Page 1

OPTISWITCH 4000/5000

Technical Datasheet

Vibration level switches for liquids

• Operates up to 250°C / 480°F and 64 bar / 925 psi

• Pump dry-run detection

• High reliability due to permanent fault monitoring function

Page 2

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

Universal liquid level switches

OPTISWITCH 4000/5000 series is a level sensor that uses a vibrating fork for detecting level. It is designed for

use in all liquids. It is not affected by foam and external vibration. It is also unaffected by variations of product

properties such as ε

1 OPTISWITCH 4000

2 OPTISWITCH 5100

3 OPTISWITCH 5200

, viscosity etc.

r

Highlights

• Output options: relay, transistor, NAMUR,

contactless electronic switch and 2-wire

• 5000 series: Plastic, aluminium or stainless

steel housings

• LED signal lamp for indicating the switching

condition (with plastic housing only)

• 5000 series: Large choice of materials for

wetted parts. This includes 316L, Hastelloy C4,

enamel, ECTFE and PFA.

• 5000 series. Probe length: 53...6000 mm /

2...236"

• Repeatability: +/-2 mm

• Thread connections G/NPT ¾; flange sizes from

DN25 PN40; Triclamp 1" or 2" and other

hygienic fittings

Industries

• Chemicals

• Food & Beverage

• Water & Wastewater

• Oil & Gas

Applications

• Reactors

• Hygienic and sanitary applications

• Process and storage tanks for liquids

• Dry-run and overfill protection

2

www.krohne.com

Page 3

Features and Options

OPTISWITCH 4000 - The economical

version

Simple and robust measuring system, virtually

•

unaffected by the chemical and physical

properties of liquids

• Easily mountable in pipelines from DN 25,

vessels and tanks

• Outputs: contactless electronic switch or

transistor

OPTISWITCH 5100, 5150 - The compact

version

• Standard or HT version, large array of process

fittings, housings and electronics

• Outputs: relay, transistor, 2wire, NAMUR or

contactless electronic switch

• Process connection option for high temperature

up to 250°C / 482°F

• With all relevant approvals (ATEX etc.)

• Version OPTISWITCH 5150 with polished tuning

fork e.g. for food processing

OPTISWITCH 5200, 5250 - The special

version with probe extension

• Standard or HT version, large array of process

fittings, housings and electronics

• Probe length up to 6000 mm / 236"

• Outputs: relay, transistor, 2wire, NAMUR or

contactless electronic switch

• Process connection option for high temperature

up to 250°C / 482°F

• With all relevant approvals (ATEX etc.)

