Parr Instrument 6400 User Manual

587M

6400

Automatic Isoperibol Calorimeter

Operating Instruction Manual

For models produced after October 2010

www.parrinst.com

Table of Contents6400

1

Preface 4

Scope 4

Related Instructions 4

Purpose 4

Explanation of Symbols 5

Safety Information 5

Intended Usage 5

General Specifications 6

Environmental Conditions 6

Provisions for Lifting and Carrying 6

Cleaning & Maintenance 6

Chapter 1 8

Installation 8

Environmental Conditions 8

Swagelok Tube Fittings 8

Required Consumables, Utilities and Power Requirements 9

Electrical Connection 9

Front Panel Meter 9

Water Connection 11

Gas Connection 12

Bomb Exhaust Connections 12

Communication Connections 13

Printer Connections 13

Balance Connections 13

Chapter 2 16

Quick Start 16

Initial Fill 16

Quick Start 16

Chapter 3 18

Operation 18

Menu System 18

Menu Keys 18

Control Keys 18

Programming 19

Default Settings 19

Sample Preparation 19

Test Process 22

Closing the bomb 22

Cool/Rinse 26

Drain

Fill Cycle 23

Pre-Period 24

Bomb Firing 25

Post-Period 25

Chapter 4 28

Menu Descriptions 28

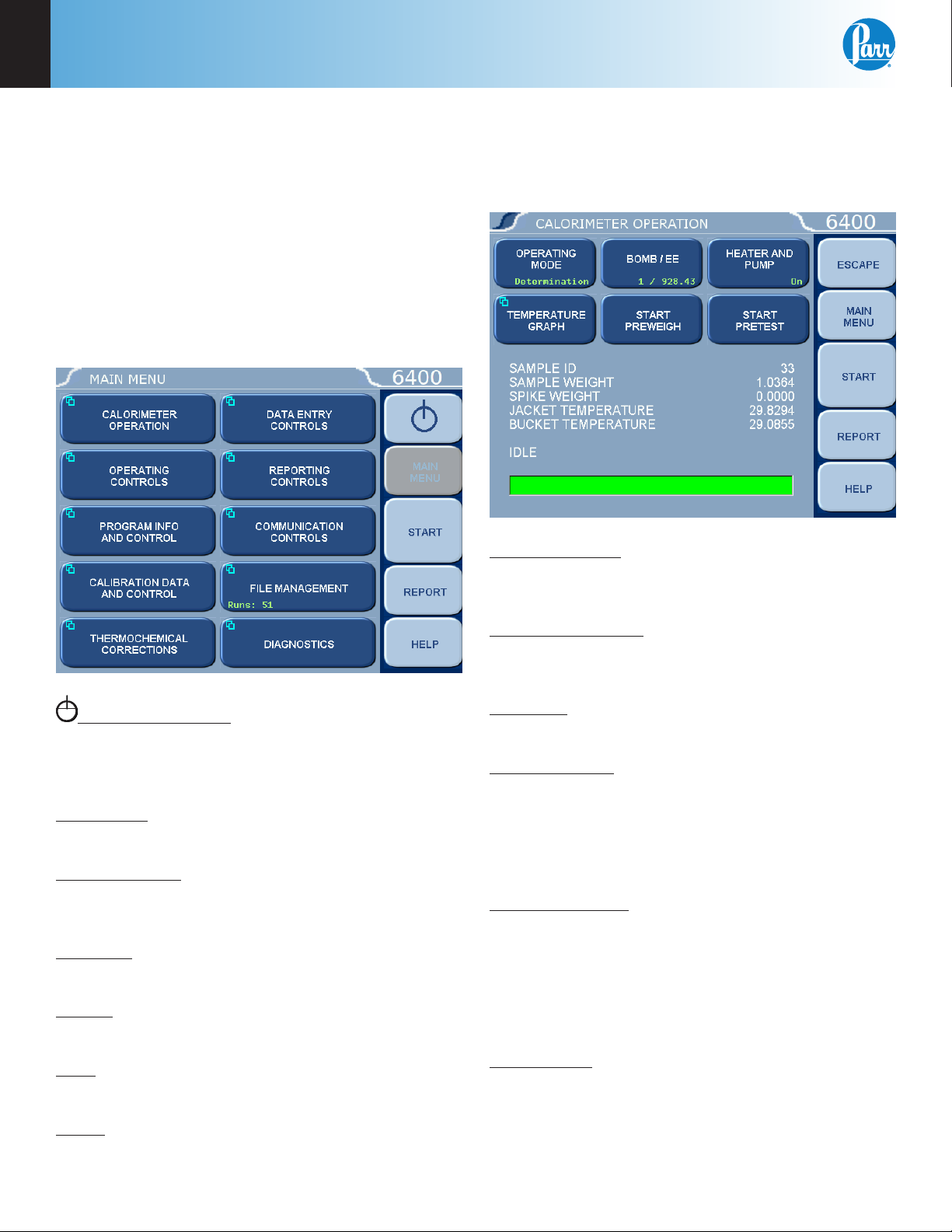

Main Menu 28

Calorimeter Operation Menu 28

Temperature vs. Time Plot 29

Temperature Plot Setup Menu 29

Operating Controls Menu 30

Spiking Controls 30

Bomb Rinse Tank Controls 31

Program Information and Control Menu 32

Software & Hardware Info 32

User/Factory Settings 33

Calibration Data and Controls Menu 34

Bomb 1 35

Control Plot Chart Plot 35

Thermochemical Corrections Menu 36

Calculation Factors Menu 37

Net Heat/Dry Heat Factors 38

Data Entry Controls Menu 38

Net Heat Data Entry Controls 39

Auto Sample ID Controls 39

Moisture Data Entry Controls 40

Preweigh Sample ID Controls 40

Reporting Controls Menu 40

Communication Controls Menu 41

Balance Port Communications 41

Balance Port Settings 42

File Management Menu 43

Run Data File Manager 43

Diagnostics Menu 44

Data Logger Controls 44

Data Log Items 45

User Defined Buttons 45

I/O Diagnostics:

Parr Instrument Company

Table of Contents

2

Chapter 5 46

Reports 46

Reports 46

Chapter 6 48

Standardizations 48

Standardizing the Calorimeter 48

Standard Materials 48

Automatic Statistical Calculations 48

Chapter 7 52

Calculations 52

Calculating the Heat of Combustion 52

General Calculations 52

Thermochemical Corrections 52

ASTM and ISO Methods Differ 53

Thermochemical Calculation Details 54

Acid and Sulfur Corrections 54

ASTM Treatment for Acid and Sulfur 56

ISO Calculations 56

Spiking Samples 57

Conversion to Other Moisture Bases 57

Conversion to Net Heat of Combustion 57

Chapter 8 58

Computer Communications 58

Computer Connections 58

Samba Server Feature (Optional) 59

Bar Code Port 66

Chapter 9 68

Memory Management 68

Clearing Memory 68

Removable SD Memory 68

Chapter 10 70

Maintenance 70

Inspection of Critical Sealing Surfaces 70

Bomb Removal 70

Fuses 71

Daily Maintenance 71

Quarterly Maintenance 71

50 to 100 Test Maintenance 71

500 Test Maintenance 71

5000 Test Maintenance 72

6400 Maintenance Checklist 73

Chapter 11 74

Troubleshooting 74

Bomb Exhaust Troubleshooting 74

Jacket Temperature Troubleshooting 75

Error List 76

Chapter 12 78

Technical Service 78

Return for Repair 78

Chapter 13 80

Parts Lists 80

Principal Assemblies in Calorimeter 80

A1250DD2 Controller Assembly 80

A1265DD Bucket and Stirrer Tube Assembly 80

A1255DD Bucket Stirrer Assembly 81

A1266DD Cover Assembly 81

A1457DD Accessory/Installation Kit 81

Chapter 14 82

Drawings 82

1138 Parts Diagram Key 83

Chapter 15 104

Tables 104

www.parrinst.com

Table of Contents6400

3

Figures

Figure 1-1

Swagelok Tube Fittings 8

Figure 1-2

6400 Calorimeter Back Panel 10

Figure 1-3

6400 External Plumbing 11

Figure 1-4

6400 Calorimeter Peripherals 14

Figure 1-5

Multiple Alternate Configurations 14

Figure 3-1

Volatile Sample Technique 21

Figure 3-2

Cotton Thread Assembly 22

Figure 3-3

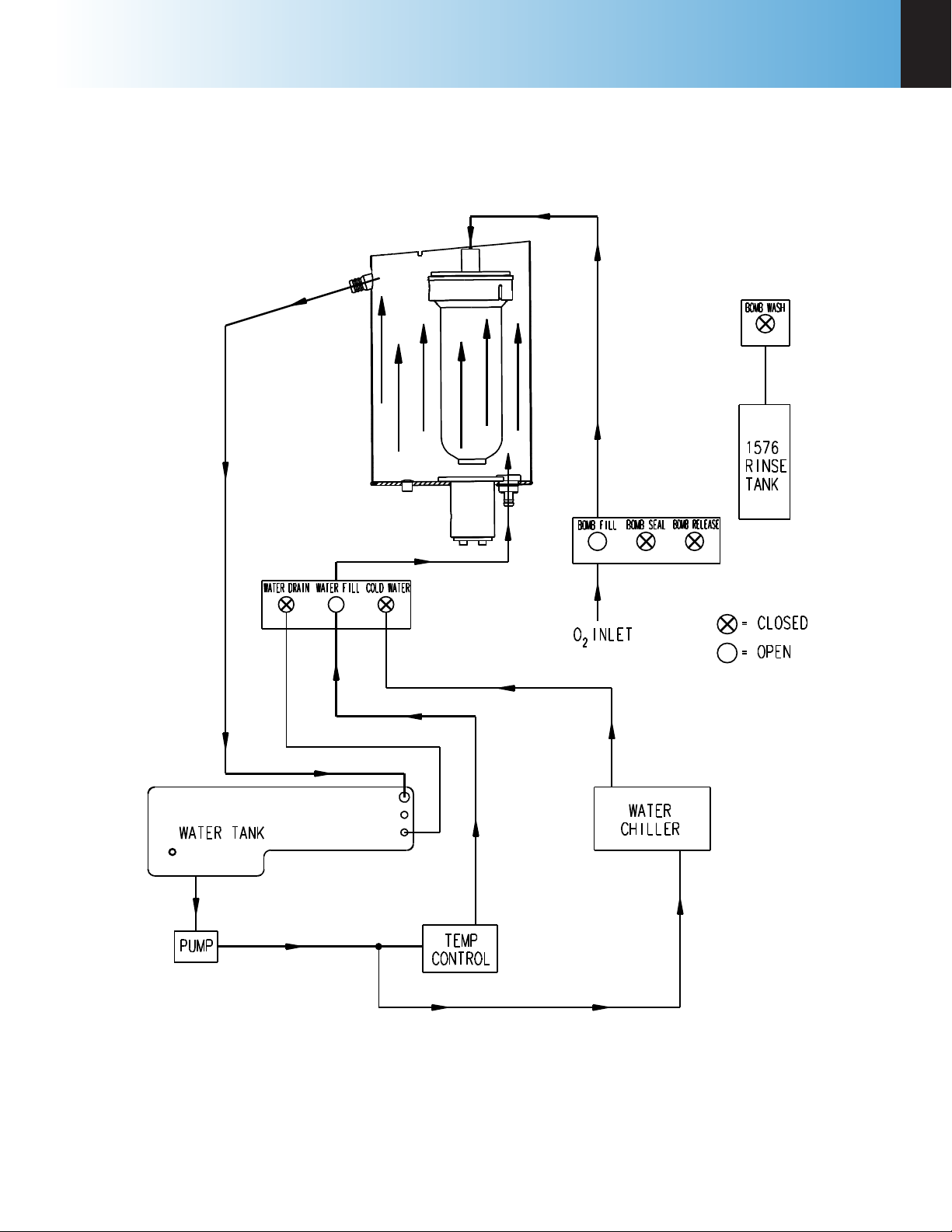

Bucket Fill Flow Diagram 23

Figure 3-4

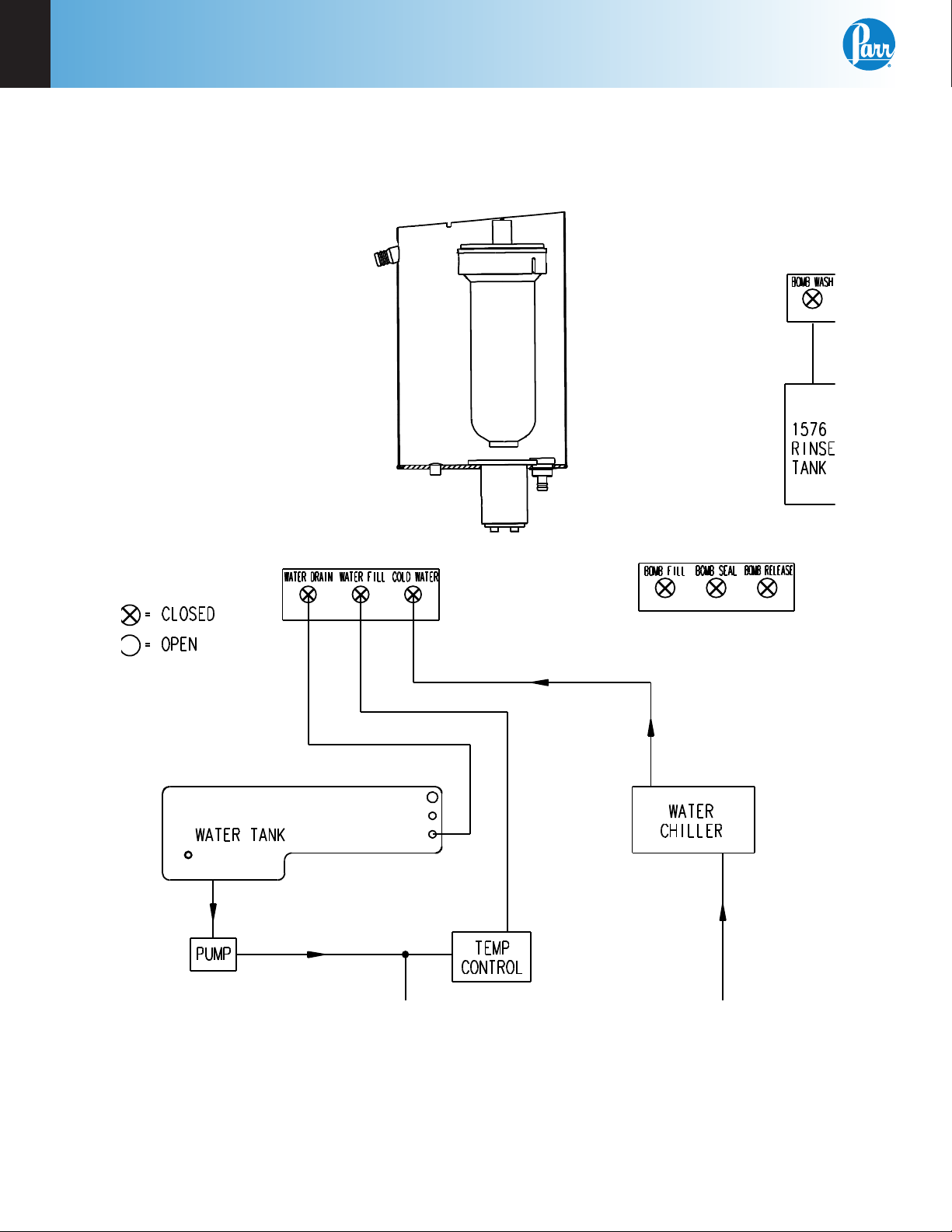

Pre-Period/Post-Period Flow Diagram 24

Figure 3-5

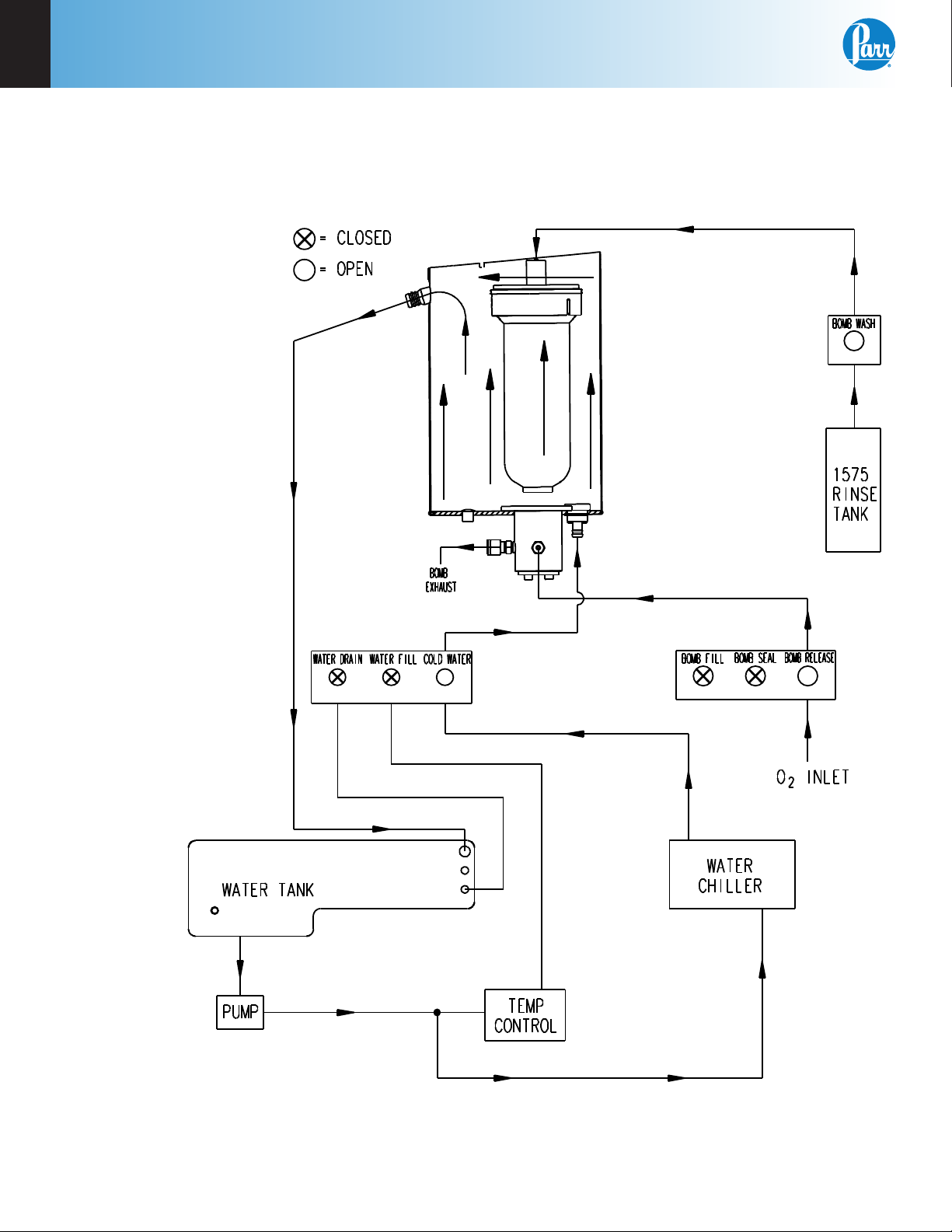

Rinse & Cool Flow Diagram 26

Figure 3-6

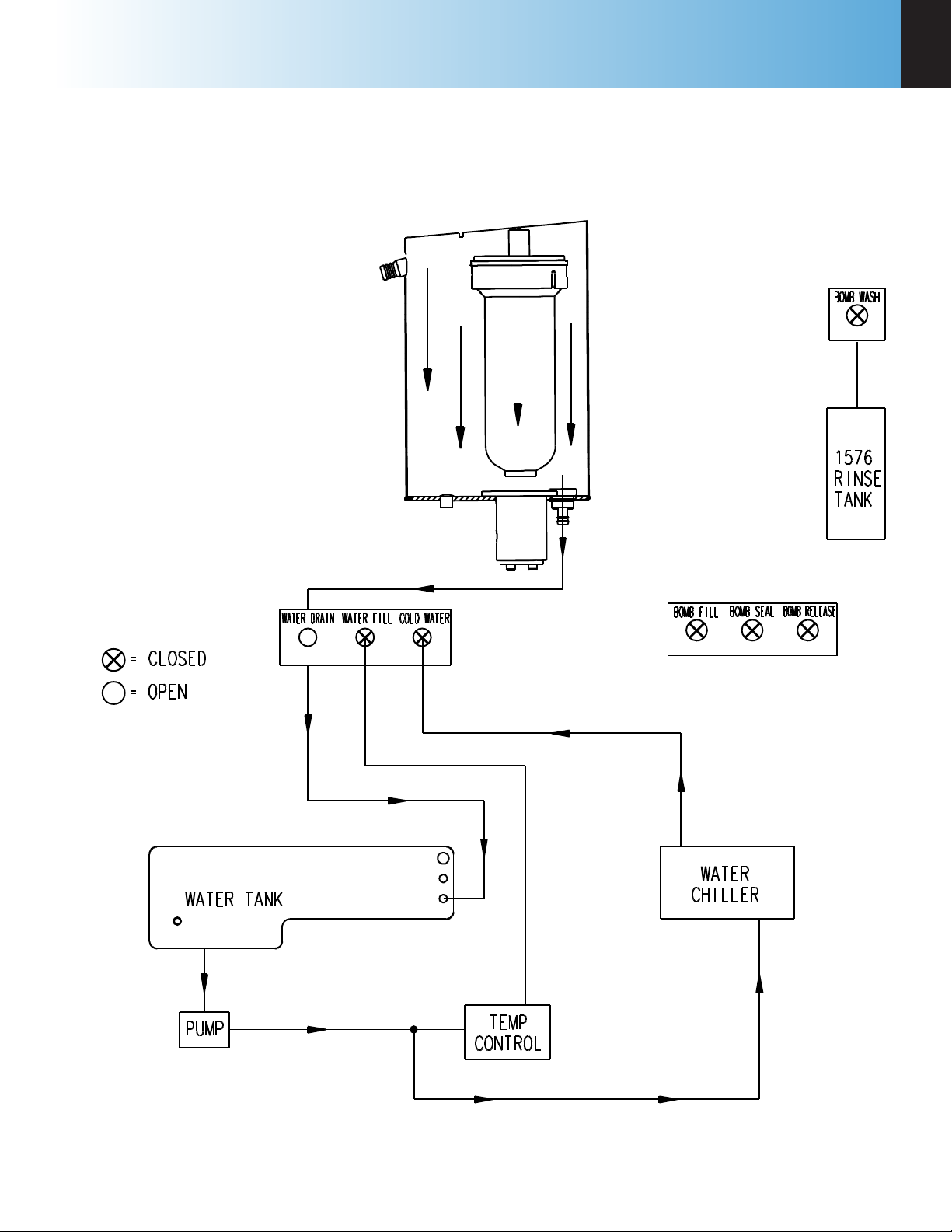

Drain Flow Diagram 27

Figure 14-1

1138 Parts Diagram 82

Figure 14-2

6400 Cutaway Right 84

Figure 14-3

6400 Cutaway Left 85

Figure 14-4

6400 Cover Open 86

Figure 14-5

A1250DD2 Control Schematic 87

Figure 14-6

A1251DD Oxygen Solenoid Assembly 88

Figure 14-7

A1447DD Water Solenoid Assembly 88

Figure 14-8

A1456DD Rinse Valve Assembly 89

Figure 14-9

6400 Internal Plumbing Diagram 90

Figure 14-10

6400 Water Tank and Jacket Cooling Solenoid 91

Tables

Table 6-1

Calorimeter Control Limit Values in J/g When Benzoic

Acid is Used as a Test Sample 49

Table 6-2

Calorimeter Control Limit Values in cal/g When Benzoic

Acid is Used as a Test Sample 50

Table 6-3

Calorimeter Control Limit Values in BTU/lb When Benzoic

Acid is Used as a Test Sample 51

Table 8-1

6400 Data File Naming Convention 66

Table 8-2

6400 Calorimeter Run Data Template 67

Table 15-1

Factory Default Settings 104

Table 15-2

Settings for ISO & BSI Methods 106

Figure 14-11

A1455DD Propeller Assembly 92

Figure 14-12

A1448DD Temperature Control Assembly 92

Figure 14-13

A1268DD Stirrer Motor and Mount 93

Figure 14-14

6400 Bucket Assembly 94

Figure 14-15

6400 Air Can Assembly, Cutaway Left 95

Figure 14-16

6400 Air Can Assembly, Cutaway Front 96

Figure 14-17

A1450DD Bomb Head Assembly, View 1 97

Figure 14-18

A1450DD Bomb Head Assembly, View 2 98

Figure 14-19

A1050DD Rinse Collection Assembly 99

Figure 14-20

Wiring Diagram 100

Figure 14-21

Wiring Diagram 101

Figure 14-22

Fuse Diagram 102

Preface

Parr Instrument Company

4

Preface

Scope

This manual contains instructions for installing and

operating the Parr 6400 Calorimeter. For ease of

use, the manual is divided into 15 chapters.

1. Installation

2. Quick Start

3. Operation

4. Menu Descriptions

5. Reports

6. Standardizations

7. Calculations

8. Computer Communications

9. Memory Management

10. Maintenance

11. Troubleshooting

12. Technical Service

13. Parts Lists

14. Drawings

15. Tables

Subsections of these chapters are identified in the

Table of Contents.

To assure successful installation and operation, the

user must study all instructions carefully before

starting to use the calorimeter to obtain an under-

standing of the capabilities of the equipment and the

safety precautions to be observed in the operation.

Related Instructions

Additional instructions concerning the installation

and operation of various component parts and

peripheral items used with the 6400 Calorimeter

should be made a part of these instructions. Addi-

tional instructions for the optional printer are found

in the respective printer package and should be

made a part of this book.

No. Description

201M Limited Warranty

207M Analytical Methods for Oxygen Bombs

230M Safety in the Operation of Laboratory

and Pressure Vessels

483M Introduction to Bomb Calorimetry

Note: The unit of heat used in this manual is

the International Table calorie, which is equal

to 4.1868 absolute joules.

Purpose

Heats of combustion, as determined in an oxygen

bomb calorimeter such as the 6400 Automatic

Isoperibol Calorimeter, are measured by a substitu-

tion procedure in which the heat obtained from the

sample is compared with the heat obtained from a

standardizing material. In this test, a representative

sample is burned in a high-pressure oxygen atmo-

sphere within a metal pressure vessel or “bomb”.

The energy released by the combustion is absorbed

