Parkside PISG 120 A1 Operation And Safety Notes

INVERTER WELDER PISG 120 A1

GB

CY

INVERTER WELDER

Operation and Safety Notes

Translation of the original instructions

HR

INVERTER APARAT ZA

ZAVARIVANJE

Upute za posluživanje i za Vašu sigurnost

Prijevod originalnih uputa za uporabu

RS

INVERTER - APARAT ZA

ZAVARIVANJE

Prevod originalnog uputstva za upotrebu

BG

ИНВЕРТОРЕН ЗАВАРЪЧЕН

УРЕД

Указания за монтаж, работа и безопасност

Превод на оригиналното ръководство за

експлоатация

IAN 310850

RO

APARAT DE SUDURĂ CU

INVERTOR

Indicații de montare, operare și siguranță

Traducerea instrucţiunilor de utilizare originale

DE

AT CH

INVERTER-SCHWEISSGERÄT

Bedienungs- und Sicherheitshinweise

Originalbetriebsanleitung

RS

HR

BG

RO

GB

CY

Before reading, unfold the page containing the illustrations and familiarise yourself with all

functions of the device.

HR

Prije nego što pročitate tekst, otvorite stranicu sa slikama i upoznajte se na osnovu toga sa

svim funkcijama uređaja.

RS

Pre čitanja rasklopite obe strane sa slikama te se upoznajte sa svim funkcijama uređaja.

RO

Desfaceți înainte să citiți pagina cu ilustrații și apoi familiarizați-vă cu toate funcțiile

aparatului.

BG

Преди да прочетете, отворете страницата с фигурите и след това се запознайте

с всички функции на уреда.

DE AT CH

Klappen Sie vor dem Lesen die beiden Seiten mit den Abbildungen aus und machen Sie

sich anschließend mit allen Funktionen des Gerätes vertraut.

GB / CY Operation and Safety Notes Page 5

HR Upute za posluživanje i za Vašu sigurnost Stranica 21

RS Prevod originalnog uputstva za upotrebu Strana 37

RO Indicații de montare, operare și siguranță Pagina 55

BG Указания за монтаж, работа и безопасност Страница 71

DE / AT / CH Montage-, Bedienungs-, und Sicherheitshinweise Seite 91

10

1

2

9

3

5

(rot)

+

–

(schwarz)

4

8

6 7 11

A B

8 7

C1 C2

C3 C4

11

7

D

5

Table of contents

List of pictograms used .........................................................................Page 6

Introduction ..............................................................................................Page 7

Intended use ................................................................................................Page 7

Parts Description ..........................................................................................Page 7

Technical specifications .................................................................................Page 7

Scope of delivery ......................................................................................... Page 7

Safety instructions ..................................................................................Page 8

Safety hazards during arc welding .................................................................Page 9

Safety notices specific to the welding shield ....................................................Page 12

Tight and moist spaces ..................................................................................Page 12

Protective clothing .......................................................................................Page 13

Protecting against rays and burns ..................................................................Page 13

Prior to commissioning .........................................................................Page 13

Installing the welding shield ...............................................................Page 13

Start up .....................................................................................................Page 14

Welding .....................................................................................................Page 15

Maintenance and Cleaning ..................................................................Page 15

Information about warranty and service processing ...................Page 16

Warranty terms ............................................................................................Page 16

Extent of warranty ........................................................................................Page 16

Processing of warranty claims ........................................................................Page 17

Environmental instructions and disposal information ..................Page 17

EU Conformity Declaration ...................................................................Page 17

