Northstar 6000I INSTALLATION MANUAL

6000i

NETWORKED NAVIGATION SYSTEM

INSTALLATION MANUAL

Revision G

Part Number GM6KIM

Northstar

a unit of Brunswick New Technologies Marine Electronics

30 Sudbury Road

Acton, Massachusetts 01720

www.NorthstarNav.com

Service: 978/897-6600

Sales: 800/628-4487

Contents

SECTION ONE: Introducing the 6000i - - - - - - - - - - - - - - - - 1

Checking the 6000i package - - - - - - - - - - - - - - - - - - 1

SECTION TWO: Installing and wiring the 6000i - - - - - - - - - - - - 5

Bench-testing the 6000i - - - - - - - - - - - - - - - - - - - - 5

Mounting the 6000i - - - - - - - - - - - - - - - - - - - - - - 5

Wiring the 6000i - - - - - - - - - - - - - - - - - - - - - - - - 8

SECTION THREE: Installing and wiring the antenna - - - - - - - - - 13

Choosing the best mounting location - - - - - - - - - - - - - 13

Mounting and wiring the AN150-P antenna - - - - - - - - - - 15

SECTION FOUR: Networking the Northstar 6000i - - - - - - - - - - 17

Restrictions on networking - - - - - - - - - - - - - - - - - - 18

Connecting a network of two devices - - - - - - - - - - - - - 19

Connecting a network of more than devices - - - - - - - - - - 19

Networking setup - - - - - - - - - - - - - - - - - - - - - - 17

SECTION FIVE: Checking out the system - - - - - - - - - - - - - - 27

Turning the 6000i on and off - - - - - - - - - - - - - - - - - 27

Checking satellite status - - - - - - - - - - - - - - - - - - - 27

Checking DGPS status - - - - - - - - - - - - - - - - - - - - 28

Installation-test checklist - - - - - - - - - - - - - - - - - - - 28

SECTION SIX: Interfacing the 6000i system - - - - - - - - - - - - - 31

The NMEA connector - - - - - - - - - - - - - - - - - - - - 32

Configuring the RS-232 port - - - - - - - - - - - - - - - - - 38

Using the Aux Port - - - - - - - - - - - - - - - - - - - - - - 39

Connecting the 6000i to a remote display - - - - - - - - - - - 43

Connecting the 6000i to a video camera - - - - - - - - - - - - 43

SECTION SEVEN: Troubleshooting and servicing the 6000i system - - 45

Troubleshooting installation problems - - - - - - - - - - - - - 45

Getting technical support - - - - - - - - - - - - - - - - - - - 47

APPENDIX A: 6000i system technical specifications - - - - - - - - - 51

SECTION ONE: Introducing the

6000i

Checking the 6000i package

The Northstar 6000i is a networked color GPS navigation family that you can

connect to a wide variety of optional equipment, including the Northstar 491

echo sounder, Northstar radar, and VGA displays. Other optional interfaces include any NTSC- or

PAL-compatible video sources, such as a video camera, TV, DVD, or VCR. For installation instructions

for the Northstar 491 or Northstar radar, see the Northstar 491 Installation Manual (P/N GM495) or

the Northstar Radar Installation Manual (P/N GMKRadIM or GMRad2KIM).

