OHAUS TD52 Instruction Manual

折ↅ

∎䞷広㢝

Interfaz E/S Discreta

Manual de instrucciones

Interface discrète I/O

Manuel d’instruction

Discrete I/O-Schnittstelle

Bedienungsanleitung

Modulo d’Interfaccia I/O

TD52 Indicator

Discrete I/O Option

Instruction Manual

Manuale di Istruzioni

I/O 折

EN-1

CAUTION: Read all safety warnings before installing, making connections, or servicing the

Discrete I/O PCB. Failure to comply with these warnings could result in personal injury

and/or property damage. Retain all instructions for future reference.

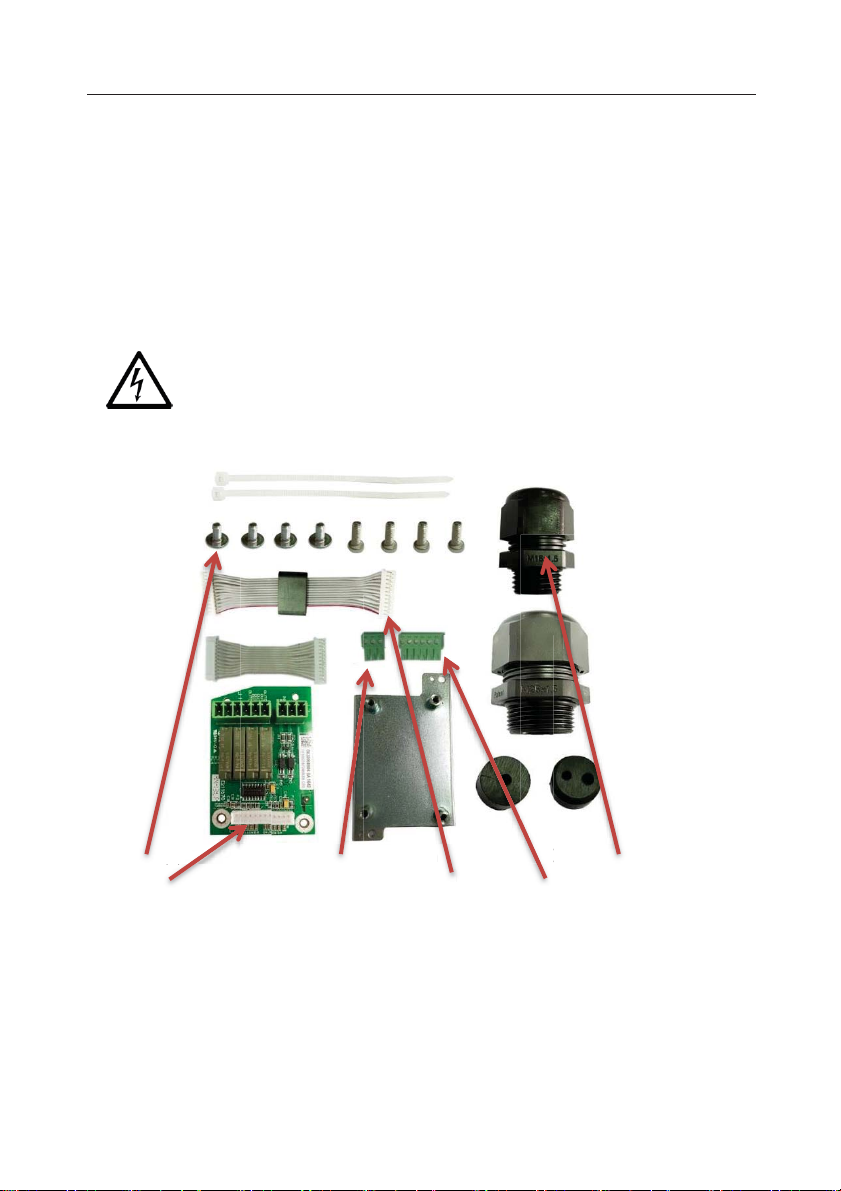

Screws (4)

Connector, 3 Pin

Cable Gland

I/O PCB

Cable to mainboard

Connector, 6 Pin

()

board

C

d

C

)

ector, 3 P

o

n

INTRODUCTION

This discrete I/O interface Kit is for use with OHAUS TD52P and TD52XW indicators.

