Konica Minolta FS-111, FS-211 Manual

SERVICE MANUAL

Models

FS-111/FS-211

JANUARY 2004

CSM-FS111/211

KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC.

FS-111/211

SERVICE MANUAL

JANUARY 2004

Used on Konica Models 7085/FORCE 85: FS-111/211 7255/7272: FS-111

IMPORTANT NOTICE

Because of the possible hazards to an inexperienced person servicing this equipment, as well as the risk of damage to the equipment, Konica Minolta Business Solutions U.S.A., Inc. strongly recommends that all servicingbeperformedbyKonica-trainedservicetech- nicians only.

Changes may have been made to this equipment to improve its performance after this service manual was printed. Accordingly, Konica Minolta Business Solutions U.S.A., Inc., makes no representations or warranties, either expressed or implied, that the information contained in this service manual is complete or accurate. It is understood that the user of this manual must assume all risks or personal injury and/or damagetotheequipmentwhileservicingtheequipmentfor which this service manual is intended.

Corporate Publishing Department

© 2004, KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC. All rights reserved.

Printed in U.S.A.

CONTENTS

CONTENTS

SAFETY AND IMPORTANT WARNING ITEMS |

|

1. OUTLINE |

|

||

Refer to the 7155/7165/7255/7272 Service Manual |

FS-111/FS-211 PRODUCT SPECIFICATIONS |

...... 1-1 |

|||

CENTER CROSS SECTION |

1-3 |

||||

|

|

||||

|

|

DRIVE SYSTEM DIAGRAM .................................... |

1-4 |

||

|

|

[1] |

Paper Conveyance Drive ............................ |

1-4 |

|

|

|

[2] |

Stacker Drive .............................................. |

1-5 |

|

|

|

[3] Folding Drive (FS-211 only) ........................ |

1-6 |

||

|

|

PAPER CONVEYANCE PROCESS ....................... |

1-7 |

||

|

|

[1] |

Paper Conveyance Process ....................... |

1-7 |

|

|

|

[2] |

Non-Sort Mode............................................ |

1-8 |

|

|

|

[3] |

Sort, Group Mode ....................................... |

1-9 |

|

|

|

[4] |

Sub-tray Mode .......................................... |

1-10 |

|

|

|

[5] |

Staple Mode .............................................. |

1-11 |

|

|

|

[6] Booklet Mode (FS-211 only) ..................... |

1-13 |

||

2. UNIT EXPLANATION

EXTERNAL SECTION ............................................ |

2-1 |

|

[1] |

Composition ................................................ |

2-1 |

[2] |

Mechanisms ................................................ |

2-1 |

CONVEYANCE SECTION ...................................... |

2-2 |

|

[1] |

Composition ................................................ |

2-2 |

[2] |

Mechanisms ................................................ |

2-3 |

[3] |

M1 (FNS Conveyance) Control ................... |

2-7 |

[4] |

Gate Control................................................ |

2-9 |

[5] |

M13 (Stacker Entrance) Control ............... |

2-12 |

[6] |

M5 (Alignment Plate/Upper) Control ......... |

2-14 |

[7] |

M15 (Alignment Plate/Lower) Control |

|

|

(FS-211 only) ............................................ |

2-15 |

[8] |

M2 (Roller Shift) Control ........................... |

2-16 |

[9] |

M7 (Paper Exit Roller) Control .................. |

2-17 |

[10] |

SD4 (Paper Exit Opening) Control ............ |

2-19 |

[11] |

M8 (Paper Exit Opening) Control .............. |

2-20 |

STAPLER UNIT ..................................................... |

2-21 |

|

[1] |

Composition .............................................. |

2-21 |

[2] |

Mechanisms .............................................. |

2-22 |

[3] |

Stapler Control .......................................... |

2-26 |

MAIN TRAY UNIT ................................................. |

2-30 |

|

[1] |

Composition .............................................. |

2-30 |

[2] |

Mechanisms .............................................. |

2-30 |

[3] |

Main Tray Up/Down Control...................... |

2-31 |

FOLDING UNIT (FS-211 ONLY) ........................... |

2-32 |

|

[1] |

Composition .............................................. |

2-32 |

[2] |

Mechanisms .............................................. |

2-33 |

[3] |

Folding-Unit Control .................................. |

2-34 |

3. DISASSEMBLY/ASSEMBLY

EXTERNAL SECTION ............................................ |

3-1 |

|

[1] |

Removing and Reinstalling |

|

|

the Rear Cover............................................ |

3-1 |

[2] |

Removing and Reinstalling |

|

|

the Front Cover ........................................... |

3-1 |

[3] |

Removing and Reinstalling |

|

|

the Top Cover ............................................. |

3-1 |

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

CONTENTS

[4] |

Removing and Reinstalling |

|

|

the Paper Exit Cover ................................... |

3-2 |

[5] |

Removing and Reinstalling |

|

|

the Main Tray .............................................. |

3-2 |

[6] |

Removing and Reattaching |

|

|

the Front Side Cover ................................... |

3-3 |

[7] |

Removing and Reinstalling |

|

|

the Paper Exit Stopper Plate ....................... |

3-3 |

PAPER FEED UNIT ................................................ |

3-5 |

|

[1] Replacing a Paper Exit Roller |

|

|

|

(Sponge Roller) ........................................... |

3-5 |

[2] |

Removing and Reinstalling |

|

|

the Paper Exit Unit/Shift Unit ...................... |

3-5 |

[3] |

Removing and Reinstalling |

|

|

the Stacker/Stapler Unit .............................. |

3-8 |

STAPLER UNIT ..................................................... |

3-11 |

|

[1] Exchanging the clincher (FS-211 only) ..... |

3-11 |

|

[2] Removing and Reinstalling a Stapler |

|

|

|

(For FS-111) ............................................. |

