Page 1

Operation and

Maintenance

Manual

M0068760 (en-us)

March 2016

2806F-E18TA Industrial Engine

P84 (Engine)

Page 2

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to premature failures, product damage, personal injury or

death.

Page 3

M0068760 3

Table of Contents

Table of Contents

Foreword ........................................................... 4

Safety Section

Safety Messages............................................... 5

Additional Messages ......................................... 6

General Hazard Information.............................. 6

Burn Prevention............................................... 10

Fire Prevention and Explosion Prevention...... 10

Crushing Prevention and Cutting Prevention.. 12

Mounting and Dismounting ............................. 13

Before Starting Engine .................................... 13

Engine Starting................................................ 13

Refill Capacities............................................... 56

Maintenance Recommendations .................... 71

Maintenance Interval Schedule....................... 74

Warranty Section

Warranty Information..................................... 102

Reference Information Section

Reference Materials ...................................... 103

Index Section

Index.............................................................. 106

Electrical System............................................. 13

Engine Electronics........................................... 14

Product Information Section

Model Views .................................................... 15

Product Identification Information ................... 21

Operation Section

Lifting and Storage .......................................... 23

Features and Controls..................................... 29

Engine Diagnostics ......................................... 40

Engine Starting................................................ 44

Engine Operation ............................................ 48

Engine Stopping .............................................. 52

Cold Weather Operation ................................. 54

Maintenance Section

Page 4

4 M0068760

Foreword

Foreword

Literature Information

This manual contains safety, operation instructions,

lubrication and maintenance information. This

manual should be stored in or near the engine area in

a literature holder or literature storage area. Read,

study and keep it with the literature and engine

information.

English is the primary language for all Perkins

publications. The English used facilitates translation

and consistency.

Some photographs or illustrations in this manual

show details or attachments that may be different

from your engine. Guards and covers may have been

removed for illustrative purposes. Continuing

improvement and advancement of product design

may have caused changes to your engine which are

not included in this manual. Whenever a question

arises regarding your engine, or this manual, please

consult with your Perkins dealer or your Perkins

distributor for the latest available information.

Safety

This safety section lists basic safety precautions. In

addition, this section identifies hazardous, warning

situations. Read and understand the basic

precautions listed in the safety section before

operating or performing lubrication, maintenance and

repair on this product.

Operation

Operating techniques outlined in this manual are

basic. They assist with developing the skills and

techniques required to operate the engine more

efficiently and economically. Skill and techniques

develop as the operator gains knowledge of the

engine and its capabilities.

The operation section is a reference for operators.

Photographs and illustrations guide the operator

through procedures of inspecting, starting, operating

and stopping the engine. This section also includes a

discussion of electronic diagnostic information.

Maintenance

The maintenance section is a guide to engine care.

The illustrated, step-by-step instructions are grouped

by service hours and/or calendar time maintenance

intervals. Items in the maintenance schedule are

referenced to detailed instructions that follow.

Recommended service should be performed at the

appropriate intervals as indicated in the Maintenance

Interval Schedule. The actual operating environment

of the engine also governs the Maintenance Interval

Schedule. Therefore, under extremely severe, dusty,

wet or freezing cold operating conditions, more

frequent lubrication and maintenance than is

specified in the Maintenance Interval Schedule may

be necessary.

The maintenance schedule items are organized for a

preventive maintenance management program. If the

preventive maintenance program is followed, a

periodic tune-up is not required. The implementation

of a preventive maintenance management program

should minimize operating costs through cost

avoidances resulting from reductions in unscheduled

downtime and failures.

Maintenance Intervals

Perform maintenance on items at multiples of the

original requirement. We recommend that the

maintenance schedules be reproduced and

displayed near the engine as a convenient reminder.

We also recommend that a maintenance record be

maintained as part of the engine's permanent record.

Your authorized Perkins dealer or your Perkins

distributor can assist you in adjusting your

maintenance schedule to meet the needs of your

operating environment.

Overhaul

Major engine overhaul details are not covered in the

Operation and Maintenance Manual except for the

interval and the maintenance items in that interval.

Major repairs should only be carried out by Perkins

authorized personnel. Your Perkins dealer or your

Perkins distributor offers a variety of options

regarding overhaul programs. If you experience a

major engine failure, there are also numerous after

failure overhaul options available. Consult with your

Perkins dealer or your Perkins distributor for

information regarding these options.

California Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause cancer,

birth defects, and other reproductive harm. Battery

posts, terminals and related accessories contain lead

and lead compounds. Wash hands after handling.

Page 5

M0068760

5

Safety Section

Safety Messages

Safety Section

i06599865

Safety Messages

There may be several specific safety messages on

your engine. The exact location and a description of

the safety messages are reviewed in this section.

Become familiar with all safety messages.

Ensure that all the safety messages are legible.

Clean the safety messages or replace the safety

messages if the words cannot be read or if the

illustrations are not visible. Use a cloth, water, and

soap to clean the safety messages. Do not use

solvents, gasoline, or other harsh chemicals.

Solvents, gasoline, or harsh chemicals could loosen

the adhesive that secures the safety messages. The

safety messages that are loosened could drop off the

engine.

Replace any safety message that is damaged or

missing. If a safety message is attached to a part of

the engine that is replaced, install a new safety

message on the replacement part. Your Perkins

distributor can provide new safety messages.

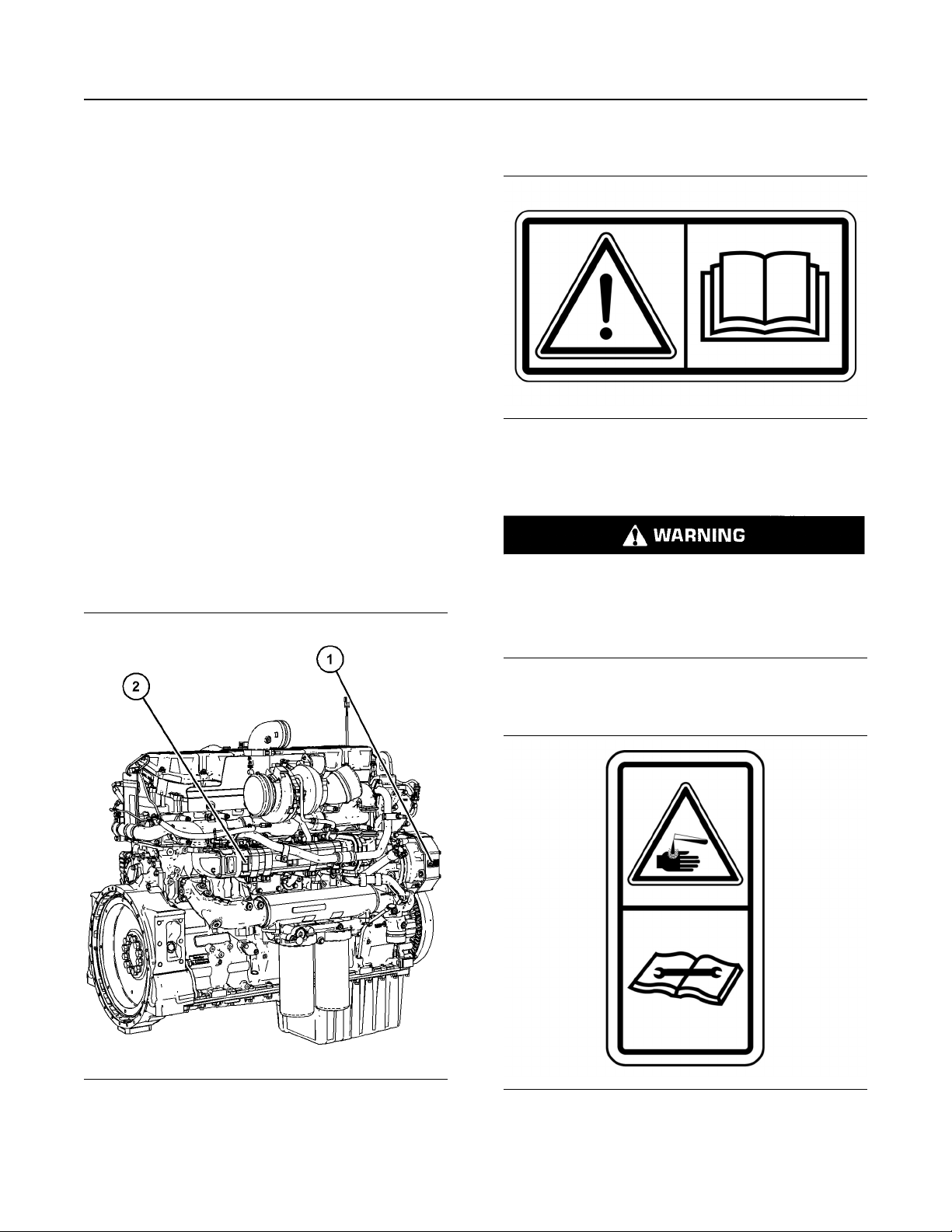

Universal Warning (1)

Illustration 2 g01370904

One safety message is on the left side of the valve

mechanism cover. One safety message is on the

right side of the engine gear case.

Do not operate or work on this equipment unless

you have read and understand the instructions

and warnings in the Operation and Maintenance

Manuals. Failure to follow the instructions or

heed the warnings could result in serious injury

or death.

Illustration 1 g06040012

Typical example

(1) Universal warning label

(2) Sulfuric Acid Burn label

Sulfuric Acid Burn (2)

Illustration 3 g01382725

The safety message for sulfuric acid burn is on the

side of the exhaust cooler.

Page 6

6 M0068760

Safety Section

Additional Messages

This notice should be located next to the battery

disconnect switch.

Sulfuric Acid Burn Hazard may cause serious

personal injury or death.

The exhaust gas cooler may contain a small

amount of sulfuric acid. The use of fuel with sul-

fur levels greater than 15 ppm may increase the

amount of sulfuric acid formed. The sulfuric acid

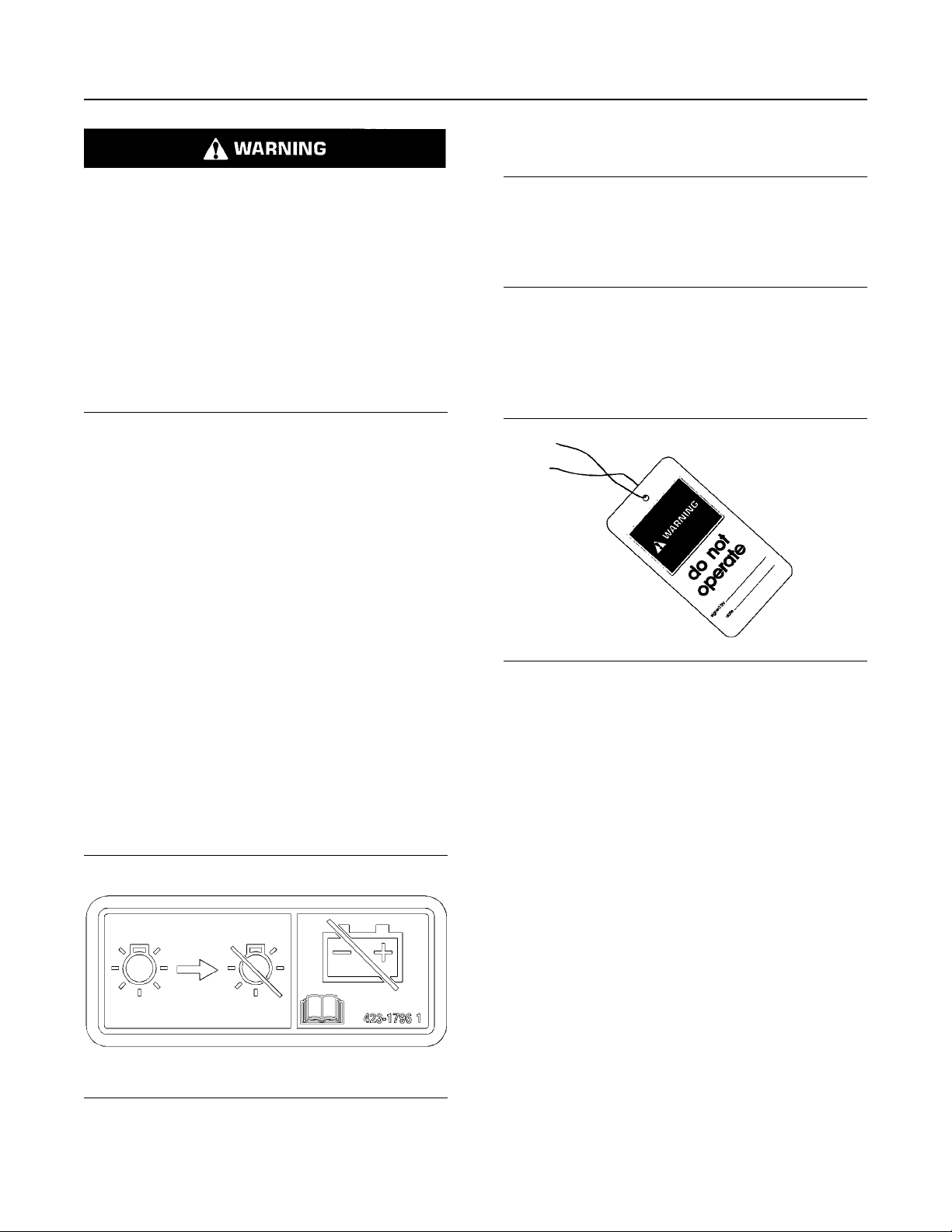

Do not turn the battery power disconnect switch off

until indicator lamp has turned off. If the switch is

turned off when the light is illuminated then the DEF

system will not purge and DEF could freeze and

cause damage to the pump and lines.

NOTICE

may spill from the cooler during service of the engine. The sulfuric acid will burn the eyes, skin

and clothing on contact. Always wear the appropriate personal protective equipment (PPE) that

is noted on a material safety data sheet (MSDS)

for sulfuric acid. Always follow the directions for

General Hazard Information

i06078546

first aid that are noted on a material safety data

sheet (MSDS) for sulfuric acid.

i06599922

Additional Messages

There are several specific messages on this engine.

