Page 1

Model No. NCCEL09940

www.nordictrack.com

Visit our website at

Serial No. _

Serial Number

Decal

QUESTIONS?

As a manufacturer, we are committed to providing complete

customer satisfaction. If you

have questions, or if there are

missing parts, please call:

1-888-936-4266

USER’S MANUAL

Mon.–Fri. 8h00 until 18h30 EST

(excluding holidays).

CAUTION

Read all precautions and instructions in this manual before using

this equipment. Keep this manual

for future reference.

Page 2

TABLE OF CONTENTS

IMPORTANT PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

BEFORE YOU BEGIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

HOW TO USE THE ELLIPTICAL EXERCISER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

MAINTENANCE

CONDITIONING GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

PART LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

EXPLODED DRAWING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

HOW TO ORDER REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Back Cover

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Back Cover

AND TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

NordicTrack is a registered trademark of ICON IP, Inc.

2

Page 3

17

20

97

98

98

98

98

98

98

69

98

98

2

26

86

105

68

26

86

23

85

85

96

25

86

24

105

26

68

86

26

22

21

19

18

15

98

98

98

98

108

98

98

16

114

116

115

106

107

108

98

69

121

31

120

118

123

123

124

124

123

123

118

120

110

31

122

122

108

119

119

110

110

110

98

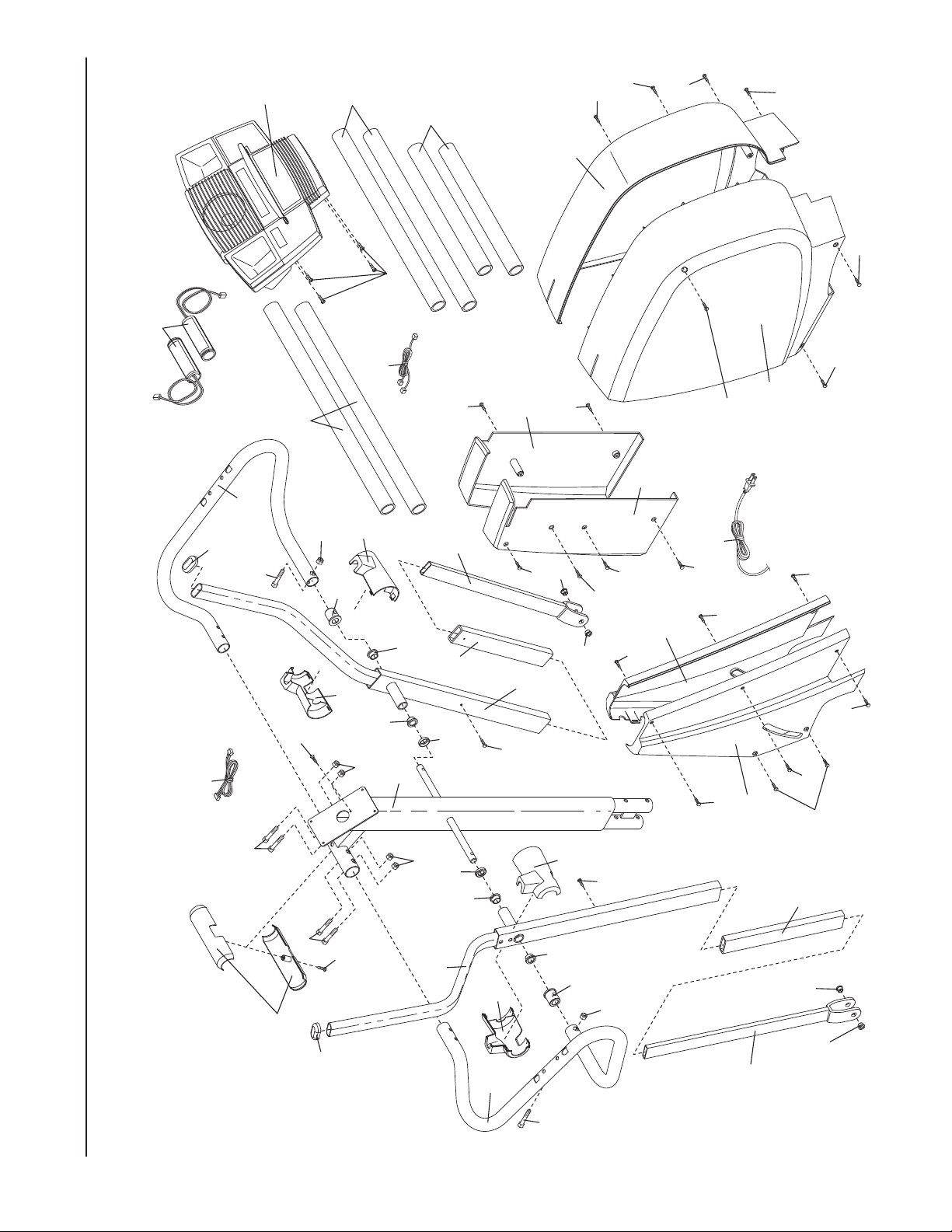

EXPLODED DRAWING—Model No. NCCEL09940 R0604A

To identify the parts shown below, see the PART LIST on pages 24 and 25.

26

Page 4

Key No.

Qty. Description Key No. Qty. Description

105 2 M8 x 38mm Button Bolt

106 2 Upper Foam Grip

107 2 Lower Foam Grip

108 3 M4 x 25mm Tek Screw

109

110 4 Wheel Bushing

111 2 M8 x 19mm Patch Screw

112 2 Wheel

113 1 Belt

114 1 Pulse Extension Wire

115 1 Upper Wire Harness

116 1 Power Cord

117 1 Power Socket

Note: # indicates a non-illustrated part. Specifications are subject to change without notice. See the back cover

of this manual for information about ordering replacement parts.

2 7.6mm Spacer

118 2 Upper Body Arm

119 2 Weld Spacer

120 2 Sleeve

121 2 Upper Body Foam Grip

122

123 4 Upper Body Bushing

124 2 M5 x 5mm Screw

125 2 M4 x 19mm Round Head Screw

126 1 Stop Bracket

127 1 Nylon Zip Tie

# Allen Wrench

# User’s Manual

2 Upper Body Endcap

25

Page 5

PART LIST—Model No. NCCEL09940 R0604A

To locate the parts listed below, see the EXPLODED DRAWING on page 26 and 27.

