Page 1

– 1 –

GB

This installation manual describes how to install the Simple MA Remote Controller for use with

Mitsubishi Building Air Conditioning System, direct expansion type CITY MULTI air conditioner indoor

units (“-A” type and later), and Mitsubishi M-Series and P-Series packaged air conditioners.

Please be sure to read this installation manual and Instruction Book that are supplied with the Remote

Controller before proceeding with the installation. Failure to follow the instructions may result in

equipment damage.

For information on how to wire and install the air conditioning units, refer to the installation manual.

After the installation, hand over this manual to users.

• Read the following safety precautions prior to installation.

• Observe these precautions carefully to ensure safety.

• After reading this manual, provide this manual to end user for future reference.

• Keep this manual for future reference and refer to it as necessary. This manual should be made

available to those who repair or relocate the controller. Make sure that the manual is forwarded to

future end users.

WARNING

1 Safety Precautions

WARNING

Indicates a risk of death or serious injury if you misuse the PAC-YT53CRAU.

CAUTION

Indicates a risk of serious injury or structural damage if you misuse the

PAC-YT53CRAU.

General precautions

All electric work must be performed by qualified personnel.

Do not install the unit in a place where large amounts of

oil, steam, organic solvents, or corrosive gases, such

as sulfuric gas, are present or where acidic/alkaline

solutions or sprays are used frequently. These

substances can compromise the performance of the

unit or cause certain components of the unit to corrode,

which can result in electric shock, malfunctions,

smoke, or fire.

To reduce the risk of shorting, current leakage, electric

shock, malfunctions, smoke, or fire, do not wash the

controller with water or any other liquid.

To reduce the risk of electric shock, malfunctions,

smoke or fire, do not operate the switches/buttons or

touch other electrical parts with wet hands.

To reduce the risk of injury or electric shock, stop the

operation and switch off the power supply before

cleaning, maintaining, or inspecting the controller.

To reduce the risk of injury or electric shock, before

spraying a chemical around the controller, stop the

operation and cover the controller.

To reduce the risk of injury, keep children away while

installing, inspecting, or repairing the unit.

Properly install all required covers to keep moisture

and dust out of the controller. Dust accumulation and

water can cause electric shock, smoke, or fire.

CITY MULTI Control System

and Mitsubishi M-Series and P-Series Air Conditioners

Simple MA Remote Controller PAC-YT53CRAU

Installation Manual

WT06429X01

GB

For distribution to dealers and contractors

F

Page 2

– 2 –

GB

CAUTION

WARNING

CAUTION

WARNING

CAUTION

Precautions during installation

Precautions during wiring

To reduce the risk of electric shock or malfunctions, do

not touch the touch panel, switches, or buttons with a

pointy or sharp object.

To reduce the risk of damage to the controller, do not

directly spray insecticide or other flammable sprays on

the controller.

To reduce the risk of injury and electric shock, avoid

contact with sharp edges of certain parts.

To reduce the risk of injury, wear protective gear when

working on the controller.

Consult your dealer for the proper disposal of the

controller.

Do not install the unit where there is a risk of leaking

flammable gas.

If flammable gas accumulates around the unit, it may

ignite and cause a fire or explosion.

To reduce the risk of shorting, current leakage, electric

shock, malfunctions, smoke, or fire, do not install the

controller in a place exposed to water or in a

condensing environment.

Controller must be installed by qualified personnel

according to the instructions detailed in the Installation

Manual.

Improper installation may result in electric shock or fire.

Install the top case into the bottom case until it clicks.

To reduce the risk of damage to the controller,

malfunctions, smoke, or fire, do not connect the power

cable to the signal terminal block.

Properly secure the cables in place and provide

adequate slack in the cables so as not to stress the

terminals. Improperly connected cables may break,

overheat, and cause smoke or fire.

To reduce the risk of injury or electric shock, switch off

the main power before performing electrical work.

All electric work must be performed by a qualified

electrician according to the local regulations,

standards, and the instructions detailed in the

Installation Manual.

To reduce the risk of electric shock, install a breaker

and a residual current circuit breaker on the power

supply.

To reduce the risk of electric shock, smoke, or fire,

install a breaker for each controller.

Use properly rated breakers and fuses (breaker, local

switch <switch + fuse>, no-fuse breaker).

Breaker with a breaking capacity greater than the

specified capacity may cause electric shock,

malfunctions, smoke, or fire.

To reduce the risk of current leakage, overheating,

smoke, or fire, use properly rated cables with adequate

current carrying capacity.

Proper grounding must be provided by a licensed

electrician.

Do not connect the grounding wire to a gas pipe, water

pipe, lightning rod, or telephone wire.

Improper grounding may result in electric shock,

smoke, fire, or malfunction due to electrical noise

interference.

To reduce the risk of electric shock, shorting, or

malfunctions, keep wire pieces and sheath shavings

out of the terminal block.

To reduce the risk of shorting, current leakage, electric

shock, or malfunctions, keep the cables out of contact

with controller edges.

To reduce the risk of electric shock, malfunctions, or

fire, seal the gap between the cables and cable access

holes with putty.

Page 3

– 3 –

GB

WARNING

CAUTION

Precautions for moving or repairing the controller

Additional precautions

The controller should be repaired or moved only by

qualified personnel.

Do not disassemble or modify the controller.

Improper installation or repair may cause injury, electric

shock, or fire.

To reduce the risk of electric shock, shorting, or

malfunctions, keep wire pieces and sheath shavings

out of the terminal block.

To avoid damage to the unit, use appropriate tools to

install, inspect, or repair the unit.

This controller is designed for exclusive use with the

Building Management System by Mitsubishi Electric.

The use of this controller for with other systems or for

other purposes may cause malfunctions.

To avoid discoloration, do not use benzene, thinner, or

chemical rag to clean the controller.

To clean the controller, wipe with a soft cloth soaked in

water with mild detergent, wipe off the detergent with a

wet cloth, and wipe off water with a dry cloth.

To avoid damage to the controller, provide protection

against static electricity.

Take appropriate measures against electrical noise

interference when installing the air conditioners in

hospitals or facilities with radio communication

capabilities.

Inverter, high-frequency medical, or wireless

communication equipment as well as power

generators may cause the air conditioning system to

malfunction. Air conditioning system may also

adversely affect the operation of these types of

equipment by creating electrical noise.

To avoid malfunctions, do not bundle power cables and

signal cables together, or place them in the same

metallic conduit.

Leave the circuit board and its protective film on the

case.

To avoid damage to the controller, do not overtighten

the screws.

Use a flat-head screwdriver with a blade width of 5 mm

(7/32 inch).

Do not turn the flat-head screwdriver with fitting it in the

latch strongly.

To avoid deformation and malfunction, do not install

the remote controller in direct sunlight or where the

ambient temperature may exceed 40ºC (104ºF) or

drop below 0ºC (32ºF).

Do not install the controller on the control panel door.

Vibrations or shocks to the controller may damage the

controller or cause the controller to fall.

Secure the cable with a clamp.

Do not use solderless terminals to connect cables to

the terminal block.

Solderless terminals may come in contact with the

circuit board and cause malfunctions or damage the

controller cover.

After connecting the connector, install the top case

properly.

Page 4

– 4 –

GB

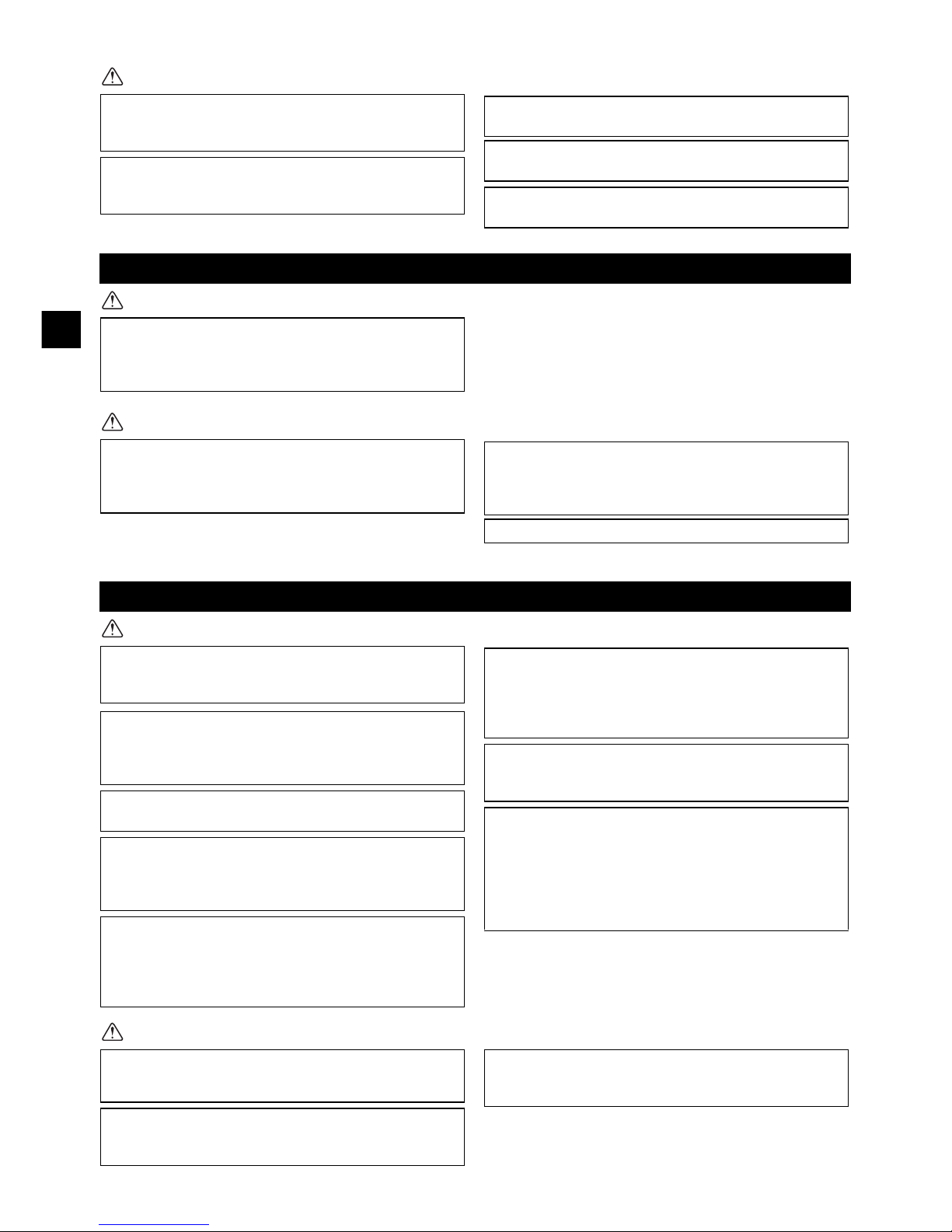

The following parts are included in the box.

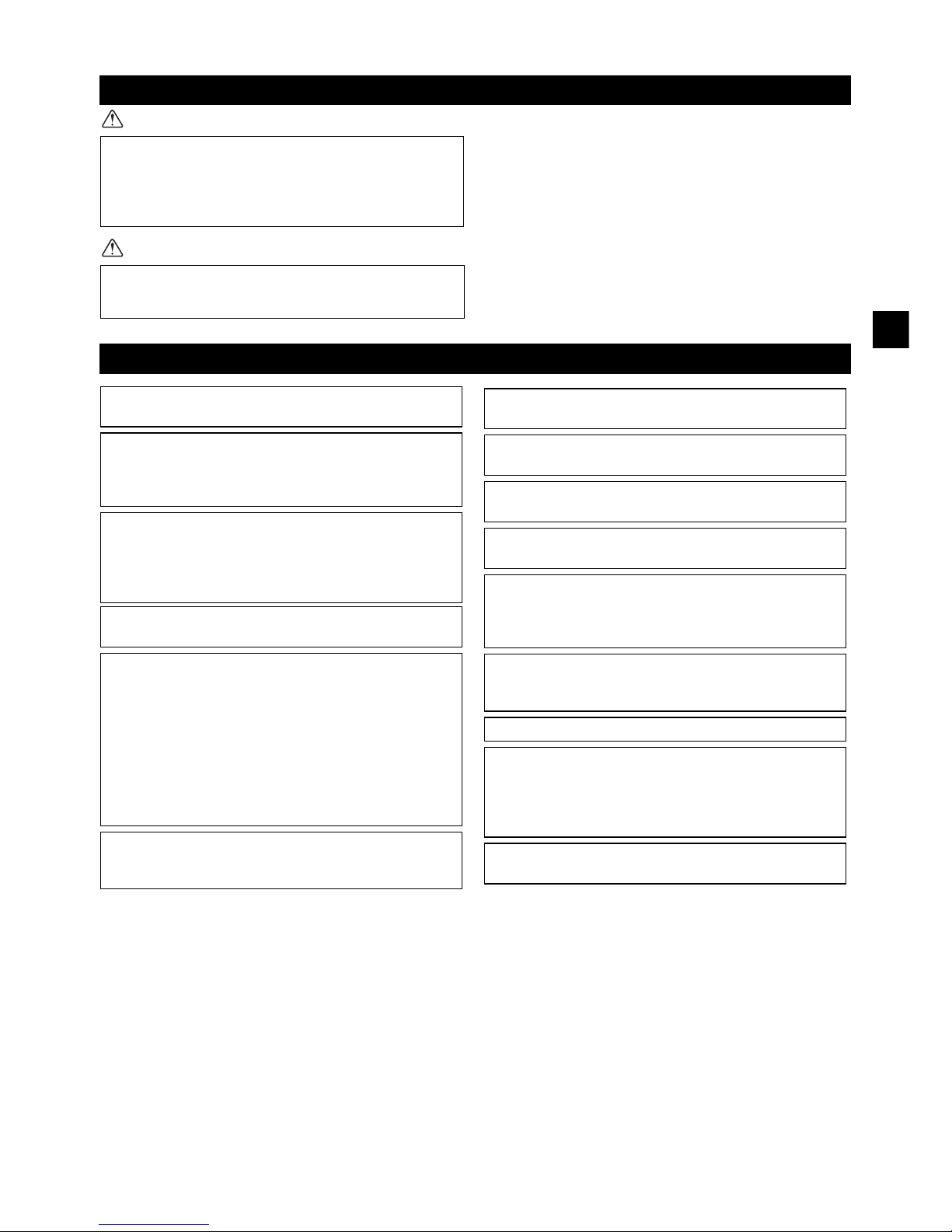

(1) Field-supplied parts

The following parts are field-supplied parts.

