Page 1

Nokia Customer Care

2112 (RH-57) Series Transceivers

Troubleshooting — BB

Issue 1 07/2004 Company Confidential ©2004 Nokia Corporation

Page 2

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Contents Page

Baseband Troubleshooting........................................................................................................................... 4

2112 Baseband Module Overview .......................................................................................................... 4

Baseband and RF Architecture ................................................................................................................5

Power Up and Reset ....................................................................................................................................6

Power Up - Power Key............................................................................................................................. 8

Power Up - Charger ................................................................................................................................. 8

Power Up - RTC Alarm............................................................................................................................. 9

Power Off .......................................................................................................................................................9

Power Consumption and Operation Modes ......................................................................................... 9

Power Distribution ....................................................................................................................................10

Clock Distribution ......................................................................................................................................12

RFClk (19.2 MHz Analog)..................................................................................................................... 12

RFConvClk (19.2 MHz digital)............................................................................................................ 14

CBUS Clk Interface ................................................................................................................................ 15

DBUS Clk Interface ................................................................................................................................ 15

SleepCLK (Digital) .................................................................................................................................. 16

SleepCLK (Analog).................................................................................................................................. 16

Flash Programming ...................................................................................................................................17

Connections to Baseband.................................................................................................................... 17

Baseband Power Up .............................................................................................................................. 17

Flash Programming Indication ........................................................................................................... 17

Flashing..................................................................................................................................................... 18

Flash Programming Error Codes ........................................................................................................ 20

Charging Operation ...................................................................................................................................21

Battery ...................................................................................................................................................... 21

Charging Circuitry ................................................................................................................................. 21

Charger Detection.................................................................................................................................. 22

Charge Control ....................................................................................................................................... 23

Audio .............................................................................................................................................................23

Display and Keyboard ...............................................................................................................................23

Flashlight.................................................................................................................................................. 24

Accessories ..................................................................................................................................................24

Charging ................................................................................................................................................... 25

Tomahawk Headset Detection ........................................................................................................... 26

FBus Detection........................................................................................................................................ 27

Accessory Detection Through ACI..................................................................................................... 28

SIM CAR .......................................................................................................................................................29

Test Points ...................................................................................................................................................31

Troubleshooting .........................................................................................................................................33

Top Troubleshooting Map ........................................................................................................................34

Phone is Totally Dead ........................................................................................................................... 36

Flash Programming Does Not Work ................................................................................................. 37

Power Does Not Stay on or the Phone is Jammed ....................................................................... 39

Charger ..................................................................................................................................................... 41

Audio Faults............................................................................................................................................. 42

Display Faults.......................................................................................................................................... 46

Keypad Faults.......................................................................................................................................... 48

Page 2 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 3

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Flashlight.................................................................................................................................................. 50

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 3

Page 4

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Baseband Troubleshooting

2112 Baseband Module Overview

The baseband module of the 2112 transceiver is a CDMA single-band engine. The

baseband architecture is based on the DCT4 Apollo engine.

The 2112 cellular baseband consists of three ASICs: Universal Energy Management

(UEM), Universal Phone Processor (UPP), and a 64 megabit FLASH.

The baseband architecture supports a power-saving function called sleep mode. Sleep

mode shuts off the VCTCXO, which is used as the system clock source for both the RF and

the baseband. During sleep mode, the system runs from a 32 kHz crystal and all the RF

regulators (VR1A, VR1B, VR2, … VR7) are off. The sleep time is determined by network

parameters. Sleep mode is entered when both the MCU and the DSP are in standby mode

and the normal VCTCXO clock is switched off. The phone is waken up by a timer running

from this 32 kHz clock supply. The period of the sleep/wake up cycle (slotted cycle) is

1.28N seconds, where N= 0, 1, 2, depending on the slot cycle index.

2112 supports standard Nokia 2-wire and 3-wire chargers (ACP-x and LCH-x). However,

the 3-wire chargers are treated as 2-wire chargers. The PWM control signal for

controlling the 3-wire charger is ignored. UEM ASIC and EM SW control charging.

BL-5C Li-ion battery is used as main power source and has nominal capacity of 850 mAh.

Page 4 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 5

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

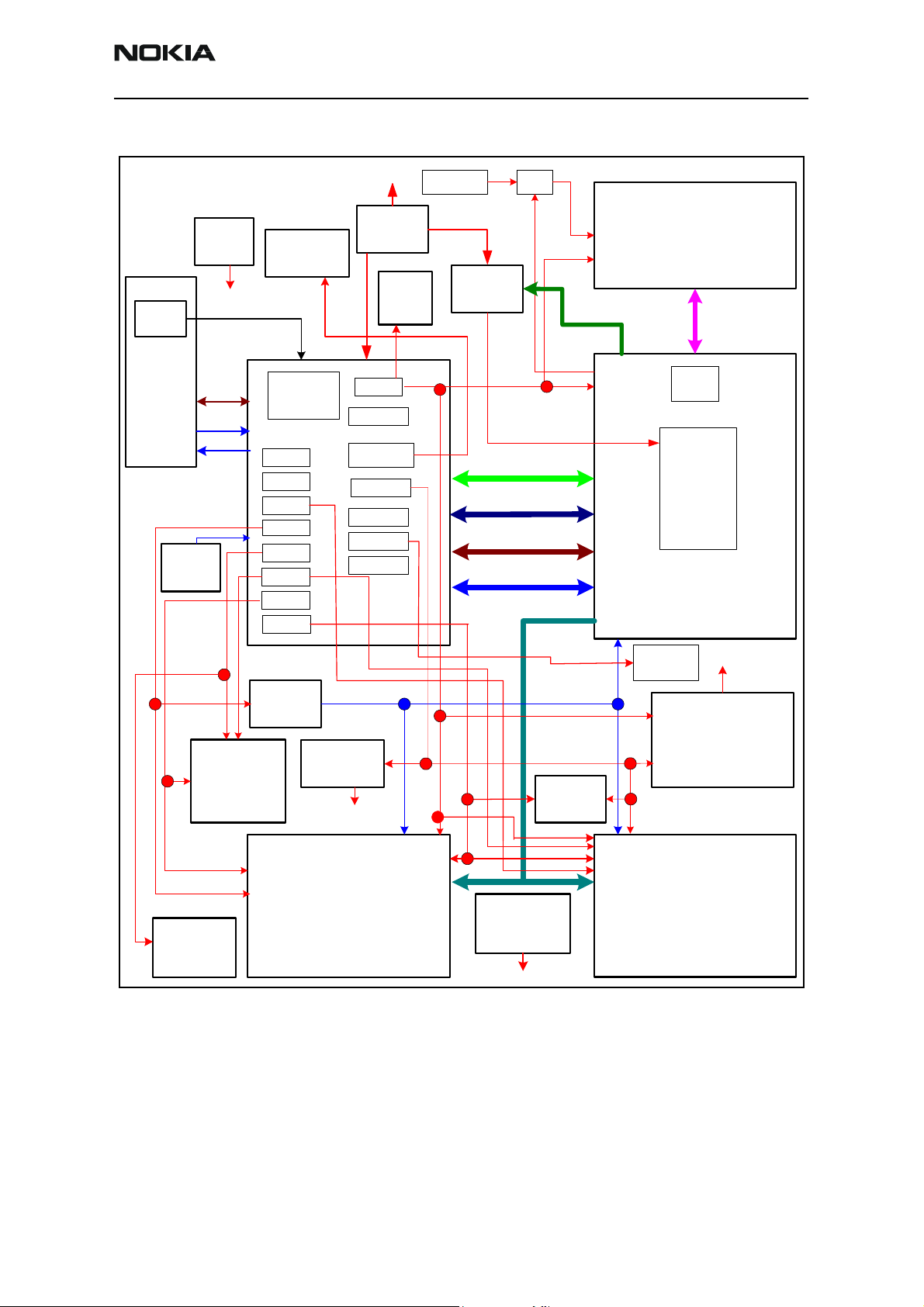

Baseband and RF Architecture

Charger

Bottom

Conn.