The exact location of the messages and the

description of the information are reviewed in this

section. Become familiar with all messages.

Make sure that all the messages are legible. Clean

the messages or replace the messages if you cannot

read the words. Replace the illustrations if the

illustrations are not legible. When you clean the

messages, use a cloth, water, and soap. Do not use

solvent, gasoline, or other harsh chemicals to clean

the messages. Solvents, gasoline, or harsh

chemicals could loosen the adhesive that secures the

messages. Loose adhesive will allow the messages

to fall.

Replace any message that is damaged, or missing. If

a message is attached to a part that is replaced,

install a message on the replacement part. Any

Perkins distributor can provide new messages.

Illustration 5 g00104545

Attach a “Do Not Operate” warning tag or a similar

warning tag to the start switch or to the controls

before the engine is serviced or before the engine is

repaired. Attach the warning tags to the engine and

to each operator control station. When appropriate,

disconnect the starting controls.

Do not allow unauthorized personnel on the engine,

or around the engine when the engine is being

serviced.

• Tampering with the engine installation or

tampering with the OEM supplied wiring can be

dangerous. Personal injury, death and/or engine

damage could result.

• Vent the engine exhaust to the outside when the

engine is operated in an enclosed area.

Illustration 4 g03422039

Purge notice message

• If the engine is not running, do not release the

secondary brake or the parking brake systems

unless the vehicle is blocked or unless the vehicle

is restrained.

• Wear a hard hat, protective glasses, and other

protective equipment, as required.

Page 7

M0068760

7

Safety Section

General Hazard Information

• When work is performed around an engine that is

operating, wear protective devices for ears in

order to help prevent damage to hearing.

• Do not wear loose clothing or jewelry that can

snag on controls or on other parts of the engine.

• Ensure that all protective guards and all covers

are secured in place on the engine.

• Never put maintenance fluids into glass

containers. Glass containers can break.

• Use all cleaning solutions with care.

• Report all necessary repairs.

Unless other instructions are provided, perform the

maintenance under the following conditions:

• The engine is stopped. Ensure that the engine

cannot be started.

• The protective locks or the controls are in the

applied position.

• Engage the secondary brakes or parking brakes.

• Block the vehicle or restrain the vehicle before

maintenance or repairs are performed.

• Disconnect the batteries when maintenance is

performed or when the electrical system is

serviced. Disconnect the battery ground leads.

Tape the leads in order to help prevent sparks. If

equipped, allow the diesel exhaust fluid to be

purged before disconnecting the battery.

• Start the engine from the operators station (cab).

Never short across the starting motor terminals or

the batteries. This action could bypass the engine

neutral start system and/or the electrical system

could be damaged.

Engine exhaust contains products of combustion

which may be harmful to your health. Always start the

engine and operate the engine in a well ventilated

area. If the engine is in an enclosed area, vent the

engine exhaust to the outside.

Cautiously remove the following parts. To help

prevent spraying or splashing of pressurized fluids,

hold a rag over the part that is being removed.

• Filler caps

• Grease fittings

• Pressure taps

• Breathers

• Drain plugs

Use caution when cover plates are removed.

Gradually loosen, but do not remove the last two

bolts or nuts that are located at opposite ends of the

cover plate or the device. Before removing the last

two bolts or nuts, pry the cover loose in order to

relieve any spring pressure or other pressure.

• If equipped, disconnect the connectors for the unit

injectors that are located on the valve cover base.

This action will help prevent personal injury from

the high voltage to the unit injectors. Do not come

in contact with the unit injector terminals while the

engine is operating.

• Do not attempt any repairs or any adjustments to

the engine while the engine is operating.

• Do not attempt any repairs that are not

understood. Use the proper tools. Replace any

equipment that is damaged or repair the

equipment.

• For initial start-up of a new engine or for starting

an engine that has been serviced, make

provisions to stop the engine if an overspeed

occurs. The stopping of the engine may be

accomplished by shutting off the fuel supply and/

or the air supply to the engine. Ensure that only

the fuel supply line is shut off. Ensure that the fuel

return line is open.

Illustration 6 g00702020

• Wear a hard hat, protective glasses, and other

protective equipment, as required.

• When work is performed around an engine that is

operating, wear protective devices for ears in

order to help prevent damage to hearing.

• Do not wear loose clothing or jewelry that can

snag on controls or on other parts of the engine.

• Ensure that all protective guards and all covers

are secured in place on the engine.

• Never put maintenance fluids into glass

containers. Glass containers can break.

Page 8

8 M0068760

Safety Section

General Hazard Information

• Use all cleaning solutions with care.

• Report all necessary repairs.

Unless other instructions are provided, perform

the maintenance under the following conditions:

• The engine is stopped. Ensure that the engine

cannot be started.

• Disconnect the batteries when maintenance is

performed or when the electrical system is

serviced. Disconnect the battery ground leads.

Tape the leads in order to help prevent sparks.

• Do not attempt any repairs that are not

understood. Use the proper tools. Replace any

equipment that is damaged or repair the

equipment.

Pressurized Air and Water

Pressurized air and/or water can cause debris and/or

hot water to be blown out. This action could result in

personal injury.

When pressurized air and/or pressurized water is

used for cleaning, wear protective clothing, protective

shoes, and eye protection. Eye protection includes

goggles or a protective face shield.

The maximum air pressure for cleaning purposes

must be below 205 kPa (30 psi). The maximum

water pressure for cleaning purposes must be below

275 kPa (40 psi).

Fluid Penetration

Pressure can be trapped in the hydraulic circuit long

after the engine has been stopped. The pressure can

cause hydraulic fluid or items such as pipe plugs to

escape rapidly if the pressure is not relieved

correctly.

Do not remove any hydraulic components or parts

until pressure has been relieved or personal injury

may occur. Do not disassemble any hydraulic

components or parts until pressure has been relieved

or personal injury may occur. Refer to the OEM

information for any procedures that are required to

relieve the hydraulic pressure.

Illustration 7 g00687600

Always use a board or cardboard when you check for

a leak. Leaking fluid that is under pressure can

penetrate body tissue. Fluid penetration can cause

serious injury and possible death. A pin hole leak can

cause severe injury. If fluid is injected into your skin,

you must get treatment immediately. Seek treatment

from a doctor that is familiar with this type of injury.

Containing Fluid Spillage

Care must be taken to ensure that fluids are

contained during performance of inspection,

maintenance, testing, adjusting, and repair of the

product. Be prepared to collect the fluid with suitable

containers before opening any compartment or

disassembling any component containing fluids.

Dispose of all fluids according to local regulations

and mandates.

Static Electricity Hazard when

Fueling with Ultra-low Sulfur Diesel

Fuel

The removal of sulfur and other compounds in ultralow sulfur diesel fuel (ULSD fuel) decreases the

conductivity of ULSD and increases the ability of

ULSD to store static charge. Refineries may have

treated the fuel with a static dissipating additive.

Many factors can reduce the effectiveness of the

additive over time. Static charges can build up in

ULSD fuel while the fuel is flowing through fuel

delivery systems. Static electricity discharge when

combustible vapors are present could result in a fire

or explosion. Ensure that the entire system used to

refuel your machine (fuel supply tank, transfer pump,

transfer hose, nozzle, and others) is properly

grounded and bonded. Consult with your fuel or fuel

system supplier to ensure that the delivery system

complies with fueling standards for proper grounding

and bonding.

Page 9

M0068760 9

Safety Section

General Hazard Information

• Avoid brushing materials that contain asbestos.

Avoid static electricity risk when fueling. Ultralow sulfur diesel fuel (ULSD fuel) poses a greater

static ignition hazard than earlier diesel formulations with a higher sulfur contents. Avoid death

or serious injury from fire or explosion. Consult

with your fuel or fuel system supplier to ensure

the delivery system is in compliance with fueling

standards for proper grounding and bonding

practices.

Inhalation

• Avoid grinding materials that contain asbestos.

• Use a wet method in order to clean up asbestos

materials.

• A vacuum cleaner that is equipped with a high

efficiency particulate air filter (HEPA) can also be

used.

• Use exhaust ventilation on permanent machining

jobs.

• Wear an approved respirator if there is no other

way to control the dust.

• Comply with applicable rules and regulations for

the work place. In the United States, use

Occupational Safety and Health Administration

(OSHA) requirements. These OSHA requirements

can be found in “29 CFR 1910.1001”.

• Obey environmental regulations for the disposal of

asbestos.

• Stay away from areas that might have asbestos

particles in the air.

Dispose of Waste Properly

Illustration 8 g00702022

Exhaust

Use caution. Exhaust fumes can be hazardous to

health. If you operate the equipment in an enclosed

area, adequate ventilation is necessary.

Asbestos Information

Perkins equipment and replacement parts that are

shipped from Perkins engine company limited are

asbestos free. Perkins recommends the use of only

genuine Perkins replacement parts. Use the following

guidelines when you handle any replacement parts

that contain asbestos or when you handle asbestos

debris.

Use caution. Avoid inhaling dust that might be

generated when you handle components that contain

asbestos fibers. Inhaling this dust can be hazardous

to your health. The components that may contain

asbestos fibers are brake pads, brake bands, lining

material, clutch plates, and some gaskets. The

asbestos that is used in these components is usually

bound in a resin or sealed in some way. Normal

handling is not hazardous unless airborne dust that

contains asbestos is generated.

If dust that may contain asbestos is present, there

are several guidelines that should be followed:

• Never use compressed air for cleaning.

Illustration 9 g00706404

Improperly disposing of waste can threaten the

environment. Potentially harmful fluids should be

disposed of according to local regulations.

Always use leakproof containers when you drain

fluids. Do not pour waste onto the ground, down a

drain, or into any source of water.

Diesel Exhaust Fluid

Diesel Exhaust Fluid (DEF) may cause eye irritation

and can be moderately irritating to the skin. Exposure

to decomposition products may cause a health

hazard. Serious effects may be delayed following

exposure.

Page 10

10 M0068760

Safety Section

Burn Prevention

DEF is not expected to produce significant adverse

health effects when the recommended instructions

for use are followed.

• Do not breathe DEF vapor or mist.

• Do not eat, drink, or smoke when using DEF.

• Avoid DEF contact with eyes, skin, and clothing.

• Wash thoroughly after handling DEF.

i06086863

Burn Prevention

Coolant

When the engine is at operating temperature, the

engine coolant is hot. The coolant is also under

pressure. The radiator and all lines to the heaters or

to the engine contain hot coolant. Any contact with

hot coolant or with steam can cause severe burns.

Allow cooling system components to cool before the

cooling system is drained.

Check that the coolant level after the engine has

stopped and the engine has been allowed to cool.

Ensure that the filler cap is cool before removing the

filler cap. The filler cap must be cool enough to touch

with a bare hand. Remove the filler cap slowly in

order to relieve pressure.

Do not smoke while checking the battery electrolyte

levels. Batteries give off flammable fumes which can

explode.

Always wear protective glasses when you work with

batteries. Wash hands after touching batteries. The

use of gloves is recommended.

Engine and Aftertreatment System

Do not touch any part of an operating engine or

engine aftertreatment system. Allow the engine or the

engine aftertreatment system to cool before any

maintenance is performed on the engine or the

engine aftertreatment system. Relieve all pressure in

the appropriate system before any lines, fittings, or

related items are disconnected.

Aftertreatment System and Diesel

Exhaust Fluid

Diesel Exhaust Fluid (DEF) temperatures can reach

65° to 70°C (149.° to 126°F) during normal engine

operation. Stop the engine. Wait for 15 minutes in

order to allow the DEF system to be purged and the

DEF to cool before service or repair is performed.

i05945996

Fire Prevention and Explosion

Prevention

Cooling system conditioner contains alkali. Alkali can

cause personal injury. Do not allow alkali to contact

the skin, the eyes, or the mouth.

Oils

Skin may be irritated following repeated or prolonged

exposure to mineral and synthetic base oils. Refer to

your suppliers Material Safety Data Sheets for

detailed information. Hot oil and lubricating

components can cause personal injury. Do not allow

hot oil to contact the skin. Appropriate personal

protective equipment should be used.

Diesel Fuel

Diesel may be irritating to the eyes, respiratory

system, and skin. Prolonged exposure to diesel may

cause various skin conditions. Appropriate personal

protective equipment should be used. Refer to

supplier Material safety Data sheets for detailed

information.

Batteries

The liquid in a battery is an electrolyte. Electrolyte is

an acid that can cause personal injury. Do not allow

electrolyte to contact the skin or the eyes.

Illustration 10 g00704000

All fuels, most lubricants, and some coolant mixtures

are flammable.

Flammable fluids that are leaking or spilled onto hot

surfaces or onto electrical components can cause a

fire. Fire may cause personal injury and property

damage.

After the emergency stop button is operated, ensure

that you allow 15 minutes, before the engine covers

are removed.

Page 11

M0068760 11

Safety Section

Fire Prevention and Explosion Prevention

Determine whether the engine will be operated in an

environment that allows combustible gases to be

drawn into the air inlet system. These gases could

cause the engine to overspeed. Personal injury,

property damage, or engine damage could result.

If the application involves the presence of

combustible gases, consult your Perkins dealer and/

or your Perkins distributor for additional information

about suitable protection devices.

Remove all flammable combustible materials or

conductive materials such as fuel, oil, and debris

from the engine. Do not allow any flammable

combustible materials or conductive materials to

accumulate on the engine.

Store fuels and lubricants in correctly marked

containers away from unauthorized persons. Store

oily rags and any flammable materials in protective

containers. Do not smoke in areas that are used for

storing flammable materials.

Do not expose the engine to any flame.

Exhaust shields (if equipped) protect hot exhaust

components from oil or fuel spray in case of a line, a

tube, or a seal failure. Exhaust shields must be

installed correctly.

Do not weld on lines or tanks that contain flammable

fluids. Do not flame cut lines or tanks that contain

flammable fluid. Clean any such lines or tanks

thoroughly with a nonflammable solvent prior to

welding or flame cutting.