• Version OPTISWITCH 5150 with polished tuning

fork e.g. for food processing

www.krohne.com

3

Page 4

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

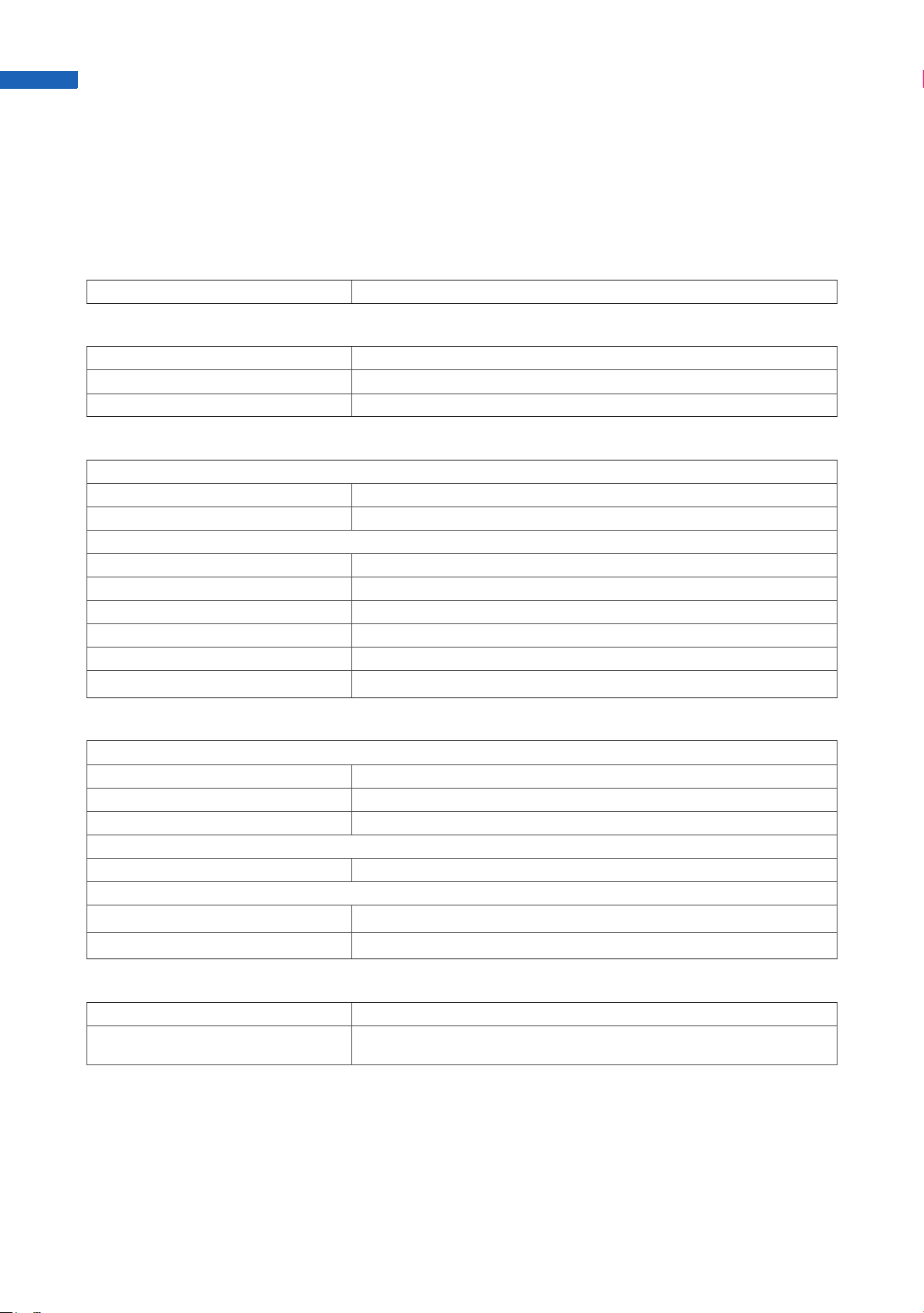

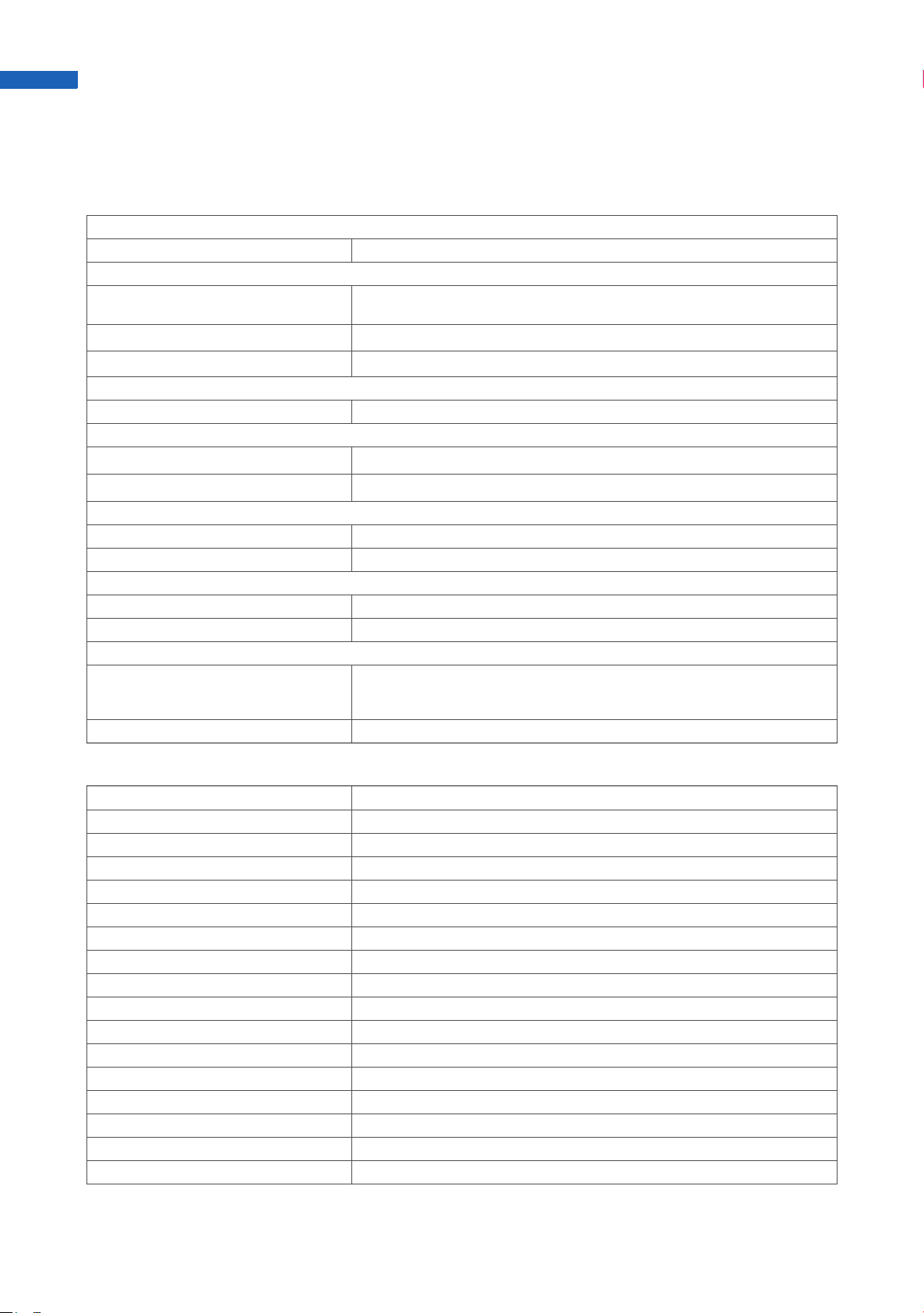

Technical data

OPTISWITCH 4000 C

Function

Measurement parameter Level detection of liquids

Measurement accuracy

Hysteresis Approx. 2 mm / 0.08" with vertical installation

Integration time Approx. 500 ms

Frequency Approx. 1200 Hz

Operating conditions

Temperature

Temperature

TemperatureTemperature

Ambient temperature on housing -40…+70°C / -40…+158°F

Storage and transport temperature -40…+80°C / -40…+176°F

Process temperature

Process temperature

Process temperatureProcess temperature

Standard -40…+100°C / -40…+212°F

High temperature version (optional) -40…+150°C / -40…+302°F

Temperature shock No limitation

Process pressure -1…64 bar / -14.5…928 psi

Viscosity (dynamic) 0.1...10.000 mPa s (requirement: with SG=1)

Density

>0.7 g/cm2 / >0.025 lbs/in

2

Materials

Wetted parts

Wetted parts

Wetted partsWetted parts

Process fitting – thread 316L

Gaskets Klingersil C-4400

Vibrating element 316L

Non-wetted parts

Non-wetted parts

Non-wetted partsNon-wetted parts

Housing 316L and plastic PEI

Surface quality

Surface quality

Surface qualitySurface quality

Standard

Hygienic version

Ra = approx. 3.2 μm / 1.26-4"

Ra < 0.8 μm / 3.15-5"

Process connection

Thread G¾ A; ¾ NPT; G1 A; 1 NPT

Hygienic fittings Bolting DN 25 PN 40; bolting DN 40 PN 40; Tri-Clamp 1"; Tri-Clamp 1½";

