Page 1

Inverter

8400

Inverter Drives 8400 motec_ _ _ _ _ _ _ _ _ _ _

E84DGxxxx...

Reference manual EN

Ä.Z>óä

13572994

L

Page 2

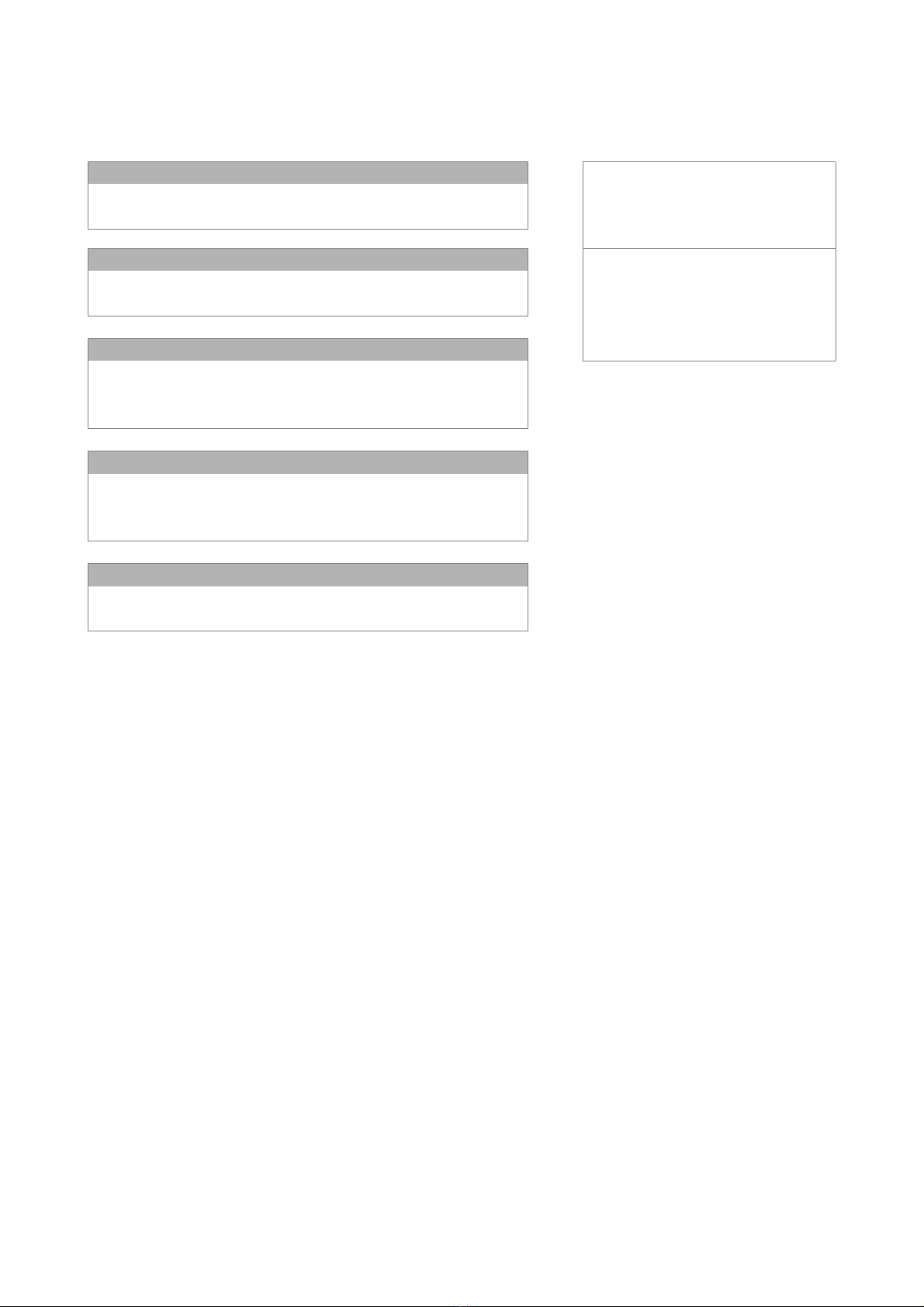

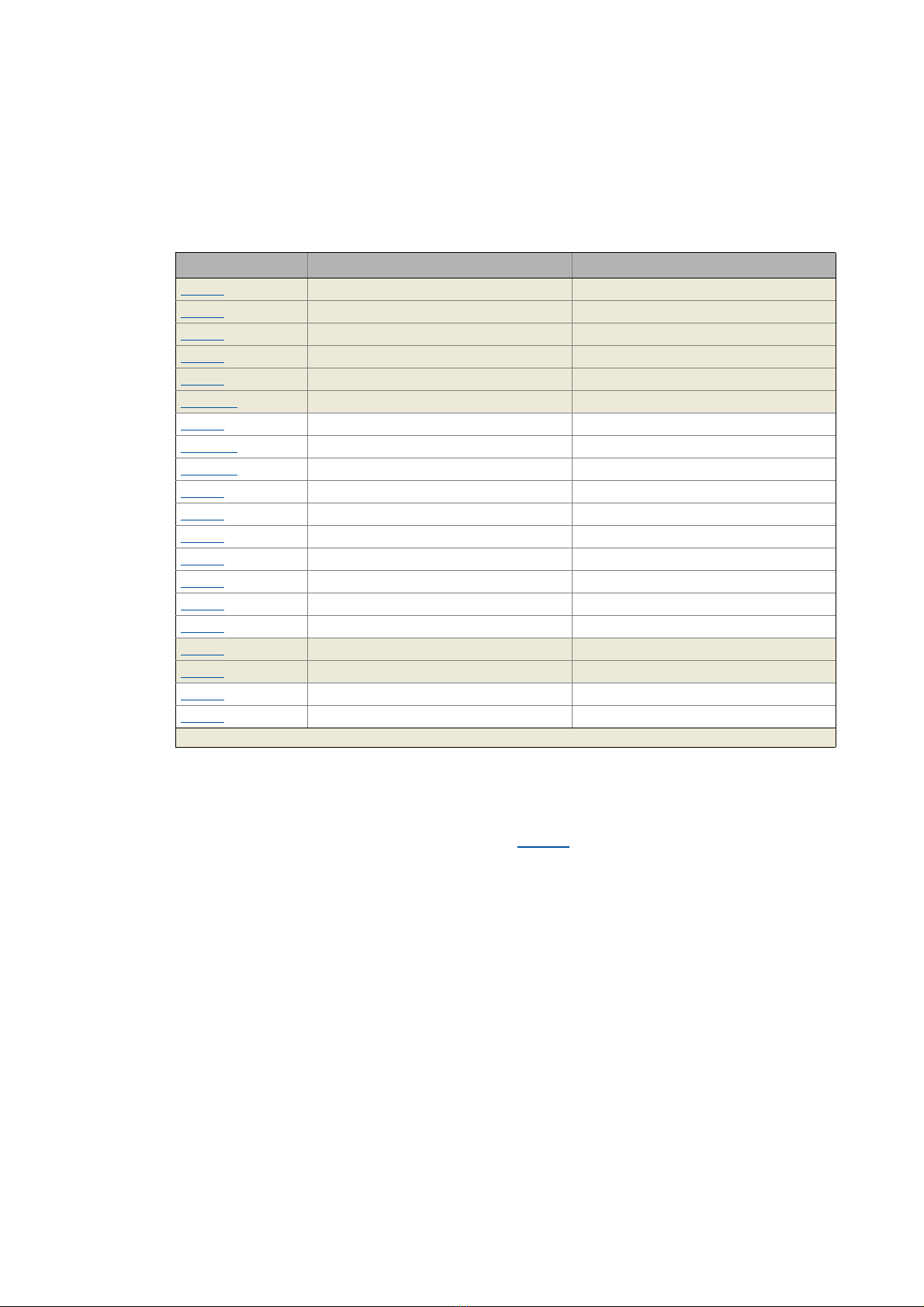

Overview of technical documentation for Inverter Drives 8400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Project planning, selection & ordering Legend:

8400 motec hardware manual Printed documentation

Catalogue Online documentation

(PDF/Engineer online help)

Mounting & wiring Abbreviations used:

MA 8400 motec BA Operating instructions

MA for the accessories KHB Communication manual

MA Mounting instructions

Parameter setting SW Software/reference manual

BA for diagnosis terminal

SW 8400 motec This documentation

KHB for communication unit

Drive commissioning

SW 8400 motec This documentation

chapter "Commissioning"

chapter "Diagnostics & error management"

Networking

KHB for communication unit

MA for the accessories

2 Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 3

Contents

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 12

1.1 Document history _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 13

1.2 Conventions used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 14

1.3 Terminology used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 15

1.4 Definition of the notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 17

2 Introduction: Parameterising the inverter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 19

2.1 Integrated technology applications _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 21

2.2 Selection of the appropriate commissioning tool _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 22

2.2.1 Overview: Accessories for commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 23

2.3 General notes on parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 24

2.3.1 Changing the parameterisation with the keypad _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 25

2.3.2 Change parameter settings with PC and Lenze software _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 28

2.3.3 User menu for quick access to frequently used parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 29

2.4 Handling the memory module _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 30

2.5 Device identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

2.5.1 Automatic acceptance of the device name in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 32

3 Commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 33

3.1 Safety instructions with regard to commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 34

3.2 Preconditions for commissioning with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 35

3.3 Trouble-shooting during commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 35

3.4 Commissioning wizard 8400 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 36

3.5 Commissioning of the "Actuating drive speed" technology application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 37

3.5.1 Prepare inverter for commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 38

3.5.2 Creating an »Engineer« project & going online _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 39

3.5.3 Parameterising the motor control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 40

3.5.4 Parameterise application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 42

3.5.5 Save parameter settings safe against mains failure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

3.5.6 Enabling the inverter and selecting the speed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 44

3.6 Commissioning of the "Switch-off positioning" technology application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 45

3.6.1 Prepare inverter for commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 47

3.6.2 Creating an »Engineer« project & going online _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 48

3.6.3 Parameterising the motor control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 49

3.6.4 Parameterise application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 51

3.6.5 Save parameter settings safe against mains failure _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

3.6.6 Enable inverter and test application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 53

3.7 PC manual control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 54

3.8 Control via Field Package ("key-operated switch operation") _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 58

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 3

Page 4

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

4 Device control (DCTRL) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 61

4.1 Device commands (C00002/x) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 63

4.1.1 Load Lenze setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 65

4.1.2 Load parameter set 1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 66

4.1.3 Save parameter settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 67

4.1.4 Import EPM data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 67

4.1.5 Enable/inhibit inverter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

4.1.6 Activate/deactivate quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 68

4.1.7 Reset error _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 69

4.1.8 Delete logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 69

4.1.9 Identify motor parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

4.1.10 CAN reset node _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 70

4.1.11 Device search function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 71

4.2 Device state machine and device states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 72

4.2.1 Init _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 74

4.2.2 MotorIdent _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

4.2.3 SafeTorqueOff _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 75

4.2.4 ReadyToSwitchOn _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 76

4.2.5 SwitchedOn _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 77

4.2.6 OperationEnabled _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 78

4.2.7 Trouble _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 79

4.2.8 Fault _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 80

4.3 Auto-start option "Inhibit at power-on" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 81

4.4 Energy saving mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 83

4 Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 5

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 Motor control (MCTRL) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 85