5GB/CY

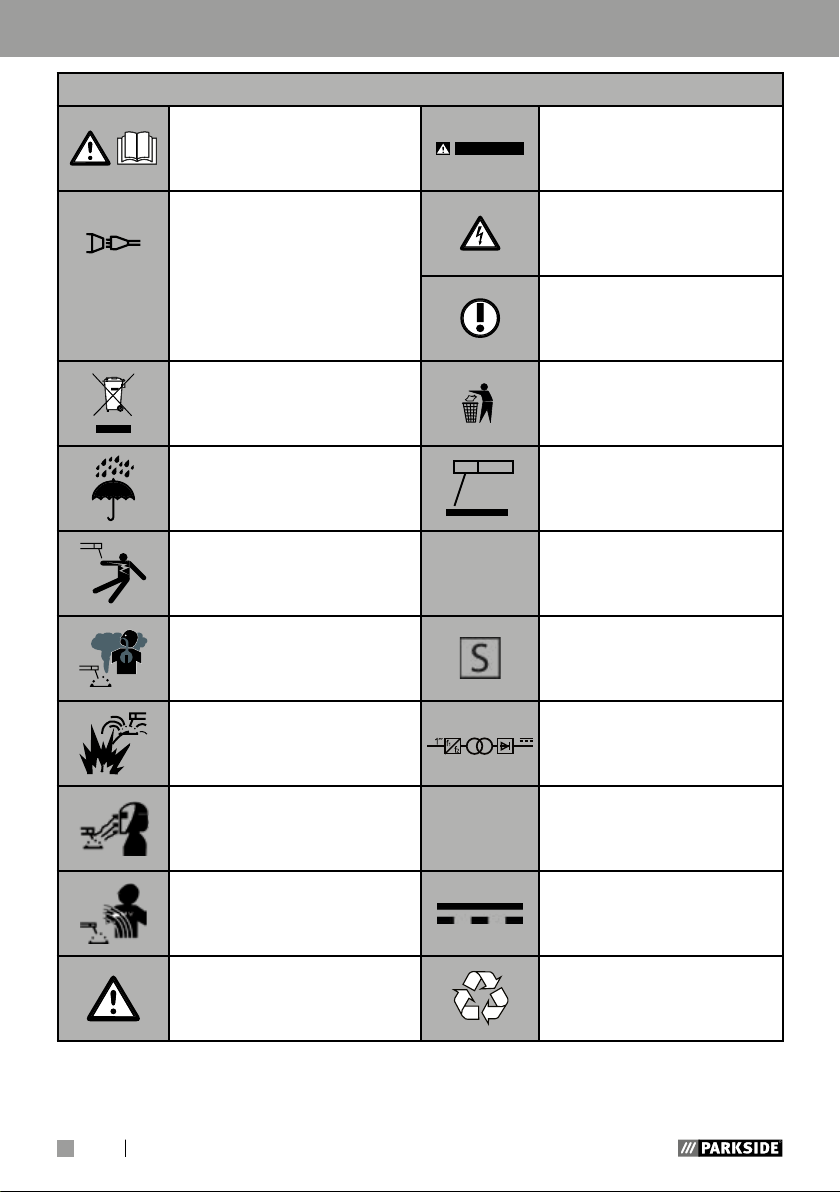

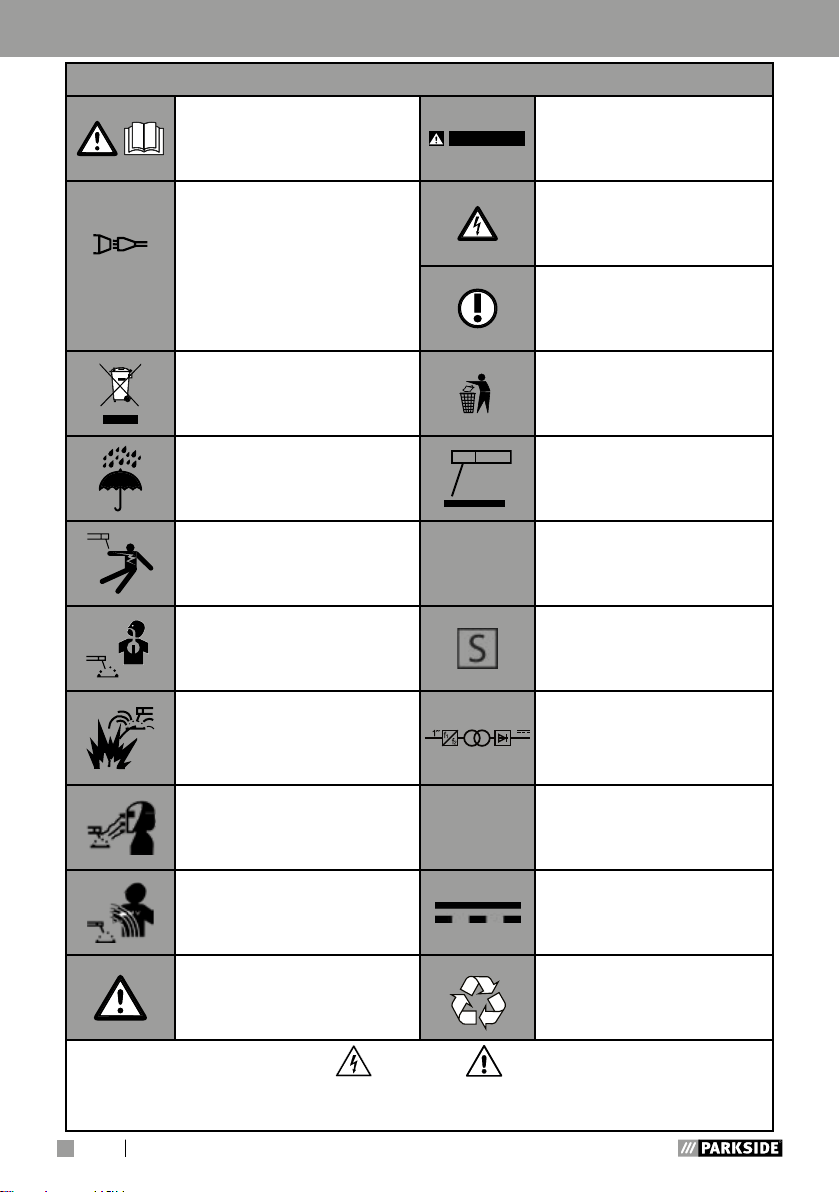

List of pictograms used

List of pictograms used

1~50Hz

Caution!

Read instructions for use!

Power input;

phase number, as well as

Alternating current symbol

and rated value of the frequency

Do not dispose of electrical

equipment in household

waste!

Do not use the device outdoors and never in rain!

Electric shock from the welding electrode can be fatal

Inhaling welding smoke can

be hazardous to your health.

WARNING

IP21S

Potential of serious to

fatal injuries.

Caution! Risk of electric

shock!

Important notice!

Dispose of packaging and

device in an environmentallyfriendly way!

Manual arc welding with

covered electrodes

Protection type

Suitable for welding with

increased electric risk

Welding sparks can cause an

explosion or fire.

Arc rays can damage the

eyes and injure the skin.

Electromagnetic fields can

interfere with the functionality

of pacemakers.

Attention, potential dangers!

6 GB/CY

Single phase static frequency

converter-transformer

rectifier

H

Insulation class

Direct current

Made from recycling

material.

Introduction

INVERTER WELDER

PISG 120 A1

z Introduction

Congratulations! You have

chosen a high-quality unit

from our company. Familiarise yourself with the product before using it

for the first time. In addition, please carefully

refer to the instructions for use and the safety

instructions below. Initial operation of this

tool must be performed by trained personnel.

KEEP OUT OF THE REACH OF

CHILDREN!

z Intended use

This welding tool is suitable for welding

metals such as carbon steel, alloy steel, other

stainless steels, copper, aluminium, titanium,

etc. The product has a control lamp, a thermal protection indicator, and a cooling fan.

It further has a strap to safely lift and move

the product. Improper product handling

can be dangerous to persons, animals and

objects. Only use the product as described

and for its indicated purpose. Keep these

instructions in a safe place. When passing

this product on to others, please also include

all the documents. Any use other than the intended is prohibited and potentially dangerous. Damages resulting from non compliance

or misuse are not covered by the warranty

and are not included in the manufacturer‘s

liability.

Note: Classification per EMV standard:

Class A per IEC 60974-10

Warning: Equipment categorised Class A

are intended for industrial use. When used

in other areas, electromagnetic tolerance

may not be warranted or failures may occur.

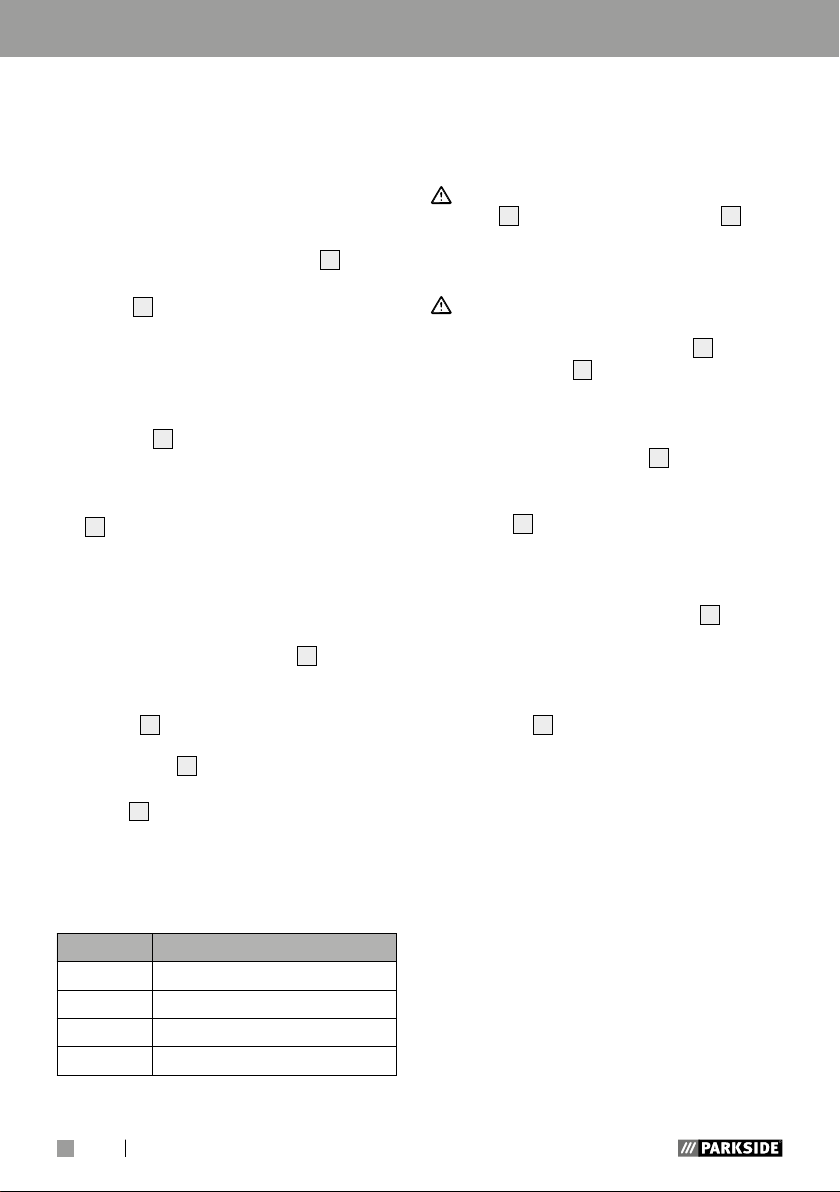

z Parts Description

Carrying strap

1

Overheating control lamp

2

Control knob

3

Earth terminal

4

Electrode holder

5

Combination wire brush with chipping

6

hammer

Welding shield

7

Grip

8

ON / OFF switch

9

Mains lead

10

11

Protection glass

z Technical specifications

Mains connection: 230 V~ 50 Hz

Max. welding current

and the respective

conventional load voltage: 10 A/20,4 V -

120 A/24,8 V

Rated value of the

Mains voltage: U

: 230 V

1

Highest rated value

of the mains current: I

: 25,2 A

1max

Maximum effective

input current: I

: 13,8 A

1eff

Rated value of the

no-load voltage: U

: 70 V

0

Protection class: IP21S

Weight: 3,2 kg

Duty cycle X: 30 %

Falling characteristic

z Scope of delivery

1 Inverter welder

1 Welding shield

2 Welding cables

1 Combination wire brush with chipping

hammer

1 Carrying strap

5 Welding electrodes (2 x 1.6 mm;

2 x 2.0 mm; 1 x 2.5 mm)

1 Instructions for use

7GB/CY

Safety instructions

z Safety instructions

Please carefully read the instructions for use and follow the specified notices. Familiarise yourself

with the tool, its proper use and

the safety notices using these instructions for use. The nameplate

contains all the technical data for

this welding tool, please learn

about the technical facts of this

tool.

