KROHNE OPTIFLEX2200C User Manual

Supplementary instructions

Supplementary instructions

OPTIFLEX 2200 C

OPTIFLEX 2200 C

OPTIFLEX 2200 COPTIFLEX 2200 C

Supplementary instructions Supplementary instructions

2-wire / Guided Radar (TDR) Level Meter

Safety manual

Safety manual

Safety manualSafety manual

© KROHNE 01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

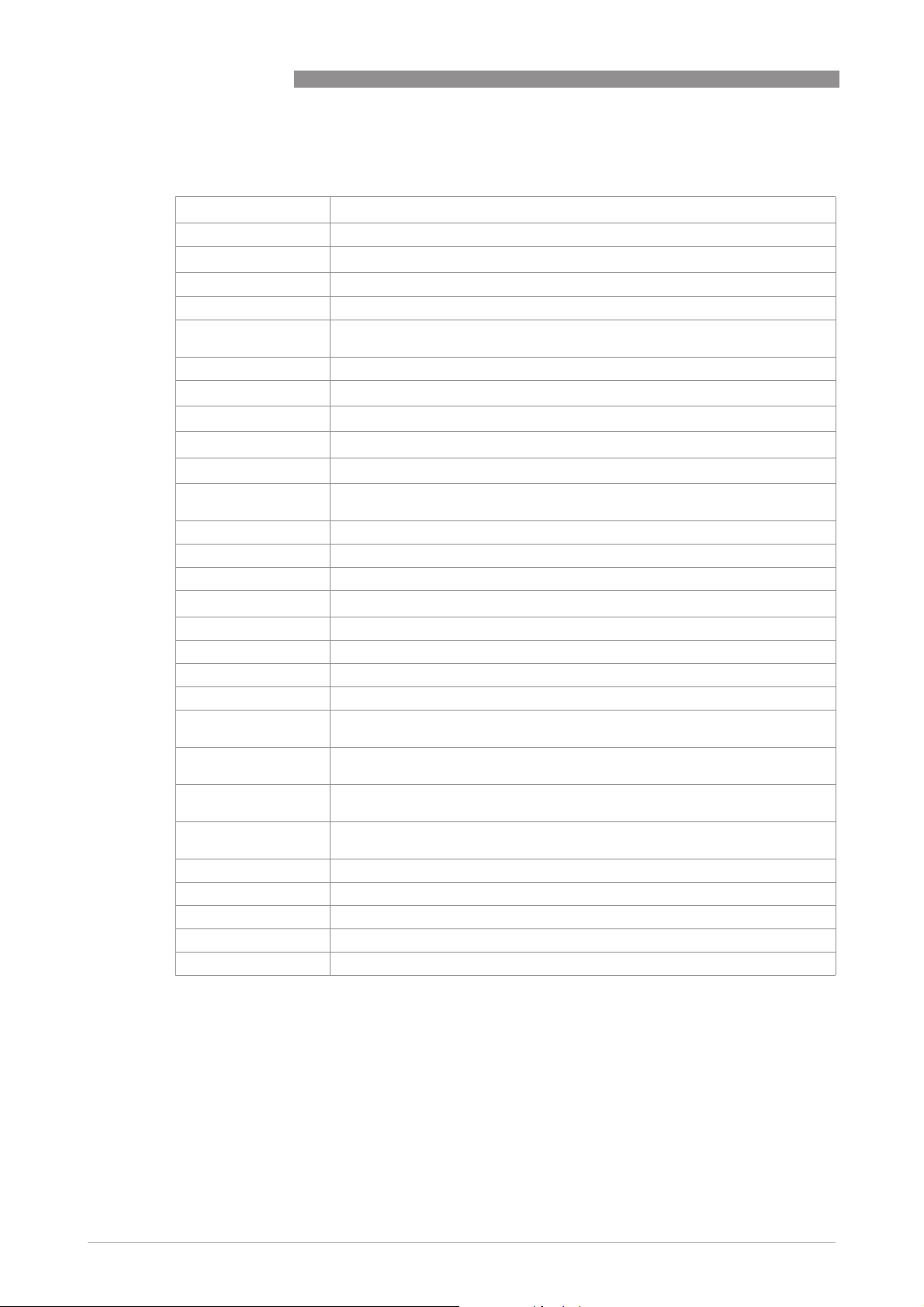

CONTENTS

OPTIFLEX 2200 C

1 Introduction 4

1.1 Scope of the document..................................................................................................... 4

