Maytag ATB2130AR series, ATB1836AR series, ATB1838AE series, ATB1830AR series, ATB2136AR series Service Manual

...

Service

This manual is to be used by qualified appliance

technicians only. Maytag does not assume any

responsibility for property damage or personal

injury for improper service procedures done by

an unqualified person.

18 & 21

Cubic Foot

Top Mount

Refrigerators

This Base Manual covers general information

Refer to individual Technical Sheet

for information on specific models

This manual includes, but is

not limited to the following:

ATB1821AR*

ATB1830AR*

ATB1836AR*

ATB1838AE*

ATB1832AR*

ATB2130AR*

ATB2132AR*

ATB2136AR*

ATB2138AR*

ATF2136AR*

ATF2138AR*

CTB1821AR*

CTN1821AE*

CTL1821AE*

CTB2121AR*

CTF2126AR*

MTB1891AR*

MTB1893AR*

MTB1895AE*

MTB2193AR*

MTB2195AR*

MTF2193AR*

MTF2195AE*

16025860

Replaces 16023446

January 2005

!

!

!

!

Important Information

Important Notices for Servicers and Consumers

Maytag will not be responsible for personal injury or property damage from improper service procedures. Pride and

workmanship go into every product to provide our customers with quality products. It is possible, however , that

during its lifetime a product may require service. Products should be serviced only by a qualified service technician

who is familiar with the safety procedures required in the repair and who is equipped with the proper tools, parts,

testing instruments and the appropriate service information. IT IS THE TECHNICIANS RESPONSIBILITY TO

REVIEW ALL APPROPRIATE SERVICE INFORMATION BEFORE BEGINNING REPAIRS.

WARNING

To avoid risk of severe personal injury or death, disconnect power before working/servicing on appliance to avoid

electrical shock.

To locate an authorized servicer, please consult your telephone book or the dealer from whom you purchased this

product. For further assistance, please contact:

Customer Service Support Center

CAIR Center

Web Site Telephone Number

WWW.AMANA.COM ............................................... 1-800-843-0304

WWW.JENNAIR.COM ............................................ 1-800-536-6247

WWW.MAYTAG.COM............................................. 1-800-688-9900

CAIR Center in Canada..........................................1-800-688-2002

Amana Canada Product .... ....... ....... ........................ 1-866-587-2002

Recognize Safety Symbols, Words, and Labels

DANGER

DANGER—Immediate hazards which WILL result in severe personal injury or death.

WARNING

WARNING—Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION

CAUTION—Hazards or unsafe practices which COULD result in minor personal injury, product or property

damage.

