MAN TGA Operator Manual

Guidelines to fi tting bodies

TRUCKNOLOGY

(TGA)

Edition 2012 Version 1.1

®

GENERATION A

PUBLISHER

MAN Truck & Bus AG

(mentioned in the text below “MAN“)

SMTST Department

Dachauer Str. 667

D - 80995 Munich

E-Mail:

esc@man.eu

Fax:

+ 49 (0) 89 1580 4264

www.manted.de

We reserve the right to make changes in the course of technical development.

© 2012 MAN Truck & Bus Aktiengesellschaft

Reprinting, reproduction or translation, even of excerpts, is not permitted without the written permission of MAN.

All rights, in particular under copyright, are strictly reserved by MAN.

Trucknology

Where designations are trademarks they are, even without the

®

and MANTED® are registered trademarks of MAN Truck & Bus AG

®

or ™ sign, acknowledged as the proprietor‘s protected marks.

TRUCKNOLOGY

®

GENERATION A (TGA)

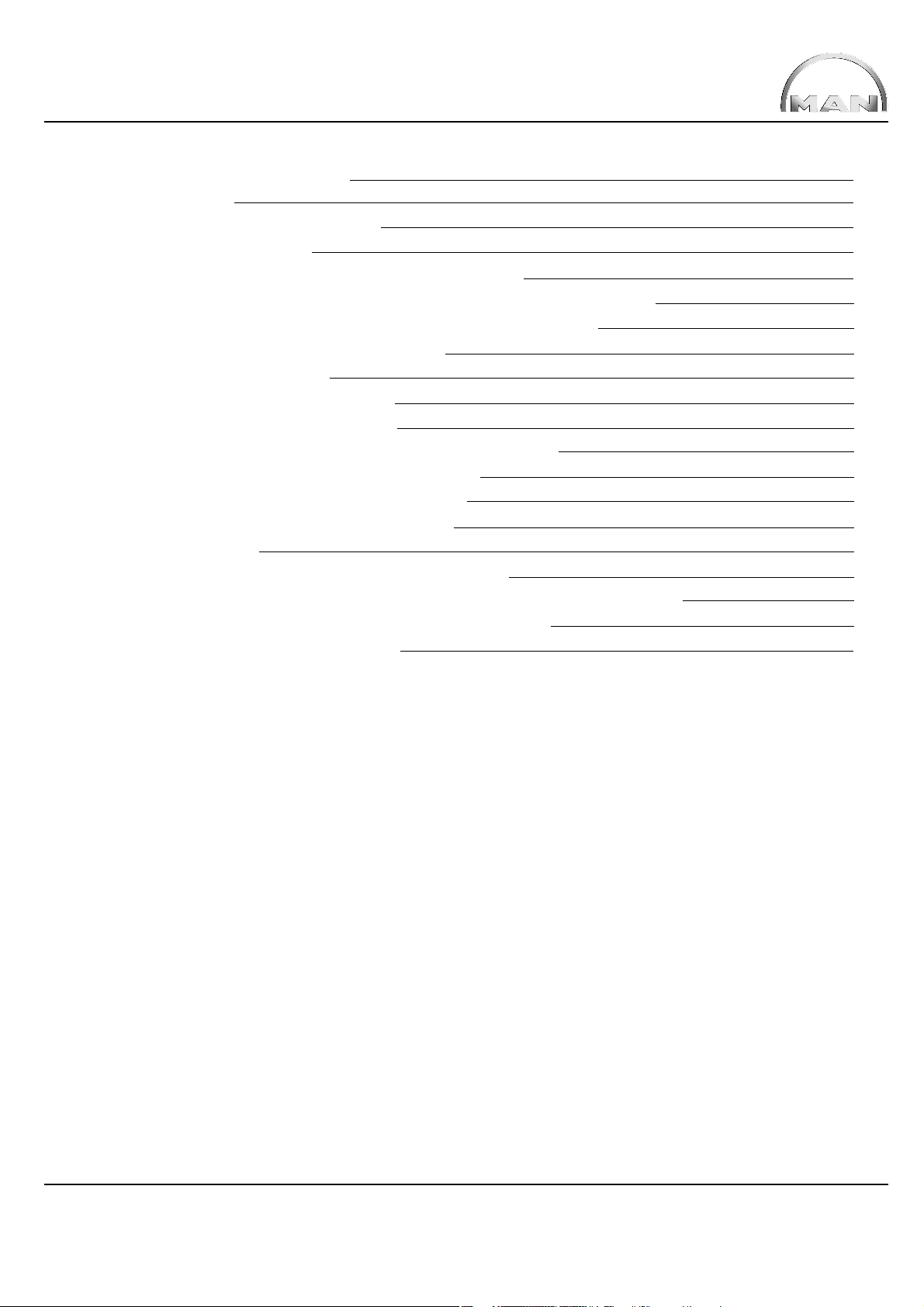

1. Applicability and legal agreements

1.1 Applicability

1.2 Legal agreements and approval procedure

1.2.1 Preconditions

1.2.2 Responsibility

1.2.3 Quality assurance

1.2.4 Approval

1.2.5 Submission of documents

1.2.6 Registration

1.2.7 Liability for defects

1.2.8 Product liability

1.2.9 Operational reliability and road safety

1.2.10 Manuals from body and conversion companies

1.2.11 Limitation of liability for accessories/spare parts

2. Product designations

2.1 Vehicle designation and wheel formula

2.1.1 Door designation

2.1.2 Variant descriptor

2.1.3 Wheel formula

2.1.4 Suffi x

2.2 Model number, vehicle identifi cation number, vehicle number, basic vehicle number

2.3 Use of logos

2.4 Cabs

2.5 Engine variants

3. General

3.1 Axle overload, one-sided loading

3.2 Minimum front axle load

3.3 Wheels, rolling circumference

3.4 Permissible overhang

3.5 Theoretical wheelbase, overhang, theoretical axle centreline

3.6 Calculating the axle load and weighing procedure

3.7 Checking and adjustment procedures once body has been fi tted

3.8 Notes on MAN Hydrodrive

®

1

1

1

1

2

2

3

3

4

7

8

8

10

11

11

11

11

11

12

13

14

18

19

21

22

22

24

25

25

26

28

29

30

TRUCKNOLOGY® GENERATION A (TGA) I

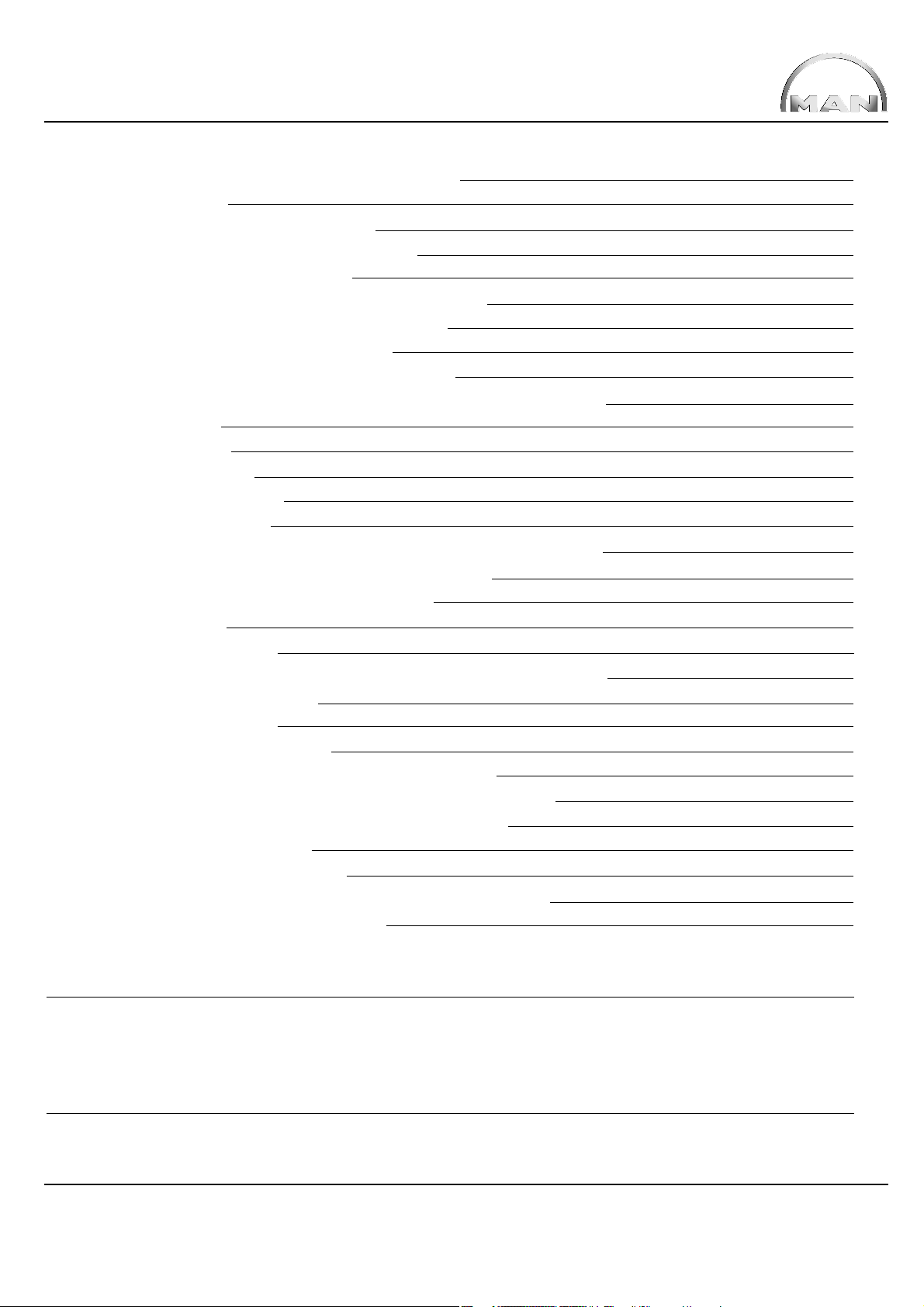

4. Modifying the chassis

4.1 Frame material

4.1.1 Subframe material

4.2 Corrosion protection

4.3 Drill holes, riveted joints and screw connections on the frame

4.4 Modifying the frame

4.4.1 Welding the frame

4.4.2 Modifying the frame overhang

4.4.3 Modifi cations to the wheelbase

4.5 Retrofi tting additional equipment add-on components or accessories

4.5.1 Retrofi tting additional or larger fuel tanks after factory delivery

4.6 Propshafts

4.6.1 Single joint

4.6.2 Jointed shaft with two joints

4.6.3 Three-dimensional propshaft layout

4.6.3.1 Propshaft train

4.6.3.2 Forces in the propshaft system

4.6.4 Modifying the propshaft layout in the driveline of MAN chassis

4.7 Modifying the wheel formula

4.7.1 Safety-related components

4.8 Coupling devices

4.8.1 Basics

4.8.2 Trailer coupling, D value

4.9 Tractor units and converting the vehicle type - truck / tractor

4.9.1 Articulated vehicles

4.9.2 Converting trucks into tractor units or tractor units into trucks

4.10 Modifying the cab

4.10.1 General

4.10.2 Spoilers, roof extensions, roofwalk

4.10.3 Roof sleeper cabs

4.11 Add-on frame components

4.11.1 Rear underride guard

4.11.2 FUP - front underride protection

4.11.3 Sideguards

4.12 Modifi cations to engine systems

4.12.1 Modifi cations to the air intake and exhaust gas routing

4.12.2 Additional requirements if changes are made to the AdBlue

®

system/exhaust

system on Euro5 vehicles

4.12.3 Engine cooling

4.12.4 Engine encapsulation, noise insulation

4.13 Fitting other manual gearboxes, automatic transmissions and transfer boxes

30

30

35

35

35

38

38

40

42

48

48

49

49

50

51

52

52

53

53

53

55

55

56

56

56

59

59

59

59

62

63

63

65

66

68

68

70

70

78

78

78

TRUCKNOLOGY® GENERATION A (TGA) II

5. Bodies

5.1 General

5.1.1 Machinery Directive

5.1.2 CE marking

5.2 Corrosion protection

5.3 Subframes

5.3.1 General

5.3.2 Permissible materials, yield points

5.3.3 Subframe design

5.3.4 Attaching subframes and bodies

5.3.5 Screw connections and riveted joints

5.3.6 Flexible connection

5.3.7 Rigid connection

5.4 Bodies

5.4.1 Testing of bodies

5.4.2 Platform and box bodies

5.4.3 Tail-lifts

5.4.4 Interchangeable containers

5.4.5 Self-supporting bodies without subframe

5.4.6 Single-pivot body

5.4.7 Tank and container bodies

5.4.8 Tippers

5.4.9 Set-down, sliding set-down and sliding roll-off tippers

5.4.10 Propping air-sprung vehicles

5.4.11 Loading cranes

5.4.12 Cable winches

5.4.13 Transport mixers

5.4.14 Car transporter

78

78

80

82

83

83

83

84

86

87

88

91

94

94

94

95

96

104

105

105

108

110

111

112

113

123

123

124

TRUCKNOLOGY® GENERATION A (TGA) III

6. Electrics, electronics, wiring

6.1 General

6.2 Routing cables, earth cable

6.3 Handling batteries

6.3.1 Handling and maintaining the batteries

6.3.2 Handling and maintaining batteries with PAG technology

6.4 Additional wiring diagrams and wiring harness drawings

6.5 Fuses, additional power consumers

6.6 Lighting installations

6.7 Electromagnetic compatibility

6.8 Radio equipment and aerials

6.9 Interfaces on the vehicle, preparations for the body

6.9.1 Electrical connections for tail-lifts

6.9.2 Start-stop control on frame end

6.9.3 Tapping into the speed signal

6.10 Electronics

6.10.1 Display and instrumentation concept

6.10.2 Diagnostics concept and parameterisation using MAN-cats

6.10.3 Parameterisation of the vehicle electronics

6.10.4 ESP yaw rate sensor

125

125

125

125

125

126

127

127

130

130

131

133

133

133

133

134

134

®

134

134

135

TRUCKNOLOGY® GENERATION A (TGA) IV

7. Power take-off (See separate booklet)

8. Brakes, lines

8.1 ALB, EBS braking system

8.2 Brake and compressed air lines

8.2.1 Basic principles

8.2.2 Voss 232 system plug connectors

8.2.3 Installing and attaching lines

8.2.4 Compressed air loss

8.3 Connecting additional air consumers

8.4 Retrofi tting continuous brakes not manufactured by MAN

9. Calculations

9.1 Speed

9.2 Effi ciency

9.3 Tractive force

9.4 Gradeability

9.4.1 Distance travelled on uphill or downhill gradients

9.4.2 Angle of uphill or downhill gradient

9.4.3 Calculating the gradeability

9.5 Torque

9.6 Power output

9.7 Rotational speeds for power take-offs at the transfer case

9.8 Driving resistances

9.9 Turning circle

9.10 Axle load calculation

9.10.1 Performing an axle load calculation

9.10.2 Calculation of weight with trailing axle lifted

9.11 Support length for bodies without subframes

9.12 Coupling devices

9.12.1 Trailer coupling

9.12.2 Rigid drawbar trailers / central axle trailers

9.12.3 Fifth-wheel coupling

136

136

136

136

136

137

138

140

140

142

142

142

143

144

145

145

145

146

150

151

153

154

157

159

159

162

164

165

165

165

167

The ESC numbers stated in the illustrations are purely for internal reference.

They are of no consequence to the reader.

If not otherwise stated: all dimensions in mm, all weights and loads in kg

TRUCKNOLOGY® GENERATION A (TGA) V

1. Applicability and legal agreements

1.1 Applicability

The statements in this guide are binding. If technically feasible, exceptions will be approved only if a written request has been

submitted to the SMTSE-ESC department at MAN, (see „Publisher“ above).

1.2 Legal agreements and approval procedure

1.2.1 Preconditions

In addition to this Guide, the company carrying out the work must observe all

• laws and decrees

• accident prevention regulations

• operating instructions

relating to the operation and construction of the vehicle. Standards are technical standards; they are therefore minimum requirements.

Anyone who does not endeavour to observe these minimum requirements is regarded as operating negligently.

Standards are binding when they form part of regulations.

Information given by MAN in reply to telephone enquiries is not binding unless confi rmed in writing. Enquiries are to be directed to

the relevant MAN department. Information refers to conditions of use that are usual within Europe. Dimensions, weights and other basic

data that differ from these must be taken into consideration when designing the body, mounting the body and designing the subframe.

The company carrying out the work must ensure that the entire vehicle can withstand the conditions of use that it is expected

to experience.

For certain types of equipment, such as loading cranes, tail-lifts, cable winches etc, the respective manufacturers have developed

their own body regulations. If, when compared with this MAN Guide, they impose further conditions, then these too must be observed.

References to

• legal stipulations

• accident prevention regulations

• decrees from professional associations

• work regulations

• other guidelines and sources of information

are not in any way complete and are only intended as ideas for further information.

They do not replace the company’s obligation to carry out its own checks.

Fuel consumption is considerably affected by modifi cations to the vehicle, by the body and its design and by the operation of equipment

driven by the vehicle’s engine. It is therefore expected that the company carrying out the work implements a design that facilitates

the lowest possible fuel consumption.

TRUCKNOLOGY® GENERATION A (TGA) 1

1.2.2 Responsibility

The responsibility for proper

• design

• production

• installation of bodies

• modifi cation to the chassis

always lies fully with the company that is manufacturing the body, installing it or carrying out modifi cations (manufacturer’s liability).

