Page 1

r

C

M150 & M200

Self-Propelled Windrowe

OPERATOR’S MANUAL

Revision

Part #169017 $25

Page 2

This Manual contains instructions for “SAFETY”, “OPERATION”, and “MAINTENANCE/SERVICE” for your new MacDon

Model M150 and M200 Self-Propelled Windrower.

Diesel engine exhaust and some of its constituents are known

to the State of California to cause cancer, birth defects, and

other reproductive harm.

Battery posts, terminals and related accessories contain lead

and lead components.

CALIFORNIA

Proposition 65 Warning

Wash hands after handling.

Page 3

1 INTRODUCTION

This instructional manual contains information on the MacDon Model M150 and M200 Self-Propelled Windrowers that

are designed to cut and lay in windrows, a wide variety of grain, hay and specialty crops. Windrowing allows starting

the harvest earlier, protects the crop from wind damage, and gives you more fle x ibility in scheduling combine time.

The power unit (referred to in this manual as the “Windrower”), when coupled with one of the specially designed

auger, rotary, or draper headers, provides a package which incorporates many features and improvements in design.

This manual must be used in conjunction with your Header Operator's Manual.

CAREFULLY READ ALL THE MATERIAL PROVIDED BEFORE ATTEMPTING TO UNLOAD, ASSEMBLE, OR USE

THE MACHINE.

Use this manual as your first source of information about the machine. If you follow the instructions given in this

manual, your M150 and M200 Windrower will work well for many years. If you require more detailed service

information, check with your MacDon Dealer.

Use the Table of Contents and the Index to guide you to specific areas. Study the Table of Contents to familiarize

yourself with how the material is organized.

Keep this manual handy for frequent reference, and to pass on to new operators or owners. Call your MacDon Dealer

if you need assistance, information, or additional copies of this manual. A manual storage case is provided in the cab.

NOTE: The M150 and M200 Windrowers are du al direction, m eaning that the Wi ndrowe r can be driven in the cabforward or the engine-forward modes. Right-Hand and Left-Hand designations are therefore determined by the

Operator’s position, facing the direction of travel. This manual uses the terms right cab-forward, left cab-forward, right

engine-forward, and left engine-forward when referencing specific locations on the machine.

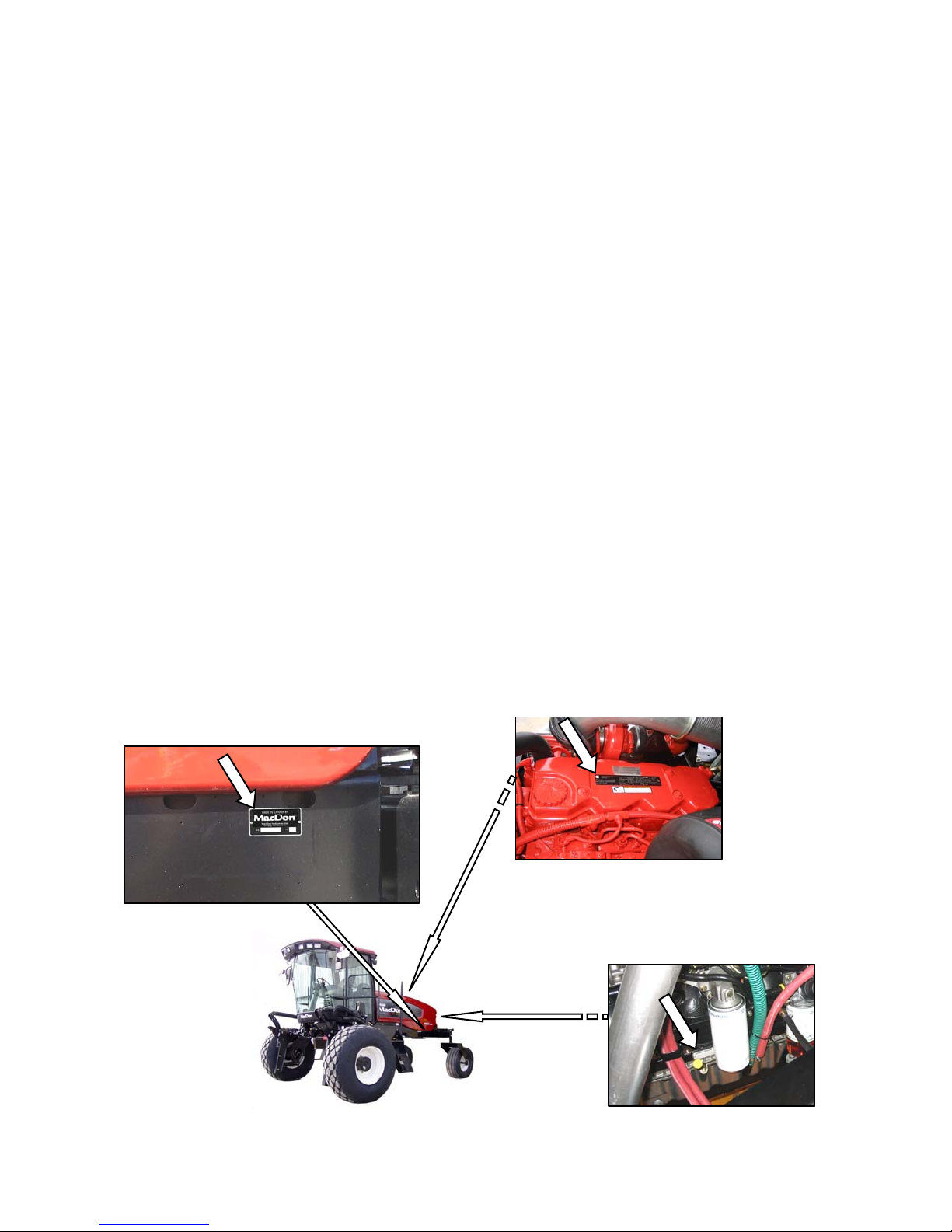

RECORD THE SERIAL NUMBERS IN THE SPACES BELOW.

Windrower ___________________________

Serial Number plate is located on the left cabforward side of the main frame, near the rear

corner.

Published: September, 2010

M150 Diesel Engine_____________________________

Serial Number plate is located on the top face of the

engine cylinder head cover.

M200 Diesel Engine_____________________________

Serial Number plate is located on the lower right cab-

forward side of the engine block.

Form 169017 / 169087 / 169095 1 Revision C

Page 4

TABLE OF CONTENTS

Section/Title Page

INTRODUCTION ...............................................................................................................................1

1

2 SAFETY ............................................................................................................................................6

2.1 SAFETY ALERT SYMBOL .......................................................................................................6

2.2 SIGNAL WORDS ......................................................................................................................6

2.3 SAFETY SIGNS ........................................................................................................................6

2.3.1 Safety Sign Installation .................................................................................................................. 6

2.3.2 Safety Sign Locations .................................................................................................................... 6

2.4 GENERAL SAFETY ................................................................................................................11

3 DEFINITIONS ..................................................................................................................................13

4 SPECIFICATIONS ..........................................................................................................................14

4.1 WINDROWER DIMENSIONS .................................................................................................14

4.2 SPECIFICATIONS ..................................................................................................................15

5 OPERATOR’S STATION ................................................................................................................17

5.1 OPERATOR CONSOLE .........................................................................................................17

5.2 OPERATOR PRESENCE .......................................................................................................18

5.2.1 Header Drive ................................................................................................................................ 18

5.2.2 Engine and Transmission ............................................................................................................ 18

5.3 SEAT ADJUSTMENTS ...........................................................................................................18

5.4 TRAINING SEAT ....................................................................................................................19

5.5 SEAT BELTS ..........................................................................................................................19

5.6 STEERING COLUMN ADJUSTMENT ...................................................................................19

5.7 LIGHTS ...................................................................................................................................20

5.7.1 Cab-Forward Lighting - Field ....................................................................................................... 20

5.7.2 Engine-Forward Lighting - Road .................................................................................................. 21

5.7.3 Cab-Forward Lighting - Road (Optional) ...................................................................................... 21

5.7.4 Beacon Lighting - Export (N.A. Optional) ..................................................................................... 22

5.7.5 Slow Moving Vehicle (SMV) Signs ............................................................................................... 22

5.8 WINDSHIELD WIPERS ..........................................................................................................23

5.9 REAR VIEW MIRRORS ..........................................................................................................23

5.10 CAB TEMPERATURE ............................................................................................................23

5.10.1 Heater Shut-Off Valve .................................................................................................................. 23

5.10.2 Air Distribution ............................................................................................................................. 23

5.10.3 Controls ....................................................................................................................................... 24

5.10.4 A/C Compressor Protection ......................................................................................................... 24

5.11 INTERIOR LIGHTS .................................................................................................................24

5.12 OPERATOR AMENITIES .......................................................................................................25

5.13 RADIOS ..................................................................................................................................26

5.13.1 AM/FM Radio ............................................................................................................................... 26

5.13.2 Antenna Mounting ........................................................................................................................ 26

5.14 HORN .....................................................................................................................................26

5.15 ENGINE CONTROLS/GAUGES .............................................................................................27

5.16 WINDROWER CONTROLS ...................................................................................................28

5.17 HEADER CONTROLS ............................................................................................................29

5.17.1 Header Engage Switch ................................................................................................................ 29

5.17.2 Header Drive Reverse Button ...................................................................................................... 29

5.17.3 Ground Speed Lever (GSL) Header Switches ............................................................................. 30

5.17.4 Console Header Switches ............................................................................................................ 32

5.18 CAB DISPLAY MODULE (CDM) ............................................................................................33

5.18.1 Engine and Windrower Functions ................................................................................................ 33

5.18.2 Header Functions ........................................................................................................................ 33

5.18.3 Operating Screens ....................................................................................................................... 34

5.18.4 Cab Display Module (CDM) Warnings/Alarms ............................................................................. 41

5.18.5 Cab Display Module (CDM) Programming ................................................................................... 44

5.18.6 Setting Guidelines ........................................................................................................................ 50

5.18.7 CDM and WCM Fault Codes ....................................................................................................... 50

6 OPERATION ...................................................................................................................................51

6.1 OWNER/OPERATOR RESPONSIBILITIES ...........................................................................51

Form 169017 / 169087 / 169095 2 Revision C

Page 5

TABLE OF CONTENTS

SYMBOL DEFINITIONS ......................................................................................................... 51

6.2

6.2.1 Engine Functions ......................................................................................................................... 51

6.2.2 Windrower Operating Symbols .................................................................................................... 51

6.2.3 Header Functions ........................................................................................................................ 52

6.3 WINDROWER OPERATION .................................................................................................. 53

6.3.1 Operational Safety ....................................................................................................................... 53

6.3.2 Break-In Period ............................................................................................................................ 53

6.3.3 Pre-Season Check ...................................................................................................................... 54

6.3.4 Daily Check ................................................................................................................................. 54

6.3.5 Engine Operation ......................................................................................................................... 55

6.3.6 Driving The Windrower ................................................................................................................ 59

6.3.7 Adjustable Caster Tread Width .................................................................................................... 65

6.3.8 Transporting ................................................................................................................................ 66

6.3.9 Storage ........................................................................................................................................ 76

6.4 HEADER OPERATION ........................................................................................................... 77

6.4.1 Header Lift Cylinder Stops ........................................................................................................... 77

6.4.2 Header Flotation .......................................................................................................................... 78

6.4.3 Levelling ...................................................................................................................................... 81

6.4.4 Header Drive ............................................................................................................................... 82

6.4.5 Header Angle ............................................................................................................................... 83

6.4.6 Cutting Height .............................................................................................................................. 85

6.4.7 Double Windrowing ..................................................................................................................... 87

6.5 D SERIES HEADER OPERATION ......................................................................................... 88

6.5.1 Header Attachment ...................................................................................................................... 88

6.5.2 Header Detachment .................................................................................................................... 91

6.5.3 Header Position ........................................................................................................................... 94

6.5.4 Reel Fore-Aft Position ................................................................................................................. 94

6.5.5 Reel Height .................................................................................................................................. 94

6.5.6 Reel Speed .................................................................................................................................. 94

6.5.7 Draper Speed .............................................................................................................................. 97

6.5.8 Knife Speed ................................................................................................................................. 99

6.5.9 Deck Shift (Optional) ................................................................................................................. 100

6.6 A SERIES HEADER OPERATION ....................................................................................... 101

6.6.1 Header Attachment .................................................................................................................... 101

6.6.2 Header Detachment .................................................................................................................. 104

6.6.3 Auger Speed.............................................................................................................................. 106

6.6.4 Reel Speed ................................................................................................................................ 107

6.6.5 Knife Speed ............................................................................................................................... 108

6.7 R SERIES HEADER OPERATION ....................................................................................... 109

6.7.1 Header Attachment .................................................................................................................... 109

6.7.2 Header Detachment .................................................................................................................. 112

6.7.3 Disc Speed ................................................................................................................................ 114

6.7.4 Converging Drum Assemblies - Grass Seed Header ................................................................ 115

7 MAINTENANCE AND SERVICING .............................................................................................. 116

7.1 PREPARATION FOR SERVICING ...................................................................................... 116

7.1.1 Welding Precautions .................................................................................................................. 116

7.2 RECOMMENDED SAFETY PROCEDURES ....................................................................... 116

7.3 MAINTENANCE SPECIFICATIONS .................................................................................... 117

7.3.1 Recommended Fuel, Fluids and Lubricants .............................................................................. 117

7.3.2 Recommended Torques ............................................................................................................ 118

7.3.3 Conversion Chart ....................................................................................................................... 120

7.4 ENGINE COMPARTMENT HOOD ....................................................................................... 121

7.5 MAINTENANCE PLATFORMS ............................................................................................. 122

7.5.1 Opening/Closing Platforms ........................................................................................................ 122

7.5.2 Opening/Closing Platform for Major Servicing ........................................................................... 122

7.6 LUBRICATING THE WINDROWER ..................................................................................... 124

7.6.1 Procedure .................................................................................................................................. 124

7.6.2 Lubrication Points ...................................................................................................................... 124

7.7 OPERATOR’S STATION ...................................................................................................... 126

7.7.1 Seat Belts .................................................................................................................................. 126

7.7.2 Safety Systems .......................................................................................................................... 126

7.7.3 GSL Adjustments ....................................................................................................................... 127

7.7.4 Steering Adjustments ................................................................................................................ 128

Form 169017 / 169087 / 169095 3 Revision C

Page 6

TABLE OF CONTENTS

7.7.5 Park Brake ................................................................................................................................. 130

7.7.6 HVAC System ............................................................................................................................ 132

7.8 CUMMINS ENGINE (M150) ................................................................................................ 135

7.8.1 General Engine Inspection ......................................................................................................... 135

7.8.2 Manually Turning Engine ........................................................................................................... 135

7.8.3 Oil Level ..................................................................................................................................... 136

7.8.4 Changing Oil and Oil Filter ......................................................................................................... 137

7.8.5 Air Intake System ....................................................................................................................... 139

7.8.6 Fuel System ............................................................................................................................... 142