3-12 |

[3] Removing and Reinstalling a Stapler |

|

|

|

(For FS-211) ............................................. |

3-12 |

MAIN TRAY SECTION .......................................... |

3-14 |

|

[1] |

Removing and Reinstalling |

|

|

the Up-Down Stay ..................................... |

3-14 |

[2] Exchanging the Up-Down Wire ................. |

3-14 |

|

FOLDING UNIT (FS-211 ONLY) ........................... |

3-16 |

|

[1] |

Removing and Reinstalling |

|

|

the Folding Unit ......................................... |

3-16 |

[2] |

Removing and Reinstalling |

|

|

the Adjustment Cover ............................... |

3-17 |

SAFETY WARNINGS

[1] Modifications Not Authorized by Konica Minolta

Konica Minolta equipment is renowned for their high reliability. This reliability is achieved through high-quality design and a solid service network.

Unauthorized modifications involve a high risk of degradingperformanceandsafety.Suchmodificationsaretherefore strictly prohibited. The points listed below are not exhaustive, but they illustrate the reasoning behind this policy.

PROHIBITED ACTIONS :

PROHIBITED ACTIONS :

(1)Using extension cables or a different power cord than specified by Konica Minolta.

(2)Using other fuses than specified by Konica Minolta. Safety will not be assured, leading to a risk of fire and injury.

(3)Disabling fuses or bridging fuse terminals with wire, metal clips, solder or similar. (This applies also to thermal fuses.)

(4)Removing air filters (except for replacement).

(5)Disabling relay functions (such as wedging paper between relay contacts, etc.).

(6)Disabling safety functions (interlocks, safety circuits, etc.). Safety will not be assured, leading to a risk of fire and injury.

(7)Performing actions to equipment not described in the instruction manual or the service handbook.

(8)Using parts other than specified by Konica Minolta.

[2] Checkpoints When Performing Onsite Service

Konica Minolta equipment is extensively tested before shipping, to ensure that all applicable safety standards are met, in order to protect the customer and customer engineer from the risk of injury. However, in daily use, any electrical equipment may be subject to parts wear and eventual failure. In order to maintain safety and reliability, thecustomerengineermustperformregularsafetychecks.

1. Advance Preparation for Safety Checks

CAUTION:

CAUTION:

(1)Wear clothing that facilitates work and is designed for safety.

(2)Carry out all procedures carefully to prevent injury.

(3)Be sure to disconnect the power cord of the equipment from the AC outlet.

Simply turning off the power switch is not sufficient, because paper feed units or other electrical equipment may be powered also when the power switch is turned off.

(4)Proceed with special care when performing operation checks or adjustment while the unit is powered. When carrying out operation checks or adjustment while external covers are removed, the risk of electrical shock exists when touching partswhichcarryhighvoltageorelectricalcharge. The risk of injury exists when touching moving parts such as gears or chains.

2. Safety Checkpoints

The following list is not exhaustive, but it includes actions which must be carried out at every on-site service.

CAUTION:

CAUTION:

(1)Check external covers and the frame for sharp edges, burrs, or nicks.

(2)Check external covers and hinges for loosening or damage.

(3)Check wiring for squeezing or damage.

(4)Check power cord for insulation problems (conductor must not be exposed).

(5)Check power cord and cable ties etc. for loosening from frame.

WARNING:

WARNING:

(1)Verify that the equipment is properly grounded. If a problem is detected, establish a proper ground connection.

(2)Connecting the ground lead to an improper point such as listed below results in a risk of explosion and electric shock.

Unsuitable ground points:

-Gas pipe

-Lightning rod

-Telephone line ground

-Plastic water pipe or water pipe or faucet that has not been approved by authorities for grounding use

3. Description of Safety Checks

CAUTION:

CAUTION:

(1)Before performing safety check work, read all relevantdocumentation(servicehandbook,technical notices, etc.) and proceed according to the prescribed procedure, using only the prescribed tools. Do not carry out any adjustments not described in the documentation.

(2)If the power cord is damaged, replace it only with the specified power cord. If the power cord insulation has been damaged and there are exposed sections, shortcircuits and overheating may occur, leading to a serious fire risk.

(3)Do not route the power cord so that it can be stepped on or pinched. Otherwise overheating may occur, leading to a serious fire risk.

(4)When disconnecting any cables, always grasp the connector and not the cable (especially in the case of AC and high-voltage leads).

(5)Carefully remove all toner remnants from electrical parts, electrodes, etc.

(6)Make sure that wiring cannot come into contact with sharp edges, burrs, or other pointed parts.

(7)Double-check to make sure that all screws, components, wiring, connectors, etc. that were removed for safety check maintenance have been reinstalled in the original location. (Pay special attentiontoforgottenconnectors,pinchedcables, forgotten screws, etc.)

(8)When installation and preventive maintenance, verify that the power cord has been securely plugged into the AC outlet. Contact problems may lead to increased resistance, overheating, and the risk of fire.

WARNING:

WARNING:

Before disassembling or adjusting the equipment, make sure that the power cord has been disconnected.

[3] Handling of Materials for Servicing

CAUTION: Alcohol-based and acetonebased cleaners are highly flammable and must be handled with care. When using these materials for cleaning parts, observe the following precautions.

