MAN TGE Service Manual 101

MAN GUIDE 101

TGE basics

With its new TGE, MAN is joining the world of transporters for the first time. What started in the past at 7.5 tons, now begins at maximum permissible weight of 3.0 tons. Using the new TGE, MAN transfers the usually customer-focussed truck business to the category of delivery trucks. The TGE from MAN is a light commercial vehicle which - flanked by its big brothers - inspires users with enthusiasm who have performed professional work with heavy trucks for a long time. Excellent TGE sales consultants will always provide a customized solution.

MAN as a full-range offerer

up to 18.4 cubic metres of loading space

engines from 75 kW to 130 kW

standard safety by emergency brake assistants

service and use around the clock

For example, MAN identifies the target groups in the logistic and construction area. Also, sectoral requirements from handicraft and passenger transportation businesses can be future applications of the light “truck” from the MAN Truck & Bus company. All applications have the following in common: Thanks to the lowest cW-value of 0.33 and the lowest consumption of its class as well as the lowest maintenance and repair costs, the best Total Cost of Ownership (TCO) of the new MAN TGE is inspiring.

In addition to the panel van and the glazed estate car, the chassis with their single-compartment and twincompartment cabs increase the offer of body types. Two wheelbases, three roof heights and three vehicle lengths are options. Always available: the loading space illuminated by LED lamps.

Also, there are lots of drive types. Depending on the maximum permissible gross weight, front-wheel or rear-wheel and all-wheel drives are possible, optionally coupled with a 6-speed manual gearbox or an 8-speed automatic transmission. 2.0L engines with 75 kW / 102 HP, 90 kW / 122 HP, 103 kW / 140 HP, and 130 kW / 177 HP are available.

With its standard emergency brake assist (EBA), MAN considerably contributes to road-traffic safety. To this effect, distance sensors review critical distances to the vehicle in the front, helping reduce the stopping distance. In addition, the integrated city emergency brake function automatically decelerates the vehicle at low speeds and thus reduces one of the most frequent causes of accidents. The adaptive cruise control system provides great convenience on long highway distances. The fatigue detection system and the multi-collision brake have been designed for the safety of everybody.

m001_002

2

CONTENTS

14

16 22

38

4 INTRODUCTION

14 VEHICLE BODY

16 POWER UNITS

22 POWER TRANSMISSION

30 RUNNING GEAR

38 ELECTRICAL SYSTEM

52HEATING AND AIR CONDITIONING

59RADIO, TELEPHONE AND NAVIGATION

52 |

59 |

The MAN TGE Guide teaches the basics of design and function for sales and after-sales of new vehicle models, new

vehicle components or new technologies. Note The MAN TGE Guide is not a sales manual and not a repair guide! The specified values are for the sake of ease of

understanding only and refer to the data status valid at the time the MAN TGE Guide was created. The contents are not updated.

For customer advice, maintenance and repair work, please use the appropriate technical literature.

Reference

3

INTRODUCTION

Die Trucknology Generation

With the newly developed MAN TGE, MAN Truck & Bus is now for the first time making its commercial vehicle expertise in the range from 3.0 to 41 tons (50 tons) available to all customers, as a full-range supplier.

The TGX, TGS, TGM and TGL series offer the customer the optimum vehicle base for individual transport solutions with total weights from 7.49 to 41 tons (50 tons) and engine outputs from 150 hp to 640 hp. The MAN TGE now rounds this off between 3.0 and 5.5 tons total weight and an engine output of 105 hp to 175 hp and three drive variants.

MAN TGX To be successful in international longdistance traffic, to shift up a gear in terms of transport performance and to put the brakes on costs. This is what the MAN TGX stands for, setting the standard for maximum energy efficiency, reliability and economy with its exhaust gas-optimized engines of up to 640 hp.

MAN TGS The MAN TGS is uniquely versatile: Whether for heavy-duty local transport, on construction sites, in municipal transport or as a specialist for special tasks, the xxx is a versatile truck that is perfectly tailored to every sector of industry.

MAN TGM In distribution traffic and also in medium-heavy traction traffic, the MAN TGM is heavily involved. With tonnages of between 13 and 26 tons and a first-class payload, it offers economical transport solutions for construction sites.

