https://truckmanualshub.com/man-truck-service-manuals-electrical-wiring-diagrams-spare-parts-catalogand-error-codes-manuals-free-download/

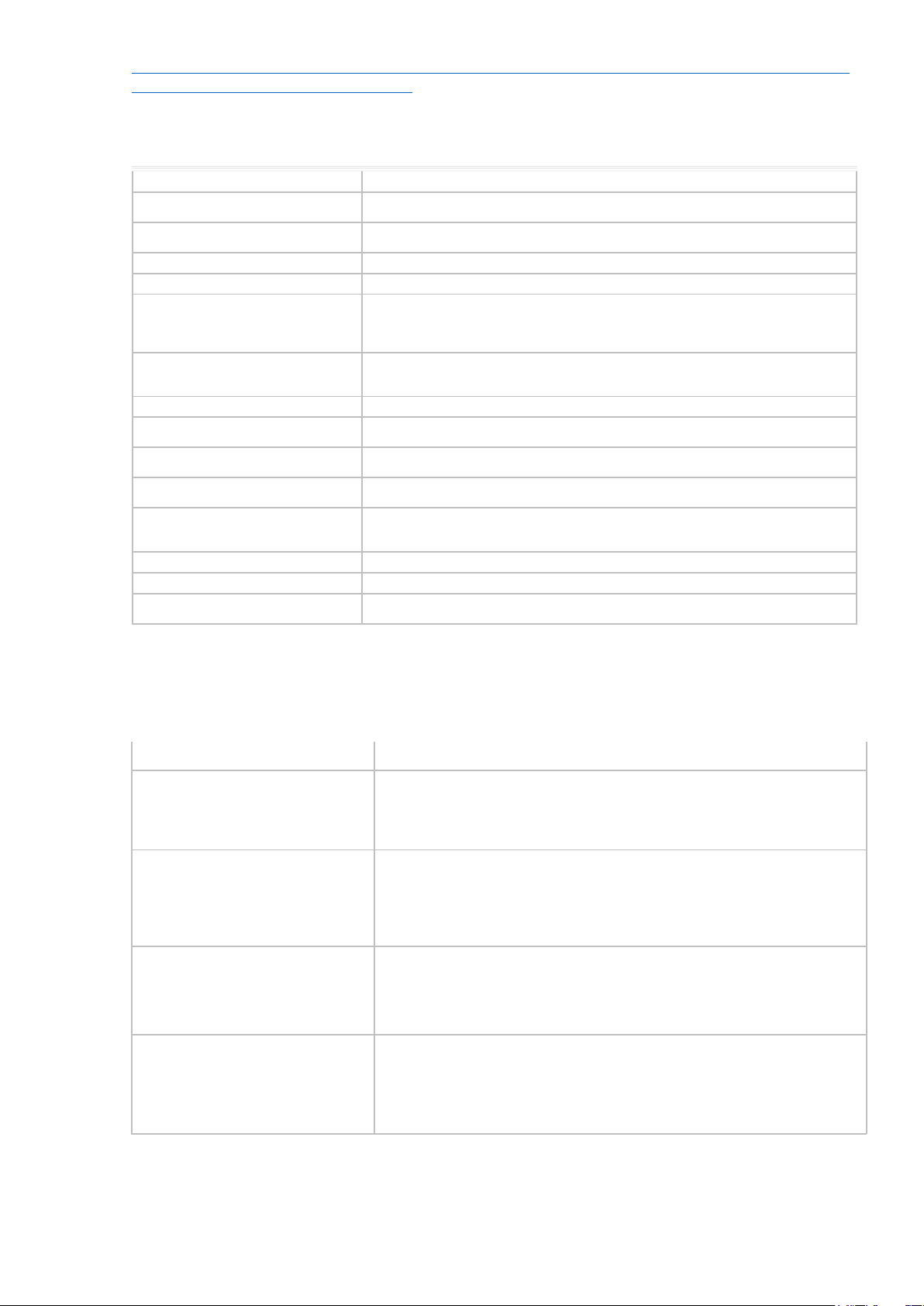

MAN ECU EDC7 Engine Fault Codes List

609

1 CAN module.

651

Bank1, the injector 1 (four-cylinder engine cylinder №1; six engine

cylinder №1; eight-cylinder engine main №1, №5 slave cylinder; tencylinder engine main №1, №6 slave cylinder; twelve-cylinder engine

№1 main cylinder № 12 slave).