This device may be used by

children aged 16 years and

up, as well as by persons with

reduced physical, sensory or

mental capacities, or lacking

experience and / or knowledge, so long as they are

supervised or instructed in the

safe use of the device and understand the associated risks.

Do not allow children to play

with the appliance. Cleaning

and user maintenance should

not be performed by children

without supervision.

Only have repairs and / or

maintenance performed by

electrically skilled persons.

Only use the welding cables

included (PISG 120 A1,

H01N2-D1x10 mm2).

During use the equipment

should not be located directly

against a wall, be covered,

or be jammed between other

equipment to ensure ample air

can be taken in through the

ventilation louvres. Verify the

equipment is correctly connected to the mains voltage. Avoid

any tensile load on the mains.

Unplug the mains plug from

the socket before transferring

the equipment to a different

location.

Always switch the equip-

ment off with the ON / OFF

switch when not in use. Set

the electrode holder down on

an insulated pad and allow

to cool for 15 minutes before

removing the electrodes from

the holder.

Pay attention to the condition

of the welding cables, the electrode holders and the earth

terminals. Worn insulation and

conducting parts can produce

hazards and reduce the welding quality.

Arc welding produces sparks,

melted metal parts and smoke.

Therefore note: Remove any

flammable substances and

/ or materials from the work

area and its immediate surroundings.

Ensure the work area is venti-

lated.

8 GB/CY

Safety instructions

Do not weld atop containers,

receptacles or pipes, which

do or did contain flammable

liquids or gasses.

WARNING

Avoid any direct

contact with the welding

circuit. The no-load voltage

between the electrode holder

and earth terminal can be dangerous, there is a risk of electric shock.

Do not store or use the equip-

ment in a moist or wet environment or in the rain. The Protection Provision IP21S applies in

this respect.

Protect the eyes with the ap-

propriate safety glass (DIN

Grad 9-10) to be installed in

the included welding shield.

Use gloves and dry protective clothing free from oil and

grease to protect the skin from

ultraviolet rays and the arc.

WARNING

Do not use the

welding power source to thaw

pipes.

a relatively long time. Therefore do not touch the work

piece with bare hands.

Arc welding releases noxious

fumes. Be careful not to inhale

these as best possible.

Protect yourself from the danger-

ous effects of the arc and keep

persons not involved in the work

at least 2 m away from the arc.

ATTENTION!

Depending on mains condi-

tions at the connection point,

operating the welding equipment may interfere with the

voltage supply for other loads.

When in doubt, please contact

your power supply company.

Operating the welding equip-

ment may interfere with the

functionality of other devices,

e.g. hearing aids, pacemakers, etc.

z Safety hazards

during arc welding

Remember:

The arc ray can damage the

eyes and cause burns to the

skin.

Arc welding produces sparks

and drops of molten metal, the

welded work piece begins to

glow and remains very hot for

Arc welding produces a variety

of safety hazards. It is therefore

particularly important for the

welder to observe the following

rules to avoid putting himself and

others in danger and to prevent

damage to persons and the

equipment.

9GB/CY

Safety instructions

Only have work to the mains

voltage end, e.g. to cables,

plugs, outlets, etc. performed

by a electrically skilled person

in accordance with national

and local regulations.

In the event of an accident,

immediately disconnect the

welding equipment from the

mains voltage.

If electrical contact voltage

occurs, immediately switch

the equipment off and have

it inspected by an electrically

skilled person.

Always ensure good electrical

contacts on the welding current end.

Always wear insulating gloves

on both hands whilst welding.

These will protect from electric

shock (no-load voltage of the

welding current), from hazardous rays (heat and UV rays)

and glowing metal and weld

splashes.

Wear solid, insulating shoes.

The shoes should also insulate

when exposed to moisture.

Low shoes are not suitable, as

glowing metal drops falling

could cause burns.

Wear suitable protective cloth-

ing, no synthetic garments.

Do not look into the arc with

unprotected eyes, only use a

welding shield with approved

protective glass per DIN. In

addition to light- and heat rays

which could result in blinding

or burns, the arc also emits UV

rays. Without adequate protection, this invisible ultraviolet

radiation causes very painful

conjunctivitis which is only

noticed a few hours later. UV

rays further cause burns similar to a sunburn in unprotected

areas of the body.

Persons near the arc or assis-

tants must also be informed of

the risks and outfitted with the

necessary protection. If necessary, set up protective panels.

Ensure an adequate supply of

fresh air whilst welding, particularly in small spaces, as it

produces smoke and harmful

gasses.

Do not weld containers in

which gasses, fuels, mineral

oils, etc. were stored - even if

emptied a long time ago - as

residue poses an explosion

hazard.

Special regulations apply in

rooms posing fire- and explosion hazards.

Welded joints exposed to

great strain and needing to

meet certain safety requirements must be made by spe-

10 GB/CY

Safety instructions

cially trained and certified

welders. Examples are pressure vessels, running rails, tow

couplings, etc.

ATTENTION! Always connect

the earth terminal as close as

possible to the point of weld to

provide the shortest possible path

for the welding current from the

electrode to the earth terminal.

Never connect the earth terminal

to the housing of the welding

equipment!

Never connect the earth terminal

to earthed parts far away from

the work piece, e.g. a water pipe

in another corner of the room.

This could otherwise damage the

protective bonding system of the

room you are welding.

Danger of electric shock:

Electric shock from a

welding electrode can be

fatal. Do not weld in rain or

snow. Wear dry insulating

gloves. Do not touch the electrode with bare hands. Do not

wear wet or damaged gloves.

Protect yourself from electric

shock by insulating from the work

piece. Do not open the equipment housing.

Danger due to welding

smoke:

Inhaling welding smoke can

jeopardize your health. Keep

your head out of the smoke. Use

facilities in open areas. Use ventilation to remove smoke.

Do not use the welding equip-

ment in the rain.

Do not use the welding equip-

ment in a moist environment.

Only place the welding equip-

ment in a level location.

The output is rated at an ambi-

ent temperature of 20 °C. The

welding time may be reduced

in higher temperatures.

Danger due to welding

sparks:

Welding sparks can cause an explosion or fire. Keep flammables

away from the welding area.

Do not weld next to flammables.

Welding sparks can cause a fire.

Keep a fire extinguisher nearby

and an observer ready to use it.

Do not weld on top of drums or

any closed containers.

Danger due to arc rays:

Arc rays can damage the eyes

11GB/CY

Safety instructions

and injure the skin. Wear a hat

and safety goggles. Wear hearing protection and a closed,

high shirt collar. Wear welding

helmets and proper filter sizes.

Wear full personal protection.

Danger due to

electromagnetic fields:

Welding current produces electromagnetic fields. Do not use along

with medical implants. Never

wrap the welding cables around

the body. Consolidate welding

cables.

z Safety notices specific to

the welding shield

Using a hot light source (e.g.

lighter) always check the welding shield is working properly

before starting to weld.

Welding splashes can damage

the glass shield. Replace damaged or scratched glass shields

immediately.

Promptly replace damaged or

heavily soiled / splashed components.

The equipment may only be

operated by persons who have

turned 16.

Familiarise yourself with the

safety instructions for welding.

Also refer to the safety instructions of your welding equipment.

Always use the welding shield

when welding. Failure to use

the shield may result in serious

injuries to the retina.

