Page 1

Page 2

Page 3

MELDAS is a registered trademark of Mitsubishi Electric Corporation.

Other company and product names that appear in this manual are trademarks or

registered trademarks of their respective companies.

Page 4

Page 5

Introduction

Thank you for selecting the Mitsubishi numerical control unit.

This instruction manual describes the handling and caution points for using this AC

servo/spindle.

Incorrect handling may lead to unforeseen accidents, so always read this instruction

manual thoroughly to ensure correct usage.

Make sure that this instruction manual is delivered to the end user.

Always store this manual in a safe place.

In order to confirm if all function specifications described in this manual are applicable,

refer to the specifications for each CNC.

Notes on Reading This Manual

(1) Since the description of this specification manual deals with NC in general, for the

specifications of individual machine tools, refer to the manuals issued by the

respective machine manufacturers. The "restrictions" and "available functions"

described in the manuals issued by the machine manufacturers have precedence

to those in this manual.

(2) This manual describes as many special operations as possible, but it should be

kept in mind that items not mentioned in this manual cannot be performed.

Page 6

Page 7

Precautions for safety

Please read this manual and auxiliary documents before starting installation, operation,

maintenance or inspection to ensure correct usage. Thoroughly understand the device, safety

information and precautions before starting operation.

The safety precautions in this instruction manual are ranked as "WARNING" and "CAUTION".

Note that some items described as

the situation. In any case, important information that must be observed is described.

The signs indicating prohibited and mandatory matters are explained below.

DANGER

WARNING

CAUTION

When there is a potential risk of fatal or serious injuries if

handling is mistaken.

When a dangerous situation, or fatal or serious injuries may

occur if handling is mistaken.

When a dangerous situation may occur if handling is mistaken

leading to medium or minor injuries, or physical damage.

CAUTION

may lead to major results depending on

Indicates a prohibited matter. For example, "Fire Prohibited"

is indicated as .

Indicates a mandatory matter. For example, grounding is

indicated as

.

After reading this specifications and instructions manual, store it where the user can access it

easily for reference.

The numeric control unit is configured of the control unit, operation board, servo drive unit,

spindle drive unit, power supply, servomotor and spindle motor, etc.

In this section "Precautions for safety", the following items are generically called the "motor".

• Servomotor

• Linear servomotor

• Spindle motor

In this section "Precautions for safety", the following items are generically called the "unit".

• Servo drive unit

• Spindle drive unit

• Power supply unit

• Scale interface unit

• Magnetic pole detection unit

POINT

Important matters that should be understood for operation of this machine

are indicated as a POINT in this manual.

Page 8

1. Electric shock prevention

Do not open the front cover while the power is ON or during operation. Failure to observe this

could lead to electric shocks.

Do not operate the unit with the front cover removed. The high voltage terminals and charged

sections will be exposed, and can cause electric shocks.

Do not remove the front cover and connector even when the power is OFF unless carrying

out wiring work or periodic inspections. The inside of the units is charged, and can cause

electric shocks.

Since the high voltage is supplied to the main circuit connector while the power is ON or

during operation, do not touch the main circuit connector with an adjustment screwdriver or

the pen tip. Failure to observe this could lead to electric shocks.

Wait at least 15 minutes after turning the power OFF, confirm that the CHARGE lamp has

gone out, and check the voltage between P and N terminals with a tester, etc., before starting

wiring, maintenance or inspections. Failure to observe this could lead to electric shocks.

Ground the unit and motor following the standards set forth by each country.

Wiring, maintenance and inspection work must be done by a qualified technician.

Wire the servo drive unit and servomotor after installation. Failure to observe this could lead to

electric shocks.

Do not touch the switches with wet hands. Failure to observe this could lead to electric shocks.

Do not damage, apply forcible stress, place heavy items on the cables or get them caught.

Failure to observe this could lead to electric shocks.

WARNING

2. Injury prevention

The linear servomotor uses a powerful magnet on the secondary side, and could adversely

affect pacemakers, etc.

During installation and operation of the machine, do not place portable items that could

malfunction or fail due to the influence of the linear servomotor's magnetic force.

Take special care not to pinch fingers, etc., when installing (and unpacking) the linear

servomotor.

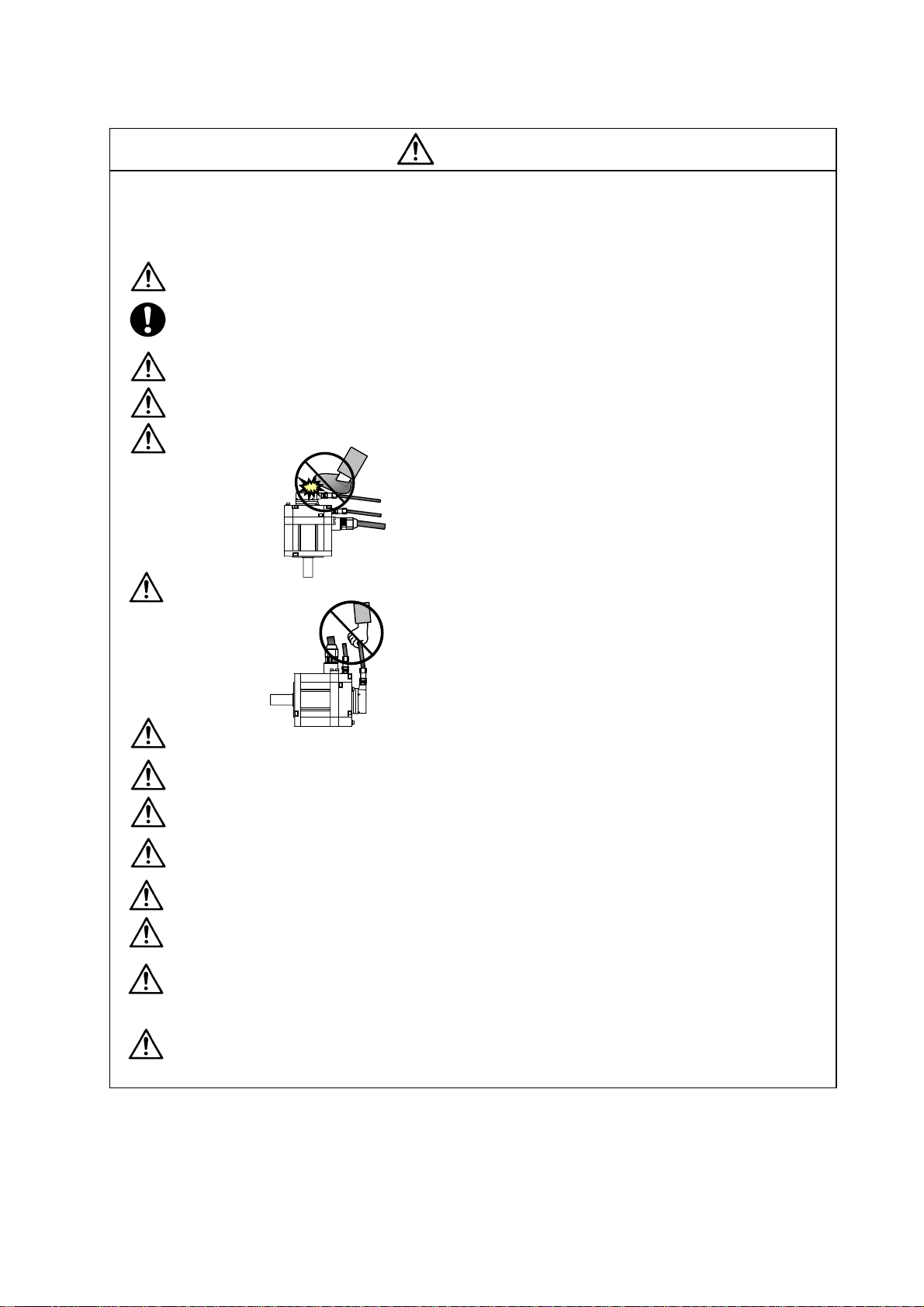

In the system where the optical communication with CNC is executed, do not see directly the

light generated from CN1A/CN1B connector of drive unit or the end of cable. When the light

gets into eye, you may feel something is wrong for eye.

(The light source of optical communication corresponds to class1 defined in JISC6802 or

IEC60825-1.)

Page 9

1. Fire prevention

Install the units, motors and regenerative resistor on non-combustible material. Direct

installation on combustible material or near combustible materials could lead to fires.

Always install a circuit protector and contactor on the servo drive unit power input as explained

in this manual. Refer to this manual and select the correct circuit protector and contactor. An

incorrect selection could result in fire.

Shut off the power on the unit side if a fault occurs in the units. Fires could be caused if a large

current continues to flow.

When using a regenerative resistor, provide a sequence that shuts off the power with the

regenerative resistor's error signal. The regenerative resistor could abnormally overheat and

cause a fire due to a fault in the regenerative transistor, etc.

The battery unit could heat up, ignite or rupture if submerged in water, or if the poles are

incorrectly wired.

Cut off the main circuit power with the contactor when an alarm or emergency stop occurs.

2. Injury prevention

Do not apply a voltage other than that specified in this manual, on each terminal. Failure to

observe this item could lead to ruptures or damage, etc.

CAUTION

Do not mistake the terminal connections. Failure to observe this item could lead to ruptures or

damage, etc.

Do not mistake the polarity (

damage, etc.

Do not touch the radiation fin on unit back face, regenerative resistor or motor, etc., or place

parts (cables, etc.) while the power is turned ON or immediately after turning the power OFF.

These parts may reach high temperatures, and can cause burns or part damage.

Structure the cooling fan on the unit back face, etc., etc so that it cannot be touched after

installation. Touching the cooling fan during operation could lead to injuries.

+

,

). Failure to observe this item could lead to ruptures or

Page 10

CAUTION

3. Various precautions

Observe the following precautions. Incorrect handling of the unit could lead to faults, injuries and

electric shocks, etc.

(1) Transportation and installation

Correctly transport the product according to its weight.

Use the motor's hanging bolts only when transporting the motor. Do not transport the

machine when the motor is installed on the machine.

Do not stack the products above the tolerable number.

Follow this manual and install the unit or motor in a place where the weight can be borne.

Do not get on top of or place heavy objects on the unit.

Do not hold the cables, axis or detector when transporting the motor.

Do not hold the connected wires or cables when transporting the units.

Do not hold the front cover when transporting the unit. The unit could drop.

Always observe the installation directions of the units or motors.

Secure the specified distance between the units and control panel, or between the servo drive

unit and other devices.

Do not install or run a unit or motor that is damaged or missing parts.

Do not block the intake or exhaust ports of the motor provided with a cooling fan.

Do not let foreign objects enter the units or motors. In particular, if conductive objects such as

screws or metal chips, etc., or combustible materials such as oil enter, rupture or breakage

could occur.

The units and motors are precision devices, so do not drop them or apply strong impacts to

them.

Page 11

CAUTION

Store and use the units under the following environment conditions.

Environment

Ambient

temperature

Ambient

humidity

Atmosphere

Altitude

Vibration/impact

(Note 1) For details, confirm each unit or motor specifications in addition.

(Note 2) -15°C to 55°C for linear servomotor.

Operation: 0 to 55°C (with no freezing),

Storage / Transportation: -15°C to 70°C

Operation: 90%RH or less

(with no dew condensation)

Storage / Transportation: 90%RH or less

(with no dew condensation)

With no corrosive gas, inflammable gas, oil mist, dust or conductive fine particles

Operation/Storage: 1000 meters or less above

Transportation: 13000 meters or less above sea

Unit Motor

(with no freezing)

sea level,

level

According to each unit or motor specification

Operation: 0 to 40°C (with no freezing),

Storage: -15°C to 70°C

Operation: 80%RH or less

(with no dew condensation),

Storage: 90%RH or less

(with no dew condensation)

Indoors (no direct sunlight)

Operation: 1000 meters or less above sea level,

Storage: 10000 meters or less above sea level

(Note 2)

(with no freezing)

Securely fix the servomotor to the machine. Insufficient fixing could lead to the servomotor

slipping off during operation.

Always install the servomotor with reduction gear in the designated direction. Failure to do so

could lead to oil leaks.

Structure the rotary sections of the motor so that it can never be touched during operation.

Install a cover, etc., on the shaft.

When installing a coupling to a servomotor shaft end, do not apply an impact by hammering,

etc. The detector could be damaged.

Do not apply a load exceeding the tolerable load onto the servomotor shaft. The shaft could

break.

Store the motor in the package box.

When inserting the shaft into the built-in IPM motor, do not heat the rotor higher than 130°C.

The magnet could be demagnetized, and the specifications characteristics will not be

ensured.

Always use a nonmagnetic tool (explosion-proof beryllium copper alloy safety tool: NGK

Insulators, etc.) when installing the linear servomotor.

Always provide a mechanical stopper on the end of the linear servomotor's travel path.

If the unit has been stored for a long time, always check the operation before starting actual

operation. Please con t a ct t h e S e rv i c e C e n t er , S e rv i c e St a t i o n , S al e s O f f i c e o r d el a y e r.

Page 12

(2) Wiring

CAUTION

Correctly and securely perform the wiring. Failure to do so could lead to abnormal operation of

the motor.

Do not install a condensing capacitor, surge absorber or radio noise filter on the output side of

the drive unit.

Correctly connect the output side of the drive unit (terminals U, V, W). Failure to do so could

lead to abnormal operation of the motor.

When using a power regenerative power supply unit, always install an AC reactor for each

power supply unit.

In the main circuit power supply side of the unit, always install an appropriate circuit protector

or contactor for each unit. Circui t protector or contactor cannot be shared by several units.

Always connect the motor to the drive unit's output terminals (U, V, W).

Do not directly connect a commercial power supply to the servomotor. Failure to observe this

could result in a fault.