652

Bank2 injector 1 (four-cylinder engine cylinder №3; six engine cylinder

№5; №2 eight-cylinder engine cylinder head, the cylinder №7 slave;

№5 ten-cylinder engine cylinder head, the cylinder №10 slave; twelvecylinder engine №5 main cylinder № 8 slave).

653

Bank1, injector 2 (four-cylinder engine cylinder №4; six engine

cylinder №3; eight-cylinder engine main №3, №6 slave cylinder; №2

ten-cylinder engine cylinder head, the cylinder №7 slave; twelve-

cylinder engine №3 main cylinder № 10 slave).

654

Bank2, injector 2 (four-cylinder engine cylinder №2; №6 cylinder six-

cylinder engine, eight-cylinder engine main №4, №8 slave cylinder;

№3 ten-cylinder engine cylinder head, the cylinder №8 slave; twelvecylinder engine №6 main cylinder № 7 slave).

Code (SPN)

Description

81

The difference between exhaust pressures.

94

fuel feed pressure.

98

Oil level.

100

Oil pressure.

102

Pressure supercharging charge air pipe after intercooler (intercooler).

105

Combustion air temperature before entering the cylinders (after AGR).

108

Atmosphere pressure.

110

The coolant temperature.

168

Voltage batteries.

171

Ambient temperature.

173

exhaust gas temperature before further purification.

175

The fuel temperature.

175

oil temperature.

190

The engine speed.

https://truckmanualshub.com/man-truck-service-manuals-electrical-wiring-diagrams-spare-parts-catalogand-error-codes-manuals-free-download/

