Page 1

920 Absorber Module

Manual

8.920.8004EN

Page 2

Page 3

Metrohm AG

CH-9100 Herisau

Switzerland

Phone +41 71 353 85 85

Fax +41 71 353 89 01

info@metrohm.com

www.metrohm.com

920 Absorber Module

2.920.0010

8.920.8004EN

Manual

09.2013 zst

Page 4

Teachware

Metrohm AG

CH-9100 Herisau

teachware@metrohm.com

This documentation is protected by copyright. All rights reserved.

Although all the information given in this documentation has been

checked with great care, errors cannot be entirely excluded. Should you

notice any mistakes please send us your comments using the address

given above.

Documentation in additional languages can be found on

http://documents.metrohm.com.

Page 5

■■■■■■■■■■■■■■■■■■■■■■

Table of contents

1 Introduction 1

1.1 Instrument description ......................................................... 1

1.2 Intended use ......................................................................... 2

1.3 About the documentation ................................................... 2

1.3.1 Content and scope .................................................................. 2

1.3.2 Symbols and conventions ........................................................ 3

1.4 Safety instructions ................................................................ 4

1.4.1 General notes on safety ........................................................... 4

1.4.2 Electrical safety ........................................................................ 4

1.4.3 Tubing and capillary connections ............................................. 5

1.4.4 Flammable solvents and chemicals ........................................... 5

1.4.5 Recycling and disposal ............................................................. 5

2 The Combustion IC system 7

Table of contents

2.1 Overview ................................................................................ 7

2.2 System description ............................................................... 8

2.3 Sequence of a determination .............................................. 9

3 Overview of the instrument 11

3.1 Front .................................................................................... 11

3.2 Rear ...................................................................................... 15

4 Installation 17

4.1 Setting up the instrument .................................................. 17

4.1.1 Packaging .............................................................................. 17

4.1.2 Checks .................................................................................. 17

4.1.3 Location ................................................................................ 17

4.2 Overview ............................................................................. 17

4.3 Dosino for ultrapure water ................................................ 20

4.3.1 Assembling the Dosino .......................................................... 23

4.3.2 Feeding the capillary into the instrument ............................... 23

4.3.3 Connecting the ports – Overview ........................................... 24

4.3.4 Inserting the Dosino in the instrument ................................... 33

4.3.5 Connecting the Metrosep I Trap 1 ......................................... 34

4.3.6 Connecting the ultrapure water bottle ................................... 36

920 Absorber Module

4.4 Dosino for the absorber solution ...................................... 39

4.4.1 Assembling the Dosino .......................................................... 40

4.4.2 Connecting the ports – Overview ........................................... 41

4.4.3 Inserting the Dosino in the instrument ................................... 46

4.4.4 Connecting the T connection ................................................. 47

■■■■■■■■

III

Page 6

Table of contents

■■■■■■■■■■■■■■■■■■■■■■

4.4.5 Connecting the Metrosep A Trap 1 ........................................ 49

4.4.6 Connecting the bottle with the absorber solution .................. 52

4.5 10-port valve ....................................................................... 54

4.5.1 Connecting the ports ............................................................. 55

4.5.2 Connecting the bottle with the standard solution .................. 58

4.5.3 Connecting the bottle with the check standard ...................... 59

4.5.4 Function of the 10-port valve ................................................. 60

4.6 6-port valve ......................................................................... 61

4.6.1 Connecting the ports ............................................................. 62

4.6.2 Mode of operation of the 6-port valve ................................... 65

4.7 Absorber tube ..................................................................... 67

4.8 Connecting the drainage tubing and leak sensor ............ 70

4.8.1 Installing the drainage tubing ................................................ 71

4.8.2 Connecting the leak sensor .................................................... 72

4.9 Connecting the instrument ................................................ 73

4.9.1 Connecting the instrument to the PC ..................................... 73

4.9.2 Connecting the instrument to power supply .......................... 73

4.10 Connecting the 920 Absorber Module to the remaining

components ........................................................................ 74

4.10.1 Connecting the Combustion Module inlet: water infeed ........ 74

4.10.2 Connecting the Combustion Module outlet: Absorber solu-

tion ....................................................................................... 76

4.10.3 Connecting the 930 Compact IC Flex ..................................... 78

5 Start-up 79

6 Operation and maintenance 81

6.1 General ................................................................................ 81

6.2 Door ..................................................................................... 81

6.3 Dosino .................................................................................. 81

6.4 Dosing unit .......................................................................... 81

6.5 Metrosep I Trap 1 ............................................................... 82

6.6 Metrosep A Trap 1 ............................................................. 82

6.7 10-port valve ....................................................................... 82

6.8 6-port valve ......................................................................... 82

6.9 Absorber tube ..................................................................... 83

6.10 Quality Management and qualification with

Metrohm ............................................................................. 85

7 Troubleshooting 86

7.1 Problems and their solutions ............................................. 86

■■■■■■■■

IV

7.2 Problems with the Dosino ................................................. 86

920 Absorber Module

Page 7

■■■■■■■■■■■■■■■■■■■■■■

8 Technical specifications 87

Table of contents

7.3 Problems with the dosing units ........................................ 86

8.1 Reference conditions .......................................................... 87

8.2 Ambient conditions ............................................................ 87

8.3 Housing ............................................................................... 87

8.4 Dosino .................................................................................. 88

8.5 10-port valve ....................................................................... 88

8.6 6-port valve ......................................................................... 88

8.7 Absorber tube ..................................................................... 89

8.8 Leak sensor ......................................................................... 89

8.9 Power connection ............................................................... 89

8.10 Interfaces ............................................................................. 89

8.11 Safety specification ............................................................ 90

8.12 Electromagnetic compatibility (EMC) ................................ 90

9 Warranty (guarantee) 91

10 Accessories 93

10.1 Scope of delivery ................................................................ 93

10.2 Optional accessories ........................................................ 102

Index 104

920 Absorber Module

■■■■■■■■

V

Page 8

Table of figures

Table of figures

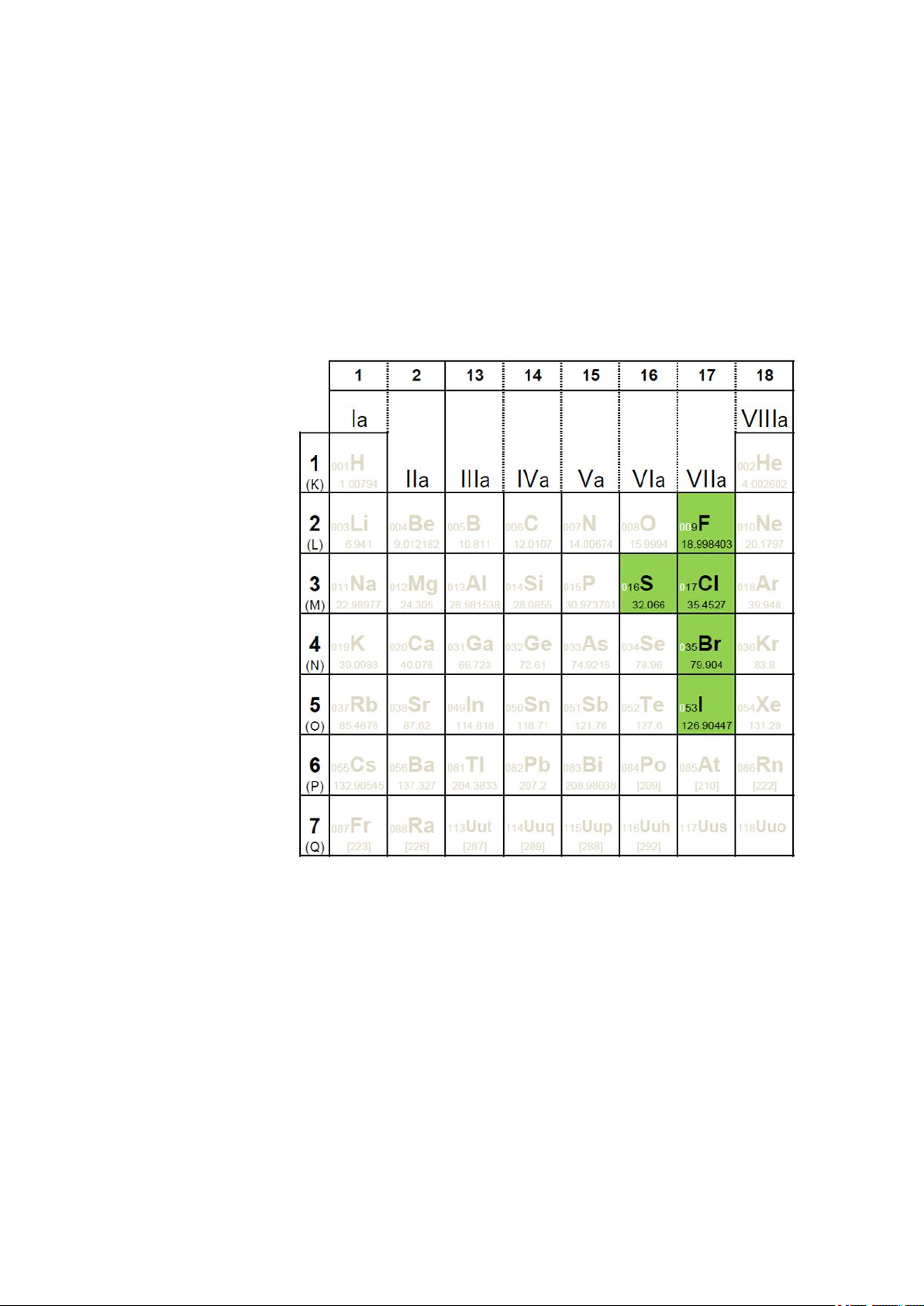

Figure 1 Detectable elements .......................................................................... 7

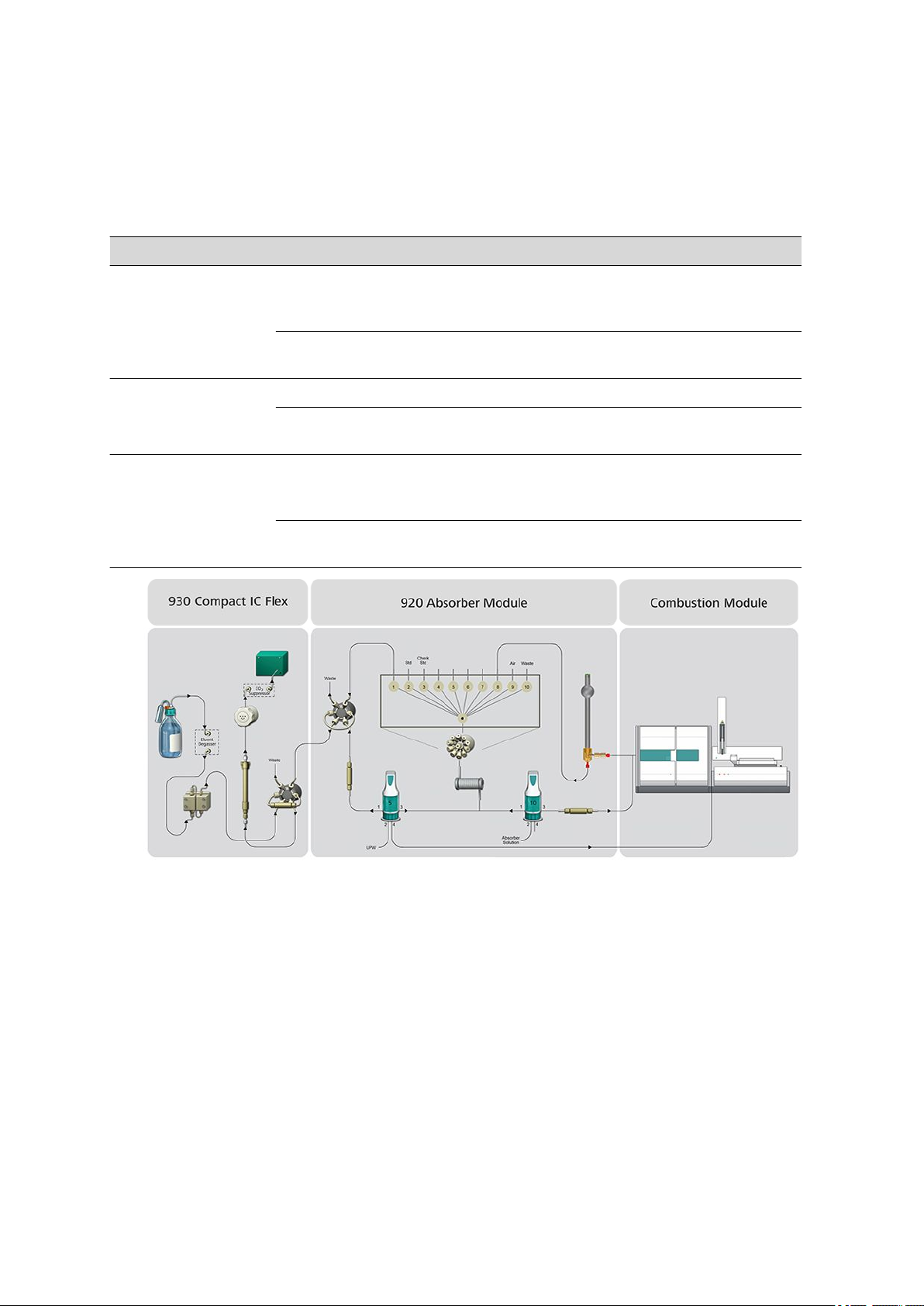

Figure 2 Overview - CIC system ....................................................................... 8