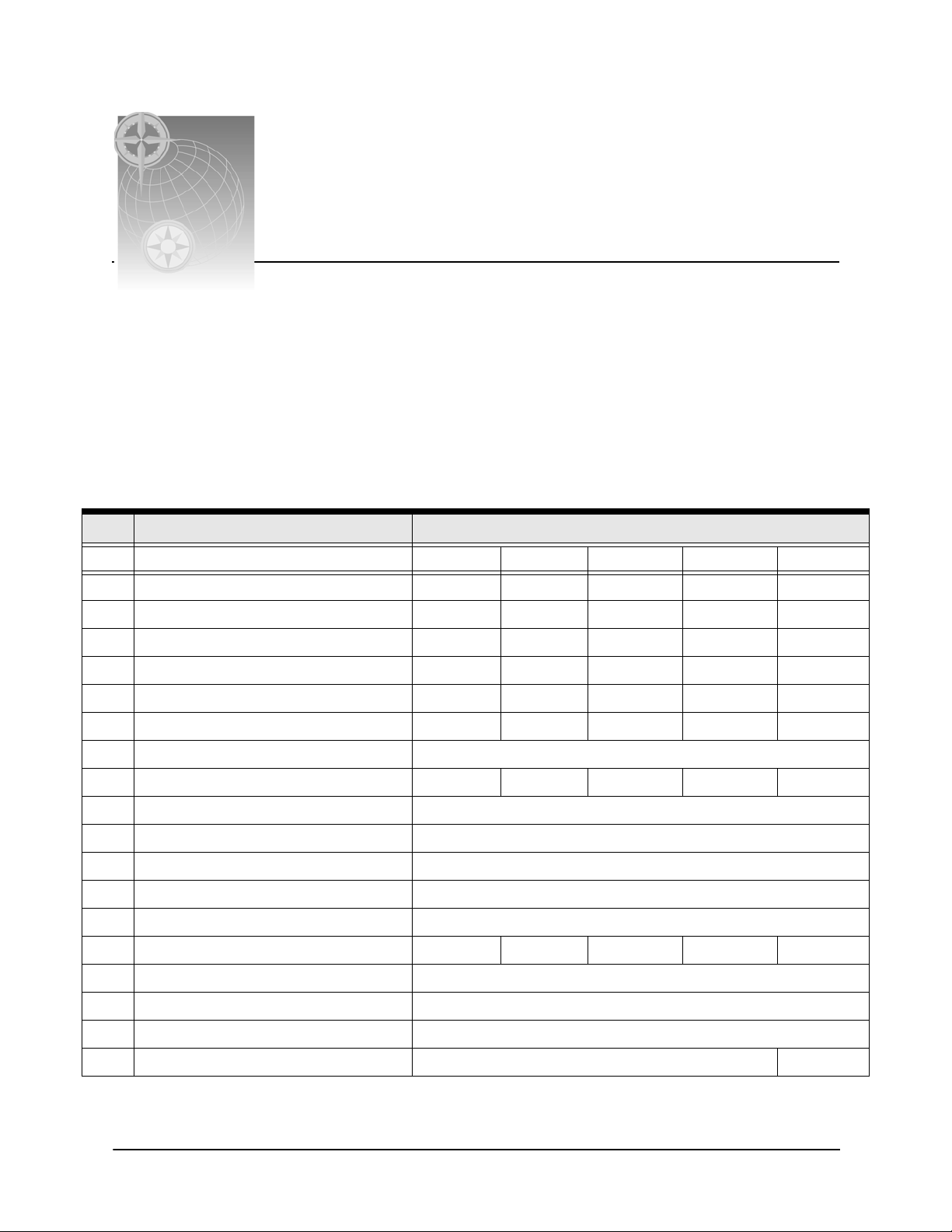

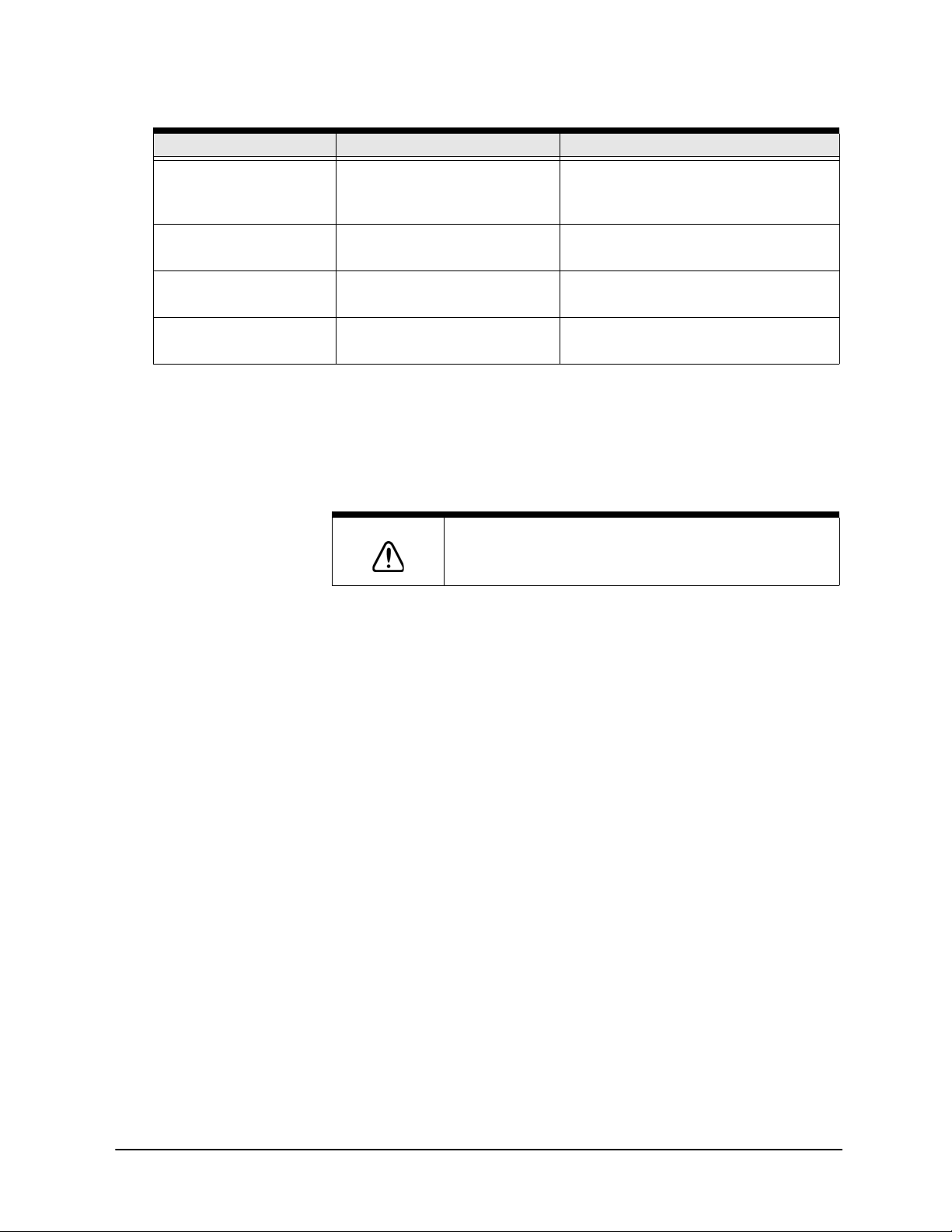

Tab l e 1: 6000i parts list

Qty Part name Part number

6.4” unit 8.4” unit 10.4” unit 12” Unit 15” unit

1 6000i unit 6K6 6K8 6K10 6K12 6K15

1 Flush-mount hardware kit 6K6FM-A 6K8FM-A 6K10FM-A 6K12FM-A

1 Flush-mount gasket — — — HG420 HG412

1 Flush-Mounting Template GT6K6 GT6K8 GT6K10 GT6K12 GT15

1 Yoke-mount kit 6K6YM-A 6K8YM-A 6K10YM-A — —

1 Sunshield XP793 XP784 XP789 XP821 XP817

1 WAAS/GPS antenna and cable AN150-P (AN-156-P Optional)

1 TNC connector for antenna cable — — — — KC285

1 10-foot power cable with 7-amp fuse WA535-B

1 10-foot NMEA interface cable WA215

1 Connector dust cover KC398

1Northstar 6000i Installation Manual GM6KIM

1Northstar 6000i Operator’s Manual GM6KUM

1 Quick Pocket Reference — — —

1 Owner registration card GD671

1 Limited Warranty Statement GD683

1 Navionics slip sheet GM988

GM6K12QR

6K15FM-A

—

1 Parts kit (see next page) 6K-PK 15-PK

6000i Installation Manual, Rev. G Page 1

SECTION ONE: Introducing the 6000i

To connect multiple units using Northstar’s N2 technology, Ethernet cables must be purchased

separately (see ”SECTION FOUR: Networking the Northstar 6000i” starting on page 17).

