Page 1

M A G N E T IC M O T O R

DRIVE UNIT

SERIES

INSTRUCTION M ANUAL

H igh P erform ance & H igh Function

M D -C X 5 2 2 -0 .4 K to 3 .7 K

PRE-O PERATION

IN F O R M A T IO N

C hapter 1

INSTALLATION

W IRING

HOW TO USE THE

PARAM ETER UNIT

OPERATION

TROUBLESHOOTING

SPECIFICATIONS

Chapter 2

C h a p te r 1

Chapter 3

C hapter 4

C hapter 5

Chapter 6

Chapter 7

PARAM ETER

FUNCTIONS

C hapter 8

Page 2

Please read here first

Thank you for choosing the Mitsubishi Magnetic Motor Drive Unit. This instruction

manual gives handling information and precautions for use of the drive unit.

Incorrect handling of the equipment may cause an unexpected fault. To optimize the

unit capability, please read this manual carefully before using the equipment.

General precautions

Please forward this instruction manual to the end user.

Many of the diagrams and drawings in this instruction manual show the drive

unit without a cover, or partially open. Never run the drive unit in this

manner. Always replace the cover and follow this instruction manual when

operating the drive unit.

After reading this manual, store it carefully in a plac e where it is easily

accessible for the operator.

This instruction manual is subject to modifications for specifi ca t ion changes

and manual improvements. After such modifications hav e been made, the

instruction manual will be published as a revised version with a new number

located on the bottom left of the back cover.

For safe operation of this product

This product has not been designed or manufactured for use in or with a

device or system which will be used unde r ci rcu mstances where life may be

endangered.

Consult with Mitsubishi if you are planning to use this product for special

purposes, e.g. equipment or systems designed for manned transport

vehicles, medical purpose s, a erospace, nuclear power, electric power or

undersea junctions.

This product has been man ufactured under strict quality control. However,

when installing the product w here serious accident s or losses could occur if

the product fails, install appr opriate safety devices in the system.

Do not use this product with any load oth er than the specified motor.

You cannot use a single driv e unit w i th tw o or more motors.

1

Page 3

Please read here first (Continued)

Safety Instructions

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the drive unit until you

have read through this i nstruction manual and app ended documents carefully

and can use the equipment c or re ctly. Do not use the drive unit until you hav e a

full knowledge of the equipment, safety information and instructions.

In this instruction manual, the safety instruction levels are classified into

"WARNING" and "CAUTION".

Assumes that incorrect handling may cause

WARNING

CAUTION

hazardous conditions, resulting in severe injury or

death.

Assumes that incorrect handling may cause

hazardous conditions, resulti ng in medium or slight

injury, or may cause phy sic al damage only.

Note that the CAUTION level may lead to a serious consequence a ccording to

conditions. Please follow the instructions of both levels because they are

important to personal safety.

NOTICE

MEMO

denotes the items which do not corres pond to "WARNING" or

"CAUTION" but should be o bserved by the customer.

denotes the items which the user should know for ope ratio n.

2

Page 4

1. Usage

WARNING

The MELIPM series motor is a synchronous motor with high-performance

magnets built in its rotor. Therefore, after the drive unit is powered off, there

are high voltages at the motor ter mi nals while the motor is running. Before

starting wiring or maintenance and inspection, make sure that the motor has

stopped. In any application wh er e the motor is rotated by a load su ch as a

fan or blower, connect a low -voltage manual switch on the drive unit' s output

side, open the switch, and start w iring or maintenance and inspe ction. Not

doing so can cause an electric shock.

Never disassem ble or modify the unit. Doing so can cause an electric shock,

fire or injury.

Do not use the unit with any load other than th e specified motor. Doing so

can cause a fire or injury.

Provide safety devices for the whole system, e.g. emergency brakes, to

ensure that the machine or device is not placed in hazardous c onditions

when the drive unit fails.

CAUTION

If a holding brake is required, prepare it separately. Injury may result.

Before operating the drive unit which had been stored for an extended

period of time, perform inspection and test operation on the unit before

using. Not doing so may cau s e accidents.

2. Transportation

CAUTION

Do not stack the drive unit boxes higher than the number indicat ed on the

package. Doing so can cause injury .

Confirm the weight before carrying the drive unit. Not doin g so can cause

injury.

When carrying the drive unit, do not exert a force partially, i.e. do not hold

the front cover. Doing so can cause the unit to drop, leading to injury .

The drive unit is precision piece of equipment. Do not drop it or subject it to

impact, this may damage the drive unit.

3. Installation

CAUTION

Do not install or operate the drive unit if it is damaged or has parts missing.

Such installation or operati on c an cause accidents.

Always install the drive unit in the specified orie ntation and environment. Not

doing so can cause a fire or a ccidents.

Install the drive unit on an incombustible material such as metal. Not doing

so can cause a fire.

Do not place combustible materials nearby. Doing so can cause a fire.

Install the drive unit in a load-bearing place. Not doing so can cause

accidents.

Prevent screws, metal piece s or other conductive foreign matter, or wood

scrap, oil or other flammable forei gn matter from entering the drive unit.

They can cause a fire or accidents.

3

Page 5

4. Wiring

WARNING

Any person who is involv ed in the wiring of this equipment should b e fully

competent to do the work. Otherwise, an electric shock or fire can occur.

Install a no-fuse breaker or earth leakage circuit breake r. Othe rwise, a drive

unit failure can cause large currents to flow, resulting in a fire.

Always install the unit before wiring. Otherw is e, an electric shock or fire can

occur.

Before restarting wiring after pow er-on, make sure that the motor is at a stop,

wait for more than 10 minutes after switching power off, and confirm that the

DC voltage across the DC terminals P/+ and N/- is low enou gh to do the

work. Immediately after power-off, the DC terminals P/+, N/- are charged

with more than 200V (residual voltage of th e inter nal capacitor). Therefore,

an electric shock may occur.

Even after power-off, the motor connection terminals U, V, W have high

voltages while the motor is running. Alw ays start wiring after confirming that

the motor has stopped. Not doing so can cause an electric shock.

Earth the drive unit. Not doing so can cause an electric shock o r fire.

CAUTION

Make sure that the input power supply voltage matches the rated voltage

specifications. Mismatc h c an cause a fire or accidents.

Check the terminal layout and ter minal symbols to ensure that connection s

are correct. Wrong connection s can cause a fire or accidents.

Do not connect a power supply to the motor connection ter minals U, V, W.

Doing so can caus e a fire or accidents.

Connect the motor connection terminals U, V, W to match the motor phase

sequence. Wrong connections can cause a ccidents due to reverse rotation

of the motor.

Do not connect a resistor across the DC terminals P/+-N/-. Doing so can

cause a fire or accidents.

Take measures to prevent peripheral sensors and equipment from

malfunctioning due to electromagnetic noises. Not doing so can cause

accidents.

Take measures to prevent peripheral power capacitors and generators from

overheating or being damaged due to power harmonics. Not d oing so can

cause a fire.

Connect the power capacitor, surge suppressor an d r adio noise filter (FR-

BIF option) on the power supply side. Connection on the output side can

cause a fire.

4

Page 6

5. Operation

WARNING

Always replace the front cover befo re switching input power on. While power

is on, do not remove the front cover. D oing so can cause an electric shock.

Operate the switches with dry hands. Not doing so can cause an electric

shock.

Prepare an emergency stop switch separately. The "STOP/RESET" key of

the parameter unit is valid for stop ping only when the function setting has

been made. Not using a se parate emergency stop switch can cause

accidents.

When the stall prevention function is activated, operation will be performed

independently of the preset acceleration/deceleration time and preset speed.

Design the machine to ensu re safety if the stall prevention function is

activated. Not doing so can c ause accidents.

At the occurrence of an alarm, turn off the run signal before resetting the

alarm. The drive unit will restart abruptly if you reset the alarm with the run

signal on. It can cause injury.

At occurrence of an alarm, turn off the run sig nal. If you do not turn off the

run signal, the alarm may be reset due to power OFF-ON at occur rence of

an instantaneous pow er failure or like, restarting the drive unit suddenly. It

can cause injury.

CAUTION

You can set the motor speed easily between low speed and high speed. Set

the speed command which will not exceed the permissible range of machine

design. Not doing so can cause accidents.

If the motor is rotated by the load, ensure that the motor will not exceed its

maximum speed. The drive unit may be damaged.

While power is on or some time after power-off, do not touch the heat sink

and brake resistor as they are hot. You may get burnt.

The electronic overcurrent protection function for motor overheat protection

is initialized when the drive unit is reset. Frequent resetting of the drive unit

will disable motor overheat protection. The motor may be burnt if it is

operated under overload.

5

Page 7

6. Maintenance, Inspection and Part (Cooling Fan) Replacement

WARNING

Any person who is involved in maintenance, inspection or part replacement

should be fully competent to do the work. Otherwise, an electric shock or

injury can occur.

Before starting maintenance, inspection or part replacement, make sure that

the motor is at a stop, wait for more than 10 minutes after switching power

off, and confirm that the DC voltage across the DC terminals P/+ and N/- is

low enough to do the work. Immediately after power-off, the DC terminals

P/+, N/- are charged with more than 200V (residual voltage of the internal

capacitor). Therefore, an electric shock may oc cur.

Even after power-off, the motor connection terminals U, V, W have high

voltages while the motor is running. Always start the work after confirming

that the motor has stopped. Not doing so can cause an electric shock.

Do not conduct a pressure test. A pressure test can damage the drive unit.

Do not perform an insulation resistance test on the control circuit using a

megger. Such a test can damage the d rive unit.

While power is on, do not replace the cooling fan. Replacing the cooling fan

during power-on c an be hazardous.

7. Disposal

CAUTION

Dispose of the drive unit as general industrial waste. Its solder (lead) can

cause environmental c ontamination.

