Page 1

761 SD Compact IC

CH-9101 Herisau/Schweiz

E-Mail info@metrohm.com

Internet www.metrohm.com

8.761.1043

Instructions for Use

Page 2

Page 3

CH-9101 Herisau/Schweiz

E-Mail info@metrohm.com

Internet www.metrohm.com

761 SD Compact IC

761 SD Compact IC

POWER

8.761.1043 Instructions for Use

8.761.1043 02.2004 / chs

Page 4

Teachware

Metrohm AG

Oberdorfstrasse 68

CH-9101 Herisau

teachware@metrohm.com

1. Edition 2004

These instructions are protected by copyright. All rights reserved.

Although all the information given in these instructions has been checked with great care, errors

cannot be entirely excluded. Should you notice any mistakes please inform the author at the

address given above.

Page 5

Table of contents

Table of contents

1 Introduction ................................................................ 1

1.1 Instrument description ................................................................................1

1.2 Parts and controls .......................................................................................3

1.2.1 Front view ........................................................................................................... 3

1.2.2 Rear view ............................................................................................................ 4

1.2.3 Connection schematic ....................................................................................... 5

1.3 Information on the Instructions for Use .....................................................7

1.3.1 Organisation ....................................................................................................... 7

1.3.2 Notation and pictograms.................................................................................... 8

1.4 Safety notes .................................................................................................9

1.4.1 Electrical safety................................................................................................... 9

1.4.2 General precautionary rules ............................................................................... 9

2 Installation ............................................................... 10

2.1 Flow chart ..................................................................................................10

2.2 Setting up the instrument..........................................................................11

2.2.1 Packaging.........................................................................................................11

2.2.2 Check................................................................................................................ 11

2.2.3 Location ............................................................................................................ 11

2.3 Description of the connections.................................................................12

2.3.1 Connection of capillaries/tubing ...................................................................... 12

2.3.2 Connection between capillaries/tubing............................................................ 13

2.3.3 Filter unit PEEK ................................................................................................. 14

2.4 Connection of the detector block .............................................................15

2.5 Installation of the MPak cabinet and connection of the drain tubes ......16

2.5.1 Installing the MPak cabinet .............................................................................. 16

2.5.2 Drain tube for inner compartment.................................................................... 16

2.5.3 Drain tube for MPak cabinet............................................................................. 16

2.6 Installing the eluent path ..........................................................................17

2.6.1 High-pressure pump – Removing the transport security screws .................. 17

2.6.2 Connection MPak → high-pressure pump ...................................................... 17

2.6.3 Connection high-pressure pump → injection valve ........................................ 18

2.6.4 Connection injection valve → suppressor .......................................................19

2.6.5 Connection suppressor → detector................................................................. 19

2.6.6 Connection detector → suppressor................................................................. 19

2.6.7 Connection suppressor → waste..................................................................... 20

2.7 Installing the regenerant path...................................................................20

2.7.1 Fitting the pump tubing for regenerant ............................................................ 20

2.7.2 Connection regenerant-MPak → pump tubing → suppressor → waste ........ 21

2.8 Installing the sample path.........................................................................23

2.8.1 Fitting the pump tubing for sample.................................................................. 23

2.8.2 Connection sample vessel → pump tubing → injection valve → waste ........ 24

2.9 Connecting the 766 IC Sample Processor ...............................................26

2.9.1 Installing the 766 IC Sample Processor ........................................................... 26

2.9.2 Connecting the 766 IC Sample Processor....................................................... 26

2.10 Fitting the rear panel .................................................................................27

2.11 Mains connections ....................................................................................28

2.11.1 Setting the mains voltage ................................................................................. 28

2.11.2 Fuses ................................................................................................................29

2.11.3 Mains cable and mains connection .................................................................29

2.11.4 Switching the instruments on/off ...................................................................... 29

761 SD Compact IC / Instructions for Use 8.761.1043

I

Page 6

Table of contents

2.12 Connection to the PC ................................................................................30

2.12.1 Connecting cable 6.2134.100 .......................................................................... 30

2.12.2 Software installation ......................................................................................... 30

2.12.3 Basic settings «IC Net»..................................................................................... 31

2.12.4 Basic settings «IC Cap» ................................................................................... 33

2.13 Deaerating the pump and rinsing the pulsation dampener ....................34

2.13.1 Deaerating the pump ....................................................................................... 34

2.13.2 Rinsing the pulsation dampener ...................................................................... 35

2.14 Rinsing before fitting the column .............................................................37

2.15 Precolumn and separating column ..........................................................39

2.15.1 Metrosep RP Guard ......................................................................................... 39

2.15.2 Metrosep A Supp 1 HS separating column ..................................................... 40

2.16 Attaching tubing to side panels ................................................................42

3 «IC Net» ..................................................................... 43

3.1 «IC Net» – User interface for the 761 SD Compact IC..............................43

3.1.1 Systems - Methods .......................................................................................... 43

3.1.2 Opening a system ............................................................................................ 43

3.1.3 Opening a method ........................................................................................... 44

3.1.4 Connect a system ............................................................................................ 44

3.1.5 Instrument icon................................................................................................. 45

3.1.6 System parameters for linked system ............................................................. 45

3.1.7 Hardware settings ............................................................................................ 50

3.2 Systems supplied ......................................................................................54

3.2.1 System "startup.smt" ........................................................................................ 54

3.2.2 System "manual.smt"........................................................................................ 55

3.2.3 System "auto.smt" ............................................................................................ 56

3.2.4 System "shutdown.smt".................................................................................... 61

4 «IC Cap» ....................................................................64

4.1 «IC Cap» introduction ................................................................................64

4.1.1 Login................................................................................................................. 64

4.1.2 User interface ................................................................................................... 64

4.2 «IC Cap» - Configuration ...........................................................................66

4.2.1 Predefined configurations ................................................................................ 66

4.2.2 Configuration "manual.cfg"............................................................................... 66

4.2.3 Configuration "auto.cfg" ................................................................................... 72

5 Operation .................................................................. 77

5.1 Operation with manual sample change....................................................77

5.1.1 Control with «IC Net» (manual operation) ........................................................ 77

5.1.2 Control with «IC Cap» (manual operation) ....................................................... 81

5.2 Operation with automated sample change ..............................................84

5.2.1 Control with «IC Net» (automated operation)................................................... 84

5.2.2 Control with «IC Cap» (automated operation) ................................................. 86

6 Notes – Maintenance – Faults .................................. 88

6.1 Practical notes on ion chromatography ...................................................88

6.1.1 Separating columns ......................................................................................... 88

6.1.2 High-pressure pump ........................................................................................ 88

6.1.3 Eluents.............................................................................................................. 89

6.1.4 Peristaltic pump................................................................................................ 89

6.1.5 Suppressor module.......................................................................................... 89

6.1.6 Connections ..................................................................................................... 90

761 SD Compact IC / Instructions for Use 8.761.1043

II

Page 7

Table of contents

6.2 Maintenance and servicing .......................................................................91

6.2.1 General information .......................................................................................... 91

6.2.2 Passivation........................................................................................................ 91

6.2.3 Shutdown.......................................................................................................... 91

6.2.4 Changing separating columns......................................................................... 92

6.2.5 Maintenance work on the pump head ............................................................. 92

6.2.6 Regeneration of the suppressor module .........................................................98

6.2.7 Cleaning the suppressor ................................................................................ 100

6.2.8 Replacing the suppressor .............................................................................. 102

6.2.9 Replacing the pump tubing............................................................................ 103

6.3 Faults and malfunctions..........................................................................104

6.3.1 Error messages .............................................................................................. 104

6.3.2 Malfunctions and their rectification ................................................................ 104

6.4 Diagnostic tests / Validation / GLP.........................................................106

7 Appendix ................................................................. 107

7.1 Technical data .........................................................................................107

7.1.1 Conductivity measurement ............................................................................ 107

7.1.2 Conductivity detector ..................................................................................... 107

7.1.3 Injection valve ................................................................................................. 108

7.1.4 High-pressure pump ...................................................................................... 108

7.1.5 Peristaltic pump.............................................................................................. 109

7.1.6 Suppressor module........................................................................................ 109

7.1.7 Leak detector.................................................................................................. 109

7.1.8 RS232 interface .............................................................................................. 109

7.1.9 Remote interface ............................................................................................ 110

7.1.10 Mains connection ...........................................................................................110

7.1.11 Safety specifications....................................................................................... 111

7.1.12 Electromagnetic compatibility (EMC)............................................................. 111

7.1.13 Ambient temperature...................................................................................... 111

7.1.14 Housing .......................................................................................................... 111

7.2 Standard equipment................................................................................112

7.3 Optional accessories ..............................................................................118

7.3.1 6.5328.000 SD Spare Part Set ....................................................................... 118

7.3.2 Other optional accessories ............................................................................120

7.4 Warranty and conformity.........................................................................121

7.4.1 Warranty.......................................................................................................... 121

7.4.2 Declaration of Conformity............................................................................... 122

7.4.3 Quality Management Principles .....................................................................123

7.5 Index.........................................................................................................124

761 SD Compact IC / Instructions for Use 8.761.1043

III

Page 8

Table of contents

List of figures

Figure 1: Front of the 761 SD Compact IC ............................................................... 3

Figure 2: Rear panel 761 SD Compact IC ................................................................ 4

Figure 3: Connection schematic for 761 SD Compact IC ........................................ 5

Figure 4: Connectors for capillaries........................................................................ 13

Figure 5: PEEK couplings....................................................................................... 13

Figure 6: Connecting the filter unit PEEK ............................................................... 14

Figure 7: Position of the detector block 40 ............................................................ 15

Figure 8: Pump tubing for regenerant path ............................................................ 21

Figure 9: Flow schematic regenerant flow.............................................................. 22

Figure 10: Pump tubing for sample path.................................................................. 24

Figure 11: Flow schematic sample stream............................................................... 25

Figure 12: Rear panel ............................................................................................... 27

Figure 13: Setting the mains voltage........................................................................ 29

Figure 14: Connection of precolumn and separating column.................................. 41

Figure 15: Components of the pump head.............................................................. 94

Figure 16: Replacement of the piston seal 76.......................................................... 94

Figure 17: Components of inlet valve 77 and outlet valve 78.................................. 97

Figure 18: Assembling the suppressor .................................................................. 101

761 SD Compact IC / Instructions for Use 8.761.1043

IV

Page 9

1.1 Instrument description

1 Introduction

1.1 Instrument description

The 761 SD Compact IC is a version of the time-proven 761 Compact

IC which has been developed specifically for soft drink analysis. The

761 SD Compact IC is designed for determining phosphoric acid and

its intermediate products in soft drinks but also continues to offer all

functionalities of the original version.

The advantages of the 761 SD Compact IC over the conventional

methods of phosphoric acid analysis in soft drinks are its short analysis

times, its ease of operation and the option for automated sampling.

There is no need for time-consuming sample preparation and only

small quantities of chemicals are consumed (more environmentally

friendly).

The 761 SD Compact IC has a very compact housing accommodating

all equipment required for ion-chromatographic determination:

• Injection valve – this supplies the sample to the eluent stream by

switching over the flow paths.

• High-pressure pump – extremely low-pulsation dual piston pump

with a flow range of 0.2 to 2.5 mL/min and a maximum pressure

of 25 MPa (250 bar).