within the calorimeter and the resulting temperature

change is recorded.

Customer Service

Questions concerning the installation or operation of this instrument

can be answered by the Parr Customer Service Department:

1-309-762-7716 • 1-800-872-7720 • Fax: 1-309-762-9453

E-mail: parr@parrinst.com • http://www.parrinst.com

Note About Nomenclature:

Historically, burning a sample enclosed in a high pressure oxygen

environment is known as Oxygen Bomb Calorimetry and the vessel

containing the sample is known as an Oxygen Bomb. The terms

bomb and vessel are used interchangeably.

Preface

6400

www.parrinst.com

5

Safety Information

To avoid electrical shock, always:

1. Use a properly grounded electrical outlet of

correct voltage and current handling capability.

2. Ensure that the equipment is connected to

electrical service according to local national

electrical codes. Failure to properly connect may

create a fire or shock hazard.

3. For continued protection against possible

hazard, replace fuses with same type and rating

of fuse.

4. Disconnect from the power supply before

maintenance or servicing.

To avoid personal injury:

1. Do not use in the presence of flammable or

combustible materials; fire or explosion may

result. This device contains components which

may ignite such material.

2. Refer servicing to qualified personnel.

Intended Usage

If the instrument is used in a manner not specified

by Parr Instrument Company, the protection pro-

vided by the equipment may be impaired.

Explanation of Symbols

I On Position

O Off Position

~ Alternating Current

This CAUTION symbol may be present on the Product Instrumenta-

tion and literature. If present on the product, the user must consult

the appropriate part of the accompanying product literature for more

information.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precau-

tions for handling electrostatic sensitive devices.

Protective Earth (PE) terminal. Provided for connection of the protec-

tive earth (green or green/yellow) supply system conductor.

Chassis Ground. Identifies a connection to the chassis or frame of the

equipment shall be bonded to Protective Earth at the source of supply

in accordance with national and local electrical code requirements.

Earth Ground. Functional earth connection. This connection shall be

bonded to Protective earth at the source of supply in accordance with

national and local electrical code requirements.

Preface

Parr Instrument Company

6

General Specifications

Electrical Ratings

120VAC, 5.0 Amps. 50/60 Hz

240VAC, 3.0 Amps. 50/60 Hz

Before connecting the calorimeter to an electrical

outlet, the user must be certain that the electrical

outlet has an earth ground connection and that the

line, load and other characteristics of the installation

do not exceed the following limits:

Voltage: Fluctuations in the line voltage should not

exceed 10% of the rated nominal voltage shown on

the data plate.

Frequency: Calorimeters can be operated from

either a 50 or 60 Hertz power supply without affect-

ing the operation or calibration.

Current: The total current drawn should not exceed

the rating shown on the data plate on the calorim-

eter by more than 10 percent.

Environmental Conditions

Operating: 15 ºC to 30 ºC; maximum relative humid-

ity of 80% non-condensing. Installation Category II

(over voltage) in accordance with IEC 664. Pollution

degree 2 in accordance with IEC 664.

Altitude Limit: 2,000 meters.

Storage: -25 ºC and 65 ºC; 10% to 85% relative humidity.

Provisions for Lifting and Carrying

Before moving the instrument, disconnect all con-

nections from the rear of the apparatus. Lift the

instrument by grabbing underneath each corner.

Cleaning & Maintenance

Periodic cleaning may be performed on the exterior

surfaces of the instrument with a lightly dampened

cloth containing mild soap solution. All power

should be disconnected when cleaning the instru-

ment. There are no user serviceable parts inside the

product other than what is specifically called out

and discussed in this manual. Advanced trouble-

shooting instructions beyond the scope of this

manual can be obtained by calling Parr Instrument

Company in order to determine which part(s) may

be replaced or serviced.

www.parrinst.com

7

Notes

6400

1

Installation

Parr Instrument Company

8

chaPter 1

Installation

Note: Some of the following manual sections

contain information in the form of warnings,

cautions and notes that require special at-

tention. Read and follow these instructions

carefully to avoid personal injury and dam-

age to the instrument. Only personnel quali-

fied to do so, should conduct the installation

tasks described in this portion of the manual.

Environmental Conditions

The 6400 Calorimeter is completely assembled and

given a thorough test before it is shipped from the

factory. If the user follows these instructions, instal-

lation of the calorimeter should be completed with

little or no difficulty. If the factory settings are not

disturbed, only minor adjustments will be needed to

adapt the calorimeter to operating conditions in the

user’s laboratory.

This apparatus is to be used indoors. It requires at

least 4 square feet of workspace on a sturdy bench

or table in a well-ventilated area with convenient

access to an electric outlet, running water and a

drain.

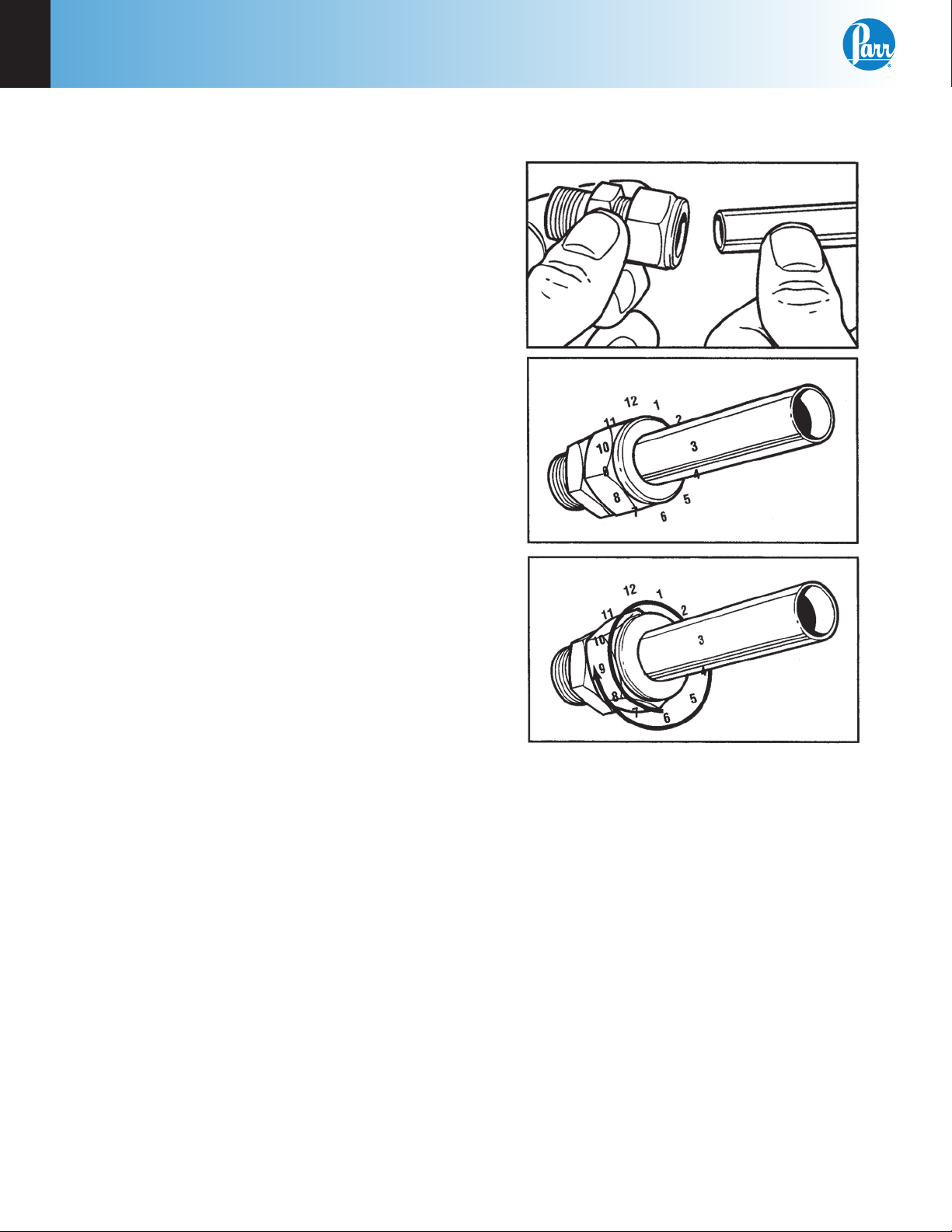

Swagelok Tube Fittings

When Swagelok Tube Fittings are used, the instruc-

tions for installation are:

1. Simply insert the tubing into the Swagelok Tube

Fitting. Make sure that the tubing rests firmly

on the shoulder of the fitting and that the nut is

finger-tight.

