Page 1

Service Manual

of

PM-8000

Portable Patient Monitor

Page 2

Page 3

Copyright

SHENZHEN MINDRAY® BIO-MEDICAL ELECTRONICS CO., LTD. 2002

Version: 2.0

Issued date: 2005/07/24

P/N: 8000-20-10282

Statement

SHENZHEN MINDRAY

®

BIO-MEDICAL ELECTRONICS CO., LTD. (hereinafter called Mindray)

owns all rights to this unpublished work and intends to maintain this work as confidential. Mindray

may also seek to maintain this work as an unpublished copyright. This publication is to be used solely

for the purposes of reference, operation, maintenance, or repair of Mindray equipment. No part of this

can be disseminated for other purposes.

In the event of inadvertent or deliberate publication, Mindray intends to enforce its rights to this work

under copyright laws as a published work. Those having access to this work may not copy, use, or

disclose the information in this work unless expressly authorized by Mindray to do so.

All information contained in this publication is believed to be correct. Mindray shall not be liable for

errors contained herein nor for incidental or consequential damages in connection with the furnishing,

performance, or use of this material. This publication may refer to information and protected by

copyrights or patents and does not convey any license under the patent rights of Mindray, nor the rights

of others. Mindray does not assume any liability arising out of any infringements of patents or other

rights of third parties.

Content of this manual is subject to changes without prior notice.

PROPERTY OF

SHENZHEN MINDRAY

ALL RIGHTS RESERVED

Responsibility on the manufacturer party

Service Manual of PM-8000 Portable Patient Monitor (V2.0) I

®

BIO-MEDICAL ELECTRONICS CO., LTD.

Page 4

Mindray is responsible for safety, reliability and performance of this equipment only in the condition

that:

• all installation, expansion, change, modification and repair of this equipment are conducted by

Mindray qualified personnel; and,

• applied electrical appliance is in compliance with relevant National Standards; and,

• the monitor is operated under strict observance of this manual.

′ NOTE ′

This equipment is not intended for family usage.

Warning

This monitor is not a device for treatment purpose.

It is important for the hospital or organization that employs this equipment to carry out a reasonable

maintenance schedule. Neglect of this may result in machine breakdown or injury of human health.

Upon request, Mindray may provide, with compensation, necessary circuit diagrams, calibration

illustration list and other information to help qualified technician to maintain and repair some parts,

which Mindray may define as user serviceable.

II Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 5

Warranty

Workmanship & Materials

Mindray guarantees new equipment other than accessories to be free from defects in workmanship and

materials for a period of one year (six months for multi-site probes and SpO2 sensor) from date of

shipment under normal use and service. Mindray's obligation under this warranty is limited to repairing,

at Mindray’s option, any part which upon Mindray's examination proves defective.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF MERCHANT ABILITY OR

FITNESS FOR ANY PARTICULAR PURPOSE.

Exemptions

Mindray's obligation or liability under this warranty does not include any transportation or other

charges or liability for direct, indirect or consequential damages or delay resulting from the improper

use or application of the product or the substitution upon it of parts or accessories not approved by

Mindray or repaired by anyone other than a Mindray authorized representative.

This warranty shall not extend to any instrument which has been subjected to misuse, negligence or

accident; any instrument from which Mindray's original serial number tag or product identification

markings have been altered or removed, or any product of any other manufacturer.

Safety, Reliability and Performance

Mindray is not responsible for the effects on safety, reliability and performance of the PM-8000

Portable Patient Monitor if:

■ assembly operations, extensions, re-adjusts, modifications or repairs are carried out by persons

other than those authorized by Mindray.

■ the PM-8000 Portable Patient Monitor is not used in accordance with the instructions for use, or

the electrical installation of the relevant room does not comply with NFPA 70: National Electric

Code or NFPA 99: Standard for Health Care Facilities (Outside the United States, the relevant

room must comply with all electrical installation regulations mandated by the local and regional

bodies of government).

Service Manual of PM-8000 Portable Patient Monitor (V2.0) III

Page 6

Return Policy

Return Procedure

In the event that it becomes necessary to return a unit to Mindray, the following procedure should be

followed:

1. Obtain return authorization. Contact the Mindray Service Department and obtain a Customer

Service Authorization (Mindray) number. The Mindray number must appear on the outside of the

shipping container. Return shipments will not be accepted if the Mindray number is not clearly

visible. Please provide the model number, serial number, and a brief description of the reason for

return.

2. Freight policy. The customer is responsible for freight charges when equipment is shipped to

Mindray for service (this includes customs charges).

Company Contact

Address: Mindray building keji 12th road south hi-tech industrial

park nanshan Shenzhen, P.R.China

Phone: +86 755 26582658/26582888

Fax: +86 755 26582680

Free hot line: +86 800 830 3312

EC Representative

Name: Shanghai International Holding Corp. GmbH(Europe)

Address: Eiffestrasse 80 D-20537 Hamburg Germany

Phone: +49 40 2513174

Fax: +49 40 255726

IV Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 7

Preface

This manual gives detailed description to PM-8000 Portable Patient Monitor concerning its

performance, operation, and other safety information. Reading through this manual is the first step for

the user to get familiar with the equipment and make the best out of it.

Following symbols indicates some important facts that you have to pay special attention to:

Warning Points to be noted to avoid injury to the patient and the operator.

Caution Points to be noted to avoid damage to the equipment.

′ NOTE ′ Points to be noted.

This manual is intended for persons who are trained in the use of this field and have adequate

experience in operation of monitoring equipment.

Service Manual of PM-8000 Portable Patient Monitor (V2.0) V

Page 8

Page 9

Content

Chapter 1 Introduction ........................................................................................................................1-1

I. General.................................................................................................................................... 1-1

II. Appearance............................................................................................................................ 1-2

2.1 Screen display ................................................................................................................. 1-2

2.2 Button Functions............................................................................................................. 1-6

2.3 Interfaces................................................................................................................... 1-8

2.4 Built-in rechargeable battery...................................................................................... 1-10

III. Hardware principle................................................................................................................ 1-11

3.1 Power board ............................................................................................................ 1-12

3.2 PM-8000 main control board .................................................................................. 1-13

3.3 Structure diagram .................................................................................................... 1-14

3.4 Description .............................................................................................................. 1-14

3.5 Button schematic diagram and principle................................................................. 1-16

3.6 Maintenance part of TR60-A recorder.......................................................................... 1-17

Chapter 2 Monitor Functions and Principles ......................................................................................2-1

I. Introduction ............................................................................................................................... 2-1

II. ECG/RESP parameters............................................................................................................. 2-2

2.1 ECG................................................................................................................................. 2-2

2.2 RESP ............................................................................................................................... 2-2

2.3 NIBP ............................................................................................................................... 2-3

2.4 SpO2 ............................................................................................................................... 2-3

2.5 TEMP.............................................................................................................................. 2-4

2.6 IBP .................................................................................................................................. 2-4

Chapter 3 Checks and Tests................................................................................................................3-1

I. System checks......................................................................................................................... 3-1

II. Testing and calibrating each parameter.................................................................................... 3-9

Chapter 4 Troubleshooting .................................................................................................................4-1

I. Disassembly graph of each part of PM-8000............................................................................. 4-1

II. Troubleshooting guidance ........................................................................................................ 4-2

Chapter 5 Installation..........................................................................................................................5-1

I. Unpack inspection................................................................................................................. 5-1

II. Preparations before power-on................................................................................................ 5-1

III. Turn on the power................................................................................................................... 5-1

IV. Other precautions.................................................................................................................... 5-1

Chapter 6 Basic Operations ................................................................................................................6-1

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1

Page 10

I. Basic operation guidance........................................................................................................... 6-1

II. Use PM-8000............................................................................................................................ 6-1

Chapter 7 Cleaning and Disinfection..................................................................................................7-1

I. Maintenance checks................................................................................................................ 7-1

II. General cleaning....................................................................................................................... 7-1

III. Sterilization ............................................................................................................................. 7-2

IV. Precautions and cleaning ........................................................................................................ 7-3

V. IBP transducer cleaning and disinfection(reusable) ........................................................... 7-4

VI. TEMP sensor cleaning and disinfection (reusable) ............................................................. 7-6

Chapter 8 Maintenance .......................................................................................................................8-1

Chapter 9 Network Link .....................................................................................................................9-1

I. Network performance ............................................................................................................. 9-1

II. Application ............................................................................................................................... 9-1

Appendix I: System Alarm Prompt................................................................................................... AI-i

Appendix II: Product Specifications................................................................................................ AII-i

1. Classification...........................................................................................................................AII-i

2. Specifications..........................................................................................................................AII-i

2 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 11

Chapter 1 Introduction

I. General

Environment:

Temperature

Working 0 ~ 40 °C

Transport and Storage -20 ~ 60 °C

Humidity

Working 15% ~ 95%

Transport and Storage 10% ~ 95%

Introduction

Altitude

Working -500 to 4,600m

Transport and Storage -500 to 13,100m

Power Supply

100~240 (V)AC, 50/60 Hz

Pmax=100VA

FUSE T 1.6A

PM-8000 Portable Patient Monitor (Figure 1-1) is adaptable to adult, pediatric and neonatal

usage. It can monitor vital signals such as ECG, Respiratory Rate, SpO2, NIBP, TEMP and IBP. It

integrates parameter measuring modules, display and recorder into one device, featuring in

compactness, lightweight and portability. Replaceable built-in battery facilitates the transportation of

patient. Large high-resolution display provides clear view of 5 waveforms and full monitoring

parameters.

PM-8000 Portable Patient Monitor performs monitoring of:

ECG

Heart Rate (HR)

2-channel ECG waveforms

Arrhythmia and S-T segment analysis(optional)

RESP

SpO2

NIBP

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1-1

Respiratory Rate (RR)

Respiration Waveform

Oxygen Saturation (SpO2), Pulse Rate (PR)

SpO2 Plethysmogram

Systolic Pressure (NS), Diastolic Pressure (ND), Mean Pressure (NM)

Page 12

Introduction

TEMP

IBP

PM-8000 provides extensive functions as visual & audible alarm, storage and report printout for

trend data, NIBP measurements, and alarm events, and drug dose calculation, etc.

Temperature DATA

IBP SYS, DIA, MAP

IBP waveform

II. Appearance

The POWER switch is on the right quarter of the front panel (②). The POWER indicator(④)

and the BATT indicator (③) light when the device is powered on. The ALARM indicator flashes or

lights when alarm occurs (①). Sockets for the sensors are on the right side. The recorder socket is on

the left side. Other sockets and power plug-in are at the back.。

Figure 1-1 Front view of PM-8000 Portable Patient Monitor

2.1 Screen display

The display of PM-8000 may be color or monochrome liquid crystal. (The monitor of PM-8000 is

available in both monochrome and color liquid crystal).Patient parameters, waveforms, alarm messages,

bed numbers, date, system status and error messages can be displayed on the screen.

