Page 1

Model 912 / 922

AUGER HEADER and

Model 722

HAY CONDITIONER

Model 933

Grass Seed Special

AUGER HEADER

OPERATOR’S MANUAL

Form 46620 Issue 01/06

Sugg. Retail: $15.00

Page 2

Inside Front Cover

(blank)

Page 3

INTRODUCTION

Your new Model 912 or 922 Auger Header and 722 Hay Conditioner, teamed with the MacDon Self Propelled

Windrower power unit is designed to cut, condition, and lay in windrows, a wide variety of hay and specialty

crops. The Model 933 Grass Seed Special Header is designed specifically for the unique requirements of

growers of this crop.

The header, conditioner and power unit provides a package which incorporates many features and

improvements in design requested by Owner/Operators like yourself.

NOTE: This manual contains information on the Auger Header and Hay Conditioner. It is to be used in

conjunction with the Self-Propelled Windrower Operator's manual, which provides information on the power

unit (tractor).

CAREFULLY READ BOTH MANUALS TO BECOME FAMILIAR WITH ALL RECOMMENDED

PROCEDURES BEFORE ATTEMPTING TO UNLOAD, ASSEMBLE OR USE THE WINDROWER, OR

HEADER.

Use this manual as your first source of information about the machine. If you follow the instructions given in

this manual, your Windrower will work well for many years.

The manual contains instruction for "Safety", "Operation" and "Maintenance/Service". In addition, "Unloading

and Assembly" information is given towards the back of this book.

Use the Table of Contents and the Index to guide you to specific areas. Study the Table of Contents to

familiarize yourself with how the material is organized.

Keep this manual handy for frequent reference and to pass on to new operators or owners. Call your

Windrower dealer if you need assistance, information, or additional copies of the manuals.

NOTE: Right hand (R/H) and left hand (L/H) designations are determined from the operator's position, facing

forward.

Form # 46620 Issue 01/06

1

Page 4

TABLE OF CONTENTS

PAGE

INTRODUCTION.........................................................................................................................................1

SERIAL NUMBER LOCATIONS .................................................................................................................4

SAFETY

Safety Alert Symbol................................................................................................................................5

Signal Words..........................................................................................................................................5

Safety Signs...........................................................................................................................................6

General Farm Safety...........................................................................................................................7,8

SPECIFICATIONS

Auger Header and Hay Conditioner.......................................................................................................9

Hardware Torque Specifications..........................................................................................................10

Hydraulic Fittings Torque Specifications..............................................................................................11

OPERATION

Your Responsibilities as an Owner/Operator.......................................................................................12

To the New Operator............................................................................................................................12

Attaching the Hay Conditioner ..................................................................................................... 13 - 15

Detaching the Hay Conditioner .......................................................................................................16,17

Break-In Period ....................................................................................................................................18

Pre-Starting Checks: Annual................................................................................................................19

Pre-Starting Checks: Daily...................................................................................................................20

Operate Correctly.................................................................................................................................20

Header Controls...................................................................................................................................21

Header Lift Cylinder Stops ...................................................................................................................21

Operating Variables .............................................................................................................................22

Lean Bar Position.................................................................................................................................22

Ground Speed......................................................................................................................................23

Reel Speed ..........................................................................................................................................24

Reel Pick-Up Finger Pitch....................................................................................................................25

Cutting Height ......................................................................................................................................26

Skid Shoes ......................................................................................................................................26

Gauge Rollers .................................................................................................................................26

Header Angle .......................................................................................................................................27

Header Flotation...................................................................................................................................27

Auger Mounted Crop Deflectors/Stripper Bar Extensions/Short Spare Stripper..................................28

Hay Conditioner Roll Intermesh ...........................................................................................................29

Hay Conditioner Roll Tension Springs .................................................................................................30

Auger Feed Pan/Rock Drop Tine Position Relative to Hay Conditioner ..............................................30

Hay Conditioner Forming Shields ...................................................................................................31,32

Windrow Width ................................................................................................................................31

Rear Deflector .................................................................................................................................31

Forming Shield Height.....................................................................................................................32

Forming Shield Deflector Fins..............................................................................................................32

Haying Tips: .........................................................................................................................................33

Topsoil Moisture ..............................................................................................................................33

Climate and Topography .................................................................................................................33

Windrow Characteristics..................................................................................................................33

Raking and Tedding ........................................................................................................................33

Chemical Drying Agents..................................................................................................................33

"Grass Seed Special" Header..............................................................................................................34

Unplugging the Header ........................................................................................................................35

Hydraulic Conditioner Roll Opener..................................................................................................35

Transporting the Header ......................................................................................................................36

Lifting the Header in Working Position.........................................................................................

Storage Procedure...............................................................................................................................37

........36

Form # 46620 Issue 01/06

2

Page 5

TABLE OF CONTENTS

PAGE

MAINTENANCE/SERVICE

Service Procedures..............................................................................................................................38

Recommended Lubricants ...................................................................................................................39

Enclosed Drive Lubricant Capacities ...................................................................................................39

Sealed Bearing Installation ..................................................................................................................39

Greasing the Header and Hay Conditioner.................................................................................. 40 - 43

Sickle and Sickle Drive

Sickle Lubrication ............................................................................................................................44

Sickle Sections ................................................................................................................................44

Sickle Removal................................................................................................................................44

Head Needle Bearing Installation....................................................................................................45

Sickle Installation.............................................................................................................................45

Sickle Storage (Spare Sickle)..........................................................................................................45

Standard Sickle Guards and Hold-Downs.......................................................................................46

Stub Guards and Hold-Downs.........................................................................................................47

Hold Downs – Cast (Optional).........................................................................................................47

Double Sickle Timing.......................................................................................................................48

Changing Double Sickle Speed.......................................................................................................48

Tightening Double Sickle Drive Belts ..............................................................................................49

Tightening Single Sickle Drive Belt .................................................................................................49

Wobble Box Maintenance ...............................................................................................................50

Reel and Reel Drive

Reel Position - Fore and Aft ............................................................................................................51

Replacing Reel Fingers - 922 & 933 Headers.................................................................................52

Reel Speed - 912 Header................................................................................................................52

Reel Drive Belt Tension - 912 Header.............................................................................................52

Reel Drive Chain Tension - 922 & 933 Headers .............................................................................53

Hydraulic Reel Drive - 922 & 933 Headers .....................................................................................53

Auger and Auger Drive

Auger Position .................................................................................................................................54

Auger Speed ...................................................................................................................................55

Auger Drive Belt/Chain Tension ......................................................................................................55

Hay Conditioner

Hay Conditioner Roll Timing............................................................................................................56

Hay Conditioner Drive Belt ..............................................................................................................57

Hay Conditioner Gear Case Lubricant ............................................................................................58

Maintenance Schedule.........................................................................................................................59

Maintenance Record............................................................................................................................60

TROUBLE SHOOTING ..................................................................................................................... 61 - 65

ATTACHMENTS

Tall Crop Kit .........................................................................................................................................66

Gauge Rollers ......................................................................................................................................66

Adjustable Skid Shoes .........................................................................................................................66

Replacement Reel Bat Kits ..................................................................................................................67

Stub Guards.........................................................................................................................................67

Conditioned Windrow Side Delivery System........................................................................................67

Hydraulic Conditioner Roll Opener.......................................................................................................67

UNLOADING.............................................................................................................................................68

ASSEMBLY....................................................................................................................................... 69 - 79

INDEX .................................................................................................................................................80, 81

Form # 46620 Issue 01/06

3

Page 6

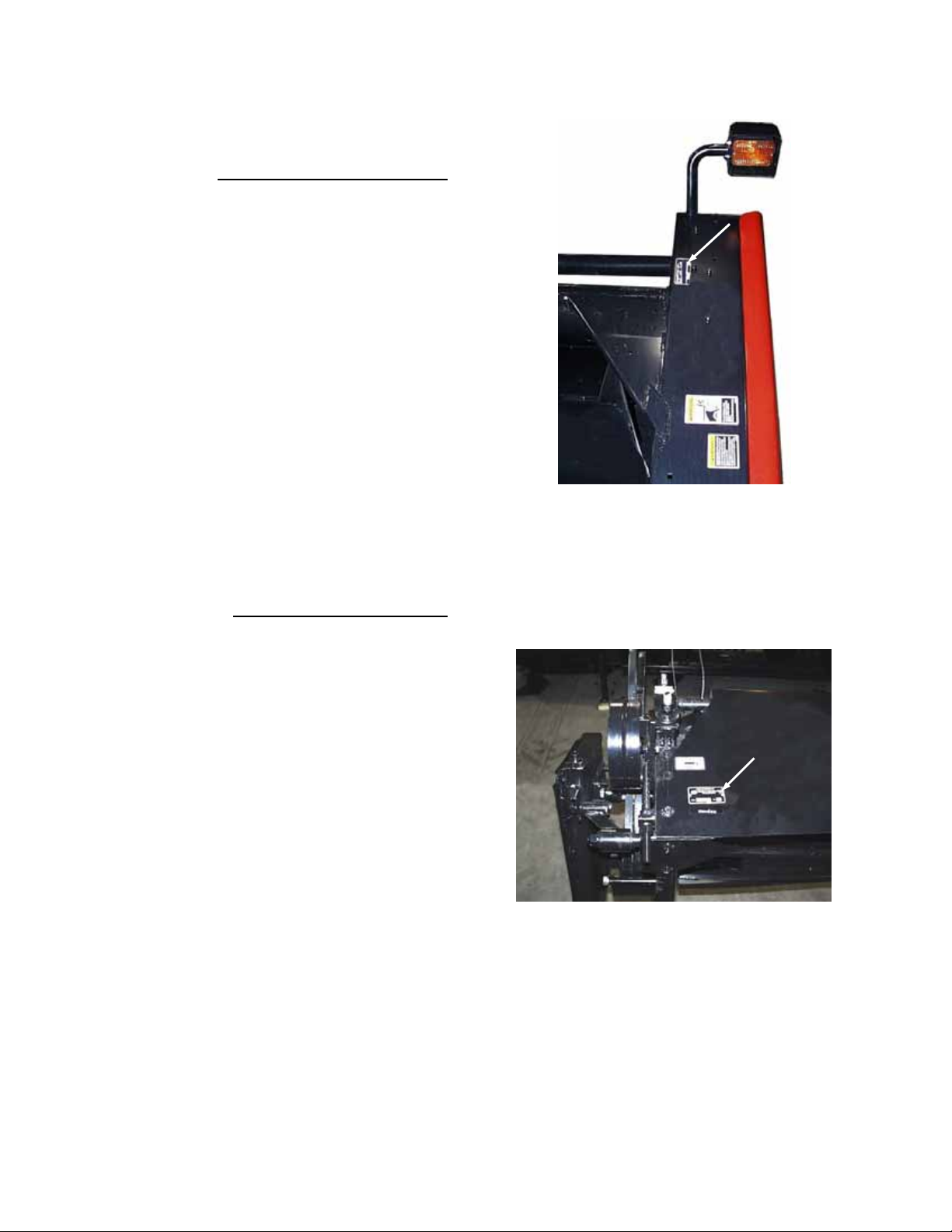

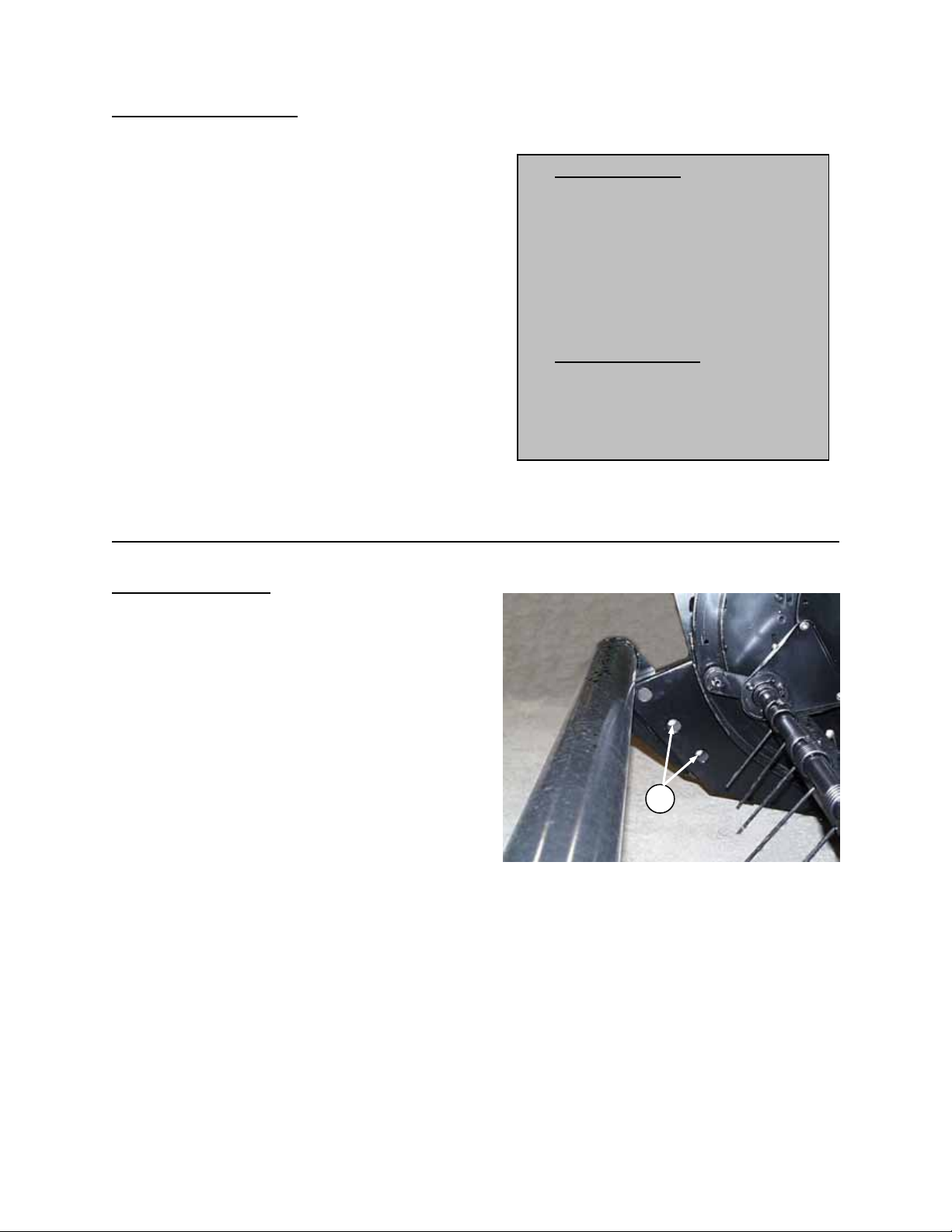

SERIAL NUMBER LOCATIONS

Record the serial numbers in the space provided.

