Lancia Kappa K 107 1995, Kappa 1995 User Manual

Lancia Kappa 2.0 Sedan

1995, 107 Kw, Petrol

Technical

data

Notes Specified value Measured value

|

Vehicle identification |

|

|

|

|

No. of cylinders |

Type 5/DOHC |

||

|

Capacity (Fiscal) |

cc |

1998 |

|

|

Compression ratio |

:1 |

10,0 |

|

|

Suitable for unleaded petrol |

|

Yes |

|

|

Minimum octane rating |

RON |

95 |

|

|

Ignition system |

Type Motronic |

||

|

Ignition system |

Description Map-DI |

||

|

Trigger location |

|

Cam/ Crankshaft |

|

|

Fuel system |

Make Bosch |

||

|

Fuel System |

Type Motronic M2.10 |

||

|

Fuel System |

Description MFI-s |

||

|

Air metering |

Type Mass |

||

|

Combined ignition and fuel ECM |

|

Yes |

|

|

Diagnostic socket |

|

Yes |

|

|

Ignition system |

|

|

|

|

Ignition coil |

Make Bosch |

||

|

Ignition coil |

Type 0 221 152 067 |

||

|

Ignition coil supply voltage |

+ with ballast V |

11,0 |

|

|

Primary resistance |

Ohm |

0,4 |

|

|

Secondary resistance |

Ohm |

8500 |

|

|

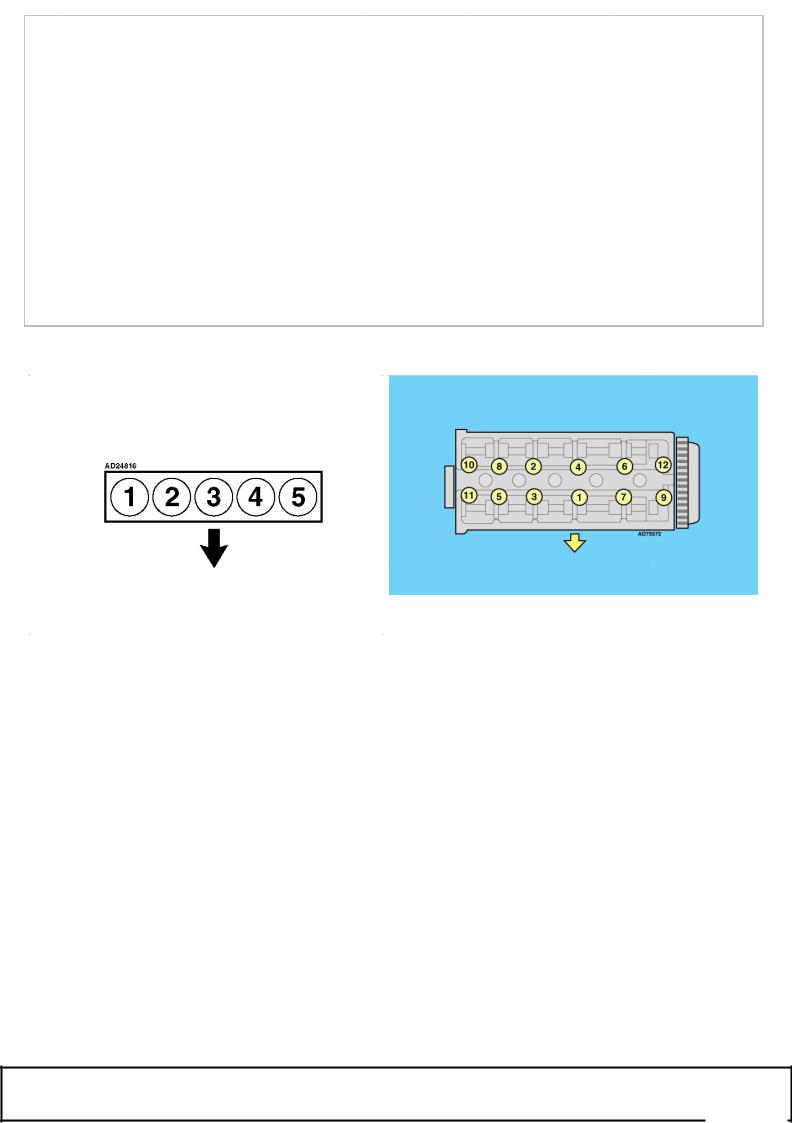

Firing order |

|

1-2-4-5-3 |

|

|

Tuning and emissions |

|

|

|

|

Ignition timing - basic BTDC |

°Engine/rpm Not adjustable |

||

|

Ignition advance checks |

°Engine/rpm ECM Controlled |

||

|

Idle speed |

rpm Not adjustable |

||

|

Oil temperature for CO test |

°C 60 |

||

|

CO level at idle speed - tailpipe (Cat) |

Vol. % CO |

0,35 Max Not adjustable |

|

|

CO level at idle speed - sample pipe |

Vol. % CO |

0,4±0,1 |

|

|

HC level at idle speed |

ppm |

90 Max |

|

|

CO2 level at idle speed |

Vol. % CO2 |

13 Min |

|

|

O2 level at idle speed |

Vol. % O2 |

0,1-0,5 |

|

|

Increased idle speed for CO test |

rpm |

2500-2900 |

|

|

CO content at increased idle speed |

Vol. % |

0,3 |

|

|

Lambda at increased idle |

λ |

0,97-1,03 |

|

|

Spark plugs |

|

|

|

|

Spark plugs |

Original equipment Champion |

||

|

Spark plug |

Type RC7BMC |

||

|

Electrode gap |

mm 0,5 |

||

|

Spark plugs |

Make Autolite |

||

|

Spark plug |

Type APP3922 |

||

|

Electrode gap |

mm 0,9 |

||

|

Spark plugs |

Make Beru |

||

|

Spark plug |

Type 14FR-6LDU |

||

|

Electrode gap |

mm 0,8 |

||

|

Spark plugs |

Make Champion |

||

|

Spark plug |

Type RC7BMC |

||

|

Electrode gap |

mm 0,5 |

||

|

Spark plugs |

Make NGK |

||

|

Spark plug |

Type BKR6EKC |

||

|

Electrode gap |

mm 0,9 |

||

|

Fuel system |

|

|

|

|

System pressure without vacuum |

bar |

3,0 |

|

|

RPM/TDC sensor |

Ohm |

774-946 |

|

|

Oxygen sensor heater |

Ohm |

2,5-4,5 |

|

|

Service checks and adjustments |

|

|

|

|

|

|

|

|

|

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|

|||

Valve clearance -INLET Valve clearance -EXHAUST Oil pressure

Lubricants and capacities

Engine oil grade - moderate climate Engine oil classification

Engine oil grade - alternative - moderate climate Engine oil classification - alternative - moderate climate Engine with filter