6

Page 8

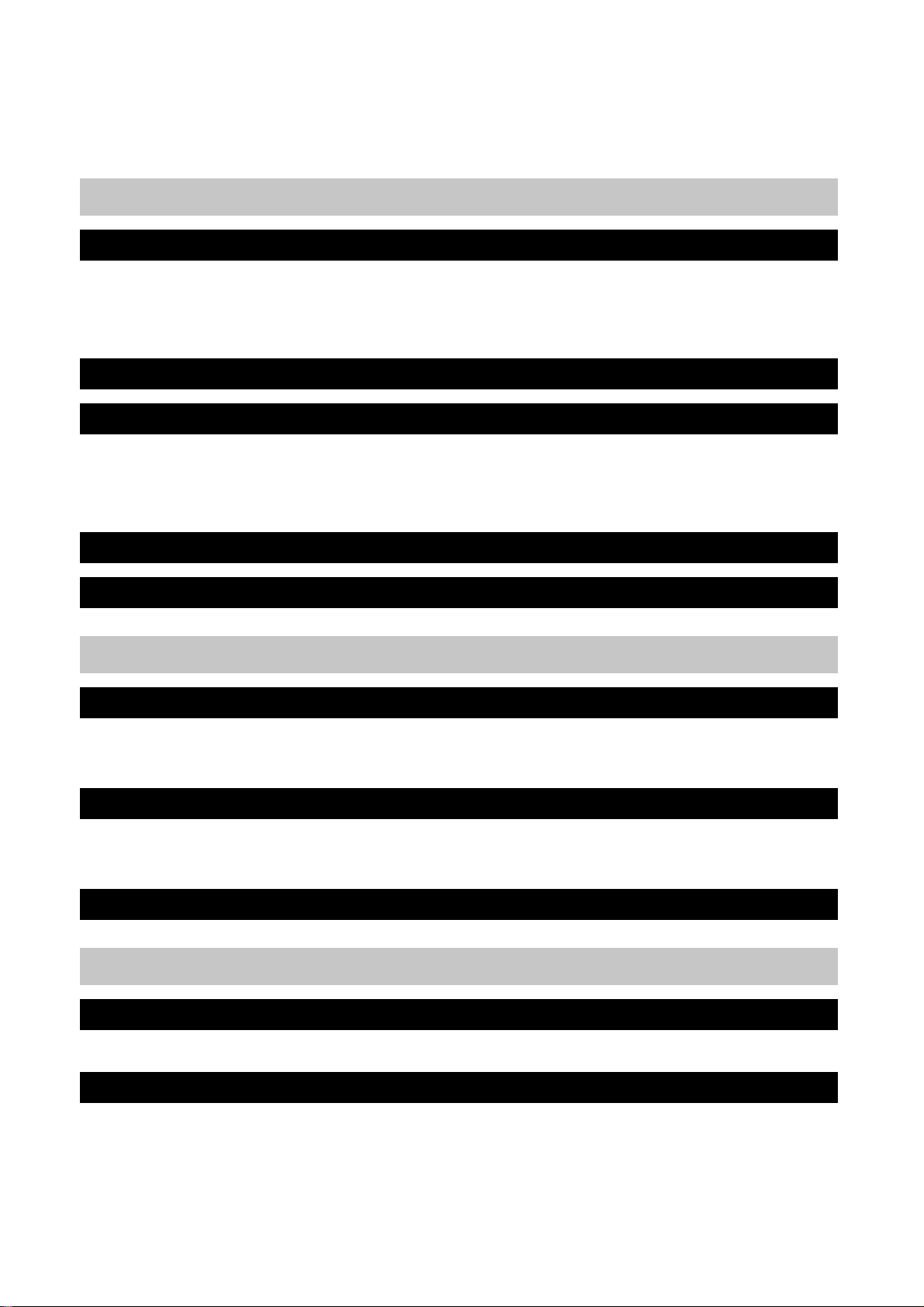

CONTENTS

Page

1. PRE-OPERATION INFORMATION 1-1

1.1 Checking the Product 1-1

1.1.1 Contents.................................................................................. 1-1

1.1.2 Type........................................................................................ 1-1

1.1.3 Drive units to be used with motors.......................................... 1-1

1.2 Parts Identification 1-2

1.3 Handling of Covers and the Like 1-3

1.3.1 Removal and reinstallation of the front cover (Lower)............. 1-3

1.3.2 Removal and reinstallation of the wiring cover........................ 1-3

1.3.3 Removal and reinstallation of the operation panel.................. 1-4

1.4 Transportation 1-5

1.5 Storage 1-5

2. INSTALLATION 2-1

2.1 Checking the Installation Environment 2-1

2.1.1 Operating environment............................................................ 2-1

2.1.2 Installation in control box......................................................... 2-2

2.2 Preparation of Peripheral Devices 2-3

2.2.1 Basic configuration.................................................................. 2-3

2.2.2 Selection of peripheral devices............................................... 2-4

2.3 Installation Method 2-6

3. WIRING 3-1

3.1 Pre-Wiring Instructions 3-2

3.1.1 Terminal connection diagram.................................................. 3-2

3.2 Wiring of the Main Circuit Terminals 3-3

3.2.1 Terminals ................................................................................ 3-3

3.2.2 Terminal layout and connection specifications........................ 3-3

3.2.3 Wiring of the AC power input terminals R, S, T....................... 3-3

7

Page 9

3.2.4 Wiring of the motor connection terminals U, V, W...................3-4

3.2.5 Wiring of the ground terminals

3.2.6 Wiring of the DC reactor connection terminals P/+, P1........... 3-5

3.2.7 Wiring of the brake resistor connection terminals P/+, PR...... 3-5

3.2.8 Wiring of the DC terminals P/+, N/-......................................... 3-5

..........................................3-4

3.3 Wiring of the Control Circuit Terminals 3-6

3.3.1 Terminals................................................................................. 3-6

3.3.2 Terminal layout and connection specifications........................ 3-9

3.3.3 Wiring of the contact input terminals......................................3-10

3.3.4 Wiring of the speed command input terminals .......................3-11

3.3.5 Wiring of the transistor output terminals.................................3-11

3.3.6 Wiring of the contact output terminals....................................3-12

3.3.7 Wiring of the instrument connection terminals........................3-12

3.4 Wiring of the PU Connector 3-13

3.4.1 Pin layout................................................................................3-13

3.4.2 Using the cable to connect the parameter unit.......................3-13

3.4.3 System configuration examples

for communication operations................................................3-13

3.4.4 Wiring methods for communication operation........................3-15

4. HOW TO USE

THE FR-PU04 PARAMETER UNIT 4-1

5. OPERATION 5-1

5.1 Power On 5-1

5.2 Setting of Operation Mode 5-1

5.3 Starting operation 5-2

6. TROUBLESHOOTING 6-1

6.1 Message Appearing on the Parameter Unit 6-1

6.1.1 Protective function activated....................................................6-1

6.1.2 Alarm function activated.......................................................... 6-4

6.1.3 Others...................................................................................... 6-5

6.2 Motor operation out of ordinary 6-6

8

Page 10

6.3 Maintenance and Inspection 6-7

6.3.1 Inspection................................................................................ 6-7

6.3.2 Wear parts............................................................................... 6-9

6.3.3 Cooling fan replacement method ...........................................6-10

7. SPECIFICATIONS 7-1

7.1 Standard Specifications 7-1

7.1.1 Rating specifications............................................................... 7-1

7.1.2 Common specifications........................................................... 7-2

7.1.3 Outline drawings...................................................................... 7-4

8. PARAMETER FUNCTIONS 8-1

8.1 Protection and Editing of the Parameters 8-1

8.2 Parameter Unit Operation Selection 8-2

8.3 Selection of the Speed Command 8-3

8.3.1 Selection of the analog speed command specifications.......... 8-3

8.3.2 Variable-speed operation using contact input signals............. 8-4

8.4 Selection of the Control Circuit Contact Input Terminal

Functions 8-5

8.5 Setting of the Operation Pattern 8-6

8.5.1 Running speed region............................................................. 8-6

8.5.2 Acceleration time and deceleration time ................................. 8-8

8.5.3 Selection of regenerative brake unit........................................ 8-9

8.5.4 Stall prevention operation level............................................... 8-9

8.5.5 Other settings.........................................................................8-10

8.6 Communication operation from the PU connector 8-11

8.7 Monitoring of Operation Status 8-22

8.7.1 Selection of paremeter unit display data................................8-22

8.7.2 Selection of the control circuit output terminal functions........8-23

8.7.3 Detection of running speed....................................................8-23

8.7.4 Detection of output current.....................................................8-24

8.7.5 Selection of the instrument connection terminal functions.....8-25

APPENDIX 1 PARAMETER LIST (NUMERICAL ORDER) 8-26

9

Page 11

1. PRE-OPERATION INFORMATION

t

1. PRE-OPERATION INFORMATION

1.1 Checking the Product

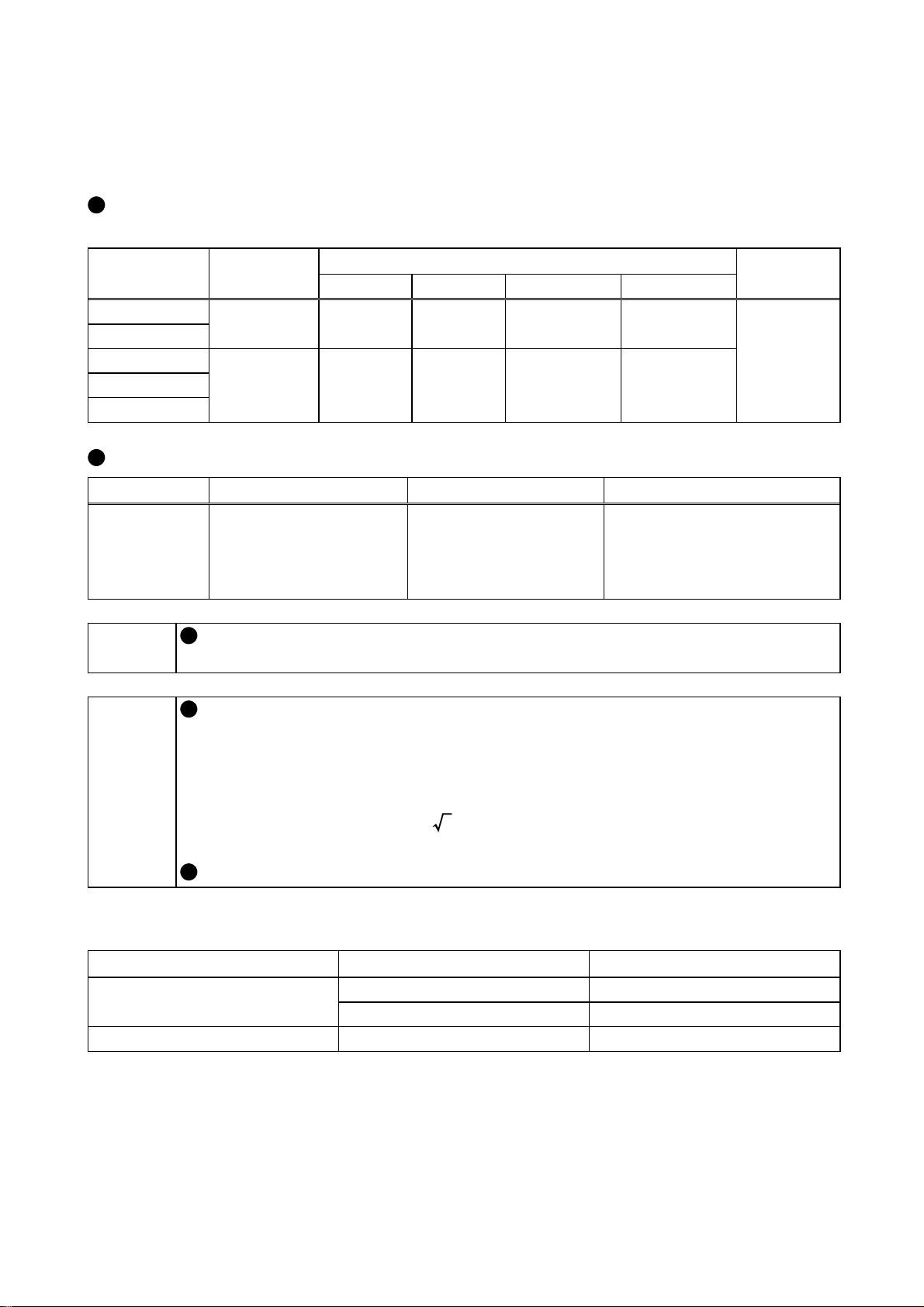

Unpack the drive unit, inspect the contents, and check the name plate to ensure

that the product agrees with y our order.

1.1.1 Contents

Contents Quantity

Drive unit 1

Instruction manual 1

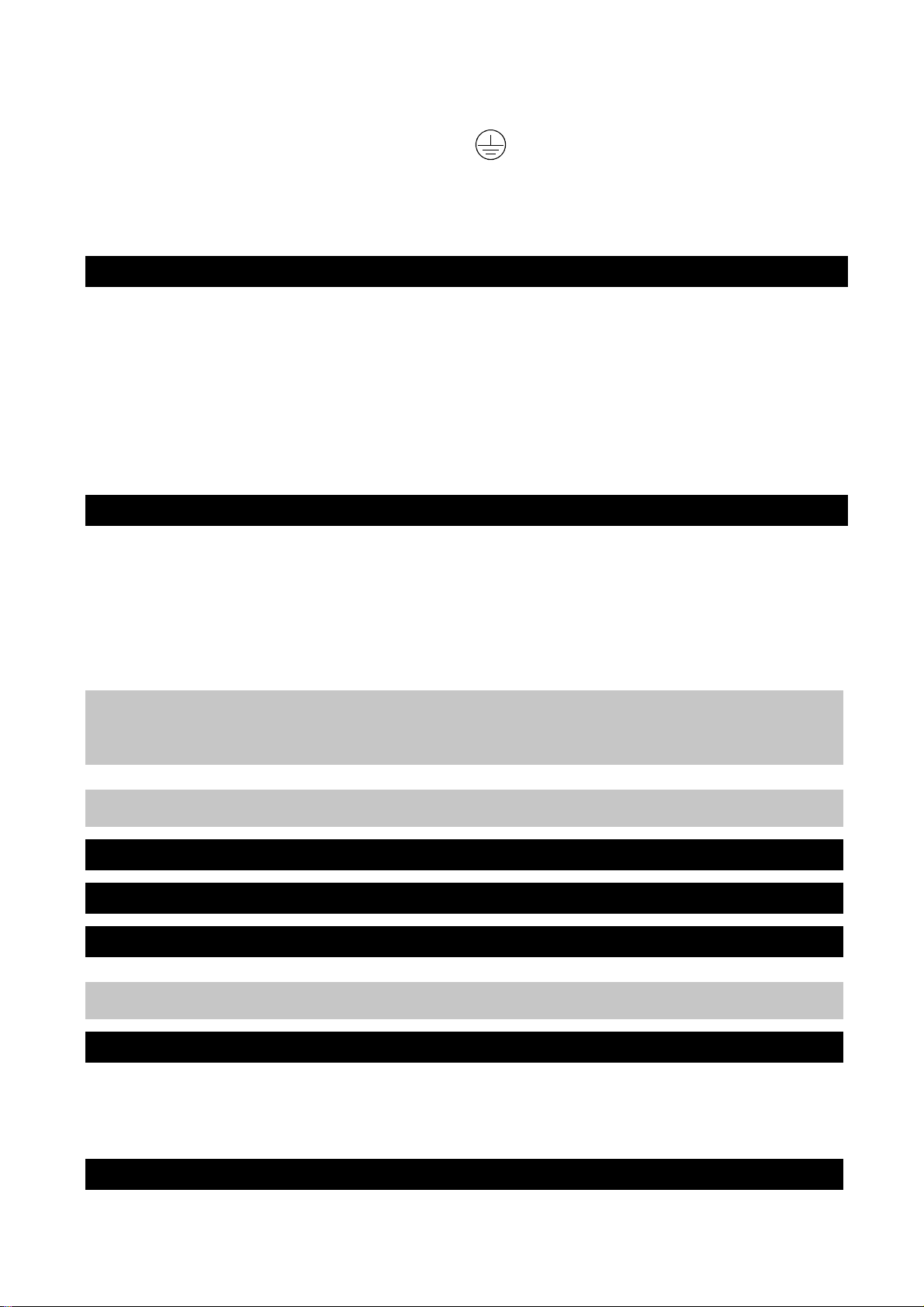

1.1.2 Type

Locations of the capacity plate and name plate and definitions of their

descriptions

Capacity

plate

Capacity plate

MD-CX522-0.4K/

Drive unit type

Name

plate

Input ra ting

Output rating

Serial number

Serial number

Name plate

MITSUBISHI

MODEL

MD-CX522-0.4K

INPUT :

XXXXX

OUTPUT :

XXXXX

SERIAL :

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

MELIPM

Drive uni

type

PASSED

Type

C X 5 2 2M D - - K

Series

Capacity

Power supply: 3-phase 200V

1.1.3 Drive units to be used with motors

Use the drive unit with the specified dedic ated motor. In this case, confirm that

the capacity and rated speed of the drive unit always match those of the motor.

