Parkside PKGA 40-Li A1 Translation Of The Original Instructions

CORDLESS MULTI-TOOL PKGA 40-Li A1

CORDLESS MULTI-TOOL

Translation of the original instructions

IAN 313870

AKKU-KOMBIGERÄT

Originalbetriebsanleitung

Before reading, unfold the page containing the illustrations and familiarise yourself with all functions

of the device.

Klappen Sie vor dem Lesen die Seite mit den Abbildungen aus und machen Sie sich anschließend mit

allen Funktionen des Gerätes vertraut.

IE / NI Translation of the original instructions Page 5

DE / AT / CH Originalbetriebsanleitung Seite 34

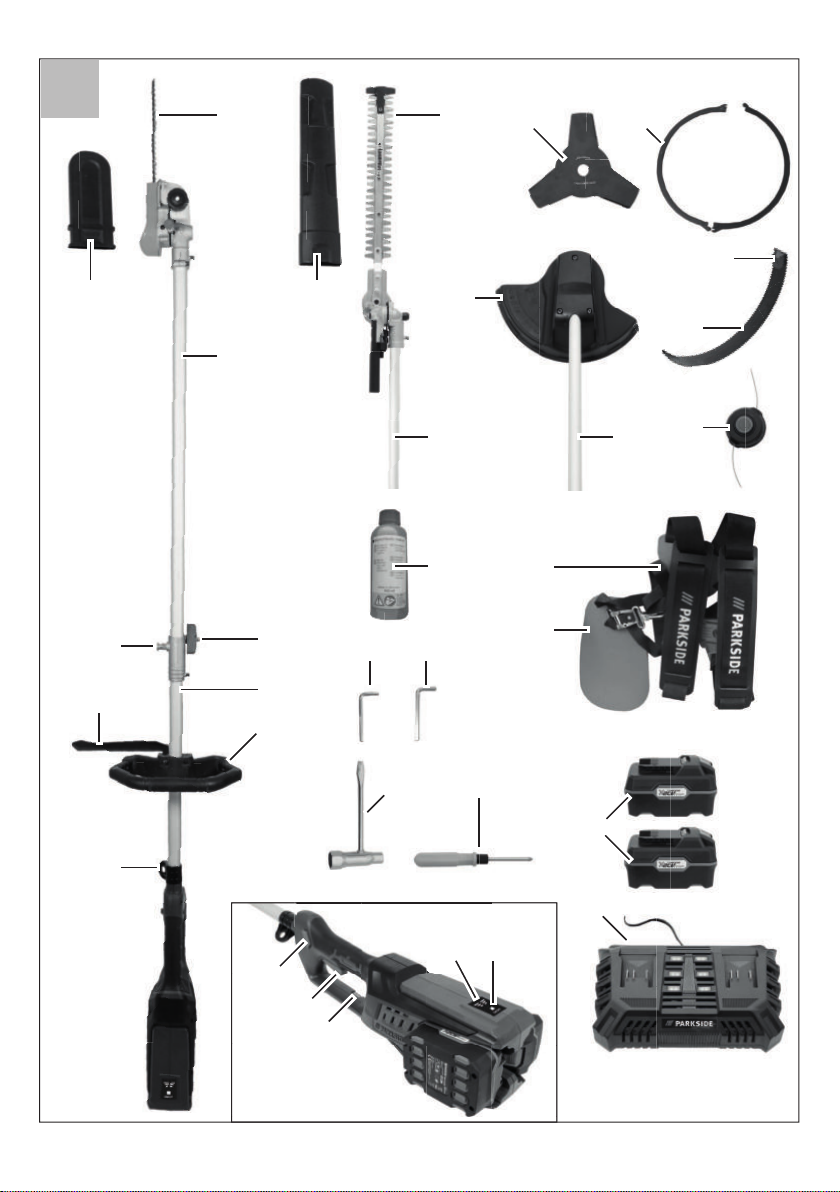

A

1 11 12 13

15

9 10

2

8

7

6

3

4

5

21 22

23 24

2

18

14

19

20

25

16

17

2

29

30

31

27

26

28

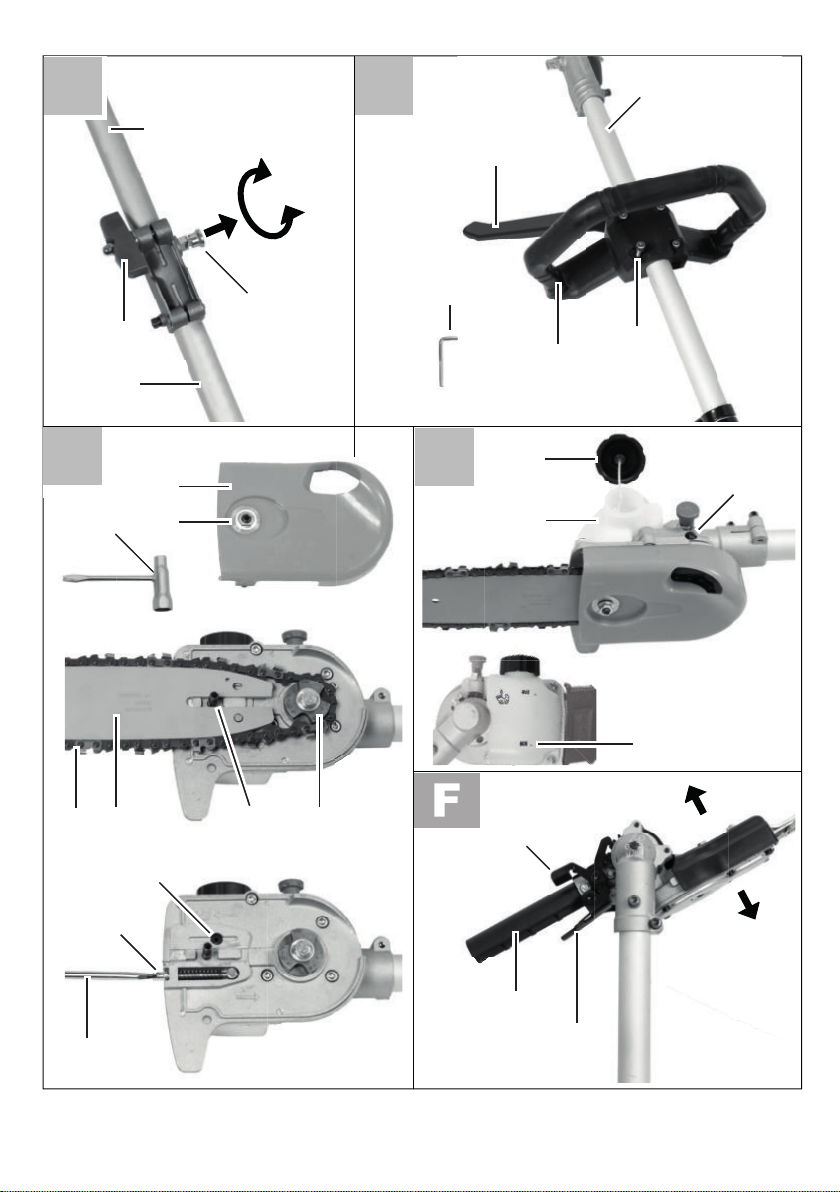

3

D

B

C

4

23

2

8

3

4

E

33

34

21

7

5

41

39

32

42

12335 36

62

38

4

37

40

45

43

44

Content

NIIE

Introduction .................................6

Intended Use ................................6

General Description ......................6

Extent of delivery .............................6

Overview ........................................7

Safety features ................................. 8

Function Description .........................8

Technical Data ..............................8

Notes on Safety ...........................9

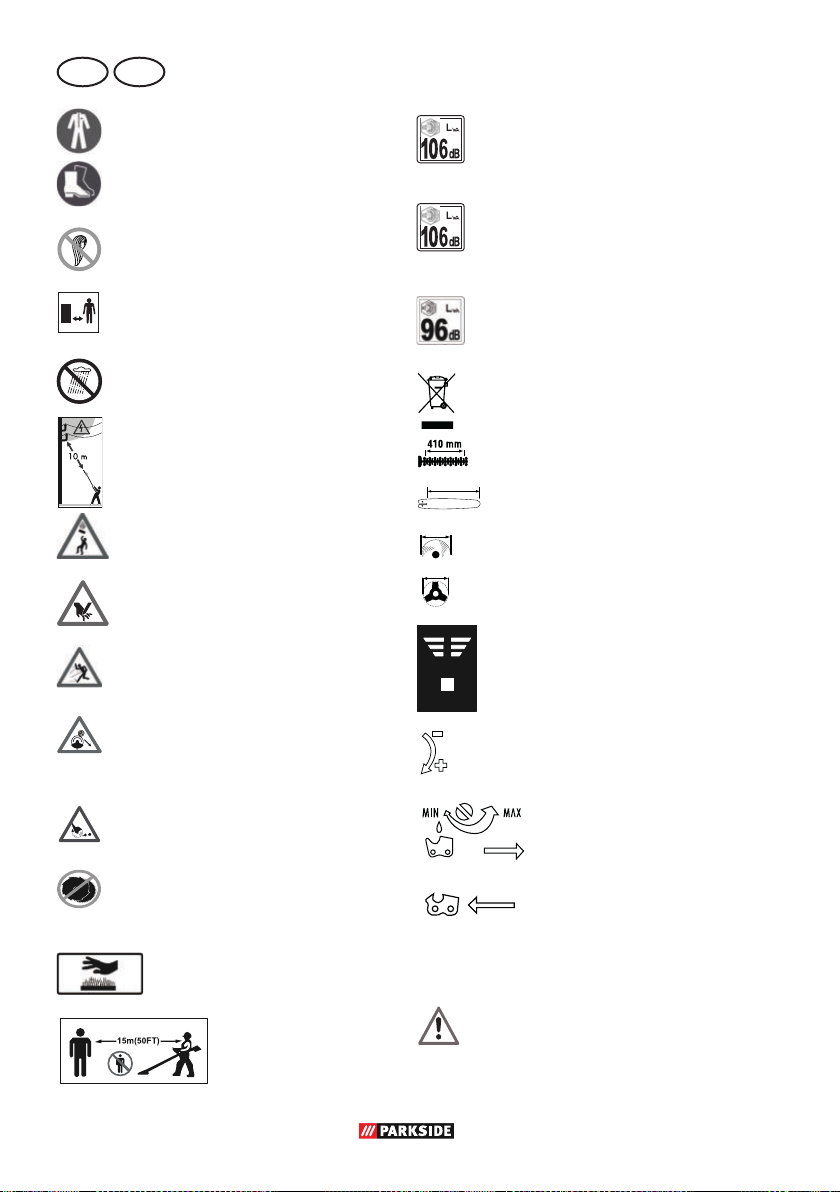

Symbols in the manual ...................... 9

Symbols on the Equipment ................9

General Notes on Safety .................10

General safety instructions

for power tools ..............................11

Hedge trimmer safety warnings .......13

Safety information for chainsaws .....14

Kickback causes and how to avoid

them with pole-mounted pruners ....... 15

Safety information for lawn

and lawn edge trimmers .................16

Brush cutter - kickback causes

and how to avoid them

with a 3-tooth blade ....................... 17

Additional safety instructions ...........17

Assembly ...................................18

Remove/insert battery ....................18

Mounting the tubular shaft ............... 18

Mounting the round handle .............18

Mounting the saw chain ..................19

Mounting the protective cover .......... 19

Removing/mounting the

protective cover extension ...............19

Initial Operation .........................20

Chain lubrication ...........................20

Swivelling Out the Blade Beam ........ 20

Pivoting the pole-mounted pruner .....21

Putting on the carrying harness ........ 21

Sliding the carrying eye ..................21

Assemble the 3-tooth blade .............22

Mount the spool ............................. 22

Extend the thread ........................... 22

Switching on and off ......................23

Working with the hedge trimmer ......23

Working with the

pole-mounted pruner.......................23

Working using the thread spool ....... 24

Working with the 3-tooth blade ........24

Putting down the device .................. 24

Cutting techniques using

the hedge trimmer .......................... 25

Cutting techniques using

the pole-mounted pruner .................25

Working Safely ..........................26

Maintenance/Cleaning ...............26

Cleaning ....................................... 27

Service intervals............................. 27

Service intervals table ..................... 27

Sharpening the cutting teeth ............27

Servicing the blade bar ..................28

Turning the blade bar .....................28

Replacing the spool ........................ 28

Sharpen the line cutter .................... 29

Winding up the spool ..................... 29

Lubricating the gears ......................29

Storage ......................................29

Transport ...................................30

Waste Disposal and

Environmental Protection ...........30

Guarantee .................................30

Repair Service ............................31

Service-Center ............................31

Importer ....................................31

Spare Parts/Accessories .............32

Trouble Shooting ........................33

Translation of the original

EC declaration of conformity ......66

Exploded Drawing ..................... 68

5

IE NI

Introduction

Congratulations on the purchase of your

new device. With it, you have chosen a

high quality product.

During production, this equipment has been

checked for quality and subjected to a nal

inspection. The functionality of your equipment is therefore guaranteed. It cannot be

ruled out that residual quantities of lubricants will remain on or in the equipment in

isolated cases. This is not a fault or defect

and it represents no cause for concern.

The operating instructions constitute

part of this product. They contain

important information on safety, use and

disposal.

Before using the product, familiarise yourself with all of the operating and safety

instructions. Use the product only as de-

scribed and for the applications specied.

Keep this manual safely and in the event

that the product is passed on, hand over

all documents to the third party.

Intended Use

With the hedge trimmer attachment, this

device is intended for cutting and trimming

hedges, bushes and ornamental shrubs.

The pole-mounted pruner attachment is

intended for trimming large branches

and limbs. The trimmer and 3-tooth blade

attachment is intended for cutting grass

in the garden, along ower beds, around

trees or fence posts, and light undergrowth. The device is intended for use in

residential applications.

This device is not intended for commercial

use. Any other use that is not expressly

permitted in these instructions may result in

damage to the device and pose a serious

hazard to the user.

The equipment is designed for use by

adults. Adolescents over the age of 16

may use the device only under supervision. Local regulations may specify an age