Auger Header:

Plate is located on top of left-hand end sheet.

Hay Conditioner:

Plate is located on left side of top sheet.

NOTE: When ordering parts and service, be sure

to give your dealer the complete and proper serial

number.

AUGER HEADER SERIAL PLATE LOCATION

HAY CONDITIONER SERIAL PLATE

LOCATION

Form # 46620 Issue 01/06

4

Page 7

SAFETY

SAFETY ALERT SYMBOL

This safety alert symbol indicates important safety messages in this

manual and on safety signs on the header.

This symbol means:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Carefully read and follow the safety message accompanying this symbol.

Why is SAFETY important to you?

· ACCIDENTS DISABLE AND KILL

3 BIG REASONS · ACCIDENTS COST

· ACCIDENTS CAN BE AVOIDED

SIGNAL WORDS

Note the use of the signal words DANGER, WARNING, and CAUTION with safety messages. The appropriate

signal word for each message has been selected using the following guidelines:

DANGER – Indicates an imminently hazardous situation that, if not avoided, will result in death or

serious injury.

WARNING – Indicates a potentially hazardous situation that, if not avoided, could result in death or

serious injury. It is also used to alert against unsafe practices.

CAUTION – Indicates a potentially hazardous situation that, if not avoided, may result in minor or

moderate injury. It is also used as a reminder of good safety practices.

Form # 46620 Issue 01/06

5

Page 8

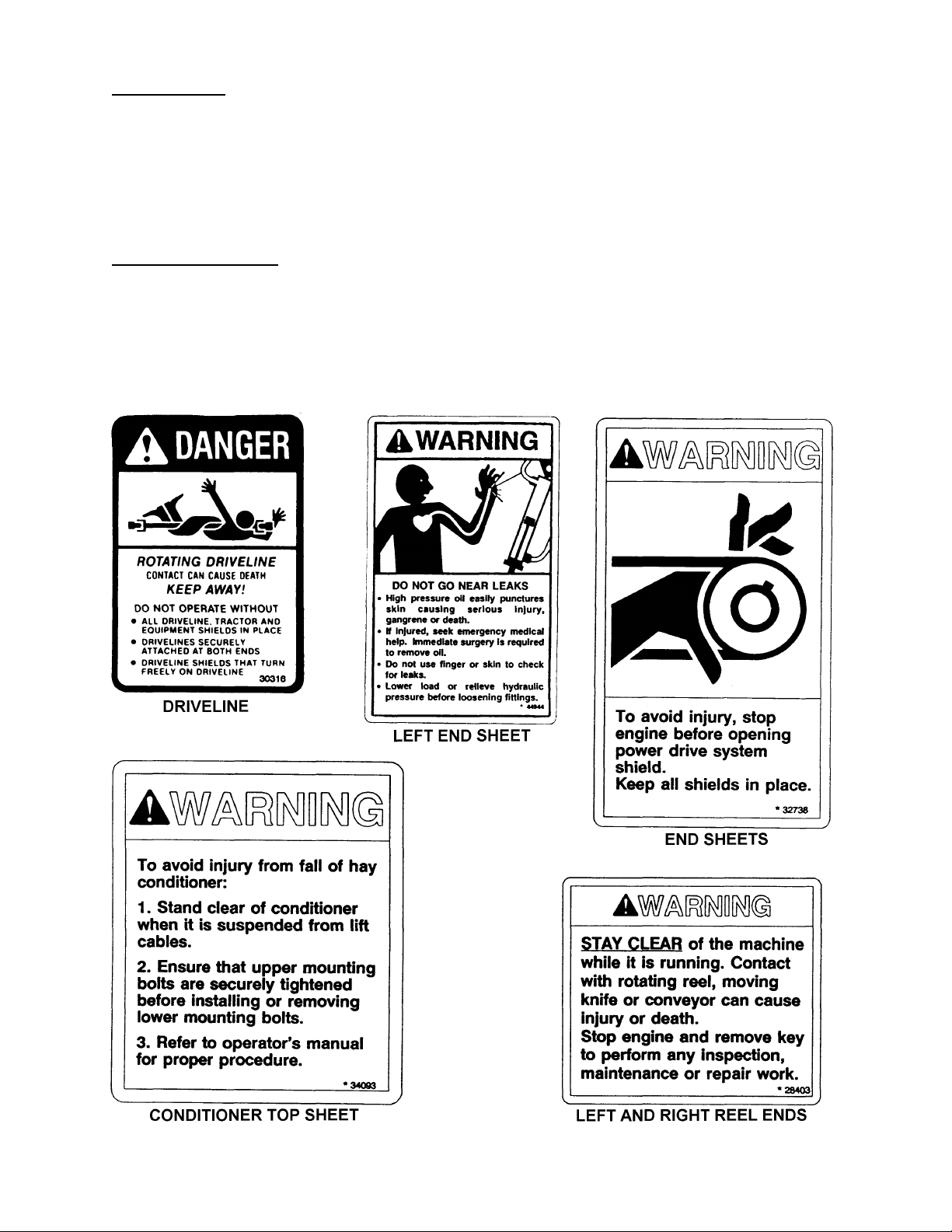

SAFETY

SAFETY SIGNS

· The safety signs reproduced below appear on the header at the locations listed.

· Keep safety signs clear and legible at all times.

· Replace safety signs that are missing or become illegible.

· If original parts on which a safety sign was installed are replaced, be sure the repair part also bears

the current safety sign.

· Safety signs are available from your Dealer Parts Department. The part number is printed in the

lower R/H corner of each safety sign.

To install safety signs:

1. Be sure the installation area is clean and dry.

2. Decide on the exact position before you remove the backing paper.

3. Remove the smaller portion of the split backing paper.

4. Place the sign in position and slowly peel back the remaining paper, smoothing the sign as it is

applied.

5. Small air pockets can be smoothed out or pricked with a pin.

Form # 46620 Issue 01/06

6

Page 9

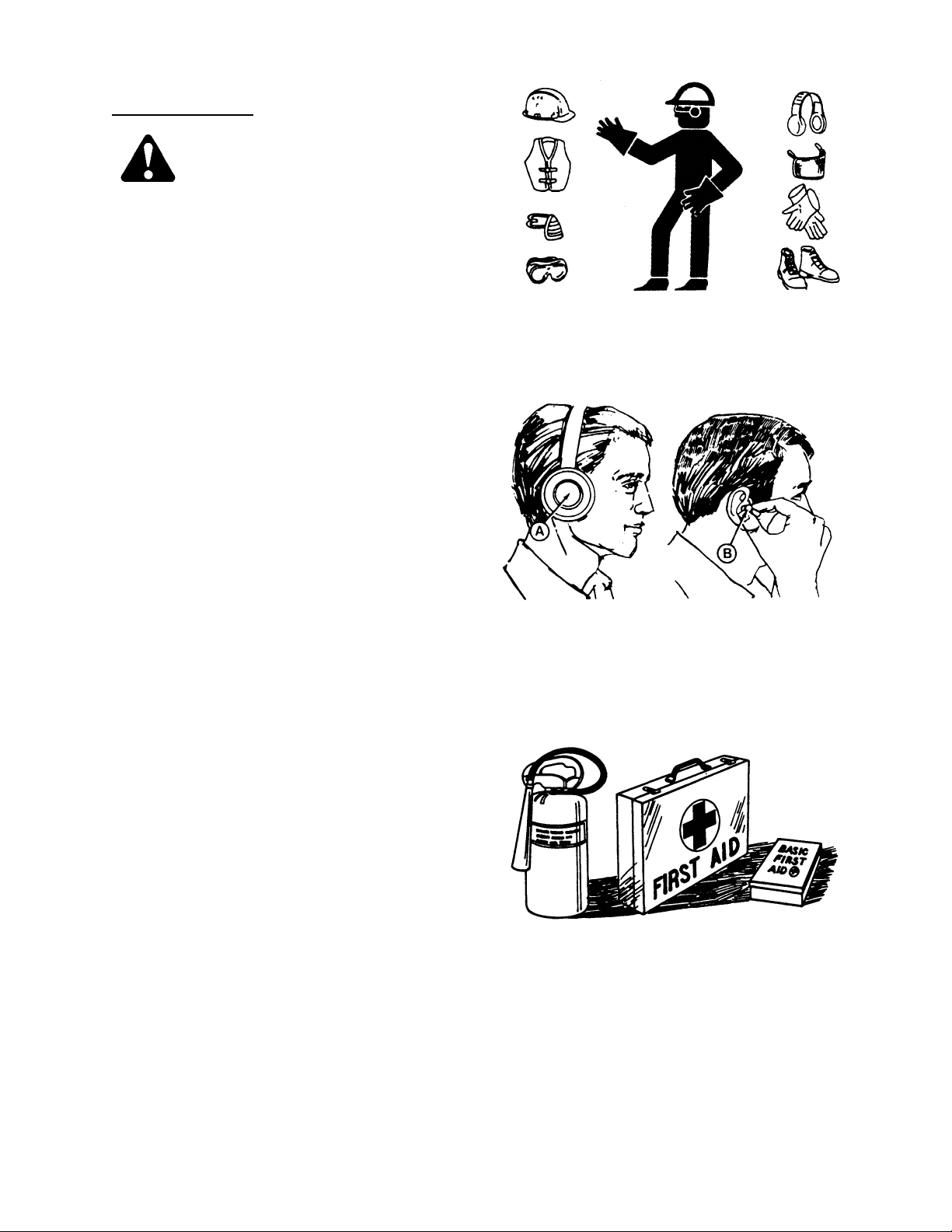

SAFETY

GENERAL SAFETY

The following are general farm

safety precautions that should be

part of your operating procedure for

all types of machinery.

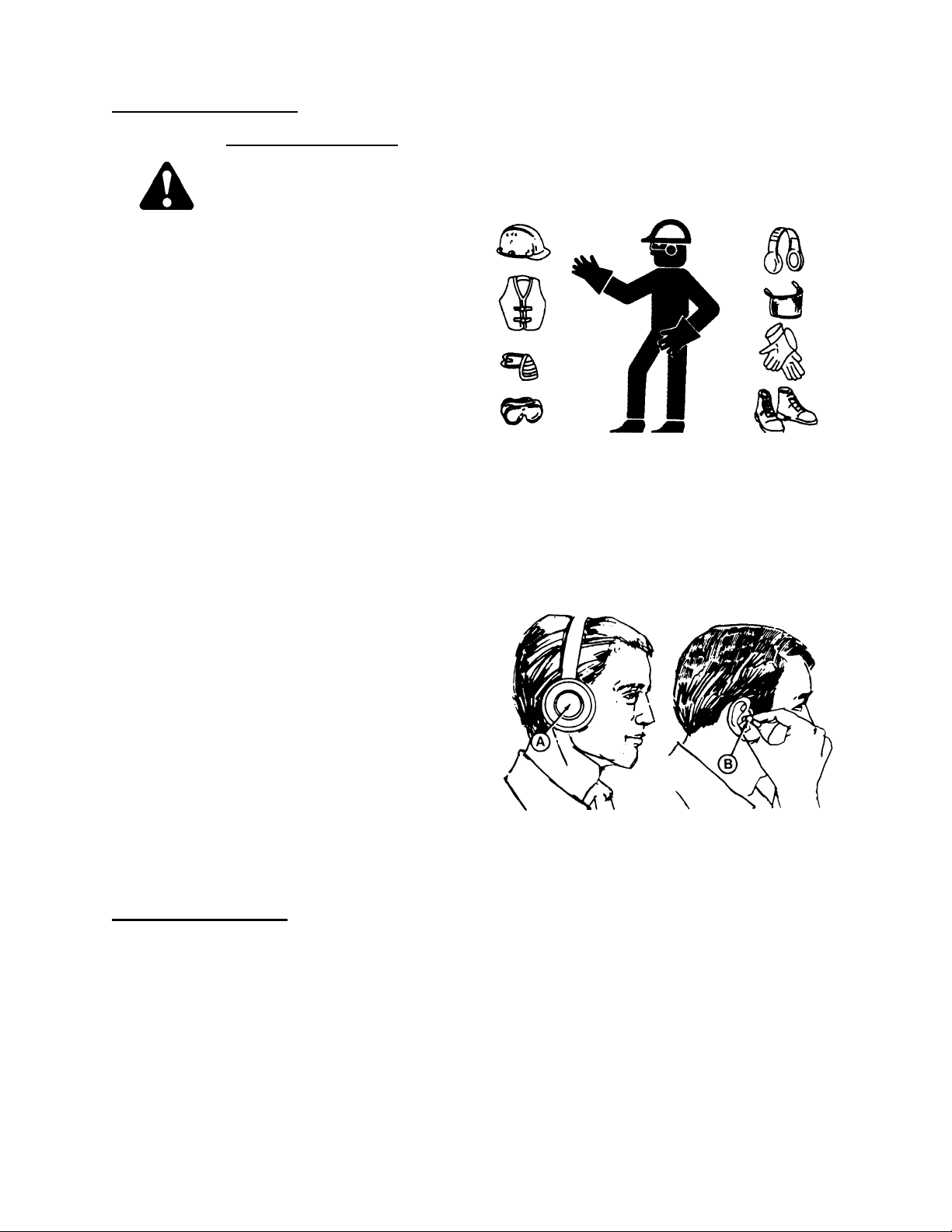

1. Protect yourself.

When assembling, operating and servicing

machinery wear all the protective clothing

and personal safety devices that COULD be

necessary for the job at hand. Don't take

chances.

