Page 1

Technical Datasheet

Technical Datasheet

OPTIMASS 2000

OPTIMASS 2000

OPTIMASS 2000OPTIMASS 2000

Technical DatasheetTechnical Datasheet

Sensor for bulk mass flow

• Large diameter for bulk measurement and custody transfer of liquids and gases

• Stainless Steel measuring tubes (NACE Compliant)

• Super Duplex option offering a maximum operating pressure of 180 barg

The documentation is only complete when used in combination with the relevant

documentation for the converter.

© KROHNE 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 2

CONTENTS

OPTIMASS 2000

1 Product features 3

1.1 The solution for bulk mass flow measurement............................................................... 3

1.2 Features and options........................................................................................................ 5

1.3 Meter / converter combinations....................................................................................... 6

1.4 Measuring principle (twin tube) ....................................................................................... 6

2 Technical data 8

2.1 Technical data................................................................................................................... 8

2.2 Measuring accuracy ....................................................................................................... 13

2.3 Guidelines for maximum operating pressure................................................................ 14

2.4 Dimensions and weights ................................................................................................ 16

2.4.1 Flanged versions................................................................................................................... 16

2.4.2 Hygienic versions .................................................................................................................. 21

2.4.3 Heating jacket version .......................................................................................................... 23

2.4.4 Purge port option .................................................................................................................. 24

3 Installation 25

3.1 Intended use ................................................................................................................... 25

3.2 Mounting restrictions ..................................................................................................... 25

3.2.1 General installation principles ............................................................................................. 25

3.2.2 Sunshades............................................................................................................................. 27

2

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 3

OPTIMASS 2000

1.1 The solution for bulk mass flow measurement

Whilst the OPTIMASS 2000 has been developed to meet the demanding custody transfer

requirements of the oil and gas industry, it is well suited to bulk measurement in many

applications. The option of Super Duplex (UNS S32750) provides a maximum operating pressure

of 180 barg.

A high level of performance makes the OPTIMASS 2000 suitable for the bulk measurement of

petroleum and oil as well as products like syrup, molasses and raw chemicals.

Combined with the power of the MFC 300, the OPTIMASS 2000 will provide accurate

measurement of volume, mass; density and concentration.

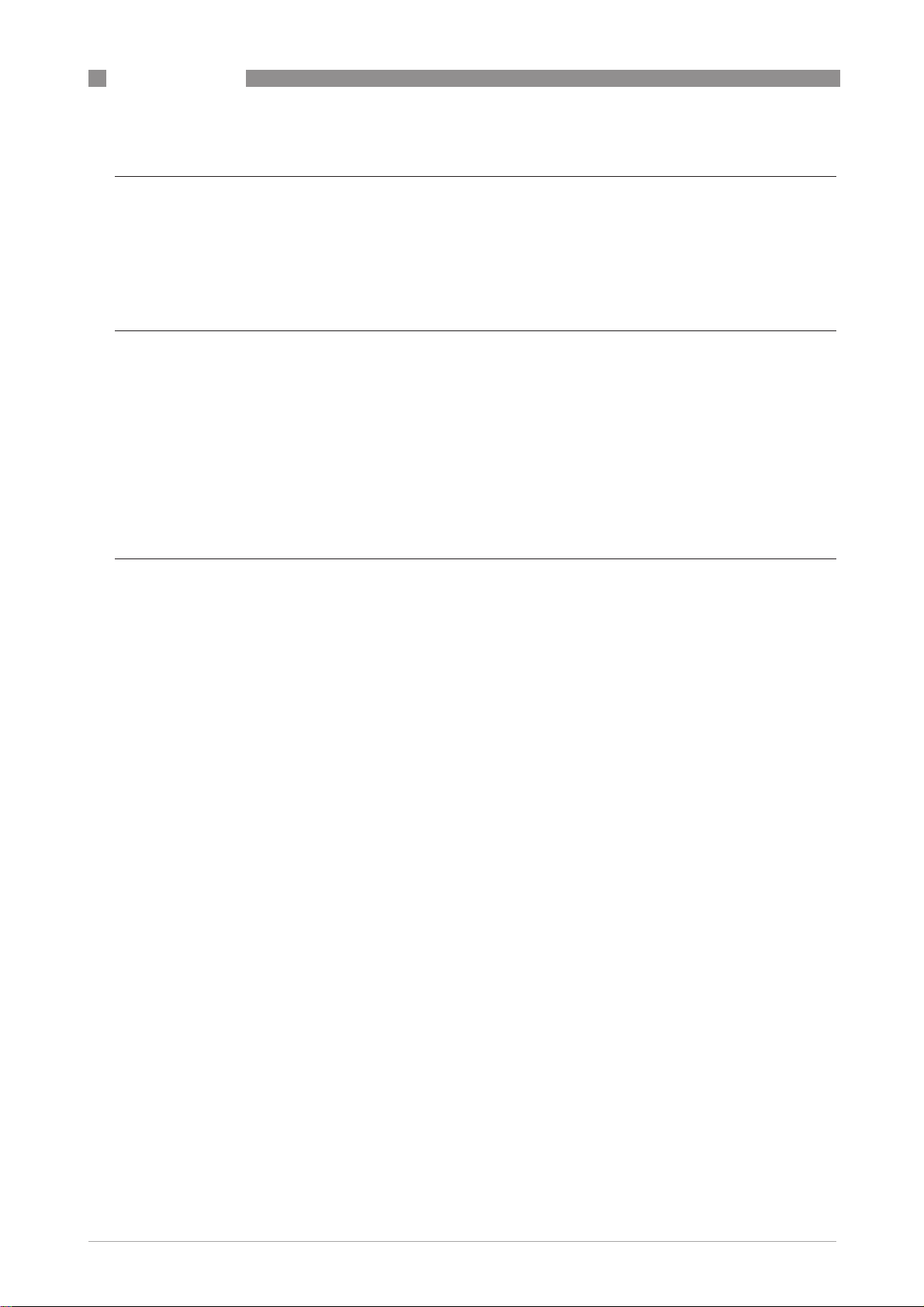

PRODUCT FEATURES 1

1 Comprehensive diagnostic capabilities.

2 Standard electronics for all sensors with redundant storage of calibration and sensor data.

3 Standard flange process connections available.

4 Modular electronics with a range of output options (see separate documentation for details).

1 Remote terminal box

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

3

Page 4

1 PRODUCT FEATURES

Highlights

• Innovative twin measuring tube design with large tube size, provide high flow rate capacity