Sleep Clk

32 KHz

Audio

MBus

FBusRx

FBusT

x

SIM Reader

UEM

VR1A

VR1B

VR2

VR3

VR4

VR5

VR6

VR7

VBatt

Battery

JTAG

VIO

VANA

V SIM

Vflash1

Vflash2

Dlight

Klight

DC/DC

VPPPRODTP

CBus

u

B

D

MBus

FBus

GenIO

Control

s

Flash

C

ExtBus

UPP

Core

Alfred

Front

End

VCTCXO

19.2 MHz

RF

System

Connector

V Bat

Bus

UHF

SYNTH

Yoda

PA

VBatt

Figure 1: 2112 Power Distribution Diagram

Flashlight

V Bat

LCD/Key

Jedi

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 5

Page 6

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

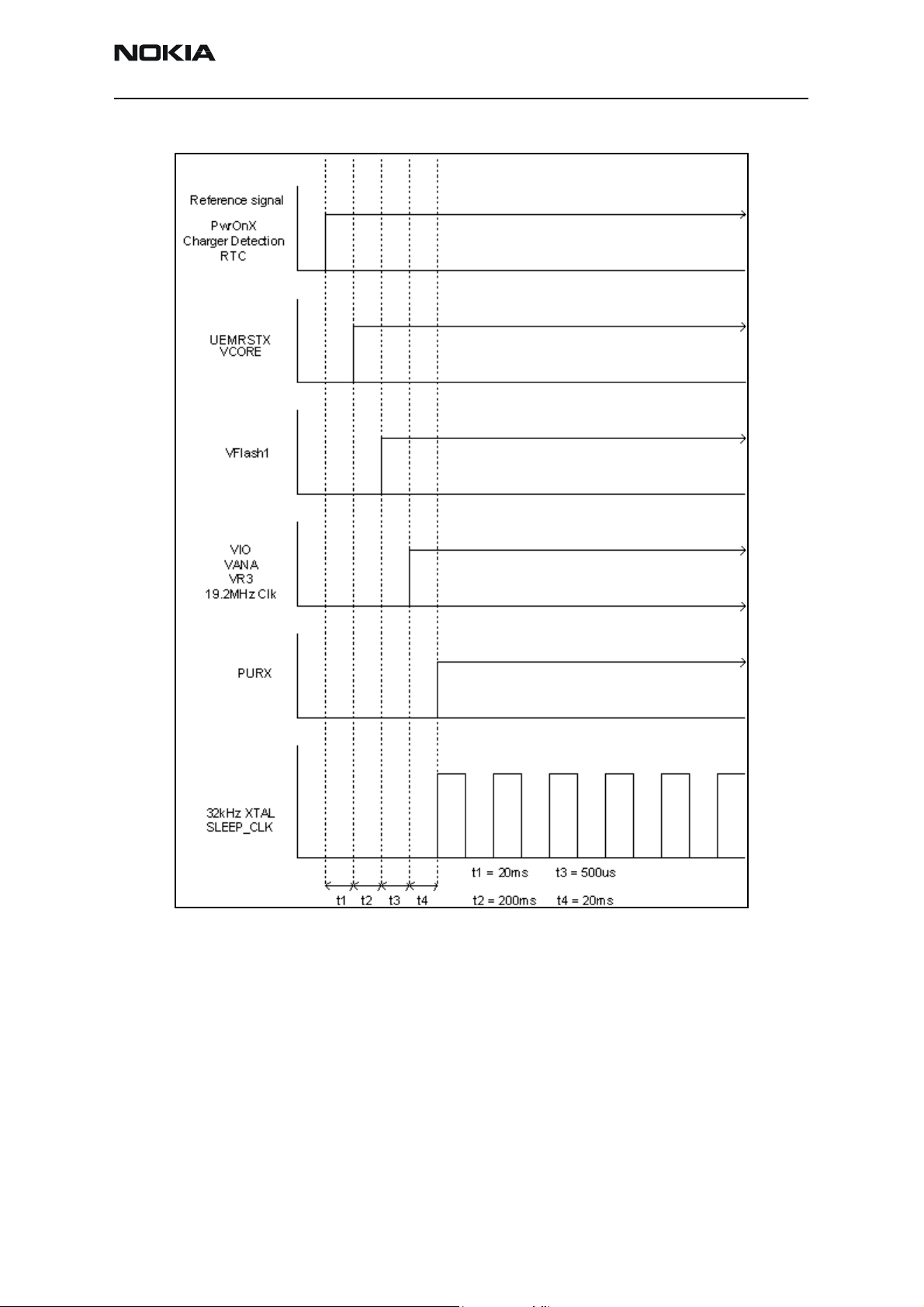

Power Up and Reset

Power up and reset are controlled by the UEM ASIC. The baseband can be powered up in

the following ways:

• Pressing the Power button, which means grounding the PWRONX pin of the UEM

• Connecting the charger to the charger input

• Initiating the RTC Alarm, when the RTC logic has been programmed to give an

alarm

After receiving one of the above signals, the UEM counts a 20 ms delay and then enters

reset mode. The watchdog starts, and if the battery voltage is greater than Vcoff+, a

200 ms delay is started to allow references (etc.) to settle. After this delay elapses, the

VFLASH1 regulator is enabled. Then, 500 us later, the VR3, VANA, VIO, and VCORE are

enabled. Finally, the Power Up Reset (PURX) line is held low for 20 ms. This reset (PURX)

is sent to the UPP. Resets are generated for the MCU and the DSP. During this reset

phase, the UEM forces the VCTCXO regulator on — regardless of the status of the sleep

control input signal to the UEM. The FLSRSTx from the UPP is used to reset the flash

during power up and to put the flash in power down during sleep. All baseband

regulators are switched on when the UEM is powered on. The UEM internal watchdogs

are running during the UEM reset state, with the longest watchdog time selected. If the

watchdog expires, the UEM returns to the power off state. The UEM watchdogs are

internally acknowledged at the rising edge of the PURX signal to always give the same

watchdog response time to the MCU.

The following timing diagram represents the UEM start-up sequence from reset to

power-on mode.

Page 6 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 7

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Figure 2: Power-on sequence and timing

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 7

Page 8

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Power Up - Power Key

When the power key is pressed, the UEM enters the power-up sequence. Pressing the

power key causes the PWRONX pin on the UEM to be grounded. The UEM PWRONX

signal is not part of the keypad matrix. The power key is only connected to the UEM. This

means that when pressing the power key an interrupt is generated to the UPP that starts

the MCU. The MCU then reads the UEM interrupt register and notices that it is a

PWRONX interrupt. The MCU reads the status of the PWRONX signal using the UEM

control bus (CBUS). If the PWRONX signal stays low for a certain time the MCU accepts

this as a valid power-on state and continues with the SW initialization of the baseband.

If the power key does not indicate a valid power-on situation, the MCU powers off the

baseband.

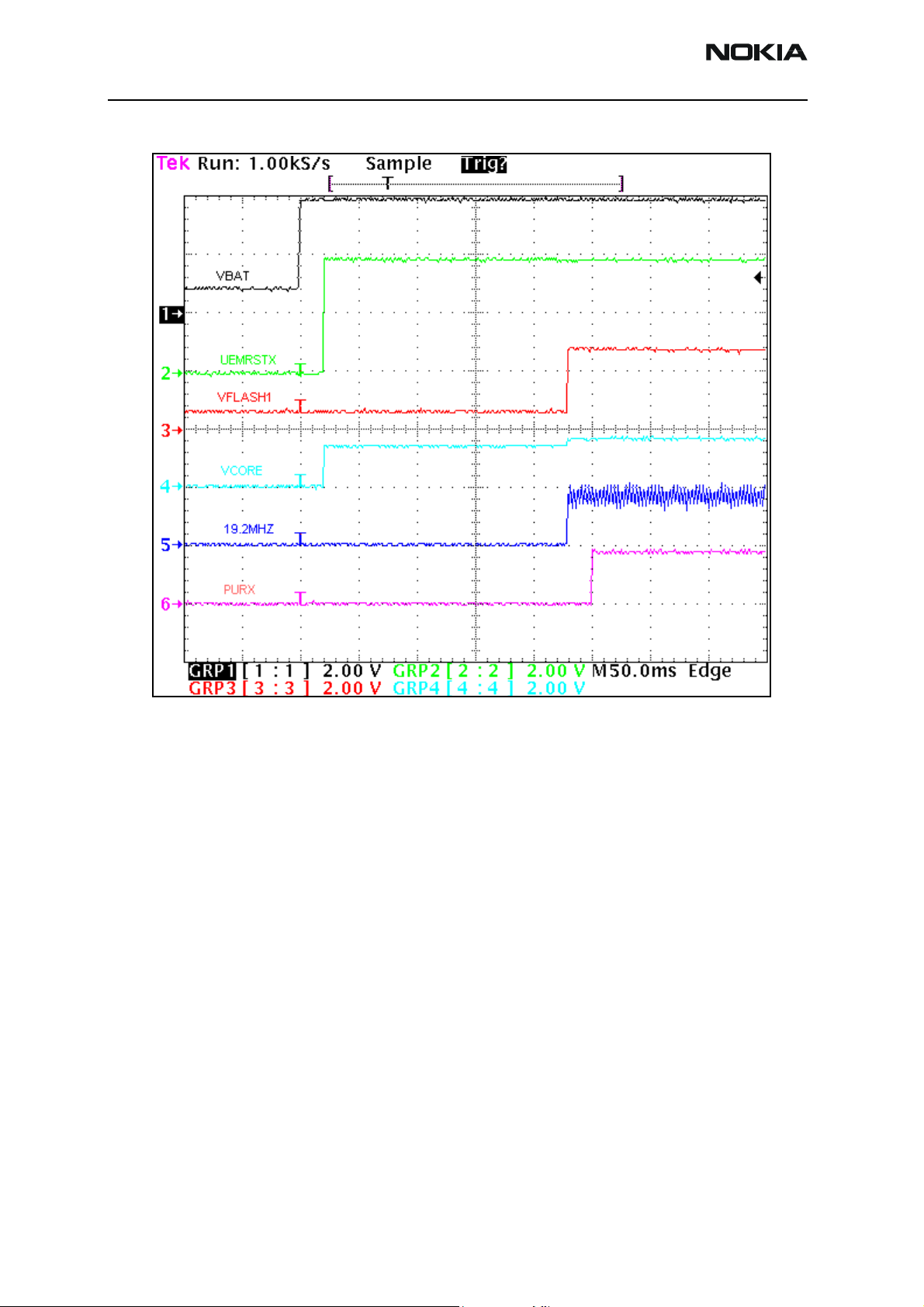

Power Up - Charger

In order to be able to detect and start charging in cases where the main battery is fully

discharged (empty) and hence UEM has no supply (NO_SUPPLY or BACKUP mode of

UEM), charging is controlled by start-up charging circuitry.

Whenever the VBAT level is detected to be below the master reset threshold (V

charging is controlled by START_UP charge circuitry. Connecting a charger forces the

Figure 3: Measured power-on sequence and timing

MSTR-

),

Page 8 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 9

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

VCHAR input to rise above the charger detection threshold (VCH

start-up charging is initiated. The UEM generates 100 mA constant output current from

the connected charger’s output voltage. The battery’s voltage rises at it charges, and

when the VBAT voltage level is detected to be higher than master reset threshold limit

(V

), the START_UP charge is terminated.

MSTR+

Monitoring the VBAT voltage level is done by charge control block (CHACON). A

MSTRX=‘1’ output reset signal (internal to the UEM) is given to the UEM’s reset block

when the VBAT>V

If the VBAT is detected to fall below V

cancelled. It will restart if a new rising edge on VCHAR input is detected (VCHAR rising

above VCH

DET+

Power Up - RTC Alarm

If phone is in POWER_OFF mode when RTC alarm occurs, the wake-up procedure occurs.

After the baseband is powered on, an interrupt is given to MCU. When an RTC alarm

occurs during ACTIVE mode, the interrupt is generated to the MCU.