(2) Field-supplied tools

• Flat-tip screwdriver (Width: 3 - 5 mm (1/8 - 7/32 inch))

• Knife or Nipper

• Miscellaneous tools

2 Component names and supplied parts

*3 ISO metric screw thread

*4 Remote controller cable is not included.

3 Field-supplied parts/Required tools

Parts name Qty. Notes

Single switch box 1 Not required for direct wall installation

Thin metal conduit Necessary

Lock nut and bushing Necessary

Cable cover Necessary Required for routing remote controller cable along a wall

Putty Reasonable

Molly anchor Necessary

Remote controller cable

(Use a 0.3 mm² (AWG22) 2-core

sheathed cable.)

Necessary If you need to use a cable extension longer than 10 m (32 ft),

select an electric wire that meets the following specifications:

Wire specification VCTF or CVV (2-core):

1.25 mm² (stranded 16 AWG) or equivalent

Parts name Qty. Appearance

Remote controller (top case) 1 Right figure *1

Remote controller (bottom case) 1 Right figure *2

Roundhead cross slot screws M4×30 2 *3

Wood screw 4.1×16

(for direct wall installation)

2*3

Installation Manual (this manual) 1

Instruction Book 1

Bottom case *2

Top case *1

h

16 (5/8) 16 (5/8)

25 (1)

25 (1)

102 (4)

54 (2-1/8)

20

(13/16)

10

(3/8)

44 (1-3/4)

1.5 (1/16) or less

83.5±0.4 (3-3/8±1/32)

ø6 (1/4OD)

20 (13/16)

6

(1/4)

ø6 (1/4OD)

20 (13/16)

Switch box

unit: mm (in)

Page 5

– 5 –

GB

The wiring is different when the remote controller is connected to a CITY MULTI control system (“-A”

type and later) and when it is connected to a M-Series and P-Series air conditioner (A control type).

The wiring also differs with the system configuration. Check the system used.

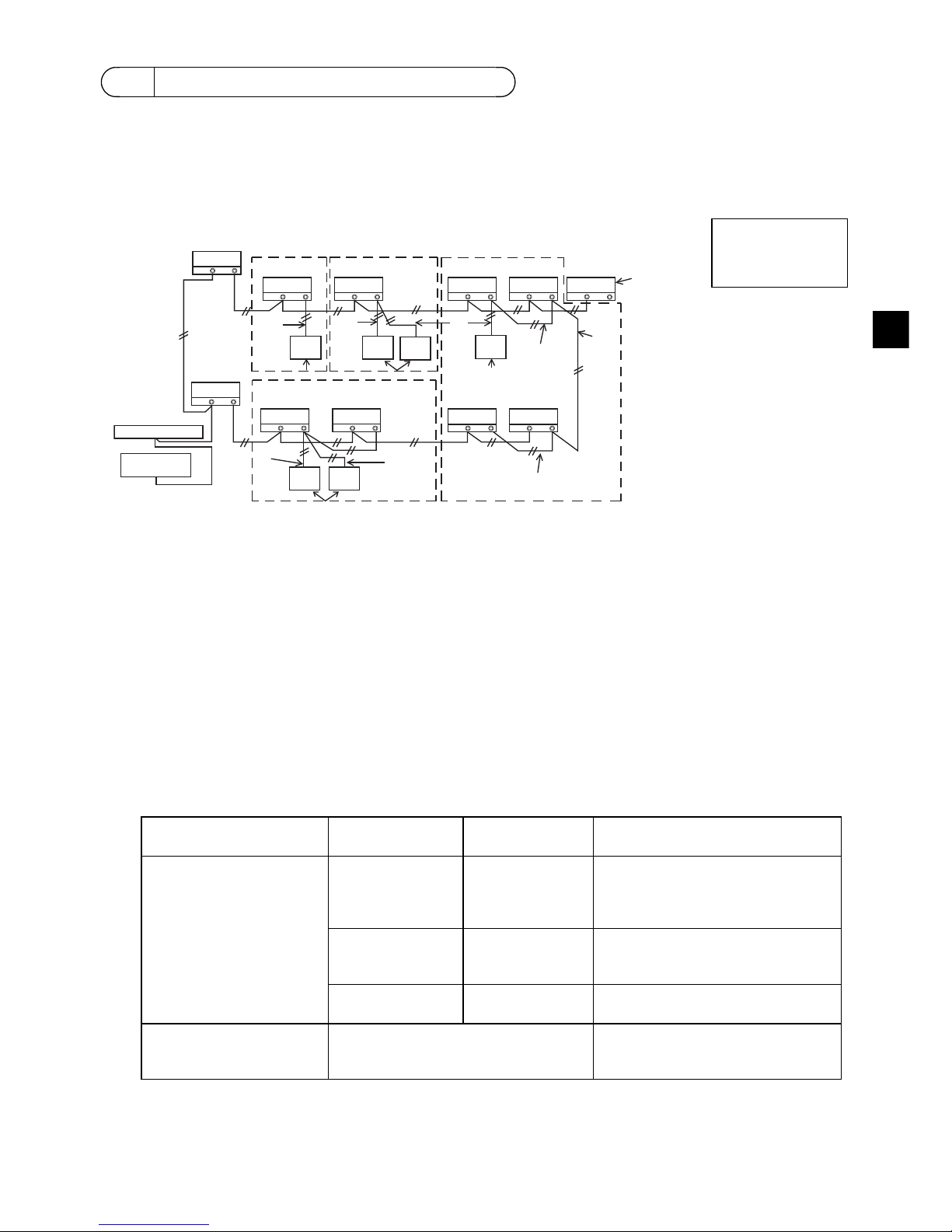

1. Connecting to CITY MULTI control system

The numbers (1) to (4) in the figure correspond to items (1) to (4) in the following description.

(1) Wiring from the remote controller

• Connect to the MA remote controller terminal block (TB15) on the indoor unit.

• The terminal block has no polarity. Connect to the terminal block at the rear bottom of the remote

controller.

(2) Operating in a group (Groups 03, and 04 above)

• Interconnect the MA remote controller terminal block (TB15) of the indoor units you want to

operate as a group, and connect the MA remote controller to that point.

• When the remote controller is used in combination with the system controller as shown in the

figure above, group setting at the system controller (central controller in the figure above) is

necessary.

(3) Number of connectable remote controllers (groups 02 and 04)

• A main remote controller and one sub remote controller, a total of two, can be connected to a

group made up of indoor units.

NOTE: When using this Simple MA remote controller in combination with other MA remote

controllers, be sure to follow the compatibility rules below.

4 How To Wire Transmission Line

Connect to TB15

on the indoor unit.

a Outdoor unit

b Indoor unit

c LOSSNAY or

OA processing unit

d Main Remote Controller

e Sub Remote Controller

f Central controller

g Power supply unit for

transmission line

Indoor unit function Main remote

controller

Sub remote

controller

Compatibility

Models applicable for

AUTO (dual set point) and

SETBACK mode

This Simple MA

remote controller

This Simple MA

remote controller

Compatible, and AUTO (dual set

point) and SETBACK mode can be

used depending on the indoor units

to be connected.

Other MA remote

controllers

This Simple MA

remote controller

Compatible, but AUTO (dual set

point) and SETBACK mode cannot

be used.

This Simple MA

remote controller

Other MA remote

controllers

Incompatible

Models not applicable for

AUTO (dual set point) and

SETBACK mode

Combination with all of the above Compatible

TB5 TB15

TB5 TB15

bb

TB5 TB15

c

TB5 TB15

b

TB5 TB15

b

TB5 TB15

b

TB5 TB15

b

TB7 TB3

TB5 TB15

TB5 TB15

TB7 TB3

(1)

(1)

(3)

(3)

(1)

(3)

(3)

(2)

(2)

(2)

(4)

(1)

(1)

a

a

dde d

ed

bb

g

f

Address = 51

Address = 01 Address = 02

Address = 55

Address = 08

Address = 07

Address = 03

Address = 04 Address = 09

Address = 06

Address = 05

Group 01 Group 02 Group 03

Group 04

Page 6

– 6 –

GB

(4) To interlock to a LOSSNAY or OA processing unit, make the following settings using the remote

controller. (For a description of how to set an interlock, see section .)

Set the LOSSNAY or OA processing unit address and the address of all the indoor units you want

to interlock.

(5) Total length of remote controller wiring

• The simple MA controller can be wired up to 200 m (656 ft). Procure 0.75 - 1.25 mm

² (stranded 16

- 28 AWG), 2-core cable at the installation site.

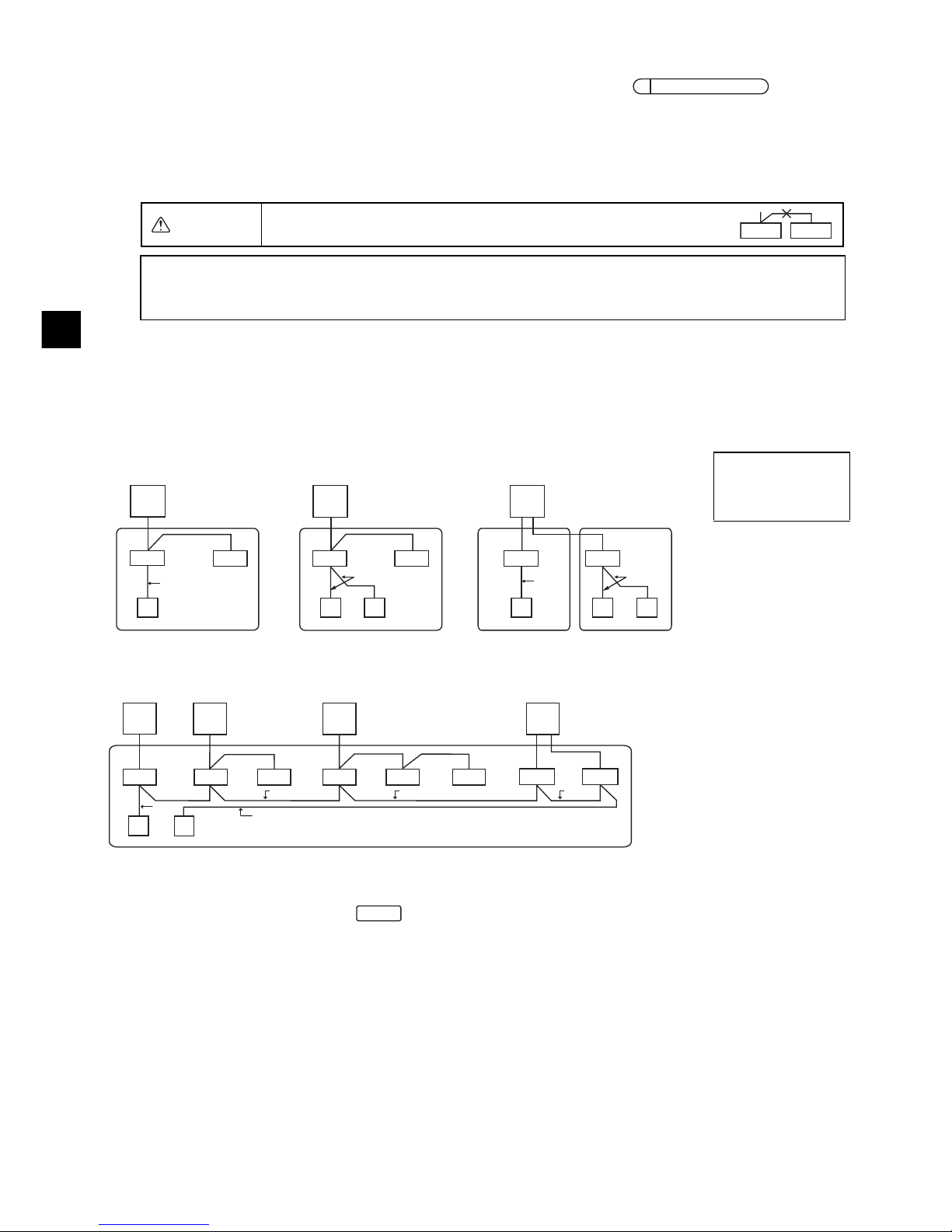

2. Connecting to M-Series and P-Series air conditioner

The remote controller wiring depends on the system configuration. Check the system configuration.

Wire the remote controller as shown in the example below.

The numbers (1) to (3) in the figure correspond to items (1) to (3) in the following description.

[1] Connecting the remote controller for each refrigerant system (Standard 1:1, simultaneous twin,

simultaneous triple, simultaneous four, individual twin)

[2] When grouping by different refrigerant systems

* Set the refrigerant address using the outdoor unit dip switches. (For more information, refer to the

outdoor unit installation manual.)

* All the indoor units enclosed in are controlled as one group.

(1) Wiring from remote controller

• Connect to indoor unit TB5 (remote controller terminal block). (The terminal block has no polarity.)