2. Before tightening the Swagelok nut, scribe the

nut at the 6 o’clock position.

3. While holding the fitting body steady with a

back-up wrench, tighten the nut 1-1/4 turns.

Watch the scribe mark, make one complete revo-

lution and continue to the 9 o’clock position.

4. For 3/16” and 4mm or smaller tube ttings, tight-

en the Swagelok nut 3/4 turns from nger-tight.

Figure 1-1

Swagelok Tube Fittings

Swagelok tubing connections can be disconnected

and retightened many times. The same reliable leak-

proof seal can be obtained every time the connec-

tion is remade using the simple two-step procedure.

1. Insert the tubing with pre-swaged ferrules into

the fitting body until the front ferrule seats.

2. Tighten the nut by hand. Rotate the nut to the

original position with a wrench. An increase in

resistance will be encountered at the original

position. Then tighten slightly with a wrench.

Smaller tube sizes (up to 3/16” or 4mm) take less

tightening to reach the original position than

larger tube sizes.

Installation

6400

1

www.parrinst.com

9

The type of tubing and the wall thickness also has

an effect on the amount of tightening required.

Plastic tubing requires a minimal amount of ad-

ditional tightening while heavy wall metal tubing

may require somewhat more tightening. In general,

the nut only needs to be tightened about 1/8 turn

beyond finger tight where the ferrule seats in order

to obtain a tight seal.

Over tightening the nut should be avoided. Over

tightening the nut causes distortion (flaring) of the

lip of the tube fitting where the ferrule seats. This

in turn causes the threaded portion of the body to

deform. It becomes difficult to tighten the nut by

hand during a subsequent re-tightening when the

fitting body becomes distorted in this manner.

Required Consumables, Utilities and Power

Requirements

The 6400 Calorimeter requires availability of

oxygen, 99.5% purity, with appropriate connection,

2500 psig, maximum.

The 6400 Calorimeter requires availability of ni-

trogen or air, oil and water free, with appropriate

connection, 2500 psig, maximum.

Approximately 16L of distilled water are required to

fill the external pressurized rinse tank.

Approximately 2L of distilled, de-ionized, or tap

water, with a total hardness of 85 ppm or less, are

required for filling the internal cooling reservoir.

The power requirements for the sub-assemblies of

the 6400 Calorimeter are:

Calorimeter

5.0 Amps @ 120 VAC

3.0 Amps @ 240 VAC

Printer

(100 to 240 VAC, 50/60 Hz) 0.35 Amps

Electrical Connection

Plug the power line into any grounded outlet provid-

ing proper voltage that matches the specification on

the nameplate of the calorimeter. Grounding is very

important not only as a safety measure, but also to

ensure satisfactory controller performance. If there

is any question about the reliability of the ground

connection through the power cord, run a separate

earth ground wire to the controller chassis.

Turn the power switch to the ON position. After

a short time, the Parr logo will appear on the LCD

display followed by a running description of the in-

strument boot sequence. When the boot sequence

is complete, the Main Menu is displayed.

Front Panel Meter

The panel meter on the front of the calorimeter

controls the temperature of the water in the internal

cooling resorvoir. The setpoint is locked at 15 °C.

A red light will flash in the upper left corner of the

display when the water is being cooled.

1

Installation

Parr Instrument Company

10

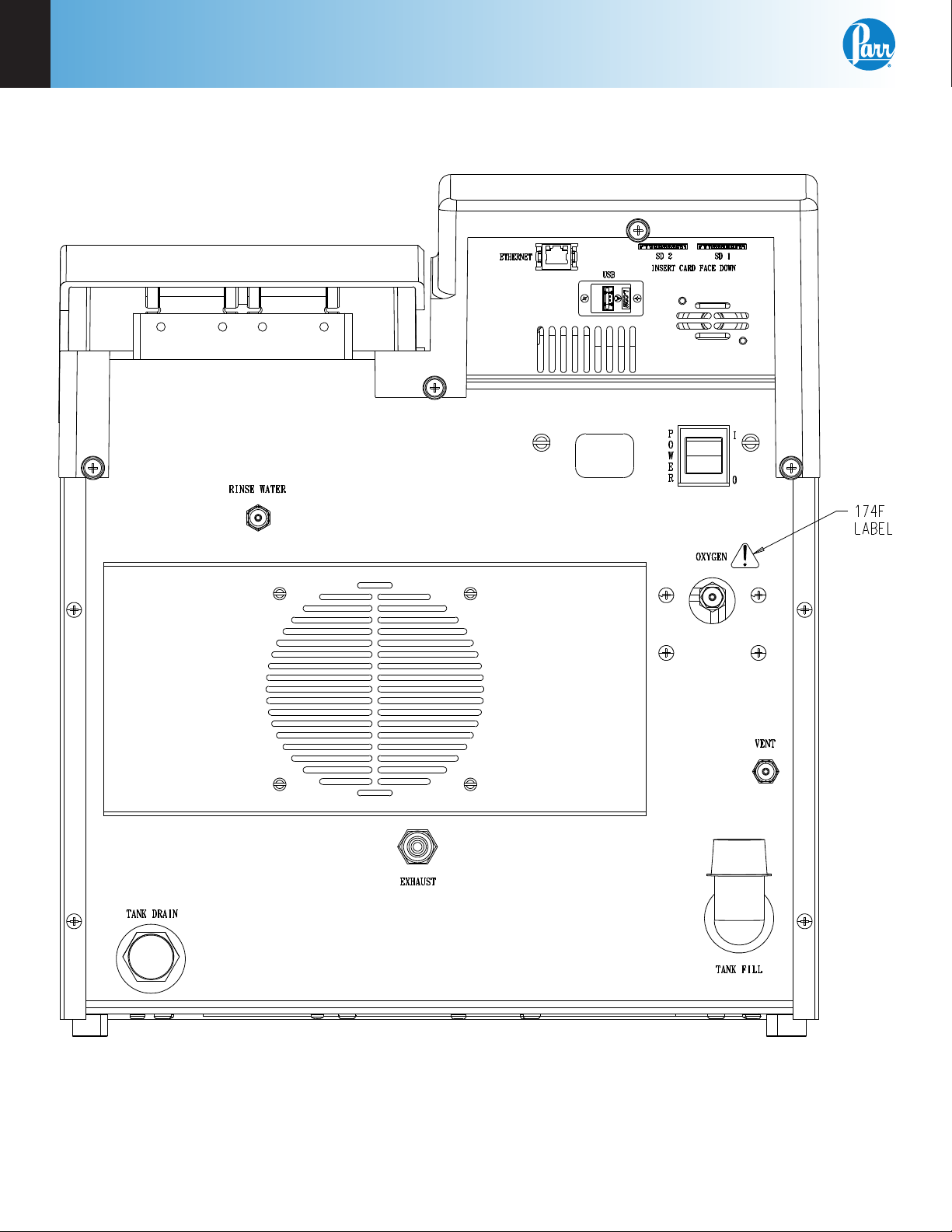

Figure 1-2

6400 Calorimeter Back Panel

Installation

6400

1

www.parrinst.com

11

Water Connection

Remove the cap plug on the water filling elbow and

fill the internal reservoir tank with water having a

total hardness of 85 ppm or less, until the water level

is at the bottom of the filling elbow. The calorimeter

water tank will initially accept about 2 liters.

Fill the external rinse tank with about 16 liters of

distilled water through the large opening at the top

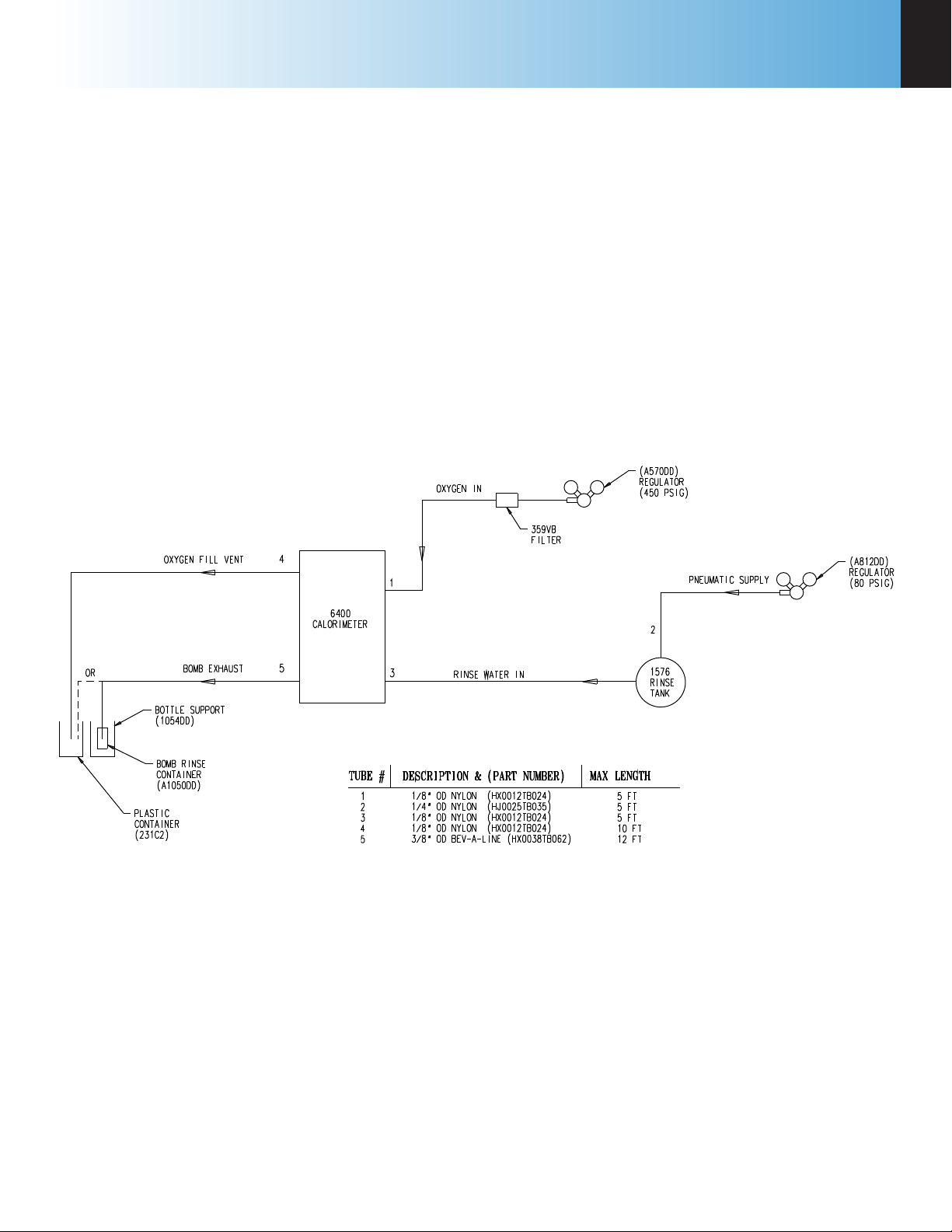

Figure 1-3

6400 External Plumbing

of the tank. The cover for this opening is removed

by lifting up on the handle, pushing down on the lid,

tilting and removing. Replace and close the cover

after filling.