Power Off

).

and the UEM enters into the reset sequence.

MSTR+

during start-up charging, charging is

MSTR

) and by detection,

DET+

The baseband switches to power-off mode if any of following occurs:

• Power key is pressed

• Battery voltage is too low (VBATT < 3.2 V)

• Watchdog timer register expires

The UEM controls the power-down procedure.

Power Consumption and Operation Modes

In POWER-OFF mode, the power (VBAT) is supplied to the UEM, vibra, LED, PA, and PA

drivers (Tomcat and Hornet). During this mode, the current consumption is approximately

35 uA.

In the SLEEP mode, both processors (MCU and DSP) are in stand-by mode. The phone

enters sleep mode only when both processors make this request. When the SLEEPX signal

is detected low by the UEM, the phone enters sleep mode. The VIO and VFLASH1

regulators are put into low quiescent current mode, VCORE enters LDO mode, and the

VANA and VFLASH2 regulators are disabled. All RF regulators are disabled during sleep

mode. When the SLEEPX signal is detected high by the UEM, the phone enters ACTIVE

mode and all functions are activated.

Sleep mode is exited either by the expiration of a sleep clock counter in the UEM or by

some external interrupt (generated by a charger connection, key press, headset

connection, etc.).

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 9

Page 10

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

In sleep mode, the VCTCXO is shut down and the 32 kHz sleep clock oscillator is used as

a reference clock for the baseband.

In ACTIVE mode, the phone is in normal operation, scanning for channels, listening to a

base station, transmitting and processing information. There are several sub-states in the

active mode depending on the phone present state of the phone, such as burst reception,

burst transmission, if the DSP is working, etc.

In active mode, SW controls the UEM RF regulators: VR1A and VR1B can be enabled or

disabled. VSIM can be enabled or disabled and its output voltage can be programmed to

be 1.8 V or 3.3 V. VR2 and VR4—VR7 can be enabled or disabled or forced into low

quiescent current mode. VR3 is always enabled in active mode and disabled during Sleep

mode and cannot be control by SW in the same way as the other regulators. VR3 will

only turn off if both processors request to be in sleep mode.

CHARGING mode can be performed in parallel with any other operating mode. A BSI

resistor inside the battery pack indicates the battery type/size. The resistor value

corresponds to a specific battery capacity. This capacity value is related to the battery

technology.

The battery voltage, temperature, size, and charging current are measured by the UEM,

and the charging software running in the UPP controls it.

The charging control circuitry (CHACON) inside the UEM controls the charging current

delivered from the charger to the battery and phone. The battery voltage rise is limited

by turning the UEM switch off when the battery voltage has reached 4.2 V. The charging

current is monitored by measuring the voltage drop across a 220 mOhm resistor.

Power Distribution

In normal operation, the baseband is powered from the phone‘s battery. The battery

consists of one Lithium-Ion cell capacity of 850 mAh and some safety and protection

circuits to prevent harm to the battery.

The UEM ASIC controls the power distribution to the whole phone through the BB and RF

regulators excluding the power amplifier (PA), which has a continuous power rail directly

from the battery. The battery feeds power directly to the following parts of the system:

•UEM

•PA

•Vibra

•Display

• Keyboard lights

The heart of the power distribution to the phone is the power control block inside the

UEM. It includes all the voltage regulators and feeds the power to the whole system. The

UEM handles hardware power-up functions so the regulators are not powered and the

power up reset (PURX) is not released if the battery voltage is less than 3 V.

Page 10 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 11

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

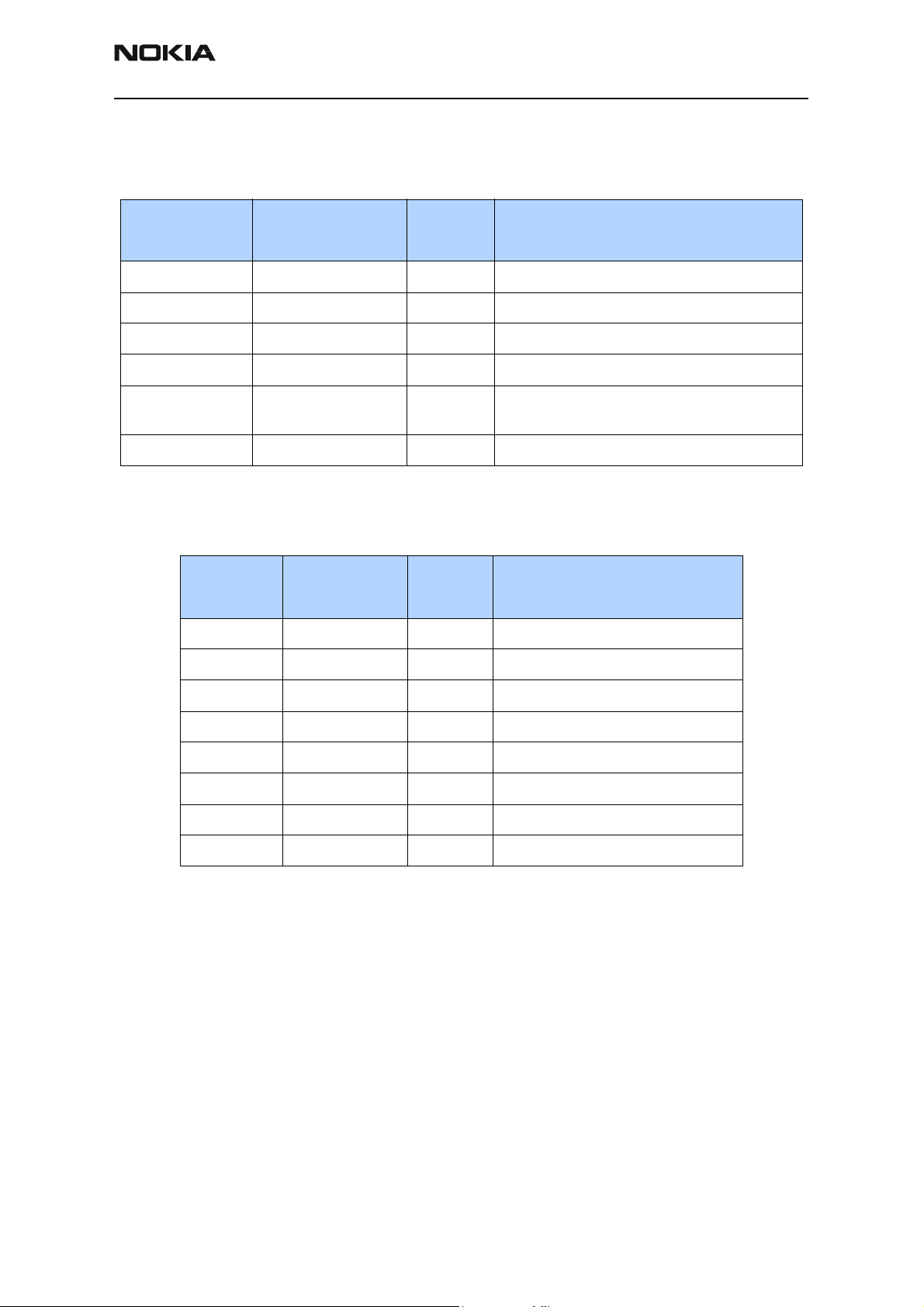

The 2112 baseband is powered from five different UEM regulators (see Table 1).

Table 1: Baseband Regulators

Regulator

VCORE 300 1.57/1.35 Power up default 1.57V and 1.35 in Sleep Mode.

VIO 150 1.8 Enabled always except during power-off mode

VFLASH1 70 2.78 Enabled always except during power-off mode

VFLASH2 40 2.78 Enabled only when data cable is connected

VANA 80 2.78 Enabled only when the system is awake (Off

VSIM 25 3.0 Enabled only when SIM card is used

Maximum

Current (mA)

Vout (V) Notes

during sleep and power off-modes)

Table 2 includes the UEM regulators for the RF.

Table 2: RF Regulators

Regulator

VR1A 10 4.75 Enabled when cell transmitter is on

VR1B 10 4.75 Enabled when the transmitter is on

Maximum

Current (mA)

Vout (V) Notes

VR2 100 2.78 Enabled when the transmitter is on

VR3 20 2.78 Enabled when SleepX is high

VR4 50 2.78 Enabled when the receiver is on

VR5 50 2.78 Enabled when the receiver is on

VR6 50 2.78 Enabled when the transmitter is on

VR7 45 2.78 Enabled when the receiver is on

The charge pump that is used by VR1A is constructed around the UEM. The charge pump

works with the Cbus (1.2 MHz) oscillator and gives a 4.75 V regulated output voltage to

the RF.

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 11

Page 12

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Clock Distribution

RFClk (19.2 MHz Analog)

The main clock signal for the baseband is generated from the voltage and temperature

controlled crystal oscillator VCTCXO (G500). This 19.2 MHz clock signal is generated at

the RF and is fed to Yoda pin 18 (TCXO_IN). Yoda then converts the analog sine

waveform to a digital waveform with a swing voltage of 0 tot 1.8 V and sends it to the

UPP from pin 16 at Yoda (19.2 Out) to the UPP pin M5 (RFCLK).