CAUTION: Alcohol-based and acetonebased cleaners are highly flammable and must be handled with care. When using these materials for cleaning parts, observe the following precautions.

(1)Disconnect the power cord from the AC outlet.

(2)Use only a small amount of cleaner at a time and take care not to spill any liquid. If this happens, immediately wipe it off.

(3)Perform cleaning only in an environment where sufficient ventilation is assured. Breathing large quantities of organic solvents can lead to discomfort.

(4)Do not replace the cover or turntheuniton before any solvent remnants on the cleaned parts have fully evaporated.

[4] Measures to Take in Case of an Accident

(1)If an accident has occurred, the distributor who has been notified first must immediately take emergency measures to provide relief to affected persons and to prevent further damage.

(2)If a report of a serious accident has been received from a customer, an on-site evaluation must be carried out quickly and Konica Minolta must be notified.

(3)To determine the cause of the accident, conditions and materials must be recorded through direct onsite checks, in accordance with instructions issued by Konica Minolta.

(4)For reports and measures concerning accidents, consult your superior, and follow the regulations set in "Standards for the Control Program for Measures Against Electrical Equipment Accidents".

[5] Conclusion

(1)Safety of users and customer engineers depends highly on accurate maintenance and administration. Therefore, safety can be maintained by the appropriate by the proper daily service work conducted by the customer engineer.

(2)When performing service, equipment on the site must be tested for safety. The customer engineer must verify the safety of parts and ensure appropriate management of the equipment.

1 OUTLINE

1

OUTLINE

1 OUTLINE

Blank page

FS-111/FS-211

FS-111/FS-211 PRODUCT SPECIFICATIONS

[1] Type

FS-111: Finishing device implementing offset collation (sort,group), stapling, and sub-tray eject

FS-211: Finishing device implementing offset collation(sort,group), stapling, sub-tray eject (booklet), stapling-and-folding, and folding

[2] Functions

Type of Paper: Same as the main body.

Paper Size:

FS-111/211 |

FS-211only |

|

|

Non sort Sort/ Staple |

Sub-tray Booklet |

group |

|

A3

B4

F4

A4R A/B A4 Stan- B5R dard B5 A5R

A5

B6R

11x17

8.5x14

8.5x

11R

By 8.5x11 inch 5.5x

8.5R

5.5x

8.5

Wide paper

Paper Stacking Capacity (80g/m2 or 20 lbs): Sub-tray exit mode:

Maximum 200 sheets (same-size sheets only)

Non-Staple, Sort, and Group modes:

Maximum 1500 sheets (A3, B4, F4, 11x17, 8.5x14)

Maximum 3000 sheets (A4, A4R, B5, B5R, 8.5x11, 8.5x11R)

Maximum 500 sheets (A5, A5R, B6R, 5.5x8.5, 5.5x8.5R)

Staple Mode:

Staple Mode:

Maximum 1000 sheets (same-size sheets only)

Original Main-tray |

A3, 11x17 |

|

Other paper types |

||

capacity Pages |

|

|

|

|

|

|

|

|

|

|

|

2 to 9 |

50 stacks |

|

100 (50) stacks |

||

10 to 20 |

50 stacks |

|

50 stacks |

||

21 to 30 |

30 stacks |

|

30 stacks |

||

31 to 40 |

25 stacks |

|

25 stacks |

||

41 to 50 |

20 stacks |

|

20 stacks |

||

51 to 60 |

|

|

|

|

* 15 stacks |

|

|

|

|

||

61 to 100 |

|

|

|

|

* 10 stacks |

|

|

|

|

||

|

( |

) A5, 5.5x8.5 only |

|||

|

|

|

* FS-111 only |

||

Booklet Mode (FS-211 only):

•Stapling-and-folding

20 booklets of 5 folded sheets each (20 pages/ booklet;eq. to 400 pages)

•Folding

33 booklets of 3 folded sheets each (12 pages/ booklet; eq. to 396 pages)

Paper curling: Maximum 10mm

Copy paper (5 sheets) |

Amount of Curll |

Booklet-mode folding level (FS-211 only)

(80g/m2 or 20 lbs)

Height of folding

Folded |

A3, 11x17 |

B4, 8.5x14 |

A4R, 8.5x11R |

Pages |

|

|

|

|

|

|

|

0 to 5 |

25mm or less |

25mm or less |

25mm or less |

6 to 10 |

50mm or less |

50mm or less |

Not specified* |

11 to 16 |

Not specified* |

Not specified* |

Not specified* |

|

|

|

|

*The height of folding may be larger after exit, although the booklet must be folded with ease manually along the line once made by folding.

Amount of sort offsetting

30mm (after sorting and grouping)

|

MODEL |

MANUAL |

REVISED EDITION |

DATE |

PAGE |

METHOD |

|

7075/7085 |

SERVICE HANDBOOK |

1 - 1 |

Apr. 2003 |

1-1 |

REPLACEMENT |

|

|

|||||

|

|

|||||

|

|

|

|

|

|

|

1 OUTLINE

1 OUTLINE

FS-111/FS-211

[3] Staple Mode

Number of sheets to be stapled:

FS-111: 50 sheets maximum (the length in the paperfeeddirectionis400mmormore) 100sheetsmaximum(exceptforpaper mentioned above in parentheses)

*Theheightmustbe10mmorlesswhen using 80g/m2 or 20 lbs quality paper.

FS-211: 50 sheets maximum

*Theheightmustbe5mmorlesswhen using 80g/m2 or 20 lbs quality paper.

