Page 1

Nokia Customer Care

2112 (RH-57) Series Transceivers

System Module

Issue 1 07/2004 Company Confidential ©2004 Nokia Corporation

Page 2

2112 (RH-57)

System Module Nokia Customer Care

Contents Page

Introduction ..................................................................................................................................................... 3

Baseband Module ........................................................................................................................................ 3

UEM .............................................................................................................................................................. 4

BB-RF Interface Connections ...................................................................................................................6

UPP................................................................................................................................................................ 9

NOR Flash Memory and SRAM .......................................................................................................... 10

User Interface Hardware .........................................................................................................................10

LCD............................................................................................................................................................. 10

Keyboard................................................................................................................................................... 11

Power Key ................................................................................................................................................ 11

Lights......................................................................................................................................................... 11

Flashlight.................................................................................................................................................. 11

Vibra .......................................................................................................................................................... 11

Audio Hardware .........................................................................................................................................12

Earpiece .................................................................................................................................................... 12

Microphone ............................................................................................................................................. 12

MIDI Speaker........................................................................................................................................... 12

Audio Amplifier Interface.................................................................................................................... 12

Battery ..........................................................................................................................................................12

Battery Connector ................................................................................................................................. 13

Accessories Interface ................................................................................................................................14

System Connector.................................................................................................................................. 14

Charger IF................................................................................................................................................. 16

Test Interfaces ............................................................................................................................................16

Production Test Pattern ....................................................................................................................... 16

General Information About Testing ......................................................................................................19

Phone Operating Modes ...................................................................................................................... 19

RF Module ....................................................................................................................................................19

Requirements .......................................................................................................................................... 19

Antenna .................................................................................................................................................... 19

Transmitter .............................................................................................................................................. 20

Synthesizer .............................................................................................................................................. 22

Receiver ................................................................................................................................................... 24

Page 2 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 3

2112 (RH-57)

Nokia Customer Care System Module

Introduction

The 2112 is available as a CDMA single-band engine (800 MHz CDMA). There are several

different operational modes, which have different states controlled by the cellular SW.

Some examples include:

• Idle State (on ACCH)

• Camping (on DCCH)

• Scanning

•Conversation

• No Service Power Save (NSPS)

In the power-off mode, only the circuits needed for power-up are supplied.

In the idle mode, circuits are powered down and only the sleep clock is running.

In the active mode, all the circuits are supplied with power, although some parts might

be in idle state part of the time.

The charge mode is effective in parallel with all previous modes. The charge mode itself

consists of two different states, the fast charge and the maintenance mode.

The Local Mode is used for alignment and testing.

Baseband Module

The baseband module is an 800 MHz CDMA DCT4 transceiver based on the DCT4 Apollo

engine. The baseband consists of three ASICs:

• Universal Energy Management (UEM)

• Universal Phone Processor (UPP)

• 64-megabit FLASH

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 3

Page 4

2112 (RH-57)