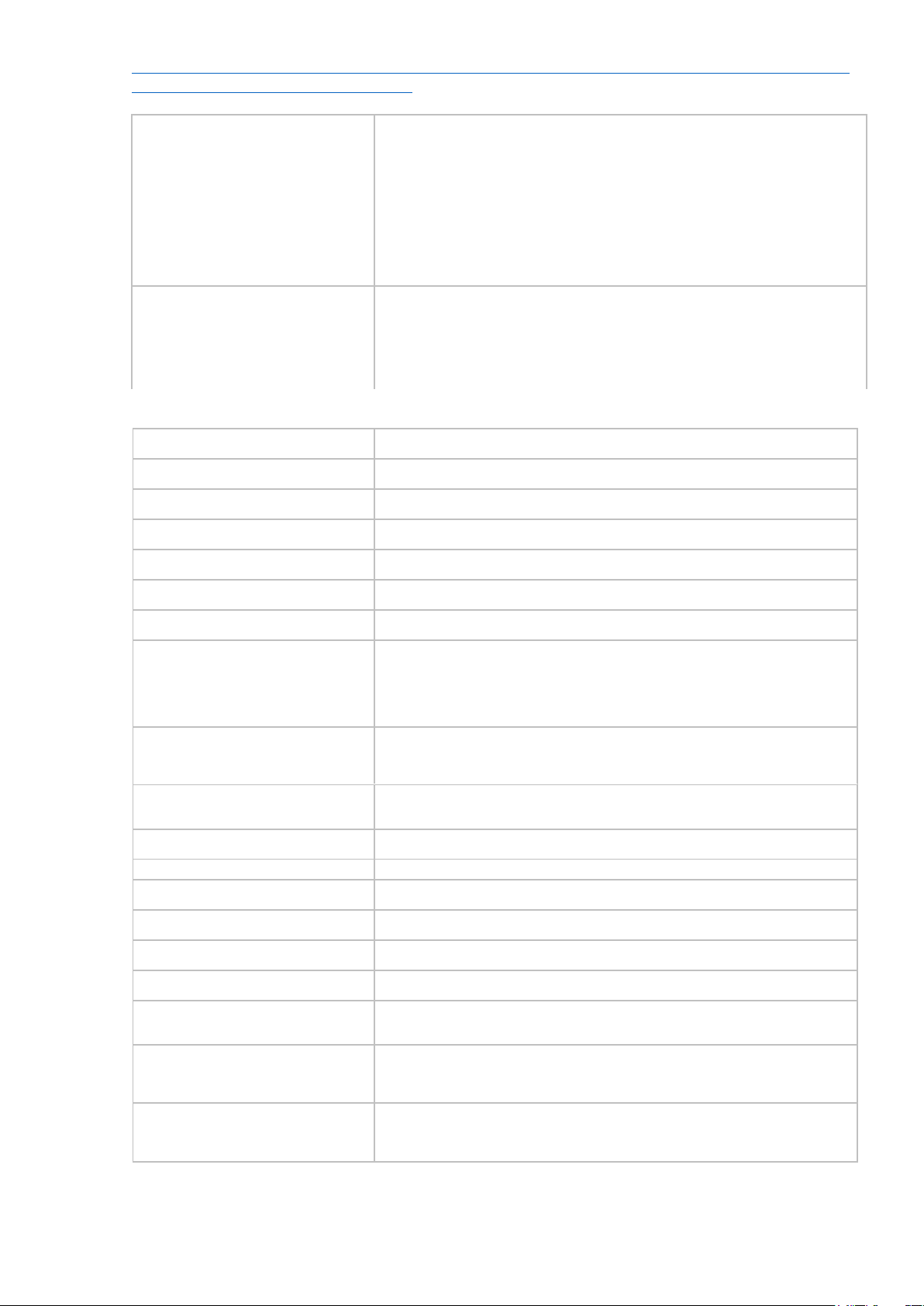

655

Bank1, an injector 3 (six engine cylinder №4; №4 ten-cylinder engine

cylinder head, the cylinder №9 slave; twelve-cylinder engine №2 main

cylinder №11 slave).

656

Bank2, an injector 3 (six engine cylinder №4; twelve cylinder engine

cylinder №2

the main cylinder №11

slave).

959

Time and date (incorrect value seconds).

960

Time and date (incorrect value minutes).

961

Time and date (incorrect value hours).

962

Time and date (incorrect value days).

963

Time and date (month incorrect value).

964

Time and date (s wrong value).

1079

a pressure sensor supply line.

1080

fuel pressure sensor supply low pressure circuit, the boost pressure

sensor, oil pressure sensor, and exhaust pressure sensor.

1131

The temperature of the charge air boost in the tube after the

intermediate cooler (intercooler).

2039

FFR1 (driving motor unit or computer).

3004

Control deviation AGR.

3007

Invalid query DM4.

3009

Too high engine speed.

3014

Main relay (inside the control unit).

3016

FFR1: Invalid message due to engine brake.

3017

FFR1: Wrong message on a given moment.

3018

FFR1: Invalid message for limit controller.

3020

FFR1: Invalid message due EDR (the maximum speed limiter).

3022

FFR1: Setting ZDR (intermediate speed regulation).

https://truckmanualshub.com/man-truck-service-manuals-electrical-wiring-diagrams-spare-parts-catalogand-error-codes-manuals-free-download/