5.1 Special features of the 8400 motec _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 86

5.2 Motor selection/Motor data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 87

5.2.1 Selecting a motor from the motor catalogue in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ 93

5.2.2 Automatic motor data identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 95

5.3 Selecting the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 97

5.3.1 Selection help _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 100

5.4 Defining current and speed limits _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 101

5.5 V/f characteristic control (VFCplus) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

5.5.1 Parameterisation dialog/signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 103

5.5.2 Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 105

5.5.2.1 Define V/f characteristic shape _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 105

5.5.2.2 Defining current limits (Imax controller) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 106

5.5.3 Optimising the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 107

5.5.3.1 Adapting the V/f base frequency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 108

5.5.3.2 Adapting the Vmin boost _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 109

5.5.3.3 Optimising the Imax controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 110

5.5.3.4 Torque limitation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 111

5.5.3.5 Optimising the starting performance after a controller enable _ _ _ _ _ _ _ _ 112

5.5.4 Remedies for undesired drive behaviour _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 113

5.6 V/f characteristic control - energy-saving (VFCplusEco) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 114

5.6.1 Parameterisation dialog/signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 115

5.6.2 Comparison of VFCplusEco - VFCplus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 117

5.6.3 Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 118

5.6.4 Optimising the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 119

5.6.4.1 Improving the behaviour at high dynamic load changes _ _ _ _ _ _ _ _ _ _ _ _ 120

5.6.4.2 Adapting the slope limitation for lowering the Eco function _ _ _ _ _ _ _ _ _ _ 120

5.6.4.3 Optimising the cos/phi controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 121

5.6.4.4 Optimising the starting performance after a controller enable _ _ _ _ _ _ _ _ 122

5.6.5 Remedies for undesired drive behaviour _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 123

5.7 V/f control (VFCplus + encoder) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 124

5.7.1 Parameterisation dialog/signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 125

5.7.2 Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 127

5.7.2.1 Define V/f characteristic shape _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 128

5.7.2.2 Defining current limits (Imax controller) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 129

5.7.2.3 Parameterising the slip regulator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 130

5.7.3 Optimising the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 134

5.7.3.1 Optimising the starting performance after a controller enable _ _ _ _ _ _ _ _ 134

5.8 Sensorless vector control (SLVC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 135

5.8.1 Parameterisation dialog _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 136

5.8.2 Types of control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 137

5.8.2.1 Speed control with torque limitation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 138

5.8.2.2 Torque control with speed limitation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 139

5.8.3 Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 141

5.8.3.1 Reduction of the speed overshoot _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 142

5.8.4 Optimising the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 143

5.8.4.1 Optimising the starting performance after a controller enable _ _ _ _ _ _ _ _ 143

5.8.5 Remedies for undesired drive behaviour _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 144

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 5

Page 6

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.9 Sensorless control for synchronous motors (SLPSM) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 145

5.9.1 Parameterisation dialog/signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 148

5.9.2 Increasing the acceleration of the drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 151

5.9.3 Types of control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 151

5.9.4 Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 153

5.9.5 Optimising the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 154

5.9.5.1 Optimise current controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

5.9.5.2 Optimise speed controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 155

5.9.5.3 Current-dependent stator leakage inductance Ppp(I) _ _ _ _ _ _ _ _ _ _ _ _ _ _ 159

5.9.5.4 Optimising the starting performance after a controller enable _ _ _ _ _ _ _ _ 161

5.9.6 Pole position identification without motion _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 162

5.9.7 Field weakening for synchronous motors _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 164

5.10 Parameterisable additional functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 168

5.10.1 Selection of switching frequency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 168

5.10.2 Flying restart function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 171

5.10.3 DC-injection braking _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 173

5.10.3.1 Manual DC-injection braking (DCB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 174

5.10.3.2 Automatic DC-injection braking (auto DCB) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 174

5.10.4 Slip compensation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 177

5.10.5 Oscillation damping _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 178

5.10.6 Mass inertia precontrol _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 179

5.11 Encoder/feedback system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 181

5.11.1 Encoder evaluation method _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 184

5.12 Braking operation/brake energy management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 186

5.12.1 Settings for mountable brake resistors _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 186

5.12.2 Settings for internal brake resistor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 188

5.12.3 Voltage limits for braking operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 188

5.12.4 Response to an increase of the DC-bus voltage _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 188

5.12.4.1 Inverter motor brake _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 190

5.12.4.2 Degradation of braking energy by motor overmagnetisation _ _ _ _ _ _ _ _ _ 193

5.13 Power and energy display _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 194

5.14 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 195

5.14.1 Device overload monitoring (Ixt) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 196

5.14.2 Motor load monitoring (I2xt) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 197

5.14.3 Motor temperature monitoring (PTC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 200

5.14.4 Brake resistor monitoring (I2xt) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 201

5.14.5 Mains phase failure monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 203

5.14.6 Maximum current monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 203

5.14.7 Current monitoring for overload _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 204

5.14.8 Motor speed monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 205

5.14.9 Encoder open-circuit monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 205

6I/O terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 206

6.1 Digital terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 207

6.1.1 Configuring DI1 and DI2 as frequency inputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 211

6.2 Analog terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 214

6.2.1 Parameterising analog input _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 215

6.3 User-defined terminal assignment _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 217

6.3.1 Source-destination principle _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 218

6.3.2 Changing the terminal assignment with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 219

6.3.3 Changing the terminal assignment via configuration parameters _ _ _ _ _ _ _ _ _ _ _ _ _ 220

6.4 Electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 223

6 Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 7

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

7 Technology applications _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 225

7.1 Selection of the technology application and the control mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 226

7.2 TA "Actuating drive speed" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 227

7.2.1 Basic signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 228

7.2.1.1 "GeneralPurpose" functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 231

7.2.2 Interface description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 232

7.2.2.1 wDriveControl control word _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 238

7.2.2.2 Status word _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 238

7.2.3 Terminal assignment of the control modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 240

7.2.3.1 Terminals 0 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 241

7.2.3.2 Terminals 2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 242

7.2.3.3 Terminals 11 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 242

7.2.3.4 Terminal 16 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 243

7.2.3.5 Network (MCI/CAN) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 243

7.2.3.6 Network (AS-i) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 245

7.2.4 Setting parameters (short overview) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 246

7.2.5 Pre-assignment of the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 247

7.2.5.1 Input connections _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 247

7.2.5.2 Output connections _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 250

7.2.5.3 Internal signal flow for control via terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 252

7.2.5.4 Internal signal flow for control via network (MCI/CAN) _ _ _ _ _ _ _ _ _ _ _ _ _ 253

7.2.5.5 Internal signal flow for control via network (AS-i) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 254

7.3 TA "Actuating drive speed (AC Drive Profile)" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 256

7.3.1 Basic signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 257

7.3.2 Scaling of the speed and torque values (Ref from Net) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 259

7.3.3 Interface description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 261

7.3.3.1 "AC Drive Profile" control word _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 261

7.3.3.2 "AC Drive Profile" status word _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 262

7.3.4 Setting parameters (short overview) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 262

7.3.5 Internal signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 263

7.4 TA "Switch-off positioning" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 265

7.4.1 Functional principle _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 267

7.4.2 Basic signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 269

7.4.3 Interface description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 271

7.4.3.1 wDriveControl control word _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 271

7.4.3.2 wDeviceStateWord status word _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 272

7.4.4 Terminal assignment of the control modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 273

7.4.4.1 Terminals 0 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 274

7.4.4.2 Terminals 2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 275

7.4.4.3 Terminals 11 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 276

7.4.4.4 Terminal 16 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 277

7.4.4.5 Network (MCI/CAN) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 278

7.4.4.6 Network (AS-i) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 279

7.4.5 Setting parameters (short overview) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 280

7.4.6 Pre-assignment of the application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 281

7.4.6.1 Input connections _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 281

7.4.6.2 Output connections _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 284

7.4.6.3 Internal signal flow for control via terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 286

7.4.6.4 Internal signal flow for control via network (MCI/CAN) _ _ _ _ _ _ _ _ _ _ _ _ _ 287

7.4.6.5 Internal signal flow for control via network (AS-i) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 288

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 7

Page 8

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

8Basic functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 289

8.1 Parameter change-over _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 290

8.1.1 Configuring the list using the »Engineer« parameterisation dialog _ _ _ _ _ _ _ _ _ _ _ _ 290

8.1.2 Configuring the list by means of parameterisation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 293

8.1.3 Selecting a value set _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 294

8.1.4 Activating the writing of the parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 294

8.2 Holding brake control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 295

8.2.1 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 296

8.2.1.1 Functional changes from firmware version 05.00.00 _ _ _ _ _ _ _ _ _ _ _ _ _ _ 298

8.2.1.2 Functional changes from firmware version 07.00.00 _ _ _ _ _ _ _ _ _ _ _ _ _ _ 298

8.2.1.3 Functional changes from firmware version 09.00.00 onwards _ _ _ _ _ _ _ _ _ 299

8.2.1.4 Operating mode _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 299

8.2.1.5 Functional settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 301

8.2.1.6 Switching thresholds _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 302

8.2.1.7 Application and release time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 304

8.2.1.8 Motor magnetising time (only with asynchronous motor) _ _ _ _ _ _ _ _ _ _ _ 306

8.2.1.9 Actual value monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 306

8.2.2 Process when brake is released _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 307

8.2.3 Process when brake is closed _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 308

8.2.4 Behaviour in case of pulse inhibit _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 310

8.2.5 Feedforward control of the motor before release _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 311

8 Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 9

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 Diagnostics & error management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 312