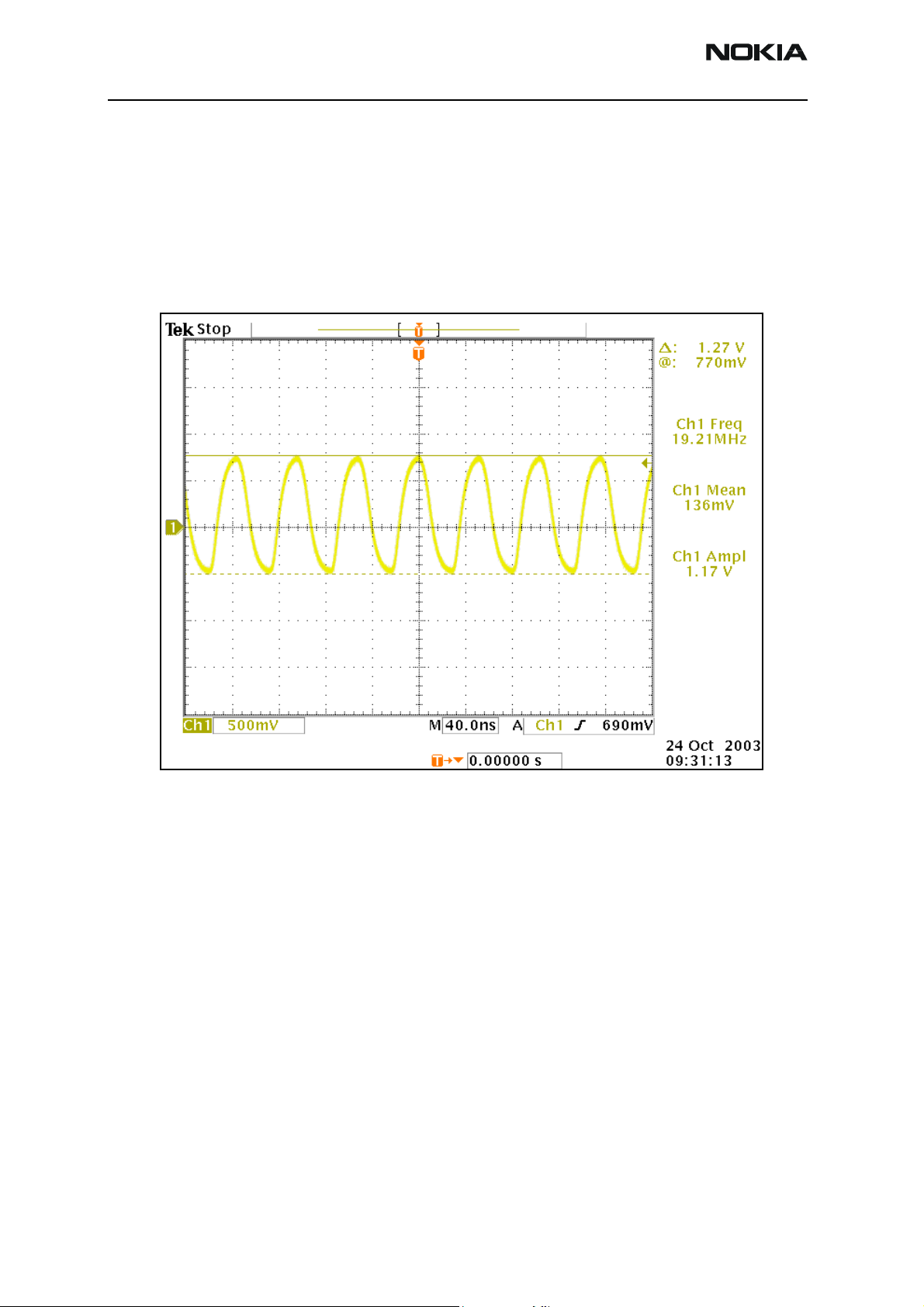

Figure 4: Waveform of the 19.2 MHz clock (VCTCXO) going to the Yoda ASIC

Page 12 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 13

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

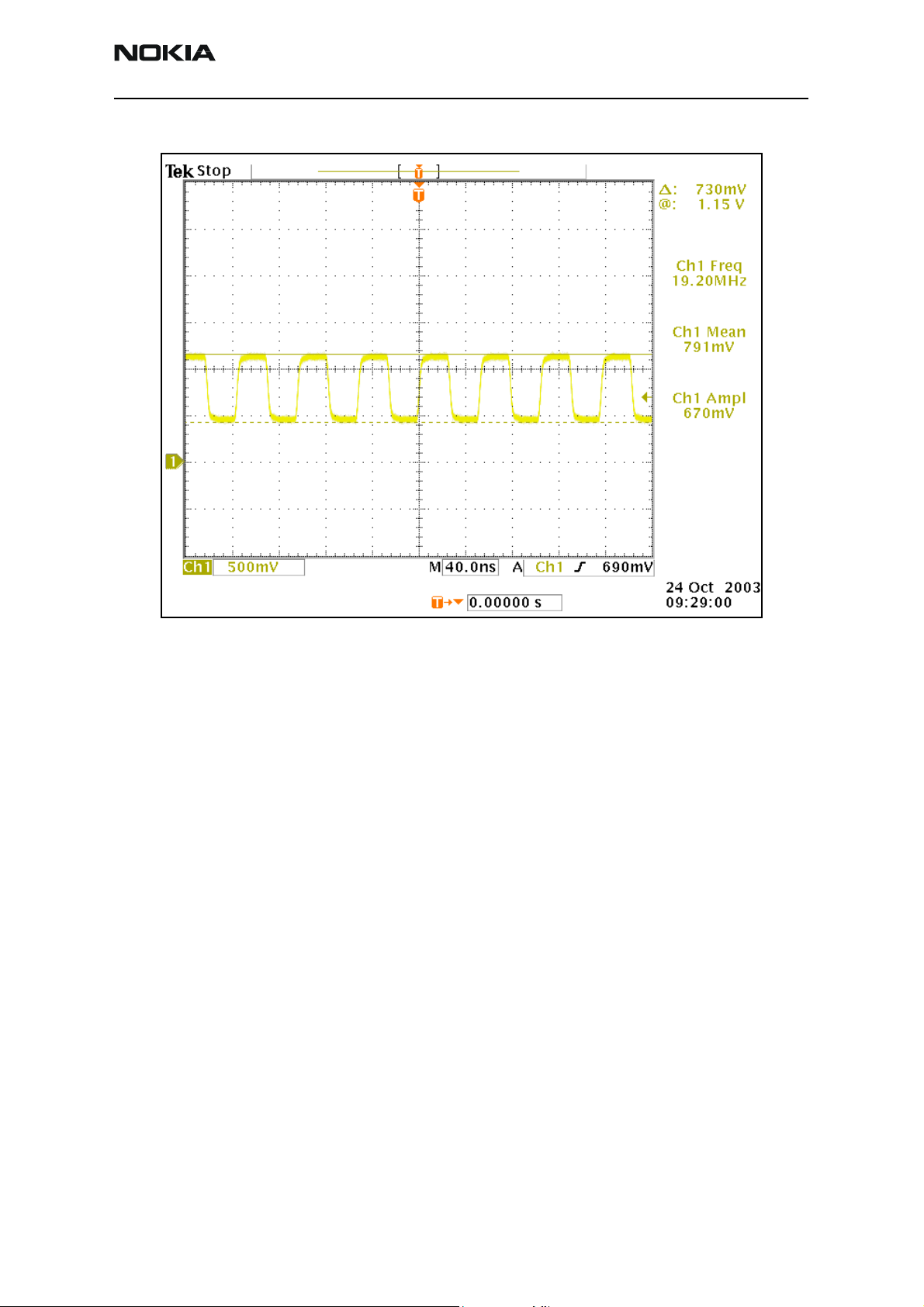

Figure 5 shows the RFCLK signal for the UPP.

Figure 5: Waveform of the 19.2 MHz Clk going to the UPP for Yoda ASIC at C711

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 13

Page 14

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

RFConvClk (19.2 MHz digital)

The UPP distributes the 19.2 MHz internal clock to the DSP and MCU, where the SW

multiplies this clock by seven for the DSP and by two for the MCU.