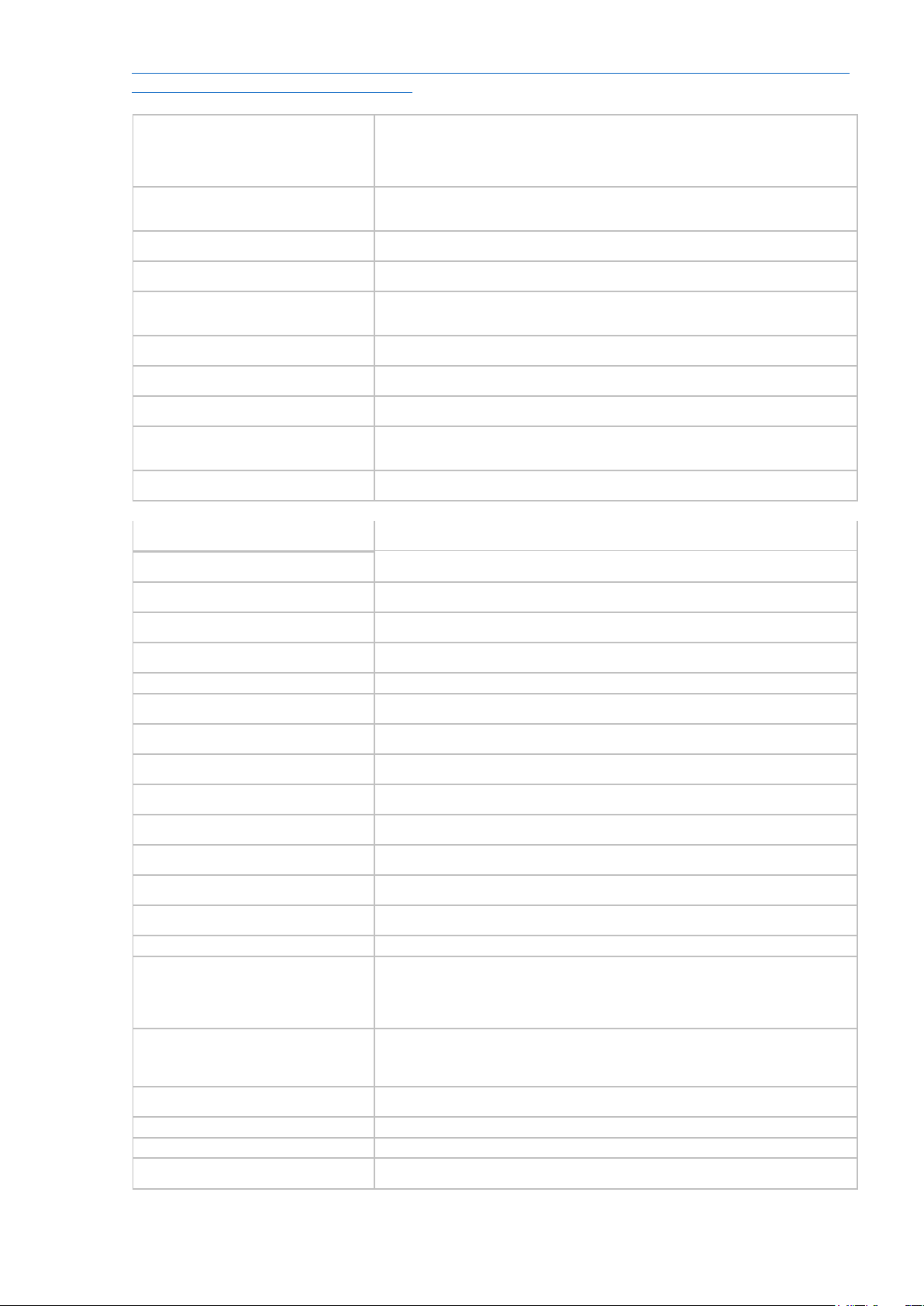

3023

FFR1: Invalid request message "MEOS" (an instant increase in engine

speed).

3024

FFR1: Invalid request message off of a linear function.

3025

FFR1: Checking the number of reserved memory.

3029

FFR2: Wrong message, the installation of idling.

3030

FFR2: Invalid message for limit controller.

3031

FFR2: Setting too high LLR.

3032

FFR2: Invalid request message idling.

3033

FFR2: Error messages start request.

3034

FFR2: Error message engine stop request.

3035

FFR2: Checking the number of reserved memory.

3038

FFR3: Error in the notice of the parking lot.

3039

FFR3: Checking the number of reserved memory.

3045

The starter.

3046

The atmospheric pressure sensor ..

3063

Inertia phase has not been completed.

3064

EDC standalone mode.

3069

Redundant control speed.

3076

Wrong Number (ID) FFR unit.

3077

No number (ID) FFR unit.

3081

Disable wastegate.

3082

The accuracy of the oil pressure sensor readings.