• Easily drained and easy to clean

• Optional heating jacket

• High accuracy for custody transfer

• Optimised flow divider for minimum pressure loss

• Modular electronics concept: electronics and sensor are easy to replace

• Super Duplex option for operating pressures up to 180 barg

• Secondary containment up to 150 barg

Industries

• Oil & Gas

• Waste Water

• Chemical

• Paper & Pulp

• Food & Beverage

• Pharmaceutical

• Fresh Water

OPTIMASS 2000

Applications

• Bulk loading/unloading

• Custody transfer for volume and mass

• High Volume

• Pipeline measurement applications

4

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 5

OPTIMASS 2000

1.2 Features and options

Features

Connection options

PRODUCT FEATURES 1

• Flow rates up to 2,300,000 kg/h /

84,510 lbs/min.

• Integrated electronics.

• Self Draining.

• Best in class for zero stability.

• Standard flanges with ratings up to

1500 lbs / PN160.

• Supports a wide range of industry standard hygienic

connections.

• Hygienic connections (DN100 only) for bulk

measurement in the food/beverage industry.

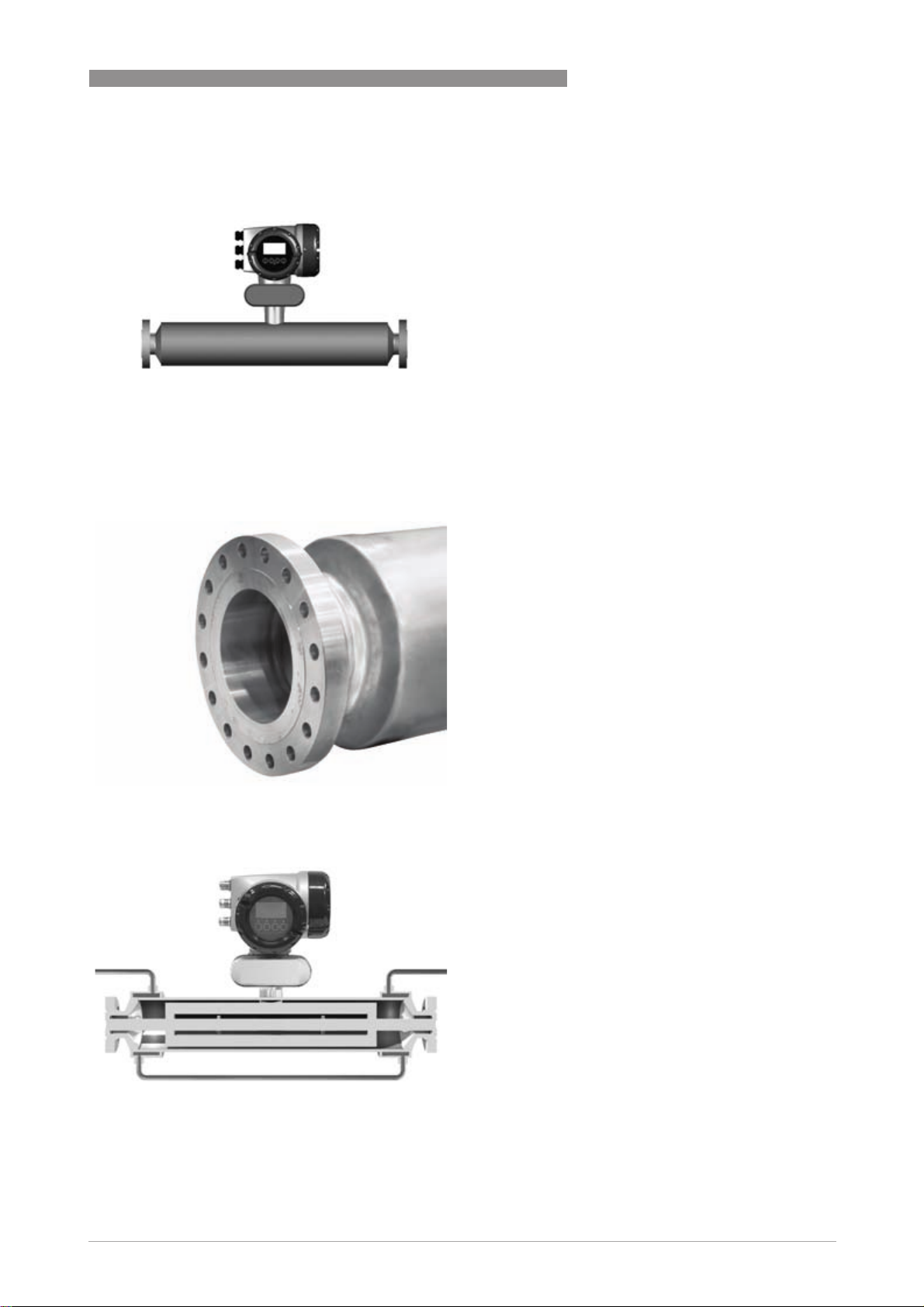

Heating jacket and purge port

• Heating jacket option for use with temperature

dependant products.

• Prevents solidification of process product.

• Purge port option for protection in the event of

measuring tube faliure.

• Allows hazardous chemicals to be drained away

safely.

• Can also be used for the early detection of

measuring tube failure where highly toxic

chemicals are being measured.