• Pulsation dampener – the pulsation dampener protects the sepa-

rating column reliably against damage even in the case of low-level

pressure fluctuations.

• Column chamber – perfect insulation of the housing not only cre-

ates thermally stable conditions for the separating column, but also

shields the system against electromagnetic interference.

• Column – Metrosep A Supp 1 HS anion column as IC separating

column; Metrosep RP Guard as protective precolumn.

• Suppressor – the Metrohm-Suppressor-Module (MSM) which is

already integrated features stable pressure characteristics, automatic regeneration, high performance and optimum reproducibility.

• Peristaltic pump – integrated, two-channel peristaltic pump with a

flow rate of 0.5 to 0.6 mL/min for regeneration of the suppressor

module and aspiration of the sample for manual operation.

• Detector – conductivity detector with excellent temperature stabil-

ity. The detector temperature fluctuates by less than 0.01°C and

can be matched optimally to ambient conditions.

761 SD Compact IC / Instructions for Use 8.761.1043

1

Page 10

1 Introduction

All components coming into contact with eluent and sample are metalfree. Ready-to-use eluents in certified MPaks are supplied for soft drink

analysis.

The 761 SD Compact IC is operated by means of a PC connected to

the RS232 interface. The 761 SD Compact IC can be controlled by the

«IC Net» software or by the “master” «IC Cap» software.

The systems required for soft drink analysis (and the methods linked to

them) are supplied on the installation CD.

The following instrument versions are available:

• 2.761.0420 761 SD Compact IC

• 2.761.0520 761 SD Compact IC with IC Sample Processor 766

for automated sample change

Principle:

The eluent flows on the eluent path through the injection valve into the

separating column and then into the detector. The sample flows on the

sample path also through the injection valve and the red sample loop

visible at the centre of the injection valve. At a specific instant (<Inject>; controlled by the program), the flow paths in the injection valve

are switched and the sample loop is reintegrated in the eluent path (it is

now no longer a part of the sample path). The sample quantity which is

located in the sample loop at the switchover instant is then entrained

with the eluent stream, thus entering the separating column (where the

actual chromatographic separation of the components occurs) and, finally, chromatographically separated, into the conductivity detector.

2

761 SD Compact IC / Instructions for Use 8.761.1043

Page 11

1.2 Parts and controls

1.2 Parts and controls

In this section you will find the numbers and designations of the parts

and controls of the 761 SD Compact IC. The numbering applies

throughout the instructions for use, i.e. bold numbers in the text (e.g.

4

) refer to the parts and controls illustrated here.

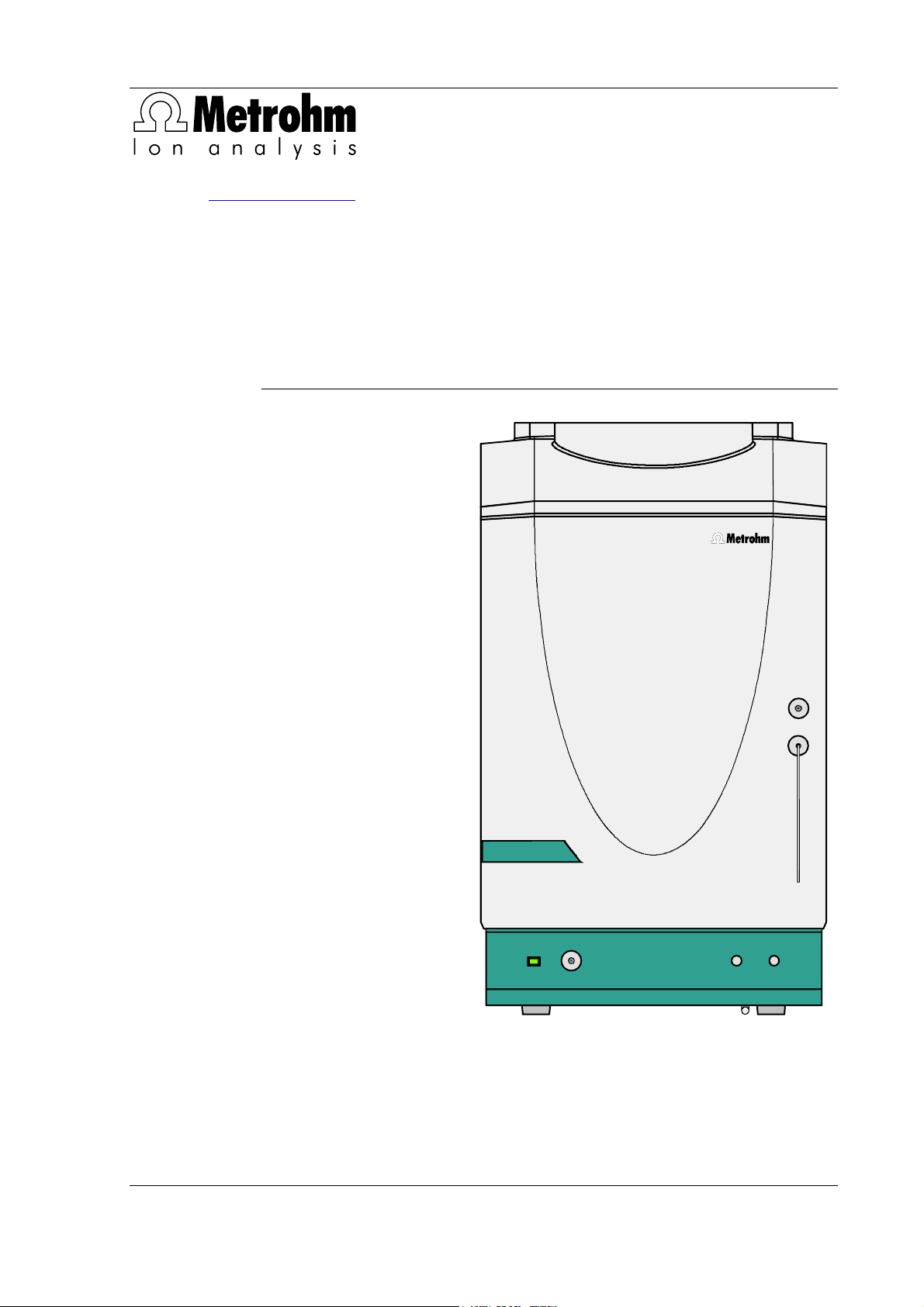

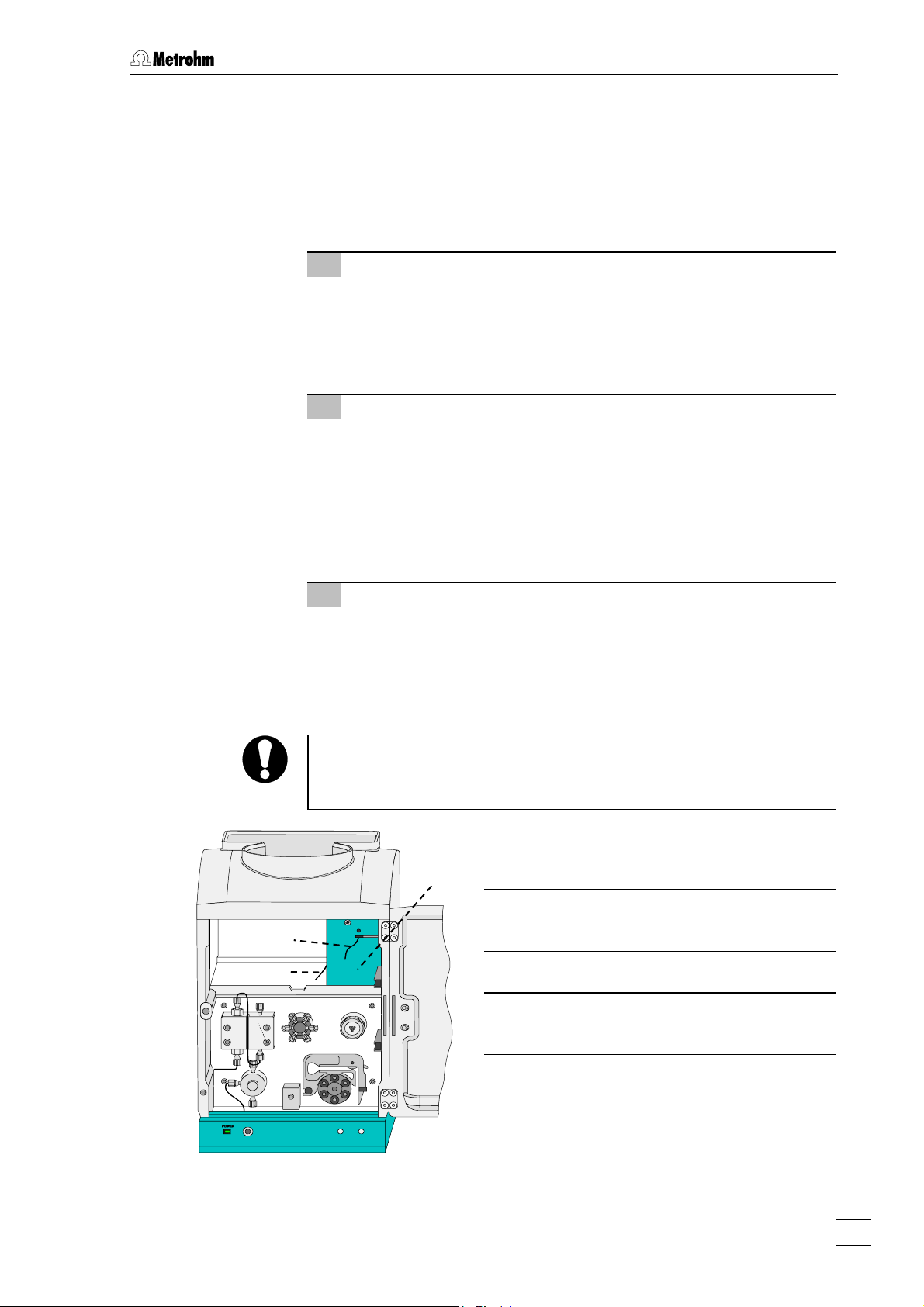

1.2.1 Front view

761 SD Compact IC

6

7

POWER

Figure 1: Front of the 761 SD Compact IC

1

2

3

4

5

Door to inner compartment

1

Feedthrough for aspirating tubing

2

Aspirating tubing

3

for sample

Feedthrough for capillaries

4

761 SD Compact IC / Instructions for Use 8.761.1043

Connection for drain tube

5

for discharging escaped fluid from the

inner compartment

Connection purge valve

6

Pilot lamp

7

This is on when the instrument is

switched on

3

Page 12

1 Introduction

1.2.2 Rear view

8

10

11

17

18

19

Type 1.761.