3083

The accuracy of the pressure sensor in the fuel line.

3085

Wrong message "Vehicle distance".

3086

AGR actuating device, the end position.

3087

Oil pressure sensor.

3088

charge air boost pressure sensor pipe after intercooler (intercooler).

3089

Temperature sensor combustion air before entering the cylinder (after

AGR).

3091

Coolant temperature sensor.

3092

Time and date.

3093

Time and date.

3097

fuel temperature sensor.

https://truckmanualshub.com/man-truck-service-manuals-electrical-wiring-diagrams-spare-parts-catalogand-error-codes-manuals-free-download/

3099

The pressure sensor in the pipeline.

3100

The fuel pressure sensor (low-pressure circuit).

3671

Calibration memory EEPROM.

3673

Module CAN2.

3674

FFR1: Disabling memory unit 8 bytes / bits 5-8.

3676

Incorrect excessive tripping mechanism (After run test).

3678

Voltage capacitor unit 1.

3679

Voltage capacitor unit 2.

3687

The pressure relief valve.

3693

Switching voltage injector.

3732

overvoltage test.

3735

Block Temperature EDC.

3736

The output stage.

3737

Master / Slave Work.

3738

The unevenness of the cylinder.

3739

The unevenness of the cylinder.

3773

Master / Slave mode.

3775

Line Pressure.

3776

Line Pressure.

3777

Line Pressure.

3778

Line Pressure.

3779

Line Pressure.

3780

Line Pressure.

3781

The pressure relief valve.

3782

fuel feed pressure.

3783

FFR2: Errors in the reports of the specified acceleration noise control

unit (NORD).

3784

A mistake by the Smoke-ID message.

3785

Dust filter PM-Kat (solids catalyst).

3786

The temperature of the particle filter.

3787

Recovery of the dust filter.

3789

Comparative differential sensor or exhaust gas pressure sensor.

3790

The accuracy of exhaust pressure difference.

3792

Sensor additional purification of exhaust gases before temperature.

https://truckmanualshub.com/man-truck-service-manuals-electrical-wiring-diagrams-spare-parts-catalogand-error-codes-manuals-free-download/

3793

exhaust gas temperature sensor after a post-treatment (physical

parameters).

3794

exhaust gas temperature sensor after a posttreatment.

3795

The throttle valve AGR.

3796

The output stage (Highside) EGR 2.

3797

The output stage (Highside) the amount of oxygen in the exhaust gas

sensor (lambda probe).

3798

Output stage OBD lamp.

3800

The output stage (Highside) a bypass valve for exhaust gas

turbocharger.

3801

The output stage (Highside) NT circuit cutoff valve.

3802

The output stage (Highside) off the compressed air valve.

3803

Error in sending messages CAN1 (FFR / EDC-CAN).

3804

Error in sending messages CAN1 (FFR / EDC-CAN).

3805

Error in sending messages on CAN2 (Master-Slave CAN).

3806

Error CAN2 (OBD-CAN).

3806

Error CAN2 (Master-Slave CAN).

3807

Error sending FFR1 (FFR / EDC-CAN).

3808

error while sending

FFR2 (FFR / EDC-CAN).

3809

Error sending FFR3 (FFR / EDC-CAN).

3810

Error time and date (FFR / EDC-CAN).

3811

Identification of additional purification of exhaust gases before

temperature.

3812

Identification of the exhaust temperature after the post-treatment.

3813

starter protector.

3814

Duration off control units.

3819

CAN3 (CAN exhaust gas treatment systems).

3820

Checking CAN1 (oil temperature and the ambient air).

3821

Checking CAN3 (CAN exhaust gas treatment systems).

3822

Break (timeout) in sending messages CAN3 (CAN exhaust gas

treatment systems).

https://truckmanualshub.com/man-truck-service-manuals-electrical-wiring-diagrams-spare-parts-catalogand-error-codes-manuals-free-download/

3823

Ignition.

3830

Misfiring.

3831

Misfiring.

3832

Misfiring.

3833

Misfiring.

3834

Misfiring.