Key No. Qty. Description Key No. Qty. Description

1 1 Frame

2

3 1 Ramp

4 1 Left Pedal Leg

5 1 Right Pedal Leg

6 1 Rear Stabilizer

7 1 Rear Stabilizer Cover

8 1 Front Stabilizer

9 1 Front Stabilizer Cover

10 1 Left Pedal

11 1 Right Pedal

12 1 Incline Motor

13 1 Incline Axle

14 1 Pivot Axle

15 1 Left Side Shield

16 1 Right Side Shield

17 1 Console

18 1 Right Flywheel Cover

19 1 Left Flywheel Cover

20 2 Pulse Sensor w/Wire

21 1 Right Incline Cover

22 1 Left Incline Cover

23 1 Right Handlebar

24 1 Left Handlebar

25 1 Upper Handlebar Cover

26 2 Handlebar Cover

27 1 Frame Cover

28 2 Pedal Wheel

29 4 Wheel Bearing

30 2 Frame Bushing

31 2 Upper Body Leg

32 1 “C” Magnet

33 1 Magnet Bracket

34 1 Left Crank Arm

35

36 1 Flywheel

37 1 Magnet

38

39 1 Control Box Cover

40 1 Control Board

41 1 Control Box

42 1 Lower Wire Harness

43 1 Crank

44 2 Crank Bearing

45

46 4 Foot

47 4 Ramp Bushing

48 2 Ramp Cover

49 1 Incline Sensor

50 1 Sensor Cover

51 4 Pedal Leg Bushing

52 1 Resistance Motor

1 Upright

2

1

1 Idler

29.5mm Pulley Spacer

Pulley

53 1 Reed Switch Bracket

54

55 1 Reed Switch/Wire

56 1 Return Spring

57 1 Guide Rod

58 1 Resistance Cable

59 1 Flywheel Axle

60 2 Flywheel Bearing

61 2 Eye Bolt

62 2 Adjustment Bracket

63 2 M8 x 47mm Button Screw

64 2 M6 Washer

65 2 M8 x 79mm Bolt Set

66 2 M8 Washer

67 2 M10 x 50mm Bolt Set

68 2 Handlebar Bushing

69 2 M4 x 16mm Round Head Screw

70 2 M10 x 108mm Button Screw

71 1 M8 Tek Washer

72 1 M11 x 40mm Bolt Set

73 2 M10 Split Washer

74 1 M8 x 25mm Button Bolt

75 1 M10 x 19mm Button Bolt

76 4 M6 x 16mm Patch Screw

77 4 M5 Nut

78 4 M5 x 16mm Bolt

79 4 M5 Washer

80 2 M6 x 18mm Bolt

81 1 M6 x 25mm Bolt

82 2 5/16” x 25mm Flange Screw

83 4 M8 x 54mm Button Screw

84 8 M8 x 44mm Button Screw

85 4 M8 x 41mm Button Bolt

86 6 M8 Jam Nut

87

88 3 M8 Nylon Locknut

89 1 M10 Nylon Locknut

90

91 2 M6 Nylon Locknut

92 2 Snap Ring

93 2 M8 x 54mm Button Screw

94 4 #8 x 9.5mm Screw

95 4 M4 x 19mm Screw

96 1 M4 x 12mm Round Head Screw

97

98 24 M4 x 16mm Screw

99 2 Ramp Spacer

100 4 M5 Nylon Locknut

101 2 31.5mm Pulley Spacer

102 1 Right Crank Arm

103 1 Flywheel Spacer

104 2 Support Plate

1 Clamp

8

3

2 M4 x 25mm Screw

M4 x 38mm Screw

M6 Nut

24

Page 6

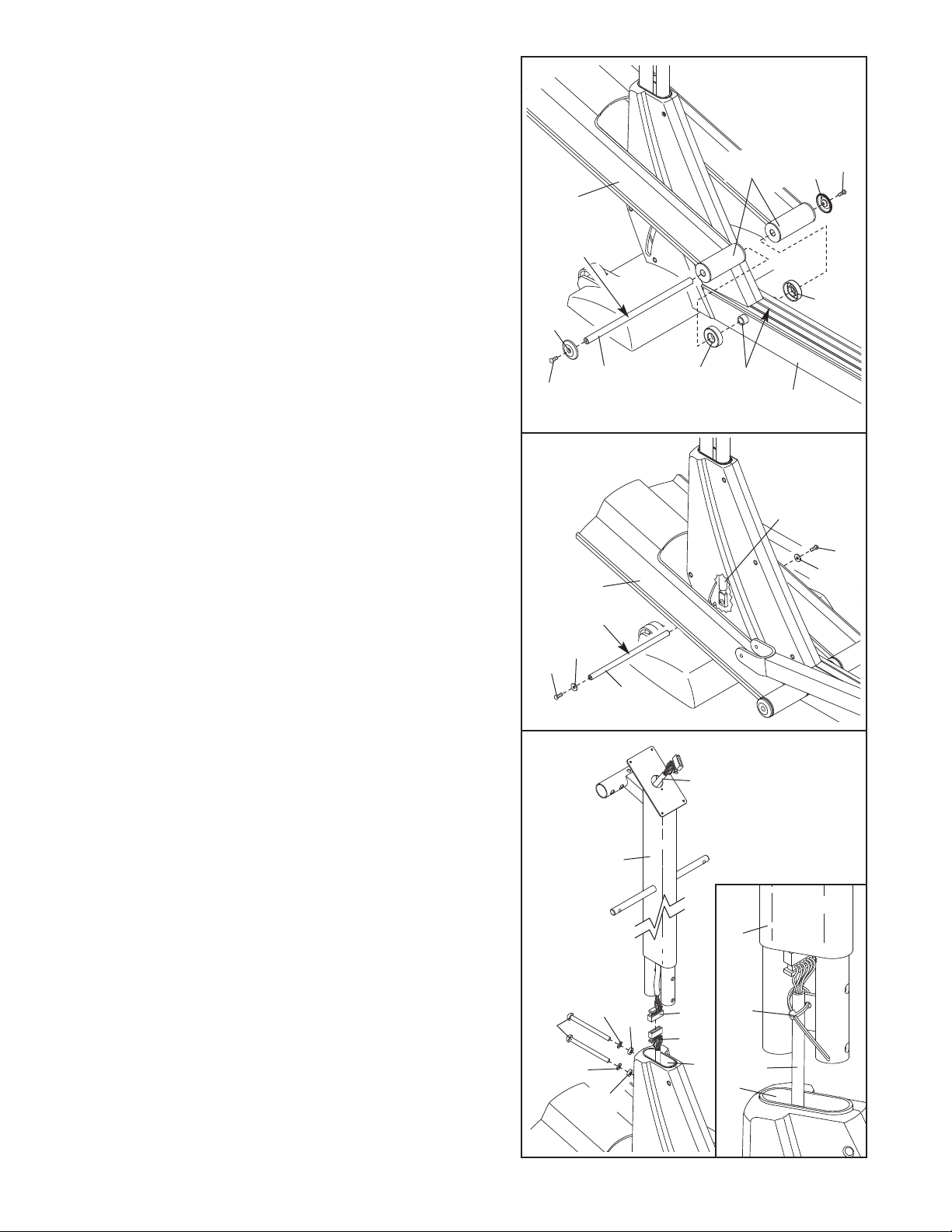

2. Identify the Pivot Axle (14), which is the longer of the

two axles. Slide a Ramp Cover (48) onto an M6 x

16mm Patch Screw (76) as shown.

Screw into one end of the Pivot Axle. Apply a small

amount of the included grease to the Pivot Axle.

Have a second person hold the two Ramp Spacers

(99) against the sides of the Frame (1) so they cover

the indicated tubes on the Frame. Lift the Pedal Legs

(not shown) out of the way and align the round tubes

on the Ramp (3) with the Ramp Spacers.

that the Ramp is turned as shown in drawing 3

below. Insert the Pivot Axle (14) into the Ramp, the

Ramp Spacers, and the Frame. If necessary, tap the

Pivot Axle with a rubber mallet to insert it.

Tighten the Patch

Make sure

2

48

3

Grease

Tubes

48

76

99

Slide the other Ramp Cover (48) onto an M6 x 16mm

Patch Screw (76) as shown.

into the open end of the Pivot Axle (14).

3. Slide an M6 Washer (64) onto an M6 x 16mm Patch

Screw (76). Tighten the Patch Screw into one end of

the Incline Axle (13). Apply a small amount of grease

to the Incline Axle.

Raise the Ramp (3). Insert the Incline Axle (13) into

the welded tube under one side of the Ramp, through

the motor screw, and then into the welded tube under

the other side of the Ramp. As you insert the Incline

Axle through the motor screw, make sure that the

motor screw does not turn.

Slide an M6 Washer (64) onto an M6 x 16mm Patch

Screw (76). Tighten the Patch Screw into the open

end of the Incline Axle (13).

4. Have another person hold the Upright (2) in the position shown.

Connect the Upper Wire Harness (115) to the Lower

Wire Harness (42). Insert the connectors on the Wire

Harnesses up into the Upright (2).

upper end of the Upper Wire Harness to remove

the slack from the Wire Harnesses. See the inset

drawing. Attach the Lower Wire Harness to the Upright

with the Nylon Zip Tie (127). Pull the Nylon Zip Tie

tight and cut of

f the excess.

Tighten the Patch Screw

Carefully pull the

3

4

76

76

14

3

Grease

64

Tubes

99

1

Motor

Screw

76

64

13

Pull

2

Do not pinch

the Wire

Harnesses

(115, 42)

during this

step.

2

Insert the Upright (2) into the Frame (1).

avoid pinching the Wire Harnesses (115, 42). Attach

the Upright with two M10 x 108mm

(70), two M10 Split W

Spacers (109).

the Spacers are facing the Upright. Be careful to

avoid damaging the W

Button Screws. Do not tighten the Button Screws

yet.