System Module Nokia Customer Care

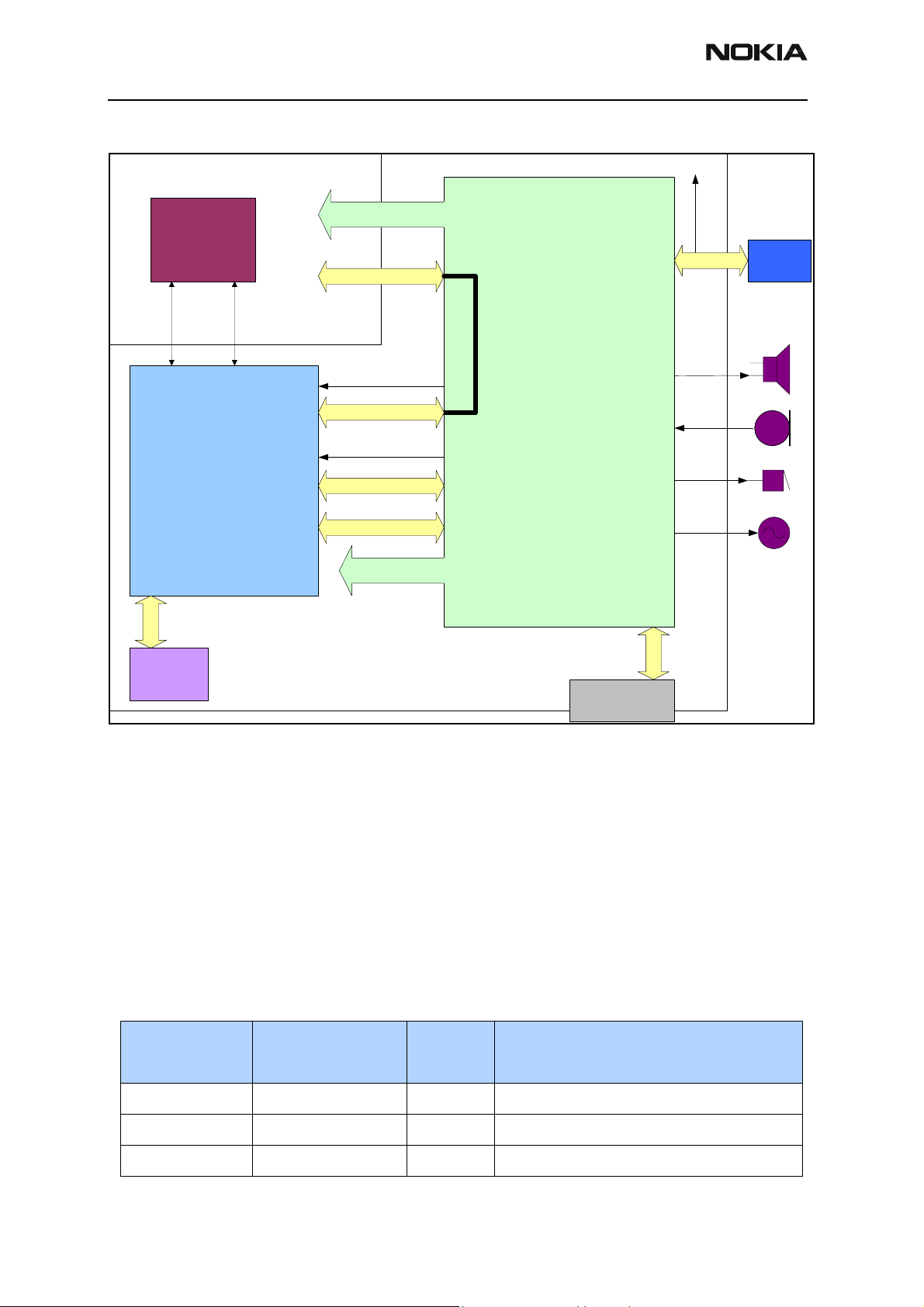

PA Supply

RF Supplies

Apollo

BATTERY

RF RX/TX

RFIC CTRL 19.2 MHz

UEM

Ear

MIC

Buzzer

Vibra

MEMADDA

MEMCONT

FLASH

UPP

PURX

RF RX/TX

Sleep Clock 32 kHz

CBUS/DBUS

AUDIO

BB Supplies

UEM

External Audio

Charger

Connection

DCT4 System

Connector

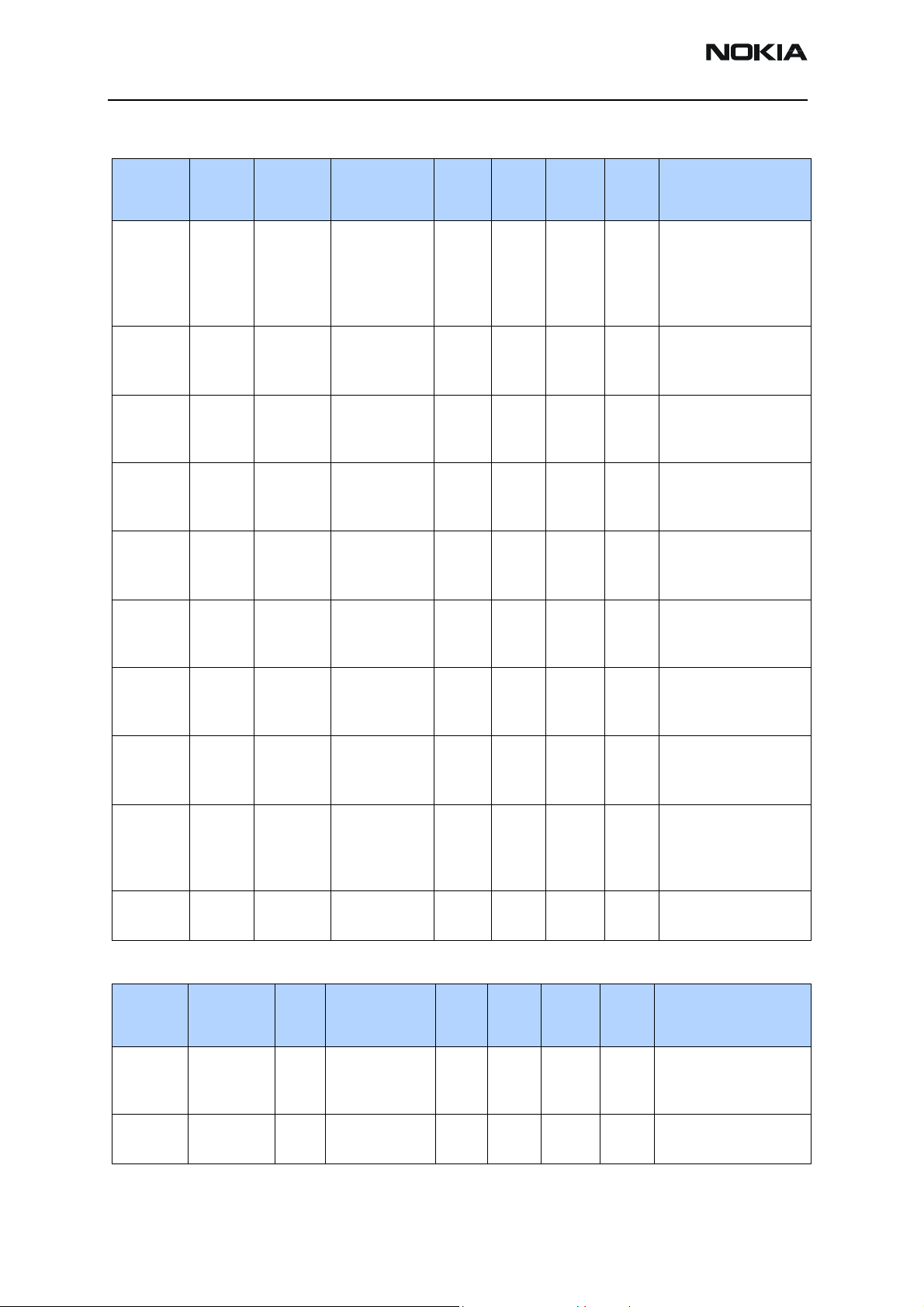

Figure 1: Baseband module diagram

The UEM is the Universal Energy Management IC for DCT4 digital handportable phones.

In addition to energy management, it performs all the baseband mixed-signal functions.

Most UEM pins have 2kV ESD protection. Those signals that are considered to be exposed

more easily to ESD have 8kV protection inside the UEM. Such signals are all audio,

headset, BSI, Btemp, Fbus, and Mbus signals.

The baseband is powered from five different UEM regulators.