Wiring must be kept in good condition. Ensure that all

electrical wires are correctly installed and securely

attached. Check all electrical wires daily. Repair any

wires that are loose or frayed before you operate the

engine. Clean all electrical connections and tighten

all electrical connections.

Eliminate all wiring that is unattached or

unnecessary. Do not use any wires or cables that are

smaller than the recommended gauge. Do not

bypass any fuses and/or circuit breakers.

Arcing or sparking could cause a fire. Secure

connections, recommended wiring, and correctly

maintained battery cables will help to prevent arcing

or sparking.

Illustration 11 g00704059

Use caution when you are refueling an engine. Do

not smoke while you are refueling an engine. Do not

refuel an engine near open flames or sparks. Always

stop the engine before refueling.

Avoid static electricity risk when fueling. Ultra-low

Sulfur Diesel fuel (ULSD fuel) poses a greater static

ignition hazard than earlier diesel formulations with a

higher sulfur content. Avoid death or serious injury

from fire or explosion. Consult your fuel or fuel

system supplier to ensure that the delivery system is

in compliance with fueling standards for proper

grounding and bonding practices.

Ensure that the engine is stopped. Inspect all lines

and hoses for wear or for deterioration. Ensure that

the hoses are correctly routed. The lines and hoses

must have adequate support and secure clamps.

Oil filters and fuel filters must be installed correctly.

The filter housings must be tightened to the correct

torque. Refer to the Disassembly and Assembly

manual for more information.

Page 12

12 M0068760

Safety Section

Crushing Prevention and Cutting Prevention

Do not store ether cylinders in living areas or in the

engine compartment. Do not store ether cylinders in

direct sunlight or in temperatures above 49° C

(120° F). Keep ether cylinders away from open

flames or sparks.

Lines, Tubes, and Hoses

Do not bend high-pressure lines. Do not strike highpressure lines. Do not install any lines that are

damaged.

Leaks can cause fires. Consult your Perkins dealer or

your Perkins distributor for replacement parts.

Replace the parts if any of the following conditions

are present:

• End fittings are damaged or leaking.

• Outer coverings are chafed or cut.

Illustration 12 g00704135

Gases from a battery can explode. Keep any open

flames or sparks away from the top of a battery. Do

not smoke in battery charging areas.

Never check the battery charge by placing a metal

object across the terminal posts. Use a voltmeter or a

hydrometer.

Incorrect jumper cable connections can cause an

explosion that can result in injury. Refer to the

Operation Section of this manual for specific

instructions.

Do not charge a frozen battery. A frozen battery may

cause an explosion.

The batteries must be kept clean. The covers (if

equipped) must be kept on the cells. Use the

recommended cables, connections, and battery box

covers when the engine is operated.

Fire Extinguisher

Make sure that a fire extinguisher is available. Be

familiar with the operation of the fire extinguisher.

Inspect the fire extinguisher and service the fire

extinguisher regularly. Obey the recommendations

on the instruction plate.

Ether

• Wires are exposed.

• Outer coverings are ballooning.

• Flexible parts of the hoses are kinked.

• Outer covers have embedded armoring.

• End fittings are displaced.

Make sure that all clamps, guards, and heat shields

are installed correctly. During engine operation,

correct installation will help to prevent vibration,

rubbing against other parts, and excessive heat.

i02143194

Crushing Prevention and

Cutting Prevention

Support the component correctly when work beneath

the component is performed.

Unless other maintenance instructions are provided,

never attempt adjustments while the engine is

running.

Stay clear of all rotating parts and of all moving parts.

Leave the guards in place until maintenance is

performed. After the maintenance is performed,

reinstall the guards.

Ether is flammable and poisonous.

Do not smoke while you are replacing an ether

cylinder or while you are using an ether spray.

Keep objects away from moving fan blades. The fan

blades will throw objects or cut objects.

When objects are struck, wear protective glasses in

order to avoid injury to the eyes.

Chips or other debris may fly off objects when objects

are struck. Before objects are struck, ensure that no

one will be injured by flying debris.

Page 13

M0068760 13

Safety Section

Mounting and Dismounting

i05768982

Mounting and Dismounting

Do not climb on the engine or the engine

aftertreatment system. The engine and

aftertreatment system have not been designed with

mounting or dismounting locations.

Refer to the OEM for the location of foot and hand

holds for your specific application.

i04257031

Before Starting Engine

NOTICE

For initial start-up of a new or rebuilt engine, and for

start-up of an engine that has been serviced, make

provision to shut the engine off should an overspeed

occur. This may be accomplished by shutting off the

air and/or fuel supply to the engine.

Engine exhaust contains products of combustion

which may be harmful to your health. Always

start and operate the engine in a well ventilated

area and, if in an enclosed area, vent the exhaust

to the outside.

Inspect the engine for potential hazards.

Do not start the engine or move any of the controls if

there is a “DO NOT OPERATE” warning tag or similar

warning tag attached to the start switch or to the

controls.

Before starting the engine, ensure that no one is on,

underneath, or close to the engine. Ensure that the

area is free of personnel.

If equipped, ensure that the lighting system for the

engine is suitable for the conditions. Ensure that all

lights work properly, if equipped.

All protective guards and all protective covers must

be installed if the engine must be started in order to

perform service procedures. To help prevent an

accident that is caused by parts in rotation, work

around the parts carefully.

i02583384

Engine Starting

Do not use aerosol types of starting aids such as

ether. Such use could result in an explosion and

personal injury.

If a warning tag is attached to the engine start switch

or to the controls DO NOT start the engine or move

the controls. Consult with the person that attached

the warning tag before the engine is started.

All protective guards and all protective covers must

be installed if the engine must be started in order to

perform service procedures. To help prevent an

accident that is caused by parts in rotation, work

around the parts carefully.

Start the engine from the operator's compartment or

from the engine start switch.

Always start the engine according to the procedure

that is described in the Operation and Maintenance

Manual, “Engine Starting” topic in the Operation

Section. Knowing the correct procedure will help to

prevent major damage to the engine components.

Knowing the procedure will also help to prevent

personal injury.

To ensure that the jacket water heater (if equipped) is

working correctly, check the water temperature

gauge and/or the oil temperature gauge during the

heater operation.

Engine exhaust contains products of combustion

which can be harmful to your health. Always start the

engine and operate the engine in a well ventilated

area. If the engine is started in an enclosed area,

vent the engine exhaust to the outside.

Note: The engine may be equipped with a device for

cold starting. If the engine will be operated in very

cold conditions, then an extra cold starting aid may

be required. Normally, the engine will be equipped

with the correct type of starting aid for your region of

operation.

i06088340

Electrical System

Do not start an engine when the governor linkage is

disconnected.

Do not bypass the automatic shutoff circuits. Do not

disable the automatic shutoff circuits. The circuits are

provided in order to help prevent personal injury. The

circuits are also provided in order to help prevent

engine damage.

Never disconnect any charging unit circuit or battery

circuit cable from the battery when the charging unit

is operating. A spark can cause the combustible

gases that are produced by some batteries to ignite.

Page 14

14 M0068760

Safety Section

Engine Electronics

To help prevent sparks from igniting combustible

gases that are produced by some batteries, the

negative “−” jump-start cable should be connected

last from the external power source to the negative

“−” terminal of the starting motor. If the starting motor

is not equipped with a negative “−” terminal, connect

the jump-start cable to the engine block.

Check the electrical wires daily for wires that are

loose or frayed. Tighten all loose electrical wires

before the engine is started. Repair all frayed

electrical wires before the engine is started. Refer to

the “Engine Starting” section of this Operation and

Maintenance Manual for specific starting instructions.

Grounding Practices

Proper grounding for the engine electrical system is

necessary for optimum engine performance and

reliability. Improper grounding will result in

uncontrolled electrical circuit paths and in unreliable

electrical circuit paths.

Uncontrolled electrical circuit paths can result in

damage to main bearings, to crankshaft bearing

journal surfaces, and to aluminum components.

Engines that are installed without engine-to-frame

ground straps can be damaged by electrical

discharge.

To ensure that the engine and the engine electrical

systems function properly, an engine-to-frame

ground strap with a direct path to the battery must be

used. This path may be provided by way of a starting

motor ground, a starting motor ground to the frame,

or a direct engine ground to the frame.

All grounds should be tight and free of corrosion. The

engine alternator must be grounded to the negative

“-” battery terminal with a wire that is adequate to

handle the full charging current of the alternator.

The following actions are available for engine

monitoring control: WARNING, DERATE and

SHUTDOWN. These engine monitoring modes can

limit engine speed and/or the engine power.

Many of the parameters that are monitored by the

ECM can be programmed for the engine monitoring

functions. The following parameters can be

monitored as a part of the Engine Monitoring System:

• Operating Altitude

• Engine Coolant Level

• Engine Coolant Temperature

• Engine Oil Pressure

• Engine Speed

• Fuel Temperature

• Intake Manifold Air Temperature

• System Voltage

The Engine Monitoring package can vary for different

engine models and different engine applications.

However, the monitoring system and the engine

monitoring control will be similar for all engines.

Note: Many of the engine control systems and

display modules that are available for Perkins

Engines will work in unison with the Engine

Monitoring System. Together, the two controls will

provide the engine monitoring function for the specific

engine application. Refer to the Troubleshooting

Manual for more information.

i06091234

Engine Electronics

Tampering with the electronic system installation

or the OEM wiring installation can be dangerous

and could result in personal injury or death and/

or engine damage.

This engine has a comprehensive, programmable

Engine Monitoring System. The Engine Control

Module (ECM) will monitor the engine operating

conditions. If any of the engine parameters extend

outside an allowable range, the ECM will initiate an

immediate action.