7.8.7 Engine Cooling System .............................................................................................................. 147

7.8.8 Gearbox ..................................................................................................................................... 150

7.8.9 Exhaust System ......................................................................................................................... 152

7.8.10 Belts ........................................................................................................................................... 153

7.8.11 Engine Speed ............................................................................................................................ 154

7.9 CAT ENGINE (M200) .......................................................................................................... 155

7.9.1 General Engine Inspection ......................................................................................................... 155

7.9.2 Oil Level ..................................................................................................................................... 155

7.9.3 Changing Oil and Oil Filter ......................................................................................................... 156

7.9.4 Air Intake System ....................................................................................................................... 157

7.9.5 Aspirator Hose and Check Valve Replacement ......................................................................... 159

7.9.6 Fuel System ............................................................................................................................... 161

7.9.7 Engine Cooling System .............................................................................................................. 166

7.9.8 Gearbox ..................................................................................................................................... 170

7.9.9 Exhaust System ......................................................................................................................... 172

7.9.10 Belts ........................................................................................................................................... 173

7.10 COOLING BOX .................................................................................................................... 175

7.10.1 Cooling Box Screen ................................................................................................................... 175

7.10.2 Cooling Box Maintenance .......................................................................................................... 177

7.11 ELECTRICAL SYSTEM ....................................................................................................... 179

7.11.1 Battery ....................................................................................................................................... 179

7.11.2 Headlights - Engine-Forward ..................................................................................................... 184

7.11.3 Field lights - Cab-Forward .......................................................................................................... 186

7.11.4 Flood Lights - Forward ............................................................................................................... 186

7.11.5 Flood Lights - Rear .................................................................................................................... 187

7.11.6 Red and Amber Lights ............................................................................................................... 188

7.11.7 Red Tail Lights (If Installed) ....................................................................................................... 189

7.11.8 Beacons (If Installed) ................................................................................................................. 189

7.11.9 Gauge Light ............................................................................................................................... 191

7.11.10 Dome Light ................................................................................................................................ 191

7.11.11 Ambient Light ............................................................................................................................. 191

7.11.12 Turn Signal Indicators ................................................................................................................ 191

7.11.13 Circuit Breakers and Fuses ........................................................................................................ 192

7.12 HYDRAULIC SYSTEM ........................................................................................................ 195

7.12.1 Oil Level ..................................................................................................................................... 195

7.12.2 Changing Hydraulic Oil .............................................................................................................. 196

7.12.3 Hydraulic Oil Cooler ................................................................................................................... 196

7.12.4 Hydraulic Oil Filters .................................................................................................................... 196

7.12.5 Header and Reel Hydraulics ...................................................................................................... 197

7.12.6 Traction Drive Hydraulics ........................................................................................................... 199

7.12.7 Hoses and Lines ........................................................................................................................ 200

7.13 WHEELS AND TIRES ......................................................................................................... 201

7.13.1 Drive Wheels ............................................................................................................................. 201

7.13.2 Caster Wheels ........................................................................................................................... 204

7.14 MAINTENANCE SCHEDULE .............................................................................................. 208

7.14.1 Break-In Inspections .................................................................................................................. 208

7.14.2 Interval Maintenance ................................................................................................................. 209

8 TROUBLESHOOTING ................................................................................................................. 212

8.1 ENGINE ............................................................................................................................... 212

8.2 ELECTRICAL ....................................................................................................................... 215

8.3 HYDRAULICS ...................................................................................................................... 215

8.4 HEADER DRIVE .................................................................................................................. 216

8.5 TRACTION DRIVE .............................................................................................................. 216

8.6 STEERING AND GROUND SPEED CONTROL ................................................................. 217

Form 169017 / 169087 / 169095 4 Revision C

Page 7

TABLE OF CONTENTS

CAB AIR ................................................................................................................................ 218

8.7

8.8 OPERATOR’S STATION ...................................................................................................... 220

9 OPTIONS / ATTACHMENTS ........................................................................................................ 221

9.1 REEL DRIVE AND LIFT PLUMBING ................................................................................... 221

9.2 WINDROWER HYDRAULIC COMPLETION FOR DRAPER HEADER REEL FORE-AFT . 221

9.3 DOUBLE WINDROW ATTACHMENT .................................................................................. 221

9.4 REVERSER VALVE AND PLUMBING ................................................................................. 221

9.5 BOOSTER SPRING KIT ....................................................................................................... 221

9.6 INTERNAL BOOSTER SPRING KIT .................................................................................... 221

9.7 LIGHT HEADER FLOTATION KIT ....................................................................................... 221

9.8 WINDSHIELD SHADES ....................................................................................................... 221

9.9 DISC HEADER VALVE ......................................................................................................... 221

9.10 AM/FM RADIO ...................................................................................................................... 221

9.11 CENTER-LINK SELF-ALIGNMENT KIT ............................................................................... 221

9.12 PRESSURE SENSOR KIT ................................................................................................... 221

9.13 HYDRAULIC CENTER-LINK ................................................................................................ 221

9.14 WEIGHT BOX ....................................................................................................................... 221

9.15 TOWING HARNESS ............................................................................................................. 221

9.16 SWATH ROLLER ................................................................................................................. 221

9.17 WARNING BEACONS .......................................................................................................... 222

9.18 AUTO-STEER ....................................................................................................................... 222

9.19 LIGHTING AND MARKING KIT FOR CAB-FORWARD ROAD TRAVEL ............................ 222

9.20 FAN AIR BAFFLE KIT .......................................................................................................... 222

INDEX ......................................................................................................................................................... 223

CDM / WCM FAULT CODES ..................................................................................................................... 226

M150 AND M200 ENGINE ERROR CODES .............................................................................................. 227

Form 169017 / 169087 / 169095 5 Revision C

Page 8

SAFETY

2 SAFETY

2.1 SAFETY ALERT SYMBOL

This safety alert symbol indicates important safety

messages in this manual and on safety signs on

the machine.

This symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Carefully read and follow the safety message

accompanying this symbol.

WHY IS SAFETY IMPORTANT TO YOU?

ACCIDENTS DISABLE AND KILL.

ACCIDENTS COST.

ACCIDENTS CAN BE AVOIDED.

WARNING

Indicates a potentially hazardous situation

that, if not avoided, could result in death or

serious injury. It is also used to alert against

unsafe practices.

CAUTION

Indicates a potentially hazardous situation

that, if not avoided, may result in minor or

moderate injury. It is also used as a reminder

of good safety practices.

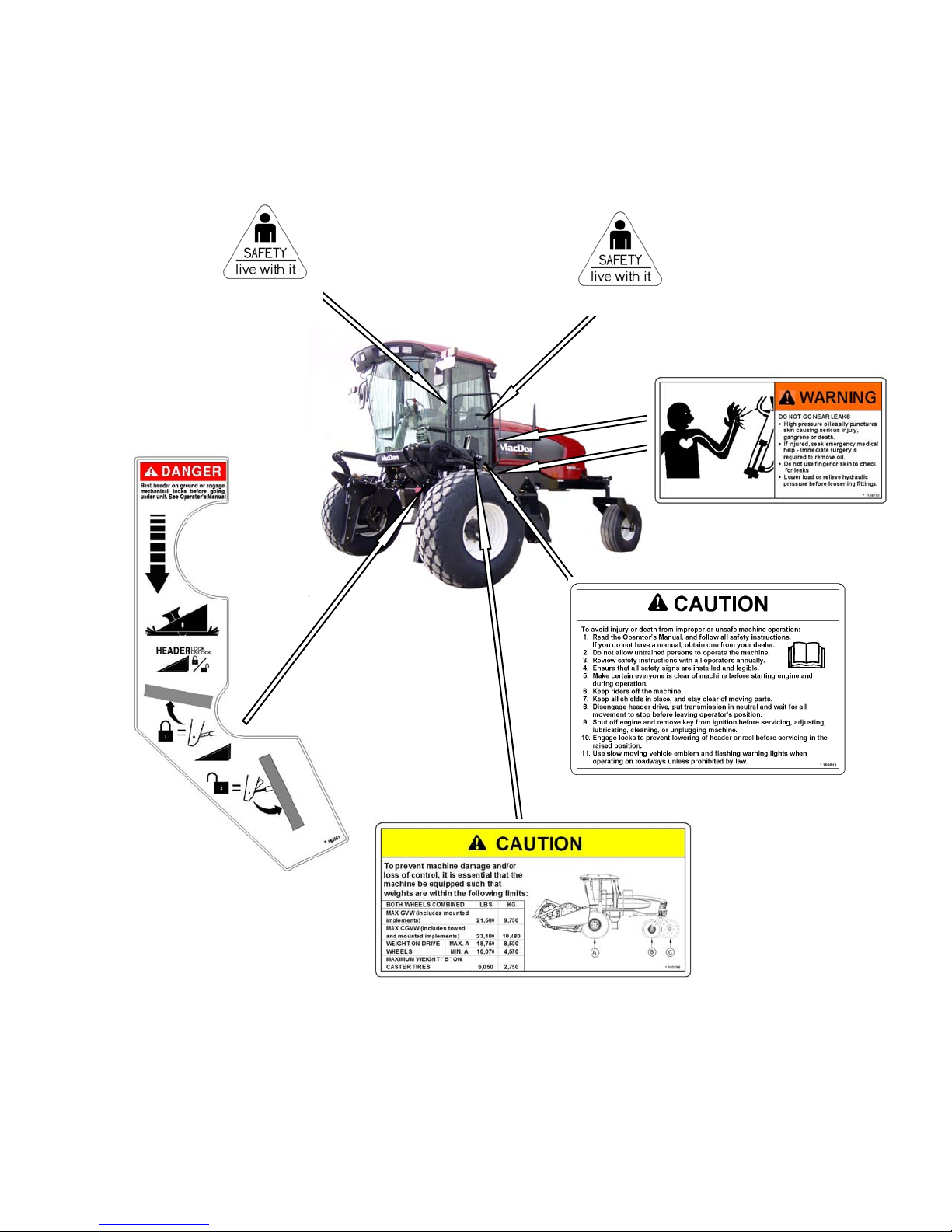

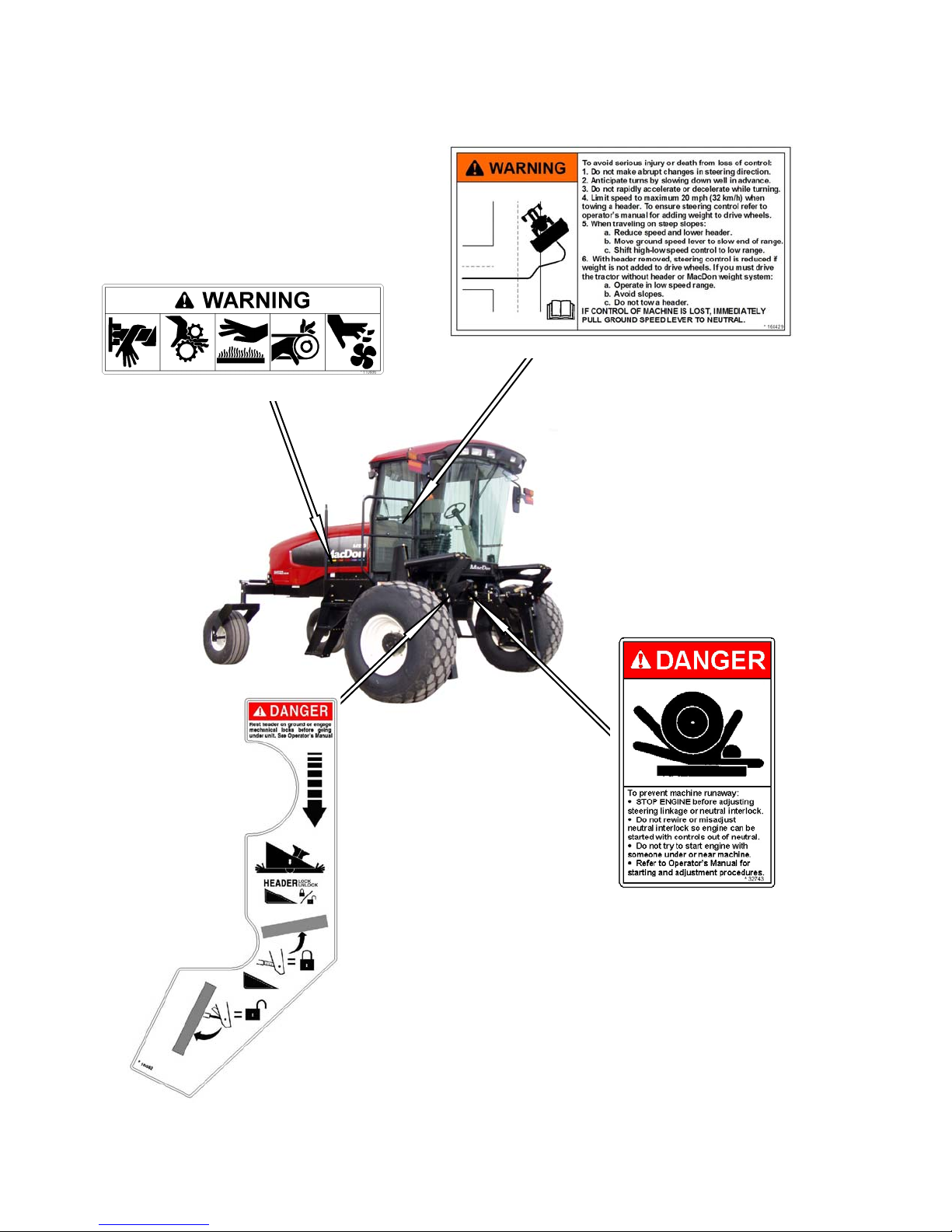

2.3 SAFETY SIGNS

2.3.1 SAFETY SIGN INSTALLATION

Refer to the illustration on this and following

pages, and proceed as follows:

a. Be sure the installation area is clean and dry.

b. Decide on the exact location before you remove

the decal backing paper.

c. Remove the smaller portion of the split backing

paper.

d. Place the sign in position and slowly peel back th e

remaining paper, smoothing the sign as it is

applied.

e. Small air pockets can be smoothed out or pricked

with a pin.

2.3.2 SAFETY SIGN LOCATIONS

2.2 SIGNAL WORDS

Note the use of the signal words DANGER,

WARNING, and CAUTION with safety messages.

The appropriate signal word for each message

has been selected using the following guidelines:

DANGER

Indicates an imminently hazardous situation

that, if not avoided, will result in death or

serious injury.

Form 169017 / 169087 / 169095 6 Revision C

The safety signs (decals) appear on the wind rower

at the locations approximately as shown.

• Keep safety signs clean and legible at all

times.

• Replace safety signs that are missing or

become illegible.

• If original parts on which a safety sign was

installed are replaced, be sure the repair part

also bears the current safety sign.

• Safety signs are available from your MacDon

Dealer Parts Department.