16025860 2 ©2005 Maytag Services

Table of Contents

Important Information ................................................. 2

Model Identification.................................................... 4

Component Testing

Compressor ............................................................ 5

Resistance Test .......................................................5

Ground Test............................................................. 5

Operation T est......................................................... 5

Capacitor................................................................. 6

Condenser...............................................................6

Overload / Relay...................................................... 7

Temperature Control ............................................... 7

Ice Maker ................................................................ 7

Condenser Motor.....................................................7

Evaporator Fan Motor ............................................. 7

Upper Freezer Light Switch .....................................8

Drier ........................................................................ 8

Defrost Timer .......................................................... 8

Evaporator............................................................... 9

Defrost Heater......................................................... 9

Defrost Thermostat ................................................. 9

Service Procedures

Service Equipment ................................................ 10

Drier Replacement ................................................ 10

Refrigerant Precautions............................................ 11

Line Piercing V alves .............................................. 11

Open Lines............................................................ 11

Compressor Operational Test................................ 11

Dehydrating Sealed Refrigeration System ............. 12

Leak Testing .......................................................... 12

Restrictions ...........................................................13

Evacuation and Charging ......................................... 14

Evacuation ............................................................ 14

Charging................................................................ 15

Refrigerant Charge ...................................................15

HFC134a Service Information .................................. 16

Health, Safety , and Handling ................................. 16

Comparison of CFC12 and HFC134a Properties .. 16

Replacement Service Compressor ..........................17

Compressor Testing Procedures ........................... 17

Refrigerant Flow ....................................................... 18

Cabinet Air Flow ....................................................... 19

Troubleshooting Chart .........................................20-22

System Diagnosis

Symptoms of an Overcharge................................. 23

Symptoms of Refrigeration Shortage.....................23

Symptoms of a Restriction .................................... 24

Symptoms of Air in System ................................... 24

Symptoms of Low or High Ambient ....................... 25

T emperature Installation........................................ 25

Heat Load..............................................................25

Disassembly Procedures

Door Removal

Freezer Door .........................................................26

Fresh Food Door ................................................... 26

Refrigerator Compartment

Light Bulb .............................................................. 27

Light Bulb Assembly.............................................. 27

Defrost Timer ........................................................ 27

Light Switch ...........................................................27

Cold Control .......................................................... 27

Freezer Compartment

Evaporator Cover .................................................. 27

Freezer T emperature Control ................................ 27

Evaporator Fan, Evaporator Motor ........................ 27

Defrost Terminator (Thermostat) ........................... 27

Defrost Heater....................................................... 27

Evaporator Removal.............................................. 28

Bottom of Cabinet

Front Roller Assembly ........................................... 28

Rear Roller Assembly............................................ 28

Condensate Drain Pan .......................................... 28

Machine Compartment

Condenser Fan & Fan Motor .................................28

Compressor .......................................................... 28

Overload/Relay/Capacitor......................................28

Condensate Drain Tube ........................................ 28

Condenser Removal.............................................. 28

Appendix A

Ice Maker Service Instructions ............................ A-2

Appendix B

Owners Manual ................................................... B-2

©2005 Maytag Services 3 16025860

Model Identification

Top Mount Refrigerator models vary in trim and

accessories, but all models have the same basic

construction. "Operating Instructions" and "Service

Instructions" apply to all cabinets unless stated

otherwise.

A T B 1 8 0 4 A R W

R = Regular

E = Energy Model

Brand

A = Amana

M = Maytag

` C = Magic Chef

Product

T ⎯ Top M ount

16025860 4 ©2005 Maytag Services

For positive identifications of individual units, state

complete serial number, model, and type. This

information is found on the serial plate located on front

upper right hand corner of foodliner or on some

models, exterior back of the outer casing.

An explanation of coding contained in Type position is

shown below.

Model Identification

Color

W ⎯ White

Q ⎯ B isque

Energy

Feature Package

1 - 3 ⎯ Good

4 - 6 ⎯ Better

7 ⎯ Best

Special Features

0 ⎯ Brand Base

Capacity

18 or 21 ⎯ C ubic Foot

Configuration

B ⎯ P rovisional

L ⎯ Left H and (Non P rovisional)

N ⎯ Right Hand(N on Provisional)

Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Compressor

When compressor electrical circuit is

energized, the start winding current

causes relay to heat. After an amount of

starting time, the start winding circuit

turns off. The relay will switch off the start

winding circuit even though compressor

has not started (for example, when

attempting to restart after momentary

power interruption).

With “open” relay, compressor will not

start because there is little or no current

to start windings. Overload protection will

open due to high locked rotor run winding

current.

With “shorted” relay or capacitor,

compressor will start and overload

protector will quickly open due to high

current of combined run and start

windings.

With open or weak capacitor,

compressor will start and run as normal

but will consume more energy.

Resistance test

1. Disconnect power to unit.

2. Discharge capacitor by shorting across terminals with a resistor for 1 minute.

NOTE: (Some compressors do not use a run capacitor.)

3. Remove leads from compressor terminals.

4. Set ohmmeter to lowest scale.

5. Check for resistance between

Terminals “S” and “C”, start winding

Terminals “R” and “C”, run winding

If either compressor winding reads open (infinite or very high resistance) or

dead short (0 ohms), replace compressor.

