Page 1

MANUAL

IMPAC Pyrometers

ISR 6 Advanced

Page 2

Confidential Information

Service Centers

LumaSense Technologies, Inc.

LumaSense Technologies GmbH

Global and Regional Centers

Our Headquarter

s

Americas, Australia, & Other Asia

Europe, Middle East, Africa

Brazil

India

China

E-mail

info@lumasenseinc.com

support@lumasenseinc.com

Website

http://w

ww.lumasenseinc.com

The material contained herein consists of information that is the property of LumaSense

Technologies and intended solely for use by the purchaser of the equipment described in this

manual. All specifications are subject to change without notice. Changes are made periodically

to the information in this publication, and these changes will be incorporated in new editions.

LumaSense Technologies prohibits the duplication of any portion of this manual or the use

thereof for any purpose other than the operation or maintenance of the equipment described

in this manual, without the express written permission of LumaSense Technologies.

Copyright

© LumaSense Technologies 2013. All rights reserved.

Trademarks

IMPAC is a trademark of LumaSense Technologies.

All other trademarks are trademarks, registered trademarks, and/or service marks of their

respective holders.

North America

Sales & Service

Santa Clara, CA, USA

Ph: +1 800 631 0176

Ph: +1 408 727 1600

Fax: +1 408 727 1677

LumaSense Technologies, Inc.

Santa Clara, CA, USA

Ph: +1 800 631 0176

Fax: +1 408 727 1677

LumaSense, Vendas Brasil

Campinas, Brasil

Ph: +55 19 3367 6533

Fax: +55 19 3367 6533

eusupport@lumasenseinc.com

supportdk@lumasenseinc.com

Other Than North America

Sales & Support

Frankfurt, Germany

Ph: +49 (0) 69 97373 0

Fax: +49 (0) 69 97373 167

LumaSense Technologies, Inc.

Santa Clara, CA, USA

Ph: +1 800 631 0176

Fax: +1 408 727 1677

LumaSense Technologies, India

Mumbai, India

Ph: + 91 22 67419203

Fax: + 91 22 67419201

LumaSense Technologies GmbH

Frankfurt, Germany

Ph: +49 (0) 69 97373 0

Fax: +49 (0) 69 97373 167

LumaSense Technologies, China

Shanghai, China

Ph: +86 133 1182 7766

Fax: +86 21 5877 2383

Part No 03 904 014 - EN

Revision D

November 2013

Page 3

Contents

1 General Information ...................................................................................................... 5

1.1 Information about the user manual ..................................................................... 5

1.1.1 Legend ................................................................................................................. 5

1.1.2 Terminology ........................................................................................................ 5

1.2 Safety ..................................................................................................................... 5

1.3 Limit of liability and warranty ............................................................................. 5

1.4 Unpacking the Instrument .................................................................................... 6

1.5 Service Request, Repair, or Support ..................................................................... 6

1.6 Shipments to LumaSense for Repair .................................................................... 7

1.7 Disposal / decommissioning ................................................................................. 7

2 Introduction ................................................................................................................... 9

2.1 Appropriate use ..................................................................................................... 9

2.2 Scope of delivery ................................................................................................... 9

2.3 Technical Data ....................................................................................................... 9

2.4 Dimensions .......................................................................................................... 11

2.5 Physical User Interface ........................................................................................ 11

2.6 Accessories (optional) ......................................................................................... 12

2.6.1 Mounting ........................................................................................................... 12

2.6.2 Cooling Jacket ................................................................................................... 12

2.6.3 Air Purge............................................................................................................ 12

2.6.4 Vacuum support ................................................................................................ 12

2.6.5 Scanning Mirror ................................................................................................. 12

2.6.6 Flange System .................................................................................................... 12

2.7 Transport, Packing, Storage ................................................................................ 13

3 Controls and Installation ............................................................................................ 15

3.1 Electrical Installation .......................................................................................... 15

3.1.1 Pin assignment of the connector....................................................................... 15

3.1.2 Connecting the pyrometer to a PC .................................................................... 16

3.1.3 Connection to RS485 ......................................................................................... 17

3.1.4 Connection schematic for analyzing devices..................................................... 17

3.2 Sighting................................................................................................................ 18

3.2.1 Viewfinder ......................................................................................................... 18

3.2.2 Laser Targeting Light ........................................................................................ 18

3.3 Optics ................................................................................................................... 19

3.3.1 Spot Sizes ........................................................................................................... 19

3.3.2 Deviation from the focused measuring distance .............................................. 20

3.3.3 Adjusting the required measuring distance ...................................................... 20

4 Settings / parameter descriptions .............................................................................. 21

4.1 Temperature Display ........................................................................................... 21

4.2 Emissivity ε .......................................................................................................... 21

4.3 Emissivity Slope K ............................................................................................... 21

4.3.1 Slope Adjustment .............................................................................................. 22

4.3.2 Temperature Errors Cause by Non-Graybodies ................................................. 22

ISR 6 Advanced Manual Contents · iii

Page 4

4.4 Transmittance t.................................................................................................... 23

4.5 Response Time (t90) .............................................................................................. 23

4.6 Clear Peak Memory (t

) ................................................................................... 23

CLEAR

4.6.1 Single and Double Storage Modes .................................................................... 24

4.6.2 Clear Time Settings ............................................................................................ 24

4.7 Analog Output ..................................................................................................... 25

4.8 Relative Signal Strength ..................................................................................... 25

4.9 “Dirty Window” Warning .................................................................................... 25

4.10 Minimum Intensity Switch-Off Level.................................................................. 25

4.11 Operating Modes ................................................................................................. 26

4.12 Sub Range ............................................................................................................ 26

4.13 Device Address .................................................................................................... 26

4.14 Focused Distance ................................................................................................. 27

4.15 Baud Rate ............................................................................................................. 27

4.16 Pyrometer Internal Temperature ........................................................................ 27

5 Software InfraWin ....................................................................................................... 29

5.1 Connecting the pyrometer to a PC ..................................................................... 29

5.2 Installation........................................................................................................... 29

5.3 Program start....................................................................................................... 29

5.4 Basic settings ....................................................................................................... 30

5.4.1 Open/Save .......................................................................................................... 30

5.4.2 1 measure… ....................................................................................................... 30

5.4.3 Print ................................................................................................................... 30

5.4.4 Close .................................................................................................................. 30

5.4.5 Test .................................................................................................................... 30

5.5 Relative Signal ..................................................................................................... 31

5.6 Warning Level / Switch-Off Level ........................................................................ 32

5.7 Emissivity Slope K: AutoFind .............................................................................. 32

5.8 Measurement online trend ................................................................................. 33

5.9 Listing (analyzing) ............................................................................................... 33

5.10 Output .TXT file (analyzing) ................................................................................ 34

5.11 Trend output (analyzing) .................................................................................... 34

5.12 PC sampling rate (time interval between two measurements) ........................ 34

5.13 Spot size calculator ............................................................................................. 34

5.14 Search I/O Module................................................................................................ 35

6 Maintenance ................................................................................................................ 37

6.1 Cleaning ISR 6 Window ....................................................................................... 37

6.2 Calibration ........................................................................................................... 37

6.2.1 Laboratory Calibration ...................................................................................... 37

6.2.2 On-Site Calibration ............................................................................................ 37

7 Data format UPPÒ (Universal Pyrometer Protocol) .................................................... 39

8 Reference Numbers ..................................................................................................... 43

8.1 Reference numbers instrument .......................................................................... 43

8.2 Reference numbers accessories .......................................................................... 43

9 Troubleshooting .......................................................................................................... 45

Index .................................................................................................................................. 49

ISR 6 Advanced Manual Contents · iv

Page 5

1 General Information

1.1 Information about the user manual

Congratulations on choosing the high quality and highly efficient IMPAC Series 6-TV pyrometer.

This manual provides important information about the instrument and can be used as a work of

reference for installing, operating, and maintaining your IMPAC Series 6-TV pyrometer. It is

important that you carefully read the information contained in this manual and follow all safety

procedures before you install or operate the instrument.

To avoid handling errors, keep this manual in a location where it will be readily accessible.

1.1.1 Legend

Note: The note symbol indicates tips and useful information in this manual. All notes

should be read to effectively operate the instrument.

Laser Beam Safety Warning: The laser beam safety warning symbol signifies hazards

relating to the built-in laser targeting light.

Warnings and Cautions: The general warnings and cautions symbol signifies the

potential for bodily harm or damage to equipment.

MB Shortcut for Temperature range (in German: Messbereich)

1.1.2 Terminology

The terminology used in this manual corresponds to the VDI- / VDE-directives 3511, Part 4.

1.2 Safety

This manual provides important information on safely installing and operating the

IMPAC ISR 6 pyrometer. Several sections of this manual provide safety warnings to avert danger.

These safety warnings are specified with a warning symbol. You must read and understand the

contents of this manual before operating the instrument even if you have used similar

instruments or have already been trained by the manufacturer.

It is also important to continually pay attention to all labels and markings on the instrument and

to keep the labels and markings in a permanent readable condition.

Warning: The pyrometer is only to be used as described in this manual. It is

recommended that you only use accessories provided by the manufacturer.

1.3 Limit of liability and warranty

All general information and notes for handling, maintenance and cleaning of this instrument

are offered according to the best of our knowledge and experience.

All IMPAC Series 6-TV pyrometers from LumaSense Technologies have a regionally effective

warranty period. Please check our website at http://info.lumasenseinc.com/warranty for up-todate warranty information. This warranty covers manufacturing defects and faults which arise

during operation, only if they are the result of defects caused by LumaSense Technologies.

ISR 6 Advanced Manual General Information · 5

Page 6

The warranty is VOID if the instrument is disassembled, tampered with, altered, or otherwise

damaged without prior written consent from LumaSense Technologies; or if considered by

LumaSense Technologies to be abused or used in abnormal conditions.

The Windows compatible software was thoroughly tested on a wide range of Windows

operating systems and in several world languages. Nevertheless, there is always a possibility that

a Windows or PC configuration or some other unforeseen condition exists that would cause the

software not to run smoothly. The manufacturer assumes no responsibility or liability and will

not guarantee the performance of the software. Liability regarding any direct or indirect

damage caused by this software is excluded.

There are no user-serviceable components in the instrument

· Disassembly of the instrument is not allowed. The warranty is VOID if the instrument is

disassembled, tampered with, altered, or otherwise damaged without prior written

consent from LumaSense Technologies; or if considered by LumaSense Technologies to

be abused or used in abnormal conditions.

1.4 Unpacking the Instrument

Before shipment, each instrument is assembled, calibrated, and tested at the LumaSense Factory.

When unpacking and inspecting your system components, you need to do the following:

1. Check all materials in the container against the enclosed packing list.

LumaSense Technologies cannot be responsible for shortages against the packing list

unless a claim is immediately filed with the carrier. Final claim and negotiations with the

carrier must be completed by the customer.

2. Carefully unpack and inspect all components for visible damage. If you note any damage

or suspect damage, immediately contact the carrier and LumaSense Technologies, Inc.

3. Save all packing materials, including the carrier’s identification codes, until you have

inspected all components and find that there is no obvious or hidden damage.

Note: LumaSense encourages you to register your product with us to receive updates,

product information, and special service offers:

http://info.lumasenseinc.com/registration.

1.5 Service Request, Repair, or Support

Contact LumaSense Technologies Technical Support in case of a malfunction or service request.

Provide clearly stated details of the problem as well as the instrument model number and serial

number. Upon receipt of this information, Technical Support will attempt to locate the fault

and, if possible, solve the problem over the telephone.

If Technical Support concludes that the instrument must be returned to LumaSense Technologies

for repair, they will issue a Return Material Authorization (RMA) number.

Return the instrument upon receipt of the RMA number, transportation prepaid. Clearly

indicate the assigned RMA number on the shipping package exterior. Refer to Section 1.6,

Shipments to LumaSense for Repair, for shipping instructions.

ISR 6 Advanced Manual General Information · 6

Page 7

Technical Support can be contacted by telephone or email:

Santa Clara, California

· Telephone: +1 408 727 1600 or +1 800 631 0176

· Email: support@lumasenseinc.com

Frankfurt, Germany

· Telephone: +49 (0) 69 97373 0

· Email: eusupport@lumasenseinc.com

Erstein, France

· Telephone +33 (0)3 88 98 98 01

· Email: eusupport@lumasenseinc.com

1.6 Shipments to LumaSense for Repair

All RMA shipments of LumaSense Technologies instruments are to be prepaid and insured by

way of United Parcel Service (UPS) or preferred choice. For overseas customers, ship units airfreight, priority one.

The instrument must be shipped in the original packing container or its equivalent. LumaSense

Technologies is not responsible for freight damage to instruments that are improperly packed.

Contact us to obtain an RMA number (if one has not already been assigned by Technical

Support). Clearly indicate the assigned RMA number on the shipping package exterior.

Send RMA Shipments to your nearest technical service center:

Santa Clara, California Frankfurt, Germany

LumaSense Technologies, Inc.