1.2 Revision history ................................................................................................................ 4

1.3 Device description ............................................................................................................ 5

1.4 Related documentation .................................................................................................... 5

1.5 Terms and definitions....................................................................................................... 6

2 System description 7

2.1 Peripheral equipment ...................................................................................................... 7

2.2 Software for use with the device...................................................................................... 7

3 Installation 8

4 Electrical connection 9

5 Start-up 10

5.1 General notes ................................................................................................................. 10

5.2 Device parameters ......................................................................................................... 10

6 Specification of safety function 11

6.1 Preliminary requirements.............................................................................................. 11

6.2 Safety function definition................................................................................................ 11

6.2.1 General notes........................................................................................................................ 11

6.2.2 Limits of application.............................................................................................................. 11

6.2.3 Safety function characteristics............................................................................................. 12

7 Operation 13

7.1 Conditions of use ............................................................................................................ 13

7.2 Failure state ................................................................................................................... 13

7.3 Operation mode .............................................................................................................. 14

7.4 Error conditions.............................................................................................................. 15

7.5 User parameters ............................................................................................................16

7.5.1 Limits for supervisor menu functions related to probe configuration ................................ 16

7.5.2 Limits for supervisor menu functions related to device configuration ............................... 17

8 Service 19

8.1 Periodic maintenance..................................................................................................... 19

8.2 Keep the device clean..................................................................................................... 19

8.3 Availability of services .................................................................................................... 19

8.4 Proof tests ...................................................................................................................... 19

2

www.krohne.com 01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

OPTIFLEX 2200 C

CONTENTS

8.5 Calibration procedure .................................................................................................... 22

8.5.1 General notes........................................................................................................................ 22

8.5.2 Current output check............................................................................................................ 23

8.5.3 Measuring range check (in process conditions) .................................................................. 24

8.6 Troubleshooting.............................................................................................................. 25

8.7 Returning the device to the manufacturer..................................................................... 25

8.7.1 General information.............................................................................................................. 25

8.7.2 Form (for copying) to accompany a returned device............................................................ 26

9 Technical data 27

9.1 General notes ................................................................................................................. 27

9.2 Assumptions ................................................................................................................... 27

9.3 Characteristics for the device safety function ............................................................... 28

9.4 SIL-specific technical data ............................................................................................. 29

9.5 Support for SIL-approved devices.................................................................................. 30

10 Appendix 31

10.1 Start-up report ............................................................................................................. 31

10.2 Proof test report form (for copying) ............................................................................. 32

11 Notes 33

www.krohne.com01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

3

1 INTRODUCTION

1.1 Scope of the document

This document supplies functional safety data about the device. This data agrees with the

IEC 61508 standard.

WARNING!

The data in this supplement only contains the data applicable to the SIL approval. The technical

data for the standard version in the handbook (document [N1]) shall be valid in its current

version, provided that it is not rendered invalid or replaced by this supplement.

INFORMATION!

Installation, commissioning and maintenance may only be carried out by approved personnel.

1.2 Revision history

Edition Date Description

1 June 1, 2012 First issue.

2 June 13, 2012 Correction of characteristics for the device safety function.

3 January 31, 2013 New edition (2010) of the international standard IEC 61508.

OPTIFLEX 2200 C

4

www.krohne.com 01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

OPTIFLEX 2200 C

1.3 Device description

This device is a 2-wire level transmitter that uses TDR (Time Domain Reflectometry) / Guided

Radar technology. It measures the distance of liquids, liquid gases, pastes, powders, slurries

and granular products.

Measurements are given through a 4...20 mA current output and can be displayed via a DTM

(device type manager) for remote communication or an integrated display screen with wizarddriven set-up and online help functions. Only the 4...20 mA current output is used as the safety

function.

