Page 1

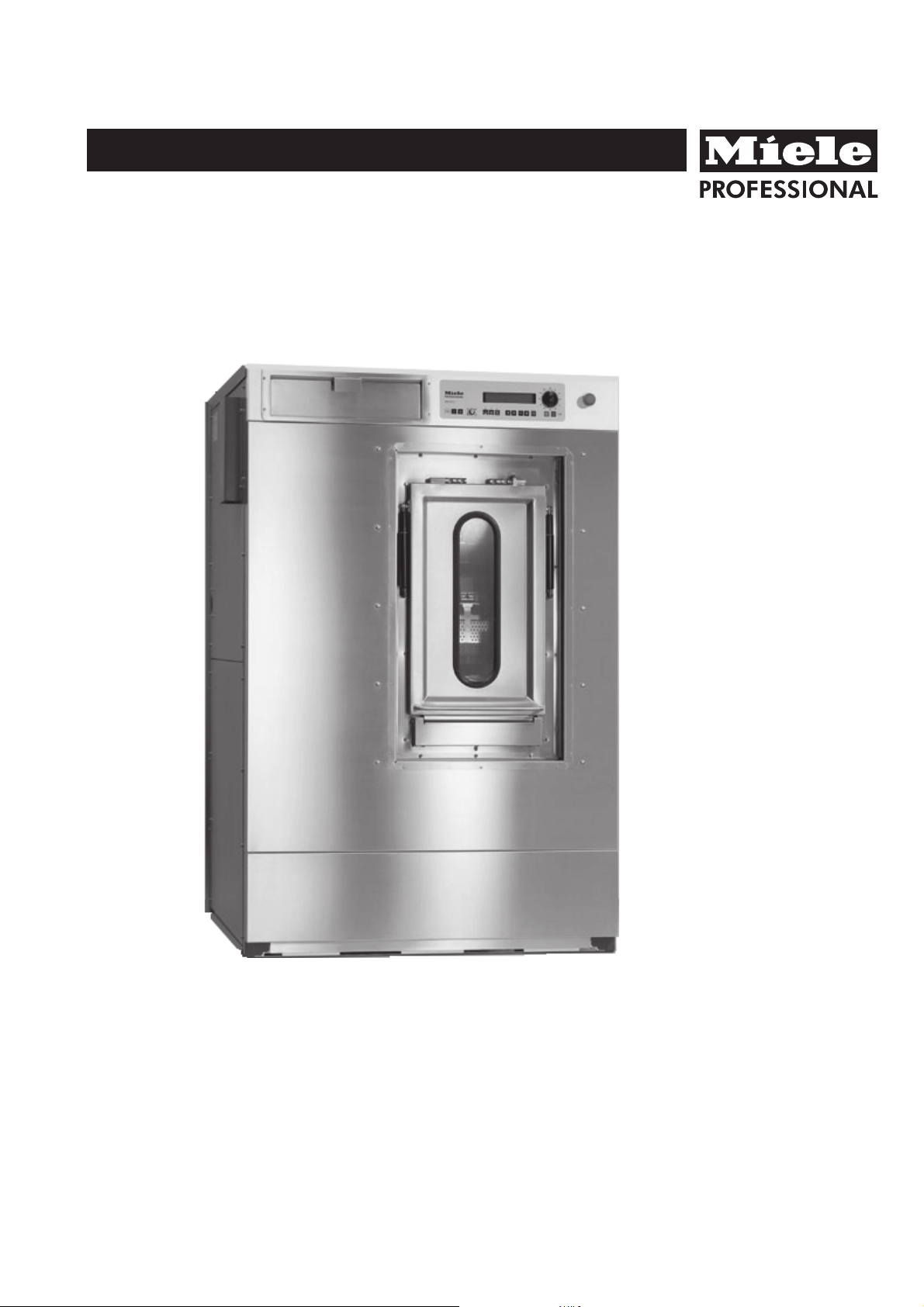

Operating instructions

Washer-Extractor

WS 5243

WS 5323

To avoid the risk of accidents or damage to the machine it is en - GB

essential to read these instructions before installing,

commissioning and using it for the first time.

M.-Nr. 05 730 941

Page 2

2 M.-Nr. 05 730 941

Page 3

Contents Indice

Warning and Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Guide to the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Guide to the controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the local language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Setting the current time of day and date . . . . . . . . . . . . . . . . . . . . . . . . . 13

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Open the drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Close the drum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Load weight / Adding detergent . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Selecting a disinfection programme . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Unloading the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Selecting an “unlocked” programme . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

To change the temperature and the spin speed . . . . . . . . . . . . . . . . . . . . . 19

Additional functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

With Pre-wash / Starching / Without a spin . . . . . . . . . . . . . . . . . . . . . . . . 21

Programme interruption / Delay Start . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Locked programmes (Disinfecting programmes) . . . . . . . . . . . . . . . . . . . . . 23

Locating the drum door to the "Clean side" . . . . . . . . . . . . . . . . . . . . . . . . 23

Hot water rinse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connecting a printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Liquid dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Problem solving guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power cut during a wash programme . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Emergency door release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

After sales service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Explanation of the symbols on the data plate . . . . . . . . . . . . . . . . . . . . . 32

Notes for the installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Transit bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Electrical connection / Steam connection . . . . . . . . . . . . . . . . . . . . . . . . . 35

EU Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Page

The washer-extractor must be installed by

an approved service technician or

authorised Service Dealer.

This booklet is part of a set which comprises:

- Profitronic programming instructions

- Programme surveys

- Detergent dispensing charts

The set is supplied with the machine.

M.-Nr. 05 730 941 3

Page 4

Warning and Safety instructions

Read the operating instructions through before using this machine for the first time.

This way you will avoid the risk of

accidents or damage to the machine.

Appropriate use of the machine

This washer extractor is only intended for

items of laundry which have not been impregnated with dangerous or inflammable substances.

Only machine wash articles which have

a care label stating they are suitable for

machine washing.

Temperatures, holding times, suds ratio

and disinfecting agents must meet the requirement of national Health and Safety guidelines for disinfecting procedures and the

required levels of microbiological hygiene for

infection prophylaxis.

If items being processed have to meet par-

ticular quality standards, e.g. particulate

free rinse results, the procedure must be validated and the user must make regular quality

checks to ensure appropriate standards are

being maintained.

On no account must solvents of the kind

used for dry cleaning be used in this machine. Danger of fire or explosion.

Never use or store petrol or petroleum

based substances or any easily inflammable substances near the machine. Do not

use the machine lid as a resting place.

Danger of fire or explosion.

Technical and electrical safety

The electrical safety of this appliance can

only be guaranteed when continuity is

complete between the appliance and an effective earthing system which complies with local

and national regulations.

It is most important that this basic safety requirement is regularly tested by a qualified

electrician. The manufacturer cannot be held

responsible for the consequences of an inadequate earthing system.

Do not damage, remove or bypass the

safety features and controls on the machine.

Where there is any damage to the ma-

chine or to the cable insulation the machine must not be used until it has been

repaired.

Any removable outer panels must be in

place, and all moving or electrical parts

shielded before the machine is operated.

The machine is only completely isolated

from the electricity supply either when

switched off at the wall isolator, or the mains

fuse is withdrawn from the socket.

Repairs to machines operating with elec-

tricity or steam should only be undertaken

by a suitably qualified service engineer to ensure safety. Unauthorised repairs could be

dangerous.

Faulty components should only be ex-

changed for Miele original spare parts.

Only when these parts are fitted can the

safety standards of the machine be guaranteed.

The very best materials are used in the

manufacture of this machine, and every

care is taken in its manufacture. However,

with time, deterioration of parts can occur, especially with rubber components such as

hoses. This should be borne in mind if operating the machine without supervision. Check

the inlet hoses regularly for signs of deterioration and replace in good time, to avoid leaks

and subsequent damage.

Local regulations regarding regular inspec-

tion and maintenance of this machine

must be observed.

4 M.-Nr. 05 730 941

Page 5

Warning and Safety instructions

Use of the machine

This washer extractor is not intended for

use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience or knowledge,

unless they have been given supervision or instruction concerning its use by a person responsible for their safety.

Never allow children to play in, on or near

the washer extractor, or to operate it themselves. Please supervise its use by the elderly or infirm.

Remember that the door porthole glass

can become hot during the operation of

the machine. Do not let children touch it .

Always make sure the drum is stationary

before reaching in to remove washing.

Reaching into a moving drum is extremely

dangerous.

It is the operator’s responsibility to ensure

that the standard of disinfection in thermal

as well as chemo thermal procedures is maintained (in accordance with § 18 IFSG) by

carrying out suitable validation tests. These

procedures should be checked on a regular

basis, either thermo-electrically using loggers,

or bacteriologically with bio indicators. The

operator must pay particular attention to maintaining the correct parameters in the procedure, including temperature and with chemo

thermal programmes the chemical concentration used. Disinfection programmes must not

be interrupted, as this can have a limiting effect on the disinfection result.

Water used for washing and rinsing must

not be used as drinking water. It must be

discharged into a proper sewerage system.

The machine should only be operated un-

supervised when there is a floor drain

(gully) in the direct vicinity of the machine.

If you are not sure about a particular agent,

contact the manufacturer of that agent for advice.

If you accidentally spill an agent containing

chlorides on the machine it should be rinsed

off with water and dried using a soft cloth.

Always follow the instructions of the

chemical manufacturer when using cleaning agents and special application chemicals.

Only use such chemicals for the purpose and

in the situation specified by the manufacturer

in order to avoid the danger of adverse

chemical reactions and material damage.

If in doubt check the suitability of the product

for use in this machine with the manufacturer

before using it.

Where a chemical cleaning agent is rec-

ommended on technical application

grounds, this does not imply that the manufacturer of the machine takes responsibility for

the effect of the chemical on the material of

the items being cleaned or on the machine.

Please be aware that changes in formulation,

storage conditions etc., which may not be publicised by the chemical producer, can have a

negative effect on the cleaning result.

Proprietary dyes, dye removers and de-

scaling agents may only be used in this

machine if the manufacturer expressly states

that they are suitable for use in a washing machine. Follow the manufacturer’s instructions

on using them.

Laundry that was soiled with biological

oils or fat should be washed using a suitable detergent and/or wash programme. It

must also be inspected after washing. If oils

or fat are not sufficiently removed they could

cause the laundry to self ignite during the

drying process.

On no account use high pressure

cleaners or hose down the machine.

