Page 1

workshop manual

for

diesel

;_

-1

.,

~

engines

~-.

, J

~-·

• .

...,.

,,

•

4.154

PRINTED IN U.S.A.

Page 2

workshop

manual

for

4.154

diesel

©

Perkins

32500 Van Born Road

P.O. Box 697 • Wayne, Michigan 48184 • U.S.A.

1976

Engines.

engines

Inc.

Publication No.

This publication supersedes the previous edition

numbered

publication

Tills

territories where

emission, noise, safety factors etc., then

tions, data and dimensions

such a

nance)

the local regulations when in use.

way

or

repairing an engine, it does

Published

of

Perkins Engines Ltd., and printed

Abbey Printers, High Street, Spalding, Lines.

by

601

SEA

1076/1024

601SER1024.

is

written for world-wide

legal

requirements govern smoke

given

that, after servicing, (preventive mainte-

the Service Publications Department

must

use.

all

be

applied

not

contravene

in

England by

instruc-

In

in

Page 3

PERKINS COMPANIES

AUSTRALIA

BRAZIL

Perkins Engines Division

P.O.

Box 156, Dandenong, Victoria 3175, Australia.

Telephone:

Motores Perkins

Cai.:a Postal 30.028, c Sao Paulo, Estado

Telephone:

792-Q431.

443-1499. TeleK: 23715.

S.A.

Telex:

AA 30816.

Cables:

de

Cables:

'Perkoil'.

Sao Paulo, Brazil.

'Perkoil' Sao Paulo.

FRANCE

GERMANY

GREAT

BRITAIN

Moteurs Perkins S.A.

55 Boulevard Ornano, 93203 Saini-Denis, France.

Telephone.

Perkins

8752 Kleinostheim, Postfach 12. Germany.

Telephone:

Perkins Engines Limited

Peterborough, England

243-04:40.

Motoren G.m.b.H.

Telex.

06027/8081.

PEt

Telex·

SNA.

62251

4188869.

Saint-Denis.

Cables:

'Perkoil' Paris.

Telephone Peterborough 67411. Telex 32501. Cables : 'Perkoil' Peterborough.

ITALY

SOUTH AFRICA

t,I.S.A.

Motori Perkins

22100 Como-Camerlata. Via Pasquale Paoli

Telephone· 504885.

Perkins Engines (Pty,)

P.O. Box 31285.

Telephone Johannesburg 725-5715.

Perkins

32500 Van

P.O.

Box

Tel.. (313)

S.pA

Telex·

ltd.

61h

Floor, Noswal Hall, Braamfonlein. Johannesburg, South Afnca.

Engines,

Born

Road

697 • Wayne,

595-9600

•1elex:

38063.

Cables·

Inc.

Michigan

23-4002

Telex·

48184 • U.S.A.

9/A,

Italy.

'Perkoil' Camerlata.

5430037.

Cables:

'Perkoil'

ASSOCIATE COMPANIES & MANUFACTURING LICENSEES

ARGENTINA

INDIA

JAPAN

KOREA

MEXICO

SPAIN

YUGOSLAVIA

Perkins Argentina S.A.LC.

Bolivar

366,

Buenos Aires. Argentina.

Telephone : 33-8231/36. Telex : 121162. Cables : 'Perkinsa'

Simpson & Co. Ltd.

P.O. Box 303, 2021203 Mount Road. Madras

Telephone:

Toyo Kogyo Co. Ltd.

6047 Fuchu-Machi, Aki-gun, Hiroshima, Japan.

Telephone:

Hyundai

Telephone.

Motores Perkins S.A.

Tiber No. 68 1er Piso, Me)(ico

Telephone: 528-61-67.

Motor Iberica

Carretera del Aero-Club, Carabanchel Alto, Madrid, Spain.

Telephone:

lndustrija Motora Rakovica

Patrijarha Dimltrija 7-13

Rakovica, Belgrade, Yugoslavia.

Telephone:

Cables:

Madras

Hiroshima 82-1111. Tela)(: 652-333.

Motor

27-5111/9, 27-6111/9.

208

562.043/562-322/562-992.

'lndmotor'

83091

(PABX-10

Co., Bae Jae Building,

SDF.

Telex:

Perkoil Mex 071-71-347.

S.A. (Division Zona

52-40,

208

96-40.

Belgrade.

Telex:

2}

208

2,

lines}.

98-40.

Telex:

India.

Telex:

41-538.

Cables·

55-4

Seosomoon-Dong, Seodaemoon-Ku, Seoul.

2391s.

Cables:

Cables:

Telex:

27324.

11341

YU

IMR.

Cables:

'Toyoko' Hiroshima.

Hyuildaimotor, SeouL

'Simpsons'

'Perkoilmex'.

Cables:

"Perki-e"

Madrid.

In addition to the above, there are Perkins Distributors in the majority

throughout

or

to one

the

world. For further details, apply to Perkins Engines Ltd., Peterborough.

of

the above companies.

of

countries

Page 4

CONTENTS

General Information

Cylinder Head

Pistons and

Cylinder Block and Uners

Crankshaft and

Timing Case

Connecting Rods

Main

Bearings

and

Drive

Flywheel and Flywheel Housing

Timing

Lubricating System

Cooling System

Fuel System

Air

Cleaner

Electrical System

Exhauster

Marine Engines

Lubricating

Glossary

of

Oils

Terms

Approved Service Tools

Examples

of

Service Facilities

Index

3

SECTION A

SEcnON

SECTION C

SECTION

SECTION E

SECTION

SECTION G

SECTION H

SECTION J

SECTION K

SECTION

SECTION M

SECTION

SECTION P

SECTION

Appendix

Appendix

Appendix

Appendix

Appendix

B

D

F

L

N

Q

FOREWORD

This Workshop Manual has been compiled for use

normal workshop

therefore, have been omitted

removal, dismantling, assembly

it

is

omitted from the text. Similarly, references

cleaning

removal

stood that these procedures will be carried

follows that any open ports

injection equipment, exposed by dismani:ling, will be blanked

re-assembled,

between the minimum and maximum dimensions which are

Manufacturing Data and Dimensions for the relevant component parts

quoted

turing tolerance". This tolerance

and its numerical value

quality

If

corresponding shaft have worn and

place

good workshop practice will ensure that consideration will be given

to

tion

Throughout this manual, whenever the

the

wheel end

joint

of

bum

in each

of

workmanship.

when carrying out a major overhaul it

in

the bush it may be necessary

the advisability

of

life that will involve labour costs at an early date.

engine is referred to, it

of

practice. Mention

faces, cleaning before inspection and re-assembly and

and scale have largely been omitted, it being under-

to

prevent the ingress

of

the sections in this manual

of

returning worn parts

the engine.

in order

or

of

is an expression

is

that

of

to

refitting

high precision components, e.a. fuel

is

side

avoid repetition. Where the

of

foreign matter. The difference

necessary

of

that

the majority

to

renew the bush only, however,

"left"

as

viewed from

in

certain accepted practices

of

out

is

as

the accuracy

is

to

conjunction with

a part

is

straightforward

to

renewing joints,

where applicable.

off

until

given in the

known

as

"the

an aid

found that a bush and

of

service with an expecta-

or

"right"

manufac·

to

manufacture

of

the desired

wear has taken

hand side

the

rear

or

fly-

It

as

of

Page 5

4

Unified

All

proprietary

American

The

block

number

mation

of

would

Another

where

fuel

engine

for

Threads a

THREADS

ENGINE

immediately

should

or

both

be I 54 U 251.

possible,

injection

when

this

system

equipment

Pipe

ordering

letters

and

later

viewed

nd

used

Series.

NUMBE

he

quoted

parts.

and

system

be

pump

would

Engi

ne Numb

on

the

4.154

arc

R is

behind

standardised

from

located

in full

The

figures,

of

on

the

the

be

GA

13870U500256D.

the

engine

engine

rear. A typical

er

Location

engine

Unified

on

fuel

when

number

an

example

numb<!ring will,

on a pad

left

hand

excepting

Series

the

cylinder

pump.

seeking

of

near

side

and

This

infor-

consists

wh1ch

the

of

the

number

This

manual

Department

endeavour

contained

but

due

turers

reserve

without

noti

is

of

is

made

herein

to

continuous

ce.

produced

Perkins

to

is correct

the

right

by

the

Service

Engines Limited

ensure

that

the

at the

to

alter

date

this

development the

Location

Publications

and

information

of

publication,

manufac-

specification

every

of

Engi

ne

Number

Page 6

5

ENGINE

VIEWS

View of Front

Perkins engines are built to individu

suit the applications for which they are intended and

the engine views

particular specification.

Left Hand Side

do

not necessarily typify any

of

4.154 Engine

al

requirements to

Page 7

6

View

of

Rear Right Hand Side

of

4.154 Engine

Page 8

7

Page 9

8

Page 10

----9

Page 11

10

~

e

-!'

<

.:::

•

'i

i

u

1

Cl>

.ii::

..

Q

i

u

.r

.§

!-<

....