SMS

4

www.krohne.com

Page 5

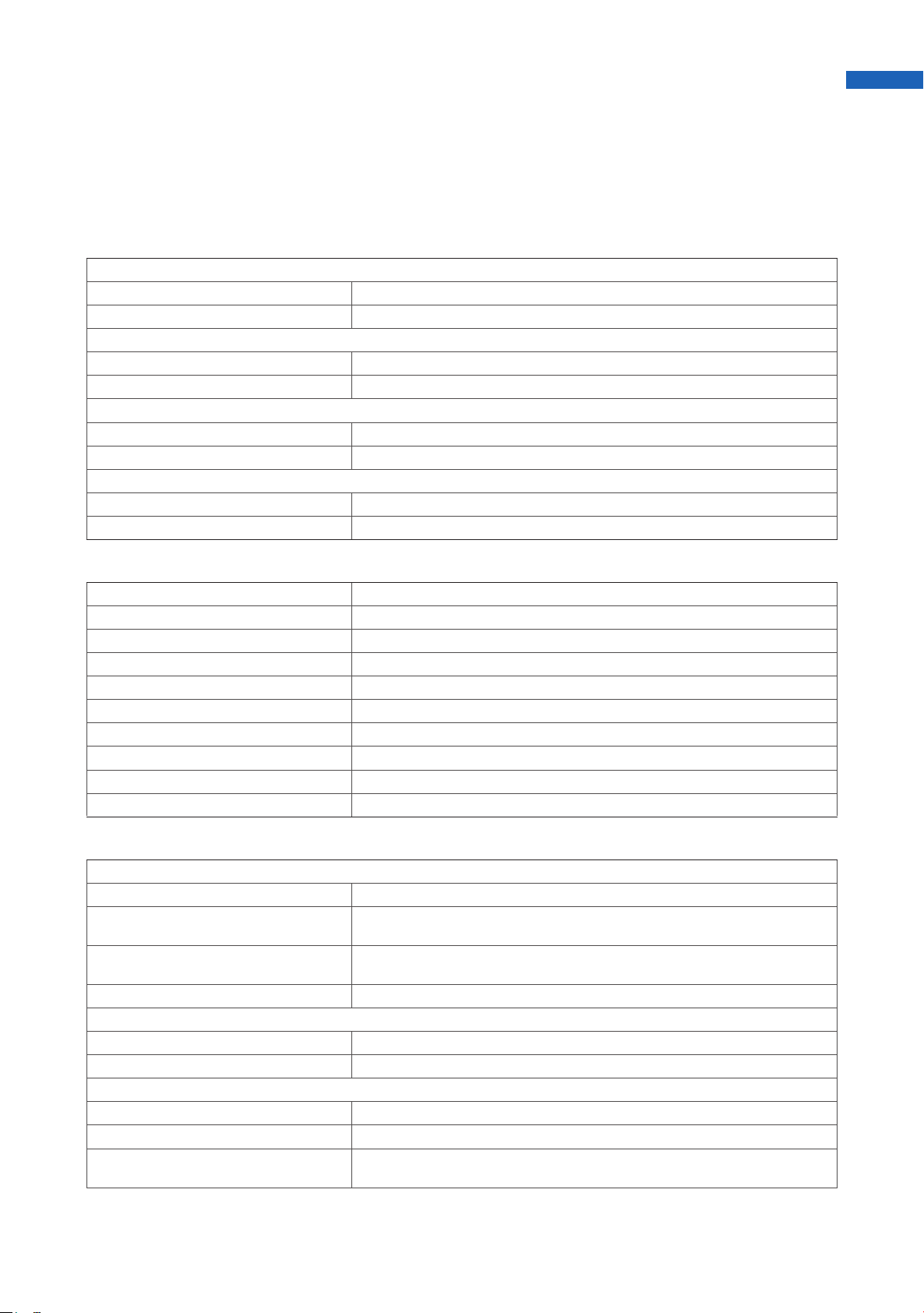

Power Supply

Transistor output

Transistor output

Transistor outputTransistor output

Supply voltage 10…55 VDC

Power consumption Max. 0.5 W

Contactless electronic switch

Contactless electronic switch

Contactless electronic switchContactless electronic switch

Supply voltage 20…253 VAC, 50/60 Hz, 20…253 VDC

Power consumption Approx. 3 mA (via load circuit)

Operating elements

Operating elements

Operating elementsOperating elements

Control lamp Illuminated lens for indication of the switching condition.

Mode adjustment Min./max. adjustment through electrical connection

Electromechanical data

Electromechanical data

Electromechanical dataElectromechanical data

Plug connection 1x plug M12x1 or 1x plug DIN 43650

Screwed terminals For wire cross-section up to 1.5 mm²

Output

Transistor output

Transistor output Floating transistor output, overload and permanently shortcircuit-proof

Transistor outputTransistor output

Load current Max. 250 mA

Voltage loss Max. 1 V

Turn-on voltage Max. 55 VDC

Blocking current <10 μA

Modes (adjustable) Min. / max.

Delay time When immersed: approx. 0.5 s; when uncovered: approx. 1 s

Contactless electronic switch

Contactless electronic switch Contactless electronic switch

Contactless electronic switchContactless electronic switch

Modes (adjustable) Min. / max.

Delay time When immersed: approx. 0.5 s; when uncovered: approx. 1 s

Approvals

Protection category

Protection category

Protection categoryProtection category

Valve plug IP 65

Valve plug with IDC method of

termination

M12x1 plug connection (only with

transistor output)

Overvoltage category III

Protection class

Protection class

Protection classProtection class

Transistor output II

Contactless electronic switch I

CE conformity

CE conformity

CE conformityCE conformity

EMC (89/336/EEC) Emission EN 61326: 1997 (class B), immunity EN 61326: 1997/A1: 1998

LVD (73/23/EEC) EN 61010-1: 2001

SIL conformity OPTISWITCH fulfills the requirements of functional safety according to

IP 67

IP 66/IP 67

IEC 61508.

