Technical Datasheet

Technical Datasheet

OPTISONIC 3400

OPTISONIC 3400

OPTISONIC 3400OPTISONIC 3400

•

Measurement of (non- ) conductive, low and high viscous liquids, from -200°C to

+250°C media temperature

•

Accurate bi-directional measurement that starts from zero flow

•

Advanced signal converter, covering all I/O 's and communication protocols

Technical DatasheetTechnical Datasheet

© KROHNE 2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

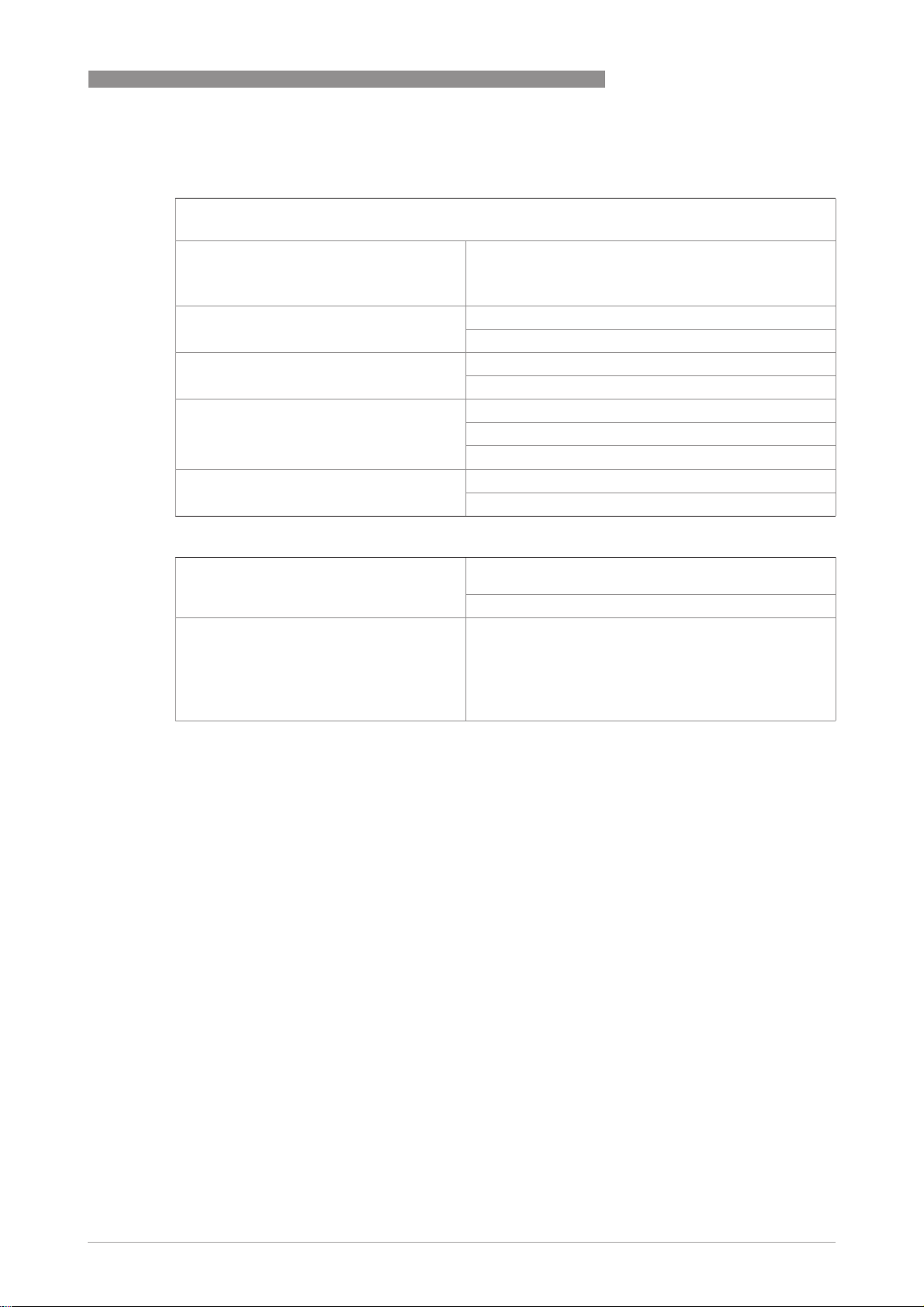

CONTENTS

OPTISONIC 3400

1 Product features 4

1.1 Multipurpose, all round ultrasonic flow meter in all process industries ....................... 4

1.2 Variants............................................................................................................................. 6

1.3 Features............................................................................................................................ 7

1.4 Measuring principle.......................................................................................................... 8

2 Technical data 9

2.1 Technical data................................................................................................................... 9

2.2 Dimensions and weights ................................................................................................ 21

2.2.1 Variants ................................................................................................................................. 21

2.2.2 Standard flow sensor............................................................................................................ 22

2.2.3 Variant flow sensor; XXT - High Viscosity and Cryogenic (SS) versions. ............................. 28

2.2.4 Signal converter housing ...................................................................................................... 34

3 Installation 35

3.1 Intended use ................................................................................................................... 35

3.2 General notes on installation ......................................................................................... 35

3.3 Vibration.......................................................................................................................... 35

3.4 Installation requirements signal converter................................................................... 36

3.5 Installation conditions ....................................................................................................36

3.5.1 Inlet and outlet...................................................................................................................... 36

3.5.2 Bends in 2 or 3 dimensions................................................................................................... 36

3.5.3 T-section ............................................................................................................................... 37

3.5.4 Bends .................................................................................................................................... 37

3.5.5 Open feed or discharge......................................................................................................... 38

3.5.6 Position of pump ................................................................................................................... 38

3.5.7 Control valve ......................................................................................................................... 38

3.5.8 Down going pipeline over 5 m /16 ft length.......................................................................... 39

3.5.9 Insulation............................................................................................................................... 39

3.5.10 Mounting ............................................................................................................................. 40

3.5.11 Flange deviation .................................................................................................................. 40

3.5.12 Mounting position................................................................................................................ 40

4 Electrical connections 41

4.1 Safety instructions.......................................................................................................... 41

4.2 Signal cable (remote versions only)............................................................................... 41

4.3 Power supply .................................................................................................................. 42

4.4 Inputs and outputs, overview ......................................................................................... 43

4.4.1 Combinations of the inputs/outputs (I/Os) ........................................................................... 43

4.4.2 Description of the CG number .............................................................................................. 44

4.4.3 Fixed, non-alterable input/output versions.......................................................................... 45

4.4.4 Alterable input/output versions............................................................................................ 46

5 Applications 47

2

www.krohne.com 2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

OPTISONIC 3400

CONTENTS

5.1 Device Configuration Form ............................................................................................ 47

6 Notes 49

www.krohne.com2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

3

1

PRODUCT FEATURES

OPTISONIC 3400

1.1 Multipurpose, all round ultrasonic flow meter in all process industries

The OPTISONIC 3400

OPTISONIC 3400 flowmeter is an unique, 3-beam, inline, ultrasonic flowmeter, designed

OPTISONIC 3400 OPTISONIC 3400

especially for measuring homogeneous conductive and non-conductive liquids, with high

accuracy and reproducibility, over a long period of time. KROHNE is a main supplier for

ultrasonic in-line process flowmeters for liquids with the largest installed base / proven record

in terms of robustness and measurement accuracy.

Building on vast knowledge and expertise, KROHNE now introduces the OPTISONIC 3400

flowmeter is able to measure:

• conductive and non-conductive liquids

• cryogenic - and high process temperatures

• standard and straightforward applications and applications that require high performance

• non-viscous aqueous liquids and extreme viscous liquids

• low pressure ratings and extreme pressure ratings

1 High performance signal converter for all applications

2 Robust body without moving parts

OPTISONIC 3400 . This

OPTISONIC 3400 OPTISONIC 3400

The OPTISONIC 3400

OPTISONIC 3400 ...features advanced meter diagnostics.

OPTISONIC 3400 OPTISONIC 3400

This provides extensive self-checking of internal circuits and information regarding the health of

the measuring sensor, but just as importantly, vital information about the process and process

conditions.

®

Fieldbusses are, HART

NE 107. These advanced diagnostic features makes process life comfortable, reliable and

accurate over a long period of time.

