Page 1

workshop

manual for

4.108

4.107 and

4.99

diesel engines

©

Perkins Engines Limited

Peterborough England

1983

All

Rights

Reserved

Publication

No.

601

SER 0383 1072

This

publication

supersedes

the

previous

edition

numbered

601 SER 12771072

This

publication

is

written

for

world

wide

use. In

territories

where

legal

requirements

govern

smoke emission,

noise, safety

factors

etc., then all instructions,

data

and

dimensions

given must be

applied

in such a way that,

after

servicing

(preventive

maintenance)

or

repairing an engine,

it

does

not

contravene

the

local

regulations

in use.

Published

by

the

Technical Publications

Department

of

Perkins Engines

Ltd.

and Printed in England

by

Warners (Midlands) pic

Page 2

Page 2

I

PERKINS

COMPANIES

I AUSTRALIA

Perkins Engines Australia Pty. Ltd.

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

FRANCE

GERMANY

ITALY

JAPAN

SINGAPORE

UNITED KINGDOM

U.S.A.

Suite 2,

364

Main Street, Mornington

3931,

Victoria, Australia.

Telephone:

597

51877.

Telex: Perkoil

AA30816.

Fax:

597

58793.

Moteurs Perkins S.A.

9-11 Avenue Michelet,

93583

Saint Ouen, Cedex, France.

Telephone:

(1)

40104200.

Telex:

642924F.

Fax:

(1)

40104245.

Perkins Motoren G.m.b.H.

8752

Kleinostheim, Postfach

1180,

West

Germany.

Telephone: Kleinostheim

6027

5010.

Telex:

4188869A

PER

D.

Fax:

6027

501124.

Motori Perkins S.p.A.

Via Soc rate 8,

22070

Casnate con Bernate (Como), Italy.

Telephon: (031)

452332.

Telex:

380658

Perkit

I.

Fax: (031)

452335.

Massey Ferguson Perkins Engines K.K.

Reinanzaka Building,

6th

Floor, 14-2 Akasaka, 1-chome, Minato-ku,

Tokyo

107,

Japan.

Telephone: (03)

5867377.

Telex: Perkoil

J2424823.

Fax: (03)

582-1596.

Perkins Engines Asia Pacific,

4 Kian Teck Drive, Singapore

2262.

Telephone:

2656333/2653223.

Telex Perkoil RS37729. Fax:

2641188.

Perkins Engines Limited,

Eastfield, Peterborough,

PE1

5NA, England.

Telephone:

(0733)

67474.

Telex

32501

Perken

G.

Fax:

(0733)

582240.

Perkins Engines (Shrewsbury) Limited,

Sentinel Works, Shrewsbury

SY1

4DP, England.

Telephone:

(0743)

52262.

Telex:

35171/2

PESL

G.

Fax:

(0743)

69911.

Perkins Engines Inc.,

1700

Bellemeade Court, Lawrenceville, Georgia

30245,

U.S.A.

Telephone:

404

822

3000.

Telex:

544141

Perken Law. Fax:

4048223006.

Perkins Engines Latin America Inc.,

Suite

620,999

Ponce de Leon Boulevard, Coral Gables, Florida

33134,

U.S.A.

Telephone:

305

442

7413.

Telex:

32501

Perken

G.

Fax:

305

442

7419.

In addition

to

the above, there are Perkins

distributors

in

most

countries. Perkins Engines Ltd., Peterborough

or

one

of

the

above

companies can give details.

Page 3

Page 3

FOREWORD

This

workshop

manual has been

compiled

for

use in

conjunction

with

normal

workshop

practice.

Mention

of

certain

accepted

practices

therefore, has been purposely

omitted

in

order

to

avoid

repetition.

Reference to renewing

joints

and cleaning off

joint

faces has to a

great

extent

been

omitted

from

the text, it being understood

that

this will be

carried

out

where

applicable.

Similarly,

it

is

understood

that

in reassembly and inspection, all parts are

to

be

thoroughly

cleaned

and where present,

burrs

and scale are to be removed.

It

follows

that any open ports

of

high

precision components, e.g., fuel

injection

equipment,

ex-

posed

by

dismantling, will be

blanked

off until reassembled, to prevent the

ingress

of

foreign

matter.

: When setscrews

or

studs are fitted into holes which are

tapped

through

into

the

inside

of

: the engine, a

suitable

sealant must be used on the threads.

Throughout

this manual, whenever the

"left"

or

"right"

hand side

of

the

engine

is

referred

to, it is

that

side

of

the

engine

as viewed from the flywheel end.

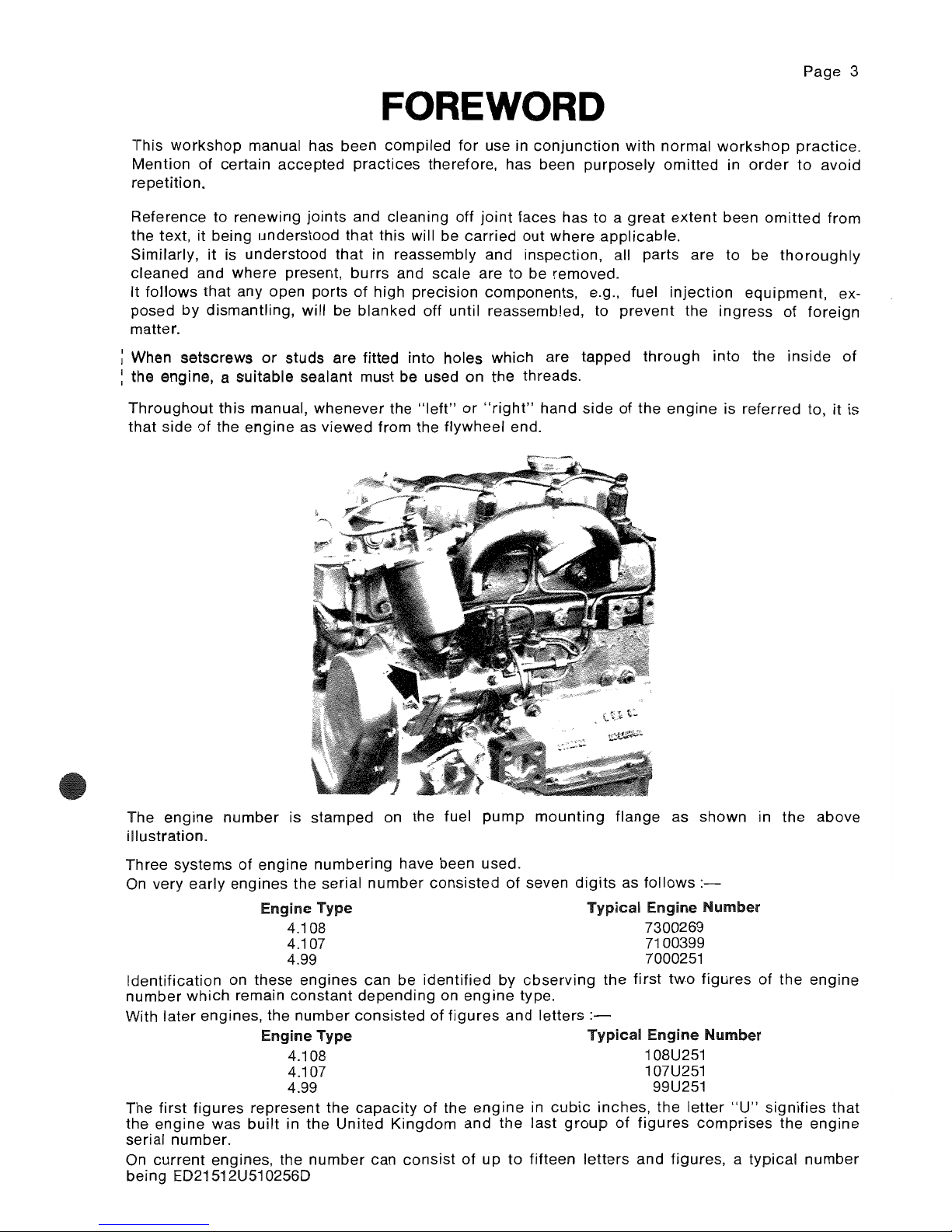

The

engine

number

is stamped on the fuel

pump

mounting

flange

as shown in

the

above

illustration.

Three systems

of

engine

numbering

have been used.

On

very early engines the serial

number

consisted

of

seven

digits

as

follows

:-

Engine Type

Typical

Engine

Number

4.108 7300269

4.107 7100399

4.99 7000251

Identification

on these

engines

can be

identified

by

cbserving

the

first

two

figures

of

the

engine

number

which

remain

constant

depending

on

engine

type.

With

later

engines, the

number

consisted

of

figures

and

letters

Engine Type

Typical

Engine

Number

4.108 108U251

4.107 107U251

4.99 99U251

The first

figures

represent the

capacity

of

the

engine

in

cubic

inches,

the

letter

"U"

signifies

that

the

engine

was

built

in the

United

Kingdom

and

the

last

group

of

figures

comprises

the engine

serial number.

On

current

engines, the

number

can

consist

of

up

to

fifteen

letters

and

figures, a typical

number

being ED21512U510256D

Page 4

Page4

~

Safety precautions

THESE SAFETY PRECAUTIONS ARE IMPORTANT. Reference must also be made to the local

regulations in the country of operation.

Do not use these engines in marine applications.

Do

not

change the specification

of

the engine.

Do

not

smoke when you

put

fuel in the tank.

Clean away any fuel which has fallen and move material which has fuel contamination to a safe

place.

Do

not

put

fuel in the tank during engine

operation

(unless really necessary).

Never clean, lubricate

or

adjust the engine

during

operation (unless you have had the

correct

training when extreme caution must be used to prevent

injury).

Do not make any adjustments you do not understand.

Ensure the engine is not in a position to cause a concentration of toxic emissions.

Persons in the area must be kept clear during

engine

and equipment

or

vehicle operation.

Do not permit loose clothing

or

long

hair

near parts which move.

Keep away from parts which turn during operation. Note that fans can

not

be seen clearly while

the engine is run.

Do not run the engine with any safety guards removed.

Do not remove the radiator cap while the

engine

is hot and the

coolant

is

under

pressure as

dangerous

hot

coolant

can be discharged.

Do

not

use salt water in the cooling system

or

any

other

coolant which can cause corrosion.

Keep sparks

or

fire away from batteries (especially during charge)

or

combustion can occur.

The battery fluid can burn and is also dangerous to the skin and especially the eyes.

Disconnect the battery terminals before you make a repair to the electrical system.

Only one person must be in control of the engine.

Ensure the engine is only operated from the

control

panel

or

operators position.

If your skin comes into

contact

with high pressure fuel,

get

medical assistance immediately.

Diesel fuel can cause skin damage to some persons. Use protection on the hands (gloves

or

special skin protection

solutions).

Do

not

move equipment unless the brakes are in

good

condition.

Ensure that the transmission drive control is in

"Out

of

Drive"

position

before the engine is

started.

Fit only

correct

Perkins Parts.

Page 5

CONTENTS

ENGINE VIEWS

TECHNICAL DATA

OPERATING AND MAINTENANCE

FAULT FINDING

CYLINDER HEAD

PISTONS AND CONNECTING RODS

CYLINDER BLOCK AND LINERS

CRANKSHAFT AND MAIN BEARINGS

TIMING CASE AND DRIVE

TIMING

LUBRICATING SYSTEM

COOLING SYSTEM

AIR CLEANERS AND FUEL SYSTEM

FLYWHEEL AND HOUSING

ELECTRICAL EQUIPMENT

ENGINES

FOR

REFRIGERATION UNITS

APPROVED LUBRICATING OILS

APPROVED SERVICE TOOLS

INDEX

A

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

R

Appendix

Page 5

Page 6

Page 6

EXAMPLES

OF

SERVICE

FACILITIES

Service

If any problems

occur

with

your

engine

or

the components fitted to it,

your

Perkins

distributor

can make the necessary repairs and will ensure that only the

correct

parts are fitted and

that

the

work

is

done

correctly.

Certain

components

can be supplied by

your

Perkins

distributor

through

the Perkins

Power

exchange

system. These will enable you to red uce the

cost

of

some repairs.

Extended Warranty

The

engine

warranty period can be extended to

two

years. For details,

get

in

contact

with

your

nearest Perkins

distributor.

Service Literature

Users handbooks and other service

publications

are available from

your

Perkins

distributor

at a

nominal cost.

Training

Local training on

correct

engine operation,

overhaul

and service is available

at

some Perkins

distributors. If

special

training is needed,

your

Perkins

distributor

can give

details

on

how

to

get

this at the

Product

Education Department, Peterborough,

or

other main centres.