1

1-1

Page 12

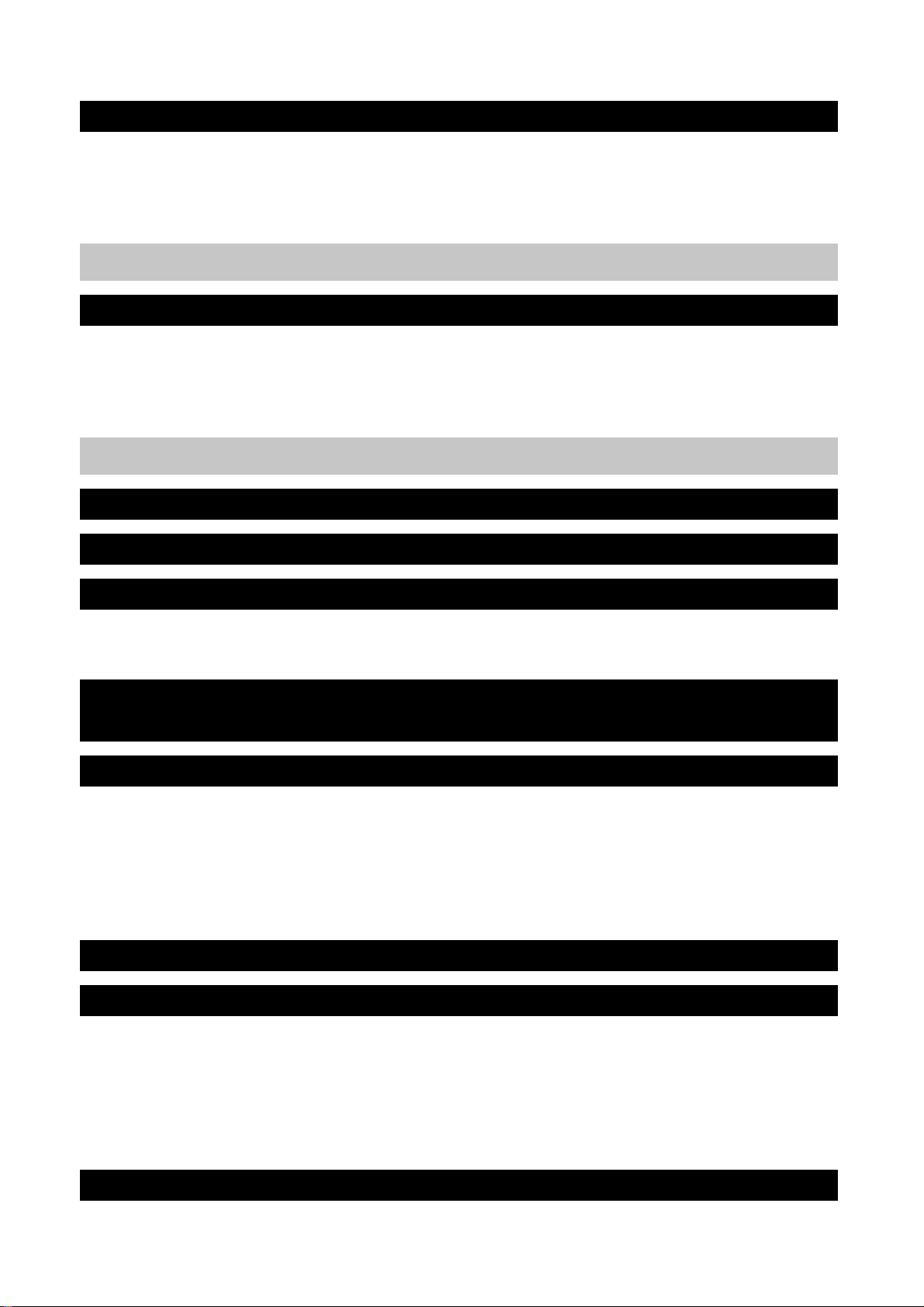

1.2 Parts Identification

Appearance of drive unit

Without front cover (Lower)

1. PRE-OPERATION INFORMATION

Front cover (Upper)

Name plate

Front cover (Lower)

Capacity pl ate

Wiring cover

Without front cover (Upper)

Control circuit terminal block

Main circuit terminal block

Wiring cover

PU connector

POWER lamp (Yellow)

ALARM lamp (Red)

1-2

Page 13

1. PRE-OPERATION INFORMATION

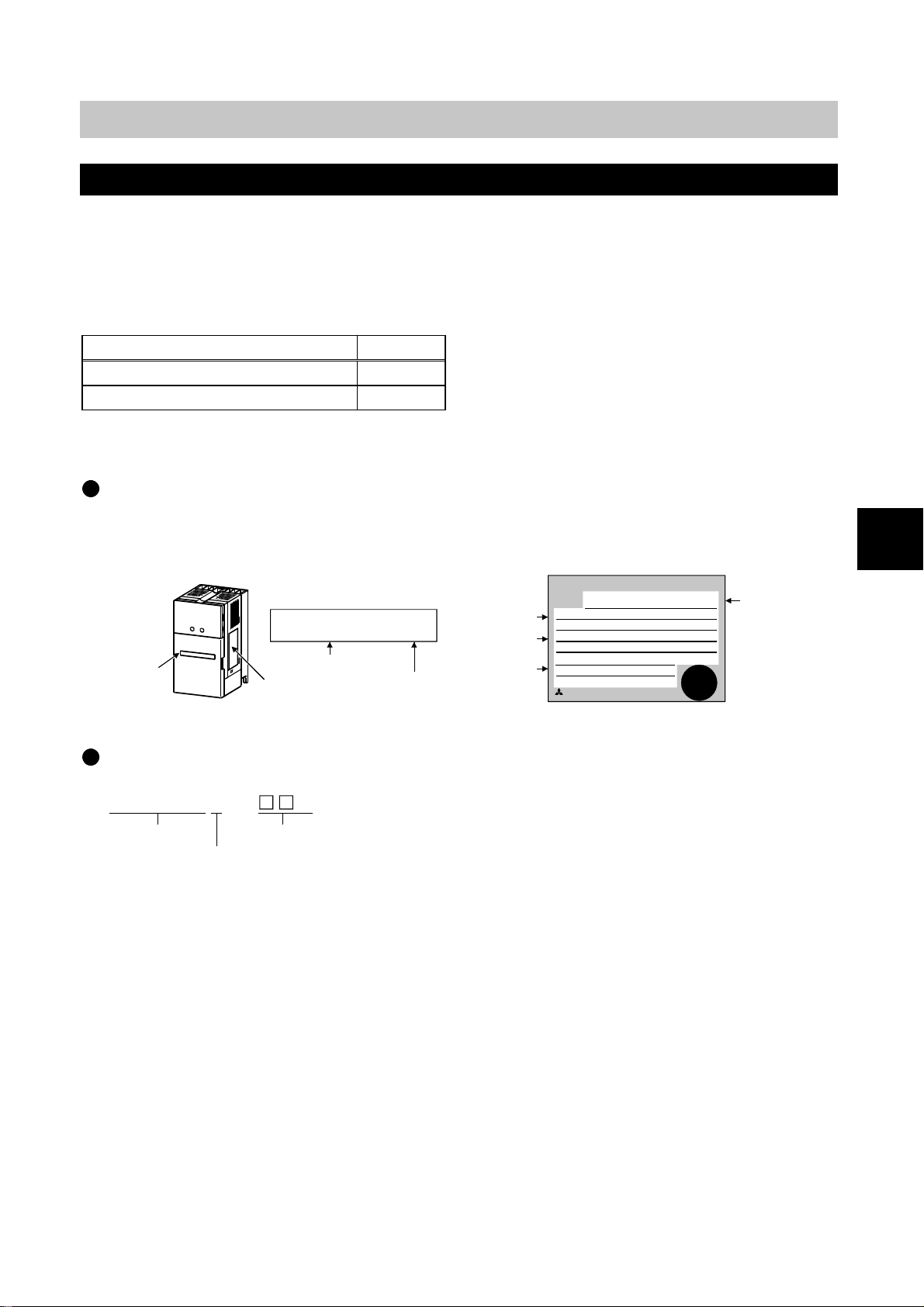

1.3 Handling of Covers and the Like

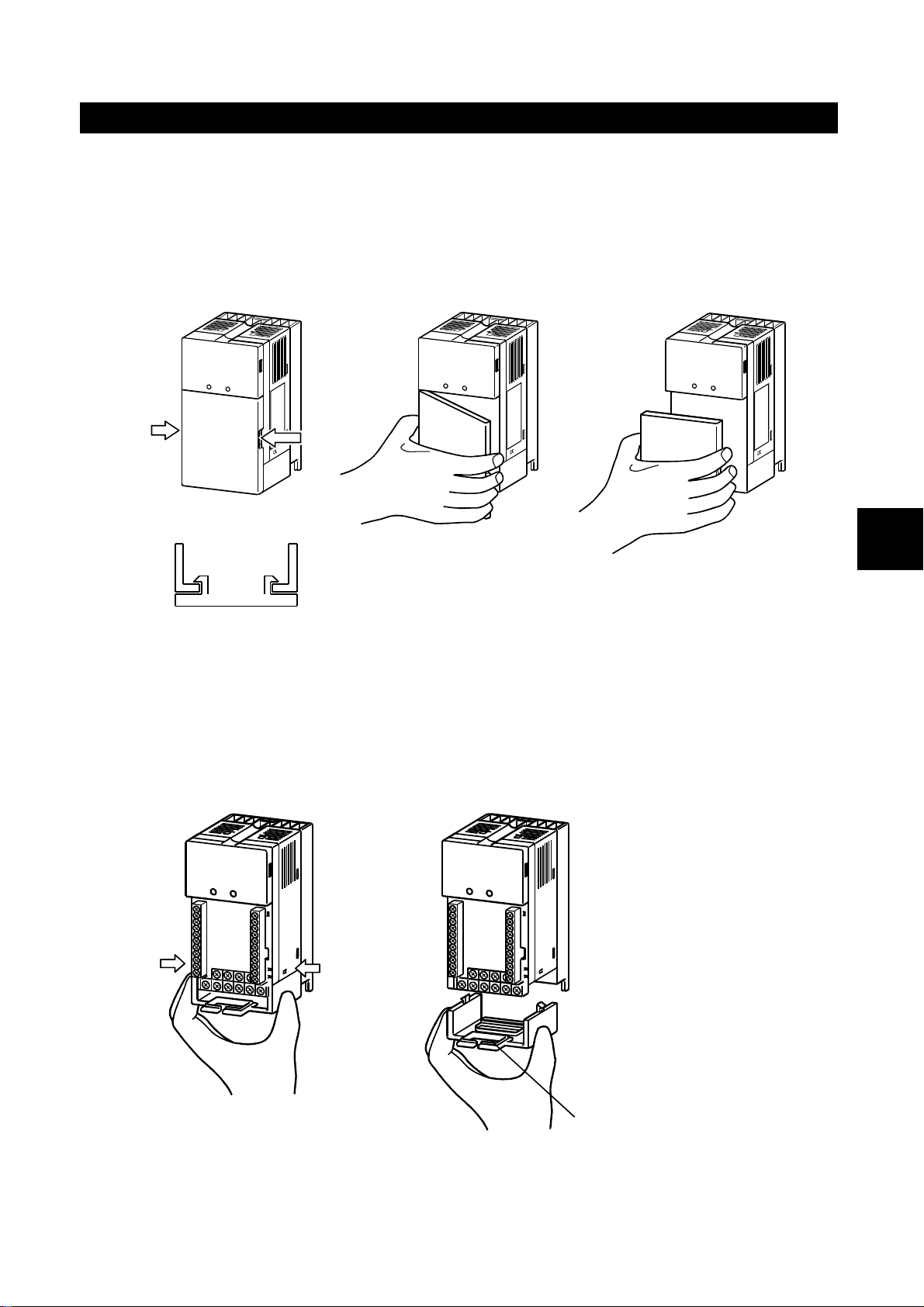

1.3.1 Removal and reinstallation of the front cover (Lower)

The front cover is fastened by the latches in positions A and B.

Push either A or B in the direction of arrow, and using the other end as a supp ort,

pull the front cover toward you to remove.

1) 2) 3)

A

B

To reinstall the front cover, fasten it with the latches securely.

1.3.2 Removal and reinstallation of the wiring cover

The wiring cover is fastened by the latches in positions 1 an d 2.

Push either 1 or 2 in the direction of arrow, and pull the wiring cover downward to

remove.

1

1)

2)

Wiring hole

Run the cables through the wiring hole and reinstall the cover securely in the

original position.