Always wear protective clothing

when welding.

Never use the welding shield

without protective glass, as the

optics can otherwise be damaged.

Replace the protective glass ear-

ly to ensure good visibility and

fatigue-proof working.

z Tight and moist spaces

When working in tight, moist

or hot spaces, use insulating

pads and intermediate layers

in addition to gauntlet gloves

made from leather or other

insulating materials to insulate

the body from earth.

When using welding equip-

ment in electrically dangerous

conditions, e.g. in tight spaces

from conductive walls (kettles,

pipes, etc.), in wet spaces

(soaking of work clothes), the

output voltages of the welding

equipment may not be higher

than 48 Volts (rms value) in

12 GB/CY

Safety instructions / Prior to commissioning / Installing the welding shield

open loop. Based on the output voltage this welding equipment may be used in these

conditions.

z Protective clothing

Whilst working the welder

must be protected against rays

and burns all over the body

with the appropriate clothing

and face protection. Remember the following steps:

Put on protective clothing

before welding.

Put on gloves.

Open windows or vent to

ensure air supply.

Wear safety goggles and a

mask.

Wear gauntlet gloves made

from suitable material (leather)

on both hands. These must be

in good condition.

Wear suitable aprons to pro-

tect the clothing from sparks

and burns. When required

based on the working method,

e.g. welding overhead, wear

a protective suit and, if necessary, a head guard.

z Protecting against

rays and burns

sign „Danger! Do not look into

flames!“ to indicate the risk to

the eyes. If possible, shield the

work areas to protect persons

nearby. Keep unauthorised

persons away from the welding area.

Walls in the direct vicinity

of fixed work areas should

be neither light coloured

nor glossy. Protect windows

against rays passing through

or reflecting at a minimum to

head height, e.g. with suitable

paint.

z Prior to commissioning

Take the device and accessories out of

the packaging and check

for damages (e.g. transport damages).

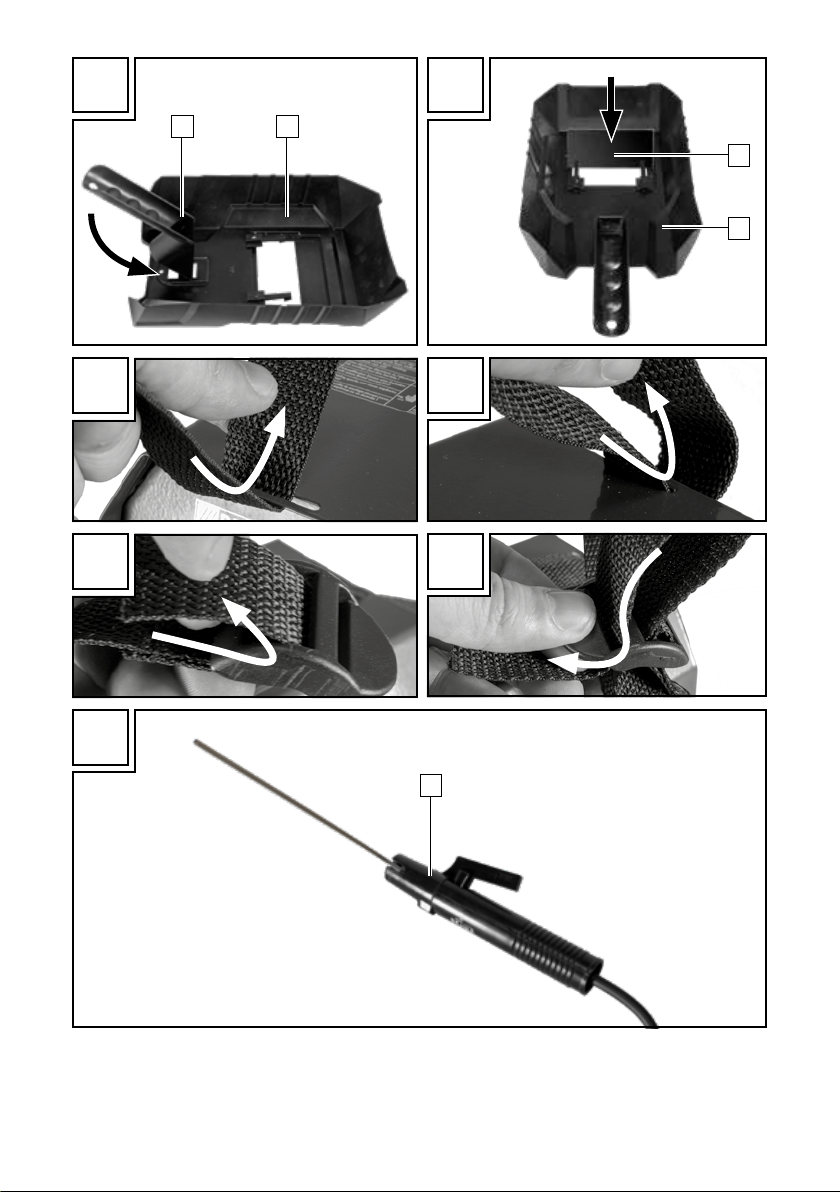

Fasten the carrying strap to the device

(see Fig. C1 – C4).

11

on the

5

and the

Connect the electrode holder

earth terminal

chine.

Insert an electrode into the electrode

clamp device (see Fig. D).

4

to the welding ma-

z Installing the welding

shield

Install the handle 8 on the welding

Install the protective glass

7

shield

welding shield

as shown in Fig. A.

7

as shown in Fig. B.

Mark the work area with a

13GB/CY

Start up

z Start up

Note: The welding tool is suitable for weld-

ing with electrodes.

Use electrode retaining clips without pro-

truding retaining screws meeting today‘s

safety standards.

Be sure the ON / OFF switch

position “O“ (“OFF“) or the main supply

10

cable

is not plugged into the mains

socket.

Connect the welding cables according

to polarity and electrode manufacturer

instructions.

To do so, connect the port of the earth

terminal

4

(black) with the appropriate

outlet on the inverter welding machine

(black, marked with “-”).

Connect the port of the electrode holder

5

(red) with the appropriate outlet on

the inverter welding device (red, marked

with “+”),

Put on suitable protective clothing

according to provisions and prepare the

work area.

Connect the earth terminal

workpiece.

Secure the electrode in the electrode

holder

5

.

Switch on the device by setting the ON /

OFF switch

9

to the “I“ (“ON“) position.

Set the welding current with the control

3

knob

according to the electrode used.

Note: Please see the table below for the

welding current according to electrode

diameter.

Ø Electrode welding current

1.6 40 – 55 A

2.0 55 – 65 A

2.5 65 – 80 A

3.2 80 – 120 A

4

9

is set to

to the

Note: For the welding currents of 80 A to

120 A, please use welding electrodes with

a diameter of 3.2 mm (not included in the

scope of delivery).

Attention: Do not bring the earth

terminal

4

and the electrode holder 5/

electrodes into direct contact with one

another.

Attention: When welding with elec-

trodes (MMA - manual metal arc

welding) the electrode holder

earth terminal

4

lug must be connected

5

and the

to positive (+) or negative (-) according

to the welding rod specifications.

Hold the welding shield

7

in front of

your face and begin welding.

To stop working, set the ON / OFF

9

switch

to the “O“ (“OFF“) position.

ATTENTION!

When the thermal overload protection is

triggered, the yellow control lamp

2

lights

up. In this case, no further welding is

possible. The device is still in operation for

the fan to cool the device. As soon as the

device is ready for use again, the yellow

control lamp

2

switches off automatically.

The welding function is now given again.

ATTENTION!

Be careful not to rub the welding rod against

the workpiece. This could damage the

workpiece and make it difficult to strike an

arc. Maintain the proper distance to the

workpiece after striking the arc. The distance

should correlate to the diameter of the

welding rod used. Maintain this distance as

accurately and consistently as possible whilst

welding. The angle between the welding

rod and the working direction should be

between 20 and 30 °.

14 GB/CY

Start up / Welding / Maintenance and Cleaning

ATTENTION!