limit for the user. Do not use the device in

the rain.

The operator or user is responsible for accidents or damage to other people or their

property.

The manufacturer is not liable for damages

caused by unspecied use or incorrect

operation.

General Description

The illustration of the principal

functioning parts can be found

on the front and back foldout

pages.

Extent of delivery

- Motor unit

- Hedge trimmer attachment with protective cover

- Pole-mounted pruner attachment with

protective cover

- Trimmer attachment with spool and

3-tooth blade

- Carrying harness

- Round handle

- 2 x hexagon socket wrench (AF 4 mm,

AF 5 mm)

- Mounting key (AF 10 mm, AF 19 mm)

- Phillips screwdriver

- Oil bottle

- Assembly materials

- Operating instructions

6

NIIE

A

C

Overview

1 Saw chain

2 Front tubular shaft

3 Buttery screw

4 Tubular shaft on the appliance

housing

5 Round handle, front handgrip

6 Carrying eye

7 Leg protection

8 Lock, tubular shaft

9 Transport protection cap, saw

chain

10 Transport protection cap, cutter

bar

11 Cutter bar

12 3-tooth blade

13 Transport protection, 3-tooth bla-

de

14 Protective cover

15 Thread cutter

16 Extension, protective cover

17 Spool cap

18 Saw chain oil

19 Carrying harness

20 Body protection

21 Hexagon socket wrench

(AF 4 mm)

22 Hexagon socket wrench

(AF 5 mm)

23 Mounting key

(AF 10 mm, AF 19 mm)

24 Phillips screwdriver

25 Rechargeable battery

26 Charger

27 Battery charge level indicator

28 On/off switch

29 Safety switch

30 Start switch

31 Hexagon socket wrench storage

33 Chain wheel cover

34 Nut, chain wheel cover

35 Blade bar

36 Chain sprocket

37 Bar bolt

38 Chain tensioning screw

39 Oil tank

40 “MIN” marking,

oil level indicator

41 Oil tank cover

42 Adjusting screw, oil feed

43 Handle, cutter bar adjustment

44 Safety lever, cutter bar

45 Lock lever, cutter bar

46 Lock, pole-mounted pruner

47 Lug, quick-release device

48 Screw, carrying eye

49 Phillips screwdriver,

protective cover

50 Cover, protective cover

51 Screws, cover

52 Mounting spindle

53 Washer

54 Conical spring washer

55 Nut

56 Extension, protective cover

57 Click lock

58 Spool

59 Thread outlet eye

60 Notch, spool

61 Groove, spool

32 Hexagon socket screw, round

handle assembly

62 Oil passage

7

IE NI

A

63 Lubrication nipple, pole-mounted

pruner

64 Lubrication nipple, hedge trim-

mer

65 Screw, gear lubrication

Safety features

29 Safety switch

The switch lock must be unlocked

in order to switch on the device.

30 Start switch

The device switches off immedia-

tely once the start switch is released.

19 Carrying harness

Ensures the load is evenly spread

across the shoulders, back, hips

and thighs.

Function Description

The device is powered by an electric

motor. The device is equipped with a

hedge trimming attachment (with safety

cutter bars), a pole-mounted pruning

attachment (with blade and saw chain)

and a lawn trimming attachment (with

thread spool or 3-tooth blade). The device

can only be operated whilst the safety

switch is pressed to protect the user.

Please refer to the descriptions below for

information on how the operating elements

work.

Technical Data

4 in 1 Cordless

combination tool ................PKGA 40-Li A1

Motor voltage U ......................... 40 V

Motor idle speed n

Protection type.................................IPX0

Weight (operationally ready)

Pole-mounted pruner ............ ca. 4.6 kg

Hedge trimmer .................... ca. 5.0 kg

Trimmer .............................. ca. 4.4 kg

Brush cutter ......................... ca. 4.5 kg

Hedge trimmer

Cutting length ......................... 410 m m

Max. recommended

branch thickness .......................15 mm

Idle speed n

Cuts/min ....................................240 0

Vibration on handgrip

(a

) ..............3.649 m/s2; K= 1.5 m/s

h

Vibration on round handle

(a

) .............. 4 .676 m/s2; K= 1.5 m/s

h

Sound pressure level

(L

) ................ 86.3 dB(A); KpA= 3 dB

pA

Sound power level (L

measured 100.9 dB(A), K

guaranteed ...................... 106 dB(A)

Pole-mounted pruner

Blade ............Oregon 8" 080SDEA318

Chain .................. Oregon 8" 91P033X

Chain speed v

Oil tank volume ........ 120 cm

Vibration on handgrip

(a

) ..............3.649 m/s2; K= 1.5 m/s

h

Vibration on round handle

(a

) .............. 4 .676 m/s2; K= 1.5 m/s

h

Sound pressure level

(L

) ................. 87.1 dB(A); KpA= 3 dB

pA

Sound power level (L

measured .101,5 dB(A), K

guaranteed ...................... 106 dB(A)

.................7500 rpm

0

........................1200 rpm

0

)

WA

.........................10 m/s

0

WA

)

= 1.97 dB

WA

3

/ 120 ml

= 2,38 dB

WA

2

2

2

2

8

NIIE

Trimmer

Cutting diameter,

spool ........................ 30 cm / 300 mm

String thickness .................1.8 - 2.0 mm

String length ................................. 5 m

Speed, spool n .................... 7000 rpm

Max. speed, spool n

........13300 rpm

max

Vibration on handgrip

(a

) ..............3,649 m/s2; K= 1,5 m/s

h

Vibration on round handle

(a

) ..............4,676 m/s2; K= 1,5 m/s

h

Sound pressure level

(L

) ................ 86,3 dB(A); KpA= 3 dB

pA

Sound power level (L

measured .. 93,7 dB(A), K

WA

)

= 2,62 dB

WA

guaranteed ........................ 96 dB(A)

Brush cutter

Cutting diameter, 3-tooth blade ...25 cm

Speed, blade n .................... 7300 rpm

Max. speed, blade n

...... 10000 rpm

max

Vibration on handgrip

(a

) ..............3,649 m/s2; K= 1,5 m/s

h

Vibration on round handle

(a

) ..............4,676 m/s2; K= 1,5 m/s

h

Sound pressure level

(L

) ................ 86,3 dB(A); KpA= 3 dB

pA

Sound power level (L

measured .. 93,7 dB(A), K

WA

)

= 2,62 dB

WA

guaranteed ........................ 96 dB(A)

tool from the stated value depending on the

manner in which the power tool is used.