When installed, the system software allows the relay to be programmed in a variety of ways.

BASIC APPLICATIONS

Applications include driving external Over/Accept/Under displays, motor controls for semi-automatic

filling systems, sorting systems, interfacing to industrial PLC systems, etc. The Relay outputs can also

be used as slave relays to drive high power relays in larger systems.

For the setup in each application, please refer to the instruction manual supplied with scale.

Set up the discrete I/O controls as described in the I/O menu section of that manual.

KIT CONTENTS

ws(4

ect

i

able Glan

EN-2

CAUTION: THE INSTALLATION AND WIRE CONNECTIONS TO THE DISCRETE I/O

PERSONNEL, SUCH AS AN ELECTRICIAN.

WARNING: BEFORE MAKING CONNECTIONS TO THE RELAY TERMINALS,

CONNECTIONS.

WARNING: WHEN MAKING ANY LINE VOLTAGE CONNECTIONS TO THE

Rib

Load cell cable male connector

Interface option cover

INTERFACE INSTALLATION

BOARD SHOULD ONLY BE DONE BY AUTHORIZED AND QUALIFIED

POWER OFF THE SYSTEM AND REMOVE ALL EXTERNAL AC POWER

DISCRETE I/O, FOLLOW NATIONAL ELECTRICAL CODE (NEC) OR LOCAL

AUTHORITY WIRING STANDARDS AND SAFETY PRACTICES.

For TD52P:

1. Separate the indicator from the base by loosening load cell cable male connector.

Remove the interface option cover.