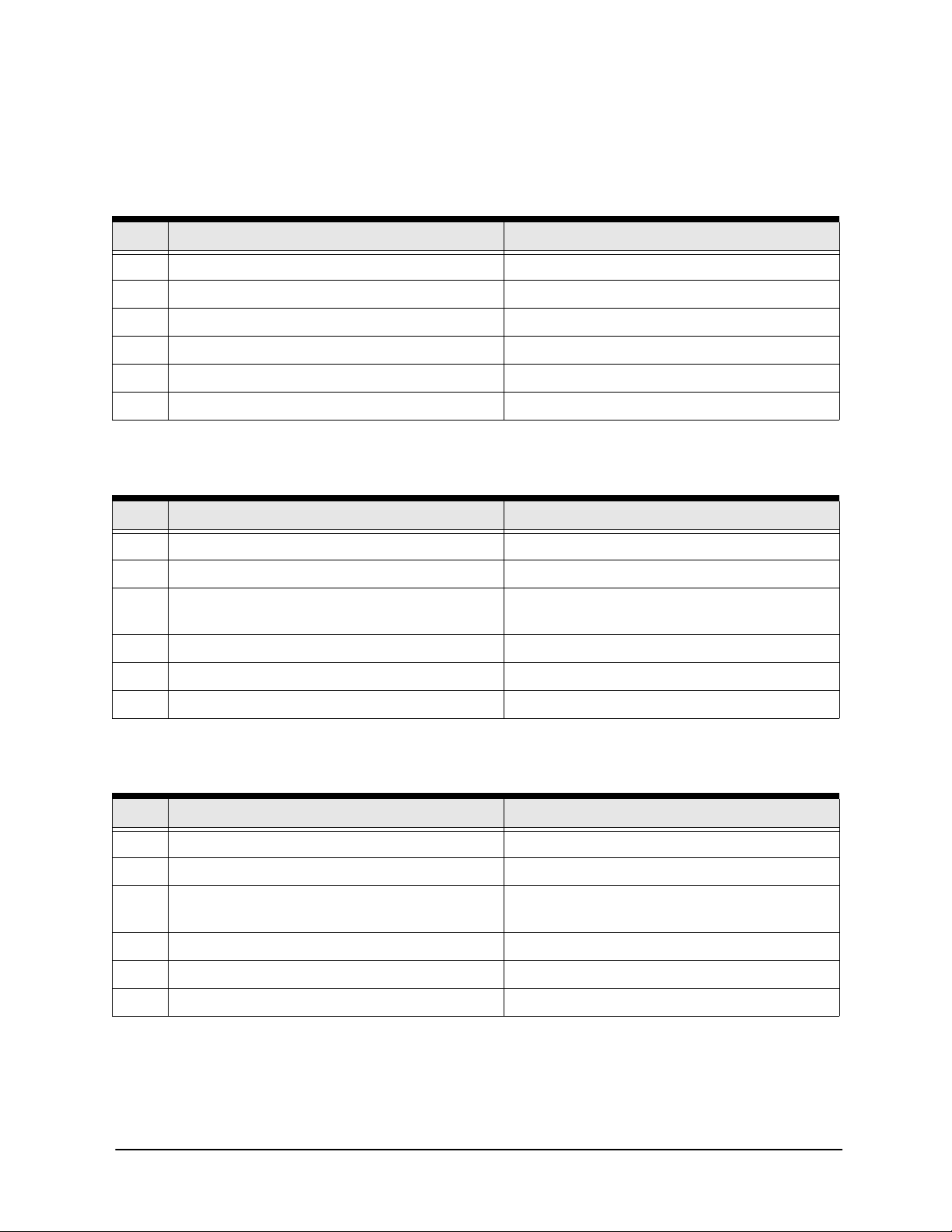

Table 2: Parts Kit contents for 6.4”, 8.4”, and 10.4” 6000i (P/N 6K-PK)

Qty Part name Part number

1 Spare fuse (7A fast-blow 5 x 20mm) FF211

4 Hex nut, 6-32, for flush-mounting HN300

4 Threaded stud, 6-32, for flush mounting HS610

4 Lockwasher, # 6, for flush mounting HW300

4 Flat washer, #6, for flush mounting HW405

1 TNC connector for antenna cable KC285

Table 3: Parts Kit contents for 12-inch 6000i (P/N 6K12-PK)

Qty Part name Part number

1 Spare fuse (7A fast-blow 5 x 20mm) FF211

12 Hex nut, 8-32, for flush-mounting HN421

12 Threaded stud, 8-32 x 2 1/4, for flush

mounting

12 Lockwasher, #8, for flush mounting HW400

12 Flat washer, #8, for flush mounting HW405

1 TNC connector for antenna cable KC285

Table 4: Parts Kit contents for 15-inch 6000i (P/N 15-PK)