INFORMATION!

The manufacturer designed and developed the device for safety integrity level (SIL) 2.

Data for the SIL approval is not taken from field experience (i.e. it is not

this method can give unrealistic data if assumptions are too optimistic.

When the device detects a measurement error, it supplies an output current less than 3.6 mA.

Although the device can be set to a high error value (≥ 21 mA), some hardware failures can cause

the device to give a low error value (≤ 3.6 mA). For more data, refer to

menu functions related to device configuration

INTRODUCTION 1

“

proven in use”) because

Limits for supervisor

on page 17 (2.4.2 RANGE I).

Refer also to "Device description" in the handbook (document [N1]).

1.4 Related documentation

[N1] OPTIFLEX 2200 Handbook

[N2] IEC 61508-1 to 7:2010 Functional safety of electrical / electronic / programmable

electronic safety-related systems

[N3] NAMUR Recommendation NE 043 Standardization of the Signal Level for the Failure

Information of Digital Transmitters

[N4] NAMUR Recommendation NE 053 Software of Field Devices and Signal Processing

Devices with Digital Electronics

[N5] OPTIFLEX 2200 Supplementary Instructions for ATEX applications

www.krohne.com01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

5

1 INTRODUCTION

1.5 Terms and definitions

OPTIFLEX 2200 C

DC

D

Diagnostic Coverage of dangerous failures

Firmware Software embedded in the device.

FIT

Failure In Time (1×10-9 failures per hour)

FMEDA Failure Modes, Effects and Diagnostics Analysis

HFT Hardware Fault Tolerance

High demand or

continuous mode

Where the frequency of demands for operation made on a safety-related system

is greater than one time per year

I/O Input / output

λ

DD

λ

DU

λ

SD

λ

SU

Rate for dangerous detected failure

Rate for dangerous undetected failure

Rate for safe detected failure

Rate for safe undetected failure

Low demand mode Where the frequency of demands for operation made on a safety-related system

is no greater than one time per year

MTBF Mean Time Between Failures

MTTF Mean Time To Failure

MTTR Mean Time To Recovery

PFD

AVG

Average Probability of Failure on Demand

PFH Probability of a dangerous Failure per Hour

SFF Safe Failure Fraction

SIL Safety Integrity Level

SIS Safety Integrated System

TDR Time Domain Reflectometry. The measuring principle. For more data, refer to

“Technical Data” in the handbook (document [N1]).

TBF Tank bottom following. A device measurement mode. For more data, refer to

“Technical Data” in the handbook (document [N1]).

Type A system "Non-complex" system (all failure modes are well defined). For more data, refer

to subsection 7.4.3.1.2 of IEC 61508-2.

Type B system "Complex" system (all failure modes are not well defined). For more data, refer

to subsection 7.4.3.1.2 of IEC 61508-2.

T[Proof] Proof Test Interval

T[Repair] Time to Repair

T[Test] Internal Diagnostics Test Interval

1oo1 1 out of 1 channel architecture (single architecture performs the safety function)

1oo1D 1 out of 1 channel architecture with diagnostics

6

www.krohne.com 01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

OPTIFLEX 2200 C

2.1 Peripheral equipment

You can use the device with the equipment that follows:

• A logic solver that can read 4...20 mA current input and low error alarm signals

• A PC or workstation (this is used only to change parameters)

®

• A HART

For more data, refer to "Start-up" in the handbook (document [N1]).

Handheld Controller (this is used only to change parameters)

2.2 Software for use with the device

You can change device parameters with the software that follows:

• PACTware™

• AMS™ Device Manager

For more data, refer to "Start-up" in the handbook (document [N1]).

SYSTEM DESCRIPTION 2

www.krohne.com01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

7

3 INSTALLATION

WARNING!

If the device is to agree with the requirements for functional safety given in IEC 61508, you must

obey the installation instructions given in the handbook (document [N1]). The device must be

installed by approved personnel.

If the device was delivered without a probe, then calibrate the device to make sure that the safety

function operates correctly. This maintenance task must be done and recorded by approved

personnel. For more data, refer to

For more data, refer to "Installation" in the handbook (document [N1]).