9.1 Basics on error handling in the inverter _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 312

9.2 LED status display _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 313

9.3 Drive diagnostics with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 314

9.3.1 Display details of the current error _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 316

9.3.2 Display of DIP switch positions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 317

9.3.2.1 DIP switch / potentiometer assignment 0 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 318

9.3.2.2 DIP switch / potentiometer assignment 1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 320

9.4 Drive diagnostics via bus system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 322

9.5 Logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 323

9.5.1 Functional description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 323

9.5.2 Reading out logbook entries _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 324

9.5.3 Exporting logbook entries to a file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 324

9.6 Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 325

9.6.1 Monitoring configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 326

9.6.2 Setting the error response _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 327

9.7 Maloperation of the drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 328

9.8 Error messages of the operating system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 331

9.8.1 Structure of the 32-bit error number (bit coding) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 331

9.8.1.1 Error type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 331

9.8.1.2 Error subject area _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 332

9.8.1.3 Error ID _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 332

9.8.1.4 Example for bit coding of the error number _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 333

9.8.2 Structure of the 16 bit error number (bit coding) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 334

9.8.3 Reset error message _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 335

9.8.4 Short overview (A-Z) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 336

9.8.5 Cause & possible remedies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 338

10 Communication _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 352

10.1 General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 352

10.2 Selection of the communication in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 353

10.3 Control mode "Network (MCI/CAN)" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 354

10.3.1 Pre-assignment of the data words _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 355

10.3.2 Port block "LP_Network_In" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 356

10.3.3 Port block "LP_Network_Out" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 357

11 Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 358

11.1 Structure of the parameter descriptions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 359

11.1.1 Data type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 360

11.1.2 Parameters with read-only access _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 360

11.1.3 Parameters with write access _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 361

11.1.3.1 Parameters with setting range _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 361

11.1.3.2 Parameters with selection list _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 361

11.1.3.3 Parameters with bit-coded setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 362

11.1.3.4 Parameters with subcodes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 363

11.1.4 Parameter attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 364

11.2 Parameter list _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 365

11.3 Selection list - analog signals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 475

11.4 Selection list - digital signals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 477

11.5 Table of attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 480

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 9

Page 10

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

12 Function library _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 487

12.1 L_MPot_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 488

12.1.1 Activate & control motor potentiometer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 490

12.1.2 Deactivate motor potentiometer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 491

12.2 L_NSet_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 492

12.2.1 Main setpoint path _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 494

12.2.2 JOG setpoints _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 494

12.2.3 Setpoint inversion _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 494

12.2.4 Skip frequency function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 495

12.2.5 Ramp function generator for the main setpoint _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 498

12.2.6 S-ramp _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 498

12.3 L_PCTRL_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 499

12.3.1 Control characteristic _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 503

12.3.2 Ramp function generator _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 504

12.3.3 Operating range of the PID process controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 504

12.3.4 Evaluation of the output signal _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 504

12.3.5 Control functions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 505

12.4 L_RLQ_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 506

12.5 L_Compare_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 508

12.5.1 Function 1: nIn1 = nIn2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 509

12.5.2 Function 2: nIn1 > nIn2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 510

12.5.3 Function 3: nIn1 < nIn2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 511

12.5.4 Function 4: |nIn1| = |nIn2| _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 512

12.5.5 Function 5: |nIn1| > |nIn2| _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 512

12.5.6 Function 6: |nIn1| < |nIn2| _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 512

12.6 L_Counter_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 513

12.7 L_DigitalDelay_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 515

12.7.1 Application example: Debouncing a digital input _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 517

12.8 L_DigitalDelay_2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 518

12.9 L_DigitalLogic_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 519

12.10 L_DigitalLogic_2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 521

12.11 L_JogCtrlExtension_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 523

12.12 LS_AnalogInput _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 526

12.13 LS_Convert_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 527

12.13.1 Conversion formulae _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 528

12.13.2 Function 19: Counting and providing external encoder pulses _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 529

12.14 LS_Convert_2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 530

12.14.1 Conversion formulae _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 531

12.15 LS_Convert_3 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 532

12.15.1 Conversion formulae _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 533

12.16 LS_DigitalInput _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 534

12.17 LS_DigitalOutput _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 535

12.18 LS_DisFree _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 536

12.19 LS_DisFree_a _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 537

12.20 LS_DisFree_b _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 538

12.21 LS_DriveInterface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 539

12.22 LS_ParFix _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 542

12.23 LS_ParFree _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 543

12.24 LS_ParFree_a _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 544

12.25 LS_ParFree_b _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 545

12.26 LS_SetError_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 546

12.27 LS_ParReadWrite_1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 547

12.28 LS_WriteParamList _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 549

10 Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 11

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

13 Application examples _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 550

13.1 Sequence control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 550

13.2 Delayed disconnection in partial-load operation ("Sleep Mode") _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 553

13.3 Motor load test _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 555

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 556

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ 566

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 11

Page 12

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 About this documentation

Danger!

The inverter is a source of danger which may lead to death or the severe injury of

persons.

To protect yourself and others against these dangers, observe the safety instructions

before switching on the inverter.

Please read the safety instructions in the mounting instructions and the hardware

manual for the 8400 motec inverter. Both documents are supplied with the inverter.

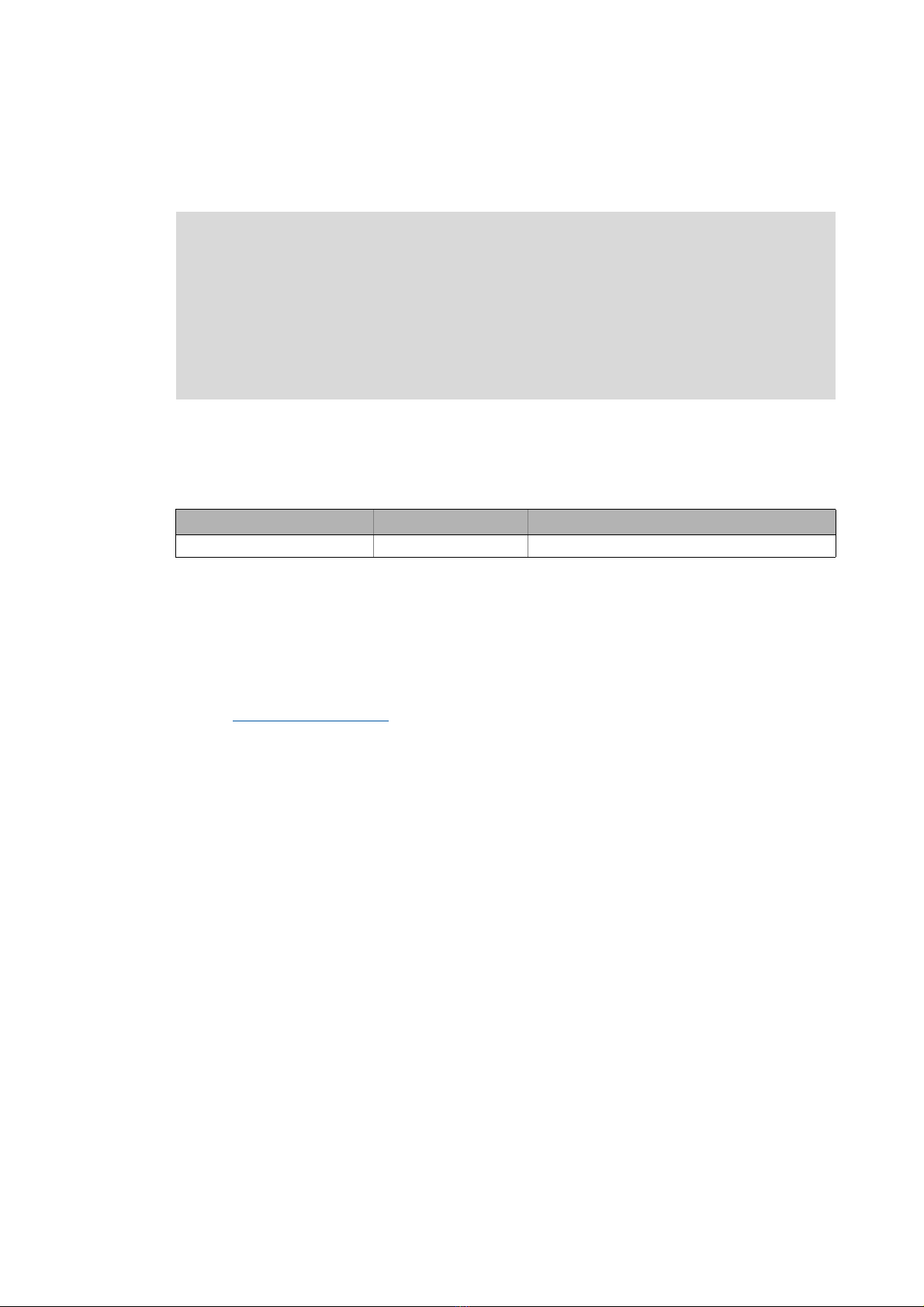

This software manual contains information regarding the parameterisation of the 8400 motec

inverter by means of the L-force »Engineer«.

The information in this software manual applies to the 8400 motec inverter with the following

nameplate data:

Product range Type designation From software version

8400 motec E84DGDVBxxxxxxx 01.00

All screenshots provided in this documentation are application examples. Depending on the

software version of the inverter and the version of the »Engineer« software installed, the

screenshots in this documentation may differ from the representation in the »Engineer«.

Tip!

Information and tools regarding the Lenze products can be found on the Internet:

http://www.lenze.com

Download

12 Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 13

1 About this documentation

1.1 Document history

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

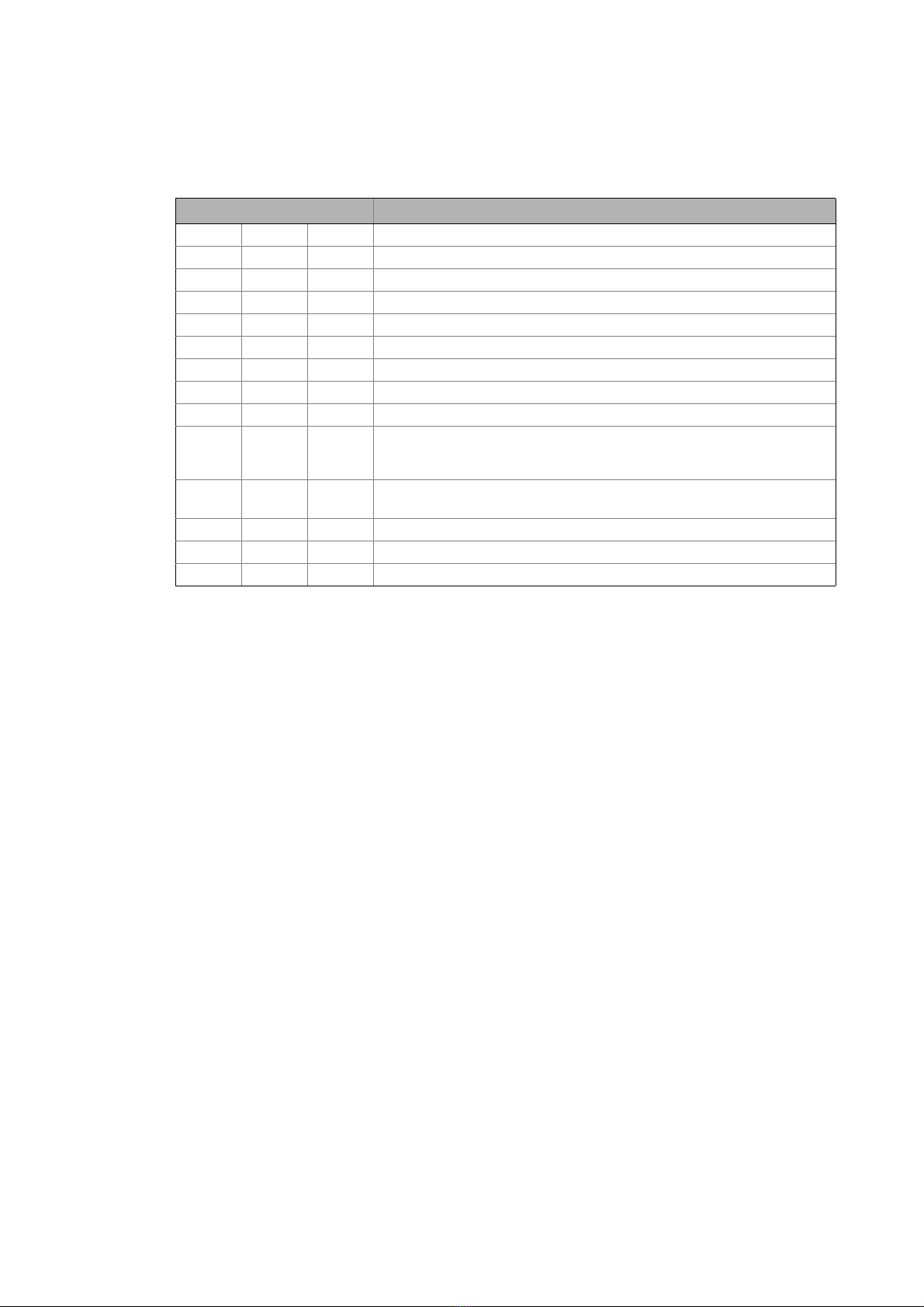

1.1 Document history

Version Description

10.0 08/2019 TD06 Error corrections & supplements for 8400 motec (FW11.01.00)

