Page 1

CH-9101 Herisau/Switzerland

Phone ++41 71 353 85 85

Fax ++41 71 353 89 01

Internet www.metrohm.ch

E-Mail info@metrohm.ch

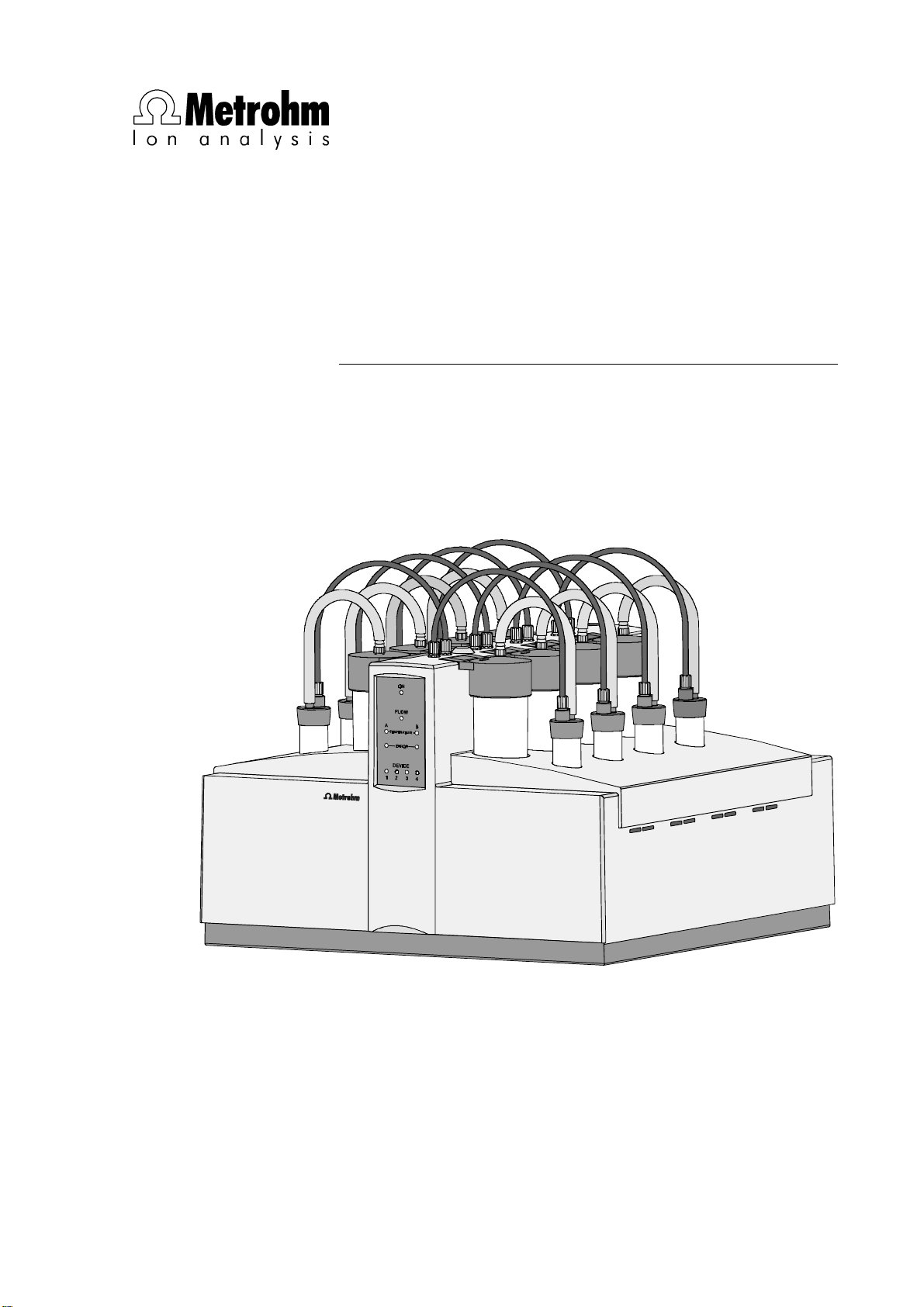

763 PVC Thermomat

with «763 PVC Thermomat 1.0» PC program

763 PVC Thermomat

8.763.1003 Instructions for Use

26.10.1999 / dö

Page 2

Contents

Table of contents

1 Introduction............................................................................................................1

1.1 Determination of thermal stability........................................................1

1.2 Instrument description.................................................................................2

1.3 Operating elements........................................................................................3

1.4 Information about these Instructions for Use................................6

1.4.1 Organization................................................................................................. 6

1.4.2 Notation and pictograms............................................................................ 7

1.5 Safety notes.........................................................................................................8

1.5.1 Electrical safety ........................................................................................... 8

1.5.2 General precautionary rules...................................................................... 8

2 Installation..............................................................................................................9

2.1 Setting up the instrument...........................................................................9

2.1.1 Packaging ..................................................................................................... 9

2.1.2 Check............................................................................................................. 9

2.1.3 Location ........................................................................................................ 9

2.2 Attaching the accessories.......................................................................10

2.2.1 Accessories for external gas supply...................................................... 10

2.2.2 Reaction and measuring vessels............................................................ 10

2.2.3 Exhaust collection tube (option)............................................................. 11

2.3 Mains connection..........................................................................................13

2.3.1 Checking the mains voltage....................................................................13

2.3.2 Exchange of fuses.....................................................................................13

2.3.3 Mains cable and mains connection........................................................ 14

2.3.4 Switching the instrument on/off ............................................................. 14

2.4 Connection to the PC..................................................................................15

2.4.1 Connection PVC Thermomat – PC.......................................................... 15

2.4.2 Software installation.................................................................................15

2.4.3 Basic settings............................................................................................. 16

3 Operating tutorial....................................................................................... 19

3.1 Determinations...............................................................................................19

3.1.1 Installation..................................................................................................19

3.1.2 Preparing for determinations .................................................................. 20

3.1.3 Carrying out determinations.................................................................... 22

3.2 Results .................................................................................................................24

3.2.1 Determination overview............................................................................ 24

3.2.2 Determination and method data ............................................................. 26

3.2.3 Graphics......................................................................................................28

763 PVC Thermomat I

Page 3

Contents

4 Operation...............................................................................................................31

4.1 Fundamentals of the operation............................................................ 31

4.1.1 Starting/closing the program.................................................................. 31

Start the «763 PVC Thermomat» program................................................31

Close the «763 PVC Thermomat» program..............................................31

4.1.2 Glossary...................................................................................................... 32

4.1.3 Control window ......................................................................................... 33

Open ........................................................................................................33

Arrangement.............................................................................................33

Menus ......................................................................................................33

Icons.........................................................................................................34

Close ........................................................................................................34

4.1.4 Results window ......................................................................................... 35

Open ........................................................................................................35

Arrangement.............................................................................................35

Menus ......................................................................................................35

Icons.........................................................................................................36

Close ........................................................................................................36

4.1.5 Overview of file types............................................................................... 37

4.1.6 Context-sensitive menus......................................................................... 37

4.1.7 Mouse functions........................................................................................ 37

4.1.8 Help.............................................................................................................. 37

4.2 Instrument and software settings...................................................... 38

4.2.1 Communication ......................................................................................... 38

4.2.2 User permissions...................................................................................... 39

Functions for groups................................................................................39

Functions for users ..................................................................................40

4.2.3 Timer............................................................................................................ 41

4.2.4 Gas flow control........................................................................................ 41

4.2.5 Recording temperature ............................................................................ 42

4.2.6 Options........................................................................................................ 43

Save settings............................................................................................43

Clear sample ID1 history..........................................................................43

4.3 Program information................................................................................... 44

4.3.1 Unit information......................................................................................... 44

4.3.2 Status overview......................................................................................... 45

4.3.3 Events overview ........................................................................................ 46

Event window ...........................................................................................46

Menus ......................................................................................................47

Icons.........................................................................................................47

Filter..........................................................................................................47

Parameter for event recording .................................................................47

763 PVC ThermomatII

Page 4

Contents

4.4 Calibration functions ..................................................................................48

4.4.1 Determination of cell constants.............................................................. 48

Manual entry of cell constants ................................................................ 48

Automatic determination of cell constants.............................................. 48

4.4.2 Determination of Delta T .......................................................................... 50

Preparations ............................................................................................ 50

Carrying out............................................................................................. 52

4.5 Methods...............................................................................................................54

4.5.1 Method handling........................................................................................ 54

Create method......................................................................................... 54

Open method .......................................................................................... 54

Method manager..................................................................................... 54

Save method ........................................................................................... 55

Print method report.................................................................................. 55

4.5.2 Method parameters ................................................................................... 55

Overview.................................................................................................. 55

Parameters .............................................................................................. 56

Evaluation ................................................................................................ 58

Induction time.......................................................................................... 59

Stability time ............................................................................................ 59

Curves ..................................................................................................... 60

Formulas.................................................................................................. 61

Standards ................................................................................................ 62

Documentation........................................................................................ 63

Description .............................................................................................. 64

4.6 Determinations............................................................................................... 65

4.6.1 Flow chart ................................................................................................... 65

4.6.2 Sample preparation................................................................................... 66

4.6.3 Prepare instruments and accessories................................................... 66

Clean instruments and accessories........................................................ 66

Prepare measuring vessels..................................................................... 67

Prepare reaction vessels......................................................................... 68

4.6.4 Carry out determinations......................................................................... 69

Select method ........................................................................................ 69

Switch on heating.................................................................................... 69

Enter sample identifiers........................................................................... 70

Insert reaction vessels............................................................................. 70

Start determination .................................................................................. 70

Live curve ................................................................................................ 71

Live parameters....................................................................................... 71

Stop determination .................................................................................. 72

4.7 Results..................................................................................................................73

4.7.1 Determination overview............................................................................ 73

Open determination overview ................................................................. 73

Format determination overview............................................................... 74

Mark determinations................................................................................ 78

Find determination .................................................................................. 78

Delete determinations ............................................................................. 79

Sort and filter determinations .................................................................. 80

763 PVC Thermomat III

Page 5

Contents

4.7.2 Determination and method data............................................................. 84

Open view ................................................................................................84

Determination...........................................................................................84

Results......................................................................................................85

Method .....................................................................................................86

Parameters...............................................................................................87

Evaluation.................................................................................................88

Formulas ..................................................................................................89

Standards.................................................................................................90

Curves ......................................................................................................90

Documentation.........................................................................................91

Warnings ..................................................................................................92

4.7.3 Graphics and reevaluation ...................................................................... 93

Single graph.............................................................................................93

Multiple graph ..........................................................................................93

Live graph.................................................................................................94

Switch zoom on/off ..................................................................................95

Switch autoscaling on/off.........................................................................95

Switch offset on/off...................................................................................95

Copy graph to clipboard..........................................................................95

Print graph................................................................................................95

Reevaluation.............................................................................................96

4.7.4 Extrapolation.............................................................................................. 99

Extrapolation window ...............................................................................99

Print extrapolation results.......................................................................100

Settings for extrapolation .......................................................................101

Parameters for extrapolation..................................................................101

4.7.5 Recalculation ........................................................................................... 102

Recalculation window ............................................................................102

Method ...................................................................................................102

Formulas ................................................................................................103

Standards...............................................................................................104

4.7.6 Data export and printing........................................................................ 106

Copy to clipboard ..................................................................................106

Export to other database........................................................................106

Export to Microsoft Word .......................................................................106

Export to Microsoft Excel .......................................................................106

Export of measured values ....................................................................107

Export of determination and method data.............................................107

Printing of results in the control window ................................................108

Printing of data in the results window ....................................................109

4.7.7 Options...................................................................................................... 110

Program settings....................................................................................110

Report settings.......................................................................................110

Company settings..................................................................................111

Results....................................................................................................112

Scaling....................................................................................................112

Extrapolation ..........................................................................................113

Live graph...............................................................................................114

Options for the administrator .................................................................114

Save settings..........................................................................................115

4.7.8 Windows................................................................................................... 115

Tile windows vertically............................................................................115

Tile windows horizontally........................................................................115

Cascade windows..................................................................................115