Gearbox oil grade Gearbox 4/5 speed Cooling system Brake fluid

Tightening torques

Cylinder head instructions

Cylinder head

Stage 1

Stage 2

Stage 3

Stage 4

Other tightening torques

Main bearings

Main bearings

Main bearings

Big end bearings

Big end bearings

Oil pump to cylinder block

39Sump bolts Sump drain bolt

Flywheel/driveplate Crankshaft pulley/damper Camshaft sprocket/gear Camshaft/rocker cover

Inlet manifold to cylinder head Exhaust manifold to cylinder head Spark plugs

Engine coolant temperature (ECT) sensor Oxygen sensor (Lambda)

Knock sensor (KS) Engine oil pressure switch Front hub

Rear hub

Steering track rod end Brake disc to hub

Brake caliper carrier to hub Brake disc to hub

Brake caliper carrier to hub ABS sensor

ABS sensor Road wheels

Starting and charging

Battery

Starter motor

Starter motor

Minimum starting voltage

Maximum cranking amps

Alternator/Regulator

mm 0,38±0,04 cold mm 0,43±0,04 cold

bar/rpm 4,0/4000

SAE 15W/40

API/ACEA SG/A2-96

SAE 10W/30 Semi-Synth.

API/ACEA SG/A3-96 litres 5,4

SAE 75W/90 litres 2,0 litres 8,3

Type DOT 3/4

Renew bolts No

Tighten 40 Nm

Tighten 90°

Tighten 90°

Tighten 90°

Renew bolts/nuts No Stage 1 25 Nm Stage 2 100°

Renew bolts/nuts No

Stage 1 25 Nm+60°

9 Nm

20 Nm

160 Nm

360 Nm

118 Nm

8 Nm

25 Nm

25 Nm

27 Nm

20 Nm

50-60 Nm

25 Nm

22 Nm

60 Nm+52°

320 Nm

38 Nm

Front 20 Nm

Front 160 Nm

Rear 12 Nm

Rear 55 Nm

Front 10 Nm

Rear 10 Nm

98 Nm

V/RC(Ah) 12/90 (60)

Make Marelli

Type E70R-12v-1,4kW

V 8,1

A 162-198

Make Marelli

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

Alternator/Regulator |

Type A127I |

Alternator output at engine speed |

A/V/rpm 100/14/3500 |

Voltage regulator |

Type 24TR/B |

Regulated voltage |

V 14,3-14,6 |

Brake disc and drum dimensions

Minimum disc thickness - ventilated |

Front 20,2 mm |

Minimum disc thickness |

Rear 9,2 mm |

Disc runout |

Front 0,15 mm |

Disc runout |

Rear 0,15 mm |

Minimum pad thickness |

Front 1,5 mm |

Minimum pad thickness |

Rear 1,5 mm |

Handbrake travel |

No. of notches 5-6 |

Air conditioning

|

Air conditioning refrigerant |

Type R134a |

32 |

Air conditioning refrigerant quantity |

grams |

33 |

Air conditioning oil |

Type |

38 |

Air conditioning oil quantity |

cmł |

|

|

|

|

|

|

Cylinder layout |

|

Tightening sequence |

|

|

|

|

|

|

|

|

|

|

|

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

Wheel alignment

Telephone:

Fax:

VAT Registration No.:

Kappa 1995-02 |

|

|

|

Rim size |

Tyre size |

Model Front bar(psi) |

Rear bar(psi) |

|

|

|

|

4x15 |

125/90 R 15 96M |

4,2 (60) |

4,2 (60) |

6,5x15 |

195/65 R 15 91V |

2,2 (31) |

2,2 (31) |

|

|

|

|

6,5x15 |

205/60 R 15 91V |

2,2 (31) |

2,2 (31) |

6,5x15 |

205/60 R 15 91W |

2,2 (31) |

2,2 (31) |

|

|

|

|

6,5x16 |

205/55 R 16 89W |

2,2 (31) |

2,2 (31) |

7,5x16 |

205/55 R 16 91W |

2,2 (31) |

2,2 (31) |

|

|

|

|

7,5x16 |

215/55 R 16 91W |

2,2 (31) |

2,2 (31) |

|

|

|

|

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.12.02. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