This also applies if MAN has expressly approved the body or the modifi cation. Bodies/conversions that have been approved in writing

by MAN do not release the body manufacturer from his responsibility for the product. Should the company carrying out the work detect

a mistake either in the planning stage or in the intentions of

• the customer

• the user

• its own personnel

• the vehicle manufacturer

then that mistake must be brought to the attention of the respective party.

The company is responsible for seeing that the vehicle’s

• operational safety

• traffi c safety

• maintenance possibilities and

• handling characteristics

do not exhibit any disadvantageous properties.

With regard to traffi c safety, the company must operate in accordance with the state of the art and in line with the recognised rules in

the fi eld in matters relating to

• the design

• the production of bodies

• the installation of bodies

• the modifi cation of chassis

• instructions and

• operating instructions.

Diffi cult conditions of use must also be taken into account.

1.2.3 Quality assurance

In order to meet our customers’ high quality expectations and in view of international product/manufacturer liability legislation an

on-going quality monitoring programme is also required for conversions and body manufacture/installation. This requires a functioning

quality assurance system. It is recommended that the body manufacturer sets up and provides evidence of a quality system that

complies with the general requirements and recognised rules (e.g. DIN EN ISO 9000 et seq. or VDA 8).

Evidence of a qualifi ed system can be provided for example by:

TRUCKNOLOGY® GENERATION A (TGA) 2

If MAN is the party awarding the contract for the body or conversion evidence of qualifi cation will be requested.

MAN Truck & Bus AG reserves the right to carry out its own system audit in accordance with VDA 8 or a corresponding process check at

the supplier’s premises. VDA volume 8 has been agreed with the following body manufacturers’ associations:

ZKF (Zentralverband Karosserie- und Fahrzeugtechnik – Central Association of Body and Vehicle Engineering) and

BVM (Bundesverband Metall Vereinigung Deutscher Metallhandwerke – Federation of German Metal Trades Associations).

It has also been agreed with the ZDH (Zentralverband des Deutschen Handwerks – Central Association of German Craft Trades).

Documents:

VDA Volume 8

„Minimum quality assurance requirements for trailer, body manufacturers“, obtainable from the Verband der Automobilindustrie e.V

(VDA) (German Engine Industry Association), http://www.vda-qmc.de.

1.2.4 Approval

Approval from MAN for a body or a chassis modifi cation is not required if the bodies or modifi cations are carried out in accordance with

this Guide. If MAN approves a body or a chassis modifi cation, then this approval refers

• In the case of bodies only to the body’s fundamental compatibility with the respective chassis and the interfaces to the body

(e.g. dimensions and mounting of the subframe)

• In the case of chassis modifi cations only to the fact that, from a design point of view, the modifi cations to the chassis in

question are fundamentally permissible.

The approval note that MAN enters on the submitted technical documents does not indicate a check on the

• Function

• Design

• Equipment of the body or the modifi cation.

Observance of this Guide does not free the user from responsibility to perform modifi cations and manufacture bodies properly from

a technical point of view. The approval note only refers to such measures or components as are to be found in the submitted technical

documents.

MAN reserves the right to refuse to issue approvals for bodies or modifi cations, even if a comparable approval has already been issued.

Later submissions for approval are not automatically treated the same as earlier ones, because technical advances achieved in

the interim period have to be taken into account.

MAN also reserves the right to change this Guide at any time or to issue instructions that differ from this Guide for individual chassis.

If several identical chassis have the same bodies or modifi cations MAN can, to simplify matters, issue a collective approval.

1.2.5 Submission of documents

Documents should only be sent to MAN if bodies/conversions diverge from this Guide. If this is the case then technical documents that

require approval or inspection must have been received by the SMTSE-ESC Department at MAN (for address see “Publisher” above).

Fitting bodies/conversion work requires prior writtien permission from MAN.

For an approval process to proceed swiftly, the following are required:

• Documents should be submitted in duplicate

• The number of individual documents should be kept to a minimum

• All the technical data and documents must be submitted.

TRUCKNOLOGY® GENERATION A (TGA) 3

The following information should be included:

• Vehicle model (see Chapter 2.2 for model code) with

- cab design

- wheelbase

- frame overhang

• · Vehicle identifi cation number or vehicle number (if already available, see Chapter 2.2)

Identifi cation of deviations from this Guide to Fitting Bodies in all documentation!

• Loads and their load application points:

- Forces from the body

- Axle load calculation

• Special conditions of use:

• Subframe:

- Material and cross-sectional data

- Dimensions

- Type of section

- Arrangement of cross members in the subframe

- Special features of the subframe design

- Cross-section modifi cations

- Additional reinforcements

- Upsweeps, etc.

• Means of connection:

- Positioning (in relation to the chassis)

- Type

- Size

- Number.

The following are not suffi cient for inspection or approval:

• Parts lists

• Brochures

• Photographs

• Other not binding information.

Drawings are only valid if they bear the number that has been assigned to them. It is therefore not permitted to draw in the bodies or

modifi cations on chassis drawings that have been provided by MAN and to submit these for approval.

1.2.6 Registration

National legislation on the registration of modifi ed vehicles shall be complied with.

Modifi cations made to the chassis shall be presented to a technical vehicle inspection centre for approval.

The company carrying out the work shall remain responsible, also after registration of the vehicle, should the competent authorities issue

a registration certifi cate with a lack of knowledge relating to the operational safety of the product.

TRUCKNOLOGY® GENERATION A (TGA) 4

Multi-stage co-operation modules in accordance with 2007/46/EC

I. Process

In line with the multi-stage process in accordance with Annex XVII of Directive 2007/46/EC each manufacturer is responsible for

the approval and conformity of production of all systems, components or separate technical units manufactured by him or added by him

to the previously built stage.

In accordance with 2007/46/EC the bodybuilder is a manufacturer in the second or further production stage.

II. Responsibilities

The bodybuilder shall always remain responsible:

• For modifi cations made by him to the basic vehicle.

• For parts already approved at an earlier stage if modifi cations made to the basic vehicle cause the approvals issued earlier

for this vehicle to be no longer applicable.

• For ensuring that modifi cations he has carried out comply with the corresponding national/international legislation,

in particular those of the target country.

• For ensuring that modifi cations he has carried out are presented to a technical vehicle inspection centre for approval.

• For ensuring that compliance with legislation is documented in a corresponding manner (test report and/or approval or

other documentation in accordance with the legal requirements of the target country).

MAN, as the manufacturer of the basic vehicle, shall always remain responsible:

• For providing upon request by the bodybuilder the available homologation documentation (EC/ECE approvals)

for the scope of supply of the basic vehicle in electronic form.

III. Identifi cation of the vehicle

The respective vehicle shall be given a vehicle identifi cation number („VIN“) which MAN issues as the manufacturer of the incomplete

basic vehicle.

The requirements set forth in Annex XVII to Directive 2007/46/EC and the associated procedure instructions published together

with it shall always apply.

IV. Conformity of production (CoP)

The requirements set forth in the specifi c EC Directives and Annex X to Directive 2007/46/EC together with the requirements set forth in

Annex 2 to the ECE Agreement of 1958 shall always apply.

V. Provision of documentation for registration/the subsequent build stages

In accordance with Annex XVII to Directive 2007/46/EC MAN, as manufacturer of the basic vehicle, shall provide the bodybuilder(s) with

the available EC/ECE system approvals together with the Certifi cate of Conformity (CoC)

1)

Only if the vehicle is EG-compliant and MAN has printed a CoC.

1)

available for the basic vehicle in electronic form.

Case 1: Registration in Germany

If MAN serves as general contractor („single invoice transactions“) the bodybuilder(s) is/are under an obligation,

as manufacturer of the second stage(s), to provide the following documentation in electronic form:

Case A: The specifi c conditions of delivery provide for the acceptance/approval and registration process to be carried

out by the vehicle manufacturer (MAN).

1. In the case of an existing and valid whole vehicle type-approval in accordance with 2007/46/EC

for the manufacturing stages, a CoC.