Q

.t

>

1

]

~

~

_;

Page 12

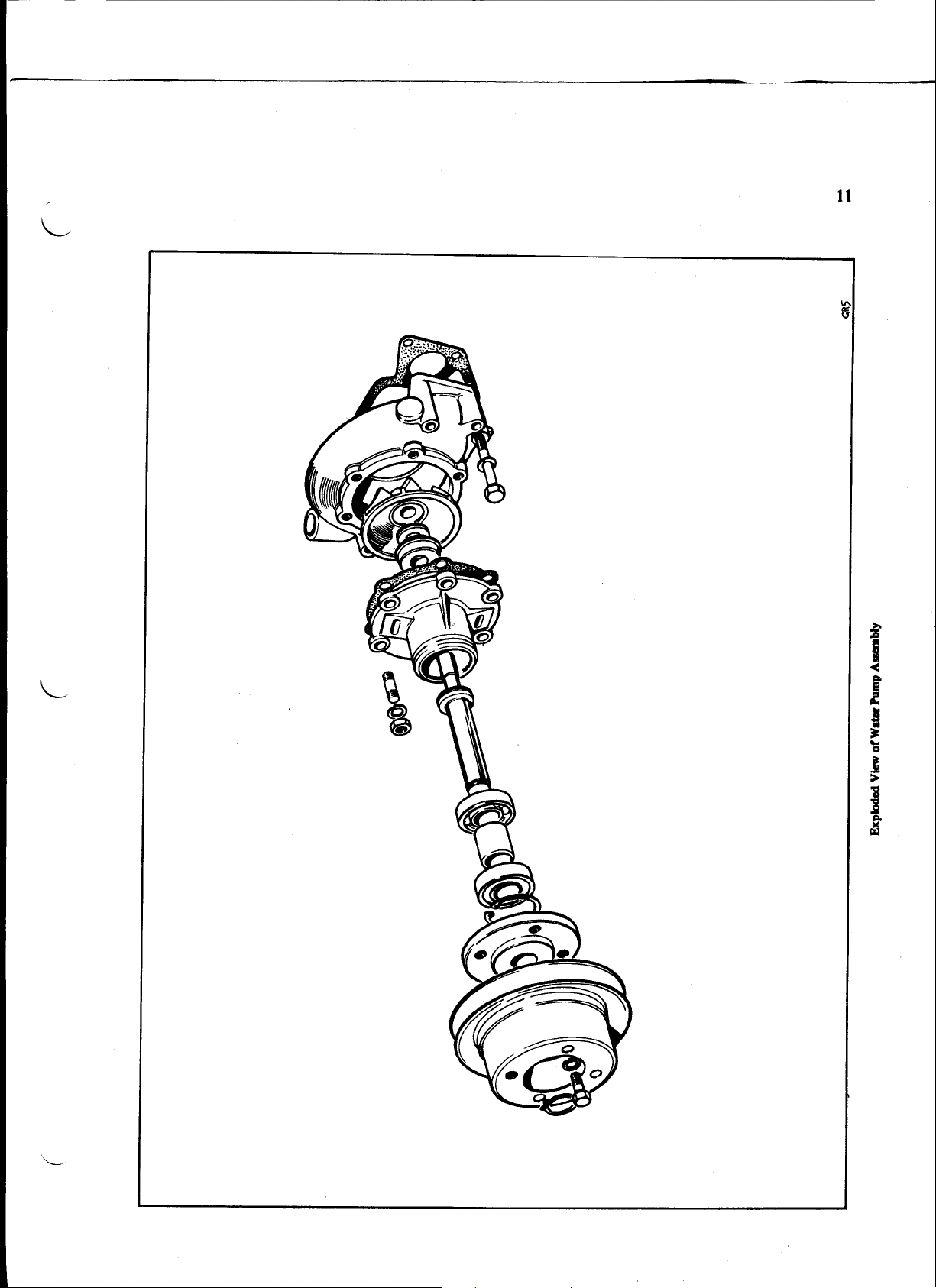

11

Page 13

General Information

At

Type

Bore (Nominal, see page

Stroke

Capacity

Compression Ratio

Combustion

Firing Order

Valve

Automotive type Applications

Hydraulic Governor

Maximum Torque

System

Tip Clearance

Section

GENERAL

ENGINE DATA

D.l.)

RATING DETAILS

INFORMATION

'A'

Four

Cylinder,

3.5 in (88,9 mm)

4.0 in (101

153.9 in

21.5:1

Indirect Injection, Ante-Chamber

(Perkins

1-3-4-2

0.012 in (0,30 mm) Cold

70

bhp

113 lbf ft ( 15.6 kgf

Four

Stroke, In-Line

,6

mm)

3

(2,523 litres)

.

"H"

type)

at 3,600 rev/ min

m)

at 2,000 rev/min

Agricultural type Applications

Mechanical Governor

Maximum Torque

Intennittently Operated Industrial Applications

Mechanical Governor

Maximum Torque

Variable Speed Light Duty Industrial Applications

Hydraulic Governor

Maximum Torque

Continuously Operated Industrial Applications

Mechanical Governor

Minimum Governed

Note: The above ratings can vary according

Service Department, Perkins Engines, Ltd., Peterborough.

Speed

to

application.

62

bhp

113 lbf

bhp

62

113 lbf

70

bhp

ll3lbf

55

bhp

1800 rev/min

For

details

at 3,000 rev/min

ft

( 15,6 kgf m) at 2,000 rev/min

at 3000 rev/min

ft

( 15,6 kgf m) at 2,000 rev/min

at 3,600 rev/min

ft

(15,6 kgf

at 3,000 rev/min

of

m)

at 2,000 rev/min

individual ratings, apply

to

Page 14

General Information

A2

APPROXIMATE ENGINE WEIGHTS DRY

Engines with standard basic components, i.e. fuel injection

electrics.

lb

Automotive

Industrial

Agricultural

of

Installed approximate weight

starter

motor,

air cleaner,

engines including all components, and flywheel, flywheel housing

but

without

Automotive

Industrial

Agricultural

clutch.

DE-RATING

Where engines are called upon

The following table

a particular engine rating are not available.

is

given

to

operate in rarefied atmospheres occasioned

as

a general guide, which may be applied

430

400

430

lb

555

550

565

FOR

pump,

water and lubricating oil pumps, filters and

kg

195

180

195

kg

251

250

255

ALTITUDE

on

a percentage basis, where specific figures for

by

altitude,

or

they

should be de-rated.

backplate, fan,

Altitude

0 -

2,000

ft

(600

2,000 4,000 6,000

8,000

10,000 -

4,000

6,000

-

8,000

-

10,000 ft

12,000 ft

ft

ft

ft

metre)

( 1200 metre)

(I

800

metre)

(2400

metre)

(3000

metre)

(3600metre)

Any necessary adjustments in this respect

territory concerned. For

or

to

Overseas Companies listed

any

further information apply

on

Page 2.

..................

....................

....................

....................

....................

....................

to

the fuel pump, should

to

Maximum Fuel Delivery

Measured at

,

..

.

.

.

.

.

be

carried

800

rev /min Pump Speed

No change

6%

12%

18%

24%

30%

out

by

De-ratilll

the

C.A.V. dealer for the

Service Department, Perkins Engines Ltd., Peterborough,

Page 15

The

following wear limits indicate

serviced

or

replaced.

SERVICE WEAR LIMITS

the

condition when it is recommended

that

Generai Information

the

respective items should be

A3

Cylinder Head Bow

Maximum Bore Wear

(when reboring

Crankshaft Main and

Maximum Crankshaft End Float

Valve

Stem

Diametrical Clearance

Valve

H.ead

Rocker Clearance

Camshaft

Camshaft End Float

Idler Gear End Float

Top

Max.

or

new liners are necessary)

to

Guide Bore

Thickness

Journals

Piston Ring

on

Big

End Journals

at

Outer

Shaft

Lift

Edge

RECOMMENDED

The following figures will apply

Component

Cylinder Head Setscrews (also

Secure Rocker

Main Bearing Setscrews .............................................. .

Connecting Rod Nuts

Connecting

Flywheel Setscrews .................................................... ..

Crankshaft Pulley Retaining

Power Take-off Pulley Setscrews ...............................

Camshaft Gear Setscrew .............................................. .

Idler Gear Hub

Dynamo

Alternator Pulley

Atorniser Securing

Lubricating Oil Filter Bowl Securing

Setscrews ......................................................... ..

Pump

Fuel

Shaft bracket) ................................... ...

Rod

Nuts (phosphated) ........................... ..

to

Pulley

Cylinder Block Nuts ....................... .

Nut

.................................................... .

Nut

Nut

Drive Gear Securing Setscrews ................. ..

with

the

components lightly oiled before assembly.

(non

phosphated) ..................... .

Setscrews ...................... ..

................................................

..............................................

Transverse

Longitudinal 0.006 in (0,15 mm)

Ovality 0.0005 in

Wear

Inlet

Exhaust

Ovality and Wear 0.002 in (0,05 mm)

TORQUE

Screw

..

..

..