www.krohne.com

5

Page 6

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

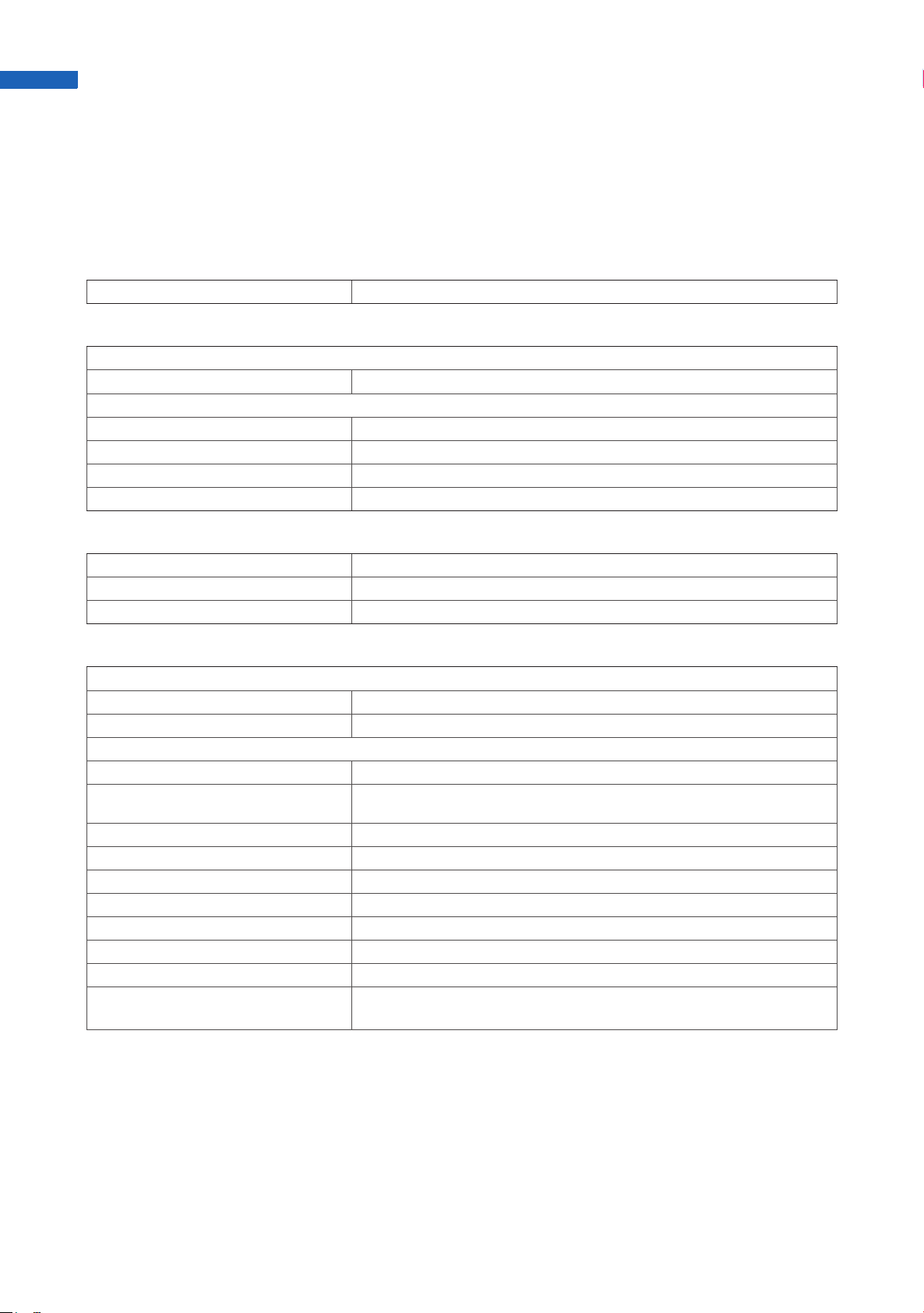

OPTISWITCH 5000 C series

Function

Measurement parameter Level detection of liquids

Design

Sensor length

Sensor length

Sensor lengthSensor length

OPTISWITCH 5100 C, 5150 C See chapter "Dimensions".

OPTISWITCH 5200 C, 5250 C

316L, 2.4610 (Hastelloy C4) 80...6000 mm / 3...236"

2.4610 (Hastelloy C4) enamelled 80...1500 mm / 3...59"

1.4435 (316L) ECTFE coated 80...3000 mm / 3...118"

1.4435 (316L) PFA coated 80...3000 mm / 3...118"

Measurement accuracy

Hysteresis Approx. 2 mm / 0.08" with vertical installation

Integration time Approx. 500 ms

Frequency Approx. 1200 Hz

Operating conditions

Temperature

Temperature

TemperatureTemperature

Ambient temperature on housing -40…+70°C / -40…+158°F

Storage and transport temperature -40…+80°C / -40…+176°F

Process temperature

Process temperature

Process temperatureProcess temperature

316L / Hastelloy C4 (2.4610) -50…+150°C / -58…+302°F

Process temperature with temperature

adapter

316L / Hastelloy C4 (2.4610) -50…+250°C / -58…+482°F

enamelled -50…+200°C / -58…+392°F

with ECTFE coating -50…+150°C / -58…+302°F

with PFA coating -50…+150°C / -58…+302°F

Temperature shock No limitation

Process pressure -1…64 bar / -14.5…928 psi

Viscosity (dynamic) 0.1...10.000 mPa s (requirement: with SG=1)

Density

Option

0.7...2.5 g/cm2 / 0.025...0.09 lbs/in2; 0.5...2.5 g/cm2 / 0.018...0.09 lbs/in2 by