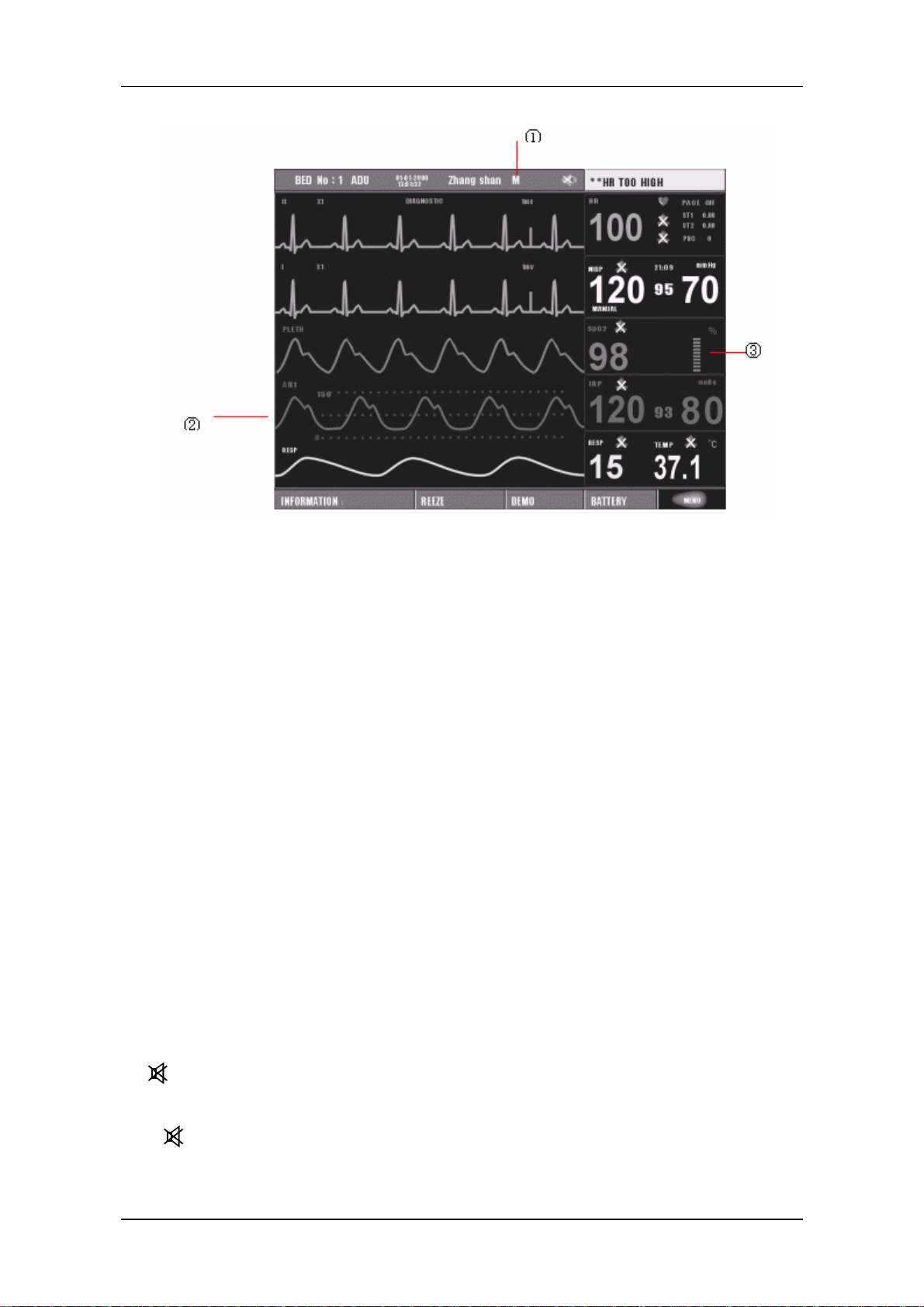

The screen is divided into three areas: ← message area①; ↑ waveform area②; → parameter area

1-2 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 13

Introduction

Figure 1-2 PM-8000 main screen

Message Area(①)

The Message Area is at the top of the screen and used to display operating state of the monitor and

status of the patient.

The messages and their meanings are:

【BED No】 Bed number of the patient being monitored

【3/1/2001】 Current date

【10:23:45】 Current time

【M/F】 Sex of the patient being monitored

【NAME】 name of the patient being monitored. When the user is entering patient name,

the name will be displayed at this position. If no patient name is entered, this

position will be blank.

Other information in the Message Area comes up only with respective monitoring status. They are:

1. Signs indicating the operating status of the monitor and the sensors are displayed at the right side of

time numeric. When appears, this message will cover the sex and name information of the patient.

2. “

” Indicates that all sounds are disabled manually. It appears when SILENCE button is pressed

for more than 1 seconds.

3. “!

ALARM SETUP menu, this mark appears indicating that the operator has permanently closed the

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1-3

” is the sign indicating that the alarm volume is closed. When select the “OFF” option in the

Page 14

Introduction

audio alarm function. This audio alarm function can resume only after the operator discharges the setup

of Close Alarm Volume.

′ NOTE ′

When “!

the operator should be careful in using this function. One method of discharging this

status is in the ALARM SETUP menu, select the item that the alarm volume is in

Non-close. Another method is to press the SILENCE button so as to make the mark

” sign appears, the system can not give any audio alarm prompt. Therefore,

change into a

restores the normal alarm status.

4. Alarm message is displayed always at the extreme right area on the screen.

5. When waveforms on the screen are frozen, “FREEZE” window appears at the bottom of the screen.

. Then press SILENCE button again, the system will immediately

Waveform/Menu Area(②)

Five waveforms can be displayed at the same time. The waveforms from up to down are: 2 channels of

ECG waveforms, SpO2 Plethysmogram, IBP, RESP (possibly coming from ECG module). Waveforms

to be displayed are user-selectable. Refer to Tracing Waveforms Selection in Operation Manual for

details.

The names of the waveforms are displayed to their left. The names of ECG and IBP are user-selectable.

Refer to Chapter ECG/RESP Monitoring and Chapter IBP Monitoring in Operation Manual for

details. Gain and filter of this ECG channel are displayed as well. A 1mv scale is marked on the right

of ECG waveform. The IBP waveform scale is displayed in IBP wave area. The three dot lines from up

to down respectively represent the highest scale, reference scale and lowest scale of the waveform.

These values can be manually set. Refer to Chapter IBP Monitoring in Operation Manual for IBP

setup.

The same menu always appears at a fixed area on the screen. When the menu is displayed, some

waveforms become invisible. The size of the menu is also fixed, covering the lowest 3, 4 or 5

waveforms. If the system exits the menu, the screen will restore its previous look.

The waveforms are refreshed in a user-set rate. Refer to the related chapters for details of sweep speed.

Parameter Area(③)

Parameters are displayed at a fixed position (①~⑩). They are (from top to bottom):

1-4 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 15

Introduction

ECG

NIBP

SpO2

IBP

Figure 1-3 Main Screen

Heart Rate (①, Unit: bpm) ⎯

⎯

ST-segment analysis of Channel 1 & 2 (②, Unit: mv)

⎯

Arrhythmia (PVCs) events (③, Unit: event/min)

⎯

(From left to right) Systolic, Mean, Diastolic (④, Unit: mmHg or kPa)

⎯

SpO2 (⑤, Unit: %)

⎯

Blood Pressure: Systolic, Mean, and Diastolic values are displayed from left to right. (⑥,

Unit: mmHg or kPa)

RESP

⎯

Respiration Rate (⑦, Unit: breath/min)

TEMP

⎯

Temperature (⑧, Unit:℃ or ℉)

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1-5

Page 16

Introduction

The above monitoring results are displayed in the Parameter Area.

The parameters refresh every second, except that the NIBP value refreshes each time when the

measurement is over.

User can select the monitor parameters, and the screen display will change accordingly.

Alarm indicator and alarm status:

In normal mode, no indicator lights.

In alarm mode, the alarm indicator lights or flashes. The color of the indicator indicates the alarm level.

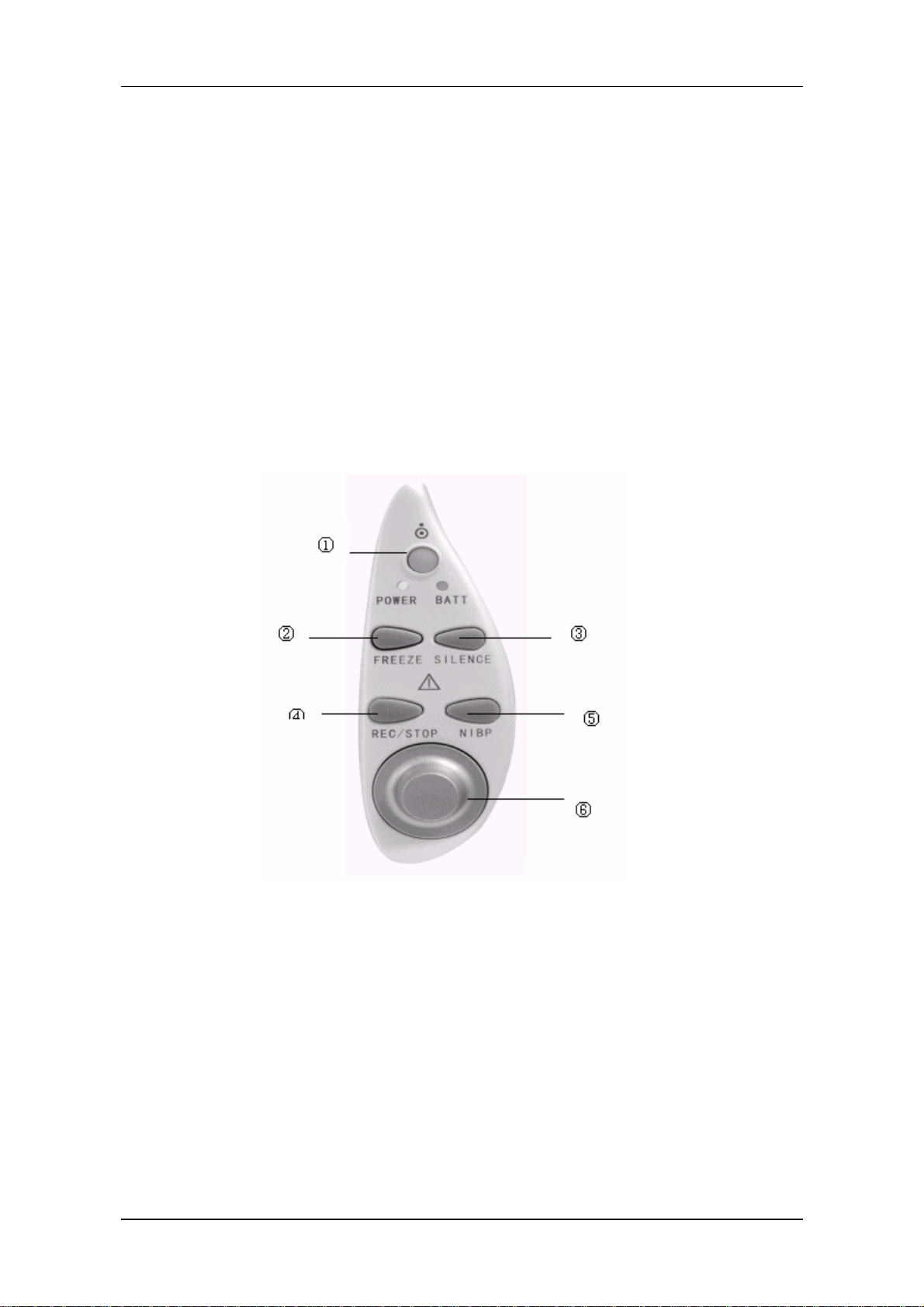

2.2 Button Functions

Figure 1-4 PM-8000 Buttons and Knob

All the operations of PM-8000 can be performed through using the buttons and the rotary knob at the

bottom of the screen. Above the buttons are their respective names. They are (from left to right):

①POWER

Press to turn on/off the monitor.