Safety precautions aimed at protecting

the user should be based on estimated

exposure under actual usage conditions

(all parts of the operating cycle are to be

considered, including, for example, times

during which the power tool is turned off

2

and times when the tool is turned on but is

running idle).

2

Notes on Safety

This section describes the basic safety

rules when working with the device.

Symbols in the manual

Warning symbols with infor-

mation on damage and injury

2

2

prevention.

Instruction symbols with information

on preventing damage.

Wear cut-resistant gloves.

Help symbols with information on

improving tool handling.

Noise and vibration values have been determined according to the standards and

regulations mentioned in the declaration of

conformity.

The stated vibration emission value was

measured in accordance with a standard

testing procedure and may be used to

compare one power tool to another.

The stated vibration emission value may

also be used for a preliminary exposure

assessment.

Warning: The vibration emission value

may differ during actual use of the power

Symbols on the Equipment

Caution!

Read through the instruction manual

carefully.

Wear safety goggles!

Wear hearing protection!

Wear a safety helmet!

Wear cut-resistant gloves.

9

IE NI

8 " / 195 mm

30 cm

25 cm

Wear cut-resistant work clothing.

Wear anti-slip safety shoes.

Do not leave long hair uncovered.

Keep hair away from moving parts.

Keep the equipment away from

nearby people.

Do not use the device in the rain or

on wet hedges.

Danger of death by electrocution!

Keep at least 10m away from

power lines.

Caution! Falling objects. Particu-

larly when cutting overhead.

Caution! Risk of injury from blades

in operation.

Danger due to ejected parts! Keep

other people away.

Attention! Kickback - be aware that

you may experience kickback while

working with the machine.

Information of the acoustic power

level L

WA

in dB.

(hedge trimmer attachment)

Information of the acoustic power

level L

WA

in dB.

(pole-mounted pruner attachment)

Information of the acoustic power

level L

WA

in dB.

(Trimmer and 3-tooth blade)

Machines are not to be place with

domestic waste.

Cutting length

Blade bar length

Cutting diameter (spool)

Cutting diameter (3-tooth blade)

Battery charge level indicator

ON/OFF

On/off switch

Direction of rotation, nut, chain

wheel cover

Danger due to ejected parts! Keep

other people away.

Do not use any circular- or multi-

toothed saw blades.

Risk of injury!

Caution! Hot surface.

Risk of burns.

Maintain a safe distance of at least 15 m

from other people.

10

Chain lubrication

Direction of rotation,

screw

Direction of travel,

saw chain

General Notes on Safety

Before working with the equipment,

familiarise yourself with all operating components. Practice handling the equipment and have the

NIIE

function, operation and working

methods explained to you by an experienced user or specialist. Ensure

that you can shut off the equipment

immediately in an emergency. Inappropriate use of the device may

result in serious injury.

In the case of an accident or malfunction

during operation, the device must be

switched off immediately and the battery

removed. Treat injuries appropriately or

consult a doctor. For the correction of

faults, read the “Troubleshooting” chapter

or contact our service centre.

RESIDUAL RISKS

Even if properly operating and handling

this electric tool, some residual risks will

remain. Due to its construction and build,

this electric tool may present the following

hazards:

a) Cuts

b) Ear damage if working without ear

protection.

c) Damage to your health caused by

swinging your hands and arms when

operating the appliance for longer periods of time or if the unit is not held or

maintained properly.

General safety instructions

for power tools

WARNING! Read all safety

directions and instructions.

Omissions in the compliance with

safety directions and instructions

can cause electrical shock, re

and/or severe injuries.

Retain all safety directions and instructions for future use.

The term “Power Tools” used in the safety

instructions refers to mains-operated power

tools (with power cord) and to battery-operated power tools (without power cord).

1) Work area safety

a) Keep work area clean and well

lit. Cluttered or dark areas invite ac-

cidents.

b) Do not operate power tools in

explosive atmospheres, such as

in the presence of ammable

Iiquids, gases or dust. Power tools

create sparks which may ignite the

dust or fumes.

c) Keep children and bystanders

away while operating a power

tool. Distractions can cause you to

lose control.

2) Electrical safety

Caution: This is how to avoid ac-

cidents and injuries by an electric

shock:

a) Power tool plugs must match

the outlet. Never modify the

plug in any way. Do not use

any adapter plugs with earthed

(grounded) power tools. Unmodi-

ed plugs and matching outlets will

reduce risk of electric shock

b) Avoid body contact with

earthed or grounded surfaces,

such as pipes, radiators, ranges

and refrigerators. There is an

increased risk of electric shock if your

body is earthed or grounded.

c) Do not expose power tools to

rain or wet conditions. Water

11

IE NI

entering a power tool will increase the

risk of electric shock.

d) Do not abuse the cord. Never

use the cord for carrying, pulling

or unplugging the power tool.

Keep cord away from heat, oil,

sharp edges or moving parts.

Damaged or entangled cords increase

the risk of electric shock.

e) When operating a power tool

outdoors, use an extension cord

suitable for outdoor use. Use of a

cord suitable for outdoor use reduces

the risk of electric shock.

f) If operating a power tool in a

damp location is unavoidable,

use a residual current device

(RCD) protected supply. Use of an

RCD reduces the risk of electric shock.

3) Personal safety

Caution: This is how to avoid acci-

dents and injuries:

a) Stay alert, watch what you are

doing and use common sense

when operating a power tool.

Do not use a power tool while

you are tired or under the inuence of drugs, alcohol or medication. A moment of inattention white

operating power tools may result in

serious personal injury.

b) Use personal protective equip-

ment. Always wear eye protection. Protective equipment such as

dust mask, non-skid safety shoes, hard

hat, or hearing protection used for

appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting.

Ensure the switch is in the offposition before connecting to

power source and/or battery

pack, picking up or carrying

the tool. Carrying power tools with

your nger on the switch or energising

power tools that have the switch on

invites accidents.

d) Remove any adjusting key or

wrench before turning the power tool on. A wrench or a key left at-

tached to a rotating part of the power

tool may result in personal injury.

e) Do not overreach. Keep proper

footing and balance at all times.

This enables better control of the power

tool in unexpected situations.

f) Dress properly. Do not wear

loose clothing or jewellery.

Keep your hair, clothing and

gloves away from moving

parts. Loose clothes, jewellery or

long hair can be caught in moving

parts.

g) If dust extraction and collection

devices can be installed, make

sure that these are connected

and used correctly. Using a dust

collector can reduce hazards caused

by dust.

4) Power tool use and care

a) Do not force the power tool.

Use the correct power tool for

your application. The correct pow-

er tool will do the job better and safer

at the rate for which it was designed.

b) Do not use the power tool if the

switch does not turn it on and

off. Any power tool that cannot be

controlled with the switch is dangerous

and must be repaired.

c) Remove the plug from the

wall socket and/or remove the

rechargeable battery before

12

NIIE

you change the settings of the

device, change accessory parts

or put away the device. Such pre-

ventive safety measures reduce the risk

of starting the power tool accidentaIly.

d) Store idle power tools out of

the reach of children and do not

allow persons unfamiliar with

the power tool or these instructions to operate the power tool.

Power tools are dangerous in the

hands of untrained users.

e) Maintain power tools. Check

for misalignment or binding

of moving parts, breakage of

parts and any other condition

that may affect the power tool’s

operation. If damaged, have

the power tool repaired before

use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and

clean. Properly maintained cutting

tools with sharp cutting edges are less

Iikely to bind and are easier to control.

g) Use the power tool, accessories

and tool bits etc. in accordance

with these instructions, taking into account the working

conditions and the work to be

performed. Use of the power tool

for operations different from those

intended could result in a hazardous

situation.

5) Use and treatment of the battery-powered tool

a) Only recharge batteries using chargers

recommended by the manufacturer. If

a charger that has been designed for

a particular type of battery is used to

charge other batteries, there is a risk

of re.

b) Only use the battery that is intended in

an electric tool. The use of other batte-

ries may create a re hazard and lead

to injury.

c) When not in use, keep batteries away

from paper clips, coins, keys, nails,

screws or other small metal objects that

could cause the contacts to be bridged.

A short circuit between battery contacts

can result in burns or a re.

d) When misused, uid may leak from the

battery. Avoid any contact with it. On

accidental contact, wash in running

water. If the uid comes into contact

with the eyes, seek medical assistance

also. Leaking battery uid can cause

skin irritation or burns.

6) Service

a) Have your power tool serviced

by a qualied repair person using only identical replacement

parts. This will ensure that the safety

of the power tool is maintained.

Hedge trimmer safety

warnings

Preparation

• THIS HEDGE TRIMMER CAN CAUSE

SERIOUS INJURIES! Read the instructions carefully regarding the correct

handling, preparation and maintenance, for starting and stopping the

hedge trimmer. Familiarise with all controls and the proper use of the hedge

trimmer.

• Caution! Notice overhead power lines.

• Use of the hedge trimmer should be

avoided when people, especially

children, are nearby.

• If the cutting unit contacts a foreign

body or if the operating noises increa-

13

IE NI

se or the hedge trimmer vibrates with

unusually high force, turn off the motor

and let the hedge trimmer come to a

standstill. Pull the mains plug or remove the battery and take the following

measures:

- check for damages;

- check for loose parts and fasten all

loose parts;

- replace damaged parts with equivalent parts or have them repaired.

Operation

• Switch the appliance off and remove

the mains plug or battery before:

- cleaning or removing a blockage;

- inspection, servicing or work on the

hedge trimmer;

- adjusting the working position of the

cutting unit;

- leaving the hedge trimmer unattended.

• Always ensure that the hedge trimmer

is properly placed in one of the indicated working positions before the motor

is started.

• Do not use the hedge trimmer with a defective or strongly worn-out cutting unit.

• To avoid the risk of re, ensure that the

motor is free from deposits and leaves.

• Always ensure that all handles and

safety devices are mounted when you

use the hedge trimmer. Never try to

use an incomplete hedge trimmer or a

hedge trimmer with impermissible mo-

dications.