|

Dimensions |

|

Notes |

Specified value |

Measured value |

Wheelbase |

mm 2700 |

|

Track - front/rear |

mm 1546/1527 |

|

|

Tightening torques |

|

Notes |

Specified value |

Measured value |

Tightening torque - steel wheels |

98 Nm |

|

Tightening torque - alloy wheels |

98 Nm |

|

|

Checking range - Front wheels |

|

Notes |

Specified value |

Measured value |

Load positioning |

unladen |

|

Toe-in (N = negative, toe-out) |

mm 0 - 2 |

|

Toe-in |

deg 0° - 0°20' |

|

Toe-in |

deg-1/100 0 - 0,33 |

|

Camber |

deg 0°35'N - 1°15'N |

|

Camber |

deg-1/100 0,58N - 1,25N |

|

Castor |

deg 2°50' - 3°30' |

|

Castor |

deg-1/100 2,83 - 3,50 |

|

|

Setting data - Four wheels |

|

Notes |

Specified value |

Measured value |

Load positioning |

unladen |

|

Toe-in (N = negative, toe-out) |

mm 1±1 |

|

Toe-in |

deg 0°10'±10' |

|

Toe-in |

deg-1/100 0,17±0,17 |

|

Camber |

deg 0°55'N±20' |

|

Camber |

deg-1/100 0,92N±0,33 |

|

Camber adjustment |

Not adjustable |

|

Castor |

deg 3°10'±20' |

|

Castor |

deg-1/100 3,17±0,33 |

|

Castor adjustment |

Not adjustable |

|

Lock angles - max. inner |

deg 37°±30' |

|

Lock angles - max. inner |

deg-1/100 37±0,50 |

|

Lock angles - max. outer |

deg 32°40' |

|

Lock angles - max. outer |

deg-1/100 32,67 |

|

Rear toe-in |

mm 2,5±1 |

|

Rear toe-in |

deg 0°23'±10' |

|

Rear toe-in |

deg-1/100 0,38±0,17 |

|

Rear toe-in adjustment |

$ADJ |

|

Rear camber |

deg 0°45'N±20' |

|

Rear camber |

deg-1/100 0,75N±0,33 |

|

Rear camber adjustment |

Not adjustable |

|

|

|

|

Rear toe-in adjustment

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

Timing belt replacement intervals

Important note

Important note

The intervals and procedures given are subject to alteration by the manufacturer at any time. Check the regularly updated Timing Belts section on our website to ensure that you are kept informed of any changes that may occur between issues of the Autodata CD. http://www.autodata-cd.com

Timing belt replacement intervals

The information relating to timing belt replacement intervals is additional to the main purpose of this CD, but is included to provide guidance to garages and for customer advice.

Where possible the recommended intervals have been compiled from vehicle manufacturers' information. In a few instances no recommendation has been made by the manufacturer and the decision to replace the belt must be made from the evidence of a thorough examination of the condition of the existing belt.

Apart from the visible condition of the belt, which is explained fully later in this section, there are several other factors which must be considered when checking a timing belt:

1.Is the belt an original or a replacement.

2.When was the belt last replaced and was it at the correct mileage.

3.Is the service history of the vehicle known.

4.Has the vehicle been operated under arduous conditions which might warrant a shorter replacement interval.

5.Is the general condition of other components in the camshaft drive, such as the tensioner, pulleys, and other ancillary components driven by the timing belt, typically the water pump, sound enough to ensure that the life of the replacement belt will not be affected.

6.If the condition of the existing belt appears good, can you be satisfied that the belt will not fail before the next check or service is due.

7.If the belt does fail, have you considered the consequences. If the engine is an INTERFERENCE type then considerable expensive damage may well be the result.

8.The cost of replacing a belt as part of a routine service could be as little as 5 to 10% of the repair cost following a belt failure. Make sure your customer is aware of the consequences.

9.If in doubt about the condition of the belt - RENEW it.

Replacement Interval Guide

Replacement Interval Guide

Lancia recommend check & replace if necessary every 60,000 km and replacement every 105,000 km.

The previous use and service history of the vehicle must always be taken into account.

Check For Engine Damage

Check For Engine Damage

CAUTION: This engine has been identified as an INTERFERENCE engine in which the possibility of valve-to-piston damage in the event of a timing belt failure is MOST LIKELY to occur.

A compression check of all cylinders should be performed before removing the cylinder head.

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

Repair Times - hrs

Repair Times - hrs

Kappa 2,0/2,4 5 Cyl. 1995-04

Remove and install |

|

2,45 |

|

|

|

|

|

|

Remove and install - AC |

|

2,65 |

|

|

|

Special Tools

Special Tools

Tensioner pulley locking pin - Lancia No.1860830000.

Camshaft locking tools - Lancia No.1860819000.

Special Precautions

Special Precautions

Disconnect battery earth lead.

DO NOT turn crankshaft or camshaft when timing belt removed.

Remove spark plugs to ease turning engine.

Turn engine in normal direction of rotation (unless otherwise stated).

DO NOT turn engine via camshaft or other sprockets.

Observe all tightening torques.

Removal

Removal

1.Raise and support front of vehicle.

2.Remove:

RH front wheel.

Wheel arch liner.

3.Turn auxiliary drive belt tensioner pulley anti-clockwise. Use suitable spanner.

4.Lock tensioner pulley. Use tool No.1860830000 [1] .

5.Remove:

Auxiliary drive belt.

Engine upper torque link.

Spark plug cover.

Cylinder head covers.

Timing belt cover [2] .

Crankshaft pulley (6 bolts) [3] .

6.Turn crankshaft to TDC on No.1 cylinder [4] .

7.Ensure both camshafts at TDC on No.1 cylinder. If not: Turn crankshaft one turn clockwise.

8.Remove third bearing cap from exhaust camshaft [5] .

9.Remove fourth bearing cap from inlet camshaft [7] .

NOTE: Mark bearing caps before removal for identification.

10.Fit locking tools in place of bearing caps [6] & [8] . Tool No.1860819000.

NOTE: Locking tools are marked 'exhaust' and 'inlet'. Ensure locking tools aligned with respective cam profiles to prevent damage.

11.Slacken tensioner sprocket nut [9] . Turn tensioner sprocket anti-clockwise to release tension on belt. Lightly tighten nut.

12.Remove timing belt.

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

Installation

Installation

1.Ensure crankshaft at TDC on No.1 cylinder. Ensure timing marks aligned [4] .

2.Ensure locking tools located correctly in camshafts [6] & [8] .

3.Slacken bolts of each camshaft sprocket [10] .

4.Fit timing belt in following order:

Crankshaft sprocket.

Guide pulley.

Exhaust camshaft sprocket.

Inlet camshaft sprocket.

Water pump sprocket.

Tensioner sprocket.

5.Ensure marks on belt aligned with marks on sprockets [11] .

6.Slacken tensioner sprocket nut [9] .

7.Push on tensioner sprocket to pre-tension belt [12] . Lightly tighten nut.

8.Tighten bolts of each camshaft sprocket [10] . Tightening torque: 28 Nm.