You may need:

· a hard hat.

· protective shoes with slip resistant soles.

· protective glasses or goggles.

· heavy gloves.

· wet weather gear.

· respirator or filter mask.

· hearing protection. Be aware that prolonged

exposure to loud noise can cause

impairment or loss of hearing. Wearing a

suitable hearing protective device such as

earmuffs (A) or earplugs (B) protects

against objectionable or loud noises.

2. Provide a first-aid kit for use in case of

emergencies.

3. Keep a fire extinguisher on the machine. Be

sure the extinguisher is properly maintained

and be familiar with its proper use.

4. Keep young children away from machinery

at all times.

5. Be aware that accidents often happen when

the operator is tired or in a hurry to get

finished. Take the time to consider the

safest way. Never ignore warning signs of

fatigue.

PROTECT YOURSELF

PROTECT AGAINST NOISE

BE PREPARED FOR EMERGENCIES

Form # 46620 Issue 01/06

7

Page 10

SAFETY

GENERAL SAFETY

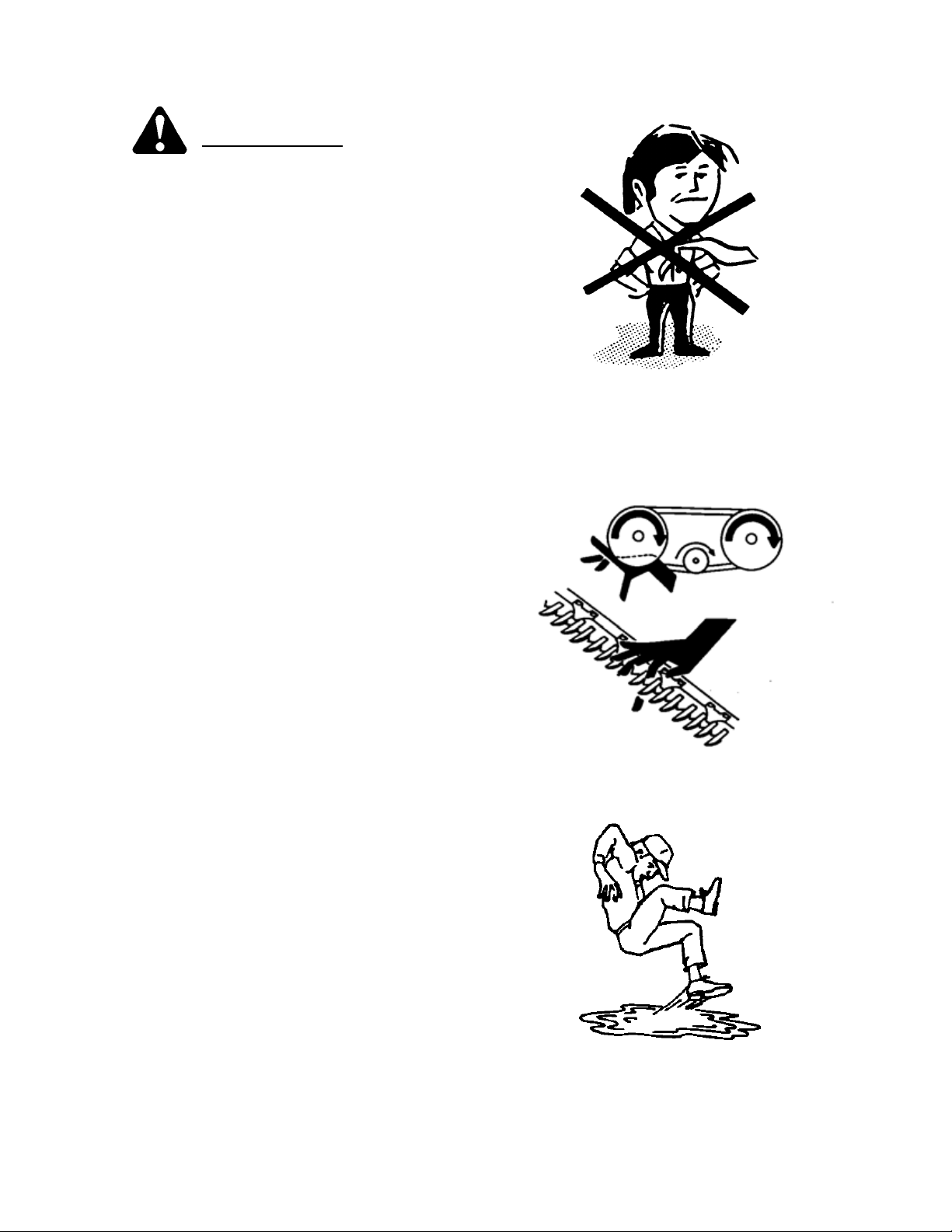

6. Wear close-fitting clothing and cover long

hair. Never wear dangling items such as

scarves or bracelets.

7. Keep hands, feet, clothing and hair away

from moving parts. Never attempt to clear

obstructions or objects from a machine

while the engine is running.

8. Keep all shields in place. Never alter or

remove safety equipment. Make sure

driveline guards can rotate independently of

the shaft and can telescope freely.

9. Use only service and repair parts made or

approved by the equipment manufacturer.

Substituted parts may not meet strength,

design, or safety requirements.

10. Do not modify the machine. Unauthorized

modifications may impair the function

and/or safety and affect machine life.

11. Stop engine and remove key from ignition

before leaving operator's seat for any

reason. A child or even a pet could engage

an idling machine.

12. Keep the area used for servicing machinery

clean and dry. Wet or oily floors are

slippery. Wet spots can be dangerous when

working with electrical equipment. Be sure

all electrical outlets and tools are properly

grounded.

13. Use adequate light for the job at hand.

14. Keep machinery clean. Straw and chaff on a

hot engine are a fire hazard. Do not allow oil

or grease to accumulate on service

platforms, ladders or controls. Clean

machines before storage.

15. Never use gasoline, naphtha or any volatile

material for cleaning purposes. These

materials may be toxic and/or flammable.

16. When storing machinery, cover sharp or

extending components to prevent injury

from accidental contact.

(continued)

KEEP SERVICE AREA CLEAN AND DRY

NEVER WEAR LOOSE

OR DANGLING CLOTHES

KEEP AWAY FROM MOVING PARTS

Form # 46620 Issue 01/06

8

Page 11

SPECIFICATIONS

AUGER HEADERS:

AVAILABLE SIZES 912 Single Sickle Header: 12 ft., 14 ft.

922 Double Sickle Header: 14 ft., 16 ft., 18 ft.

CUT WIDTHS 12' 3" (3.73 m) / 14' 3" (4.34 m) / 16' 3" (4.95 m) / 18' 3" (5.56 m)

SINGLE SICKLE DRIVE "C" belt to enclosed oil bath wobble box

DOUBLE SICKLE DRIVE Timing belts to enclosed oil bath wobble boxes

SINGLE SICKLE SPEED 1450 S.P.M.

DOUBLE SICKLE SPEED 1875* or 1450 S.P.M. (* - factory assembled)

STANDARD SICKLE TYPE Over-serrated (bolted) sections, double heat-treated guards

GRASS SEED SICKLE TYPE Fixed lower stub guards, over-serrated (bolted) sections and forged

CUTTERBAR RANGE 6 in. (150 mm) below ground to 35.5 in. (900 mm) above ground

GUARD ANGLE measured with cutterbar on ground:

Tractor models:

XX52/XX52i c/w shallow angle kit

XX52/XX52i w/o shallow angle kit

XX40/XX50

DELIVERY OPENING WIDTH 912/922 Header: 60 in. (1524 mm)

AUGER DRIVE 912 Header: "C" belt to chain final drive

AUGER SPEED 912 Header: 210 rpm standard, 186 rpm optional

AUGER TYPE 24 in. (610 mm) diameter - center feed

REEL DRIVE 912 Header: "C" belt from auger drive

REEL SPEED 912 Header: 71 rpm Standard, 63 or 80 rpm Optional

REEL TYPE 912/922 Header: 5 Bat (standard)

HEADER WEIGHT 12' 912 single sickle - 2435 lbs. (1105 kg)

722 HAY CONDITIONER:

TYPE Crimper - Intermeshing steel rolls, Header mounted

ROLL WIDTH 63.5 in. (1615 mm)

ROLL DIAMETER 8.7" (220 mm)

SPEED 850 rpm

WEIGHT 730 lbs. (330 kg)

933 Grass Seed Header (Double Sickle): 12 ft., 14 ft.

adjustable upper hold-downs

(measured to guard tip)

8° to 16° below horizontal

8° to 16° below horizontal

11° to 18° below horizontal

933 Grass Seed Header: 68, 59, or 50 in. (1720, 1490, 1260 mm)

922/933 Header: Enclosed gearbox

922 Header: 205 rpm standard, 170 rpm optional

933 Grass Seed Header: 12’ & 14’ = 170 rpm, 16’ = 205 rpm

922/933 Header: Hydraulic to chain final drive

922 Header: 30 to 75 rpm (variable from cab)

933 Grass Seed Header: 30 to 69 rpm (variable from cab)

933 Grass Seed Header: 6 bat standard

Pick-up Reel, cam action, replaceable steel fingers

14' 912 single sickle - 2644 lbs. (1199 kg)

14' 922 double sickle - 2821 lbs. (1280 kg)

16' 922 double sickle - 3114 lbs. (1410 kg)

18' 922 double sickle - 3413 lbs. (1550 kg)

12' 933 Grass Seed double sickle - 2680 lbs. (1220 kg)

14' 933 Grass Seed double sickle - 2900 lbs. (1315 kg)

16’ 933 Grass Seed double sickle – 3193 lbs (1451 kg)

Form # 46620 Issue 01/06

9

Page 12

[

[

]

[.4]

[

]

[

[

]

[4]

[7]

[7]

[11]

[18]

[26]

[37]

[52]

[66]

[92]

[

[

]

[

[

]

[

[

]

[

[

]

[

[

]

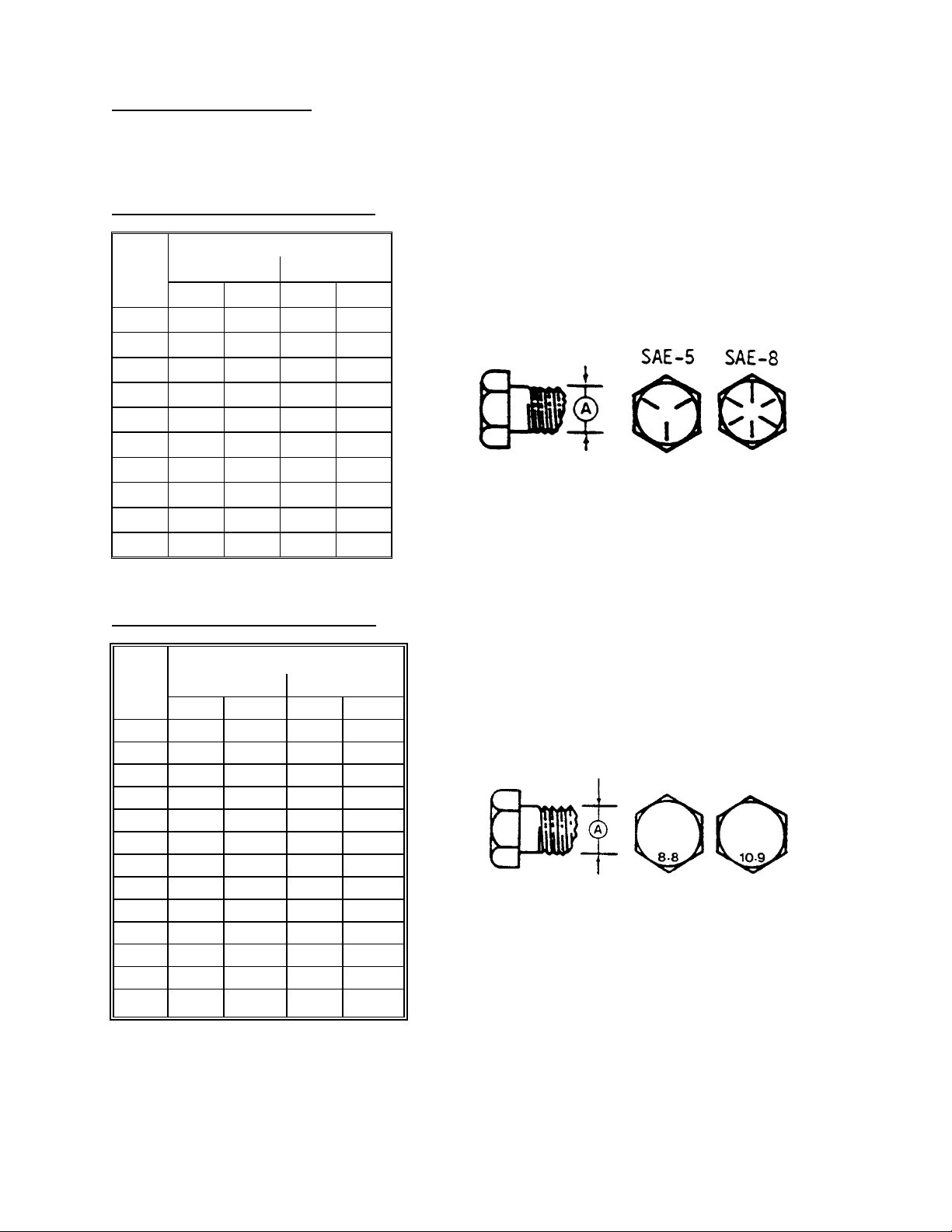

CHECKING BOLT TORQUE

TORQUE SPECIFICATIONS

The tables shown below give correct torque values for various bolts and capscrews. Tighten all bolts to the

torques specified in chart unless otherwise noted throughout this manual. Check tightness of bolts periodically,

using bolt torque chart as a guide. Replace hardware with the same strength bolt.

ENGLISH TORQUE SPECIFICATION

Bolt

Dia.