WARNING - Fire Hazard -

For continued protection replace only

with the same type and rating of fuse

Analog Output

Remote

Detector Block

RS 232

Waste B

Made by Metrohm Herisau Switzerland

9

Waste A

11

12

Transport securit y screws

13

14

100-120V:

220-240V:

Fuse

1,0A(T)

0,5A(T)

15

16

Figure 2: Rear panel 761 SD Compact IC

Opening for outlet capillaries

8

for discharge of eluent, regeneration

solution and sample solution

Opening for inlet capillaries

9

for supply of eluent, regeneration solution and sample solution

Opening for detector cable

10

Knurled screw

11

for fastening the rear panel

Detachable rear panel

12

Access to the inner compartment

Transport security screws

13

to secure the pump head when the instrument is transported

Mains switch

14

to switch instrument on and off:

I = ON 0 = OFF

20

21

Mains connection plug

15

Mains connection, see section 2.11

Fuse holder

16

Changing the fuses, see section 2.11.2

Serial number

17

Analogue output

18

output for analogue signal

Remote interface

19

Remote-I/O lines for connection of external devices

Connection for detector block

20

RS232 interface

21

PC connection

4

761 SD Compact IC / Instructions for Use 8.761.1043

Page 13

1.2 Parts and controls

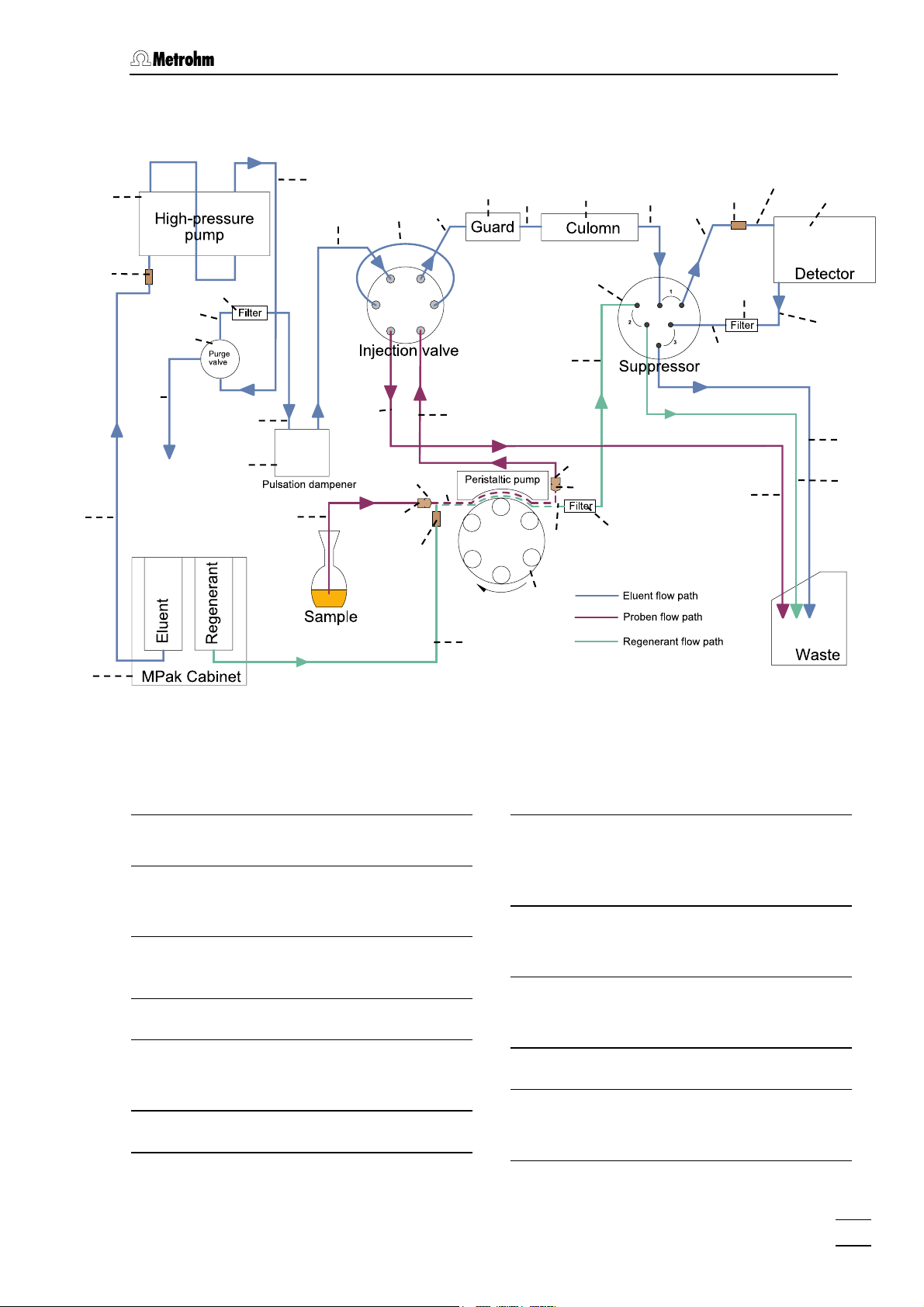

1.2.3 Connection schematic

23

24

55

27

28

26

56

29

30

25

31

32 33

34

35 37

36

43

54

38

56

39

40

41

42

48

45

47

44

50

63

64

3

50

61

65

48

56

46

55

49

22

Figure 3: Connection schematic for 761 SD Compact IC

3 Aspirating tubing

for sample

MPak cabinet

22

for suspending eluent and regenerant bag

Tubing connection to MPak

23

6.1837.000

Pump head 6.2824.100

24

Connection capillary

25

Connection between pump head and

purge valve, permanently mounted

Purge valve

26

23

Connection capillary

27

PEEK capillary 6.1831.010 for

deaerating,

length L = 15 cm

Connection capillary

28

PEEK capillary 6.1831.010,

length L = 13 cm

Connection capillary

29

PEEK capillary 6.1831.010,

length L = 13 cm

Pulsation dampener 6.2620.150

30

Inlet capillary for injector

31

PEEK capillary 6.1831.010,

length L = 24 cm

761 SD Compact IC / Instructions for Use 8.761.1043

5

Page 14

1 Introduction

Sample loop 1.5 µL (6.1825.240)

32

PEEK sample loop

Column connection capillary

33

PEEK capillary 6.1831.010,

length L = 30 cm

Metrosep RP Guard 6.1011.020

34

Precolumn for protecting the separating column

Connection capillary

35

PEEK connection capillary between

precolumn and separating column

Metrosep A Supp 1 HS separating

36

column (6.1005.350)

IC separating column

Suppressor inlet capillary for elu-

37

ent ("Eluent")

PTFE capillary, permanently mounted

on suppressor, labelled "Eluent"

Suppressor outlet capillary for

38

eluent ("Detector")

PTFE capillary permanently mounted

on suppressor, labelled "Detector"

Inlet capillary to detector block

39

PEEK capillary, permanently

mounted

Detector block 1.732.0420

40

Outlet capillary from detector

41

block

PEEK capillary, permanently

mounted

Suppressor inlet capillary for elu-

42

ent ("H2O")

PTFE capillary, permanently mounted

on suppressor, labelled "H2O"

Suppressor module

43

Suppressor outlet capillary for

44

eluent ("Waste")

PTFE capillary, permanently mounted

on suppressor, leading to the waste,

labelled "Waste"

On instrument version 2.761.0520 with automated sample change

with the 766 IC Sample Processor, the aspirating tubing

by the PEEK capillary tubing

ple Processor) installed on the 766 IC Sample Processor. See Section

2.9. for installation of the 766 IC Sample Processor.

Suppressor inlet capillary for re-

45

generant

PTFE capillary, permanently mounted

on suppressor, labelled "H2SO4"

Suppressor outlet capillary for

46

regenerant ("Waste")

PTFE capillary, permanently mounted

on suppressor, leading into the

waste, labelled "Waste"

Connection capillary

47

PTFE capillary 6.1803.030, connection between pump tubing and injection valve

Connection capillary

48

PTFE capillary 6.1803.030, connection between injection valve and

waste container

Pump drive of the peristaltic

49

pump

Drive of the two-channel-peristaltic

pump for pumping sample and regenerant

50 Pressure screw 6.2744.010

54 PEEK coupling 6.2744.040

55 PEEK coupling 4.455.4500

Coupling for "tubing connection to

MPak"

56 Filter unit PEEK 6.2821.120

61 Pump tubing 6.1826.110 for H2SO

63 PEEK coupling 6.2744.030

64 Pump tubing 6.1826.110 for sam-

ple

65 PEEK coupling 6.2744.160

with tubing security device

3

is replaced

18

(see Instructions for Use 766 IC Sam-

4

6

761 SD Compact IC / Instructions for Use 8.761.1043

Page 15

1.3 Information on the Instructions for Use

1.3 Information on the Instructions for Use

Please read through these Instructions for Use carefully before you put

the 761 SD IC Compact IC into operation. The Instructions for Use

contain information and warnings to which the user must pay attention

in order to assure safe operation of the instrument.

1.3.1 Organisation

These Instructions for Use 8.761.1043 for the 761 SD Compact IC

provide a comprehensive overview of installation, startup procedure,

operation, fault rectification and technical specifications of this instrument. The Instructions for Use are organised as follows:

Section 1 Introduction

General description of instrument, parts and controls and safety notes

Section 2 Installation

Installation and connection of the instrument, of the accessories and of the software

Section 3 «IC Net»

Explanatory information on the user interface of the «IC

Net» control software

Section 4 «IC Cap

Explanatory information on the user interface

of the «IC Cap» control software

Section 5 Operation

Description of operation with manual and

automatic sample change, with «IC Net» and

«IC Cap» in each case

Section 6 Notes – Maintenance – Faults

Notes on ion chromatography, maintenance, fault

rectification, diagnostic tests and validation

Section 7 Appendix

Technical data, standard equipment, options, warranty, declarations of conformity and index

To find the required information on the instruments, you will find it an

advantage to use either the Table of contents or the Index at the

back.

761 SD Compact IC / Instructions for Use 8.761.1043

7

Page 16

1 Introduction

1.3.2 Notation and pictograms

The following notations and pictograms (symbols) are used in these Instructions for Use:

Fill Menu item, parameter or entry

value

in the software

SYSTEM STATE Program window

in the software

<OK> Button

in the software

20 Part or control of 761 SD

18 Part or control of 766

Hazard

This symbol draws attention to a

possible danger to life or of injury if

the associated directions are not

followed correctly. .

Warning

This symbol draws attention to

possible damage to instruments or

instrument parts if the associated

directions are not followed correctly.

Caution

This symbol marks important information. First read the associated

directions before you continue.

Comment

This symbol marks additional information and tips.

8

761 SD Compact IC / Instructions for Use 8.761.1043

Page 17

1.4 Safety notes

1.4 Safety notes

1.4.1 Electrical safety

While electrical safety in the handling of the 761 SD Compact IC is assured in the context of the specifications IEC/EN 61010-1 (prot. class 1,

degree of protection IP20), the following points should be noted:

• Mains connection

Setting of the mains voltage, checking the mains fuse and the

mains connection must be effected in accordance with the instruc-

tions in section 2.11.

• Opening the 761 SD Compact IC

If the 761 SD Compact IC is connected to the power supply, the instrument must not be opened nor must parts be removed from it, otherwise there is a danger of coming into contact with components

which are live. Hence, always disconnect the instrument from all voltage sources before you open it and ensure that the mains cable is

15

disconnected from mains connection

!

• Protection against static charges

Electronic components are sensitive to static charging and can be

destroyed by discharges. Before you touch any of the components

inside the 761 SD Compact IC, you should earth yourself and any

tools you are using by touching an earthed object (e.g. housing of the

instrument or a radiator) to eliminate any static charges which exist.

1.4.2 General precautionary rules

• Handling of solvents

Check all lines of the IC system periodically for possible leaks. Follow

the relevant instructions regarding the handling of flammable and/or

toxic solvents and their disposal.