ashers (73), and two 7.6mm

Make sure that the curved sides of

ire Harnesses with the

Be careful to

Button Screws

6

70

73

73

109

109

1

15

42

127

1

42

1

Page 7

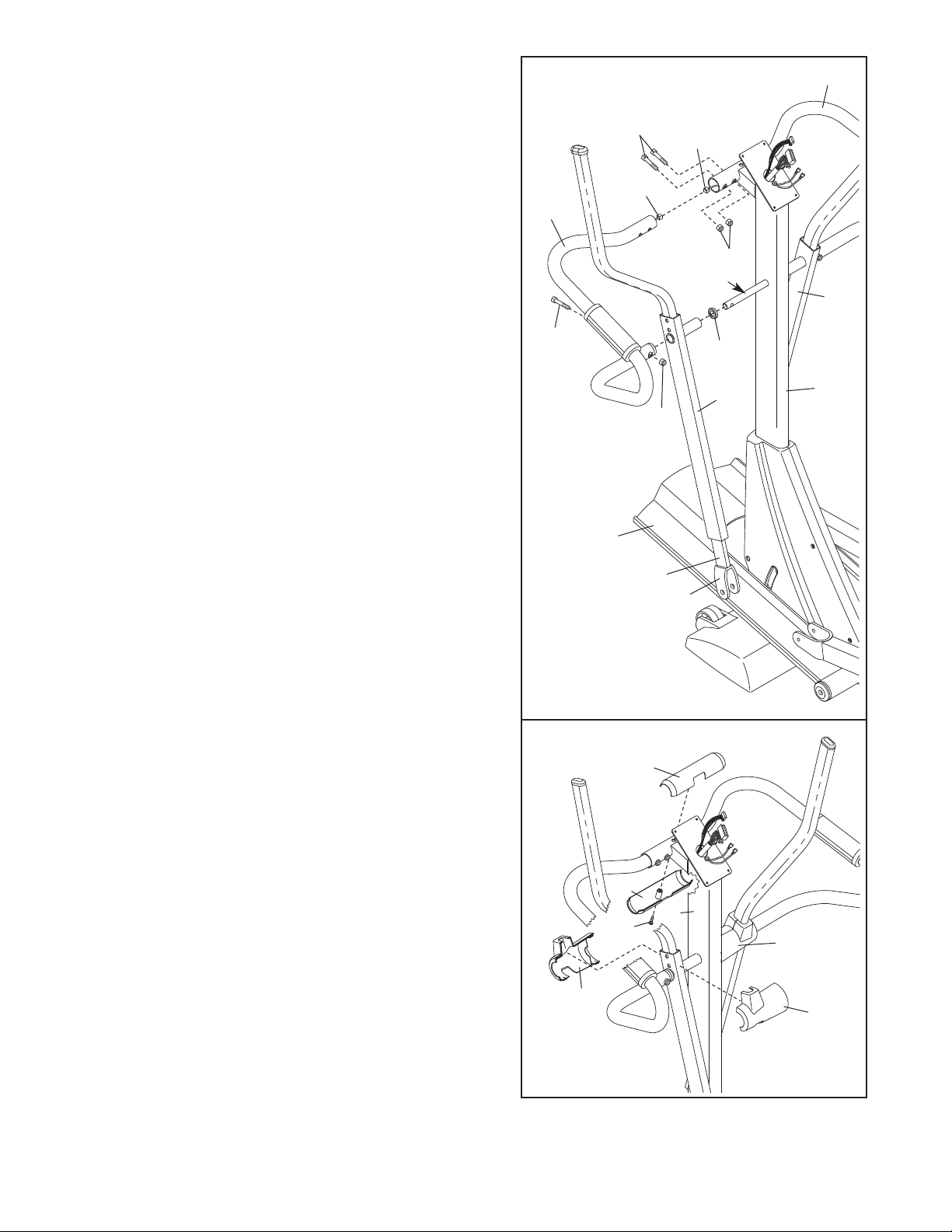

Slide a Weld Spacer (119) onto the axle on the left

5.

side of the Upright (2), with the open side of the Weld

Spacer facing the Upright.

Apply a small amount of

grease to the axle.

Apply a small amount of the included Teflon

®

lubricant

to a paper towel. Rub a thin film of the lubricant onto

one of the Upper Body Legs (31). Insert the Upper

Body Leg into one of the Upper Body Arms (118) as

shown. Hold the Upper Body Arm with one hand, hold

the Upper Body Leg with your other hand, and slide

the Upper Body Arm onto the axle on the left side of

the Upright (2). Then, slide the Upper Body Leg out of

the Upper Body Arm until it rests on the Ramp (3).

5

23

85

14

1

20

24

86

Grease

118

Have another person hold the Left Handlebar (24)

near the Upright (2) as shown. Connect the left Pulse

Sensor Wire (20) to the Pulse Extension Wire (114).

Slide the upper end of the Left Handlebar (24) into the

tube on the front of the Upright (2), while sliding the

lower end of the Left Handlebar onto the axle on the

left side of the Upright. Attach the upper end of the

Left Handlebar with two M8 x 41mm Button Bolts (85)

and two M8 Jam Nuts (86);

be careful not to damage

the Wires (20, 114) as you insert the Button Bolts.

Make sure that the Jam Nuts are resting in the

hexagonal holes in the Left Handlebar. Attach the

lower end of the Left Handlebar with an M8 x 38mm

Button Bolt (105) and an M8 Jam Nut (86).

Attach the other Upper Body Arm (118) and the Right

Handlebar (23) to the Upright (2) in the same way.

6. Look inside one of the Handlebar Covers (26) and

locate the square tabs connecting the two halves.

Gently lift the tabs and disconnect the halves.

6

105

3

Lubricate

25

86

31

119

118

2

Hold the two halves of the Handlebar Cover (26)

around the tube on the left side of the Upright (2).

Align

the halves and press them together until they lock.

Attach the other Handlebar Cover (26) to the right side

of the Upright (2) in the same way

.

Hold the halves of the Upper Handlebar Cover (25)

around the tube on the front of the Upright (2);

be

careful not to damage the Wires (not shown).

Attach the Upper Handlebar Cover with an M4 x 12mm

Round Head Screw (96).

7

25

2

96

26

26

26

Page 8

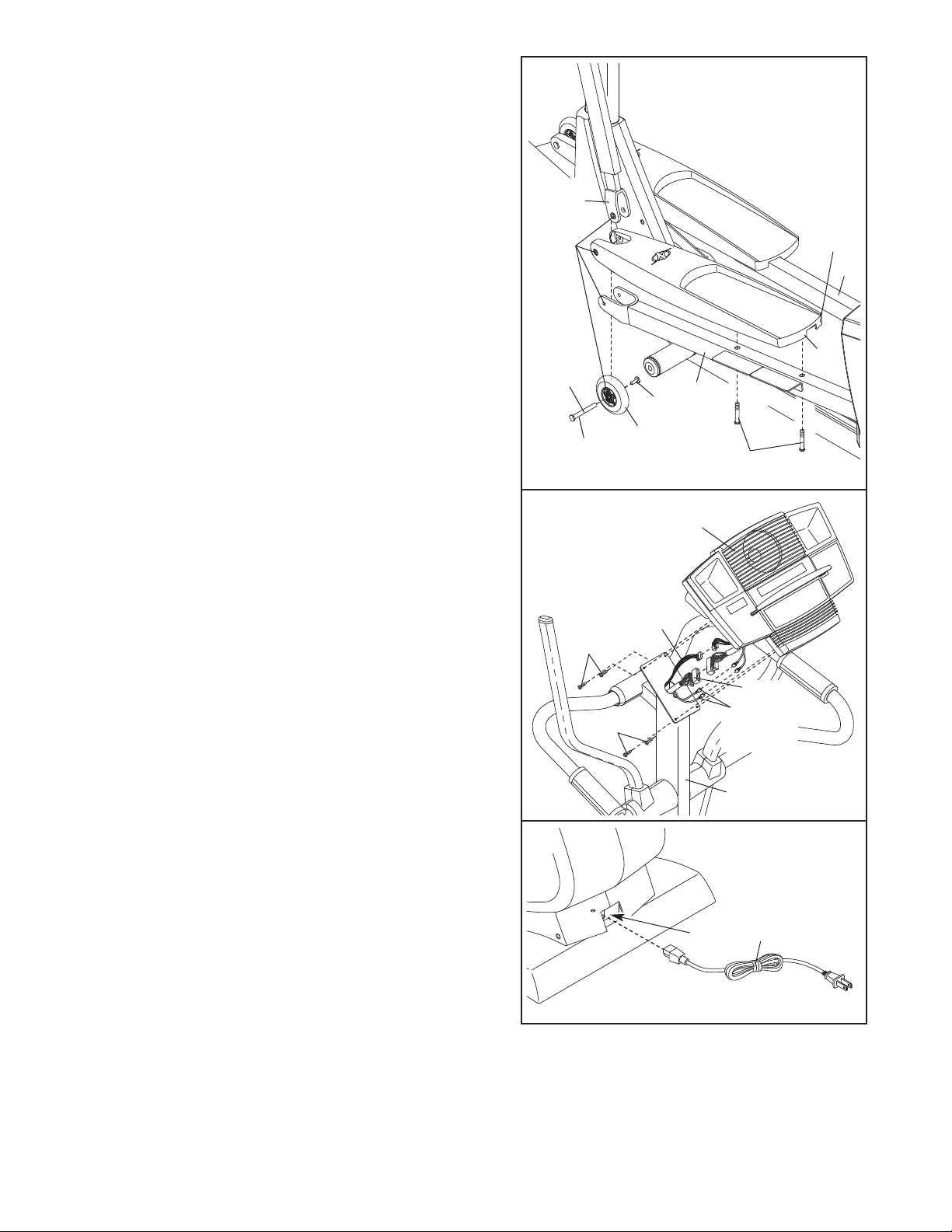

Apply a liberal amount of grease to the long side of

7.

each M8 x 79mm Bolt Set (65).

