Page 1

Mobile Twin Shaft Mixers

MTS

Page 2

Technical Data

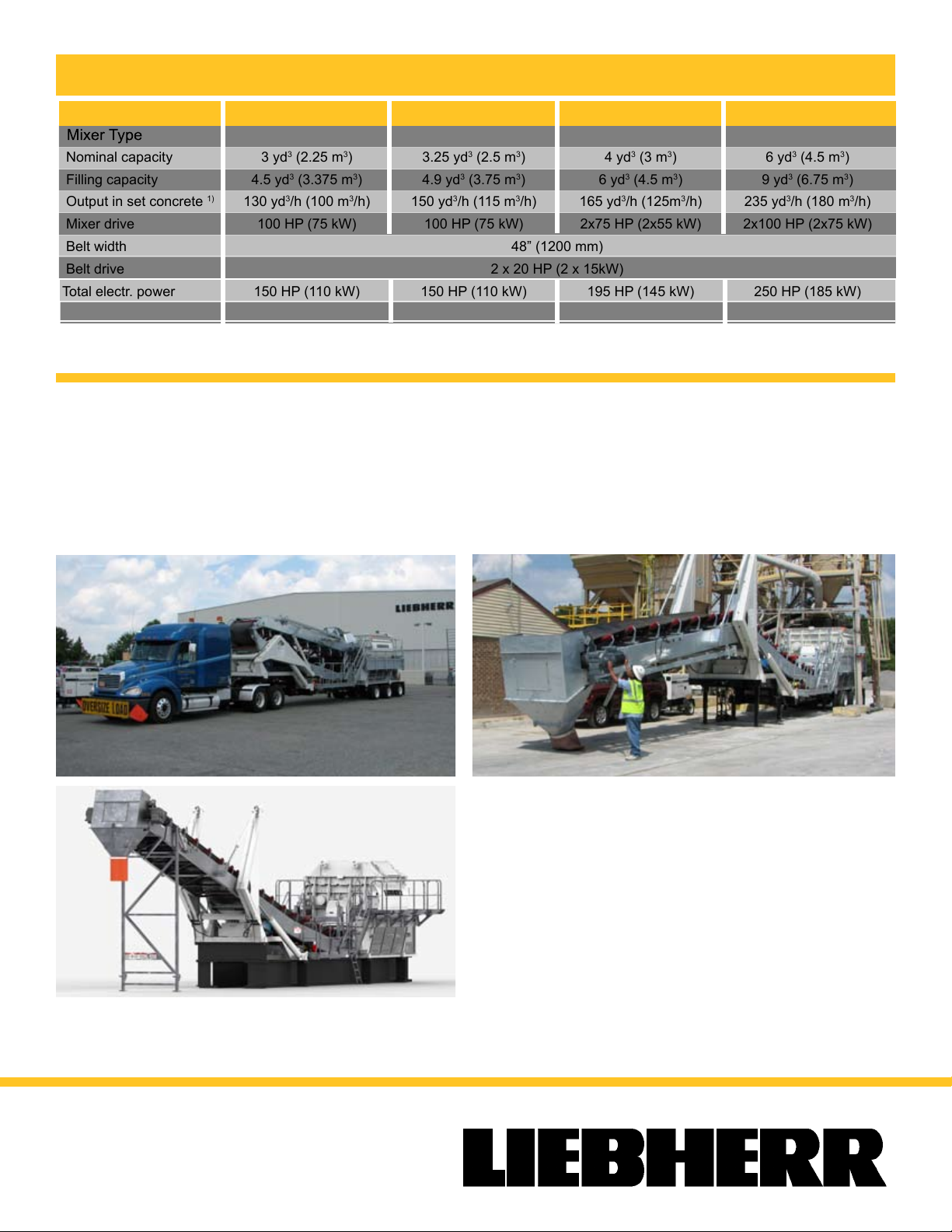

Type: MTS 2.25 MTS 2.5 MTS 3.0 MTS 4.5

Mixer Type DW 2.25 DW 2.5 DW 3.0 DW 4.5

Nominal capacity 3 yd3 (2.25 m3) 3.25 yd3 (2.5 m3) 4 yd3 (3 m3) 6 yd3 (4.5 m3)

Filling capacity 4.5 yd3 (3.375 m3) 4.9 yd3 (3.75 m3) 6 yd3 (4.5 m3) 9 yd3 (6.75 m3)

Output in set concrete

Mixer drive 100 HP (75 kW) 100 HP (75 kW) 2x75 HP (2x55 kW) 2x100 HP (2x75 kW)

Belt width 48” (1200 mm)

Belt drive 2 x 20 HP (2 x 15kW)

Total electr. power 150 HP (110 kW) 150 HP (110 kW) 195 HP (145 kW) 250 HP (185 kW)

Total weight (approx.) 31.1 MT 32.6 MT 33.3 MT 34.6 MT

1) Cycle Time: 85 sec.

Cycle times may increase and output decrease depending on the rating and design of the whole plant in which the mixer is installed.

Operation

The low prole allows setting up the mobile twin shaft mixer under a typical dry-batch plant without or minor

modications to the plant. The plant with the attached twin shaft mixer can now produce high quality concrete

mixes such as roller compacted concrete (RCC), cement treated base (CTB), self compacted concrete (SCC),

zero slump concrete, etc. More exibility and variability increases the application possibility of the plant and

generates more revenue.

1)

130 yd3/h (100 m3/h) 150 yd3/h (115 m3/h) 165 yd3/h (125m3/h) 235 yd3/h (180 m3/h)

Easy Transport & Installation

Transport height

13’-4” (4.06 m)

Skid mounted unit

Lowered position for easy maintenance

Features

- Hydraulic unfolding of conveyor into 3 positions:

1) truckmixer loading 2) dumptruck loading 3) service

- 48” belt guarantees maximum output

- Discharge of concrete with slump 0-6” (0-150mm)

- Adjustable mixer discharge gate

- Galvanized belt frame, platforms, and railings

- Easy access for cleaning, inspection & service

- Trailer with airbags and adjustable support legs

- Trailer is NAFTA compliant

Optional

High pressure cleaner with spraygun and retractable water hose • cable remote control • additional folding platforms around the mixer • skid-mount instead of trailer for stationary installations

LIEBHERR CONCRETE TECHNOLOGY CO.

4100 Chestnut Ave, Newport News, VA 23607

Ph: (757) 928-8547 Fax: (757) 928-2489

Toll Free: (866) 879-6312

www.liebherr.us Mail: info.lct@liebherr.com

Loading...

Loading...