1-3

Page 14

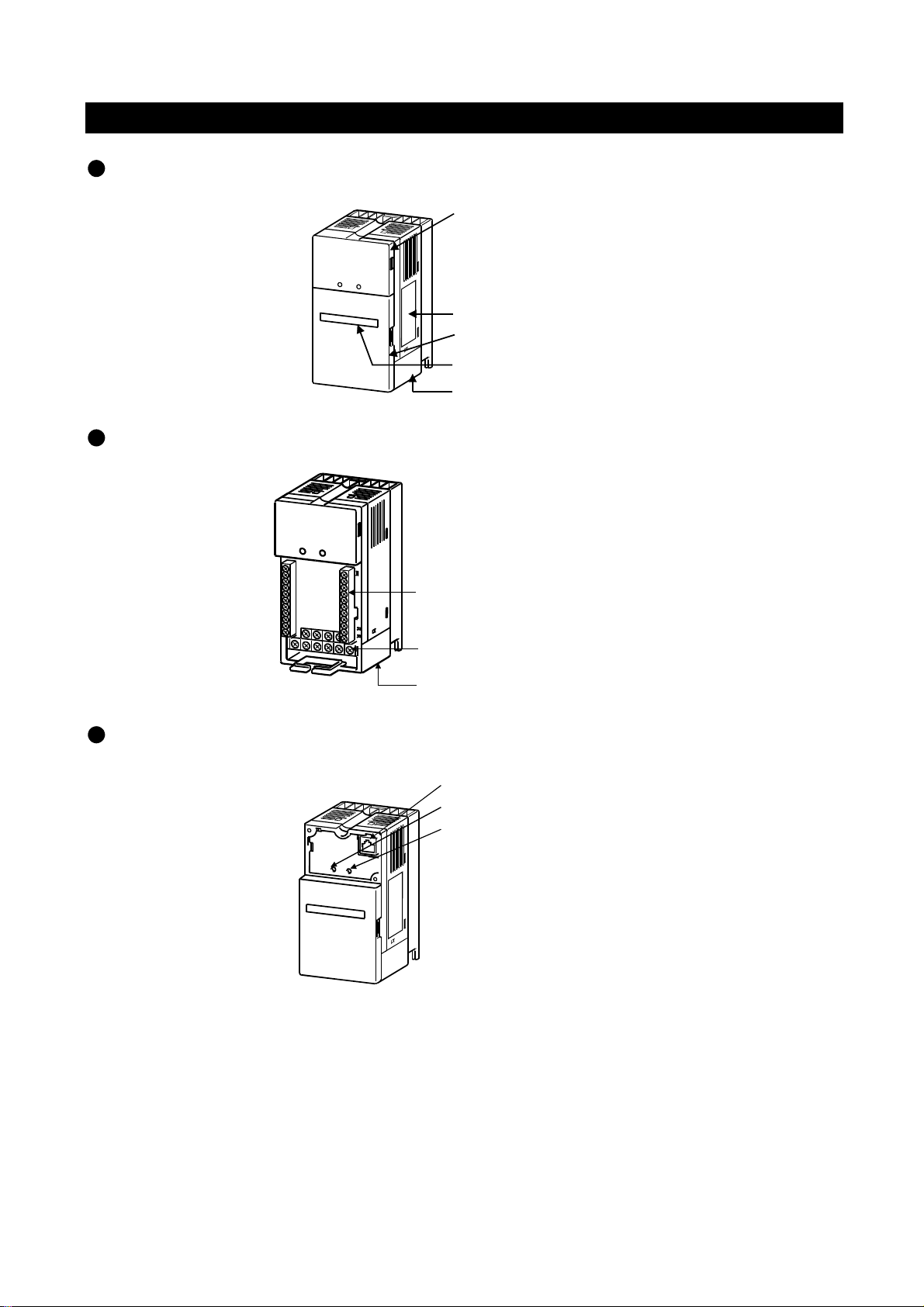

1. PRE-OPERATION INFORMATION

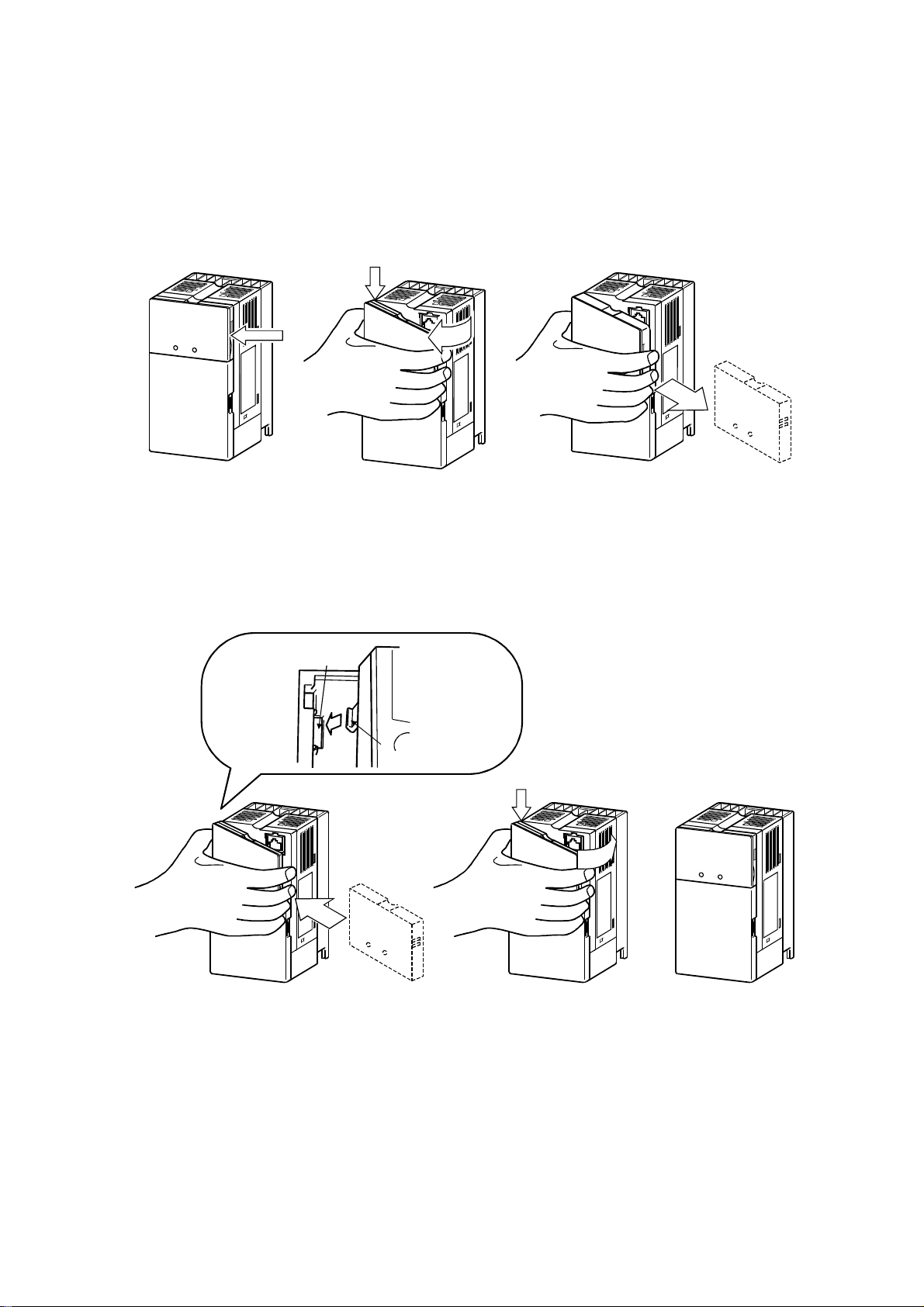

1.3.3 Removal and reinstallation of the operation panel

Hold down the arrow part A, and using the arrow part B as a support, pull the

right hand side of the operation panel toward you and remov e the panel

rightward.

A

2)

B

3)

1)

If the operation panel is remov ed in any other method, force will be applied to the

internal connector, damaging the panel.

To reinstall, insert the tab (left side) of the o peration panel into the mounting

position of the drive unit and push in the right hand side tab.

Mounting position

1)

Operation panel

Tab

2)

A

3)

1-4

Page 15

1. PRE-OPERATION INFORMATION

1.4 Transportation

When carrying, always support the whole drive unit.

1.5 Storage

Store the drive unit in the following environment.

Ambience

Ambient temperature

Storage temperature

Ambient humidity

Vibration

If the specification value of humidity is satisfied, c on densation

and/or freezing will occur in places where temperatures vary greatly.

NOTICE

Avoid storing the equipment in su c h places.

Avoid placing the unit directly on the floor. Place it on a stand or

shelf.

No corrosive gas, flammable gas, oil mist, dust and dirt.

No exposure to direct sunlight. No salt.

-10°C to +50°C (non-freezing)

-20°C to +65°C (applies to short-time transit)

90%RH or less (non-condensing)

5.9m/s2 (conformance with JIS C 0040)

1

1-5

Page 16

2. INSTALLATION

2. INSTALLATION

This chapter gives pre paratory information on installation and w iring of the drive

unit.

The Japanese harmonic suppression guidelines for suppression of

harmonics were established by the Ministry of Economy, Trade and

Industry (formerly Ministry of International Trade and Indu stry) in

September, 1994.

NOTICE

2.1 Checking the Installation Environment

2.1.1 Operating environment

To comply with the regulation levels determined by the Japan

Electrical Manufacturers' As sociation in accordance with the

"harmonic suppre s sion guideline for household appliances and

general-purpose products", connect the optional power factor

improving reactor (FR -BEL or FR-BAL).

General operating environment

Install the unit in the following environ ment.

Ambience

Ambient temperature

Ambient humidity

Altitude

Vibration

Indoors (No corrosive gas, flammable gas, oil mist, dust and dirt

No exposure to direct sunlight. No salt.)

-10°C to +50°C (non-freezing)

90%RH or less (non-condensing)

Maximum 1000m

5.9m/s2 (conformance with JIS C 0040)

CAUTION

Install the equipment on a non-flammable material. Not doing so can

cause a fire.

Do not place flammable materials near the equipment. Do ing so can

cause a fire.

Install the unit in a load-bearing place. No t doing so can cause an

accident.

Noise environment

Since drive is an electronic pie c e of equipment, the drive unit may malfunction if

there are machines whi ch g enerate large noises (e.g. welder, power equipment)

in the periphery. Fit surge suppressors, noise filters and/or like to the noise

sources, install the driv e unit as far away as possible from noise sources, or

place shielding plates and th e like to fully suppress noises.

2

CAUTION

The drive unit itself can be the source o f nois es. Take noise

suppression measures to pr event peripheral equipment from

malfunctioning due to noises.

2-1

Page 17

2. INSTALLATION

V

p

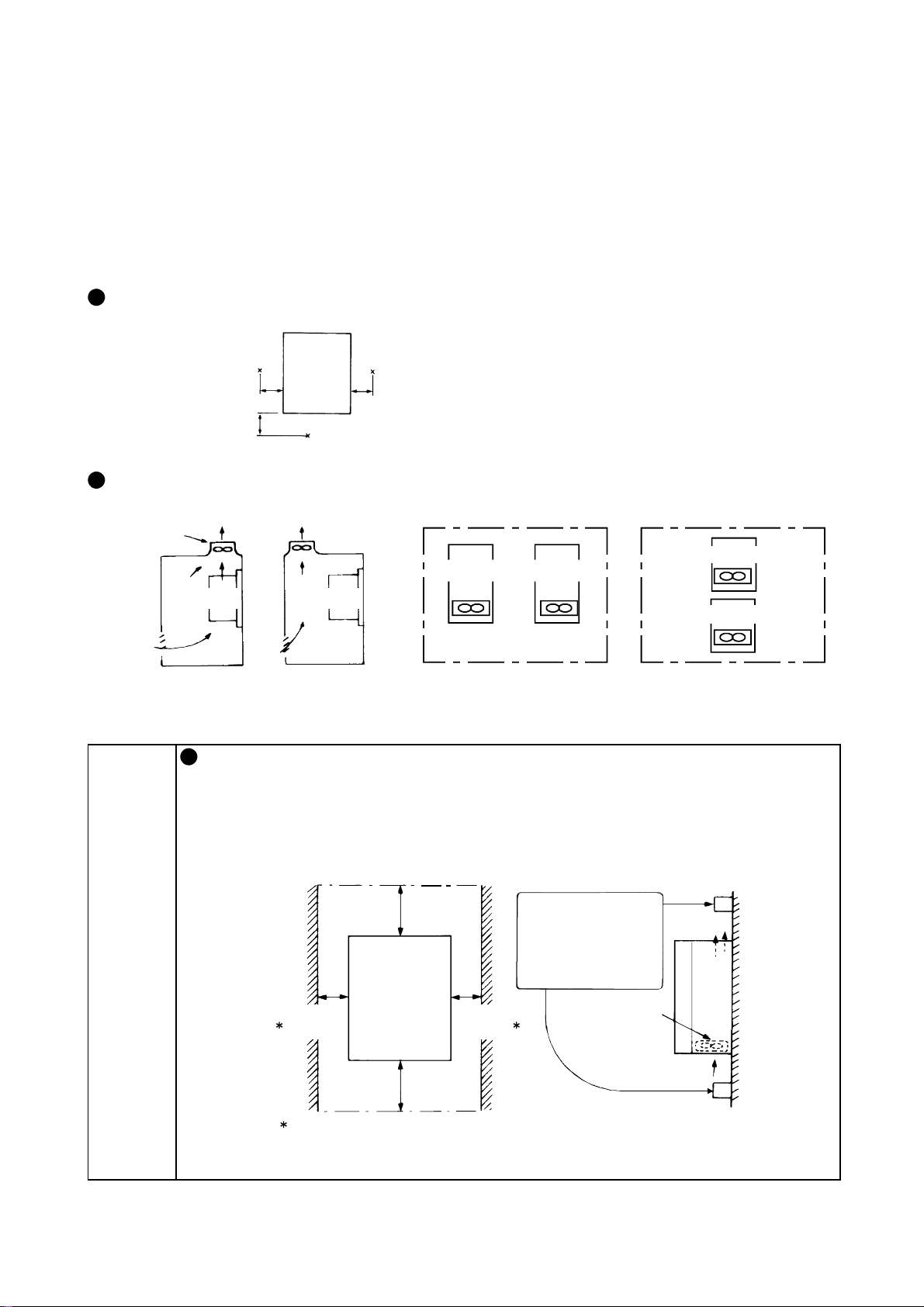

2.1.2 Installation in control box

When installing the drive unit in a cont rol box, the internal temperature of the

control box must not excee d the permissible value due to drive-unit generated

heat and peripheral-g enerated heat.

Placing a heat sink outside the control box can reduce the heat generated inside

the control box.

Measurement positions of ambient te mperatures

Drive

5cm 5cm

5cm

Layout of drive units within control box

entilation fan

Drive unit

(Correct example) (Incorrect example)

unit

Measurement position

Drive unit

Measurement position

Drive unit Drive unit

Position of ventilation fan

Leave the specified clearances between the drive unit and control

box walls or other equipment. Not doing so can cause a failure. In

addition, improper convection of air in the control box w ill reduce the

heat dissipation effect. Fully consider the equipment layout in the

control box and the use of a cooling fan for ventilation, for example.

Drive unit

Drive unit

Built-in cooling fans

(Incorrect example)(Correct example)

Accommodation of two or more drive units

NOTICE

10cm

or more

1cm

or more

These clearances are also required for

lacement of the cooling fan.

re

Drive unit

10cm

or more

1cm

or more

Leave sufficient

clearances above

and under the drive

unit to ensure

adequate ventilation.