9.0 09/2018 TD23 Extension to POWERLINK

8.1 02/2018 TD23 Error corrections & supplements

8.0 01/2018 TD23 Extended by new functions for 8400 motec V10.00.00, error corrections

7.0 06/2017 TD23 Extended by new functions for 8400 motec V09.00.00, error corrections

6.0 12/2014 TD06 Extended by new functions for 8400 motec V07.00.00

5.0 09/2014 TD05 Extended by new functions for 8400 motec V06.01.00

4.1 08/2013 TD05 Corrections

4.0 07/2013 TD05 Extended by new functions for 8400 motec V05.00.00

3.0 09/2012 TD05 • Extended by new functions for 8400 motec V03.00.00, V03.01.00, V04.00.00

2.0 02/2011 TD05 • Extended by new functions for 8400 motec V02.00.00

1.2 10/2010 TD05 Corrections

1.1 05/2010 TD05 Corrections

1.0 04/2010 TD05 First edition

and V04.01.00

• Changed to new layout

• Extended by chapter "Application examples"

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 13

Page 14

1 About this documentation

1.2 Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2 Conventions used

This Software Manual uses the following conventions to distinguish between different types of

information:

Type of information Highlighting Examples/notes

Numeric notation

Decimal separator Point The decimal point is always used.

For example: 1234.56

Text

Version information Blue text colour All information that only applies to or from a certain

Program name » « The Lenze »Engineer« PC software...

Window italics The Message window... / The dialog box Options...

Variable names By setting bEnable to TRUE...

Control element Bold The OK button... / The Copy command... / The Properties

Sequence of menu

commands

Shortcut <bold> Use <F1> to open the online help.

Hyperlink Underlined

Symbols

Page reference ( 14) Optically highlighted reference to another page. It is

Step-by-step instructions

software version of the inverter is marked accordingly in this

documentation.

Example: This function extension is available from software

version V3.0!

tab... / The Name input field...

If several commands must be used in sequence to carry out a

function, the individual commands are separated by an

arrow: Select File

If a shortcut is required for a command to be executed, a "+"

has been put between the key identifiers: With

<Shift>+<ESC> ...

Optically highlighted reference to another topic. It is

activated with a mouse-click in this online documentation.

activated with a mouse-click in this online documentation.

Step-by-step instructions are indicated by a pictograph.

Open to...

14

All information that only applies to or from a certain software version of the inverter is marked

accordingly in this documentation.

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 15

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

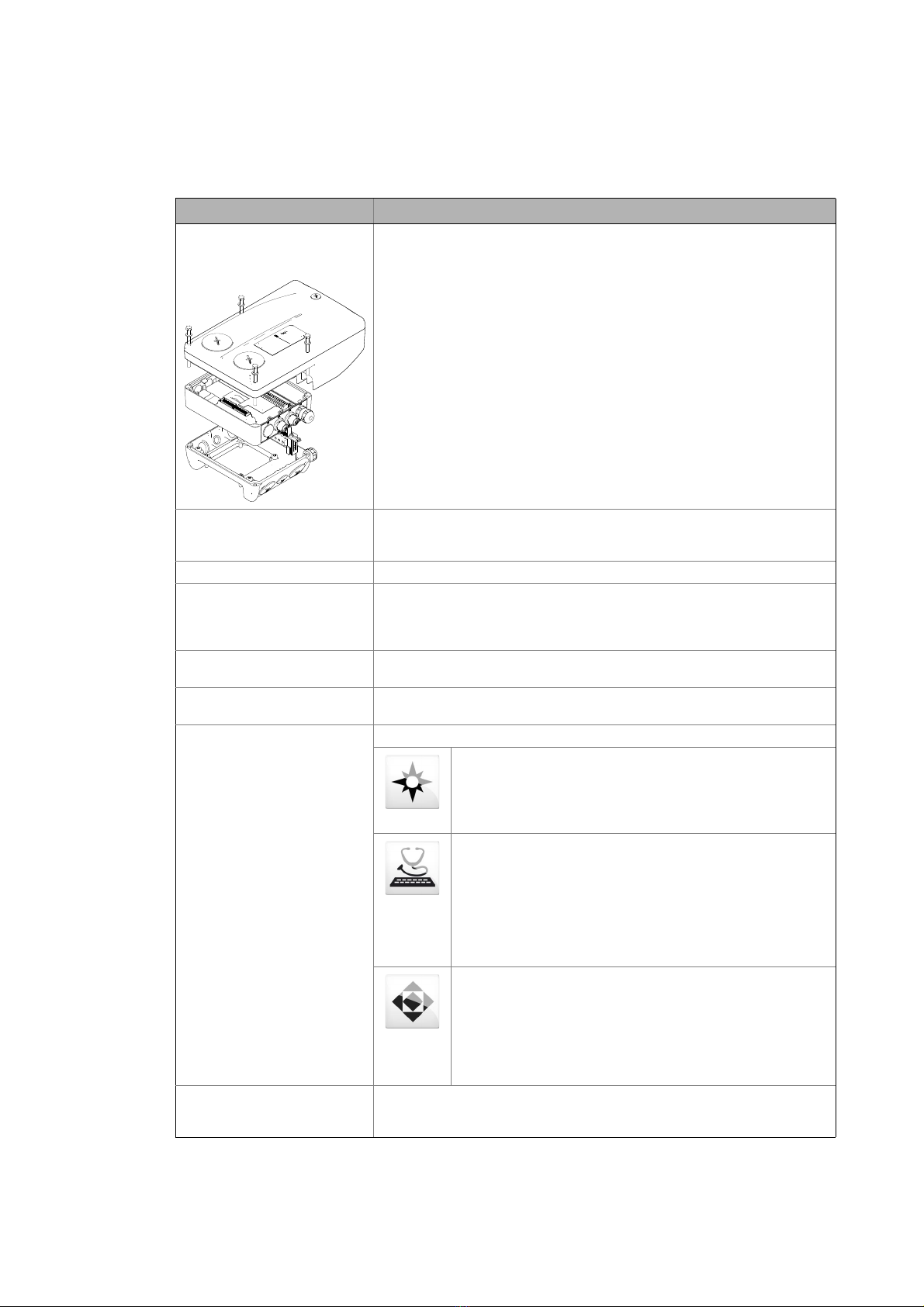

1.3 Terminology used

Term Meaning

Drive Unit

Communication unit

Wiring Unit

The 8400 motec inverter has a modular structure that includes the following

modules: "Drive Unit", "Communication Unit", and "Wiring Unit".

• The drive unit is available in different power settings.

• In case of the communication unit you can select between:

• Without fieldbus (basic I/O, standard I/O, extended I/O)

• AS interface (without safety/with safety STO)

• CANopen (without safety/with safety STO)

• EtherCAT (without safety/with safety STO)

• EtherNET/IP (without safety/with safety STO)

• PROFIBUS (without safety/with safety STO)

• PROFINET (without safety/with safety STO)

• POWERLINK (without safety/with safety STO)

• The wiring unit provides flexible connection possibilities for a simple

integration into the power supply of the machine.

Application A technology application is a drive solution equipped with Lenze's experience

and know-how in which function and system blocks interconnected to a signal

flow are the basis for implementing typical drive tasks.

ASM Async. motor

Service brake The service brake serves to shutdown rotary or translatory masses in motion in

a controlled manner. The energy to be dissipated in this process is converted into

heat in the form of friction energy. This process is a regular and recurring

operating mode.

Code Parameter which serves to parameterise and monitor the inverter. In normal

usage, the term is usually referred to as "Index".

Display code Parameter that displays the current status or value of an input/output of a

system block.

Engineering tools Software solutions for easy engineering in all project stages

»EASY Navigator« – ensures easy operator guidance

• All convenient Lenze engineering tools at a glance

• Tools can be quickly selected

• The clear structure simplifies the engineering process from the

start

»EASY Starter« – easy-to-use tool for service technicians

• Specifically designed for commissioning and maintaining Lenze

devices

• Graphic user interface with very few icons

• Easy to run online diagnostics, set parameters and perform

commissioning

• No risk of accidentally changing an application

• Loading off-the-shelf applications onto the device

»Engineer« – multi-device engineering

• For all products in our L-force portfolio

• Practical user interface

• Graphic interfaces make it easy to navigate

• Can be applied in every phase of a project (project planning,

commissioning, production)

• Parameter setting and configuration

EPM Memory module on which all parametes of the drive system are saved non-

volatilely. These include the parameters of the inverter and communicationrelevant parameters for the communication unit used.

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 15

Page 16

1 About this documentation

1.3 Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Term Meaning

Function block A function block can be compared with an integrated circuit that contains a

DC injection brake The DC injection brake is to brake and/or hold the motor. For this purpose, the

Holding brake The holding brake serves to hold the rotor by means of a mechanical unit.

Diagnosis terminal / keypad The diagnosis terminal combines the keypad with a housing and a connecting

LA Abbreviation: Lenze Application block

Lenze setting This setting is the default factory setting of the device.

LP Abbreviation: Lenze Port block

LS Abbreviation: Lenze System block

Port block Block for implementing the process data transfer via a fieldbus

QSP Quickstop

SLVC Motor control: Sensorless vector control ("SensorLess Vector Control")

Subcode If a code contains several parameters, they are stored in "subcodes".

System block In the application, system blocks provide interfaces to basic functions and to the

USB diagnostic adapter The USB diagnostic adapter is used for the operation, parameterisation, and

VFCplus Motor control: V/f characteristic control ("Voltage Frequency

VFCplusEco Motor control: V/f characteristic control - energy-saving

certain control logic and delivers one or several values when being executed.

• Each function block has a unique identifier, e.g. "L_MPot_1" (motor

potentiometer function)

8400 motec creates a quasi DC field at the stator of the asynchronous machine.

The energy to be dissipated is converted into heat in the rotor.

cable. The diagnosis terminal serves to check or change individual settings. In a

quick commissioning menu, the inverter can be parameterised in the basic

settings by means of the diagnosis terminal.

Note: If this documentation contains descriptions of settings with the keypad,

use the diagnosis terminal instead for the 8400 motec, since the keypad cannot

directly be plugged into the diagnostic interface of the 8400 motec.

• Example: "LA_NCtrl" – block for the "actuating drive speed" application.

• Example: "LP_Network_In" – port block for fieldbus communication.

• Example: "LS_DigitalInput" – system block for digital input signals.

This Manual uses a slash "/" as a separator between code and subcode

(e.g. "C00039/1").

This term is also referred to as "subindex" in common parlance.

hardware of the inverter (e.g. to the digital inputs).

diagnostics of the inverter. Data are exchanged between the PC (USB

connection) and the inverter (diagnostic interface on the front) via the

diagnostic adapter.