②FREEZE

When in normal mode, press to enter Freeze mode to freeze all the waveforms

on the screen. When in Freeze mode, press to restore the waveform

refreshing.

1-6 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 17

Introduction

③SILENCE

Press to suspend alarm for 3 minutes (it can be selected in ALARM SETUP

menu). Press this button for more than 1 seconds to disable all sound signals

(heart, beat, pulse tone, key sound), and audio alarm. A symbol “ ” displays

in the Message Area. Press this key again to restore all sound signals and

remove the “

” symbol.

NOTE:

If new alarm occurs under Alarm Suspension/Silence state,

Suspension/Silence state will change. For specific rules, see Chapter

Alarm.

NOTE:

Whether an alarm will be reset depends on the status of the alarm cause.

But by pressing SILENCE button can permanently shut off audio sound

of the ECG Lead Off and SpO2 Sensor Off alarm.

④REC/STOP

⑤START

⑥Rotary Knob

Rotary Knob

Press to start a real time recording. The recording time is set in RT

REC TIME of RECORD submenu (Refer to related sections for

details). Press during recording to stop the recording. When in

FREEZE mode, press to select the waveforms for report printout.

Refer to Chapter Recording for details.

Press to inflate the cuff to start a blood pressure measurement. When

measuring, press to cancel the measurement and deflate the cuff.

This knob can be used to select and change the settings. Operation

can be performed by turning it clockwise, counterclockwise or

pressing it down.

The square frame that moves when the knob is being turned is called "cursor". Operation can be

executed at any place where the cursor can stay. When no menu is displayed, turning the knob

clockwise can select following hot keys:

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1-7

Page 18

Introduction

Channel 1 ECG lead

Channel 1 ECG gain

ECG filter

Channel 2 ECG lead

Channel 2 ECG gain

IBP Label

ECG menu

SpO2 menu

NIBP menu

IBP menu

RESP menu

TEMP menu

When the current cursor is placed at any of the first six items, the user can change the current settings.

When at any of the last six items, related parameter menu could be called up for setting changes.

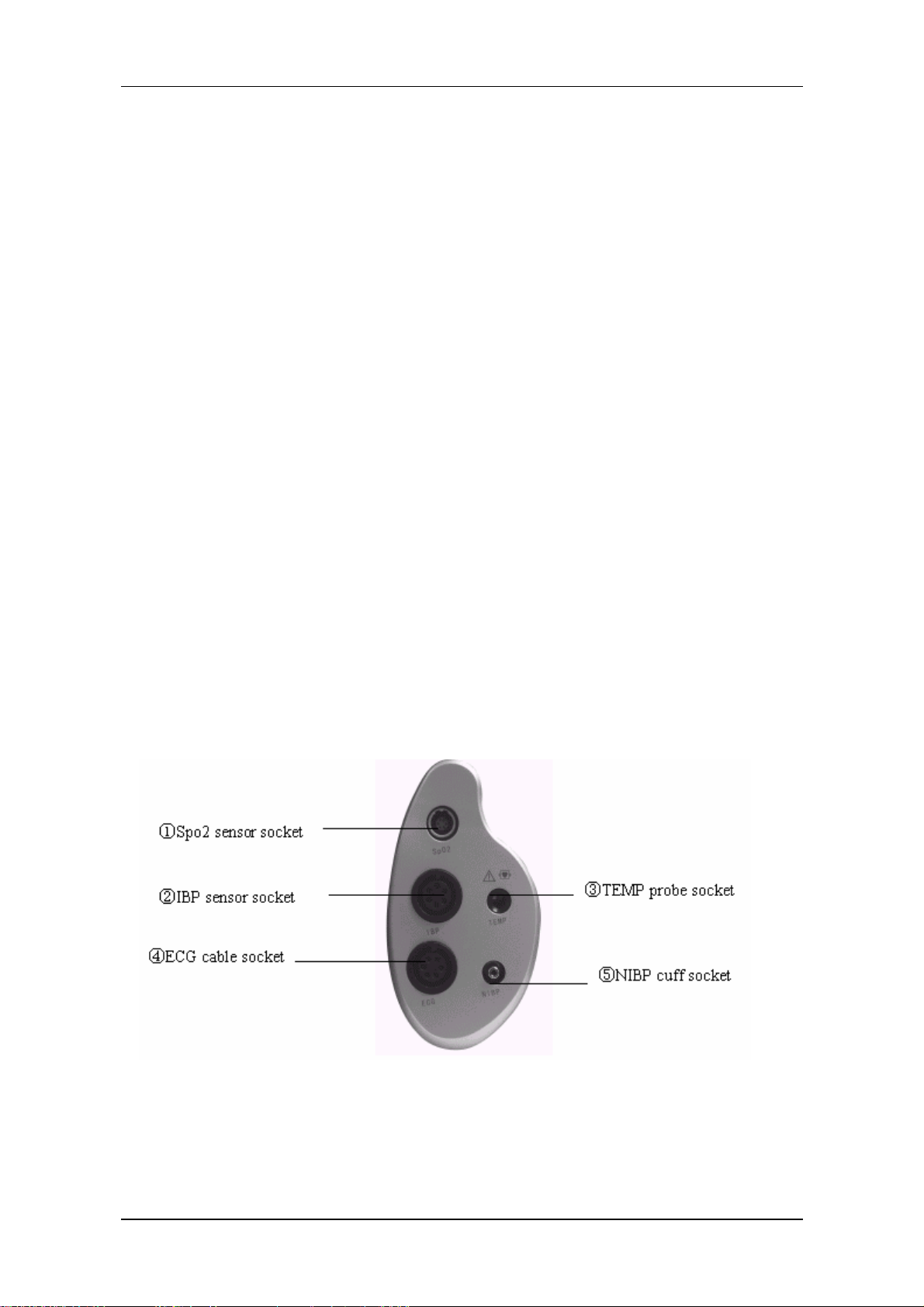

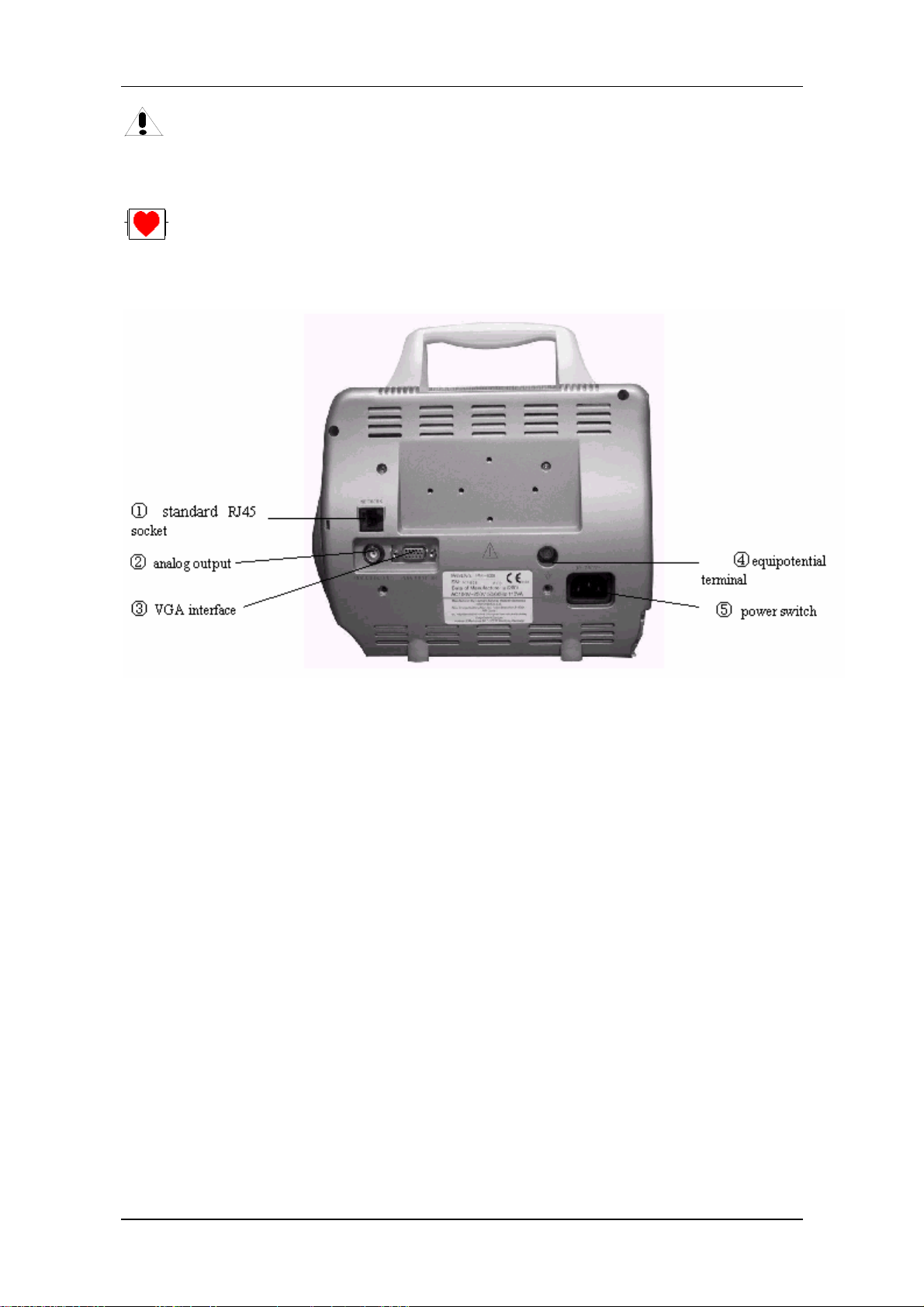

2.3 Interfaces

For the convenience of operation, different interfaces are in different parts of the monitor.