MAN TGL The MAN TGL is the solution for fresh produce, construction, municipal use, furniture transport, trade and industry. The 7.49 to 12 ton trucks are very manoeuvrable and combine maximum payload with dynamic driving characteristics.

The MAN TGE with its powerful commercial vehicle roots is ideally MAN TGE

equipped to meet the diverse challenges of the transporter market from 3.0 to 5.5 tons. The MAN TGE always offers the right solution for tough everyday working conditions, be it in the forest, on the construction site or in the confusing urban jungle. With its outstanding driving comfort, numerous assistance systems and a driver‘s cab at passenger car level, it is the new benchmark in the transporter segment.

4

The production site

Since the laying of the foundation stone |

The production of the MAN TGE began |

in November 2014, Europe‘s most |

here on April 3, 2017, of which 100,000 |

modern plant of this kind has been built |

units per year are to be produced by up |

in Wrzesnia, a city with around 30,000 |

to 3,000 employees, together with the |

inhabitants about 50 kilometres east of |

identical VW Crafter. |

Poznan, in just 23 months. |

|

In addition to the production halls for vehicle assembly, a modern paint shop and a supplier park with logistics areas were built on the site. The development of the supplier network and the service sector has also created numerous new jobs in the vicinity of the plant.

m001_216 |

m001_217 |

m001_215

5

The product features of the MAN TGE

The following overview shows the 25 most important unique selling propositions and „Best in Class“ characteristics.

The safest transporter in its class thanks to versatile equipment and assistance systems:

Emergency brake assistant as standard

Automatic Post-Collision Braking System

Automatic Distance Control (ACC)

Trailer manoeuvring assist

Lane departure warning

Lane change assistant with parking assistant

Cornering light

Headlights in LED technology

Side wind assistant

ESC with combination stabilization

Most comfortable driver‘s workplace:

Well designed storage compartment concept

Ergonomic seats with optional massage function

230 V socket in the cab

Innovative media systems

|

Clear displays and instruments |

m001_004 |

|

Economy to the limit:

State-of-the-art engine-gearbox configurations

Streamlined body shape

Lightweight construction in every detail

Integration into fleet management systems

Versatile solution for every application:

Front, rear and all-wheel drive

Manual and automatic transmissions

Three possible vehicle lengths

Three possible roof heights

Four different body shapes

Universal floor with preparations for built-in components

Optional longitudinal and transverse rails in the loading floor

Rear end free from technical equipment for various conversion

solutions |

m001_005 |

6

The notable characteristics of the MAN TGE

Vehicle front in striking MAN family design

Modern workstation with ergonomic control panel and clearly arranged instruments

LED headlights

Adjustable driver and front passenger seats – also as swing seat and AGR seat (with seal of approval from the campaign for healthy backs) with electrical lumbar support

Loadspace with universal floor and a wide variety of installation options

Tail light clusters with connecting character line

m001_082

7

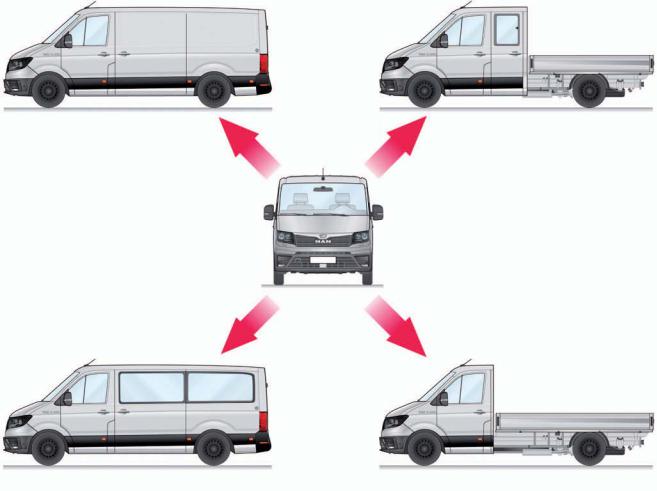

Derivatives

Panel van |

Double cab |

Window van |

Single cab |

m001_218

The MAN TGE has an extensive range of models to choose the vehicle best suited to customer requirements. In total, there is a choice of 69 body and powertrain variants.