Page 9

Safety Sign Locations (continued)

SAFETY

IN CAB #32744

BELOW DOOR HANDLE #32744

FRONT OF PLATFORM #134070

(HORIZONTAL FORMAT), AND

ON OIL RESERVOIR UNDER HOOD

(BOTH SIDES) #44944 (VERTICAL FORMAT)

LIFT LINKAGES #163561

Form 169017 / 169087 / 169095 7 Revision C

BEHIND DOOR ON SILL #109843

BEHIND DOOR ON SILL - LH SIDE ONLY

#160396

Page 10

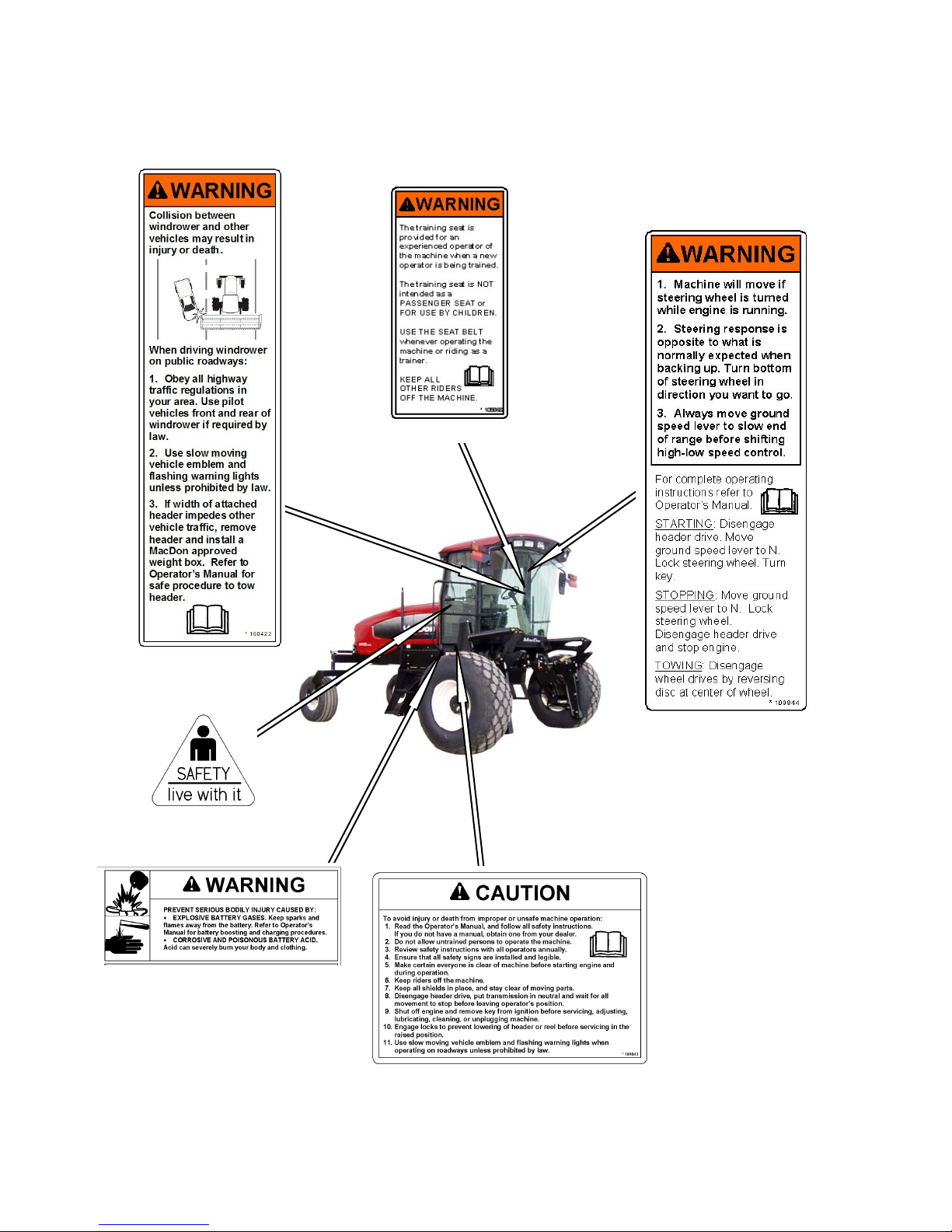

Safety Sign Locations

SAFETY

(continued)

IN CAB #109868

IN CAB #160422

BEL0W DOOR HANDLE #32744

FRONT OF PLATFORM #110989

IN CAB #109844

BEHIND DOOR ON SILL #109843

Form 169017 / 169087 / 169095 8 Revision C

Page 11

Safety Sign Locations (continued)

SAFETY

ON FAN SHROUD #134068

ON FRAME #42130

ON FRAME #110986

Form 169017 / 169087 / 169095 9 Revision C

Page 12

Safety Sign Locations

ON FRAME #110986

SAFETY

(continued)

ON DRINK COOLER #160429

ON LIFT LINKAGE #163562

Form 169017 / 169087 / 169095 10 Revision C

INSIDE FRAME #32743

Page 13

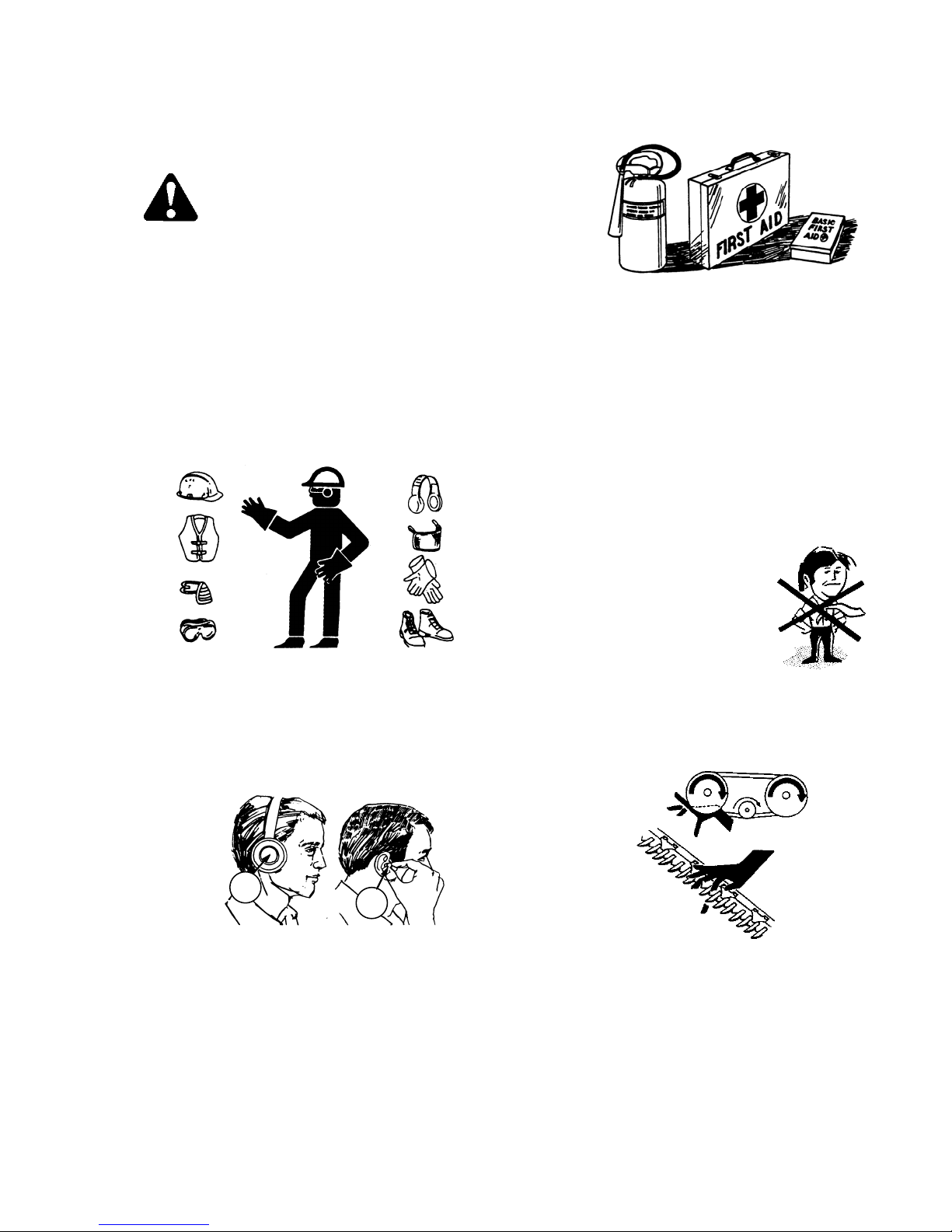

2.4 GENERAL SAFETY

CAUTION

The following are general farm safety

precautions that should be part of your

operating procedure for all types of

machinery.

Protect yourself.

• When assembling, operating and servicing

machinery, wear all the protective clothing

and personal safety devices that COULD

be necessary for the job at hand. Don't

take chances.

• You may need:

SAFETY

• Provide a first-aid kit for use in case of

emergencies.

• Keep a fire extinguisher on the machine.

Be sure the extinguisher is properly

maintained and be familiar with its proper

use.

• Keep young children away from machinery

at all times.

• Be aware that accidents often happen

when the operator is tired or in a hurry to

get finished. Take the time to consider the

safest way. Never ignore warning signs of

fatigue.

• a hard hat.

• protective shoes with slip resistant

soles.

• protective glasses or goggles.

• heavy gloves.

• wet weather gear.

• respirator or filter mask.

A

B

• hearing protection. Be aware that

prolonged exposure to loud noise

can cause impairment or loss of

hearing. Wearing a suitable hearing

protective device such as ear muffs

(A) or ear plugs (B) protects against

objectionable or loud noises.

• Wear close-fitting

clothing and cover

long hair. Never wear

dangling items such

as scarves or

bracelets.

• Keep hands, feet, clothing and hair away

from moving parts. Never attempt to clear

obstructions or objects from a machine

while the engine is running.

• Keep all shields in place. Never alter or

remove safety equipment. Make sure

driveline guards can rotate independently

of the shaft and can telescope freely.

• Use only service and repair parts made or

approved by the equipment manufacturer.

Substituted parts may not meet strength,

design, or safety requirements.

Form 169017 / 169087 / 169095 11 Revision C

(continued next page)

Page 14

• Do not modify the machine. Unauthorized

modifications may impair the function

and/or safety and affect machine life.

• Stop engine and remove key from ignition

before leaving Operator’s seat for any

reason. A child or even a pet could engage

an idling machine.

SAFETY

• Keep the area used for servicing

machinery clean and dry. Wet or oily floors

are slippery. Wet spots can be dangerous

when working with electrical equipment.

Be sure all electrical outlets and tools are

properly grounded.

• Use adequate light for the job at hand.

• Keep machinery clean. Straw and chaff on

a hot engine are a fire hazard. Do not allow

oil or grease to accumulate on service

platforms, ladders or controls. Clean

machines before storage.

• Never use gasoline, naphtha or any volatile

material for cleaning purposes. These

materials may be toxic and/or flammable.

• When storing machinery, cover sharp or

extending components to prevent injury

from accidental contact.

Form 169017 / 169087 / 169095 12 Revision C

Page 15

SPECIFICATIONS

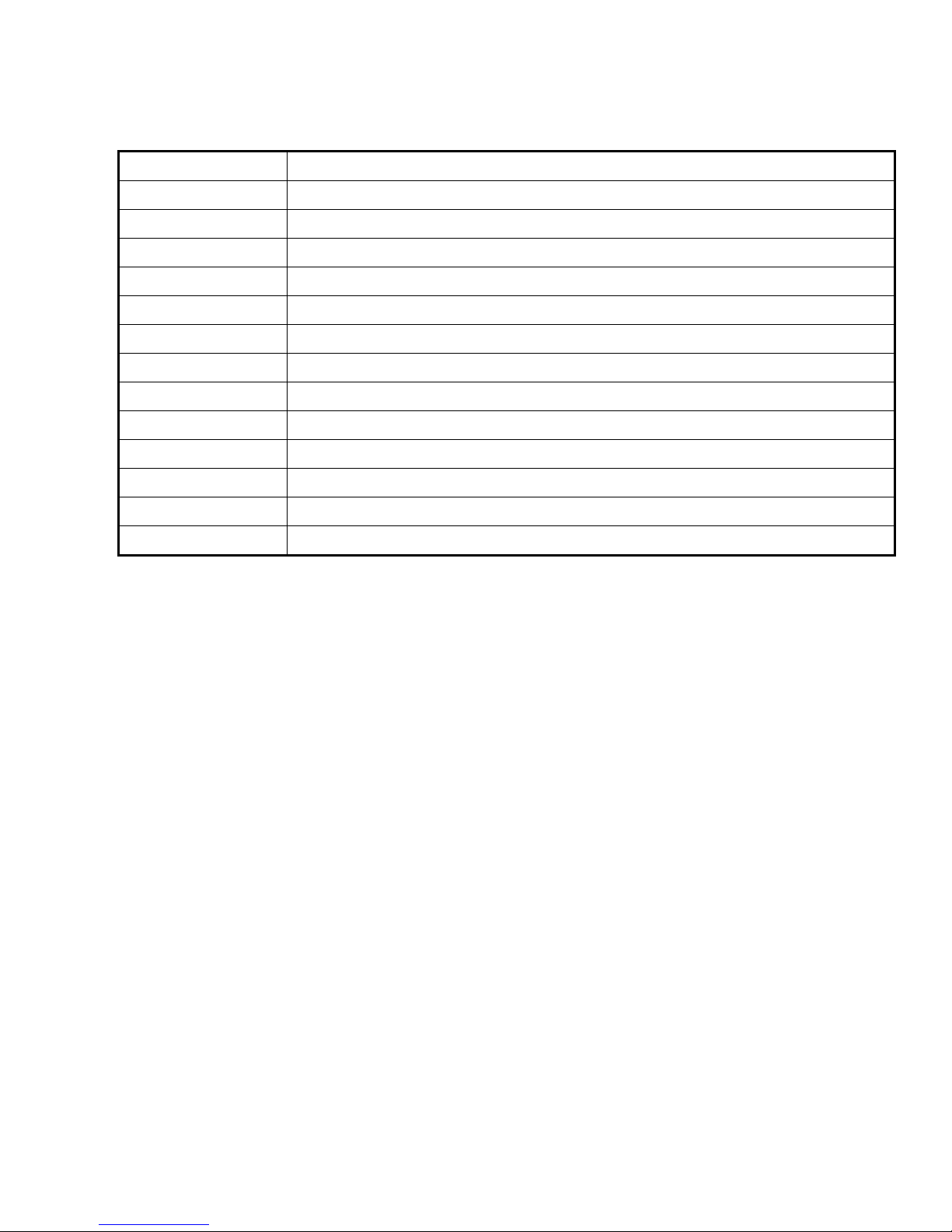

3 DEFINITIONS

TERM DEFINITION

API American Petroleum Institute

ASTM American Society of Testing And Materials

Cab-Forward Windrower operation with the operator and cab facing in the direction of travel