Page 15

M0068760 15

Product Information Section

Model Views

Product Information

Section

Model Views

i06609024

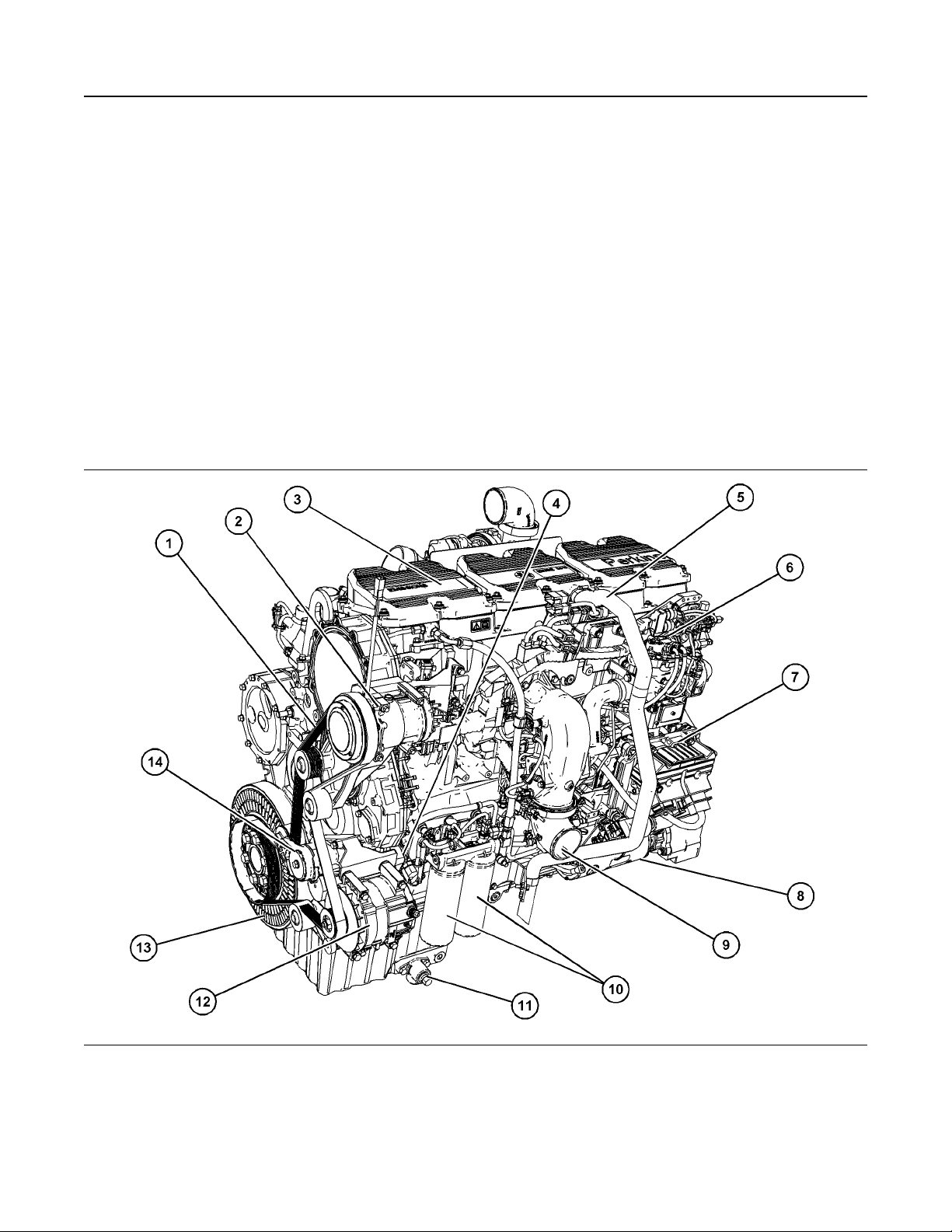

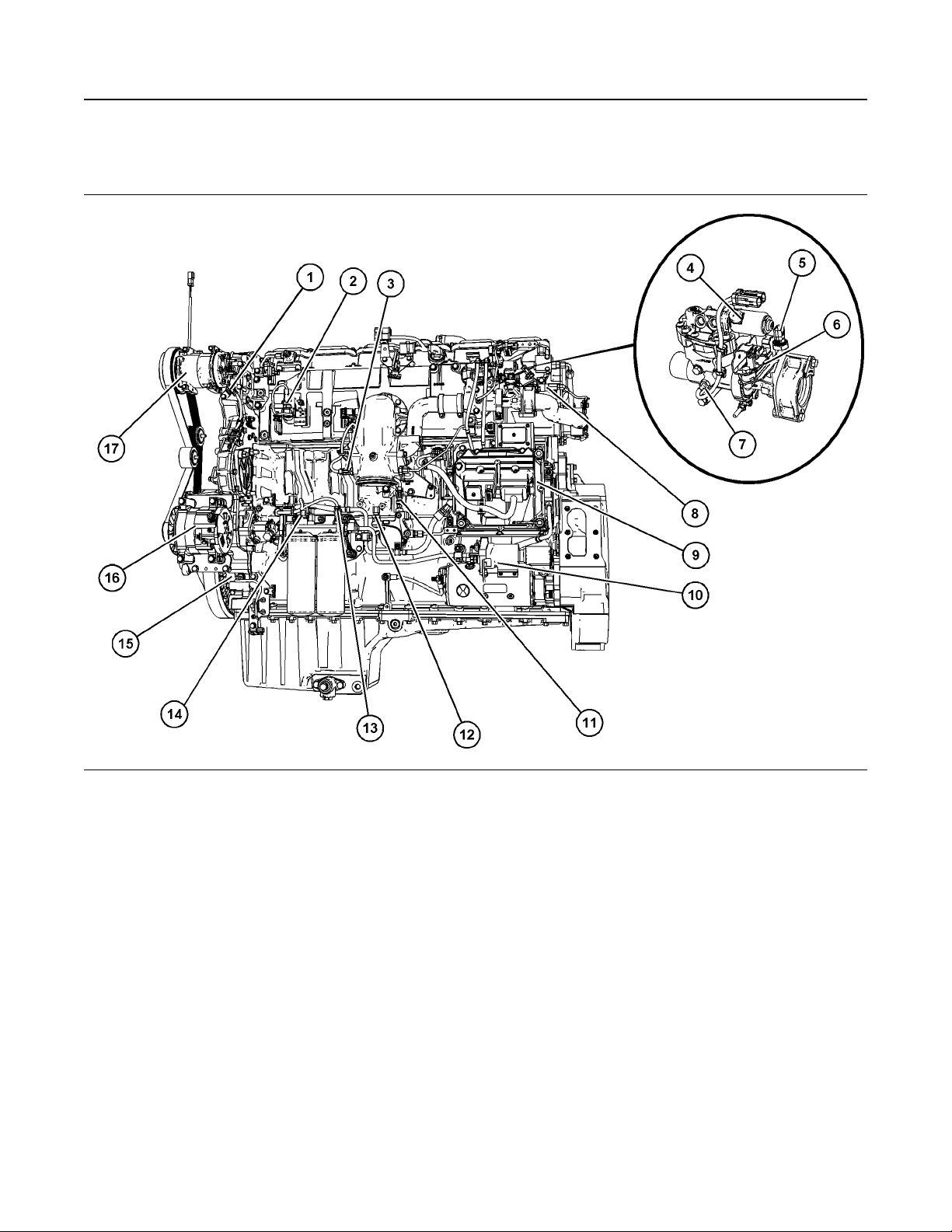

Model View Illustrations

The following model views show typical features of

the engine. Due to individual applications, your

engine may appear different from the illustrations.

Engine Views

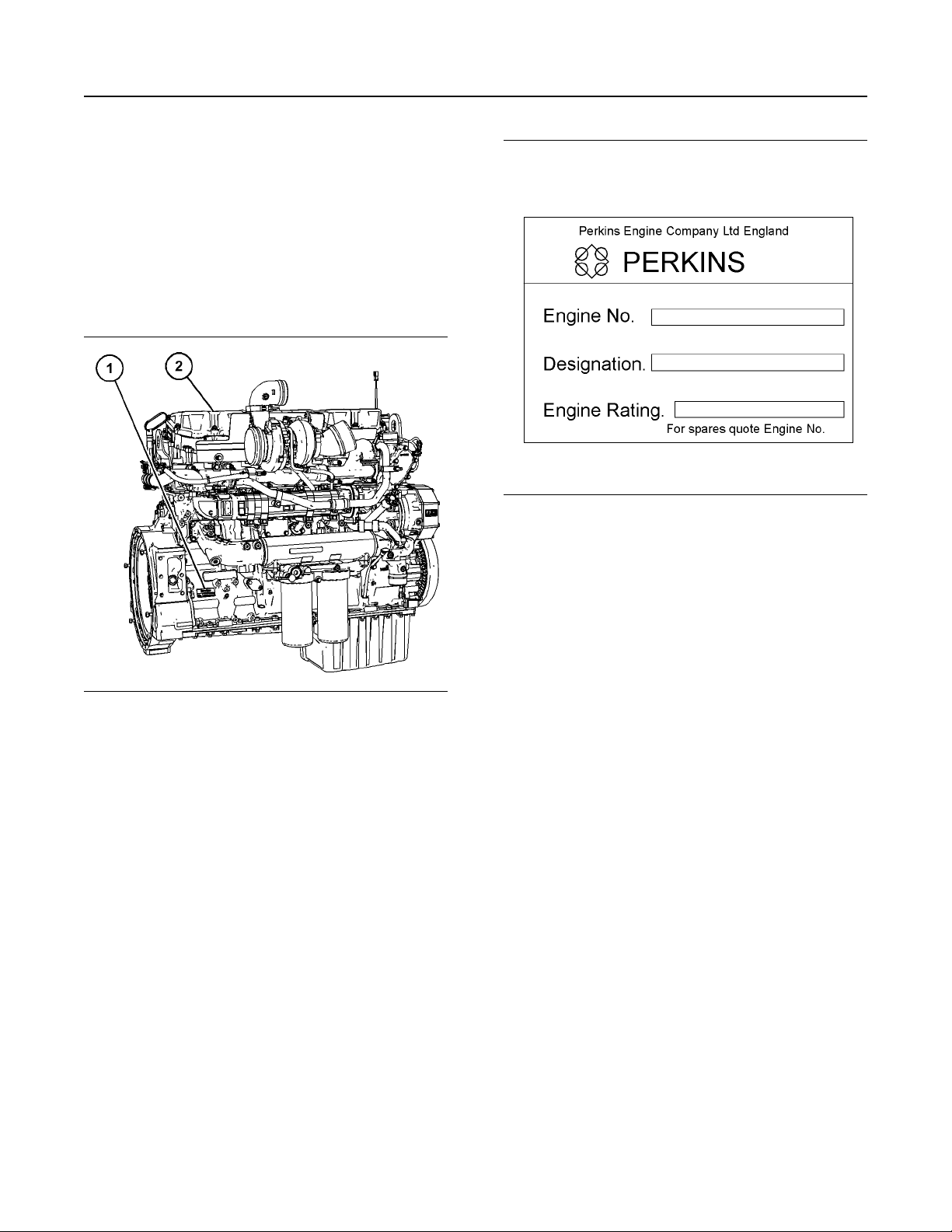

Illustration 13 g06045642

Typical example

(1) Drive belt

(2) Refrigerant compressor

(3) Valve mechanism cover

(4) Fuel pump

(5) Breather outlet hose

(6) NOx Reduction System (NRS) valve

(7) Electronic control modules

(8) Starting motor

(9) Air intake

(10) Secondary fuel filters

(11) Adaptor of oil drain

(12) Alternator

(13) Vibration damper

(14) Belt tensioner

Page 16

16 M0068760

Product Information Section

Model View Illustrations

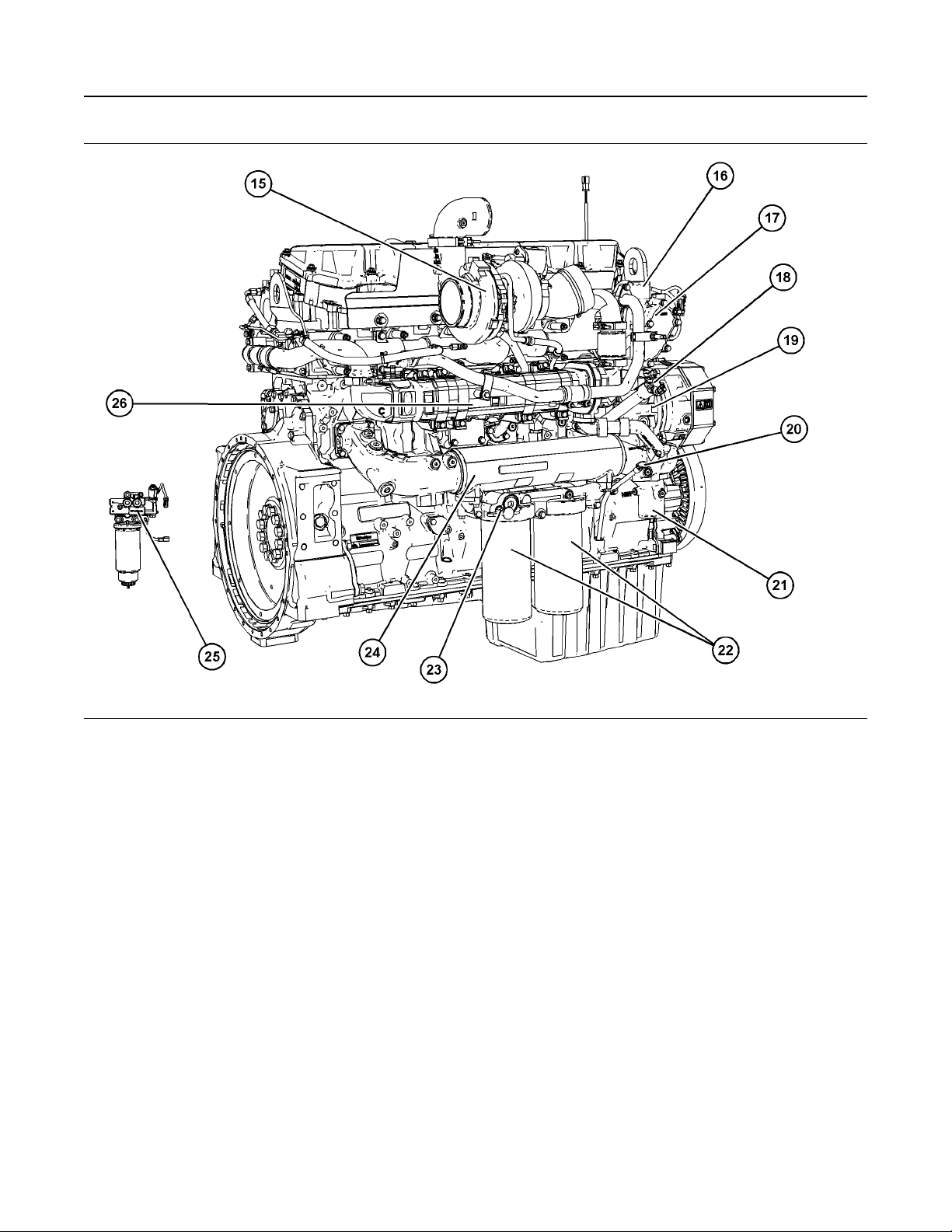

Illustration 14 g06045668

Typical example

(15) Turbocharger

(16) Coolant outlet

(17) Water temperature regulator housing

(18) Oil filler cap

(19) Coolant pump

(20) Oil gauge (Dipstick)

(21) Coolant intake

(22) Oil filters

(23) Oil sample valve

(24) Oil cooler

(25) Fuel priming pump and primary fuel

filter

(26) NRS cooler

Page 17

M0068760 17

Product Information Section

Model View Illustrations

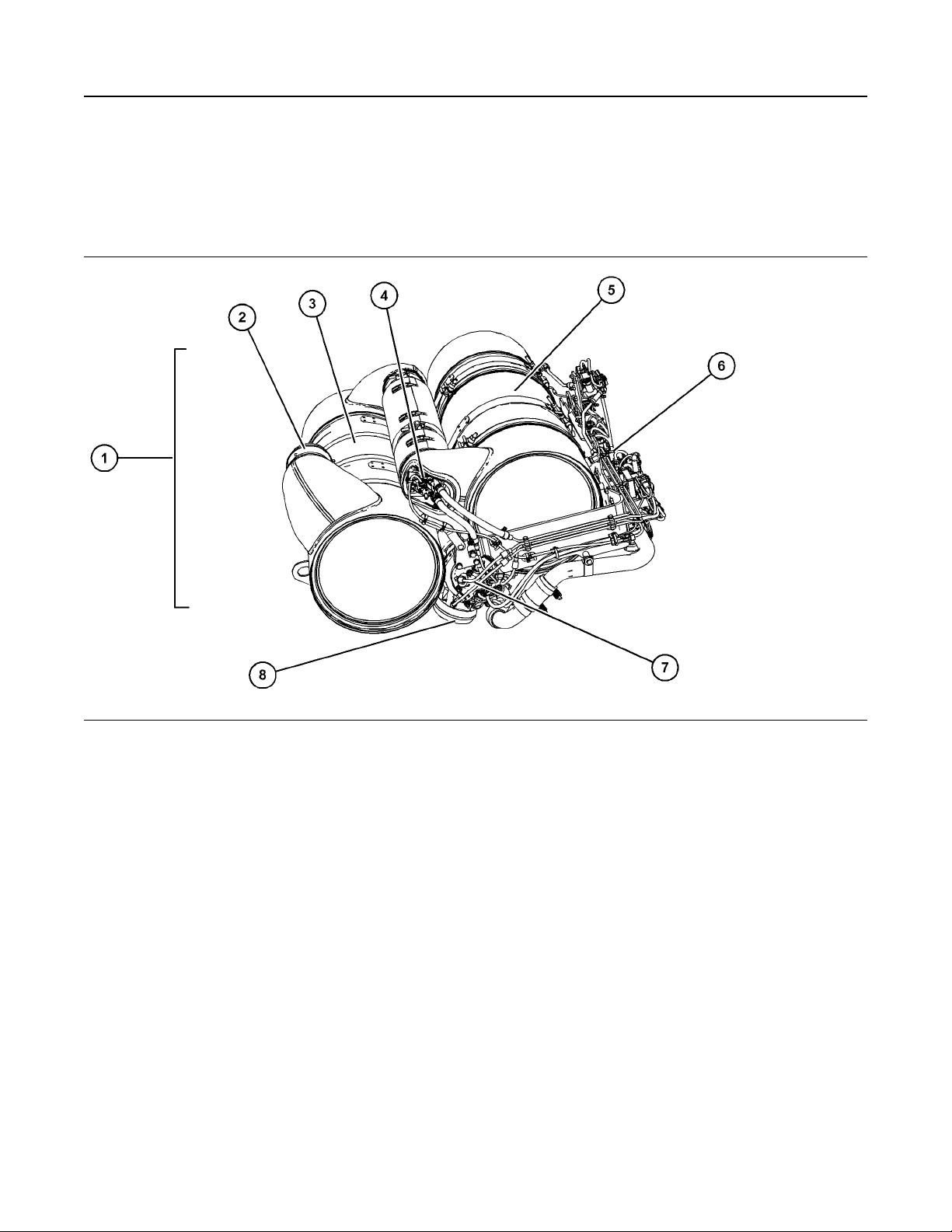

Aftertreatment System

The aftertreatment items are supplied loose by

Perkins.