HS605

Qty Part name Part number

1 Spare fuse (7A fast-blow 5 x 20mm) FF211

12 Hex nut, 8-32, for flush-mounting HN421

12 Threaded stud, 8-32 x 2 1/4, for flush

mounting

12 Lockwasher, #8, for flush mounting HW400

HS605

12 Flat washer, #8, for flush mounting HW405

1 TNC connector for antenna cable KC285

Page 2 6000i Installation Manual, Rev. G

SECTION ONE: Introducing the 6000i

Table 5: 6000i Optional equipment

Part name Part number

Ethernet cables See Section 4

Remote control and batteries 6KRMC-A

Spare batteries for remote control BL134

Additional antenna cable WC255 or WC263

Northstar Echosounder

Northstar Radar

6000i Installation Manual, Rev. G Page 3

SECTION ONE: Introducing the 6000i

Page 4 6000i Installation Manual, Rev. G

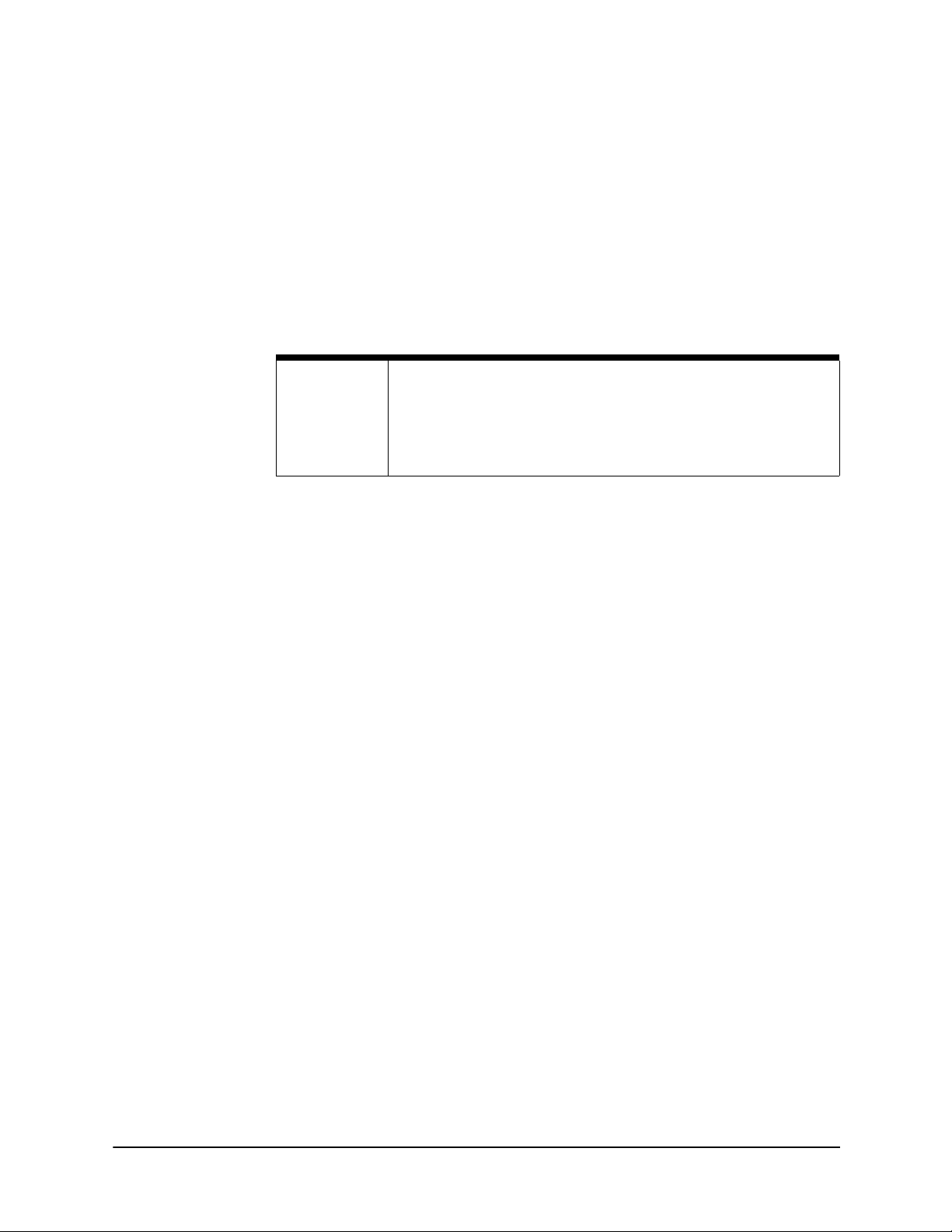

SECTION TWO: Installing and wiring the 6000i

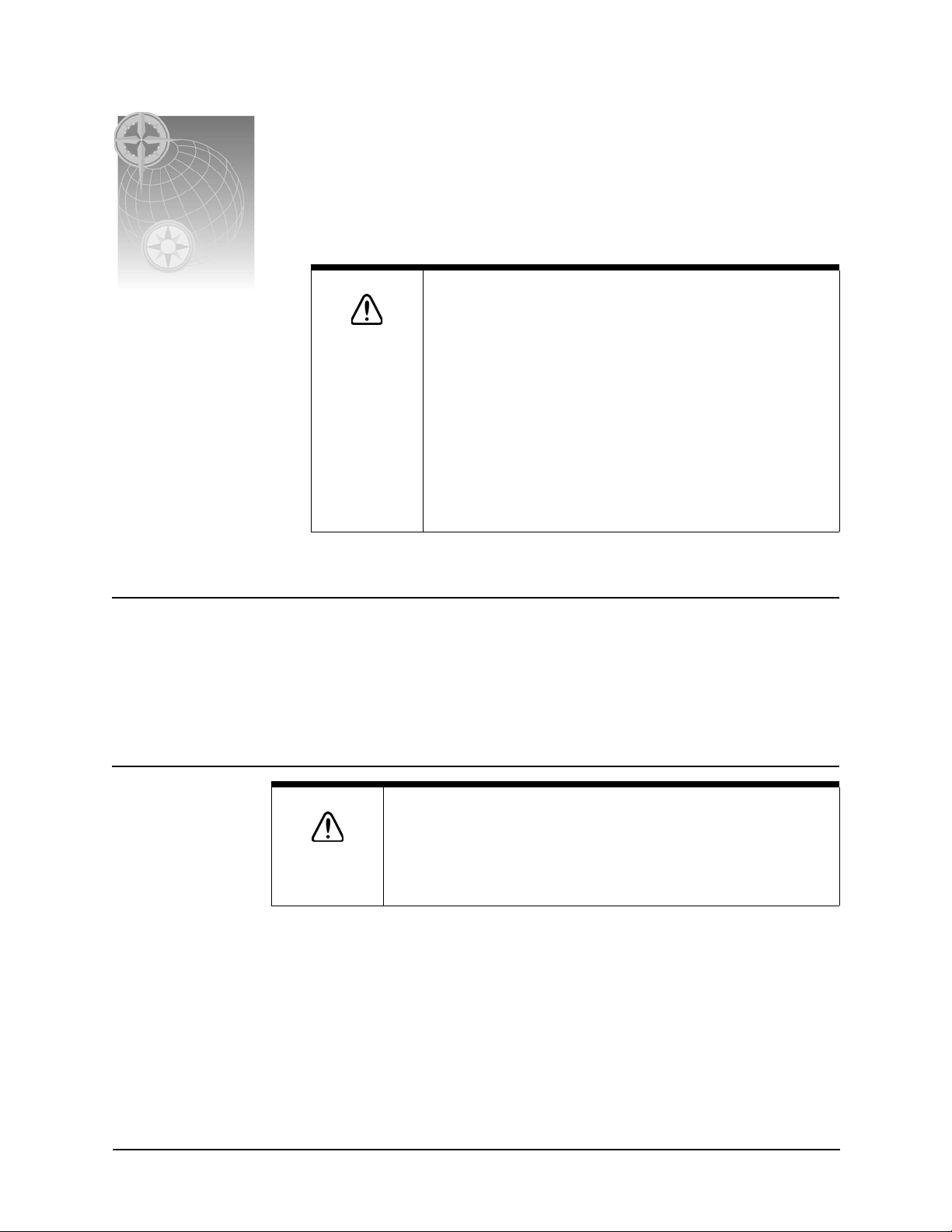

WARNING!

Before starting the installation, be sure to turn electrical power

off. If power is left on or turned on during the installation, fire,

electrical shock, or other serious injury may occur.

Be sure that the voltage of the power supply is compatible with

the 6000i’s voltage rating of 10 to 36 volts DC. Connecting to the

wrong power supply can cause fire or damage to the equipment.

Be sure to ground the equipment to prevent elec trical sh ock a nd

mutual interference.

Be sure to use a 7-amp fast-blow fuse in the supplied power

cable. Using the wrong fuse can cause fire or damage to the

6000i.

Bench-testing the 6000i

Northstar recommends bench-testing the 6000i with a GPS antenna before installing it onto the

vessel. Bench testing ensures that the equipment is fully operational, and lets the unit collect the

current almanac and ephemeris data and a local position fix, which results in less on-board

installation time.

Mounting the 6000i

CAUTION!

Choosing the best mounting location

Choose the mounting location carefully before you drill or cut. The 6000i should be installed in an

accessible, dry location where the operator can easily use the controls and clearly see the display

screen. Be sure to leave a direct path for all of the cables. The display screen is high-contrast and

anti-reflective, and is viewable in direct sunlight, but for best results, install the 6000i out of direct

sunlight. The chosen location should have minimal glare from windows or bright objects. If the

6000i is yoke-mounted low, tilt the unit back for best viewing contrast.

6000i Installation Manual, Rev. G Page 5

Proper installation of the Northstar 6000i is critical to accurately receive

and effectively use GPS/WAAS signals under a wide variety of weather

conditions.

Keep the following safe compass distance from the 6000i: 1.0m

standard, 0.8m steering.