"A"

1/4" 12 [9] 15 [11]

5/16" 24 [18] 34 [25]

3/8" 43 [32] 56 [41]

7/16" 68 [50] 95 [70]

1/2" 102 [75] 142 [105]

9/16" 149 [110] 202 [149]

5/8" 203 [150] 271 [200]

3/4"

7/8" 569 [420] 813 [600]

1" 867 [640] 1205 [890]

METRIC TORQUE SPECIFICATIONS

Bolt

Dia.

"A"

M3 0.5

M4

M5

M6

M8

M10 50

M12 90

M14 140

M16 225

M20 435

M24 750

M30 1495

M36 2600 [1917] 3675 [2710]

Torque figures indicated above are valid for non-greased or non-oiled threads and heads unless otherwise

specified. Do not grease or oil bolts or capscrews unless specified in this manual. When using locking

elements, increase torque values by 5%.

* Torque value for bolts and capscrews are identified by their head markings.

NC Bolt Torque*

SAE 5 SAE 8

N·m [lb-ft] N·m [lb-ft]

359 [265]

Bolt Torque*

8.8

3

6

10

25

lb-ft] N·m

2.2] 4.5

103] 200

166] 310

321] 610

553] 1050

1103] 2100

N·m

495 [365]

1.8

9

15

35

70

125

10.9

lb-ft

1.3

3.3

148

229

450

774

1550

Form # 46620 Issue 01/06

10

Page 13

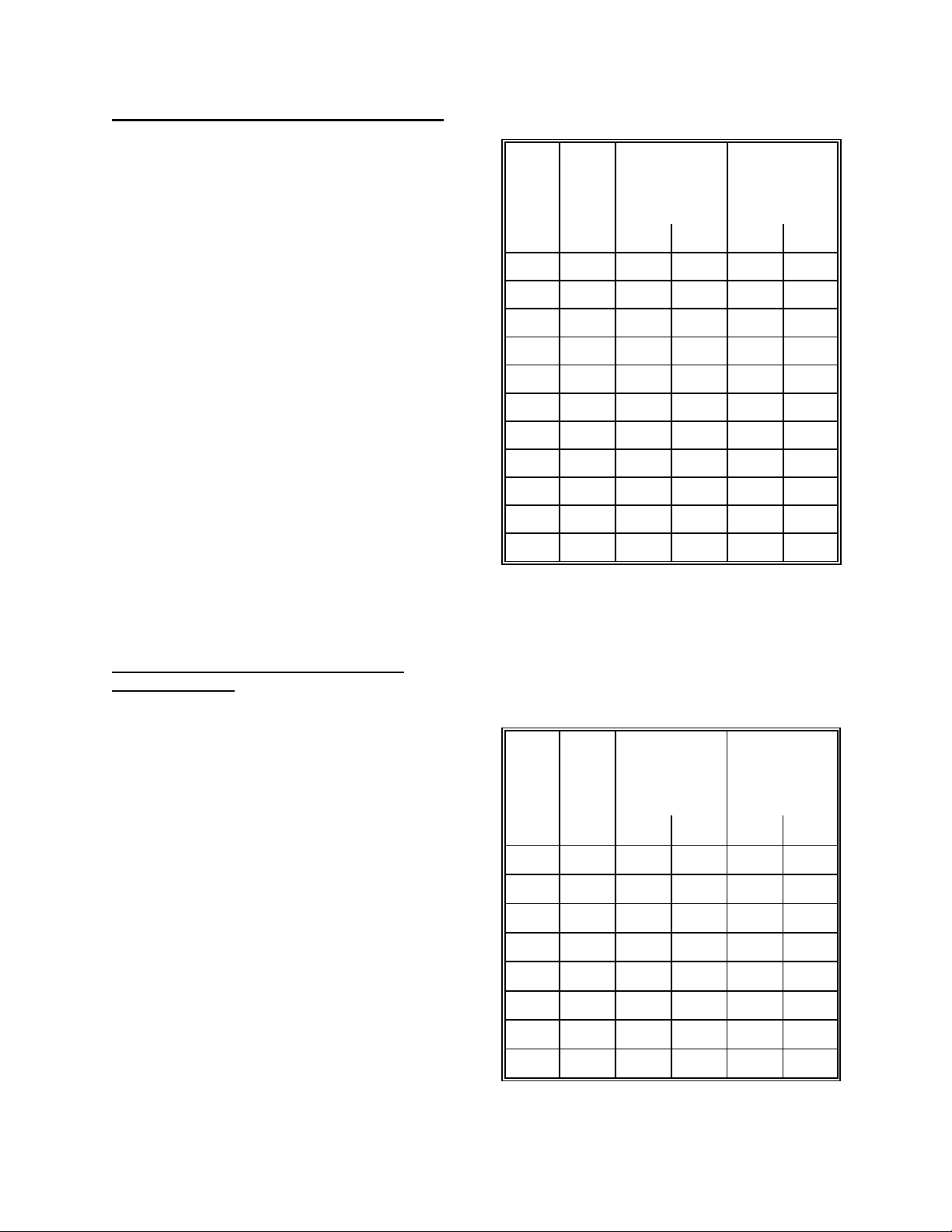

TORQUE SPECIFICATIONS

TIGHTENING HYDRAULIC O-RING FITTINGS*

1. Inspect O-ring and seat for dirt or obvious

defects.

2. On angle fittings, back the lock nut off until

washer bottoms out at top of groove.

3. Hand tighten fitting until back up washer or

washer face (if straight fitting) bottoms on face

and O-ring is seated.

4. Position angle fittings by unscrewing no more

than one turn.

5. Tighten straight fittings to torque shown.

6. Tighten angle fittings to torque shown while

holding body of fitting with a wrench.

* The torque values shown are based on

lubricated connections as in reassembly

.

Size

(in.)

Nut Size

Across

Flats

(in.)

Thread

3/8 1/2 8 [6]

7/16 9/16 12 [9]

1/2 5/8 16 [12]

9/16 11/16 24 [18]

3/4 7/8 46 [34]

7/8 1 62 [46] 1-1/2 1/4

1-1/16 1-1/4 102 [75]

1-3/16 1-3/8 122 [90]

1-5/16 1-1/2 142 [105] 3/4 1/8

Torque Value*

Recommended

Turns to Tighten

(after finger

tightening)

N·m [lb-ft] Flats Turns

2 1/3

2 1/3

2 1/3

2 1/3

2 1/3

1 1/6

1 1/6

TIGHTENING HYDRAULIC FLARE-TYPE

TUBE FITTINGS*

1. Check flare and flare seat for defects that

might cause leakage.

2. Align tube with fitting before tightening.

3. Lubricate connection and hand tighten swivel

nut until snug.

4. To prevent twisting the tube(s), use two

wrenches. Place one wrench on the connector

body and with the second tighten the swivel

nut to the torque shown.

* The torque values shown are based on

lubricated connections as in reassembly.

1-5/8 1-7/8 190 [140] 3/4 1/8

1-7/8 2-1/8 217 [160] 1/2 1/12

Tube

Size

O.D.

(in.)

Nut Size

Across

Flats

(in.)

Torque Value*

Recommended

Turns to Tighten

(after finger

tightening)

N·m [lb-ft] Flats Turns

3/16 7/16 8 [6]

1 1/6

1/4 9/16 12 [9]

1 1/6

5/16 5/8 16 [12]

1 1/6

3/8 11/16 24 [18]

1 1/6

1/2 7/8 46 [34]

1 1/6

5/8 1 62 [46]

1 1/6

3/4 1-1/4 102 [75] 3/4 1/8

7/8 1-3/8 122 [90] 3/4 1/8

Form # 46620 Issue 01/06

11

Page 14

OPERATION

YOUR RESPONSIBILITIES AS AN OWNER/OPERATOR

CAUTION:

1. It is your responsibility to read and

understand this manual and the Windrower

Operator's Manual completely before

operating the header. Contact your dealer if

an instruction is not clear to you.

2. Follow all safety messages in the manual

and on safety signs on the machine.

3. Remember that YOU

Good safety practices protect you and the

people around you.

4. Before allowing anyone to operate the

machine, for however short a time or

distance, make sure they have been

instructed in its safe and proper use.

5. Review the manual and all safety related

items with all operators annually.

6. Be alert for other operators not using

recommended procedures or not following

safety precautions. Correct these mistakes

immediately, before an accident occurs.

7. Do not modify the machine. Unauthorized

modifications may impair the function

and/or safety and affect machine life.

8. The safety information given in this manual

does not replace safety codes, insurance

needs, or laws governing your area. Be sure

your machine meets the standards set by

these regulations.

TO THE NEW OPERATOR

It's natural for an operator to be anxious to get

started with a new machine. Please take the time

to familiarize yourself with the header by reading

the Operator's Manuals and safety signs before

attempting operation.

are the key to safety.

Form # 46620 Issue 01/06

12

Page 15

OPERATION

ATTACHING THE HAY CONDITIONER

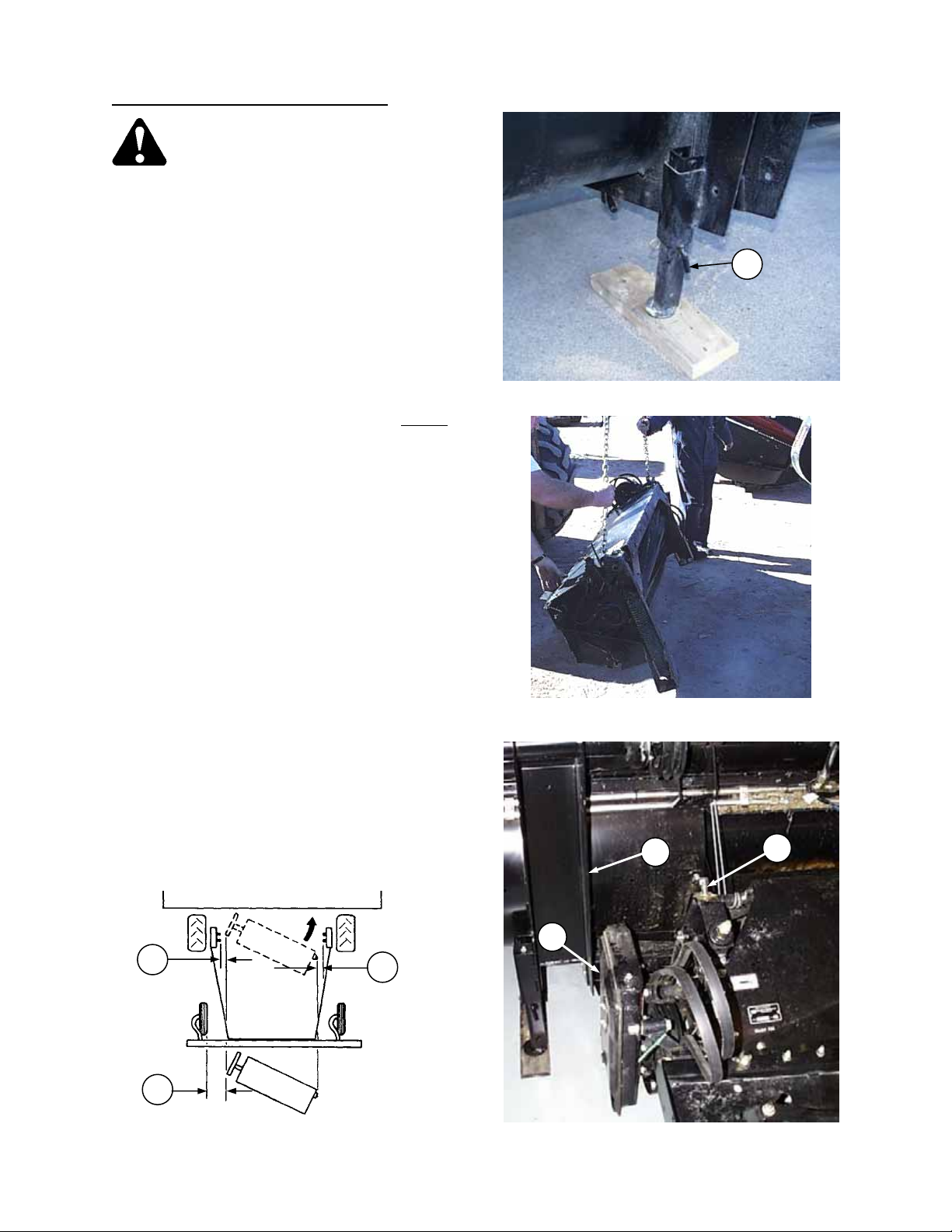

WARNING: Avoid possible injury or

death from fall of hay conditioner:

a. Be sure header stand is secure, with L-pin

(L) engaged and locked with hairpin. In soft

conditions, use a 2 x 4 block under stand.

b. Stand clear of hay conditioner whenever it

is suspended from lift cables only. Keep

hands clear of conditioner and header when

winching.

c. Be sure that upper mounting bolts are

securely tightened before installing or

removing lower mounting bolts. Hay

conditioner weighs approximately 730 lbs.

(330 kg) and will fall suddenly if lift system

becomes disengaged.

HEADER STAND – LOCKED & SECURE

IMPORTANT: For ease of installation, detach

header from tractor before attaching hay

conditioner to header. See Windrower Tractor or

Adapter Operator's Manual.

1. To move conditioner, attach chain hooks to

conditioner side frames as shown (or to U-bolt

on top sheet if present) and lift with forklift.

Position hay conditioner behind header,

approximately in center of swath opening. Be

sure mounting hardware (A) (5/8 mounting bolt,

flatwasher, lockwasher and nut) is in place on

both sides.

NOTE: Watch clearance at gear case (B) and L/H

header leg (C).

If no means of moving the conditioner is available,

use the tractor to position the header as shown

below, then detach header from tractor.

ATTACH CHAIN AT SIDE FRAMES OR U-BOLT

a. Position tractor and header in front of hay

conditioner at angle shown below.

b. Check alignment of hay conditioner with tractor

to ensure sufficient clearance at (D), (E) & (F).

c. Slowly drive tractor straight back so the hay

conditioner is positioned as shown by dotted

lines.

d. Detach header from tractor and back away.

e. Manually rotate right side of hay conditioner so

winch cables can be installed.