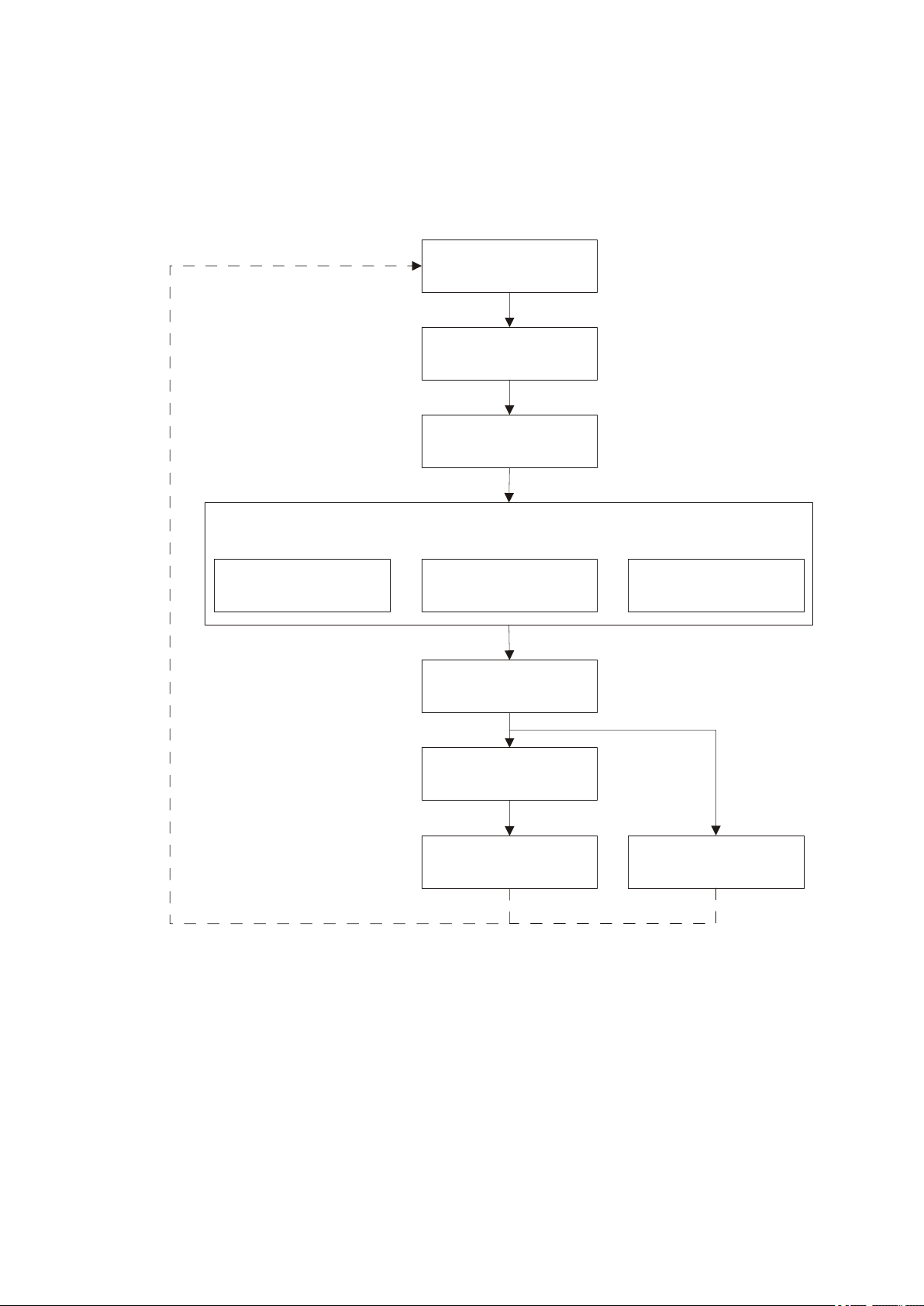

Figure 3 Sequence of the determination ......................................................... 9

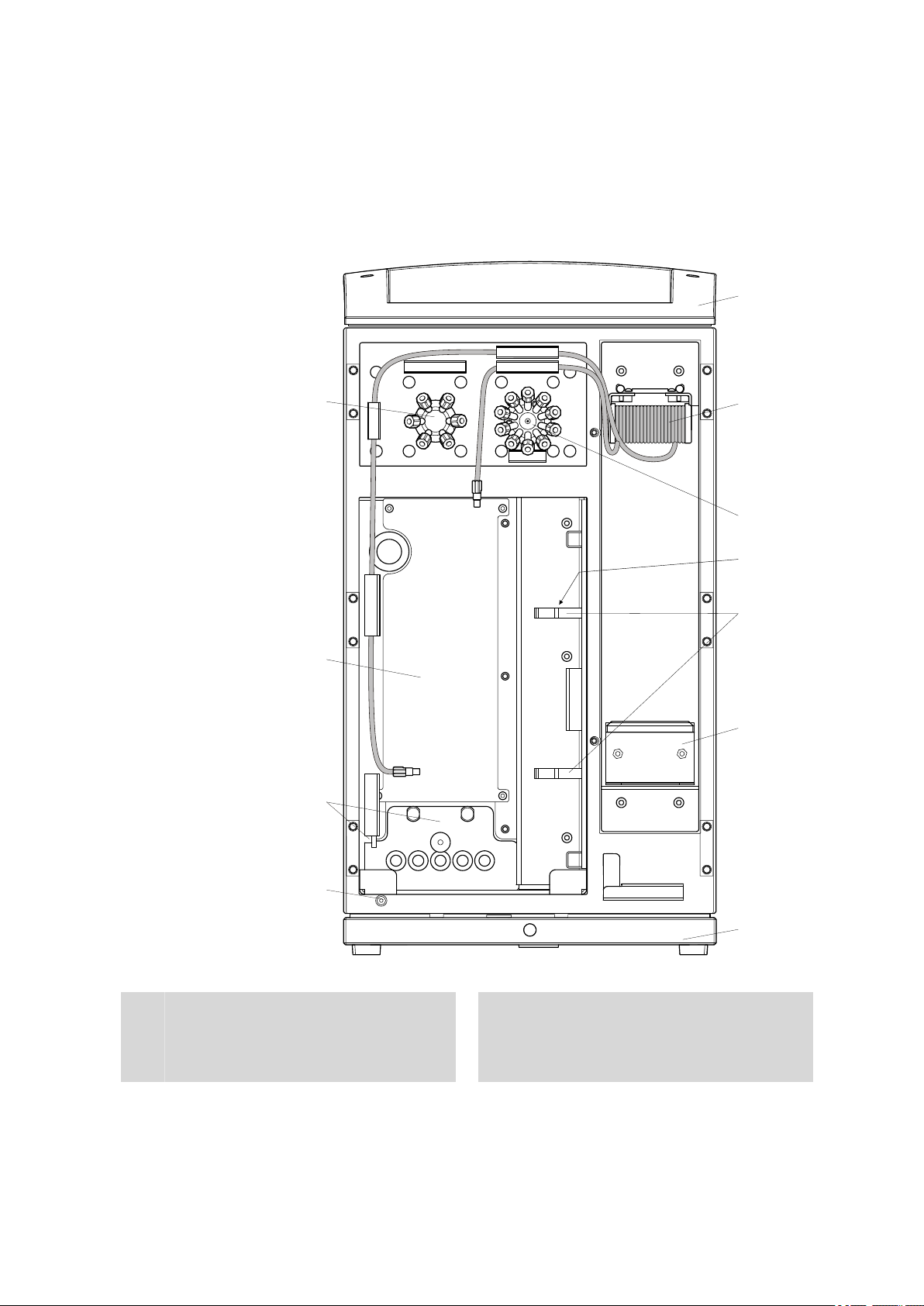

Figure 4 920 Absorber Module – Front ......................................................... 11

Figure 5 920 Absorber Module – Front ......................................................... 13

Figure 6 920 Absorber Module – Rear ........................................................... 15

Figure 7 Capillaries and tubings in use – Overview ........................................ 18

Figure 8 Installing the Dosino for ultrapure water .......................................... 20

Figure 9 Connect the Dosino for ultrapure water .......................................... 25

Figure 10 Installing the Dosino for the absorber solution ................................. 39

Figure 11 Connect the Dosino for the absorber solution .................................. 42

Figure 12 Feed the capillary for the absorber solution into the instrument ....... 50

Figure 13 Connecting the 10-port valve .......................................................... 54

Figure 14 Connecting the 10-port valve .......................................................... 56

Figure 15 10-port valve – Ports ....................................................................... 60

Figure 16 10-port valve – Normal valve switchover and with a secured port .... 61

Figure 17 Connecting the 6-port valve ............................................................ 62

Figure 18 Connecting the 6-port valve ............................................................ 64

Figure 19 6-port valve – Ports ......................................................................... 65

Figure 20 6-port valve – Valve positions .......................................................... 66

Figure 21 Connect the absorber tube .............................................................. 67

Figure 22 Combustion tube – Inlet .................................................................. 75

Figure 23 Combustion tube – Outlet ............................................................... 76

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

VI

920 Absorber Module

Page 9

■■■■■■■■■■■■■■■■■■■■■■

1 Introduction

1.1 Instrument description

The 920 Absorber Module forms part of the Combustion IC system, which

includes a Combustion Module and an ion chromatograph in addition to

the 920 Absorber Module. The Combustion IC system can be used for

digesting solid and liquid combustible samples. The Combustion IC system's prime application is the determination of halogenides and sulfur.

The 920 Absorber Module is the connecting link between combustion and

IC analysis in the Combustion IC system. The 920 Absorber Module

absorbs the combustion gases in an aqueous medium and transfers it into

the ion chromatography system. The 920 Absorber Module performs the

necessary Liquid Handling and enables the application of various sample

preparation techniques, such as matrix elimination, preconcentration and

automated calibration.

1 Introduction

The 920 Absorber Module is comprised of the following modules:

Dosino for ultrapure water

A Dosino with a 5 mL dosing unit is inserted in the back in the 920

Absorber Module. This Dosino serves to dose water for the water infeed

during combustion and for the transfer of the absorption solution to the

IC instrument. Furthermore, it is used for the Liquid Handling.

Dosino for the absorber solution

A Dosino with a 10 mL dosing unit is inserted in the front of the 920

Absorber Module. This Dosino serves to dose the absorber solution into

the absorber tube.

10-port valve

The 10-port valve is the centerpiece of the Liquid Handling; it serves as a

switch-over point between the various liquid flows.

6-port valve

The 6-port valve serves as a switch-over point between the two liquid

flows. The sample loop allows a precisely defined sample amount to be

measured before it is transferred to the analyzer.

920 Absorber Module

Absorber tube

The combustion gases are absorbed by a solution in the absorber tube.

■■■■■■■■

1

Page 10

1.2 Intended use

Leak sensor

The leak sensor detects leaking liquid that collects in the instrument's base

tray. Liquid that leaks in the instrument is routed to the base tray using

drainage tubing and detected there.

1.2 Intended use

The 920 Absorber Module represents the connecting link between combustion and IC analysis in a Combustion IC system. It absorbs the combustion gases in an absorber solution and transfers the resulting sample to an

ion chromatograph. Furthermore, the 920 Absorber Module allows additional sample preparation techniques to be applied.

The present instrument is suitable for processing chemicals and flammable

samples. Usage of the 920 Absorber Module therefore requires the user

to have basic knowledge and experience in handling toxic and caustic

substances. Knowledge with respect to the application of the fire prevention measures prescribed for laboratories is also mandatory.

■■■■■■■■■■■■■■■■■■■■■■

1.3 About the documentation

CAUTION

Please read through this documentation carefully before putting the

instrument into operation. The documentation contains information

and warnings which the user must follow in order to ensure safe operation of the instrument.

1.3.1 Content and scope

This manual focuses on the 920 Absorber Module instrument, which

forms part of the Combustion IC system.

Separate manuals exist for the other modules of the Combustion IC system:

■ Manuals for the Combustion Module including Auto Boat Drive (ABD)

and optional sampler (MMS 5000) from Analytik Jena (PDFs available

on the enclosed CD)

■ Manual for 930 Compact IC Flex

■ Manual for 800 Dosino

■ Manual for 807 Dosing Unit

■■■■■■■■

2

920 Absorber Module

Page 11

■■■■■■■■■■■■■■■■■■■■■■

1.3.2 Symbols and conventions

The following symbols and formatting may appear in this documentation:

Method Dialog text, parameter in the software

File ▶ New Menu or menu item

[Next] Button or key

1 Introduction

Cross-reference to figure legend

The first number refers to the figure number, the second to the instrument part in the figure.

Instruction step

Carry out these steps in the sequence shown.

WARNING

This symbol draws attention to a possible life-threatening hazard or risk of injury.