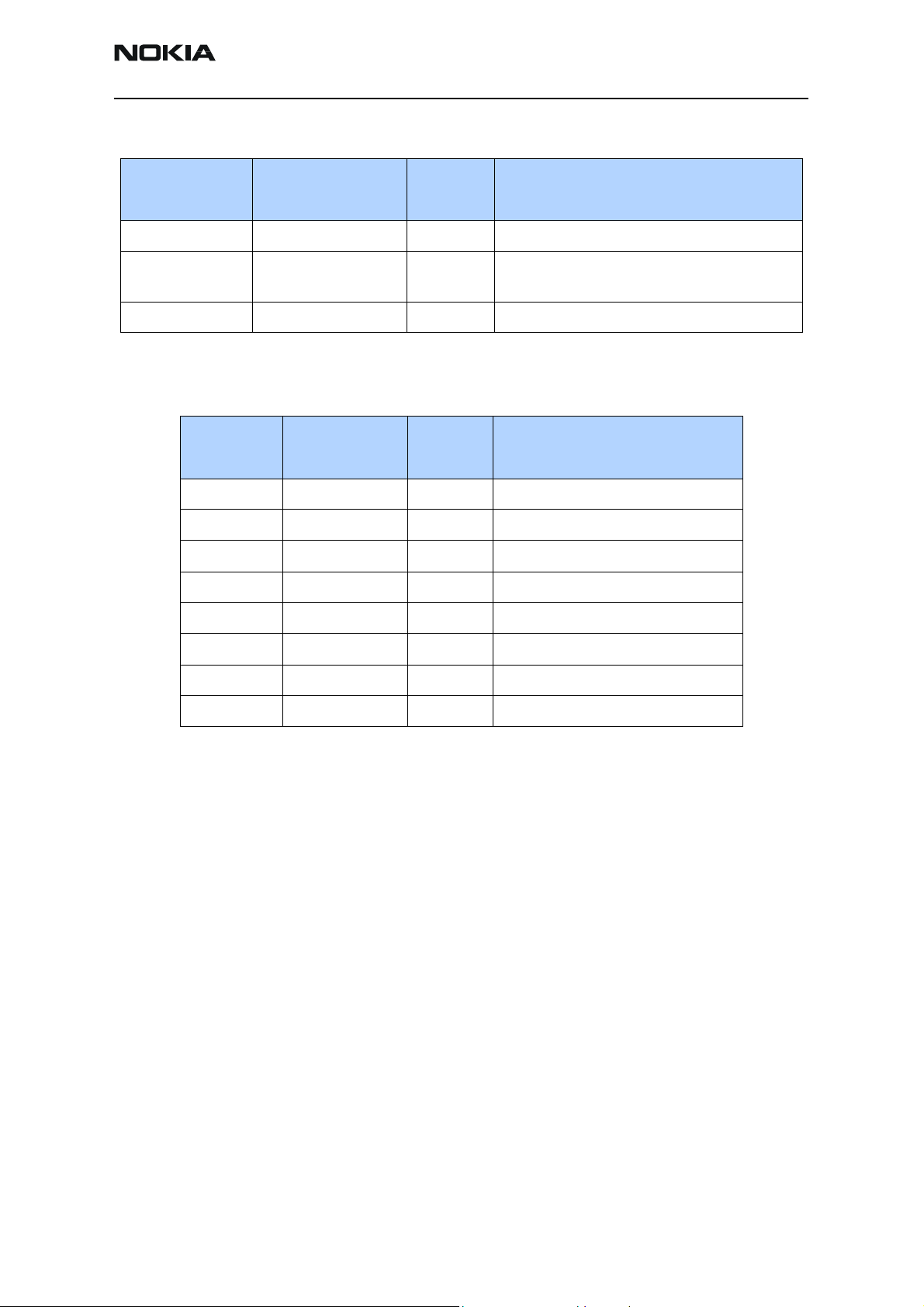

Table 1: Baseband Regulators

Regulator

Maximum

Current (mA)

Vout (V) Notes

VCORE 300 1.57/1.35 Power up default 1.57V and 1.35 in Sleep Mode.

VIO 150 1.8 Enabled always except during power-off mode

VFLASH1 70 2.78 Enabled always except during power-off mode

Page 4 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 5

2112 (RH-57)

Nokia Customer Care System Module

Table 1: Baseband Regulators (Continued)

Regulator

VFLASH2 40 2.78 Enabled only when data cable is connected

VANA 80 2.78 Enabled only when the system is awake (Off

VSIM 25 3.0 Enabled only when SIM card is used

Maximum

Current (mA)

Vout (V) Notes

during sleep and power off-modes)

Table 2 includes the UEM regulators for the RF.

Table 2: RF Regulators

Regulator

VR1A 10 4.75 Enabled when cell transmitter is on

VR1B 10 4.75 Enabled when the transmitter is on

VR2 100 2.78 Enabled when the transmitter is on

VR3 20 2.78 Enabled when SleepX is high

VR4 50 2.78 Enabled when the receiver is on

Maximum

Current (mA)

Vout (V) Notes

VR5 50 2.78 Enabled when the receiver is on

VR6 50 2.78 Enabled when the transmitter is on

VR7 45 2.78 Enabled when the receiver is on

The charge pump that is used by VR1A is constructed around the UEM. The charge pump

works with the Cbus (1.2 MHz) oscillator and gives a 4.75 V regulated output voltage to

the RF.

RF Interface

In addition to the RF regulators mentioned, the UEM handles the interface between the

baseband and the RF section. It provides A/D and D/A conversion of the in-phase and

quadrature receive and transmit signal paths, and also A/D and D/A conversions of

received and transmitted audio signals to and from the UI section. The UEM supplies the

analog AFC signal to the RF section according to the UPP DSP digital control. It also

converts the PA temperature into real data for the DSP. The UPP controls the RFIC

through the 3-wire RFIC bus. In addition, the UPP provides a PDM regulator for RF

interface (RX/TX AGC control).

Charging Control

The CHACON block of the UEM controls charging. Needed functions for charging controls

are the PWM-controlled battery charging switch, charger-monitoring circuitry, battery

voltage monitoring circuitry, and RTC supply circuitry for backup battery charging. In

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 5

Page 6

2112 (RH-57)

System Module Nokia Customer Care

addition, external components are needed for EMC protection of the charger input to the

baseband module. The DCT4 baseband is designed to electrically support both DCT3 and

DCT4 chargers.

Digital Interface

Data transmission between the UEM and the UPP is implemented using two serial

connections: DBUS (9.6 MHz) for the DSP and CBUS (1.2 MHz in CDMA) for the MCU. The

UEM is a dual-voltage circuit. The digital parts run from 1.8 V and the analog parts run

from 2.78 V. The Vbat (3.6 V) voltage regulator inputs are also used.

Audio Codec

The baseband supports two external microphone inputs and one external earphone

output. The inputs can be taken from an internal microphone, from a headset

microphone, or from an external microphone signal source through a headset connector.

The output for the internal earpiece is a dual-ended output, and the differential output is

capable of driving 4Vpp to the earpiece with a 60 dB minimum signal to total distortion

ratio. Input and output signal source selection and gain control is performed inside the

UEM ASIC according to control messages from the UPP. Both the buzzer and external

vibra alert control signals are generated by the UEM with separate PWM outputs.

MIDI

The MIDI audio signal generated by the DSP and UEM audio CoDec is routed to the XEAR

output of the UEM. An audio amplifier (LM4890) is used to boost enough power for the

speaker.

UI Drivers

The vibra, display LED, and keyboard LEDs are driven by open collector output drivers

inside the UEM. These drivers can generate PWM square wave signals to these devices.

AD Converters

There is an 11-channel analog-to-digital converter in the UEM. The AD converters are

calibrated in the production line.