Disinfecting and cleaning agents often

have compounds containing chlorides in

them. If these agents dry on to stainless steel

surfaces, the residual chlorides will attack the

steel and can cause rusting.

To protect your machine from rust damage, we

recommend only using chloride free disinfecting and cleaning agents for washing and disinfecting programmes and for cleaning stainless

steel surfaces of the machine itself.

M.-Nr. 05 730 941 5

Page 6

Warning and Safety instructions

Use of accessories

Accessory parts may only be fitted when

expressly approved by Miele. If other

parts are used, guarantee, performance and

product liability claims may be invalidated.

Chlorine and component damage

Notes on using chlorine bleach and perchlorethylene

Frequent use of chlorine increases the

risk of component damage.

The use of agents containing chlorine, such

as sodium hypochlorite and chlorine bleach in

powder form, can damage the protective surface of stainless steel and cause corrosion.

Factors affecting this are chlorine concentration levels, contact time and temperature. It is

therefore advisable to avoid the use of such agents. Oxygen based bleaching agents

should be used instead.

Disposal of old machines

When disposing of an old machine, dis-

connect it from all services and make the

door lock inoperative, so that children cannot

accidentally shut themselves in. Make appropriate arrangements for the safe disposal of

the machine.

All personnel working with this machine

must be fully trained in all aspects of its

use and safety.

Keep these instructions in a safe place.

If, however, chlorine based bleaching agents

have to be used for particular types of soiling,

then anti-chlorine measures must also be carried out. If this is not done irreparable damage can occur to components in the

machine and to laundry.

Anti-chlorine treatment

Anti-chlorine treatment has to be carried out

immediately after chlorine bleach has been

used. Hydrogen peroxide and oxygen based

cleaning and bleaching agents must only be

used in programmes specified for their use.

Any wash performance problems should be

discussed with the manufacturer of the cleaning / bleaching product in the first instance.

With thiosulfate, especially when used with

hard water, gypsum can form, which can lead

to incrustations on laundry or deposits in the

machine.

The exact quantity of additives and the treatment temperatures required must be set and

tested on site in accordance with the dosage

recommendations of the detergent and additive manufacturers. The laundry must also be

tested to make sure it contains no active chlorine residues after processing.

6 M.-Nr. 05 730 941

Page 7

Caring for the environment

Disposal of the packing material

The transport and protective packing has

been selected from materials which are environmentally friendly for disposal and can normally be recycled. Packaging e.g. cling film,

polystyrene and plastic wrappings must be

kept out of the reach of babies and young

children. Danger of suffocation. Rather than

just throwing these materials away, please ensure that they are recycled.

Disposal of your old machine

Electrical and electronic machines often contain materials which, if handled or disposed of

incorrectly, could be potentially hazardous to

human health and to the environment. They

are, however, essential for the correct functioning of your machine. Please do not therefore dispose of it with your household waste.

Please dispose of it at your local community

waste collection/recycling centre, and ensure

that it presents no danger to children while

being stored for disposal.

It should be unplugged or disconnected from

the mains electricity supply by a competent

person. See the "Warning and Safety" section

of this booklet for further details.

M.-Nr. 05 730 941 7

Page 8

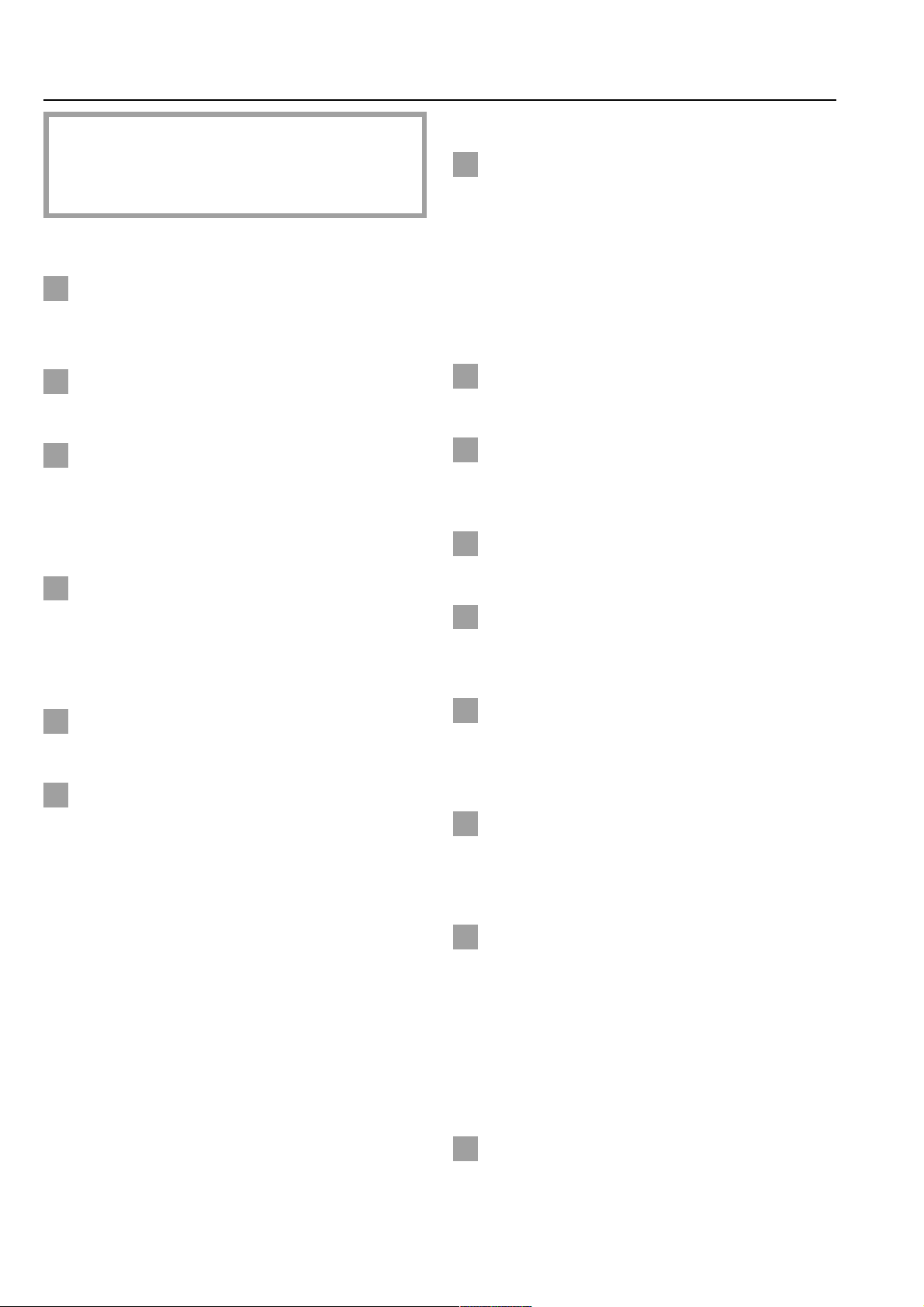

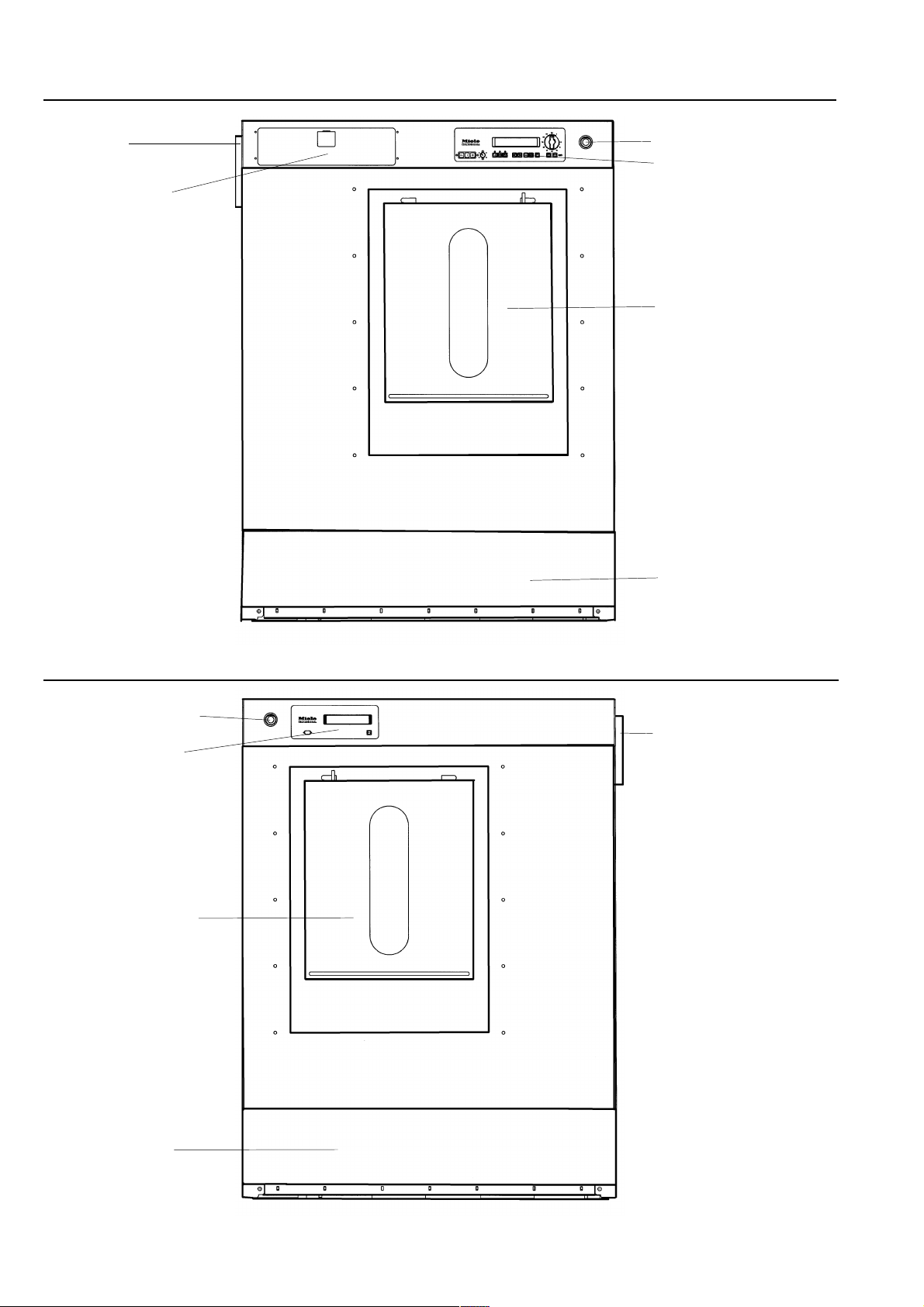

Guide to the machine

Overflow Emergency stop switch

Control panel

Detergent

dispenser drawer

Door "Unclean side"