3301 Leonard Court

Santa Clara, CA 95054 USA

Telephone: +1 408 727 1600

+1 800 631 0176

Email: support@lumasenseinc.com

LumaSense Technologies GmbH

Kleyerstr. 90

60326 Frankfurt

Germany

Telephone: +49 (0)69-97373 0

Email: eusupport@lumasenseinc.com

1.7 Disposal / decommissioning

Inoperable IMPAC pyrometers must be disposed of in compliance with local regulations for

electro or electronic material.

ISR 6 Advanced Manual General Information · 7

Page 8

To ensure consistent document formatting, this page was intentionally left blank.

ISR 6 Advanced Manual General Information · 8

Page 9

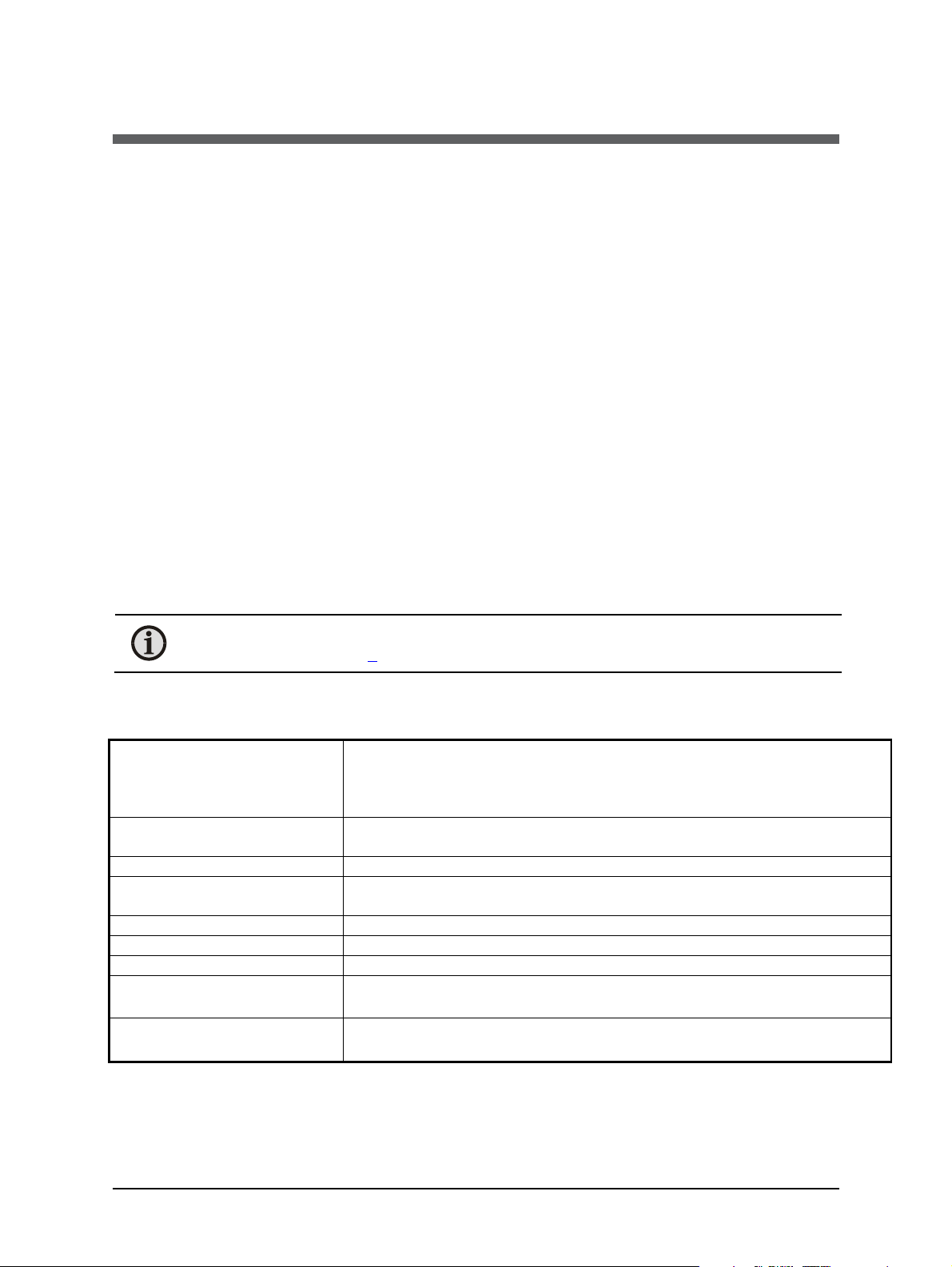

2 Introduction

600 to 1400

°C

(MB14)

SubRange:

A

ny range adjustable within the temperature range

,

minimum span

Spectral

R

ange

s:C

hannel 1: 0.9 µm, channel 2: 1.05 µm

Resolution:

0.1°Cor 0.2°F

at interface

;

< 0.0

015

% of sele

cted sub range at analog

Emissivity

e

:

0.050

to

1.000 in steps of 1/1000 (1

-

color mode)

Transmittance

t

:

0.

050to1.000 in steps of 1/1000 (1

-

color mode)

Emissivity

S

lope K

:

0.800

to 1.20

0 in steps of 1/1000 (2

-

color mode)

Measurement

U

ncertainty:

amb

.

< 1500

°C: 0.3%

of reading in °C + 2

°C

Repeatability:

amb

.

0.15

% of reading in °C + 1

°C

2.1 Appropriate use

The IMPAC ISR 6 pyrometer is a stationary, digital pyrometer for non-contact temperature

measurement metals, ceramics, graphite, etc. in ranges between 600 and 3000 °C.

The pyrometer measures in 2-color mode (ratio principle) in which two adjacent wavelengths

are used to calculate the temperature. This technique offers the following advantages when

compared with standard one-color pyrometers:

· The temperature measurement is independent of the emissivity of the object in wide

ranges.

· The measuring object can be smaller than the spot size.

· Measurements are unaffected by dust and other “grey” contaminants in the field of

view or by dirty viewing windows.

The pyrometer can also be switched to 1-color mode and used like a conventional pyrometer.

2.2 Scope of delivery

Pyrometer, PC adjustment, and evaluation software InfraWin, works certificate, and operating

instructions.

Note: A connection cable is not included with the instrument and has to be ordered

separately (see Chapter 8, Reference numbers).

2.3 Technical Data

Measurement

Temperature Ranges:

(K = 1, t90 = 1 s, T

(K = 1, t90 = 1 s, T

= 25°C)

= 25°C)

700 to 1800 °C (MB18)

800 to 2500 °C (MB25)

1000 to 3000 °C (MB30)

50 °C

output, min. 0.1°C, 16 bit; 1°C or 1°F on display

> 1500 °C: 0.6% of reading in °C

ISR 6 Advanced Manual Introduction · 9

Page 10

Optics

Optics:

M

anually

focusable from rear

cover

with

Distance ratio:

MB 14

approximately

100 : 1

Relative

H

umidity:

N

on condensing conditions

Display (in rear cover):

LED, 4 digit matrix, 5 mm hi

gh

Parameters:

Adjustable via interface:

2-color / 1

-

color temperature signal,

Analog

O

utput:

A

djustable 0

to

20 mA

; or 4 to

20 mA, linear

Digital

I

nterface:

RS485 addressable (half

-

duplex)

Switch

OffL

imit:

2% to 50% (adjustable via interface

)

“Dirty Window”

W

arning:

R

elay contact, max. continuous current 0.4 A,

setting of the

warning

Exposure

T

ime

t90:

<2 ms

(with dynamical adaption at low

signal levels);

adjustable to

min;

Maxim

umValue

S

torage:

Power

S

upply:

24 V DC ± 25%

, ripple must be less than 50mV

Sighting: Built-in laser aiming light (max. power level < 1 mW,

l = 630-680 nm, CDRH class II) or through-lens sighting

measuring distance a = 210 to 5000 mm

MB 18 approximately 190 : 1

MB 25 and MB 30 approximately 350 : 1

Environment

Protection Class: IP 65 IEC 60529 (value in mated condition)

Operating Position: Any

Ambient Temperature:

Note: During operation the

instruments will warm up and might

reach an intrinsic temperature of up

to 58 °C

0 to 65°C at housing

Storage Temperature: -20 to + 80°C

Weight: 0.6 kg

Housing: Stainless steel

CE-label: According to EU directives about electromagnetic immunity

Interface

Connection: 12-pin connector

Communication

for 2-color or 1-color temperature signal or measuring distance

accordingly emissivity slope or emissivity, temperature sub range,

settings for maximum value storage, address, baud rate, switch off limit,

warning level lens contamination monitoring system, transmittance,

response time t90, 0 to 20 mA or

4 or 20 mA analog output range, °C/°F.

Readable via interface: measured value, internal temperature of the

unit, measuring distance.

Baud rate: 1200 to 115.2 kBd

(on request RS232, not addressable)

level: 0 (off) to 99%

0.01 s; 0.05 s; 0.25 s; 1 s; 3 s; 10 s

Built-in single or double storage. Clearing with adjusted time t

(off; 0.01

clear

s; 0.05 s; 0.25 s; 1 s; 5 s; 25 s), via interface, automatically with the next

measuring object, external contact, hold-function

Electrical

ISR 6 Advanced Manual Introduction · 10

Page 11

Power

C

onsumption:

Max. 3 W ( incl. laser)

Load

(analog output)

:

0 to 500 W

Isolation:

P

ower supply, analog output and digital interface are electrically

with Through Lens

with Laser

All dimensions in mm

isolated from each other

Note: The calibration / adjustment of the instruments was carried out in accordance

with VDI/VDE directive “Temperature measurement in industry, Radiation

thermometry, Calibration of radiation thermometers”, VDI/VDE 3511, Part 4.4.

For additional details on this directive, see http://info.lumasenseinc.com/calibration or

order the directive from “Beuth Verlag GmbH” in D-10772 Berlin, Germany.