CDM Cab Display Module

DWA Double Windrow Attachment

Engine-Forward Windrower operation with the operator and engine facing in the direction of travel

ISC Integrated Speed Control

N-DETENT The slot opposite the neutral position on operator’s console

rpm Revolutions per minute

SAE Society Of Automotive Engineers

WCM Windrower Control Module

Windrower Windrower with header attached

Windrower Tractor Power unit only. (Windrower without the header attached)

Form 169017 / 169087 / 169095 13 Revision C

Page 16

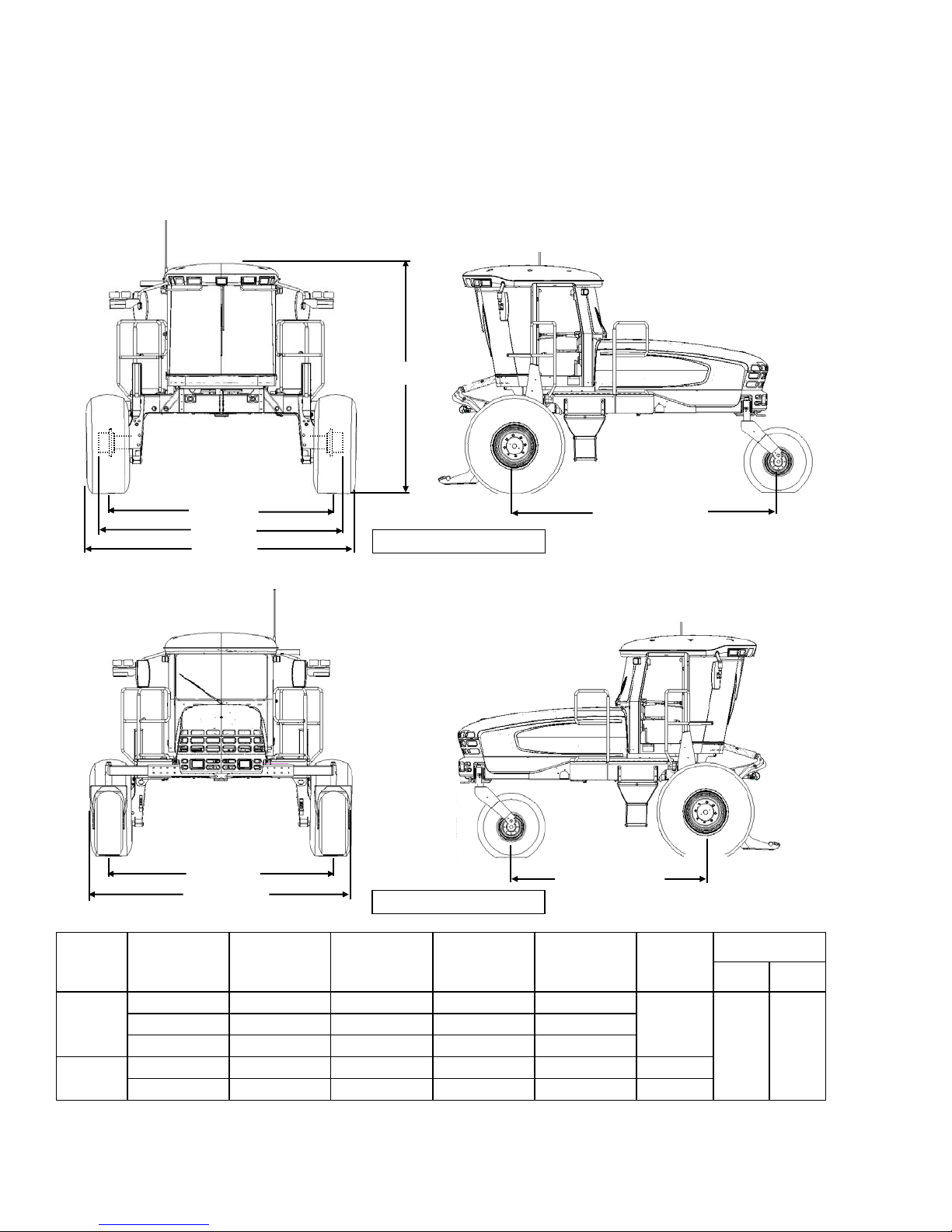

SPECIFICATIONS

4 SPECIFICATIONS

4.1 WINDROWER DIMENSIONS

Dimensions are with 18.4 - 26 drive tires and forked casters.

133 in. (3378 mm)

45.7 in. (1160

DRIVE

TIRE

CASTER

TIRE

TREAD

HUBS

TIRES

TREAD

CASTERS

WHEEL

POSITION

Inner / Outer - 138.7 (3522) - -

Outer / Outer 134.2 (3410) 146.1 (3712) - 157.1 (3990)

Inner / Inner 120.1 (3050) 131.6 (3342) - 150.0 (3810)

Minimum 93.2 (2367) - 115.4 (2932) - Maximum 135.8 (3448) - 158.0 (4013) - -

TREAD

Inch (mm)

CAB - FORWARD

ENGINE - FORWARD

HUBS

Inch (mm)

CASTERS

Inch (mm)

Inch (mm)

WHEEL BASE

WHEEL BASE

TIRES

SHIPPING

Inch (mm)

142.9

(3630)

WHEEL BASE

Inch (mm)

CAB

FWD

158.3

(4021)

ENG

FWD

120.7

(3066)

Form 169017 / 169087 / 169095 14 Revision C

Page 17

SPECIFICATIONS

4.2 SPECIFICATIONS

M150 M200

ENGINE

Type Cummins QSB -130 4 Cyl. Turbo Cat C6.6 6 Cyl. Turbo

Displacement 275 cu.in. (4.5 L) 403 cu.in. (6.6 L)

Power

Bore 4.04 in. (102 mm) 4.13 in. (105 mm)

Stroke 5.39 in. (137 mm) 5.00 in. (127 mm)

Maximum RPM (no load) 2270 - 2330 2250 - 2300

Idle RPM 1100 1100

Rated

Peak

130 hp (97 kW) @ 2200 rpm 213 hp (159 kW) @ 2200 rpm

140 hp (104 kW) @ 2000 rpm 220 hp (164 kW) @ 2000 rpm

ELECTRICAL SYSTEM

Recommended Battery (2)

Alternator 130 amp 120 amp

Starter

Working Lights

12 Volt, Min. 750CCA, Max Dim - 13 x 6.81 x 9.43 in. (330 x 173 x 240 mm).

Group Rating 31A. Heavy Duty / Off Road / Vibration Resistant.

TRACTION DRIVE

Type Hydrostatic, 3 Speed Electric Shift

Wet Type

11

Field (Cab-Forward)

Speed

Transmission

Final Drive

Wheel Motor Displ.

Reverse (Cab-Forward)

Transport (Engine-Forward)

Type

Displacement

Flow

Type

Ratio

Low Range

Mid Range

High Range

SYSTEM CAPACITIES

Fuel Tank

Cooling

Hydraulic Reservoir

HEADER DRIVE

Type Hydraulic, Load Sensing Variable Displacement

Displacement

Pump A - 0 - 2.75 cu.in. (0 - 45 cc)

Pump B - 0 - 2.32 cu.in. (0 - 38 cc)

Low Range 0 - 11 mph (17.7 km/h)

Mid Range 0 - 16 mph (25.7 km/h)

6 mph (9.6 km/h)

High Range 0 - 23 mph (37 km/h)

2 Piston Pumps - 1 per Drive Wheel.

2.65 cu.in. (44 cc)

40 U.S. gpm (151 L/min)

Planetary Gearbox

30.06 : 1

4.15 cu.in. (68 cc)

2.93 cu.in. (48 cc)

2.0 cu.in. (33 cc)

97 U.S. Gallons (378 L)

5.1 U.S. Gallons (20 L)

17.2 U.S. Gallons (66 L)

Pumps A & B - 0 - 3.11 cu.in. (0 - 51 cc)

Piston Pumps

Form 169017 / 169087 / 169095 15 Revision C

Flow

Max

Pressure

Pump A

Pump B

Pump A

Pump B

0 - 27 U.S. gpm (102 L/min) 0 - 39 U.S. gpm (148 L/min)

0 - 24 U.S. gpm (91 L/min) 0 - 34 U.S. gpm (128 L/min)

4000 psi (27.58 MPa) 4800 psi (33.10 MPa)

3200 psi (22.06 MPa) 4800 psi (33.10 MPa)

(continued next page)

Page 18

SPECIFICATIONS

M150 M200

HEADER LIFT/TILT

Type

Gear Pumps (2)

System Pressure (Relief / Max)

Displacement 0.84 cu.in. (13.8 cc)

Flow 11.5 U.S. gpm (46.5 L/min)

HEADER FLOTATION

Primary Adjustment

Fine Adjustment

Automatic

CAB

Width

Dimensions

Seat

Windshield Wiper

Heater

Air Conditioning

Electrical Outlets

Mirrors

Radio

Depth

Height

Volume

Driver

Training

Front

Rear

SYSTEM MONITORING

Speeds

Header

TIRE OPTIONS

Size

Pressure

Rear

Drive

Rear

Drive

FRAME AND STRUCTURE

Dimensions

Frame to Ground (Crop Clearance)

Weight

SK

NG Header Compatibility

DK

Base

Max GVW

Max CGVW

2500 psi (17.24 MPa)

Manual, External, Draw-Bolt With Springs (1 per side)

Hydraulic, In-Cab Switch

Hydraulic, 3 Programmable Settings For All Headers

(Deck Shift Compensation On Draper Headers)

63 in. (1600 mm)

68.3 in. (1735 mm) (at top of window)

64.6 in. (1640 mm)

125 cu.ft. (3540 L)

Adjustable Air-Ride Suspension, Seat Belt

Folding, Cab Mounted, Seat Belt

31.5 in. (800 mm) Blade

22 in. (560 mm) Blade

Two Speakers and Antenna Factory Installed. Radio Dealer Installed

One Inside (Transport), Two Outside (Field)

24,000 Btu/h (7038 W)

28,280 Btu/h (8288 W)

Two Live, Three On Ignition

Ground (mph or km/h), Engine (rpm), Knife (spm), Disc (rpm),

Height, Angle, Float, Optional Knife or

18.4 - 26 Bar, 18.4 - 26 Turf, 600-65 R28 Bar, 23.1 - 26 Turf, 580-70 R26 Turf

Reel (rpm or mph/km/h), Conveyor (Ref. No.)

Reel Drive Pressure

7.5 - 16SL Single Rib, 10 x 16 Front Steer Tire

16.5L - 16.1 Rib Implement Flotation, Forked Caster

Bar - 32 psi (221 kPa), Turf - 20 psi (138 kPa)

Refer to Section 4.1 WINDROWER DIMENSIONS

45.7 in. (1160 mm)

10,700 lb (4858 kg) 11,400 lb (5176 kg)

21,500 (9750 kg)

23,100 lb (10,480 kg)

A30S Auger, D50, D60S Harvest Header

A30D, A40D Auger, D60D Harvest Header

R80 Disc Rotary Header

NOTES: 1. Specifications and design are subject to change without notice, or obligation to revise previously sold units.

2. Weights do not include options

Form 169017 / 169087 / 169095 16 Revision C

.

Hydraulic

Height, Angle, Float, Knife Drive and

Reel Drive Pressures

10 psi (69 kPa)

Page 19

OPERATOR’S STATION

(

5 OPERATOR’S STATION

The Operator’s station is designed for operating

the windrower in a cab-forward mode (working

mode), or in an engine-forward mode (transport

mode).

The operator station, which includes the seat,

console, and steering column, pivots 180° so that

the operator maintains access to the windrower

controls and gauges regardless of the direction of

travel.

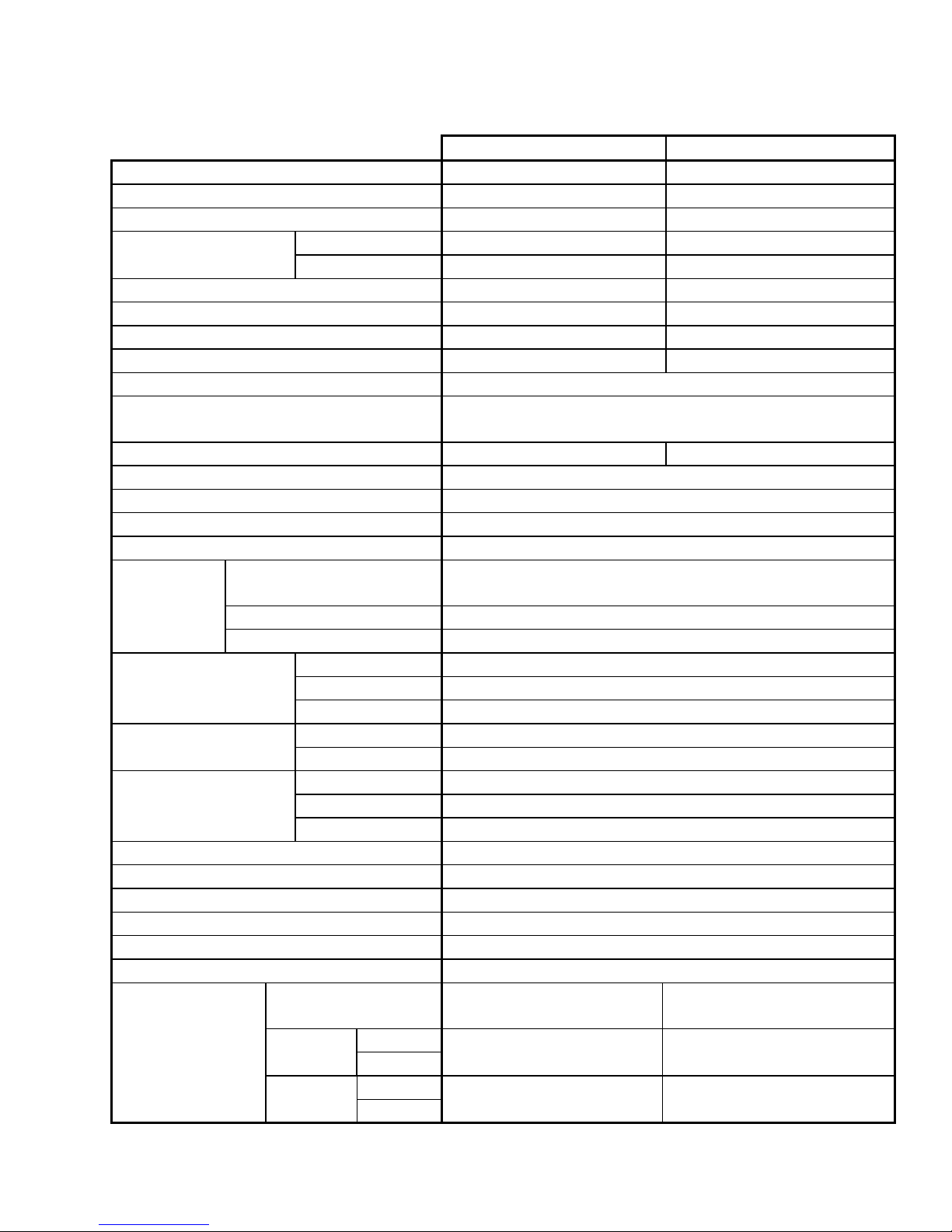

5.1 OPERATOR CONSOLE

ENGINE / WINDROWER

CAB DISPLAY MODULE

CDM)

HEADER

CONTROLS

SECTION 5.17

A

a. Pull lever (A), and slide console fore or aft to

desired position. The height also increases

slightly as the console is moved aft. Release lever

to lock console.