WARNING

This symbol draws attention to a possible hazard due

to electrical current.

WARNING

This symbol draws attention to a possible hazard due

to heat or hot instrument parts.

WARNING

This symbol draws attention to a possible biological

hazard.

CAUTION

This symbol draws attention to possible damage to

instruments or instrument parts.

NOTE

This symbol highlights additional information and

tips.

920 Absorber Module

■■■■■■■■

3

Page 12

1.4 Safety instructions

1.4 Safety instructions

1.4.1 General notes on safety

WARNING

This instrument may only be operated in accordance with the specifications in this documentation.

This instrument has left the factory in a flawless state in terms of technical

safety. To maintain this state and ensure non-hazardous operation of the

instrument, the following instructions must be observed carefully.

1.4.2 Electrical safety

The electrical safety when working with the instrument is ensured as part

of the international standard IEC 61010.

WARNING

■■■■■■■■■■■■■■■■■■■■■■

Only personnel qualified by Metrohm are authorized to carry out service

work on electronic components.

WARNING

Never open the housing of the instrument. The instrument could be

damaged by this. There is also a risk of serious injury if live components

are touched.

There are no parts inside the housing which can be serviced or replaced

by the user.

Mains voltage

WARNING

An incorrect mains voltage can damage the instrument.

Only operate this instrument with a mains voltage specified for it (see

rear panel of the instrument).

■■■■■■■■

4

920 Absorber Module

Page 13

■■■■■■■■■■■■■■■■■■■■■■

Protection against electrostatic charges

WARNING

Electronic components are sensitive to electrostatic charges and can be

destroyed by discharges.

Do not fail to pull the mains cable out of the mains connection socket

before you set up or disconnect electrical plug connections at the rear

of the instrument.

1.4.3 Tubing and capillary connections

CAUTION

Leaks in tubing and capillary connections are a safety risk. Tighten all

connections well by hand. Avoid applying excessive force to tubing

connections. Damaged tubing ends lead to leakage. Appropriate tools

can be used to loosen connections.

1 Introduction

Check the connections regularly for leakage. If the instrument is used

mainly in unattended operation, then weekly inspections are mandatory.

1.4.4 Flammable solvents and chemicals

WARNING

All relevant safety measures are to be observed when working with

flammable solvents and chemicals.

■ Set up the instrument in a well-ventilated location (e.g. fume cup-

board).

■ Keep all sources of flame far from the workplace.

■ Clean up spilled liquids and solids immediately.

■ Follow the safety instructions of the chemical manufacturer.

1.4.5 Recycling and disposal

This product is covered by European Directive 2002/96/EC, WEEE – Waste

from Electrical and Electronic Equipment.

920 Absorber Module

The correct disposal of your old equipment will help to prevent negative

effects on the environment and public health.

■■■■■■■■

5

Page 14

1.4 Safety instructions

■■■■■■■■■■■■■■■■■■■■■■

More details about the disposal of your old equipment can be obtained

from your local authorities, from waste disposal companies or from your

local dealer.

■■■■■■■■

6

920 Absorber Module

Page 15

■■■■■■■■■■■■■■■■■■■■■■

2 The Combustion IC system

2.1 Overview

Combustion is a sample preparation technique that uses burning to digest

a sample. Solid, liquid and gaseous samples that are flammable can be

digested using combustion. Combustion IC is particularly suited for determining the following elements:

2 The Combustion IC system

920 Absorber Module

Figure 1

An additional instrument is required for the determination of gaseous

samples: the LPG/GSS Module (2.136.0720).

Detectable elements

■■■■■■■■

7

Page 16

2.2 System description

■■■■■■■■■■■■■■■■■■■■■■

2.2 System description

Depending on the application, the Combustion IC system consists of the

following instruments:

Type of sample Instruments Manufacturer

solid/liquid samples only ■ Combustion Module with Auto Boat Drive (ABD)

(2.136.0700)

■ optional: sampler (MMS 5000)

■ 920 Absorber Module (2.920.0010)

■ 930 Compact IC Flex Oven SeS/PP/Deg (2.930.2560)

gaseous samples only ■ Combustion Module with LPG/GSS Module (2.136.0730) Analytik Jena

■ 920 Absorber Module (2.920.0010)

■ 930 Compact IC Flex Oven SeS/PP/Deg (2.930.2560)

solid, liquid and gaseous

samples

■ Combustion Module with Auto Boat Drive (ABD)

(2.136.0700)

■ LPG/GSS Module (2.136.0720)

■ 920 Absorber Module (2.920.0010)

■ 930 Compact IC Flex Oven SeS/PP/Deg (2.930.2560)