The OPTISONIC 3400

OPTISONIC 3400 ...features velocity of sound

OPTISONIC 3400 OPTISONIC 3400

Another unique feature of the OPTISONIC 3400 is the free of charge measurement of velocity of

sound per acoustic path. For instance, this can supply information about pollution in the liquid,

or changes in the process conditions.

7, Foundation Fieldbus, Profibus PA/DP and Modbus, all with NAMUR

4

www.krohne.com 2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

OPTISONIC 3400

Highlights

• Advanced signal converter with full range of I/O 's and communication protocols

• Diagnostic functions according to NAMUR NE107

• Improved user interface: optical- and push buttons

• Completely welded construction, wear and maintenance free

• Full bore, unobstructed sensor tube, without pressure loss and without moving parts

• Accurate bi-directional flow measurement, with three beams to measure continuously, and

starts measurement at nearly zero flow

• Multipurpose, all round, ultrasonic flowmeter for single phase liquids

Industries

• Chemicals

• Petrochemicals

• Oil & Gas

• Energy

• Water (utilities)

PRODUCT FEATURES

1

Applications

• Conductive and non-conductive liquids

• Cryogenic- and high process temperature, low and extreme high pressure range

• Expanded applicability; for standard and high performance applications

• Measuring aqueous liquids as well as extreme viscous oils

• High turn down ratio; e.g. transportation pipeline measurements

• Broad pressure and temperature range (e.g. midstream oil measurements)

• Multiple products; e.g. allocation measurements in on/off loading

• Water utilities in all process industries; make-up water, boiler feed water, demineralized

water

www.krohne.com2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

5

1

PRODUCT FEATURES

1.2 Variants

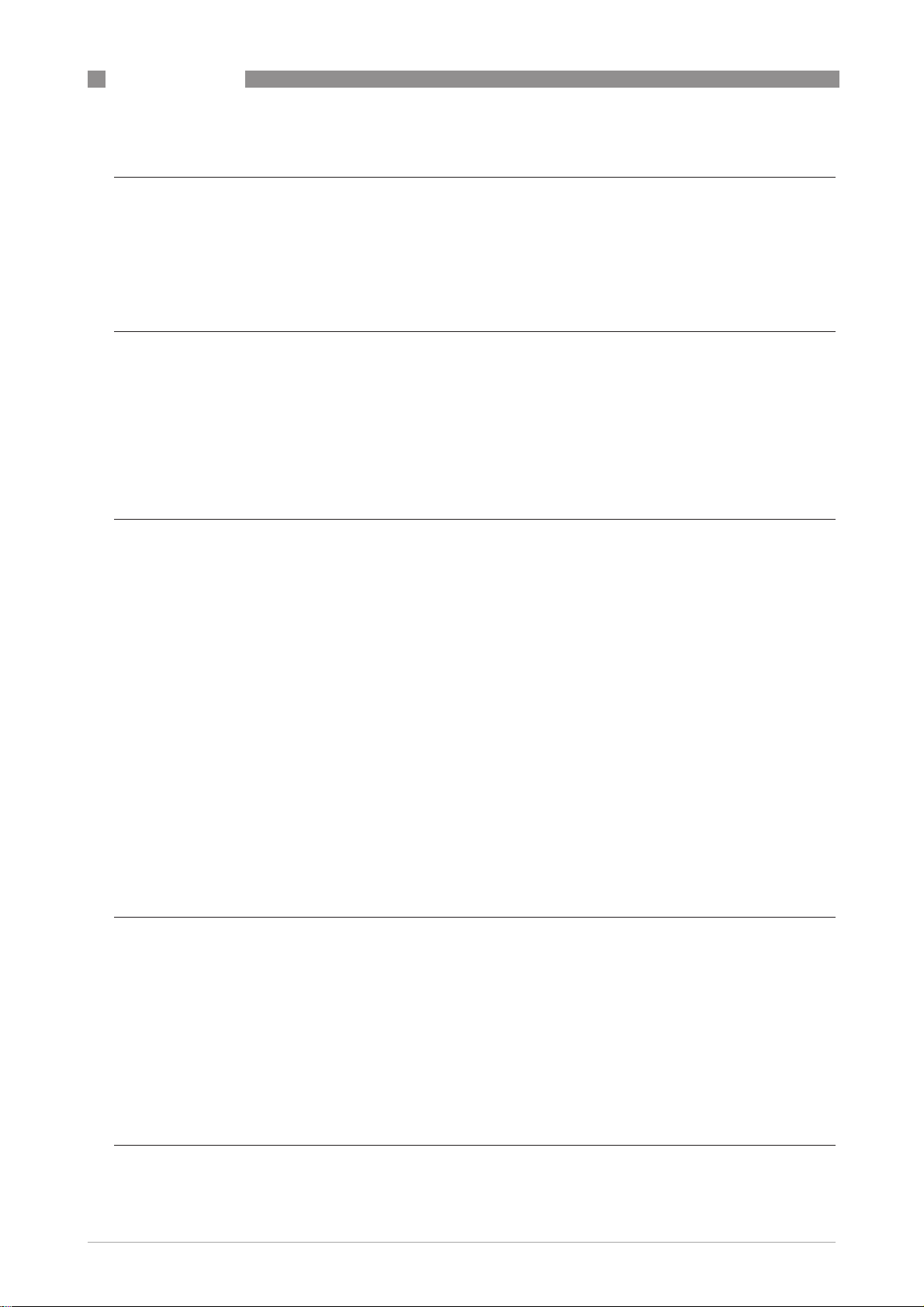

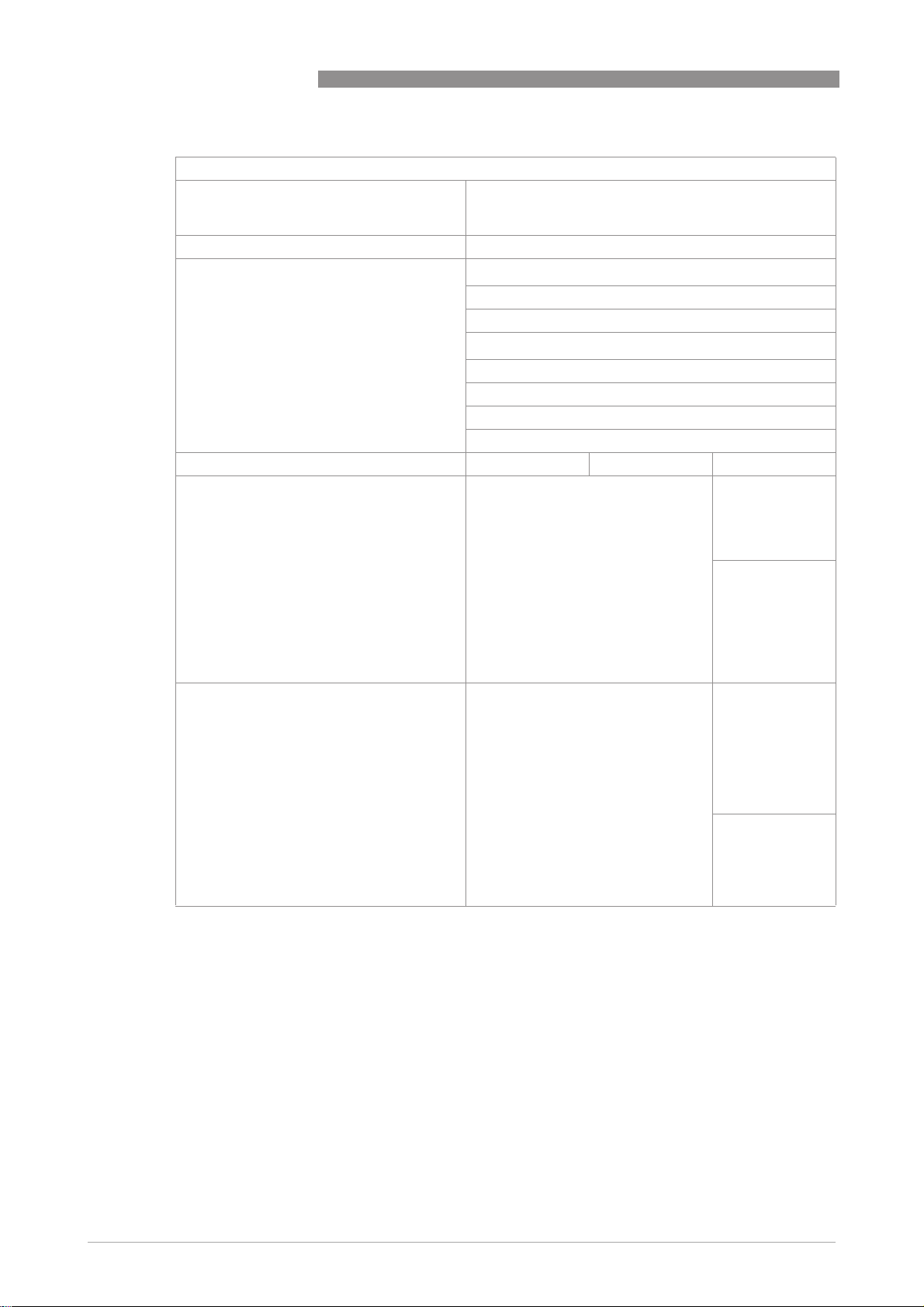

An OPTISONIC 3400

OPTISONIC 3400 flowmeter consists of an OPTISONIC 3000 flow sensor and an UFC 400

OPTISONIC 3400OPTISONIC 3400

signal converter. The standard version is available as a compact and remote version. Next to

standard, also variants for demanding applications can be supplied.

