Page 1

User Manual

KLEIBER 740

INFRARED PYROMETER

for non-contact temperature measurement

Issue 10/2008

Page 2

Address/Copyright

© 2007 IMPAC Sensor GmbH is a subsidiary company of IMPAC group.

Any reproduction of this user manual or part thereof, its storage on electronic media

and translation of the manual into foreign languages without written approval of the

company

is strictly forbidden.

LumaSense Technologies GmbH

Kley erstr. 90

D - 60326 Frankfurt

Germany

Phone: +49-69-97373-0

Fax: +49-69-97373-167

E-Mail: impac@Lumasenseinc.com

Internet: www.Lumasenseinc.com

LumaSense Technologies GmbH

Page 3

Table of Contents

Table of Contents

Table of Contents ......................................................................................................................... 3

Table of Illustrations......................................................................................................................4

1 Basic Information .................................................................................................................. 1

1.1 Notes for the User Manual ............................................................................................ 1

1.2 Purpose......................................................................................................................... 1

1.3 Intended Use................................................................................................................. 2

1.4 Warranty and Liability ...................................................................................................2

1.5 Scope of Delivery.......................................................................................................... 3

2 Technical Data...................................................................................................................... 4

3 Safety.................................................................................................................................... 6

3.1 Symbols and Signal Words Used ................................................................................. 6

3.2 General Safety Notes.................................................................................................... 7

4 Technical Description ...........................................................................................................8

4.1 System Design/Principle of Operation ..........................................................................8

4.1.1 Optics........................................................................................................................ 8

4.1.2 Operating and display elements.............................................................................. 10

4.1.3 Connections and interfaces..................................................................................... 10

5 Transport and Storage........................................................................................................ 13

5.1 Transport of the pyrometer ......................................................................................... 13

5.2 Storage of the pyrometer ............................................................................................14

6 Starting Up.......................................................................................................................... 15

6.1 Installation Site Requirements ....................................................................................15

6.2 Installation................................................................................................................... 16

6.2.1 Fix and connect the pyrometer................................................................................ 16

6.2.2 Align pyrometer....................................................................................................... 17

7 Operation of the pyrometer................................................................................................. 18

7.1 Setting the Vario optic................................................................................................. 18

7.2 Adjusting the Parameters............................................................................................ 19

8 Troubleshooting .................................................................................................................. 20

9 Maintenance and Care ....................................................................................................... 21

9.1 General information .................................................................................................... 21

9.2 Cleaning the Optics..................................................................................................... 21

10 Accessories.....................................................................................................................22

11 Taking out of service, Disposal ....................................................................................... 23

11.1 Taking out of service................................................................................................... 23

11.2 Disposal ...................................................................................................................... 23

KLEIBER 740

Page 4

Table of Illustrations

Table of Illustrations

Fig. 1

Structure of the pyrometer.................................................................................................. 8

Fig. 2 Vario optics ......................................................................................................................... 9

Fig. 3 Macro optics measuring set-up (KS/ KG 740).................................................................... 9

Fig. 4 Macro optics measuring set-up (KGA 740) ........................................................................ 9

Fig. 5 Operating and display elements ....................................................................................... 10

Fig. 6 Connecting plug for 5-pin connecting cable .....................................................................11

Fig. 7 Cooling water connections (tube screw connector ¼") .................................................... 11

Fig. 8 Pyrometer connections ..................................................................................................... 16

Fig. 9 Pyrometer wire connection with configuration .................................................................. 17

Fig. 10 Setting the vario optic................................................................................................... 18

KLEIBER 740

Page 5

1 Basic Information

1.1 Notes for the User Manual

This user manual describes the structure of the KLEIBER 740 infrared pyrometer for non-

contact temperature measurement and gives the operators all the necessary information

related to installation, operation, de-installation along with information related to

maintenance and repairs of the pyrometer. When malfunctions occur, the user manual

provides suggestions for their potential causes and their repair.

This user manual is intended for qualified service and maintenance personnel with

appropriate technical expertise including a basic knowledge of temperature measuring

technology.

Before you use the pyrometer for temperature measurement, you must have read and

understood these operating instructions! Keep the manual so that it is available at all times.

Take into account all the requirements given in this user manual. This is a pre-condition for

Basic Information

the correct and professional use of the pyrometer,

proper maintenance, cleaning and care of the pyrometer

prevention of risks and strict observance of the essential technical safety regulations.

Document structure and Symbols

Operating instructions to be performed in sequence are numbered in chronological order.

They are grouped together in operational units and accompanied by the corresponding

results.

Listings without a sequential order are presented as bullet points and items in sub-lists are

preceded by dashes.

Safety precautions are shown with pictograms and key words. They provide information

about the type, source and consequences of the hazard, and safety precautions. The

meanings of the pictograms and key words are explained in the "Safety Instructions"

chapter.