After welding, the welding clamp and

the welding rod must be set down on the

insulated holder. The fusion slag can only

be removed once the rod has cooled down.

To re-weld the interrupted weld, the fusion

lag must first be removed from the welding

position.

ATTENTION!

A voltage 10 % below the rated input voltage of the welding tool may result in:

A drop in the current of the tool.

The arc stopping or becoming unstable.

ATTENTION!

The arc radiation may cause inflamma-

tion of the eye and skin burns.

Spray and fusion slag may cause eye

injuries and burns.

Wear tinted eye goggles or a face

shield.

The face shield must comply with safety

standard EN175.

Only use welding cables included in

delivery (10 mm2).

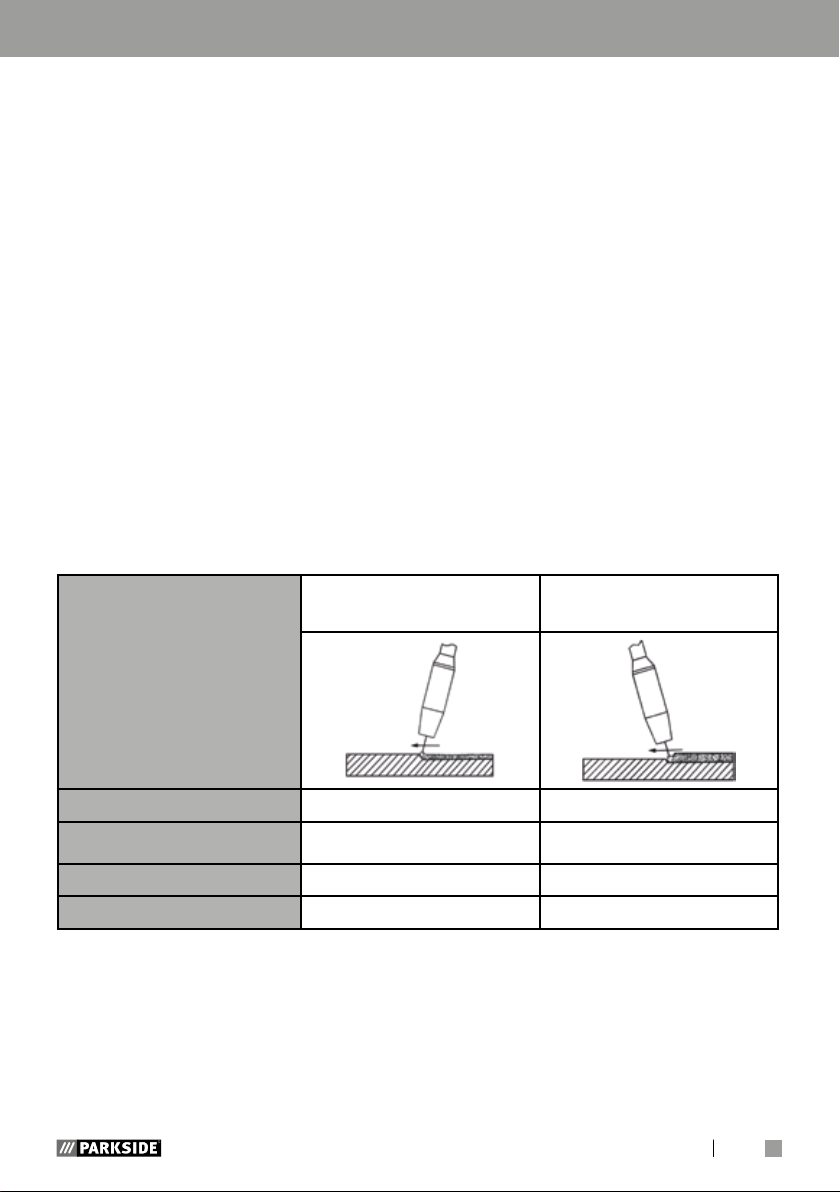

z Welding

Choose from welding with the tool directed towards the unwelded or the welded part.

The following illustrates how the direction of movement has on the quality of the weld:

Towards the unwelded

part:

Towards the welded

part:

Weld penetration

Weld width

Welding bead

Weld imperfections

Note: Determine which welding method is

more suitable for yourself after welding a test

piece.

Note: Once it has worn down completely,

the electrode must be replaced.

larger smaller

greater less

less greater

flatter higher

z Maintenance and Cleaning

Note: The welding tool requires regular

maintenance and reconditioning to work

properly and to comply with safety requirements. Improper and incorrect operation

may result in malfunctions and damage the

tool.

15GB/CY

Maintenance and Cleaning / Information about warranty and service ...

Before performing maintenance work or

repairs on the welding tool, disconnect

the power cable

to ensure the tool is safely isolated from

the power supply.

Clean the exterior of the welding tool

regularly. Use compressed air, cotton

waste or a brush to remove dirt and dust.

Note: The following kinds of maintenance

work must be performed only by suitably-qualified personnel.

Current regulators, earthing equipment,

internal cables, the blowpipe coupler

and adjusting screw should be maintained regularly. Tighten loose screws

and replace rusty screws (M4 × 10

replacement screws are available from

your local DIY store.).

Regularly check the leakage resistance of

the welding tool. Use suitable measuring

instruments for this purpose.

In the event of a defect or if components

need to be replaced, please contact the

correspond ing professional.

10

from the power outlet

safely. This document is required as your

proof of purchase.

Should this device show any fault in materials or manufacture within three years

from date of purchase, it will be repaired

or replaced - at our choice - by us free of

charge. This warranty is conditional on the

defective device and the receipt of purchase

(store receipt) being presented within the

three year warranty period, and that there

is a brief written description of the nature of

the defect and of the date it arose.

If the defect is covered by our warranty,

we will return the repaired equipment or

replacement thereof. A repair or exchange

of the equipment does not extend a new

warranty period.

z Extent of warranty

The appliance has been manufactured to

strict quality guidelines and meticulously

examined before delivery.

z Information about

warranty and service

processing

Creative Marketing & Consulting

GmbH warranty

Dear customer, the warranty for this device

is 3 years from the date of purchase. In the

event of product defects, you have legal

rights against the retailer of this product.

Your statutory rights are not limited in any

way by our warranty detailed below.

z Warranty terms

The warranty period begins on the date of

purchase. Please retain the original receipt

16 GB/CY

The warranty applies to faults in material or

manufacture. This warranty does not apply

to product parts subject to normal wear and

tear and which can therefore be considered

as wear items, or to damage to fragile parts,

e.g. switches, storage batteries or glass

parts.

This warranty becomes void if the device

has been damaged or improperly used or

maintained. All instructions provided in the

operating instructions must be followed strictly to constitute proper use of the product.

Purposes and practices which the operating

instructions warn of or advise against must

be avoided without fail.

This product is intended for private, non-commercial use only. Any incorrect or improper

use of the device, use of force and changes

... / Environmental instructions and ... / EU Conformity Declaration

not performed by our authorized service

branch will void the warranty.

z Processing of warranty

claims

Please follow the instructions below to ensure

your claim is processed quickly:

When inquiring about your product please

have your receipt and product number (e.g.

IAN) ready as your proof of purchase.

The product number can be found on the

type plate, an engraving, the cover page of

your instructions (bottom left) or the decal at

the back or bottom. In the event of malfunctions or other defects please first contact

the service department below by phone or

e-mail.

A product recorded as defective, along with

the proof of purchase (sales receipt) and

a description of the defect and when it occurred, can then be returned free of charge

to you to the service address provided.

Notice:

Download this and many other

manuals, product videos and

software from www.lidl-service.com.

How to contact us:

Please note that the following address is not

a service address.

Please first contact the service point named

above.

Address:

C. M. C. GmbH

Katharina-Loth-Str. 15

DE-66386 St. Ingbert

GERMANY

z Environmental instructions

and disposal information

Don‘t waste,

recycle!

Device, accessories and packaging

should be recycled in an environmentally friendly manner.