• Periodic exchange of pump tubing

Pump tubing is consumable material and must be replaced from time

to time (see Section 6.2.9). Please take suitable measures to ensure

that any leakage on pump tubing or connections in unattended continuous operation does not cause damage (position the instrument at

the bottom and provide a receptacle for catching escaping fluid).

761 SD Compact IC / Instructions for Use 8.761.1043

9

Page 18

2 Installation

2 Installation

2.1 Flow chart

The following flow chart provides an overview of all installation work.

You will find more detailed information in the relevant section.

Setting up sect. 2.2

Installing detektor block sect. 2.4

Installing drain tubes

Installing eluent flow path sect. 2.6

Installing regenerant flow path sect. 2.7

Installing sample flow path

766 IC Sample

Processor

No

Replace rear panel

Mains connection

sect. 2.5

sect. 2.8

Yes

sect. 2.10

sect. 2.11

Connection to 766 IC Sample Processor

sect

. 2.9

Connecting PC sect

Installing software

Deaerating/Rinsing sect

Install guard and column sect. 2.15

10

761 SD Compact IC / Instructions for Use 8.761.1043

. 2.12

sect. 2.12.2

. 2.13 / 2.14

Page 19

2.2 Setting up the instrument

2.2 Setting up the instrument

2.2.1 Packaging

The 761 SD Compact IC is supplied together with the separately

packed accessories in special packagings containing shock-absorbing

foam linings designed to provide excellent protection. The instrument

itself is packed in an evacuated polyethylene bag to prevent the ingress

of dust. Please store all these special packagings as only they assure

transport of the instrument free from damage.

2.2.2 Check

After receipt, immediately check whether the shipment is complete and

has arrived without damage (compare with delivery note and list of

accessories in section 7.2). In the case of transport damage, see

instructions in section 7.4.1 "Warranty".

2.2.3 Location

Position the instrument in the laboratory at a location convenient for operation, free from vibrations and protected against a corrosive atmosphere and contamination by chemicals.

To avoid disturbing temperature influences on the insulated column

compartment, the instrument must be protected against direct

sunlight.

761 SD Compact IC / Instructions for Use 8.761.1043

11

Page 20

2 Installation

2.3 Description of the connections

2.3.1 Connection of capillaries/tubing

The connections for eluent, sample and regenerant consist of:

• PEEK capillaries 6.1831.010 (inner diameter = 0.25 mm)

• PTFE microcapillaries 6.1803.030 (inner diameter = 0.5 mm)

• PTFE tubing connections to the MPaks 6.1837.000 (inner di-

ameter = 1.5 mm)

The PEEK capillaries and PTFE microcapillaries can be connected either with PEEK pressure screws 50 6.2744.010 (long) or PEEK

pressure screws 51 6.2744.070 (short, for connection to the IC

pump).

The "PTFE tubing connection to the MPak" 23 can be connected to the

PEEK pressure screw 52 4.422.4510 (wide).

The connectors must be fitted to the capillaries as follows in this case:

Capillaries provided with new connectors must feature a flawless, flat

cut edge. In order to ensure this, it is best to use the tubing cutter

6.2621.080.

1 Fit pressure screw

Slide the corresponding pressure screw (50, 51 or 52), as

shown in Figure 4 onto the capillary 53 (23 for MPak connection).

2 Insert the capillary into the connection

Slide the end of the capillary fully into the corresponding

connector (in order to avoid dead volume).

3 Tighten the pressure screw

Firmly tighten the pressure screw (50, 51 or 52) by hand (do not

use tools).

12

761 SD Compact IC / Instructions for Use 8.761.1043

Page 21

2.3 Description of the connections

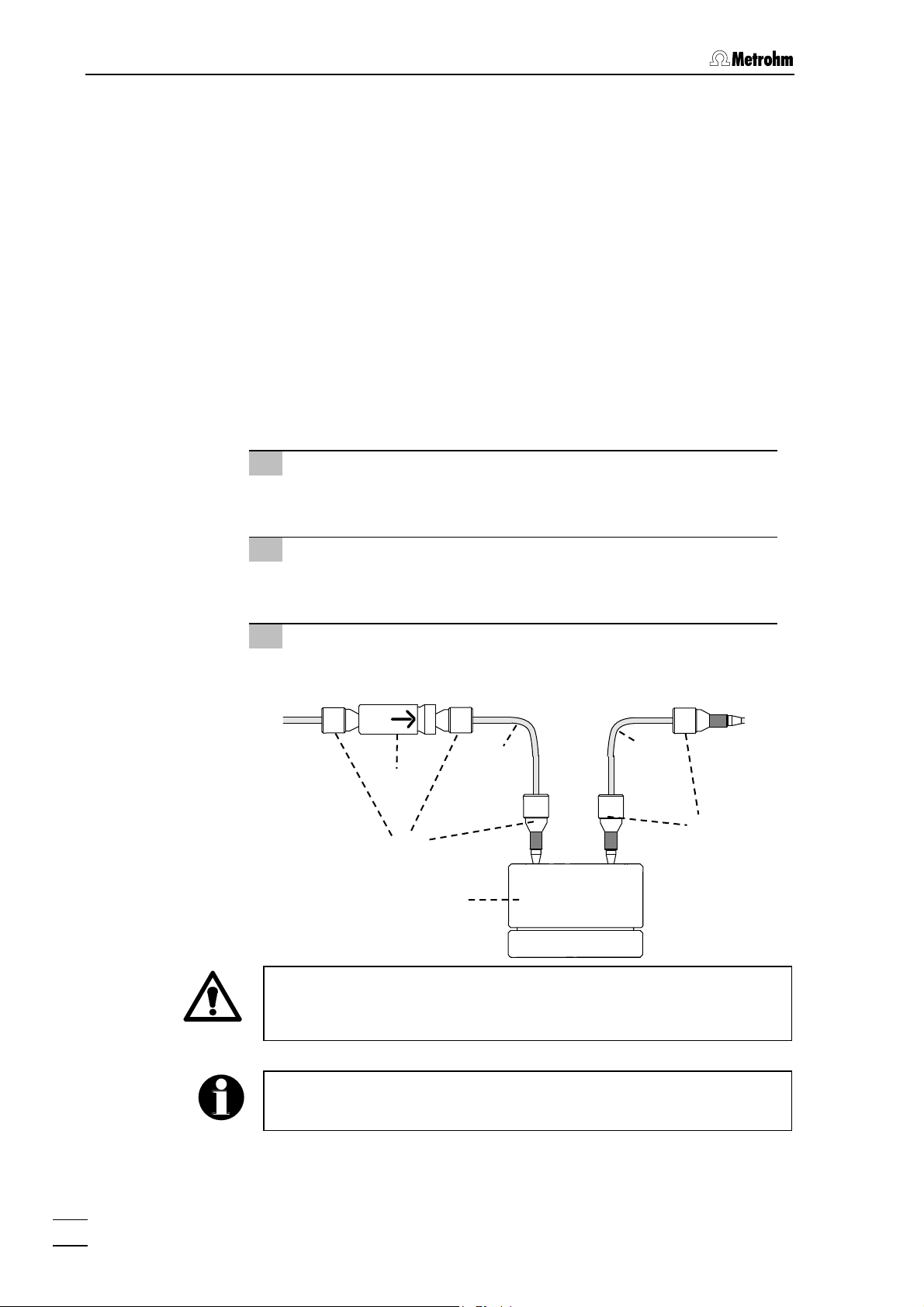

50

23 Tubing connection to MPak

6.1837.000

Pressure screw 6.2744.010

50

53

51

Pressure screw 6.2744.070

51

for IC pump

Pressure screw 4.422.4510

52

23

52

for tubing connection 23 to MPak

Capillary

53

PEEK capillary 6.1831.010 or PTFE-

Figure 4: Connectors for ca-

microcapillary 6.1803.030

pillaries

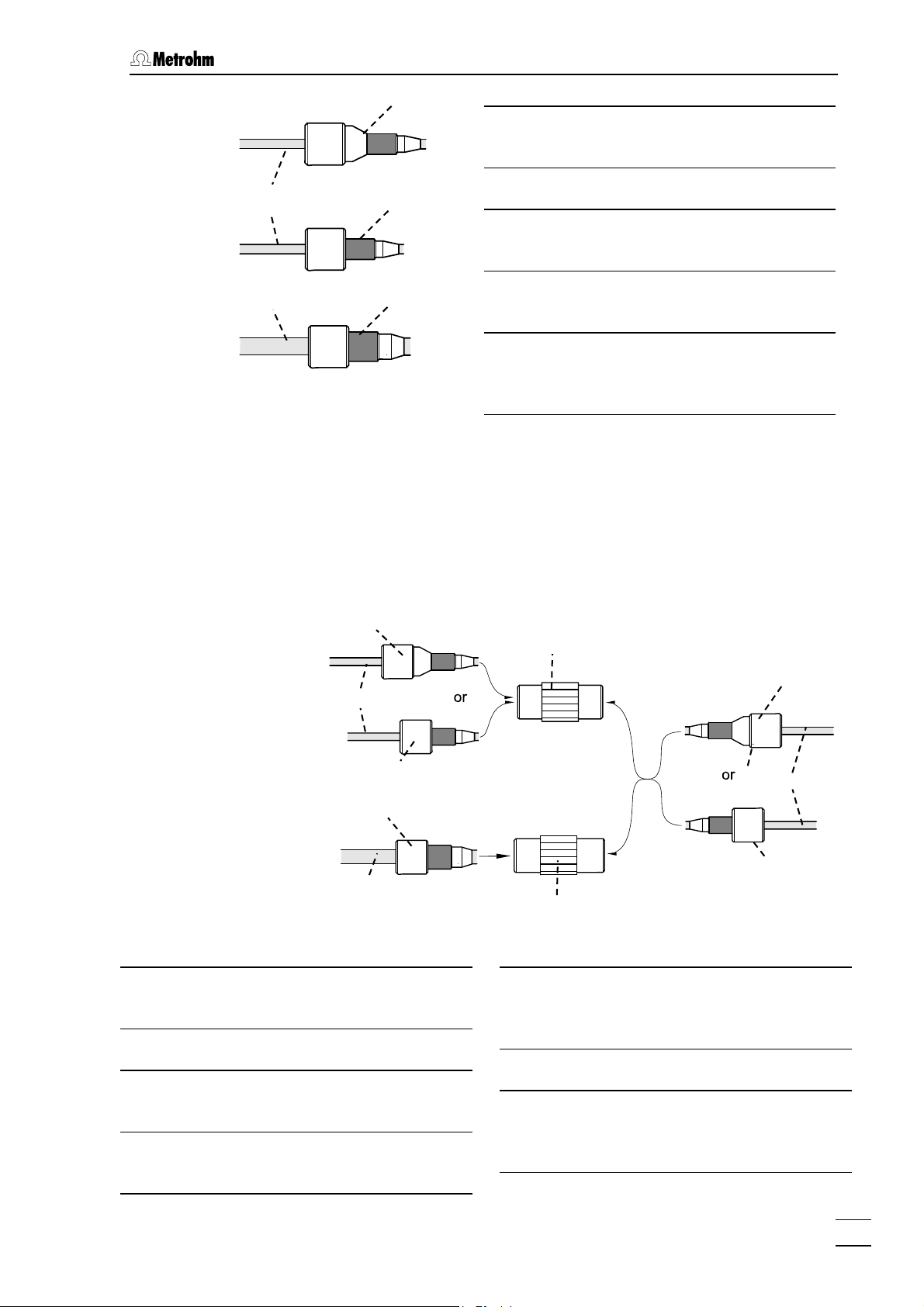

2.3.2 Connection between capillaries/tubing

Capillaries and tubing can be connected together using PEEK couplings. If PEEK capillaries 6.1831.010 and/or PTFE microcapillaries

6.1803.030 are to be connected together, use the PEEK coupling

6.2744.040. If the "tubing connection to the MPak" is to be connected,

use the PEEK coupling 4.422.4500.