Staple position:

|

FS-111 |

FS-211 |

|

|

|

A |

9.0mm±3mm |

8.5mm±3mm |

|

(adjustment possible) |

(adjustment possible) |

|

|

|

B |

9.0mm±3mm |

8.5mm±3mm |

|

|

|

C |

82.5mm±3mm |

82.5mm±3mm |

|

|

|

D |

9.0mm±3mm |

8.5mm±3mm |

|

(adjustment possible) |

(adjustment possible) |

|

|

|

E |

15.0mm±3mm |

14.0mm±3mm |

|

|

|

Single staple |

Two staples |

Single |

(rear) |

|

staple |

|

|

(front) |

Booklet mode (stitch-and-fold) |

|

|

|

(FS-211 only) |

|

Staple capacity: 5000 staples/cartridge

Binding Staples:

|

FS-111 |

FS-211 |

|

(Binding staples for 100 sheets) |

(Binding staples for 50 sheets) |

|

|

|

A |

13.5mm |

12.0mm |

|

|

|

B |

13.2mm |

8.0mm |

|

|

|

A

B

[4] Booklet Mode (FS-211 only)

Stapling-and-fold:

Stapling-and-fold:

Maximum 20 sheets (80g/m2 or 20 lbs paper) Maximum 19 sheets (80g/m2 or 20 lbs paper)

+1 sheet (200g/m2 or 45 lbs paper)

Folding:

Maximum 3 sheets (80g/m2 or 20 lbs paper)

[5] Option

PI-108 (Cover sheet feeder)

[6] Machine Data

Power Source:

24 VDC, 5 VDC (supplied from the main body)

Maximum Power |

|

Consumption: |

100VA |

Weight: |

|

FS-111: |

Approx. 65kg |

FS-211: |

Approx. 80kg |

External Dimensions:

|

|

|

(unit: mm) |

|

|

656 |

85 |

781 |

|

|

367 |

|

|

|

|

|

|

1095 |

1151 |

[7] |

Maintenance |

|

|

|

Maintenance: Same as the main body. Service Life: Same as the main body.

[8] Machine Operating Environment

Temperature: |

10to30½C(50½Fto86½F) |

Humidity: |

10 to 80% RH |

Note: The information herein may subject to change for improvement without notice.