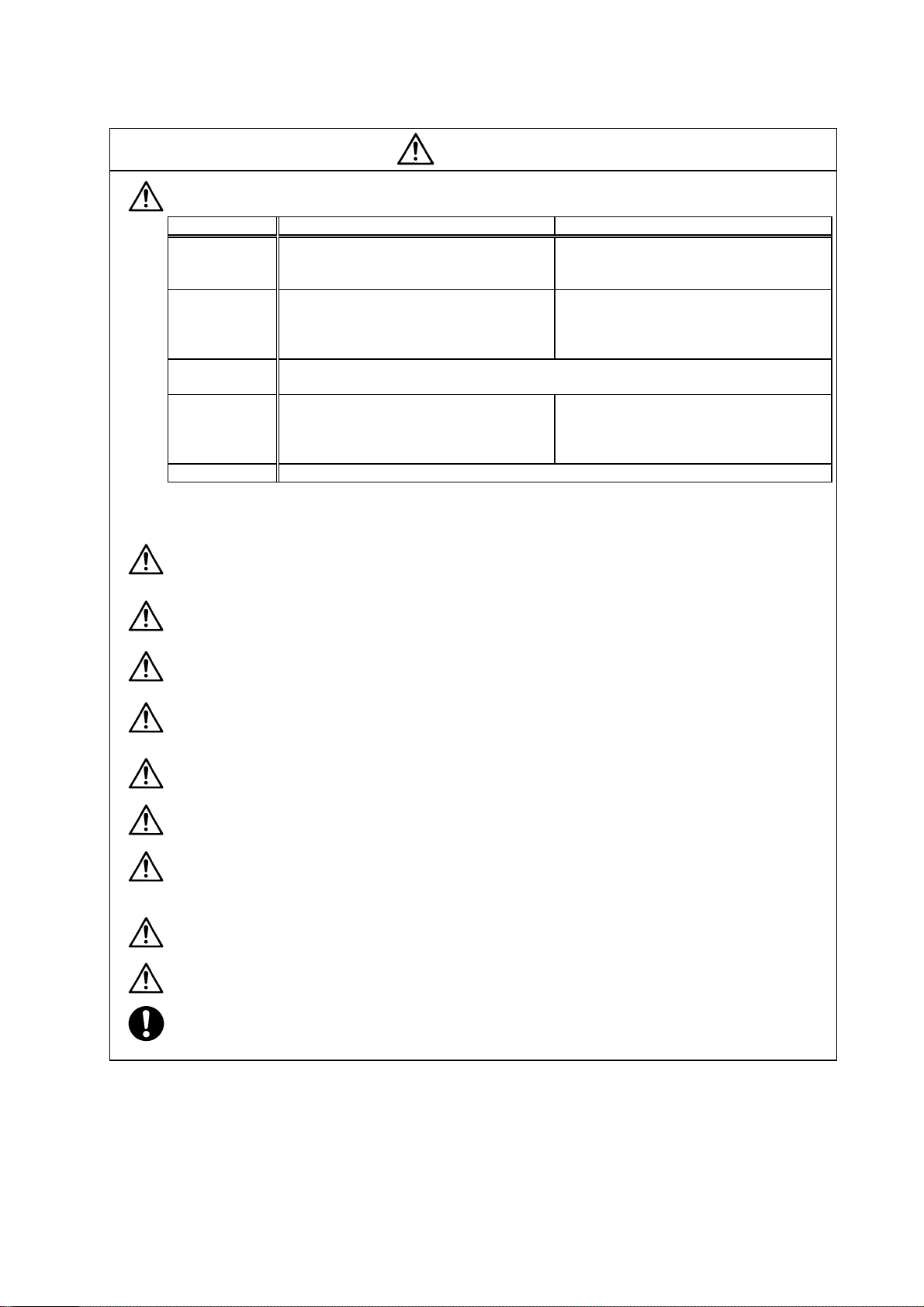

When using an inductive load such as a relay, always connect a diode as a noise measure

parallel to the load.

When using a capacitance load such as a lamp, always connect a protective resistor as a noise

measure serial to the load.

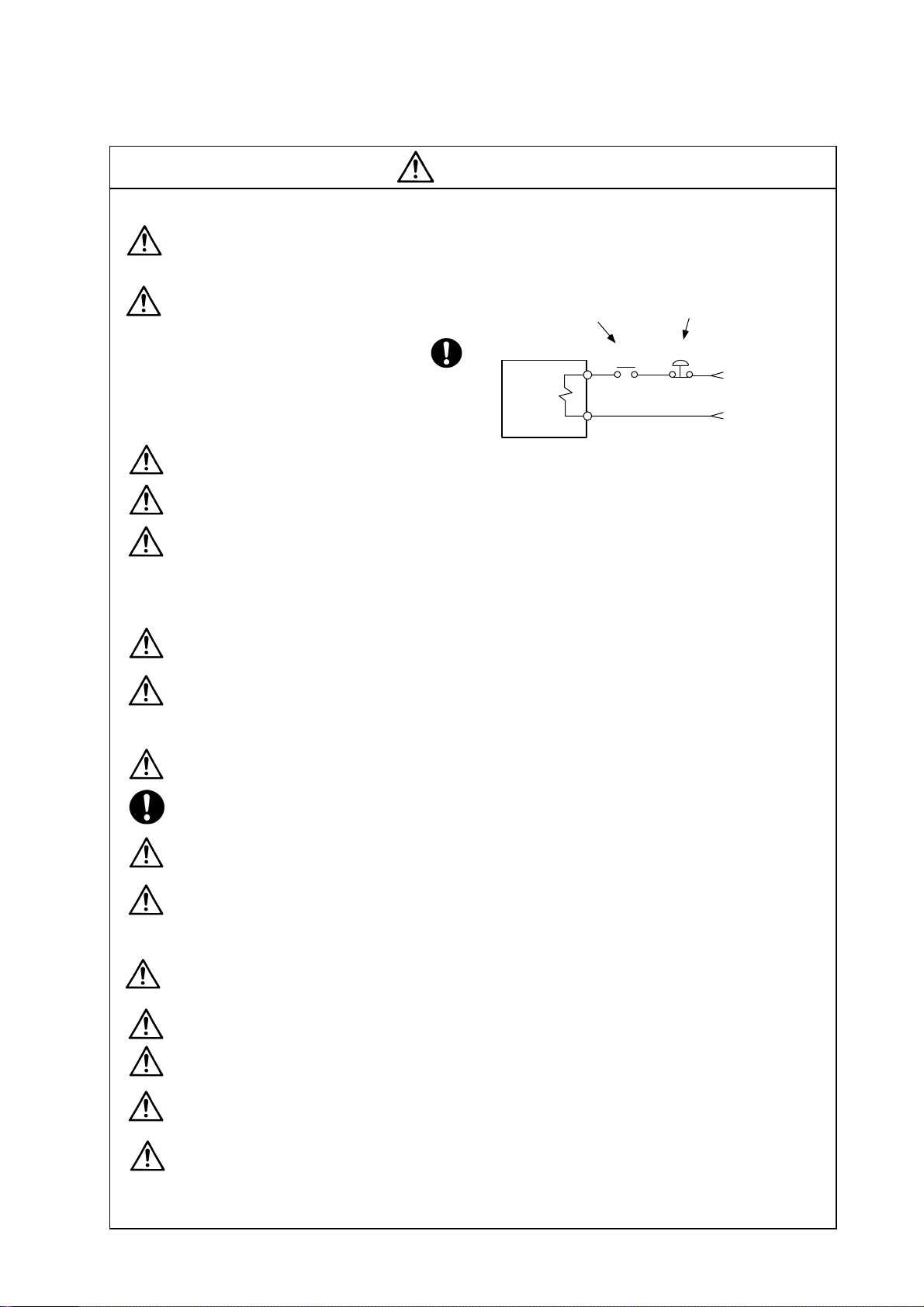

Do not reverse the direction of a diode

which connect to a DC relay for the

control output signals such as

Servodrive unit

COM

(24VDC)

Servodrive unit

COM

(24VDC)

contractor and motor brake output, etc.

to suppress a surge. Connecting it

backwards could cause the drive unit to

malfunction so that signals are not

Control output

signal

RA

Control output

signal

output, and emergency stop and other

safety circuits are inoperable.

RA

Do not connect/disconnect the cables connected between the units while the power is ON.

Securely tighten the cable connector fixing screw or fixing mechanism. An insecure fixing could

cause the cable to fall off while the power is ON.

When using a shielded cable instructed in the instruction manual, always ground the cable with

a cable clamp, etc.

Always separate the signals wires from the drive wire and power line.

Use wires and cables that have a wire diameter, heat resistance and flexibility that conforms to

the system.

Page 13

(3) Trial operation and adjustment

Check and adjust each program and parameter before starting operation. Failure to do so could

lead to unforeseen operation of the machine.

Do not make remarkable adjustments and changes of parameter as the operation could

become unstable.

The usable motor and unit combination is predetermined. Always check the models before

starting trial operation.

If the axis is unbalanced due to gravity, etc., balance the axis using a counterbalance, etc.

The linear servomotor does not have a stopping device such as magnetic brakes. Install a

stopping device on the machine side.

(4) Usage methods

In abnormal state, install an external emergency stop circuit so that the operation can be

stopped and power shut off immediately.

Turn the power OFF immediately if smoke, abnormal noise or odors are generated from the unit

or motor.

CAUTION

Do not disassemble or repair this product.

Never make modifications.

When an alarm occurs, the machine will start suddenly if an alarm reset (RST) is carried out

while an operation start signal (ST) is being input. Always confirm that the operation signal is

OFF before carrying out an alarm reset. Failure to do so could lead to accidents or injuries.

Reduce magnetic damage by installing a noise filter. The electronic devices used near the

unit could be affected by magnetic noise. Install a line noise filter, etc., if there is a risk of

magnetic noise.

Use the unit, motor and regenerative resistor with the designated combination. Failure to do so

could lead to fires or trouble.

The brake (magnetic brake) of the servomotor are for holding, and must not be used for normal

braking.

There may be cases when holding is not possible due to the magnetic brake's life, the machine

construction (when ball screw and servomotor are coupled via a timing belt, etc.) or the

magnetic brake’s failure. Install a stop device to ensure safety on the machine side.

After changing the programs/parameters or after maintenance and inspection, always test the

operation before starting actual operation.

Do not enter the movable range of the machine during automatic operation. Never place body

parts near or touch the spindle during rotation.

Follow the power supply specification conditions given in each specification for the power (input

voltage, input frequency, tolerable sudden power failure time, etc.).

Set all bits to "0" if they are indicated as not used or empty in the explanation on the bits.

Do not use the dynamic brakes except during the emergency stop. Continued use of the

dynamic brakes could result in brake damage.

If a circuit protector for the main circuit power supply is shared by several units, the circuit

protector may not activate when a short-circuit fault occurs in a small capacity unit. This is

dangerous, so never share the circuit protector.

Page 14

(5) Troubleshooting

If a hazardous situation is predicted during power failure or product trouble, use a servomotor

with magnetic brakes or install an external brake mechanism.

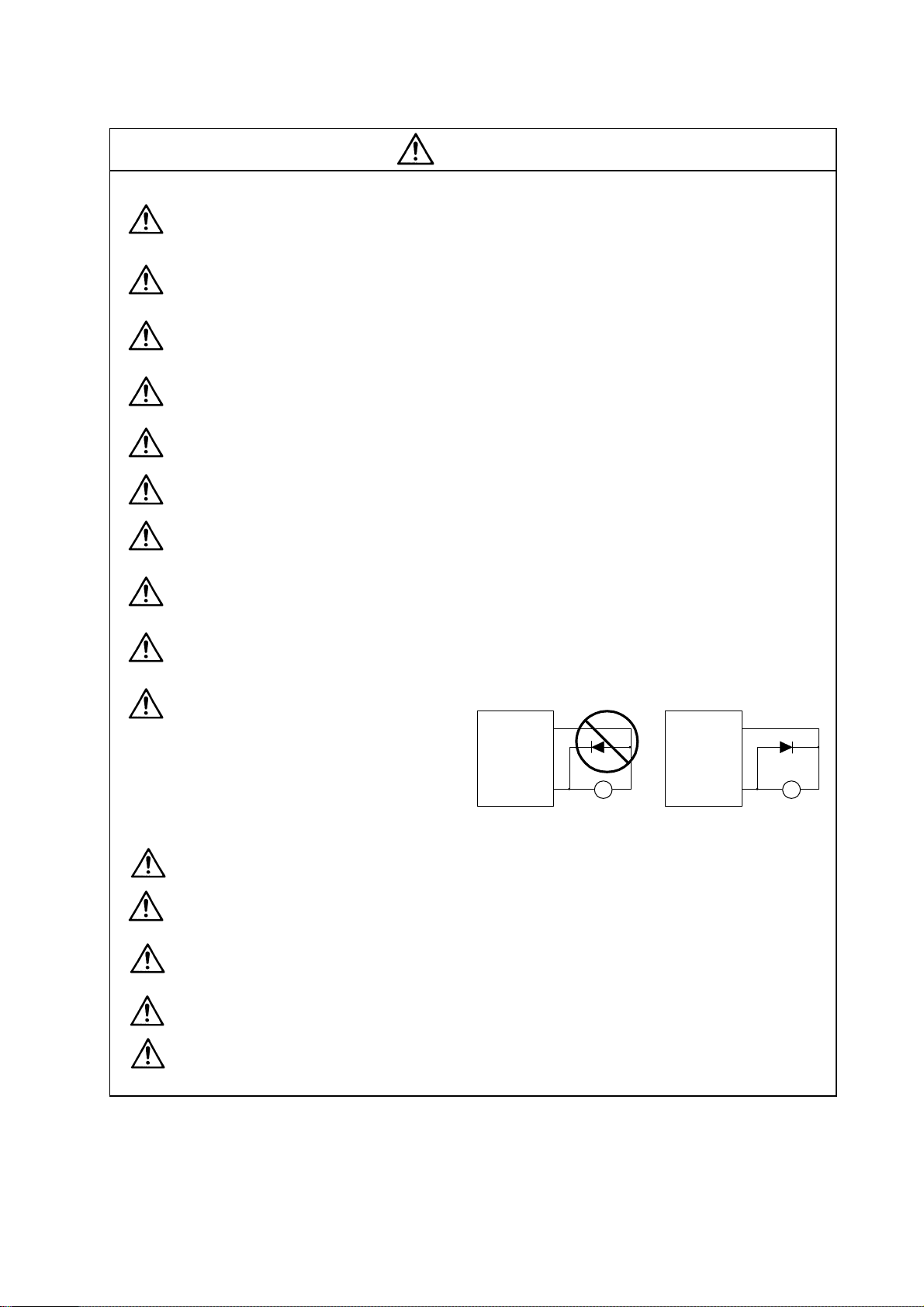

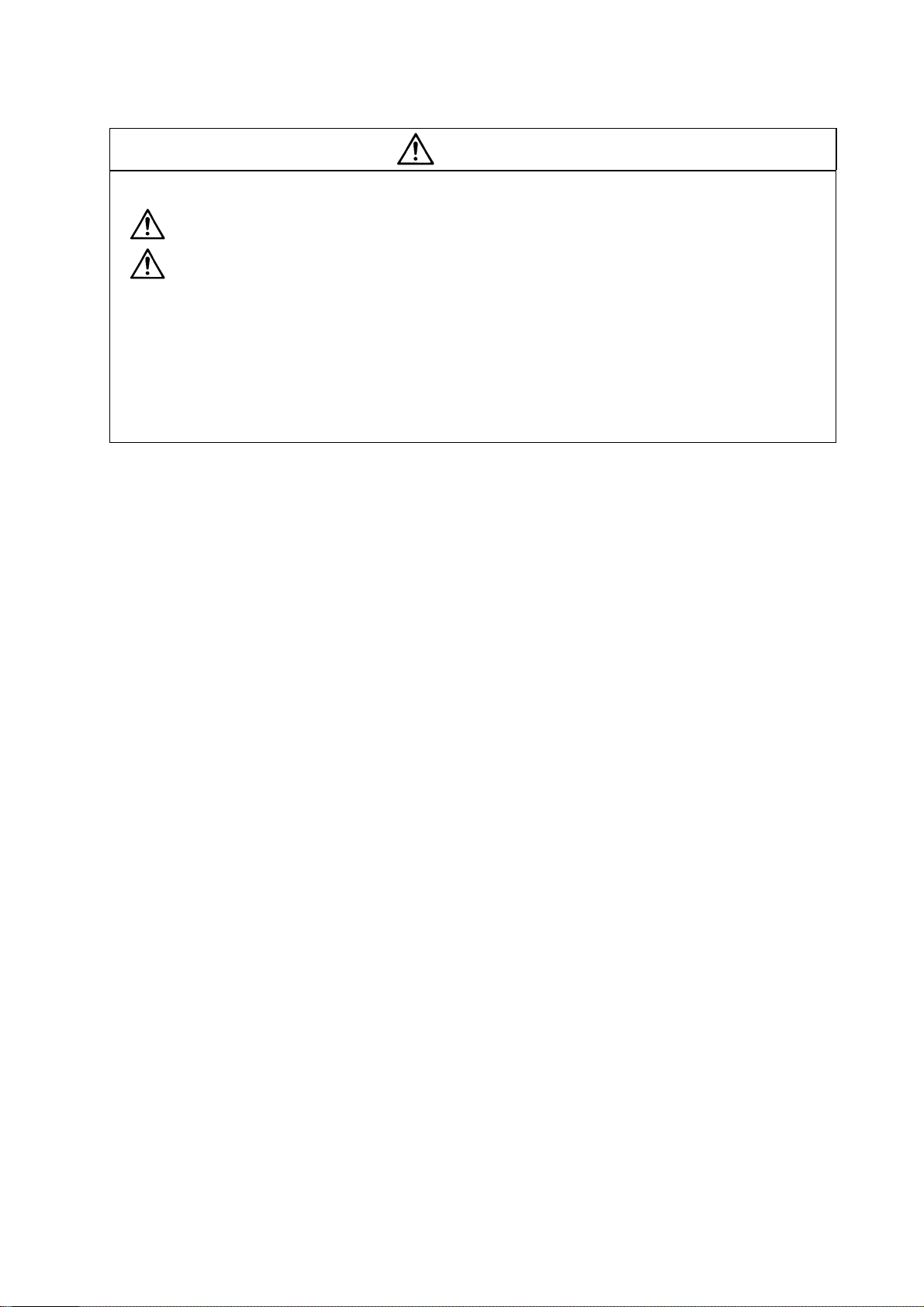

Use a double circuit configuration

that allows the operation circuit for

the magnetic brakes to be operated

even by the external emergency

stop signal.