According to European Directive

2012/19/ EU, used electrical devices

must be collected separately for

environmentally compatible recycling

or recovery.Please return this device to

an approved waste management company or use your municipal waste collection

service. Please ensure you comply with

local regulations. If you have any questions,

please contact your local authority or waste

management company.

GB/CY

Name: C.M.C. GmbH

Website: www.cmc-creative.de

E-mail: service.gb@cmc-creative.de

service.ie@cmc-creative.de

Phone: 0-808-189-0652

(£ 0,10 / Min.)

Registered office: Germany

IAN 310850

z EU Conformity Declaration

We,

C. M. C. GmbH

Responsible for documentation:

Alexander Hoffmann

Katharina-Loth-Str. 15

DE-66386 St. Ingbert

GERMANY

declare in our sole responsibility that the

product

17GB/CY

EU Conformity Declaration

Inverter welder

Art.-No.: 2177

Year of manufacture: 2019/15

IAN: 310850

Model: PISG 120 A1

meets the basic safety requirements of European Directives

EC Low Voltage Directive

2014 / 35 / EU

EC Directive for Electromagnetic

Compatibility

2014 / 30 / EU

RoHS Directive

2011 / 65 / EU

and its amendments.

The object of the declaration described

above meets the requirements of Directive

2011 / 65 / EU of the European Parliament

and Council dated 8th June 2011, restricting

the use of certain hazardous substances in

electrical appliances and electronics.

The conformity assessment is based on the

following harmonised standards:

EN 60974-1:2012

EN 60974-10:2014/A1:2015

St. Ingbert, 10.12.2018

On behalf of M. Sc. Alexander Hoffmann

– Quality Assurance –

18 GB/CY

19GB/CY

20 GB/CY

Popis sadržaja

Tablica korištenih piktograma .......................................................... Stranica 22

Uvod.................................................................................................................Stranica 23

Korištenje sukladno odredbama......................................................................Stranica 23

Opis dijelova....................................................................................................Stranica 23

Tehnički podaci................................................................................................Stranica 23

Obim isporuke ................................................................................................. Stranica 24

Sigurnosne napomene ........................................................................... Stranica 24

Izvori opasnosti prilikom elektrolučnog zavarivanja ........................................ Stranica 26

Sigurnosne napomene specične za masku za zavarivanje...........................Stranica 28

Zaštitna odjeća ................................................................................................Stranica 29

Prije puštanja u rad .................................................................................Stranica 30

Montiranje maske za zavarivanje .................................................... Stranica 30

Puštanje u režim rada ............................................................................ Stranica 30

Zavarivanje .................................................................................................. Stranica 32

Održavanje i čišćenje ............................................................................. Stranica 33

Napomene za garanciju i odvijanje servisa ............................... Stranica 33

Uvjeti garancije................................................................................................Stranica 33

Obim garancije ................................................................................................ Stranica 33

Odvijanje u slučaju garancije ..........................................................................Stranica 34

Napomene za okolicu i podaci za uklanjanje na otpad .......Stranica 35

Originalna EZ izjava o sukladnosti .................................................Stranica 35

21HR

Tablica korištenih piktograma

Tablica korištenih piktograma

1~50Hz

Oprez!

Pročitajte uputu za rukovanje!

Mrežni ulaz;

Broj faza kao i simbol izmjenične struje i dimenzionirana

vrijednost frekvencije

Električne uređaje nemojte

uklanjati u kućni otpad!

Ne koristite uređaj u prirodi

i nikada ako pada kiša!

Električni udar elektrode

za zavarivanje može biti

smrtonosan

Udisanje dima od zavarivanja može ugroziti vaše

zdravlje.

UPOZORENJE

IP21S Vrsta zaštite

Moguće teške

do smrtne ozljede.

Oprez!

Opasnost od strujnog

udara!

Važna napomena!

Ambalažu i uređaj ekološki

uklonite na otpad!

Elektrolučno ručno

zavarivanje s obloženim

štapnim elektrodama

Namijenjena za zavarivanje

pod povišenom električnom

opasnošću

22 HR

Iskre od zavarivanja mogu

prouzročiti eksploziju ili

požar.

Elektrolučni bljesci mogu

oštetiti oči i ozlijediti kožu.

Elektromagnetska polja

mogu ometati funkciju pejsmejkera.

Pozor, moguće opasnosti!

H Klasa izolacije

OPREZ

UPOZORENJE: Mogućnost strujnog udara !

Ne otvarati kućište proizvoda !

Jednofazni statičan pretvarač frekvencije-transformatorispravljač

Istosmjerna struja

Izrađeno od recikliranog

materijala.

Uvod

INVERTER APARAT ZA

ZAVARIVANJE PISG 120 A1

z Uvod

Čestitamo! Odlučili ste za uređaj visoke

kvalitete. Prije prvog

puštanja u režim rada

upoznajte se s proizvodom. Za to pozorno pročitajte sigurnosne

napomene. Puštanje ovog proizvoda u

režim rada smije vršiti samo za to obučeno osoblje.

NE DOPUSTITE DA DOSPIJE

U DJEČJE RUKE!

z Korištenje sukladno

odredbama

Ovaj je uređaja za zavarivanje namijenjen

za zavarivanje metala kao što su ugljični čelik, legirani čelik, drugi nehrđajući

čelici, bakar, aluminij, titan, itd. Proizvod

raspolaže kontrolnom lampicom, prikazom toplotne zaštite i ventilatorom za

hlađenje. Uz to je opremljen remenom za

sigurno podizanje i pokretanje proizvoda.

Nestručno rukovanje proizvodom može

biti opasno za lica, životinje i materijalne vrijednosti. Proizvod koristite samo

kako je opisano te za navedena područja primjene. Ovu uputu dobro čuvajte.

Prilikom prosljeđivanja proizvoda trećem

licu također predajte i sve dokumente.

Svaka primjena koja odstupa od korištenja u skladu s odredbama, zabranjena je i

potencijalno opasna. Štete uslijed neobraćanja pozornosti ili pogrešne primjene ne

pokrivaju se garancijom te ne spadaju u

područje odgovornosti proizvođača.

Napomena: Kategorizacija prema EMV

direktivi: Klasa A sukladno IEC 60974-10

Upozorenje: Kao klasa A klasicirani uređaji su predviđeni za primjenu u

industrijskom sektoru. U slučaju primjene

u drugim sektorima elektromagnetska

podnošljivost se obzirom na okolnosti ne

može garantirati, odnosno može doći do

slučajeva smetnje.

z Opis dijelova

1

Pojas za nošenje

2

Kontrolna lampica za pregrijavanje

3

Okretni gumb

4

Stezaljka za masu

5

Držač elektroda

6

Kombinirana žičana četka s čekićem za

šljaku

7

Maska za zavarivanje

8

Ručka

9

Prekidač za UKLJ / ISKLJ

10

Mrežni kabel

11

Zaštitno staklo

z Tehnički podaci

Mrežni priključak:

Maks. struja zavarivanja

i odgovarajući normirani

radni napon: 10A / 20,4 V 120 A/24,8 V

Dimenzionirana vrijednost

mrežnog napona: U

Najveća dimenzionirana

vrijednost mrežne struje: I

Maksimalna efektivna

ulazna struja: I

Dimenzionirana vrijednost

napona praznog hoda: U

Vrsta zaštite: IP21S

230 V~ 50 Hz

: 230 V

1

: 25,2 A

1max

: 13,8 A

1e

: 70 V

0

23HR

Uvod / Sigurnosne napomene

Težina: 3,2 kg

Trajanje uključivanja X: 30 %

Opadajuća karakteristična linija

z Obim isporuke

1 invertor uređaja za zavarivanje

1 maska za zavarivanje

2 voda za zavarivanje

1 kombinirana žičana četka s čekićom

za šljaku

1 pojas za nošenje

5 elektroda za zavarivanje

(2 x 1,6 mm; 2 x 2,0 mm; 1 x 2,5 mm)

1 uputa za rukovanje

z Sigurnosne napomene

Molimo brižljivo pročitajte

instrukciju za uporabu te obratite pozornost na opisane

napomene. Uz pomoć instrukcije za uporabu upoznajte se s uređajem, njegovom

pravilnom uporabom te sa

sigurnosnim napomenama. Na

tipskoj pločici stoje svi tehnički

podaci ovog uređaja za zavarivanje, molimo informirajte se

o tehničkim datostima ovog

uređaja.