Ground test

1. Disconnect power to refrigerator.

2. Discharge capacitor, if present, by shorting terminals through a resistor.

3. Remove compressor leads and use an ohmmeter set on highest scale.

4. Touch one lead to compressor body (clean point of contact) and other probe

to each compressor terminal.

• If reading is obtained, compressor is grounded and must be replaced.

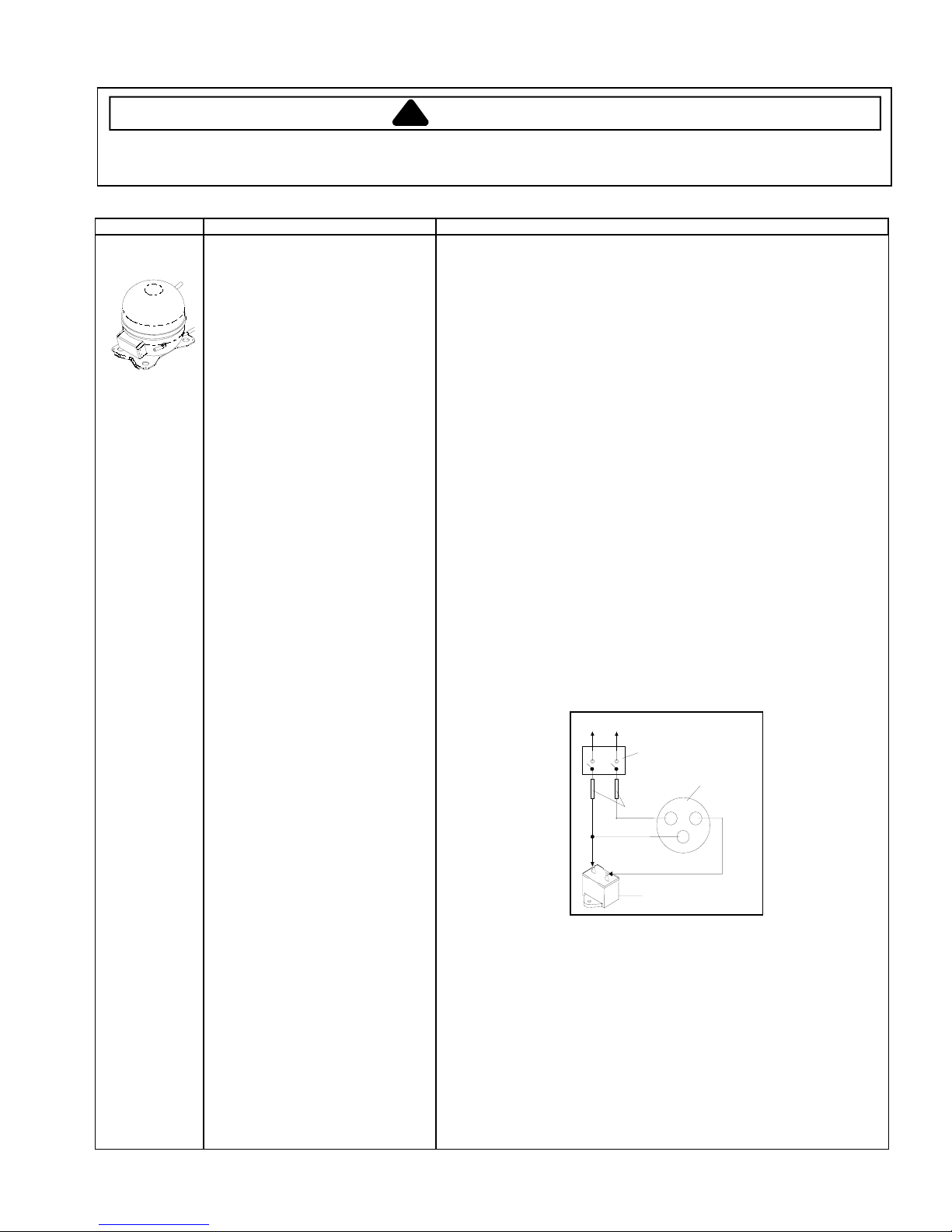

Operation test

If voltage, capacitor, overload, and motor winding tests do not show cause for

failure, perform the following test:

1. Disconnect power to refrigerator.

2. Discharge capacitor, if present, by shorting terminals through a resistor.

3. Remove leads from compressor terminals.

4. Wire a test cord to power switch.

5. Place time delayed fuse with UL rating equal to amp rating of motor in test

cord socket. (Refer to Technical Data Sheet)

6. Remove overload and relay.

7. Connect start, common and run leads of test cord on appropriate terminals of

compressor.

8. Attach capacitor leads of test cord together. If capacitor is used, attach

capacitor lead to a known good capacitor of same capacity.

To AC supply

Switch

Compressor

Fuses

CRS

Capacitor

Test configuration

9. Plug test cord into wattmeter to determine start and run wattage and use a

multimeter to check for low voltage, which can also be a cause of a

compressor not starting.

10. With power to multimeter, press start cord switch and release.

• If compressor motor starts and draws normal wattage, compressor is okay

and trouble is with either the capacitor, relay/overload, temperature

control, or elsewhere in system.

• If compressor does not start when direct wired, recover refrigerant at high

side. After refrigerant is recovered, repeat compressor direct wire test. If

compressor runs after recovery but would not run when direct wired

before recover, a restriction in sealed system is indicated.

• If compressor does not run when wired direct after recovery, replace faulty

compressor.

©2005 Maytag Services 16025860

5

Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Capacitor

Condenser Condenser is a long folded tube

Run capacitor connects to relay terminal

3 and L side of line.

Some compressors do not require a run

capacitor; refer to the Technical Data

Sheet for the unit being serviced.

construction located in machine

compartment.

Condenser is on high pressure discharge

side of compressor. Condenser function

is to transfer heat absorbed by refrigerant

to ambient.

Higher pressure gas is circulated through

condenser where, as gas temperature is

reduced, It condenses into a high

pressure liquid state. Heat transfer takes

place because discharged gas is at a

higher temperature than air that is

passing over condenser. It is very

important that adequate air flow over

condenser is maintained.

Condenser is air cooled by condenser fan

motor. If efficiency of heat transfer from

condenser to surrounding air is impaired,

condensing temperature will increase.

High liquid temperature means liquid will

not remove as much heat during boiling

in evaporator as under normal conditions.

This would be indicated by high than

normal head pressures, long run time,

and high wattage. Remove any lint or

other accumulation, that would restrict

normal air movement through condenser.

From the condenser the refrigerant flows

into a post condenser loop which helps

control exterior condensation on flange,

center mullion, and around freezer door.

Refrigerant flows through the drier to the

capillary tube to the evaporator and back

to the compressor through suction line.

To avoid electrical shock which can cause severe personal injury or death,

discharge capacitor through a resistor before handling.

1. Disconnect power to refrigerator.

2. Disconnect the capacitor wires if present.

3. Discharge capacitor by shorting across terminals with a resistor for 1 minute.

4. Check resistance across capacitor terminals with ohmmeter set on “X1K”

scale.

• Good—needle swings to 0 ohms and slowly moves back to infinity.

• Open—needle does not move. Replace capacitor.

• Shorted—needle moves to zero and stays. Replace capacitor.

• High resistance leak—needle jumps toward 0 and then moves back to

constant high resistance (not infinity).

Leaks in condenser can usually be detected by using an electronic leak detector

or soap solution. Look for signs of compressor oil when checking for leaks that

may indicate the location of the leak. A certain amount of compressor oil is

circulated with refrigerant.

Leaks in post condenser loop are rare because loop is a one-piece steel tube.

“For small leaks”

1. Separate condenser from rest of refrigeration system and pressurize

condenser up to a maximum of 235 PSI with a refrigerant and dry nitrogen

combination.