• Always use both hands when the

hedge trimmer is equipped with two

handles.

• Always familiarise with your surroundings and pay attention to potential

dangers that you cannot hear because

of the noise the hedge trimmer makes.

• Keep cable away from cutting area.

During operation the cable may be

hidden in shrubs and can be accidentally cut by the blade.

• Keep all parts of the body away from

the cutter blade. Do not remove cut

material or hold material to be cut

when blades are moving. Make sure

the switch is off when clearing jammed

material. A moment of inattention

while operating the hedge trimmer

may result in serious personal injury.

• Children must never use the hedge

trimmer.

Maintenance and storage

• If the hedge trimmer is taken out of operation for purposes of maintenance, inspection or storage, turn off the motor,

unplug the mains plug or remove the

battery and make absolutely sure that

all rotating parts have come to a standstill. Let the machine cool down before

you check or adjust it, etc.

• Carry the hedge trimmer by the

handle with the cutter blade

stopped. When transporting

or storing the hedge trimmer

always t the cutting device

cover. Proper handling of the hedge

trimmer will reduce possible personal

injury from the cutter blades.

Safety information for

chainsaws

• When in operation, keep all

body parts away from the saw

chain. Before you start the saw,

ensure that the saw chain is not

touching anything. When using a

chainsaw, losing concentration for just

a moment can lead to clothing or body

parts being caught up in the saw chain.

• Always hold the chainsaw with

your right hand on the rear

14

NIIE

handle and left hand on the

front handle. Holding the chainsaw

the other way around increases the

risk of injuries and is not permitted.

• Wear protective goggles and

hearing protection. Further

protective equipment for the

head, hands, legs and feet is

required. Appropriate protective

clothing reduces the risk of injury from

ying chip material and accidental

contact with the saw chain.

• Do not use the chainsaw to

work on trees. Operating a chain-

saw on a tree poses the risk of injury.

• Ensure you are standing rmly

and only use the chainsaw

if the ground beneath you is

solid, secure and even. Slippery

ground or unstable surfaces such as on

a ladder can lead to loss of balance

or loss of control over the chainsaw.

• If working on a branch under

tension, be aware that it will

spring back. Once the tension in the

wood bres has been released, the

branch may hit the user and/or control

over the chainsaw may be lost.

• Be particularly careful when

cutting brushwood and young

trees. The thin material may become

caught in the saw chain and hit you or

cause you to lose balance.

• Carry the chainsaw by the front

handle when it is switched off

with the saw chain pointing

away from your body. Always

place the protective cover onto

the chainsaw when transporting or storing it. Careful handling

of the chainsaw reduces the probability of accidentally coming into contact

with the running saw chain.

• Observe the instructions for lubrication, chain tensioning and

replacing accessories. An impro-

perly tensioned or lubricated chain

may rip apart or increase the risk of

kickback.

• Keep handles dry, clean and

free from oil and grease. Greasy,

oily handles are slippery and lead to

loss of control.

• Only saw wood. Do not use the

chainsaw for unintended applications - example: do not use

the chainsaw to saw through

plastic, masonry or construction

materials not made from wood.

Use of the chainsaw for unintended

applications can lead to hazardous

situations.

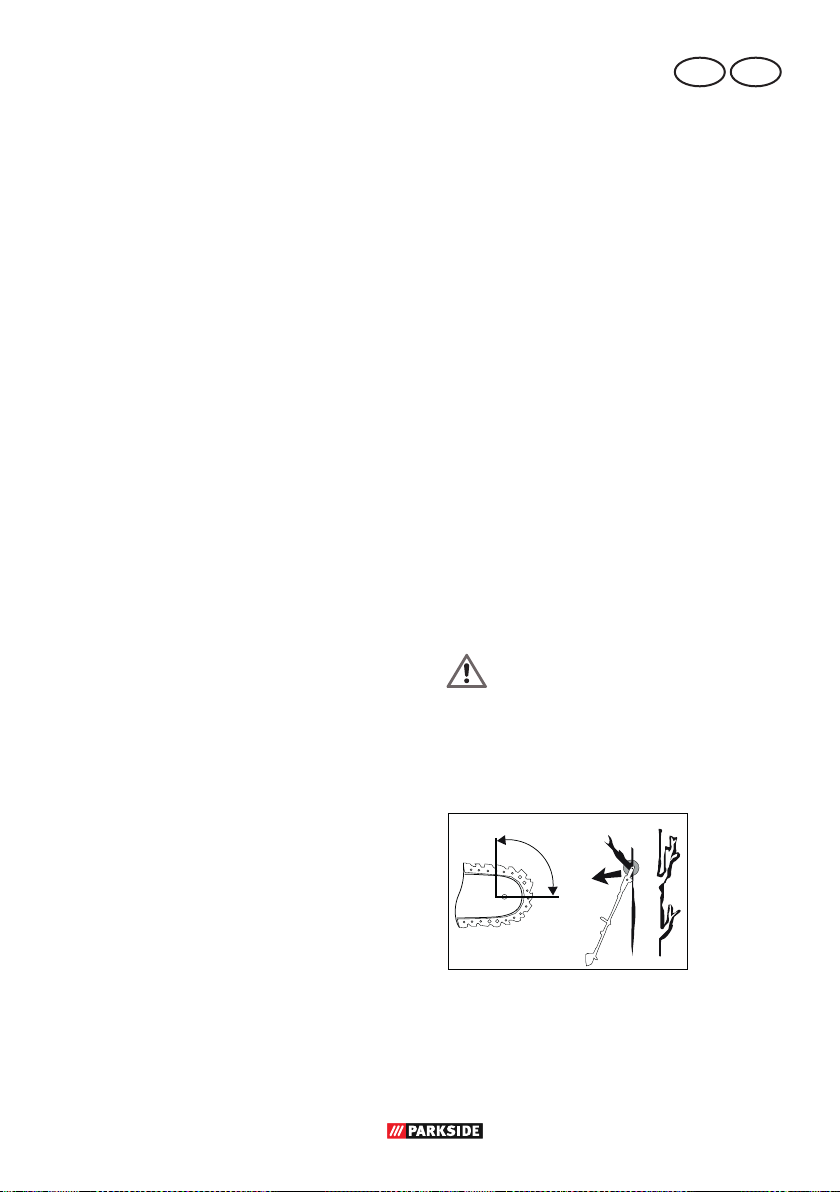

Kickback causes and how

to avoid them with polemounted pruners

Caution - kickbacks! Be aware that

you may experience kickback while

working with the device. There is a

risk of injury. Kickbacks can be avoided through taking the appropriate

care and using the correct sawing

technique.