switching over

6

www.krohne.com

Page 7

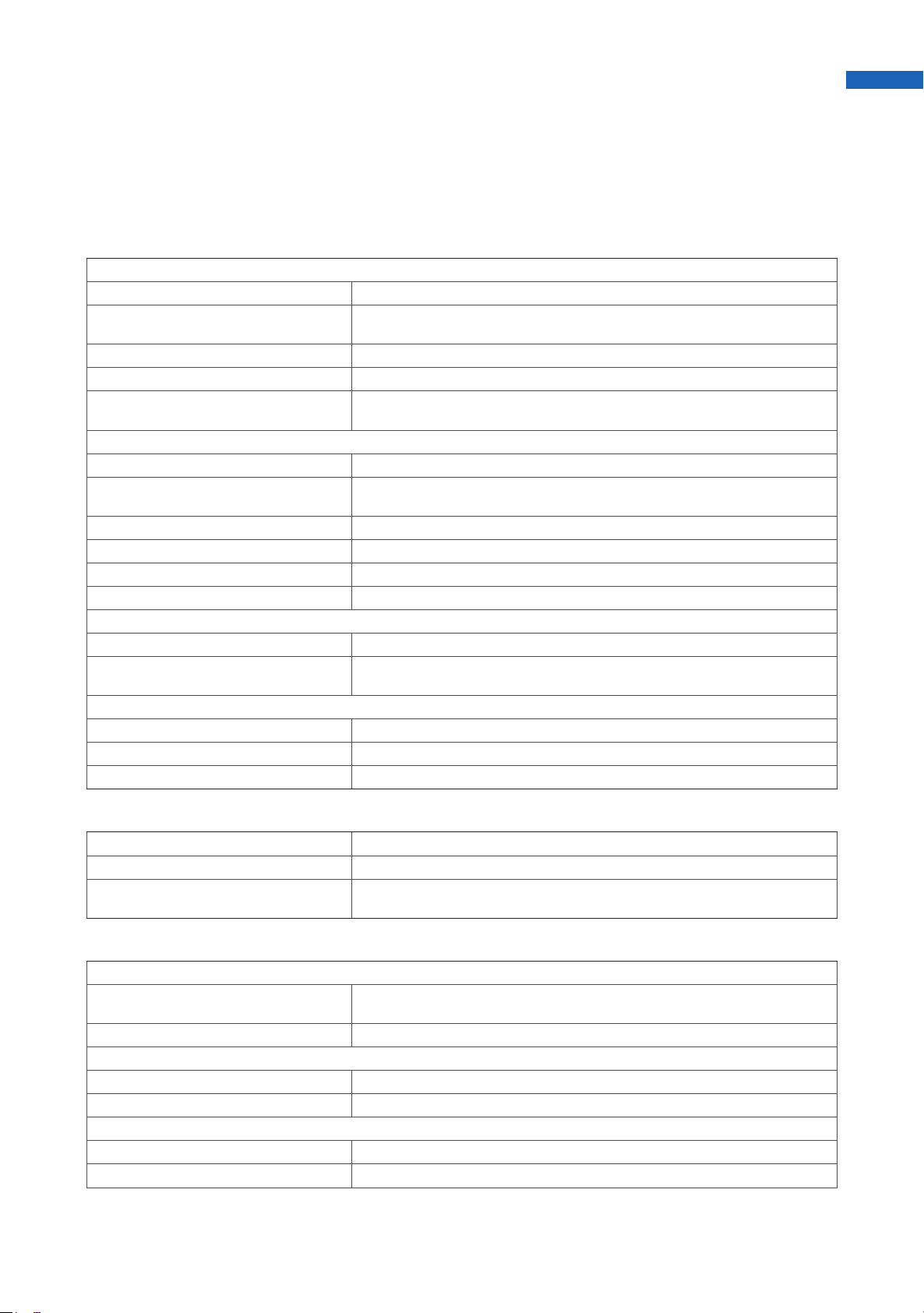

Materials

Wetted parts

Wetted parts

Wetted partsWetted parts

Process fitting – thread 316L; 2.4602 (Hastelloy C4)

Process fitting – flange 316L; 316L with Hastelloy C4 coating; steel enamelled; 316L with ECTFE

Gaskets Klingersil C-4400

Tuning fork 316L / 2.4610 (Hastelloy C4)

Extension tube ø21.3 mm / ø0.84" 316L; 2.4610 (Hastelloy C4); 2.4610 (Hastelloy C4) enamelled; 316L with

Non-wetted parts

Non-wetted parts

Non-wetted partsNon-wetted parts

Housing Plastic PBT (Polyester), Alu-die casting powder-coated, 316L

Gasket ring between housing and

housing cover

Peephole in housing cover PMMA (Makrolon)

Ground terminal 316L

Temperature adapter (Option) 316L

Gastight leadthrough (Option) 316L / glass

Surface quality

Surface quality

Surface qualitySurface quality

Standard (OPTISWITCH 5100 C, 5200 C) Ra = approx. 3.2 μm / 1.26-4"

Hygienic version

(OPTISWITCH 5150 C, 5250 C)

Coatings

Coatings

CoatingsCoatings

ECTFE Approx. 0.5…0.8 mm / 0.02…0.03"

PFA Approx. 0.3…0.5 mm / 0.01…0.02"

Enamel Approx. 0.8 mm / 0.03"

coating; 316L with PFA coating

ECTFE coating; 316L with PFA coating

NBR (stainless steel housing), silicone (Alu / plastic housing)

Ra < 0.8 μm / 3.15-5"

Process connection

Thread G¾ A; ¾ NPT; G1 A; 1 NPT

Flanges DIN: ≥DN25; ANSI: ≥1"

Hygienic fittings (OPTISWITCH 5150 C,

5250 C)

Bolting DN 40 PN 40; Tri-Clamp 1"; Tri-Clamp 1½" PN 10; cone DN 25 PN

40; Tuchenhagen Varivent DN 50 PN 10

Power Supply

Relay output

Relay output

Relay outputRelay output

Supply voltage 20…253 VAC, 50/60 Hz, 20…72 VDC (at U >60 VDC, the ambient temperature

Power consumption 1…8 VA (AC); ca. 1.3 W (DC)

Transistor output

Transistor output

Transistor outputTransistor output

Supply voltage 10…55 VDC

Power consumption Max. 0.5 W

Contactless electronic switch

Contactless electronic switch

Contactless electronic switchContactless electronic switch

Supply voltage 20…253 VAC, 50/60 Hz, 20…253 VDC

Power consumption Approx. 3 mA (via load circuit)

can be max. 50°C / 122°F)

www.krohne.com

7

Page 8

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

Two-wire output

Two-wire output

Two-wire outputTwo-wire output

Supply voltage 10…36 VDC (via the signal conditioning instrument)

NAMUR output

NAMUR output

NAMUR outputNAMUR output

Supply voltage (standard

characteristics)

Open-circuit voltage U0 approx. 8.2 V

Shortcircuit current IU approx. 8.2 mA

Operating elements

Control lamp Control lamp (LED) for indication of the switching condition.

Density switch (electronics versions: relay, transistor, contactless electronic switch, two-wire, NAMUR outputs)

0.5

0.7

Mode switch (electronics versions: relay output, transistor output, contactless electronic switch)

A Max. detection or overfill protection

B Min. detection or dry run protection

Characteristics reversal (electronics version: NAMUR output)

Max. Falling characteristics (Low current when immersed)

Min. Rising characteristics (High current when immersed)

Electromechanical data

Cable entry/plug (dependent on the

version) - Single chamber housing

Screwed terminals For wire cross-section up to 1.5 mm²

For connection to amplifier according to NAMUR IEC 60947-5-6, approx.

8.2 V

0.5...2.5 g/cm2 / 0.018...0.9 oz/in

0.7...2.5 g/cm2 / 0.025...0.9 oz/in

1x cable entry M20x1.5 (cable ø5…9 mm), 1x blind stopper M20x1.5;

attached 1x cable entry M20x1.5 or 1x cable entry ½ NPT, 1x blind stopper

½ NPT, 1x cable entry ½ NPT

2

2

Output

Relay output

Relay output Relay output (DPDT), 2 floating spdts

Relay outputRelay output

Turn-on voltage Min.: 10 mV; max.: 253 VAC/DC

Switching current Min.: 10 μA; max.: 5 A AC, 1 A DC

Breaking capacity Max.: 1250 VA, 50 W

Contact material (relay contacts) AgCdO and Au plated

Modes (adjustable) Min. / max.

Delay time When immersed: approx. 0.5 s; when uncovered: approx. 1 s

Transistor output

Transistor output Floating transistor output, overload and permanently shortcircuit proof

Transistor outputTransistor output

Load current Max. 400 mA

Voltage loss Max. 1 V

Turn-on voltage Max. 55 VDC

Blocking current <10 μA

Modes (adjustable) Min. / max.

Delay time When immersed: approx. 0.5 s; when uncovered: approx. 1 s

Contactless electronic switch

Contactless electronic switch Contactless electronic switch

Contactless electronic switchContactless electronic switch

Modes (adjustable) Min. / max.

