It could result in a fire. Follow all warnings and instructions in the operator’s manual for the appliance

you are using.

The lighter receptacle may be used to power auxiliary

equipment that does not draw more than 20 amperes

maximum.

Gauges And Displays

On the pages that follow you will find descriptions of some

of the gauges on your instrument panel. For more information about using them in driving, see "

& OPERATING THE VEHICLE". Also check the Index under the name of the gauge or function you want to know

more about.

WARNING! Do not ignore a warning light or

buzzer. These signals tell you something is

wrong with your vehicle. It could be a failure in

an important system, such as the brakes, which

couldleadtoanaccident. Havetheappropriate

system checked immediately.

PART 7: STARTING

– 42 – Y53-6015 R(08/07)

Page 47

PART 4: CONTROLS AND DISPLAYS Speedometer-Message Center (SMC)

Speedometer-Message Center (SMC)

NOTE: All of the warning lights and alarms for functions monitored by the multiplex instrumentation

system are contained within the individual gauges

of the system. The alarms for other controls or

systems that you may have will be displayed separately on the instrument panel. They are described

further in "

THE VEHICLE" of this manual.

PART 7: STARTING & OPERATING

112 43

The speedometer-message center (SMC) is a combination

of a speedometer and a message center. The speedometer indicates your vehicle’s speed in both miles and kilometers per hour. The message center contains a 7- character, segmented LCD scree n that can display the following

items:

•Odometer

• Trip1odometer

R(08/07) Y53-6015 – 43 –

Page 48

Speedometer-Message Center (SMC) PART 4: CONTROLS AND DISPLAYS

• Trip2odometer

• Hourmeter

•Clock

• Clock alarm

• Warning and Diagnostic messages (see "

strumentation Syst e m Alarm Summary")

A Select/Reset switch on the right side of the dash controls

the display.

The odometer is normally displayed on the screen. To

choose another function, press and release the Select

switch until it appears.

• The odometer reads m iles & tenths; e.g., 123456.7

• The Trip 1 odometer reads miles & tenths; e.g.,

1234.5T1

• The Trip 2 odometer reads miles & tenths; e.g.,

1234.5T2

• The hourmeter reads in hours; e.g., 12345HR

• The clock reads in hours & minutes, with A.M. or P.M.

indicated at the end; e.g., _ _ 12:34A (or P).

• If the clock alarm is set and activated, the display will

appear as * _ 12:34A (or P).

• The clock alarm reads in hours & minutes, with A.M.

or P.M. indicated as shown; e.g., AL12:34A (or P).

Multiplex In-

To set or reset a function, follow the procedures below.

NOTE: Neither the odometer nor the hourmeter can

be reset.

1.TurntheignitionswitchtoON.

2. Choose the desired function.

3. Set or reset the f unction:

• Trip Odometers: Press and hold the Reset switch

until the mileage is reset to zero; this will take about

3 seconds.

•Clock

Press & release the Reset switch; the hours digit

will flash.

A. Press & hold the Select switch; the hours digits

will increase until the switch is released. Scroll

through 12 hours to change between A.M. and

P. M .

B. Press & release the Reset switch; the hours dig-

its will stop flashing, and the minutes digits will

begin to flash.

C. Press & hold the Select switch; the minutes digits

will increase until the switch is released.

D. Press & release the Reset switch; the minutes

digits will stop flashing. The clock is now set.

– 44 – Y53-6015 R(08/07)

Page 49

PART 4: CONTROLS AND DISPLAYS Speedometer-Message Center (SMC)

•ClockAlarm

A. Press & release the Reset switch; the hours digit

will flash.

B. Press & hold the Select switch; the hours digits

will increase until the switch is relea se d. Scroll

through 12 hours to change between A.M. and

P. M .

C. Press & re lea se the Reset switch; the hours dig-

its will stop flashing, and the minutes digits will

begin to flash.

D. Press & hold the Select switch; the minutes digits

will increase until the switch is released.

E. Press & release the Reset switch; the m inutes

digits will stop flashin g. The alarm is now s et and

activated (the “*” symbol will show in the clock

display to indicate this).

– To t urn the alarm OFF or ON, p res s & hold the

Select sw itch for 3 seconds while v iewing any

display.

– To deactivate the buzzer when the alarm

sounds, press & release the Select switch.

(Note: The alarm will automatically deactivate

after 60 seconds.)

NOTE: When the ignition is OFF, the SMC will be

in a “sleep” (blank) mode. To “awaken” it, press

the “Select” switch. The SMC will function normally

while awake; it will return to a “sleep” mode 20 seconds after a switch is last pressed.

Further use and operation of the S MC is covered in "

7: STARTING & OPERATING THE VEHICLE" of this manual.