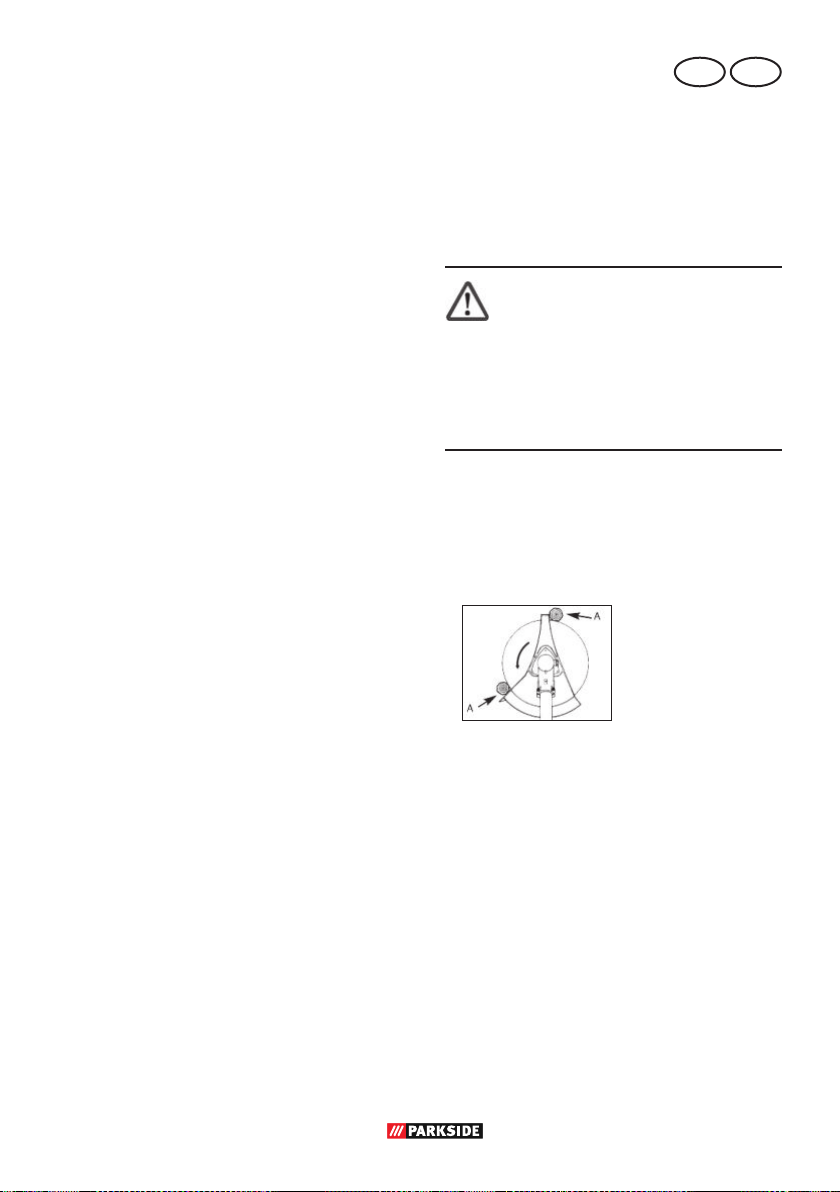

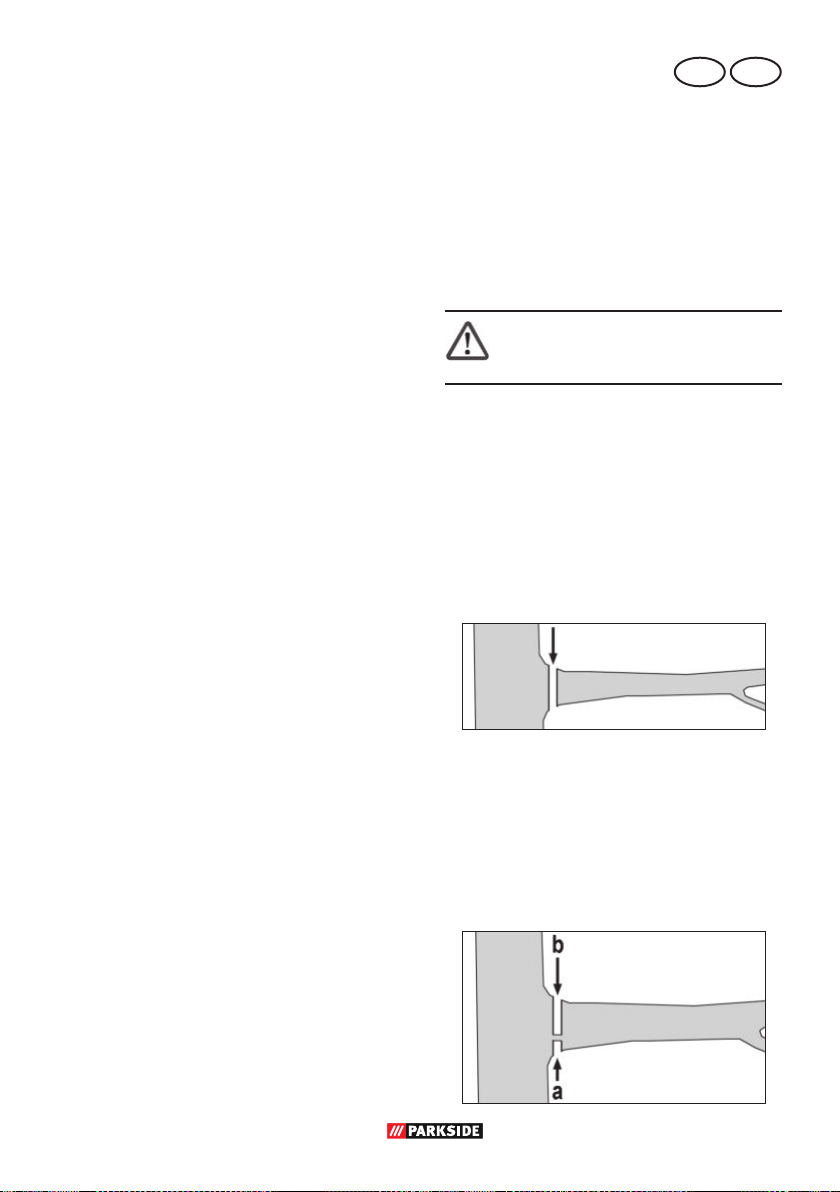

a

Bild 1

• Kickbacks may occur if the tip of the

guide rail touches an object, or if the

wood bends and the saw chain gets

caught in the cut (see Fig. b).

b

15

IE NI

• Under some circumstances, contact with

tip of the rails can lead to an unexpected

backwards reaction movement during

which the guide rails move upwards and

strike the operator (see Fig. a).

• If the saw chain becomes stuck along

the top edge of the guide rail, the rail

can kick back heavily towards to the

operator.

• Each of these reactions can lead to you

losing control of the saw and potentially

being seriously injured. Do not rely exclusively on the safety devices built into the

chainsaw. As user of the chainsaw, you

should undertake various measures to

enable accident- and injury-free working.

A kickback is caused by wrongly or incorrectly operating the electric tool. It can be

avoided by suitable cautionary measures,

such as described below:

• Hold the saw rmly with both

hands with thumbs and n-

gers surrounding the chainsaw

handles. Place your body and

arms in a position where you

can withstand the kickback

forces. The user will be capable of

withstanding the kickback forces if suitable measures are undertaken. Never

let go of the chainsaw.

• Avoid an abnormal body posture.

This will enable better control over the

chainsaw in unforeseen situations.

• Always use the replacement

rails and saw chains specied

by the manufacturer. Incorrect

replacement rails and saw chains can

cause the chain to break apart and/or

may lead to kickback.

• Comply with the manufacturer’s

instructions for sharpening and

maintaining the saw chain.

Depth limiters placed too low increase

the potential for kickbacks.

• Do not saw with the tip of the

blade bar (see Fig. b). There is a

risk of kickback.

• Ensure there are no objects on

the ground which could cause

you to stumble.

Safety information for lawn

and lawn edge trimmers

Training

a) Read the instructions carefully. Familiarise

yourself with the controls and proper use.

b) Never allow people who are not fami-

liar with the instructions or children

to use the machine. Local regulations

may specify an age limit for the user.

c) Children, individuals with limited phy-

sical, sensory or mental capabilities, as

well as those who have insufcient experience or knowledge or are not familiar

with the instructions must never be permitted to use the device. Local regulations

may specify an age limit for the user.

d) Note that the user is responsible for

any accidents or risks to others and

their propert y.

Preparation

a) Before use, check the machine for da-

maged, missing or incorrectly installed

safety devices or covers.

b) Never use the device if people – espe-

cially children – or pets are nearby.

Operation

a) Always wear eye protection, long

trousers and sturdy shoes whenever

using the machine.

b) Do not use the machine in poor we-

ather, especially if there is a risk of

lightning.

16

NIIE

c) Use the machine only in daylight or

with good articial lighting.

d) Never use the machine if the cover or

guard is damaged, or without a cover

or guard.

e) Only switch on the motor when your

hands and feet are out of the range of

the cutting unit.

f) Always disconnect the machine from

the power supply (i.e. remove the removable battery)

1) whenever leaving the machine unattended,

2) before removing blockages,

3) before checking, cleaning or modifying the machine,

4) after contact with a foreign object,

5) if the machine begins to vibrate in an

unusual way.

g) Be careful to avoid injuries to your feet

and hands by the cutting unit.

h) Make sure to keep the ventilation

openings free of foreign objects.

i) Never replace a non-metallic cutting

unit with a metallic cutting unit.

j) Avoid an abnormal body posture,

keep your balance at all times and ensure secure footing on slopes.

Walk when holding the device in your

hand. Do not run!

k) Never operate the machine with defec-

tive guards or covers or without protection or without guards.

Maintenance and storage

a) Always disconnect the machine from

the power supply (i.e. remove the removable battery) before performing

maintenance or cleaning.

b) Only use spare and accessory parts

recommended by the manufacturer.

c) Regularly inspect and maintain the

machine. Only have maintenance performed by a contract workshop.

d) When the machine is not being used,

store it out of the reach of children.

Brush cutter - kickback

causes and how to avoid

them with a 3-tooth blade

In the event of a kickback, the

operator will feel a powerful

blow from the combination

machine. This may lead to losing control of the device and

serious injury. You can avoid

kickbacks through caution

and proper technique.

While working with the 3- tooth blade there is a risk of kickback if the blade edge

hits an obstacle (stone, wood).

• Hold the device with both hands.

• Make sure there are no obstacles on the

ground and do not

use the 3-tooth blade

near fences, metal

posts or similar. Use

only properly sharpened tools. To cut thick

stems, switch the device to position A.

Additional safety

instructions

• If possible, connect the device only to

a socket with a residual current device

(RCD) with a tripping current of not

more than 30 mA.

• If replacement of the connecting cable

becomes necessary, this is to be carried out by the manufacturer or its agent

in order to avoid safety risks.

• Hold the electric tool only by the in-

sulated gripping surfaces, as the saw

chain may come into contact with con-

17

IE NI

B

C

cealed power lines. Contact with a live

wire can also cause a charge in metal

parts of the appliance and result in an

electric shock.

• Carefully inspect the surface to be cut,

and remove all wires and other foreign

bodies.

• Check the appliance before each use

for obvious defects such as loose,

worn or damaged parts. Check the

appliance for signicant damage or

defects if it is dropped.

Attention! Observe the

safety and operating information in the operating instructions for your Parkside

X 20 V Team series rechargeable battery.

Assembly

Remove the battery from the

device before carrying out

any work on the device.

Only use original parts.

The device can be used with either

the hedge trimmer, pole-mounted

pruner or trimmer attachment, either with spool or 3-tooth blade.

Dismantling is carried out in reverse

order.

Remove/insert battery

1. To remove the battery (25) from the

device, press the release button on the

battery and pull the battery out.

2. To insert the battery (25), push the

battery along the guide rail into the

device. You will hear it click into place.

Only insert the rechargeable

batteries once the device is

completely assembled. Risk

of injury!

Mounting the tubular

shaft

Before mounting, remove the pro-

tective cap(s) from the front tubular

shaft (2).

1. Loosen the buttery screw (3).

2. Pull the lock (8) outward and turn it left

or right as far as it goes.

3. Slide the front tubular shaft (2) onto the

tubular shaft on the device housing (4).

4. Pull the lock (8) outward and turn it

back to its original position.

5. Turn the front tubular shaft (2) with a

gentle rotating movement until the lock

(8) clicks into place in the bore on the

front tubular shaft (2).

6. Fix the tubular shaft in place with the

buttery screw (3).

Onlytightenthebuttery

screw(3)nger-tight.The

use of maximum manual

force will damage the tubular shaft.

Mounting the round

handle

The round handle must be

mounted with a spacing of

at least 25 cm to the device

handle!

The leg protection must al-

ways be mounted on the

operator side!

18

NIIE

A

1. Place the round handle (5) onto the

tubular shaft of the device housing (4).

Choose a position within the

levelled adjustment range marked on the bottom of the tubular shaft.

2. Position the leg protection (7) onto the

round handle (5) from below.

3. Fix the round handle (5) and the leg

protection (7) with the four hexagon

socket screws (32) using the hexagon

socket wrench (21) from the

storage (

Mounting the saw chain

Pay attention to the correct rotation

direction of the saw chain. This is

indicated on the chain wheel cover

(33) and above the bar bolt (37).

Tension the saw chain in accor-

dance with the rst 5-6 steps.

1. Place the device on a level surface.

2. Remove the chain wheel cover (33) by

loosening the nut (34) with the mounting key (23).

3. Place the sawing chain (1) into the blade groove. Place the sawing chain (1)

into the chain sprocket (36).