Identify the Left Pedal (10), which has a notch near

the right side. Place the Left Pedal on the Left Pedal

Leg (4). Have a second person hold the bracket on the

left Upper Body Leg (31) inside of the bracket on the

Left Pedal Leg, and hold a Wheel (28) inside of the

bracket on the left Upper Body Leg.

7

31

Align the indicated holes, and attach the Left Pedal

(10), the left Upper Body Leg (31), and the Wheel (28)

to the Left Pedal Leg (4) with an M8 x 79mm Bolt Set

(65). Attach the other end of the Left Pedal to the Left

Pedal Leg with two M8 x 54mm Button Screws (83).

Repeat this step on the right side of the elliptical

exerciser.

See step 4. Tighten the two M10 x 108mm Button

Screws (70).

8. Have another person hold the Console (17) near the

Upright (2).

Connect the Upper Wire Harness (115) to the wire harness on the Console (17). Connect the Pulse

Extension Wire (114) to the pulse wire on the Console.

Next, locate the two ground wires that are attached

with a screw to the Upright (2). Connect the ground

wires to the two smallest wires on the Console.

Carefully insert all excess wiring up into the Console

(17) and down into the Upright (2). Attach the Console

to the Upright with four M4 x 16mm Screws (98).

(Note: The Screws may be shipped in the console

box.) Be careful to avoid pinching the wires.

Holes

Grease

65

8

Do not pinch

the wires

during this step.

98

98

Notch

5

10

4

65

28

83

17

114

115

Ground

Wires

2

9. Plug the Power Cord (116) into the Power Socket

(117) at the rear of the elliptical exerciser.

10.Make sure that all parts of the elliptical exerciser are properly tightened. Cover the floor beneath the

elliptical exerciser to protect the floor from damage. Note: Some extra hardware may be left over.

The elliptical exerciser is now fully assembled. If you have purchased the optional chest pulse sensor

(see page 21), refer to page 9.

9

16

117

1

8

Page 9

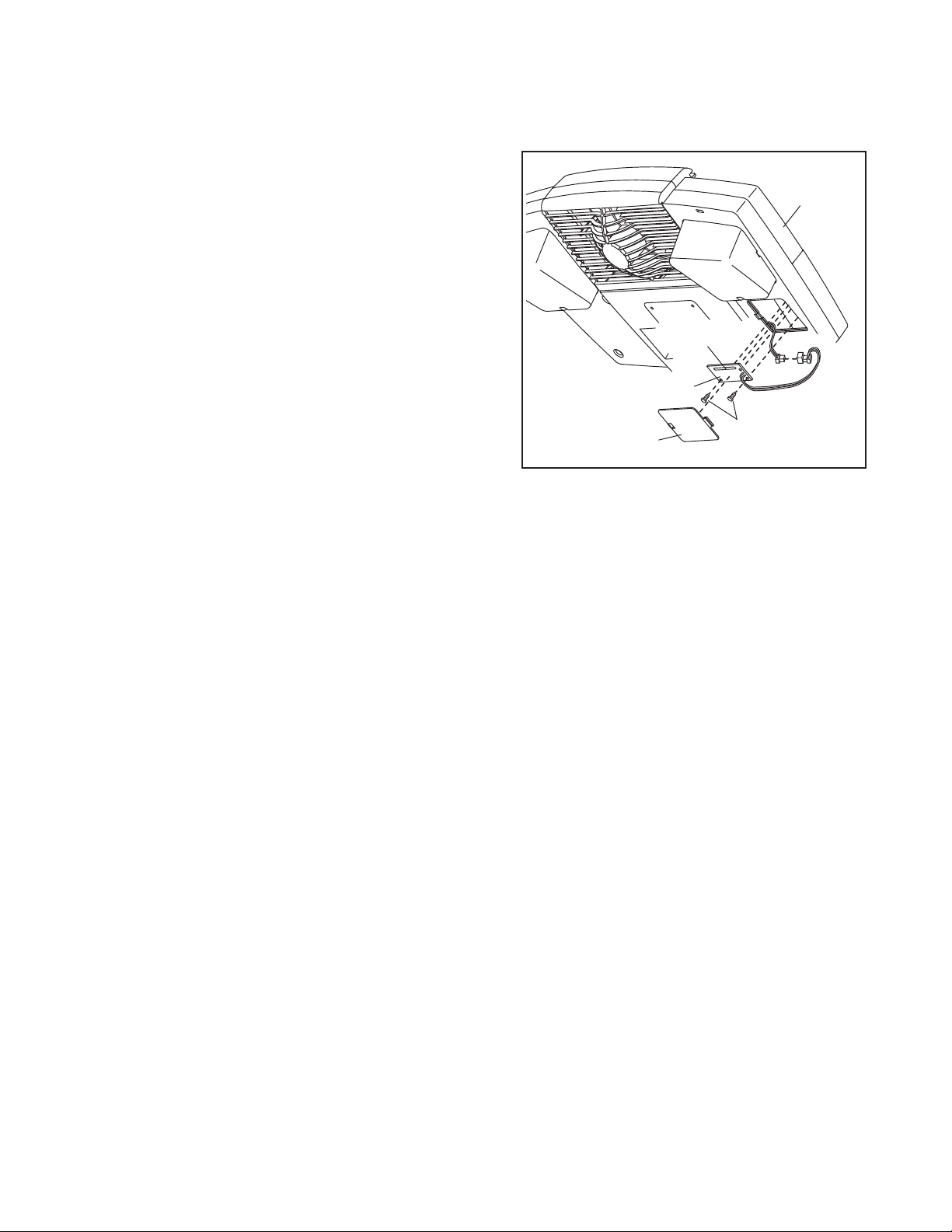

INSTALLING THE RECEIVER FOR THE OPTIONAL CHEST PULSE SENSOR

If you have purchased the optional chest pulse sensor (see page

receiver included with the optional chest pulse sensor.

1. Look under the Console (17) and locate the access

cover. Remove the access cover.

2. Hold the receiver in the position shown, with the small

cylinder at the top. Using the two screws included with

the chest pulse sensor, attach the receiver to the two

plastic posts (not shown) inside the access opening in

the back of the Console (17).

3. Connect the wire on the receiver to the indicated wire

on the Console (17). Make sure that the connectors on

the wires snap together. Discard the other wires included with the chest pulse sensor.

4. Reattach the access cover to the Console (17).

Access Cover

21), follow the steps below to install the

17

Cylinder

Receiver

Screws

9

Page 10

HOW TO USE THE ELLIPTICAL EXERCISER

HOW TO PLUG IN THE POWER CORD

This product

must be

grounded.

If it should

malfunction

or break

down,

grounding

provides a

path of least

resistance for

electric

current to reduce the risk of electric shock. This product is equipped with a cord having an equipmentgrounding conductor and a grounding plug.

power cord into an appropriate outlet that is properly installed and grounded in accordance with all

local codes and ordinances. This product is for

use on a nominal 120-volt circuit. Important: The

elliptical exerciser is not compatible with GFCIequipped outlets.

Grounded Outlet

Grounded Outlet Box

Grounding Plug

Grounding Pin

Plug the

The green-colored rigid ear, lug, or the like extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box cover.

Whenever the adapter is used, it must be held in

place by a metal screw. Some 2-pole receptacle out-

let box covers are not grounded. Contact a quali

fied electrician to determine if the outlet box cover

is grounded before using an adapter.

Note: When the power cord is plugged in, the elliptical exerciser’s incline system may automatically

calibrate itself. During the calibration process, two

dashes (– –) will appear in the left display of the

console and the ramp will move to the highest

position and then return to the lowest position.

The calibration process will last for one to two

minutes.

EXERCISING ON THE ELLIPTICAL EXERCISER

To mount the elliptical exerciser, hold the handlebars

and step onto the pedal that is in the lowest position.

Next, step onto the other pedal. Push the pedals until

they begin to move with a continuous motion.

-

DANGER: Improper connection of

the equipment-grounding conductor can result

in an increased risk of electric shock. Check

with a qualified electrician or serviceman if

you are in doubt as to whether the product is

properly grounded. Do not modify the plug

provided with the product—if it will not fit the

outlet, have a proper outlet installed by a qualified electrician.

A temporary

adapter may

be used to

connect the

power cord

to a 2-pole

receptacle

as shown at

the right if a

properly

grounded

outlet is not

available. The temporary adapter should be used only

until a properly grounded outlet can be installed by a

qualified electrician.