PART

R(08/07) Y53-6015 – 45 –

Page 50

Air Application Gauge PART 4: CONTROLS AND DISPLAYS

Tachometer

11244B

Your tachometer measures the engine speed in revolutions- per-minute (RPM). Watching your tachometer is important to driving efficiently. It will let you match driving

speed and gear selection to the operating range of your

engine. If your engine speed gets too high, you can select

a higher gear to lower the RPM. If your engine speed drops

too low, you can select a lower gear to raise the RPM.

Air Application Gauge

114 58

This gauge will show you how much air pressure is being

applied from your foot brake valve or trailer brake hand

valve.

– 46 – Y53-6015 R(08/07)

Page 51

PART 4: CONTROLS AND DISPLAYS Primary And Secondary Air Pressure Gauges (Air Reservoir)

Primary And Secondary Air Pressure

Gauges (Air Reservoir)

These air pressure gauges indicate the amount of air pressure in the brake system in pounds per square inch (psi).

The primary gauge shows the front reservoir air pressure:

114 65

The secondary gauge indicates pressure in the rear reservoir:

114 64

R(08/07) Y53-6015 – 47 –

Page 52

Engine Oil Pressure Gauge PART 4: CONTROLS AND DISPLAYS

WARNING! The air pressure warning light and

the audible alarm indicate a dangerous situation. There is not enough air pressure in the

reservoirs for repeated braking and the brake

system has failed. If air pressure falls below 60

psi (414 kPa) the spring brakes could suddenly

apply, causing a w heel lockup, loss of control,

or your vehicle to be overtaken by following vehicles. You could be in an accident and severely

injured. Ifthesealarmscomeonwhileyouare

driving, bring your vehicle to a safe stop right

away. If the light and alarm do not turn off at

start-up, do not try to drive the vehicle until the

problem is found and fixed.

Engine Oil Pressure Gauge

11241A

It is important to maintain oil pressure within acceptable

limits. Your engine manual will give normal operating pressures for your engine.

CAUTION: Continuing to operate your vehicle

with insufficient oil pressure will cause serious

engine damage.

– 48 – Y53-6015 R(08/07)

Page 53

PART 4: CONTROLS AND DISPLAYS Water Temperature Gauge

• If your oil pressure fails to rise within 10 seconds after

your engine starts, stop the engine and determine the

cause.

• If your oil pressure suddenly drops while you are driving,bringthevehicletoastopassoonaspossibleina

safe locat i on off the road an d turn off the engine. Wait

a few minutes to allow oil to drain into the oil pan, and

then check the oil level. Add oil if necessary. If the

problem persists, contact an authorized service center.

Check the engine manufacturer’s manual for the correct oil

pressure ranges for your engine.

Water Temperature Gauge

11242A

The water temperature gauge shows the temperature of

the engine coolant. Under normal operating conditions the

water temperature gauge should register between 165° 205° F (74° and 90° C), depending on the engine. Under certain conditions, somewhat higher temperatures may

be acceptable. But the maximum allowable temperature is

225° F (107° C) with the cooling system pressurized, ex-

R(08/07) Y53-6015 – 49 –

Page 54

Water Temperature Gauge PART 4: CONTROLS AND DISPLAYS

cept for certain special engines. Check your engine manual to be sure.

Engine Overheating

WARNING! Do not remove the radiator fill cap

while the engine is hot. Scalding steam and

fluid under pressure may escape and cause

serious personal injuries. You could be badly

burned.

• Wait until the coolant temperature is below

122°F (50°C).

• Protect face, hands, and arms by covering

the cap with a large, thick rag to protect

against escaping fluid and steam.

• Carefully and slowly turn the cap one-quarter of a turn or until it reaches the first stop—

allowing excess pressure to escape—push

down and turn for final removal.

Wait until the coolant temperature is below 122° F (50° C).

Protect your face, hands, and arms by covering the cap

with a large, thick rag to protect you against escaping fluid

and steam. Before you completely remove the cap, carefully and slowly turn the cap part way to allow excess pressure to escape. Then push down and turn for fina l r emoval.

The cooling system may overheat if the coolant level is

below normal or if there is a sudden loss of coolant (such

as a worn hose splitting). It may also temporarily overheat

during severe operating conditions such as climbing a long

hill on a hot day or stopping after high-speed driving.

If the “Engine Coolant Temperature” warning light comes

on, or you have any other reason to suspect the engine

may be overheating:

• Stop the vehicle, but DON’T TURN OFF THE ENGINE

unless a low water warning device indicates a loss of

coolant.

• With the transmission in neutral, check to be certain

the oil pressure gauge reads normal. Increase the

engine speed to about 1100 - 1200 R PM, maximum.

