Page 1

OPTIMASS Coriolis Mass Flowmeter

Application Information Sheet

Company name:

Address:

City, State, Zip:

End user (destination)

General Information

Equipment tag #

Piping information,

Meter orientation,

Agency approvals,

FM Class 1, Div 1

Process conditions

Medium name,

Flow conditions,

Flow rate,

System pressure,

Medium temperature,

Medium properties,

Are there solids present?

Is the fluid abrasive?

Is entrained air present?

Signal converter/ transmitter

Converter type,

Remote/ field-mounted

Converter housing,

Power supply,

IO communications,

Base IO module:

1st IO module:

2nd IO module:

Measuring functions,

General concentration

API gravity

Normal

Normal

Normal

Density

Standard (mass flow rate, volumetric flow rate, totalized flow, referred density, temperature)

HART

12-24 VDC

Default

Die-cast aluminum

Integral/ compact-mounted

Contiuous service

Pipe size:

Horizontal

Without

Alcohol

NaOH

Foundation Fieldbus

Modbus

100-230 VAC

1/2" NPT (3 x compact / 5 x remote)

Stainless steel

Remote/ wall-mounted

No

No

No

Batching service

FM Class 1, Div 2

Custody transfer

Vertical

Schedule:

Direct Digital (DDC)

Material:

Baume 144.3

Concentration by mass

Profibus PA

Polycarbonate

remote signal cable length:

Yes

Yes

Yes

Sp. gravity

Minimum

Minimum

Minimum

liquid state

Inclined

describe:

describe:

describe:

describe:

Baume 145.0

Profibus DP

gas state

Maximum

Maximum

Maximum

Viscosity

units:

psia°FPlato

Brix

psig°Cbara

barg

Cable connection,

page 1 of 2

3 x M20 x 1,5

3 x PF 1/2"

Contact name:

Phone number:

Email address:

Page 2

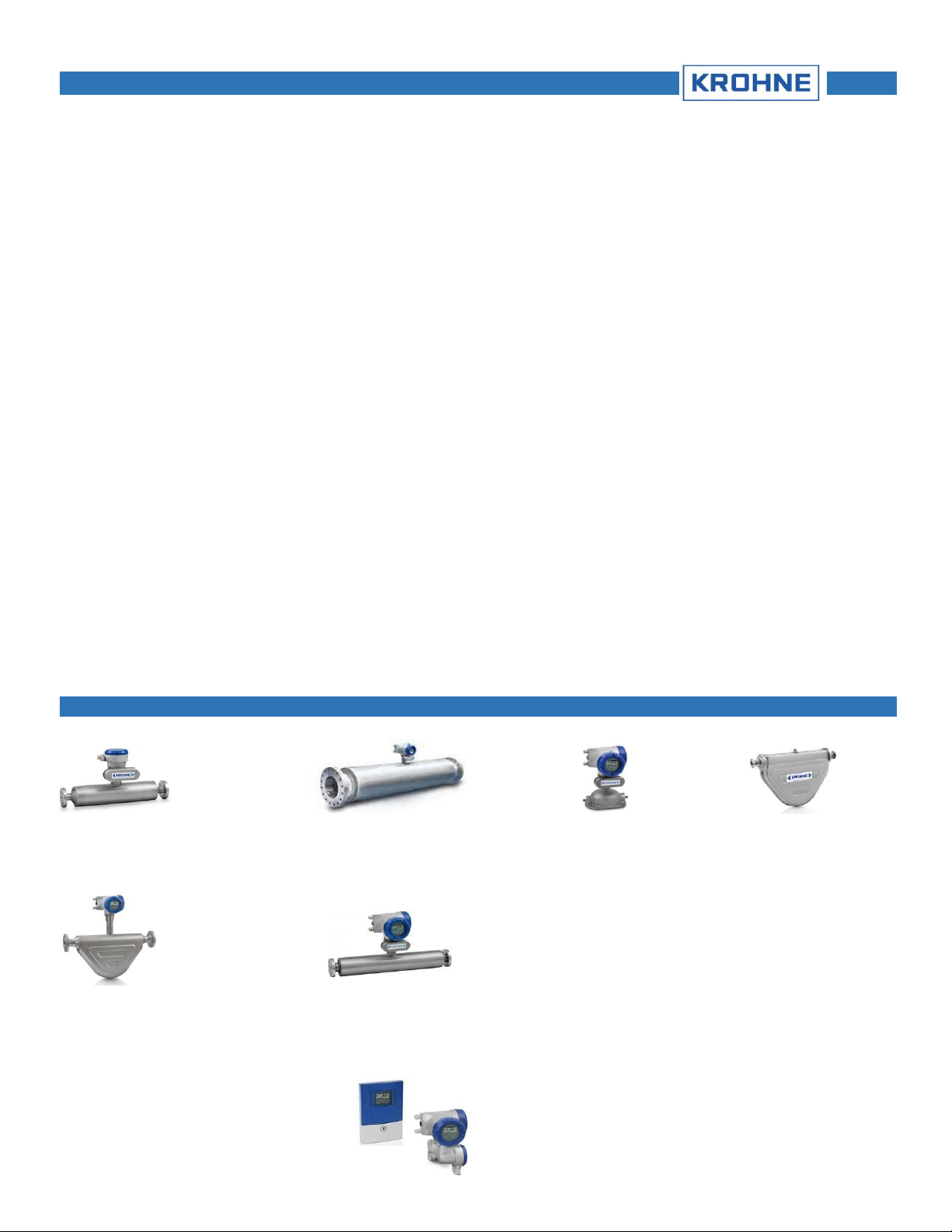

OPTIMASS 1000 OPTIMASS 2000 OPTIMASS 3000 OPTIMASS 4011

OPTIMASS 6000 OPTIMASS 7000

Signal converter/ transmitter types

Communications protocol

• Integral/ compact-mounted

• HART

• Remote/ field-mounted • Foundation Fieldbus

• Remote/ wall-mounted

• Modbus

• Direct Digital (DDC) Modbus • Profibus PA / DP

3-year extended guarantee

(requires approval)

KROHNE Coriolis Mass Flowmeters

• High performance Coriolis

• Process or custody transfer applications

• Single straight measuring tube

Mass flow sensor

Measuring tube,

316/316L dual certified SST

Tube surface finish,

Secondary containment,

Calibration,

Process connections,

Raised face

Extended options,

Purge fittings

Cleaning/ degreasing

Documentation (QA/QC)

KROHNE standard (IOM + calibration certificate)

General arrangement drawing (GA)

Construction drawing (GA) for approval

Material certificates of pressure bearing parts

Size:

Liquid/ steam heating jacket

3-point mass

304/304L SST

Standard finish

316L SST

RTJ

5-point mass

316L SST

polished 0.8 µm

318 SST

ASME 150#

Duplex SST

polished 0.5 µm

No secondary containment (Hermetically sealed) 316/316L casing & bridge

ASME 300#

inch NPT

Insulation - casing ONLY (standard high temperature)

Insulation - casing ONLY (cryogenic / low temperature)

Adjustment for gas measurement

Hastelloy C22

polished 0.4 µm

ASME 600#

Sanitary

Titanium

ASME 900#

Tantalum

ASME 1500#

Positive material identification (PMI)

Test report including pressure test

Radiographic examination (RT)

Liquid (dye) penetrant examination

Welding book (WPQ, WPS & PQR)

Inspection certificate

Certificate of compliance

• Excellent price to performance ratio

• Twin straight measuring tubes

• Extreamely low flow rates

• High performance Coriolis

• Cryogenic / High temperatures to 752 °F

• Entrained gas management (EGM)

100% entrained gas immunity

• Designed for bulk measurement

• Process or custody transfer applications

• Twin straight measuring tubes

• Designed for filling

machines

Notes/ comments:

Loading...

Loading...