Grounded Outlet Box

Adapter

Lug

Metal Screw

Handlebar

Pedals

To dismount the elliptical exerciser, wait until the pedals come to a complete stop. The elliptical exerciser

does not have a free wheel; the pedals will contin

ue to move until the flywheel stops. When the ped

als are stationary, step off the highest pedal first.

Then, step of

f the lowest pedal.

-

-

10

Page 11

CONSOLE DIAGRAM

Note: If there is a sheet of clear plastic on the face of the console, remove it before using the console.

Left Display

Matrix

Training Zone Bar

FEATURES OF THE CONSOLE

The advanced console offers a selection of features

designed to make your workouts more enjoyable and

effective. When the manual mode of the console is

selected, the resistance of the elliptical exerciser and

the angle of the ramp can be changed with the touch

of a button. As you exercise, the console will provide

continuous exercise feedback. You can even measure

your heart rate using the handgrip pulse sensor. Note:

For information about an optional chest pulse sensor, see page 21.

The console also offers six resistance and pace programs. Each program automatically changes the resistance of the elliptical exerciser and prompts you to

increase or decrease your pace as it guides you

through an effective workout.

In addition, the console features two heart rate programs that automatically change the resistance of the

elliptical exerciser and prompt you to vary your pace to

keep your heart rate near a target level as you exercise.

The console also features iFIT.com interactive technology. Having iFIT.com technology is like having a personal trainer in your home. Using the included audio

cable, you can connect the elliptical exerciser to your

home stereo, portable stereo, computer, or VCR and

play special iFIT.com CD and video programs (iFIT.com

CDs and videocassettes are available separately).

iFIT.com CD and video programs automatically control

the resistance of the elliptical exerciser and prompt

you to vary your pace as a personal trainer coaches

you through every step of your workout. High-energy

music provides added motivation.

iFIT.com CDs and videocassettes, call toll-free

1-888-963-4266.

With the elliptical exerciser connected to your computer, you can also go to our Web site at www.iFIT.com

and access programs directly from the internet.

Explore www.iFIT.com for more information.

To purchase

11

Page 12

HOW T

O USE THE MANUAL MODE

Monitor your progress with the matrix,

5

raining Zone bar, and the two displays.

T

the

Press any button on the console or begin

1

pedaling to turn on the console.

Make sure that the power cord is properly

plugged in (see page 10). Next, press any button

on the console or begin pedaling to turn on the

console. After a few seconds, the console displays will light. A tone will then sound and the

console will be ready for use.

Select the manual mode.

2

When the power is

turned on, the

manual mode will

be selected. If you

have selected a

program or the

iFIT.com mode,

select the manual mode by pressing the Program

Select button repeatedly until a track appears in

the matrix.

Begin pedaling and change the resistance of

3

the elliptical exerciser as desired.

As you pedal,

change the resistance of the elliptical exerciser by

pressing the

Resistance buttons. There are

ten resistance levels. Note: After the Resistance

buttons are pressed, it will take a moment for the

elliptical exerciser to reach the selected resistance level.

The matrix

When the manual

mode or the

iFIT.com mode is

selected, the matrix

will show a track

representing 1/4

mile. As you exercise, the indicators around the

track will light, one at a time, until the entire track

is lit. When you have completed a lap, a new lap

will begin.

The Training Zone

—The Training

bar

Zone bar will show

your pace and the

approximate intensity level of your

exercise. For example, if three or four indicators in the bar are lit, the

bar shows that your pace is ideal for fat burning.

During programs, the Training Zone bar will also

prompt you to increase or decrease your pace.

The left display—

The left display will

show the elapsed

time, the resistance

level of the elliptical

exerciser, and the

total number of revolutions you have pedaled. The display will

change from one number to the next every few

seconds, as shown by the indicators around the

display. Note: When a program is selected, the

display will show the time remaining in the program instead of the elapsed time.

—

Adjust the angle of the ramp as desired.

4

As you pedal,

change the angle

of the ramp by

pressing the

Ramp buttons.

There are five

ramp angles.

Note: After the Ramp buttons are pressed, it will

take a moment for the ramp to reach the selected angle.

12

The right

display—

display will show

your heart rate,

your pedaling pace

(in revolutions per

minute), the angle

of the ramp, and the approximate number of calories you have burned.

from one number to the next every few seconds,

as shown by the indicators around the display.

The display will also show your heart rate when

you use the handgrip pulse sensor or the optional

chest pulse sensor.

The right

The display will change

Page 13

Measure your heart rate if desired.

6

Note: If you hold the handgrip pulse sensor

and wear the optional chest pulse sensor at

the same time, the console may not display

your heart rate accurately.

If there are

thin sheets of

plastic on the

metal contacts

on the handgrip pulse

sensor, peel

off the plastic.

To measure

your heart rate,

hold the contacts; your

palms must be resting on the upper contacts, and

your fingers must be touching the lower contacts.

Avoid moving your hands.

When your pulse is

detected, the Heart

Rate indicator

above the right display will begin to

flash, one or two

dashes (– –) will

appear in the right display, and then your heart rate

will be shown. For the most accurate heart rate

reading, hold the contacts for at least 15 seconds.

Contacts

Note: If you continue to hold the pulse sensor, the

right display will show your heart rate for up to 30

seconds.

rate along with the other modes.

If your heart rate is not shown, make sure that

your hands are positioned as described. Be careful not to move your hands excessively or to

squeeze the metal contacts too tightly. For optimal performance, clean the metal contacts using

a soft cloth; never use alcohol, abrasives, or

chemicals.

Turn on the fan if desired.

The display will then show your heart

7

To turn on the fan at low speed, press the Fan

button. Pivot the fan to the desired angle. To turn

on the fan at high speed, press the Fan button a

second time. To turn off the fan, press the Fan

button a third time.

When you are finished exercising, the console

8

will automatically turn off.

If the pedals are not moved for several seconds, a

tone will sound, the console will pause, and the

left display will begin to flash.

If the pedals are not moved for about five minutes, the console will turn off and the displays will

be reset.

13

Page 14

HOW TO USE RESISTANCE AND PACE

PROGRAMS

Press any button on the console or begin

1

pedaling to turn on the console.

See step 1 on page 12.

Select one of the six resistance and pace

2

programs.

When the power is

turned on, the

manual mode will

be selected. To

select a resistance

and pace program,

press the Program

Select button repeatedly until a “P 1,” “P 2,” “P 3,”

“P 4,” “P 5,” or “P 6” appears in the right display.

When a resistance and pace program is selected,

the matrix will show the first seven pace settings

for the program. The left display will show how

long the program will last.

Press the Program Start button or begin

3

pedaling to start the program.

Each program is divided into several time segments of different lengths. One pace setting and

one resistance setting are programmed for each

segment. (The same pace setting and/or resistance setting may be programmed for two or more

consecutive segments.)

The pace setting

for the first segment will be

shown in the flashing Current

Segment column

of the matrix. (The

resistance settings

are not shown in the matrix.) The pace settings

for the next several segments

columns to the right.

As you exercise, the

you to keep your pedaling pace near the pace

Current Segment

will be shown in the

Training Zone bar will help

setting for the current segment. The

lit indicators in the

bar will show your

actual pace. If an

indicator to the

right of the lit indicators is flashing

(see drawing a),

increase your pace.

If an indicator to

the left of any lit

indicator is flashing

(see drawing b), decrease your pace. When no

indicator is flashing, your pace matches the pace

setting for the current segment. Important: The

pace settings are intended only to provide

motivation. Your actual pace may be slower

than the current pace setting. Make sure to

exercise at a pace that is comfortable for you.

When only three seconds remain in the first segment of the program, both the Current Segment

column and the column to the right will flash, a

series of tones will sound, and all pace settings

will move one column to the left. The pace setting

for the second segment will then be shown in the

flashing Current Segment column and the resistance of the elliptical exerciser will automatically

change to the resistance setting for the second

segment.

Note: If all of the indicators in the Current Segment

column are lit after the pace settings have moved

to the left, the pace settings will move downward

so only the highest indicators appear in the matrix.

The program will continue until the pace setting

for the last segment is shown in the Current

Segment column of the matrix and no time

remains in the program.

Note: During the program, you can override the

resistance setting for the current segment, if

desired, by pressing the Resistance buttons.

However

resistance will automatically change if a dif

resistance is programmed for the next segment. If

you stop pedaling for several seconds, a tone will

sound and the program will pause.

program, simply resume pedaling.

, when the next segment begins, the

a

b

ferent

o restart the

T

14

Page 15

Adjust the angle of the ramp as desired

4

See step 4 on page 12.

Monitor your progress with the two displays.

5

See step 5 on page 12.

Measure your heart rate if desired.

6

See step 6 on page 13.

Turn on the fan if desired.

7

See step 7 on page 13.

.