Service panel

WS 5243/5323 "Unclean side"

Emergency stop

switch Overflow

Control panel

Door "Clean side"

Service panel

WS 5243/5323 "Clean side"

8 M.-Nr. 05 730 941

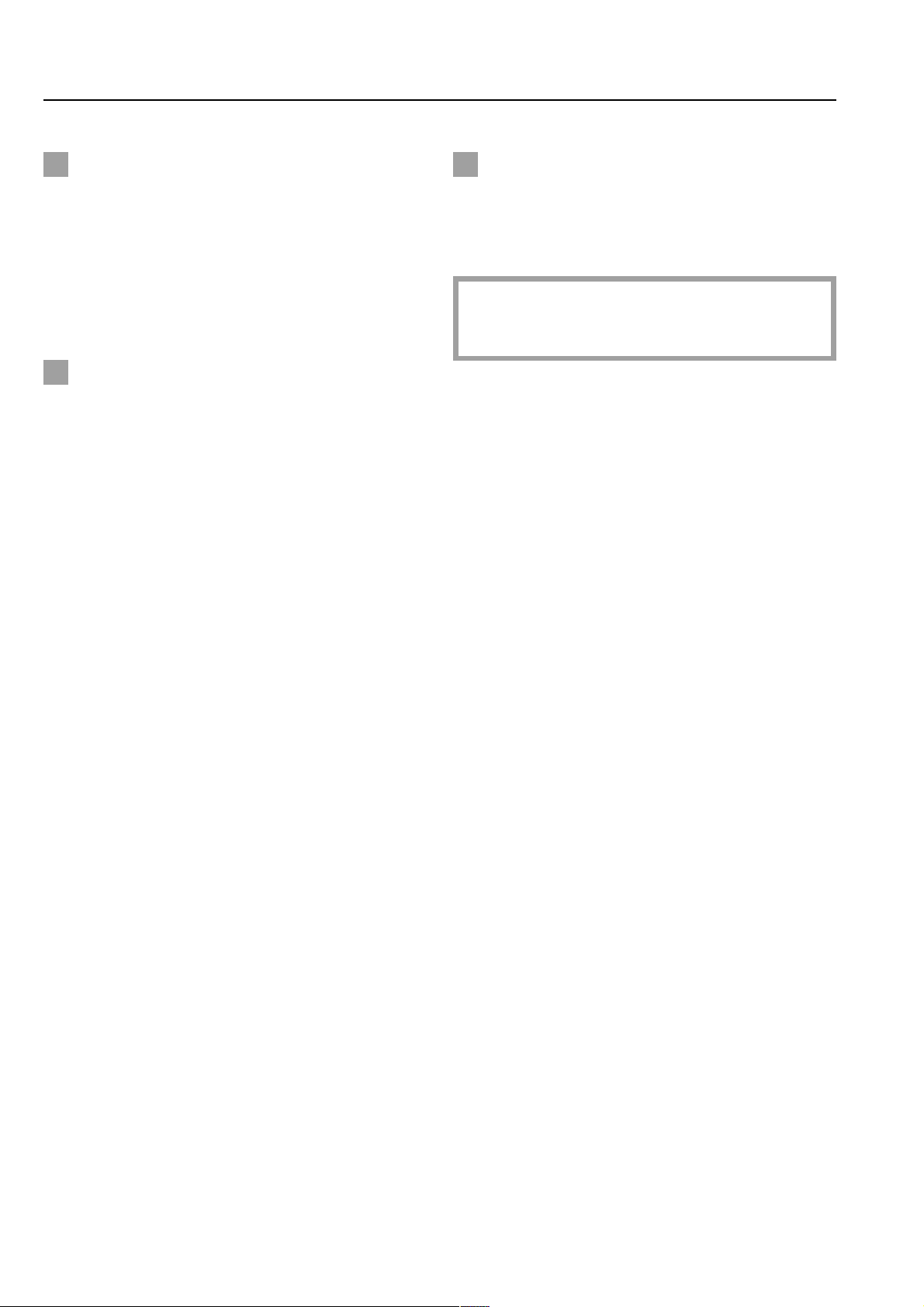

Page 9

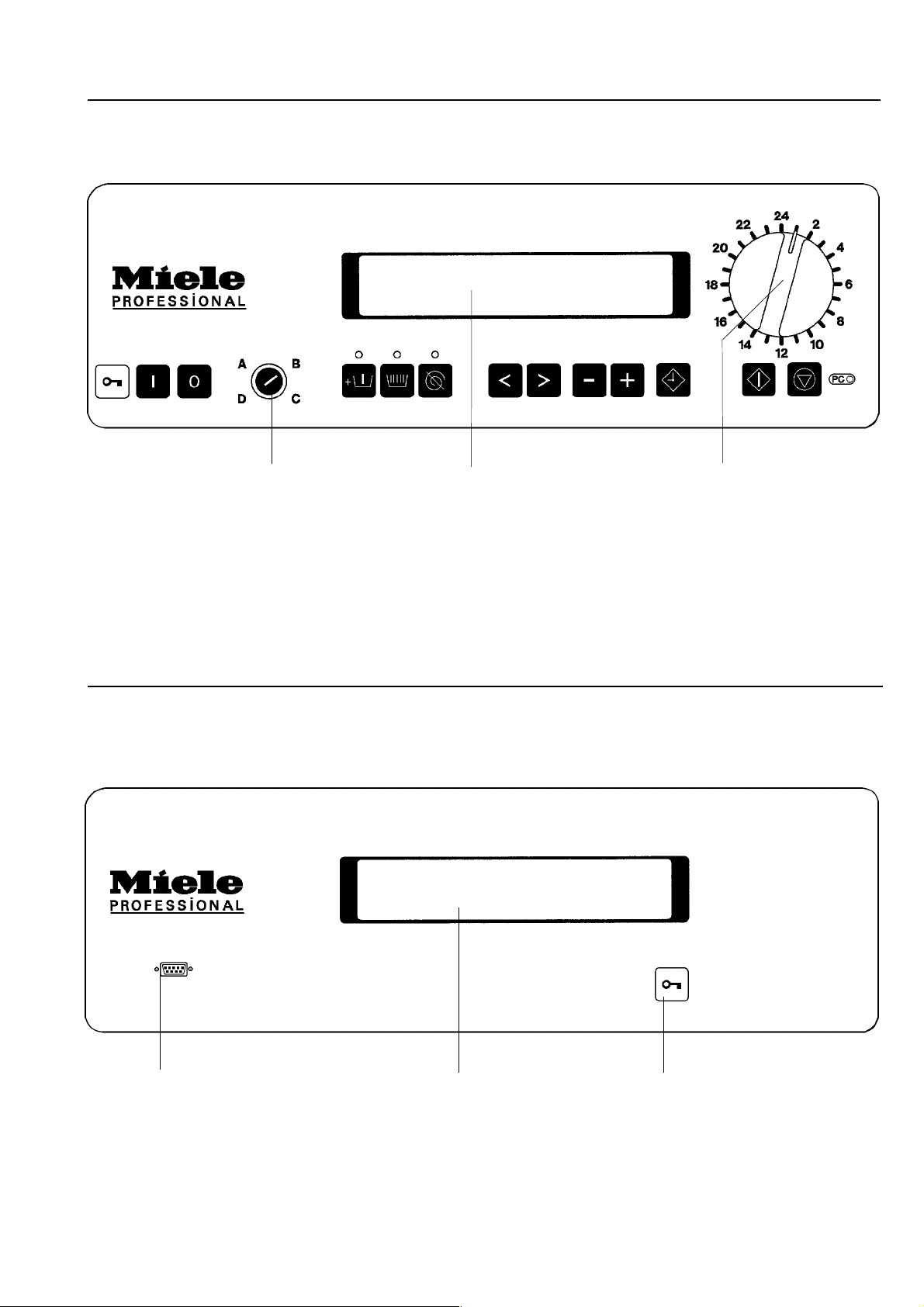

Guide to the machine

Control panel "Clean side" (loading side)

Key switch Display Programme selector

Mains on Y switch Block plus T button Cursor 1 2 buttons Start X button

Mains off Z switch Starch hold U button Plus 4 Minus 3 buttons End 7 button

Door 5 button Without spin V button Delay start W button 9 Optical

interface

Control panel "Clean side" (Side for unloading disinfected laundry)

Printer socket Display Door 5 button

A printer can be connected to the machine

for printing out programme reports.