2. Alternatively to 1: The test reports and approval documentation required for national individual approval procedures

in accordance with Section 13 of the EC vehicle approval Directive.

TRUCKNOLOGY® GENERATION A (TGA) 5

The latest time for submitting the above stated documentation in printable form is the day the completed vehicle is returned to

the contractually agreed place of delivery.

The documentation shall be sent to the following e-mail address: documents@de.man-mn.com.

In cases where MAN receives a CoC from the bodybuilder, then original certifi cates may only be generated by MAN on behalf

of the bodybuilder.

Case B: The acceptance/approval and registration process is to be carried out by the contract partner

or by the manufacturer of the fi nal completion stage of the vehicle.

1. None. The registration process is the responsibility of the contract partner or the manufacturer of the fi nal completion

stage of the vehicle.

In all other cases the acceptance/approval and registration process is to be carried out by the manufacturer of the fi nal completion stage

of the vehicle or by the corresponding contract partner.

Case 2: Registration outside Germany but inside the area of application of Directive 2007/46/EC

If MAN serves as general contractor then the bodybuilder is under an obligation, as the fi nal stage manufacturer, to provide in

electronic form, all the necessary approval/registration documentation for all modifi cations made during the subsequent

manufacturing stages of the respective responsible sales organisation or importer which exceed the scope of the basic vehicle.

Irrespective of any general contractor status of the importers, the acceptance/approval and registration process is to be carried out

by the manufacturer of the fi nal completion stage of the vehicle or by the corresponding contract partner.

The importer in the respective country or the corresponding contract partner have the authority and responsibility

for the registration process.

MAN does not provide national data for registration purposes that exceeds that for incomplete vehicles set forth in Annex IX to Directive

2007/46/EC in its current form and as amended from time to time. This also applies in particular to national model codes and encrypted

basic technical data.

MAN as a manufacturer reserves the right – following corresponding feasibility studies and economic implementation – and after

reaching corresponding specifi cally applicable agreements with national sales organisations and importers, to provide data for national

registration which exceeds the scope of that set forth above (e.g. vehicle’s manufacturing plates etc.).

Corresponding enquiries shall be sent to the following e-mail address: documents@de.man-mn.com

VI. Confi dentiality agreement

The bodybuilder may not forward the approval documentation provided by MAN to any third parties without obtaining prior,

express permission from MAN.

The forwarding of documentation that is directly associated with the registration of the vehicle in question to persons of the institutions

listed below is excepted:

• MAN sales partners

• Technical vehicle inspection centres or testing organisations

• Approving authorities

• Registration authorities or licensing centres acting for the government

TRUCKNOLOGY® GENERATION A (TGA) 6

Type approval/homologation for

TiB (Truck in the Box),

CiB (Chassis in the Box),

BiB (Bus in the Box),

CKD (Complete Knocked Down),

SKD (Semi Knocked Down),

PKD (Partly Knocked Down)

For these versions MAN is not considered to be the manufacturer within the meaning of Directive 2007/46/EC – therefore,

the responsibility for the homologation and registration process lies with the manufacturer of these vehicles.

In principle, the substance of the contracts respectively concluded with MAN shall apply.

In principle, MAN does not provide registration-related data for completed vehicles. Exceptions include homologation documentation

for components subject to approval such as the engine. Such documentation will be provided by MAN in electronic form.

This does not however, preclude MAN from reserving the right – following corresponding feasibility studies and economic

implementation – and after reaching corresponding specifi cally applicable agreements with national sales organisations and importers,

from providing data for national registration which exceeds the scope of that set forth above (e.g. vehicle’s manufacturing plates etc.).

Corresponding enquiries shall be sent to the homologation department at MAN.

1.2.7 Liability for defects

Liability claims in respect of defects only exist within the framework of the purchasing contract between buyer and seller.

In accordance with this, liability for defects lies with the respective seller of the goods.

Claims against MAN are not valid if the fault that is the subject of the complaint was due to the fact that

• This Guide was not observed

• In view of the purpose for which the vehicle is used, an unsuitable chassis has been selected

• The damage to the chassis has been caused by

- the body

- the type of body mounting or how the body has been mounted

- the modifi cation to the chassis

- improper use.

TRUCKNOLOGY® GENERATION A (TGA) 7

1.2.8 Product liability

Any faults in the work that are identifi ed by MAN are to be corrected. Insofar as is legally permissible, MAN disclaims all liability,

in particular for consequential damage.

Product liability regulates:

• The liability of the manufacturer for its product or component

• The compensation claim made by the manufacturer against whom a claim has been made against the manufacturer of

an integral component, if the damage that has occurred is due to a fault in that component.

The company that has made the body or carried out the modifi cation is to relieve MAN of any liability to its customer or other third party

if the damage that has occurred is due to the fact that

• The company did not observe this Guide

• The body or chassis modifi cation has caused damage on account of its faulty

- design

- manufacture

- installation

- instructions

• The fundamental rules that are laid down have not been complied with in any other way.

1.2.9 Operational reliability and road safety

In order to ensure operational reliability and road safety and to maintain the validity of the warranty, the bodybuilder must observe

the instructions given in these guidelines exactly. MAN shall not be liable for non-compliance.

Before commencing work on the body, making modifi cations or starting installation work, the bodybuilder must also have knowledge

of the sections of the operator‘s manual that relate to the work he is completing. It will otherwise be impossible to recognise risks and

other persons may be endangered.

MAN cannot be liable for reliability, safety and suitability if:

• Bodies are not designed and fi tted in accordance with these guidelines

• Original parts or approved parts are replaced with other parts

• Unauthorised modifi cations are made to the vehicle

Approvals by third parties, for example Technical Inspection Agencies or approvals from public authorities, shall not be considered

suffi cient for precluding safety risks.

TRUCKNOLOGY® GENERATION A (TGA) 8

Companies carrying out work on the chassis/vehicle are liable for any damage that may be caused by poor functional and operational

safety or inadequate operating instructions.

Therefore, MAN requires the body manufacturer or vehicle conversion company to:

• Ensure the highest possible safety, in line with the state of the art

• Provide comprehensible, sufficient operating instructions

• Provide permanent, easily visible instruction plates on hazardous points for operators and/or third parties

• Observe the necessary protection measures (e.g. fire and explosion prevention)

• Provide full toxicological information

• Provide full environmental information.

Safety is top priority! All available technical means of avoiding incidents that will undermine operational safety are to be implemented.

This applies equally to

• Active safety = prevention of accidents. This includes:

- Driving safety achieved by the overall vehicle design, including the body

- Safety as a consequence of the driver’s well-being achieved by keeping occupant stress caused by vibrations,

noise, climatic conditions etc. to a minimum

- Safety as a consequence of observation and perception, in particular through the correct design of lighting systems,

warning equipment, providing sufficient direct and indirect visibility

- Safety as a consequence of operating equipment and controls this includes optimising the ease of operation of all

equipment, including that of the body.

• Passive safety = avoidance and reduction of the consequences of accidents. This includes:

- Exterior safety such as the design of the outside of the vehicle and body with respect to deformation behaviour and

the installation of protective devices

- Interior safety including the protection of occupants of vehicles and cabs that are installed by the body builders.

Climatic and environmental conditions have effects on:

• Operational safety

• Readiness for use

• Operational performance

• Service life

• Cost-effectiveness.

Climatic and environmental conditions are, for example:

• The effects of temperature

• Humidity

• Aggressive substances

• Sand and dust

• Radiation.

Suffi cient space for all parts required to carry out a movement, including all pipes and cables, must be guaranteed. The operating

instructions for MAN trucks provide information about the maintenance points on the vehicle. Regardless of what type of body is fi tted,

good access to the maintenance points must be ensured in all cases. It must be possible to carry out maintenance unhindered and

without having to remove any components. Suffi cient ventilation and/or cooling of the components is to be guaranteed.

TRUCKNOLOGY® GENERATION A (TGA) 9

1.2.10 Manuals from body and conversion companies

In the event of a body being added or modifi cations to the vehicle being carried out, the operator of the vehicle is also entitled to receive

operating instructions from the conversion company. All specifi c advantages offered by the product are of no use if the customer is

not able to:

• Handle the product safely and properly

• Use it rationally and effortlessly

• Maintain it properly

• Master all of its functions.

As a result, every vehicle body builder and converter must check his technical instructions for:

• Clarity

• Completeness

• Accuracy

• Comprehensibility

• Product-specifi c safety instructions.

Inadequate or incomplete operating instructions carry considerable risks for the user. Possible effects are:

• Reduced benefi t, because the advantages of the product remain unknown

• Complaints and annoyance

• Faults and damage, which are normally blamed on the chassis

• Unexpected and unnecessary additional cost through repairs and time lost

• A negative image and thereby less inclination to buy the same product or brand again.

Depending on the vehicle body or modifi cation, the operating personnel must be instructed about operation and maintenance.

Such instruction must also include the possible effects on the static and dynamic performance of the vehicle.

1.2.11 Limitation of liability for accessories/spare parts

Accessories and spare parts that MAN has not manufactured or approved for use in its products may affect the traffi c safety and

operational safety of the vehicle and create hazardous situations. MAN Truck & Bus AG (or the seller) accepts

no liability for claims of any kind resulting from a combination of the vehicle together with an accessory that was made by another

manufacturer, regardless of whether MAN Truck & Bus AG (or the seller) has sold the accessory itself or fi tted it to the vehicle

(or the subject of the contract).

TRUCKNOLOGY® GENERATION A (TGA) 10

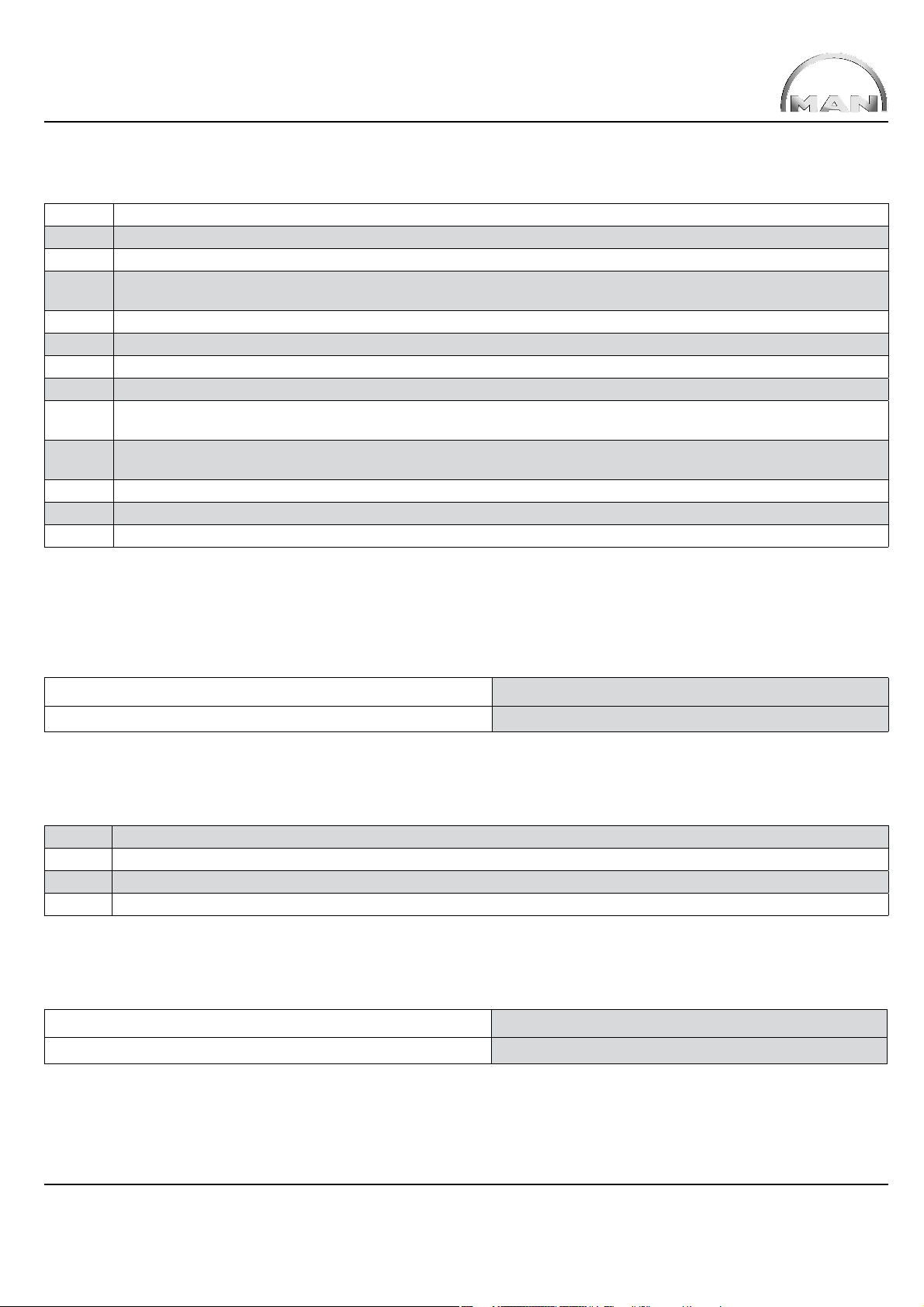

2. Product designations

2.1 Vehicle designation and wheel formula

To enable unique and easily comprehensible identifi cation of the different variants new vehicle designations have been systematically

introduced. The vehicle designation system is based on three levels:

- Door designation

- Variant descriptor (in the sales and technical documentation e.g. data sheets, chassis drawings)

- Model code.