Clean Emission Module

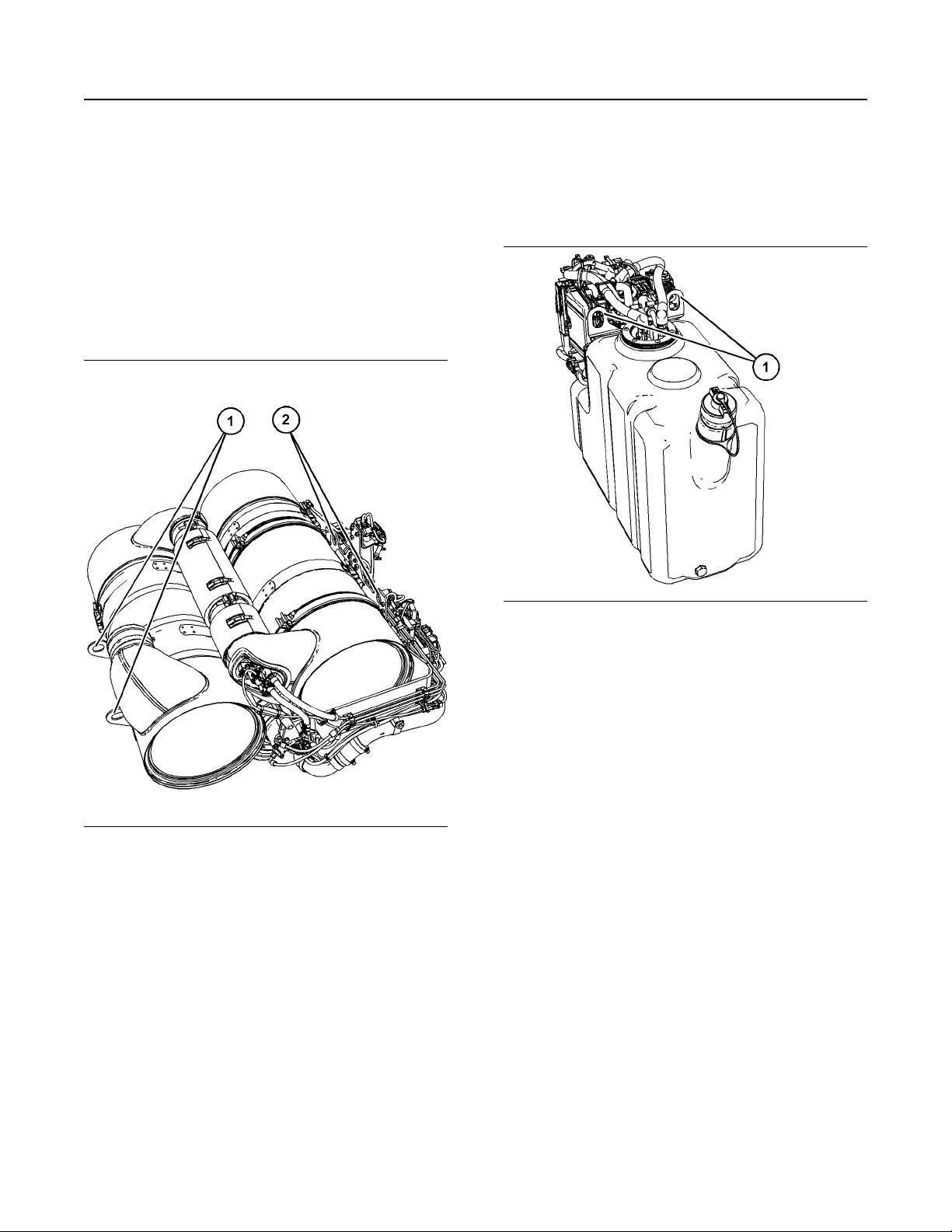

Illustration 15 g06044166

Typical example

(1) Clean Emission Model (CEM)

(2) Exhaust outlet

(3) Selective Catalytic Reduction (SCR)

(4) DEF Injector

(5) Diesel Particulate Filter (DPF).

(6) CEM sensors and fuel system

(7) Aftertreatment Regeneration Device

(ARD)

(8) Exhaust Inlet

Page 18

18 M0068760

Product Information Section

Product Description

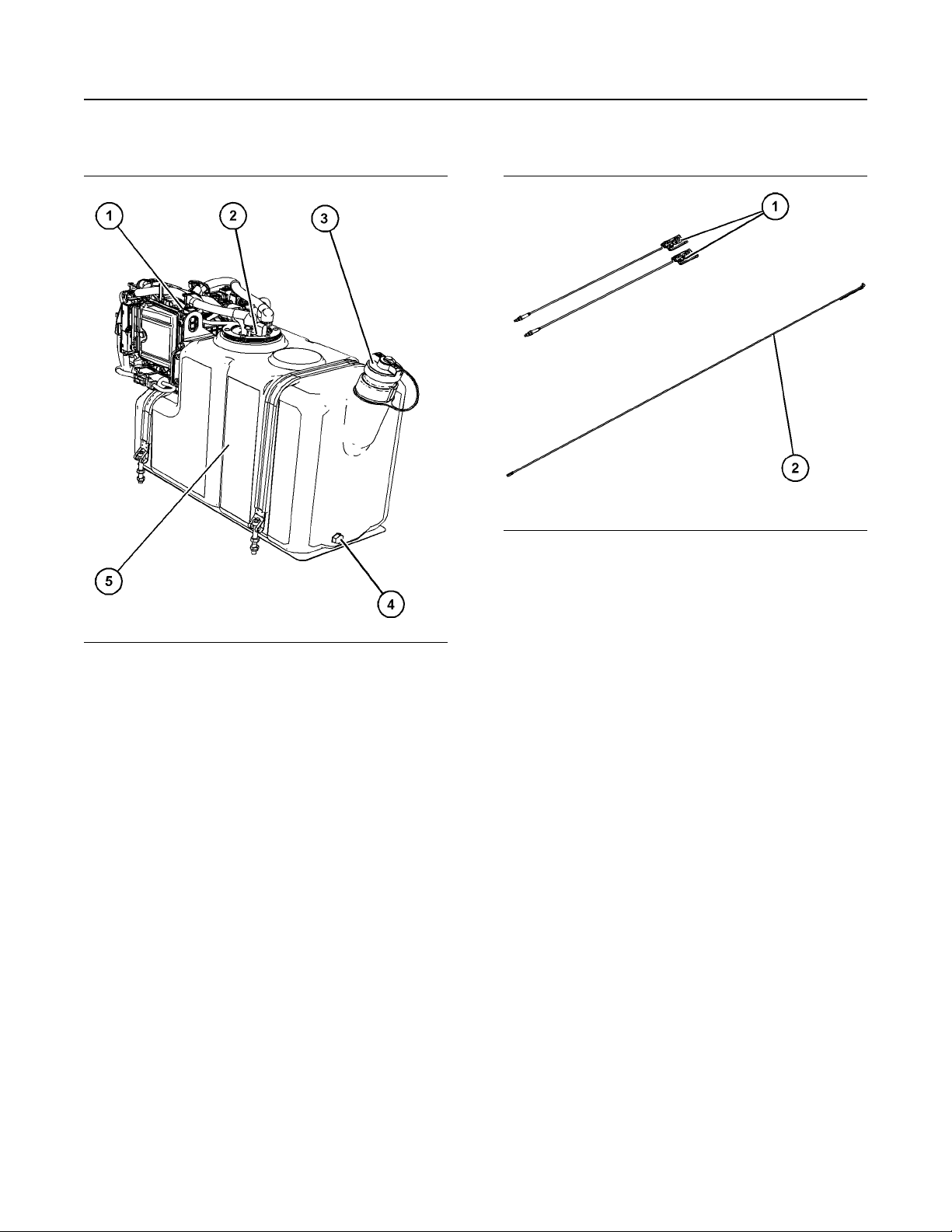

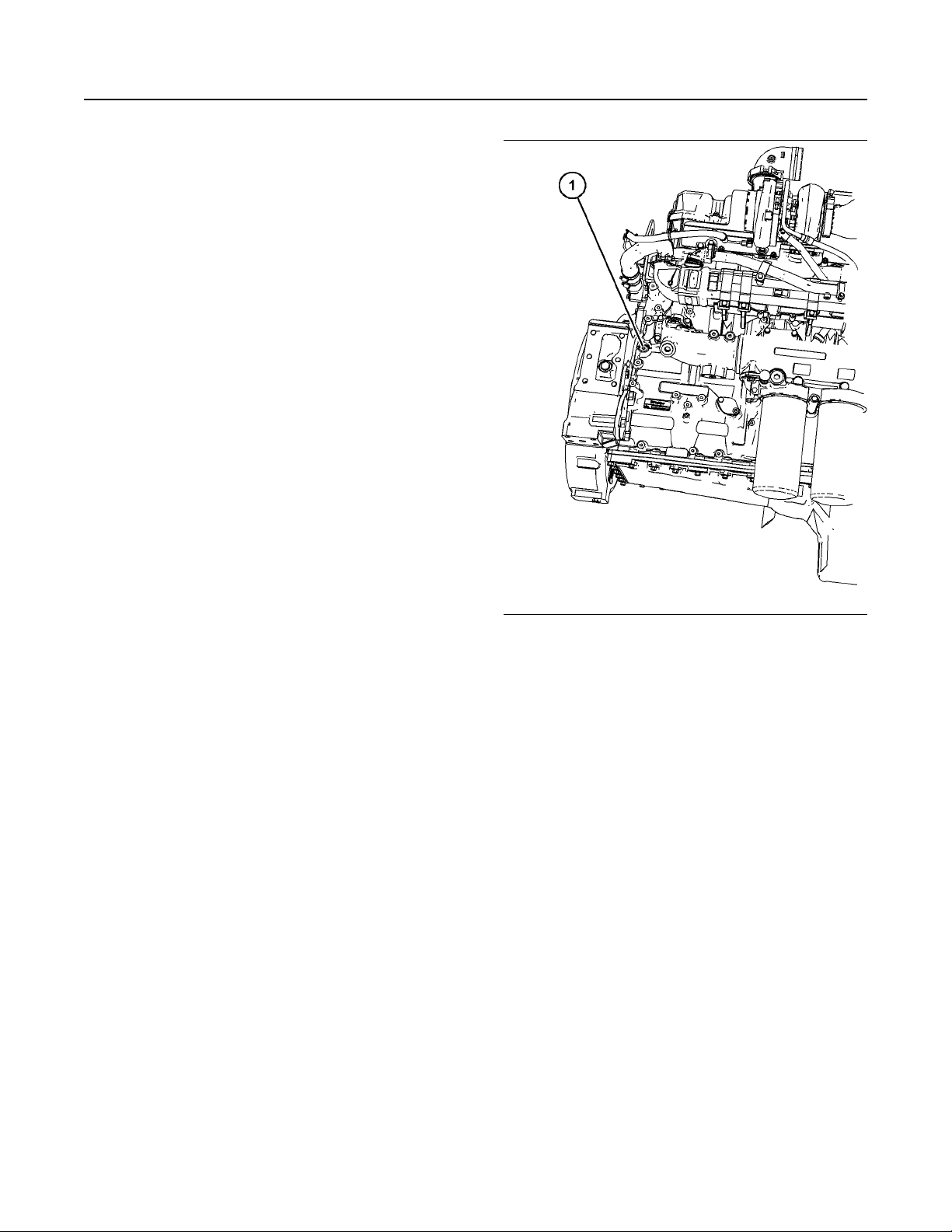

Pump Electronic Tank Unit (PETU)

NOx Sensors and DEF Heated line

Illustration 17 g06044238

Typical example

(1) NOx sensors

(2) DEF heated line

Illustration 16 g06044127

Typical example

(1) DEF pump electronics containing filter

(2) DEF tank header

(3) DEF filler cap

(4) DEF tank drain

(5) DEF tank

i06601272

Product Description

The Perkins 2806F-E13TA Industrial Engine have the

following characteristics:

• Four-stroke cycle

• Mechanically actuated, electronically controlled

fuel injection system

• Turbocharged

• Air to air charged cooled

• Aftertreatment system

The Clean Emissions Module (CEM) is constructed

of four main items, the diesel Aftertreatment

Regeneration Device (ARD) oxidation catalyst, the

diesel particulate filter, and the Selective Catalytic

Reduction (SCR). The SCR requires the use of

Diesel Exhaust Fluid (DEF) to be injected into the

system in order to lower the emissions from the

engine. The (DEF) is stored and controlled by the

pump electronic tank unit. The DEF tank can be

installed separate from the electronic pump unit.

Page 19

M0068760 19

Product Information Section

Product Description

Engine Specifications

Note: The front end of the engine is opposite the

flywheel end of the engine. The left and the right

sides of the engine are determined from the flywheel

end. The number 1 cylinder is the front cylinder.