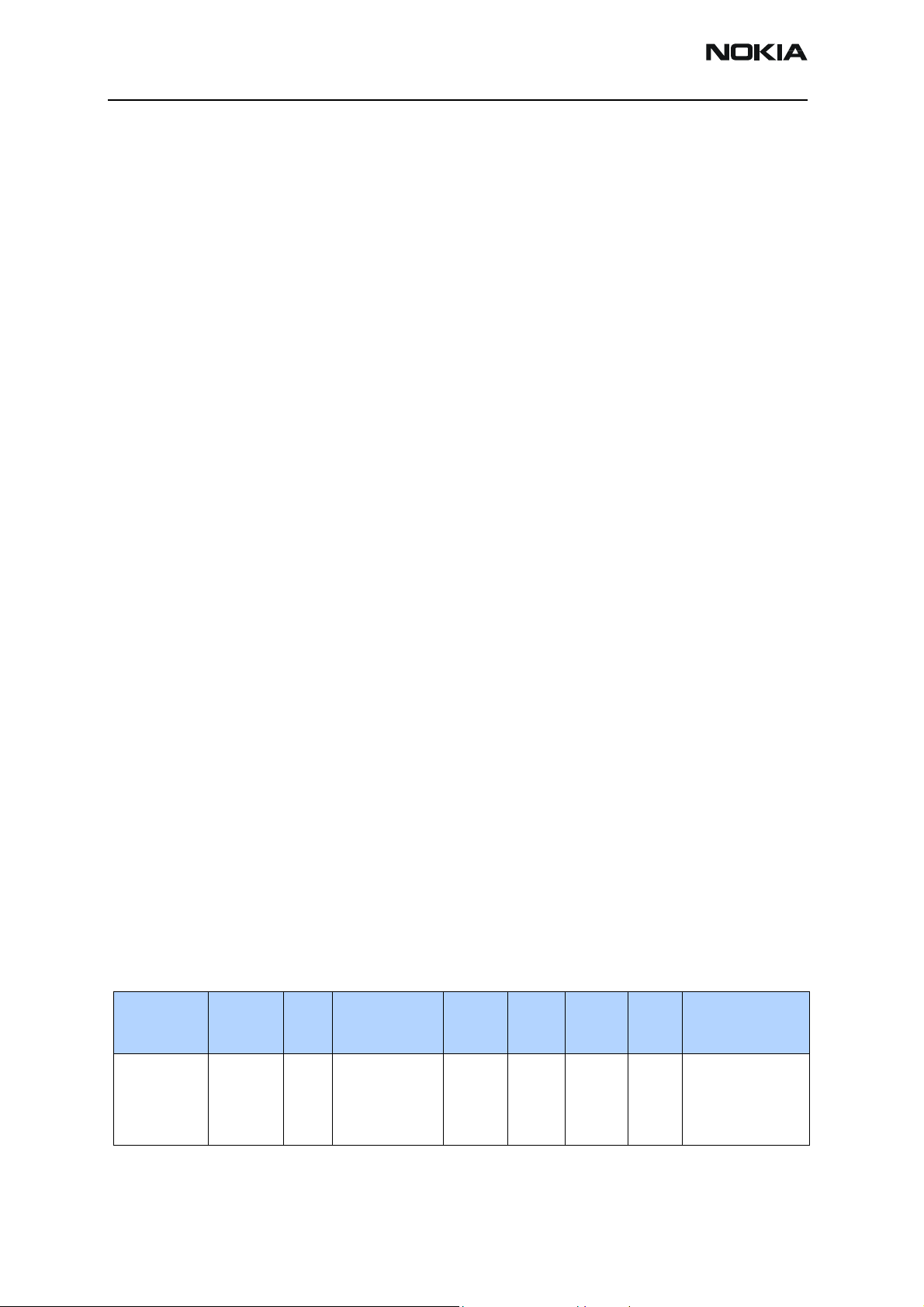

BB-RF Interface Connections

All the signal descriptions and properties in the following tables are valid only for active

signals.

Signal

Name

From To Parameter Min Type Max Unit Function

Table 3: PDM Interface

RX_IF_AGC UPP

GenIO 9

Yoda Voltage Min

Max

-------------Clk Rate

(1)

0.0

1.75

------

1.8

----

9.6

0.1

1.86

-----

19.2

V

----MHz

Controls gain of

VGA r in receiver

Page 6 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 7

2112 (RH-57)

Nokia Customer Care System Module

Table 3: PDM Interface (Continued)

Signal

Name

TX_IF_AGC UPP

TX_RF_AGC UPP

Signal

Name

TX_Gate UPP

From To Parameter Min Type Max Unit Function

GenIO 7

GenIO 26

From To Parameter

Gen IO 8

pullup

Jedi Voltage Min

Max

-------------Clk Rate

Jedi Voltage Min

Max

-------------Clk Rate

Jedi and

PA Gating

Transistors

(1)

(3)

Table 4: General I/O Interface

“0” Transmitter Off

“1” Transmitter On

Timing Accuracy

0.0

1.75

-----

0.0

1.75

------

0.1

1.8

-----

9.6

1.8

-----

9.6

1.86

-----

19.2

0.1

1.86

------

19.2

Input

Characteristics

1.38 1.88 V

0 0.4 V

4 chips, and can be

up to a total of

255 chips

V

----MHz

V

----MHz

Controls gain of

VGA in IF VGA

Controls gain of

TX driver

Function

Punctures the PAs and

the Jedi ASIC

Digital Into RF

D0 UPP

Gen IO 10

D1 UPP

Gen IO 13

D2 UPP

Gen IO 12

Signal

Name

19.2M_UPP Yoda UPP Frequency

AFC UEM VCT

From To Parameter Min Type Max Unit Function

PMIC Voltage Min

PMIC Voltage Min

PMIC Voltage Min

-------------Signal amplitude

Voltage Min

CXO

Max

--------------Settling time

0.4V max

Max

Max

Max

Table 5: VCTCXO Interface

-----

0.5

0.0

2.4

------ -----

(4)

1.72V-1.86V

0.4V max

1.72V-1.86V

0.4V max

1.72V-1.86V

19.2

-----

1.0

--

-----

1.5

0.1

2.55

-----

0.2

Enable PMIC

Set PMIC output voltage

Set PMIC output voltage

MHz

----Vpp

V

----ms

High stability

clock signal for

logic circuits, AC

coupled

sinewave.

Automatic

frequency

control signal for

VCTCXO

Digital Into RF

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 7

Page 8

2112 (RH-57)