Analytik Jena

Metrohm

Metrohm

Analytik Jena

Metrohm

■■■■■■■■

8

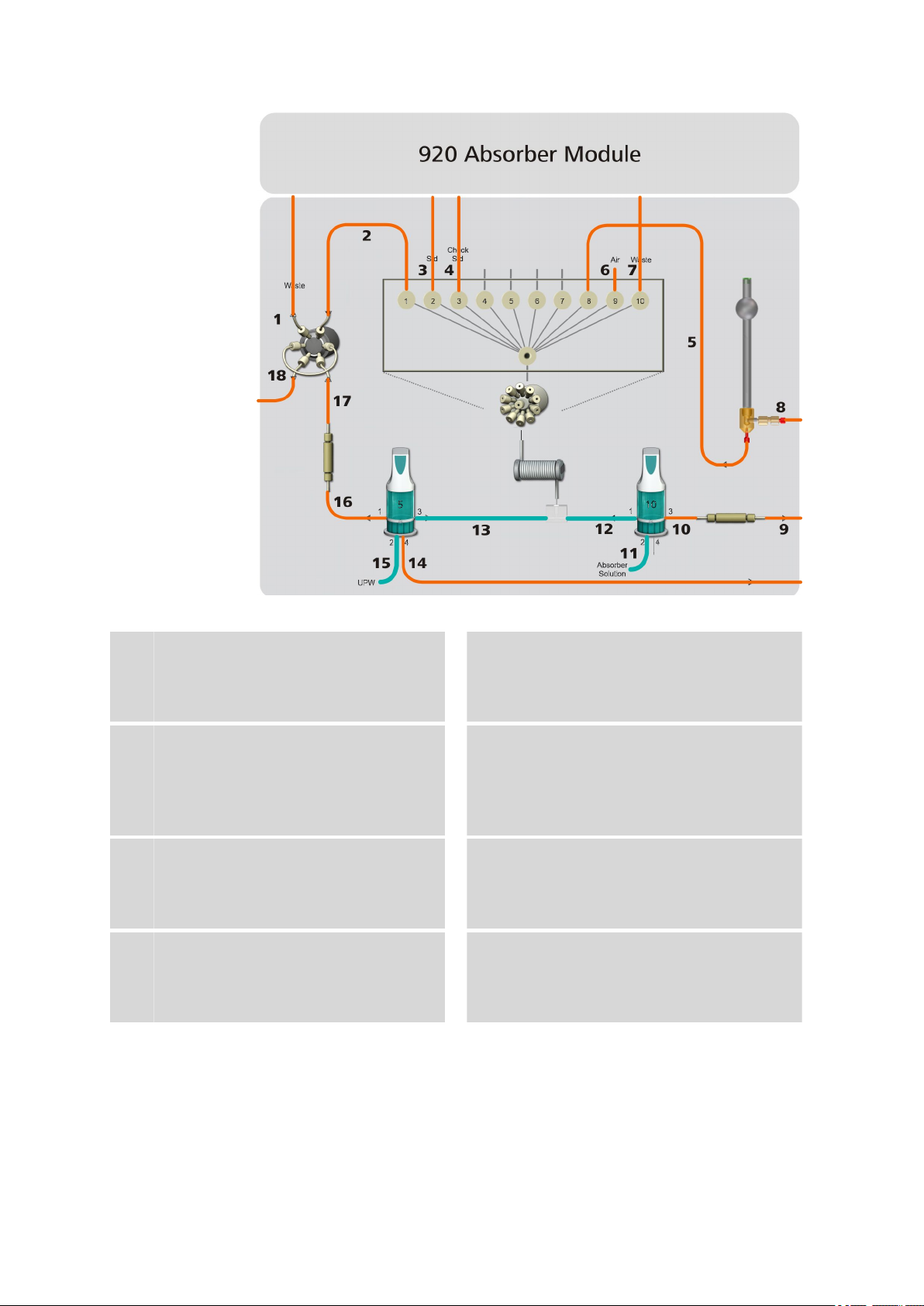

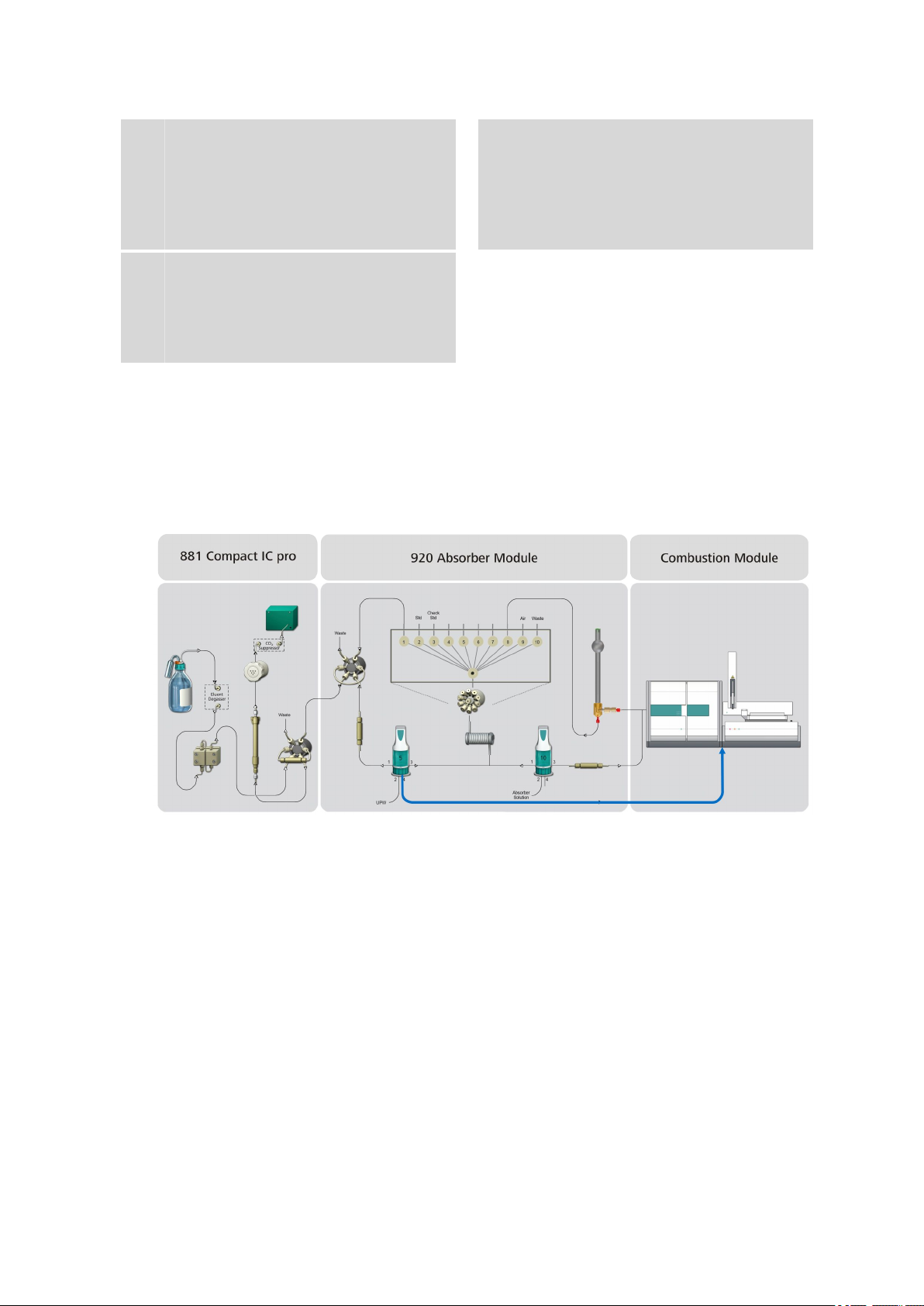

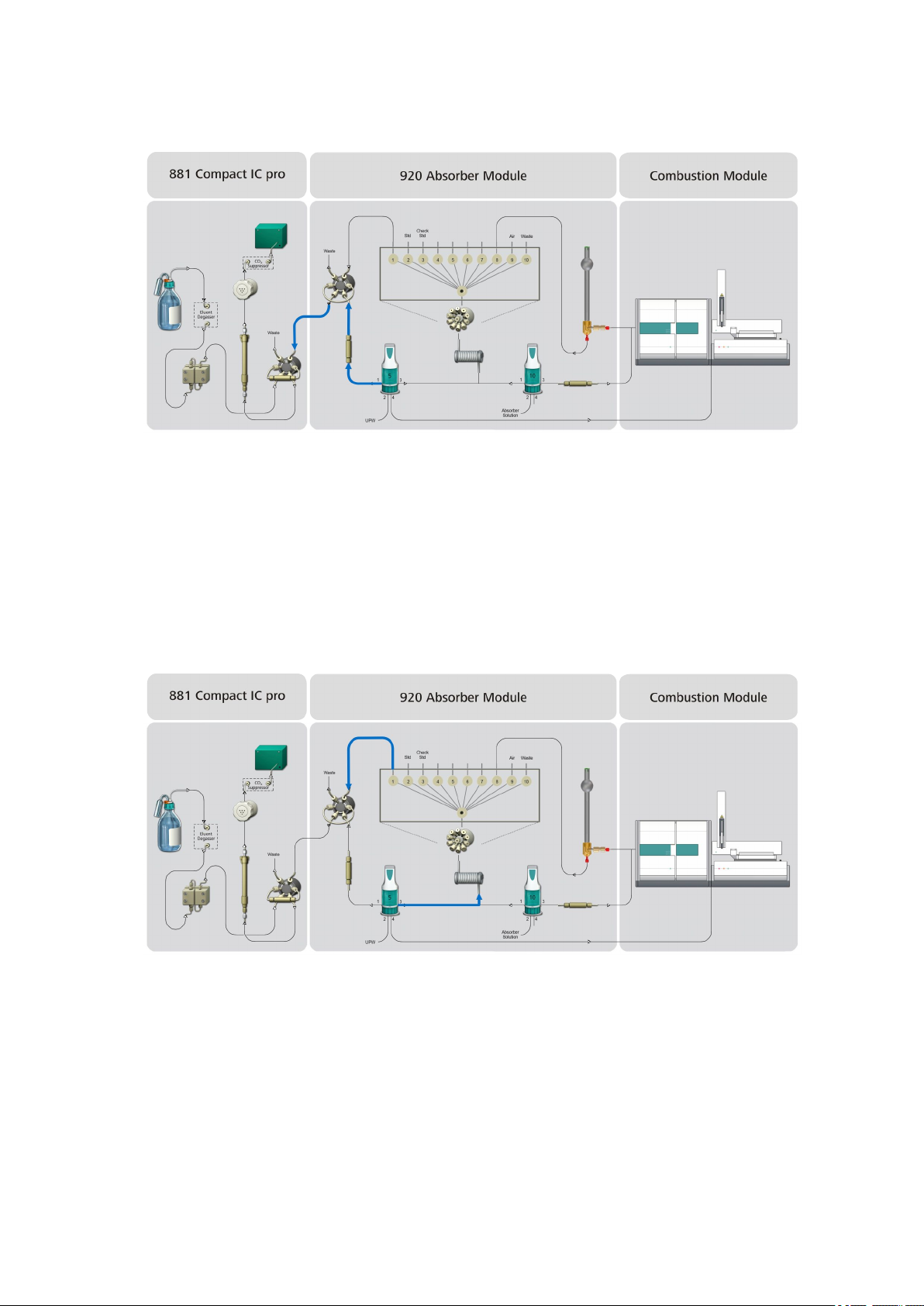

Figure 2 Overview - CIC system

The sample is combusted in the Combustion Module.

The gases generated during combustion are dissolved into an absorber

solution in the 920 Absorber Module and are optimized for analysis using

suitable sample preparation techniques.

In the end, the absorption solution is preconcentrated in an ion chromatograph and analyzed.

The entire process is controlled and monitored using MagIC Net software.

The analysis data is saved in the software's database.

920 Absorber Module

Page 17

■■■■■■■■■■■■■■■■■■■■■■

Start determination

(CIC system)

Rinse absorber tube and

provide absorber solution

(920 Absorber Module)

Sample input

(Combustion Module)

Rinse capillary f. combustion

gases w. absorber solution

(920 Absorber Module)

Absorption of

combustion gases

(920 Absorber Module)

Optional: Water infeed

(920 Absorber Module)

Combustion

(Combustion Module)

Fill loop with

absorption solution

(920 Absorber Module)

Matrix elimination

(930 Compact IC Flex)

Re-rinse absorber tube

(920 Absorber Module)

IC determination

(930 Compact IC Flex)

2.3 Sequence of a determination

A determination in the Combustion IC system runs according to the following diagram:

2 The Combustion IC system

Figure 3 Sequence of the determination

920 Absorber Module

■■■■■■■■

9

Page 18

2.3 Sequence of a determination

■■■■■■■■■■■■■■■■■■■■■■

NOTE

Do not mix these up!

■ Absorber solution: e.g. H

■ Absorption solution: Combustion gases dissolved in the absorber

solution for oxidizing sulfur oxides.

2O2

solution.

The determination is controlled entirely by MagIC Net. You can find a

detailed description of the sequence in the online help for MagIC Net

under the title "Combustion sequence".

■■■■■■■■

10

920 Absorber Module

Page 19

■■■■■■■■■■■■■■■■■■■■■■

1

2

6

11

7

9

10

3

5

4

8

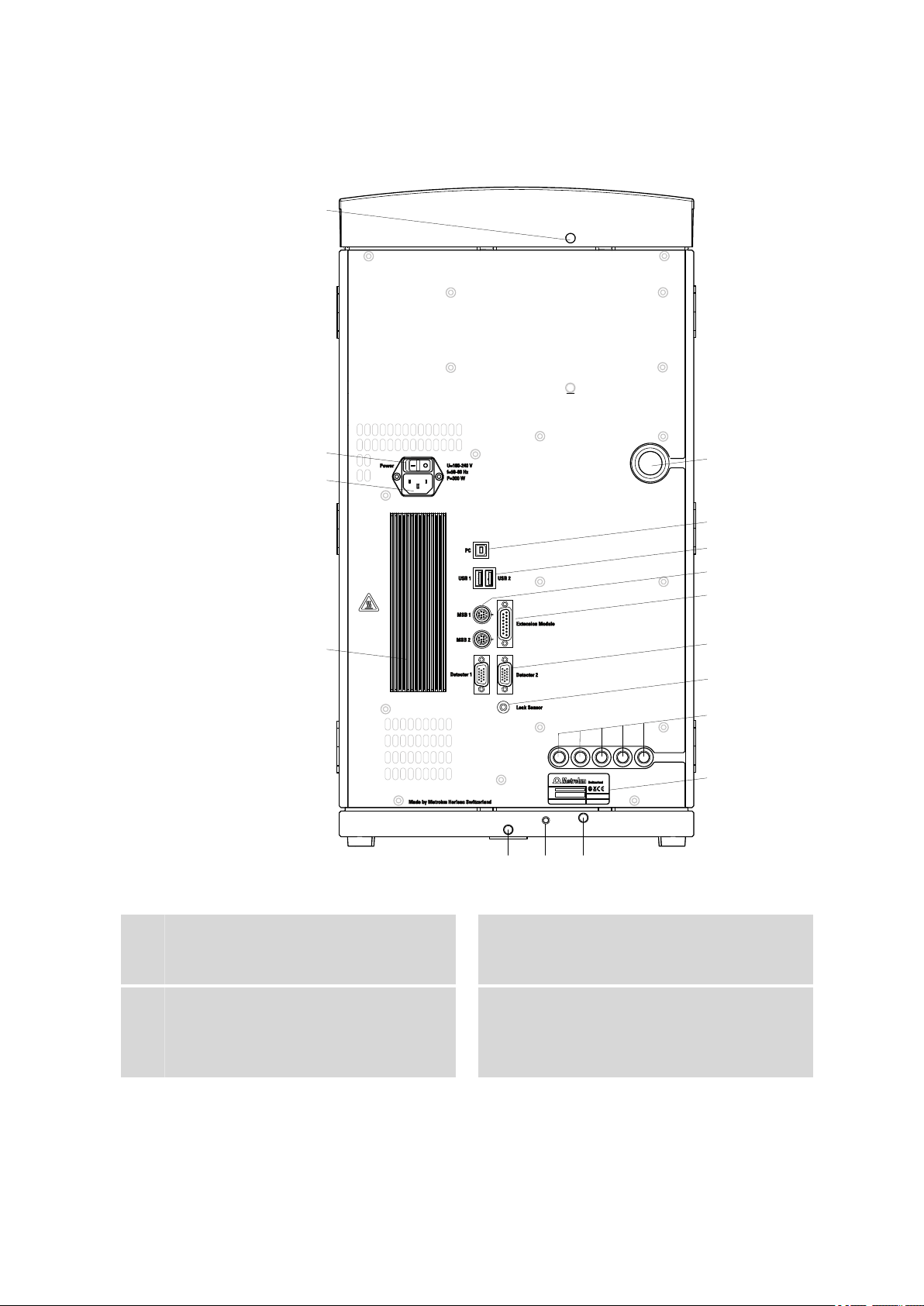

3 Overview of the instrument

3.1 Front

Module overview

3 Overview of the instrument

Figure 4 920 Absorber Module – Front

Bottle holder

1

Protects the instrument from contamination

and provides the space for the liquid containers.

Transfer tubing

2

Pre-installed. Connects the 10-port valve

with the Dosino.

920 Absorber Module

■■■■■■■■

11

Page 20

3.1 Front

■■■■■■■■■■■■■■■■■■■■■■

10-port valve

3

For the software-controlled connection of

10 ports.

Holding clamps

5

To hold the absorber tube.

Base tray

7

Equipped with a leak sensor.

Dosino holder

9

Two holders for the two Dosinos. One on

the back panel and one on the side panel.

6-port valve

11

For sample preparation and sample transfer

to the analysis instrument.

Holding clamps

4

Two holding clamps that hold the trap columns.

Bottle holder

6

Provides space for a 100 mL bottle, e.g., for

the standard solution.

Standby indicator

8

Flashes while the instrument is being

started.

Lights up when the instrument is ready for

operation.

Accessory space

10

Space for the Dosinos, the trap columns and

the absorber tube.

■■■■■■■■

12

920 Absorber Module

Page 21

■■■■■■■■■■■■■■■■■■■■■■

5

2

1

1

1

1

1

1

6

1

1

1

1

3

3

44

3

3

Capillary feedthroughs and cable

feed-throughs

3 Overview of the instrument

Capillary guides

1

To arrange capillaries and tubings in the

instrument.

Figure 5 920 Absorber Module – Front

Capillary guide

2

For the combustion gas inlet capillary.

920 Absorber Module

■■■■■■■■

13

Page 22

3.1 Front

■■■■■■■■■■■■■■■■■■■■■■

Capillary feed-throughs

3

Between instrument and base tray. For feeding capillaries from the front to the sides of

the instrument.

Capillary openings

5

For guiding capillaries and tubings out of the

instrument.

Capillary feed-throughs

4

Between instrument and base tray. For feeding capillaries from the front to the rear of

the instrument.

Cable opening

6

For guiding Dosino cables out of the instrument.

■■■■■■■■

14

920 Absorber Module

Page 23

■■■■■■■■■■■■■■■■■■■■■■

11

1

8

2

3

5

6

11

13

14

10

4

9

12

7

11

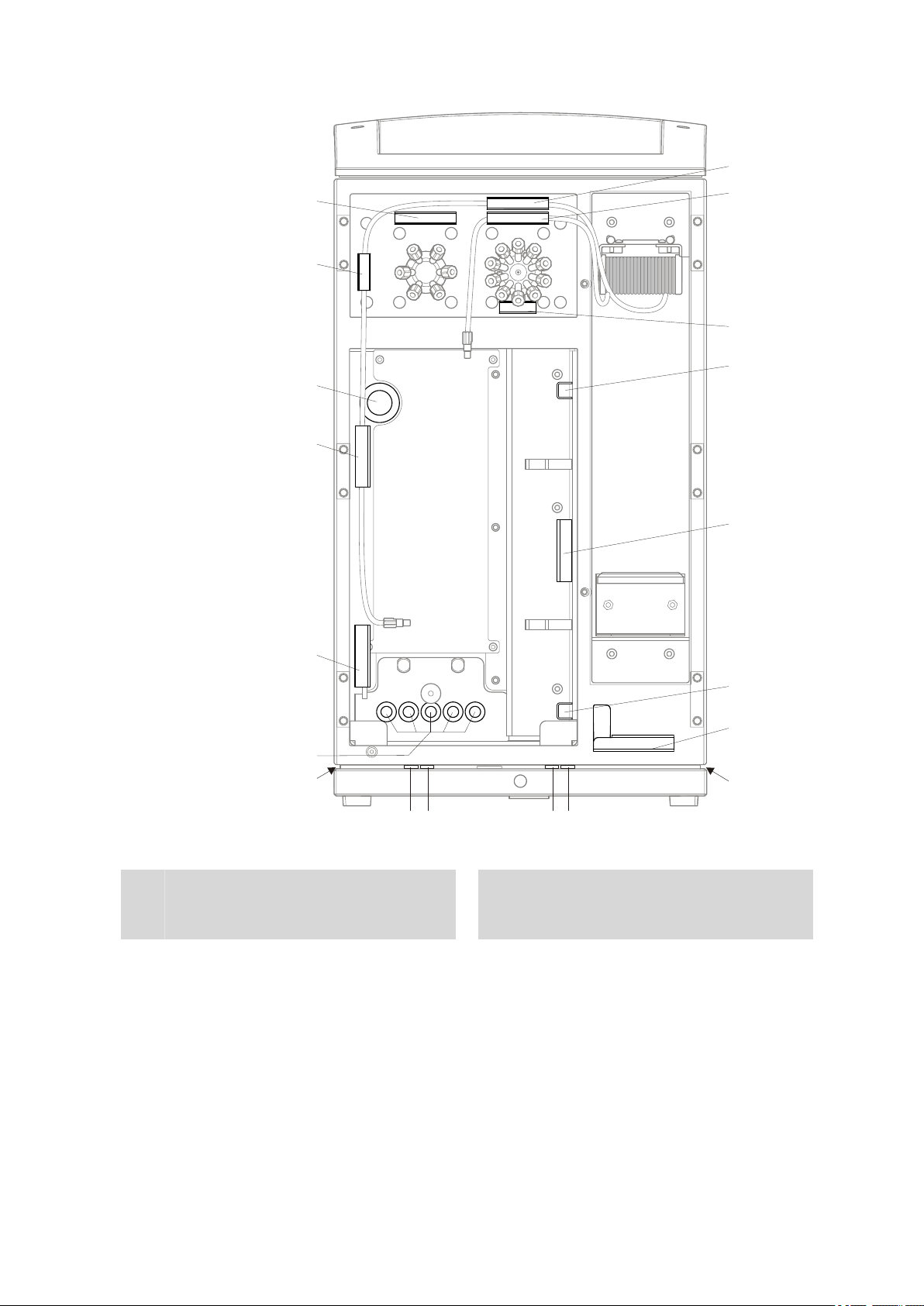

3.2 Rear

3 Overview of the instrument

Figure 6 920 Absorber Module – Rear

Cable opening

1

For guiding Dosino cables out of the instrument.