Return the idle speed to normal after 2 or 3 minutes.

If the warning light doesn’t go off or the temperature

gauge doesn’t begin to drop, then turn the engine off.

• If the overheating came from severe operating conditions, the temperature should have cooled by this

– 50 – Y53-6015 R(08/07)

Page 55

PART 4: CONTROLS AND DISPLAYS Fuel Gauge

time. If it has not, stop the engine and let it cool before

checking to see if the coolant is low.

Fuel Gauge

114 35

WARNING! Do not remove a fuel tank cap near

an open flame. Hot fuel vapors are combustible

and can cause an explosion or fire resulting in

injury or death.

The fuel gauge shows the approximate amount of fuel in

the fuel tanks. You will want to keep your fuel tanks at least

half full to reduce condensation of moisture in the tanks.

This moisture can damage your engine.

WARNING! Carrying additional fuel containers

in your vehicle is dangerous. Full or empty,

they may leak, explode, and cause or feed a fire.

Don’t carry extra fuel containers - even empty

ones.

R(08/07) Y53-6015 – 51 –

Page 56

Front Drive Axle or Rear Drive Axle Temperature Gauge PART 4: CONTROLS AND DISPLAYS

Transmission Temperatu re Gauge

114 27

Your Transmission Temperature Gauge indicates the temperature of the oil in your transmission. Watch this gauge to

know when your transmission is overheating. If it is, have

it checked by an authorized service representative. Maximum transmission temperature may vary, depending upon

the transmission and type of lubricant. It is typically 250° F

(121° C); check your transmission’s owner’s manual.

Front Drive Axle or Rear Drive Axle

Temperature Gauge

114 25

– 52 – Y53-6015 R(08/07)

Page 57

PART 4: CONTROLS AND DISPLAYS Manifold Pressure Gauge

CAUTION: Driving with very hot temperatures in

your rear drive axles can cause serious damage

to axle bearings and seals. Check axle lubrication if a driver temperature alarm sounds.

These gauges indicate the temperature of the lubricant in

your vehicle’s axle(s). These temperatures will vary with

thekindofloadyouarecarryingandthedrivingconditions

you encounter. Maximum axle temperature may vary, depending upon the axle and type of lubricant. Very high temperatures signal a need to have your axle(s)’ lubrication

checked.

Manifold Pressure Gauge

11453-1

Your manifold pressure gauge indicates the power your engine is putting out by showing the amount of turbo boost.

If the pressure indicated by your manifold pressure gauge

goes down, there may be something wrong with your engine. Have it checked by a qualified service person.

R(08/07) Y53-6015 – 53 –

Page 58

Air Filter Restriction Indicator Gauge PART 4: CONTROLS AND DISPLAYS

Voltmeter

114 97

Your voltmeter displays the battery voltage. Normally, it

should show 12V to 14V (volts).

NOTE: Even with a healthy charge/start system,

the voltmeter may fall well below 12V during engine cranking. If voltage drops below 12V and stays

there, have the electrical system checked.

Air Filter Restriction Indicator Gauge

114 95

This gauge indicates the condition of the engine air cleaner

and is measured by inches of water (H2O). A clean filter

should register 7” H2O (may vary with system design); a

filter whose life is over will register approximately 20” H2O

(for Cummins engines) or 25” H2O (for Caterpillar engines).

– 54 – Y53-6015 R(08/07)

Page 59

PART 4: CONTROLS AND DISPLAYS Shift Pattern Display

CAUTION: Continued operation with the Air

Filter Restriction Gauge reading 25” H2O may

cause damage to the engine. Inspect the filter

and replace if necessary. Holes in the paper

element render an air cleaner useless and may

cause the Air Filter Restriction Gauge to give

a false reading, even if the element is clogged.

Replace the element if it is damaged.

Warning Light Bar

Warning Light Bar

WARNING! Ignoring a warning light could lead

to an accident. These signals tell you something is wrong with your vehicle. It could be

a failure in an important system, such as the

brakes. Never ignore a warning signal. Have

the appropriate system checked right away.

The warning lights and buzzer may indicate something is

wrong with one of the vital systems on your vehicle. Check

the lights frequently, and respond properly as soon as you

see one go on (see "

could save you from a serious accident.

R(08/07) Y53-6015 – 55 –

ABS Warning Lamp s"). These lights

When you turn on your ignition, the warning light bar icons

will turn on for 3 - 5 seconds, as a test to let you know they

are working.

Shift Pattern Display

The correct shift pattern for your vehicle appears on your

control panel or windshield o r on a medallion in the shift

knob. It is important that you know more about your transmission than just the shift pattern. Please read the manufacturer’s manual that is included with your vehicle.