System Module Nokia Customer Care

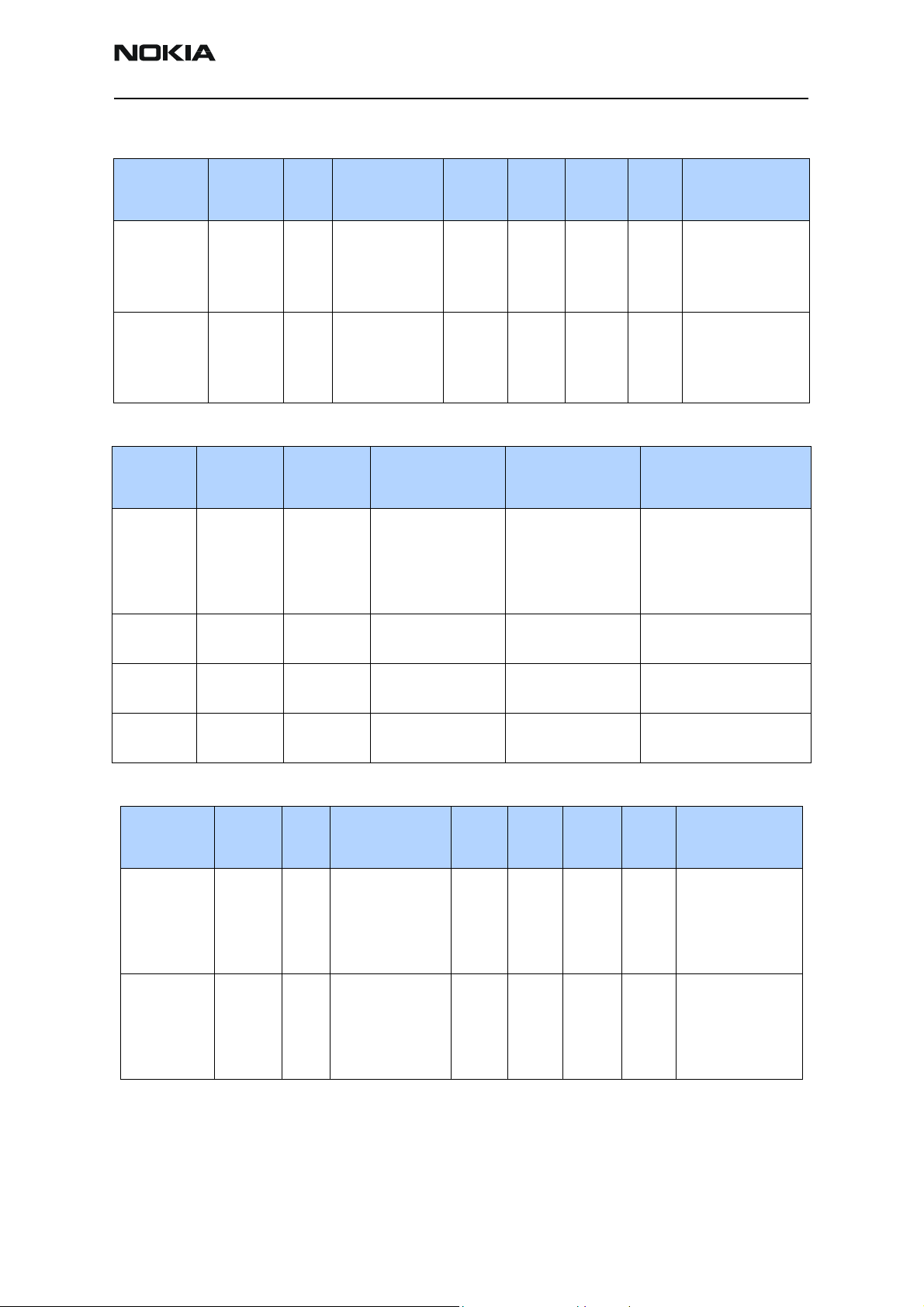

Table 6: Regulated Supplies from UEM to RF

Signal

Name

VBAT Battery PA &

VR1A UEM PA Vref Voltage

VR2 UEM Jedi Voltage

VR3 UEM VCTCXO,

VR4 UEM Alfred Voltage

VR5 UEM Jedi Voltage

From To Parameter Min Type Max Unit Function

Voltage

UEM,

external

driver

amps

Yoda

-------------

Current

-------------

Current

-------------

Current

Voltage

-------------

Current

-------------

Current

-------------

Current

3.2

----0

4.6

----0

2.70

-----

2.70

-----

2.70

-----

2.70

-----

3.5

-----

-

4.75

----4

2.78

-----

2.78

-----

2.78

-----

2.78

-----

5.1

----2A

peak

4.9

----5

2.86

----100

2.8

----20

V

-----

V

----mA

V

----mA

V

----mA

V

----mA

V

----mA

Battery supply. Lower

limit is to guarantee

regulator PSRR

Charge pump + linear regulator.

Linear regulator

Low noise linear regulator for VCTCXO

Low lq linear

regulator

Low lq linear

regulator

VR6 UEM Yoda Voltage

-------------

Current

VR7 UEM Jedi Voltage

-------------

Current

VIO UEM Jedi,

Yoda

Vref_rf01 UEM Yoda Voltage 1.334 1.35 1.366 V Voltage refer for Yoda

Signal

Name

PA_TEMP Thermistor UEM Input voltage

PWROUT Jedi UEM Input voltage

From To Parameter Min Type Max Unit Function

Voltage 1.70 1.8 1.88

Table 7: Slow A/D Converters

range

range

2.70

------

2.70

------

0 2.78 V PA temperature sen-

0 2.78 V Buffered output of TX

2.78

-----

2.78

-----

-----50

V

----mA

V

----mA

V

----mA

Low lq linear

regulator

Low noise linear regulator for

synthesizer

Supply for RF-BB digital signal interface

and some digital

parts of RF

I/or de-modulator

sor output voltage

Analog Out of RF

output detector

Page 8 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 9

2112 (RH-57)

Nokia Customer Care System Module

Table 8: RF-BB Analog Signals

Signal

Name

RX_IP_RF

RX_IN_RF

RX_QP_RF

RX_QN_RF

TX_IP_RF

TX_IN_RF

TX_QP_RF

TX_QN_RF

Signal

Name

RF_BUS_CLK

RF_BUS_DATA

RF_BUS_EN1X

From To Parameter Min Type Max Unit Function

Yoda UEM Differential volt-

age swing (static)

--------------DC level

--------------Input Bandwidth

UEM Jedi Differential volt-

age swing (static)

----------------DC level

-----------------

-3 dB Bandwidth

Table 9: RFIC Control

0.3

-----

1.3

-----

0.4

-----

1.65

----650

0.5

-----

1.35

-----

0.8

----

1.7

----

1.0

-----

1.4

----615

1.2

----

1.75

----1950

Vpp

---V

---kHz

Vpp

---V

---kHz

Differential in-phase

and quadrature RX

baseband signal

Analog Out of RF

Differential quadrature phase TX baseband signal for RF

modulator

Analog into RF

From To Parameter Min Type Max Unit Function

UPP Jedi,

Yoda

High-level input

voltage, V

Low-level input

voltage, V

IH

IL

1.72

1.8

1.86

0.4

V

V

Serial Clock =

Digital Into RF

Bidirectional Serial

Date = Digital I/O

UPP

High-level out-

put voltage, V

Low-level out-

put voltage, V

Clock

OH

OL

1.72

1.8

9.6

1.86

0.4

V

V

MHz

Latch enable for

Jedi and Yoda =

Digital Into RF

The 2112 uses a UPP8Mv3.5 ASIC with an 8Mbit RAM size. The UPP ASIC is designed to

operate in a DCT4 engine, and is designed as part of the DCT4 common baseband task

force. The DCT4 processor architecture consists of both DSP and MCU processors.

The UPP is internally partitioned into two main parts: the Brain and the Body.

The Brain consists of the processor and memory system (i.e., processor cores, mega-cells,

internal memories, peripherals, and the external memory interface). The following blocks

are included:

• DSP Subsystem (DSPSS)

• MCU Subsystem (MCUSS)

• Emulation control EMUCtl

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 9

Page 10

2112 (RH-57)

System Module Nokia Customer Care

• Program/data RAM PDRAM

• Brain Peripherals–subsystem (BrainPer)

The Body consists of the NMP custom cellular logic functions. These contain all

interfaces and functions needed for interfacing with other DCT4 baseband and RF parts.

The following sub-blocks are included:

•MFI

•SCU

•CTSI

•RxModem

• AccIF

•UIF

•Coder

• GPRSCip

•BodyIF

• SIMIF

•PUP

• CDMA (Corona)

NOR Flash Memory and SRAM

This device is a 64Mbit, mixed burst, multi-bank Flash and 8Mbit Muxed fCMOS SRAM

combined in a multi-chip package memory.

The 64Mbit Flash memory is organized as 8M x 16 bit, and the 8Mbit SRAM is organized

as 512K x 16 bit. The Flash memory architecture is designed to divide its memory arrays

into 263 blocks, which provides highly flexible erase and program capability. This device

is capable of reading data from one bank while programming or erasing in the other

banks with multi-bank organization.