1.2 Purpose

The KLEIBER 740 pyrometer is particularly intended for the non-contact measurement of

surface temperatures on metal, ceramic, plastics and is specially designed for industrial

applications as well as applications in the area of research and development.

The 740 also enables you to solve high speed applications in laser areas by using laser

rejection filters and challenging temperature measurement on silicon or tungsten.

KLEIBER 740 1

Page 6

Basic Information

1.3 Intended Use

The KLEIBER 740 pyrometer is to be used exclusively for the non-contact measurement of

surface temperatures of the materials specified in section

area are not allowed! Any damage resulting from this is the sole responsibility of the

operator.

Proper use of the plant also includes:

the observance of the requirements of these operating instructions for transport and

storage, assembly, operation and care of the pyrometer

1.2. Any applications beyond that

the observance of the power requirements specified in section

and environmental conditions

the compliance with the legal accident prevention and environmental regulations

Among applications/conditions for which the pyrometer is not intended for use are in

particular:

the use of the pyrometer within medical areas

the use of the pyrometer in the food industry

the use of the pyrometer in areas where there is danger of explosion

the use of the pyrometer outside of the operating and environmental conditions

specified in section

2

1.4 Warranty and Liability

The LumaSense Sensor GmbH offers a warranty of 2 years for the pyrometer starting from

the date of billing. The warranty covers manufacturing defects as well as defects which are

determined during operation and which can be imputed to defects of LumaSense Sensor

GmbH. In these cases, the pyrometer will be repaired free of charge. The freight charges

are the responsibility of the respective sender.

2 and the operating

LumaSense Sensor GmbH reserves the right to exchange the equipment or parts of the

instrument instead of a repair. After a repair, LumaSense Sensor GmbH offers a warranty of

12 months on all repaired and/or exchanged instrument components.

Deviations from the proper use described in this user manual will result in restricted

warranty and liability or the loss in case of damage. Damage to wearing parts

(e.g. fuses) is excluded from the guarantee.

Warranty and liability claims for personal injuries and/or material damage are excluded if

this or these result from one or more of the following causes:

Improper use of the pyrometer

inappropriate operation and servicing of the pyrometer

unauthorized modifications to the pyrometer without prior consultation with LumaSense

Sensor GmbH

rough, mechanical actions or deliberate destruction of the pyrometer

2 KLEIBER 740

Page 7

Connection error (overvoltage)

Frost damage by not observing the permitted environmental conditions and/or by

inappropriate storage

Malfunctions that are caused by non-conformance to this user manual

1.5 Scope of Delivery

The scope of delivery of the pyrometer includes:

High speed infrared pyrometer KLEIBER 740

(KS 740 or KG 740 or KGA 740)

Vario optics (optional macro optics)

retaining pin ∅ 14.9 mm, length 100 mm

water cooling connection

inspection sheet

Basic Information

user manual

IMPORTANT

The connecting cable is not included in scope of delivery. Please order it according to the

length required.