Page 7

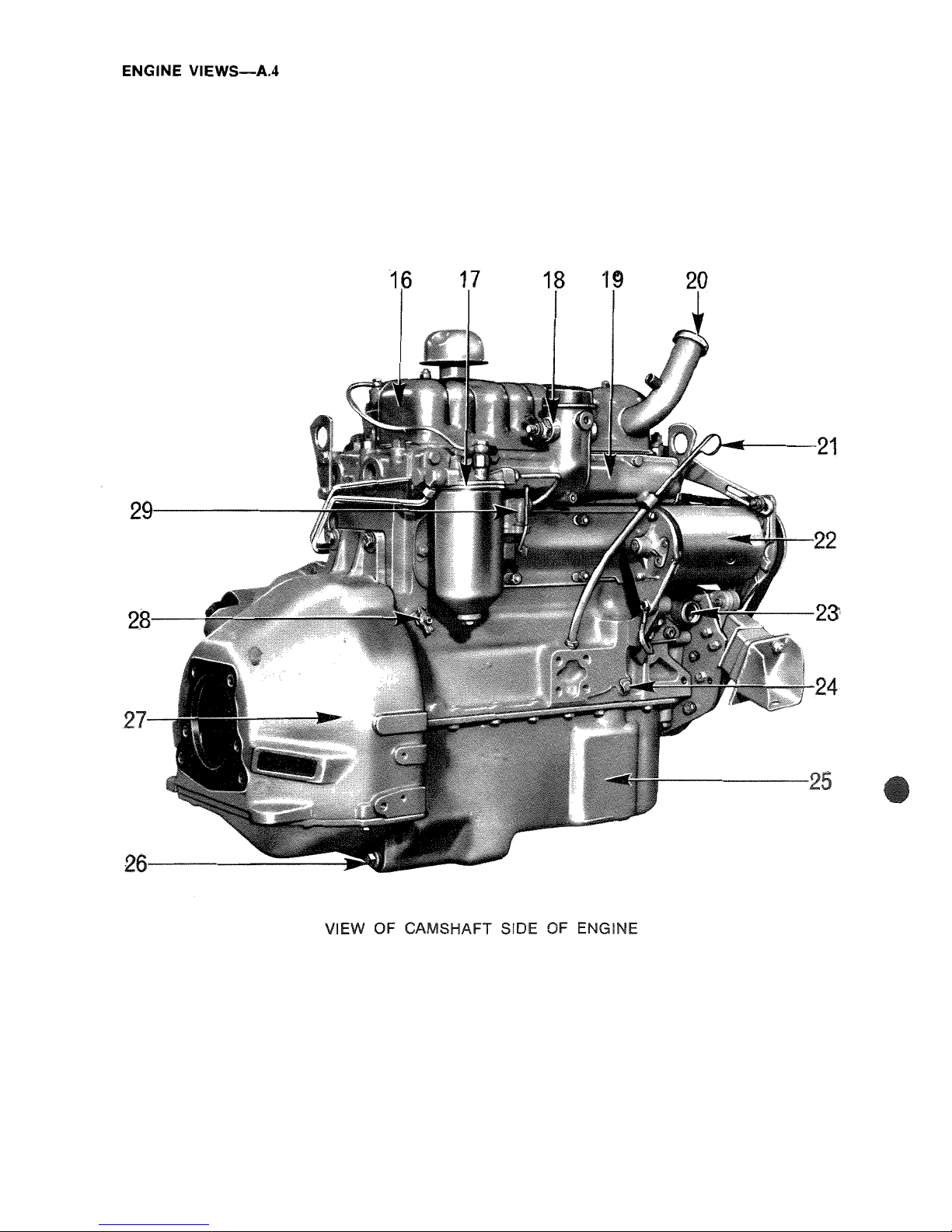

SECTION A

Engine

Views

Page 8

ENGINE

VIEWS-A.2

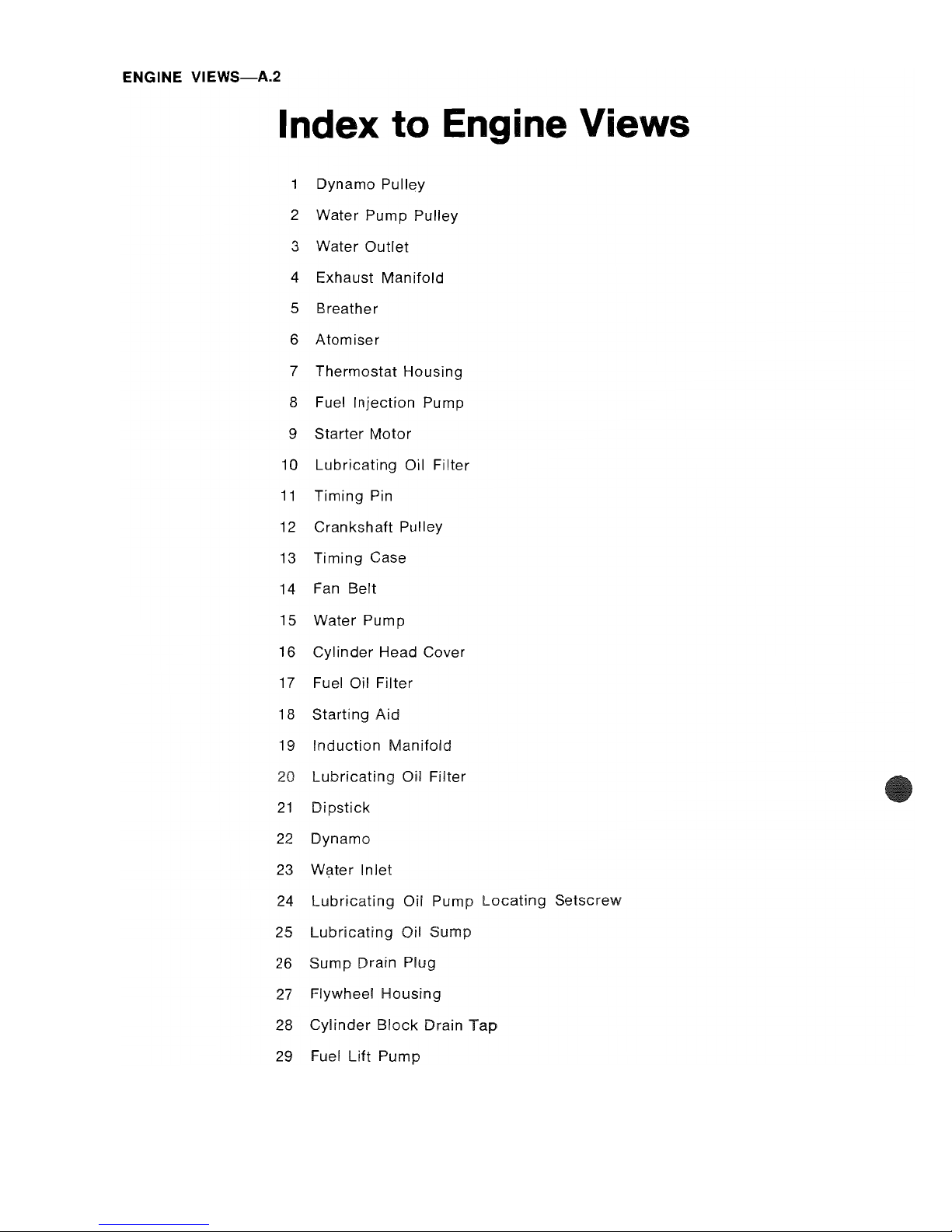

Index to Engine Views

Dynamo Pulley

2 Water

Pump

Pulley

3 Water

Outlet

4

Exhaust

Manifold

5

Breather

6

Atomiser

7

Thermostat

Housing

8 Fuel

Injection

Pump

9 Starter

Motor

10

Lubricating

Oil

Filter

11

Timing Pin

12

Crankshaft

Pulley

13

Timing

Case

14 Fan

Belt

15 Water

Pump

16

Cylinder

Head Cover

17

Fuel Oil

Filter

18 Starting

Aid

19

Induction

Manifold

20 Oil Filter

21

Dipstick

22 Dynamo

23 W?ter

Inlet

24

Lubricating

Oil Pump

Locating

Setscrew

25

Lubricating

Oil

26

Sump

Drain

Plug

27 Flywheel

Housing

28

Cylinder

Block

Drain

Tap

29 Fuel

Lift

Pump

Page 9

ENGINE

VIEWS-A.3

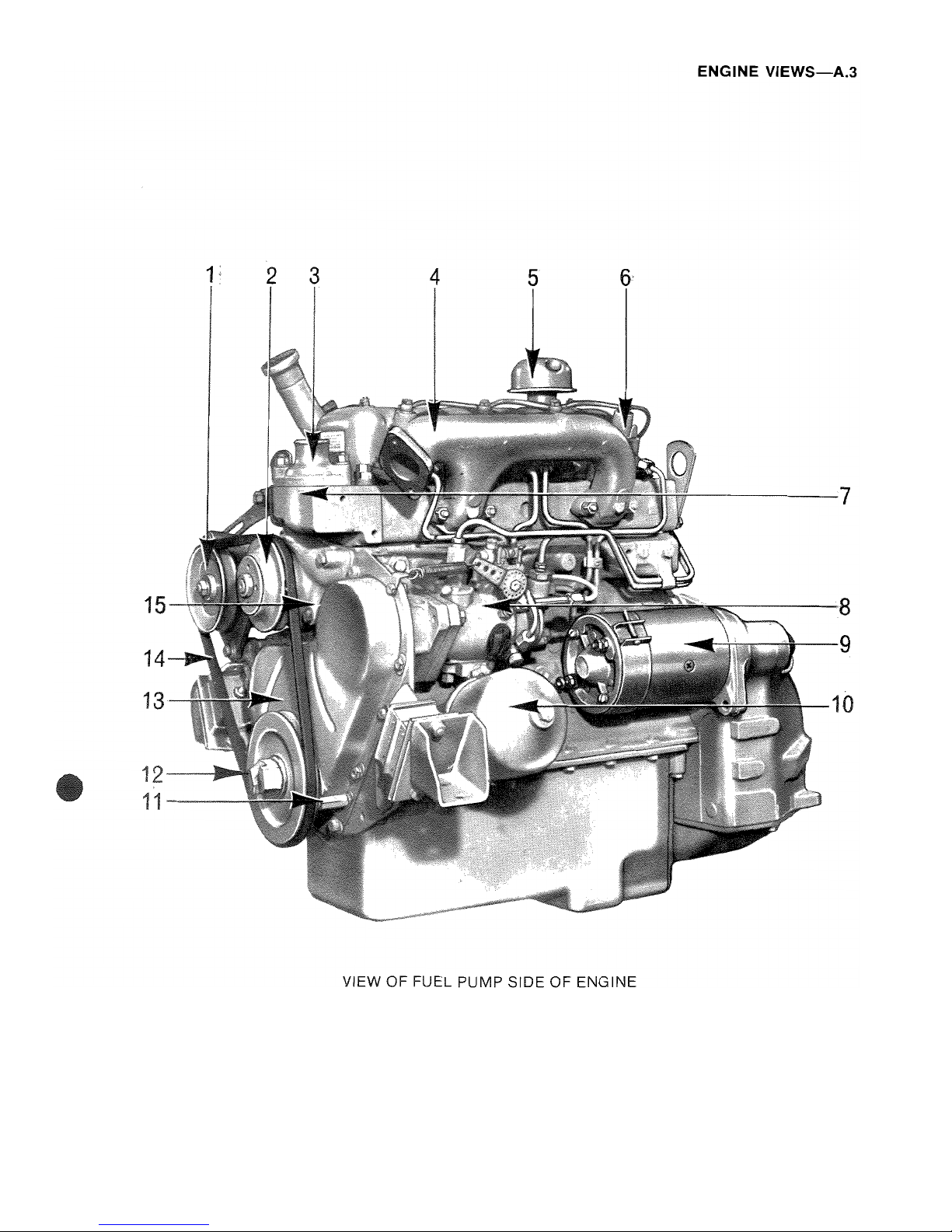

2 3

4

5

-----7

9

VIEW OF FUEL PUMP SIDE OF ENGINE

Page 10

ENGINE

VIEWS-A.4

1

17

1

20

VIEW OF CAMSHAFT SIDE OF ENGINE

Page 11

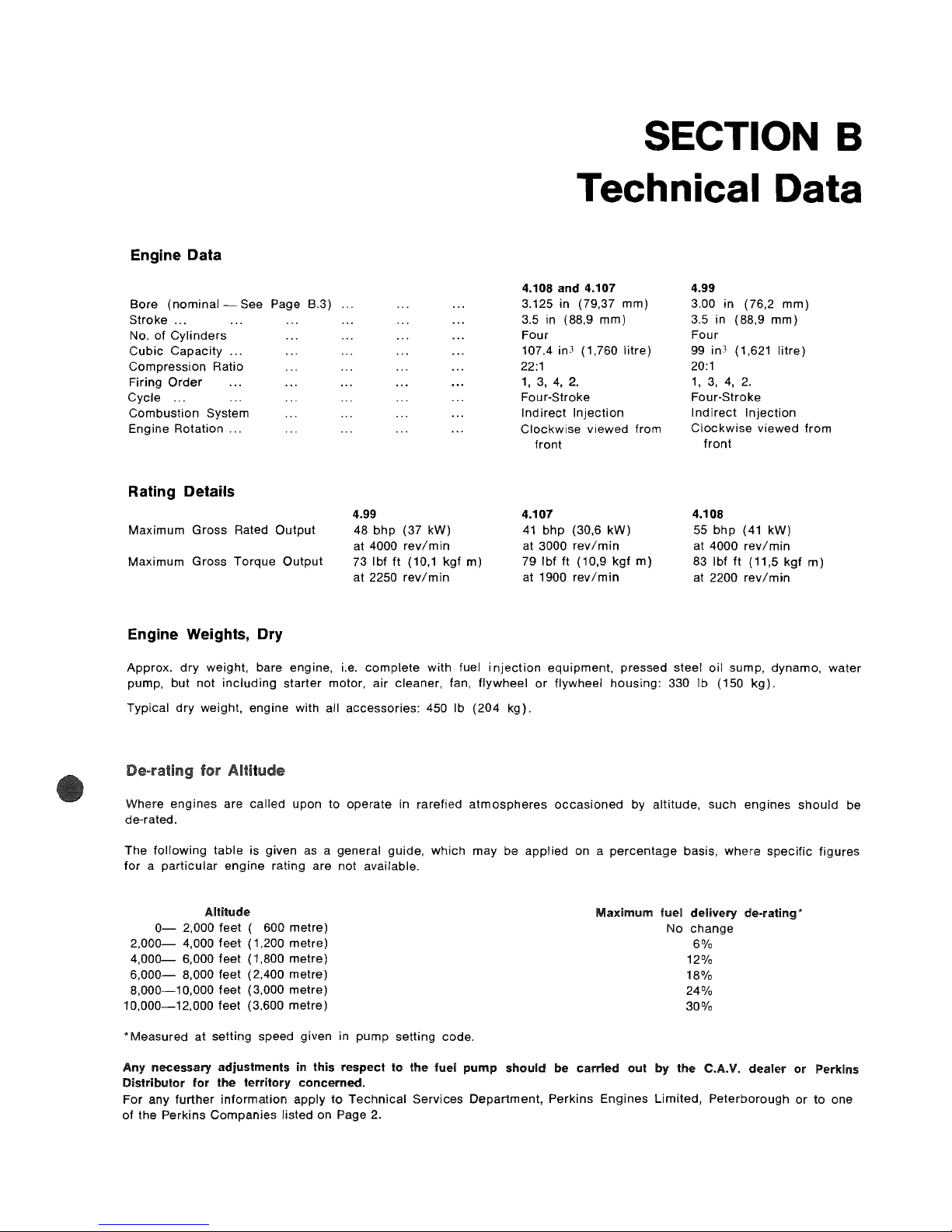

Engine Data

Bore

(nominal-

See Page B.3) ...

Stroke

...

No.

of

Cylinders

Cubic

Capacity

...

Compression Ratio

Firing

Order

Cycle

'"

Combustion

System

Engine Rotation

...

Rating Details

4.99

Maximum

Gross

Rated

Output

Maximum

Gross

Torque

Output

Engine Weights, Dry

48

bhp

(37 kW)

at 4000

rev/min

73 Ibf

ft

(10,1 kgf

m)

at 2250

rev/min

SECTION B

Technical Data

4.108 and 4.107

3.125 in (79,37

mm)

3.5 in (88,9

mm)

Four

107.4 in3 (1,760

litre)

22:1

1,3,4,2.

Four-Stroke

Indirect

Injection

Clockwise

viewed from

front

4.107

41

bhp

(30,6

kW)

at 3000

rev/min

79 Ibf

ft

(10,9

kgf

m)

at 1900

rev/min

4.99

3.00 in (76,2

mm)

3.5 in (88,9

mm)

Four

99 in3 (1,621

litre)

20:1

1, 3, 4, 2.

Four-Stroke

Indirect

Injection

Clockwise

viewed

from

front

4.108

55

bhp

(41 kW)

at 4000

rev/min

83 Ibf

ft

(11,5

kgf

m)

at 2200

rev/min

Approx.

dry

weight, bare engine, i.e.

complete

with

fuel

injection

equipment,

pressed steel

oil

sump, dynamo,

water

pump,

but

not

including

starter

motor,

air

cleaner, fan,

flywheel

or

flywheel housing: 330 Ib (150

kg).