• Order designation: E94AZCUS

Control")

In this motor control mode, the inverter adapts the motor voltage to the

requirements of the load. Especially at speeds lower than 50 % of the rated

speed and a reduced torque, losses in the motor and in the inverter can be

reduced. Hence, the usually bad efficiency of the drive in the partial load

operational range is significantly increased.

16

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 17

1 About this documentation

1.4 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.4 Definition of the notes used

The following signal words and symbols are used in this Software Manual to indicate dangers and

important information:

Safety instructions

Structure of the safety instructions:

Pictograph and signal word!

(characterise the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous

situations)

Pictograph Signal word Meaning

Danger! Danger of personal injury through dangerous electrical voltage

Danger! Danger of personal injury through a general source of danger

Stop! Danger of damage to material assets

Application notes

Pictograph Signal word Meaning

Note! Important note to ensure trouble-free operation

Reference to an imminent danger that may result in d eath or se riou s per sonal injury

if the corresponding measures are not taken.

Reference to an imminent danger that may result in d eath or se riou s per sonal injury

if the corresponding measures are not taken.

Reference to a possible danger that may result in property damage if the

corresponding measures are not taken.

Tip! Useful tip for easy handling

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 17

Page 18

1 About this documentation

1.4 Definition of the notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

This page has been left blank intentionally,

to present the following information more clearly.

18

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 19

2 Introduction: Parameterising the inverter

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Introduction: Parameterising the inverter

Being a component of a machine which includes a speed-variable drive system, the inverter needs

to be adjusted to its drive task and the motor. The inverter is adjusted by changing parameters

which are saved in the memory module. The parameters can be accessed by keypad (diagnosis

terminal), by »EASY Starter« or by the »Engineer«. Access is also possible by a master control via

fieldbus communication. For this purpose, various communication units are available, e.g. AS-i,

CANopen, and PROFIBUS.

Danger!

In general, changing a parameter causes an immediate response in the inverter!

• This may lead to an undesirable response at the motor shaft when the inverter has

been enabled!

• Setpoint sources, for instance, may switch over all of a sudden (e.g. when configuring

the signal source for the main setpoint).

Certain device commands or settings which may cause critical states of drive behaviour

constitute exceptions. Such parameter changes are only possible if the inverter is

inhibited. Otherwise, a corresponding error message will be issued.

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 19

Page 20

2 Introduction: Parameterising the inverter

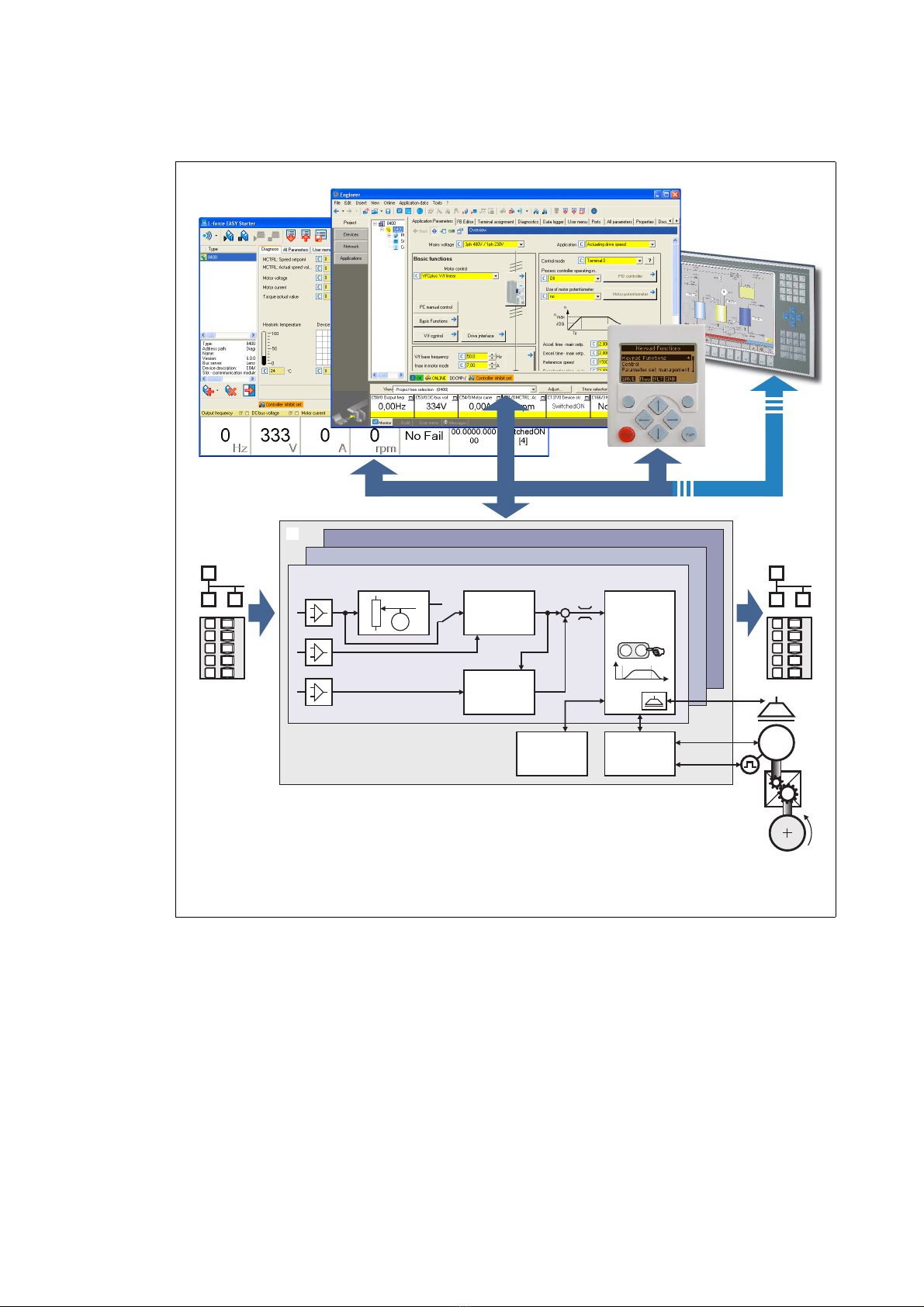

M

...

M

n

t

è

ç

02

1

Switch-off positioning

Actuating drive speed

Setpoint

generator

Process

controller

Motion

Control

Kernel

Device

control

Motor

control

Signal

inputs

Signal

outputs

Parameterisation

Fieldbus

L-force EASY Starter

L-force Engineer

Keypad

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Signal inputs for control and setpoint signals

Signal flow of the integrated technology application (see the following subchapter)

Signal outputs for status and actual value signals

[2-1] Adaptation of the drive solution via parameter setting

20 Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 21

2 Introduction: Parameterising the inverter

2.1 Integrated technology applications

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.1 Integrated technology applications

The following technology applications integrated in the inverter 8400 motec provide the main

signal flow for the implementation of a general or a special drive solution:

Technology application "Actuating drive speed"

This preset technology application serves to solve speed-controlled drive tasks, e.g.

conveyor drives (interconnected), extruders, test benches, vibrators, travelling drives,

presses, machining systems, metering units.

Technology application "actuating drive speed (AC Drive profile)"

This technology application available from version 04.01.00 provides a speed and

torque control by means of "AC Drive Profile". For this purpose, the Communication

Unit EtherNet/IP™ is required.

"Switch-off positioning" technology application

This technology application available from version 05.00.00 is used to solve speedcontrolled drive tasks which require a pre-switch off or stopping at certain positions,

e.g. roller conveyors and conveying belts. The pre-switch off is implemented by

connecting switch-off sensors.

Detailed information on each technology application can be found in the main chapter

entitled "Technology applications

". ( 225)

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 21

Page 22

2 Introduction: Parameterising the inverter

2.2 Selection of the appropriate commissioning tool

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2 Selection of the appropriate commissioning tool

There are several possibilities for commissioning the 8400 motec inverter:

Commissioning via keypad X400 (or diagnosis terminal X400)

The keypad is an alternative to the PC for the local operation, parameterisation, and

diagnostics in a simple manner. The keypad is especially suited for test and

demonstration purposes and for the case that only few parameters have to be

adapted.

Note:

• Use the diagnosis terminal for the 8400 motec inverter. The diagnosis terminal

combines the keypad with a housing and a connecting cable.

• The description how to make the settings with the keypad also applies to the

diagnosis terminal.

Commissioning with PC and »EASY Starter«

The »EASY Starter« is a Lenze tool for easy online diagnostics, parameter setting and

commissioning of the inverter.

Commissioning with PC and »Engineer«

The »Engineer« is a Lenze engineering software for parameter setting across all

devices, configuring and diagnosing individual components (as for instance inverters,

industrial PCs, motors, I/O systems) and machine control systems.

Tip!

The Engineering tools »EASY Starter« and »Engineer StateLevel« are provided free of charge

in the internet:

http://www.Lenze.com

For communication between PC and inverter, the USB diagnostic adapter can be used for

instance (see the following subchapter).