50

53

51

52

23

Figure 5: PEEK couplings

23 Tubing connection to MPak

6.1837.000

50 Pressure screw 6.2744.010

51 Pressure screw 6.2744.070

for IC pump

52 Pressure screw 4.422.4510

for tubing connection 23 to MPak

54

55

53 Capillary

PEEK capillary 6.1831.010 or PTFEmicrocapillary 6.1803.030

PEEK coupling 6.2744.040

54

PEEK coupling 4.455.4500

55

coupling for "tubing connection to the

MPak"

50

53

51

761 SD Compact IC / Instructions for Use 8.761.1043

13

Page 22

2 Installation

Capillaries may also be connected together via PEEK inline filters, see

Section 2.3.3.

2.3.3 Filter unit PEEK

Three PEEK filter units 6.2821.120 should be fitted in the 761 SD

Compact IC.

The first one should be fitted between IC pump head 24 and pulsation

dampener 30. It serves to avoid contamination by abrasive particles of

the piston seals.

The two other filter units are installed upstream of the suppressor module. One upstream of the inlet capillary 42 (labelled "H2O") in the return

path from the detector to the suppressor in the eluent path (see Section

2.6.6). The other one upstream of the inlet capillary 45 (labelled

"H2SO4"), between peristaltic pump and suppressor module in the regenerant path (see Section 2.7.2). They serve to protect the suppressor

module against foreign particles and bacterial growth.

For the connection of the filter unit, please note the flow direction arrow printed on the housing.

53

50

Figure 6: Connecting the filter unit PEEK

50 Pressure screw 6.2744.010

53 Capillary

PEEK capillary 6.1831.010 or PTFEmicrocapillary 6.1803.030

Filter unit PEEK 6.2821.120

56

56

50

53

14

761 SD Compact IC / Instructions for Use 8.761.1043

Page 23

2.4 Connection of the detector block

w

2.4 Connection of the detector block

The metal-free detector block 1.732.0420 which must be fitted in the

instrument and connected belongs to the scope of delivery of the 761

SD Compact IC. Proceed as follows:

1 Note the cell constant

• The cell constant c = XX.X /cm, measured at the works, is

printed on the rear side of the detector block. Note this value;

it must subsequently be entered in the software in order to

ensure that an exact display of the conductivity is obtained

(see Section 2.12.3).

2 Install detector block

• Unscrew the two upper knurled screws 11 from the upper

rear panel 12 of the 761 SD Compact IC, slacken the t

lower knurled screws 11 a little and remove the rear panel

(see Figure 2).

• Position the detector block 40 from the rear onto the space

provided in the 761 SD Compact IC and push it fully to the

front (see Figure 7).

o

39

41

3 Connect detector block

• Pull the grey connecting cable permanently attached to the

detector block 40 out through the opening (where the upper

rear panel 12 previously was) on the rear of the 761 SD

Compact IC and plug it in to connection 20 "Detector Block"

of the 761 SD Compact IC.

Since other connections need to be routed through the rear openings

of the 761 SD Compact IC later on, you should not fit the rear panel

back on until the end of the installation procedure (see Section 2.10).

40

39 Inlet capillary to detector block

PEEK capillary, permanently attached

40 Detector block 1.732.0420

41 Outlet capillary from detector block

PEEK capillary, permanently attached

12

40

Figure 7: Position of the detector block

761 SD Compact IC / Instructions for Use 8.761.1043

15

Page 24

2 Installation

39

The inlet and outlet capillaries (

block must be fitted in the eluent path as described in Sections 2.6.5

and 2.6.6.

and 41) to and from the detector

2.5 Installation of the MPak cabinet and connection of the drain tubes

2.5.1 Installing the MPak cabinet

Install the MPak cabinet as shown on the drawing accompanying the

package. Position it next to the 761 SD Compact IC and suspend the

eluent and regenerant MPaks from the crossbars. Since eluent and regenerant are supplied from the rear to the 761 SD Compact IC, the outlets of the MPaks should point to the rear.

2.5.2 Drain tube for inner compartment

The 761 SD Compact IC features a connector (5) for escaped fluids on

the front panel. A drain tube can be fitted to the connector. Proceed as

follows:

1 Connect drain tube

• Plug the silicone tube 6.1816.020 onto the nipple.

2 Route the drain tube into an outlet

• Route the other end of the drain tube into an outlet and se-

cure it at this point.

2.5.3 Drain tube for MPak cabinet

The basin of the MPak cabinet 22 features a connection for fluids escaping from the MPaks to which a drain tube can be fitted. Proceed as

follows:

1 Connect drain tube

• Plug the silicone tubing 6.1816.020 onto the nipple.

2 Route the drain tube into an outlet

• Route the other end of the drain tube into an outlet and se-

cure it there.

16

761 SD Compact IC / Instructions for Use 8.761.1043

Page 25

2.6 Installing the eluent path

2.6 Installing the eluent path

2.6.1 High-pressure pump – Removing the transport security screws

The pump head is locked with three transport security screws 13 in order to prevent damage to the pump drive during transport (see Figure

2). These transport security screws must be removed before placing

the high-pressure pump into operation. Also remove the red sticker attached to the pump head 24.

The three transport security screws must be refitted every time before

a major transport operation of the pump in order to avoid damage to

the pump head.

2.6.2 Connection MPak → high-pressure pump

The eluent MPak must be connected to the pump head 24 via the tubing connection 23 6.1837.000.

First connect the end at the pump head and then, not before, connect

the end at the MPak output. The eluent will start to drain out if you

connect the end at the MPak output first.

Procedure when connecting the tubing connection:

1 Connect the tubing connection using the PEEK

coupling to the pump head

• Connect the tubing connection 23 6.1837.000 using the

PEEK coupling 55 (already pre-fitted to the tubing) to the

capillary inlet of the pump head 24.

23

2 Connect the tubing connection to the eluent MPak

outlet

• Connect the other end of the tubing connection 23 to the elu-

52

ent MPak outlet (pierce the connection and turn it through 90°

clockwise).

55

51 53

761 SD Compact IC / Instructions for Use 8.761.1043

17

Page 26

2 Installation

2.6.3 Connection high-pressure pump → injection valve

In order to protect the column material against hammering effects owing to injection, the supplied pulsation dampener 6.2620.150 must

be fitted between high-pressure pump and injection valve of the 761 SD

Compact IC.

Connection between pump head and injection valve (see Figure 3):

Pump head 24 → connection capillary 25 → purge valve 26 → connection capillary 28 → inline filter 56 → connection capillary 29 →

pulsation dampener 30 → connection capillary 31 → injection valve

When delivered, a PEEK coupling 54 is fitted in place of the pulsation

dampener 30 between connection capillary 29 and 31. The PEEK coupling should be removed and the pulsation dampener should be fitted

at the same position. Proceed as follows:

1 Position the pulsation dampener

Place the pulsation dampener 30 6.2620.150 in the inner compartment of the 761 SD Compact IC on the bottom.

2 Remove the PEEK coupling

Remove the PEEK coupling 54 located between connection

capillary 29 and 31.

3 Connect the pulsation dampener

Connect the connection capillary 29 and connection capillary 31

to the pulsation dampener.

29

31

56

50

50

30

The pulsation dampener is filled with isopropanol and must be rinsed

with eluent before connection of a separating column (see Section

2.13.2).

The pulsation dampener 6.2620.150 can be operated in both directions.

18

761 SD Compact IC / Instructions for Use 8.761.1043

Page 27

2.6 Installing the eluent path

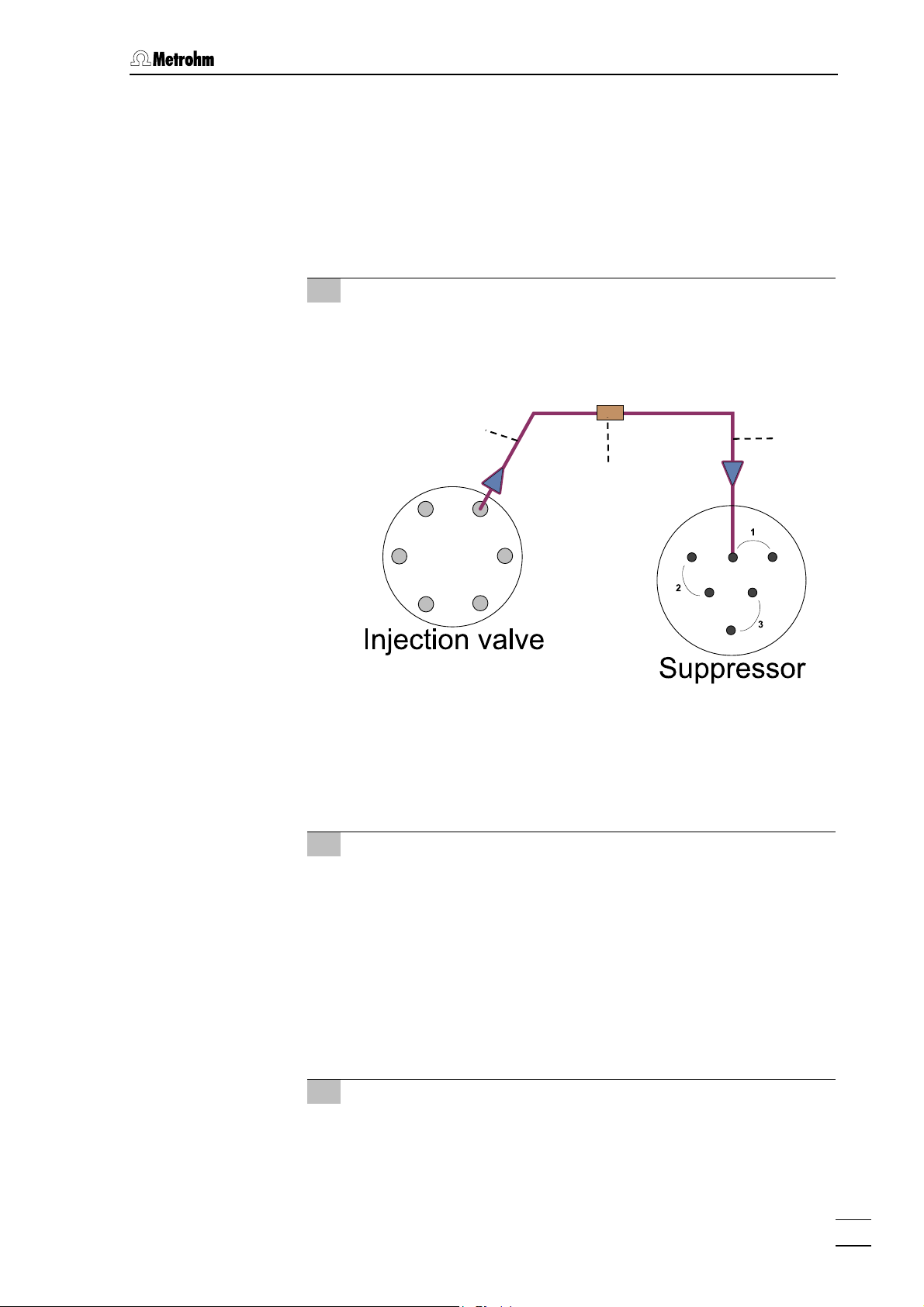

2.6.4 Connection injection valve → suppressor

The precolumn and the separating column are fitted between injection

valve and suppressor in the operational system (see Figure 3). How-

ever, since the system should first be rinsed without columns (so as not

to damage them), the columns may be fitted only later (see Section

2.15). A PEEK coupling 54 is fitted as a temporary replacement.