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

5

Page 6

1 PRODUCT FEATURES

OPTIMASS 2000

1.3 Meter / converter combinations

Converter MFC 010 MFC 300

Configuration Compact Compact Remote field Remote wall Remote rack

OPTIMASS 2000 2010C 2300C 2300F 2300W 2300R

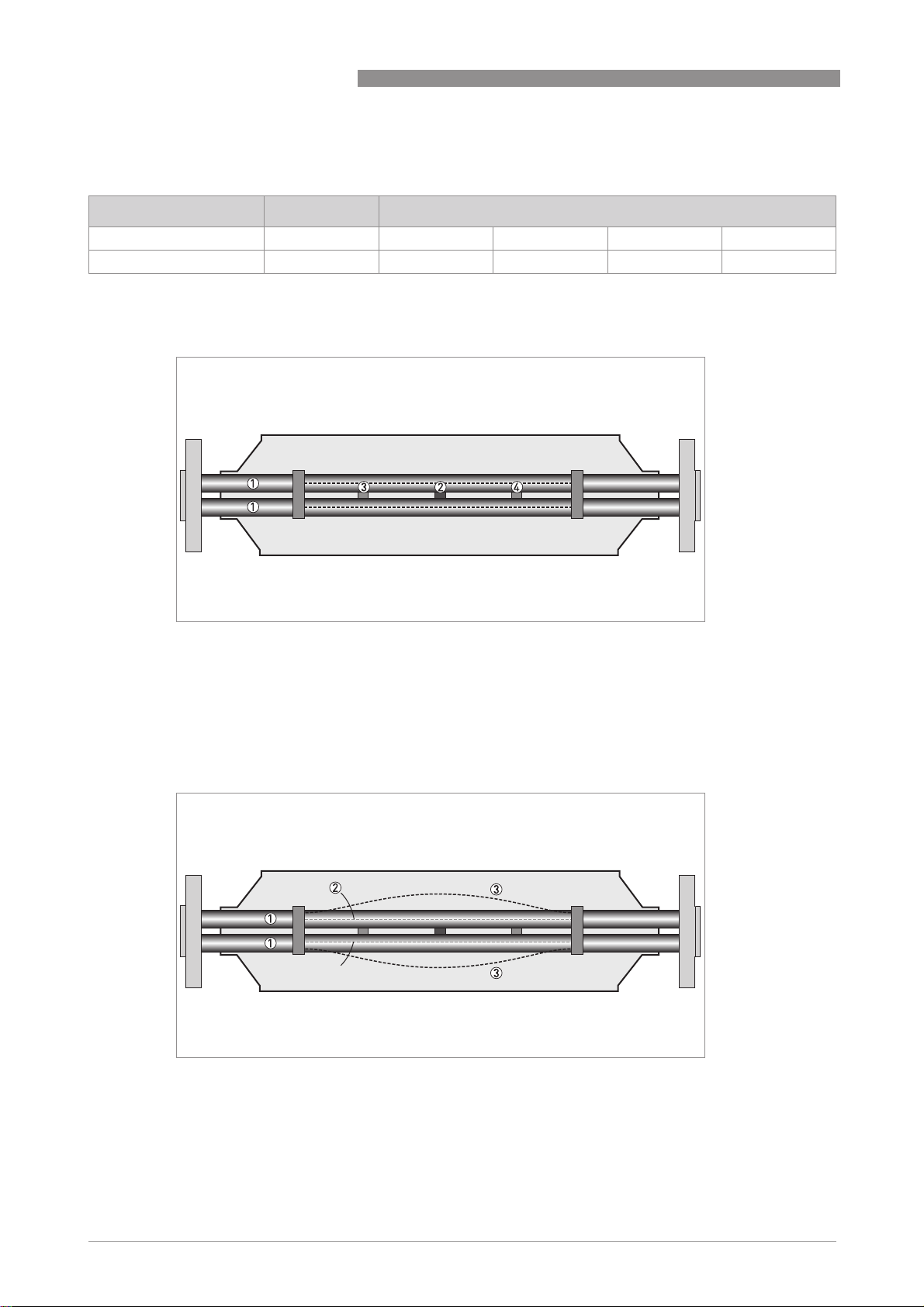

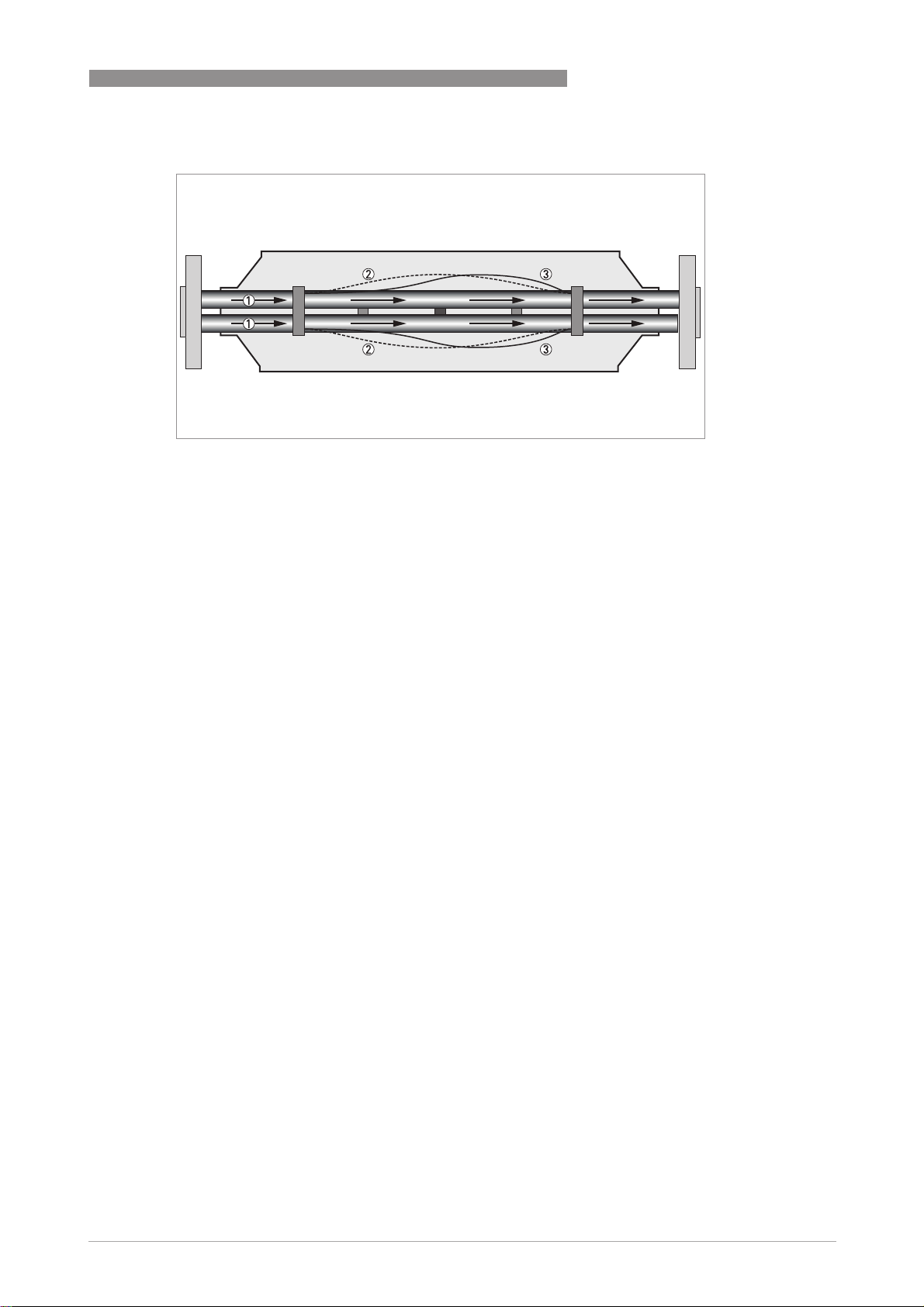

1.4 Measuring principle (twin tube)

Static meter not energised and with no flow

1 Measuring tubes

2 Drive coil

3 Sensor 1

4 Sensor 2

A Coriolis twin tube mass flowmeter consists of two measuring tubes 1 a drive coil 2 and two

sensors (3 and 4) that are positioned either side of the drive coil.

Energised meter

1 Measuring tubes

2 Direction of oscilation

3 Sine wave

When the meter is energised, the drive coil vibrates the measuring tubes causing them to

oscillate and produce a sine wave 3. The sine wave is monitored by the two sensors.

6

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 7

OPTIMASS 2000

Energised meter with process flow

1 Process flow

2 Sine wave

3 Phase shift

When a fluid or gas passes through the tubes, the coriolis effect causes a phase shift in the sine

wave that is detected by the two sensors. This phase shift is directly proportional to the mass

flow.

Density measurement is made by evaluation of the frequency of vibration and temperature

measurement is made using a Pt500 sensor.

PRODUCT FEATURES 1

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

7

Page 8

2 TECHNICAL DATA

OPTIMASS 2000

2.1 Technical data

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local representative.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Measuring principle Coriolis mass flow

Application range Mass flow and density measurement of fluids, gases and solids

Measured values Mass, density, temperature

Calculated values Volume, referred density, concentration, velocity

Design

Basic System consists of a measuring sensor and a converter to process the

Features Fully welded maintenance free sensor with dual-straight measuring tube

Variants

Variants

VariantsVariants

Compact version Integral converter

Remote version Available with field, wall or 19" rack mount versions of the converter

Modbus version Sensor with integral electronics providing Modbus output for connection to a

output signal

PLC

Measuring accuracy

Mass

Mass

MassMass

Liquid ±0.1% of actual measured flow rate + zero stability

Gas ±0.5% of actual measured flow rate + zero stability