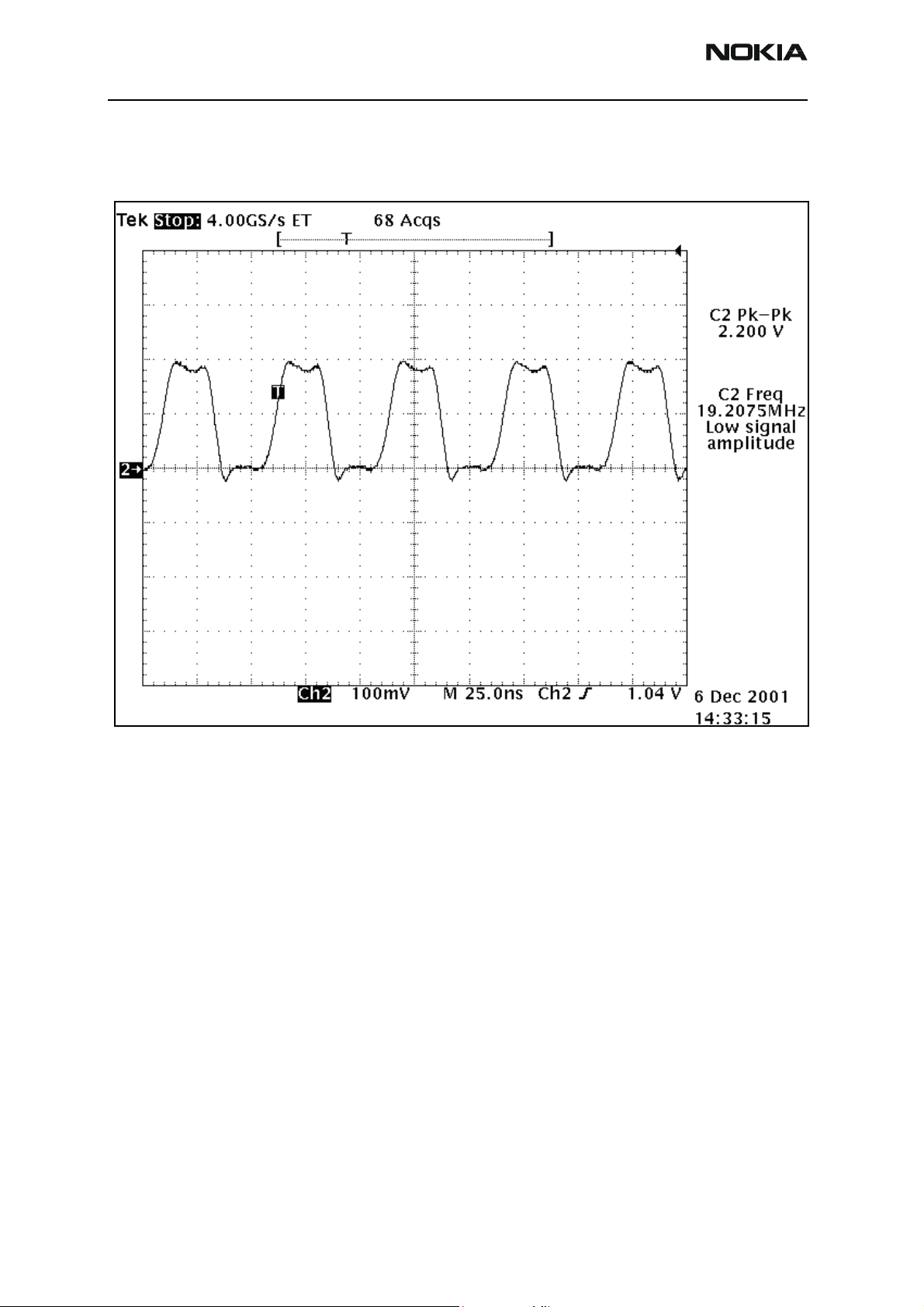

Figure 6: RFCovCLk waveform

Page 14 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 15

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

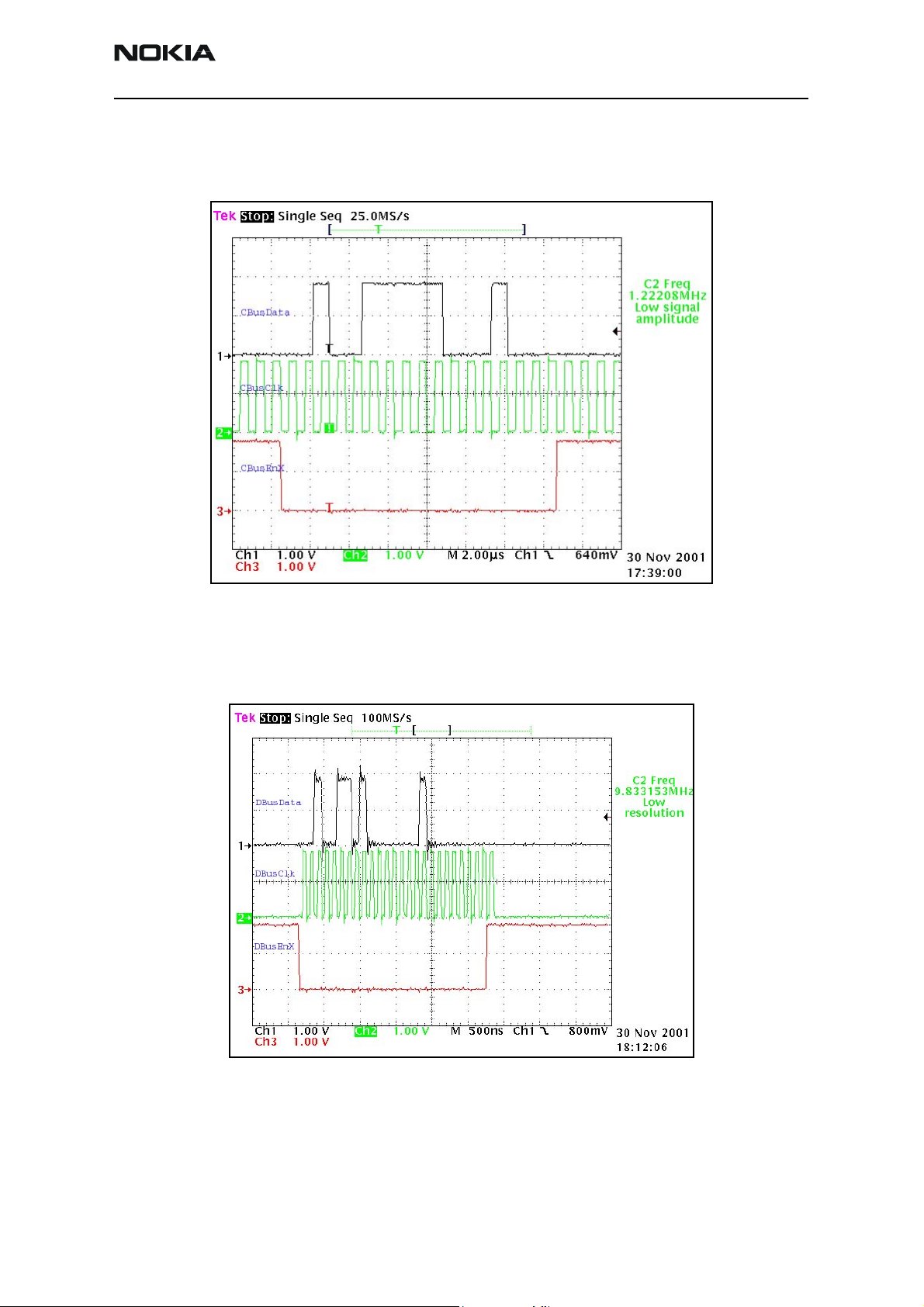

CBUS Clk Interface

A 1.2 MHz clock signal is used for CBUS, which is used by the MCU to transfer data

between the UEM and UPP.

DBUS Clk Interface

A 9.6 MHz clock signal is used for DBUS, which is used by the DSP to transfer data

between the UEM and UPP.

Figure 7: Cbus data transfer

Figure 8: Dbus data transferring

The system clock is stopped during sleep mode by disabling the VCTCXO power supply

(VR3) from the UEM regulator output by turning off the controlled output signal SleepX

from the UPP.

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 15

Page 16

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

SleepCLK (Digital)

The UEM provides a 32 kHz sleep clock for internal use and to the UPP, where it is used

for sleep mode timing.

SleepCLK (Analog)

When the system enters sleep mode or power off mode, the external 32 KHz crystal

provides a reference to the UEM RTC circuit to turn on the phone during power off or

sleep mode.

Figure 9: 32 kHz Digital output from UEM

Figure 10: 32 kHz analog waveform at 32 KHz crystal input

Page 16 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 17

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Flash Programming

Connections to Baseband

The flash programming equipment is connected to the baseband using test pads for

galvanic connection. The test pads are allocated in such a way that they can be accessed

when the phone is assembled. The flash programming interface uses the VPP, FBUSTX,

FBUSRX, MBUS, and BSI connections for the connection to the baseband. The connection

is through the UEM, which means that the logic levels corresponding to 2.78 V. Power is

supplied using the battery contacts.

Baseband Power Up

The baseband power is controlled by the flash prommer in production and in

reprogramming situations. The baseband powers up by applying supply voltage to the

battery terminals. Once the baseband is powered, flash programming indication begins

(see the following "Flash Programming Indication" section).

Flash Programming Indication

Flash programming is indicated to the UPP using the MBUSRX signal between the UPP

and UEM. The MBUS signal from the baseband to the flash prommer is used as a clock

for the synchronous communication. The flash prommer keeps the MBUS line low during

UPP boot to indicate that the flash prommer is connected. If the UPP MBUSRX signal is

low on UPP, the MCU enters flash programming mode. In order to avoid accidental entry

to the flash-programming mode, the MCU waits for a specified time to get input data

from the flash prommer. If the timer expires without any data being received, the MCU

continues the boot sequence. The MBUS signal from the UEM to the external connection

is used as a clock during flash programming. This means that the flash-programming

clock is supplied to the UPP on the MBUSRX signal.

The flash prommer indicates flash programming/reprogramming to the UEM by writing

an 8-bit password to the UEM. The data is transmitted on the FBUSRX line and the UEM

clocks the data on the FBUSRX line into a shift register. When the 8 bits have been

shifted in the register, the flash prommer generates a falling edge on the BSI line. This

loads the shift register content in the UEM into a compare register. If the 8 bits in the

compare register matches with the default value preset in the UEM, the flash prommer

pulls the MBUS signal to UEM low in order to indicate to the MCU that the flash

prommer is connected. The UEM reset state machine performs a reset to the system,

PURX low for 20 ms. The UEM flash programming mode is valid until the MCU sets a bit

in the UEM register that indicates the end of flash programming. Setting this bit also

clears the compare register in the UEM, which was loaded at the falling edge of the BSI

signal. The UEM watchdogs are disabled during the flash programming mode. Setting the

bit indicating the end of flash programming enables and resets the UEM watchdog timer

to its default value. Clearing the flash programming bit also causes the UEM to generate

a reset to the UPP.

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 17

Page 18

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

The BSI signal is used to load the value into the compare register. In order to avoid

spurious loading of the register, the BSI signal is gated during UEM master reset and

during power on when PURX is active. The BSI signal should not change states during

normal operation unless the battery is extracted. In this case, the BSI signal will be

pulled high. Note that a falling edge is required to load the compare register.

Flashing

Flash programming is done through the VPP, FBUSTX, FBUSRX, MBUS, and BSI signals.

When the phone enters the flash programming mode, the prommer indicates to the UEM

that flash programming will take place by writing an 8-bit password to the UEM. The

prommer sets the BSI value to “1” and then uses FBUSRX for writing and MBUS for

clocking. The BSI is then set back to “0”.

The MCU uses the FBUSTX signal to indicates to the prommer that it has been noticed.

After this, it reports the UPP type ID and is ready to receive the secondary boot code to

its internal SRAM.

FLASH_1

CH1 = BSI

CH2 = MBUS

CH3 = FBUSTX

CH4 = FBUSRX

Measure points

Production test pattern

(J396)

Figure 11: Flashing starts by BSI being pulled up and password being sent to UEM

This boot code asks the MCU to report the phone’s configuration information to the

prommer, including the flash device type. The prommer can then select and send

algorithm code to the MCU SRAM (and SRAM/Flash self-tests can be executed).

Page 18 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 19

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

FLASH_2

CH1 = PURX

CH2 = MBUS

CH3 = FBUSTX

CH4 = FBUSRX

Measure points

Produc tio n te s t pa tter n

(J396)

Figure 12: Flashing, continued

Channel 2 (MBUS) is toggled three times for MCU initialization. At Channel 3 (FBUSTX)

low, the MCU indicates that the prommer has been noticed.