B

THROTTLE

WINDROWER CONTROLS

SECTION 5.16

The console contains controls to operate the

windrower, as well as amenities for the operator.

The console position is adjustable to suit each

particular operator. The console is attached to the

seat, and does not require adjustment when

repositioning the Operator’s seat.

b. To adjust only fore-aft, loosen nuts (B) under

console and move as required.

c. Tighten nuts.

Form 169017 / 169087 / 169095 17 Revision C

Page 20

OPERATOR’S STATION

5.2 OPERATOR PRESENCE

The Operator Presence System is a safety feature

that is designed to deactivate or alarm selected

systems when the operator is not seated at the

Operator’s station.

These systems include:

• Header Drive

• Engine and Transmission

5.2.1 HEADER DRIVE

• Requires the operator to be seated in the seat

in order to engage the header drive.

• Power is maintained to the header drive for 5

seconds after the operator leaves the seat,

and then the header shuts down.

• After the header has shutdown automatically,

the header engage switch must be moved to

“OFF” position, and back to the “ON” position

again to restart the header.

5.2.2 ENGINE AND TRANSMISSION

• The engine will not be allowed to start when

the header drive switch is engaged.

• The engine will not be allowed to start when

the transmission is not locked in neutral.

• The engine will shutdown when the windrower

is moving at 5 mph (8 km/h) or less, and the

operator leaves the seat.

• If the operator leaves the seat and the

transmission is not locked in neutral, after 5

seconds the lower display will flash “NOT IN

NEUTRAL” accompanied by an alarm.

• When the seat is in between cab-forward and

engine-forward positions, the engine will shut

off if the transmission is not locked in the

neutral position. The lower display will flash

“LOCK SEAT BASE” until the seat base is

locked into position.

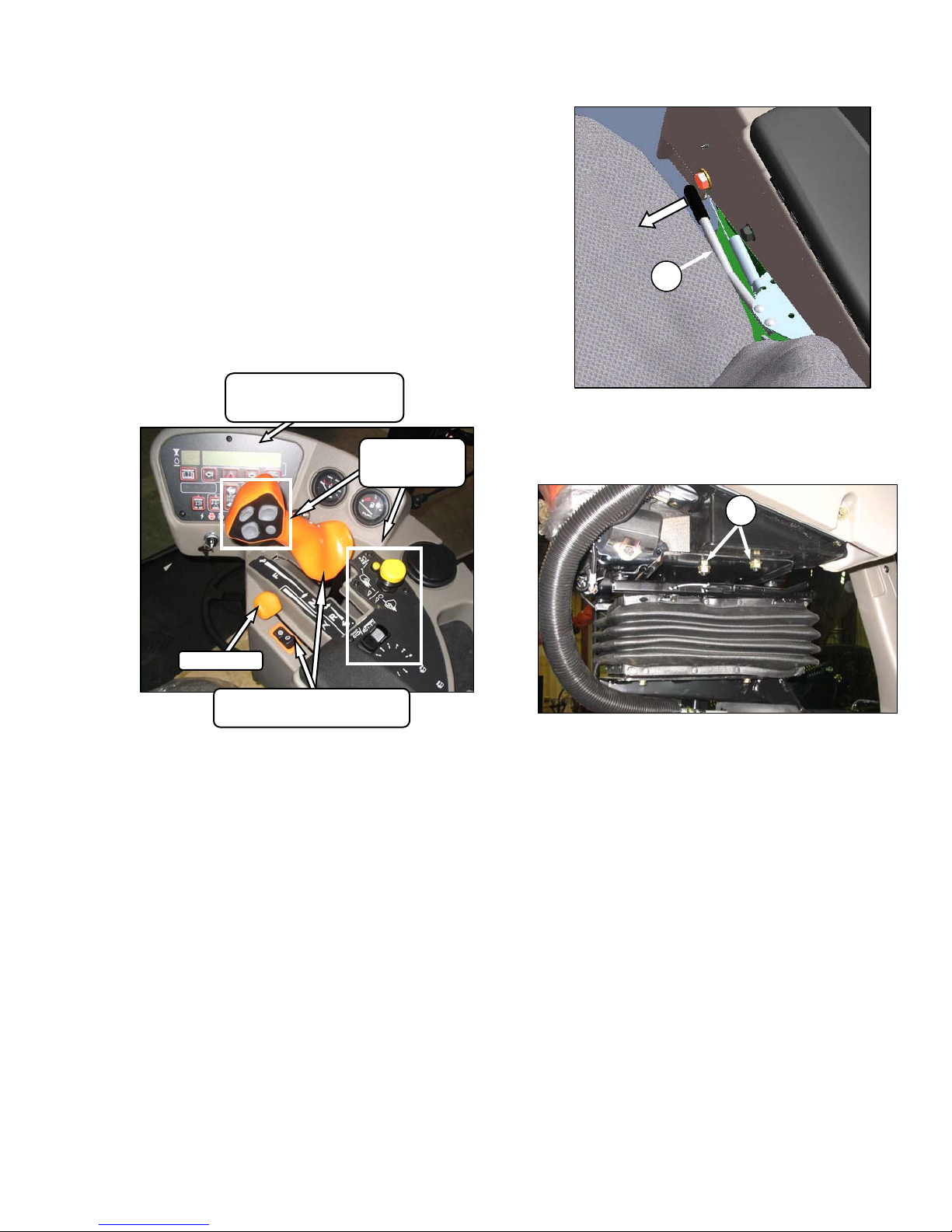

5.3 SEAT ADJUSTMENTS

The Operator’s seat has several adjustments.

Refer to the following illustration for the location

and description of each adjustment.

SEAT FORE-AFT POSITION

Adjusts Fore-Aft Position

Pull Lever Up To Release.

Move Seat Forward or Rearward.

Release Lever.

OPERATOR WEIGHT AND SEAT HEIGHT

Controls Suspension Stiffness and Seat Height

INCREASE - Press Upper Switch.

DECREASE - Press Lower Switch.

VERTICAL DAMPENER

Adjusts Suspension Dampening

INCREASE - Turn Knob Counter Clockwise

DECREASE - Turn Knob Clockwise

SEAT FORE-AFT ISOLATOR LOCK

Locks Seat Fore-Aft Isolator

LOCK - Push Lever Down.

UNLOCK - Pull Lever Up.

Raise Arm Rest For Easier

ARM REST

Access To Seat.

Lower Arm Rest After Seat

Belt Is Buckled.

LUMBAR SUPPORT

Adjusts Stiffness of Seat Back

INCREASE - Rotate Knob Upward.

DECREASE - Rotate Knob Downward.

ARM REST ANGLE

Adjusts Angle of Arm Rest

INCREASE - Rotate Knob Clockwise.

DECREASE - Rotate Knob Counter

Clockwise.

SEAT BACK ANGLE

Pull Lever Up To Release.

Position Seat Back As Desired.

Release Lever.

Form 169017 / 169087 / 169095 18 Revision C

Page 21

OPERATOR’S STATION

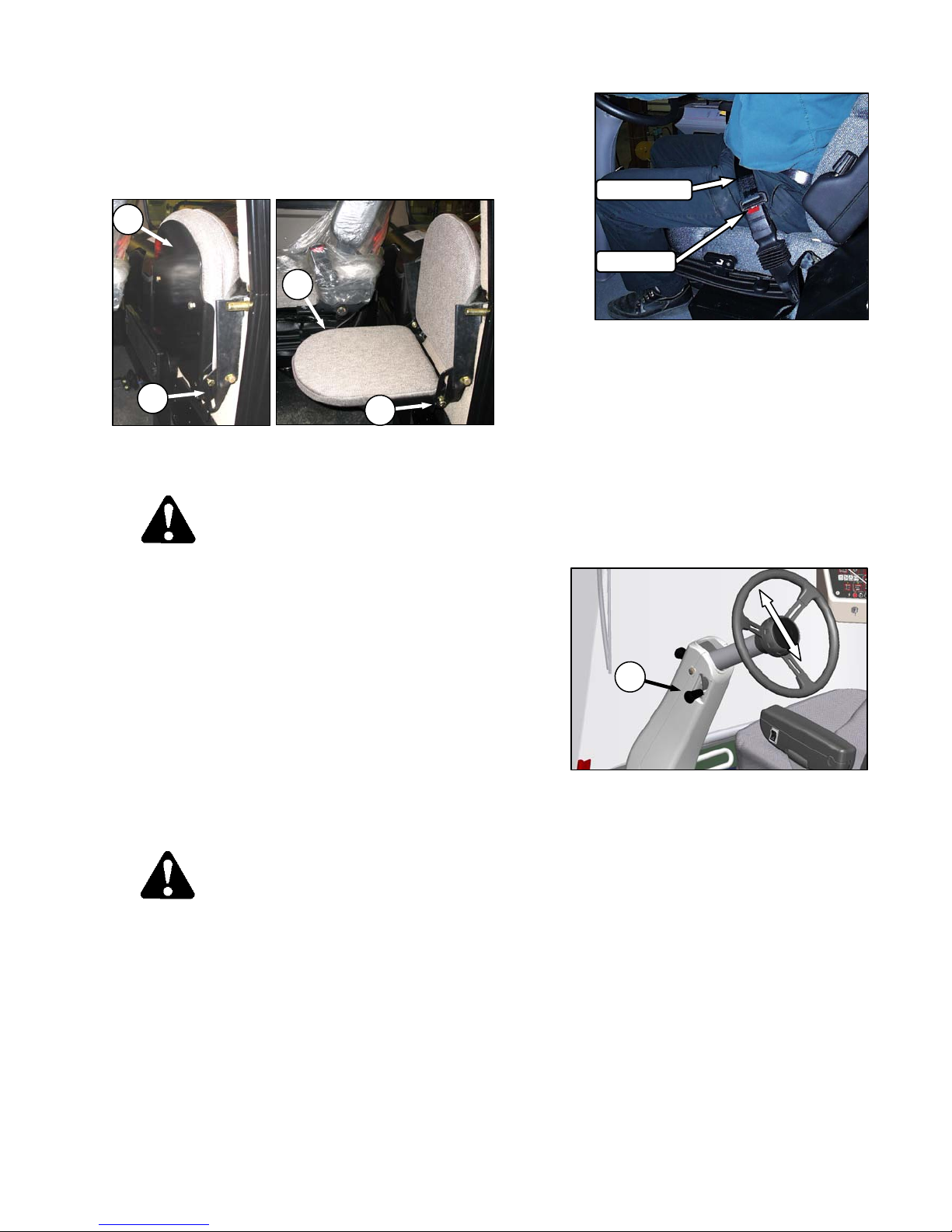

5.4 TRAINING SEAT

A wall mounted fold-up training seat, complete

with seat belt, is provided for use as described

below.

B

B

A

• To lower seat, lift latch (A), and lower seat (B).

• For storage, lift seat (B), and secure with latch (A).

A

WARNING

• The training seat is provided for an

experienced operator of the machine when

a new operator is being trained.

SEAT BELT

RELEASE

a. To fasten seat belt, pull belt completely across

your body. Push the metal eye into the buckle until

it locks. Adjust the position of the belt as low on

your body as possible.

b. To release, push the red button in the end of the

buckle, and separate the buckle and metal eye.

5.6 STEERING COLUMN ADJUSTMENT

The steering column can be adjusted to suit each

particular operator, and for easier entry to and e xit

from the seat.

• The training seat is NOT intended as a

PASSENGER SEAT or FOR USE BY

CHILDREN.

• USE THE SEAT BELT whenever operating

the machine, or riding as a trainer.

• KEEP ALL OTHER RIDERS OFF THE

MACHINE.

5.5 SEAT BELTS

The windrower is equipped with a seat belt on the

Operator’s and Trainer’s seats.

WARNING

• Before starting engine, securely fasten

your seat belt, and ensure trainer’s seat

belt is fastened if occupied. The seat belt

can help ensure your safety if it is used

and maintained.

• Never wear a seat belt loosely or with slack

in the belt system.

• Never wear the belt in a twisted condition

or pinched between the seat structural

members.

C

a. Hold onto steering wheel, lift handle (C), and

move steering wheel up or down to desired

position.

b. Release handle (C) to lock steering wheel

position.

Form 169017 / 169087 / 169095 19 Revision C

Page 22

OPERATOR’S STATION

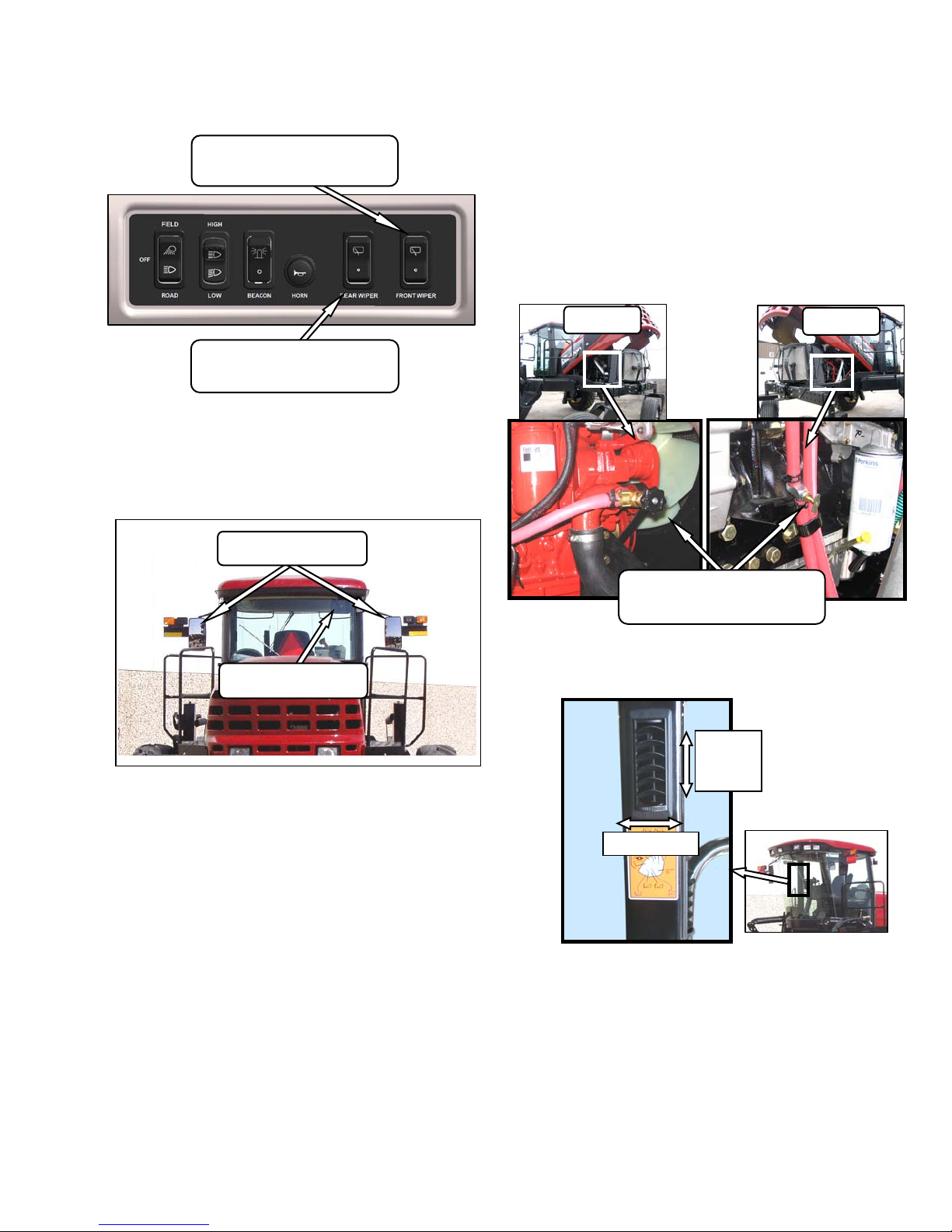

5.7 LIGHTS

LIGHTS

Controls field and transport lights

Field

Off

Road

BEACON

Controls Beacons On Cab

Standard for Export.