The four basic variants panel van, window van and platform van with single or double cab meet the highest demands in their respective customer segments.

The individual body shapes can be further customized with different wheel bases and roof heights.

In addition to the standard body shapes, the following derivatives are also available for extensive customeroriented special configurations:

Carriage with flat frame chassis

Cowl panel

Platform

8

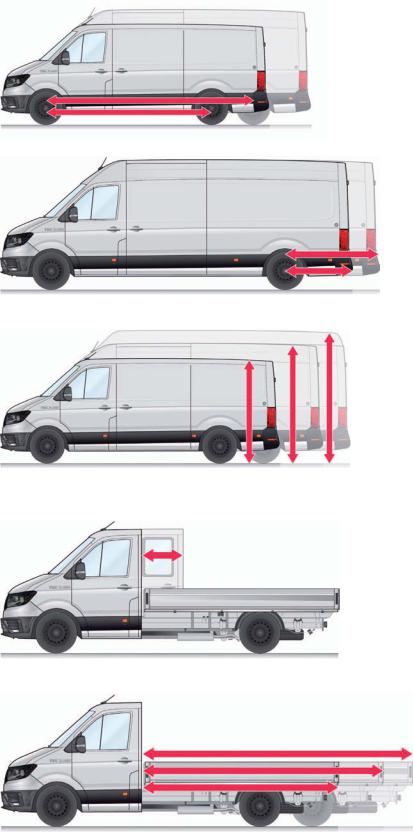

Dimension variants

Wheelbases

Two wheelbases are available.

Standard wheelbase: 3640 mm (L3)

Long wheelbase: 4490 mm (L4/L5)

Rear overhangs

Two rear overhang lengths are available for the long wheelbase.

|

Long: |

1346 mm (L3/L4) |

|

Extra long : |

1901 mm1) (L5) |

Roof heights (panel van, window van)

Three roof heights are available.

Normal roof: |

2355 |

/ 2390 mm2) (H2) |

|

High roof: |

2590 |

/ 2625 |

- 2637 mm 2) (H3) |

Super high roof: |

2798 |

/ 2830 |

- 28351), 2) mm (H4) |

Cabs (platform van, chassis)

Two cab sizes are available for the transport of additional persons:

Single cab with maximum seat configuration 2+1

Double cab with maximum seat configuration 6+1

Platform lengths

Ex factory, three platform lengths are available with single cab (SC) and a further platform length for double cab (DC).

|

Standard single cab: |

3500 mm |

|

Long single cab: |

4300 mm |

Extra long single cab: 4700 mm

Standard double cab: 2700 mm

Long double cab: |

3500 mm |

1)Not with window van.