Arrange icons.........................................................................................115

Close all windows ..................................................................................115

763 PVC ThermomatIV

Page 6

Contents

4.8 GLP ...................................................................................................................... 116

4.8.1 General information about GLP and validation.................................. 116

4.8.2 GLP properties.........................................................................................117

4.8.3 GLP status................................................................................................117

4.8.4 GLP tests...................................................................................................118

GLP temperature test ............................................................................ 118

GLP conductivity test............................................................................. 123

GLP gas flow test .................................................................................. 126

4.8.5 GLP results............................................................................................... 128

Print GLP certificate............................................................................... 128

View GLP results.................................................................................... 128

Print GLP results.................................................................................... 130

5 Maintenance – Faults..........................................................................131

5.1 Maintenance and service......................................................................131

5.1.1 Care............................................................................................................131

5.1.2 Maintenance by Metrohm service.........................................................131

5.2 Faults and malfunctions........................................................................ 132

5.2.1 Error messages in the PC program...................................................... 132

5.2.2 Status and error messages on the instrument................................... 132

6 Appendix .............................................................................................................135

6.1 Technical data ............................................................................................. 135

6.1.1 General information................................................................................135

6.1.2 Temperature regulation and measurement......................................... 135

6.1.3 Conductivity measurement.................................................................... 136

6.1.4 Gas flow regulation................................................................................. 136

6.1.5 GLP test set.............................................................................................. 136

6.1.6 RS232 interface........................................................................................136

6.1.7 Mains connection....................................................................................137

6.1.8 Safety specifications............................................................................... 137

6.1.9 Electromagnetic compatibility (EMC) .................................................. 137

6.1.10 Ambient temperature.............................................................................. 138

6.1.11 Housing..................................................................................................... 138

6.2 Standard equipment................................................................................. 139

6.3 Optional accessories............................................................................... 142

6.4 Warranty and conformity....................................................................... 143

6.4.1 Warranty....................................................................................................143

6.4.2 Software license ...................................................................................... 143

6.4.3 EU Declaration of conformity................................................................ 144

6.4.4 Certificate of conformity and system validation................................ 145

6.5 Index...................................................................................................................146

763 PVC Thermomat V

Page 7

Contents

List of figures

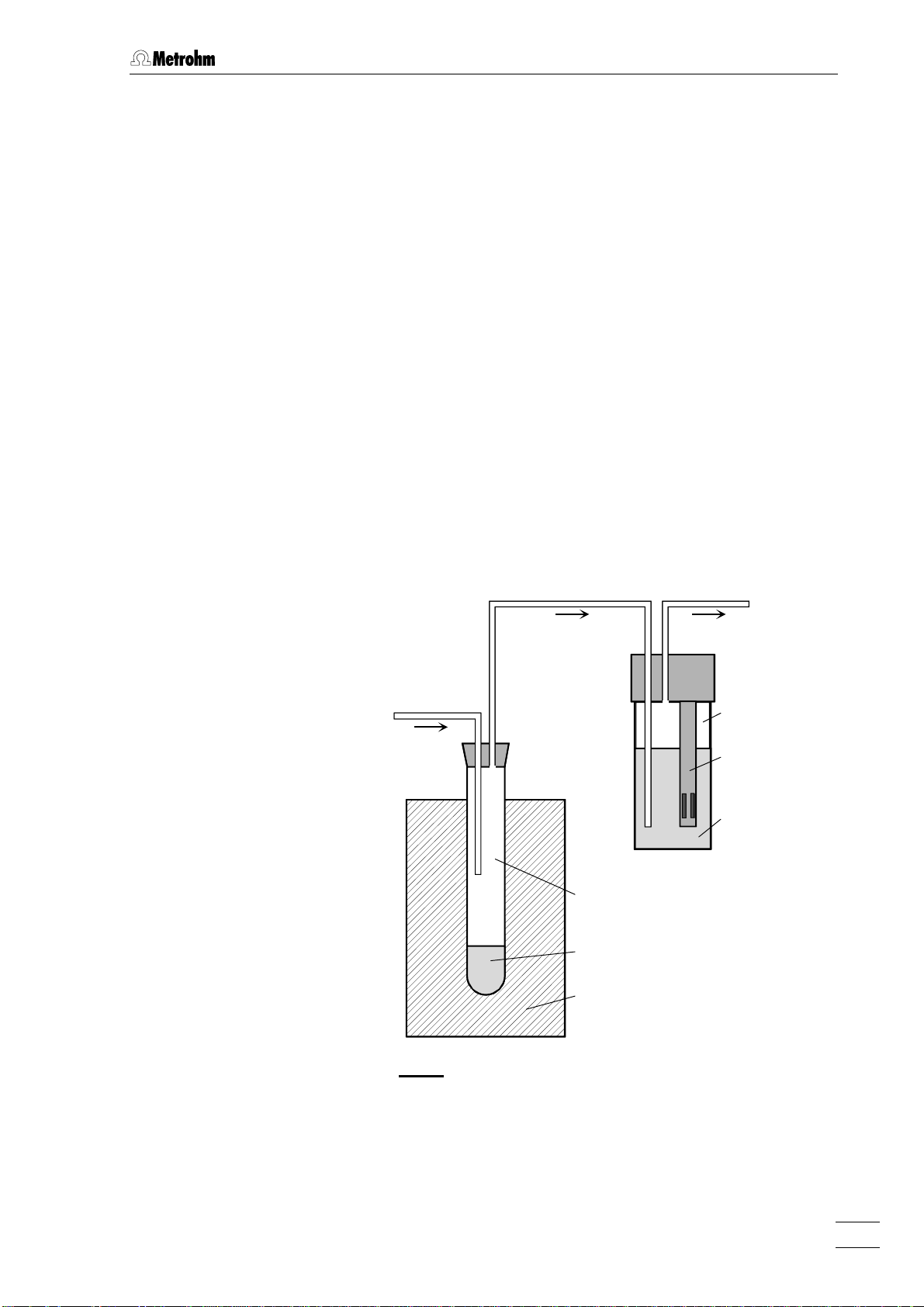

Fig. 1: Schematic measuring arrangement ............................................................... 1

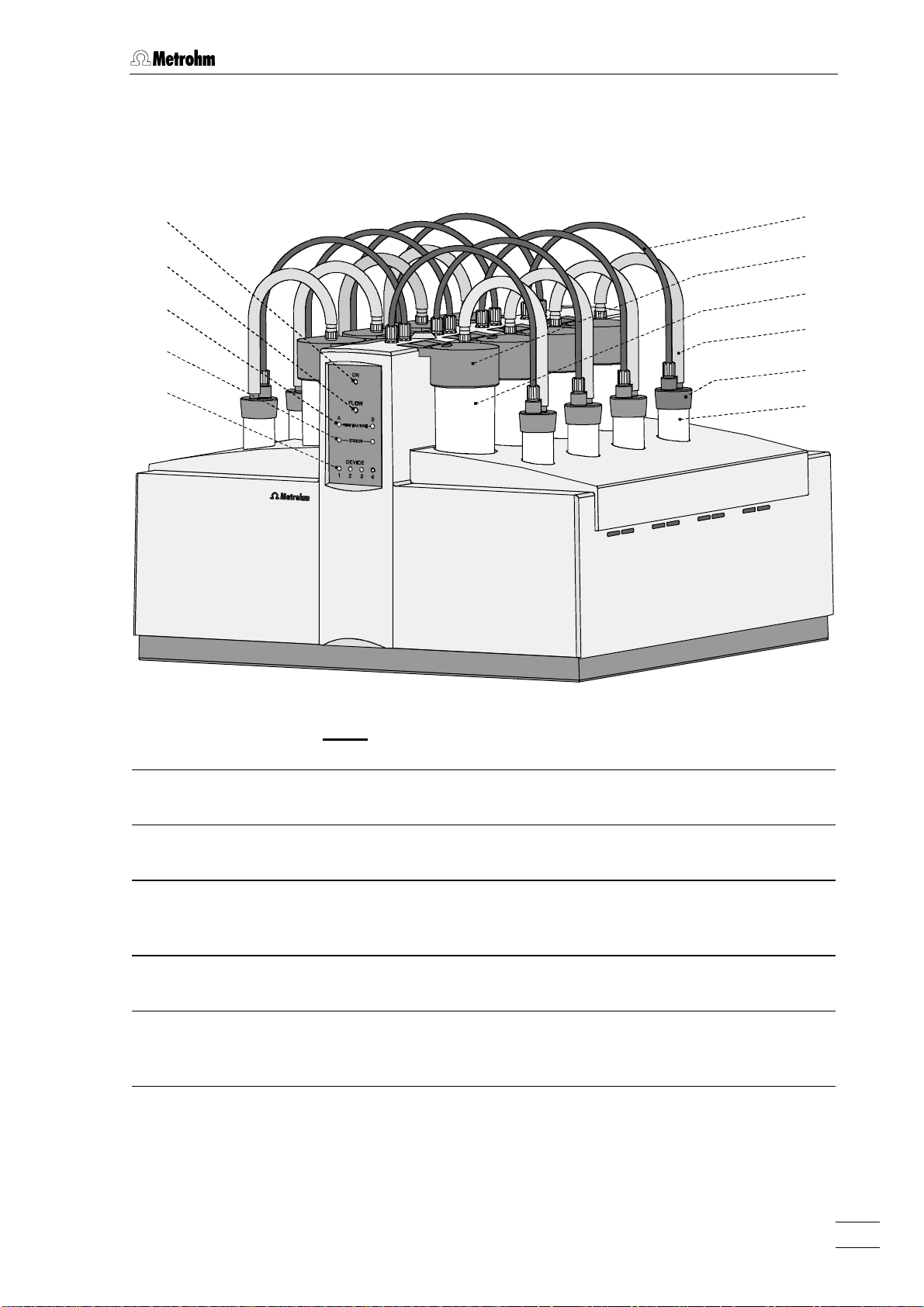

Fig. 2: Front of the 763 PVC Thermomat ................................................................... 3

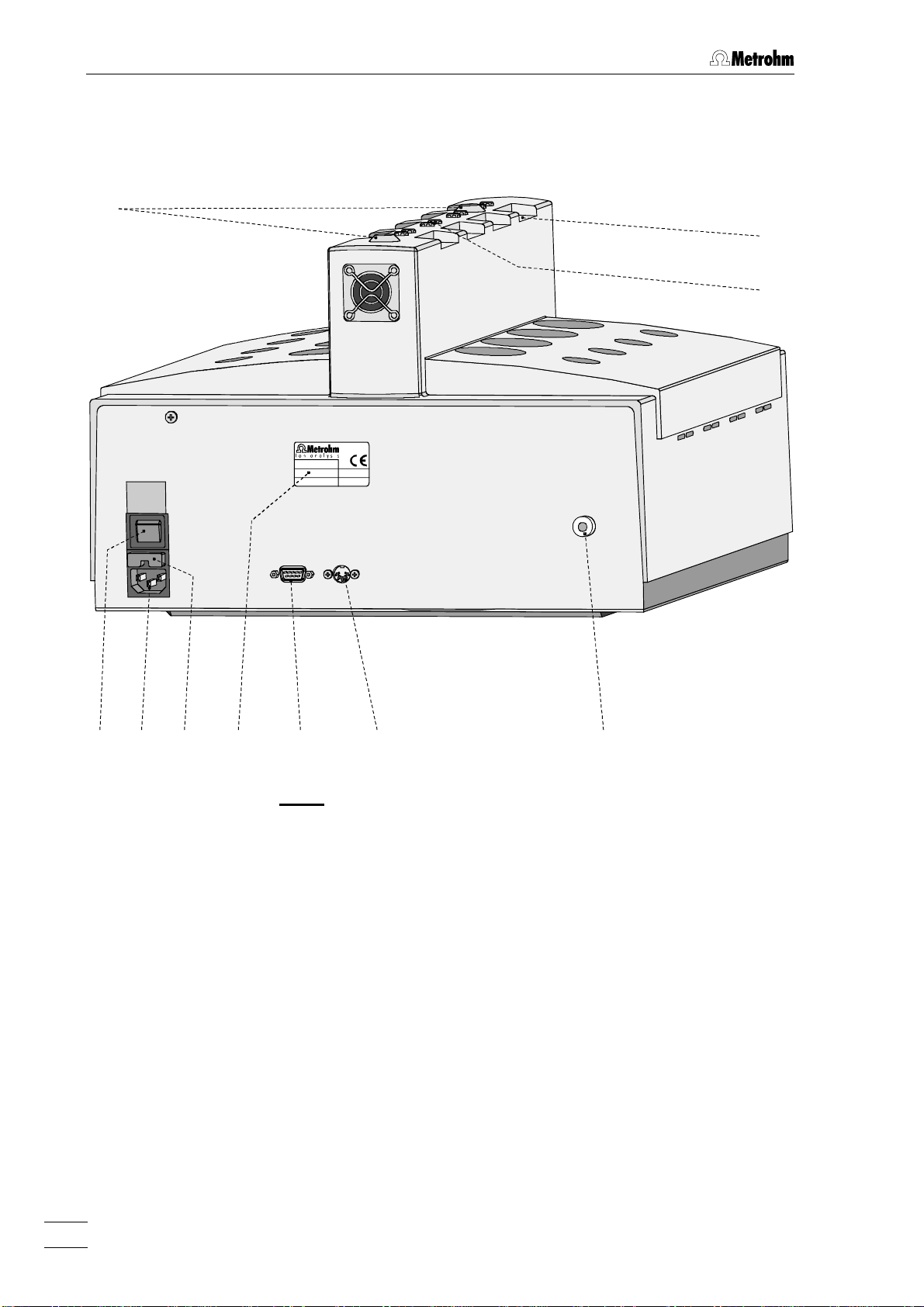

Fig. 3: Rear of the 763 PVC Thermomat.................................................................... 4