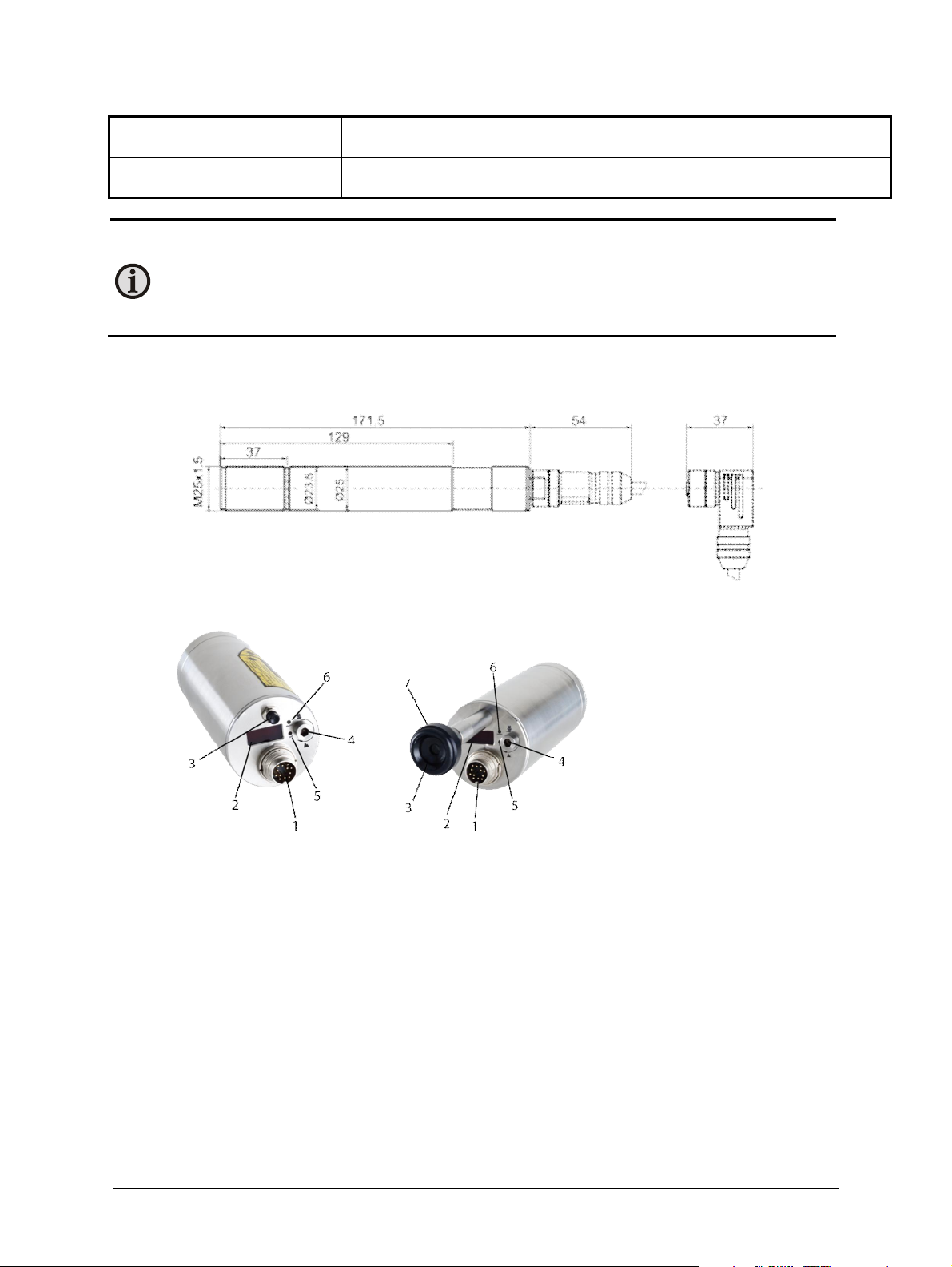

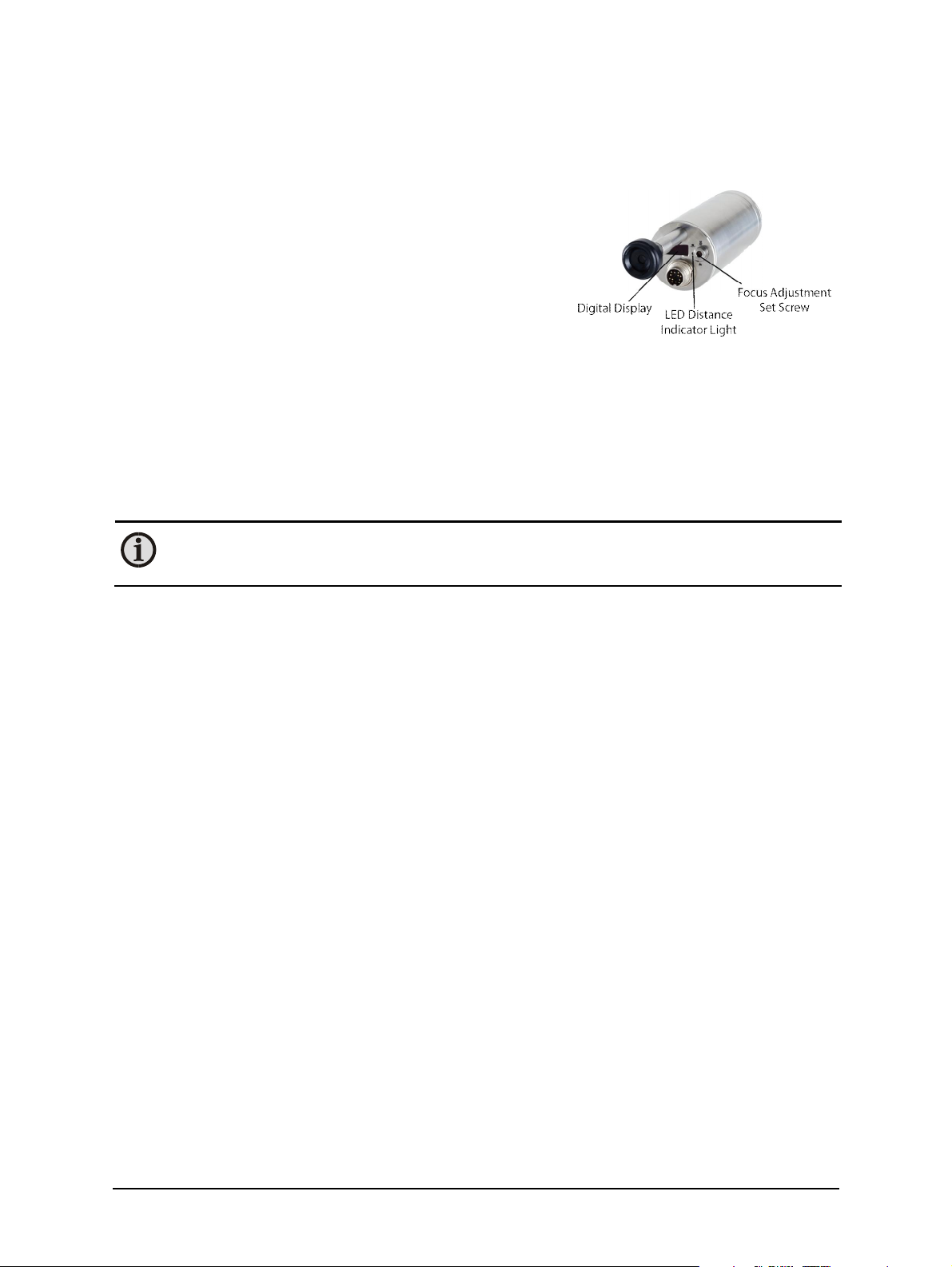

2.4 Dimensions

2.5 Physical User Interface

ISR 6 Advanced

1 12-Pin Connector

2 Digital Display

3 Sighting Option

4 Focus Adjustment

Set Screw

ISR 6 Advanced

5 LED Distance

Indicator Light

6 LED 1-Channel

Mode Indicator

Light

7 Viewfinder

Adjustment Ring

ISR 6 Advanced Manual Introduction · 11

Page 12

2.6 Accessories (optional)

The completely covered water cooling jacket is made from stainless

The pyrometer can be easily fixed o

n a vacuum chamber with the KF 16

Numerous accessories guarantee easy installation of the pyrometer. The following overview

shows a selection of suitable accessories. You can find the entire accessory program with all

reference numbers in Chapter 8, Reference numbers.

2.6.1 Mounting

An adjustable mounting angle is available to easily mount the

pyrometer and align it to the measured object.

2.6.2 Cooling Jacket

steel and serves to protect the pyrometer if exposed to a hot

environment. It is designed for ambient temperatures up to 180 °C.

2.6.3 Air Purge

The air purge protects the lens from contamination of dust and

moisture. It has to be supplied with dry and oil-free pressurized air and

generates an air stream shaped like a cone.

2.6.4 Vacuum support

vacuum support with sighting window.

Mounting Angle

Water cooling jacket with

integrated air purge

Air Purge

Vacuum

Support

2.6.5 Scanning Mirror

The scanning mirror unit SCA 5 allows the measured object to be

scanned over a certain range. The measuring beam of the pyrometer

moves straight in one line across the object and collects temperature

data of this line. This is useful when used in combination with the

maximum value storage (peak picker) to measure objects which move

out of the target area. The scanning angle of the mirror is 0 to 12° and

the scanning frequency 0 to 5 Hz. Both values are easily adjustable at

the scanner.

Scanning Mirror

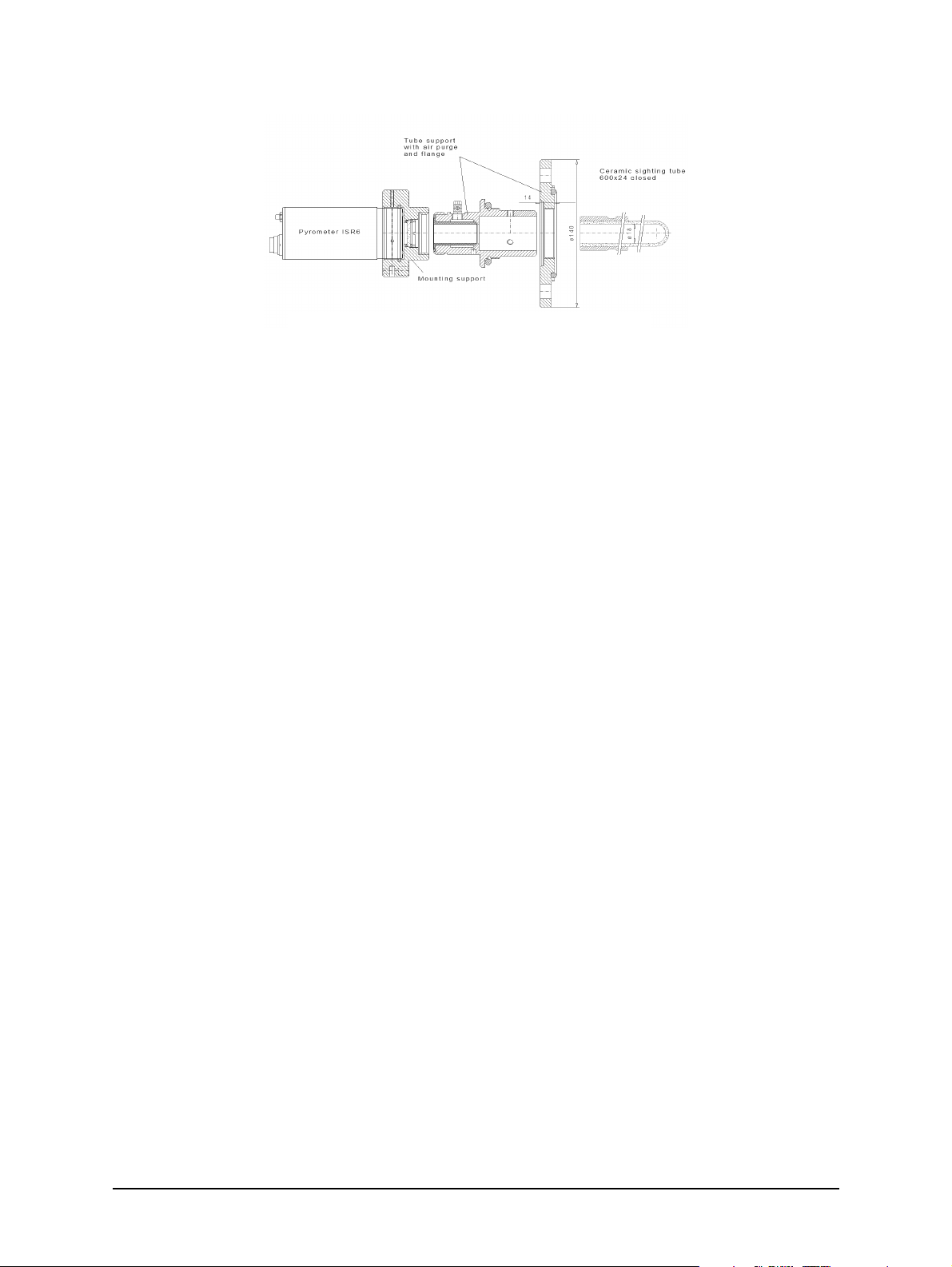

2.6.6 Flange System

The flange system is a modular mounting system to fix the pyrometer on furnaces, vacuum

chambers, etc.

ISR 6 Advanced Manual Introduction · 12

Page 13

It can consist of e.g. mounting support, tube support with air purge and flange and an open or

Schematic dra

wing of the flange system

closed ceramic sighting tube. The mounting support can be equipped with a quartz window for

vacuum applications. It may consist of an equipment rack, flange, and an open or closed ceramic

tube. The equipment rack can be equipped for vacuum applications with a fused silica.

2.7 Transport, Packing, Storage

With faulty shipping, the instrument can be damaged or destroyed. To transport or store the

instrument, please use the original box or a box padded with sufficient shock-absorbing

material. For storage in humid areas or shipment overseas, the device should be placed in

welded foil (ideally along with silica gel) to protect it from humidity.

The pyrometer is designed for a storage temperature of -20 to 80 °C with non-condensing

conditions. Storing the instrument out of these conditions can cause damage or result in

malfunction of the pyrometer.

ISR 6 Advanced Manual Introduction · 13

Page 14

To ensure consistent document formatting, this page was intentionally left blank.

ISR 6 Advanced Manual Introduction · 14

Page 15

3 Controls and Installation

K

white

+24 V DC power supply

A

brown

0 V DC power supply

L

green

+ I

out.

analog output

B

yellow

–

I

out.

analog output

Targeting light activate /

External clearing of max. value

G

red

DGND

(GND for interface)

F

black

B1 (RS485) or RxD (RS232)

C

violet

A1 (RS485) or TxD (R

S232)

D

gray/pink

B2 (RS485) (bridged with F)

E

red/blue

A2 (RS485) (bridged with C)