2)Single/twin tyres

m001_219

m001_220

m001_221

m001_222

m001_223

9

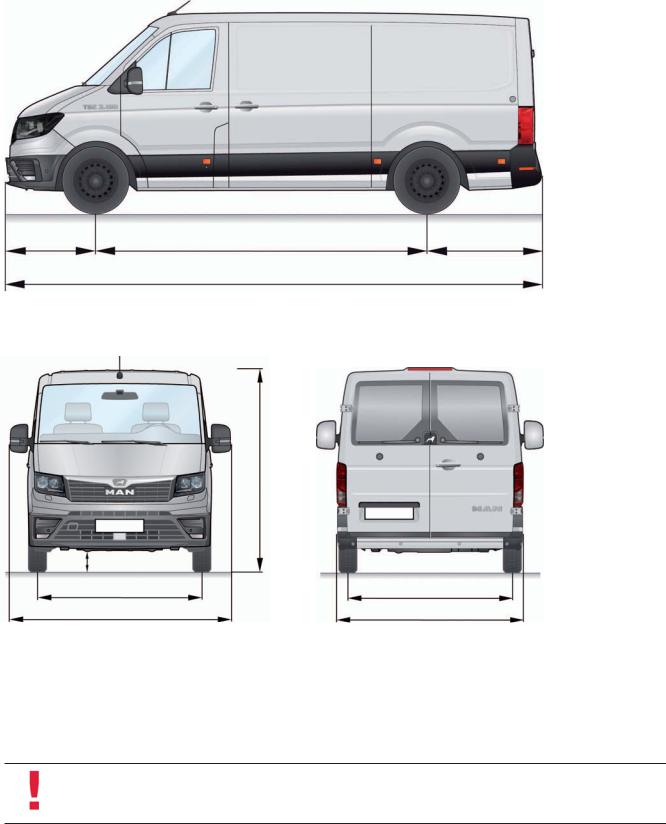

Technical data

Panel van, window van

1000 |

3640 – 4490 |

1346 – 1901 |

5986 – 7391

m001_224

2355 – 2835

210 / 2141) |

|

|

1773 |

|

1766 – 1788 / 16011) |

2425 – 2427 |

|

2040 / 20691) |

|

m001_225 |

m001_008 |

|

|

All figures are in millimetres. 1) Single/twin tyres

Note

The illustrations only show selected variants and their dimensions/dimension areas. For the complete technical data for the entire model range, please refer to the current sales literature.

10

Single cab, double cab

3500 – 4700

2305 – 2327

1000 3640 – 4490 1514 – 1914

6204 – 7404

m001_226

2700 – 3500

2321 – 2352

1000 3640 – 4490 1514 – 1564

6204 – 7004

m001_227

All figures are in millimetres.

11

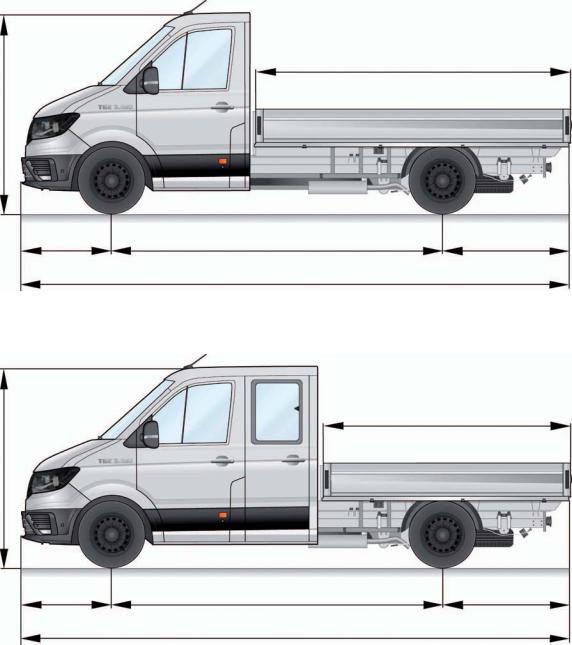

Load compartment measurements

A

B |

|

D |

C

m001_228

|

A |

|

Sliding door width |

1311 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

B |

|

Sliding door height |

1430 |

– 1587 |

/ 1668 – 18221) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

C |

|

Maximum loadspace length |

3201 |

– 46065) |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

D |

|

Maximum loadspace height |

1568 |

– 2196 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

E |

|

Height of rear wing door |

1451 |

– 1605 |

/ 1684 – 18401) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

F |

|

Loading height/loadsill |

|

|

|

|

570 – 725 / 1000 – 10502) |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

G |

|

Maximum loadspace width |

1832 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

H |

|

Width between wheel housings |

1375 |

– 1380 |

/ 10303) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

I |

|

Maximum platform height |

400 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

J |

|

Maximum platform width external |

2098 |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

Window van, panel van |

Flatbed |

|

|

||||||||

E

K

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H |

|

|

|

|

|

|

|

J |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

m001_012 |

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||||||

|

K |

|

Maximum loadspace area |

|

|

|

|

5,16 – 8,99 m2 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Maximum trailer weight |

|

|

3000 |

/ 3500 kg4) |

|

|||||

|

|

|

|

Gross vehicle weight |

3500 |

– 5500 kg |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All figures are in

millimetres for vehicles

with front-wheel drive.