Recorder is on the left side of the monitor while sockets for patient cables and sensors are on the right

side. See the figure below:

Figure 1-5 Right side view

1-8 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 19

Introduction

This symbol means “BE CAREFUL". Refer to the manual.

Indicates that the instrument is IEC-60601-1 Type CF equipment. The unit displaying this

symbol contains an F-Type isolated (floating) patient applied part providing a high degree of

protection against shock, and is suitable for use during defibrillation.

Figure 1-6 Rear panel

Monitor interface for external: standard VGA color monitor.

Working mode: 640 × 480, 16 color, APA mode.

Signal: analog R G B 0.7 Vpp / 750 ohm

Hor. / Vert. TTL pos. / Neg.

Interface D-sub 15 pin

Pin 1. Red Video

Pin 2. Green Video

Pin 3. Blue Video

Pin 4. Ground

Pin 5. NC

Pin 6. Red Ground

Pin 7. Green Ground

Pin 8. Blue Ground

Pin 9. NC

Pin 10. Ground

Pin 11. NC

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1-9

Page 20

Introduction

Pin 12. NC

Pin 13 Horizontal Sync.

Pin 14. Vertical Sync.

Pin 15. NC

Appliance: (Installation)

1) Install the VGA monitor at a place at least 1.5m away from the patient.(The VGA monitor

must be installed at least 1.5m away from the patient.)This monitor is used only as an

assistant monitoring device.

2) Plug the cable into proper socket before powering on the VGA monitor.

3) It is allowable to power on the VGA monitor and PM-8000 at the same time. Or power on

PM-8000 after turning on VGA monitor.

4) Adjust brightness and contrast properly.

(Socket ④)

Equipotential grounding terminal for connection with the hospital’s grounding system.

ANALOG OUTPUT (Socket ②)

Analog signal output terminal for connection with oscillometer and pen recorder.

The connection terminal is a BNC Jack.

Network Interfaces (Socket ①): Standard RJ45 Socket.

Warning

Through network interface only MINDRAY Clinical Information Center can be connected in.

Warning

Accessory equipment connected to the analog and digital interfaces must be certified according

to the respective IEC standards (e.g. IEC 60950 for data processing equipment and IEC 60601-1

for medical equipment). Furthermore all configurations shall comply with the valid version of

the system standard IEC 60601-1-1. Everybody who connects additional equipment to the signal

input part or signal output part configures a medical system, and is therefore responsible that the

system complies with the requirements of the valid version of the system standard IEC 60601-1-1.

If in doubt, consult the technical service department or your local representative.

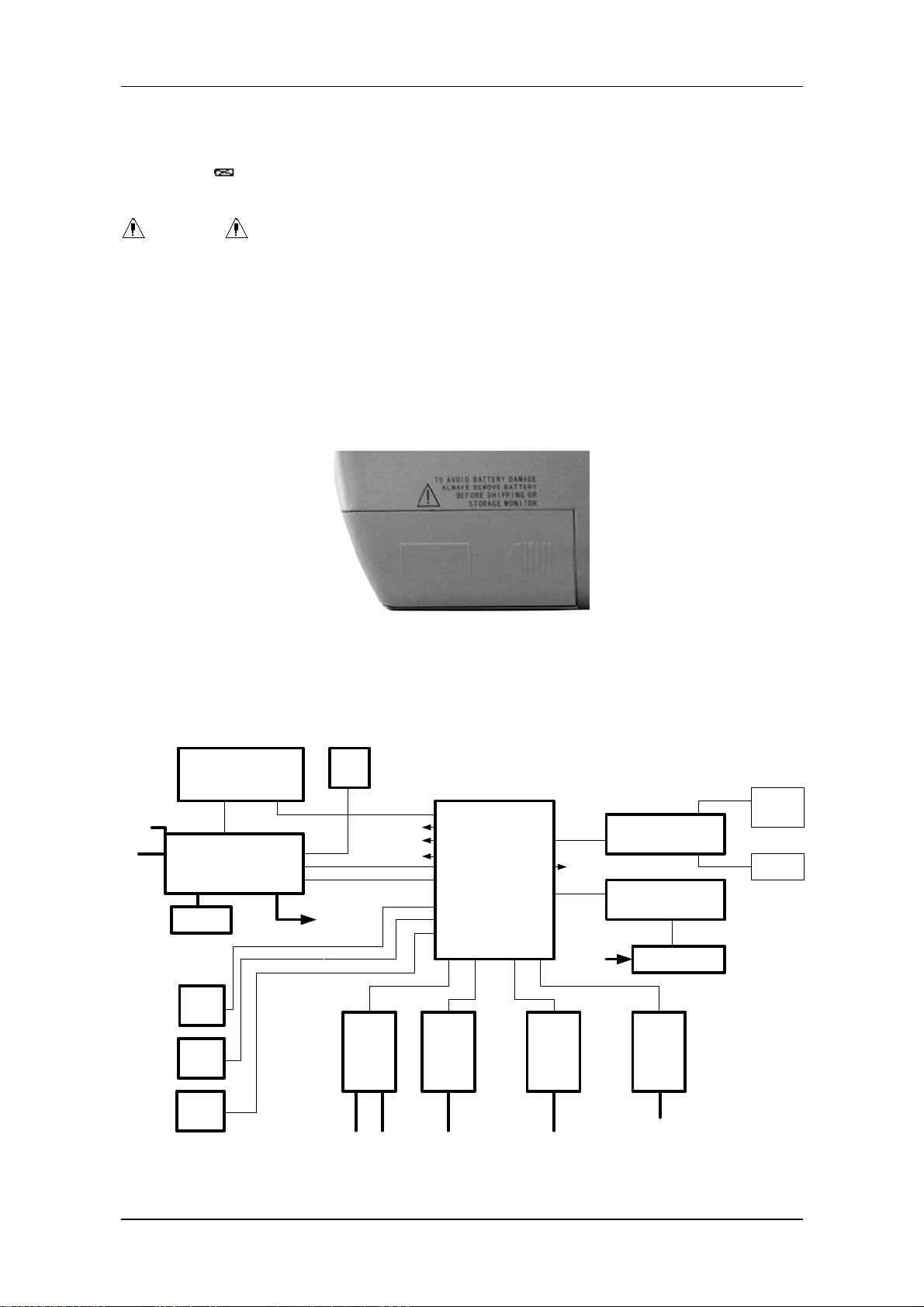

2.4 Built-in rechargeable battery

PM-8000 Portable Patient Monitor is equipped with a rechargeable battery. The battery in the Monitor

can automatically recharge when AC INPUT is connected until it is full. A symbol “

1-10 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

” is displayed

Page 21

Introduction

on the bottom of the screen to indicate the status of recharging, in which the black part represents the

relative electric energy of the battery. If the battery is not installed in PM-8000, battery state will be

displayed as “

” to indicate the state. Under the cable socket is the battery slot with cover.

Warning

Don’t pull off battery when the monitor is working.

When operating on battery, the monitor will prompt alarm and shut off automatically when the energy

is low. When the electric energy is going out, the monitor will sound continuous level 1 alarm beeping

and display “BATTERY TOO LOW” in the Message Area. Connect the monitor to AC power at this

moment can recharge the battery while operating. If keep operating on the battery, the monitor will

shut off automatically (about 5 minutes since alarming) upon exhaustion of the battery.

Figure 1-7 Battery slot cover

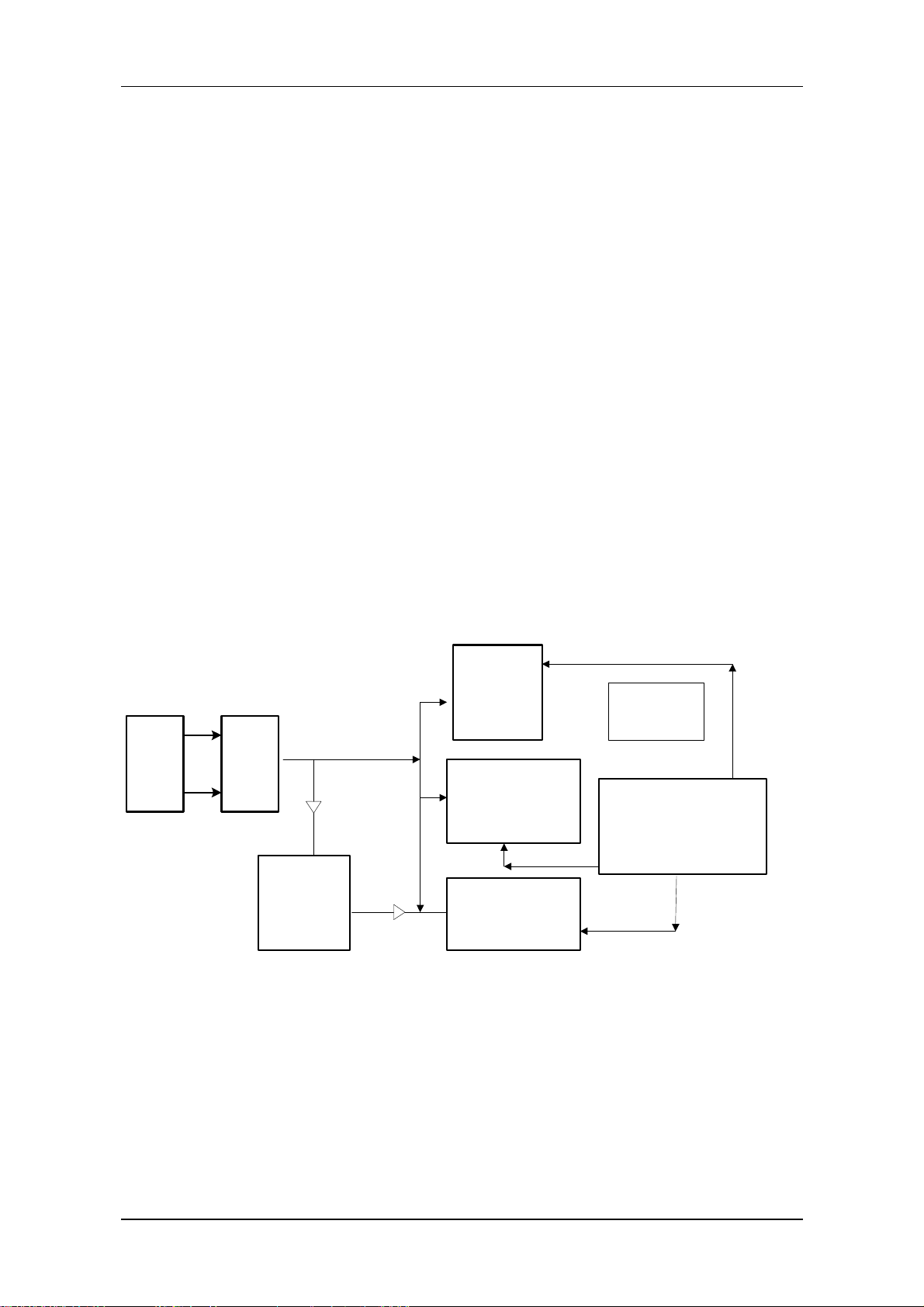

III. Hardware principle

PM-8000 block diagram

TFT Disp lay

8.4 inchs

Main

Power

Input

X16

Power Supply P C B

J3

B a tte r y

VG A

interface

NET

In te rfa c e

Analog

output

800 X 600

X14

J6

X15

J5

J4

J2

TO X4

FAN

P14

P7(BDM)

P8

P5

P10

P13

NIBP

Module

Cuff

NIBP

P1

P4(TFT_DIGTAL)

P2(CRT)

P3(FOR 9000 VGA)

P12

P11

H o s t P .C .B .