USB connection sockets

3

Two USB connection sockets for connecting

instruments with USB connector, labeled

with USB 1 and USB 2.

PC connection socket

2

For connecting a PC with a USB cable.

MSB connection sockets

4

Two MSB connection sockets for connecting

instruments with MSB connector, labeled

with MSB 1 and MSB 2.

920 Absorber Module

■■■■■■■■

15

Page 24

3.2 Rear

■■■■■■■■■■■■■■■■■■■■■■

Extension Module connection socket

5

Connection socket for an 872 Extension

Module or an 891 Professional Analog Out.

Leak sensor connection socket

7

For connecting the leak sensor connection

cable.

Type plate

9

With article number and barcode.

Drain nozzle

11

Enables liquids that have leaked from the

bottle holder and inside the instrument to

drain.

Power socket

13

For connecting the power supply cable.

Detector connection sockets

6

Two connection sockets for connecting up

to two detectors, labeled as Detector 1

and Detector 2.

Capillary openings

8

Five openings on the back panel for guiding

capillaries and and tubings out of the instrument.

Leak sensor cable

10

Extractable. Coiled up in the base tray. Must

be connected to the leak sensor connection

socket.

Heat sink

12

To remove heat from inside the instrument.

Caution: May become hot.

On/off switch

14

For switching the instrument on and off.

■■■■■■■■

16

920 Absorber Module

Page 25

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

4.1 Setting up the instrument

4.1.1 Packaging

The instrument is supplied in highly protective special packaging together

with the separately packed accessories. Keep this packaging, as only this

ensures safe transportation of the instrument.

4.1.2 Checks

Immediately after receipt, check whether the shipment has arrived complete and without damage by comparing it with the delivery note.

4.1.3 Location

The instrument has been developed for operation indoors and may not be

used in explosive environments.

4 Installation

Place the instrument in a location of the laboratory which is suitable for

operation, free of vibrations, protected from corrosive atmosphere, and

contamination by chemicals.

The instrument should be protected against excessive temperature fluctuations and direct sunlight.

4.2 Overview

Installation of the 920 Absorber Module

The 920 Absorber Module is provided with a wide array of accessories.

These accessory parts have to be installed before the instrument can be

put into operation.

Procedure

We suggest proceeding as follows to simplify the complex installation:

1. Install the Dosino for ultrapure water including a trap column and

2. Install the Dosino for the absorber solution including a trap column,

3. Connect the 10-port valve and install the bottles for the standard

4. Connect the 6-port valve (see Chapter 4.6, page 61).

5. Install and connect the absorber tube (see Chapter 4.7, page 67).

6. Connect the Combustion Module and the 930 Compact IC Flex (see

ultrapure water bottle (see Chapter 4.3, page 20).

bottle with absorber solution and T connector (see Chapter 4.4, page

39).

solution and a check standard (see Chapter 4.5, page 54).

Chapter 4.10, page 74).

920 Absorber Module

■■■■■■■■

17

Page 26

4.2 Overview

Capillaries and tubings

■■■■■■■■■■■■■■■■■■■■■■

Figure 7 Capillaries and tubings in use – Overview

PTFE capillary, 0.75 mm ID / 3 m

1

(6.1803.160)

Connection between the 6-port valve and

the waste container.

PTFE capillary, 0.75 mm ID / 3 m

3

(6.1803.160)

Approx. 80 cm. Connection between the

10-port valve and the bottle with the standard solution.

PTFE capillary, 0.75 mm ID / 3 m

5

(6.1803.160)

Approx. 60 cm. Connection between the

10-port valve and the absorber tube.

PTFE capillary, 0.75 mm ID / 3 m

7

(6.1803.160)

Connection between the 10-port valve and

the waste container.

PEEK capillary, 0.5 mm ID / 15 cm

2

(6.1831.040)

Connection between the 6-port valve and

the 10-port valve.

PTFE capillary, 0.75 mm ID / 3 m

4

(6.1803.160)

Approx. 80 cm. Connection between the

10-port valve and the bottle with the check

standard.

PTFE capillary, 0.75 mm ID / 3 m

6

(6.1803.160)

Approx. 5 cm. For aspirating air segments.

PTFE capillary, 1/8 in. / 1/16 in. ID / 1.5

8

m

Connection between the absorber tube and

the Combustion Module.

■■■■■■■■

18

920 Absorber Module

Page 27

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

PTFE capillary, 0.5 mm ID / 3 m

9

(6.1803.030)

Connection between the Metrosep A Trap 1

- 100/4.0 trap column (6.1014.000) and the

Combustion Module.

FEP tubing M6 for 920, 150 cm

11

(6.1838.020)

Aspiration tubing for the absorber solution.

Connection between the Dosino with the

absorber solution and the bottle with the

absorber solution.

FEP tubing M6 for 920, 9 cm

13

(6.1838.040)

Connection between the Dosino with ultrapure water and the T connector.

FEP tubing M6 for 920, 150 cm

15

(6.1838.020)

Aspiration tubing for ultrapure water. Connection between the Dosino with the water

bottle.

PTFE capillary, 0.5 mm ID / 3 m

10

(6.1803.030)

Approx. 20 cm. Connection between the

Dosino with the absorber solution and the

Metrosep A Trap 1 - 100/4.0 trap column

(6.1014.000).

FEP tubing M6 for 920, 9 cm

12

(6.1838.040)

Connection between the Dosino with the

absorber solution and the T connector.

PTFE capillary, 0.5 mm ID / 3 m

14

(6.1803.030)

Connection between the Dosino with ultrapure water and the Combustion Module.

PTFE capillary, 0.5 mm ID / 3 m

16

(6.1803.030)

Approx. 30 cm. Connection between the

Dosino with ultrapure water and the Metrosep I Trap 1 - 100/4.0 trap column

(6.1014.200).

PTFE capillary, 0.5 mm ID / 3 m

17

(6.1803.030)

Approx. 40 cm. Connection between the

Metrosep I Trap 1 - 100/4.0 trap column

(6.1014.200) and the 6-port valve.

PTFE capillary, 0.5 mm ID / 3 m

18

(6.1803.030)

Connection between the 6-port valve and

the 930 Compact IC Flex.

Colored sleeves Different liquids move throughout the 920 Absorber Module. In order to

provide you an overview of the different flow paths, we recommend using

the provided colored sleeves as follows to code the capillaries that route

the distinct liquids:

Table 1 Recommended color codes for the flow paths

Liquid Colored sleeve

Ultrapure water blue

Absorber solution yellow

Standard solution black

Check standard red

Waste white

920 Absorber Module

■■■■■■■■

19

Page 28

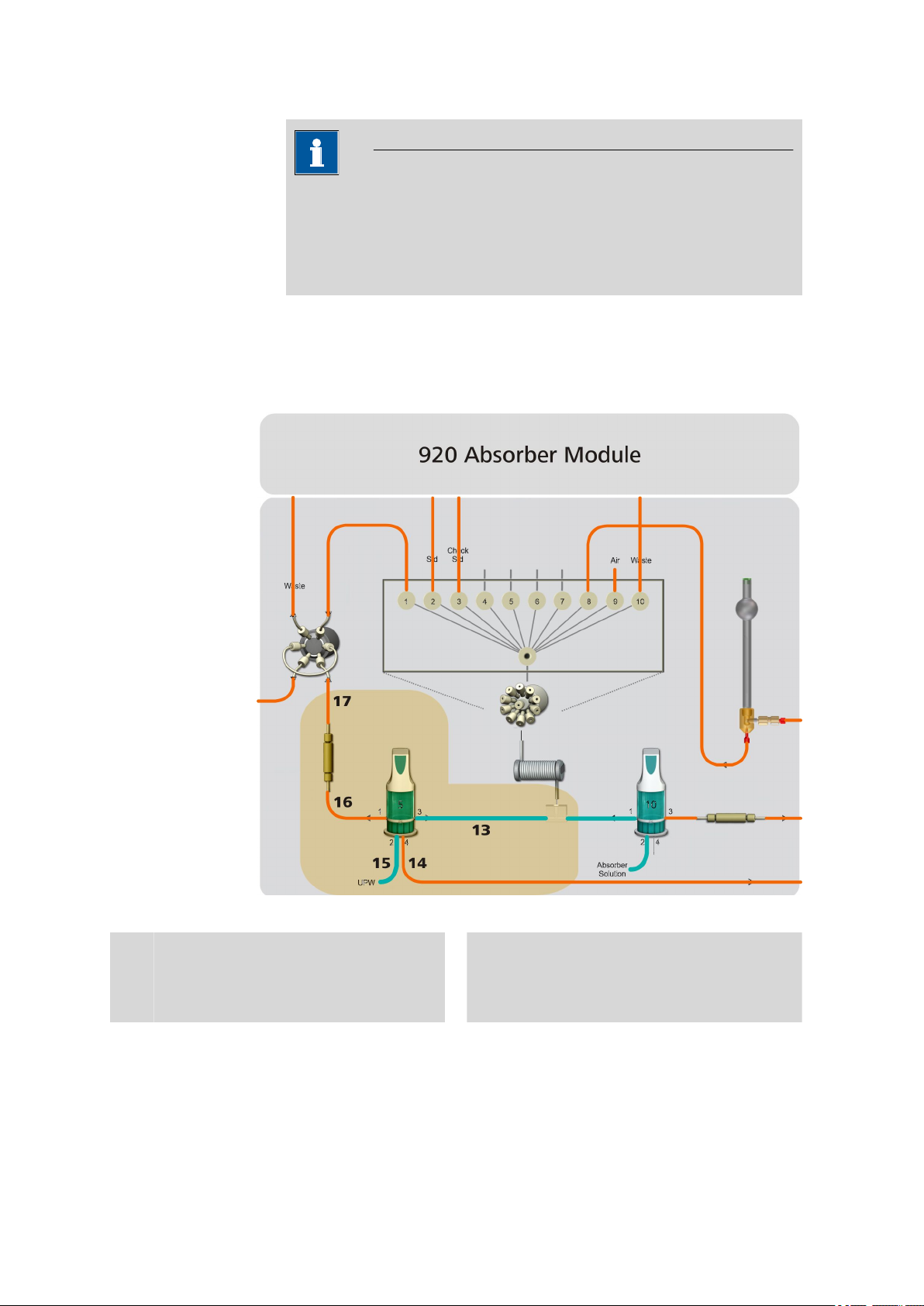

4.3 Dosino for ultrapure water

NOTE

The colored sleeves are heat-shrink tubing; this means they shrink when

they are exposed to heat.

Slip the colored sleeve over the capillary and secure it to the desired

spot by heating it, for example by using a hairdryer.

4.3 Dosino for ultrapure water

The Dosino for ultrapure water is installed first.

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

20

Figure 8

FEP tubing M6 for 920, 9 cm

13

(6.1838.040)

Connection between the Dosino with ultrapure water and the T connection.

Installing the Dosino for ultrapure water

PTFE capillary, 0.5 mm ID / 3 m

14

(6.1803.030)

Connection between the Dosino with ultrapure water and the Combustion Module.

920 Absorber Module

Page 29

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

FEP tubing M6 for 920, 150 cm

15

(6.1838.020)

Aspiration tubing for ultrapure water. Connection between the Dosino with the water

bottle.

PTFE capillary, 0.5 mm ID / 3 m

17

(6.1803.030)

Approx. 40 cm. Connection between the

Metrosep I Trap 1 - 100/4.0 trap column

(6.1014.200) and the 6-port valve.

The Dosino is equipped with a 5 mL dosing unit and is inserted in the back

in the accessory space (4-10). It has three tasks:

■ Dosing the water infeed during combustion.