Repeatability Better than 0.05% plus zero stability (includes the combined effects of

Zero stability

Zero stability

Zero stabilityZero stability

S100 < 7 kg/h

S150 < 18 kg/h

S250 < 50 kg/h

Reference conditions

Reference conditions

Reference conditionsReference conditions

Product Water

Temperature +20°C / +68°F

Operating pressure 1 barg / 14.5 psig

Effect on sensor zero point caused by a shift in process temperature

Effect on sensor zero point caused by a shift in process temperature

Effect on sensor zero point caused by a shift in process temperatureEffect on sensor zero point caused by a shift in process temperature

Stainless Steel 0.0004% per 1°C / 0.000022% per 1°F

Effect on sensor zero point caused by a shift in process pressure

Effect on sensor zero point caused by a shift in process pressure

Effect on sensor zero point caused by a shift in process pressureEffect on sensor zero point caused by a shift in process pressure

Stainless Steel 0.0002% of the max flow rate per 1 bar

Density

Density

DensityDensity

Measuring range

Accuracy

repeatability, linearity and hysteresis)

per 1 psig

400...3000 kg/m3 / 25...187 lbs/ft

±2 kg/m3 / ±0.13 lbs/ft

3

3

. / 0.0000014% of the max flow rate

rel

8

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 9

OPTIMASS 2000

TECHNICAL DATA 2

On site calibration

Temperature

Temperature

TemperatureTemperature

Accuracy ±1°C / ±1.8°F

±0.5 kg/m3 / ±0.033 lbs/ft

3

Operating conditions

Maximum flow rates

Maximum flow rates

Maximum flow ratesMaximum flow rates

S100 420000 kg/h / 14698 lbs/min

S150 900000 kg/h / 33804 lbs/min

S250 2300000 kg/h / 84510 lbs/min

Custody transfer flow rates (mass)

Custody transfer flow rates (mass)

Custody transfer flow rates (mass)Custody transfer flow rates (mass)

S100 11000...220000 kg/h / 404...8083 lbs/min

S150 25000...500000 kg/h / 919...18371 lbs/min

S250 60000...1200000 kg/h / 2205...44092 lbs/min

Custody transfer flow rates (volume)

Custody transfer flow rates (volume)

Custody transfer flow rates (volume)Custody transfer flow rates (volume)

S100

S150

S250

Ambient temperature

Ambient temperature

Ambient temperatureAmbient temperature

Compact version with Aluminium

converter

Compact version with Stainless Steel

converter

Remote versions -40...+65°C / -40…+149°F

Process temperature

Process temperature

Process temperatureProcess temperature

Flanged connection -45…+130°C / -49…+266°F

Hygienic connection (S100 only)