2. Break off the rib of the accessory cover as shown.

EN-3

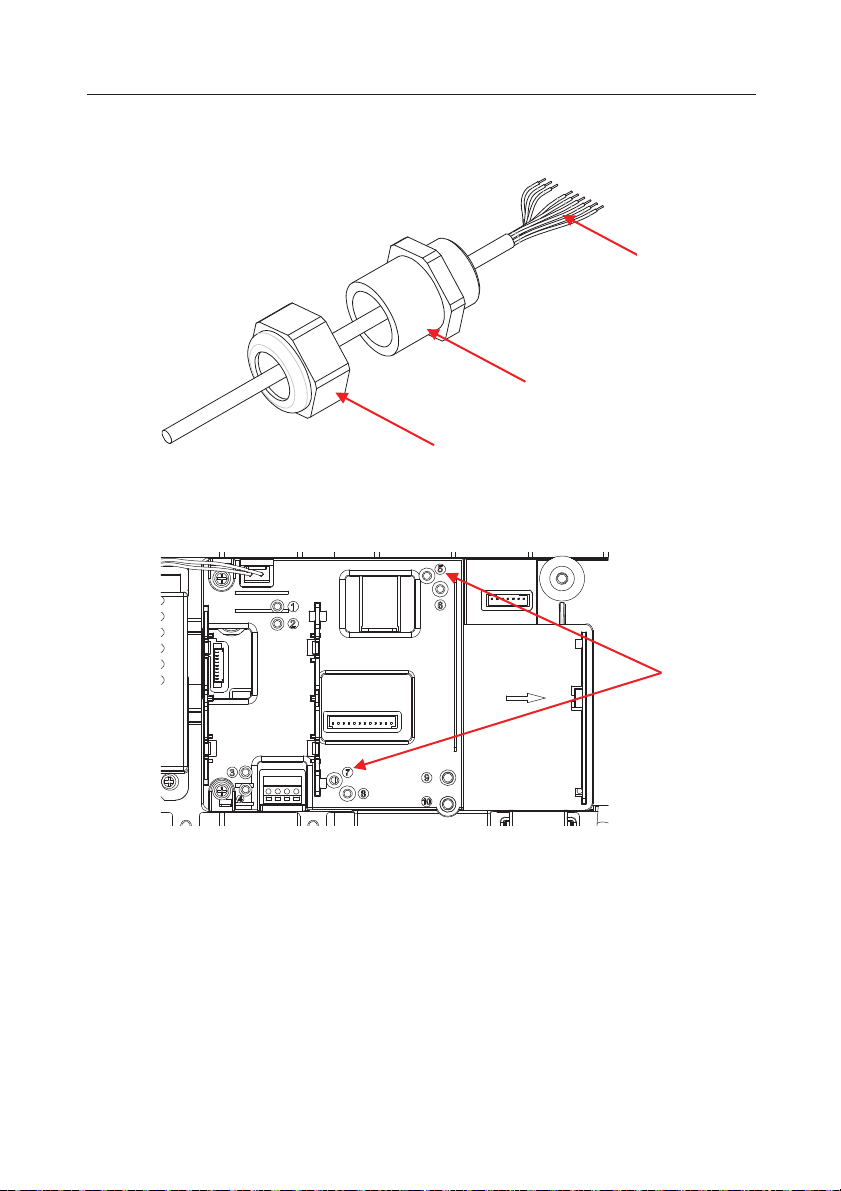

Cable

Ferrite

Main board

connector 2

12 Pin Connector

Screw

3. Connect the cable to the main board connector 2 as shown. Place the ferrite in the slot of

the rear housing as shown.

4. Install the relay board. Secure it with the 2 screws. Connect the cable to the relay board

12 pin connector.

EN-4

3 Pin / 6 Pin Connector

Nylon cable ties

Relay Cable

Screw

Load cell cable male

M25 Hole plug

5. Connect the relay cable to the 3 pin and 6 pin connectors. Fix the relay cable with the

nylon cable tie to avoid falling off from the terminal block.

6. Put the interface option cover back on the terminal.

For TD52XW:

1. Remove the interface option cover. Remove the 6 screws with sealed washers. Remove

the M25 hole plug as shown.

connector

EN-5

cable

Ferrite

Main board connector 2

2. Rotate the rear housing down a way from the front housing as shown.

3. Connect the cable to the main board connector 2. Place the ferrite in the slot of the

internal cover as shown.

EN-6

Relay Output Cable

M25 Gland

Cap Nut

Boss Post 5, 7

4. Disassemble the cable gland by loosening the cap nut and removing the rubber seal.

Pass the relay output through the cap nut, then spread the rubber seal and place it over

the cable. Now pass the cable through the body of the cable gland.

5. Install the relay board. Secure it with 2 screws. (Note: boss post is 5 and 7.)

Connect the cable to the relay board 12 pin connectors. Put the relay cable through the

M25 hole. Connect it to the 3 pin and 6 pin connectors.

EN-7

Screw

12Pin

Connector

3Pin / 6pin

Connector

Relay cable

Relay cable

M25 Gland

6. Put the rear housing back on the front housing. Re-install the 6 screws.

7. Fasten the M25 gland to the rear housing.

EN-8

Rubber Seal

Cap nut of M25 gland

Screw

M25 hole plug

Load cell cable male connector

8. Push the rubber seal into the M25 cable gland.

9. Fasten the cap nut of M25 gland.

For TD52XW with reversed rear cover:

1. Remove the interface option cover. Remove the 6 screws with sealed washer. Remove

the M25 hole plug as shown.

EN-9

Cable

Main board connector 2

Boss post 6,8

2. Take the rear housing down from the front housing as shown.

3. Connect the cable to the main board connector 2.

4. Install the relay board. Secure the relay board with 2 screws (Note: the boss post is 6, 8).

Connect the cable to the relay board 12 pin connector (Note: the ferrite needs to be

positioned nearby the accessory board 12 pin connector).

EN-10

12 Pin connector

Ferrite

Screw

Relay output

M25 Gland

Cap nut

Relay cable

3 Pin / 6 Pin Connector

5. Disassemble the cable gland by loosening the cap nut and removing the rubber seal.

Pass the relay output through the cap nut, then spread the rubber seal and place it over

the cable. Now pass the cable through the body of the cable gland.