3835

Misfiring.

3836

Determination of the amount of oxygen sensor values in the exhaust

gases (a lambda probe).

3837

Controlling the amount of oxygen sensor values in the exhaust gas

(lambda probe).

3838

The internal resistance of the amount of oxygen sensor in the exhaust

gases (a lambda probe).

3839

The internal resistance of the amount of oxygen sensor in the exhaust

gases (a lambda probe).

3843

coolant temperature.

3844

The temperature of the charge air before entering the cylinder.

3845

Ambient temperature.

3846

Control block.

3847

The temperature of the charge air boost in the tube after the

intermediate cooler (intercooler).

3849

SCR catalyst

3850

Regulation of a closed system of exhaust gas recirculation.

3851

AGR valve position.

3852

Identification temperature AGR.

3853

Setting value AGR

3854

a block temperature sensor EDC №2.

3855

Supply amount of oxygen in the exhaust gases (a lambda probe).

3856

The calibration sensor value the amount of oxygen in the exhaust gases

(a lambda probe).

3857

Communication SPI amount of oxygen in the exhaust gas sensor

(lambda probe).

3858

Low amounts of oxygen sensor in the exhaust gas (lambda probe).

https://truckmanualshub.com/man-truck-service-manuals-electrical-wiring-diagrams-spare-parts-catalogand-error-codes-manuals-free-download/

3859

Calibration value for the amount of oxygen sensor temperature of the

exhaust gas (lambda probe).

3863

shift control.

3864

P1 control injection.

3865

Control injection P2.

3866

M1 control injection.

3867

P0 injection control.

3868

Identification temperature after the charge air intercooler (intercooler).

3871

Identification temperature within EDC unit.

3872

2 Identification temperature within EDC unit.

3873

restore control.

3874

volume correction factor is too large segment 0.

3875

volume correction factor is too large segment 1.

3876

volume correction factor is too large segment 2.

3877

volume correction factor is too large segment 3.

3878

volume correction factor is too large segment 4.

3879

volume correction factor is too large segment 5.

3880

The output stage 12 for a LIN bus B.

3919

Heating NOx sensor.

3920

NOx concentration.

3921

O2 concentration.

3923

Coolant temperature 2.

3925

The coolant temperature sensor 2.

3926

The control pressure in line gradient sensor (RDS).

3927

Supply amount of oxygen in the exhaust gases (a lambda probe).

3929

C Control AGR oxygen sensor in the exhaust gas (lambda

probe). Error MIL (light

Fault indication).

3930

C Control AGR oxygen sensor in the exhaust gas (Oxygen sensor).

Error PR (power reduction).

3931

The output stage (Lowside) inlet air flap.

https://truckmanualshub.com/man-truck-service-manuals-electrical-wiring-diagrams-spare-parts-catalogand-error-codes-manuals-free-download/

3932

The output stage (Lowside) the charge air pressure control ..

3936

Too high pressure charge air.

3938

No adaptation of the amount of oxygen in the exhaust gas sensor

(lambda probe).

3942

The pressure of the charge air intercooler after a low pressure.

3943

Pressure sensor charge air intercooler after a low pressure.

3944

The temperature of the charge air intercooler after a low pressure.

3945

Combustion air temperature sensor after the low-pressure intercooler.

3946

A cooler discharge high-pressure air.

3947

A cooler discharge low-pressure air.

3963

Error LIN (Local Area Network).

3964

transmission gap of LIN messages.

3965

Error LIN (Local Area Network).

3966

Self oil level sensor.

3972

Control of the low NOx values.

3973

The pressure of the charge air in the high pressure circuit.

3974

The pressure of the charge air in the low pressure circuit.

3975

The gap sensor wires.

3976

Control fault status of the amount of oxygen in the exhaust gas sensor

(lambda probe).

3978

Electrical failure the amount of oxygen in the exhaust gas sensor

(lambda probe).

3979

Supply amount of oxygen in the exhaust gases (a lambda probe).

3980

Oil pressure.

3981

High exhaust backpressure.

3983

The regulator AGR.

Loading...

Loading...