Download Software downloads

22

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 23

2 Introduction: Parameterising the inverter

2.2 Selection of the appropriate commissioning tool

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

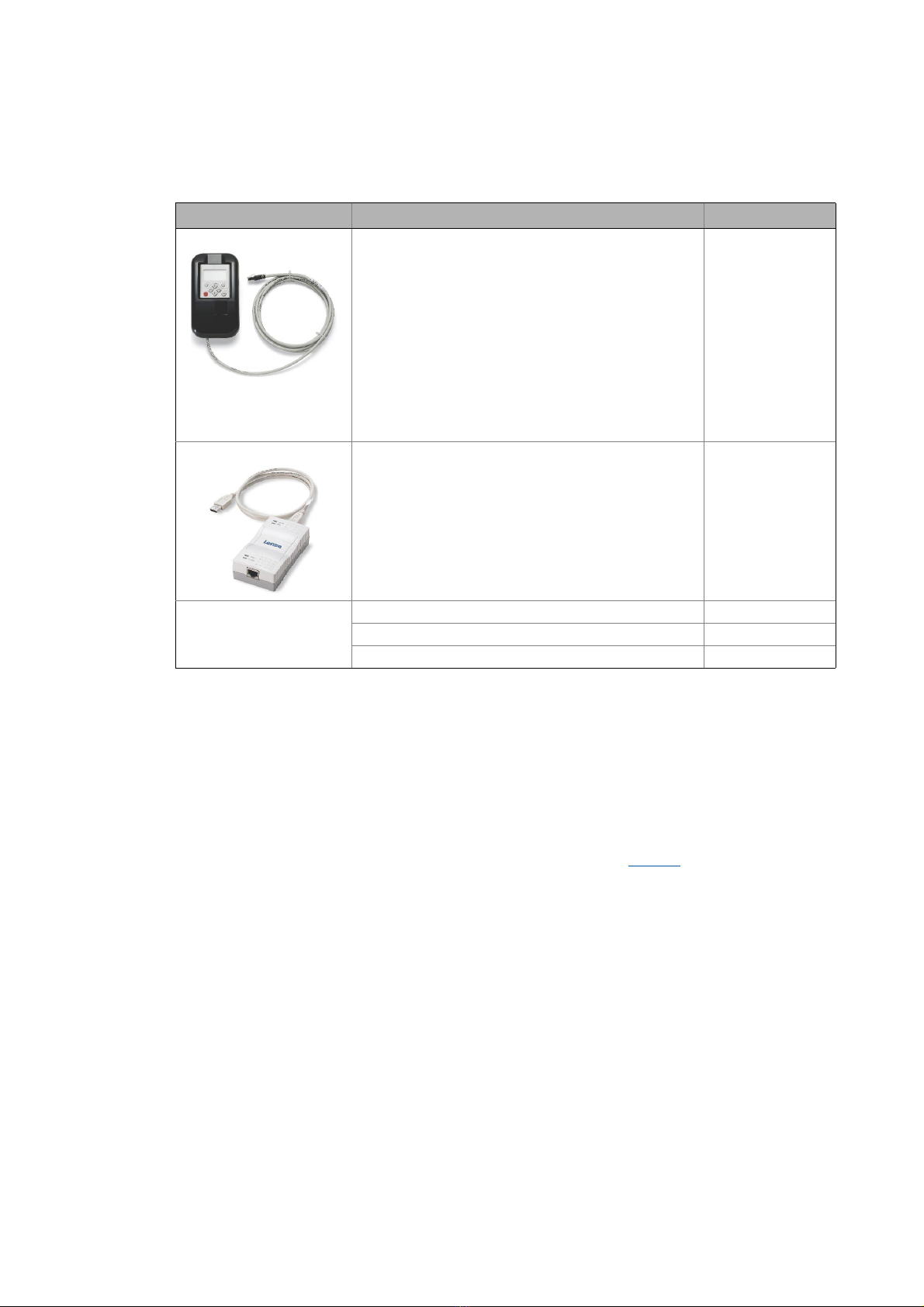

2.2.1 Overview: Accessories for commissioning

Version Features Product key

Diagnosis terminal X400 Keypad X400 in a robust housing, also suitable for

installation into the control cabinet door.

• Supports hot plugging

• Graphic display with plain texts

• Backlighting

• Easy user guidance

• 4 navigation keys, 2 context-sensitive keys

•Adjustable RUN/STOP function

• Incl. 2.5 m cable

• Enclosure IP20; in case of front installation in control

cabinet IP65

• Can be used for L-force Inverter Drives 8400 and Servo

Drives 9400

USB diagnostic adapter For electrical isolation of your PC and the inverter.

• Supports hot plugging

• Diagnostic LED for data transfer display

• plug and play

• Input-side voltage supply via USB connection from PC

• Output-side voltage supply via the diagnostic interface of

the inverter

• Connecting cables can be selected in various lengths:

EZAEBK2001

E94AZCUS

Connecting cable for

USB diagnostic adapter

2.5 m length EWL0070

5 m length EWL0071

10 m length EWL0072

Fast communication via diagnostic interface

From version 06.01.00, the diagnostic interface also supports the fast communication with

57,600 Baud (instead of 4,800 Baud).

• If no read or write access takes place via the diagnostic interface for 3.5 s, it is changed over to

normal communication again with 4,800 Baud.

• 57,600 Baud are only possible if the 8400 motec comes with the fast diagnostic interface and

an »Engineer« from version 2.19 or a keypad from firmware version 4.2 is connected.

• The current baud rate of the diagnostic interface is displayed in C01905

.

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 23

Page 24

2 Introduction: Parameterising the inverter

2.3 General notes on parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3 General notes on parameters

All parameters for inverter parameterising or monitoring are saved as so-called "codes".

• The codes are numbered and indicated by the prefix "C" before the code, e.g. "C00002".

• Moreover, each code has a name and specific attributes, as for example access type (reading,

writing), data type, limit values and default setting ("Lenze setting").

• For the sake of clarity, some codes contain "subcodes" for saving parameters. This Manual uses

a slash "/" as a separator between code and subcode, e.g. C00115/1".

• According to their functionality, the parameters are divided into three groups:

• Setting parameters: For specifying setpoints and for setting device / monitoring functions.

• Configuration parameters: For configuring signal connections and terminal assignments.

• Diagnostic/display parameters: For displaying device-internal process factors, current actual

values and status messages. These are read-only parameters.

24

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 25

2 Introduction: Parameterising the inverter

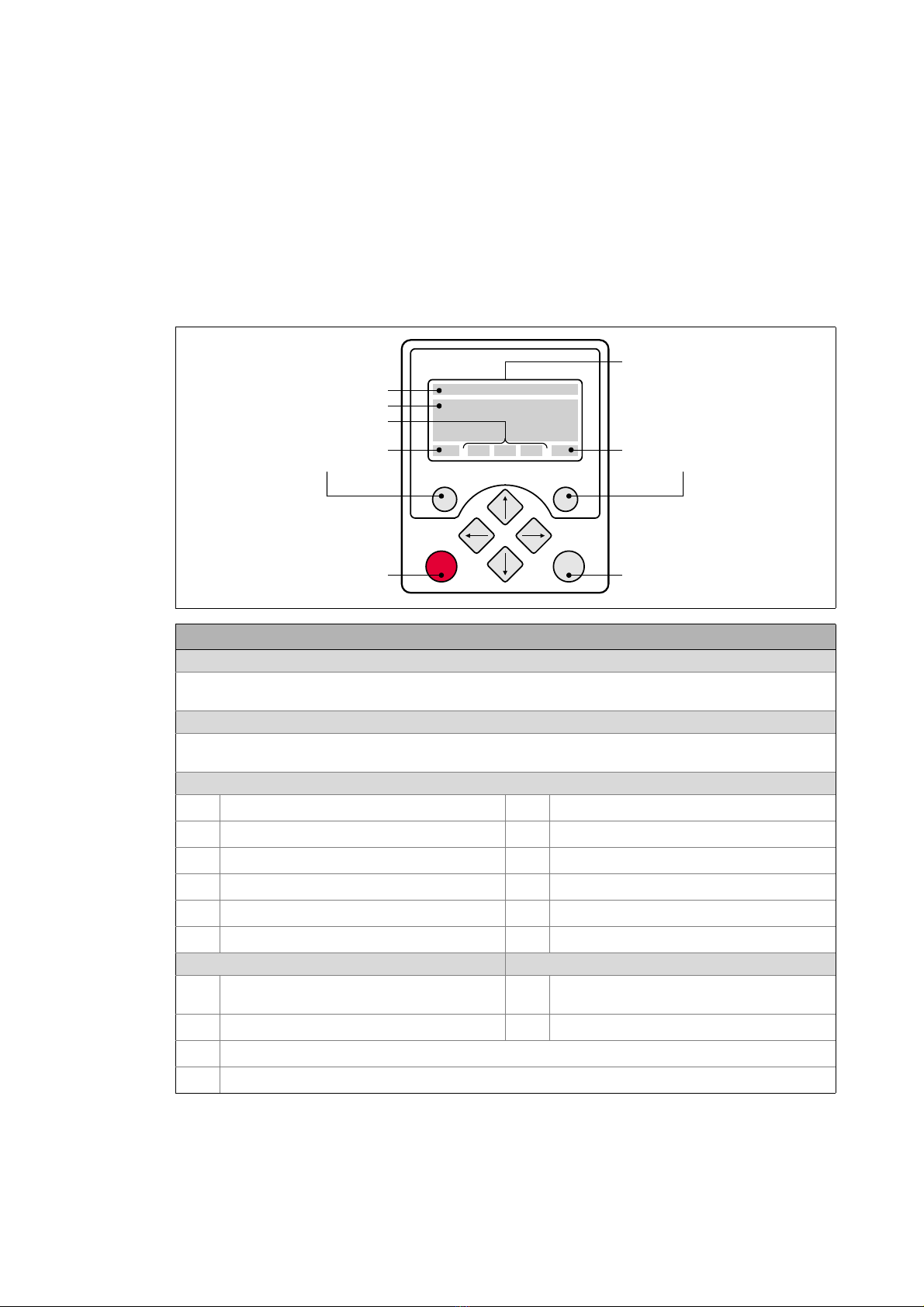

stop run

Headline

Triple-line display

Current function

right function key

Current function

left function key

LCD display

Device state

In manual control mode:

Start motor

In manual control mode:

Stop motor

2.3 General notes on parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3.1 Changing the parameterisation with the keypad

Simply connect the diagnosis terminal to the diagnostic interface being located on the top of the

device.

• The connecting cable can also be connected to the diagnostic interface during operation and

removed again.

Keypad display and control elements

LCD display

Headline

In the menu level: Menu name

In the parameter level: Parameter name

Three-part display

In the menu level: List of available menus

In the parameter level: Code/subcode and setting or actual value

Device status

Inverter is switched on

Inverter is enabled

Inverter is inhibited

Quick stop active

Current limit exceeded

Speed controller 1 in the limitation

Function - left function key Function - right function key

Change parameter setting

(change to editing mode)

Back to main menu

Parameter can only be changed when the inverter is inhibited

Save all parameter settings in the memory module safe against mains failure

Pulse inhibit active

System fault active

"Fault" device status is active

"Trouble" device status is active

"TroubleQSP" device status is active

A warning is indicated

Accept change in the inverter

(no saving with mains failure protection

Abort (discard change)

)

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 25

Page 26

2 Introduction: Parameterising the inverter

2.3 General notes on parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Control elements

Execute the function assigned to the function key (see LCD display)

Execute the stop function set in C00469 (Lenze setting: Inhibit inverter)

Deactivate stop function again (Lenze setting: Enable inverter again)

In the menu level: Select menu/submenu

In the parameter level: Select parameter

In the editing mode: Change marked digits or select list entry

In the menu level: Select submenu/change to parameter level

In the editing mode: Cursor to the right

In the menu level: One menu level higher (if available)

In the parameter level: Back to the menu level

In the editing mode: Cursor to the left

Menu structure

In the keypad, the parameters are classified into various menus and submenus.

•The USER menu includes a selection of frequently used parameters.

•The Code list contains all parameters.

•The Go to param function enables you to reach the corresponding parameter directly.

•The Logbook logs all errors and their chronological history.

•The Diagnostics menu contains diagnostic/display parameters for displaying device-internal

process factors, current actual values and status messages.

26

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 27

2 Introduction: Parameterising the inverter

Load Lenze setting

C00002/001

Off / Finished

EDIT

Par1 8400 protec

SAVE

Code list

Go To Param

USER - Menu

Fixed setpoint 1

C00039/001

40.00 %

EDIT

Fixed setpoint 2

60.00 %

EDIT

C00039/002

Fixed setpoint 2

C00039/002

ESC

60.00 %

OK

1.

2.

3.

5.

4.

6.