6. Put the relay cable through the M25 hole. Connect it to the 3 pin and 6 pin connectors.

EN-11

Relay cable

M25 Gland

Rubber Seal

Cap nut of M25 gland

7. Put the rear housing back on the front housing. Re-install the 6 screws.

8. Fasten the M25 gland to the rear housing.

9. Push the rubber seal into the M25 cable gland.

10. Fasten the cap nut of the M25 gland.

EN-12

Notes:

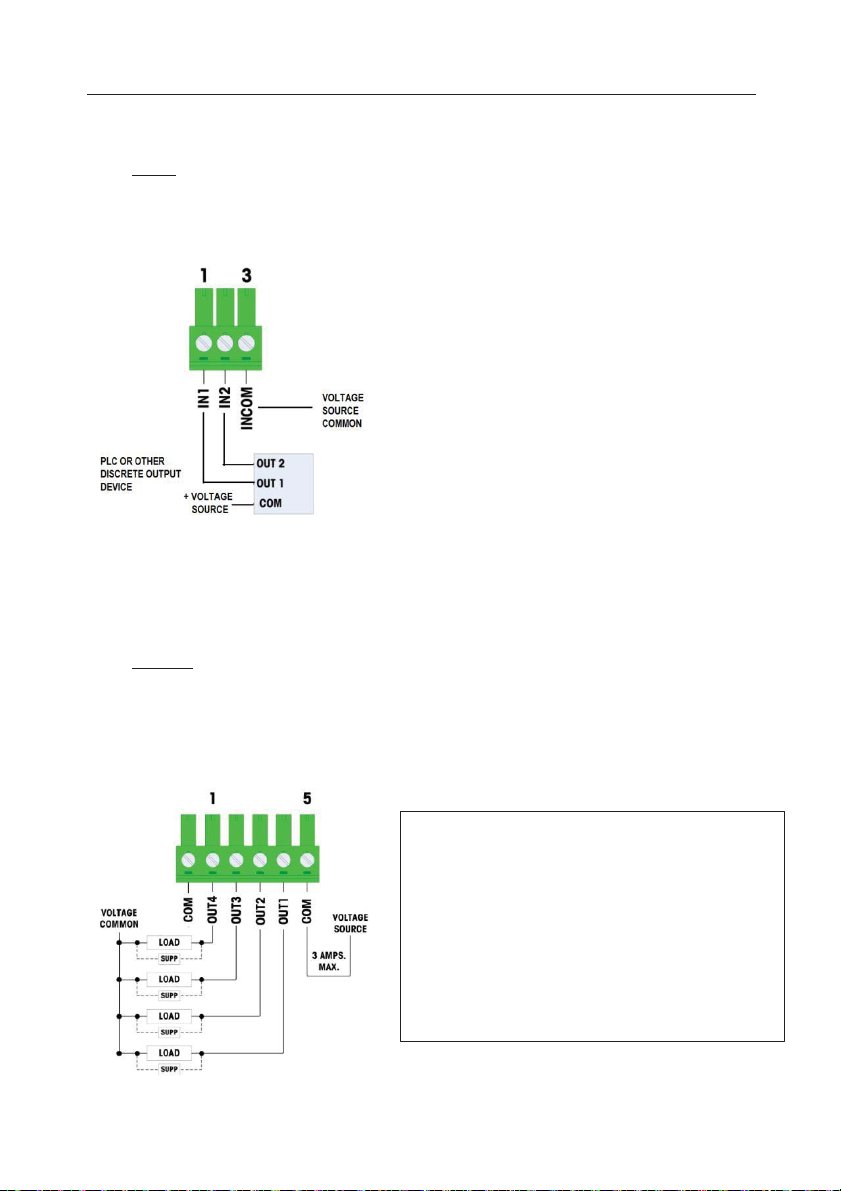

CONNECTION

x INPUT

The discrete I/O interface enables other devices such as PLCs to provide the trigger voltage (typically

12 VDC or 24 VDC, maximum 30 VDC) to turn the inputs “on”.

An example of wiring to the inputs with the +V to the common is shown:

Note:

1. Voltage: 5~30 VDC, 10 mA maximum current. Voltage polarity cannot be reversed.

2. Do not bundle input wiring with power wiring or any other high energy cables.

3. Wire size: 18 AWG (0.832 mm

24 AWG (0.205 mm

x OUTPUT

The four dry-contact normally open relay outputs can switch up to 250 VAC or 30 VDC voltages at 1A

maximum.