OPTISONIC 3000

OPTISONIC 3000

OPTISONIC 3000OPTISONIC 3000

Flow sensor variants for demanding applications

Flow sensor variants for demanding applications

Flow sensor variants for demanding applicationsFlow sensor variants for demanding applications

A full range of flow sensors to cover simple to difficult applications, such as:

• For extended process temperatures up to 250°C / 482°F (remote version)

• Cryogenic version: for extreme low process temperatures, as low as -200°C / [-328°F

(remote version, IP68)

• Flow sensor ≥ 14" and UFC 400 remote converter (aluminium or stainless steel housing)

• High viscous liquids: range from 100...1000 cSt

OPTISONIC 3400

Variants available on request

Including heating jacket

Including heating jacket

Including heating jacketIncluding heating jacket

• for steam or thermal oil tracing of the

flowmeter

• suitable for standard and variant for

extended process temperatures (remote)

Flangeless, weld-in connections

Flangeless, weld-in connections

Flangeless, weld-in connectionsFlangeless, weld-in connections

• greenfield

• flexibility in inner pipe diameters

6

www.krohne.com 2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

OPTISONIC 3400

1.3 Features

PRODUCT FEATURES

Engineers favorite flow meter

Engineers favorite flow meter

Engineers favorite flow meterEngineers favorite flow meter

- All welded sensor construction

- Patented inert metal transducer technology

- No moving parts

- Full bore unobstructed sensor

- No need for auxiliary parts

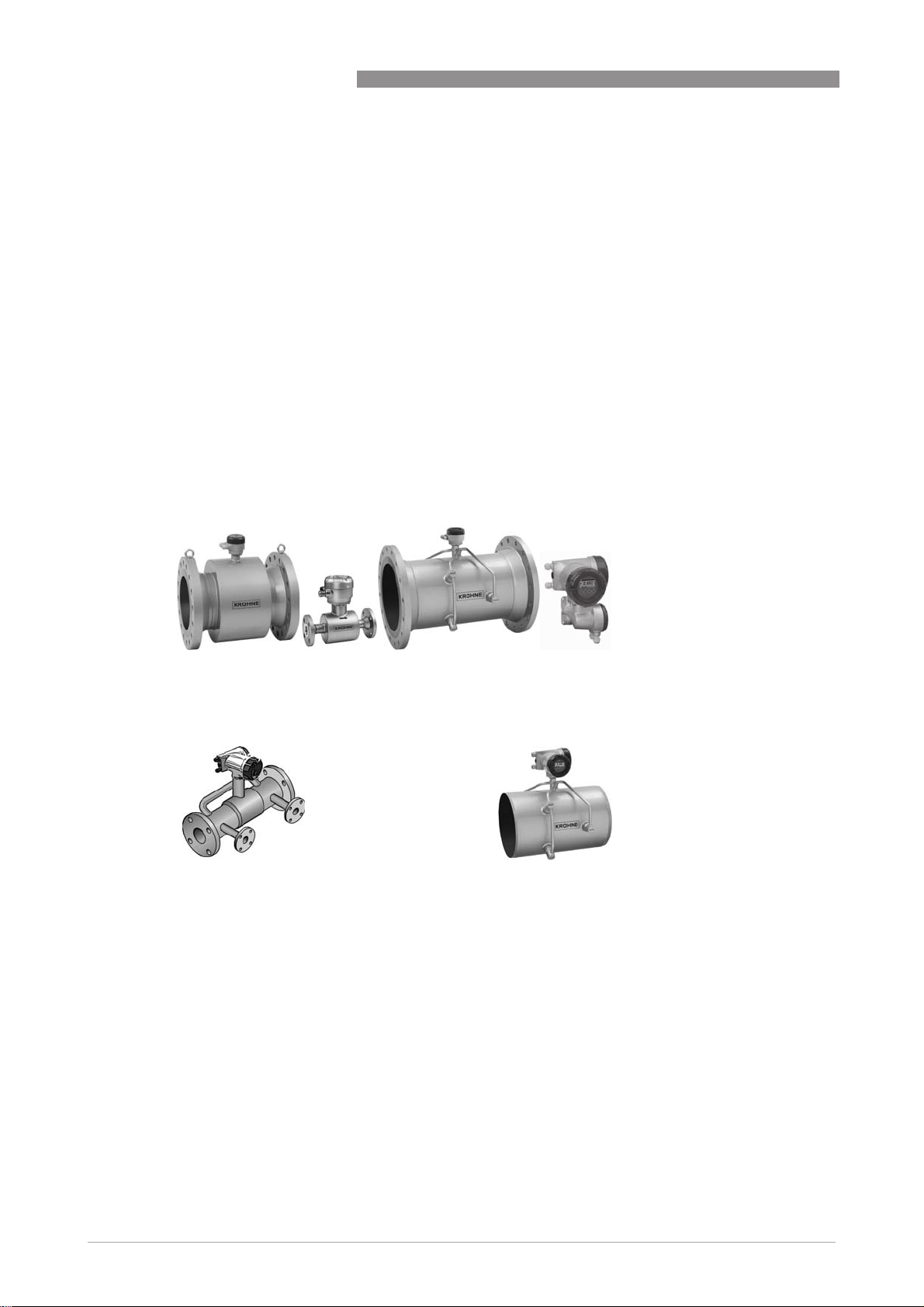

UFC 400 signal converter - Compact and

UFC 400 signal converter - Compact and

UFC 400 signal converter - Compact and UFC 400 signal converter - Compact and

Remote/field

Remote/field

Remote/fieldRemote/field

- Display with 4 optical -or push buttons

- Many I/O configurations available

®

- Fieldbusses HART

- Optional Foundation Fieldbus, ITK6, Modbus

/RS485, Profibus PA/DP

(all included with NAMUR NE107 diagnostics)

- One universal software for all applications

7 (and HART registration)

1

Failure

Output signal invalid

Check function

Output signal (temporarily) invalid

Out of specification

Unreliability of output signal

Maintenance required

Output signal still valid

UFC 400 diagnostic capabilities:

UFC 400 diagnostic capabilities:

UFC 400 diagnostic capabilities: UFC 400 diagnostic capabilities:

NE107

NE107

NE107NE107

NE107 icons for status messages

and error handling

- visible on UFC 400 display

- via all communication protocols

- Status messages are grouped by

problem source

- User can change group or priority

www.krohne.com2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

7

1

PRODUCT FEATURES

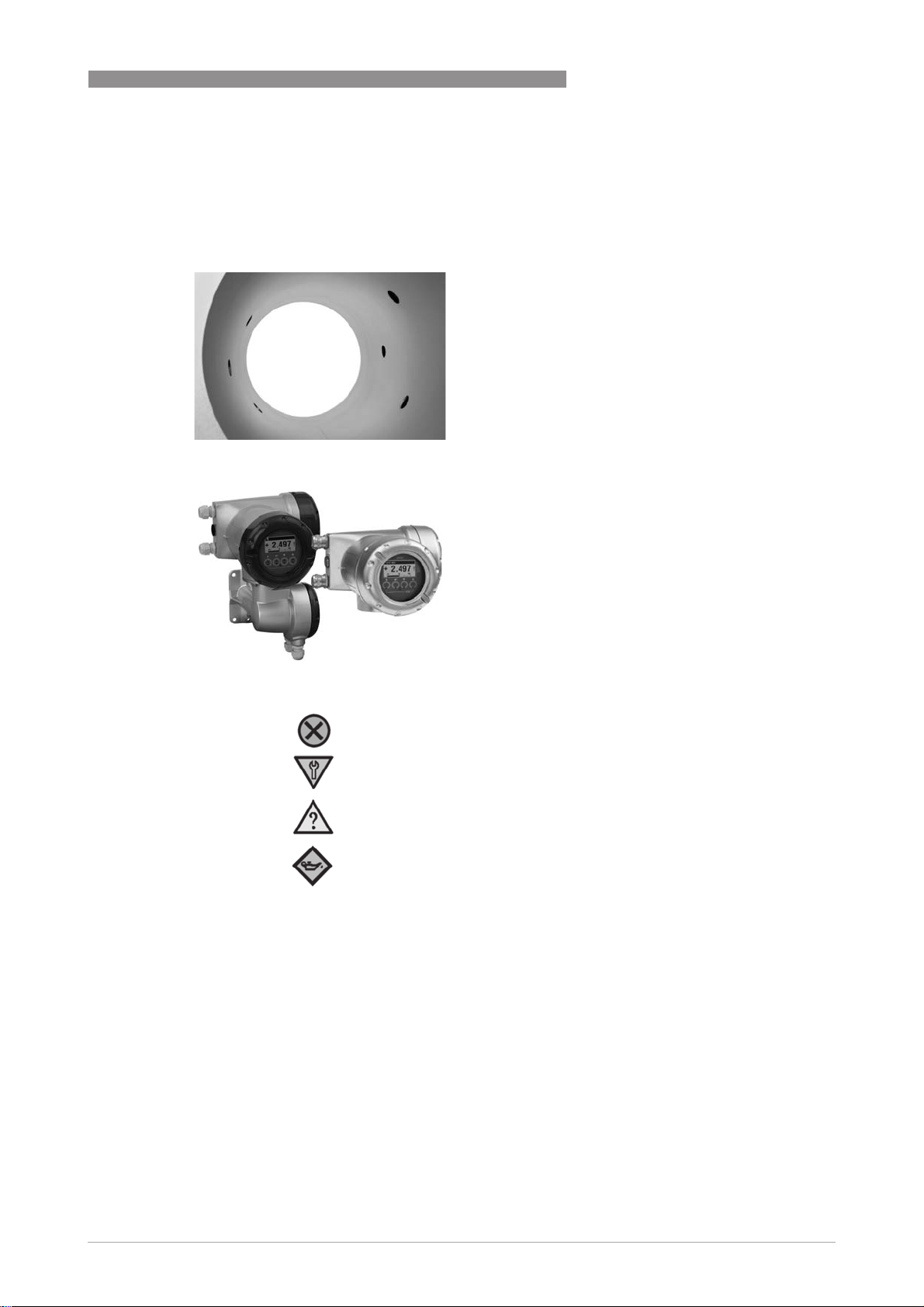

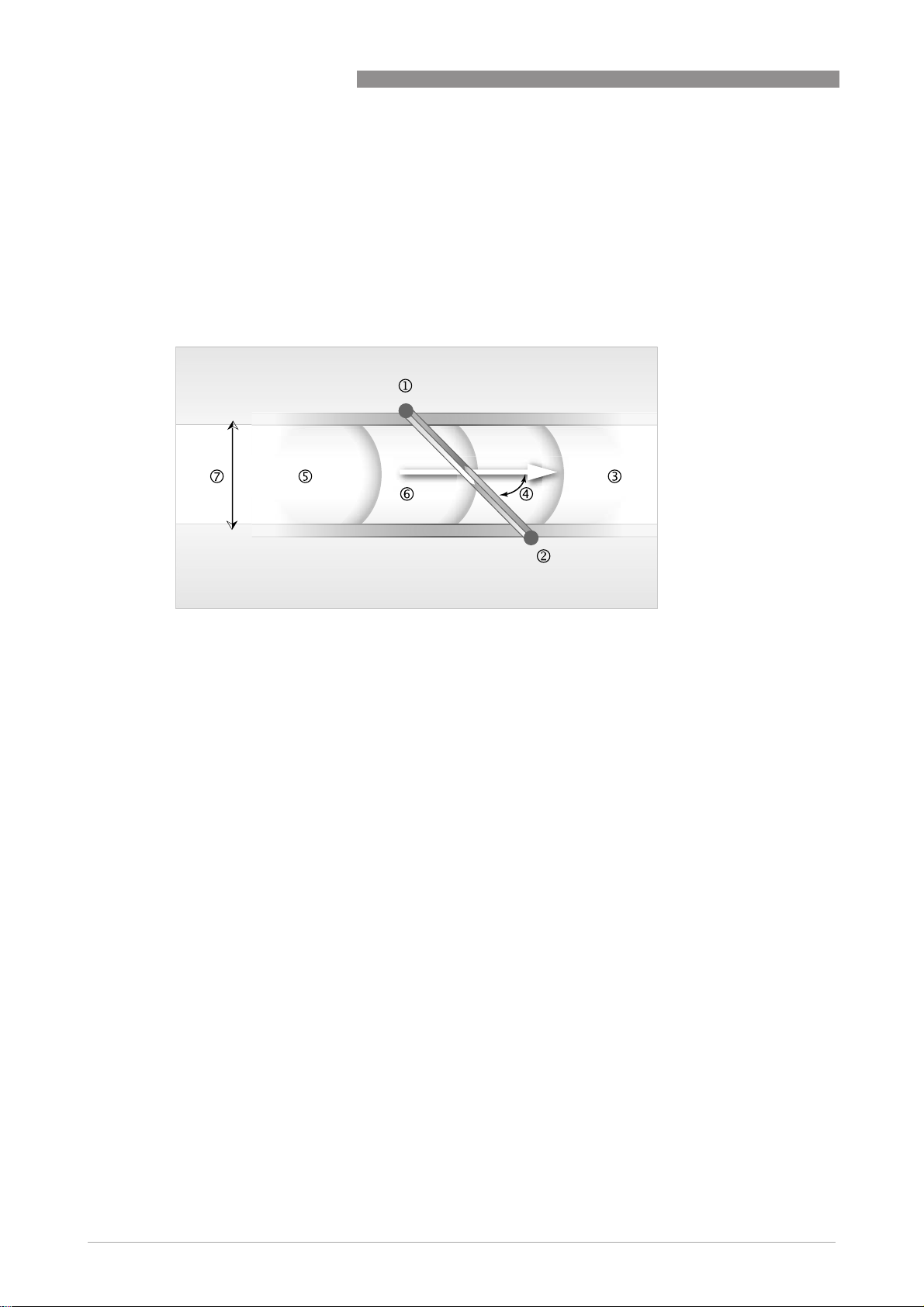

1.4 Measuring principle

• Like canoes crossing a river, acoustic signals are transmitted and received along a diagonal

measuring path.

• A sound wave going downstream with the flow travels faster than a sound wave going

upstream against the flow.

• The difference in transit time is directly proportional to the mean flow velocity of the medium.