M.-Nr. 05 730 941 9

Page 10

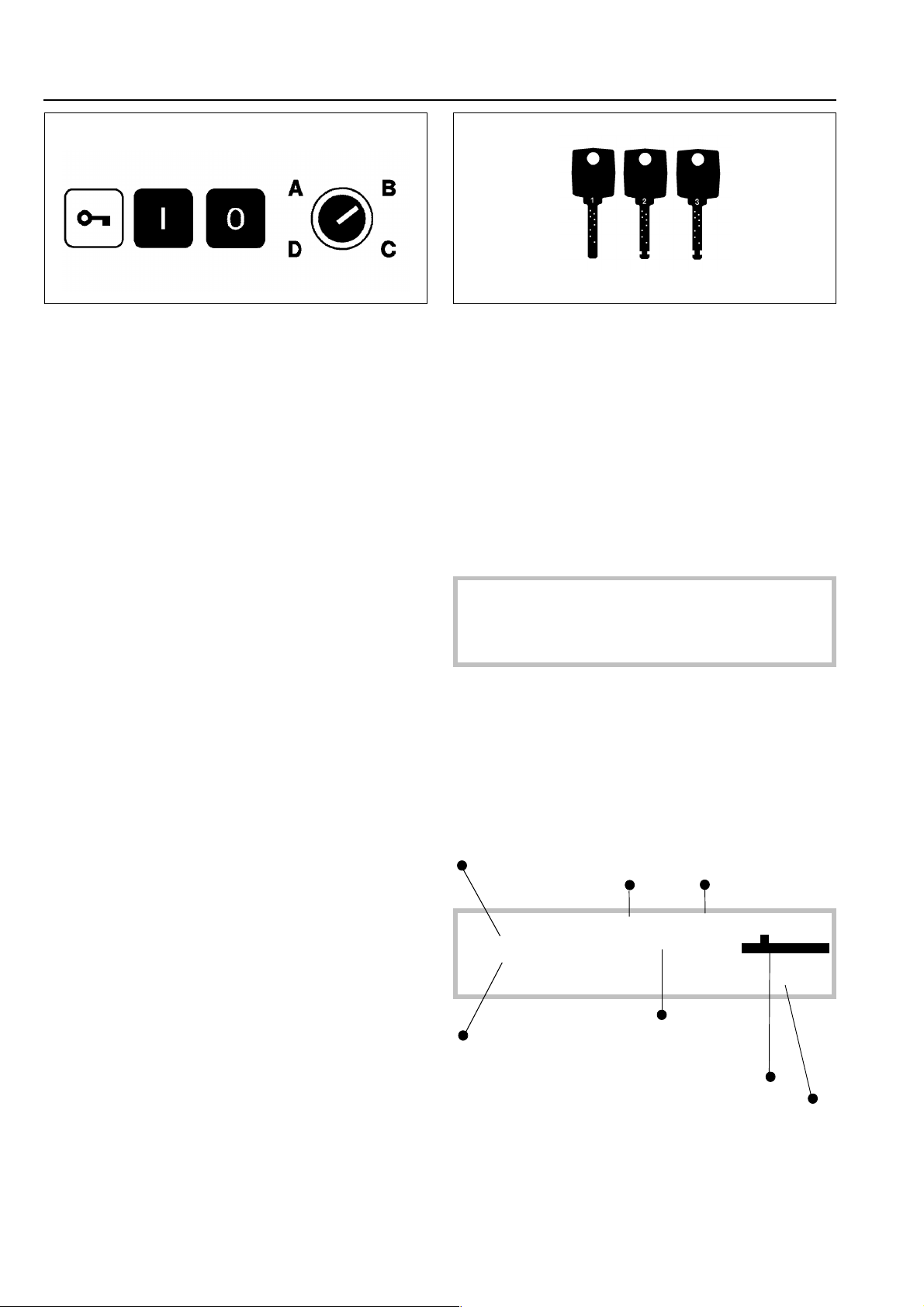

Guide to the machine

1 2 3

Mains on Y switch

Mains off Z switch

Door 5 button

Key switch

Position A – Free access

At this operating level only those programmes can be started which have

been allocated free access.

See Programming Instructions for

allocation of free access.

Position B - Operation

All programmes can be started at this

operating level. The display field will

show the programme which corresponds

to the setting to which the programme selector has been turned.

Keys for the key switch

Key 1 (2 supplied) for operating levels A

and B.

Key 2 for operating levels

A, B, C.

Key 3 for operating levels

A, B, C, D.

PROGRAMME 1 TH-Disinfection

>95°C< Main wash 1

Rinses 3 1000 RPM

Display

The Display content shows after the machine is switched on. It shows which programme has been selected in 4 lines

each 40 digits long.

à

Position C - Programming

In this position programming, copying,

deleting, altering, printing out, giving or

barring free access and creating new programme sequences can be carried out.

See Programming Instructions.

Position D - Unlocking

At this operating level barred programmes can be unlocked. Locked Programmes (e.g. Disinfection programmes)

can not be cancelled once they have

started.

If the key switch is turned to position D in

such a programme, the programme running is unlocked and can be cancelled.

See Programming Instructions.

After Programme start:

Required temp. and name of current prog. block

Programme number Programme name

PROGRAMME 1 TH-Disinfection

60°C Pre-wash 25°C

95°C Main wash

Actual temp.

Required temp. and name of

following prog. block

Time line for current prog. block

Points to a further display line

à

10 M.-Nr. 05 730 941

Page 11

Guide to the machine

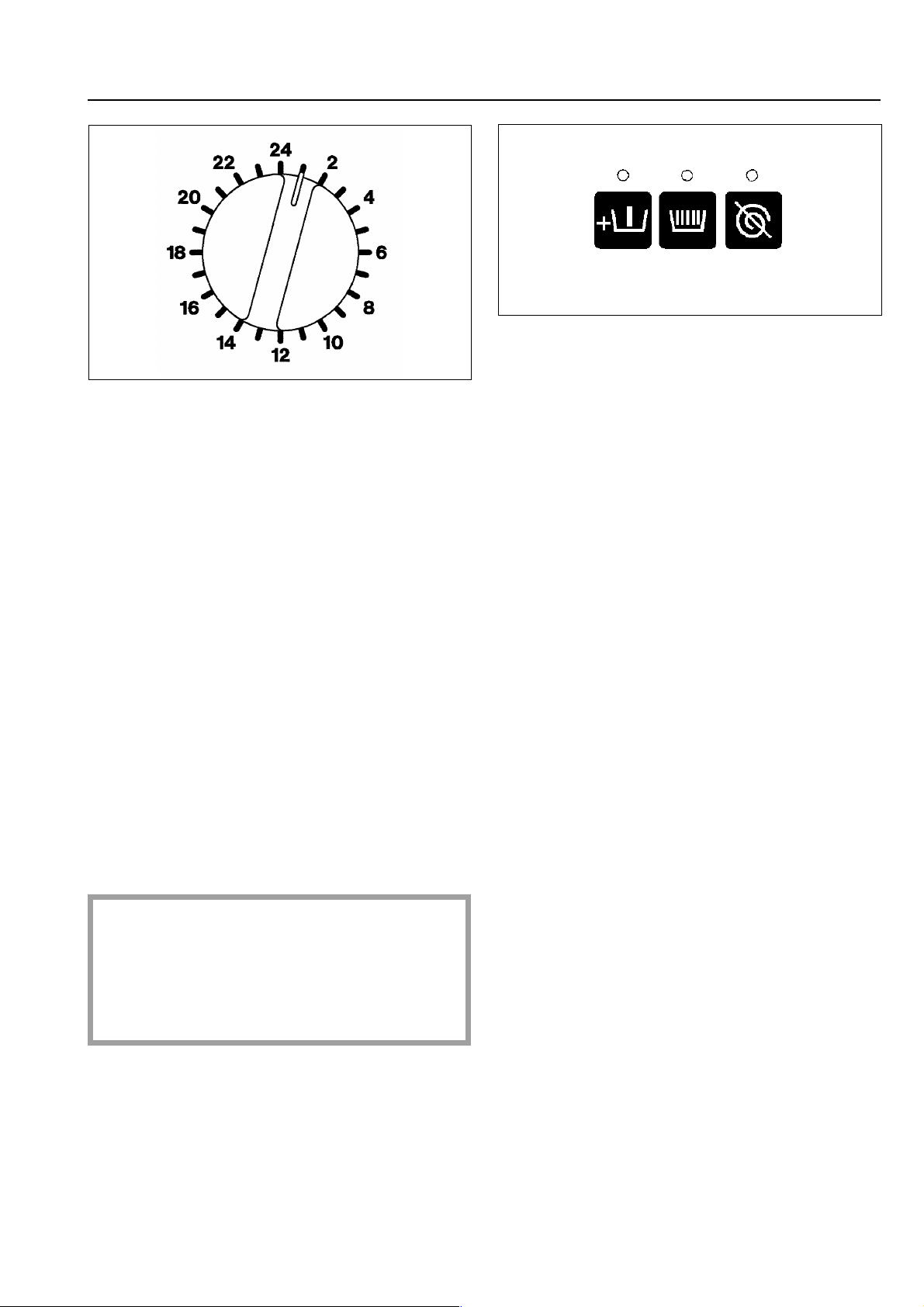

Programme selector switch

Programme numbers 1 - 24 can be selected directly. Programme numbers 25 99 can be selected using selector position 24 together with the "Plus 4 " button. The name of the selected programme and its corresponding number

appear in the display. See the Programme Survey for allocation of programme positions. Disinfection programmes are locked and cannot be

interrupted, stopped or cancelled after a

programme has been started. The programme finishes on the "Clean side".

If the programme selector switch is

turned to another position after the start

of the programme, the first line of the display flashes. The programme does not

however change.

Block+ T button with indicator light

When the button is pressed the light

above it comes on. The corresponding

programme block (e.g. Pre-wash) is

added to the programme. Pressing on

the button a second time de-selects the

function.

Starch hold U button with indicator light

Press this button if the washing is to be

starched. The light comes on.

Without spin V button with indicator light

Press this button if a final spin is not required after the final rinse. The light

comes on.

Disinfection programmes are locked 1

minute after a programme has started.

They cannot then be interrupted,

stopped or shortened.

The programme finishes on the "Clean

side".

M.-Nr. 05 730 941 11

Page 12

Guide to the machine

Start X button

Press to start the selected programme.

End 7 button

Pressing on this button halts a programme (Stop mode). Pressing once

again on the button immediately terminates a programme. A halted programme can be continued in the relevant

programme stage by pressing Start X

button.

Delay start W button

If this button is pressed before the start

of a programme, the display indicates

that a start time should be selected. If

the button is pressed again the Delay

start option is cancelled.

If this button is pressed after the start of

a programme the current time of day and

date are shown.

9

9 Optical interface

Data transfer to and from the machine’s

controls and a PC can take place using

the relevant software. Connection is

made via the optical interface on the control panel.

Cursor 1 2 buttons

The cursor buttons 1 2 are used to

scroll forwards or backwards into the

input fields or onto the next display (this

appears as > < flashing in the display).

After the start of the programme it is

possible in Stop mode to scroll block by

block backwards or forward in the programme. Pressing continuously on the

button scrolls quickly through the options.

4 Plus 3 Minus buttons

Once an input field has been selected it

is possible to make a modification. Pressing continuously on the button runs

quickly through the options.