2. Recheck for leaks.

To avoid severe personal injury or death from sudden eruption of high

pressures gases, observe the following:

Protect against a sudden eruption if high pressures are required for leak

checking.

Do not use high pressure compressed gases in refrigeration systems

without a reliable pressure regulator and pressure relief valve in the

lines.

WARNING

!

WARNING

!

16025860

6

©2005 Maytag Services

Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Overload / Relay

Temperature

control

Ice maker Optional on some models.

Condenser motor

Evaporator fan

motor

When voltage is connected and relay is

cool, current passes through relay to start

winding.

After a short time, current heats the

resistor in relay and resistance will raise

blocking current flow through relay.

Start winding remains in the circuit through

run capacitor.

Solid state relay plugs directly on

compressor start and run terminals. Relay

terminals 2 and 3 are connected within

relay. Run capacitor is connected to relay

terminal 3. L2 side of 120 VAC power is

connected to relay terminal 2.

Temperature control uses a capillary tube

to sense the temperature in the

compartment. Depending upon the

temperature it senses it will open or close

a single pole, single throw switch.

Temperature control controls run cycle

through defrost timer.

Altitude Adjustment

When altitude adjustment is required on a

G.E. control, turn altitude adjustment

screw 1/7 turn counter clockwise for each

1,000 feet increase in altitude up to 10,000

feet. One full turn equals 10,000 feet

maximum.

In most cases the need for altitude

adjustments can be avoided by simply

turning temperature control knob to colder

setting.

See “Ice Maker” section for service

information.

Condenser fan moves cooling air across

condenser coil and compressor body.

Condenser fan motor is in parallel circuit

with compressor.

Evaporator fan moves air across

evaporator coil and through the refrigerator

and freezer compartment.

1. Disconnect power to the refrigerator.

2. Remove relay cover and disconnect leads.

3. Check resistance across terminals 2 and 3 with an ohmmeter:

Normal = 3 to 12 ohms

Shorted = 0 ohms

Open = infinite ohms

Check for proper calibration with thermocouple capillary in air supply well by

recording cut-in and cut-out temperatures at middle setting. Refer to tech sheet

for model being serviced for expected temperatures.

Check control contacts are opening by disconnecting electrical leads to control

and turning control knob to coldest setting. Check for continuity across

terminals.

Altitude Counter in Feet

Feet Above

Sea Level

2,000

4,000

6,000

8,000

10,000

Check resistance across windings If open replace motor.

1. Disconnect power to unit.

2. Disconnect fan motor leads.

3. Check resistance from ground connection solder. Trace to motor frame must

not exceed .05 ohms.

4. Check for the proper operating voltage at the connector to motor with unit in

refrigeration mode and compressor operating.

Turn Screw

Clockwise (Angular

Degrees)

30

81

129

174

216

©2005 Maytag Services 16025860

7

Component Testing

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Switch, upper

freezer light

Drier

Defrost timer Timer motor operates only when fresh

Single pole, single throw switch

completes circuit for light when door is

open.

Drier is placed at post condenser loop

outlet and passes liquefied refrigerant to

capillary.

Desiccant (20) 8 x 12 4AXH - 7 M>S> Grams

food control is closed.

After specified amount of actual

operating time, inner cam in timer throws

the contacts from terminal 4, compressor

circuit, to terminal 2, defrost

thermostat/defrost heater circuit.

After specified defrost cycle time, timer

cam resets the circuitry through terminal

4 to compressor.

Check resistant across terminals.

Switch arm depressed

“NO” terminals Open

Switch arm up

“NO” terminals Closed

Drier must be changed every time the system is opened for testing or

compressor replacement.

NOTE: Drier used in R12 sealed system is not interchangeable with

drier used in R134a sealed system.

Before opening refrigeration system, recover HFC134a refrigerant for safe

disposal.