SECTION TWO: Installing and wiring the 6000i

Mounting dimensions

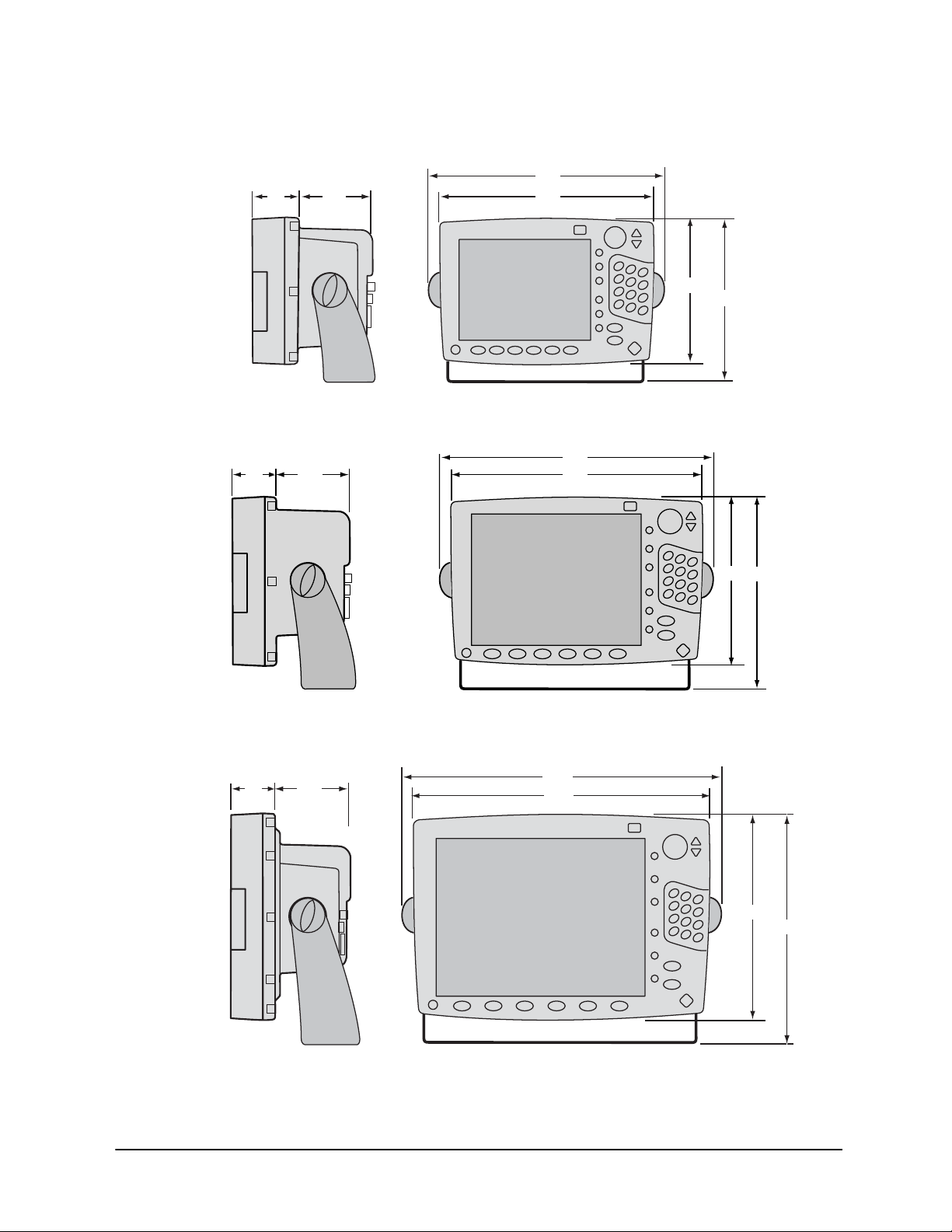

Figures 1 – 5 show the overall unit dimensions.

1.8

3.12

10.1

9.1

Dimensions in inches

Dimensions in inches

1.8

3.12

6.4"

8.4"

6.25

7.5

Figure 1: Dimensions (6.4” unit)

12

11

7.6

9

Figure 2: Dimensions (8.4” unit)

1.8

3.12

Dimensions in inches

Page 6 6000i Installation Manual, Rev. G

13.5

12.5

10.4"

8.75

Figure 3: Dimensions (10.4” unit)

9.75

SECTION TWO: Installing and wiring the 6000i

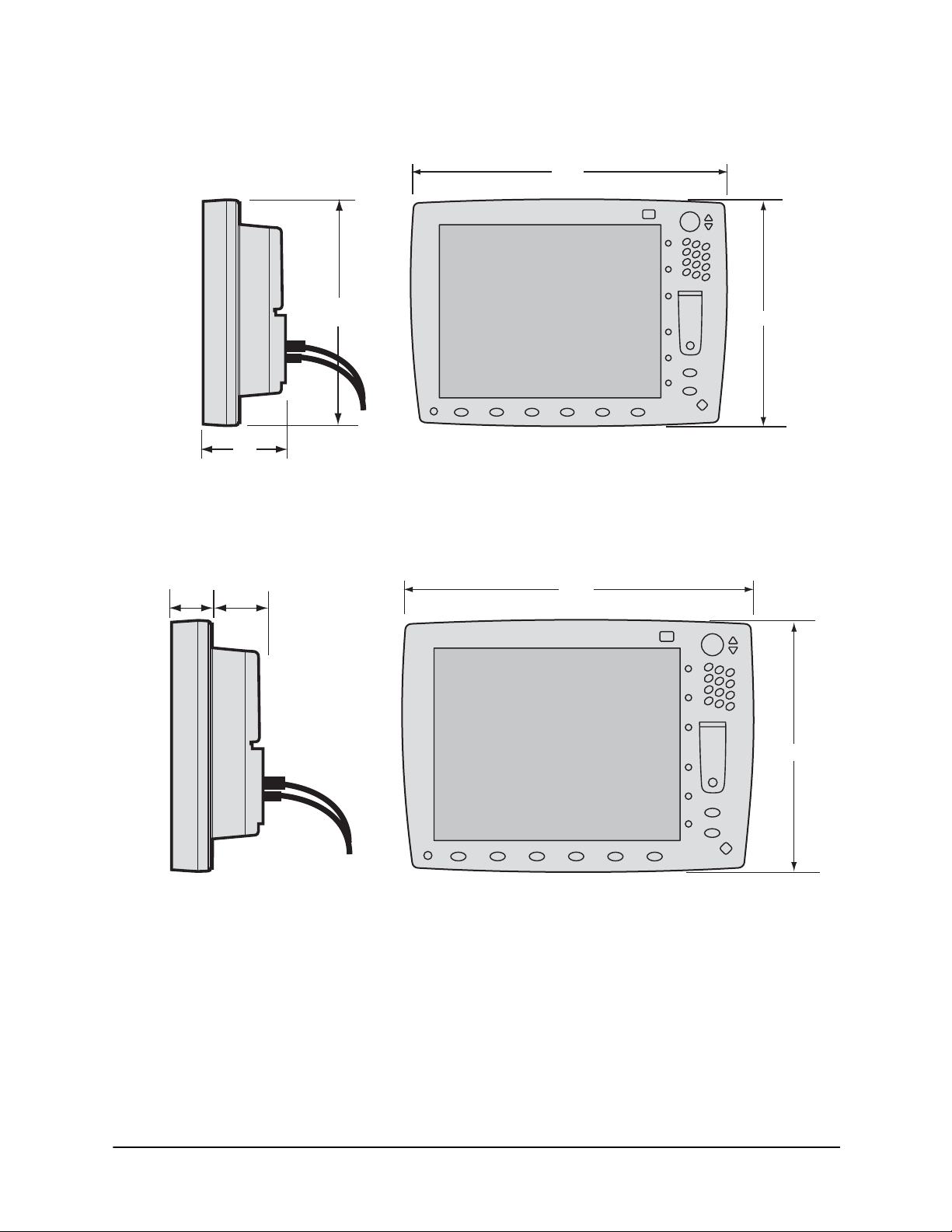

14.0

4.4

Dimensions in inches

10.5

12"

10.5

Figure 4: Dimensions (12” unit)

(Flush-mount only)

Figure 5: Dimensions (15” unit)Dimensions in inches

(Flush-mount only)

Flush-mounting

When flush mounting, leave sufficient clearance space behind the unit for all of the cables and

connectors. Clearance is also required on the right side of the unit for opening the chart cartridge

door (not necessary for the 12” or 15” units). Flush mounting requires good ventilation behind the

mounting panel. Poor ventilation may cause the 6000i to overheat, which, in turn, will cause the

screen brightness to dim. For overall width and height requirements, see the Northstar 6000i

6000i Installation Manual, Rev. G Page 7

SECTION TWO: Installing and wiring the 6000i

Flush-Mounting Template, which you can use to drill the mounting holes and cut the mounting panel

in the exact recommended locations.