• For simultaneous multi type, when mixing various types of indoor units, always connect the

remote controller to the indoor unit with the most functions (wind velocity, vane, louver, etc.).

(2) When grouping with difference refrigerant systems

• Group using the remote controller wiring. Connect the remote controller to an arbitrary indoor unit

of each refrigerant system you want to group.

• When mixing different types of indoor units in the same group, always make the outdoor unit

connecting the indoor unit with the most functions (wind velocity, vane, louver, etc.) the Main unit

(refrigerant address = 00). Also, when the Main unit is the simultaneous multi type, always satisfy

the conditions of (1) above.

• The Simple MA Remote Controller can control up to 16 refrigerant systems as one group.

CAUTION

Remote controllers cannot be wired together. Only one wire

can be connected to the remote controller terminal block.

Connect to TB5

on the indoor unit.

a Outdoor unit

b Indoor unit

d Main Remote Controller

(Simple MA Controller)

e Sub Remote Controller

(Simple MA Controller)

7

Ventilation Setting

ed

NOTE: When interlocking the MA remote controller with a LOSSNAY or OA processing unit,

always set the address of all the indoor units in the group and the address of the

LOSSNAY or OA processing unit.

(1)

(3)

TB5

TB4

TB1

TB4

(3)

(3)

(1)

TB4

TB4

TB5

TB1

TB4

TB5

TB1

TB1

TB4

TB5

(1)

(1)

(3)

(3)

(3)

a

bb

d

a

bb

de

a

bb

dde

Refrigerant

address = 00

Refrigerant

address = 00

Refrigerant

address = 00

Refrigerant

address = 00

Simultaneous twin Simultaneous twin Individual twin

TB4

TB4

TB4

TB4TB4

TB4

TB4TB4

TB1 TB1 TB1

TB1TB1

TB5

TB5

TB5

TB5

TB5

(2)

(1)

(3)

(3)

(1)

(2) (2)

(2)

aa a a

bbbbbbbb

de

Standard 1:1 Simultaneous twin

Simultaneous triple

Individual twin

Refrigerant

address = 01

(Sub)

Refrigerant

address = 03

(Sub)

Refrigerant

address = 04

(Sub)

Refrigerant

address = 00

(Main)

Refrigerant

address = 02

(Sub)

Page 7

– 7 –

GB

(3) Up to two remote controllers can be connected to one group

• When two remote controllers are connected to one group, always set the Main remote controller

and Sub remote controller.

• When only one remote controller is connected to one group, set it as the Main controller. When

two remote controllers are connected to one group, set the Main remote controller and Sub

remote controller. (For a description of how to set the Main/Sub switch, see step 5 in section

.)

NOTE: When using this Simple MA remote controller in combination with other MA remote

controllers, be sure to follow the compatibility rules below.

(4) Total length of remote controller wiring

• The Simple MA Remote Controller can be wired up to 200 m (656-1/8 ft).

Procure 0.75 ~ 1.25 mm

² (16 ~ 28 AWG), 2-core cable at the installation site.

This remote controller is for the wall installation. It can be installed either in the switch box or directly

on the wall. When performing direct wall installation, wires can be thread through either back or top of

the remote controller.

(1) Selecting an installation site

Install the remote controller (switch box) on the site where the following conditions are met.

(a) A flat surface

(b) A place where the remote controller can measure the accurate indoor temperature

Sensors to monitor indoor temperature are on the indoor unit and on the remote controller. When

the room temperature is monitored with the sensor on the remote controller, the built-in sensor on

the Main remote controller monitors the room temperature. When using the sensor on the remote

controller, follow the instructions below.

Indoor unit function Main remote

controller

Sub remote

controller

Compatibility

Models applicable for

AUTO (dual set point) and

SETBACK mode

This Simple MA

remote controller

This Simple MA

remote controller

Compatible, and AUTO (dual set

point) and SETBACK mode can be

used depending on the indoor units

to be connected.

Other MA remote

controllers

This Simple MA

remote controller

Compatible, but AUTO (dual set

point) and SETBACK mode cannot

be used.

This Simple MA

remote controller

Other MA remote

controllers

Incompatible

Models not applicable for

AUTO (dual set point) and

SETBACK mode

Combination with all of the above Compatible

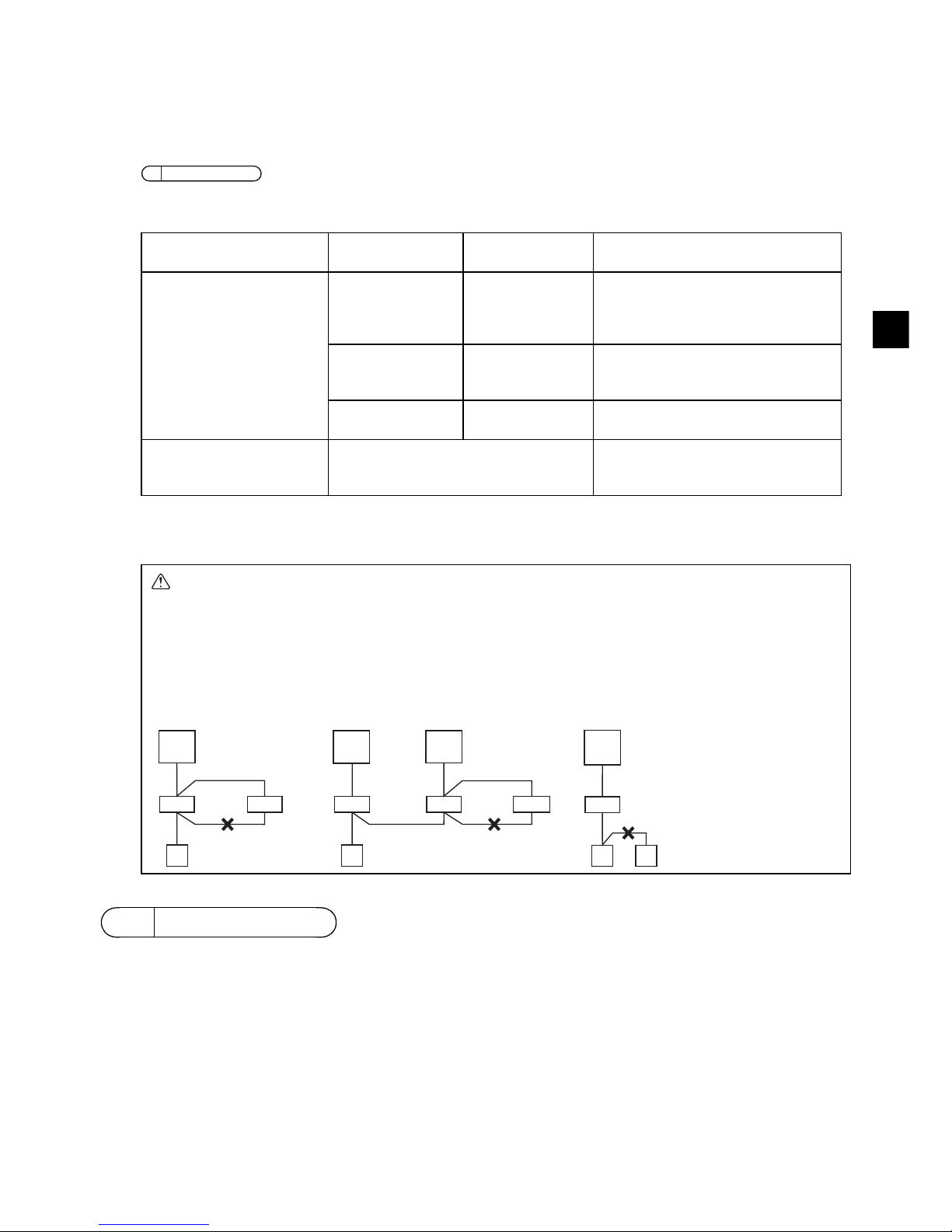

CAUTION - The wiring cannot be connected to TB5 of the indoor unit of the same

refrigerant system. If so connected, the system will not operate normally.

- Remote controllers cannot be wired together. Only one wire can be connected

to the remote controller terminal block.

- When connecting to TB5, connect up to two wires of the same size to one

terminal block.

a Outdoor unit

b Indoor unit

d Main Remote Controller

e Sub Remote Controller

5How To Install

5

How To Install

d

d

TB4

TB4

TB4

TB4

TB4

TB4

TB1

TB1 TB1

TB1

TB5

TB5

TB5

TB5 TB5 TB5

a

bbb bbb

de

aa a

Refrigerant

address = 00

Refrigerant

address = 00

Refrigerant

address = 01

Refrigerant

address = 00

Simultaneous twin Standard 1:1 Simultaneous twin Standard 1:1

Page 8

– 8 –

GB

• To monitor the accurate indoor temperature, install the remote controller away from direct

sunlight, heat sources, and the supply air outlet of the air conditioner.

• Install the remote controller in a location that allows the sensor to measure the representative

room temperature.

• Install the remote controller where no wires are routed around the temperature sensor on the

controller. (If wires are routed, the sensor cannot measure accurate indoor temperature.)

(2) Installation space

Leave a space around the remote controller as shown in the figure shown below, regardless of

whether the controller is installed in the switch box or directly on the wall. Removing the remote

controller will not be easy with insufficient space.

Also, leave an operating space in front of the remote controller.

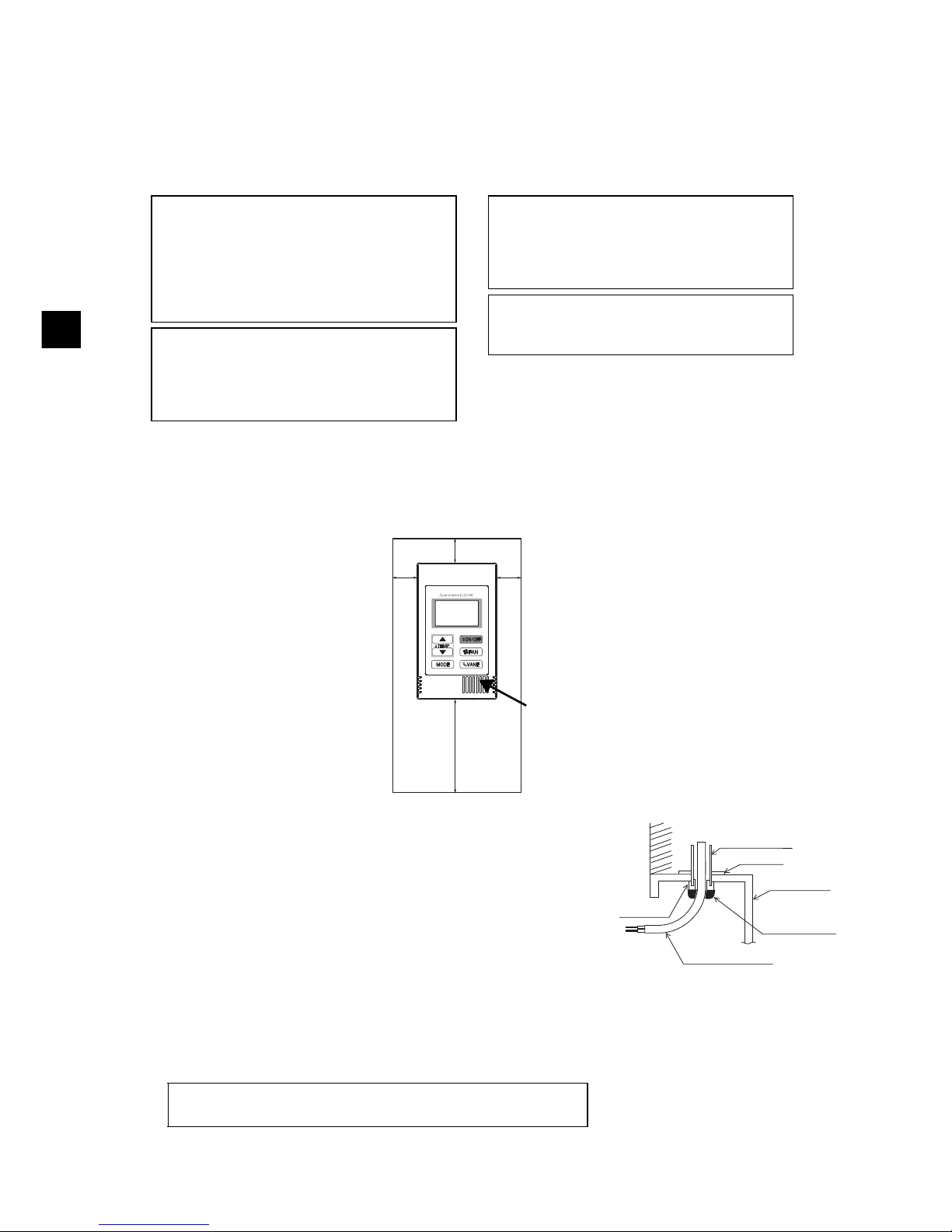

(3) Installation work

Controller can be installed either in the switch box or directly on the

wall. Perform the installation properly according to the installation

method.

1 Drill a hole in the wall.

■ Installation using a switch box

• Drill a hole in the wall, and install the switch box on the wall.

• Connect the switch box to the conduit tube.

■ Direct wall installation

• Drill a hole in the wall, and thread the cable through it.

2 Seal the cable access hole with putty

■ Installation using a switch box

• Seal the remote controller cable access hole at the

connection of switch box and conduit tube with putty.

Do not install the controller in a place where

the difference between the remote controller

surface temperature and the actual room

temperature will be great.

If the temperature difference is too high,

room temperature may not be adequately

controlled.

To reduce the risk of malfunctions, do not

install the controller in a place where water

or oil may come into contact with the

controller, or in a condensing or corrosive

environments.