|

MODEL |

MANUAL |

REVISED EDITION |

DATE |

PAGE |

METHOD |

|

7075/7085 |

SERVICE HANDBOOK |

1 - 2 |

Apr. 2003 |

1-2 |

REPLACEMENT |

|

|

|||||

|

|

|||||

|

|

|

|

|

|

|

FS-111/FS-211

CENTER CROSS-SECTION

|

|

Sub-tray |

|

Shift unit |

|

Main tray |

Paper exit unit |

|

|

|

|

|

|

Gate |

|

|

Sub-tray gate |

|

|

By-pass gate |

|

|

Flat-stapling stopper |

|

|

Stapler unit |

Stacker unit |

|

|

|

|

Stapling and |

|

|

folding stopper |

|

Booklet tray |

Folding unit |

|

|

|

Folding stopper |

Area within dotted lines: |

|

|

|

FS-211 only |

1 OUTLINE

1 - 3

1 OUTLINE

FS-111/FS-211

DRIVE SYSTEM DIAGRAM

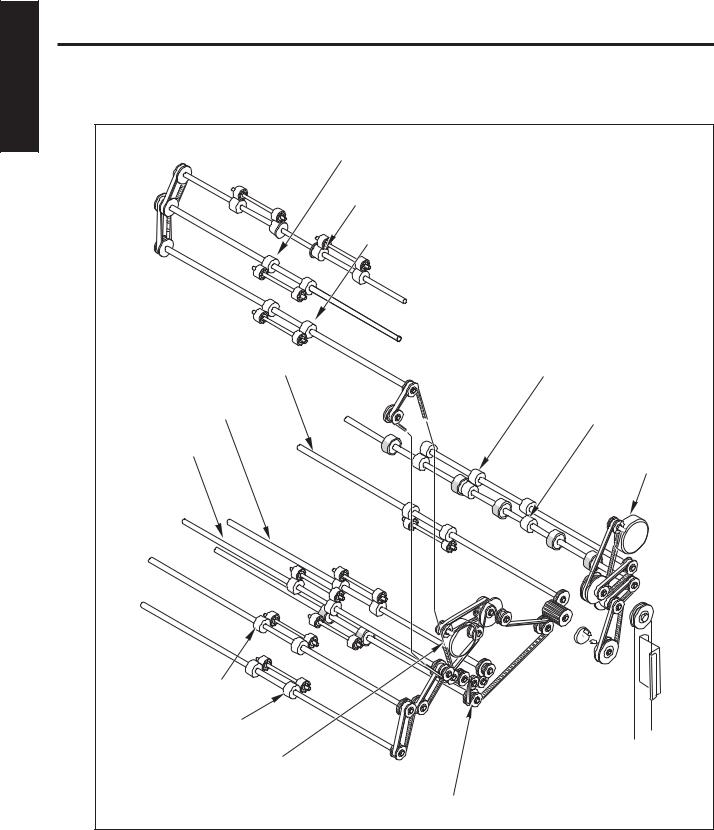

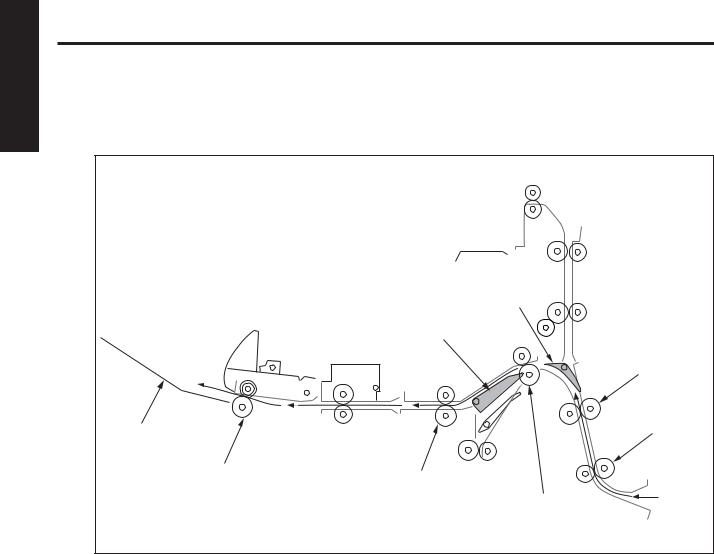

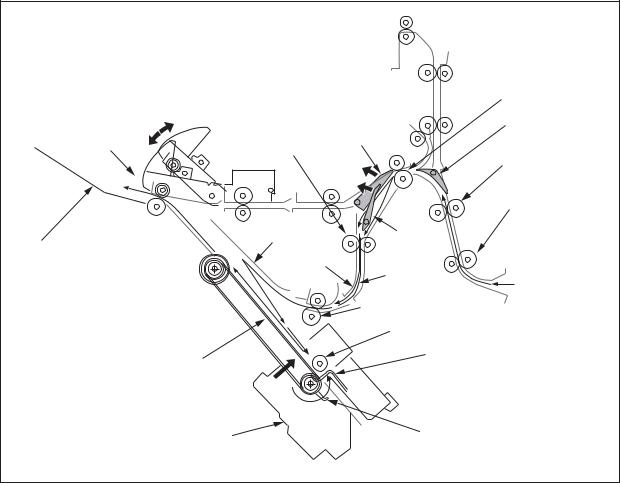

[1] Paper Conveyance Drive

Sub-tray paper exit roller (B)

Sub-tray paper exit roller (C)

Sub-tray paper exit roller (A)

Conveyance slide shaft |

Nip paper exit roller |

Conveyance roller (D) |

Paper exit roller |

Conveyance roller (C) |

Paper exit roller |

|

motor (M7) |

Conveyance roller (B)

Conveyance roller (A)

FNS conveyance motor (M1)