P17(FOR 509C)

P15

P16

P6

P9

X5

ECG /

RESP/

TEM P

P.B.C.

X9 X10 X11 X12

TEM P

ECG

ECG

TEMP

Cable

Sensor

X6 X7

SPO 2

P.C.B.

SPO2

SpO2

Sensor

From J2

Key & Alarm P .C .B .

J7

X1

R ecorder M odule

X2

X3

R e c o rd e r P .S .

X4

X8

IB P

P.C.B.

IB P

IBP

Cable

Alarm

J9

J8

L E D

Speaker

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1-11

Page 22

Introduction

Figure 1-8 PM-8000 connection diagram

Following are brief description of basic function and operating principle of each part.

3.1 Power board

PM-8000 power board specifications:

AC input voltage:100~240VAC

AC input current: <1.6A

AC voltage frequency: 50/60HZ

Two-way output voltage: 5V/12V, normal working current is 1.5A for 5V, 2A for 12V.

Two-way output voltage has functions of short-circuit, over-current and over-voltage protection.

The power board has reset function.

The power board can manage the charging process of lead-acid battery (12V/2.3AH). The

charging time is about 6 hours.

Schematic diagram of power board:

AC

input

AC/DC

Battery

and

Charging

Managerent

circuit

Figure 1-9 circuit diagram of PM-8000 power board

5VDC-DC

BUCK

converter

REC POWER

SOURCE

12V output

Voltage

test

Power on/off

control circuit

Testing key points:

Connect AC power (at this time, the Charge indicator of the battery should light on).

Test before power on the monitor.

Use multimeter to measure the DC voltage of the capacitor C12, which should be within the range

of 107 ~ 354V.

Use oscillograph to measure between the PIN1 of Q1 and the negative electrode of C12, a driving

1-12 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 23

waveform with the frequency being about 110KHz should exist.

Use multimeter to measure the DC voltage of the capacitor C19, which should be 17.5V.

Use multimeter to measure the DC voltage of the capacitor C24, which should be 13.8V (voltage

after removing battery).

Use multimeter to measure the capacitor C47, which should be 5V.

Tests after powering on the monitor:

Use multimeter to measure the regulator ZD3 whose DC voltage should be 5V.

Use multimeter to measure the regulator ZD4 whose DC voltage should be 12V.

Use multimeter to measure the capacitor C54 whose DC voltage should be 17.2V.

3.2 PM-8000 main control board

Power supply

Introduction

Input voltage: +12V±5%;

+5V±5%;

The main control board uses the COLDFIRE series embedded microprocessor 5206e

manufactured by MOTOROLA Company. It also adopts 3.3V low-voltage power supply to reduce the

power consumption. Other main components on the main control board include: Flash, SRAM, FPGA,

network controller, etc, all of which require 3.3V power. The capacity of the Flash has been increased

to 2MB, which employs two parallel-connected 512Kx16 chips and therefore uses 32-bit character

width to support CPU to operate at the highest possible speed instead of accessing to DRAM for

operation. The main control board has also a 4MB memory, which is made up of two

parallel-connected 1M ×16-bit chips. Because no executing program is required to be loaded, only

one RTC is used. This chip uses one 225maH dry cell as the spare power supply. In addition, one 2KB

2

E

PROM is used to store parameters. The main control board supports a resolution of 800x600 and

provides three interfaces: a LVDS interface, a 6BIT DIGITAL interface, and a VGA interface. The

monitor displays both characters and waveforms in an overlapping way on the whole screen in the

same color. The characters and waveforms can be browsed in a scrolling way. The support system

needs 10 serial ports, and the baud rate (4800/9600/19.2k/38.4k/76.8k) can be online selected by

software and interface buffer drives. The main control board adopts the network controller AX88796

(3.3V, 10MHz), which has inside 16K high-speed buffer SRAM. The MAX5102 8-bit single-way D/A

converter is used to fulfil analog output. 5V and 12V stabilized voltage supplies are introduced from

the power board, and therefore 3.3V and 2.5V working supplies are respectively generated. Among

them, 2.5V is to be used for the internal verification of FPGA.

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1-13

Page 24

Introduction

3.3 Structure diagram

FPGA

RTC/E2PRO

M/Watch

Display

driving

circuit

Interrupt

manageme

nt circuit

DRAM

CPU

Multi-way

serial

Figure 1-10 Structure diagram

3.4 Description

Flash/

SRAM

Network

controller

Audio

alarm/spare

battery

3.3V low-voltage power supply component is adopted. The external power is 5V, which is converted

by the DC/DC converter into 3.3V and 2.5V, the latter voltage being especially used for FPGA. The

main control board are connected with the external devices via following interfaces and input: the

power supply connected with the interface board, the 9-way serial port, TFT interface, analog VGA

interface, network interface, analog output and a spare serial port, etc. The BDM interface is reserved

on the board for the aim of software testing and download.

■ CPU

It use Coldfire5206e. Clock rate is 54MHz, working voltage is 3.3V.

■ FLASH

It use tow parallel-connected 512Kx16 FLASH memories. The output terminal PP1 of CPU is used to

realize write-protection of FLASH. It is effective in low-level state.。

■ DRAM

PM-8000 main control board uses two parallel-connected 1Mx16 DRAM, which construct 4M address

space.

■ Display

The resolution is 800x600. Frequency is 38MHz. It works in an appropriate SVGA mode. VRAM

adopts 16-bit structure and is divided into character screen and waveform screen. On the left side of the

1-14 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 25

Introduction

character screen is the corresponding waveform screen. The right side to the character screen is used to

display data and flashing alarms. The user can select color and dot energy. Besides the user can scroll

the waveform for clear and complete observation.

■ LVDS interface

Through the way of time-sharing sampling, the LVDS interface converts multi-way CMOS/TTL

signals into one-way low-voltage double-frequency difference signals, which are further to be output to

the outside). LVDS interface is generally realized by special integrated circuit. The special LVDS chip

used for display is DS90CF363A. This chip converts 18-way display pixel signals and 3-way display

control signals with a total of 21-way messages into 3-way LVDS signals. Four ways of difference

signals including these 3 ways of signals and a way of phase-locked frequency are transmitted to the

display screen. On the one side of the screen, these signals are restored for driving the screen. The

working frequency of DS90CF363A is 20~65MHz.

■ Reset and parameter storage

The main control board uses an integrated chip CS124C161, which has the functions of both power-on

reset and parameter storage. This chip has a E

2

PROM with the capacity of 2K. It can be used to

on-line modify and store various nonvolatile parameters of the host. The power-on reset and

WATCHDOG functions are used to realize reset function of the main control board. When J1 is open

circuit, the software can also disable WATCHDOG by using the output wire PP0 of CPU in order to

realize the selftest of WATCHDOG. The bus interface of this chip is I

2

C.

■ Data storage

The Main control board uses one non-power-down SRAM having its internal battery to store

monitoring data. Its capacity is 2M.

■ Network controller

The network controller adopts special chip AX88796. Its working clock is 25MHz. It also has internal

16K high-speed buffer SRAM. The data bus of this chip is 16-bit width.

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1-15

Page 26

Introduction

3.5 Button schematic diagram and principle

CPU

(A T89C 2051)

BUTTON

Watch dog

RAM

128x8

RC

FILTER

serial com m unica te

Alarm indicato r

POWER

CONVERSION

Main control

board

control c ircu it

speaker

ENCO DER

button and encoder

scan circ u it

audible effect

generating/

contol circuit

button signal

input

FLASH

volume

control

2KX8

BANDPASS

Figure 1-11 Button schematic diagram

3.5.1 Principle introduction:

The circuit has three main parts;

■ Alarm audio signal circuit: audible effect generating circuit is made up of nine components, which

are U3, D1, D2, D3, Q1, C2, R15 and R9. The length of the generated aftersound is controlled by the

discharge loop constructed by C2 and R15. P3.5 is used to generate alarm square waveforms (about

700Hz). When P3.3 is 1 and Q1 is on, alarm is activated, C2 is quickly charged to the full capacity and

R10 outputs to the next phase. When P3.3 is 0, alarm is terminated, C2 discharges by using R15 so as

to produce aftersound effect. D3 and D9 are used to overlap heart beat sound. When P3.2 is 1, the

square waveform of P3.5 generates “heart beat sound” and “rotary encoder sound” through controlling

the time length of the conduction of P3.2. Together with R17, R18 or R19, R10 may respectively

construct potential-dividing network of different proportion, and consequently control the state of P3.4

and P3.7, decide make-and-break of Q2 and Q3 so as to realize the function of adjusting 3-level sound

volume.

■ RC bandpass filter: The alarm signal is square waveform with the frequency of about 700Hz. To

remove the DC component (low-frequency component) in the square waveform, a one-phase bandpass

filter is added before LM386. This filter is made up of R22, C13, C11 and the input resistance Rin of

LM386.

■ Audio amplifying circuit constructed by LM386: Generation of the visual alarm signal: The

flashing of the indicator in red or green is realized by controling the state of singlechip P1.6 and P1.7.

Scanning of buttons and encoder: Determine whether a button or the encoder is pressred through the

way of scanning the state of singlechips P1.0~P1.2. Determine whether encoder is turned and its

turning direction by scanning the state of P1.4 and P1.5.

3.5.2 Important measurement points

1-16 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 27

1. Test if the 5V power supply works normally (after fuse FU1);

2. Test if the crystal oscillator starts oscillating when the voltage is about between 1.5~3.5V.

3.6 Maintenance part of TR60-A recorder

3.6.1 Diagram

Introduction

Power

8.3v->5v

5v

power 8.3v->3.3v

Motor

driver

Thermal Head

cpld 9536

cpu

ad

Opto

Senser

signal

Figure 1-12 Schematic diagram of TR60-A drive board

The main function parts of the recorder are:

3.6.2 Thermal head

The thermal head is the pivot component of recorder. It is PTMBL1300A thermal head manufactured

by ALPS company.

3.6.3 CPU system

The CPU system is the core of the drive board. Its task is to receive the data from the host and generate

lattice messages after calculation using specified algorithm. These messages are then sent to the

thermal head to be printed out. The CPU system can at the same time collect messages about both

thermal head and drive board, have these messages displayed and sent to the host.