Cooling fan built

in the drive unit

Cooling

air

2-2

Page 18

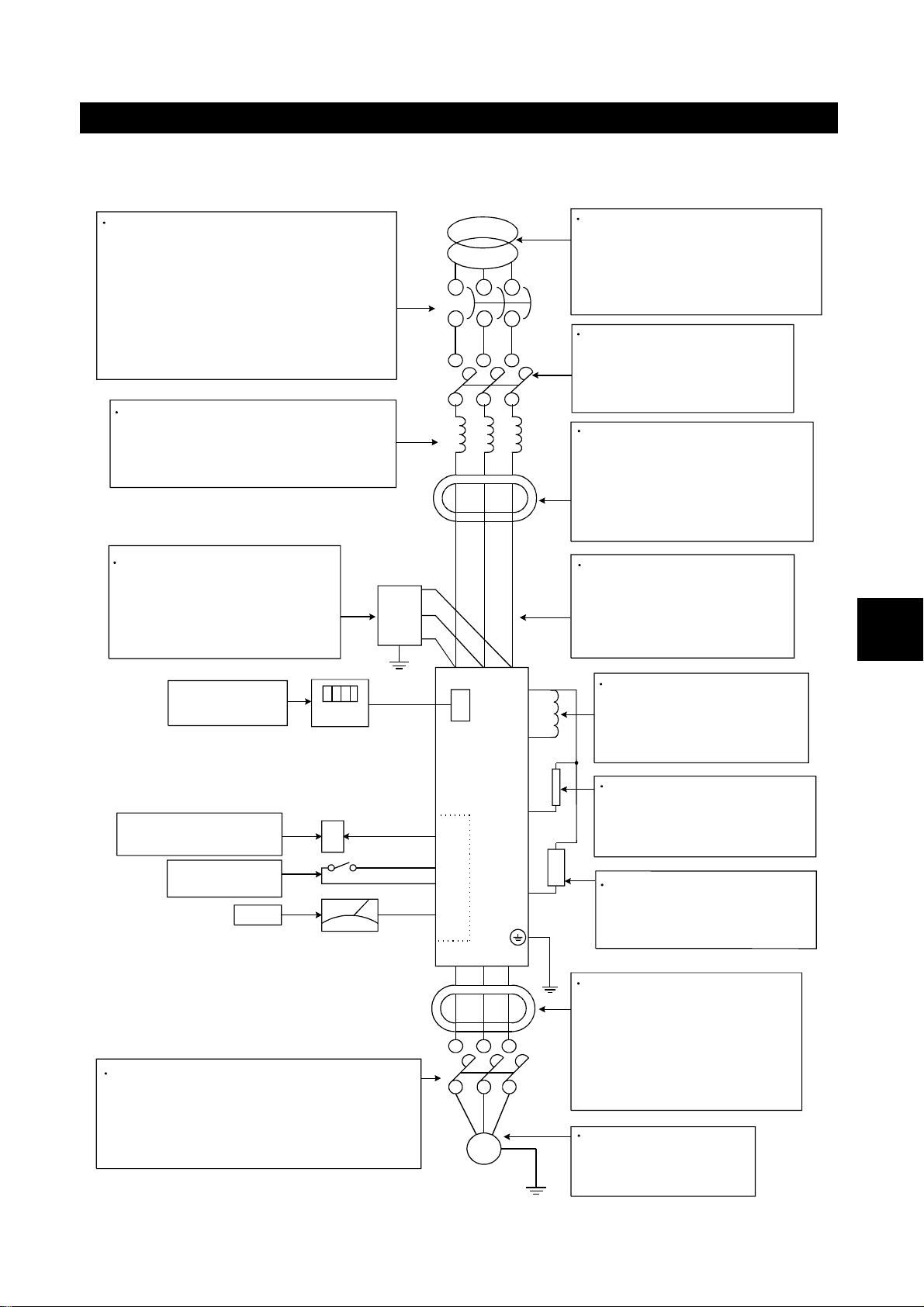

2.2 Preparation of Peripheral Devices

2.2.1 Basic configuration

2. INSTALLATION

No-fuse breaker or earth leakage

circuit breaker

Always connect either of the above for

circuit (wiring) protection. Make selection

in accordance with the selection table.

Choose the earth leakage circuit breaker

which has harmonic suppression.

Refer to: 2.2.2 Selection of peripheral

devices

Reactor (FR-BAL)

Install it for power factor improvement,

power coordination, or harmonic

suppression.

Radio noise filter (FR-BIF)

Connect it to reduce radio noise

in the AM frequency band.

This filter is designed for use on

the input side only.

Power equipment capacity

As the power equipment capacity,

select the kVA value not less than

the one given in the specifications.

Refer to: Chapter 7, 7.1.1

Rating specifications

Magnetic contactor

Make selection in accordance

with the selection table.

Refer to: 2.2.2 Selection of

peripheral devices

Line noise filter

(FR-BSF01) (FR-BLF)

Connect it to reduce high

frequency noises outgoing to the

power supply side.

Its effect is higher as the number

of wire turns is greater.

Main circuit cables

Choose the wire size in

accordance with the selection

table.

Refer to: 2.2.2 Selection of

peripheral devices

2

Parameter unit

(FR-PU04)

Analog signal

setting potentiometer

Contact signal

switch

Meter

Low-voltage manual switch

Connect it in any application where the

motor is run by the load after the drive unit

has been powered off.

Refer to: Page 3, 1. Usage

RST

PU

connector

I/O

UVW

V

U

Motor

M

P/+

P1

PR

N/-

W

Reactor (FR-BEL)

Install it for power factor

improvement, power

coordination, or harmonic

suppression.

Brake resistor (MRS)

(FR-ABR)

Connect it to increase braking

capabili ty for de cele ration.

BU brake unit, Discharge

resistor

Connect it to increase braking

capabili ty for de cele ration.

Line noise filter

(FR-BSF01) (FR-BLF)

Connect it to reduce high

frequency noises outgoing to

the output side.

When installing it on the output

side, do not turn the wire more

than four times.

Magnetic motor

Use the specified motor.

It cannot be run using

commercial power.

2-3

Page 19

2. INSTALLATION

2.2.2 Selection of peripheral devices

(1) Wire size

AC power input terminals R, S, T, motor connection terminals U, V, W, DC

reactor connection terminals P/+, P1, DC te rminals P/+, N/-, ground terminals

Capacity (K)

0.4

0.75

1.5

2.2

3.7

Control circuit terminals (all terminals)

Capacity Terminal Screw Size

All capacities M2.5 0.3 to 0.75

Terminal

Screw Size

M3.5 2 2 2 2

M4 2 to 5.5 2 to 5.5 2 to 5.5 2 to 5.5

R, S, T U, V, W P/+, P1, N/- Connection

Wire Sizes, Unit: mm

Wire Size, Unit: mm

2

Wire Type

Power

cable 600V

vinyl wi r e

equivalent

2

Twisted shielded wire,

polyethylene insulated vinyl

wire for instrumentation or

equivalent

Wire Type

or

Refer to the corresponding instruction manual for wires connection

MEMO

of a stand-alone option conne cted to the DC terminals P/+, N/-.

Choose the size of the wires connected to the motor connection

terminals so that a voltage drop due to the w ires is less than 4V.

The minimum wire siz e in the above selection table a s sumes that

the wiring length is less than 20m.

NOTICE

A voltage drop can be found by the following expression:

Line voltage drop (mV) =

Use the ground cable which is as thick as possible.

(2) Crimping terminals

Wire Size, Unit: mm

2

3.5/5.5 M4 5.5-4

2

3 × wire resistance (Ω/km)

× wiring length (m) × current (A)

Terminal Screw Size Crimping Terminal Size

M3.5 2-3.5

M4 2-4

2-4

Page 20

(3) No-fuse breakers, magnetic contactors

2. INSTALLATION

No-Fuse Breaker

Capacity (K)

0.4 30AF/5A

0.75 30AF/10A

1.5 30AF/15A

2.2 30AF/15A 30AF/20A S-N11, S-N12

3.7 30AF/30A S-N20

With power factor

improving reactor

Without power factor

improving reactor

Magnetic Contactor

With power factor

improving reactor

S-N10

If the magnetic contactor does not have power factor improving react or, s elect

the magnetic contactor as indicat ed in the following table depending on the

power equipment capacity and the w i ring length from the power equipment to the

drive unit.

Power Supply

Capacity

Wiring length

Capacity

(K)

0.4

0.75

1.5 S-N21 S-N25 S-N50

2.2 S-N11, S-N12

3.7 S-N20

Less than

50kVA

50kVA or More

20m or more 10m to 20m Less than 10m

S-N18 S-N21 S-N21

2

(4) Earth leakage circui t breakers

Selection method

Use the earth leakage circuit breaker which ha s harmonic/surge su ppression.

Our product: Progressiv e Super Series NV-SF, NV-CF

Earth Leakage Circuit Breaker

Capacity (K)

0.4 30AF/5A

0.75 30AF/10A

1.5 30AF/15A

2.2 30AF/15A 30AF/20A

3.7 30AF/30A

With power factor

improving reactor

Leakage currents from the wiring and motor include frequency

Without power factor

improving reactor

components of a higher degrees than those from the commercial

power supply. Therefore, the earth leakage cir cuit br eaker which is

not a harmonic/surge suppression produc t can cause unnecessa ry

MEMO

operations.

<Measures again st u nnecessary operations >

•

Minimize the wiring distance of I/O cables.

•

Run I/O cables away (mor e than 30cm) from the earth.

2-5

Page 21

2. INSTALLATION

2.3 Installation Method

1) Remove the front covers. (Up per and lower)

2) Remove the wiring cover.

3) Pass screws or bolts into the four mountin g holes and secure the drive unit.

(Three mounting holes for 0.75K or les s)

CAUTION

Prevent screws, metal pieces and other conductive foreign matter and

oil and other flammable foreign matter from entering the drive unit.

Securely screw or bolt the unit to the m ounting surface vertically

without looseness. Always install the unit in the specified mounting

orientation. Not doing so can cause a failure.

Do not drop the unit, or subject it to impact.

4) Replace the removed cover. Leave the cover re moved when continuing the

wiring work.

Fully check that the front cover has been mounted securely.

Insecure mounting can cause a drop due to vibration.

The front cover (Lower) is fitted wi th the c apacity plate and the drive

NOTICE

unit with the name plate. The same serial number is printed on

these plates. Always reinstall the c over to the drive unit from where

it had been removed.

2-6

Page 22

3. WIRING

3. WIRING

This chapter describes the wiring of the drive unit.

WARNING

Any person who is involved in the wiring of this equipment should be

fully competent to do the work. Otherwise, an electric shock or fire can

occur.

Always install the unit before wirin g. Otherwise, an electric shock or

fire can occur.

Before restarting wiring after switching power "ON", make sure that the

motor is at a stop, wait for more than 10 minutes after switching power

"OFF", and confirm that the DC voltage across the DC terminals P/+

and N/- is low enough to do wiring. Immediately after power "OFF", the

DC terminals P/+, N/- are charged with more than 200V (residual

voltage of the internal capacitor). Therefore, an electric shock may

occur.

Even after power-off, the motor connection terminals U, V, W hav e high

voltages while the motor is running. Always start wiring after

confirming that the mo tor has stopped. Not doing so can cause an

electric shock.

CAUTION

Take measures to prevent peripheral sensors and equipm ent from

malfunctioning due to electromagne tic noises. Not doing so can cause

accidents.

Take measures to prevent peripheral power capacitors and generators

from overheating or being damaged du e to power harmonics. Not

doing so can cause a fire.

Do not leave wire offcuts in the drive unit. Doing so can cause a fault,

failure or malfunction.

If the machine must not be restarted when power is restored after a

power failure, provide a magnetic contactor on the power supply side

and also make up a sequence which will not turn "ON" the start signal

automatically when power is restored.

Tighten the terminal screws to the specified torque. Undertightening

can cause an inter-terminal short circuit or malfunction. Overtightening

can cause the screws and unit to be damaged, resulting in a short

circuit, malfunction or the like.

3

3-1

Page 23

3. WIRING

3.1 Pre-Wiring Instructions

3.1.1 Terminal connection diagram

The following shows the wiring of all terminals. After confirming the function of

each terminal, wire necess ary terminals according to your application. When the

Parameter unit is used to perfor m operation, merely doing the main ci rc uit wiring

enables the motor to run.

Main circuit terminal

Control circuit terminal

Motor

Ground

Jumper

Power factor improving reactor

FR-BEL (option)

Brake resistor

R

Running

Up to speed

Transistor

output common

+

Calibration

resistor

Pulse output

(0 to 1440

pulses/s)

FR-ABR (option)

Contact output

terminals

Transistor

output

terminals

Meter

connection

terminals

3-phase AC

power supply

Contact input

terminals

Speed

command

input

terminals

NFB

External transistor common

Forward

rotation start

Reverse

rotation start

High speed

Middle speed

Low speed

Output stop

Reset

Voltage

Speed setting

potentiometer

Common

input

Drive unit

PU connector

R

(RS-485)

S

T

U

V

W

P1

PC

P/+

STF

STR

PR

RH

RM

N/-

RL

A

B

MRS

RES

C

RUN

FU

Contact

input

SD

common

10(+5V)

DC0 to 10V

2

DC0 to 5V

5(Analog common)

4

(Keep this terminal open)

Switched

SE

FM

SD

*This resistor is not needed when you use the

parameter unit (FR-PU04) to make calibration. This

resistor is used when you need to calibrate the meter

nearby because the meter is at a remote location, for

example. Note that when you connect the calibration

resistor, the meter may not deflect to the full scale. In

this case, use the parameter unit with the resistor to

make calibration .

3-2

Page 24

3.2 Wiring of the Main Circuit Terminals

3.2.1 Terminals

Symbols Name Description

R, S, T

U, V, W

P/+, PR

P/+, P1

P/+, N/- DC terminals Connect to the BU brake unit (option).