Optional for N.A.

On - Off

HIGH / LOW LIGHTS

Controls High / Low Beam For Road Lights

High - Low

The field and transport light switches are located

on a panel in the cab headliner. Refer to

illustrations on following pages for location of

lights.

5.7.1 CAB-FORWARD LIGHTING - FIELD

FIELD LIGHTS

The lighting is dependent upon the position of the

Operator’s station (i.e. cab-forward mode or

engine-forward mode).

The position of the Operator’s station

automatically determines the lighting.

IMPORTANT

Red reflector tape is applied to aft locations

to be visible in engine-forward mode.

Only amber tape is allowed in cab-forward

mode.

FRONT - CAB FWD

FIELD LIGHTS

SWATH LIGHTS

REAR - CAB FWD

Form 169017 / 169087 / 169095 20 Revision C

Page 23

OPERATOR’S STATION

5.7.2 ENGINE-FORWARD LIGHTING ROAD

The following lights are on / functional when the

switch is in the ROAD position. The hazard lights

must be activated with the switch on the CDM

when driving on the road.

TURN SIGNALS / HAZARDS - AMBER

5.7.3 CAB-FORWARD LIGHTING - ROAD

(OPTIONAL)

If equipped, the following lights are functional

when the switch is in the ROAD position. The

hazard lights must be activated with the switch on

the CDM when driving on the road.

IMPORTANT

Optional red tail lighting and marking kit

must be installed so that road travel in the

cab-forward mode complies with road travel

regulations. See your MacDon Dealer.

HIGH / LOW LIGHTS - ROAD

FRONT - ENG FWD

TURN SIGNALS / HAZARDS - AMBER

TAIL / BRAKE LIGHTS - RED

REAR - ENG FWD

HI/LO LIGHTS

-ROAD

TURN SIGNALS/HAZARDS - AMBER

FRONT – CAB FWD

TURN SIGNALS/HAZARDS - AMBER

TAIL LIGHTS – RED

OPTIONAL BRAKE LIGHTS

SMV SIGN

OPTIONAL

REAR – CAB FWD

Form 169017 / 169087 / 169095 21 Revision C

Page 24

OPERATOR’S STATION

5.7.4 BEACON LIGHTING - EXPORT (N.A.

OPTIONAL)

The beacon lights are functional when the ignition

and the beacon switches are on.

The beacons must be used when driving on the

road.

BEACON LIGHTS - AMBER

5.7.5 SLOW MOVING VEHICLE (SMV)

SIGNS

ENGINE - FORWARD

The Slow Moving Vehicle (SMV) signs must be

visible when travelling on the road.

CAB - FORWARD

Form 169017 / 169087 / 169095 22 Revision C

Page 25

OPERATOR’S STATION

5.8 WINDSHIELD WIPERS

FRONT WIPER SWITCH

Controls Front Windshield Wiper

ON / OFF

REAR WIPER SWITCH

Controls Rear Windshield Wiper

ON / OFF

The windshield wiper controls are located in the

cab headliner. The illustration above designates

the controls as in the cab-forward mode.

5.9 REAR VIEW MIRRORS

REAR VIEW MIRRORS

CAB - FORWARD

5.10 CAB TEMPERATURE

The cab environment is controlled by a climatecontrol system that provides clean air-conditioned

or heated air for the operator.

The heater / evaporator / blower assembly is

located under the cab floorboard, and is

accessible from beneath the windrower.

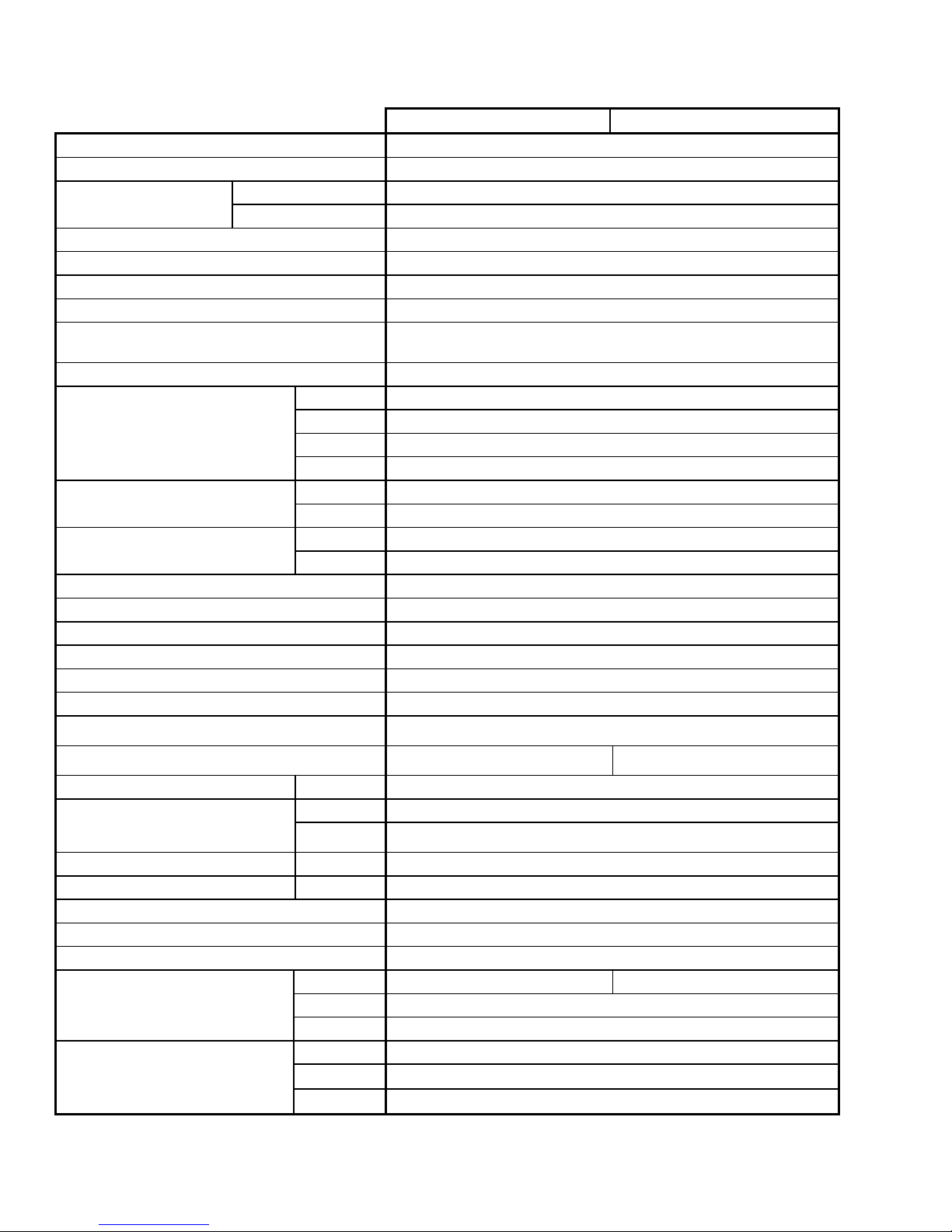

5.10.1 HEATER SHUT-OFF VALVE

M150

HEATER SHUT-OFF VALVE

OPEN - Counter Clockwise

CLOSE - Clockwise

M200

REAR VIEW MIRROR

ENGINE - FORWARD

Two adjustable outside mounted mirrors provide

rear view vision when the windrower is operated in

the cab-forward mode.

A single interior mounted mirror provides rear view

vision in the engine-forward mode.

A shut-off valve at the engine allows the cab

heater to be isolated from the engine coolant.

OPEN

CLOSE

The valve must be open to provide heat to the

cab, but for maximum cooling, the valve can be

closed.

5.10.2 AIR DISTRIBUTION

Cab air distribution is controlled through

adjustable air vents. They are located in the cab

posts to provide window and operator ventilation

as shown in illustration.

Form 169017 / 169087 / 169095 23 Revision C

Page 26

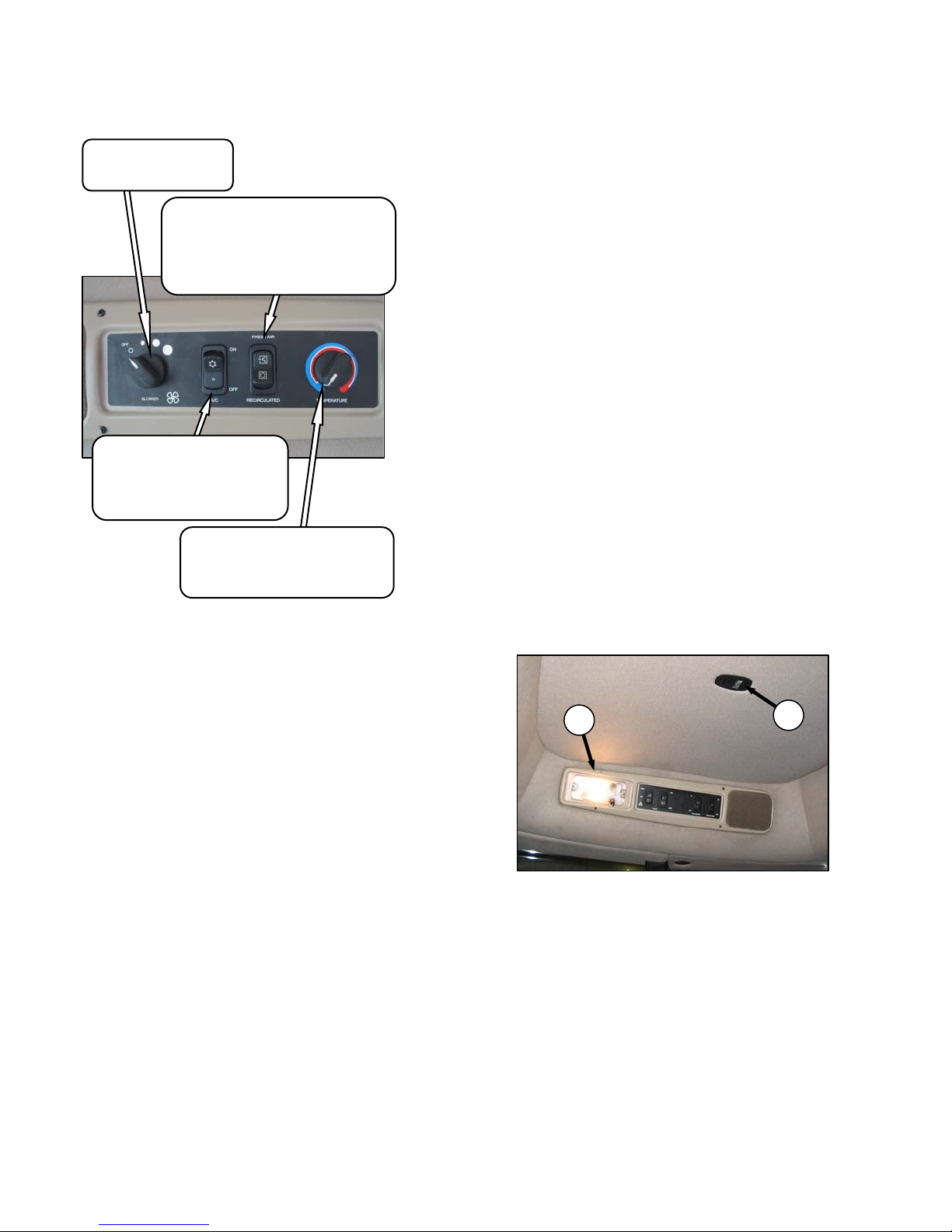

5.10.3 CONTROLS

BLOWER SWITCH

Controls Blower Speed

OFF / LO / MEDIUM / HI

FRESH AIR - Starts Booster Fan and

Filtered Outside Air Drawn Into Cab.

RECIRCULATE - Stops Booster Fan

and Cab Air Is Recirculated.

OUTSIDE AIR SWITCH

Controls Air Source

OPERATOR’S STATION

5.10.4 A/C COMPRESSOR PROTECTION

The compressor is protected from excessivel y low

and high pressures by two switches that shutdown

the compressor to prevent damage to the system.

• The LOW pressure switch opens when the

pressure falls to 5.1 - 10.9 psi (35 - 75 kPa),

and shuts down the compressor. When the

pressure rises to 17.6 - 26.4 psi (121 - 182

kPa), the switch closes, and allows the

compressor to run.

• The HIGH pressure switch opens and stops

the compressor when the pressure rises to

315 - 335 psi (2172 - 2310 kPa). When the

pressure falls to 220 - 280 psi (1517 - 1930

kPa), the switch closes, and allows the

compressor to run.

AIR CONDITIONING SWITCH

Controls A/C System

OFF - A/C Does Not Operate.

ON - A/C Operates With Blower

Switch On.

TEMPERATURE CONTROL

Controls Cab Temperature

INCREASE - Clockwise

DECREASE - Counter Clockwise

IMPORTANT

To distribute the oil throughout the system,

perform the following steps whenever the

machine is first started after storage for

more than one week:

a. Turn blower switch to the first position. Turn

temperature control switch to maximum heating,

and A/C control to “OFF”.

b. Start engine, and operate at low idle until engine is

warm.

c. Click A/C switch from "OFF" to "ON" for one

second, then back to "OFF" for 5 to 10 seconds.

Repeat this step ten times.