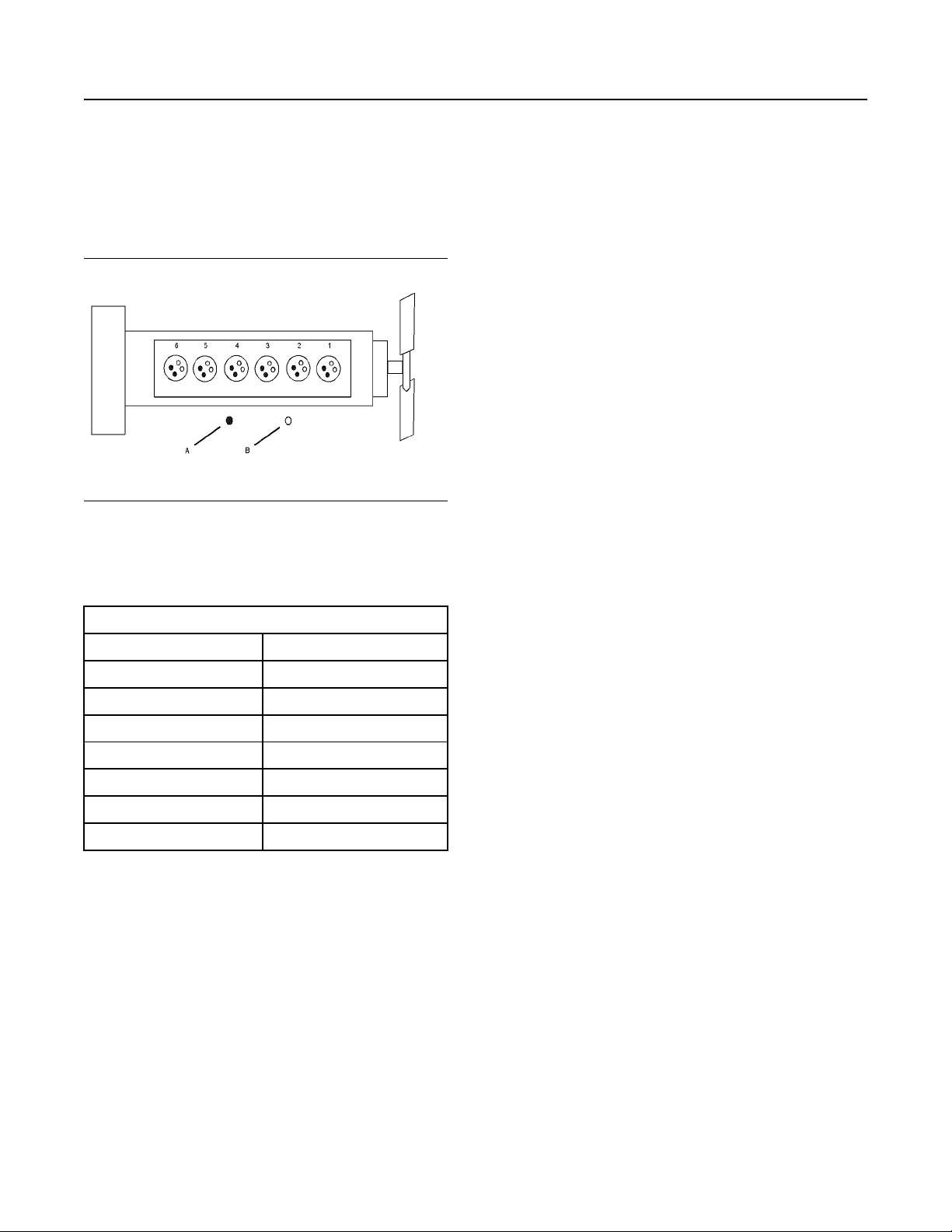

Illustration 18 g01387009

Cylinder and valve location

(A) Exhaust valve

(B) Inlet valve

Table 1

Engine Specifications

Engine

Arrangement and Cylinders In-Line 6 cylinder

Bore 145 mm (5.7 inch)

Stroke 183 mm (7.2 inch)

Aspiration

2806F

ATAAC

(1)

• Torque rise shaping

• Injection timing control

• System diagnostics

• Aftertreatment regeneration control

• NOX reduction system control

Extra Features

The following extra features provide increased

engine fuel economy and serviceability:

• Cold starting capability

• Tampering detection

• Diagnostics

Engine Diagnostics

The engine has built-in diagnostics to ensure that all

the components are functioning properly. Under

certain conditions, the engine horsepower and the

vehicle speed may be limited. An electronic service

tool may be used to display the diagnostic code.

There are two categories of codes: diagnostic code

and event code. These two categories of codes may

be in two different states: active and logged.

Most of the diagnostic codes are logged and stored in

the ECM. For additional information, refer to

theOperation and Maintenance Manual, Engine

Diagnostictopic (Operation Section).

Engine Service Life

Displacement 18.1 L (1105 cubic inch)

Firing Order

Rotation (flywheel end)

(1)

Air-to-air aftercooled

1-5-3-6-2-4

Counterclockwise

Electronic Engine Features

The engine is designed for electronic controls. The

integral on board computer controls the operation of

the engine. Current operating conditions are

monitored. The Electronic Control Module (ECM)

controls the response of the engine to these

conditions and to the demands of the operator. These

conditions and operator demands determine the

precise control of fuel injection by the ECM. The

electronic engine control system provides the

following features:

• Engine speed governor

• Automatic air/fuel ratio control

Engine efficiency and maximum utilization of engine

performance depend on the adherence to proper

operation and maintenance recommendations. In

addition, use recommended fuels, coolants, and

lubricants. Use the Operation and Maintenance

Manual as a guide for required engine maintenance.

Expected engine life is predicted by the average

power that is demanded. The average power that is

demanded is based on fuel consumption of the

engine over a time. Reduced hours of operation at

full throttle and/or operating at reduced throttle

settings result in a lower average power demand.

Reduced hours of operation will increase the length

of operating time before an engine overhaul is

required. For more information, refer to the Operation

and Maintenance Manual, “Overhaul Considerations”

topic.

Aftermarket Products and Perkins

Engines

Perkins does not warrant the quality or performance

of non-Perkins fluids and filters.

Page 20

20 M0068760

Product Information Section

Product Description

When auxiliary devices, accessories, or

consumables (filters, additives, catalysts, ) which are

made by other manufacturers are used on Perkins

products, the Perkins warranty is not affected simply

because of such use.

However, failures that result from the installation

or use of other manufacturers devices,

accessories, or consumables are NOT Perkins

defects. Therefore, the defects are NOT covered

under the Perkins warranty.

Page 21

M0068760 21

Product Information Section

Product Identification Information

Product Identification

Information

i06601446

Plate Locations and Film

Locations

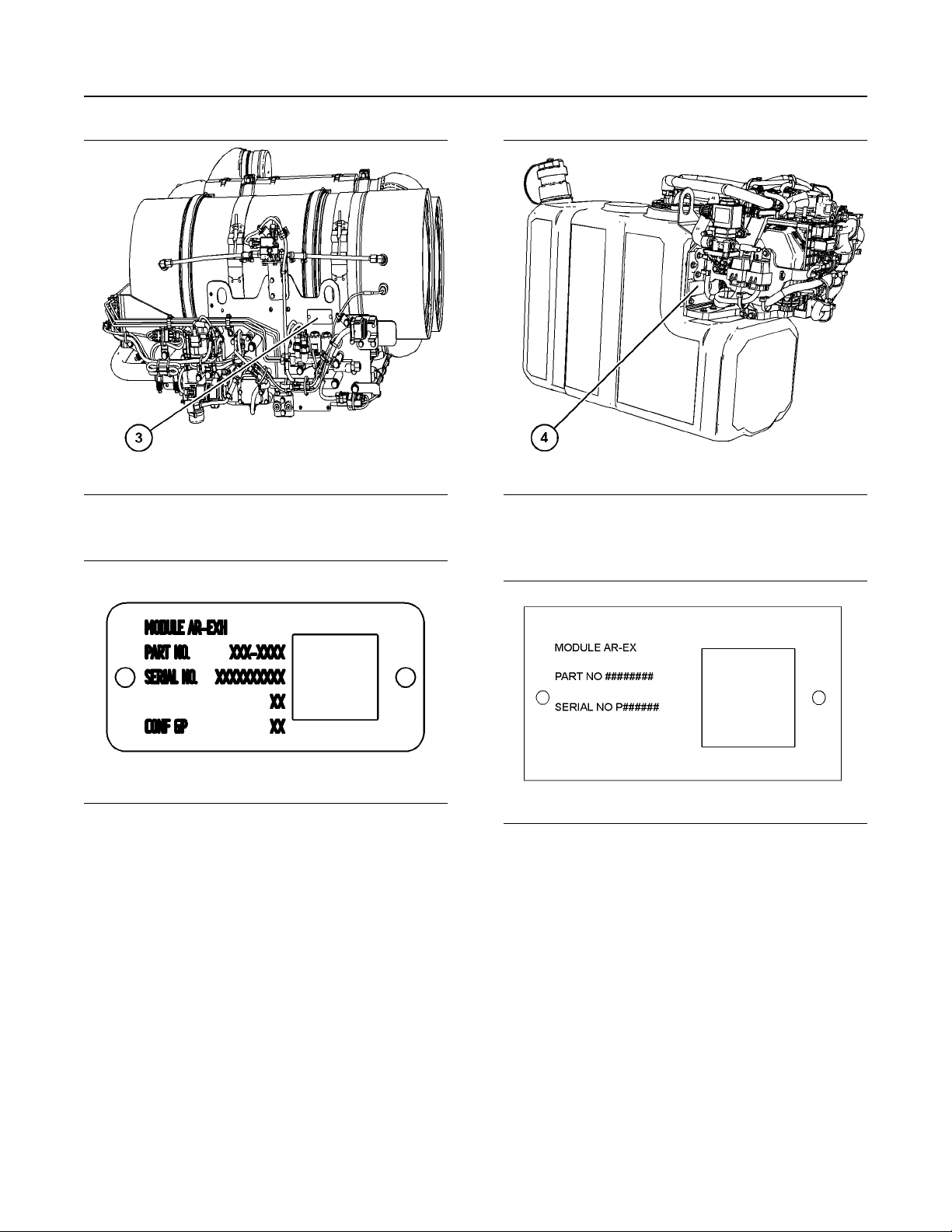

Illustration 19 g06040639

(1) Serial number plate

(2) Information plate

The engine serial number plate is on the right side of

the engine block, toward the back.

Illustration 20 g01403841

Serial number plate

The following information is stamped on the serial

number plate: engine serial number, engine model,

and arrangement number.

The engine information plate is on top of the valve

cover near the middle of the engine.

The following information is on the information plate:

engine serial number, engine model, engine

arrangement number, maximum altitude of the

engine that is necessary to achieve the rated power,

horsepower, high idle, full load rpm, fuel settings, and

other information

The Clean Emission Module (CEM) identification

plate is on the bracket assembly on the CEM.

Page 22

22 M0068760

Product Information Section

Emissions Certification Film

Illustration 21 g06040627

(3) CEM Identification plate

Illustration 22 g02236574

CEM identification plate

The CEM identification plate contains the following

information: part number, serial number, change

level, and configuration ID code. This information

may be needed by the Perkins distributor when

inquiries are being made on the CEM.

Illustration 23 g06040642

Typical example

(4) PETU Plate location

Illustration 24 g03049116

Typical example PETU serial plate

Record the information on the CEM and PETU serial

plates. The information will be required by your

Perkins distributor to identify replacement part

numbers.

Pump Electronic Tank Unit (PETU)

and Pump Electronic Unit (PEU)

Note: Some applications may not have a diesel

exhaust fluid tank installed into to the electronic unit.

i05951816

Emissions Certification Film

Note: This information is pertinent in the United

States, in Canada and in Europe.

The emissions label is located on the top of the valve

mechanism cover.

Page 23

M0068760 23

Operation Section

Lifting and Storage

Operation Section

Lifting and Storage

i06602132

Product Lifting

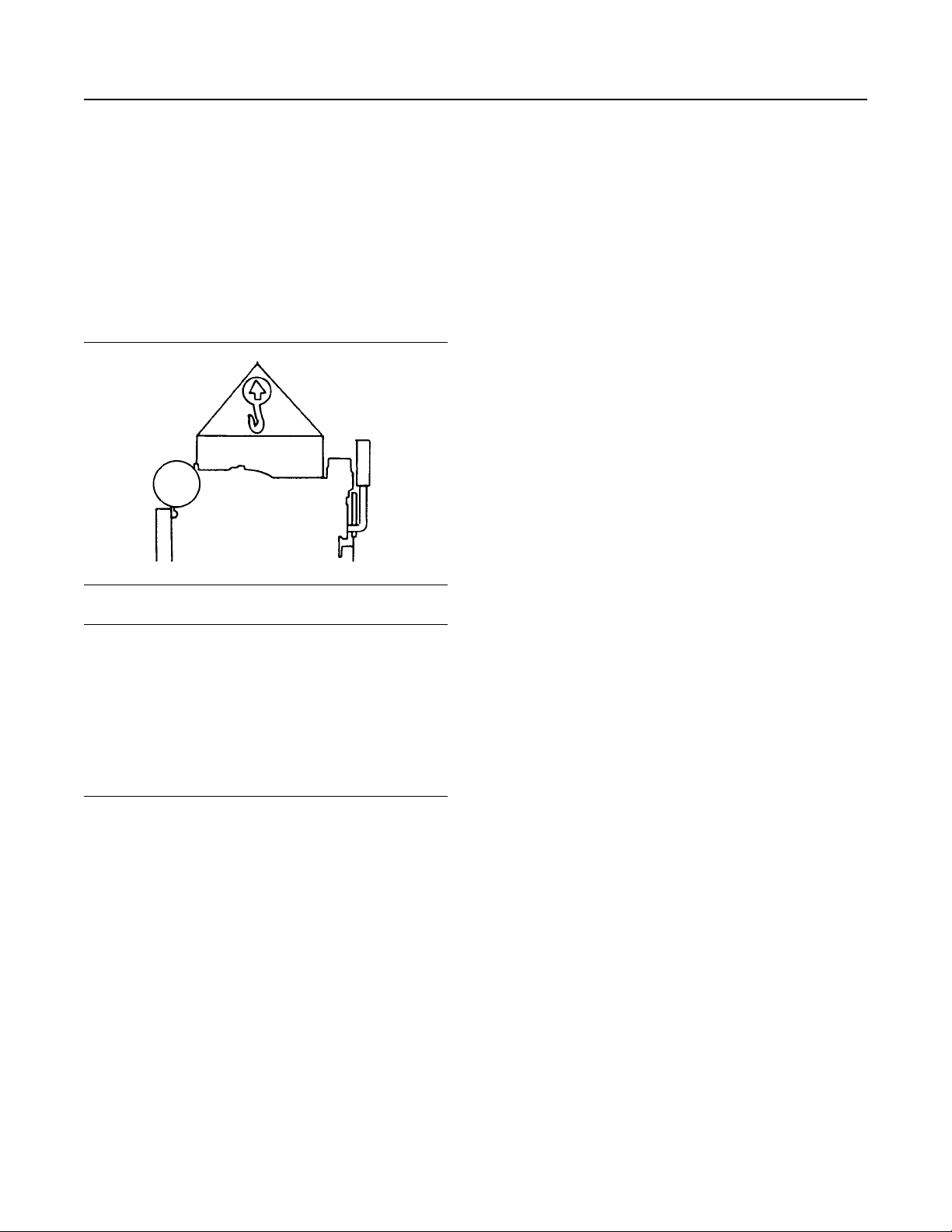

Illustration 25 g00103219

Never bend the eyebolts and the brackets. Only load

the eyebolts and the brackets under tension. Remember that the capacity of an eyebolt is less as the

angle between the supporting members and the object becomes less than 90 degrees.