CAUTION!

Use the supplied flush-mount template to cut the hole for the 6000i, and use the supplied gasket

between the 6000i and the instrument panel to help seal against water penetration. The use of

anti-seize compound on the flush-mount studs and nuts is recommended.

The parts kit contains the appropriate number of threaded studs, flat washers, lock washers, and hex

nuts for flush mounting.

When flush mounting, be sure to mount the 6000i on a flat surface.

Mounting on a curved surface can result in water leaks. Do not

overtighten the mounting screws; you may damage the case and

compromise its waterproof seal. This type of physical damage will

void the warranty.

Yoke-mounting

For recommended mounting clearances, see Figures 1 – 3 on the previous pages. Leave additional

clearance for opening the cartridge door on the right side of the unit. The 12- inch and 15-inch

models are designed for flush-mounting only.

When yoke-mounting, the four plastic “poker chips” are inserted into the holes in the unit and the

yoke. It may be helpful to apply a dab of RTV or other adhesive to keep them in place during

installation, especially if the unit will be removed and replaced frequently.

Wiring the 6000i

Avoiding cable wiring shortcuts

Most installation problems are caused by shortcuts taken with system cables. When wiring the

6000i, follow the guidelines below.

DON’T DO THIS!

• Don’t make sharp bends in the cables

• Don’t run cables in a way that allows water

to flow down into the connectors

• Do make drip and service loops

• Do tie-wrap all cables to keep them secure

• If cables are shortened, lengthened, or

re-terminated, do seal and protect all wiring

connections

• Do leave room at the back to install and

remove cables

DO THIS!

Page 8 6000i Installation Manual, Rev. G

SECTION TWO: Installing and wiring the 6000i

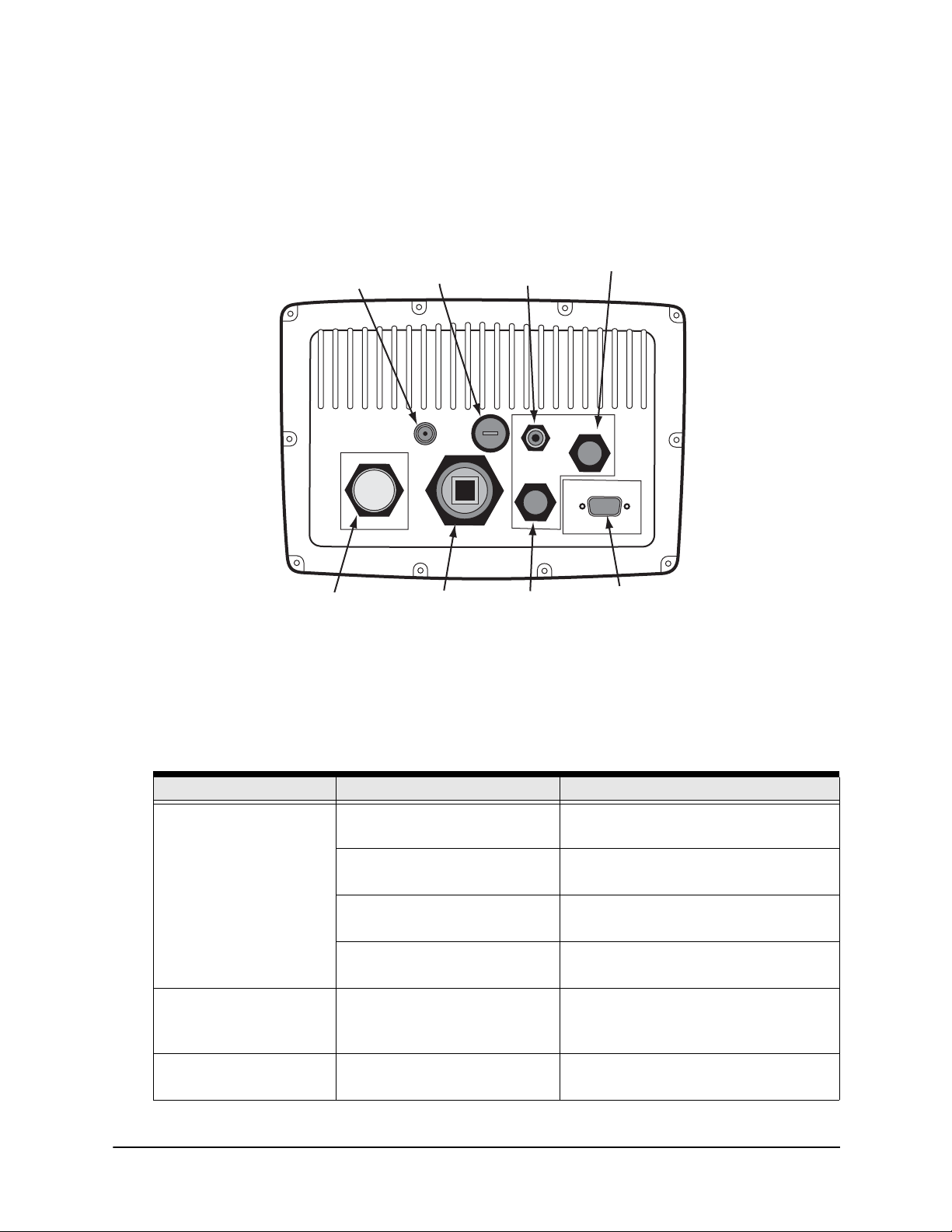

The interface connectors

Interface connectors are shown in Figure 6: ”Interface connectors,” below. The functions of these

connectors are described in Table 6. Interfacing is described in detail in Section Six, beginning on

page 31.