2.1.1 Door designation

The door designation comprises:

Model range + permissible weight + engine power

TGA 18.400

Model range + Permissible weight + Engine power

TGA 18 .400

Abbreviated notation of model range TGA = Trucknology® Generation A,

technically permissible weight in [t],

engine power [DIN-hp] rounded to the nearest 10hp

2.1.2 Variant descriptor

The variant descriptor = vehicle designation which comprises the door designation + wheel formula + suffi x.

The terms ‘wheel formula’ and ‘suffi x’ are defi ned in the following sections.

Model range + permissible weight + engine power + wheel formula + suffi x

TGA 25.480 6x2-2 LL-U

Model range + Permissible weight + Engine power

TGA 25 .480 6x2-2 LL-U

Wheel formula Suffi x

TRUCKNOLOGY® GENERATION A (TGA) 11

2.1.3 Wheel formula

The wheel formula stipulates the number of axles and provides additional identifi cation of drive, steered and leading/trailing axles.

Wheel formula is a commonly used, but not standardised term. It is “wheel locations” that are counted and not the individual wheels.

Twin tyres are therefore regarded as one wheel.

The following two examples illustrate the wheel formula:

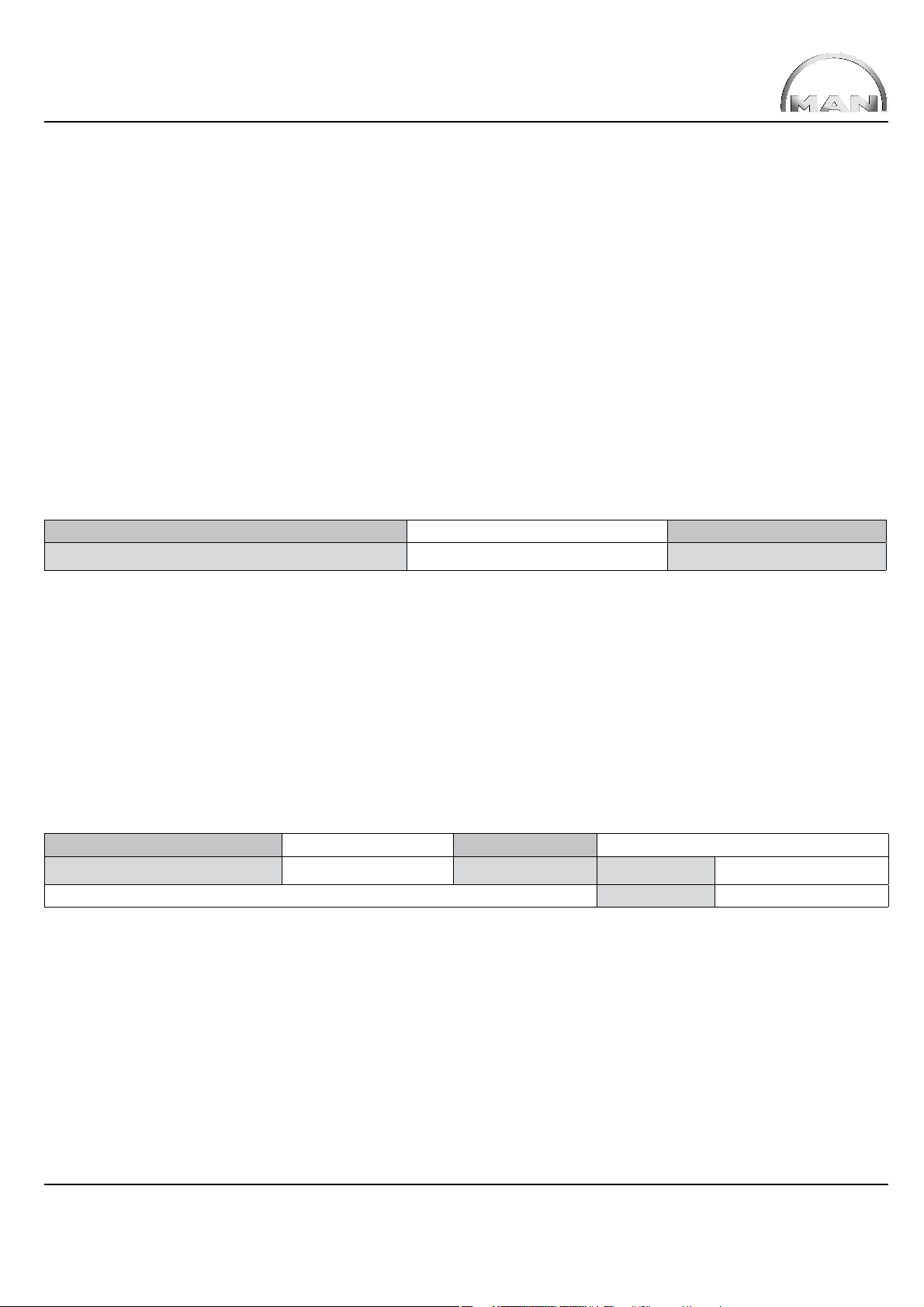

Tabl e 1: Wheel formula examples

6 x 2 - 4

6 x 2 / 4

6 = Total number of wheel locations, i.e. 3 axles

x = No function

2 = Number of driven wheels

- = Trailing axle behind the rear drive-axle assembly

/ = Leading axle ahead of the rear drive-axle assembly

4 = Number of steered wheels

The number of steered wheels is only stated if, aside from steered front wheels, leading axles or trailing axles are also involved.

A leading axle is located “ahead of” a rear drive-axle assembly and a trailing axle is “behind” the rear drive-axle assembly.

A slash “/” represents a leading axle and a hyphen “-” represents a trailing axle.

If a chassis is fi tted with both leading and trailing axles the number of steered wheels follows the hyphen “-”.

If the vehicle is fi tted with MAN HydroDrive

e.g. 6x4H = a front axle with MAN HydroDrive

®

hydrostatic front axle drive then the wheel formula receives an additional H,

®

, 2 rear axles, one of which is driven.

Currently the following wheel formulae are available ex-works:

Tabl e 2: TGA wheel formulae

4x2 Two-axle vehicle with one drive axle

4x4 Two-axle vehicle with two drive axles “All-wheel drive”

4x4H Two-axle vehicle with two drive axles, front axle with MAN HydroDrive

®

6x2/2 Three-axle vehicle with non-steered “Pusher” leading axle

6x2/4 Three-axle vehicle with steered leading axle

6x2-2 Three-axle vehicle with non-steered trailing axle

6x2-4 Three-axle vehicle with steered trailing axle

6x4 Three-axle vehicle with two driven non-steered rear axles

6x4/4 Three-axle vehicle with 2 driven axles (fi rst and last axles), steered leading axle

6x4-4 Three-axle vehicle with 2 driven axles, (fi rst and second axles), steered trailing axle

®

6x4H/2 Three-axle vehicle with MAN HydroDrive

6x4H/4 Three-axle vehicle with MAN HydroDrive

6x4H-2 Three-axle vehicle with MAN HydroDrive

front axle drive, one driven rear axle, non-steered leading axle

®

front axle drive, one driven rear axle, steered leading axle

®

front axle drive, one driven rear axle, non-steered trailing axle

6x4H-4 Three-axle vehicle with MAN HydroDrive® front axle drive, one driven rear axle, steered trailing axle

TRUCKNOLOGY® GENERATION A (TGA) 12

Tabl e 2: TGA wheel formulae (continuation)

6x6 Three-axle vehicle with all-wheel drive

6x6-4 Three-axle vehicle with all-wheel drive, steered and driven trailing axle

6x6H Three-axle vehicle with all-wheel drive, front axle with MAN HydroDrive

8x2-4 Four-axle vehicle with one drive axle, two steered front axles, non steered trailing axle or four-axle vehicle with three rear

axles with front and trailing axles steered

8x2-6 Four-axle vehicle with one drive axle, two steered front axles, steered trailing axle

8x4 Four-axle vehicle with two steered front axles and two driven rear axles

8x4/4 Four-axle vehicle with one front axle, one steered leading axle and two driven rear axles

8x4-4 Four-axle vehicle with one front axle, two driven rear axles and one steered trailing axle

8x4H-4 Four-axle vehicle with two steered front axles (2nd front axle with MAN HydroDrive

a non-steered trailing axle

8x4H-6 Four-axle vehicle with two steered front axles (2nd front axle with MAN HydroDrive®), one driven rear axle and

a steered trailing axle

8x6 Four-axle vehicle “All wheel drive” with two front axles (2nd driven) and two driven rear axles

8x6H Four-axle vehicle “All wheel drive” with two front axles (2nd front axle with MAN HydroDrive

8x8 Four-axle vehicle “All wheel drive” with two front axles and two rear axles, all driven

®

®

), one driven rear axle and

®

) and two driven rear axles

2.1.4 Suffi x

The suffi x to the vehicle designation defi nes the type of suspension, differentiates trucks from tractor units and describes special

product features.

TGA 25.480 6x2-2 LL-U

Suffi x

Types of suspension (Digits 1 and 2 of suffi x)

Tabl e 3: Ty p e s o f suspension

BB Leaf suspension on front axle(s), leaf suspension on rear axle(s)

BL Leaf suspension on front axle(s), air suspension on rear axle(s)

LL Air suspension on front axle(s), air suspension on rear axle(s)

BH Leaf suspension on front axle(s), hydropneumatic on rear axle(s)

Semitrailer tractor units are designated with an ‘S’ suffi x. Trucks have no special designation.

Example for semitrailer tractor:

TGA 33.440 6x6 BBS

S = Semitrailer tractor

TRUCKNOLOGY® GENERATION A (TGA) 13

Special product (design) features are added separately following a hyphen ‘-’ after the fi rst section of the suffi x:

Example for special product features:

TGA 18.350 4x2 BLS -TS

-TS = Weight optimised version for silo tanker

Table 4: Designations for special designs produced to-date (to be supplemented with further designs)

-U For low design ‘Ultra’ e.g.: TGA 18.410 4x2 LLS-U

-TS Weight optimised version for silo tanker, e.g.: TGA 18.400 4x2 BLS-TS

-WW “World wide” variant, eligible for licensing outside Europe only, e.g. TGA 40.460 6x6 BB-WW

-LE “Low entry” cab with lowered entry, e.g.: TGA 28.310 6x2-4 LL-LE

-CKD “Completely knocked down”, for assembly in MAN factory of the recipient country, e.g.: TGA 40.480 6x4-4 WW-CKD

2.2 Model number, vehicle identifi cation number, vehicle number, basic vehicle number

The three-digit model number, also called model code, provides a technical identifi cation of the MAN chassis and also identifi es

to which vehicle range it belongs. This number is part of the 17-digit vehicle identifi cation number (VIN) and is located at digits 4 to 6 in

the VIN. The basic vehicle number, formulated for sales purposes, also contains the model number at digits 2 to 4.

The seven-fi gure vehicle number describes the technical equipment on a vehicle; it contains the model number at digits 1 to 3, followed

by a four-digit sequential number. The vehicle number is to be found in the vehicle papers and on the vehicle’s manufacturing plate.

The vehicle number can be quoted instead of the 17-digit vehicle identifi cation number in the event of any technical queries regarding

conversions and bodies. Table 5 gives some examples of the model number, vehicle identifi cation number, basic vehicle number and

vehicle number.