■ Dosing the transfer water for matrix elimination of the sample.

■ Liquid Handling.

Dosing the water infeed during combustion

PTFE capillary, 0.5 mm ID / 3 m

16

(6.1803.030)

Approx. 30 cm. Connection between the

Dosino with ultrapure water and the Metrosep I Trap 1 - 100/4.0 trap column

(6.1014.200).

920 Absorber Module

Feeding water in at the combustion tube's inlet supports the combustion

process and increases the recovery rate, particularly for fluoride. To do so,

the Dosino aspirates the ultrapure water from the bottle and doses a very

small amount through port 4 to the combustion tube's inlet. The time and

quantity of the water infeed are defined in MagIC Net™.

■■■■■■■■

21

Page 30

4.3 Dosino for ultrapure water

■■■■■■■■■■■■■■■■■■■■■■

Dosing transfer water for the sample

The transfer water transports the sample to the IC instrument. In order to

obtain accurate analysis results, the transfer water has to be free of ionic

contamination. To remove all traces of ionic contamination, a Metrosep I

Trap 1 – 100/4.0 (6.1014.200) column is used between the Dosino for

ultrapure water and the 6-port valve.

The Dosino aspirates ultrapure water from the bottle and starts by dosing

it to the Metrosep I Trap 1 – 100/4.0 (6.1014.200) through port 1 and to

port 5 of the 6-port valve from there.

Liquid Handling

A Dosino can either aspirate or discharge defined quantities of liquids via

its four ports. In conjunction with the 10-port valve, it is used to transport

liquids through the Combustion IC system. This process is called Liquid

Handling.

■■■■■■■■

22

Port 3 of the Dosino is connected to transfer tubing and is used for Liquid

Handling.

920 Absorber Module

Page 31

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

Recommended procedure for installation

1. Assemble the Dosino (see Chapter 4.3.1, page 23).

2. Guide the capillary for the infeed of water during combustion into

the instrument (see Chapter 4.3.2, page 23).

3. Connect port 2 and port 4 (see "Connecting port 2 and port 4",

page 26).

4. Connect port 1 and port 3 (see "Connecting port 1 and port 3",

page 30).

5. Place the Dosino in the instrument (see Chapter 4.3.4, page 33).

6. Connect the Metrosep I Trap 1 - 100/4.0 trap column and insert it in

the instrument (see Chapter 4.3.5, page 34).

7. Connect the ultrapure water bottle (see Chapter 4.3.6, page 36).

4.3.1 Assembling the Dosino

Accessories

For this step you need:

■ 800 Dosino (2.800.0010)

■ Dosing Unit 5 mL (6.3032.150)

Attaching the Dosino on the Dosing Unit

The manual for the 800 Dosino describes how to attach a dosing unit correctly on the 800 Dosino.

CAUTION

Please read through the correct procedure in the manual for the 800

Dosino before you attach the Dosino on the dosing unit.

Plugging in the connection cable

Route the connection cable for the Dosino out the back panel of the

1

instrument through the cable opening (6-1).

Plug the plug from the connection cable into the MSB 2 socket.

2

Next step Feed the capillary for the water infeed (8-14) into the instrument.

4.3.2 Feeding the capillary into the instrument

Accessories

For this step you need:

■ PTFE capillary (6.1803.030)

■ Colored sleeves, blue

920 Absorber Module

■■■■■■■■

23

Page 32

4.3 Dosino for ultrapure water

6.1803.030

1.

2.

3.

■■■■■■■■■■■■■■■■■■■■■■

Feeding the capillary for the water infeed into the instrument

The arrows in the figure point in the direction the capillaries have to be

pushed.

1

Feeding the capillary for the water infeed into the instrument

■ Slide a blue colored sleeve over the capillary far enough that it

remains visible outside the instrument.

■ Push the capillary into the capillary feed-through at the bottom of

the right side of the instrument until it comes out the front.

■ Bend the capillary and push it through the neighboring cable

feed-through until it comes out the rear of the instrument.

■ Push the capillary into the instrument through one of the five

capillary openings on the back panel.

Next step

Connect the ports (see Chapter 4.3.3, page 24).

4.3.3 Connecting the ports – Overview

Using ports

■■■■■■■■

24

The ports on the Dosino for ultrapure water are used as follows:

Port … … is used for … … and is connected to

1 Dosing transfer water Metrosep I Trap 1 - 100/4.0 trap

2 Aspirating ultrapure water Water bottle

3 Liquid Handling T connection

4 Water infeed during combustion Combustion tube's inlet in the

column (6.1014.200) inlet

Combustion Module

920 Absorber Module

Page 33

■■■■■■■■■■■■■■■■■■■■■■

2.800.0020

6.3032.150

6.2057.230

6.1618.020

6.1805.040

6.1808.280

6.2744.080

6.27440350

6.1803.030

6.1838.020

6.2744.080

6.2744.350

6.1803.030

(30 cm)

Port 3

Port 1

Port 2

Port 4

4 Installation

Accessories The following accessories have to be connected to the Dosino for ultra-

pure water:

Port Install this accessory

1

2

3

4

■ PTFE capillary (6.1803.030), approx. 30 cm (8-16)

■ Pressure screw (6.2744.350)

■ Coupling (6.2744.080)

FEP tubing M6 for 920, 150 cm (6.1838.020) (8-15)

FEP tubing M6 for 920, 9 cm (6.1805.040) (8-13)

■ PTFE capillary (6.1803.030) (8-14)

■ Pressure screw (6.2744.350)

■ Coupling (6.2744.080)

■ Blue colored sleeve

For this step you also need:

■ Thread adapter (6.1618.020)

■ Dosino holder (6.2057.230)

■ Capillary cutter (6.2621.080)

920 Absorber Module

Figure 9

Connect the Dosino for ultrapure water

■■■■■■■■

25

Page 34

4.3 Dosino for ultrapure water

6.2744.080

6.2744.350

6.1803.030

■■■■■■■■■■■■■■■■■■■■■■

Connecting port 2 and port 4

Port 2 and port 4 of the Dosino are on the bottom of the instrument.

These ports are connected first.

Accessories The following accessories have to be connected to these two ports:

Port Install this accessory

2

4

FEP tubing M6 for 920, 150 cm (6.1838.020) (8-15)

■ PTFE capillary (6.1803.030) (8-14)

■ Pressure screw (6.2744.350)

■ Coupling (6.2744.080)

■ Adapter Dosino port 4 (6.1808.280)

For this step you also need:

■ Thread adapter (6.1618.020)

■ Dosino holder (6.2057.230)

■ Colored sleeves, blue

Preparing

Before you can connect the capillary and the aspiration tubing, you have

to:

■ Install the coupling for the connection between the capillary and Dos-

ino.

■ Thread the capillary for the water infeed and the aspiration tubing

through the thread adapter and the Dosino holder.

1

Mounting the coupling

The ports on the Dosino are intended for tubing with an M6 connector. If capillaries are connected to the ports, a coupling has to be

installed at the end.

■■■■■■■■

26

■ Optional: Guide a blue colored sleeve over the end of the capil-

lary.

920 Absorber Module

Page 35

■■■■■■■■■■■■■■■■■■■■■■

6.1838.020

6.2057.230

6.1618.020

6.1803.030

4 Installation

■ Push the pressure screw over the end of the PTFE capillary far

enough that a few millimeters of the capillary extend beyond the

tip of the pressure screw.

■ Attach the coupling on the pressure screw and tighten it by hand.

2

Threading the Dosino holder thread adapter

■ Start by threading the FEP tubing through the thread adapter

from below and then through the Dosino holder.

■ Start by threading the PTFE capillary through the thread adapter

from below and then through the Dosino holder.

The capillary for the water infeed and the water aspiration tubing can

now be connected to the Dosino. Proceed as follows:

Connecting port 2

Prerequisites

■ FEP tubing M6 to 920 150 cm (6.1838.020) is threaded in through the

thread adapter (6.1618.020) and the Dosino holder (6.2057.230).

920 Absorber Module

■■■■■■■■

27

Page 36

4.3 Dosino for ultrapure water

Port 2

6.1805.040

■■■■■■■■■■■■■■■■■■■■■■

1

Mounting the FEP tubing

Tighten the FEP tubing on port 2 of the dosing unit.

2

Routing the FEP tubing out of the instrument

Guide the loose end of the FEP tubing out of the 920 Absorber Module through one of the capillary openings on the back panel of the

instrument.

Connecting port 4

Prerequisites:

■ The PTFE capillary (6.1803.030) is threaded in through the thread

adapter (6.1618.020) and the Dosino holder (6.2057.230).

■ The coupling is installed on the end of the capillary.

■■■■■■■■

28

920 Absorber Module

Page 37

■■■■■■■■■■■■■■■■■■■■■■

Port 4

6.1808.280

6.2744.080

6.2744.350

6.1803.030

4 Installation

1

Mounting the adapter

Attach the Adapter Dosino port 4 (6.1808.280) onto port 4 of the

dosing unit.

2

Mounting the capillary

Tighten the PTFE capillary on the Adapter Dosino port 4.

Tightening the Dosino holder

Prerequisites:

FEP tubing (6.1838.020) and the PTFE capillary (6.1803.030) are threaded

in through the thread adapter (6.1618.020) and the Dosino holder

(6.2057.230) and are connected to ports 2 and 4.

920 Absorber Module

■■■■■■■■

29

Page 38

4.3 Dosino for ultrapure water

■■■■■■■■■■■■■■■■■■■■■■

Tighten the Dosino holder (6.2057.230) with the thread adapter

1

(6.1618.020) on the bottom of the dosing unit.

Next step ■ Connect the ports 1 and 3.

Connecting port 1 and port 3

Port 1 on the left side of the Dosino is used for dosing water, which is

used for transferring the sample from the 6-port valve to the analysis

instrument. The transfer water is purified using a Metrosep I Trap 1 –

100/4.0 (6.1014.200) trap column so that it does not contaminate the

sample with undesired anions and cations.

Port 3 on the right side of the Dosino is used for connecting transfer tubing. It is used for Liquid Handling.

Accessories

The following accessories have to be connected to these two ports:

■■■■■■■■

30

920 Absorber Module

Page 39

■■■■■■■■■■■■■■■■■■■■■■

6.2744.080

6.2744.350

6.1803.030

4 Installation

Port Install this accessory

1

3

■ 30 cm of the PTFE capillary (6.1803.030) (8-16)

■ Pressure screw (6.2744.350)

■ Coupling (6.2744.080)

FEP tubing M6 for 920, 9 cm (6.1805.040) (8-13)

For this step you also need:

■ Capillary cutter (6.2621.080)

Connecting port 1

1

Cutting the PTFE capillary to size

■ Cut off a piece from the PTFE capillary that is approx. 30 cm long

using the capillary cutter.

2

Mounting the coupling

920 Absorber Module

■ Push the pressure screw over the end of the PTFE capillary far

enough that a few millimeters of the capillary extend beyond the

tip of the pressure screw.

■ Attach the coupling on the pressure screw and tighten it by hand.

■■■■■■■■

31

Page 40

4.3 Dosino for ultrapure water

Port 1

6.2744.080

6.2744.350

6.1803.030

Port 3

6.1805.040

3

Connecting the PTFE capillary

■ Tighten the coupling to port 1 of the dosing unit.

Connecting port 3

■■■■■■■■■■■■■■■■■■■■■■

1

Mounting the FEP tubing

Tighten the FEP tubing on port 3 of the dosing unit.

Next step Place the Dosino for ultrapure water into the instrument.

■■■■■■■■

32

920 Absorber Module

Page 41

■■■■■■■■■■■■■■■■■■■■■■

1.

2.

4.3.4 Inserting the Dosino in the instrument

CAUTION

Space is limited in the 920 Absorber Module.

When you insert the fully connected Dosino into the instrument, ensure

that none of the tubing or capillaries are bent or kinked. Turn the Dosino so that the capillaries and tubing can be as straight as possible.

Inserting the Dosino in the instrument

4 Installation

Next step

920 Absorber Module

Place the Dosino holder onto the mounting bolts and fix it in place

1

using the knurled screw.

Connect

capillary/tubing at port

…

1 Metrosep I Trap 1 - 100/4.0 (6.1014.200) trap column inlet (see

2 Water bottle (see Chapter 4.3.6, page 36)

… to

Chapter 4.3.5, page 34)

■■■■■■■■

33

Page 42

4.3 Dosino for ultrapure water

■■■■■■■■■■■■■■■■■■■■■■

Connect

capillary/tubing at port

…

3 T connection (see Chapter 4.4.4, page 47)

4 Combustion oven inlet (see Chapter 4.10.1, page 74)

… to

4.3.5 Connecting the Metrosep I Trap 1

The Metrosep I Trap 1 – 100/4.0 trap column (6.1014.200) removes disruptive interfering anions and cations from the ultrapure water used for

transferring the absorption solution from the absorber tube to the 6-port

valve. The use of trap column ensures that the analysis is not distorted by

unwanted contamination.

The Metrosep I Trap 1 – 100/4.0 is used between the Dosino for ultrapure

water and the 6-port valve.