The connection between the calorimeter and the

1576 Rinse Tank should be made with a piece of 1/8”

nylon pressure hose (HX0012TB024). See Figure 1-3.

1

Installation

Parr Instrument Company

12

Gas Connection

Make the connections to the oxygen supply at this

time. Refer to Figure 1-3. 1/8” O.D. nylon pressure

hose (HX0012TB024) is used to connect the oxygen

supply. The inlet connection incorporates a flow

restrictor just behind the inlet connection. When

making the oxygen connection, a back-up wrench

should be placed on the restrictor to insure a secure

connection and to prevent over tightening the flow

restrictor. The delivery pressure for oxygen should

be set to 450 psig. To install the regulator, unscrew

the protecting cap from the tank and inspect the

threads on the tank outlet to be sure they are clean

and in good condition. Place the ball end of the

regulator in the tank outlet and draw up the union

nut tightly, keeping the gages tilted slightly back

from an upright position. Open the tank valve and

check for leaks. The bomb must never be filled to

more than 600 psig (40 atm).

Make the connections to the nitrogen supply at this

time. 1/4” O.D. nylon pressure hose (HJ0025TB035)

is used to connect the A812DD Nitrogen Regulator

to the 1576 Rinse Tank. When making the nitrogen

connection, a back-up wrench should be placed on

the fitting to insure a secure connection and to pre-

vent over tightening the flow restrictor. The delivery

pressure for nitrogen should be set at 80 psig. To

install the regulator, unscrew the protecting cap

from the tank and inspect the threads on the tank

outlet to be sure they are clean and in good condi-

tion. Place the ball end of the regulator in the tank

outlet and draw up the union nut tightly, keeping the

gages tilted slightly back from an upright position.

Open the tank valve and check for leaks.

Note: A hissing sound will occur while the

rinse tank is being pressurized. This is nor-

mal. Adjust the pneumatic supply regulator

to 80 psig as needed.

During extended periods of inactivity, close the tank

valve to prevent depleting the tank in the event of

a leak. Close the tank valve prior to removing the

regulator when changing tanks. Do not use oil or

combustible lubricants in connection with any part

of the oxygen filling system. Keep all threads, fit-

tings and gaskets clean and in good condition.

Note: To release the pressure inside the rinse

tank turn off the gas supply and open the gas

relief valve lever. Gas will exhaust through

the relief valve. Once the pressure has equal-

ized remove the lid to refill the rinse tank.

Bomb Exhaust Connections

The exhaust and vent connections at the rear of the

calorimeter, are made with the dual tube A1006DD

assembly. The end of the assembly with the bomb

exhaust diffuser should be placed into the 10 liter

carboy (231C2). The carboy should be placed at or

below the level of the calorimeter to facilitate com-

plete draining of these lines.

Alternatively:

The A1050DD Bomb Rinse Container Assembly is

available as an accessory to the 6400 Calorimeter.

See Figure 14-19. This device allows for complete

and systematic recovery of the bomb combustion

products. These combustion products include the

initial line exhaust after the fill cycle and the por-

tion expelled during the bomb rinse cycle. The

Bomb Rinse Container Assembly is connected to

the rear of the calorimeter, in place of the portion

of the waste tube assembly that is connected to the

bomb exhaust fitting. Combustion products are

discharged from the bomb in two steps. The first

step occurs during the initial rapid release of the

residual bomb gases. The 1053DD bottle has suf-

ficient strength and volume to deal effectively with

this sudden pressure release. Gas is expelled from

the four holes on the perimeter of the 1052DD bottle

cap, leaving any discharged liquid in the bottle. As

an additional safety measure, the bottle is supported

in a 1054DD acrylic cylinder which serves to keep

the bottle upright and contained in the unlikely

event the bottle ruptures. At the end of the bomb

exhaust step the aqueous combustion products

reside in the bomb, associated tubing as well as the

1053DD bottle. The bomb rinse step flushes these

combustion products from the bomb and the tubing

into the 1053DD bottle. The bottle can then be

unscrewed from the assembly and capped, until the

sample is to be analyzed. Some users find it useful

to add the contents of the rinsed combustion cap-

sule to the washings collected in the bottle. Three

1053DD bottles are provided with the assembly.

Additional bottles may be ordered separately from

Parr.

Installation

6400

1

www.parrinst.com

13

Mettler 011/012 Interface

The ID field must contain

“S_” to indicate a stable

mass. The data field con-

tains the current mass, right

justified, with a decimal

point. The balance should

be configured to send con-

tinuously.

Sartorius Interface

The polarity field must con-

tain either a “+” or a space.

Leading zeros in the data

field are blanked, except

for the one to the left of the

decimal point. The stability

field must contain “g_” for

the calorimeter to accept a

mass. The balance should

be configured to transmit data upon receipt of

the following command string:

[ESC] P [CR] [LF]

Note: The automatic data output option

should not be used.

Generic Interface

The data field should con-

sist of 9 numeric characters

(0 through 9, +, - and space)

terminated with a carriage

return (CR). Leading zeros may be blanked as

spaces and are counted. Non-numeric charac-

ters are ignored and will reset the input buffer if

the data field has not been filled. Any characters

received after filling the data field and before the

carriage return are ignored.

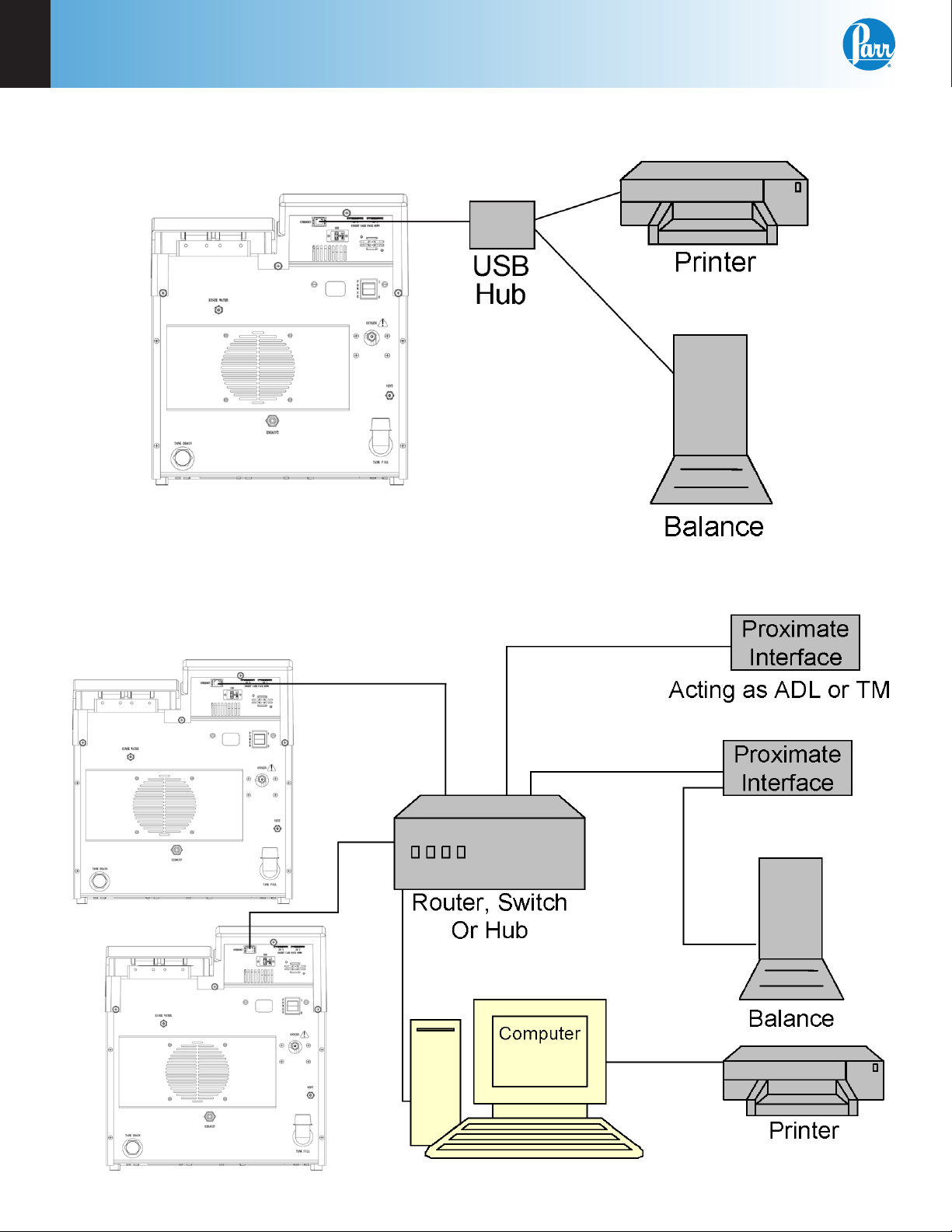

Communication Connections

There is a Universal Serial Buss (USB) port at the

rear of the calorimeter.

The USB port is used to connect to external devices

such as a printer or balance. Multiple devices can be

attached by installing a USB hub.

The 6400 Calorimeter is also equipped with an RJ45

Ethernet port for connection to a computer.

The 6400 will also allow the user to specify the

IP addresses of one or more Balance Interface

devices on the network by selecting the Network

Data Device menu in the Communications Controls

menu. Balance Interface devices are polled from

device 1 to 15 for sample and/or spike weights when

the weight entry mode is set to Network.

Printer Connections

The printer settings are on the Communication

Controls Menu. The default parameters for the 6400

are set up for use with the Parr 1758 Printer.

Balance Connections

The 6400 Calorimeter supports input from multiple

balance types. Additionally, a generic input driver

is provided for communications with balances that

do not conform to the eight supported protocols.

A new feature supported by all balance input driv-

ers is the ability to change the expected number

of characters in the data field. The number of data

characters indicated for each of the drivers, below,

are default values. This feature virtually eliminates

the need for balance input drivers to be re-written

in the event the balance manufacturer elects to alter

the output string of a balance when new models are

introduced.

The format of an unknown balance can be deter-

mined by logging the balance output to the printer

attached to the calorimeter. Those protocols which

send a command string to the balance will do so

while logging is active. In order for the logging to

produce meaningful results, the cable connecting

the balance to the balance input port of the calo-

rimeter must be correctly wired or configured. In

addition, the specifics of the data frame, such as the

baud rate, # of data bits, parity, # of stop bits and

handshaking (if used) must be the same for both the

balance and the calorimeter.

Field Length

ID 2

space 1

data 9

space 1

g 1

CR 1

LF 1

Field Length

polarity 1

space 1

data 8

space 1

stability 2

CR 1

LF 1

Field Length

data 8

CR 1

1

Installation

Parr Instrument Company

14

Figure 1-4

6400 Calorimeter Peripherals

Figure 1-5

Multiple Alternate Configurations

www.parrinst.com

15

Notes

6400

1

2

Quick Start

Parr Instrument Company

16

chaPter 2

Quick Start

Initial Fill

When you first fill the calorimeter with water the

main reservoir will be filled. There is also a cooling

water reservoir that is filled from the main reservoir.

Once the calorimeter has been filled with water and

all external connections made:

1. Turn on the calorimeter.

2. Once at the Main Menu go to the Calorimeter Op-

eration screen and turn ON the heater and pump.