Typical

dry

weight, engine with all accessories: 450 Ib

(204

kg).

Where

engines

are

called

upon to

operate

in rarefied

atmospheres

occasioned

by altitude,

such

engines

should

be

de-rated.

The

following

table

is given as a general guide,

which

may

be

applied

on a

percentage

basis,

where

specific

figures

for a particular

engine

rating are not available.

Altitude

0-

2,000 feet ( 600

metre)

2,000-

4,000

feet

(1,200

metre)

4,000-

6,000

feet

(1,800

metre)

6,000-

8,000 feet (2,400

metre)

8,000-10,000

feet

(3,000

metre)

10,000-12,000

feet

(3,600

metre)

* Measured

at

setting

speed given in

pump

setting

code.

Maximum

fuel

delivery

de-rating*

No

change

6%

12%

18%

24%

30%

Any

necessary

adjustments

in

this

respect

to

the fuel

pump

should

be

carried

01.11

by

the C.A.V.

dealer

or

Perkins

Distributor

for

the

territory

concerned.

For any

further

information

apply

to

Technical

Services

Department,

Perkins

Engines

Limited,

Peterborough

or

to one

of

the Perkins

Companies

listed on Page 2.

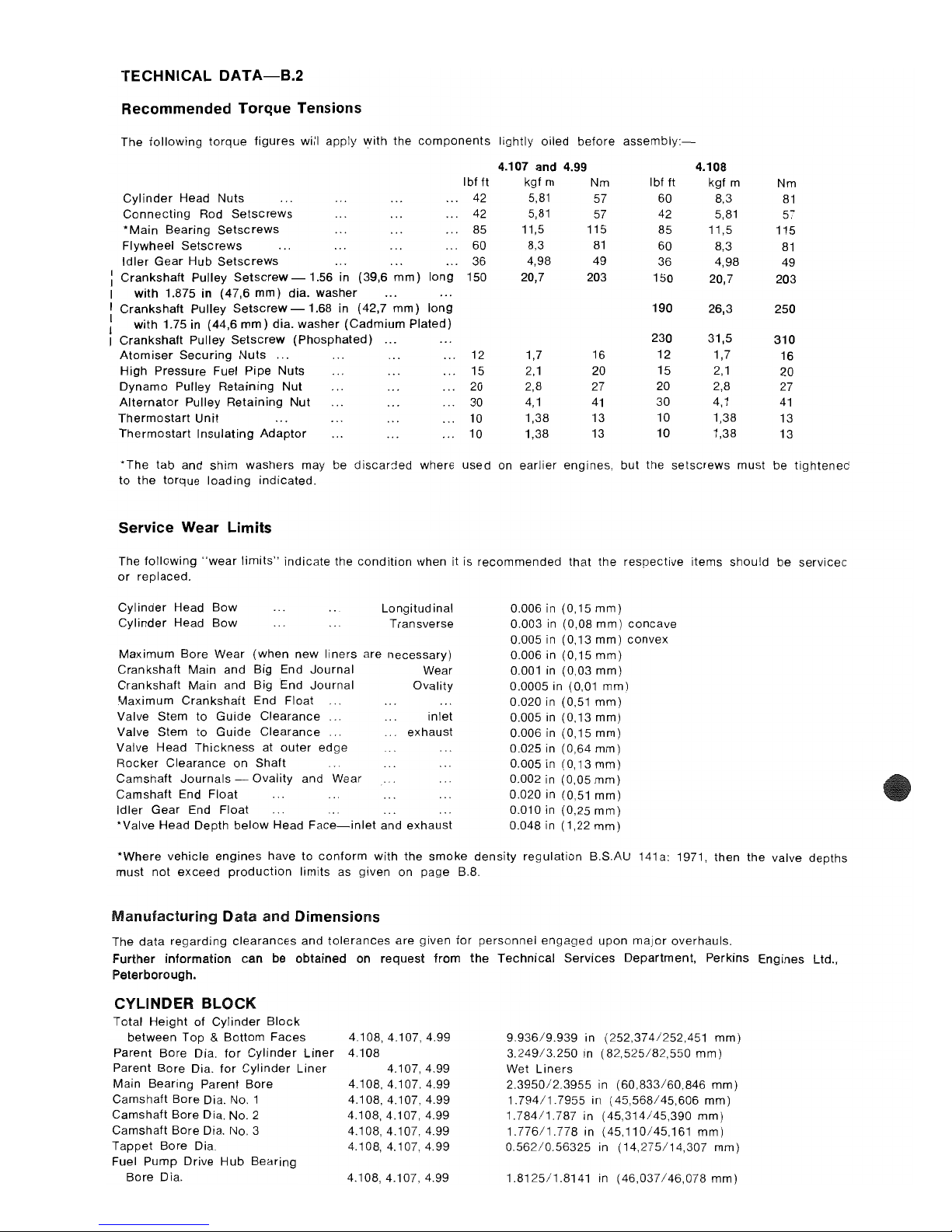

Page 12

TECHNICAL

DATA-B.2

Recommended Torque Tensions

The

following

torque

figures

will

apply

with

the

components

lightly oiled

before

assembly:-

4.107 and

4.99 4.108

Ibf

ft

kgf m

Nm

Ibf

ft

kgf

m

Nm

Cylinder

Head

Nuts

42

5,81

57 60 8,3

81

Connecting

Rod

Setscrews

42

5,81

57

42

5,81

57

*

Main

Bearing

Setscrews

85

11,5 115

85 11,5

115

Flywheel

Setscrews

60

8,3

81

60

8,3

81

Idler

Gear

Hub

Setscrews

36

4,98 49 36 4,98

49

Crankshaft

Pulley

Setscrew-1.56

in (39,6

mm)

long

150 20,7

203

150 20,7

203

with

1.875

in

(47,6

mm)

dia.

washer

Crankshaft

Pulley

Setscrew

-1.68

in (42,7

mm)

long

190

26,3

250

with

1.75 in (44,6

mm)

dia.

washer

(Cadmium

Plated)

Crankshaft

Pulley

Setscrew

(Phosphated)

230

31,5

310

Atomiser

Securing

Nuts

.,

.

12 1,7

16

12

1,7

16

High

Pressure Fuel

Pipe

Nuts 15

2,1

20

15

2,1

20

Dynamo

Pulley

Retaining

Nut

20 2,8 27

20 2,8

27

Alternator

Pulley

Retaining

Nut

30

4,1

41

30

4,1

41

Thermostart

Unit

10 1,38 13

10 1,38

13

Thermostart

Insulating

Adaptor

10 1,38 13

10

1,38

13

*The

tab

and

shim

washers

may be

discarded

where

used

on

earlier

engines, but

the

setscrews

must be

tightened

to

the

torque

loading

indicated.

Service Wear Limits

The

following

"wear

limits"

indicate

the

condition

when it is

recommended

that

the

respective

items

should

be

servicec

or

replaced.

Cylinder

Head

Bow

Cylinder

Head

Bow

Longitud

inal

Transverse

Maximum

Bore Wear

(when

new

liners

are

necessary)

Crankshaft

Main and Big End

Journal

Wear

Crankshaft

Main and Big End

Journal

Ovality

Maximum

Crankshaft

End Float

Valve Stem to

Guide

Clearance

inlet

Valve Stem to

Guide

Clearance

Valve Head

Thickness

at

outer

edge

Rocker

Clearance

on Shaft

Camshaft

Journals

Ovality

and Wear

Camshaft

End Float

Idler

Gear End

Float

exhaust

*Valve Head Depth

below

Head

Face-inlet

and

exhaust

0.006 in (0,15

mm)

0.003

in

(0,08

mm)

concave

0.005 in (0,13

mm)

convex

0.006 in

(0,15mm)

0.001

in

(0,03

mm)

0.0005 in (0,01

mm)

0.020 in (0,51

mm)

0.005

in

(0,13

mm)

0.006

in

(0,15

mm)

0.025 in (0,64

mm)

0.005 in

(0,13mm)

0.002 in (0,05

mm)

0.020 in (0,51

mm)

0.010 in (0,25

mm)

0.048 in (1,22

mm)

*Where

vehicle

engines

have

to

conform

with

the

smoke

density

regulation

B.S.AU

141

a:

1971, then

the

valve

depths

must

not

exceed

production

limits

as given on page B.8.

Manufacturing

Data

and

Dimensions

The

data

regarding

clearances

and

tolerances

are

given for

personnel

engaged

upon

major

overhauls.

Further

information

can

be

obtained

on

request

from

the

Technical

Services

Department,

Perkins Engines Ltd.,

Peterborough.

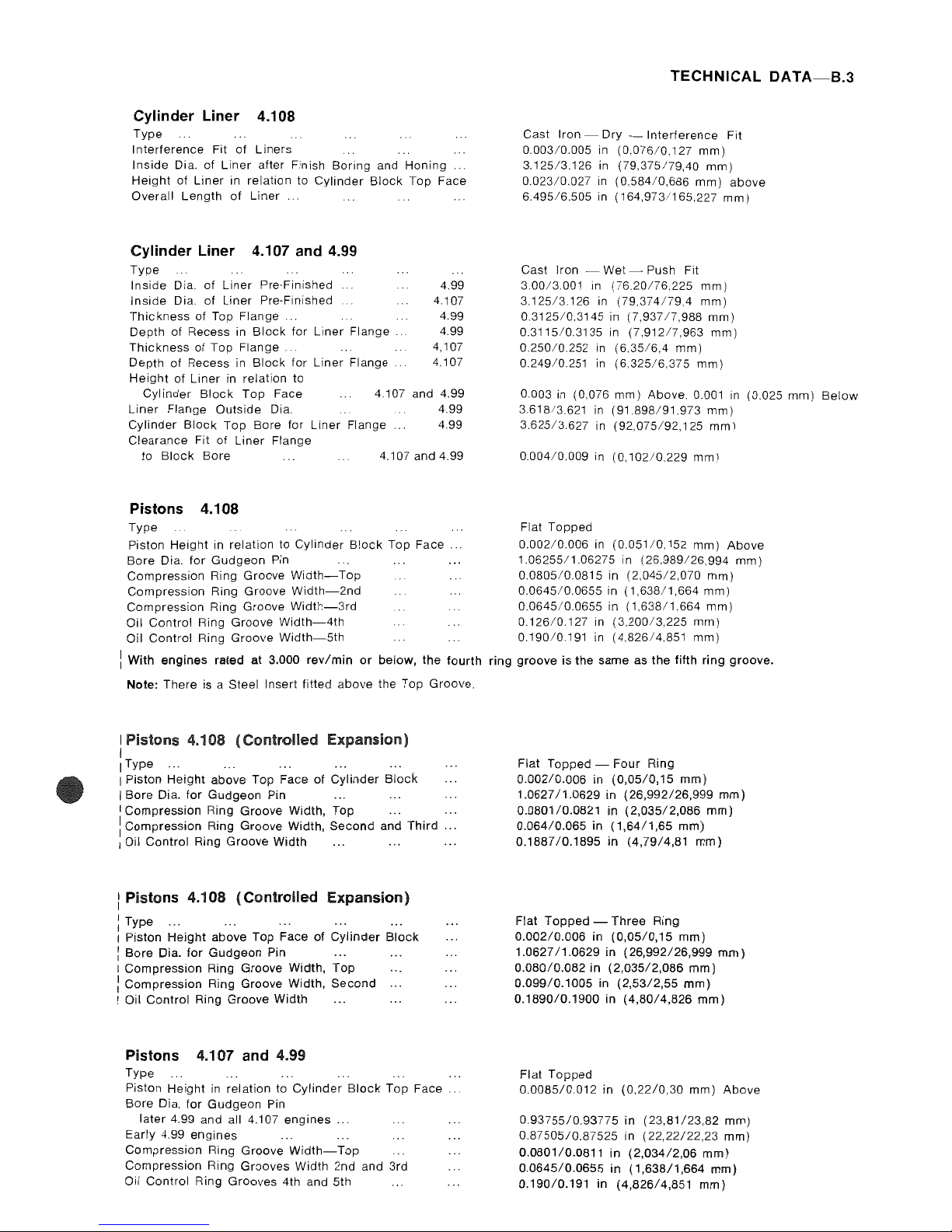

CYLINDER BLOCK

Total

Height

of

Cylinder

Block

between

Top & Bottom

Faces

Parent

Bore

Dia.

for

Cylinder

Liner

Parent Bore Dia.

for

Cylinder

Liner

Main Bearing Parent

Bore

Camshaft

Bore

Dia.

No.1

Camshaft Bore Dia.

No.2

Camshaft

Bore

Dia.

No.3

Tappet

Bore Dia.

Fuel

Pump

Drive

Hub

Bearing

Bore

Dia.

4.108,4.107,4.99

4.108

4.107,4.99

4.108,4.107,4.99

4.108,4.107,4.99

4.108,4.107,4.99

4.108,4.107,4.99

4.108,4.107,4.99

4.108,4.107,4.99

9.936/9.939

in

(252,374/252,451

mm)

3.249/3.250

in

(82,525/82,550

mm)

Wet

Liners

2.3950/2.3955

in

(60,833/60,846

mm)

1.794/1.7955

in

(45,568/45,606

mm)

1.78411.787

in

(45,314/45,390

mm)

1.776/1.778

in

(45,110/45,161

mm)

0.562/0.56325

in

(14,275/14,307

mm)

1.812511.8141 in

(46,037/46,078

mm)

Page 13

Cylinder Liner 4.108

Type

Interference

Fit

of

Liners

Inside

Dia. of

Liner

after Finish Boring and Honing

Height

of

Liner

in relation to Cylinder

Block

Top Face

Overall Length

of

Liner

Cylinder Liner 4.107 and 4.99

Type

Inside

Dia.

of

Liner

Pre-Finished

4.99

Inside

Dia.

of

Liner Pre-Finished 4.107

Thickness

of Top

Flange.

4.99

Depth of Recess in

Block

for Liner

Flange.

4.99

Thickness

of Top

Flange..

4,107

Depth of Recess in

Block

for

Liner Flange 4,107

Height

of Liner

in

relation to

Cylinder

Block

Top

Face 4,107 and 4.99

Liner

Flange Outside Dia. 4.99

Cylinder

Block

Top Bore for

Liner

Flange 4.99

Clearance Fit of

Liner

Flange

to

Block

Bore 4.107 and 4.99

Pistons 4.108

Type

Piston Height in relation to Cylinder

B!ock

Top

Face.

Bore Dia.

for

Gudgeon

Pin

Compression Ring Groove

Width-Top

Compression Ring Groove

Width-2nd

Compression Ring Groove

Width-3rd

Oil Control Ring Groove

Width-4th

Oil Control Ring Groove

Width-5th

i With

engines

rated at 3.000

rev/min

or

below,

the

fourth

Note: There is a Steel Insert fitted above the Top Groove.

I Pistons 4.108

(Controlled

Expansion)

I

IType

...

I Piston

Height

above Top Face of

Cylinder

Block

I Bore Dia.

for

Gudgeon Pin

I Compression Ring Groove Width,

Top

1 Compression Ring Groove Width,

Second

and

Third

.. .