Screen only for cable extension,

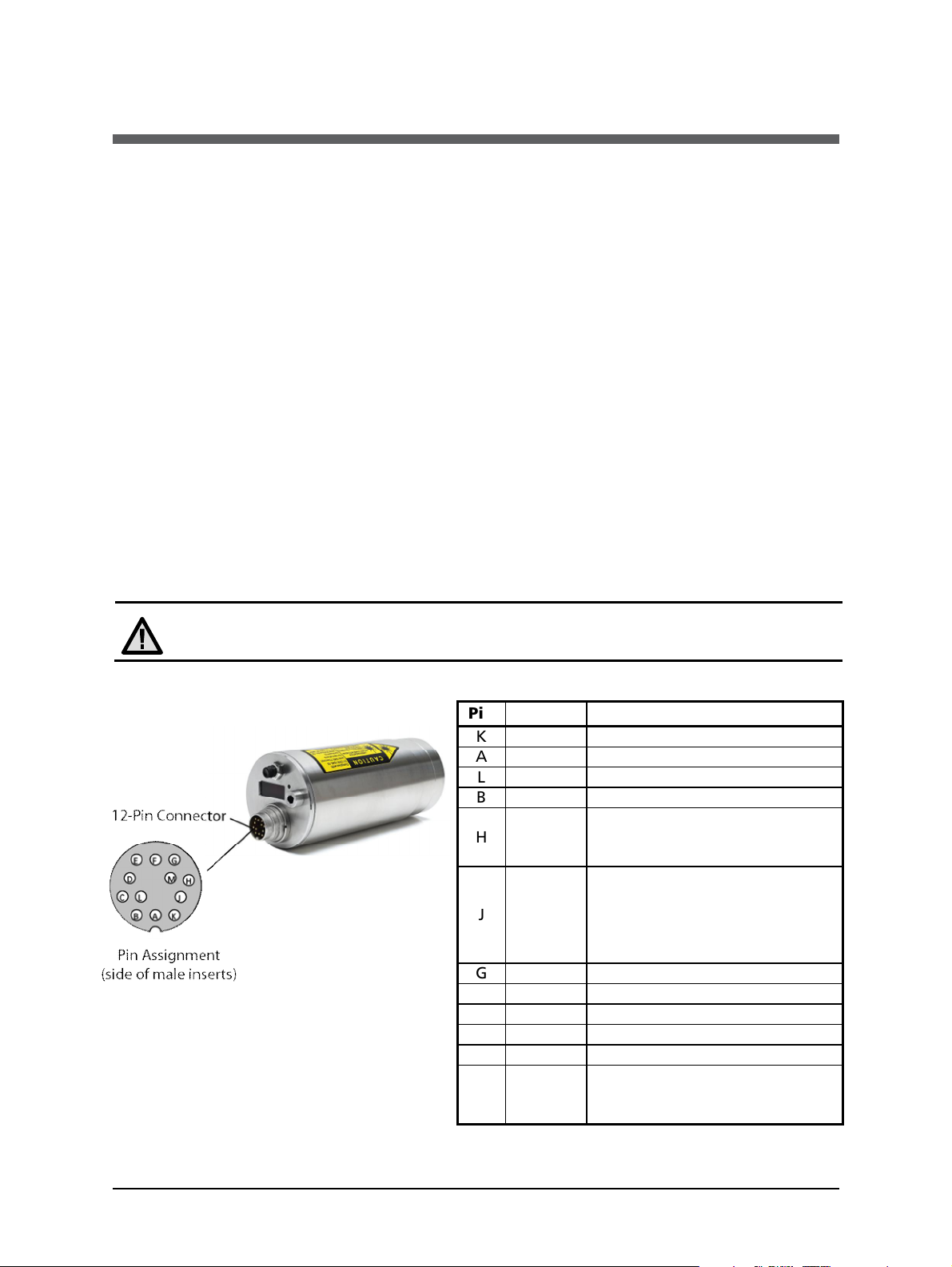

3.1 Electrical Installation

The pyrometer is powered by 24 V DC ± 25% (very well stabilized, ripple max. 50 mV). It is

important to ensure correct polarity when connecting the device to the power supply.

To meet the electromagnetic requirements (EMV), a shielded connecting cable must be used.

LumaSense offers connecting cables, which are not part of the standard scope of delivery.

The shield of the connecting cable has to be connected only on the pyrometer’s side. If the

connecting cable is extended, the shield of the extension also needs to be extended. The shield

must be open on the power supply side (switch board), to avoid ground loops.

The connecting cable has wires for the power supply, interface, analog output, external laser

switch, and external clear of maximum value storage via contact and 12 pin connector. The cable

includes a short adapter cable with a 9-pin D-SUB connector. This connector may be used in

combination with the RS485 to USB adapter.

Once the instrument has been connected to the power supply, it is immediately ready for use.

Although it does not need to be warmed up, it does need to run for approximately 15 to 30

minutes before achieving full accuracy. The instrument can be switched off by interrupting the

power supply or unplugging the electrical connector.

Attention:

When connecting the power supply, ensure the polarity is correct.

3.1.1 Pin assignment of the connector

Pin Color Function

H gray

J pink

deactivate via external switch

(bridged with K)

storage (bridge to K), hold

function, or output for “dirty

window” monitoring (*see

notes below)

ISR 6 Advanced Manual Controls and Installation · 15

M orange

don’t connect to the

switchboard

Page 16

The connector pin J can be used for 3 different functions:

1. External clearing of the maximum value storage:

When the pyrometer is in operating mode, pin J can be used for external clearing of

maximum value storage. When external clearing is selected from the t

menu, pin J is connected for a short time to pin K (power supply voltage) to clear the

stored maximum value.

The function “external clearing” is triggered with the following conditions:

· The clear time is set to “extern”.

· The “dirty window” warning system is switched off. This can be done through the

InfraWin software in the “color-bar” window.

· The warning level “dirty window” must be set to 0%.

2. Hold function:

When the hold function mode is activated, the current temperature reading is frozen as

long as pin J and pin K are connected. (See section 4.6 for clear time for the maximum

value storage).

3. “Dirty Window” Warning system:

The pyrometer is equipped with a “dirty window” warning system. The accuracy of the

pyrometer will be seriously affected if the lens is not clean and the sight path is obscured

by dirt, process material, smoke or steam (this can also happen if the object is smaller

than the spot size of the pyrometer).

dropdown

clear

To avoid incorrect measurements, a warning signal can be set to detect when the signal

level becomes too low or reaches a certain level. When activated, a built in relay (max.

continuous current 0.4 A) connects pin J to pin K (power supply voltage).

The setting of the warning level (0 to 99%) can be done through the “color-bar”

window of the InfraWin software. If the warning level “dirty window” is set to 0%

(factory setting), the “dirty window” warning system is switched off and pin J can

perform one of the functions of “external clearing” or “hold”.

The “dirty window” warning system is triggered with the following conditions:

· The clear time is not set to “extern” or “hold”.

· The pyrometer is operating in “2-color mode”.

3.1.2 Connecting the pyrometer to a PC

The pyrometer is equipped with an RS485 serial interface. With the RS485, long transmission

distances can be realized and the transmission is, to a large extent, free of problems. The RS485

also allows several pyrometers to be connected in a bus system.

If an RS485 connection is not available at the PC, it can be accomplished using the RS485 to USB

connector. When using a RS485 to USB adapter, make sure that the adapter is fast enough to

receive the pyrometer’s answer to an instruction of the master. Most of the commonly used

adapters are too slow for fast measuring equipment, so it is recommended to use the

LumaSense adapter (order no. 3 826 720).

ISR 6 Advanced Manual Controls and Installation · 16

Page 17

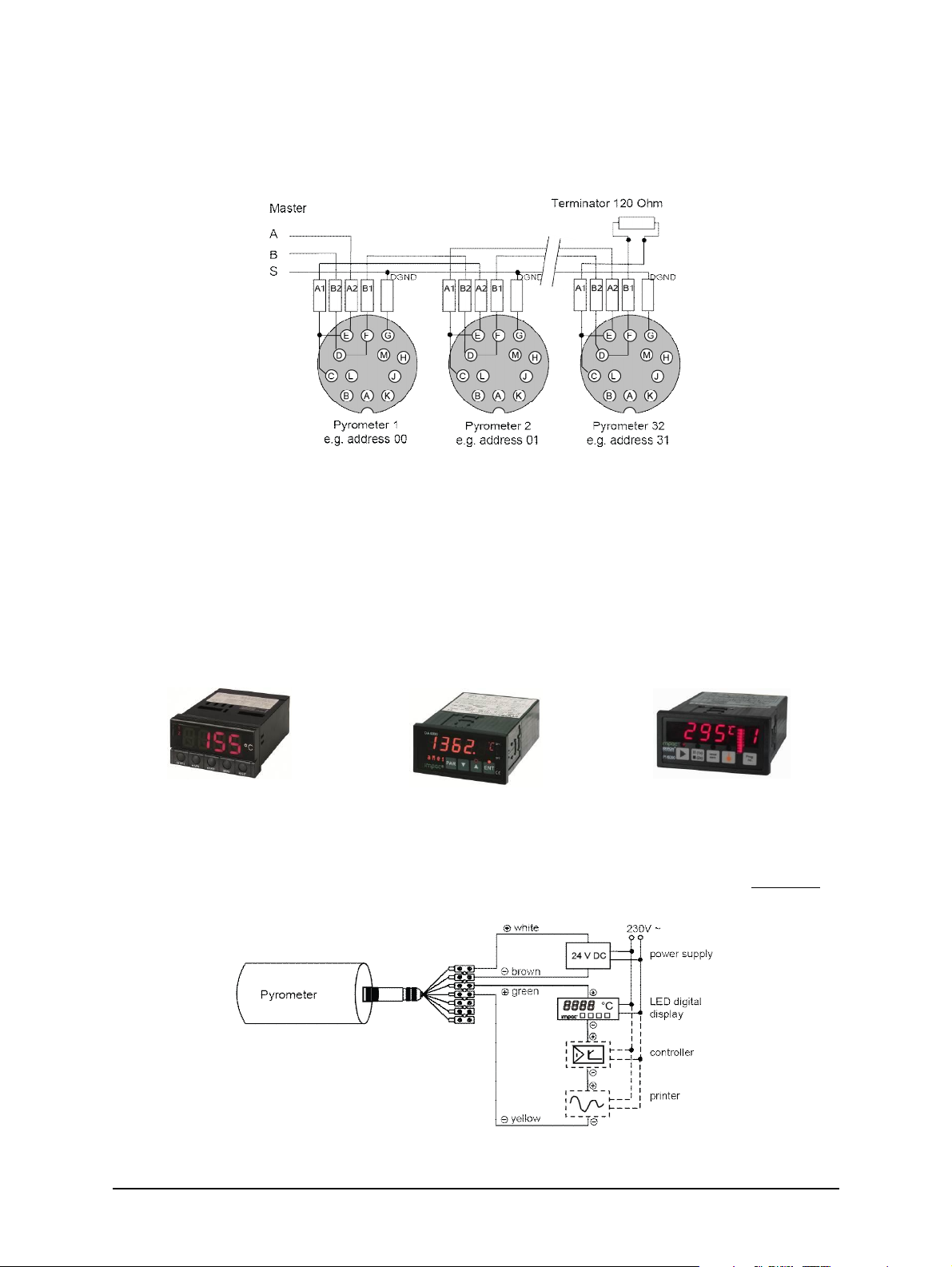

3.1.3 Connection to RS485

Half-duplex mode: A1 and A2 as well as B1 and B2 are bridged in the 12-pin round connector of

the connecting cable, to prevent reflections due to long stubs.

RS485 Bus System

It also safeguards against the interruption of the RS485 Bus System should a connecting plug be

pulled out. The master labels mark the connections on the RS485 converter. The transmission

rate of the serial interface in Baud (Bd) is dependent on the length of the cable. Values between

1200 and 115200 Bd may be set.

3.1.4 Connection schematic for analyzing devices

For temperature indication of the pyrometer, LumaSense offers pure indicators (series DA 4000).

LumaSense also offers indicators with features to change pyrometer parameters (DA 6000 and

DA 6000-N) as well as a fast digital PID controller PI 6000.

Digital Display Parameterizing Indicator Digital Controller

Additional analyzing instruments, including LED digital displays only need to be connected to a

power supply and the analog outputs of the pyrometer (exception: the digital display DA 6000

can also be connected with its serial interface, whereas the digital display DA 6000-N has to be

connected with its serial interface).

Connection Schematic for Analyzing Devices

ISR 6 Advanced Manual Controls and Installation · 17

Page 18

Instruments like an analog controller or printer can be connected to the display in a series as

shown above (total load of resistance max. 500 Ohm).