L

C

A

B

D

F

CHECK CLEARANCES IF POSITIONING

HEADER WITH TRACTOR

Form # 46620 Issue 01/06

E

POSITION HAY CONDITIONER

FOR INSTALLATION

13

Page 16

OPERATION

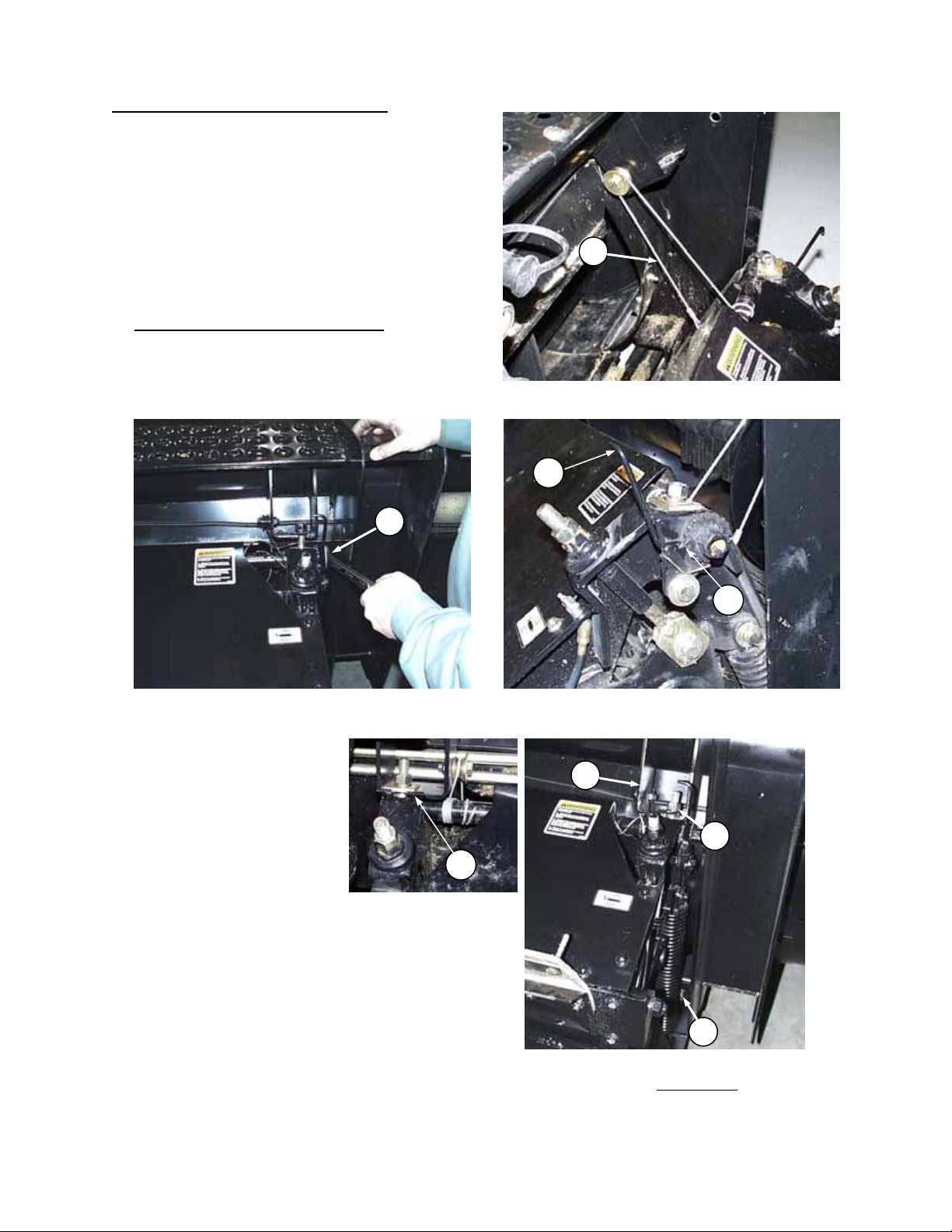

ATTACHING THE HAY CONDITIONER

2. Attach winch cables (G) both sides.

NOTE: Ensure cable is correctly routed over pulley

as shown, not crossing over.

3. Standing clear of the hay conditioner

inch wrench on winch nut (H). Keeping hands clear

of conditioner, pull wrench upward to raise the

conditioner into position. After each upward pull on

wrench, push lever (A) forward to ensure winch

pawl engages ratchet wheel at (B).

RAISE HAY CONDITIONER WITH WINCH

4. As hay conditioner reaches

mounted position, slide top

mounting bolts (J) into

header mounting brackets

(K) with square washer, lock

washer and hex nut on top.

NOTE: On left side, be sure

square washer is captured

behind welded stop (C) on

mounting bracket, not resting

on top.

5. TIGHTEN BOLTS (J), BOTH SIDES, SECURELY

BEFORE PROCEEDING TO STEP 6. Use winch

to take up any slack in cables once bolts (J) are

tight.

6. Install and tighten lower mounting bolts (L). (5/8 x

1-1/2 carriage bolt [head to rear], flat washer, lock

washer and hex nut.

(continued)

, use a 1-1/8

H

C

G

ATTACH WINCH CABLES

A

B

ENSURE WINCH PAWL ENGAGES WHEEL

K

J

L

INSTALL AND TIGHTEN MOUNTING

BOLTS – TOP FIRST

Form # 46620 Issue 01/06

14

Page 17

OPERATION

S

ATTACHING THE HAY CONDITIONER

7. Install belt over pulley (M) on header drive

shaft. *

NOTE: Do not pry belt over pulley. Loosen or

remove spring-loaded idler to allow installation.

(If idler is removed, take note of hardware

positioning for re-assembly.)

* IMPORTANT: Before first use, position drive

pulley (M) on shaft to align the belt. See

"Attaching the Hay Conditioner" in Assembly

section.

8. Adjust belt tension. See "Hay Conditioner Drive

Belt" in Maintenance/Service section.

9. Attach header to tractor. See Windrower

Tractor or Adapter Operator's manual.

10. Attach forming shield rear support straps to

lower brackets at (N).

NOTE: See Assembly section for instruction

regarding attaching forming shields to

conditioner and/or tractor.

11. Adjust header float springs for additional

weight. See Windrower Tractor or Adapter

Operator's manual.

(continued)

M

INSTALL BELT AND ADJUST TENSION

N

ATTACH FORMING SHIELD REAR SUPPORT

Form # 46620 Issue 01/06

15

Page 18

OPERATION

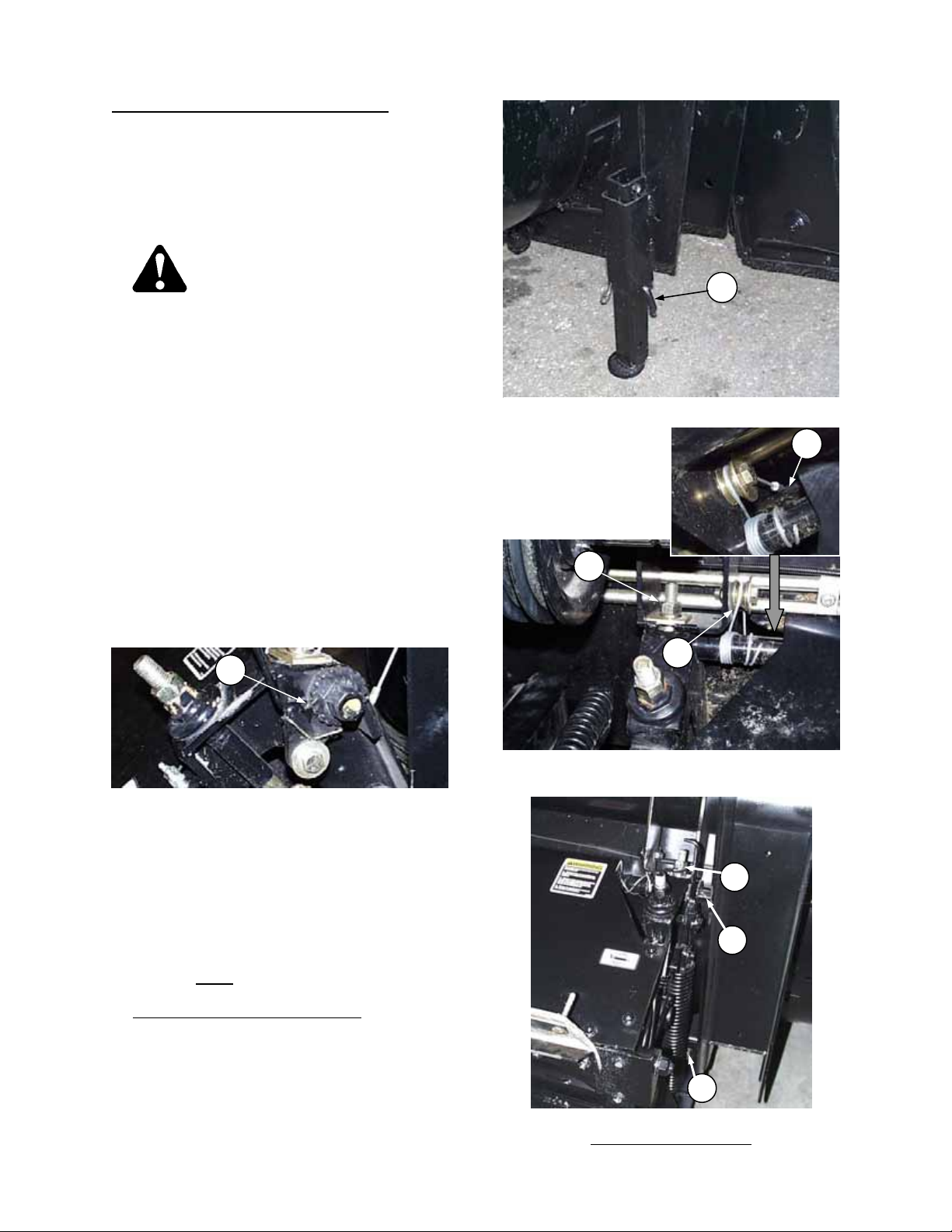

DETACHING THE HAY CONDITIONER

1. For ease of removal, first detach the header

from the tractor. See Windrower Tractor or

Adapter Operator's Manual.

NOTE: If front of conditioner forming shield is

attached to conditioner, remember to detach

rear support straps at lower brackets.

WARNING: Avoid possible injury

or death from fall of hay

conditioner:

a. Be sure header stand is secure, with L-pin

(L) engaged and locked with hairpin. In soft

conditions, use a 2 x 4 block under stand.

b. Be sure that upper mounting bolts (F) are

securely tightened before installing or

removing lower mounting bolts. Hay

conditioner weighs approximately 730 lbs.

(330 kg) and will fall suddenly if lift system

becomes disengaged.

c. Check that winch cables are:

• properly routed over pulleys (D)

• tightly wrapped around winch tube

• secured at hook (A) on front face of

conditioner

• If necessary, take up cable slack by

pulling up on 1-1/8 inch wrench on winch

nut (E).

d. Check that winch pawl is engaged in ratchet

wheel at (B).

B

HEADER STAND – LOCKED & SECURE

L

A

F

D

CABLES TIGHT AND PROPERLY ROUTED

& TOP MOUNTING BOLTS TIGHT

e. Stand clear of hay conditioner whenever it

is suspended from lift cables only. Keep

hands clear of conditioner and header when

winching.

F

2. Loosen idler adjuster and remove drive belt

from header pulley. See "Hay Conditioner Drive

Belt" in Maintenance/Service section for

adjuster details.

E

3. Remove lower

conditioner mounting bolts (C).

4. Standing clear of hay conditioner

, loosen and

disengage top mounting bolts (F) from brackets

on header.

C

REMOVE MOUNTING BOLTS -

LOWER BOLTS FIRST

Form # 46620 Issue 01/06

16

Page 19

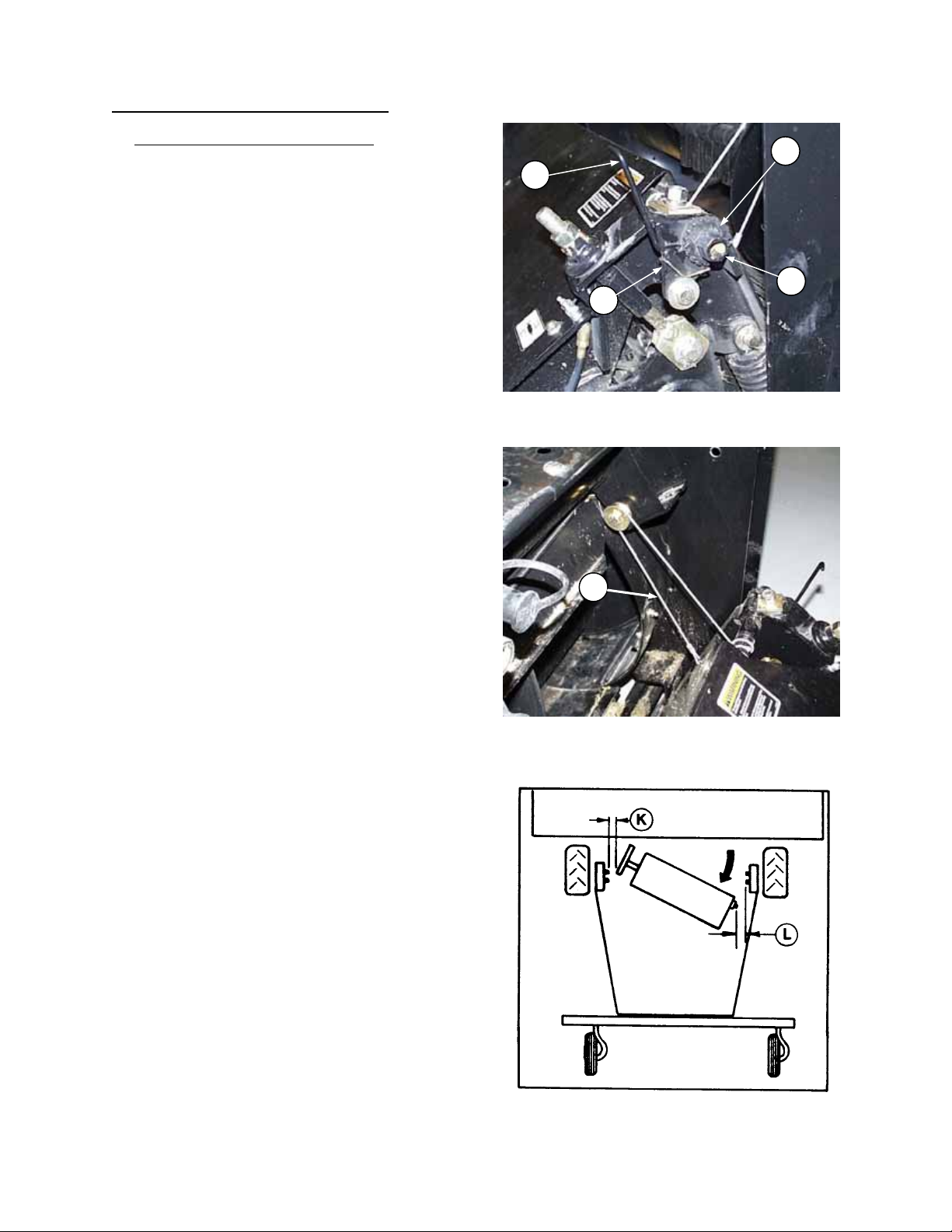

OPERATION

DETACHING THE HAY CONDITIONER

5. Standing clear of hay conditioner

follows. Use a long wrench and keep hands

clear of conditioner and header when winching.

a. Position a 1-1/8 wrench on winch nut (E) and

pull firmly up. Pull lever (G) back to disengage

winch pawl (H) from ratchet wheel (J).

b. Turn winch nut (E) down as far as possible and

push lever (G) forward, ensuring winch pawl

(H) engages ratchet wheel (J).

c. Remove and reposition the wrench on the

winch nut and repeat steps 5a and 5b until the

conditioner is on the ground and winch cables

(D) are slack.