KLEIBER 740 3

Page 8

Technical Data

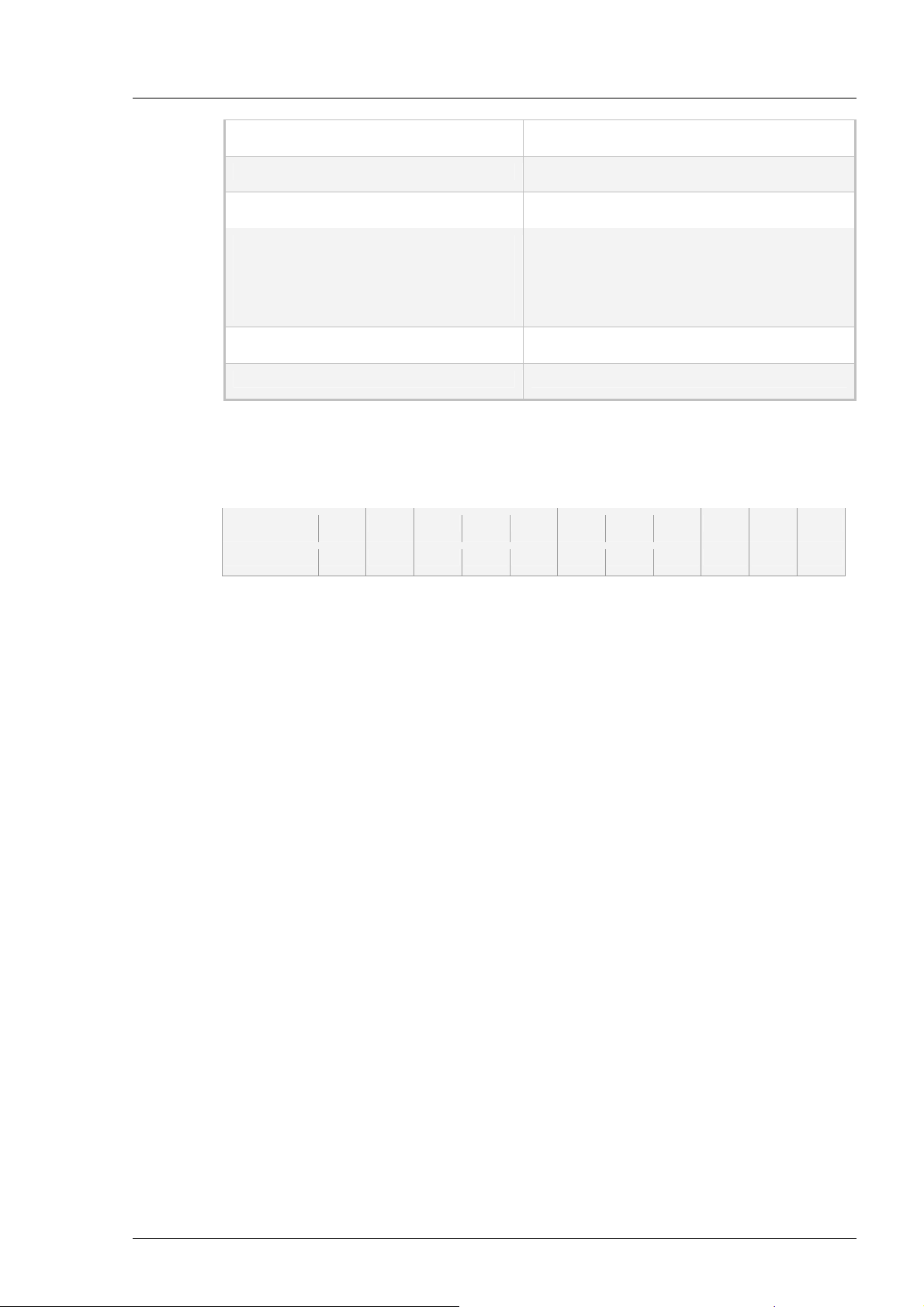

2 Technical Data

Manufacturer's data

Manufacturer LumaSense Sensor GmbH

Name of the pyrometer KLEIBER 740

Design data

Length (basic instrument) 170 mm

Width 170 mm

Height 70 mm

Length with maximum extension of optics:

with straight connector

with angled connector

Weight approx. 1.2 kg

Characteristic data

Measurement range in °C/ Spectral range in

µm

Measurement outlet

analogue

Accuracy: 0.75 % of measured value (at 25°C, ε=1)

Reproducibility: < 0,3 % of measured value (at 25°C, ε=1)

320 mm

300 mm

KS 740

[600 … 1.600] °C [0.85 … 1.05] μm

[800 … 2.300] °C [0.85 … 1.05] μm

KG 740

[300 … 1.400] °C [1.58 … 1.80] μm

[800 … 2.500] °C [1.58 … 1.80] μm

KGA 740

[160 … 1.000] °C [1.58 … 2.20] μm

[300 … 2.300] °C [2.00 … 2.20] μm

[0 … 20] mA or [4 … 20] mA,

maximum burden 500 Ω, galvanically separated

Response time t95 6 µs via voltage output

9 µs via current output

Emissivity (ε) adjustable from 0.1…1

Vario optic (standard) for measuring distances and measuring fields

please refer to table next below

Macro optic (optional) measuring distance: 288 mm (KS 740 and KG 740)

290 mm (KGA 740)

measuring field: ∅ 0.7 mm (KS 740 and KG 740)

∅ 1.0 mm (KGA 740)

Sighting mechanism LED pilot light or optional through lens sighting

Operating temperature [0 … +40] °C

[0 … +80] °C with water cooling

4 KLEIBER 740

Page 9

Technical Data

Storage temperature [-20 … +70] °C

Power supply 24 V DC, 0.2 A or 24 V AC, 0.2 A

Degree of protection: IP 54 according to DIN 40 050

Cooling

− connection

− flow rate

− pressure

− coolant temperature

Test base EN 55 011 : 1998, limit class A

CE marking according to EU regulations

tube screw connector ¼ "

at least 1 l/min

maximum 6 bar

[10 … 35] °C

Vario optic

a*1 in mm 450 600 800 1000 1200 1400 1600 1800 2000 2500 3000

M*2 in mm 2.5 4.0 6.0 8.0 10.5 11.5 13.0 14.0 15.0 20.0 28.0

*1 Distance from optics front edge

2

*

Measuring field diameter

KLEIBER 740 5

Page 10

Safety

3 Safety

3.1 Symbols and Signal Words Used

The following symbols and key words are used in the user manual to indicate hazards and

instructions. Safety precautions always appear before an action.

DANGER

Indicates a potentially dangerous situation. Failure to abide may result in light or minor

injury and damage.