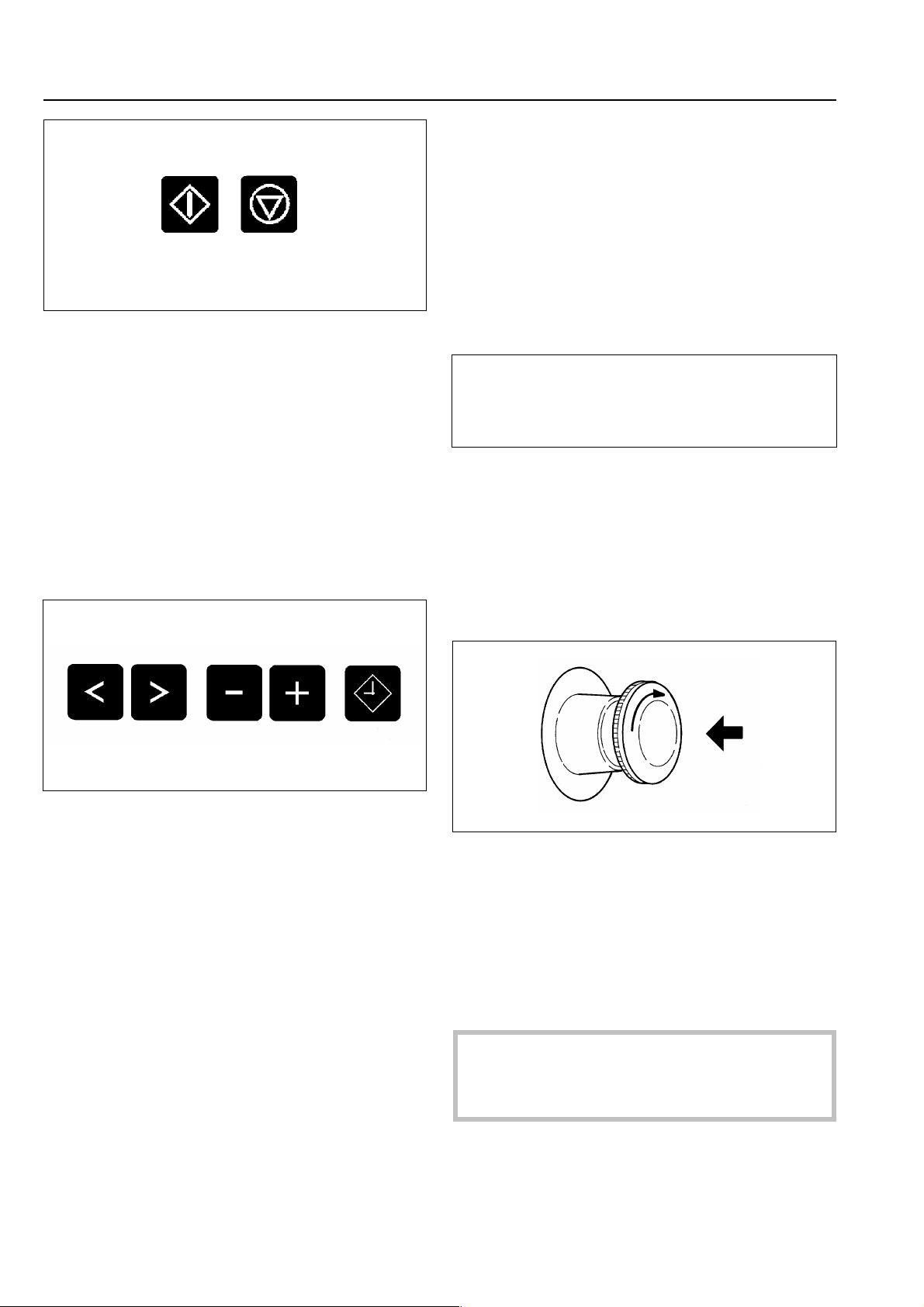

Emergence Stop Switch

Only to be used in an emergency.

After removing the cause of danger this

switch can be re-set by turning the

ribbed disc in a clockwise direction.

After re-setting the following appears in the

display:

PROGRAMME 1 TH-Disinfection

PROGRAMME STOP

THROUGH POWER CUT

Please press the Start button.

The drum turns to the "Unclean side".

Press the Start X button again to continue

the interrupted programme.

12 M.-Nr. 05 730 941

Page 13

Operation

Setting the local language*

(if necessary)

To set the local language the programming

mode must be accessed by pressing simultaneously on the "Mains on” switch and the

“Start” button. Normally German and one

other language are available.

Switch on the on-site mains switch.

Turn the key switch to position B (Operation).

Switch the machine on by pressing the

Mains off Z switch.

Press the Start X button and the Mains

on Y switch at the same time and keep

pressed in until the following appears in

the display:

SETTING LOCAL LANGUAGE

>DEUTSCH< ENGLISH

After selection press Start button.

Select the required language with the Cursor 1 2 buttons.

- The display will immediately convert into

the language selected.

Setting current time and date *

Switch the machine off with the Mains off

Z switch.

Turn the key switch to position B.

Press the Delay start W button and the

Mains on Y button at the same time and

keep pressed in until the following appears in the display:

SETTING TIME AND DATE

Time of day >14< : 30 hrs

Date 23. 09. 1998

After selection press Start button.

Use the Cursor 2 button to position the

cursor on the input field for hours and set

the hours with the Plus 4 or Minus 3

buttons.

Use the Cursor 2 button to position the

cursor on the input field for minutes and

set the minutes with the Plus 4 or Minus

3 buttons.

Position the Cursor on Date and use the

4 Plus 3 Minus buttons to set the date.

Confirm your selection by pressing the

Start X button.

- The complete display contents (not

visible) are converted into the language selected.

Position the Cursor on the month and set

the month.

Position the Cursor on the year and set

the year.

Confirm your selection by pressing the

Start X button.

If the “Delay start” button is pressed during a running programme the current time

of day and date are shown.

* Pauses between programming steps must not last

longer than 25 seconds, otherwise the display returns

to the basic stage, (such as On) and the changes are

not stored in memory.

M.-Nr. 05 730 941 13

Page 14

Operation

The washer-extractor must be commissioned by an approved Customer Service

technician or authorised Service Dealer.

COMMISSIONING

Open the on-site water stopcocks, (and

the supply valves for steam, if relevant for

the version of the machine).

Switch on the electricity supply at the

mains (on site).

Turn the key switch to position B (Operation).

The functions described below refer only to

Operating level B.

Press the Mains on Y switch.

Unlock the door on the "Unclean side" by

pressing the Door 5 button.

Open the drum:

Press down on the safety lock and at the

same time push down on both sides of the

drum opening to release the locking mechanism.

Carefully allow the two sides to open and secure the top half of the drum in the retainer.

Lift the door up.

Gas pressure stays raise the door upwards.

Empty all pockets

Foreign objects, (eg nails, coins, paper

clips etc) can cause damage to textiles

and components in the machine.

Load the laundry.

Do not exceed maximum permitted loads.

See next page for details.

Close the drum:

Release the top half of the drum from its

holder.

14 M.-Nr. 05 730 941

Page 15

Operation

If any fluff has built up around the drum door it

must be removed.

The locking mechanism must also be

checked on a regular basis to ensure that it is

working correctly.

First bring down the half with the safety

lock and then bring down the other half

making sure the locking mechanism visibly engages and is secure.

When closing the drum make sure laundry

does not get trapped between the two sections.

Pull the machine door downwards and

with both hands use even pressure to lock

the door. Do not slam the door down to

shut it.

Do not pull the door towards you when

closing it as this can prevent it from engaging in the locking mechanism and prevent

the door from closing. If this does happen

you will need to contact the Customer Service Dept.

If having closed the door you want to open it

again, e.g. to add another item of laundry,

you can do so within 20 seconds of closing it

as it takes this long before the lock is activated.

To ensure that the drum door is correctly

closed. the arrow on the safety lock must

be completely visible.

If these procedures are not followed there

is a danger of the drum door opening and

causing considerable damage.

M.-Nr. 05 730 941 15

Adding detergent.

See next section.

Page 16

Operation

Load weight (dry laundry)

WS 5243 WS 5323

max. 24 kg max. 32 kg

Load weights for individual programmes

are quoted in the Programme Survey.

Adding detergent

Add detergent for the:

1 3 4 5 2

- Main wash to compartment 2

- Pre-wash to compartment 1

- Fabric conditioner to compartment 3

- Liquid bleach to compartment 4

- Liquid detergent to compartment 5

Liquid detergent must not be filled higher

than the level marker, as otherwise it will get

through the siphon and into the detergent dispenser drawer before it is needed.

Detergent dispensing

Avoid dispensing more than the required

amount as this can cause excessive foaming.

Only use low lather detergents.

Dispense according to the detergent manufacturer’s recommendations.

The amount to dispense will depend on:

– the amount of laundry

– the water hardness level in your area

– the type and amount of soiling

Bleaching agents

Only use bleaching agents on textiles which

have the symbol y on the wash care label.

Liquid bleaching agents must only be dispensed through designated dispenser compartment (4). The agent will then be

dispensed automatically during the 2nd rinse

(cold bleaching). Liquid bleaching agents

should only be used on coloured textiles

which have a wash care label stating that

they are colour fast and suitable for bleaching.

For cold bleaching the 4th rinse must be

programmed into the machine (see the

Profitronic programming manual for further

details on how to do this).

Water hardness levels

Hardness

range

I soft 0 – 1.3 0 - 7

II medium 1.3 – 2.5 7 - 14

III hard 2.5 – 3.8 14 - 21

IV very hard over 3.8 over 21

If you do not know the hardness level of the

water in your area you should contact your

local water authority for information.

Water

quality

Harness

level in

mmol/l

German

hardness

level °d

16 M.-Nr. 05 730 941

Page 17

Selecting a disinfection programme

Disinfection programmes are locked. The

wash temperature cannot be changed.

Disinfection programmes are locked 1 minute

after a programme has started. They cannot

then be interrupted, stopped or shortened.

The door on the “Clean side” cannot be opened until a programme has finished and disinfection has been sucessfully achieved.

Turn the programme selector switch to the

required programme.

The display will then show for example the following:

PROGRAMME 1 TH-Disinfection

95°C Main wash 1

Rinses 3 800 RPM

With Pre-wash

To select the “With Pre-wash” programme

block press the Block + T button. The indi-

cator light above the button will light up.

When pressing the Block + T button the following will show in the display:

PROGRAMME 1 TH-Disinfection

>60°C<Pre-wash 1

95°C Main wash 1

Rinses 3 800 RPM

The programme sequence is shown in the display after the start of the programme.

PROGRAMME 1 TH-Disinfection

60°C Pre-wash 20°C

95°C Main wash

à

The 2nd display line shows the actual suds

temperature, in this instance of the Pre-wash,

with the time line extending to the right. The

following programme block, in this instance

the Main wash, is shown underneath it.