1)Normal roof / High roof, Super high roof

2)Panel, window / platform

3)Single / twin tyres

4)Front and four-wheel drive / rear-wheel drive

5)incl. 15 cm subfloor storage compartment

I

F

m001_229

12

The vehicle concept

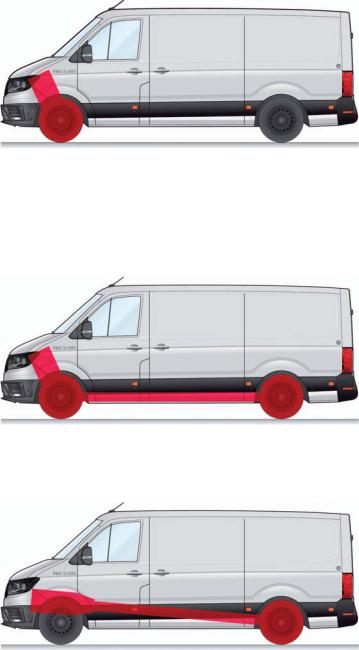

Drive system types

Prior to the development of the MAN |

were taken into account in the design |

For the first time, three types of drive are |

TGE, intensive customer surveys were |

process. |

used in the MAN TGE and VW Crafter. |

conducted and market requirements |

|

|

Front-wheel drive

The drive unit is installed transversally. Features are:

low loadspace floor (about -100 mm), thereby increasing the loadspace volume and reducing the loadsill height

Rear end without drive technology

Driveline with reduced weight (approx. 100 kg less), lower fuel consumption

Applications include courier and logistics services, joiners/plumbers/ glaziers, etc. and rescue services.

All-wheel drive 4x4

The drive unit is installed transversally. Features are:

Electronically controlled multi-plate clutch

Optimum traction

Particularly suitable for regions with poor weather conditions or roads

Applications include the building trade and forestry as well as the police and military.

Rear wheel drive

The drive unit is in inline installation. Features are:

Good traction for high loads

Higher gross vehicle weight rating possible (up to 5.5 t)

Single or twin tyres at rear

Use of auxiliary drives on the gearbox

(e.g. for body manufacturer) possible Applications include service vehicles and mobile workshops with heavy built-in components as well as special bodies.

m001_230

m001_231

m001_232

13

VEHICLE BODY

Body structure

The body of the MAN TGE has been completely redesigned. In addition to the modular design, the developers

focused on optimizing weight and aerodynamics as well as crash safety.

These goals were achieved, among other things, by the use of higheststrength hot-formed steels. Compared to conventional steels, these are considerably stronger at a similar weight and thus make the MAN TGE lighter and safer.

m001_083

The following components are made |

Front roof side members |

A-pillar bottom part |

from hot-formed steel: |

Sill panel reinforcement |

Front bulkhead |

|

Corner reinforcement on the rear roof |

Longitudinal member reinforcement |

|

|

for driver‘s cab |

14

Modular structure

Use of as many identical parts as possible was an important goal during development of the body structure. The

objective was to allow the numerous |

manufactured with great synergy |

derivatives and variants such as different |

effects. |

wheelbases and roof heights to be |

|

Vehicle front end the |

Vehicle rear end different depending on |

m001_084 |

|

same for all variants |

the variant, in this case short wheelbase |

||

|

with low loadspace floor (-100 mm)

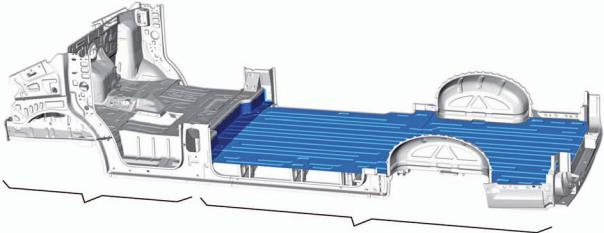

Floor structure

The floor structure of the MAN TGE is the same for all variants in the vehicle front end area. At the rear end, however, there are significant differences regarding the floor panel, longitudinal members, wheel housings and the corresponding connecting parts as well

as reinforcements. Their configuration and design are determined by the following factors:

Type of drive

Wheelbase

Rear overhang

Type of body

Single or twin tyres on the rear axle

15

POWER UNITS

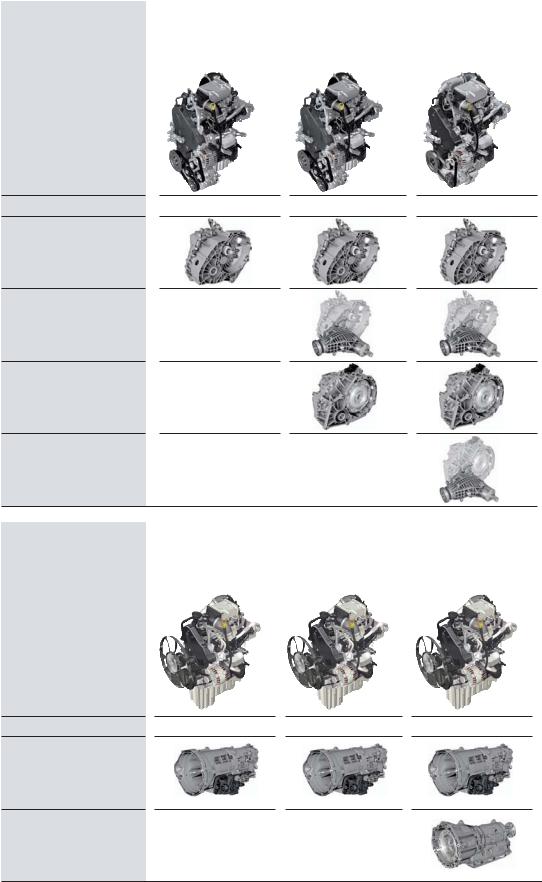

Engine/gearbox combinations

Transverse |

2.0l Turbo diesel |

2.0l Turbo diesel |

2.0l Biturbo diesel |

installation |

75 kW |

103 kW |

130 kW |

|

DAUB |

DAUA |

DAVA |

6-speed Manual gearbox

0AX front-wheel drive

6-speed Manual gearbox

0AX four-wheel drive

8-speed Automatic gearbox

09Q front-wheel drive

8-speed Automatic gearbox

09Q four-wheel drive

Longitudinal |

2.0l Turbo diesel |

2.0l Turbo diesel |

2.0l Biturbo diesel |

installation |

90 kW |

103 kW |

130 kW |

|

DASA |

DASB |

DAWB |

6-speed Manual gearbox

0F6 rear-wheel drive

8-speed Automatic gearbox

0DR rear-wheel drive

16

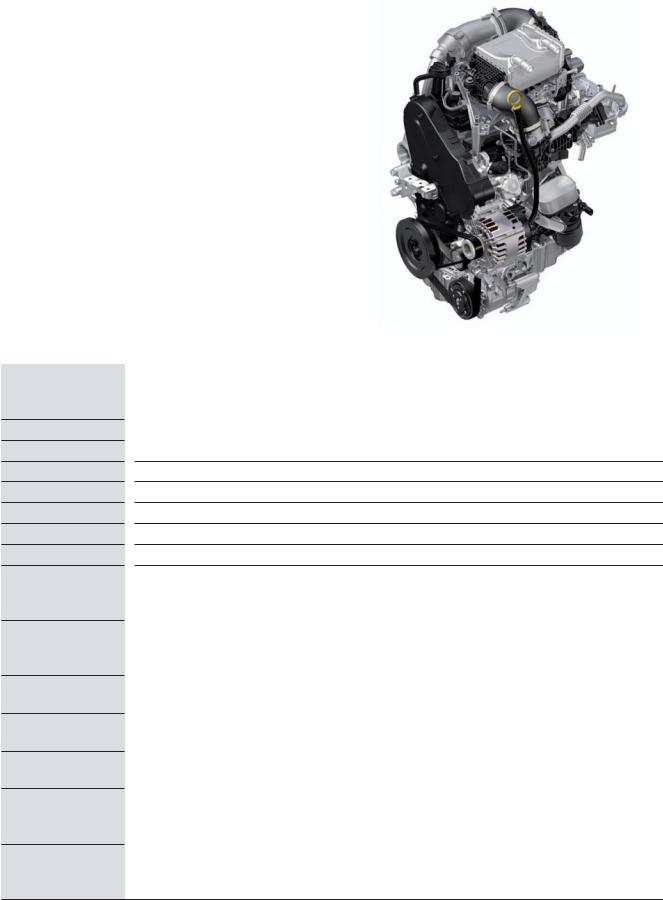

The 2.0 l turbo diesel engines

In the MAN TGE, only 2.0-litre turbo diesel engines from the MDBnutz modular diesel construction kit are used. The use of a uniform engine geometry with many identical parts creates high synergy effects and reduces manufacturing and maintenance costs.