If the air conditioning system is shutdown by either

switch, locate the source of the problem, and

correct it before operating the system.

• The Windrower Control Module (WCM)

monitors the compressor operation, and when

it senses rapid pressure changes that cause

the compressor to rapidly engage and

disengage, a “CHECK A/C SYSTEM” will

appear on the CDM display.

5.11 INTERIOR LIGHTS

B

A

Form 169017 / 169087 / 169095 24 Revision C

Two interior lights are installed in the cab

headliner.

A low intensity LED light (A) is located directly

overhead to provide ambient lighting if desired,

and functions only when the road/field light switch

is on.

An on-off switch is located on the light.

The other interior light (B) is located on the

headliner switch panel and the push-on, push-off

button is located on the light.

Page 27

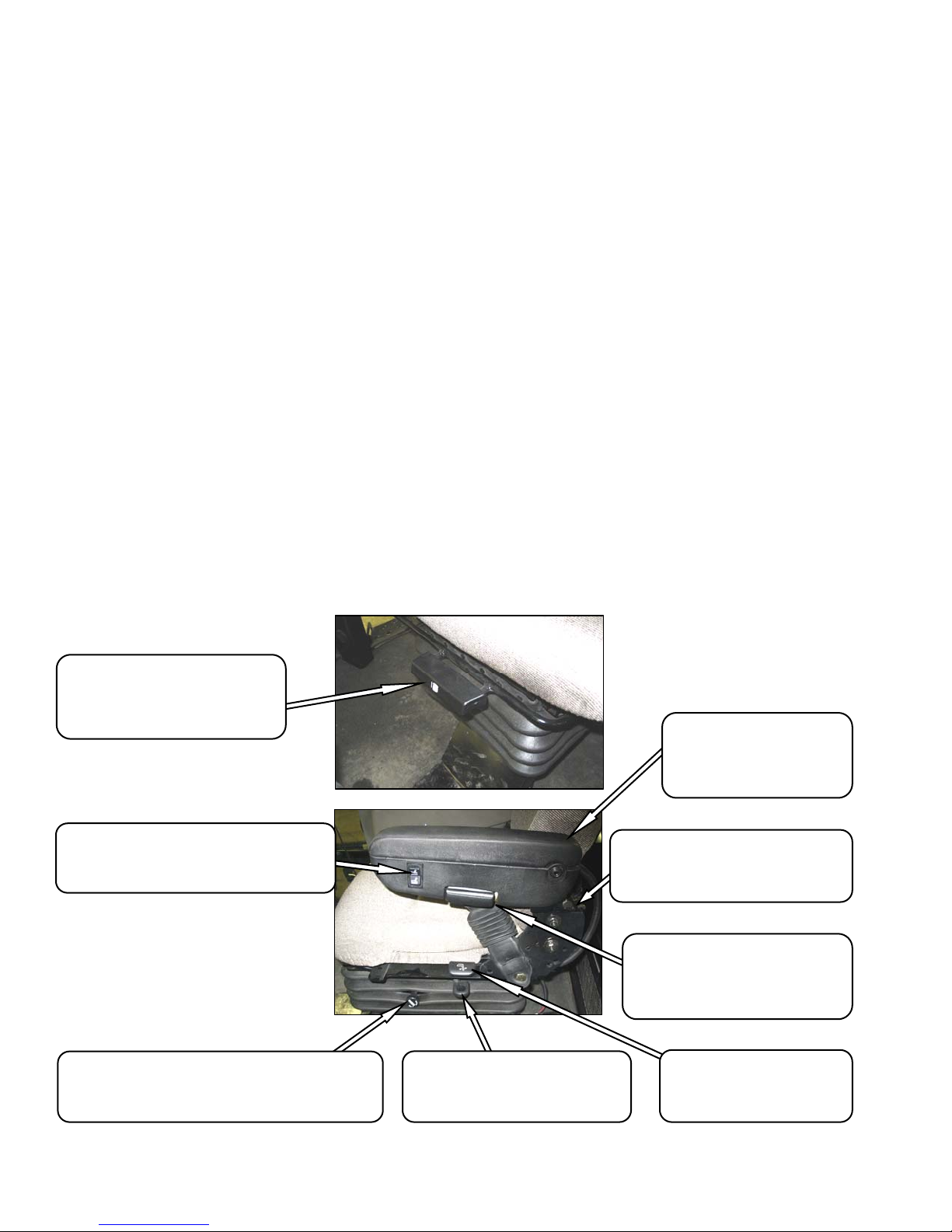

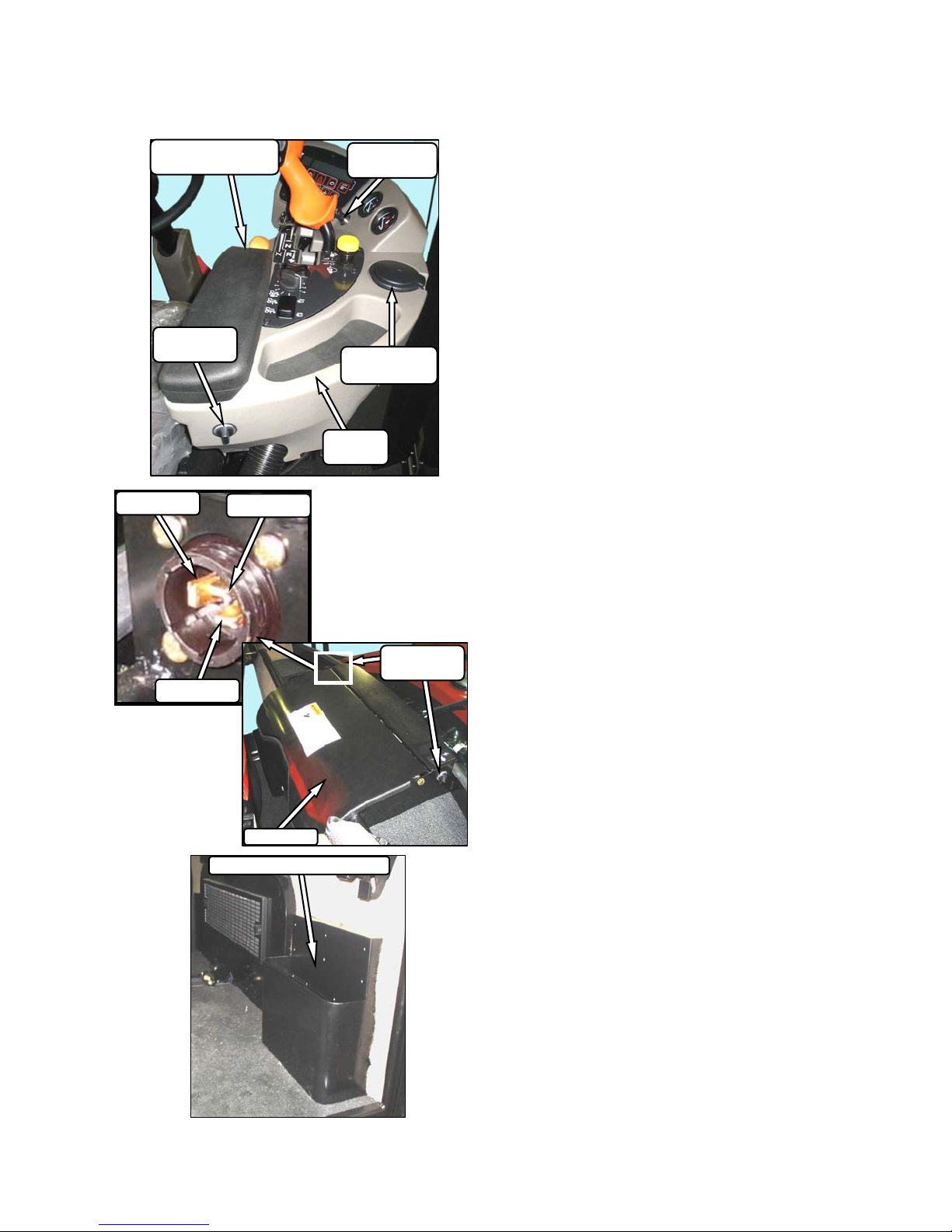

5.12 OPERATOR AMENITIES

OPERATOR’S STATION

UTILITY TRAY

UNDER ARMREST

AUXILIARY

POWER

SWITCHED

CIGARETTE

LIGHTER

ASHTRAY /

CUPHOLDER

UTILITY

TRAY

BATTERY

GROUND

AUXILIARY

POWER

COOLER

MANUAL STORAGE CASE

Form 169017 / 169087 / 169095 25 Revision C

Page 28

5.13 RADIOS

5.13.1 AM/FM RADIO

OPERATOR’S STATION

B

A

B

A radio is available as optional equipment from

your MacDon Dealer, and a space (A) is provided

in the cab headliner to accommodate the

installation. Two pre-wired speakers (B) have

been factory installed in the headliner.

Refer to M150 and M200 Self-Propelled

Windrower Unloading and Assembly instructional

manual for radio installation procedures.

Operating instructions are supplied with the radio.

11 GA. OR 3.0 mm CQHRS

IMPORTANT

Antenna base can only be installed on the

LH and RH rear cab roof bolts.

5.14 HORN

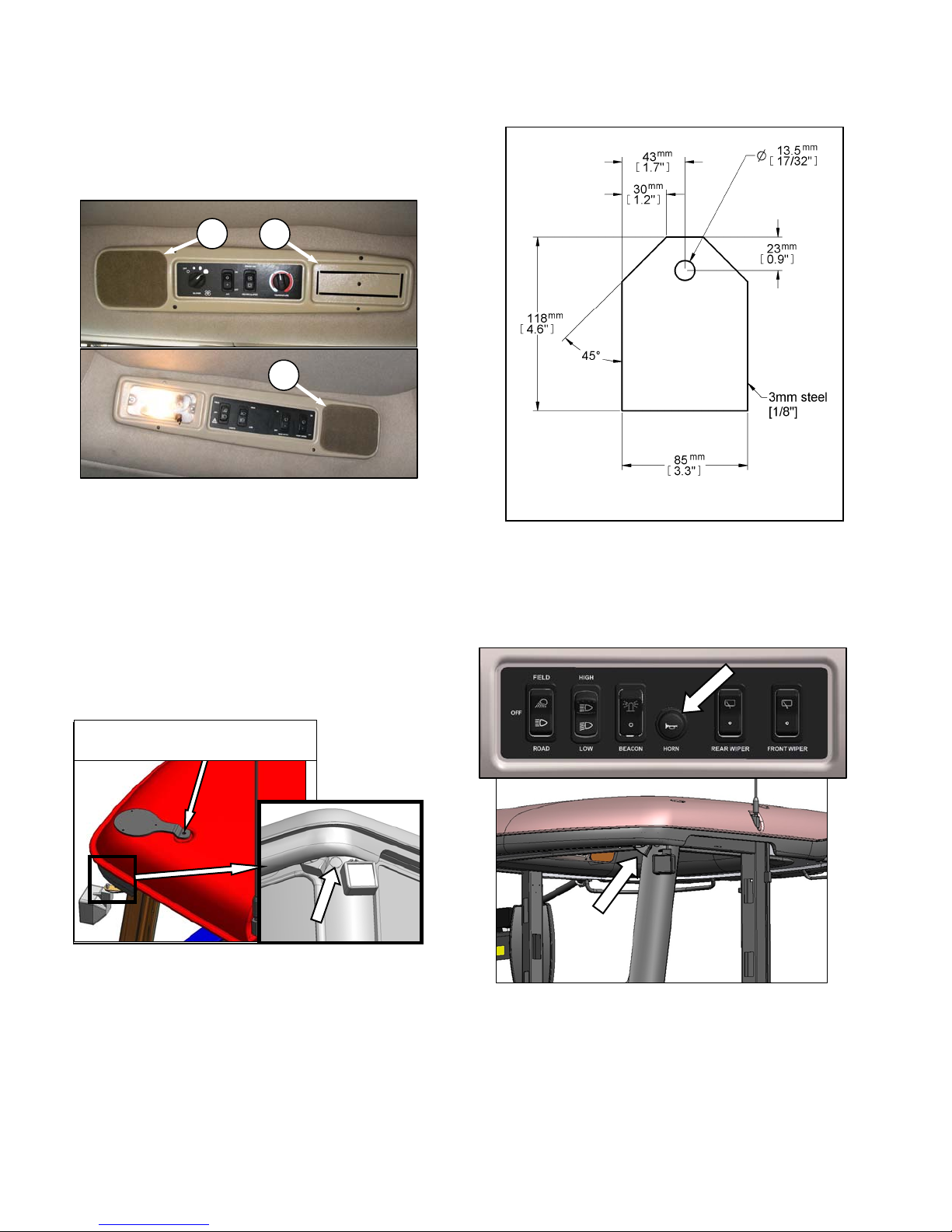

5.13.2 ANTENNA MOUNTING

REMOVE EXISTING BOLT AND

REINSTALL WITH ANTENNA BASE

A roof mounted antenna base for installing a

magnetic antenna is available as an option from

your MacDon Dealer.

Order part #160288, or see illustration for part

dimensions for a “homemade” version. It

accommodates most CB, 2-way radio and satellite

radio antennas.

A knockout for the antenna lead is provided on the

cab post.

The horn is activated by pushing the button

located on the panel in the headliner. The ignition

switch must be on.

Sound the horn three times prior to starting the

engine.

Form 169017 / 169087 / 169095 26 Revision C

Page 29

OPERATOR’S STATION

5.15 ENGINE CONTROLS/GAUGES

All engine controls and gauges are conveniently

located on the Operator’s console.

Refer to the following illustration for the location

and a description of each.

ACC - Fully Counter Clockwise

IGNITION SWITCH

OFF - All Electrical Systems Off

RUN - Clockwise

START- Fully Clockwise To Crank Engine

Release and Switch Returns to RUN

REMOVE KEY WHEN WINDROWER NOT IN USE.

KEY ALSO LOCKS DOORS.

ENGINE TEMPERATURE

Indicates Engine Coolant Temperature

Normal Running 180°- 225°F (82°-107°C).

Warning Tone Over 230°F (110°C).

FUEL

Indicates Fuel Level In Tank

E - Empty

F - Full

FULL

CLOSED

THROTTLE

Controls Engine RPM.

FULL - Push Lever Forward

OPERATING - See Section 6.3.6

CLOSED - Pull Lever Back

Form 169017 / 169087 / 169095 27 Revision C

Page 30

5.16 WINDROWER CONTROLS

TURN SIGNALS

Activates Turn Signals On Windrower and Header

Momentary Switches On Monitor

OPERATOR’S STATION

GROUND SPEED LEVER (GSL)

Controls Speed and Direction of Movement

F - Forward

N - Neutral

N-DETENT - Engages Neutral Interlock and Applies

Park Brake When Steering Locked In Center

R - Reverse

Activates Signals On Windrower Tractor and Header

HAZARD WARNING LIGHTS

Momentary Switch On Monitor

GROUND SPEED RANGE SWITCH

Shifts Transmission Speed Range

H - 0 - 23 mph (37 km/h). ENGINE-FORWARD ONLY.