Tabl e 5: Example vehicle designation, model number, vehicle identifi cation number, basic vehicle number and vehicle number

Vehicle designation Model number

Model code

TGA 18.440 4x2 BLS

TGA 26.410 6x2-4 LL

TGA 33.540 6x4 BB

H06

H21

H26

Vehicle identifi cation number

(VIN)

WMAH06ZZ14M000479

WMAH21ZZ94G144924

WMAH26ZZ75M350354

Basic vehicle

number

LH06AG53

LH21E 05

LH26LR04

Vehicle number

H060057

H210058

H261158

TRUCKNOLOGY® GENERATION A (TGA) 14

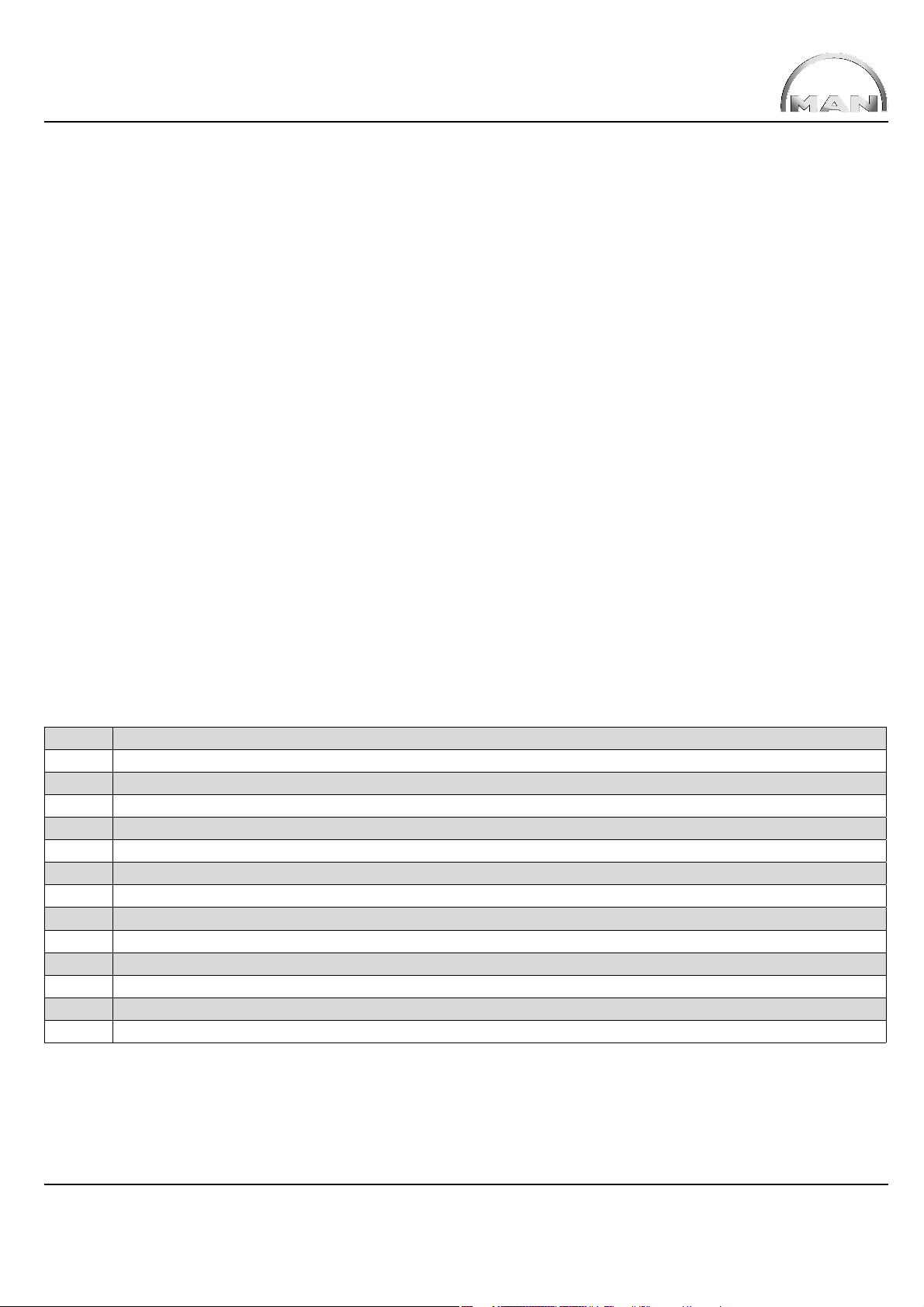

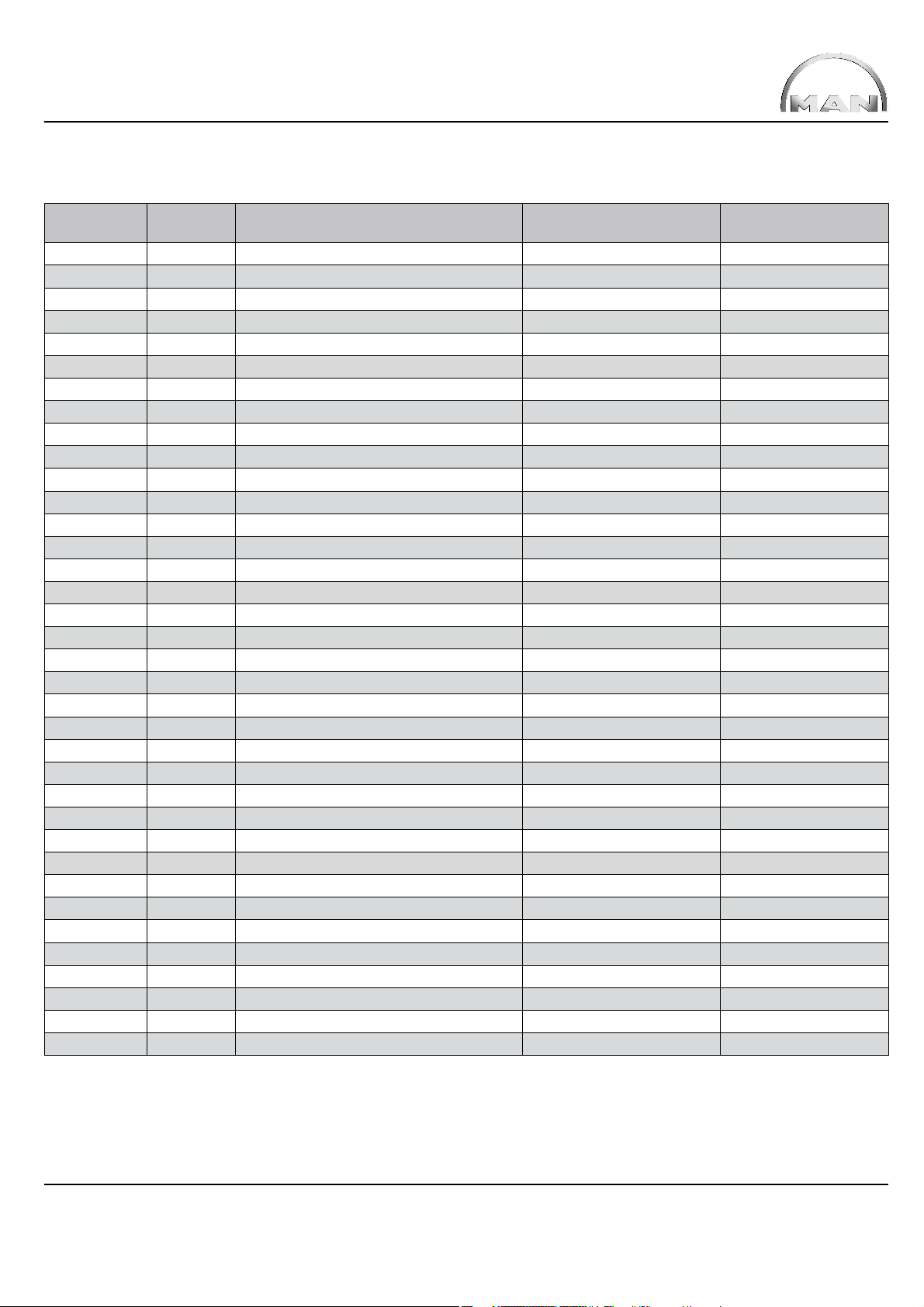

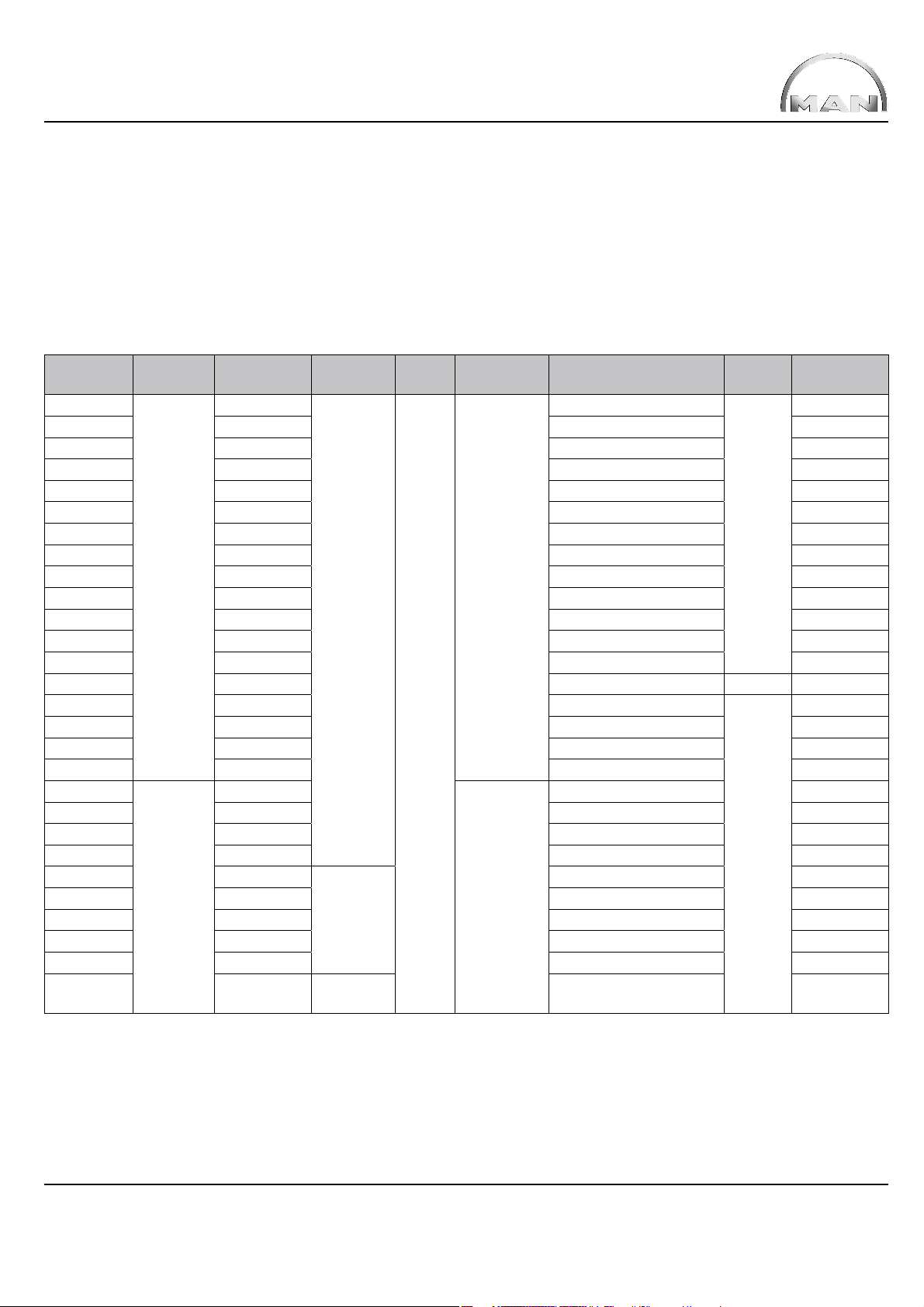

Table 6: Model numbers, tonnage class, vehicle designation and suspension on the TGA