The relay outputs are not polarity-sensitive since they are dry contact outputs.

An example of wiring to the outputs is given below:

2

) maximum

2

) minimum

1. Dry contact relays.

2. Relay contact rating:

AC: 24-250 VAC, 1.0 AMP. INTO resistive load.

DC: 5-45 VDC ,1.0 AMP. INTO resistive load.

Maximum switching power: 250VA, 30 W.

3. Maximum output circuit current = 3 AMPS.

4. All inductive loads must be suppressed.

5. Wire size: 18 AWG (0.832 mm

24 AWG (0.205 mm

2

) Maximum

2

) Minimum

EN-13

Mark

Standard

2014/30/EU (EMC). The EU Declaration of

Disposal

In conformance with the European Directive 2012/19/EU on Waste Electrical and

Electronic Equipment (WEEE) this device may not be disposed of in domestic waste.

This also applies to countries outside the EU, per their specific requirements.

Please dispose

point specified for electrical and electronic equipment. If you have any questions,

please contact the responsible authority or the distributor from which you purchased

this device.

Should this device be passed on to other parties (for private or professional use), the

content of this regulation must also be related.

For disposal instructions in Europe, refer to www.ohaus.com/weee.

Thank you for your contribution to environmental protection.

COMPLIANCE

This product complies with the applicable harmonized standards of EU

Directives 2011/65/EU (RoHS) and

Conformity is available online at www.ohaus.com/ce.

FCC Note

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instructio n manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful inte rference in which case

the user will be required to correct the interference at his own expense.

Industry Canada Note

This Class A digital apparatus complies with Canadian ICES-003.