I Oil Control Ring Groove Width

...

...

..

.

: Pistons 4.108

(Controlled

Expansion)

: Type

...

I Piston Height above Top Face

of

Cylinder

Block

:

Bore

Dia.

for

Gudgeon Pin

I CompreSSion Ring Groove Width,

Top

: Compression Ring Groove Width,

Second

I Oil Control Ring Groove Width

Pistons 4.107 and 4.99

Type

Piston Height in relation to

Cylinder

Block

Top Face ..

Bore Dia.

for

Gudgeon

Pin

later 4.99 and all 4.107

engines

...

Early 4.99

engines

Compression Ring Groove

Width-Top

Compression Ring Grooves Width 2nd and 3rd

Oil Control Ring Grooves 4th and 5th

TECHNICAL

DATA-B.3

Cast Iron - Dry -

Interference

Fit

0,003/0.005

in

(0,076/0.127

mm)

3.12513.126

in

(79,375179,40

mm)

0.023/0.027

in

(0,584/0,686

mm)

above

6.495/6.505

in

(164,973/165,227

mm)

Cast Iron - Wet Push Fit

3,00/3.001

in

(7620176.225

mm)

3.125/3,126

in

(79,374179.4

mm)

0.312510.3145

in

(7,93717,988

mm)

0.3115/0.3135

in

(7,91217,963

mm)

0.25010,252

in

(6.35/6,4

mm)

0.249/0,251

in

(6.325/6,375

mm)

0.003 in (0,076 mm) Above. 0.001

in

(0.025 mm)

Below

3.61813.621

in

(91.898/91,973

mm)

3.625/3,627

in

(92,075/92,125

mm)

0,00410.009

in

(0,102/0.229

mm)

Flat Topped

0.00210.006

in

(0,051/0.152

mm)

Above

1.06255/1.06275

in

(26,989/26.994

mm)

0.080510.0815

in

(2,045/2,070

mm)

0.0645/0.0655

in

(1,638/1,664

mm)

0.0645/0.0655

in

(1,638/1,664

mm)

0.126/0.127

in

(3.200/3,225

mm)

0.19010.191 in

(4,826/4.851

mm)

ring

groove

is

the

same as

the

fifth

ring

groove.

Flat

Topped

- Four Ring

0.002/0.006

in

(0,05/0,15

mm)

1.062711.0629

in

(26,992/26,999

mm)

0.080110.0821

in

(2,035/2,086

mm)

0.06410.065

in

(1,64/1,65

mm)

0.1887/0.1895

in (4,7914,81

mm)

Flat

Topped -Three

Ring

0.002/0.006

in

(0,05/0,15

mm)

1.062711.0629

in

(26,992/26,999

mm)

0.080/0.082

in

(2,035/2,086

mm)

0.09910.1005

in

(2,53/2,55

mm)

0.1890/0.1900

in

(4,8014,826

mm)

Flat

Topped

0.0085/0.012

in

(0,2210,30

mm)

Above

0.93755/0.93775

in

(23,81/23,82

mm)

0.87505/0.87525

in

(22,22122,23

mm)

0.0801/0.0811

in

(2,034/2,06

mm)

0.0645/0.0655

in

(1,638/1,664

mm)

0.190/0.191

in

(4,826/4,851

mm)

Page 14

TECHNICAL

DATA-B.4

Piston Rings 4.108

Top-Compression

Second and Third Compression

Fourth-Oil

Control

Fifth-Oil

Control

Top Compression Ring Width

Ring Clearance in

Grove

...

Second and Third Compression Ring Width

Ring Clearance in

Groove

Fifth

Scraper

Ring Width

...

Ring Clearance in

Groove

Ring

Gap-Top

Compression

Ring

Gap-Second

and Third Compression .

Ring

Gap-Fifth

Scraper

...

Parallel Faced

Internally Stepped

Laminated Segment

'*

Slotted Scraper

0.0771/0.0781 in

(1,958/1,984

mm)

0.0024/0.0044 in

(0,061/0,112

mm)

0.0615/0.0625 in (1,562/1,587

mm)

0.00210.004 in

(0,051/0,102

mm)

0.1865/0.1875 in

(4,737/4,762

mm)

0.0025/0.0045 in

(0,063/0,114

mm)

0.00910.017 in

(0,229/0,432

mm)

0.00910.017 in

(0,229/0,432

mm)

0.00910.017 in

(0,229/0,432

mm)

:*

Engines rated at 3,000

revlmin

and

below

have a slotted scraper fitted in the fourth

groove

which

has the same

I width, clearance and gap as the fifth ring.

: Piston Rings

4.108(Controlied

Expansion -

Four

Ring)

, Top Compression

I Second and Third Compression

I Fourth Oil Control

I Top Compression Ring Width

I Ring Clearance in

Groove

...

: Second and Third Compression Ring Width

Ring Clearance in

Groove

I Oil Control Ring Width

...

I Ring Clearance in Groove

J Ring Gap, Top

...

. ..

I Ring Gap, Second and Third

I Ring Gap, Oil Control

Chrome Insert - Parallel Faced

Internally Stepped

Spring Loaded Scraper

0.077/0.078

in

(1,96/1,98

mm)

0.002/0.005 in

(0,05/0,13

mm)

0.0615/0.0625 in (1,5611,59

mm)

0.0015/0.0035

in (0,0410,09

mm)

0.186/0.1865

in

(4,72/4,74

mm)

0.0022/0.0035

in (0,0510.09

mm)

0.012/0.023

in

(0,30/0,58

mm)

0.009/0.020

in

(0,23/0,50

mm)

0.010/0.021 in

(0,25/0,53

mm)

: Piston Rings 4.108

(Controlled

Expansion -

Three

Ring)

I Top Compression

: Second Compression

I Third Oil Control

I Top Compression Ring Width

I Clearance in

Groove

...

: Second Compression Ring Width

I Clearance in

Groove

I Oil Control Ring Width

: Clearance in

Groove

I Ring Gap, Top

...

I Ring Gap, Second

I Ring Gap, Oil Control

Piston Rings

4.99

Vehicle

Top Compression

Second and Third Compression

Fourth and Fifth Oil Control

Piston Rings 4.107

and

4.99

and

Industrial

Top Compression

'Second

and Third Compression

Fourth-Oil

Control

Fifth-Oil

Control

Chrome,

Taper

Faced

Internally Stepped, Taper Faced

Spring Loaded Scraper

0.0765/0.0775

in

(1,943/1,969

mm)

0.0025/0.0055

in

(0,063/0,140

mm)

0.097/0.098

in

(2,46/2,49

mm)

0.0015/0.0035

in

(0,039/0,089

mm)

0.1865/0.1875

in

(4,737/4,763

mm)

0.0015/0.0035

in

(0,039/0,089

mm

0.01210.023 in

(0,31/0,59

mm)

0.009/0.020

in

(0,23/0,51

mm

0.012/0.023

in

(0,31/0,59

mm

Parallel Faced Chrome Plated

Internally Stepped

Slotted

Scraper

Parellel Cast Iron

Internally Stepped

Chrome

Plated Spring Loaded

Scraper

Slotted

Scraper

•

4.99

Agricultural

engines have taper faced cast iron

compression

rings fitted in the second and

third

ring grooves.

Top Compression Ring Width

Ring Clearance in

Groove

Second and

Third

Compression Ring

Width.

Ring Clearance in Groove

Fourth and Fifth Scraper Ring Width

Ring Clearance in Groove

Ring

Gap-Compression

Rings Chrome Vehicle

Ring

Gap-Oil

Control Rings Cast Iron Vehicle

Ring

Gap-Compression

Rings Cast Iron

Agricultural and Industrial

0.0771/0.0781 in

(1,96/1,984

mm)

0.002/0.004

in

(0,051/0,102

mm)

0.0615/0.0625

in

(1,562/1,587

mm)

0.00210.004 in

(0,051/0,102

mm)

0.1865/0.1875

in (4,73714,762

mm)

0.0025/0.0045

in

(0,064/0.114

mm)

0.01210.020 in

(0,30/0,50

mm)

0.009/0.017

in

(0,30/0,432

mm)

0.009/0.017

in

(0,30/0,432

mm)

Page 15

Gudgeon

Pin 4.108

Type

Outside

Dia.

of

Gudgeon

Pin

Length

of

Gudgeon Pin

Fit

in Piston Boss

Gudgeon

Pin 4.107 and 4.99

Type

Outside Dia.

of

Gudgeon

Pin

(Later

Engines)

Outside

Dia.

of

Gudgeon

Pin

(Earlier

Engines)

Fit

in Piston Boss

Small

End Bush 4.108

Type

Length

of

Small

End

Bush

Outside

Dia.

of

Small

End Bush

Inside

Dia.

before

Reaming

Inside

Dia.

after

Reaming

Clearance

between Small End Bush and Gudgeon Pin

Small

End Bush 4.107 and 4.99

Type

Length

of

Small End Bush

Outside Dia.

of

Small End Bush

on

later

4.99 and all 4.107 engines

Early 4.99

engines

Inside

Dia.

after

Reaming on

later

4.99

and

a/l 4.107 engines

Early 4.99 engines

Clearance

between Small End Bush and Gudgeon Pin

TECHNICAL

DATA-B.S

Fully Floating

1.0625/1.0627 in

(26,987/26,993

mm)

2,673/2,687 in

(67,894/68,250

mm)

Transition

Fully Floating

0.9375

in/0.9377

in

(23,812/23,817

mm)

0.875/0.8752 in

(22,225/22,23

mm)

Transition

Steel Backed, Lead

Bronze

Lined

0.935/0.955

in

(23,749/24,257

mm)

1.221/1.222

in

(31,013/31,039

mm)

1.0495/1.0545 in

(26,657/26,784

mm)

1.06315/1.0632

in

(27,004/27,005

mm)

0.00045/0.0007 in

(0,0114/0,0178

mm)

Steel Backed, Lead

Bronze

Lined

0.865/0.885

in

(22,00/22,48

mm)

1.06511.066 in

(27,05/27,08

mm)

1.0025/1.0035

in (25,46125,49 mm)

0.9382/0.93875

in

(23,83/23,84

mm)

0.8757/0.87625

in

(22,24/22,26

mm)

0.0005/0.00125

in (0,0110,03

mm)

Note. Bushes

to

be reamed

to

suit respective Gudgeon Pins, and are

provided

with

a reaming allowance.

nSI::ti§11n Rod 4.108

Type 'H'

Section

Cap

Location

to

Connecting

Rod

Big End Parent

Bore

Dia.

Small End Parent Bore Dia.

Length from Centre Line

of

Big End

to

Centre Line

of

Small End

Big End

Setscrew

Connecting

Rod End Float

Connecting

Rod 4.107 and 4.99

Type

Cap

Location

to

Connecting

Rod

Big End Parent Bore Dia.

Small End Parent Bore Dia.

on

later

4.99 and all 4.107 engines

Early 4.99

engines

Length from Centre Line

of

Big End to Centre Line

of

Small End

Big End Setscrew

Connecting

Rod End Float

on

later

4.99

and

all 4.107 engines

Early 4.99 engines

Serrations, Offset 45

to

the Horizontal

2.146/2.1465 in

(54,508/54,521 mm)

1.21875/1.21975 in (30,956/30,981

mm)

6.217/6.219

in

(157,912/157,963

mm)

0.375 in

(i

in)

U.N.F.

0.006510.0105 in

(0,165/0,267

mm)

'H'

Section

Serrations,

Offset

45'

to

the

Horizontal

2. i 46/2.1465

in (54,508/54,521 mm)

1.0625/1.0635

in (26,99/27,01

mm)

1.00/1.001

in

(25,4/25,43mm)

6.405/6.407

in

(162,69/162,74

mm)

0.375 in

(i

in)

U.N.F.

0.0065/0.0105

in (0,1610,27

mm)

0.0075/0.0105

in

(0,19/0,27

mm)

Page 16

TECHNICAL

DATA-B.G

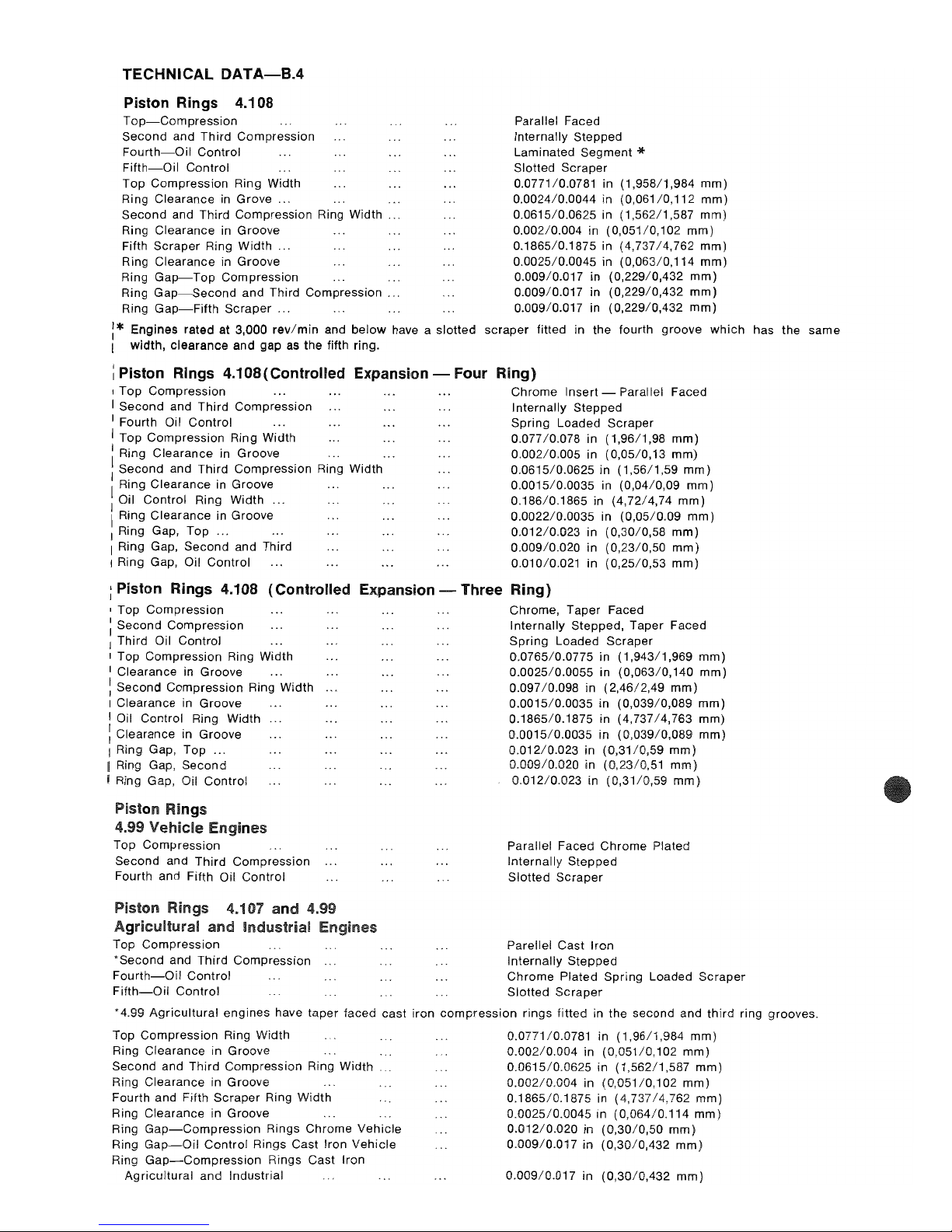

Connecting Road Alignment

4.108,4.107,4.99

Large

and

small

end

bores

must be

square

and

parallel

with

each

other

within

the

limits

of

::'::0.010 in

(0,25

mm)

mea-

sured

5 in (127

mm)

each

side

of

the

axis

of

the

rod

on

test

mandrel

as

shown

in Fig. B.1.