9.Remove locking tools from camshafts [6] & [8] .

10.Fit bearing caps in correct locations. Tighten bolts to 15 Nm.

11.Turn crankshaft two turns in normal direction of rotation.

12.Ensure timing marks aligned [4] .

13.Slacken tensioner sprocket nut [9] .

14.Tensioner sprocket should operate and marks align [13] .

15.Tighten tensioner sprocket nut [9] . Tightening torque: 25 Nm.

16.Install components in reverse order of removal.

17.Fit auxiliary drive belt. Remove locking pin from tensioner pulley.

18.Tighten crankshaft pulley bolts. Tightening torque: 28 Nm.

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

Service indicator

Switch ignition ON.

Press button [A] Fig. 26994.

Press button [B] to reset the display.

Switch ignition OFF.

Fig. 26994

26994

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

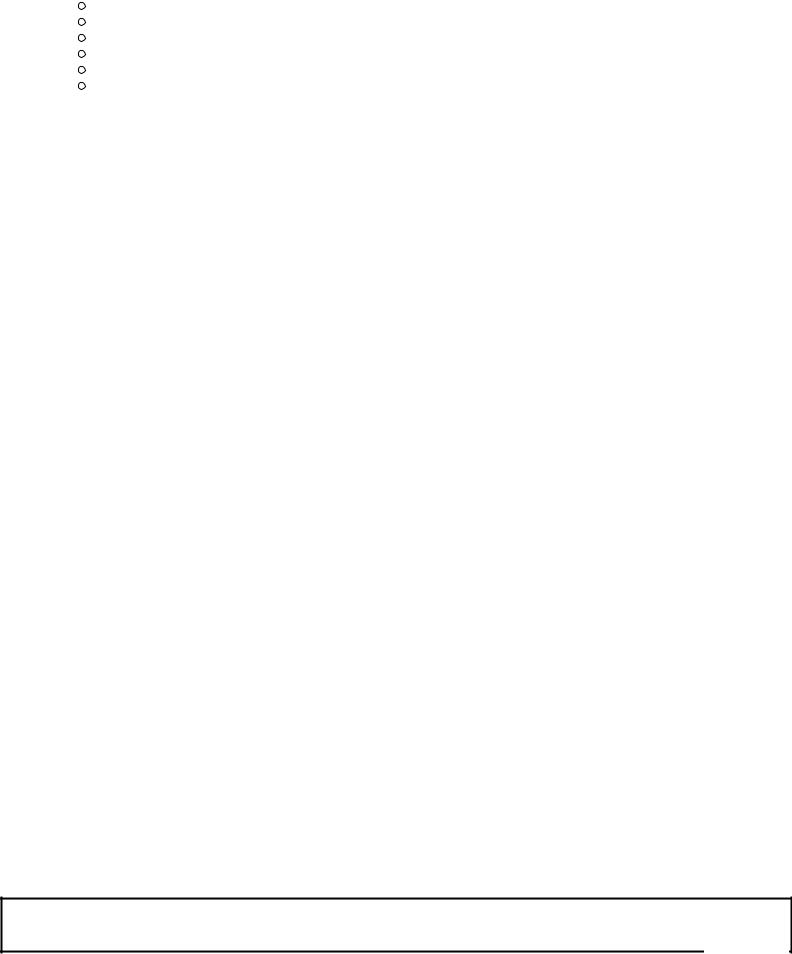

Engine management pin data

Terminal side

Wire side

Component/circuit description

AC compressor clutch relay

AC compressor clutch relay

AC refrigerant pressure switch

Battery

Camshaft position (CMP) actuator relay

Camshaft position (CMP) actuator relay

Camshaft position (CMP) actuator relay

Camshaft position (CMP) sensor

Camshaft position (CMP) sensor

Crankshaft position (CKP) sensor

Crankshaft position (CKP) sensor

Earth

Earth

Earth

Earth

Earth

Engine control relay

ECM |

Signal |

Condition |

pin |

|

|

32 |

|

Engine idling - AC |

|

OFF |

|

|

|

|

|

|

Engine idling - AC |

32ON - AC compressor ON

40

|

Oscilloscope setting |

|

Typical value |

(Suggested settings - |

Wave form |

|

Voltage/time per division) |

|

11-14 V

0-1 V

Connected pin - no test data available or random digital signal

18 |

Ignition OFF |

11-14 V |

|

52 |

Ignition ON |

11-14 V |

|

52 |

Engine idling |

11-14 V |

|

52 |

Engine idling - |

0-1 V briefly |

|

accelerate briefly |

|||

|

|

||

8 |

Engine idling |

2 V/50 ms |

|

12 |

Ignition ON |

5 V |

|

48 |

Engine idling |

5 V/2 ms |

|

(49) |

|||

|

|

||

49 |

|

Reversed |

|

Engine idling |

5 V/2 ms |

||

(48) |

|||

|

|

||

2 |

Ignition ON |

0 V |

|

14 |

Ignition ON |

0 V |

|

19 |

Ignition ON |

0 V |

|

24 |

Ignition ON |

0 V |

|

42 |

Ignition ON |

0 V |

|

36 |

Ignition OFF |

11-14 V |

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

Engine control relay

Engine control relay

Engine coolant temperature (ECT) sensor

Engine coolant temperature (ECT) sensor

Engine coolant temperature (ECT) sensor

Evaporative emission (EVAP) canister purge valve

Evaporative emission (EVAP) canister purge valve

Evaporative emission (EVAP) canister purge valve

Fuel pump relay

Fuel pump relay

Heated oxygen sensor (HO2S)

Heated oxygen sensor (HO2S)