PROGRAMME 1 TH-Disinfection

95°C Main wash 20°C

Rinse 1

à

When the Pre-wash programme block has finished, the Main wash programme block appears in the 2nd line of the display, with the

actual suds temperature, and the time line extending off to the right. The next programme

block, here Rinse 1, is shown underneath it.

If an arrow appears in the last line at the right

hand side ( à ), this indicates that there is another display line to follow.

Pressing the cursor 2 button brings up

further information relating to the PROGRAMME in the lower lines.

Programme end display

After water from the last heating phase has

To change the spin speed

drained away or after the last “Cool Down”

the programme end time is shown in hours

The following programme change can be

and minutes.

made before a programme is started:

The spin speed can be changed in 100 rpm

stages from 0 to 300 to a max. of 950 rpm. on

the WS 5243 and to 800 rpm. on the WS

5323.

Programme end 11 : 25 hrs

PROGRAMME 1 TH-Disinfection

Rinse 1

Rinse 2

à

Press the Start X button

– the programme begins.

M.-Nr. 05 730 941 17

Page 18

Unloading the machine

Open the door on the “Clean side” (unloading side) at the end of a programme

At the end of the Programme, with a stationary drum and no more water in the machine

the following display is shown (for example):

PROGRAMME 1 TH-Disinfection

PROGRAMME END

DOOR IS UNLOCKED

To open the door of the "Clean side" press

the Door 5 button and lift the door up.

If a disinfecting programme has been interrupted or if there has been a fault during

the programme it will have to be repeated

in order to ensure that the disinfection parameters have been successfully achieved.

Unlock the drum door and release both

sides of the door upwards. Secure the top

half in its retainer.

Remove all the laundry.

If this was the last wash load of the day, or for

a longer period:

Close the drum.

To ensure that the drum door is correctly

closed the arrow on the safety lock must

be completely visible.

Pull the machine door downwards and

with both hands use even pressure to lock

the door. Do not slam the door down to

shut it.

Do not pull the door towards you when

closing it as this can prevent it from engaging in the locking mechanism and prevent

the door from closing. If this does happen

you will need to contact the Customer Service Dept.

The doors on the "Clean side" (Unloading

side) must be properly closed again after

removing laundry from the machine.

After closing the door the drum opening automatically turns to the “Unclean side”.

Open the door on the "Unclean side".

Press the Mains off Z switch to switch off

the machine.

Switch off the electricity mains supply (at

the wall switch).

Turn off the stopcocks and valves on site

for water, and for steam if applicable.

18 M.-Nr. 05 730 941

Page 19

Selecting an “unlocked” programme

Turn the key switch to position B "Operation".

Press the Mains on Y switch.

Turn the programme selector switch to the

required programme.

The display will then show for example:

PROGRAMME 25 COTTONS

>95°C<Main wash 1

Rinses 3 800 RPM

With Pre-wash

To select the “With Pre-wash” programme

block press the Block + T button. The indi-

cator light above the button will light up.

When pressing the Block + T button the following will show in the display:

PROGRAMME 25 COTTONS

>60°C<Pre-wash 1

95°C Main wash 1

Rinses 3 800 RPM

To change the temperature and the spin speed

The following programme changes can be

made before a programme is started:

Position the cursor on the input field for

the spin speed and set the required spin

speed with the Plus 4 or Minus 3 buttons.

Press Start X in to start the programme.

Once the programme has started the programme sequence will show in the display.

PROGRAMME 25 COTTONS

60°C Pre-wash 20°C

95°C Main wash

à

The 2nd display line shows the actual suds

temperature, in this instance of the Pre-wash,

with the time line extending to the right. The

following programme block, in this instance

the Main wash, is shown underneath it.

PROGRAMME 25 COTTONS

95°C Main wash 20°C

Rinse 1

à

When the Pre-wash programme block has finished, the Main wash programme block appears in the 2nd line of the display, with the

actual suds temperature , and the time line extending off to the right. The next programme

block, here Rinse 1, is shown underneath it.

The temperature in 1 °C stages from cold,

15 to max. 95 °C.

The spin speed can be changed in 100 rpm

stages from 0 to 300 to a max. of 950 rpm on

the WS 5243 and to 800 rpm on the WS 5323.

PROGRAMME 25 COTTONS

>60°C<Pre-wash 1

95°C Main wash 1

Rinses 3 800 RPM

Use the Cursor 2 button to position the

cursor on the input field for the pre-wash

temperature and set the required temperature (60 °C in this example with the Plus

4 or Minus 3 buttons.

Use the Cursor 2 button to position the

cursor on the input field for the main wash

temperature and set the required temperature with the Plus 4 or Minus 3 buttons.

If an arrow appears in the last line at the right

hand side ( à ), this indicates that there is another display line to follow. Pressing the cursor 2 button brings up further information

relating to the PROGRAMME in the lower

lines.

Programme end display

After water from the last heating phase has

drained away or after the last “Cool Down”

the programme end time is shown in hours

and minutes.

PROGRAMME 25 COTTONS

Rinse 1

Rinse 2

Programme end 11 : 25 hrs

à

M.-Nr. 05 730 941 19

Page 20

Selecting an “unlocked” programme

Open the door on the “Unclean side” (loading side) at the end of a programme

At the end of the Programme the door on the

“Unclean side” can be released. If there is no

more water in the machine and the drum is

stationary the following display is shown (for

example):

PROGRAMME 25 COTTONS

PROGRAMME END

DOOR IS UNLOCKED

To open the door of the "Unclean side"

press the Door 5 button and lift the door

up.

Unlock the drum door and release both

sides of the door upwards. Secure the top

half in its retainer.

Remove all the laundry.

If this was the last wash load of the day, or for

a longer period:

Leave the drum door open.

Switch off the machine by pressing the

Mains off Z switch.

Switch off the electricity mains supply (at

the wall switch).

Turn off the stopcocks and valves on site

for water or steam.

If the programme is interrupted (e.g.) when

there is water in the machine, or during the

spin, the following display messages might

appear:

PROGRAMME 25 COTTONS

PROGRAMME END

DOOR IS LOCKED

THERE IS WATER IN THE MACHINE

or:

PROGRAMME 25 COTTONS

PROGRAMME END

DOOR IS LOCKED

DRUM IS NOT YET STATIONARY

Select SEPARATE DRAIN or SEPARATE SPIN

and start the programme. At the end of the

programme open the door.

20 M.-Nr. 05 730 941

Page 21

Additional functions

With Pre-wash

A pre-wash can be selected for heavily soiled

laundry.

The pre-wash programme block can be selected before starting a programme by pressing the Block + T button. The indicator light

above the button lights up.

Starching

Starching can be selected before starting a

programme by pressing the Starch hold U

button. The indicator light above the button

lights up.

PROGRAMME 25 COTTONS

Rinse 3

STARCH HOLD

Press the starch and starch hold button.

When the starch stage is reached in the programme, the words "Starch hold" will start

flashing in the display.

Without spin

Without spin can be selected before starting a

programme by pressing the Without spin V

button. The indicator light above the button

lights up.

PROGRAMME 25 COTTONS

Rinse 3

WITHOUT SPIN

Press the without spin or end button.

When the spin stage is reached in the programme, the words "Without spin" will start

flashing in the display. (If you want to continue the programme with a spin, press the

Without spin V button again). To finish the

programme without a spin, simply press the

End 7 button, and the programme will finish

with water still in the machine.

To open the door, select the SEPARATE

DRAIN programme and press the Start X button.

The programme is continued by pressing the

Starch hold U button (the indicator light goes

out) and the Start X button. Make up the

starch solution following the manufacturer’s instructions on the packaging, then add it to the

inflowing water via the correct dispensing

compartment. The wash time is automatically

increased by 4 minutes.

Adding the starch directly into the drum

When the starch programme stage is

reached, "Starch hold" flashes in the display.

Open the drum door on the unclean side, and

add the starch solution prepared according to

the manufacturer’s instructions. Shut the

drum door. The message "Power cut programme stop" will then appear in the display.

Press the Start X button.

The following message will appear in the display again:

PROGRAMME 25 COTTONS

Rinse 3

STARCH HOLD

Press the starch and starch hold button.

Skipping programme stages

The order of the programme in progress can

be skipped or programme blocks can be repeated.

Press the End 7 button, and the programme

will stop.

PROGRAMME 25 COTTONS

Main wash

PROGRAMME STOP

Programme stop flashes in the display.

Use the 2 cursor to skip the programme

block by block to the end.

Use the 1 cursor to skip the programme

block by block back to the beginning.

At the position required, press the Start X button to continue the programme.

Press the Starch hold U button (the indicator

light goes out); the programme continues.

M.-Nr. 05 730 941 21

Page 22

Additional functions

Interrupting a programme

To stop a programme, press the End 7 but-

ton.

To continue the programme again, press the

Start X button.

Cancelling a programme

To cancel a programme press the End 7 button twice in succession.

If the programme has been cancelled with

water in the drum or during a spin, for

example, the following message will appear in

the display:

PROGRAMME 25 COTTONS

PROGRAMME END

DOOR IS LOCKED

WATER IS IN THE MACHINE

or:

PROGRAMME 25 COTTONS

PROGRAMME END

DOOR IS LOCKED

DRUM IS NOT YET STATIONARY

To open the door, select SEPARATE DRAIN

or SEPARATE SPIN and press the Start X

button. On completion, the door can be opened.

The following (example) will appear in the display:

PROGRAMME 1 TH-Disinfection

Start time >14< : 30 hrs

After the time has been set

press the Start button.

The current time of day is always displayed

first.

The cursor points to the input field for the

"hour".

Select the Start hour using the Plus and

Minus 4 3 buttons.

Position the cursor on the input field for

the minutes, and select the minutes using

the Plus and Minus 4 3 buttons.

Press the Start X button. Delay start is

confirmed, and the following (example)

shows in the display:

PROGRAMME 1 TH-Disinfection

>95°< Main wash 1

Start time 18 : 30 hrs

When the start time is reached, the programme starts and the programme sequence

shows in the display.

Delay start

A later start time for the programme can be

selected using the Delay start button.

To set the start time

Switch on the machine, and select the required programme with the programme selector.

The following (example) will appear in the display:

PROGRAMME 1 TH-Disinfection

>95°< Main wash 1

Rinses 3 800 rpm

Press the Delay start W button.

If the Delay start W button is pressed during

the programme, the actual time of day and

date are shown.

To cancel Delay start:

Before pressing the Start button:

Press the Delay start W button.