FLASH_3

CH1 = PURX

CH2 = MBUS

CH3 = FBUSTX

CH4 = FBUSRX

Measure points

Produc tio n te s t pa tter n

(J396)

Data transfer has

started (Fbus_Rx)

Figure 13: Flashing, continued 2

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 19

Page 20

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Flash Programming Error Codes

The following characteristics apply to the information in Table 3.

• Error codes can be seen from the test results or from Phoenix's flash-tool.

• Underlined information means that the connection under consideration is being

used for the first time.

Table 3: Flash Programming Error Codes

Error Description Not Working Properly

C101 "The Phone does not set FbusTx line high after

the startup."

C102 "The Phone does not set FbusTx line low after

the line has been high. The Prommer generates

this error also when the Phone is not connected to the Prommer."

C103 " Boot serial line fail." Mbus from Prommer->UEM->UPP(MbusRx)(SA1)

C104 "MCU ID message sending failed in the Phone." FbusTx from UPP->UEM->Prommer

C105 "The Phone has not received Secondary boot

codes length bytes correctly."

C106 "The Phone has not received Secondary code

bytes correctly."

C107 "The Phone MCU can not start Secondary code

correctly."

Vflash1

VBatt

BSI and FbusRX from prommer to UEM.

FbusTx from UPP->UEM->Prommer(SA0)

PURX(also to Safari)

VR3

Rfclock(VCTCXO->Safari->UPP)

Mbus from Prommer->UEM->UPP(MbusRx)(SA0)

FbusTx from UPP->UEM->Prommer(SA1)

BSI and FbusRX from prommer to UEM.

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

Mbus from Prommer->UEM->UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

Mbus from Prommer->UEM->UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

UPP

C586 "The erasing status response from the Phone

informs about fail."

C686 "The programming status response from the

Phone informs about fail."

Cx81 "The Prommer has detected a checksum error

in the message, which it has received from the

Phone."

Cx82 "The Prommer has detected a wrong ID byte in

the message, which it has received from the

Phone."

Flash

Flash

FbusTx from UPP->UEM->Prommer

FbusTx from UPP->UEM->Prommer

Page 20 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 21

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Table 3: Flash Programming Error Codes (Continued)

Error Description Not Working Properly

A204

Cx83

Cx84

Cx85

Cx87 "Wrong MCU ID." RFClock

Startup

for

flashing

"The flash manufacturer and device IDs in the

existing algorithm files do not match with the

IDs received from the target phone."

"The Prommer has not received phone

acknowledge to the message."

"The phone has generated NAK signal during

data block transfer."

"Data block handling timeout"

Required startup for flashing Vflash1

Flash

UPP

VIO/VANA

Signals between UPP-Flash

Mbus from Prommer->UEM->UPP(MbusRx)

FbusRx from Prommer->UEM->UPP

FbusTx from UPP->UEM->Prommer

UPP(Vcore)

VBatt

Charging Operation

Battery

The 2112 uses a Lithium-Ion cell battery with a capacity of 850 mAh. Reading a resistor

inside the battery pack on the BSI line indicates the battery size. The phone measures the

approximate temperature of the battery on the BTEMP line with an NTC resistor on the

PCB.

The temperature and capacity information are needed for charge control. These resistors

are connected to the BSI pin of the battery connector and the BTEMP of the phone. The

phone has 100 kΩ pull-up resistors for this line so that they can be read by A/D inputs in

the phone.

Charging Circuitry

The UEM ASIC controls charging depending on the charger being used and the battery

size. External components are needed for EMC, reverse polarity, and transient protection

of the input to the baseband module. The charger connection is through the system

connector interface. The baseband is designed to support DCT3 chargers from an

electrical point of view. Both 2- and 3-wire type chargers are supported. However, the

3-wire chargers are treated as a 2-wire charger.

Figure 14: BL-5C battery pack pin order

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 21

Page 22

2112 (RH-57)

y

Troubleshooting — BB Nokia Customer Care

R200

V100 batter

Charger Detection

Connecting a charger creates voltage on the VCHAR input of the UEM. Charging starts

when the UEM detects the VCHAR input voltage level above 2 V (VCHdet+ threshold).

The VCHARDET signal is generated to indicate the presence of the charger for the SW.

The EM SW controls the charger identification/acceptance. The charger recognition is

initiated when the EM SW receives a ”charger connected” interrupt. The algorithm

basically consists of the following three steps:

1. Check that the charger output (voltage and current) is within safety limits.

2. Identify the charger as a two-wire or three-wire charger.

3. Check that the charger is within the charger window (voltage and current).

If the charger is accepted and identified, the appropriate charging algorithm is initiated.

X102

1

F100

1.5A

Figure 15: Charging circuitry

L1002

________

42R/100MHz

V100

"VCHARIN"

C106

1n0

0

2

CHARGER(4:0)

Figure 16: Charging circuit

Page 22 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 23

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Charge Control

In active mode, charging is controlled by the UEM’s digital part. Charging voltage and

current monitoring is used to limit charging into safe area. For this reason, the UEM has

the following programmable charge cut-off limits:

• VBATLim1=3.6 V (Default)

• VBATLim2L=5.0 V

• VBATLim2H=5.25 V

VBATLim1, 2L, 2H are designed with hystereses. When the voltage rises above VBATLim1,

2L, 2H+ charging is stopped by turning the charging switch off. No change is done in

operational mode. After the voltage has decreased below VBATLim-, charging restarts.

There are two PWM frequencies in use depending on the type of the charger. A 2-wire

charger uses a 1 Hz, while a 3-wire charger uses a 32Hz. The duty cycle range is 0% to

100%. The maximum charging current is limited to 1.2 A.

UEM Pins

N10

R200

VBAT

M10

Audio

.22 Ohms

C201

1uF

Figure 17: Charging circuity at the battery

C202

10nF

The audio control and processing is provided by UEM, which contains the audio codec,

and the UPP, which contains the MCU and DSP blocks. These blocks handle and process

the audio data signals.

The baseband supports three microphone inputs and two earpiece outputs. The

microphone inputs are MIC1, MIC2, and MIC3. MIC1 input is used for the phone's

internal microphone; MIC2 input is used for headsets (HDB-4). MIC3 is not used. Every

microphone input can have either a differential or single-ended AC connection to UEM

circuit. The internal microphone (MIC1) and external microphone (MIC2) for Tomahawk

accessory detection are both differential. The microphone signals from different sources

are connected to separate inputs at UEM. Inputs for the microphone signals are

differential types. Also, MICBIAS1 is used for MIC1 and MICBIAS2 is used for MIC2. The

2112 also supports a hands-free speaker (B301), which is driven by an IHF audio amplifier

(N150).

Display and Keyboard

The 2112 uses LEDs for LCD and keypad illumination. There is one LED for the LCD and

four LEDs for the keypad. KLIGHT is the signal used to drive the LED driver for the LCD

and keyboard. This signal turns on the LED driver (N302).

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 23

Page 24

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

The 2112 also uses an IOS LCD. The interface uses a 9-bit data transfer and is quite

similar to the DCT3 type interface, except the Command/Data information is transferred

together with the data.

Flashlight

The flashlight is driven by the white LED driver and controlled by the UEM. The

TK65600B-G is an active-high enable device, which is tied to the DLIGHT signal from the

UEM.

Accessories

The 2112 supports Tomahawk and Universal Headset accessories, differential and singleended, respectively. Detection of the Tomahawk accessories is done through the ACI

signal where the Universal Headset is detected on GenIO (12).

Figure 18: Waveform for the LCD Interface

Figure 19: Tomahawk connector pin out

Page 24 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 25

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

The pin out on the Tomahawk connector is as follows:

•Charger

• Charger GND

•ACI

•Vout

•USB Vbus

• USB D+ / Fbus Rx

• USB D- / Fbus Tx

• Data GND

•XMic N

•XMic P

•HSear N

You can perform the following in Tomahawk accessories:

Charging

Charging through Tomahawk is accomplished in the same manner as through the

charger connector. Pin 1 of the Tomahawk is physically connected to the charger

connector. When the phone is connected to a desktop charger (e.g., DCV-15), it charges

in the same manner as it does with the charger connector.

Figure 20 shows the actual charging sequence. The channels on the diagram are:

•HSear P

•HSear R N

•HSear R P

• Charging

• Accessory detection

• FBUS communication

• Fully differential audio interface for mono- and stereo outputs

• CH1 = Charging current across the .22 Ohm (R200) resistor on UEMK

• CH2 = Charger voltage measure at V100

• CH3 = Battery voltage measure at R200

•CH4 = PURX

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 25

Page 26

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

In Channel 4, PURX is released, which this indicates when the phone operation goes from

RESET mode to POWER_ON mode.