4. Place the blade bar (35) and saw

chain (1) onto the rail bolts (37). When

the nose on the right below the guide

bolt (37) sits in the lower round recess

on the blade bar, the blade bar is placed correctly. It is normal for the saw

chain (1) to sag.

5. Pre-tension the saw chain (1) by turning

the screw (38) in a clockwise direction

with the mounting key (23).

6. Put the chain wheel cover (33) back in

position. Tighten the chain wheel cover

nut (34).

31).

Caution! The pole-mounted pruner

can be prone to leaks.

Mounting the protective

cover

The protective cover (14) must be mounted

to the front tubular shaft (2) with the retainer for spool and 3-tooth blade.

1. Screw the protective cover (14) to the

front tubular shaft (2) using the two

small Phillips screws (49). Use the Phillips screwdriver (24) for this.

2. Fasten the cover (50) to the protective

hood (14). Use the hexagon socket

wrench (22) and the three screws (51).

Removing/mounting

the protective cover

extension

If using the 3-tooth blade, the protective

cover extension must be removed.

If using the spool, the extension must be

mounted.

Removing the protective cover

extension:

1. Unlock the lock for the protective cover

extension (56) using a Phillips-head

screwdriver on the side of the string

cutter (15).

2. Remove the protective cover extension

(56).

Mounting the protective cover

extension:

1. Slide the extension (56) onto the protective cover (14). Begin on the side

without the string cutter (15).

2. Slide the extension (56) up until it clicks

into place.

19

IE NI

Initial Operation

Do not use the equipment wi-

thout the hand guard. Wear

suitable clothing and work

gloves when working with

the equipment.

Ensure that the equipment is

functional before each use.

The On/Off switch and the

safety switch must not be

held closed. They must switch

off the motor when on is

released. Should a switch

be damaged, stop working

with the equipment. Ensure

that the mains voltage value matches the label on the

equipment.

Note noise protection and local

specications. The use of the equipment on certain days (e.g. Sundays

and national holidays), at certain

times of day (lunch times, night time

quiet periods) or in special areas

(e.g. health resorts, clinics etc.) is

restricted or forbidden.

Chain lubrication

Filling with chain oil:

• Check the oil level indicator on the oil

tank (

oil if the minimum mark „MIN“ (

is reached on the oil level indicator. The

oil tank holds about 120 ml of oil.

• Use bio-oil containing additives to reduce friction and wear. You can order this

from our service centre.

Alternatively, use chain lubricating oil

with a low proportion of adhesion additives.

• Empty the oil tank if it will not be used for

a prolonged period of time (6-8 weeks).

1. Unscrew the oil tank cap (41) and pour

the chain oil into the tank.

2. Wipe away any spilt oil and close the

oil tank cap (41).

3. You can regulate the oil ow with the

adjusting screw (42).

39) regularly and top-up the

40)

Always turn off the device

and let the motor cool down

beforellingwithchainoil.

Overowingoilcancausea

re.

Swivelling Out the

Blade Beam

The blade bar and saw chain must

never be operated without oil. If the

pole-mounted pruner is used with

too little oil, the cutting performance

and lifespan of the saw chain will

decrease as the saw chain will become blunt more quickly. You can

identify when there is too little oil

if smoke develops or the blade bar

changes colour.

The oil ows to the blade bar as soon as

the motor starts working.

20

The blade bar must be checked

regularly for wear and reground. A

blunt blade bar causes the device

to overload. Any damage that results is not covered by the warranty.

1. Hold the safety blade beam on the

handle to adjust the blade beam (43).

2. Unlock the safety lever (44) and keep

it pressed.

3. By simultaneously exerting pressure on

the lock lever (45), you will loosen the

xation of the cutter bar.

NIIE

A

A

4. The safety blade beam can now be

swivelled out. Use the stop stages and

allow the stop lever (45) to click back

in. You can choose 12 stop stages.

5. Then, release the safety lever (44)

again and ensure that it latches back

into its initial position.

Pivoting the pole-

mounted pruner

1. Pull the lock (46) outward and turn it

90°.

2. Hold the pole-mounted pruner at the

protective transport (9) and turn it to

the desired position.

There are ve possible positions.

3. Fix the pole-mounted pruner by pulling

the lock (46) outward and turning it

90° back to the original position.

Putting on the carrying

harness

The body protection (20) on

the carrying harness must

be placed between the body

and the device.

Always wear the carrying

harness when working with

the 3-tooth blade! Always

turn the device off before

taking off the carrying harness. Accident hazard.

Generally, we recommend using the

carrying harness whenever using

the device.

The carrying harness is

equipped with a quick-release device. Pulling the tab (47)

releases the device quickly

from the carrying harness in

a dangerous situation.

1. Wear the carrying harness (19) like a

backpack. The clip must be situated on

the chest.

2. Adjust the strap length so that the body

protection (20) is level with the hip.

3. Attach the snap hook to the eyelet (6)

on the tube shaft of the device.

Place the body protection (20) on

your hip between your body and

the device.

While wearing the carrying harness,

ensure that the pad is placed on your

shoulders to increase comfort.

Sliding the carrying eye

Select the appropriate position for the

carrying harness eyelet according to

whether you are using a spool/3-toothed

blade or pruner/hedge trimmer.

You can slide the carrying eye (

better distribute the weight of the device.

1. Loosen the screw (48) on the eyelet

(6) for the carrying harness, using the

hexagon socket wrench (21) from the

storage (

2. Slide the eyelet (6) to the appropriate

position.

3. Tighten the screw (48) again.

For the trimmer/3-tooth blade operation:

Without touching it by hand, the device

attached to the harness should

allow the spool to rest lightly on the

ground

balance the blade approximately 20

cm above the ground.

31).

6) to

21

IE NI

A

A

1. Loosen the screw (48) on the carrying

harness eye with the hexagon socket

wrench (22) and tighten it slightly.

2. Depending on the cutting tool, balance

the tool according to the criteria mentioned above by moving the eyelet (6)

along the tube shaft (4).

3. Tighten the screw (48) when the device

is in the desired position.

Assemble the 3-tooth

blade

Whenever you use the 3-too-

th blade, the protective cover

without extension must be

used. (See Chapter: “Removing/mounting the protective

cover extension”)

1. Remove the rechargeable batteries.

2. Place the device on the ground in a

stable position.

3. Block the mounting spindle (52) using

the hexagon socket wrench (22) as depicted.

4. Place the 3-toothed blade onto the

mounting spindle (52). The blade can

be used on both sides.

5. Fasten the blade using the thinner washer (53), conical spring washer (54)

and nut (55).

Insert the nut (55) into the conical

spring washer (54) as shown.

Use the assembly key (23) to secure it.

6. Remove the hexagon socket

wrench (22)!

Dismantling is carried out in reverse

order.

Mount the spool

The protective cover must be

mounted with the extension

when using the thread spool.

(See Chapter: “Removing/

mounting the protective cover extension”)

Do not replace the non-me-

tallic laments of the spool

end with metallic laments!

Risk of injury!

1. Remove the rechargeable batteries.

2. Place the device on the ground in a

stable position.

3. Block the mounting spindle (52) using

the hexagon socket wrench (22) as depicted.

4. Place the thin washer (53) on the

mounting spindle (52).

5. Screw the spool cap (17) anticlock-

wise back onto the mounting spindle

(52).

Dismantling is carried out in reverse

order.

Extend the thread

Your device is equipped with a double-string activated touch control, i.e. the

two strings are extended when you tap the

cutting head on the ground.

1. Hold the device in operation over a

grassy area and lightly tap the cutting

head a few times on the ground. This

causes the thread to lengthen.

2. The protective cover (

into the protective cover (

the thread to the desired length.

15) inserted

14) cuts

22

NIIE

A

A

A

If the thread ends can not be

lengthened:

• Turn off the device.

• Press the core insert as far as it will go

and pull rmly on the end of the string.

If no line ends are visible:

• Replace the spool (see chapter on

‘Replacing the spool’).

Attention! Thread remnants

can be projected and lead to

injuries.

Switching on and off

The device has a central on/off

switch (28).

After 2 minutes of non-use, the device

switches off automatically and must

be switched on again via the central

on/off switch (28) before reuse.

As soon as a rechargeable battery

is removed, the device also switches

off automatically.

Ensure your stance is stable and

hold the appliance tightly with both

hands and away from your body.

Before switching the apparatus on,

make sure that it is not touching

any objects.

4. Turn the device off using the on/off

switch (28).

Working with the hedge

trimmer

While cutting, make sure that you

do not touch any objects, such as

wire fences or plant supports. This

can cause damage to the cutter bar.

• To avoid eye injuries, always wear

safety goggles while working with the

hedge trimmer.

• Always hold the device tightly with

both hands, with one hand on the rear

handle and the other hand on the front

round handle (

Your thumb and ngers must tightly

clasp the handles.

• Check the carrying harness (

comfortable positioning which facilitates holding the hedge trimmer.

• If the blades become jammed with

solid objects, switch the device off

immediately, pull the mains plug, and

remove the object.

• Avoid over-stressing the device while

working.

5).

19) for

Working with the polemounted pruner

1. Turn the device on using the on/off

switch (28). The charge status indicator

(27) lights up as long as the device is

switched on.

2. To start, press and hold the safety

switch (29) while pressing the start

switch (30). The hedge trimmer runs at

top speed. You can release the safety

switch (29) again.

3. To switch it off, release the start switch

(30).

If the saw chain gets stuck,

do not attempt to pull out the

pruner with force. There is a

risk of injury. Turn the motor

off and use a lever arm or

wedge to release the pruner.

• You will have better control over the

device if you saw using the lower edge

of the blade bar (saw chain in pulling

direction) and not using the upper edge

23

IE NI

A

A

of the blade bar (saw chain in pushing

direction).

• The saw chain must not touch the

ground or any object while sawing

through the material or thereafter.

• Ensure that the saw chain does not get

stuck while sawing. The log must not

break or splinter.

• Please also observe the precautionary

measures to protect against kickback

(see the safety information).

• Remove branches hanging downwards

by sawing from the top of the branch.

• Twisted branches must be individually

cut down to size.

Working using the thread

spool

• In small grass areas hold the device at

an angle of about 30° and swing the

cutting head evenly to the right and

left with a semi-circular movement.