Nominal pressure at 20

Nominal pressure at 20°C / 68

Nominal pressure at 20Nominal pressure at 20

Measuring tube (Duplex UNS S31803)

Measuring tube (Duplex UNS S31803)

Measuring tube (Duplex UNS S31803) Measuring tube (Duplex UNS S31803)

PED 97/23/EC -1…150 barg / -14.5…2175 psig

FM -1…140 barg / -14.5…2030 psig

CRN / ASME B31.3 -1…100 barg / -14.5…1450 psig

Measuring tube (Super Duplex UNS S32750)

Measuring tube (Super Duplex UNS S32750)

Measuring tube (Super Duplex UNS S32750) Measuring tube (Super Duplex UNS S32750)

PED 97/23/EC -1…180 barg / -14.5…2610 psig

FM -1…140 barg / -14.5…2030 psig

CRN / ASME B31.3 (pending) -1…130 barg / -14.5…1885 psig

Outer cylinder

Outer cylinder

Outer cylinderOuter cylinder

Non PED / CRN approved Typical burst pressure > 100 barg / 1450 psig

PED approved secondary containment -1...40 barg / -14.5...580 psig

Effect on sensor zero point caused by a shift in process temperature

Effect on sensor zero point caused by a shift in process temperature

Effect on sensor zero point caused by a shift in process temperatureEffect on sensor zero point caused by a shift in process temperature

Stainless Steel 0.0004% per 1°C / 0.000022% per 1°F

C / 68°F

C / 68C / 68

F

FF

11...220 m3/h / 1660...33210 bbl/day

25...500 m3/h / 3774...75478 bbl/day

60...1200 m3/h / 9057...181147 bbl/day

Assumes operating density 1000 kg/m3 / 62.4 lb/ft

-40...+60°C / -40…+140°F

Extended temperature range: 65°C / 149°F for some I/O options. For more

information contact manufacturer.

-40...+55°C / -40…+130°F

-1...150 barg / -14.5...2175 psig (Duplex option)

3

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

9

Page 10

2 TECHNICAL DATA

Effect on sensor zero point caused by a shift in process pressure

Effect on sensor zero point caused by a shift in process pressure

Effect on sensor zero point caused by a shift in process pressureEffect on sensor zero point caused by a shift in process pressure

Stainless Steel 0.0002% of the max flow rate per 1 bar

per 1 psig

Fluid properties

Fluid properties

Fluid propertiesFluid properties

Permissible physical condition Liquids, gases, slurries

Permissible gas content (volume) Contact manufacturer for information.

Permissible solid content (volume) Contact manufacturer for information.

Protection category (acc. to EN 60529) IP 67, NEMA 4X

Installation conditions

Inlet runs None required

Outlet runs None required

Materials

Measuring tube Stainless Steel UNS S31803 (1.4462)

Optional UNS S32750 (1.4410)

Spigot Stainless Steel UNS J92205 (1.4470)

Optional UNS J93404 (1.4469)

Flanges Stainless Steel AISI 316 / 316L (1.4401 / 1.4404) dual certified

Optional Stainless Steel UNS S31803 (1.4462) (NACE approved)

Optional UNS S32750 (1.4410) (NACE approved)

Outer cylinder Stainless Steel AISI 304 / 304L (1.4301 / 1.4307) dual certified

Optional Stainless Steel AISI 316 / 316L (1.4401 / 1.4404) dual certified

Optional Stainless Steel UNS S31803 (1.4462) 1

Heating jacket version

Heating jacket version

Heating jacket versionHeating jacket version

Heating jacket Stainless Steel 316L (1.4404)

Note: the outer cylinder is in contact with the heating medium

All versions

All versions

All versionsAll versions

Sensor electronics housing Stainless Steel 316L (1.4409)

Optional Stainless Steel 316 (1.4469)

Junction box (remote version) Die cast Aluminium (polyurethane coating)

. / 0.0000014% of the max flow rate

rel

OPTIMASS 2000

Process connections

Flange

Flange

FlangeFlange

DIN DN100…300 / PN16…160

ASME 4...12" / ASME 150…1500

JIS 100A / 10...20K

Hygienic

Hygienic

HygienicHygienic

Tri-clover 4"

Tri-clamp DIN 32676 DN100

Tri-clamp ISO 2852 4"

DIN 11864-2 Form A DN100

Male thread DIN 11851 DN100

Male thread SMS 4"

Male thread IDF / ISS 4"

Male thread RJT 4"

10

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 11

OPTIMASS 2000

TECHNICAL DATA 2

Electrical connections

Electrical connections For full details, including: power supply, power consumption etc., see

I/O For full details of I/O options, including data streams and protocols, see

technical data for the relevant converter.

technical data for the relevant converter.

Approvals

Mechanical

Mechanical

MechanicalMechanical

Electromagnetic compatibility (EMC)

acc. to CE

European Pressure Equipment Directive PED 97-23 EC (acc. to AD 2000 Regelwerk)

Factory Mutual / CSA Class I, Div 1 groups A, B, C, D

ANSI / CSA (Dual Seal) 12.27.901-2003

Hygienic 3A 28-03

Custody Transfer MID 2004/22/EC MI-005

ATEX (acc. 94/9/EC)

ATEX (acc. 94/9/EC)

ATEX (acc. 94/9/EC)ATEX (acc. 94/9/EC)

OPTIMASS 2300C non Ex i Signal outputs

OPTIMASS 2300C non Ex i Signal outputs

OPTIMASS 2300C non Ex i Signal outputsOPTIMASS 2300C non Ex i Signal outputs

Ex d connection compartment II 2 G Ex d [ib] IIC T6....T1

Ex e connection compartment II 2 G Ex de [ib] IIC T6....T1

OPTIMASS 2300C Ex i signal outputs

OPTIMASS 2300C Ex i signal outputs

OPTIMASS 2300C Ex i signal outputsOPTIMASS 2300C Ex i signal outputs

Ex d connection compartment II 2(1) G Ex d [ia/ib] IIC T6....T1

Ex e connection compartment II 2(1) G Ex de [ia/ib] IIC T6....T1

OPTIMASS 2000 / 2010C

OPTIMASS 2000 / 2010C II 2 G Ex ib IIC T6…T1

OPTIMASS 2000 / 2010COPTIMASS 2000 / 2010C

1 Where this option is ordered, the electronics stem material is UNS J92205 (1.4470)

Namur NE 21/5.95

2004/108/EC (EMC)