CAUTION

Shut off with the servomotor

brake control output.

Servomotor

Magnetic

brake

Shut off with NC brake

control PLC output.

MBR

EMG

24VDC

Always turn the input power OFF when an alarm occurs.

If an alarm occurs, remove the cause, and secure the safety before resetting the alarm.

Never go near the machine after restoring the power after a power failure, as the machine

could start suddenly. (Design the machine so that personal safety can be ensured even if the

machine starts suddenly.)

(6) Maintenance, inspection and part replacement

Always backup the programs and parameters before starting maintenance or inspections.

The capacity of the electrolytic capacitor will drop over time due to self-discharging, etc. To

prevent secondary disasters due to failures, replacing this part every five years when used

under a normal environment is recommended. Contact the Service Center, Service Station,

Sales Office or delayer for repairs or part replacement.

Do not perform a megger test (insulation resistance measurement) during inspections.

If the battery low warning is issued, back up the machining programs, tool data and

parameters with an input/output unit, and then replace the battery.

Do not short circuit, charge, overheat, incinerate or disassemble the battery.

The heat radiating fin used in some units contains substitute Freon as the refrigerant.Take

care not to damage the heat radiating fin during maintenance and replacement work.

(7) Disposal

Do not dispose of this type of unit as general industrial waste. Always contact the Service

Center, Service Station, Sales Office or delayer for repairs or part replacement.

Do not disassemble the unit or motor.

Dispose of the battery according to local laws.

Always return the secondary side (magnet side) of the linear servomotor to the Service

Center or Service Station.

When incinerating optical communication cable, hydrogen fluoride gas or hydrogen chloride

gas which is corrosive and harmful may be generated. For disposal of optical communication

cable, request for specialized industrial waste disposal services that has incineration facility

for disposing hydrogen fluoride gas or hydrogen chloride gas.

Page 15

CAUTION

(8) Transportation

The unit and motor are precision parts and must be handled carefully.

According to a United Nations Advisory, the battery unit and battery must be transported

according to the rules set forth by the International Civil Aviation Organization (ICAO),

International Air Transportation Association (IATA), International Maritime Organization

(IMO), and United States Department of Transportation (DOT), etc.

(9) General precautions

The drawings given in this manual show the covers and safety partitions, etc., removed to provide a

clearer explanation. Always return the covers or partitions to their respective places before starting

operation, and always follow the instructions given in this manual.

Page 16

{ Treatment of waste {

The following two laws will apply when disposing of this product. Considerations must be made to each

law. The following laws are in effect in Japan. Thus, when using this product overseas, the local laws will

have a priority. If necessary, indicate or notify these laws to the final user of the product.

1. Requirements for "Law for Promotion of Effective Utilization of Resources"

(1) Recycle as much of this product as possible when finished with use.

(2) When recycling, often parts are sorted into steel scraps and electric parts, etc., and sold to scrap

contractors. Mitsubishi recommends sorting the product and selling the members to appropriate

contractors.

2. Requirements for "Law for Treatment of Waste and Cleaning"

(1) Mitsubishi recommends recycling and selling the product when no longer needed according to

item (1) above. The user should make an effort to reduce waste in this manner.

(2) When disposing a product that cannot be resold, it shall be treated as a waste product.

(3) The treatment of industrial waste must be commissioned to a licensed industrial waste treatment

contractor, and appropriate measures, including a manifest control, must be taken.

(4) Batteries correspond to "primary batteries", and must be disposed of according to local disposal

laws.

Page 17

Compliance to European EC Directives

1. European EC Directives

The European EC Directives were issued to unify Standards within the EU Community and to smooth

the distribution of products of which the safety is guaranteed. In the EU Community, the attachment of

a CE mark (CE marking) to the product being sold is mandatory to indicate that the basic safety

conditions of the Machine Directives (issued Jan. 1995), EMC Directives (issued Jan. 1996) and the

Low-voltage Directives (issued Jan. 1997) are satisfied. The machines and devices in which the servo

is assembled are a target for CE marking.

The servo is a component designed not to function as a single unit but to be used with a combination

of machines and devices. Thus, it is not subject to the EMC Directives, and instead the machines and

devices in which the servo is assembled are targeted.

This servo complies with the Standards related to the Low-voltage Directives in order to make CE

marking of the assembled machines and devices easier. The EMC INSTALLATION GUIDELINES (IB

(NA) 67303) which explain the servo amplifier installation method and control panel manufacturing

method, etc., has been prepared to make compliance to the EMC Directives easier. Contact

Mitsubishi or your dealer for more information.

2. Cautions of compliance

Use the standard servo amplifier and EN Standards compliance part (some standard models are

compliant) for the servomotor. In addition to the items described in this instruction manual, observe

the items described below.

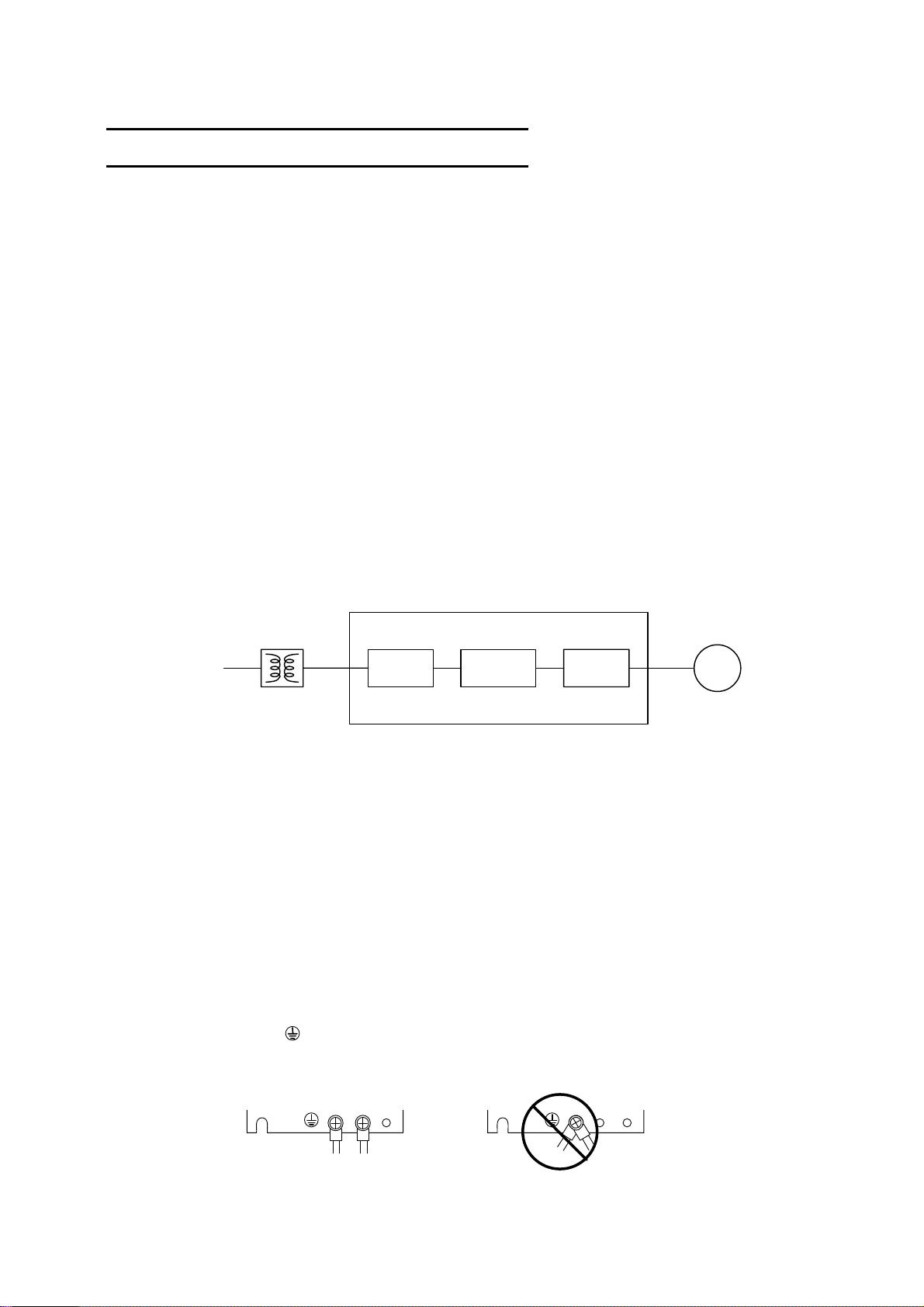

(1) Configuration

Insulation

transformer

Control panel

Breaker

Magnetic

contactor

(MC)

Servo

amplifier

Motor

Use a type B (AC/DC detect abl e type) breaker

(2) Environment

The servo amplifier must be used within an environment having a Pollution Class 2 or less

(Pollution Class 1 or 2) as stipulated in the IEC60664. For this, install the servo amplifier in a

control panel having a structure (IP54) into which water, oil, carbon and dust cannot enter.

(3) Power supply

① The servo amplifier must be used with the overvoltage category II conditions stipulated in

IEC60664. For this, prepare a reinforced insulated transformer that is IEC or EN Standards

complying at the power input section.

② When supplying the control signal input/output power supply from an external source, use a 24

VDC power supply of which the input and output have been reinforced insulated.

(4) Installation

① To prevent electric shocks, always connect the servo amplifier protective earth (PE) terminal

(terminal with

mark) to the protective earth (PE) on the control panel.

② When connecting the earthing wire to the protective earth (PE) terminal, do not tighten the wire

terminals together. Always connect one wire to one terminal.

PE termi nal PE termi nal

Page 18

(5) Wiring

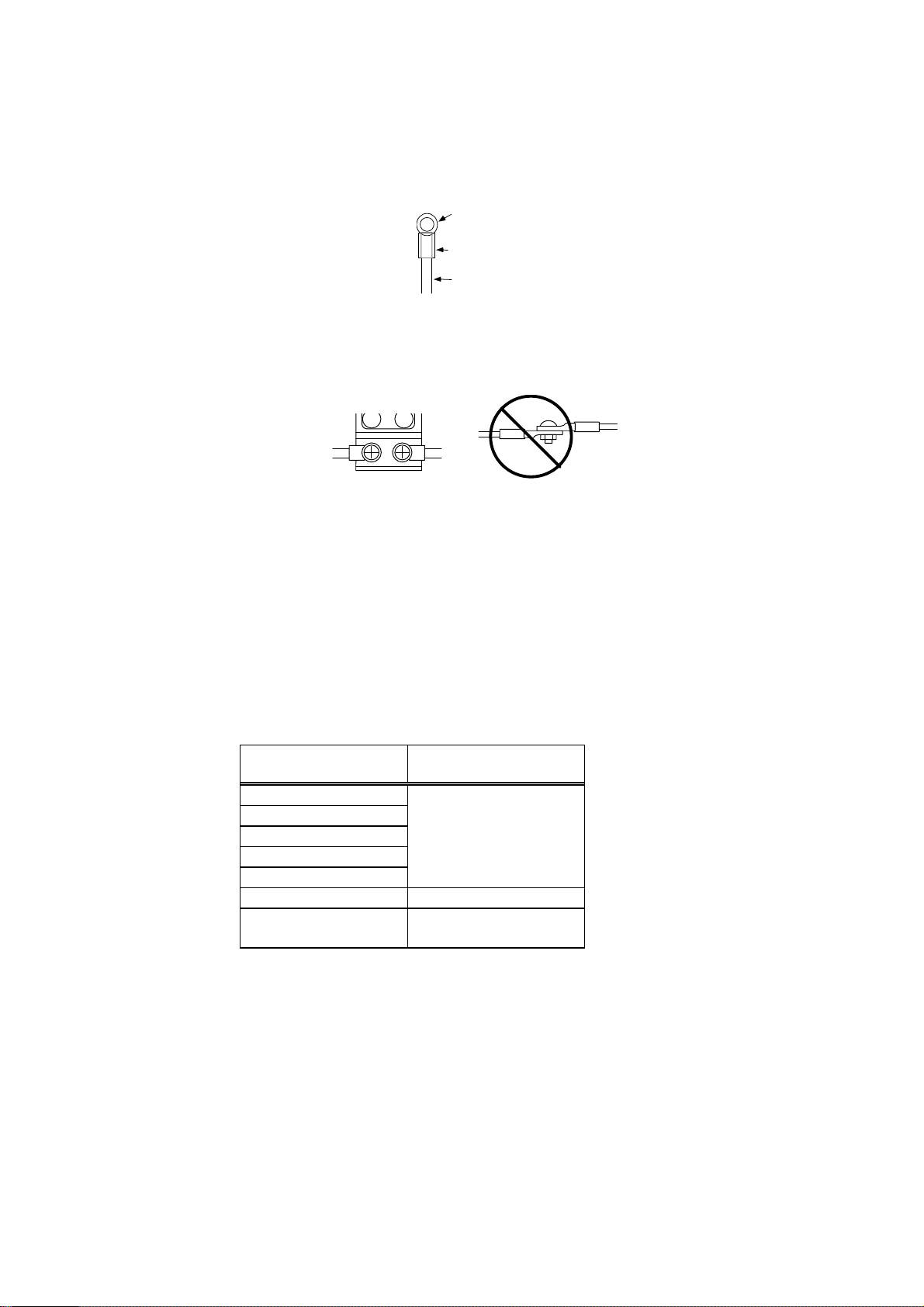

① Always use crimp terminals with insulation tubes so that the wires connected to the servo

amplifier terminal block do not contact the neighboring terminals.

Crimp terminal

Insulation tube

Wire

② Connect the HC-MF Series servomotor power lead to the servo amplifier using a fixed terminal

block. Do not connect the wires directly. (EN standards compliance parts of the HA-FF motor

have cannon plug specifications.)

(6) Peripheral devices

① Use a circuit protector and magnetic contactor that comply with the EN/IEC Standards

described in Chapter 7 Peripheral Devices.

② The wires sizes must follow the conditions below. When using other conditions, follow Table 5

of EN60204-1 Appendix C.

• Ambient temperature: 40°C

• Sheath: PVC (polyvinyl chloride)

• Install on wall without duct or conduit

(7) Servomotor

A servomotor that complies with the EN Standards as a standard, and an EN Standards

compatible part are available.

Motor series name

HCSeries

HCR Series

HA Series

HC-SF Series

HC-RF Series

HA-FF Series HA-FFC-UE

HC-MF Series

Refer to "Chapter 6 Dedicated Options" for the connectors and detector cables, and use the EN

Standards compatible parts.