• The best results are obtained with a

maximum grass length of 15 cm. If the

grass is taller, it is recommended to

mow several times.

• To cut around trees, fence posts or

other obstacles, slowly move the device around the obstacle and cut with

the thread ends.

• Avoid any contact with xed obstacles

(rocks, walls, picket fences, etc.). The

thread would wear out quickly. Use the

edge of the protective cover to keep

the device at the correct distance.

Attention! Do not lay the

cutting head on the ground

during operation!

Working with the 3-tooth

blade

Always wear the harness

and suitable protection clothing when working with the

device. Wear eye, hearing

and head protection.

Ensure that the blade is in-

stalled correctly. Replace damaged or blunt tool parts.

There is a risk of injury.

Only use the blade to work on

open, even areas. Carefully inspect

the area to be cut and remove all

foreign bodies. Avoid hitting stones, metal or other obstacles. The

blade can be damaged and there

is a risk of kickback by the machine.

• When working, hold the cutter above

the ground and slowly swivel the device back and forth like a scythe in an

equal arch.

• Do not hold the cutting head at an

angle.

• Do not use the device to cut wild

growth or brushwood.

• Regularly check the blades for damage

and replace as needed.

Putting down the device

• Place the device on the ground with the

motor housing rst.

• The cutting unit (

be placed on the ground without being

subjected to any pressure.

• Do not apply any static pressure

whatsoever to the cutting

unit (

1/11/12/17).

1/11/12/17) must

24

NIIE

Cutting techniques using the

hedge trimmer

• Cut thick branches beforehand using a

branch clippers.

• The double-sided cutter bar enables

cutting in both directions or, with a

swinging action, from one side to the

other.

• In case of vertical cutting, move the

hedge trimmer uniformly forward or up

and down in an arc movement.

• In case of horizontal cutting, move

the hedge trimmer in a sickle-shaped

movement to the edge of the hedge, so

that cut branches fall to the ground.

• In order to achieve long straight lines,

the placing of tensioned guiding cords

is recommended.

Cutting Shaped Hedges:

It is recommended that hedges be cut in

a trapezoidal shape, in order to prevent

stripping off of the lower branches. This corresponds to the natural plant growth and

allows the hedge to thrive optimally. During

cutting, only the new annual growths are

reduced and thus a dense branching and a

good screen will develop.

1. Cut the sides of a hedge rst. To do

this, move the hedge trimmer in the

direction of growth from bottom to top.

If you cut down from the top, the thinner branches will move out, which may

result in some areas having sparse

growth or holes.

2. Cut the top edge, according to taste,

in a at shape, roof shape or rounded

shape

3. Trim young plants to the required

shape. The main growth should remain undamaged until the hedge has

reached the planned height. All other

shoots are lopped off to half size.

Care of Free-Growing Hedges:

Free-growing hedges are not shaped

when cut, although they must be regularly

maintained so the hedge does not become

too high.

Cutting techniques using the

pole-mounted pruner

Be aware of the risk of kick-

back as well as falling branches

and branches on the ground.

• Sawing off small branches:

Place the locating surface of the saw

against the branch in order to prevent

jerky movements of the saw when you

begin to cut it. Guide the saw with

light pressure from the top to the bottom through the branch.

Watch out for premature breakage of

the branch if you have misjudged the

size and weight.

• Sawing off larger branches:

In the case of larger branches, select

a relief cut rst of all to ensure that the

sawing process is controlled. To do

this, saw an incision (a) into the bottom third of the branch (with the upper

side of the blade). Then saw from top

to bottom towards the rst cut (with the

underside of the blade) (b).

25

IE NI

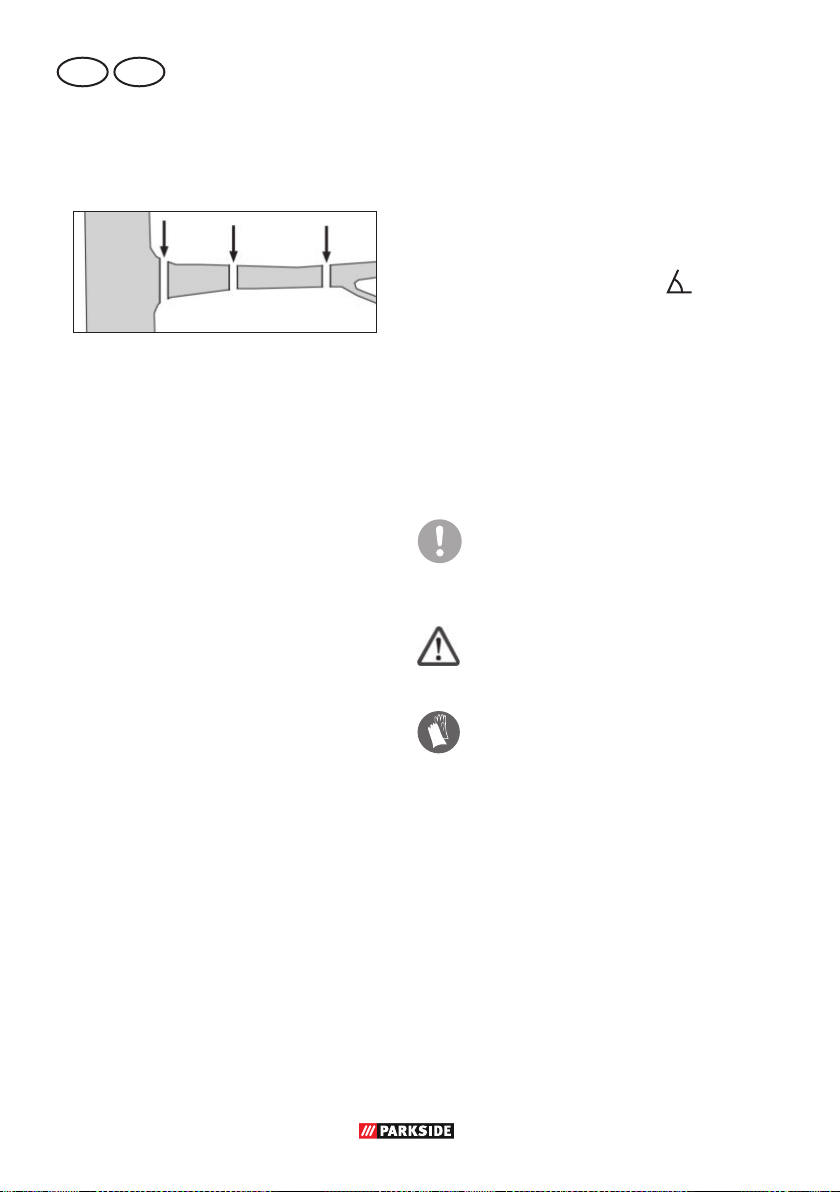

• Sawing in sections:

Saw off large or long branches in sec-

tions so that you have control over the

place where the branch section lands.

• Saw the lower branches of the tree off

rst in order to make it easier for the

branches that have been cut off to fall

to the ground.

• After the cut is completed, the weight

of the saw increases abruptly for the

operator, as the saw is no longer

supported on the branch. There is a

danger that you will lose control of the

device.

• You should only pull the saw out of the

cut with the saw chain running in order

to avoid jamming.

• Do not saw with the tip of the cutting

equipment.

• Do not saw the bulge at the base of

the branch because this will prevent

the tree from healing.

Working Safely

gloves or taking regular breaks. Note

that a personal tendency for poor circulation, low outdoor temperatures, or

high gripping forces during work will

reduce the length of use.

• While using the pole pruner/hedge

trimmer, pay attention to the specied

working angle of max. 60°

der to ensure that you work safely with

the device.

• Always stand on the slope above or to

the side of the branch to be sawn.

• Hold the device as close as possible

to your body. This will ensure the best

balance.

in or-

Maintenance/Cleaning

Repair and servicing work not

described in this manual should

always be carried by our Service

Centre. Use only original parts.

Remove the rechargeable battery

from the device before cleaning

and maintenance.

Wear gloves when working with

the blade, saw chain and cutter

bar.

• Do not use the high pruning saw when

standing on a ladder or in an unsafe

position.

• Do not be tempted to make unconsidered cuts. Doing so may endanger

both yourself and others.

• Children must be supervised to ensure

that they do not play with the equipment.

• Long use of the equipment can result in

vibration-related circulatory disorders

in the hands. However, the length of

use can be extended by using suitable

26

Carry out the following maintenance and

cleaning work regularly. This will guarantee a long and reliable service life.

• Before each use, check the hedge trimmer for obvious defects such as loose,

worn or damaged parts. Check the secure seating of the bolts in the cutter bar.

• Do not use the unit if the blades are

blunt or worn. This will overstress the

motor and gearbox of the machine.

• Check coverings and safety devices

for damage and correct seating. Replace these where necessary.

Cleaning

NIIE

Remove the rechargeable battery

from the device before cleaning.

• Clean the appliance after each use.

Clean the motor housing with a damp

cloth or a brush. The device must neither be sprayed with water nor be put

into water.

• Keep the ventilation channels of the

device clean. Use a damp cloth or

brush to do this.

• Do not use any cleaning agents or

solvents. This could damage the device

irreparably. Chemical substances may

attack the plastic parts of the device.

• Always keep the device clean. After

each use of the device,

you must

- clean the blade

(with an oily cloth);

- oil the cutter bar

with an oil can/spray.

Service intervals

Carefully perform the maintenance tasks listed in the following table on a regular basis.

Regular servicing of your unit will extend the life of your equipment. Additionally, you

will achieve optimum cutting performance and prevent accidents.