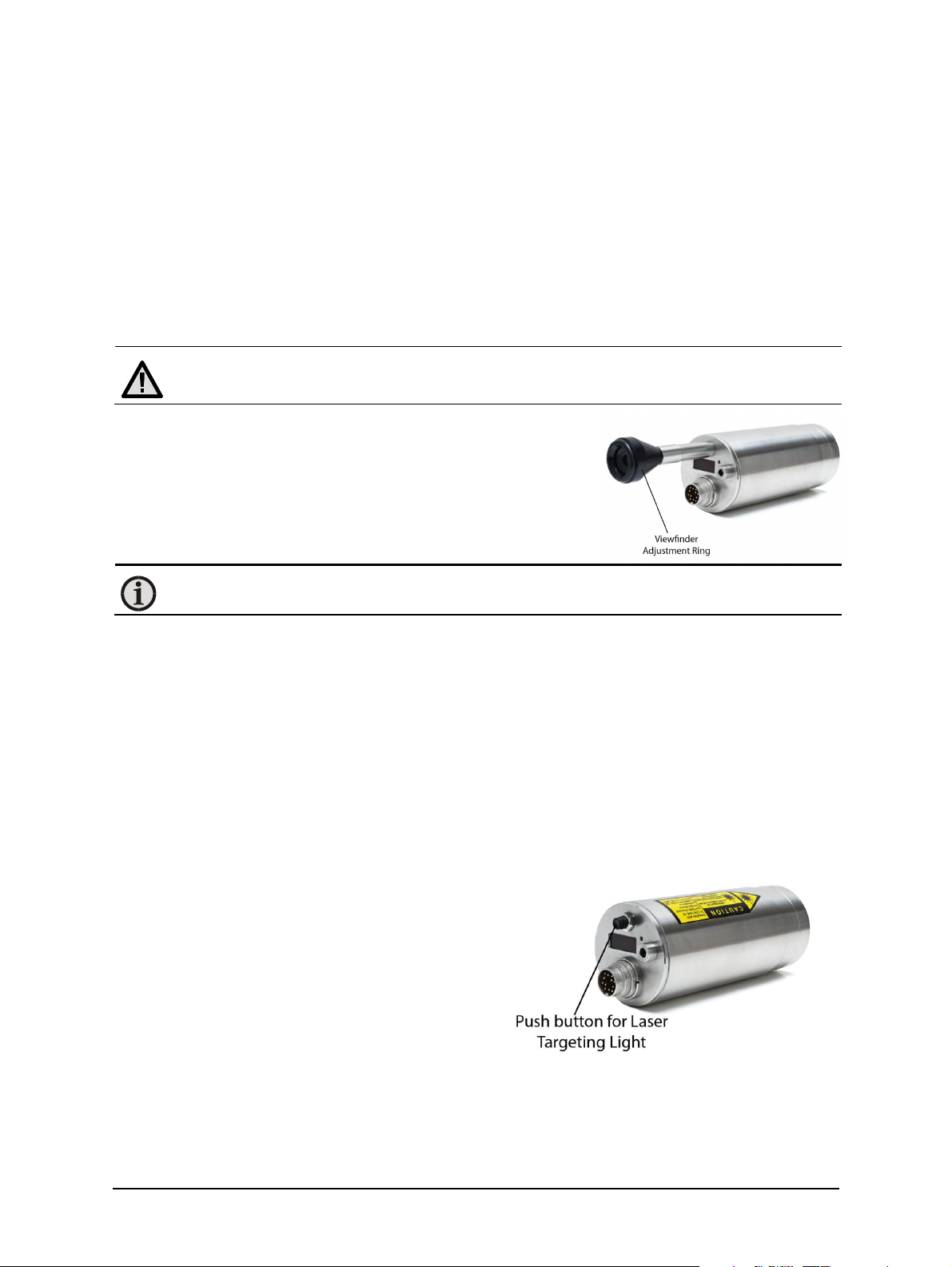

3.2 Sighting

The ISR 6 Advanced can be purchased with Through-Lens Sighting or with a Laser targeting

light. These sighting options allow you to easily align the pyrometer to the measuring object.

3.2.1 Viewfinder

The ISR 6 Advanced can be equipped with a viewfinder which offers through-lens sighting. The

viewfinder is true-sided and parallax-free. A circle marks the position of the measuring spot, but

not the exact spot size.

Warning: To ensure eye protection, make sure you use the shaded filter when viewing

objects with temperatures of 1500 °C or higher.

The viewfinder is equipped with an adjustable eye-protection

filter, which allows you to view hot objects without exposing

your eye to high intensity light. When you are viewing hot

objects, turn the adjustment ring on the viewfinder so the

filter will let in less light.

When you are viewing low temperature objects, turn the

viewfinder adjustment ring so the filter will let in more light.

Note: You can turn the adjustment ring on the viewfinder in both a clockwise and

counterclockwise direction to change the filter from light to dark.

3.2.2 Laser Targeting Light

The ISR 6 Advanced can be equipped with a laser targeting light to assist with aligning the

pyrometer to the measuring object. The laser targeting light is a visible red light with a

wavelength between 630 and 680 nm and a maximum power of 1 mW. The laser is classified as

product of laser class II.

The laser spot marks the center of the measuring spot on the target. The diameter does not

correspond to the spot size. The smallest diameter of the laser spot approximately indicates the

measuring distance.

Never look directly into the laser beam. The beam and spot can be watched safely from side.

Also make sure that the beam will not be reflected into eyes of people by mirrors or shiny

surfaces.

The laser targeting light can be switched on and

off by pressing the button of the rear cover of

the housing.

The laser targeting light can also be switched on

and off by using an external contact (see section

3.1.1 “Connector Pin Assignment”) or through

the InfraWin software. If it is not switched off by

one of the above-mentioned methods, it will be

switched off automatically after approximately 2

minutes.

To prevent damage to the laser, the targeting light is also switched off automatically if the

internal temperature of the pyrometer exceeds 61 °C. It can only be used again once the

temperature falls below 61 °C.

ISR 6 Advanced Manual Controls and Installation · 18

Page 19

Note: The laser warning signs on the pyrometer should be easily viewable at all times,

Temperature Range

600 …

700 …

800 …

1000 …

Measuring Distance

2102.1

1.1

0.6

0.6

30031.6

0.9

0.9

50052.7

1.5

1.5

80084.2

2.3

2.3

1300

136.9

3.7

3.7

2000

20

10.6

5.8

5.8

5000

502715

15

even after it has been installed.

Laser Beam Safety Warning: The instrument is equipped

with a class II laser that emits radiation. To reduce the risk of

injury to the eyes, do not look directly into the targeting laser

and do not point the targeting laser into anyone's eyes.

3.3 Optics

3.3.1 Spot Sizes

The ISR 6 Advanced has a Vario optics, which can be manually adjusted at all distances between

210 mm and 5000 mm.

The table of spot sizes in relation to measuring distance shows examples of the pyrometer’s spot

size M [mm] in relation to the measuring distance a [mm] (min. 90% of the radiation intensity).

Increasing or decreasing the measuring distance will change the spot size.

Aperture D for all temperature ranges is 13 to 15 mm with the aperture being the effective

diameter of the lens. This is dependent on the optical setting. The largest value applies to a very

small measuring distance, while the minimum value applies to the largest measuring distance.

Note: In the 1-color (mono) mode, the pyrometer can measure objects at any distance

(whether focused or non-focused). However, the object has to be bigger than or at

least as big as the spot size of the pyrometer in the measuring distance.

In the 2-color (ratio) mode, the object can be somewhat smaller than the spot

diameter.

1400 °C

a [mm]

1800°C

Spot Diameter M [mm]

2500°C

3000°C

ISR 6 Advanced Manual Controls and Installation · 19

Examples of Spot Sizes in Relation to Measuring Distance

Page 20

Focused spot sizes between the listed distances can be found by linear interpolation between

the listed values. For example, for range 600 to 1400 °C, the spot size at 1600 mm distance

would be about 16 mm.

Note: Effective aperture D for all temperature ranges is 12 mm (focused to longest

distance) to 16 mm (focused to shortest distance).

3.3.2 Deviation from the focused measuring distance

Spot sizes for non-focused distances (shorter or longer than the focused distance) may be

calculated by using the formula below.

Formula for Calculating Spot Sizes

The InfraWin software also includes a Spot Size Calculator that calculates the data for the

non-focused regions, if you enter the values of aperture D, focused measurement distance a,

and focused measuring field diameter M as found in the above table (see section 3.3.1).

3.3.3 Adjusting the required measuring distance

The measuring distance can be set using the Focus

Adjustment Screw on the back of the device. The

focused distance value can be adjusted at all distances

between 210 mm and 5000 mm. To focus, turn the focus

adjustment set screw to make the target image appear

sharp and clear.

The LED Distance Indicator Light (labeled mm) will turn

red and the approximate focused measuring distance in

mm will automatically be shown on the Digital Display for a few seconds after making an

adjustment using the Focus Adjustment Set Screw.

Note: The optics are manually focusable with a measuring distance of a = 210 to

5000 mm.

Note: Turning the focus adjustment screw counterclockwise will shorten the

measuring distance.

Turning the focus adjustment screw clockwise will lengthen the measuring distance.

ISR 6 Advanced Manual Controls and Installation · 20

Page 21

4 Settings / parameter descriptions

The pyrometer is equipped with a wide range of settings for optimal adaptation to the required

measuring condition and to measure the temperature correctly.

The digital PC interface allows you to exchange data with a PC either by using the

supplied InfraWin software or by using the Universal Pyrometer Protocol (UPP)

commands with your own communication program (see Chapter 7 for the UPP Data

Format commands).

Selecting the pyrometer parameters window shows the current settings of the pyrometer. You

can change a value by typing a value in an input box or by selecting a preset value from the list

field.

The following settings can be made through the RS485 to USB connection.

4.1 Temperature Display

The Digital Display on the back of the pyrometer will show the temperature measurement in

either °C or °F. You can select which temperature scale you wish to use through the InfraWin

software or by using the UPP Data Format commands.

The Measuring Value can also be viewed at any time through the InfraWin Software or by using

the UPP Data Format commands

4.2 Emissivity ε

Different materials have different emissivities ranging between 0% and 100%. The emissivity is

also dependent upon on the surface condition of the material, the spectral range of the

pyrometer, and the measuring temperature. The emissivity setting of the pyrometer has to be

adjusted accordingly.

Emissivity settings between 20% and 100% can be established through the InfraWin software or

by using the UPP Data Format commands.

Note: Emissivity e Settings: 5% to 100% in steps of 1/1000 (1-color mode).

4.3 Emissivity Slope K

In 2-color (ratio) mode, the pyrometer is measuring simultaneously with 2 sensors in adjacent

wavelengths. It calculates the temperature by ratioing the radiation intensities of the two

wavelengths. This ratio technique eliminates a number of factors that degrade the accuracy of

conventional 1-color instruments. For example, with ratio pyrometers, measurement is

independent of emissivity in wide areas. They are also unaffected by dust in the field of view

and unaffected by dirty viewing windows or lenses, etc. as long as these disturbances are “grey”

(not colored).

In some cases the emissivities of the two wavelengths can differ so that it is necessary to correct

the ratio of the two emissivities (K = e1 / e2) to get a correct temperature reading. This

correction can be done by adjusting the emissivity slope setting K using the InfraWin software or

the UPP data format commands.

The K-factors of metals are normally slightly higher than 1. For a correct measuring result, it is

recommended that you make a comparison test. This comparison test may be performed by

ISR 6 Advanced Manual Settings / parameter descriptions · 21

Page 22

using a thermocouple probe or by knowing one process temperature point precisely from other

sources. The K-factor can then be adjusted until the pyrometer shows the same temperature

value.

The ISR 6 is factory calibrated for graybody targets that exhibit equal changes in emissivity

within its two spectral bands.

Note: Emissivity Slope K Settings: 0.800 to 1.200 in steps of 1/1000 (2-color mode).

4.3.1 Slope Adjustment

In some cases the emissivities of the two wavelengths can differ so that it is necessary to correct

the ratio of the two emissivities (K = e1 / e2) to get a correct temperature reading. This

correction can be done by adjusting the emissivity slope setting K using the InfraWin software or

the UPP data format commands.

The K-factors of metals are normally slightly higher than 1. For a correct measuring result, it is

recommended that you make a comparison test. This comparison test may be performed by

using a thermocouple probe or by knowing one process temperature point precisely from other

sources. The K-factor can then be adjusted until the pyrometer shows the same temperature

value.

The ISR 6 Advanced is factory calibrated for graybody targets that exhibit equal changes in

emissivity within its two spectral bands.

4.3.2 Temperature Errors Cause by Non-Graybodies

A graybody target has emissivity that is the same at each of the two wavelengths used for

measurements and is constant throughout the temperature range. The ratio of the emissivities,

e1 / e2= 1 and stays constant regardless of the target temperature. When a target deviates from

this, that is when e1 / e2 does not equal 1.0 and a slope adjustment is required. For many

materials, this is a one-time adjustment.

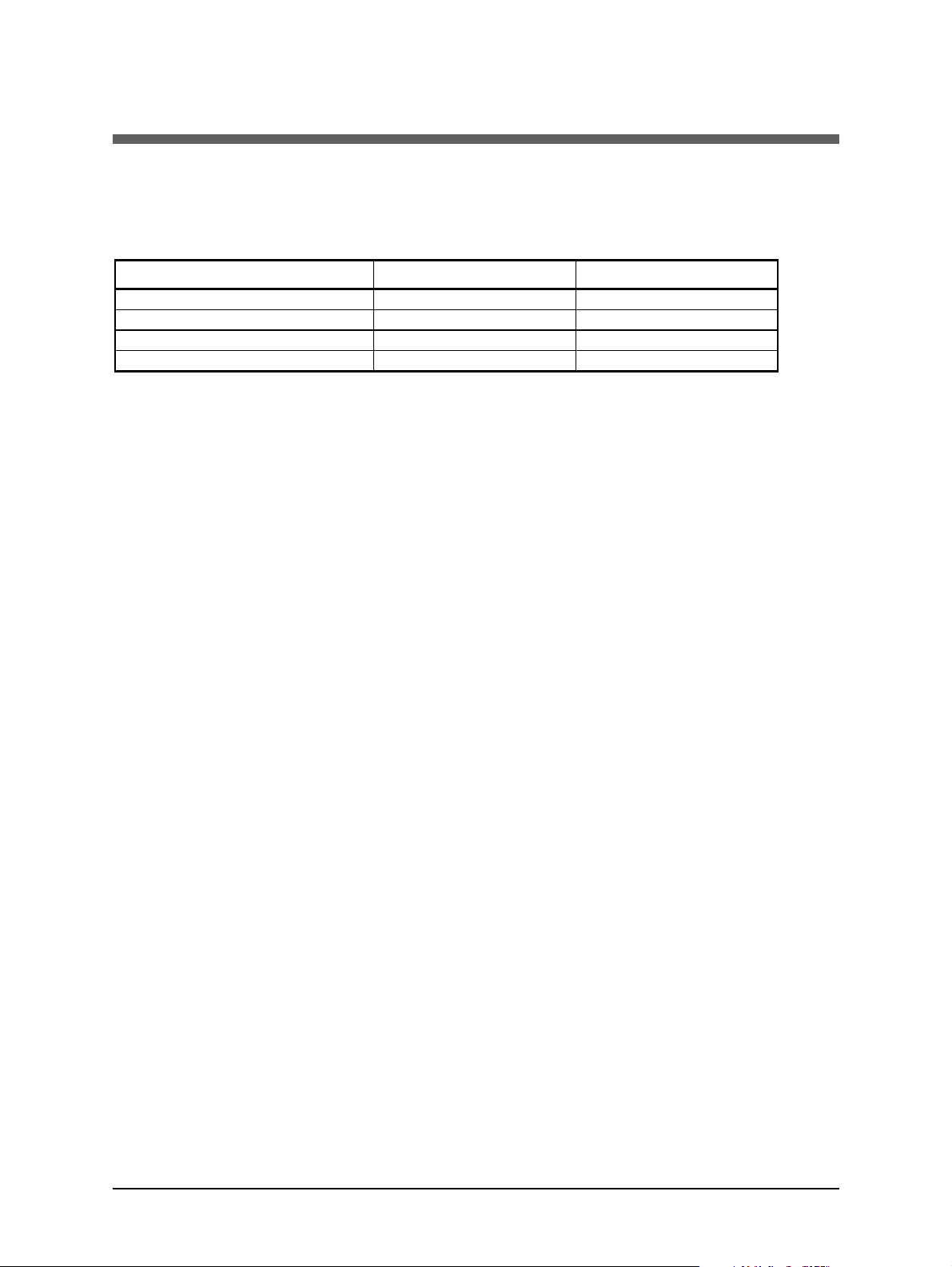

The following table illustrates the ISR 6 reading errors that can occur when the slope setting

differs from the actual material emissivity ratio.