2.3 General notes on parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

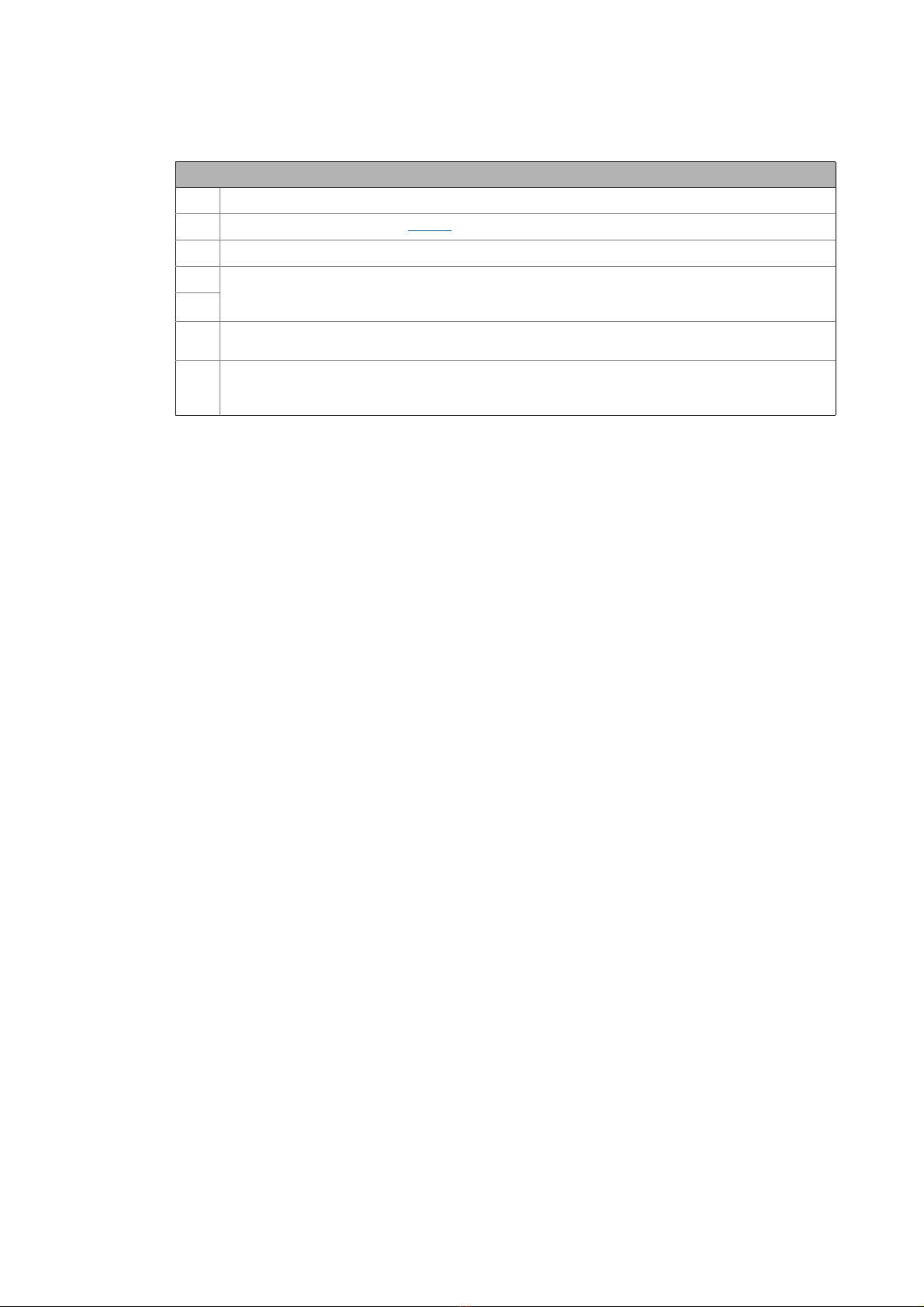

General operation

1. Use the / navigation keys to select the

desired menu.

•Use the / navigation keys to reach a

higher/lower menu level.

•Use the function key to return to the

main menu.

2. Use the / navigation keys to select the

parameter to be set within a submenu.

3. In order to select another subcode in case of a

parameter with subcodes:

• Press the navigation key to change to the

editing mode for the subcode.

• Use the navigation keys to set the desired

subcode.

4. Use the function key to switch over to the

editing mode.

5. Use the navigation keys to set the desired value.

6. Use the function key to accept the change

and to leave the editing mode.

•Use the function key to leave the editing

mode without accepting the change.

[2-2] Example: Changing parameters with the keypad

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 27

Page 28

2 Introduction: Parameterising the inverter

2.3 General notes on parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

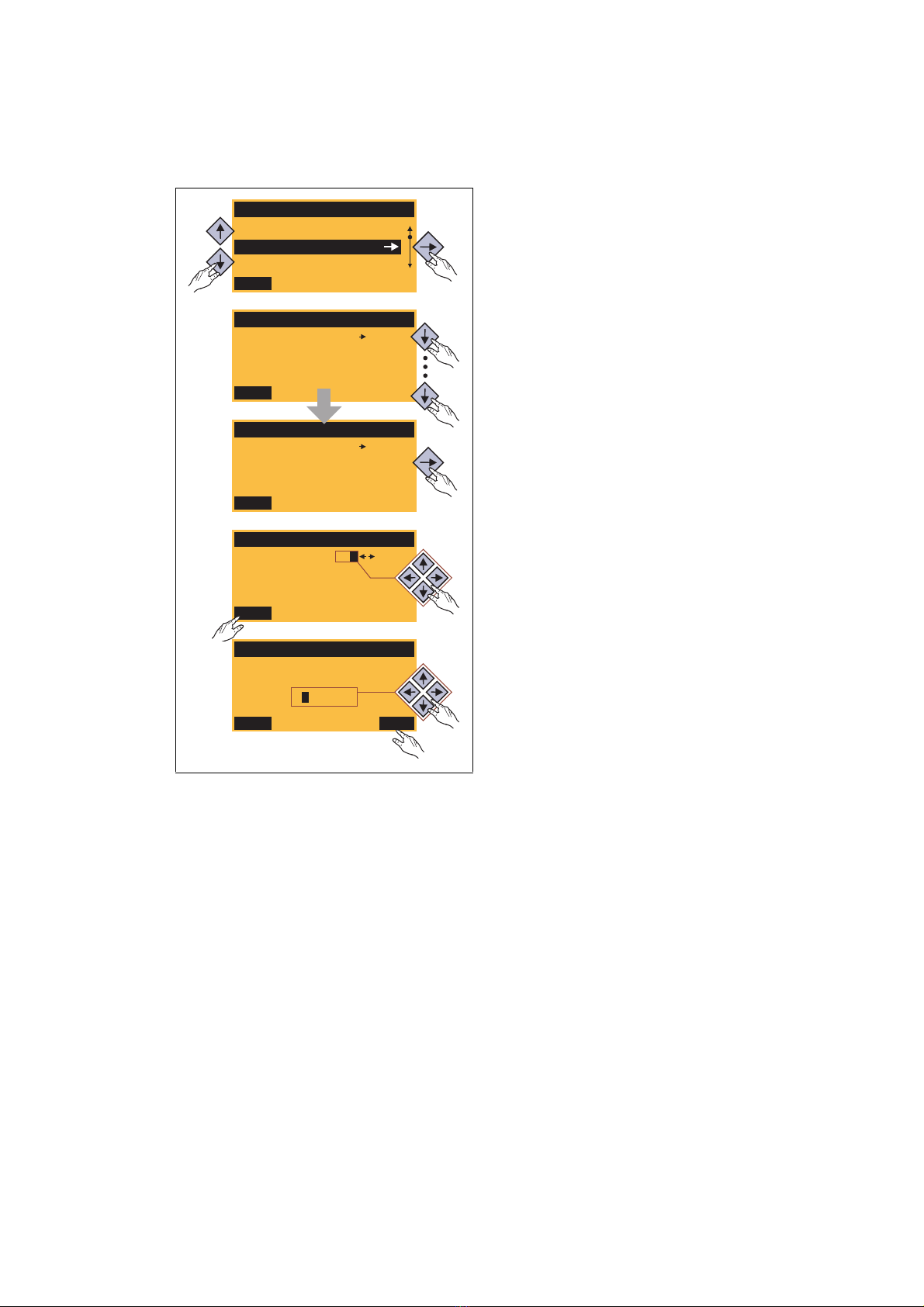

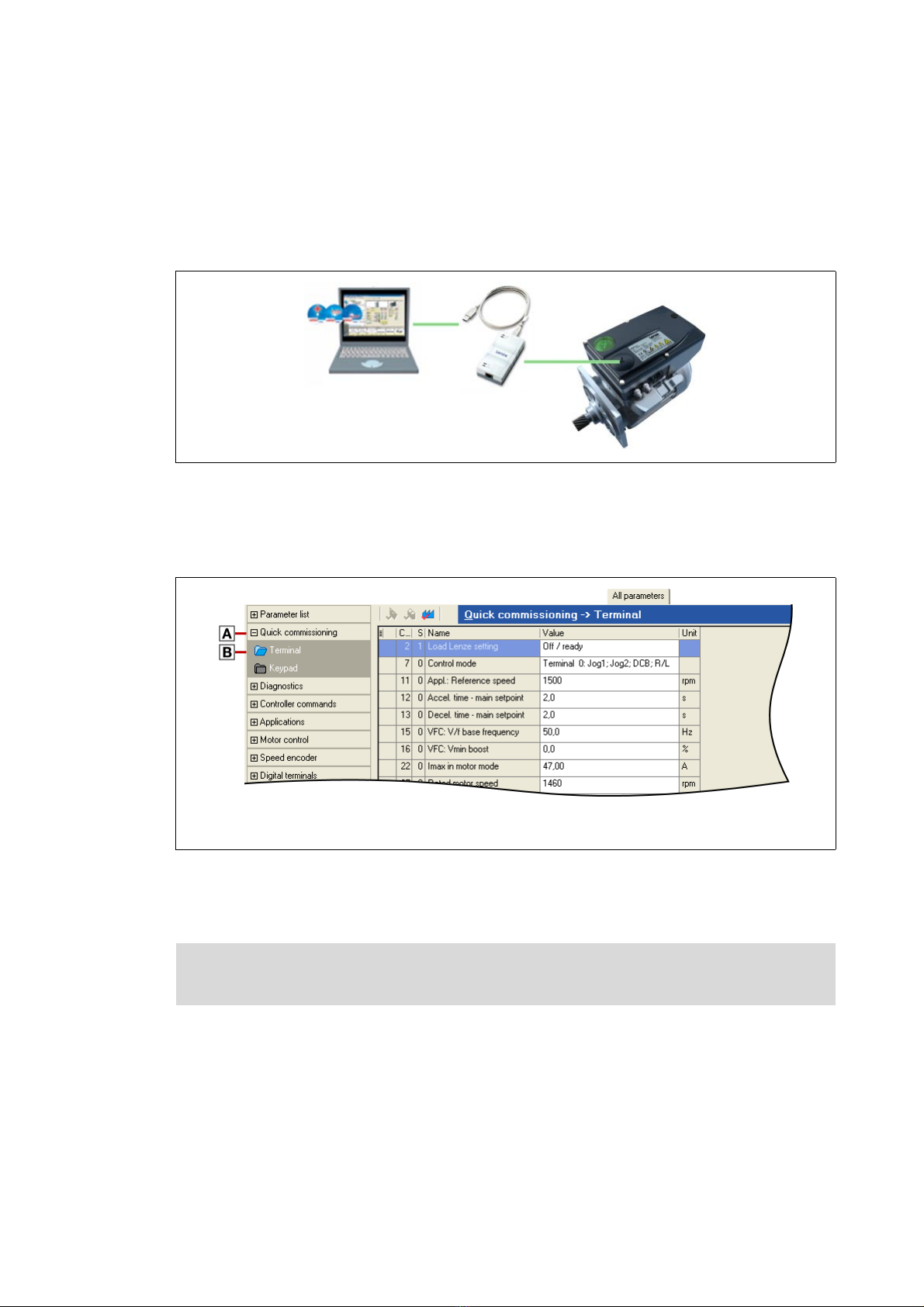

2.3.2 Change parameter settings with PC and Lenze software

For communication between the PC (including the L-force »EASY Starter« or L-force »Engineer«

software) and the inverter, the USB diagnostic adapter can for instance be used, see the following

illustration. The USB diagnostic adapter is the connection between the PC (free USB port) and the

inverter (diagnostic interface).