Delay time When immersed: approx. 0.5 s; when uncovered: approx. 1 s

8

www.krohne.com

Page 9

Two-wire output

Two-wire output

Two-wire outputTwo-wire output

Suitable signal conditioning instruments SU 501

Output signal

Min. mode Vibrating element uncovered: 16 mA ±1 mA; vibrating element covered:

8mA±1mA

Max. mode Vibrating element uncovered: 8 mA ±1 mA; vibrating element covered:

16 mA ±1mA

Fault signal <2 mA

Modes (adjustable) Min. / max. (changeover with the signal conditioning instrument)

Delay time When immersed: approx. 0.5 s; when uncovered: approx. 1 s

NAMUR output

NAMUR output Two-wire NAMUR output

NAMUR outputNAMUR output

Current consumption

Falling characteristics ≥2.2 mA uncovered / ≤1 mA covered

Rising characteristics ≤1 mA uncovered / ≥2.2 mA covered

Fault signal ≤1 mA

Necessary processing system NAMUR processing system according to IEC 60947-5-6

(EN 50227/DIN 19234)

Modes (NAMUR output adjustable to

falling or rising characteristics)

Min.: rising characteristics (High current when immersed); max.: falling

characteristics (Low current when immersed)

Approvals

ATEX ATEX II 1G, 1/2G, 2G EEx ia IIC T6 1

ATEX II 1/2G, 2G EEx d IIC T6 2

ATEX II 1/2D IP6X T

Ship approval GL & LR

WHG German Federal Water Act 3

Protection category IP 66/IP 67

Overvoltage category III

Protection class

Protection class

Protection classProtection class

Transistor output, two-wire output,

NAMUR output

Relay output, contactless electronic

switch

CE conformity

CE conformity

CE conformityCE conformity

EMC (89/336/EEC) Emission EN 61326/A1: 1998 (class B), susceptibility EN 61326: 1997/A1:

LVD (73/23/EEC) EN 61010-1: 1993

SIL conformity OPTISWITCH fulfills the requirements of functional safety according to

1 this approval is for 2-wire and NAMUR electronics. It can be combined with either WHG or with ship approval.

2 only for the plastic-coated aluminium housing with a ½ NPT cable gland. An optional temperature adapter can be used without a gas-

tight bushing.

3 only for contactless electronic switch, relay and transistor electronics.

II

I

1998

IEC 61508.

www.krohne.com

9

Page 10

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

Dimensions and Weights

OPTISWITCH 4000 - Standard version:

From left to right: thread (M12x1, valve plug DIN 43650 and valve plug DIN 43650 with IDC

method of termination)

1 M12x1

2 Thread G¾ A, G1 A, ¾ NPT, 1 NPT

3 Switching point

10

www.krohne.com

Page 11

Dimensions in mm

a b c d e f g h L

[mm]

Thread G¾ A, G1 A, ¾ NPT or

1NPT (M12x1)

Thread G¾ A, G1 A, ¾ NPT or

1 NPT (valve plug DIN 43650)

Thread G¾ A,G1 A, ¾ NPT or

1 NPT(valve plug DIN 43650 with

IDC method of termination)

1 with G¾ A, ¾ NPT: 66 mm; with G1 A, 1 NPT: 69 mm

132.5 10.0 WS 32 - - 21.3 13.0 40.0 L 1

158.0 35.0 - 27.0 36.0 - - - -

165.0 42.0 - 28.0 42.0 - - - -

Dimensions in inches

a b c d e f g h L

Thread G¾ A, G1 A, ¾ NPT or 1

NPT (M12x1)

Thread G¾ A, G1 A, ¾ NPT or

1 NPT (valve plug DIN 43650)

Thread G¾ A, G1 A, ¾ NPT or

1 NPT(valve plug DIN 43650 with

IDC method of termination)

1 with G¾ A, ¾ NPT: 2.6"; with G1 A, 1 NPT: 2.7"

5.22 0.39 WS 32 - - 0.84 0.51 1.57 L 1

6.22 1.38 - 1.06 1.42 - - - -

6.50 1.65 - 1.10 1.65 - - - -

[inches]

www.krohne.com

11

Page 12

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

OPTISWITCH 4000 - Hygienic version:

From left to right: Tri-Clamp (valve plug DIN 43650); Bolting (valve plug DIN 43650);

SMS 1145 (valve plug DIN 43650)

1 Switching point

12

www.krohne.com

Page 13

DImensions in mm

a b c L

[mm]

Tri-Clamp (valve plug DIN 43650) 101.0 13.0 40.0 L 1

Bolting (valve plug DIN 43650) 115.0 - - L 1

SMS 1145 (valve plug DIN 43650) 105.0 - - L 1

1 53 mm

Dimensions in inches

a b c L

[inches]

Tri-Clamp (valve plug DIN 43650) 3.98 0.51 1.57 L 1

Bolting (valve plug DIN 43650) 3.53 - - L 1

SMS 1145 (valve plug DIN 43650) 4.13 - - L 1

1 2.1"

www.krohne.com

13

Page 14

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

OPTISWITCH 4000 - High temperature version:

From left to right: thread (M12x1, valve plug DIN 43650 and valve plug DIN 43650 with IDC

method of termination)

1 M12x1

2 Thread G¾ A, G1 A, ¾ NPT, 1 NPT

3 Switching point

www.krohne.com

14

Page 15

Dimensions in mm

a b c d e f g h L

[mm]

Thread G¾ A, G1 A, ¾ NPT or

1NPT (M12x1)

Thread G¾ A, G1 A, ¾ NPT or

1 NPT (valve plug DIN 43650)

Thread G¾ A, G1 A, ¾ NPT or

1 NPT (valve plug DIN 43650 with

IDC method of termination)

1 with G¾ A, ¾ NPT: 66 mm; with G1 A, 1 NPT: 69 mm

162.5 10.0 WS 32 - - 21.3 13.0 40.0 L 1

188.0 35.0 - 27.0 36.0 - - - -

182.0 42.0 - 28.0 42.0 - - - -

Dimensions in inches

a b c d e f g h L

Thread G¾ A, G1 A, ¾ NPT or

1NPT (M12x1)

Thread G¾ A, G1 A, ¾ NPT or

1 NPT (valve plug DIN 43650)

Thread G¾ A, G1 A, ¾ NPT or

1 NPT (valve plug DIN 43650 with

IDC method of termination)

1 with G¾ A, ¾ NPT: 2.6"; with G1 A, 1 NPT: 2.7"