Proceed as follows:

1 Fit the PEEK coupling 54

Connect the column connection capillary 33 to the "suppressor

inlet capillary for eluent ("Eluent")" 37 via the PEEK coupling 54

(see Section 2.3.2).

Temporary connection schematic (c.f. Figure 3):

33

2.6.5 Connection suppressor → detector

From the suppressor, the eluent stream is routed on to the detector

(see Figure 3). The connection is made using a PEEK coupling. Proceed as follows:

1 Fit the PEEK coupling 54

Connect the "suppressor outlet capillary for eluent ("Detector")"

38 via the PEEK coupling 54 (see Section 2.3.2) to the "inlet ca-

pillary to detector block" 39.

37

54

2.6.6 Connection detector → suppressor

Downstream of the detector, the eluent flow is routed back into the

suppressor. It rinses the suppressor there after its regeneration phase.

A filter unit PEEK is fitted between detector and suppressor. Proceed as

follows:

1 Fit the filter unit PEEK

Connect the "outlet capillary from detector block" 41 via the filter

unit PEEK 54 (see Section 2.3.3) to the "suppressor inlet capillary for eluent ("H2O")" 42.

761 SD Compact IC / Instructions for Use 8.761.1043

19

Page 28

2 Installation

2.6.7 Connection suppressor → waste

Route the "suppressor outlet capillary for eluent ("Waste")" 44 at the rear

out of the 761 SD Compact IC into a waste container.

2.7 Installing the regenerant path

The regenerant (100 mmol/L H2SO4) is aspirated with the peristaltic

pump from the regenerant MPak and forced into the suppressor via the

filter unit PEEK. From the suppressor, it is then routed into a waste container (see Figure 9).

2.7.1 Fitting the pump tubing for regenerant

One channel of the two-channel peristaltic pump is used to pump the

regenerant. Fit a pump tubing 61 6.1826.110 as follows:

1 Disengage the tubing cartridges

• Detach and disengage the two tubing cartridges 57 above

the pump drive 49 by pressing in the snap-action lever 59 on

the retaining bracket.

• Press the pressure lever 58 down fully.

2 Fit the couplings 60

• Fit one coupling 60 6.2744.110 onto each end of the pump

tubing 61 6.1826.110. Moistening the tip of the coupling

lightly will make it easier to slip it on.

3 Fit the pump tubing

• Insert the fitted pump tubing 61 as shown in Figure 8 into the

tubing cartridge. The left-hand stopper 62 should latch into

the corresponding fixture on the left-hand side of the tubing

cartridge.

4 Reengage the tubing cartridge

• Reengage the tubing cartridge with pump tubing 61 in the re-

taining bracket. Engage it at the left first and then press the

right-hand side down until the snap-action lever 59 engages.

Ensure that the pump tubing is not kinked when doing this.

• Leave the other tubing cartridge outside. It is fitted with the

pump tubing for the sample path (see Section 2.8.1).

20

761 SD Compact IC / Instructions for Use 8.761.1043

Page 29

2.7 Installing the regenerant path

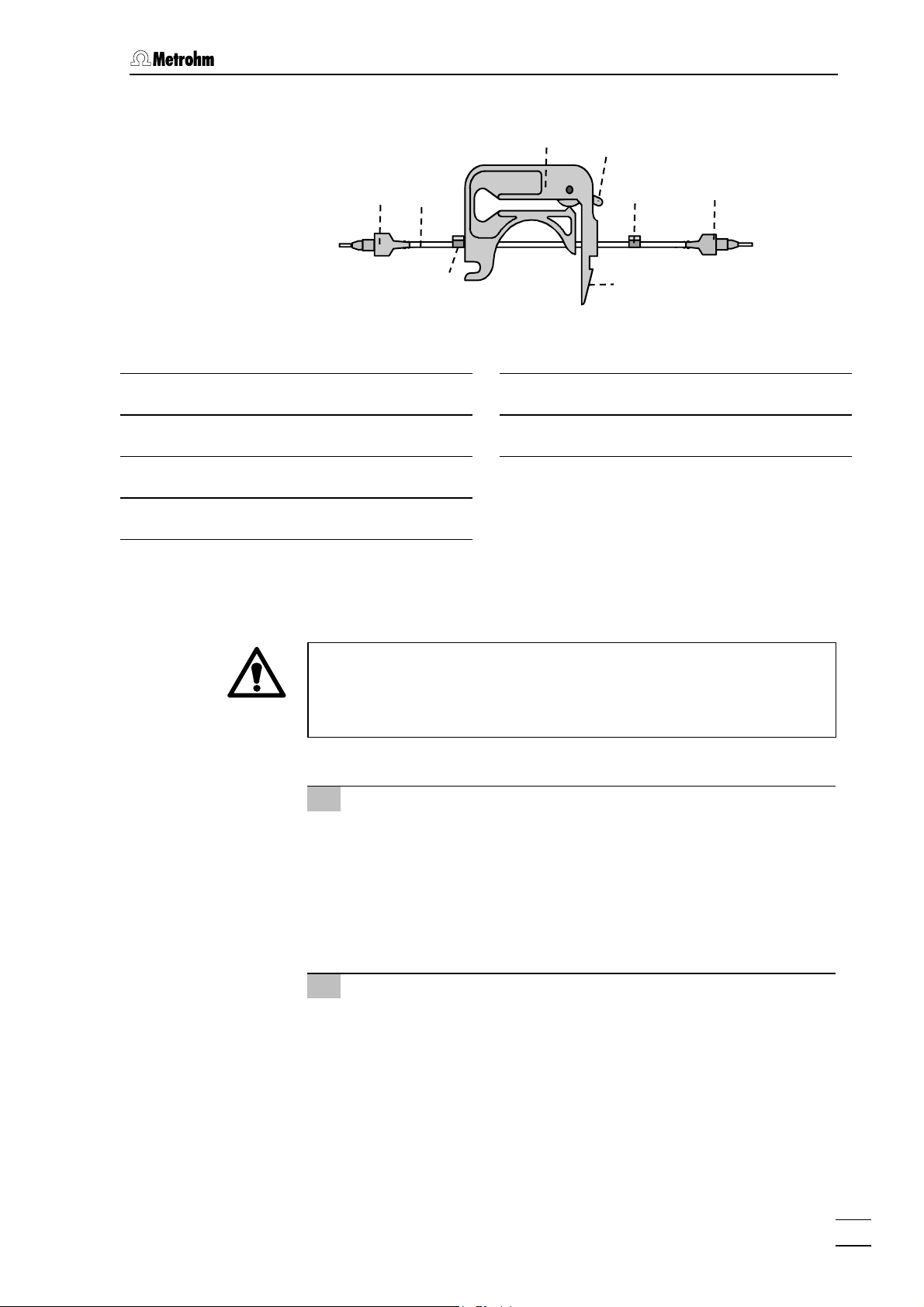

Tubing cartridge

57

Pressure lever

58

Snap-action lever

59

Coupling 6.2744.110

60

57

58

60

61

62

62

59

Figure 8: Pump tubing for regenerant path

Pump tubing 6.1826.110 for H

61

Stopper orange-yellow

62

60

2SO4

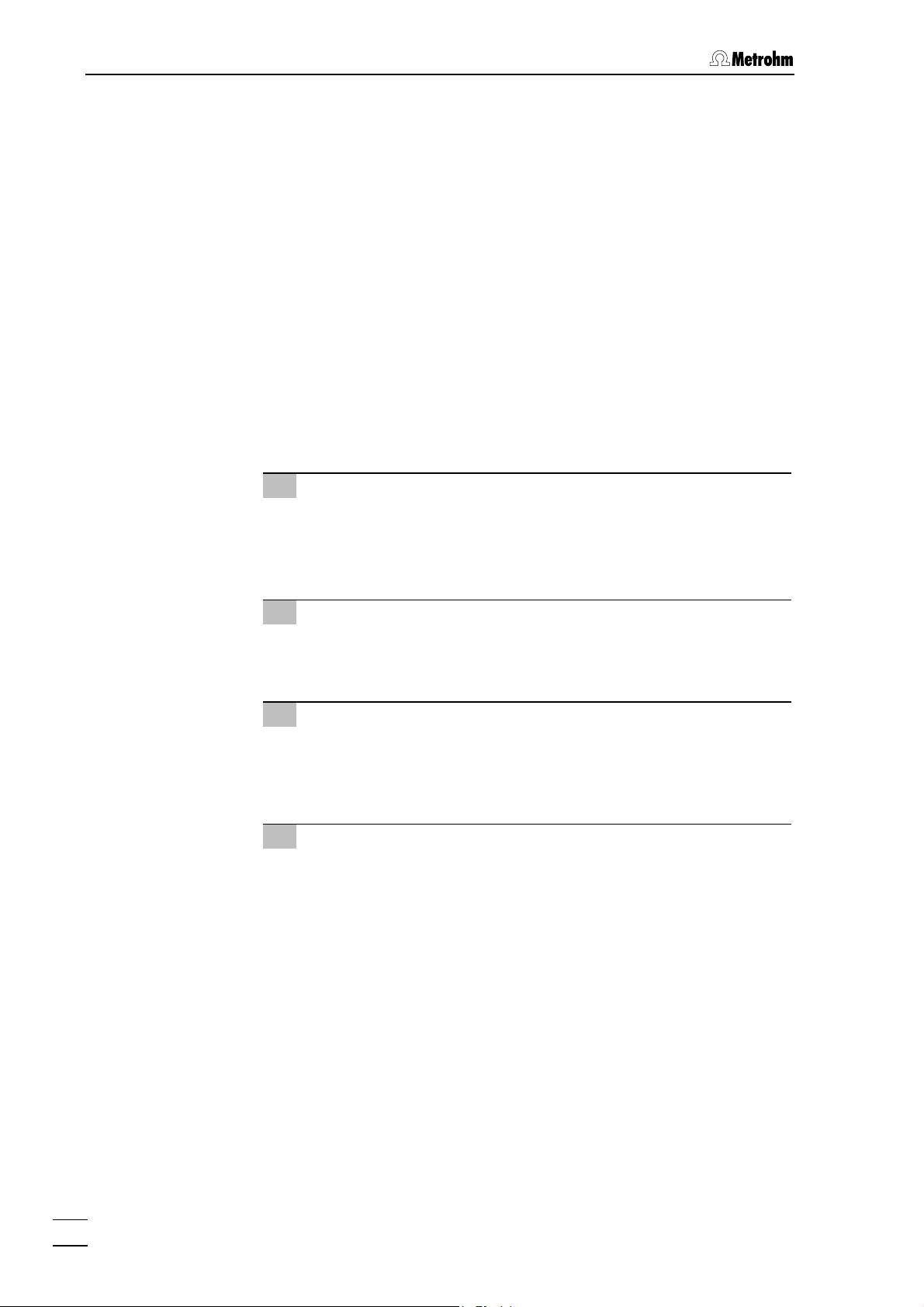

2.7.2 Connection regenerant-MPak → pump tubing → suppressor

→ waste

The connections to the pump tubing, suppressor and waste must be

connected first. Then, and not before, connect the end at the MPak

outlet. If the end at the MPak outlet is connected first, the regenerant

(H

Proceed as follows:

1 Connection Pump tubing - Suppressor

2 Connection Suppressor - Waste

) will begin to escape.