2006/95/EC (Low Voltage Directive)

Class II, Div 1 groups E, F, G

Class III, Div 1 hazardous areas

Class I, Div 2 groups A, B, C, D

Class II, Div 2 groups F, G

Class III, Div 2 hazardous areas

ASME BPE

II 2 D Ex tD A21 IP6x T160°C

II 2 D Ex tD A21 IP6x T160°C

II 2(1) D Ex tD [iaD] A21 IP6x T160°C

II 2(1) D Ex tD [iaD] A21 IP6x T160°C

II 2 D Ex ibD 21 T165 °C

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

11

Page 12

2 TECHNICAL DATA

ATEX (acc. 94/9/EC) temperature limits

OPTIMASS 2000

Ambient temp.

T

°C

amb

OPTIMASS 2000 / 2010C with or without

heating jacket / insulation

OPTIMASS 2300C Aluminium converter

housing - with or without heating jacket

/ insulation

OPTIMASS 2300C Stainless Steel

converter housing - with or without

heating jacket / insulation

1 depending on I/O option. Please call for more information.

40 65 T6 T80

65 75 T5 T95

40 50 T6 T80

50 65 T5 T95

60 60 T4-T1 T90

65 1 65 T4-T1 T95

40 50 T6 T80

50 65 T5 T95

55 55 T5-T1 T85

Max. medium

temp. T

75 T5 T95

110 T4 T130

130 T3-T1 T150

110 T4 T130

130 T3-T1 T150

65 T5 T95

100 T4 T130

130 T3-T1 T160

100 T4-T1 T130

65 T5 T95

100 T4 T130

120 T3-T1 T150

75 T4-T1 T105

°C

m

Temp. class Max. surface

temp. °C

Maximum end loadings

S100 S150 S250

Flanges

Flanges

FlangesFlanges

20°C 40 barg 150kN 350kN 550kN

100 barg 100kN 120kN 60kN

150 barg

180 barg

130°C 32 barg 150kN 280kN 400kN

80 barg 60kN 50kN 50kN

115 barg

130 barg

Hygienic (all connections)

Hygienic (all connections)

Hygienic (all connections)Hygienic (all connections)

130°C 10 barg 5kN - -

12

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 13

OPTIMASS 2000

2.2 Measuring accuracy

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

TECHNICAL DATA 2

X flow rate [%]

Y measuring error [%]

Measuring error

The measuring error is obtained from the combined effects of accuracy and zero stability.

Reference conditions

Product Water

Temperature +20°C / +68°F

Operating pressure 1 barg / 14.5 psig

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

13

Page 14

2 TECHNICAL DATA

2.3 Guidelines for maximum operating pressure

Notes:

• Ensure that the meter is used within its operating limits

• All hygienic process connections have a maximum operating rating of 10 barg

at 130°C / 145 psig at 266°F

Pressure / temperature de-rating, all meter sizes in metric (flanged connections as

Pressure / temperature de-rating, all meter sizes in metric (flanged connections as

Pressure / temperature de-rating, all meter sizes in metric (flanged connections as Pressure / temperature de-rating, all meter sizes in metric (flanged connections as

per EN 1092-1:2007)

per EN 1092-1:2007)

per EN 1092-1:2007)per EN 1092-1:2007)

OPTIMASS 2000

X temperature [°C]

Y pressure [barg]

1 Measuring tube (UNS S32750) PED certification

2 Measuring tube (UNS S31803) PED certification

3 Measuring tube (UNS S31803 / S32750) FM certification

4 Measuring tube (UNS S31803) CRN certification

Linear de-rating of PED certified secondary containment

Outer cylinder material -45°C 20°C 130°C

304 / L or 316 / L 40 barg 40 barg 32 barg

UNS S31803 150 barg 150 barg 100 barg

14

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 15

OPTIMASS 2000

Pressure / temperature de-rating, all meter sizes, in imperial (flanged connections as

Pressure / temperature de-rating, all meter sizes, in imperial (flanged connections as

Pressure / temperature de-rating, all meter sizes, in imperial (flanged connections as Pressure / temperature de-rating, all meter sizes, in imperial (flanged connections as

per ASME B16.5)

per ASME B16.5)

per ASME B16.5)per ASME B16.5)

TECHNICAL DATA 2

X temperature [°F]

Y pressure [psig]

1 Measuring tube (UNS S32750) PED certification

2 Measuring tube (UNS S31803) PED certification

3 Measuring tube (UNS S31803 / S32750) FM certification

4 Measuring tube (UNS S31803) CRN certification

Linear de-rating of PED certified secondary containment

Outer cylinder material -49°F 68°F 266°F

304 / L or 316 / L 580 psig 580 psig 464 psig

UNS S31803 2175 psig 2175 psig 1450 barg

Flanges

• DIN flange ratings are based on EN 1092-1 2007 table G.4.1 material group 14EO

• ASME flange ratings are based on ASME B16.5 2003 table 2 material group 2.2

• JIS flange ratings are based on JIS 2220: 2001 table 1 division 1 material group 022a

Notes

• The maximum operating pressure will be either the flange rating or the measuring tube

rating, WHICHEVER IS THE LOWER!

• The manufacturer recommends that the seals are replaced at regular intervals. This will

maintain the hygienic integrity of the connection.

WHICHEVER IS THE LOWER!

WHICHEVER IS THE LOWER!WHICHEVER IS THE LOWER!

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

15

Page 16

2 TECHNICAL DATA

2.4 Dimensions and weights

2.4.1 Flanged versions

1

C1

D

A

OPTIMASS 2000

E

H

2

C2

1 Compact version

2 Remote version

D

B

E

A

B

FG

C2

H

Meter weights (PN40 flanges).