Tomahawk Headset Detection

Accessory detection on the Tomahawk is done digitally. The pins used for this accessory

detection are:

• Pin 2 (Charge GND)

• Pin 3 (ACI)

•Pin 4 (Vout)

Figure 20: Charging sequence

Page 26 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 27

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

FBus Detection

FBus communication in Tomahawk is done through the following lines:

• Pin 2 (Charge GND)

• Pin 3 (ACI)

•Pin 4 (Vout)

• Pin 6 (FBus Rx)

• Pin 7 (FBus Tx)

Figure 21: Waveform showing Tomahawk accessory detection

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 27

Page 28

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Figure 22: Waveform showing Tomahawk FBus communication

Accessory Detection Through ACI

USB and Audio on (mono or stereo)/FM radio communication in Tomahawk is done

through the following signals:

Table 4: Accessory Detection Signals

USB Audio/FM

Pin 5 (USB Vbus) Pin 9 (XMic N)

Pin 6 (USB +) Pin 10 (SMIC P)

Pin 7 (USB -) Pin 11 (HSEAR N)

Pin 8 (Data GND) Pin 12 (HSEAR P)

Pin 13 (HSEAR R N)

Pin 14 (HSEAR R P)

Page 28 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 29

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

SIM CAR

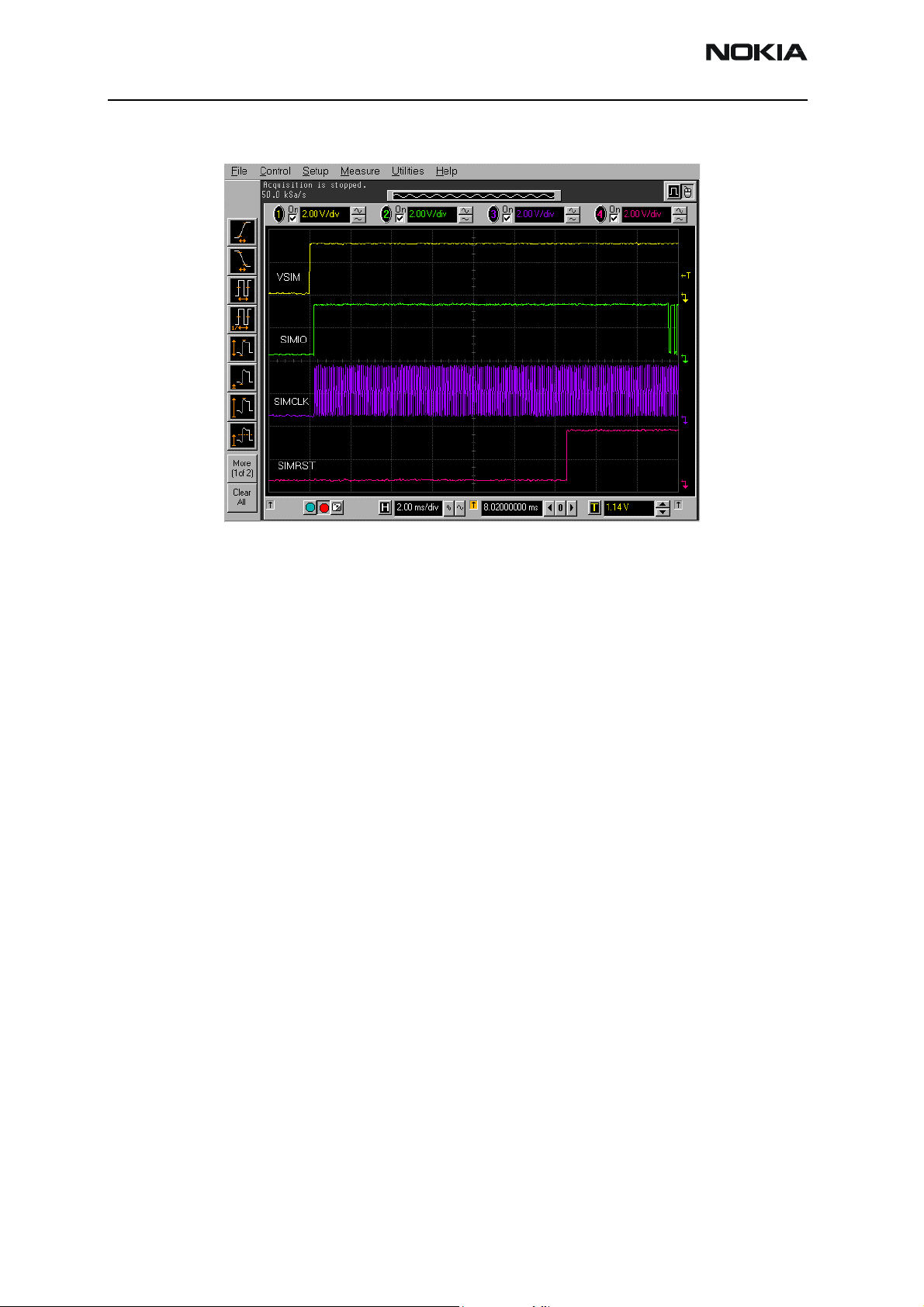

The 2112 supports SIM CAR. Use the waveform in Figure 24 to verify that the sim_vcc,

sim_i/o, cim_clk, and sim_rst signals are activated in the correct sequence at power up.

This picture may be taken when the SIM CAR is installed on the phone to measure the

signals when the phone is turned on. The figure shows the proper waveforms when the

interface is working. See Figure 26 on page 32 for the test point’s location.

Figure 23: Waveform showing accessory detection through ACI

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 29

Page 30

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Figure 24: RUIM signal waveform

Page 30 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 31

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Test Points

Figure 25: Test points (bottom)

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 31

Page 32

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Figure 26: BB test points (top)

Page 32 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 33

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

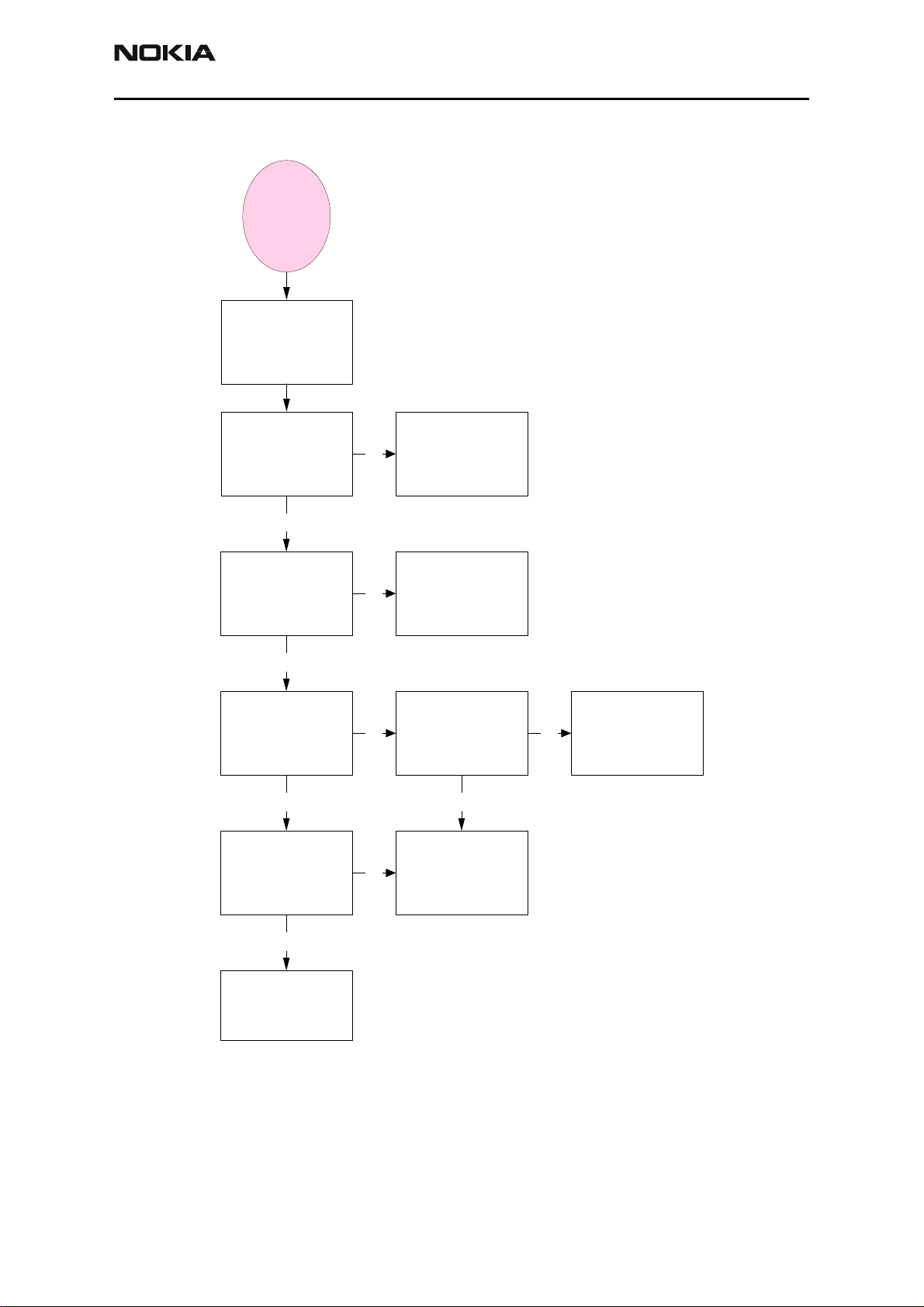

Troubleshooting

The following hints should help finding the cause of the problem when the circuitry

seems to be faulty. Troubleshooting instructions are divided into the following sections:

• Top troubleshooting map

• Phone is totally dead

• Power does not stay on or the phone is jammed

• Flash programming does not work

• Display is not working

• Audio fault

• Charging fault

First, carry out a through visual check of the module. Ensure in particular that:

• There are no mechanical damages

• Soldered joints are okay

• ASIC orientations are okay

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 33

Page 34

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Top Troubleshooting Map

Top

P hone totally dead

NO

Flas h programming

does n't work

NO

P hone does n't start

up or phone is

jammed

NO

YES

YES

YES

Phone

dead

Flash

faults

Phone is

jammed

C harging does n't

work

NO

YES

Top page 2

Charger

faults

Page 34 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 35

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Top 2

Audio faults

NO

Dis play o r L E Ds not

working

NO

Keypad doesn't work

YES

YES

YES

Audio

faults

Dis play

faults

Keypad

faults

END

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 35

Page 36

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Phone is Totally Dead

¾ If current is zero , che ck the battery connector

Phone is

dead

to make sure Vbat makes contact.

¾ If current is too hig h, ch eck for shor ts.

¾ Make sure all BB regulators are at their

respective voltage levels (VANA, VIO,

VCORE, VFlash1, and VR3). See phone's top

view diagram for test point s.

Phone current is

zero or too high?

NO

Phone current is

<=30 mA

NO

Phone current is

35 mA

YES

YES

YES

NO

¾ Make sure the system Cl k i s 19. 2MHz and tha t

the sleep Clk is 32K H z

¾ Make sure PURX and SleepX signals are high

(1.8V)

Is phone flash

programming OK?