3.6.4 Power conversion

The thermal head requires two power supplies: 8.3V and 5V. CPU needs 3.3V power. 5V and 3.3V are

generated on the drive board. Components using these two power supplies are SPX5205M5 and

AS1117.

3.6.5 Motor drive

A small motor is used to control the paper movement at the thermal head. The processor on the drive

board uses two motor drives IC LB1843V to control and drive the motor. These two ICs are able to

drive the motor using constant-current. The logic drive level of the thermal head used on the

CPLD9536 drive board is 5V CMOS. The processor works under 3.3V. The system uses a CPLD

X9536XL, by which the output logic of the OC gate is generated, therefore converting 3.3V level into

5V.

3.6.6

Test points are listed out in the table below:

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 1-17

Page 28

Introduction

No. Name Position Function

1 VH P1.1 or P1.2 Power input: 7.8~8.4V

2 GND P1.4 or TP16 Power and signal grounding termals

3 VPP U3.8 Thermal head heating and motor power: 8~8.4V

4 VDD U9.2 Logic component power of the drive board:

3.0~3.6V

5 VCC U4.5 Logic power of the thermal head: 4.75~5.25V

6 RESET TP30 CPU reset signal, high level after power-on:

(>2.4V)。

1-18 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 29

Monitoring Functions and Principles

Chapter 2 Monitor Functions and Principles

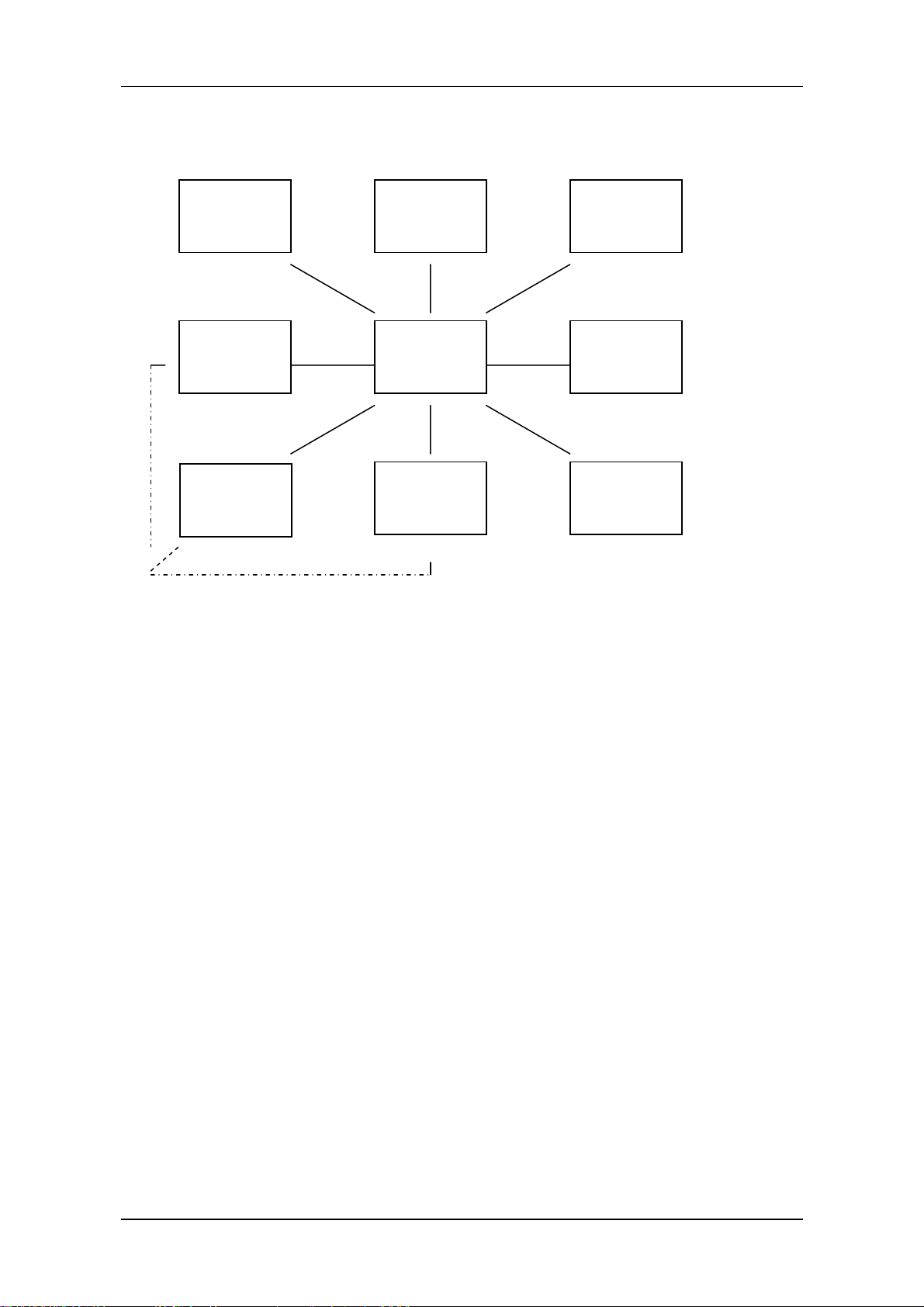

I. Introduction

PM-8000 portable patient monitor uses parameter module as the basic unit to acquire signals. The

results are transmitted to the main control board via keyset to finally process and display the data and

waveforms. The commands of the main control board and status messages of modules are transmitted

also through the keyset. The keyset is additionally used to realize power switching and conversion. The

structure of the whole system is shown in the figure below:

---------------------------------------- Medical Staff ----------------------------------------

------------------------------------------------ Patient ---------------------------------------------

keyboard Display Recorder

Power

ECG/RESP

/TEMP

NIBP

Main

control

board

SpO2

Network

interface

IBP

Figure 2-1 System structure diagram

As shown in the above figure, the four modules of parameters execute real-time monitoring of NIBP,

SpO2, ECG/RESP/TEMP, IBP respectively through using cuff and measuring cables. The results are

transmitted to the main control board for display. When required, the results can also be printed out via

recorder. Coming up is the detailed information of functions.

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 2-1

Page 30

Introduction

II. ECG/RESP parameters

2.1 ECG

Main functions concerning ECG

1)lead: 3-lead, 5-lead

2)lead method; I, II, III, avR, avL, avF, V, CAL

3)Floating input

4)right-foot drive

5)lead-off detection

6)dual-channel ECG amplification, simultaneously processing ECG signals of any two leads.

The ECG circuit is responsible for processing the ECG signals of human body. The circuit consists of

following parts;

1) input circuit: the ECG electrodes are connected into the circuit through the cable. This circuit is

mainly used to protect ECG input stage, filter the signals so as to remove the outside interference.

2) buffer amplifying circuit: used to convert the impedance of ECG signals, so as to ensure that the

ECG has a very high input impedance but only low output impedance.

3) right-foot drive circuit: the middle output point of the buffer amplifying circuit is reversely

amplified and then fed to the RL of the 5-lead ECG to maintain the human body in a equipotential state.

This method can reduce the interference and raise the common-mode rejection ratio of the circuit.

4) lead-off detection: based on the theory that the lead-off may cause the output of the buffer

amplifying circuit to change, we can use the comparator to accurately determine if the lead has fallen

off. In this way, the level can also be converted into TTl level for the singlechip to test.

5) lead connection circuit: under the control of singlechip and as per requirement, we can connect

different lead electrodes into the main amplifying circuit for amplification.

6) main amplifying circuit: a measurement amplifier constructed by three standard operation

amplifiers.

7) Last stage processing circuit: used mainly to couple ECG signals, program control the magnitude of

the gain, filter the waveform and move the level, amplify the signal and send it to the analog-to-digital

converter.

2.2 RESP

The Monitor measures temperature by measuring the changes in resistance of a thermistor located in

the temperature lead. When a person is respiring, his chest goes up and down. This movement equals to

2-2 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 31

Monitoring Functions and Principles

the impedance changes between electrodes RL and LL. The monitor converts the high-frequency

signals passing through RL and LL into amplitude-modulated high-frequency signals, which are then

demodulated and amplified into electronic signals varying with the respiration changes and then

transmitted to analog-digital converter. RESP module is made up of a respiration circuit board and a

coupling transformer. The circuit includes such parts as oscillation, coupling, demodulation,

preliminary amplification, and high-gain amplification, etc.

2.3 NIBP

The monitor measures non-invasive blood pressure using the oscillometric method. Following are

detailed measurement procedures. Inflate the cuff encircled around the upper arm until the pressure in

the cuff blocking the blood flow in the artery of the upper arm. Then deflate the cuff according to the

requirement of a certain algorithm. With the pressure decreasing in the cuff, the artery blood will

palpitate with the pulse, which results in pulsation in the cuff. Through the pressure sensor connected

with the inflating pipe of the cuff, a pulsation signal palpitating with the pulse will be generated. After

being filtered by a high-pass filter (about 1Hz), this signal becomes pulsating signal and is amplified.

Then the amplified signal is converted into digital signal by A/D. After using the single chip to process

this digital signal, we may obtain systolic pressure, diastolic pressure and mean pressure. Be careful to

choose appropriate cuffs for neonatal, pediatric and adult patients so as to avoid generating

measurement errors. NIBP module also has protection circuit to prevent the cuff from being inflated to

a very high pressure. The main operating modes of NIBP are;

1) adult/pediatric/neonate: select according to the patient shape, weight and age.

2) manual measurement, auto measurement, continuous measurement. Manual measurement is also

called single measurement. It means the monitor only performs one measurement for each time. Auto

measurement means to perform one measurement within selected cycle. Time interval can be set up as

1, 2, 3, 4, 5, 10, 15, 30, 60, 90, 120, 180, 240 and 480 minutes. Continuous measurement means after

being activated, the monitor will perform quick measurement continuously within 5 minutes.

Continuous measurement is effective in monitoring changes of blood pressure.

2.4 SpO2

SpO2 Plethysmogram measurement is employed to determine the oxygen saturation of hemoglobin in

the arterial blood. If, for example, 97% hemoglobin molecules in the red blood cells of the arterial

blood combine with oxygen, then the blood has a SpO2 oxygen saturation of 97%. The SpO2 numeric

on the monitor will read 97% .The SpO2 numeric shows the percentage of hemoglobin molecules

which have combined with oxygen molecules to form oxyhemoglobin. The SpO2/PLETH parameter

can also provide a pulse rate signal and a plethysmogram wave. Arterial oxygen saturation is measured

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 2-3

Page 32

Introduction

by a method called pulse oximetry. It is a continuous, non-invasive method based on the different

absorption spectra of reduced hemoglobin and oxyhemoglobin. It measures how much light, sent from

light sources on one side of the sensor, is transmitted through patient tissue (such as a finger or an ear),

to a receiver on the other side.