TABLE OF EXPECTED ERROR WHEN EMISSIVITY OF ONE

WAVELENGTH IS 1% DIFFERENT FROM THE SECOND WAVELENGTH

TEMPERATURE ERROR DEG.

°F °C °F °C

1300 700 18 10

1500 815 20 11

1700 926 22 12

1900 1040 25 14

2100 1150 25 14

2300 1260 27 15

2500 1370 29 16

3000 1650 36 20

3500 1925 45 25

4000 2200 54 30

5000 2760 72 40

ISR 6 Advanced Manual Settings / parameter descriptions · 22

Page 23

The table shows typical errors that can result when the emissivity of one wavelength differs

from the other wavelength by only 1%. The errors can get quite large as temperatures increase.

This error can be much larger than a 1-color IR pyrometer would produce for 1% emissivity

change. Therefore, it is important to select the proper mode (2-color vs. 1-color) on the ISR 6 to

measure a specific material.

Another source of error is dust or smoke in the optical path which alters the transmission in one

wavelength more than the other. If the “dust” transmits 1% less energy at wavelength 1 than at

wavelength 2, the error table above also applies. Since not all smoke, dust, or dense steam

transmits equally at each wavelength, errors may become larger than expected for a 2-color

instrument. Usually the smoke and dust are the result of the material being processed and can

be cleared from the sight path by a fan or air purge tube.

In some materials, the emissivity may change at different rates with material temperature. Some

materials exhibit great changes in emissivity with temperature or time as oxidation modifies the

surface finish of the material. Such materials are not suited for measurement with 2-color

instruments. When problems are compounded with spectrally absorbing dust or smoke

(described above), obtaining reliable temperature readings with any 2-color instrument may be

impossible. In cases like this, a single color instrument using the shortest wavelength possible

would be the better choice. If this problem is encountered, switch the ISR 6 to 1-color mode. In

some situations, the single color mode will outperform the ratio mode.

4.4 Transmittance t

Transmittance is a parameter that can compensate for signal loss due to external windows etc.

For example, if the emissivity of the material is 0.6 and the transmittance of an additional

window is 0.9, then the product would be 0.54 which is well inside the allowed range.

The product of transmittance and emissivity (t x e) must not be less than 20%.

Note: Transmittance t Settings: 5% to 100% in steps of 1/1000 (1-color mode)

4.5 Response Time (t90)

The response time t90 is the time interval for the analog output of the pyrometer to go from a

low temperature value up to 90% of the temperature step to a high value when measuring an

abrupt increase from said low to said high temperature.

Independently of this, the pyrometer performs a measurement every 10 ms and updates the

analog output. Slower response times can be used to achieve a constant temperature reading

for measuring objects that have rapidly fluctuating temperatures.

The response time is set using the InfraWin software or by using the UPP Data Format

commands. When the setting is set to min., the ISR 6 Advanced operates using a time constant

of <2 ms (with dynamic adaption at low signal levels). The response time can be extended to

0.01 s; 0.05 s; 0.25 s; 1 s; 3 s; 10 s.

Note: Settings for Response Time t90 : min, 0.01 s; 0.05 s; 0.25 s; 1 s; 3 s; 10 s

4.6 Clear Peak Memory (t

The integrated maximum value storage is activated when the parameter tclear is set to

something other than “OFF” or “HOLD”.

CLEAR

)

ISR 6 Advanced Manual Settings / parameter descriptions · 23

Page 24

If the maximum value storage is switched on, the highest last temperature value will always be

displayed and stored. As such, it may be beneficial to periodically clear and reset the stored

maximum values in order to obtain new temperature readings.

This storage also has to be cleared at regular intervals when fluctuating object temperatures

cause the display or the analog outputs to change too rapidly or when the pyrometer is not

constantly viewing an object to be measured.

Note: Settings for Clear Peak Memory t

: OFF, 0.01 s, 0.05 s, 0.25 s, 1.0 s, 5.0 s,

CLE AR

25.0 s, EXTERN, AUTO, HOLD

4.6.1 Single and Double Storage Modes

Depending upon the selected settings, the maximum value storage will either work in single

storage mode or in double storage mode.

Single Storage

Mode:

Double Storage

Mode:

Note: The maximum value storage setting coincides with adjustments made to the

response time.

The response time setting (working like a low-pass filter) is applied first. After that,

the maximum storage is processed. So when using both, the maximum storage takes

the peak of the signal that was previously smoothed by the response time filter.

Single storage mode is used when you want to reset the stored value using

an external impulse via one contact closure from an external relay (such as

between two measured objects). The relay contact is connected directly to

the pyrometer between pins J and K. This mode allows a new value to be

established after each impulse from the reset signal. Single storage mode

also comes into effect when the Clear Peak Memory t

is set to AUTO.

clear

Double storage mode comes into effect when selecting one of the reset

intervals. This mode utilizes two memories. With the first memory, the

highest measured value is held and is deleted alternately in the time

interval set (clear time). The other memory retains the maximum value

throughout the next time interval. The disadvantages of fluctuations in the

display with the clock frequency are thereby eliminated.

So when using both, the maximum storage takes the peak of the signal that was

previously smoothed by the response time filter.

4.6.2 Clear Time Settings

The following settings are available through the InfraWin software or by using the UPP data

format commands.

OFF When set to OFF, the maximum value storage is switched off and all new

temperature values are measured but not stored.

0.01s…25.0s If the clear time is set between 0.01 s and 25.0 s, the maximum value is

held in double storage mode. After the entered time, the value will be

cleared alternately from one of the storages, while the value of the other

storage is shown.

EXTERN

ISR 6 Advanced Manual Settings / parameter descriptions · 24

With the external clearing function, the storage operates in single storage

mode. The values are immediately cleared from the storage by contacting

the wires connected to pins J and K, if the EXTERN mode was selected.

Page 25

AUTO The AUTO mode is used for discontinuous measuring tasks. For example,

when objects are being transported on a conveyer belt and pass the

measuring beam of the pyrometer only for a few seconds. In this case, the

maximum value for each object has to be obtained.

With the AUTO mode, the maximum value is stored until a new hot object

appears in the measuring beam. The temperature, which has to be

recognized as “hot” is defined by the low limit of the adjusted sub range.

The stored maximum value will be deleted once the temperature of the new

hot object exceeds the low limit of the sub range by 1% (transition in

positive direction) or by at least 2 °C. This is also valid if the sub range equals

the basic range.

HOLD The HOLD function allows you to freeze the current temperature reading at

any moment. This feature is activated using an external switch that has been

connected between connector pins J and K.

The temperature reading will remain frozen as long as the contact remains

closed.

4.7 Analog Output

The analog output has to be selected according to the signal input of the connected instrument

(controller, PLC, etc.). If 4 to 20 mA is set, the analog output gives 3.9 mA for temperatures

below lower range limit.

Note: Settings for Analog Output : 0 to 20mA or 4 to 20mA

4.8 Relative Signal Strength

Relative signal strength stands for the product of emissivity, surface coverage, and transmission

of the material between the object and the pyrometer. Refer to Section 4.8 for more

information on Relative Signal.

4.9 “Dirty Window” Warning

The ISR 6 Advanced pyrometers are equipped with a warning level “dirty window” monitoring

system. A correct temperature measurement might be impossible if the ratio pyrometer is

working at a too low signal level. To avoid these wrong measurements in advance, a warning

signal can be set to a certain contamination level. A built-in relay switch can be used to switch to

a warning signal when the incoming radiation becomes too low.

The warning level can be set between 0 and 99%. 0% means the “dirty window” warning

system is switched off (factory setting) and the relay can perform the function external clearing

of maximum value storage, when it is activated (see section 4.6.2 Clear Time Settings).

Note: Settings for “Dirty Window” Warning: 0 (off) to 99%.

4.10 Minimum Intensity Switch-Off Level

The minimum intensity switch-off level is a function that is used to avoid measuring errors

caused by signals which are too low. This may e.g. be caused by a dirty viewing window, dust in

the field of view, or when the spot is not filled by the measuring object.

ISR 6 Advanced Manual Settings / parameter descriptions · 25

Page 26

Note: Settings for Minimum Intensity Switch-Off Level: 2% to 50%

Ratio pyrometers are able to measure temperatures correctly even with very low signals. If the

signal is too low for a correct measurement, the pyrometer interrupts the measurement and

displays 1 °C below of beginning of the temperature range.

Although the factory default is set to 10%, switch-off limit can be adjusted between 2 and 50%,

depending on the application.

Note: The smaller the value, the higher the chance that daylight or reflections will

affect a correct temperature measurement.

4.11 Operating Modes

Ratio (2-color) mode is the factory default operating mode for the ISR 6 pyrometer. However,

the device can be set to mono (1-color) mode using the InfraWin software or by using the UPP

Data Format commands.

With 1-color mode, the device adjustments are simplified by

sending the emissivity corrected one channel temperature to the

analog output.

For a correct measurement in the 1-color mode, it is necessary to

adjust the emissivity using the InfraWin software or by using the

UPP Data Format commands. This emissivity is the relationship

between the emission of a real object and the emission of a

blackbody radiation source (this is an object which absorbs all

incoming rays and has an emissivity of 100%) at the same

temperature.

4.12 Sub Range

You have the opportunity to choose a sub range (minimum span 50 °C) within the basic

measuring range of the pyrometer. This sub range corresponds to the analog output.

Example: Range 700…1800 °C, Sub Range 925…975 °C.

The sub range setting also affects the maximum value storage when the Clear Peak Memory

t

is set to AUTO. For more information on the t

clear

Note: Settings for Sub Range: Any range adjustable within the temperature range

with a minimum span of 50 °C.

AUTO setting, refer to Section 4.6.

clear

4.13 Device Address

When connecting several pyrometers to one serial interface with RS485, it is necessary for each

instrument to have its own device address for communication purposes. First, it is necessary to

connect each instrument separately to give it an address. After that, all instruments can be

connected and addressed individually.

Note: Settings for Device Address:

Individual Addresses: 00…97 Global Addresses: 98, 99

Only via own communication program with interface command (not possible with

InfraWin, because InfraWin automatically detects a connected pyrometer): If parameters should

be changed simultaneously on all pyrometers, the global Address 98 can be used. This allows

ISR 6 Advanced Manual Settings / parameter descriptions · 26

Page 27

you to program all pyrometers at the same time, regardless of the addresses that have already

been assigned. If the address of a pyrometer is unknown, it is possible to communicate with it

using the global Address 99 (connect only one pyrometer).

4.14 Focused Distance

The focused distance value can be adjusted at all distances

between 210 mm and 5000 mm using the Focus Adjustment

Screw on the back of the device.

The LED Distance Indicator Light will turn red and the

focused measuring distance in mm will automatically be

shown on the Digital Display within a few seconds of

making an adjustment using the Focus Adjustment Set Screw.

The focused distance can be viewed at any time through the InfraWin software or by using the

UPP Data Format commands.

4.15 Baud Rate

The transmission rate of the serial interface in Baud (Bd) is dependent on the length of the

cable. A maximum cable length for 19200 Bd with RS485 is 2 km. The baud rate is reduced by

50% if the transmission distance is doubled.

Note: Settings for Baud Rate: 1200, 2400, 4800, 9600, 19200, 38400, 57600, or

115200.