NO

YES

Phone is

jammed

Flash

faults

Is phone in Local

Mode?

YES

Check BSI line X103,

NO YES

R202, R206, C100,

C111. Are they OK?

NO

Change UEM

Repair

OK restart

Page 36 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 37

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Flash Programming Does Not Work

Flash

faults

The phone does not

set Flashbus TXD

line high after the

startup

NO

The phone does not

set Flashbus TXD

line low after the line

has been high

Change

UEM

YES

Measure BSI pulse during

YES NO

Flash programming. Is it

OK?

YES

Measure FBusRX (2.78V)

signal during flash

programming from

NO

production pattern. Is it

OK?

YES

Measure test point

FBusTx (J411) (1.8V) and

production pattern signal

NO

FBusTxO (2.78V) during

flash programming. Are

they the same?

YES

Check BSI line X103,

R202, R206, C100,

C111, C240

Reflow or

change UEM

Change UPP

NO

Is there a pulse

on J411?

YES

Is there a pulse

on FBusTx?

NO

Flash

faults,

page 2

YES

Measure MBus (2.78V). Is

it OK?

NO

NO

Reflow or

change UEM

Reflow or

change UEM

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 37

Page 38

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Flash

faults,

page 2

Can you read the

manufacturer ID and

the device ID?

YES

Is the phone totally

dead?

NO

Phone doesn't start

up or the phone is

jammed

NO

Reflow or change

Flash

YES

YES

Phone

dead

Phone is

jammed

NO

Retest

Page 38 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 39

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Power Does Not Stay on or the Phone is Jammed

Phone is

jammed

Measure VIO,

VCORE, VFlash1,

VANA, and VR3

voltages. Are they

OK?

YES

Measure 32kHz

Sleep Clk from

testpoint. Is it OK?

YES

Measure 19.2MHz RF

Clk at testpoint

C510. Is it OK?

Check VBATT, VIO,

VCORE, VFlash1,

VANA, VR3 capacitors.

NO

NO NO

NO

Are they OK?

NO

Measure the 32kHz

Clk crystal. Is it OK?

YES

YES

Check BSI/BTEMP

lines and VBATT

lines. If OK, reflow

or change UEM

Repair

Change B200

Reflow or change

UEM

YES

Measure PURX and

SleepX at test points

J402 and J403. Are

they high (1.8V)?

YES

Phone is

jammed,

page 2

Measure the

19.2MHz Clk coming

from the VCTCXO at

C728 and C711. Is it

NO

OK?

YES

Check G502, C522, C521,

R517, R516. If OK, change

NO

G501. Check C728. If OK,

change N700.

Change UPP

Change UEM

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 39

Page 40

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Phone is

jammed,

page 2

Phone shutdown

after 32 seconds

NO

Measure DBusEN

interface signal at

test point J413. Is it

OK?

YES

YES

NO

Reflow or

change UPP.

Is the ESN present

in the phone?

YES

Has the phone been

fully erased and

reflashed for this

problem?

YES

Measure watchdog

signal at CBusEN

interface at test

point J406. Is it OK?

YES

NO

NO

NO

Rebuild the ESN

Perform a full

erase and reflash

the phone

Reflow or change

UPP and reflash.

Reflow or change

UEM and reflash.

Read phone info. Is

it OK?

YES

Retest

Measure FBusRxO

NO NO

signal during phone

info read. Is it OK?

YES

Measure FBusTx

NO

signal during phone

info read from test

point J411. Is it OK?

YES

Reflow or change

UEM.

Reflow or change

UPP.

Reflow or change

UEM.

Page 40 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 41

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Charger

Charger

fau lts

Connect Charger.

M ake su re battery is

connected.

Battery bar doesn't

w o r k ( s c ro ll)

YES

Measure voltage

o v er V 1 0 0 . Is it >3 .0

Vdc?

YES

Read BT EM P value.

Is it ~ 25C (0 3 19)?

YES

Rem ove (fuse) F100

and m easure

current.

Is it ~ 8 5 0 mA ?

NO

NO

NO

NO

Retest

Check DC jack,

F100, L100, V100,

C106

C h e c k N T C. Is it

OK?

YES

Change UEM

NO

Replace NTC

YES

Retest

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 41

Page 42

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Audio Faults

Audio

faults

Is the earpiece

working?

YES

NO YES

Change earpiece. Is

it working now?

NO

Set phone in Local Mode. Use

Phoenix Troubleshooting >

Phone Control > Phone State

Tab > select Local Mode > click

Execute. Then use Audio Test >

HP microphone in/HP speaker

out > Loop ON to enable the

earpiece. Inject a 1KHz sine

signal 200mVp-p on XMIC.

Is the signal coming

out of the UEM on

NO

EARP and EARN?

Retest

Check R178. If OK,

then change

earpiece.

YES

Check L102, R150,

R152, R155, R151,

Audio

faults,

page 2

C181, C153, C151,

C152, C156. If OK,

change UEM.

Page 42 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 43

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Audio

faults,

page 2

Is the

microphone

working?

YES

Change the

NO YES

microphone. Is it

working now?

NO

Set the phone in Local Mode.

Use Phoenix Troubleshooting >

Phone Control > Phone State

Tab > Select Local Mode >

Execute. Then use Audio Test >

HP microphone in/HP speaker

out > Loop On to enable

earpiece. Talk through the

microphone.

Measure MICB1

voltage from MICP

NO

pads. Is it ~2.1V?

Retest

Check

connections at

C180 and R170. If

OK, change UEM

Audio

faults,

page 3

YES

Is the signal going

to the UEM at MICP

and MICN at R170?

YES

Is the signal going

out of the UEM at

XEAR, pin 11 and 12

on the bottom

connector (X101)?

YES

Check connections

at R171, R172, R173,

NO

C171, C172, C169,

C179, C178. If OK,

change microphone

Check L103, R168,

NO

R105. If OK, change

UEM

Retest

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 43

Page 44

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Audio

faults,

page 3

Is interna l handsfr e e

speaker (IHF)

working?

YES

Select a ring tone

and measure signals

NO YES

at L150 and L151. Is

signal OK?

NO

Measure GenIO28. Is

it OK (1 .8 V )?

YES

NO

Set the phone in Local

Mode. Use Phoenix

Troubleshooting > P ho n e

Control > Phone State Tab >

select Local Mode >

Execute. Then use Audio

test > HP microphone in/Ext

Speaker out > Loop ON. To

enable IHF turn on GenIO

(10). Measure and check IHF

testpoints J150, J151. Is it

OK?

NO

Change B301

Change UPP

Change IHF

YES

Change the UPP

Audio

faults,

page 4

Page 44 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 45

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Audio

faults,

page 4

Measure VBATT

Is Vibra working?

NO NO

voltage pin 1 of

M300. Is it OK?

YES

Check VBATT line

YES

Use UI Menu > Profile > Normal >

Customize > Vibrating Alert > Select On

> then go back to Customize menu >

Ringing Tone > Try any ring tone and

vibra should work.

Measure the UEM

signal on pin 2 of

M300. Is the signal

NO

OK?

YES

Change the UEM

Change Vibra

END

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 45

Page 46

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Display Faults

Display

faults

Are the keyboard

LEDs turned on

when the phone is

turned on or when

making a phone

call?

NO YES

Measure VBATT

voltage at L301. Is it

okay?

NO

Check VBATT line

and C303, C316, and

L300.

YES

Display

faults 2

Measure the driver

signal from UEM at

J336. Is the signal

okay?

YES

NO

Change UEM

Check N302 driver

signal at C304. If not

OK, change N302.

Page 46 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 47

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Display

faults,

page 2

Does the Display

start?

YES

Try changing

NO YES

display module.

Does it work?

NO

Measure VIO and

Flash1.

NO

Check LCD signals

LCDCSX (pin5),

LCDCLK (pin4),

LCDSDA (pin3), and

NO

LCDRESX (pin2) at

X302. Signals OK?

Retest

Change UEM

Change UPP

YES

Change Display

END

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 47

Page 48

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Keypad Faults

Keypad

faults

Is the power key

working?

YES

Keypad

faults,

page 2

NO NO

Measure voltage at

YES

Measure voltage at

S300 when power

key is pressed. Is it

high?

NO

S302. Is it high?

Check S302. Is

YES

it OK?

Change S300

NO

Check S302, C310,

and R306. If OK,

change UEM

YES

Phone is

dead

Phone is

jammed

Page 48 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Page 49

2112 (RH-57)

Nokia Customer Care Troubleshooting — BB

Keypad

faults ,

page 2

Are the UI modules

keys working?

YES

END

Change keypads

NO

module. Is it

working?

NO

Measure ROW 0-5

(P10-P15) signals

between UPP and

keypad at J325,

J320, J321, J322,

J323. Are they

~1.8V?

YES

Measure COL 1-5

(P1-P5) signals

between UPP and

keypad at J331,

J324, J337, J326,

J327, J328, J329. A re

they ~1.8V

YES

NO

NO

Retest

Make sure

there are no

shorts on

Z300. If OK,

change UPP

Make sure

there are no

shorts on

Z300. If OK,

change UPP

Issue 1 07/2004 ©2004 Nokia Corporation Company Confidential Page 49

Page 50

2112 (RH-57)

Troubleshooting — BB Nokia Customer Care

Flashlight

Flashlight

faults

Are the flashlight

LEDs turned on

when the phone is

turned and when

pressing the UP

key?

YES

Flashlight

OK

NO

Measure VBATT

voltage at R303. Is it

OK?

YES

Measure the driver

signal DLIGHT at

D301 J336, and

Q301. Is the signal

OK?

YES

Check VBATT line at

NO

the battery

connector

NO

Change the UEM

Check N302, L301,

L300, C316, C304,

R300, R302, R304,

Check solder joints

at D305. If bad,

replace LEDs.

R2310.

YES

Page 50 ©2004 Nokia Corporation Company Confidential Issue 1 07/2004

Loading...

Loading...