With

the

small

end

bush

fitted, the

limit

of

::'::0.010 in (0,25

mm)

is

reduced

to

::'::0.0025 in (0,60

mm).

-

--

Ej~

.=

E

=

-.::t

Sin

.-It')

-

..

=N

-

~

00

127mm

+1

+.

...J

"

B1

Crankshaft

4.108,4.107,4.99

Overall

Length

Main

Journal

Dia. Nos. 1 and 2

Main

Journal

Dia.

No.3

Main

Journal

Length

No.

Main

Journal

Length

No.2

Main

Journal

Length

NO.3

Main

Journal

Fillet

Radii

Crankpin

Dia.

Crankpin

Length

Crankpin

Fillet

Radii

Surface

Finish-All

Journals

Main

Journal

and

Crankpin

Regrind

Undersizes

Oil Seal

Helix

Dia.

Oil Seal Helix

Width

Oil Seal

Helix

Depth

Flange

Dia.

Flange

Width

Spigot

Bearing

Recess Depth

Spigot

Bearing

Recess

Bore

Crankshaft

End Float

Crankshaft

Thrust

Washers 4.108,

4.1

Type

Position

in

Engine

Thrust

Washer

Thickness

(STD)

Thrust

Washer

Thickness

(O/S)

Thrust

Washer

Outside

Dia.

Thrust

Washer

Inside

Dia.

Main

Bearings

4.108, 4.101, 4.99

Type

Shell

Width

Outside

Dia.

of

Main

Bearing

Inside

Dia.

of

Main

Bearing

Running

Clearance-Nos. 1 and

2 .

Running

Clearance-No.

3

Steel

Thickness

Aluminium

Thickness

,;

i..-

4.99

....

~

-

c:

E

I

.-

E

Sin

=-.::t

--

-

'-It')

-

..

C?N

127mm

=0

+1+.

t-.

...J

'f

-

:..,...

21.125 in (536,575

mm)

2.248/2.2485

in

(57,099/57,112

mm)

2.2475/2.248

in

(57,086/57,099

mm)

1.40625 in (35,719

mm)

1.496/1.504

in

(37,998/38,202

mm)

1.499/1.502

in

(38.075/38,151

mm)

0.12510.141 in

(3,175/3,581

mm)

1.9993/2.0001

in

(50,78/50,80

mm)

1.1875/1.1895

in

(30.162/30,213

mm)

0.15625/0.17187

in

(5/32/11/64

in)

(3,969/4,366

mm)

8-16

micro-in

(0,2

- 0,4

micron)

0.010.0.020,0.030

in (0,25, 0.51.0.76

mm)

2.21075/2.21175

in

(56,153/56.178

mm)

0.050/0.080

in

(1,270/2,032

mm)

0.004/0.008

in

(0,102/0.203

mm)

3.9985/3.9995

in

(101,562/101,587

mm)

0.500 in (12,700

mm)

0.875 in (22,225

mm)

1.250 in (31,750

mm)

0.002/0.015

in

(0.0508/0.381

mm)

Steel

BaCked-Lead

Bronze

Faced

Rear

Main

Bearing

0.089/0.091

in

(2,261/2,311

mm)

0.0965/0.1005

in

(2,451/2,553

mm)

3.24513.255 in

(82,423/82.677

mm)

2.590/2.600

in

(65.786/66,040

mm)

Pre-finished,

Steel

Backed.

Aluminium

Tin

Lined

1.245/1.255

in

(31.623/31.877

mm)

2.3955 in (60,846

mm)

2.2505/2.2515

in

(57,163/57,188

mm)

0.002/0.0035

in

(0.051/0,089

mm)

0.0025/0.004

in

(0,063/0.102

mm)

0.060 in (1,524

mm)

Max.

0.01210.01225

in

(0.305/0,311

mm)

Page 17

Connecting Rod Bearings 4.108, 4.107, 4.99

Type

Shell

Width

Outside Dia. of Can. Rod Bearing .

Inside Dia.

of

Can. Rod Bearing

Running Clearance

Steel

Thickness

.

Aluminium

Thickness

Camshaft 4.108,4.107,4.99

No. 1

Journal

Length

No.1

Journal

Dia.

No.1

Cylinder

Block

Camshaft Bore Dia.

No. 1

Journal

Running Clearance

No. 2

Journal

Length

No. 2

Journal

Dia.

No.2

Cylinder

Block

Camshaft Bore Dia.

No.2

Journal

Running Clearance

No. 3

Journal

Length

No. 3

Journal

Dia

NO.3

Cylinder

Block

Camshaft Bore Dia.

NO.3

Journal

Running Clearance

...

Cam

Lift

Oilways

for

Rocker Shaft Lubrication

Camshaft Thrust Plates 4.108, 4.107, 4.99

Type

Thrust Plate Outside Dia.

Cylinder

Block

Recess Dia. for Thrust Plate

Clearance Fit of Thrust Plate in Recess

Thrust Plate Inside Dia.

Thrust Plate Thickness

Cylinder

Block

Recess Depth

for

Thrust Plate

Thrust Plate

Height

in relation to

Cylinder

Block

Face

Camshaft End Float

Valve and Fuel Pump Timing

Refer to

later

section on timing (page

K.1

) .

CYLINDER HEAD

4.1

Overall Length of Cylinder Head

Overall Depth

of

Cylinder

Head

4.1

4.99

Skimming

Allowance

on

Cylinder

Head Face

Pressure

for

Water

Leakage Test

Valve Seat

Angle

Bore in

Cylinder

Head for Guide

Bore in

Cylinder

Head

for

Combustion

Chamber

Inserts

Depth of Bore in

Cylinder

Head for

Combustion Chamber Inserts

Combustion Chamber Inserts 4.108, 4.101,4.99

Outside Dia.

of

Insert

Depth

of

Insert

...

Height

of

Insert in relation

to

Cylinder

Head Face

Clerance Fit

of

Insert in

Cylinder

Head Bore

Method

of

Location

in

Cylinder

Head

Valve Guides

(inlet)

4.108,4.107,4.99

Inside Dia.

Outside Dia.

Interference fit

of

Guide in

Cylinder

Head Bore

Overall length of Guide ."

Guide Protrusion Above

Top

Face

of

Cylinder

Head

TECHNICAL

DATA-B.7

Pre-finished, Steel Backed,

Aluminium

Tin

Lined

0.870/0.880 in (22,098/22,325

mm)

2.1465 in (54,521

mm)

2.0015/2.0025 in (50,838/50,863

mm)

0.0014/0.0032 in (0,036/0,081

mm)

0.060 in (1,524

mm)

Max_

0.012/0.01225 in (0,305/0,311

mm)

1.347/1.351 in (34,214/34,315

mm)

1.791/1.792 in (45,491/45,517

mm)

1.794/1.7955 in (45,568/45,606

mm)

0.002/0.0045 in (0,051/0,114

mm)

1,250 in (31,750

mm)

1.781/1.782 in (45,237/45,26'3

mm)

1,784/1,787 in (45:314/45,390

mm)

0.002/0.006 in (0,051/0,152

mm)

1.000 in (25,400

mm)

1.773/1.774 in (45,034/45,060

mm)

1.776/1.778 in (45,110/45,161

mm)

0.002/0.005 in (0,051/0,127

mm)

0.2592/0.2622 in

(6,58/6,66

mm)

No. 2

Journal

180'

Oil Impregnated Sintered Iron

2.555/2.557 in (64,897/64,948

mm)

2.5585/2.5685 in (64,986/65,240

mm)

0.0015/0.013 in (0,038/0,330

mm)

1.500 in (38,100

mm)

0.160/0.162 in (4,060/4,115

mm)

0.158/0.164 in (4,009/4,166

mm)

0.004 in (0,102

mm)

above

or

below

0.003/0.009 in (0,076/0,228 mm)

20.000 in (508,000

mm)

2.617

/2.633

in (66,472/66,878

mm)

NIL-On

no

account

can the

cylinder

head face be

skimmed

20

Ibflin

2

(1,4

kgflcm2)

-138

kN/m

2

45°

0.4995/0.5005 in (12,687/12,713

mm)

1.250/1.252

in (31,750/31,801

mm)

0.373/0.376

in (9,474/9,550

mm)

1.248/1.249

in (31,699/31,724

mm)

0.374/0.375

in (9,499/9,525

mm)

0.002 in (0,051

mm)

above

or

below

0.001/0.004

in

(0,025/0,102

mm)

By

Cylinder

Block

Face and Expansion Washer

0.3141/0.3155 in (7,978/8,014

mm)

0.5021/0.5026 in (12,753/12,766

mm)

0.0016/0.0031 in (0,041/0,079

mm)

2.130

in

(54,102

mm)

6.800/0.815

in

(20,320/20,701

mm)

Page 18

TECHNICAL

DATA-B.B

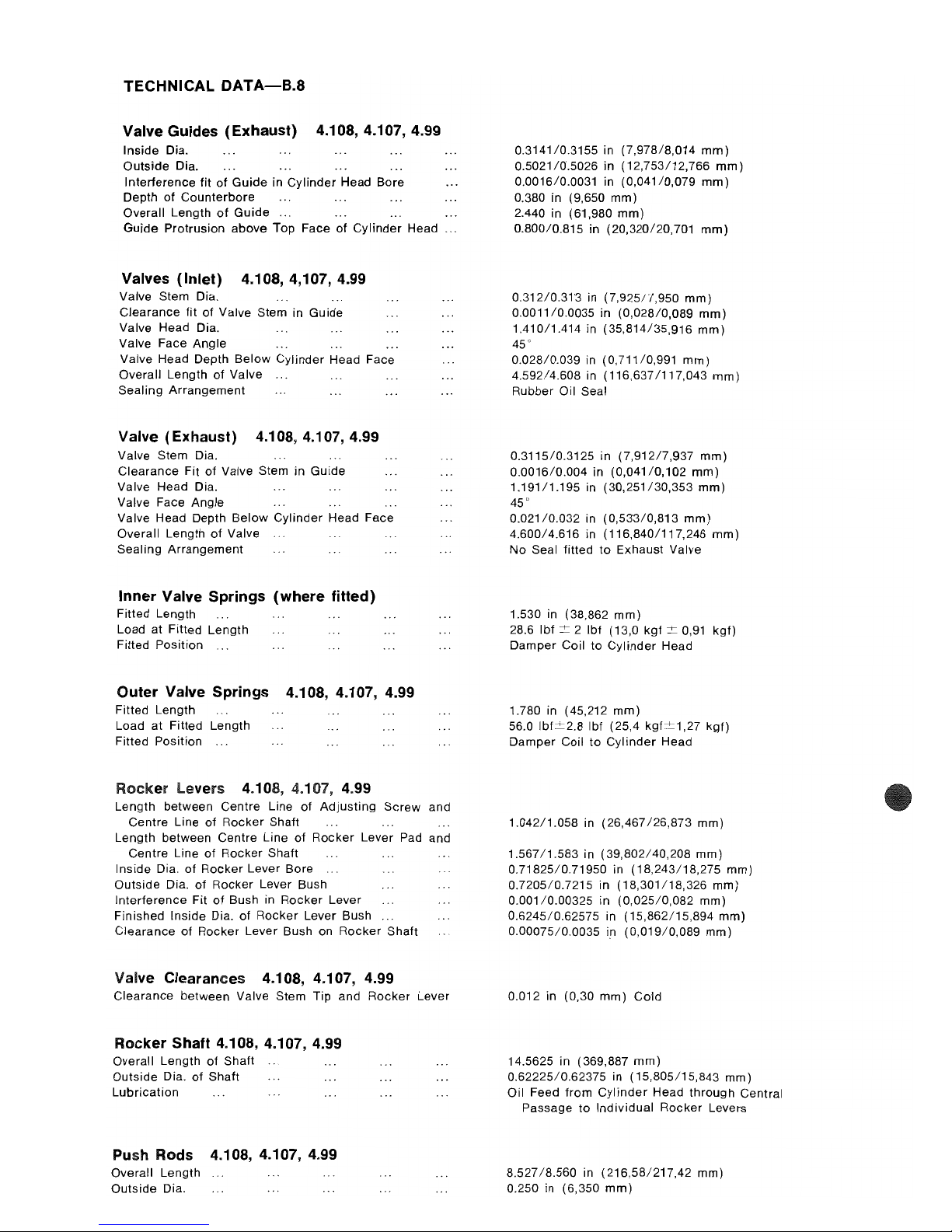

Valve Guides (Exhaust)

4.10B,

4.107, 4.99

Inside Dia.

Outside

Dia.

Interference

fit

of

Guide in Cylinder Head Bore

Depth

of

Counterbore

Overall Length

of

Guide

'"

Guide

Protrusion above Top Face

of

Cylinder

Head

Valves (Inlet) 4.10B, 4,107, 4.99

Valve Stem Dia.

Clearance fit of Valve Stem in Guide

Valve Head Dia.

Valve Face Angle

Valve Head Depth

Below

Cylinder Head Face

Overall Length of Valve

Sealing Arrangement

Valve (Exhaust) 4.108,4.107,4.99

Valve Stem Dia.

Clearance Fit of Valve Stem in Guide

Valve Head Dia.

Valve Face Angle

Valve Head Depth

Below

Cylinder Head Face

Overall Length

of

Valve

Sealing Arrangement

Inner Valve Springs (where fitted)

Fitted Length

Load

at

Fitted Length

Fitted Position

Outer Valve Springs

Fitted Length

Load

at

Fitted Length

Fitted Position

4.10B,

4.107, 4.99

Rockel'

level's

4.108, 4.107, 4.99

Length between Centre Line of

Adjusting

Screw and

Centre Line of Rocker Shaft

Length between Centre Line of Rocker Lever

Pad and

Centre Line of Rocker Shaft

Inside Dia. of Rocker Lever Bore

Outside Dia. of Rocker Lever Bush

Interference Fit

of

Bush in Rocker Lever

Finished Inside Dia. of Rocker Lever Bush

Clearance of Rocker Lever Bush on

Rocker

Shaft

Valve Clearances 4.108, 4.107, 4.99

Clearance between Valve Stem Tip and Rocker Lever

Rocker

Shaft 4.108, 4.107, 4.99

Overall Length of Shaft

Outside Dia. of Shaft

Lubrication

Push Rods

Overall Length

Outside Dia.