Intermediate conveyance roller

1 - 4

FS-111/FS-211

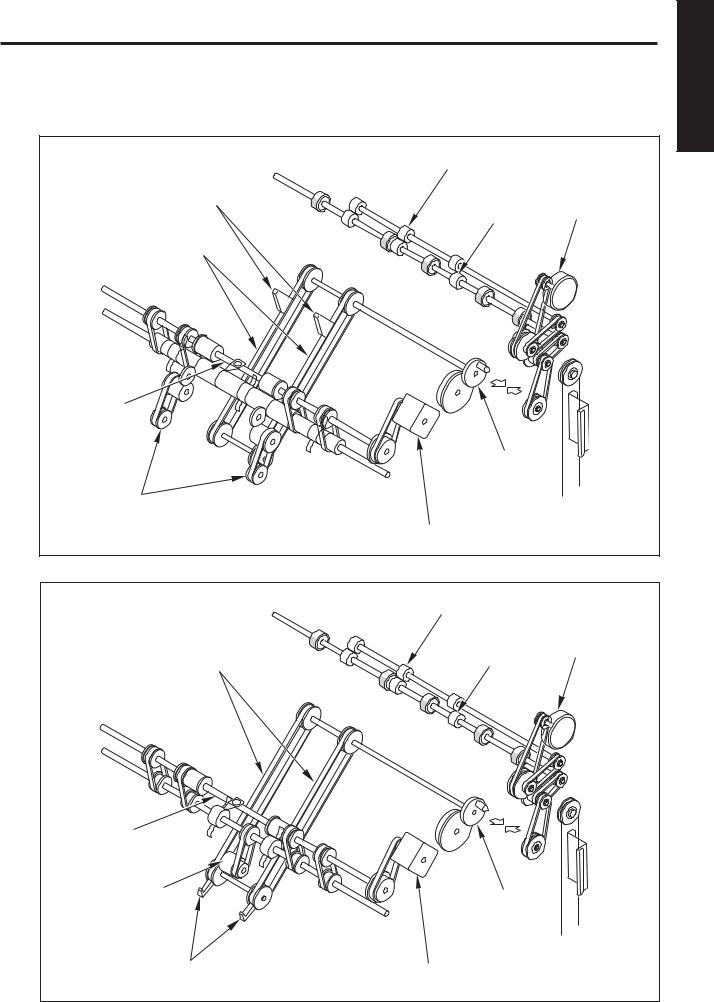

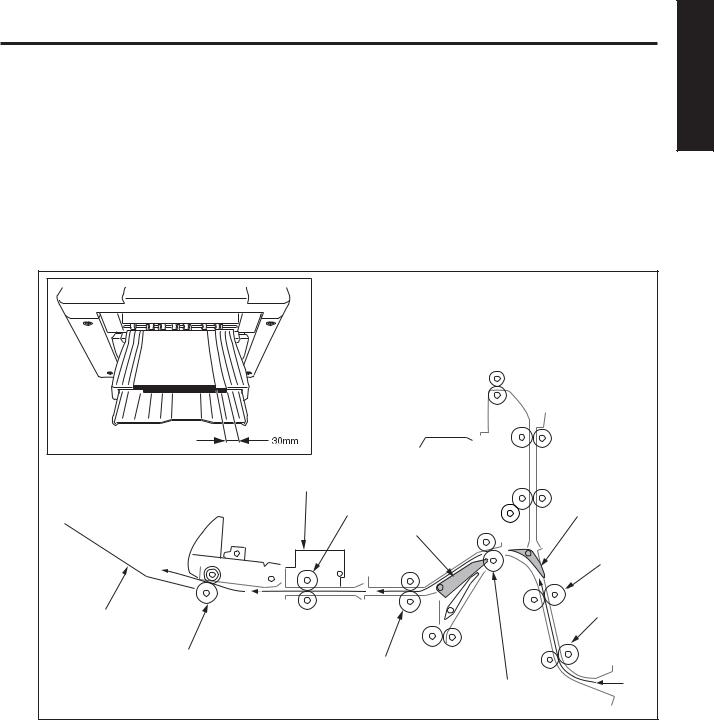

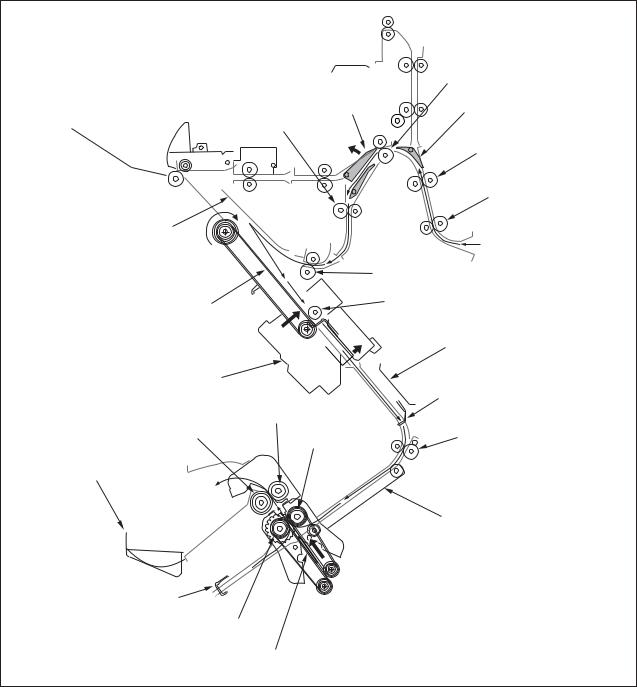

[2]Stacker Drive

(FS-111)

|

Nip paper exit roller |

|

Paper exit arms |

|

Paper exit roller |

|

motor (M7) |

|

|

Paper exit roller |

|

|

|

|

Paper exit belts |

|

|

Stacker entrance |

|

|

roller |

|

|

|

Coupling |

|

Swivel roller |

|

|

|

Stacker entrance motor (M13) |

|

(FS-211) |

|

|

Nip paper exit roller |

|

Paper exit roller |

|

motor (M7) |

Paper exit belts |

Paper exit roller |

|

|

Stacker |

|

entrance roller |

|

Swivel roller |

Coupling |

|

|

Paper exit arms |

Stacker entrance motor (M13) |

|

1 - 5 |

1 OUTLINE

1 OUTLINE

FS-111/FS-211

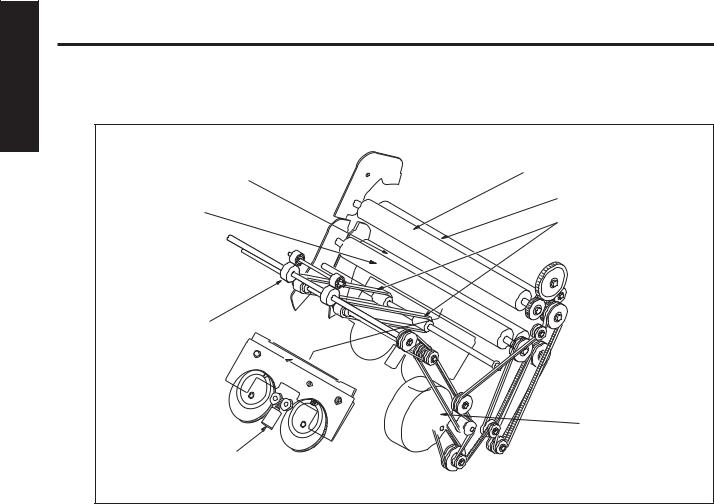

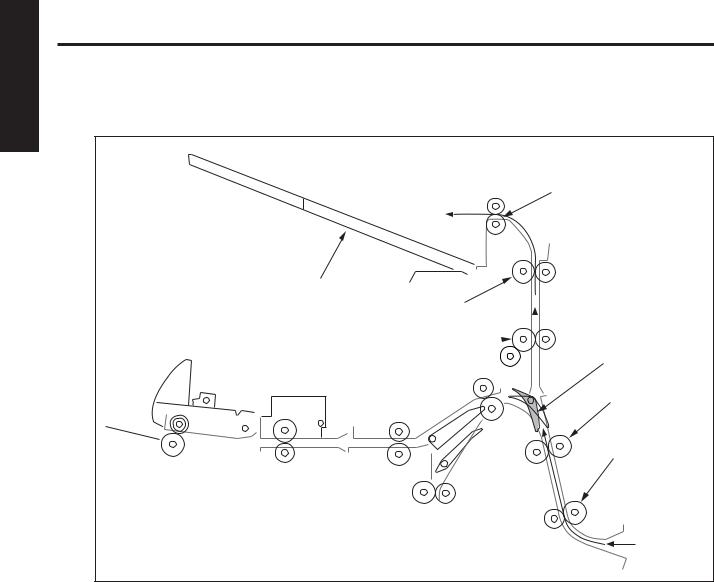

[3] Folding Drive (FS-211 only)