Weight [kg]

S100 S150 S250

Aluminium (compact) 84.8 211.5 444.5

Stainless Steel (compact) 90.1 216.8 449.8

Aluminium (remote) 80.8 207.5 440.5

Stainless Steel (remote) 81.7 208.4 441.4

Weight [lbs]

S100 S150 S250

Aluminium (compact) 187 466 980

Stainless Steel (compact) 198 478 991

Aluminium (remote) 178 457 971

Stainless Steel (remote) 180 459 973

For meter weights with different flange ratings, please contact the manufacturer.

16

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 17

OPTIMASS 2000

TECHNICAL DATA 2

Measuring tube in Stainless Steel

Dimensions [mm]

S100 S150 S250

A 219 ±5 323 ±5 406 ±5

C1 (compact) 370 ±5 422 ±5 463 ±5

C2 (remote) 293 ±5 345 ±5 386 ±5

D 160

E 60

F 123.5

G 137

H 98.5

Dimensions [inches]

S100 S150 S250

A 8.6 ±0.2 12.7 ±0.2 16 ±0.2

C1 (compact) 14.6 ±0.2 16.6 ±0.2 18.2 ±0.2

C2 (remote) 11.5 ±0.2 13.6 ±0.2 15.2 ±0.2

D 6.3

E 2.4

F 4.9

G 5.4

H 3.9

Flange connections

Dimension B [mm]

S100 S150 S250

PN16

PN16

PN16PN16

DN100 1284 - -

DN150 1284 1581 -

DN200 - 1581 -

DN250 - - 1960

DN300 - - 1960

PN40

PN40

PN40PN40

DN100 1310 - -

DN150 1330 1621 -

DN200 - 1647 -

DN250 - - 2030

DN300 - - 2050

PN63

PN63

PN63PN63

DN100 1336 - -

DN150 1370 1661 -

DN200 - 1691 -

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

17

Page 18

2 TECHNICAL DATA

Dimension B [mm]

S100 S150 S250

DN250 - - 2070

DN300 - - 2100

PN100

PN100

PN100PN100

DN100 1360 - -

DN150 1410 1701 -

DN200 - 1731 -

DN250 - - 1977

DN300 - - 2160

PN160

PN160

PN160PN160

DN100 1380 - -

DN150 1436 1727 -

DN200 - 1751 -

DN250 2130

DN300 - - 2170

ASME 150

ASME 150

ASME 150ASME 150

4" 1334 - -

6" 1358 1649 -

8" - 1675 -

10" - - 2024

12" - - 2050

ASME 300

ASME 300

ASME 300ASME 300

4" 1352 - -

6" 1378 1669 -

8" - 1695 -

10" - - 2056

12" - - 2082

ASME 600

ASME 600

ASME 600ASME 600

4" 1398 - -

6" 1428 1719 -

8" - 1751 -

10" - - 2138

12" - - 2146

ASME 900

ASME 900

ASME 900ASME 900

4" 1422 - -

6" 1474 1765 -

8" - 1809 -

10" - - 2202

12" - - 2234

ASME 1500

ASME 1500

ASME 1500ASME 1500

4" 1442 - -

6" 1554 - -

OPTIMASS 2000

18

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 19

OPTIMASS 2000

TECHNICAL DATA 2

Dimension B [mm]

S100 S150 S250

8" - 1911 -

10" - - 2400

12" - - 2400

JIS 10K

JIS 10K

JIS 10KJIS 10K

100A 1332 - -

JIS 20K

JIS 20K

JIS 20KJIS 20K

100A 1332 - -

Dimension B [inches]

S100 S150 S250

PN16

PN16

PN16PN16

DN100 50.5 - -

DN150 50.5 62.2 -

DN200 - 62.2 -

DN250 - - 77.2

DN300 - - 77.2

PN40

PN40

PN40PN40

DN100 51.5 - -

DN150 52.6 64 -

DN200 - 65.5 -

DN250 - - 80.7

DN300 - - 82.3

PN63

PN63

PN63PN63

DN100 53.2 - -

DN150 52.3 67 -

DN200 - 65 -

DN250 - - 84.8

DN300 - - 81.5

PN100

PN100

PN100PN100

DN100 53.9 - -

DN150 55.5 66.6 -

DN200 - 68.3 -

DN250 - - 83.5

DN300 - - 85.9

PN160

PN160

PN160PN160

DN100 54.3

DN150 56.5 68 -

DN200 68.9 -

DN250 83.9

DN300 - - 85.4

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

19

Page 20

2 TECHNICAL DATA

Dimension B [inches]

S100 S150 S250

ASME 150

ASME 150

ASME 150ASME 150

4" 52.5 - -

6" 53.4 65 -

8" - 66 -

10" - - 80.4

12" - - 81.5

ASME 300

ASME 300

ASME 300ASME 300

4" 53.2 - -

6" 54.2 65.8 -

8" - 66.8 -

10" - - 81.7

12" - - 82.7

ASME 600

ASME 600

ASME 600ASME 600

4" 54.9 - -

6" 56.1 67.8 -

8" - 68.9 -

10" - - 85

12" - - 85.2

ASME 900

ASME 900

ASME 900ASME 900

4" 55.2 - -

6" 57.9 69.5 -

8" - 71.2 -

10" - - 87.5

12" - - 88.7

ASME 1500

ASME 1500

ASME 1500ASME 1500

4" 56.8 - -

6" 61.2 - -

8" - 75.3 -

10" - - 94.5

12" - - 94.5

JIS 10K

JIS 10K

JIS 10KJIS 10K

100A 52.5 - -

JIS 20K

JIS 20K

JIS 20KJIS 20K

100A 52.5 - -

OPTIMASS 2000

20

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 21

OPTIMASS 2000

2.4.2 Hygienic versions

Hygienic connections: all welded versions

S100 S150 S250

TECHNICAL DATA 2

Dimension B [mm]