When it is necessary to remove a component at an

angle, only use a link bracket that is properly rated for

the weight.

Use a hoist to remove heavy components. Use an

adjustable lifting beam to lift the engine. All

supporting members (chains and cables) should be

parallel to each other. The chains and cables should

be perpendicular to the top of the object that is being

lifted.

Some removals require lifting the fixtures to obtain

proper balance and safety.

To remove the engine ONLY, use the lifting eyes that

are on the engine.

Lifting eyes are designed and installed for the

specific engine arrangement. Alterations to the lifting

eyes and/or the engine make the lifting eyes and the

lifting fixtures obsolete. If alterations are made,

ensure that proper lifting devices are provided.

Consult your Perkins distributor for information

regarding fixtures for proper engine lifting.

NOTICE

Page 24

24 M0068760

Operation Section

Product Lifting

Engine Lifting

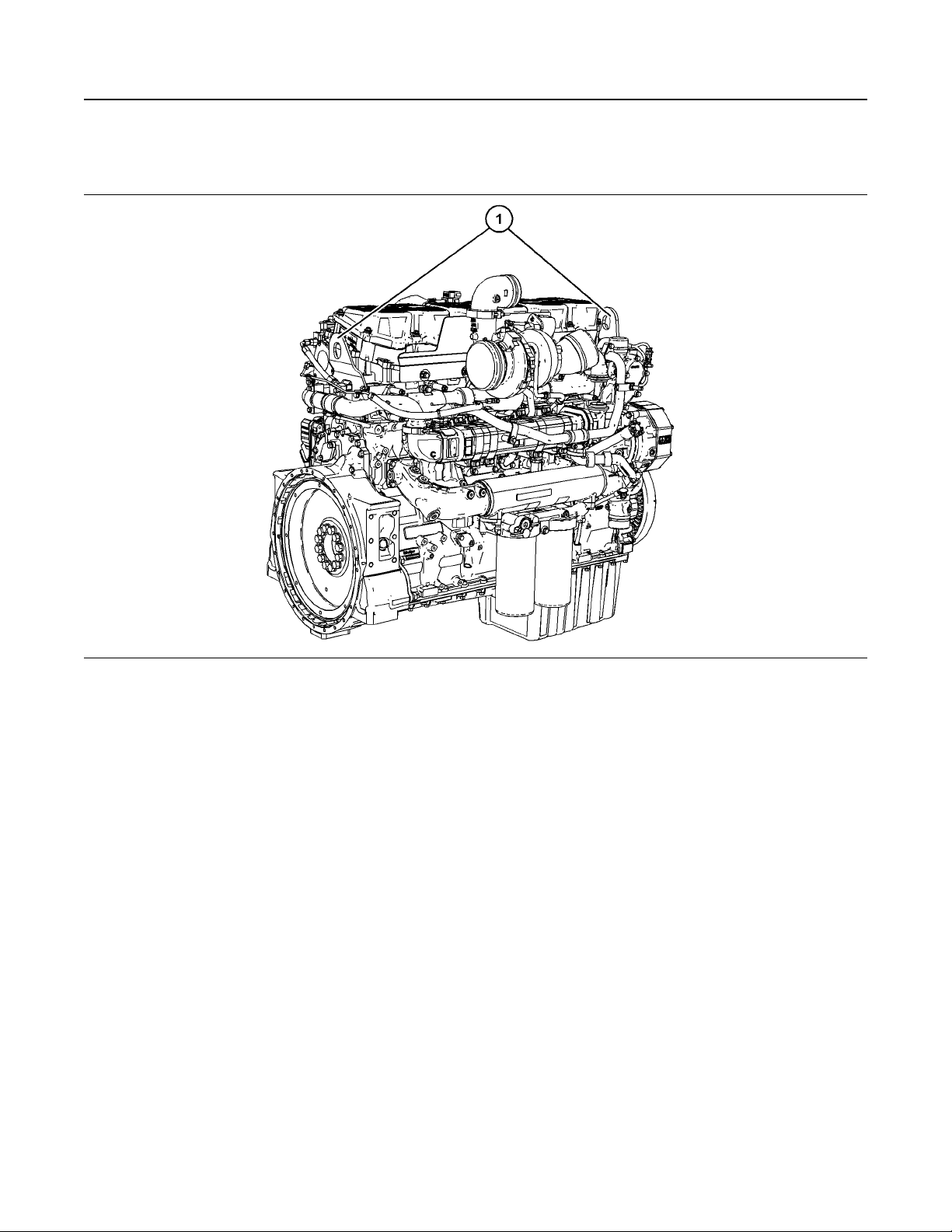

Illustration 26 g06044076

Typical example

(1) Engine lifting eyes

Page 25

M0068760 25

Operation Section

Product Storage

Use an appropriate spreader set so that lifting chains

are perpendicular to the engine.

Radiator Only

Detach the radiator, and mounting bracket at the

engine front support. Add eyebolts or lifting brackets

to the threaded holes marked for lifting.

Clean Emission Module (CEM)

Lifting

Ensure that all 4 lifting eyes are used when lifting the

CEM. Only use the lifting eyes (1) and lifting eyes (2)

for lifting the CEM, refer to illustration 27 .

Pump Electronic Tank Unit (PETU)

Illustration 27 g06042325

Typical example

(1) CEM lifting eyes

(2) CEM lifting eyes

Illustration 28 g06041037

Typical example

(1) PETU lifting eyes

i06605082

Product Storage

(Engine and Aftertreatment)

Your Perkins distributor can help in preparing the

engine for extended storage periods.

Some applications, the engine can be equipped with

delayed engine shutdown. Allow at least 2 minutes

after the engine has stopped before you turn the

battery disconnect switch to OFF. Disconnecting the

battery power too soon will prevent purging of the

DEF fluid lines after the engine is shut down. Also,

during the 2 minutes the engine electronic control

module is active storing information from the engine

and aftertreatment sensors.

Condition for Storage

An engine can be stored for up to 6 months provided

all the recommendation are adhered to.

Page 26

26 M0068760

Operation Section

Engine and Aftertreatment

Engine

1. Clean the engine of any dirt, rust, grease, and oil.

Inspect the exterior. Paint areas that contain paint

damage with a good quality paint.

2. Remove dirt from the air cleaners. Check all seals,

gaskets, and the filter element for damage.

3. Apply lubricant to all points in this Operation and

Maintenance Manual, “Maintenance Interval

Schedule”.

4. Drain the crankcase oil. Replace the crankcase oil

and change the oil filters. For the proper

procedure, refer to this Operation and

Maintenance Manual.

5. Add Volatile Corrosion Inhibitor (VCI) oil to the

crankcase oil. The volume of VCI oil in the

crankcase oil should be 3 to 4 percent.

Note: If the engine crankcase is full, drain enough

engine oil so the mixture can be added.

6. Remove the air filter elements. Turn the engine at

cranking speed with the throttle control in FUEL

OFF position. Use a sprayer to add a mixture of 50

percent VCI oil and 50 percent engine oil into the

air inlet or turbocharger inlet.

Note: The mixture of VCI oil can be added to the inlet

by removing the plug for checking turbocharger boost

pressure. The minimum application rate for the VCI

oil mixture is 5.5 mL per L (3 oz per 1000 cu in) of

engine displacement.

7. Use a sprayer to apply a mixture of 50 percent VCI

oil and 50 percent crankcase oil into the exhaust

openings. The minimum application rate for the oil

mixture is 5.5 mL per L (3 oz per 1000 cu in) of

engine displacement. Seal the exhaust pipe and

seal any drain holes in the muffler.

8. Remove the fuel from the secondary fuel filter

housing. Alternately, empty and reinstall the spinon fuel filter element to remove any dirt and water.

Drain any sleeve metering fuel pump.

Clean the primary fuel filter. Fill with calibration

fluid or kerosene. Install the primary fuel filter and

operate the priming pump. This procedure will

send clean oil to the secondary filter and the

engine.

Open the fuel tank drain valve to drain any water

and dirt from the fuel tank. Apply a spray of

calibration fluid or kerosene at the rate of

30 mL per 30 L (1 oz per 7.50 gal US) of fuel tank

capacity to prevent rust in the fuel tank. Add

0.15 mL per L (.02 oz per 1 gal US) of commercial

biocide such as Biobor JF to the fuel.

Apply a small amount of oil to the threads on the

fuel tank filler neck and install the cap. Seal all

openings to the tank to prevent evaporation of the

fuel and as a preservative.

9. Remove the fuel injectors. Apply 30 mL (1 oz) of

the mixture of oils (50 percent VCI oil and 50

percent engine oil) into each cylinder.

Use a bar or a turning tool to turn over the engine

slowly. This procedure puts the oil on the cylinder

walls. Install all fuel injectors and tighten to the

correct torque. Refer to Disassembly and

Assembly Manual for more information.

10. Spray a thin amount of a mixture of 50 percent

VCI oil and 50 percent engine oil onto the following

components: flywheel, ring gear teeth, and starter

pinion. Install the covers to prevent evaporation of

the vapors from the VCI oil.

11. Apply a heavy amount of Multipurpose Grease to

all outside parts that move, such as rod threads,

ball joints, linkage.

Note: Install all covers. Ensure that tape has been

installed over all openings, air inlets, exhaust

openings, the flywheel housing, the crankcase

breathers, the dipstick tubes.

Ensure that all covers are airtight and

weatherproof. Use a waterproof weather resistant

tape such as Kendall No. 231 or an equivalent. Do

not use duct tape. Duct tape will only seal for a

short time.

12. Under most conditions, removing the batteries is

the best procedure. As an alternative, place the

batteries in storage. As needed, periodically

charge the batteries whilst the batteries are in

storage.

If the batteries are not removed, wash the tops of

the batteries until the tops are clean. Apply an

electrical charge to the batteries to obtain a

specific gravity of 1.225.

Disconnect the battery terminals. Place a plastic

cover over the batteries.

13. Remove the drive belts from the engine

14. Place a waterproof cover over the engine. Ensure

that the engine cover is secure. The cover should

be loose enough to allow air to circulate around

the engine to prevent damage from condensation.

15. Attach a tag with the storage date to the engine.

16. Remove the waterproof cover at 2 month or 3-

month intervals to check the engine for corrosion.

If the engine has signs of corrosion, repeat the

protection procedure.

Page 27

M0068760 27

Operation Section

Engine and Aftertreatment

Coolant System

Completely fill the cooling system before storage.

Refer to this Operation and Maintenance Manual,

“Fluid Recommendations” for more information about

coolants.

Aftertreatment

The engine must be allowed to perform a Diesel

Exhaust Fluid (DEF) purge before the battery

disconnect switch is turned off. Some applications,

the engine can be equipped with delayed engine

shutdown. Allow 2 minutes after the engine has

stopped before disconnecting the battery disconnect

switch.

The exhaust outlet of the aftertreatment must be

capped. To prevent damage to the exhaust outlet

connection during storage, the weight of the CEM

must not act on the exhaust outlet.

1. Ensure normal engine shutdown, allow the DEF to

be purged. Do not disconnect the battery

disconnect switch, allow 2 minutes after key off

before disconnection.

2. Fill the tank with DEF that meets all the

requirement defined in ISO 22241-1.

3. Ensure that all DEF lines and electrical connection

are connected prior to prevent crystal from

forming.

4. Ensure that the DEF filler cap is correctly installed.

Remove Engine from Storage

1. Remove all outside protective covers.

2. Change the oil and filters.

3. Check the condition of the fan and alternator belts.

Replace the belts, if necessary. Refer to this

Operation and Maintenance Manual, “Belts Inspect/Adjust/Replace” for the correct procedure.

4. Replace the fuel filter elements.

5. Remove the plastic covers from the air cleaner

elements.

6. Use a bar or a turning tool to turn the engine in the

normal direction of rotation. The procedure

ensures that no hydraulic locks or resistance exist.

7. Before starting the engine, remove the valve cover

or covers. Put a large amount of engine oil on the

camshaft, cam followers, and valve mechanism to

prevent damage to the mechanism.