4.16 Pyrometer Internal Temperature

The internal temperature of the pyrometer can be read through the PC interface using the

InfraWin software or by using the UPP Data format commands. It is a few degrees higher than

the ambient temperature due to the heat generated by the electronics.

When using the Laser Targeting Light, the targeting light is switched off automatically if the

internal temperature of the pyrometer exceeds 55 °C. This safety feature is used to prevent

damage to the laser. It can only be used again once the temperature falls below 55 °C.

ISR 6 Advanced Manual Settings / parameter descriptions · 27

Page 28

To ensure consistent document formatting, this page was intentionally left blank.

ISR 6 Advanced Manual Settings / parameter descriptions · 28

Page 29

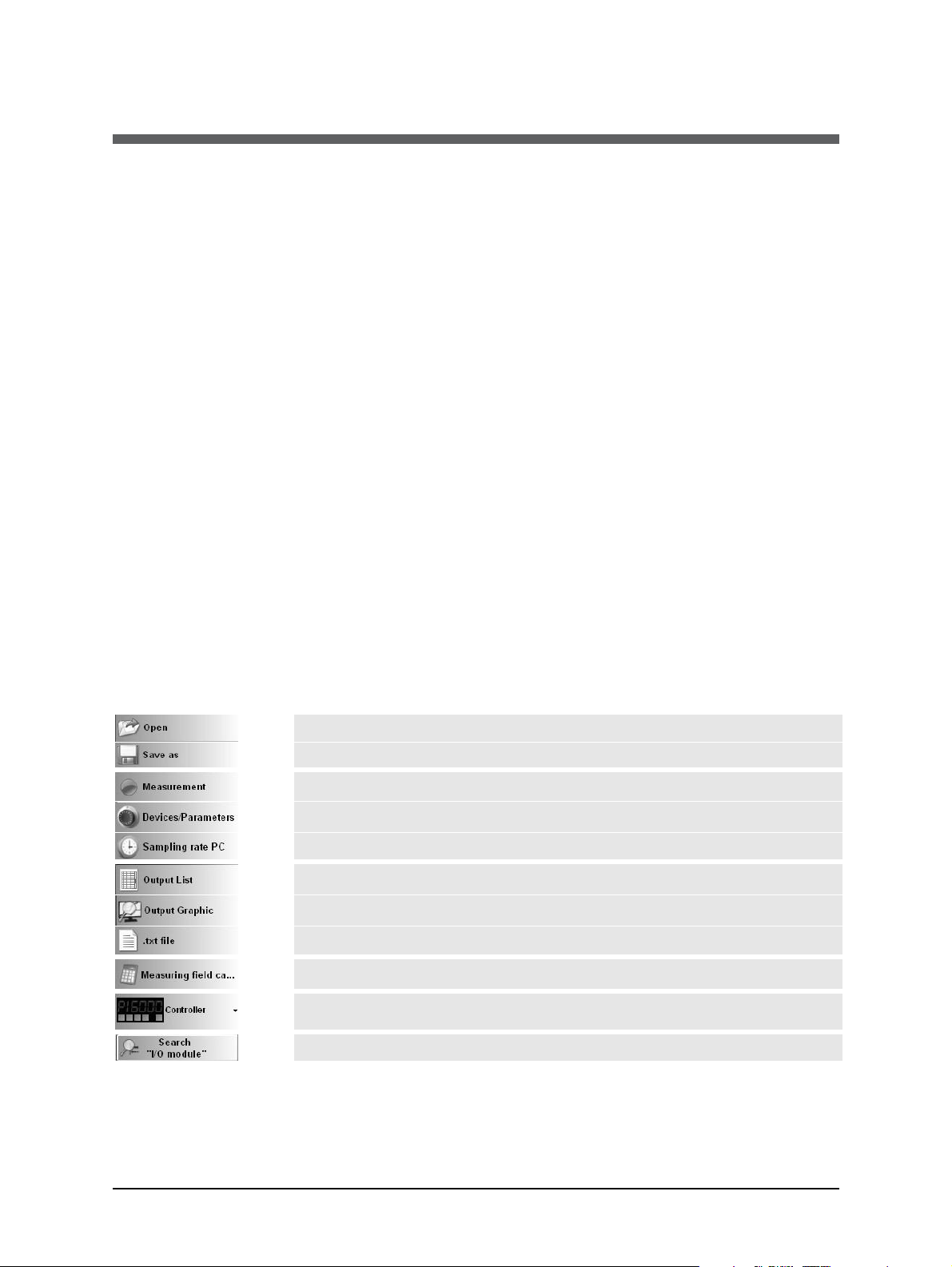

5 Software InfraWin

The operating and analyzing InfraWin software is included with delivery of the pyrometer. In

addition to allowing you to make parameter adjustments, the InfraWin software also provides

temperature indication, data logging, and measurement analysis features.

This section gives an overview about the functions of the software. It also provides a description

of the individual icons found in the program's help menu. Click on the F1 button after loading

InfraWin or click on the ? in the menu bar.

The following descriptions refer to software InfraWin version 5.0. The latest version is available

for free as download from the homepage www.lumasenseinc.com.

5.1 Connecting the pyrometer to a PC

The program InfraWin can operate up to two devices. Two devices using RS485 may be operated

simultaneously by the same interface, if two different addresses have been properly entered

(see section 4.13 Device Address for more information).

5.2 Installation

To install the InfraWin software, select setup.exe from the InfraWin-CD or from the downloaded

and unpacked zip file from the internet and then follow the installation instructions.

5.3 Program start

The first time you load InfraWin 5, you will be prompted to select a default language. The

InfraWin software is available in German, English, Spanish, French, Portuguese, and Chinese.

Once installed, click Language/Languages if you would like to select another language.

On the start page, the screen shows the following start menu icons.

Opens a saved file

Storage of measured values for further processing

Starts measurement for the selected device

Setting of the parameters of the instruments

Time interval between two measurements

Listing of measured or stored values in tabular form

Processing of measured (stored) readings in graph form

Processing of measured (stored) readings in a text file

Calculation of spot sizes in various measuring distances

Only if available: controls the programmable controller PI 6000

Search I/O module

ISR 6 Advanced Manual Software InfraWin · 29

Page 30

5.4 Basic settings

All preset values for the device

can be displayed and modified,

if necessary under the

Devices/Parameters window.

Changing an existing pyrometer

setting can be accomplished by typing

a value in an input box or by selecting

a preset value from the list field.

Choose the correct settings for your

application from the displayed options.

This window contains the parameter

settings described in Chapter 4,

Parameters.

5.4.1 Open/Save

The open and save buttons enable you to save customized configurations, which can

then be opened and reused at any time.

5.4.2 1 measure…

The 1 measur… function shows the current measuring temperature in the

pyrometer parameters window for approximately 1 second.

5.4.3 Print

The print icon will generate a screenshot of the parameter form and allow you to

send it a printer.

5.4.4 Close

The close icon will close the pyrometer parameters window.

5.4.5 Test

Clicking on the Test

icon will open a

window that allows you to

directly communicate with the

pyrometer using the UPP

(Universal Pyrometer Protocol)

Data Format commands.

After entering an interface

command (00 is the adjusted

address ex works, ms is the

command reading

temperature value) and

clicking on Send, the window

shown to the right will be

opened.

This window already shows the answer of the pyrometer in 1/10°. The actual temperature

reading is 699.0 °C.

Len indicates the length of the answered data string, incl. Carriage Return (Chr(13)).

ISR 6 Advanced Manual Software InfraWin · 30

Page 31

In the lower part of the window, the connection with the preset baud rate can be checked. Here

the command was sent 100 times with 19200 baud. It has taken 0.800 seconds without

transmission errors.

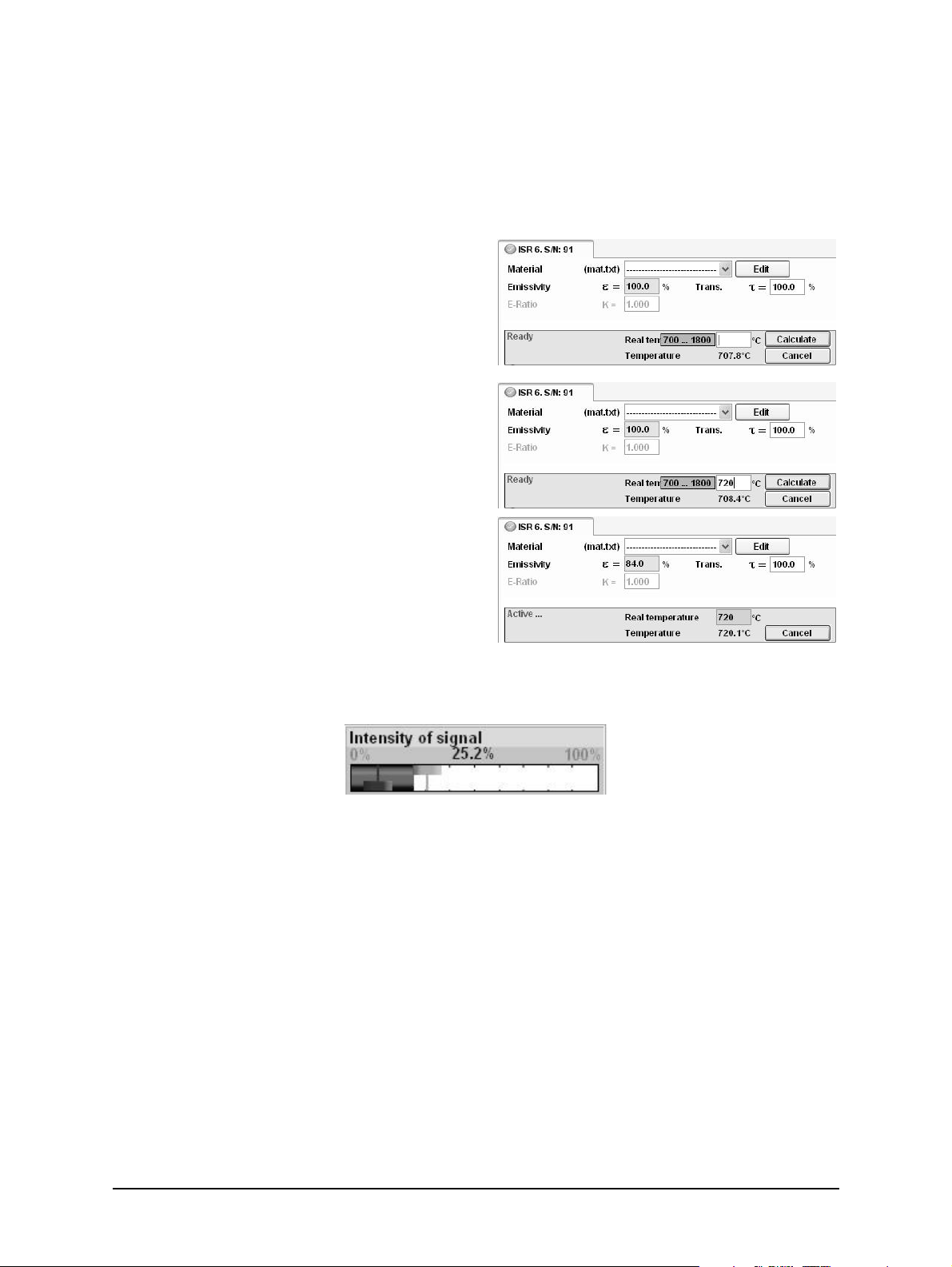

Emi: AutoFind: If the true temperature of the measured object is known, you can calculate the

emissivity of the measured object using the Emi: AutoFind function:

A measured temperature is displayed with the

current set emissivity (in this example 100%)

(here: 707.8 °C).

If you press Emi: Autofind a window will open

which allows you to enter the “true”

temperature (here 720 °C).

Once the temperature entry has been entered

and confirmed with Calculate, InfraWin will

then calculate the emissivity which occurs with

the new temperature (here 84.0%). This is

displayed immediately and can be used for

further temperature measurement.