07802

Page 60

Mirrors PART 4: CONTROLS AND DISPLAYS

Mirrors

WARNING! Optional convex outside rear-view

mirrors make objects appear smaller and farther away than they really are. You could have

an accident if you were too close to another vehicle or other object. Keep plenty of space between your vehicle and others when you turn or

change lanes. Remember that other objects are

closer than they seem.

Your vehicle is equipped with outside mirrors to enable you

to see to the sides and behind your vehicle. Be sure they

are adjusted properly before you drive off. You will have

the best field of view to the side if you adjust each mirror

so you can just see the side of your vehicle in the inboard

part of the mirror.

– 56 – Y53-6015 R(08/07)

Page 61

PART 5: SEAT AND RESTRAINT SYSTEMS Seat Belts And Their Proper Use

PART 5: SEAT AND RESTRAINT SYSTEMS

Seat

For information on the features and adjustment of the seat,

see the seat manufacturer’s literature included with the vehicle.

WARNING!

• Do not drive or ride wit h your seat back in

the reclined position. You could be injured

by sliding under the seat belts in a collision.

• Do not adjust the driver’s seat while the vehicle is moving. The seat could move suddenly

and unexpectedly and can cause you to lose

control of the vehicle. Make all adjustments

to the seat while the vehicle is stopped. After adjusting the seat and before driving off,

ensure that the seat is firmly latched in position.

R(08/07) Y53-6015 – 57 –

Seat Belts And Their Proper Use

Seat (or safety) belts have proven to be the single most

effective means available for reducing the risk of serious

injury and death in motor vehicle accidents. It’s not just an

opinion -- it’s a fact: Seat belts save lives.

WARNING! Do not drive vehicle without your

seat belt and your riders’ belt fastened. Riding without a safety belt properly fastened can

lead to increased injury or death in an emergency. Unbelted riders could be thrown into the

windshield or other parts of the cab or could be

thrown out of the cab. They could strike another

person. Injuries can be much worse when riders are unbelted. Always fasten your seat belt.

Page 62

Lap/Shoulder Belt PART 5: SEAT AND RESTRAINT SYSTEMS

1. Grasp the belt tongue and pull the belt in a continuous

slow motion across your chest and lap.

2. Insert the belt tongue into the buckle on the inboard

side of the seat.

3. Push down until the tongue locks securely (with an audible click). Pull on the belt to check for proper fastening.

02998

Person In Crash, Unbelted

• Pull the shoulder section to make sure the belt fits

snugly across the chest.

• The shoulder belt must be positioned over the

Lap/Shoulder Belt

shoulder— it must never rest against the neck.

• Belts should fit snugly across the pelvis and chest.

The combination lap-shoulder belt is equipped with a lock-

Make sure any slack is wound up on the retractor.

ing mechanism. The system adjusts automatically to a person’s size and movements as long as the pull on the belt

To unfasten the belt:

is slow. Hard braking or a collision locks the belt. The belt

will also lock when driving up or down a steep hill or in a

sharp curve. To fasten the belt,

1. Push in the release button on the buckle. The belt will

spring out of the buckle.

– 58 – Y53-6015 R(08/07)

Page 63

PART 5: SEAT AND RESTRAINT SYSTE MS Proper Safety Belt Adjustment

Proper Safety Belt Adjustment

Your combination lap-shoulder belt may need adjustment.

Adjust safety belts properly.

• The lap belt should be worn as low and tight on the

hips as possible. Make sure any slack is taken up by

the belt mechanism.

• The shoulder belt should fit snugly across your body.

01888

Unfastening a belt

2. To release a locked belt, lean back to take the body

pressure off of the belt.

3. To store a lap-shoulder belt, allow the belt to wind up

on the retractor by guiding the belt tongue until the belt

comestoastop.

It should be positioned midway over the shoulder

(nearer to the door); it should never res t against your

neck. It you put the belt under your arm, it can’t protect

you properly.

• Be sure, also, that your belt is not too loose. A loose

belt could allow you to slide under it in an accident, and

that could bring the belt up around your abdomen.

• Do not twist the belt in the process of pu tting it on. A

twisted belt will not work as well to protect you.

R(08/07) Y53-6015 – 59 –

Page 64

Proper Safety Belt Adjustment PART 5: SEAT AND RESTRAINT SYSTEMS

belts

Safety Restraint Belts

WARNING!

• Always wear your seat belt low over your

pelvic bones.

• You can be seriously injured if your belt is

buckled too high. In a crash, it would apply force to your abdomen, not your pelvic

juries.

• Do not drive with your seat belt loose. A seat

belt that is too loose can allow you to fall too

far forward, possibly causing head and neck

injuries. You could strike the wheel or the

windshield. Adjust your belt so that there is

no more than 1 in. (25mm) of slack.