(8) Enforcement of EMC test

The EMC test for a machine or device incorporating a servo amplifier must match the magnetism

compatibility (immunity and emission) standards in the state that the working environment and

electric device specifications are satisfied.

Refer to the EMC INSTALLATION GUIDELINES (IB (NA) 67303) for the EMC Directive measures

for the servo amplifier.

EN Standards

compatible part

Complies as a standard

HC-MF-UE

HC-MF-S15

Page 19

Instruction Manual for Compliance with UL/c-UL Standard

The instructions of UL/c-UL listed products are described in this manual.

The descriptions of this manual are conditions to meet the UL/c-UL

standard for the UL/c-UL listed products. To obtain the best performance,

be sure to read this manual carefully before use.

To ensure proper use, be sure to read specification manual carefully for

each product before use.

1. Operation surrounding air ambient temperature

The recognized operation ambient temperatures of each unit are as

shown in the table below. The recognized operation ambient

temperatures are the same as an original product specification for all

of the units.

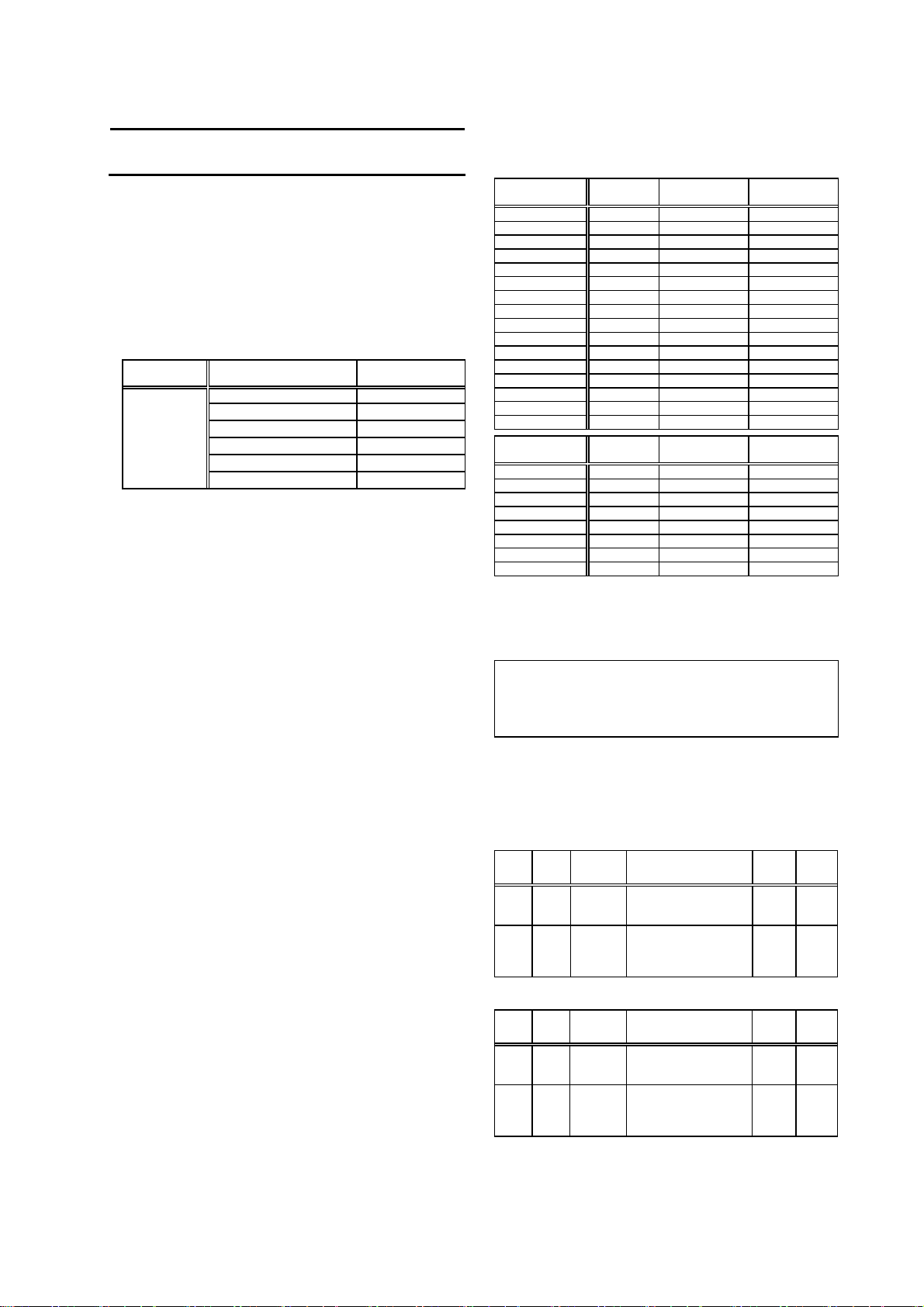

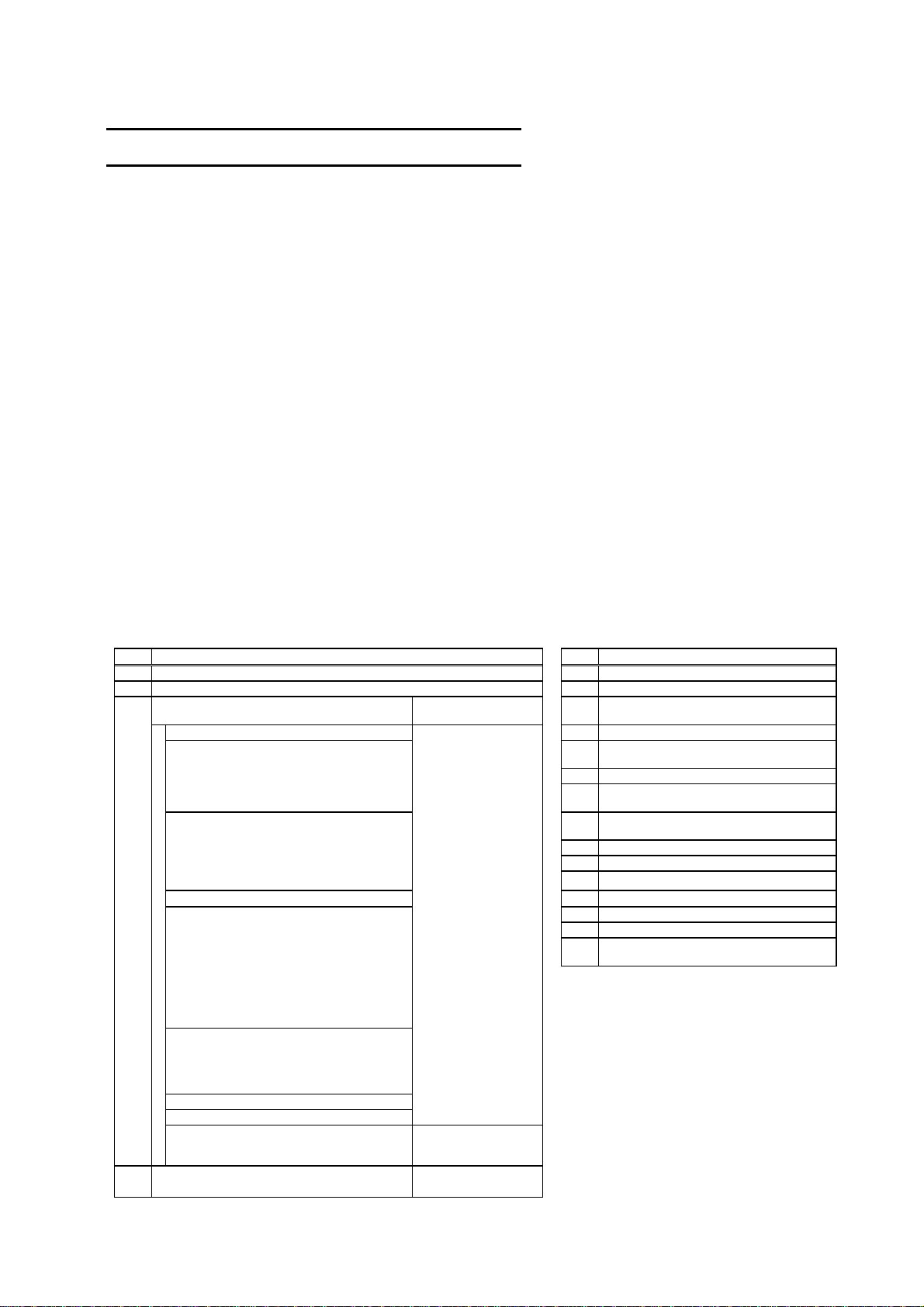

Classification Unit name

AC servo/

spindle system

2. Notes for AC servo/spindle system

2-1 General Precaution

It takes 10 minutes to discharge the bus capacitor. (The capacitor

discharge time is one minute for MDS-B-SVJ2-01, 03, 04; two minutes

for MDS-B-SVJ2-06 and three minutes for MDS-B-SVJ2-07, 10, 20.)

When starting wiring or inspection, shut the power off and wait for

more than 15 minutes to avoid a hazard of electrical shock.

2-2 Installation

MDS-B-SVJ2, MDS-B-SPJ2 and MR-J2-CT Series have been

approved as the products which have been installed in the electrical

enclosure.

The minimum enclosure size is based on 150 percent of each

MDS-B-SVJ2, SPJ2 and MR-J2-CT Series combination. And also,

design the enclosure so that the ambient temperature in the enclosure

is 55°C (131°F) or less, refer to the specifications manual.

(MDS-B-SVJ2: BNP-B3937, MDS-B-SPJ2: BNP-B2164, MR-J2-CT:

BNP-B3944)

"The user must include the use of a 100 cfm fan spaced 4 in. above

the drive."

2-3 Short-circuit ratings

Suitable for use in a circuit capable of delivering not more than 100 kA

rms symmetrical amperes, 500 volts maximum.

(MDS-B-SVJ2, MDS-B-SPJ2 and MR-J2-CT Series)

operation ambient

temperature

Power supply unit 0~55°C

Servo drive unit 0~55°C

Spindle drive unit 0~55°C

Option unit 0~55°C

Battery unit 0~55°C

Servo motor, Spindle motor 0~40°C

2-4 Peripheral device

To comply with UL/c-UL Standard, use the peripheral devices which

conform to the corresponding standard.

- Fuses

Applicable

drive unit

UL Fuse

type

UL Voltage

rating, Vac

UL Current

rating, A

MDS-B-SVJ2-01 K5 250 10

MDS-B-SVJ2-03 K5 250 10

MDS-B-SVJ2-04 K5 250 15

MDS-B-SVJ2-06 K5 250 20

MDS-B-SVJ2-07 K5 250 20

MDS-B-SVJ2-10 K5 250 25

MDS-B-SVJ2-20 K5 250 40

MDS-B-SPJ2-02 K5 250 10

MDS-B-SPJ2-04 K5 250 15

MDS-B-SPJ2-075 K5 250 20

MDS-B-SPJ2-15 K5 250 40

MDS-B-SPJ2-22 K5 250 40

MDS-B-SPJ2-37 K5 250 60

MDS-B-SPJ2-55 K5 250 90

MDS-B-SPJ2-75 K5 250 125

MDS-B-SPJ2-110 K5 250 175

Applicable

drive unit

UL Fuse

type

UL Voltage

rating, Vac

UL Current

rating, A

MR-J2-10CT K5 250 10

MR-J2-20CT K5 250 10

MR-J2-40CT K5 250 15

MR-J2-60CT K5 250 20

MR-J2-70CT K5 250 20

MR-J2-100CT K5 250 25

MR-J2-200CT K5 250 40

MR-J2-350CT K5 250 70

- Circuit Breaker for of spindle motor Fan

Select the Circuit Breaker by doubling the spindle motor fan rated.

A rush current that is approximately double the rated current will

flow, when the fan is started

<Notice>

- For installation in United States, branch circuit protection must be

provided, in accordance with the National Electrical Code and any

applicable local codes.

- For installation in Canada, branch circuit protection must be

provided, in accordance with the Canada Electrical Code and any

applicable provincial codes.

2-5 Motor Over Load Protection

Servo drive unit MDS-B-SVJ2, MDS-B-SPJ2 and MR-J2-CT series

have each solid state motor over load protection.

current is the same as rated current.)

When adjusting the level of motor over load, set the parameter as

follows.

2-5-1 MDS-B-SVJ2 Series

Para-

Parameter

abbr.

Parameter

name

time

constant

detection

level

Setting procedure

Set the time constant for

overload detection.

(Unit: 1 second.)

Set the overload current

detection level with a

percentage (%) of the

meter

No.

SV021 OLT Overload

SV022 OLL Overload

stall rating.

2-5-2 MDS-B-SPJ2 Series

Para-

Parameter

abbr.

Parameter

name

meter

No.

SP063 OLT Overload

time

constant

SP064 OLL Overload

detection

level

Setting

procedure

Set the time constant for

overload detection.

(Unit: 1 second.)

Set the overload current

detection level with a

percentage (%) of the

rating.

2-5-3 MR-J2-CT Series

The overload current detection level is 150% of the rated current.

(The motor full load

Standard

60s 1~300s

150% 1~500

Standard

60s 0~1000

120% 0~200

setting

value

setting

value

Setting

range

%

Setting

range

s

%

Page 20

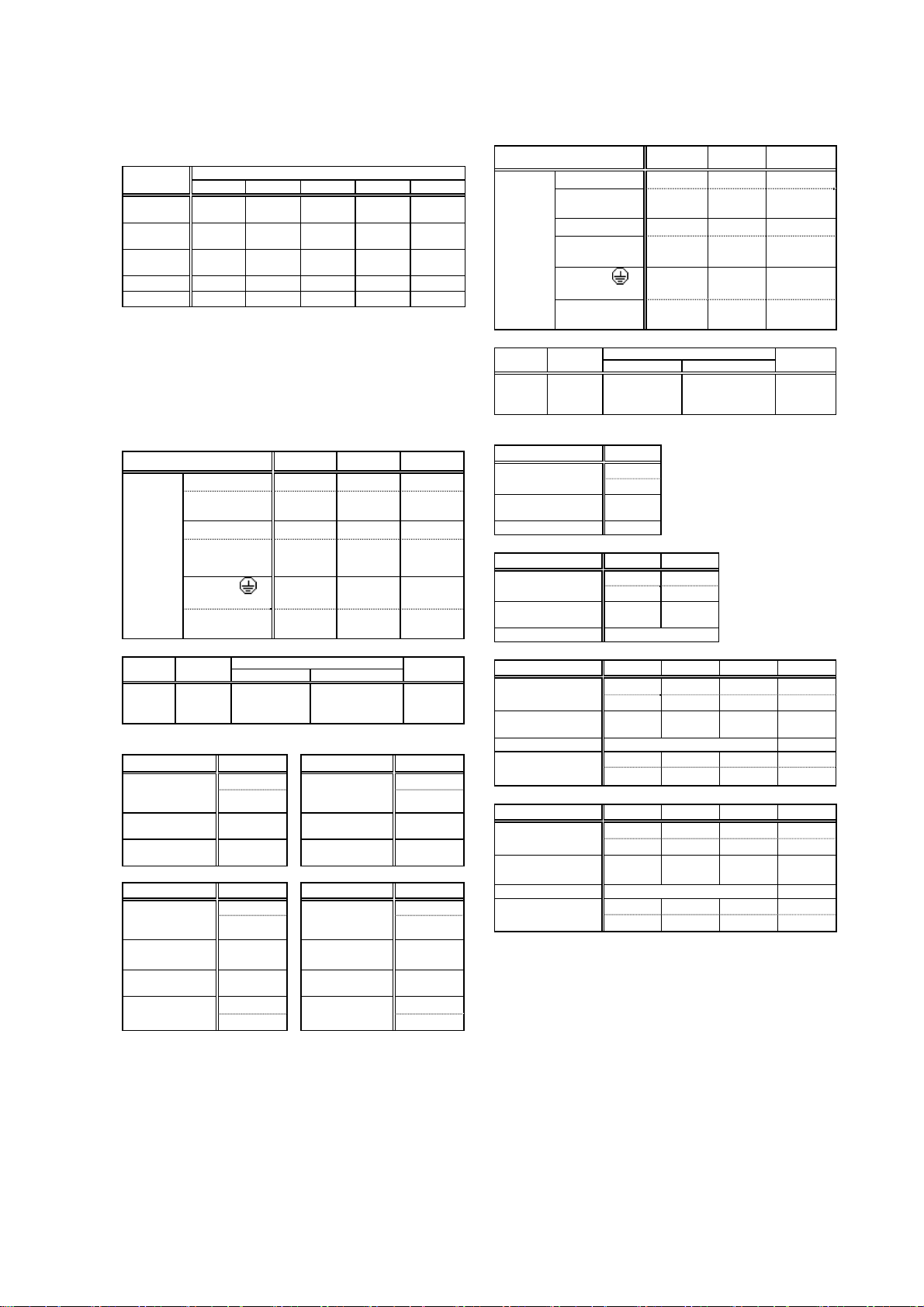

2-6 Flange of servo motor

Mount the servo motor on a flange which has the following size or

produces an equivalent or higher heat dissipation effect:

Flange size

(mm)

HC HC-RF HC-MF HA-FF HC-SF

150x150x6

250x250x6

250x250x12

300x300x12

- -

- -

0.5~

1.5kW

- -

300x300x20 2.0kW

Servo motor

under

100W

200W

1.0~

2.0kW

400W 400,600W

750W

- - -

under

100W

200,

300W

- -

-

-

0.5~

1.5kW

2.0kW

2-7 Field Wiring Reference Table for Input and Output

Use the UL-approved Round Crimping Terminals to wire the input and

output terminals of MDS-B-SVJ2, MDS-B-SPJ2 and MR-J2-CT Series.