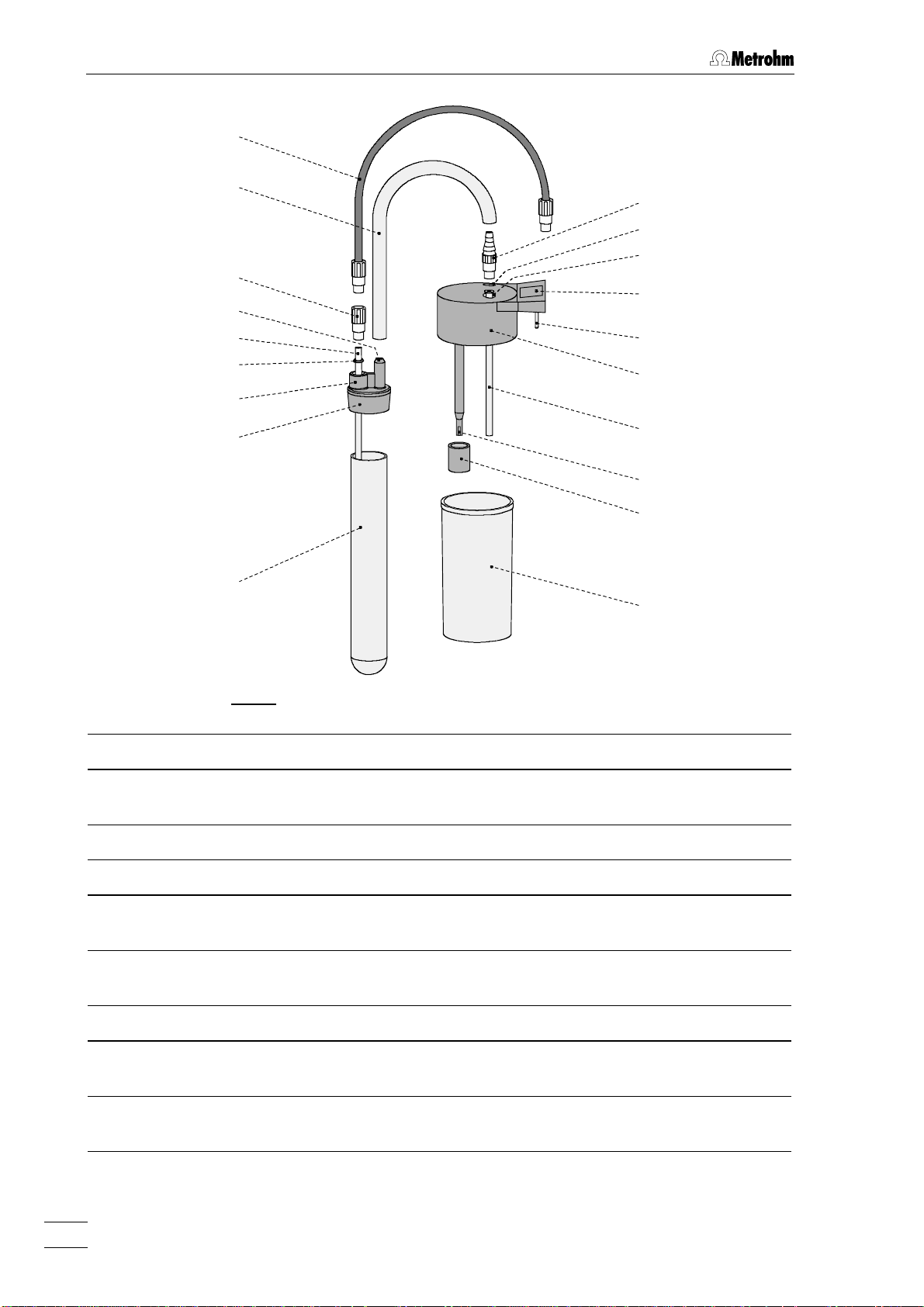

Fig. 4: Installation of reaction and measuring vessels ............................................ 12

Fig. 5: Accessories for Delta-T determination ......................................................... 51

Fig. 6: Accessories for GLP temperature test........................................................ 121

Fig. 7: Indicator lamps ........................................................................................... 132

List of numbered parts and controls

11 Reaction vessel............................. 3,12,51

22 Reaction vessel cover................... 3,12,51

33 Connecting tubing ............................. 3,13

44 Measuring vessel............................... 3,13

55 Measuring vessel cover.....................3,13

66 Connecting tubing ....................... 3,12,51

77 Mains pilot lamp ..............................3,132

88 Gas flow display .............................3,132

99 Temperature display........................ 3,132

1010 Error display.....................................3,132

1111 Instrument display ...........................3,132

1212 Mains switch........................................... 5

1313 Mains connection plug ........................... 5

1414 Fuse holder.............................................5

1515 Model plate............................................. 5

1616 PC connection ........................................5

1717 Pt100 connection....................................5

1818 Connection "N2 in"................................... 5

2222 Connection piece..................................12

2323 Opening "Out" .......................................12

2424 Opening "In" ..........................................12

2525 Marking field..........................................12

2626 Connection plug....................................12

2727 PTFE tube..............................................12

2828 Electrodes .............................................12

2929 Protective ring .......................................12

3030 Connection nipple............................12,51

3131 Connection.......................................12,51

3232 Gas inlet tube (short) ............................12

3333 Sealing ring ......................................12,51

3434 Connection.......................................12,51

3535 Gas inlet tube (long)..............................51

3636 Temperature sensor Pt100.............51,121

3737 Distance piece ...............................51,121

3838 PTFE cylinder ......................................121

3939 Hexagonal screw.................................121

1919 Gas supply connection........................... 5

2020 Electrode connection.............................. 5

2121 Mounting for exhaust collection tube .....5

4040 Allen key..............................................121

4141 Aluminium cylinder..............................121

763 PVC ThermomatVI

Page 8

1.1 Determination of thermal stability

1 Introduction

1.1 Determination of thermal stability

The determination of the thermal stability of polyvinyl chloride according

to DIN 53 381, part 1, is based on the fact that PVC decomposes at

higher temperatures with the release of HCl. The hydrochloric acid

formed is taken up by a gas stream (normally N2) and transferred into

the measuring vessel where it is absorbed in the measuring solution

(dist. water). The decomposition process is monitored by measuring

the conductivity of the aqueous HCl solution. Both the stability time and

the induction time are determined. The stability time is defined as the

time required to achieve a conductivity difference of 50 µS/cm. The in-

duction time is the time that elapses before the conductivity starts to

rise sharply. The method is used for testing PVC in all stages of processing as well as for testing stabilizers.

N

2

Reaction vessel

PVC

Heating block

Fig. 1: Schematic measuring arrangement

Measuring

vessel

Conductivity

measuring cell

Measuring

solution

763 PVC Thermomat 1

Page 9

1 Introduction

1.2 Instrument description

The 763 PVC Thermomat is a PC-controlled instrument for determining the thermal stability of PVC and similar halogenated plastics and is

available in the following two versions:

• 2.763.0014 PVC Thermomat for 230 V, 50……60 Hz

• 2.763.0015 PVC Thermomat for 115 V, 50……60 Hz

The 763 PVC Thermomat is equipped with two heating blocks each

with 4 measuring positions. Each block can be individually heated, i.e.

2 sets of 4 samples can be measured at two different temperatures or 8

samples can be measured at the same temperature. Measurements at

the individual measuring positions can be started individually.

The complete operation of the 763 PVC Thermomat is carried out via a

PC connected to the RS232 interface with the aid of the «763 PVC

Thermomat» control and evaluation program. Up to 4 instruments can

be connected to 1 PC allowing a maximum of 32 samples to be analyzed at the same time. The evaluation algorithm of the PC program

determines the point of inflection of the Thermomat curve and therefore

the induction time fully automatically. Apart from the induction time,

the so-called stability time, i.e. the time taken until a certain alteration

in the conductivity is reached, can also be determined. The results obtained can be subjected to further mathematical processes. In particular, induction times can be converted to the standard temperatures

contained in the relevant standards.

Each Thermomat curve can also be evaluated manually. A PC-supported tangent method is available for this in which the tangents can be

applied to the curve as required. This means that evaluations are possible even in extreme cases.

The results of the determinations are stored in a database together

with all the data concerning the method and determination. In the results display part of the program determinations can be searched for,

sorted, filtered, exported and printed out. Apart from the graphical display of single and multiple curves it is also possible to carry out recalculations with altered parameters and to extrapolate the results to a

particular temperature.

GLP (Good Laboratory Practice) and instrument validation are continuously increasing in importance. In the 763 PVC Thermomat GLP tests

are provided for the measurement of temperature, conductivity and gas

flow. They determine whether and which tests are to be carried out. The

time interval between the tests and the required accuracy can also be

laid down as required. If the GLP function is selected then on each result report a remark will be made as to whether the GLP test requirements have been fulfilled. As an option Metrohm offers a GLP test set

(6.5616.000), with which the most important tests can be carried out.

763 PVC Thermomat2

Page 10

1.3 Operating elements

1.3 Operating elements

77

88

99

1010

1111

763 PVC Thermomat

66

55

44

33

22

11

Fig. 2: Front of the 763 PVC Thermomat

11 Reaction vessel (6.1429.040) 77 Mains pilot lamp

lit up when instrument switched on

22 Reaction vessel cover (6.2753.100) 88 Gas flow display

lit up when gas flow switched on

33 Connecting tubing (6.1816.010)

between reaction vessel and measuring

vessel

44 Measuring vessel (6.1428.100) 1010 Error display (red)

55 Measuring vessel cover (6.0913.130)

with built-in conductivity measuring cell

66 Connecting tubing (6.1805.080)

for gas supply into reaction vessel

99 Temperature display

flashes when heating switched on

lit up when temperature reached

lit up at error

1111 Instrument display

indicates numbers (1…4) of units

connected

763 PVC Thermomat 3

Page 11

1 Introduction

2121

Made by Metrohm Herisau Switzerland

2020

1919

Type:

Nr.:

f:

U:

S:

N in

Fuse

100-115V: 4A(TH)

220-240V: 2A(TH)

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

RS 232

Pt 100

1212 1313 1414 1515 1616 1717 1818

Fig. 3: Rear of the 763 PVC Thermomat

2

763 PVC Thermomat4

Page 12

1212 Mains switch

to switch instrument on and off:

I = ON 0 = OFF

1313 Mains connection plug

mains connection, see section 2.3

1414 Fuse holder

changing the fuses, see section 2.3

1515 Model plate

indicating mains voltage and serial

number

1616 PC connection

RS232 interface

1.3 Operating elements

1717 Pt100 connection

Connection for external temperature

sensor

1818 Connection "N2 in"

1919 Gas supply connection

for connection tubing 66

2020 Electrode connection

for measuring vessel cover 55

2121 Mounting

for 6.2757.000 Exhaust collection tube

(option)

763 PVC Thermomat 5

Page 13

1 Introduction

1.4 Information about these Instructions for Use

Please read through these Instructions for Use carefully before you put

the 763 PVC Thermomat into operation. The Instructions for Use

contain information and warnings to which the user must pay attention

in order to assure safe operation of the instrument.