4.108, 4.107, 4.99

0.3141/0.3155 in

(7,978/8,014

mm)

0.5021/0.5026 in

(12,753/12,766

mm)

0.001610.0031 in

(0,041/0,079

mm)

0.380 in (9,650

mm)

2.440 in (61,980

mm)

0.80010.815 in (20,320/20,701

mm)

0.312/0.313

in (7,92511,950

mm)

0.0011/0.0035 in

(0,028/0,089

mm)

1.410/1.414

in

(35,814/35,916

mm)

45'

0.028/0.039 in (0,711/0,991

mm)

4.592/4.608

in

(116,637/117,043

mm)

Rubber Oil Seal

0.3115/0.3125 in (7,91217,937

mm)

0.0016/0.004

in

(0,041/0,102

mm)

1.19111.195 in

(30,251/30,353

mm)

45°

0.021/0.032

in (0,53'3/0,813

mm)

4.60014.616 in

(116,840/117,246

mm)

No Seal fitted to Exhaust Valve

1.530 in (38,862

mm)

28.6 Ibf::'::: 2 Ibf (13,0 kgf::':::

0,91

kgf)

Damper Coil to

Cylinder

Head

1.780 in (45,212

mm)

56.0

Ibf::':::2.8

Ibf (25,4 kgf::':::1,27

kg!)

Damper Coil to

Cylinder

Head

1.042/1.058

in

(26,467/26,873

mm)

1.567/1.583

in

(39,802/40,208

mm)

0.71825/0.71950

in

(18,243/18,275

mm)

0.720510.7215 in

(18,301/18,326

mm)

0.00110.00325 in

(0,025/0,082

mm)

0.6245/0.62575

in

(15,862/15,894

mm)

0.00075/0.0035

in (0,01910,089 mm)

0.012 in (0,30

mm)

Cold

14.5625 in (369,887

mm)

0.62225/0.62375

in

(15,805/15,843

mm)

Oil Feed from

Cylinder

Head through Central

Passage

to

Individual

Rocker Levers

8.527/8.560

in

(216,58/217,42

mm)

0.250 in (6,350

mm)

Page 19

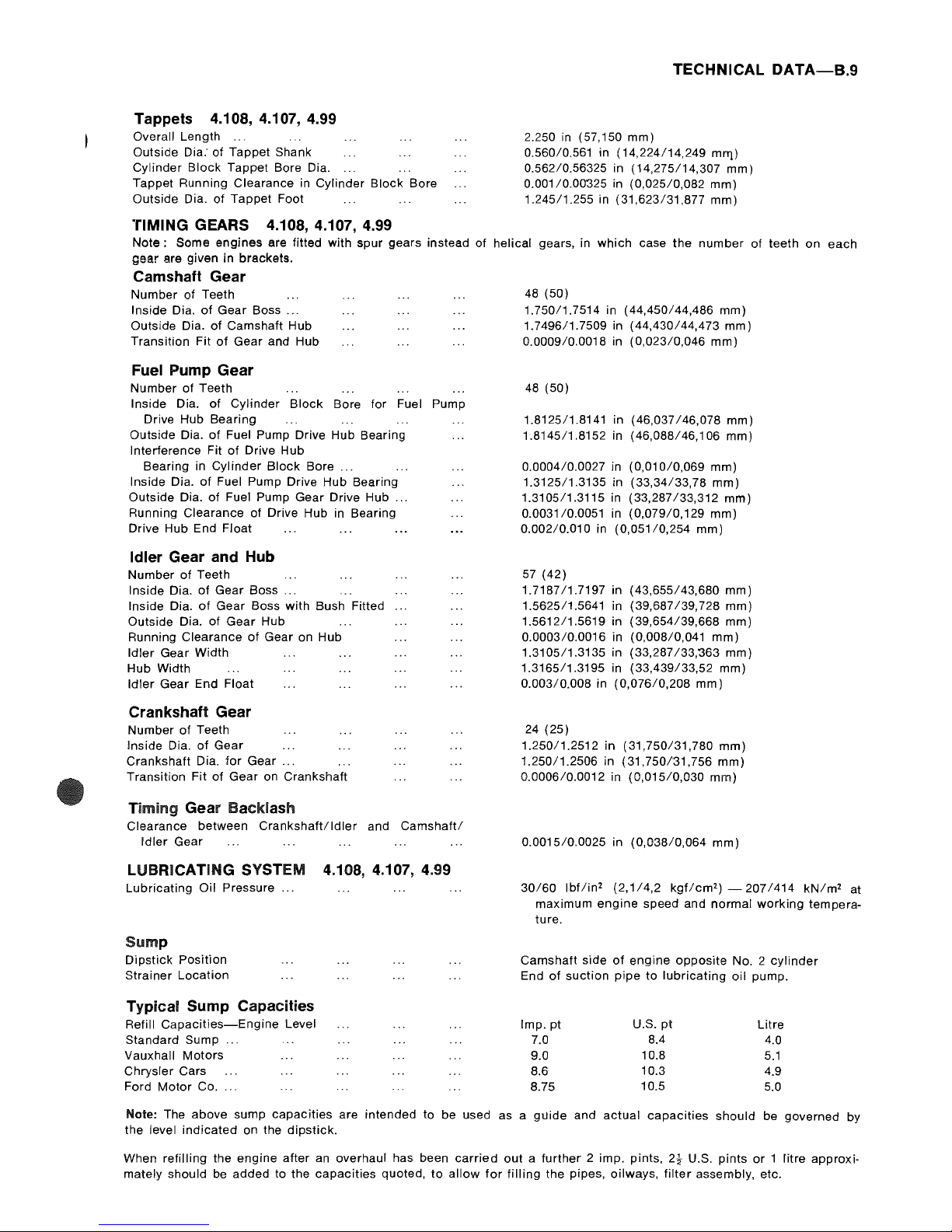

Tappets 4.108, 4.107, 4.99

Overall Length

Outside Dia: of

Tappet

Shank

Cylinder

Block

Tappet Bore Dia.

Tappet Running Clearance in Cylinder

Block

Bore

Outside Dia. of

Tappet

Foot

TIMING GEARS 4.108, 4.107, 4.99

TECHNICAL

DATA-B.9

2.250

in

(57,150

mm)

0.560/0.561 in

(14,224/14,249

mll'l)

0.56210.56325 in

(14,275/14,307

mm)

0.001/0.00"325 in

(0,025/0,082

mm)

1.245/1.255

in

(31,623/31,877

mm)

Note:

Some

engines

are fitted with spur gears instead of helical gears, in

which

case the

number

of teeth

on

each

gear

are given

in

brackets.

Camshaft Gear

Number

of Teeth

Inside Dia.

of

Gear

Boss

...

Outside Dia. of Camshaft Hub

Transition

Fit

of

Gear and Hub

Fuel Pump Gear

Number

of Teeth

Inside Dia.

of

Cylinder

Block

Bore for Fuel Pump

Drive Hub Bearing

Outside Dia.

of

Fuel Pump Drive Hub Bearing

Interference Fit

of

Drive Hub

Bearing in

Cylinder

Block

Bore

...

Inside Dia.

of

Fuel Pump Drive Hub Bearing

Outside Dia.

of

Fuel Pump Gear Drive Hub

...

Running Clearance

of

Drive Hub in Bearing

Drive Hub End

Float

Idler Gear and Hub

Number

of

Teeth

Inside Dia.

of

Gear

Boss

...

Inside Dia.

of

Gear

Boss with Bush Fitted ...

Outside Dia. of

Gear

Hub

Running Clearance

of

Gear on Hub

Idler

Gear Width

Hub Width

Idler

Gear End Float

Crankshaft Gear

Number

of

Teeth

Inside Dia.

of

Gear

Crankshaft Dia.

for

Gear

...

Transition Fit of

Gear

on Crankshaft

Timing Gear Backlash

Clearance between

Crankshaft!ldler

and

Camshaft!

Idler

Gear

LUBRICATING SYSTEM

4.108,4.107,4.99

48

(50)

1.750/1.7514 in

(44,450/44,486

mm)

1.7496/1.7509 in

(44,430/44,473

mm)

0.000910.0018 in

(0,023/0,046

mm)

48

(50)

1.8125/1.8141 in

(46,037/46,078

mm)

1.814511.8152 in

(46,088/46,106

mm)

0.0004/0.0027 in

(0,010/0,069

mm)

1.3125/1.3135

in

(33,34/33,78

mm)

1.3105/1.3115 in

(33,287/33,312

mm)

0.0031/0.0051 in

(0,079/0,129

mm)

0.00210.010 in

(0,051/0,254

mm)

57

(42)

1.7187/1.7197

in

(43,655/43,680

mm)

1.562511.5641 in (39,687139,728

mm)

1.5612/1.5619

in

(39,654/39,668

mm)

0.0003/0.0016

in (0,008/0,041

mm)

1.3105/1.3135

in

(33,287/33,363

mm)

1.316511.3195 in

(33,439/33,52

mm)

0.00310.008 in

(0,076/0,208

mm)

24

(25)

1.25011.2512 in

(31,750/31,780

mm)

1.250/1.2506

in

(31,750/31,756

mm)

0.000610.0012 in

(0,015/0,030

mm)

0.0015/0.0025

in

(0,038/0,064

mm)

Lubricating Oil Pressure

...

30/60

Ibflin

2

(2,1/4,2

kgflcm2)

-2071414

kN/m

2

at

Sump

Dipstick

Position

Strainer Location

Typical Sump Capacities

Refill

Capacities-Engine

Level

Standard Sump

...

Vauxhall

Motors

Chrysler Cars

Ford

Motor

Co

....

maximum

engine

speed and normal

working

tempera-

ture.

Camshaft side

of

engine

opposite

No.2

cylinder

End

of

suction

pipe

to

lubricating

oil pump.

Imp.

pt

U.S.

pt

Litre

7.0

8.4

4.0

9.0

10.8

5.1

8.6

10.3

4.9

8.75

10.5

5.0

Note: The above sump

capacities

are intended

to

be used as a gUide and

actual

capaCities should be governed by

the level

indicated

on the

dipstick.

When refilling the engine

after

an overhaul has been

carried

out a further

2 imp. pints,

2!

U.S.

pints

or 1 litre

approxi-

mately should be added

to

the

capacities

quoted,

to

allow

for

filling

the pipes, oilways,

filter

assembly, etc.

Page 20

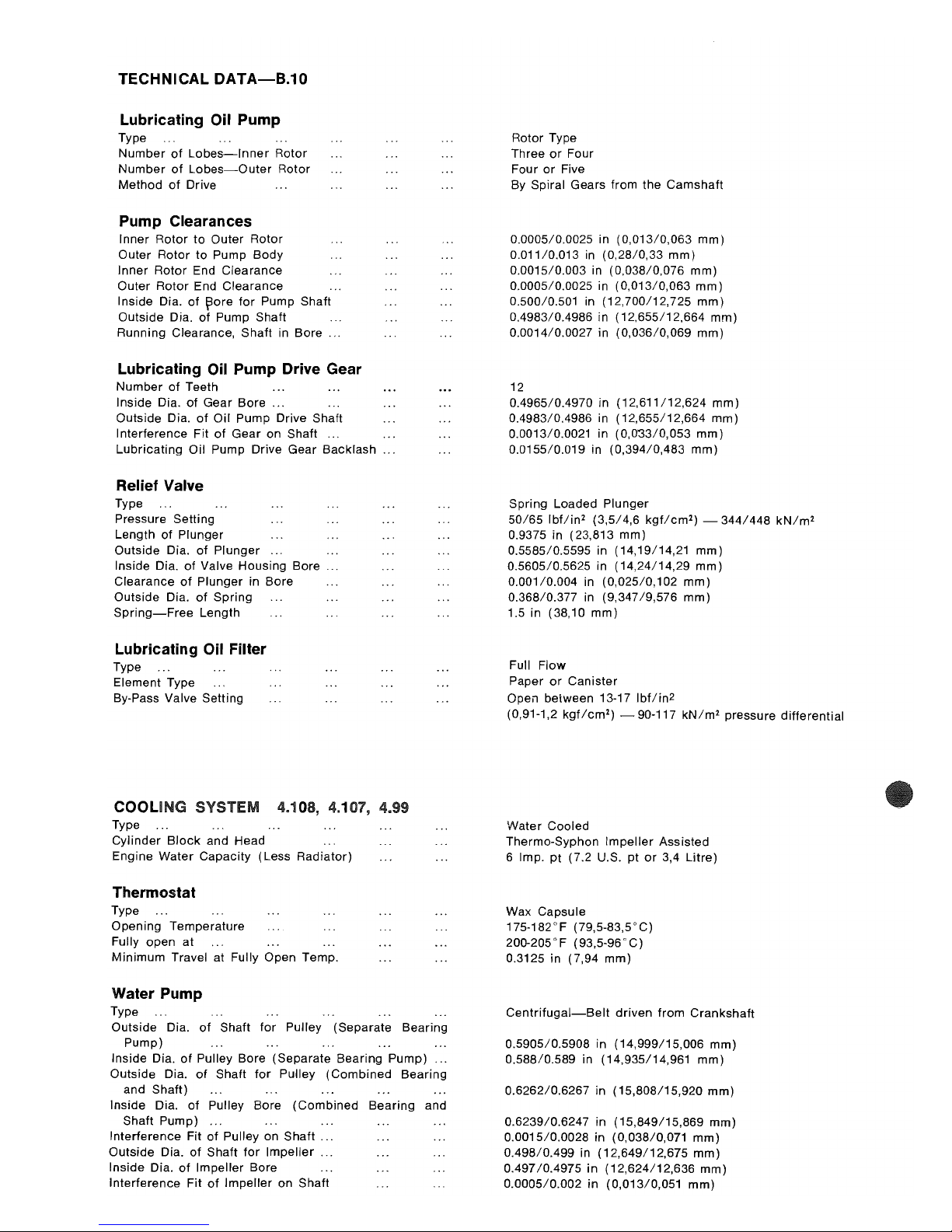

TECHNICAL

DATA-B.10

Lubricating Oil Pump

Type

Number

of

Lobes-Inner

Rotor

Number

of

Lobes-Outer

Rotor

Method

of

Drive

Pump Clearances

Inner

Rotor

to

Outer Rotor

Outer Rotor

to

Pump Body

Inner Rotor End Clearance

Outer

Rotor End Clearance

Inside Dia.

of

~ore

for

Pump Shaft

Outside Dia.

of

Pump Shaft

Running Clearance, Shaft in Bore ...

Lubricating Oil Pump Drive Gear

Number

of

Teeth

Inside Dia. of Gear

Bore

...

Outside Dia.

of

Oil Pump Drive Shaft

Interference Fit of Gear on Shaft ...

Lubricating Oil Pump Drive Gear Backlash

...

Relief Valve

Type

Pressure Setting

Length

of

Plunger

Outside Dia.

of

Plunger

...

Inside Dia.

of

Valve Housing Bore ...

