Page 1

OPTISONIC 3400 Liquid Ultrasonic Flowmeter

Application Information Sheet

Company name:

Address:

City, State, Zip:

End user (destination)

Contact name:

Phone number:

Email address:

General Information

Equipment tag #

Piping information,

Flow orientation,

Agency approvals,

Process conditions

Fluid name,

Flow conditions,

Bi-directional flow,

Flow rate,

System pressure,

Fluid temperature,

Fluid properties,

Does fluid contain any solids?

Is gas / entrained air present?

Signal converter/ transmitter

Converter type,

Cable entry,

Power supply,

IO communications,

Converter housing,

Base IO module:

1st IO module:

2nd IO module:

Measuring functions,

Size:

Normal

Normal

Normal

✔

Horizontal

Without

Continuous service

No

Density

Integral-mounted

Die-cast aluminum

Standard

24 VDC

HART

Volumetric flow rate, totalized flow, velocity of sound (VOS), flow direction, signal strength

Foundation Fieldbus

100-230 VAC

3 x 1/2" NPT

Stainless steel

Remote-mounted

No

No

Yes

Batching service

FM Class 1, Div 1

Vertical, flow down

Schedule:

Minimum

Minimum

Minimum

Sp. gravity

describe:

Material:

FM Class 1, Div 2

Yes

Yes

(remote signal cable length)

3 x M20 x 1,5

RS485 Modbus

3 x PF 1/2

Profibus PA

describe % & size:

describe % & size:

Maximum

Maximum

Maximum

Viscosity

Vertical, flow up

Pipe ID

(required if line to be pigged)

units:

psig

°F

psia

°C

bara

barg

page 1 of 2

Page 2

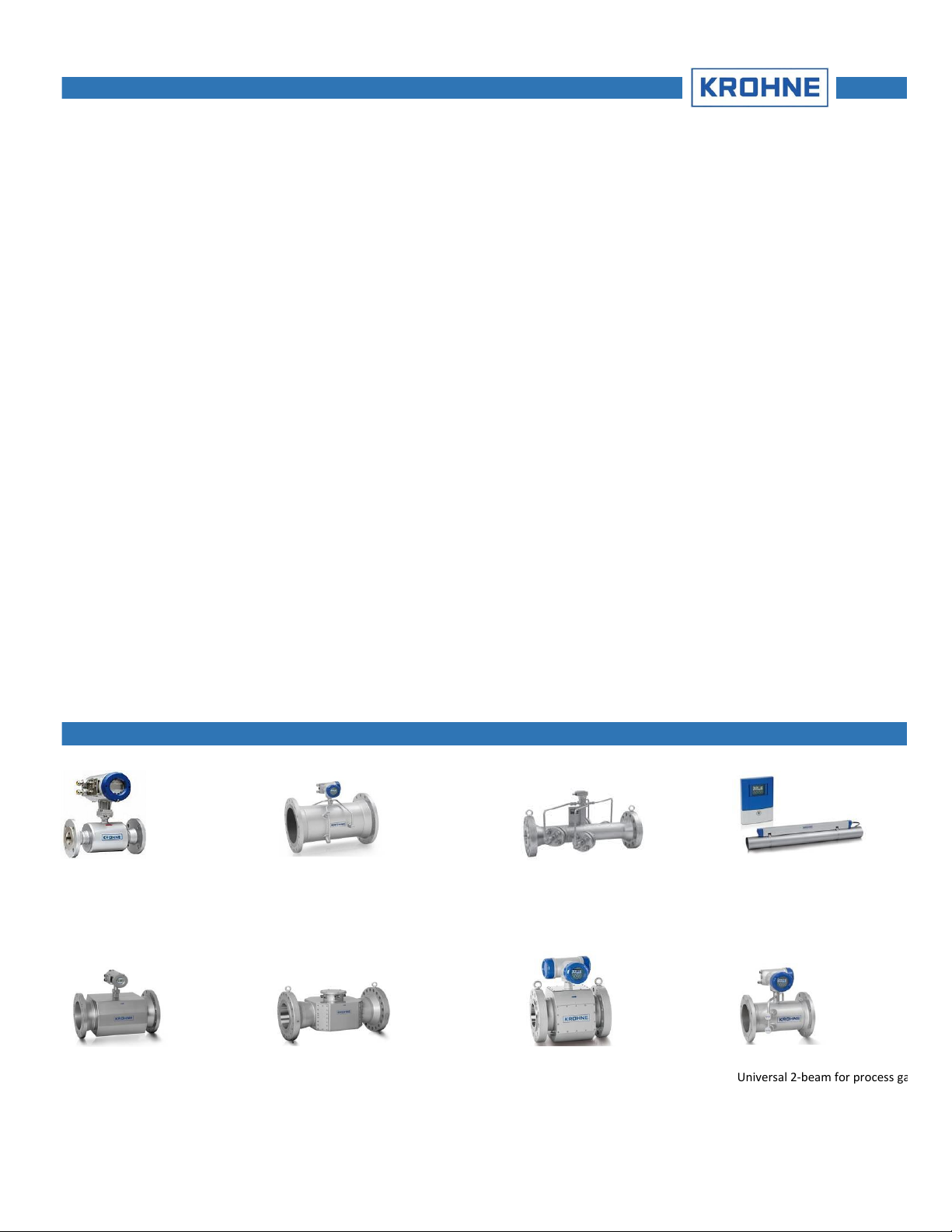

UFM 3030

OPTISONIC 3400

UFM 530 HT OPTISONIC 6300/6400

3-beam inline liquid UFM Multi-purpose liquid UFM

High-temperatures up to 932°F

Stationary or portable clamp-on

± 0.5% of measured value ± 0.3% of measured value ± 1.0% measured value for liquids

Advanced diagnostics & converter

ALTOSONIC III ALTOSONIC V ALTOSONIC V12 OPTISONIC 7300

Custody transfer 3-beam for Custody transfer 5-beam for Custody transfer 12-chord design Universal 2-beam for process gas

light hydrocarbons heavy crude oil products for gas measurement ± 1% accuracy of measured value

KROHNE Ultrasonic Flowmeters

Flow sensor

Measuring tube,

Flange material,

Sensor housing,

Process connections,

Raised face

Calibration,

Paint system,

Documentation (QA/QC)

KROHNE standard (IOM + service handbook on CD + copy of calibration certificate)

General arrangement drawing (GA)

Construction drawing (GA) for approval

Welding book (WPQ, WPS & PQR)

Stress calculations, ASME

Visual examination report, ASME

Liquid (dye) penetrant examination (PT)

Radiographic examination (RT)

✔

Carbon steel

Carbon steel

Carbon steel

Size:

2-point

Standard

Declaration of material compliance

Test report including pressure test

Hardness test report

Hardness inspection

Positive material identification (PMI)

Material certificates (pressure parts)

NACE MR0175

316L SST

316L SST

316L SST

ASME 150#

RTJ

Custom:

Offshore paint system

316Ti SST

ASME 300#

Duplex SST

ASME 600#

Customer paint specifications:

Hastelloy C4

ASME 900#

Inconel

ASME 1500#

Quality and production plan

Progress reports

Inspection & test plan (ITP)

ITP with customer approval

Manufactures record book

Pressure test procedure

Calibration procedure

Penetrant test procedure

Radiographic procedure

PMI procedure

Painting procudure

Notes/ comments:

page 2 of 2

2-beam for process gases

Coating report

Certificate of compliance

Loading...

Loading...