- 0 -16 mph (25.7 km/h). CAB-FORWARD ONLY.

L - 0 -11 mph (17.7 km/h)

AUTO-STEER ENGAGEMENT SWITCH

Engages Auto-Steer System (If compatible system is installed).

ENGAGE - Click To Engage.

DISENGAGE - Turn Steering Wheel To Disengage.

FAST

N-DETENT

SLOW

REVERSE

Form 169017 / 169087 / 169095 28 Revision C

Page 31

OPERATOR’S STATION

5.17 HEADER CONTROLS

All header controls are conveniently located on the

Operator’s console, and on the GSL handle.

NOTE

Some controls are optional equipment, and

may not be present in your unit. Some

controls may be installed, but will be nonfunctional for certain headers.

5.17.1 HEADER ENGAGE SWITCH

5.17.2 HEADER DRIVE REVERSE BUTTON

HEADER REVERSE

ENGAGE - Push / Hold / Engage Header

DISENGAGE - Release Button

NOTE

The optional hydraulic reversing kit must be

installed.

IMPORTANT

To prevent improper operation and damage

to the reel on D Series draper headers

when the reverser kit is installed:

ENGAGE - Push Center and Pull Up

HEADER DRIVE

DISENGAGE - Push Down

Engages and disengages header drive.

IMPORTANT

Always move throttle lever back to idle

before engaging header drive. Do not

engage header with engine at full RPM.

If switching between A40D auger header

and D50 or D60 draper header, the hose

plumbing to the reverser valve must be

changed to suit the header type. Refer to

Instruction Form #169213 that was supplied

with the reversing kit.

• Reverses knife and conditioner on D Series draper

headers.

• Reverses reel, auger, knife and conditioner on A

Series auger headers.

• Not applicable for R Series rotary headers.

NOTE

To re-engage header drive, push down, and

pull up header drive knob.

Form 169017 / 169087 / 169095 29 Revision C

Page 32

OPERATOR’S STATION

5.17.3 GROUND SPEED LEVER (GSL)

HEADER SWITCHES

B

A

The GSL (A) contains switches for the following

header functions that are most often adjusted

while in operation to suit changing crop conditions.

All are momentary type switches.

5.17.3.1 Display Selector Switch

DISPLAY

SELECTOR

Selects and displays the settings in the CDM (B)

top line read-out for each of the header controls.

• Press switch to scroll through settings.

5.17.3.2 Reel Position Switches

The reel position switches perform the following

functions, depending on CDM programming, and

which header is attached:

A decal that identifies the switch functions is

located on the cab post above the Operator’s

console.

REEL FORWARD

REEL DOWN

DWA DOWN

REEL UP

REEL AFT

DWA UP

• Double Windrow Attachment (DWA) Position

on Draper and Auger Headers. See Section

6.4.7

• Reel Fore-Aft Position and Height on Draper

Headers. See Sections 6.5.4 and 6.5.5.

• Grass Seed Drum Position on Rotary

Headers. See Section 6.7.4.

• Center-link Assist Cylinder. See Sections

6.5.1, 6.6.1, or 6.7.1.

NOTE

Refer to the specific Header section in this

instructional manual for detailed switch

operating modes.

Form 169017 / 169087 / 169095 30 Revision C

Page 33

OPERATOR’S STATION

5.17.3.3 Header Position Switches

REEL / DISC

SPEED

FAST

SLOW

Press and hold switch at location shown to move

header. Release switch at desired position.

NOTE

Refer to the specific Header section in this

instructional manual for detailed switch

operating modes.

5.17.3.4 Reel and Disc Speed Switches

HEADER UP

HEADER

HEADER DOWN

HEADER

TILT UP

Press and hold switch at location shown to change

reel or disc speed. Release switch at desired

speed.

• Auger Header

A30 - Not applicable.

A40 - Auger speed is automatically

maintained when reel speed is

changed.

IMPORTANT

Reel speed on auger header must not

exceed 85 rpm.

IMPORTANT

Auger speed must not exceed 320 rpm.

• Draper Header

Reel speed is limited in INDEX

HEADER SPEED mode.

• Rotary Header

Conditioner speed automatically

adjusts when disc speed is changed.

NOTE

Refer to the specific Header section in this

instructional manual for detailed switch

operating modes.

Form 169017 / 169087 / 169095 31 Revision C

Page 34

OPERATOR’S STATION

5.17.4 CONSOLE HEADER SWITCHES

The Operator’s console contains switches for the

following header functions.

5.17.4.1 Deck Shift / Float Preset Switch

LEFT SIDE

DELIVERY

CENTER

DELIVERY

RIGHT SIDE

DELIVERY

• Draper Header with Deck Shift Option

Controls deck shifting for double

windrowing options with a draper

header.

FLOAT

PRESET 1

FLOAT

PRESET 2

FLOAT

PRESET 3

• Draper Header with Fixed Decks / Auger

Header / Rotary Header

Selects pre-programmed header float

settings. Refer to Section 6.4.2

Header Flotation, for instructions to

preset the float.

NOTE

Refer to the specific Header section in this

instructional manual for detailed switch

operating modes.

Form 169017 / 169087 / 169095 32 Revision C

Page 35

OPERATOR’S STATION

5.18 CAB DISPLAY MODULE (CDM)

5.18.1 ENGINE AND WINDROWER

FUNCTIONS

GROUND SPEED

mph or kph

ENGINE RPM

ENGINE WARNING LIGHTS

Engine Pre-Heat / Water In Fuel /

Do Not Operate / Stop Engine

IGNITION SWITCH POSITIONS

Accessory / Stop / Run / Start

Engine / Windrower Functions

DISPLAY

HAZARD WARNING LIGHTS SWITCH

Activates Hazard Warning Lights

Cancels Turn Signal

SELECT SWITCH

Allows Operator To Select

Display Item On Lower Line

Push To Select

TURN SIGNAL SWITCHES

Activates Turn Signals on Windrower and Header

Push-On / Push-Off

5.18.2 HEADER FUNCTIONS

DISPLAY

Header Functions

RETURN TO CUT HEIGHT SWITCH

Allows Cutting Height Pre-Set.

Push-On / Push-Off

Illuminates In On Position

NOTE

HEADER MUST BE ENGAGED.

HEADER INDEX SWITCH

Links Reel and Conveyor Speed to Ground Speed.

Push-On / Push-Off

Illuminates In On Position

Allows Operator To Select Display Item.

SELECT SWITCH

Bottom Line

Push To Select

FLOAT SWITCH - HEADER RIGHT SIDE

Changes Header Float

Push + to Increase / Push - to Decrease

Remembers Setting With Deck Shift Option If

Activated With Float Setting Switch

FLOAT SWITCH - HEADER LEFT SIDE

Same As Above

AUGER / DRAPER SPEED ADJUST

Changes Auger / Draper Speed INDEX with INDEX SWITCH ON

Changes Auger / Draper SPEED with INDEX SWITCH OFF

Push Upper Switch to Increase

Push Lower Switch to Decrease

Form 169017 / 169087 / 169095 33 Revision C

Page 36

OPERATOR’S STATION

5.18.3 OPERATING SCREENS

The M150 and M200 Windrower Cab Display

Module (CDM), and the Windrower Control

Module (WCM) provide information on several

functions for the engine, header, and windrower.

DISPLAY

The information displayed in various operating

modes is described in the following sections:

UPPER LINE

LOWER LINE

DISPLAY SELECTOR

FOR LOWER LINE

DISPLAY SELECTOR

FOR UPPER LINE

IGNITION ON / ENGINE NOT RUNNING

DISPLAY (Upper Line) (2 - 3 Seconds) DESCRIPTION

HEADER DISENGAGED

IN PARK

ENGINE - FORWARD / ENGINE RUNNING

(Scroll Through Display with CDM Switch or GSL Switch)

DISPLAY DESCRIPTION

ROAD GEAR (Upper Line)

#####.# ENGINE HRS (Upper or Lower Line)

#####.# HEADER HRS (Upper or Lower Line)

###### TOTAL ACRES (Upper or Lower Line)

###### TOTAL HECT (if Metric)

##.# HEADER HEIGHT (Upper or Lower Line)

##.# HEADER ANGLE (Upper or Lower Line)

##.# VOLTS (Upper or Lower Line)

Indicates Header Engage Switch Is Off.

Indicates GSL In Neutral Detent.

Ground Speed Range Switch In High Range.

Total Engine Operating Time.

Total Header Operating Time.

Total Area Cut By Machine.

Distance Setting (00.0 - 10.0) Between Cutterbar and

Ground.

Angle Setting (00.0 - 10.0) Header Relative to

Ground.

Engine Electrical System Operating Voltage.

SCROLL (Lower Line)

Form 169017 / 169087 / 169095 34 Revision C

Displays Above Items After 2 - 3 Seconds.

Press SELECT to cancel.

Page 37

OPERATOR’S STATION

CAB - FORWARD / ENGINE RUNNING / HEADER DISENGAGED

(Scroll Through Display with CDM Switch or GSL Switch)

DISPLAY (Lower or Upper Line) DESCRIPTION

#####.# ENGINE HRS

#####.# HEADER HRS

###.# SUB ACRES

###.# SUB HECTARES (If Metric)

###### TOTAL ACRES

###### TOTAL HECT (If Metric)

##.# HEADER HEIGHT

##.# HEADER ANGLE

##.# L FLOAT R ##.#

##.# VOLTS

SCROLL (Lower Line)

Total Engine Operating Time.

Total Header Operating Time.

Area Cut Since Last Reset. To Reset, Display SUB

ACRES On Lower Line And Hold Down Program Switch

Until Display Resets (5 - 7 Seconds).

Total Area Cut By Machine.

Distance Setting (00.0 - 10.0) Between Cutterbar and

Ground.

Angle Setting (00.0 - 10.0) Header Relative to Ground.

Float Setting (0.0 - 10.0).

Engine Electrical System Operating Voltage.

Displays Above Items After 2 - 3 Seconds.

Press SELECT to cancel.

Form 169017 / 169087 / 169095 35 Revision C

Page 38

OPERATOR’S STATION

CAB - FORWARD / ENGINE RUNNING / HEADER ENGAGED

AUGER HEADER

(Scroll Through Display with CDM Switch or GSL Switch)

DISPLAY (Lower or Upper Line) DESCRIPTION

#####.# ENGINE HRS

#####.# HEADER HRS

##.# ACRES/HOUR

##.# HECTARES/HOUR (If Metric)

###.# SUB ACRES

###.# SUB HECTARES (If Metric)

###### TOTAL ACRES

###### TOTAL HECT (If Metric)

##.## REEL RPM

##.## REEL SENSOR (If Sensor Disabled)

##.# AUGER SPEED

#### KNIFE SPEED

#### KNIFE SENSOR (If Sensor Disabled)

##.# HEADER HEIGHT

##.# HEIGHT SENSOR (If Sensor Disabled)

##.# HEADER ANGLE

##.# TILT SENSOR (If Sensor Disabled)

Total Engine Operating Time.

Total Header Operating Time.

Actual Cutting Rate In Acres (Hectares) / Hour.

Area Cut Since Last Reset.

To Reset, Display SUB ACRES On Lower Line And

Hold Down Program Switch Until Display Resets

(5 - 7 Seconds).

Total Area Cut By Machine.

Reel Rotational Speed.

Auger Rotational Speed (4.7 - 9.9).

Knife Speed In Strokes Per Minute.

Distance Setting (00.0 - 10.0) Between Cutterbar and

Ground.

Angle Setting (00.0 - 10.0) Header Relative To Ground.

##.# L FLOAT R ##.#

FLOAT SENS DISABLED (If Sensor Disabled)

LOAD|■■■■■_____| ####

(If Metric) #####

##.# VOLTS

Left And Right Float Setting (0.0 - 10.0).

Bar Graph Representing Hydraulic Operating Pressure.

Full Scale Is Pre-Programmed Overload Pressure

(M150: 2500 - 4000 PSI; M200: 2500 - 4800 PSI).

If Sensor Disabled, LOAD Does Not Display. See Note.

Engine Electrical System Operating Voltage.

SCROLL

SUB-MENU (Lower Line Only)

#### KNIFE SPEED

##.# HEADER HEIGHT

LOAD|■■■■■■■■■■■■| ####

NOTE: The LOAD sensor is factory installed on M200 (optional for M150) to monitor knife/conditioner circuit pressure.

To monitor reel circuit pressure, relocate sensor as per Instructional Manual #169031 which is available through your MacDon

Dealer.

Form 169017 / 169087 / 169095 36 Revision C

Displays Sub-Menu After 2 - 3 Seconds.

Press SELECT to cancel.

Scroll Through Sub-Menu Display with CDM Switch

Page 39

OPERATOR’S STATION

CAB - FORWARD / ENGINE RUNNING / HEADER ENGAGED

DRAPER HEADER / INDEX SWITCH OFF

(Scroll Through Display with CDM Switch or GSL Switch)

DISPLAY (Lower or Upper Line) DESCRIPTION

#####.# ENGINE HRS

#####.# HEADER HRS

##.# ACRES/HOUR

##.# HECTARES/HOUR (If Metric)

###.# SUB ACRES

###.# SUB HECTARES (If Metric)

###### TOTAL ACRES

###### TOTAL HECT (If Metric)

##.## REEL MPH

##.## REEL KPH (If Metric)

##.## REEL SENSOR (Sensor Disabled)

##.# DRAPER SPEED

#### KNIFE SPEED

#### KNIFE SENSOR (Sensor Disabled)

##.# HEADER HEIGHT

##.# HEIGHT SENSOR (Sensor Disabled)

##.# HEADER ANGLE

##.# TILT SENSOR (Sensor Disabled)

Total Engine Operating Time.

Total Header Operating Time.

Actual Cutting Rate In Acres (Hectares)/Hour.

Area Cut Since Last Reset.

To Reset, Display SUB ACRES On Lower Line And Hold

Down Program Switch Until Display Resets

(5 - 7 Seconds).

Total Area Cut By Machine.

Reel Peripheral Speed.

Draper Speed (0.0 - 11.0).

Knife Speed In Strokes Per Minute.

Distance Setting (00.0 - 10.0) Between Cutterbar and

Ground.

Angle Setting (00.0 - 10.0). Header Relative To Ground.

##.# L FLOAT R ##.#

LOAD|■■■■■_____| ####

(If Metric) #####

##.# VOLTS

Left And Right Float Setting (0.0 - 10.0).

Bar Graph Representing Hydraulic Operating Pressure.

Full Scale Is Pre-Programmed Overload Pressure

(M150: 2500 -4000 PSI; M200: 2500 - 4800 PSI).

If Sensor Disabled, LOAD Does Not Display. See Note.

Engine Electrical System Operating Voltage.

SCROLL

SUB-MENU (Lower Line Only)

#### KNIFE SPEED

##.# HEADER HEIGHT

LOAD|■■■■■■■■■■■■| ####

Displays Sub-Menu After 2 - 3 Seconds.

Press SELECT to cancel.