Uređaj mogu koristiti djeca

od 16 godina pa naviše te

lica sa smanjenim psihičkim,

senzoričkim ili mentalnim

sposobnostima ili nedostat

-

kom iskustva i znanja, ako

su pod nadzorom ili ako su

podučeni vezano za sigurnu

uporabu uređajem te razumiju opasnosti koje mogu biti

rezultat toga. Djeca se ne

smiju igrati uređajem. Djeca

bez nadzora ne smiju pro

-

voditi čišćenje i korisničko

održavanje.

Neka popravke ili/ i radove

na održavanju provode samo

kvalicirani elektrostručnjaci.

Koristite samo vodove za

zavarivanje koji su sadržani

u obimu isporuke (PISG 120

2

A1, H01N2-D1x10 mm

).

Tijekom režima rada uređaj

ne bi trebao stajati direktno

na stjenki, ne bi trebao biti

pokriven ili uglavljen između

drugih uređaja, kako bi se

kroz proreze za prozračivanje

moglo primiti dovoljno zra

-

ka. Uvjerite se da je uređaj

pravilno priključen na mrežni

napon. Izbjegavajte svako

vučno opterećenje mrežnog

voda. Mrežni utikač izvucite

iz utičnice prije no što uređaj

postavite na neko drugo

mjesto.

Ako uređaj nije u režimu

rada, uvijek ga isključite

pomoću prekidača za UKLJ/

ISKLJ. Držač elektroda

24 HR

UPOZORENJE

UPOZORENJE

Sigurnosne napomene

položite na izoliranu podlogu i

tek nakon 15 minuta hlađenja

uzmite elektrode iz držača.

Pazite na status kabela za

zavarivanje, držača elektroda

te stezaljki mase. Istrošenosti

na izolaciji i na dijelovima koji

provode struju mogu izazvati

opasnosti i smanjiti kvalitetu

zavarivačkoga rada.

Elektrolučno zavarivanje

proizvodi iskre, otopljene

dijelove metala te dim. Stoga obratite pozornost: Sve

zapaljive tvari i / ili materijale

uklonite s radnog mjesta i iz

njegove neposredne okolice.

Pobrinite se za ventilaciju

radnoga mjesta.

Nemojte zavarivati na sprem-

nicima, buradima ili cijevima,

koje sadrže ili su sadržale

zapaljive tekućine ili plinove.

Izbjegavajte

svaki direktan kontakt sa

strujnim kolom zavarivanja.

Napon praznog hoda između

kliješta elektrode i stezaljke

mase može biti opasan, postoji opasnost od električnog

udara.

Uređaj nemojte skladištiti ili

koristiti u vlažnoj ili mokroj

okolici ili po kiši. Ovdje vrijedi zaštitna odredba IP21S.

Oči zaštitite sa za to

određenim zaštitnim staklima

(DIN stupanj 9-10), koja se

pričvršćuju na isporučenu

zaštitnu masku za zavarivanje. Koristite rukavice te suhu

zaštitnu odjeću, koja je bez

ulja i masti, kako biste kožu

zaštitili od ultraljubičaste radijacije elektroluka.

I

zvor struje za

zavarivanje nemojte koristiti

za odmrzavanje cijevi.

Obratite pozornost:

Radijacija elektroluka može

oštetiti oči i izazvati opekline

na koži.

Elektrolučno zavarivanje

proizvodi iskre i kapi otopljenog metala, radni komad,

koji se zavaruje, se počinje

žariti i relativno dugo ostaje

vreo. Stoga radni komad ne

dodirujte golim rukama.

Prilikom elektrolučnog zava-

rivanja oslobađaju se pare

koje su štetne po zdravlje.

Pazite na to da da ih, ukoliko

je moguće, ne udišete.

Zaštitite se od opasnih efe-

kata elektroluka te lica koja

ne učestvuju u radu udaljite

najmanje 2 m od elektroluka.

POZOR!

Tijekom režima rada uređaja

25HR

Sigurnosne napomene

za zavarivanje, ovisno

o mrežnim uvjetima na

priključnoj točki, može doći

do smetnji u opskrbi naponom za ostale potrošače. U

slučaju sumnje se obratite

Vašoj tvrtki za opskrbu energijom.

Tijekom režima rada uređaja

za zavarivanje može doći

do funkcijskih smetnji drugih

uređaja, npr. slušnog aparata, pejsmejkera itd.

z Izvori opasnosti pri-

likom elektrolučnog

zavarivanja

Prilikom elektrolučnog zavarivanja rezultira čitav niz

izvora opasnosti. Stoga je za

zavarivača osobito važno,

obratiti pozornost na slijedeća

pravila, kako ne bi ugrozio

sebe ni druge i kako bi izbjegao

štete po ljude i uređaj.

Neka radove na stra-

ni mrežnog napona, npr.

na kabelima, utikačima,

utičnicama itd. izvede samo

elektrostručnjak prema nacionalnim i lokalnim propisima.

U slučaju nezgoda uređaj za

zavarivanje smjesta isključite

s mrežnog napona.

Ako nastupe električni dodir-

ni naponi, smjesta isključite

uređaj te ga dajte kontrolirati

od strane elektrostručnjaka.

Na strani struje za zavari-

vanje uvijek pazite na dobre

električne kontakte.

Prilikom zavarivanja na

obadvije ruke uvijek nosite

izolirajuće rukavice. One

štite od električnih udara

(napon praznog hoda strujnog kola za zavarivanje), od

štetnih radijacija (toplina i

UV-radijacije) te od užarenih

metala i udarnog prskanja.

Nosite čvrste, izolirane cipe-

le. Cipele se trebaju izolirati

i kod vlage. Polucipele nisu

prikladne, pošto užarene

kapi metala, koje padaju,

mogu prouzročiti opekline.

Nosite prikladnu zaštitnu

odjeću, nikako sintetičke

komade odjeće.

Nezaštićenim očima nemojte

gledati u elektroluk, koristite

samo masku za zavarivanje

s propisanim zaštitnim staklom prema DIN-u. Elektroluk

emitira svjetlosne te toplinske bljeskove, koji mogu

prouzročiti zasljepljivanje

odnosno opeklinu, također

UV-bljeskovi. Ova nevidljiva

ultraljubičasta radijacija u

slučaju nedovoljne zaštite

26 HR

Sigurnosne napomene

tek nekoliko sati kasnije

prouzroči uočljivu, veoma bolnu upalu vežnjače.

Osim toga UV-radijacija na

nezaštićenim dijelovima tijela izaziva opeklinu kao kod

sunčanja.

Licima ili pomoćnicima koji

se nalaze u blizini elektroluka također se mora ukazati

na opasnosti i opremiti ih

s neophodnim zaštitnim

sredstvima. Ako je neophodno, postavite zaštitne stjenke.

Prilikom zavarivanja, osobito

u malim prostorijama, morate se pobrinuti za dovoljan

dotok svježeg zraka, pošto

nastaju dim i štetni plinovi.

Na spremnicima, u kojima

se skladište plinovi, goriva,

mineralna ulja ili sl., – iako

su već odavno ispražnjeni

– ne smiju se poduzimati

radovi na zavarivanju, pošto

uslijed ostataka postoji

opasnost od eksplozije.

U prostorijama s opasnošću

od vatre i eksplozije vrijede

osobiti propisi.

Zavarene veze, koje

su izložene velikim

opterećenjima i moraju

ispunjavati određene sigurnosne zahtjeve, smiju izvo-

diti samo osobito obrazovani

te provjereni zavarivači.