Calibration procedure

OPTIFLEX 2200 C

on page 22.

8

www.krohne.com 01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

OPTIFLEX 2200 C

WARNING!

If the device is to agree with the requirements for functional safety given in IEC 61508, you must

obey the electrical connection instructions given in the handbook (document [N1]). The device

must be installed by approved personnel.

DANGER!

If the device is for use in potentially explosive atmospheres, you must obey the electrical

connection instructions given in the supplementary instructions for ATEX applications

(document [N5]). We recommend that you use a galvanically-isolated power supply.

If the device was delivered without a probe, then calibrate the device to make sure that the safety

function operates correctly. This maintenance task must be done and recorded by approved

personnel. For more data, refer to

For more data, refer to “Electrical connection” in the handbook (document [N1]).

ELECTRICAL CONNECTION 4

Calibration procedure

on page 22.

www.krohne.com01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

9

5 START-UP

5.1 General notes

DANGER!

Before you energize the device, make sure that the polarity and the supply voltage are correct.

DANGER!

Make sure that the device and the installation agree with the requirements of the Ex certificate

of compliance. For more data, refer to the supplementary instructions for Ex approvals.

Do a check of the device and tank before you energize the device:

• Are all the wetted components (probe, flange and gaskets) resistant to the product in the

tank?

• Does the information on the signal converter nameplate agree with the operating data? Does

the order code on the nameplate show the SIL option (xF20xxx1xxxxxx)?

• Are the process temperature and pressure in the limits for operation of the device?

• Did you correctly install the device on the tank?

• Do the electrical connections agree with the national electrical codes?

OPTIFLEX 2200 C

Complete the start-up report on page 31.

WARNING!

If the device was delivered without a probe, then do a device calibration to make sure that the

safety function operates correctly. For more data about the procedure, refer to Calibration

procedure on page 22

The manufacturer offers a range of services to support the customer. These services include

repair, maintenance, technical support and training.

5.2 Device parameters

WARNING!

The device agrees with the data given in the customer order. If you change the configuration of

the device after its delivery, the manufacturer does not accept responsibility for the incorrect

configuration of the SIL-approved version of the device. Use device parameters that are

applicable to the application, because conditions at the plant can have an effect on the functional

saftey of the measuring system.

For more data about device configuration, refer to the "Start-up" and "Operation" chapters in the

handbook (document [N1]). Also refer to

.

User parameters

on page 16.

10

www.krohne.com 01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

OPTIFLEX 2200 C

6.1 Preliminary requirements

WARNING!

The data in this supplement only contains the data applicable to the SIL approval. The technical

data for the standard version in the handbook (document [N1]) shall be valid in its current

version, provided that it is not rendered invalid or replaced by this supplement.

6.2 Safety function definition

6.2.1 General notes

The device contains a safety function that agrees with the standard (document [N2]). This safety

function operates if there is a large difference between the level measurement and the level

shown as a current output.

If the device senses that there is a difference of more than 2.5% between the level measurement

and the level shown as a current output, then the current output changes to an error signal

(≤ 3.6 mA) in less than 10 seconds. The safety integrity level of this safety function is SIL2.

SPECIFICATION OF SAFETY FUNCTION 6

INFORMATION!

If menu item 2.4.5 ERROR DELAY = 0 s, then the current output changes to an error signal

(≤ 3.6 mA) in less than 10 seconds. If menu item 2.4.5 ERROR DELAY is more than 0 seconds,

then the current output changes to an error signal (≤ 3.6 mA) in 10 seconds + 2.4.5 ERROR

DELAY.

6.2.2 Limits of application

This version of the device has the restrictions that follow:

• Distance is measured in Automatic mode

• Only the compact version (the signal converter is attached directly to the probe) can be used.

• It is a 2-wire loop-powered device.

For more data, refer to

Automatic mode (only one product in the tank is permitted).

Automatic modeAutomatic mode

SIL-specific technical data

on page 29.

www.krohne.com01/2013 - 4000738603 - AD SIL OPTIFLEX 2200 R03 en

11

Loading...

Loading...