TENSIONS

Size

1/2 in

1/2 in

7/16 in

7/16 in

1/2

in

5/8

in

3/8 in

1/2 in

5/16 in

7/16 in

7/16 in

5/16 in

1/2 in

5/16

in

0.003 in (0,08 mm) concave

0.005 in (0,13 mm) convex

0.006 in (0,15 mm)

0.001 in (0,03 mm)

0.020 in (0,51 mm)

0.005 in (0,13 mm)

0.006 in (0,15 mm)

0.045 in

0.005 in (0,13 mm)

O.Ql

O.Ql

0.008 in (0,20 mm)

lbfft

85

85

45

60

80

123

32

50

21

20

30

12

10

21

(O,Ql

mm)

(1,14

mm)

5 in (0,38 mm)

5 in (0,38 mm)

kgfm

11,7

11,7

6,2

8,3

11,1

17,0

4,5

6,9

2,9

2,8

4,15

1,7

l ,38

2,9

If

Connecting

Rod

Nuts are removed,

they

should

be

replaced

by

new ones.

Page 16

•

General Information

A4

OPERATING INSTRUCTIONS

Starting the engine.

If the weather or engine

tion

"R"

run position. Adjust the accelerator

position and engage the starter

starter

"heat

engine starts release the starter switch

position.

Always be sure that the starter pinion and flywheel

have stopped rotating before re-engaging the starter

motor, otherwise the ring

To

A spring loaded

normal engine controls and functions by cutting off

the fuel at the fuel injection pump.

the knob and hold in this position until the engine

ceases

the

experienced

stops

"off"

and ensure the engine stop control

motor

start"

Stop

the engine

to

rotate. Ensure

"run"

rotilting; the switch can then be turned to the

position to switch

is

warm, turn switch

to

switch in a

position, see Fig.

stop

position, otherwise difficulty may be

in

restarting the engine. When the engine

motor

<;lockwise

or

pinion may be damaged.

control

that

off

the electrical auxiliaries.

direction

A.l.

As

is

located near the

To

the control returns to

to

posi-

is

in

the

the

the

to

the

as

the

"run"

the fully open

by turning

soon

to

operate, pull

At

oc.•~+

Cold Starting

stop

Switch on, ensuring the engine

"run"

position. Turn on the fuel supply tap

cold starting aid reservoir where fitted. Turn the

starter switch

for fifteen

With the accelerator

the

starter switch to the

by engaging

start after twenty seconds, return the switch

"heat"

the starter

position.

should be released

on

the

off.

to

the

"heat"

to

twenty seconds.

the

starter motor.

position for

motor

As

cold starting reservoir (where fitted) turned

by switching to

soon.

as

to

position and hold it there

in

the

fully open position,

"heat

ten

seconds and then re-engage

the

engine starts,

the

"run"

control

start"

If

the engine does not

the

position, and

is

in the

of

the

the

turn

to

the

start"

switch

the

tap

position, there-·

"heat

Page 17

PREVENTIVE MAINTENANCE

General Information

AS

DAILY

level

of

Check

Check level

vehicle or machine

Check lubricating oil pressure (where gauge

In extreme dust conditions, empty dust bowl

type air cleaner.

Under adverse agricultural conditions, clean chaff

screens, radiators and centrifugal pre-filters.

4,000

MONTHS, whichever is the soonest.

Drain and renew lubricating oil - Lubricating oil

meet

must

specification in the appendix.

Renew element in lubricating oil filter.

Empty

Check fan belt tension -

3,000 rev/min the fan belt tension should

monthly.

Clean water trap.

Check engine for oil and water leakage.

Where fitted, lubricate dynamo rear bush.

coolant.

of

lubricating oil in sump (make sure the

is

standing level).

MILES

dry

(6,000

the approved specification. See oil

air cleaner dust bowl.

km)

1~0

HOURS

For

engines rated at above

is

be

checked

fitted).

on

dry

or

The Kilometre conversions

They are periods in Kilometres which should

of

in place

Operators

above

application, therefore he should

maintenance for his engine with the schedule specified

the engine

shorter periods also bearing in mind that on

low mileage work, the hours run are more applicable

than the mileage covered.

Whilst

maintenance,

3

local regulations concerning your vehicle or machine

and ensure that the engine

regulations.

Running-in Procedure

New

at full power

or

20 hours. Neither should they be run without any

load upon them.

To assist in the initial bedding in

such

should be used at

output

after which it may be operated at full power.

Do

for an extended period, nor by running the engine

at idling speeds with no load.

POST DELIVERY CHECKOVER

miles in relevant countries.

of

Preventative Maintenance schedule

by

or

as

not

4.154 engines are reminded that the

the manufacturer

is

fitted, and where necessary adapt the

we

have given specific periods for preventive

you

should have due regard for the

replacement engines should not be operated

output

piston rings, bearings, seals etc., the engine

for the first 500 miles (800 km) or 20 hours,

"run

about

in"

an engine by applying a small load

of

miles are

of

the application

is

operating within those

for the first 500 miles (800 km)

80%

of

not

accurate.

be used

is

c;ompare the routine

of

its maximum power

general in

to

which

stop-start

the moving parts

12,000 MILES (18,000 km)

MONTHS, whichever is

Tractor and Industrial applications, renew the final

fuel filter element;

Check and adjust tappets.

Check hoses and clips.

Clean element

not

indicated earlier)

24,000 MILES (36,000 .Ion)

Vehicle

element.

72,000 MILES (108,000

Arrange for examination

equipment, i.e. Compressor/Exhauste"r, Starter Motor,

Dynamo etc.

Service atomisers.

of

dry type air cleaner,

Applications, renew the final fuel filter

km)

450

the

soonest.

900

HOURS

2,700 HOURS

and

service

HOURS

or

renew, (if

of

proprietary

or

12

After a customer has taken deliveryof his engine, a

general checkover must be carried

500/1,000 miles

service and must include the retightening

cylinder head setscrews in the correct sequence. With

the engine thoroughly warmed through, the checkover comprises the following:-

Drain the lubricating oil sump and refill

1.

correct level with clean new engine oil (Do

overfill).

Renew lubricating oil filter element (canister).

2.

Tighten the cylinder head setscrews in the

3.

correct sequence (see

torque

Reset the valve tip clearances

4.

mm)

Check oil feed

5.

Check the tension

6.

Check the tightness

7.

screws, mountings, etc.

Start the engine and check for any fuel, coolant

8.

or

lubricating oil leaks.

Adjust idling speed

9.

(800/

1,600 km) or

of

80-85

(see page 8.5).

to

rockers.

fig.

lbf

of

the fan belt (see page K.2.)

if

necessary.

out

after the first

20/40

hours m

of

the

to

the

not

8.2)

and to the correct

ft (11,06-11,75 kgf m).

to

0.012 in (0,30

of

all

external nuts, set-

Page 18

General Information A6

PRESERVATION

OF

LAID-UP ENGINE

Batteries

Where an application which

engine

is

to

able that some measure

engine

intervening period before operations are

menced.

It

is recommended, therefore,

procedure be adopted and applied immediately the

unit

is

I.

2. Run the engine until well warmed through.

3. Discard the paper element in the full flow

4. Clean

5. Fill the lubricating oil sump

be laid-up for several months, it

to

ensure

that

withdrawn from service.

Thoroughly clean all external parts

engine.

Stop

the engine and drain the lubricating oil

sump.

cating oil filter, clean the filter bowl and fit a

new element. Fill the filter bowl (where

sible) with a new oil

list

of

approved lubricating oils appears in the

appendix.

out

the engine breather pipe.

with clean new lubricating oil

as

grade,

referred

is

powered. by a Perkins

of

protectic.n be afforded the

it suffers no

to

in

ill

effect during the

that

the following

of

an approved grade. A

to

the correct level

of

(3)

above.

an approved

is

advis-

recom-

of

lubri-

pos-

the

(a) Remove the

engine and

water, making sure

the separators

cov:ered.

(b) Recharge the

source

(c)

Screw home the vent plugs and clean the

battery

ture.

Clean the terminals and lightly smear

(d)

them with petroleum jelly.

(e)

Store in a cool, dry, dust-free place.

no account should the battery

where there

(f)- Recharge once a

rate

of

battery

top

of

supply.

removing all dust, dirt and mois-

is

charge,

or

up the cells with distilled

or

battery

a risk

batteries from the

that

the

top

separator guards are just

from a separate

of

freezing.

month

to

a state

edges

at

the

of

free gassing.

be

normal

of

On

left

Starters and Generators

Clean the terminals and lightly smear them with

petroleum .ielly

open, the

protected against water falling

If

gener:ttor

the machine

starter

is

and control panel must be

to

dire"ctly

stand in the

onto

them.

6. Carry

7. Drain water by opening all the drain taps

8. Remove the atomisers and spray into the

9. Replace the atomisers (using new

I

0. Remove the air cleaner and any air intake pipe

II.