HOW T

Each heart rate program helps you to keep your heart

rate near a certain percentage of your maximum heart

rate during your workout. (Your maximum heart rate is

estimated by subtracting your age from 220. For

example, if you are 30 years old, your maximum heart

rate is 190.) Heart rate program 1 is designed to keep

your heart rate between 50% and 80% of your maximum heart rate while you exercise; heart rate program 2 is designed to keep your heart rate between

50% and 85% of your maximum heart rate.

Follow the steps below to use a heart rate program.

O USE HEART RATE PROGRAMS

When the program is finished, the console

8

will automatically turn off.

See step 8 on page 13.

Press any button on the console or begin

1

pedaling to turn on the console.

See step 1 on page 12.

Select one of the heart rate programs.

2

When the power is

turned on, the manual mode will be

selected. To select

a heart rate program, press the

Program Select

button repeatedly until an “H 1” or “H 2” appears

in the right display.

Enter your age.

3

When a heart rate

program is selected, the word “AGE”

and the current

age setting will

flash in the left dis-

You must

.

play

enter your age to use a heart rate program. If

you have already entered your age, press the

Enter button and go to step 4. If you have not

entered your age, press the + or – button repeat

edly to enter your age, and then press the Enter

button.

-

15

Once you have entered your age, it will be saved

in memory.

Page 16

Hold the handgrip pulse sensor.

4

o use a heart rate program, you must use the

T

handgrip pulse sensor (see step 6 on page 13)

or the optional chest pulse sensor

handgrip pulse sensor, it is not necessary to hold

the handgrips continuously during the program.

However, you should hold the handgrips frequently for the program to operate properly.

time you hold the handgrips, keep your hands

on the metal contacts for at least 30 seconds.

Note: When you are not holding the handgrips,

the letters “PLS” will appear in the right display

instead of your heart rate.

Press the Program Start button or begin

5

pedaling to start the program.

Each heart rate program consists of 20 oneminute segments. One resistance setting and

one heart rate setting are programmed for each

segment. (The same resistance setting and/or

heart rate setting may be programmed for two or

more consecutive segments.)

. If you use the

Each

odically compare

your heart rate to

the heart rate set

ting for the current

segment; if neces

sary, an indicator

in the bar will then

flash to prompt you

to increase or

decrease your

pace to bring your

heart rate closer to

the current heart

rate setting. If an indicator to the

indicators is flashing (see drawing a), increase

your pace. If an indicator to the left of any lit indicator is flashing (see drawing b), decrease your

pace. When no indicator is flashing, your heart

rate is near the current heart rate setting.

Important: The heart rate settings are intended only to provide motivation. Your actual

heart rate may be slower than the current

heart rate setting. Make sure to exercise at a

pace that is comfortable for you.

-

a

-

b

right of the lit

The resistance

setting for the first

segment will be

shown in the flashing Current

Segment column

of the matrix. The

resistance settings

for the next several segments will be shown in the

columns to the right.

When only three seconds remain in the first segment of the program, both the Current Segment

column and the column to the right will flash, a

series of tones will sound, and all resistance set

tings will move one column to the left. The resis

tance setting for the second segment will then be

shown in the flashing Current Segment column

the resistance of the elliptical exerciser will

and

automatically adjust to the resistance setting for

the second segment.

As you exercise, the Training Zone bar will help

you to keep your heart rate near the heart rate

setting for the current segment.

in the bar will show your actual pace. When you

hold the handgrip pulse sensor or wear the

optional chest pulse sensor

Current Segment

The lit indicators

, the console will peri-

The program will continue until the resistance setting for the last segment is shown in the Current

Segment column of the matrix and no time

remains in the program.

Note: During the program, you can manually override the resistance setting for the current segment, if desired, with the Resistance buttons.

However, when the next segment begins, the

elliptical exerciser will automatically adjust to the

resistance setting for the next segment. If you

stop pedaling for several seconds, a tone will

sound and the program will pause. To restart the

program, simply resume pedaling.

-

-

Monitor your progress with the two displays.

6

See step 5 on page 12.

urn on the fan if desired.

T

7

See step 7 on page 13.

When the program is finished, the console

8

will automatically turn off.

See step 8 on page 13.

16

Page 17

HOW TO CONNECT YOUR CD PLAYER, VCR,

LINE OUT

PHONES

LINE OUT

PHONES

PHONES

PHONES

AUDIO OUT

RIGHT

LEFT

PHONES

OR COMPUTER

o use iFIT.com CDs

T

, the elliptical exerciser must be

connected to your portable CD player, portable stereo,

home stereo, or computer with CD player. See pages

17 and 18 for connecting instructions. To use iFIT.com

videocassettes, the elliptical exerciser must be connected to your VCR. See page 19 for connecting

instructions. To use iFIT.com programs directly from

our Web site, the elliptical exerciser must be connected to your home computer. See page 18 for connecting instructions.

HOW TO CONNECT YOUR PORTABLE CD PLAYER

HOW TO CONNECT YOUR PORTABLE STEREO

Note: If your stereo has an RCA-type

AUDIO OUT

jack, see instruction A below. If your stereo has a

1/8” LINE OUT jack, see instruction B. If your

stereo has only a PHONES jack, see instruction C.

A. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the cable

into the adapter. Plug the adapter into an AUDIO

OUT jack on your stereo.

A, B

Note: If your CD player has separate LINE OUT and

PHONES jacks, see instruction A below. If your CD

player has only one jack, see instruction B.

A. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into the LINE OUT jack on your CD player.

Plug your headphones into the PHONES jack.

A

Audio

Cable

Head-

phones

B. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into a 1/8”

Y-adapter (available at electronics

stores). Plug the Y-adapter into the PHONES jack

on your CD player. Plug your headphones into the

other side of the Y-adapter.

Adapter

Audio Cable

B. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into the LINE OUT jack on your stereo. Do

not use the adapter.

C. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into a 1/8” Y-adapter (available at electronics

stores). Plug the Y-adapter into the PHONES jack

on your stereo. Plug your headphones into the

other side of the Y-adapter.

C

Audio

Cable

1/8”

Y-adapter

B

Headphones

1/8”

Audio

Y-adapter

Cable

Headphones

17

Page 18

HOW TO CONNECT YOUR HOME STEREO

CD

VCR

Amp

LINE OUT

LINE OUT

CD

VCR

Amp

LINE OUT

LINE OUT

PHONES

HOW TO CONNECT YOUR COMPUTER

Note: If your stereo has an unused LINE OUT jack,

see instruction A below. If the LINE OUT jack is

being used, see instruction B.

A. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into the adapter. Plug the adapter into the

LINE OUT jack on your stereo.

A

Audio

Adapter

Cable

B. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into the adapter. Plug the adapter into an

RCA Y-adapter (available at electronics stores).

Next, remove the wire that is currently plugged into

the LINE OUT jack on your stereo and plug the

wire into the unused side of the Y-adapter. Plug the

Y-adapter into the LINE OUT jack on your stereo.

If your computer has a 1/8” LINE OUT jack,

Note:

see instruction A. If your computer has only a

PHONES jack, see instruction B.

A. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into the LINE OUT jack on your computer.

A

Audio

Cable

B. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into a 1/8” Y-adapter (available at electronics

stores). Plug the Y-adapter into the PHONES jack

on your computer. Plug your headphones or speakers into the other side of the Y-adapter.

B

B

Audio

Cable

1/8”

Y-adapter

Headphones/Speakers

RCA

Audio

Cable

ire removed from

W

LINE OUT

Y-adapter

Adapter

jack

18

Page 19

HOW TO CONNECT YOUR VCR

AUDIO OUT

RIGHT

LEFT

VIDEO AUDIO

ANT

. IN

RF OUT

IN

OUT

CH

3

4

VIDEO AUDIO

ANT

. IN

RF OUT

IN

OUT

CH

3

4

Note: If your VCR has an unused

AUDIO OUT jack,

see instruction A below. If the AUDIO OUT jack is

being used, see instruction B. If you have a TV

with a built-in VCR, see instruction B. If your VCR

is connected to your home stereo, see HOW TO

CONNECT YOUR HOME STEREO on page 18.

B. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into the adapter

. Plug the adapter into an

RCA Y-adapter (available at electronics stores).

Next, remove the wire that is currently plugged into

the AUDIO OUT jack on your VCR and plug the

wire into the unused side of the Y-adapter. Plug the

Y-adapter into the AUDIO OUT jack on your VCR.

A. Plug one end of the audio cable into the jack

beneath the console. Plug the other end of the

cable into the adapter. Plug the adapter into the

AUDIO OUT jack on your VCR.