2SO4

• Screw the filter unit PEEK 56 6.2821.120 onto the coupling 60

6.2744.110 at the right-hand end (flow outlet) of the pump

tubing 61 fitted in the peristaltic pump. Note the flow direction

arrow on the filter unit.

• Firmly screw the "suppressor inlet capillary for regenerant

("H2SO4")" 45 onto the filter unit 56 with a pressure screw 50

6.2744.010 (see also Section 2.3.3).

• Route the "suppressor outlet capillary for regenerant

("Waste")" 46 at the rear out of the 761 SD Compact IC into a

waste container.

761 SD Compact IC / Instructions for Use 8.761.1043

21

Page 30

2 Installation

3 Connection MPak pump tubing

The regenerant MPak and pump tubing are connected using the

"tubing connection to MPak" 23 6.1837.000:

• First connect the end which is to be connected to the pump

tubing!

• Pressure screw 52 4.422.4510 and coupling 55 4.455.4500

are already pre-fitted on the "tubing connection to MPak" 23

6.1837.000. Screw this coupling 55 4.455.4500 onto the coupling 60 6.2744.110 plugged onto the left-hand end of the

pump tubing (flow inlet).

• Latch the other end of the "tubing connection to MPak" 23

6.1837.000 at the outlet of the regenerant MPak.

52

23

60

55

Figure 9: Flow schematic regenerant flow

23 Tubing connection to MPak

6.1837.000

45 Suppressor inlet capillary for re-

generant

PTFE capillary, permanently attached

to the suppressor, labelled "H2SO4"

46 Suppressor outlet capillary for re-

generant ("Waste")

PTFE capillary, permanently attached

to the suppressor; leads in to the

waste, labelled "Waste"

60

50

46

61

56

45

52 Pressure screw 4.422.4510

for "tubing connection to MPak" 23

55 PEEK coupling 4.455.4500

Coupling for "tubing connection to

MPak" 23

56 Filter unit PEEK 6.2821.120

60 Coupling 6.2744.110

61 Pump tubing 6.1826.110 for H2SO4

50 Pressure screw 6.2744.010

22

761 SD Compact IC / Instructions for Use 8.761.1043

Page 31

2.8 Installing the sample path

2.8 Installing the sample path

The sample is aspirated with the peristaltic pump from the sample vessel into the injection valve and finally ejected into a waste container.

See Section 2.9. for connection of the 766 IC Sample Processor

(supplied together with instrument version 2.761.0520).

2.8.1 Fitting the pump tubing for sample

The second channel of the two-channel peristaltic pump is used to

pump the sample. Fit the pump tubing 64 6.1826.110 as follows:

1 Disengage the tubing cartridges

• The tubing cartridge for the pump tubing should still be out-

side from installing the regenerant path. If not, remove it as

specified in Section 2.7.1.

2 Fit the coupling 63

• Plug a coupling 63 6.2744.030 onto the left-hand of the pump

tubing 64 6.1826.110. Lightly moistening the tip of the coupling will make it easier to slip on.

3 Fit the coupling with tubing security device 65

Fit a coupling with tubing security device 65 6.2744.160 onto the

right-hand end of the pump tubing 64 6.1826.110 (see Figure

10):

• Dismantle the tubing security device and first slide the un-

ion nut and the thrust piece onto the tubing.

• Plug the tubing onto the coupling and screw the union nut

onto the coupling in order to lock the tubing.

4 Insert the pump tubing

• Insert the fitted pump tubing 64, as shown in Figure 10, into

the tubing cartridge. The left-hand stopper 62 should engage

in the corresponding fixture on the left-hand side of the tubing

cartridge when doing this.

5 Reengage the tubing cartridge

• The tubing cartridge with the pump tubing 61 for the regener-

ant path should already be engaged (see Section 2.7.1).

Slide it to the rear.

• Engage the tubing cartridge with pump tubing 64 for the

sample path at the front into the retaining bracket. Engage it

at the left first and then push the right-hand side down until

the snap-action lever 59 engages. Ensure that the pump tubing is not kinked when doing this.

761 SD Compact IC / Instructions for Use 8.761.1043

23

Page 32

2 Installation

57

58

62

63

Figure 10: Pump tubing for sample path

57 Tubing cartridge

58 Pressure lever

59 Snap-action lever

62 Stopper orange-yellow

64

59

63

64

65

62

PEEK coupling 6.2744.030

Pump tubing 6.1826.110 for sample

PEEK coupling 6.2744.160

with tubing security device

65

2.8.2 Connection sample vessel → pump tubing → injection valve

→ waste

Proceed as follows in order to make the connections for the sample

path:

1 Connection Sample vessel - pump tubing

The sample is aspirated with the aspirating tubing 3:

• The aspirating tubing 3 is routed through the "feedthrough for

aspirating tubing" 2 out of the front door into the sample vessel. It is fixed in position on the feedthrough 2 with a rotary

nipple (see Section 2.9.2 if using the 766 IC Sample Processor).

• Detach the other end of the aspirating tubing 3 with pressure

screw 50 from the injection valve (it is fitted there only for delivery purposes) and screw it firmly onto the PEEK coupling

63 on the left-hand end of the pump tubing (flow inlet) (see

Figure 11).

24

761 SD Compact IC / Instructions for Use 8.761.1043

Page 33

2.8 Installing the sample path

2 Connection pump tubing - injection valve

• The sample is forced into the injection valve via the connec-

tion capillary 47.

• Detach the connection capillary 47 with the two pressure

screws 50 from the outlet of the injection valve and from the

opening in the door (it is fitted there only for delivery purposes).

• Screw the ends of the connection capillary 47 to the inlet of

the injection valve and to the PEEK coupling 65 on the righthand end of the pump tubing (flow outlet) using one pressure

screw 50 (see Figure 11).

3 Connection injection valve - waste container

The connection capillary 48 routes the sample from the injection

valve into the waste:

• Connect the supplied PTFE capillary 6.1803.030 with a pres-

sure screw 50 6.2744.010 to the outlet of the injection valve.

• Route the other end at the rear out of the 761 SD Compact IC

into the waste container. Wait until after the rear panel has

been fitted to cut it to size (see Section 2.10).

50

3

Figure 11: Flow schematic sample stream

3 Aspirating tubing

for sample

47 Connection capillary

PTFE capillary 6.1831.030, connection

pump tubing - injection valve

48 Connection capillary

PTFE capillary 6.1831.030, connection

injection valve - waste container

63

64

48

50

65

47

63 PEEK coupling 6.2744.030

64 Pump tubing 6.1826.110 for sample

65 PEEK coupling 6.2744.160

with tubing security device

50 Pressure screw 6.2744.010

The sample stream should be routed into a waste container downstream of the injection valve (see Section 2.8.2.).

761 SD Compact IC / Instructions for Use 8.761.1043

25

Page 34

2 Installation

2.9 Connecting the 766 IC Sample Processor

On instrument version 2.761.0520, the related 766 IC Sample Processor

should now be installed and connected.

The 766 IC Sample Processor is an automatic sampler for ion chromatography. The instrument accommodates max. 127 samples (sample

vessels: 2.5 mL or 11 mL) which are automatically transferred to the

sample loop attached to the injection valve of the 761 SD Compact IC.

Sample changing and filling of the sample loop are each started by a

signal output on the 761 SD Compact IC (761 SD Compact IC as "master").

2.9.1 Installing the 766 IC Sample Processor

Please refer to the supplied Instructions for Use 766 IC Sample Processor (8.766.1001) for installation of the 766 IC Sample Processor.

2.9.2 Connecting the 766 IC Sample Processor

Connect the 766 IC Sample Processor as follows:

1 Electrical connection 761 – 766

• Connect the remote end of cable 6.2125.110 to the RS232

connection 32

Sample Processors.

• Connect the other end to the COM2 output of the PC.

2 Tubing connection 766 – injection valve

• Undo the rotary nipple which is screwed in on the inner com-

partment side of the "feedthrough for aspirating tubing" 2.

• Pull the aspirating tubing 3 fully out of the "feedthrough for

aspirating tubing" 2 and unscrew it from the injection valve.

• Cut the PEEK capillary tubing 18

766) installed on the 766 IC Sample Processor to the required

length.

• Pull the free end of the PEEK capillary tubing 18

tions for Use 766) through the "feedthrough for aspirating tubing" 2 into the inner compartment of the 761 SD Compact IC

and screw it on to the inlet of the injection valve which is now

free (see also Figure 11) using a PEEK pressure screw

6.2744.010.

• Screw the rotary nipple on the inner compartment side of the

"feedthrough for aspirating tubing" 2 back on and thus fix the

transfer tubing 18

(see Instructions for Use 766) of the 766 IC

(see Instructions for Use 766) in position.

(see Instructions for Use

(see Instruc-

26

761 SD Compact IC / Instructions for Use 8.761.1043

Page 35

2.10 Fitting the rear panel

2.10 Fitting the rear panel

Now refit the rear panel which was removed during installation (Section

2.4). Place the incoming and outgoing cables and tubing at the rear

into the openings in the rear panel.

Figure 12: Rear panel

8 Opening for outlet capillaries

for discharge of eluent, regeneration

and sample solution

9 Opening for inlet capillaries

for supply of eluent, regeneration and

sample solution

10

Waste B

8

Waste A

9

11

10 Opening for detector cable

11 Knurled screws

for fastening the rear panel

Metrohm recommends the following distribution over the openings:

Connection Opening leads to

• Suppressor outlet capillary for eluent ("Waste") 44

• Suppressor outlet capillary for regenerant ("Waste") 46

8

• Waste container

• Connection capillary 48

• Tubing connection to eluent MPak 23

• Tubing connection to regenerant MPak 23

• Detector connection cable

9

10

• Eluent MPak

• Regenerant MPak

• Input

"Detector Block"

Then fit the rear panel, fit the upper 2 knurled screws 11 and firmly

screw all 4 knurled screws 11 tight.

761 SD Compact IC / Instructions for Use 8.761.1043

27

Page 36

2 Installation

2.11 Mains connections

Next connect the 761 SD Compact IC to the electrical mains. Separating column and precolumn will not yet have been fitted. They are fitted

only after rinsing the new equipment components (see Section 2.15).

Follow the instructions below for connecting to the power supply. If the

instrument is operated with a mains voltage set wrongly and/or wrong

mains fuse, there is a danger of fire!