Crimp the terminals with the crimping tool recommended by the

terminal manufacturer.

Following described crimping terminals and tools type is example of

Japan Solderless Terminal Mfg. Co., Ltd.

2-7-1 Servo Drive Unit (MDS-B-SVJ2 Series)

Capacity [kW]

0.1~0.7

D, C, P, N Note 1 M4 M4

Screw torque

[Ib in/ N m]

5.3/0.6 11/1.3 11/1.3

L11, L21 Note 1 M4 M4

Terminal

Screw Size

Screw torque

[lb in/ N m]

U, V, W,

L1,L2,L3

Screw torque

[lb in/ N m]

5.3/0.6 11/1.3 11/1.3

M4 M4 M4

11/1.3 11/1.3 11/1.3

Note1 Control circuit terminal block (MDS-B-SVJ2-01~07)

Terminal

D, C, P

L11, L21

Wire size

(AWG)

#14/75℃

Terminal bar model

Single-wire Double-wire

AI2.5-8BU

AI2.5-8BU-1000

AI-TWIN2x2.5-10BU

AI-TWIN2x2.5-13BU

Crimping terminals and tools type are example of Phoenix-contact

L11, L21 D, C, P

Capacity [kW] 1.0, 2.0 Capacity [kW] 1.0, 2.0

Wire Size (AWG)

/Temp rating

Note 2

Crimping

terminals type

Crimping tools

type

#14/60℃ #14/60℃

#14/75℃

V2-4

YNT-1614

Wire Size (AWG)

terminals type

Crimping tools

L1, L2, L3 U, V, W

Capacity [kW]

Wire size (AWG)

/Temp rating

Note 2

Crimping

terminals type

Crimping tools

type

Earth wire size

(AWG)

0.1~2.0

#14/60℃ #14/60℃

#14/75℃

R2-4

YHT-2210

#14/60℃ #14/60℃

#14/75℃

Capacity [kW]

Wire size (AWG)

terminals type

Crimping tools

Earth wire size

Note 2 75°C : Grade heat-resistant polyvinyl chloride insulated wires

(HIV)

Use copper wire only.

Above listed wire are for use in the electric cabinet on

machine or equipment.

1.0 2.0

/Temp rating

Note 2

Crimping

type

/Temp rating

Note 2

Crimping

type

(AWG)

Crimping

tools type

CRIMPFOX-

UD6

#14/75℃

R2-4

YHT-2210

0.1~2.0

#14/75℃

R2-4

YHT-2210

#14/75℃

2-7-2 Spindle Drive Unit (MDS-B-SPJ2)

Capacity [kW]

D, C, P, N Note1 M4 M4

Screw torque

[Ib in/ N m]

L11, L21 Note1 M4 M4

Terminal

screw size

Screw torque

[lb in/ N m]

U, V, W,

L1,L2,L3

Screw torque

[lb in/ N m]

Note1 Control circuit terminal block (MDS-B-SPJ2-02~075)

Terminal

D, C, P

L11, L21

Wire size

(AWG)

#14/75℃

Crimping terminals and tools type are example of Phoenix-contact.

L11, L21

Capacity [kW]

Wire size (AWG)

/Temp rating Note 2

Crimping terminals

type

Crimping tools type YNT-1614

D, C, P

Capacity [kW] 1.5

Wire Size (AWG)

/Temp rating Note 2

Crimping terminals

type

Crimping tools type YHT-2210

L1, L2, L3

Capacity [kW]

Wire Size (AWG)

/Temp rating Note 2

Crimping terminals

type

Crimping tools type YHT-2210 YHT-8S

Earth wire size

(AWG)

U, V, W

Capacity [kW]

Wire size (AWG)

/Temp rating Note 2

Crimping terminals

type

Crimping tools type YHT-2210 YHT-8S

Earth wire size

(AWG)

Note 2 75°C : Grade heat-resistant polyvinyl chloride insulated wires

(HIV)

Use copper wire only.

Above listed wire are for use in the electric cabinet on

machine or equipment.

0.2~0.75 1.5~3.7 5.5~11.0

5.3/0.6 10.4/1.2 10.4/1.2

5.3/0.6 10.4/1.2 17.4/2.0

M4 M4 M4

10.4/1.2 10.4/1.2 10.4/1.2

Terminal bar model

Single-wire Double-wire

AI2.5-8BU

AI2.5-8BU-1000

AI-TWIN2x2.5-10BU

AI-TWIN2x2.5-13BU

Crimping

tools type

CRIMPFOX-

UD6

1.5~11.0

#14/60℃

#14/75℃

V2-4

2.2~11.0

#14/60℃ #12/60℃

#14/75℃ #14/75℃

R2-4 5.5-S4

0.2~3.7

5.5 7.5 11.0

#14/60℃ #12/60℃ #10/60℃ #8/60℃

#14/75℃ #12/75℃ #10/75℃ #8/75℃

R2-4 5.5-S4 5.5-S4 TU8-4

#14/60℃ #12/60℃ #10/60℃ #8/60℃

#14/75℃ #12/75℃ #10/75℃ #8/75℃

0.2~3.7

5.5 7.5 11.0

#14/60℃ #12/60℃ #10/60℃ #8/60℃

#14/75℃ #12/75℃ #10/75℃ #8/75℃

R2-4 5.5-S4 5.5-S4 TU8-4

#14/60℃ #12/60℃ #10/60℃ #8/60℃

#14/75℃ #12/75℃ #10/75℃ #8/75℃

Page 21

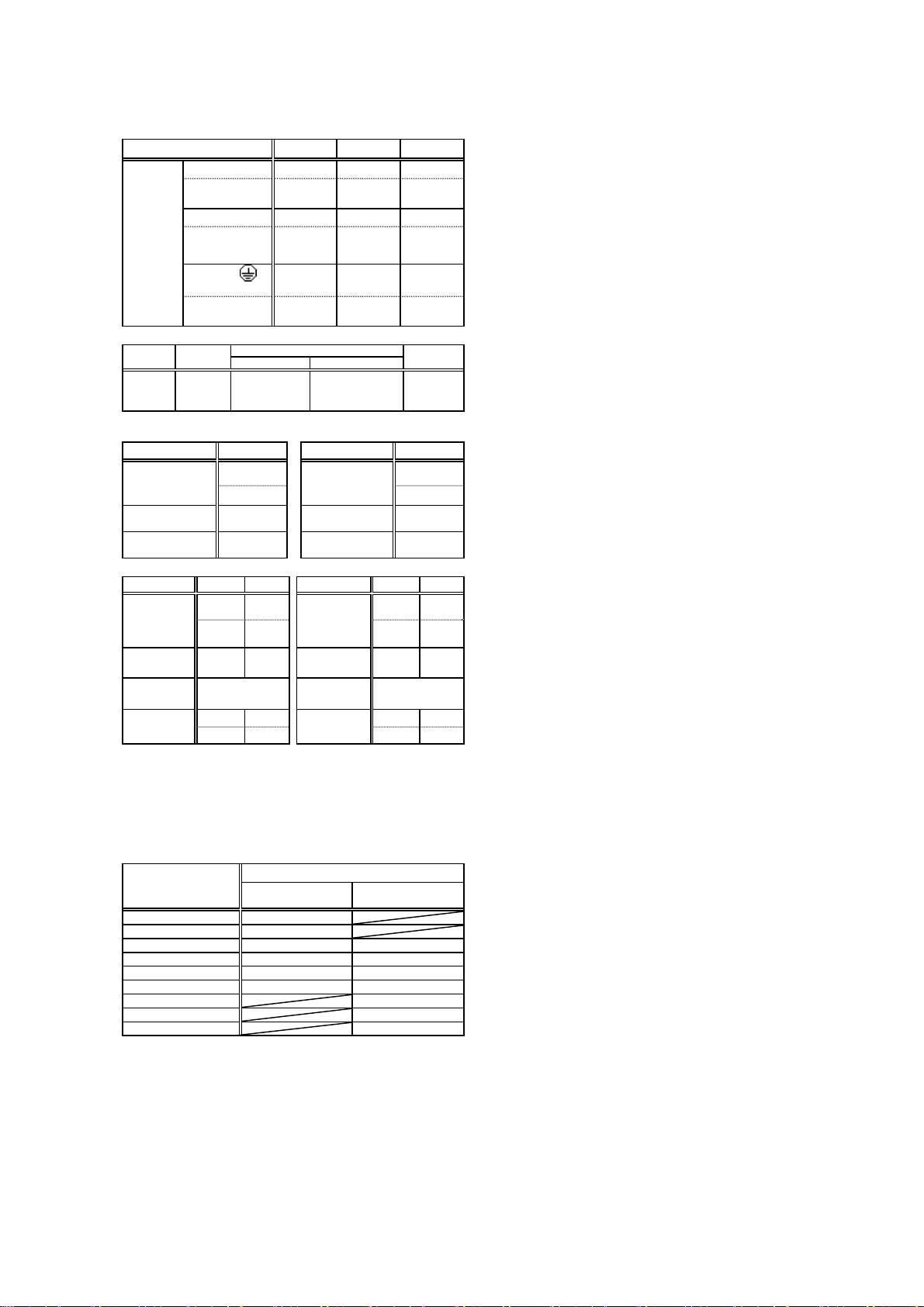

2-7-3 Servo Drive Unit (MR-J2-CT Series)

Capacity [kW]

0.1~1.0

2.0 3.5

D, C, P, N Note 1 M4 M4

Screw torque

[Ib in/ N m]

5.3/0.6 11/1.3 11/1.3

L11, L21 Note 1 M4 M4

Terminal

screw size

Screw torque

[lb in/ N m]

U, V, W,

L1,L2,L3

Screw torque

[lb in/ N m]

5.3/0.6 11/1.3 11/1.3

M4 M4 M4

11/1.3 11/1.3 11/1.3

Note1 Control circuit terminal block (MR-J2-10~100)

Terminal

D, C, P

L11, L21

Wire size

(AWG)

#14/75℃

Terminal bar model

Single-wire Double-wire

AI2.5-8BU

AI2.5-8BU-1000

AI-TWIN2x2.5-10BU

AI-TWIN2x2.5-13BU

Crimping

tools type

CRIMPFOX-

UD6

Crimping terminals and tools type are example of Phoenix-contact

L11, L21 D, C, P

Capacity [kW] 2.0 , 3.5 Capacity [kW] 2.0 , 3.5

Wire size (AWG)

/Temp rating

Note 2

Crimping

terminals type

Crimping tools

type

#14/60℃ #14/60℃

#14/75℃

V2-4

YNT-1614

Wire size (AWG)

/Temp rating

Note 2

Crimping

terminals type

Crimping tools

type

#14/75℃

R2-4

YHT-2210

L1, L2, L3 U, V, W

Capacity [kW]

Wire size

(AWG)

/Temp rating

Note 2

Crimping

terminals type

Crimping tools

type

Earth wire size

(AWG)

0.1~2.0

#14/60℃ #10/60℃ #14/60℃ #10/60℃

#14/75℃ #10/75℃

R2-4 5.5-S4

#14/60℃ #12/60℃ #14/60℃ #12/60℃

#14/75℃ #12/75℃

3.5 Capacity [kW]

Wire size (AWG )

YHT-2210

Crimping tools

Earth wire size

/Temp rating

Note 2

Crimping

terminals type

type

(AWG)

0.1~2.0

#14/75℃ #10/75℃

R2-4 5.5-S4

YHT-2210

#14/75℃ #12/75℃

Note 2 75°C : Grade heat-resistant polyvinyl chloride insulated wires

(HIV)

Use copper wire only.

Above listed wire are for use in the electric cabinet on

machine or equipment.