OPTISONIC 3400

Figure 1-1: Measuring principle

1 Transducer A

2 Transducer B

3 Flow velocity

4 Angle of incidence

5 Velocity of sound of liquid

6 Path length

7 Inner diameter

8

www.krohne.com 2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

OPTISONIC 3400

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

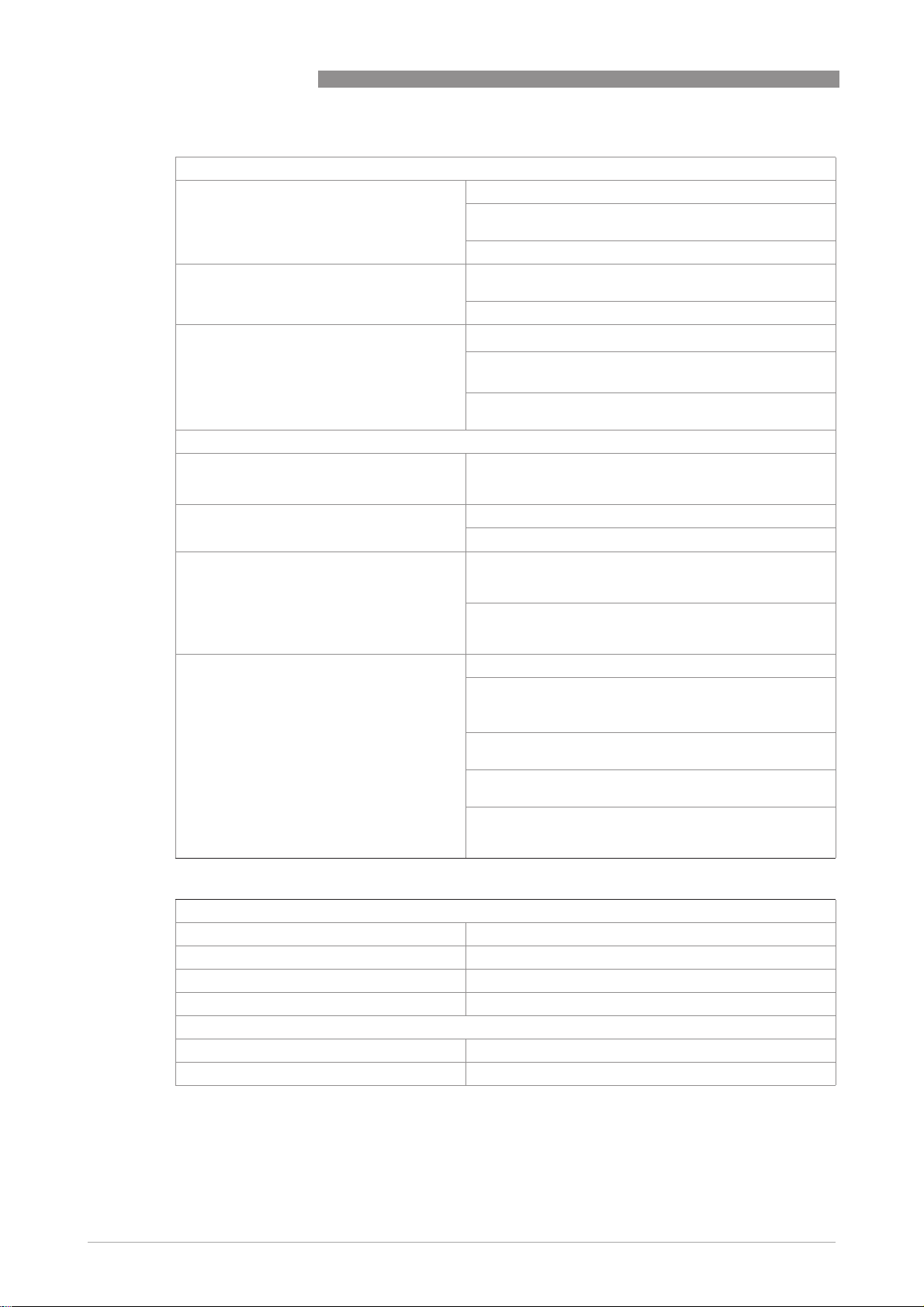

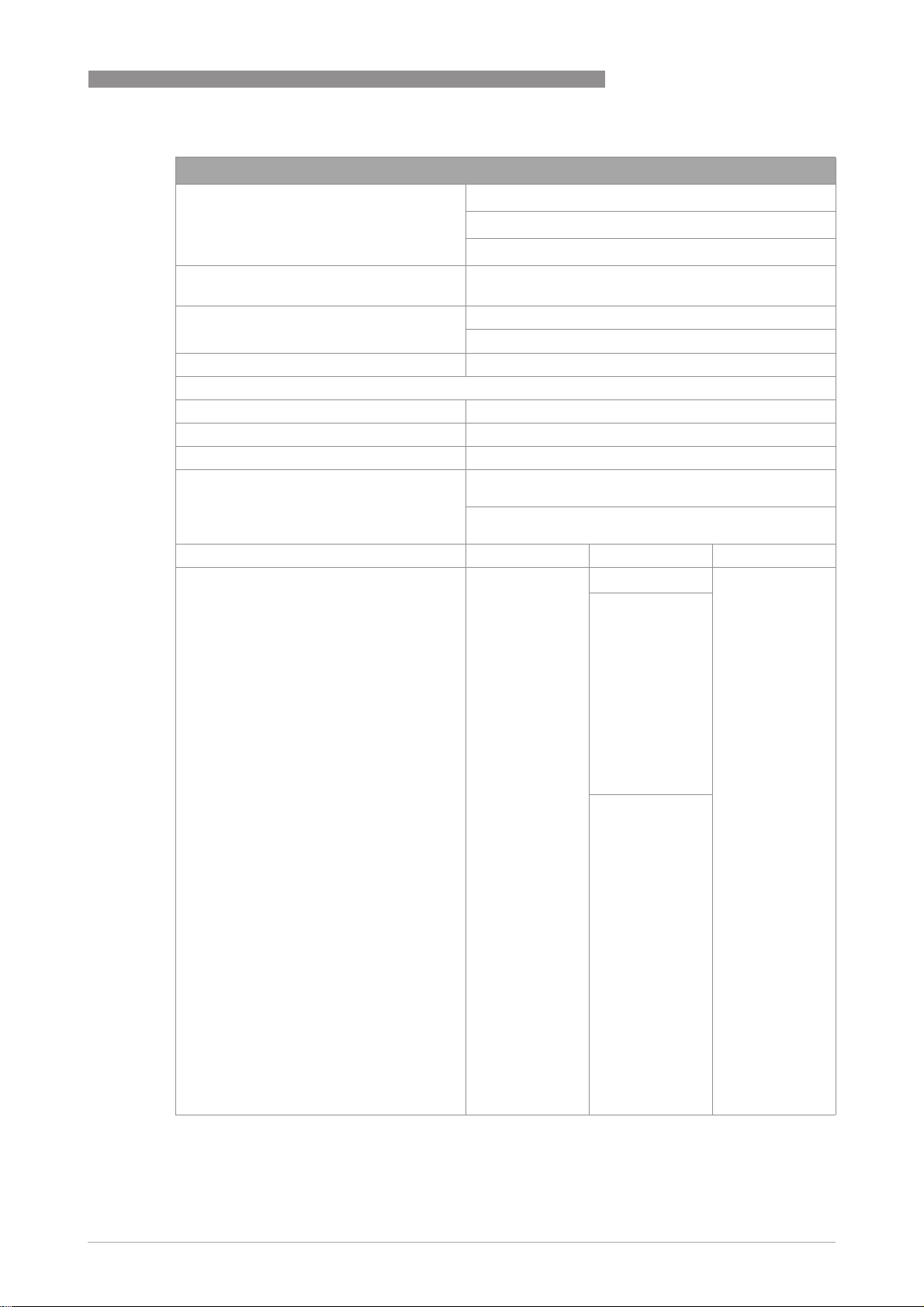

Measuring system

Measuring principle Ultrasonic transit time

Application range Flow measurement of (non) conductive fluids

Measured value

Measured value

Measured valueMeasured value

Primary measured value Transit time

Secondary measured values Volume flow, mass flow, flow speed, flow direction,

TECHNICAL DATA

velocity of sound, gain, signal to noise ratio, reliability of

flow measurement, totalised volume or mass

2

Design

Features 3 parallel acoustic paths fully welded.

Modular construction The measurement system consists of a measuring sensor

Compact version OPTISONIC 3400

Remote version OPTISONIC 3000 F with UFC 400 signal converter

Nominal diameter DN25...3000 / 1...120"

Measurement range 0.3...20 m/s / 0.98...65 ft/s

Signal converter

Signal converter

Signal converterSignal converter

Inputs / outputs

Totaliser 2 (optional 3) internal totalisers with a max. of 8 digits

Verification and self-diagnostics Integrated verification, diagnostic functions: measuring

Communication interfaces

and a signal converter.

Current (incl. HART®), pulse, frequency and/or status

output, limit switch and/or control input (depending on

the I/O version)

(e.g. for totalising volume and/or mass units)

device, process, measured values, device configuration,

etc.