Primjeri su kotlovi pod tlakom, tračnice, kuke prikolica

itd.

POZOR! Stezaljku mase uvijek priključite što je moguće

bliže mjestu zavarivanja, tako

da struja za zavarivanje može

uzeti najkraći mogući put od

elektrode do stezaljke mase.

Stezaljku mase nikada nemojte

povezati s kućištem uređaja

za zavarivanje! Stezaljku

mase nikada nemojte povezati na uzemljene dijelove, koji

se nalaze daleko od radnog

komada, npr. cijev za vodu u

drugom kutu prostorije. U suprotnom bi moglo doći do toga

da sustav zaštitnih provodnika

prostorije, u kojoj zavarujete,

bude oštećen.

Uređaj za zavarivanje ne

koristite po kiši.

Uređaj za zavarivanje ne

koristite u vlažnoj okolici.

Uređaj za zavarivanje pos-

tavite samo na jedno ravno

mjesto.

Izlaz je dimenzioniran na

temperaturu okolice od 20

°C. Vrijeme zavarivanja se

na višim temperatura smije

reducirati.

27HR

Sigurnosne napomene

Ugroženost uslijed

električnog udara:

Električni udar neke

elektrode za zavarivanje može biti smrtonosan.

Nemojte zavarivati po kiši i

snijegu. Nosite suhe izolirane rukavice. Elektrodu

nemojte hvatati golim rukama. Nemojte nositi vlažne ili

oštećene rukavice. Od

električnog udara zaštitite se

izoliranjem u odnosu na

radni komad. Ne otvarajte

kućište mehanizma.

Ugroženost uslijed dima

od zavarivanja:

Udisanje dima od zavari-

vanja može ugroziti zdravlje.

Glavu nemojte držati u dimu.

Mehanizme koristite u otvorenim sektorima. Koristite

odzračivanje za uklanjanje

dima.

Ugroženost uslijed iskri

od zavarivanja:

Iskre od zavarivanja mogu

prouzročiti eksploziju ili

požar. Zapaljive tvari udaljite

od zavarivanja. Nemojte zavarivati pored zapaljivih tvari.

Iskre od zavarivanja mogu

prouzročiti požare. Pripremite aparat za gašenje požara

u blizini i promatrača, koji ga

smjesta može koristiti. Nemojte zavarivati na bubnjevima ili nekakvim zatvorenim

spremnicima.

Ugroženost uslijed bljeskova elektroluka:

Elektrolučni bljeskovi mogu

oštetiti oči i ozlijediti kožu.

Nosite šešir i zaštitne

naočale. Nosite zaštitu sluha

i visoko zatvoreni ovratnik

košulje. Nosite zaštitne kacige za zavarivanje i prikladne

veličine ltra. Nosite potpunu

tjelesnu zaštitu.

Ugroženost uslijed

elektromagnetskih polja:

Struja za zavarivanje proiz-

vodi elektromagnetna polja.

Ne koristite zajedno s medicinskim implantatima. Vodove za zavarivanje nikada ne

umotavajte oko tijela. Spojite

vodove za zavarivanje.

z Sigurnosne napomene

specične za masku

za zavarivanje

Prije početka radova se uz

pomoć svijetlog izvora svjetla

(npr. vozilo) uvjerite u propis

-

nu funkciju maske za zavarivanje.

28 HR

Sigurnosne napomene

Vrhom za zavarivanje može

se oštetiti zaštitno staklo. Oštećena ili izgrebena

zaštitna stakla smjesta izmijenite.

Bez odgode zamijenite

oštećene ili jako zaprljane

odnosno poprskane komponente.

Uređaj smiju u rad pustiti

samo lica, koja su napunila

16. godinu života.

Upoznajte se sa sigurnosnim

propisima za zavarivanje. Uz

to također obratite pažnju

na sigurnosne napomene za

Vaš uređaj za zavarivanje.

Prilikom zavarivanja uvijek

nosite masku za zavarivanje.

Nekorištenje može dovesti

do teških ozljeda mrežnice.

Tijekom zavarivanja uvijek

nosite zaštitnu odjeću.

Zaštitnu masku nikada ne-

mojte koristiti bez zaštitnog

stakla, pošto se inače može

oštetiti optička jedinica.

Za dobru vidljivost i rad bez

zamora blagovremeno zamijenite zaštitno staklo.

Uske i vlažne prostorije

Prilikom radova u uskim,

vlažnim ili vrelim prostorijama morate koristiti izolirane

podloge i međuslojeve, dalje

rukavice od kože s posuvratkom ili drugih izolacijskih

materijala, kako biste tijelo

izolirali od zemlje.

Prilikom korištenja uređaja

za zavarivanje pod

električno opasnim uvjetima,

npr. U uskim prostorijama od

električno provodnih stjenki

(kotao, cijevi itd.), u vlažnim

prostorijama (ovlaživanje

radne odjeće), izlazni napon uređaja za zavarivanje

u praznom hodu ne smije

biti veći od 48 V (efektivna

vrijednost). Ovaj uređaj za

zavarivanje se na osnovu izlaznog napona smije koristiti

u ovim slučajevima.

z Zaštitna odjeća

Tijekom rada zavarivač

po cijelom tijelu mora biti

zaštićen odgovarajućom

odjećom te zaštitom za

lice od radijacije i opeklina.

Morate obratiti pozornost na

slijedeće korake:

Prije radova na zavarivan-

ju obucite zaštitno odijelo

Stavite rukavice.

Otvorite prozor ili ventila-

tor, kako biste garantirali

dovod zraka.

29HR

... / Prije puštanja u rad / Montiranje maske za zavarivanje / Puštanje ...

Nosite zaštitne naočale

i zaštitu za usta.

Na obadvjema rukama mo-

rate nositi rukavice s posuvratkom od prikladnog materijala (koža). One se moraju

nalaziti u prikladnom stanju.

Radi zaštite odjeće od leta

iskri i opeklina morate nositi

prikladne pregače. Ako vrsta

radova, npr. zavarivanje

iznad glave, to zahtijeva,

morate nositi zaštitno odijelo

i, ako je neophodno, također

zaštitu za glavu.

Zaštita od bljeskova

i opeklina

Na radnom mjestu

zahvaljujući plakatu „Oprez!

Ne gledajte u plamenove!”

napomenite na ugroženost

očiju. Radna mjesta, ako je

moguće, zaklonite tako da

lica, koja se nalaze u blizini,

budu zaštićena. Neovlašteni

se moraju udaljiti od radova

na zavarivanju.

U neposrednoj blizini sta-

cionarnih radnih mjesta

stjenke ne bi trebale biti ni

svijetle boje niti sjajne. Prozori se najmanje do visine

glave moraju osigurati od

propuštanja ili reeksije,

npr. zahvaljujući prikladnom

premazu.

z Prije puštanja u rad

Izvadite aparat i pribor iz pakiranja i

provjerite jesu li oštećeni (npr. prilikom

transporta).

Pričvrstite remen za nošenje na aparat

(vidi sl. C1-4).

Spojite držač elektrode

za uzemljenje

zavarivanje.

Umetnite elektrodu u stezaljku držača

elektroda (vidi sl. D).

4

z Montiranje maske

za zavarivanje

Ručku 8 montirajte na masku za

zavarivanje

no na slici A.

Zaštitno staklo

za zavarivanje

ljeno na slici B.

7

, kao što je predstavlje-

11

7

z Puštanje u režim rada

Napomena: Uređaj za zavarivanje

je namijenjen za zavarivanje pomoću

elektroda.

Koristite stezaljke držača za elektro-

de bez stršećih vijaka držača, koji

odgovaraju današnjem standardu

sigurnosti.

Uvjerite se da je prekidač za UKLJ /

9

ISKLJ

(„OFF”) odnosno da kabel za glavnu

opskrbu nije utaknut u utičnicu.

postavljen na poziciju „O”

5

i stezaljku

na aparat za

montirajte na masku

, kao što je predstav-

30 HR

Loading...

Loading...