The sensor measurement wavelengths are nominally 660nm for the Red LED and 940nm for Infrared

LED. Maximum optical power output for LED is 4 mW. The amount of light transmitted depends on

many factors, most of which are constant. However, one of these factors, the blood flow in the arteries,

varies with time, because it is pulsating. By measuring the light absorption during a pulsation, it is

possible to derive the oxygen saturation of the arterial blood. Detecting the pulsation gives a PLETH

waveform and pulse rate signal. The SpO

value and the PLETH waveform can be displayed on the

2

main screen.

2.5 TEMP

Technical specifications:

Measurement and alarm range: 0 ~ 50 °C

Resolution: 0.1°C

Accuracy: ±0.1°C

Refreshing time: about 1 second

Average time constant: < 10 seconds

2.6 IBP

IBP monitors arterial pressure, central venous pressure and pulmonary arterial pressure.

Measurement method:

Stab and implant the catheter into the blood vessel of the part to be measured. The end of the catheter

located outside human body connects directly with the pressure transducer. Injectate normal saline into

the catheter. Because the liquid can transfer pressure, the pressure inside the blood vessel can be

transferred to the outside pressure transducer. In this way we can at any time obtain the dynamic

waveform of the changing pressure inside the vessel. By using specified calculating formula, we can

calculate systolic, diastolic and mean pressures.

2-4 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 33

Checks and Tests

Chapter 3 Checks and Tests

I. System checks

For the conventional testing contents of PM-8000 portable patient monitor, please refer to its Operation

Manual. The information in this chapter is only a brief introduction. The following sections are used to

emphasize important tests and the information not clearly specified in the Operation Manual.

1. Device appearance and installation checks

1)The shell of the device is clean and has no scratches. The installation is stable. When shaking the

device, these are no inside leftovers.

2)Buttons are smooth and free for operation.

3)Labels are complete and sufficient and correct in delivering information.

4)Standard configuration is complete, the sockets are installed safely.

5)Perform vibration test on the overall device before performing following operating tests.

2.Safety tests

2.1.Test equipment

1. Safety analyzer 501 PRO 1

2. Leakage current/grounding resistance measurement kit: 1

3. Connection kit of the application part: 1

4. Tinsel 20cm X 10cm 1

2.2.Test procedures

2.2.1 Leakage current to earth

2.2.1.1 Connection graph for testing is as shown in figure 3-1:

Connect one end of the 3-core power wire to AC220V network power, the other end

to the leakage current testing kit (A). Insert the 3-core power wire of safety

analyzer (B) into power output socket of (A). Connect the 3-core power wire of the

device being tested ① into AC output of 501. Connect the sensor of the

application part based on the requirements of (C). Connect the red measurement

clip RED of 501 to the ground protection PE terminal. Connect the SUM terminal

of (C) to the P terminal of (A). Locate all switches to “OFF” position.

(A)-----grounding resistance/leakage current measurement kit

(B)-----501 safety analyzer

(C)-----application part processing kit

① ------device being tested

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 3-1

Page 34

Checks and Tests

⑤ ------application part

RED---501 red measurement clip

SUM--- kit post

Figure 3-1 Leakage current testing connection

between grounding terminal and the earth

2.2.1.2 Adjust input voltage: When the device being tested is in shutdown state,

connect leakage current measurement kit (A) with the input network voltage

AC220V. Adjust the booster to raise the testing voltage to 110% (that is 253V) of

the nominal voltage 230V. This voltage is monitored by the voltage meter of (A).

Then turn on the device to let the device be in the operating state, micro-adjust the

booster to make the output voltage keep stablely at 253V. Press the [Ground] key

of the 501 tester and disconnect the grounding wire.

2.2.1.3 Leakage current between network source and earth in normal state: press

the [Leakage] key of the 501 tester and read the leakage current value on it.

Connect SW12, in the condition that the application part is connected to the earth,

respectively press and release [Polarity] key to toggle between the null line and the

live wire. Then disconnect SW12 and cut off the connection between the

application part and the earth. Respectively press and release the [Polarity] key.

The maximum value of these four measurements should be less than 0.5mA.

2.2.1.4 Leakage current between network source and the earth in single fault

condition:

Leakage current when connection between null line and live wire is being cut off:

press the [Leakage] key of the 501 tester. Then press the [neutral] key of the 501

tester, disconnect N line. Respectively press and release the [Polarity] key to

toggle between null line and live wire, and imitate the condition that L line is

3-2 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 35

Checks and Tests

disconnected. Read the leakage current value on the 501 tester. Connect SW12,

respectively press and release the [Polarity] key. Disconnect SW12, respectively

press and release the [Polarity] key. The maximum value of these four

measurements should be less than 1.0mA.

2.2.2 Shell leakage current:

2.2.2.1 Connection graph for testing is shown in figure 3-2:

Connect one end of the 3-core power wire to AC220V network power, the other end

to leakage current testing kit (A). Insert the 3-core power wire of safety analyzer

(B) into power output socket of (A). Connect the 3-core power wire of the device

being tested① into AC output of 501. Connect the sensor of the application part

based on the requirements of (C). Stick the tinsel A on any position of ① (never

let A touch live part, protection earth and the application part).Connect the red

clip RED of the 501 tester onto the tinsel A. Connect the SUM terminal of (C) to

the P terminal of (A). Locate all switches to “OFF” position.

Figure 3-2 Connection graph for leakage current

testing between the shell and the earth

(A)-----grounding resistance/leakage current measurement kit

(B)-----501 safety analyzer

(C)-----application part processing kit

① ------device being tested

⑤ ------application part

A-------tinsel

RED---red measurement clip of 501

SUM---kit post

2.2.2.2 leakage current between the shell to protection earth in the normal state:

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 3-3

Page 36

Checks and Tests

(adjust the input voltage by referring to 3.1.2) press the [Leakage] of the 501

tester and read the leakage current value on the 501. Connect SW, respectively

press and release the [Polarity] key. Disconnect SW, respectively press and release

the [Polarity] key. The maximum value of these four measurements should be less

than 0.1mA.

2.2.2.3 Leakage current between the shell and protection earth in single fault

condition:

2.2.2.3.1 Leakage current when ground wire is disconnected: press the [Leakage]

key of the 501 tester. Press the [Ground] key and disconnect the ground wire.

Connect SW and respectively press and release the [Polarity] key. Disconnect SW,

respectively press and release the [Polarity] key. The maximum value of these four

measurements should be less than 0.5mA.

2.2.2.3.2 Leakage current when null line and live wire are disconnected: press the

[Leakage] key of the 501 tester. Press the [Neutral] key of the 501 tester.

Disconnect N line, respectively press and release the [Polarity] key and toggle

between null line and live wire. Imitate the condition that L line is disconnected

and read the leakage current value on the 501 tester. Connect SW, respectively

press and release the [Polarity] key. Disconnect SW and respectively press and

release the [Polarity] key. The maximum value of these four measurements should

be less than 0.5mA.

2.3 Patient leakage current of the application part::

2.2.3.1 Connection graph for testing is shown in figure 3-3:

Connect one end of the 3-core power wire to AC220V network source, the other

end to leakage current testing kit (A). Insert the 3-core power wire of the 501

analyzer into its output socket. Connect the 3-core power wire of the device being

to be tested ① into AC output of 501. Connect the sensors including RA, LA, LL,

RL, V, NIBP, SpO2, TEMP1, TEMP2 and IBP of the application part based on the

requirements of (C). Connect the output SUM of (C0 to the RA post of the 501

tester. Locate all the switches on the connecting kit of the application part to [OFF]

position.

3-4 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 37

Checks and Tests

Figure 3-3 Connection graph for leakage current testing

between application part (patient) and the earth

(A)-----grounding resistance/leakage current testing kit

(B)-----501 safety analyzer

(C)-----application part processing kit

① -----device being tested

⑤ -----application part

P3----sensor connected with the patient

RA----RA terminal of ECG measuring post of 501

SUM--- kit post

2.2.3.2 Patient leakage current in the normal state: (adjust the input voltage by

referring to 3.1.2) Press the [ECG leak] key of 501, then press the arrow on the

panel of 501 to select the RA-GND item. The measured leakage current should be

less than 0.01mA.

2.2.3.3 Patient leakage current in single fault condition:

2.2.3.3.1 Press the [ECG leak] key of 501, then press the arrow on the panel of 501

to select the RA-GND item. Take turns to operate the [Ground] key (for

disconnecting the ground wire), the [Neutral] key (for disconnecting the null line)

and the [Polarity] key (for toggling between null line and live wire). Test the AC

leakage current in the above these fault conditions. The maximum current value

should be less than 0.05mA.

2.2.3.3.2 Press the [DC Only] key of 501, take turns to operate the [Ground] key

(for disconnecting the ground wire), the [Neutral] key (for disconnecting the null

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 3-5

Page 38

Checks and Tests

line) and the [Polarity] key (for toggling between null line and live wire). Test the

DC leakage current in the above three fault conditions, the maximum current value

should be less than 0.05mA.

2.2.3.4 Patient leakage current of the application part when network voltage is

added.

2.2.3.4.1 Press the [ECG leak] key of 501, then press the arrow on the panel of 501

to select the RA-GND item. Press the [Isolation] key and add network voltage. Test

the leakage current of the added network voltage. The maximum current value

should be less than 0.05mA.

2.2.4 Patient auxiliary current:

2.2.4.1 Connection graph for testing is shown in figure 3-4

Connect one end of the 3-core power wire to AC220V network electical source, the

other end to leakage current testing kit (A). Insert the 3-core power wire of the 501

analyzer into its output socket. Connect the 3-core power wire of the device being

to be tested ① into AC output of 501. Connect the sensors of the application part

according to the requirements of (C). Connect the output RA-P of (C) to the RA

binding post of 501. Short-circuit connect LA-P, LL-P, RL-P, V-P, NIBP-P,

SpO2-P, TEMP1-P, TEMP2-P, IBP-P respectively onto the SUM binding post. Then

through SUM, use lead to to connect them to the LL binding post.

(A)-----grounding resistance/leakage current measurement kit

(B)-----501 safety analyzer

(C)-----application part processing kit

① -----device being tested

⑤ -----application part

P3----sensors connected to the patient

RA----RA terminal of the ECG measuring post of 501

LL----LL terminal of the ECG measuring post of 501

SUM---kit post

3-6 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 39

Checks and Tests

Figure 3-4 Connection graph for testing patient auxillary

leakage current

2.2.4.2 Patient auxiliary current in the normal state (adjust the input voltage by

referring to 3.1.2)

AC auxiliary current of the RA lead of ECG to other application parts: position the

RA on the connection kit of the application part to “ON” and other switches to

“OFF”. Connect RA-P to the RA binding post of 501. Connect other patient parts

to LL through SUM. Press the [ECG leak] key of 501, then press the arrow on the

panel of 501 to select the RA-LL item. The tested current value should be less than

0.01mA.