Transverse installation |

Longitudinal installationtion |

m001_140 |

m001_141 |

The engines of the MAN TGE have been specially designed for commercial vehicles to meet the high requirements in terms of mileage, driving resistance, driving profile and service life. Adjustments were made, for example, to the intercooling, the cylinder head, the variable-length intake manifold, the EGR cooler, the turbochargers and the oil pan.

The installation position is adapted to the commercial vehicle design.

Depending on the drive concept used, the engines are installed transversely or longitudinally - an absolute special feature within a vehicle series.

In addition, transversely installed engines are installed at an angle of 8° to the front in order to make optimum use of the available installation space. Longitudinally installed engines have a larger oil pan and an increased oil quantity.

Engines with one or two turbochargers are used. A total of up to four power stages are available, ranging from 75 kW to 130 kW. The after-treatment of the exhaust gases is carried out by an SCR system for nitrogen oxide reduction. Additional options, e. g. different generators and compressors, are possible with the accessory drive used.

17

Technical data

The engine is part of the engine series EA288nutz and is installed in this design – beside the MAN GTE – only in the VW Transporter and Crafter. The engine is available in the EU6 plus and EURO VI exhaust emission standards, depending on the application.

Technical features

Liquid-cooled charge air cooler

High-pressure exhaust gas recirculation

Delphi common rail direct injection

Liquid-cooled injector for reducing agent

Injectors with solenoid valve

m001_052

Single-plunger high-pressure pump (monoturbo), double-plunger high-pressure pump (biturbo)

Motor designation

Engine code

Capacity

Type

Valves per cylinder

Bore

Stroke

Compression ratio

Maximum output at rpm

Max. torque at rpm

Engine management

Fuel

Forced induction

Exhaust gas recirculation

Emission standard2)

2.0 l Turbo diesel |

|

2.0 l Turbo diesel |

|

2.0 l Turbo diesel |

|

2.0 l Biturbo diesel |

75 kW |

|

90 kW |

|

103 kW |

|

130 kW |

|

|

|

|

|

|

|

DAUB |

|

DASA |

|

DAUA / DASB1) |

|

DAVA / DAWA |

1968 cm3

4-cylinder in-line engine

4

81.0 mm

95.5 mm

15.5 : 1

75 kW |

|

90 kW |

|

|

|

103 kW |

|

130 kW |

at 3250 – 3500 |

|

at 3250 – 3500 |

|

|

|

at 3500 – 3600 |

|

at 3600 |

|

|

|

|

|

|

|

|

|

300 Nm |

|

300 Nm |

|

|

|

340 Nm |

|

410 Nm |

at 1400 – 2250 |

|

at 1400 – 2250 |

|

|

|

at 1600 – 2250 |

|

at 1500 – 2000 |

|

|

|

|

|

|

|

|

|

|

|

|

Delphi DCM6.2 |

|

|

|||

|

|

|

|

|

|

|

|

|

DIN EN 590 |

|

DIN EN 590 |

|

|

|

DIN EN 590 |

|

DIN EN 590 |

|

|

|

|

|

|

|

|

|

Mono turbo |

|

Mono turbo |

|

|

|

Mono turbo |

|

Biturbo |

|

|

|

|

|

|

|

|

|

yes |

|

yes |

|

|

|

yes |

|

yes |

|

|

|

|

|

|

|

|

|

EU6 plus |

|

EURO VI |

|

|

|

EU6, EU6 plus |

|

EU6, EU6 plus, |

|

|

|

|

|

|

|

|

EURO V/VI |

1)Longitudinal/transversal

2)EU6 plus: Light duty homologation <2840 kg reference weight (roller test bench) EURO VI: Heavy duty homologation >2380 kg reference weight (engine test bench)

18

Ancillary drive

An ancillary drive with modular expansion capability is used in response to the wide variety of customer requirements. In addition to the usual units such as an alternator and air conditioner compressor, it is also possible to drive an additional air conditioner compressor

or additional alternator. In vehicles with bodies such as camper vans or refrigerated vans, this allows the required form of energy to be provided, e.g. for air conditioning, cooling or driving electrically operated ancillaries.