2-8 Spindle Drive / Motor Combinations

Following combinations are the Standard combinations

Drive unit

MDS-B-SPJ2-02 0.2

MDS-B-SPJ2-04 0.4

MDS-SPJ2-075 0.75 0.75

MDS-B-SPJ2-15 1.5 1.5

MDS-B-SPJ2-22 2.2 2.2

MDS-B-SPJ2-37 3.7 3.7

MDS-B-SPJ2-55 5.5

MDS-B-SPJ2-75 5.5, 7.5

MDS-B-SPJ2-110 7.5, 11

Applicable spindle motor (kW)

SJ-P Series SJ-PF Series

3.5

Page 22

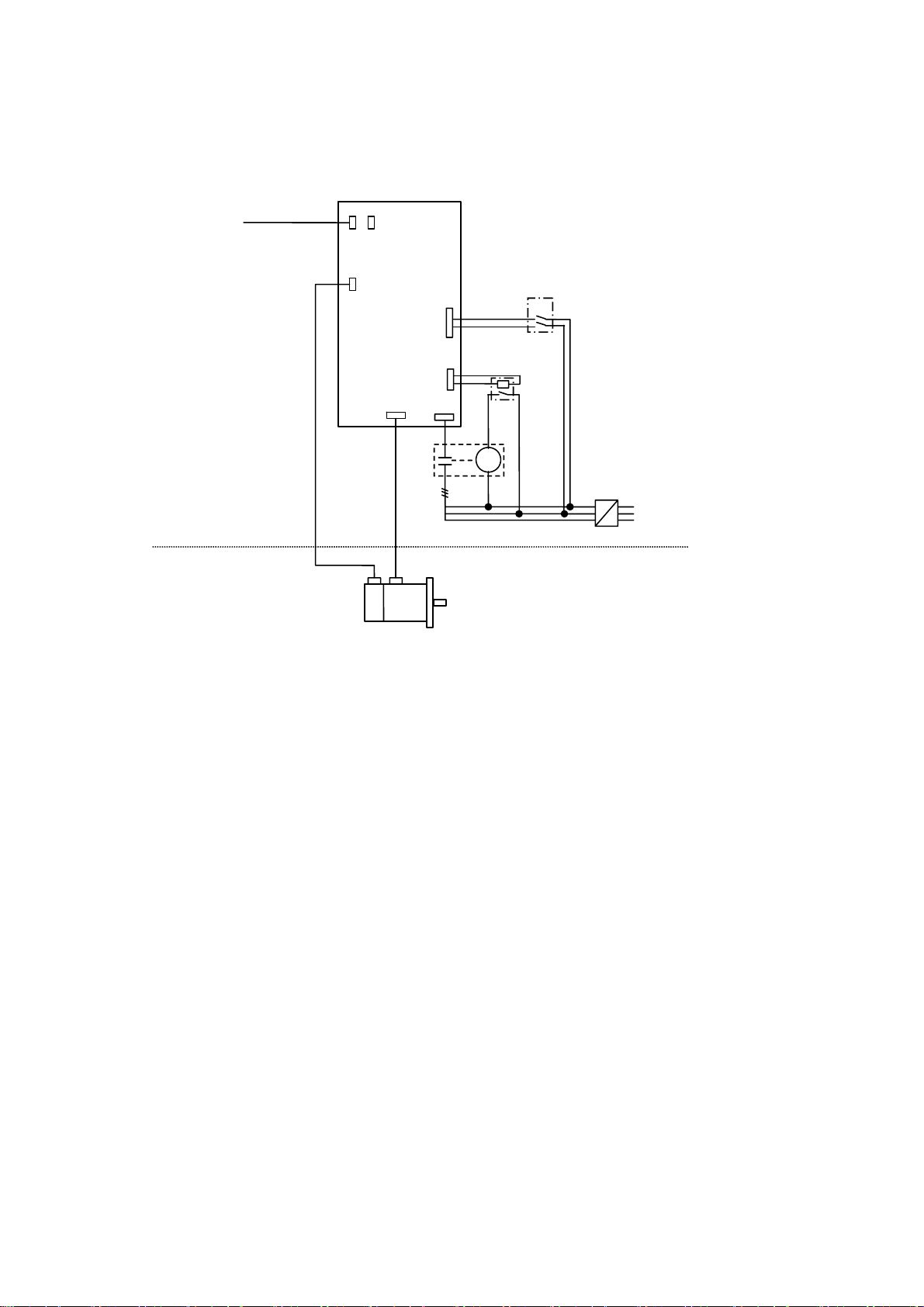

3. AC Servo/Spindle System Connection

From NC

Regarding the connection of

NC, see the NC manual book.

MDS-B-SVJ2

/MDS-B-SPJ2

/MR-J2-CT

CN1BCN1A

CN2

L11/L21

Note: It recommends installing.

CB

Enclosure Side

Machine Side

U,V,W

Contactor

Servo / Spindle Motor

Encoder

CN3

L1,L2,L3

MC

Relay

Refer to the following specification manuals.

MDS-B-SVJ2: BNP-B3937

MDS-B-SPJ2: BNP-B2164

MR-J2-CT: BNP-B3944

Fuse

or

Circuit Breaker

3 phases

200 to 230Vac

Input

Page 23

Compliance to Transportation Restrictions for Lithium Batteries

1. Restriction for packing

The United Nations Dangerous Goods Regulations "Article 12" became effective from 2003. When

transporting lithium batteries with means subject to the UN Regulations, such as by air transport,

measures corresponding to the Regulations must be taken. The UN Regulations classify the batteries

as dangerous goods (Class 9) or not dangerous goods according to the lithium content.

To ensure safety during transportation, lithium batteries (battery unit) directly exported from Mitsubishi

are packaged in a dedicated container (UN package) for which safety has been confirmed. When the

customer is transporting these products with means subject to the UN Regulations, such as air

transport, the shipper must follow the details explained in the section "1-2 Handling by user".

1-1 Target products

The following Mitsubishi NC products use lithium batteries. The UN Regulations classify the batteries

as dangerous goods (Class 9) or not dangerous goods according to the lithium content. If the batteries

subjected to hazardous materials are incorporated in a device and shipped, a dedicated packaging

(UN packaging) is not required. However, the item must be packed and shipped following the Packing

Instruction 912 specified in the IATA DGR (Dangerous Goods Regulation) book.

Also, all lithium battery products incorporated in a machinery or device must be fixed securely in

accordance with the Packing Instruction 900 and shipped with protection in a way as to prevent

damage or short-circuits.

(1) Products requiring dedicated packaging (Materials falling under Class 9)

Mitsubishi type

(Type for

arrangement)

MDS-A-BT-4

MDS-A-BT-6

MDS-A-BT-8

FCU6-BT4-D1

CR23500SE-CJ5

(Note1)

Battery type

ER6-B4-11 2.6g For servo

ER6-B6-11 3.9g For servo

ER6-B8-11 5.2g For servo

Combination of

ER6-B4D-11 and ER6

CR23500SE-CJ5 1.52g For NC(M500) Battery cell

(2) Products not requiring dedicated packaging (Materials not falling under Class 9)

Mitsubishi type

(Type for

arrangement)

MDS-A-BT-2

FCU6-BTBOX series

CR2032

(for built-in battery)

CR2450

(for built-in battery)

ER6, ER6V series

(for built-in battery)

A6BAT (MR-BAT)

Q6BAT

MR-J3BAT

(Note 1) When CR23500SE-CJ5 is incorporated in the unit, this battery is not subject to the regulation.

(Note 2) Dedicated packaging is required if the shipment exceeds 12 batteries/24 battery cells. Package the batteries so that

(Note 3) The battery units labeled as "FCUA-" instead of "MDS-A-" also use the same battery.

(Note 4)

this limit is not exceeded.

Always use the cell battery (A6BAT) in combination with the dedicated case (MDS-BTCASE). Maximum 8 (either 2, 4, 6

or 8) cell batteries (A6BAT) can be installed to the dedicated case (MDS-BTCASE).

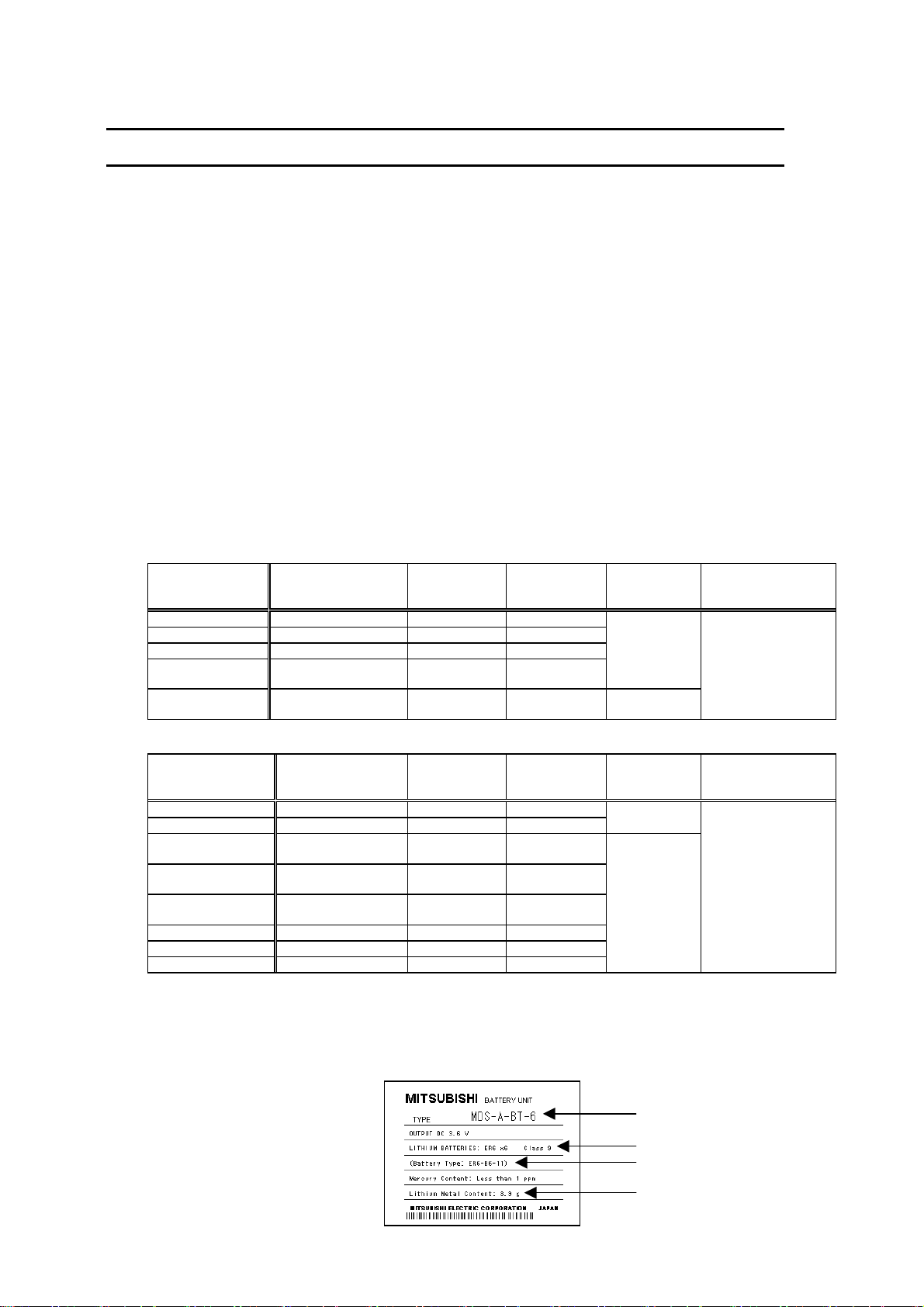

Example) Rating nameplate

for battery units

Battery type

ER6-B2-12 1.3g For servo

2CR5 1.96g For NC/ servo

CR2032 0.067g For NC

CR2450 0.173g For NC

ER6, ER6V 0.7g For NC/servo

ER17330V 0.48g For servo

Q6BAT 0.49g For NC

ER6V 0.65g For servo

Lithium metal

content

2.6g+0.65g For NC/ servo

Lithium metal

content

Application Battery class

Application Battery class

Outline dimension

drawing

Battery

Battery

Battery cell

For each outline

dimension drawing of

servo, refer to the

section “6-2 Battery

option”.

Outline dimension

drawing

For each outline

dimension drawing of

servo, refer to the

section “6-2 Battery

option”.

Mitsubishi type

Safety class

Battery manufacturer type

Lithium metal content

Page 24

1-2 Handling by user

The following technical opinion is solely Mitsubishi's opinion. The shipper must confirm the latest IATA

Dangerous Goods Regulations, IMDG Codes and laws and orders of the corresponding export

country. These should be checked by the company commissioned for the actual transportation.

IATA : International Air Transport Association

IMDG Code : A uniform international code for the transport of dangerous goods by seas

determined by IMO (International Maritime Organization).

■ When shipping isolated lithium battery products (Packing Instruction 903)

(1) Reshipping in Mitsubishi UN packaging

Mitsubishi packing applies the isolated battery's safety test and packaging specifications

complying with the UN Regulations (Packing Instruction 903).

The user only needs to add the following details before shipping. (Consult with the shipping

company for details.)

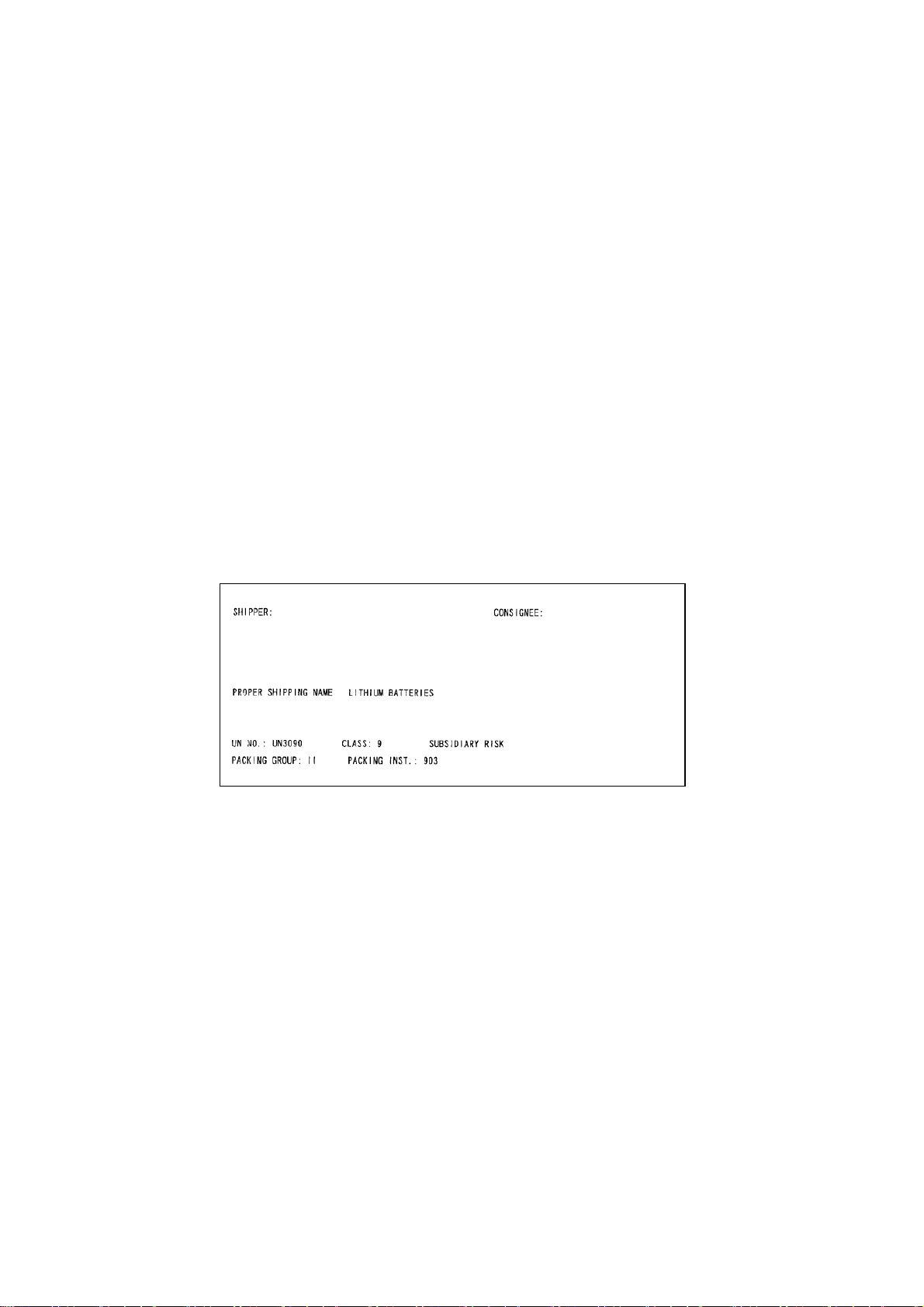

(a) Indication of container usage mark on exterior box (Label with following details

recorded.)

• Proper shipping name (Lithium batteries)

• UN NO. (UN3090 for isolated battery, UN3091 for battery incorporated in a device or

included)

• Shipper and consignee's address and name

(b) Preparation of shipping documents (Declaration of dangerous goods)

(Refer to "3. Example of hazardous goods declaration list" in this section.)

(2) When packaged by user

The user must follow UN Regulations when packing, preparing for shipping and preparing the

indications, etc.