12. Remove cylinder head cover. lubricate

out

cribed in the appropriate Fuel Pump section.

on the cylinder block and the radiator.

ensure complete draining,

remove the drain taps entirely and check that

the holes are

reasonable drainage period, refit the taps

open position.

cylinder bores

oil, divided between all cylinders.

and slowly

revolution.

which may be fitted between the air cleaner

and air intake.

orifice with waterproofed adhesive tape

other

Remove the exhaust pipe, and seal

orifice with adhesive tape as in

rocker assembly with engine oil and replace

cover.

attention

rotate

suitable medium.

to

the fuel

not

blocked by scale. After a

i pint (70 cm

the crankshaft one complete

Carefully seal the air intake

it

is

3

(I

pump

preferable

)

of

lubricating

joint

the

0) above.

as

both

in

washers)

or

some

manifold

des-

To

to

the

the

the

Fuel Injection Pump

Drain all fuel oil from the fuel tanks and filters.

I.

Put into the fuel tank at least a gallon

the oils listed

Inhibiting

construction

oil

is

inadequate, break the fuel feed line before

the first filter and connect a small capacity

auxiliary tank.

Prime the system as detailed

2.

Start

3.

4.

s.

the engine and run it until the oil has

circulated through the. injection

pipes and injectors, which will be after it has

run light, at

least fifteen minutes.

Stop

the engine.

Seal

the

waterproofed adhesive tape

of

water condensation during the lay-up period.

under

the

Fuel

of

about

air vent in the tank

"Recommended

System".

the

fuel

tank,

half maximum speed, for at

If,

because

this

on

page L.7.

or

filler cap with

to

reduce

of

one

Oils for

of

quantity

pump,

the

of

the

of

feed

risk

13. Remove the fan belt and retain this for refitting

when

the

engine

is

to

be returned

to

service.

Page 19

The proprietary brands

mended for

panies. They may

world,

to

the

the

purpose

not

but

suitable oils may be obtained

appropriate companies. The specification

of

oils listed are recom-

by

the

be available in all parts

should include the following:-

Viscosity: The viscosity should

centistokes

likely

at

to

the

be experienced

Pour Point: Must be at least

not

lowest ambient temperature

on

l5°F

the lowest ambient temperature likely

on

experienced

be lower

be met during

The oils selected are

calibrating

or

testing pumps.

restarting and should preferably

than

the lowest temperature likely to

the

lay-up period.

not

necessarily suitable for

respective oil com-

of

by

the

reference

be greater than 22

restarting.

(9°C) lower

than

to

be

General Information A 7

PREPARING THE ENGINE FOR RETURN

SERVICE

When

the

engine

is

to

lowing procedure must be

1.

Thoroughly clean all external parts

observed:-

engine.

be returned

2. Carry

3. Ensure

out

cribed in

attention

the

Fuel Pump Section

that

the

cylinder block and rlJdiator

to

drain taps are correctly fitted in the closed

position and fill the system with clean coolant.

Check visually for leaks and remedy where

necessary.

4.

Rotate

freedom

the

water

of

the water pump seals.

pump

to

the

fuel pump

by hand

service,

on

Page A.8.

to

the

of

a!l

TO

fol-

the

des-

ensure

Caution

is

When oil

be allowed

being drained from the system it must not

to

fall on electrical equipment.

RECOMMENDED OILS FOR INHIBITING THE

FUEL SYSTEM

Lowest

Temperature

During

Lay-up

Esso

IL81S

Esso·IL1047

Shell

Calibration

Shell

Calibration

Shell

Fusus

Shell

Fuses

In

Note:

ture likely

........................

..... • .................

Fluid

"C" (U.K.)

Fluid

"B"

"A"

•...................

"A"

R1476

(Overseas)

(Old

Type)

choosing a suitable oil

to

be met

by

the

engine during

.

.

••.•••

...

.....

the

25°F

(-4°C)

0°F

(-l8°C)"

0°F (-l8°C)

-70°F

(-57°C)

-l5°F

(-26°C)

25°F (-l4°C)

lowest tempera-

the

lay-up

period should be estimated, and the oil should be

that

the

such

as,

or

lower

made

to

been at least

table for

temperature given in the table

than

restart

not

this estimate. No

the

en~ne

l5°F

(9 C) above

less

than

24

until

hours; otherwise there may

the

be difficulty in obtaining a free flow

attempt

temperature has

that

.Df

is

as low

should be

shown in the

fuel.

5. Refit the fan belt and adjust

to

the correct

tension.

6. Remove the cylinder head cover, lubricate the

rocker assembly with engine oil and replace the

cover.

7. Remove the adhesive tape from

the

orifice and refit

gauze

is

clean and if

with clean engine oil to

8.

Refit any air intake pipe between the air cleaner and

the

air intake

air cleaner. Ensure that the

it

is the oil bath type, fill

the

whiCh

the

air intake

correct level.

may have been

removed during laying-up procedure.

9. Remove the adhesive tape from the exhaust

the

manifold orifice and refit

exhaust pipe

using new joints.

10. Connect

fully charged and topped

the

battery

or

batteries

up

as

necessary with

into

circuit,

distilled water.

Starters and Dynamos

11. Wipe the grease from

that

all connections are sound.

fitted with a Bendix

the

terminals and check

type

If

of

drive, which proves

the

starter is

sluggish in engagement when operated, the

starter

motor

should be removed and the drive

cleaned thoroughly in a suitable cleaning fluid.

Lubricate with a little light engine oil before

replacement.

12. Check the level and condition

the

sump. Change the oil

the

engine in

the

normal manner checking

13.

oil in

Start

for oil pressure and dynamo charge

ately.

the

14. Whilst

temperature it

running normally and

engine is attaining normal running

is

advisable

that

it is free from water,

fuel and lubricating oil leaks.

to

of

if

check

the

lubricating

necessary.

immedi-

that

it

is

Page 20

General Information

D.P.A.

Distributor

Remove the adhesive tape from the fuel tank

1.

vent or filler cap.

Drain the fuel tank

2.

and condensed water, and refill the tank with

fuel oil.

3. Fit a new filter element and

oil flows free from air bubbles (see page L.8)

4. Air vent and prime the pump (see page L.7).

Pump

AS

to

remove any remaining oil

vent the filter until

NOTE:

If

the foregoing instructions are observed, the

laying-up and returning to service should be carried

out efficiently and without adverse affect on the

engine. Perkins Engines Ltd., however, cannot accept

liability for direct or consequential damage that

might arise following periods

of

laying-up.

FROST

Precautions against damage

if the engine

weather either by adequately draining the water

system or where this is not convenient, an anti-freeze

of

corrosion inhibitor may be used.

Should it be your policy

When draining a cooiing system, ensure that the

PRECAUTIONS

by

is

to be left exposed to inclement

reputable make and incorporating a suitable

damage by adding anti-freeze to the cooling system,

is

advisable that the manufacturers

mixture be contacted to ascertain whether their

products are suitable for

to ensure that their products will have no harmful

effect on the cooling system generally.

perience that the best results are obtained from

anti-freeze which conforms to British Standard 3151

or has been tested in accordance with

5 to

give

at least

The coolant solution containing

freeze manufactured to BS.3151 in water in a properly

maintained engine should maintain its anti-freeze and

anti-corrosive properties throughout the winter season

and in general, a safe life

ably be expected.

vehicle or machine

as

is

frost should

to

protect engines from frost

use

in Perkins Engines, also

good a result

25

of

12 months may reason-

on level ground.

be

taken

of

the relevant

It

is

our ex-

BS.5ll

7,

Clause

as

BS.315l.

per cent anti-

it

When

the engine

drained, but rotation

by:-

(a) Locking

drain hole being blocked

(b) The locking of the seal through the freezing

globules of moisture between the seal and the

insert.

Operators are therefore advised to-take these

tions when operating in temperatures below freezing

point:

1.

Before starting the engine,

by

hand, this will indicate if freezing has taken

place.

free any ice formation.

If

2.

3.

After an anti-freeze solution has been used, the

cooling system should be thoroughly flushed in

accordance with the anti-freeze manufacturer's

instructions before refilling with normal coolant.

it is impossible

the engine should be filled with warm water.

To

when all water has been drained, run the engine

for a few seconds at

ing any moisture remaining in pump.

is

drained the water

of

the pump may be prevented

of

the impeller

If

freezing has taken place, this should

avoid this trouble. the operator should.

by

by

to

tum

1dung speed, thus

pump

ice due

tum

to

sediment.

the water pump

the

pump

is

also

the pump

precau-

by

hand,

<11Spers-

of

If

the foregoing action

should be experienced,

cannot be held responsible for any frost damage

corrosion which may be incurred.

is

taken, no harmful effects

but

Perkins Engines Ltd.,

or

Page 21

fault finding chart

General Information

A9

FauH

Low cranking speed

Will not start

Difficult starting

Lack

of

power

Misfiring

Excessive fuel consumption

Black exhaust

Blue/white exhaust

Low oil pressure

Knocking

Erratic running

Vibration

High

oil

pressure

Overheating

Excessive crankcase pressure

Poor compression

Starts, and stops

Poulble

1,

5,

5,

8,

8,

Cause

2,

3,

4.

6,

7,

8,

9.

10.

12. 13, 14,

7.

8,

9,

10, 11, 12. 13,

9,

10,

1~

12, 13. 14. 18, 19,

9,

10. 12, 13, 14, 16. 18. 19.

11, 13, 14, 16, 18, 19,

11,

13,

14,

16.

18, 19,

4,

16.

18. 19,

20,

25, 27.