6.40 0.39 WS 32 - - 0.84 0.51 1.57 L 1

7.40 1.38 - 1.06 1.42 - - - -

7.15 1.65 - 1.10 1.65 - - - -

[inches]

www.krohne.com

15

Page 16

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

OPTISWITCH 5000 series - Housing

From left to right: Plastic, Stainless steel and Aluminium housing

1 M20x1,5 / ½ NPT

2 M20x1,5

Dimensions and Weights

Dimensions Weight Dimensions Weight

[mm] [kg] [inches] [lbs]

a b c a b c

Plastic Housing 69 Ø77 112 0.76 2.72 Ø3.0 4.41 1.68

Stainless steel housing 69 Ø77 117 1.53 2.72 Ø3.0 4.61 3.37

Aluminium housing 116 84 114 1.17 4.57 3.31 4.49 2.58

16

www.krohne.com

Page 17

OPTISWITCH 5100 C, 5150 C, 5200 C, 5250 C - Temperature adapter

Dimensions in mm and inches

a b a b

[mm] [inches]

Temperature adapter 178 Ø34 7 Ø1.34

www.krohne.com

17

Page 18

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

OPTISWITCH 5100 C, 5150 C

c

b

a

d

123

b

a

b

b

a

e

b

a

1 Thread

2 Tri-Clamp (OPTISWITCH 5150)

3 Cone DN 25 (OPTISWITCH 5150)

4 Bolting DN 40 (OPTISWITCH 5150)

5 Flange

6 Gas-tight leadthrough

7 Temperature adapter

4

b

a

5

b

7

6

18

www.krohne.com

Page 19

Dimensions in mm

a b c d

[mm]

Thread 66 18.5 WS 32 (G¾A;

¾ NPT); WS 41

(G1A; 1 NPT)

Tri-Clamp (OPTISWITCH 5150) 53 36 - Cone DN 25 (OPTISWITCH 5150) 55 57 - Bolting DN 40 (OPTISWITCH 5150) 53 50 Ø33.7 Flange 53 19 - Gas-tight leadthrough - 34 - Temperature adapter - 178 - -

G¾A, ¾ NPT;

G1A, 1 NPT

Dimensions in inches

a b c d

[inches]

Thread 2.6 0.72 WS 32 (G¾A;

¾ NPT); WS 41

(G1A; 1 NPT)

Tri-Clamp (OPTISWITCH 5150) 2.09 1.41 - Cone DN 25 (OPTISWITCH 5150) 2.17 2.24 - Bolting DN 40 (OPTISWITCH 5150) 2.09 1.97 Ø1.33 Flange 2.09 0.75 - Gas-tight leadthrough - 1.34 - Temperature adapter - 7.0 - -

G¾A, ¾ NPT;

G1A, 1 NPT

www.krohne.com

19

Page 20

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

OPTISWITCH 5200 C, 5250 C

1 Thread

2 Tri-Clamp (OPTISWITCH 5250)

3 Cone DN 25 (OPTISWITCH 5250)

4 Bolting DN 40 (OPTISWITCH 5250)

5 Flange

6 Gas-tight leadthrough

7 Temperature adapter

www.krohne.com

20

Page 21

Dimensions in mm

a b c d

[mm]

Thread L 1 18.5 WS 32 (G¾A;

¾ NPT); WS 41

(G1A; 1 NPT)

Tri-Clamp (OPTISWITCH 5250) L 1 36 - Cone DN 25 (OPTISWITCH 5250) L 1 57 - Bolting DN 40 (OPTISWITCH 5250) L 1 50 Ø33.7 Flange L 1 19 - Gas-tight leadthrough - 34 - Temperature adapter - 178 - -

1 Ordered sensor length

G3/4A, ¾ NPT;

G1A, 1 NPT

Dimensions in inches

a b c d

[inches]

Thread L 1 0.72 WS 32 (G¾A;

¾ NPT); WS 41

(G1A; 1 NPT)

Tri-Clamp (OPTISWITCH 5250) L 1 1.41 - Cone DN 25 (OPTISWITCH 5250) L 1 2.24 - Bolting DN 40 (OPTISWITCH 5250) L 1 1.97 Ø1.33 Flange L 1 0.75 - Gas-tight leadthrough - 1.34 - Temperature adapter - 7.0 - -

1 Ordered sensor length

G¾A, ¾ NPT;

G1A, 1 NPT

www.krohne.com

21

Page 22

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

Notes

22

www.krohne.com

Page 23

Notes

www.krohne.com

23

Page 24

OPTISWITCH 4000/5000 nnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnn

n

KROHNE Product Overview

• Electromagnetic flowmeters • Level measuring instruments

• Variable area flowmeters • Pressure gauges

• Mass flowmeters • Temperature measuring instruments

• Ultrasonic flowmeters • Water solutions & analysis

• Vortex flowmeters • Oil and gas turnkey solutions

• Flow controllers

Addresses:

Great Britain

Germany

Northern sales office

KROHNE Messtechnik GmbH & Co. KG

Bremer Str. 133

D-21073 Hamburg

Phone:+49 (0)40 767 3340

Fax:+49 (0)40 767 33412

nord@krohne.de

ZIP code: 10000 - 29999, 49000 - 49999

Western and middle sales office

KROHNE Messtechnik GmbH & Co. KG

Ludwig-Krohne-Straße

D-47058 Duisburg

Phone:+49 (0)203 301 416

Fax:+49 (0)203 301 10416

west@krohne.de

ZIP code: 30000 - 34999, 37000 48000, 50000 - 53999, 57000 - 59999,

98000 - 99999

Southern sales office

KROHNE Messtechnik GmbH & Co. KG

Landsberger Str. 392

D-81241 Munich

Phone:+49 (0)89 121 5620

Fax:+49 (0)89 129 6190

sued@krohne.de

ZIP code: 0 - 9999, 80000 - 89999,

90000 - 97999

Southwestern sales office

KROHNE Messtechnik GmbH & Co. KG

Rüdesheimer Str. 40

D-65239 Hochheim/Main

Phone: +49(0)6146) 827 30

Fax:+49 (0)6146 827 312

rhein-main@krohne.de

ZIP code: 35000 - 36999, 54000 56999, 60000 - 79999

Instrumentation and control

equipment catalog

TABLAR Messtechnik GmbH

Ludwig-Krohne-Straße 5

D-47058 Duisburg

Phone:+49 (0)2 03 305 88 0

Fax:+49 (0)2 03 305 8888

kontakt@tablar.de www.tablar.de

KROHNE sales

companies

International

Australia

Australia

AustraliaAustralia

KROHNE Australia Pty Ltd

Quantum Business Park 10/287

Victoria Rd Rydalmere NSW 2116

Phone: +61 2 8846 1700

Fax: +61 2 8846 1755

krohne@krohne.com.au

Austria

Austria

AustriaAustria

KROHNE Gesellschaft m.b.H.