CAUTION

Indicates a potentially damaging situation. Failure to abide may result in damage to the

product or to anything near the product.

IMPORTANT

Indicates useful tips and other specifically useful information that allow any dangerous or

damaging situations to be avoided.

REFERENCE TO ENVIRONMENTAL PROTECTION

Important instructions for protecting the environment

6 KLEIBER 740

Page 11

3.2 General Safety Notes

The KLEIBER 740 pyrometer has been built in accordance with the currently valid standards

of the technology and the recognized safety regulations and ensures the highest safety

level.

The fundamental safety and occupational safety requirements of applicable laws, standards,

and guidelines have been taken into account in the pyrometer design. The safety of the

pyrometer is confirmed by the declaration of conformity and the CE mark.

All information related to safety is with reference to the regulations of the European Union

currently in force. In other countries, applicable laws, national directives and safety

regulations have to be met.

Apart from the safety instructions given in these operating instructions, you should also take

into account the generally valid regulations for accident prevention and environmental

protection as well as the regulations of the respective professional associations and strictly

comply with them.

Safety

Note the general safety instructions:

Commissioning of the pyrometer may only be carried out by persons qualified to do

so, taking the safety instructions into account.

Pay attention to the installation site requirements and notes for commissioning (see

section

Only use the original cables provided as accessories for the connection of the

pyrometer. Other cables, especially cables manufactured by yourself, are not

permitted.

Lay all cables and cooling water pipes in such a way that they are not exposed to any

tension and are not clamped or squashed.

Before start-up, carry out a visual inspection for damage to the components of the

pyrometer (housing, optics, cable and pipes). Never operate the pyrometer with

damaged components.

6).

KLEIBER 740 7

Page 12

Technical Description

4 Technical Description

4.1 System Design/Principle of Operation

Fig. 1 shows the basic structure of the pyrometer. The basic parts of a pyrometer are the

lens, aperture, filter detector, and the signal processing unit. The infrared radiation coming

in from the object to be measured is gathered by the lens. The aperture blocks unwanted

rays at the edges. The filter permits only the desired spectral range to enter. The rays then

pass through to the detector which transforms the infrared radiation into electric signals.

These signals are then linearised in the signal processing unit and changed into a standard

output signal which can then be read in the display, and be used for process control.

The operating elements as well as the connections/interfaces are located at the back of the

pyrometer (see pages

The coolant connections are located under the instrument.

10 to Fehler! Textmarke nicht definiert.).

Fig. 1 Structure of the pyrometer

4.1.1 Optics

Depending on the application (measuring distance, measuring field diameter, etc.), the

pyrometer is equipped with a vario-optic or a macro-optic.

Vario optics

The Vario optic can be adjusted to the required measuring distance and allows small

measuring fields for various distances to the object being measured. The object being

measured can be at an arbitrary distance, but must be at least as large as the measuring

field at that distance (see section

7.1).

8 KLEIBER 740

Page 13

Technical Description

Fig. 2 Vario optics

1 Object to be measured

2 Measuring field

3 Optical ray from vario tube

4 Ring nut

Macro optics

The macro-optics is a fixed optics for very small measuring fields, i.e. a certain measuring

field diameter is given for a certain measuring distance.

Fig. 3 Macro optics measuring set-up (KS/ KG 740)

Fig. 4 Macro optics measuring set-up (KGA 740)

1 Object to be measured

2 Measuring field ∅ = 0.7 mm (KS/ KGA 740), ∅ = 1.0 mm (KGA 740)

3 Macro tube

4 Pyrometer front edge

IMPORTANT

The macro tube cannot be adjusted. The distances mentioned must be respected

absolutely in order to ensure the small measuring field.