Modbus RS485, HART® 7, Foundation Fieldbus ITK6,

Profibus PA/DP Profile 3.02

www.krohne.com2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

9

2

TECHNICAL DATA

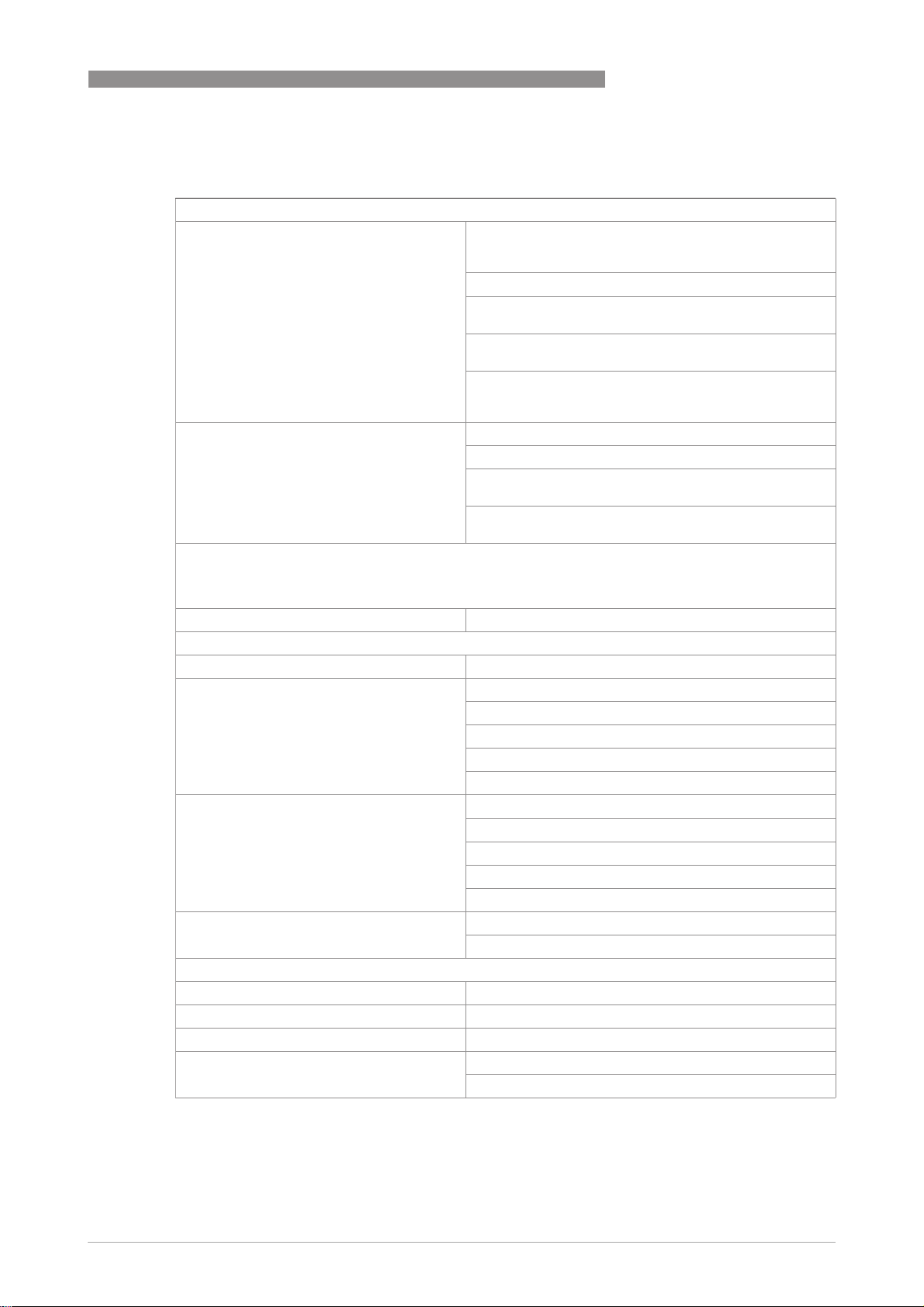

Display and user interface

Display and user interface

Display and user interfaceDisplay and user interface

Graphic display LC display, backlit white

Operating elements 4 optical and push buttons for operator control of the

Remote operation

Display functions

Display functions

Display functionsDisplay functions

Operating menu Programming of parameters at 2 measured value pages,

Language of display texts ( as language

package)

Measurement functions Units:

Diagnostic functions Standards:

OPTISONIC 3400

Size: 128x64 pixels.

Corresponds to 59x31 mm = 2.32"x1.22"

Display turnable in 90° steps.

signal converter without opening the housing.

Option: Infrared interface (GDC)

PACTwareTM including Device Type Manager (DTM)

HART® handheld communicator (Emerson), AMS

(Emerson), PDM (Siemens)

All DTM's and drivers will be available at the internet

homepage of the manufacturer.

1 status page, 1 graphic page (measured values and

descriptions adjustable as required)

Standard: English, French, German, Dutch

Russia: English, German, Russian

Units: Metric, British and US units selectable as desired

Units:Units:

from lists for volume/mass flow and counting, velocity,

temperature.

Measured values:

Measured values: volume flow, mass flow, flow speed,

Measured values:Measured values:

velocity of sound, gain, signal to noise ratio, flow

direction, diagnostics

Standards: VDI/NAMUR NE 107

Standards:Standards:

Status messages:

Status messages: Output of status messages via display,

Status messages:Status messages:

current and/or status output, HART

interface

Sensor diagnostics:

Sensor diagnostics: per acoustic path velocity of sound,

Sensor diagnostics:Sensor diagnostics:

flow speed, gain, signal to noise ratio

Process diagnostics:

Process diagnostics: empty pipe, signal integrity, cabling,

Process diagnostics:Process diagnostics:

flow conditions

Signal converter diagnostics:

Signal converter diagnostics: data bus monitoring, I/O

Signal converter diagnostics:Signal converter diagnostics:

connections, electronics temperature, parameter and

data integrity

®

or via other bus

10

Measuring accuracy

Reference conditions

Reference conditions

Reference conditions Reference conditions

Medium Water

Temperature 20°C / 68°F

Pressure 1 bar / 14.5 psi

Inlet section 10 DN

Maximum measuring error

Maximum measuring error

Maximum measuring errorMaximum measuring error

Standard: ±0.3% +2 mm/s of actual measured flow rate

Repeatability ±0.2%

www.krohne.com 2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

OPTISONIC 3400

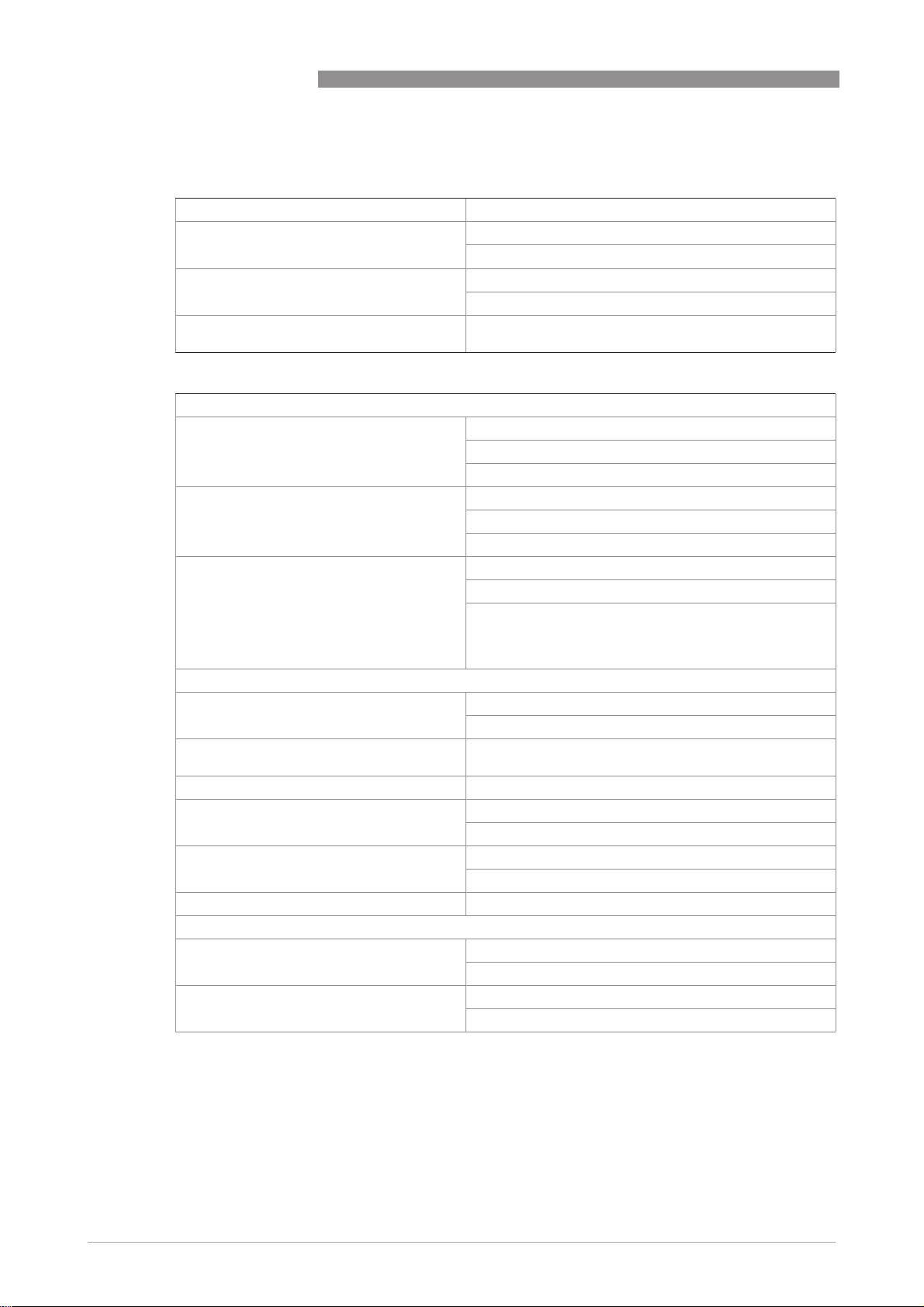

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process temperature Compact version:

Ambient temperature Depending on the version and combination of outputs

Protect inside electronics against self-heating (increasing of the electronics temperature will lead to a

reduction of the corresponding service life by a factor 2 for each step of 10°C / 50°F increase).

Protect the signal converter from external heat sources such as direct sunlight, as higher temperatures

reduce the life cycle of all electronic components.

Storage temperature -50…+70°C / -58…+158°F

Pressure

Pressure

PressurePressure

Atmospheric

EN 1092-1 DN25…80: PN 40

ASME B16.5 1…24": 150 lb RF

JIS DN25...40: 20K

Properties of medium

Properties of medium

Properties of mediumProperties of medium

Physical condition Liquid, single phase (well mixed, rather clean)

Permissible gas content ≤ 2% (volume)

Permissible solid content ≤ 5% (volume)

Viscosity Standard:

TECHNICAL DATA

Compact version: -45...+140°C / -49...+284°F

Compact version:Compact version:

(for stainless steel housing at ambient temperature ≤

45°C / +113°F)

Remote version:

Remote version: -45...+180°C / -49...+356°F

Remote version:Remote version:

Extended temperature version:

Extended temperature version: -45...+250°C / -49...+482°F

Extended temperature version:Extended temperature version:

(only remote version)

Cryogenic version:

Cryogenic version: -200...+180°C / -328...+356°F (only

Cryogenic version:Cryogenic version:

remote version, IP68, complete stainless steel)

Carbon steel flanges;

minimal process temperatures acc. to EN1092: -10°C /

+14°F; ASME: -29°C / -20°F

-40…+65°C / -40…+149°F

Option (stainless steel converter housing): -40...+60°C /

-40...+140°F

Ambient temperatures below -25°C / -13°F may affect the

readability of the display.

DN100…150: PN 16

DN200…1000: PN 10

DN1200…3000: PN 6

Higher pressure ratings on request

1…24": 300 lb RF

1…24": 600 lb RF

1...24": 900 lb RF

Larger diameters on request.

DN50...300: 10K

Standard: Up to 100 cSt (for all diameters)

Standard:Standard:

Option:

Option: High viscosity variant up to 1000 cSt

Option:Option:

2

www.krohne.com2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

11

2

TECHNICAL DATA

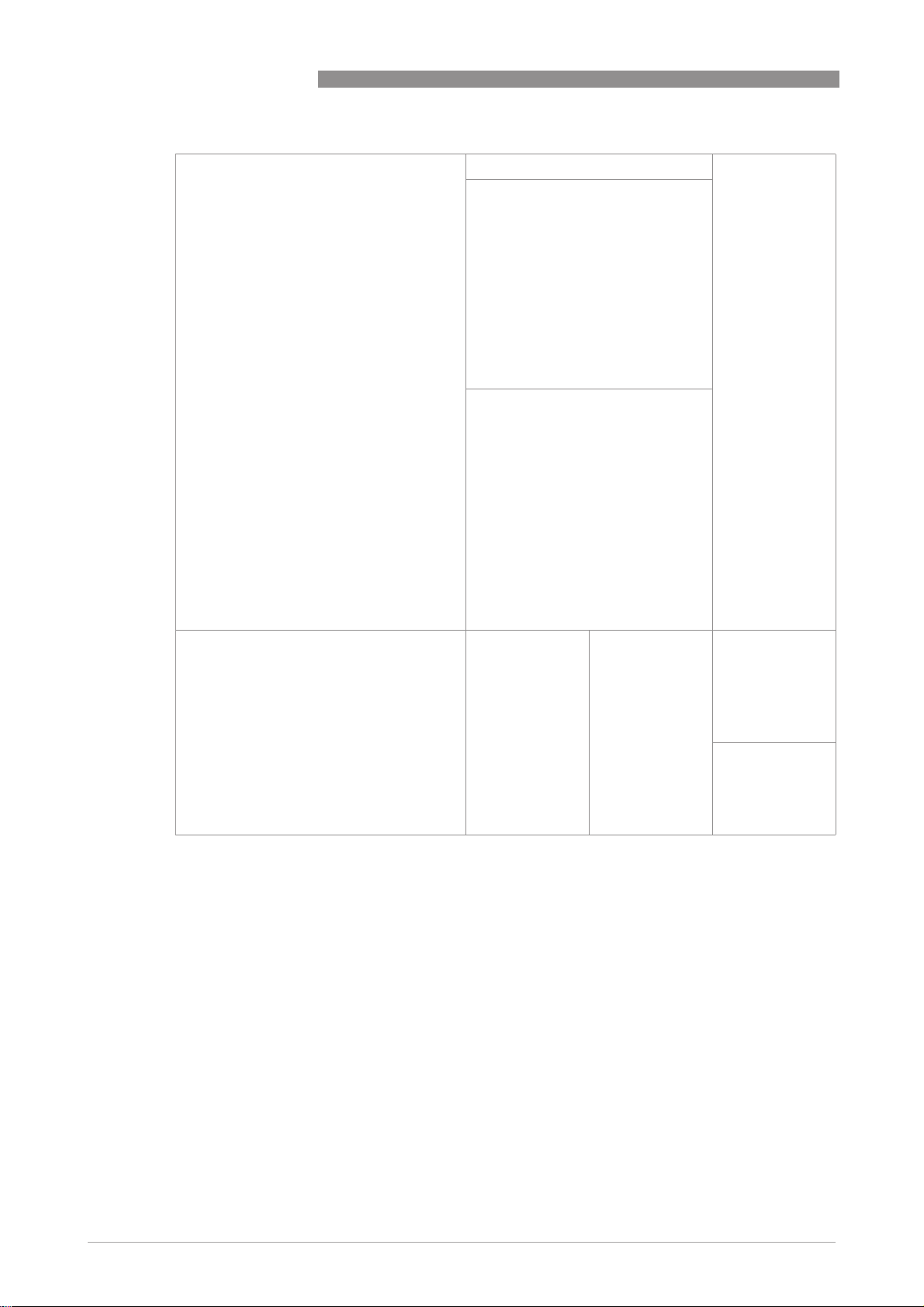

Installation conditions

Installation conditions

Installation conditionsInstallation conditions

Installation For detailed information refer to

Inlet run Minimal 5 DN (straight inlet)

Outlet run Minimal 3 DN (straight outlet)

Dimensions and weights For detailed information refer to

Materials

Materials

MaterialsMaterials

Measuring sensor

Measuring sensor

Measuring sensorMeasuring sensor

Flanges

(wetted)

Measuring Tube

(wetted)

Measuring sensor housing DN25...300 / 1"...12": Carbon steel

Transducer

Transducers (wetted) Stainless steel 1.4404 (AISI 316L)

Transducer holders

incl. caps

Tube transducer cabling Stainless steel 1.4404 (AISI 316L)

Connection box and connection box support

(remote version only)

Coating (measuring sensor) Standard: Polyurethane

NACE conformity On request; wetted materials conform NACE MR 175/103

Signal converter

Signal converter

Signal converterSignal converter

Housing Versions C and F: Die-cast aluminium

Coating Standard: Polyurethane

OPTISONIC 3400

Installation

If no details are known, minimal 10 DN recommended

If no details are known, minimal 5 DN recommended

on page 35.