Modecenterstraße 14

A-1030 Vienna

Phone:+43 (0)1/203 45 32

Fax:+43 (0)1/203 45 32 99

info@krohne.at

Belgium

Belgium

Belgium Belgium

KROHNE Belgium N.V.

Brusselstraat 320

B-1702 Groot Bijgaarden

Phone:+32 (0)2 4 66 00 10

Fax:+32 (0)2 4 66 08 00

krohne@krohne.be

Brazil

Brazil

Brazil Brazil

KROHNE Conaut Controles

Automaticos Ltda.

Estrada Das Águas Espraiadas, 230

C.P. 56 06835 - 080 EMBU - SP

Phone:+55 (0)11-4785-2700

Fax:+55 (0)11 4785-2768

conaut@conaut.com.br

China

China

ChinaChina

KROHNE Measurement Instruments

(Shanghai) Co. Ltd., (KMIC)

Room 1501

1033 Zhaojiabang Ro ad

Shanghai 200030

Phone: +86 21 6487 9611

Fax:+86 21 6438 7110

info@krohne-asia.com

Czech Republic

Czech Republic

Czech RepublicCzech Republic

Krohne CZ, spol. s r.o.

Sobìsická 156

63800 Brno

Phone: +420 (0)545.242 627

Fax: +420 (0)545 220 093

brno@krohne.cz

France

France

FranceFrance

KROHNE S.A.S.

Les Ors BP 98

F-26103 ROMANS Cedex

Phone:+33 (0)4 75 05 44 00

Fax:+33 (0)4 75 05 00 48

info@krohne.fr

Great Britain

Great BritainGreat Britain

KROHNE Ltd.

Rutherford Drive

Park Farm Industrial Estate

Wellingborough

Northants NN8 6AE

Phone:+44 (0)19 33 408 500

Fax:+44 (0)19 33 408 501

info@krohne.co.uk

CIS

CIS

CISCIS

Kanex KROHNE Engineering AG

Business-Centre Planeta

Office 404 ul.

Marxistskaja 3

109147 Moscow/Russia

Phone:+7 (0)095 911 7165

Fax:+7 (0)095 742 8873

krohne@dol.ru

India

India

IndiaIndia

Krohne Marshall Ltd.

A-34/35, M.I.D.C. Industrial Area,

H-Block

Pimpri Poona 411018

Phone:+91 (0)202 744 2020

Fax:+91 (0)202 744 2020

pcu@vsnl.net

Iran

Iran

IranIran

KROHNE Liaison Office

North Sohrevardi Ave. 26,

Sarmad St., Apt. #9

Tehran 15539

Phone: +9821 8874 5973

Fax: +9821 8850 1268

krohne@krohneiran.com

Italy

Italy

ItalyItaly

KROHNE Italia Srl.

Via V. Monti 75

I-20145 Milan

Phone:+39 02 4300 661

Fax:+39 02 4300 6666

info@krohne.it

Korea

Korea

KoreaKorea

KROHNE Korea

Room 508 Miwon Bldg 43

Yoido-Dong Youngd eungpo-Ku

Seoul, Korea

Phone: 00-82-2-782-1900

Fax: 00-82-2-780-1749

mail@krohne.co.kr

Netherlands

Netherlands

NetherlandsNetherlands

KROHNE Nederland B.V.

Kerkeplaat 14

NL-3313 LC Dordrecht

Phone:+31 (0)78 630 6200

Fax:+31 (0)78 630 6405

Service Direct: +31 (0)78 630 6222

info@krohne.nl

Norway

Norway

NorwayNorway

KROHNE Norway A.S.

Ekholtveien 114

NO-1521 Moss

Phone:+47 (0)69 264 860

Fax:+47 (0)69 267 333

postmaster@krohne.no

Poland

Poland

PolandPoland

KROHNE Polska Sp.z.o.o.

ul. Stary Rynek Oliwski 8a

80-324 Gdansk

Phone: +48 (0)58 520 9211

Fax.:+48 (0)58 520 9212

info@krohne.pl

Switzerland

Switzerland

SwitzerlandSwitzerland

KROHNE AG

Uferstr. 90

CH-4019 Basel

Phone:+41 (0)61 638 30 30

Fax:+41 (0)61 638 30 40

info@krohne.ch

Singapore

Singapore

SingaporeSingapore

Tokyo Keiso - KROHNE (Singapore)

Pte. Ltd.

14, International Bus iness Park,

Jurong East

Chiyoda Building, #01-01/02

Singapore 609922

Phone: (65) 6567 4548

Fax : (65) 6567 9874

tks@tokyokeiso-krohne.com.sg

Republic of South Africa

Republic of South Africa

Republic of South AfricaRepublic of South Africa

KROHNE Pty. Ltd.

Bushbock Close

Corporate Park South

Midrand, Gauteng

P.O. Box 2069

Midrand, 1685

Tel.: +27 (0)11 314 1391

Fax: +27 (0)11 314 1681

midrand@krohne.co.za

Spain

Spain

SpainSpain

I.I. KROHNE IBERIA, S.r.l.

Poligono Indust rial Nilo

Calle Brasil, nº. 5

28806 Alcalá de Henares Madrid

Phone: +34 (0)91 883 2152

Fax: +34 (0)91 883 4854

krohne@krohne.es

USA

USA

USAUSA

KROHNE, Inc.

7 Dearborn Road

Peabody, MA 01960

Phone: +1 (800) FLOWING

Phone: +1 (978) 535 6060 (in MA)

info@krohne.com

Representatives

Algeria

Argentina

Cameroon

Canada

Chile

Columbia

Croatia

Denmark

Ecuador

Egypt

Finland

Gabon

Ghana

Greece

Hong Kong

Hungary

Indonesia

Iran

Ireland

Israel

Ivory Coast

Japan

Jordan

Kuwait

Libya

Lithuania

Malaysia

Mauritius

Mexico

Morocco

New Zealand

Peru

Portugal

Romania

Saudi Arabia

Senegal

Slovakia

Slovenia

Sweden

Taiwan

Thailand

Tunisia

Turkey

Venezuela

Yugoslavia

Other countries

KROHNE Messtechnik GmbH & Co. KG

Ludwig-Krohne-Str. 5

D-47058 Duisburg

Phone:+49 (0)203 301 0

Fax:+49 (0)203 301 389

export@krohne.de

© KROHNE 10/2007 4000113601 - TD OPTISWITCH 4-5000 R01 en Subject to change without notice

www.krohne.com

Loading...

Loading...