To avoid deformation and malfunction, do

not install the remote controller in direct

sunlight or where the ambient temperature

may exceed 40ºC (104ºF) or drop below 0ºC

(32ºF).

Do not install the remote controller directly

onto electrically conductive objects such as

metal plate that has not been painted.

Important

.

30

(1-3/16)

30

(1-3/16)

30 (1-3/16)

120 (4-3/4)

Temperature sensor

unit: mm (in)

External dimensions of remote controller

Minimum required space

around the remote

controller

Wall

Conduit tube

Locknut

Switch box

Seal the gap

with putty.

Remote

controller cable

Bushing

To reduce the risk of electric shock, malfunctions, or fire, seal

the gap between the cables and cable access holes with putty.

Page 9

– 9 –

GB

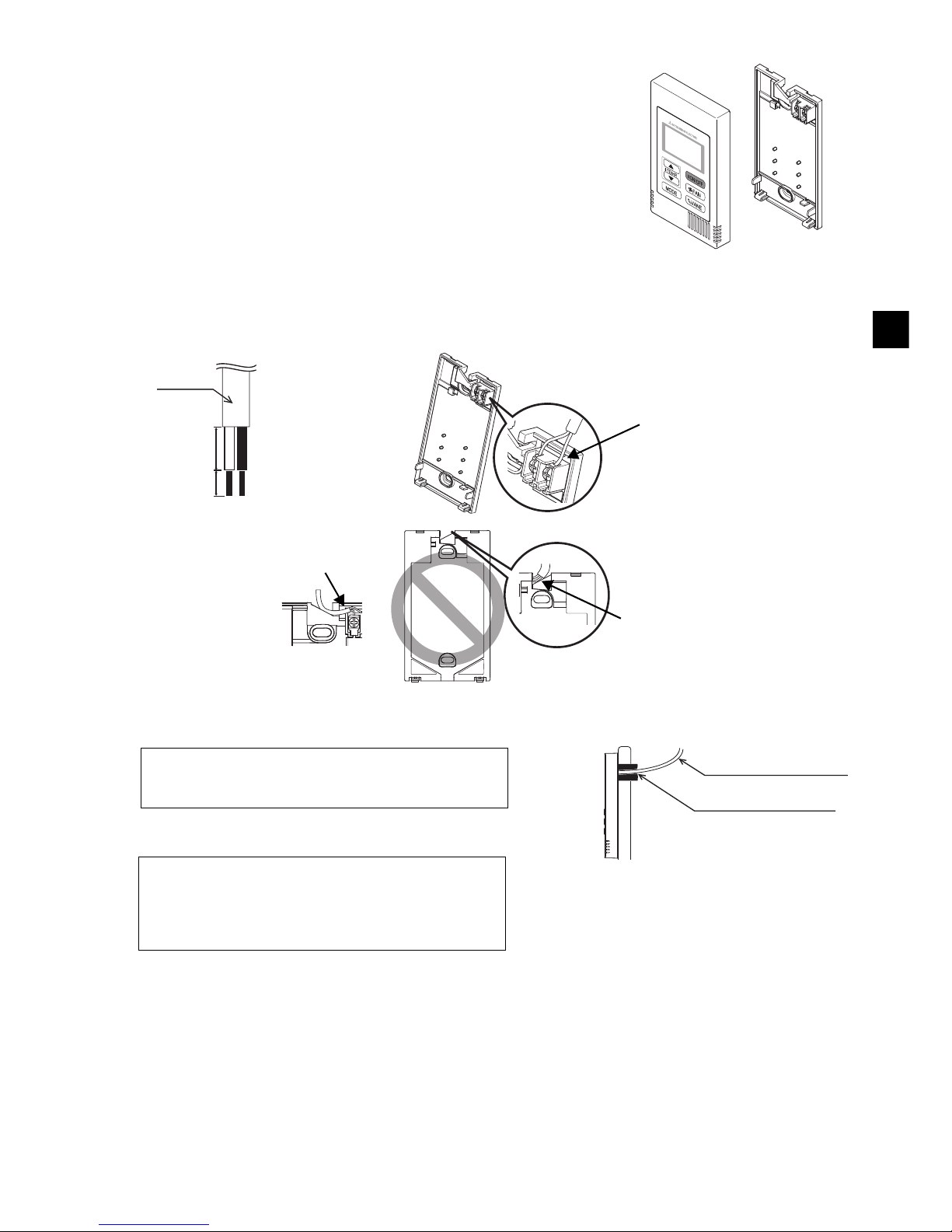

3 Prepare the bottom case of the remote controller.

4 Connect the remote controller cable to the terminal block on the bottom case.

Peel off the remote controller cable sheath as shown below to connect to the terminal block properly.

Secure the remote controller cable so that the peeled part of the cable will fit into the case.

■ Direct wall installation

• Seal the hole through which the cable is threaded with putty.

Top case Bottom case

16 (21/32)

6 (1/4)

Sheath

Unit: mm (in)

Connect the cable.

(non-polarized)

2-core wire must not be

seen on the back.

Insert the sheathed part of the cable inside

the case, and then secure the cable.

Seal the gap with putty.

Route the cable behind

the remote controller.

Remote controller cable

To reduce the risk of electric shock, shorting, or

malfunctions, keep wire pieces and sheath shavings

out of the terminal block.

Do not use solderless terminals to connect cables to

the terminal block.

Solderless terminals may come in contact with the

circuit board and cause malfunctions or damage the

controller cover.

Important

Page 10

– 10 –

GB

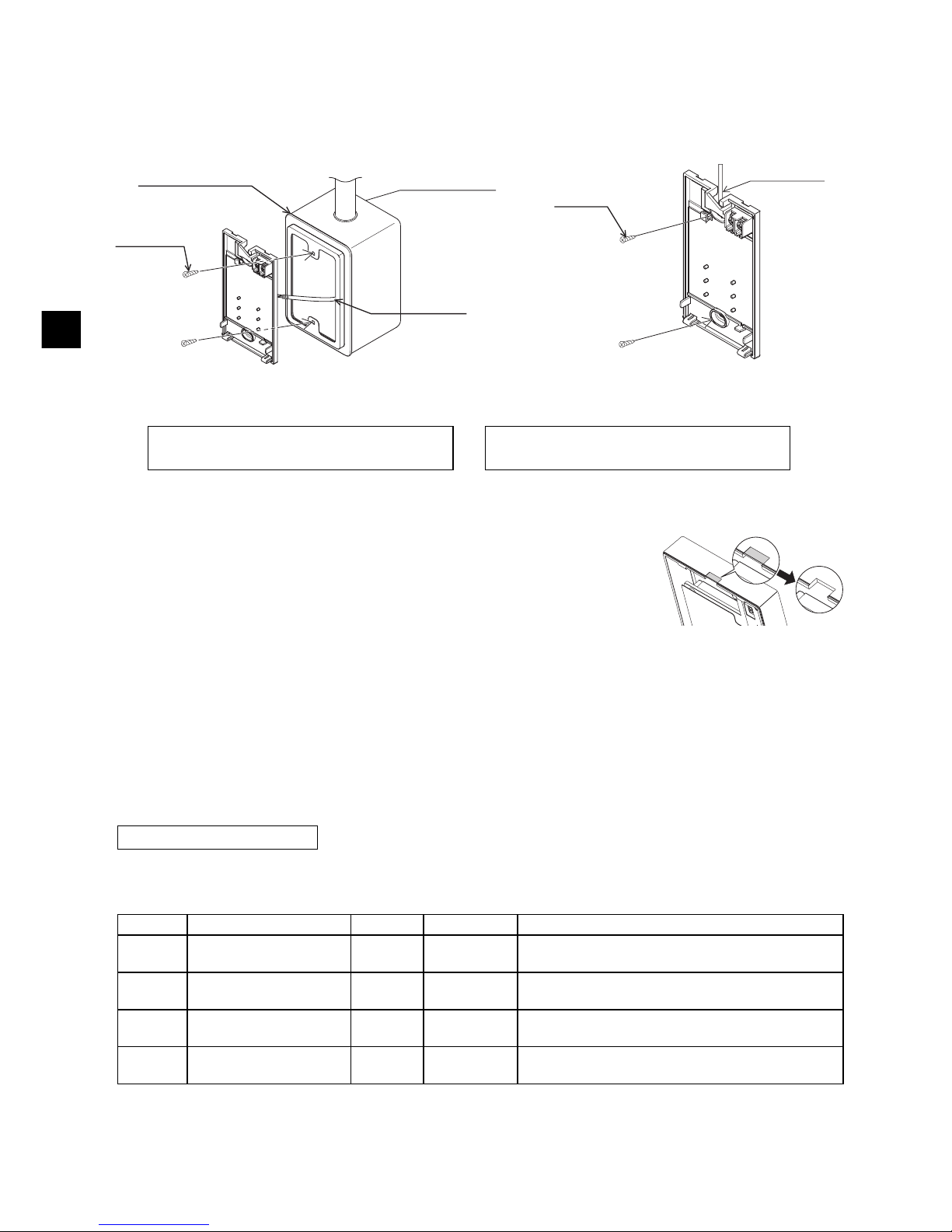

5 Install the bottom case.

Be sure to secure two places of the bottom case.

6 Cut out the cable access hole.

■ Direct wall installation (when running the cable along the wall)

• Cut out the thin-wall part on the cover (the shaded area in the right

figure) with a knife or a nipper.

• Thread the cable from the groove behind the bottom case through

this access hole.

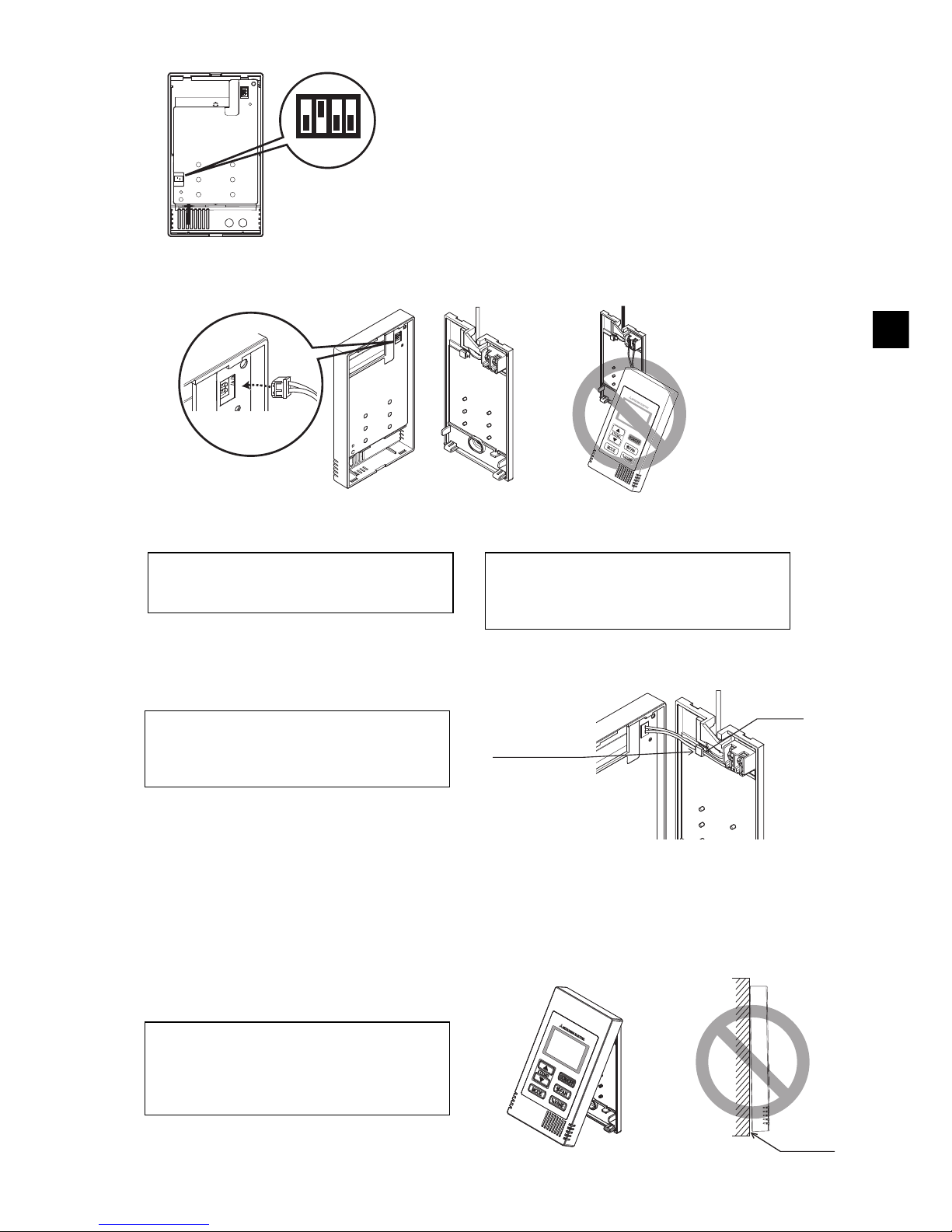

7 Set the dip switches on the top case.

When using two remote controllers in one group, set the dip switches.

When using two remote controllers in one group, specify the main and sub remote controllers using

dip switch No. 1 shown below.

• When connecting only one remote controller to one group, it is always the main remote controller.

When connecting two remote controllers to one group, set one remote controller as the main

remote controller and the other as the sub remote controller.

• The factory setting is “Main”.

There are switches on the back of the top case. Remote controller Main/Sub and other function

settings are performed using these switches. Ordinarily, only change the Main/Sub setting of SW1.

(The factory settings are ON for SW1, 3, and 4 and OFF for SW2.)

