Parr Instrument 6510 User Manual

Operating Instruction Manual |

454M |

|

6510 |

Water Handling System

6510 Water Handling System Operating Instruction Manual

Operating Instructions

For the 6510 Water Handling System

Purpose

The 6510 Water Handling System acts as a cooling and circulating water source for maintaining a constant jacket temperature in the 6200 Isoperibol Calorimeter. It also provides a convenient and consistent means for filling the bucket in a Parr 6200 or 6100 Compensated Jacket Calorimeter. Either one or two 6200 Calorimeters can be served from a single 6510 System.

Explanation of Symbols

I |

On position |

|

|

O |

Off position |

|

|

~ |

Alternating Current (AC) |

|

|

|

|

|

This CAUTION symbol may be present on |

|

the Product Instrumentation and literature. If |

|

present on the product, the user must |

|

consult the appropriate part of the |

|

accompanying product literature for more |

|

information. |

|

|

|

ATTENTION, Electrostatic Discharge (ESD) |

|

hazards. Observe precautions for handling |

|

electrostatic sensitive devices. |

|

|

|

Protective Earth (PE) terminal. Provided |

|

for connection of the protective earth (green |

|

or green/yellow) supply system conductor. |

|

|

|

Chassis Ground. Identifies a connection to |

|

the chassis or frame of the equipment shall |

|

be bonded to Protective Earth at the source |

|

of supply in accordance with national and |

|

local electrical code requirements. |

|

|

|

Earth Ground. Functional earth connection. |

|

NOTE: This connection shall be bonded to |

|

Protective earth at the source of supply in |

|

accordance with national and local electrical |

|

code requirements. |

|

|

- 2 -

6510 Water Handling System Operating Instruction Manual

Safety Information

To avoid electrical shock, always:

1.Use a properly grounded electrical outlet of correct voltage and current handling capability.

2.Ensure that the equipment is connected to electrical service according to local national electrical codes. Failure to properly connect may create a fire or shock hazard.

3.For continued protection against possible hazard, replace fuses with same type and rating of fuse.

4.Disconnect from the power supply before maintenance or servicing.

To avoid personal injury:

1.Do not use in the presence of flammable or combustible materials; fire or explosion may result. This device contains components which may ignite such material.

2.Refer servicing to qualified personnel.

Intended Usage

If the instrument is used in a manner not specified by Parr Instrument Company, the protection provided by the equipment may be impaired.

General Specifications

Electrical Ratings

115VAC, 2.0 Amps. 50/60 Hz

230VAC, 2.0 Amps, 50/60 Hz

Before connecting the water handling system to an electrical outlet, the user must be certain that the electrical outlet has an earth ground connection and that the line, load and other characteristics of the installation do not exceed the following limits:

Voltage: Fluctuations in the line voltage should not exceed 10% of the rated nominal voltage shown on the data plate.

Frequency: Water handling systems can be operated from either a 50 or 60 Hertz power supply without affecting their operation or calibration.

Current: The total current drawn should not exceed the rating shown on the data plate on the water handling system by more than 10 percent.

Environmental Conditions

Operating: |

15 ºC to 30 ºC; maximum relative humidity of 80% non-condensing. |

|

Installation Category II (overvoltage) in accordance with IEC 664. |

|

Pollution degree 2 in accordance with IEC 664. |

|

Altitude Limit: 2,000 meters. |

Storage: |

-25 ºC and 65 ºC; 10% to 85% relative humidity. |

- 3 -

6510 Water Handling System Operating Instruction Manual

Description

The system consists of a 20 liter, temperature controlled, tank with a built in circulating pump, an attached glass delivery pipet and provision for continuous filtration of all water in the system. This is a closed circuit system in which water is re-used continuously.

When the 6510 System is used with a 6200 Calorimeter, water from the tank is delivered to the temperature control manifold at the rear of the calorimeter and returned in a closed loop, thereby maintaining a constant temperature in the calorimeter.