[2-3] Exemplary constellation for parameterising the inverter

The All parameters tab in the »EASY Starter« and the »Engineer« provides a quick access to all

parameters of the inverter.

The given categories and subcategories correspond 1:1 to the menus and submenus of the keypad:

Category

Subcategories

[2-4] All parameters tab in the »Engineer«

Moreover, the »Engineer« provides a commissioning interface on the Application parameters tab

where you can commission the application in a few steps.

28

Detailed information on how to handle the »Engineer« can be found in the integrated

online help that you can call with the [F1] function key.

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 29

2 Introduction: Parameterising the inverter

2.3 General notes on parameters

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.3.3 User menu for quick access to frequently used parameters

When a system is installed, parameters must be changed time and again until the system runs

satisfactorily. The user menu of the inverter contains a selection of frequently used parameters to

be able to access and change these parameters quickly:

Parameters Name Lenze setting

C00051 MCTRL: Actual speed value -

C00053 DC-bus voltage -

C00054 Motor current -

C00061 Heatsink temperature -

C00137 Device status -

C00166/3 Mess. - status det. error -

C00011 Appl.: Reference speed 1500 rpm

C00039/1

C00039/2

C00012 Acceleration time - main setpoint 2.0 s

C00013

C00015

C00016

C00022

C00120

C00087

C00099 Firmware version -

C00200 Firmware product type -

C00105

C00173

Greyed out = display parameter

Preset setpoint 1 40.0 %

Preset setpoint 2 60.0 %

Deceleration time - main setpoint 2.0 s

VFC: V/f base frequency 50 Hz

VFC: Vmin boost 0.0 %

Imax in motor mode depending on the device power

Setting of motor overload (I2xt) 100.00 %

Rated motor speed 1460 rpm

Decel. time - quick stop 5.0 s

Mains voltage 0: "3ph 400V"

Tip!

The user menu can be freely configured in C00517

In the »Engineer«, you can configure the user menu comfortably via the User menu tab (see

»Engineer« online help).

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 29

.

Page 30

2 Introduction: Parameterising the inverter

2.4 Handling the memory module

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.4 Handling the memory module

Danger!

After power-off, wait at least three minutes before working on the inverter. When

removing the memory module, ensure that the inverter is deenergised.

All parameters of the drive system are saved non-volatilely on the memory module. These include

the parameters of the inverter and communication-relevant parameters for the communication

unit used.

The plug-in version is especially suited for

• restoring an application after replacing a device.

• duplicating identical drive tasks within the frequency inverter series8400 motec, e.g. by using

the optionally available EPM Programmer.

Note!

• When the device is switched on, all parameters are automatically loaded from the

memory module to the main memory of the inverter.

• When the DIP1 switch on the S1 DIP switch is in the "ON" position, the inverter

works with the settings made via DIP switches S1 and S2 and displays them in the

corresponding codes.

• The 8400 BaseLine and 8400 motec inverters use the same (grey) memory module.

When handling the memory module, a distinction is drawn between the following scenarios:

Delivery status

• The memory module is plugged into the EPM slot of the drive unit.

• The Lenze setting of the parameters is stored in the memory module.

• The memory module is available as a spare part - without any data.

During operation

• Parameter sets can be saved manually.

• Parameter sets can be loaded manually.

• Parameter changes can be saved automatically.

The memory module can be shifted between these inverters, but the inverter must be

parameterised newly afterwards.

30

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 31

2 Introduction: Parameterising the inverter

2.4 Handling the memory module

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Replacement of the inverter

• In the event of a device replacement, the entire parameter data of an axis can be copied to the

replacement device by "taking along" the memory module, so that additional PC or diagnosis

terminal operations are not required.

• When replacing the inverter, the versions of the old and new device are of importance. Before

data are actually transferred, the versions are checked internally. As a general principle, the

following applies:

• Parameter sets of old devices with V 1.0 can be processed on new devices ≥ V1.0

(downward compatibility).

• Parameters of devices with higher versions are not supported on devices with lower versions.

An error message will be issued if the parameter set versions of the two devices are not

compatible.

Saving the parameters in the memory module safe against mains failure

Inverter parameter changes via the »Engineer«, the diagnosis terminal, or a master control via

fieldbus communication will be lost after mains switching of the inverter unless the settings have

been explicitly saved.

You have several options to avoid data loss by saving the parameter sets in the memory module:

• Automatic saving of parameter changes

• Manual saving of parameter settings

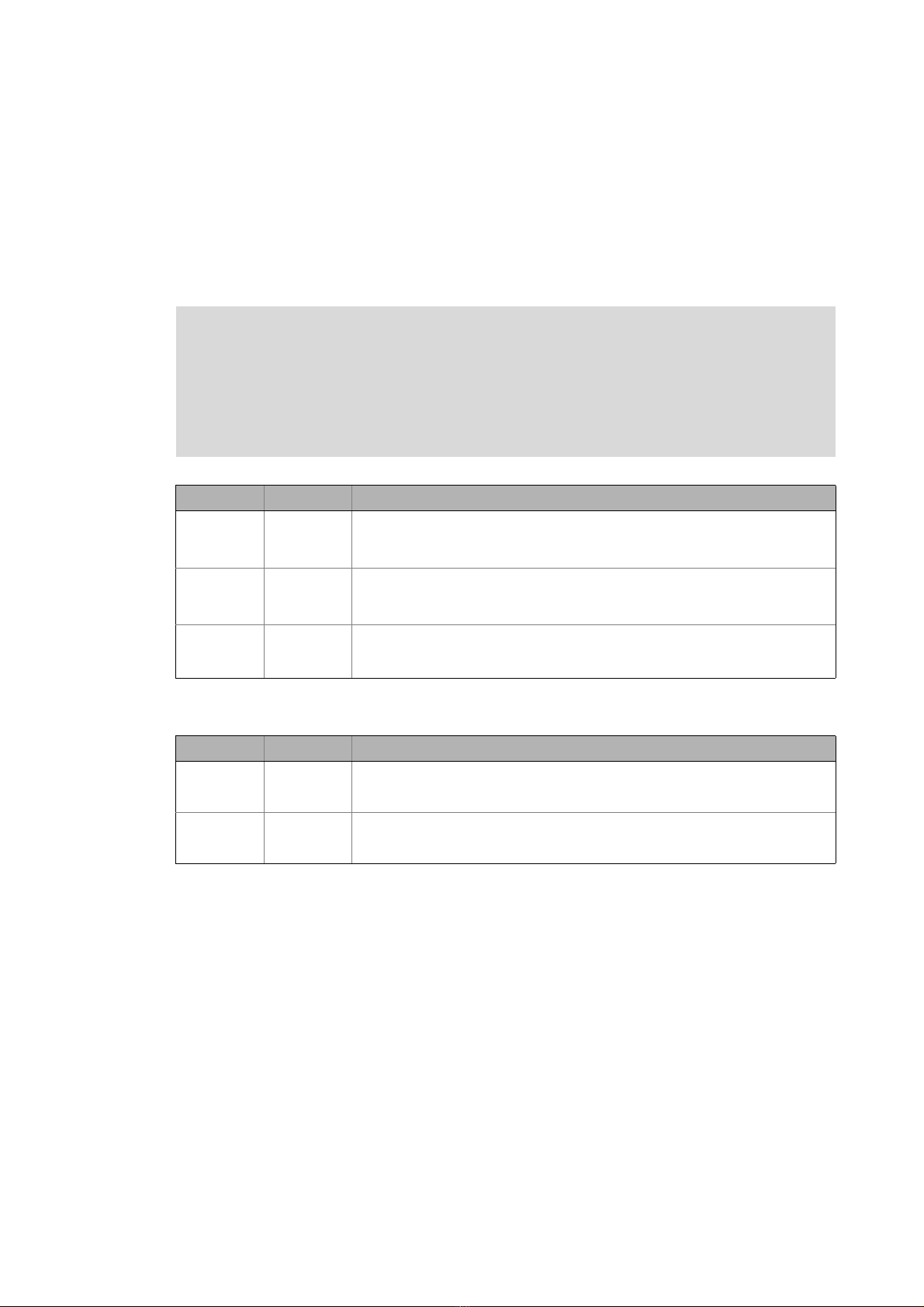

Parameter set transfer using the »Engineer«

When an online connection to the inverter has been established, the following transfer functions

can directly be executed via the Toolbar or the Online menu using the L-force »Engineer«:

Symbol Menu command Shortcut

Download parameter set <F5>

Upload parameter set from device <F7>

Save parameter set

( 67)

( 67)

Tip!

Detailed information on parameter set transfers using the »Engineer« can be found in the

»Engineer« online help.

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 31

Page 32

2 Introduction: Parameterising the inverter

2.5 Device identification

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.5 Device identification

For device identification, any device name (e.g. wheel drive) with max 32 characters can be set in

C00199/1

2.5.1 Automatic acceptance of the device name in the »Engineer«

If a device name is assigned in C00199/1 and the inverter in the »Engineer« is added to the project

via the Insert Insert device detected online... function, the device name stored in C00199/1

wheel drive) is used as device designation in the Project view instead of the type (8400 motec):

This mechanism also functions in reverse direction:

If you rename the inverter in the project view via <F2>, you will be asked afterwards if you want to

take over the changed name in C00199/1

for the inverter and saved in the memory module with mains failure protection.

(here:

:

32

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06

Page 33

3 Commissioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3 Commissioning

The 8400 motec inverter is commissioned in one of the following ways:

• Commissioning via PC / »Engineer«

• The »Engineer« provides for convenient access to all parameters of the 8400 motec inverter

and hence offers full flexibility in the commissioning process.

• Commissioning with diagnosis terminal

(If only a few parameters have to be adapted)

With regard to this, please observe the Note

for the SLVC control mode, which is provided from version V09.00.00 onwards.

• Commissioning via the DIP switches/potentiometers at the 8400 motec

(for simple applications)

This chapter provides information on how to commission the 8400 motec using the »Engineer«.

concerning the simplified commissioning process

Information on how to commission the 8400 motec via the DIP switches/

potentiometers can be found in the mounting instructions!

Information on how to commission the 8400 motec using the diagnosis terminal can be

found in the hardware manual!

Lenze · 8400 motec · Reference manual · DMS 10.0 EN · 08/2019 · TD06 33

Page 34

3 Commissioning

3.1 Safety instructions with regard to commissioning

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

3.1 Safety instructions with regard to commissioning

General safety instructions

In order to prevent injury to persons or damage to material assets

• check before connecting the mains voltage

• the wiring for completeness, short circuit, and earth fault

• the "emergency stop" function of the entire system