After pressing the Start button:

Press the End 7 button.

22 M.-Nr. 05 730 941

Page 23

Notes

Locked programmes (Disinfecting programmes)

If a disinfection programme is interrupted

or if there is a fault during the disinfecting

phase (wash time 2), the whole programme must be repeated to ensure that

disinfection is achieved.

Turn the key switch to position D "Unlocking".

At this operating level barred programmes

can be unlocked.

Press the End 7 button.

Turn the key switch to position B "Operation".

The programme can now be repeated.

Locating the drum door to the "Clean side"

The DOOR LOCATING programme rotates

the drum opening to the “Clean side”. Unfinished laundry can be transported from the

“Clean side” to the “Unclean side”.

The DOOR LOCATING programme can also

be used to transport laundry in the drum to

the “Clean side”. It is the user’s responsibility

to ensure that the laundry is hygienically

clean before it is removed from the machine.

Rinsing with hot water

Rinsing with hot water is a benefit for machines connected to a hot water supply.

Standard programmes

1 Cottons 95°C and

2 Cottons 60°C

are programmed to rinse with hot water.

If a hot water supply is available it is an advantage to run the final rinse with hot water.

This reduces the residual moisture content of

the laundry after spinning and the laundry retains heat.

If the laundry is then tumble dried or ironed

straight after the wash programme savings

will be made in the time it takes to process it

and in the amount of energy required.

Connecting a printer

Printer - operation:

A report of a whole programme or a section of

a programme can be printed. See the programming instructions supplied with the

machine.

To print a wash report the machine will have

to be reprogrammed by a Miele Service technician.

To operate a printer with a parallel interface

an interface adapter is needed between the

serial interface and the parallel interface.

M.-Nr. 05 730 941 23

Page 24

Liquid dispensing

Dispenser pump Suction pipe

1 3 2

4 5

Amount to be dispensed

Follow the detergent manufacturer’s guidelines.

Always follow the instructions of the chemical

manufacturer when using cleaning agents

and special application chemicals. Only use

such chemicals for the purpose and in the

situation specified by the manufacturer in

order to avoid the danger of adverse

chemical reactions and material damage.

If in doubt check the suitability of the product for use in this machine with the manufacturer before using it.

Correct dosage also depends on the viscosity

of the liquid detergent. It should be allowed

to adapt to the normal room temperature before being used.

1 = Hose connection socket (suction side)

2 = Hose connection socket (pressure side)

3 = Leakage outlet (in case of damaged hose)

4 = Suction inlet opening

5 = Level checker for empty indicator

When a dispenser container is empty the

pump and the machine switch themselves off automatically.

PROGRAMME -- - - - - - - - -

PROGRAMME STOP

DISPENSING SYSTEM FAULT

Dispensing container 1 empty.

At the same time the machine indicates

a lack of liquid detergent.

Cleaning and care the dispensing system

Rinse the dispensing system through with hot

water every 2 weeks, or before shutting the

dispenser pumps down for any length of time,

to avoid the system getting clogged up.

Rinse out the suction pipes as well with

water.

Put the suction pipes in a container with

warm water, (40 - 50 °C) .

In the Service programme switch in each

pump, until the dispensing system is

rinsed through.

Check the connection points, hoses and

washers for leaks.

The programme will continue automatically once the container has been refilled.

24 M.-Nr. 05 730 941

Page 25

Liquid dispensing

Commissioning the dispensing pumps

Before the liquid dispensing pumps can be

used the liquid detergent must be drawn into

the system and the amount to be dispensed

set. The Service Programme is used for this.

Drawing in the liquid detergent

Feed the suction pipes into the liquid detergent containers.

Service operation:

Switch off the machine.

In operating mode B, turn the programme

selector switch to 24.

Switch on the machine, and within 4 seconds, press the Block + T button 4 times

in quick succession. This brings you into

Service operation.

The cursor will be on the Service programme.

SERVICE - OPERATION

>SERVICE PROGRAMMES< MACHINE DATA

After selection press Start button.

Press the Start X button.

à

SERVICE - OPERATION SERVICE PROGS

SERVICE PROGRAMME 2

Dispenser valve >D1< Disp. time 20 Secs.

Cancel with the End button.

Cancel with the End 7 button.

Repeat the whole process with D2 and D3.

SERVICE - OPERATION

>SERVICE PROGRAMMES< MACHINE DATA

After selection press Start button.

Press the Start X button, select SERVICE

PROGRAMME 2 and press the Start X

button.

To exit from Service operation:

Cancel with the End 7 button and switch

off the machine.

Switch the machine on and select Programme 8 SEPARATE RINSE and SPIN

to flush the liquid agent out of the machine.

To correct the amount dispensed by the

pumps

(should the dispensing times set not be long

enough)

à

SERVICE - OPERATION SERVICE PROGS

SERVICE PROGRAMME >1<

After selection press Start button.

Press the Plus 4 button to select SERVICE PROGRAMME 2 and press the Start

X button.

SERVICE - OPERATION SERVICE PROGS

SERVICE PROGRAMME 2

Dispenser valve >D1< Disp. time 0 Secs.

After selection press Start button.

Use the Plus 4 to select D1, use the 2

cursor button to move to the input field for

dispensing time and use the Plus 4 button to enter a dispensing time of approx.

20 secs. Press the Start X button and the

hoses for pump 1 will be filled.

à

The amount to be dispensed is measured out

in litres in the Service programme. The procedure is similar to the one for drawing up the

liquid detergent. The dispensing time decided

on is then set in the Operating mode C Programming in the step programming.

The maximum pump throughput is approx.

168 ml/min. for all pumps.

These figures are only intended as a guide

and will vary according to the medium.

Feed the suction pipe into a deep measuring container with sufficient liquid detergent and keep it at the full level.

Continue as for Drawing in liquid deter-

gent.

M.-Nr. 05 730 941 25

Page 26

Problem solving guide

Power cut during a wash programme

With a short power cut:

The programme remains in the last position,

and when power is restored the following

message appears in the Display:

PROGRAMME 25 COTTONS

PROGRAMME STOP

THROUGH POWER CUT

Please press the Start button.

The drum rotates to the "Unclean side".

Press the button Start X button to continue

the programme.

If a disinfection programme is interrupted

or if there has been a fault during the disinfecting phase (wash time 2), the whole programme will have to be repeated to ensure

that disinfection is achieved.

With an extended power cut:

Switch off the machine.

Switch off the electricity supply at the

mains switch (isolator).

Turn off the stopcocks and valves on site

for water or steam.

Emergency door release:

To remove the laundry the drain valve will

need to be opened manually and the drum

door unlocked manually on the “Unclean

side” and the drum turned to the correct position.

Contact the customer Service Department

for instructions on how to do this.

Cancel the disinfecting programme and repeat it

Turn the key switch to position D "Unlocking".

At this operating level barred programmes

can be unlocked.

Press the End 7 button.

Turn the key switch to position B "Oper-

ation".

Add detergent

Press the Start X button

– the programme is repeated.

After removing the laundry ensure that all

removable parts of the machine casing are

refitted correctly in position.

26 M.-Nr. 05 730 941

Page 27

Problem solving guide

Fault messages

Repairs to machines operating with electricity or steam should only be undertaken

by a suitably qualified service engineer to

ensure safety. Unauthorised repairs could

be dangerous.

If a programme has been interrupted or if

there has been a fault during the disinfecting phase (wash time 2) the whole programme will have to be repeated to ensure

that disinfection has been achieved.

Faults that occur before or after the start of a

programme are displayed flashing in the display.

PROGRAMME 25 COTTONS

PROGRAMME STOP

HEATING SYSTEM FAULT

Short circuit on heater sensor 1.

Call the Service Department.

PROGRAMME 25 COTTONS

PROGRAMME STOP

HEATING SYSTEM FAULT

Cut-out of heating sensor 1.

Call the Service Department.

PROGRAMME 25 COTTONS

PROGRAMME STOP

HEATING SYSTEM FAULT

Call the Service Department.

PROGRAMME 25 COTTONS

PROGRAMME STOP

THROUGH POWER CUT

Press the Start button.

When power is restored press the Start X

button. This fault message can also indicate

that the winding protection of the drive motor

has overheated. - Allow the motor to cool

down.

PROGRAMME 25 COTTONS

PROGRAMME STOP

WATER INLET FAULT

Open water stopcock and press "Start button".

Open water stopcock and press the Start X

button.

PROGRAMME 25 COTTONS

PROGRAMME STOP

DRAIN FAULT

Clean drain system and press Start button.

Check the drainage system on site and press

the Start X button. A defective drain valve

should only be repaired by the service department or their authorised agent.

PROGRAMME 25 COTTONS

PROGRAMME STOP

DRIVE SYSTEM FAULT

Multiplug drive variants lacking.

Call the Service Department.

PROGRAMME 25 COTTONS

95°C Main wash 20 °C

Rinses 1

DRIVE SYSTEM FAULT

Clean the ventilation slot on the side wall for

the cooling fan.

Call the Service Department, if there is still no

drum movement 30 minutes after this message appeared.

PROGRAMME 25 COTTONS

PROGRAMME STOP

PEAK LOAD CUT OUT ACTIVE

At the end of the peak load cut out function

the programme continues automatically.

M.-Nr. 05 730 941 27

Page 28

Problem solving guide

PROGRAMME 25 COTTONS

PROGRAMME STOP

IMBALANCE SWITCH

Press the On-Off switch.

Press the Mains off Z and the Mains on Y

switches.

PROGRAMME 25 COTTONS

PROGRAMME STOP

PRESSURE MONITOR FAULT

Call the Service Department.

PROGRAMME 25 COTTONS

PROGRAMME STOP

DISPENSING SYSTEM FAULT

Dispensing container 1 empty.

Change the dispensing container.

Possible reasons for increased levels of

foaming:

– detergent type

Only use detergent formulated for use in

commercial washer extractors. Domestic

laundry detergent is not suitable.

– overdosing of detergent

Dispense detergent following the detergent manufacturer’s instructions on the

packaging and in accordance with local

water hardness levels.

– detergent creates too much foam

Use a lower foaming detergent or contact

your detergent application specialist.

– very soft water

PROGRAMME 25 COTTONS

PROGRAMME STOP

HEATING SYSTEM FAULT

Dry step switch has cut out.

Call the Service Department.

Large articles of laundry stretching during

the spin cycle

Large articles of laundry (e.g. table cloths) might

stretch during the spin cycle. This can generally

be prevented by reprogramming the machine.