2.11.1 Setting the mains voltage

Before switching on the 761 SD Compact IC for the first time, check that

the mains voltage set on the instrument (see Figure 13) matches the local mains voltage. If this is not the case, you must reset the mains voltage on the instrument as follows:

1 Disconnect mains cable

Disconnect mains cable from mains connection plug 15 of the

761 SD Compact IC.

2 Remove fuse holder

Using a screwdriver, loosen the fuse holder 16 below the mains

connection plug 15 and take it out completely.

3 Check and change the fuse

Carefully remove the fuse installed for the desired mains voltage

out of the fuse holder 16 and check its specifications (the position of the fuse in the fuse holder is marked by the white arrow

imprinted next to the mains voltage range):

100…120 V 1.0 A (slow-blow) Metrohm No. U.600.0016

220…240 V 0.5 A (slow-blow) Metrohm No. U.600.0013

4 Insert fuse

Change the fuse if necessary and reinsert it in the fuse holder

16.

5 Fit the fuse holder

Depending on the desired mains voltage, insert the fuse holder

16 in the 761 SD Compact IC so that the corresponding mains

voltage range can be read normally and the adjacent white arrow points to the white bar imprinted below the fuse holder (see

Figure 13).

28

761 SD Compact IC / Instructions for Use 8.761.1043

Page 37

2.11 Mains connections

V

220 – 240 V

14

15

16

2.11.2 Fuses

100 –120

14 Mains switch

Switch for switching the instrument on

and off:

I = ON 0 = OFF

15 Mains connection plug

Mains connection, see Section 2.11.3

16 Fuse holder

220 - 240 V

100 - 120 V

100 - 120 V

220 - 240 V

Figure 13: Setting the

mains voltage

One of the two fuses 1 A/slow-blow for 100…120 V or 0.5 A/slow-blow

for 220…240 V is installed in the fuse holder 16 of the 761 SD Compact

IC as standard.

Ensure that the instrument is never put into operation with fuses of another type; otherwise there is a danger of fire!

For checking or changing fuses, proceed as described in Section

2.11.1.

2.11.3 Mains cable and mains connection

Mains cable

The instrument is supplied with one of three mains cables

• 6.2122.020 with plug SEV 12 (Switzerland, …)

• 6.2122.040 with plug CEE(7), VII (Germany, …)

• 6.2133.070 with plug NEMA 5-15 (USA, …)

which are three-cored and fitted with a plug with an earthing pin. If a different plug has to be fitted, the yellow/green lead (IEC Standard) must

be connected to protective earth (protection class 1).

Any break in the earthing inside or outside the instrument can make it

a hazard!

Mains connection

Plug the mains cable into the mains connection plug 15 of the 761 SD

Compact IC (see Figure 13).

2.11.4 Switching the instruments on/off

The 761 SD Compact IC is switched on and off using the mains switch

14. When the instrument is switched on, the mains pilot lamp 7 lights.

761 SD Compact IC / Instructions for Use 8.761.1043

29

Page 38

2 Installation

2.12 Connection to the PC

The next step is to connect the 761 SD Compact IC to the PC.

2.12.1 Connecting cable 6.2134.100

Always switch off the 761 SD Compact IC and PC before you connect

the two instruments with cable 6.2134.100.

Connect the RS 232 interface 21 on the 761 SD Compact IC to the serial COM1 port of the PC using the connecting cable 6.2134.100 (9pin/9-pin).

2.12.2 Software installation

The CD A.705.001 with software package «SD Analyzer 1.0» is supplied

with the 761 SD Compact IC. The two programs «IC Net» (see Section

3) and «IC Cap» (see Section 4), and in addition to the «Autodatabase»,

are installed when installing «SD Analyzer 1.0». The software runs under

the Windows 2000 and Windows XP operating systems and must be installed as follows:

1 Install program

• Insert the installation CD A.705.001 into your CD-ROM drive.

• Select

stallation CD. Follow the on-screen prompts of the Setup

program.

Metrohm recommends that you install the software in the stated default destination folder C:\Metrohm\SD Analyzer. If you install it to another location, you must (if you wish to work with «IC Cap») adapt the

path for chromatogram directory (in the Processing registry tab of the

METHOD SETUP window) for all used methods (see Section 3.1.3 and

the Software Instructions for Use «IC Net 2.3» Section 7.3.4).

2 766 IC Sample Processor

During installation, you will see the prompt "Do you work with

766 IC sample processor". Your selection will determine what

configuration is loaded in «IC Cap» when you install it (see also

Section 4.2).

Run in the Start menu and open file Setup.exe on the in-

30

761 SD Compact IC / Instructions for Use 8.761.1043

Page 39

2.12 Connection to the PC

3 Files

The installation program copies the files from the installation CD

to the directory which you specify and also creates the following

subdirectories:

\Metrohm\Sd Analyzer\Ic Net\

Data Directory for data files (*.chw) and

batch reprocessing files (

Devices Directory for device drivers (*.dev)

ExcelReport Directory for the Excel reports

ICCap Directory for «IC Cap» installation files and

«IC Cap» configuration files (

Methods Directory for method files (*.mtw)

Reports Directory for report files (*.txt)

and graphic files (

Systems Directory containing system files (*.smt) and

sample table files (

*.wmf)

*.que).

*.bar)

*.cfg)

4 Registration

• Please send us your registration card 8.761.8047 as soon as

possible so that we can register you as an official purchaser.

As a registered purchaser, you will receive any revised program versions at a special price.

The installed files are generally not write-protected. To prevent these

files from being deleted by mistake, switch on the write-protection or

make a backup copy in another directory.

2.12.3 Basic settings «IC Net»

The procedure for starting and quitting the software is described in the

Software Instructions for Use «IC Net 2.3» Section 2.

Add User window (see below) opens the first time you launch the

The

program after installing the software and a user with Administrator access rights is created.

You are advised to create the other users straight after installation. See

Software Instructions for Use «IC Net 2.3», Section 3.2 for creating users.

761 SD Compact IC / Instructions for Use 8.761.1043

31

Page 40

2 Installation

Enter cell constant

Now enter the cell constant (see Section 2.4) printed on the detector

block. Proceed as follows:

1 Open and connect a system

• Click on File / Open / System in the main window. In the window

which now opens, select file

startup.smt and click on <Open>.

You will see the following system window:

• Select the

Connect to workplace menu item of the Control menu

in this window.

2 Open the window for hardware settings

• Click with the right mouse button on the 761 image in the sys-

tem window and choose menu item

Hardware. You will see the

following window for the hardware settings:

3 Enter the cell constant

• Enter the cell constant printed on detector block 1.732.0420

in field

• Click on

Cell constant.

<OK> to save the settings and close the window.

32

761 SD Compact IC / Instructions for Use 8.761.1043

Page 41

2.12 Connection to the PC

2.12.4 Basic settings «IC Cap»

Logging in

The first time you start the «IC Cap» software, you must log in without

User or Password. The particular configuration loaded the first time you

open the program depends on whether you work with or without 766 IC

Sample Processor (you must make this selection during the installation

process, see Section 2.12.2).

Without 766 IC Sample Processor:

manual.cfg (see Section 4.2.2)

With 766 IC Sample Processor: auto.cfg (see Section 4.2.3)

The first time you log in, you should define the Administrator and other

users.

Defining Administrator/Users

In order to do this, open the

mouse button (see Section 4.2). Then, in the General tab of the

FIGURATION

Level (level: Administrator) and Password. For the Administrator, enter

the same

window, define the Administrator by entering User with

user with the same password which you already defined in «IC

CONFIGURATION window with the right

CON-

Net».

Then define the other users. For the users, enter the same

same

password which you already defined in «IC Net». See the Adminis-

user with the

trator Manual «IC Cap 2.0», Section 3.2 for creating users.

The users are a part of the configuration and are saved together with

it.

Save configuration

Select the Miscellaneous tab in the

CONFIGURATION window and

click on the <Store Configuration> button. Save the configuration

under a separate name.

Close the software again (see Administrator Manual «IC Cap 2.0» Sec-

tion 3.2).

761 SD Compact IC / Instructions for Use 8.761.1043

33

Page 42

2 Installation

2.13 Deaerating the pump and rinsing the pulsation dampener

The high-pressure pump must be deaerated and the isopropanol-filled

pulsation dampener must be rinsed before placing into operation for

the first time.

2.13.1 Deaerating the pump

1 Prepare for deaeration

• Open the rotary knob on the purge valve 26 by approx. ½ a

turn counter-clockwise.

• Remove the plastic stopper from the connection 6 on the

front panel of the 761 SD Compact IC (see Figure 1).

• Push the syringe 6.2816.020 (without needle) fully into the

connection 6.

2 Open and connect the system

• Launch the «IC Net» PC program if it has not already been

launched.

• Choose

dow which now opens, select file

<Open>. You will now see the following system window:

File / Open / System in the main window. In the win-

startup.smt and click on

• Select the

this window.

34

761 SD Compact IC / Instructions for Use 8.761.1043

Connect to workplace item from the Control menu in

Page 43

2.13 Deaerating the pump and rinsing the pulsation dampener

3 Open the control window

• Double-click on the 761 image in the System window. You will

see the window for manual operation of the 761 SD Compact

IC (see below).

4 Deaerate the pump

• Ensure that the "tubing connection to the eluent MPak" 23 is

connected to the eluent MPak.

• Click on the

<On> button for IC pump to switch on the high-

pressure pump.

• Aspirate air with the syringe inserted in connection 6 until elu-

ent flows into the syringe.

• Click on the

<Off> button for IC pump, to switch the high-

pressure pump back off.

• Close the rotary knob on the purge valve 26 by turning it

clockwise.

• Remove the syringe from the connection 6.

2.13.2 Rinsing the pulsation dampener

The pulsation dampener must be rinsed before using it for the first time

so as to remove the isopropanol which is located in the flow area of the

eluent on delivery.

The isopropanol should not be rinsed through the suppressor and the

detector. Consequently, the column connection capillary

currently connected to the suppressor via the PEEK coupling) must be

detached from the PEEK coupling and routed into a beaker.

33

(which is

761 SD Compact IC / Instructions for Use 8.761.1043

35

Page 44

2 Installation

1 Detach the column connection capillary 33 from the

PEEK coupling

• Undo the pressure screw 50 with which the column connec-

tion capillary 33 is screwed to the PEEK coupling 54 (transition to the suppressor). Take this end of the capillary and

route it into a beaker.

The column connection capillary 33 should now connect the injection valve to the beaker.

2 Open and connect the system

• Open the startup.smt system, connect it and make the same

settings as described in Section 2.13.1.

3 Rinse the pulsation dampener

• Click on the <On> button for IC pump to switch on the high-

pressure pump and rinse the pulsation dampener 30 filled

with isopropanol for approx. 10 minutes with eluent.

• Click on the

<Off> button for IC pump to switch the high-

pressure pump back off again.

4 Connect the column connection capillary 33 back to

the PEEK coupling

• Take the end of the column connection capillary 33 out of the

beaker and screw it back onto the PEEK coupling 54 (as a

transition to the suppressor) with a pressure screw 50.

36

761 SD Compact IC / Instructions for Use 8.761.1043

Page 45

2.14 Rinsing before fitting the column

w

2.14 Rinsing before fitting the column

Before the column is fitted, you should rinse again for 10 minutes. During this rinsing time, the connections should be checked for leaks and

the pressure of the peristaltic pump should be set optimally.

1 Check the fluid connections

• Immerse the aspirating tubing for sample 3 into a sample

vessel filled with ultra-pure water.