Water should start to circulate in the tubing.

3. Press Escape to get back to the Main Menu. Then

press Diagnostics and then I/O Diagnostics.

4. Use the side arrow keys(< >) until the description

reads H2O Cool.

5. Unlock and remove the vessel head.

6. Press “1” to turn on the H2O Cool. You should

hear a click and then gurgling coming from the

bomb cylinder.

7. Once the gurgling stops turn off the H2O cool by

pressing “O”.

8. Refill the main reservoir through the elbow at

the back of the calorimeter.

The above procedure will only need to be done

when the calorimeter is first filled with water after

receiving it.

Quick Start

1. Turn on the heater and pump in the Calorimeter

Operation menu. Allow at least 20 minutes for

the calorimeter to warm up.

2. Initiate a pretest to run the calorimeter through

the ll and cool/rinse cycles. This function is

used to pre-condition the calorimeter if it has

been sitting idle for an extended period of time

(greater than 15 minutes).

3. Prepare and weigh the sample to 0.0001g.

4. Gently tap capsules that contain powdered

samples to compact the material. (Pellets are

easier to handle than loose samples and they

burn slower in the bomb, thereby reducing the

chances for incomplete combustion).

5. Carefully place the capsule into the capsule

holder, attach 10 cm of ignition thread and install

the bomb head in the calorimeter.

6. Close the calorimeter cover making sure that the

latch is engaged.

7. Select determination or standardization as ap-

propriate on the Calorimeter Operation page, by

toggling the OPERATING MODE key. Press the

START Key. The calorimeter will now prompt the

operator for sample ID number, Bomb ID num-

ber, sample weight and spike weight in accor-

dance with the instructions set into the operating

controls page.

8. The calorimeter will now take over and conduct

the test. During the time it is establishing the ini-

tial equilibrium, it will display PREPERIOD on the

status bar. Just before it res the bomb, it will

sound a series of short beeps to warn the user

to move away from the calorimeter. Once the

bomb has been fired, the status bar will display

POSTPERIOD. The calorimeter will check to make

certain that a temperature rise occurs and will

then look for the final equilibrium conditions to

be met. If it fails to meet either the initial or final

equilibrium conditions, or if it fails to detect a

temperature rise within the allotted time, the test

will terminate and advise the user of the error.

9. At the conclusion of the test, the calorimeter will

signal the user.

10. Open the cover and remove the head. Examine

the interior of the bomb for soot or other evi-

dence of incomplete combustion. If such evi-

dence is found, the test will have to be discarded.

If using the optional A1050DD Rinse Container

Assembly:

1. Titrate the bomb washings with a standard

sodium carbonate solution using methyl orange,

red or purple indicator. A 0.0709N sodium car-

bonate solution is recommended for this titra-

tion to simplify the calculation. This is prepared

by dissolving 3.76 grams of Na

2

CO

3

in the water

and diluting to one liter. NaOH or KOH solutions

of the same normality may be used.

2. Analyze the bomb washings to determine the

sulfur content of the sample if it exceeds 0.1%.

Methods for determining sulfur are discussed in

Analytical Methods for Oxygen Bombs, No. 207M.

www.parrinst.com

17

Notes

6400

2

3

Operation

Parr Instrument Company

18

chaPter 3

Operation

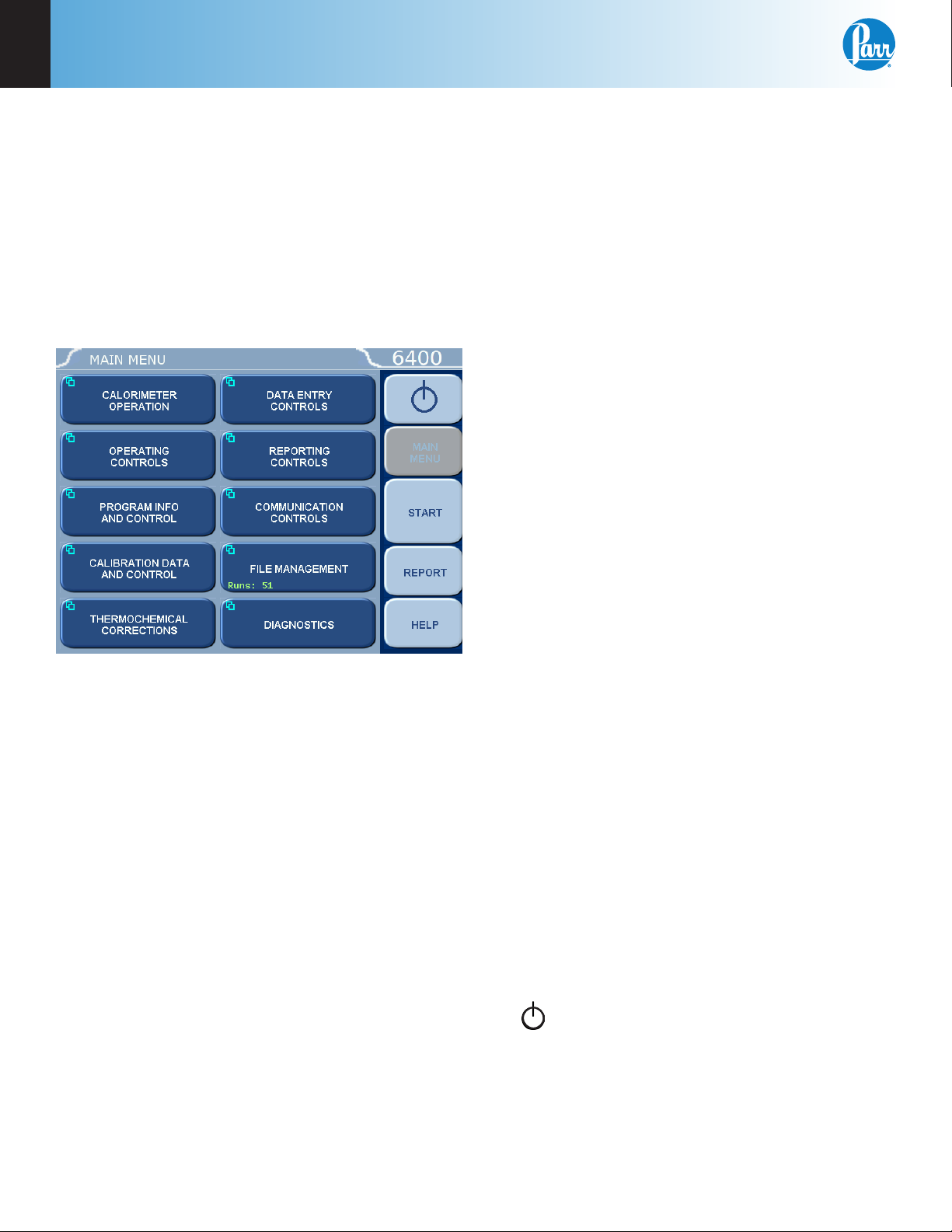

Menu System

All configurations and operations are handled by

a menu-driven system operated from the bright

touch screen display. The settings and controls are

organized into ten main sections as displayed on the

MAIN MENU.

Note: Keys with a “double box” in the upper

left hand corner lead to sub-menus.

Menu Keys

The controls that change the data field information

in the menus will be one of the following:

1. Toggles. These data elds contain ON/OFF or

YES/NO choices. Simply touching the key on the

screen toggles the choice to the other option.

The current setting is displayed in the lower

right corner of the key.

2. Option Selection. These data fields contain a list

of options. Touching the key on the screen steps

the user through the available choices. The cur-

rent setting is displayed in the lower right corner

of the key.

3. Value Entry Fields. These data fields are used to

enter data into the Calorimeter. Touching the key

on the screen brings up a sub-menu with a key

pad or similar screen for entering the required

value. Some keys lead to multiple choices.

Always clear the current value before entering a

new value. Once entered the screen will return

to the previous menu and the new value will be

displayed in the lower right corner of the key.

4. Data Displays. Most of these keys display values

that have been calculated by the calorimeter

and are informational only. Certain ones can be

overridden by the user entering a desired value

through a sub-menu. The value is displayed in

the lower right corner of the key.

Note: Some keys will respond with an op-

portunity for the user to confirm the speci-

fied action to minimize accidental disruptions

to the program and/or stored data.

Control Keys

There are five control keys which always appear

in the right column of the primary displays. These

keys are unavailable when they are gray instead of

white.

1. Escape. This key is used to go up one level in

the menu structure.

2. Main Menu. This key is used to return to the

main menu touch screen from anywhere in the

menu structure.

3. Start. This key is used to start a test.

4. Abort. When a test is running the Start button

changes to Abort. When pressed it will terminate

the current test or pre-test.

5. Report. This key is used to access the test re-

sults stored in the calorimeter, to enter thermo-

chemical corrections, and to initiate a report on

the display or printer.

6. Help. This key is used to access help screens

related to the menu currently displayed on the

touch screen.

7. This key appears in the Escape key loca-

tion when the main menu is displayed. This key

is used to shut down the calorimeter program

before turning off the power.

Operation

6400

3

www.parrinst.com

19

Programming

The program in the 6400 Calorimeter can be exten-

sively modified to tailor the unit to a wide variety

of operating conditions, reporting units, laboratory

techniques, available accessories and communica-

tion modes. In addition, the calculations, thermo-

chemical corrections and reporting modes can be

modified to conform to a number of standard test

methods and procedures. Numerous provisions are

included to permit the use of other reagent concen-

trations, techniques, combustion aids and short cuts

appropriate for the user’s work.

Note: Changes to the program are made

by use of the menu structure. Any of these

items can be individually entered at any time

to revise the operating program.

Default Settings

Units are pre programmed with default settings.

See Table 15-1 for a listing of the factory default

settings. A more in-depth explanation of these pa-

rameters is found on the corresponding parameter

group help pages. These default settings remain

in effect until changed by the user. Should the user

ever wish to return to the factory default settings, go

to the Program Info and Control Menu, User/Factory

Settings, touch Reload Factory Default Settings and

YES. Non-volatile memory is provided to retain any

and all operator initiated program changes; even

if power is interrupted or the unit is turned off. If

the unit experiences an intentional or unintentional

“Cold Restart”, the controller will return to the last

known settings.

The default parameters of the 6400 Calorimeter can

be changed to guarantee that the calorimeter, when

cold restarted, will always be in the desired configu-

ration before beginning a series of tests. Users who

wish to permanently revise their default settings

may do so using the following procedure:

• Establish the operating parameters to be stored

as the user default settings.

• Go to the Program Info and Control Menu, User/

Factory Settings, User Setup ID, and enter the

desired User Setup ID.

• Select Save User Default Settings

To re-load the user default setting, go to the Pro-

gram Info and Control Page, User/Factory Settings,

Re-load User Default Settings, and YES.

Sample Preparation

Sample Size

To stay within safe limits, the bomb should never be

charged with a sample which will release more than

8000 calories when burned in oxygen. The initial

oxygen pressure is set at 30 atmospheres (450 psig).

This generally limits the mass of the combustible

charge (sample plus benzoic acid, gelatin, firing oil

or any combustion aid) to not more than 1.1 grams.

To avoid damage to the bomb and calorimeter,

and possible injury to the operator, it should be

a standing rule in each laboratory that the bomb

must never be charged with more than 1.5 grams of

combustible material.

When starting tests with new or unfamiliar materi-

als, it is always best to use samples of less than 0.7

grams with the possibility of increasing the amount if

preliminary tests indicate no abnormal behavior and

the sample will not exceed the 8000 calorie limit.