KLEIBER 740 9

Page 14

Technical Description

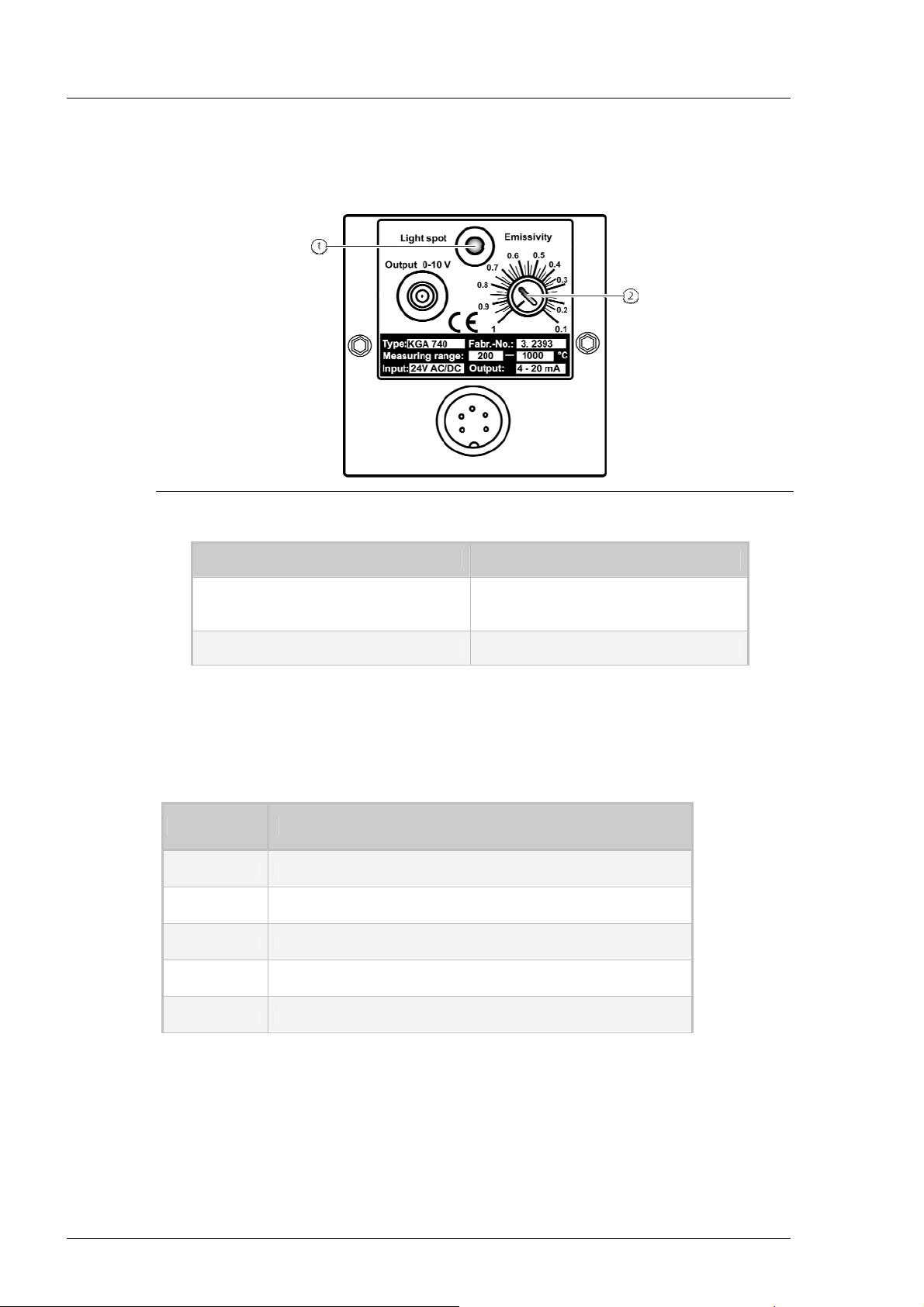

4.1.2 Operating and display elements

The controls and indicators are located on the rear side of the device. For the meaning of

individual elements refer to legend

Fig. 5, for operation of the pyrometer see section 7.

Fig. 5 Operating and display elements

Operating and display element Meaning

1 Push button for pilot light switch on/ off the pilot light

(optional through lens sighting)

2 Potentiometer [emissivity] adjustment of emissivity from 0.1 … 1

4.1.3 Connections and interfaces

The 5-pole plug to connect the instrument is at the rear side of the unit (see Fig. 66). The

contacts of the 5-pole plug are arranged as follows:

Plug pin Meaning

1 Supply voltage +24 V (DC or AC)

2 Supply voltage 0 V (DC or AC)

3 ground output

4 Analogue output [0 (4) … 20] mA

5 empty

10 KLEIBER 740

Page 15

Technical Description

3

4

Fig. 6 Connecting plug for 5-pin connecting cable

Operating and display element Meaning

3 BNC Output BNC output 0 … 10 V for connection to

storage oscilloscope

4 5-pin plug connection Power supply connection and output

[0(4) … 20] mA

Cooling water connection

At ambient temperatures of more than 40°C the pyrometer must be operated with the

associated cooling! The two connections for the connection of a cooling circuit are located

under the instrument (see

The following should be taken into account when connecting a cooling circuit:

Flow rate at least 1 l/min

Pressure: maximum 6 bar

Coolant temperature 10 °C to 35 °C

Fig. 77).

Fig. 7 Cooling water connections (tube screw connector ¼")

Cold tap water is usually sufficient for cooling. It should not be so strongly cooled that

condensation develops on the instrument. Take into account the environmental conditions

(air temperature and humidity) with respect to the cooling.

KLEIBER 740 11

Page 16

Technical Description

Mounting

There is a retaining pin (scope of delivery) through which the pyrometer can be fixed using

various brackets.

We recommend fixing the pyrometer using the retaining pin and optional available ball and

socket mounting support with clamp or thread. This mounting plate ensures secure

assembly of the pyrometer as well as optimal adjustment with respect to the object being

measured (for order data see page 22).