The Flash memory performs a program operation in units of 16 bits (Word) and erases in

units of a block. Single or multiple blocks can be erased. The block erase operation is

completed for typically 0.7 sec.

The 8Mbit Muxed fCMOS SRAM supports low data retention voltage for the battery

backup operation with a low data retention current.

User Interface Hardware

LCD

The 2112 uses a black and white, 96 X 65 display. The LCD is controlled by UI SW and

control signals.

Page 10 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 11

2112 (RH-57)

Nokia Customer Care System Module

Keyboard

The keyboard design is a 4-way scroll with navigation keys, two soft keys, and 12 number

keys. The power key is located on top.

Power Key

All signals for the keyboard come from the UPP ASIC, except the power key signal, which

is connected directly to the UEM. Pressing the power key creates an interrupt and

connects the PWONX to the GND.

Lights

The 2112 has six white LEDs for keyboard lighting purposes. The LEDs for the display are

integrated into the display module.

Display lighting and keyboard lights are controlled by the UEM Klight signal (8-bit

register DriverPWMR, bits 7...4). The Klight output is a Pulse Width Modulation (PWM)

signal, which is used to control the average current going through the LEDs. A step-up

converter and a constant current source are used to ensure that the LEDs provide

uniform intensity.

Flashlight

The flashlight feature is driven by the White LED Driver and controlled by the UEM. The

circuit for the flashlight is driven by TK11851TL. In this situation, the driver is used as a

boost DC/DC. Vout is set using three precision resistors in R300, R316, and 317.

Vout = Vfb * (1+ (R316+R317)/ R300). The TK11851L is an active-high enable device,

whose enable signal is tied to Klight/Dlight signals from the UEM. When Klight goes high

it turns on the TK11851TL driver and the V301 transistor, which allows a path to GND.

Vibra

The vibra is located on the bottom of the D-cover and is connected by spring connectors

on the PWB.

The vibra is controlled by a VIBRA PWM signal from the UEM. This signal allows control

of both frequency and pulse width of the signal. Pulse width is used to control the

current when the battery voltage changes. Frequency control searches for optimum

frequency to ensure silent and efficient vibrating.

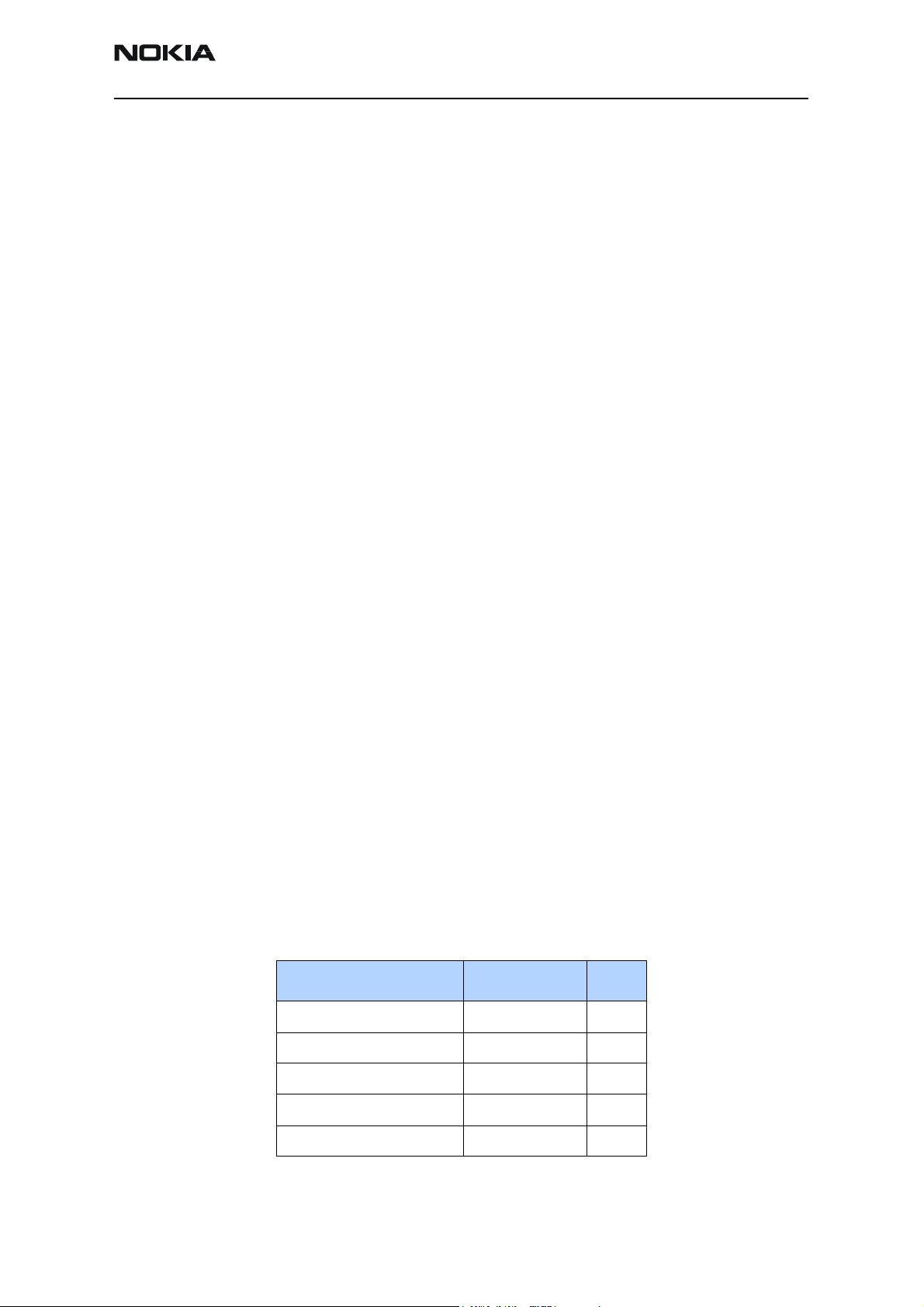

Table 10: Vibra Parameters

Parameter Requirement Unit

Rated DC voltage 1.3 V

Rated speed 9500 ± 3000 rpm

Rated current 115 ± 20 mA

Starting current 150 ± 20 mA

Armature resistant 8.6 ohm

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 11

Page 12

2112 (RH-57)

System Module Nokia Customer Care

Table 10: Vibra Parameters (Continued)

Parameter Requirement Unit

Rated DC voltage available 1.2 to 1.7 V

Starting DC voltage min 1.2 V

Audio Hardware

Earpiece

The 2112 uses the 13 mm speaker capsule that is used in DCT3. The speaker is dynamic,

very sensitive, and capable of producing relatively high sound pressure at low

frequencies. The speaker capsule and surrounding mechanics comprise the earpiece.

Microphone

The microphone is an electric microphone with an omnidirectional polar pattern.

It consists of an electrically polarized membrane and a metal electrode, both of which

form a capacitor. Air pressure changes (i.e., sound) move the membrane, which causes

voltage changes across the capacitor. Since the capacitance is typically 2 pF, a FET buffer

is needed inside the microphone capsule for the signal generated by the capacitor. The

microphone needs bias voltage as a result of the FET.