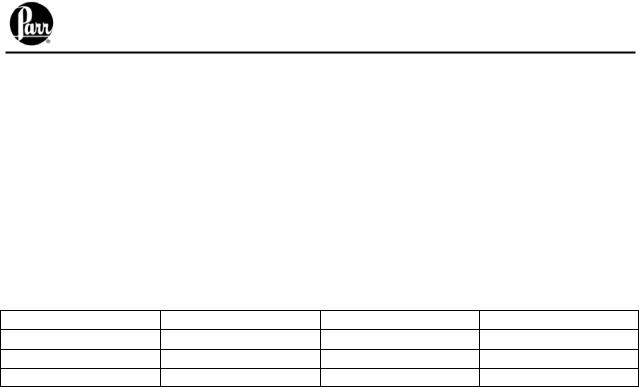

The water handling system can be used to supply water not only to the calorimeter jacket but also to the bucket through an attached delivery pipet. The choice of oxygen bomb size will dictate the pipet choice as follows:

Oxygen Bomb |

Pipet Volume |

Pipet Part Number |

Support Assembly |

1108 |

2000 mL |

167HW |

A335HW |

1104 |

1850 mL |

167HW2 |

A335HW |

1109 |

450 mL |

167HW3 |

A335HW2 |

A maximum of two pipets may be installed on the water handler. Only one pipet may be filling the bucket at any one time.

Temperature controlled water flows continuously through the glass delivery pipet and back to the tank to maintain a constant water temperature in the pipet for filling the calorimeter bucket with repeatable volumes. Flow through the pipet stops when the stopcock is opened to fill the calorimeter bucket. The pipet refills automatically when the stopcock is turned back to a closed position. At the end of each test, the user will empty the bucket water into the reservoir where it is released slowly into the tank so as not to cause a sudden change in temperature.

NOTE: Do not leave the stopcock dry as the Teflon will seize in the glass.

Incorporated in the system is a solid-state water chiller that is capable of removing and dissipating the heat in the returned bucket water produced during calorimetric testing, thus maintaining the water at a constant temperature for repeatable test temperatures.

Required Accessories and Utilities

Approximately 15 L of water with a total hardness of less than 85 ppm is required for filling the tank of the system.

- 4 -

6510 Water Handling System Operating Instruction Manual

Installation

Install the 6510 System near the calorimeter so that the water connections are kept short. The water system can be installed in any convenient location however care should be taken that heat from the compressor on the left side of the Water Handling System not reach the calorimeter. Additionally, air must be allowed to move freely around the cooling fan on the back of the 6510 System. The supply voltage must be within ± 10% of marked nominal voltage on the instrument. The supply voltage receptacle must have an earth ground connection.

Make the tubing connections as illustrated in Figure-1.

Note: It is critical to keep the tubing between the calorimeter and the water system as short as possible and eliminate any uphill runs or kinks. This will impede the free flow of water from the calorimeter.

Pipet Installation

The A335HW pipet support brackets can be installed on either side of the water handling system. There are four mounting screws (TA1632PP06) located on each side of the water handler. The pipet is installed by slightly tilting and inserting the round top portion of the pipet into the hole in the pipet support. The lower support bracket holds the pipet from underneath by inserting the pipet into the slotted end of the bracket.

Insert the 148C, 3-way PTFE stopcock plug into the pipet and secure it using only enough tension on the spring loaded retaining nut to prevent leakage. Insert the short

3/8” OD Nylon tube into a three-inch length of black latex tubing furnished with the system. Attach the tubing to the discharge tube that extends downward from the stopcock. This provides a flexible tip to prevent breakage if the bucket were to strike the discharge tube during the filling operation. Extending the discharge tube into the bucket also minimizes splashing of the water while the bucket is filling.

The pipet outlet on the back panel is a 3/8” tube connection. A 219HW barb connector is provided to install the JR0056TB125A tubing. Install a 6” piece of JR0056TB125A tubing on the barb connector. Install the 149C in-line filter; make sure the arrow on the filter is pointing towards the pipet. Install JR0056TB125A tubing from the 149C filter to the bottom port of the pipet. The pipet return on the back panel is a ½” tube connection.

A 309HW barb connector is provided to install the JR0056TB125A tubing. Install tubing from the 309HW barb connector to the top port on the pipet.

Note: It is critical to keep the tubing from the pipet to the water handler as short as possible. Any extra tubing can create a downward loop in the tube and potentially back up the water, restricting the flow.

- 5 -

Loading...

Loading...