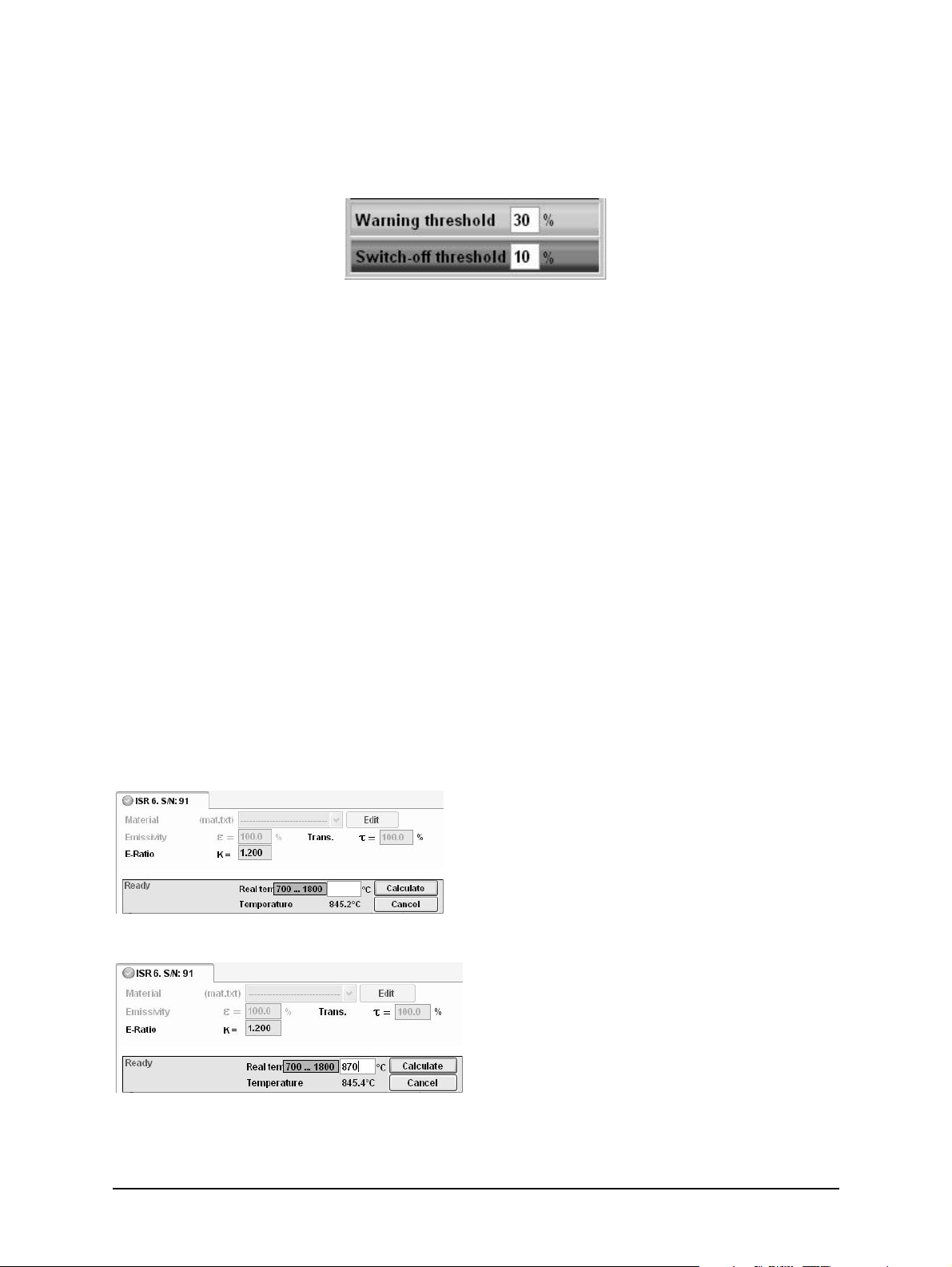

5.5 Relative Signal

The relative signal bar graph provides and indication of the signal strength.

InfraWin Software Relative Signal Indicator

In the above image, the relative signal bar indicates a signal intensity of 25.2%. This can be

caused by the object’s emissivity, contamination of the optics or viewing window, dust in the

field of view, or a small measuring object.

Normally, this bar graph is used to monitor if the signal level due to contamination of optics or

window decreases over time. It shows the measured intensity compared to the intensity a

blackbody radiation source would have at the determined ratio temperature of the pyrometer.

The shown relative signal depends on the entered emissivity slope K (a wrong adjustment results

in relative signals above 100%).

ISR 6 Advanced Manual Software InfraWin · 31

Page 32

5.6 Warning Level / Switch-Off Level

In addition to the relative signal bar graph, the warning level and the switch-off level are

indicated as vertical lines in colors corresponding to the windows below.

The ISR 6 pyrometers are equipped with a warning level “dirty window” monitoring system.

A correct temperature measurement might be impossible if the ratio pyrometer is working at a

too low signal level. To avoid these wrong measurements in advance, a warning signal can be

set to a certain contamination level. A built-in relay switch can be used to switch to a warning

signal when the signal becomes too low. When this happens, the built-in indicator of the

pyrometer starts blinking, but will continue the measurement.

The warning level can be set between 0 and 99%. 0% means the “dirty window” warning

system is switched off (factory setting) and the relay can perform the the function external

clearing of maximum value storage or external hold, when one of them is activated.

The switch-off level is a function used to avoid measuring errors caused by too low signals.

Ratio pyrometers are able to measure temperatures correctly even with very low signals. For

example, through a dirty viewing window, or if dust exists in the field of view, or if the spot is

not filled by the measuring object.

If the signal is too low for a correct measurement, the pyrometer interrupts the measurement

and displays 1° below the beginning of the temperature range. Although the factory default is

set at 10%, the switch-off limit can be adjusted between 2% and 50%, depending on the

application.

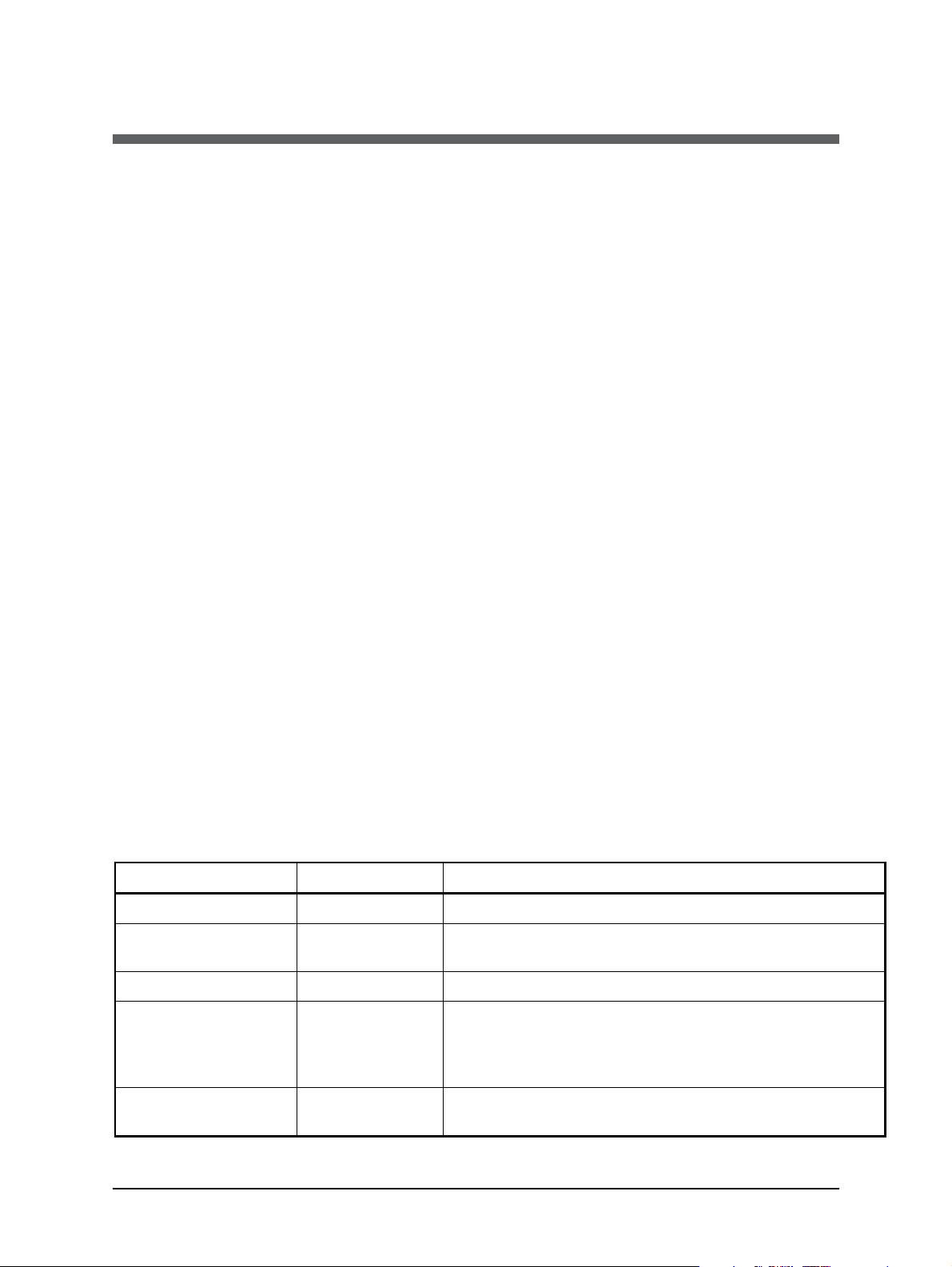

5.7 Emissivity Slope K: AutoFind

InfraWin also offers an input field K for the emissivity slope. If the emissivity is changed, the

temperature change connected with this can be directly affected.

If the true temperature of the measured object is known, you can calculate the emissivity slope

of the measured object using the K: AutoFind function:

A measured temperature is displayed with

the current set emissivity slope. In this

example, the emissivity slope is set at 1.000

and the resulting temperature reading is

845.2 °C.

If you press the K: Autofind button, a

window will open which allows you to

enter the true temperature.

In this example, we have entered a

temperature of 870 °C.

Once you enter the temperature value, you

can press the OK button to set the

temperature value and close the

temperature window.

ISR 6 Advanced Manual Software InfraWin · 32

Page 33

Once the temperature entry has been entered

and confirmed with OK, InfraWin will then

calculate the emissivity slope. The new

emissivity slope will immediately appear along

with the new temperature, which can be used

for further temperature measurement.

5.8 Measurement online trend

The measurement

function allows you to

access a number of input tabs located on

the left side of the screen. The main or

home tab is the Output Screen. You can

toggle the input tabs on and off by

clicking them. This window displays:

· temperature as graphical diagram

· internal temperature of the

instrument

· current temperature

· quantity of the measured values and file size of the current measurement

The example shows a sample reading over the period of approximately 15 seconds with a

temperature range between 699 and 713 °C. The final temperature (at the end of the reading) is

699.0 °C.

The Mark Zone button allows you to color mark a temperature range for easier recognition.

The Threshold button allows you to set a temperature value as a baseline to prevent recording

values above or below the baseline temperature. This allows you to keep the output file size

small.

The Scaling Trend button allows you to scale temperature trend view.

Note: The measuring values of “measurement online trend” are automatically saved

as "standard.i12". Should you need to edit the data later, you need to save the file as

another .i12-file because old values are over-written when a new measurement is

taken.

Files from older program versions (.i10-files) can be opened and saved as .i12.

5.9 Listing (analyzing)

For analyzing the

measured values in this

field, all measured data appears in a numeric

list.

The column between time and temperature

provides a time resolution of milliseconds.

The value specifies the time in seconds after

midnight (0:00 h). The amount of data

depends on the frequency that readings were

taken (settings at 5.9 PC sampling rates). As

ISR 6 Advanced Manual Software InfraWin · 33

Page 34

the amount of data increases, so does the amount of storage space required to save it. In order

to save room, all .i12 data files are stored by a binary code.

5.10 Output .TXT file (analyzing)

The same file as under Output listing may be converted into a text file and

can be easily opened, for example with Microsoft Excel. With the standard

import settings, Excel automatically formats the columns accordingly (with tabs as separators).

5.11 Trend output (analyzing)

The graph’s curve depicts the temperature

change over time within the specified

temperature range.

Additionally, other information appears in this

window; such as recorded time (x-axis) and

temperature in degrees (y-axis) as well as the

time and temperature at the vertical cursor line

which can be dragged with the mouse.

Selecting the Trend output initially causes all

the saved data to be displayed.

If the data exceeds an amount that can be reasonably represented, you may “Zoom“ in on a

partial segment using the mouse (such as the segment represented in the example). Under

“Total” you can return to the representation of the entire curve.

Note: The last reading is saved in the standard.i12 file and automatically appears in

this form upon opening Listing or Trend output.

Selecting file open with another file, the previous file will be overwritten and replaced by the standard.i12 file.

5.12 PC sampling rate (time interval between two

measurements)

This function sets a time interval. After

each interval, one measured value is

stored on the PC. Longer time intervals will result in

creating smaller stored file sizes. This function is mainly

used for long term measurements.

5.13 Spot size calculator

The InfraWin Spot Size Calculator

calculates the data for the nonfocused regions. To calculate data, enter the values

of aperture D, focused measurement distance a,

and focused measuring field diameter M as found

in the documentation relating to the optics

supplied with your specific pyrometer.

After entering the aperture and the main spot size,

the input of interim values calculates spot sizes in

different measuring distances of the fixed optics.

ISR 6 Advanced Manual Software InfraWin · 34

Page 35

5.14 Search I/O Module

The I/O Module allows

accessories to connect to

the software and is used to trigger

measurement externally or to send a signal

(like a relay) under certain conditions.

ISR 6 Advanced Manual Software InfraWin · 35

Page 36

To ensure consistent document formatting, this page was intentionally left blank.

ISR 6 Advanced Manual Software InfraWin · 36

Page 37

6 Maintenance

6.1 Cleaning ISR 6 Window

Because there are no moving parts in the ISR 6, the only regular maintenance required is a

periodic inspection of the front window for build-up of foreign particles which, in time, can