Idle air control (IAC) valve

Idle air control (IAC) valve

Ignition coil - cylinder 1

Ignition coil

Ignition coil - cylinder 2

Ignition coil

Ignition coil - cylinder 3

Ignition coil

Ignition coil - cylinder 4

Ignition coil

Ignition coil - cylinder 5

Ignition coil

Ignition switch

Immobilizer control module - diagnostic link

Injector 1

Injector 1

Injector 2

Injector 2

Injector 3

Injector 3

36

37

30

45

45

5

5

5

3

3

10

28

4

22

1

1

20

20

39

39

21

21

38

38

27

55

17

17

16

16

15

15

Ignition ON

Ignition ON

Ignition ON

Ignition ON - coolant temp. 10°C

Ignition ON - coolant temp. 80°C

Ignition ON

Engine idling

Engine hot - valve operating

Ignition ON

Engine cranking

Engine idling

Engine idling - engine hot

Engine idling

Engine idling

Ignition ON

Engine idling

Ignition ON

Engine idling

Ignition ON

Engine idling

Ignition ON

Engine idling

Ignition ON

Engine idling

Ignition ON

Ignition ON

Engine idling - engine hot

Ignition ON

Engine idling - engine hot

Ignition ON

Engine idling - engine hot

0 V

11-14 V

0 V

3,5 V

0,6 V

11-14 V

11-14 V

|

10 V/20 ms |

0-1 V briefly then 11-14 |

|

V |

|

0-1 V |

|

0 V |

|

0,1-1 V fluctuating |

0,2 V/1 sec. |

|

5 V/5 ms |

|

5 V/5 ms |

11-14 V |

|

|

5 V/2 ms |

11-14 V |

|

|

5 V/2 ms |

11-14 V |

|

|

5 V/2 ms |

11-14 V |

|

|

5 V/2 ms |

11-14 V |

|

|

5 V/2 ms |

11-14 V |

|

Connected pin - no test |

|

data available or |

|

random digital signal |

|

11-14 V |

|

2,5-3,5 ms |

10 V/2 ms |

11-14 V |

|

2,5-3,5 ms |

10 V/2 ms |

11-14 V |

|

2,5-3,5 ms |

10 V/2 ms |

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

Injector 4 |

35 |

|

Injector 4 |

35 |

|

Injector 5 |

34 |

|

Injector 5 |

34 |

|

Instrumentation control module/heater |

41 |

|

function control module |

||

|

||

Instrumentation control module/heater |

|

|

function control module - malfunction |

51 |

|

indicator signal |

|

|

Intake air temperature (IAT) sensor |

30 |

|

Intake air temperature (IAT) sensor |

54 |

|

Intake manifold air control relay - 2,4 |

23 |

|

Knock sensor (KS) 1 |

11 |

|

Knock sensor (KS) 1 |

30 |

|

Knock sensor (KS) 2 |

29 |

|

Knock sensor (KS) 2 |

30 |

|

Mass air flow (MAF) sensor |

7 |

|

Mass air flow (MAF) sensor |

7 |

|

Mass air flow (MAF) sensor |

26 |

|

Tachometer |

6 |

|

Throttle position (TP) sensor |

12 |

|

Throttle position (TP) sensor |

30 |

|

Throttle position (TP) sensor |

53 |

|

Throttle position (TP) sensor |

53 |

|

Transmission control module (TCM) |

43 |

|

Vehicle speed sensor (VSS) |

9 |

Ignition ON |

11-14 V |

|

|

Engine idling - |

2,5-3,5 ms |

10 V/2 ms |

|

engine hot |

|||

|

|

||

Ignition ON |

11-14 V |

|

|

Engine idling - |

2,5-3,5 ms |

10 V/2 ms |

|

engine hot |

|||

|

|

||

|

Connected pin - no test |

|

|

|

data available or |

|

|

|

random digital signal |

|

|

|