Clearance

of

Plunger in Bore

Outside Dia.

of

Spring

Spring-Free

Length

Lubricating Oil Filter

Type

Element Type

By-Pass Valve Setting

COOLING SYSTEM 4.108, 4.101, 4.99

Type

Cylinder

Block

and Head

Engine Water Capacity (Less Radiator)

Thermostat

Type

Opening Temperature

Fully open

at

Minimum

Travel

at

Fully Open Temp.

Water Pump

Type

Outside Dia.

of

Shaft

for

Pulley (Separate Bearing

Pump)

Inside Dia.

of

Pulley Bore (Separate Bearing Pump)

Outside Dia.

of

Shaft

for

Pulley

(Combined

Bearing

and

Shaft)

Inside Dia.

of

Pulley Bore

(Combined

Bearing

and

Shaft Pump)

...

Interference Fit

of

Pulley on

Shaft

.. .

Outside Dia. of Shaft

for

Impeller

.. .

Inside Dia.

of

Impeller Bore

Interference Fit

of

Impeller on Shaft

Rotor Type

Three

or

Four

Four

or

Five

By

Spiral Gears from the

Camshaft

0.0005/0.0025 in

(0,013/0,063

mm)

0.01110.013 in

(0,28/0,33

mm)

0.0015/0.003 in

(0,038/0,076

mm)

0.0005/0.0025 in

(0,013/0,063

mm)

0.50010.501 in

(12,700/12,725

mm)

0.4983/0.4986 in

(12,655/12,664

mm)

0.0014/0.0027 in

(0,036/0,069

mm)

12

0.496510.4970 in

(12,611/12,624

mm)

0.4983/0.4986 in

(12,655/12,664

mm)

0.001310.0021 in

(0,033/0,053

mm)

0.0155/0.019

in

(0,394/0,483

mm)

Spring Loaded Plunger

50/65

Ibflin2 (3,5/4,6

kgflcm2) -344/448

kN/m

2

0.9375 in (23,813

mm)

0.5585/0.5595 in (14,19/14,21

mm)

0.5605/0.5625 in (14,24/14,29

mm)

0.001/0.004 in (0,025/0,102

mm)

0.368/0.377 in (9,347/9,576

mm)

1.5 in (38,10

mm)

Full Flow

Paper

or

Canister

Open between 13-17

Ibflin

2

(0,91-1,2

kgflcm2)

90-117

kN/m

2

pressure

differential

Water Cooled

Thermo-Syphon

Impeller

Assisted

6 Imp.

pt

(7.2 U.S.

pt

or

3,4

Litre)

Wax Capsule

175-182°F (79,5-83,5°C)

200-205°F (93,5-96°C)

0.3125 in (7,94

mm)

Centrifugal-Belt

driven

from

Crankshaft

0.5905/0.5908 in (14,999/15,006

mm)

0.588/0.589 in (14,935/14,961

mm)

0.6262/0.6267 in (15,808/15,920

mm)

0.6239/0.6247 in (15,849/15,869

mm)

0.0015/0.0028 in (0,038/0,071

mm)

0.498/0.499 in (12,649/12,675

mm)

0.497/0.4975

in (12,624/12,636

mm)

0.0005/0.002 in (0,013/0,051

mm)

Page 21

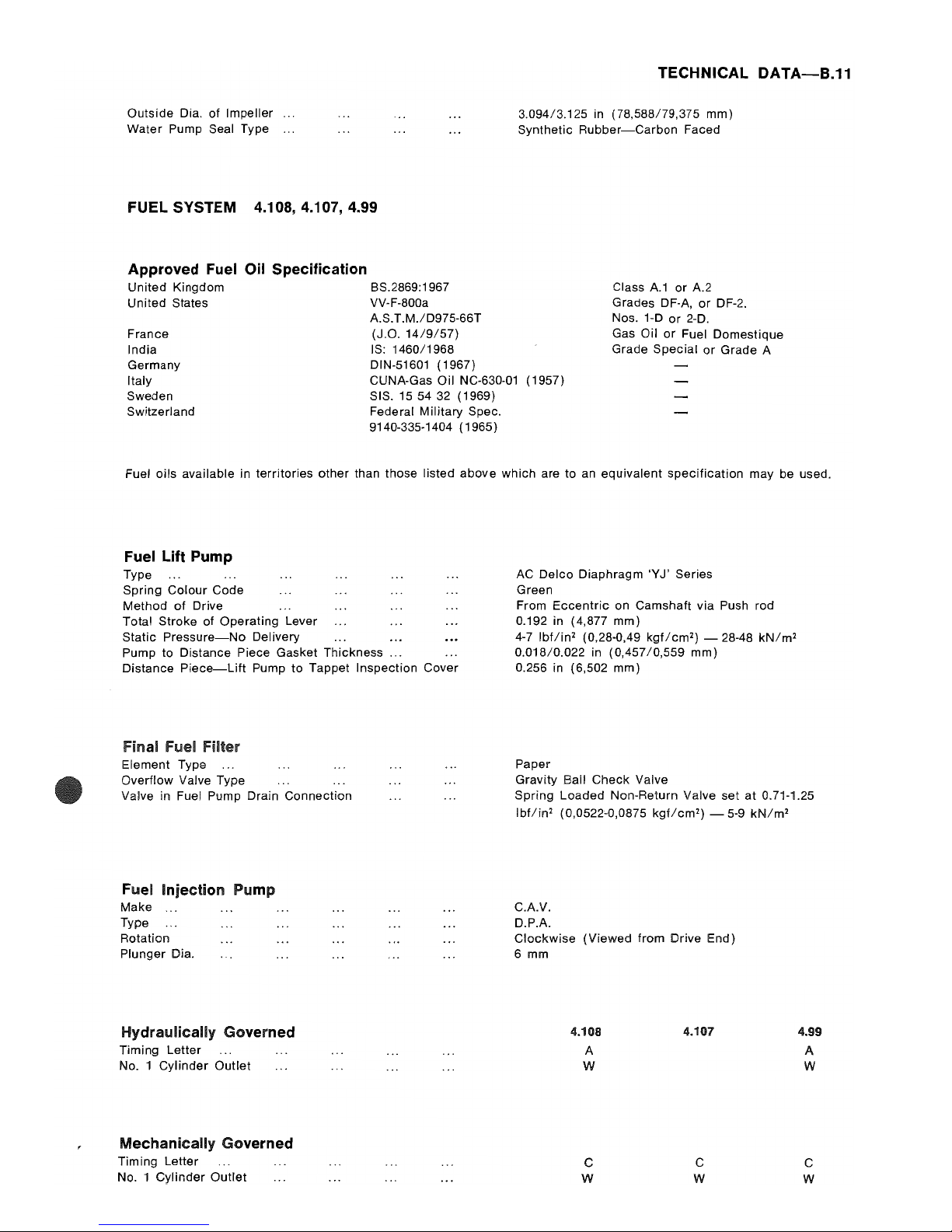

Outside

Dia. of

Impeller

Water

Pump Seal Type

FUEL SYSTEM 4.108,4.107,4.99

Approved Fuel Oil Specification

United Kingdom 8S.2869:1967

United States VV-F-800a

AS.T.M.lD975-66T

France

(J.O.

14/9/57)

India

IS: 1460/1968

Germany DIN-51601 (1967)

TECHNICAL

DATA-B.11

3.094/3.125 in (78,588179,375

mm)

Synthetic

Rubber-Carbon

Faced

Class

A1

or

A2

Grades OF-A,

or

DF-2.

Nos.

1-0

or

2-D.

Gas Oil

or

Fuel Domestique

Grade

Special

or

Grade A

Italy CUNA-Gas Oil NC-630-01 (1957)

Sweden SIS.

155432

(1969)

Switzerland Federal

Military

Spec.

9140-335-1404 (1965)

Fuel

oils

available in territories

other

than those listed

above

which are to an

equivalent

specification

may be used.

Fuel Lift Pump

Type

Spring

Colour

Code

Method

of

Drive

Total Stroke

of

Operating Lever

Static

Pressure-No

Delivery

Pump to Distance Piece Gasket Thickness

...

Distance

Piece-Lift

Pump

to

Tappet Inspection Cover

Final Fuel Filter

Element Type

Overflow Valve Type

Valve in Fuel Pump Drain Connection

Fuel Injection Pump

Make

Type

Rotation

Plunger Dia.

Hydraulically Governed

Timing Letter

No. 1

Cylinder

Outlet

Mechanically Governed

Timing Letter

No. 1

Cylinder

Outlet

AC

Delco

Diaphragm 'Y J' Series

Green

From

Eccentric

on Camshaft via Push rod

0.192 in (4,877

mm)

4-7

Ibflin

2

(0,28-0,49

kgflcm2)

- 28-48

kN/m

2

0.018/0.022 in (0,457/0,559

mm)

0.256 in (6,502

mm)

Paper

Gravity

8all

Check

Valve

Spring Loaded Non-Return Valve set

at

0.71-1.25

Ibflin

2

(0,0522-0,0875

kgflcm2)

- 5-9

kN/m

2

CAV.

D.P.A.

Clockwise

(Viewed

from Drive End)

6 mm

4.108

A

W

C

W

4.107

c

W

4.99

A

W

C

W

Page 22

TECHNICAL

DATA-B.12

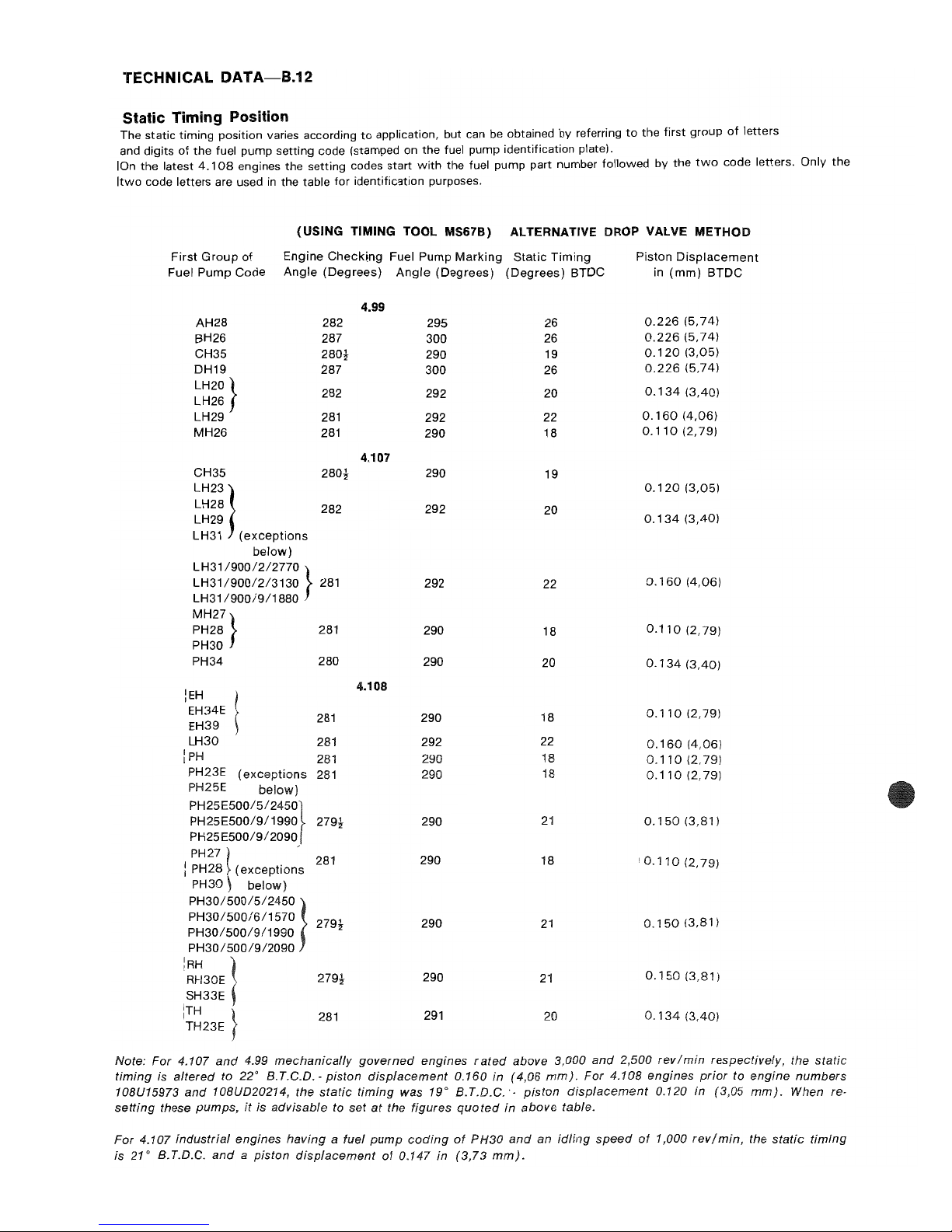

Static Timing Position

The static timing position varies according

to

application, but can

be

obtained by referring

to

the first group

of

letters

and digits

of

the

fuel pump setting code (stamped on the fuel pump identification plate).

IOn the latest

4.108

engines the setting codes start

with

the fuel pump part number followed by

the

two

code letters. Only

the

Itwo

code letters are used

in

the table for identification purposes.

(USING TIMING TOOL MS67B)

ALTERNATIVE DROP VALVE METHOD

First

Group

of

Engine

Checking

Fuel Pump

Marking

Static

Timing

Piston

Displacement

Fuel

Pump

Code

Angle

(Degrees)

Angle

(Degrees)

(Degrees)

BTDC

in

(mm)

BTDC

4.99

AH28

282

29S

26

0.226

(5,74)

BH26

287

300

26

0.226

(5,74)

CH3S

280~

290 19

0.120

(3,05)

DH19

287

300

26

0.226

(5,74)

LH20 }

282

292

20

0.134

(3,40)

LH26

LH29

281

292

22

0.160

(4,06)

MH26

281

290

18

0.110

(2,79)

4.107

CH3S

280~

290

19

LH23}

0.120

(3,05)

LH28

282

292

20

LH29

0.134

(3,40)

LH31

(exceptions

below)

LH31

1900/2/2770

}

LH31

1900/2/3130

281

292

22

0.160

(4,06)

LH31

1900/9/1880

MH27}

PH28

281

290

18

0.110

(2,79)

PH30

PH34

280

290

20

0.134

(3,40)

iEH

4.108

EH34E

281

290

18

0.11

°

(2,79)

EH39

LH30

281

292

22

0.160

(4,06)

IpH

281

290 18

0.1 0

(2,79)

PH23E

(exceptions

281

290 18

0.110

(2,79)

PH25E

below)

PH2SESOO/S/24S0}

PH2SESOO/9/1990

279~

290

21

0.150

(3,81)

PH2SESOO/9/2090

PH27

~

-

281

290

18

'0.110

(2,79)

i PH28

(exceptions

PH30 be/ow)

PH30/S00/5/24SO }

PH30/S00/6/1S70

279t

290

21

0.150

(3,81)

PH30/S00/9/1990

PH30/S00/9/2090

:RH

1

RH30E

279~

290

21

0.150

(3,81)

SH33E

ITH }

281

291

20

0.134

(3,40)

ITH23E .