4,

36.

37, 38,

39,

40,

9,

14, 16. 18, 19,

7,

8,9,

10, 11,

13.

14,

20,

4,

38,

41.

12,

23. 25,

22, 26,

13.

26,

11, 13, 14, 16, 18. 19,

25,

31, 33, 34,

11,

19,

25, 28.

45,

29,

55.

31, 32.

10, 11, 12.

14.

20, 22,

20,f2.

31.

42, 43.

28.

14.

16.

29.

30, 33,

24, 25,

33,

15.

16. 17,

15, 16, 18. 19.

20, 21, 22.

20,

25, 26. 28. 29,

23.

24,

25, 27, 28,

24.

25, 27,

33.

34. 35.

44,

58.

29.

31.

33. 35,

20.

21. 23, 26,

45. 48, 49.

45,

47,

50, 51. 52, 53. 54. 57.

34.

46,

59.

KEY TO FAULT FINDING CHART

1.

Battery capacity low. 31. Worn cylinder bores.

2.

Bad electrical connections.

3.

Faulty starter motor.

4.

Incorrect grade of lubricating oil.

5.

Low cranking speed.

6.

Fuel tank empty.

7.

Faulty stop control operation.

8.

Blocked fuel feed pipe. 38. Inaccurate gauge.

9.

Faulty fuel lift pump.

10.

Choked fuel filter.

11.

Restriction in

12.

Air in fuel system.

13.

Faulty fuel injection pump.

14.

Faulty atomisers

15.

lncor'l-ect use of cold start equipment.

air

cleaner.

or

incorrect type.

16. Faulty cold starting equipment.

17. Broken fuel injection pump drive.

18.

Incorrect fuel pump timing.

19. Incorrect valve timing.

20.

Poor compression.

21.

Blocked fuel tank vent.

22.

Incorrect type or grade

23.

Sticking throttle or-restricted movement.

24.

Exhaust pipe restriction.

25.

Cylinder head gasket leaking. 55. Choked breather pipe.

26.

Overheating.

27.

Cold running. 57. Coolant level too low.

28.

Incorrect tappet adjustment.

29.

Sticking valves.

30.

Incorrect

h_igh

pressure pipes.

of

fuel.

32.

Pitted valves and seats.

33.

Broken, worn

34.

Worn valve stems and guides.

35.

Overfull air cleaner

36.

Worn

or

37.

Insufficient oil in sump.

39.

Oil pump worn.

40.

Pressure relief valve sticking open.

41.

Pressure. relief valve sticking closed.

42.

Broken relief valve spring.

43.

Faulty suction pipe.

44.

Choked oil filter.

45.

Piston seizure/pick up.

46.

Incorrect piston height.

47.

Damaged fan.

48.

Faulty engine mounting (Housing).

49.

Incorrectly aligned flywheel housing,

50.

Faulty thermostat.

51.

Restriction in water jacket.

damaged bearings.

52. Loose fan belt.

53.

Choked radiator.

54.

Faulty water pump.

56.

Damaged valve stem oil deflectors

58.

Blocked sump strainer.

Broken valve spring.

59.

18,

19.

20. 22,

31, 32. 33.

20, 21, 22. 24, 29.

23.

24. 25, 26. 27.

30,

32.

29.

31.32.

28. 29.

31,

32,

45,

56.

36.

45, 46,

28. 29.

30. 33.

or

sticking piston ring/s.

or

use of incorrect grade of oil.

33.

59.

31. 32. 33.

31, 32.

33.

35,

45.

(if

33.

59.

or

flywheel.

fitted).

Page 22

Section

Cylinder Head B 1

' ,

B

CYLINDER

The cylinder head

of

"cross flow" design with the exhaust and inlet

ing

ports

on

rod operated through the rocker gear mounted

top

cover which

the right hand side

a synthetic rubber oil deflecting seal,

exhaust valves are provided with two springs retained

by a hardened cap and split conical cotters. All valves

Cylinder

opposing sides. The overhead valves are push

of

the cylinder head, covered by a pressed steel

Head

is

a one piece high duty iron cast-

is

provided with a breather pipe fitted

of

the engine. Each inlet

both

CYLINDER HEAD DIMENSIONS

Overall depth

Skimming allowance

Pressure for Water Leak Test

Valve seat angle

Bore for Valve Guide

Bore for

Depth

of

Cylinder Head

Combustion Chamber Inserts

of

bore for Inserts

on

the

to

valve

has

inlet and

HEAD

operate in cast iron guides pressed into the head. The

upper

hemispherical in shape, being formed by an inserted

machined plug containing a throat connecting the

chamber to the cylinder.

cylinder head through jets

fishtail area in the combustion chamber inserts. The

cylinder head

twenty setscrews, seven

rocker shaft

part

of

the combustion chamber

Coolant is delivered

to

the valve bridge and

is

secured

to

the cylinder head.

3.248/3.252 in (82,5/82,6 mm)

Nil

30 lbf/in2 (2.11 kgf/cm

45°

0.500/0.5()1

1.375/1.3766 in (34,92/34,96 mm)

0.425/0.4281 in (10,79/

in (12,7/12,73 mm)

to

the cylinder block by

of

which also secure the

2

)

10,87 mm)

to

is

the

Combustion Chamber Inserts

Outside diameter

Clearance fit

Combustion Chamber Insert thickness

Height

Method

Valve Guides, Inlet

Outside diameter

Interference fit

Overall length

Guide protrusion above

Valve Guide bore diameter

of

of

Insert in relation

of

location

and Exhaust

of

of

Insert

Insert in Bore

to

of

Guide

of

Guide in Bore

Guide

Cylinder Head Top Face

Cylinder Head face

1.3724/1.374 in (34,86/34,9 mm)

0.001/0.0042 in (0,02/0,11 mm)

0.4252/0.426 in

0.001 in (0,02 mm) above,

0.0029 in (0,07 mm) below.

By

Cylinder Block Face and Expansion Washer.

0.50125/0.50175 in (12,73/12,74 mm)

0.00025/0.00175 in (0,01/0,04 mm)

2.13 in (54,10 mm)

0.638/0;662 in ( 16,20/16,81 mm)

0.3145/0.3155 in (7,99/8,01 mm)

(10,80/ 10,82 mm)

Page 23

Cylinder Head

Valves. Inlet

82

Valve

stem

Clearance

Valve head

Valve face angle

depth

Valve

Overall length

Sealing Arrangement

Valves, Exhaust

Valve stem

C'learance fit

Valve head

Valve face angle

depth

Valve

Overall

Sealing arrangement

Valve Springs Inner

Fitted

Load at fitted length

Free length

Valve Springs Outer

Fitted

Load at

Free length

diameter

fit

of

Valve

diameter

below Cylinder Head face

diameter

of

diameter

below Cylinder Head face

length

length

length

fitted

stem

of

Valve

Valve sten: in Guide

of

Valve

length

in Guide

(Production)

(Service)

(Production)

(Service)

0.312/0.313

0.0015/0.0035

1.591/1.598

45°

0.029/0.041

0.060

in

(1,52

4.503/4.521

Synthetic

0.312/0.313

0.0015/0.0035

1.3937/1,4016

45°

0.027/0.040

0.060

4.503/4.5.21 in

in

Rubber

(I

,52

Nil

1.49 in (

28 ± 1.4

1.74 in

1.59 in

40±

1.8

37,84

lbf

(44,19

(40,38

2.0lbf(l8,1

r in

(45,97

(12,7

in (7

,92/7,95

in

(0,04/0,09

in

(40,41/40,59

in

(0,74/1,04

mm)

in (

114,38/114,83

Deflector

in (7 ,92/7,95

in

(0,04/0,09

in

(35,4/35,6

in

(0,69/1,02

mm)

(114,38/114,83

mm)

± 0,65 kgf)

mm)

mm)

± 0,91 kgf)

mm)

mm)

mm)

mm)

mm)

mm)

mm)

mm)

mm)

mm)

mm)

Rocker Levers

Rocker

Outside

Interference fit

Inside

Rocker Shaft

Outside

C'learance fit

Lubrication

Push Rods

Overall length

Outside

lever bore

diameter

diameter

diameter

of

diameter

diameter

of

Bush

of

Bush in bore

of

Bush

of

Shaft

Rocker

Lever Bush

(fitted)

on

Shaft

0.7188/0.7196

0.7199/0.7207

0.0003/0.0019

0.625/0.6258

0.6234/0.6244

0.0006/0.0024

No.