Model number Tonnage Designation , xxx stands for

Engine Suspension

various engine powers

H01 18 t TGA 18.xxx 4x2 BLS-TS D28 R6 BL

H02 18 t TGA 18.xxx 4x2 BB D28 R6 BB

H03 18 t TGA 18.xxx 4x2 BB D20/D26 R6 BB

H05 18 t TGA 18.xxx 4x2 BL D28 R6 BL

H06 18 t TGA 18.xxx 4x2 BL D20/D26 R6 BL

H07 18 t ECT 18.ISM 4x2 BL ISM

e

H08 18 t TGA 18.xxx 4x2 BLS-TS D20/D26 R6 BL

H09 18 t TGA 18.xxx 4x2 LL D28 R6 LL

H10 18 t TGA 18.xxx 4x2 LL D20/D26 R6 LL

H11 40 t TGA 40.xxx 6x4 BB-WW-CKD D20/D26 R6 BBB

H12 18 t TGA 18.xxx 4x2 LLS-U D28 R6 LL

H13 18 t TGA 18.xxx 4x2 LLS-U D20/D26 R6 LL

H14 18 t TGA 18.xxx 4x2 LL-U D28 R6 LL

H15 18 t TGA 18.xxx 4x2 LL-U DD20/D26 R6 LL

H16 26 t TGA 26.xxx 6x2-4 BL D08 R6 BLL

H17 26 t TGA 26.xxx 6x2-2, 6x2-4 BL D28 R6 BLL

H18 26 t TGA 26.xxx 6x2-2, 6x2-4 BL D20/D26 R6 BLL

H19 26 t TGA 26.xxx 6x2-4 LL D08 R6 LLL

H20 26 t TGA 26.xxx 6x2-2, 6x2-4 LL D28 R6 LLL

H21 26 t TGA 26.xxx 6x2-2, 6x2-4 LL D20/D26 R6 LLL

H22 18 t TGA 18.xxx 4x4H BL D20/D26 R6 BL

H23 26 t TGA 26.xxx 6x2/2, 6x2/4 BL D28 R6 BLL

H24 26 t TGA 26.xxx 6x2/2, 6x2/4 BL D20/D26 R6 BLL

H25 26/33 t TGA 26/33.xxx 6x4 BB D28 R6 BBB

H26 26/33 t TGA 26/33.xxx 6x4 BB D20/D26 R6 BBB

H27 26 t ECT 26.ISM 6x2-2, 6x2-4 BL ISM

e

H28 33 t TGA 33.xxx 6x4 BB-WW D28 R6 BBB

H29 26/33 t TGA 26/33.xxx 6x4 BL D28 R6 BLL

H30 26/33 t TGA 26/33.xxx 6x4 BL D20/D26 R6 BLL

H31 26 t ECT 26.ISM 6x2-2 LL ISM

H32 26 t ECT 26.ISM 6x2/2 BL ISM

e

e

H33 40 t TGA 40.xxx 6x4 BB-WW D28 R6 BBB

H34 40 t TGA 40.xxx 6x4 BB-WW D20/D26 R6 BBB

H35 26 t TGA 26.xxx 6x4H-2 BL, 6x4H-4 BL D20/D26 R6 BLL

H36 35 t TGA 35.xxx 8x4 BB D28 R6 BBBB

H37 35 t TGA 35.xxx 8x4 BB D20/D26 R6 BBBB

BL

BLL

LLL

BLL

TRUCKNOLOGY® GENERATION A (TGA) 15

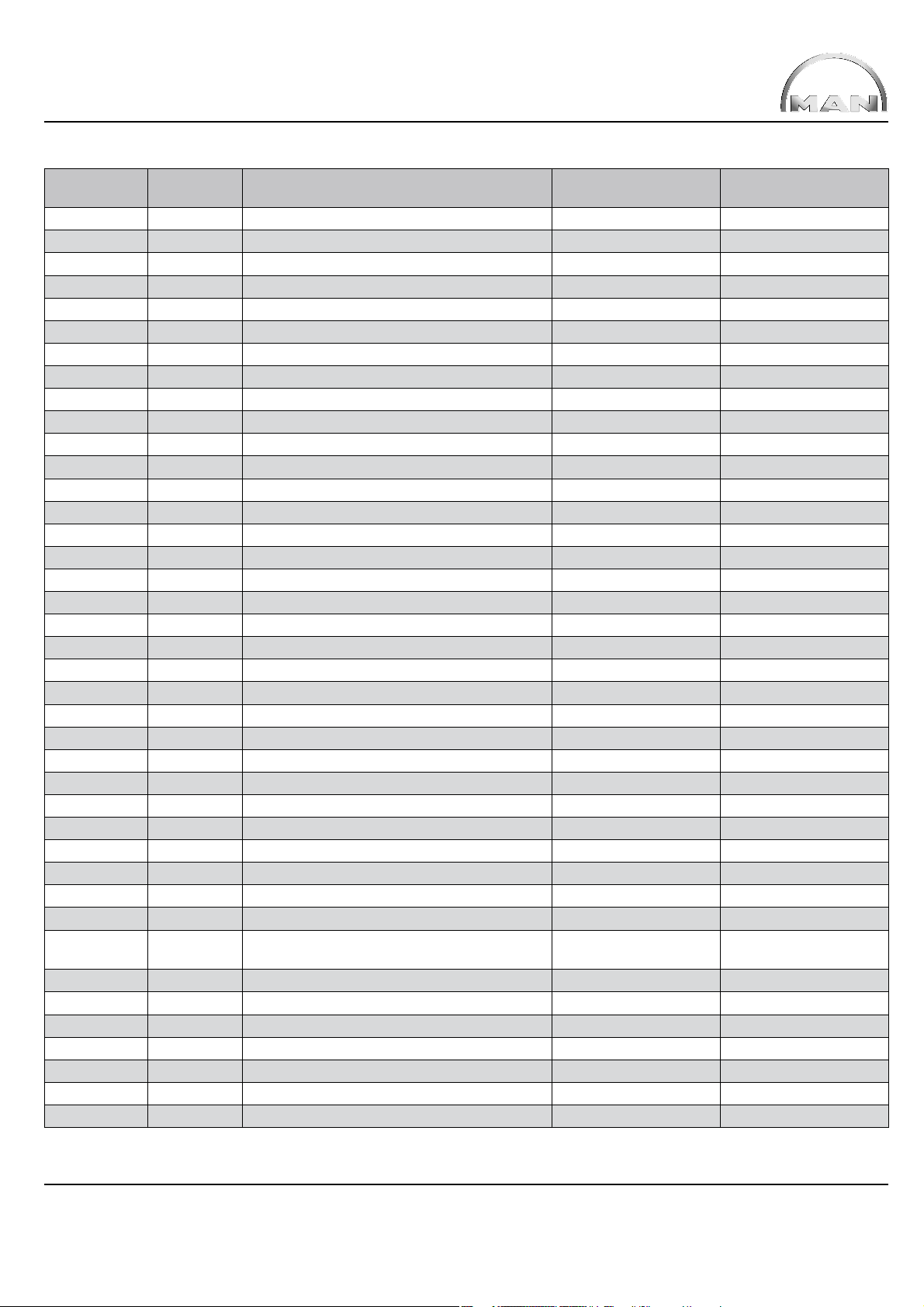

Model number Tonnage Designation , xxx stands for

various engine powers

H38 41 t TGA 41.xxx 8x4 BB D28 R6 BBBB

H39 41 t TGA 41.xxx 8x4 BB D20/D26 R6 BBBB

H40 35 t TGA 35.xxx 8x4 BL D28 R6 BBLL

H41 35 t TGA 35.xxx 8x4 BL D20/D26 R6 BBLL

H42 26 t TGA 26.xxx 6x4H/2 BL, 6x4H/4 BL D20/D26 R6 BLL

H43 19 t TGA 19.xxx 4x2 BBS-WW D28 R6 BB

H44 25 t TGA 25.xxx 6x2-2 LL-U D28 R6 LLL

H45 25 t TGA 25.xxx 6x2-2 LL-U D20/D26 R6 LLL

H46 41 t TGA 41.xxx 8x4 BB-WW D28 R6 BBBB

H47 26/33 t TGA 26/33.xxx 6x6H BB D20/D26 R6 BBB

H48 32 t TGA 32.xxx 8x4 BB D28 R6 BBBB

H49 32 t TGA 32.xxx 8x4 BB D20/D26 R6 BBBB

H50 35 t TGA 35.xxx 8x6H BB D20/D26 R6 BBBB

H51 18 t TGA 18.xxx 4x4 BB D28 R6 BB

H52 18 t TGA 18.xxx 4x4 BB D20/D26 R6 BB

H54 33 t TGA 33.xxx 6x6 BB-WW D28 R6 BBB

H55 26/33 t TGA 26/33.xxx 6x6 BB D28 R6 BBB

H56 26/33 t TGA 26/33.xxx 6x6 BB D20/D26 R6 BBB

H57 40 t TGA 40.xxx 6x6 BB-WW D28 R6 BBB

H58 40 t TGA 40.xxx 6x6 BB-WW D20/D26 R6 BBB

H59 35 t TGA 35.xxx 8x6H BL D20/D26 R6 BBLL

H60 19 t TGA 19.xxx 4x2 BBS-WW-CKD D28 R6 BB

H61 18 t TGA 18.xxx 4x2 BLS-WW-CKD D28 R6 BL

H62 33 t TGA 33.xxx 6x4 BB-WW-CKD D28 R6 BBB

H63 26 t TGA 26.xxx 6x4 BL-WW-CKD D28 R6 BLL

H64 19 t TGA 19.xxx 4x2 BBS-WW-CKD D20/D26 R6 BB

H65 18 t TGA 18.xxx 4x2 BLS-WW-CKD D20/D26 R6 BL

H66 33 t TGA 33.xxx 6x4 BB-WW-CKD D20/D26 R6 BBB

H67 26 t TGA 26.xxx 6x4 BL-WW-CKD D20/D26 R6 BLL

H68 40 t TGA 40.xxx 6x4 BB-WW-CKD D28 R6 BBB

H69 39 t TGA 39.xxx 8x2-4 BL D20/D26 R6 BBLL

H70 18 t TGA 18.xxx 4x4 BL D28 R6 BL

H71 28 t TGA 28.xxx 6x2-4 BL

TGA 28.xxx 6x2-4 LL

H72 26/33 t TGA 26/33.xxx 6x6 BL D28 R6 BLL

H73 35/41 t TGA 35/41.xxx 8x6 BB D28 R6 BBBB

H74 28 t TGA 28.xxx 6x2-4 BL D20/D26 R6 BLL

H75 28 t TGA 28.xxx 6x2-4 LL D20/D26 R6 LLL

H76 35/41 t TGA 35/41.xxx 8x8 BB D28 R6 BBBB

H77 28 t TGA 28.xxx 6x4-4 BL D20/D26 R6 BLL

H80 18 t TGA 18.xxx 4x4 BL D20/D26 R6 BL

Engine Suspension

D28 R6 BLLLLL

TRUCKNOLOGY® GENERATION A (TGA) 16

Model number Tonnage Designation , xxx stands for

various engine powers

H81 28 t TGA 28.xxx 6x4-4 BL D28 R6 BLL

H82 26/33 t TGA 26/33.xxx 6x6 BL D20/D26 R6 BLL

H83 28 t TGA 28.xxx 6x6-4 BL D20/D26 R6 BLL

H84 28 t TGA 28.xxx 6x4-4 BL D20/D26 R6 BLL

H85 28 t TGA 28.xxx 6x2-2 LL D20/D26 R6 LLL

H86 28 t TGA 28.xxx 6x2-2 BL D28 R6 BLL

H87 28 t TGA 28.xxx 6x2-2 LL D28 R6 LLL

H88 35 t TGA 35.xxx 8x2-4, 8x2-6 BL D28 R6 BBLL

H89 28 t TGA 28.xxx 6x2-2 BL D20/D26 R6 BLL

H90 35 t TGA 35.xxx 8x2-4, 8x2-6 BL D20/D26 R6 BBLL

H91 35 t TGA 35.xxx 8x4-4 BL D28 R6 BLLL

H92 35 t TGA 35.xxx 8x4-4 BL D20/D26 R6 BLLL

H93 35/41 t TGA 35/41.xxx 8x6 BB D20/D26 R6 BBBB

H94 41 t TGA 41.xxx 8x4/4 BB

TGA 41.xxx 8x4/4 BL

H95 41 t TGA 41.xxx 8x4/4 BB

TGA 41.xxx 8x4/4 BL

H96 35/41 t TGA 35/41.xxx 8x8 BB D20/D26 R6 BBBB

H97 18 t TGA 18.xxx 4x2 LL-LE D20/D26 R6 LL

H98 26 t TGA 26.xxx 6x2/4 LL-LE D20/D26 R6 LLL

H99 28 t TGA 28.xxx 6x2-4 LL-LE D20/D26 R6 LLL

HH1 26/33 t TGA 26/33.xxx 6x6H BL D20/D26 R6 BLL

HH2 28 t TGA 28.xxx 6x4H-4 D20/D26 R6 BLL

HH4 35 t TGA 35.xxx 8x4H-4, 8x4H-6 BL D20/D26 R6 BBLL

HV1 26 t TGA 26.xxx 6X2-2, 6X2-4 BL-WW D20/D26 R6 BLL

HV2 26/33 t TGA 26/33.xxx 6X4 BL-WW D20/D26 R6 BLL

HV3 39 t TGA 39.xxx 8X2-4 BL-WW D20 R6 BBLL

HV4 28 t TGA 28.xxx 6X2-2 BL-WW D20/D26 R6 BLL

HV5 18 t TGA 18.xxx 4X4 BB-WW D20 R6 BB

HV6 35/41 t TGA 35/41.xxx 8X8 BB-WW D20 R6 BBBB

HV7 28 t TGA 28.xxx 6X2-2 BL-WW-CKD D20/D26 R6 BLL

HV8 32 t TGA 32.xxx 8X4 BB-WW D20 R6 BBBB

HW1 19 t TGA 19.xxx 4x2 BBS-WW D20/D26 R6 BB

HW2 33 t TGA 33.xxx 6x4 BB-WW D20/D26 R6 BBB

HW3 41 t TGA 41.xxx 8x4 BB-WW D20/D26 R6 BBBB

HW4 33 t TGA 33.xxx 6x6 BB-WW D20/D26 R6 BBB

HW5 19 t TGA 19.xxx 4x2 BLS-WW-CKD D20/D26 R6 BL

HW6 41 t TGA 41.xxx 8x4 BB-WW-CKD D20/D26 R6 BBBB

HW7 19 t TGA 19.xxx 4x2 BLS-WW D20/D26 R6 BL

HW8 33 t TGA 33.xxx 6x4 BBS-WW D20/D26 R6 BBB

HW9 33 t TGA 33.xxx 6x4 BBS-WW-CKD D20/D26 R6 BBB

Engine Suspension

D28 R6 BLBB

D28 V10 BLBB

BLLL

BLLL

TRUCKNOLOGY® GENERATION A (TGA) 17

2.3 Use of logos

MAN logos on the chassis may not be removed or modifi ed in any way without prior approval from MAN.