MIDI Speaker

Musical Instrument Digital Interface (MIDI) defines the data interchange format. By

implementing a MIDI engine, enriched sound effects are achieved, which include ring

tones, UI event sounds, and music for games and entertainment.

The MIDI data stream is a unidirectional, asynchronous bit stream at maximum

31.25 kbits/sec with 10 bits transmitted per byte (a start bit, 8 data bits, and one stop

bit).

MIDI data includes two categories of signals: MIDI tones and Alerting Tones. Both are

generated from the DSP and sent to the MIDI speaker.

Audio Amplifier Interface

Because the audio output from the UEM is not strong enough to produce enough power

for the speaker, an audio amplifier is required. The MIDI audio signal generated by the

DSP and UEM audio CoDec is routed to the XEAR output of the UEM. An audio amplifier

is used to boost enough power for the speaker. GENIO (28) is used to enable/disable the

audio amplifier as needed.

Battery

An 850 mAh Li-ion battery (BL-5C) is standard in the 2112. The battery block contains

BSI resistors for battery identification. The BSI fixed resistor value indicates the

chemistry and default capacity of a battery. This resistor is connected to the BSI pin of

Page 12 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 13

2112 (RH-57)

Nokia Customer Care System Module

the battery connector. The phone has pull-up resistors (R202) for these lines so that they

can be read by A/D inputs in the phone. There also are spark caps in the BSI line to

prevent ESD. The battery also has internal protection for overvoltage and overcurrent.

Figure 2: Battery interface

Battery Connector

The 2112 uses a spring-type battery connector. This ensures a more reliable connection

between the battery and PWB

Figure 3: Battery pack pin order

Table 11 shows the properties for the battery pack pins.

Table 11: Battery Pin Properties

Signal

Name

1 VBAT (+) (batt.) VBAT I/O

2 BSI BSI (batt.) UEM Out

3 GND GND GND

Connected

From - To

Batt I/O

Signal Properties A/D

Levels Freq/Timing

Description

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 13

Page 14

2112 (RH-57)

System Module Nokia Customer Care

Accessories Interface

System Connector

The 2112 uses Tomahawk accessories via the Tomahawk connector. The Tomahawk

bottom connector consists of a charging plug socket and a Tomahawk System connector

(see figures that follow). The minimum configuration for the Tomahawk interface

includes charging, mono audio, power out, ACI, and Fbus. The USB and stereo audio out

are optional.

The Tomahawk system connector includes:

• Charging

Pads for 2 -wire charging in cradles

•Audio

• 2 -wire fully differential output audio

• 2-wire differential mic input

•Power out

• 2.78V 70 mA output to accessories

• Detection/controlling

•ACI

• Point to point bi-directional data line

•Fbus

• Standard Fbus

• AT command mode (Nokia Serial Bus)

• Phone message mode

• Fast Fbus, fast data bus to add on modules

Page 14 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 15

2112 (RH-57)

Nokia Customer Care System Module

Metal shield

Plastic housing

9.50

Figure 4: Tomahawk system connector

Contacts (14 pieces)

Locking holes for

accessories (2 pieces)

6.50

5.70

6.55

5.40

1.00

2.70

21.20

PWB

0.30

Metal

shielding

ACI

Vout

Charge GND

Shielding GND

USB Vbus

USB D+ / Fbus RX

USB D- / Fbus TX

XMIC P

XMIC N

DATA GND

HSEAR P

HSEAR N

HSEAR R P

HSEAR R N

Figure 5: Mechanical dimensions and signals of Tomahawk bottom connectors

An accessory is detected by the ACI-line. All accessories will generate interrupt while

inserted or removed from the phone’s Tomahawk system connector. Insertion of an

accessory will generate HEADINT interrupt by pulling the ACI line down. Vout is enabled

by the UPP. The MBUS line is connected to the HEADINT line. If the HEADINT interrupt

from low to high transition occurs within 20msec, either a more advanced accessory is

connected or a basic headset is connected.

3.50

Shielding GND

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 15

Page 16

2112 (RH-57)

System Module Nokia Customer Care

Charger IF

The charger connection is implemented through the bottom connector. The DCT-4

bottom connector supports charging with both plug chargers and desktop stand

chargers.

There are three signals for charging. The charger GND pin is used for both desktop and

for plug chargers as well as the charger voltage. The PWM control line, which is needed

for 3-wire chargers, is connected directly to the GND in the PWB so the 2112 engine

does not provide any PWM control to chargers. Charge controlling is done inside the

UEM by switching the UEM internal charger switch on/off.

The fuse (F100) protects from high currents (e.g., when broken or pirate chargers are

used). The L100 protects the engine from RF noises that may occur in a charging cable.

V100 protects the UEM ASIC from reverse-polarity charging and from high-charging

voltage. The C106 is also used for ESD and EMC protection.

Test Interfaces

Production Test Pattern

The interface for 2112 production testing is a 5-pin pad layout in the BB area (see

Figure 6). A production tester connects to these pads using spring connectors. The

interface includes MBUS, USRX, FBUSTX, VPP, and GND signals. The pad size is 1.7mm.

The same pads also are used for AS test equipment, such as a module jig and a service

cable.

Figure 6: 5-pin layout in BB area

Page 16 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 17

2112 (RH-57)

Nokia Customer Care System Module

Figure 7: Test points (bottom)

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 17

Page 18

2112 (RH-57)

System Module Nokia Customer Care

Figure 8: Test points (top)

Page 18 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 19

2112 (RH-57)

Nokia Customer Care System Module

General Information About Testing

Phone Operating Modes

The phone has three different modes for test/repair. Modes can be selected with suitable

resistors connected to BSI lines as follows:

Table 12: Test/Repair Modes

Mode BSI Resistor Notes

Normal 75k

Local 3.3k

Test 6.8k Recommended with baseband testing. Similar to

Local mode, but making a phone call is possible.

The MCU software enters automatically to Local or Test mode at start-up if

corresponding resistors are connected.

Note: The baseband does not wake up automatically when the battery voltage is connected (Normal

Mode).

RF Module

Requirements

The 2112 supports CDMA 800 MHz as described in the following documents:

• IS2000-2-A Physical Layer Standard for CDMA2000 Spread Spectrum Systems

• IS-98D (Draft 4) Recommended Minimum Performance Standard for Spread

Antenna

An internal antenna is used.