Connected pin - no test |

|

|

|

data available or |

|

|

|

random digital signal |

|

|

Ignition ON |

0 V |

|

|

Ignition ON - 20°C |

3 V |

|

Engine idling - accelerate briefly

Engine running

Engine idling - accelerate briefly

Engine running

Engine idling - engine hot

Engine idling - accelerate briefly

Ignition ON

Engine idling

Ignition ON

Ignition ON

Ignition ON - throttle closed

Ignition ON - throttle fully open

Ignition ON - vehicle pushed

Connected pin - no test data available or random digital signal

50 mV/1 ms

0 V

50 mV/1 ms

0 V

0,7-1,3 V

4,2 V briefly

0 V

30 Hz |

2 V/20 ms |

5 V

0 V

0,1-0,7 V

4-4,8 V

Connected pin - no test data available or random digital signal

0 V or 11-14 V

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

12. Digital, DC, frequency modulated |

2. Analogue, AC, frequency modulated |

20. Digital, DC, pulse width modulated or |

|

|

digital, DC, frequency modulated |

21. Analogue, DC |

25. Digital, DC, pulse width modulated or |

33. Digital, DC, frequency modulated |

|

digital, DC, frequency modulated |

|

35. Digital, DC, pulse width modulated |

38. Analogue, AC |

55. Digital, DC, frequency modulated |

input/output signal

input/output signal

input signal

input signal

output signal

output signal

ECM switched earth

ECM switched earth

ECM earth circuit

ECM earth circuit

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

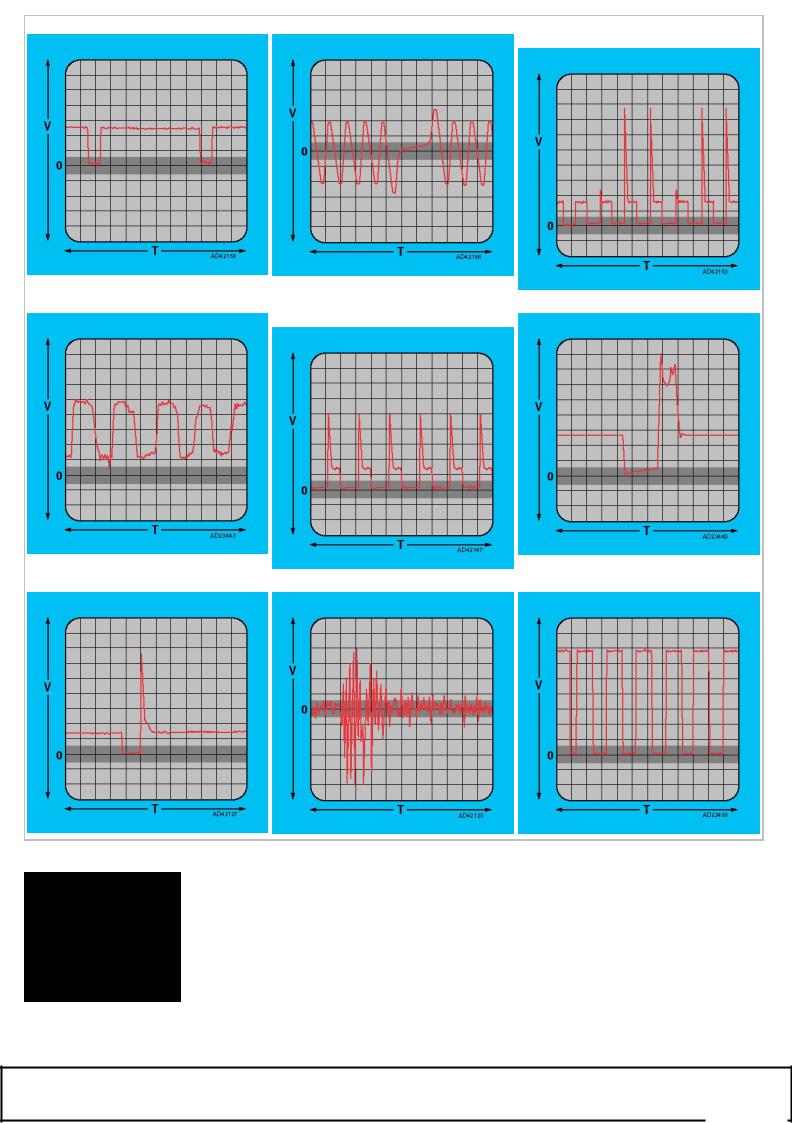

Battery replacement

Fig. 3

3

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

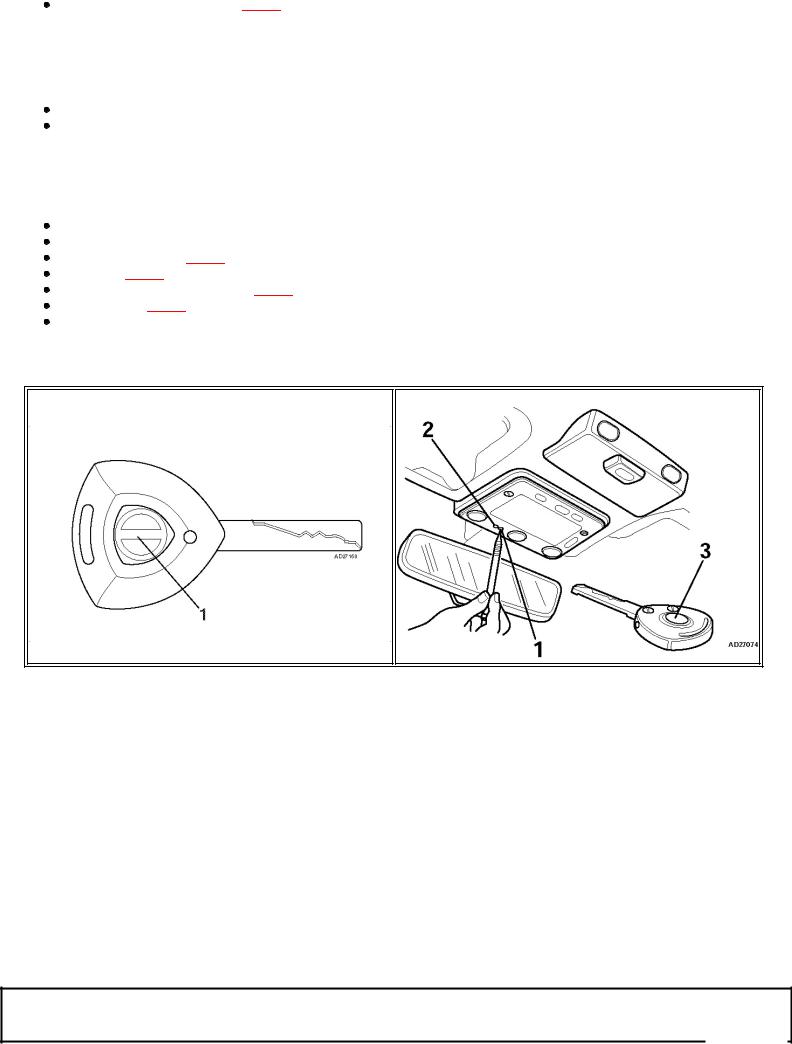

Immobilizer

System operation

Arms automatically when ignition key is removed.

Programming

When

Key remote control added or replaced.

System malfunction.

How

NOTE: A maximum of 8 keys can be programmed. NOTE: Immobilizer LED located in centre console.

Obtain all keys.

Insert master key into ignition switch. Switch ignition ON.

Wait for LED to extinguish. Switch ignition OFF.

Carry out the following within 10 seconds: Remove master key.

Insert non programmed key into ignition switch. Switch ignition ON.

Wait for LED to extinguish. Switch ignition OFF. Remove key.

Repeat above procedure to program remaining keys. After programming last key proceed as follows: Insert master key into ignition switch.

Switch ignition ON.

Wait for LED to extinguish. Switch ignition OFF.

Switch ignition ON. Wait approximately 3 seconds.

Ensure immobilizer LED illuminates for approximately 0,7 second and then goes out to indicate correct programming.

3

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

Remote alarm

System operation

Pressing key lock/unlock button Fig. 1 [1] activates alarm and central locking.

Programming

When

Key added or replaced.

System malfunction.

How

NOTE: A maximum of 8 keys can be programmed.

Obtain all keys.

Distance from receiver: At least 20 cm.

Press and hold button Fig. 2 [1].

Check LED Fig. 2 [2] flashes.