(a) Packing a lithium battery falling under Class 9

• Consult with The Ship Equipment Inspection Society of Japan for details on packaging.

• Prepare for shipping as explained in "(1) Reshipping in Mitsubishi UN packaging".

The Ship Equipment Inspection Society of Japan

Headquarters Telephone: 03-3261-6611 Fax: 03-3261-6979

(b) Packing a lithium battery not falling under Class 9

• Cells and batteries are separated so as to prevent short circuits and are stored in a strong

outer packaging. (12 or less batteries, 24 or less cells.)

• Prepare for the certificates or test results showing compliance to battery safety test.

The safety test results have been obtained from the battery manufacturer. (Consult with

Mitsubishi when the safety test results are required.)

• Prepare for shipping as explained in "(1) Reshipping in Mitsubishi UN packaging".

Shipper information

Example of completing form

Consignee information

Page 25

■ When shipping lithium batteries upon incorporating in a machinery or device

(Packing Instruction 900)

Pack and prepare for shipping the item in accordance with the Packing Instruction 900 specified in

the IATA DGR (Dangerous Goods Regulation) book. (Securely fix the batteries that comply with the

UN Manual of Tests and Criteria to a machinery or device, and protect in a way as to prevent

damage or short-circuit.)

Note that all the lithium batteries provided by Mitsubishi have cleared the UN recommended safety

test; fixing the battery units or cable wirings securely to the machinery or device will be the user’s

responsibility.

Check with your shipping company for details on packing and transportation.

■ When shipping a device with lithium batteries incorporated (Packing Instruction 912)

A device incorporating lithium batteries does not require a dedicated packaging (UN packaging).

However, the item must be packed, prepared for shipping and labeled following the Packing

Instruction 912 specified in the IATA DGR (Dangerous Goods Regulation) book.

Check with your shipping company for details on packing and transportation.

The outline of the Packing Instruction 912 is as follows:

• All the items in the packing instructions for shipping the isolated lithium battery products

(Packing Instruction 903) must be satisfied, except for the items related to container,

short-circuit, and fixation.

• A device incorporating lithium batteries has to be stored in a strong water-proofed outer

packaging.

• To prevent an accidental movement during shipment, securely store the item in an outer

packaging.

• Lithium content per device should be not more than 12g for cell and 500g for battery.

• Lithium battery mass per device should be not more than 5kg.

1-3 Reference

Refer to the following materials for details on the regulations and responses.

Guidelines regarding transportation of lithium batteries and lithium ion batteries (Edition 2)

• • • • • Battery Association of Japan

Page 26

2. Issuing domestic law of the United State for primary lithium battery

transportation

Federal Aviation Administration (FAA) and Research and Special Programs Administration (RSPA)

announced an additional regulation (interim final rule) for the primary lithium batteries transportation

restrictions item in "Federal Register" on Dec.15 2004. This regulation became effective from Dec.29,

2004.

This law is a domestic law of the United States, however if also applies to the domestic flight and

international flight departing from or arriving in the United States. Therefore, when transporting lithium

batteries to the United State, or within the United State, the shipper must take measures required to

transport lithium batteries.

Refer to the Federal Register and the code of Federal Regulation ("2-4 Reference”) for details.

2-1 Outline of regulation

(1) Transporting primary lithium battery by passenger aircraft is forbidden.

• Excluding primary lithium battery for personal use in a carry-on or checked luggage

(Lithium metal content should be not more than 5g for cell and 25g for battery. For details on

the lithium metal content, refer to "1-1 Target products".)

(2) When transporting primary lithium battery by cargo aircraft, indicate that transportation by

passenger aircraft is forbidden on the exterior box.

2-2 Target products

All NC products for which the lithium batteries are used are subject to the regulation.

(Refer to the table "1-1 Target products".)

2-3 Handling by user

The "2-1 Outline of regulation" described above is solely Mitsubishi's opinion. The shipper must

confirm orders of "2-4 Reference" described below for transportation method corresponding the

regulation. Actually, these should be checked by the company commissioned for the actual lithium

buttery transportation.

(1) Indication of exterior box

When transporting primary lithium battery by cargo aircraft, indicate that transportation by

passenger aircraft is forbidden on the exterior box.

Display example

FORBIDDEN FOR TRANSPORT ABOARD PASSENGER AIRCRAFT.

• The character color must be displayed with contrast. (black characters against white

background, black characters against yellow background, etc.)

• The height (size) of characters to be displayed is prescribed depending on the packaging mass.

When the total mass is over 30kg: at least 12mm

When the total mass is less than 30kg: at least 6mm

PRIMARY LITHIUM BATTERIES

2-4 Reference

(1) Federal Register (Docket No. RSPA-2004-19884 (HM-224E) ) PDF format

http://www.regulations.gov/fredpdfs/05-11765.pdf

(2) 49CFR (Code of Federal Regulation, Title49) (173.185 Lithium batteries and cells.)

http://www.access.gpo.gov/nara/cfr/waisidx_00/49cfr173_00.html

(3) DOT regulation body (Department of Transportation)

http://hazmat.dot.gov/regs/rules/final/69fr/docs/69fr-75207.pdf

Page 27

3. Example of hazardous goods declaration list

This section describes a general example of the hazardous goods declaration list. For details,

please inquire each transportation company.

This will be applied only to the batteries described in "1. Restriction for Packing".

(1) Outline of hazard

Principal hazard and effect

Specific hazard

Environmental effect

Possible state of emergency

(2) First-aid measure

Inhalation

Skin contact

Eye contact

Ingestion

(3) Fire-fighting measure

Appropriate fire-extinguisher

Special fire-fighting measure

Protectors against fire

(4) Measure for leakage

Environmental precaution

How to remove

(5) Handling and storage

Cautions for safety

handling

Handling

Appropriate storage

Storage

condition

Material to avoid

(6) Physical/chemical properties

Physical form

Shape

Smell

Appearance

pH

Boiling point/Boiling

range,

Melting point,

Decomposition

temperature,

Flash point

Not found.

As the chemical substance is stored in a sealed metal container, the battery itself is

not hazardous. But when the internal lithium metal attaches to human skin, it

causes a chemical skin burn. As a reaction of lithium with water, it may ignite or

forms flammable hydrogen gas.

Not found.

Damages or short-circuits may occur due to external mechanical or electrical

pressures.

If a person inhales the vapor of the substance due to the battery damage, move the

person immediately to fresh air. If the person feels sick, consult a doctor

immediately.

If the content of the battery attaches to human skin, wash off immediately with

water and soap. If skin irritation persists, consult a doctor.

In case of contact with eyes due to the battery damage, rinse immediately with a

plenty of water for at least 15 minutes and then consult a doctor.

If swallowed, consult a doctor immediately.

Dry sand, dry chemical, graphite powder or carbon dioxide gas

Keep the battery away from the fireplace to prevent fire spreading.

Fire-protection gloves, eye/face protector (face mask), body/skin protective cloth

Dispose of them immediately because strong odors are produced when left for a

long time.

Get them absorbed into dry sand and then collect the sand in an empty container.

Do not peel the external tube or damage it.

Do not dispose of the battery in fire or expose it to heat.

Do not immerse the battery in water or get it wet.

Do not throw the battery.

Do not disassemble, modify or transform the battery.

Do not short-circuit the battery.

Avoid direct sunlight, high temperature and high humidity.

(Recommended temp. range: +5 to +35 oC, humidity: 70%RH or less)

Flammable or conductive material (Metal: may cause a short-circuit)

Solid

Cylinder type

Odorless

Not applicable (insoluble)

No information

Page 28

(7) Stability and reactivity

Stability

Condition to avoid

Hazardous decomposition

products

(8) Toxicological information

As the chemical substance is stored in a sealed metal container, the battery has no harmfulness.

Just for reference, the table below describes the main substance of the battery.

(Lithium metal)

Acute toxicity

Local effect

(9) Ecological information

Mobility,

Persistence/Decomposability,

Bio-accumulation potential,

Ecological toxicity

(10) Caution for disposal

Dispose of the battery following local laws or regulations.

Pack the battery properly to prevent a short-circuit and avoid contact with water.

Stable under normal handling condition.

Do not mix multiple batteries with their terminals uninsulated. This may cause a

short-circuit, resulting in heating, bursting or ignition.

Irritative or toxic gas is emitted in the case of fire.

No information

Corrosive action in case of skin contact

Not found.

Page 29

Compliance with Restrictions in China

1. Compliance with China CCC certification system

1-1 Outline of China CCC certification system

The Safety Certification enforced in China included the "CCIB Certification (certification system based

on the "Law of the People’s Republic of China on Import and Export Commodity Inspection" and

"Regulations on Implementation of the Import Commodities Subject to the Safety and Quality

Licensing System" enforced by the State Administration of Import and Export Commodity Inspection

(SACI) on import/export commodities, and the "CCEE Certification" (certification system based on

"Product Quality Certification Management Ordinance" set forth by the China Commission for

Conformity Certification of Electrical Equipment (CCEE) on commodities distributed through China.

CCIB Certification and CCEE Certification were merged when China joined WTO (November 2001),

and were replaced by the "China Compulsory Product Certification" (hereinafter, CCC Certification)

monitored by the State General Administration of Quality Supervision, Inspection and Quarantine

(AQSIQ) of the People's Republic of China.

The CCC Certification system was partially enforced from May 2002, and was fully enforced from May

2003. Target commodities which do not have CCC Certification cannot be imported to China or sold in

China. (Indication of the CCIB or CCEE mark has been eliminated from May 1, 2003.)

CCIB : China Commodity Inspection Bureau

CCEE : China Commission for Conformity Certification of Electrical Equipment

CCC : China Compulsory Certification

1-2 First catalogue of products subject to compulsory product certification

The First Catalogue of Products subject to Compulsory Product Certification, covering 132 items (19

categories) based on the CCIB products (104 items), CCEE products (107 items) and CEMC products

(Compulsory EMC Certification products) was designated on December 3, 2001.

Class Product catalogue Class Product catalogue

1 Electric Wires and Cables (5 items) 5 Electric tools (16 items)

2 Switches, Installation protective and connection devices (6 items) 6 Welding machines (15 items)

Low-voltage Electrical Apparatus (9 items) Compulsory Certification

3

Circuit-breakers (including RCCB, RCBO, MCB) 8 Audio and video equipment (16 items)

Low-voltage switchers

(disconnectors, switch-disconnectors, and

fuse-combination devices.

Other protective equipment for circuits

(Current limiting devices, circuits protective

devices, over current protective devices,

thermal protectors, over load relays,

low-voltage electromechanical contactors and

motor starters)

Relays (36V < Voltage ≤ 1000V)

Other switches

(Switches for appliances, vacuum switches,

pressure switches, proximity switches, foot

switches, thermal sensitive switches, hydraulic

switches, push-button switches, position limit

switches, micro-gap switches, temperature

sensitive switches, travel switches,

change-over switches, auto-change-over

switches, knife switches)

Other devices

(contactors, motor starters, indicator lights,

auxiliary contact assemblies, master

controllers, A.C. Semiconductor motor

controllers and starters)

Earth leakage protectors

Fuses

Low-voltage switchgear CNCA-01C-010:2001

4 Small power motors (1 item)

(Note)

Regulations

CNCA -01C -011: 2001

(Switch and Control

Equipment)

CNCA -01C -012: 2001

(Installation Protective

Equipment)

(Low-voltage

switchgear)

CNCA-01C-013:2001

(Small power motors)

(Note) When the servomotor or the spindle motor of which output is 1.1kW or less (at 1500 r/min) is used, NC could have been

considered as a small power motor. However, CQC (China Quality Certification Center) judged it is not.

7 Household and similar

electrical appliances

9 Information technology

equipment

10 Lighting apparatus (2 items)

11 Telecommunication terminal

equipment

12 Motor vehicles and Safety

Parts

13 Tyres (4 items)

14 Safety Glasses (3 items)

15 Agricultural Machinery (1 item)

16 Latex Products (1 item)

17 Medical Devices (7 items)

18 Fire Fighting Equipment (3 items)

19 Detectors for Intruder Alarm

Systems

(18 items)

(12 items)

(9 items)

(4 items)

(1 item)

Page 30

1-3 Precautions for shipping products

As indicated in 1-2, NC products are not included in the First Catalogue of Products subject to

Compulsory Product Certification. However, the Customs Officer in China may judge that the product

is subject to CCC Certification just based on the HS Code.

NC cannot be imported if its HS code is used for the product subject to CCC Certification. Thus, the

importer must apply for a "Certification of Exemption" with CNCA.

Exemption for details on applying for an exemption.

(Note 1) The First Catalogue of Products subject to Compulsory Product Certification (Target HS

Codes) can be confirmed at http://www.cqc.com.cn/Center/html/60gonggao.htm.

(Note 2) HS Code: Internationally unified code (up to 6 digits) assigned to each product and used for

customs.

(Note 3) CNCA: Certification and Accreditation Administration of People's Republic of China

(Management and monitoring of certification duties)

Note 2

Note 3

Refer to 1-4 Application for

Page 31

1-4 Application for exemption

Following "Announcement 8" issued by the Certification and Accreditation Administration of the

People's Republic of China (CNCA) in May 2002, a range of products for which application for CCC

Certification is not required or which are exempt from CCC marking has been approved for special

circumstances in production, export and management activities.

An application must be submitted together with materials which prove that the corresponding product

complies with the exemption conditions. Upon approval, a "Certification of Exemption" shall be issued.

<Range of products for which application is exempt>

Range of products not

requiring application

Range of products for

which application is

exempted

The following documents must be prepared to apply for an exemption of the "Import Commodity

Safety and Quality License" and "CCC Certification".

(1) Formal Application

(a) Relevant introduction and description of the company.

(b) The characteristics of the products to be exempted.

(c) The reason for exemption and its evidence (ex. customs handbook).

(d) The name, trademark, quantity, model and specification of the products to be exempted.

(Attach a detail listing of these items for a large quantity of products. When importing

materials for processing and repair equipments, submit a list of the importing materials for

each month and repair equipments.)

(e) Guarantee for the safety of the products; self-declaration to be responsible for the safety

during the manufacturing and use.

(f) To be responsible for the authenticity and legitimacy of the submitted documents.

Commitment to assist CNCA to investigate on the authenticity of the documents (When

CNCA finds it necessary to investigate on the authenticity of the documents.)

(2) Business license of the company (Copy)

(3) Product compliance declaration

Indicate which standard’s requirements the products comply with or submit a test report (Copy is

acceptable. The report can be prepared in a manufacturer’s laboratory either at home or

overseas.)

(4) Import license (Only if an import license is needed for this product. Copy is acceptable.)

(5) Quota certificate (Only if a quota certificate is needed for this product. Copy is acceptable.)

(6) Commercial contract (Copy is acceptable.)

(7) If one of item (4), (5) or (6) cannot be provided, alternative documents, such as bill of

lading, the invoice, and other evidential documents must be submitted.

(a) Items brought into China for the personal use by the foreign embassies, consulates, business

agencies and visitors

(Excluding products purchased from Service Company for Exporters)

(b) Products presented on a government-to-government basis, presents

(c) Exhibition products (products not for sale)

(d) Special purpose products (e.g., for military use)

Products not requiring application for CCC Certification are not required to be CCC marked or

certified.

(e) Products imported or manufactured for research and development and testing purposes

(f) Products shipped into China for integration into other equipment destined for 100% re-export to a

destination outside of China

(g) Products for 100% export according to a foreign trade contract (Excluding when selling partially

in China or re-importing into China for sales)

(h) Components used for the evaluation of an imported product line

(i) The products imported or manufactured for the service (service and repairs) to the end-user. Or

the spare parts for the service (service and repairs) of discontinued products.