1.4.1 Organization

These 8.763.1003 Instructions for Use for the 763 PVC Thermomat

provide a comprehensive overview of the installation, startup procedure, operation, fault rectification and technical specifications of this instrument. The Instructions for Use are organized as follows:

Section 1 Introduction

Measuring method, description of instrument,

operating elements and safety notes

Section 2 Installation

Installation of accessories, mains connection,

connection to PC

Section 3 Operating tutorial

Introduction to the operation using an example

Section 4 Operation

Detailed description of the operation

Section 5 Maintenance – Faults

Maintenance, fault display and fault rectification

Section 6 Appendix

Technical data, standard equipment, options, warranty, declarations of conformity, index

To find the required information on the instruments, you will find it an

advantage to use either the Table of contents or the Index at the

back.

You will find additional information on the PVC Thermomat method in

the relevant "Application Bulletins", which are available on request

free of charge from your Metrohm agency, as well as in the

"Application Notes" concerning the PVC Thermomat method, which

can be downloaded from the Internet under «www.metrohm.ch».

763 PVC Thermomat6

Page 14

1.4.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

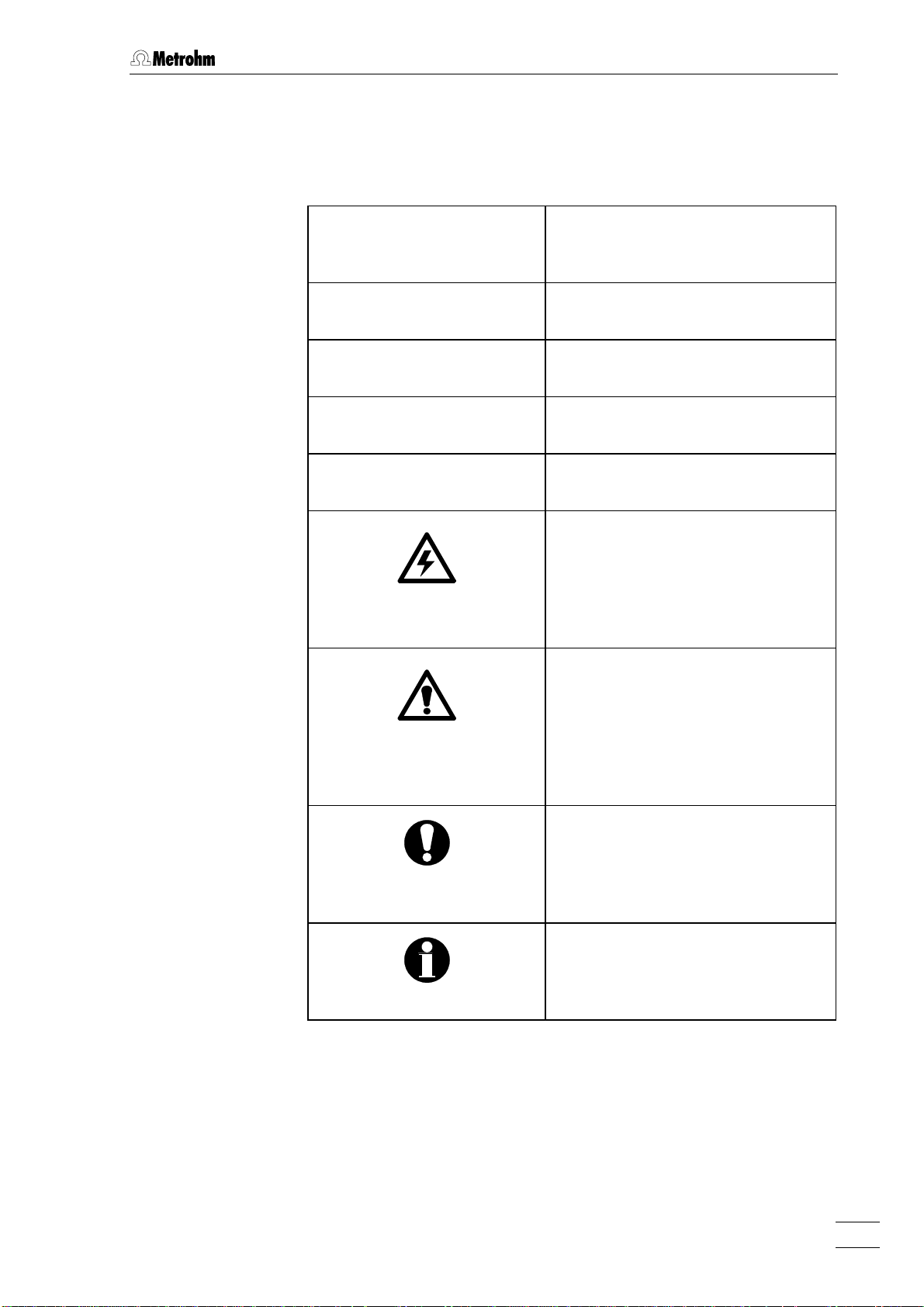

Range Menu item, parameter or

763 PVC THERMOMAT RESULTS Program window

<OK> Button

[ Ctrl ] Key

3535 Operating element of 763

1.4 Information about these Instructions for Use

entry value

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly.

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important information. First read the associated

directions before you continue.

Comment

This symbol marks additional information and tips.

763 PVC Thermomat 7

Page 15

1 Introduction

1.5 Safety notes

1.5.1 Electrical safety

While electrical safety in the handling of the 763 PVC Thermomat is assured in the context of the specifications IEC 1010-1 (protection class 1,

degree of protection IP20), the following points should be noted:

• Mains connection

Setting of the mains voltage, checking the mains fuse and the

mains connection must be effected in accordance with the instruc-

tions in section 2.3.

• Opening the 763 PVC Thermomat

If the 763 PVC Thermomat is connected to the power supply, the

instrument must not be opened nor must parts be removed from it,

otherwise there is a danger of coming into contact with components

which are live. Hence, always disconnect the instrument from all

voltage sources before you open it and ensure that the mains cable

is disconnected from mains connection 1313 !

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 763 PVC Thermomat, you should earth yourself and any

tools you are using by touching an earthed object (e.g. housing of the

instrument or a radiator) to eliminate any static charges which exist.

1.5.2 General precautionary rules

• Take care with hot reaction vessels

Avoid any contact with hot reaction vessels. Place them in the supplied vessel holder to cool them down.

763 PVC Thermomat8

Page 16

2 Installation

2.1 Setting up the instrument

2.1.1 Packaging

The 763 PVC Thermomat is supplied together with the separately

packed accessories in special packaging containing shock-absorbing

foam linings designed to provide excellent protection. The instrument

itself is packed in an evacuated polyethylene bag to prevent the ingress

of dust. Please store all these special packaging as only they assure

transport of the instrument free from damage.

2.1.2 Check

2.1 Setting up the instrument

2.1.3 Location

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 6.2). In the case of transport damage, see

instructions in section 6.4.1 "Warranty".

Position the instrument in the laboratory at a location convenient for operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals. It is advisable to set up the instrument in a fume cupboard to guard against odor emission, but the

PC can be positioned outside on the regular laboratory bench.

In order to improve accessibility to the measuring places the instrument can also be placed on the 6.2059.000 Rotation ring, which is

available as an option.

763 PVC Thermomat 9

Page 17

2 Installation

2.2 Attaching the accessories

2.2.1 Accessories for external gas supply

Nitrogen (N2) is required for external gas supply to the 763 PVC Thermomat. The following accessories must be mounted on the rear panel

of the PVC Thermomat:

1 Fitting the connecting tubing

• Screw one end of connecting tubing 6.1805.030 (150 cm)

onto connection 1818 "N2 in" on the rear panel of the PVC

Thermomat (see Fig. 3).

• Screw the 6.1808.020 connection piece onto the other end of

connecting tubing 6.1805.030.

2 Connect up gas supply

• Attach the gas supply from the cylinder containing nitrogen to

the tubing nozzle of 6.1808.020 Connection piece.

• Set gas pressure at the nitrogen cylinder to ca. 1.5 bar using

the reducing valve.

2.2.2 Reaction and measuring vessels

Fig. 4 shows the details of how the accessories for measuring the thermal stability are to be attached and connected to each other. Proceed

as follows:

1 Fitting the measuring vessel cover

• Insert PTFE tube 2727 from above into opening 2424 "In" of

measuring vessel cover 55.

• Screw connection piece 2222 into opening 24 24 of measuring

vessel cover 55.

2 Inserting the measuring vessel in the instrument

• Fill 60 mL dist. water into measuring vessel 44.

• Place measuring vessel cover 55 on measuring vessel 44.

• Insert measuring vessel 44 with attached measuring vessel

cover 55 into the opening provided for it on the 763 PVC

Thermomat and connect measuring vessel cover 55 with con-

nection plug 2626 to electrode connection 2020 (see Fig. 3).

3 Fitting the reaction vessel

• Insert gas inlet tube 3232 from below into connection 3434 of

reaction vessel cover 22.

• Push sealing ring 3333 over the upper end of gas inlet tube 3232.

• Screw connection nipple 3030 loosely into connection 3434 and

press gas inlet tube 3232 against connection nipple 3030 from

below; then fix gas inlet tube 3232 to reaction vessel cover 22 by

firmly tightening connection nipple 3030.

763 PVC Thermomat10

Page 18

2.2 Attaching the accessories

• Place reaction vessel cover 22 on reaction vessel 11.

• Connect the white connecting tubing 33 to connection 3131 of

reaction vessel cover 22 (see Fig. 3).

4 Inserting the reaction vessel into the instrument

• Place the sample in the reaction vessel (see section 4.6.2).

• When the required temperature has been reached insert

reaction vessel 11 with attached reaction vessel cover 22 in the

openings provided for it on the 763 PVC Thermomat.

5 Making the tubing connections

• Connect the white connecting tubing 3 3 attached to reaction

vessel cover 22 to connection piece 2222 of measuring vessel

cover 55.

• Screw one end of brown connecting tubing 66 to connection

nipple 3030 of reaction vessel cover 22.

• Screw the other end of brown connecting tubing 66 to the

corresponding connection 1919 on the 763 PVC Thermomat

(see Fig. 3).

The 6.1428.020 transparent glass measuring vessel

available as an option can be used instead of the

6.1428.100 polycarbonate measuring vessel; in

contrast to the polycarbonate vessel this can be

cleaned with acetone.

2.2.3 Exhaust collection tube (option)

For selective exhaust lead off the 6.2757.000 Exhaust collection

tube available as an option can be fitted to the 763 PVC Thermomat. In

addition to the exhaust collection tube 8 x 6.1816.010 Silicone tubing

(22 cm) must also be ordered. Attach the exhaust collection tube as

described below:

1 Positioning the exhaust collection tube

• Place the exhaust collection tube with the two supports in the

two mountings 2121 (see Fig. 3) on the 763 PVC Thermomat so

that the connection for leading off the exhaust is located to

the rear.

2 Connecting the measuring vessel

• Screw a connection piece 2222 into opening 2323 of the measur-

ing vessel cover 55.