■ Installation using a switch box ■ Direct wall installation

Setting the dip switches

SW No. SW contents Main ON OFF Comment

1

Remote controller

Main/Sub setting

Main Sub

Set one of the two remote controllers at one

group to “ON”.

2

Temperature display

units setting

Celsius Fahrenheit

When the temperature is displayed in

[Fahrenheit], set to “OFF”.

3

Cooling/heating

display in AUTO mode

Yes No

When you do not want to display “Cooling” and

“Heating” in the AUTO mode, set to “OFF”.

4

Indoor temperature

display

Yes No

When you do not want to display the indoor

temperature, set to “OFF”.

Remote

controller

cable

Refer to 4.

Refer to 1.

Single switch box

Roundhead

cross slot

screws

Seal the cable

access hole

with putty.

Refer to 4.

Wood

screws

Remote

controller cable

To avoid deformation and damage to the

bottom case, do not overtighten the screws.

To avoid damage to the bottom case, do not

make holes on it.

Important

Page 11

– 11 –

GB

8 Connect the connector to the top case.

Connect the connector on the bottom case to the socket on the top case.

9 Insert the wires into the clamp.

0 Install the top case on the bottom case.

Two mounting tabs are at the top of the top case.

Hook those two tabs onto the bottom case, and click the top case into place. Check that the case is

securely installed and not lifted.

1 2 3 4

ON

OFF

Connect the

connector.

To prevent malfunctions, do not remove the

protective sheet or the circuit board from the

top case.

To prevent cable breakage and

malfunctions, do not hang the top controller

casing hang by the cable as shown in the

figure above.

Important

Clamp

Insert the wires.

Hold the wires in place with the clamp to

prevent undue force from being applied to

the terminal block and causing cable

breakage.

Important

Wall

Should not

be lifted.

When attaching the top casing to the bottom

casing, push it until it they click into place.

If they are not properly locked into place,

they may fall, causing personal injury,

controller damage, or malfunctions.

Important

Page 12

– 12 –

GB

■ Direct wall installation (when running the cable along the wall)

• Thread the cable through the access hole at the top of the remote controller.

• Seal the cut-out part of the cover with putty.

• Use a cable cover.

• Uninstalling the top case

1 Uninstalling the top case

Insert a flat-tip screwdriver with a blade width of 3-5 mm (1/8-7/32

inch) into the latches at the bottom of the remote controller and lift

the latches. Then, pull up the top case.

Seal the gap

with putty.

Use a cable

cover.

Thread the cable through the top of the

remote controller.

To prevent damage to the controller casing,

do not force the flat-tip screwdriver to turn

with its tip inserted in the slot.

Do not insert the flat-tip screwdriver too far.

Doing so will damage the circuit board.

Important

Page 13

– 13 –

GB

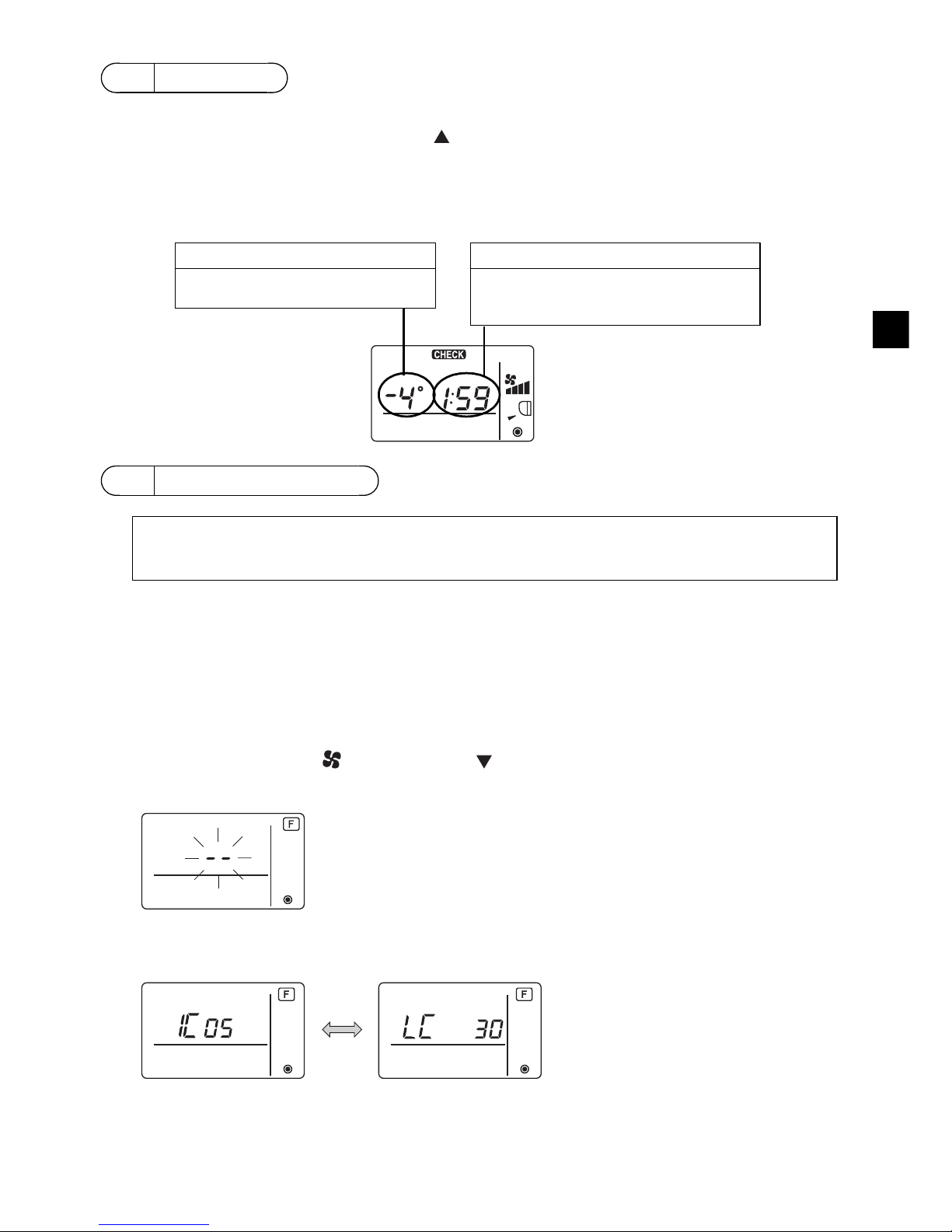

1. Before making a test run, refer to the “Test Run” section of the indoor unit installation manual.

2. When the [ON/OFF] button and [TEMP. ] button are pressed simultaneously for 2 seconds or

longer, test run is performed.

3. Stop the test run by pressing the [ON/OFF] button.

4. If trouble occurred during the test run, refer to the “Test Run” section of the indoor unit installation

manual.

Perform this operation when you want to register the LOSSNAY or OA processing unit, confirm the

registered units, or delete the registered units controlled by the remote controller.

The following uses indoor unit address 05 and LOSSNAY or OA processing unit address 30 as an

example to describe the setting procedure.

[Setting Procedure]

1 Stop the air conditioner using the remote controller [ON/OFF] button.

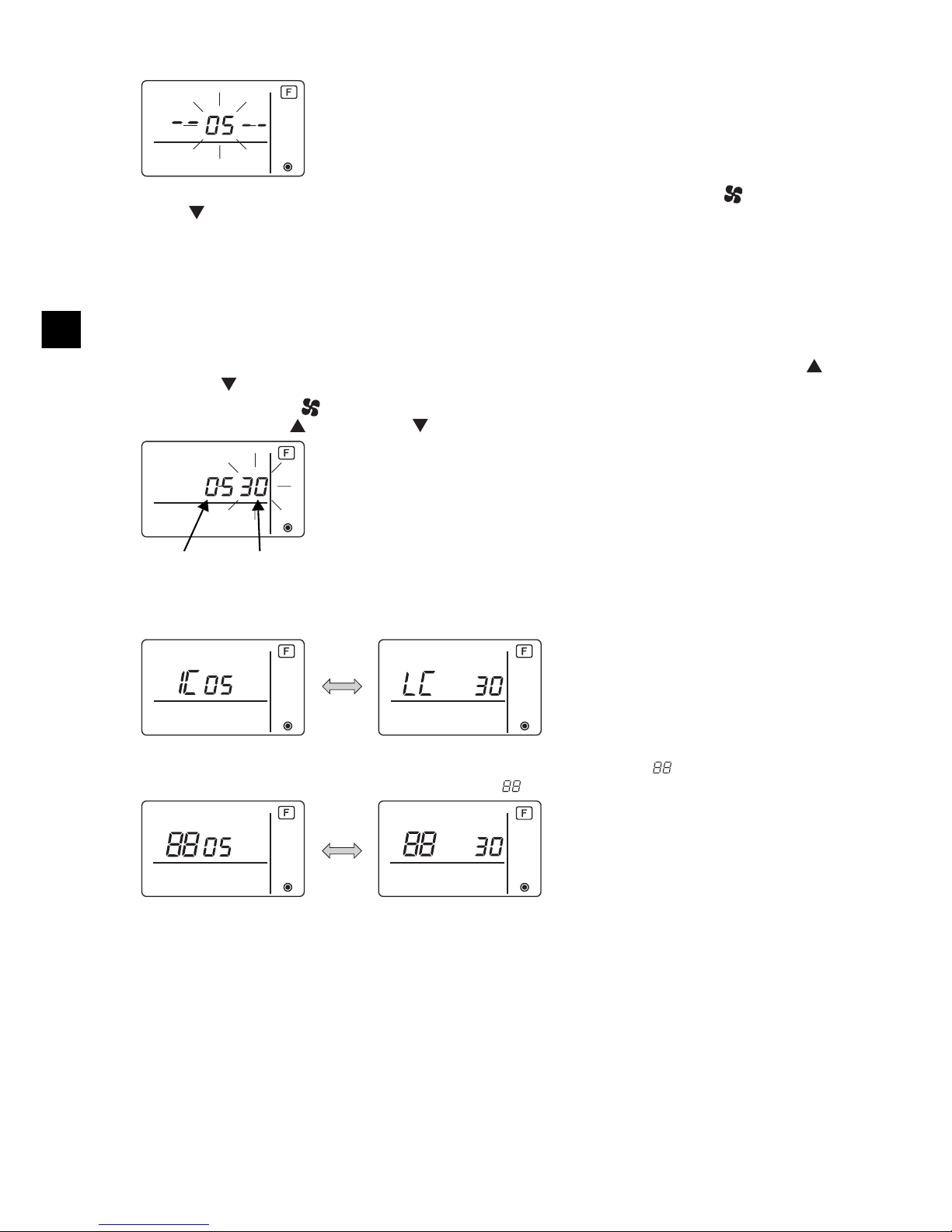

2 Press and hold down the [ FAN] and [TEMP. ] buttons at the same time for two seconds. The

display shown below appears. The remote controller confirms the registered LOSSNAY or OA

processing unit addresses of the currently connected indoor units.

3 Registration confirmation result

- The indoor unit address and registered LOSSNAY or OA processing unit address are displayed

alternately.

6 Test Run

7 Ventilation Setting

COOL

VENTI.

Indoor unit piping temperature

Display range: -4ºF (-20ºC) to 158ºF (70ºC)

“-4ºF” or “158ºF” flashes on the display.

Test run time

The remaining time for test run is displayed.

Display range: 2:00 to 0:01

After two hours, the test run stops automatically.

Make this setting only when interlocked operation with LOSSNAY or OA processing unit is

necessary with CITY MULTI models.

(This setting cannot be made with M-Series and P-Series air conditioners.)

<Indoor unit address and indoor unit display>

<LOSSNAY address display and LOSSNAY display>

Page 14

– 14 –

GB

- When LOSSNAY or OA processing unit are not registered

4 If registration is unnecessary, end registration by pressing and holding down the [ FAN] and

[TEMP. ] buttons at the same time for two seconds.

If a new LOSSNAY or OA processing unit must be registered, go to step 1. Registration

procedure.

If you want to confirm another LOSSNAY or OA processing unit, go to step 2. Confirmation

procedure. To delete a registered LOSSNAY or OA processing unit, go to step 3. Deletion

procedure.

<1. Registration procedure>

5 Set the address of the indoor unit to be interlocked with the LOSSNAY unit using the [TEMP.

]

and [TEMP. ] buttons. (01 to 50)

6 After setting, press the [ FAN] button and set the Lossnay address you want to register by

operating the [TEMP. ] and [TEMP. ] buttons. (01~50)

7 Press the [ON/OFF] button, and register the set indoor unit address and LOSSNAY address.

- Registration end display

The indoor unit address and “IC” and LOSSNAY address and “LC” are alternately displayed.

- Registration error display

If the address is not registered correctly, the indoor unit address and [ ], and the registered

LOSSNAY (or OA processing unit address) and [ ] are alternately displayed.

Cannot be registered because the registered indoor unit or LOSSNAY or OA processing unit does

not exist.

Cannot be registered because another LOSSNAY or OA processing unit was registered at the

registered indoor unit.