6. Detach winch cables (D) from pulleys on

header.

7. When attaching header to tractor:

If no means of moving the conditioner away

from the header is available, manually rotate

right side of hay conditioner as shown to

maximize clearance. Be sure that there is

sufficient clearance to hydraulic lines at (K) and

(L).

(continued)

, lower as

J

G

E

H

LOWER CONDITIONER WITH WINCH

D

DETACH WINCH CABLES

ROTATE CONDITIONER FOR CLEARANCE

IF ATTACHING HEADER TO TRACTOR

Form # 46620 Issue 01/06

17

Page 20

OPERATION

BREAK-IN PERIOD

1. After attaching header to windrower tractor for

the first time, operate the machine slowly for 5

minutes, watching and listening FROM THE

OPERATOR'S SEAT for binding or interfering

parts.

CAUTION: Before investigating an

unusual sound or attempting to

correct a problem; shut off engine,

engage park brake and remove key.

2. Check all belts after 5 hours

stretch. Tighten as necessary. (See

Maintenance/Service section.

Continue to check the belts periodically for the

first 50 hours.

3. Tighten any loose hardware after 5 hours

operation. See Specifications section for

recommended torque’s.

4. Tighten the bottom and side wobble box

mounting bolts (C) after 10 hours

and every 100 hours thereafter. Torque to 200

ft.lbs. (270 N⋅m), starting with the side

mounting bolts.

5. Change wobble box lubricant after 50 hours

operation and every 1000 hours (or 3 years)

thereafter. See Maintenance/Service section.

6. Until you become familiar with the sound and

feel of your new header, be extra alert and

attentive.

operation for initial

operation

TIGHTEN WOBBLE BOX MOUNTING BOLTS

Form # 46620 Issue 01/06

18

Page 21

OPERATION

PRE-STARTING CHECKS

Do the following at the start of each operating

season.

1. Review the Operator’s Manual to refresh

2. Review all safety signs and other decals on

3. Be sure all shields and guards are properly

4. Reaquaint yourself with the controls before

Also:

5. Adjust tension on all belts and chains. See

6. Perform all annual maintenance. See

CAUTION:

your memory on safety and operating

recommendations.

the machine and note hazard areas.

installed and secured. Never alter or

remove safety equipment.

beginning operation.

Maintenance/Service section.

Maintenance/Service section.

Form # 46620 Issue 01/06

19

Page 22

OPERATION

PRE-STARTING CHECKS

Do the following each day before start-up:

CAUTION:

1. Clear the area of other persons, pets, etc.

Keep children away from machinery. Walk

around the header to be sure no one is under,

on or close to it.

2. Remove foreign objects from the machine and

surrounding area.

3. Wear close fitting clothing and protective

shoes with slip resistant soles.

As well, carry with you any protective clothing

and personal safety devices that COULD be

necessary through the day. Don’t take

chances.

You may need:

- a hard hat

- protective glasses or goggles

- heavy gloves

- respirator or filter mask

- wet weather gear

4. Protect against noise. Wear suitable hearing

protective devices such as (A) earmuffs or ear

plugs (B) to protect against objectionable or

uncomfortable loud noise.

5. Check the machine for leaks or any parts that

are missing, broken, or not working correctly.

Use proper procedure when searching for

pressurized fluid leaks. See “Hydraulic Reel

Drive” in Maintenance/Service section.

6. Clean lights and reflectors on the header.

7. Perform all daily maintenance. See

Maintenance/Service section.

OPERATE CORRECTLY

IMPORTANT: See Windrower Operator’s

Manual for information on the following:

Start-Up Procedure

Driving the Windrower

Stopping Procedure

Form # 46620 Issue 01/06

20

PROTECT YOURSELF

PROTECT AGAINST NOISE

Page 23

OPERATION

HEADER CONTROLS

CAUTION: Be sure all bystanders are

clear of machine before starting

windrower or engaging any header

drives.

See the Windrower Tractor Operator's Manual for

identification of in-cab controls for:

• Header Drive Clutch

• Header Height

• Ground Speed

• Reel Speed

• Hydraulic Conditioner Roll Opener (Option)

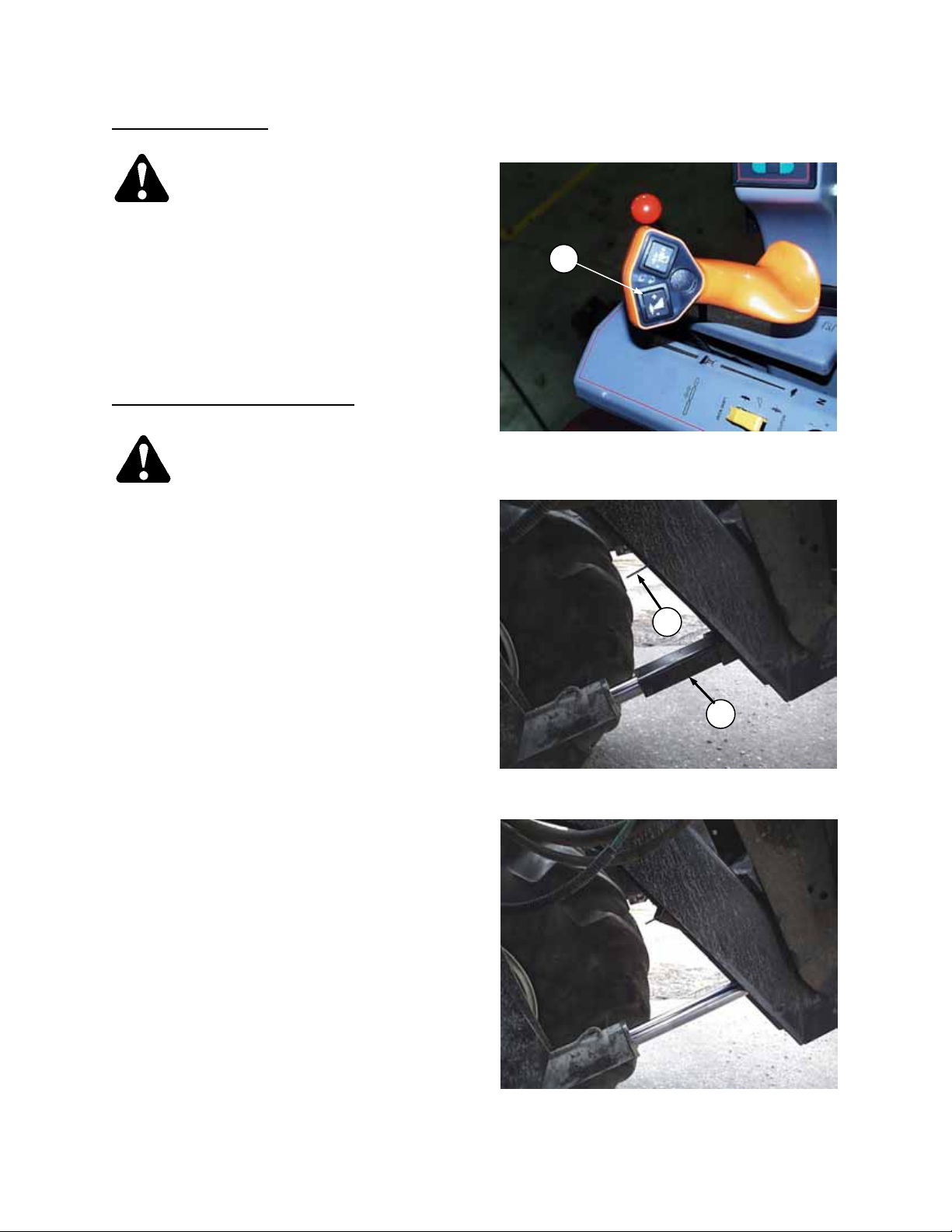

HEADER LIFT CYLINDER STOPS

DANGER: To avoid bodily injury or

death from fall of raised header,

always engage cylinder stops before

going under header for any reason.

Cylinder stops are located on both header lift

cylinders on windrower.

To engage cylinder stops:

1. Press top of header height switch (A) to raise

header to maximum height.

2. Lift retainer (B) up to release cylinder stop (C).

Lower stop onto cylinder.

3. To store, push up on stop (C) until retainer

locks in storage position.

A

HEADER HEIGHT SWITCH

B

C

LIFT CYLINDER STOP - ENGAGED

LIFT CYLINDER STOP - STORAGE

Form # 46620 Issue 01/06

21

Page 24

OPERATION

A

OPERATING VARIABLES

Satisfactory function of the header and hay

conditioner in all situations requires making proper

adjustments to suit various crops and conditions.

Correct operation reduces crop loss and allows

cutting of more acres. As well, proper adjustments

and timely maintenance will increase the length of

service you receive from the machine.

The variables listed here and detailed on the

following pages will affect the performance of the

header and conditioner. You will quickly become

adept at adjusting the machine to give you the

desired results.

LEAN BAR POSITION

IMPORTANT: To prevent structural damage to

header, do not operate with lean bar removed.

Use the lean bar adjustment to accommodate

different crop heights.

The lean bar should strike the upper portion of

crop, leaning it away from the header and

exposing the stalks to the sickle.

To raise or lower lean bar, re-position hardware

(A) in adjustment holes as required.

NOTE: In very tall crops, to prevent pinning of crop

around lean bar, extensions are available. See

“Tall Crop Kit” in Attachments section.

UGER HEADER

1. Lean Bar Position

2. Ground Speed

3. Reel Speed

4. Reel Pick-Up Finger Pitch

5. Cutting Height

6. Header Angle

7. Header Flotation

8. Auger Mounted Crop Deflectors

HAY CONDITIONER

9. Roll Intermesh

10. Roll Tension

11. Feed Pan Position

12. Forming Shields

OPERATING VARIABLES

LEAN BAR ADJUSTMENT

A

Form # 46620 Issue 01/06

22

Page 25

OPERATION

GROUND SPEED

Ground speed of windrower should be such that

sickle can cut crop smoothly and cleanly.

See Windrower Tractor Operator's Manual for

identification and instructions for use of ground

speed control.

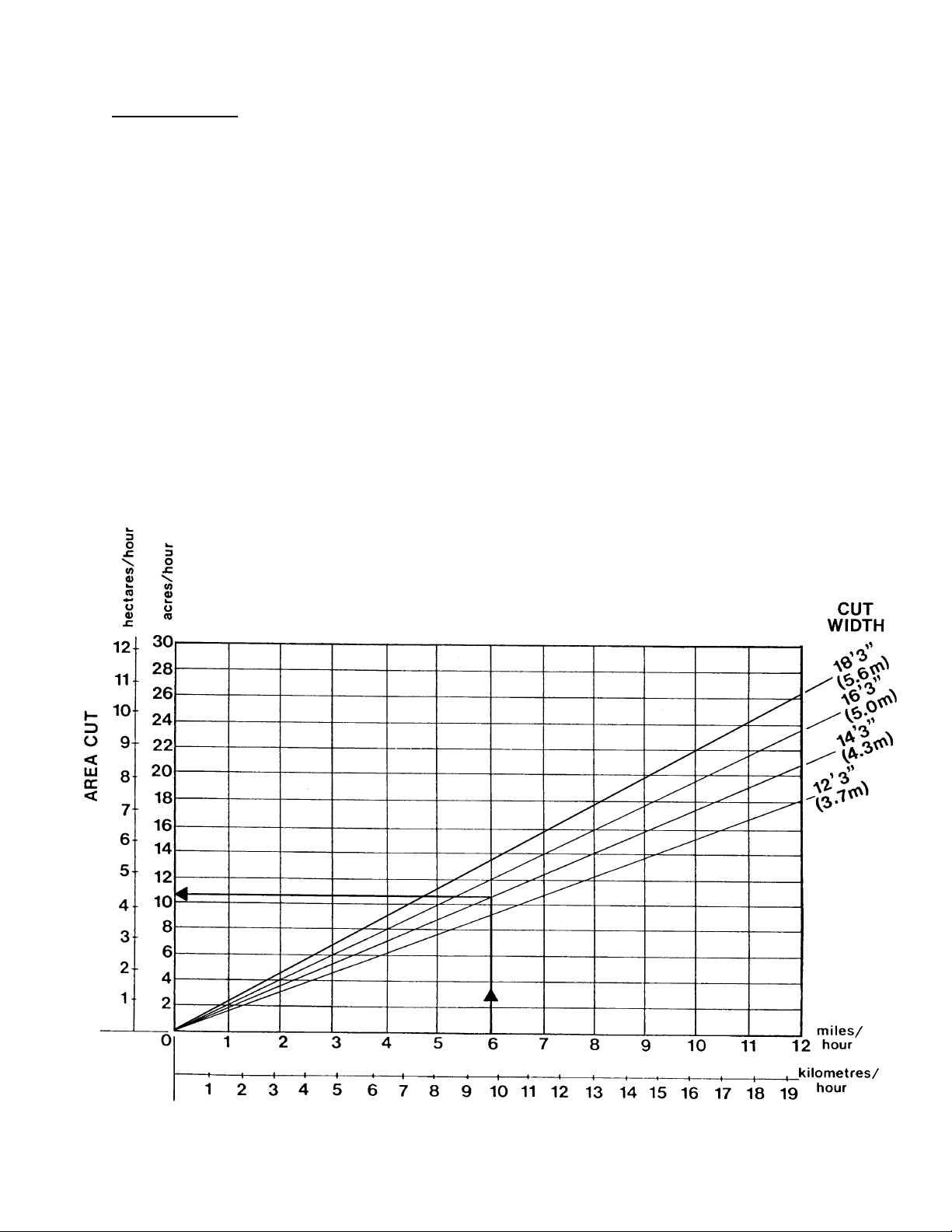

The chart below indicates the relationship between

ground speed and area cut for the three auger

header sizes.