I Bracket

to

Rocker

8.5102/8.5412

0.247/0.25

Levers

in

in

(18,26/18,28

in

(18,29/18,30

in

(0,01/0,05

in

(15,87/15,89

in

(IS

,83/15,86

in

(0,01/0,06

through

(6,27/6,35

Shaft

in

(216,16/216,94

mm)

mm)

mm)

mm)

mm)

mm)

mm)

mm)

Page 24

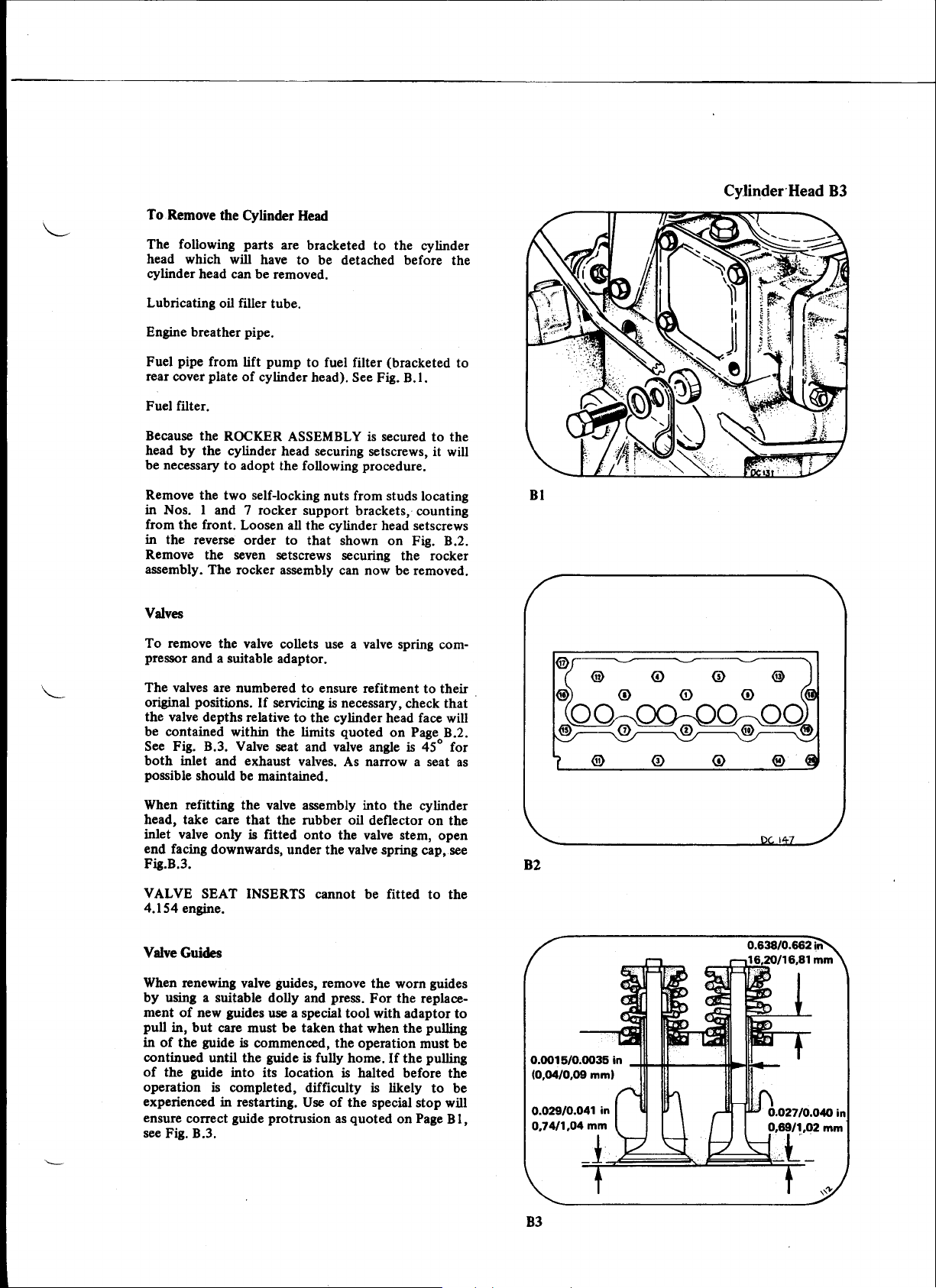

To Remove the Cylinder Head

The following parts are bracketed

head which will have

to

be detached before the

cylinder head can be removed.

Lubricating oil filler tube.

Engine breather pipe.

to

Fuel pipe from lift pump

rear covet plate

of

cylinder head). See Fig.

fuel filter (bracketed

Fuel filter.

to

the cylinder

B.l.

to

Cylinder· Head

BJ

Because the

head

be necessary

ROCKER ASSEMBLY is secured

by

the cylinder head securing setscrews, it will

to

adopt the following procedure.

to

the

Remove the two self-locking nuts from studs locating

in Nos. 1 and 7 rocker support brackets,- counting

from the front. Loosen all the cylinder head setscrews

in the reverse order to

that

shown

on

Fig. B.2.

Remove the seven setscrews securing the rocker

assembly. The rocker assembly can now be removed.

Valves

To remove the valve collets use a valve spring compressor and a suitable adaptor.

The valves are numbered

original positions.

the valve depths relative

be contained within the limits quoted

See Fig. B.3. Valve seat and valve angle

both

inlet and exhaust valves.

If

servicing

to

ensure refitment

is

to

necessary, check that ·

the cylinder head face will

As

narrow a seat

on

Page B.2.

is

to

45° for

their

as

possible should be maintained.

When refitting the valve assembly into the cylinder

head, take care

inlet valve only

the rubber oil deflector

is

fitted

onto

the valve stem, open

on

the

that

end facing downwards, under the valve spring cap, see

Fig.B.3.

Bl

82

VALVE SEAT INSERTS cannot be fitted

to

the

4.154 engine.

Valve

Guides

When renewing valve guides, remove the worn guides

by

using a suitable dolly and press.

ment

of

pull in,

in

continued until the guide

of

operation

experienced in restarting.

new guides use a special tool with adaptor

but

of

care must be taken

the guide is commenced, the operation must be

is

fully home.

the guide into its location

is

completed, difficulty

Use

ensure correct guide protrusion

For

the replace-

that

when the pulling

If

is

of

the special stop will

as

quoted

the pulling

halted before the

is

likely

on

Page B 1,

to

to

be

see Fig. B.3.

83

Page 25

Cylinder Head

84

Valve Springs

84

0

0

0

0

c

Check the

specific lengths against the figures quoted on

8.2,

fatigue.

overhaul

Rocker Shaft Assembly

When

support brackets for re-assembly,

feed to the rockers

cylinder head, and a drilling in the base

support bracket locates with this hole,

Also note that the rocker shaft locating scallop

towards the front

Rocker Levers

If

rocker lever bushes are found

replacement, rocker levers complete with bushes

ready to fit are available.

Rocker level bushes are also available separately.

With early engines, the oil hole in the bush should

align with the oil hole in the rocker lever, but with

later engines, after fitting the bush, it should be

drilled with a 2 mm drill in line with the oil hole in

the rocker lever. With the latter operation, ensure

that all machining swarf

the rocker shaft.

valve

springs for pressures developed at

and for any signs

It

is

advisable to fit new springs when an

is

undertaken.

dismantling, take note

of

is

at the forward end

of

the shaft.

is

8.4.

The oil

of

Page 7.

Page

of

of

No. l

the

the

of

deterioration caused by

of

the order

see

Fig.

see

to

be in need

removed before assembling

is

BS

)

0·001in 0,02

O·OOZiin

n

m•

O,Olmm

above

-

n

DC

14-3

Combustion Chamber Inserts

To

·remove the inserts

through the atomiser bore and tap out.

To replace, locate the inserts

sion washers,

turning whilst the engine

When

cylinder head face should be checked against the

figures quoted on

Cylinder Head Distortion

The limits for cylinder head bow are given in

SERVICE WEAR LIMITS on Page A.3.

tion reveals a dimension in excess

quoted, a replacement cylinder head

as

no

allowance for skimming

Cylinder Head Gasket

Fit a new gasket when replacing the cylinder head.

This

is

the cylinder block top face.

see

fitted, the height

fitted DRY, and

Fig.

Page

use

a short length

by

means

8.5,

to prevent the inserts from

is

in service.

of

the insert in relation

8.1,

see

Fig.

is

provided.

is

located by two dowels in

See Fig.

of

8.6.

If

of

is

recommended,

8.7.

of

bar

the expan-

to

the

examina-

the limits

86

Page 26

Refitment

Before refitting the cylinder head, ensure that the

oilway in the block

clean. Examine the PUSH

fit into their location.

The rocker assembly

and

through Nos. I and 7 rocker support brackets and

secured by two nuts. The rocker shaft

positioned

securing stud. (Take care that the oilway in the base

of

No. I support bracket

corresponding oilway in the head. After fitting the

cylinder head, replace the seven longest setscrews

through the support brackets into the head and secure

finger tight.

Replace the remaining thirteen setscrews and tighten

them all progressively in the sequence shown in Fig.

B.2, until a final torque

kgf

should

Retighten the two rocker assembly securing nuts.

Valve Oearances

The

cold at

following

(a) With the valves rocking on No. 4 cylinder (the

of

Cylinder Head

top

face and cylinder head is

RODS

for straightness, and

is

is

located by two studs in the cylinder head

by

the scallop which locates on the front

m)

is

achieved. This final torque tightening stage

be

repeated.

valve

tip clearance should be set with the engine

0.012 in (0,3 mm)

procedure:-

period between the opening

and the. closing

clearance on No. 1 cylinder.

fitted before securing the head,

is

is

clean and aligns with the

of

80-851bfft

see

Fig. B.8, using the

of

the exhaust valve), set the

of

the inlet

(II,l-11,7

correctly

valve

Cylinder Head

(b) With the valves rocking on No. 2 cylinder, set

the clearance on No. 3 cylinder.