Spectrum Mobile Stations

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 19

Page 20

2112 (RH-57)

System Module Nokia Customer Care

Transmitter

Antenna

Antenna

Antenna

Antenna

I

I

I

From

From

From

From

Baseband

Baseband

Baseband

Baseband

Q

Q

Q

BB I LPF

457.2MHz

VHF LO

VHF LO

VHF LO

VHF LO

÷2/÷4

÷2/÷4

÷2/÷4

÷2/÷4

IQ Modulator

0º

0º

0º

90º

90º

90º

90º

IF VGA

(IF AGC PDM)

UHF LO

UHF LO

UHF LO

0º

0º

0º

0º0º

90º

90º

90º

1052.61-107757MHz

Figure 9: RF transmitter block diagram

Upconverter

0º

0º

0º

0º

0º

0º

0º0º

90º

90º

90º

90º

90º

90º

90º

90º

RF VGA

(RF AGC PDM)

TP1

Bandpass

Tx SAW

To Baseband

To Baseband

To Baseband

PWR Amplifier

TP2 TP3

Power

Power

Power

Power

Detector

Detector

Detector

Detector

Isolator

Isolator

Isolator

TP4

Cell RX

Cell RX

Cell RX

Cell RX

Duplexer

Duplexer

Duplexer

Duplexer

Page 20 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 21

2112 (RH-57)

Nokia Customer Care System Module

The transmit chain up to the RF driver stage is integrated into one transmit-integrated

circuit (Jedi) with external power amplifiers (PA). The channel spacing is 30 kHz.

All data transmitted on the channel is convolutionally encoded and block-interleaved.

Modulation is 64-ary orthogonal (RC1 and RC2) and the direct sequence is spread by a

quadrature pair of PN sequences at a fixed chip rate. The data is filtered, O-QPSK

modulated, and up-converted to the appropriate transmission frequency. RC3 and RC4

use HPSK modulation at data rates up to 153.6 kBPS (RC3) and 115.2 kBPS (RC4).

The baseband I/Q signals are converted to an IF frequency in the I/Q modulator by

quadrature mixing. The modulated IF signals go through a variable gain amplifier

(IF AGC) and then are routed to the Cell Tx path. The path consists of an upconverter and

a variable gain RF amplifier. The IF signal is converted up to RF with a differential output

upconverter and then fed to the RF amplifier. The RF amplifier has variable gain

capability (RF AGC) with up to 40 dB of dynamic gain control.

The output of Jedi’s Cell RF amplifier is connected to an RF filter to reject TX noise in the

RX band. The output of the RF filter goes to the PA, to an isolator, and finally to the

antenna.

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 21

Page 22

2112 (RH-57)

System Module Nokia Customer Care

Synthesizer

Figure 10 illustrates the synthesizers and how they interconnect in the system.

CELL:457.2MHz

CELL:457.2MHz

JEDI

JEDI

367.2MHz

367.2MHz

VHF

VHF

counter

counter

Yoda

Yoda

19.2MHz

19.2MHz

VCTCXO

VCTCXO

19.2MHz to

19.2MHz to

UPP

UPP

VHF

VHF

counter

counter

UHF

UHF

counter

counter

Figure 10: Synthesizer system block diagram

CELLl Band UHF VCO

CELLl Band UHF VCO

Page 22 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 23

2112 (RH-57)

Nokia Customer Care System Module

1st TX VHF LO Synthesizer (Jedi)

The TX VHF synthesizer is integrated within the Jedi RFIC and generates the LO signals

for the IQ-modulator in Jedi. The synthesizer has an internal VCO with an external

resonator. The VCO operates at two times the Cell IF frequencies. A band-switch signal

(VCO_Band) is used to shift the center frequency of the external resonator.

The synthesizer is a dual-modulus prescaler and utilizes a phase detector with a charge

pump that sinks or sources currents, depending on the phase difference between the

detector input signals. The width of the pulses depends on the phase difference between

the signals at input of the phase detector. The main divider, auxiliary divider, and

reference divider are programmable through the serial interface to Jedi.

The TX VHF synthesizer generates 457.2MHz, and the comparison frequency is 30 kHz.

2nd RX VHF LO Synthesizer (Yoda)

The RX VHF synthesizer is integrated within the Yoda RFIC and generates the LO signals

for the IQ demodulator in Yoda. The synthesizer has an internal VCO with an external

resonator. The VCO operates at two times the common 183.6 MHz (367.2 MHz) RX IF

frequency.

The synthesizer is a dual-modulus prescaler and utilizes a phase detector with a charge

pump that signals or sources currents, depending upon the phase difference between the

detector input signals. The width of the pulses depends on the phase difference between

the signals at input of the phase detector. The main divider, auxiliary divider, and

reference divider are programmable through the serial interface to Yoda.

The RX VHF synthesizer generates 367.2 MHz.

VCTCXO - System Reference Oscillator

The VCTCXO provides the frequency reference for all the synthesizers. It is a voltagecontrolled, temperature-compensated, 19.2MHz crystal oscillator that can be pulled over

a small range of its output frequency. This allows for an AFC function to be implemented

for any frequency accuracy requirements. This is done by DSP processing of received I/Q

signals.

Closed loop AFC operation allows very close frequency tracking of the base station to be

done in CDMA mode. This enables the unit to track out aging effects and gives the

required center frequency accuracy in Cell band.

The most practical way of clock distribution is driving the two chips (Yoda and Jedi)

directly from the VCTCXO. An internal buffer is used to drive the UPP in order to isolate

the UPP’s digital noise from the VCTCXO, which prevents contamination of the 19.2 MHz

reference onto the PLL chips of the system. Because the VCTCXO output is a sinewave,

clock distribution does not cause any clock signal integrity problems, even for relatively

long traces (which might occur in the case of a digital square waveform with fast

transition times). The VCTCXO output is AC, coupled to Yoda, Jedi, and the digital ASICs.

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 23

Page 24

2112 (RH-57)

÷

System Module Nokia Customer Care

Receiver

LNA SW Control

I/Q Down

Converter

CDMA

BB Filter

TX

Antenna

Duplexer

LNA

CELL

SAW

Loop Filter

RFA

UHF VCO

1052.61-1077.57

UHF Synthsizer

JEDI

IFA

IF SAW

VCTCXO

VGA

CDMA

BB Filters

2

BB AMP

To BB

BB AMP

VHF PLL

367.2 MHz

Bias and Control

Reference Clock

To Base-Band

AFC

Figure 11: Receiver block diagram

Page 24 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 25

2112 (RH-57)

Nokia Customer Care System Module

The receiver is a dual conversion I/Q receiver with a first IF of 183.6 MHz. The front-end

RFIC (Alfred) contains a low noise amplifier (LNA), a radio frequency amplifier (RFA), a

down-converter, an intermediate frequency amplifier (IFA), and a local oscillator

amplifier (LOA). Between the LNA and the RFA is a bandpass filter, which rejects out-ofband spurious and acts as image rejection. The IF filter is between the Alfred IC and the

Yoda IC. The purpose of this filter is to guarantee rejection in adjacent and alternate

channels.

The RX IF ASIC Yoda is used to convert the IF down to baseband I and Q. The ASIC

contains a VGA section, an IQ demodulator, and baseband filters (BBFIL) for CDMA. Fix

gain baseband amplifier (BBAMP), and RX VHF PLL. The I/Q BB signals are output to the

UEM chip for analog-to-digital conversion and further signal processing.

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 25

Page 26

2112 (RH-57)

System Module Nokia Customer Care

This page intentionally left blank.

Page 26 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Loading...

Loading...