763 PVC Thermomat 11

Page 19

2 Installation

66

3030

3131

3232

3333

3434

33

2222

2323

2424

2525

2626

55

22

2727

2828

2929

11

44

Fig. 4: Installation of reaction and measuring vessels

11 Reaction vessel (6.1429.040) 2626 Connection plug

22 Reaction vessel cover (6.2753.100) 2727 PTFE tube (6.1819.080)

for air supply into measuring vessel

33 Connecting tubing (6.1816.010) 2828 Electrodes

44 Measuring vessel (6.1428.100) 2929 Protective ring (4.422.0520)

55 Measuring vessel cover (6.0913.130)

with built-in conductivity measuring cell

66 Connecting tubing (6.1805.080)

for gas supply to reaction vessel

2222 Connection piece (6.1808.050) 3232 Gas inlet tube (6.2418.110)

2323 Opening "Out"

for measuring vessel exhaust

2424 Opening "In"

for measuring vessel inlet

3030 Connection nipple (6.1808.090)

3131 Connection

for connecting tubing 33

3333 Sealing ring (6.1454.040)

3434 Connection

for connection nipple 3030

2525 Marking field

for entering the cell constant

763 PVC Thermomat12

Page 20

• Connect one end of the 6.1816.010 Silicone tubing to connection piece 2222.

• Plug the other end of the 6.1816.010 Silicone tubing into the

corresponding exhaust collection tube opening.

• Close the unused openings on the exhaust collection tube

with the included E.400.0010 stoppers.

3 Connecting the exhaust collection tube

• Attach a piece of suitable tubing to the exhaust collection

tube connection and connect it to an active aspirating device

(e.g. water-jet pump).

2.3 Mains connection

2.3 Mains connection

Follow the instructions below for connecting to the power supply. If

the instrument is operated with a mains voltage set wrongly and/or

wrong mains fuse, there is a danger of fire!

2.3.1 Checking the mains voltage

Before switching on the 763 PVC Thermomat for the first time, check

that the mains voltage indicated on the model plate 1515 (see Fig. 3)

matches the local mains voltage. If this is not the case, call the

Metrohm service.

2.3.2 Exchange of fuses

Two fuses 4 A/slow-blow for 115 V or 2 A/slow-blow for 230 V are installed in fuse holder 1414 of the 763 PVC Thermomat as standard.

Ensure that the instrument is never put into operation with fuses of

another type, otherwise there is danger of fire!

For changing fuses, proceed as follows:

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 1313 of the

763 PVC Thermomat.

2 Remove fuse holder

Using a screwdriver, loosen fuse holder 1414 above the mains

connection plug 1313 and take out completely.

763 PVC Thermomat 13

Page 21

2 Installation

3 Change fuses

Remove old fuses carefully from fuse holder 1414 and replace

them with two new fuses which are suitable for the set mains

voltage, type TH (slow-blow, with high switching capacity):

115 V 4 A (TH) Metrohm-No. U.600.0022

230 V 2 A (TH) Metrohm-No. U.600.0107

4 Install fuse holder

Push fuse holder 1414 back into the instrument until it clicks into

position.

2.3.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a

different plug has to be fitted, the yellow/green lead (IEC standard)

must be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into mains connection plug 1313 of the 763 PVC

Thermomat (see Fig. 3).

2.3.4 Switching the instrument on/off

The 763 PVC Thermomat is switched on and off using mains switch 1212.

When the instrument is switched on, the mains pilot lamp 77 "ON" (see

Fig. 2) lights up.

763 PVC Thermomat14

Page 22

2.4 Connection to the PC

2.4.1 Connection PVC Thermomat – PC

Always switch off 763 PVC Thermomat and PC before you connect the

two instruments with the 6.2134.100 Cable.

The PC program «763 PVC Thermomat» allows a maximum of 4 PVC

Thermomats to be controlled. The following possibilities exist for connecting these PVC Thermomats to serial PC interfaces:

• Connection to built-in COM interfaces on the PC

• Connection to an additional built-in interface extension board

• Connection to a softswitch (order number: 2.145.0014 for 230 V,

2.145.0015 for 115 V) which is connected to one of the COM interfaces.

Connect the PC connection 1616 at the 763 PVC Thermomat to one of the

serial COM ports at the PC or to a softswitch using the 6.2134.100 Cable (9 pin/9 pin). If only a 25-pin COM interface is available on the PC

then the 6.2125.110 Adapter cable or a commercially available adapter

must be used.

2.4 Connection to the PC

2.4.2 Software installation

The PC program «763 PVC Thermomat 1.0» is required for the operation of the 763 PVC Thermomat; this is contained on the 6.6037.000

CD included in the accessories. This program runs under Windows NT

(recommended, especially if several instruments are connected), Windows 95 and Windows 98 operating systems and is installed as follows:

1 Install program

• For Windows NT: log in as operator with administrator rights.

• Insert 6.6037.000 Installation CD into CD drive.

• Select <Start> and Run. Browse for the setup.exe file on the

installation CD and click on <OK>.

• Click on "763" and follow the instructions given in the setup

program.

The software package will be installed in the desired directory. In addition to the program files, the following folders are

installed:

Database Folder for database files (*.mrd)

Log Folder for event log files (*.mel) and temperature

Template Folder with empty database (Default.mrd) and

recording files (*.txt)

copy of the result program (Nachaus.prg)

2 Registration

• Please send us your 8.763.8007 Registration card as soon as

possible.

763 PVC Thermomat 15

Page 23

2 Installation

2.4.3 Basic settings

When the program is started for the first time several basic settings

must be made for the 763 PVC Thermomat. Proceed as follows:

1 Switch on instruments

2 Start program and login

• Check if the PVC Thermomat has been connected correctly to

the PC (see section 2.4.1).

• Switch on the PVC Thermomat using mains switch 1212.

• Switch on the PC.

• Double-click the software icon to start the program. The

program window with the opening picture is opened and the

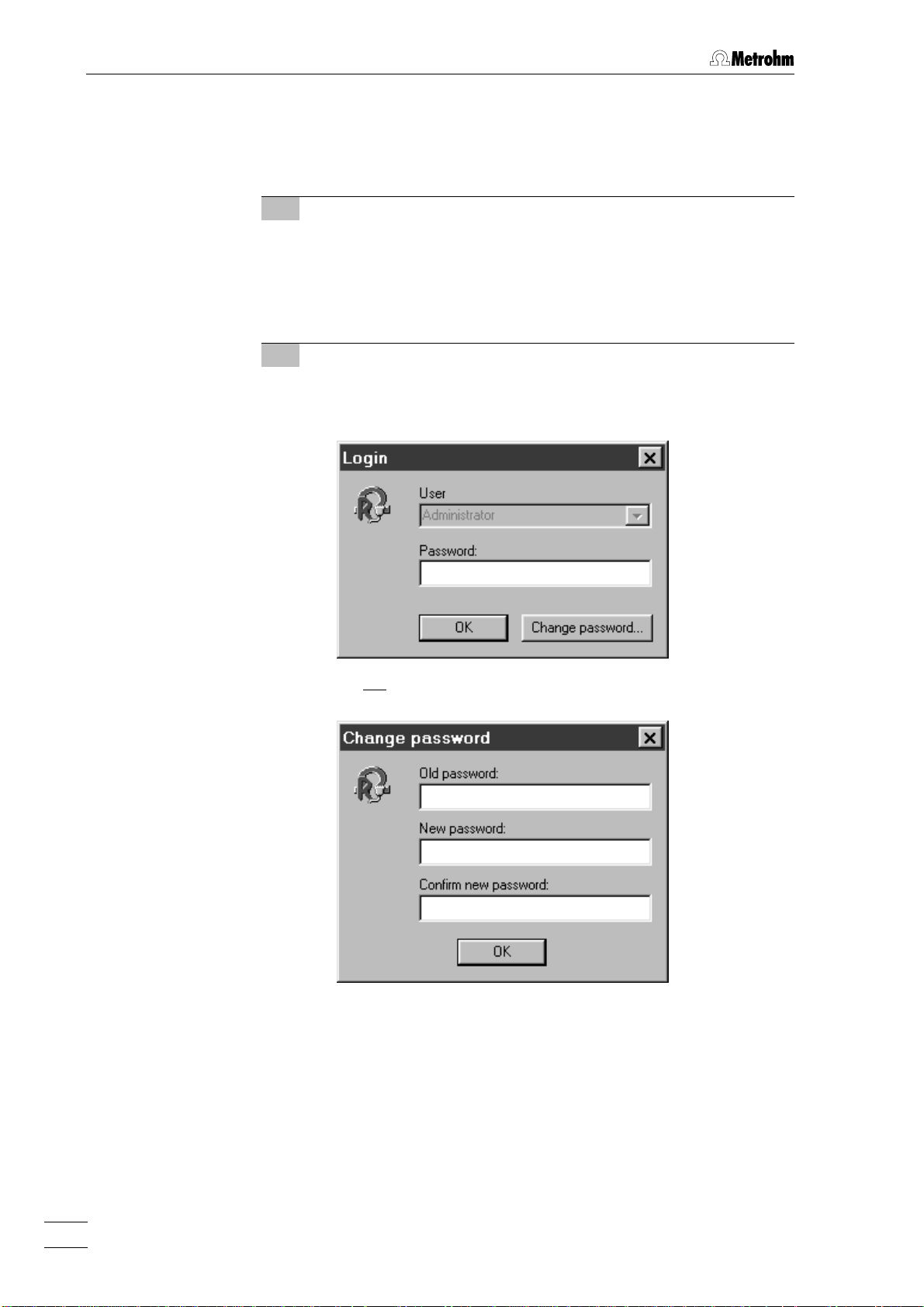

Login window appears on the screen:

• Do not enter any password here, just click on <Change pass-

word>. The following window appears:

• Leave the Old password field empty. Under New password enter

the required password which will in future allow you to log in

as Administrator. Confirm the new password by renewed entry

in the Confirm new password field and click on <OK>.

• Enter the new Password again in the Login window. You are

now logged in as Administrator.

• Confirm the message There are no units configured yet with

<OK>. The 763 PVC THERMOMAT CONTROL window appears.

763 PVC Thermomat16

Page 24

2.4 Connection to the PC

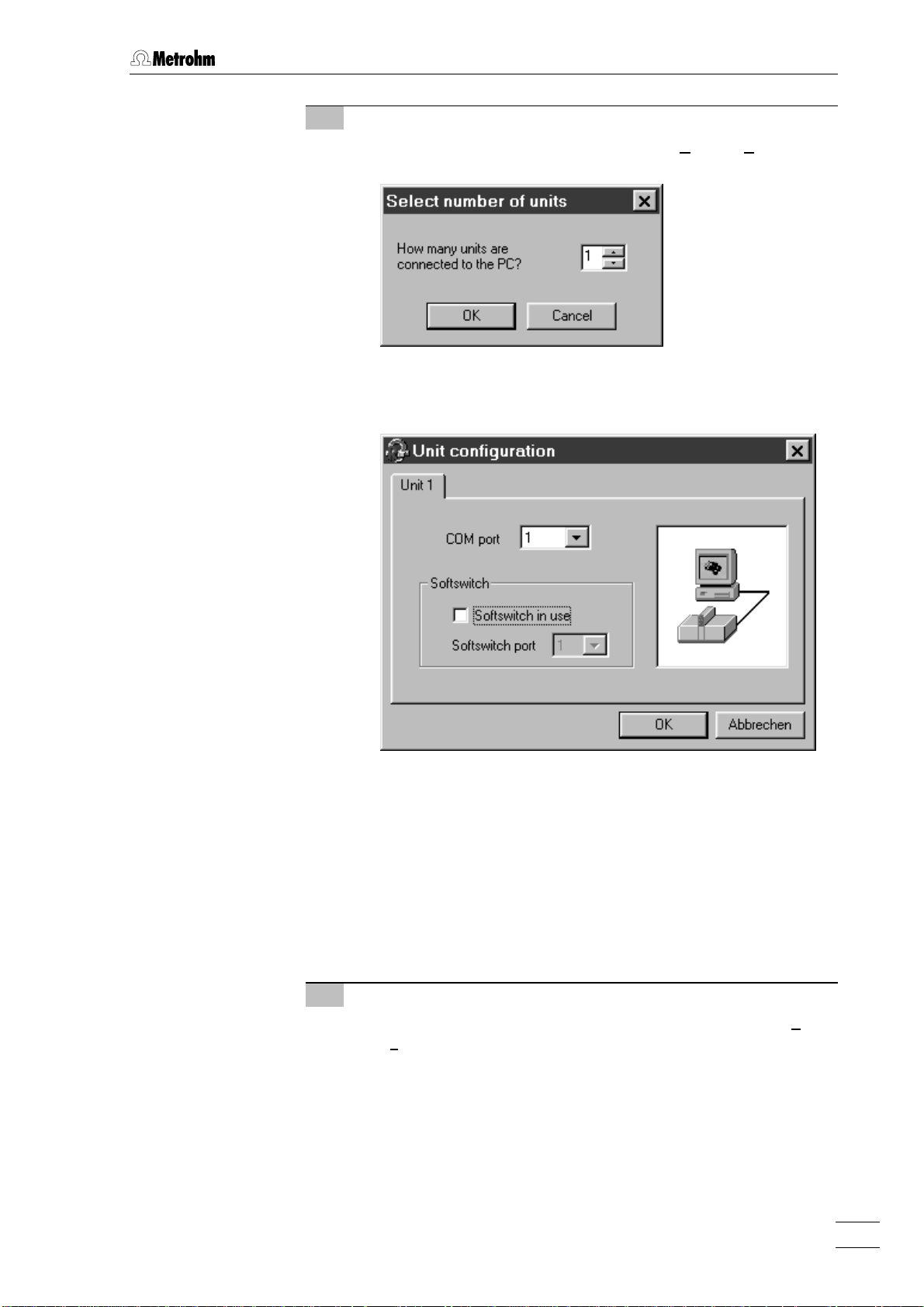

3 Communication settings

• Click on 763 PVC THERMOMAT CONTROL / Options / Communica-

tion to open the Select number of units window:

• Enter the number of PVC Thermomats (1…4) connected to

the PC and click on <OK>. The Unit configuration window appears:

• Under COM port select for each instrument the number of the

serial interface (1…8) to which this instrument is connected. If

a softswitch is used then the option Softswitch in use must be

switched on. Under COM port the number of the serial interface to which the softswitch is connected is selected; under

Softswitch port the number of the interface on the softswitch to

which the instrument is connected is selected.

• Click on <OK> to close the Unit configuration window.

• Confirm the message which then appears with <OK>.

4 Close the program and start it up again

• Close the program with 763 PVC THERMOMAT CONTROL / File /

Exit.

• Restart the «PVC Thermomat 1.0» program by double-

clicking the program icon.

• In the Login window enter the Password for the administrator.

The control window appears. In the status line the message

Unit#: Ready should appear for all connected instruments.

763 PVC Thermomat 17

Page 25

2 Installation

763 PVC Thermomat18

Page 26

3 Operating tutorial

This section introduces you to the operation of the 763 PVC Thermomat by means of a brief operating tutorial which describes the basic

operating steps needed for performing determinations and display of

results.

For further explanations of the operation, please refer to section 4.

3.1 Determinations

3.1 Determinations

The determination of induction and stability time of a PVC sample at

200 °C and a gas flow of 7 L/h is used an illustrative example. Please

note that the steps and parameter settings described apply only to

this example. If you use a different sample and different parameters,

the procedures described in the tutorial must be modified appropriately.

3.1.1 Installation

Before you start this brief tutorial, the 763 PVC Thermomat must be

correctly installed as described in section 2. In what follows, the most

important points for the installation are listed once again (for details,

see the sections mentioned).

⇒ Setting up instrument section 2.1

⇒ Installing air supply accessories section 2.2.1

⇒ Installing reaction and measuring vessels section 2.2.2

⇒ Mains connection section 2.3

⇒ Connection to PC section 2.4

763 PVC Thermomat 19

Page 27

3 Operating tutorial

3.1.2 Preparing for determinations

Before starting determinations, the method must be selected, the

heating must be started and the reaction and measuring vessels must

be prepared. Proceed as follows:

1 Switch on 763 PVC Thermomat

⇒ Switch on 763 PVC Thermomat with mains switch 1212 on the

rear of the instrument. After the instrument has been switched

on the mains pilot lamp 77 lights up.

2 Switch on PC

⇒ Switch on PC and start «763 PVC Thermomat» program.

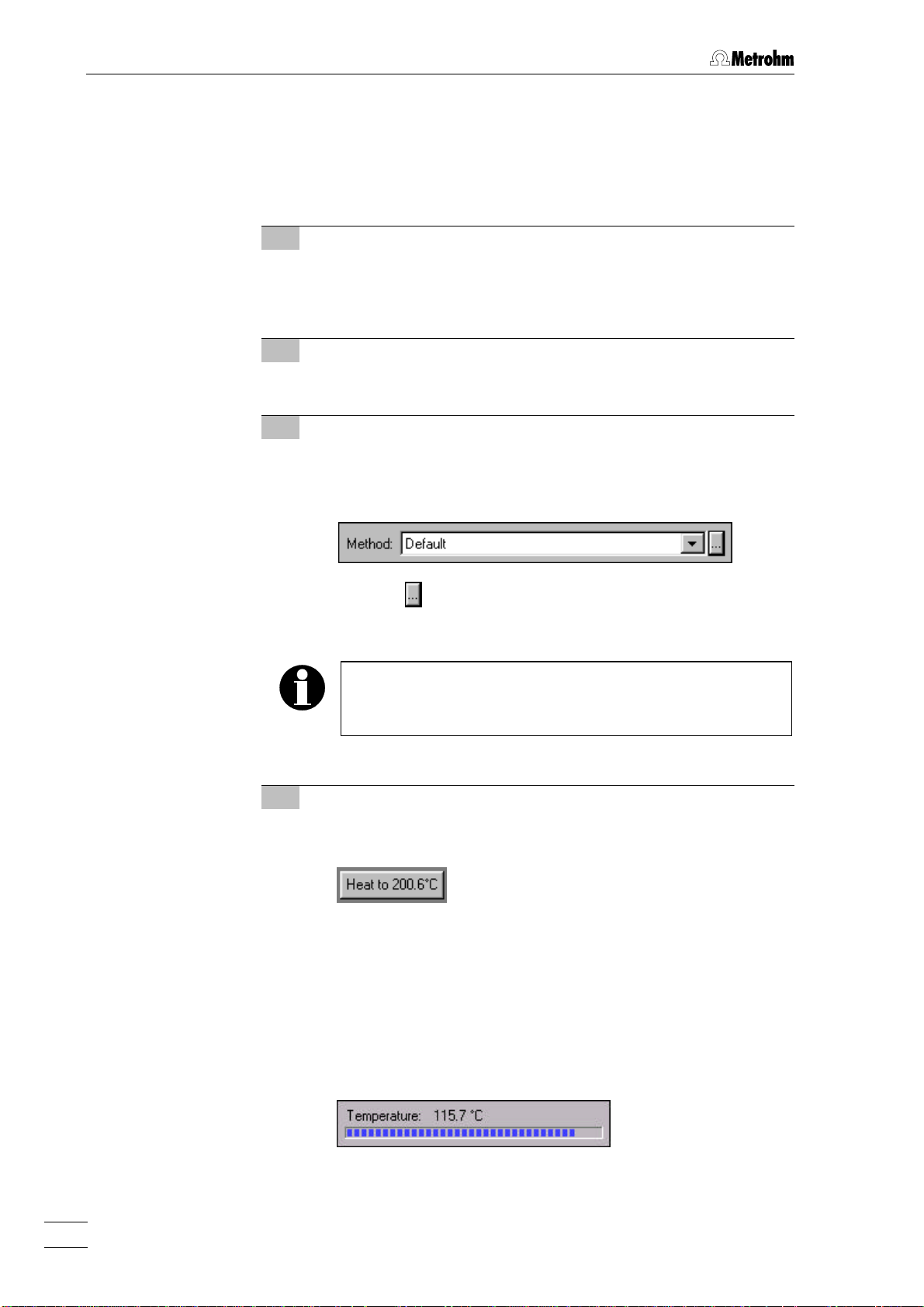

3 Select method "Default"

⇒ In the opened control window, select the determination

method Default for Block A (and – if more than 4 samples are

to be determined – also for Block B) in the Method field.

⇒ Click on , if you want to change the parameters of the

default method (details see section 4.5.2).

The determinations described in this tutorial have been

carried out using the default settings (Temperature = 200 °C,

Delta T = 0.6 °C, Gas flow = 7 L/h, etc.).

4 Start heating

⇒ To start the heating of Block A and – if desired – of Block B

click on the following button:

As soon as the heating is switched on the color of the frame

of this button switches to red. At the same time the temperature display 99 "TEMPERATURE" LED on the 763 PVC Ther-

momat starts to blink for the selected block.

The actual temperature is shown digitally beside the button. A

bar below shows the absolute variation of the actual temperature from the target temperature; the bar length corresponds to 50 °C.

763 PVC Thermomat20

Page 28

3.1 Determinations

5 Prepare measuring vessels

⇒ Clean the used measuring vessels and their covers (details

see section 4.6.3).

⇒ Fill each cleaned measuring vessel 4 4 with 60 mL distilled

water.

⇒ Place the measuring vessel cover 55 fitted with a PTFE tube

2727 on the measuring vessel 44 (see Fig. 4).

⇒ Place the measuring vessel 44 with its cover 55 in one of the

openings provided for it on the 763 PVC Thermomat and

connect the electrode plug 2626 on the cover to the corre-

sponding socket 2020 on the 763 PVC Thermomat.

6 Prepare reaction vessels

⇒ Weigh out 0.5 g PVC into the reaction vessels 1.

⇒ Take the upper rim of the reaction vessel 1 in your hand (e.g.

in the space between thumb and index finger) and rotate the

glass though 360°. This provides the degreased glass with a

thin grease film, without which it is very difficult to remove the

cover from the vessel after the determination.

⇒ Insert an gas inlet tube 32 into the reaction vessel cover 2

and fasten it by screwing down the connection nipple 30 (see

Fig. 4).

⇒ Place the reaction vessel cover 2 on the reaction vessel 1.

Rotate the cover so that the air inlet tube 32 is as close as

possible to the vessel wall.

⇒ Fasten the white connecting tubing 3 on to the connection 31

of the reaction vessel cover 2.

⇒ Place the prepared reaction vessel into the vessel holder.