Indoor unit address

LOSSNAY or OA processing unit address

Page 15

– 15 –

GB

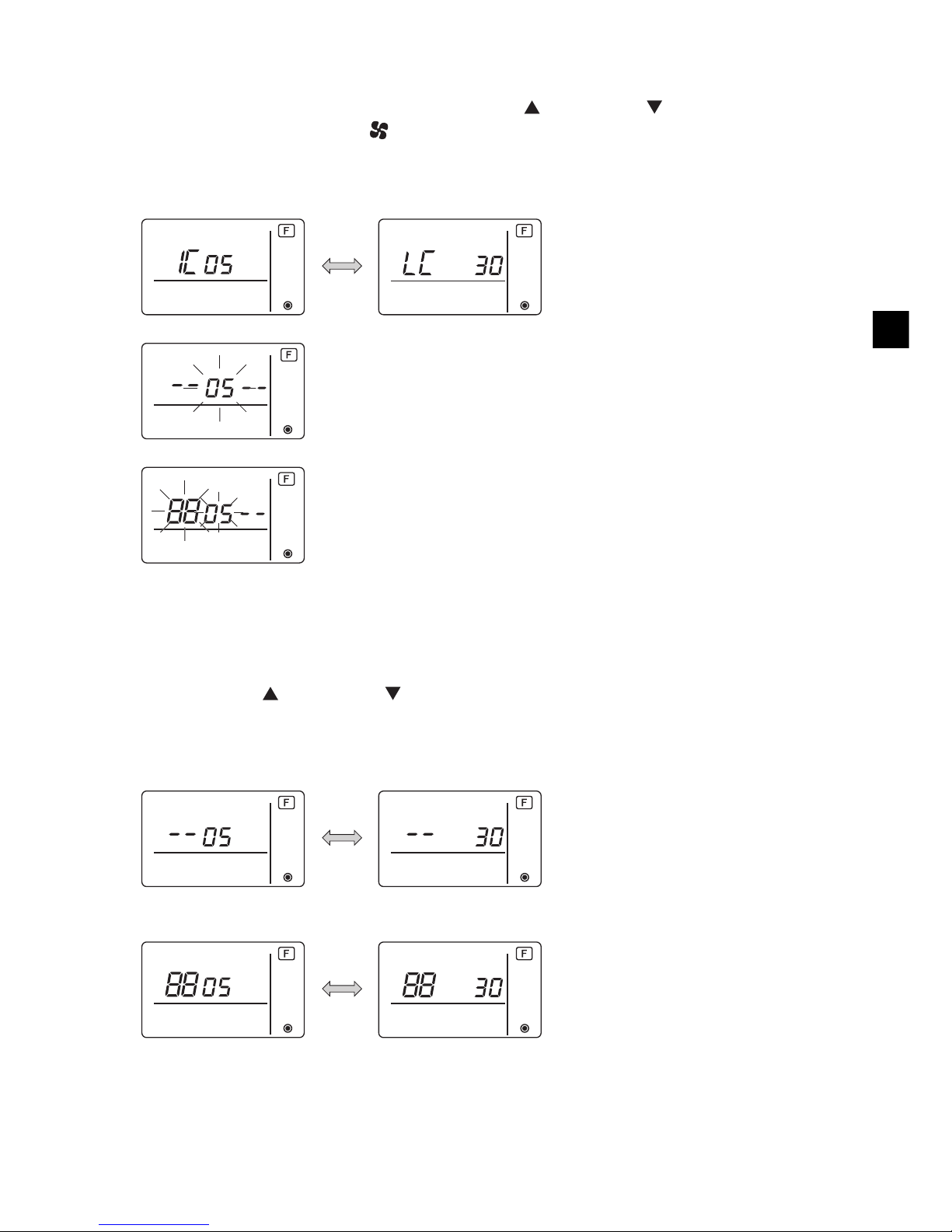

<2. Confirmation procedure>

8 Set the address of the indoor unit connected by the remote controller whose LOSSNAY or OA

processing unit you want to confirm using the [TEMP. ] and [TEMP. ] buttons. (01 to 50)

9 Press the [ON/OFF] button and [ FAN] button simultaneously for 2 seconds, and check the

LOSSNAY address registered at the set indoor unit address.

- Confirmation end display (When LOSSNAY is connected.)

The indoor unit address and “IC” and registered LOSSNAY address and “LC” are alternately

displayed.

- Confirmation end display (When LOSSNAY or OA processing unit is not connected.)

- Registered indoor unit address does not exist.

<3. Deletion procedure>

Use this procedure when you want to delete registration of indoor units connected by the remote

controller and LOSSNAY or OA processing unit.

0 Confirm (see 2. Confirmation procedure) the LOSSNAY or OA processing unit you want to delete

and display the indoor units and LOSSNAY or OA processing unit confirmation results.

a Press the [TEMP. ] and [TEMP. ] buttons simultaneously for 2 seconds, and delete

registration of the LOSSNAY or OA processing unit address registered at the set indoor unit.

- Deletion end display

Indoor unit address and “– –” and registered LOSSNAY or OA processing unit address and “– –”

are alternately displayed.

- Deletion error display

When deletion was not performed properly.

Page 16

– 16 –

GB

Set the functions of each indoor unit from the remote controller, as required. The functions of each

indoor unit can be selected only from the remote controller.

Set the functions by selecting the necessary items from Table 1.

Table1. Function selection contents

(For a detailed description of the factory settings and mode of each indoor unit, refer to the indoor unit installation manual.)

* Static pressure setting can be made by using Mode 08 in combination with Mode 10 depending on

the indoor unit model. Refer to the Indoor unit Installation Manual for details.

* For mode numbers other than listed above, refer to the indoor unit installation manual.

8 Function Selection for M-Series and P-Series

Mode

No.

Mode Settings

Setting

No.

Check Unit numbers

01 Automatic recovery

after power failure

Disable 1 Set "00" for the Unit number.

These settings apply to all the

connected indoor units.

Enable (Four minutes of standby time is required

after the restoration of power.)

2

02 Thermistor selection

(Indoor temperature

detection)

Average temperature reading of the indoor units

in operation

1

Thermistor on the indoor unit to which the remote

controller is connected (fixed)

2

Built-in sensor on the remote controller 3

03 LOSSNAY connection Not connected 1

Connected (without outdoor air intake by the

indoor units )

2

Connected (with outdoor air intake by the indoor

units )

3

04 Power voltage 240 V 1

220 V, 230 V 2

05 AUTO mode Enable (Automatically the unit achieves effective

energy saving operation.)

1

Disable 2

07 Filter sign 100 hours 1 Set "01” to “04” or “AL” for the

Unit number.

These settings apply to each

indoor unit.

• If "01” (“02”, “03”, “04") is

set for the Unit number, the

settings apply only to the

specified indoor unit

regardless of the number of

connected indoor units (one

through four units).

• If "AL" is set for the Unit

number, the settings apply

to all the connected indoor

units regardless of the

number of connected

indoor units (one through

four units).

2500 hours 2

Not displayed 3

08 Fan speed Silent mode (or standard) 1

Standard (or High ceiling 1) 2

High ceiling (or High ceiling 2) 3

09 No. of air outlets 4 directional 1

3 directional 2

2 directional 3

10 Installed options No 1

(High performance filter)

Ye s 2

11 Vane setting No vanes (or the vane setting No.3 is effective.) 1

Equipped with vanes

(The vane setting No.1 is effective.)

2

Equipped with vanes

(The vane setting No.2 is effective.)

3

Make the following settings for M-Series and P-Series if necessary.

(This setting cannot be made with CITY MULTI Control System. To make CITY MULTI indoor

unit settings from the remote controller, refer to section .)

9 Function Selection for CITY MULTI

NOTE: When the indoor unit functions were changed using the function selection after

installation is complete, always indicate the set contents by entering check marks or

other marks in the appropriate check field of Table 1.

Page 17

– 17 –

GB

[Function selection flow]

First grasp the function selection flow. The following describes setting of “Thermistor selection” of

Table 1 as an example.

(For the actual setting procedure, see [Setting procedure] 1 to 0.)

[Setting procedure] (Set only when change is necessary.)

1 Check the set contents of each mode. When the set contents of a mode were changed by function

selection, the functions of that mode also change.

Check the set contents as described in steps 2 to 7 and change the setting based on the entries

in the Table 1 check field. For the factory settings, refer to the indoor unit installation manual.

-------------------------------------------------------------------------------------------------------------------------------------

2 Set the remote controller to Off.

Press and hold down the D [ FAN] and the C [TEMP. ] buttons at the same time for two

seconds or longer.

“ (FUNCTION)” blinks for a while, then the remote controller display changes to the display

shown below.

3 Set the outdoor unit refrigerant address No.

When the B [TEMP. ] and C [TEMP. ] buttons are pressed, the refrigerant address No.

decreases and increases between 00 and 15.

Set it to the refrigerant address No. whose function you want to select.

(This step is unnecessary for single refrigerant system.)

1 Check the function selection set contents.

2 Switch to the FUNCTION SELECTION mode.

(Press D and C simultaneously in the remote

controller OFF state.)

3 Refrigerant address specification

→ 00 (Outdoor unit specification)

(Unnecessary for single refrigerant system)

4 Unit address No. specification

(Buttons B, C and D)

→ 00 (Indoor unit specification)

5 Register (Press button A.)

6 Mode No. Selection

→ 02 (Thermistor selection)

7 Setting No. selection

(Buttons B, C and D)

→ 3 (Built-in sensor on the remote controller)

8 Register (Press button A.)

(Specified indoor unit

→ Fan operation)

End?

0 Ending function display

(Press buttons D and C simultaneously.)

9

Change

refrigerant

address and unit

address No.?

Ye s

No

Yes

No

.

A

D

C

B

Refrigerant address

display

Page 18

– 18 –

GB

* If the remote controller enters the OFF state after the “ (FUNCTION)” and room temperature

displays “ ” have flashes for two seconds, communication is probably abnormal. Make sure there

are no noise sources near the transmission line.

4 Set the indoor unit address No.

Press the D [ FAN] button. The unit address No. display “– –” flashes.

When the B [TEMP. ] and C [TEMP. ] buttons are pressed, the unit address No. changes in

the order of 00 ↔ 01 ↔ 02 ↔ 03 ↔ 04 ↔ AL. Set it to the unit address No. of the indoor unit whose

functions you want to set.

* When setting mode 1 ~ 6, set the unit address No. to “00”.

* When setting modes 7 to 14:

- When setting for each indoor unit, set the unit address No. to “01-04”.

- When batch setting for all indoor units, set the unit address No. to “AL”.

5 Refrigerant address and unit address No. registration

Press the A [ON/OFF] button. The refrigerant address and unit address No. are registered.

After a while, the mode No. display “– –” flashes.

* When “ ” flashes at the room temperature display, the selected refrigerant address is not in the

system. When “F” is displayed at the unit address No. display, and when it flashes together with

the refrigerant address display, the selected unit address No. does not exist. Correctly set the

refrigerant address and unit address No. by repeating steps 3 and 4.

When registered using the A [ON/OFF] , the registered indoor unit begins fan operation.

When you want to know the location of the indoor units of the unit address No. whose functions

were selected, check here.

When the unit address No. is 00 or AL, all the indoor units of the selected refrigerant address

perform the fan operation.

* When grouping by different refrigerant systems and an indoor unit other than the specified

refrigerant address performs the fan operation, the refrigerant address set here is probably

duplicated.

Recheck the refrigerant address at the outdoor unit dip switches.

NOTE: If you make a mistake during operation, end function selection by step 0 and repeat

selection from step 2.

Unit address No.

display

Mode No. display

EX): When refrigerant address 00, unit address No. = 02 registered

Refrigerant address 00

Indoor unit

Outdoor unit

Registration

Simple MA Controller

Fan operation

Unit address

No. 01

Unit address

No. 02

Unit address

No. 03

Page 19

– 19 –

GB

6 Mode No. selection

Select the mode No. you want to set with the B [TEMP. ] and C [TEMP. ] buttons. (Only the

settable mode numbers can be selected.)

7 Select the setting contents of the selected mode.

When the D [ FAN] button is pressed, the current setting No. flashes. Use this to check the

currently set contents.

Select the setting No. using the B [TEMP. ] and C [TEMP. ] buttons.

8 The contents set at steps 3 to 7 are registered.

When the A [ON/OFF] button is pressed, the mode No. and setting No. flash and registration

begins. The flashing mode No. and setting No. change to a steady light and setting ends.

* When “ ” flashes at the Mode No. display, communication is probably abnormal.

Make sure there are no noise sources near the transmission line.

-------------------------------------------------------------------------------------------------------------------------------------

9 To select more functions, press the D [ FAN] and repeat steps 3 to 8.

-------------------------------------------------------------------------------------------------------------------------------------

0 End function selection.

Press and hold down the C [TEMP. ] and D [ FAN] buttons at the same time for two seconds

or longer.

After a while, the function selection display disappears and the remote controller returns to the air

conditioner off display.

* Do not operate the air conditioner from the remote controller for 30 seconds after the end of

function selection.

Mode No. display

Mode No. 02 = Thermistor selection

Setting No. display

Setting No. 1 =

Average temperature

reading of the indoor

units in operation

Setting No. 3 =

Built-in sensor on the

remote controller

NOTE: When the functions of an indoor unit were changed by function selection after the end

of installation, always indicate the set contents by entering check marks or other marks

in the appropriate check field of Table 1.

Page 20

– 20 –

GB

Set the functions of each indoor unit from the remote controller, as required.

Refer to the Indoor unit Installation Manual for factory settings, mode No., and the setting No. of the

indoor units.

■ Setting the indoor unit Setting Value

4Press the [TEMP. ] and the [TEMP. ] buttons to set the address of the indoor unit whose

settings to be made. (0 to 50)

5Press the [MODE] button, then press the [TEMP. ] and the [TEMP. ] buttons to set the

Function Setting No. to be set. (000 to 255)

6Press the [MODE] button, then press the [TEMP. ] and the [TEMP. ] buttons to set the

Function Setting Value. to be set (00 to 15)

7Press the [ON/OFF] button to set the settings.

9 Function Selection for CITY MULTI

1 Press the [ON/OFF] button to stop the operation of the air conditioner.

2 Press and hold down the [MODE] and the [ FAN] buttons at the same time for two seconds

or longer to check the current settings.