Dimensions and weights

on page 21.

DN25...3000 / 1"...120": Carbon steel

Option: Stainless steel 1.4404 (AISI 316(L))

Other materials on request.

DN25...3000 / 1"...120": Carbon steel

Option: Stainless steel 1.4404 (AISI 316(L))

Other materials on request.

Option: Stainless steel 1.4404 (AISI 316(L))

For XXT, HV variant and DN25...3000 / 1"...120": Carbon

steel

For Cryogenic variant and DN25...3000 / 1"...120":

Stainless steel 1.4404 (AISI 316(L))

Other materials on request.

DN350...3000 / 14"...120"; Stainless steel 1.4404 (AISI

316L)

Standard: Die-cast aluminium; polyurethane coated

Option: Stainless steel 316 (1.4408)

Option: Offshore coating

Option: Stainless steel 316 (1.4408)

Option: Offshore coating

12

www.krohne.com 2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

OPTISONIC 3400

Electrical connections

Electrical connections

Electrical connectionsElectrical connections

Description of used abbreviations; Q=xxx; I

= external voltage; U

General Electrical connection is carried out in conformity with the

Power supply Standard: 100…230 VAC (-15% / +10%), 50/60 Hz

Power consumption AC: 22 VA

Signal cable

(remote version only)

Cable entries Standard: M20 x 1.5 (8...12 mm)

= maximal internal voltage

int, max

TECHNICAL DATA

= maximum current; Uin = xxx; U

max

VDE 0100 directive "Regulations for electrical power

installations with line voltages up to 1000 V" or equivalent

national specifications.

Option: 24 VAC/DC (AC: -15% / +10%; DC: -25% / +30%)

DC: 12 W

MR06 (shielded cable with 6 coax cores): Ø 10.6 mm / 0.4"

5 m / 16 ft

Option: 10...30 m / 33...98 ft

Option: ½" NPT, PF ½

= internal voltage; U

int

ext

2

Inputs and outputs

General All outputs are electrically isolated from each other and

Description of used abbreviations U

from all other circuits.

All operating data and output values can be adjusted.

= external voltage; RL = load + resistance;

ext

= terminal voltage; I

U

0

Safety limit values (Ex i):

= max. input voltage; Ii = max. input current; Pi = max.

U

i

input power rating;

Ci = max. input capacity; Li = max. input inductivity

= nominal current

nom

www.krohne.com2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

13

2

TECHNICAL DATA

Current output

Current output

Current outputCurrent output

Output data Measurement of volume flow, mass flow, flow speed,

Temperature coefficient Typically ±30 ppm/K

Settings

Operating data Basic I/Os

Active U

OPTISONIC 3400

velocity of sound, gain, SNR, diagnostics (flow speed,

VoS, SNR, gain), NAMUR NE107, HART

Without HART

Without HART

Without HARTWithout HART

®

Q = 0%: 0…20 mA; Q = 100%: 10…20 mA

Error identification: 3…22 mA

With HART

With HART

With HARTWith HART

®

Q = 0%: 4…20 mA; Q = 100%: 10…20 mA

Error identification: 3…22 mA

Q = 100%: 10…20 mA

Error identification: 3…22 mA

Basic I/Os Modular I/Os

Basic I/OsBasic I/Os

= 24 VDC

int, nom

Modular I/Os Ex i

Modular I/OsModular I/Os

®

communication.

Ex i

Ex iEx i

U

int, nom

= 20 VDC

Passive U

I ≤ 22 mA

≤ 1kΩ

R

L

≤ 32 VDC

ext

I ≤ 22 mA

≥ 1.8 V

U

0

R

= (U

L, max

- U0 / I

ext

max

I ≤ 22 mA

≤ 450 Ω

R

L

U0=21V

I0=90mA

=0.5W

P

0

C0= 90 nF / L0 =

2mH

=110nF/

C

0

L0=0.5mH

U

≤ 32 VDC

ext

I ≤ 22 mA

≥ 4V

U

0

R

= (U

L, max

U

0

/ I

max

ext

-

Ui=30V

Ii= 100 mA

=1W

P

i

C

= 10 nF

i

~0mH

L

i

14

www.krohne.com 2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

OPTISONIC 3400

HART

HART

HARTHART

Description

Load

Multidrop Yes, current output = 10% e.g. 4 mA

Device drivers DD for FC 375/475, AMS, PDM, DTM for FDT

Pulse or frequency output

Pulse or frequency output

Pulse or frequency outputPulse or frequency output

Output data Volume flow, mass flow

Function Adjustable as pulse of frequency output

Pulse rate/frequency 0.01...10000 pulses/s or Hz

Settings For Q = 100%: 0.01... 10000 pulses per second or pulses

Operating data Basic I/Os Modular I/Os Ex i

Active - U

TECHNICAL DATA

®

2

HART® protocol via active and passive current output

HART® version: V7

Universal HART® parameter: completely integrated

≥ 250 Ω t HART® test point:

Note maximum load for current output!

Multidrop addresses adjustable in operation menu 0...63

per unit volume.

Pulse width: adjustable as automatic, symmetric or fixed

(0.05...2000 ms)

= 24 VDC -

nom

f

in operating

max

menu set to:

ffff

≤ 100 Hz:

100 Hz:

100 Hz: 100 Hz:

max

max

max max

I ≤ 20 mA

= 47 kΩ

R

L, max

open:

I ≤ 0.05 mA

closed:

=24V at

U

0,nom

I=20mA

F

in operating

max

menu set to:

≤ 10

100 Hz < f

100 Hz < f

100 Hz < f100 Hz < f

kHz:

kHz:

kHz:kHz:

max

max

maxmax

10

10 10

I ≤ 20 mA

RL ≤ 10 kΩ for f ≤

1 kHz

≤ 1 kΩ for f ≤

R

L

10 kHz

open:

I ≤ 0.05 mA

closed:

U

= 22.5 V at

0,nom

I=1mA

= 21.5 V at

U

0,nom

I=10mA

U

0,nom

=19V at

I=20mA

www.krohne.com2/2015 - 4002037603 TD OPTISONIC 3400 R03 en

15

2

TECHNICAL DATA

OPTISONIC 3400

Passive U

≤ 32 VDC -

ext

f

in operating menu set to:

max

≤ 100 Hz:

100 Hz:

ffff

100 Hz: 100 Hz:

max

max

maxmax

I ≤ 100 mA

R

= 47 kΩ

L, max

= (U

R

L, max

- U0) / I

ext

max

open:

I ≤ 0.05 mA at U

=32VDC

ext

closed:

=0.2V at I≤ 10 mA

U

0, max

U

= 2 V at I ≤ 100 mA

0, max

f

in operating menu set to:

max

100 Hz < f

100 Hz < f

100 Hz < f100 Hz < f

≤ 10 kHz:

max

max

maxmax

10 kHz:

10 kHz: 10 kHz:

I ≤ 20 mA

RL ≤ 10 kΩ for f ≤ 1 kHz

≤ 1 kΩ for f ≤ 10 kHz

R

L

R

= (U

L, max

- U0) / I

ext

max

open:

I ≤ 0.05 mA at U

= 32 VDC

ext

closed:

U

=1.5V at I≤ 1mA

0, max

=2.5V at I≤ 10 mA

U

0, max

U

=5.0V at I≤ 20 mA

0, max

NAMUR - Passive to

EN 60947-5-6

Passive to

EN 60947-5-6

open:

I

= 0.6 mA

nom

closed:

=3.8mA

I

nom

open:

I

=0.43mA

nom

closed:

= 4.5 mA

I

nom

Ui=30V

= 100 mA

I

i

=1W

P

i

Ci=10nF

=0mH

L

i

16

www.krohne.com 2/2015 - 4002037603 TD OPTISONIC 3400 R03 en