Modifi cations to the chassis or body that do not conform with this Guide to Fitting Bodies and that have not received MAN approval by

the SMTSE-ESC department (for address see „Publisher“ above) must receive a new vehicle identifi cation number (VIN) from

the manufacturer responsible for the modifi cation (normally the vehicle conversion company).

In such cases where the chassis/vehicle has received a new VIN, the logos on the radiator grille (MAN lettering, lion emblem) and

the doors (door designation – see Section 2.1.1) must be removed.

TRUCKNOLOGY® GENERATION A (TGA) 18

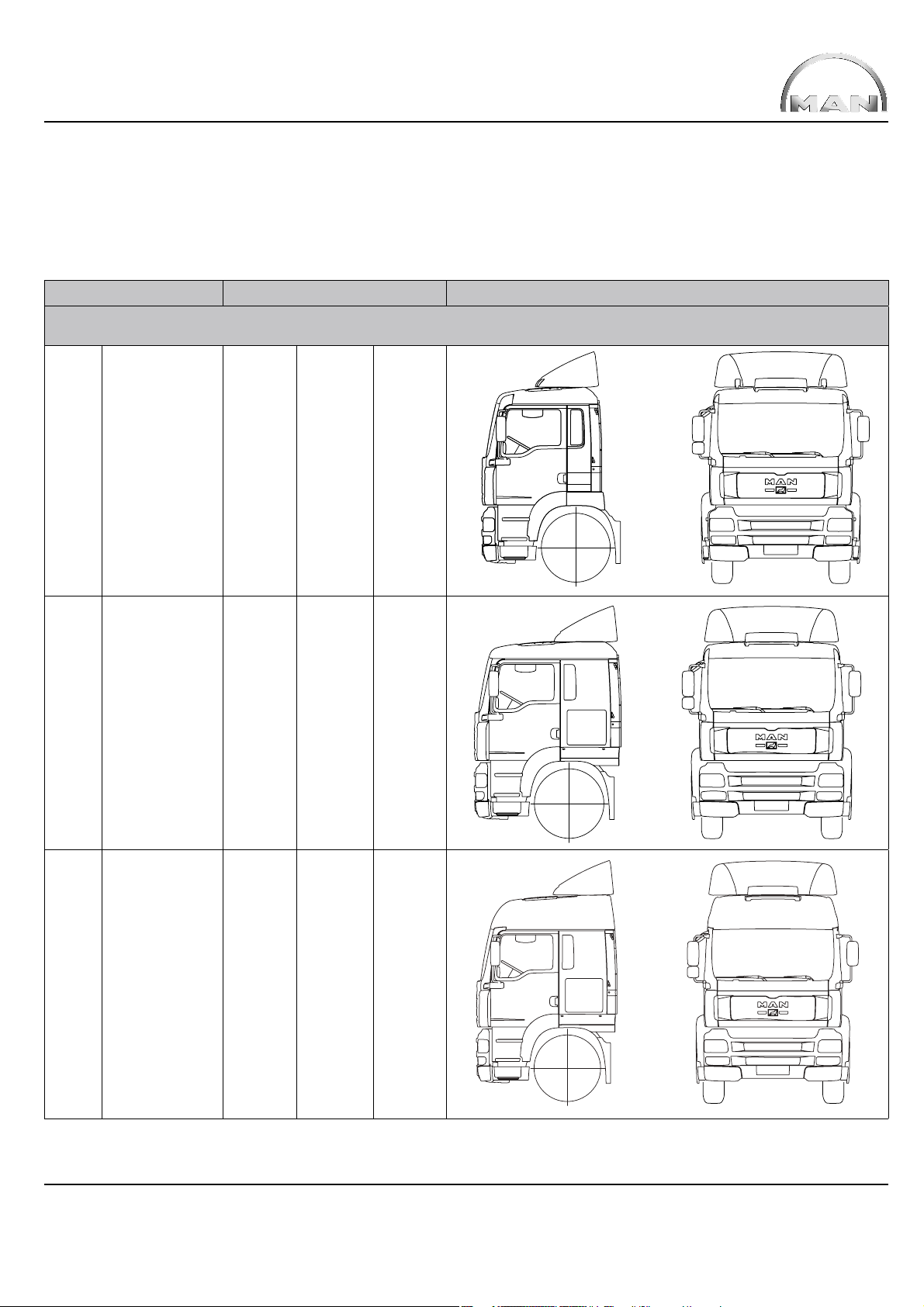

2.4 Cabs

There are 6 different Trucknology® Generation A cabs:

®

Table 7: Trucknology

Description Dimensions* Views

Name Technical Length Width High roof Side Front

description

M LHD

F99L15S

RHD

F99R15S

Generation A cabs

1.880 2.240

L LHD

F99L32S

RHD

F99R32S

LX LHD

F99L37S

RHD

F99R37S

2.280 2.240

2.280 2.240 yes

*) Dimensions refer to the cab without attachments such as mudguards, front spoiler, mirrors, roof spoiler etc.

TRUCKNOLOGY® GENERATION A (TGA) 19

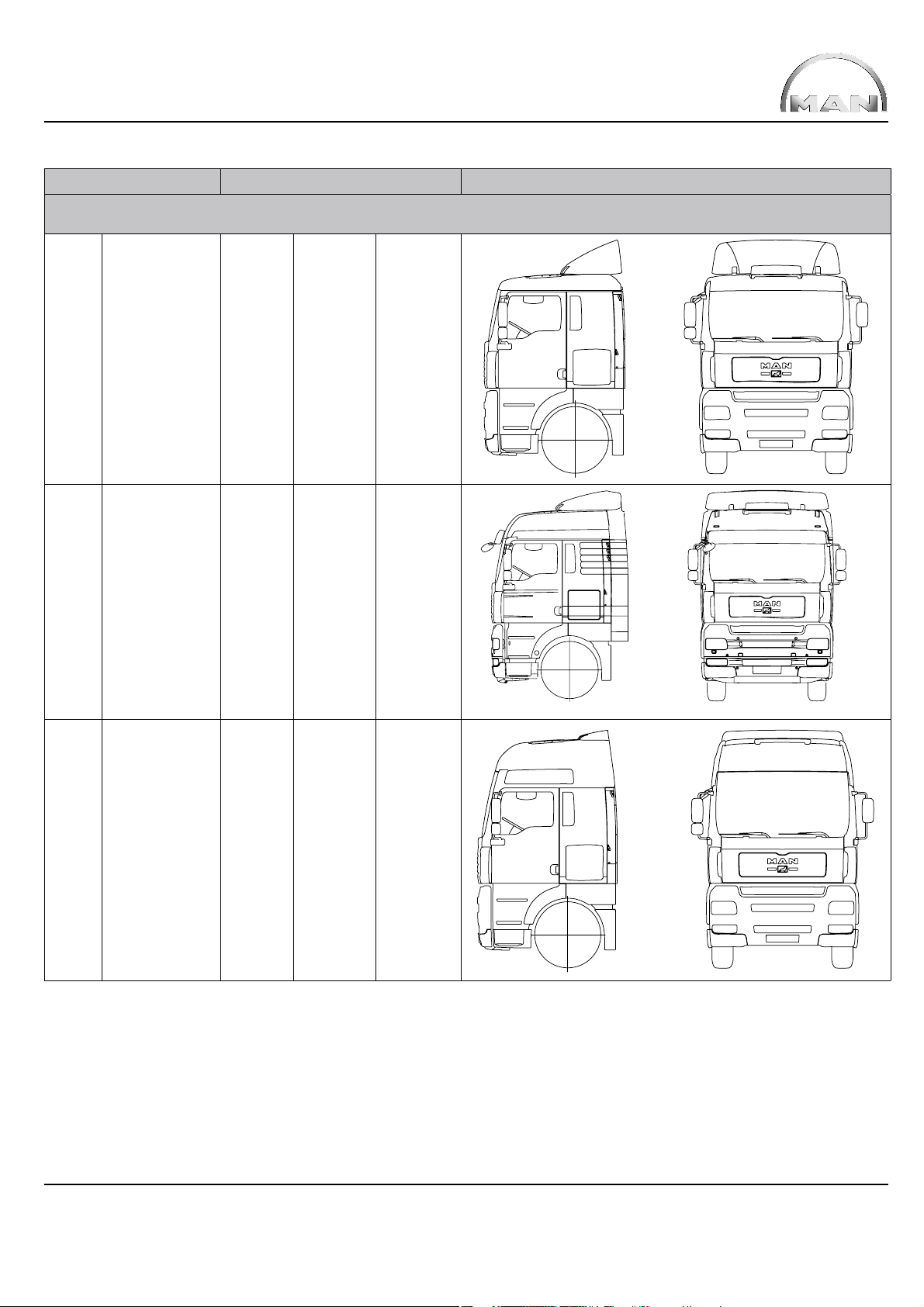

Description Dimensions* Views

Name Technical Length Width High roof Side Front

description

XL LHD

F99L40S

RHD

F99R40S

2.280 2.440

XLX LHD

F99 L47 S

RHD

F99 R47 S

XXL LHD

F99L41S

RHD

F99R41S

2.280 2.440 yes, low

2.280 2.440 yes

*) Dimensions refer to the cab without attachments such as mudguards, front spoiler, mirrors, roof spoiler etc.

TRUCKNOLOGY® GENERATION A (TGA) 20

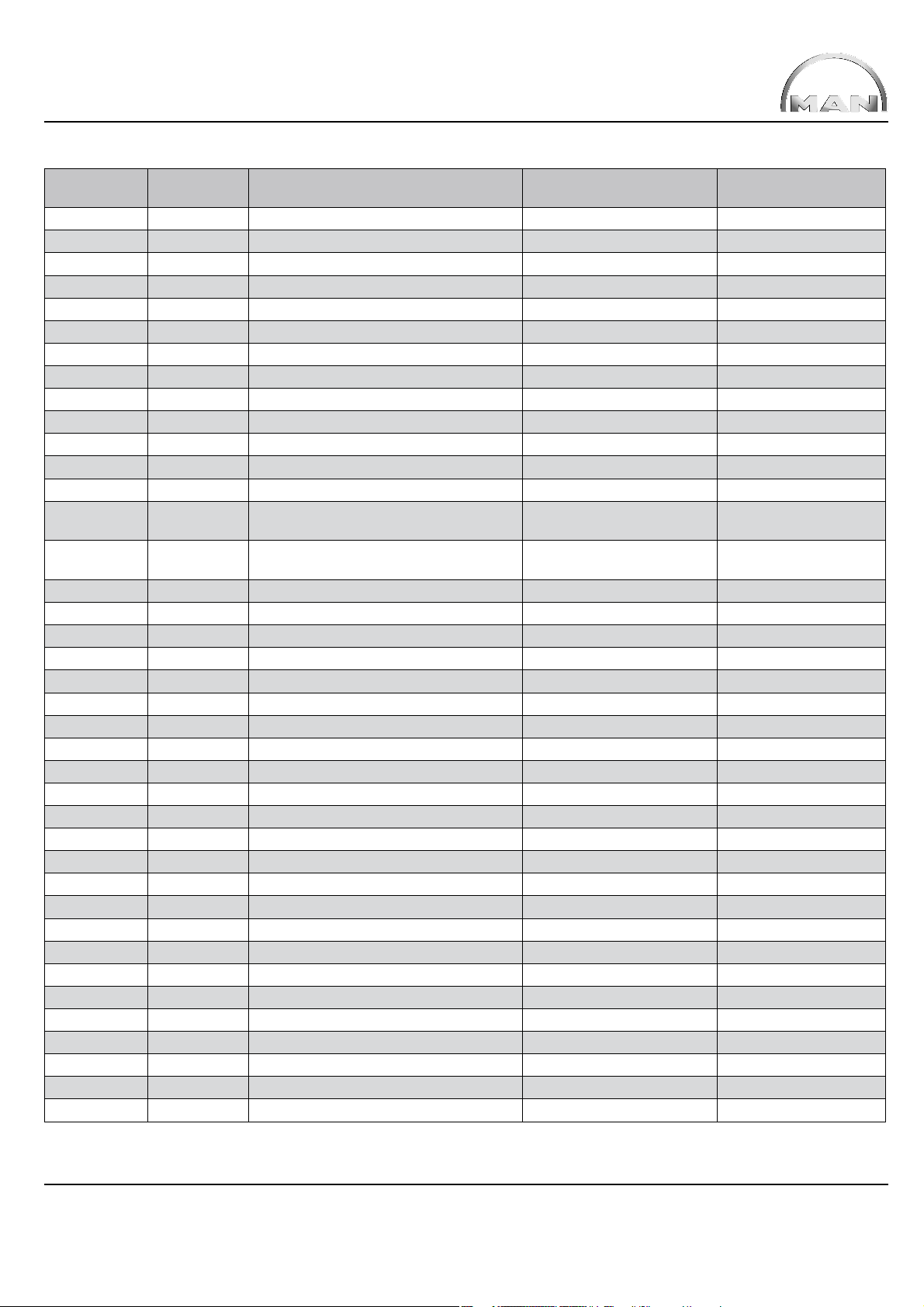

2.5 Engine variants

In-line six-cylinder Diesel engines (R6) and a V10 with 4-valve technology from the D28 family of engines are installed in the TGA

(D28 = 1st – 3rd digits of the engine designation). Engines with common rail injection are new additions to the range.