Tri-clover

Tri-clover

Tri-cloverTri-clover

4" 1223 - -

Tri-clamp DIN 32676

Tri-clamp DIN 32676

Tri-clamp DIN 32676Tri-clamp DIN 32676

DN100 1236 - -

Tri-clamp ISO 2852

Tri-clamp ISO 2852

Tri-clamp ISO 2852Tri-clamp ISO 2852

4" 1223 - -

DIN 11864-2 form A

DIN 11864-2 form A

DIN 11864-2 form ADIN 11864-2 form A

DN100 1296 - -

Dimension B [inches]

S100 S150 S250

Tri-clover

Tri-clover

Tri-cloverTri-clover

4" 48 - -

Tri-clamp DIN 32676

Tri-clamp DIN 32676

Tri-clamp DIN 32676Tri-clamp DIN 32676

DN100 48.7 - -

Tri-clamp ISO 2852

Tri-clamp ISO 2852

Tri-clamp ISO 2852Tri-clamp ISO 2852

4" 48 - -

DIN 11864-2 form A

DIN 11864-2 form A

DIN 11864-2 form ADIN 11864-2 form A

DN100 51 - -

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

21

Page 22

2 TECHNICAL DATA

OPTIMASS 2000

Hygienic connections: adapter versions (male thread)

Dimension B [mm]

S100 S150 S250

Male thread DIN 11851

Male thread DIN 11851

Male thread DIN 11851Male thread DIN 11851

DN100 1288 - -

Male thread SMS

Male thread SMS

Male thread SMSMale thread SMS

4" 1236 - -

Male thread IDF/ISS

Male thread IDF/ISS

Male thread IDF/ISSMale thread IDF/ISS

4" 1223 - -

Male thread RJT

Male thread RJT

Male thread RJTMale thread RJT

4" 1234 - -

Dimension B [inches]

S100 S150 S250

Male thread DIN 11851

Male thread DIN 11851

Male thread DIN 11851Male thread DIN 11851

DN100 50.1 - -

Male thread SMS

Male thread SMS

Male thread SMSMale thread SMS

4" 48.7 - -

Male thread IDF/ISS

Male thread IDF/ISS

Male thread IDF/ISSMale thread IDF/ISS

4" 48 - -

Male thread RJT

Male thread RJT

Male thread RJTMale thread RJT

4" 48.6 - -

22

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 23

OPTIMASS 2000

2.4.3 Heating jacket version

Dimensions [mm]

S100 S150 S250

Heating connection size 25 mm (ERMETO)

TECHNICAL DATA 2

A 254 ±2.5 355 ±2.5 444 ±2.5

B 178 ±2.0 228 ±2.0 208 ±2.0

C 28 ±2.0 28 ±2.0 6.5 ±2.0

Dimensions [inches]

S100 S150 S250

Heating connection size 1" (NPTF)

A 10 ±0.1 14 ±0.1 17.5 ±0.06

B 7 ±0.08 9 ±0.08 8.2 ±0.08

C 1.1 ±0.08 1.1 ±0.08 0.25 ±0.08

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

23

Page 24

2 TECHNICAL DATA

2.4.4 Purge port option

Dimensions [mm]

S100 S150 S250

A 70 ±1.0 100 ±1.0

B 70 ±1.0 100 ±1.0

OPTIMASS 2000

Dimensions [inches]

S100 S150 S250

A 2.75 ±0.04 4.0 ±0.04

B 2.75 ±0.04 4.0 ±0.04

24

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 25

OPTIMASS 2000

3.1 Intended use

This mass flowmeter is designed for the direct measurement of mass flow rate, product density

and product temperature. Indirectly, it also enables the measurement of parameters like total

mass, concentration of dissolved substances and the volume flow. For use in hazardous areas,

special codes and regulations are also applicable and these are specified in a separate

documentation.

3.2 Mounting restrictions

3.2.1 General installation principles

There are no special installation requirements but you should note the following

points:

• Support the weight of the meter.

• The meter can be supported on the sensor body.

• On larger meter sizes and hygienic connections, it is strongly recommended that the meter is

not supported solely by the process pipework.

• No straight runs are required.

• The use of reducers and other fittings at flanges, including flexible hoses, is allowed but you

should take care to avoid cavitation.

• Avoid extreme pipe size reductions.

• Meters are not affected by crosstalk and can be mounted in series or in parallel.

• Avoid mounting the meter at the highest point in the pipeline where air / gas can collect.

INSTALLATION 3

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

25

Page 26

3 INSTALLATION

Mounting positions

OPTIMASS 2000

26

1 The meter can be mounted at an angle but it is recommended that the flow is uphill.

2 Avoid mounting the meter with the flow running downhill because it can cause siphoning. If the meter has to be mount-

ed with the flow running downhill, install an orifice plate or control valve downstream of the meter to maintain backpressure.

3 Horizontal mounting with flow running left to right.

4 Avoid mounting meter with long vertical runs after the meter as it can cause cavitation. Where the installation includes

a vertical run after the meter, install an orifice plate or control valve downstream to maintain backpressure.

5 The meter can be mounted vertically but it is recommended that the flow is uphill.

6 Avoid mounting the meter vertically with the flow running downhill. This can cause siphoning. If the meter has to be

installed this way, install an orifice plate or control valve downstream to maintain backpressure.

www.krohne.com 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

Page 27

OPTIMASS 2000

Zero calibration

INSTALLATION 3

1 Where the meter has been installed vertically, install shut-off valves either side of the meter to assist with zero cali-

bration.

2 If the process flow cannot be stopped, install a bypass section for zero calibration.

3.2.2 Sunshades

The meter MUST be protected from strong sunlight.

1 Horizontal installation

2 Vertical installation

www.krohne.com10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en

27

Page 28

K

K

K

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature meters

• Pressure meters

• Analysis products

• Measuring systems for the oil and gas industry

• Measuring systems for sea-going tankers

© KROHNE 10/2010 - 4000228104 - TD OPTIMASS 2000 R04 en - Subject to change without notice.

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

D-47058 Duisburg (Germany)

Tel.:+49 (0)203 301 0

Fax:+49 (0)203 301 10389

info@krohne.de

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...