of this product in accordance with local regulations at the collecting

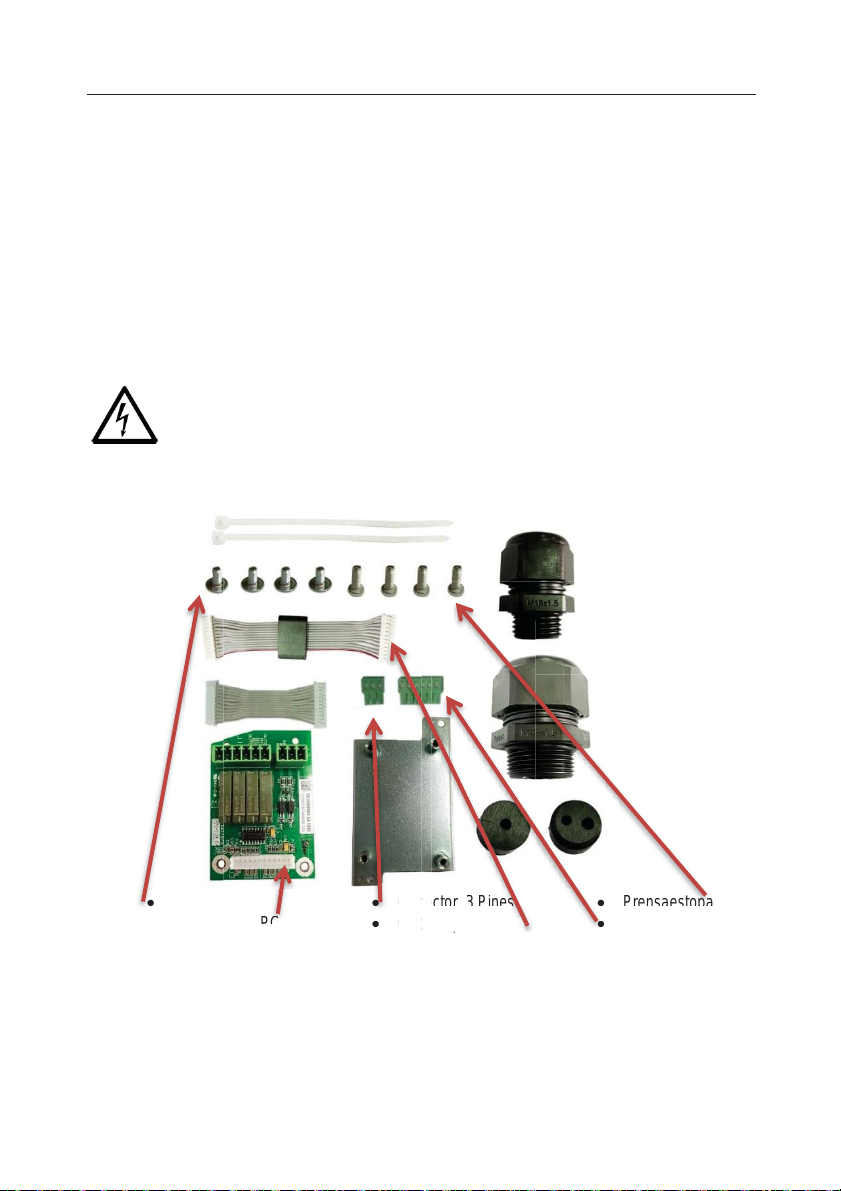

ES-1

PRECAUCIÓN: leer todas las advertencias de seguridad antes de instalar, hacer

Conserve todas las instrucciones para futura referencia.

x Tornillos (4)

x Conector, 3 Pines

x Prensaestopas

x E/S placa de PC

x Cable a placa base

x Conector, 6 Pines

Con

Cable a placa base

pl

aca base

T

s

INTRODUCCIÓN

Este kit de interfaz E/S discreta se utiliza con los Indicadores Ohaus TD52P y TD52XW.

Una vez instalado, el software del sistema permite que el relé se programe en una variedad de maneras.

APLICACIONES BÁSICAS

Las aplicaciones incluyen pantallas «Under/Accept/Over» (por debajo/aceptar/por encima), controles

de motores para sistemas de llenado semi-automáticos, sistemas de clasificación, interconexión con

los sistemas PLC industriales, etc. Las salidas de relé también se pueden utilizar como relés

esclavos para accionar relés de alta potencia en sistemas más grandes.

Para la configuración de cada aplicación, consultar el manual de instrucciones suministrado con la

báscula.

Configurar los controles de E/S discreta como se describe en la sección del menú E/S del manual.

conexiones o realizar el mantenimiento de la E/S discreta del PCB. El incumplimiento

de las instrucciones podría resultar en lesiones personales y/o daños materiales.

CONTENIDO DEL KIT

ornillo

ES-2

PRECAUCIÓN: LA INSTALACIÓN Y CONEXIONES DE CABLEADO A LA PLACA

Y AUTORIZADO, COMO POR EJEMPLO UN ELECTRICISTA.

ADVERTENCIA: ANTES DE REALIZAR CONEXIONES A LOS TERMINALES DE

EXTERNAS.

ADVERTENCIA: AL REALIZAR CUALQUIER CONEXIÓN DE VOLTAJE DE LÍNEA A

ELÉCTRICAS Y PRÁCTICAS DE SEGURIDAD.

conector macho del cable de la

Cubierta de opciones de interfaz

Costilla

INSTALACIÓN DE INTERFAZ

E/S DISCRETA SOLO DEBEN SER REALIZADAS POR PERSONAL CUALIFICADO

RELÉ, APAGUE EL SISTEMA Y ELIMINE TODAS LAS CONEXIONES ELÉCTRICAS

LA E/S DISCRETA, SIGA LOS CÓDIGOS ELÉCTRICOS NACIONALES (NEC) O

ESTÁNDARES DE LAS AUTORIDADES LOCALES PARA INSTALACIONES

Para TD52P:

1. Separe el indicador de la base aflojando el conector del cable macho para la celda de

carga. Retire la cubierta de la interfaz.

celda de carga

2.

Cortar la lengüeta de la cubierta de accesorios, como se muestra.