(c) With the valves rocking on No. I cylinder, set

the clearance on

(d) With the valves rocking on No. 3 cylinder, set

the clearance on No. 2 cylinder.

Atomisers

Refit the atomisers squarely into their locations using

a new sealing washer, and ensure that the securing

nuts are tightened evenly to a torque

(I

,4-1

,7

kgf m).

Engirie.Running Check

Before fitting the top cover, start the engine and run

at a fast idle.

Check for satisfactory oil pressure where a gauge

fitted. Check that lubricant is reaching the rocker

assembly. Check for fuel, oil and coolant leaks.

When

the engine is thoroughly warmed through, shut

down

ap~

re-torque the cylinder head securing setscrews.

clearances

Carry out this check again after

(800/I,600

When

the engine

to

0.012 in (0,30 mm).

km) or 20/40 hours in service.

No.4

is

cylinder.

cold,

re«:t

of I 0-12

the

500/1,000 miles

valve

BS

lbfft

tip

is

B1

B8

0·012in

0,30mm

clld

,,,

Page 27

• • •

Sect1on

Pistons and Connecting Rods C I

C

PISTONS

The pistons are

aluminium_alJoy, flat

rings, and one scraper ring above the gudgeon

one below

The gudgeon pins which are fully floating are located

axially in

The gudgeon pins are off-set, so ensure

and connecting rods are correctly assembled by means

of

the

rod

it.

the

numbers

big ends

manufactured

topped

pistons by circlips.

on the piston crowns and connecting

as

described later in this section.

with

AND

from high silicon

three compression

that

piR

and

the pistons

PISTON AND ROD DIMENSIONS

Pistons

Pisto!l

Type

Piston Height in relation

Bore Diameter for Gudgeon Pin

Transition fit

Compression Ring Groove Width top, 2nd and

Scraper Ring Groove Width

of

Pin in Bore

Rings

Compression,

Compression, 2nd and

Scraper,

Scraper,

Compression Ring Width,

Ring Clearance in Grooves

Scraper Ring Width,

Ring Clearance in Groove

Scraper Ring Width,

Ring Clearance in Groove

Compression Ring Gap,

Compression Ring Gaps, 2nd and 3rd

Scraper Ring Gap,

Scraper Ring Gap,

top

4th

5th

4th

5th

to

3rd

top,

4th

5th

top

Cylinder Block

4th

and

5th

2nd and

3rd

CONNECTING

The

connecting rods are manufactured from

molybdenum alloy steel stampings with an

section shank. The big ends are split at

the

rod axis, with each cap secured by

bolts. The big end bearing

placeable thin wall aluminium-tin steel backed shell

bearings, and

backed

Top

Face 0.000/0.004/

3rd

bronze

Flat topped

1.2495/1.250

0.00024

interference (0,001/0,01 mm)

0.096/0.097

0.1895/0.1905

Chrome plated

Internally stepped

Chrome plated, slotted

Slotted

0.093/0.0938

0.0022/0.004

0.1868/0.1875

0.002/0.0038

0.1865/0.1875

0.002/0.004

0.014/0.019

0.011/0.016

0.014/0.019

0.011/0.016

in clearance/0.00046

RODS

the

small end bores are fitted

lined bushes.

in

(0,00/0,lO mm) above

in (31 ,74/31,75 mm)

in

(2,44/2,46

in

(4,81/4,84

or

Chrome

in

(2,36/2,38

in

(0,05/0,10

in (

4,74/4,76

in

(0,05/0,10

in

(4,74/4,76

in

(0,05/0,10

in

(0,35/0,48

in

(0,28/0,41

in

(0,35/0,48

in (0,28/0,41 mm)

ri$tht

two

boreS are fitted with re-

in

mm)

mm)

inlay

mm)

mm)

mm)

mm)

mm)

mm)

mm)

mm)

mm)

"H"

an.llles

nuts and

with

steel

to

The Ring Gaps

larger diameter bore.

in diameter above

Gudgeon

Connecting

quoted

3.501

Pins

Type

Outside Diameter

Clearance fit

Rods

Type

Big

End

Small End

Connecting

Length

of

Small End

above are

0.003

in (0.08

in

(88,93 mm).

in Small End Bush

Parent

Bore

Parent

Bore

Rod

Big

from centre line

End

a~

measured in a 3.501 in (88,93 mm) diameter bore.

mm)

should be added to the figures given for every 0.001 in

Fully floating

1.24976/1.24996

0.00054/0.00175

"H"

Section

Width

of

Big End

to

centre line

2.395/2.3955

1.375/1.376

1.361/1.363 in

6.8115/6.8135

in

(60,83/60,84

in

(34,92/34,95

(34,57/34,62

in

If

gaps are measured in a

(0,03

in (31 ,74/31,75

in

(0,01/0,04

(173,01/173,06

mm)

mm)

mm)

mm)

mm)

mm)

mm)

increase

Page 28

Pistons and Connecting Rods C2

Connecting Rod End

Big

End Bolt Size

Thread

Type

of

of

Big End

Bolt

Float

Nut

0.0095/0.0131

7/16in(ll,ll

U.N.F.

Self Locking

in

(0,24/0,33

mm)

mm)

Note: When

Connecting

Large and small

Big

End nuts are removed, they must be replaced

Rod

alignment

end

Connecting Rod bores must be square and parallel with

in (0,25 mm) measured 5 in ( 127 mm) each side

the small

end

bush fitted, the limit

of±

0.010

II-~

.!:

~

~~

~·

~N

C:>O

+I +I

~

II

Small

End

Bushes

Cl

of

the axis

in (0,25 mm)

5in

127mm

-

by

of

the rod

is

reduced

5in

127mm

new ones.

on

to±

o e

- e

";g

'?N

i'jc:i

~~

each

other

within

the

test mandrel as shown in

0.0025

in

(0,06

mm).

-u

the

limits

Fig.

of±

C.

0.010

I.

With

Type

Length

Out~ide

of

Small End Bush

Diameter

Interference

Inside Diameter (finished bore in position

reaming)

Connecting Rod Bearings

Type

Shell Width

Outside Diameter

Inside Diameter

Connecting Rod Bearing Running Clearance

Steel Thickness

Aluminium

Fit

Tin

Thickness

of

Bush

of

of

Bearings

in

Rod

Bearings

after

Steel Backed, Bronze lined

1.047/1.055 in

1.3785/1.380

0.0025/0.005

1.2505/1.25

Steel

backed,

1.1208/1.1280

2.3955 in (60,85

2.2504/2.2515

0.0014/0.003

0.0467/0.0582

0.0138/0.0256

(26,59/26,80

in

(35,01/35,05

in

(0,06/0,13

15

in

(31,

Aluminium

in

(28,47

mm)

in

(57

,16/57,19

in

(0,04/0,08

in

(I

,19/1,48

in

(0,35/0,65

76/31 ,79

/28.,65

Tin

mm)

mm)

mm)

mm)

lined

mm)

mm)

mm)

mm)

mm)

Page 29

Remova1

of

Piston and Rods

Sump

On

some applications it will be found necessary

remove the engine from the chassis because the engine

support brackets are fastened

The pistons and connecting rods are removed from

the cylinder block through the

bores, see Fig. C.2.

Big

End Bearings

If

examination reveals

renew big end bearings, they should be suitably

marked

to

ensure ret'itment

to

the sump.

top

of

that

there is no necessity

to

their original positions.

the cylinder

to

to

Pistons and Connecting Rods C3

Gudge«,m

To

the pistons, immerse the pistons in a warm liquid

I00-120°F (40-50°C), when the pins, after removal

of

Pistons and Rings

If

able dependant upon the condition

Production

Service Standard -

Cylinder bore -

Pins

facilitate the removal

the circlips, can

new pistons are to be fitted, three grades are avail-

Standard-

be

of

the gudgeon pins from

easily withdrawn.

of

the

liners.

Piston topping allowance

tive to height above cylinder

top

face

is

block

in

(0,00/0,10 mm).

The piston

and

will

of

limit

Where engines have

conform

regulation B.S.AU14Ia:I971,

then

pistons must

topped

tion limits.

3.5010/3.5020 in

piston height.

to

standard production

to

0.000/0.004

is

minimum topped

not

exceed the top

the smoke density

be

maintain produc-

used and

rela-

to

{88,93/88,95 mm)

Service

Cylinder bore -

(0, 76

0.030 in mm)

Oversize

Two pistons are available: one

untapped

the

lation and one with minimum

topping which will

the

3.5310/3.5320 in

B.S.

top

limit

for topping

AU

14la:l971

of

piston height.

not

to

meet

regu-

exceed

(89,69/89,71 mm)

The maximum permissible worn ring lift

piston ring with a new ring fitted

mm).