The … … is connected to

Inlet Dosino for ultrapure water

Outlet 6-port valve

Accessories The following accessories have to be connected to the trap column:

On … Install this accessory

Inlet

Outlet

■ 30 cm of the PTFE capillary (6.1803.030) (8-16)

■ Pressure screw (6.2744.010)

■ 40 cm of the PTFE capillary (6.1803.030) (8-17)

■ Pressure screw (6.2744.010)

Connecting the Metrosep I Trap 1 – 100/4.0

NOTE

The trap column is sealed with threaded stoppers at both ends.

Remove these threaded stoppers before connecting the capillaries.

■■■■■■■■

34

920 Absorber Module

Page 43

■■■■■■■■■■■■■■■■■■■■■■

6.1014.200

6.1803.030 (40 cm)

6.2744.010

6.1014.200

6.27440.10

6.1803.030 (30 cm)

1

3

2

4

1

4 Installation

CAUTION

Flow can only move through the trap column in one direction. This flow

direction is marked on the column with an engraved arrow.

Be absolutely sure to note this flow direction when connecting the

capillaries.

Threaded stopper

1

Flow direction indicator

3

920 Absorber Module

Column outlet

2

Column inlet

4

1

Removing the threaded stoppers

Remove the threaded stoppers at the inlet and outlet of the Metrosep I Trap 1 – 100/4.0.

2

Connecting the capillaries

■ Screw the loose end of the PTFE capillary connected to port 1 of

the Dosino for ultrapure water to the inlet of the trap column

using a pressure screw.

■■■■■■■■

35

Page 44

4.3 Dosino for ultrapure water

■■■■■■■■■■■■■■■■■■■■■■

■ Cut off a piece from the PTFE capillary (6.1803.030) that is

approx. 40 cm long using the capillary cutter (6.2621.080) and

tighten it onto the outlet of the trap column using a pressure

screw.

Inserting the trap column in the instrument

Insert the Metrosep I Trap 1 – 100/4.0 in the instrument as follows:

Fasten the Metrosep I Trap 1 – 100/4.0 in place in the rear holding

1

bracket (4-4) of the 920 Absorber Module using the column head.

Next step Tighten the loose end of the PTFE capillary at the outlet of the trap col-

umn to port 5 of the 6-port valve (see Chapter 4.6, page 61).

4.3.6 Connecting the ultrapure water bottle

The ultrapure water bottle has to be connected to port 2 of the Dosino

for ultrapure water.

Accessories

For this step you need:

■ Clear glass bottle 2 L (6.1608.070) filled with ultrapure water.

■ Bottle attachment (6.1602.160)

■ FEP tubing M6 to 920 150 cm (6.1838.020) (8-15).

■ Adsorber tube (6.1609.000)

■ Cotton

■ Adsorber granulate

■■■■■■■■

36

920 Absorber Module

Page 45

■■■■■■■■■■■■■■■■■■■■■■

6.1609.000

6.1602.160

6.1608.070

6.1446.080

6.1838.020

6.2023.020

1

2

4 Installation

Connecting the bottle with ultrapure water

Cotton

1

Screw the bottle attachment onto the bottle.

1

Insert a sealing ring from the 6.1602.160 accessory set into the bot-

2

tle attachment's M6 opening.

Adsorber granulate

2

Put the loose end of the FEP tubing through the bottle attachment's

M6 opening and tighten it.

NOTE

The end of the aspiration tubing has to reach to the bottom of the

bottle.

920 Absorber Module

■■■■■■■■

37

Page 46

4.3 Dosino for ultrapure water

■■■■■■■■■■■■■■■■■■■■■■

Fill the adsorber tube with a little cotton and adsorber granulate and

3

seal it with the plastic cover.

Place the adsorber tube into the large opening of the bottle attach-

4

ment and fasten it in place with the SGJ clip.

Seal the M8 opening with a stopper.

5

■■■■■■■■

38

920 Absorber Module

Page 47

■■■■■■■■■■■■■■■■■■■■■■

4.4 Dosino for the absorber solution

4 Installation

Figure 10 Installing the Dosino for the absorber solution

PTFE capillary, 0.5 mm ID / 3 m

9

(6.1803.030)

Connection between the Metrosep A Trap 1

- 100/4.0 trap column (6.1014.000) and the

Combustion Module.

FEP tubing M6 for 920, 150 cm

11

(6.1838.020)

Aspiration tubing for the absorber solution.

Connection between the Dosino with the

absorber solution and the bottle with the

absorber solution.

The Dosino for the absorber solution is equipped with a 10 mL dosing unit

and has the following tasks:

■ Dosing the absorber solution.

■ Transferring the absorption solution to the 10-port valve.

PTFE capillary, 0.5 mm ID / 3 m

10

(6.1803.030)

Approx. 20 cm. Connection between the

Dosino with the absorber solution and the

Metrosep A Trap 1 - 100/4.0 trap column

(6.1014.000).

FEP tubing M6 for 920, 9 cm

12

(6.1838.040)

Connection between the Dosino with the

absorber solution and the T connection.

920 Absorber Module

■■■■■■■■

39

Page 48

4.4 Dosino for the absorber solution

Dosing the absorber solution

The absorber solution is dosed for the combustion tube's outlet in the

Combustion Modul. It absorbs the gases from combustion and carries

them to the absorber tube.

■■■■■■■■■■■■■■■■■■■■■■

Transferring the absorption solution to the 10-port valve

Drawing the absorption solution out of the absorber tube.

4.4.1 Assembling the Dosino

Accessories

For this step you need:

■ 800 Dosino (2.800.0010)

■ Dosing unit 10 mL (6.3032.210)

■■■■■■■■

40

Attaching the Dosino on the Dosing Unit

The manual for the 800 Dosino describes how to attach a dosing unit correctly on the 800 Dosino.

920 Absorber Module

Page 49

■■■■■■■■■■■■■■■■■■■■■■

CAUTION

Please read through the correct procedure in the manual for the 800

Dosino before you attach the Dosino on the dosing unit.

Plugging in the connection cable

Route the connection cable for the Dosino for the absorber solution

1

out of the instrument through the cable opening (6-1) in the back

panel.

Plug the plug for the connection cable into the MSB 1 socket.

2

4.4.2 Connecting the ports – Overview

Using ports

The ports on the Dosino for the absorber solution are used as follows:

4 Installation

Port … … is used for … … and is connected to

1 Liquid Handling T connection

2 Aspirating the absorber solution Bottle with absorber solution

3 Dosing the absorber solution Metrosep A Trap 1 - 100/4.0

(6.1014.000) trap column inlet

4 Not used

Accessories The following accessories have to be connected to the Dosino for the

absorber solution:

Port Install this accessory

Port 1

Port 2

Port 3

Port 4 –

FEP tubing M6 for 920, 9 cm (6.1805.040) (10-12)

FEP tubing M6 for 920, 150 cm (6.1838.020) (10-11)

■ PTFE capillary (6.1803.030), approx. 20 cm (10-10)

■ Pressure screw (6.2744.350)

■ Coupling (6.2744.080)

For this step you also need:

920 Absorber Module

■ Thread adapter (6.1618.020)

■ Dosino holder (6.2057.230)

■ Capillary cutter (6.2621.080)

■■■■■■■■

41

Page 50

4.4 Dosino for the absorber solution

2.800.0020

6.3032.210

6.2057.230

6.1618.020

6.1805.040

6.1838.020

6.2744.080

6.2744.350

6.1803.030

(20 cm)

Port 3

Port 1

Port 2

Port 4

■■■■■■■■■■■■■■■■■■■■■■

Accessories

Figure 11 Connect the Dosino for the absorber solution

Connecting port 2

Port 2 is located on the bottom of the Dosino. Port 2 is used for aspirating

the absorber solution.

The following accessories have to be connected at port 2:

Port Install this accessory

Port 2

FEP tubing M6 for 920, 150 cm (6.1838.020) (10-11)

For this step you also need:

■ Thread adapter (6.1618.020)

■ Dosino holder (6.2057.230)

■■■■■■■■

42

920 Absorber Module

Page 51

■■■■■■■■■■■■■■■■■■■■■■

6.1838.020

6.2057.230

6.1618.020

Installing the water aspiration tubing at port 2

1

Threading the Dosino holder thread adapter

Before you can connect the aspiration tubing for the absorber solution, you have to thread the aspiration tubing for the absorber solution through thread adapter and the Dosino holder.

4 Installation

920 Absorber Module

■ Start by threading the FEP tubing through the thread adapter

from below and then through the Dosino holder.

2

Connecting the FEP tubing to port 2

Tighten the FEP tubing on port 2 of the dosing unit.

3

Routing the FEP tubing out of the instrument

Guide the loose end of the FEP tubing out of the 920 Absorber Module through one of the capillary openings on the back panel of the

instrument.

Tightening the Dosino holder on the Dosino for the

absorber solution

Prerequisites:

■■■■■■■■

43

Page 52

4.4 Dosino for the absorber solution

FEP tubing (6.1838.020) is threaded in through the thread adapter

(6.1618.020) and the Dosino holder (6.2057.230) and is connected to

port 2.

■■■■■■■■■■■■■■■■■■■■■■

Tighten the Dosino holder (6.2057.230) with the thread adapter

1

(6.1618.020) on the bottom of the dosing unit.

Next step Connect the ports 1 and 3.

Connecting port 1 and port 3

Accessories

The following accessories have to be connected to these two ports:

Port Install this accessory

Port 1

Port 3

FEP tubing M6 for 920, 9 cm (6.1805.040) (10-12)

■ PTFE capillary (6.1803.030), approx. 20 cm (10-10)

■ Pressure screw (6.2744.350)

■ Coupling (6.2744.080)

■■■■■■■■

44

920 Absorber Module

Page 53

■■■■■■■■■■■■■■■■■■■■■■

Port 1

6.1532.130

6.2744.080

6.2744.350

6.1803.030

Connecting port 1

1

Mounting the FEP tubing

Tighten the FEP tubing on port 1 of the dosing unit.

4 Installation

Connecting port 3

1

Mounting the coupling

■ Push the pressure screw over the end of the PTFE capillary far

enough that a few millimeters of the capillary extend beyond the

tip of the pressure screw.

■ Attach the coupling on the pressure screw and tighten it by hand.

920 Absorber Module

■■■■■■■■

45

Page 54

4.4 Dosino for the absorber solution

Port 3

6.2744.080

6.2744.350

6.1803.030 (20cm)

2

Connecting the PTFE capillary

Tighten the coupling to port 3 of the dosing unit.

■■■■■■■■■■■■■■■■■■■■■■

Next step

Placing the Dosino for the absorber solution into the instrument.

4.4.3 Inserting the Dosino in the instrument

CAUTION

Space is limited in the 920 Absorber Module.

When you insert the fully connected Dosino into the instrument, ensure

that none of the tubing or capillaries are bent or kinked. Turn the Dosino so that the capillaries and tubing can be as straight as possible.

■■■■■■■■

46

920 Absorber Module

Page 55

■■■■■■■■■■■■■■■■■■■■■■

1.

2.

4 Installation

Inserting the Dosino in the instrument

Place the Dosino holder onto the mounting bolts and fix it in place

1

using the knurled screw.

Next step

Connect

capillary/tubing at port

…

1 T connection (see Chapter 4.4.4, page 47)

2 Bottle with the absorber solution (see Chapter 4.4.6, page 52)

3 Connect the Metrosep A Trap 1 – 100/4.0 inlet (see Chapter 4.4.5,

… to

page 49)

4.4.4 Connecting the T connection

The T connection is connected between the Dosino for ultrapure water,

the Dosino for the absorber solution and the transfer tubing.

Accessories

At inlet … Install this accessory

1 FEP tubing M6 for 920, 9 cm (6.1805.040) from Dosino for absorber

solution (7-12)

920 Absorber Module

■■■■■■■■

47

Page 56

4.4 Dosino for the absorber solution

1

2

3

6.1805.040

6.1805.040

6.1808.060

6.1562.130

■■■■■■■■■■■■■■■■■■■■■■

At inlet … Install this accessory

2 FEP tubing M6 for 920, 9 cm (6.1805.040) from Dosino for ultrapure

water (7-13)

3

Transfer tubing (4-2)

Installing the T connection

1

Connecting the FEP tubing

Screw the loose end of the FEP tubing connected to port 3 of the

Dosino for ultrapure water to an inlet (1) on the T connection.

2

Connecting the transfer tubing

Screw the longer end of the transfer tubing to the outlet (3) on the T

connection.

3

Connecting the FEP tubing

Screw the loose end of the FEP tubing connected to port 1 of the

Dosino for the absorber solution to the last inlet (2) on the T connection.

Next step ■ Connect the transfer tubing to the 10-port valve (see Chapter 4.5.1,

page 55).

■■■■■■■■

48

920 Absorber Module

Page 57

■■■■■■■■■■■■■■■■■■■■■■

4.4.5 Connecting the Metrosep A Trap 1

The Metrosep A Trap 1 – 100/4.0 (6.1014.000) trap column continues to

remove the smallest anionic contaminants in the absorber solution. The

use of trap column ensures that the analysis is not distorted by unwanted

contamination.

The Metrosep A Trap 1 – 100/4.0 is inserted between the Dosino for

absorber solution and the T connector CIC (6.7301.210) at the outlet of

the Combustion Module.