NTSC

VIDEO

INPUT

FUSE

(7 Amp)

GPS

ANTENNA

POWER

NMEA ETHERNET AUX

6.4" unit shown (all units use same connector layout)

Table 6: Interface connector functions

Connector name Connector function(s) Connects to...

NMEA

NMEA Port 1 input/output NMEA devices: autopilot, heading

(18-pin connector)

NMEA Port 2 input/output Same as NMEA Port 1, or Northstar

RS-232 Port SC-104, NMEA devices, or remote

Honk alarm/200 ppnm Remote honk alarm, or speed

Ethernet

N2 Networking Another 6000i or other

(RJ-45)

VGA

(video out)

REAR VIEW OF 6000i

Figure 6: Interface connectors

sensor, etc.

radar

power control

indicator

N2-compatible device (N2 is

Northstar’s proprietary format)

GPS

GPS antenna input AN150-P GPS antenna

(TNC coaxial 50 Ohm)

6000i Installation Manual, Rev. G Page 9

SECTION TWO: Installing and wiring the 6000i

Table 6: Interface connector functions (continued)

Connector name Connector function(s) Connects to...

AUX

(6-pin connector)

POWER (3-pin

connector)

VGA (15-pin D

connector)

NTSC VIDEO INPUT

(BNC coaxial 75 Ohm)

RS-422/NMEA input/output Northstar 491 echo sounder, or

older Northstar units for database

transfer

Power input 10 to 36 VDC, 30 watts

Video output Remote display

Video input Any NTSC-compatible video source

Electrical power requirements

The 6000i is a negative-ground system that’s reverse-polarity protected. Power requirement is 10

VDC minimum to 36 VDC maximum, using at least 16-gauge connecting wire.

CAUTION!

To protect the power wiring, Northstar strongly recommends

that you connect the 6000i to a circuit breaker or 7-amp fuse

located at the power source (battery or switch panel).

Connecting the

The 6000i is shipped with a 10-foot power cable that you can lengthen to a maximum of 25 feet:

• for a cable length up to 15 feet, use 16-gauge wire or heavier

• for a cable length from 15 to 25 feet, use 14-gauge wire or heavier

If you lengthen the power cable, use an external fuse at the battery end as an added safety

precaution. The fuse size should be chosen to be appropriate for the size of the smallest

conductor in the circuit. See the NMEA or American Boating and Yachting Counsel specifications to

find the correct fuse for your wiring.

For the best protection from noise, connect the power wiring directly to the battery or dedicated

electronics bus. The green ground wire should be connected directly to ship’s ground. The power

cable has an inline fuse to protect the vessel’s wiring, and prevent electrical fires and damage to the

unit. If you shorten or lengthen this cable, be sure to keep the inline fuse intact (or provide circuit

breaker protection).

Spare in-line fuses are not supplied with the unit and should be purchased locally to avoid loss of

function.

6000i

to ship’s power

Page 10 6000i Installation Manual, Rev. G

Connect the wires in the power cable as follows.

• red → positive (+)

• black → negative (–)

• green → ship’s ground

SECTION TWO: Installing and wiring the 6000i

NOTE:

Grounding the 6000i to the vessel usually reduces interference.

Without an earth grounding, performance may be reduced. Secure the

green wire to the vessel’s nearest grounding point. If a noise-free

earth grounding point isn’t available, cap and insulate the green

wire—it shouldn’t be used when an earth ground isn’t available, or with

systems using “floating” grounds.

6000i Installation Manual, Rev. G Page 11

SECTION TWO: Installing and wiring the 6000i

Page 12 6000i Installation Manual, Rev. G

SECTION THREE: Installing and wiring the antenna

Choosing the best mounting location

Before you drill or cut, choose a mounting location that meets the following criteria. The antenna

should be mounted:

• where there’s enough mounting clearance to easily connect the cable

• low on the vessel, and near the center, since motion caused by the vessel’s roll, pitch and

yaw can degrade speed-over-ground (SOG) and course-over-ground (COG) readings

• away from the radiation plane of any INMARSAT or radar antennas, and away from any

other high-power transmitting antennas (see Figure 8 on page 14)

• high enough to provide an unblocked view of the sky in all directions, minimizing or

eliminating any obstructions that block the antenna’s view of the sky (the system can use

satellites down to the horizon)

• away from masts or objects that could “shadow” the antenna

To avoid mutual interference among different antennas on the vessel, see the recommendations in

Figure 8 below. This figure shows the minimum distances that should separate GPS/WAAS antennas

from other antennas and physical mounting surfaces. Normally, these guidelines produce a relatively

trouble-free installation; however, since every installation is unique, you may want to adjust these

distances to the particular equipment.

Before permanently installing the antenna, try temporarily installing it and using the 6000i to see if

the location works well.

Do not open the antenna (other than removing the top to install). There aren’t any serviceable parts

inside. Unauthorized tampering will automatically void the warranty.

Antenna cable lengths

You must observe the min/max cable length requirements for the GPS antenna shown in Table 7.

Don’t lengthen on shorten the cable beyond these limits. The AN150-P antenna is normally shipped

with the 6000i. If you need to use a longer cable than can be used with that antenna, contact the

factory about substituting a higher-gain AN-156-P antenna.

6000i Installation Manual, Rev. G Page 13

Loading...

Loading...