12 KLEIBER 740

Page 17

5 Transport and Storage

5.1 Transport of the pyrometer

CAUTION

Environmental factors, impacts and the formation of water condensation may damage some

components!

When transporting the pyrometer, take suitable measures to protect all components from

environmental factors, impacts and the formation of water condensation! Temporary

storage of the pyrometer in the open air is not permitted!

Prepare the pyrometer for transport as follows:

1. Switch the pyrometer off so that there is no tension and remove the connecting cable

and the signal cable.

2. In case of usage of water cooling please remove the cooling water pipes from the

cooling water connectors and remove the water from the pyrometer.

Transport and Storage

3. Pivot the optics completely and lock these with the adjusting ring.

4. Protect the optics against scratches through suitable measures (e.g. protective cap,

foil, …).

5. Pack the pyrometer in the original packaging paying attention to the means of

transport (see transport instructions below).

The pyrometer is thus ready to be shipped.

It is advisable to use the original packaging for the shipping of the pyrometer. If the original

packaging is no longer available, the pyrometer should be shipped in a cardboard box with

shock-absorbing PE material.

When transporting the pyrometer observe the following instructions:

Take great care when transporting the pyrometer to avoid damage through the effect

of force, or careless loading or unloading.

Avoid jerks, vibrations and the formation of condensed water due to severe

temperature deviations while transporting.

In the case of overseas shipping, a suitable desiccator (e.g. Silicagel) should be

inserted and the pyrometer should be sealed together with the desiccator in a

protective plastic sheet.

If the pyrometer is not immediately installed after delivery and put into operation, then

it should be carefully stored in a location protected against dust and humidity (storage

conditions - see section

5.2).

KLEIBER 740 13

Page 18

Transport and Storage

5.2 Storage of the pyrometer

CAUTION

Environmental factors and water condensing may damage some components!

Store the pyrometer only in dry areas without large variations in temperature! The

atmosphere should be free of dust and corrosive vapours!

CAUTION

There is a danger of destruction by using freezing cooling water with a storage temperature

<0 °C!

Before storage of the pyrometer if applicable remove any remaining cooling water from the

cooling ducts of the equipment! Storage of the pyrometer with coolant remaining in the

cooling ducts is not permitted!

Store the pyrometer appropriately in the original packaging. Put a suitable desiccant inside

the packing (e.g. silica-gel) to prevent damage by moisture. Protect the pyrometer against

dust through suitable measures.

The following climatic conditions are required in the storage room of the pyrometer:

temperature range: -20 °C to +70 °C

maximum air humidity: to 70 %

atmosphere free of dust and corrosive vapours

14 KLEIBER 740

Page 19

6 Starting Up

6.1 Installation Site Requirements

CAUTION

Measurement errors and damage to the pyrometer through

– ambient temperatures too high ,

- strong contamination of the optics due to dust, smoke, steam or other causes

– air pollution,

- electromagnetic interference sources

You must take into account the following climatic conditions and the requirements of the

place of use of the pyrometer!

Climatic conditions

The following requirements must be fulfilled with respect to the climatic conditions at the

place of use of the pyrometer:

Starting Up

temperature range: 0 °C to +40 °C (up to +80°C with connected cooling)

maximum air humidity: 60 % at room temperature

Atmosphere free of dust, corrosive vapours, and fume gases

Requirements at the place of use

Take into account the following requirements at the place of use of the pyrometer:

Take care with the choice of the place of use and take into account the ergonomic and

the legal guidelines for industrial safety in order to ensure safe operation of the

pyrometer.

Set up the pyrometer on a firm, stable base. The base must be free from concussion

and vibration.

Note:

We recommend using the rail mounting plate available as an accessory for the

attachment of the pyrometer as well as a clamping attachment (see page

22).

Do not expose the system to direct sunlight or radiation from heating (e.g. radiators).

Do not set the pyrometer near strong electromagnetic fields or near electromagnetic

interference sources.

Make sure that the pilot light falls unhindered on the object being measured and that

there is nothing in the path of the rays.

KLEIBER 740 15

Page 20

Starting Up

6.2 Installation

6.2.1 Fix and connect the pyrometer

DANGER

There is danger of injury and possible equipment damage by connection of cables under

power!

Never connect cables under power! Make sure that the voltage supply is switched off before

connection of the cables to the pyrometer!

IMPORTANT

Operation of the pyrometer about ambient temperatures of more than 40°C is only

permitted with water cooling! Connect the pyrometer to a suitable cooling circuit with

ordinary tap water! The use of coolants is permitted only with the agreement of the

manufacturer!

The temperature of the cooling water must lie between 10 °C and 35 °C. Condensation buildup due to the low temperature of the cooling water is to be avoided.