In a worn cylinder bore, the piston ring gap should be

in

measured

der and checked against the dimensions

Page

C.l.

the unworn, clean portion

is

0.008

of

of

the

in

(0,20

the cylin-

quoted

top

on

C3

Page 30

Pistons and

Connecting

Rods C4

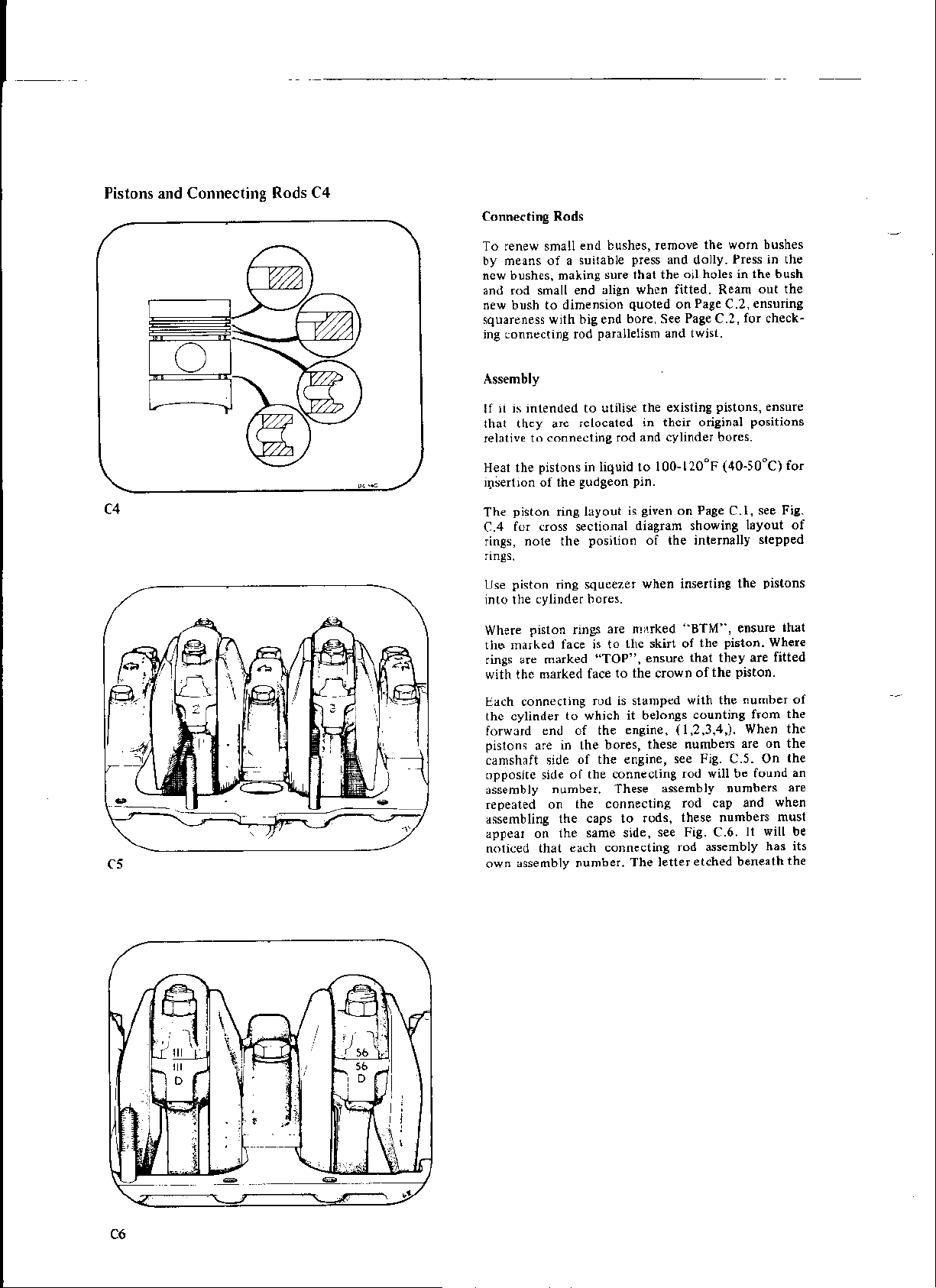

Connecting Rods

To

renew small

by means

new bushes, making sure

and rod small end align when fitted. Ream

new bush to dimension

squareness with big end bore. See

ing

mnnecting

Assembly

If

H

i~

intended to utilise the existing pistons, ensure

that they are relocated in their original positions

relative to connecting rod and cylinder bores.

Heat the pistons

il)sertwn

end

of

of

the gudgeon pin.

bushes, remove the worn bushes

a suitable press and dolly. Press in the

rod parallelism and twist.

in

liquid

that

the oil holes in the bush

quoted

to

J00-120°F

on

Page

C.2,

Page C.2, for check-

(40-50°C) for

out

the

ensuring

C4

is

given

on

Page

C.l,

they

piston.

beneath

see Fig.

are fitted

number

hom

on

On

It

will be

of

that

the

the

the

the

The piston ring layout

for cross sectional diagram showing layout

C.4

rings, note the position

rings.

Use

piston ring squce1.er when inserting the pistons

into

the cylinder bores.

Where piston rings are

the. marked face

rings

are marked

with the marked face

Each connecting rod

the cylinder to which it belongs counting

forward end

pistons are

camshaft

opposite side

assembly

repeated

assembling the caps

appear

noticed that each connecting rod assembly has its

own assembly

on

is

"TOP",

of

the engine, (1,2,3,4,). When the

in

the bores, these numbers are

side

of

the

of

the connecting rod will be found an

number.

on

the connecting rod cap and when

the same side, see Fig. C'.6.

number.

of

the internally stepped

m>!rked

to the skirt

to

the crown

is

stamped with the

engine, see Fig. C.S.

These assembly numbers are

to

The

'"BTM", ensure

of

ensure

rods, these numbers must

the piston. Where

that

of

the

letter

etched

of

C6

Page 31

assembly number

weight code.

When

refitting the connecting rod bearings, ensure

that the locating tabs

located in the machined recesses of the rod and

see

Fig.

C.

7.

(A

to F)

is

the

connecting rod

of

the bearings are correctly

cap,

Pistons and Connecting Rods

CS

Lubricate the bearing surfaces and

rod to the crankpin. Examine the securing bolts

serviceability and renew if necessary. Renew the nuts

and tighten evenly to a torque

for non-phosphated nuts or 60 lbf

phosphated nuts.

Piston height

see

Page

See

Fig.

C.

C.S.

in

relation to cylinder block top

I can

be

checked with the piston at

of

fit

the connecting

45 lbf

ft

ft

(8,3 kgf m) for

(6,2 kgf

T.D.C.

for

m)

face,

C7

cs

Page 32

-----··----

The cylinder block

crankcase in high

"dry"

type

The

crank

crankshaft axis.

case

duty

cylinder liners are fitted.

joint

Cylinder Block

Total

height

Bottom

Parent Bore diameter for Cylinder Liner

Cylinder Block recess

Cylinder Block Recess Bore

Main Bearing Parent Bore

No. 1 Bore for Camshaft

No.2

Bore for Camshaft

No.3

Bore

No.4

Bore for Camshaft

Cylinder Block

Cylinder Block Crankshaft

Washer Recess

CYLINDER

is

cast integrally with

cast iron. Flanged cast iron

face does

Face

for

not

extend

below the

CYLINDER BLOCK AND LINER DIMENSIONS

of

Cylinder Block

depth

Camshaft

Tappet

diameter

Bore

from

for Liner Flange

diameter

Thrust

Section 0

BLOCK

the

Head Face

AND

Ventilation

situated

fitted

to

11.177/11.181

3.8125/3.8135

0.150/0.152

3.990/3.995

2.916/2.917

2.0472/2.0484

2.0374/2.0386

2.0275/2.0287

2.0177/2.0189

0.5625/0.56375

3.756/3.764

• •

LINERS

on

to

the right hand side

in

in

in (74,07{74,09

in

Cylinder Block

of

the

crankcase is by a

the cylinder head

in (28

in

(96,84/96,86

(3,81/3,86

(101,35/101,47

in

(52,0/52,03

in

(5 I ,75/5 I ,78

in

(5 I ,5/51,53

in

(5

I ,25/5 I ,28

in

(14,29/14,32

(95,4/95,6

of

3,9/284,0

mm)

mm)

mm)

and

top

the engine.

mm)

mm)

mm)

mm)

mm)

mm)

mm)

mm)

Liners D 1

breather

cover, which

pipe

is

Cylinder Liners

Type

Outside

Interference fit

Cylinder Liner Finished Bore

Cylinder Liner Flange Thickness

Depth

Cylinder Liner Flange Diameter

Height

Height

Clearance fit

diameter

Bore

of

Flange BELOW

Cylinder Block

of

Liner Collar ABOVE

of

Cylinder Block

Cylinder Block Recess

Collar ABOVE

of

Liner

of

Liner in Cylinder Block Parent

of

Liner Flange

Top

Top

Face

I"'

Face

in

of

lange

of

Dry Interference

3.8145/3.8155

0.001/0.003

3.501/3.502

0.148/0.150

0.000/0.004

3.972/3.976

0.028/0.033

0.026/0.031

0.014/0.023

in

in

in (3,76/3,81

in

in

in

in