Folding roller (B)

Folding roller (A)

Folding conveyance roller

Folding knife

Folding knife motor (M19)

Pressure roller (A)

Pressure roller (B)

Folding conveyancebelts

Folding conveyance

Folding conveyance

motor (M20)

motor (M20)

1 - 6

FS-111/FS-211

PAPER CONVEYANCE PROCESS

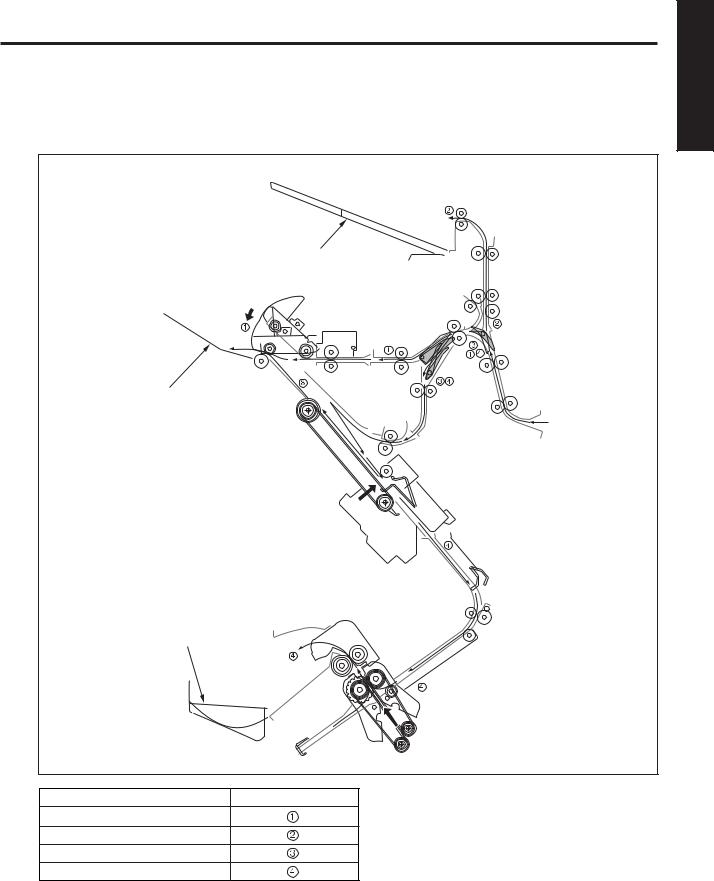

[1] Paper Conveyance Process

The FNS (finisher) provides four paper paths, as shown in the diagram below.

Face-up and face-down inversion is handled by at the main-body side by the main body’s exit page inverter.

1 OUTLINE

Sub-tray

Main tray

Booklet tray

Finishing mode |

Paper Conveyance Paths |

Sort, Group, Non-sort mode

Sub-tray mode

Staple mode

Booklet mode (FS-211 only)

1 - 7

1 OUTLINE

FS-111/FS-211

[2] Non-Sort Mode

Exit to main tray

A paper exited from the main body is conveyed and exited to the main tray.

|

|

Sub-tray gate |

|

|

Gate |

|

|

Conveyance roller (B) |

|

|

Conveyance |

Main tray |

|

roller (A) |

|

|

|

|

Paper exit roller |

Conveyance roller (D) |

|

|

|

|

|

Conveyance roller (C) |

1 - 8

FS-111/FS-211

[3] Sort, Group Mode

Exit to main tray

Paper exited from the main body is conveyed and exited to the main tray. This mode has an off-set function that allows each page of the even-numbered sets to be exited with the paper shifted 30mm to the rear.

Off-set Function

(1)The odd-numbered pages are exited to the main tray with the image side face down.

(2)The even-numbered pages are shifted 30mm to the rear by the conveyance slide shaft of the shift unit and then exited to the main tray.

|

Shift unit |

|

|

Conveyance slide shaft |

Sub-tray gate |

|

Gate |

|

|

|

Conveyance |

|

|

roller (B) |

|

|

Conveyance |

Main tray |

|

roller (A) |

|

|

|

Paper exit roller |

Conveyance roller (D) |

|

|

|

|

|

Conveyance roller (C) |

|

1 OUTLINE

1 - 9

1 OUTLINE

FS-111/FS-211

[4] Sub-tray Mode

The sub-tray gate opens. Paper exited from the main body is conveyed and exited to the sub-tray.