The … … is connected to

Inlet Dosino for the absorber solution

Outlet Combustion tube outlet on the Combustion Module

Accessories Connect the following accessories to the trap column:

On … Install this accessory

Inlet ■ Approx. 20 cm of the PTFE capillary (6.1803.030) connected to

port 3 of the Dosino for the absorber solution (10-10)

■ Pressure screw (6.2744.010)

■ Colored sleeve, yellow

4 Installation

Outlet

■ PTFE capillary (6.1803.030) (10-9)

■ Optional: Colored sleeve, yellow

920 Absorber Module

■■■■■■■■

49

Page 58

4.4 Dosino for the absorber solution

6.1803.030

The capillary for the absorber solution is fed into the instrument as follows:

■■■■■■■■■■■■■■■■■■■■■■

Feed the capillary for the absorber solution into the instrument

Figure 12 Feed the capillary for the absorber solution into the instru-

ment

■ Slide a yellow colored sleeve over the capillary far enough that it

1

remains visible outside the instrument.

■ Route one end of the PTFE- capillary (6.1803.030) to the front of

the instrument from the right side of the instrument through the

capillary feed-through between the base tray and the 920

Absorber Module.

■ Thread the end of the capillary through the bottom horizontal

capillary guide on the right inner side wall and then through the

vertical capillary guide from the bottom to the top.

■ Optional: Fasten another yellow colored sleeve to the end of the

capillary.

Connecting the Metrosep A Trap 1 – 100/4.0

NOTE

■■■■■■■■

50

The trap column is sealed with threaded stoppers at both ends.

Remove these threaded stoppers before connecting the capillaries.

920 Absorber Module

Page 59

■■■■■■■■■■■■■■■■■■■■■■

6.1014.000

3

2

4

6.1803.030

6.2744.010

6.1014.000

6.27440.10

6.1803.030 (20 cm)

1

1

4 Installation

CAUTION

Flow can only move through the trap column in one direction. This flow

direction is marked on the column with an engraved arrow.

Be absolutely sure to note this flow direction when connecting the

capillaries.

Threaded stopper

1

Flow direction indicator

3

920 Absorber Module

Column outlet

2

Column inlet

4

1

Removing the threaded stoppers

Remove the threaded stoppers at the inlet and outlet of the Metrosep A Trap 1 – 100/4.0.

2

Connecting the column's inlet

■ Screw the loose end of the PTFE capillary connected to port 3 of

the Dosino for the absorber solution in place on the inlet of the

trap column using a pressure screw (6.2744.010).

■■■■■■■■

51

Page 60

4.4 Dosino for the absorber solution

Insert the Metrosep A Trap 1 – 100/4.0 in the instrument as follows:

■■■■■■■■■■■■■■■■■■■■■■

3

Connecting the column's outlet

■ Screw the PTFE capillary (6.1803.030) with the yellow colored

sleeve (fed in from the right side of the instrument) in place on

the trap column's outlet using a pressure screw (6.2744.010).

Inserting the trap column in the instrument

Fasten the Metrosep A Trap 1 – 100/4.0 in place in the front holding

1

bracket (4-4) of the 920 Absorber Module using the column head.

Next step Connect the loose end of the PTFE capillary, 0.5 mm ID / 3 m

(6.1803.030) to the Combustion Module's outlet (see Chapter 4.10.2,

page 76).

4.4.6 Connecting the bottle with the absorber solution

The bottle with the absorber solution is connected to port 2 of Dosinos 1.

Accessories

For this step you need:

■ Clear glass bottle 2 L (6.1608.070) filled with the absorber solution

■ Bottle attachment (6.1602.160)

■ FEP tubing M6 for 920, 150 cm (6.1838.020) fastened to port 2 of the

Dosino for the absorber solution.

■ Adsorber tube (6.1609.000)

■ Cotton

■ Adsorber granulate

■■■■■■■■

52

920 Absorber Module

Page 61

■■■■■■■■■■■■■■■■■■■■■■

6.1609.000

6.1602.160

6.1608.070

6.1446.080

6.1838.020

6.2023.020

1

2

4 Installation

Connecting the bottle with the absorber solution

Cotton

1

Screw the bottle attachment onto the bottle.

1

Insert a sealing ring from the 6.1602.160 accessory set into the bot-

2

tle attachment's M6 opening.

Adsorber granulate

2

Put the loose end of the FEP tubing through the bottle attachment's

M6 opening and tighten it.

NOTE

The end of the aspiration tubing has to reach to the bottom of the

bottle.

920 Absorber Module

■■■■■■■■

53

Page 62

4.5 10-port valve

Fill the adsorber tube with a little cotton and adsorber granulate and

3

seal it with the plastic cover.

Place the adsorber tube into the large opening of the bottle attach-

4

ment and fasten it in place with the SGJ clip.

Seal the M8 opening with a stopper.

5

4.5 10-port valve

The 10-port valve can be connected after both Dosinos and the two trap

columns have been installed.

■■■■■■■■■■■■■■■■■■■■■■

■■■■■■■■

54

Figure 13

PEEK capillary, 0.5 mm ID / 15 cm

2

(6.1831.040)

Connection between the 6-port valve and

the 10-port valve.

Connecting the 10-port valve

PTFE capillary, 0.75 mm ID / 3 m

3

(6.1803.160)

Approx. 80 cm. Connection between the

10-port valve and the bottle with the standard solution.

920 Absorber Module

Page 63

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

PTFE capillary, 0.75 mm ID / 3 m

4

(6.1803.160)

Approx. 80 cm. Connection between the

10-port valve and the bottle with the check

standard.

PTFE capillary, 0.75 mm ID / 3 m

6

(6.1803.160)

Approx. 5 cm. For aspirating air segments.

4.5.1 Connecting the ports

The transfer tubing and capillaries for all of the liquids being used are connected to the 10-port valve.

Connectors

The ports of the 10-port valve are used as follows:

Port … … is used for … … is connected to

Central Aspirating and discharging differ-

1 Outlet for sample, standard solu-

5

7

ent solutions

tion, check standard

PTFE capillary, 0.75 mm ID / 3 m

(6.1803.160)

Approx. 60 cm. Connection between the

10-port valve and the absorber tube.

PTFE capillary, 0.75 mm ID / 3 m

(6.1803.160)

Connection between the 10-port valve and

the waste container.

Transfer tubing

6-port valve

2 Inlet for standard solution Bottle with standard solution

3 Inlet for check standard Bottle with check standard

4-7 Not used –

8 Inlet for sample Absorber tube

9 Aspirating air segments –

10 Outlet for waste Waste container

Accessories The following accessories have to be connected to the 10-port valve:

Port Install this accessory

Central ■ Adapter UNF 10/32 outer / M6 inner (6.2744.200)

■ Transfer tubing (6.1562.130)

1

2 ■ PTFE capillary, 0.75 mm ID / 3 m (6.1803.160), approx. 80 cm

3 ■ PTFE capillary, 0.75 mm ID / 3 m (6.1803.160), approx. 80 cm

■ PEEK capillary, 0.5 mm ID / 15 cm (6.1831.040) (13-2)

■ Pressure screw (6.2744.090)

(13-3)

■ Pressure screw (6.2744.090)

(13-4)

■ Pressure screw (6.2744.090)

920 Absorber Module

4-7 Threaded stopper (6.2744.220)

■■■■■■■■

55

Page 64

4.5 10-port valve

6.2744.090

6.1831.040

6.2744.090

6.1803.160

80 cm

6.1803.160

80 cm

6.2744.090

6.27440220

6.2744.220

6.2744.220

6.2744.220

6.2744.090

6.1803.160

60 cm

6.2744.090

6.1803.160

5 cm

6.2744.090

6.1803.160

3 m

6.2744.200

6.1462.130

1

2

3

4

5

6

7

8

9

10

■■■■■■■■■■■■■■■■■■■■■■

Port Install this accessory

8 ■ PTFE capillary, 0.75 mm ID / 3 m (6.1803.160), approx. 60 cm

(13-5)

■ Pressure screw (6.2744.090)

9 ■ PTFE capillary, 0.75 mm ID / 3 m (6.1803.160), approx. 5 cm

(13-6)

■ Pressure screw (6.2744.090)

10

■ PTFE capillary, 0.75 mm ID / 3 m (6.1803.160) (13-7)

■ Pressure screw (6.2744.090)

Connecting the 10-port valve

Connect the ports of the 10-port valve according to the following figure:

NOTE

We recommend connecting the central port first.

56

■■■■■■■■

Figure 14 Connecting the 10-port valve

1

Connecting the central port

■ Screw the adapter in place in the central port.

■ Screw one end of the transfer tubing in place on the adapter.

2

Connecting port 1

■ Screw the PEEK capillary to port 1 using a long pressure screw.

920 Absorber Module

Page 65

■■■■■■■■■■■■■■■■■■■■■■

3

Connecting port 2

■ Cut off a piece from the PTFE capillary, 0.75 mm ID / 3 m

(6.1803.160) that is approx. 80 cm long using the capillary cutter.

■ Screw this piece of capillary in place at port 2 using a long pres-

sure screw.

4

Connecting port 3

■ Cut off a piece from the PTFE capillary, 0.75 mm ID / 3 m

(6.1803.160) that is approx. 80 cm long using the capillary cutter.

■ Screw this piece of capillary in place at port 3 using a long pres-

sure screw.

5

Sealing ports 4 through 7

Ports 4 through 7 are not used.

■ Seal each of ports 4, 5, 6 and 7 with a threaded stopper.

6

Connecting port 8

■ Cut off a piece from the PTFE capillary, 0.75 mm ID / 3 m

(6.1803.160) that is approx. 60 cm long using the capillary cutter.

■ Screw this piece of capillary in place at port 8 using a long pres-

sure screw.

7

Connecting port 9

■ Cut off a piece from the PTFE capillary, 0.75 mm ID / 3 m

(6.1803.160) that is approx. 5 cm long using the capillary cutter.

■ Screw this piece of capillary in place at port 9 using a long pres-

sure screw.

8

Connecting port 10

■ Screw an entire PTFE capillary, 0.75 mm ID / 3 m (6.1803.160) in

place at port 10 using a long pressure screw.

4 Installation

Next step

920 Absorber Module

Connect

capillary/tubing at port

…

1 6-port valve (see Chapter 4.6, page 61)

2 Bottle with standard solution (see Chapter 4.5.2, page 58)

3 Bottle with check standard (see Chapter 4.5.3, page 59)

8 Absorber tube (see Chapter 4.7, page 67)

… to

■■■■■■■■

57

Page 66

4.5 10-port valve

6.1608.050

6.1602.150

6.1602.150

6.1803.160

■■■■■■■■■■■■■■■■■■■■■■

Connect

capillary/tubing at port

…

10 Waste container

… to

4.5.2 Connecting the bottle with the standard solution

The bottle with the standard solution is connected to the 10-port valve.

Accessories For this step you need:

■ Clear glass bottle 100 mL (6.1608.050) filled with standard solution

■ Bottle attachment (6.1602.150), contains 3 pressure screws

Connecting the bottle with the standard solution

■■■■■■■■

58

1

Connecting the aspirating capillary for the standard solution

■ Slide a pressure screw over the loose end of the capillary connec-

ted to port 2 of the 10-port valve (13-3).

■ Thread the capillary through one of the three openings on the

bottle attachment.

■ Screw the bottle attachment onto the bottle.

■ Push the capillary far enough into the bottle that it reaches the

bottom of the bottle. Then fix it in place with a pressure screw.

920 Absorber Module

Page 67

■■■■■■■■■■■■■■■■■■■■■■

4 Installation

Inserting the bottle with the standard solution into the

instrument

Insert the bottle with the standard solution into the bottle holder.

1

4.5.3 Connecting the bottle with the check standard

The bottle with the standard solution is connected to the 10-port valve.

Connecting the bottle with the check standard

Guide the loose end of the capillary (13-4) (connected to port 3 of

1

the 10-port valve) in through a capillary feed-through between the

device and the bottle holder on the side of the instrument.

Fasten the capillary in the bottle containing the check standard.

2

Place the bottle on the bottle holder.

920 Absorber Module

■■■■■■■■

59

Page 68

4.5 10-port valve

2

1

4.5.4 Function of the 10-port valve

The 10-port valve is used for sample preparation. For this, the central port

(15-2) can be connected to the other ten ports one after the other using

the selector (15-1).

The transfer tubing is connected to the central port. Liquids can be aspirated into the transfer tubing by one of the ten ports with the aid of a Dosino and then transported to any other port by reversing the flow.

■■■■■■■■■■■■■■■■■■■■■■

Figure 15 10-port valve – Ports

Selector

1

Can be rotated for selecting the active port.

The selector can rotate in a clockwise or counterclockwise direction. Normally, the shortest path is selected when switching over to a new port.

Secured ports

In order to avoid contamination, any given port can be defined as

"secured". The secured port is moved to during switching only if it is the

target of the switching procedure.

Central port

2

Connected to the transfer tubing.

Example:

■■■■■■■■

60

If the secured port lies along the shortest route during a valve switchover,

then the longer path will automatically be selected.

Switching from port 10 to port 7.

920 Absorber Module

Page 69

■■■■■■■■■■■■■■■■■■■■■■

X