3 When the response has been received from the indoor unit, the current settings appear. If

there is no response, nothing appears.

Make this setting only when the function settings need to be changed on CITY MULTI.

(This setting cannot be made with M-Series and P-Series Control System. To make settings

for M-Series and P-Series, refer to section .)

8

Function Selection for M-Series and P-Series

NOTE: Be sure to write down any settings that you change performing the following steps.

Air conditioner

stops.

Procedure A

2 sec.

[MODE]

+

[FAN]

Function Setting Value

Function Setting No.

Indoor unit address

Response is received.

Response has been received.

No response

No

response

Waiting for response

Page 21

– 21 –

GB

8If the set settings need to be changed, repeat steps 4 to 7.

To complete the settings, press the [MODE] and the [ FAN] buttons at the same time for two

seconds or longer.

■ Checking the indoor unit Function Setting Value

1Perform the Procedure A on the previous page.

2Press the [TEMP. ] and the [TEMP. ] buttons to set the address of the indoor unit whose

settings to be checked. (0 to 50)

3Press the [MODE] button, then press the [TEMP. ] and the [TEMP. ] buttons to set the

Function Setting No. to be checked. (000 to 255)

4Press the [ FAN] button to display the current Function Setting Value.

2 sec.

[MODE]

+

[FAN]

Response has been received.

[TEMP. ] [TEMP. ]

[MODE]

Indoor unit address setting Function Setting No. setting Function Setting Value setting

The setting for the specified

Function Setting No. has not been

completed.

Setting completed

The specified indoor unit does not

exist.

Waiting for response

Response has been received.

[MODE]

[ON/OFF]

No

response

Page 22

– 22 –

GB

5To check the settings, repeat steps 2 to 4.

To complete the checking process, press the [MODE] and the [ FAN] buttons at the same time

for two seconds or longer.

Retrieve the error history of each unit using the Simple MA controller.

1 Switch to the self-diagnosis mode.

When the A [ON/OFF] button and the C [TEMP. ] button are pressed for 5 seconds or longer,

the figure shown below is displayed.

2 Set the address or refrigerant address No. you want to self-diagnosis.

When the B [TEMP. ] and C [TEMP. ] are pressed, the address decreases and increases

between 01 and 50 or 00 and 15. Set it to the address No. or refrigerant address No. you want to

self-diagnosis.

-------------------------------------------------------------------------------------------------------------------------------------

10 Self diagnosis

Response has been received.

[TEMP. ] [TEMP. ]

Indoor unit address setting

Function Setting No. setting

[MODE]

[FAN]

Current

setting value

No

response

The setting for the specified Function Setting No. has not

been completed.

The specified indoor unit does not exist.

Waiting for response

Response has been received.

Response is

received.

Self-diagnosis address

or self-diagnosis

refrigerant address

Approximately three seconds

after the change operation, the

self-diagnosis refrigerant

address changes from flashing

to a steady light and selfdiagnosis begins.

Page 23

– 23 –

GB

3 Self-diagnosis result display <Error history> (For the contents of the error code, refer to the indoor

unit installation manual or service handbook.)

-------------------------------------------------------------------------------------------------------------------------------------

4 Error history reset

The error history is displayed in 3 self-diagnosis results display.

When the D [ FAN] button is pressed two times successively within three seconds, the selfdiagnosis object address and refrigerant address flash.

When the error history was reset, the display shown below appears.

When error history reset failed, the error contents are displayed again.

-------------------------------------------------------------------------------------------------------------------------------------

5 Self-diagnosis reset

There are the following two ways of resetting self-diagnosis.

Press the A [ON/OFF] button and the C [TEMP. ] button simultaneously for 5 seconds or

longer. → Resets self-diagnosis and returns to the state before self-diagnosis.

Press the A [ON/OFF] button. → Self-diagnosis resets and indoor units stop. (When operation is

prohibited, this operation is ineffective.)

1 First check the power mark.

When normal voltage (DC12V) is not applied to the remote

controller, the power mark goes off.

When the power mark is off, check the remote controller

wiring and the indoor unit.

2 Switch to the remote controller check mode.

When the B [TEMP. ] button and D [ FAN] button are pressed simultaneously for 5 seconds

or longer, the figure shown below is displayed.

When the A [ON/OFF] button is pressed, remote controller check begins.

-------------------------------------------------------------------------------------------------------------------------------------

11 Remote Controller Check

Error code 4 digits or

error code 2 digits

Error detection attribute

Address 3 digits or

unit address No. 2 digits

<When there is no error history> <When opposite side does not exist>

(Alternate

display)

When the air conditioner cannot be controlled from the Simple MA controller, use this function

to check the remote controller.

Power mark

Page 24

– 24 –

GB

3 Remote controller check result

<When remote controller is normal>

<When remote controller is faulty>

-------------------------------------------------------------------------------------------------------------------------------------

4 Remote controller check reset

When the B [TEMP. ] button and D [ FAN] button are pressed simultaneously for 5 seconds

or longer, remote controller diagnosis is reset and the [HO] and run lamp flash and 30 seconds later

the remote controller returns to its state before diagnosis.

Since there is no problem at the remote controller, check for other causes.

(Error display 1) “NG” flashes → Remote controller send/receive circuit abnormal

Remote controller switching is necessary.

When the problem is other than the checked remote controller

(Error display 2) “E3” “6833” “6832” flash → Cannot send

(Error display 3) “ERC” and data error count are displayed → Data error generation

There is noise on the transmission line, or the indoor unit or another remote controller is

faulty. Check the transmission line and the other remote controllers.

“Data error count” is the difference between the number of bits of remote controller send

data and the number of bits actually sent to the transmission line. In this case, the send

data was disturbed by the noise, etc. Check the transmission line.

When data error count is 02

Remote controller send data

Send data on transmission line

HEAD OFFICE: TOKYO BLDG., 2-7-3, MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

Page 25

– 1 –

F

Ce manuel d'installation décrit comment installer le contrôleur à distance simple MA en vue de son utilisation

avec le système de climatisation de bâtiment Mitsubishi, les unités intérieures de climatiseurs CITY MULTI de

type extension directe (type « -A » et ultérieurs), et les climatiseurs autonomes Mitsubishi des séries M et P.

Assurez-vous de lire ce manuel d'installation et le manuel d'instructions fourni avec le contrôleur à distance

avant de procéder à l'installation. Si les fichiers sont illisibles, veuillez contacter votre revendeur.

Pour des informations sur le câblage et l'installation des climatiseurs, reportez-vous au manuel d'installation.

Après l'installation, remettez ce manuel aux utilisateurs.

• Lisez les consignes de sécurité ci-après avant de procéder à l'installation.

• Respectez scrupuleusement ces consignes pour assurer la sécurité.

• Après avoir lu ce manuel, remettez-le à l'utilisateur final pour qu'il puisse le consulter en cas de

besoin.

• Conservez ce manuel pour pouvoir le consulter en cas de besoin. Ce manuel doit être fourni aux

personnes chargées de réparer ou de déplacer la télécommande. Assurez-vous que le manuel est

bien remis à tout futur utilisateur.

AVERTISSEMENT

1 Consignes de sécurité

AVERTISSEMENT

Signale un risque de blessure grave, voire mortelle en cas de

mauvaise utilisation du PAC-YT53CRAU.

ATTENTION

Signale un risque de blessure grave ou de dommage matériel en cas

de mauvaise utilisation du PAC-YT53CRAU.

Précautions générales

Seul un personnel qualifié est autorisé à réaliser les travaux électriques.

N'installez pas l'unité en un endroit où se trouvent de grandes

quantités d'huile, de vapeur, de solvants organiques ou de gaz

corrosifs tels du gaz sulfurique ou encore là où sont

fréquemment utilisés des aérosols ou des solutions acides/

alcalines. Ces substances peuvent affecter les performances

de l'unité ou provoquer la corrosion de certains de ses

composants, ce qui peut donner lieu à des défauts de

fonctionnement, des dégagements de fumée ou même une

électrocution ou un incendie.

Ne lavez pas la télécommande avec de l'eau ou tout autre

liquide afin de prévenir tout risque de court-circuit, de fuite

électrique, d'électrocution, de dysfonctionnement, de fumée

ou d'incendie.

N'utilisez par les commutateurs/touches ou d'autres parties

électriques avec les mains mouillées afin de prévenir tout

risque d'électrocution, de dysfonctionnement, de fumée ou

d'incendie.

Pour éviter tout risque de blessure ou d'électrocution,

éteignez la télécommande et coupez l'alimentation électrique

avant de la nettoyer, de l'examiner, ou avant toute opération

d'entretien de celle-ci.

Pour éviter tout risque de lésion ou d'électrocution, éteignez la

télécommande et couvrez-la avant de pulvériser un

quelconque produit chimique dans l'environnement de celuici.

Pour prévenir tout risque de blessure, tenez les enfants

éloignés pendant l'installation, l'inspection ou la réparation du

contrôleur.

Installez correctement toutes les protections requises pour

protéger la télécommande contre l'humidité et la poussière.

L'accumulation de poussière et d'eau peut provoquer des

électrocutions, de la fumée ou un incendie.

Système de contrôle CITY MULTI

et climatiseurs Mitsubishi séries M et P

Contrôleur à distance simple MA PAC-YT53CRAU

Manuel d’installation

WT06429X01

FR

Pour distribution aux distributeurs et aux sous-traitants

Page 26

– 2 –

F

ATTENTIO N

AVERTISSEMENT

ATTENTIO N

AVERTISSEMENT

ATTENTIO N

Précautions pendant l'installation

Précautions pendant le câblage

Pour prévenir tout risque d'endommager la télécommande, ne

pulvérisez pas d'insecticide ou tout autre aérosol inflammable

directement dessus.

Ne touchez pas l'écran tactile, les commutateurs ou les

touches avec un objet pointu ou tranchant afin de prévenir

tout risque d'électrocution ou de dysfonctionnement.

Évitez le contact avec les bords tranchants de certaines

parties afin de prévenir tout risque de blessure et

d'électrocution.

Pour prévenir tout risque de blessure, portez un équipement

de protection lors de toute intervention sur la télécommande.

Consultez votre revendeur pour en savoir plus sur la mise au

rebut appropriée du contrôleur.

N'installez pas le contrôleur dans un endroit où peut se

produire une fuite de gaz inflammable.

Si du gaz inflammable s'accumule autour de l'unité, il peut

s'enflammer et provoquer un incendie ou une explosion.

Pour prévenir tout risque de court-circuit, de fuite électrique,

d'électrocution, de dysfonctionnement, de fumée ou

d'incendie, n'installez pas le contrôleur en un endroit exposé à

l'eau ou à la condensation.

Le contrôleur doit être installé par du personnel qualifié

conformément aux instructions détaillées dans le Manuel

d'Installation. Une installation incorrecte peut être la cause

d'une électrocution ou d'un incendie.

Installez le boîtier supérieur dans le boîtier inférieur jusqu'à ce

qu'il s'enclenche.

Pour prévenir tout risque de dommage au contrôleur, de

dysfonctionnement, de dégagement de fumée ou d'incendie,

ne branchez pas le câble d'alimentation au bornier des

signaux.

Fixez correctement les câbles en place et laissez assez de

mou aux câbles pour ne pas exercer de contrainte sur les

bornes. Des câbles mal connectés peuvent se casser,

surchauffer, et provoquer de la fumée ou un incendie.

Pour prévenir tout risque de blessure et d'électrocution,

coupez l'alimentation générale avant d'effectuer un travail

électrique.

Tous les travaux électriques doivent être effectués par un

électricien qualifié conformément à la réglementation et aux

normes locales et en suivant les instructions décrites dans le

Manuel d'installation.

Pour réduire le risque d'électrocution, installez un disjoncteur

et un disjoncteur de courant résiduel sur l'alimentation.

Pour réduire le risque d'électrocution, de fumée ou d'incendie,

installez un disjoncteur par contrôleur.

Utilisez des disjoncteurs et des fusibles correctement calibrés

(disjoncteur, commutateur local <commutateur + fusible>,

disjoncteur sans fusible).

Le disjoncteur dont la capacité de disjonction est plus élevée

que la capacité spécifiée peut entraîner une électrocution, des

dysfonctionnements, de la fumée ou un incendie.

Pour prévenir tout risque de fuite électrique, de surchauffe, de

dégagement de fumée ou d'incendie, utilisez des câbles de

section appropriée pour le courant nominal spécifié.

Une mise à la terre appropriée doit être fournie par un

électricien agréé.

Ne connectez pas le fil de terre à une conduite de gaz ou

d'eau, un paratonnerre ou une ligne téléphonique.

Une mise à la terre inappropriée peut entraîner une

électrocution, de la fumée, un incendie ou un

dysfonctionnement résultant d'une interférence électrique.

Pour réduire les risques d'électrocution, de court-circuit ou de

dysfonctionnement, retirez toutes les chutes de fil et de gaine

du bornier.

Pour prévenir tout risque de court-circuit, de fuite électrique,

d'électrocution ou de dysfonctionnement, ne laissez pas les

câbles entrer en contact avec les bords vifs du contrôleur.

Pour prévenir tout risque d'électrocution, de

dysfonctionnement ou d'incendie, comblez l'espace entre les

câbles et les trous d'accès des câbles avec du mastic.

Page 27

– 3 –

F

AVERTISSEMENT

ATTENTIO NN

Précautions pour le déplacement ou la réparation la télécommande

Précautions supplémentaires

Seul un personnel qualifié doit être autorisé à réparer la

télécommande ou à la changer de place.

N'essayez pas de démonter ou de modifier vous-même la

télécommande.

Une installation ou une réparation non conforme peut

entraîner des blessures, une électrocution ou un incendie.