Sub-tray paper exit roller (C)

Sub-tray

Sub-tray paper exit roller (B)

Sub-tray paper exit roller (A)

Sub-tray gate

Conveyance roller (B)

Conveyance roller (A)

1 - 10

|

|

FS-111/FS-211 |

|

1 OUTLINE |

[5] Staple Mode |

|

|||

|

|

|||

(1) |

The gate switches to the staple mode. |

|

|

|

(2) |

For A4R paper and above, the paper exit opening opens. |

|

|

|

(3) |

The first set of paper is conveyed and stacked. |

|

|

|

|

1) |

The stacker section roller sends the paper to the flat-stapling stopper and the paper is lined up in the |

|

|

|

|

lengthwise direction. |

|

|

|

2) |

The upper alignment plate lines up paper in the widthwise direction. |

|

|

|

3) |

Paper is stapled. |

|

|

|

4) |

The first set is conveyed by the paper exit arm and exited to the main tray. |

|

|

|

|

|

|

Conveyance roller (C) |

|

Paper exit |

|

Sub-tray gate |

|

First |

opening |

Intermediate |

Gate |

|

conveyance roller |

|

|||

stapled |

|

Conveyance roller (B) |

||

|

|

|

||

|

set |

|

|

|

|

|

|

|

|

|

|

|

|

Conveyance roller (A) |

|

|

|

Alignment plate |

By-pass |

Main tray |

|

|

|

|

|

|

/upper |

gate |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Stacker entrance |

|

|

|

|

roller |

|

|

|

|

Swivel roller |

|

|

|

|

Flat-stapling stopper |

|

|

Paper exit belt |

|

|

|

|

|

Stapler unit |

Paper exit arm |

|

|

|

|

|

1 - 11

1 OUTLINE |

|

FS-111/FS-211 |

|

|

(4) The second and subsequent sets of paper are conveyed and stacked. |

||

|

|

||

|

1) |

The first page stops in the stacker entrance with the by-pass gate opened. The stacker entrance |

|

|

|

|

roller stops to wait for the previous stack to be exited. |

|

|

|

|

2) |

The by-pass gate is closed and the second page is stacked on top of the first. |

||

3) |

Once the previous stack has exited, the stack entrance roller rotates and the first and second pages |

||

|

|

|

are simultaneously sent to the stacker. |

*The above steps (1) to (3) are for paper to a maximum of A4 size.

4)The stacker section roller sends the paper to the flat-stapling stopper and the paper is lined up in the lengthwise direction.

5)The upper alignment plate lines up paper in the widthwise direction.

6)When all paper is conveyed to the stacker, the paper is stapled.

7)The second and subsequent sets are conveyed by the paper exit arm and the paper is exited to the main tray.

Paper |

|

|

|

|

Conveyance roller (C) |

|

|

|

|

|

|

exit |

opening |

|

Sub-tray gate |

||

Second |

|

|

|||

|

Intermediate |

Gate |

|||

|

conveyance roller |

||||

|

|

||||

stapled |

|

|

|||

|

|

Conveyance roller (B) |

|||

|

|

|

|||

|

set |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Conveyance roller (A) |

|

|

|

|

Alignment |

|

|

|

|

|

plate/upper |

By-pass |

Main tray |

|

|

|

|

gate |

|

|

|

|

Second sheet |

|

|

|

|

|

|

First |

|

|

|

|

|

sheet |

|

|

|

|

|

Stacker entrance roller |

|

|

|

|

|

Swivel roller |

|

|

|

|

|

Flat-stapling stopper |

|

|

|

|

Paper exit belt |

|

|

|

|

|

Stapler unit |

Paper exit arm |

1 - 12

|

FS-111/FS-211 |

|

1 OUTLINE |

|

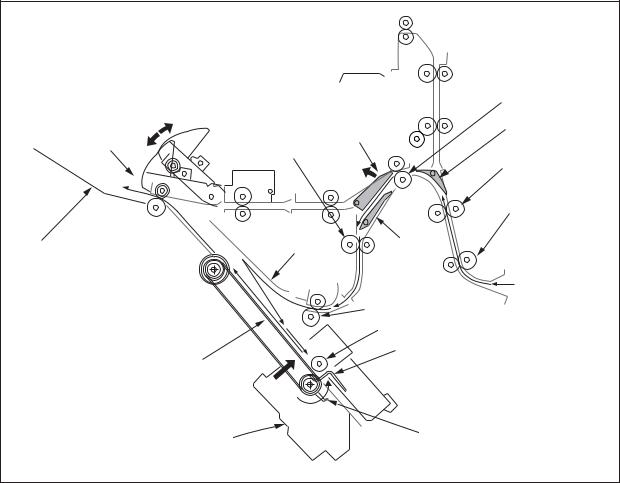

[6] Booklet Mode (FS-211 only) |

||||

|

||||

(1) |

The gate switches to the staple mode. |

|

||

(2) |

The paper exit opening opens. |

|

||

(3) |

The paper is conveyed and stacked. |

|

||

(4) |

The stacker section roller sends the paper to the stapling-and-folding stopper and the paper is lined up in the |

|

||

|

lengthwise direction. |

|

||

(5) |

The upper and lower alignment plate lines up paper in the widthwise direction. |

|

||

(6) |

If stapling-and-folding has been selected, staple the stack. |

|

||

(7) |

Release the stapling-and-folding stopper and convey the stack to the folding unit by the paper exit belt. |

|

||

(8) |

Convey the stack up to the folding stopper, fold it with the folding knife, and eject to the booklet tray. |

|

||

Conveyance roller (C)

Intermediate Gate Sub-tray gate conveyance roller

Conveyance roller (B)

Conveyance roller (A)

Upper alignment plate

|

Stacker entrance roller |

|

Paper exit belt |

|

Swivel roller |

|

|

|

|

|

Alignment plate/lower |

Stapler unit |

|

|

|

|

Stapling and folding stopper |

|

Pressure roller (A) |

|

Pressure roller (B) |

|

Folding conveyance roller |

|

Folding roller (A) |

|

|

|

|

Booklet tray

Folding conveyance belt

Folding stopper

Folding roller (B)

Folding knife

1 - 13

FS-111/FS-211

1 OUTLINE

Blank page

1 - 14

2

UNIT EXPLANATION

2 UNIT EXPLANATION

Loading...

Loading...