Install the pyrometer as follows:

1. Mount the pyrometer with the help of the retaining pin and taking into account the

conditions specified in section

6.1 for the intended place of use.

2. Connect, if necessary (only in case of ambient temperatures more than 40°C) the

water cooling (position 1,

Fig. 8).

3. Connect the coloured wires of the 5-pole connecting cable (item B,

appropriate connections of a switchboard. For wire configuration please see legend

to fig. 8.

4. Connect the 5-pole connecting cable to the pyrometer at the back of the instrument

(item 2,

Fig. 8) and to the power supply.

5. Double check stable set up of the pyrometer.

The pyrometer is ready for use and can be switched on.

Fig. 8) to

Fig. 8 Pyrometer connections

1 Cooling circuit connections

2 Connect 5-pole connecting cable.

16 KLEIBER 740

Page 21

Starting Up

Fig. 9 Pyrometer wire connection with configuration

Connector A Meaning

Pin 1 Supply voltage +24 V (DC or AC)

Pin 2 Supply voltage 0 V (DC or AC)

Pin 3 ground output

Pin 4 Analogue output [0 (4) … 20] mA

Pin 5 empty

Connector B Meaning

1 - white Supply voltage +24 V (DC or AC)

2 - brown Supply voltage 0 V (DC or AC)

3 - green ground output

4 - yellow Analogue output [0 (4) … 20] mA

5 – green-yellow shield

6.2.2 Align pyrometer

The pyrometer is equipped with an LED pilot light for accurate alignment of the sensor with

the object to be measured. Align the pyrometer with the object to be measured as follows:

1. Switch on the supply voltage to the pyrometer.

2. Allow a starting time of approx. 5 minutes for thermo-stabilization. Than the pyrometer

has stabilised and is ready to work with the given accuracy.

3. Switch on the pilot light by pressing the push button at the rear side. Make sure that

there is nothing in the path of rays.

Note:

In order to avoid measuring errors, the area of the pilot light must not be larger

than the object to be measured.

4. If you have a pyrometer with vario optic, adjust the necessary measuring distance (see

page

18).

Note:

The macro-optics cannot be adjusted.

The pyrometer is thus aligned and ready for the temperature measurement.

KLEIBER 740 17

Page 22

Operation of the pyrometer

7 Op

eration of the pyrometer

7.1 Setting the Vario optic

Adjust the necessary measuring distance with the help of the vario optic as follows:

1. If necessary switch on the pilot light by pressing the push button at the rear side.

2. Loosen the ring nut (item 1, Fig. 10) by turning it in a counter-clockwise direction.

3. Move the vario optic (item 2, Fig. 10) forwards and/or backwards, in order to adjust

the pyrometer to the required measuring distance.

Note:

The size of the pilot light is identical to the size of the measuring field. The measuring

field may not be larger than the object to be measured at the adjusted distance!

4. After adjusting the measuring distance, lock the annular nut by turning it in a

clockwise direction.

The vario optic is thus adjusted to the required measuring distance.

Fig. 10 Setting the vario optic

a*1 in mm 450 600 800 1000 1200 1400 1600 1800 2000 2500 3000

M*2 in mm 2.5 4.0 6.0 8.0 10.5 11.5 13.0 14.0 15.0 20.0 28.0

*1 Distance from optics front edge

2

Spot size diameter

*

18 KLEIBER 740

Page 23

7.2 Adjusting the Parameters Emissivity

The emissivity is the relationship between infrared energy radiated from an object an

radiation energy of a perfect emitter (black emitter) at the same temperature and the same

sp

ectral range.

e emissivity is material-dependent and of a considerable size in order to be able to

Th

termine the temperature of an object accurately without contact. The emissivity of the

de

being measured must therefore be known and be ad

object justed at the pyrometer.

the emissivity suitable for the measurement in accordance with the procedural steps

Adjust

on pag

Typical emissivities for various ma

www.kleiberinfrared.com under practical knowledge or in relevant literature.

The instrument is calibrated at black body radiation (ε = 1.00). Real objects have an

emissivity less than 1.0. This difference can be stepless adjusted between 0.1 and 1.0 with

the potentiometer at the back of the instrument.

H

e 19. The adjusted emission value is indicated in the main menu.

terials are available on our homepage at

ow to find out correct emissivity:

d the

1. First measure the real temperature of

e.g. thermocouple or resistance probes. The “black” temperature (spectral

temperature) measured with a pyrometer adjusted to emissivity = 1.0 usually gives

a m uring alue fferin to rea temperature ecause of th real e issiv y of

eas v di g l b e m it

<1.0. The value given by the instrument usually will be less than the real

tem ature he e issio atio most

per . T m n r of materials depends on temperature as well

as wave length being measured.

2. You can get a correlation of the temperat

the exact temperature with the help

After adjusting the emissivity factor through a correlation measurement you can now

measure temperatures for the calibrated temperature range at an accuracy

mentioned in the technical data.