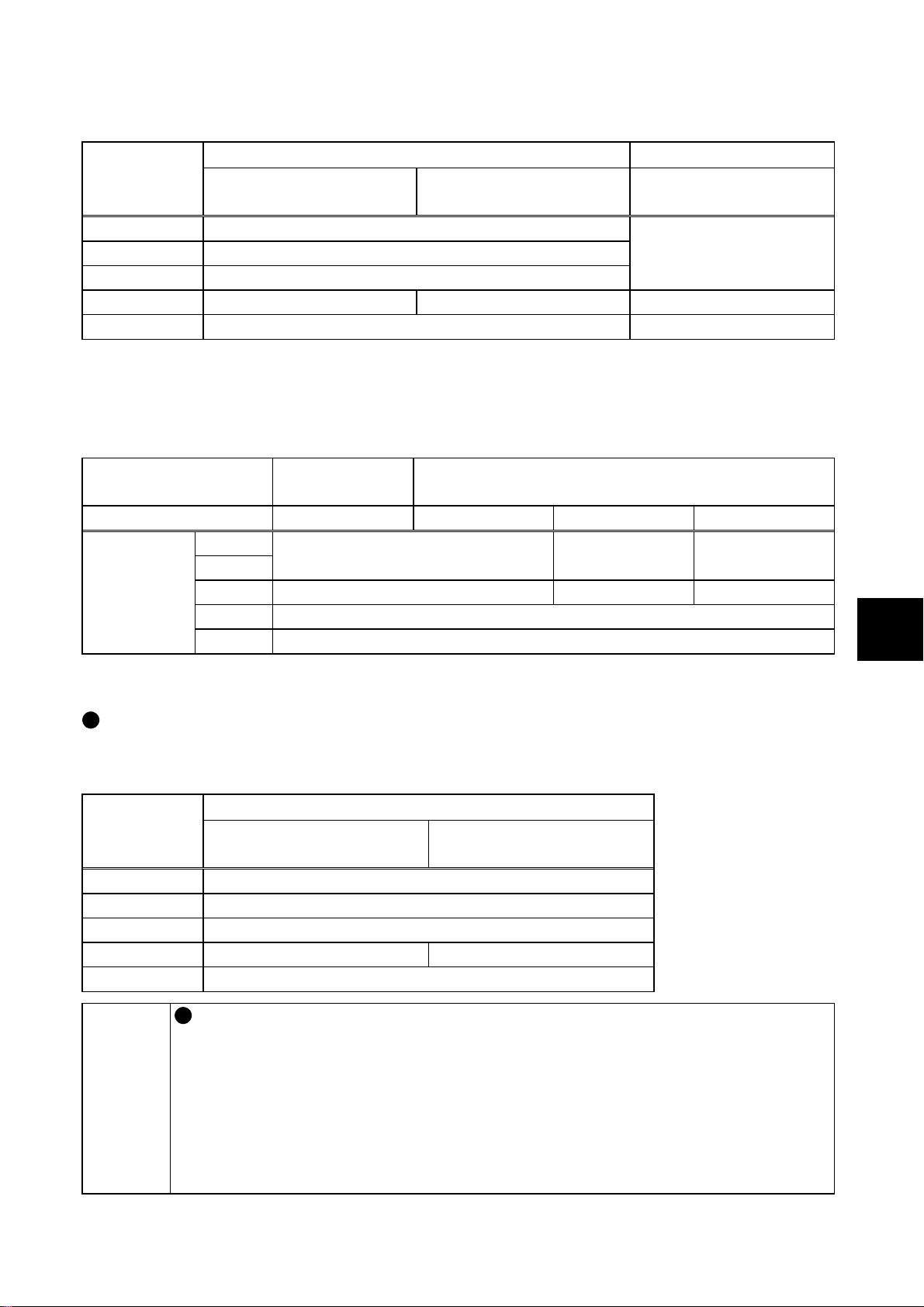

3.2.2 Terminal layout and connection specifications

AC power input

terminals

Motor connection

terminals

Brake resistor

connection terminals

DC reactor

connection terminals

Ground terminals

Connect to the commercial power supply.

Connect to a dedicated variable-speed synchronous

motor.

Connect the brake resistor (option).

Disconnect the jumper from terminals P/+-P1 and

connect the FR-BEL power factor improving DC

reactor (option).

Terminals for connection of the ground cables. (There

are two terminals.)

3. WIRING

CX522-0.4, 0.75K CX522-1.5K to 3.7K

Layout

Screw size

M3.5

N/-

P1

R/L1S/L2T/L3

P/+

PR

UVW

TB1

Tightening torque

1.2N•m

Layout

N/-

PR

TB2

Screw size

M4

P/+

P1

R/L1S/L2T/L3

UVW

TB1

Tightening torque

1.5N•m

CAUTION

Tighten the terminal screws to the specified torque. Undertightening

can cause an inter-terminal short circuit or malfunction. Overtightening

can cause the screws and unit to be damaged, resulting in a short

circuit malfunction or the like.

3.2.3 Wiring of the AC power input terminals R, S, T

Connect these terminals to the AC power supply. You need not match the phase

sequence.

3

Power supply

No-fuse breaker

RST

RST

CAUTION

Always apply power to only the AC power input terminals R, S, T.

Applying power to the other terminals will damage the unit.

3-3

Page 25

3. WIRING

3.2.4 Wiring of the motor connection terminals U, V, W

Connect these terminals to the mot or. Match the phase sequence of the motor

connection terminals U, V, W with that of the motor cables. Incorrect phase

sequence will run the motor in reverse.

UVW

UVW

Ground

terminal

Ground

Motor

CAUTION

The wiring length between the drive unit and motor should be 100m

maximum. Long wiring may cause torque to be insufficient or the

overcurrent protecti on function to be activated.

Between the drive unit and motor, do not fit a power capacitor, surge

suppressor or FR-BIF radio n oise filter (option).

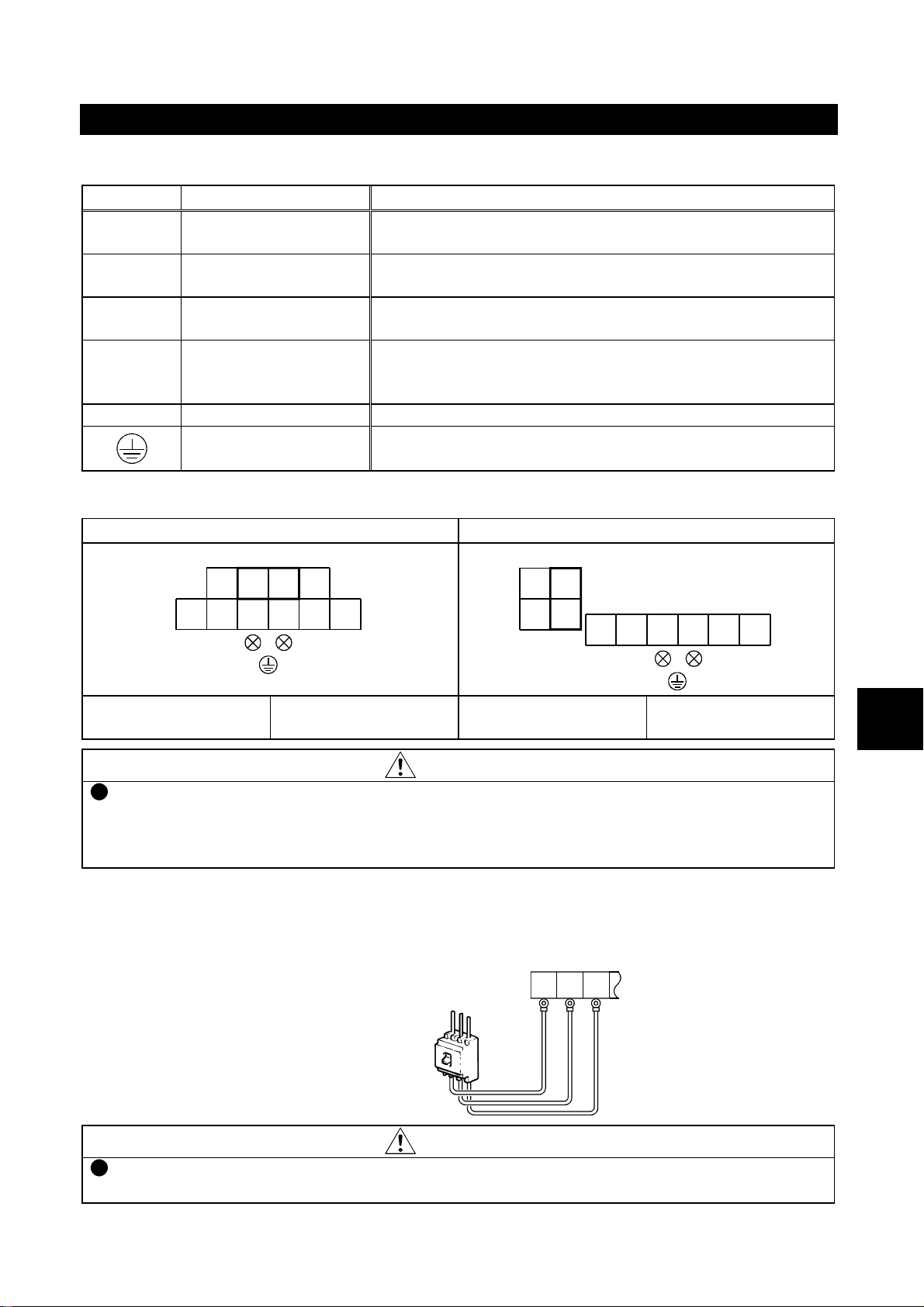

3.2.5 Wiring of the ground terminals

There are two ground terminals. Connect one ground terminal to the motor's

ground terminal and perform shared grounding on the drive unit.

Drive unit

Motor

Avoid shared grounding with the other equipment susceptible to

noise, and perform exclusive or single-point grounding.

Drive unit Drive unit

Other

equipment

Other

equipment

Drive unit

Other

equipment

NOTICE

Shared grounding

Not allowed

Exclusive grounding

Allowed

1-point grounding

Allowed

WARNING

Ground the drive unit and moto r securely to prevent an elect ric shock

due to leakage currents. (Class D grounding, grounding resistance

ΩΩΩΩ

100

For grounding, connect the cable to the exclusive ground terminal. (Do

not use the screw of the casing, chassis or the like.)

max.)

3-4

Page 26

3. WIRING

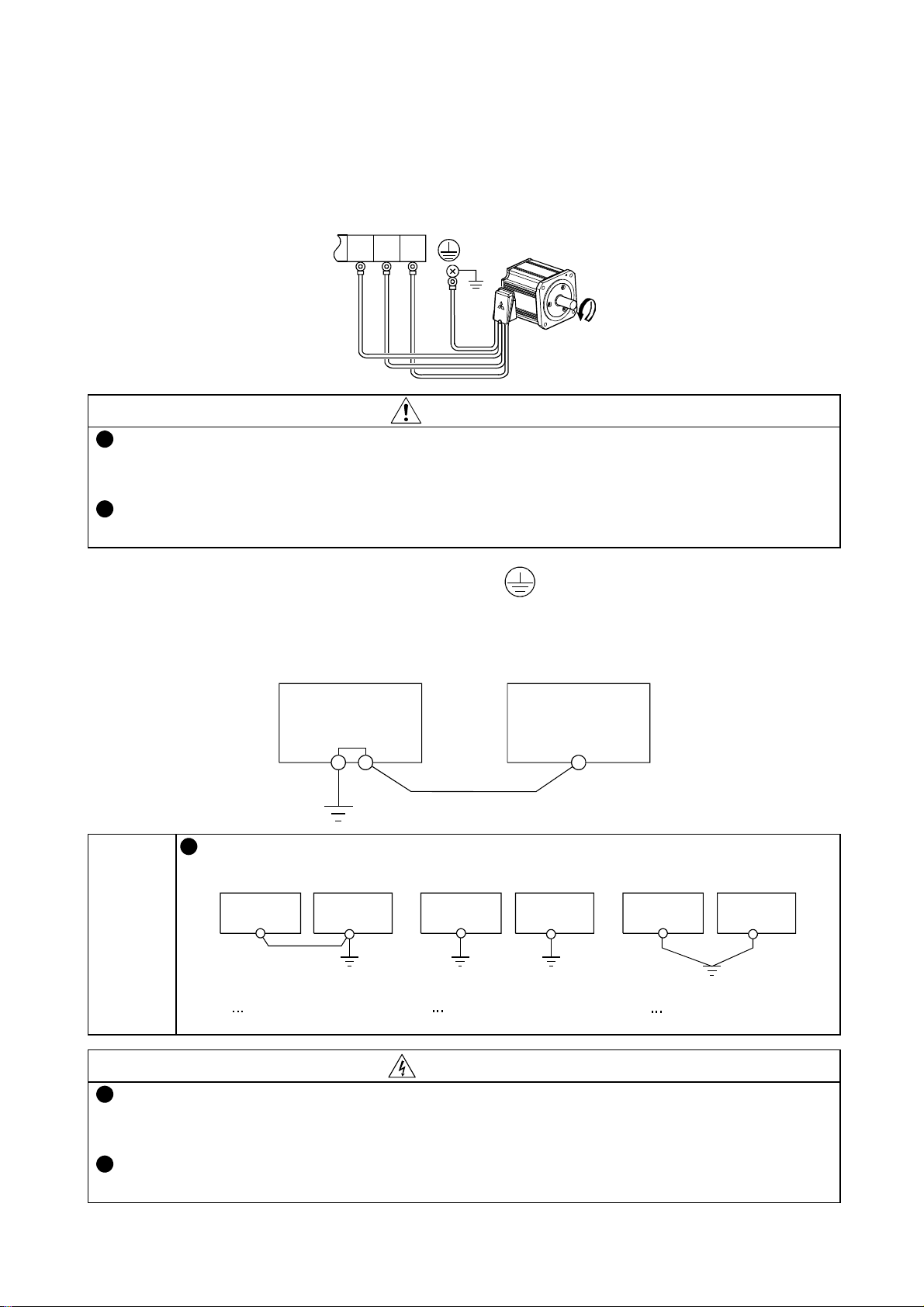

3.2.6 Wiring of the DC reactor connection terminals P/+, P1

These terminals are designed for connection of the pow er factor improving

reactor (FR-BEL).

Remove the jumper acros s the ter minals P/+-P1 and connect the DC reactor.

<Connection method>

CX522-0.4K,0.75K CX522-1.5K to 3.7K

N/-

P1

Remove jumper.

P/+

PR

FR-BEL

P/+

Remove jumper.

P1

FR-BEL

NOTICE

MEMO

The wiring distance (overall length) should be within 5m.

Without removal of the jumper, the reactor will not be active.

3.2.7 Wiring of the brake resistor connection terminals P/+, PR

These terminals are de signed for connection to the b rake resistor (heavy-duty

brake resistor).