2.2.4.3 Patient auxiliary current in single fault condition:

2.2.4.3.1 AC auxiliary current of RA lead of ECGT to other application parts (AC

value of RA). Position the RA on the connection kit of the application part to

“ON” and other switches to “OFF”. Connect RA-P to the RA post of 501. Connect

other parts to LL through SUM. Press the [ECG leak] key of 501, then press the

arrow on the panel of 501 to select the RA-LL item. Take turns to operate the

[Ground] key (for disconnecting the ground wire), the [Neutral] key (for

disconnecting the null line) and the [Polarity] key (for toggling between null line

and live wire). Test the current in the above three fault conditions, the maximum

current value should be less than 0.05mA.

2.2.4.3.2 DC auxiliary current of the RA lead of ECG to other application parts

(DC value of RA):

Press the [DC Only] key of 501, take turns to operate the [Ground] key (for

disconnecting the ground wire), the [Neutral] key (for disconnecting the null line)

and the [Polarity] key (for toggling between null line and live wire). Test the

current in the above three fault conditions, the maximum current value should be

less than 0.05mA.

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 3-7

Page 40

Checks and Tests

2.2.5 Testing grounding resistance

2.2.5.1 Connection graph for testing ground resistance is shown in figure 3-5:

Note: In the graph, P1 and P2 are two binding post of grounding resistance testing

kit. Keep the measuring wires “Black” and “Red” as short as possible. The

sectional area of the wire should be larger than 10mm

2

. It is acceptable to use more

than 3 pieces of parallel-connected 10WAG wires. GND is the grounding terminal

of either the power wire of the device being tested or the power plug. EP is the

grounding terminal to the device (for the current patient monitor, EP is

equipotential binding post). C are all the protecting metal covers (shells) that are

connected to PE. M are all metal screws that are connected onto EP. C and M are

all on the device shell.

Figure 3-5 Connection graph for testing

grounding resistance

2.2.5.2 Testing procedures

2.2.5.2.1 Between GND of power wire and EP: Zero the booster on (A), Connect

black wire of P1 to GND of the 3-core power wire, and the red wire to the EP

binding post. Connect network voltage 220V. Slowly adjust and raise the booster

output and observe the reading on current meter for (A). Continue to raise the

booster output until the reading of the current meter indicates 25A. Wait for 5

seconds and then read the value on the voltage meter (use AC voltage range of the

multimeter), which should be less than 5V.

2.2.5.2.2 Between GND of power plug and EP: Zero the booster, Connect black

wire of P1 to GND of the 3-core power wire, and the red wire to the EP binding

post. Connect network voltage 220V. Slowly adjust and raise the booster output

and observe the reading on the current meter. Continue to raise the booster output

until the reading of the current meter indicates 25A. Wait for 5 seconds and then

read the value on the voltage meter (use AC voltage range of the multimeter),

which should be less than 2.5V.

3-8 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 41

Checks and Tests

2.2.5.2.3 Between GND of power plug and each C point: Zero the booster on (A),

Connect black wire of P1 to GND of the 3-core power wire, and the red wire to the

selected C shell (cover). Connect network voltage 220V. Slowly adjust and raise

the booster output and observe the reading on the current meter. Continue to raise

the booster output until the reading of the current meter indicates 25A. Wait for 5

seconds and then read the value on the voltage meter (use AC voltage range of the

multimeter), which should be less than 2.5V.

2.2.5.2.4 Between GND of power plug and each M point: Zero the booster on (A),

Connect black wire of P1 to GND of the 3-core power wire, and the red wire to the

selected M screw. Connect network voltage 220V. Slowly adjust and raise the

booster output and observe the reading on the current meter. Continue to raise the

booster output until the reading of the current meter indicates 25A. Wait for 5

seconds and then read the value on the voltage meter (use AC voltage range of the

multimeter), which should be less than 2.5V.

II. Testing and calibrating each parameter

Testing and calibrating follow parameters are to ensure the accuracy of PM-8000 portable patient

monitor. Calibrating operation should be performed at least once a year. Calibration should be carried

out each time after maintenance.

1.Testing ECG and RESP

1)Testing tool

Human physiological signals simulator

2)Testing procedures

① Use measuring cable to connect thesimulator into the ECG socket of PM-8000

② Confirm if the number of ECG waveforms displayed on the screen is consistent with that indicated

in the ECG MENU and Factory MENU.

③ In default configuration, select lead II for ECG1 and lead I for ECG2 (if there is ECG2)

④ Check if ECG waveforms and RESP waveforms are normally displayed.

⑤ Set up the parameters of the simulator as following;

HR=30(gain×4)

RR=15

⑥ Check if the displayed ECG and RESP waveforms, HR and RR values are correct.

⑦ Change the simulator configuration

HR=240

RR=120

⑧ Check if the displayed ECG and RESP waveforms, HR and RR values are consistent with the

parameters set up on the simulator.

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 3-9

Page 42

Checks and Tests

⑨ Make the ECG lead fall off, in this condition, the PM-8000 should immediate give alarm.

2.Testing NIBP

1)Testing tool

NIBP simulator

2)Testing procedures

Use the NIBP simulator with calibrating function. Calibrate the blood pressure pump and determine its

accuracy according to the calibrating method given in the Operation Manual. If it passes the calibration,

continue to perform following tests.

① Select Adult mode for both simulator and PM-8000

② Select a group of blood pressure values within the measurement range on the NIBP simulator, such

as:

NS=90

NM=70

ND=60

③ Check if the actual measured values of PM-8000 are consistent to those set up on the simulator.

④ Change the setup values on the simulator, and test again.

⑤ Check if the actual measured values are consistent with setup one.

3.Testing SpO2

1)Testing tool

SpO2 simulator

2)Testing procedures

① Connect SpO2 simulator with the SpO2 probe of PM-8000

② Set up the parameters of SpO

SpO

=98

2

simulator as following:

2

PR=70

③ Check if the displayed SpO

and PR values on PM-8000 are consistent with those on the

2

simulator.

(Note: To observe the PR value, select PLETH as the HR source in the ECG menu.)

④ Change the setup values of SpO

and PR on the simulator.

2

⑤ Check the displayed values on PM-8000 are consistent with the setup values.

⑥ Make SpO

sensor fall off, in this condition, PM-8000 should immediately give alarm.

2

4.Testing TEMP

1)Testing tool

Human physiological signals simulator

2)Testing procedures

① Connect one end of the TEMP sensor to the simulator and the other end to the TEMP socket of

3-10 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 43

Checks and Tests

PM-8000.

② Using the simulator to set up : EMP=34℃.

③ Check if the displayed TEMP value on the screen of PM-8000 is 34℃.

④ Change the setup value of the simulator to: TEMP=40℃.

⑤ Check if the displayed TEMP value on the screen of PM-8000 is 40℃.

5 Testing IBP

1)Testing tool

Human physiological signals simulator

2)Testing procedures

Set up the BP sensitivity of the simulator to 5uv/v/mmHg, and BP to 0mmHg. Set up the name of IBP1

to ART. Access the PRESSURE ZERO option of IBP SETUP MENU of PM-8000, zero Channel 1 to

perform zero calibration for IBP. After the zero calibration is successful, exit the menu to enter the

main screen. Set up the BP of the simulator to 200mmHg. Access the CALIBRATION menu of

PM-8000 to perform calibration operation. After the calibration is successful, exit the menu.

Set up the BP of the simulator respectively to 40mmHg, 100mmHg, and 200mmHg. In the mean time,

the screen should respectively display 40±1mmHg, 100±2mmHg, and 200±4mmHg.

Set up the output of the simulator as the ART wave. As the result, the screen should display the

corresponding waveform correctly.

Plug off the IBP sensor. The screen should display “IBP: SENSOR 1 OFF!” “IBP: SENSOR 2 OFF!”.

Plug OHMEDA cable into IBP1 channel, the display of “IBP: SENSOR 1 OFF!”. Should disappear

from the screen.

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 3-11

Page 44

Page 45

Chapter 4 Troubleshooting

I. Disassembly graph of each part of PM-8000

Troubleshooting

1 Front panel assembly 6 Main bracket assembly

2 Rear panel assembly 7 Cross panhead cuspless screw PT3x10

3 Battery door 8 Cross panhead screw M3x6

4 Sockets cover 9 Cross panhead screw with gasket M3x8

5 TR60-A recorder

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 4-1

Page 46

Troubleshooting

1 Main bracket 10 back board assebmly

2 Main control board 11 TFT screen assebmly

3 6200 ECG/TEMP/RESP board 12 Power board

4 6200 SpO2 board 13 Speaker assembly

5 Battery hook 14 Cross panhead screw M3x6

6 ECG insulation film 15 Recorder power wire

7 Parameter sockets assembly 16 Recorder insulation film

8 6200 recorder power board 17 Power supply insulation film

9 NIBP/IBP bracket assembly

II. Troubleshooting guidance

In transportation, storage and use of PM-8000, various factors such as unstable network voltage,

changing environmental temperature, falling-down or impact, component aging may all result in

PM-8000 failures and therefore affect normal application of the device. In failure conditions,

professional personnel with the experience of repairing electronic medical devices should perform

component-level upkeep as per the failure classification listed in the table below. Component-level

upkeep means based on analyzing, replacing or trial-operating component, we can pinpoint the failure

on a certain component of the device, such as power board, main control board, TFT assembly,

measuring cable or parameter module, etc. Repair of only some components means component-level

repair. The repair operation must be conducted by a service engineer with abundant experience and

with the assistance of special equipment and in specific environment and conditions.

4-2 Service Manual of PM-8000 Portable Patient Monitor (V2.0)

Page 47

PM-8000 Component-level Service Table

2.1 Device failures

Failure Possible cause Solution

①fuse damage ①replace fuse

Troubleshooting

No display after power-on,

power indicator does not light

on, fan does not run.

No display after power-on or

black screen during operation,

however, power indicator

lights on and fan runs

normally.

Characters are displayed

normally, however waveforms

are displayed intermittently.

An operation or measurement

function is disabled.

②power damage ②replace power

③component short-circuit ③ anchor the short-circuit

component

①main control board failure

or display failure

① Data communication error

between main control board

and parameter module

① main control board or

corresponding component

damage

① refer to the information about

confirming display failure

①Based on error prompt, replace

main control board, keyset or

parameter module so as to

confirm the failure.

① examine main control board

and corresponding component

① moment intensive

interference of network

② poor performance of power

board

Device is occasionally stoned.

2.2 Display failures

Failure Possible cause Solution

When powering on the device,

power supply is in normal

operation, however, there is no

display or screen goes black

③poor performance of main

control board

④ bad connection of power

supply or main control

board

① backlight board damage ① connect external VGA display

② bad connecting wire of

display

① check power supply and

grounding system

② replace power board

③ replace main control board

④ replace or repair connectors

and confirm the failure

② repair or replace connecting wire

Service Manual of PM-8000 Portable Patient Monitor (V2.0) 4-3

Page 48

Troubleshooting

during normal operation.

③ damage of main control

③ replace main control board

board