Procedure:

Reprogramme programmes from switch setting 14

Drain valve: programme to no

Drain with tumble: programme to no

Spintime with drain: programme to 7 mins.

In areas with hardness level 1 dispense

less detergent in accordance with the

detergent manufacturer’s instructions.

– soiling level of the laundry

For lightly soiled laundry dispense less

detergent in accordance with the detergent manufacturer’s instructions.

– residues, e.g. detergent are left on

laundry

Run an additional pre-wash without detergent and without selecting a temperature.

Laundry which has been soaked before

washing must be thoroughly

rinsed before running a wash programme.

– small loads

Reduce the amount of detergent dispensed according to the size of the load.

– drum speed too high during the wash

(Profitronic-controls)

Reduce the drum speed and wash rhythm.

28 M.-Nr. 05 730 941

Page 29

After sales service

Should a fault occur please contact the

Service Dept.

When contacting the Service Dept, please

quote the model type and machine number

(Fabr.-Nr.), and part number (M.-Nr.). These

can be found on the data plate :

at the top of the door on the "Unclean side"

or:

on the side casing of the machine above the

ventilation grille.

Only use genuine Miele spare parts. When

ordering spare parts the Spare Parts Dept will

also need to know the model type and machine number (Fabr.-Nr.) and part number (M.Nr.).

Service interval

If the following message appears in the display after switching the machine on:

PROGRAMME 1 COTTONS

PLEASE CALL THE SERVICE DEPARTMENT

(SERVICE INTERVAL 1)

à

The machine needs to be serviced.

The Service interval display will go out after 5

seconds or by pressing the Start X button.

M.-Nr. 05 730 941 29

Page 30

Cleaning and Care

The machine should be cleaned, wherever

possible, immediately after use.

On no account use high pressure cleaners or

hose down the machine.

Build-up of rust

The drum and suds container are manufactured from rust-free stainless steel. It is, however, possible that water with a high iron

content or foreign bodies in the wash, (e.g.

paper clips or metal buttons), may lead to the

formation of superficial rust spots in the drum

and/or suds container, especially if the machine is not used for a long time. Stainless

steel components should be cleaned regularly

with a proprietary cleaning agent for stainless

steel. This must be done if rust appears!

The casing, control panel and any plastic

parts such as buttons and control switches

should be cleaned with a suitable mild cleaning agent or with a damp cloth and then

wiped dry. A proprietary stainless steel cleaning agent can be used on stainless steel parts

of the casing.

Do not use abrasive cleaning agents, as

these will scratch the surface.

If you are unsure about a particular product or

need further advice please contact your nearest Miele Sales office. See back page for address.

Do not cover or block the overflow from the

machine.

Dispenser compartments and siphons

After use these should be cleaned with warm

water to remove any detergent or other

residues. The siphon tubes in the dispenser

compartments should also be cleaned.

Pull the siphon tube out and clean with hot

water before replacing.

Check the drum door regularly for a build

up of fluff and clean as necessary. Check

the door locking mechanism regularly to

ensure it is working correctly.

Cleaning the cooling fan grille

The ventilation slits in the grille cover for the

cooling fan at the side of the machine must

never be covered over or blocked. They

should be checked regularly for a build up of

fluff and cleaned as necessary.

The filters in the water inlet valves must be

checked from time to time for soiling and

cleaned if necessary.

30 M.-Nr. 05 730 941

Page 31

Cleaning and Care

Greasing

After about 1000 running hours apply Arcanol L 100 to both grease nipples of the drum.

When not in use for a longer period of

time:

If the machine is not going to be used for a

longer period of time (4 weeks or more) the

drum bearings should be lubricated and the

drum rotated several times after the last use.

The drum should be rotated every 4 weeks to

prevent damage to the bearings.

After use do not shut the door on the

“Unclean side” but leave it slightly ajar, to

allow the machine to dry out.

M.-Nr. 05 730 941 31

Page 32

Explanation of the symbols on the data plate

1 Machine type

2 Machine number / year of manufacture*

3 Voltage / Frequency

4 Control fusing

5 Drive motor

6 Plate diameter* /Plate quantity*

7 Drum data

8 Drum diameter / Drum depth

9 Spin speed

10 Drum volume / Laundry dry weight

11 Kinetic energy

12 Ex. Time to top speed

13 Braking time

14 Heating

15 Electric heating

16 Fusing (on site)

17 Steam heating indirect

18 Steam heating direct

19 Gas heating*

20 Commissioning date

21 Water registration (DVGW-Reg.-N° in

Germany)

22 Field for test certificates/CE-.....(Product-ID-

Number/Gas*

*) does not apply to WS 5243 / 5323

Noise level

Registered on the “A” scale

During wash During spin

WS 5243 60.7 dB 81.6 dB

WS 5323 63.5 dB 80.1 dB

Measured in Germany in accordance with

DIN (IEC) 45 635 machine noise regulations

3. GSGV § 1 1.a

32 M.-Nr. 05 730 941

Page 33

Installation

This machine is for use only with articles

which have not been treated with dangerous or inflammable substances.

To avoid the possibility of frost damage on no

account install the machine in a room which is

exposed to frost.

Transit fittings

2 at the rear are each secured with 3 hex

screws (SW 15) and must only be removed

once the machine has been installed in its

final position. Ensure they are removed before commissioning.

To remove them detach the lower sides from

the machine.

The red-marked fixing brackets, 2 at the side

front and 2 at the side rear for the transport

verschlag are each secured with a hex screw

(SW 15) and must be removed.

The red marked transit fittings, 2 at the front

and

Transit fittings should be stored in a safe

place for future use. They must be refitted

if the machine is moved again.

It is essential that the machine is installed

level, and is secured (see Installation diagram

supplied).

Do not install the machine on carpeted flooring if the carpet pile blocks the ventilation gap

at the base of the machine.

After installing and connecting the machine

to the services ensure that all outer panels

have been put back in place.

M.-Nr. 05 730 941 33

Page 34

Installation

Plumbing

Connection to the water supply must be carried out by a suitably qualified and competent

person in accordance with local and national

water and safety regulations (DVGW in Germany) via a stopcock, (DIN 1988 approved in

Germany).

To ensure the machine is correctly connected

to the water supply and for drainage please

observe the installation diagram and the installation instructions supplied with the machine.

Water inlet / drainage

The inlet pressure hoses supplied with the

machine must be used for connection to the

water supply.

Water connection Australia

To prevent back-syphonage, the water connection must be via an approved Dual-CheckValve.

After installing and connecting the machine

to the services ensure that all outer panels

have been put back in place.

Before connecting the inlet hoses to the machine the filters and seals supplied in the accessory pack must first be fitted.

If replacing an inlet hose only use a hose able

to withstand a burst pressure of at least 70

bar, and a water temperature of at least 90°C.

This also applies to all connection parts.

Miele "Original" spare parts meet this requirement.

A water pressure flow rate of at least 1 bar,

maximum 10 bar is essential to ensure the

smooth operation of this machine.

Water taken into the machine must not exceed a temperature of 70°C.

Connection to cold water only

See the Installation diagram supplied.

34 M.-Nr. 05 730 941

Page 35

Installation

Electrical connection

All electrical work must be carried out by a

suitably qualified and competent person in

compliance with national and local regulations.

Please take note of the Wiring diagram and

the Installation Diagram and instructions supplied. They are important for electrical connection.

The electrical safety of this machine is in accordance with EN 60204.

The machine is supplied as standard for connection to a AC 3N 50 Hz electricity supply.

The voltage, frequency are stated on the data

plate.

Variants

The electric heater rating is set ex-works to

24 kW (WS 5243),

30 kW (WS 5323).

The minimum suds level required for activating the heating given in mm column of water

is 110 mm.

:

3 N AC 380-415 V 50-60 Hz

3 AC 220-240 V 50-60 Hz

Steam connection

Steam connection must only be undertaken

by an authorised installer.

Please take note of the Installation Diagram

and instructions supplied. They are important

for steam connection.

Do not attempt to carry out any repair work

to this machine yourself. Any damage or repair work may only be carried out by a suitably qualified and competent person in accordance with local and national safety

regulations.

Please contact the Miele Service Dept. or

your Miele supplier in the event of a fault or

any damage to the machine.

After installing and connecting the machine

to the services ensure that all outer panels

have been put back in place.

The motor is fitted with an overload protection

switch.

Connection should be made via a suitable, approved isolator, with an on-off switch which is

easily accessible for servicing.

WARNING

THIS APPLIANCE MUST BE EARTHED

M.-Nr. 05 730 941 35

Page 36

EU Declaration of Conformity

Manufacturer: Miele & Cie. KG

Address: Box

33325 Gütersloh, Germany

Product designation: Automatic washer-extractor WS 5243, 5323

The products designated comply with the conditions of the following European Directives:

Text / No. EU Council directive 98/37/EC: Machinery

Electromagnetic compatibility directive (89/336/EEC)

Introduction of the CE mark: 1999

Producer: Miele & Cie. KG, Werk Lehrte

Place, Date: Lehrte, 09.01.2003

This declaration certifies compliance with the directives named above, but does not guarantee

any specific properties. The safety instructions in the product documentation provided must be

observed.

EG - Konformitätserklärung

Hersteller: Miele & Cie. KG

Anschrift: Postfach

33325 Gütersloh

Produktbezeichnung: Waschmaschine WS 5243, WS 5323

Das bezeichnete Produkt stimmt mit den Vorschriften folgender Europäischer Richtlinien

überein:

Text/Nr. EG Maschinenrichtlinie 98/37/EG

Elektromagnetische Verträglichkeit (EMV) 89/336

Anbringung der CE-Kennzeichnung: 1999

Aussteller: Miele & Cie. KG, Werk Lehrte

Ort, Datum: Lehrte, 09.01.2003

Rechtsverbindliche Unterschrift (Dr. Dyballa)

Diese Erklärung bescheinigt die Übereinstimmung mit den genannten Richtlinien, beinhaltet

jedoch keine Zusicherung von Eigenschaften. Die Sicherheitshinweise der mitgelieferten

Produktinformation sind zu beachten.

36 M.-Nr. 05 730 941

Page 37

Guarantee

Please contact your Miele Sales Office for details

concerning guarantee terms and conditions.

See the back cover for contact details.

M.-Nr. 05 730 941 37

Page 38

Alteration rights reserved/2208

M.-Nr. 05 730 941 / 00

Loading...

Loading...