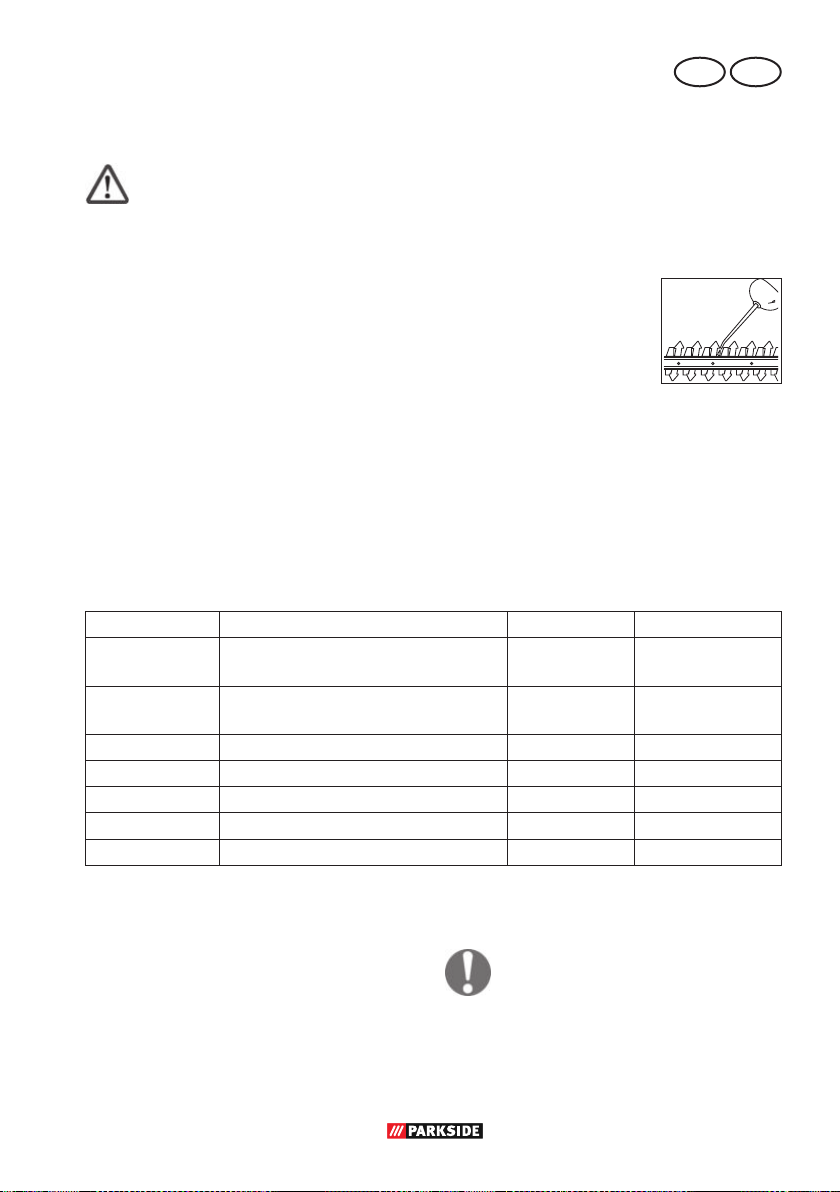

Service intervals table

Machine part Action Before each use After 10 hrs of use

Complete machine

Accessible

screws and nuts

Chain wheel Check, replace as needed

Saw chain Check, apply oil, reground or replace

Blade bar Check, rotate, clean, apply oil

Cutter head Check correct installation

Gears lubricating

Check condition, replace damaged

parts as needed

Tighten

Sharpening the cutting teeth

Have the saw chain sharpened by a specialist, or proceed in accordance with the

operating manual for your saw chain sharpening device. Sharpening a saw chain

requires some practice. Replacing the saw

chain is preferable in case of doubt.

Changing the saw chain

Never attach a new saw chain

onto worn teeth, or onto a damaged or worn blade bar.

1. Switch off the device and remove the

batteries.

27

IE NI

2. Release the nut ( 34) and remove

the chain wheel cover (

3. Remove the old saw chain (

The mounting and tensioning of the new

saw chain is described in the “Assembly”

chapter.

33).

1).

Servicing the blade bar

The blade bar has to be reversed every

8-10 operational hours in order to ensure

even wear (see the “Servicing and cleaning - rotating the blade bar” chapter”).

1. Switch off the device and remove the

batteries from the device.

2. Remove the chain wheel cover (

the saw chain (

bar (

35).

3. Check the blade bar (

Remove burrs and straighten the guide

surfaces with a at le.

4. Clean the oil passage (

sure fault-free, automatic oiling of the

saw chain during operation.

5. Mount the blade bar, saw chain and

chain wheel cover and retighten the

saw chain (see the “Assembly” chapter).

1) and the blade

35) for wear.

62) to en-

33),

Turning the blade bar

1. Switch off the device and remove the

batteries.

2. Release the nut (34) and remove the

chain wheel cover (33).

3. Remove the chain wheel cover (33)

and the blade bar (35).

4. Turn the blade bar (35) once along its

horizontal axis.

5. Insert the saw chain (1) into the blade

bar groove. Place the saw chain (1)

into the chain sprocket (36).

6. Place the blade bar (35) and saw

chain (1) onto the rail bolts (37). When

the nose on the right below the guide

bolt (37) sits in the lower round recess

on the blade bar, the blade bar is

placed correctly. It is normal for the

saw chain (1) to sag.

7. Pre-tension the saw chain (1) by turning

the screw (38) to tension the chain in a

clockwise direction.

8. Put the chain wheel cover (33) back in

position. Tighten the chain wheel cover

nut (34).

Replacing the spool

1. Remove the rechargeable batteries.

2. Place the device on the ground in a

stable position.

3. Block the mounting spindle (

using the hexagon socket wrench (

22) as depicted.

Screw the spool cap (17) clockwise

to the mounting spindle (

4. Open the spool cap (17) by rmly

pressing the quick-release catch (57)

inwards on both sides of the spool cap

(17), and remove the spool cap cover.

5. Place the new spool (58) into the spool

cap cover (17) and insert the two ends

of the thread through the thread outlets

(59). Loosen the two thread ends from

the grooves (

6. Place the spool (58) inside the lid of

the spool cap (17) and reassemble the

lid and base.

7. Screw the spool cap (17) anticlock-

wise back onto the mounting spindle (

52). Remove the hexagon so-

cket wrench (

8. Trim the thread line to approx. 15 cm.

61) on the spool.

22).

52)

52).

28

NIIE

R

o

p

e

W

i

n

d

i

n

g

A

A

A

Sharpen the line cutter

Never use the device without

a string cutter or defective

line cutter. There is a risk of

injury. If the thread trimming

blade is damaged, be sure to

contact our service centre.

Wear protective gloves in order to

avoid cutting yourself.

1. Switch off the engine and remove the

batteries.

2. Screw off the line cutter (15) from the

protective cover (14).

3. Clamp the line cutter (15) in a vice and

sharpen the knife with a at le. File

carefully, and always in one direction

only.

4. Screw the line cutter (15) back onto the

protective cover (14).

Winding up the spool

As an alternative to a new thread spool,

you can purchase a 1.8 - 2.0 mm-thick, 5

m-long nylon thread in specialist shops and

wind this yourself onto the thread spool.

1. Fold the thread in the middle and place the middle of the thread in the notch

(60) of the spool (17).

Wind up the two ends in the direction

of the arrow, which is shown on the

topside of the spool

.

2. Then clamp the end of each thread in

one of the grooves (61) on the spool (17).

Lubricating the gears

The gear units of the attachments require

lubrication after around 10 hours of operation.

Hedge trimmer/pole pruner

To do this, use the lubricating nipples

(63/64) to press up to 5 g of standard

grease into the gearbox housing with a

grease gun.

Trimmer/brush cutter

1. Release the screw (65) on the gears.

2. Insert up to 5 g of commercially-available lubricating grease into the lubrication opening on the gearbox housing.

3. Close the gears again using the screw

(65).

Storage

• Store the device in the transport pro-

tection (

location and out of reach of children.

Store the appliance in horizontal position or secured against toppling over.

• Store the 3-tooth blade (

supplied transport protection (

attached.

• For storage, you can hang the unit at

the bottom of the motor unit.

• Empty the oil tank if it will not be used

for a prolonged period of time (6-8

weeks).

• Clean the device and accessories ca-

refully before storage.

• Store the device in a dry and dustpro-

of location and out of reach of children.

• Do not wrap the device in plastic bags

as moisture and mildew may form.

• Do not lie the device down on the pro-

tective cover.

9/10) provided in a dry

12) with the

13)

29

IE NI

A

A

Transport

Never transport your appli-

ance while the appliance is

turned on! Risk of injury!

• Always use the protective

cover (

• Always carry the device with the cutting unit pointing backwards using both

hands: one on the rear handle and the

other on the front round handle (

9/10) when transporting.

5).

Waste Disposal

and Environmental

Protection

Be environmentally friendly. Return the

tool, accessories and packaging to a recy-

cling centre when you have nished with

them.

Do not dispose of waste oil in the sewer or

your drain system. Dispose of waste oil in

an environmentally friendly way - take it to

your local recycling centre.

Electrical machines do not belong

in domestic waste.

Take the equipment to a waste disposal

site. The plastic and metal parts that are

used can be separated out into pure

grade, which allows recycling. Ask our

Service Centre for details.

Guarantee

Dear Customer,

This equipment is provided with a 3-year

guarantee from the date of purchase.

In case of defects, you have statutory

rights against the seller of the product.

These statutory rights are not restricted by

our guarantee presented below.

Terms of Guarantee

The term of the guarantee begins on the

date of purchase. Please retain the original

receipt. This document is required as proof

of purchase.

If a material or manufacturing defect occurs

within three years of the date of purchase

of this product, we will repair or replace –

at our choice – the product for you free of

charge. This guarantee requires the defective equipment and proof of purchase to be

presented within the three-year period with

a brief written description of what constitutes the defect and when it occurred.

If the defect is covered by our guarantee,

you will receive either the repaired product or a new product. No new guarantee

period begins on repair or replacement of

the product.

Guarantee Period and Statutory

Claims for Defects

The guarantee period is not extended by

the guarantee service. This also applies for

replaced or repaired parts. Any damages

and defects already present at the time of

purchase must be reported immediately after unpacking. Repairs arising after expiry

of the guarantee period are chargeable.

Guarantee Cover

The equipment has been carefully produced in accordance with strict quality

guidelines and conscientiously checked

prior to delivery.

The guarantee applies for all material and

manufacturing defects. This guarantee

does not extend to cover product parts that

are subject to normal wear and may therefore be considered as wearing parts (e.g.

cutter bar, spool, 3-tooth blade, chain) or

to cover damage to breakable parts (e.g.

switches).

30

Loading...

Loading...