Change Pr. 30 and Pr. 70 setting s before use.

NOTICE

Connect only the specified brake resistor.

3.2.8 Wiring of the DC terminals P/+, N/-

These terminals are designed for connection of the B U br ake unit.

1) Connect the BU brake unit. For full infor mation, re ad the BU brake unit

instruction manual.

2) Change the Pr. 30 setting.

NFB

R

S

T

U

V

W

Motor

M

3

P/+ N/-

N

P

BU brake unit

CAUTION

Do not connect the brake r esistor or the like to the DC terminals P/+,

N/- directly. Doing so can cause a fire.

Incorrect (opposite) connection to the DC terminals P/+, N/- will

damage the drive unit.

3-5

Page 27

3. WIRING

3.3 Wiring of the Control Circuit Terminals

CAUTION

Use shielded or twisted cables for wiring the control circuit input

terminals. Also run them a way from the main circuit wiring and other

power cables. Not doing so can caus e a malfunction due to noise.

3.3.1 Terminals

(1) Contact input termin al s

Turning the signal acro s s any terminal and common terminal "ON" (closing

those terminals)/"OFF" (opening those terminals) provides the corresponding

function as described below.

The shaded terminal sy mbol s indicate that their functions can be changed.

Refer to: Chapter 8, 8.4 Selection of the Control

Circuit Contact Input Terminal Functions

Symbol Name Description

STF

STR

RES Reset

MRS Output stop

RH

RM Middle speed

RL Low speed

SD

PC

Forward

rotation start

Reverse

rotation start

High speed

Contact input

common

External

transistor

common

Turn on this signal to start forward

rotation or turn it off to stop.

Turn on this signal to start reverse

rotation or turn it off to stop.

Turn on this signal (for more than 0.1s) to reset the protective

circuit activated. Turn it off after the protective circuit is reset.

Turn on this signal (for more than 0.1s) to stop the output and

separate the motor electrically, causing it to coast. Turing it off

with the start signal input will restart the motor at the starting

speed.

Combine on/off of these signals as appropriate to select

multiple speeds.

Refer to: Chapter 8, 8.3.2 Variable-speed

operation using contact input signals

Common to the contact input terminals. (Not isolated from

terminal 5.)

Common terminal used when the contact input terminal is

connected to the transistor output (open collector output) of the

external controller. This terminal can prevent a malfunction

caused by a sneak current.

Simultaneously

turning on these

signals gives a stop

command.

MEMO

Ratings of the contact input terminals

Input resistance: 4.7kΩ, open-time v oltage: 24±3VDC,

short circuit-time current: 4 to 6mADC

Use the terminal PC as a power su pply terminal.

Can be used as a power supply for a sensor or equivalent. The

common terminal is the terminal SD (digital common).

Power supply voltage ra nge: 24±2VDC, max. permissible

current: 100mA

When the terminal is used as a pow er supply, it cannot be used as

an external transistor common terminal to prevent a sneak current.

The response time of the contact input terminal is 2 0ms±15ms.

(When the stall preventi on function is activated, response may be

slower.)

Terminals SD and 5 are not isolated.

3-6

Page 28

When a transistor is used to input the signal of the contact input

terminal, make sure that the electrical characteristics of the

transistor used sati sfy the following:

: Collector current, 10mA o r more

I

C

: Open-time collector-emitter permissible voltage, 30V or

V

CEX

more

NOTICE

V

: Conduction-time collector-emitter saturation voltage, 3V

CE(sat)

or less

: Collector shutoff curre nt (leakage current), 100uA or le ss

I

CEX

When a relay contact is used to input the signal of the contact input

terminal, use two faint signal contacts in parallel or use a twin

contact to prevent a contact fault.

(2) Speed command input terminals

Terminals used to v ary the motor speed with analog signals.

The parameter function allows you to choose the analog speed command

specifications.

Refer to: Chapter 8, 8.3.1 Selection of the analog

speed command specifications

3. WIRING

Symbol Name Rating Description

2

4 Keep this terminal open.

5

10

Voltage

input

Analog

common

Power

supply 5V

Input resistance: 10±1k

Max. permissible voltage:

20VDC

5V±0.2VDC

Permissible load current:

10mA

You can perform operation at the

Ω

speed proportional to a 0 to 10VDC (or

0 to 5VDC) voltage signal.

Common to the speed command input

terminals. Do not earth.

Can be used as a power supply for the

analog input signal, e.g. speed setting

potentiometer.

The common terminal is terminal 5.

(3) Transistor output terminals

When the function of any terminal is activated, the internal transistor (open

collector output) connected across that ter mi nal and common terminal turns

ON (conducts).

You can set the parameter function to ch ange the function of each terminal.

Refer to: Chapter 8, 8.7.2 Selection of the control

circuit output terminal functions

Chapter 8, 8.7.3 Detection of running speed

Symbol Name

RUN Running

FU

SE

Speed

detection

Transistor

output

common

ON (conducts) while the drive unit is outputting a speed command

to the motor. OFF (does not conduct) during stop or coasting.

Turns ON (conducts) when the speed output by the drive unit

reaches or exceeds the preset value. OFF (does not conduct)

when the speed is less than that.

Common to the transistor output terminals. Isolated from the

terminals SD, 5.

Description

3

3-7

Page 29

3. WIRING

Ratings of transistor output terminals

MEMO

Max. permissible voltage: 27VDC, max. permissible current:

0.1ADC

When driving a coil load, connect a diode.

NOTICE

Refer to: 3.3.5 Wiring of the transistor output

terminals

(4) Contact out put terminals

When the protective function is activated, the relay contact connected to the

terminal opens/close s.

Refer to: Chapter 6, 6.1.1 Protective function

activated

Symbol Contact Capacity Description

Normal : Terminals B-C closed

A, B, C

200VAC 0.3A or

30VDC 0.3A

Protective function activated: Ter m in a ls B- C op e n

(Terminals A-C open)

(Terminals A-C closed)

The response time of the contact output terminals i s less than

100ms. (After drive unit output shutoff)

When the drive unit is powered off, the contact output is placed in a

MEMO

normal status. Therefore, the contact output signal is not held when

power is switched off after the protective function has been

activated. When the signal must be held, provide an external

holding circuit.

(5) Instrument connectio n terminals

Used to display the motor speed externally.

You can use the parameter function to choose the item other than the motor

speed.

Refer to: Chapter 8, 8.7.5 Selection of the instrument

connection terminal functions

Symbol Name Description

The output voltage has an 8VDC pulse waveform.

The output varies in proportion to the motor speed and the average

voltage is preset to approx. 4.7V at the rated speed and 1440

pulses/s.

As a meter, use a 1mA moving-coil type DC ammeter or digital

counter.

As the common terminal, use terminal SD.

FM

Meter

connection

MEMO

The output signal from the FM ter minal is updated at intervals of

several 10ms.

3-8

Page 30

3.3.2 Terminal layout and connection specifications

Layout

Terminal layout of control circuit

3. WIRING

A

B

C

10

2

5

4

SD

STF

STR

SD

0.25N•m to 0.49 N•m

Screw size

RH

RM

RL

MRS

RES

SD

FM

PC

SE

RUN

FU

Tightening torque

M2.5

Wiring method

1) For wiring the control circuit, use cables after stripping their sheaths.

Refer to the gauge printed on the drive unit and strip the sheaths to the following

dimensions. If the sheath is stripped too much, its cable may be shorted with the

adjoining cable. If the sheath is stripped too little, the cable may come off.

7mm 1mm

+

2) When using bar terminals and solid wires for wiring, their diameters should be 0.9mm

maximum. If they are larger, the threads may be damaged during tightening.

3) Loosen the terminal screw and insert the cable into the terminal.

4) Tighten the screw to the specified torque.

Undertightening can cause cable disconnection or misoperation. Overtightening can

cause damage to the screw or unit, leading to short circuit or misoperation.

Tightening torque: 0.25N

•

m to 0.49N•m

* Use a screwdriver No. 0 to tighten.

Note: When routing the stripped cables, twist them so that they do not become loose.

In addition, do not solder it. Soldering can cause poor contact.

When using a bar terminal or a solid wire for wiring, use one of

0.9mm or less diameter. Using one of larger diameter may damage

NOTICE

the threads during tight ening.

Connect stripped cable s o that its core does not become loose . Not

doing so can cause shorting of adjacent cables.

3

3-9

Page 31

3. WIRING

3.3.3 Wiring of the contact input terminals

Use shielded or twisted shielded cables for wiring. Con nect one shield sheath to

the common terminal. Leave the other shield sheath open.

When using contact signals

The following shows the wiring of the terminals STF, STR. The sa me wiring also

applies to the other terminals.

The terminal SD is a common terminal.

Drive unit

R

STF

R

STR

DC24V

SD

When using non-contact switches

When using transistor outputs having an external power supply, such as a PLC,

to input signals, perform the followin g w iring to prevent a malfunction caused by

a sneak current from the external power supply.

The following shows the wiring of the terminals STF, STR. The sa me wiring also

applies to the other terminals.

The terminal PC is a common terminal.

PLC

1

2

9

10

Drive unit

STF

STR

PC

SD

DC24V

External power sup pl y

Do not apply voltages to the contact input termi nals.

Do not short the terminals PC and SD. Doing so will damag e the

NOTICE

unit.

When the terminal PC is used as a power supply terminal, the

wiring length should be within 30m.

3-10

Page 32

3. WIRING

3.3.4 Wiring of the speed command input terminals

Use shielded or twisted shielded cables for wiring. Con nect one shield sheath to

the terminal 5. Leave the other shiel d sheath open.

The following diagram sh ows the wiring of the terminal 2.

The same wiring also a pplies to the other terminals.

Drive unit

10

2

5

3.3.5 Wiring of the transistor output terminals

The terminal SE is a common terminal.

Drive unit

RUN

FU

SE

DC24V

1

R

R

2

R

R

9

When driving a coil load such as a relay coil, always connect the followi ng diode.

Connect the diode with co rr ect polarity. Opposite polarity will cause the drive unit

to fail.

Drive unit

3

NOTICE

RUN

Relay

SE

DC24V

Terminal SE is isolated from terminals SD and 5. Do not connect

them each other.

3-11

Page 33

3. WIRING

3.3.6 Wiring of the contact output terminals

The following wiring example assumes that when the protective circuit is

activated, the magnetic contactor (MC) on the power supply side is opened to

switch off the ma i n circuit power.

Drive unit

R

S

T

B

C

Power supply

Stop

NFB

F

Operation-ready

MC

MC

MC

3.3.7 Wiring of the instrument connection terminals

MEMO

Drive unit

FM

SD

Meter

Calibration resistor

The calibration resistor is not needed when the parameter unit is

used to make calibrat ion.

Refer to: Pr. 900 [Section 8.7. 5]

3-12

Page 34

3.4 Wiring of the PU Connector

3.4.1 Pin layout

As seen from the drive unit (receptacle side) front

3. WIRING

1) SG

2) P5S

3) RDA

4) SDB

8) to 1)

5) SDA

6) RDB

7) SG

8)P5S

Pins No. 2 and 8 (P5S) provide power to the operation panel. Do

NOTICE

not use them when making RS-48 5 c ommunication.

3.4.2 Using the cable to connect the parameter unit

Use the optional "FR-CB2 parameter unit connection cable" or c ommercially

available connector and cable for wiring.

Connector

Cable

RJ45 connector

Example: 5-554720-3, Tyco Electronics Corporation

Cable conforming to EIA568 (such as 10BASE-T cable)

Example: SGLPEV 0.5mm × 4P (Twiced pair cable, 4 pairs), Mitsubishi

Cable Industries, Ltd.

(Do not use the No. 2 and 8 pins (P5S).)

NOTICE

The maximum wiring length i s 20 m.

3.4.3 System configuration examples for communication operations

1) For RS-485 communication operation

Computer

RS-485

interface

/terminal

Splitter

10BASE-T cable

Station No. 1 Station No. 2 Station No. n

Drive unit

PU

connector

Drive unit

PU

connector

Drive unit

PU

connector

Terminating

resistor

3

3-13

Page 35

Parts used (U se commercially available parts for wiring)

3. WIRING

Connector

RJ45 connector

Example: 5-554720-3, Tyco Electronics Corporation

Cable conforming to EIA568 (such as 10BASE-T cable)

Example: SGLPEV 0.5mm × 4P (Twisted pair cable, 4 pairs), Mitsubishi

Cable

Cable Industries, Ltd.

(Do not use the No. 2 and 8 pins (P5S).)

2) For RS-232C communication operation

RS-232C

connector

RS-232C

cable

RS-485

terminal

Computer

Max. 15m

Converter

Splitter

10BASE-T cable

Station No. 1 Station No. 2 Station No. n

Drive unit

PU

connector

Drive unit

PU

connector

Drive unit

PU

connector

Terminating

resistor

Parts used (U se commercially available parts for wiring)

Connector

Cable

Commercially

available

converter

RJ45 connector

Example: 5-554720-3, Tyco Electronics Corporation

Cable conforming to EIA568 (such as 10BASE-T cable)

Example: SGLPEV 0.5mm × 4P (Twisted pair cable, 4 pairs), Mitsubishi

Cable Industries, Ltd.

(Do not use the No. 2 and 8 pins (P5S).)

Examples Model: FA-T-RS40 converter

Mitsubishi Electric Engineering Co., Ltd.

Do not connect the PU connector to th e c omputer's LAN board,

NOTICE

FAX modem socket or telephone modular connector. Doing so may

damage the drive unit due to el ectrical incompatibilities.