IMPORTANT

Please pay attention if you take over table values of emissivity to give the value of

emissivity factor at a certain wave length. Adjusting emissivity following table values is not

as exactly as adjusting following a comparing measurement.

Changing emissivity

measuring object with a contact thermometer

ure scales, if you adjust the pyrometer at

of the potentiometer of emissivity.

With the help of a suitable screw driver and without any violence you can adjust emissivity

at the rear side with the potentiometer (see Fig. 5) stepless between 0.1 and 1.

KLEIBER 740 19

Page 24

Troubleshooting

8 Troubleshooting

DANGER

There is a danger of injury and possible equipment damage through incorrect power supply

Let problems relating to an incorrect power supply be eliminated by an electrical specialist!

Do not carry out a!rbitrary work on the electrical components of the pyrometer!

Only eliminate such problems yourself when their causes obviously relate to incorrect pow

supply, under-cooling or contamination of the lens.

Do not undertake any interventions into the pyrometer. If problems arise which do not relate

to the causes mentioned above, inform the service staff of the LumaSense

(for contact data see page

Fault Cause Solution

22).

er

Sensor GmbH

Pyrometer does not provide

any measured values

If the pyrometer supplies

inaccurate measured values

or measured values which lie

outside the range to be

expected

Power supply faulty or

interrupted

dirty optics or

condensation on the lens

Cooling too strong/ weak or air

humidity too high

− Check the power supply

− Check plugs and connections

− Inspect cable

Clean optics

(see section 9.2)

Check cooling

(see page 11)

20 KLEIBER 740

Page 25

9 Maintenance and Care

Maintenance and Care

9.1 General

information

CAUTION

Humidity can lead to the destruction of the electrical and electronic components

Do not use any liquids for cleaning the pyrome

the pyrometer!

IMPORTANT

The servicing period depends particularly on the operating and environmental conditions and

is therefore to be specified by the

The pyrometer is largely maintenance-free. Its function depends, how

the condition of the optics. The optics must therefore be checked and if necessary cleaned

a to vironmen

t regular intervals according

se cessary i f the measured tem

ction 9.2). This is ne

the expected range

In the case of excessive contamination or scratches of the optics, please contact the

technical customer service (contact address - see page 22).

Check the cables and the protective housing

ating.

se

ter or cleaning the immediate environment of

operator!

the operating and en

n particular i

at regular intervals for damage and a firm

!

ever, considerably on

tal conditions (see

perature levels do not lie in

9.2 Cleaning the Optics

Clean the lens with a soft cloth or cotton pad and with white spirits. The optics is thus

cleaned and the pyrometer is again ready for use.

KLEIBER 740 21

Page 26

Accessories

10 Accessories

Electrical accessory

Connecting cable for power supply, length 1.5 m (other length on request)

BNC connecting cable, length 4 m (other length on request)

Power supply KNG-0

Power supply KNG-2

Power supply with alloy housing

Optical accessory

Through lens sighting

Macro optics

Optical scanner SC 1

Maximum value storage (only in combination with optical scanner SC 1)

Mechanical accessory

Air purge unit

Ball and socket mounting screw mounted

Ball and socket mounting clamp mounted

Order information

Please send your orders for accessories to the follo

uote the pyrometer type, the name of the accessory part, and the quantity.

q

wing address. When ordering, please

Service address:

LumaSense Sensor GmbH

Carl-Zeiss-Strasse 5

07318 Saalfeld, Germany

Phone: +49 (0) 36 71/5 27 20-0

Fax: +49 (0) 36 71/5 27 20-12

email: info@kleiberinfrared.de

22 KLEIBER 740

Page 27

Taking out of service, Disposal

11 Taking out of servic

11.1 Taking out of service

D

ANGER

Removing electrically live cables risks injury and damage to equipment.

Never remove electrically live connecting cables. Before removing a cable, ensure that the

power supply has been switched off.

Take the pyrometer out of operation as follows:

1. Switch off the power sup

cables at the rear side of the pyrometer.

ove the connections of the cooling system and empty the remaining

water from the cooling ducts of the pyrometer.

The pyrom

2. Remove the

3. If applicable switch off the cooling water supply.

4. If applicable rem

cooling

5. Dismantle the pyrometer from the mounting plate.

6. If necessary bring the optics in and tighten the annular nut.

eter is thus out of operation.

e, Disposal

ply to the pyrometer.

11.2 D

For disposal, you can return the pyrometer to LumaSense Sensor GmbH (for address see

p

use a cardboard carton with shock absorbing PE material.

REFERENCE TO ENVIRONMENTAL PROTECTION

Do not dispose of the pyrometer with domestic refuse!

isposal

age 21). For this you should pack the pyrometer appropriately in the original packaging or

KLEIBER 740 23

Loading...

Loading...