Pour réduire les risques d’électrocution, de court-circuit ou de

dysfonctionnement, retirez toutes les chutes de fil et de gaine

du bornier.

Pour prévenir tout dommage à l'unité, utilisez des outils

appropriés pour son installation, son inspection ou sa

réparation.

Ce contrôleur est exclusivement destiné à être utilisé avec le

Système de gestion d'immeuble de Mitsubishi Electric.

L'utilisation de ce contrôleur avec d'autres systèmes ou à

d'autres fins peut entraîner des dysfonctionnements.

N'utilisez pas de benzène, de diluant ou d'abrasif chimique

pour nettoyer le contrôleur, afin d'éviter de le décolorer.

Pour nettoyer le contrôleur, essuyez-le avec un chiffon doux

imbibé d'un mélange d'eau et d'un détergent doux, rincez les

restes de détergent avec un chiffon humide, puis essuyez

l'eau avec un chiffon sec.

Protégez le contrôleur contre l'électricité statique pour éviter

de l'endommager.

Prenez des dispositions appropriées contre les interférences

électromagnétiques lorsque les climatiseurs sont installés

dans des hôpitaux ou à proximité d'équipements de

radiocommunication.

Les onduleurs ainsi que les équipements médicaux à haute

fréquence ou de communication sans fil et les générateurs

d'énergie peuvent être la cause de dysfonctionnements du

système de climatisation. Le système de climatisation peut

également affecter le bon fonctionnement de ces types

d'équipement en créant du bruit électrique.

Pour prévenir tout dysfonctionnement, n'attachez pas les

câbles d'alimentation et de signaux ensemble et faites-les

passer dans des chemins de câbles différents.

Laissez la carte de circuit et son emballage protecteur sur le

boîtier.

Ne serrez pas trop les vis pour éviter d'endommager le

contrôleur.

Utilisez un tournevis à tête plate avec une lame de 5 mm

(7/32 pouce).

Ne tournez pas fermement le tournevis à tête plate dans le

loquet.

Pour prévenir toute déformation et dysfonctionnement,

n'installez par le contrôleur à distance en un endroit

directement exposé au soleil ou là où la température peut

dépasser 40 °C (104 °F) ou chuter au-dessous de 0 °C

(32 °F).

N'installez pas le contrôleur sur la porte du panneau de

commande.

Des vibrations ou des chocs subis par le contrôleur pourraient

l'endommager ou le faire tomber.

Fixez le câble avec un serre-fils.

N'utilisez pas de bornes à sertir pour raccorder les câbles au

bornier.

Ce type de borne risque d'entrer en contact avec le circuit

imprimé et de provoquer des dysfonctionnements, voire

même d'endommager le cache du contrôleur.

Une fois le connecteur branché, installez le boîtier supérieur

correctement.

Page 28

– 4 –

F

Les pièces suivantes sont incluses dans le coffret.

(1) Pièces à fournir sur le site

Les pièces suivantes sont des pièces à fournir sur le site.

(2) Outils à fournir sur site

• Tournevis à tête plate (Largeur : 3-5 mm (1/8-7/32 pouce))

• Couteau ou pince

• Outillage divers

2 Nomenclature des composants et pièces fournies

*3 Filet métrique ISO

*4 Le câble du contrôleur à distance n'est pas inclus.

3 Pièces à fournir sur le site/Outils nécessaires

Nomenclature Qté Remarques

Boîtier de connexion simple 1 Non nécessaire pour installation directe sur le mur

Conduit métallique à paroi mince Nécessaire

Écrou de blocage et presse-étoupe Nécessaire

Chemin de câble Nécessaire Nécessaire pour faire passer le câble du contrôleur à

distance le long d'un mur

Mastic Raisonnable

Boulon d'ancrage à gaine d'expansion Nécessaire

Câble du contrôleur à distance

(Utilisez un câble gainé à deux âmes

de 0,3 mm² (AWG22).)

Nécessaire Si vous devez utiliser une rallonge de plus de 10 m (32

ft), sélectionnez un câble électrique correspondant aux

spécifications suivantes :

Spécification du câble VCTF ou CVV (2 fils) :

1,25 mm² (torsadé 16 AWG) ou équivalent

Nomenclature Qté Apparence

Contrôleur à distance (

Boîtier supérieur

)1

Figure de droite

*1

Contrôleur à distance (

Boîtier inférieur

)1

Figure de droite

*2

Vis à tête ronde fente en croix M4×30 2 *3

Vis à bois 4,1×16

(pour montage direct sur le mur)

2*3

Manuel d’installation

(le présent document)

1

Manuel d'utilisation 1

Boîtier inférieur

*2

Boîtier supérieur

*1

h

16 (5/8) 16 (5/8)

25 (1)

25 (1)

102 (4)

54 (2-1/8)

20

(13/16)

10

(3/8)

44 (1-3/4)

83,5±0,4 (3-3/8±1/32)

ø6 (1/4OD)

20 (13/16)

6

(1/4)

ø6 (1/4OD)

20 (13/16)

1,5 (1/16) ou moins

Boîtier de connexion

Unité de mesure : mm (po)

Page 29

– 5 –

F

Le raccordement est différent lorsque le contrôleur à distance est connecté à un système de contrôle

CITY MULTI (de type « –A » et versions ultérieures) et lorsqu’il est connecté à un climatiseur des

séries M et P (de type de contrôle A).

Le raccordement dépend aussi de la configuration du système. Vérifiez le système utilisé.

1. Connectez le système de contrôle CITY MULTI

Les nombres (1) à (4) de l’illustration correspondent aux opérations (1) à (4) dans la description

suivante.

(1) Raccordement depuis le contrôleur à distance

• Connectez le câble au bloc de sorties du contrôleur à distance MA (TB15) situé sur l’appareil

intérieur.

• Le bloc de sorties n’a pas de polarité. Continuer jusqu’au bloc de sorties situé sur la partie

inférieure arrière du contrôleur à distance.

(2) Fonctionnement en groupe (Groupes 03 et 04 ci-dessus)

• Interconnectez le groupe de sorties (TB15) du contrôleur à distance MA des appareils intérieurs

que vous désirez combiner, et connectez le contrôleur à distance MA à cet endroit.

• Lorsque le contrôleur à distance est utilisé en association avec le contrôleur de système comme

illustré ci-dessus, il est nécessaire de régler le groupe sur le contrôleur du système (un contrôleur

central dans le schéma ci-dessus).

(3) Nombre de contrôleurs à distance pouvant être connectés (Groupes 02 et 04)

• Un contrôleur à distance principal et un contrôleur à distance secondaire, donc deux au total,

peuvent être connectés à un groupe d’appareils intérieurs.

REMARQUE : Lors de l'utilisation d'un contrôleur à distance simple MA avec d'autres contrôleurs

à distance MA, veillez à respecter les règles de compatibilité suivantes.

4 Comment brancher la ligne de transmission

Connectez le câble

au TB15 situé sur

l’appareil intérieur.

a Appareil extérieur

b Appareil intérieur

c Appareil LOSSNAY ou OA

d Contrôleur à distance

principale

e Contrôleur à distance

secondaire

f Contrôleur central

g Unité d’alimentation

électrique pour la ligne de

transmission

Fonction de l'unité intérieure Contrôleur à

distance principal

Contrôleur à

distance secondaire

Compatibilité

Modèles applicables pour

les modes AUTO (deux

points de réglage) et

INVERSION

Ce contrôleur à

distance simple

MA

Ce contrôleur à

distance simple MA

Compatibles. Les modes AUTO (deux

points de réglage) et INVERSION

peuvent être utilisés en fonction des

unités intérieures à connecter.

Autres contrôleurs

à distance MA

Ce contrôleur à

distance simple MA

Compatibles, mais les modes AUTO

(deux points de réglage) et

INVERSION ne sont pas utilisables.

Ce contrôleur à

distance simple

MA

Autres contrôleurs à

distance MA

Incompatibles

Modèles non applicables

pour les modes AUTO (deux

points de réglage) et

INVERSION

Combinaison de tous les contrôleurs à

distance ci-dessus

Compatibles

TB5 TB15

TB5 TB15

bb

TB5 TB15

c

TB5 TB15

b

TB5 TB15

b

TB5 TB15

b

TB5 TB15

b

TB7 TB3

TB5 TB15

TB5 TB15

TB7 TB3

(1)

(1)

(3)

(3)

(1)

(3)

(3)

(2)

(2)

(2)

(4)

(1)

(1)

a

a

dde d

ed

bb

g

f

Adresse = 51

Adresse = 01 Adresse = 02

Adresse = 55

Adresse = 08

Adresse = 07

Adresse = 03

Adresse = 04 Adresse = 09

Adresse = 06

Adresse = 05

Groupe 01 Groupe 02 Groupe 03

Groupe 04

Page 30

– 6 –

F

(4) Pour interverrouiller un appareil LOSSNAY ou OA, effectuez les réglages suivants en utilisant le

contrôleur à distance. (Pour l’interverrouillage, reportez-vous à la section .)

Réglez l’adresse de l’appareil LOSSNAY ou OA et celle de tous les autres appareils intérieurs

que vous voulez interverrouiller.

(5) Longueur maximum du câble du contrôleur à distance

• Le contrôleur à distance simple MA peut être installé à 200 m (656 ft) de l’appareil. Procurez-vous

des câbles à deux âmes de 0,75 à 1,25 mm

² (torsadé 16 à 28 AWG) pour l’installation.

2. Connexion à un climatiseur des séries M et P

Le raccordement du contrôleur à distance dépend de la configuration du système. Vérifiez cette

configuration et raccordez le contrôleur à distance comme indiqué dans l’exemple ci-dessous.

Les numéros (1) à (3) du schéma correspondent aux opérations (1) à (3) de la description suivante.

[1]

Connexion du contrôleur à distance pour chaque système réfrigérant (Standard 1:1, deux appareils

simultanés, trois appareils simultanés, quatre appareils simultanés, deux appareils individuels)

[2] Pour le groupement des appareils par système réfrigérant

* Réglez l’adresse du réfrigérant en utilisant les commutateurs dip de l’appareil extérieur (pour plus

d’informations, reportez-vous au manuel d’installation de l’appareil extérieur).

* Tous les appareils intérieurs repris entre sont contrôlés comme un seul groupe.

(1) Raccordement depuis le contrôleur à distance

• Connectez le câble au bloc de sorties du contrôleur à distance (TB5) situé sur l’appareil intérieur

(le bloc de sorties n’a pas de polarité).

• Pour les appareils de type multi simultané, si vous mélangez plusieurs types d’appareils

intérieurs, connectez toujours le contrôleur à distance à l’appareil intérieur qui possède le plus de

fonctions (vitesse de la soufflerie, pale, ailette, etc.).

(2) Pour le groupement avec différents systèmes réfrigérants

• Les groupes qui utilisent le raccordement par contrôleur à distance. Connectez le contrôleur à

distance à un appareil intérieur arbitraire pour chaque système réfrigérant que vous voulez

introduire dans le groupe.

• Si vous utilisez plusieurs types d’appareil intérieur dans un même groupe, considérez toujours la

connexion de l’appareil extérieur à l’appareil intérieur qui possède le plus de fonctions (vitesse de

soufflerie, pale, ailette, etc.) comme connexion principale (adresse du réfrigérant = 00). De

même, si l’appareil principal est de type multi simultané, respectez toujours les conditions

énumérées en (1) ci-dessus.

• Le contrôleur à distance simple MA peut contrôler jusqu’à 16 systèmes réfrigérants dans un seul groupe.

ATTENTION

Les contrôleurs à distance ne peuvent pas être raccordés

ensemble. Un seul câble peut être connecté au bloc de sorties

du contrôleur à distance.

Connectez le câble

au TB5 situé sur

l’appareil intérieur.

a Appareil extérieur

b Appareil intérieur

d Contrôleur à distance

principale

(

Contrôleur à distance

simple MA

)

e Contrôleur à distance

secondaire

(

Contrôleur à distance

simple MA

)

7 Réglage du ventilateur

ed

REMARQUE : Lors du verrouillage du contrôleur à distance MA avec l’appareil LOSSNAY ou OA, veuillez

toujours régler l’adresse de tous les appareils intérieurs du groupe et l’adresse de l’appareil

LOSSNAY ou OA.

(1)

(3)

TB5

TB4

TB1

TB4

(3)

(3)

(1)

TB4

TB4

TB5

TB1

TB4

TB5

TB1

TB1

TB4

TB5

(1)

(1)

(3)

(3)

(3)

a

bb

d

a

bb

de

a

bb

dde

Adresse du

réfrigérant = 00

Adresse du

réfrigérant = 00

Adresse du

réfrigérant = 00

Adresse du

réfrigérant = 00

Deux appareils simultanés Deux appareils simultanés Deux appareils individuels

TB4

TB4

TB4

TB4TB4

TB4

TB4TB4

TB1 TB1 TB1

TB1TB1

TB5

TB5

TB5

TB5

TB5

(2)

(1)

(3)

(3)

(1)

(2) (2)

(2)

aa a a

bbbbbbbb

de

Standard 1:1 Deux appareils simultanés

Trois appareils simultanés

Deux appareils individuels

Adresse du

réfrigérant = 01

(Secondaire)

Adresse du

réfrigérant = 03

(Secondaire)

Adresse du

réfrigérant = 04

(Secondaire)

Adresse du

réfrigérant = 00

(Principal)

Adresse du

réfrigérant = 02

(Secondaire)

Page 31

– 7 –

F

(3) Il est possible de connecter jusqu’à deux contrôleurs à distance à un seul groupe

• Lorsque deux contrôleurs à distance sont connectés à un seul groupe, définissez toujours un

contrôleur à distance principal et un contrôleur à distance secondaire.