1. Cut drier out of system using the following procedure. Do not unbraze

drier since this will drive moisture into the system.

2. Score capillary tube close to drier and break. Reform inlet tube to drier

allowing enough space for large tube cutter.

3. Cut circumference of drier 1 ¼" below condenser inlet tube joint to

drier.

4. Remove drier.

5. Apply heat trap paste on post condenser tubes to protect grommets

from high heat.

6. Unbraze remaining part of drier. Remove drier from system.

7. Discard drier in safe place. Do not leave drier with customer. If

refrigerator is under warranty, old drier must accompany warranty

1. To check timer motor winding, check for continuity between terminals 1 and 3

2. Depending on rotating position of the cam, terminal 1 of timer is common to

3. With continuity between terminals 1 and 4, rotate timer knob clockwise until

4. Continuing to rotate time knob until a second click is heard should restore

claim.

WARNING

!

To avoid death or severe personal injury, cut drier at correct location.

Cutting drier at incorrect location will allow desiccant beads to scatter. If

spilled, completely clean area of beads.

of timer.

both terminal 2, the defrost mode, and terminal 4, the compressor mode.

There should never be continuity between terminals 2 and 4.

audible click is heard. When the click is heard, reading between terminals 1

and 4 should be infinite and there should be continuity between terminals 1

and 2.

circuit between terminals 1 and 4.

16025860

8

©2005 Maytag Services

Component Testing

•

•

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect electrical power source to unit, unless test

procedures require power to be connected. Discharge capacitor through a resistor before attempting to service.

Ensure all ground wires are connected before certifying unit as repaired and/or operational.

Component Description Test Procedures

Evaporator The low pressure in the evaporator

Evaporator heater

(defrost)

Thermostat

(defrost)

allows liquid refrigerant exiting the

capillary to expand into a gas.

Expansion cools evaporator coil

temperature to approximately -20°F

transferring heat from freezer section to

refrigerant.

Passing through suction line back to the

compressor, the refrigerant picks up

superheat (a relationship between

pressure and temperature that assures

complete vaporization of liquid

refrigerant) as the result of capillary tube

soldered to suction line.

Refrigerant gas is circulated through the

suction line by compressor, completing

refrigeration cycle.

Activated when defrost thermostat,

defrost timer, and freezer control

complete circuit through heater.

Thermostat is in a series circuit with

terminal 2 of defrost timer, and defrost

heater.

Controls the circuit from freezer

thermostat through defrost terminator to

defrost heater. Opens and breaks circuit

when thermostat senses preset high

temperature.

Test for leaks in evaporator with electronic leak detector or with soap solution.

Compressor oil is circulated with refrigerant; check for the presence of oil when

checking for leaks.

For minute leaks

1. Separate evaporator from rest of refrigeration system and pressurize

evaporator up to a maximum of 140 PSI with a refrigerant and dry nitrogen

combination.

2. Recheck for leaks.

WARNING

!

To avoid severe personal injury or death from sudden erruption of

high pressurres gases, observe the following:

Protect against a sudden eruption if high pressures are required

for leak checking.

Do not use high pressure compressed gases in refrigeration

systems without a reliable pressure regulator and pressure relief

valve in the lines.

Check resistance across heater.

To check defrost system :

1. Thermocouple defrost thermostat and plug refrigerator into wattmeter.

2. Turn into defrost mode. Wattmeter should read specified watts (according to

Technical Data Sheet).

3. When defrost thermostat reaches specified temperature ±5°F (see Technical

Data Sheet), thermostat should interrupt power to heater.

Test continuity across terminals.

With power off and evaporator coil below freezing, thermostat should show

continuity when checked with ohmmeter. See “Heater, evaporator (defrost)”

section for additional tests.

After defrost thermostat opens, thermostat remains open until end of defrost timer

cycles and refrigerator starts cooling again. Defrost thermostat senses a preset

low temperature and resets (closes).

©2005 Maytag Services 16025860

9

Loading...

Loading...