Example shown: At a ground speed of 6 miles per

hour (9.7 km/h) with a 14 ft. header*, the area cut

per hour would be 10-1/2 to 11 acres (4-1/4 to

4-1/2 hectares).

* A 14 ft. header has a cut width of 14 ft. 3 in. (4.3 m)

A 12 ft. header has a cut width of 12 ft. 3 in. (3.7 m)

A 16 ft. header has a cut width of 16 ft. 3 in. (5.0 m)

An 18 ft header has a cut width of 18 ft. 3 in. (5.6 m)

Form # 46620 Issue 01/06

23

Page 26

OPERATION

REEL SPEED

For best feeding of crop into the sickle and auger,

reel speed should be just faster than ground

speed. This gently sweeps crop across sickle into

auger. Excessive reel speed causes undue wear

of reel components and unnecessary load on reel

drive, resulting in uneven reel motion.

922 and 933 Headers

See Windrower Tractor Operator's Manual for

identification and instructions for use of reel speed

control in cab.

NOTE: Both speed control knobs on tractor

console are used to adjust reel speed.

912 Header

See "Reel and Reel Drive" in Maintenance/

Service section for instructions regarding changing

reel speed.

Form # 46620 Issue 01/06

24

Page 27

OPERATION

REEL PICK-UP FINGER PITCH

Another factor in effective feeding of crop into the

sickle and auger is finger pitch angle (the angle the

fingers operate at in relation to the ground).

NOTE: In the illustration at right, pitch angle (A) is

more aggressive than pitch angle (B).

Generally it should not be necessary to adjust the

finger pitch angle, however in certain crop types

and conditions adjustment of the finger pitch may

be required to achieve best results.

The pitch should be just aggressive enough to

provide adequate crop lifting action for proper

cutting.

Pitch angle can be adjusted by rotating the cam.

Rotating the cam forward

results in a more aggressive

Rotating the cam rearward

results in a less aggressive

To adjust cam position

1. Loosen four bolts (C), both ends of reel.

2. Turn bolts (D) at cam end to move cam up or

down at front or rear until desired position is

obtained.

3. Tighten four bolts (C), both ends, to secure

reel position.

4. Rotate reel slowly by hand and check finger

clearance at knife and pan. Flex fingers to

simulate crop-loaded position to ensure

fingertip clearances to knife sections and

auger pan are adequate for working

conditions.

5. If necessary, adjust reel fore-aft position to

achieve proper clearances. See Maintenance/

Service section.

NOTE: For optimum header performance in all

crops, position the reel so that finger tips are as

close as possible to knife sections and auger

pan without interfering. Some contact between

finger tips and knife guards is acceptable.

Rotate tines in direction of crop load, to check

for minimum clearance as tines pass over

guards and pan.

(higher in the back),

pitch angle.

(higher in the front),

pitch angle.

:

FINGER PITCH ANGLE

FINGER PITCH ADJUSTMENT

CHECK TINE CLEARANCE

Form # 46620 Issue 01/06

25

Page 28

OPERATION

CUTTING HEIGHT

Your header will be equipped with either:

• wide adjustable outer skid shoes, or

• gauge rollers plus narrower skid shoes.

Vary the cutting height by adjusting either skid

shoe or gauge roller position. The operator can

then lower the header to the ground, allowing the

shoes or rollers to provide a consistent cutting

height.

NOTE: Lowering the skid shoes or gauge rollers

raises the cutting height. (Gauge rollers allow

higher settings than skid shoes.) This may be

desirable in stony conditions, to reduce damage to

cutting components. Other benefits include

reduced plugging due to mud or dirt build-up and

longer stubble for faster drying.

WARNING: To avoid bodily injury or

death from unexpected start-up or

fall of raised header; stop engine,

remove key and engage header lift cylinder

stops before going under header to adjust skid

shoes or gauge rollers (or for any reason).

Skid Shoes

The right and left end skid shoes are adjustable up

and down.

To adjust:

1. Remove pins (A), two per shoe.

2. Move shoe up or down to desired position and

replace pins (A).

Gauge Rollers

To adjust gauge roller height:

1. Remove pins (B), two per wheel.

2. Move roller to desired position and replace

pins (B).

LIFT CYLINDER STOP - ENGAGED

A

SKID SHOE ADJUSTMENT

B

GAUGE ROLLER ADJUSTMENT

Form # 46620 Issue 01/06

26

Page 29

OPERATION

HEADER ANGLE

The header (or guard) angle is adjustable in the following range depending on tractor model (measured with

cutterbar on ground):

Tractor models:

XX52/XX52i c/w shallow angle kit

XX52/XX52i w/o shallow angle kit

XX40/XX50

8° to 16° below horizontal

8° to 16° below horizontal

11° to 18° below horizontal

Header angle is adjusted by lengthening or shortening the tractor lift linkage center link. Choose an angle that

maximizes performance for your crop and field conditions.

IMPORTANT: A flatter header angle is recommended for normal conditions. A flatter angle reduces sickle

section breakage and reduces soil build-up at the cutterbar and/or auger pans in wet conditions or where

ground is uneven (gopher mounds, etc.).

Use a steeper angle to cut very close to the ground, or for better lifting action of down crops.

See Windrower Tractor Operator's Manual for adjustment procedure.

HEADER FLOTATION

As a starting point for normal conditions, adjust float spring tension so that 75 - 85 lbs. force (335 to 380 N) is

required to lift cutterbar off ground at each end.

Benefits of lighter float settings:

1. Less cutting component breakage in rough or stony conditions.

2. Avoids soil build-up at the cutterbar and/or auger pans in wet conditions or where ground is uneven

(gopher mounds, etc.).

Benefits of heavier float settings:

1. When cutting very close to the ground, enables cutterbar to closely follow ground contours.

Header float weight changes if lift linkage center link length is changed. Float weight also varies through

first few inches of header lift cylinder extension. Check header float weight after selecting a center link

length and with header lift cylinders fully retracted. Readjust header float springs if necessary to obtain

desired float. See Windrower Tractor Operator's Manual for adjustment procedure.

Form # 46620 Issue 01/06

27

Page 30

OPERATION

AUGER MOUNTED CROP DEFLECTORS/STRIPPERS & STRIPPER BAR EXTENSIONS:

912 & 922 HEADERS

Four rubber finger assemblies are mounted to the auger to direct crop rearward to the hay conditioner such

that material is evenly distributed across the full width of the conditioner. If too much “end feeding” of

conditioner rolls is occurring, remove two outboard rubber finger assemblies (A).

If too much “Center Feeding” of conditioner rolls is occurring, the following may be necessary:

1. Install flighting-mounted deflectors (B). Deflectors are stored under platform at (C). Depending on crop

conditions, install one or two deflectors at each side of delivery opening.

2. Replace full-length front “L” angle strippers with 1/2 length front “C” channel strippers. These 1/2 length

strippers are stored on underside of pan at (D). On-header storage of full length front strippers is not

provided.

3. Remove center stripper extensions (E) on center stripper bars at each side of delivery opening.

AUGER MOUNTED CROP DEFLECTORS

B

C

AUGER FLIGHTING DEFLECTOR

E

CENTER STRIPPER EXTENSIONS

D

FRONT STRIPPER – SHORTER “C” CHANNEL

DEFLECTOR STORAGE

STRIPPER STORAGE

Form # 46620 Issue 01/06

28

Page 31

OPERATION

(

)

HAY CONDITIONER ROLL INTERMESH

The intermeshing steel rolls of the hay conditioner

crimp the plant stems in several places, allowing

moisture release and faster drying. The degree to

which the stems are conditioned (crimped)

depends on the amount of roll intermesh.

Correct conditioning of alfalfa, clover and other

legumes is usually indicated when 90% of the

stems show crimping but no more than 5% of the

leaves are damaged. To achieve this, roll

intermesh is factory set so that dimension (D) is

approximately 5/8 inch (16 mm) for normal

operation, which corresponds to 2.5 on the roll gap

decal.

In heavy thick stemmed crops, rolls may need to

be adjusted for almost no roll intermesh (7 on roll

gap decal).

In lighter crops, a closer intermesh may be

required for optimum conditioning, however setting

rolls too close may cause excessive stem and leaf

damage.

To adjust roll intermesh

NOTE: The top face of nut (E) is used as the

indicator for the gauge decal on the threaded rod.

Each division on the roll gap decal represents a

change of approximately 1/8 inch (3mm) in roll

gap. The factory setting of 5/8 inch (16mm)-roll

gap is mark 2.5 on the decal. When adjusting roll

gap, be sure that the decal reading is the same on

both sides of the conditioner roll to achieve

consistent intermesh across the rolls.

1. Loosen nut (E).

2. Turn nut (F) clockwise to decrease intermesh,

or counter-clockwise to increase intermesh.

NOTE: Nut (F) is welded to adjuster tube so

complete assembly will turn.

3. When intermesh is correct, tighten nut (E)

while holding nut (F) with another wrench to

lock the position securely.

:

ROLL INTERMESH ADJUSTMENT

ROLL INTERMESH

FACTORY SET AT 5/8”

E

F

16 mm

ROLL INTERMESH ADJUSTMENT

Form # 46620 Issue 01/06

29

Page 32

HAY CONDITIONER ROLL TENSION SPRINGS

The conditioner roll intermesh is maintained by two

tension springs to provide roll pressure for correct

conditioning of the crop. These springs also allow

the rolls to open to allow passage of small solid

objects without damage to the rolls. The roll

tension has been factory set for normal operating

conditions and generally does not require

adjustment.

In some conditions, less aggressive conditioning

may be desirable, and roll tension can be reduced

as required. For smooth conditioner operation,

back off tension only as much as required for

desired conditioning action.

To decrease spring tension:

1. Loosen jam nut (A).

2. Turn bolt (H) out of spring to decrease tension

(easier to force rolls open.)

3. Hold spring plug (K) with a wrench and tighten

nut (A) securely against plug to secure the

position.

4. Repeat at other side.

FEED PAN/ROCK DROP TINE POSITION:

(Relative to Hay Conditioner)

Rock drop tines must be correctly positioned to

ensure proper feeding into hay conditioner. Check

also that conditioner feed pan has not become

pushed down or buckled. A damaged feed pan

can result in uneven feeding to the hay

conditioner.

To adjust position of feed pan and rock drop tines:

1. Ensure that all tine points are in line. Bend

tines to align if required.

2. Select desired setting for tine positions (see

step 4).

3. To adjust tine position, loosen bolts (J) at both

sides of delivery opening.

4. Rotate channel assembly with wrench either

upward or downward to align pointer (E) with

the center of slots in hay conditioner frame for

your specific crop conditions, as follows:

SLOT: (B) – recommended for light crop.

(C) – factory set, for medium volume crops.

(D) – recommended for heavy crop.

5. Tighten bolts (J).

Form # 46620 Issue 01/06

30

ROLL TENSION ADJUSTMENT

J

ROCK DROP TINE POSITIONING

E

ALIGN POINTER WITH CENTER OF SLOT

B

C

D

OPERATION

Page 33

OPERATION

HAY CONDITIONER FORMING SHIELDS

CAUTION: Keep forming shields installed at all times conditioner is in use. Do not allow

anyone to stand behind the machine while operating. Stones or other foreign objects may be

ejected from the conditioner with considerable force.

The side and rear deflectors, and deflector fins are adjustable to shape the windrow to your preference.

In deciding on windrow width, the following factors should be considered:

• weather conditions (rain, sun, humidity, wind)

• type and yield of crop

• drying time available

• method of processing (bales, silage, "green-feed")

A wider windrow will generally dry faster and more evenly, resulting in less protein loss. Fast drying is

especially important in areas where the weather allows only a few days to cut and bale. See "Haying Tips" in

this section for more information.

Where weather conditions permit or when drying is not critical, for example, when cutting for silage or "greenfeed", a narrower windrow may be preferred for ease of pick-up.

Windrow Width

Position the adjuster handle as required to move

the side deflectors to the desired width.

NOTE: With hardware installed in hole (A) in L/H

link as shown, deflectors will move symmetrically

about the center of the conditioner rolls. For the

most evenly formed windrows, use position (A)

for windrows up to 65 inches wide. Use hole (B)

only when windrows over 65 inches are required,

as this allows the left deflector to open to a wider

position than the right deflector. Maximum width

is with hardware in hole (B) and handle in

position (1).

Rear Deflector

The rear deflector (L) slows the crop exiting the

conditioner rolls, directs the flow downward,

and "fluffs" the material.

To start, adjust rear deflector to approximately

the mid-range position (45°). Optimum position

for best windrow uniformity must be determined

for each crop condition.

To adjust rear deflector, loosen adjuster handles

(M), one per side, position deflector and tighten

adjuster handles (M). For even windrow formation,

be sure deflector is not twisted.