An elastic belt alone is used as the poly V-belt in an engine with alternator. In all other variants, the poly V-belt is tensioned using a belt tensioner.

Basic drive |

Air conditioning drive |

|

|

Alternator |

|

|

|

Alternator |

|

|

|

||||

|

|

(various |

|

|

|

(various |

|

|

power levels) |

|

|

|

power levels) |

|

|

|

|

|

|

Air conditioner |

|

|

|

|

|

|

|

|

|

|

|

|

|

compressors |

m001_053 |

m001_054 |

|||||

Additional drive

|

|

|

|

Alternator |

|

|

|

|

Alternator |

|

|

|

|

|

|||||

|

|

|

|

(various |

|

|

|

|

(various |

|

|

|

|

power levels) |

|

|

|

|

power levels) |

|

|

|

|

Air conditioner |

|

|

|

|

Air conditioner |

|

|

|

|

|

|

|

|||

|

|

|

|

compressors |

|

|

|

|

compressors |

|

|

|

|

Additional |

|

|

|

|

Additional air |

|

|

|

|

|

|

||||

|

|

|

|

alternator |

|

|

|

|

conditioner |

|

|

|

|

(in 180 A version) |

|

|

|

|

compressor |

m001_055 |

m001_056 |

||||||||

19

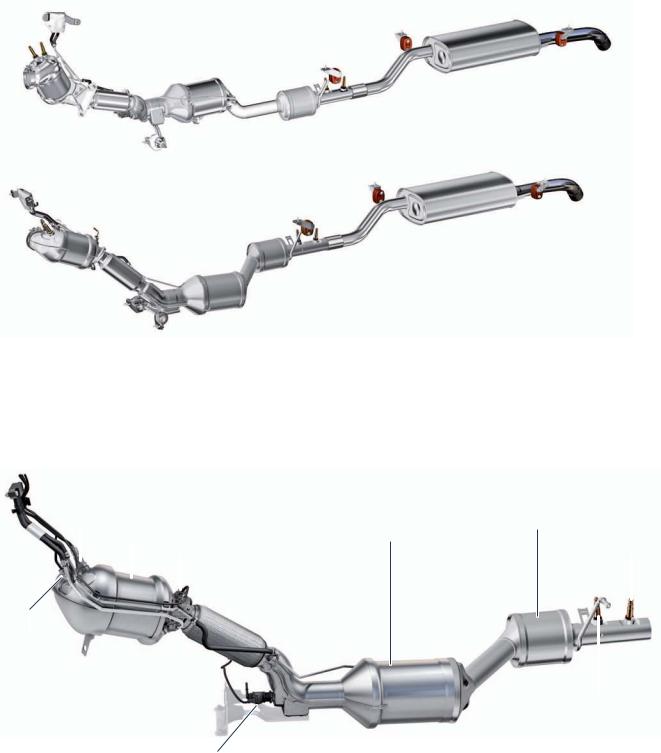

Exhaust system

The exhaust system of the MAN TGE is available in various variants. Its structure depends on the engine or body variant, for example.

Inline installation, EU6

Transverse installation, EU6

m001_058

Exhaust gas treatment

In vehicles with SCR system (EU6 exhaust standard), there is a lambda probe (oxygen sensor) in the front part of the exhaust pipe as well as three temperature sensors, the injector for reducing agent as well as the corresponding catalytic converters.

Lambda probe |

Diesel particulate filter |

Trap catalytic converter |

||||

|

Oxidising catalytic converter |

|||||

|

||||||

|

with SCR coating |

|

|

|||

|

|

|

|

|

|

|

|

|

Temperature sensor 3 |

|

Particle mass sensor |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Temperature sensor 2 |

|

|

|

sensor |

|

|

NOx |

||||

|

|

|

|||

|

Injector for reducing |

|

|

|

|

|

|

|

|

||

|

agent N474 |

|

|

|

m001_060 |

20

Loading...

Loading...