Press and hold lock/unlock button Fig. 2 [3] until LED [2] illuminates.

Release button Fig. 2 [1].

Repeat above procedure to program remaining keys.

Fig. 2

2

1

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

|

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

|

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

|

|

|||

Diagnostic

Accessing and erasing

The engine control module (ECM) fault memory can be accessed and erased using diagnostic equipment connected to the data link connector (DLC).

Trouble code identification

|

|

|

|

|

|

|

|

|

|

|

P type |

|

Fault location |

|

Probable cause |

|

|||

|

|

|

|

|

|

|

|||

|

P0 |

|

Refer to EOBD trouble code table |

|

- |

|

|||

|

|

|

|

|

|

|

|

||

|

|

1 |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EOBD codes

All EOBD codes starting with P zero have standard meanings irrespective of vehicle make or model. For EOBD codes, other than those starting P zero, refer to model specific chapters.

The following list covers all P0 codes allocated at the time of publication.

Trouble |

|

Fault location |

|

Probable cause |

code |

|

|

||

|

|

|

|

P0000

P0001

P0002

P0003

P0004

P0005

P0006

P0007

P0008

P0009

P0010

P0011

P0012

P0013

No fault found

No fault found

Fuel volume regulator control - circuit open

Fuel volume regulator control - circuit open

Fuel volume regulator control - circuit range/performance

Fuel volume regulator control - circuit range/performance

Fuel volume regulator control - circuit low

Fuel volume regulator control - circuit low

Fuel volume regulator control - circuit high

Fuel volume regulator control - circuit high

Fuel shut-off valve - circuit open

Fuel shut-off valve - circuit open

Fuel shut-off valve - circuit low

Fuel shut-off valve - circuit low

Fuel shut-off valve - circuit high

Fuel shut-off valve - circuit high

Engine position system, bank 1 - engine performance

Engine position system, bank 1 - engine performance

Engine position system, bank 2 - engine performance

Engine position system, bank 2 - engine performance

Camshaft position (CMP) actuator, intake/left/front, bank 1 - circuit malfunction

Camshaft position (CMP), intake/left/front, bank 1 - timing over-advanced/system performance

Camshaft position (CMP), intake/left/front, bank 1 - timing over-retarded

Camshaft position (CMP) actuator, intake/left/front, bank 1 - circuit malfunction

-

-

Wiring, regulator control solenoid

Wiring, regulator control solenoid

Wiring, regulator control solenoid

Wiring, regulator control solenoid

Wiring short to earth, regulator control solenoid

Wiring short to earth, regulator control solenoid

Wiring open circuit/short to positive, regulator control solenoid

Wiring open circuit, fuel shut-off valve

Wiring open circuit, fuel shut-off valve

Wiring short to earth, fuel shut-off valve

Wiring short to earth, fuel shut-off valve

Wiring short to positive, fuel shut-off valve

Wiring short to positive, fuel shut-off valve

Mechanical fault

Mechanical fault

Mechanical fault

Mechanical fault

Wiring, CMP actuator, ECM

Wiring, CMP actuator, ECM

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Wiring, CMP actuator, ECM

Wiring, CMP actuator, ECM

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

P0014

P0015

P0016

P0017

P0018

P0019

P0020

P0021

P0022

P0023

P0024

P0025

P0026

P0027

P0028

P0029

P0030

P0031

P0032

P0033

P0034

P0035

P0036

P0037

P0038

P0039

P0040

Camshaft position (CMP) actuator, exhaust/right/rear, |

|

Valve timing, engine mechanical fault, CMP actuator |

bank 1 - timing over-advanced/system performance |

|

|

|

|

Camshaft position (CMP) actuator, exhaust/right/rear, bank 1 - timing over-retarded

Crankshaft position/camshaft position, bank 1 sensor A - correlation

Crankshaft position/camshaft position, bank 1 sensor B - correlation

Crankshaft position/camshaft position, bank 2 sensor A - correlation

Crankshaft position/camshaft position, bank 2 sensor B - correlation

Camshaft position (CMP) actuator, intake/left/front, bank 2 - circuit malfunction

Camshaft position (CMP), intake/left/front, bank 2 - timing over-advanced/system performance

Camshaft position (CMP), intake/left/front, bank 2 - timing over-retarded

Camshaft position (CMP) actuator, exhaust/right/rear, bank 2 - circuit malfunction

Camshaft position (CMP), exhaust/right/rear, bank 2 - timing over-advanced/system performance

Camshaft position (CMP), exhaust/right/rear, bank 2 - timing over-retarded

Intake valve control solenoid circuit, bank 1 - range/performance

Exhaust valve control solenoid circuit, bank 1 - range/performance

Intake valve control solenoid circuit, bank 2 - range/performance

Exhaust valve control solenoid circuit, bank 2 - range/performance

Heated oxygen sensor (HO2S) 1, bank 1, heater control - circuit malfunction

Heated oxygen sensor (HO2S) 1, bank 1, heater control - circuit low

Heated oxygen sensor (HO2S) 1, bank 1, heater control - circuit high

Turbocharger (TC) wastegate regulating valve - circuit malfunction

Turbocharger (TC) wastegate regulating valve - circuit low

Turbocharger (TC) wastegate regulating valve - circuit high

Heated oxygen sensor (HO2S) 2, bank 1, heater control - circuit malfunction

Heated oxygen sensor (HO2S) 2, bank 1, heater control - circuit low

Heated oxygen sensor (HO2S) 2, bank 1, heater control - circuit high

Turbo/super charger bypass valve, control circuit - range/performance

Oxygen sensor signals swapped, bank 1 sensor 1/bank 2 sensor 1

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CKP sensor, CMP sensor, mechanical fault

Wiring, CMP actuator, ECM

Wiring, CMP actuator, ECM

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Wiring, CMP actuator, ECM

Wiring, CMP actuator, ECM

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Valve timing, engine mechanical fault, CMP actuator