(j) Products imported or manufactured for research and development, testing or measurements

(k) Other special situations

Page 32

1-5 Mitsubishi NC product subject to/not subject to CCC certification

The state whether or not Mitsubishi NC products are subject to the CCC Certification is indicated

below, based on the "First Catalogue of Products subject to Compulsory Product Certification" issued

by the State General Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) of the

People's Republic of China and the Certification and Accreditation Administration of the People's

Republic of China (CNCA) on July 1, 2002.

Model China HS Code (Note 1)

Power supply unit

Servo/spindle drive unit

Servo/spindle

NC – Not subject to CCC Certification

Display unit – Not subject to CCC Certification

85044090

85371010

85015100

85015200

(Note 1) The China HS Code is determined by the customs officer when importing to China. The

above HS Codes are set based on the HS Codes used normally when exporting from

Japan.

(Note 2) Reference IEC Standards are used as the actual IEC Standards may not match the GB

Standards in part depending on the model.

Whether or not the NC products are subject to CCC Certification was judged based on the following

five items.

(a) Announcement 33 (Issued by AQSIQ and CNCA in December 2001)

(b) HS Codes for the products subject to CCC Certification (Export Customs Codes)

* HS Codes are supplementary materials used to determine the applicable range. The applicable

range may not be determined only by these HS Codes.

(c) GB Standards (This is based on the IEC Conformity, so check the IEC. Note that some parts are

deviated.)

(d) Enforcement regulations, and products specified in applicable range of applicable standards

within

(e) "Products Excluded from Compulsory Certification Catalogue" (Issued by CNCA, November

2003)

Judgment on whether or not subject

to CCC Certification

Not subject to CCC Certification

Not subject to CCC Certification

Reference

• Outline of China's New Certification System (CCC Mark for Electric Products), Japan Electrical

Manufacturers' Association

• Outline of China's New Certification System (CCC Mark for Electric Products) and Electric

Control Equipment, Nippon Electric Control Equipment Industries Association

Page 33

2. Response to the China environment restrictions

2-1 Outline of the law on the pollution prevention and control for electronic information

products

Ministry of Information Industry (information industry ministry) issued this law on Feb.28, 2006 (Note)

(effective from Mar.1, 2007.) in order to protect the environment and the health of the people with

restricting and reducing the environmental pollution caused by the electronic information product

wastes. The restrictions are applied to containing lead (Pb), hydrargyrum (Hg), cadmium (Cd),

hexavalent chromium (Cr (VI)), polybrominated biphenyl (PBB) and polybrominated diphenyl ether

(PBDE) in two stages.

(Note) For the details, refer to the following.

http://www.mii.gov.cn/art/2006/03/02/art_524_7343.html

(1) First stage: Requirement of indicating contained substance

The producer and importer of the electronic information product are required to indicate the

hazardous substance. The concrete categories of the products belonging in the following eleven

main categories are described as subjected product list (electronic information product category

note).

• Radar device • Communication device • Radio/TV device industry product

• Computer product • Consumer-electronics device • Electronic measuring apparatus

• Electronics industry dedicated device • Electronic parts • Electronics device

• Electronics application product • Electronics dedicated material

(2) Second stage: Suppressing the amount of contained substances and compulsory CCC

Certification

The product listed in the “Electronic information product pollution priority control list” cannot be

sold in China unless it conforms to the Compulsory Product Certification System (CCC

Certification) and its cadmium usage is suppressed to 0.01w% and other substances usage less

than 0.1w%. Note that the timing when this is effective is unmentioned.

2-2 Response to the drive product for Mitsubishi NC

The drive product for NC has no items falling under the subjected product list (electronic information

product category note). However, for use with the drive product included in the subjected product or

for treating the product properly, information based on the law on the pollution prevention and control

for electronic information products” are described in the section “Appendix 9-2-3” for reference.

2-3 Indication based on “Pollution suppression marking request for electronic

information product”

(1) Electronic information product pollution suppression marking

This marking indicates the environmental protection expiration date

applied to the electronic information products sold in China according to

the law on the pollution prevention and control for electronic information

products issued on Feb.28, 2006. As long as you keep safety for this

product and follow the precautions for use, there are no serious effects on

the environment pollution, human body or property within its term

reckoned from the manufacturing date.

Note: This symbol mark is

for China only.

(Note) Equate the environmental protection expiration date of

consumables, such as enclosed battery and cooling fan, with the

product life. When disposing the product after using it properly,

obey each local laws and restrictions for collecting and recycling of

the electronic information product.

Page 34

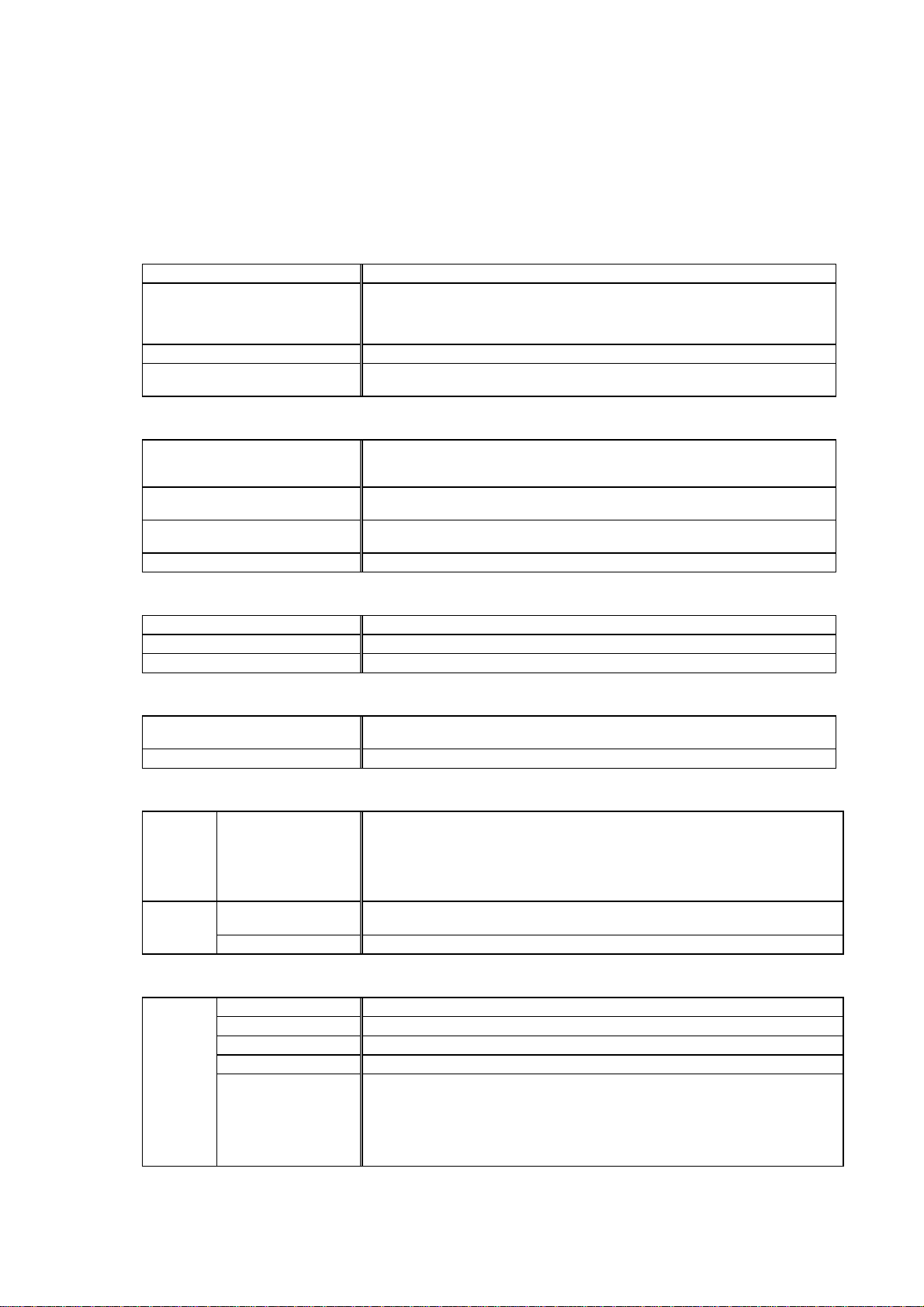

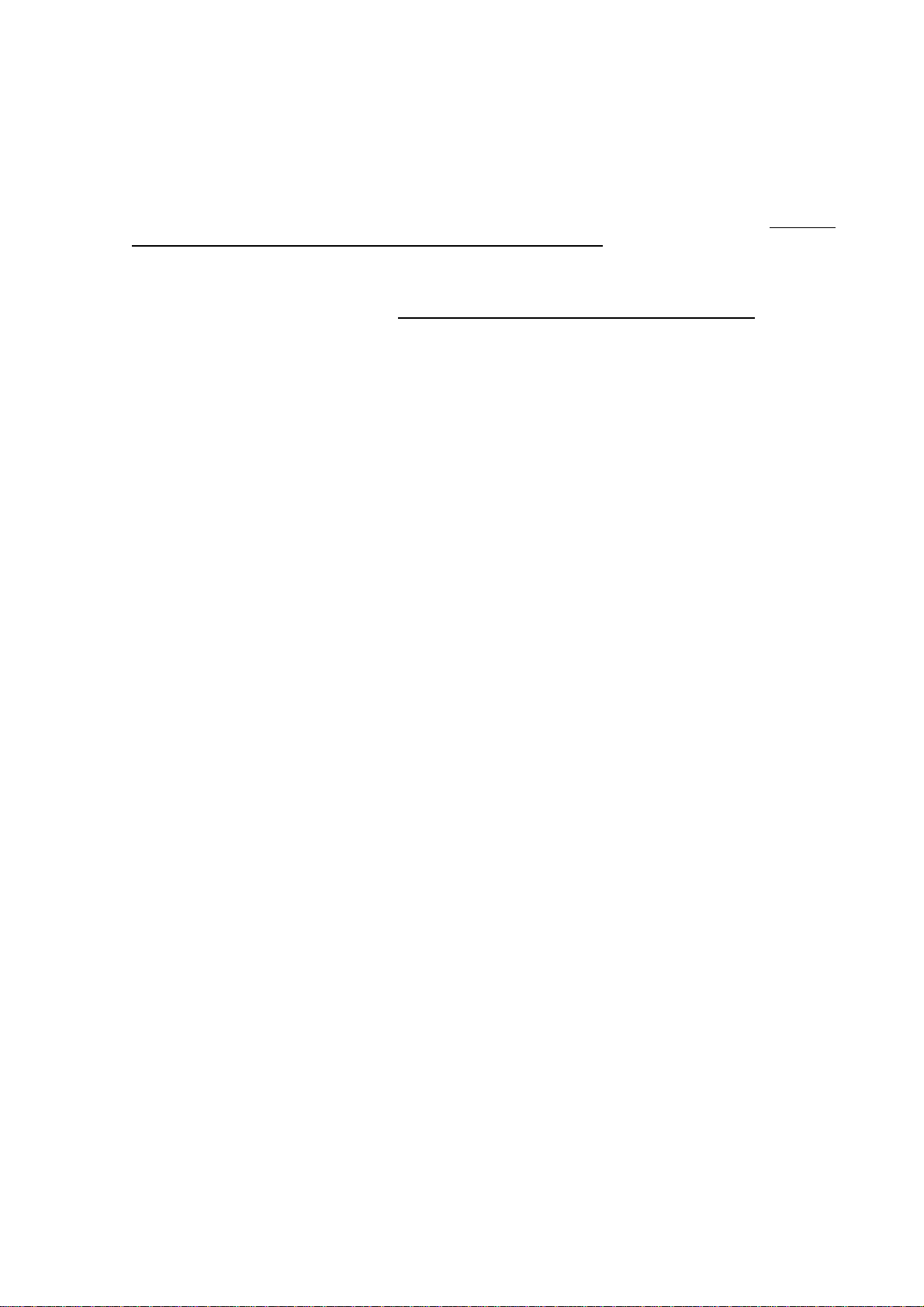

(2) The names of contained six hazardous substances and the parts containing them

The names of six substances contained in this product and the parts containing them are shown

below.

Toxic/hazardous substance or element

Parts name

Drive unit

Servo motor/spindle motor

Dedicated options (cable/connector)

Dedicated Options

(detector/AC reactor)

Dedicated Options (battery)

○: This mark means that toxic/hazardous substance content in all homogeneous materials of corresponding parts does not

exceed the standard specified in the standard of SJ/T11363-2006.

×: This mark means that toxic/hazardous substance content in the homogeneous materials of corresponding parts exceeds the

standard specified in the standard of SJ/T11363-2006.

Lead

(Pb)

× ○ ○ ○ ○ ○

× ○ ○ ○ ○ ○

× ○ ○ × ○ ○

× ○ ○ × ○ ○

× ○ ○ ○ ○ ○

Hydrargyrum

(Hg)

Cadmium

(Cd)

Hexavalent

chromium

(Cr(VI))

(PBB) (PBDE)

Page 35

Contents

Chapter 1 Preface

1-1 Inspection at purchase ............................................................................................................1-2

1-1-1 Package contents............................................................................................................1-2

1-1-2 Explanation of types ........................................................................................................1-2

1-2 Explanation of each part..........................................................................................................1-7

1-2-1 Explanation of each servo amplifier part .........................................................................1-7

Chapter 2 Wiring and Connection

2-1 System connection diagram....................................................................................................2-3

2-2 Servo amplifier main circuit terminal block, control circuit terminal block...............................2-4

2-2-1 Main circuit terminal block, control circuit terminal block signal layout ...........................2-4

2-2-2 Names and application of main circuit terminal block and control circuit terminal

block signals..2-5

2-2-3 How to use the control circuit terminal block (MDS-B-SVJ2-01~07)...............................2-6

2-3 NC and servo amplifier connection .........................................................................................2-9

2-4 Motor and detector connection..............................................................................................2-10

2-4-1 Connection of HC52, HC53, HC102* ............................................................................2-10

2-4-2 Connection of HC102, HC103, HC152*, HC152, HC153.............................................. 2-11

2-4-3 Connection of HC202*, HC202, HC203*, HC352* ........................................................ 2-12

2-4-4 Connection of HC103R, HC153R, HC203R..................................................................2-13

2-4-5 Connection of HA053N, HA13N ....................................................................................2-14

2-4-6 Connection of HA23N, HA33N ......................................................................................2-14

2-4-7 Connection of HA40N,HA43N.......................................................................................2-15

2-4-8 Connection of HA80N, HA83N ......................................................................................2-15

2-4-9 Connection of HA100N, HA103N*, HA200N*................................................................2-16

2-4-10 Connection of HC-SF52, HC-SF53, HC-SF102, HC-SF103.......................................2-17

2-4-11 Connection of HC-SF152, HC-SF153..........................................................................2-17

2-4-12 Connection of HC-SF202, HC-SF203, HC-SF352, HC-SF353................................... 2-18

2-4-13 Connection of HC-RF103, HC-RF153, HC-RF203 .....................................................2-18

2-4-14 Connection of HA-FF Series........................................................................................2-19

2-4-15 Connection of HA-FF□C-UE Series ...........................................................................2-19

2-4-16 Connection of HC-MF(-UE) Series..............................................................................2-20

2-4-17 Connection of HC-MF□-S15 Series ...........................................................................2-20

2-5 Connection of power supply..................................................................................................2-21

2-5-1 Example of connection when using converter unit........................................................2-21

2-5-2 Example of connection when controlling the contactor with the MDS-B-SVJ2.............2-23

2-6 Connection of regenerative resistor ......................................................................................2-24