A

Adapter

Audio Cable

B

RCA Y-adapter

Audio Cable

Adapter

Wire removed from

AUDIO OUT jack

19

Page 20

HOW TO USE IFIT.COM CD AND VIDEO

PROGRAMS

To use iFIT.com CDs or videocassettes, the elliptical

exerciser must be connected to your portable CD player, portable stereo, home stereo, computer with CD

player, or VCR. See HOW TO CONNECT YOUR CD

YER, VCR, OR COMPUTER on page 17. To pur-

PLA

chase iFIT.com CDs or videocassettes, call tollfree 1-888-936-4266.

your workout. Simply follow your personal trainer’s

instructions.

The program will function in almost the same way

as a resistance and pace program (see step 3 on

page 14). However, an electronic “chirping” sound

will alert you when the resistance setting and/or

the pace setting is about to change.

Note: If the resistance of the elliptical exerciser

and/or the pace setting does not change when

a “chirp” is heard:

Follow the steps below to use an iFIT.com CD or

video program.

Press any button on the console or begin

1

pedaling to turn on the console.

See step 1 on page 12.

Select the iFIT.com mode.

2

When the console

is turned on, the

manual mode will

be selected. To

select the iFIT.com

mode, press the

iFIT.com button.

The indicator above the button will light.

Insert the iFIT.com CD or videocassette.

3

If you are using an iFIT.com CD, insert the CD

into your CD player. If you are using an iFIT.com

videocassette, insert the videocassette into your

VCR.

Press the play button on your CD player or

4

VCR.

• Make sure that the indicator above the

iFIT.com button is lit.

• Adjust the volume of your CD player or VCR.

If the volume is too high or too low, the console may not detect the program signals.

• Make sure that the audio cable is properly

connected and that it is fully plugged in.

Monitor your progress with the two displays.

5

See step 5 on page 12.

Measure your heart rate if desired.

6

See step 6 on page 13.

Turn on the fan if desired.

7

See step 7 on page 13.

When the program is finished, the console will

8

automatically turn off.

See step 8 on page 13.

moment after the play button is pressed, your

A

personal trainer will begin guiding you through

20

Page 21

HOW TO USE PROGRAMS DIRECTLY FROM

OUR WEB SITE

Our Web site at www.iFIT.com allows you to play

iFIT.com audio and video programs directly from the

internet. To use programs from our Web site, the elliptical exerciser must be connected to your home computer. See HOW TO CONNECT YOUR COMPUTER

on page 18. In addition, you must have an internet

connection and an internet service provider. A list of

specific system requirements is found on our Web

site.

almost the same way as a resistance and pace

program (see step 3 on page 14). However, an

electronic “chirping” sound

resistance setting and/or the pace setting is about

to change.

Monitor your progress with the two displays.

will alert you when the

8

See step 5 on page 12.

Measure your heart rate if desired.

9

See step 6 on page 13.

Follow the steps below to use a program from our

Web site.

Press any button on the console or begin

1

pedaling to turn on the console.

See step 1 on page 12.

Select the iFIT.com mode.

2

When the console

is turned on, the

manual mode will

be selected. To

select the iFIT.com

mode, press the

iFIT.com button.

The indicator above the button will light.

Go to your computer and start an internet

3

connection.

Start your Web browser, if necessary, and go

4

to our Web site at www.iFIT.com.

Turn on the fan if desired.

10

See step 7 on page 13.

When you are finished exercising, the console

11

will automatically turn off.

See step 8 on page 13.

THE OPTIONAL CHEST PULSE SENSOR

The optional chest

pulse sensor provides

hands-free operation

and continuously monitors your heart rate

during your workouts.

To purchase the

optional chest pulse

sensor, call toll-free

1-888-936-4266.

THE OPTIONAL

INTERACTIVE STAND

Follow the desired links on our Web site to

5

select a program.

Read and follow the on-line instructions for using

a program.

Follow the on-line instructions to start the

6

program.

When you start the program, an on-screen count

down will begin.

Return to the elliptical exerciser and begin

7

pedaling.

When the on-screen countdown ends, the program will begin.

The program will function in

The new NordicTrack

ireless W

W

active stand features a

built-in CD player and a

selection of

NordicT

CDs that control the

settings of your exercise equipment without

wires or cables. While

you work out, you can listen to a virtual personal train-

er and motivating music through the stand’s high-qual-

, ported 4” stereo speakers.

ity

porates a CleanAire ionizer that keeps airborne contaminants to a minimum in your exercise room.

www

4266 for more information or to order.

orkout inter-

rack workout

.NordicTrack.com or call toll-free 1-888-936-

®

The stand even incor

21

-

Visit

Page 22

MAINTENANCE AND TROUBLESHOOTING

Inspect and properly tighten all parts of the elliptical

exerciser

ately.

For smooth

operation of the

elliptical exerciser,

and clean the

incline ramp

regularly

a soft cloth and

mild detergent.

Other parts of

the elliptical

exerciser can

also be cleaned in this way. Keep liquids off the

console. Never use abrasives or solvents.

PULSE SENSOR TROUBLESHOOTING

If the handgrip pulse sensor does not function properly, see step 6 on page 13.

HOW TO CALIBRATE THE INCLINE SYSTEM

regularly. Replace any worn parts immedi-

Incline

Ramp

inspect

using

HOW TO MOVE THE ELLIPTICAL EXERCISER

Stand in front of the elliptical exerciser, hold the handlebars firmly, and place one foot against the ramp in

the location shown below. Pull the handlebars until

the elliptical exerciser can be moved on the front

wheels, and carefully move the elliptical exerciser to

the desired location. Then, place one foot against the

ramp, and lower the elliptical exerciser. Due to the

size and weight of the elliptical exerciser, use

extreme caution while moving and lowering it.

Handlebars

Place your

foot here

If the elliptical exerciser’s incline system is not working

properly, activate the calibration process by following

the steps below.

1. Hold down the + button and the Program Select

button at the same time for about five seconds.

Note: Numbers may appear in the left and right

displays. Disregard these numbers.

2. Press the Program Select button again. Note: A

combination of letters and numbers may appear in

the displays.

3. Press the 30° Ramp button. The ramp will move all

of the way up and then all of the way down.

4. Press the Program Select button three times. The

console will then be in the normal operating mode

and the elliptical exerciser will be ready for use.

Wheel

HOW TO LEVEL THE ELLIPTICAL EXERCISER

elliptical

If the

exerciser rocks

during use, turn

one or both of

the leveling feet

under the rear

stabilizer until

the rocking

motion is eliminated.

Leveling

Foot

22

Page 23

CONDITIONING GUIDELINES

WARNING:

Before beginning this or any exercise program, consult your physician. This is espe

cially important for persons over the age of 35

or persons with pre-existing health problems.

-

During the first few minutes of exercise, your body

uses easily accessible

gy. Only after the first few minutes of exercise does

your body begin to use stored fat calories for energy.

If your goal is to burn fat, adjust the intensity of your

exercise until your heart rate is near the lowest number in your training zone as you exercise.

carbohydrate calories for ener-

The pulse sensor is not a medical device.

Various factors may affect the accuracy of

heart rate readings. The pulse sensor is

intended only as an exercise aid in determining heart rate trends in general.

The following guidelines will help you to plan your

exercise program. Remember that proper nutrition

and adequate rest are essential for successful results.

EXERCISE INTENSITY

Whether your goal is to burn fat or to strengthen your

cardiovascular system, the key to achieving the

desired results is to exercise with the proper intensity.

The proper intensity level can be found by using your

heart rate as a guide. The chart below shows recommended heart rates for fat burning, maximum fat

burning, and cardiovascular (aerobic) exercise.

For maximum fat burning, adjust the intensity of your

exercise until your heart rate is near the middle number in your training zone as you exercise.

Aerobic Exercise

If your goal is to strengthen your cardiovascular system, your exercise must be “aerobic.” Aerobic exercise is activity that requires large amounts of oxygen

for prolonged periods of time. This increases the

demand on the heart to pump blood to the muscles,

and on the lungs to oxygenate the blood. For aerobic

exercise, adjust the intensity of your exercise until

your heart rate is near the highest number in your

training zone as you exercise.

WORKOUT GUIDELINES

Each workout should include the following three parts:

A warm-up, consisting of 5 to 10 minutes of stretching

and light exercise. A proper warm-up increases your

body temperature, heart rate, and circulation in preparation for exercise.

To find the proper heart rate for you, first find your age

near the bottom of the chart (ages are rounded off to

the nearest ten years). Next, find the three numbers

above your age. The three numbers are your “training

zone.” The lower two numbers are recommended

heart rates for fat burning; the highest number is the

recommended heart rate for aerobic exercise.

Fat Burning

To burn fat effectively, you must exercise at a relatively low intensity level for a sustained period of time.