Wiring, intake valve control solenoid

Wiring, intake valve control solenoid

Wiring, exhaust valve control solenoid

Wiring, exhaust valve control solenoid

Wiring, intake valve control solenoid

Wiring, intake valve control solenoid

Wiring, exhaust valve control solenoid

Wiring, exhaust valve control solenoid

Wiring, HO2S, ECM

Wiring, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to positive, HO2S, ECM

Wiring short to positive, HO2S, ECM

Wiring, TC wastegate regulating valve, ECM

Wiring, TC wastegate regulating valve, ECM

Wiring short to earth, TC wastegate regulating valve, ECM

Wiring short to positive, TC wastegate regulating valve, ECM

Wiring, HO2S, ECM

Wiring, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to earth, HO2S, ECM

Wiring short to positive, HO2S, ECM

Wiring short to positive, HO2S, ECM

Wiring, bypass valve

Wiring, bypass valve

Wiring

Wiring

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

P0041

P0042

P0043

P0044

P0045

P0046

P0047

P0048

P0049

P0050

P0051

P0052

P0053

P0054

P0055

P0056

P0057

P0058

P0059

P0060

P0061

P0062

P0063

P0064

P0065

P0066

P0067

P0068

P0069

P0070

P0071

Oxygen sensor signals swapped, bank 1 sensor 2/bank 2 |

|

Wiring |

sensor 2 |

|

|

|

|

|

Heated oxygen sensor (HO2S) 3, bank 1, heater control - |

|

Wiring, HO2S, ECM |

circuit malfunction |

|

|

|

|

|

Heated oxygen sensor (HO2S) 3, bank 1, heater control - |

|

Wiring short to earth, HO2S, ECM |

circuit low |

|

|

|

|

|

Heated oxygen sensor (HO2S) 3, bank 1, heater control - |

|

Wiring short to positive, HO2S, ECM |

circuit high |

|

|

|

|

|

Turbo/super charger boost control solenoid - circuit open |

|

Wiring, boost control solenoid |

|

|

|

Turbo/super charger boost control solenoid - circuit |

|

Wiring, boost control solenoid, mechanical fault |

range/performance |

|

|

|

|

|

|

|

|

Turbo/super charger boost control solenoid - circuit low |

|

Wiring short to earth, boost control solenoid |

|

|

|

Turbo/super charger boost control solenoid - circuit high |

|

Wiring short to positive, boost control solenoid |

|

|

|

Turbo/super charger turbine - over-speed |

|

Mechanical fault |

|

|

|

Heated oxygen sensor (HO2S) 1, bank 2, heater control - |

|

Wiring, HO2S, ECM |

circuit malfunction |

|

|

|

|

|

Heated oxygen sensor (HO2S) 1, bank 2, heater control - |

|

Wiring short to earth, HO2S, ECM |

circuit low |

|

|

|

|

|

Heated oxygen sensor (HO2S) 1, bank 2, heater control - |

|

Wiring short to positive, HO2S, ECM |

circuit high |

|

|

|

|

|

Heated oxygen sensor (HO2S), bank 1, sensor 1 - heater |

|

Wiring, HO2S |

resistance |

|

|

|

|

|

Heated oxygen sensor (HO2S), bank 1, sensor 2 - heater |

|

Wiring, HO2S |

resistance |

|

|

|

|

|

Heated oxygen sensor (HO2S), bank 1, sensor 3 - heater |

|

Wiring, HO2S |

resistance |

|

|

|

|

|

Heated oxygen sensor (HO2S) 2, bank 2, heater control - |

|

Wiring, HO2S, ECM |

circuit malfunction |

|

|

|

|

|

Heated oxygen sensor (HO2S) 2, bank 2, heater control - |

|

Wiring short to earth, HO2S, ECM |

heater circuit low |

|

|

|

|

|

Heated oxygen sensor (HO2S) 2, bank 2, heater control - |

|

Wiring short to positive, HO2S, ECM |

circuit high |

|

|

|

|

|

Heated oxygen sensor (HO2S), bank 2, sensor 1 - heater |

|

Wiring, HO2S |

resistance |

|

|

|

|

|

Heated oxygen sensor (HO2S), bank 2, sensor 2 - heater |

|

Wiring, HO2S |

resistance |

|

|

|

|

|

Heated oxygen sensor (HO2S), bank 2, sensor 3 - heater |

|

Wiring, HO2S |

resistance |

|

|

|

|

|

Heated oxygen sensor (HO2S) 3, bank 2, heater control - |

|

Wiring, HO2S, ECM |

circuit malfunction |

|

|

|

|

|

Heated oxygen sensor (HO2S) 3, bank 2, heater control - |

|

Wiring short to earth, HO2S, ECM |

circuit low |

|

|

|

|

|

Heated oxygen sensor (HO2S) 3, bank 2, heater control - |

|

Wiring short to positive, HO2S, ECM |

circuit high |

|

|

|

|

|

Air assisted injector - range/performance problem |

|

Air assisted injector |

|

|

|

Air assisted injector - circuit malfunction/circuit low |

|

Wiring short to earth, air assisted injector, ECM |

|

|

|

Air assisted injector - circuit high |

|

Wiring short to positive, air assisted injector, ECM |

|

|

|

Manifold absolute pressure (MAP) sensor/mass air flow |

|

Wiring, MAP sensor, MAF sensor, mechanical fault |

(MAF) sensor/throttle position correlation |

|

|

|

|

|

|

|

|

Manifold absolute pressure (MAP) sensor/barometric |

|

MAP sensor, mechanical fault |

pressure (BARO) sensor correlation |

|

|

|

|

|

|

|

|

Outside air temperature sensor - circuit malfunction |

|

Wiring, outside air temperature sensor, ECM |

|

|

|

Outside air temperature sensor - range/performance |

|

Outside air temperature sensor |

problem |

|

|

|

|

Manufacturer: Lancia |

Model: Kappa 2,0 |

© Autodata Limited 2004 |

Engine code: 838A1.000 |

Output: 107 (145) 6100 |

2006.10.21. |

Tuned for: R-Cat |

Year: 1994-02 |

V5.500- |

Loading...

Loading...