Samples containing sulfur should contain no more

than 50 mg of sulfur and liberate at least 5000

calories.

Samples containing chlorine should be spiked to

insure that sample contains no more than 100 mg of

chlorine and liberates at least 5000 calories

Particle Size and Moisture Content

Solid samples burn best in an oxygen bomb when

reduced to 60 mesh, or smaller, and compressed

into a pellet with a 2811 Parr Pellet Press. Large par-

ticles may not burn completely and small particles

are easily swept out of the capsule by turbulent

gases during rapid combustion.

Note: Particle size is important because it

influences the reaction rate. Compression

into a pellet is recommended because the

pressure developed during combustion can

be reduced as much as 40% when compared

to the combustion of the material in the

powder form. In addition to giving controlled

burn rates, the formation of pellets from

sample material keeps the sample in the fuel

capsule during combustion.

Materials, such as coal, burn well in the as-received

or air-dry condition, but do not burn completely dry

samples. A certain amount of moisture is desirable

in order to control the burning rate. Moisture con-

tent up to 20% can be tolerated in many cases, but

the optimum moisture is best determined by trial

3

Operation

Parr Instrument Company

20

combustions. If moisture is to be added to retard

the combustion rate, drop the water directly onto

the loose sample or onto a pellet after the sample

has been weighed. Then let the sample stand to

obtain uniform distribution. Low volatile samples

with high water content, such as urine or blood,

can be burned in an open capsule by absorbing the

liquid on filter paper pulp or by adding a combus-

tion aid, such as ethylene glycol.

Sample Types

Because of the difference in combustion char-

acteristics of the many different materials which

may be burned in an oxygen bomb, it is difficult to

give specific directions which will assure complete

combustions for all samples.

The following fundamental conditions should be

considered when burning samples:

• Some part of the sample must be heated to its

ignition temperature to start the combustion

and, in burning, it must liberate sufficient heat

to support its own combustion regardless of the

chilling effect of the adjacent metal parts.

• The combustion must produce sufficient tur-

bulence within the bomb to bring oxygen into

the fuel cup for burning the last traces of the

sample.

• A loose or powdery condition of the sample

which will permit unburned particles to be

ejected during a violent combustion.

• The use of a sample which contains coarse par-

ticles will not burn readily. Coal particles which

are too large to pass a 60 mesh screen may not

burn completely.

• The use of a sample pellet which has been made

too hard or too soft can cause spalling and the

ejection of unburned fragments.

• The bottom of the cup should always be at least

one-half inch above the bottom of the bomb or

above the liquid level in the bomb to prevent

thermal quenching.

• If the moisture, ash and other non combustible

material in the sample totals approximately 20%

or more of the charge, it may be difficult to obtain

complete combustion. This condition can be rem-

edied by adding a small amount of benzoic acid or

other combustion aid.

Foodstuffs and Cellulosic Materials

Fibrous and fluffy materials generally require one of

three modes for controlling the burn rate. Fibrous

materials do not pelletize readily and generally

require either moisture content or a combustion aid

such as mineral oil to retard the burn rate and avoid

development of high pressures. Partial drying may

be necessary if the moisture content is too high to

obtain ignition, but if the sample is heat sensitive

and cannot be dried, a water soluble combustion aid

such as ethylene glycol can be added to promote

ignition. Material such as Napthalene should not be

burned in loose powder form but should be formed

into a pellet.

Coarse Samples

In most cases it may be necessary to burn coarse

samples without size reduction since grinding or

drying may introduce unwanted changes. There

is no objection to this if the coarse sample will

ignite and burn completely. Whole wheat grains

and coarse charcoal chunks are typical of materials

which will burn satisfactorily without grinding and

without additives or a special procedure.

Corrosive Samples

The 1138 bomb is made from alloy 20; a special

niobium stabilized stainless steel selected for its

resistance to the mixed nitric and sulfuric acids pro-

duced during the combustion process. The 1138CL

is made from the halogen resistant Hastelloy G30™.

Hastelloy 30™ is an alloy rich in cobalt and molyb-

denum and is able to resist the corrosive effects

of free chlorine and halogen acids produced when

burning samples with significant chlorine content.

While no alloy will completely resist the corrosive

atmospheres produced when burning samples

containing halogen compounds; users who intend

to test these materials are urged to select the 1138CL

Bomb. These bombs are 250 mL in volume and are

rated to a maximum working pressure of 2000 psi.

The bombs are hydrostatically tested to 3000 psi

and the sample range is ~1g or 5000 – 8000 calories.

Explosives and High Energy Fuels

Materials which release large volumes of gas

which detonate with explosive force or burn with

unusually high energy levels, should not be tested

in this calorimeter. Rather, they should be tested

in a model 6100 or 6200 Calorimeter which can be

equipped with an 1104 High Strength Oxygen Bomb

designed specifically for these types of samples.

Operation

6400

3

www.parrinst.com

21

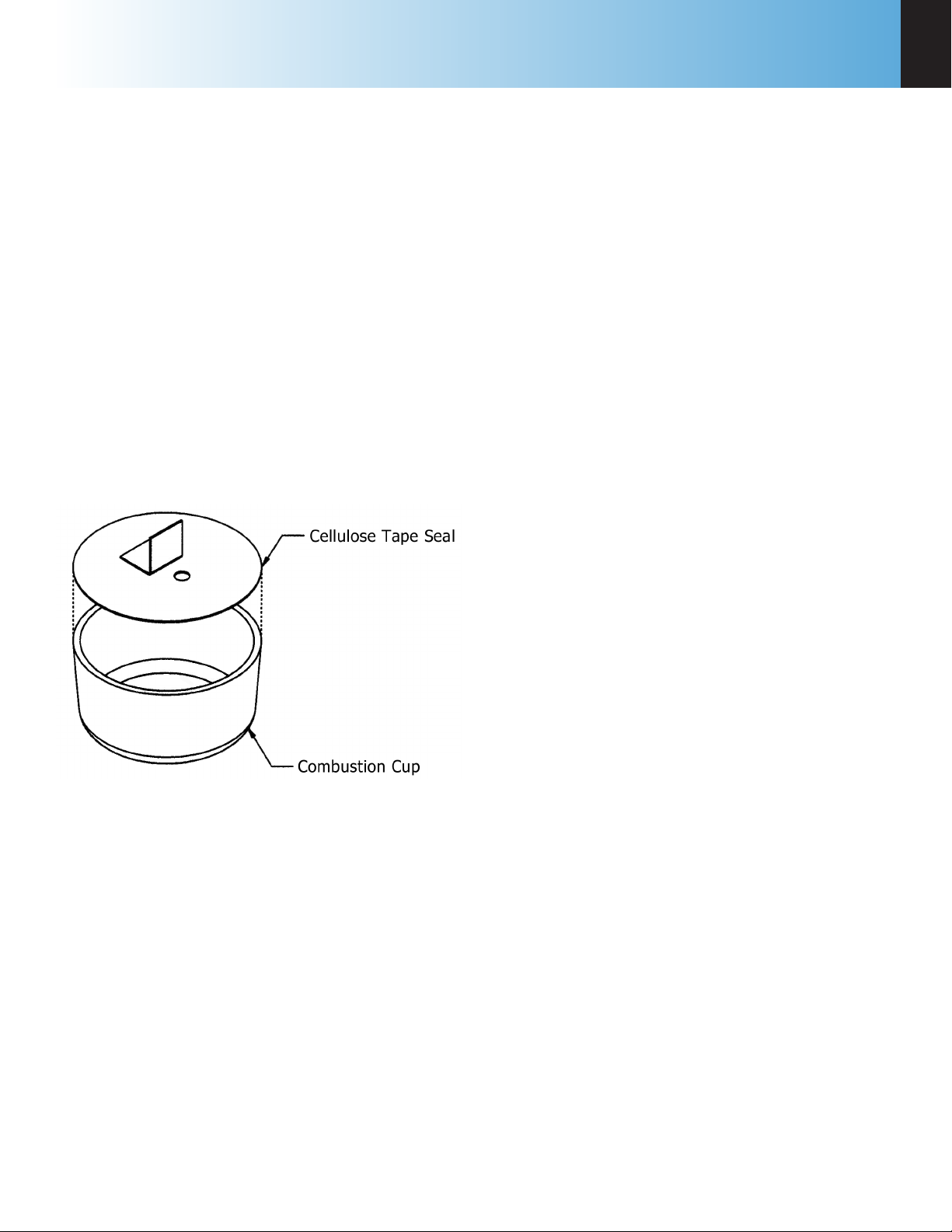

Volatile Sample Holders

Volatile samples are defined as one with an initial

boiling point below 180 ºC. Volatile samples can be

handled in a Parr 43AS Alloy Capsule which has a

sturdy wall with a flat top rim. These holders can be

sealed with a disc of plastic adhesive tape prepared

by stretching tape across the top of the cup and

trimming the excess with a sharp knife. The seal

obtained after pressing this disc firmly against the

rim of the cup with a flat blade will be adequate

for most volatile samples. The tape used for this

purpose should be free of chlorine and as low in

sulfur as possible. Borden Mystic Tape, No. M-169-C

or 3M Transparent Tape, No. 610, are recommended

for this purpose. The 3M Transparent Tape can be

ordered through Parr, Part No. 517A.

Figure 3-1

Volatile Sample Technique

The weight of the tape disc must be determined

separately and a correction applied for any elements

in the tape which might interfere with the determi-

nation. The approximate Heat of Combustion of

the tape is 6300 cal/g. An actual amount should be

determined by running a blank test with tape alone

using a sample weighing 1.0 gram. The compensa-

tion for heat of tape may be done through the spike

option; see Spike Controls, Heat of Combustion of

Spike.

Note: Tape should always be stored in a

sealed container to minimize changes in its

moisture and solvent content.

Use the following procedure when filling and han-

dling any of these tape-sealed sample holders:

1. Weigh the empty cup or capsule; then cover the

top with tape, trim with a knife and press the

trimmed edge firmly against the metal rim. Also

cut and attach a small flag to the disc (see Figure

3-1).

2. Puncture the tape at a point below the flag, then

re-weigh the empty cup with its tape cover.

3. Add the sample with a hypodermic syringe;

close the opening with the flag and re-weigh the

filled cup.

4. Set the cup in the capsule holder and arrange

the auxiliary fuse so that it touches the center of

the tape disc.

5. Just before starting the test, prick the disc with

a sharp needle to make a small opening which

is needed to prevent collapse of the disc when

pressure is applied.

6. Fill the bomb with the usual oxygen charging

pressure.

7. The calorimeter will fire the bomb and complete

the test in the usual manner.

Combustion Aids

Some samples may be difficult to ignite or they may

burn so slowly that the particles become chilled

below the ignition point before complete combus-

tion is obtained. In such cases white oil or other

suitable material of known purity can be mixed with

the sample. Ethylene glycol, butyl alcohol or decalin

may be used for this purpose.

Note: It must be remembered, that a com-

bustion aid adds to the total energy released

in the bomb and the amount of sample may

have to be reduced to compensate for the

added charge.

When benzoic acid is combusted for standardization

runs, it should be in the form of a pellet to avoid

possible damage to the bomb which might result

from rapid combustion of the loose powder.

3

Operation

Parr Instrument Company

22

Combustion Capsules

Non-volatile samples to be tested in Parr oxygen

bombs are weighed and burned in shallow capsules

measuring approximately 1” diameter and 7/16”

deep. These are available in stainless steel, fused

silica, fused quartz, and platinum alloyed with

3-1/2% rhodium.