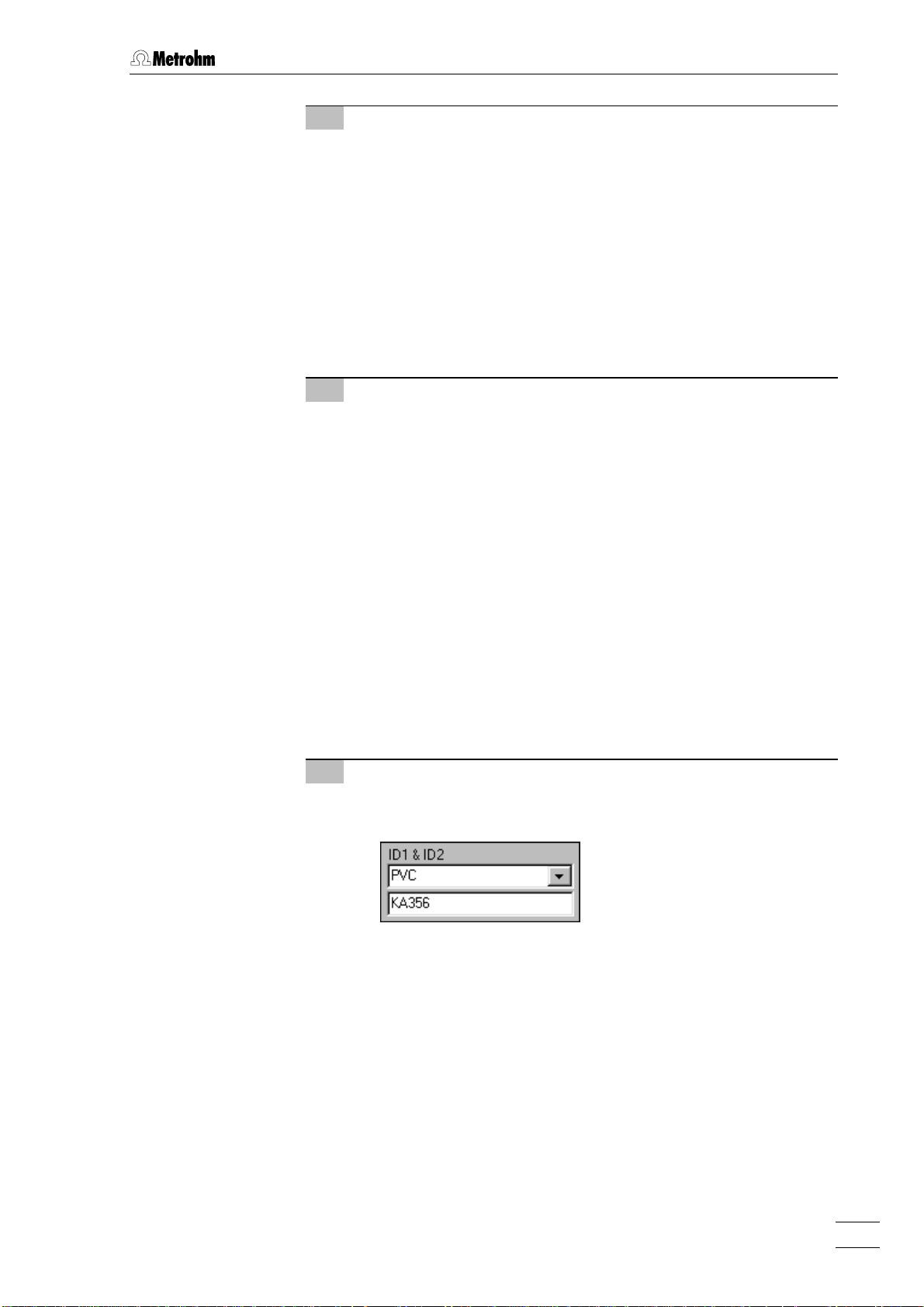

7 Enter sample identifiers

⇒ Enter the sample identifiers ID1 and ID2 in the corresponding

fields of the operating area in the control window.

763 PVC Thermomat 21

Page 29

3 Operating tutorial

3.1.3 Carrying out determinations

When the preparations are complete the determinations can be started.

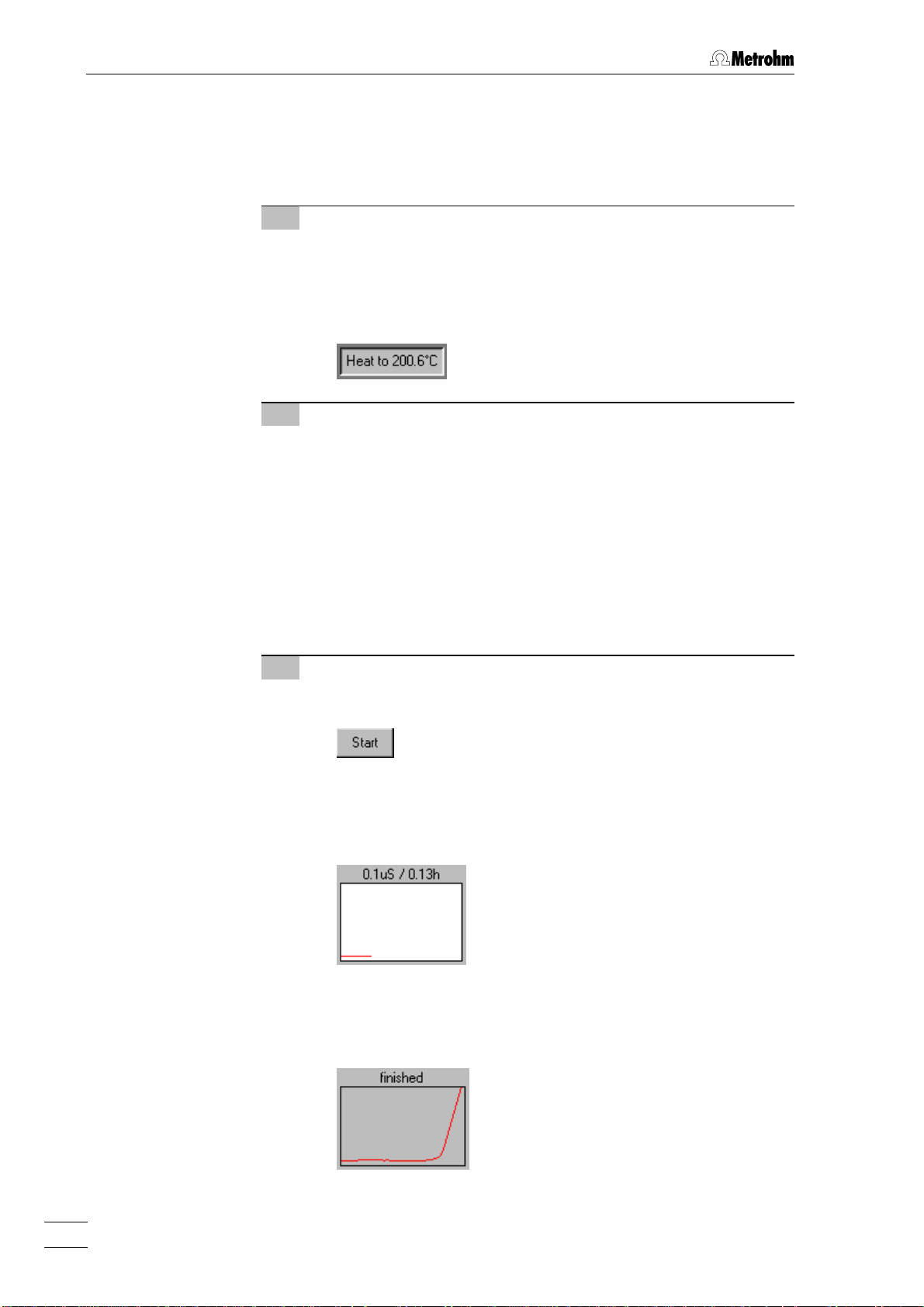

Proceed as follows:

1 Wait until the temperature has been reached

⇒ Wait until the heating block reaches the temperature defined

in the method. This condition is indicated by temperature display 99 "TEMPERATURE" which stops blinking and remains

lit up. At the same time or after a slight delay the frame color

of the <Heat to...> button turns green.

2 Insert reaction vessels

⇒ Place the prepared reaction vessels 11 in the heating block

openings on the 763 PVC Thermomat. Close any openings

which are not used with stoppers or empty reactions vessels

to protect against contamination.

⇒ Connect the white connecting tubing 33 fastened to the reac-

tion vessel cover 22 to the corresponding connection 2222 on

the measuring vessel cover 55.

⇒ Screw the brown gas supply tubing 66 onto the connection

nipple 3030 of the reaction vessel cover 22 and the correspond-

ing connection 1919 on the 763 PVC Thermomat (see Fig. 3).

3 Start determination

⇒ In the operating field of the control window for every determi-

nation you want to start you must click on the button

.

After the start of a determination the live curve of the started

determination is shown in the operating window beside the

channel number. The actual measured value appears above

the curve.

As soon as a point of inflection is found during the measurement the determination is terminated. The window with the

live curve becomes gray again and the message finished appears.

763 PVC Thermomat22

Page 30

4 Automatic report output

GLP test passed.

At the end of the determination the report defined in the

method is printed out automatically.

3.1 Determinations

Unit

Block

Channel

1

A

1

ID 1

PVC

Induction time

Stability time

Standard time

200

175

150

125

100

µS/cm

75

50

25

Serial number

Cell constant

User

01109

1

Administrator

1.27

1.33

6.45

h

h

h

Druckdatum

Bestimmungsdatum

ID 2

KA356

Delta Kappa

(F: 2.254; T: 180°C)

09.09.1999 09:34:03

23.06.1999 13:25:52

50 µS/cm

1.27

1.33

0

0.00 0.25 0.50 0.75 1.00 1.25 1.50

Method name

Creator

Temperature

Delta T

Gas flow

Start delay

Start mode

PVC 200°C

Administrator

per channel

200

0.60 °C

7°CL/h

0

min

per 2 channels

per block

h

Creation date

Stop time

Stop at conductivity

Stopat endpoint

Delta Kappa

Evaluation delay

Evaluation suppression start

Evaluation suppression end

Send to file

23.06.1999 08:27:20

0.00

h

200

µS/cm

50

µS/cm

0.00

h

0.00

h

0.00

h

763 PVC Thermomat 23

Page 31

3 Operating tutorial

3.2 Results

The demo database Demo.mrd is used as an example for the display

and further processing of the results of recorded determinations.

Please note that the steps and parameter settings described apply

only to this database. If you use a different database, the procedures

described in the tutorial must be modified appropriately.

3.2.1 Determination overview

The determination overview displays an overview table with selected

data fields of all the determinations contained in the opened database.

1 Open database "demo.mrd"

⇒ Click on or File / Results in the control window in order to

open the 763 PVC THERMOMAT RESULTS window. This loads

the Repos.mrd database and opens the determination overview as standard.

⇒ Click on File / Open database in the results window. Select the

demo.mrd database in the Open database window and click on

<Open>. A sub-window opens in the results window which

shows the data from 5 determinations in an overview table.

2 Format determination overview

⇒ Select fields: Click on or Format / Select fields in the

results window. In the Display fields window move the fields

until the fields required for the determination overview are

visible in the Display field and then click on <OK>.

⇒ Adjust field width: Mark the column in the determination

overview whose width is to be altered. Click on Format / Adjust

width in the results window. Enter the column width in the Column width window or click on <Best fit> in order to automati-

cally adapt the column width to the longest field contents.

Alternatively the column width can also be set directly by using the mouse. This is done by moving the cursor between

two columns in the title line of the table until it appears as .

The column can now be pulled to the required width with the

left-hand mouse key pressed down. A double-click on the

763 PVC Thermomat24

Page 32

selected column automatically adapts the column width to

the longest field contents (including title).

⇒ Format fields: Click on Format / Fields in the results window.

Set down the format for the fields in the determination overview in the Cells effects window and click on <OK>.

⇒ Select fonts: Click on Format / Fonts in the results window.

Select the font to be used in the determination overview in the

Font window and click on <OK>.

⇒ Save settings: Click on Options / Save settings now to save

the new format of the determination overview permanently.

3 Print determination overview

⇒ Click on or File / Print in the results window to open the

Printing of window.

3.2 Results

⇒ Select Overview table if the determination overview is to be

printed out in tabular form.

⇒ Select Overview list if the determination overview is to be

printed out as a list with all the fields selected in the determination overview.

⇒ Click on <Print>.

⇒ In the Print window select the printer, printing area and num-

ber of copies and click on <Print>.

763 PVC Thermomat 25

Page 33

3 Operating tutorial

4 Export determination overview

⇒ Copy to clipboard: Mark the lines or columns in the deter-

mination overview which are to be copied. Click on or

Edit / Copy. The marked texts are loaded into the clipboard

from where they can be further processed with other programs.

⇒ Export to other database: Mark the determinations (lines)

which are to be exported in the determination overview. Click

on Determination / Export / Export to database. In the Export data

to... window select the database to which the determinations

are to be exported and click on <Save>.

⇒ Export to Word: Mark the lines or columns in the determina-

tion overview which are to be exported. Click on or De-

termination / Export / Export to MS Word. The marked texts are

loaded into an RTF file which is automatically opened with

Microsoft Word.

⇒ Export to Excel: Mark the lines or columns in the determina-

tion overview which are to be exported. Click on or De-

termination / Export / Export to MS Excel. The marked texts are

loaded into an XLS file which is automatically opened with

Microsoft Excel.

3.2.2 Determination and method data

All the determination and method data of each determination in a determination overview can be shown, printed out and exported.

1 Display determination and method data

⇒ In the opened determination overview mark the determination

for which all parameters and results are to be displayed.