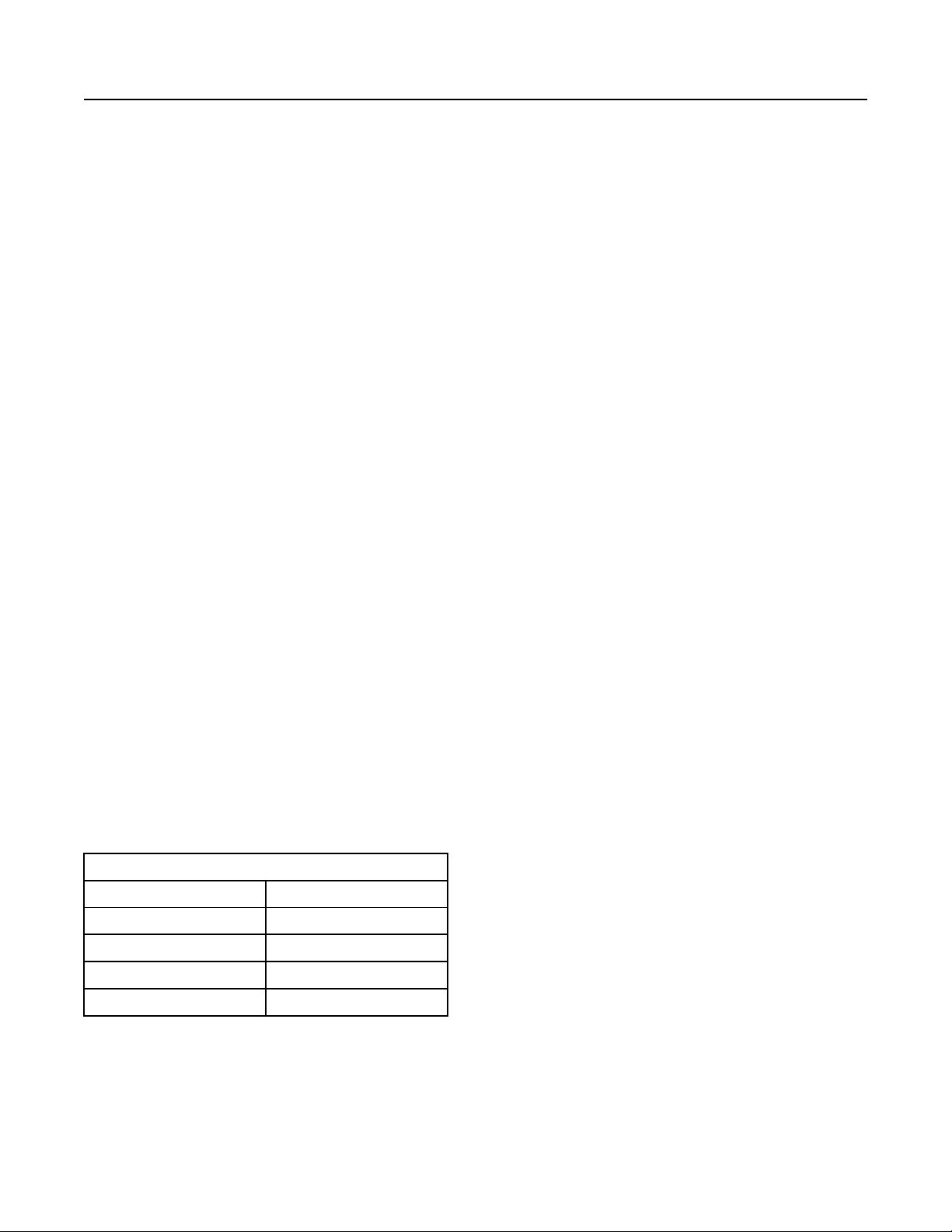

Illustration 29 g06042459

Typical example

(1) Plug

8. If an engine is stored for more than 1 year, Perkins

recommends Pre lubrication of the engine to avoid

dry starting. Use a suitable pump to put engine oil

into the engine oil system.

The pump will need to create a minimum pressure

within the engine of 0.25 bar (3.6 psi). This

pressure is needed for 15 seconds to lubricate the

internal surfaces.

Remove one of the plugs shown in illustration 29

to connect to the engine oil system. The

connection required is 9/16" x 18 tpi. Ensure that

the correct oil specification is used, refer to this

Operation and Maintenance Manual, “Fluid

Recommendations” for more information. After the

engine internal surfaces have been lubricated,

remove connector and install plug (1). Tighten plug

to a torque of 30 N·m (265 lb in). Perkins

recommends that the procedure must be

performed in a minimum ambient temperature of

10° C (50° F).

9. Check the condition of all rubber hoses. Replace

any worn hoses. Replace any damaged hoses.

10. Before start-up, test the cooling system for a 3

percent to a 6 percent concentration of coolant

conditioner. Add liquid coolant conditioner or a

coolant conditioner element, if equipped.

Page 28

28 M0068760

Operation Section

Engine and Aftertreatment

Test the coolant mixture for proper nitrite level. If

necessary, adjust the coolant mixture.

Prime the engine with clean diesel fuel before

starting.

11. Ensure that the cooling system is clean. Ensure

that the system is full. Ensure that the system has

the correct amount of supplemental cooling

system conditioner.

12. On the first day of operation, check the entire

engine several times for leaks and correct

operation.

Remove Aftertreatment from Storage

DEF has a limited life, refer to table 2 for the time and

temperature range. DEF that is outside this range

MUST be replaced.

On removal from storage the DEF quality in the tank

must be tested with a refractometer. The DEF in the

tank must meet the requirements defined in ISO

22241-1 and comply with table 2 .

1. If necessary, drain the tank and fill with DEF that

meets ISO 22241-1.

2. Replace the DEF filter, refer to this Operation, and

Maintenance Manual, “Diesel Exhaust Fluid FilterClean/Replace”.

3. Ensure that the drive belt is correctly installed.

Ensure that all engine coolant and engine oil has

the correct specification and grade. Ensure that

the coolant and the engine oil are at the correct

level. Start the engine. If a fault becomes active

turn off the engine, allow 2 minutes for the DEF

system to purge, then restart the engine.

4. If the fault continues to stay active, refer to

Troubleshooting for more information.

Table 2

DEF Storage

Temperature Duration

10° C (50° F) 36 months

25° C (77° F) 18 months

30° C (86° F) 12 months

35° C (95° F)

(1)

At 35° C, significant degradation can occur. Check every batch

before use.

(1)

6 months

Page 29

M0068760 29

Operation Section

Features and Controls

Features and Controls

i06163203

Monitoring System

The monitoring system is designed to alert the

operator to an immediate problem with any of the

engine systems that are monitored. The monitoring

system is also designed to alert the operator to an

impending problem with any of the engine systems

that are monitored. The monitoring system can be

accessed by the electronic service tool. For more

information on the electronic service tool, refer to

Troubleshooting , “Electronic Tools”.

Monitoring System Indicators

Engine Malfunction – This indicator

illuminates when there is a fault with the

engine or after treatment system.

Engine STOP – This indicator will

illuminate solid when a level 3 warning

fault has been detected by the

monitoring system.

Note: Some items have been removed from engine

for clarity.

Diesel Particulate Filter (DPF) – This

indicator will illuminate in order to show

that a regeneration is needed.

Regeneration Active – This indicator will

illuminate in order to show that a

regeneration is active and exhaust

temperatures are elevated.

Diesel Exhaust Fluid (DEF) Level – This

gauge shows the amount of DEF in the

DEF tank.

Emission Malfunction Indicator – This

indicator will illuminate when an

emissions system related to DEF or SCR

has failed. Refer to Operation and Maintenance

Manual, “Selective Catalytic Reduction Warning

System” for more information.

i06617615

Sensors and Electrical

Components

The illustrations within the following sections are

typical location of the sensors or electrical

components for an industrial engine. Specific

engines may appear different due to differences in

applications.

Page 30

30 M0068760

Operation Section

Sensors and Electrical Components

Engine

Illustration 30 g06048161

Typical example

(1) Secondary Speed/timing sensor

(2) Boost pressure sensor

(3) Inlet air temperature sensor

(4) NOx Reduction System (NRS) solenoid

(5) NRS pressure sensor

(6) NRS differential pressure sensor

(7) NRS temperature sensor

(8) Air control solenoid valve

(9) Electronic control module

(10) Starter solenoid and starting motor

(11) Oil pressure sensor

(12) Barometer pressure sensor

(13) Fuel pressure sensor

(14) Fuel temperature sensor

(15) Primary speed/timing sensor

(16) Alternator

(17) Refrigerant compressor

Page 31

M0068760 31

Operation Section

Sensors and Electrical Components

Illustration 31 g06048567

Typical example

(18) Coolant temperature sensor

Page 32

32 M0068760

Operation Section

Sensors and Electrical Components

Illustration 32 g06049146

Typical example

(19) Location for Top Dead Center (TDC) probe

Aftertreatment System

Illustration 33 g06048751

Typical example

(1) Diesel Exhaust Fluid (DEF) injector

(2) Temperature sensor

(3) Coil for spark plug

Page 33

M0068760 33

Operation Section

Sensors and Electrical Components

(4) Diesel Particulate Filter (DPF)

Differential pressure sensor

(5) DPF pressure sensor

(6) Temperature sender

(7) 40-Pin connector

(8) Selective Catalytic Reduction (SCR)

temperature sensor

(9) Fuel pilot pressure sensor

Pump Electronic Tank Unit (PETU)

(10) Fuel main pressure sensor

(11) Identification Module

(12) Temperature sender for Aftertreatment

Regeneration Device (ARD)

Illustration 34 g03393959

Typical example

(1) DEF Level Sensor and DEF Temperature

Sensor

(2) Coolant Diverter Valve

(3) Customer Connections

(4) Dosing Control Module

(5) Relays

(6) Voltage Limiting Protection Module

Page 34

34 M0068760

Operation Section

Battery Disconnect Switch

i05422613

Battery Disconnect Switch

(If Equipped)

Illustration 35 g03422039

NOTICE

Do not turn off the battery disconnect switch until the

indicator lamp has turned off. If the switch is turned

off when the indicator lamp is illuminated the Diesel

Exhaust Fluid (DEF) system will not purge the DEF. If

the DEF does not purge, DEF could freeze and damage the pump and lines.

NOTICE

Never move the battery disconnect switch to the OFF

position while the engine is operating. Serious damage to the electrical system could result.

The battery disconnect switch and the engine start

switch perform different functions. The entire

electrical system is disabled when you turn the

battery disconnect switch to the OFF position. The

battery remains connected to the electrical system

when you turn the engine start switch to the OFF

position.

Turn the battery disconnect switch to the OFF

position and remove the key when you service the

electrical system or any other engine components.

Turn the battery disconnect switch to the OFF

position and remove the disconnect switch key after

you operate the engine. This will prevent the battery

from being discharged. The following problems can

cause battery discharge:

• short circuits

• current draw via some components

• vandalism

i06605661

Selective Catalytic Reduction

Warning System

The selective catalytic reduction (SCR) system is a

system used to reduce NOx emissions from the

engine. Diesel exhaust fluid (DEF) is pumped from

the DEF tank and is sprayed into the exhaust stream.

The DEF reacts with the SCR catalyst to reduce NOx

and leaves a nitrogen and water vapor. The Exhaust

Gas Recirculation (EGR) system cools, measures,

and introduces recalculated exhaust gas into the

intake manifold to aid in NOx reduction.

Battery Disconnect Switch – The battery

disconnect switch can be used in order

to disconnect the battery from the

engines electrical system. The key must be

inserted into the battery disconnect switch

before the battery disconnect switch can be

turned.

ON – To activate the electrical system,

insert the disconnect switch key and

turn the battery disconnect switch

clockwise. The battery disconnect switch must

be turned to the ON position before you start the

engine.

OFF – To deactivate the electrical

system, turn the battery disconnect

switch counterclockwise to the OFF

position.

Stopping the engine immediately after the engine has

NOTICE

been working under load can result in overheating of

SCR components.

Refer to the Operation and Maintenance Manual,

“Engine Stopping” procedure to allow the engine to

cool and to prevent excessive temperatures in the

turbocharger housing and the DEF injector.

NOTICE

Allow at least 2 minutes after shutting down the engine before you turn the battery disconnect switch to

OFF. Disconnecting the battery power too soon will

prevent purging of the DEF lines after the engine is

shutdown.

Definitions

Observe the following definitions.

Page 35

M0068760 35

Operation Section

Selective Catalytic Reduction Warning System

Self-correct – Fault condition no longer exists. An

active fault code will no longer be active.

Notification – Action taken by the system to alert the

operator of pending Inducement.

Inducement – Engine derates, vehicle speed limits,

or other actions intended to prompt the operator to

repair or maintain the emission control system.

Inducement Categories – The Inducements are

separated into categories. DEF Level has its own

inducement fault codes and is separate from the

other inducement categories. Whilst DEF level

inducements aresimply based on the DEF level, the

other inducement categories are based on escalating

time. The escalating time inducements will always

have an associated fault code along with the

inducement fault code. The associated fault is the

root cause. The escalating time inducement fault

code is just an indicator of what level of inducement

the engine is in and how much time remains until the

next level of inducement. There are three inducement

categories (two for European Union) that will trigger

an escalating time inducement fault code.

Illustration 36 g03676102

DEF Level Normal

Inducement Strategy for DEF Level

(European Union)

Note: The associated codes for each of the

escalating time categories can be found in the

Troubleshooting Guide under SCR Warning System

Problem.

First occurrence – When an escalating time

inducement fault code becomes active for the first

time.

Repeat occurrence – When any escalating time

inducement fault code becomes active again within

40 hours of the first occurrence. Engine must run for

40 hours without tripping any escalating time

inducement fault before it can get back on first

occurrence times.

Safe Harbor Mode (Worldwide) – Safe Harbor

Mode is a 20 minute engine run time period that the

engine can be operated with full power after reaching

a level 3 inducement. Once in level 3 inducement, the

operator can perform a key cycle and the engine will

enter Safe Harbor Mode. Safe Harbor Mode can only

be implemented once. Safe Harbor Mode is not

allowed for DEF level inducements with Worldwide

configuration.

Safe Harbor Mode (European Union) – Safe

Harbor Mode is a 30 minute engine run time period

that the engine can be operated with full power after

reaching a level 3 inducement. Once in level 3

inducement, the operator can perform a key cycle

and the engine will enter Safe Harbor Mode. Safe

Harbor Mode can only be implemented up to three

times.

Illustration 37 g03676107

If the DEF level falls below 20%, an amber indicator

will illuminate next to the DEF level gauge on the