HAY CONDITIONER FORMING SHIELDS

Form # 46620 Issue 01/06

31

Page 34

HAY CONDITIONER FORMING SHIELDS

(continued)

Forming Shield Height

Depending on the amount of crop material,

the rear of the forming shield assembly can

be raised or lowered to properly deflect the

crop. For heavier crops use the higher

settings:

• XX40 & XX50 series tractors use 4

th

hole from the bottom on the rubber

5

strap.

• XX52/XX52i tractors use 1

st

or 2nd hole

th

or

from the bottom of rubber strap.

For lighter crops, lower forming shield as

required to form the most uniform windrows.

Note that too low a setting will cause

uneven and poorly formed windrows.

To adjust forming shield rear height, remove

hairpin at (N), both sides, and raise or lower

shields to desired height.

NOTE: For normal operation, front of

forming shield assembly is attached to

conditioner top cover. If desired, shield

assembly can be fully tractor mounted with

front of shield assembly attached to top rear

pin of tractor lift linkage. This

accommodates frequent removal of header

from tractor. See Assembly section for details.

Deflector Fins

Four deflector fins provided standard are stored at (K) on the top L/H side of the top cover. Additional fin

hardware required is stored at (J).

Use deflector fins as shown at (D) to evenly distribute material when laying swaths wider than 72 inches (1830

mm). Fin position can be adjusted without loosening mounting bolt. Set fins approximately parallel to side

deflectors for wide swath and adjust as required for even distribution of crop across full width. For narrow

windrow less than 72 inches (1830 mm) remove fins.

NOTE: Four additional fins (available from your dealer) may be mounted in holes (A) for even crop distribution

in swaths over 90 inches (2286 mm) wide.

HAY CONDITIONER FORMING SHIELDS

OPERATION

DEFLECTOR FINS

Form # 46620 Issue 01/06

32

Page 35

OPERATION

HAYING TIPS

There is one certainty when making hay - a fast cure will maintain top quality. It is critical to have the cured hay

baled as quickly as possible, for two reasons:

1. Every day hay lies on the ground, 5% of the protein is lost.

2. The sooner the cut hay is off, the earlier the start for next growth.

Generally, leaving the windrow as wide and thin as possible makes for the quickest curing, however there are

other factors that affect curing time:

1. TOPSOIL MOISTURE

When the ground is wetter than the hay, moisture from the soil is absorbed by the hay above it. Determine

topsoil moisture level before cutting. Use a moisture tester or estimate level:

Over 45% - WET - Soil will be muddy

25 - 45% - DAMP - Walking on soil leaves tracks

Under 25% - DRY - Soil will be dusty on top

When ground is wet due to irrigation, wait until soil moisture drops below 45%. When ground is wet due to

frequent rains, cut when weather allows and let the forage lie on wet ground until it dries to the moisture level

of the ground. At this point, the cut hay will dry no more until the ground under it dries, so consider moving the

windrow to drier ground.

On wet soil, the general rule of "wide and thin" does not apply. A narrower windrow will dry faster than hay left

flat on wet ground.

2. CLIMATE AND TOPOGRAPHY

a. Try to have as much hay cut as possible by midday, when drying conditions are best.

b. Fields sloping south get up to 100% more exposure to the sun's heat than do north sloping fields. If you

bale and chop, consider baling the south facing fields and chopping those facing north.

c. When relative humidity is high, the evaporation rate is low and hay dries slower. If there is no wind,

saturated air becomes trapped around the windrow, further hindering the drying process. Raking or

tedding will expose the hay to fresher, less saturated air. Cutting hay perpendicular to the direction of the

prevailing winds may also help.

3. WINDROW CHARACTERISTICS

See "Operating Variables" in this section. Control the factors listed to produce a windrow with the following

characteristics:

a. High and fluffy for good air flow.

process than direct sunlight.

b. Consistent formation, not bunchy.

chopper etc.

c. Even distribution, not piled in the middle or higher on one side.

side could cause stacks to lean, round bales to have one end smaller and loose, or small square bales to

be heavy on one side, causing handling and stacking problems.

d. Properly conditioned without excessive leaf damage.

4. RAKING AND TEDDING

Raking or tedding will speed up drying, however the benefits must be weighted against the additional leaf

losses which will result. When the ground beneath the down hay is dry, raking or tedding is probably not

worthwhile.

Big windrows on damp or wet ground should be turned over when they reach 40-50% moisture. Hay should

not be raked or tedded at less than 25% moisture, or excessive yield losses will result.

5. CHEMICAL DRYING AGENTS

Hay drying agents work by removing wax from legume surfaces, enabling water to escape and evaporate

faster. However, treated hay lying on wet ground will also absorb ground moisture faster.

Before deciding to use a drying agent, costs and benefits relative to your area should be carefully compared.

Always follow chemical manufacturer’s recommendations for safe handling and proper use.

The movement of air through the windrow is more important to the curing

A uniform windrow permits an even flow of material into the baler,

A windrow that is higher or heavier on one

Form # 46620 Issue 01/06

33

Page 36

OPERATION

S

JUS

"GRASS SEED SPECIAL" HEADER

The grass seed auger header has several features

to adapt it to this special application. These

features include:

Stub Guards and Hold-downs

equipped with stub guards for effective cutting in

tough grass crops. See "Sickle and Sickle Drive"

in Maintenance/Service section for maintenance of

these components.

Special Auger Design

beater supports have been removed to reduce

auger wrapping.

Slower Auger Speed

slower auger speed of 170 RPM (compared with

205 RPM for 16’ and standard header) also

reduces auger wrapping.

Adjustable Stripper Bars

stripper bars are adjustable for more effective

stripping of grass crops.

To adjust:

1. Loosen bolts (G) along upper stripper bars.

2. Slide extension bars (H) in or out to obtain

approximately 1/8 inch (3 mm) clearance to

auger flighting (J) along entire auger length.

3. Tighten bolts (G).

Auger Pan Extensions

provided to reduce delivery opening from the

maximum 68 inches (1720 mm) to 59 inches (1490

mm). A second pan extension may be ordered to

further reduce opening to 50 inches (1260 mm).

NOTE: When installing auger pan extensions (A):

1. The pan supplied is factory assembled to be

installed on the left side of the delivery

opening, with cutterbar support (D) at inboard

side. Install hardware supplied as shown.

2. Move the two upper sets of stripper bars (B)

so end of stripper is flush with edge of pan

extension. The lowest (most forward) set of

stripper bars (C) should remain in standard

pan position as shown. Reset upper stripper

bars clearance as described above.

Windrow Forming Rods

provided to assist in forming the narrow windrows

preferred for this application. Bend the rods to

modify the windrow shape. Use the forming rods in

conjunction with the auger pan extensions to

achieve the width and shape of windrows you

desire. See “forming rod installation” section.

Six-Bat Reel

for smoother reel action and better crop feed into

the header.

: A sixth bat is added to the reel body,

: The center beaters and

: For 12’ & 14’ Headers, the

: One pan extension is

: The cutterbar is

: The two upper sets of

: Forming rods are

J

G

H

TRIPPER BAR AD

INSTALLING AUGER PAN

EXTENSION

POSITION UPPER STRIPPER BARS

FLUSH WITH PAN EXTENSIONS

WINDROW FORMING RODS

TMENT

Form # 46620 Issue 01/06

34

Page 37

OPERATION

UNPLUGGING THE HEADER

WARNING: Stop engine and remove

key from ignition before removing

plugged material from header.

If the sickle plugs

:

1. Stop forward movement of the windrower and

disengage header drive clutch.

2. With header on ground, back up several feet

and engage header drive clutch.

3. If plug does not clear, disengage header drive

clutch and raise header fully.

4. Shut off engine, remove key and engage park

brake.

5. Engage header lift cylinder stops.

WARNING: Wear heavy gloves when

working around sickle.

6. Clean off cutterbar.

If plugging persists, see Trouble Shooting section.

If auger or conditioner plugs:

1. Stop forward movement of the windrower,

disengage header drive clutch and raise

header fully.

2. Shut off engine, remove key and engage park

brake.

3. Engage header lift cylinder stops.

WARNING: Wear heavy gloves when

working around sickle.

4. Clean off cutterbar and area under reel.

5. Position wrench (A) over end of drive shaft (B)

and rotate counter-clockwise (from left end)

until plug clears.

6. Store wrench in left end divider and secure

with hairpin at (C).

If plugging persists, see Trouble Shooting section.

Hydraulic Conditioner Roll Opener (Option)

For units equipped with this option, if conditioner

rolls plug during operation:

• Disengage header drives.

• Press top of switch (D) to extend the cylinders

at the sides of the conditioner frame, forcing

the rolls open.

• While holding switch (D) in the up position, set

engine throttle at half speed and engage

header drive to clear conditioner plug.

• When plug is cleared, release switch and

continue normal operation. Cylinders will

automatically retract.

For information on ordering this option, see

Attachments section in this book.

running, or if header drive is engaged with

engine running. If it becomes necessary to

manually remove a plug from the conditioner:

• Disengage header drive.

• Press top of switch (D) to extend the

• Shut off engine and remove key.

• Remove plug manually and continue

A

B

CLEARING PLUGS

C

WRENCH STORAGE

D

OPERATE HYDRAULIC ROLL OPENER

WITH REEL LIFT SWITCH

WARNING: Be aware that rolls will

close automatically if bottom of

switch (D) is pressed while engine is

cylinders at the sides of the conditioner

frame, forcing the rolls open.

normal operation.

Form # 46620 Issue 01/06

35

Page 38

OPERATION

TRANSPORTING THE HEADER

See "Transporting the Windrower" in Windrower Tractor Operator's Manual for recommended procedures for:

· Driving the Windrower on Roads

· Towing the Windrower on a Trailer

· Towing the Windrower without a Trailer

NOTE: For headers with divider rods, when transporting on a side-mount trailer, remove divider rods to narrow

the transport width.

LIFTING HEADER IN WORKING POSITION

If it is necessary to lift header once it has been lowered from shipping position to working position, see "Lifting

Vehicle Requirements" and "Chain Requirements" in Unloading & Assembly section before proceeding.

Attach one chain (C) from lifting vehicle to both ends of lean bar. Attach a second chain (D) from lifting vehicle

to center link anchor on frame tube as shown.

CAUTION: Be sure hooks are secure before lifting header. Stand clear when lifting, as

machine may swing.

LIFTING HEADER IN WORKING POSITION

Form # 46620 Issue 01/06

36

Page 39

OPERATION

STORAGE PROCEDURE

Do the following at the end of each operating season:

CAUTION:

1. Clean the windrower thoroughly. Never use gasoline, naphtha or any volatile material for cleaning

purposes. These materials may be toxic and/or flammable.

2. Store machine in a dry, protected place if possible.

3. Cover cutterbar and sickle guards to prevent injury from accidental contact.

Also:

4. Repaint all worn or chipped painted surfaces to prevent rust.

5. Loosen all drive belts.

6. Lubricate the windrower thoroughly, leaving excess grease on fittings to keep moisture out of bearing.

Apply grease to exposed threads and sliding surfaces of components.

7. Check for worn or broken components and repair or order replacements from your dealer. Attention to

these items right away will save time and effort at beginning of next season.

8. Tighten loose hardware and replace any missing hardware. See Specification section for torque charts.

9. Remove divider rods (if equipped) to reduce space required for inside storage.

10. Units with stub guards - To prevent stub guard adjuster bar bolts from becoming seized, apply penetrating

oil at bolts prior to storage.

Form # 46620 Issue 01/06

37

Page 40

MAINTENANCE/SERVICE

SERVICE PROCEDURES

CAUTION: To avoid personal injury,

before servicing machine or opening

drive covers:

1. Fully lower header. If necessary to service

in the raised position, first engage header

lift cylinder stops.

2. Disengage header drive clutch.

3. Stop engine and remove key.

4. Engage park brake.

5. Wait for all

Wear close-fitting clothing and cover long hair.

Never wear dangling items such as scarves or

bracelets.

Wear protective shoes with slip-resistant soles,

a hard hat, protective glasses or goggles and

heavy gloves.

If more than one person is servicing the

machine at the same time, be aware that

rotating a driveline or other mechanically

driven component by hand (for example to

access a lube fitting) will cause drive

components in other areas (belts, pulleys and

sickle) to move. Stay clear of drive components

at all times.

Be prepared if an accident should occur. Know

where the first aid kit and fire extinguishers are

located and how to use them.

Keep the service area clean and dry. Wet or

oily floors are slippery. Wet spots can be

dangerous when working with electrical

equipment. Be sure all electrical outlets and

tools are properly grounded.

Use adequate light for the job at hand.

Replace all shields removed or opened for

service.

Use only service and repair parts made or

approved by the equipment manufacturer.

Substituted parts may not meet strength,

design or safety requirements.

Keep the machine clean. Never use gasoline,

naphtha or any volatile material for cleaning

purposes. These materials may be toxic and/or

flammable.

moving parts to stop.

Form # 46620 Issue 01/06

38

Page 41

MAINTENANCE/SERVICE

RECOMMENDED LUBRICANTS

GREASE

Use SAE Multi-Purpose High Temperature Grease with Extreme Pressure (EP) Performance and

containing at least 1.5% molybdenum disulphide. (NLGI Grade 2)

Also acceptable is an SAE Multi-Purpose Lithium Base Grease.

GEAR LUBRICANT

Wobble Box and Hay Conditioner Gear Case: Use SAE 85W-140 gear lube (API Service Class. GL-5)

Auger Drive Gear Case: Use grease as specified above.

CAPACITIES

Wobble Box – 2.2 litres (2.3 U.S. quarts)

Hay Conditioner Gear Case - 1100 ml (1.2 U.S. quart)

Auger Drive Gear Case - 600 grams (1.5 tubes)

STORING LUBRICANTS

Your machine can operate at top efficiency only if clean lubricants are used. Use clean containers to

handle all lubricants. Store them in an area protected from dust, moisture and other contaminants.

SEALED BEARING INSTALLATION

1. Clean shaft and coat with rust preventative.

2. Install flangette, bearing, flangette and lock

collar. The locking cam is only on one side of

the bearing.

3. Install (but do not tighten) the flangette bolts.