⇒ Click on or View / Determination and method data in the

results window or double-click on the required line in the determination overview. The Determination and method data window opens in which the data are shown on several register

cards.

763 PVC Thermomat26

Page 34

3.2 Results

2 Print determination and method data

⇒ Click on or File / Print in the results window to open the

Printing of window (see section 3.2.1).

⇒ Select the All determination and method data option.

⇒ Click on <Print>.

⇒ In the Print window select the printer, printing area and num-

ber of copies and click on <Print>.

3 Export determination and method data

⇒ Mark the determinations (lines) in the determination overview

from which all data is to be exported.

⇒ Click on or Determination / Export / Determination and

method data.

⇒ In the Save to export file window select the required folder and

the file name of the *.txt export file under which the data are to

be stored and click on <Save>.

763 PVC Thermomat 27

Page 35

3 Operating tutorial

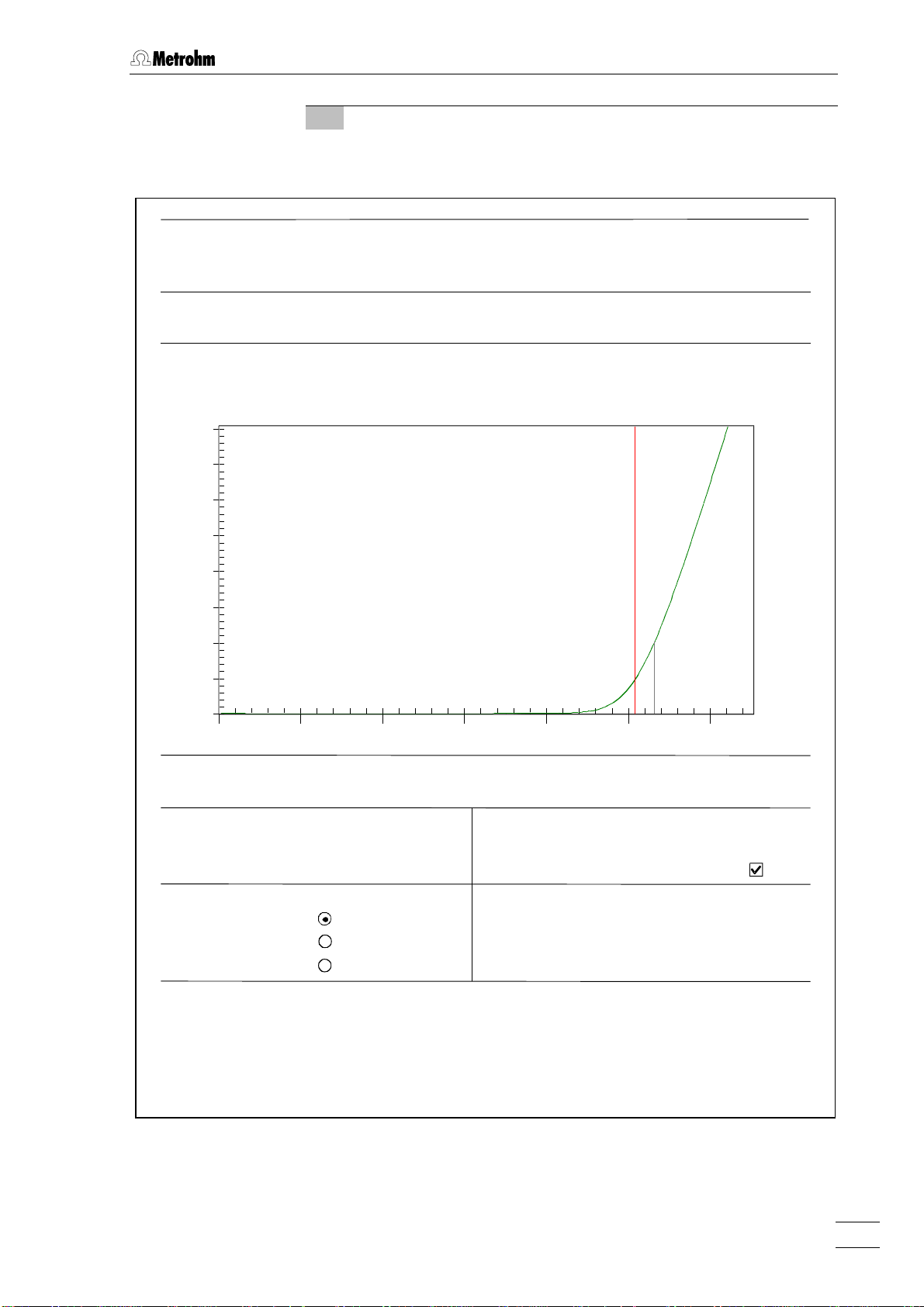

3.2.3 Graphics

Curves for each determination in a determination overview can be

shown, printed out and copied.

1 Open single graph

⇒ Mark the determination in the determination overview whose

single curve is to be displayed.

⇒ Click on or Determination / Graphics / Single graph in the

results window. A new window is opened in which the single

graph for the determination selected in the determination

overview is shown. The sample identifiers ID 1 and ID 2 are

shown in the window title. If present then the determined In-

duction time (red vertical line and numbers) and Stability time

(black vertical line and numbers) will be shown in the graphics window as well as the measuring curve (green).

2 Open multiple graph

⇒ Mark the determinations in the determination overview whose

curves are to be displayed in a multiple graph.

⇒ Click on or Determination / Graphics / Multiple graph in the

results window. A new window is opened in which all curves

for the determinations marked in the determination overview

are shown. The individual measuring curves are shown in

color, the legends referring to the colors (ID 1 and ID 2) are

located in the graph header. If present the determined Induc-

tion time ( ) and Stability time ( ) will also be shown.

763 PVC Thermomat28

Page 36

3 Open live graph

⇒ Mark the determination in the determination overview whose

curve is to be displayed.

3.2 Results

⇒ Click on or Determination / Graphics / Live graph with

reevaluation in the results window. A new window is opened in

which the measuring curve of the marked determination is

shown. If a different determination is marked in the determination overview then the curve is automatically updated. If

present then the determined Induction time (red vertical line

and numbers) and Stability time (black vertical line and numbers) will be shown in the graphics window as well as the

measuring curve (green). With <2nd derivative> the second

derivative of the measuring curve can be shown as a blue

line. The live graph offers the possibility of the manual ree-

valuation of the measuring curves (see section 4.7.3).

763 PVC Thermomat 29

Page 37

3 Operating tutorial

4 Print graphics

⇒ Open the required graph in the results window which is to be

printed.

⇒ Click on or File / Print in the results window. The curve

shown in the active graph window will be printed out.

⇒ If you want to print several single or multiple curves at the

same time first mark the required determinations in the determination overview. Click on or File / Print (see sec-

tion 3.2.1). In the Printing of... window select the option Single

graph or Multiple graph and click on <Print>.

5 Copy graphics

⇒ Open the required graph in the results window which is to be

copied.

⇒ Use the right-hand mouse key to click on the graph window

and select the option Copy in the context-sensitive menu. The

selected curve is copied into the clipboard where it can be

further processed with other programs.

763 PVC Thermomat30

Page 38

4.1 Fundamentals of the operation

4 Operation

This section describes the most important points concerning the

operation of the 763 PVC Thermomat. For further details please refer

to the on-line help in the PC program which can provide you with the

required information rapidly and conveniently from any place in the

program.

4.1 Fundamentals of the operation

4.1.1 Starting/closing the program

Start the «763 PVC Thermomat» program

Start the program

Double-click this icon or the PvcTm.exe file to start the «763 PVC

Thermomat 1.0» program. The Login window appears:

Select the desired User name and enter the Password. Then click

on <OK>.

After software installation, the program can be

started without entering a Password. For the definition of users, see section 4.2.2.

Close the «763 PVC Thermomat» program

763 PVC THERMOMAT CONTROL / File / Exit

Exit the «763 PVC Thermomat» program.

The program is also quitted by clicking on in the upper right

part of the 763 PVC THERMOMAT CONTROL window.

763 PVC Thermomat 31

Page 39

4 Operation

4.1.2 Glossary

Control window

Method

Determination

Results

The main window 763 PVC THERMOMAT CONTROL is known as the control window. It contains all the functions required for controlling the 763

PVC Thermomats connected to the PC.

A method includes all parameters for carrying out and evaluating a determination.

A determination is understood to be the automatic determination of the

induction time and/or stability time of a sample. In order to carry out a

determination a suitable method must be selected for the samples.

The results of a determination are automatically stored in the Repos.mrd

database and can be observed in the results window.

Reevaluation

Reevaluation is the subsequent reprocessing of determinations, in particular the manual determination of the induction time with the aid of

tangents.

Recalculation

Recalculation means that results, equations and standards can be calculated again at a later date.

Extrapolation

Extrapolation can be used to convert the results obtained at various

temperatures to a required target temperature. In addition, this method

can be used for converting the induction time to the standard time.

763 PVC Thermomat32

Page 40

4.1.3 Control window

The 763 PVC THERMOMAT CONTROL window is used for controlling the

PVC Thermomats, managing methods, displaying the live curves and

accessing various program functions.

Open

The 763 PVC THERMOMAT CONTROL window is opened automatically

when the program is started (see section 4.1.1).

Arrangement

The elements of the control window are the menu bar, the toolbar and

the status bar, indicating prompts, the logged-in user and the instrument status. The operating area contains a diagram of the measuring

unit of the 763 PVC Thermomat which can be used to start, display and

stop determinations.

Window title

Menu bar

Toolbar

4.1 Fundamentals of the operation

Operating area

Status bar

Logged-in user Unit statusPrompt

Menus

The control window contains the following main menus:

File Management of method files, opening the results window,

printing, new log in.

View View of toolbar and status bar, unit information, live pa-

rameters, status overview, event log overview, unit selection.

763 PVC Thermomat 33

Page 41

4 Operation

Tools Cell constants, GLP test, timer, gas flow control, start all

channels, determination of Delta T, temperature recording,

service diagnosis.

Options General settings, instrument configuration, user permis-

sions.

Help Program-specific on-line help.

Icons

The following icons are displayed in the control window:

Create new method (see section 4.5.1).

Open existing method (see section 4.5.1).

Method manager (see section 4.5.1).

Print results (see section 4.7.6).

Open results window (see section 4.1.4).

Live parameters, which can be altered during a run

(see section 4.6.4).

Status overview of the connected instruments

(see section 4.3.2).

Unit information (see section 4.3.1).

Display GLP status (see section 4.8.3).

Select unit 1...4.

Start all channels of Block A (see section 4.6.4).

Start all channels of Block B (see section 4.6.4).

Call up help.

Close

The control window is closed by clicking on 763 PVC THERMOMAT CON-

TROL / File / Exit or in the upper right part of the window.

763 PVC Thermomat34

Page 42

4.1.4 Results window

The 763 PVC THERMOMAT RESULTS window is used to display, output

and recalculate the results of determinations recorded by the 763 PVC

Thermomat. The determination data are stored in the *.mrd database

files and can be shown in this window as an overview table and as

curves. The results window can run even when the control window is

closed.

Open

The 763 PVC THERMOMAT RESULTS window is opened by clicking on

or 763 PVC THERMOMAT CONTROL / File / Results in the control win-

dow.

Arrangement

The elements of the results window are the menu bar, the toolbar and

the status bar. Within the results window sub-windows can be opened

showing determination overviews, single, multiple and live graphs.

Window title

Menu bar

Toolbar

4.1 Fundamentals of the operation

Determination

overview

Single graph

Live graph

Multiple graph

Status bar

Menus

The results window contains the following main menus:

File Open database, print, close window.

Edit Copy, mark, delete filter.

View Select display: determination overview,

method and determination data, GLP.

763 PVC Thermomat 35

Page 43

4 Operation

Determination Seek, sort, filter, graphics, extrapolation,

recalculation, export, delete.

Format Format determination overview.

Options General program settings.

Window Display of windows.

Help Program-specific on-line help.

Icons

The following icons are shown in the results window:

Print results, curves and

overview lists

Filter selection

(see section 4.7.1).

(see section 4.7.6).

Copy to clipboard

(see section 4.7.6).