Stainless steel capsules (43AS) are furnished with

each calorimeter. The stainless steel capsules will

acquire a dull gray finish after repeated use in an

oxygen bomb due to the formation of a hard, protec-

tive oxide film. This dull finish not only protects the

capsule, but it also promotes combustion and makes

it easier to burn the last traces of the sample. New

capsules are heated in a muffle furnace at 500 ºC for

24 hours to develop this protective coating uniform-

ly on all surfaces. This treatment should be repeated

after a capsule has been polished with an abrasive to

remove any ash or other surface deposits. Heating in

a muffle is also a good way to destroy any traces of

carbon or combustible matter which might remain

in the capsule from a previous test. Capsules should

be monitored for wear. Do not use the capsule if the

wall or base thickness is less than 0.025”.

Note: After heating, place the capsules in

a clean container and handle them only

with forceps when they are removed to be

weighed on an analytical balance.

When combusting samples that contain metal

particles such as aluminum or magnesium, the non-

metallic 43A3 Fused Silica or 43A3KQ Fused Quartz

Capsule is required.

When superior corrosion resistance is needed, the

43A5 Platinum Rhodium Capsule or 43A3KQ Fused

Quartz is required.

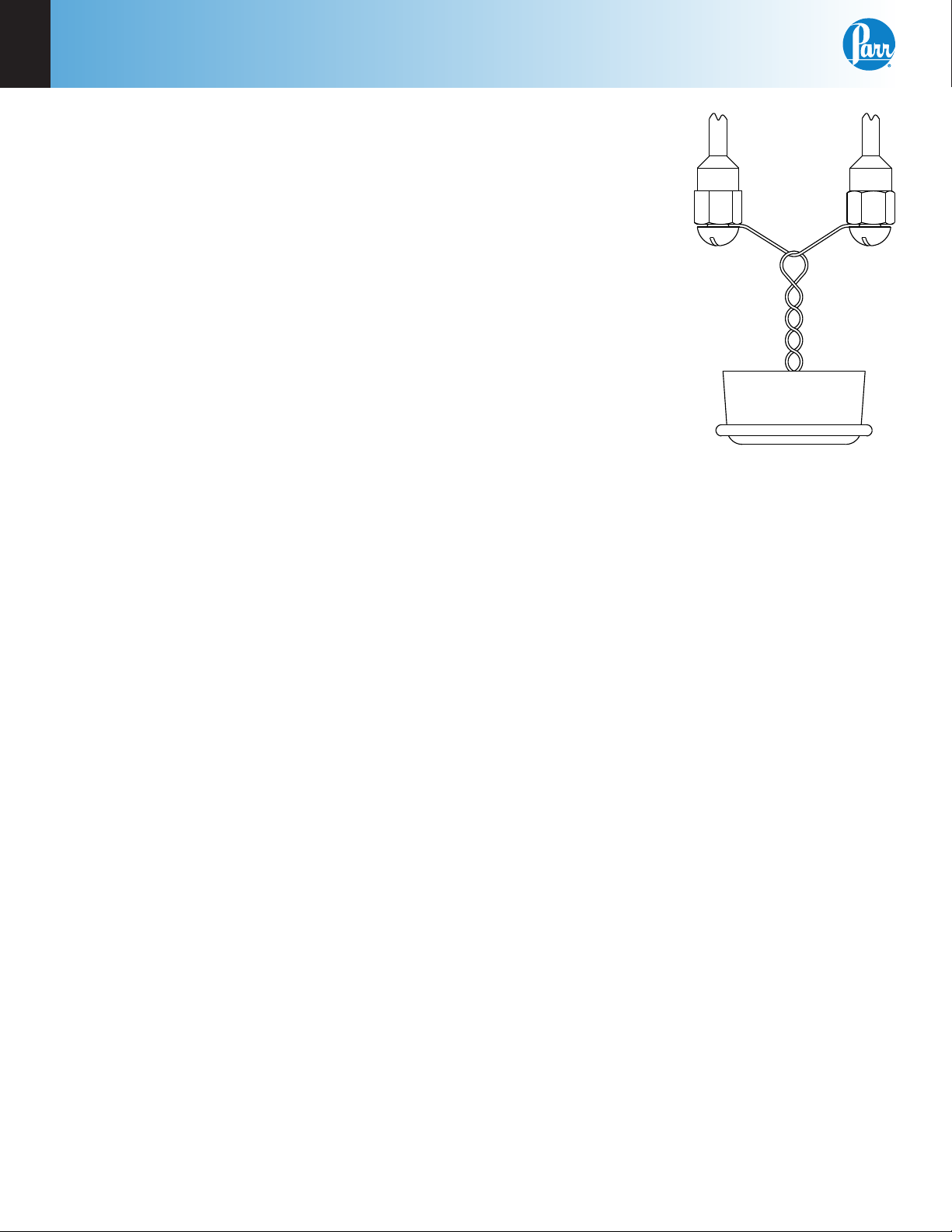

Test Process

Loading the sample

Prepare and weigh the sample to 0.0001g. Gently

tap capsules that contain powdered samples to

compact the material. (Pellets are easier to handle

than loose samples and they burn slower in the

bomb, thereby reducing the chances for incomplete

combustion).

Carefully place the

capsule into the capsule

holder. A cotton thread

(845DD2) is used as an

auxiliary fuse to ignite

the sample. Remove any

moisture from the heat-

ing wire prior to attach-

ing the cotton thread.

Four inches (10 cm) of

thread is recommended

for this auxiliary thread

which is looped over the

heating wire, doubled

on itself, twisted to form

a single strand and fed

into the sample cup to

lay on the sample. When

contact is made through

the heating wire, the

thread will ignite, drop into the sample cup and

ignite the sample. One spool of thread, part number

845DD, is 563 yards. Part number 845DD2 contains

approximately 1000 pieces of thread pre-cut to 4

inches (10 cm).

Closing the bomb

Care must be taken not to disturb the sample when

moving the bomb head from the support stand to

the bomb cylinder in the calorimeter. Check the

sealing ring to be sure that it is in good condition

and moisten it with a bit of water so that it will slide

freely into the cylinder.

Notice that the bomb head grounding lug extends

beyond the outside diameter of the bomb head. A

slot for this lug is cut into the top of the calorimeter

bucket which holds the bomb cylinder. Position

this lug approximately 20 degrees to the operators

right and slide the head into the cylinder and push it

down as far as it will go. Now rotate the bomb head

20 degrees to the left until the lug contacts the left

edge of the cut out and is pointed to the front of the

calorimeter.

Figure 3-2

Cotton Thread Assembly

Operation

6400

3

www.parrinst.com

23

Fill Cycle

Once the calorimeter is started and the cover is closed, the fill sequence begins.

Figure 3-3

Bucket Fill Flow Diagram

1. The calorimeter checks the bomb ignition circuitry for continuity.

2. The water fill solenoid opens and water is pumped from the internal tank into and through the bucket that

surrounds the bomb. Overflow from the bucket is returned to the closed water tank. Because the jacket and

bucket are both filled with water from the closed water tank, initial equilibrium will be reached quickly.

3. The oxygen fill solenoid is opened and oxygen is added slowly to the bomb to bring its pressure to

approximately 30 atm.

3

Operation

Parr Instrument Company

24

Pre-Period

At the completion of the fill sequence, the pre-period begins.

Figure 3-4

Pre-Period/Post-Period Flow Diagram

1. The water fill solenoid valve closes and isolates the water in the bucket from the rest of the system.

Water within this bucket is circulated by the stirrer. Water continues to circulate from the closed water

system through the jacket surrounding the bucket.

2. The oxygen filling valve closes and the pressure in the filling line is vented. The automatic check valve at

the top of the bomb closes and isolates the bomb from the oxygen filling line.

3. The controller monitors the operating temperature until it confirms that the initial equilibrium has been

established.

Operation

6400

3

www.parrinst.com

25

Bomb Firing

Once the initial equilibrium is confirmed, the con-

troller initiates the firing sequence. There are no

changes to the circulation pattern, as shown in

Figure 3-4, from the pre-period through the bomb

firing and post-period. A warning of short beeps is

sounded indicating the bomb is about to be fired.

Post-Period

A minimal temperature rise will confirm that the

sample has ignited. After this verification, the post-

period begins. See Figure 3-4.

1. The controller monitors the temperature rise

and determines the final temperature rise by

either the dynamic or equilibrium criteria as

established by the user.

2. Once the final temperature rise is determined,

it is recorded with the test results.

3

Operation

Parr Instrument Company

26

Cool/Rinse

At the completion of the post-period, the rinse and cool sequence begins.

Figure 3-5

Rinse & Cool Flow Diagram

1. Chilled water is circu-

lated through the bucket

to cool the bomb to the

starting temperature.

2. The release valve in the

bottom of the bomb is

opened and the residual

pressure is released

through the bomb ex-

haust line.

3. Once the excess oxygen

is vented, the bomb rinse

water from the rinse

water tank is admitted

through the bomb rinse

solenoid valve and the

check valve at the top

of the bomb. The bomb

rinse water is released to

the wash bottle.

Note: Several rinse

patterns may be con-

figured by the user to

meet various opera-

tional and analytical

requirements.

4. The bomb is filled one

more time with oxygen

to help flush

the water

residue

from the

interior of

the bomb.

Operation

6400

3

www.parrinst.com

27

Drain

At the completion of the bomb rinse sequence, the drain sequence begins.

Figure 3-6

Drain Flow Diagram

The water in the bucket is drained out of the bucket and routed to the drain connection. Once the bucket is

drained, the calorimeter may be opened to remove the bomb head and load the next sample.

4

Menu Descriptions

Parr Instrument Company

28

chaPter 4

Menu Descriptions

Note: Keys which make global changes to

the setup of the calorimeter contain a YES or

NO response to make certain that the user

wishes to proceed. This two step entry is

intended to prevent inadvertent global pro-

gram changes.

Main Menu

System Shutdown: This key appears in the

ESCAPE key location when the Main Menu is dis-

played. Pressing this button will prompt the user to

confirm a system shutdown.

Escape Key: Selecting the Escape key on any menu

will return you to the menu one level up.

Main Menu Key: Selecting the Main Menu key on

any menu will return you to the screen pictured on

the right of this page.

Start Key: Press the Start key to begin any Determi-

nation or Standardization run.

Report: Press the Report key to begin the reporting

process.

Help: Press the Help key on any screen to display

the explanation text for that screen.

Abort: This key appears in the Start key location

while a test or pretest is running. Pressing this key

will abort the test or pretest in progress.

Calorimeter Operation Menu

The Calorimeter will normally be operated from the

Calorimeter Operation Menu, although tests can

always be started from any menu screen.

Operating Mode: Sets the operating mode by

toggling between Standardization (for instrument

calibration) and Determination (for test runs).

Temperature Graph: Press this key to display a real-

time plot of the bucket and/or jacket temperature on

the Temperature vs. Time Plot screen.

Bomb/EE: Used to identify the bomb presently

installed in the Calorimeter and its EE value.

Start Preweigh: This key is used to start the sample

pre-weigh process. The user is presented with or

prompted for a sample ID. Next, the user is asked to

key in the associated sample mass or alternatively

the mass is retrieved from a connected balance or

network.

Heater and Pump: The heater and pump must only

be turned on after the calorimeter water tank is filled

with water.

Note: The heater and pump must be turned

ON to bring the jacket to the correct starting

temperature before testing can commence.

Start Pretest: This key is used to initiate a pretest

cycle. A pretest will cycle the calorimeter through

the ll and cool/rinse process. This function is used

to pre-condition the calorimeter.

Loading...

Loading...