3-14

Page 36

3.4.4 Wiring methods for communication operation

1) Wiring of one computer and one drive unit for RS-485

3. WIRING

Computer Side Terminals

Signal name Description

RDA

RDB

SDA

SDB

RSA

RSB

CSA

CSB

SG

FG

Receive data

Receive data

Send data

Send data

Request to send

Request to send

Clear to send

Clear to send

Signal ground

Frame ground

Cable connection and signal direction

10 BASE-T cable

*1

0.3mm or more

2

2) Wiring of one computer and "n" d rive units for RS-485

Cable connection and signal direction

Computer

RDA

RDB

SDA

SDB

RSA

RSB

CSA

CSB

SG

FG

*1

SG

Station No. 1

RDB

Drive unit

10 BASE-T cable

RDA

SDB

SDA

RDB

RDA

SDB

SG

Station No. 2

Drive unit

SDA

Drive unit

PU connector

RDB

RDA

SG

Station No. n

Drive unit

SDA

SDB

RDA

RDB

SG

SDB

Terminating

resistor

SDA

3

NOTICE

Communication may be affected by reflection depending on the

transmission speed a nd/or transmission distance. Connect a

Terminating resistor if refle ctio n interferes with communication. For

connection using the PU connector, use a splitter si nce the

termination resistor cannot be fitted.

Connect the Terminating resistor to only the remotest drive unit

from the computer. (Terminating resistor: 100Ω)

Connect the terminals marked *1 in accordance with the instruc t ion

manual of the computer used.

Fully check the terminal nu mbers of the computer as they differ

between models.

3-15

Page 37

4. HOW TO USE THE FR-PU04 PARAMETER UNIT

4. HOW TO USE THE FR-PU04 PARAMETER UNIT

For the way to use the FR-PU04 parameter unit, refer to the instruction manual of

the FR-PU04 parameter unit.

When the FR-PU04 parameter unit (option) is used, some of the

FR-PU04 functions are unavailable.

(1) Data may be displayed in Japanese only. It cannot be ch anged to

any other language.

(2) The parameter names (katakana char a cter s) do not appear.

(Except Pr. 900, Pr.902, Pr.903)

(3) The parameter settin g ranges do not appear.

(4) The function-by-function parameter setting feature is not available.

(5) Help function

•

The parameter list does not appear.

•

The parameter change list does not appear.

MEMO

•

The troubleshooting function is un available. "The remedy screen

for "

function does not exist.

•

The terminal assignment function is not displayed.

(6) The PU level meter ca nnot be used.

(7) Pr. 79 cannot be set.

" appears but the correspo nding parameter

Copy mode

Copying is not allowed between drive units of different capacities.

If you have made such copying accidentally, perform all clear of the

copy destination drive unit.

In addition, copying is not allowe d to drive units other than the MDCX522 series.

4

4-1

Page 38

5. OPERATION

5. OPERATION

5.1 Power On

CAUTION

If the machine should become out of control, perform test operation

after ensuring safety .

Start operation after performing test operation under light load at low

speed to ensure that operation is per formed safely.

Check that the machine ha s no damage.

Securely set the parameter v alues to match the operating machine

system environmen t.

Switch power on after making sure that the unit has been installed and wired

properly and that the start signal is OFF.

The POWER lamp is lit.

If the POWER lamp is not lit, check the following:

•

The jumper across the DC reactor connection terminals P/+-P1 is

NOTICE

fitted properly.

If the POWER lamp is lit but the parameter unit LED d oe s not

appear, check the following:

•

The terminals PC and SD are not shorted.

5.2 Setting of Operation Mode

You can choose the PU operation mode or external operation mode.

In the PU operation mode, enter a speed/operation command from the parameter

unit.

In the external operation mode, enter an external analog or contact signal as a

speed/operation com man d.

At power-on, the drive unit is placed in th e external operation mode.

key of the

key or

MEMO

To switch to the PU operation mode, press the PU

parameter unit.

To return to the external operation mode, press the EXT

switch power off once. (Y ou c annot set Pr. 79.)

5

5-1

Page 39

5. OPERATION

5.3 Starting operation

The drive unit detects the magnetic pole of the motor at every start. The

magnetic pole detection time is approx. 0.1s (85ms±15ms) after the start signal

and speed signal are i nput. During this period, the motor remains stopped and

starts running after magnetic pole detection is finished.

When inputting the speed command from the parameter unit or as a contact

signal

Start signal

Speed command

Motor speed

RUN signal

When inputting the speed command as a n analog signal

Start signal

Speed com m and

Motor speed

RUN signal

When the start signal is entered after the input of the speed

Approx. 0.1s

Approx. 0.1s

ON

ON

5 to 35ms

ON

300r/min

5 to 35ms

command, the motor starts running approx. 0.1s after the input of

the start signal.

When the analog signal is used to giv e the s peed command, the

motor starts running approx. 0.1s after the speed command has

MEMO

reached the value equivalent to 300r/min.

Turning on the reverse rotation (forward rotation) signal during

forward rotation (reverse rotation) operation decelerates the motor

to a stop, keeps it stopped for about 2s, and then starts it running in

the reverse rotation (forward rotation) direction.

ON

NOTICE

When restarting the motor after decelerating it to a stop, start the

motor after ensuring that it has stopped. If you start the motor that

has not yet come to a complete stop, sufficient starting torque may

not be provided.

Do not switch the AC input power off while the motor is running at

high speed. Doing so may activate the undervoltage pr otective

circuit instantaneously under the influence of a motor-generated

voltage.

Refer to: Chapter 6, 6.1.1 Protective function activated

5-2

Page 40

6. TROUBLESHOOTING

6. TROUBLESHOOTING

This chapter describes how to remedy a fault which occurred i n your drive unit or

motor and the maintenance and in s pection of the drive unit.

If you have found any fault, immediately perform inspection and

NOTICE

At occurrence of an alarm, turn off the operation signal before r esetting

the alarm. Resetting the alarm with the operation signal on will restart

the motor suddenly. It can cause injury.

At occurrence of an alarm, immediat ely turn off the operation signal.

Not doing so may reset the alarm due to power OFF-ON, e.g.

instantaneous power failure, restarting the motor suddenly. It can

cause injury.

take action to remove its c ause. If you cannot identify the cause and

resolve the malfunction, c ontact your sales representative

.

WARNING

6.1 Message Appearing on the Parameter Unit

6.1.1 Protective function activated

When the protective function is activated, any of the following messages may

appears on the paramet er unit. At this time, the ALARM lamp is lit, the drive unit

output is shut off, and the motor, if running, coasts.

That the protective function has been activated can be exported

MEMO

When the protective function is activated, perform inspection and take a ctio n in

accordance with Tabl e 6-1 to remove its cause.

To restart, reset the drive unit in any of the follow ing methods.

•

Switch power off once, and when the LED has gone off, switch power on

again.

•

Short the terminals RES-SD for more than 0.1s.

•

Press the STOP/RESET

from the control circuit output terminal.

Refer to: Chapter 8, 8.7.2 Selection of the control

circuit output termi nal functions

key of the parameter unit.

6

6-1

Page 41

Table 6-1

g

6. TROUBLESHOOTING

Parameter

Unit Display

Protective

Function Name

Detection Level

Acceleration-time

overcurrent

Output current is

more than 200%

of motor rating.

Constant speedtime overcurrent

Output current is

more than 200%

of motor rating.

Deceleration-time

overcurrent

Output current is

more than 200%

of motor rating.

Acceleration-time

overvo lt a g e

Main circuit DC

voltage is more

than 400V.

Constant speedtime overvoltage

Main circuit DC

voltage is more

than 400V.

Deceleration-time

overvo lt a g e

Main circuit DC

voltage is more

than 400V.

Possible Cause () and

Corrective Action (•)

The acceleration torque is beyond the drive unit

capability.

Increase the acceleration time.

•

Outputs U, V and W are in a short circuit or ground

fault.

Check the motor winding resistance.

•

Check the connection cables for damage.

•

The motor restarted during coasting .

Restart it after a complete stop.

•

Excessive load was applied instantaneously.

Outputs U, V and W resulted in a short circuit or

ground fault during constant-speed operation.

Check the motor winding resistance.

•

Check the connection cables for damage.

•

The deceleration torque is beyond the drive unit

capability.

Increase the deceleration time.

•

Outputs U, V and W resulted in a short circuit or

ground fault during deceleration operation.

Check the motor winding resistance.

•

Check the connection cables for damage.

•

The mechanical brake of the motor operat es too

early.

Delay the operation timing.

•

Surge compounded with power during acceleration

operation.

Install a reactor.

•

Fit a surge suppressor or like to the surge source.

•

The regenerative energy handling capability is

insufficient.

Fit the regenerative brake option.

•

Surge compounded with power during acceleration

operation.

•

Install a reactor.

•

Fit a sur

Load increased suddenly, activating the stall

prevention function.

The regenerative energy handling capability is

insufficient.

•

Fit the regenerative brake option.

The deceleration torque is beyond the drive unit

capability.

Increase the deceleration time.

•

The regenerative energy handling capability is

insufficient.

Fit the regenerative brake option.

•

Surge compounded with power during deceleration

operation or stop.

Install a reactor.

•

Fit a surge suppressor or like to the surge source.

•

e suppressor or like to the surge source.

6-2

Page 42

Table 6-1 (Continued)

6. TROUBLESHOOTING

Parameter

Unit Display

Protective

Function Name

Detection Level

Electronic

overcurrent

protection

Undervoltage

AC input power

supply voltage is

less than about

150V.

Fin overheat

Heat sink

temperatur e is

higher than the

permissible v alue of

the components.

PU disconnection

Stall stop

Refer to: Pr. 22

[Section 8.5.4]

Out-of-

synchronism

Possible Cause () and

Corrective Action (•)

The motor and drive unit are operated under

overload.

Reduce the load.

•

Increase the capacities of the motor and drive

•

unit.

An instantaneous voltage drop in the AC input

power supply from the starting of a large capacity

equipment, for example.

NOTICE

The AC input power supply voltage is insufficient.

MEMO

The ambient temperate exceeded the permissible

temperature.

The cooling fan failed.

MEMO

A connection fault of the parameter unit occurred.

RS-485 communication was interrupted.

The number of communication retries exceeded the

Pr. 121 setting.

Motor overload activated the stall prevention

function consecutively, stopping the motor.

Reduce the load.

•

Increase the capacities of the motor and drive

•

unit.

The load is too heavy.

Increase the acceleration time setting.

•

Reduce the load.

•

The motor being driven is other than the specified.

Use the specified motor.

•

Do not switch the AC input power off while

the motor is running at high speed. Doing

so may activate the undervoltage protective

circuit instantaneously under the influence

of a motor-generated voltage.

An alarm signal is not output if this

protective circuit is activated with the AC

input power insufficient. It is also not

recorded in the alarm history. To export as

an external signal the fact that this

protective circuit has been activated, assign

the UVT signal to the control circuit output

terminal using Pr. 190 or Pr. 194.

An alarm signal can be provided by making

control circuit output terminal assignment.

Refer to: Pr. 75 [Section 8 .2 ]

Refer to: Pr. 121 [Section 8.6]

6

6-3

Page 43

6. TROUBLESHOOTING

If any of the messages in Table 6-2 appears, the drive unit is assumed to have

failed. If the same message reappears afte r an alarm reset, immediately replace

the drive unit.

Table 6-2

Parameter

Unit Display

Protective

Function Name

CPU fault

Storage device

fault

Brake circuit fault

Possible Cause () and

Corrective Action (•)

The CPU malfunctioned or failed.

The storage device failed.

The regenerative brake circuit failed.

If E. BE reappears after a reset, immediately

•

switch power off.

Leaving power on will overheat the brake

resistor.

6.1.2 Alarm function activated

If the alarm function is activated during moto r operation, any of the displays in

Table 6-3 is provided on the parameter unit.

If you ignore the alarm message and continue operation, the fault detection

function is activated, leading to an ope ratio n stop. When you noticed that the

alarm function had been activated, immediately remove its cause.

That the alarm function has bee n activated can be exported as an

MEMO

alarm signal.

Refer to: Chapter 8, 8.7.2 Selection of the control

circuit output terminal functions

Table 6-3

Parameter

Unit Display

Protective Function Name

Detection Level

Overload 1

Pr. 22 setting [Section 8.5.4]

Overload 2

Main circuit DC voltage more

than 390V

Fan failure

Cooling fan fault

Refer to: Pr. 244 [Section 8.5.5]

6-4

Related Protective Function

Acceleration-time overcurrent, constant

speed-time overcurrent, decelerationtime overcurrent, stall stop

Deceleration-time overvoltage

Fin overheat

Page 44

6.1.3 Others

Table 6-4

6. TROUBLESHOOTING

Parameter

Unit Display

Name

Operation error

Emergency stop

operation

Possible Cause () and

Corrective Action (•)

Parameter changing operation was performed

during external operation.

The value that was set is outside the parameter

setting range.

The RES signal remains ON.

The parameter unit is in a connection fault.

Check the fitting status.

•

MEMO

MEMO

An operation error does not activate the relay

contact output.

The STOP/RESET

pressed to make a stop during external operation.

A reset cannot be made in the normal method.

key of the parameter unit was

Refer to: Pr. 75 [Section 8 .2 ]

6-5

6

Page 45

6. TROUBLESHOOTING

g

y

6.2 Motor operation out of ordinary

If any of the following faults has occurred in the motor, find out its cause and take

adequate measures.

Event Check Point

Motor remains

stopped.

Motor rotates in

opposite

direction.

Speed differs

from the settin

Acceleration/

deceleration is

not smooth.

Speed varies.

At start, motor

shaft runs in

opposite

direction

instantaneousl

Check the main

circuit.

Check the control

signals.

Check the

parameter

settings.

Check the load.

Others

Check the main

circuit.

Check the control

signals.

Check the control

signals.

Check the

.

parameter

settings.

Check the

parameter

settings.

Check the control

signals.

Check the load.

Check the

parameter

settings.

.

Possible Cause (

Corrective Action (•)

A normal power supply voltage is not applied.

The jumper across terminals P/+-P1 has been

disconnected.

The motor is not wired properly.

The switch connected between the motor and

drive unit is open.

The start signal has not been initiated.

Both the forward and reverse rotation signals

are input.

The speed setting signal is not input.

The MRS signal remains ON.

The reverse rotation prevention, Pr. 78 [Section

8.5.1], value has been set.

0 was set as the maximum speed, Pr. 1 [Section

8.5.1], value.

The load is too heavy.

(The alarm message OL appears.)

The motor shaft is locked.