Note:

For 4.107

and

4.99

mechanically

governed

engines r aled

above 3,000

and

2,SOO

rev I

min

respectively, the

static

timing

is

altered

to

22'

B.T.C.D.'

piston

displacement

0.160 in

(4,06

mmJ.

For

4.108

engines

prior

to

engine

numbers

108U15973

and

108UD20214, the

static

timing

was

19'

B.T.D.C.·,

piston

displacement

0.120 in (3,05

mm).

When re,

setting

these pumps,

it

is

advisable

to

set

at

the figures

quoted

in

above

table.

For 4.107

industrial

engines

having

a fuel

pump

coding

of

PH30

and

an

idling

speed

at

1,000

rev/min,

the

static

timing

is

21'

B.T.D.C.

and a piston

displacement

of

0.147 in

(3,73

mm).

Page 23

I

I

I

",-(I!I'"

I

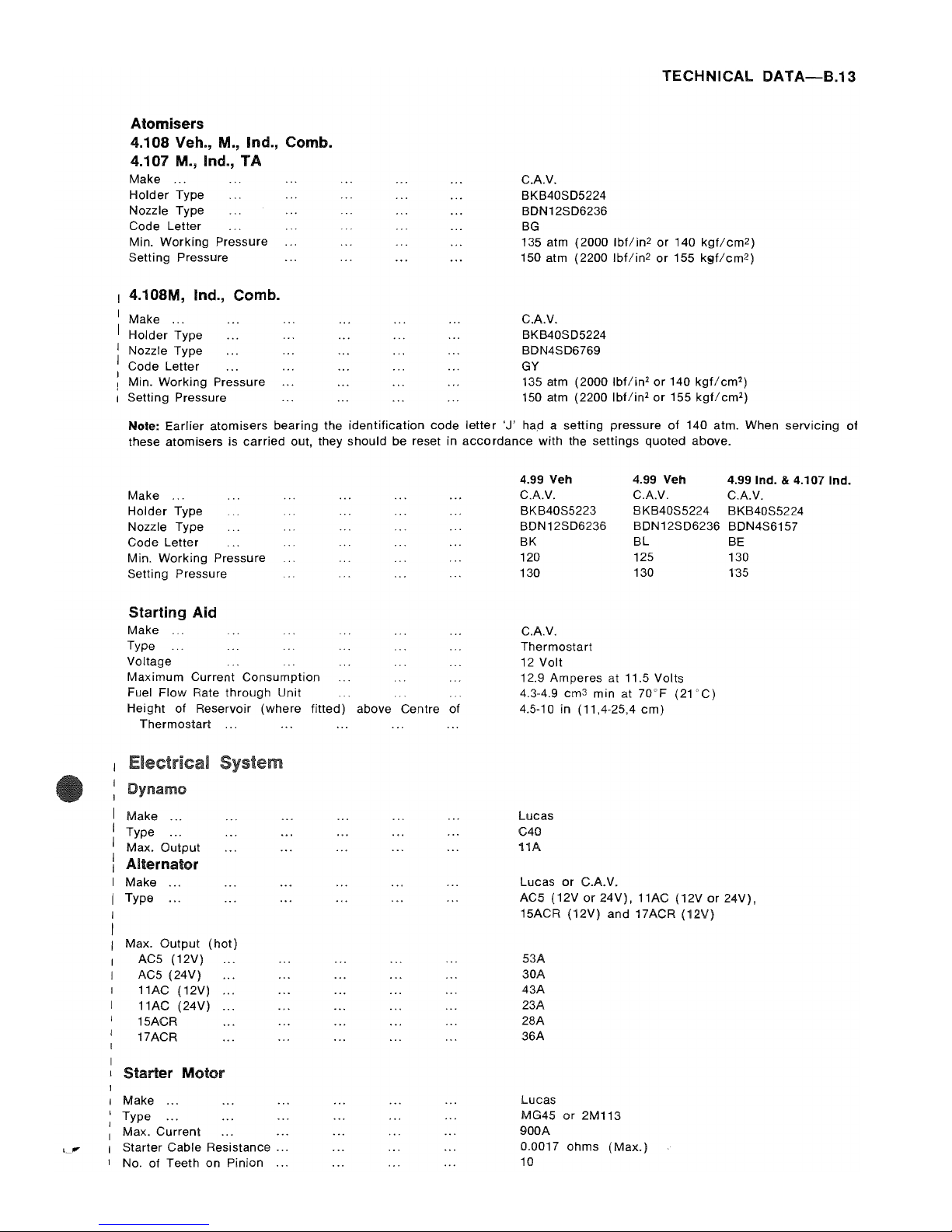

Atomisers

4.108 Veh., M., Ind., Comb.

4.107 M., Ind.,

TA

Make

...

Holder

Type

Nozzle Type

Code Letter

Min.

Working

Pressure

Setting Pressure

4.108M, Ind., Comb.

Make

...

Holder

Type

Nozzle Type

Code Letter

! Min. Working Pressure

I Setting Pressure

CAV.

BKB40S05224

BON 12S06236

BG

TECHNICAL

DATA-B.13

135 atm (2000

Ibflin2

or

140

kgf/cm2)

150 atm (2200

Ibf/in2

or

155 k9f1cm2)

CAV.

BKB40S05224

BDN4SD6769

GY

135 atm (2000

Ibflin2 or

140

kgflcm2)

150 atm (2200

Ibflin2 or

155

kgflcm2)

Note: Earlier atomisers bearing the identification code

letter

'J' had a setting pressure

of

140 atm. When

servicing

of

these atomisers is

carried

out, they should be reset in

accordance

with the settings quoted above.

Make

Holder

Type

Nozzle Type

Code Letter

Min. Working Pressure

Setting Pressure

Starting Aid

Make

Type

Voltage

Maximum Current Consumption

Fuel Flow Rate

through

Unit

Height of Reservoir (where fitted) above Centre of

Thermostart

...

Make ...

Type

...

Max. Output

Alternator

Make

Type

...

Max. Output

(hot)

AC5 (12V)

AC5 (24V)

11AC (12V)

..

11AC (24V)

15ACR

17ACR

Starter

Motor

Make

...

Type

...

Max.

Current

Starter Cable Resistance ...

No. of Teeth on Pinion

...

4.99 Veh 4.99

Veh

4.99 Ind. & 4.107 Ind.

CAV. CAV.

CAV.

BKB40S5223 BKB40S5224

BKB40S5224

BON12SD6236 BDN12SD6236 BDN4S6157

BK

120

130

CAV.

Thermostart

12

Volt

BL

125

130

12.9 Amperes

at

11.5 Volts

4.3-4.9 cm

3

min

at

70"F

(21'C)

4.5-10 in (11,4-25,4

cm)

Lucas

C40

11A

Lucas

or

C.A.V.

BE

130

135

AC5

(12Vor24V),

11AC

(12Vor24Vj,

15ACR (12V) and 17ACR

(12V)

53A

30A

43A

23A

28A

36A

Lucas

MG45

or

2M113

900A

0.0017

ohms

(Max.)

10

Page 24

Page 25

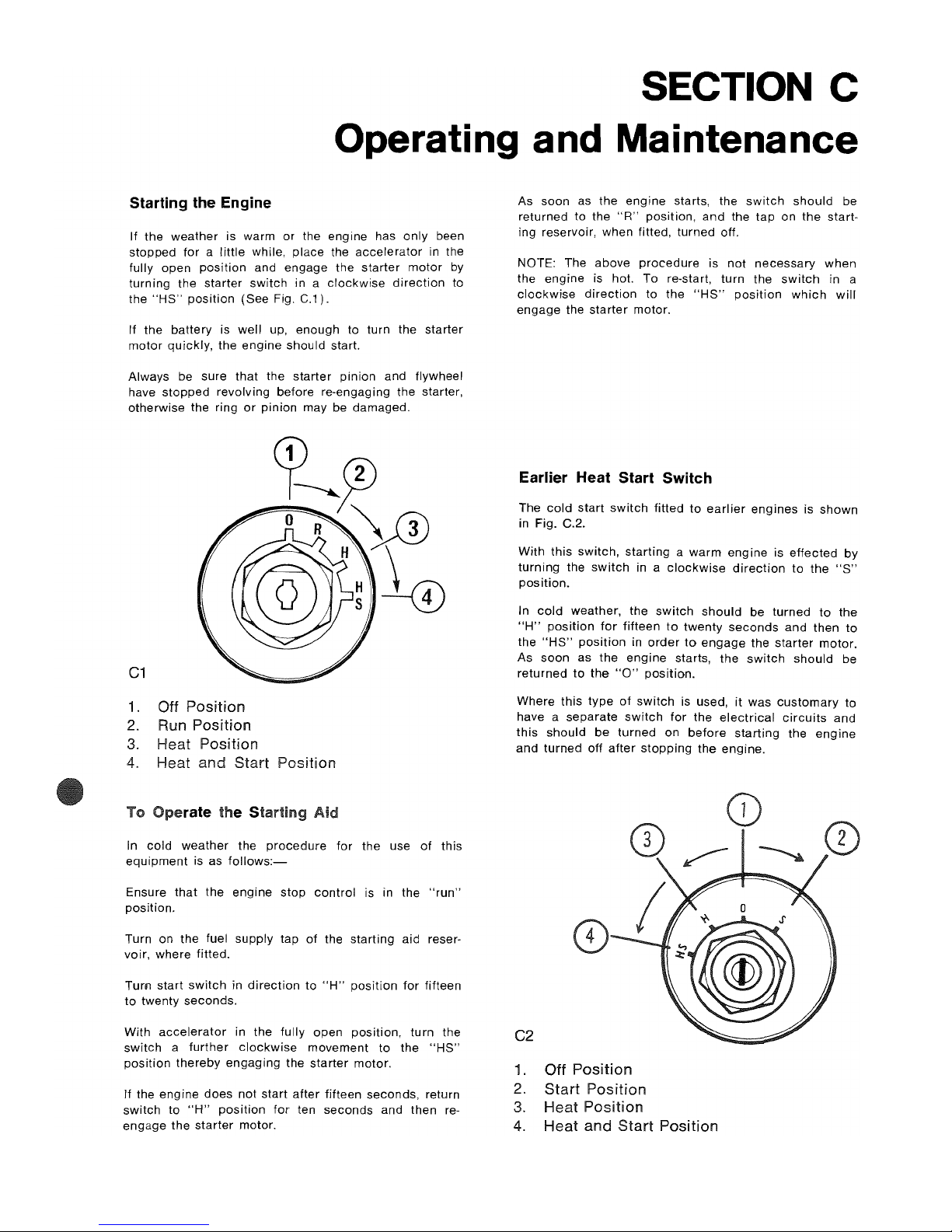

SECTION C

Operating and Maintenance

Starting the Engine

If

the

weather

is warm

or

the engine has only been

stopped

for a little

while, place the

accelerator

in the

fully open

position

and engage the

starter

motor

by

turning the

starter

switch

in a

clockwise

direction

to

the

"HS"

position

(See Fig. C.1).

If

the

battery

is

well

up, enough to turn the

starter

motor

quickly,

the

engine

should start.

Always be sure

that

the

starter

pinion

and flywheel

have

stopped

revolving before re-engaging the starter,

otherwise

the

ring

or

pinion

may be damaged.

C1

1.

Off Position

2.

Run Position

3.

Heat Position

4.

Heat and Start Position

To

Aid

In

cold

weather

the

procedure

for

the use

of

this

equipment

is as

follows:-

Ensure

that

the

engine

stop

control

is in the

"run"

position.

Turn on the fuel supply

tap

of

the starting aid reser-

voir, where fitted.

Tum

start

switch

in

direction

to

"H"

position

for

fifteen

to

twenty

seconds.

As soon as the engine starts, the

switch

should

be

returned to the

"R"

position,

and

the

tap

on

the

start-

ing reservoir, when fitted,

turned

off.

NOTE: The above

procedure

is

not

necessary

when

the

engine

is hot.

To

re-start,

turn

the

switch

in a

clockwise

direction

to the

"HS"

position

which

will

engage

the

starter

motor.

Earlier Heat Start Switch

The

cold

start

switch

fitted

to

earlier

engines

is

shown

in Fig. C.2.

With this

switch,

starting a warm

engine

is

effected

by

turning

the

switch

in a

clockwise

direction

to

the

"S"

position.

In

cold

weather, the

switch

should

be

turned

to

the

"H"

position

for

fifteen

to

twenty

seconds

and

then

to

the

"HS"

position

in

order

to

engage

the

starter

motor.

As

soon

as the

engine

starts,

the

switch

should

be

returned

to

the

"0"

position.

Where

this

type

of

switch

is used,

it

was

customary

to

have a

separate

switch

for

the

electrical

circuits

and

this

should

be

turned

on

before

starting

the

engine

and

turned

off

after

stopping

the

engine.

With

accelerator

in the fully

open

position,

turn

the C2

switch a further

clockwise

movement

to

the

"HS"

position

thereby

engaging

the

starter

motor.

If the engine

does

not start

after

fifteen seconds, return

switch

to

"H"

position

for

ten

seconds

and

then re-

engage

the

starter

motor.

1.

Off Position

2.

Start Position

3.

Heat Position

4.

Heat and

Start

Position

Page 26

OPERATING AND

MAINTENANCE-C.2

Alternative Method

With some engines, a different starter switch is pro-

vided

and the cold

start

aid is operated by means

of

a

separate push button switch.

The

cold

starting

procedure

is the same i.e.

Switch

on by turning the starter switch in a

clockwise

direction

to the first position.

Press the heater button for fifteen

to

twenty seconds

and then,

with

the

heater

button still pressed, turn the

starter

switch

in a

further

clockwise

direction

to engage

the

starter

motor. As

soon

as the engine starts, release

switch

and heater button.

I Glow Plugs

Glow

plugs are sometimes fitted to engines in applica-

tions

such as refrigeration units, fork

lift

trucks

and

other

certain 4.108

mechanically

governed engines

rated at 3,000

rev/min

and below. As the buss bar

connecting

these

glow

plugs may not be insulated,

extreme care must be exercised to keep pipes, clips

or

other

metal

objects

well clear

as

the consequences

of a

direct

short of this buss

bar

to

earth when

energised are obvious.

It must be noted

that

in

no

circumstances

should

either

or

any other unauthorised starting aids be used

at the same time as

glow

plugs.

To operate, use the

following

procedure

:-

Before operating the starter motor, press the

"Heat"

button for

20

to

30

seconds.

I With the

"Heat"

button still pressed, engage the

I starter

motor

until the

engine

starts.

I Continue

to

press the

"Heat"

button

for

a few seconds

I after the engine has started until even running has

: been obtained.

Ilf

the engine does not start, disengage the starter

I motor,

but

keep the

"Heat"

button pressed

for

a

I

further

10

to

15 seconds, when a

further

attempt should

I be made

to

start the engine, keeping the

glow

plugs

I energised whilst starting and for a few seconds after

ithe

engine

has fired until even running is obtained.

Points

to

Note

Ensure

that

the

electrical

connection