ES-3

Ferrito

Conector de la

placa principal2

Cable

Conector de 12 pines

empulgueras

3. Conectar el cable al conector 2 de la placa principal como se muestra. Colocar la ferrita

en la ranura de la carcasa trasera, como se muestra.

4. Instalar la placa de relé. Fijarla por mediación de los 2 tornillos. Conectar el cable al

conector de la placa de relé de 12 pines.

ES-4

Conector de 3 pines / 6

Brida de nylon

Cable de

empulgueras

conector macho del

carga

Tapón de orificio

M25

5. Conectar el cable de relé a los conectores de 3 y 6 pines. Fijar el cable de relé con la

brida de nailon.

pines

relé

6. Colocar la cubierta de la interfaz de nuevo en el dispositivo.

Para TD52XW:

1. Retirar la cubierta de la interfaz. Quitar los 6 tornillos con las arandelas de sellado. Retirar

el tapón M25, como se muestra.

cable de la celda de

2. Separar la carcasa trasera de la carcasa frontal como se muestra.

cable

Ferrito

Conector de la placa

ES-5

3. Conectar el cable al conector 2 de la placa principal. Colocar la ferrita en la ranura de la

cubierta interna, como se muestra.

principal2

ES-6

Salida de relé

Ghiandola M25

tuerca ciega

Publicación de

4. Desmontar el prensaestopas aflojando la tuerca ciega y retirando la junta de goma. Pasar

la salida de relé a través de la tuerca ciega, después extender la junta de goma y

colocarla sobre el cable. A continuación, pasar el cable a través del prensaestopas.

5. Instalar la placa de relé. Fijarla por mediación de los 2 tornillos. (Nota: los puntos

principales de fijación son 5 y 7).

Conectar el cable al conector de la placa de relé de 12 pines. Introducir el cable de relé en

el orificio M25. Conectarlo a los conectores de 3 y 6 pines.

jefe5,7

ES-7

tornillo

Conector

de 12 pines

Conector de 3

pines / 6 pines

Cable de

relé

Cable de relé

Ghiandola M25

6. Colocar nuevamente la carcasa trasera en la carcasa frontal. Colocar los 6 tornillos.

7. Fijar el prensaestopas M25 a la carcasa trasera.

ES-8

Junta de goma

tuerca de casquillo de

la glándula M25

tornillo

Tapón de orificio M25

Conector hembra del cable de la

celda de carga

8. Empujar la junta de goma en el prensaestopas M25.

9. Fijar la tuerca ciega del prensaestopas M25.

Para el TD52XW con cubierta trasera invertida:

1. Retirar la cubierta de la interfaz. Quitar los 6 tornillos con las arandelas de sellado. Retirar

el tapón M25, como se muestra.

2. Separar la carcasa trasera de la carcasa frontal como se muestra.

Cable

Conector de la placa

principal2

Publicación de jefe6,8

3. Conectar el cable al conector 2 de la placa principal.

ES-9

4. Instalar la placa de relé. Fijar la placa de relé por mediación de 2 tornillos (Nota: los

puntos principales son 6 y 8). Conectar el cable al conector de 12 pines de la placa de

relé (Nota: la ferrita debe colocarse cerca del conector de 12 pines de la placa de

accesorios).

ES-10

Conector de 12 pines

Ferrito

tornillo

Salida de relé

Ghiandola M25

tuerca ciega

5. Desmontar el prensaestopas aflojando la tuerca ciega y retirando la junta de goma. Pasar

la salida de relé a través de la tuerca ciega, después extender la junta de goma y

colocarla sobre el cable. A continuación, pasar el cable a través del prensaestopas.

ES-11

Cable de relé

Conector de 3 pines / 6

pines

Cable de relé

Ghiandola M25

6. Introducir el cable de relé en el orificio M25. Conectarlo a los conectores de 3 y 6 pines.

7. Colocar nuevamente la carcasa trasera en la carcasa frontal. Colocar los 6 tornillos.

8. Fijar el prensaestopas M25 a la carcasa trasera.

Loading...

Loading...