Training zone exercise, consisting of 20 to 30 minutes of exercising with your heart rate in your training

zone. (During the first few weeks of your exercise

program, do not keep your heart rate in your training

zone for longer than 20 minutes.)

A cool-down, with 5 to 10 minutes of stretching. This

will increase the flexibility of your muscles and will

help to prevent post-exercise problems.

EXERCISE FREQUENCY

To maintain or improve your condition, complete three

workouts each week, with at least one day of rest

between workouts.

cise, you may complete up to five workouts each week

if desired. The key to success is to make exercise a

regular and enjoyable part of your everyday life.

After a few months of regular exer-

23

Page 24

ASSEMBLY

M8 x 54mm Button Screw (83)–4

M8 x 44mm Button Screw (84)–8

M6 x 16mm Patch

Screw (76)–4

M8 x 41mm Button

Bolt (85)–4

M10 Split

Washer (73)–2

M4 x 12mm

Round Head

Screw (96)–1

M6 Washer

(64)–2

7.6mm Spacer

(109)–2

M8 Jam Nut

(86)–6

M4 x 16mm

Screw (98)–4

M10 x 108mm Button Screw (70)–2

M8 x 38mm Button Bolt

(105)–2

M8 x 79mm Bolt Set (65)–2

Assembly requires two people. Place all parts of the elliptical exerciser in a cleared area and remove the

packing materials. Do not dispose of the packing materials until assembly is completed. In addition to the four

included allen wrenches, assembly requires a phillips screwdriver

wrenches , a rubber mallet , and pliers .

As you assemble the elliptical exerciser, use the drawings below to identify the small parts used in assembly.

The number in parenthesis below each drawing refers to the key number of the part, from the PART LIST on

pages 24 and 25. The second number refers to the quantity used in assembly.

have been pre-assembled. If a part is not in the parts bag, check to see if it is pre-assembled.

Note: Some small parts may

, two adjustable

Identify the Front Stabilizer (8). While another person

1.

lifts the front of the Frame (1) and holds the Pedal

Legs (4, 5) in the position shown, attach the Front

Stabilizer to the Frame with four M8 x 44mm Button

Screws (84) and a Support Plate (104).

While another person lifts the rear of the Frame (1),

attach the Rear Stabilizer (not shown) to the Frame

in the same way.

1

5

1

104

84

4, 5

8

84

Page 25

BEFORE YOU BEGIN

Congratulations for selecting the new NordicTrack

CX 990 elliptical exerciser. The CX 990 is an incredibly smooth exerciser that moves your feet in a natural

elliptical path, minimizing the impact on your knees

and ankles.

adjustable resistance

most from your exercise. Welcome to a whole new

world of natural, elliptical-motion exercise from

NordicTrack.

For your benefit, read this manual carefully before

you use the elliptical exerciser. If you have any

And the unique CX 990 features

and incline to help you get the

Console

®

questions after reading this manual, call our Customer

Service Department at 1-888-936-4266, Monday

through Friday 8h00 until 18h30 Eastern Time

(excluding holidays). To help us assist you, please

note the product model number and serial number

before calling.

The serial number can be found on a decal attached

to the elliptical exerciser (see the front cover of this

manual for the location of the decal).

Before reading further, please familiarize yourself with

the parts that are labeled in the drawing below.

The model number is NCCEL09940.

Fan

Water Bottle Holder*

Handlebar

BACK

Pulse Sensor

Upright

FRONT

Ramp

Wheel

Pedal

Pedal Leg

RIGHT SIDE

Power Socket

Leveling Foot

4

*No water bottle is included

Page 26

IMPORTANT PRECAUTIONS

WARNING: T

tions before using the elliptical exerciser.

1. Read all instructions in this manual before

using the elliptical exerciser.

2. It is the responsibility of the owner to ensure

that all users of the elliptical exerciser are

adequately informed of all precautions.

3. The elliptical exerciser is intended for

in-home use only. Do not use the elliptical

exerciser in a commercial, rental, or institutional setting.

4. Place the elliptical exerciser on a level surface, with a mat beneath it to protect the

floor or carpet. Keep the elliptical exerciser

indoors, away from moisture and dust.

5. Inspect and properly tighten all parts regularly. Replace any worn parts immediately.

6. Keep children under age 12 and pets away

from the elliptical exerciser at all times.

7. The elliptical exerciser should not be used

by persons weighing more than 115 kg (250

lbs.).

o reduce the risk of serious injury, read the following important precau-

12. The pulse sensor is not a medical device.

Various factors, including the user's movement, may affect the accuracy of heart rate

readings. The pulse sensor is intended only

as an exercise aid in determining heart rate

trends in general.

13. When you stop exercising, allow the pedals

to slowly come to a complete stop. The elliptical exerciser does not have a free wheel;

the pedals will continue to move until the

flywheel stops.

14. Always unplug the power cord immediately

after use and before cleaning the elliptical

exerciser.

15. The decal shown below has been placed on

the elliptical exerciser. If the decal is missing

or illegible, please call our Customer Service

Department toll-free at 1-888-936-4266 to

order a free replacement decal. Apply the

decal in the location shown.

8. Wear appropriate exercise clothing when

using the elliptical exerciser. Always wear

athletic shoes for foot protection.

Always hold the handlebars when mounting,

9.

dismounting, or using the elliptical exerciser.

10. Keep your back straight when using the elliptical exerciser

11. If you feel pain or dizziness while exercising, stop immediately and cool down.

; do not arch your back.

WARNING: Before beginning this or any exercise program, consult your physician.

This is especially important for persons over the age of 35 or persons with pre-existing health problems. Read all instructions before using. ICON assumes no responsibility for personal injury or

property damage sustained by or through the use of this product.

3

Page 27

9

7

6

46

84

84

104

87

87

46

54

55

98

98

58

77

8

112

46

67

67

84

84

87

87

46

67

91

53

78

100

78

56

57

77

90

81

80

32

88

44

92

102

82

41

98

98

40

94

94

39

51

51

66

111

83

5

29

65

28

65

11

27

125

95

95

70

73

73

76

64

13

3

1249

50

64

76

76

48

14

47

47

99

99

47

47

48

76

65

28

65

29

29

10

83

4

88

71

60

90

61

62

37

36

60

59

103

88

61

62

30

111

66

51

51

82

34

101

35

38

63

89

45

92

75

44

63

43

74

117

72

72

1

33

52

104

79

79

93

93

35

109

109

42

29

98

113

30

126

127

Model No. NCCEL09940 R0604A

27

Page 28

HOW TO ORDER REPLACEMENT PARTS

o order replacement parts, call our customer service department toll-freeat

T

Friday 8h00 until 18h30 eastern time (excluding holidays). When ordering parts, please be prepared to give the

following information:

• The MODEL NUMBER of the product (NCCEL09940)

1-888-936-4266, Monday through

• The NAME of the product (NordicTrack

• The SERIAL NUMBER of the product (see the front cover of this manual)

• The KEY NUMBER and DESCRIPTION of the part(s) (see pages 24 to 27)

®

CX 990 elliptical exerciser)

LIMITED WARRANTY

ICON OF CANADA, INC., (ICON), warrants this product to be free from defects in workmanship and

material, under normal use and service conditions, for a period of one (1) year from the date of purchase.

This warranty extends only to the original purchaser. ICON's obligation under this warranty is limited to

replacing or repairing, at ICON's option, the product through one of its authorized service centers. All

repairs for which warranty claims are made must be pre-authorized by ICON. This warranty does not

extend to any product or damage to a product caused by or attributable to freight damage, abuse, misuse, improper or abnormal usage or repairs not provided by an ICON authorized service center

ucts used for commercial or rental purposes, or to products used as store display models. No other warranty beyond that specifically set forth above is authorized by ICON.

, to prod

-

ICON is not responsible or liable for indirect, special or consequential damages arising out of or in connection with the use or performance of the product or damages with respect to any economic loss, loss

of property

consequential damages of whatsoever nature. Some provinces do not allow the exclusion or limitation of

incidental or consequential damages. Accordingly, the above limitation may not apply to you. The warranty extended hereunder is in lieu of any and all other warranties and any implied warranties of mer

chantability or fitness for a particular purpose is limited in its scope and duration to the terms set forth

herein. Some provinces do not allow limitations on how long an implied warranty lasts. Accordingly, the

above limitation may not apply to you.

This warranty gives you specific legal rights. You may also have other rights which vary from province to

province or so specified by the retailer of your equipment.

Part No. 212531 R0604A

, loss of revenues or profits, loss of enjoyment or use, costs of removal, installation or other

ICON

OF CANADA, INC., 900 de l’Industrie, St. Jerôme, QC J7Y 4B8

2004 ICON IP, Inc.

Printed in China

©

-

Loading...

Loading...