The engine programme has been extended since 2004 with two further engine ranges – the well known engines from the D08 range and

the new D20 Common Rail range that are also available as Euro 4 engines with the PM-Kat

only installed in ERF brand trucks (see table 6, model numbers).

Table 8: TGA engines/engine designations D08D08 / D20 / D26 / D28

®

. Cummins engines of the ISMe range are

Vehicle

designation

xx.280

xx.330 240 kW / 2.400 1.250 at 1.200 - 1.800 rpm D0836LF44

xx.310 228 kW / 1.900 1.500 at 900 - 1.300 rpm D2866LF26

xx.310 228 kW / 1.900 1.550 at 1.000 - 1.300 rpm D2066LF04

xx.360 265 kW / 1.900 1.700 at 900 - 1.400 rpm D2866LF27

xx.350 257 kW / 1.900 1.750 at 1.000 - 1.300 rpm D2066LF03

xx.410 301 kW / 1.900 1.850 at 900 - 1.300 rpm D2866LF28

xx.390 287 kW / 1.900 1.900 at 1.000 - 1.300 rpm D2066LF02

xx.430 316 kW / 1.900 2.100 at 1.000 - 1.300 rpm D2066LF01

xx.460 338 kW / 1.900 2.100 at 900 - 1.300 rpm D2876LF04

xx.510 375 kW / 1.900 2.300 at 1.000 - 1.300 rpm D2876LF05

xx.480 353 kW / 1.900 2.300 at 1.000 - 1.400 rpm D2876LF12

xx.530 390 kW / 1.900 2.400 at 1.000 - 1.400 rpm D2876LF13

xx.660 485 kW / 1.900 2.700 at 1.000 - 1.600 rpm V10 D2840LF25

xx.360 265 kW / 1.900 1.800 at 1.000 - 1.400 rpm

xx.400 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF49

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF50

xx.480 353 kW / 1.900 2.300 at 1.050 - 1.400 rpm D2676LF31

xx.310

xx.350 257 kW / 1.900 1.750 at 1.000 - 1.400 rpm D2066LF13

xx.390 287 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF12

xx.430 316 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF11

xx.320 235 kW / 1.900

xx.360 265 kW / 1.900 1.800 at 1.000 - 1.400 rpm D2066LF33

xx.400 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF32

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF31

xx.480 353 kW / 1.900 2.300 at 1.050 - 1.400 rpm D2676LF01

xx.320 235 kW / 1.900 OBD 1 +

Emission

class

Euro 3

Euro 4

Power [kW]

at [rpm]

206 kW / 2.400

228 kW / 1.900

OBD

generation

No OBD

OBD 1

control

NO

X

EGR Exhaust gas

after treatment

None

With

AGR

®

PM-Kat

Max. torque

[Nm] / at [rpm]

1.100 at 1.200 - 1.800 rpm

1.550 at 1.000 - 1.400 rpm D2066LF14

1.600 at 1.000 - 1.400 rpm D2066LF35

1.600 at 1.000 - 1.400 rpm D2066LF39

Engine

type

R6

R6

Engine

designation

D0836LF41

D2066LF48

TRUCKNOLOGY® GENERATION A (TGA) 21

Vehicle

designation

xx.360 Euro 4 265 kW / 1.900 OBD 1 +

xx.400 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF37

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF36

xx.480 353 kW / 1.9 00 2.300 at 1.050 - 1.400 rpm D2676LF05

xx.400

xx.440 321 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF21

xx.400 294 kW / 1.900

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF23

xx.480 353 kW / 1.9 00 2.300 at 1.050 - 1.400 rpm D2676LF12

xx.5 40 397 kW / 1.900 2.500 at 1.050 - 1.350 rpm D2676LF11

xx.320 235 kW / 1.900

xx.360 265 kW / 1.900 1.800 at 1.000 - 1.400 rpm D2066LF27

xx.400 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF26

xx.440 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF25

xx.480 353 kW / 1.900 2.300 at 1.050 - 1.400 rpm D2676LF14

xx.5 40 397 kW / 1.900 2.500 at 1.050 - 1.350 rpm D2676LF13

xx.320* 235 kW / 1.900 1.600 at 1.000 - 1.400 rpm D2066LF20

xx.360* 265 kW / 1.900 1.800 at 1.000 - 1.400 rpm D2066LF19

xx.400* 294 kW / 1.900 1.900 at 1.000 - 1.400 rpm D2066LF18

xx.440* 324 kW / 1.900 2.100 at 1.000 - 1.400 rpm D2066LF17

xx.480* 353 kW / 1.900 2.300 at 1.050 - 1.400 rpm D2676LF16

xx.540* 397 kW / 1.900 2.500 at 1.050 - 1.350 rpm D2676LF15

* = In case of NO

rescue services and military vehicles in accordance with Annex I.6558 of Directive 2005/55/EC, version 2006/81/EC

Emission

class

Euro 5

system failure, engines fi tted with OBD 1b or OBD 2 are without torque reduction (TR). Only applies to engines for fi re services,

X

Power [kW]

at [rpm]

294 kW / 1.900

OBD

generation

NOX control

NO OBD

OBD 1

OBD 1 +

NO

control

X

EGR Exhaust gas

after treatment

With

EGR

No

EGR

PM-Kat

SCR

®

Max. torque

[Nm] / at [rpm]

1.800 at 1.000 - 1.400 rpm

1.900 at 1.000 - 1.400 rpm D2066LF22

1.900 at 1.000 - 1.400 rpm D2066LF24

1.600 at 1.000 - 1.400 rpm D2066LF28

Engine

type

R6

Engine

designation

D2066LF38

3. General

National and international regulations take priority over technically permissible dimensions and weights if they limit the technically

permissible dimensions and weights. The following data can be obtained from the quotation documents and documents contained in

MANTED® at www.manted.de:

• Dimensions

• Weights

• Centre of gravity position for payload and body (minimum and maximum position for body) for the production standard

chassis / tractor unit.

The data contained in these documents may vary depending on what technical features the vehicle is actually fi tted with upon delivery.

The critical factor is the vehicle’s actual confi guration and condition at the time delivery.

To achieve optimum payload carrying capability the chassis must be weighed before work starts on the body.

Calculations can then be made to determine the best centre of gravity position for payload and body as well as the optimum body

length. As a result of component tolerances the weight of the standard chassis is allowed to vary by ± 5%, in accordance with

DIN 70020. Any deviations from the standard equipment level will have a greater or lesser effect on dimensions and weights.

Changes in equipment may result in deviations in the dimensions and weights, particularly if different tyres are fi tted that then also lead

to a change in the permissible loads.

TRUCKNOLOGY® GENERATION A (TGA) 22

In each individual case when a body is fi tted care needs to be taken to ensure the following

• Under no circumstances may the permissible axle weights be exceeded

• A suffi cient minimum front axle load is achieved

• The position of the centre of gravity and loading must not be one-sided

• The permissible overhang (vehicle overhang) is not exceeded.

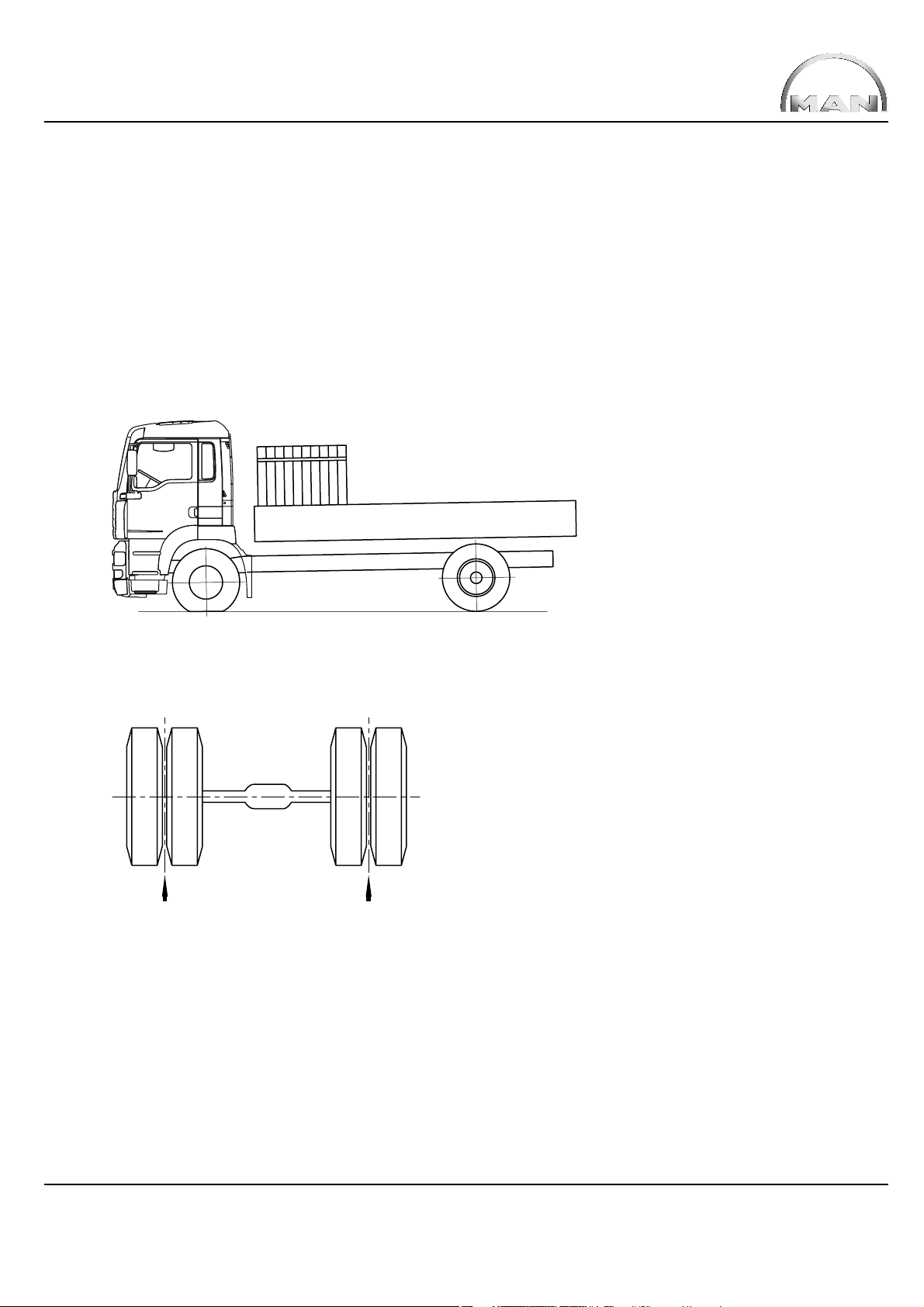

3.1 Axle overload, one-sided loading

Fig. 1: Overloading the front axle ESC-052

Fig. 2: Difference in wheel load ESC-126

G G

Formula 1: Difference in wheel load

∆G ≤ 0,05 • G

tat

The body must be designed such that one-sided wheel loads do not occur. Following checks, a maximum wheel load difference of 5 %

is permitted (where 100 % represents the actual axle load and not the permissible axle load).

TRUCKNOLOGY® GENERATION A (TGA) 23

Loading...

Loading...